Patents

Literature

207results about How to "Increase the area ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

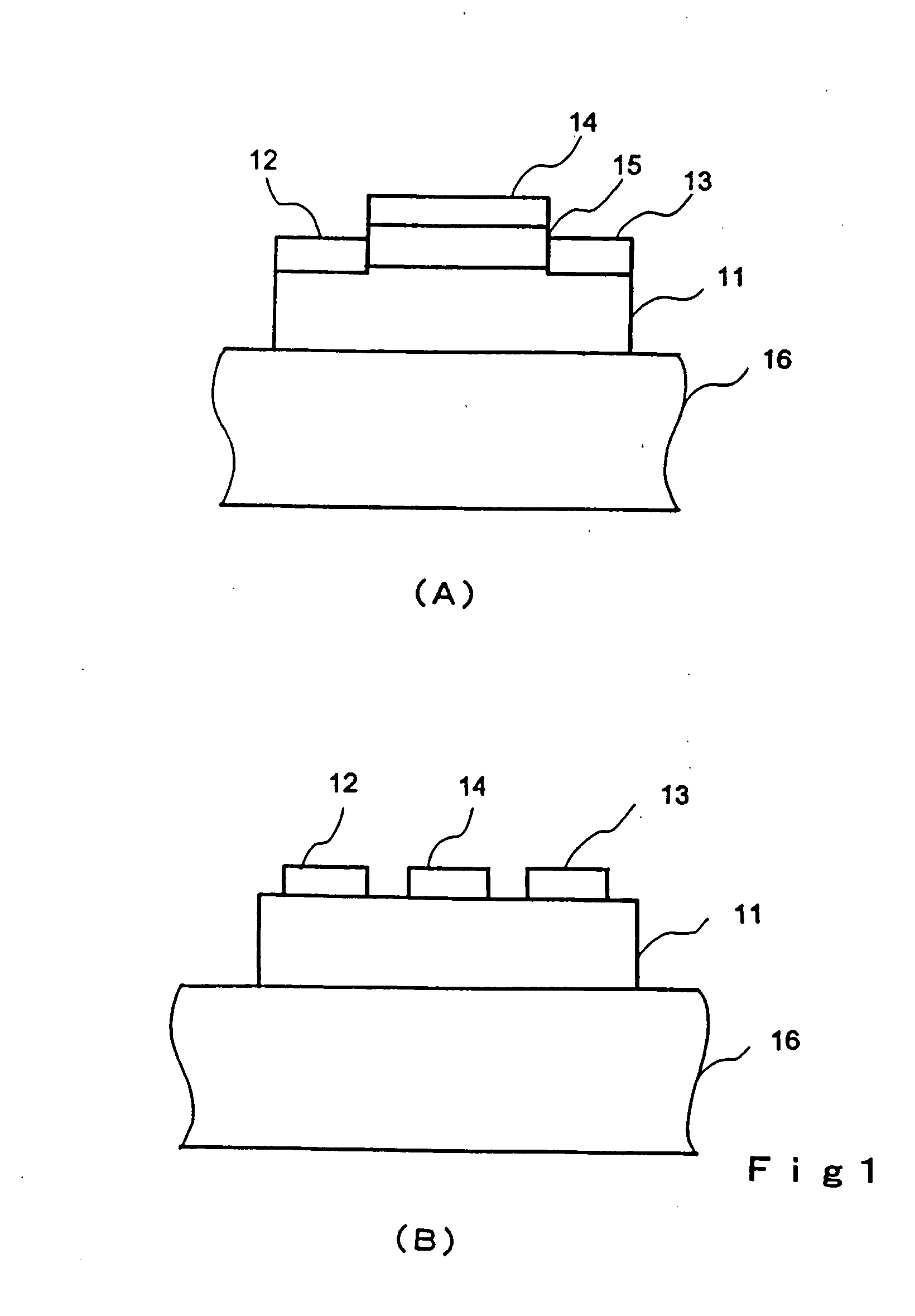

Transistor and semiconductor device

InactiveUS20050127380A1Increase brightnessIncrease ratingsTransistorLaser detailsDevice materialConductive materials

