Patents

Literature

105results about "Wheel-ballasting weights" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wheel weight

Owner:HENNESSY IND

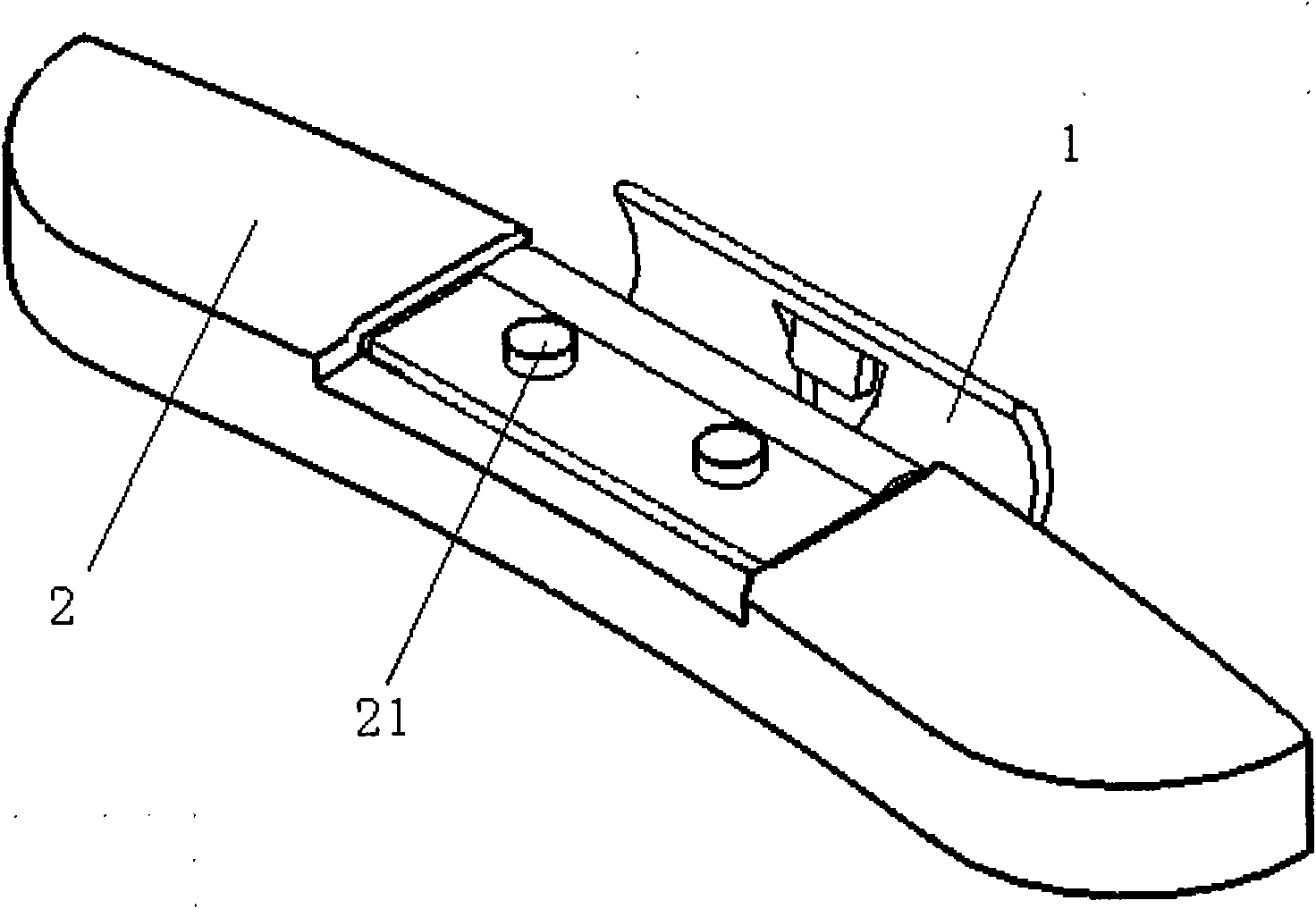

Steel automobile wheel balancing block with large gram weight and manufacture method thereof

InactiveCN101596835AGuaranteed molding accuracyGuaranteed molding effectWheel-ballasting weightsGramEngineering

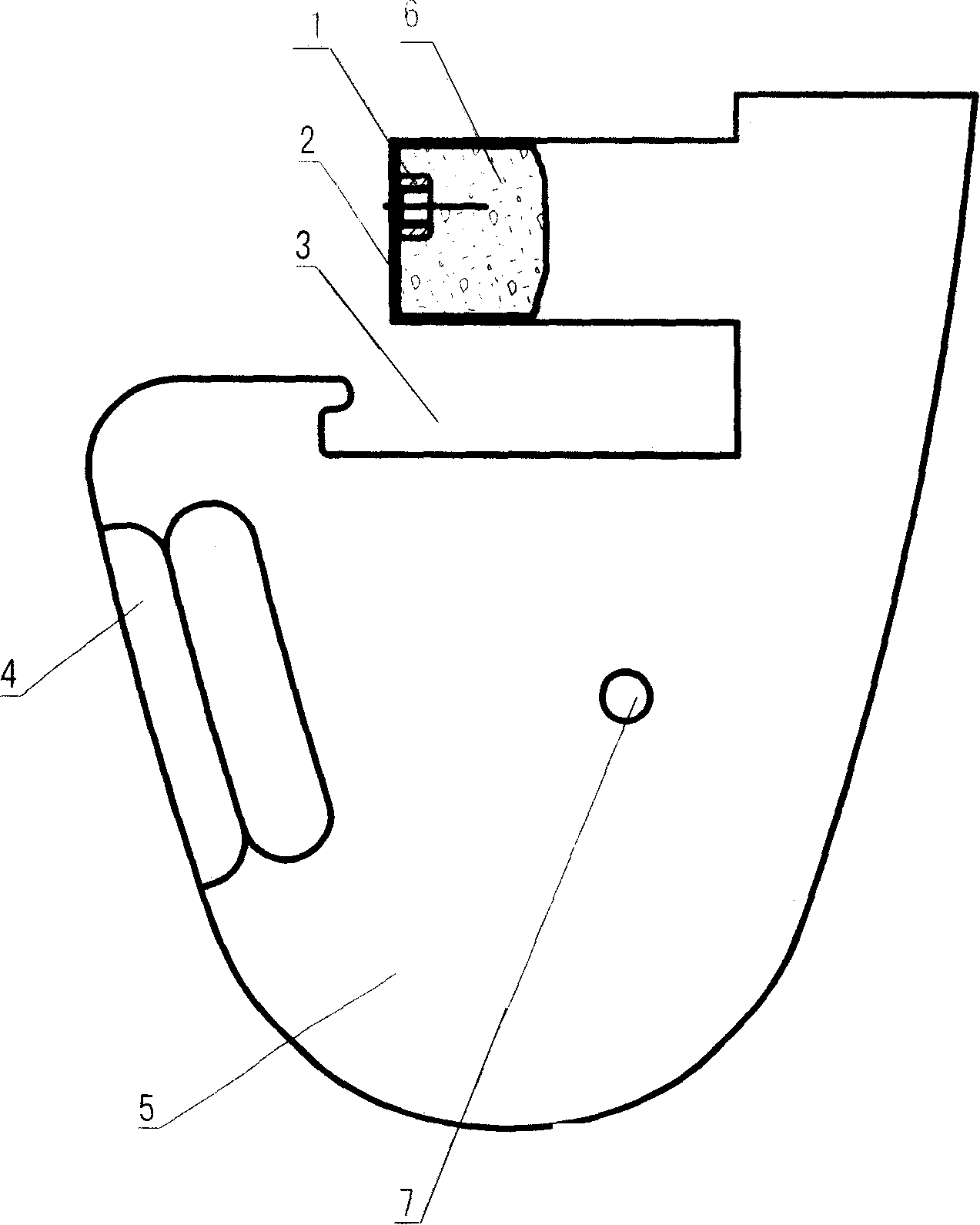

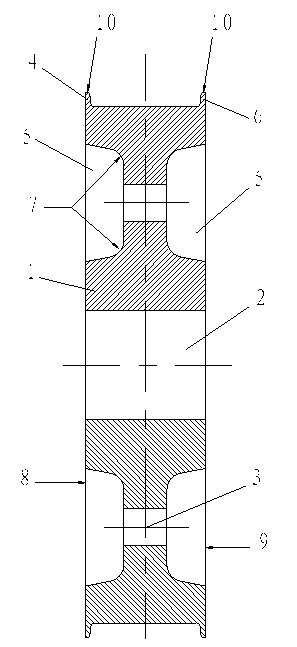

The invention discloses a steel wheel balancing block with single weight of more than 60 grams (containing 60 grams), comprising a balancing weight block and a spring hook, wherein the upper part of the spring hook is provided with a clamping part, the lower part of the spring hook is provided with a combination part which is fixed with the balancing weight block together, the upper surface of the balancing weight block is provided with a positioning groove, a protrusion is at least arranged on the bottom surface of the positioning groove, and the lower surface of the balancing weight block corresponding to the protrusion is a plane; and a rivet hole which is matched with the protrusion of the balancing weight block is arranged on the combination part of the spring hook so as to enable the spring hook to be riveted with the balancing weight block together by the protrusion. The invention also discloses a manufacture method of the balancing weight block in the balancing block, comprising the following steps: blanking and punching the positioning groove; bending blanks; cleaning the surfaces of the bent blanks; preheating; coating a lubricant; heating by induction; carrying out temperature plastic molding; deburring; carrying out surface shot blasting; pressing characters on the surface of the balancing weight block; riveting and fixing with a spring hanger; and painting on the appearance.

Owner:SHANGHAI UNIV OF ENG SCI +1

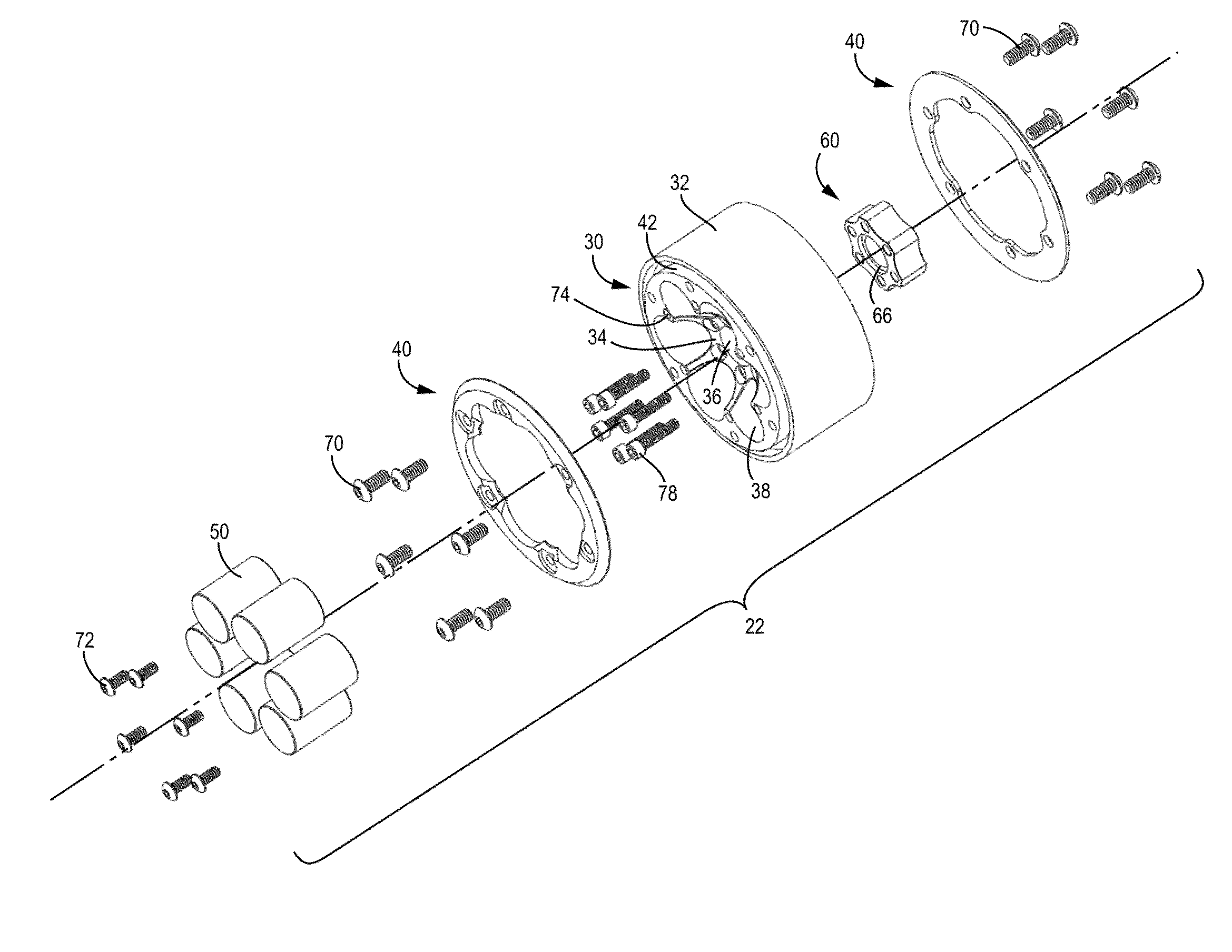

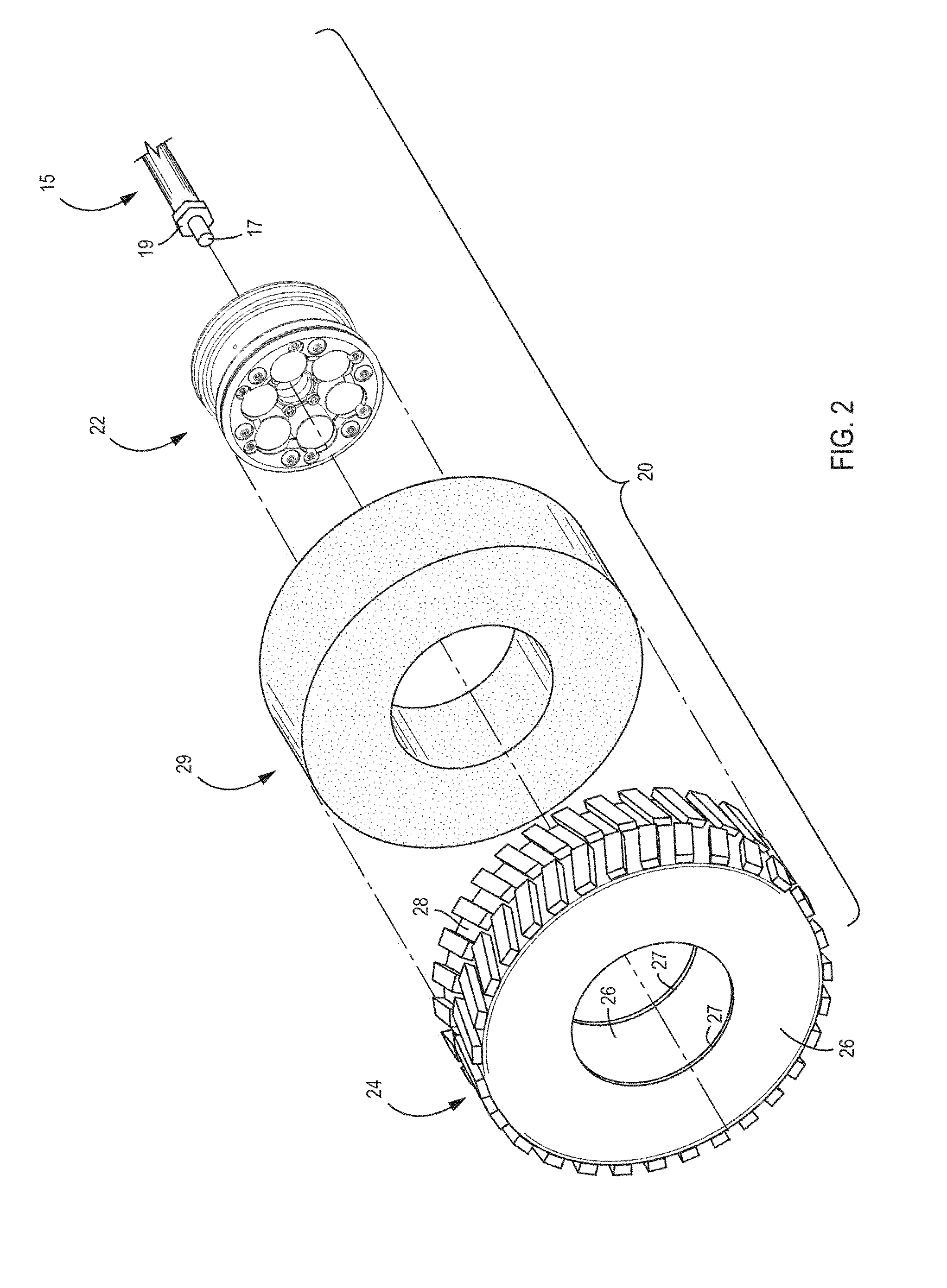

Adjustable Weighted Wheel Assembly

InactiveUS20100231030A1Avoid weightMaintain weightWheel-ballasting weightsToy vehiclesEngineeringFastener

The application discloses a wheel assembly comprising a wheel comprising a main body, a substantially cylindrical wall, a front hub face comprising a central portion connecting a hub to an outer rim, wherein the front hub face comprises a socket for receiving a removable weight, wherein the socket or the weight is configured with a stop for preventing the weight from dislodging from the socket; a back face comprising a back central portion connecting the hub to the back outer rim; and the wheel assembly comprising at least one fastener for securing the weigh in the socket on the main body of the wheel.

Owner:VANQUISH PRODS

Wheel balance weight for automobile tyre

InactiveCN1951710AEasy to bendEasy to reinforceWheel-ballasting weightsRotating bodies balancingAutomotive engineeringEngineering

Provided is a balance weight used for automobile tyre, which is mounted to wheels in a felting manner. Corresponding to inner diameter varieties of wheels provided in different standards, said balance weight is prone to bend and extend, with improving its applicability and adhesion characteristic.

Owner:DONGHWATECH

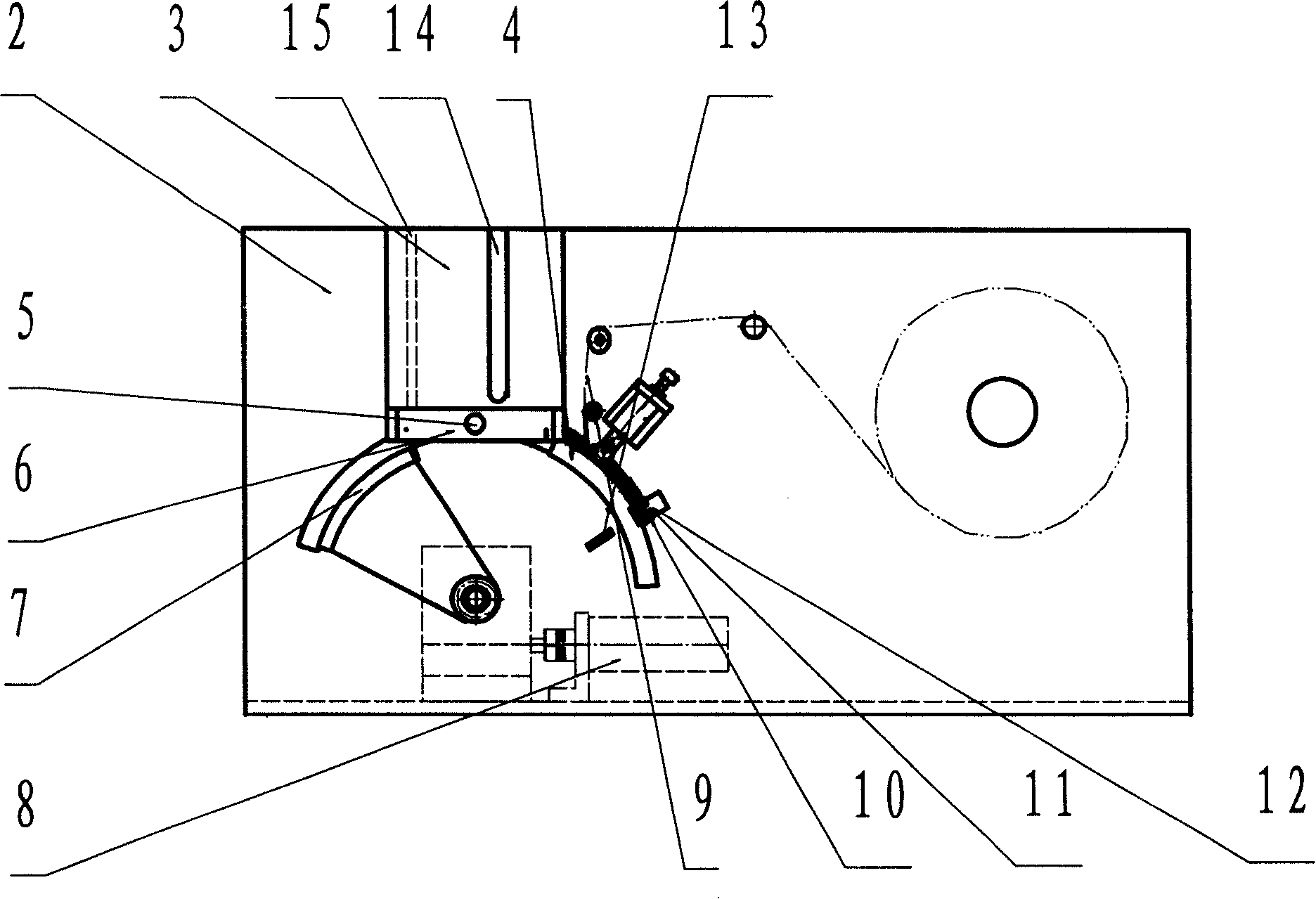

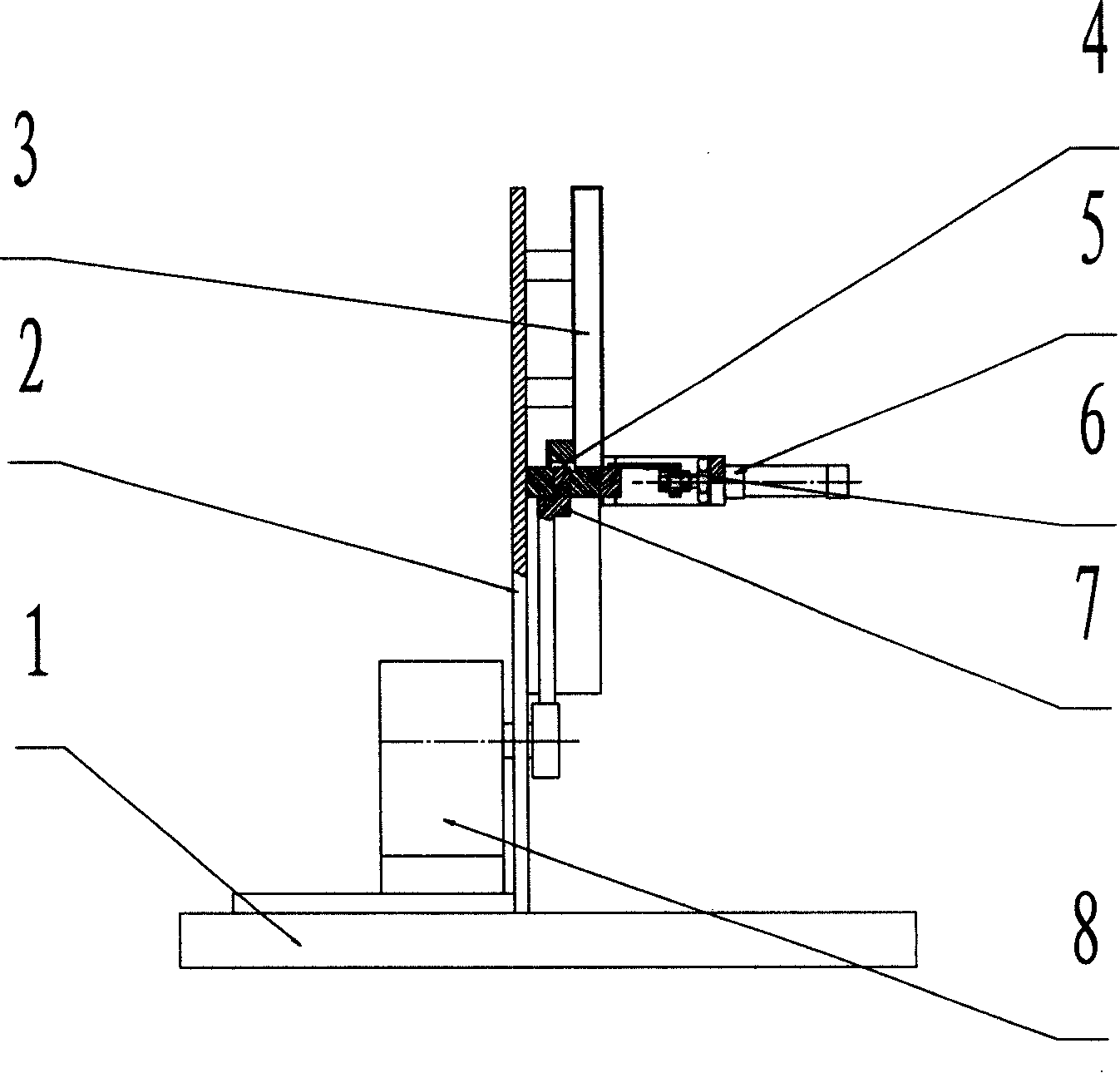

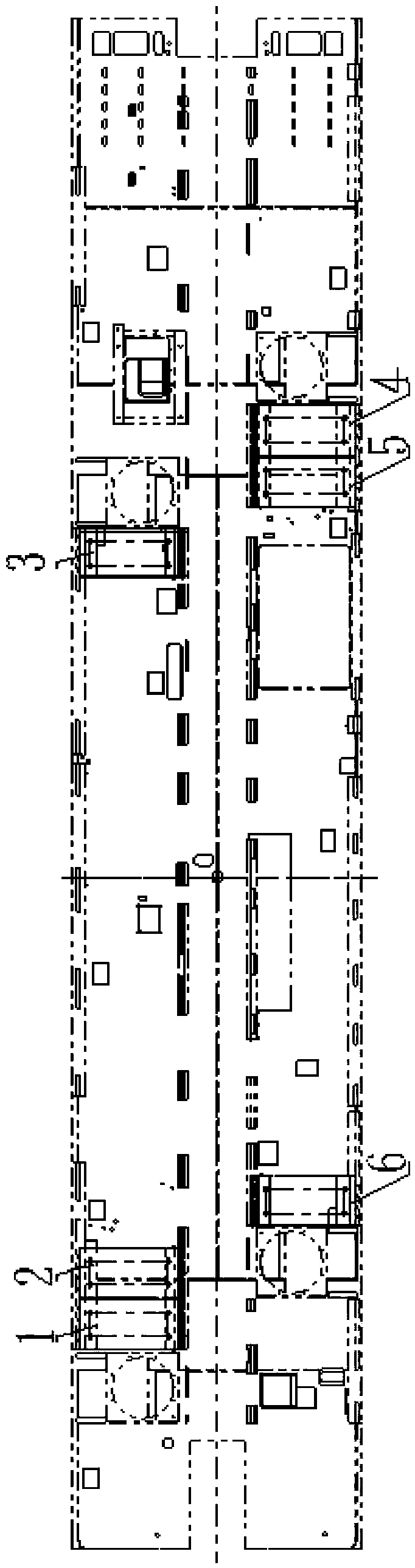

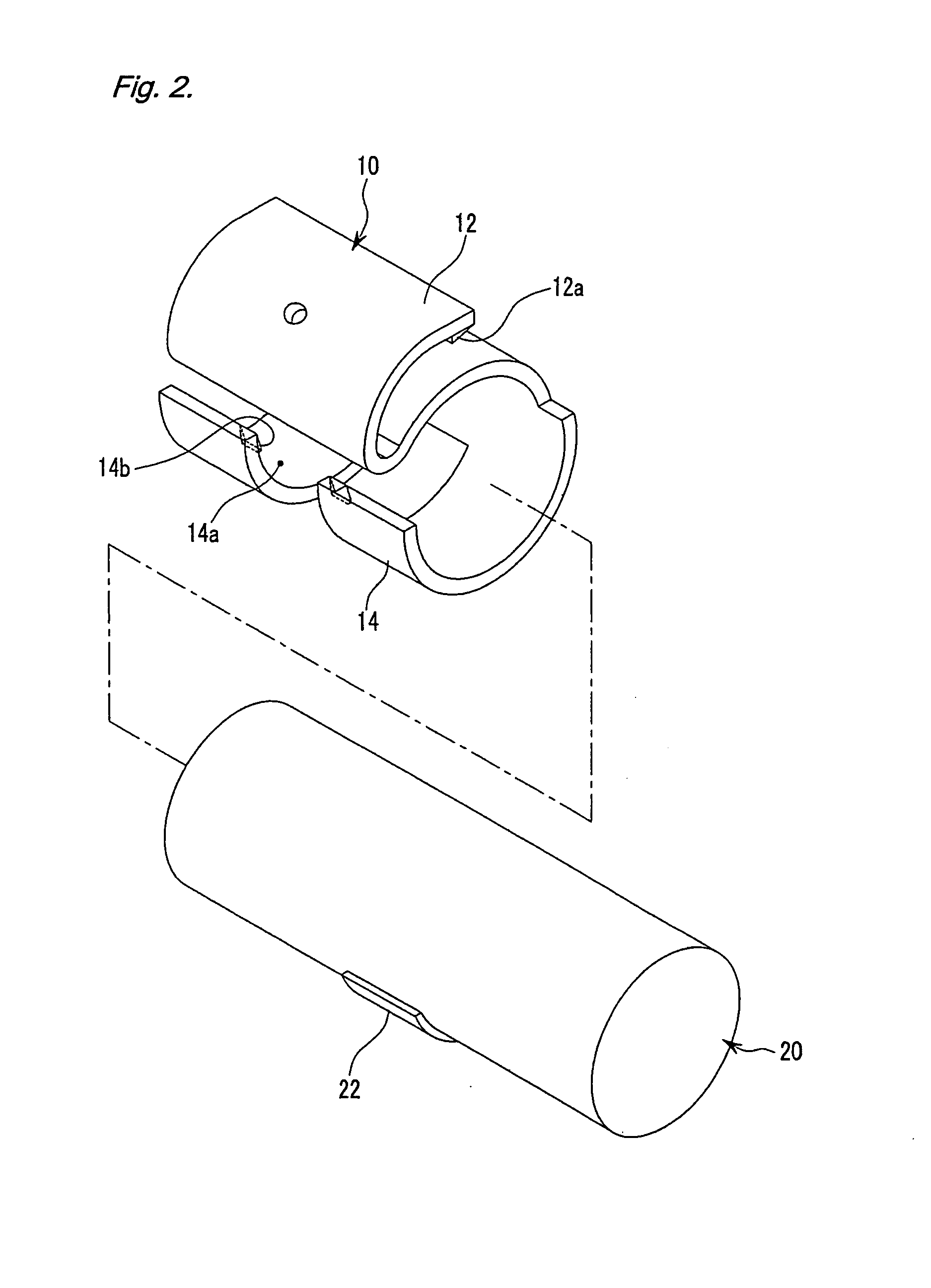

Automatic adhesive-tape application machine for sticking car hub balance block

InactiveCN101190760ARealize automatic feedingReduce labor intensityWheel-ballasting weightsRotating bodies balancingAdhesive beltTransducer

An automatic adhesive tape pasting machine used for pasting sedan hub counterbalance comprises a box body with a door opened in the front part and an internally installed vertical flat shelf which is connected with a stock bin, a chute, a transverse material pushing device, a vertical propulsion device, an adhesive tape inlet and hold-down gear, an adhesive tape cutting device and an automatic controlling system. A baffle at the front end of the stock bin is provided with a drain hole; the stock bin is internally connected with a vertical baffle which is used for adjusting the length of blank; the front end of the chute under the stock bin is provided with an opening with the same length as that of the stock bin; the upper part of the chute is provided with a rolling pinch roller; the transverse material pushing device is arranged at the lateral end in the middle of the chute and a glide block in the end is connected with a transverse horizontal propulsion plate in the same shape as the lateral shape of the blank; a vertical horizontal propulsion device on the left side of the adopts reciprocating propulsion movement with the stroke length being controlled by the signals emitted from a position transducer; the pressing force of the adhesive tape can be adjusted; the adhesive tape cutting device is provided with a thin cutting knife which makes slight up-and down and front-and-back adjustment; the whole working area is controlled by adopting closed heating constant temperature.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Wheel balance weight for automobile tire

InactiveUS20070126278A1Increased durabilityImprove reliabilityWheel-ballasting weightsHubsFlangeAutomotive engineering

Disclosed is a balance weight installed at a wheel for an automobile tire. The balance weight is provided with a “C” shaped hooking element forcibly fitted and coupled to an appropriate position on the rim flange of the wheel, thus making its installation state more stable, and providing enhanced durability and reliability.

