Patents

Literature

1973 results about "Underground pipeline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are three primary underground pipelines servicing Georgia. The Colonial (petroleum) Pipeline based in Alpharetta Georgia, the Plantation (petroleum) Pipeline and the Dixie (liquefied petroleum, or LP gas) Pipeline. All three transmission pipelines originate in Houston Texas and travel through the South East United States.

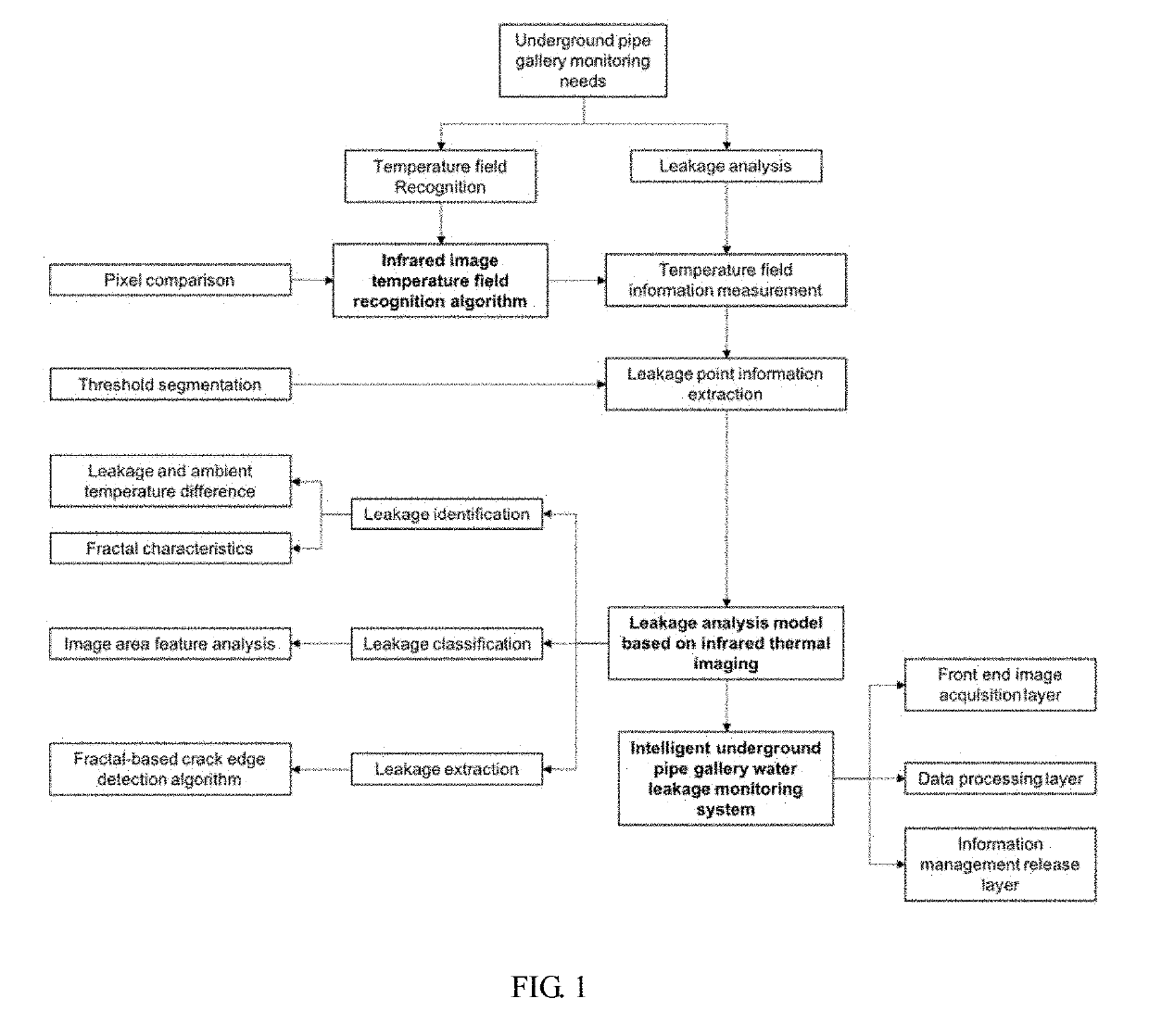

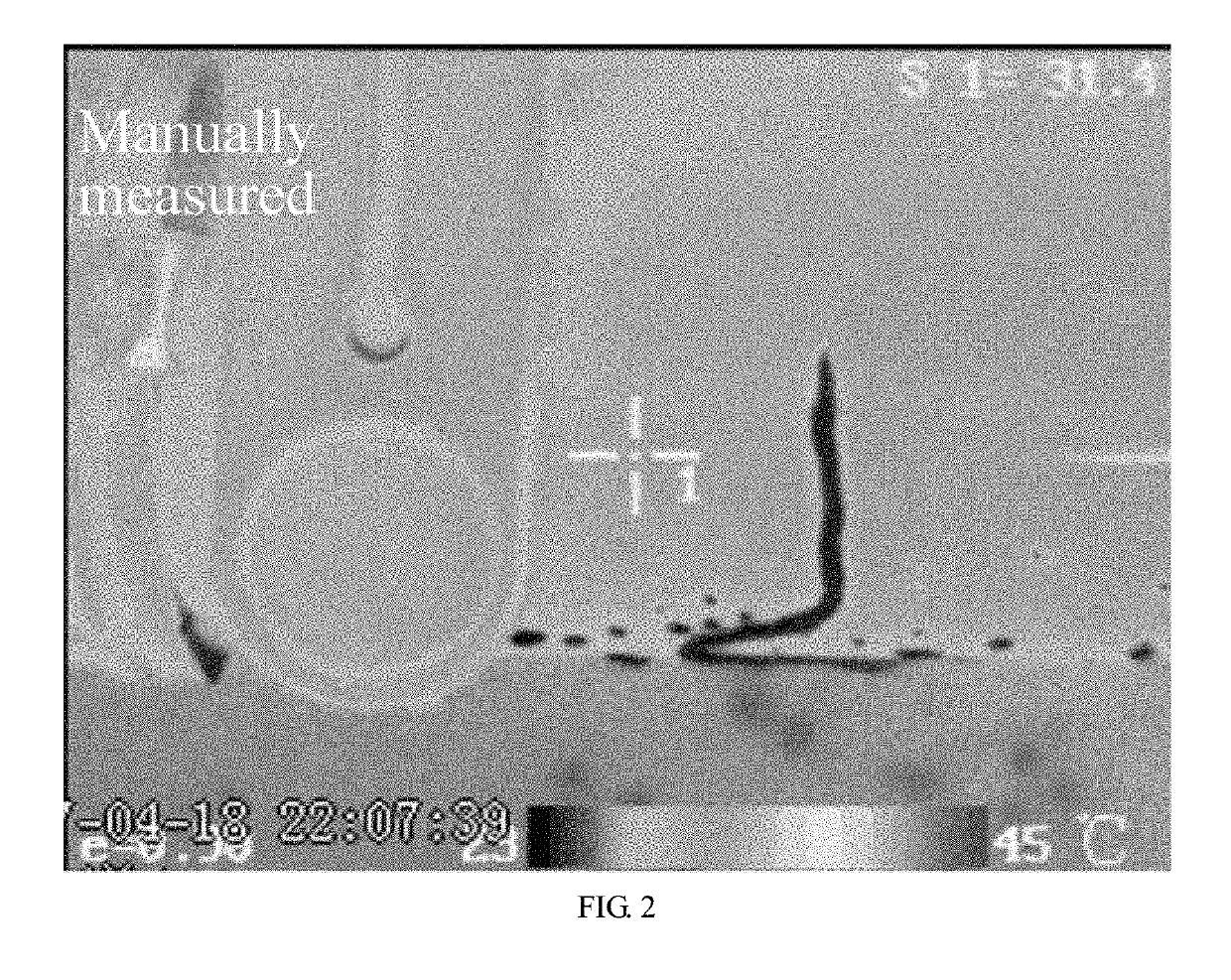

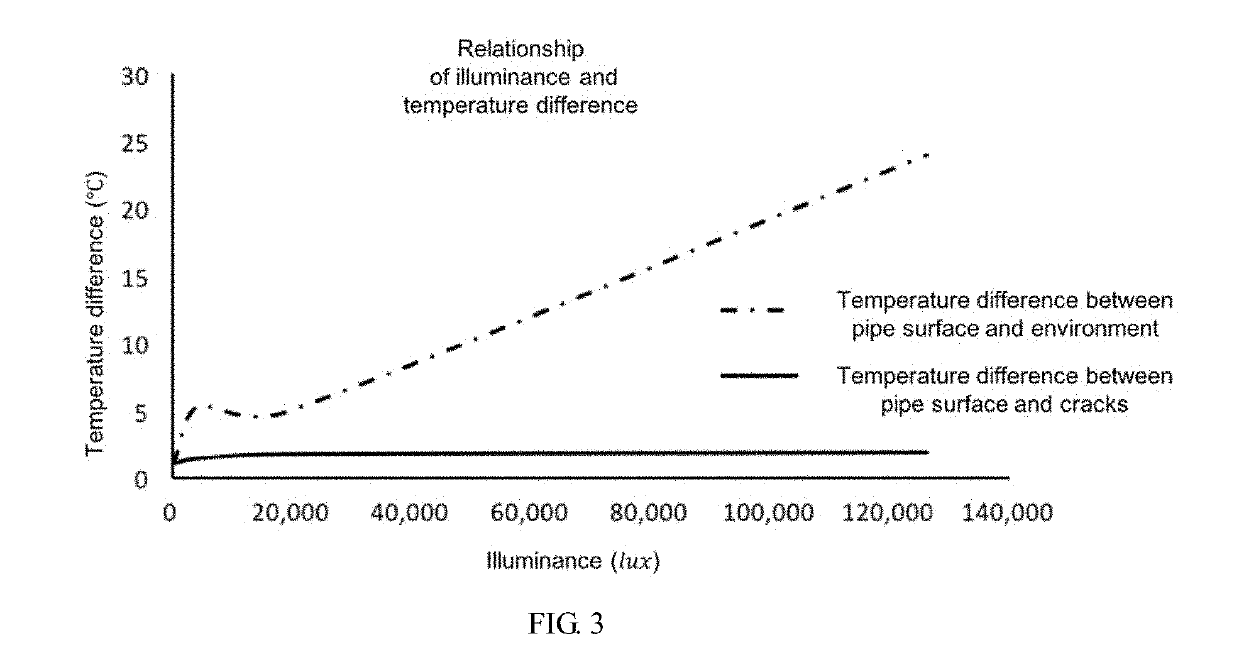

Method for leakage detection of underground pipeline corridor based on dynamic infrared thermal image processing

ActiveUS20190331301A1Little informationReduce contrastIn situ pavingsMaterial strength using tensile/compressive forcesEngineeringThermal image processing

Owner:DU YUCHUAN

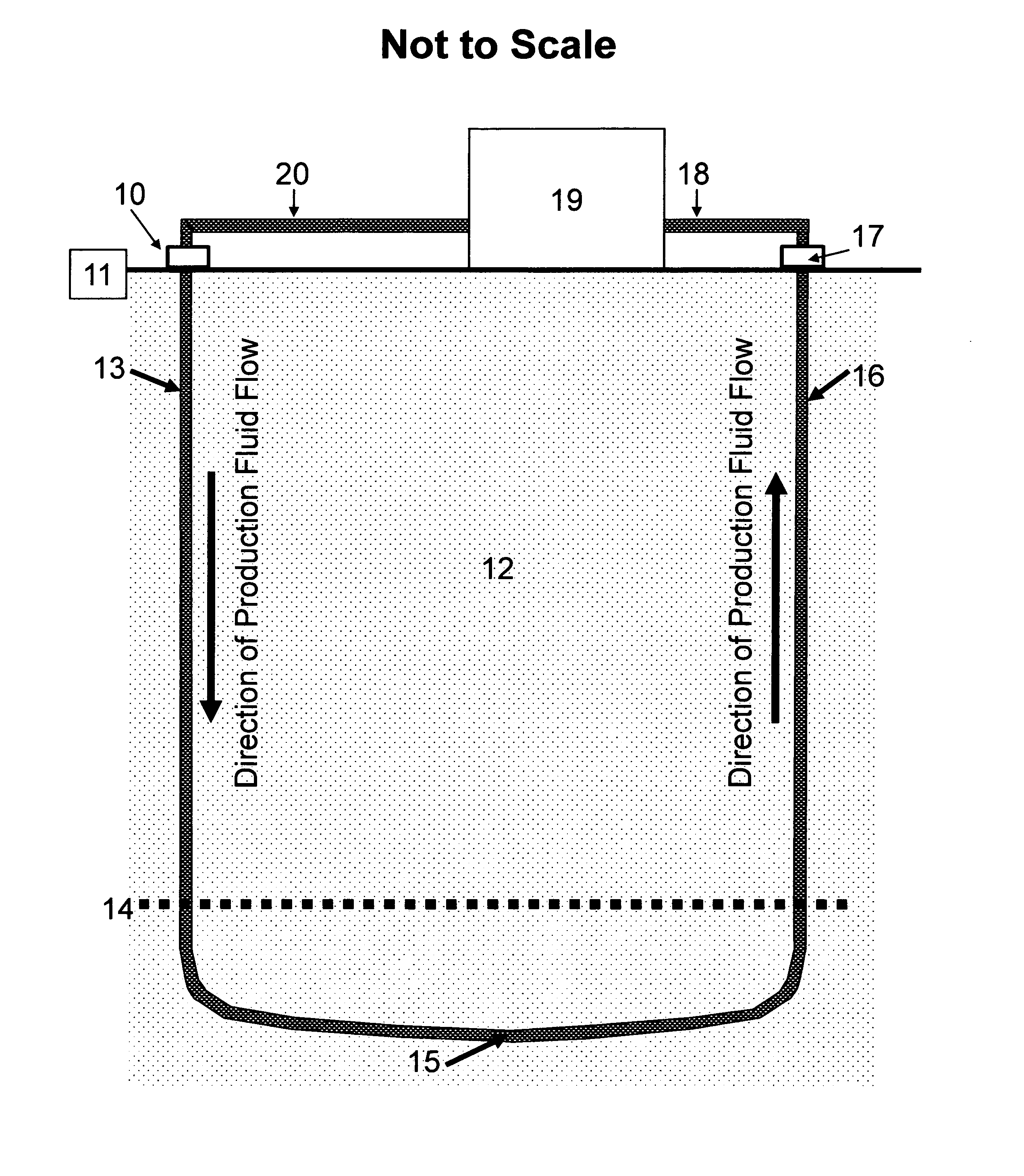

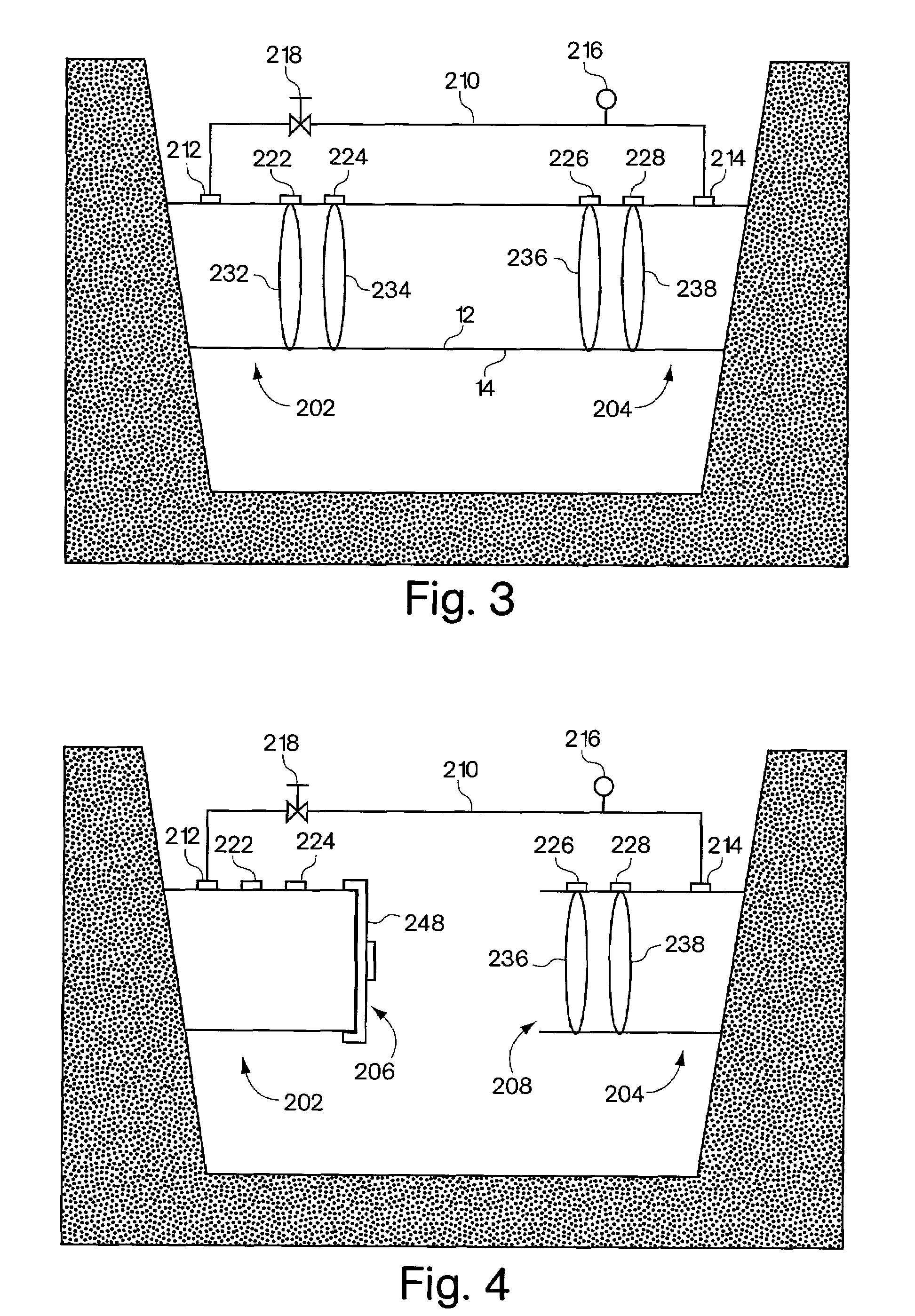

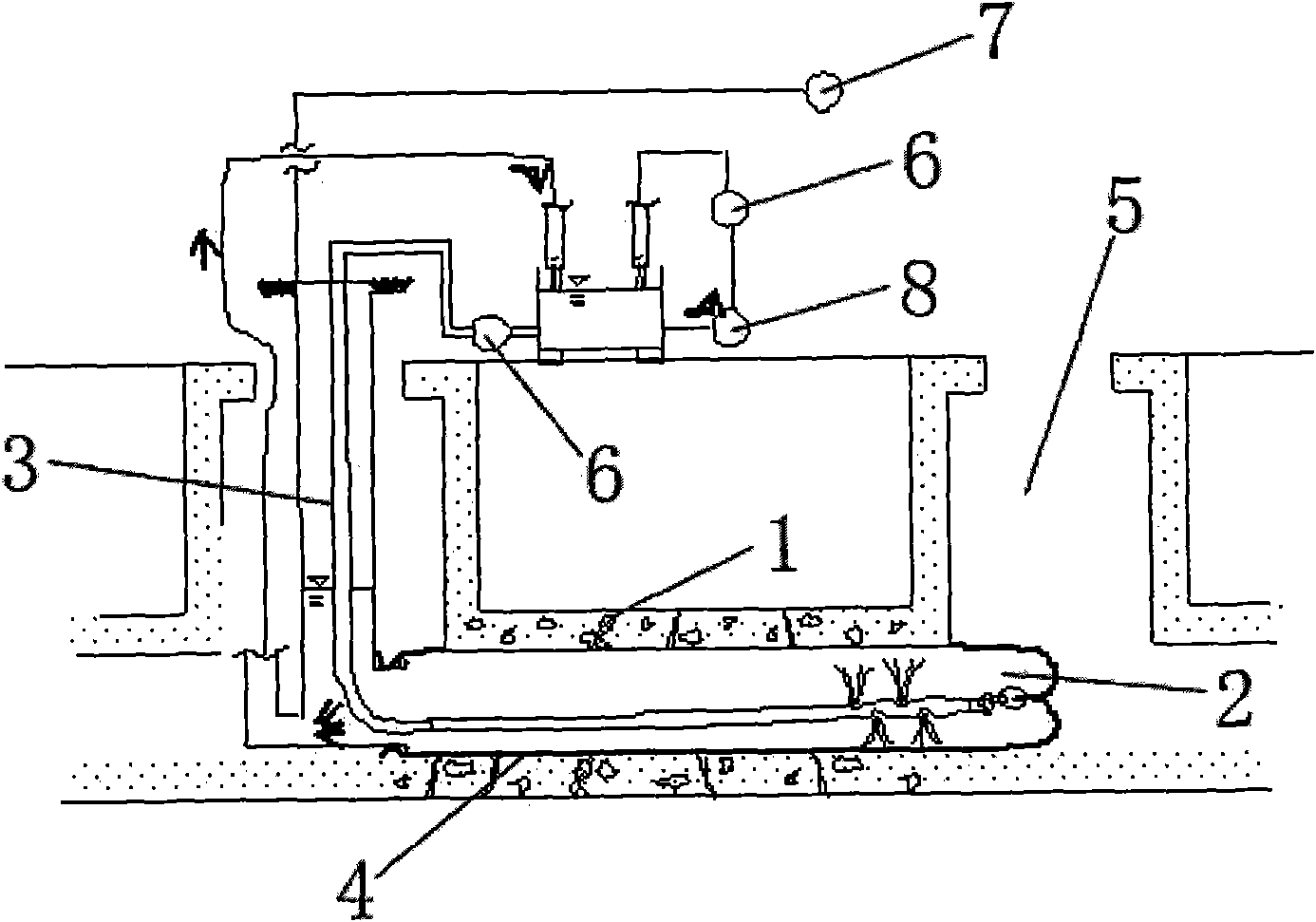

Loop geothermal system

InactiveUS20110048005A1Direct contact guaranteeRapidly and easily changeOther heat production devicesGeothermal energy generationInterstitial waterPorosity

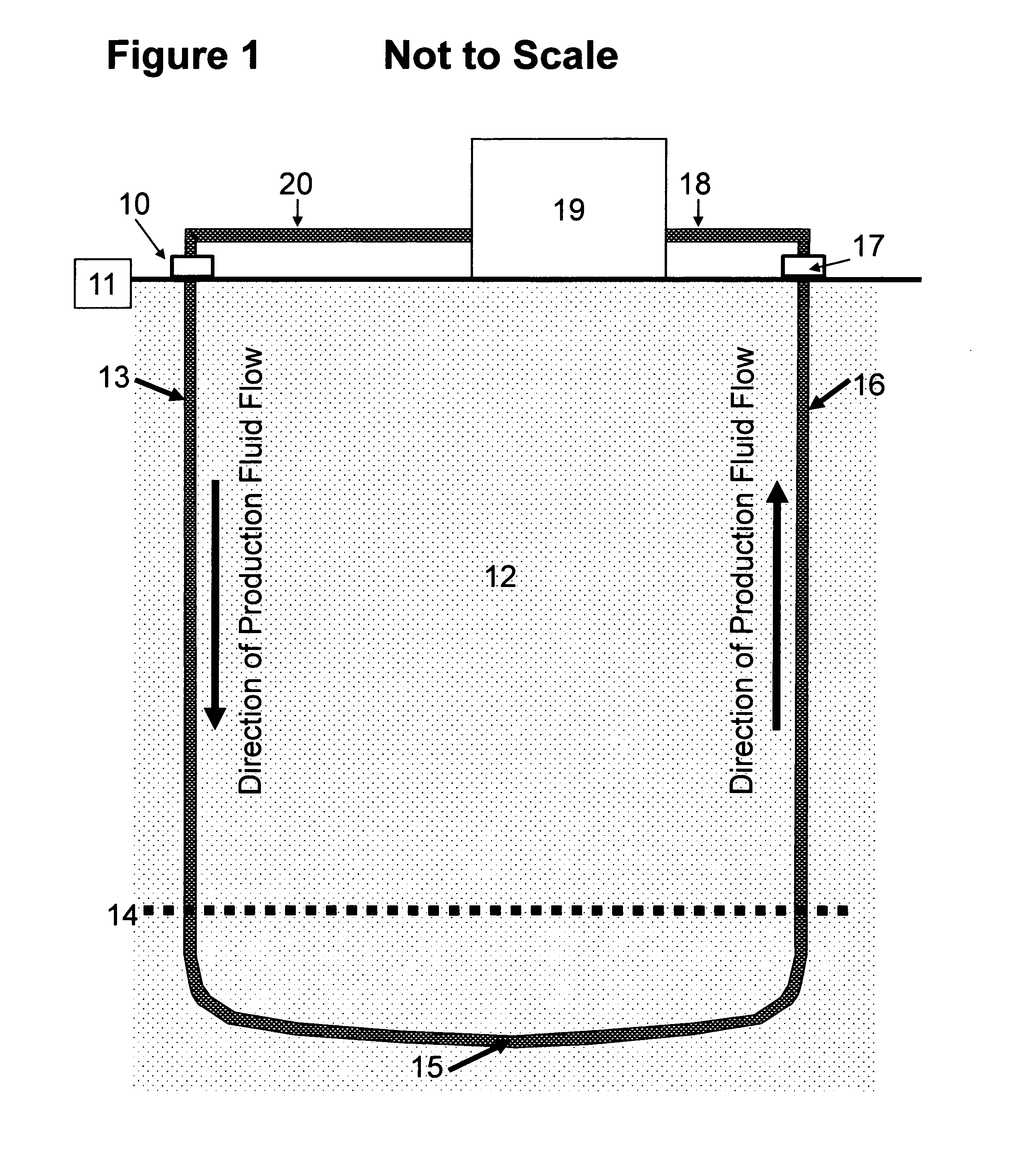

One embodiment of a system of geothermal energy production containing a production fluid circulated entirely within a continuous subterranean pipeline (13 and 16) while below the earth's surface (11) so that the production fluid is heated, via the encasing pipe, by surrounding subterranean hot rock (12). By directing the heated production fluid through said continuous subterranean pipeline up to the earth's surface and through a power plant (19), energy can be produced from the hot production fluid.This system enables energy production from subterranean rock formations of moderate temperature at moderate depths because any production fluid, such as water, hydrocarbon, or refrigerant, can be used to optimize energy production. Furthermore, natural porosity and permeability of the subterranean rock formations at moderate depths may provide sufficient natural circulation of interstitial water to assist in heat transfer from large volumes of hot rock without the need of inducing artificial fractures.

Owner:MCHARGUE TIMOTHY REED

Active-omni-directional-vision-based pipeline inside functional defect detection device and detection method

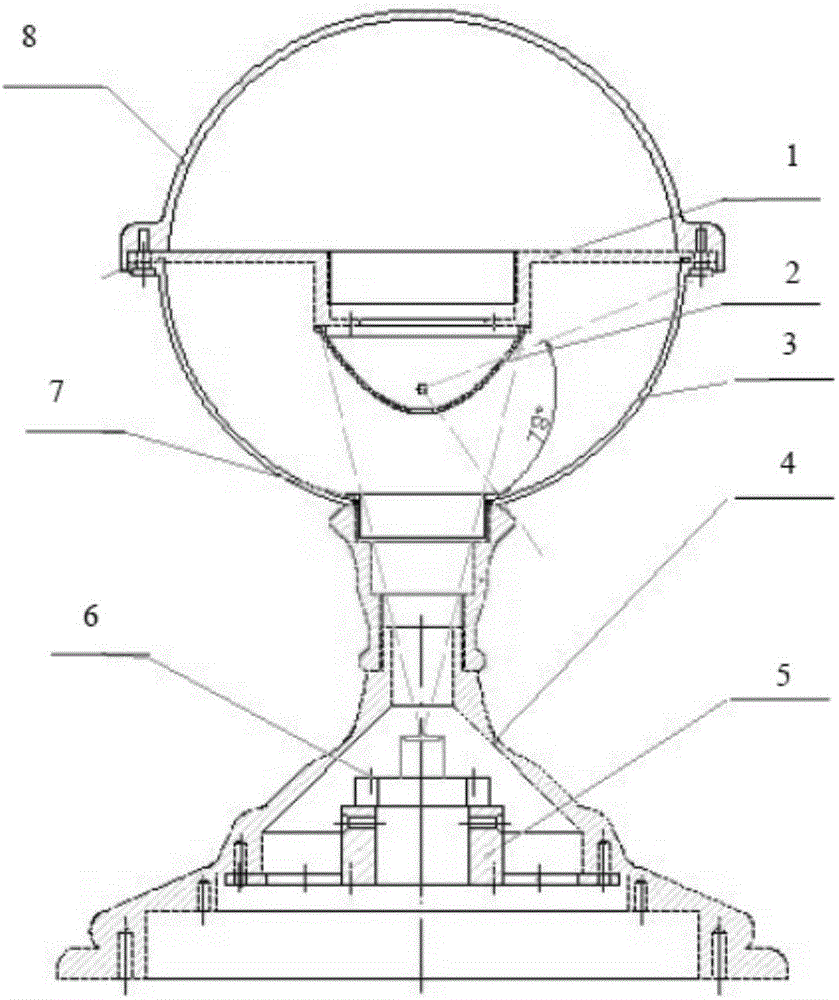

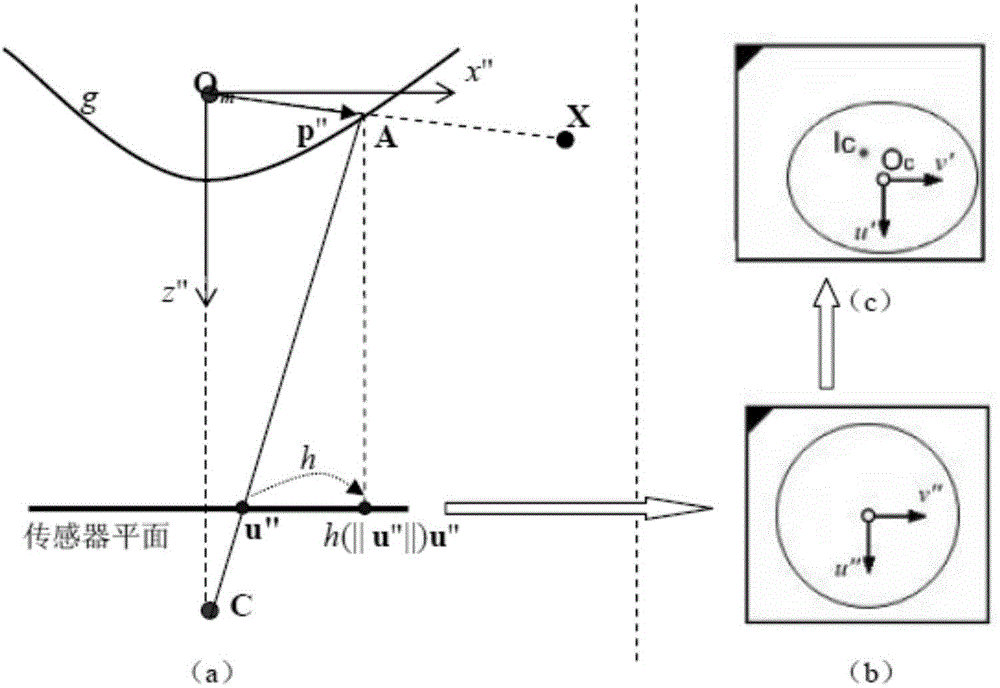

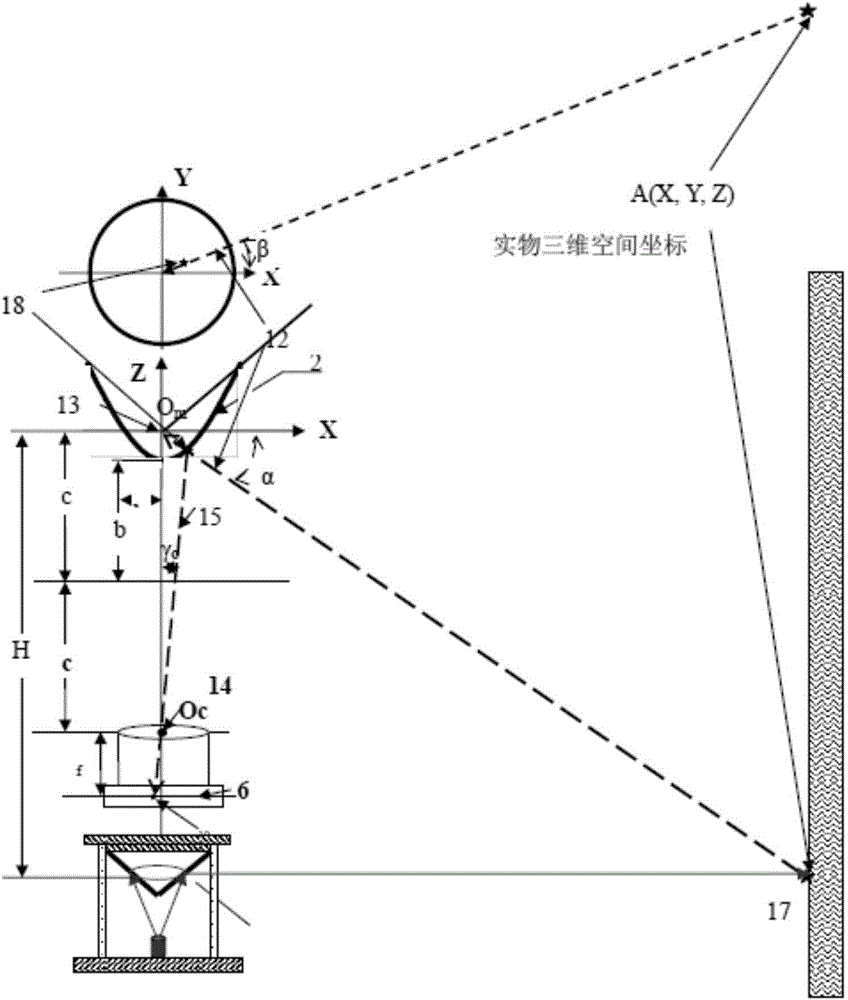

The invention discloses an active-omni-directional-vision-based pipeline inside functional defect detection device. The active-omni-directional-vision-based pipeline inside functional defect detection device comprises a camera shooting creeping system, a control cable and a detection analysis core operating system, wherein the detection analysis core operating system comprises a coordinated action control unit, a creeping system control unit, an image receiving unit, a functional defect and structural defect qualitative and quantitative analysis judgment module and a storage unit; and a pipeline inside omni-directional image and a laser scanning cross section slice image are subjected to machine vision processing analysis and the functional defect and the structural defect of the pipeline can be recognized. The invention also discloses an active-omni-directional-vision-based pipeline inside functional defect detection method. A brand new automatic pipeline health checking method is provided and can provide effective technical support for underground pipeline maintenance and completion acceptance.

