Patents

Literature

42 results about "Curb weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curb weight (American English) or kerb weight (British English) is the total mass of a vehicle with standard equipment and all necessary operating consumables such as motor oil, transmission oil, coolant, air conditioning refrigerant, and sometimes a full tank of fuel, while not loaded with either passengers or cargo.

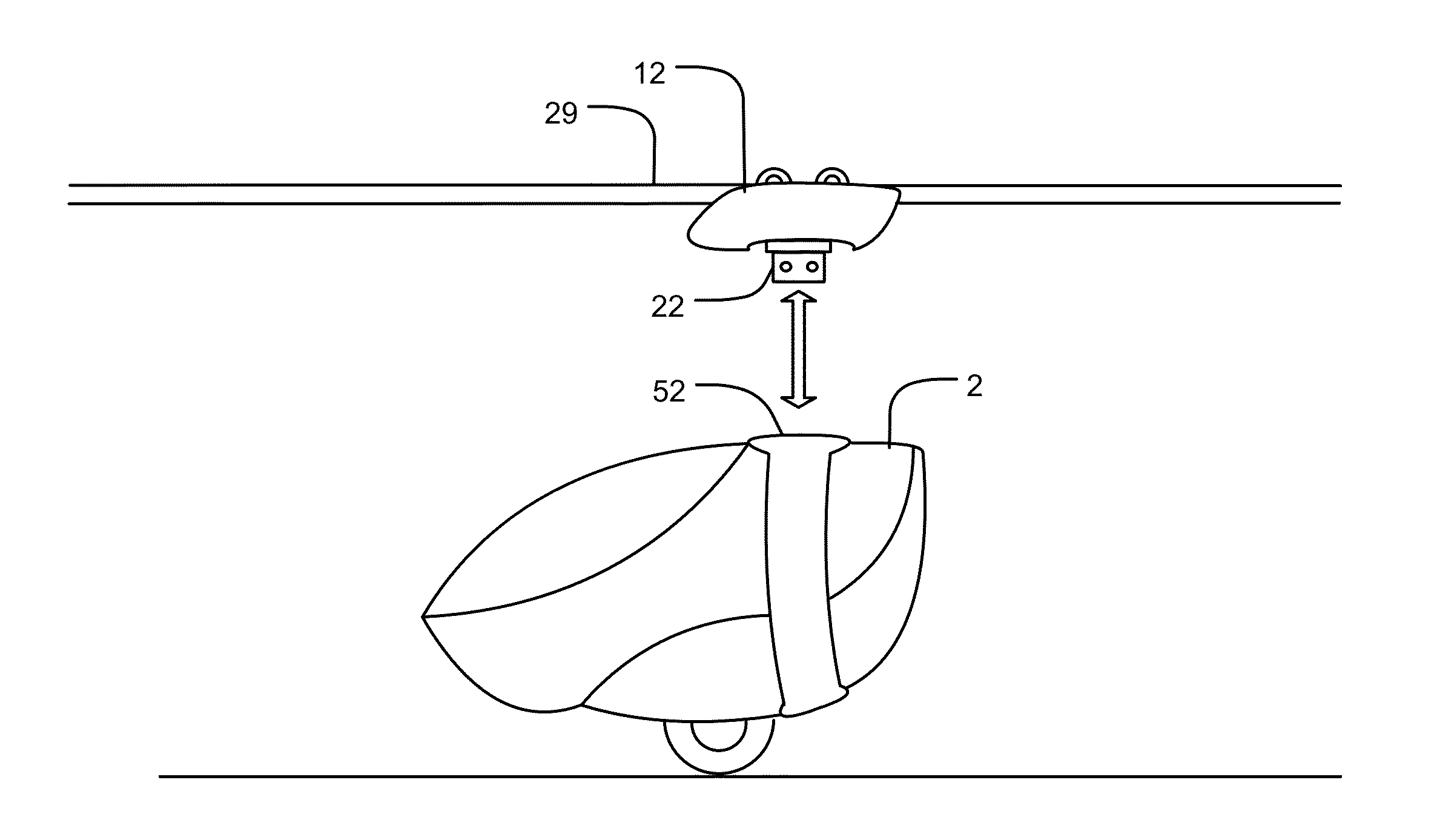

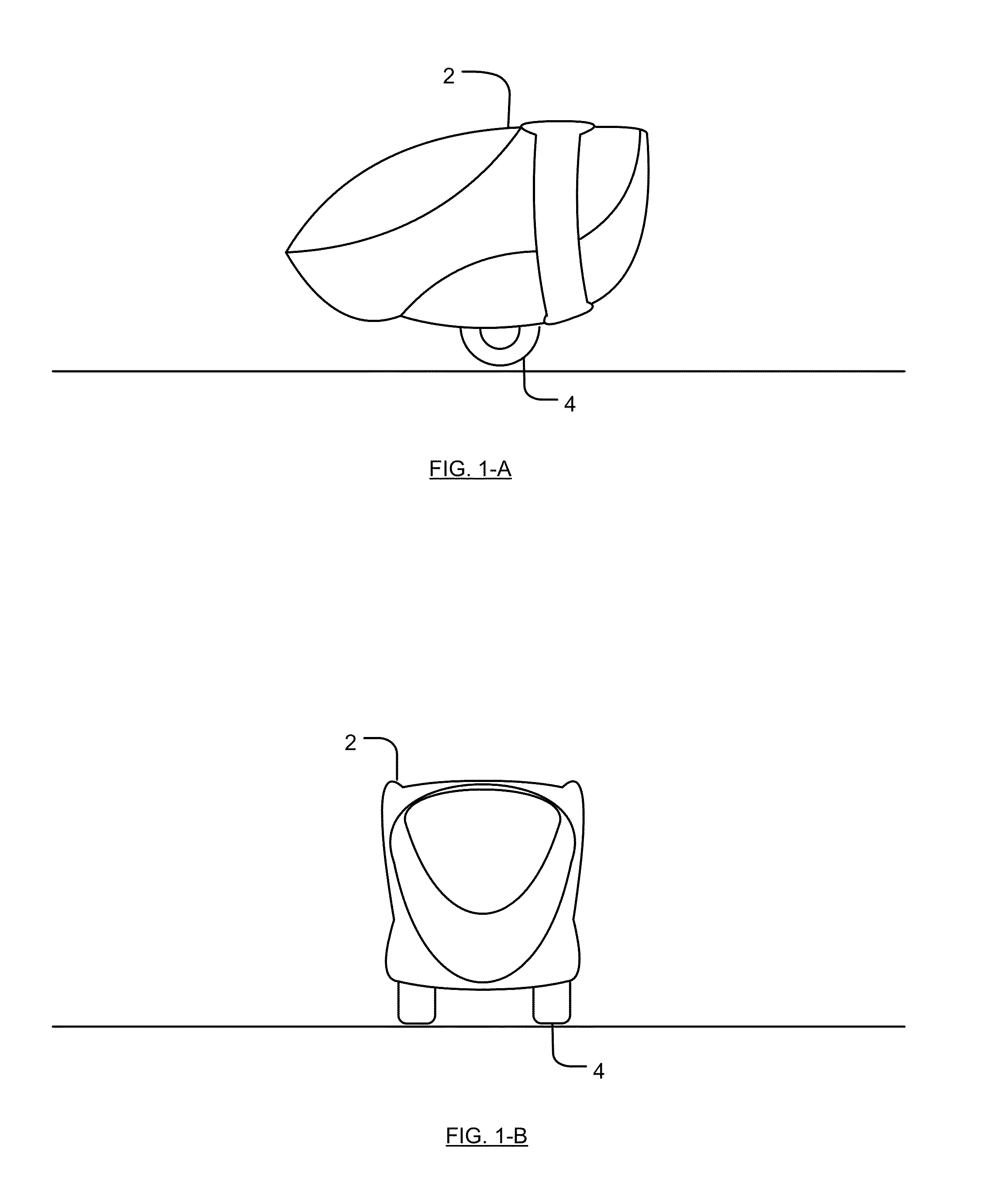

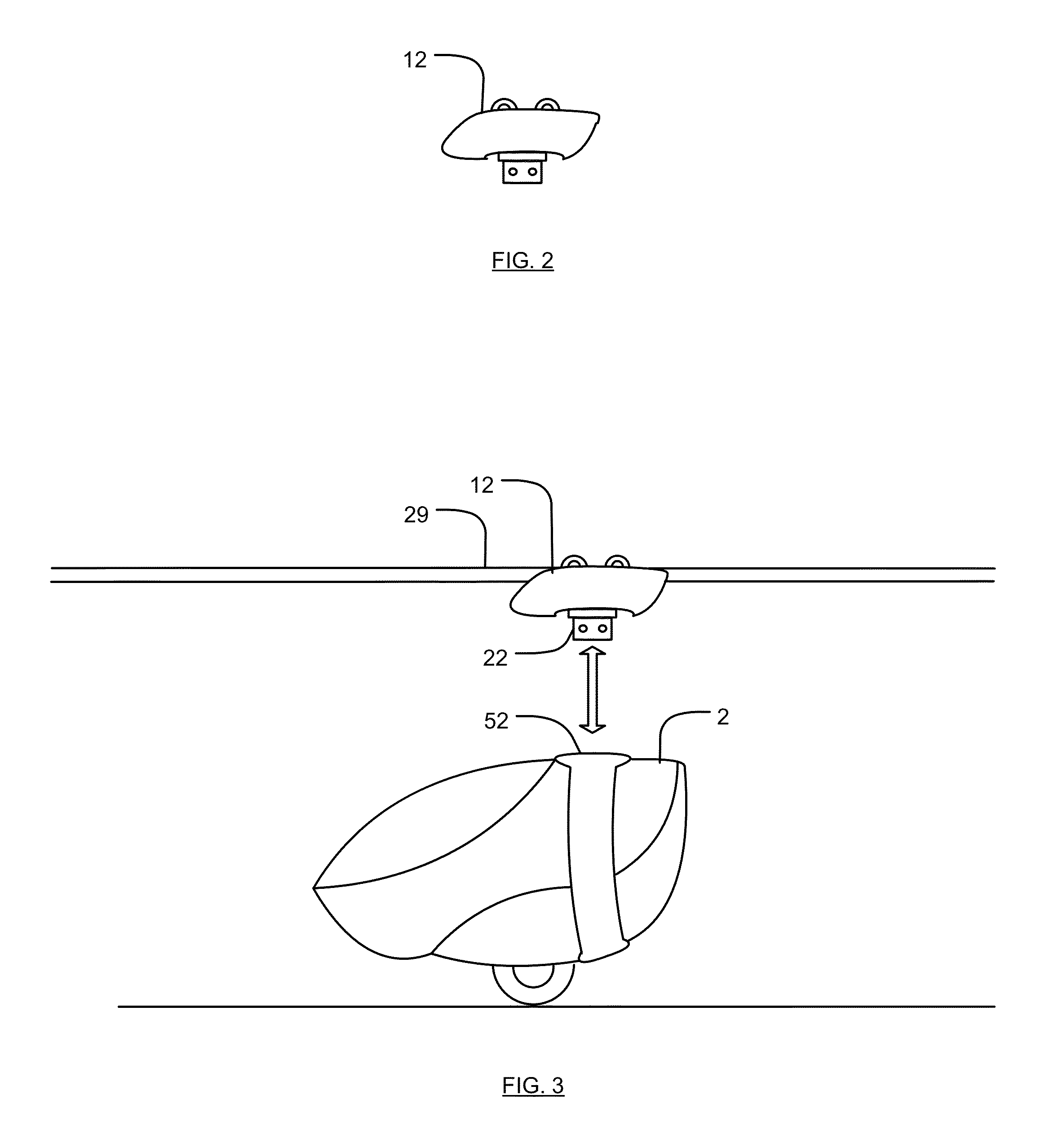

Automated vehicle conveyance apparatus transportation system

InactiveUS20130125778A1Safely and efficiently moves peopleSafely and efficiently and belongingRail switchesMonorailsCurb weightProgram instruction

The Personal Mass Transit (PMT) system utilizes a removable vehicle conveyance apparatus and method for conveying transit vehicle car-pods and their contents from one transit station to another autonomously. Vehicle conveyance apparatus are stored off-line in storage silos and other areas awaiting on-demand transit system instruction to pickup vehicles at loading points and convey them to different stations as requested by occupants or pre-programmed instructions. The PMT system further utilizes a number of transmitter-receivers nodes and control computers to manage all aspects of operation of the transportation system. Any number of different types of PMT vehicles could ride the transit system when equipped with the correct coupling points and remain under the maximum combined curb weight of any particular area or type of transit track in order to be transported on the PMT system.

Owner:LACABE KEITH ANDREW

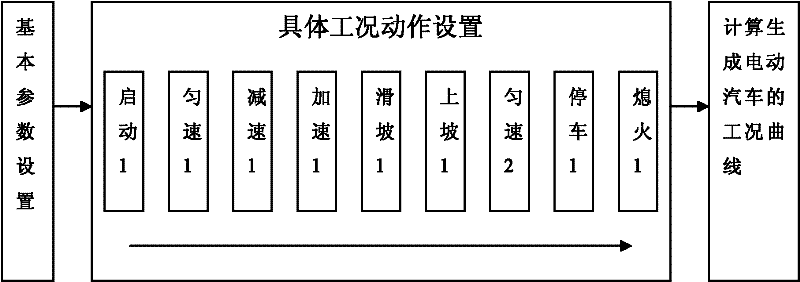

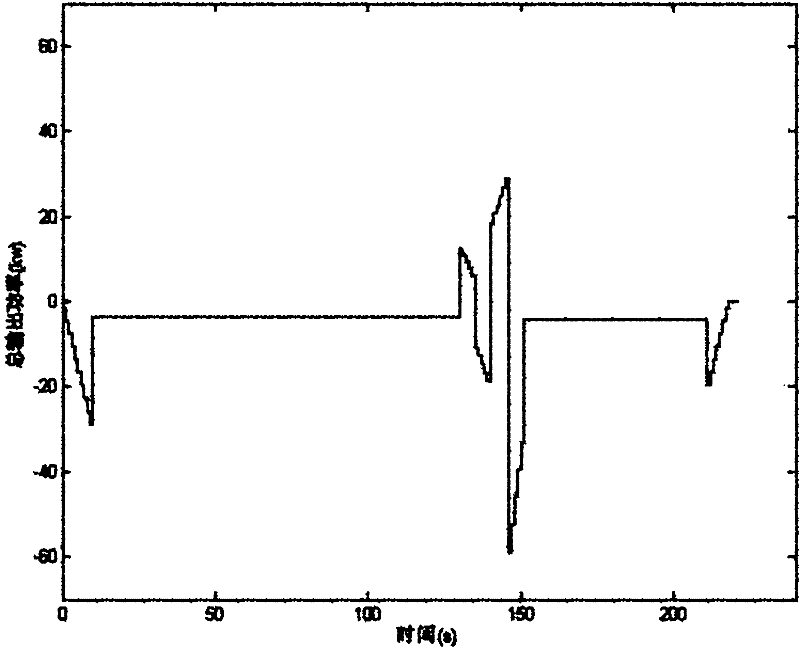

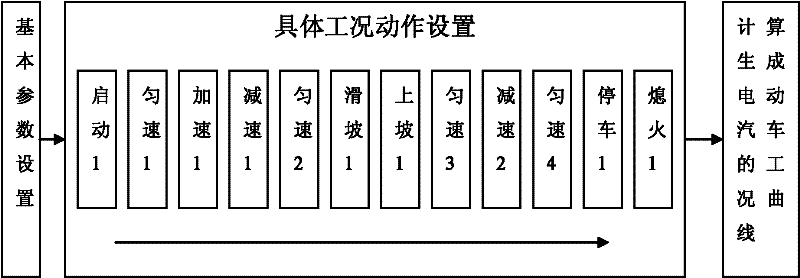

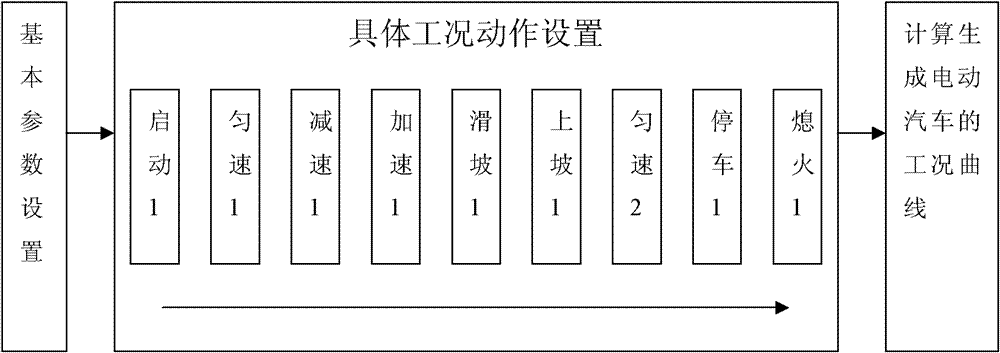

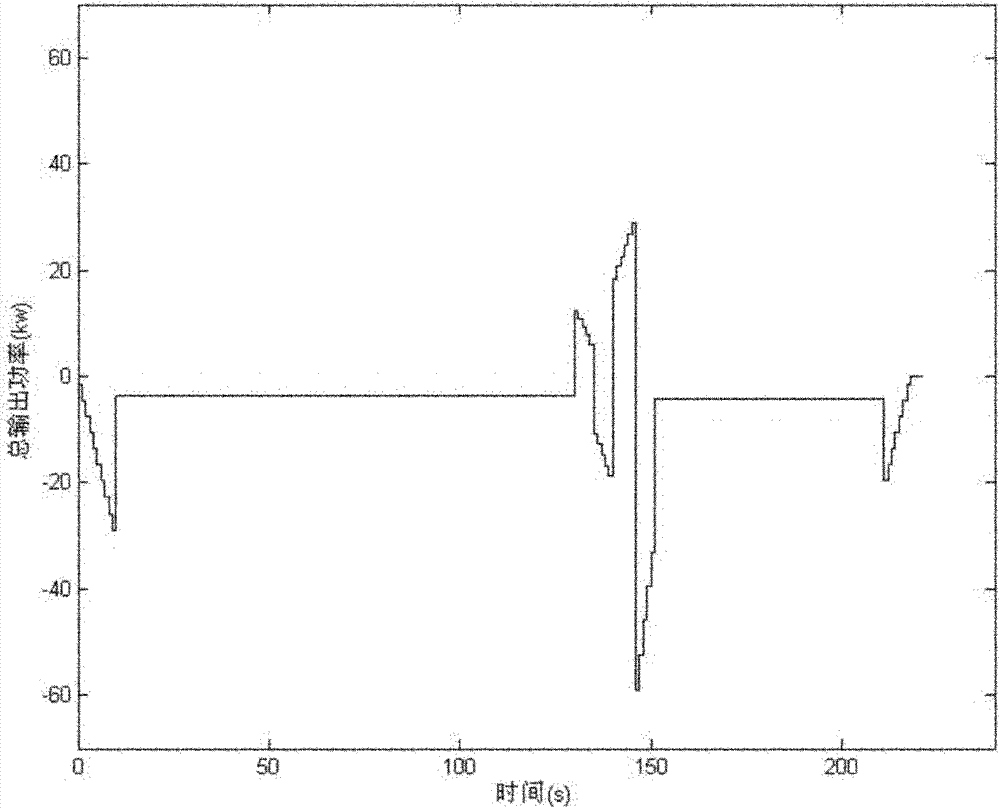

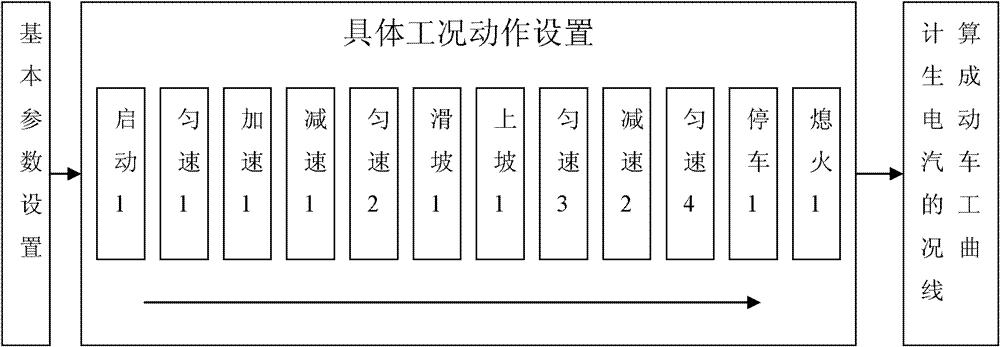

Method for simulative generation of working condition curve of electric vehicle

ActiveCN102129487AIncrease flexibilityShorten the timeVehicle testingElectrical testingPower batteryCurb weight

The invention relates to a method for the simulative generation of a working condition curve of an electric vehicle, which comprises the following steps of: setting basic information and more than one working condition action of the electric vehicle, wherein the basic information comprises vehicle shape, vehicle type, curb weight, tire tread and tire width, and the working condition action comprises working condition type and working condition parameters; calculating a quantitative relationship between output power and running time of an electric battery pack of the electric vehicle; and in accordance with the time interval of t2-t1=1s, obtaining the average output power of the electric battery pack of the electric vehicle within the time interval in order to obtain a relationship curve of the output power of electric battery pack of the electric vehicle and the time. The method for the simulative generation of the working condition curve of the electric vehicle has great flexibility, and is highly matched with the working conditions in real life, thereby remarkably reducing the time and the energy consumption required by generating a working condition simulating curve.

Owner:HANGZHOU GOLD NEW ENERGY TECH

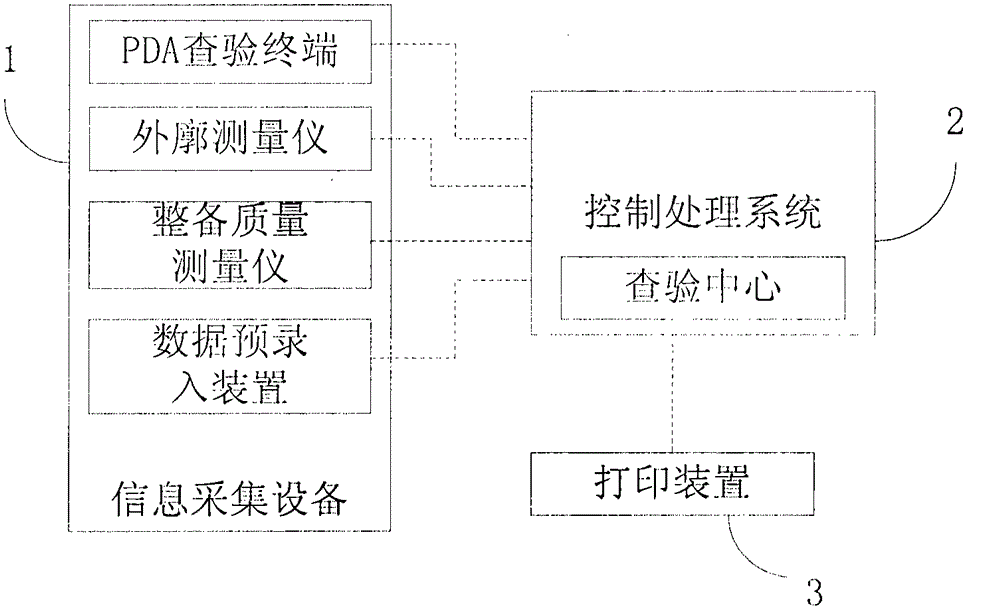

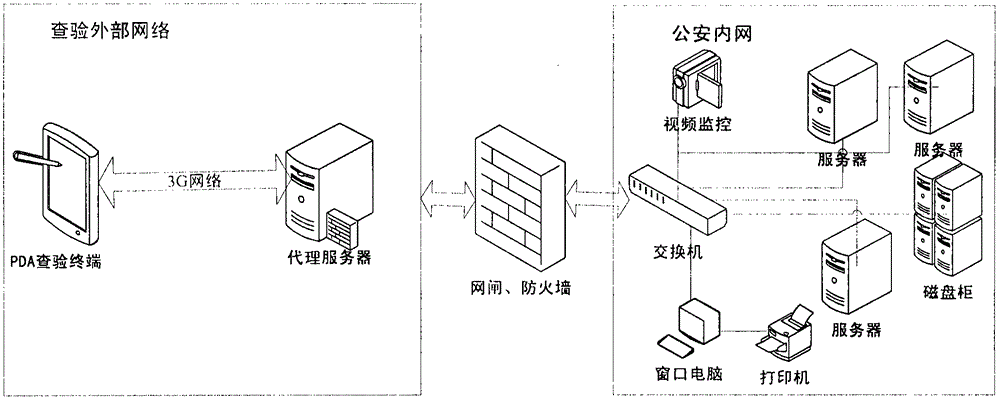

Motor vehicle information management system

InactiveCN104835008AImprove accuracySave yourself the hassle of manually filling out verbatimResourcesCurb weightMeasuring instrument

The invention provides a motor vehicle information management system which comprises information acquiring equipment, a control processing system and a printing device. The information acquiring equipment comprises a PDA inspection terminal, a contour measuring instrument, a curb weight measuring instrument and a data pre-recording device. The control processing system is used for automatically generating an application table, generating the serial number of the motor vehicle and generating a serial table. The printing device is used for printing the application table and the serial table. The PDA inspection terminal is used for photographing an appearance picture of the motor vehicle and acquiring information such as vehicle body color, VIN number, license plate number, engine number, inspection certificate, announcement information and security technical report table, performing inspection on the information and then uploading a primary inspection result and acquired data to the control processing system. The control processing system is provided with an examination center and is used for obtaining an inspection result after inspection on the data. The motor vehicle information management system does not require manual recording and filling of large volume of related data and has higher accuracy and higher efficiency.

