Radiating device and speed regulator with same

A technology of heat sink and governor, which is applied in the modification of power electronics, cooling/ventilation/heating transformation, etc., can solve the problem of large plane area of flat-panel radiator, simplify the process, reduce the volume, and facilitate disassembly and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

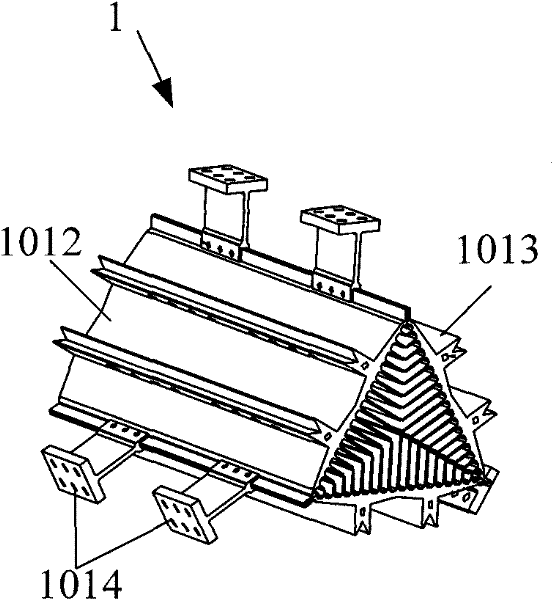

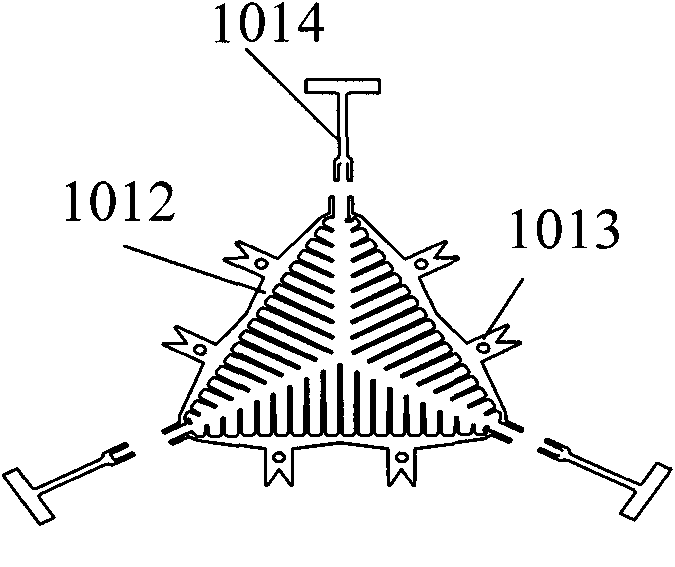

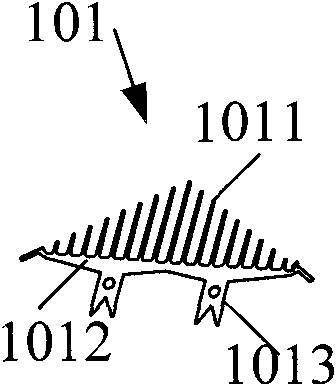

[0038] Figure 1 to Figure 6 As shown, it is an embodiment of a heat dissipation device 1 with a triangular ventilation section provided by the present invention. The heat dissipation device 1 is assembled from three identical heat dissipation units 101 , and the heat dissipation device 1 is in the shape of a triangular prism. The heat dissipation plate 1012 of each heat dissipation unit 101 forms each facet of the triangular prism, and the plurality of heat dissipation ribs 1011 on the heat dissipation unit 101 are ridge-shaped protrusions, and the lengths are orderly, and the heat dissipation ribs 1011 distributed on the three heat dissipation units 101 are The alternate butt joints form a heat dissipation layer for the heat dissipation device 1 to dissipate heat from inside to outside.

[0039] In order to install and fix the heat dissipation device 1 on the circuit board 2 , two bone positions 1013 are arranged at intervals on each heat dissipation plate 1012 of the heat ...

Embodiment 2

[0041] Based on the heat dissipation device of Embodiment 1, the present invention also provides the following governor.

[0042] Such as figure 1 with Image 6 As shown, the three circuit boards 2 of the governor are electrically connected to each other, and are fixedly connected to the heat dissipation device 1 through the bone 1013 on the heat dissipation plate 1012 of each heat dissipation unit 101 . The governor is provided with a power input terminal 8 and three power output terminals 9 , and a plurality of electronic components, such as heating power devices 201 , are arranged on the circuit board 2 .

[0043] The heating power device can be a MOSFET tube (Metal-Oxide-Semiconductor Field-Effect Transistor, Metal-Oxide-Semiconductor-Field-Effect Transistor, referred to as Metal-Oxide-Semiconductor Field-Effect Transistor). Nearly thirty-two MOSFET tubes and six capacitors are arranged on each circuit board 2 in this embodiment. Every two circuit boards 2 are electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com