Owner:ZHEJIANG UNIV OF TECH

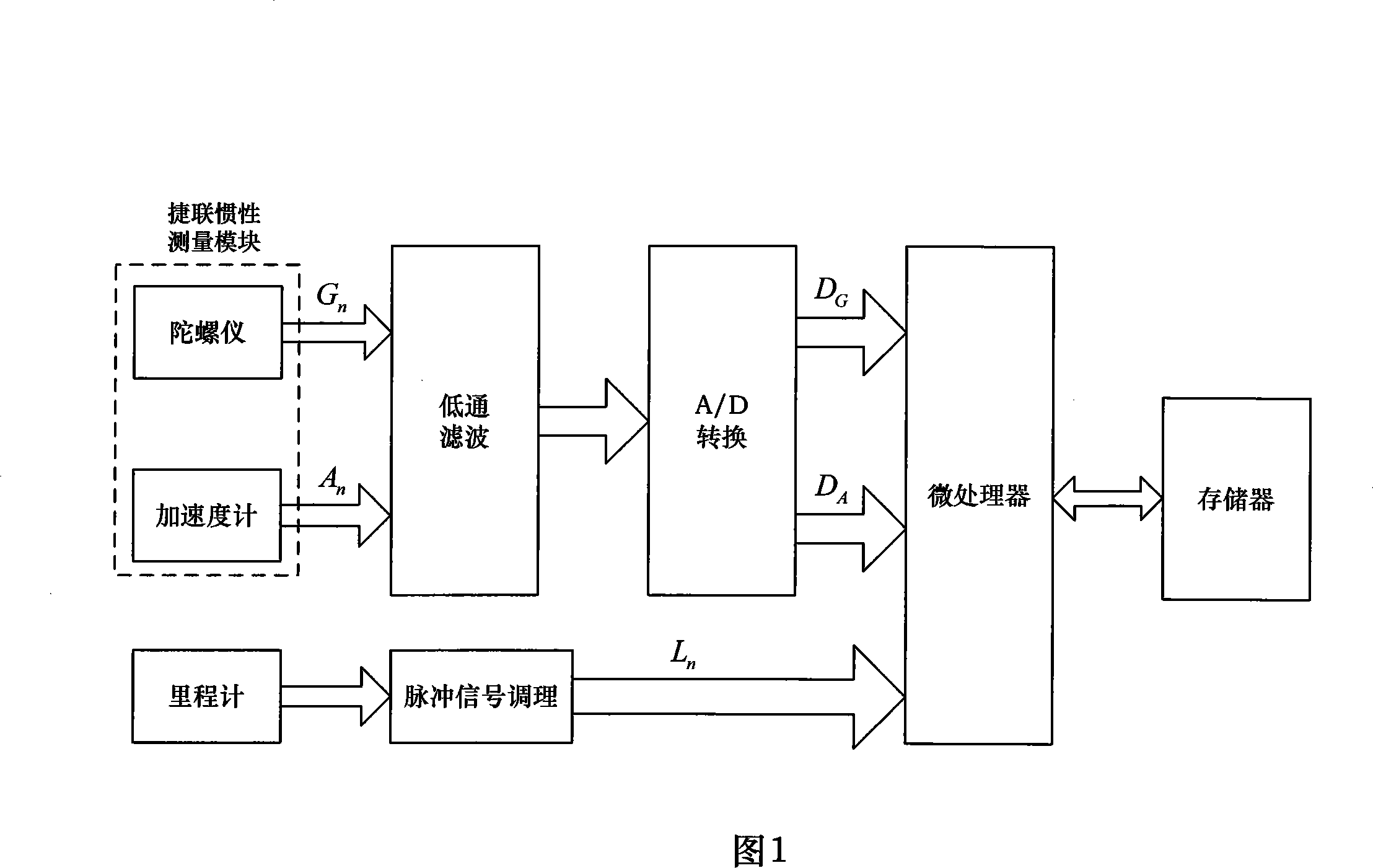

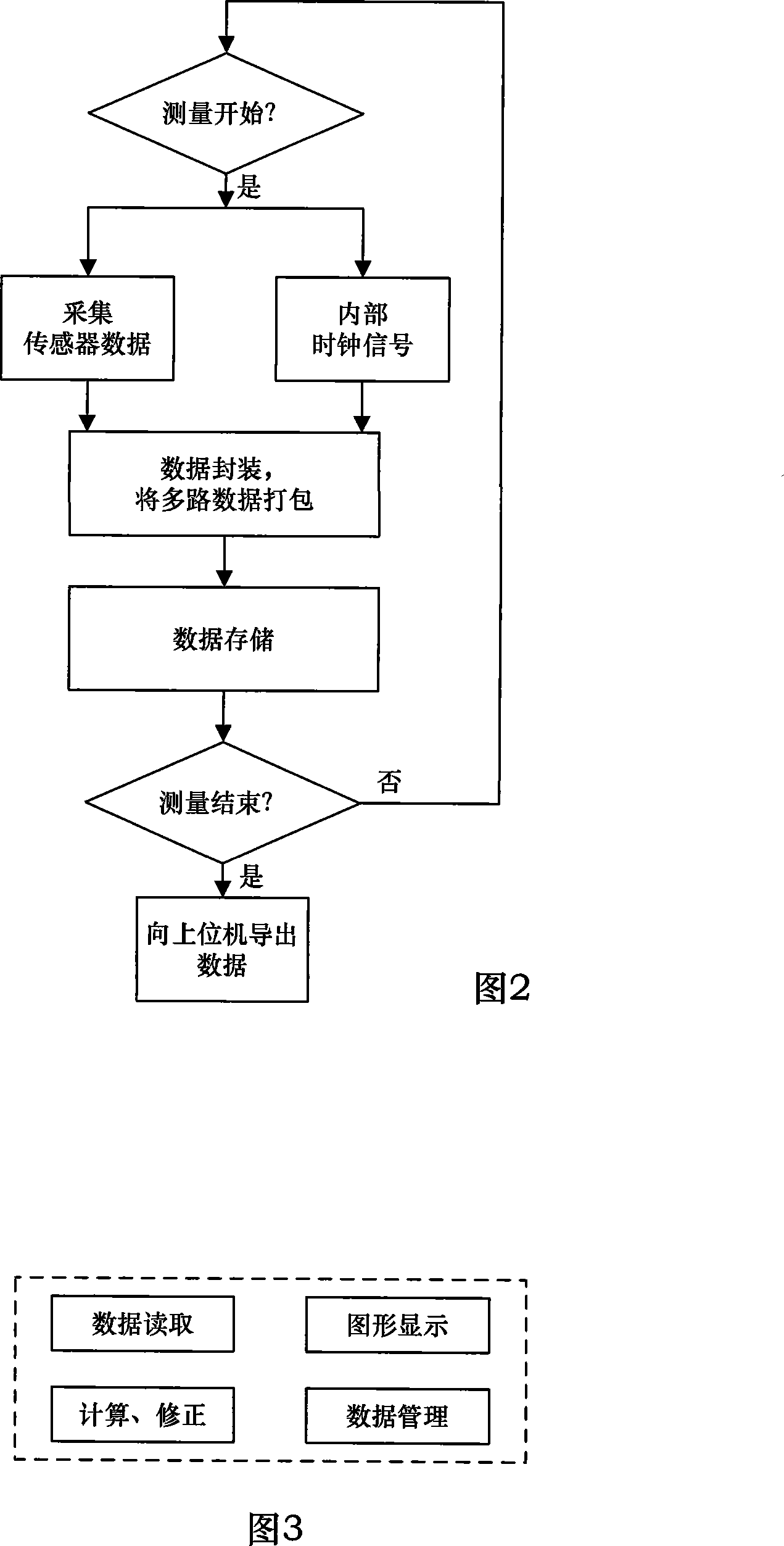

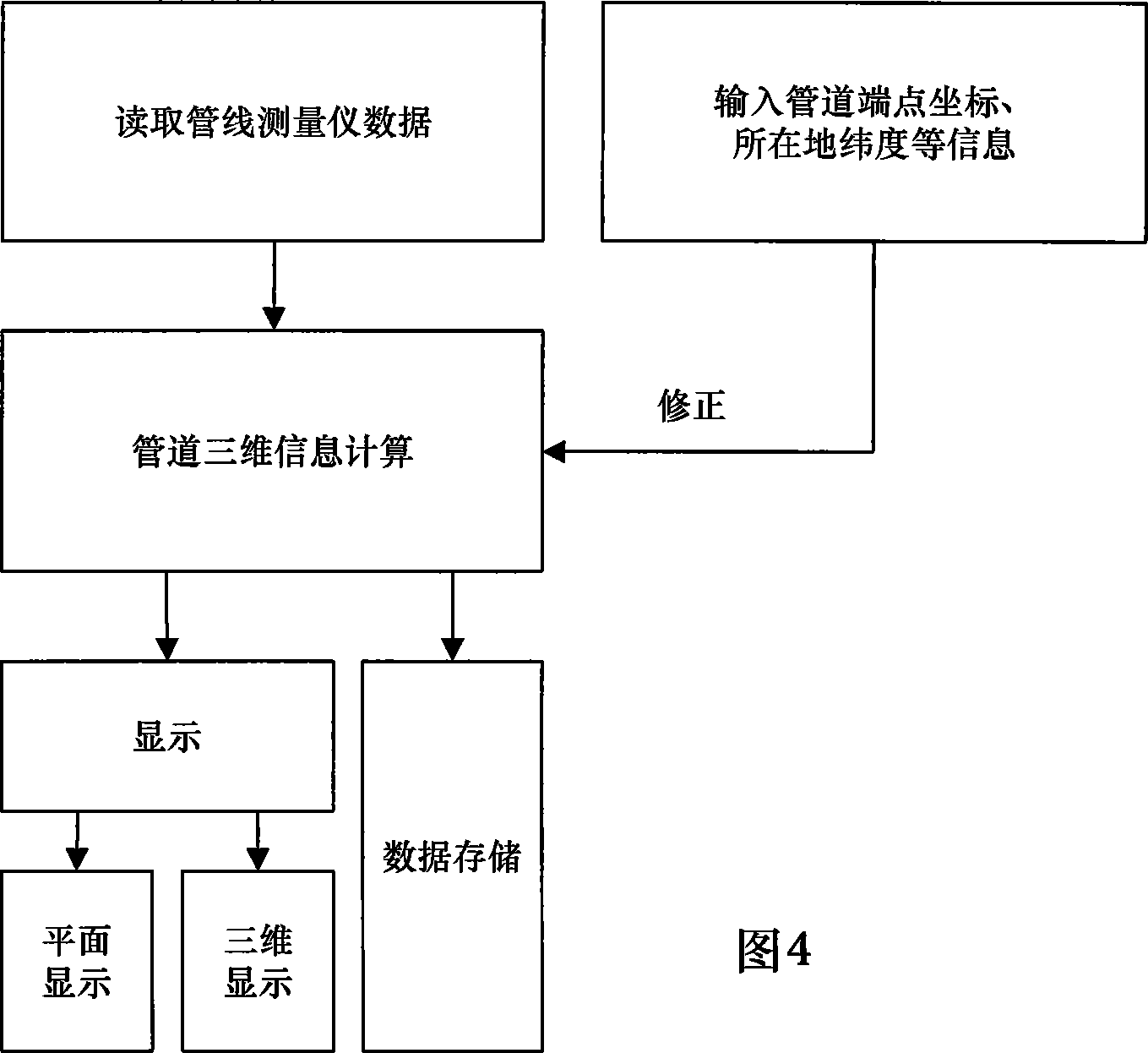

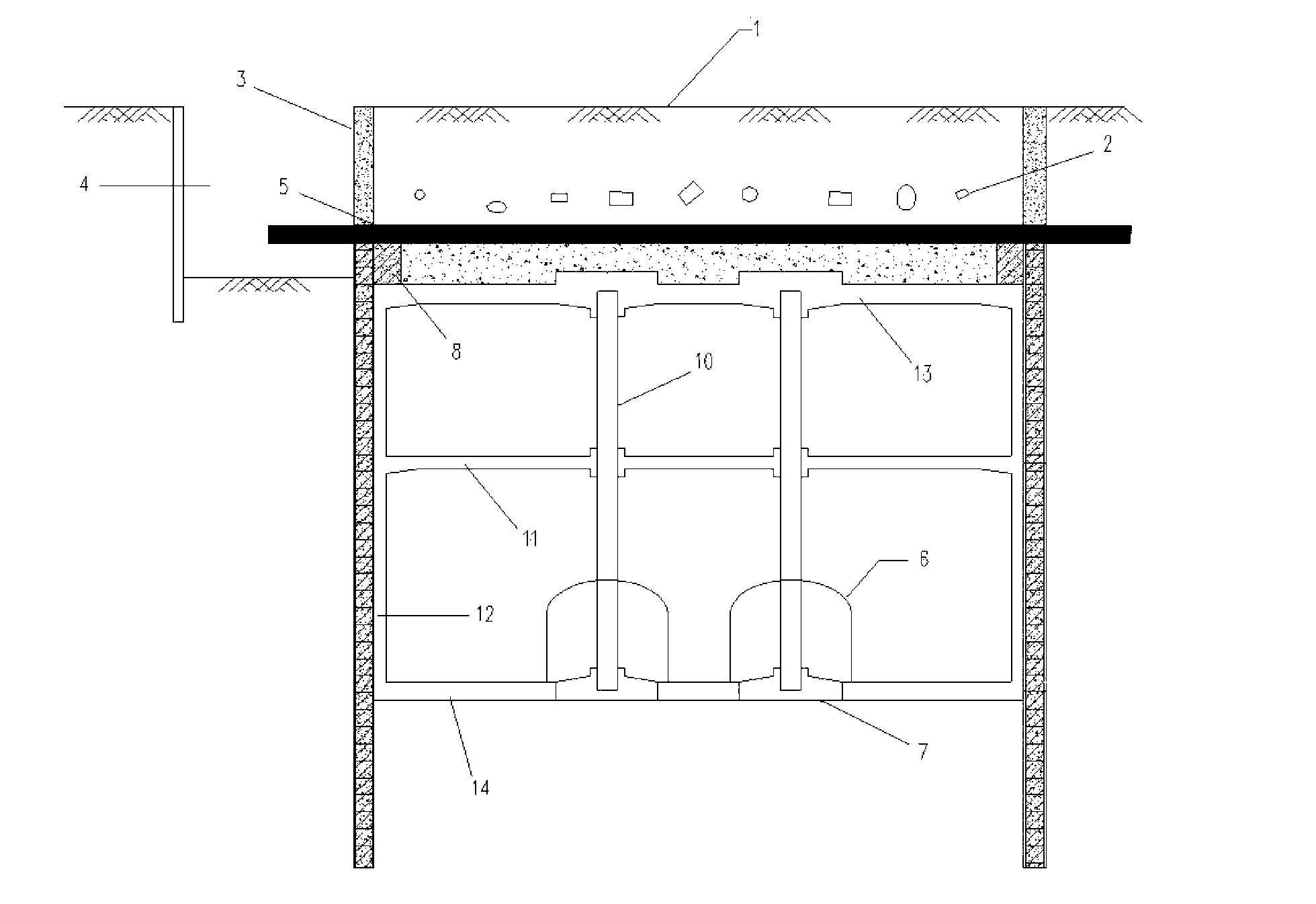

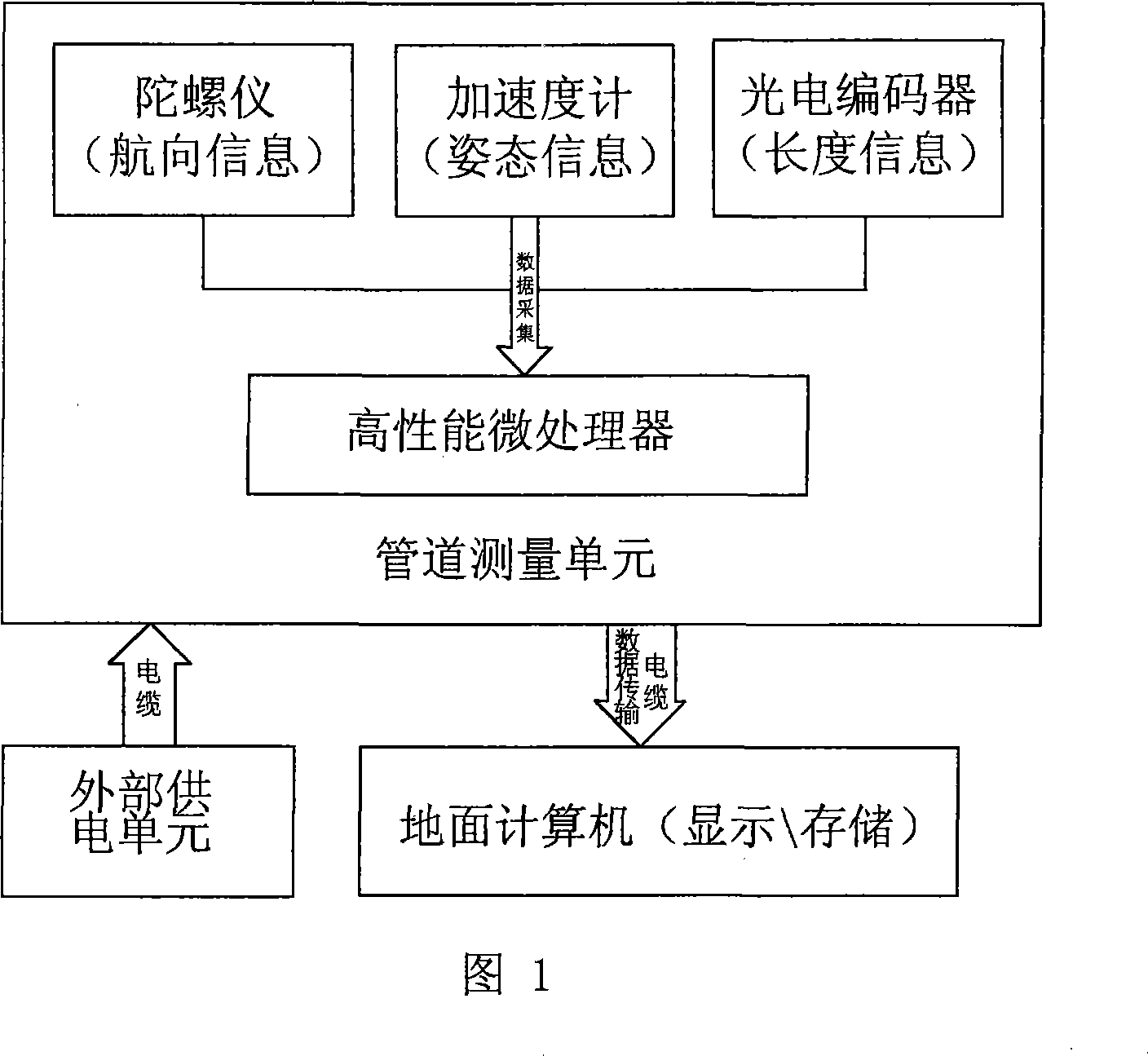

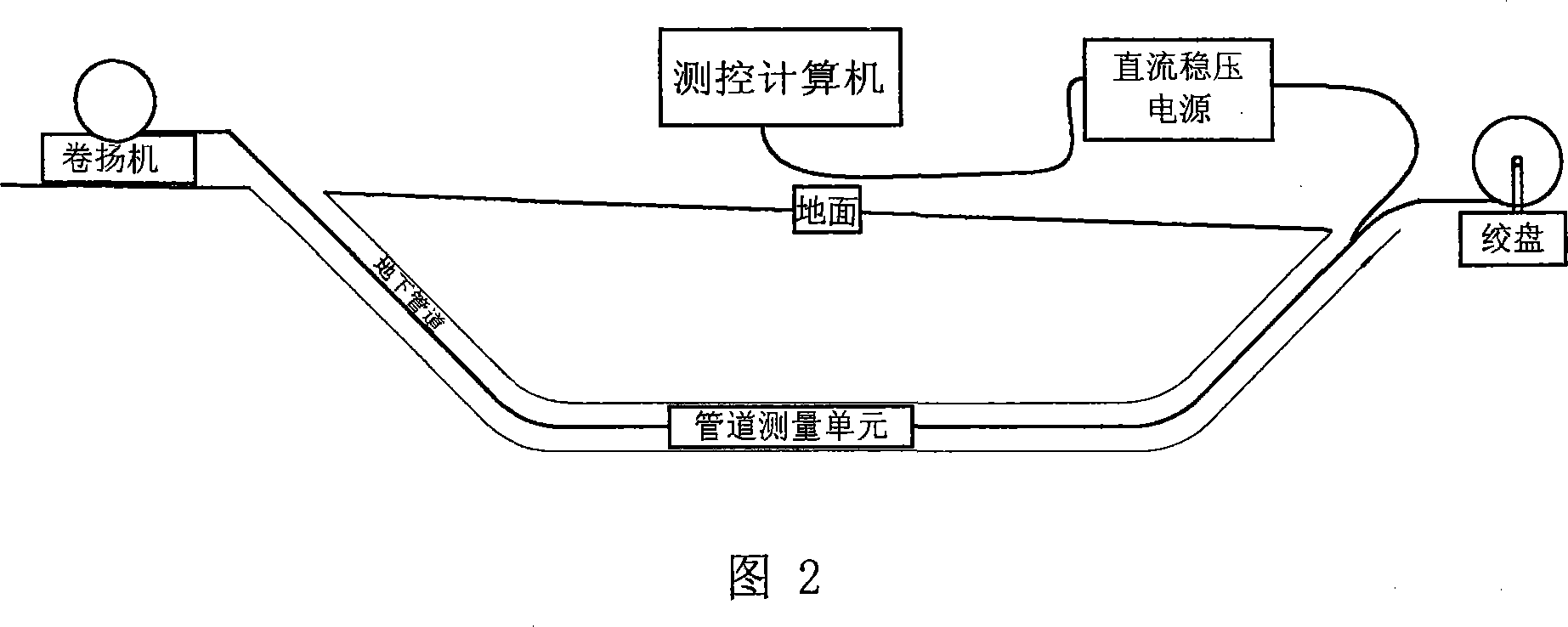

Full self-determination type underground pipeline measuring systems based on inertia technology

InactiveCN101118159ANot affectedBeacon systems using radio wavesNavigation by speed/acceleration measurementsGyroscopeLine tubing

The present invention discloses a full-autonomous underground pipeline measurement system based on an inertia technology, and the system consists of an in-pipe measurement unit, an external control unit, and a data information processing unit. The in-pipe measurement unit is arranged into a pipeline being measured and is caused to move along the central axle line of the pipeline, the three dimensional information of the pipeline can be completely gotten through measuring the moving track of the in-pipe measurement unit. The system adopts a strapped-down inertial navigation technology to measure the course heading and the attitude angle of the in-pipe measurement unit (carrier), the angular motion information of the carrier is measured according to the gyro output angle rate, each instant accurate location of the carrier can be analyzed according to the integrated angle and the displacement information, thereby the three dimensional information of the pipeline can be obtained. The operation of the in-pipe measurement unit is irrelevant to the external factor such as depth, location, peripheral electromagnetic field, etc., not limited by other conditions, the integrated course angle, the attitude angle, and the instant location information of a navigation principle are applied to any depth, and the three dimensional information of the pipeline waiting for measuring can be independently measured.