Owner:DONGHWATECH

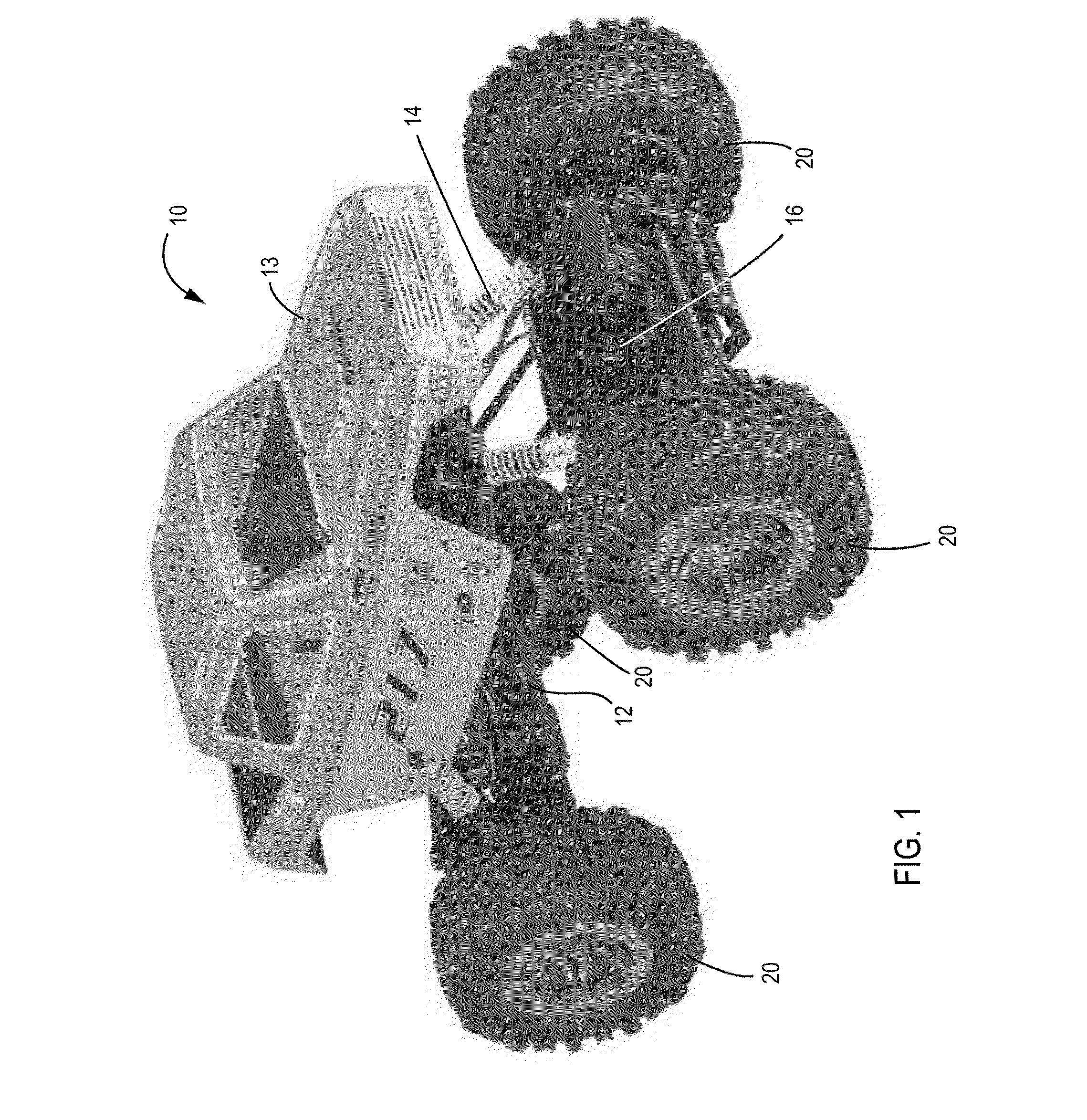

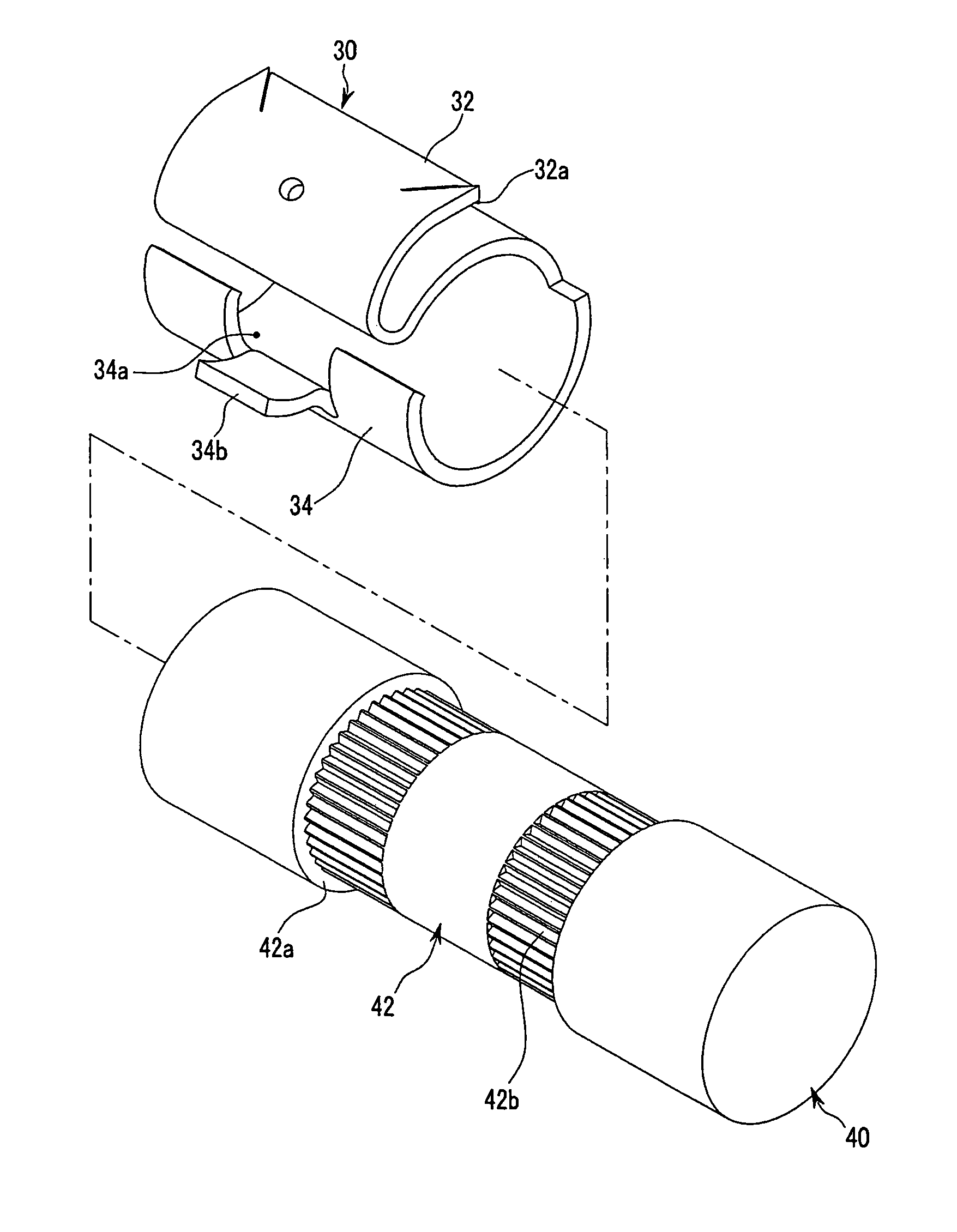

Wheel for toy vehicle

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

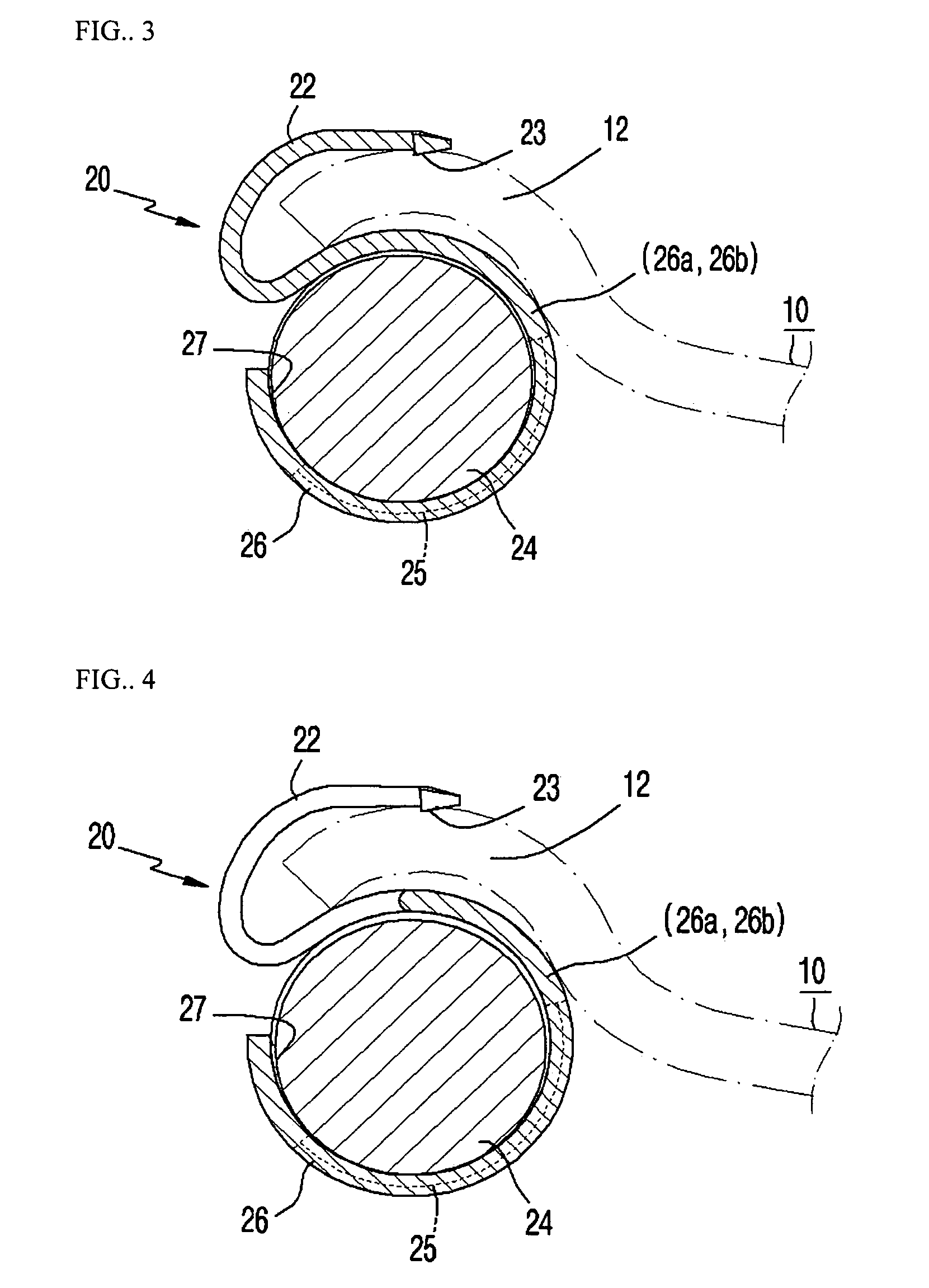

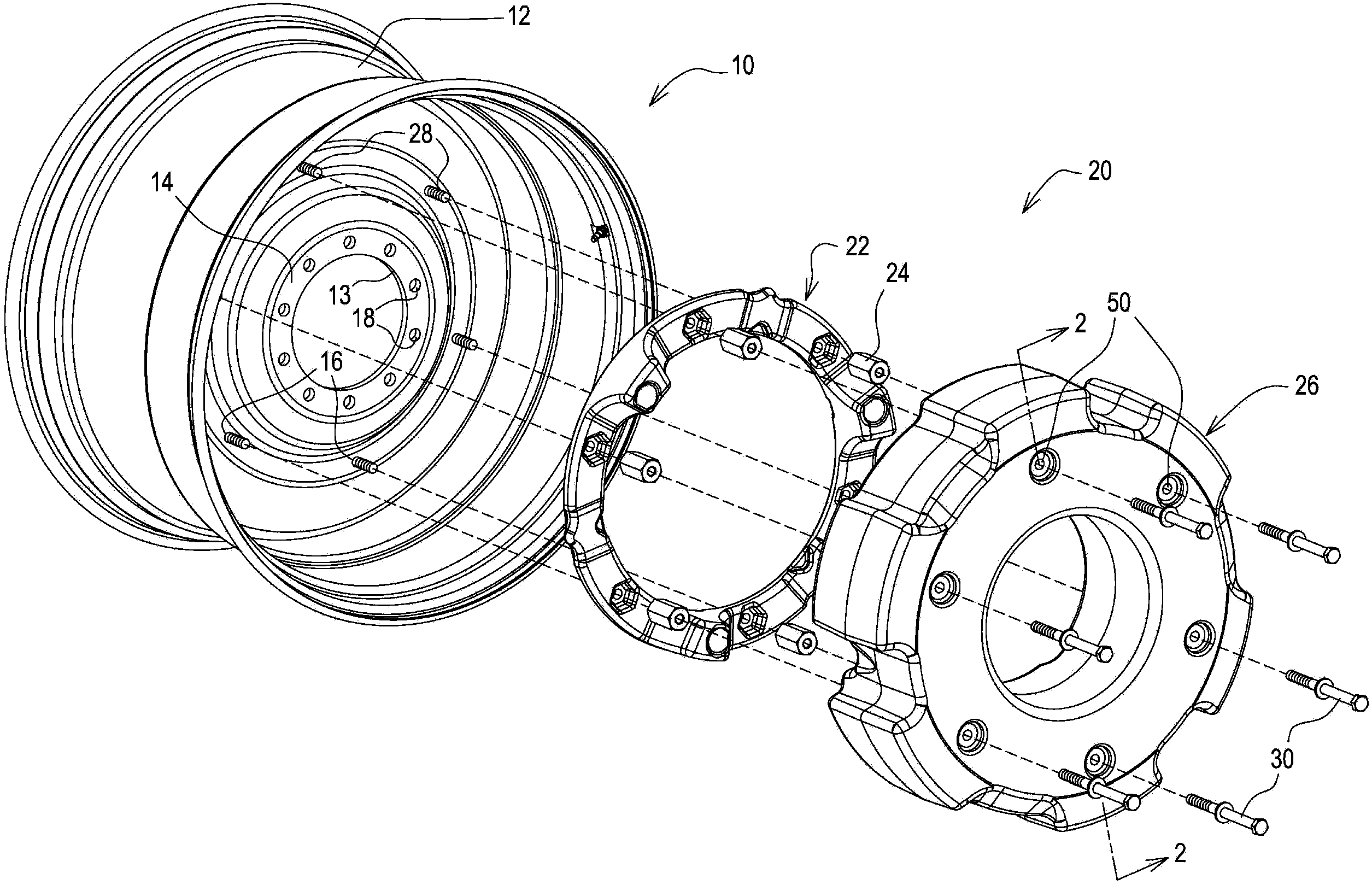

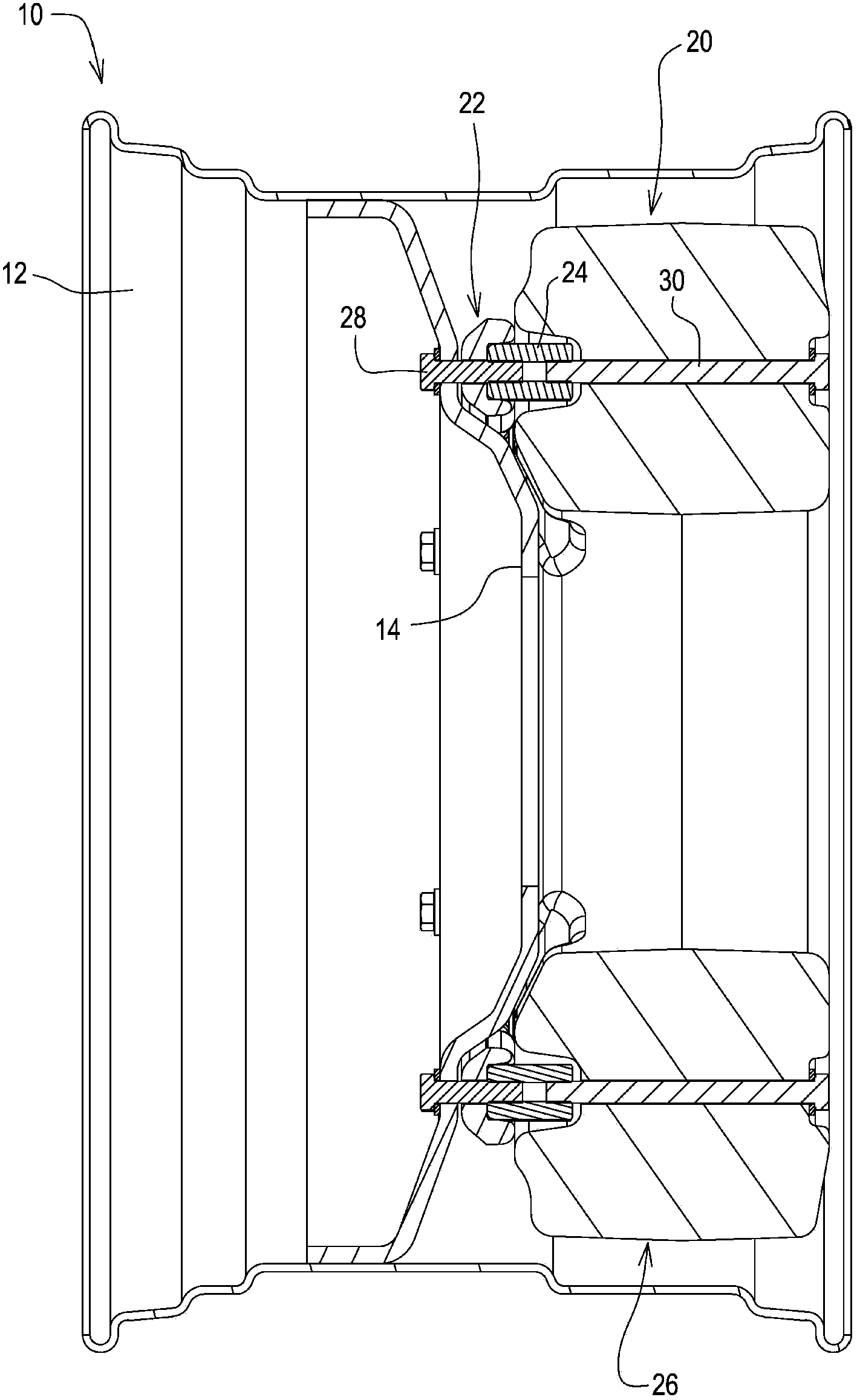

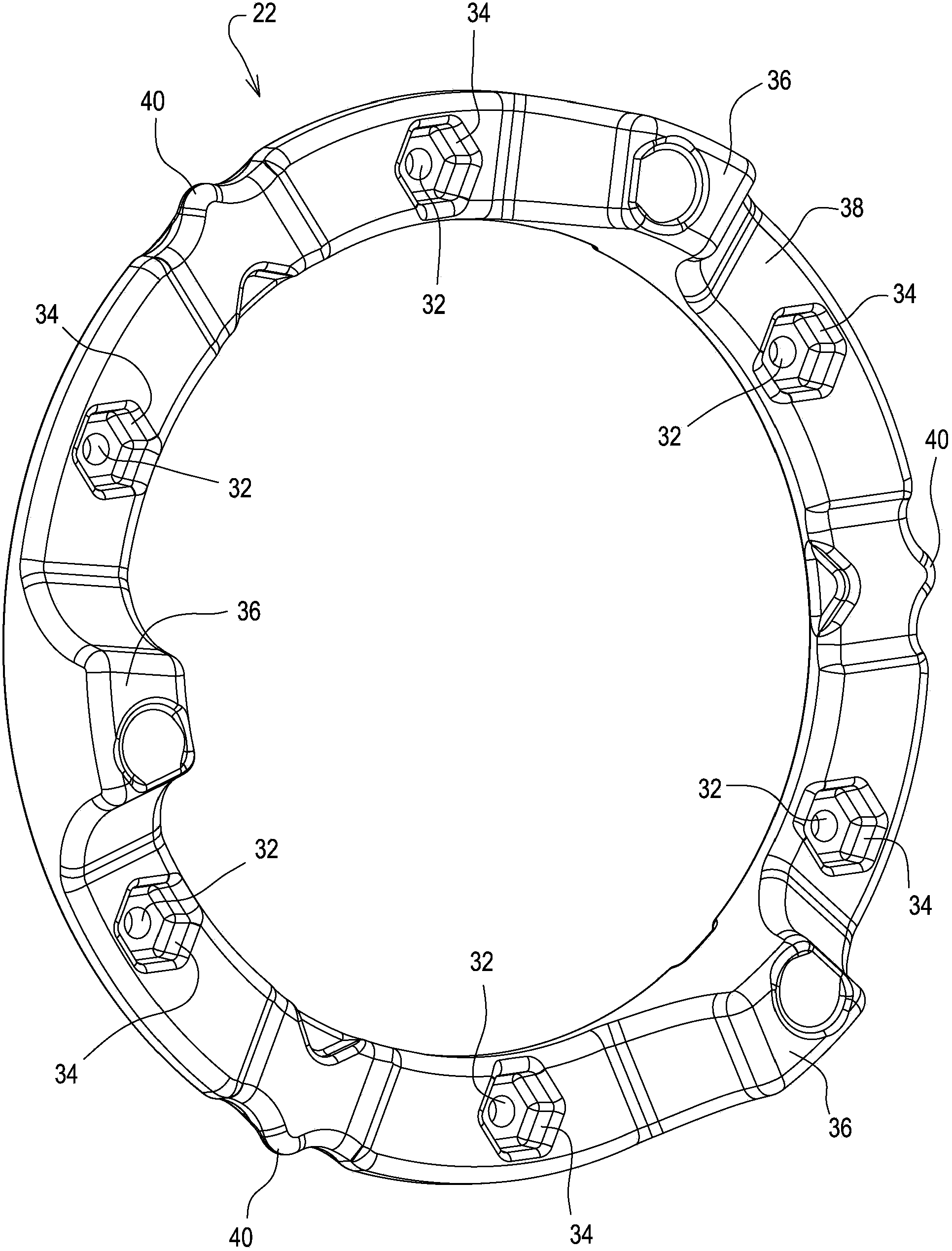

Wheel weight assembly

A wheel weight assembly for use on a vehicle wheel having a wheel disk section, the wheel weight assembly comprising: an annular starter weight mounted to the wheel disk section, the starter weight having a plurality of mounting bores extending axially therethrough; a plurality of nut members; a plurality of threaded members for attaching the starter weight to the wheel disk section, each threaded member extending through a corresponding one of the mounting bores and into a corresponding one of the nut members; an annular outer weight having a plurality of attaching bores aligned with the bores of the starter weight extending axially therethrough; and a plurality of attaching bolts, each attaching bolt extending through a corresponding one of the attaching bores and being threadably received by a corresponding one of the nut members, wherein the nut members are positioned between the starter weight and the outer weight.

Owner:DEERE & CO

Locomotive counterweight and weight and center-of-gravity adjusting method for variable axial load locomotive

ActiveCN104192158AImprove driving stabilityEasy to Modular DesignWheel-ballasting weightsRailway componentsModular designEngineering

The invention relates to a locomotive counterweight and a weight and center-of-gravity adjusting method for changing different axial loads of a locomotive through the locomotive counterweight. The locomotive counterweight comprises a fixed counterweight; the lower portion of the fixed counterweight is connected with a machine room equipment mount of a locomotive body through a connection structure; adjustable counterweights connected in a detachable manner are arranged on the upper portion of the fixed counterweight. According to the weight and center-of-gravity adjusting method, locomotive service weight, axle load and wheel load are detected, and the locomotive counterweight is adjusted in various ways according to detection results. The self-weight and center-of-gravity of the locomotive counterweight which is convenient to mount are convenient to adjust, so that the requirement for locomotive weight and the requirement for axle load and wheel load balance are accurately met; during installation of user-customized devices, the requirement for the locomotive service weight and the requirement for axle load and wheel load balance can be accurately met without making changes to the locomotive body, and modular design and manufacture of locomotives and engineering trucks are more convenient.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