Owner:HENAN GREEN ELECTRONICS TECH CO LTD

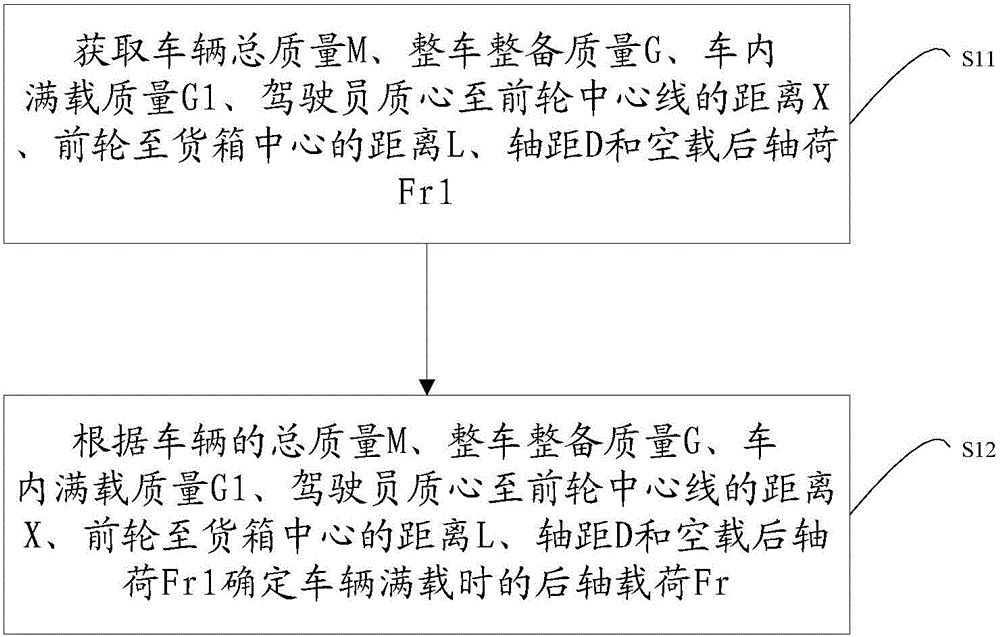

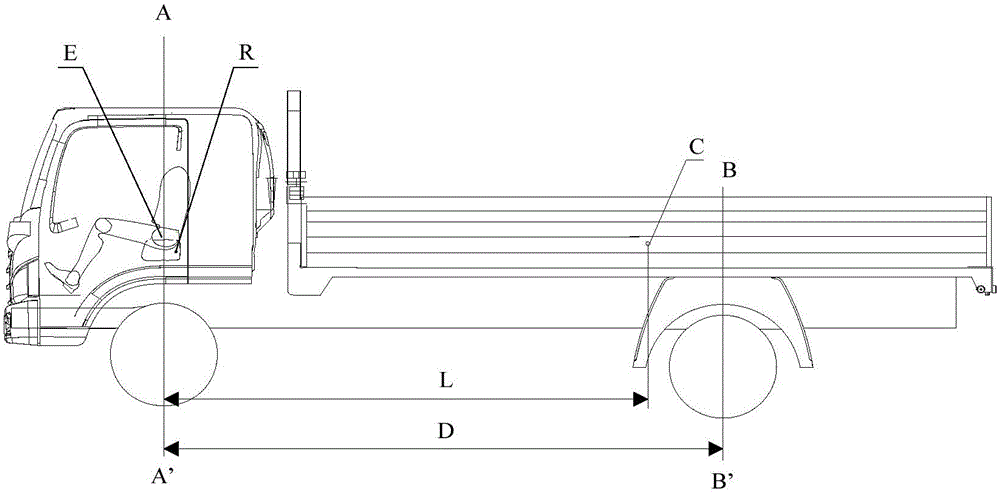

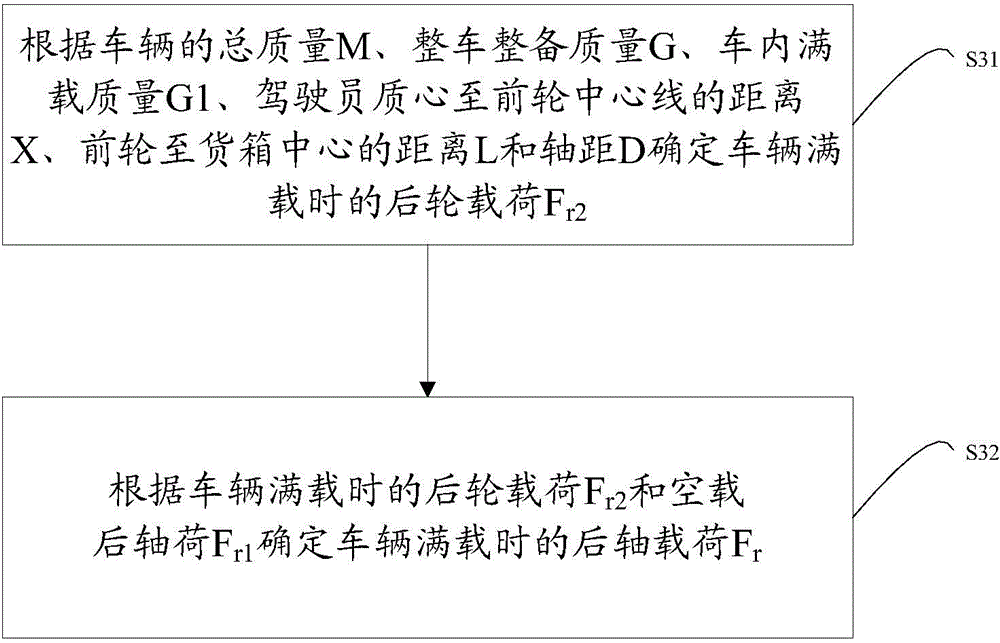

Vehicle axle load determining method and device

The invention provides a vehicle axle load determining method and a vehicle axle load determining device. The vehicle axle load determining method comprises the following steps: a step of acquiring a vehicle total weight M, a complete vehicle curb weight G, a vehicle inside full weight G1, a distance X between a barycenter of a driver and a central line of front wheels, a distance L between the front wheels and a center of a container, a wheel base D, and a no-load rear axle load Fr1; and a rear axle load determining step, namely a step of determining the rear axle load Fr during the full load of the vehicle according to the vehicle total weight M, the complete vehicle curb weight G, the vehicle inside full weight G1, the distance X between the barycenter of the driver and the central line of front wheels, the distance L between the front wheels and the center of the container, the wheel base D, and the no-load rear axle load Fr1. The vehicle axle load determining method is advantageous in that the rear axle load Fr during the full load of the vehicle can be determined according to the measurable parameters of the vehicle during the designing phase of the vehicle; by comparing with the prior art, the calculating method is simple, and the error rate is small; the rear suspension, the rear axle, and the tires, which are capable of satisfying the design requirements much better, can be selected accurately, and therefore the development time can be reduced, and the development costs can be saved.

Owner:BEIQI FOTON MOTOR CO LTD

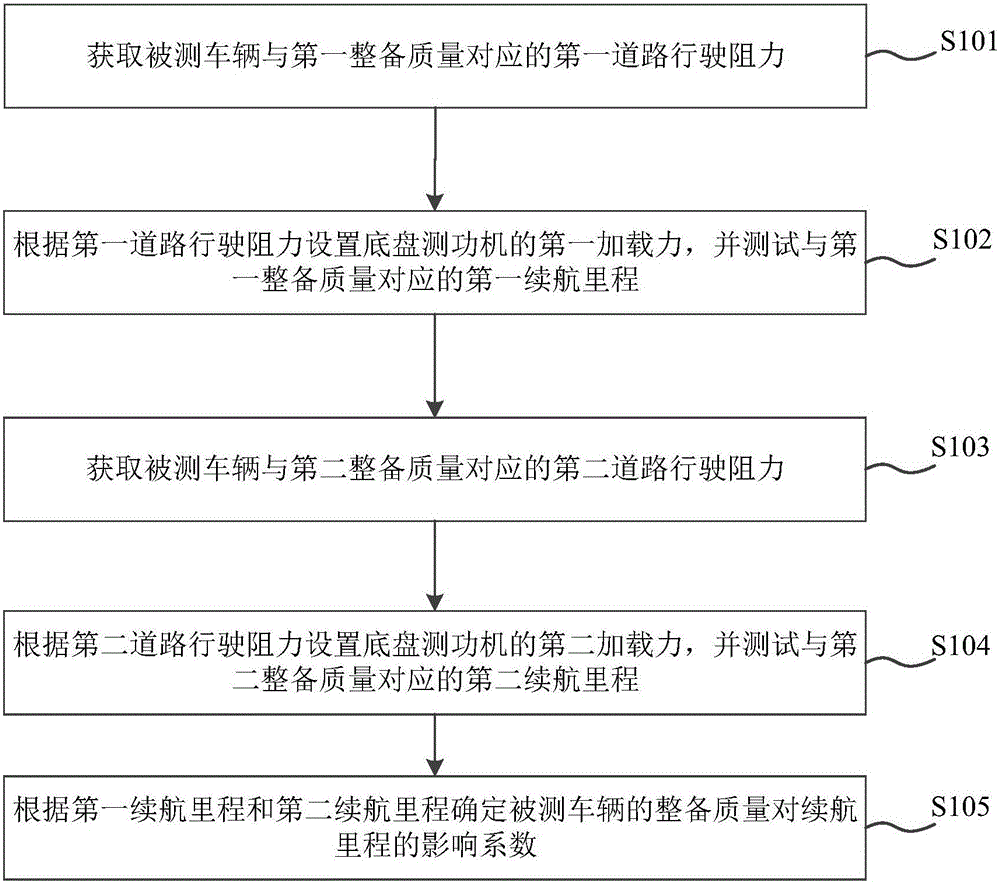

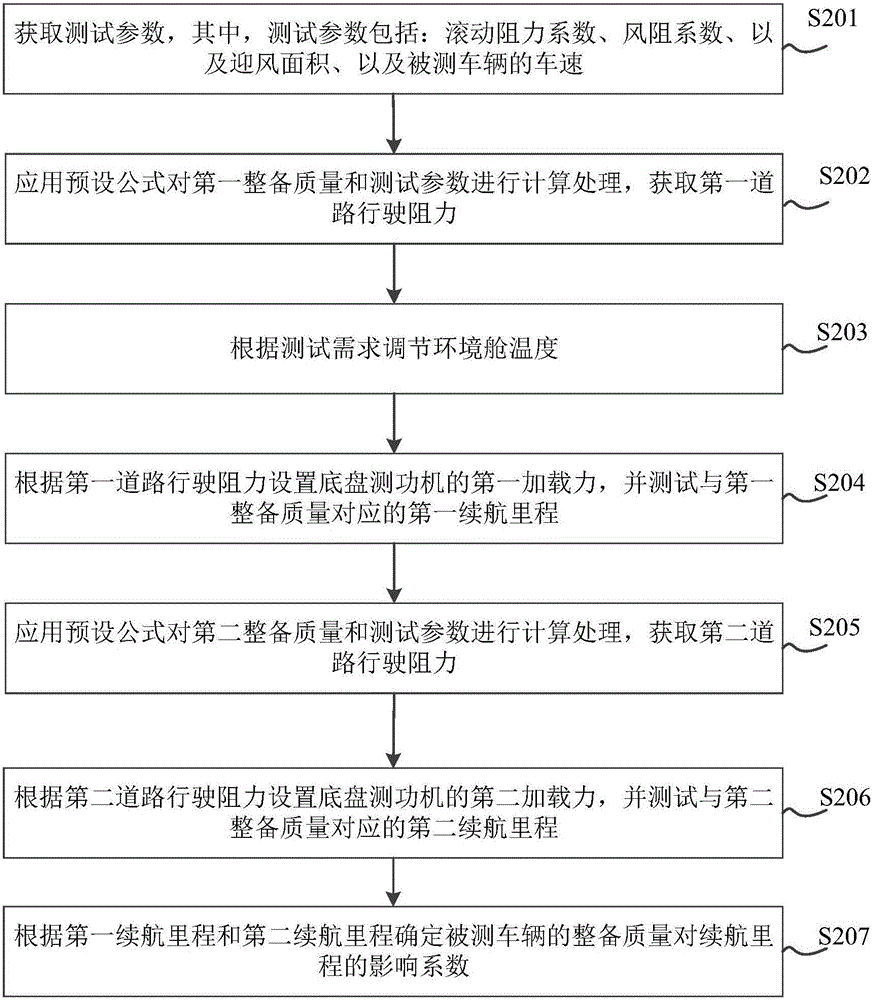

Method and device for testing driving mileage of electric automobile

ActiveCN105890914AThe test is convenient and accurateImprove securityVehicle testingCurb weightChassis dynamometer

The invention provides a method and a device for testing the driving mileage of an electric automobile. The method comprises the following steps: acquiring a first road driving resistance of a tested automobile, corresponding to a first curb weight; setting a first loading force of a chassis power tester according to the first road driving resistance and testing a first driving mileage corresponding to the first curb weight; acquiring a second road driving resistance of the tested automobile, corresponding to the second curb weight; setting a second loading force of the chassis power tester according to the second road driving resistance and testing a second driving mileage corresponding to the second curb weight; determining the influence coefficient of the curb weight of the tested automobile to the driving mileage according to the first driving mileage and the second driving mileage. According to the embodiment of the invention, the loading force of the chassis power tester can be adjusted for conveniently and accurately testing the influence of different curb weights on the driving mileage and the safety is high.

Owner:BEIJING ELECTRIC VEHICLE

Dump truck frame with alien-shaped longitudinal beams and sub-frame function

The invention provides a dump truck frame with alien-shaped longitudinal beams and a sub-frame function, wherein the front section of the left longitudinal beam of the frame has an L-shaped cross section, the rear section has a Z-shaped cross section, and a rectangular notch is cut in the rear upper part; the cross section of the L-shaped front section has a small height and a small size, the cross section of the Z-shaped rear section has a large height and a large size, and a transition section is arranged in the middle of the left longitudinal beam; and the right longitudinal beam and the left longitudinal beam are symmetrical. The dump truck frame with the alien-shaped longitudinal beams and the sub-frame function can give play to functions of a common truck frame and a dump truck sub-frame, so that no sub-frame is needed when a dump truck with the structure is used, consumption of materials can be reduced, and whole-truck curb weight can be reduced. In this way, production cost can be reduced, and economical efficiency of use is greatly improved. In addition, components such as a hydraulic oil cylinder support horizontal beam used for container lifting and an oil tank bearing horizontal beam can be connected and installed more conveniently. The dump truck frame with alien-shaped longitudinal beams and the sub-frame function can be widely applied in the damp trucks.

Owner:YUNNAN LIFAN JUNMA AUTOMOBILE

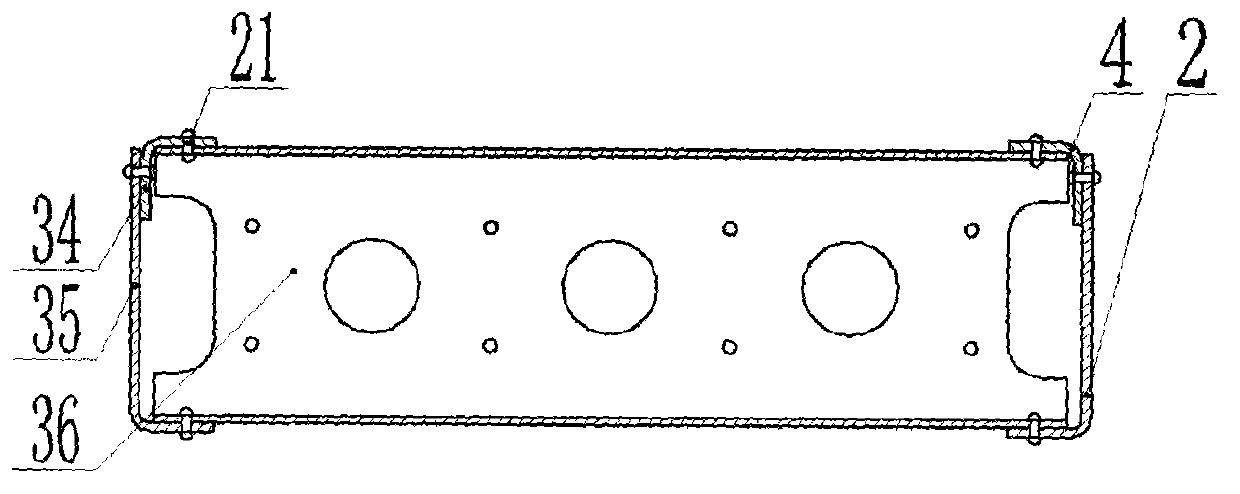

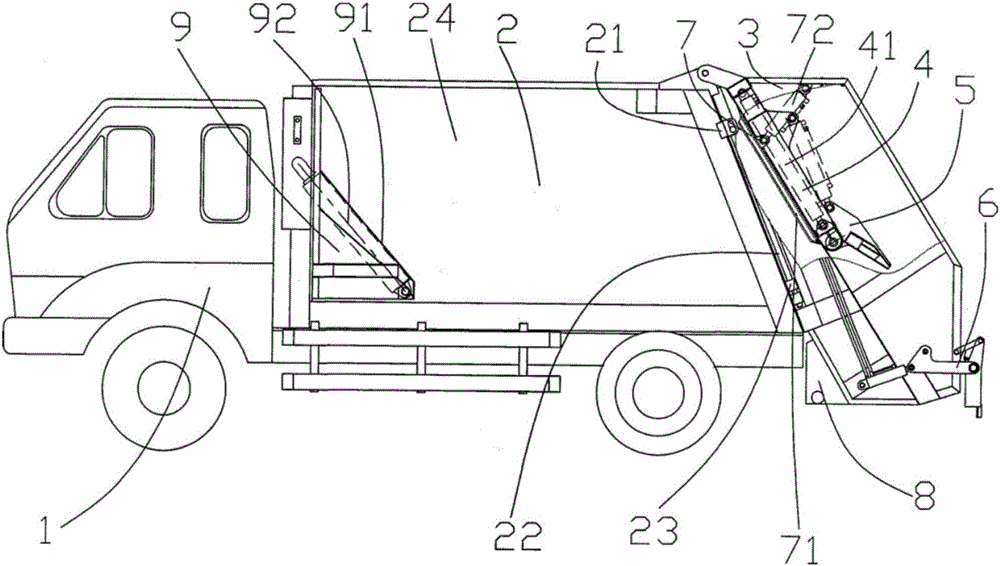

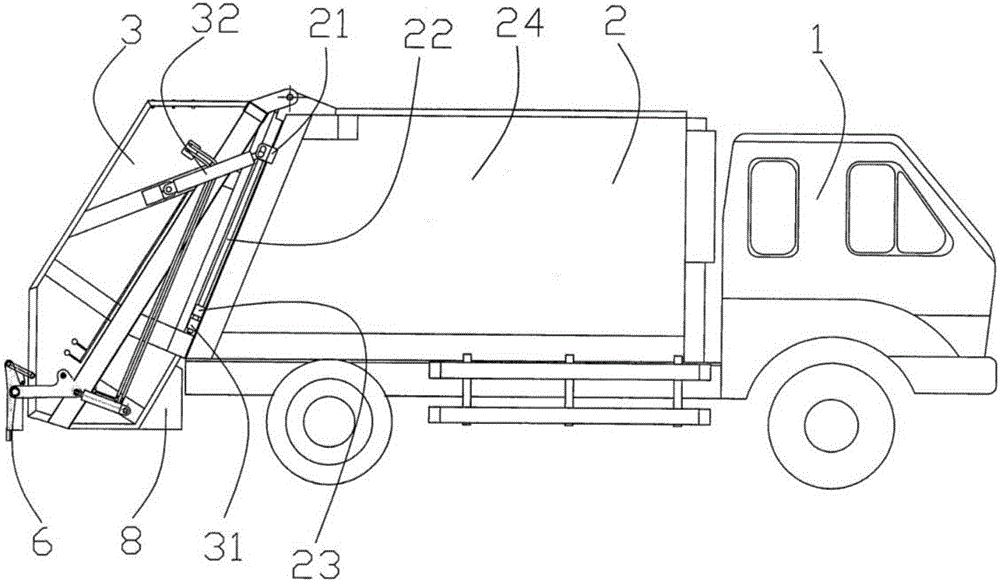

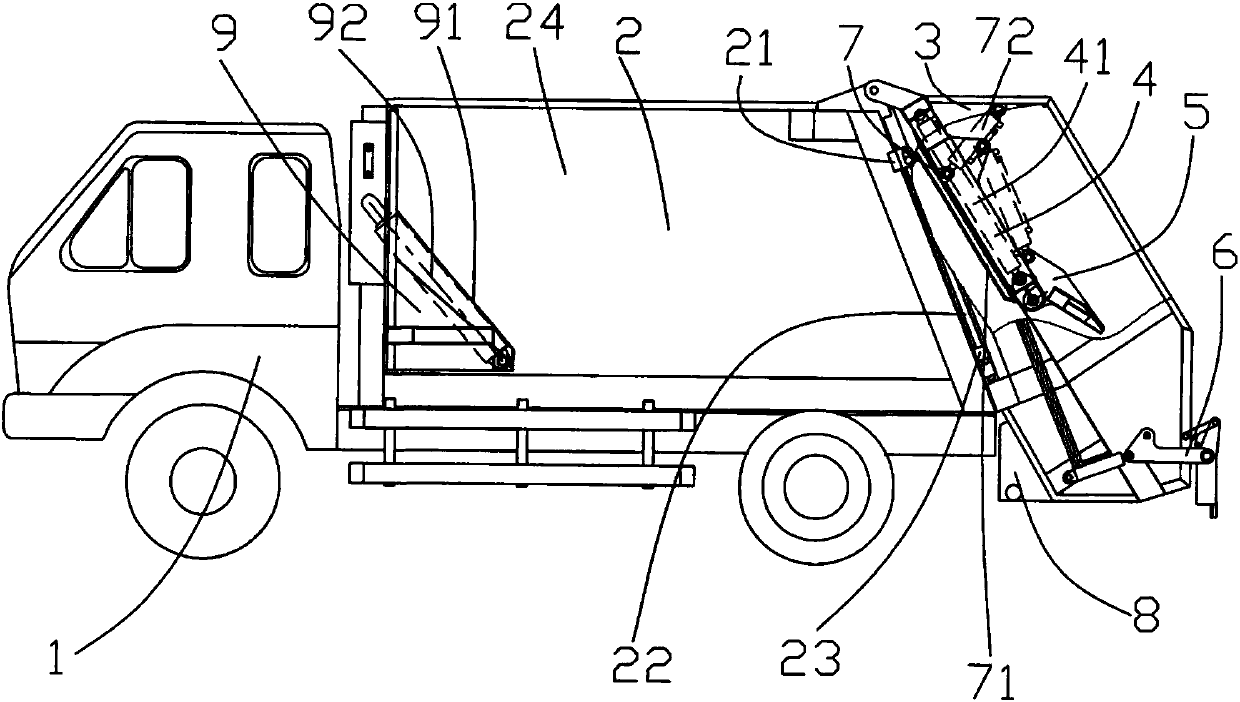

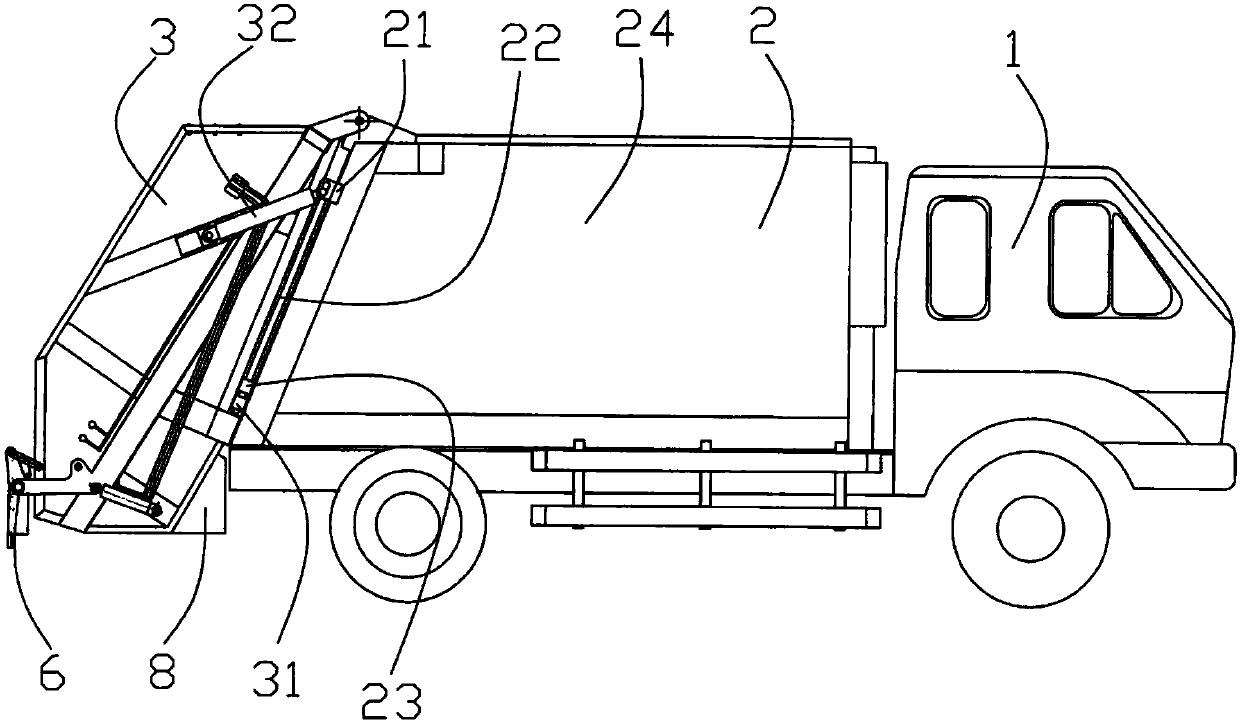

Compression protecting device of compression car

The invention discloses a compression protection device for a compression car, which comprises a matched second-class chassis of a car and a compression compartment. A rear compartment is hinged on the charging end of the compression compartment, and a lifting plate assembly is arranged inside the rear compartment. . The scraper assembly and the bucket lifting mechanism are characterized in that a pushing mechanism is installed in the rear compartment, and the pushing mechanism is equipped with a pushing plate that can be hinged to the upper front inner wall of the rear compartment, At least one pushing oil cylinder is rotatably connected to the back of the pushing plate, and the pushing oil cylinder is rotatably connected to the top inner wall of the rear compartment and is hinged. There are circular arc plates on both sides of the compression compartment, which has a compact structure, reduces the curb weight and improves the loading capacity of the vehicle; a sewage collection box is equipped to prevent sewage overflow during garbage treatment and effectively protect the surrounding environment; the upper part is set The pushing mechanism is improved, the compression ratio during garbage disposal is increased, the single garbage processing capacity of the whole vehicle is improved, and the appearance of the whole vehicle is enhanced at the same time.