Owner:BEIHANG UNIV

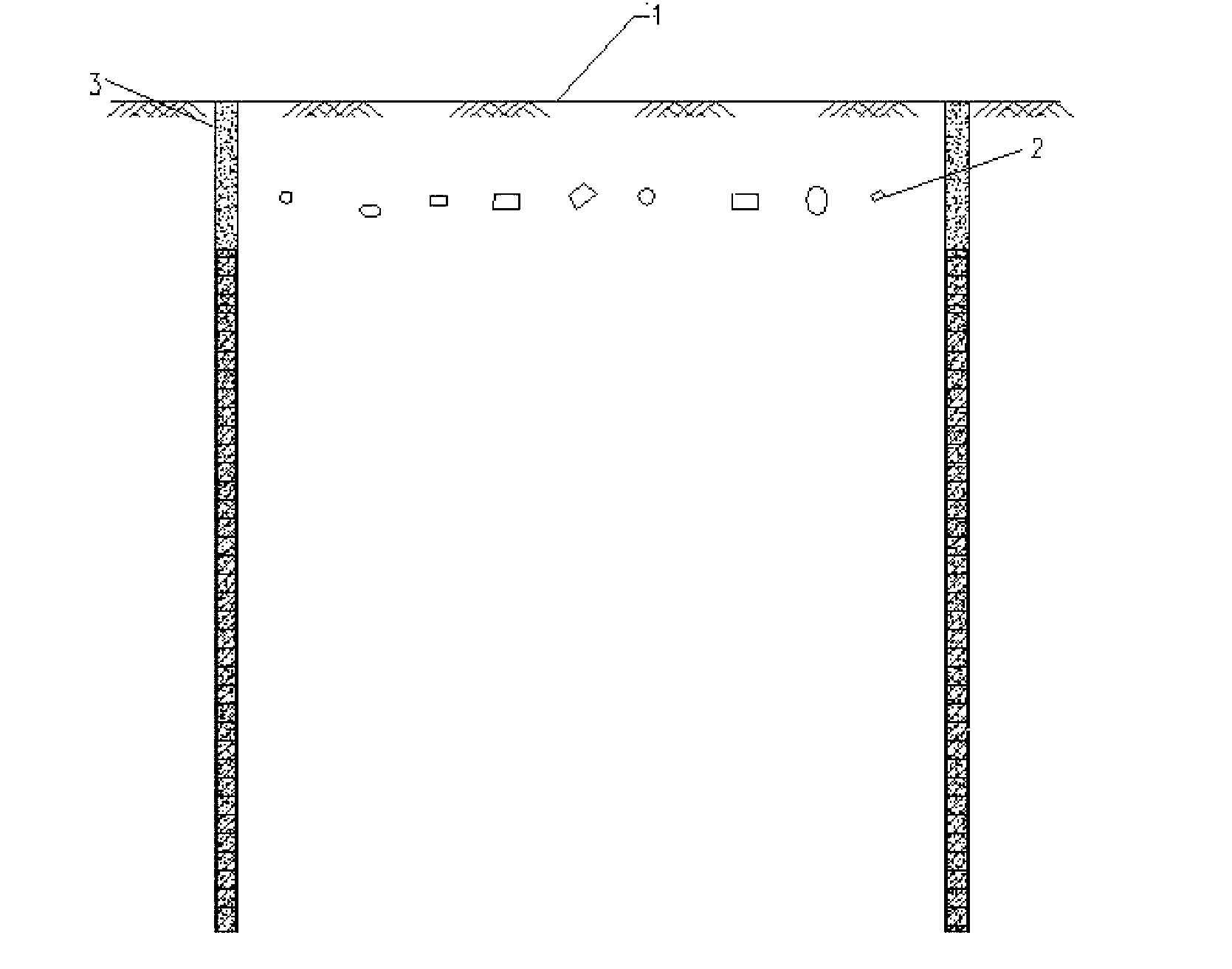

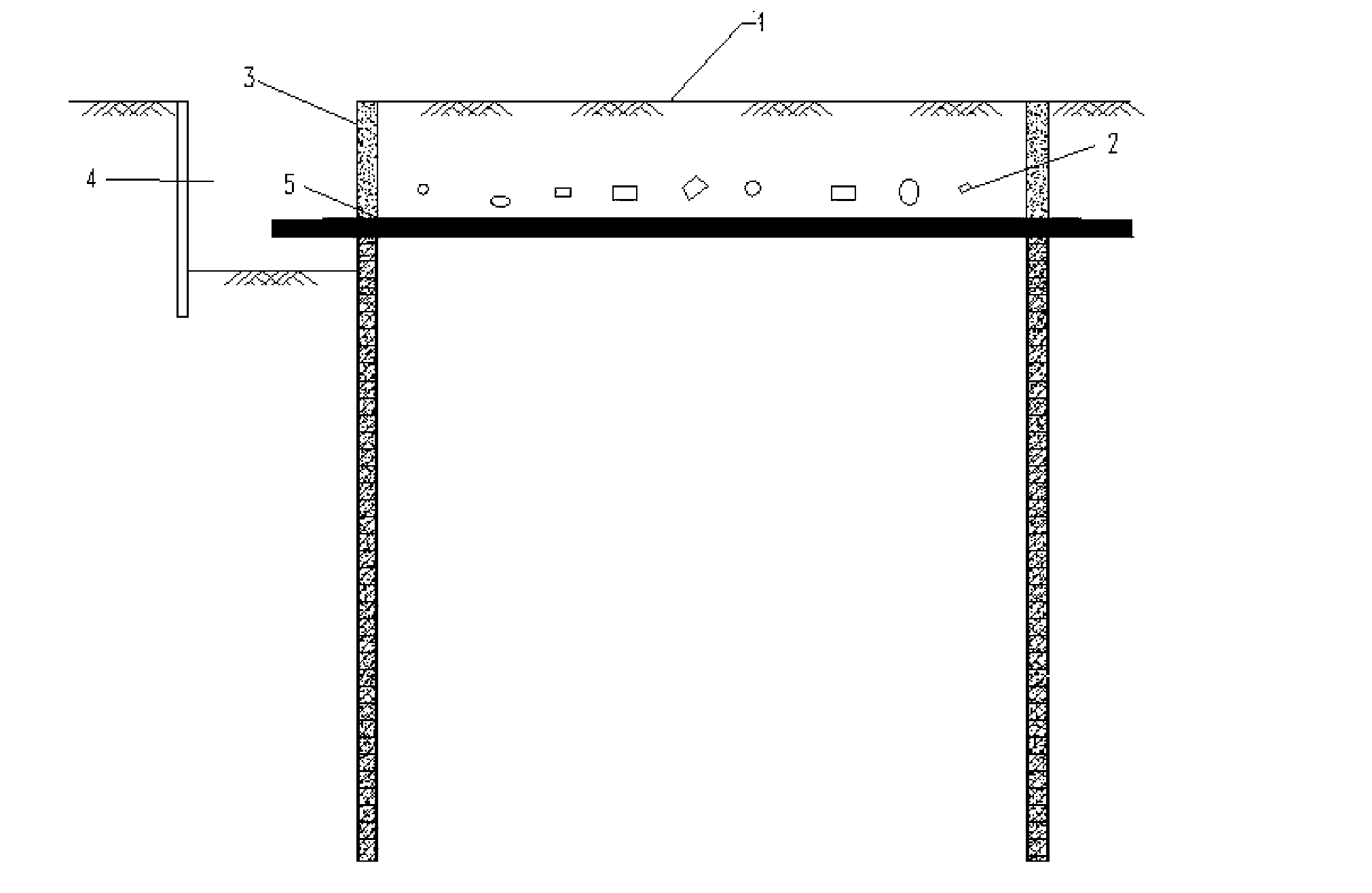

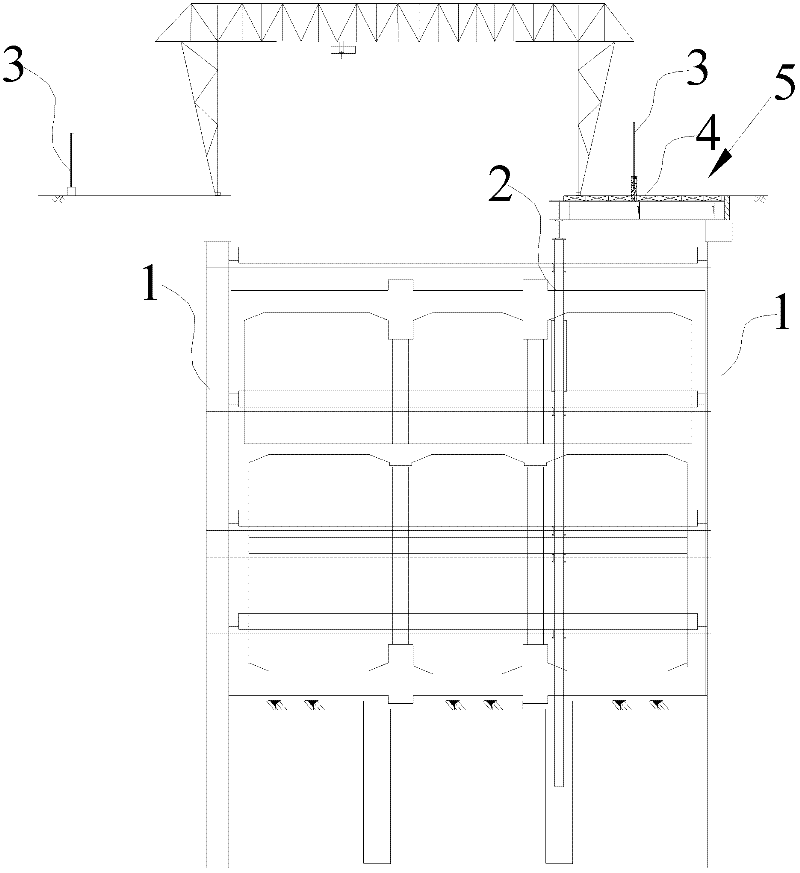

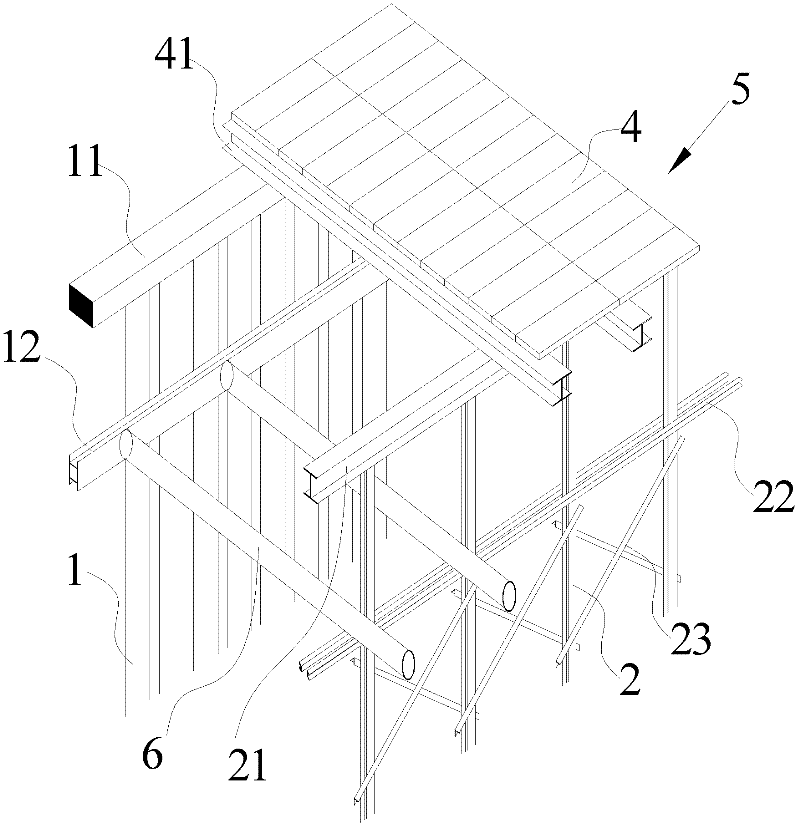

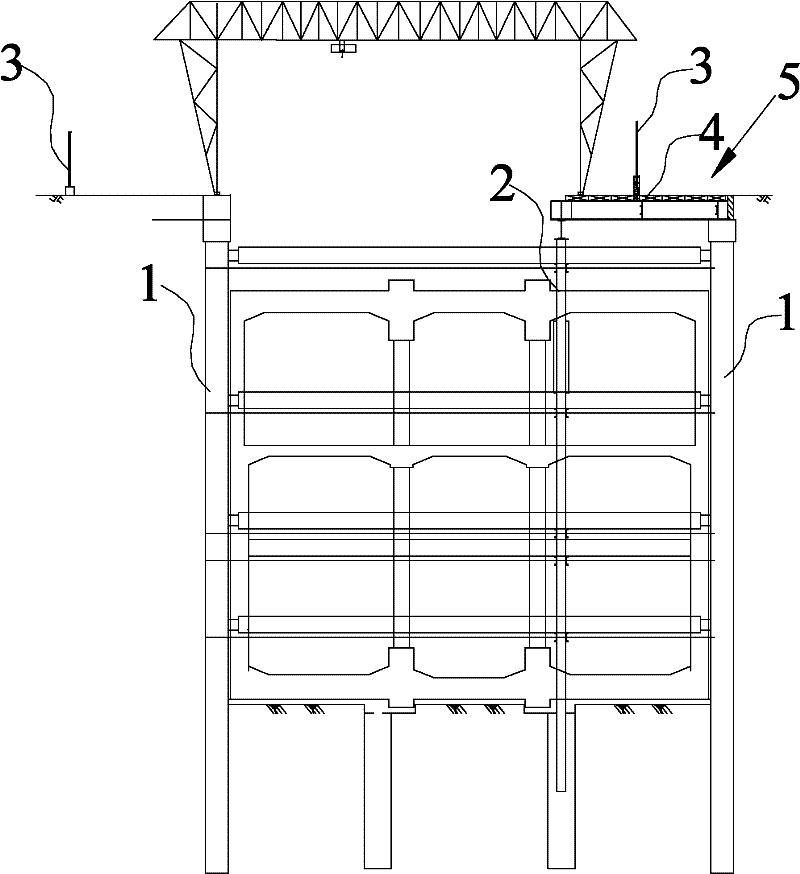

Shed-frame method for shallowly burying large-sized underground structure construction

InactiveCN102704957AGuaranteed lateral stabilityIncrease stiffnessUnderground chambersSupporting systemRoad surface

The invention relates to a shed-frame method for shallowly burying a large-sized underground structure construction. A construction principle is as follows: an envelope enclosure is adopted for retaining soil and water and resisting lateral deformation; a large-diameter pipe shed is arranged to bear the load of road surfaces and stratums and protecting underground pipelines; strip foundation construction of a center pillar in a main structure is carried out in a small pilot tunnel which is excavated with a subsurface excavation method; and under the protection of a top pipe shed frame, main structure construction is carried out with a cover-and-excavation half-top-town half-bottom-up method, and the center pillar, side walls, a center plate and a top plate which are pre-constructed well are utilized for providing vertical and horizontal support systems in an excavation space. The invention aims at providing a new method for shallowly burying the large-sized underground structure construction under an urban road; and the method is reasonable and feasible in technique and strong in operability, the quality of the main structure is guaranteed easily, construction is safe and rapid, the influences on ground transportation and the dismantlement and change to underground pipelines are reduced, and the comprehensive benefits are remarkable, therefore the shed-frame method has an important engineering application value and development prospect.

Owner:BEIJING UNIV OF TECH

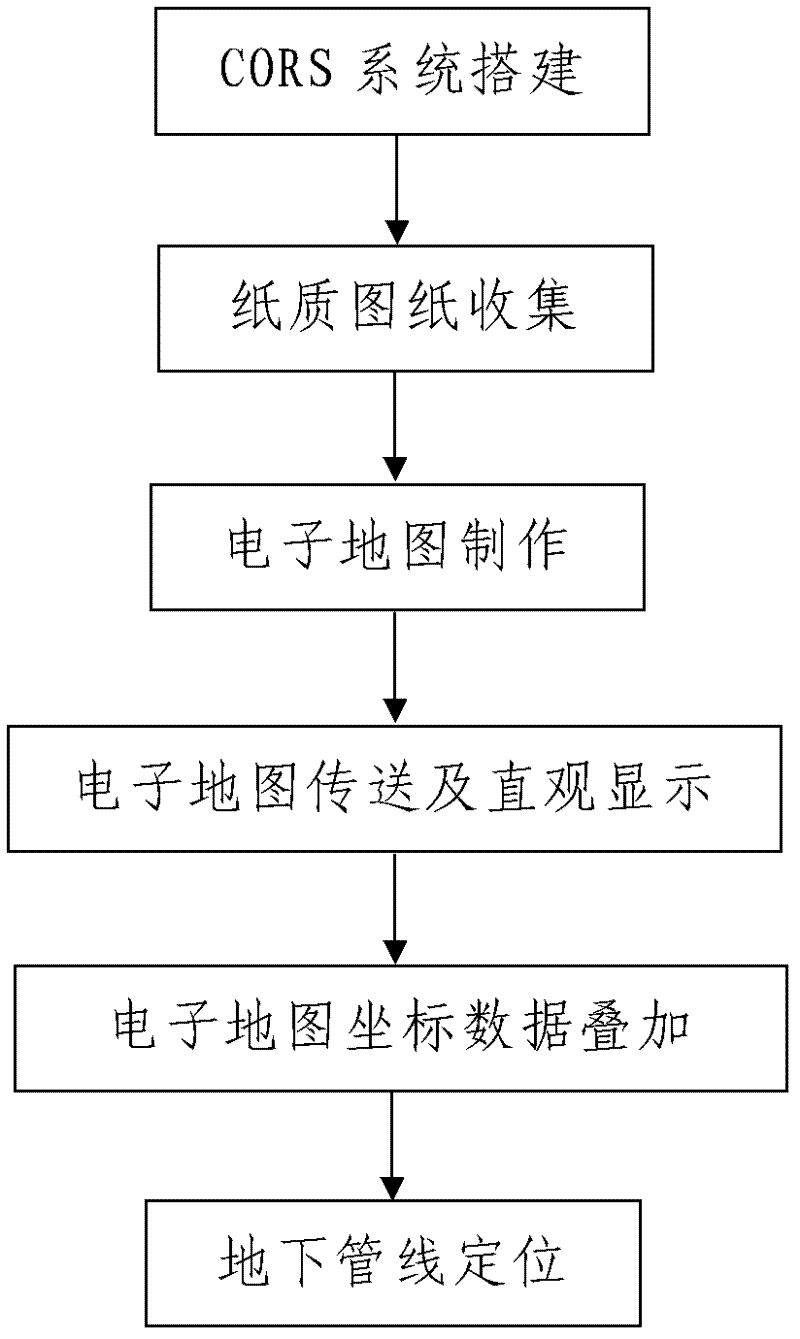

Underground pipeline positioning method based on CORS (continuous operational reference system)

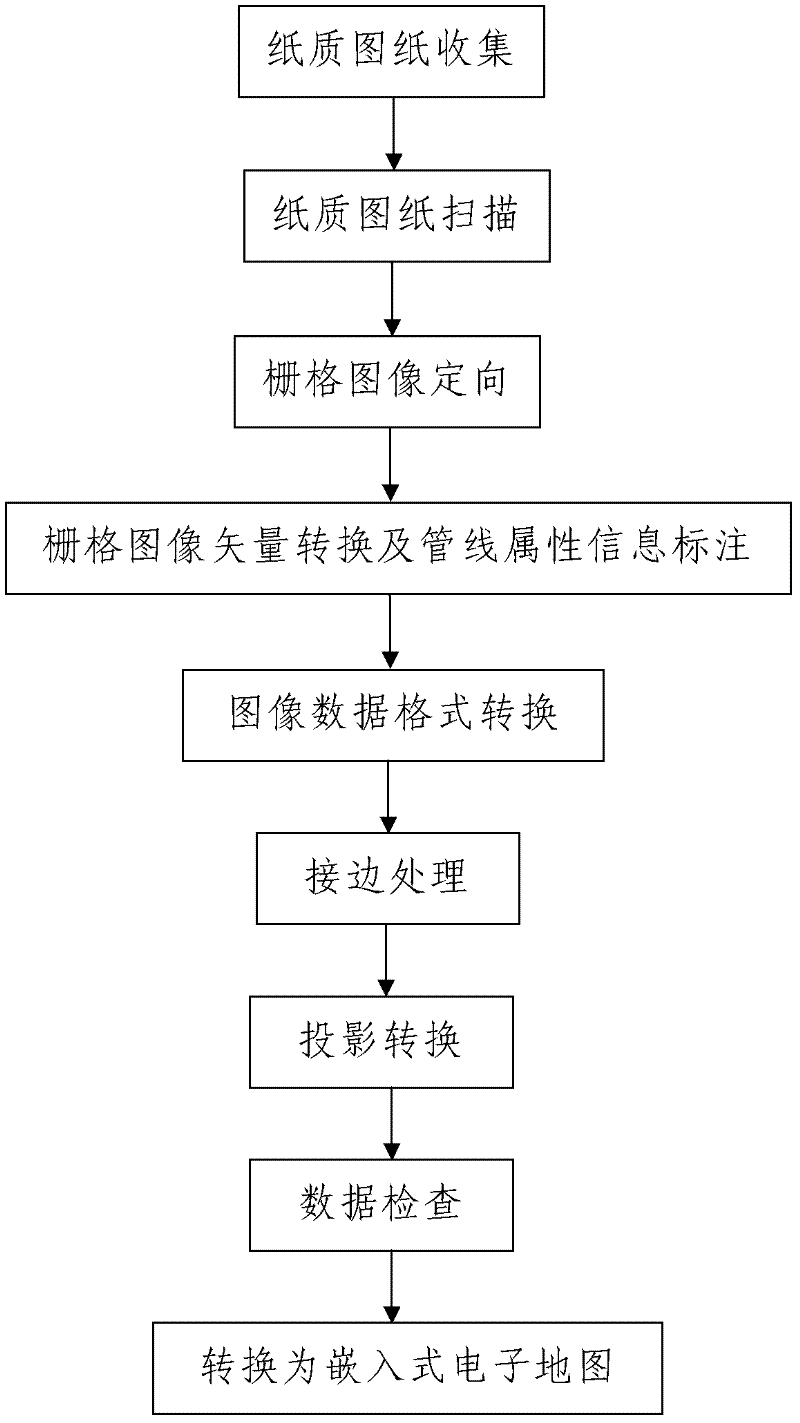

InactiveCN102509509ANavigation Accurately ImplementedPrecise positioningMaps/plans/chartsSatellite radio beaconingImage transferEngineering

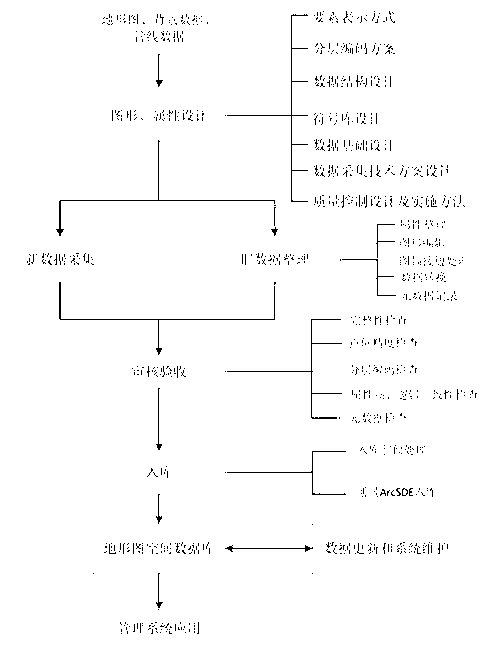

The invention discloses an underground pipeline positioning method based on a CORS (continuous operational reference system). The method comprises the following steps of: I, establishing a CORS; II, collecting paper drawings: collecting the pipeline as-built drawings of all underground pipelines paved in an area to be positioned and the topographical map around each underground pipeline respectively; III, making an electronic map, wherein the making process comprises the steps of paper map electronization treatment, drawing scanning and pretreatment, raster image transfer, raster image orientation, image sector conversion, pipeline attribution information marking, edge matching treatment, projection conversion, data check, conversion into an embedded electronic map and the like; IV, transferring and visually displaying the electronic map; V, superposing the coordinate data of the electronic map; and VI, positioning the underground pipelines. The method disclosed by the invention is easy and convenient to use and operate, has a good using effect and high practical value, and can really realize accurate positioning of the underground pipelines and effectively solve the problems of inconvenience in positioning operation, relatively bad positioning effect and the like of the existing underground pipeline positioning method.

Owner:XIAN MEIHANG INFORMATION IND

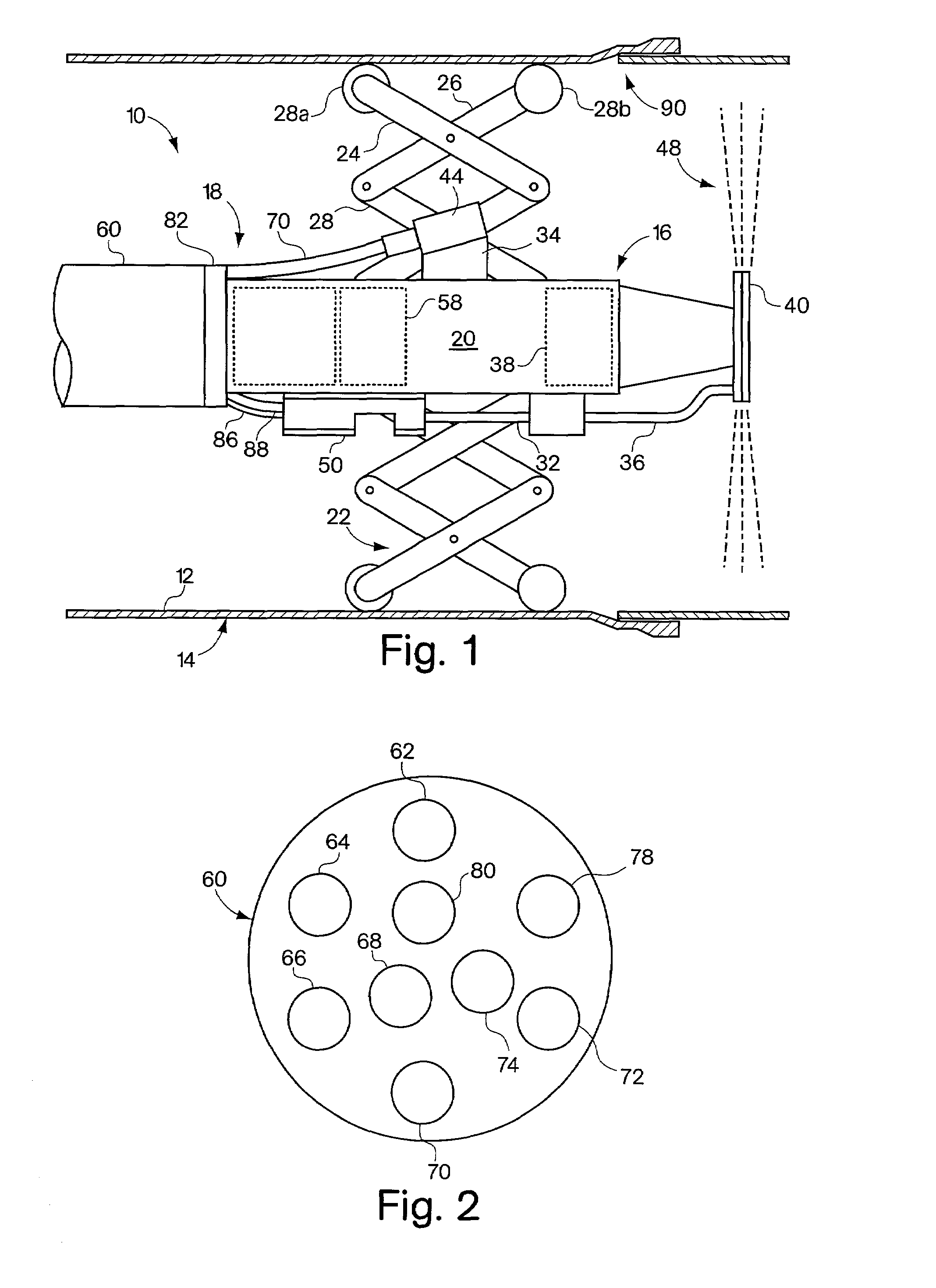

Method and apparatus for treating underground pipeline

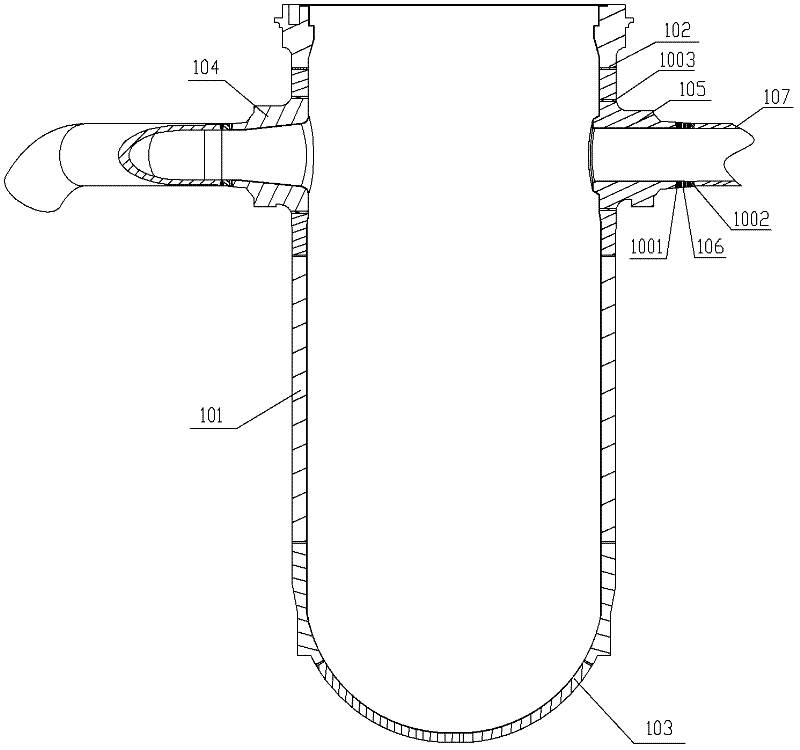

InactiveUS6966950B2Operational securityConvenient lengthSpraying apparatusLiquid/solution decomposition chemical coatingFilling materialsUnderground pipeline

A system for internally filling a joint or other discontinuity in a pipeline. The system includes a flexible conduit, a fill device removably connected to said flexible conduit, wherein the fill device is constructed and arranged to apply a fill material to an interior surface of said pipeline to fill one or more gaps in the pipeline, and a propulsion unit connected to at least one of the flexible conduit and the fill device that propels the flexible conduit through said pipeline.

Owner:NEUCO INC

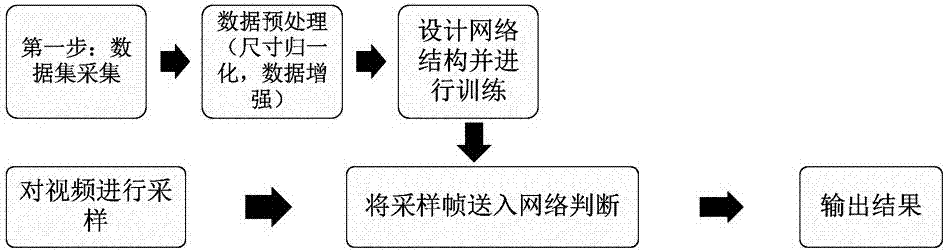

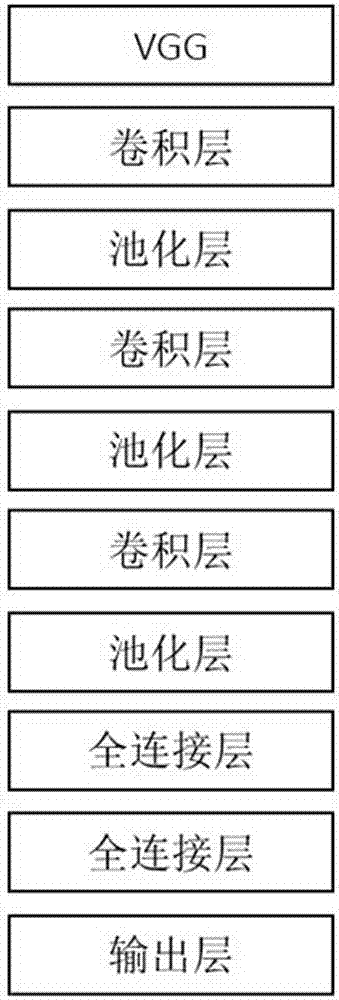

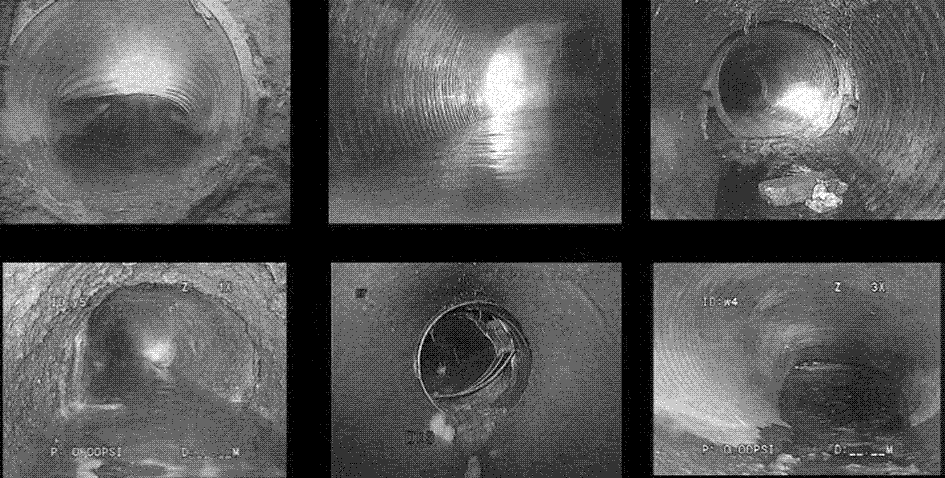

Deep learning based automatic defect identification method for underground pipeline

InactiveCN107886133AIncrease profitRealization of automatic classification and recognitionImage enhancementImage analysisNetwork ConvergenceAlgorithm

The invention discloses a deep learning based automatic defect identification method for an underground pipeline. Positive and negative sample sets, of the underground pipeline, needed by training ofconvolutional neural network (CNN) are prepared; the sample sets are preprocessed, and modified, in a batch manner, to the uniform size of 300*300, data improvement is carried out, and sample data fortraining is generated; a structure of the CNN is designed, training is carried out, and a weight connection matrix W during network convergence is obtained and used for a detection process later; aimed at video data, first and last 10 frames of a video are eliminated, a defect target frame is selected roughly, and key frames are sampled from the video every 10ms; each sampling frame of the videois input into the CNN, and whether there is a defect is determined; and according to a result of each frame in the last step, whether the video includes defects is concluded. According to the method,the utilization rate of data is improved, characteristics of a defect pipeline image are learned automatically via the convolutional network, and automatic identification for the defect pipeline is realized.