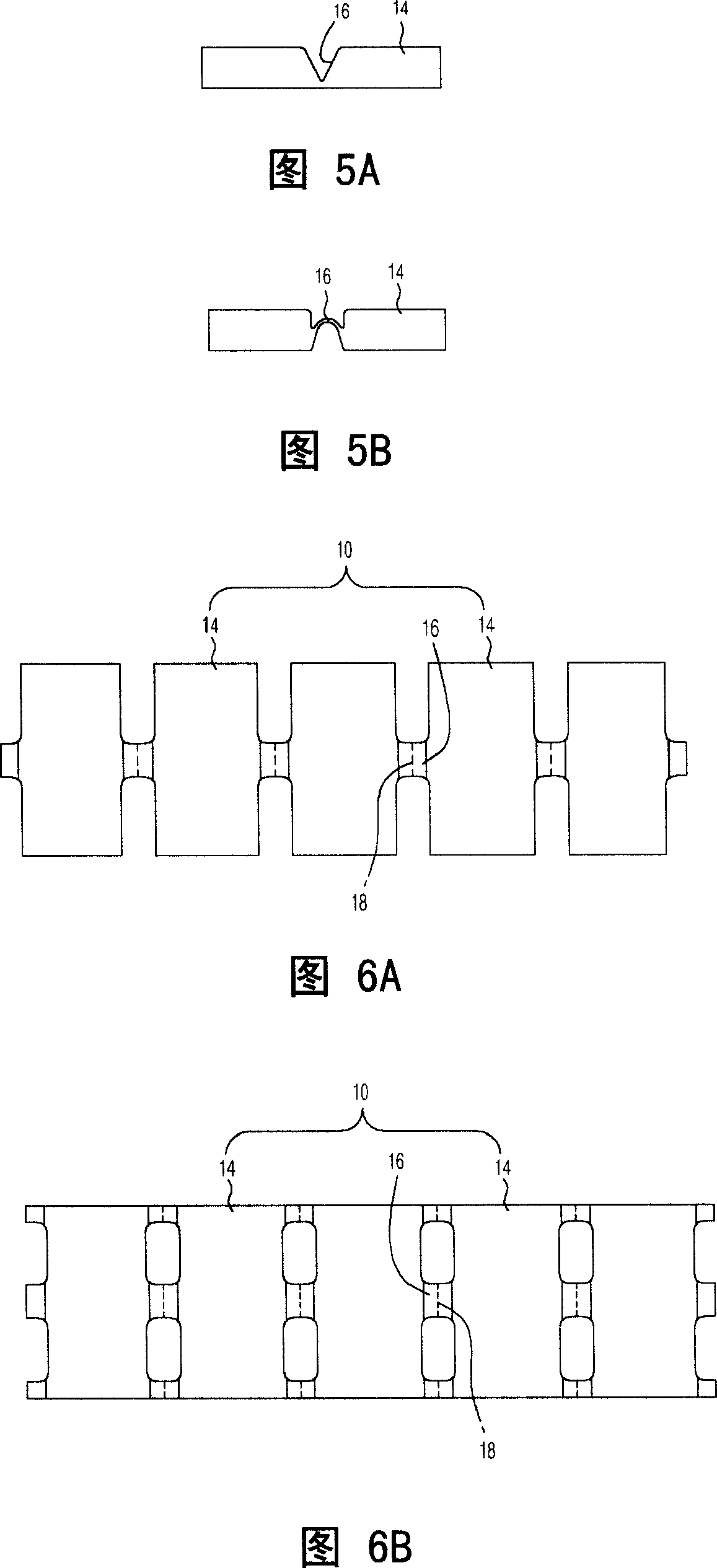

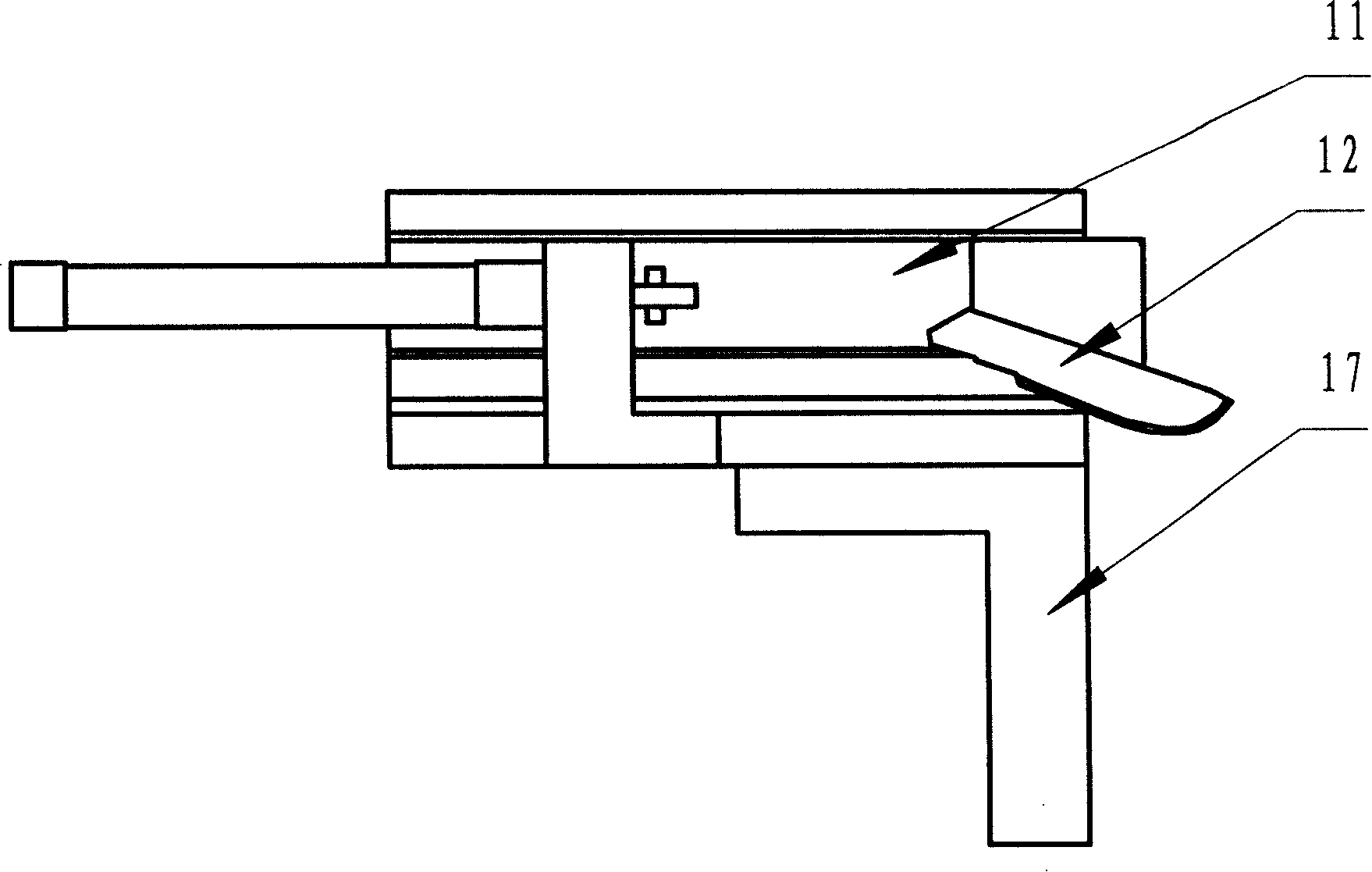

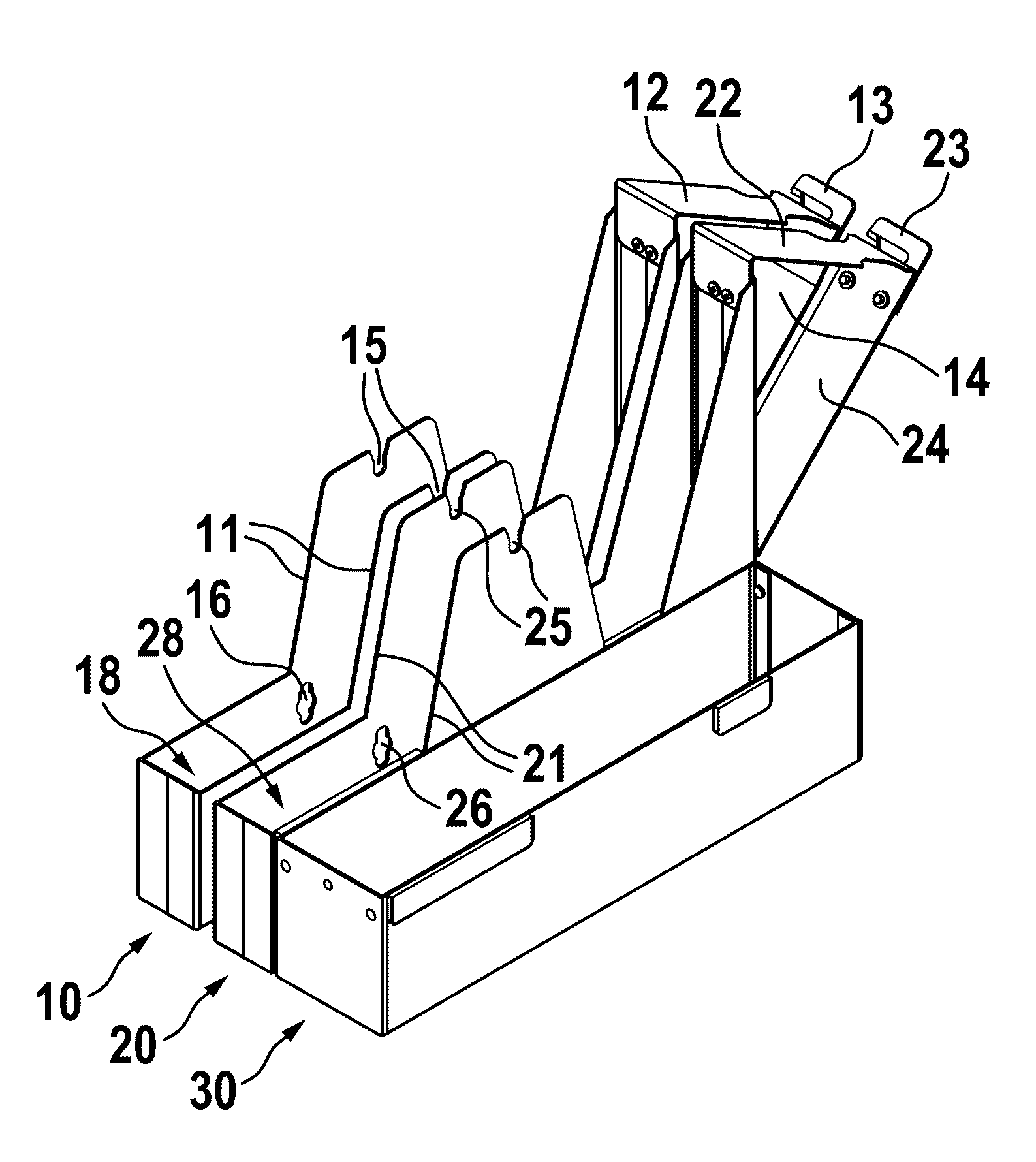

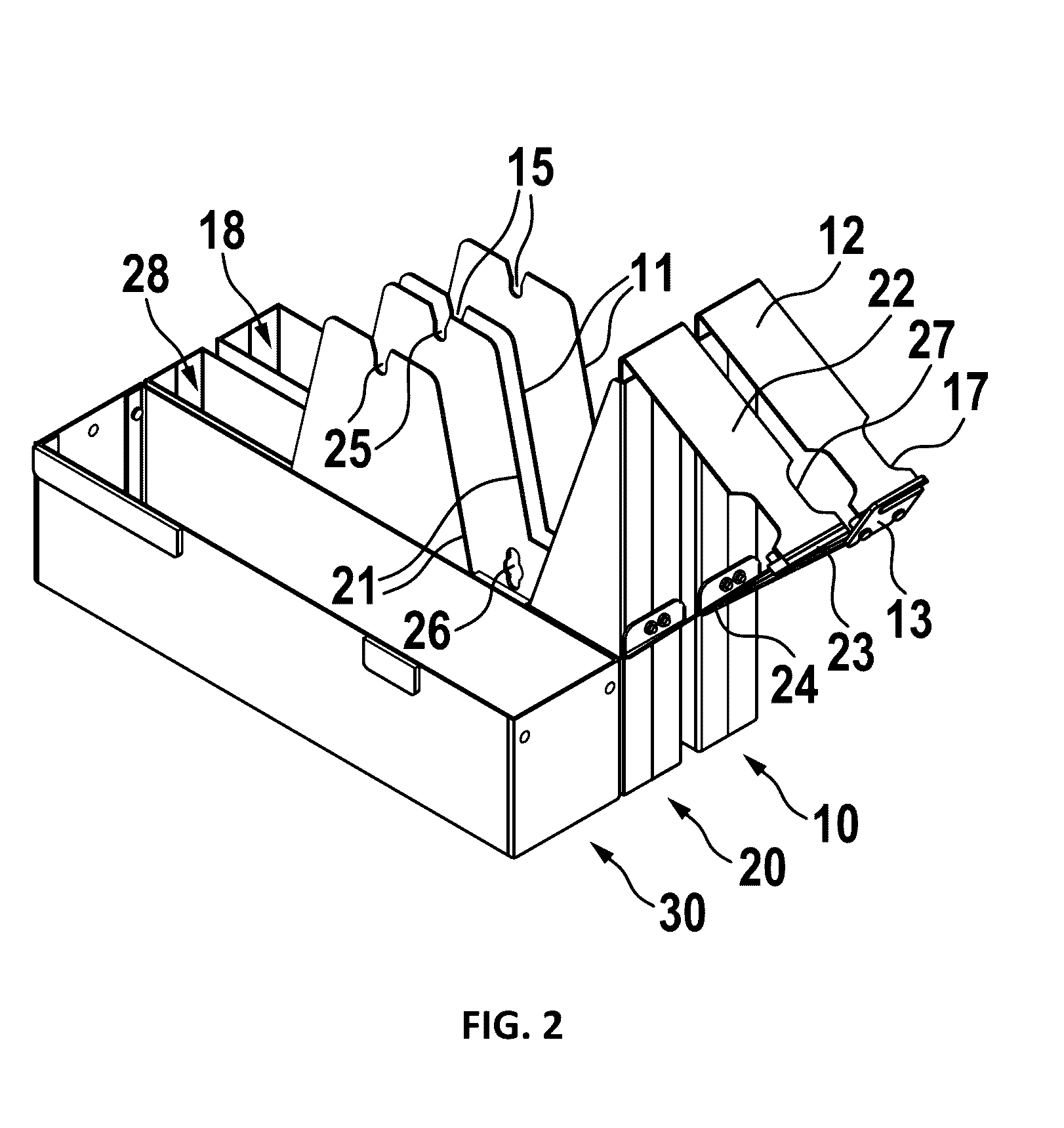

Manually Operated Balancing Weight Dispenser

ActiveUS20160319904A1Accurate balanceLow costWheel-ballasting weightsRotating bodies balancingEngineeringMechanical engineering

A balancing weight dispenser has a balancing weight storage space for storing a belt of balancing weights on a reel, a belt guide, and a cutter at one end of and / or along a length of the belt guide. The cutter comprises a knife, which is fixedly attached to the balancing weight dispenser. For delivery of a required amount of balancing weight mass, the belt of balancing weights is pulled from the reel until the desired number of balancing weights has been obtained. In the next step, the belt of balancing weights is cut, preferably between two adjacent balancing weights, to separate the selected portion of balancing weights from the remaining belt of balancing weights. The remaining belt falls back to the guide and remains in a desired position for receiving the next portion of balancing weights. This manually operated balancing weight dispenser can be provided at significantly lower costs compared to the automated high performance balancing weight dispensers as known from the prior art. It is very robust and has no serviceable parts.

