Light-weight electric automobile

A light-weight technology for electric vehicles, applied to vehicle parts, superstructures, superstructure subassemblies, etc., can solve the problems of pure electric vehicles such as increased curb weight, large battery cost ratio, and low mass-to-capacity, so as to reduce welding The investment of equipment cost, low investment cost, and the effect of improving driving mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

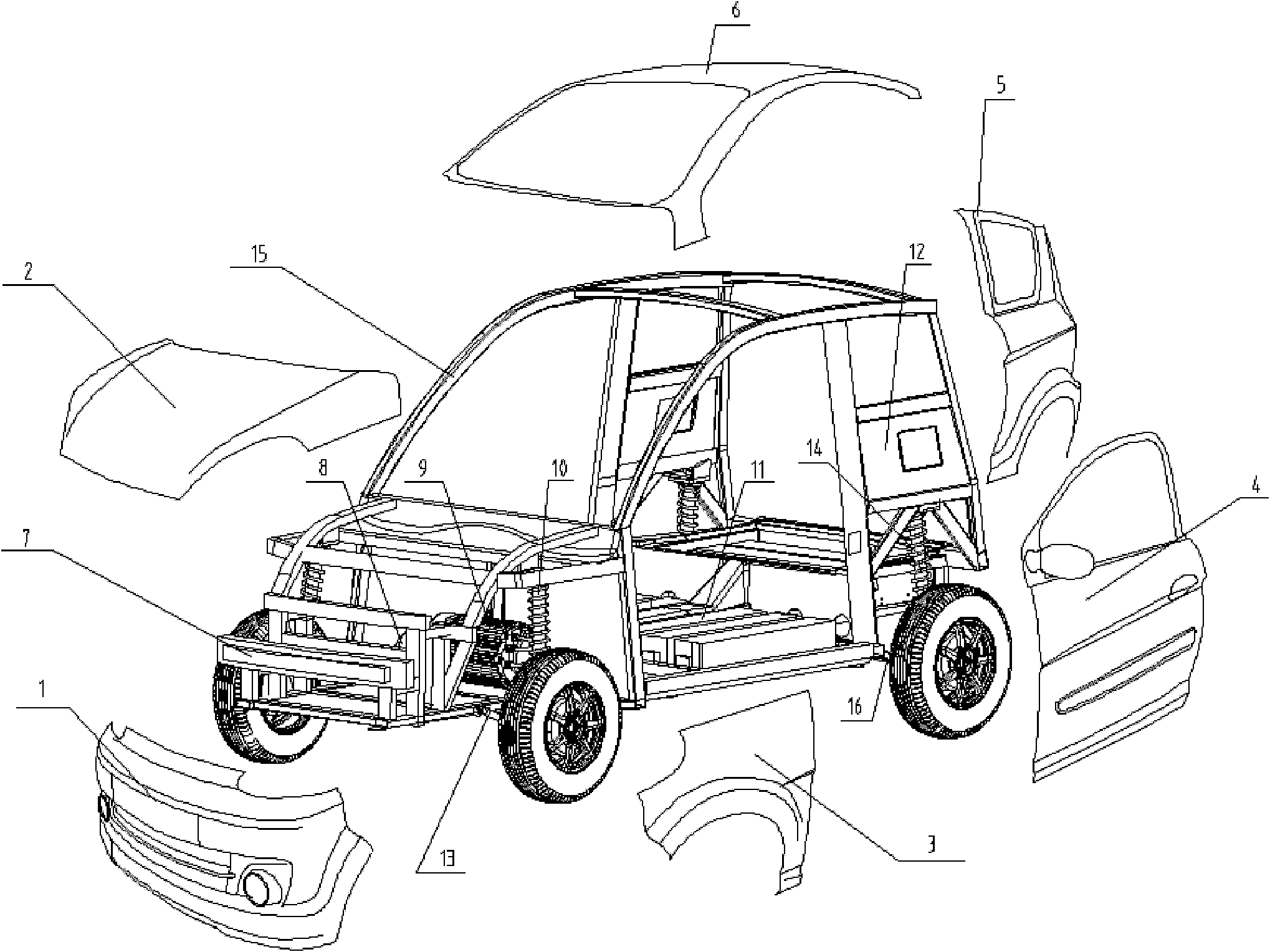

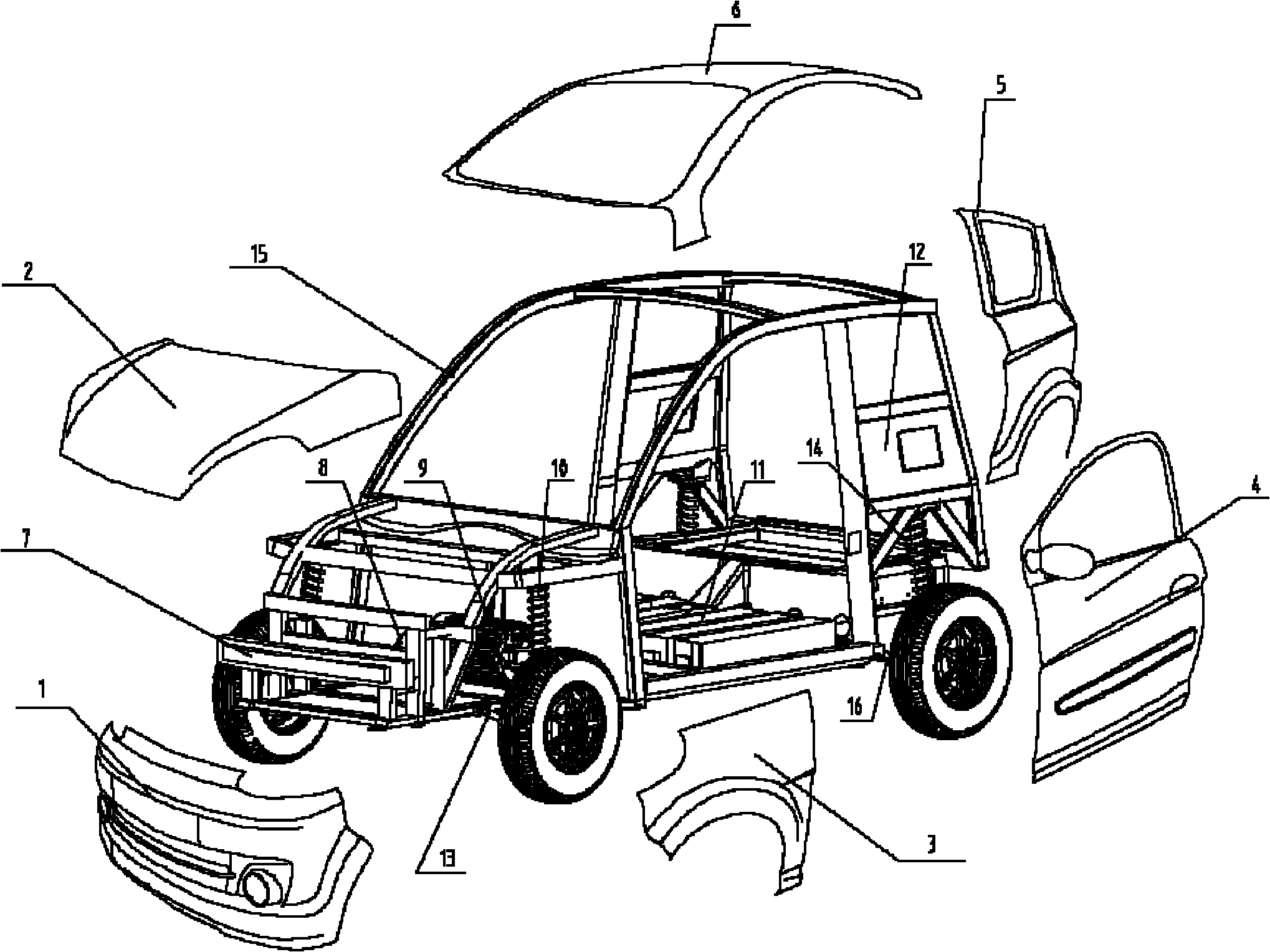

[0012] As shown in the figure, 1. bumper, 2. front hatch, 3. left and right front fenders, 4. left and right doors, 5. left and right side panels, 6. top cover, 7. front anti-collision beam, 8. deceleration Box assembly, 9. AC asynchronous motor, 10. Front shock absorption system, 11. Power battery, 12. Honeycomb aluminum, 13. Front suspension, 14. Rear shock absorption system, 15. Body frame assembly, 16. Rear suspension.

[0013] The lightweight design of the vehicle mainly focuses on the new material body panels and the all-aluminum full load-bearing body frame, and other integrated powertrains are also based on lightweight design considerations. The body cover includes front and rear bumpers 1, a front hatch 2, left and right front fenders 3, left and right doors 4, left and right side panels 5, a top cover 6, and a rear hatch.

[0014] The body cover is made of high-strength carbon fiber composite material. The carbon fiber composite material is made of two layers of T20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com