Owner:南京市测绘勘察研究院股份有限公司

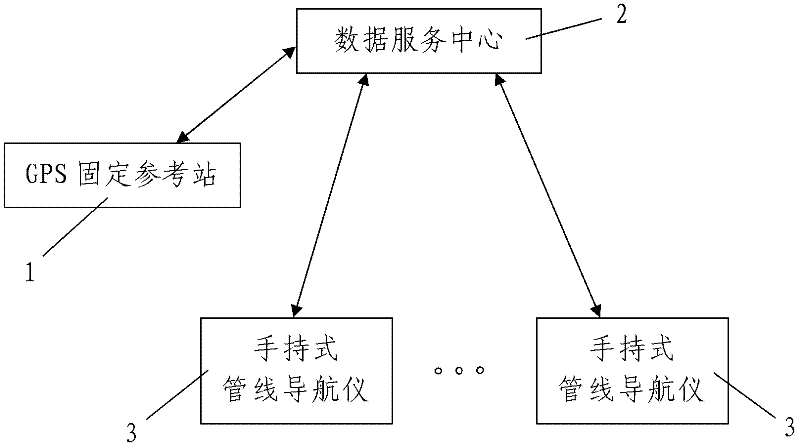

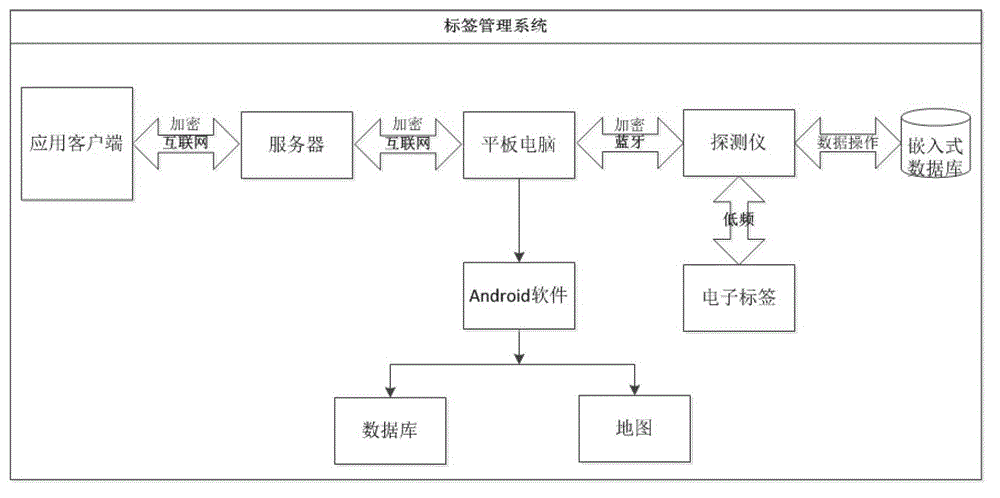

Underground pipeline locating method and device

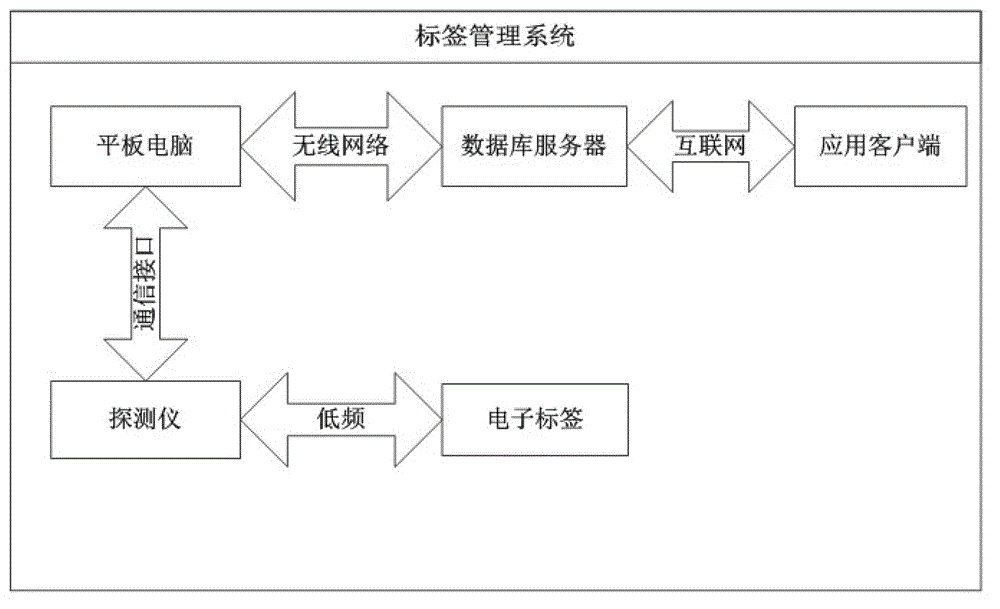

ActiveCN103064123AImprove work efficiencyGet accurate routing in timeDetection using electromagnetic wavesLongitudeHand held

The invention relates to a locating technology, and aims at providing an underground pipeline locating method and a device. The underground pipeline locating method comprises: setting a burial position of an electronic tag firstly; and then obtaining longitude and latitude coordinates of the electronic tag through a detector and transmitting the longitude and latitude coordinates of the electronic tag to a background computer management system to set up electronic tag information, and forming a pipeline geographic information system (GIS) on an electronic map of the background computer management system along with engineering information; during pipeline maintenance and locating in later period, firstly using global position system (GPS) to locate roughly according to the longitude and latitude coordinates of the electronic tag in the GIS, and then using the detector to locate accurately and amending burial depth. The underground pipeline locating method and the device are capable of intuitively and accurately displaying information of a geographic position of the underground pipeline, pipeline trend, pipeline key point information and pipeline ambient condition and the like through a hand-held terminal and a GIS map, and therefore working efficiency is greatly improved.

Owner:宁波华测电子科技有限公司

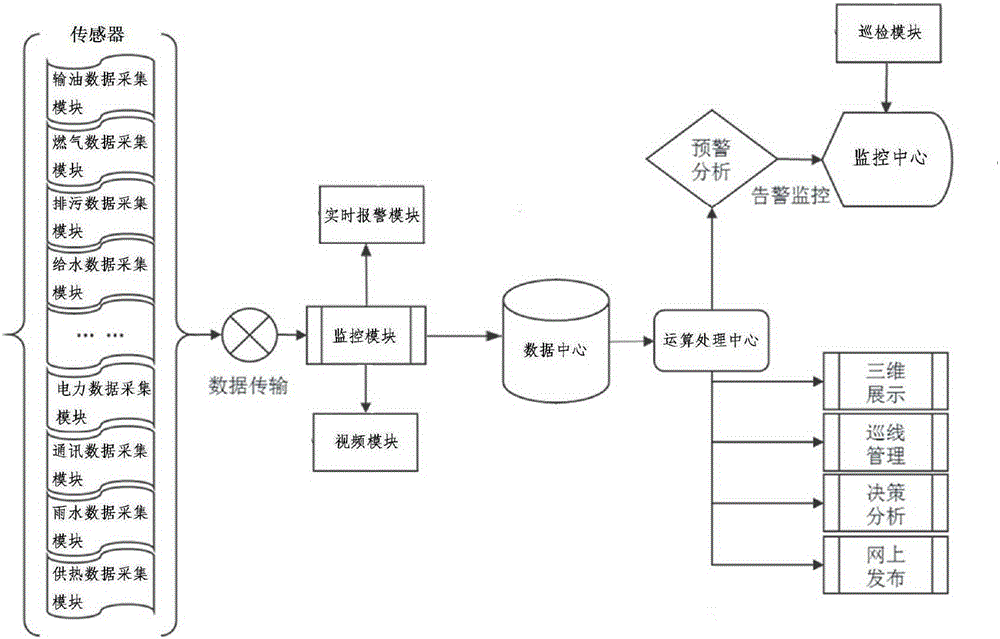

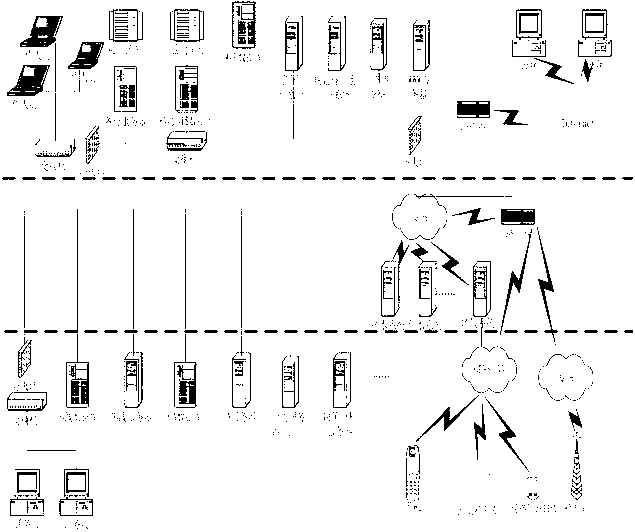

Comprehensive information management system for smart city pipeline network

InactiveCN105225069AEnsure safetyReduce breakage accidentsResourcesTransmissionData centerUnderground space

The invention discloses a comprehensive information management system for a smart city pipeline network. A monitoring module is in communication connection with a data center; an inspection module is in communication connection with a monitoring center; the data center is also connected to an operation processing center; the operation processing center carries out processing on obtained data, and respectively carries out early warning analysis, line inspection management, three-dimensional display, web publication and decision-making analysis; and the operation processing center carries out a communication connection on an early warning analysis result and the monitoring center. With a smart city as a main body framework, complete and accurate information and the underground space distribution condition are provided for urban underground pipeline infrastructures through the monitoring module; rough construction can be avoided; an accident of broken pipelines is reduced; the safety of underground pipelines is ensured; and according to the comprehensive information management system for the smart city pipeline network, a decision-making aid can be provided for accurate and efficient pipeline management, pipeline accident prevention and emergency command processing after an disaster accident.

Owner:锦瀚智慧管网技术有限公司

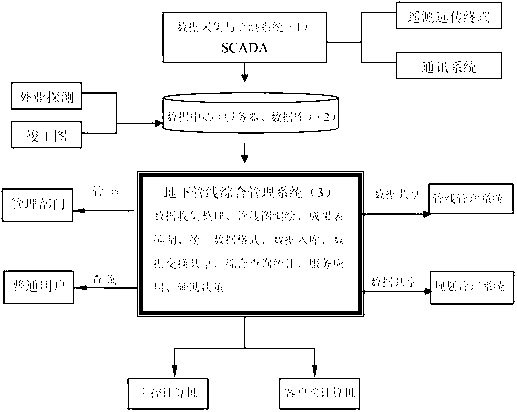

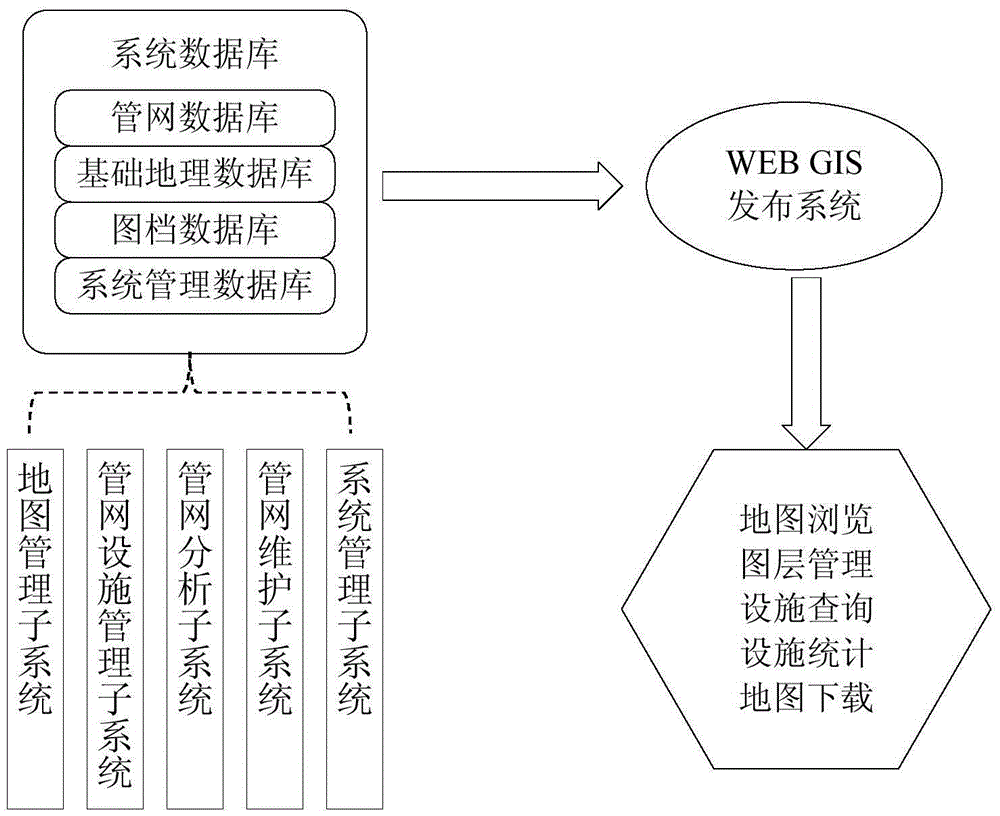

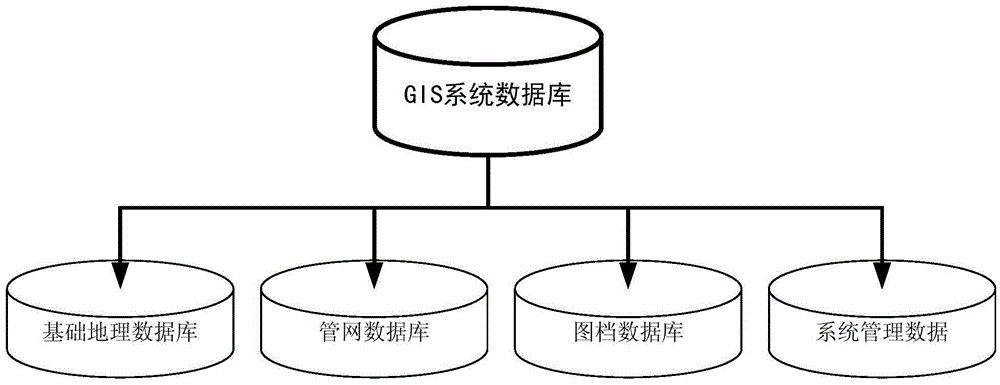

GIS (Geographic Information System)-based comprehensive management system for underground pipelines

InactiveCN102799612ARealize scientificAchieve normalizationSpecial data processing applicationsData centerMonitoring system

The invention discloses belongs to the comprehensive management on underground pipelines in cities and industrial parks and aims at comprehensively and scientifically managing relevant situations of underground pipelines and improving the accuracy and the efficiency of working; in order to achieve the purpose, the invention adopts the technical scheme as follows: a GIS (Geographic Information System)-based comprehensive management system for underground pipelines comprises a data acquiring and monitoring system, a data center and a comprehensive management system for the underground pipelines, wherein the data acquiring and monitoring system is used for acquiring data at fixed monitoring points of the underground pipelines; and the data center is used as a server and is used for monitoring a process value and being communicated with process hardware, and the process hardware serves as the data acquiring and monitoring system. The system is mainly applied to comprehensive management on the underground pipelines in the cities and the industrial parks.

Owner:TIANJIN UNIV

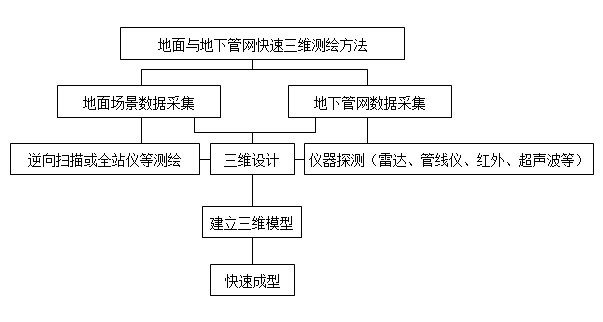

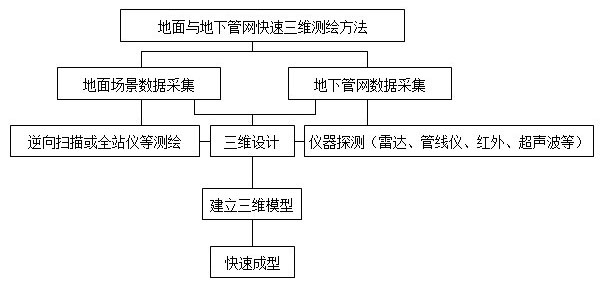

Rapid three-dimensional mapping moulding method for ground and underground pipe network

InactiveCN102087753AImprove securityQuality improvement3D modellingUrban infrastructurePhysical model

The invention relates to a rapid three-dimensional mapping moulding method for ground and an underground pipe network, which comprises the following steps of: acquiring ground scene data and underground pipe data and respectively establishing three-dimensional model images of the ground and the underground pipe network; establishing the link between the ground and underground pipe network three-dimensional model images according to coordinates and storing the link into a database; carrying out rapid moulding in sections according to the moulding range of a rapid moulding machine to obtain underground pipe network sectioned distributing physical models; and splicing the sectioned distributing physical models to obtain an underground pipe network distributing physical model. The ground scene and an underground pipeline are combined and linked by the coordinates; people at different levels can vividly and visually find out the corresponding ground scene by a failure pipeline position and establish a maintenance scheme; similarly, an underground pipe network under a ground scene can be reformed and maintained; and the invention realizes the scientific management of urban infrastructure, saves the maintenance and construction cost, reduces the generating probability of accidents and improves the engineering safety degree and quality.

Owner:ZHEJIANG SCI-TECH UNIV

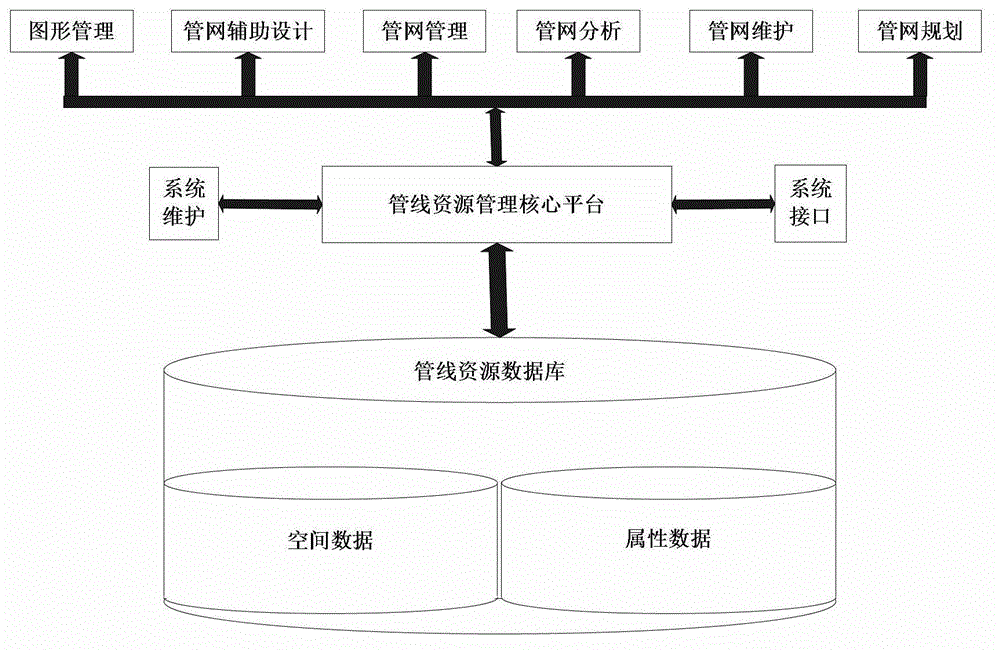

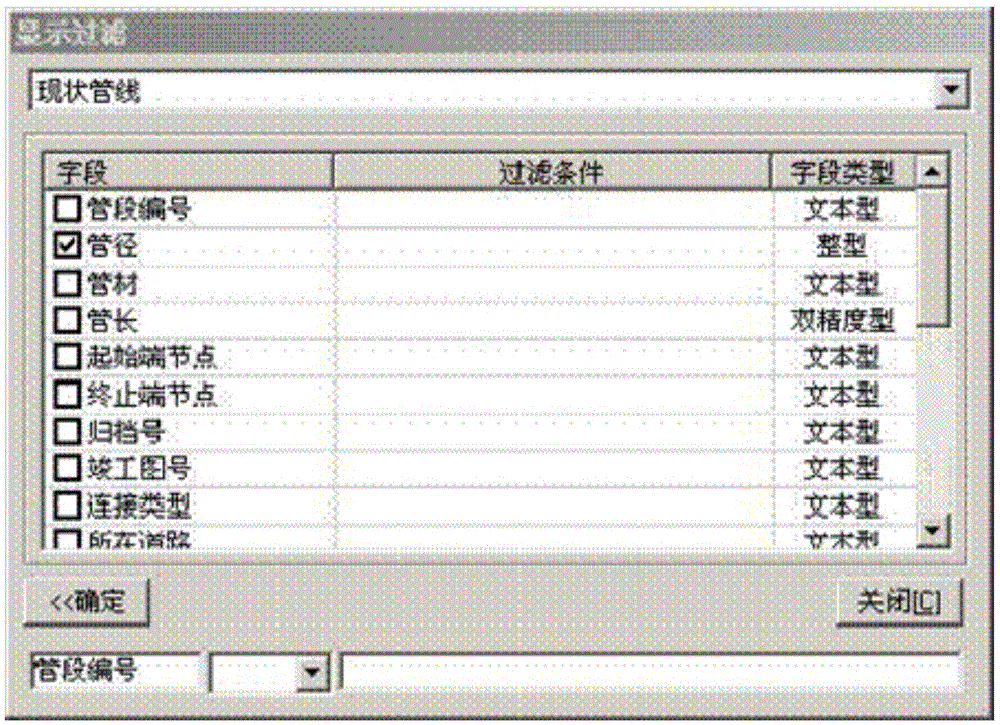

GIS-based underground pipeline operation and maintenance system

InactiveCN105550758ASolve problems that are not comprehensive, easy to lose, and not intuitiveIncomplete solutionData processing applicationsGeographical information databasesSystems managementNetwork data

The invention provides a GIS-based underground pipeline operation and maintenance system. The GIS-based underground pipeline operation and maintenance system comprises a map management sub-system, a pipe network facility management sub-system, a pipe network analysis sub-system, a pipe network maintenance sub-system, a system management sub-system, a WEBGIS pipe network figure publishing sub-system and a system database; the GIS-based underground pipeline operation and maintenance system is established on the basis of a dynamic and static water supply pipe network electronic map, performs attribute query, location, analysis and statistics of pipelines and various facilities, and outputs all kinds of statistical results; after a pipe network accident happens, a valve closing scheme and a user water cut-off notice can be provided within a short time; the scheme can be rapidly adjusted after a new condition happens; graphic and character integrated modern management of a water supply pipe network is realized; a dynamic updating mechanism of pipe network data is provided; the system is accurate and high-efficient; powerful scientific decision basis is provided for water supply planning, designing, dispatching, emergency maintenance and atlas data management; the full-computer operation process for analyzing and deciding is realized; and thus, the production efficiency and the social service level of a running-water company are increased.

Owner:无锡扬晟科技股份有限公司

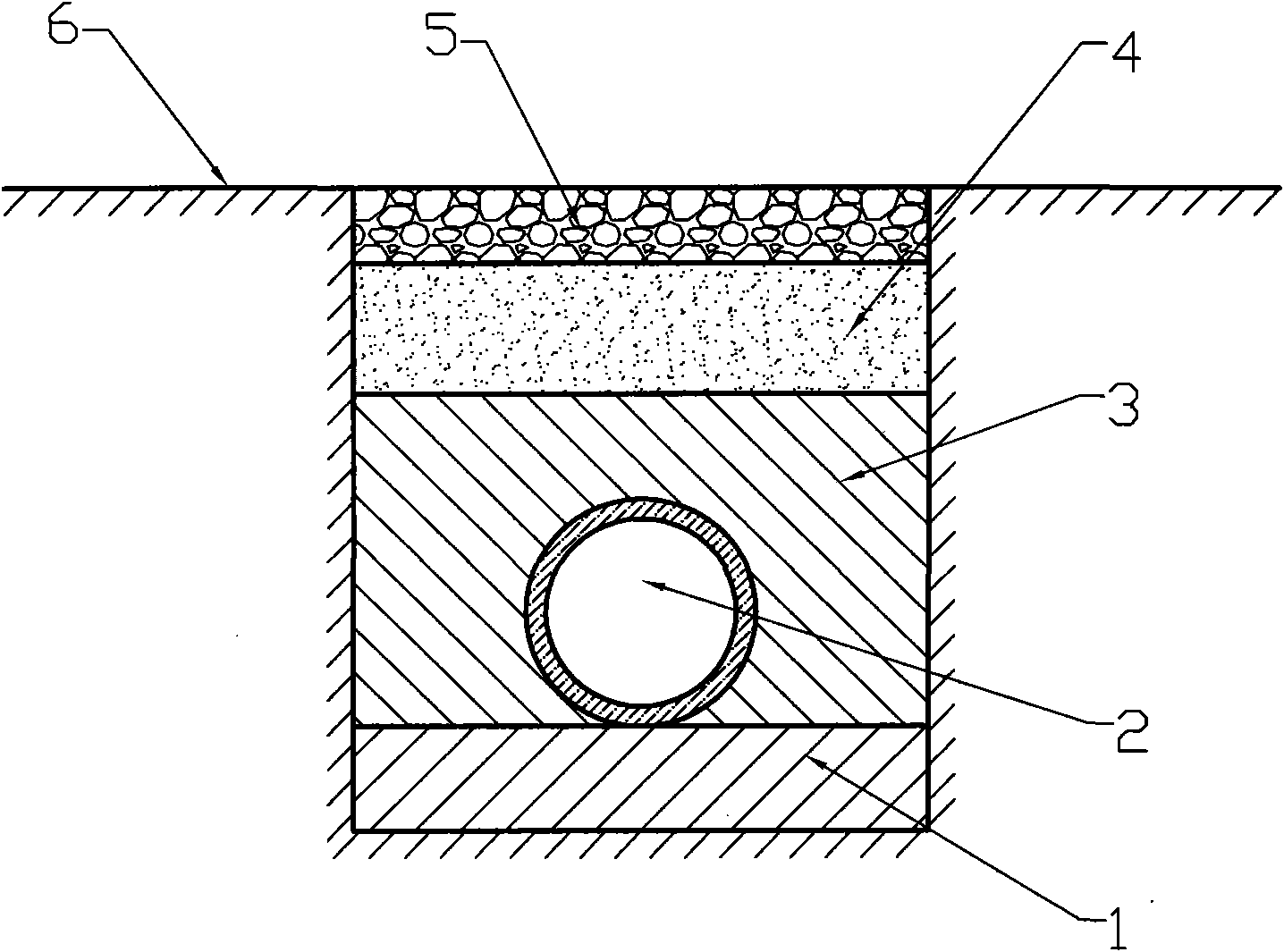

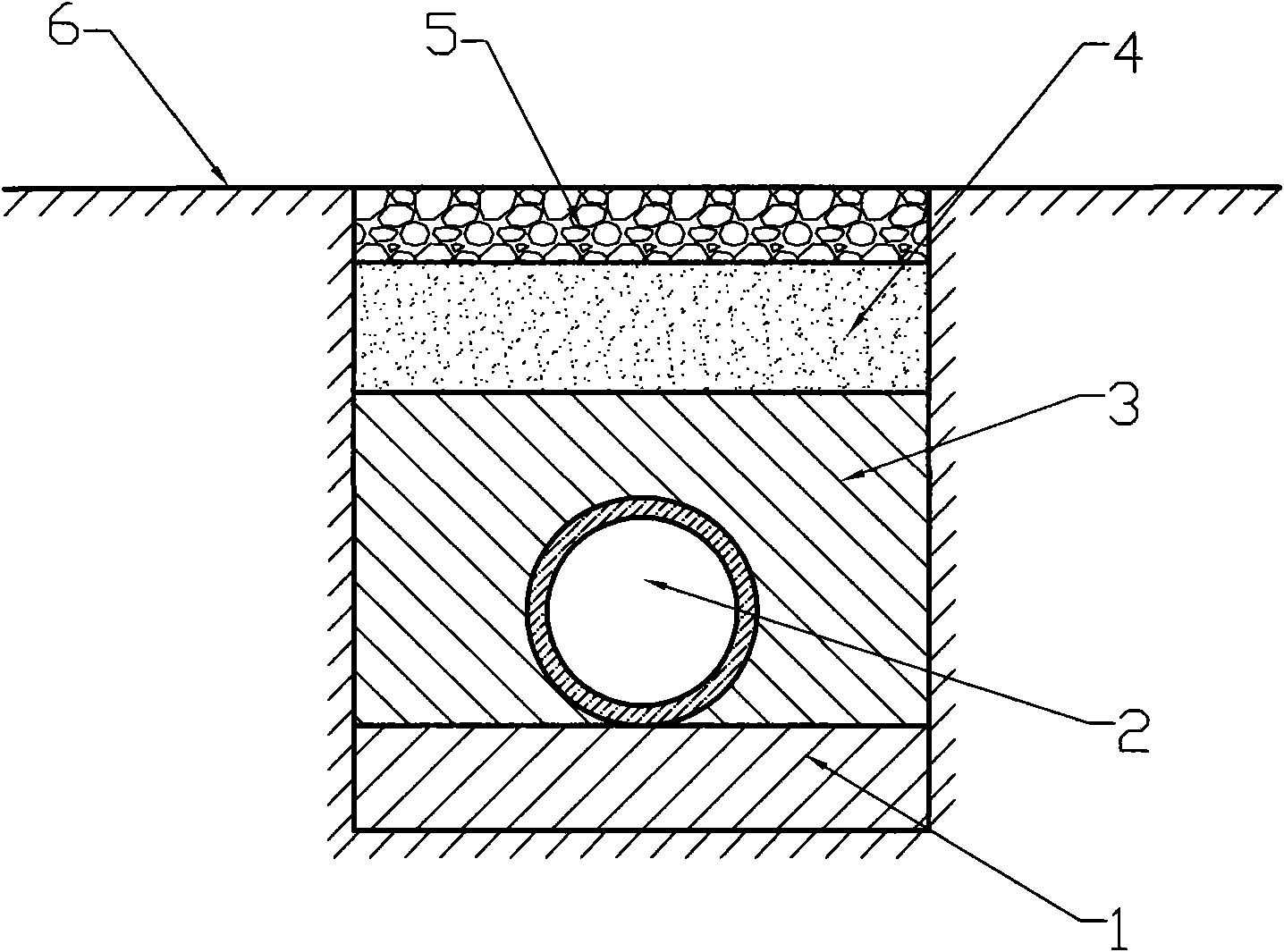

Construction method for laying water pipes

InactiveCN101775826ALow priceReduce manufacturing costPipe laying and repairService pipe systemsWater leakageEngineering

The invention relates to a construction method for laying water pipes, mainly solving the problems of high cost, transport expense and maintenance expense of a precast rigid pipe adopted for a traditional heavy-calibre water pipe. The construction method comprises the following steps of: excavating a foundation, laying a cushion layer at the bottom of a pipe ditch, laying pipelines, injecting water to make a core, filling concrete and backfilling the pipe ditch. In order to be convenient for maintenance, an operation well is arranged at the part of each three-way valve. Compared with an iron pipe and a steel pipe, a plastic flexible pipe has the advantages of greatly reduced production cost, good corrosion resistance, no water leakage, long service life, on-site construction, simple operation and improved construction efficiency. Compared with the traditional underground pipeline, the invention has simple operation for the maintenance and reduces the maintenance expense.

