Lifting self-discharging mechanism used for full electric vehicle

A technology of pure electric vehicles and self-unloading, which is applied in the direction of inclined load-carrying vehicles, etc., can solve the problems of complex structure of hydraulic lifting mechanism, high transmission efficiency of pure electric vehicles, and easy leakage of pipelines and other components, so as to achieve easy implementation , simple structure and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below with reference to the drawings and examples.

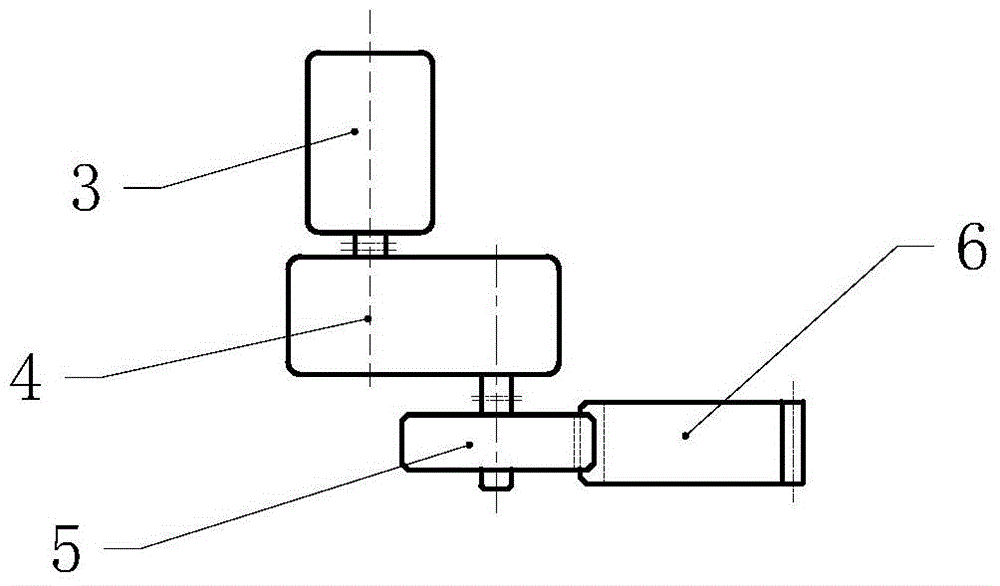

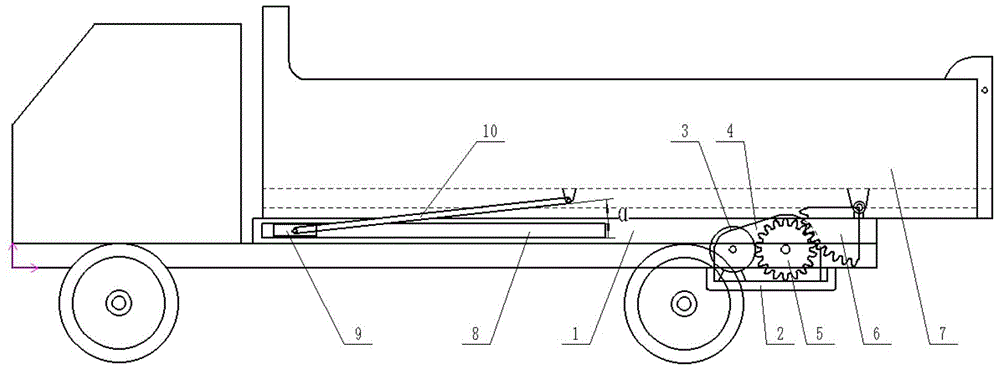

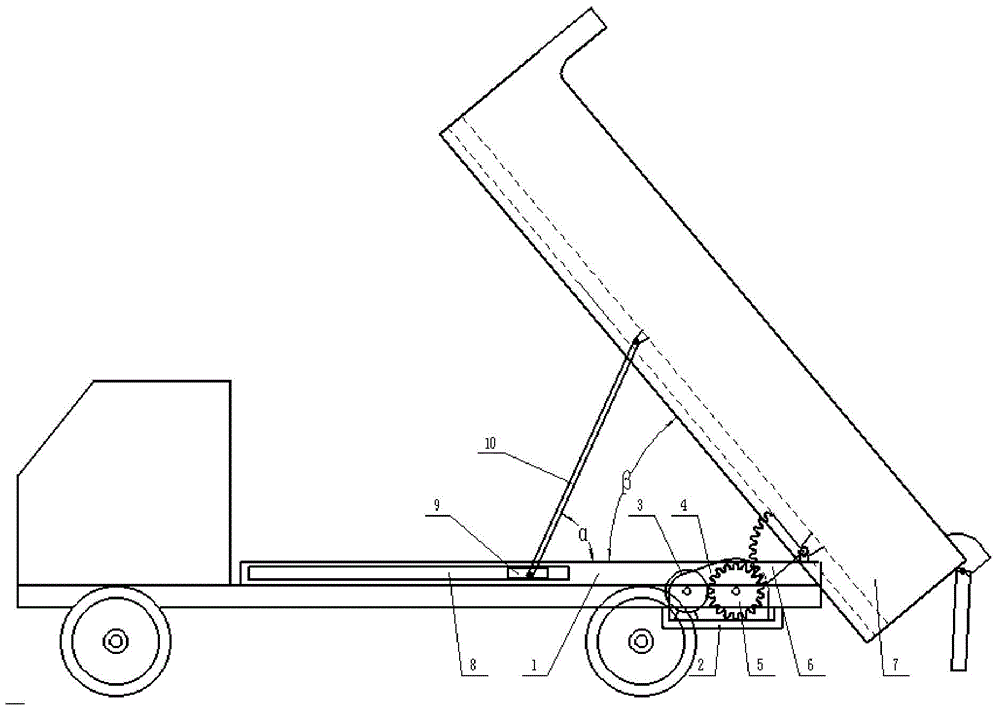

[0035] The lifting and dumping mechanism for small-tonnage pure electric vehicles provided by the present invention is a mechanically driven rear tipping dump truck lifting mechanism, and its structure is as follows figure 2 Shown: by the frame 1, the beam 2, the electric motor 3, the mechanical drive box 4, the spur gear 5, the sector gear 6, the carriage 7, the rail groove 8, the slider 9, and the tie rod 10. The lifting mechanism is powered by an electric motor and powered by an on-board power battery pack. Among them: the electric motor 3 and the mechanical drive box 4 are both installed on the rear cross beam 2 of the frame; figure 1 As shown, the output shaft of the motor 3 is coaxial with the input shaft of the mechanical drive box 4, and is connected by a coupling. The output shaft of the mechanical drive box is installed with a spur gear 5; the sector gear 6 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com