Owner:WEGMANN AUTOMOTIVE GMBH

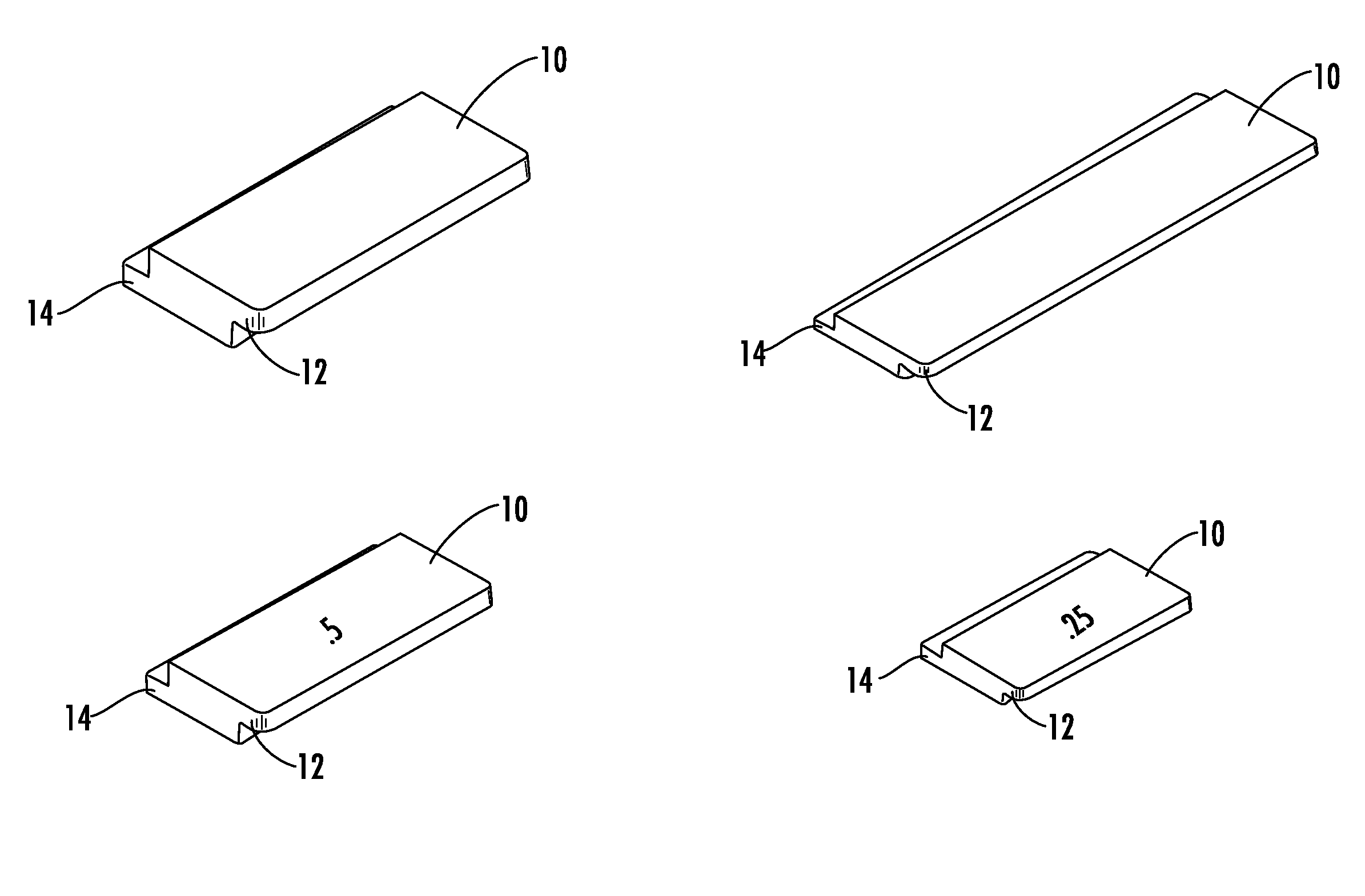

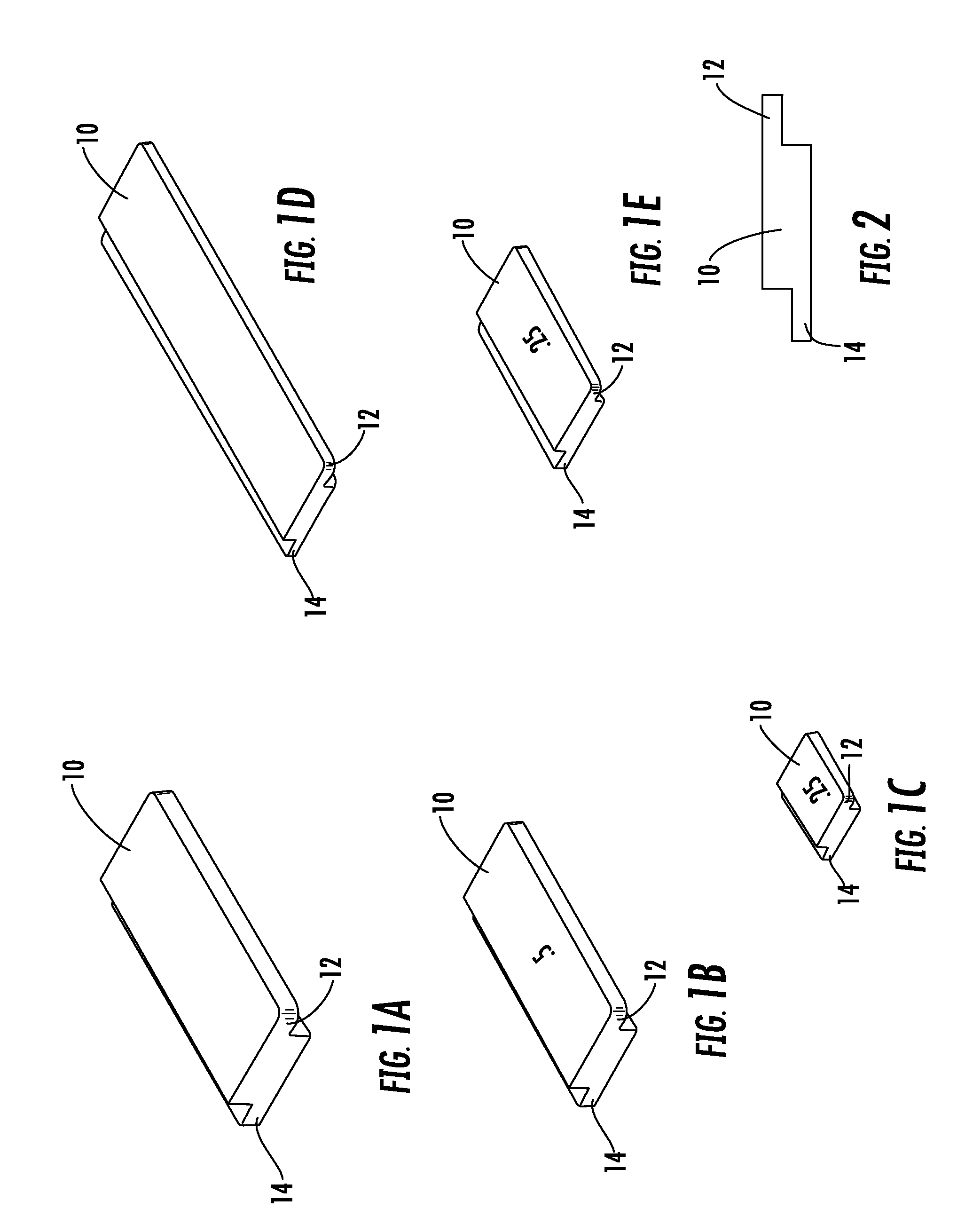

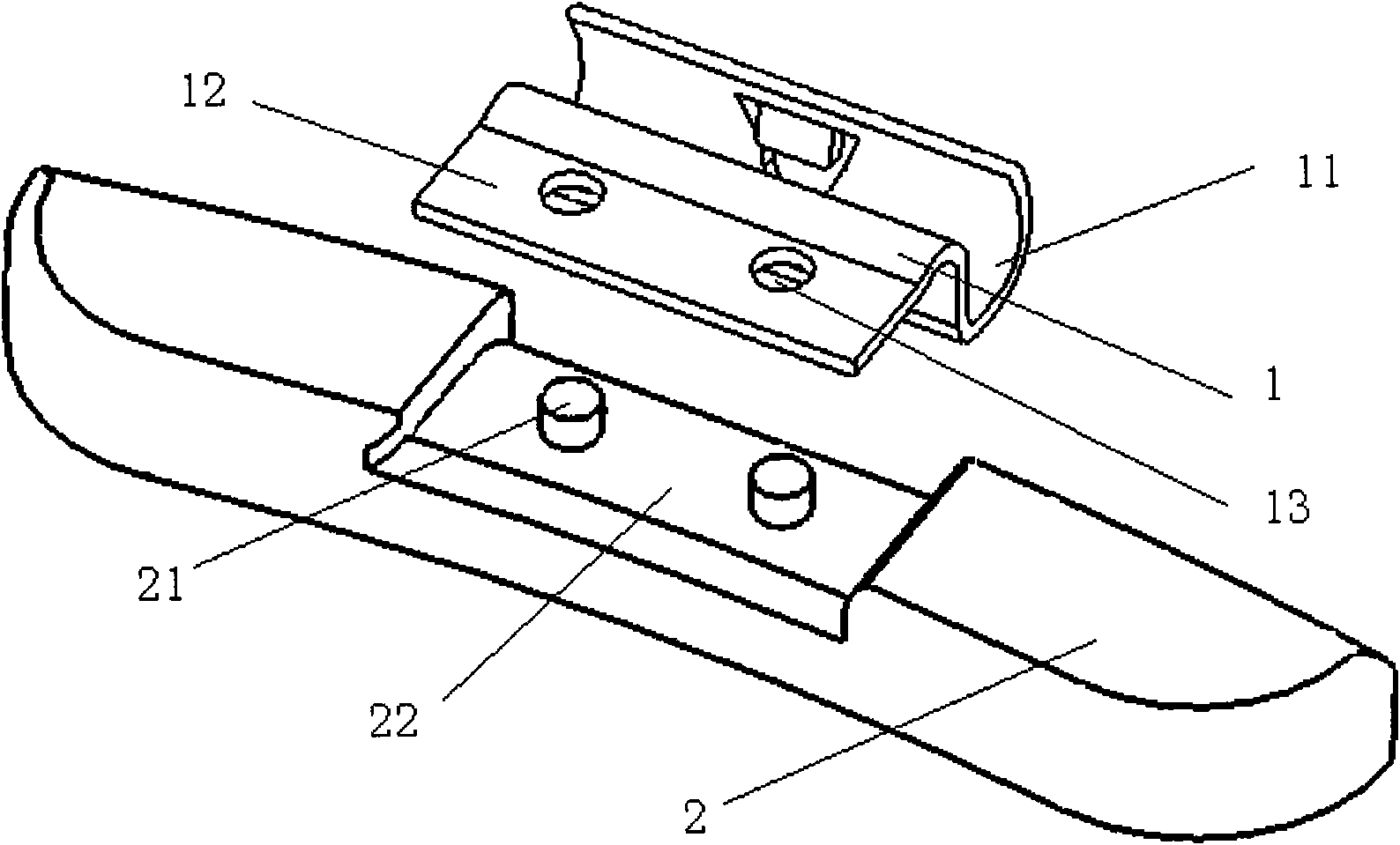

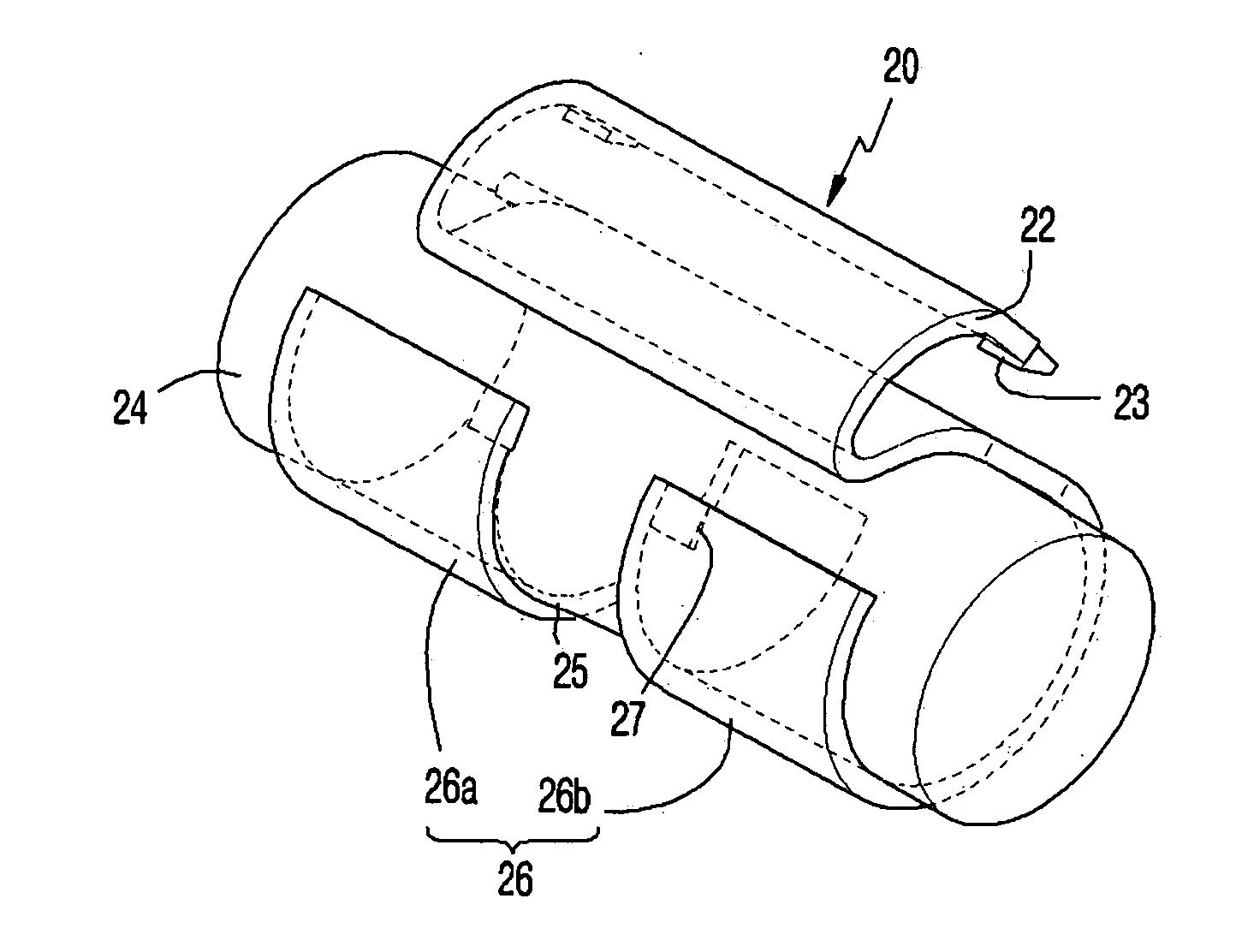

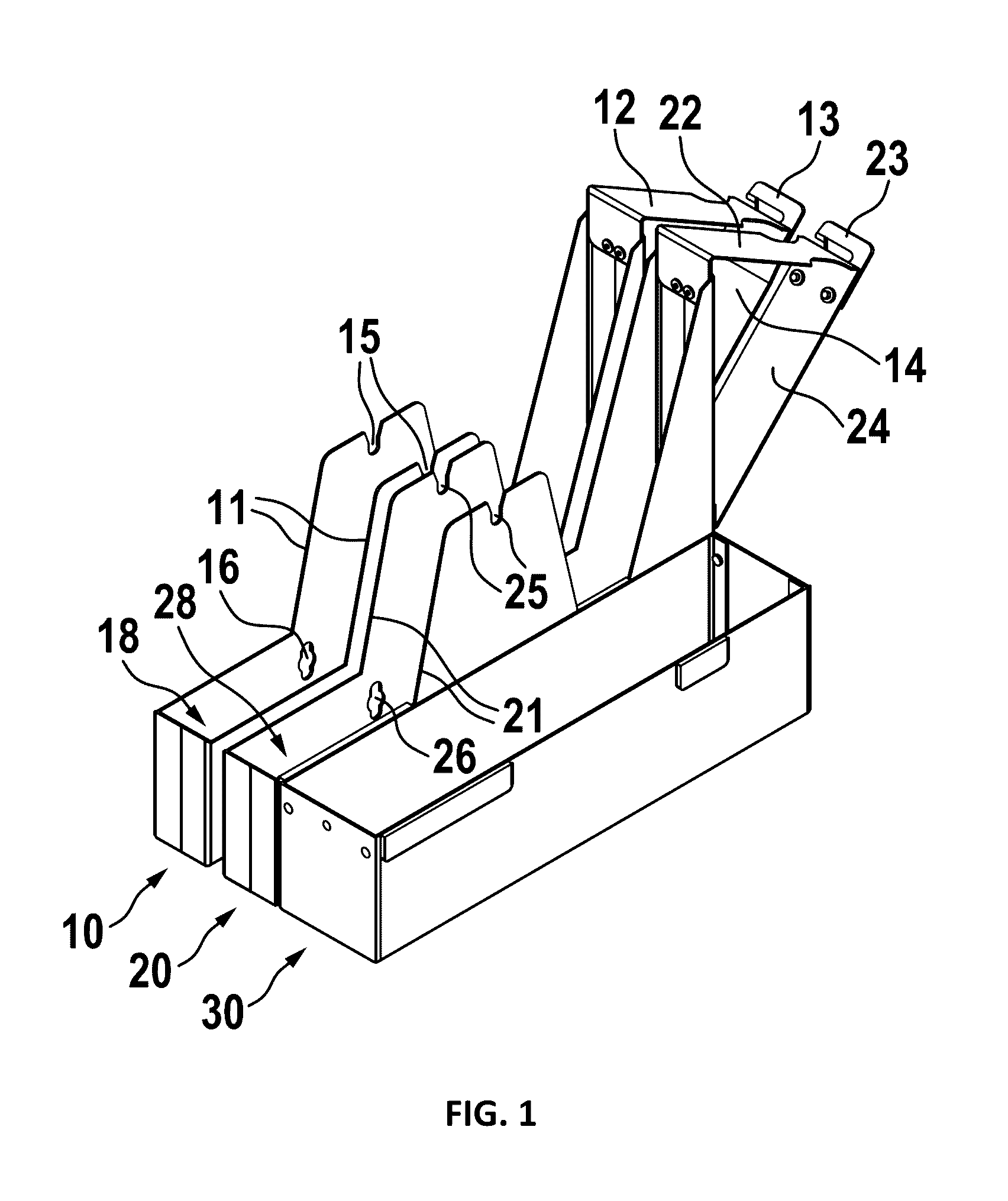

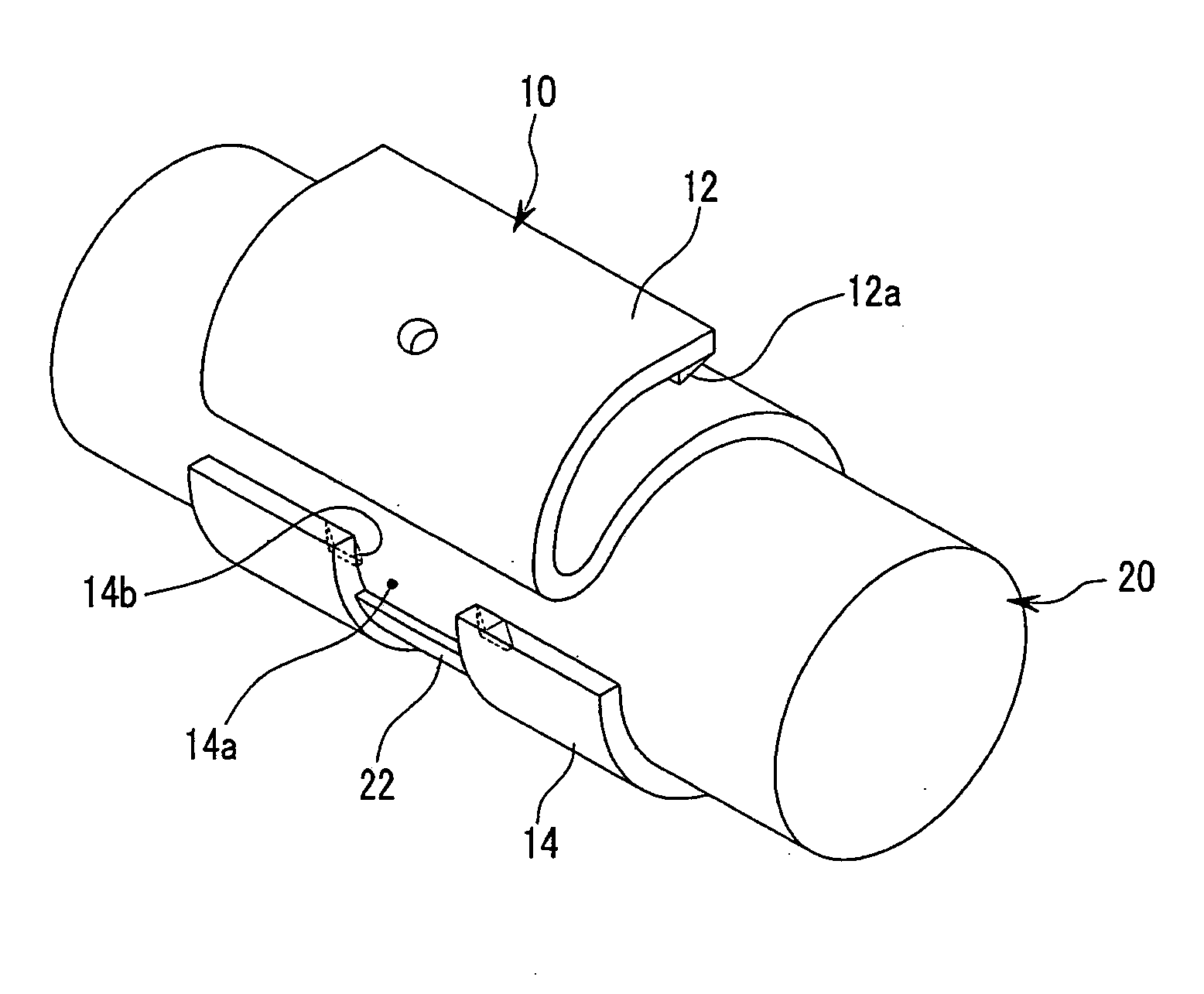

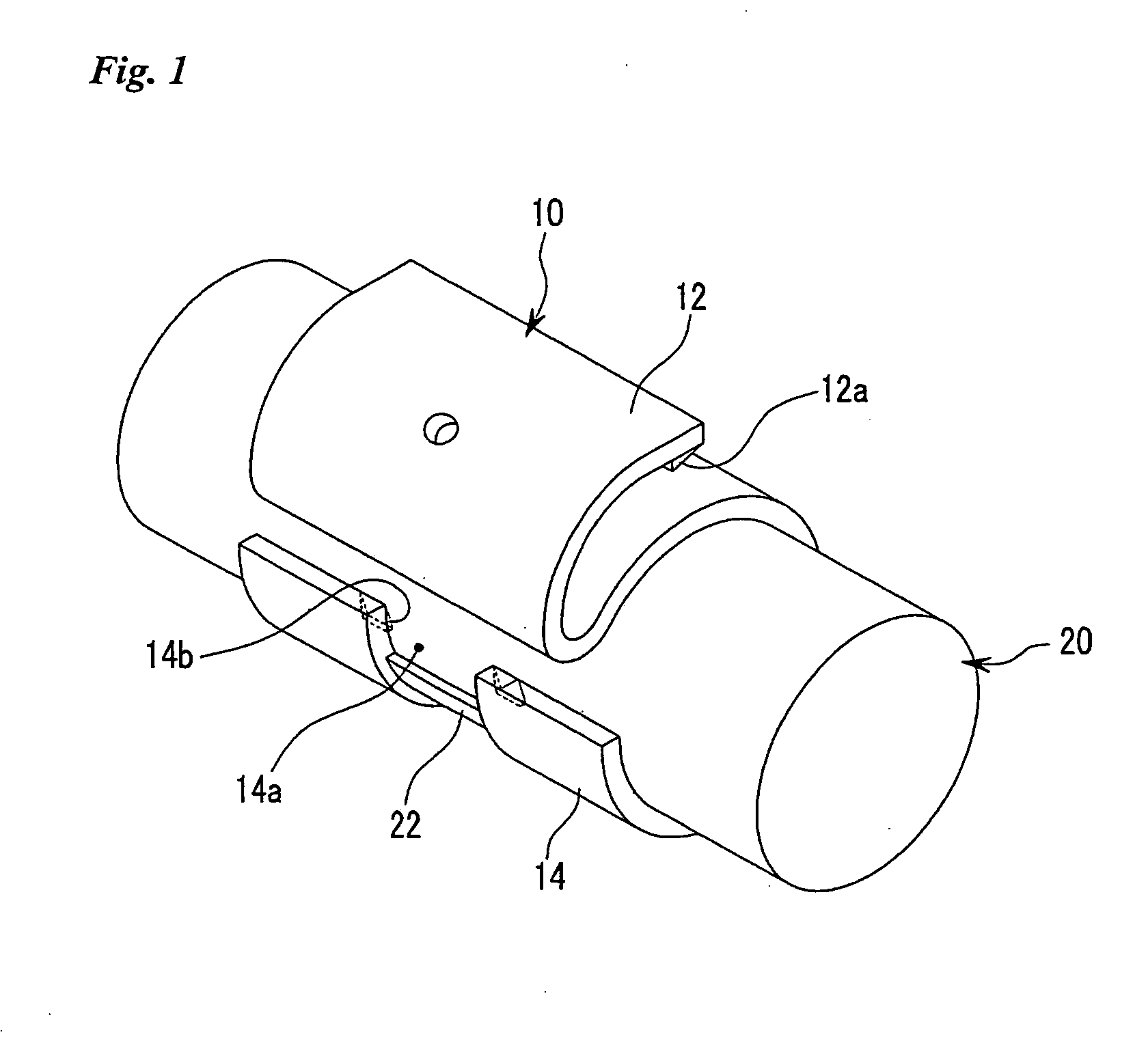

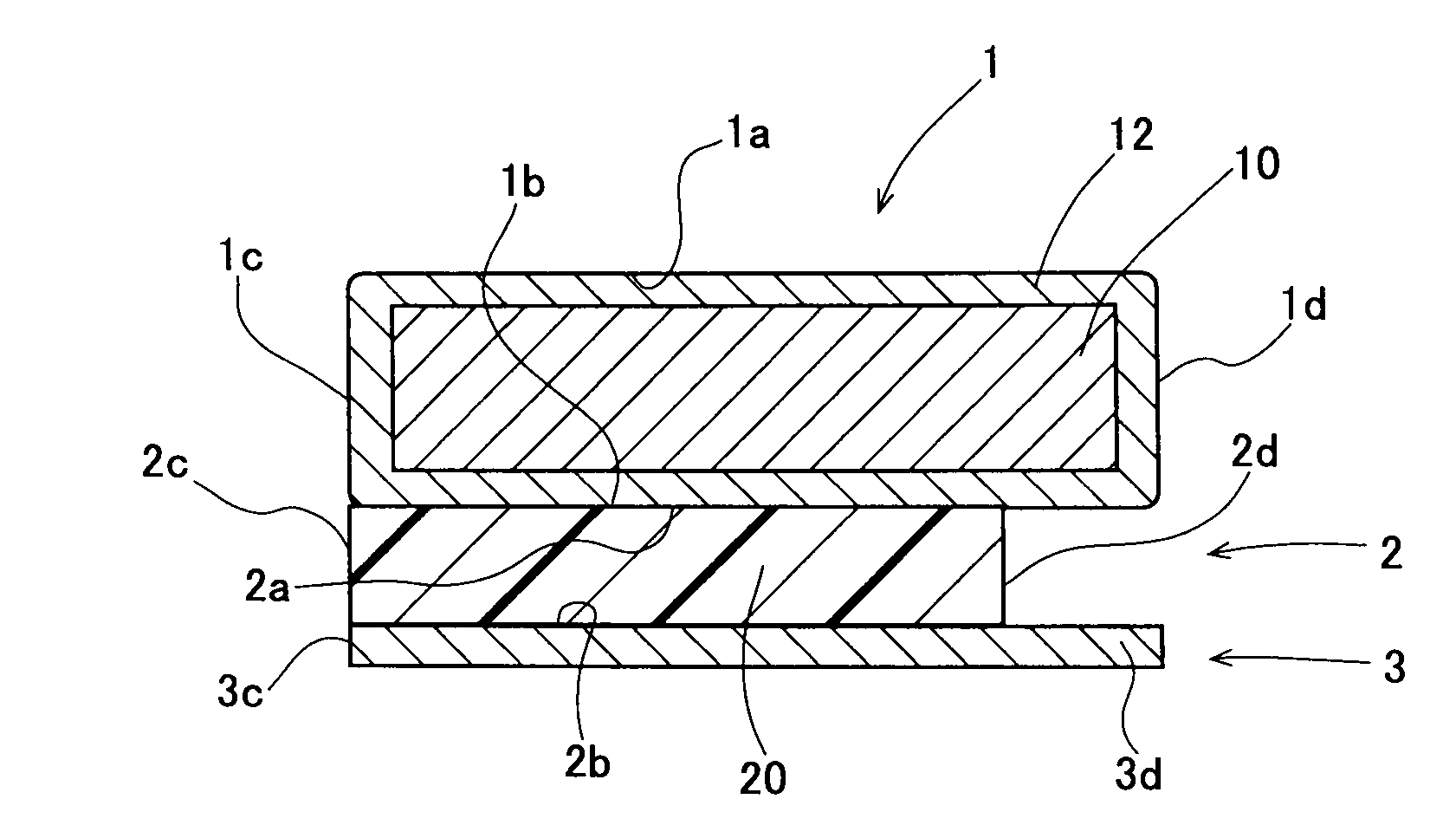

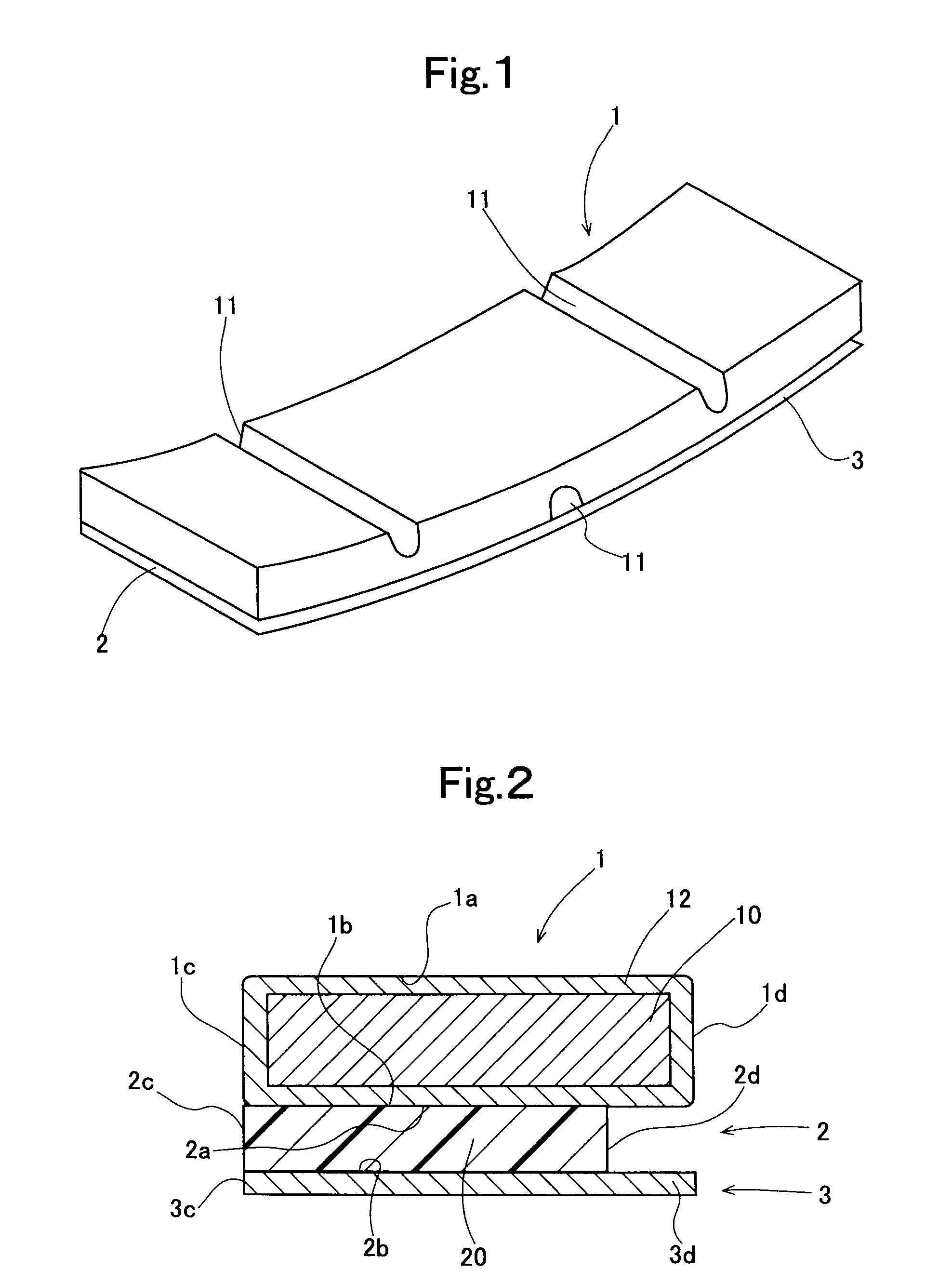

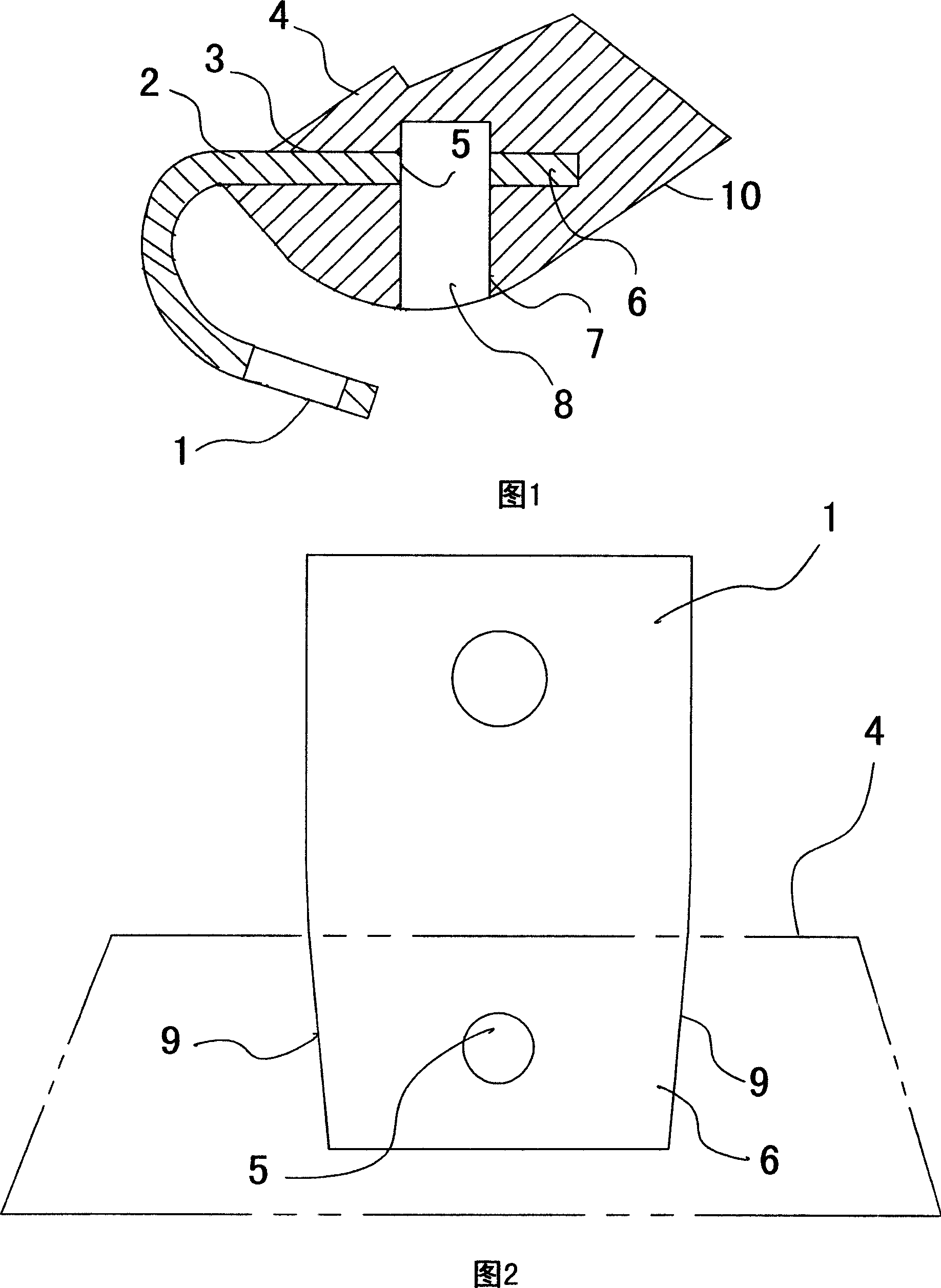

Wheel balance weight for automobile tire

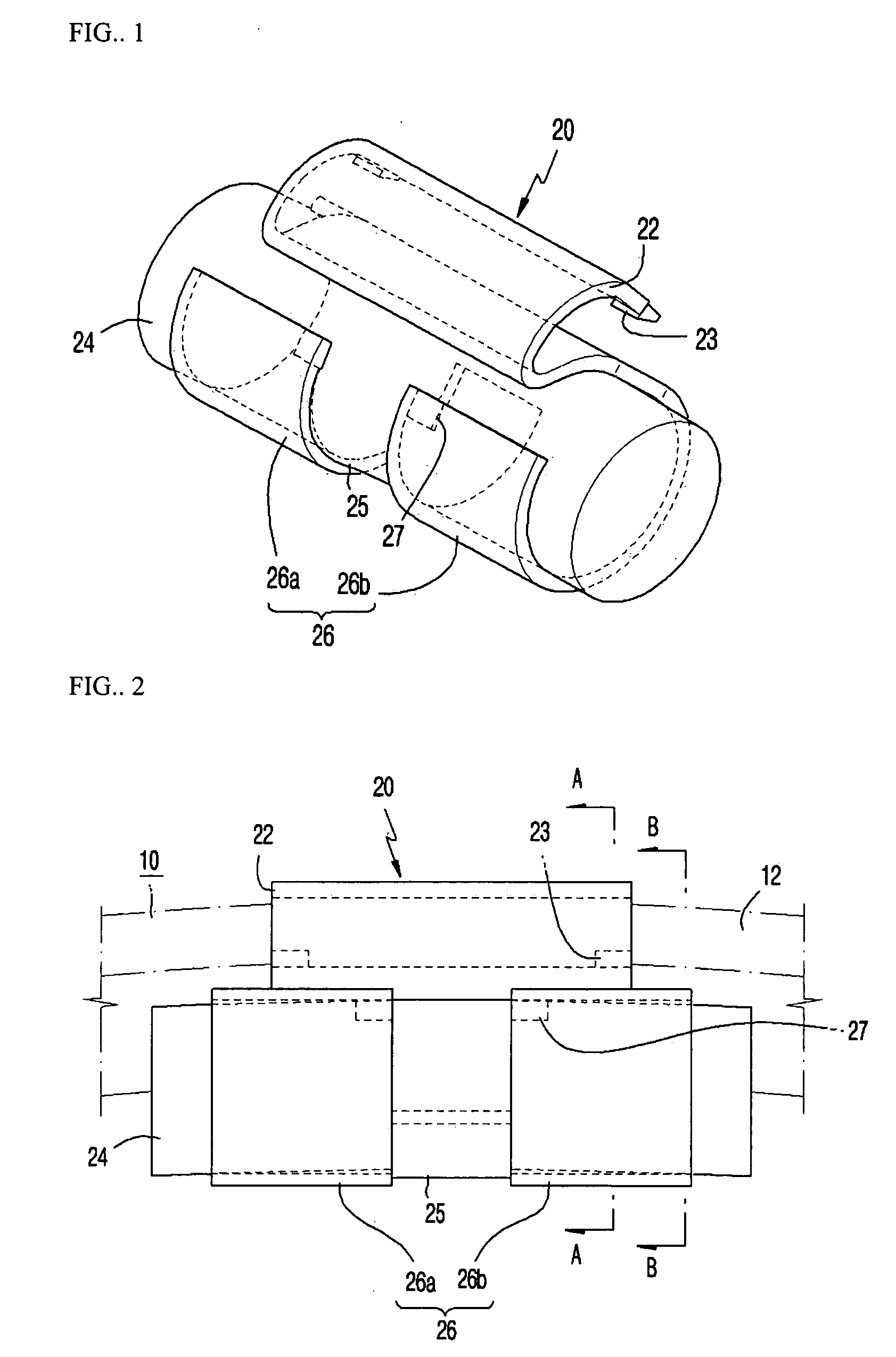

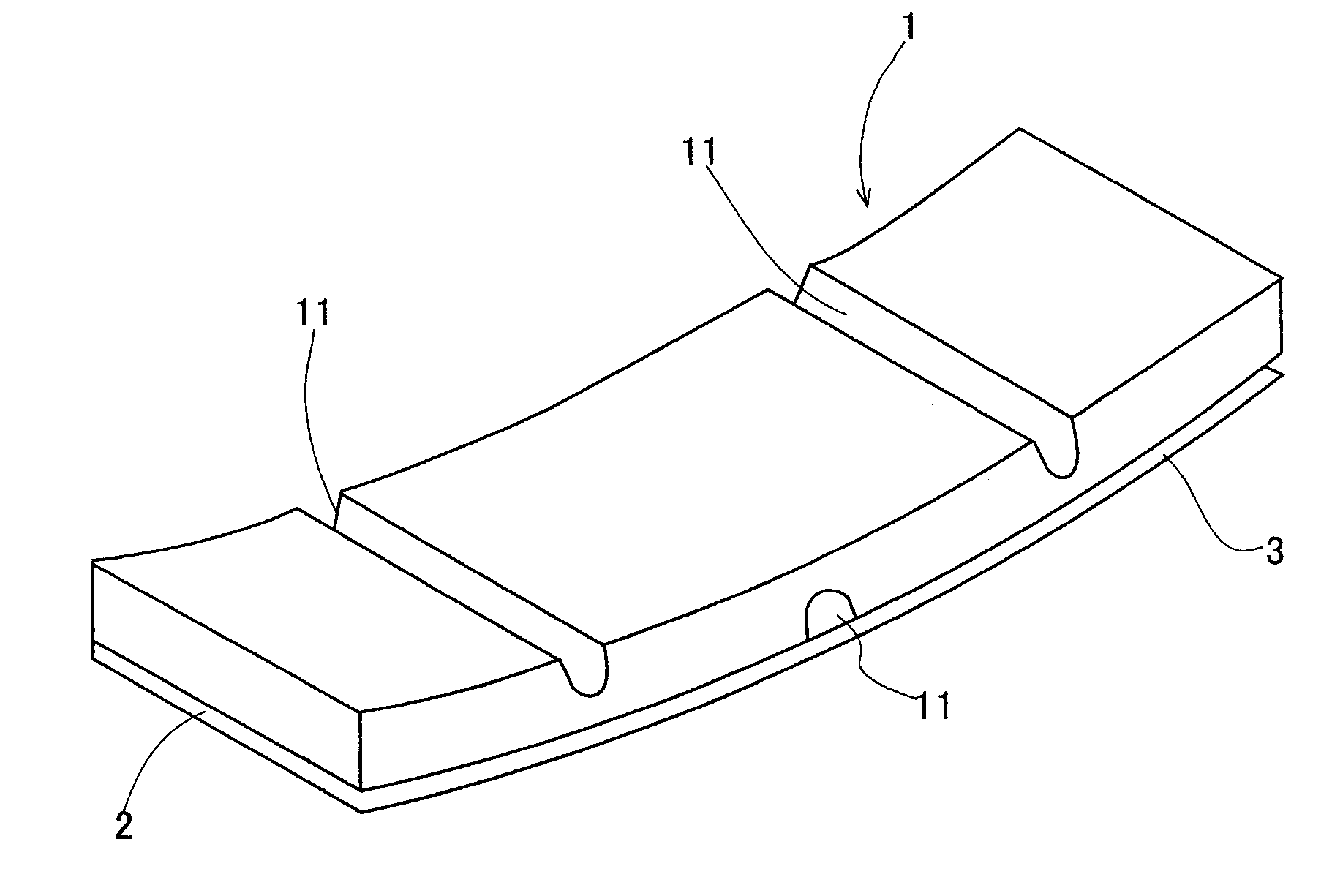

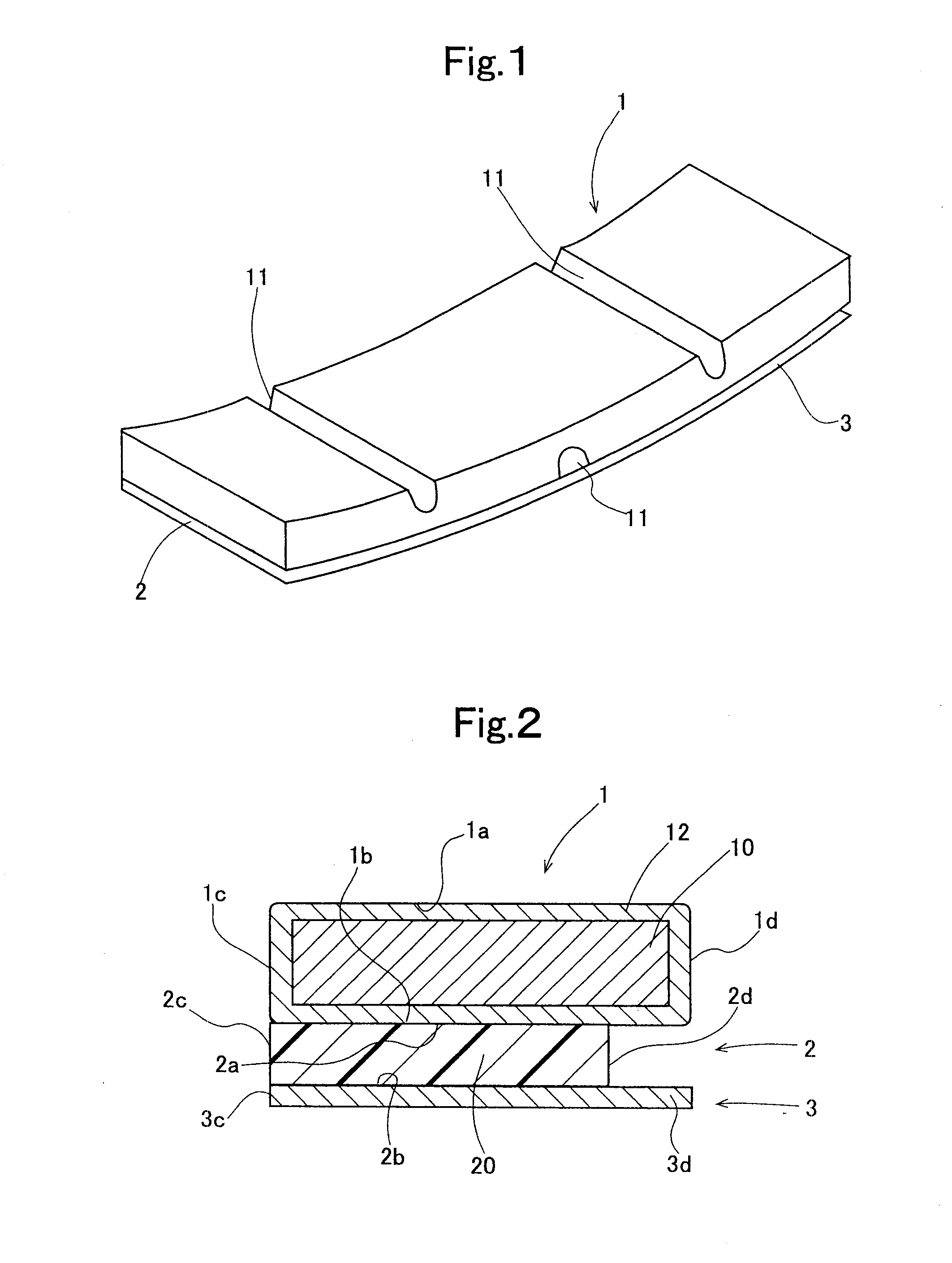

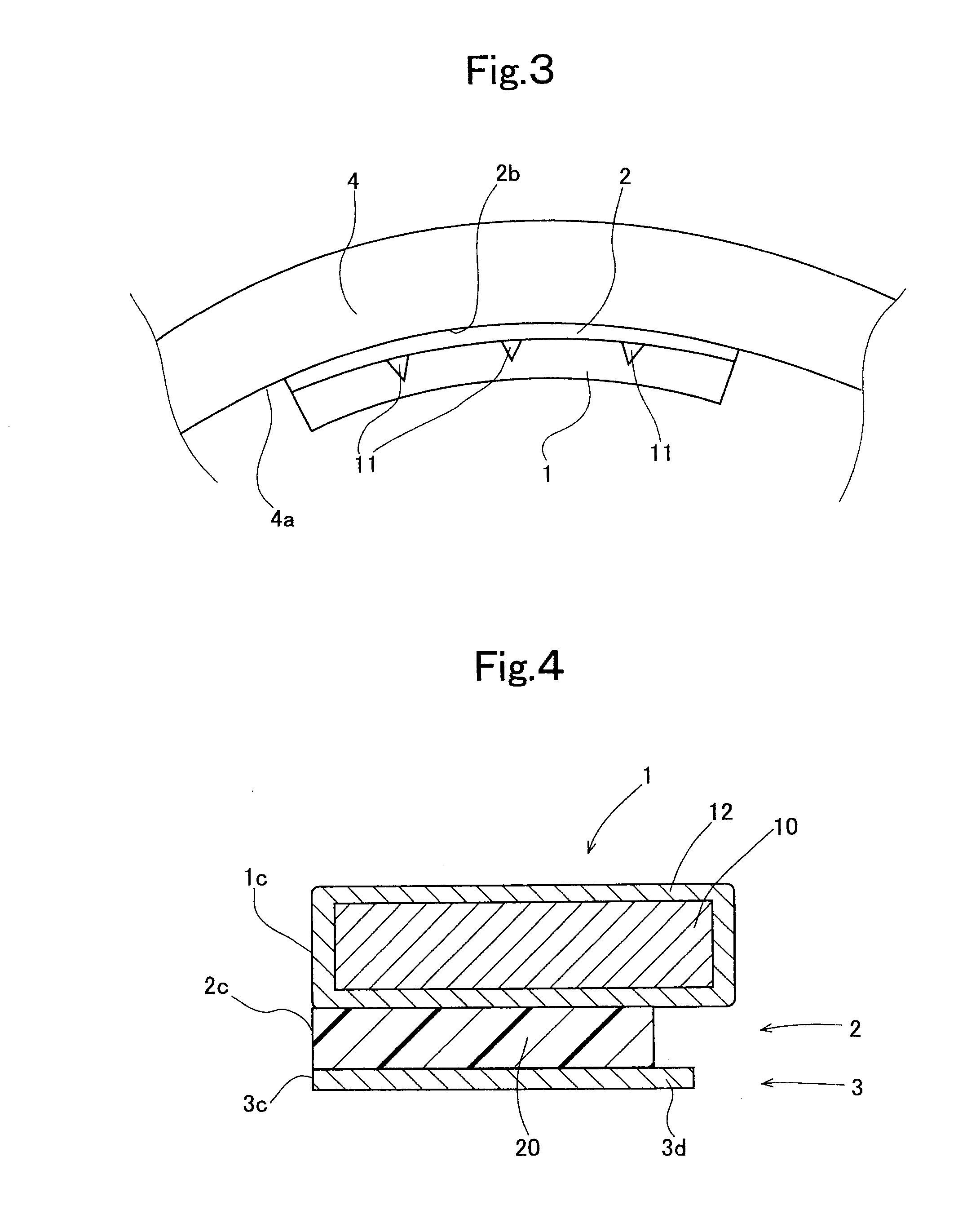

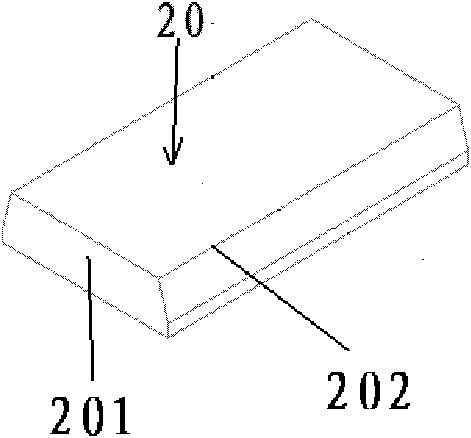

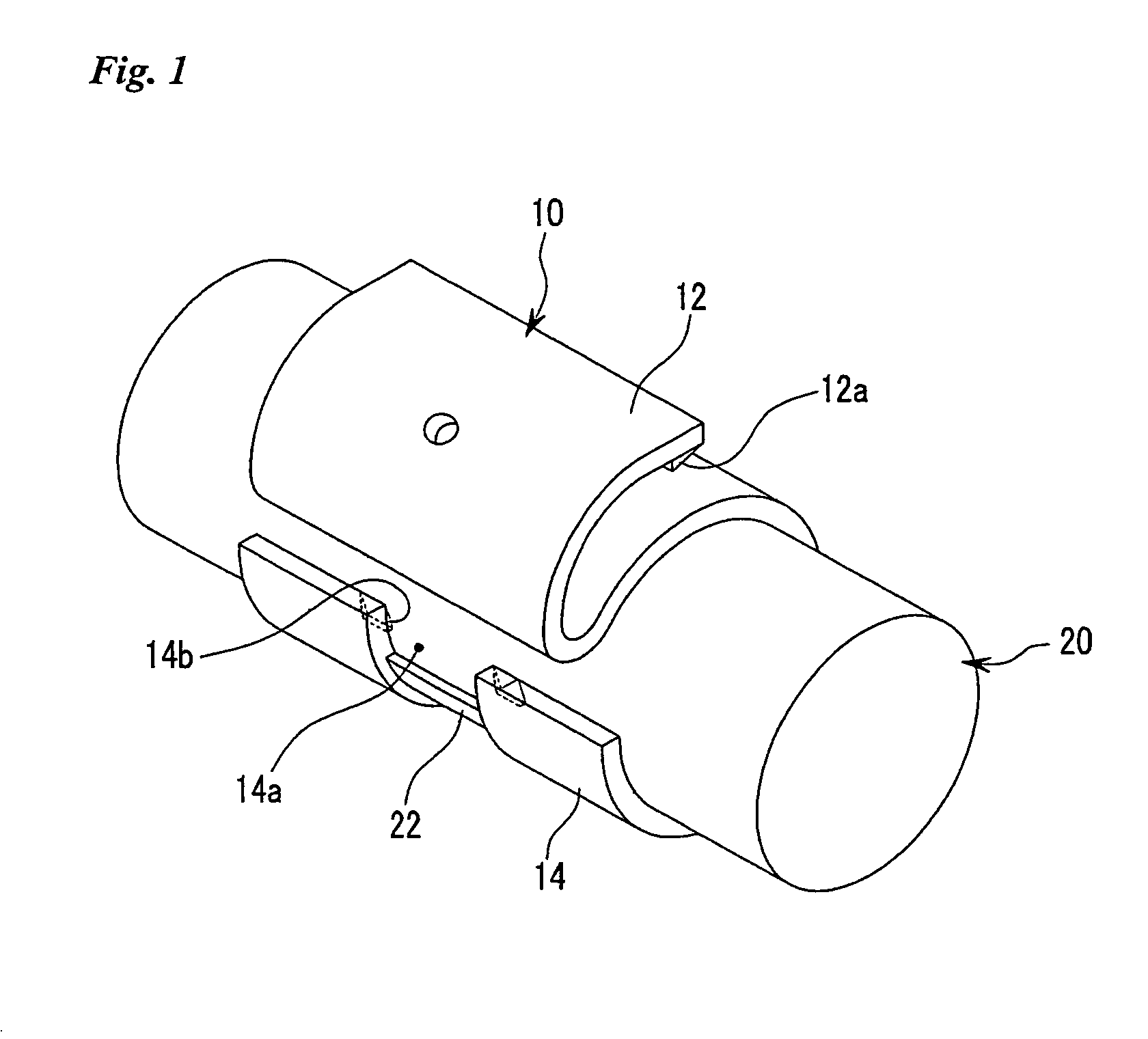

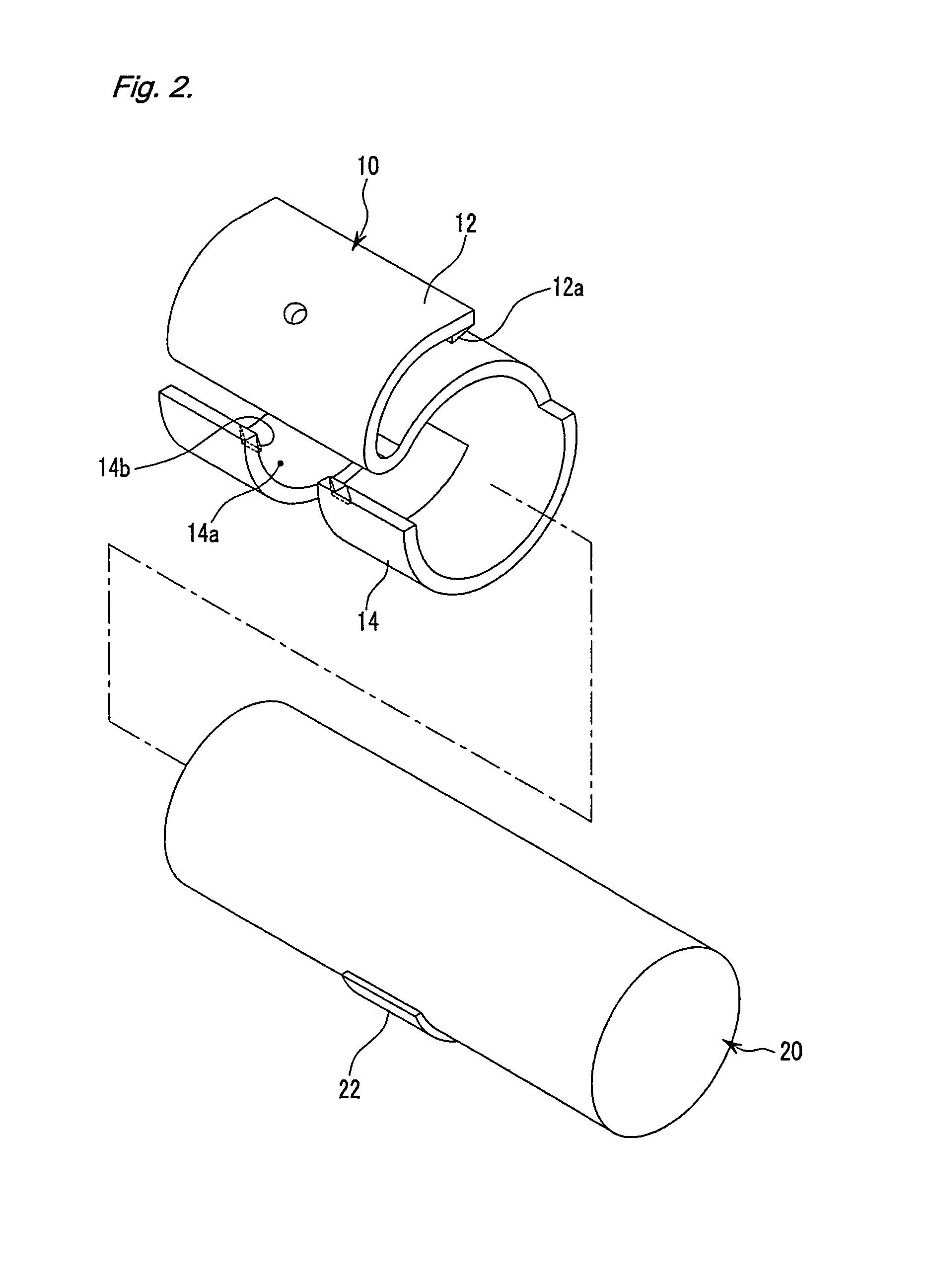

A wheel balance weight for an automobile is provided. The wheel balance weight for an automobile includes a weight holder 10 having a hooking part 12 press-fitted between a rim 7 of an automobile wheel 5 and a tire bead part 9 and an arcuate gripping part 14 provided at the other end of the hooking part 12, and a weight element 20 detachably gripped by an inner periphery of the gripping part 14 of the weight holder 10, wherein the gripping part 14 of the weight holder 10 has a cut-out part 14a formed at a center part thereof to a certain length in a circumferential direction thereof, and the weight element 20 has a fixing protrusion 22 projecting from an outer periphery thereof through the cut-out part 14a of the gripping part 14 to the exterior and fixedly hooked by the gripping part 14.

Owner:DONGHWATECH

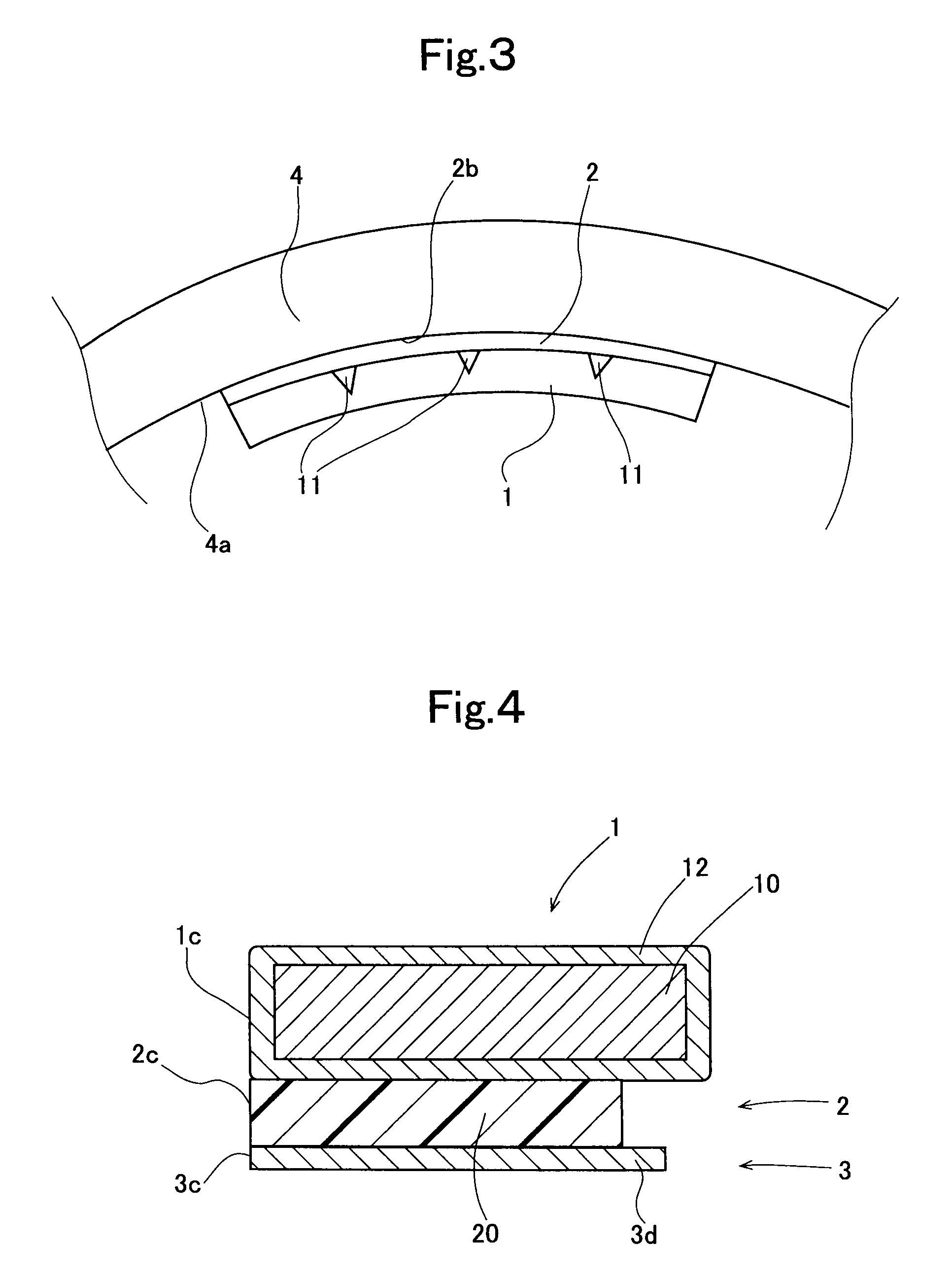

Wheel balance weight

To provide a wheel balance weight in which a release coated paper is likely to be detached when assembling it with a wheel.A wheel balance weight according to the present invention is such that, in a wheel balance weight including: a substantially-strip-shaped weight; an adhesive-tape portion whose tape front surface is fixed to a weight rear surface; and a release coated paper covering a tape rear surface, it makes the release coated paper likely to be pinched by adjusting the widths of the adhesive-tape