Owner:JINAN JINDING INFORMATION TECH

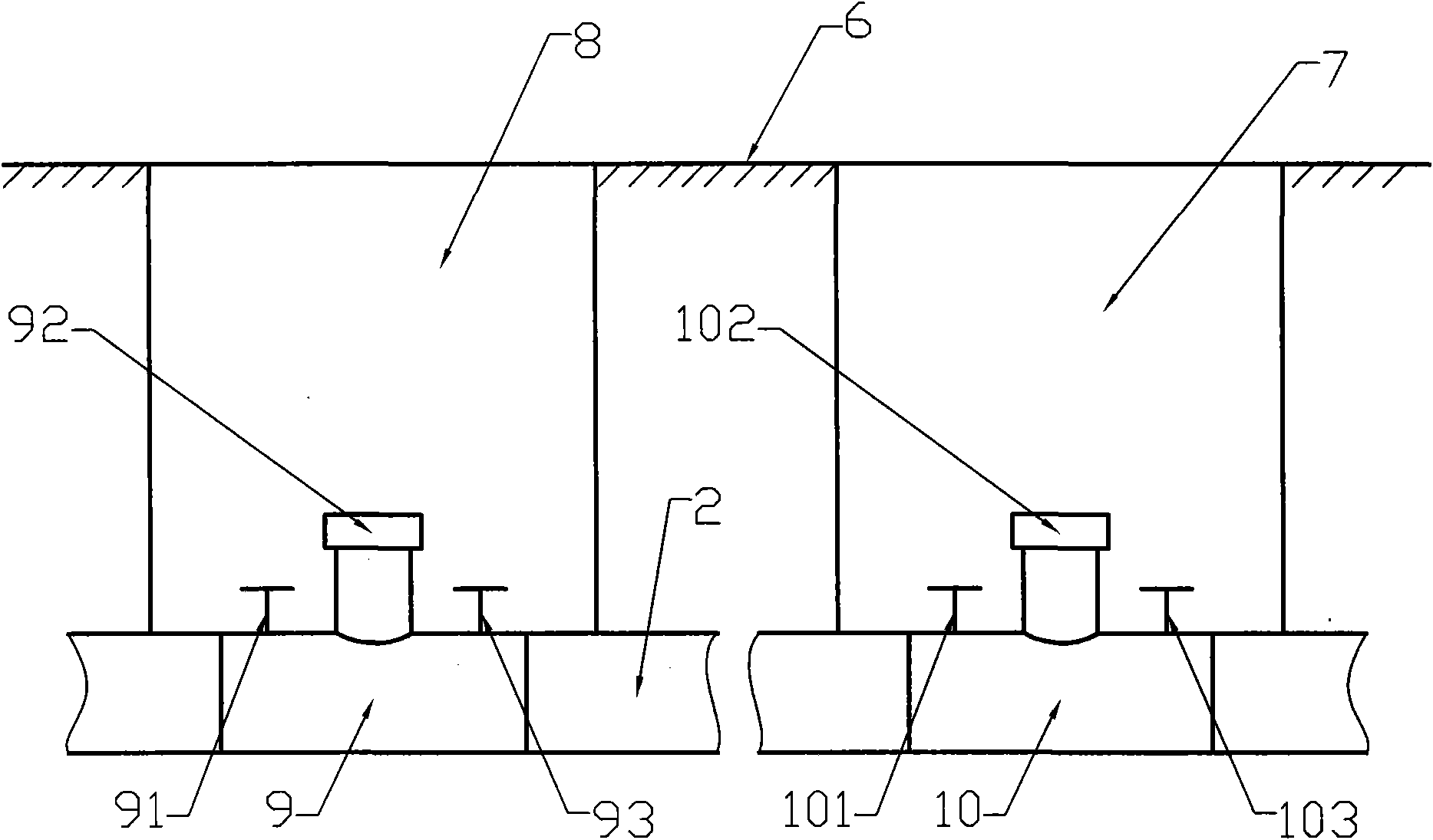

Construction method for installing underground pipes for high-tension cables by using trough

InactiveUS7740417B2Reduce construction costsWork lessArtificial islandsPipe laying and repairRoad surfaceHigh pressure

Owner:JANG YOUNG HWAN

Underground pipeline leak-detection method and apparatus

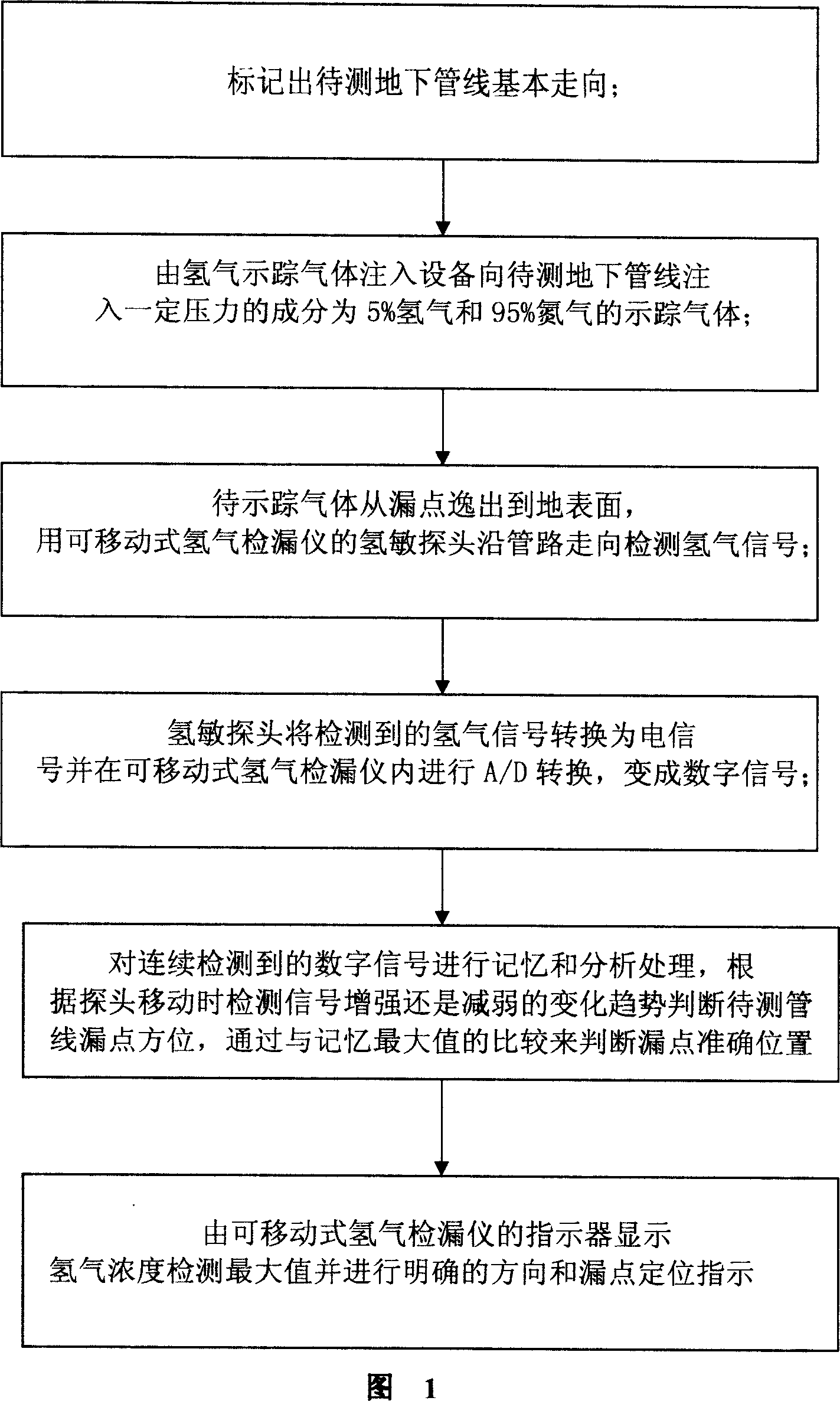

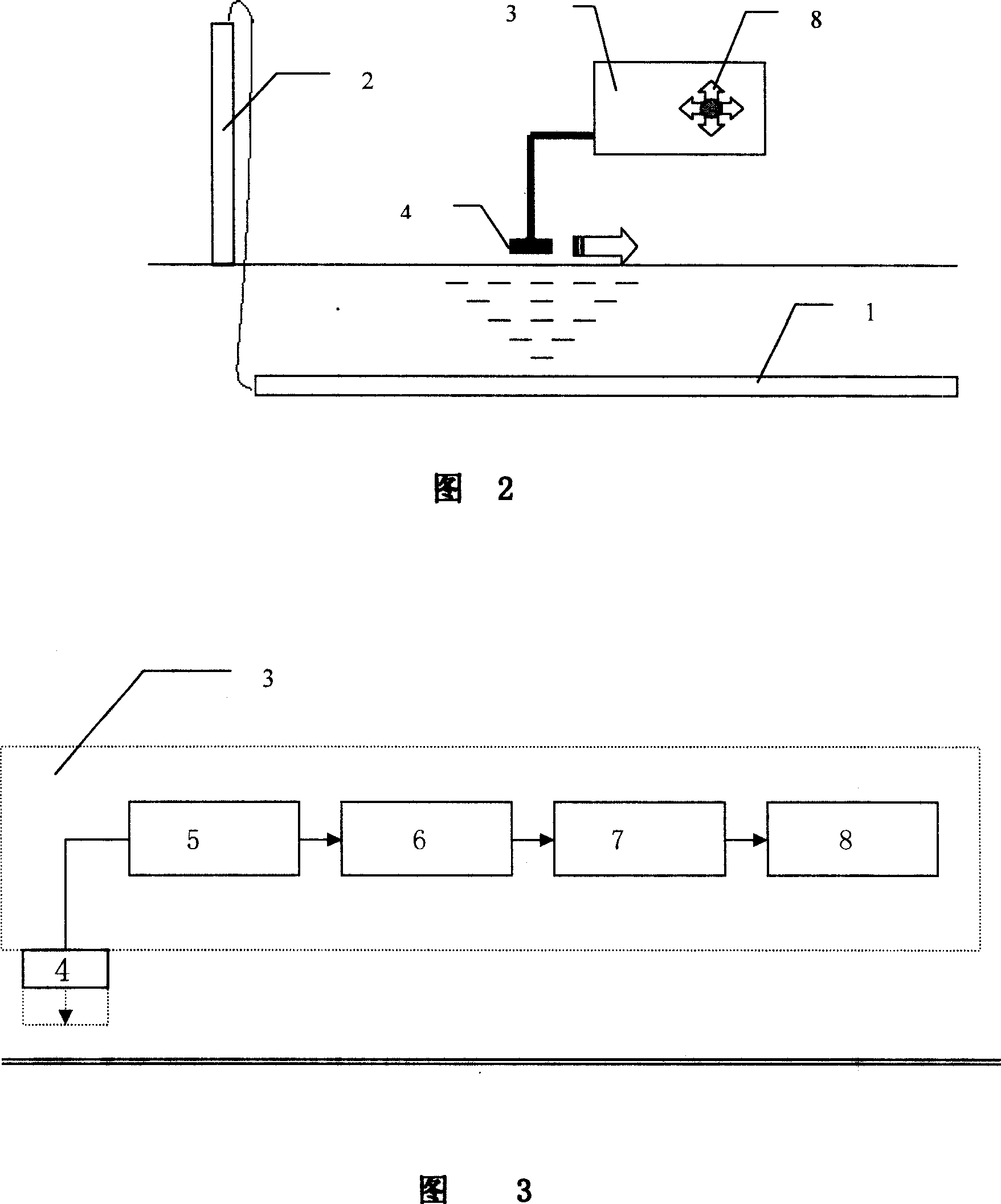

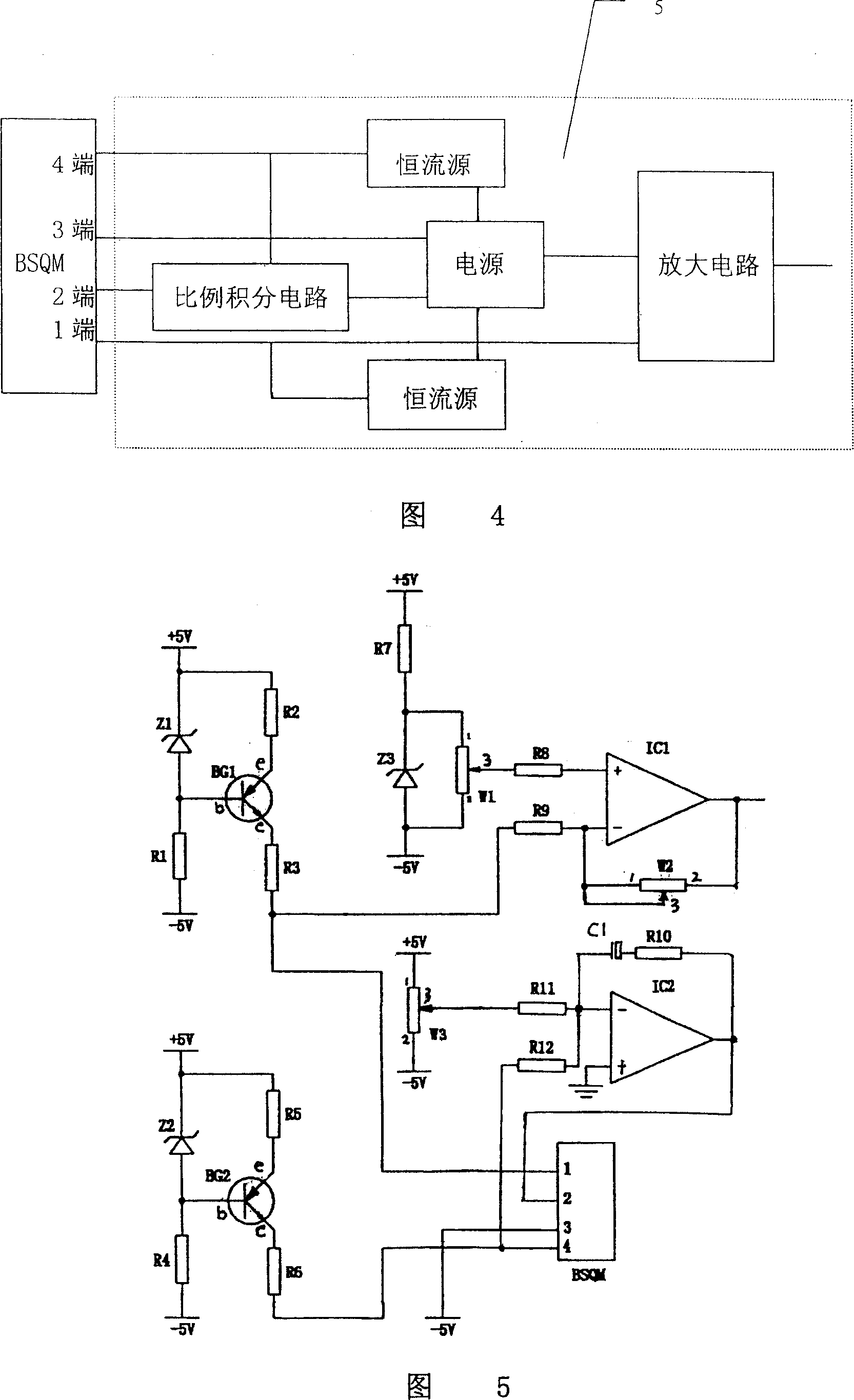

This invention provides a leakage test method and a device including: marking a basic tendency of an underground line to be tested, injecting a tracer gas in a certain pressure composition of 5% hydrogen and 95% nitrogen to the line, testing the H2 signal along the tendency of the pipeline with a H2-sensitive probe of a movable hydrogen leak detector, converting the test signal to an electric signal then converting it to a digital signal by A / D conversion, memorizing and analyzing the continuously tested digital signals to judge the leakage orientation based on the change trend weak or strong of the test signal and judging the accurate position of the leak point by comparing with the maximum value of the memory and an indicator displays the maximum value of the concentration of the tested hydrogen and indicates the location of the direction and leakage definitely. Advantage: direct indication, accurate location to reduce work intensity of test.

Owner:ZIBO SIKE OPTOELECTRONICS TECH

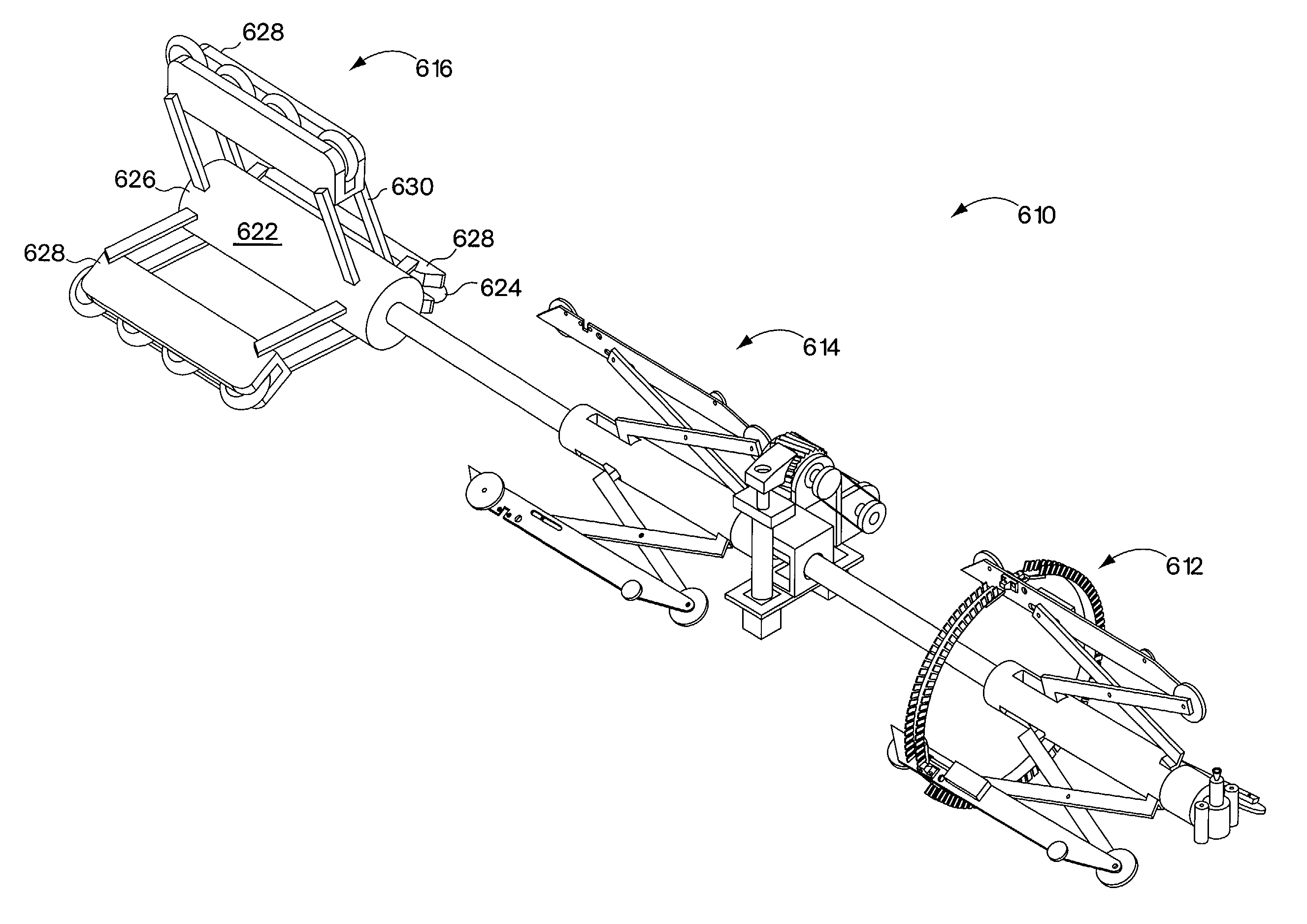

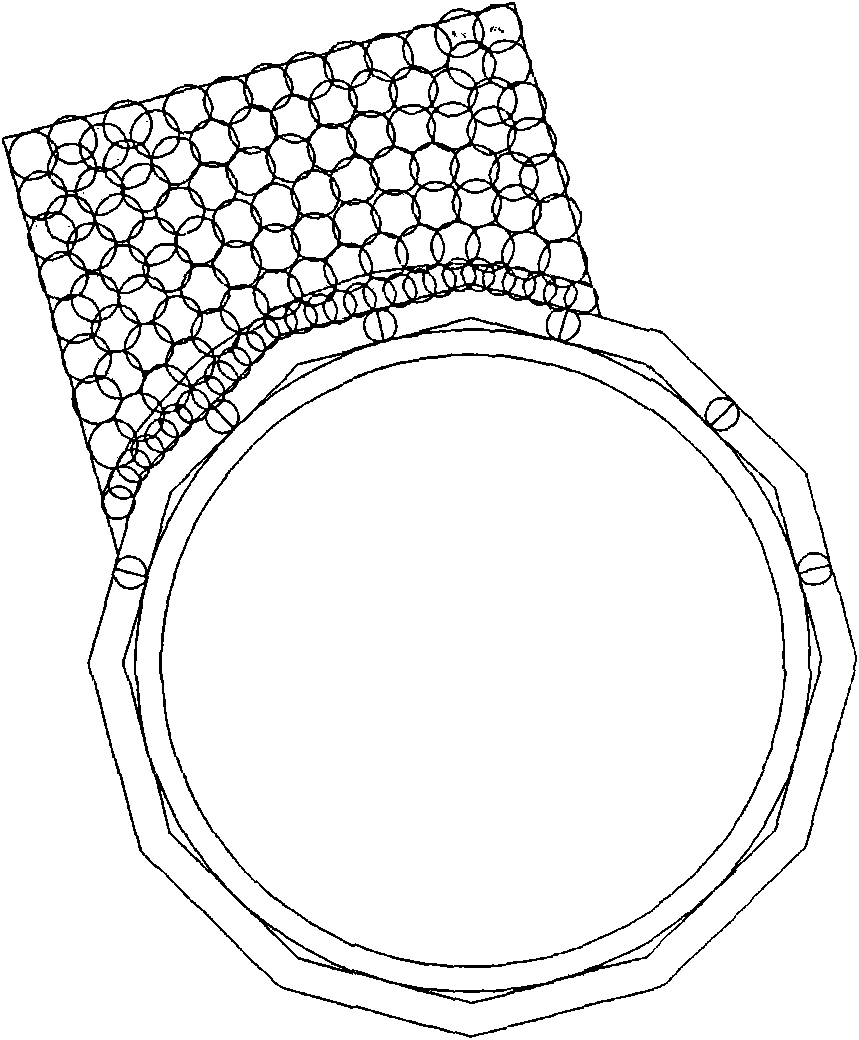

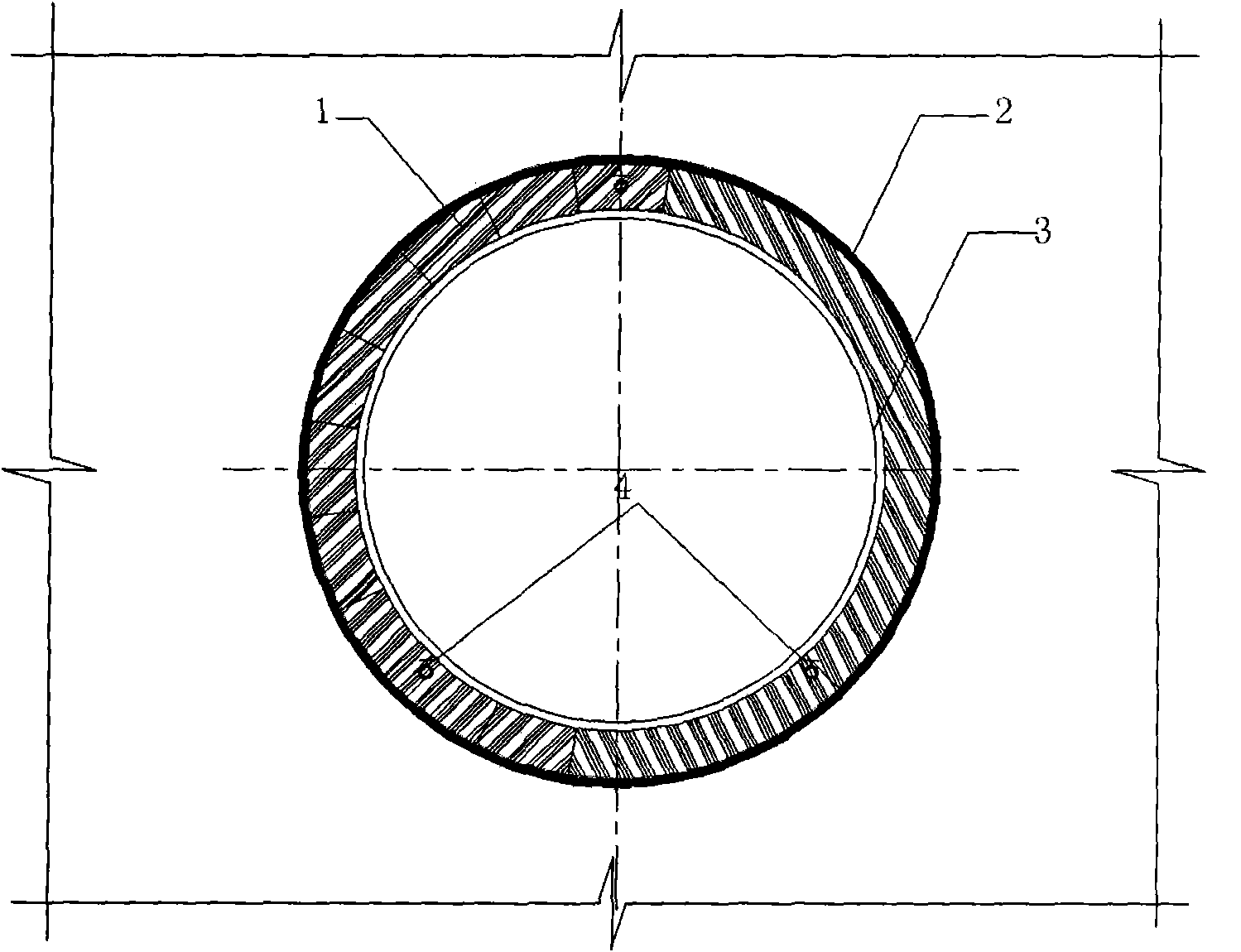

Nuclear rector pressure vessel nozzle safe end welding joint automatic ray inspection device

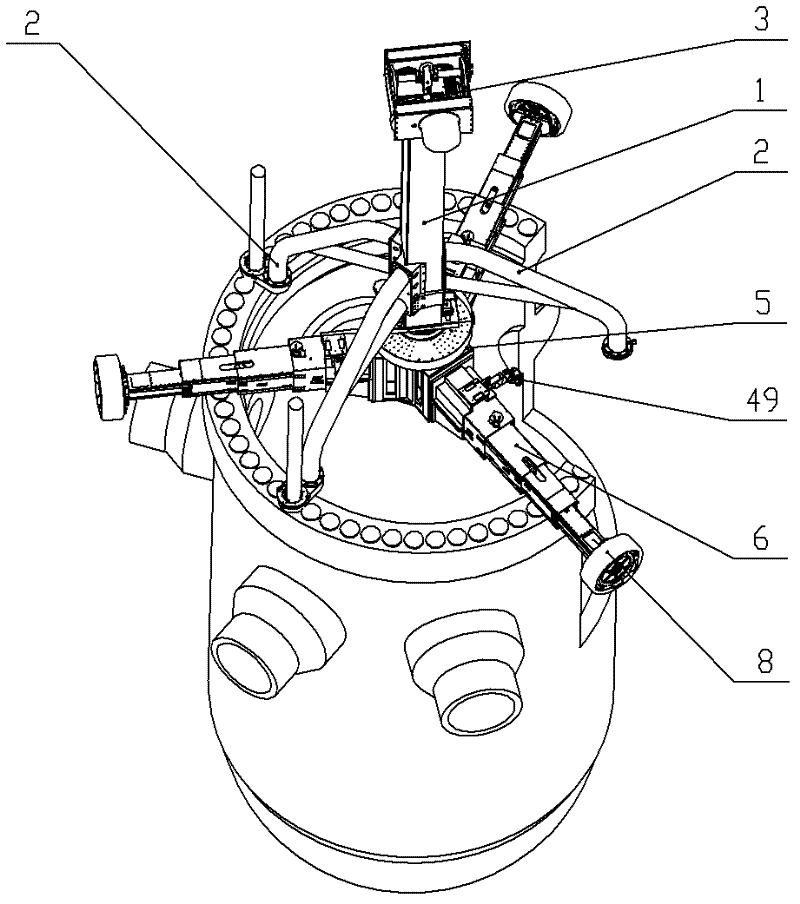

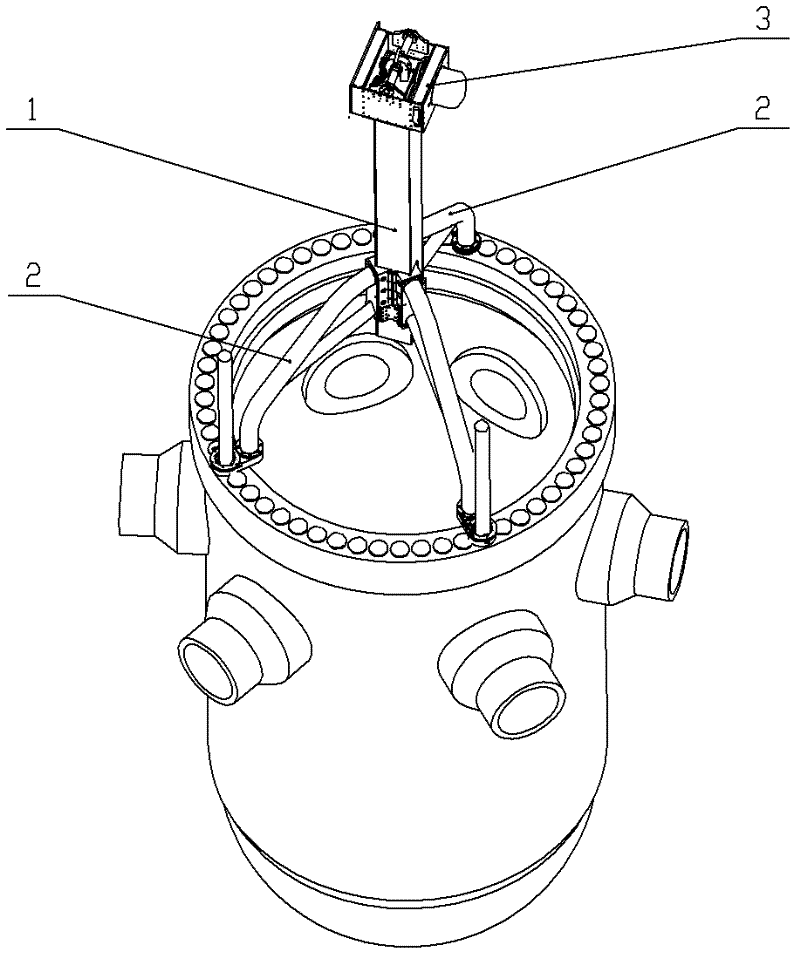

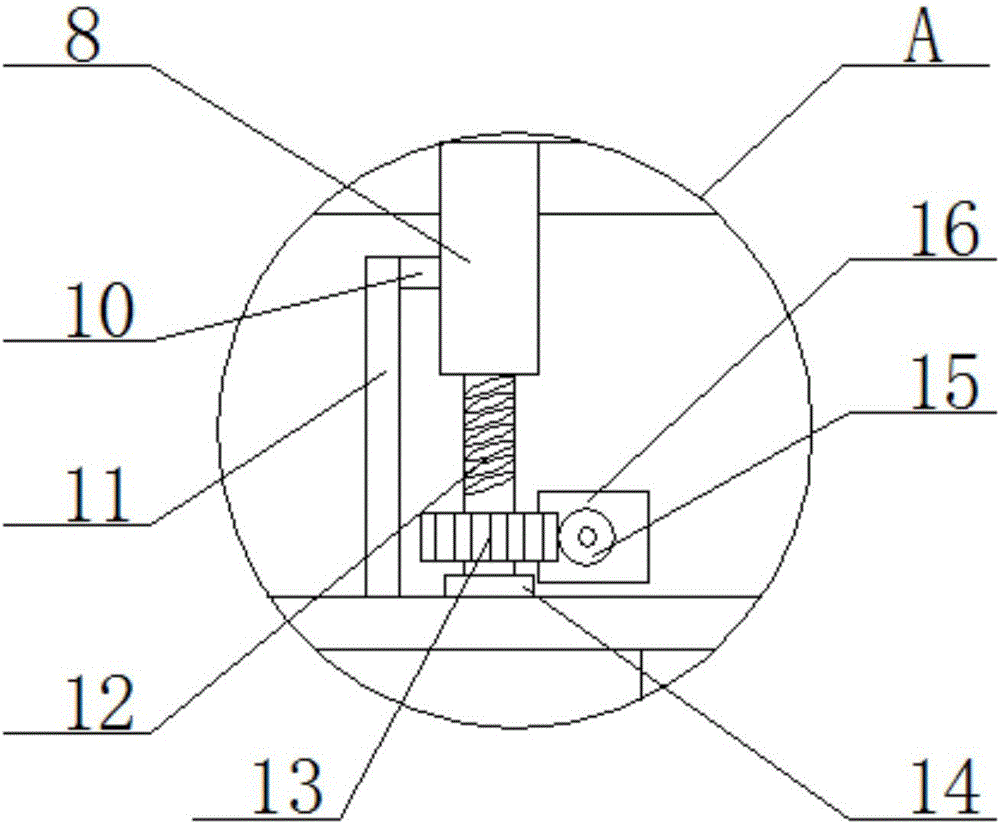

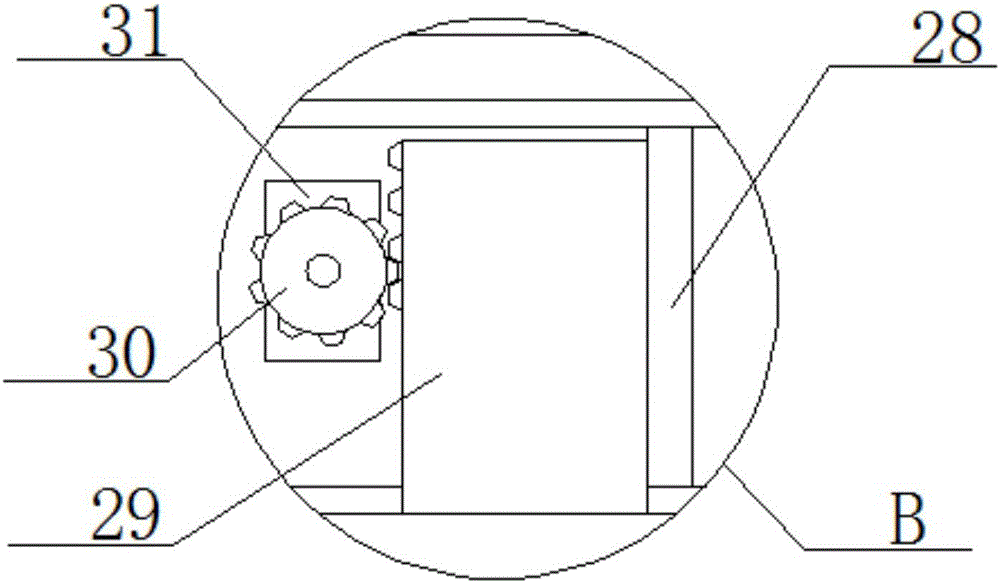

ActiveCN102509566AHigh degree of automationWith radial self-adjustingNuclear energy generationNuclear monitoringRadiation riskNuclear reactor

The invention discloses a nuclear rector pressure vessel nozzle safe end welding joint automatic ray inspection device. The device comprises a support positioning mechanism for supporting the integral device on a pressure vessel, a min rotating mechanism for adjusting an inspection angle, and three telescopic inspection arm mechanisms which are peripherally and uniformly distributed to inspect the weld joint. The structure and operation inspection device provided by the invention have high automatic degree so that the staff is free from operating near source, thereby furthest eliminating the potential radiation risk; the device can simultaneously inspect safe ends of three water inlet nozzles or three water outlet nozzles in 120 degrees with each other, improve the inspection efficiency, and shorten piling time of a nuclear power station in major overhaul period; an inspection assembly has the functions of radial self-adjusting, automatic centering and through flow, is used for solving the problem that the axial direction force on the device is overlarge due to the overlarge radial force on an air bag and the pressure difference between two sides of the air bag. The technical scheme can be widely applied to the ray inspection of other underground pipelines and has great application value.