Owner:JAPAN SCI & TECH CORP

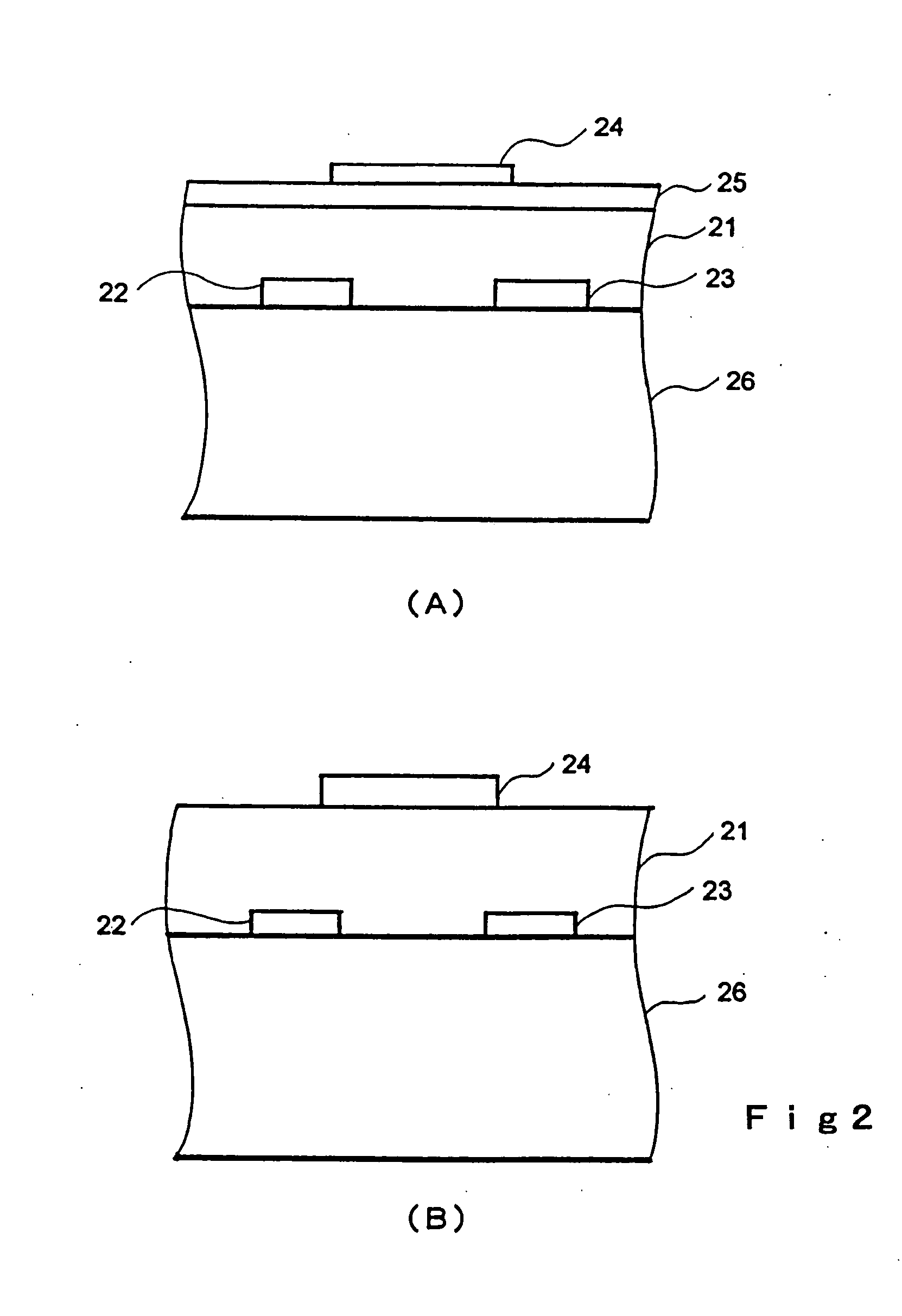

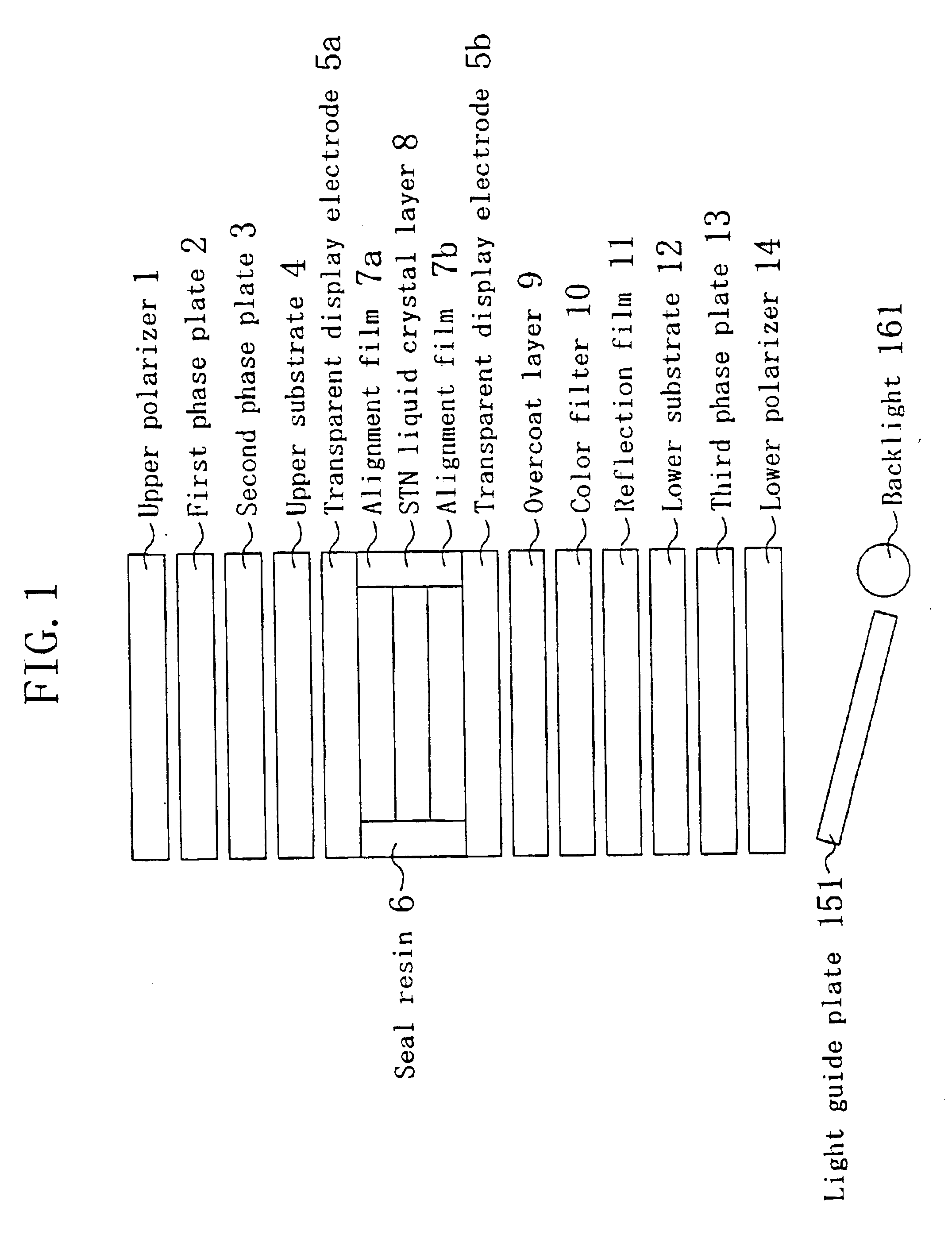

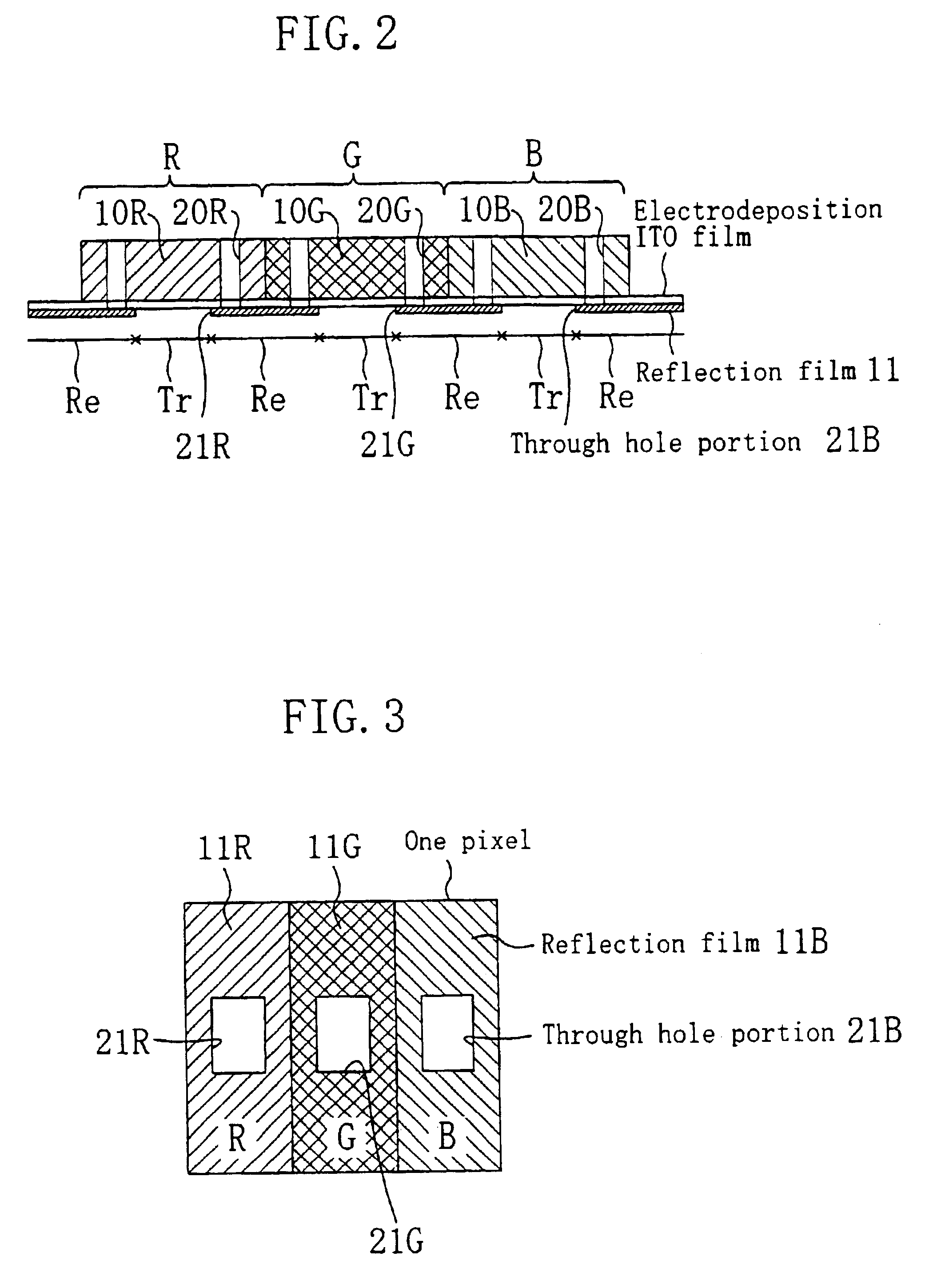

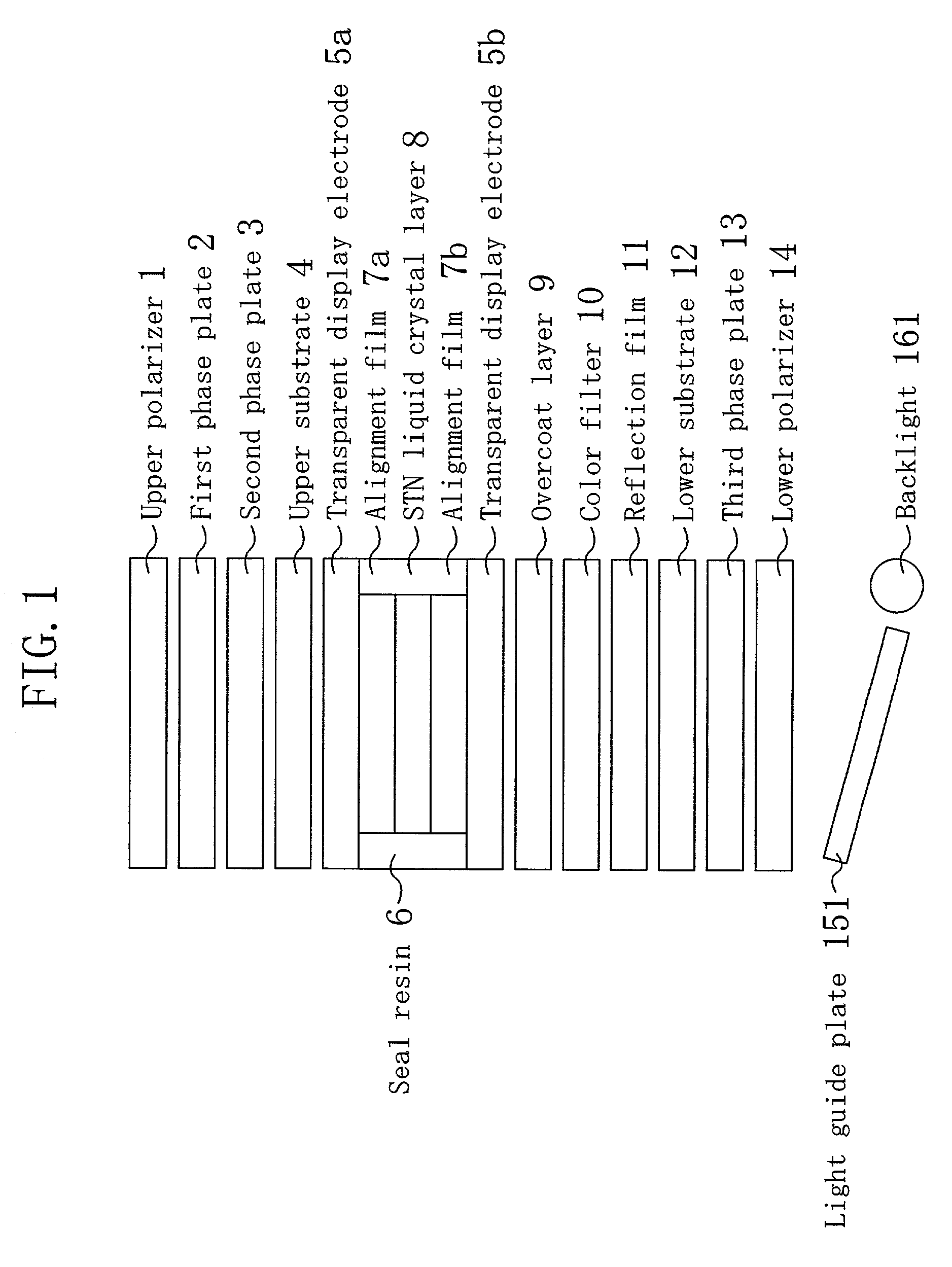