Owner:QINGDAO ALLITE AUTO TECHNIC

Automatic driving truck without cab and automatic driving control method

ActiveCN110194095AImprove transportation capacityImprove space utilizationSpeed controllerElectric devicesPower batteryCurb weight

The invention relates to an automatic driving truck without a cab and an automatic driving control method, and belongs to the field of transportation trucks. The problems of realizing vehicle loadingcapacity increasing during unmanned driving and realizing automatic control during driving of a truck in a transportation truck in the prior art are solved. An automatic driving special vehicle of theautomatic driving truck without the cab and the automatic driving control method comprises a traditional chassis component, an intelligent steering system, an intelligent braking system, an intelligent control system, a power battery system, and assemblies such as a loading compartment, the cab is removed, a steering wheel, a steering column and the like are removed, only the compartment is on the upper wing surface of a chassis. According to the automatic driving truck without the cab and the automatic driving control method, all function keys in the original cab are electrified, intelligentized, and controlled by the intelligent control system; the unmanned driving of the special truck is realized, the curb weight of the whole vehicle is decreased, and the vehicle loading weight of thewhole vehicle is increased.

Owner:BEIJING MECHANICAL EQUIP INST +1

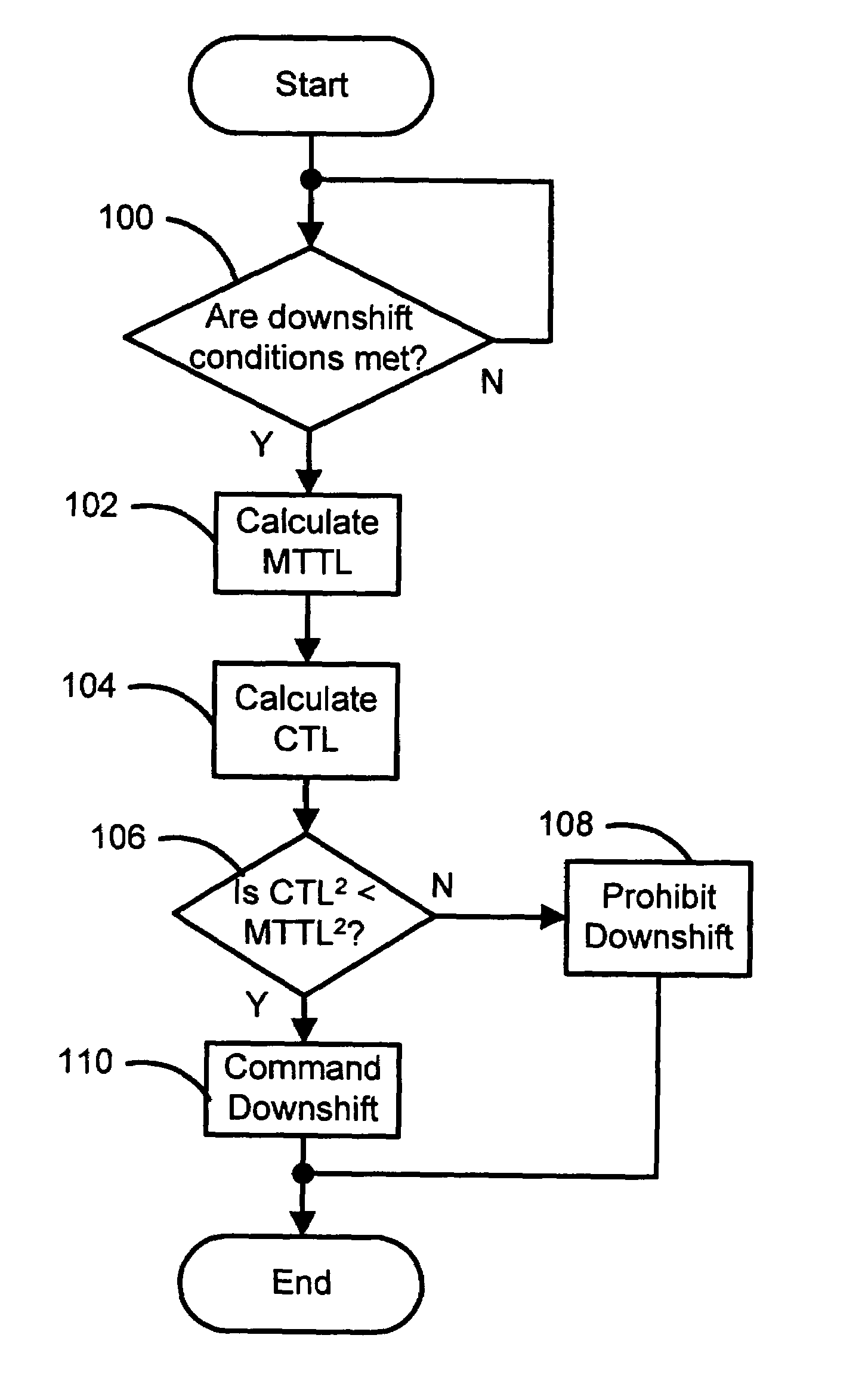

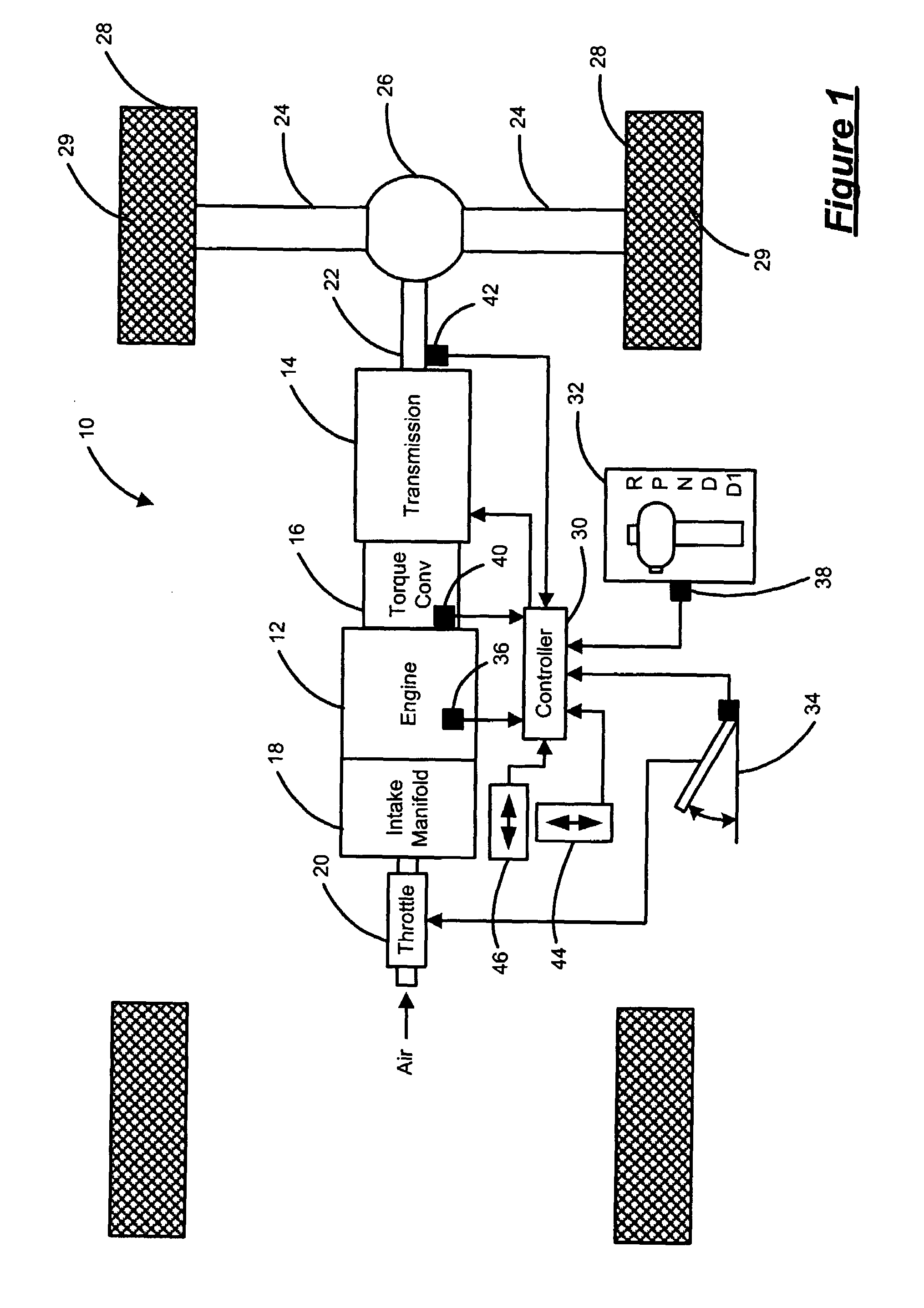

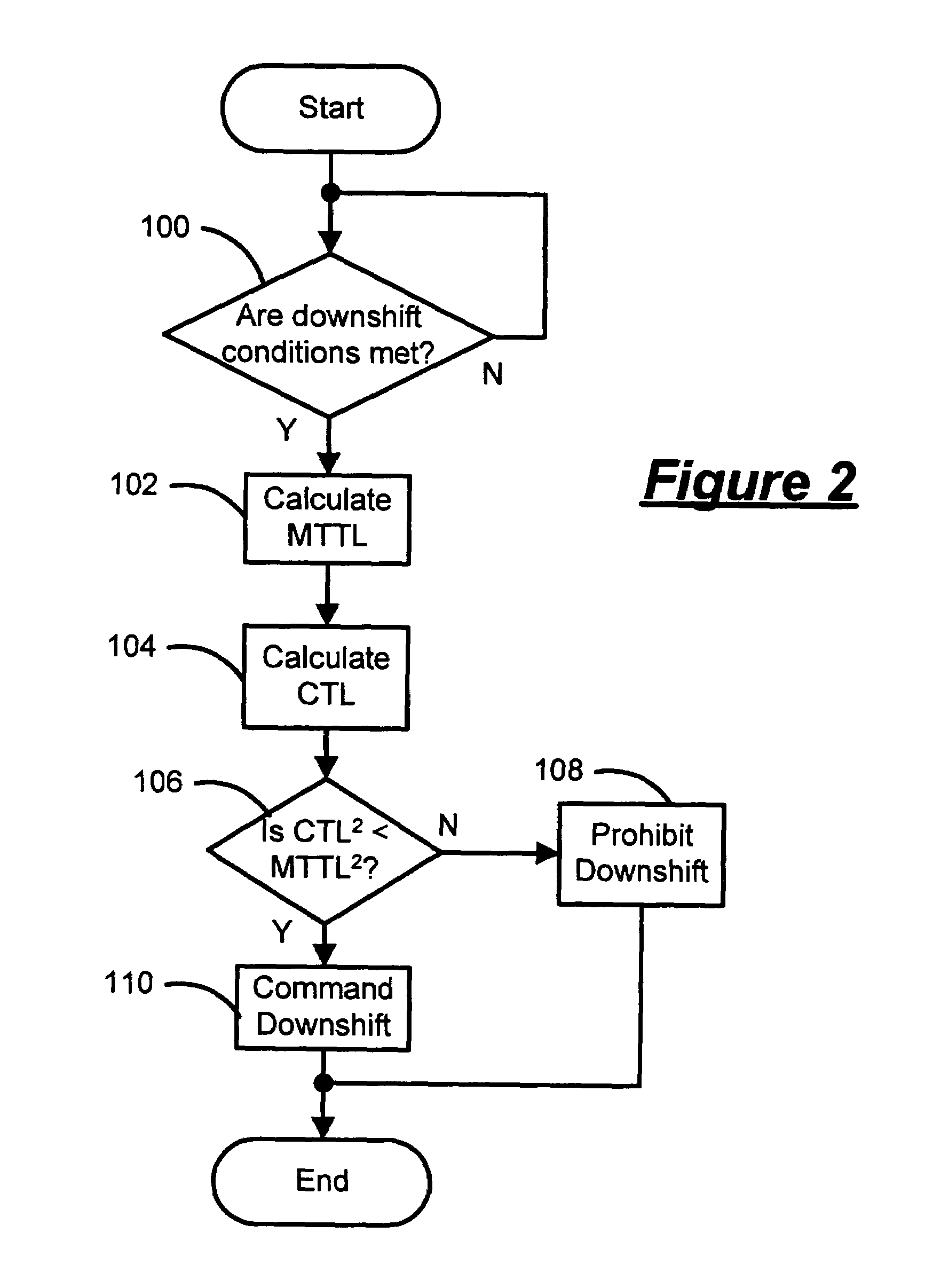

Automatic transmission downshifts based on tire adhesion limits

A shift control system that controls gear shifts in a vehicle includes a transmission and a controller. The controller detects driving conditions of the vehicle, estimates a traction load of the vehicle and determines a current traction load of the vehicle. The controller shifts the transmission based on the current traction load and the estimated traction load if the driving conditions are met. The current traction load is based on a lateral acceleration signal and a longitudinal acceleration signal. The estimated traction load is based on a curb weight of the vehicle, a weight transfer gain and an acceleration signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

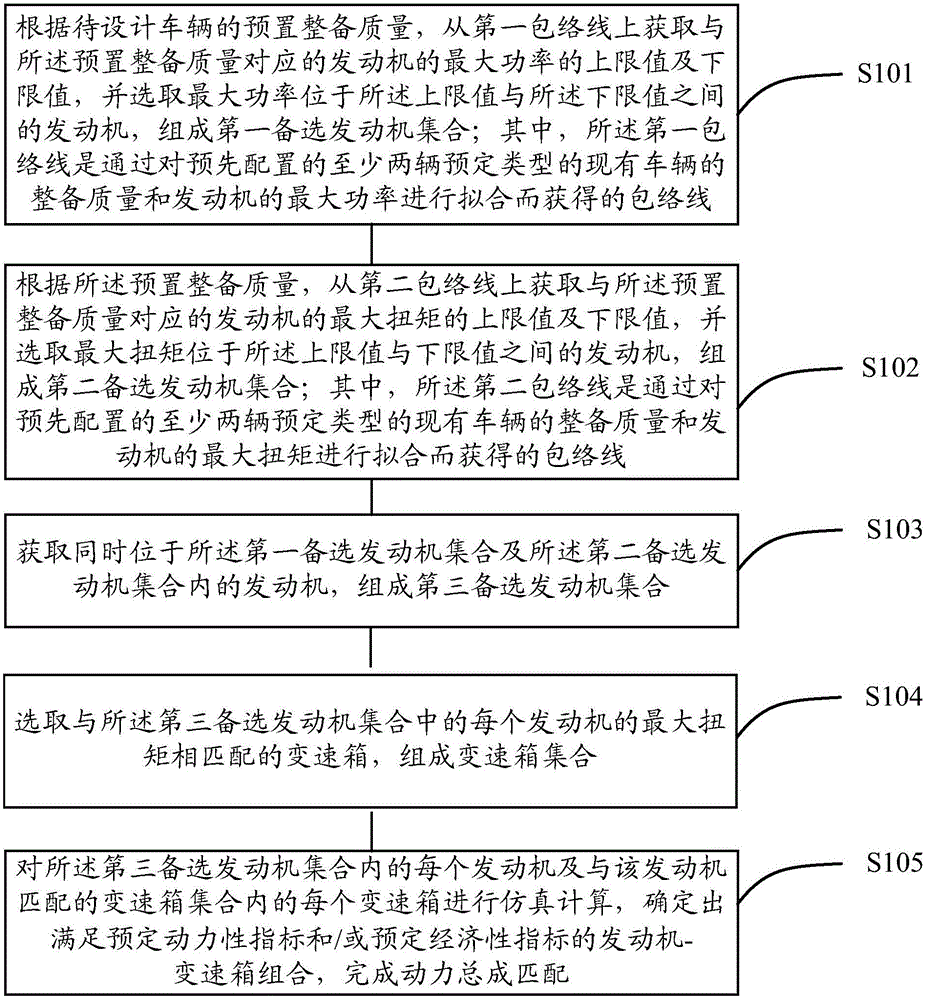

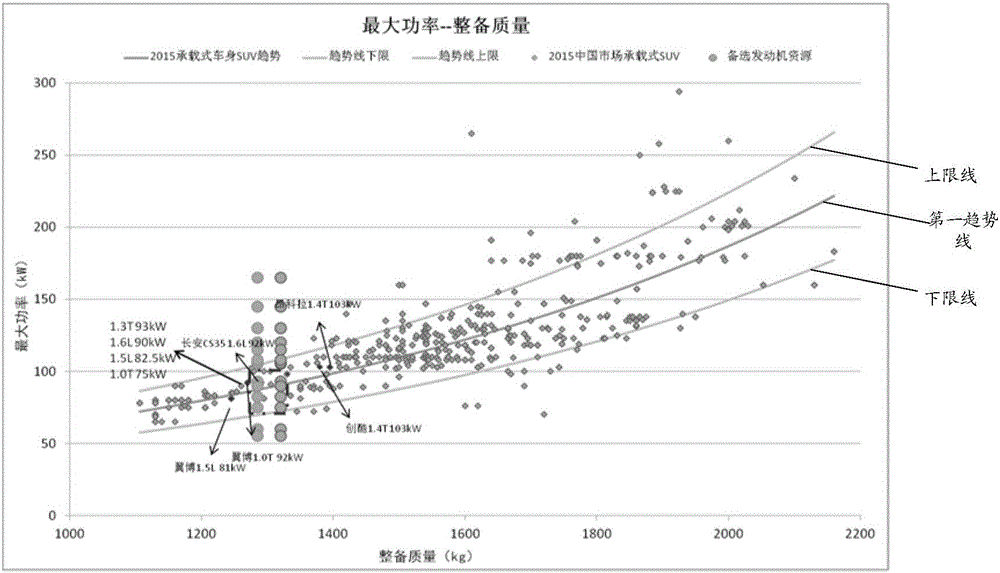

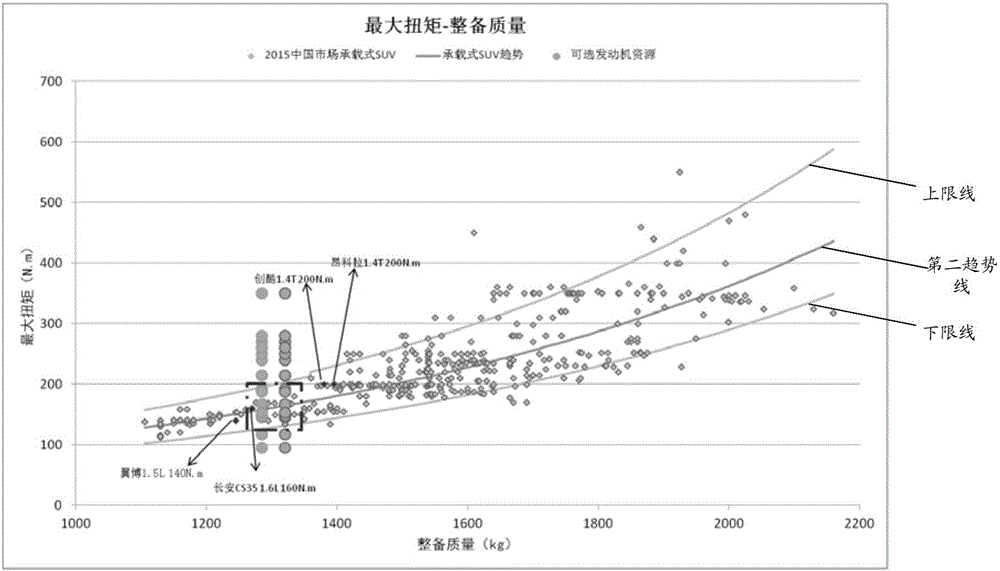

Power assembly matching method and device

ActiveCN106021741AQuick configurationQuick collectionGeometric CADDesign optimisation/simulationMaximum torqueLower limit

The invention discloses a power assembly matching method comprising the following steps: obtaining upper and lower limit values of the maximum power from a first envelope line according to preset curb weight, and forming a first standby engine set according to the upper and lower limit values; obtaining the upper and lower limit values of the maximum torque from a second envelope line according to the preset curb weight, and forming a second standby engine set according to the upper and lower limit values; obtaining engines simultaneously located in the two sets so as to form a third standby engine set; selecting gear boxes matched with each engine so as to form a gear box set; carrying out simulation calculation for each engine and each gear box in the gear box set, thus determining an engine-gear box combination, and finishing the power assembly matching. The invention also discloses a power assembly matching device so as to fast and effectively obtain an engine and gear box matching scheme, thus shortening the time consumed in the matching design phase.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

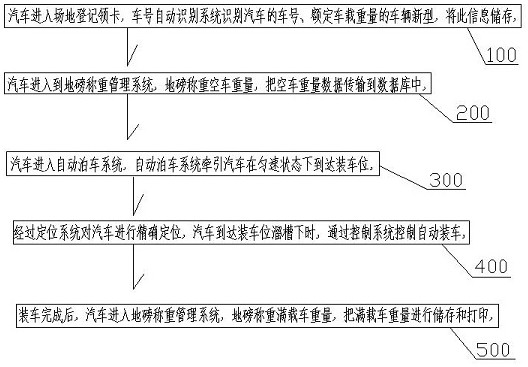

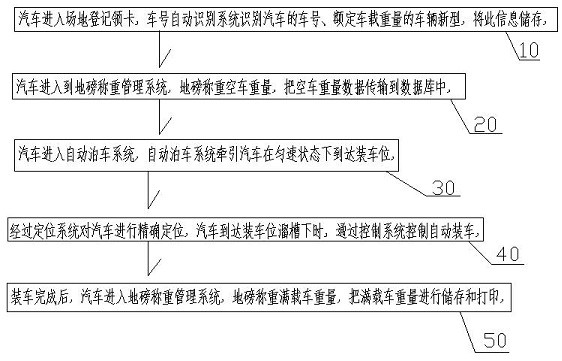

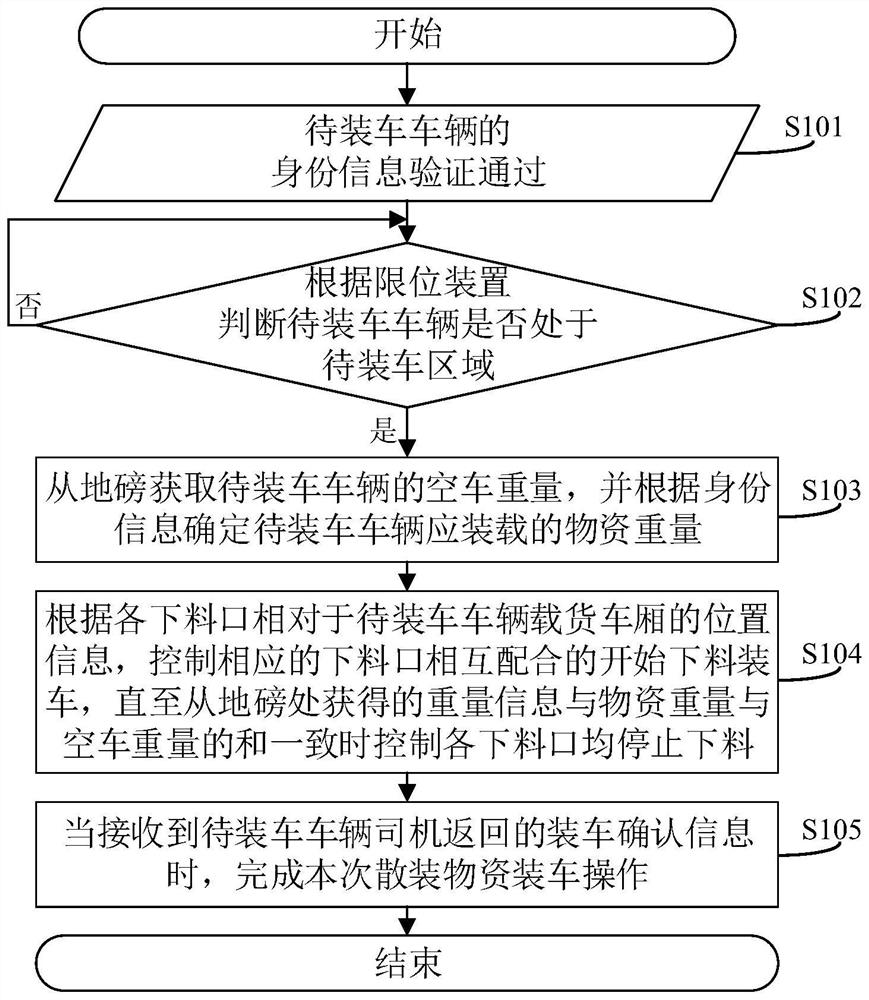

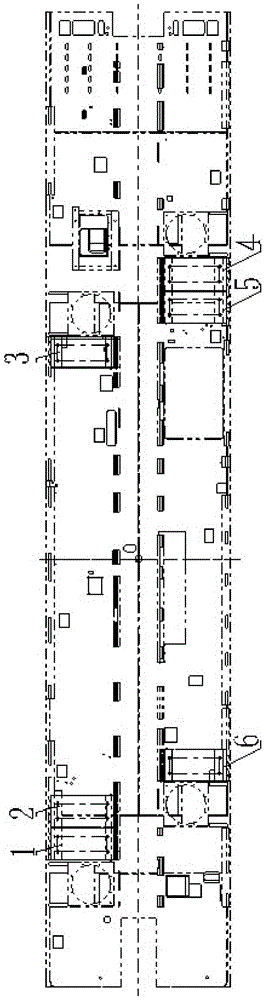

Unattended rapid quantitative vehicle loading model acquisition method and system, controller and control method

InactiveCN112744615ASolve manual semi-automatic loading operationConveyorsControl devices for conveyorsCurb weightControl system

The invention provides an unattended rapid quantitative vehicle loading model acquisition method and system, a controller and a control method. A vehicle enters a site to register a card, a vehicle number automatic identification system identifies the number of the vehicle and the vehicle with rated vehicle load capacity, and the information is stored; the vehicle enters a weighbridge weighing management system, a weighbridge weighs an empty vehicle, and empty vehicle weight data is transmitted to a database; the vehicle enters an automatic parking system, the automatic parking system pulls the vehicle to reach the loading position at a constant speed, the vehicle is accurately positioned through a positioning system, when the vehicle reaches the position below a sliding groove of the loading position, and automatic loading is controlled through a control system; and after loading is completed, the vehicle enters the weighbridge weighing management system, the weighbridge weighs the weight of the full-load vehicle, the weight of the full-load vehicle is stored and printed, the loading control problem is solved according to rapid quantitative loading of the vehicle, and the loading safety and efficiency are improved.