Owner:CGNPC INSPECTION TECH +2

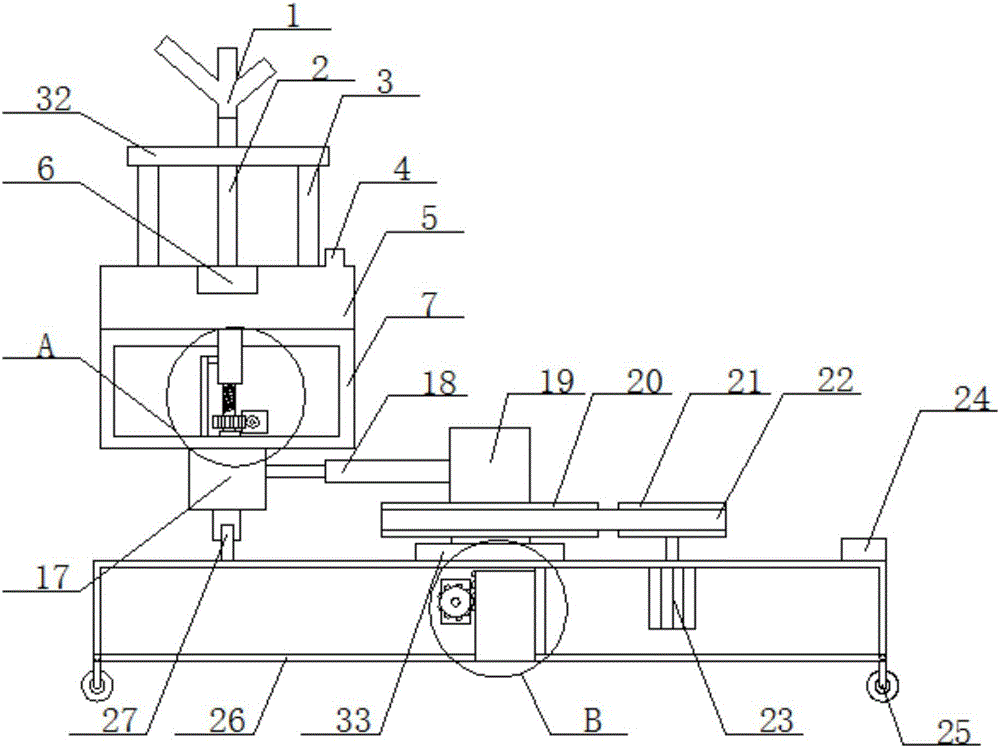

Multifunctional spray irrigation equipment for landscaping

ActiveCN106718680AReduce layingReduce the number of configurationsClimate change adaptationWatering devicesLandscapingAgricultural engineering

The invention relates to multifunctional spray irrigation equipment for landscaping. The multifunctional spray irrigation equipment comprises a second base, a rotating mechanism and a spray irrigation mechanism, wherein the rotating mechanism comprises an air cylinder, a rotating shaft, a first belt wheel, a second belt wheel, a belt, a second bearing and a second motor; the spray irrigation mechanism comprises a rocker arm type spray head, a water guide pipe, a first support rod, a support plate, a water box, a first base, a fixing block and an ascending and descending unit. The multifunctional spray irrigation equipment for landscaping has the advantages that firstly, the spray irrigation height can be regulated through the ascending and descending unit, so that various requirements of different plants on the spray irrigation height are met; secondly, the large-area spray irrigation can be realized by rotating the spray irrigation mechanism around the rotating shaft under the condition of only using the single rocker arm type spray head; through air cylinder control, the spray irrigation covering range can be adjusted, so that the laying of underground pipelines and the configuration number of spray irrigation equipment can be greatly reduced, and thus the unit area investment is reduced.

Owner:衡阳市金贝林景工程有限公司

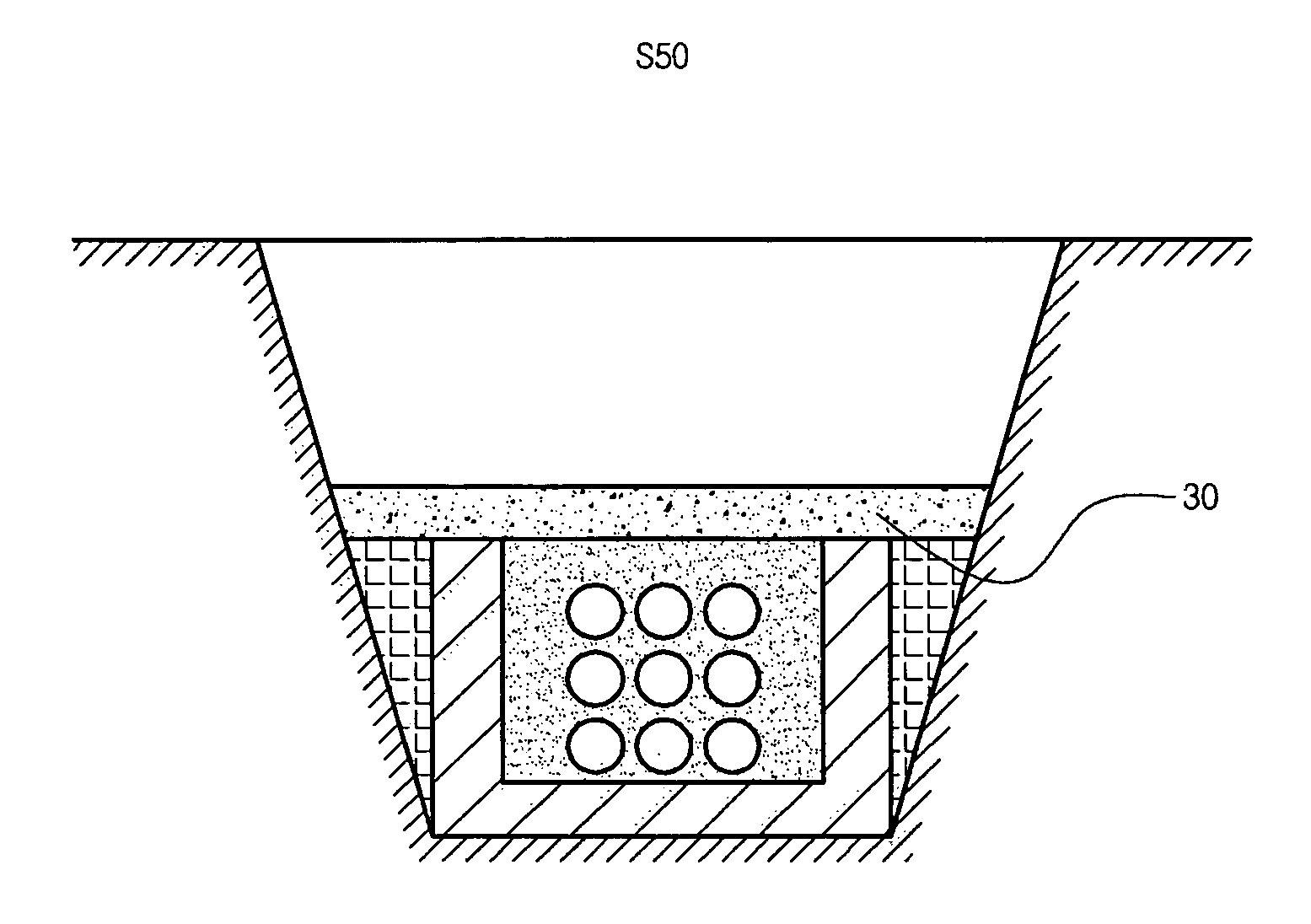

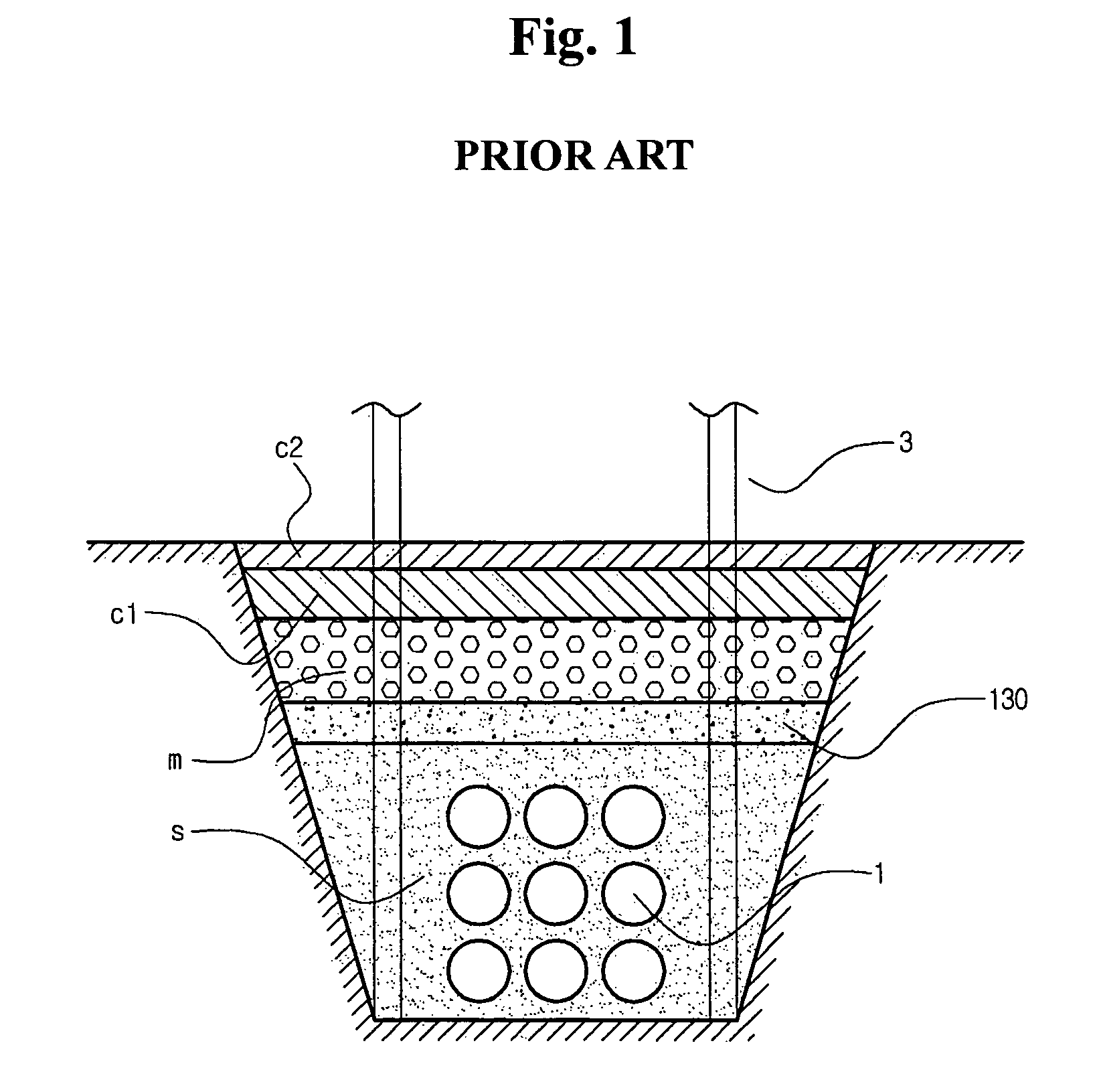

Method for building subway station

InactiveCN102505706ASolve problems such as standardized temporary protectionEnsure stabilityArtificial islandsExcavationsCovering systemRoad surface

The invention discloses a method for building a subway station, and the method comprises the following construction steps of: sorting underground pipelines, and carrying out diversion on the pipelines needing diversion; modifying traffic guide; constructing a foundation pit enclosure structure; constructing a cover system, and taking part of a constructed cover plate as a half cover part; recovering a temporary pavement on the constructed cover plate; excavating a foundation pit, carrying out suspension treatment on the pipelines which are not moved away, and transporting the soil body excavated from the open cut part out from the foundation pit; constructing a main body structure of the station, and lifting material and constructors to pass in and out from the open cut part; and backfilling earthwork, dismounting the cover system and recovering a pavement.

Owner:BEIJING MUNICIPAL CONSTR

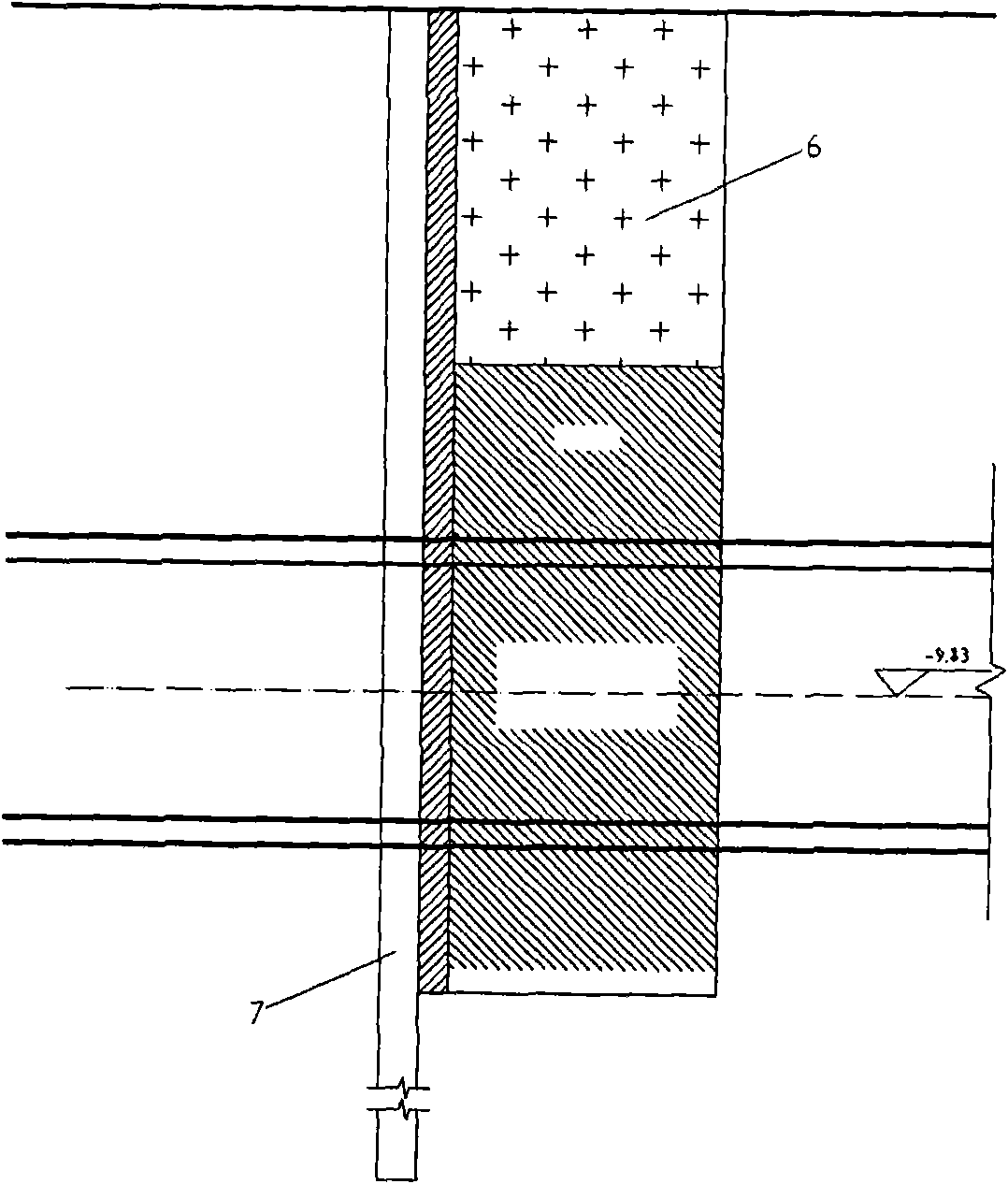

Construction method for shield holing under complicated working conditions

ActiveCN102094650AWell into the holeEnsure safetyUnderground chambersTunnel liningEngineeringCement grout

The invention relates to a construction method for shield holing under complicated working conditions. The method comprises the following steps of: 1, strengthening a shield inlet opening; 2, making a shield pass through a wall; and 3, making the shield hole, namely reducing the tunneling speed when a shield machine enters a strengthening area, wherein the tunneling speed is regulated from the original 4cm / min to the range of between 1.0 and 1.5 cm / min, and the pressure of a soil cabin is reduced to 2kg / cm<2> when the shield machine enters the strengthening area by 0 to 2.0m; the pressure of the soil cabin is reduced to 1.5kg / cm<2> when the shield machine enters the strengthening area by 2.0 to 4.0m; the pressure of the soil cabin is reduced to 1kg / cm<2> when the shield machine enters the strengthening area by 4.0 to 5.0m; and the pressure of the soil cabin is reduced to 0kg / cm<2> when the shield machine enters the strengthening area by 5.0m; and supplementing and injecting cement grout through a reserved injected hole of an air shaft bottom plate in time according to the subsidence monitoring conditions of an air shaft when the shield machine enters the bottom of the air shaft for tunneling so as to ensure the safety of the air shaft. By the construction method, the shield can favorably hole, and the safety of surrounding buildings and underground pipelines can be ensured.

Owner:SHANGHAI FOUND ENG GRP

Underground pipeline measuring system based on inertial technology and its measuring and its calculating method

InactiveCN101051089ARealize autonomous measurementHigh precisionNavigation by speed/acceleration measurementsGeological measurementsGyroscopeLine tubing

An underground pipeline measurement system based on inertia technique comprises pipe measurement unit including gyroscope for providing pipe current section course angle information, accelerator for providing pitch angle information, speedometer of photoelectric coder for measuring pipe length and microprocessor for collecting signal from various transducers and for outputting pipe 3-D information to PC computer; and external power supply unit.

Owner:SHANGHAI TRENCHLESS INFORMATION ENG +2

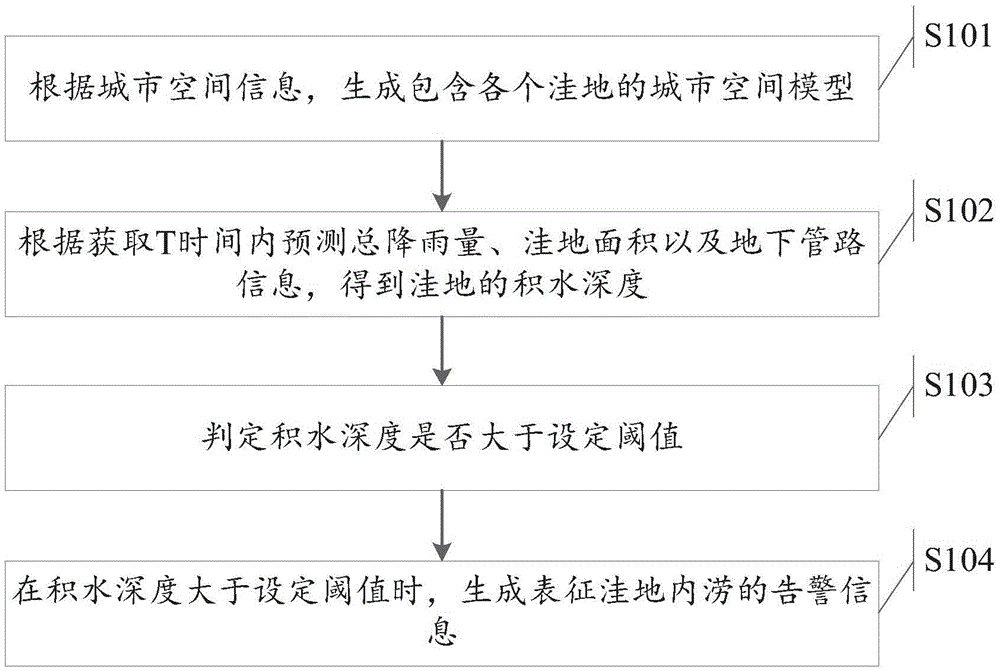

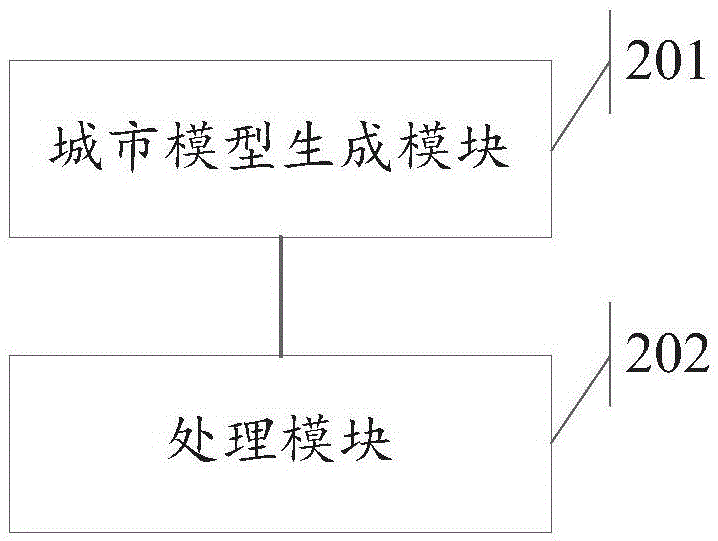

Urban water-logging analysis method and urban water-logging analysis system

InactiveCN105550803ASolve the generalization problemImprove forecast accuracyClimate change adaptationResourcesMathematical modelWater model

The invention discloses an urban water-logging analysis method and an urban water-logging analysis system in order to solve the problem in the existing water-logging analysis method that inaccurate results are caused as there is no accurate data of underground drainage facilities and a lot of variables in the model are simulated data. The method comprises the following steps: generating an urban space model containing all depressions according to urban space information; getting the water depth of each depression according to the acquired predicted total rainfall within a period of time T, the area of the depression and the underground pipeline information; judging whether the water depth is greater than a set threshold; and generating alarm information characterizing depression water-logging if the water depth is greater than the set threshold. According to the technical scheme, a rainfall model, a confluence model and an improved drainage model form a water model, the generalization problem of urban drainage system facilities in the traditional rainstorm water-logging mathematical model is solved, and the accuracy of water depth prediction is improved.