portion and release coated paper. Since the wheel balance weight according to the present invention is such that the release coated paper is less likely to be detached before the assembly operation and the release coated paper is likely to be pinched upon assemblage, the handling becomes easy and additionally the workability when assembling the wheel balance weight with a wheel has improved.

Owner:TAIHO INDUSTRIES CO LTD +1

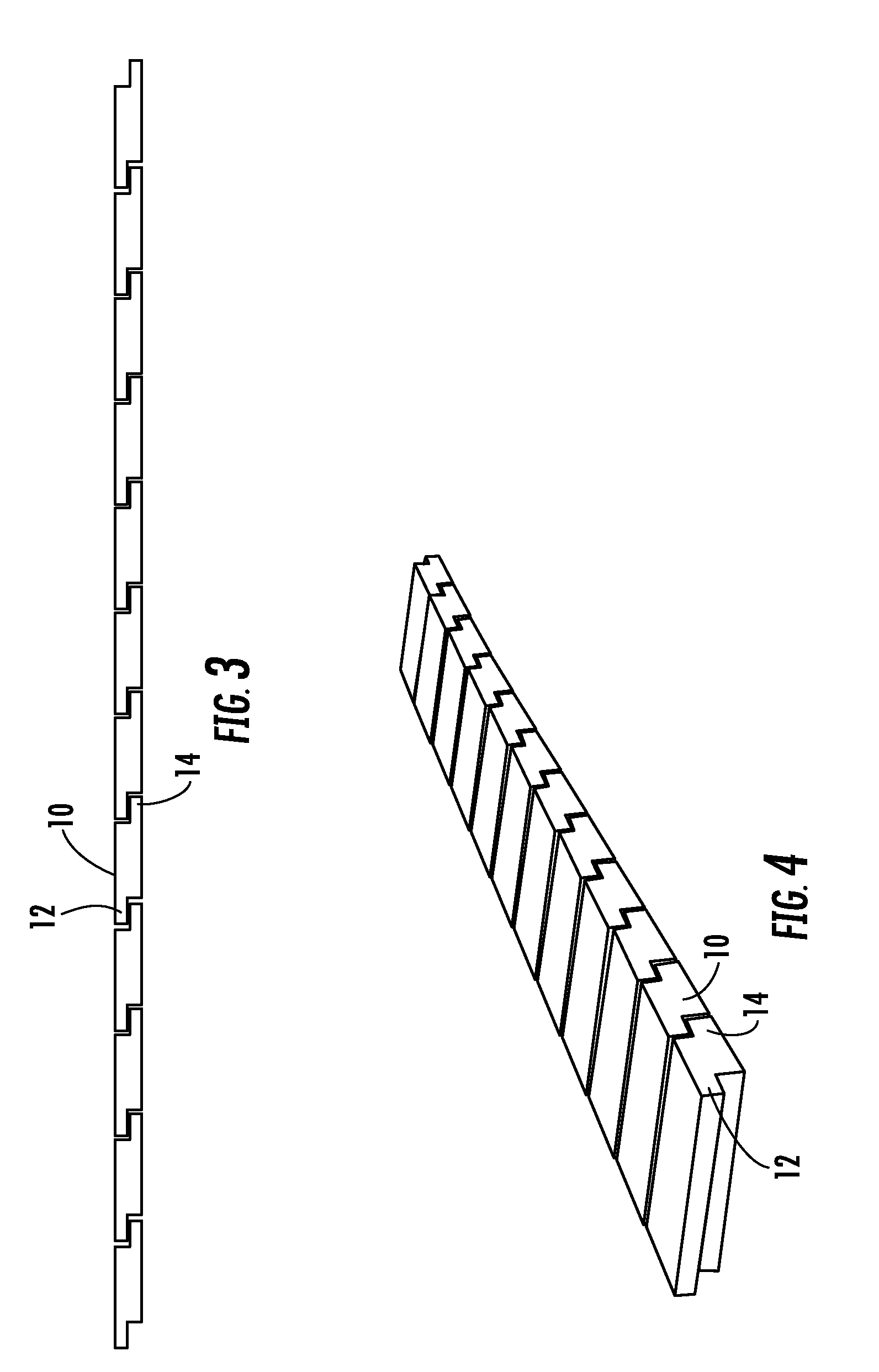

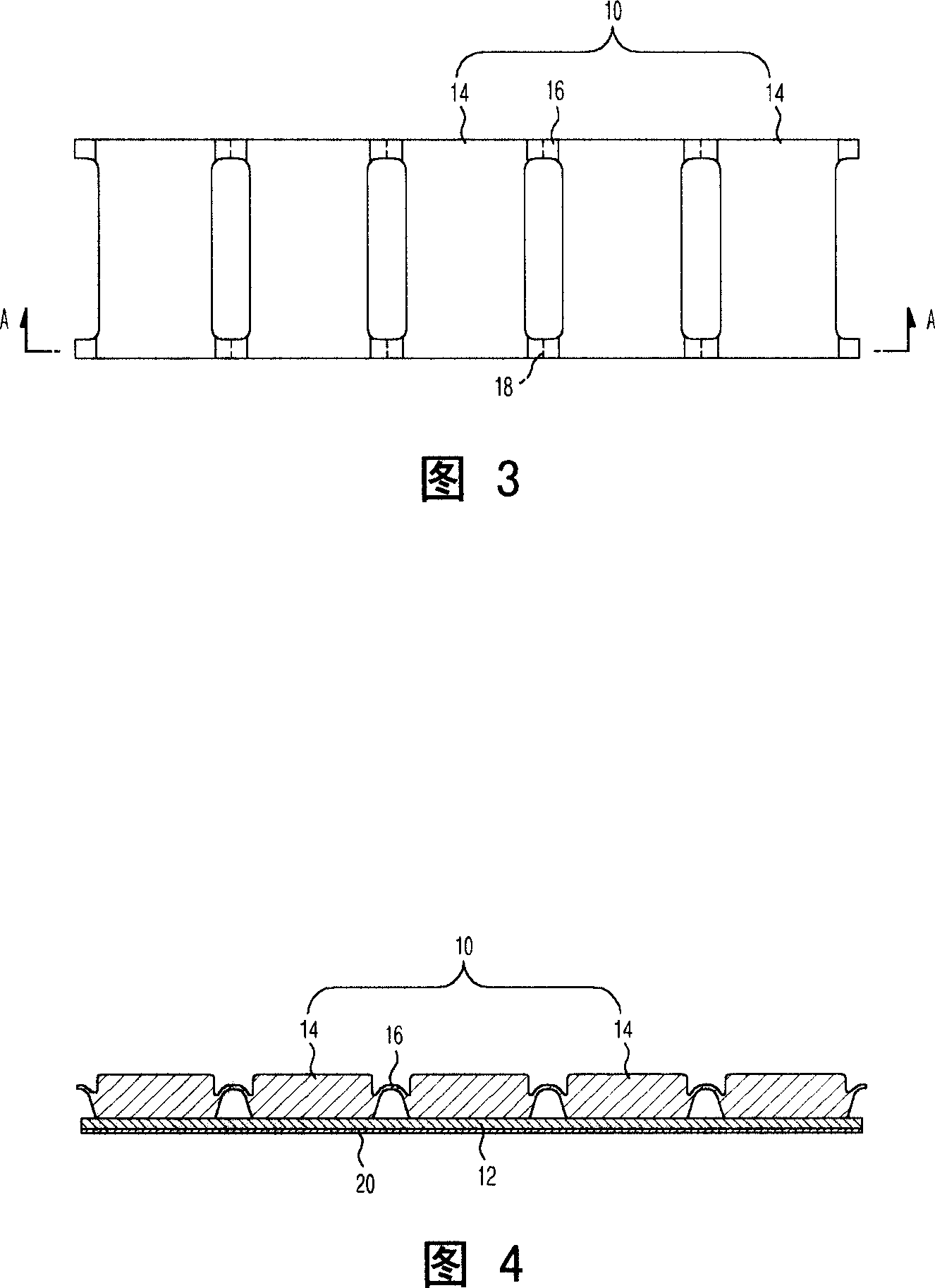

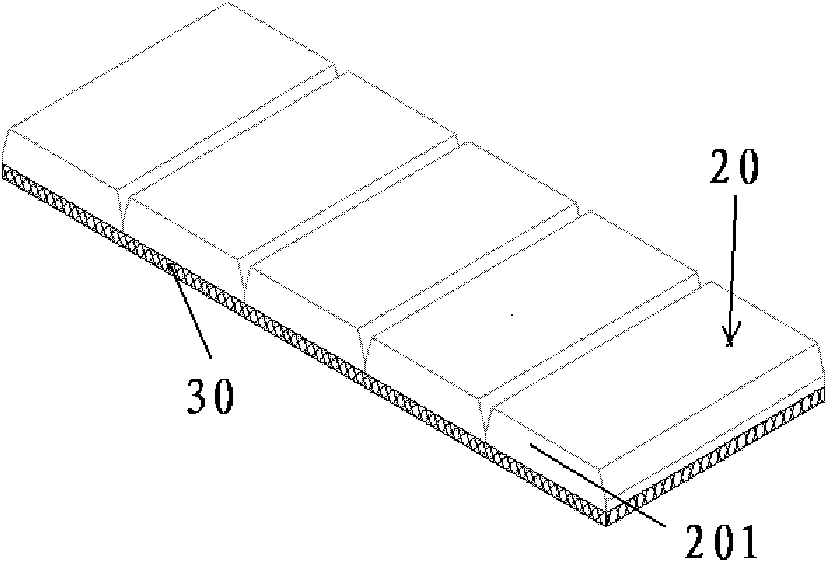

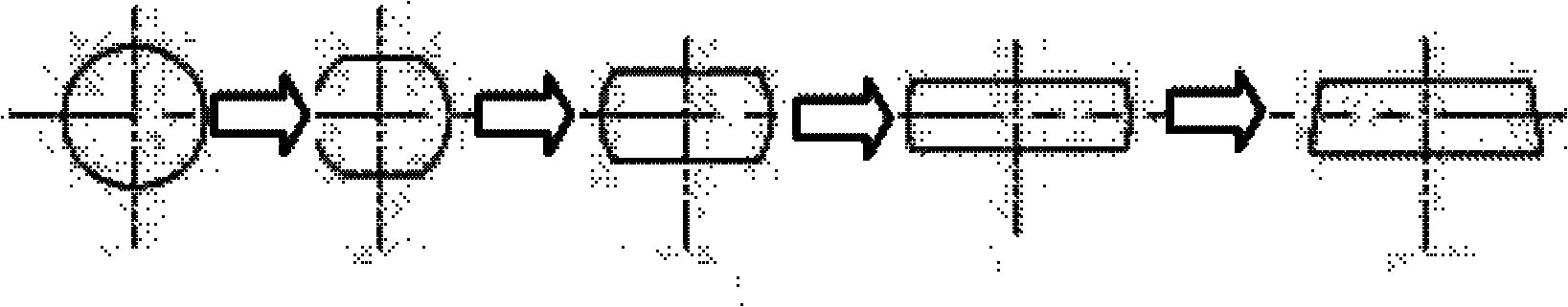

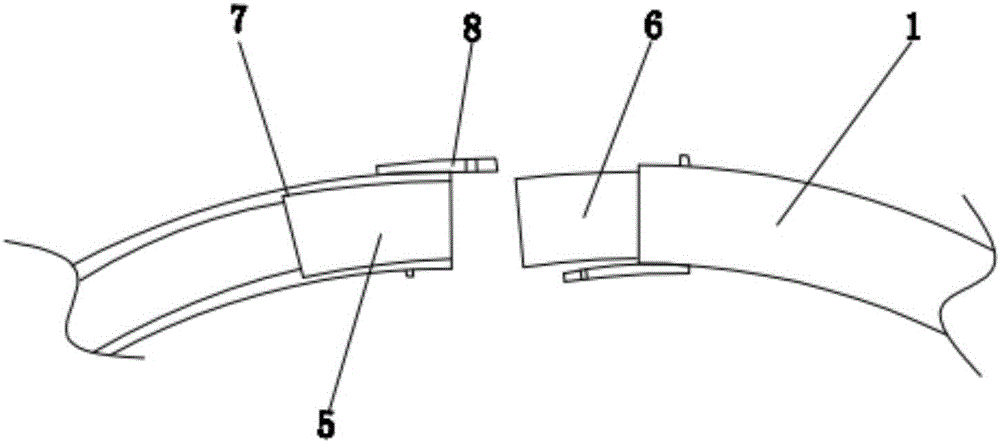

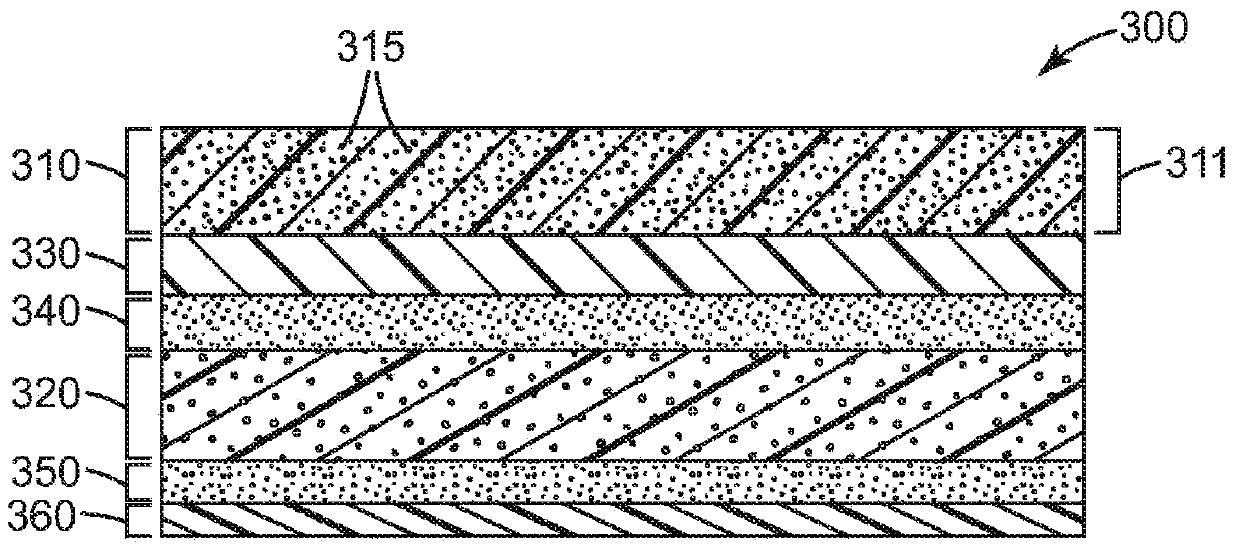

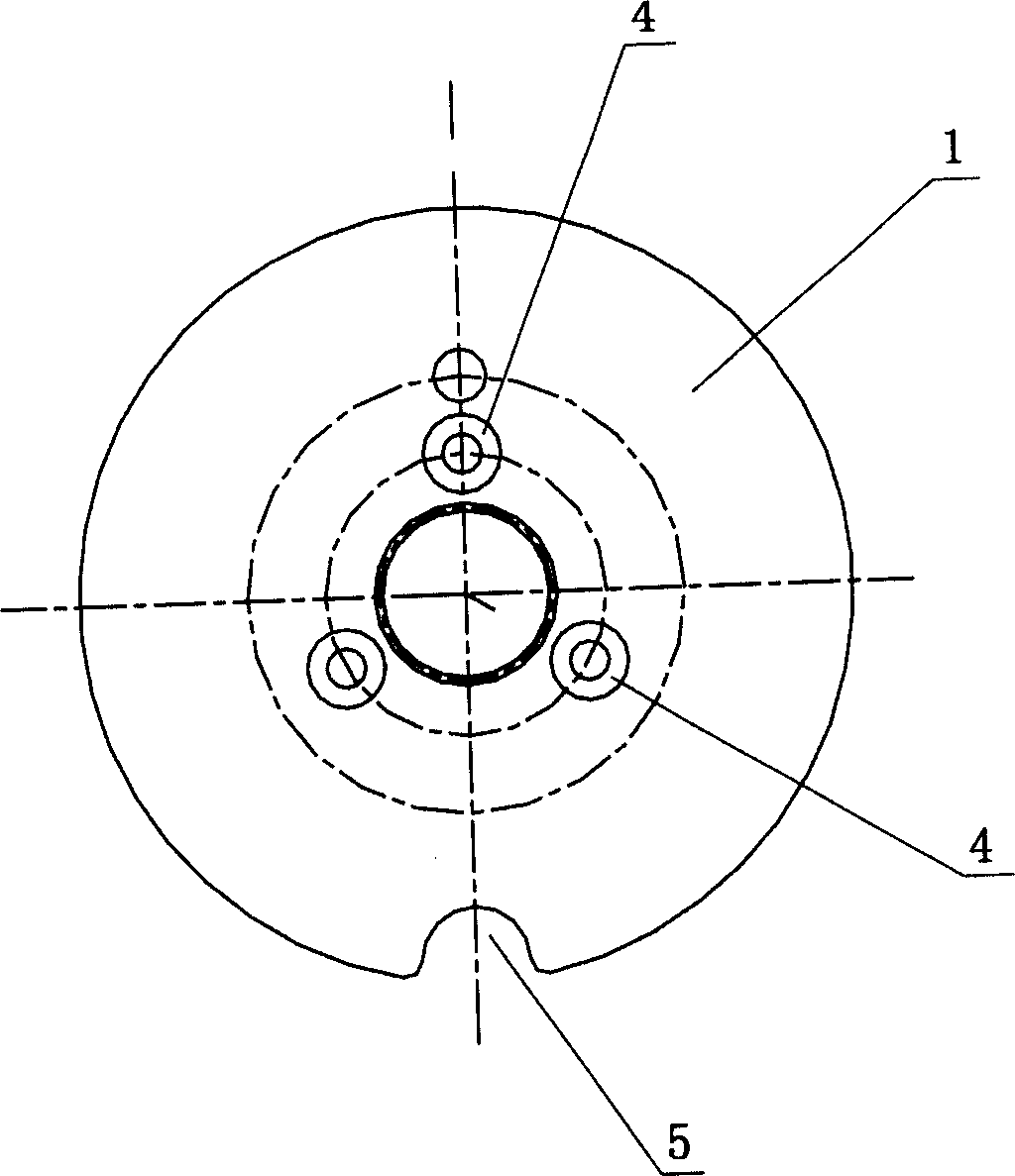

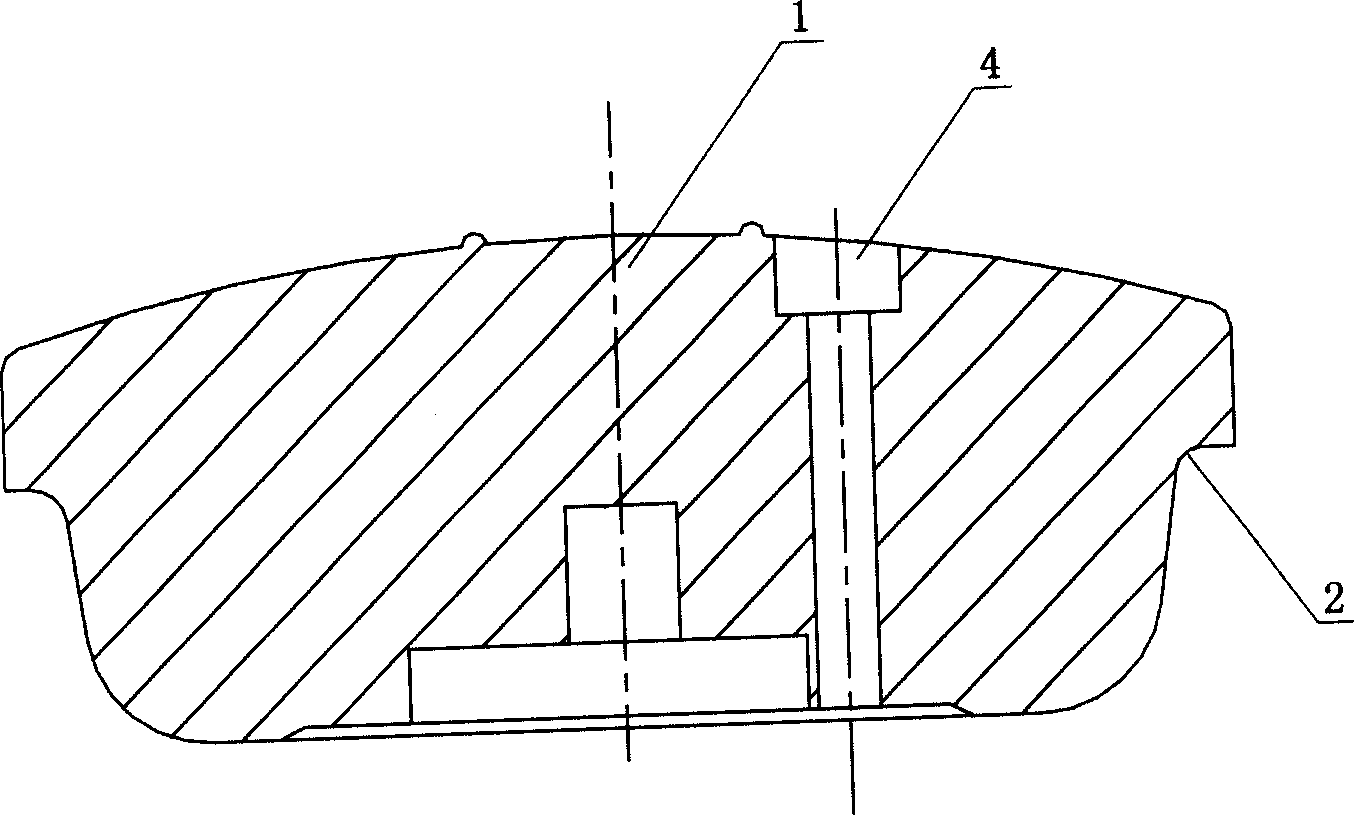

Small steel wheel balance blocks, manufacturing method thereof and stamping die

ActiveCN102922942AEven by forceSolve the slump problemShaping toolsWheel-ballasting weightsSheet steelEnergy consumption

The invention disclose small steel wheel balance blocks and a strip-shaped wheel balance block, a method for producing the small steel wheel balance blocks and a stamping die. Each small steel balance block is provided with a lower bottom surface which can be adhered to a double-faced adhesive tape; each small steel wheel balance block has a wholly press-formed integrated structure and uniform blanking sections without collapsed corners. A plurality of small steel wheel balance blocks are adhered to one side the double-faced adhesive tape to form the strip-shaped wheel balance block. The stamping die for producing the small wheel balance blocks comprises a feed section, a stamping section and a positioning section; the stamping section and the positioning section have the same length in the feed directions, so that after steel plate blank is blanked, the small steel wheel balance blocks with the same quality can be obtained on the stamping section and the positioning section of the stamping die simultaneously. According to the technical scheme, the energy consumption of production can be reduced obviously, the produced product is good in appearance, and high production efficiency is guaranteed.

