Nuclear rector pressure vessel nozzle safe end welding joint automatic ray inspection device

A technology for pressure vessels and nuclear reactors, applied in nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve the problems of low inspection efficiency and long time occupied by the reactor, and achieve the effects of improving inspection efficiency, providing economic benefits, and shortening the time occupied by the reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

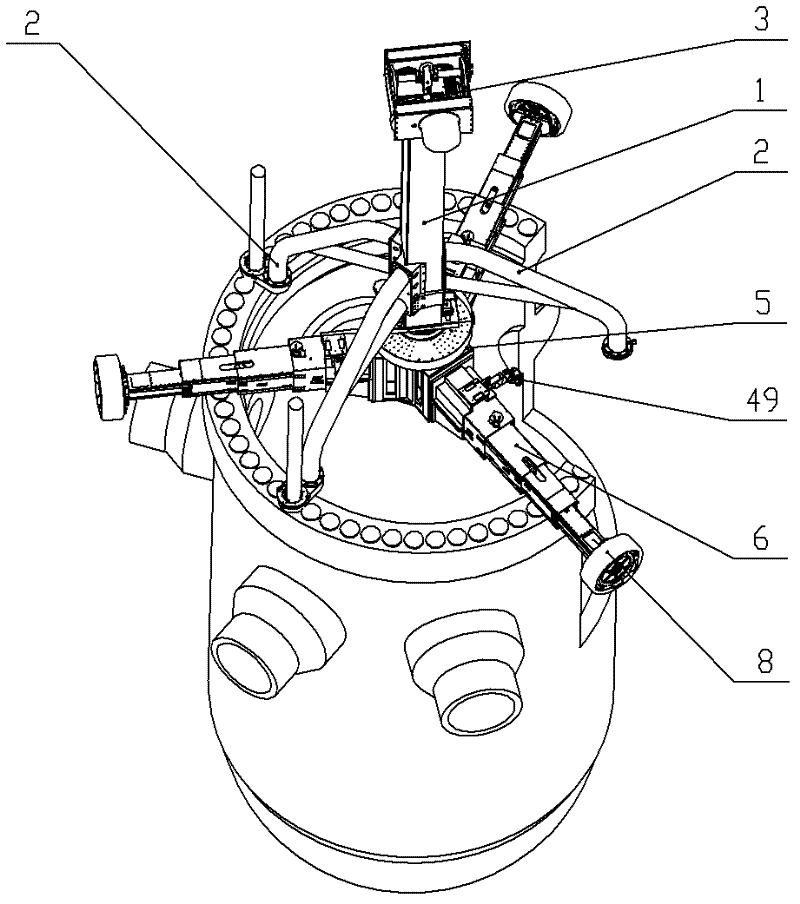

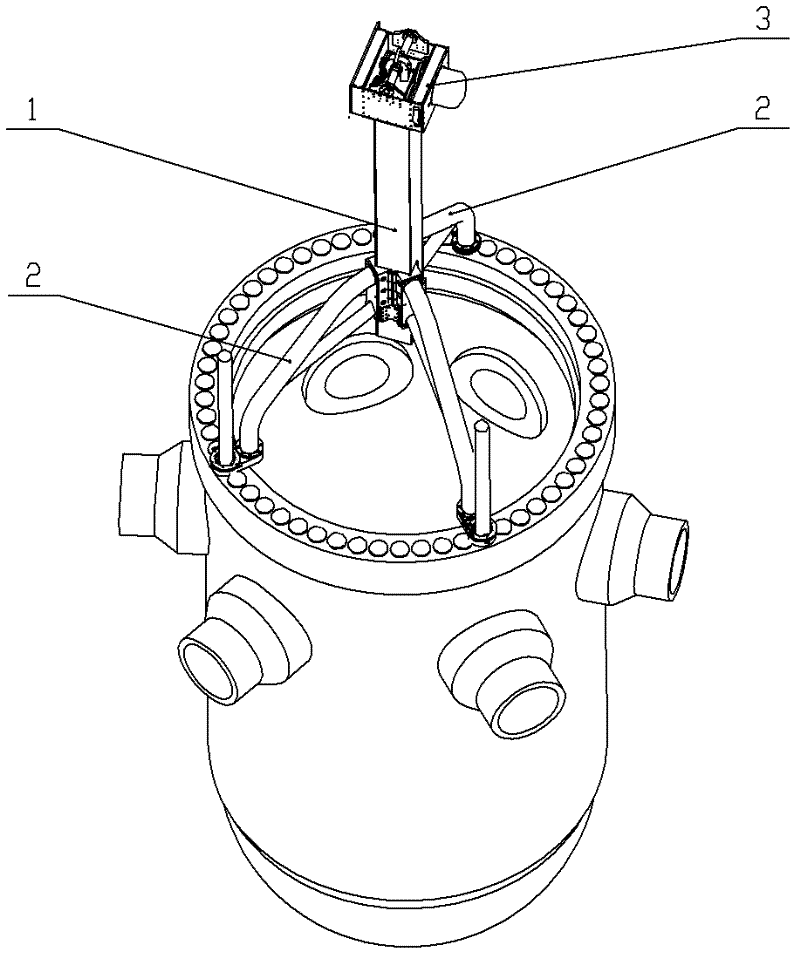

[0036] The technical scheme of the present invention is described in detail below in conjunction with the embodiment shown in the accompanying drawings:

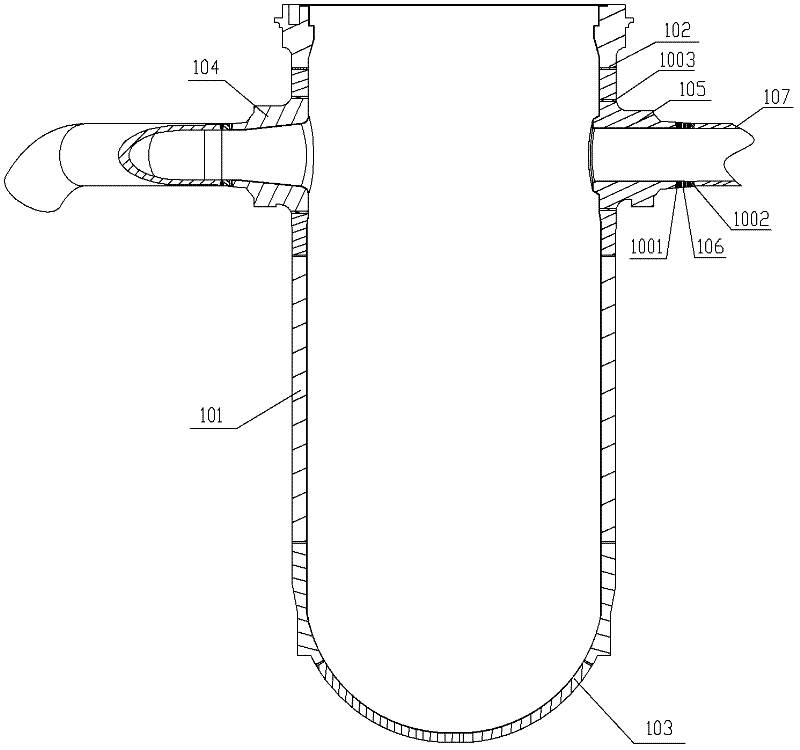

[0037] as attached figure 2 to attach Figure 13 As shown, the nuclear reactor pressure vessel nozzle safety end weld automatic ray inspection equipment of the present invention includes a support positioning mechanism, a main rotation mechanism, and three inspection arm mechanisms evenly distributed in the circumferential direction. The main function of the support positioning mechanism is to turn the entire inspection device It is positioned on the flange surface of the reactor pressure vessel and provides an upward and downward linear movement along the central axis of the reactor pressure vessel. The supporting positioning mechanism includes inner and outer double-layer square tubular columns located in the center, and one end is fixedly installed on the outer A plurality of supporting legs 2 on the column 1 are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com