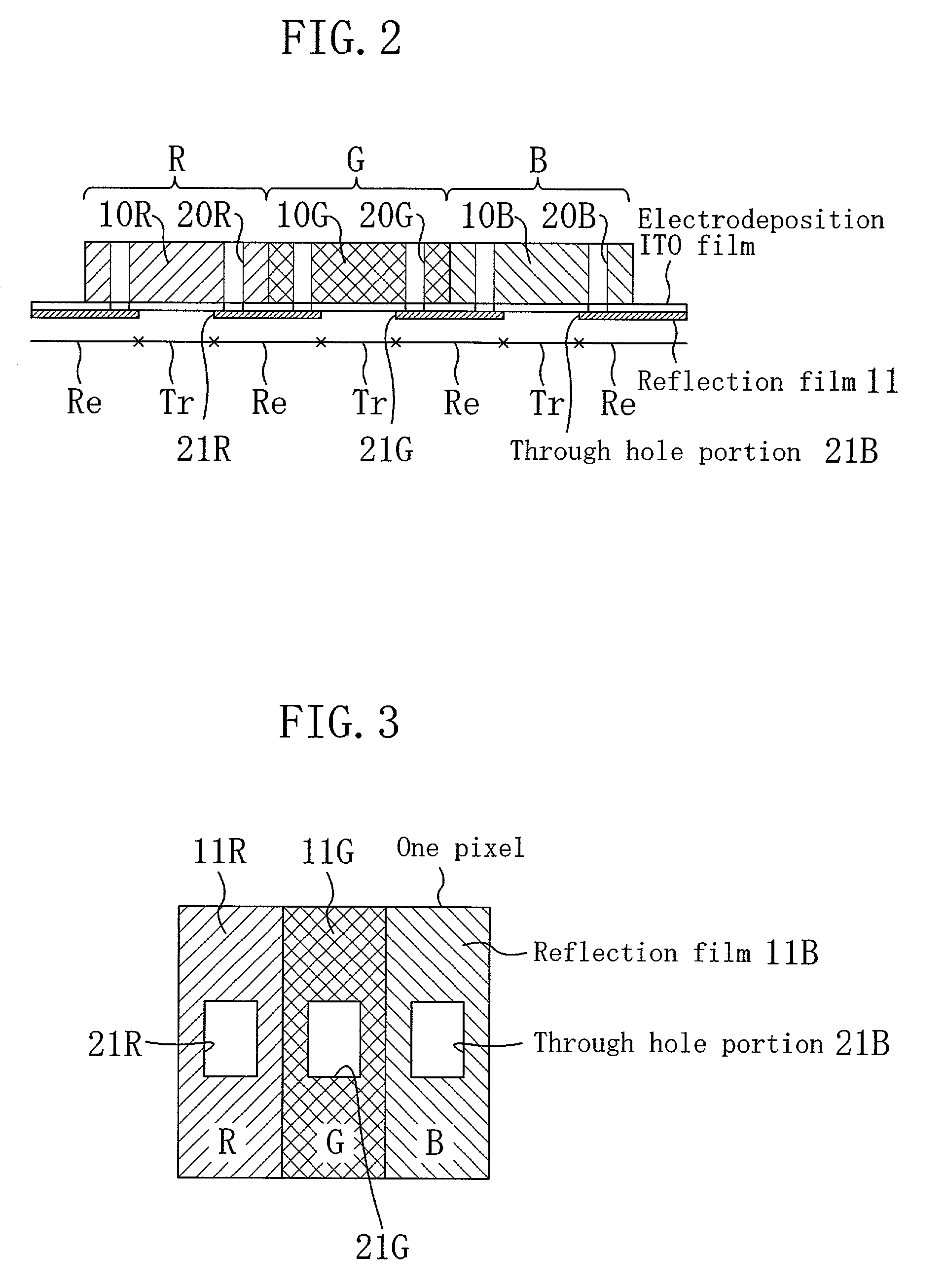

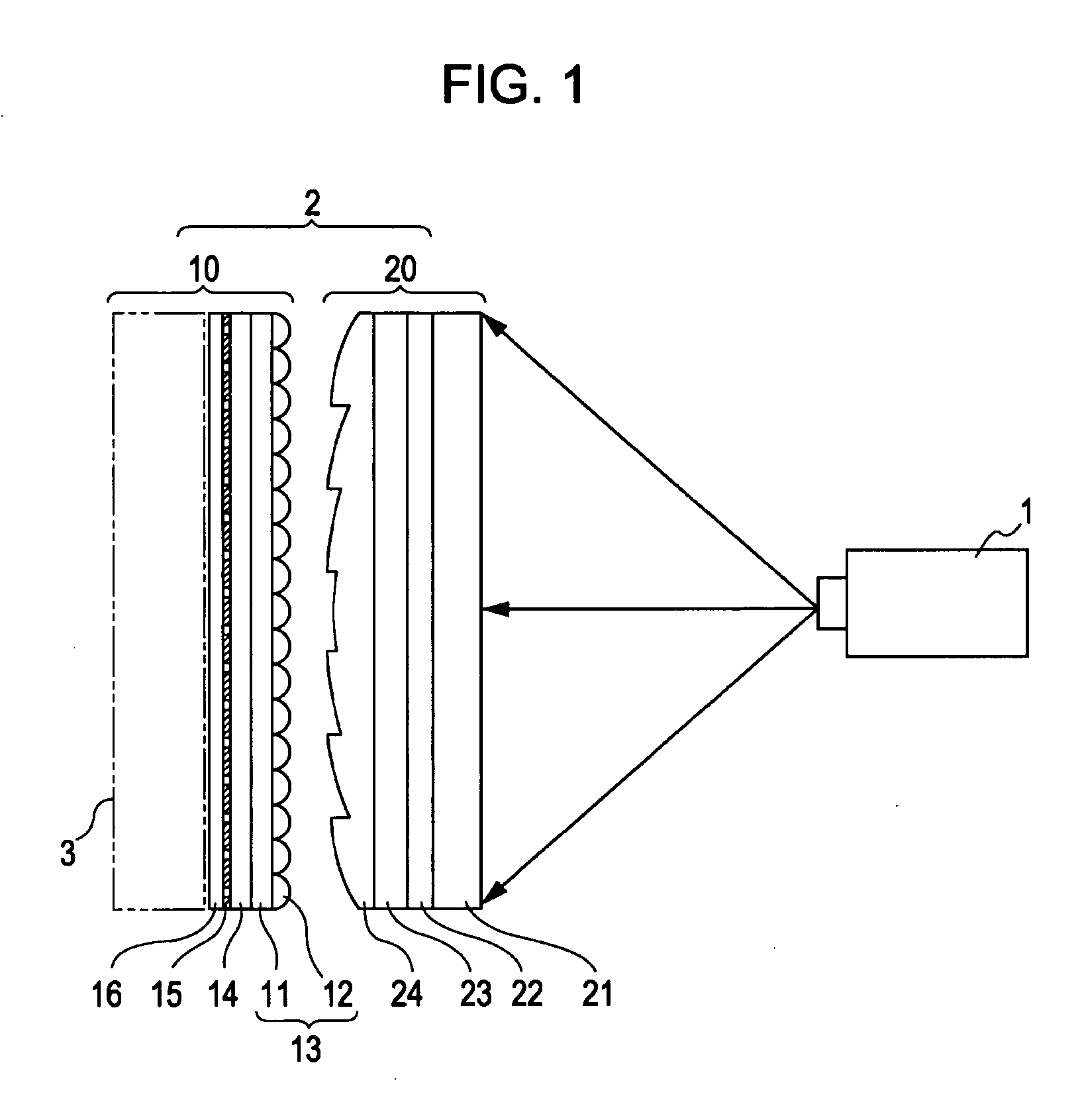

Transmission/reflection type color liquid crystal display device

InactiveUS6885418B2High color purityDisplay brightNon-linear opticsLiquid-crystal displayMatrix pattern

A liquid crystal display device, including: a first substrate; a second substrate; opposing the first substrate; a liquid crystal layer interposed between the first substrate and the second substrate; a reflection film formed on one side of the second substrate that is closer to the liquid crystal layer; and a color filter formed on the reflection film, wherein: a plurality of pixel regions are arranged in a matrix pattern, each of the pixel regions including a reflection region where light coming from the first substrate side is reflected by the reflection film back to the first substrate side, and a transmission region where light coming from the second substrate side is transmitted to the first substrate side; and the color filter includes an opening in the reflection region.