Owner:哈尔滨航天恒星数据系统科技有限公司

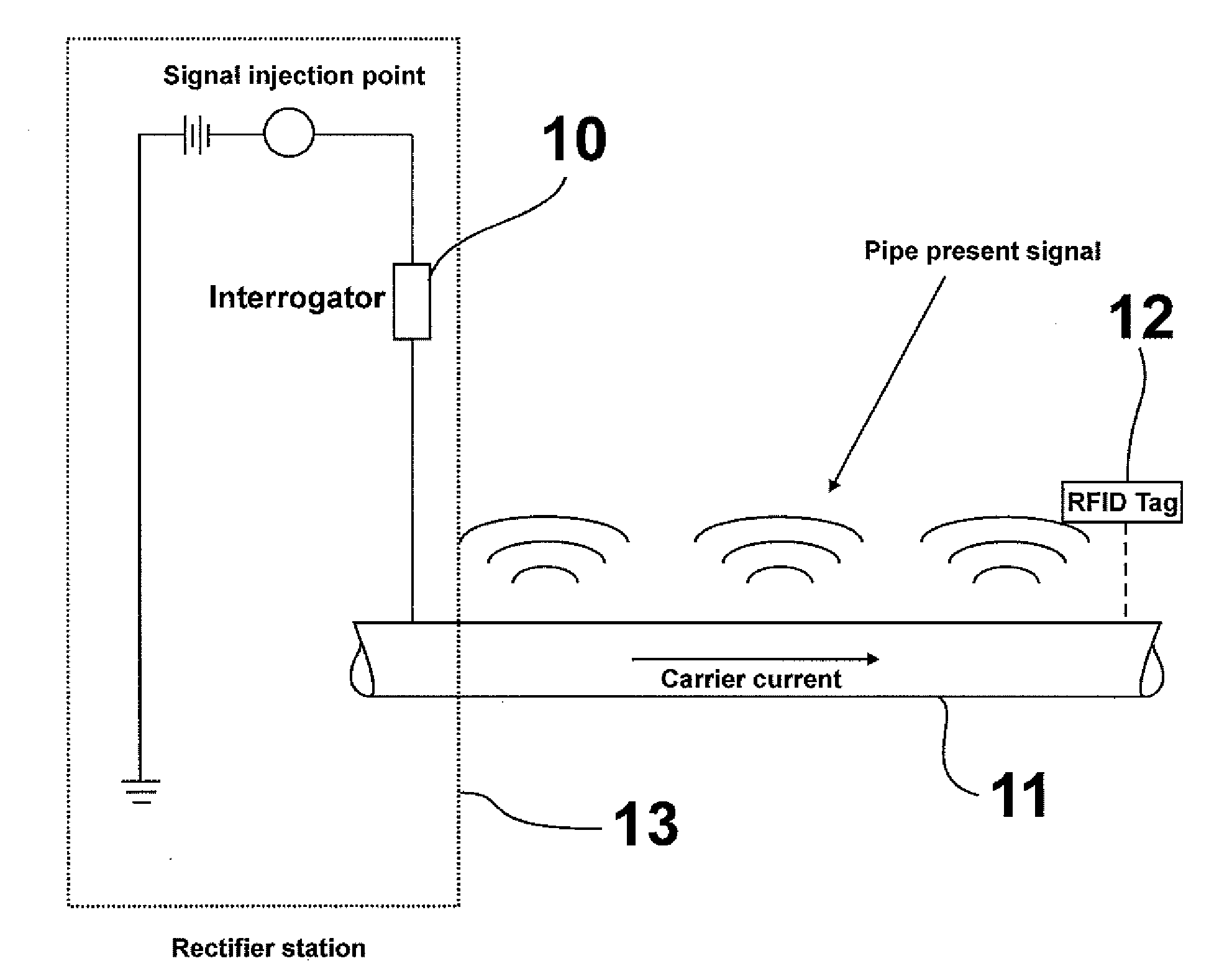

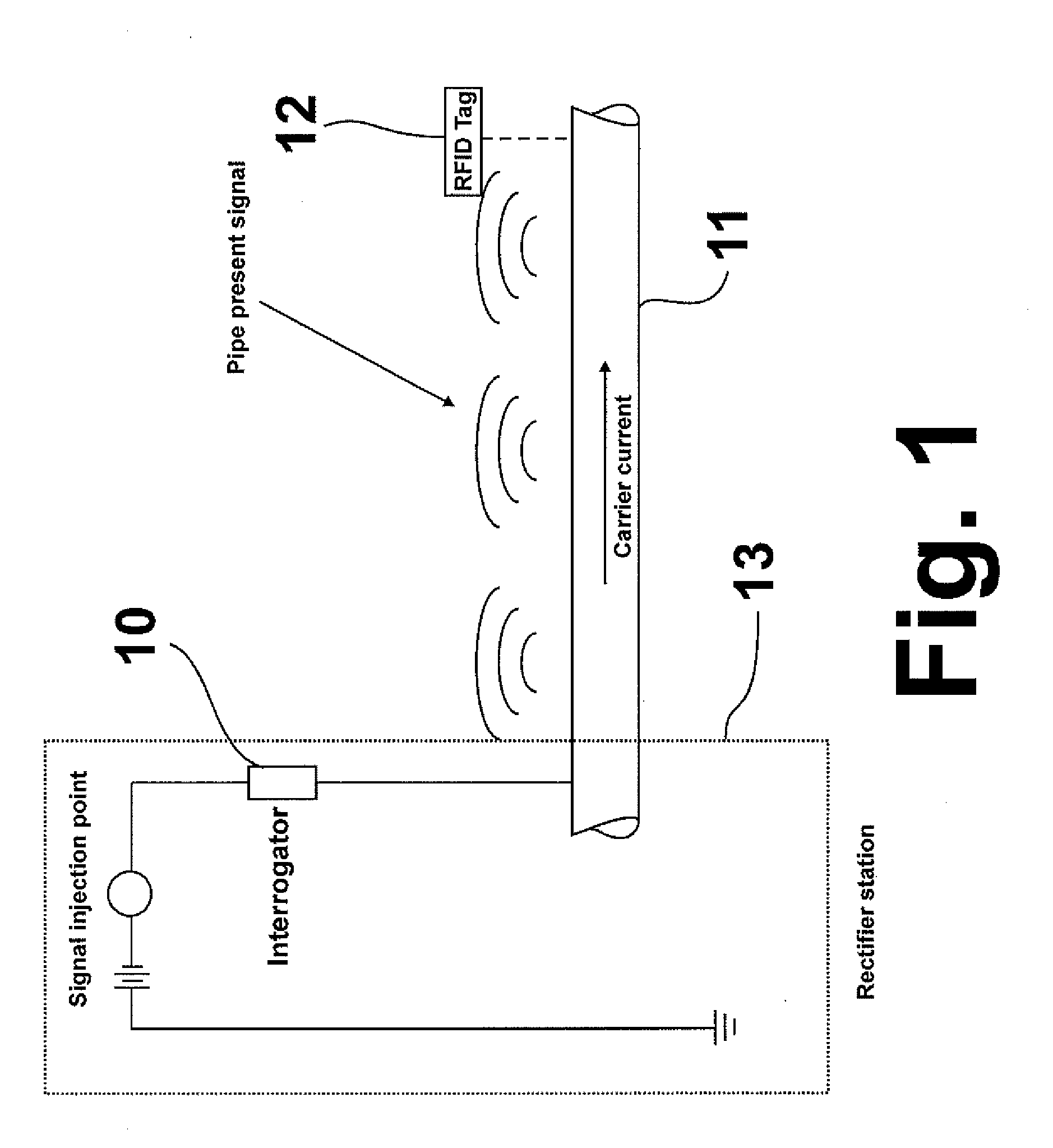

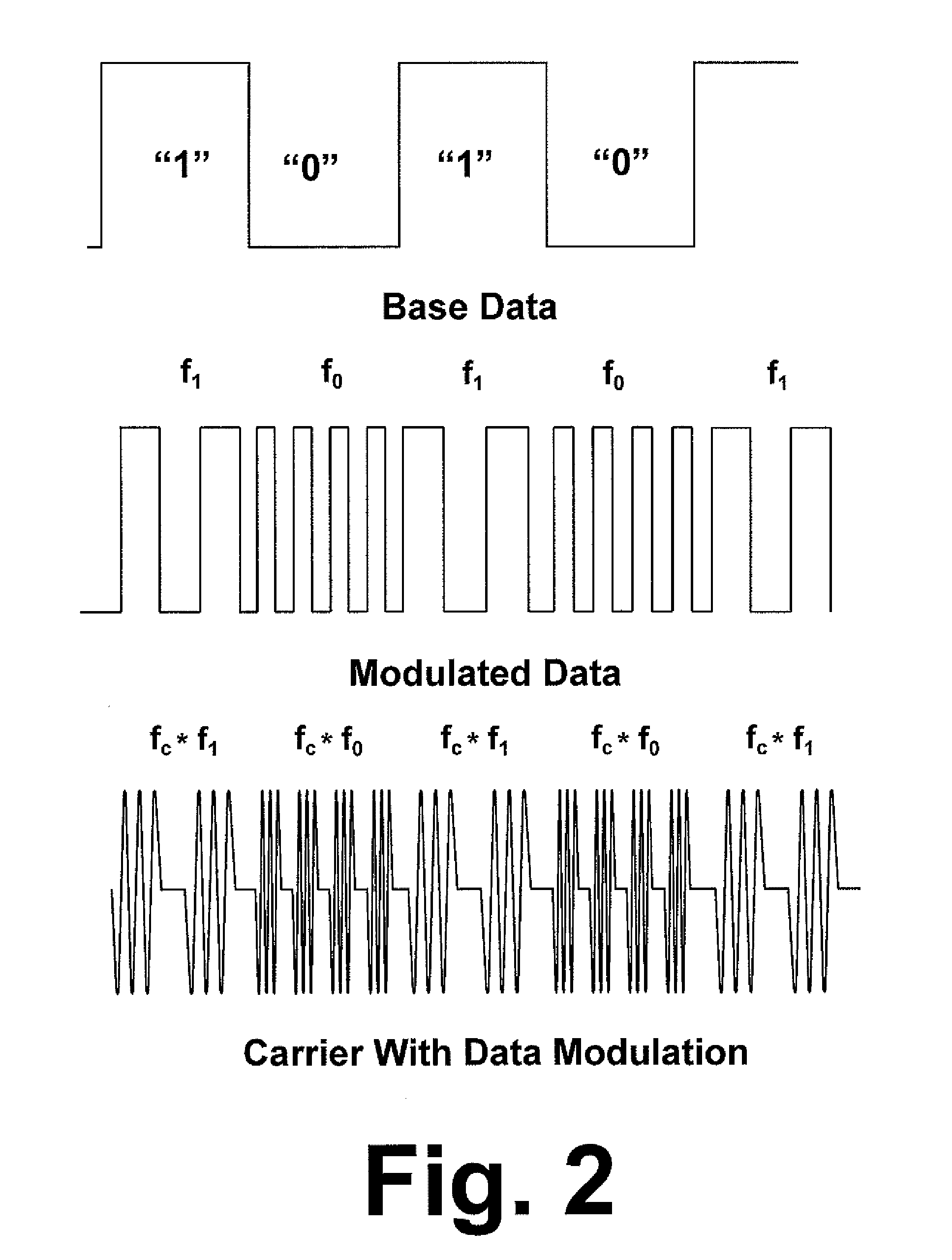

Communication method for monitoring pipelines

ActiveUS20130043887A1Modest power requirementContinuous monitoringResistance/reactance/impedencePipeline systemsEngineeringUnderground pipeline

A method for underground pipeline monitoring in which a continuous alternating electrical current having a current frequency in a range of about 1 kHZ to about 8 kHz is imparted onto a pipeline, producing an alternating magnetic field at the current frequency along the pipeline. Distributed along the pipeline is a network of RFID tag sensors which absorb an amount of energy from the alternating magnetic field. The impedance of the sensors is modulated, producing a modulated sensor impedance which is detected at a location proximate the location at which the continuous alternating electrical current is imparted onto the pipeline.

Owner:GAS TECH INST

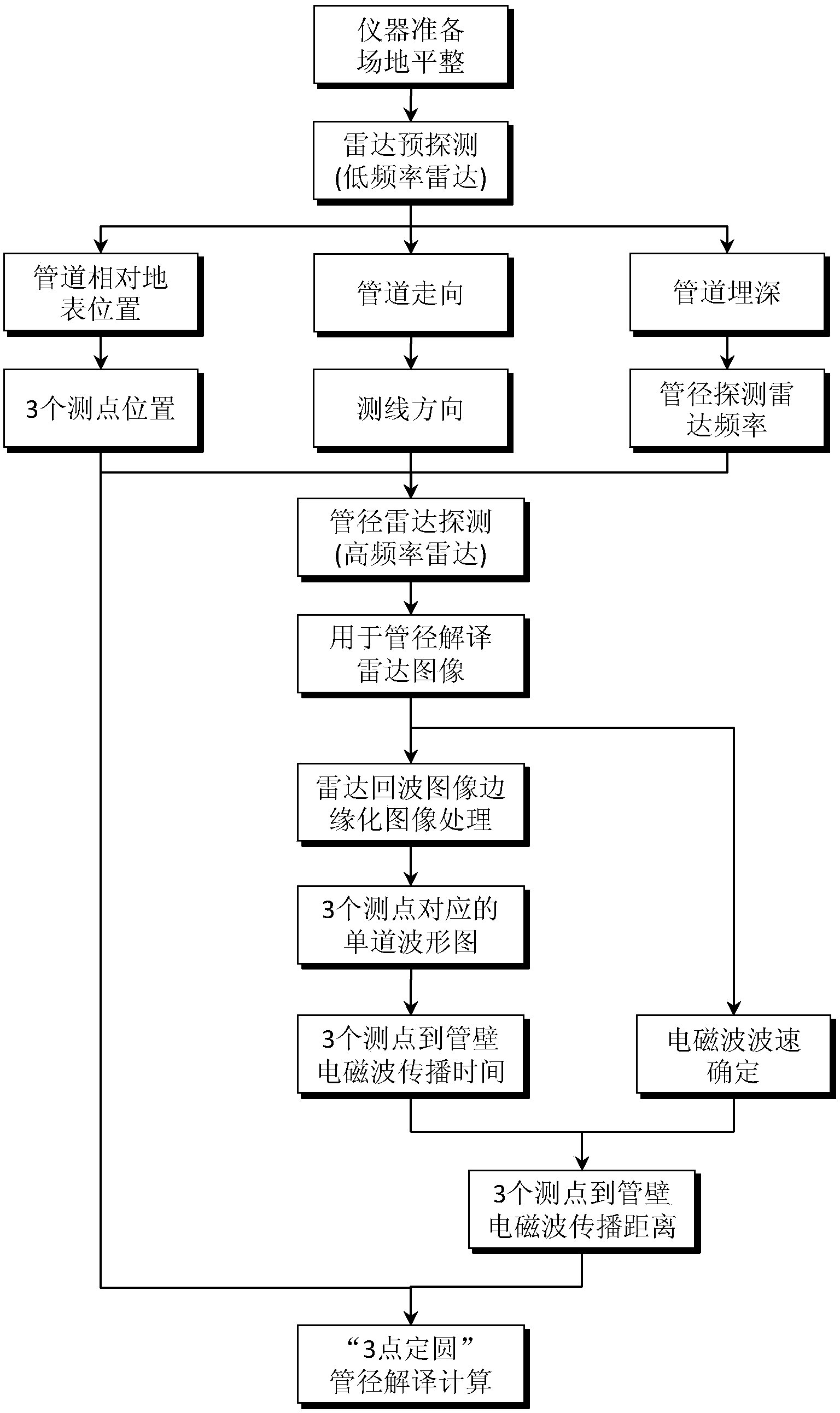

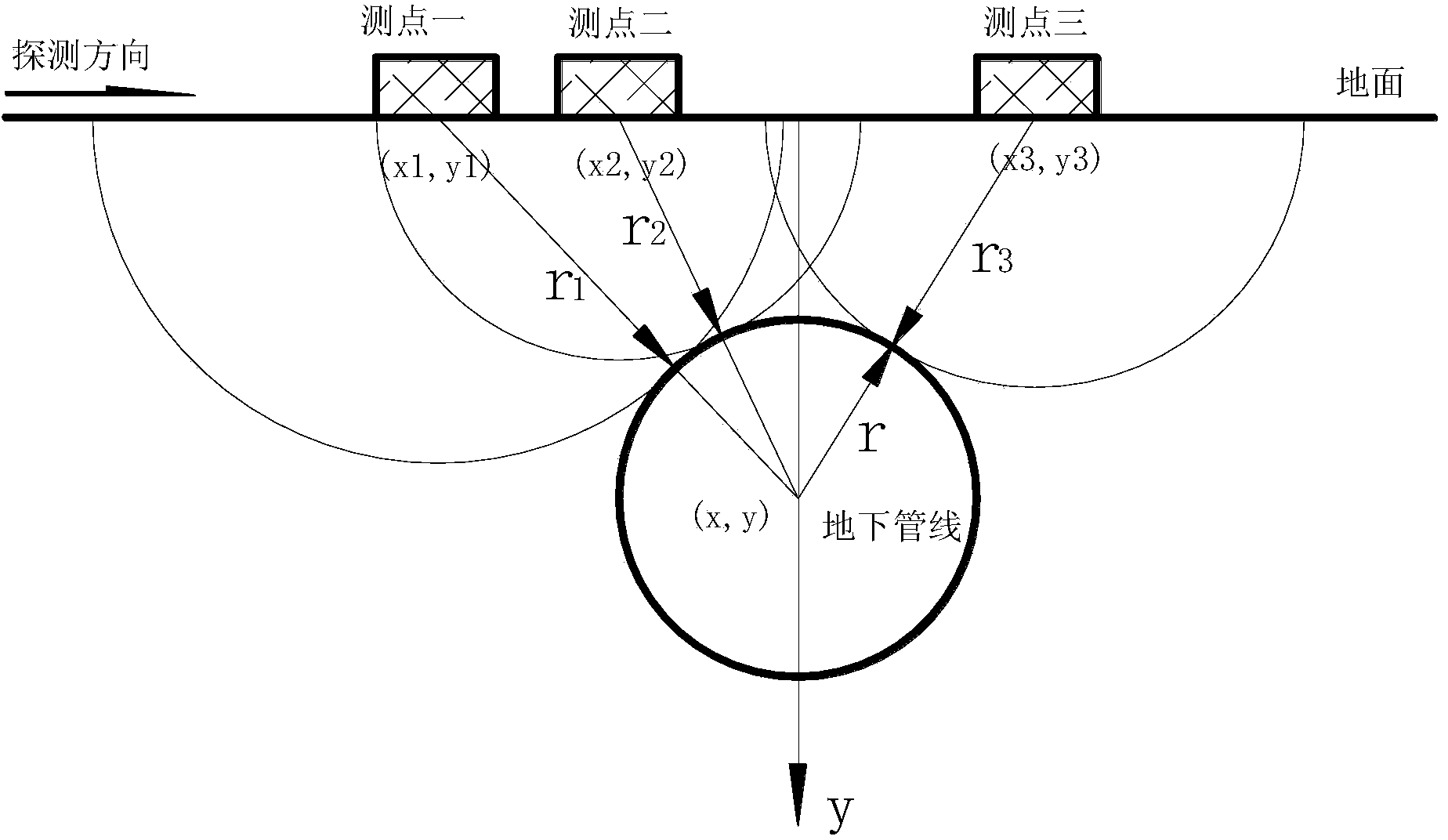

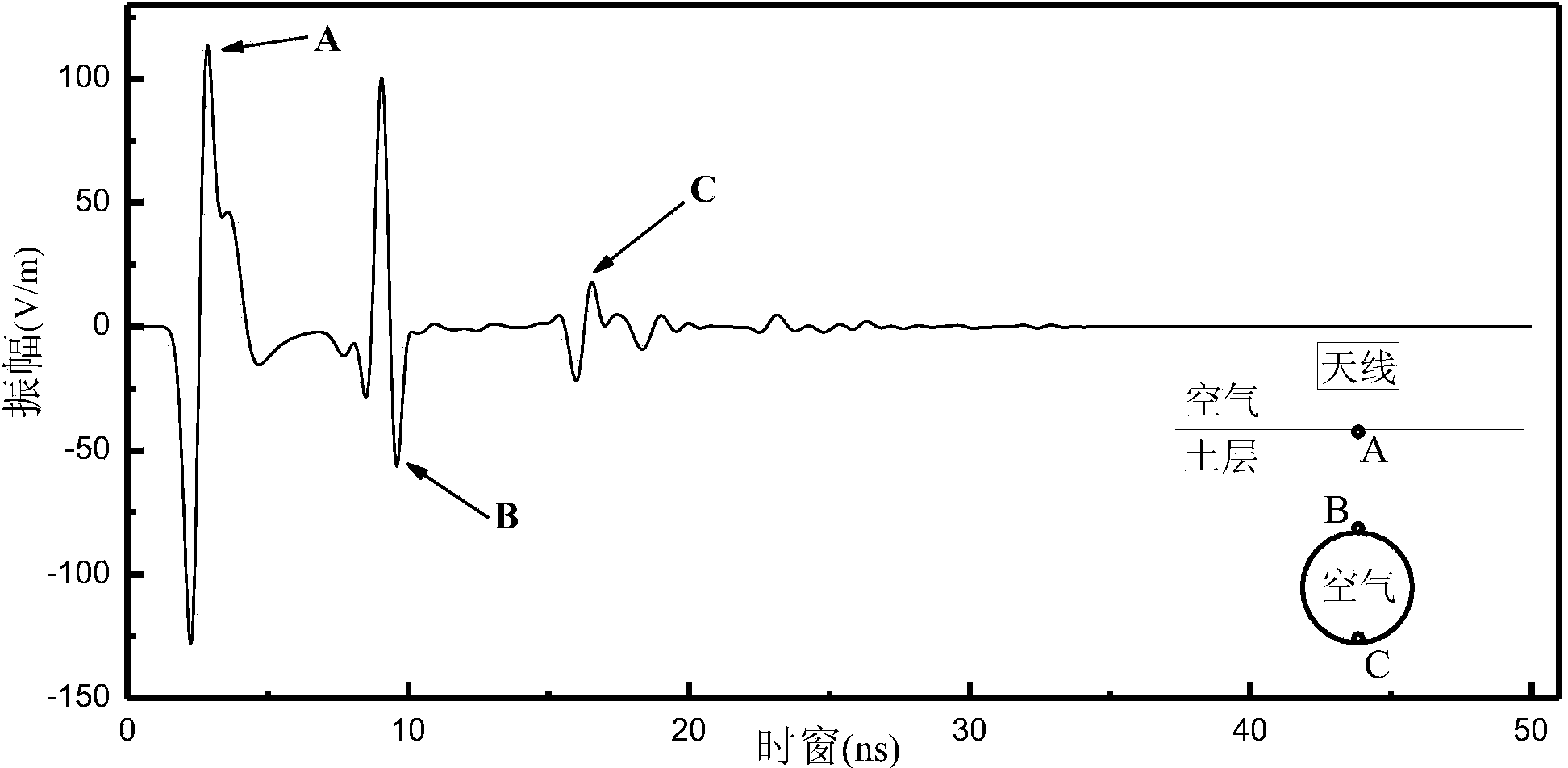

Operation period underground pipeline pipe diameter measuring method based on ground penetrating radar

InactiveCN103675922ASolve the difficulty of accurate positioningAvoid destructionDetection using electromagnetic wavesImage denoisingDielectric

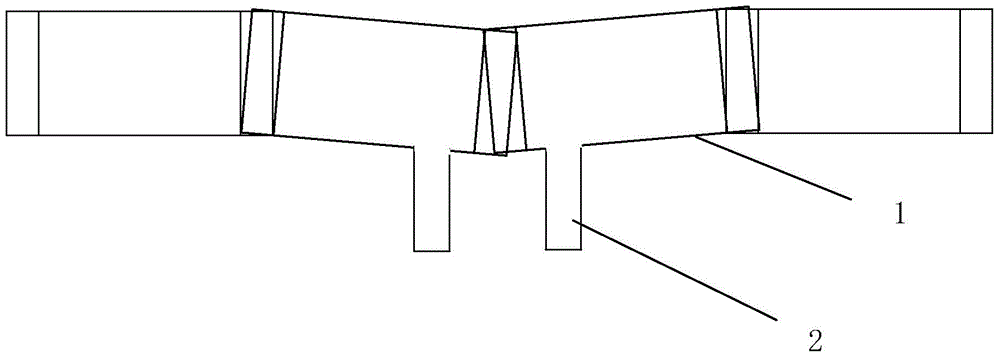

The invention provides an operation period underground pipeline pipe diameter measuring method based on a ground penetrating radar. The principle is that a ground penetrating radar electromagnetic wave reflection mechanism and a pipeline special circular shape are used for achieving underground pipeline pipe diameter detecting and interpreting under the non-excavation and non-disturbance situation when an operation period pipeline of an underground pipeline is filled with lossy dielectric. The implementation steps are that (1) on the basis that underground pipeline trend, burial depth, corresponding earth surface positions and proper radar frequency spectrum parameters are determined, ground penetrating radar detecting is carried out, and radar images of three measuring points in a radar measuring line direction above the pipeline are obtained by measuring; (2) on the basis of radar image denoising processing, electromagnetic wave single-track oscillographs corresponding to the coordinates of the three measuring points are extracted; (3) electromagnetic wave transmission time from the three measuring points to a pipe wall is determined through a single-track wave curve peak-valley value; (4) on the basis that field electromagnetic wave speed is determined, the transmission distance between the three measuring points and the pipe wall is obtained; and (5) the coordinates of the three measuring points and the electromagnetic wave transmission distance between the three measuring points and the pipe wall are used for computing the pipeline pipe diameter.

Owner:NANJING UNIV OF TECH

Underground pipeline sedimentation repair high polymer membrane bag grouting method

ActiveCN104652415AIncreased durabilityImprove performancePipe elementsEmbankmentsSocial benefitsEngineering

The invention relates to an underground pipeline sedimentation repair high polymer membrane bag grouting method. The method comprises the following steps: (1) detecting a sunken pipe segment, and determining a grouting scheme; (2) drilling a membrane bag accommodating hole; (3) placing a membrane bag; (4) injecting a high polymer material into the membrane bag; (5) lifting the pipe segment; (6) filling a gapped region and reinforcing a soft soil layer. The high polymer material is a non-water-reaction bi-component high polymer material. The method has the advantages of rapidness, minimal invasiveness, light mass, high toughness, economical efficiency, durability and the like, lifting repair of an underground sedimentation pipe segment can be rapidly realized, and a novel advanced, efficient, economical and practical scheme is provided for underground pipeline sedimentation repair. The method is successfully applied to a plurality of underground pipeline lifting projects, and has great economic and social benefits and wide development and application prospects.

Owner:SAFEKEY ENG TECHZHENGZHOU

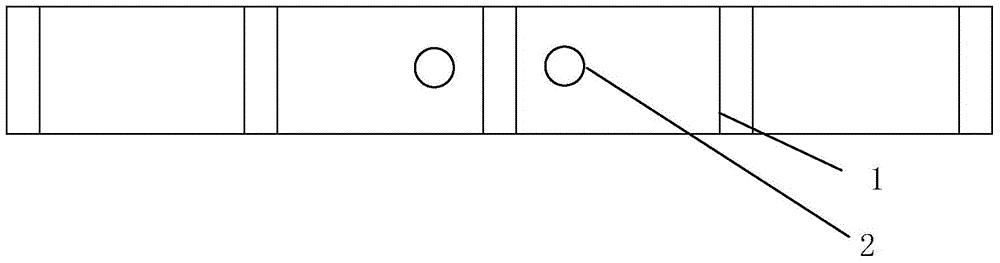

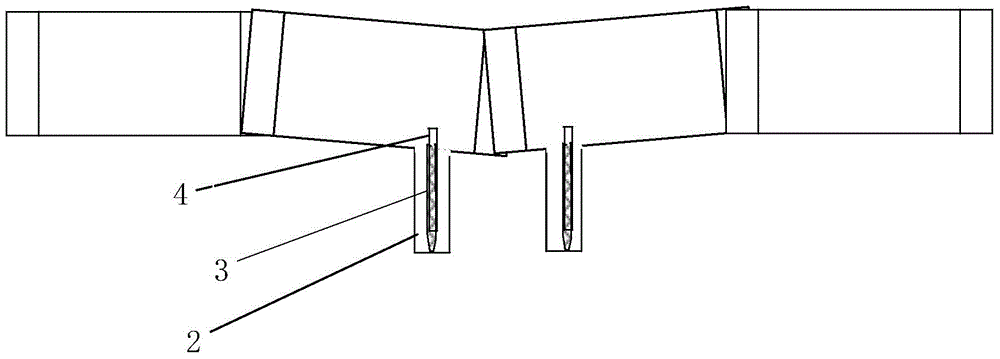

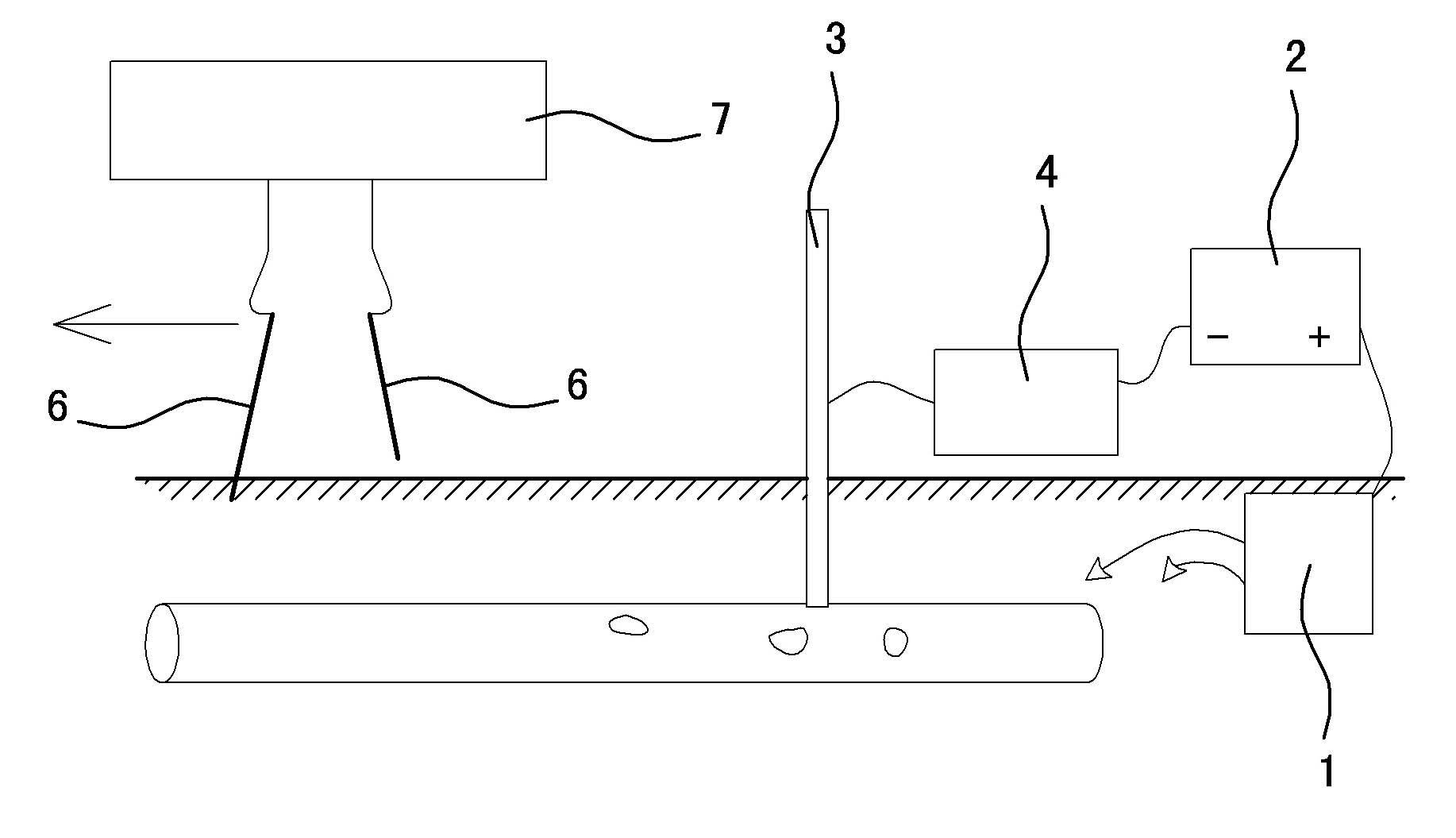

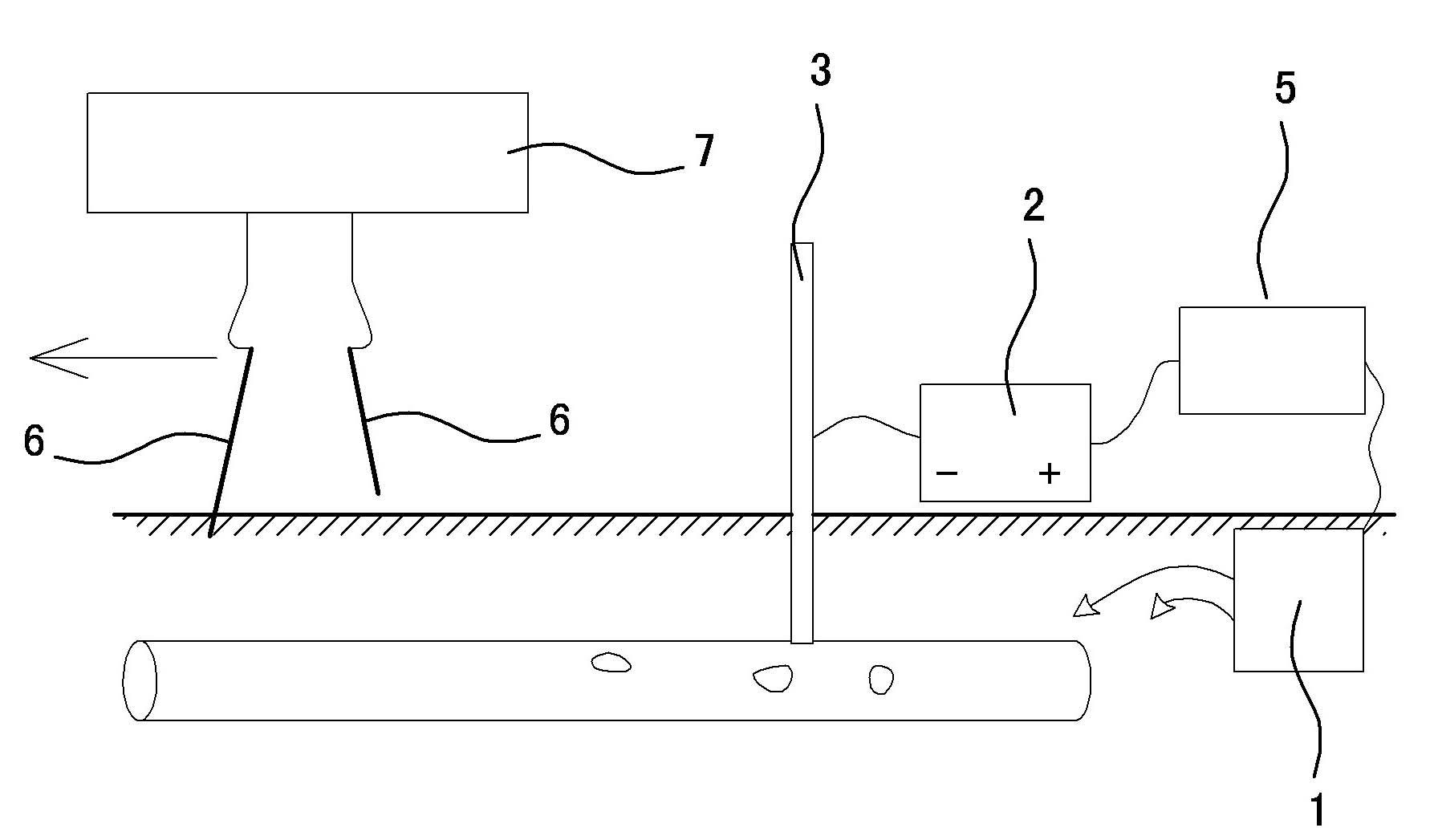

Accurate positioning and detecting method and device for damages of underground metal pipeline anticorrosive coating

ActiveCN102252168AHigh positioning accuracyImprove anti-interference abilityPipeline systemsThermodynamicsOvercurrent

The invention relates to an accurate positioning and detecting method and device for damages of an underground metal pipeline anticorrosive coating. The method comprises the following steps: a current interrupter periodically turns on or off a constant current source through the constant current source, and provides excitation signals for an underground pipeline; the ground voltages of two points along the underground pipeline route are measured by utilizing two saturation copper sulfate reference electrode detection canes which are connected with a signal measurement processor respectively; the signal measurement processor measures, records and displays the turn-on and turn-off of the pipe ground voltages; and the position of the damaged part of the underground pipeline can be determined according to the pipe ground turn-on and turn-off voltages. Through the method, the position of the damage point of the anticorrosive coating can be confirmed accurately, the detection accuracy of the damage for the underground pipeline anticorrosive coating is improved, and important guarantee is provided for mastering the normal operation situation of the pipeline, ensuring the safe operation of the pipeline and the convenience for pipeline maintenance and management.