Owner:SHANDONG TAIAN COAL MINING MACHINERY

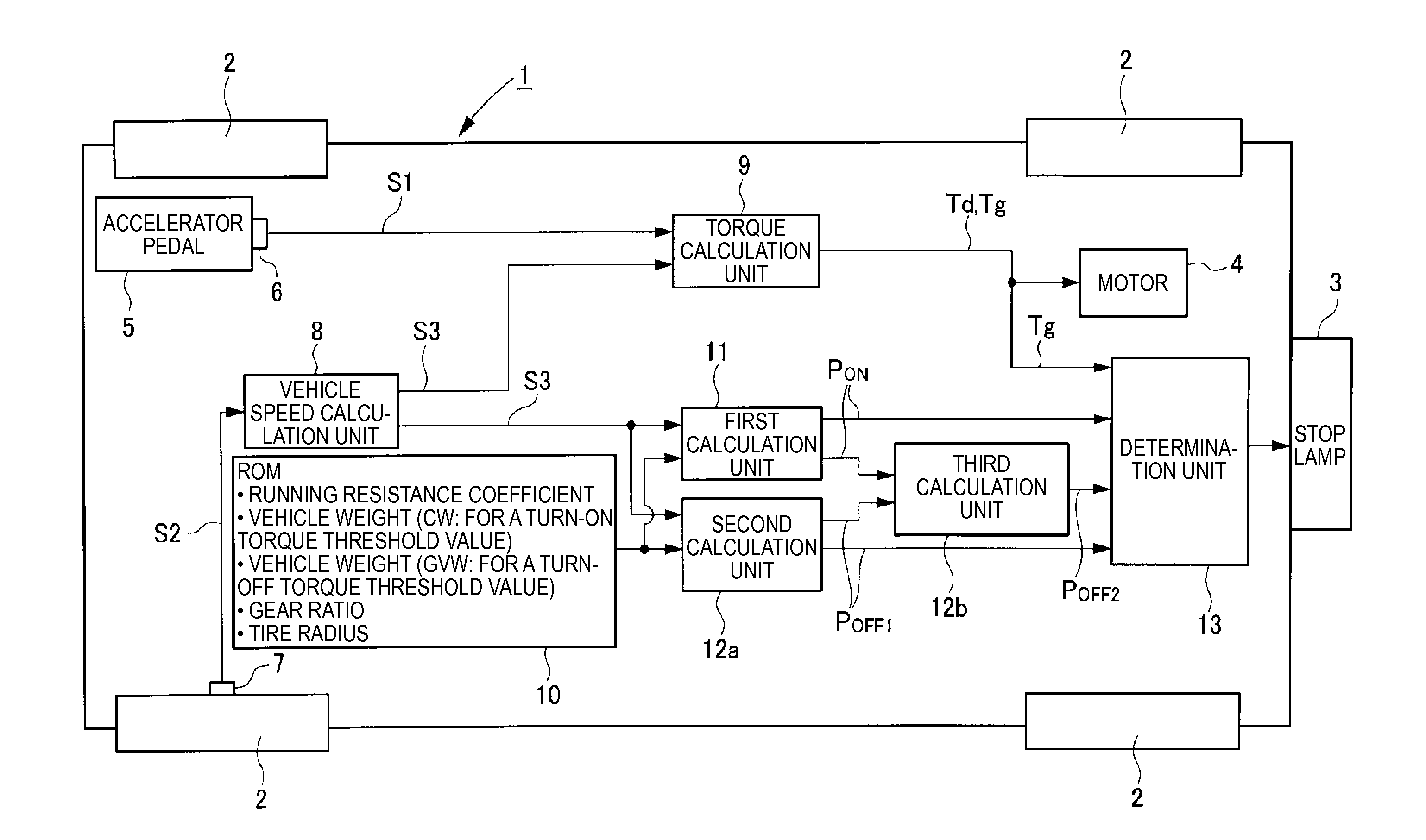

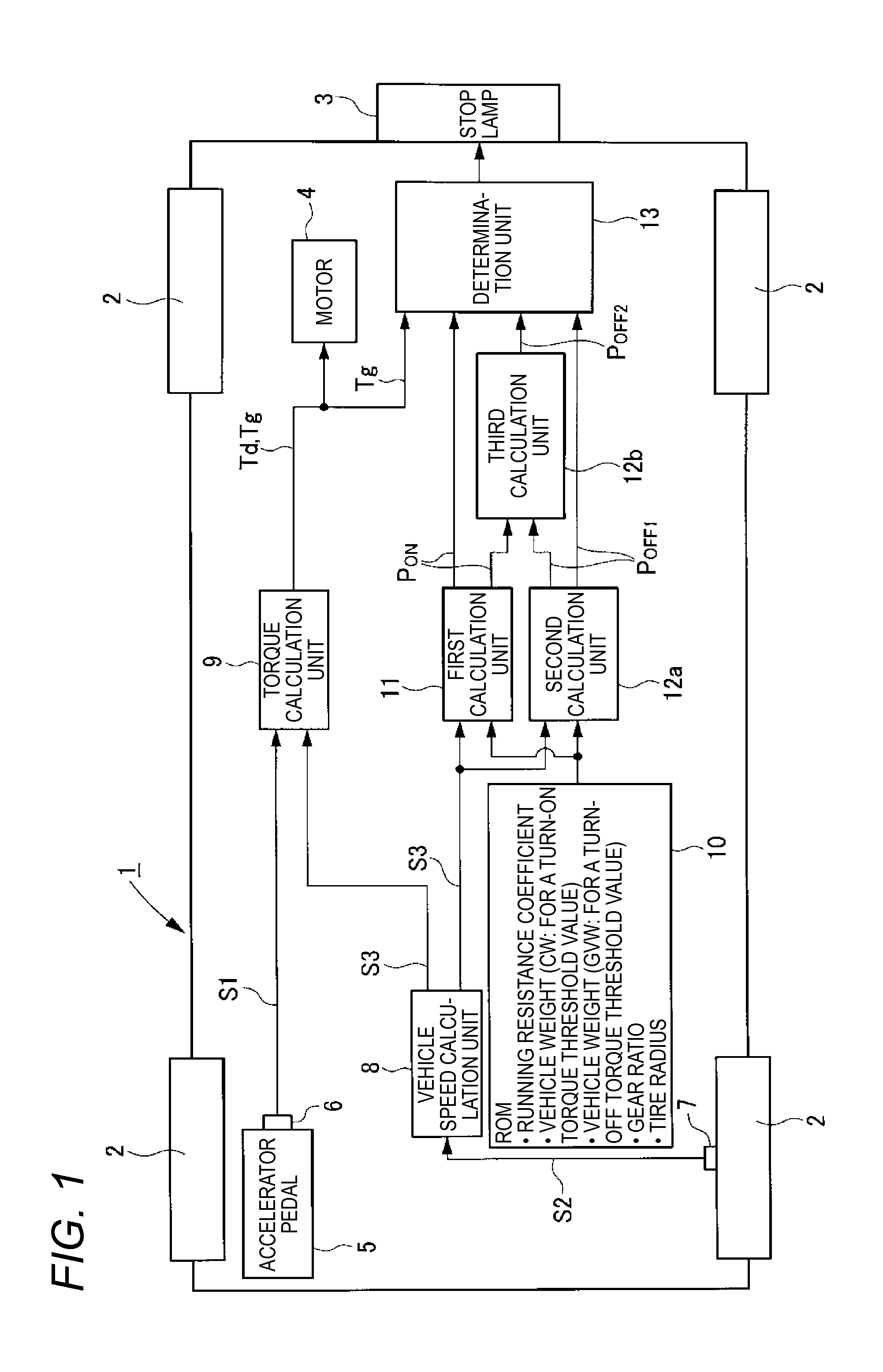

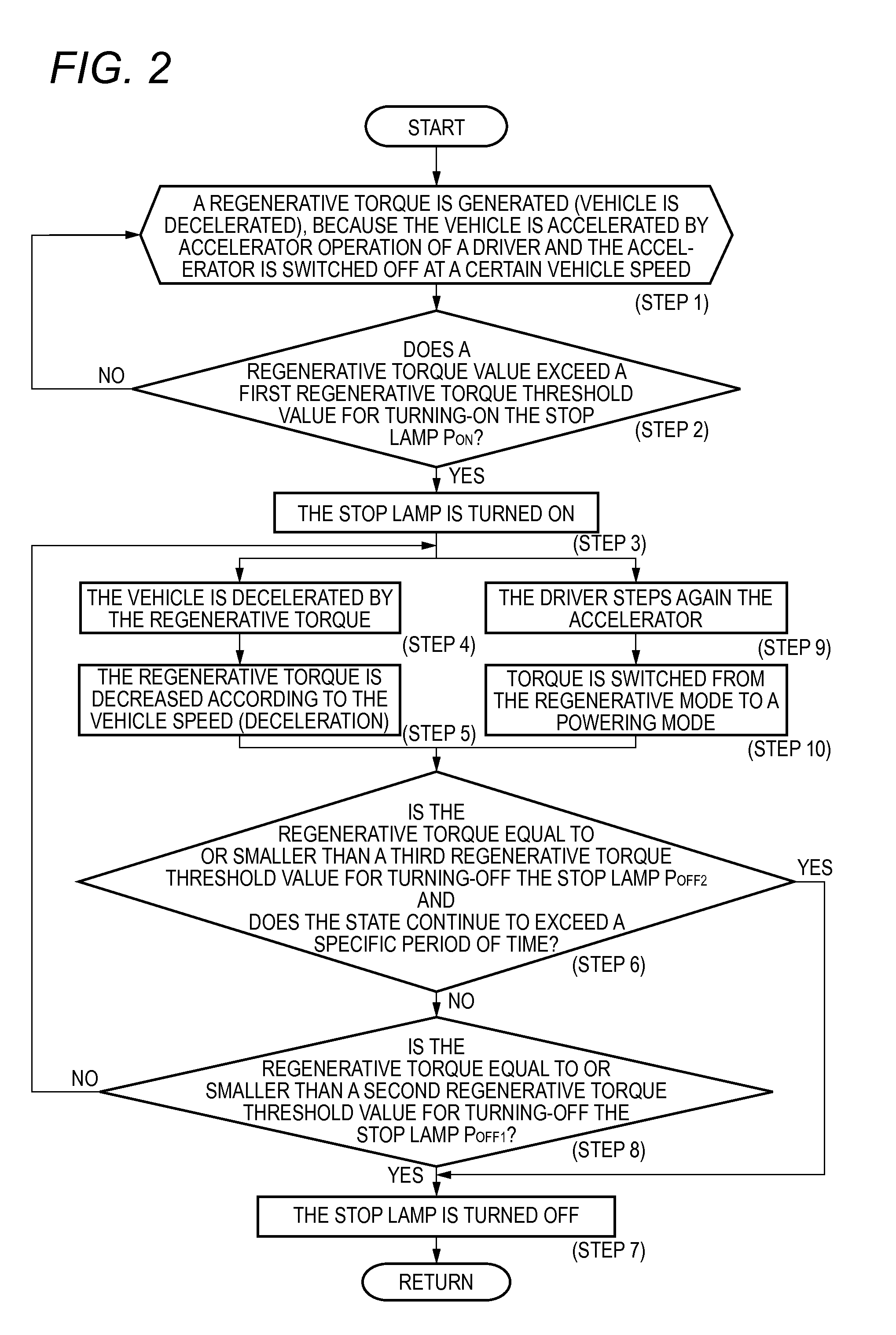

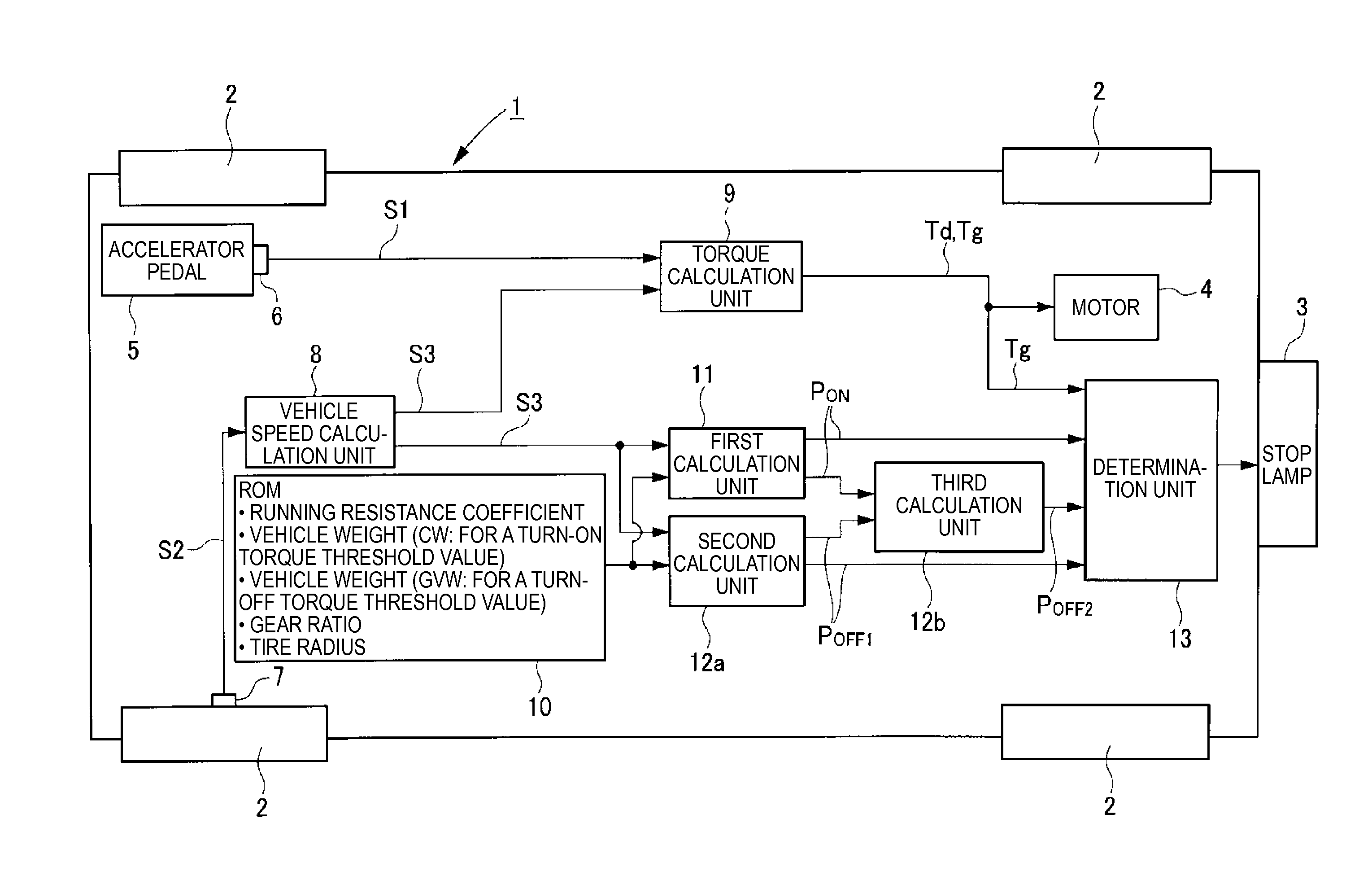

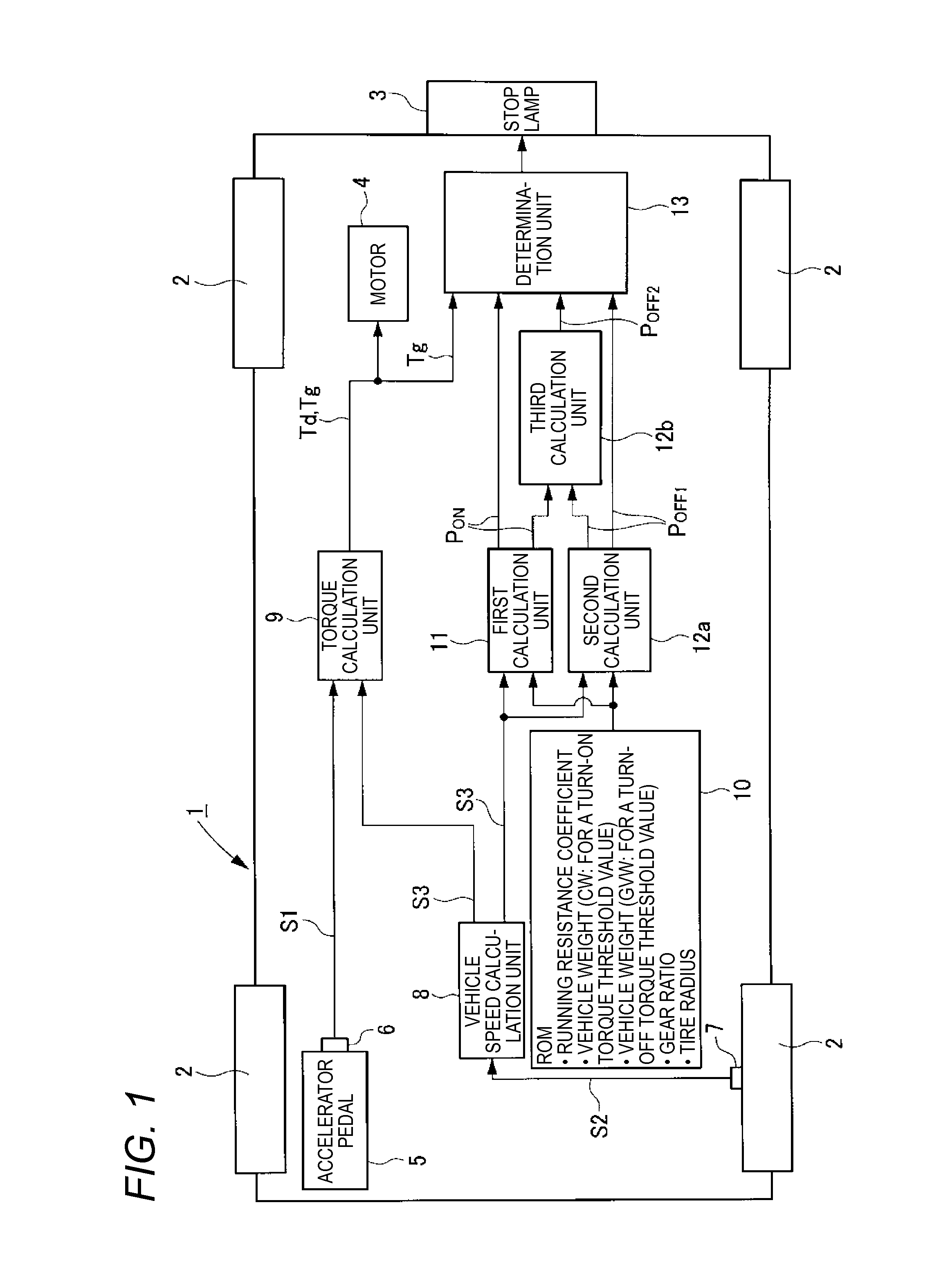

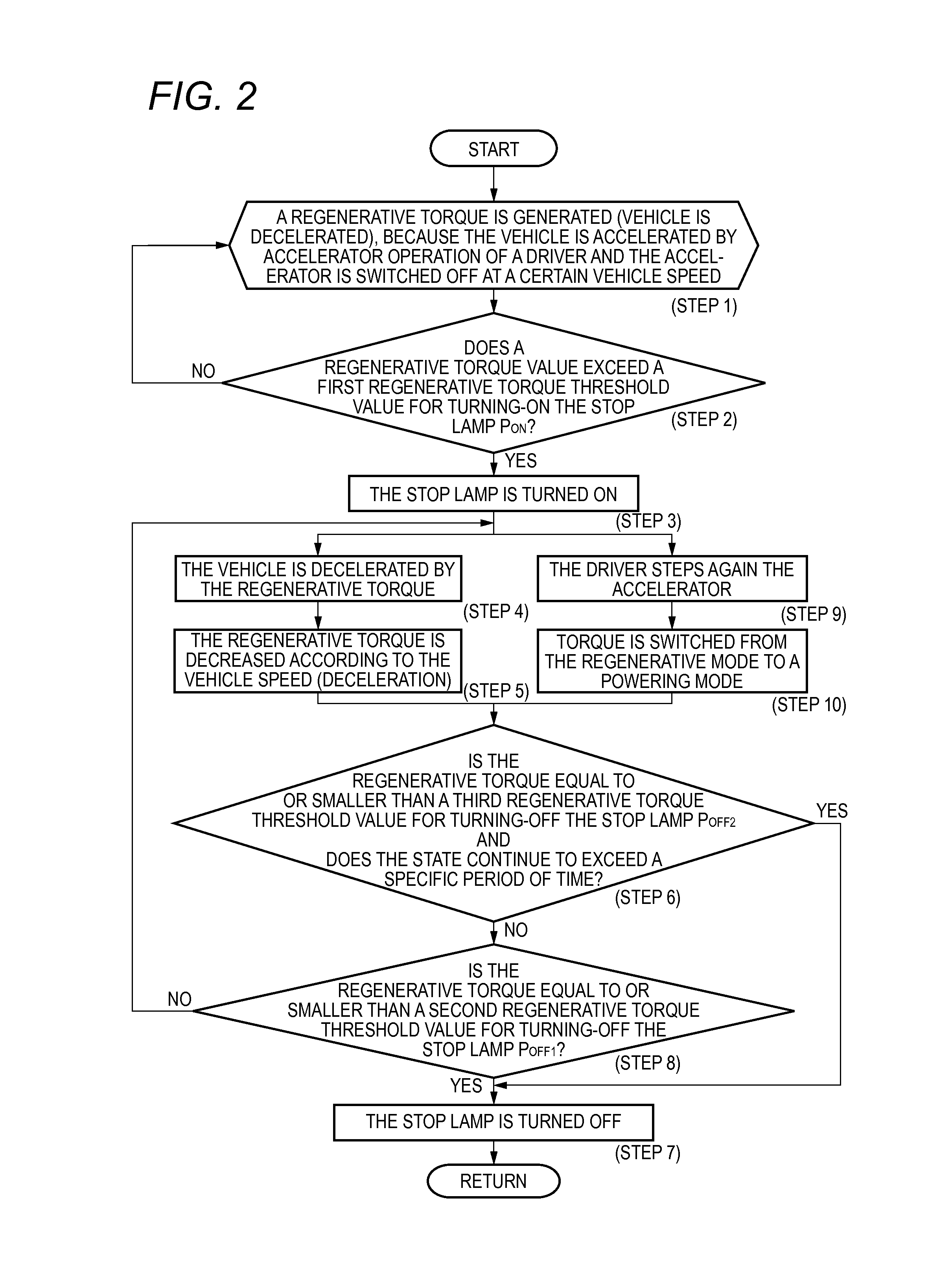

Stop lamp lighting control device for electric vehicle

A stop lamp lighting control device for an electric vehicle having an electric regenerative braking system, includes, a first calculation unit that converts a first deceleration threshold value to a first regenerative torque threshold value with a curb weight, a second calculation unit that converting a second deceleration threshold value to a second regenerative torque threshold value with a gross vehicle weight, a third calculation unit that calculates a third regenerative torque threshold value, and a determination unit that controls the stop lamp to be turned on when a regenerative torque value exceeds the first regenerative torque threshold value, the stop lamp to be turned off when the regenerative torque value is equal to or smaller than the second regenerative torque threshold value, and the stop lamp to be turned off when a given state continues.

