Adjustable Weighted Wheel Assembly

a wheel assembly and weight technology, applied in the direction of wheel ballasting weights, vehicle components, toys, etc., can solve the problems of difficult to change the number or type of weights, time-consuming and laborious process, and often crudely attached to the rim, so as to prevent the weight from dislodging, maintain the weight, and prevent the effect of weight dislodging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The invention is described in more detail hereinafter with reference to exemplary embodiments. In the figures, for the sake of clarity, the same reference numerals are used for similar components in different embodiments.

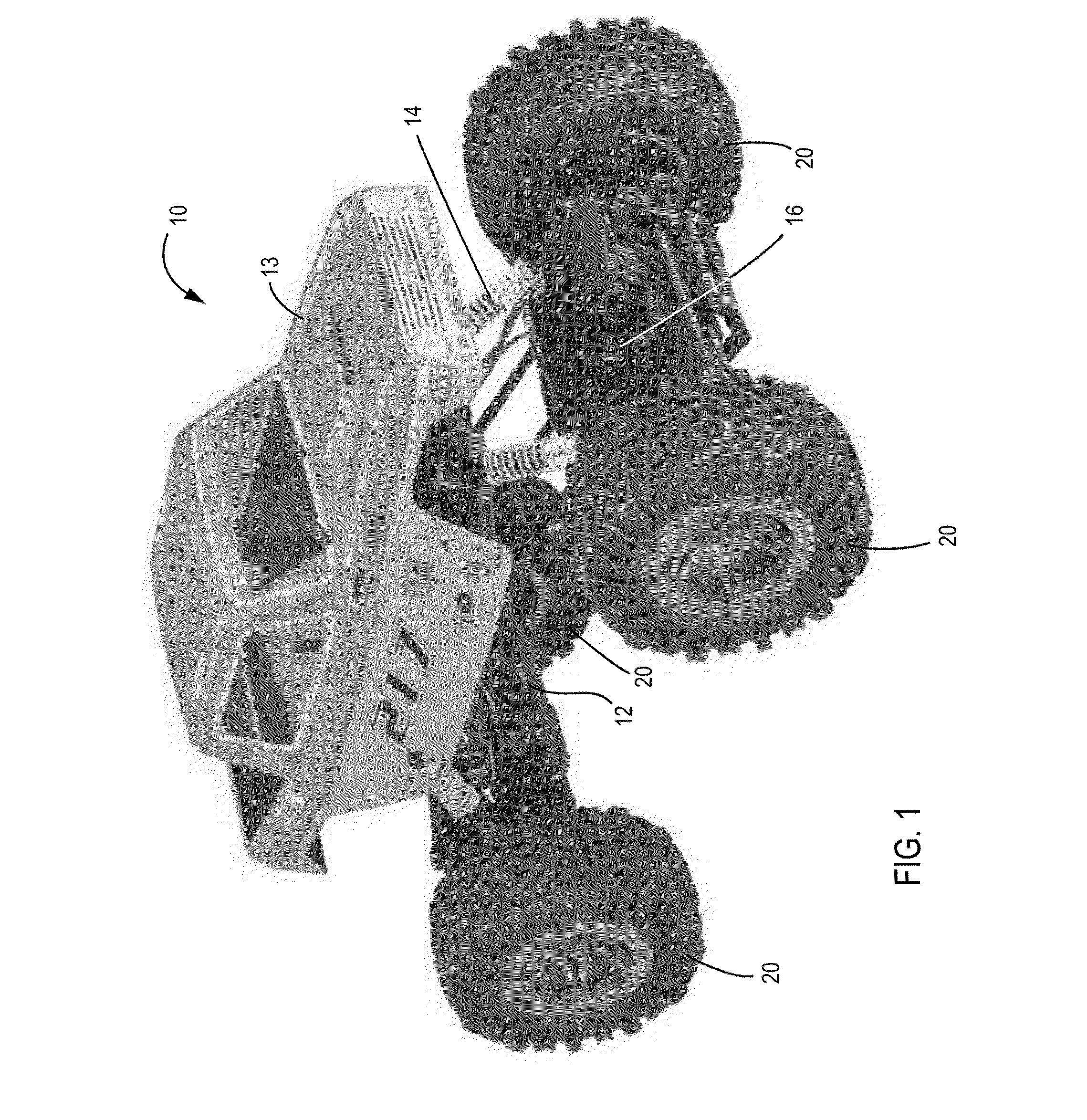

[0023]Referring to FIG. 1, a radio controlled model vehicle 10 is shown according to an exemplary embodiment. The vehicle 10 is configured to be controlled via radio waves from a handheld controller. The vehicle 10 preferably comprises a substantially chassis or frame 12. An aerodynamically shaped shell or body 13. The body 13 may include a multitude of vehicular detailing. The detailing may be three dimensional merely surface ornamentation or indicia. Such detailing may be functional or may simply simulate similar functional elements on larger vehicles.

[0024]The frame 12 is coupled to a multitude of wheels 20 (generally four) with a suspension 14. According to one embodiment, each of the wheels 20 has a suspension 14. One or more motors 16 provide power to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com