Owner:SHANGHAI UNIV OF ENG SCI +1

Wheel balance weight

To provide a wheel balance weight in which a release coated paper is likely to be detached when assembling it with a wheel.A wheel balance weight according to the present invention is such that, in a wheel balance weight including: a substantially-strip-shaped weight; an adhesive-tape portion whose tape front surface is fixed to a weight rear surface; and a release coated paper covering a tape rear surface, it makes the release coated paper likely to be pinched by adjusting the widths of the adhesive-tape portion and release coated paper. Since the wheel balance weight according to the present invention is such that the release coated paper is less likely to be detached before the assembly operation and the release coated paper is likely to be pinched upon assemblage, the handling becomes easy and additionally the workability when assembling the wheel balance weight with a wheel has improved.

Owner:TAIHO INDUSTRIES CO LTD +1

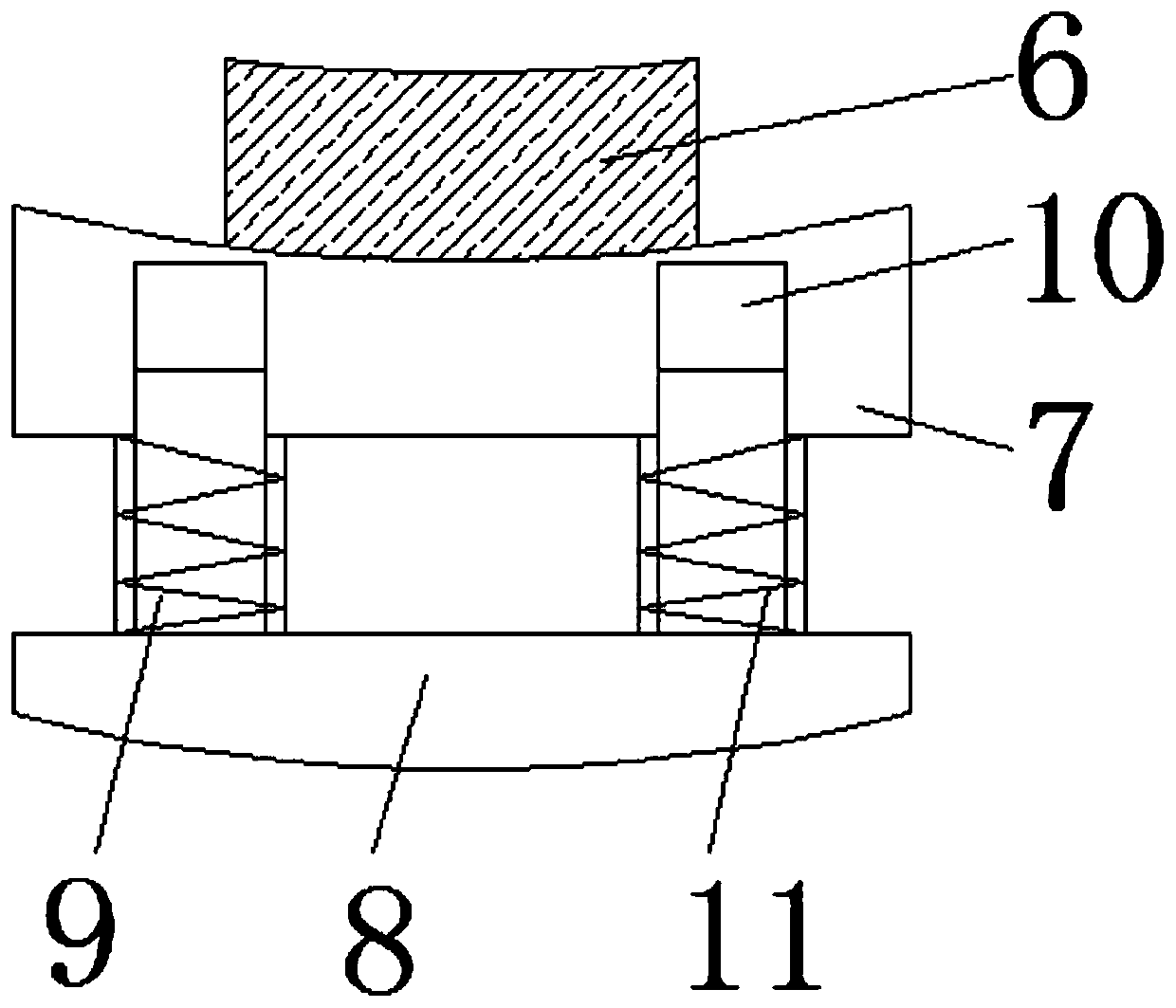

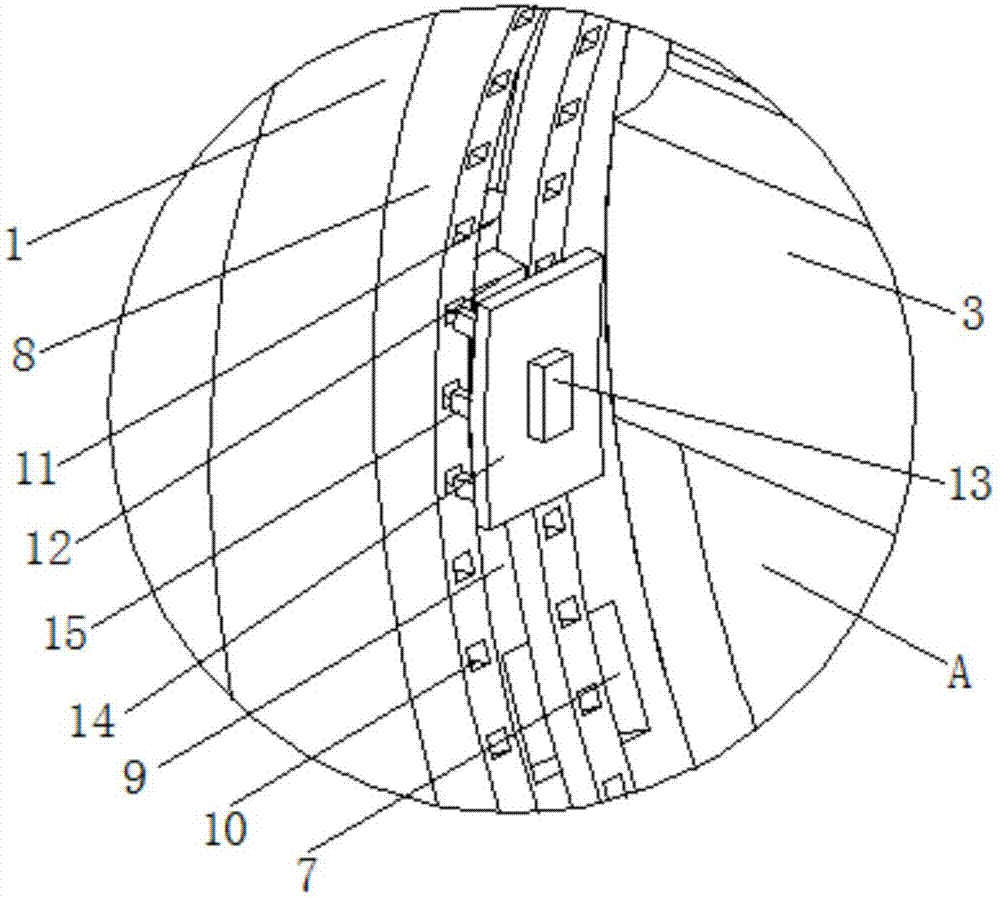

High-strength double-layer automobile hub structure

ActiveCN111497524AImprove stabilityReduce distanceWheel-ballasting weightsRimsEngineeringStructural engineering

The invention discloses a high-strength double-layer automobile hub structure in the technical field of automobile hubs. The structure comprises a rim, a sliding groove is formed in the middle of theinner wall of the rim. A balance block is arranged in the sliding groove; a fixed plate is arranged at the central position in the rim; a spoke is fixedly mounted between the fixed plate and the rim;the spoke and the rim are an integrated component; a limiting plate is fixedly mounted on the outer surface of the lower end of the balance block; a pressing plate is arranged below the limiting plate; slots are formed in positions, close to two sides, of the outer surface of the lower end of the limiting plate; straight rods are fixedly installed at the positions, corresponding to the inserting grooves, of the outer surface of the upper end of the pressing plate. The outer surface of the straight rod is sleeved with a spring, the spring is fixedly installed between the pressing plate and thelimiting plate, a user can conveniently adjust the balance of the hub in the using process, the balance block can be used repeatedly, resources are saved, the user can conveniently clean the inner side face of the hub, and the using performance of the hub is improved.

Owner:HANSHAN ZHAOXIA CASTING

Front-end weight block of tractor and manufacturing method thereof

InactiveCN101108572ASave raw materialsReduce manufacturing costWheel-ballasting weightsVehicle body stabilisationEngineeringTractor

A tractor front balancing weight is provided, which comprises a shell, a through groove which is meshed with the front hanging board at the front of the tractor and an installation surface of the fixed hanging board are arranged on the shell, the inner cavity of the shell is filled with 72 to 84 per cent iron ore, gangue powder 5 to 12 per cent, concrete 4 to 8 per cent and water 5 to 8 per cent. The shell is welded by metal board material, the whole shape of the shell is smooth arc curved surface, a hole, a portable handle are arranged on the shell. The production method of the tractor front balancing weight makes two pieces of steel boards pressed into an inner cavity shape, the balancing weight material is mixed , then fills in the inner concave cavity and vibrate, finally connect the two shells by welding, then weld the portable handle on the shell, finally proceed milling and spraying paint. The invention greatly saves metal raw material, the manufacture cost is low, the process technics is simple and the appearance is beautiful.

Owner:谢贵根

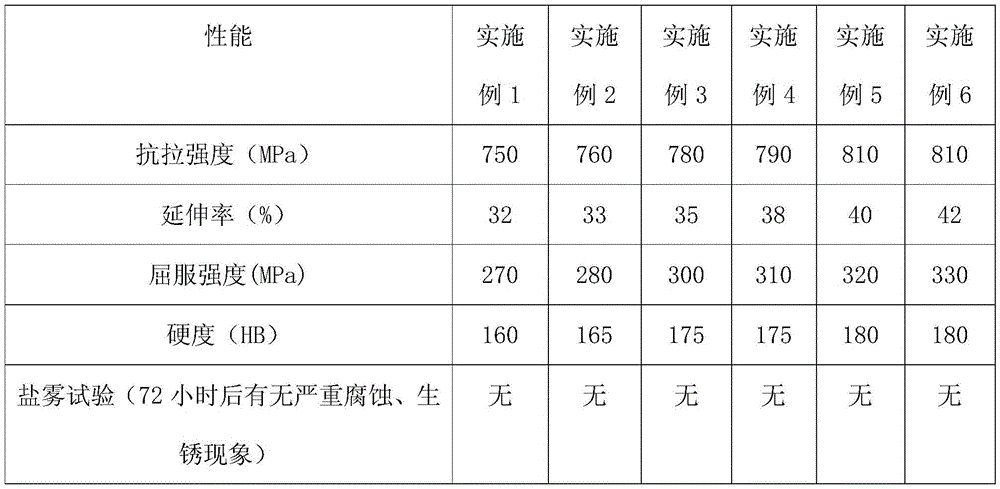

Stable and reliable automobile balancing block and production process thereof

The invention discloses a stable and reliable automobile balancing block and a production process thereof. The automobile balancing block is prepared from the following elements according to percentage by mass: 10-30% of manganese, 0.05-0.25% of thallium, 0.2-1.5% of chromium, 0.5-1.5% of silicon, 0.02-0.8% of nickel, less than or equal to 0.08% of sulfur, 0.02-0.15% of niobium, 0.5-2.5% of carbon and the balance of iron and inevitable impurities. The production process of the stable and reliable automobile balancing block comprises the following steps: adding iron into a resistance furnace; removing oxidization slag on the surface of melt after the iron is completely molten; cooling, adding preheated silicon, nickel, sulfur and niobium, and preserving heat; then adding preheated manganese, thallium, chromium and carbon, preserving heat and removing dross; refining, standing, casting and molding and carrying out ageing treatment to obtain the balancing block. The balancing block is low in cost, high in product surface quality, free of magnetism, low in deformation, excellent in product surface consistency, high in density, strong in applicability, long in service life and wide in market prospect, is stable and reliable; the performance of the balancing block is not changed at 800 DEG C.

Owner:桐乡市搏腾贸易有限公司

Improvement of the tyre of many kinds of vehicles for improving speed

InactiveCN101032913AReduce reaction forcePrevent incomingWheel-ballasting weightsRolling resistance optimizationEngineeringBody weight

The present invention relates to improvement on vehicle wheel, and features that balance weight iron is installed inside tire to increase the inertia of running wheel. One balance weight iron in the size of 1 / 2-3 / 4 volume of inner tube is screwed on the hub and between the hub and the inner tube. The improved tire with balance weight iron to increase running inertia can result in saving in energy consumption, reduction in air pollution, capacity of reducing vehicle body weight and raised vehicle safety.

Owner:宋来学

Clip hook type wheel balance block and its producing method

InactiveCN1945051ANo pollution in the processSimple processWheel-ballasting weightsRotating bodies balancingDie castingZinc alloys

The present invention discloses one kind of clip-hook type wheel balance block and its production process. The wheel balance block includes one balance block of zinc and one clip hook of steel inserted into and riveted to the balance block to form one integral body. The production process includes die casting zinc alloy into balance block with clip hook installing slot and hole for rivet in a die casting machine, installing the clip hook and riveting. The present invention and excellent manufacturability and the clip-hook type wheel balance block is firm.

Owner:毛松波

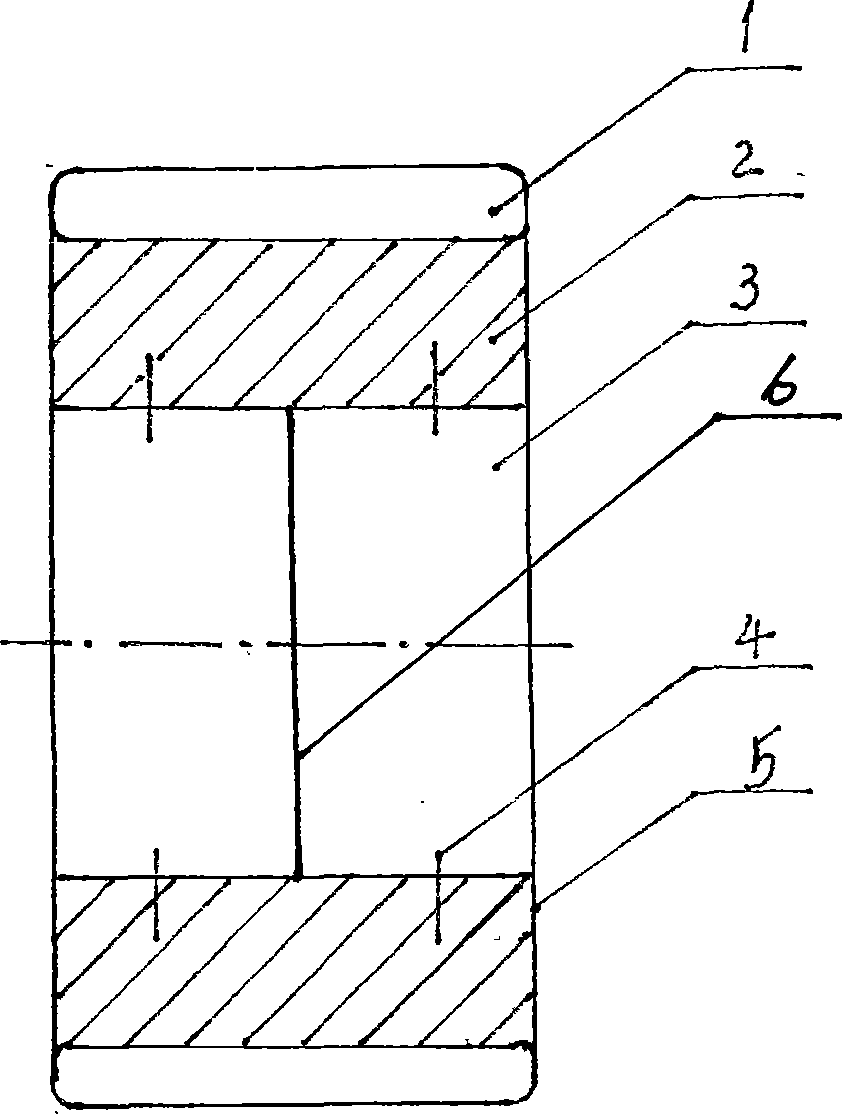

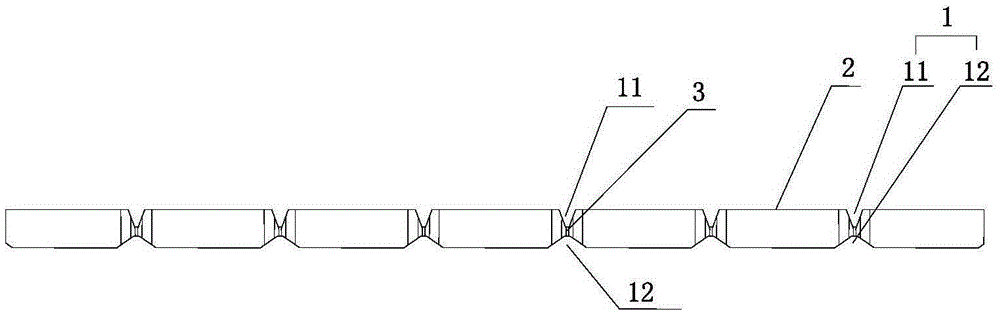

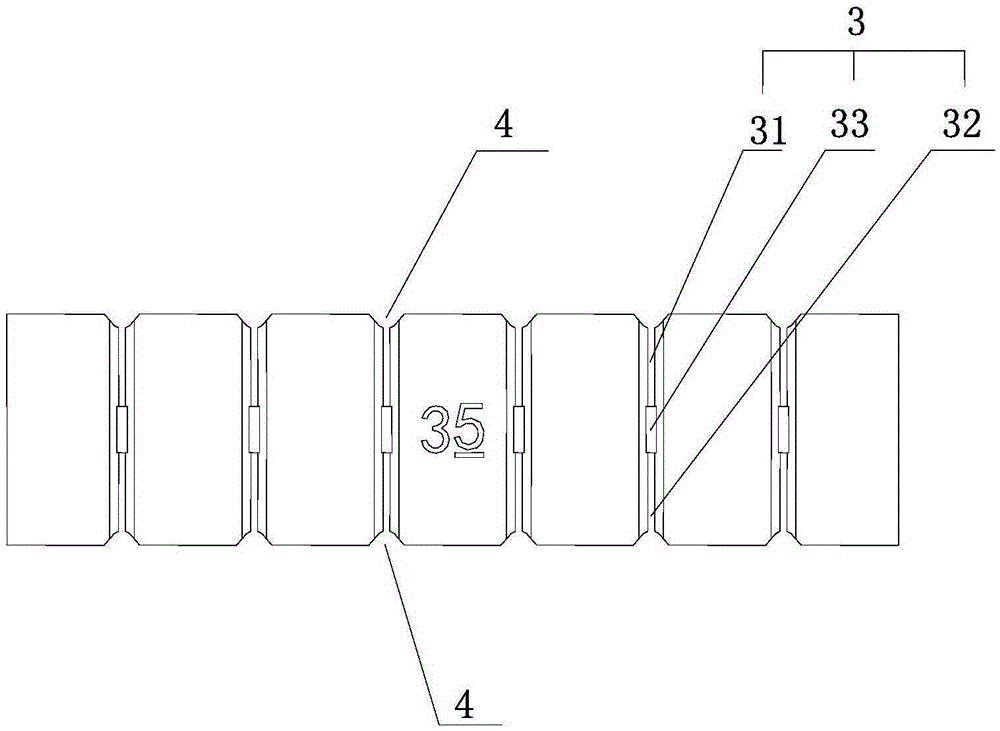

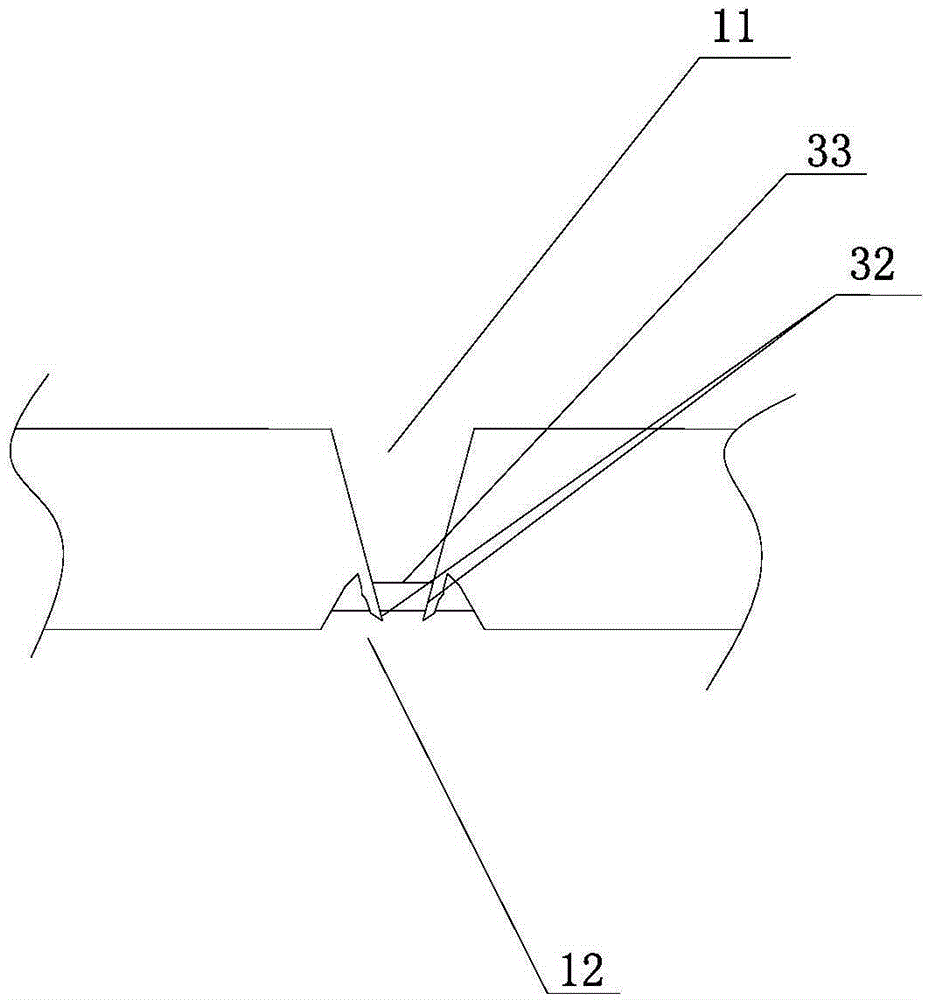

Integrated balance block and molding process thereof

ActiveCN105398284AReduce the amount of resectionIncrease profitWheel-ballasting weightsProcess operationScrap

The invention discloses an integrated balance block and a molding process thereof. The integrated balance block comprises a balance block body. The balance block body is provided with multiple pressing grooves and is cut into multiple connected sub-block bodies through the pressing grooves. Each pressing groove comprises an upper pressing groove body and a lower pressing groove body. The upper pressing groove bodies and the lower pressing groove bodies are oppositely arranged on the upper end face and the lower end face of the balance block body. The bottom faces of the upper pressing groove bodies and the bottom faces of the lower pressing groove bodies are stretched and extruded to form slice type connection belts. Each slice type connection belt comprises a first tearing belt, a second tearing belt and a connection belt body located between the first tearing belt and the second tearing belt. The portions, located at the two ends of each pressing groove, on the two sides of the balance block body are provided with avoiding grooves respectively. The molding process of the integrated balance block includes the steps of firstly, pressing groove molding, secondly, avoiding groove molding and thirdly, cutting off. By the adoption of the integrated structure design, the cut-off amount of waste is small, the material utilization rate is high, the appearance of the steel balance block can be improved, and following process operation convenience can be improved.

Owner:安徽拓扑思汽车零部件有限公司

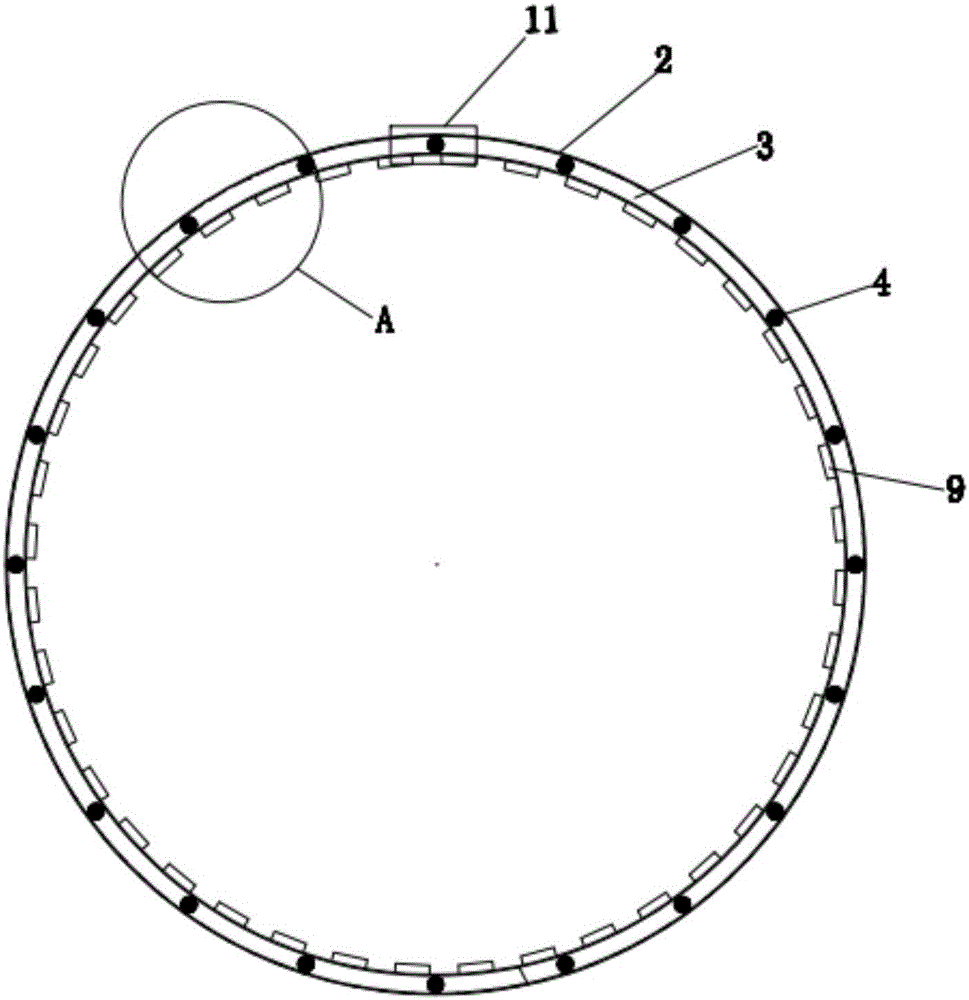

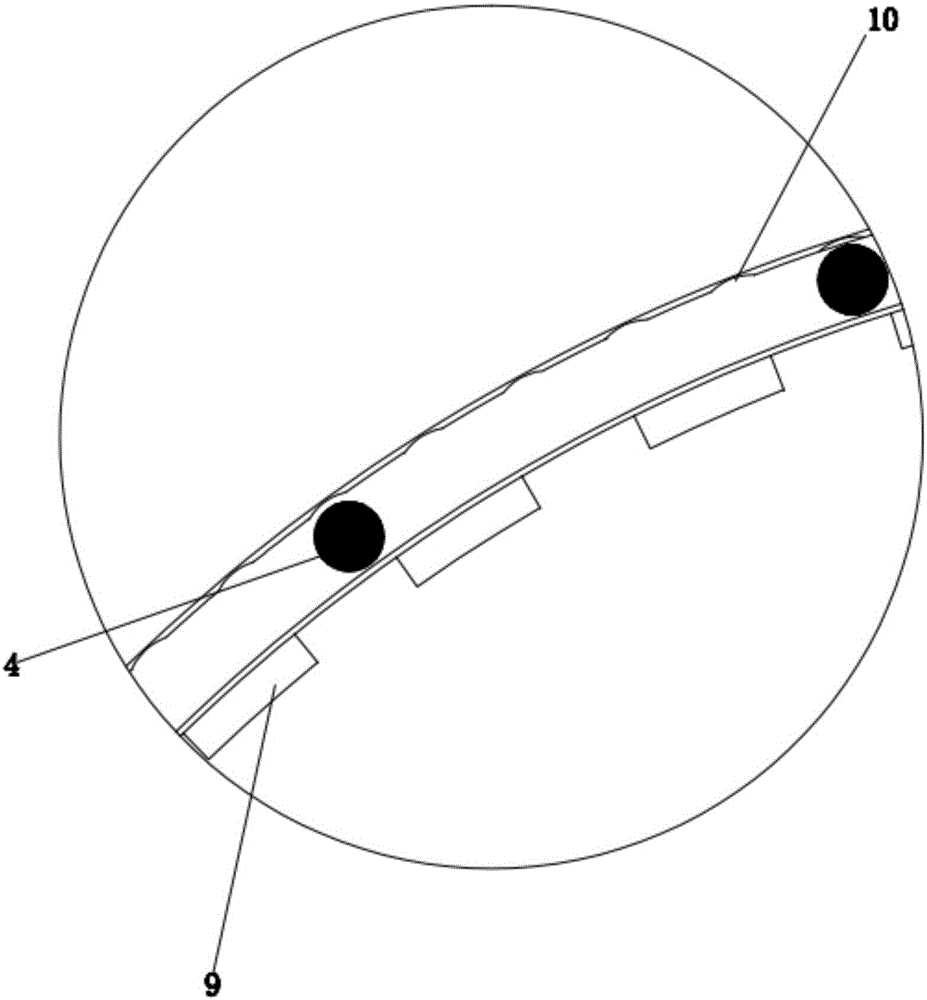

Automobile hub with balance block

InactiveCN107512136AExtended service lifeImprove stabilityWheel-ballasting weightsAnti-corrosive paintsTire beadEngineering

The invention discloses an automobile hub with a balance block. The hub comprises a steel ring, a tire bead base is arranged on the outer side surface of the steel ring, and a valve hole is formed in the middle of the left end of the outer side surface of the steel ring; wheel arms are arranged at the back end of the inner side surface of the steel ring, a fixing plate is arranged at the ends, away from the steel ring, of the wheel arms, and a center hole is formed in the middle of the side surface of the fixing plate; mounting holes which are evenly distributed are formed in the edge of the side surface of the fixing plate, the four mounting holes are evenly formed in the side surface of the fixing plate, and an annular plate is arranged on the middle of the inner side surface of the steel ring; an annular sliding groove is formed in the middle of the side surface of the annular plate, the balance block is arranged in the annular sliding groove, and the balance block is connected with the annular sliding in a sliding mode. The automobile hub with the balance block is simple in structure, the balance block can be adjusted and conveniently fixed, the service life of the balance block can be effectively prolonged, resource waste is reduced, meanwhile, the driving safety is improved, and the automobile hub is used safely and is high in practicability.