Owner:MITSUBISHI MOTORS CORP

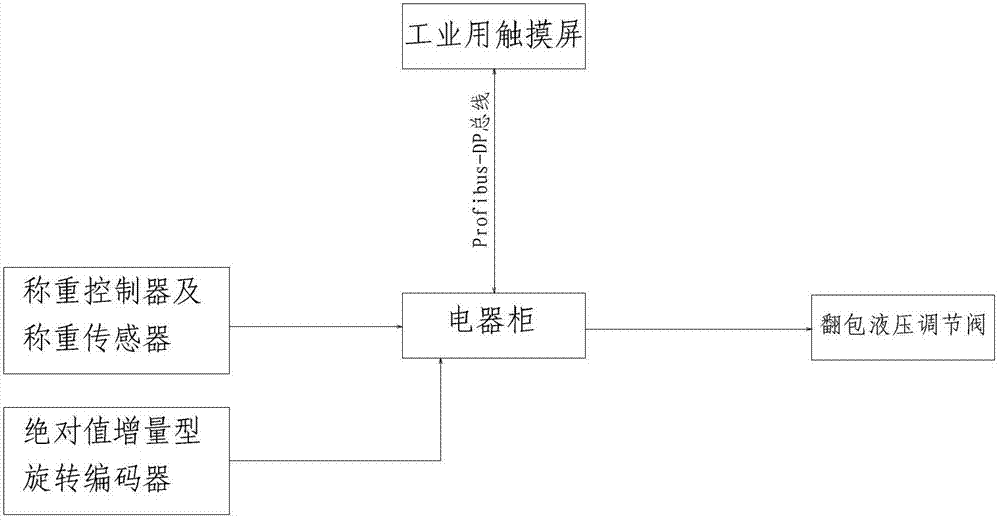

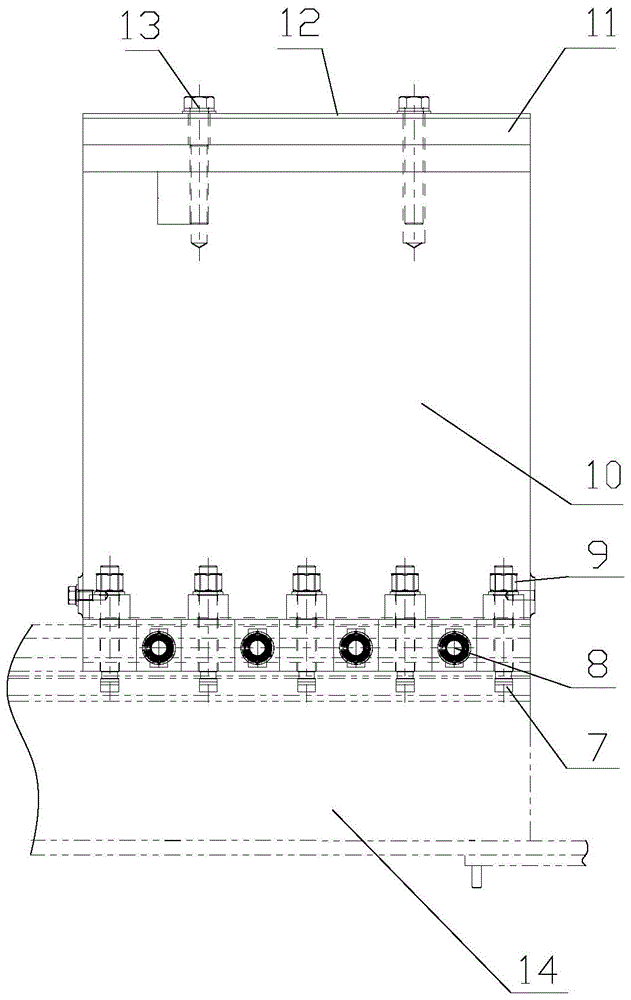

Device for automatically controlling tube weight of centrifugal casting machine

InactiveCN102773446AImprove quality and efficiencyImprove work efficiencyAutomatic controlCurb weight

The invention relates to a device for automatically controlling the tube weight of a centrifugal casting machine. The automatic device comprises an industrial touch screen, an electric cabinet, a weighing controller, a weighing sensor, an absolute value increment type rotary encoder and a turning ladle hydraulic pressure regulating valve, wherein the industrial contact screen is arranged on an operation desk; the industrial contact screen is connected with a PLC (programmable logic controller) in the electric cabinet by virtue of an industrial Ethernet, so that the functions of setting the target tube weight, setting turning ladle experience data, displaying the actual tube weight and correcting regulation parameters are achieved; the PLC is arranged inside the electric cabinet and is used for receiving the target weight data, the adjusting correction parameter and the turning ladle experience setting data coming from inputting; the analog quantity output port of the PLC controls the casting turning ladle hydraulic pressure regulating valve; the weighing controller and the weighing sensor are arranged on the centrifugal casting machine and are used for detecting the tube weight after finishing casting; the absolute value increment type rotary encoder is arranged below a casting fan-shaped ladle and used for detecting the turning angle of the fan-shaped ladle; and the turning ladle hydraulic pressure regulating valve is arranged at the hydraulic pressure valve stand of the centrifugal casting machine, connected with the turning ladle hydraulic pressure mechanism of the fan-shaped ladle and used for controlling the turning of the fan-shaped ladle. By utilizing the automatic device for controlling the tube weight of the centrifugal casting machine, the automatic adjustment of the casting pipe weight can be achieved according to a process demand.

Owner:XINXING HEBEI ENG & RES INC

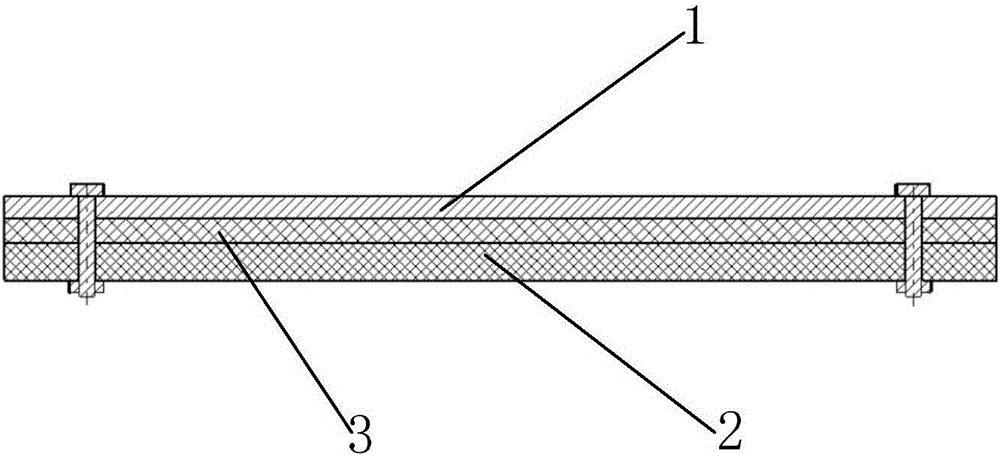

Bulletproof composite plate and car

InactiveCN106247857ALight in massReduced curb weightArmoured vehiclesVehicle componentsCurb weightFuel oil

The invention provides a bulletproof composite plate and a car. The bulletproof composite plate comprises a first plate body made from a bulletproof steel plate, a second plate body made from ultrahigh molecular weight polyethylene, and a third plate body made from ethylene vinyl acetate copolymer, wherein the first plate body and the second plate body are arranged oppositely; the third plate is arranged between the first plate body and the second plate body; and the first plate body, the second plate body and the third plate body are fixedly connected. The bulletproof composite plate formed by combining the first plate body, the second plate body and the third plate body which are made from three different materials, the bulletproof performance is improved, the weight of the bulletproof composite plate is lowered, the curb weight of the car is lowered, and the fuel oil consumption is reduced.