Owner:HUADIAN ENERGY COMPANY LIMITED

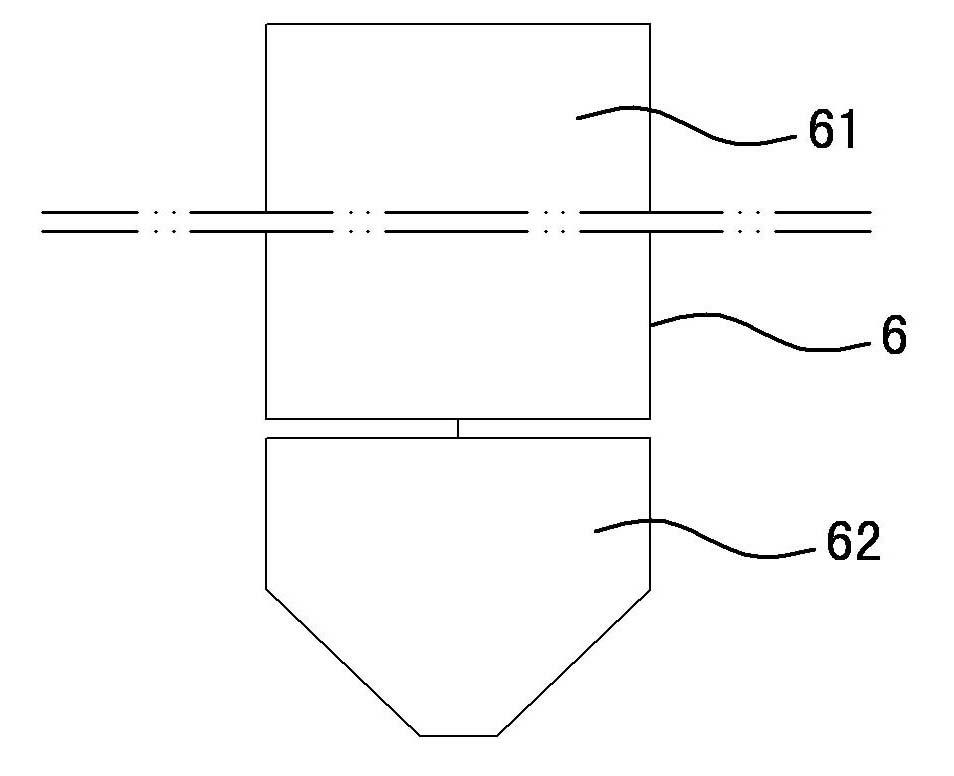

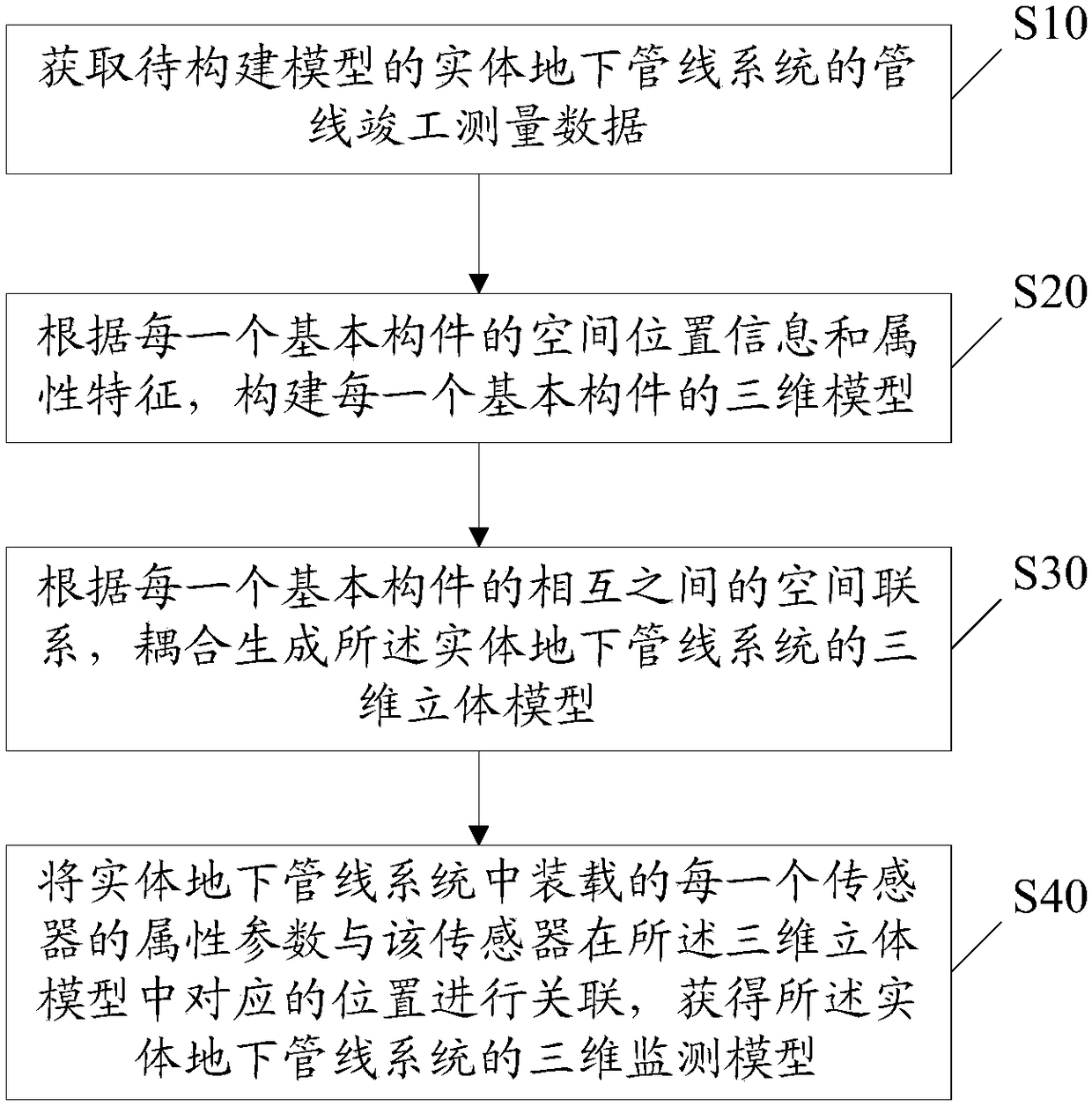

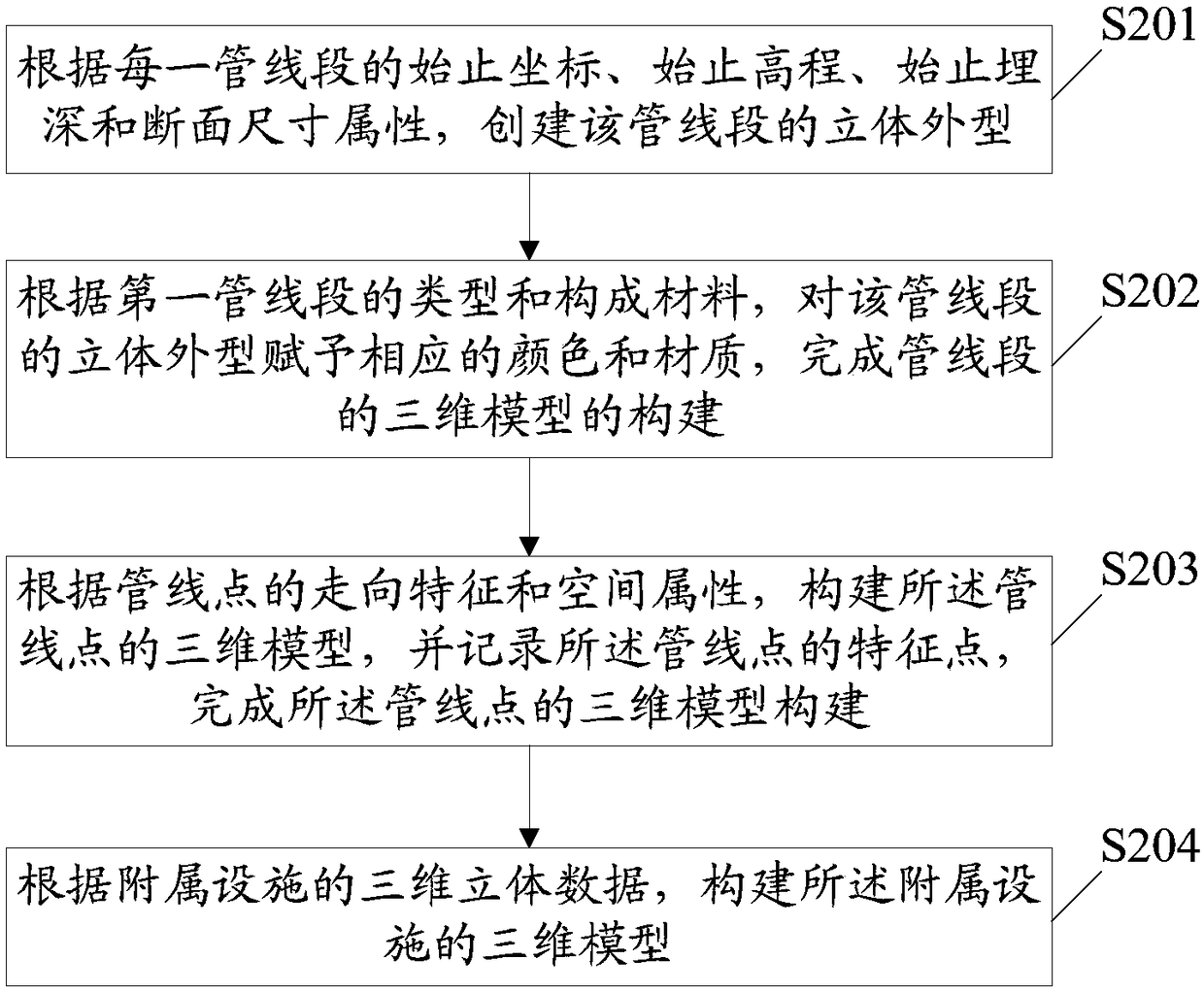

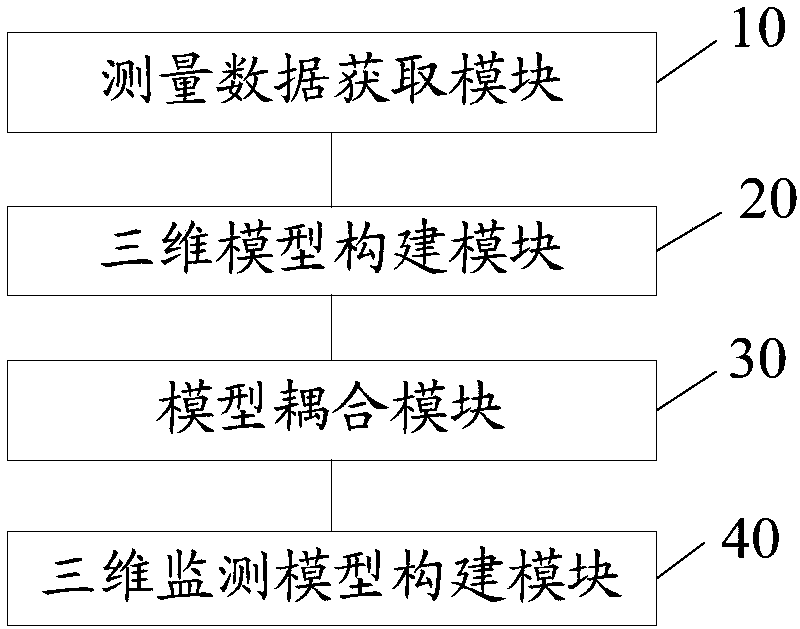

Method and device of establishment of three-dimensional monitoring model of urban underground pipelines, storage medium and terminal equipment

ActiveCN108399652AReal-time running status informationLive view3D modellingCouplingTerminal equipment

The embodiment of the invention discloses a method and a device of establishment of a three-dimensional monitoring model of urban underground pipelines, a storage medium and terminal equipment. The method includes: acquiring pipeline completion measurement data of an urban underground pipeline system of which a model is to be constructed; constructing a three-dimensional model of each basic component according to space location information and attribute features of each basic component; generating a three-dimensional stereoscopic model of the urban underground pipeline system in a coupling manner according to space connections among all the basic components; and associating real-time pipeline running state information acquired by each sensor loaded in the urban underground pipeline systemwith a corresponding location of the sensor in the three-dimensional stereoscopic model to obtain the three-dimensional monitoring model of the urban underground pipeline system. By implementing the method, the sensors are associated with the locations thereof in the three-dimensional stereoscopic model, and the formed three-dimensional monitoring model facilitates real-time acquisition of the real-time running status information of the urban underground pipelines.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

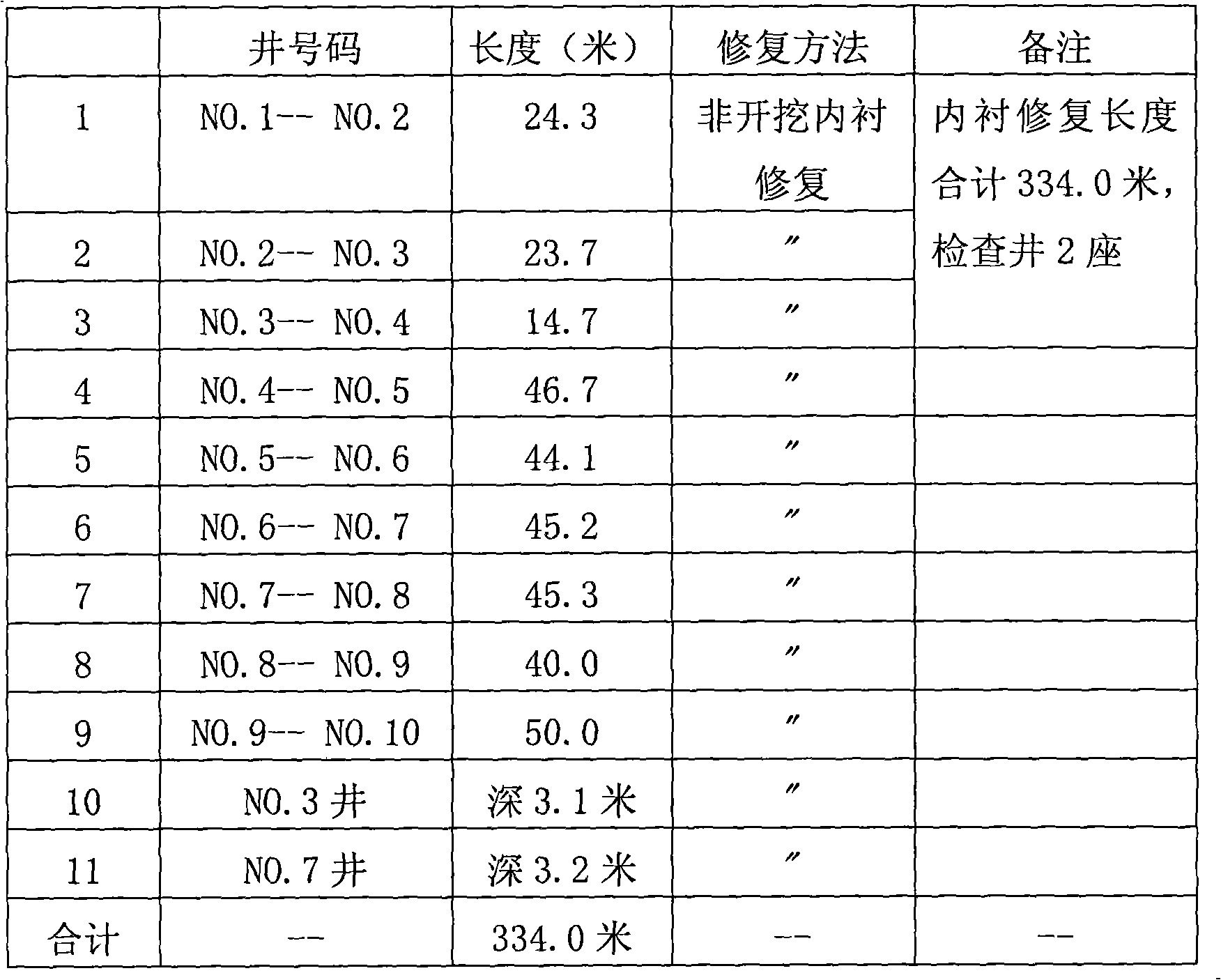

Method for repairing underground pipeline without digging

InactiveCN101649944AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a method for repairing an underground pipeline without digging, which comprises the following steps: (1) blocking and cleaning an old sewage pipeline needing repair and usingclosed circuit TV system (CCTV) equipment to detect the inner part of the pipeline; (2) delivering a waterproof barrel-shaped auxiliary lining hose pipe into the pipeline and injecting thermosetting resin to form a resin hose pipe; (3) turning over and inserting the resin hose pipe and a warm water delivery pipe for heating into the waterproof barrel-shaped auxiliary lining hose pipe; (4) expanding the resin hose pipe with water and compressed air so that the resin hose pipe is tightly attached to the inner wall of an old pipe, circularly heating by warm water and hardening and molding the thermosetting resin hose pipe so that the inner wall of the old pipe forms a new lining pipe with high strength; (5) opening pipe openings at both ends of the new lining pipe by cutting to smooth the pipeline; and (6) cutting at the extending positions of the pipe openings of the new lining pipe, which are positioned in the well wall of a check well. The method can prevent leakage, protect the pipe openings, prevent the thermosetting resin injected into the lining hose pipe from being mixed with underground water and prevent a poor phenomenon of lining material part hardening.

Owner:管丽环境技术(上海)有限公司 +1

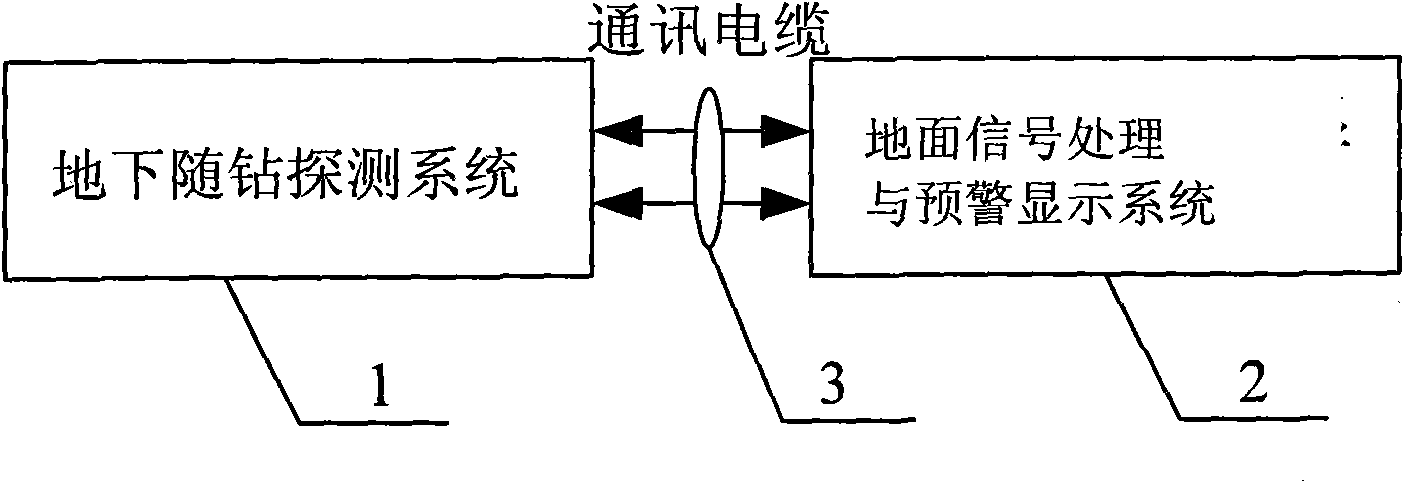

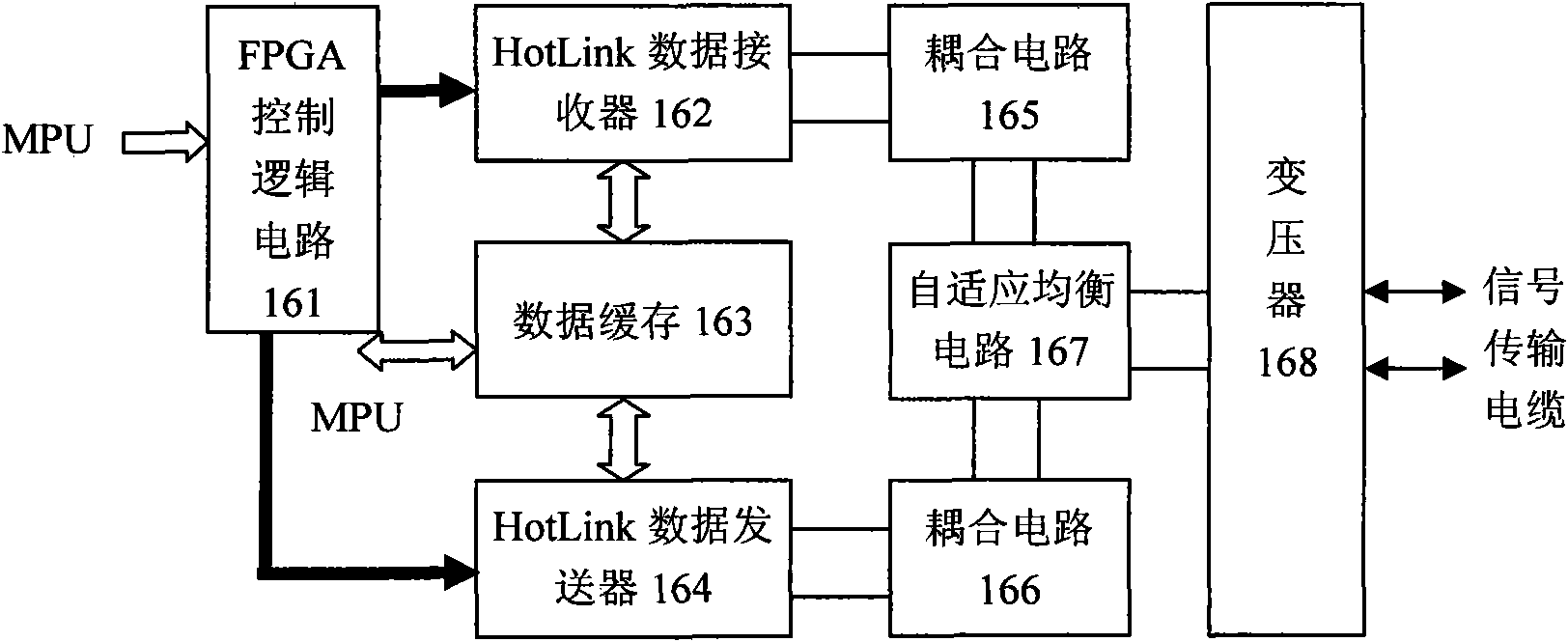

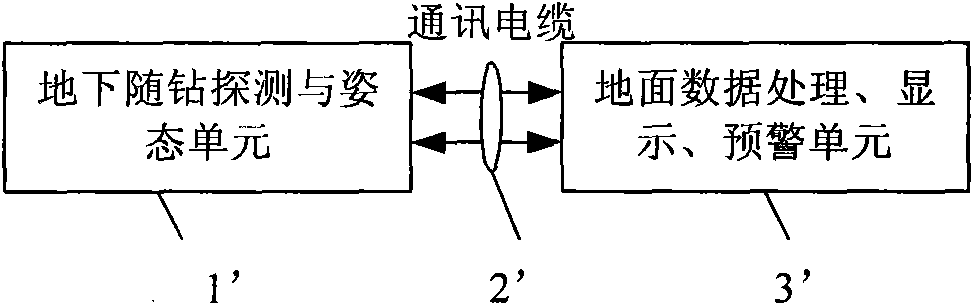

Horizontal guiding drill while-drilling detection early warning system

InactiveCN101676518AImprove detection accuracyReduce construction riskSurveyMining devicesData acquisitionAcoustic wave

The invention provides a horizontal guiding drill while-drilling detection early warning system which comprises an underground while-drilling detection system and a ground signal processing and earlywarning display system that are connected with each other by a two-core communication cable, so that high speed data communication can be realized; in the construction process, the underground while-drilling detection system works under the ground and adopts active acoustic detection technology for detecting, thus completing acquisition and transmission of data of underground pipeline detection; and the ground signal processing and early warning display system works on the ground and is used for controlling the underground while-drilling detection system, processing and displaying the detection data and alarming by sound and an indicator light according to the danger level of underground obstacles. The system combines the detection technique and the drilling construction technique so as torealize while-drilling detection early warning, can effectively detect the obstacle which is about 1m far from the advance locus of a horizontal guiding drill, has higher detection accuracy and effectively reduces the construction risk.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

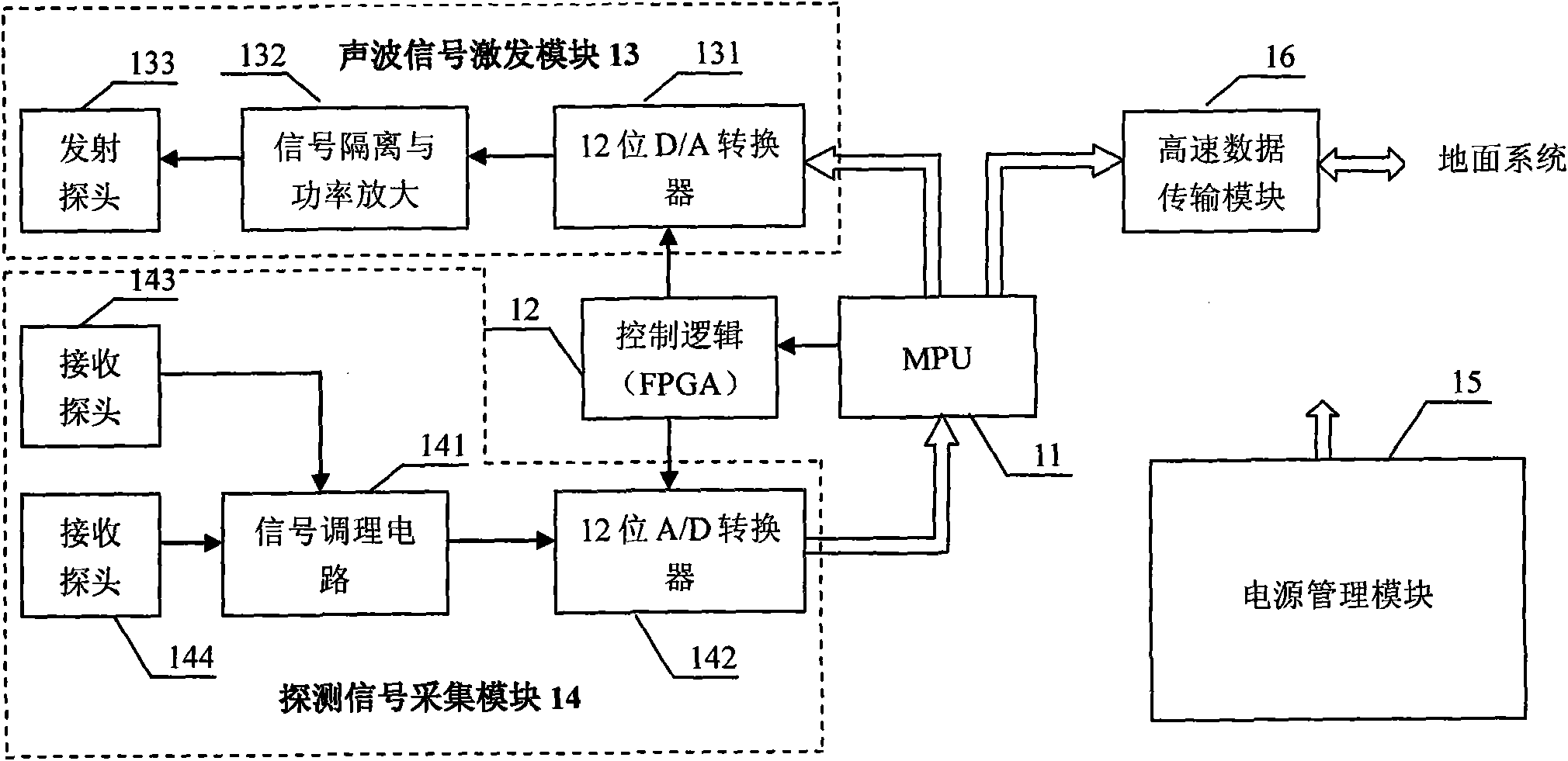

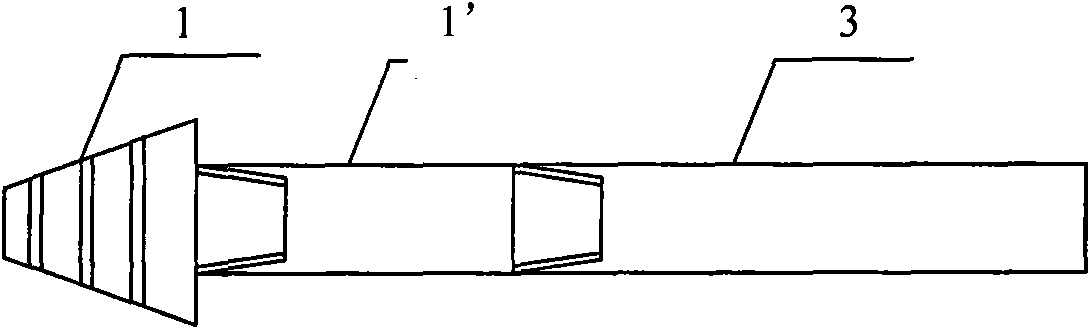

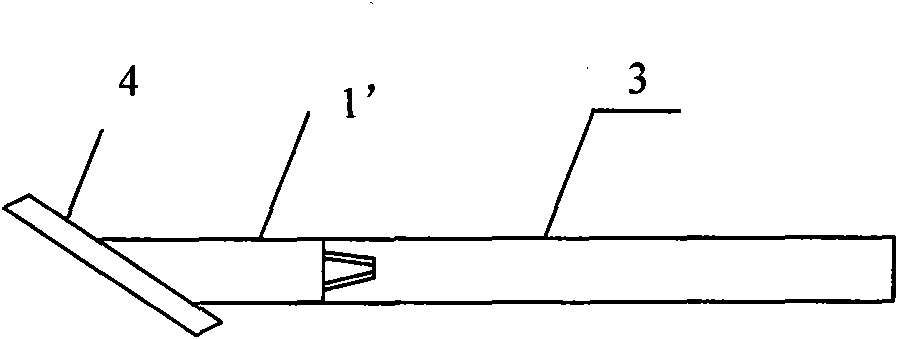

Horizontal guiding drill while-drilling acoustic wave imaging detection early warning system and detection method thereof

InactiveCN101676520AEasy to operateCompact and practical structure designSurveyMining devicesEarly warning systemData processing system

The invention relates to a horizontal guiding drill while-drilling acoustic wave imaging detection early warning system which comprises an underground while-drilling detection and attitude measurementsystem and a ground data processing system that are connected with each other by a communication cable; wherein the underground while-drilling detection and attitude measurement system is installed between a drill rod on a horizontal guiding drill and a back-drawing device (or a guide plate) and comprises a while-drilling detection system and a while-drilling attitude measurement system which arerespectively connected with the communication cable, and a power supply administration module respectively connected with the while-drilling detection system and the while-drilling attitude measurement system by circuits; when in construction by using the horizontal guiding drill, construction and detection are carried out at the same time, and underground pipelines existing near the constructionlocus can be detected in real time; when in danger, the early warning system gives an alarm to operating staff of a drilling machine; meanwhile, the construction route map of the horizontal guiding drill can be accurately drawn, and the distribution situation of the pipelines existing near the construction route can be provided by combining the detection early warning information.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com