Owner:陈伟景

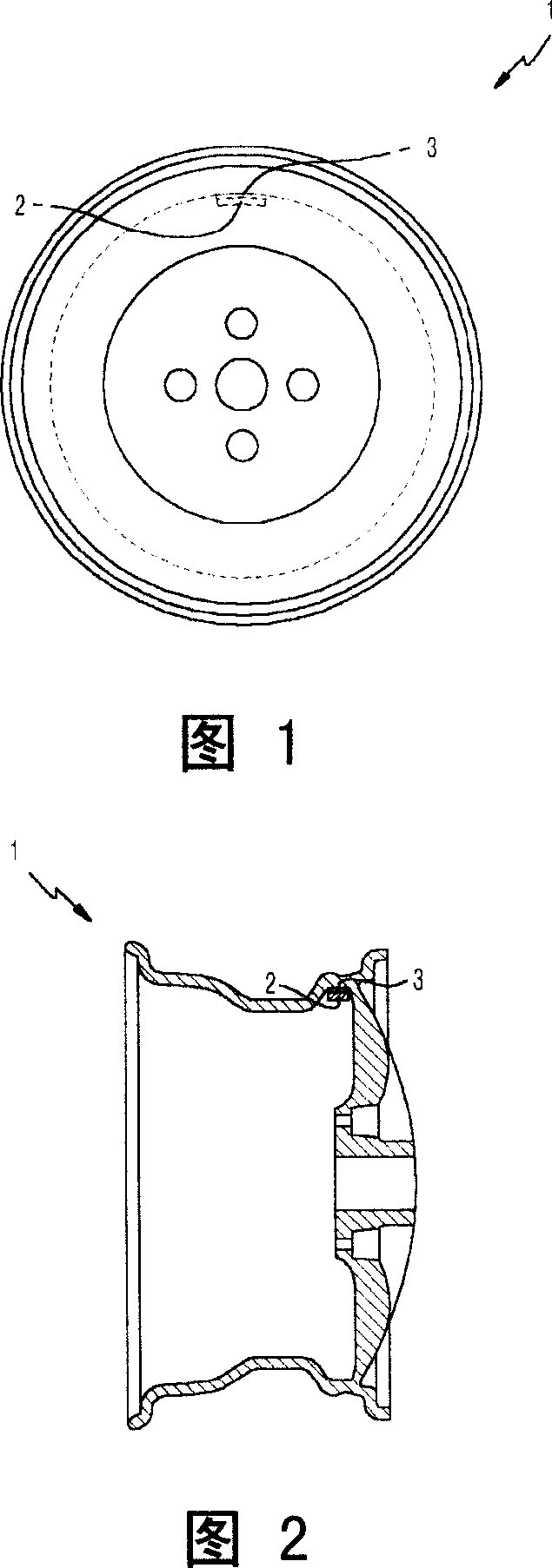

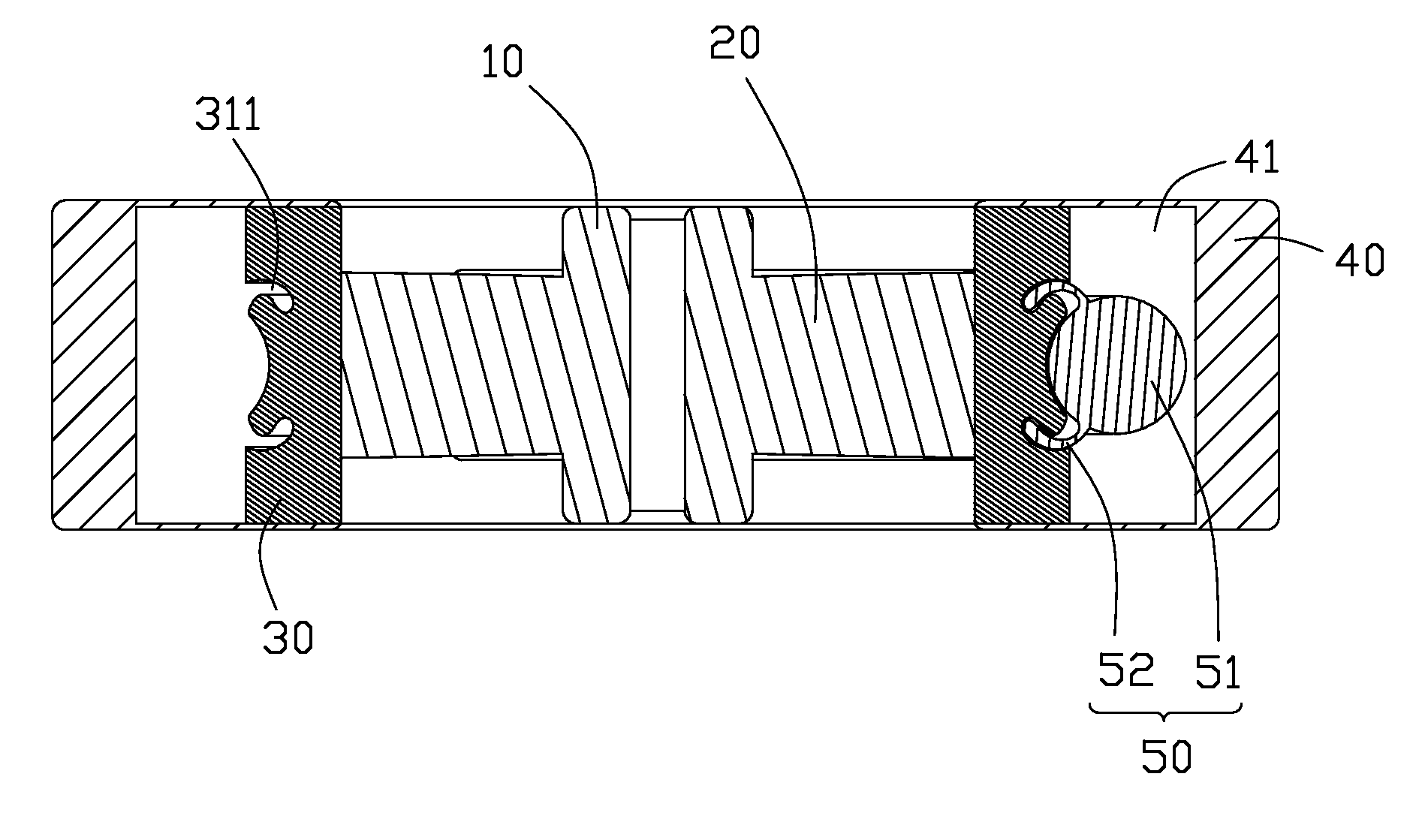

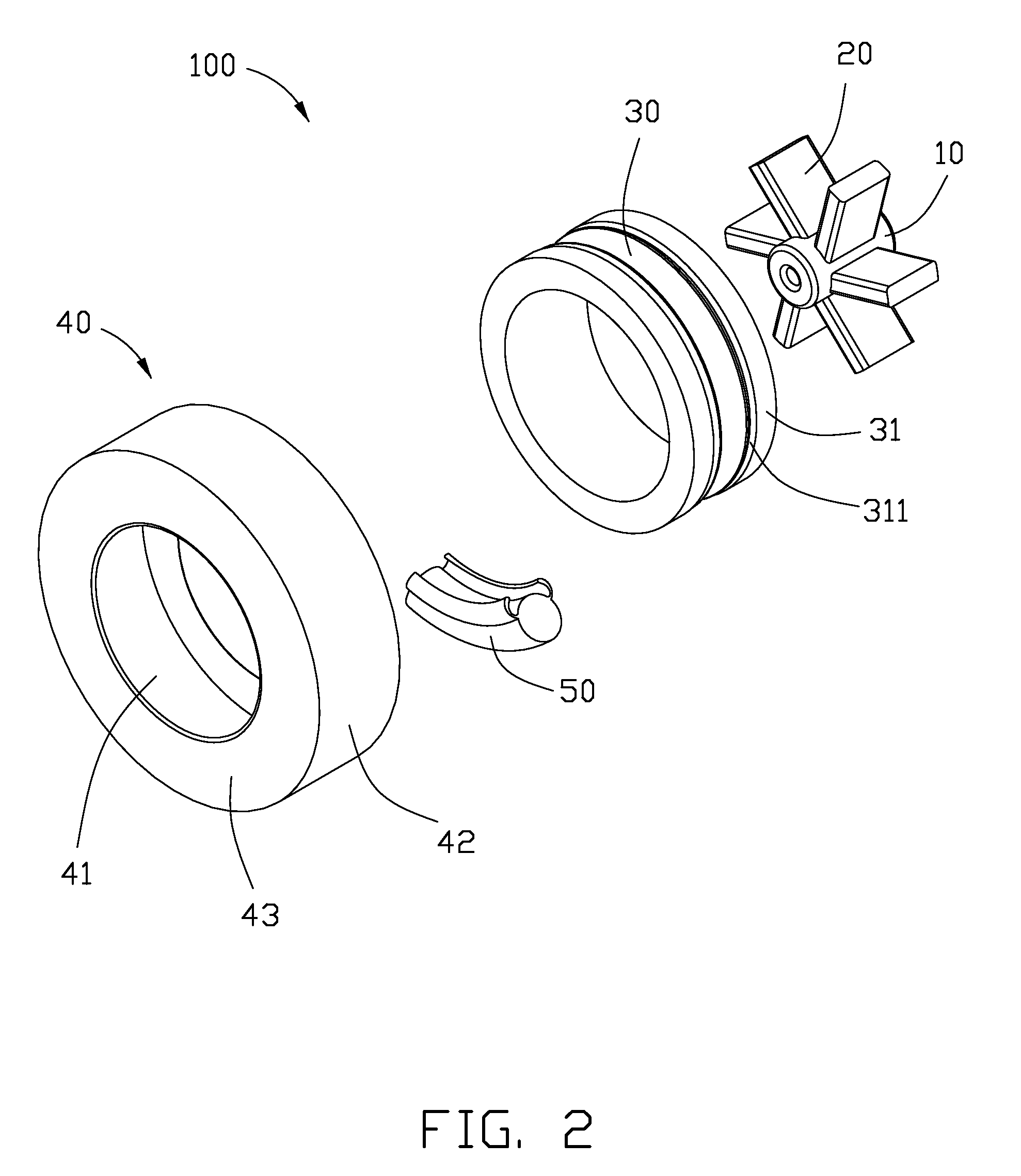

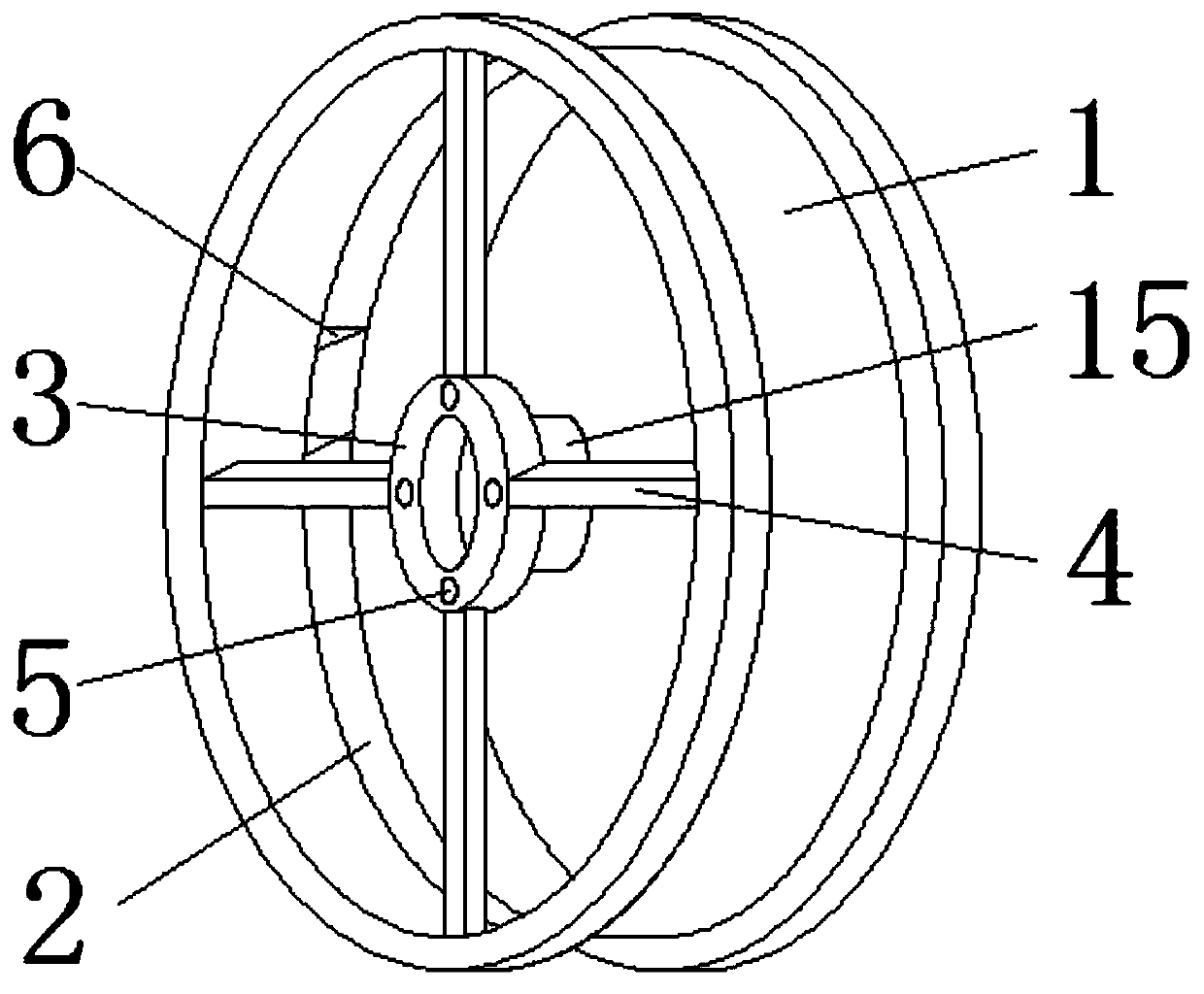

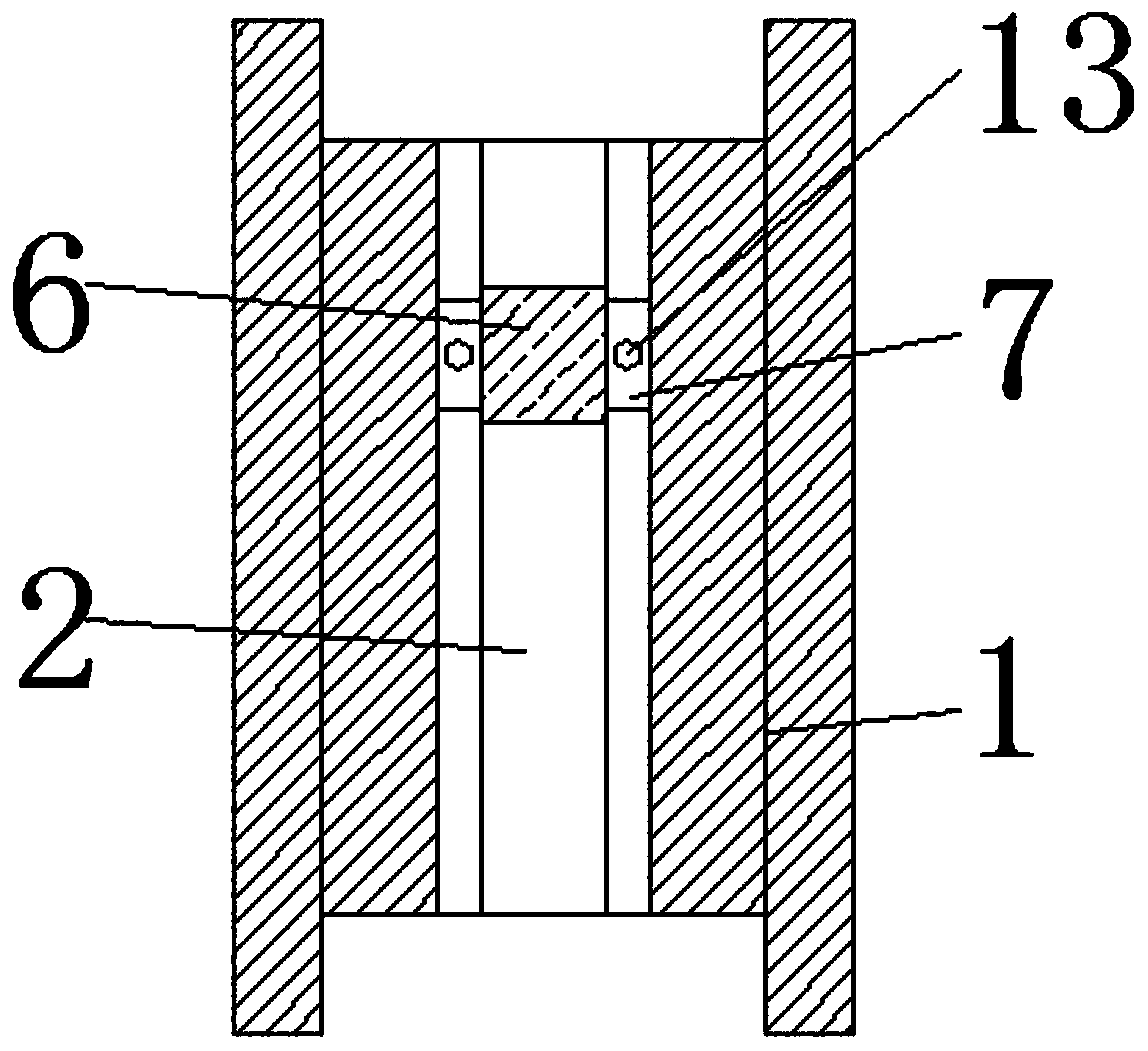

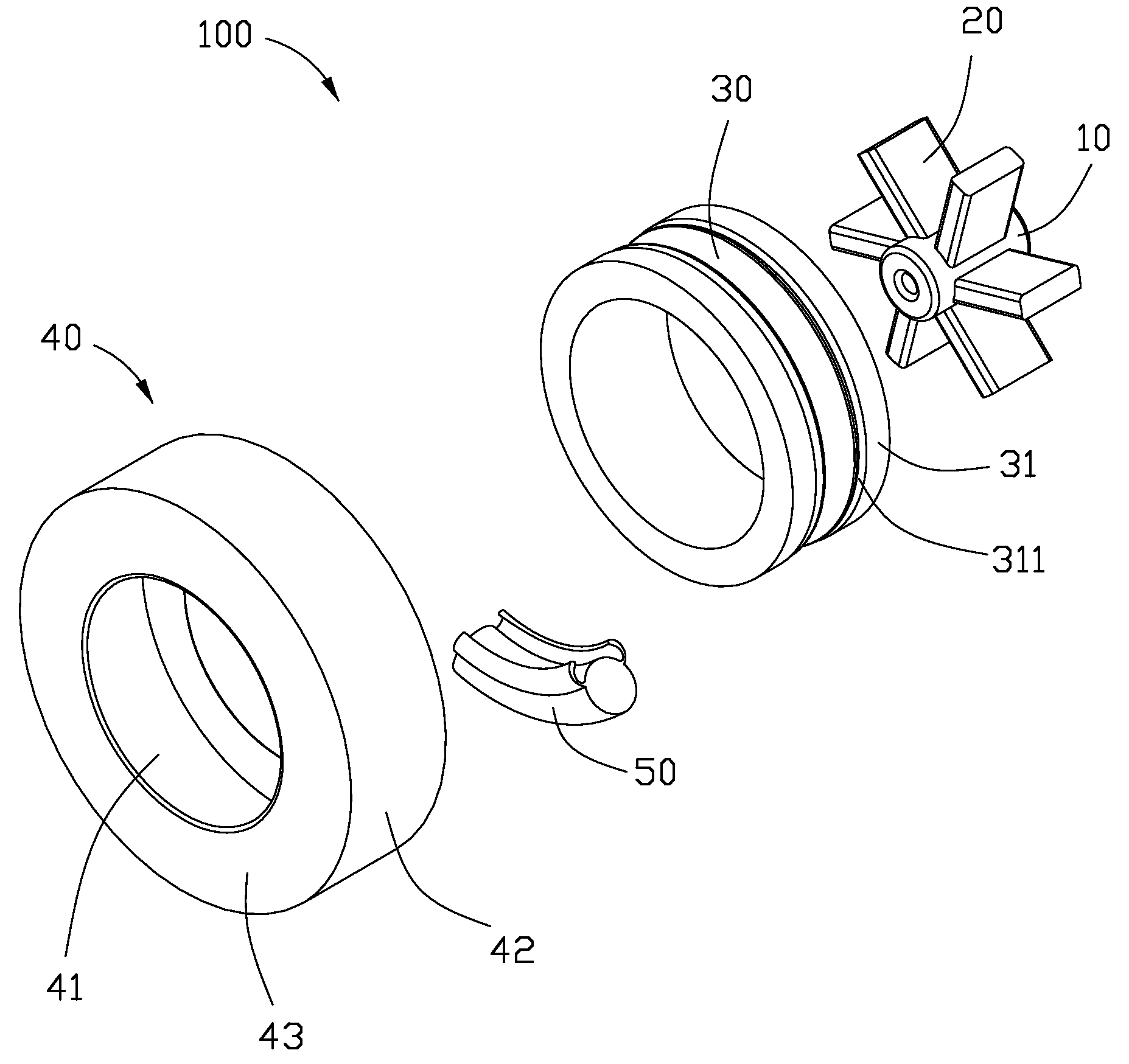

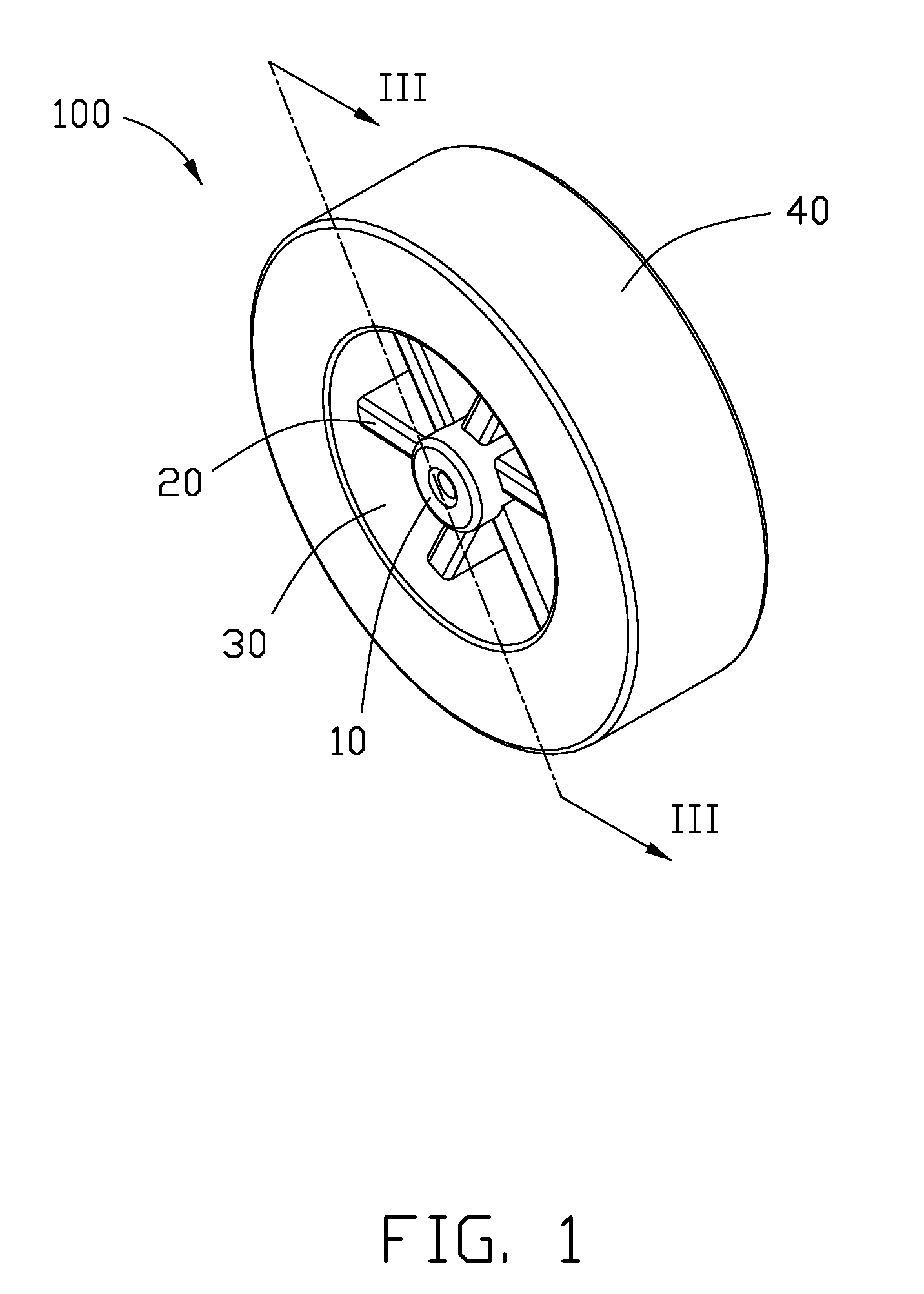

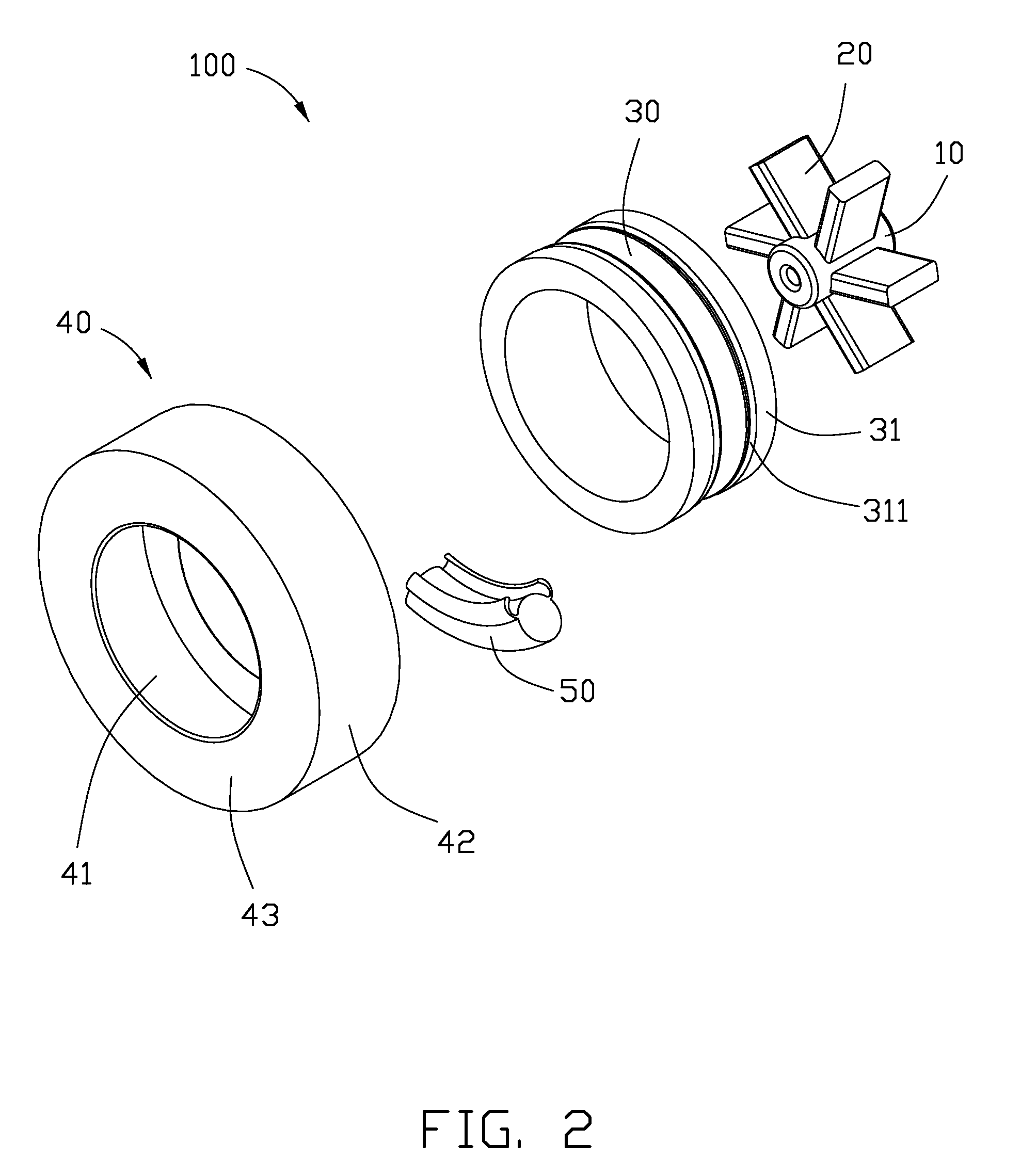

Wheel for toy vehicle

A wheel for a toy vehicle includes a rim, a tire, and a ballast. The rim includes an outer circumferential surface. The tire is attached to the outer circumferential surface of the rim. The tire and the rim cooperatively define a ring-shaped receiving channel therebetween. The ballast is received in the ring-shaped receiving channel, and slidably connected to the outer circumferential surface of the rim. The weight of the ballast is greater than the frictional force between the ballast and the rim.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

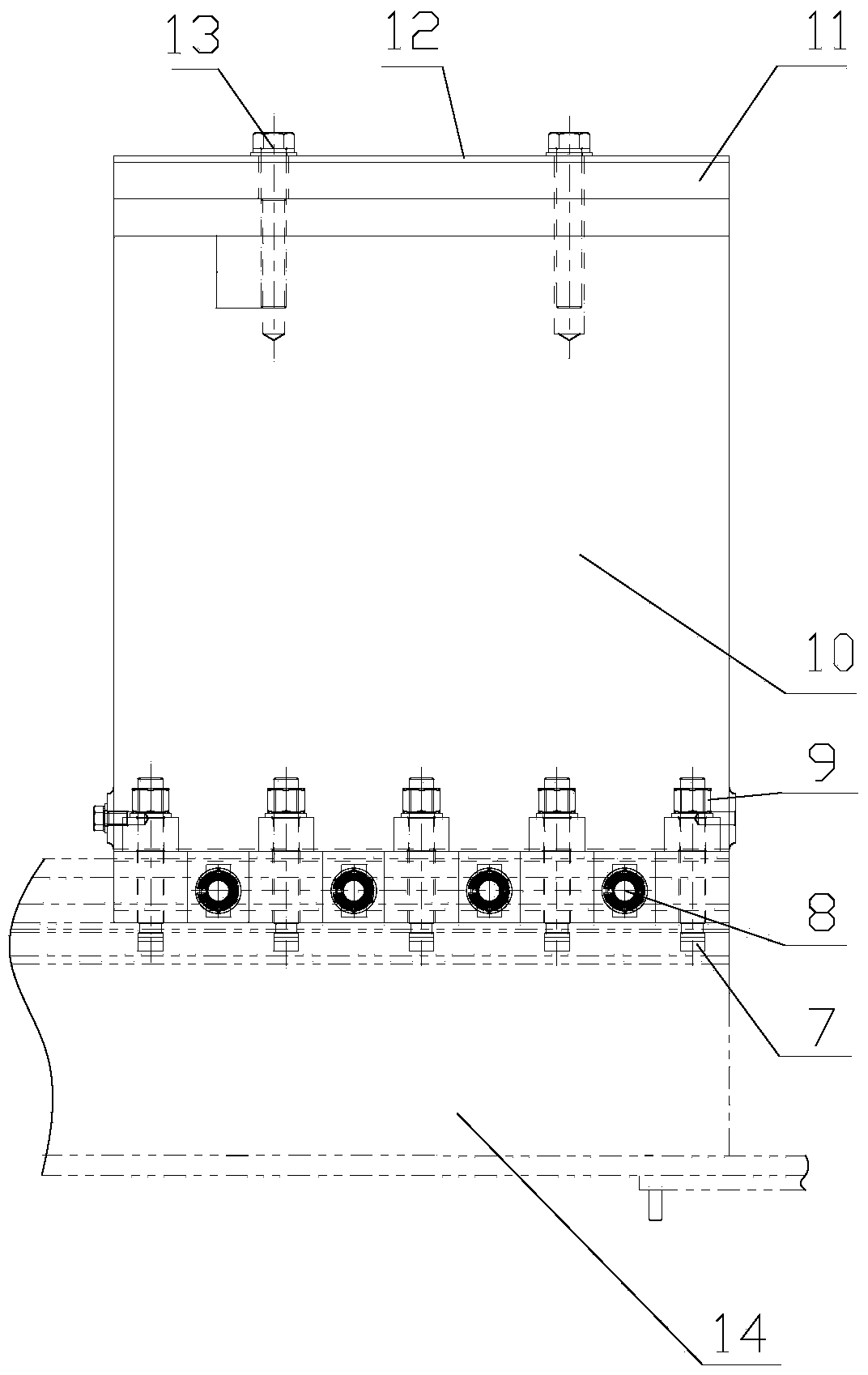

Crane cart wheel

InactiveCN103057346AReduce runoutImprove the finishWheel-ballasting weightsDynamic balanceEngineering

The invention discloses a crane cart wheel. The crane cart wheel comprises a wheel body, an axle hole, a first plane and a second plane, the first plane and the second plane are positioned on two side faces of the wheel body and are perpendicular to a central line of the axle hole, the first plane is parallel to the second plane, the wheel body is provided with a first rim, a second rim, grooves and a plurality of counterweight holes, the first rim and the second rim are positioned at the outer edge of the wheel body and arranged symmetrically, each groove is provided with two round chamfers, each of the first rim and the second rim is provided with a third plane, and each third plane is positioned on the outer plane of each of the first rim and the second rim and is perpendicular to the first plane or the second plane. The rims of the crane cart wheel are good in smoothness, excessive wear of a tire or a rolling wheel mounted together with the rims can be avoided, and accordingly service life of the tire or the rolling wheel is prolonged. The crane cart wheel is further provided with the counterweight holes capable of adjusting dynamic balance thereof, thereby being small in radial runout, good in balance and stable in operation.