Owner:BEIJING AUTOMOBILE RES GENERAL INST

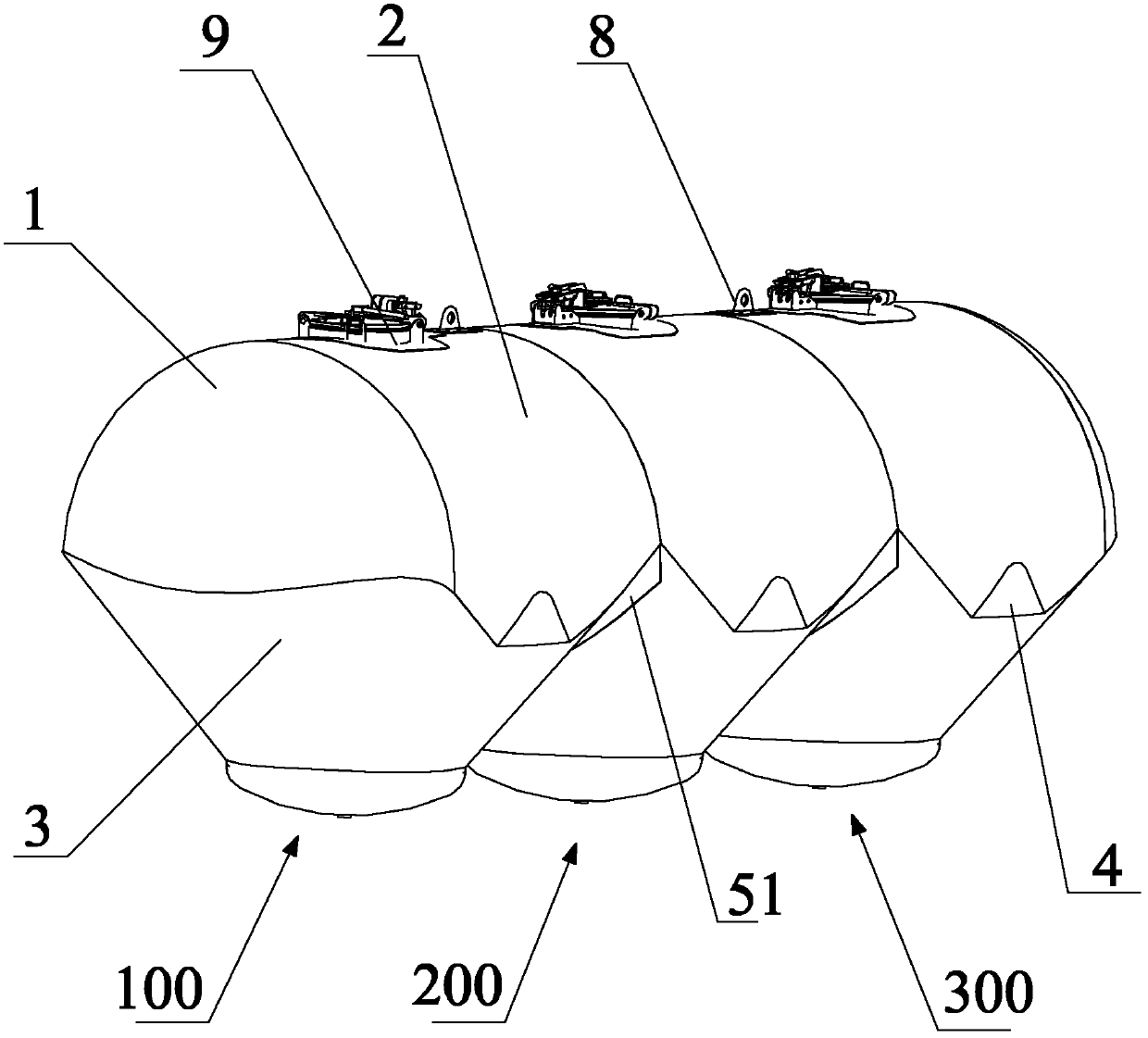

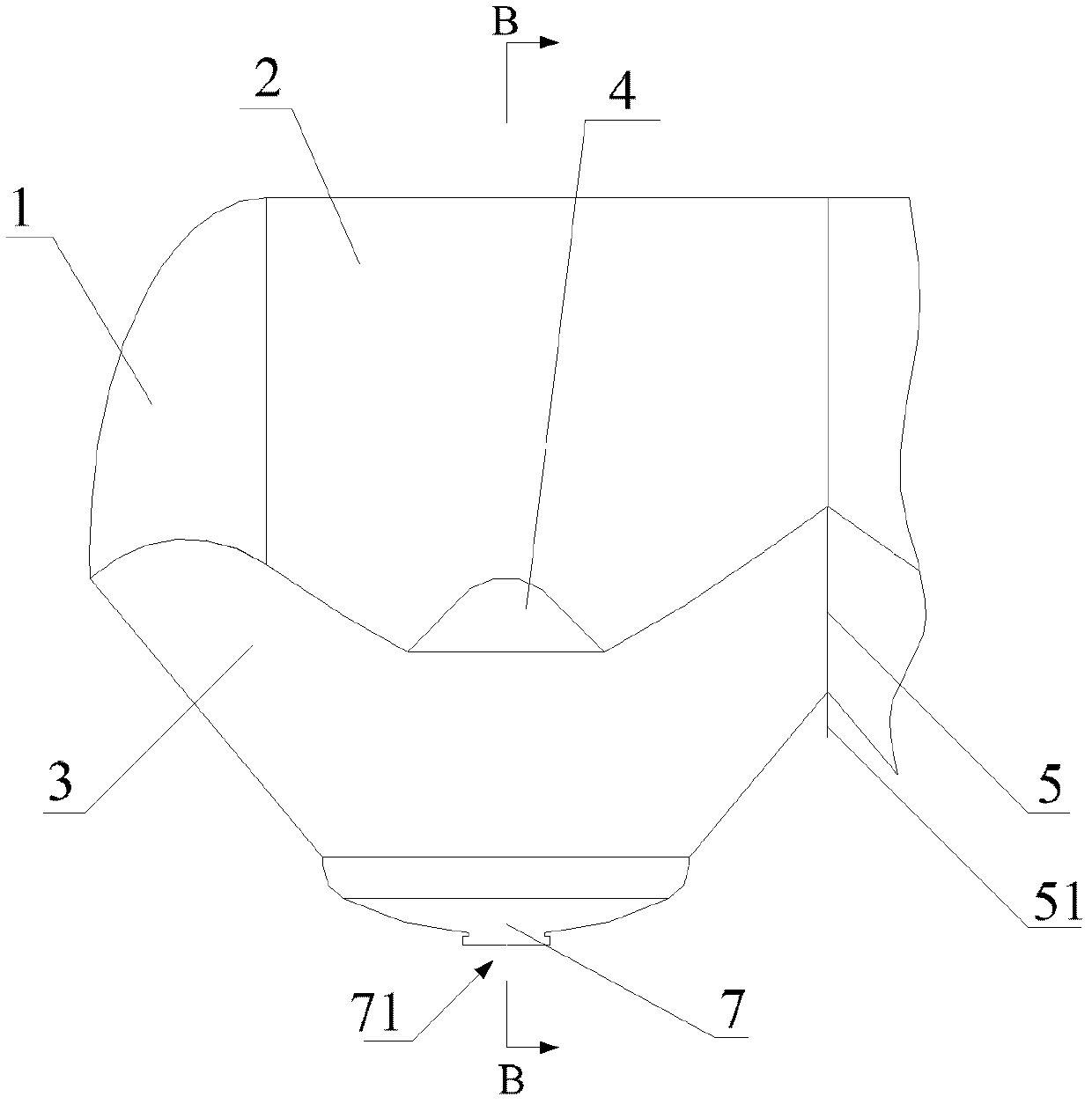

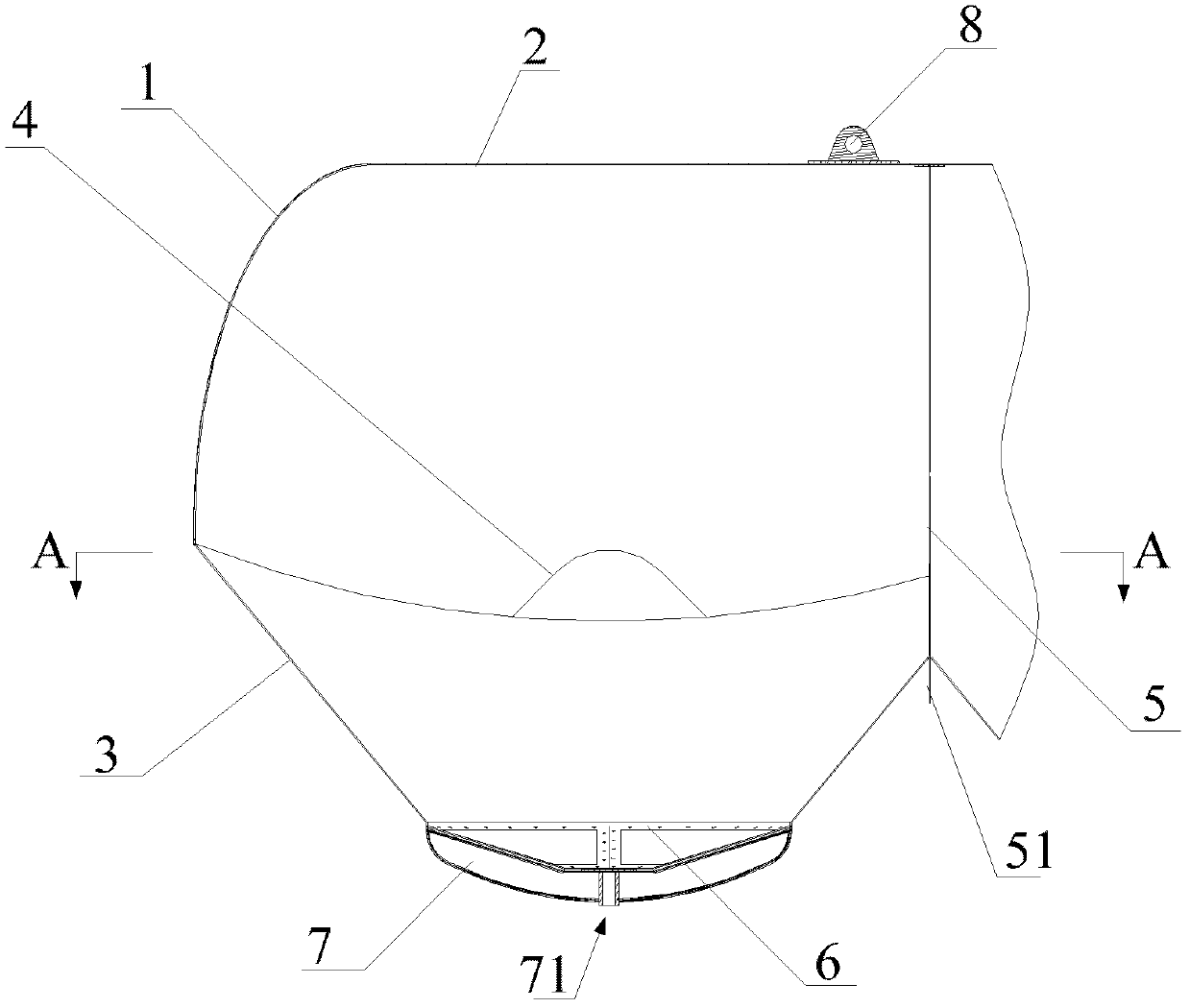

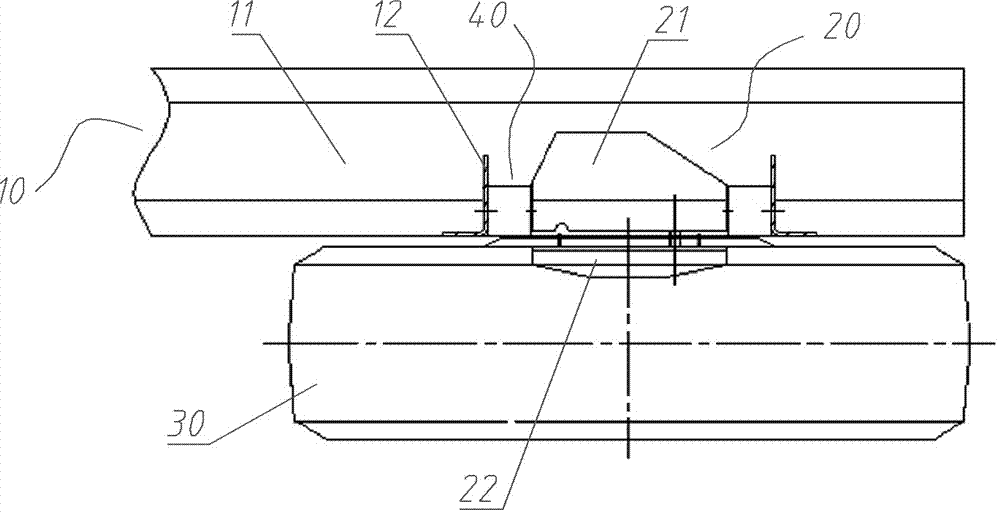

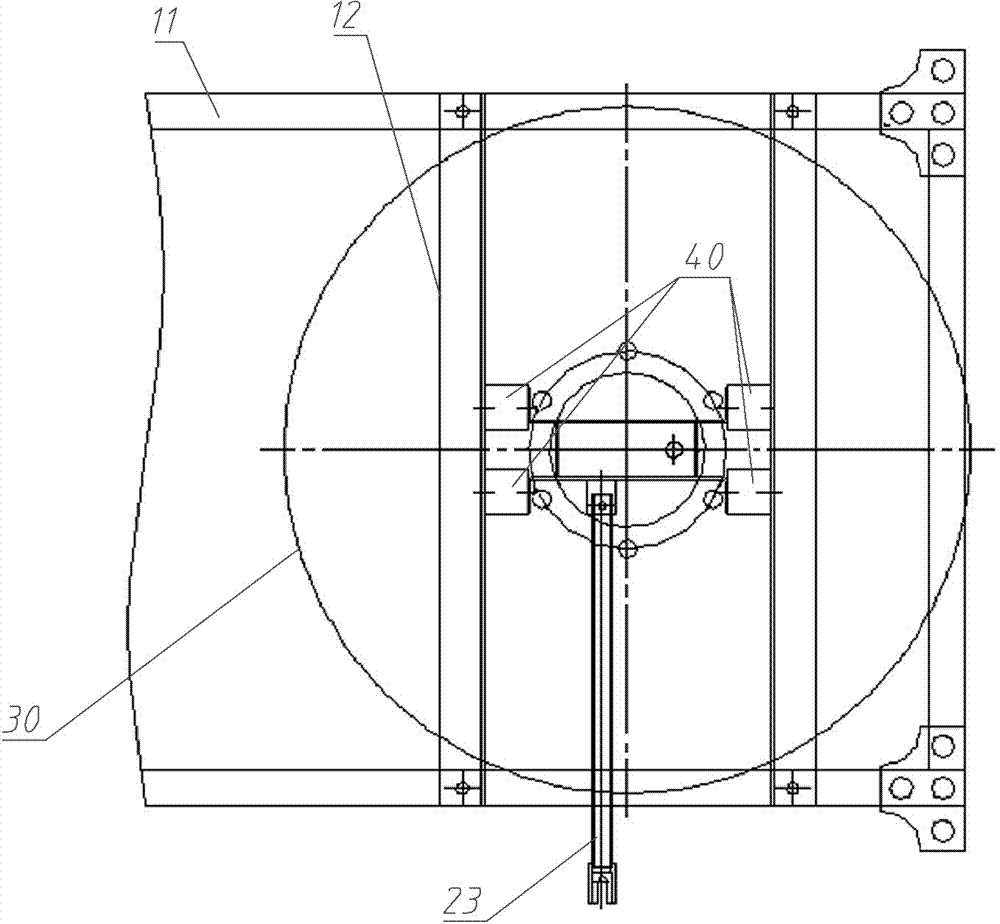

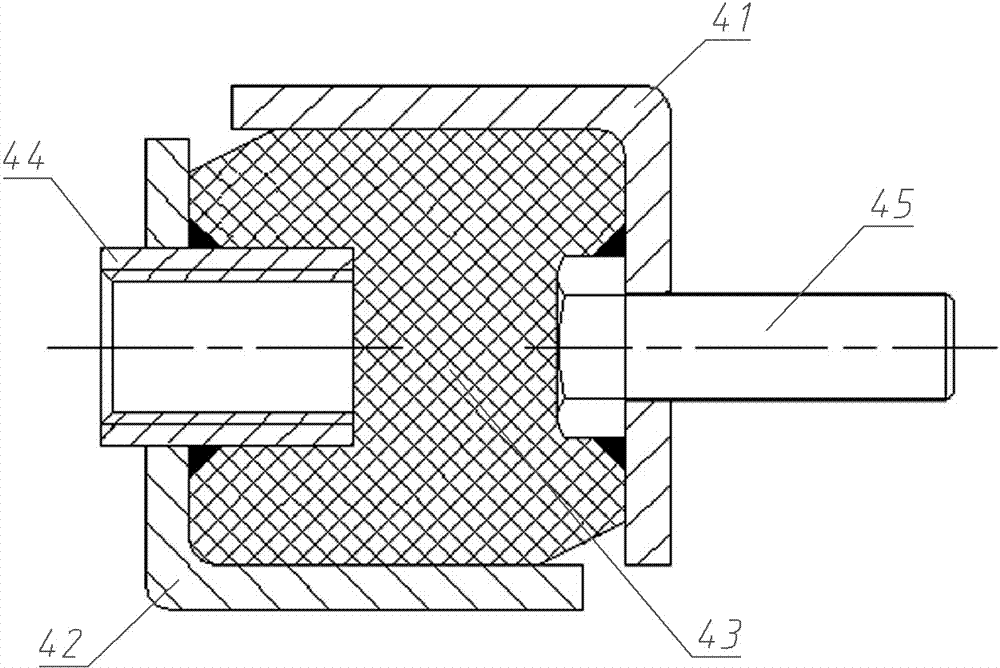

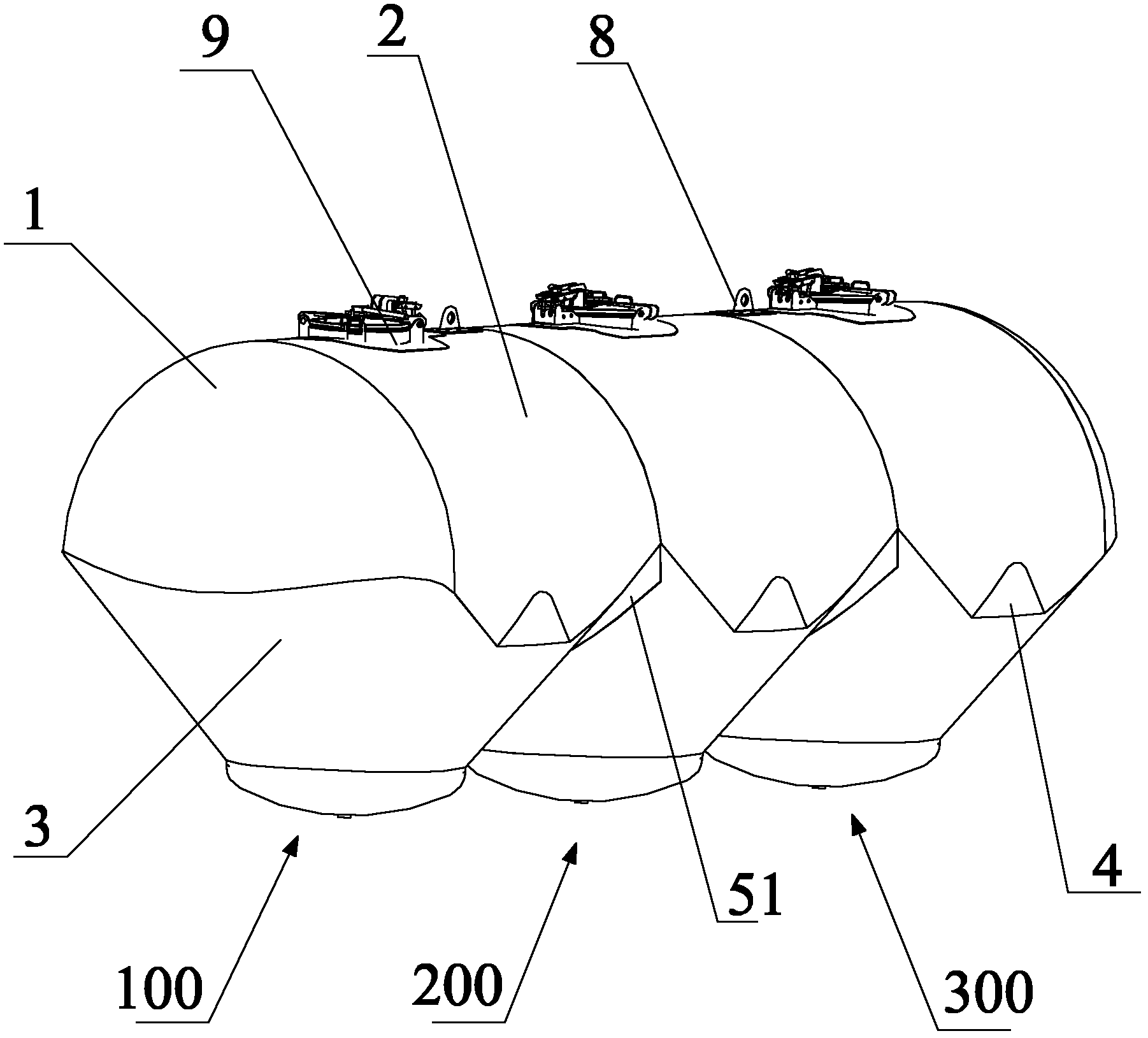

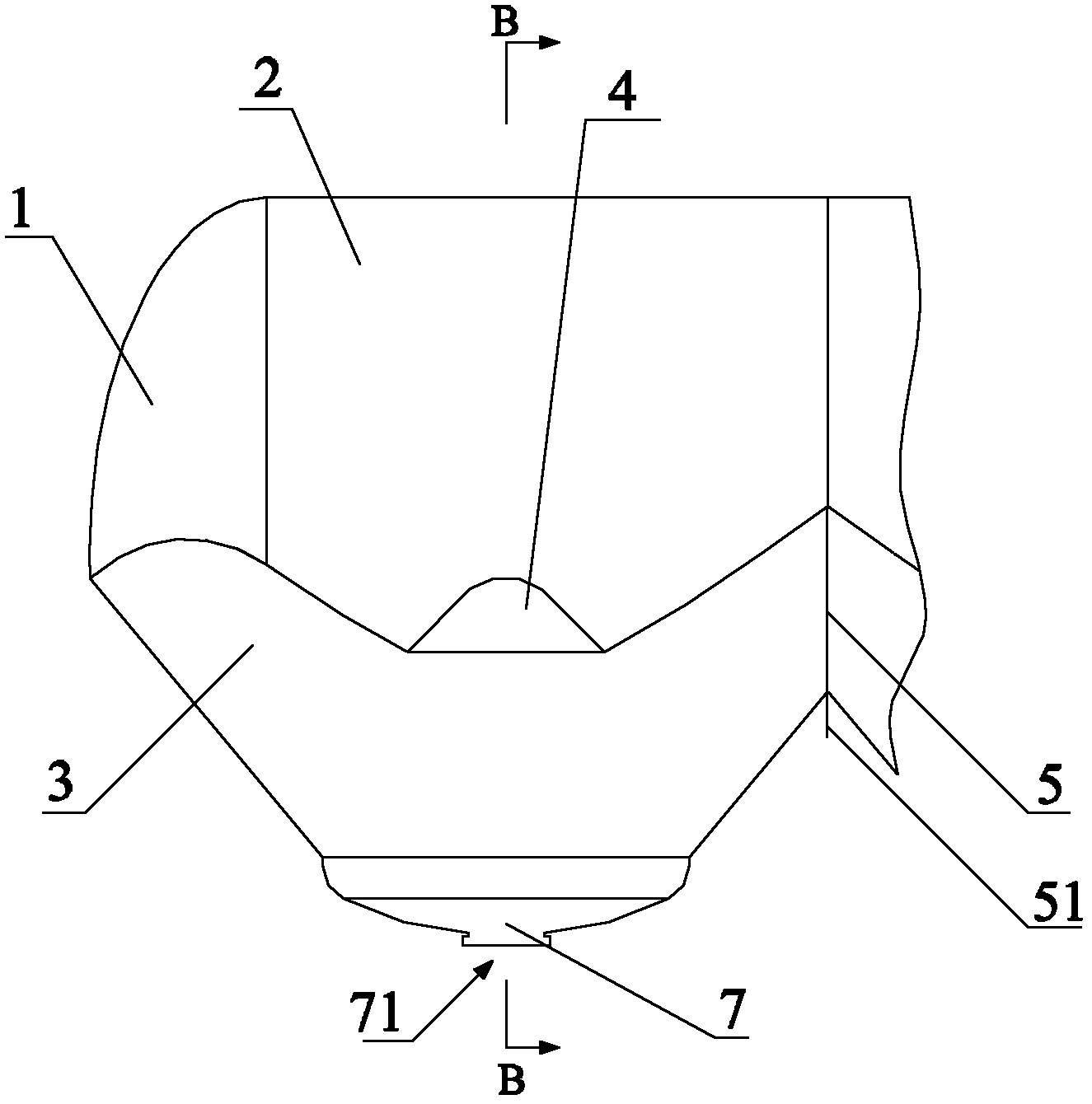

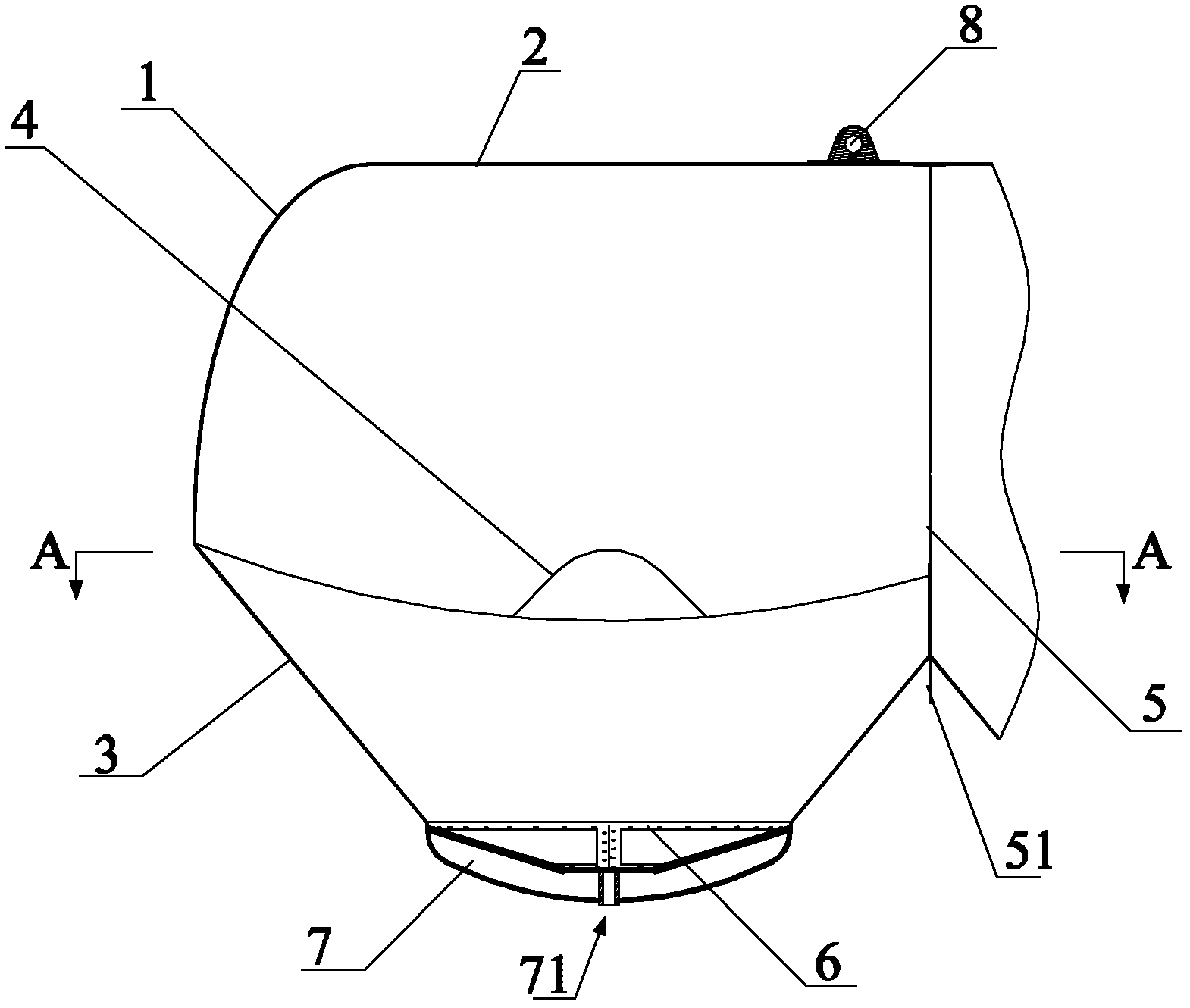

Powder materials tanker and tank assembly thereof

The invention provides a tank assembly of a powder materials tanker, which comprises cabins. Each cabin comprises a horizontal cylinder (2) and a vertical conical tube (3). One end of each horizontal cylinder (2) is connected with the corresponding vertical conical tube (2) through an end enclosure (1). The lateral side of each horizontal cylinder (2) is connected with the corresponding vertical conical tube (3) through arc boards (4). The invention further provides the powder materials tanker. According to the technical scheme, each horizontal cylinder is connected with the corresponding conical tube through the arc boards in a communicated manner, and the arc boards are angled to the vertical direction so as to facilitate loading and unloading of materials and reduce residue of the materials. The vertical conical tubes are directly used as fluidizers, so that the volume utilization rate of the tank assembly is increased, the curb weight of the tank assembly is reduced, material sliding speed is increased, and universality of the materials is improved.

Owner:SANY HEAVY IND CO LTD (CN)

Stop lamp lighting control device for electric vehicle

A stop lamp lighting control device for an electric vehicle having an electric regenerative braking system, includes, a first calculation unit that converts a first deceleration threshold value to a first regenerative torque threshold value with a curb weight, a second calculation unit that converting a second deceleration threshold value to a second regenerative torque threshold value with a gross vehicle weight, a third calculation unit that calculates a third regenerative torque threshold value, and a determination unit that controls the stop lamp to be turned on when a regenerative torque value exceeds the first regenerative torque threshold value, the stop lamp to be turned off when the regenerative torque value is equal to or smaller than the second regenerative torque threshold value, and the stop lamp to be turned off when a given state continues.

Owner:MITSUBISHI MOTORS CORP

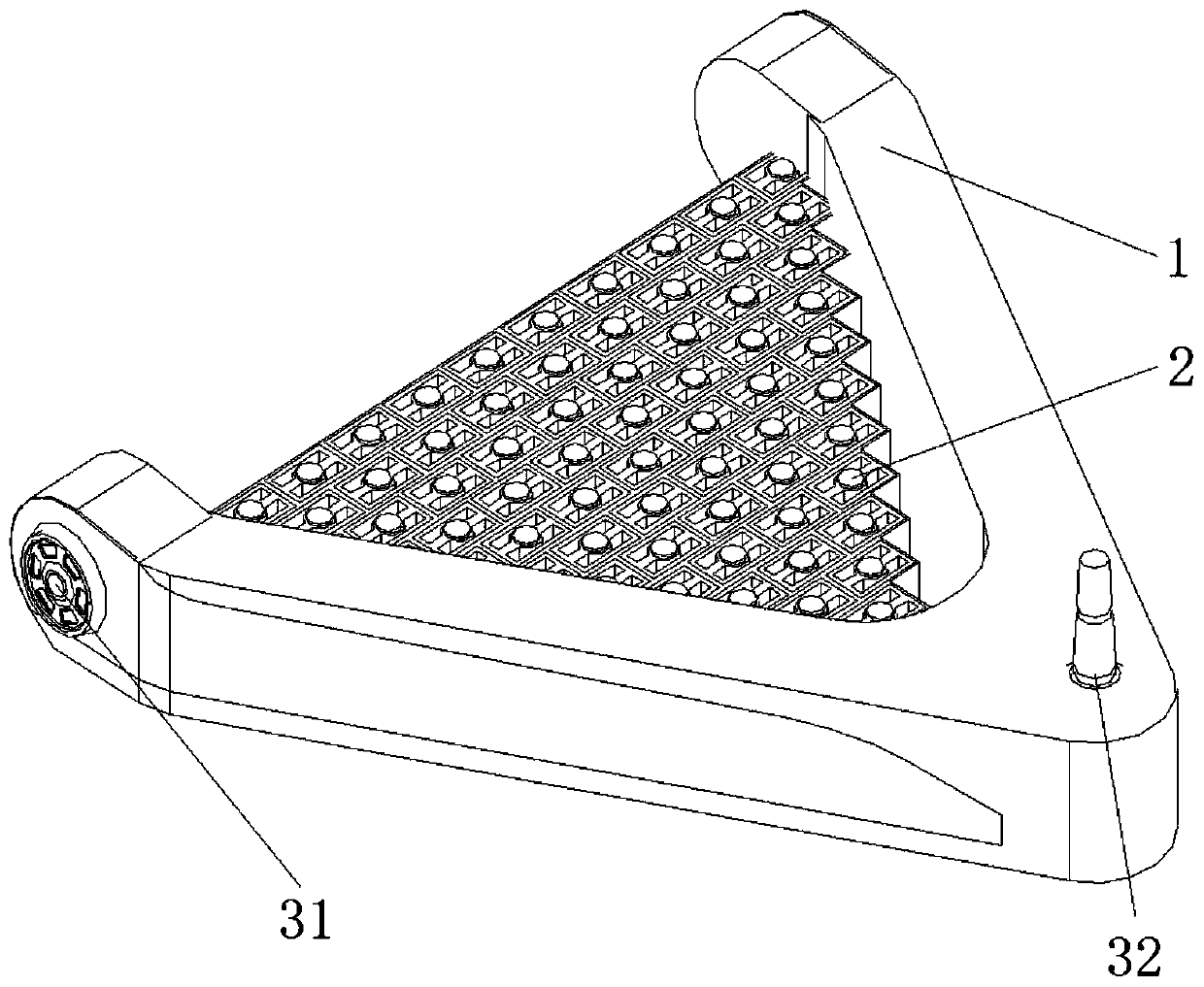

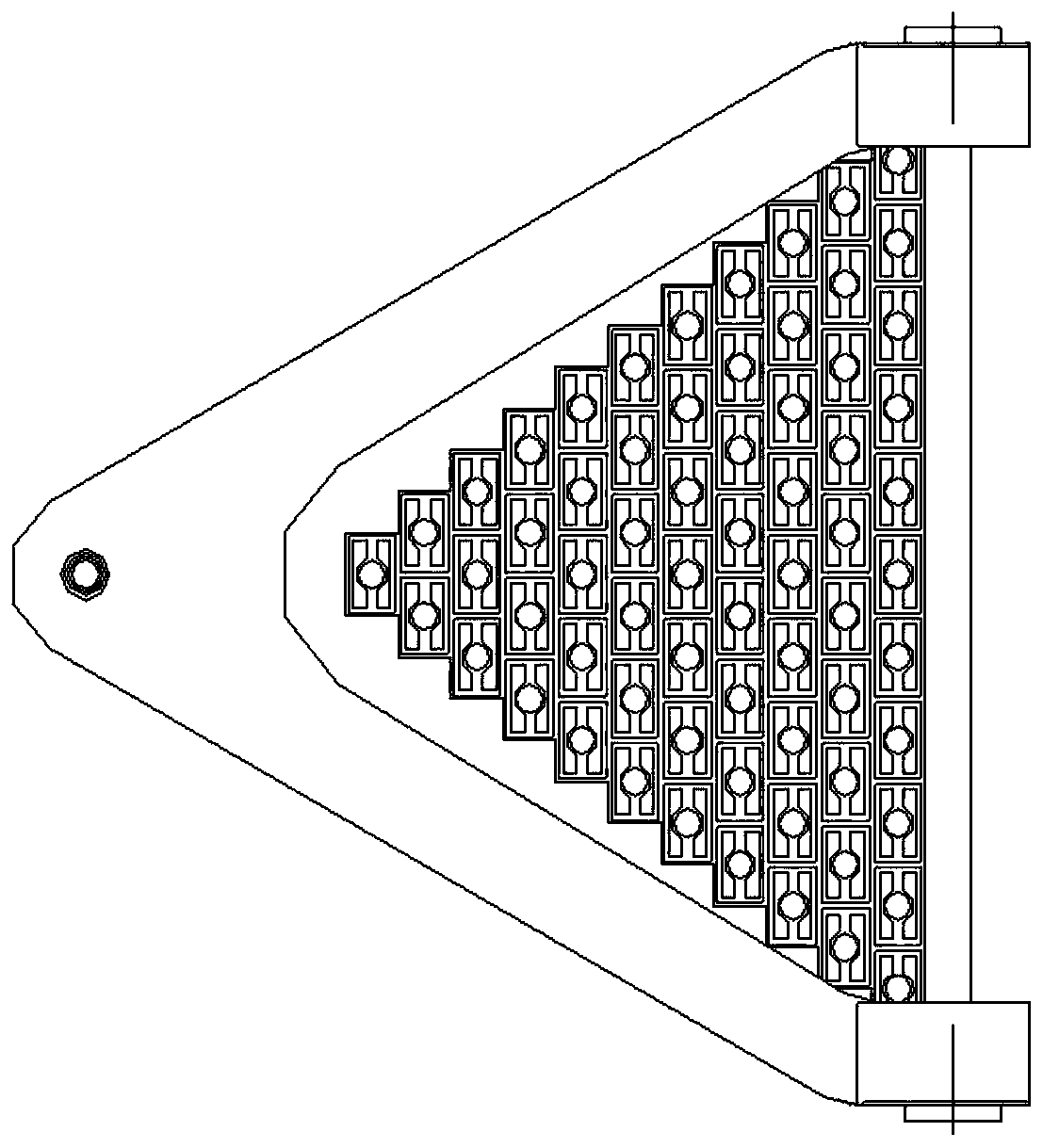

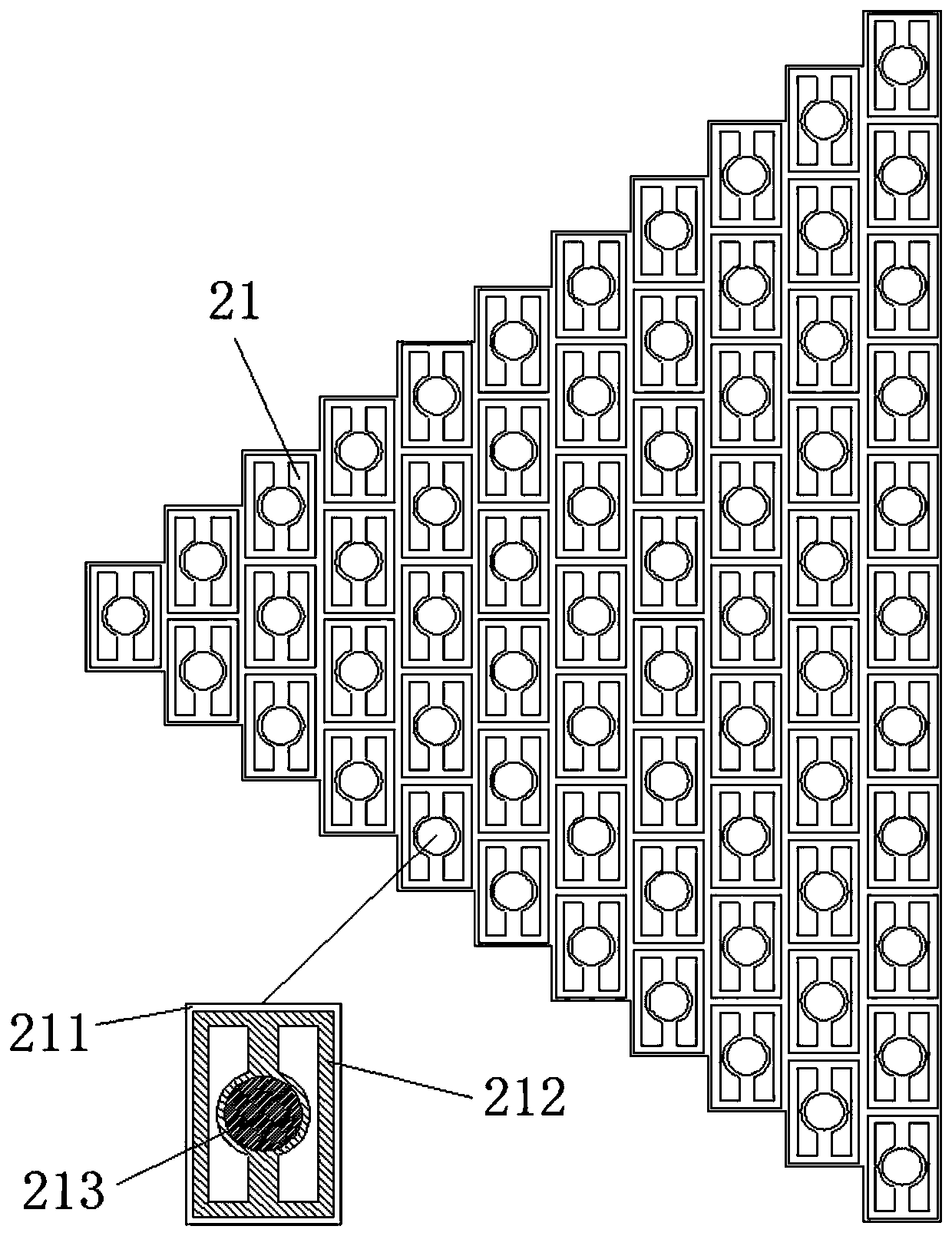

Vehicle suspension control arm based on array type shock absorber and parameter calculation method

ActiveCN111114225ADoes not significantly increase complexityNo significant increase in massResilient suspensionsPivoted suspension armsCurb weightVibration acceleration

The invention discloses a vehicle suspension control arm based on an array type shock absorber. The control arm comprises a control arm body, an array type shock absorber and a control arm connectingassembly, wherein the control arm body is the most basic structural component of the vehicle suspension control arm and used for bearing loads in the vehicle running process and providing an installation base for the array type shock absorber and the control arm connecting assembly; the array type shock absorber is installed on the control arm body and used for absorbing vibration and impact transmitted to a vehicle body from a running system in the vehicle running process; the control arm connecting assembly is installed on the control arm body and connected with a vehicle driving system anda vehicle body. The vehicle suspension control arm is used for attenuating impact and vibration transmitted to a chassis by a driving system through the array type shock absorber arranged in the control arm in the driving process of a vehicle. Therefore, the vibration acceleration energy and amplitude of the vehicle are reduced as much as possible on the premise of not obviously increasing the structural complexity and the curb weight of the vehicle suspension system.

