Shed-frame method for shallowly burying large-sized underground structure construction

An underground structure and large-scale technology, applied in the field of scaffolding method, can solve the problems of high safety risk, slow construction speed and high cost, and achieve the effect of reasonable technology, fast construction speed and large construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

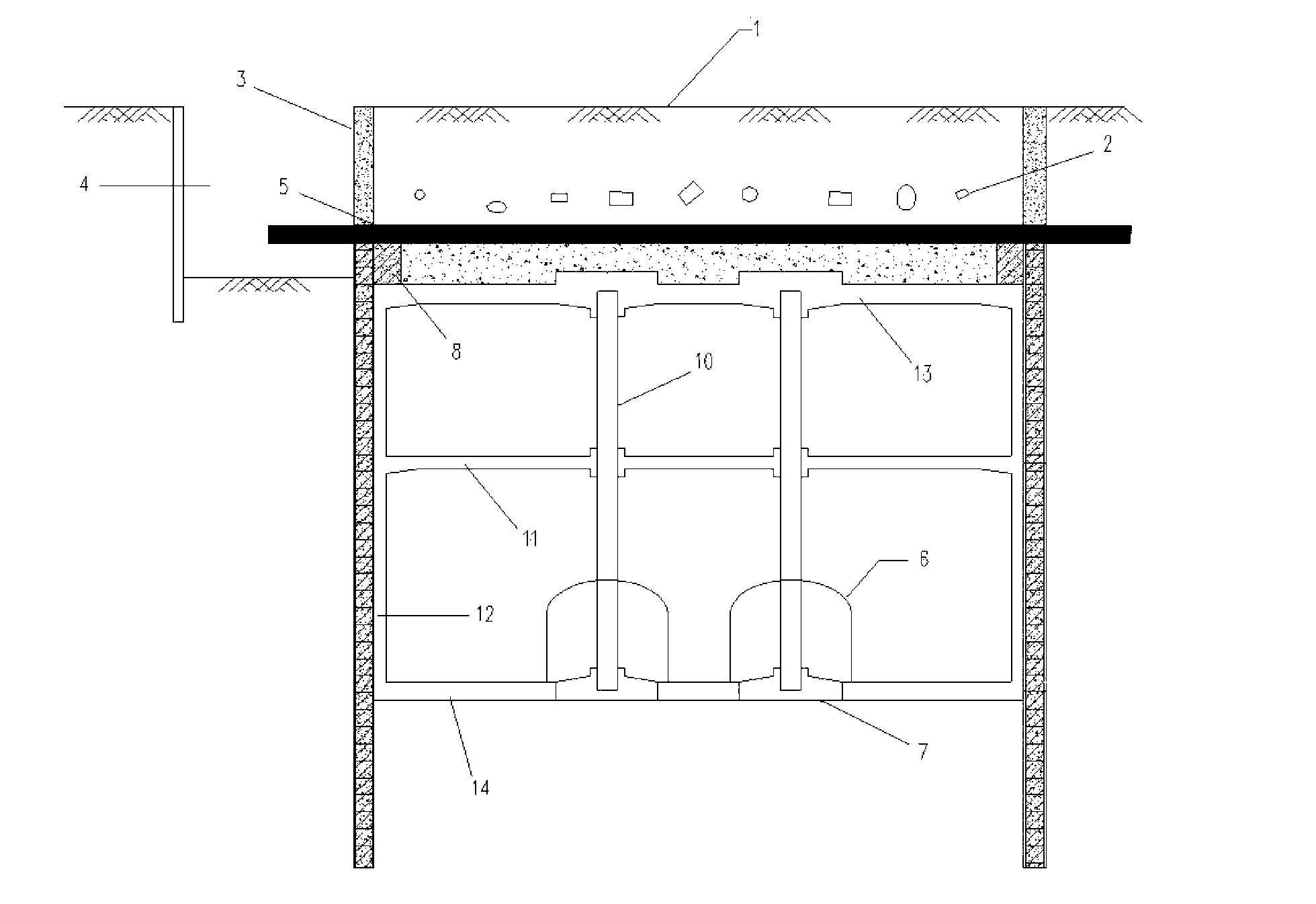

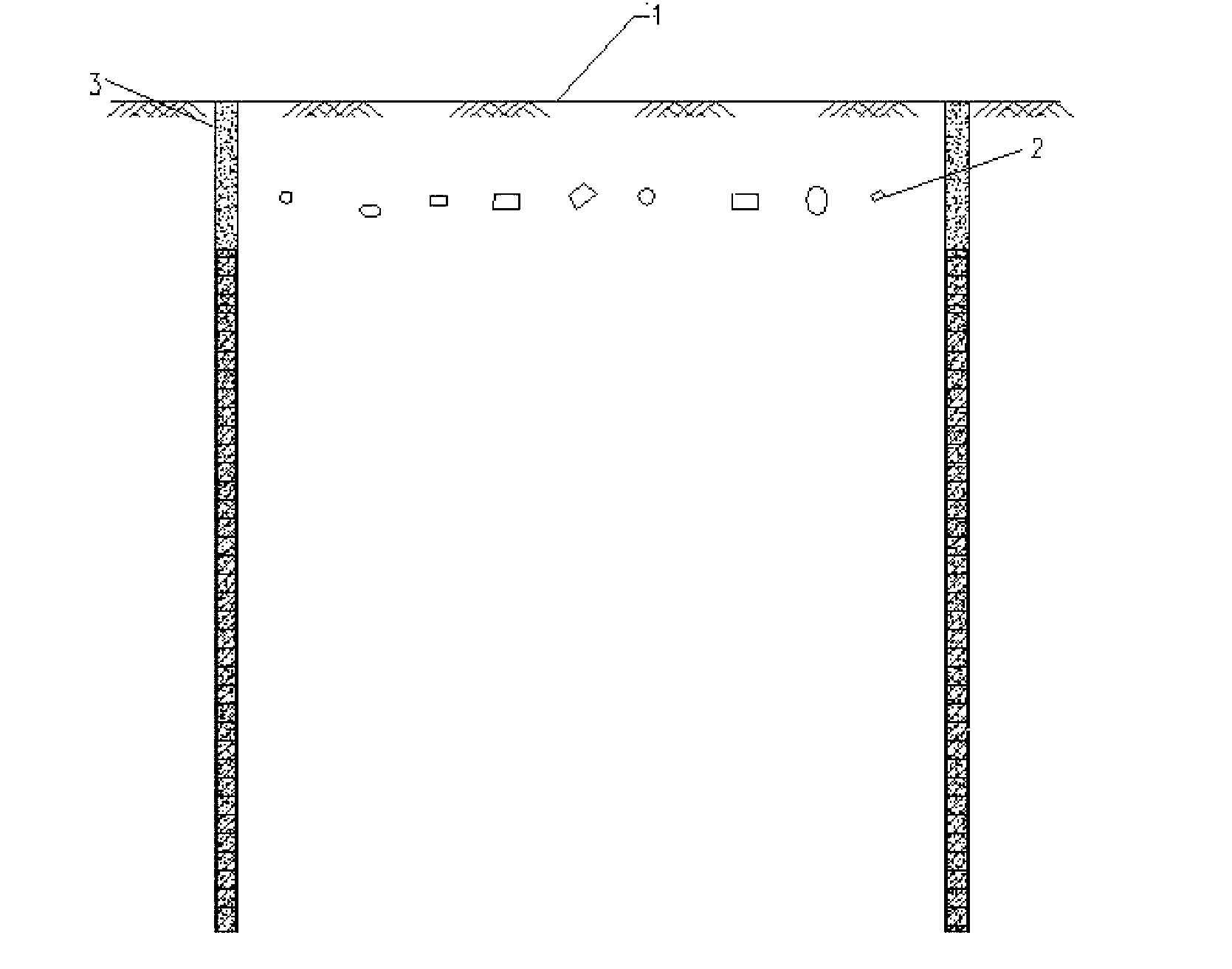

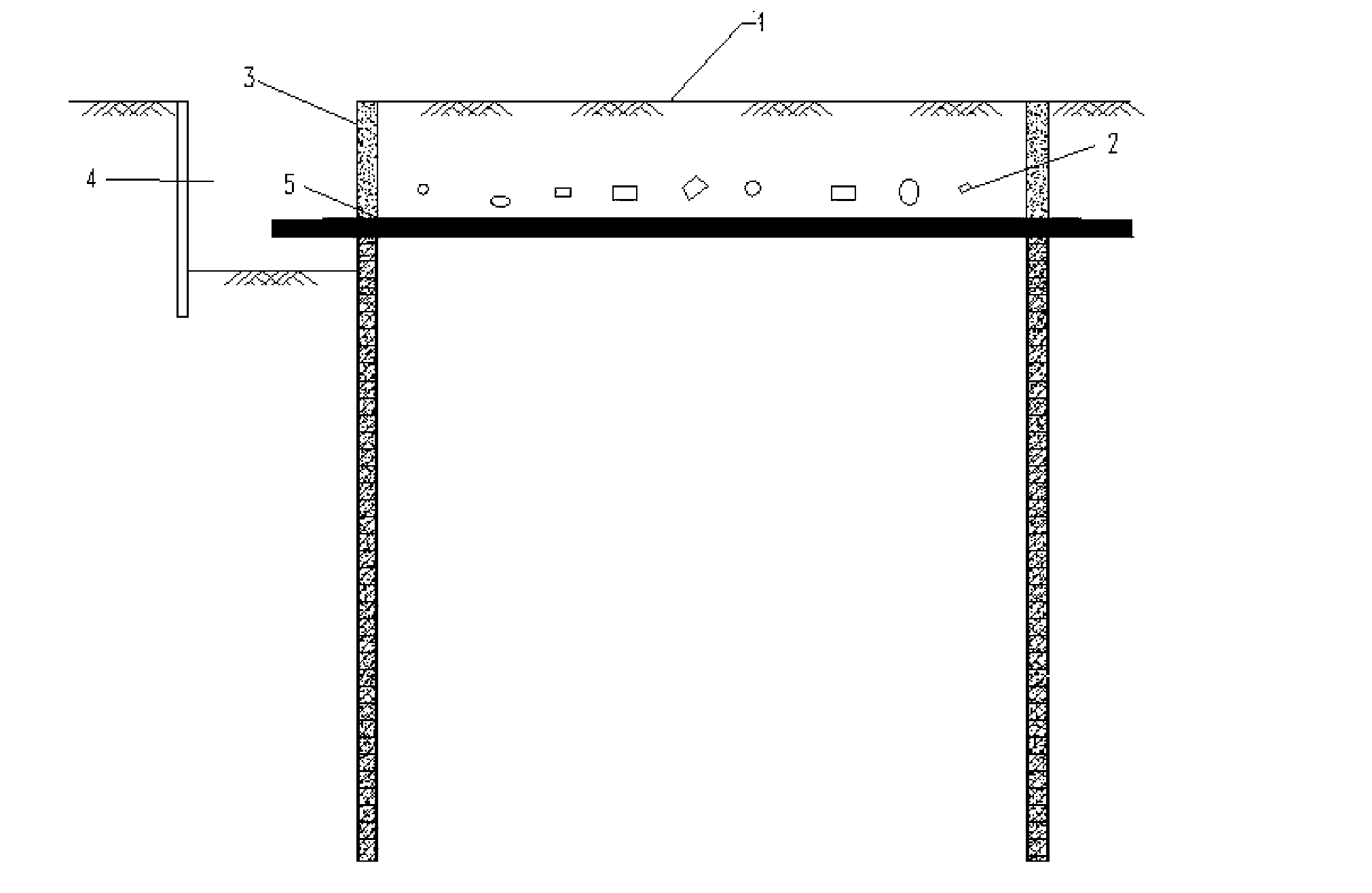

[0018] Such as Figure 1-15 As shown, an embodiment of a shallow-buried, double-layer, two-pillar, three-span subway station under an urban road of the present invention adopts a scaffolding method for constructing shallow-buried large-scale underground structures of the present invention, and its main structure is made of cast-in-situ steel bars The concrete bottom plate 14, the middle plate 11, the side wall 12 and the concrete-filled steel tube column 10 are composed (the structure is as figure 1 (Shown), the thickness of the structure top covering soil is 5.5m, the size of the excavation section is 19.7m×22.5m, the enclosure structure 3 adopts an underground continuous wall, and in conjunction with the drawings, the construction procedure of the present invention will be further described in detail.

[0019] The construction steps of the scaffolding method in this embodiment are:

[0020] The first step: adopt the method of 1 stage enclosure on the ground road surface, construc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com