Owner:CHANGSHU CITY BIXI ELEVATORING & HOISTING EQUIPMNT FACTORY

Automotive adhesion type balancing block and preparation process thereof

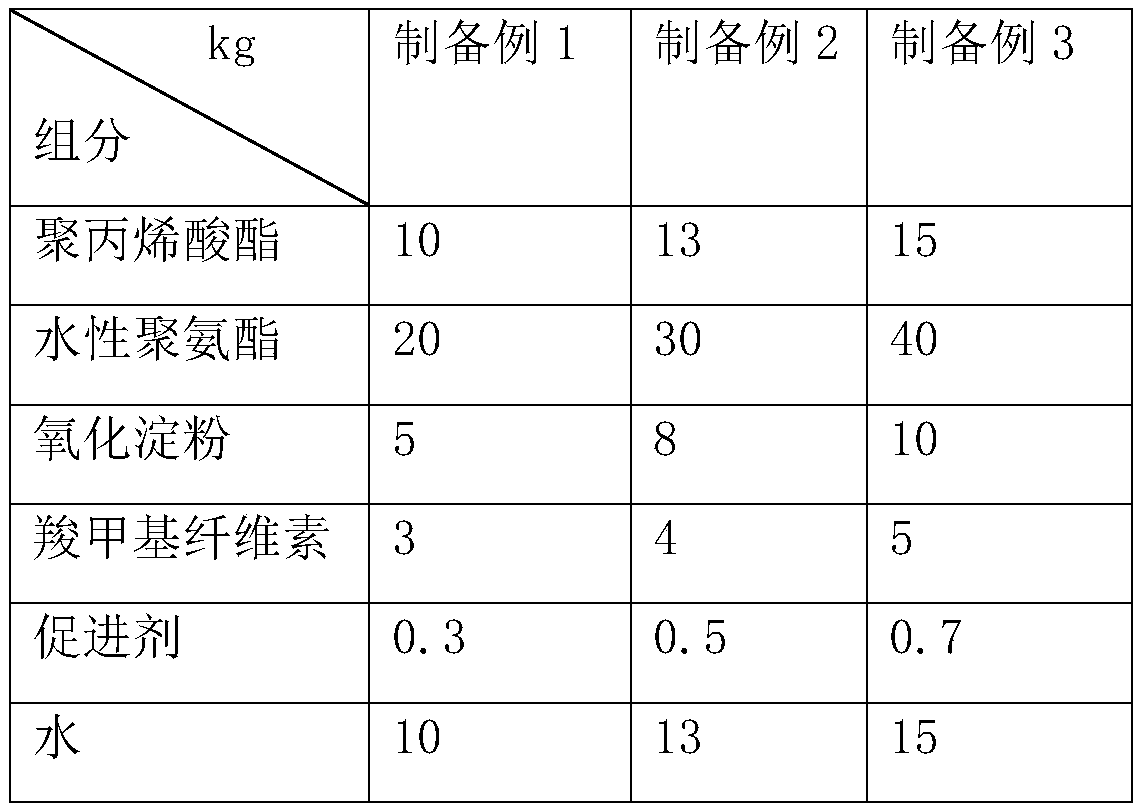

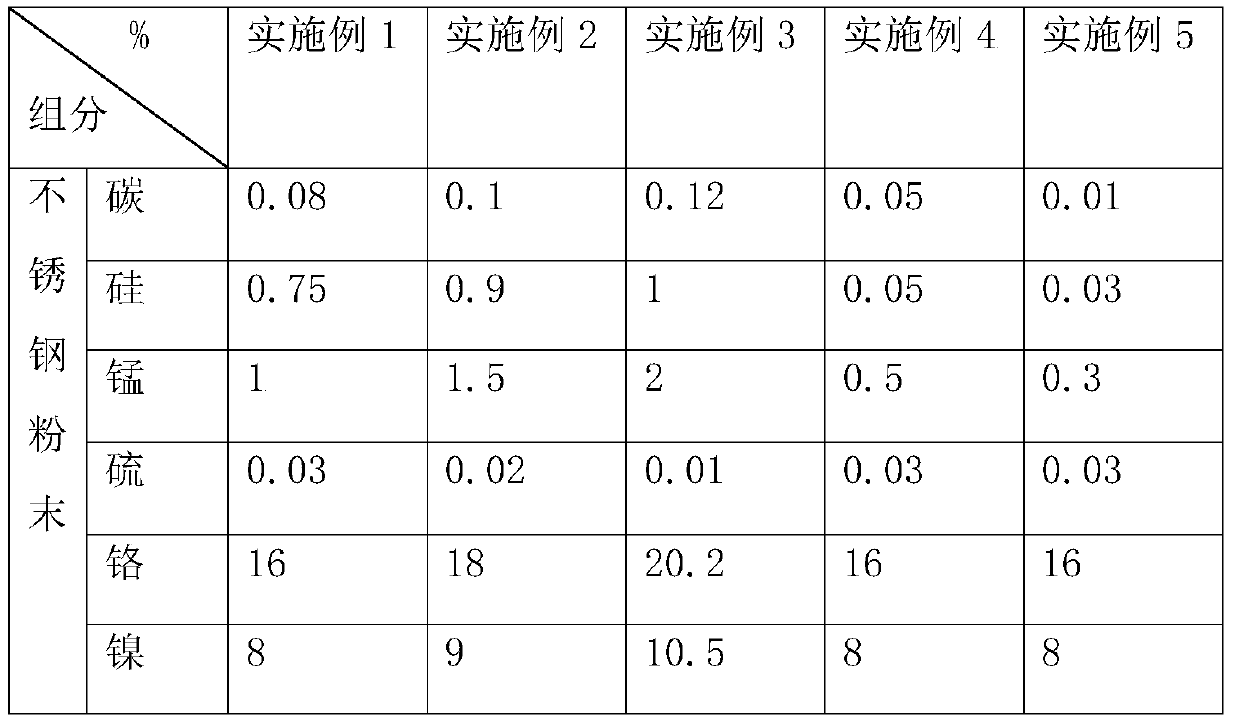

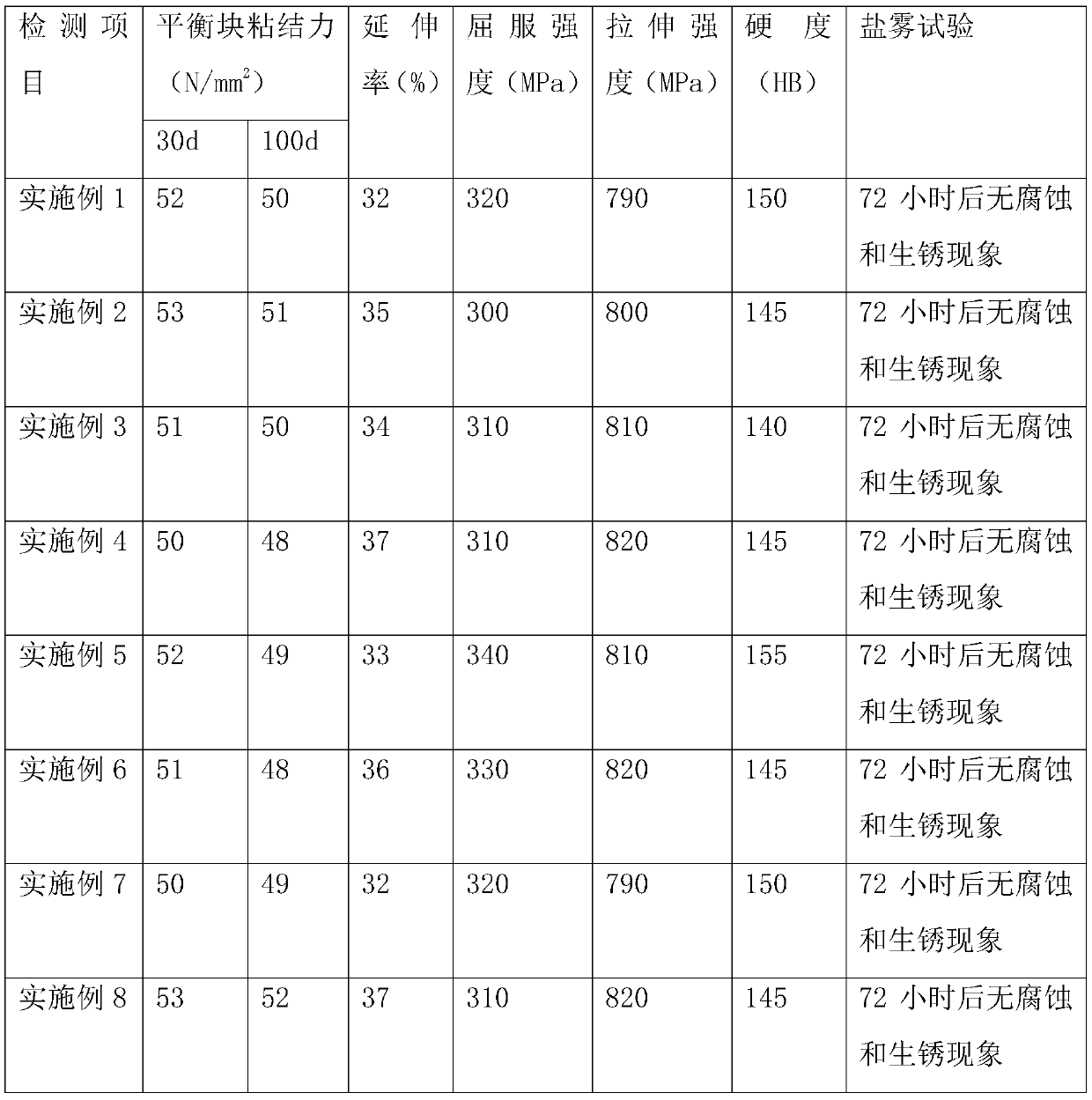

ActiveCN110682727AImprove rust resistanceGood flexibilityWheel-ballasting weightsNon-macromolecular adhesive additivesIron powderManganese

The invention discloses an automotive adhesion type balancing block and a preparation process thereof. The automotive adhesion type balancing block comprises a balancing block body, an adhesive part and release paper which are connected with one another sequentially; the balancing block body consists of stainless steel powder treated by metal powder or silicate aqueous solution, composite resin and an additive; the stainless steel powder comprises the following components in percentage by mass: less than or equal to 0.12 percent of carbon, less than or equal to 1 percent of silicon, less than2 percent of manganese, less than or equal to 0.045 percent of phosphorus, less than or equal to 0.03 percent of sulfur, 16 to 20.2 percent of chromium, 8 to 10.5 percent of nickel and the balance ofiron and unavoidable impurities; and the metal powder is prepared from mixing nickel or chromium into iron powder, the mass ratio of the iron powder to the nickel is 10:(1-2) and the mass ratio of theiron powder to the chromium is 10:(0.5-1.5). The automotive adhesion type balancing block provided by the invention has the advantages of excellent flexibility, capability of being cut into any weight, high anti-oxidation and anti-rust properties and strong and durable adhesive force.

Owner:QINGDAO CHENGYOU METAL

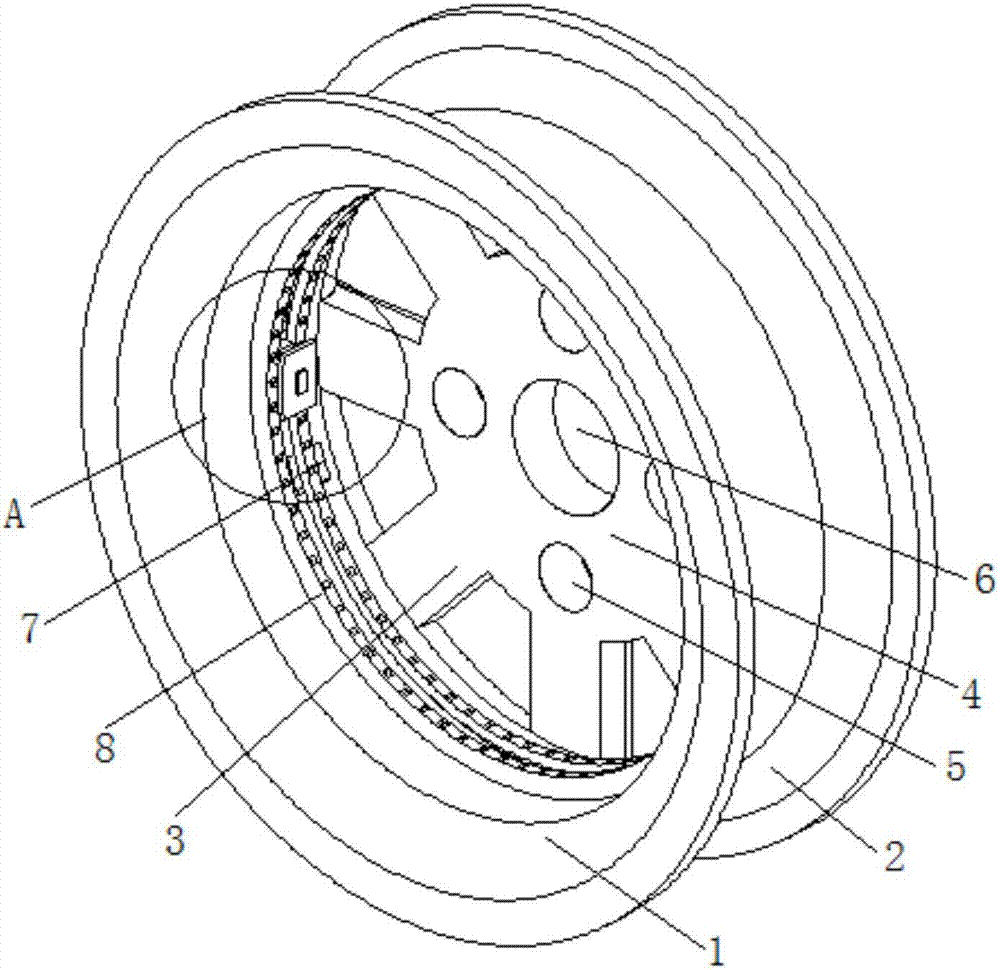

Automobile wheel and tire automatic balancing device

ActiveCN106080023AOutstanding and Beneficial Technical EffectsDoes not affect aestheticsWheel-ballasting weightsAutomotive engineering

The invention belongs to the technical field of accessories of an automobile wheel, and in particular relates to an automobile wheel and tire automatic balancing device. The device comprises a balance ring consisting of more than one arc pipe, wherein the balance ring is internally provided with an annular cavity which is internally provided with a plurality of balancing pieces. The automobile wheel and tire automatic balancing device can replace a balance weight, is a novel automobile balancing product, is simple in structure, and can keep the balance of the wheel for a long time by being placed at the middle part of the outer side of a wheel hub.

Owner:张全兴

Wheel balance weight for automobile tire

A wheel balance weight for an automobile is provided. The wheel balance weight for an automobile includes a weight holder 10 having a hook part 12 press-fitted between a rim 7 of an automobile wheel 5 and a tire bead part 9 and an arcuate gripping part 14 provided at the other end of the hook part 12, and a weight element 20 detachably gripped by an inner periphery of the gripping part 14 of the weight holder 10, wherein the gripping part 14 of the weight holder 10 has a cut-out part 14a formed at a center part thereof to a certain length in a circumferential direction thereof, and the weight element 20 has a fixing protrusion 22 projecting from an outer periphery thereof through the cut-out part 14a of the gripping part 14 to the exterior and fixedly hooked by the gripping part 14.

Owner:DONGHWATECH

Catalyzing amino-substituted organosilane ester primers

ActiveCN103827242AWheel-ballasting weightsFilm/foil adhesive primer layersPolymeric surfacePolymer science

Owner:3M INNOVATIVE PROPERTIES CO

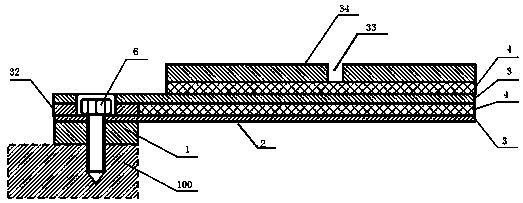

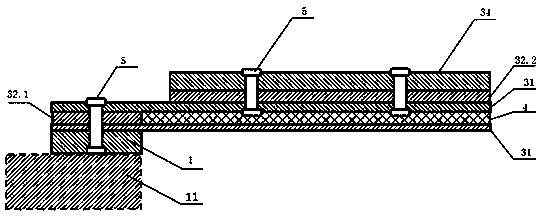

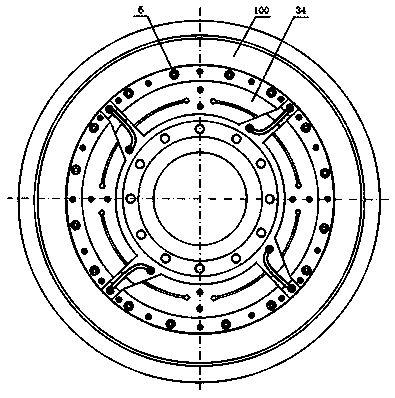

Elastic wheel noise reduction damper and assembly installation method thereof

ActiveCN110641226AReduce squealing noiseIncrease the number of resonant frequenciesWheel-ballasting weightsRail-engaging wheelsDamperVibration absorption

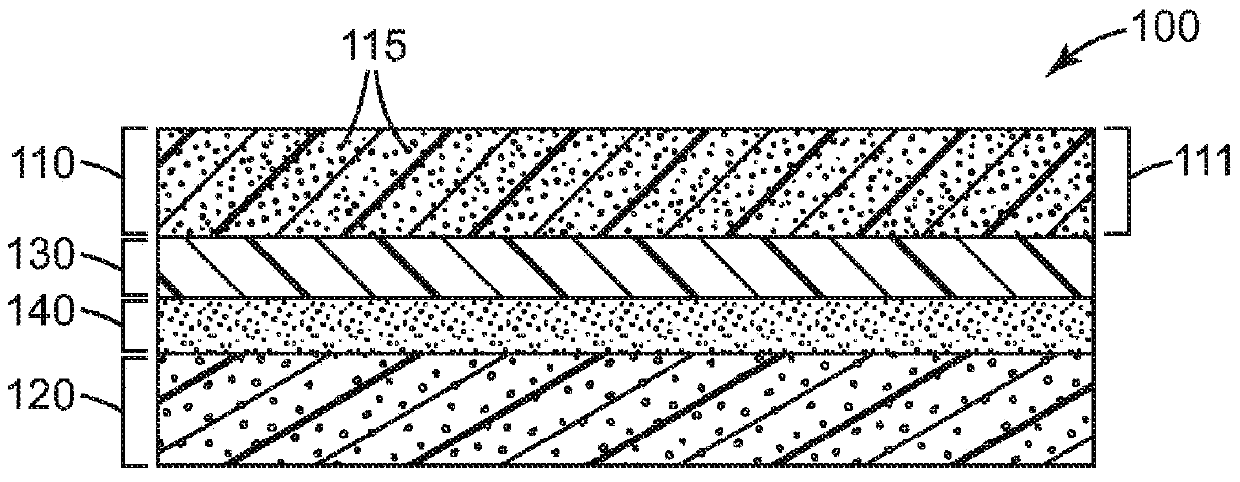

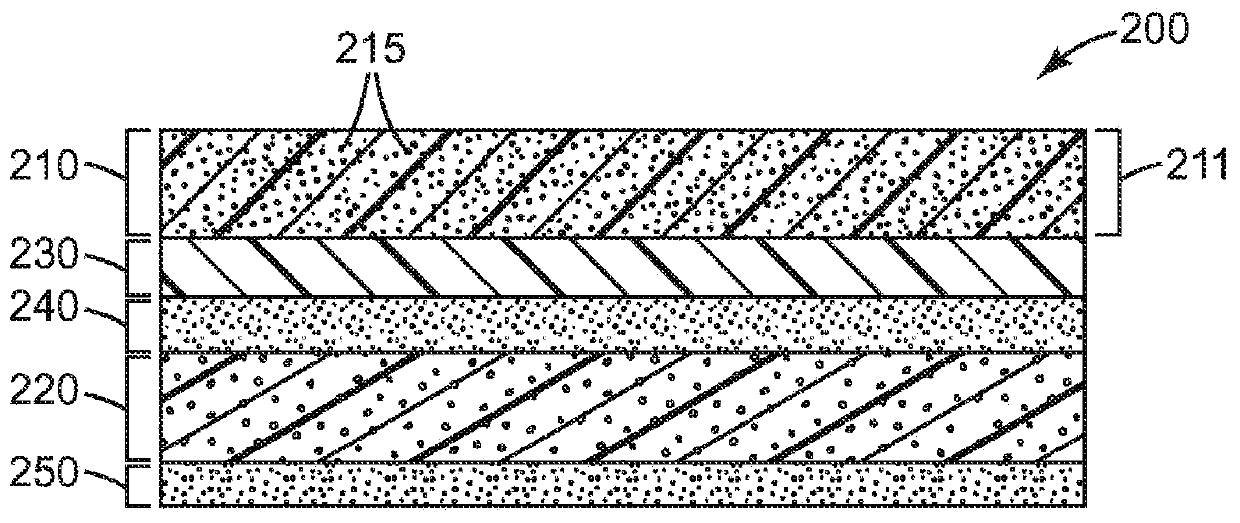

The invention discloses an elastic wheel noise reduction damper and an assembly installation method thereof. The elastic wheel noise reduction damper comprises an annular transition plate and a damperbody; and the damper body comprises sequentially laminated metal plates and rubber damping layers filled between the metal plates, the plurality of layers of metal plates are fixedly connected through rivets and are connected with the annular transition plate through rivets, and the riveting force of the rivets does not act on the rubber damping layers. According to the elastic wheel noise reduction damper and the assembly installation method thereof, most of the mass of the damper is subjected to resonance deformation sufficiently, so that the number of resonance frequencies of the damper, the vibration absorption frequency bandwidth and the energy transfer consumption efficiency are greatly improved; an integral cantilever structure of the damper and a plurality of independent cantilever resonance branches formed on a slotted plate can generate different resonance characteristics, so that the number of resonance frequencies is improved; and the matching design can be carried out onthe axial modal frequency of a wheel rim of the elastic wheel, the squeal noise generated when the elastic wheel passes through a small curve road section is effectively reduced, and the noise reduction reliability and the durability are conveniently improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

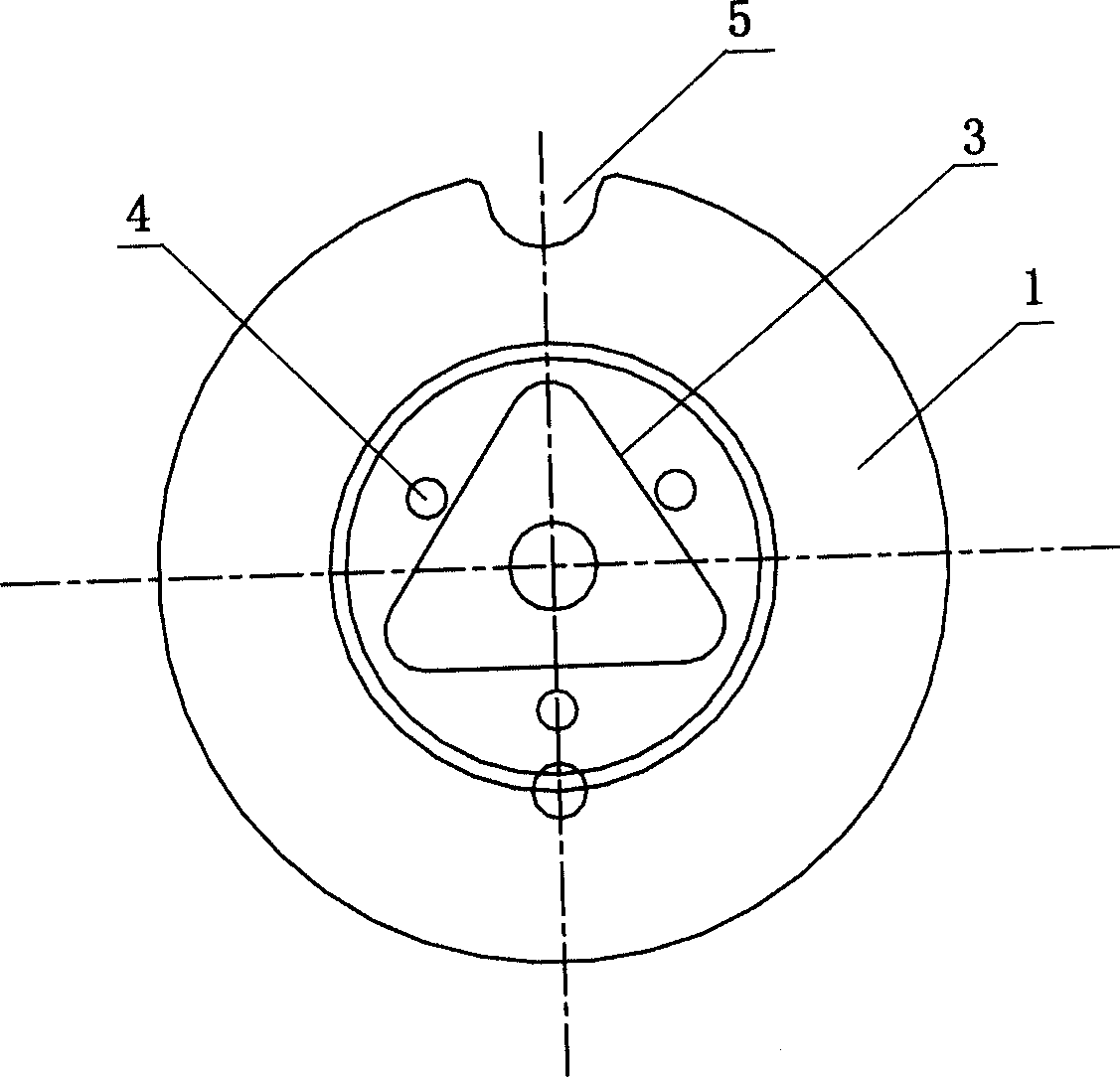

Plastic-steel counterweight

InactiveCN1621249ANovel selection of materialsGood formability of counterweightWheel-ballasting weightsMechanical engineeringHot pressing

The present invention is novel plastic-steel balance weight and its making process. The plastic-steel balance weight has 160 mm thickness, right side shape like a snail, back side with equilateral triangle notch in the center, homogeneously distributed installing holes and inflating notch in the edge. The plastic-steel balance weight is made with plastic and heavy material and through hot pressing. The present invention has the advantages of simple making process, low production cost, high durance, no environmental pollution, etc.

Owner:杨根有

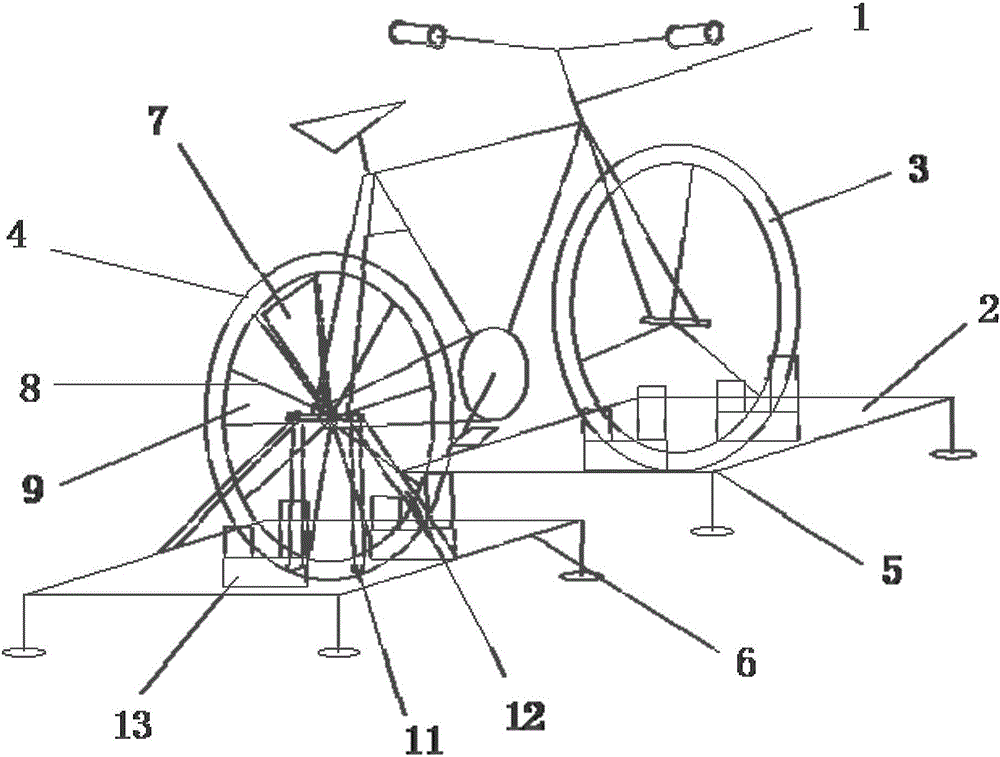

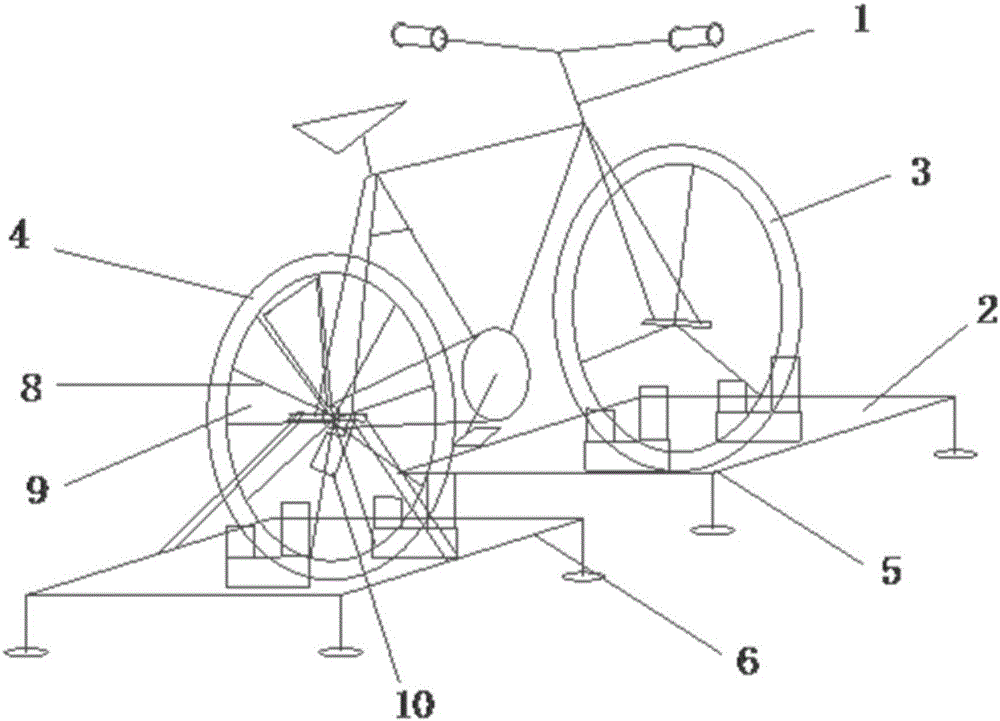

Electric bicycle suitable for indoor exercises

InactiveCN105999674ARealize the effect of indoor exerciseEasy to disassembleWheel-ballasting weightsSport apparatusMechanical engineeringElectric bicycle

The invention provides an electric bicycle suitable for indoor exercises. The electric bicycle comprises a bicycle body and fixing devices, wherein the bicycle body comprises a front wheel and a rear wheel; the fixing devices include a front wheel fixing device and a rear wheel fixing device; the front wheel fixing device is used for fixing the front wheel; and the rear wheel fixing device is used for fixing the rear wheel. The electric bicycle comprises more than one balancing weight; and the balancing weights are detachably fixed to the rear wheel. The rear wheel comprises steel rims; a hollow groove is reserved between every two adjacent steel rims; and the balancing weights are fixed to the corresponding hollow groove. The balancing weights and the corresponding hollow grooves are matched; a through hole is formed in the middle of each balancing weight; and the through holes in the balancing weights on two sides of the hollow grooves are fixed by virtue of bolts.

Owner:JIANGSU PAVEL ELECTRIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com