Owner:上海采埃孚伦福德底盘技术有限公司

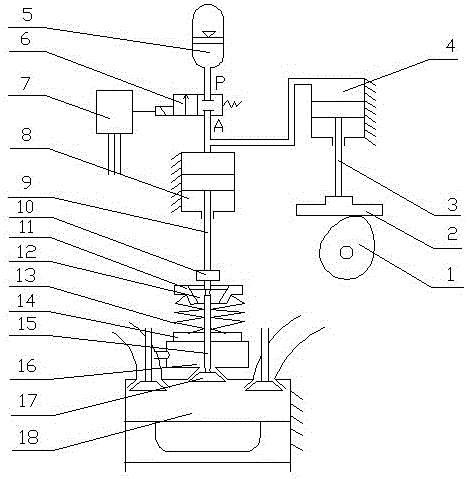

An opening and closing device for the main and auxiliary combustion chamber passage valves of a dimethyl ether engine

InactiveCN104500163BImprove combustion efficiencyReduced curb weightMachines/enginesNon-mechanical valveCurb weightCombustion chamber

The invention specifically relates to an opening and closing device for passage valves of main and auxiliary combustion chambers of a dimethyl ether engine. Its technical scheme is: the valve cam (1) is installed on the intake or exhaust camshaft, the first flat chassis (2) is in contact with the valve cam (1), and the first cylinder piston rod (3) is in contact with the first flat chassis. (2) Fixed connection, the rodless chamber of the first cylinder (4) communicates with the A port of the corresponding two-position two-way solenoid valve (6) and the rodless chamber of the second cylinder (8) through a three-way pipe joint , the accumulator (5) is connected to the P port of the two-position two-way solenoid valve (6), the two-position two-way solenoid valve (6) is externally connected to the ECU module (7), and one end of the second cylinder piston rod (9) is connected to the first The second flat chassis (10) is fixedly connected, the second cylinder piston rod (9), the second flat chassis (10) and the valve stem (15) are located on the same axis, and the valve stem (15) is sequentially installed with valve lock clips (12 ), upper valve spring seat (11) and return spring (13). The opening and closing device of the channel valve has the characteristics of variable timing and lift, which can reduce curb weight and improve combustion efficiency.

Owner:WUHAN UNIV OF SCI & TECH

Method for simulative generation of working condition curve of electric vehicle

ActiveCN102129487BIncrease flexibilityShorten the timeVehicle testingElectrical testingPower batteryCurb weight

Owner:HANGZHOU GOLD NEW ENERGY TECH

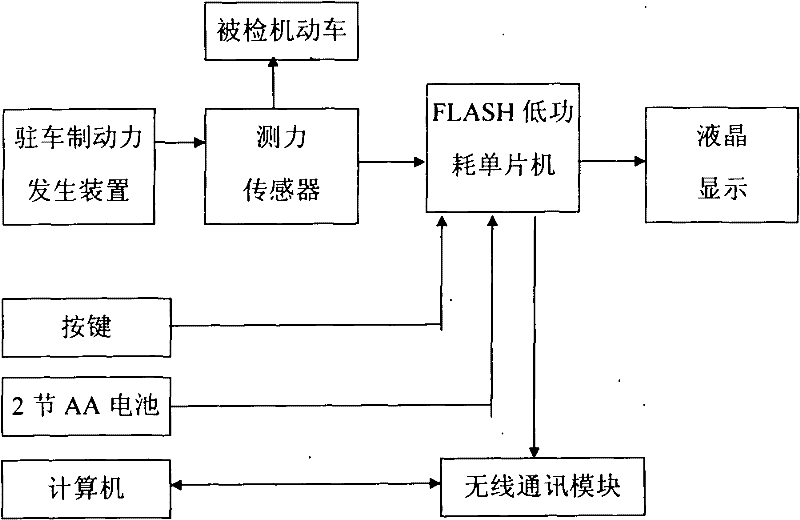

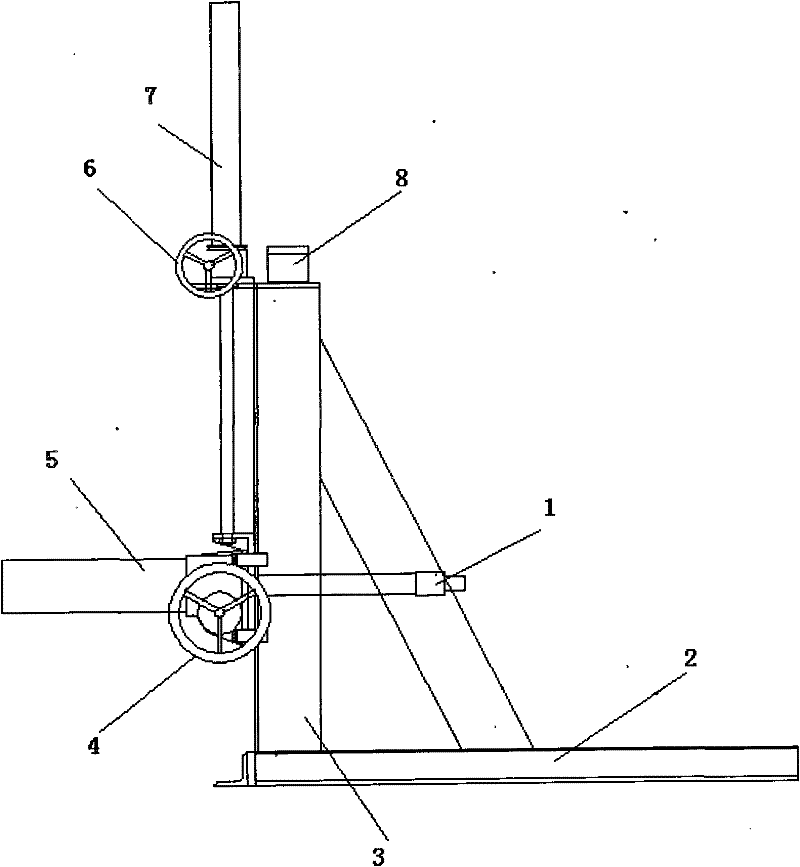

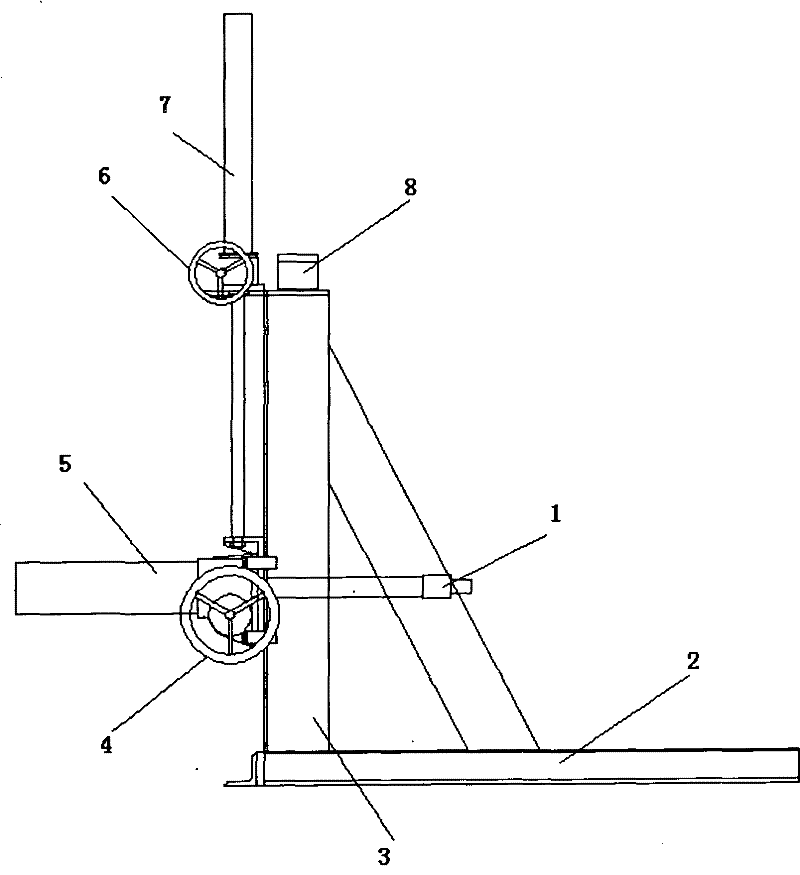

Method and system for testing parking brake performance

ActiveCN101793612BReduce volumeReduce weightVehicle testingApparatus for force/torque/work measurementElectricityCurb weight

The invention discloses a method and a system for testing parking brake performance, which overcome the defect of the method needing to build a parking slope and directly measure the traction force of a parked vehicle, a force cell is connected with the tested vehicle through a wire rope, traction force which accounts for 20 percent of the overall weight of the tested vehicle or 15 percent when the overall weight of the vehicle is less than 1.2 times as heavy as the curb weight is applied on the vehicle according to standard specifications, the parking brake performance is acceptable when thetested vehicle stays still, otherwise is unacceptable, and the acceptability or unacceptability of the parking brake performance can be judged on an on-site screen or remotely transmitted to a computer and judged in the form of reading. The testing system is small and does not require the building of a special-purposed slope, thus dispensing with land occupation and capital expenditure needed by the slope method to build the testing slope and creating favorable conditions for various vehicle testing stations to carry out the testing operation. Because the testing system adopts a zigbee wireless communication mode for the first time, the testing system reduces electricity consumption, is light, and does not have external cables.

Owner:SHANGHAI SIPAI AUTOMATION INSTR ENGCO

Compressing protecting device of compressing vehicle

The invention discloses a compressing protecting device of a compressing vehicle. The compressing protecting device comprises a vehicle second-class chassis and a compressing compartment which are assembled, a rear compartment is hinged to the upper edge of a material loading end of the compressing compartment, and a lifting plate assembly, a scrapping plate assembly and a lifting barrel mechanismare arranged in the rear compartment; the compressing protecting device is characterized in that a push pressing mechanism is installed in the rear compartment, the push pressing mechanism and a pushpressing plate which can be hinged to the front inner wall of the upper edge of the rear compartment are assembled, the back of the push pressing plate is rotatably connected with at least one push pressing oil cylinders, and the push pressing oil cylinders are rotatably connected and hinged on the top inner wall of the rear compartment. Arc-shaped plates are arranged on the two sides of the compressing compartment, the structure is compact, the curb weight is reduced, the loading capacity of the vehicle is improved, a sewage collecting tank is configured to prevent sewage overflowing in therubbish treating process, and peripheral environment is effectively protected; the push pressing mechanism is arranged on the upper portion, the compressing ratio when rubbish treatment is conducted is increased, the treating amount of rubbish of the whole vehicle in one attempt is improved, and the appearance of the whole vehicle is attractive.

Owner:QINGDAO ALLITE AUTO TECHNIC

Intelligent object information analysis platform and method

ActiveCN112825133ARun smartGuaranteed uptimeImage analysisAnti-theft cycle devicesData ingestionMaximum torque

The invention relates to an intelligent object information analysis platform and method. The platform comprises a data downloading device which is installed at the top of a helmet worn by a motorcycle rider and connected with a far-end data server through a network, wherein a motorcycle database is stored on the data server, and the empty weight and the maximum torque corresponding to each motorcycle type as well as the fastest braking time, the shortest braking distance and the fastest running speed corresponding to various oil tank states are stored in the motorcycle database by taking the motorcycle type as an index; and a vehicle type recognition mechanism which is used for performing vehicle type recognition processing on a motorcycle object with the largest area in a received filtered and sharpened image. The intelligent object information analysis platform and method are intelligent in operation, safe and reliable. Due to the fact that on-site analysis and relevant data extraction can be carried out on a motorcycle model closest to a motorcycle in a motorcycle event, reliable data are provided for a driver of the motorcycle to make an overtaking strategy.

Owner:广西微车检智能科技有限公司

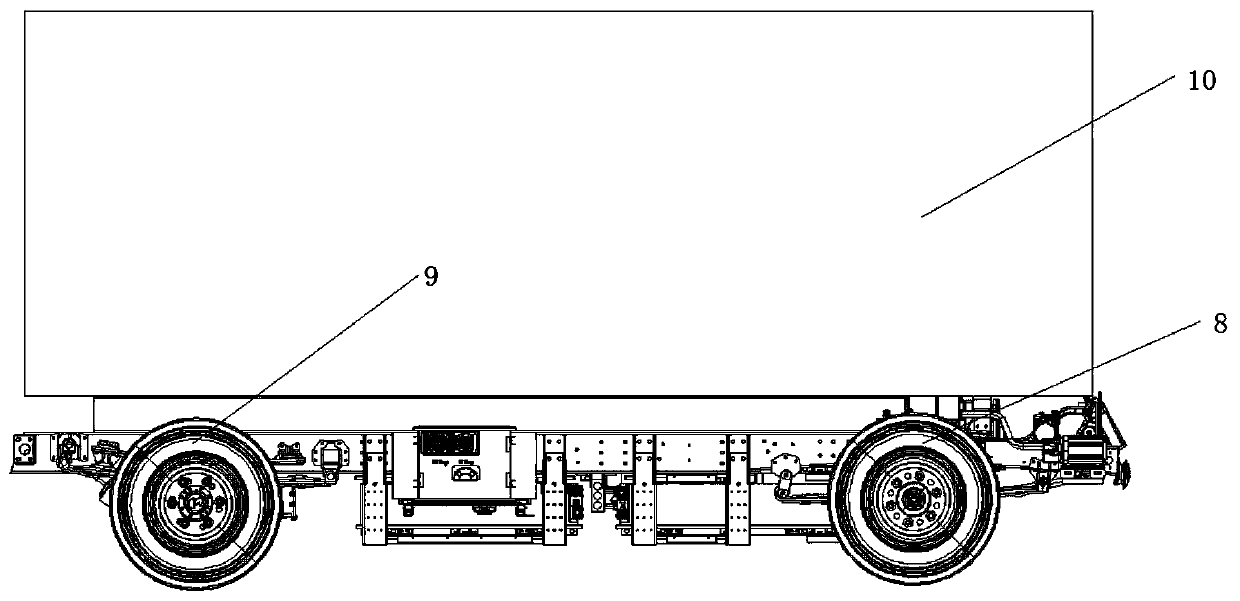

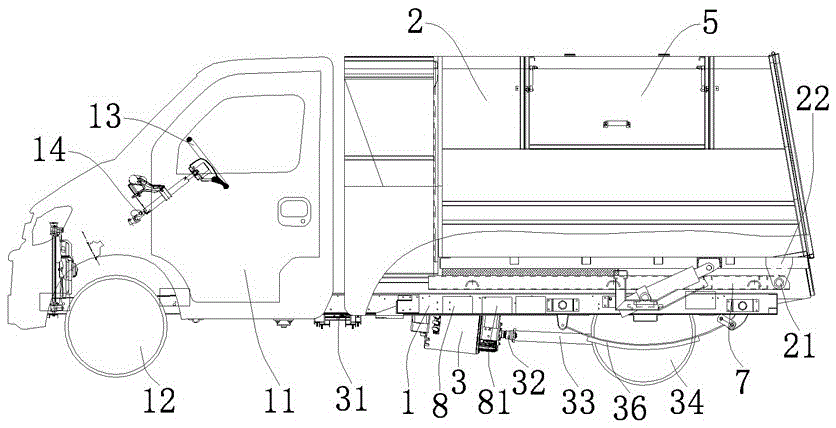

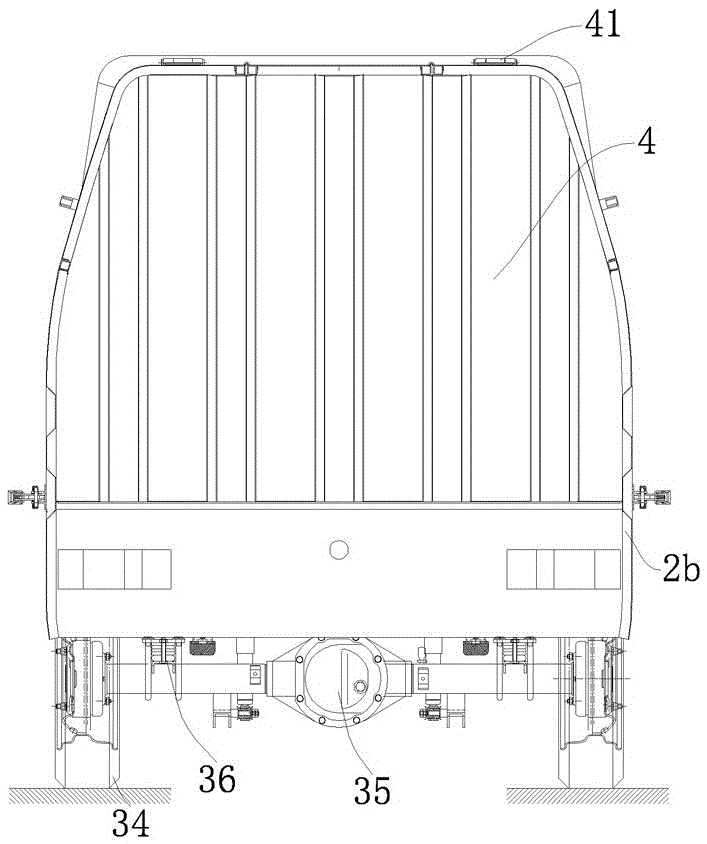

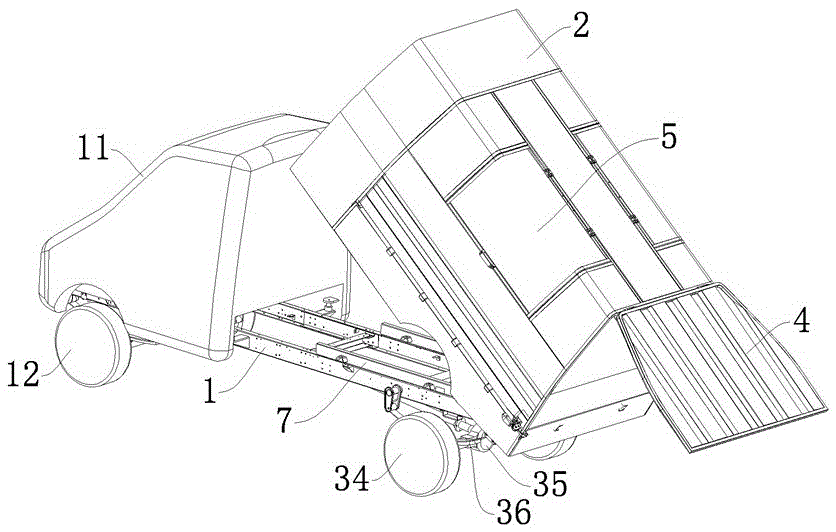

Pure electric trash collection vehicle

ActiveCN105480625ANo drippingUse energy saving and environmental protectionRefuse vehiclesPower batteryCurb weight

The invention discloses a pure electric trash collection vehicle which comprises a vehicle chassis, a cab and a trash collection tank arranged on the vehicle chassis. The vehicle chassis is an electric automobile chassis. A power battery and a drive motor for driving vehicle rear wheels to rotate are arranged at the bottom of the vehicle chassis. A tank body rear door is arranged on the rear portion of the trash collection tank. Tank body side doors capable of being automatically opened are arranged on the two sides of the trash collection tank respectively. The bottom end of the rear portion of the trash collection tank is arranged on the vehicle chassis through a rotating shaft in a rotating mode. An unloading oil cylinder for driving the trash collection tank to turn and rotate around the rotating shaft for unloading is arranged on the vehicle chassis. According to the pure electric trash collection vehicle, the drive motor, the power battery and an electronic control system serve as power, energy conservation and environment protection are better achieved in the use process, the light design method is adopted for the whole vehicle, the curb weight is greatly reduced, and the transportation efficiency is improved. In addition, the sealing structure of the trash collection tank is optimized, the sealing performance is greatly improved, and secondary pollution of trash falling, exposing, leakage and the like is eradicated.

Owner:ZHEJIANG BAOCHENG MACHINERY TECH

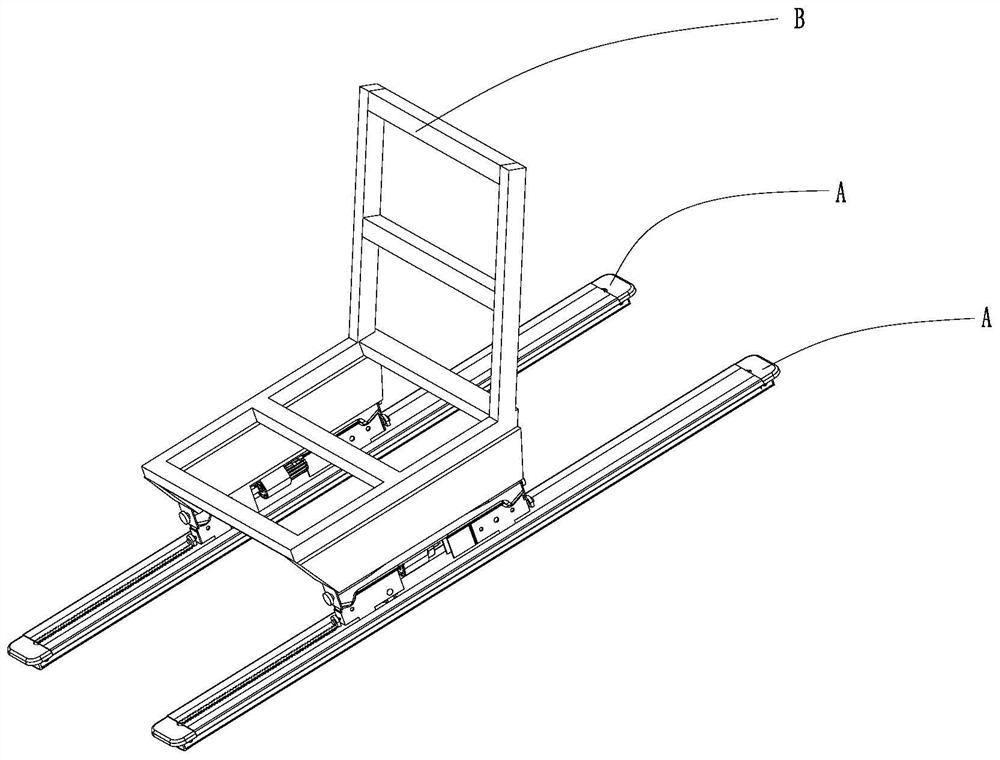

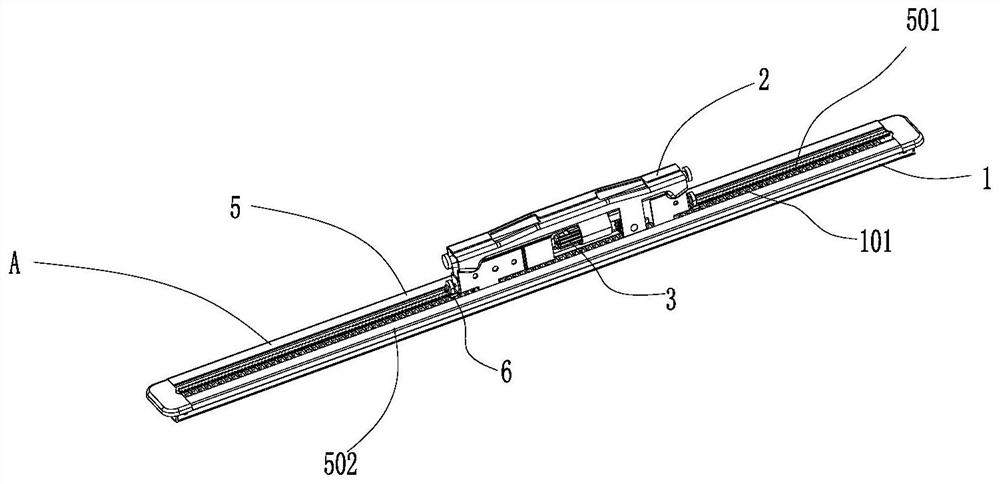

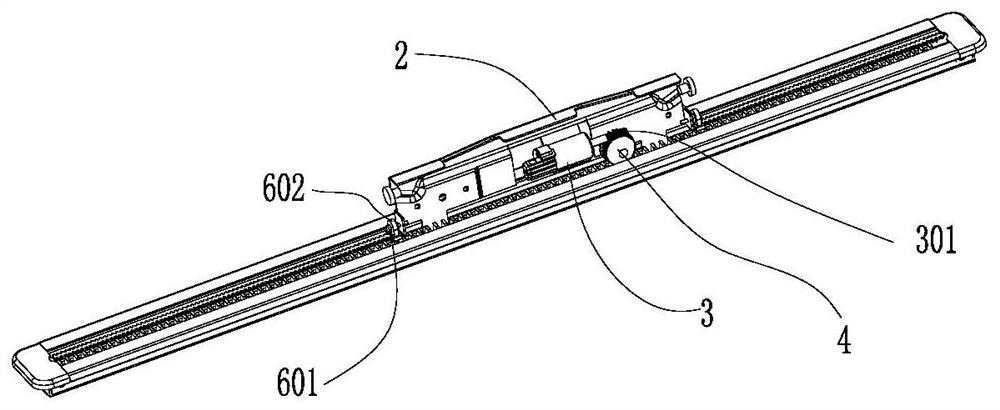

A car seat slide rail device

The invention provides a car seat slide rail device, which comprises: a slide rail, on which a rack is arranged; a seat support seat, which is slidably arranged on the slide rail, and has an accommodating cavity inside; a car seat The chair is fixedly installed on the seat support base; the drive motor is arranged in the accommodation cavity and is fixedly connected with the seat support base; the output shaft of the drive motor is a threaded screw; the transmission mechanism is arranged in the accommodation cavity , and is fixedly connected with the seat support base; the transmission mechanism includes a coaxial helical gear and a spur gear, the helical gear meshes with the threaded screw, and the spur gear meshes with the rack on the slide rail. The present invention not only simplifies the structure and reduces the curb weight by setting the self-locking transmission mechanism, but also avoids the problem of response delay of unlocking / locking, and realizes follow-up stop; the setting of the zipper type surface sealing structure prevents foreign objects from dropping The potential safety hazards caused by entering the slide rails are avoided, and dust and debris are prevented from falling and difficult to clean; at the same time, there are no seams or hidden objects on the outside, which improves the sense of quality.

Owner:DONGFENG MOTOR CO LTD

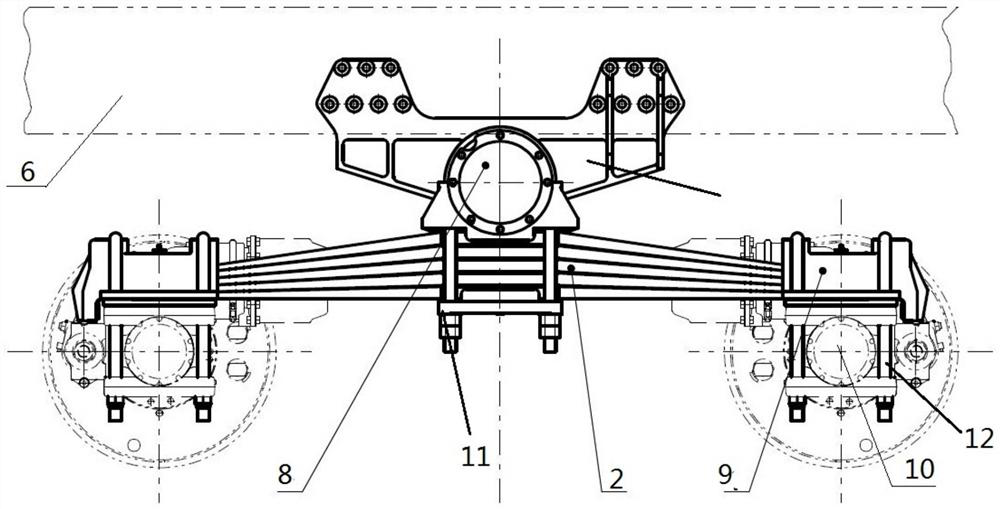

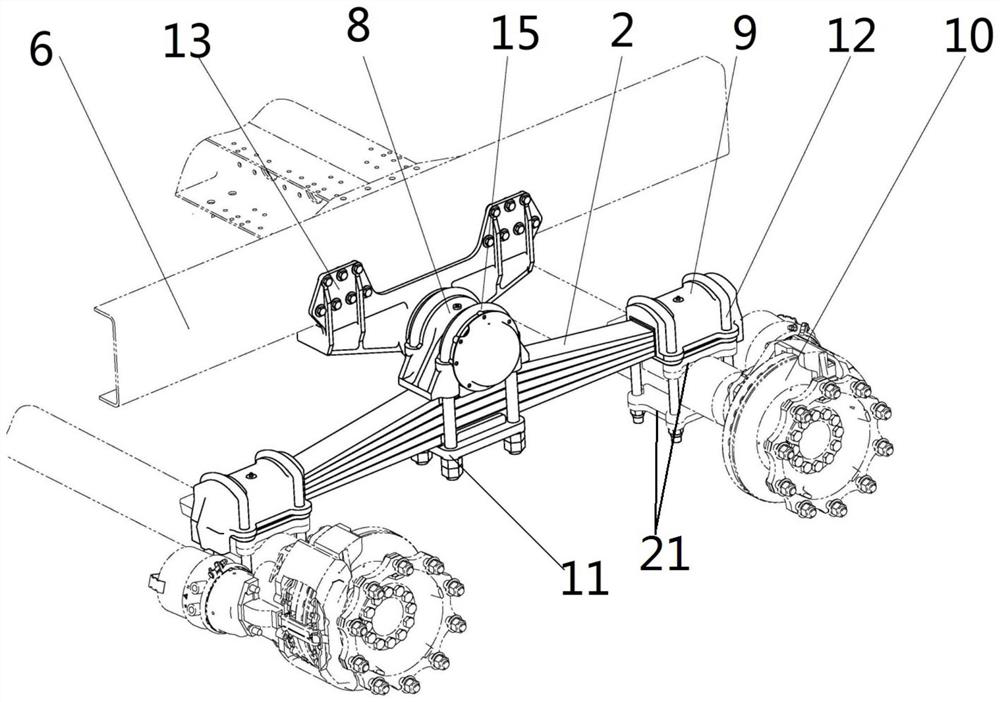

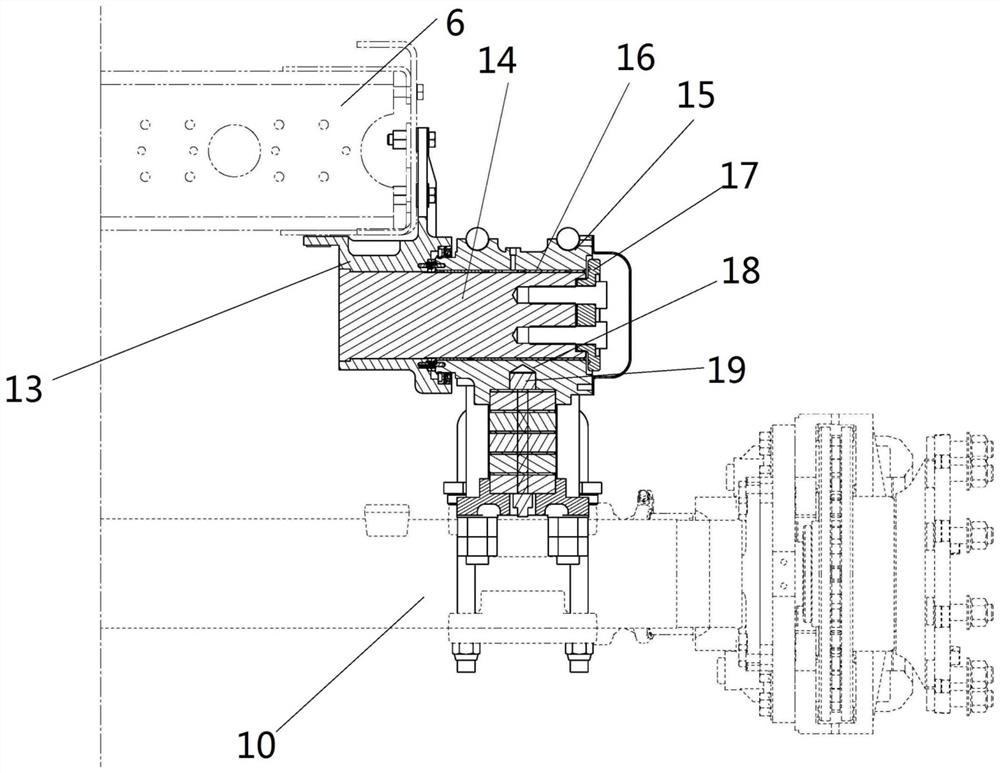

A vehicle balance suspension assembly structure

ActiveCN109955668BIncrease the relative turning heightHigh refit adaptabilityLeaf springsResilient suspensionsVehicle frameCurb weight

The invention discloses a balance suspension assembly structure for a vehicle. The vehicle frame is used as the carrier of the suspension system. Both ends of the leaf spring are fixed on the upper end of the vehicle axle through the bridge end assembly. Installed at the lower end of the balance shaft housing, when the height distance between the axle and the frame is constant, the size and weight of the balance shaft support can be optimized, reducing the curb weight. At the same time, the weight is reduced by The frame is transmitted to the balance shaft housing, and then to the leaf spring and the axle, which reduces the force on the fixed connection between the balance shaft housing and the leaf spring, and is not affected by the load, greatly improving its reliability and service life ;This device adopts the balance shaft shaft end assembly to connect the leaf spring and the frame in rotation, which has the ability of traditional balance suspension to adapt to uneven road surfaces, increases the relative rotation height between the two axles, and can adapt to complex off-road road surfaces. Simple, lightweight, and highly versatile.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

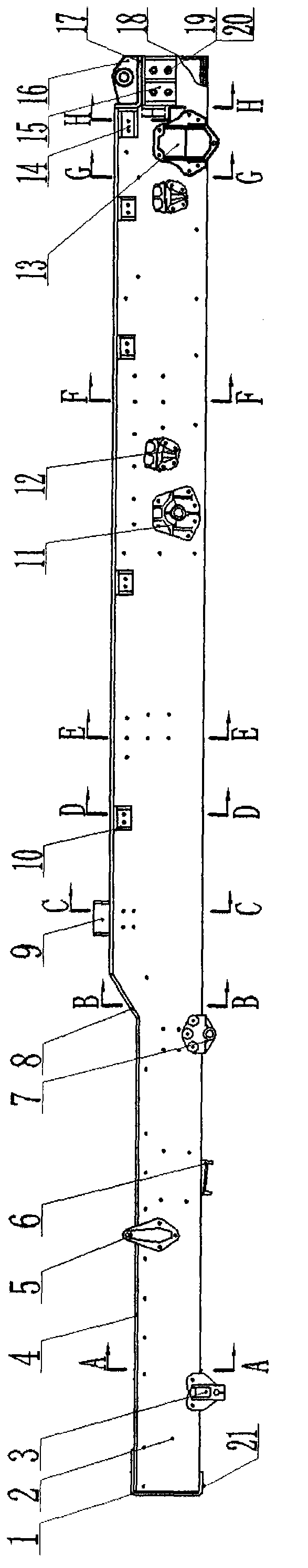

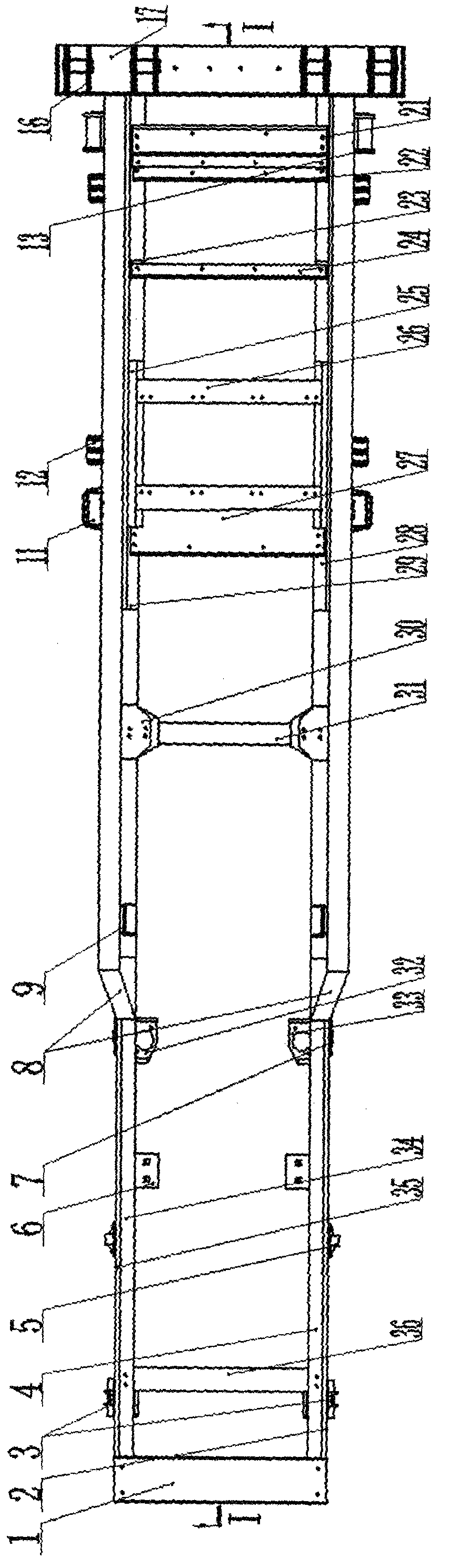

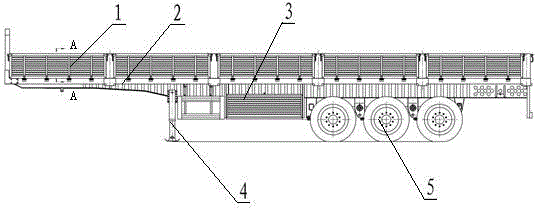

Light-weight semitrailer

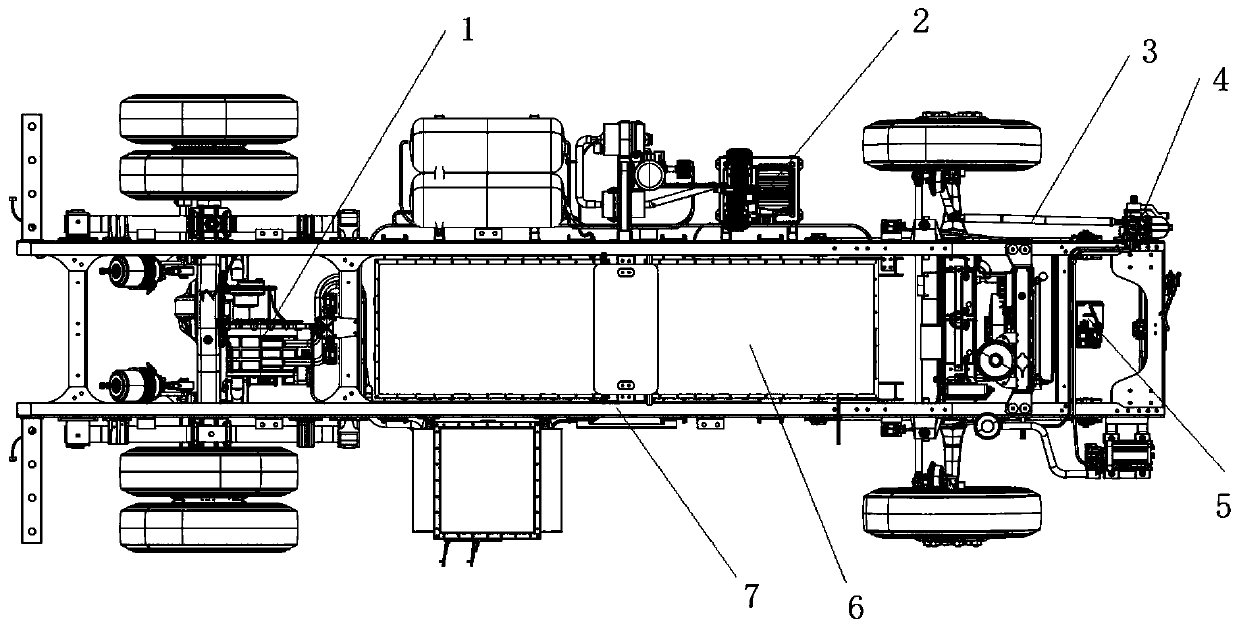

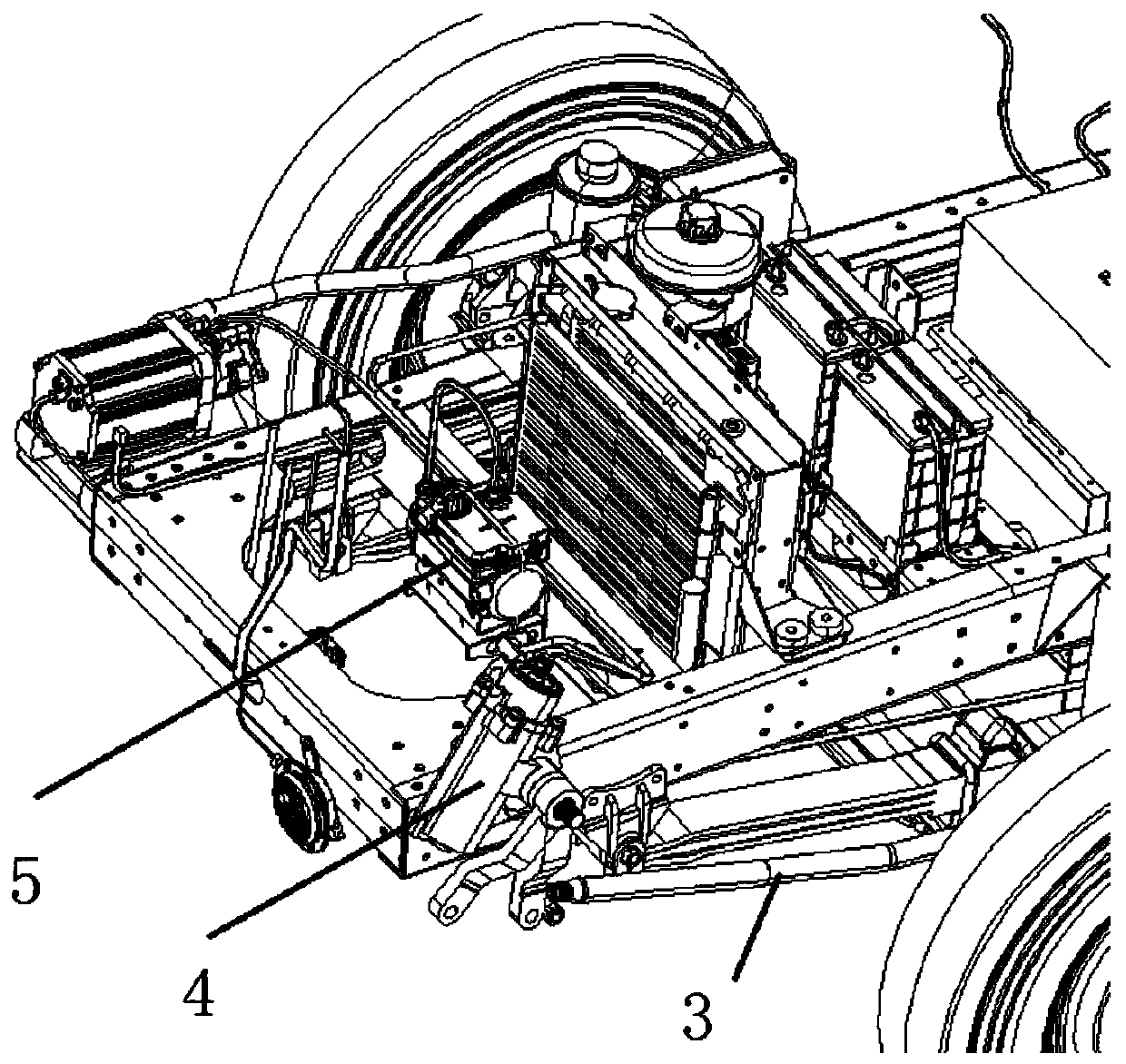

InactiveCN102745258AOutstanding FeaturesHighlight significant progressUnderstructuresTractor-trailer combinationsCurb weightSteel plates

The invention discloses a light-weight semitrailer, which comprises a compartment assembly (1), a rack assembly (2), a tool kit (3), a semitrailer supporting device (4) and a suspension brake and lighting system (5). The light-weight semitrailer is characterized in that a frame longitudinal beam (6) of the rack assembly (2) consists of an upper wing plate (8), a web (9) and a lower wing plate (10), wherein the rack assembly (2) is provided with a compartment bottom plate (7) to form a rack bottom plate assembly; the compartment bottom plate (7) is provided with the compartment assembly (1); a plurality of components on the compartment assembly (1) and the rack assembly (2) adopt a corrugated structure; the tool kit (3), the semitrailer supporting device (4) and the suspension brake and lighting system (5) are arranged below the rack bottom plate assembly; more places on a compartment and a frame adopt the corrugated structure and high-intensity steel plates so as to achieve a purpose that the curb weight of the semitrailer is lowered under the condition that the vehicle load bearing capability is not lowered, and the light-weight design of the semitrailer is realized. Compared with the traditional semitrailer, the light-weight semitrailer disclosed by the invention is characterized in that weight is lowered by about 18%, and the light-weight semitrailer is accelerated to develop.

Owner:SHANDONG PENGXIANG AUTOMOBILE

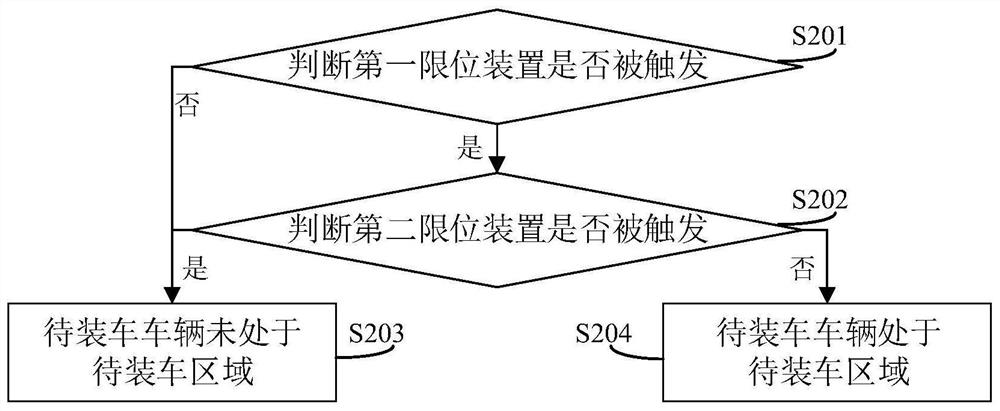

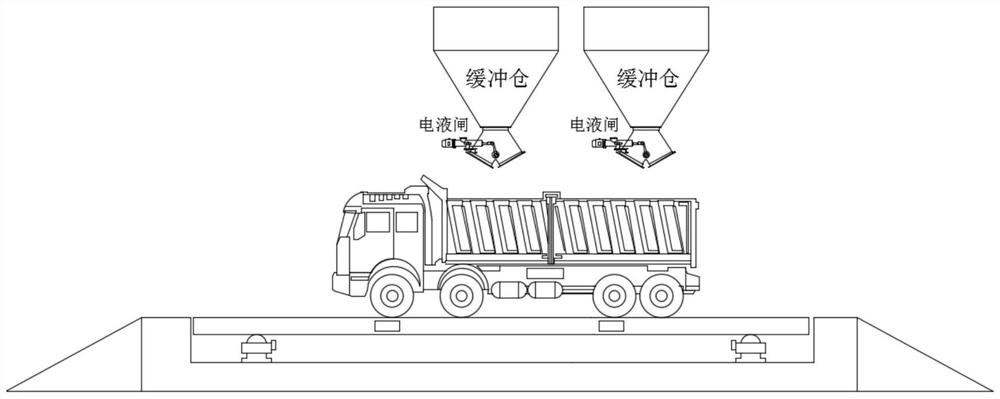

A method, system, and related device for loading bulk materials based on multiple feeding ports

ActiveCN109250530BPrevent cheatingImprove loading efficiencyLoading/unloadingAutomatic controlCurb weight

This application discloses a method for loading bulk materials based on multiple feeding ports. Based on the limit device to ensure that the vehicle is in the area to be loaded, after confirming that it is in the correct position, the multiple feeding ports above are automatically controlled to interact with each other. Cooperate to start unloading and loading until the weight information returned from the floor scale below is consistent with the sum of the empty weight of the vehicle to be loaded and the weight of the materials to be loaded, and then automatically control each unloading port to stop unloading, without manual intervention in the whole process , automatic loading can be realized based on the above logic, which not only avoids the possibility of misoperation and cheating that may occur due to manual operation, but also improves the loading efficiency as much as possible. The present application also discloses a bulk material loading system based on multiple feeding ports, an automatic loading device, and a computer-readable storage medium, which have the above-mentioned beneficial effects.

Owner:SHANDONG MATRIX SOFTWARE ENG

Vibration damping device and vehicle spare tire bracket and vehicle using the device

ActiveCN103909986BReduce vibrationDoes not increase curb weightNon-rotating vibration suppressionSpare wheel arrangementsCushioningCurb weight

The invention relates to a vibration damping device, a vehicle spare tire support and a vehicle using the device. Wherein the damping device comprises a spare tire frame connector for connecting with the spare tire frame and a vehicle frame connector for connecting with the vehicle frame, an elastic The buffer part is elastically connected by the elastic buffer part. Therefore, after the spare tire is installed on the spare tire rack, the spare tire itself can constitute the mass block of the mass spring resonance system, thereby forming a dynamic shock absorber together with the elastic buffer block to attenuate the vibration of the vehicle. Due to the vibration generated by the resonance of the unsprung mass, since the spare tire belongs to the original item on the vehicle, it will not increase the curb weight of the spare tire vehicle, and at the same time achieve a good vibration reduction effect, improve the comfort of the vehicle and the life of the vehicle.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Powder materials tanker and tank assembly thereof

The invention provides a tank assembly of a powder materials tanker, which comprises cabins. Each cabin comprises a horizontal cylinder (2) and a vertical conical tube (3). One end of each horizontal cylinder (2) is connected with the corresponding vertical conical tube (2) through an end enclosure (1). The lateral side of each horizontal cylinder (2) is connected with the corresponding vertical conical tube (3) through arc boards (4). The invention further provides the powder materials tanker. According to the technical scheme, each horizontal cylinder is connected with the corresponding conical tube through the arc boards in a communicated manner, and the arc boards are angled to the vertical direction so as to facilitate loading and unloading of materials and reduce residue of the materials. The vertical conical tubes are directly used as fluidizers, so that the volume utilization rate of the tank assembly is increased, the curb weight of the tank assembly is reduced, material sliding speed is increased, and universality of the materials is improved.

Owner:SANY HEAVY IND CO LTD (CN)

Weight and Center of Gravity Adjustment Method of Locomotive Counterweight and Locomotives with Different Axle Load Conversion

ActiveCN104192158BImprove driving stabilityEasy to Modular DesignWheel-ballasting weightsRailway componentsCurb weightWeight adjustment

The invention relates to a locomotive counterweight and a method for adjusting the weight and center of gravity of the locomotive by using the locomotive counterweight for switching between different axle loads. The locomotive counterweight includes a fixed counterweight, and the lower part of the fixed counterweight passes through The connection structure is connected with the machine room equipment installation seat of the car body, and the upper part of the fixed counterweight is provided with a plurality of adjustable counterweights connected in a detachable manner. There are weight and center-of-gravity adjustment methods for locomotives with different axle load conversions. By testing the curb weight, axle load and wheel weight of the locomotive, and adjusting the locomotive counterweight in various ways according to the measurement results. The locomotive counterweight of the present invention is convenient to install and adjust its own weight and center of gravity, so that it can accurately meet the weight requirements of the locomotive and balance requirements of the axle load and wheel weight; when installing the user's personalized equipment, there is no need to make any changes to the car body , can accurately meet the locomotive curb weight requirements and balance requirements of axle load and wheel weight, making the modular design and manufacture of locomotives and engineering vehicles more convenient.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com