Owner:SHARP KK

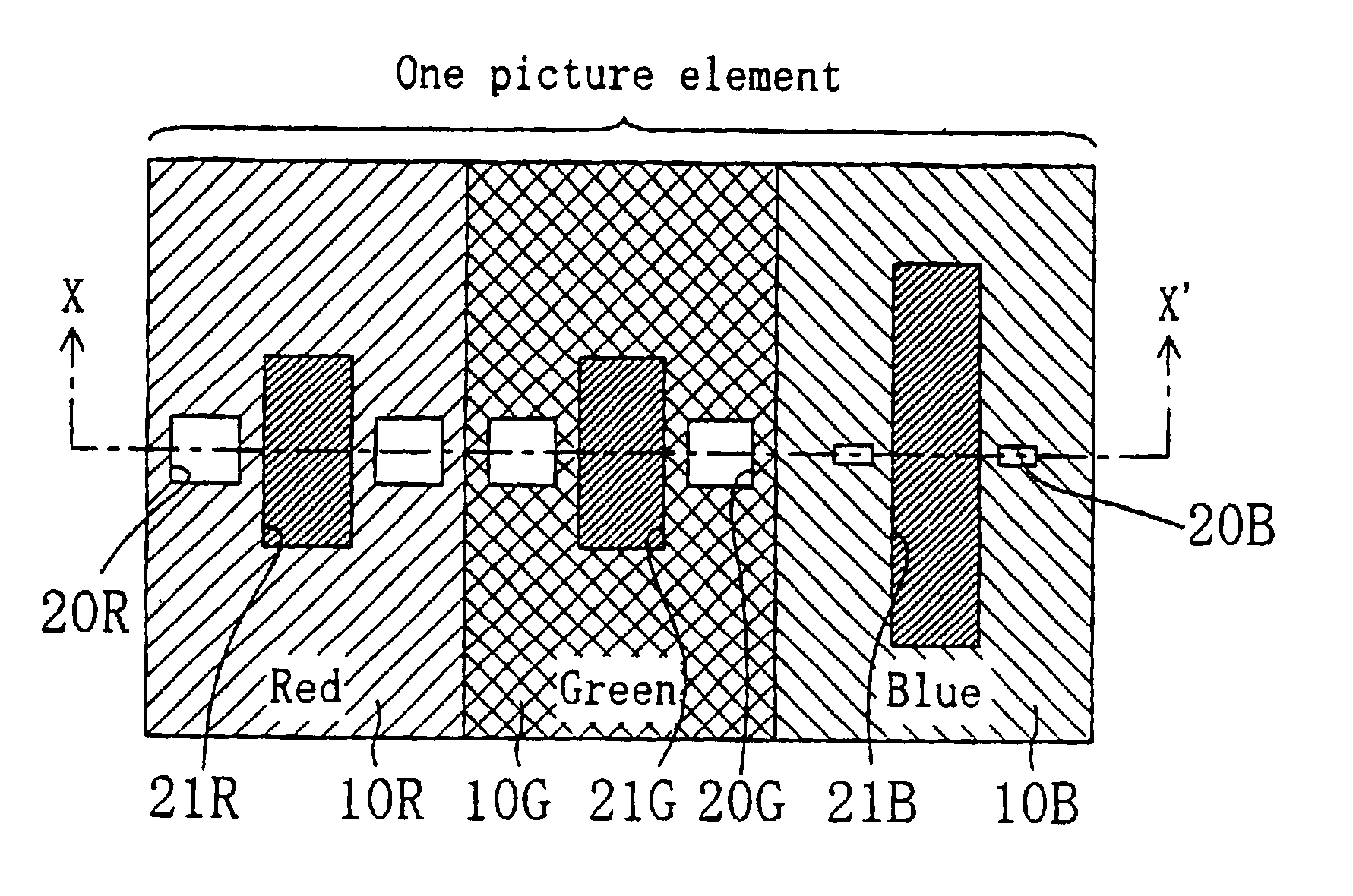

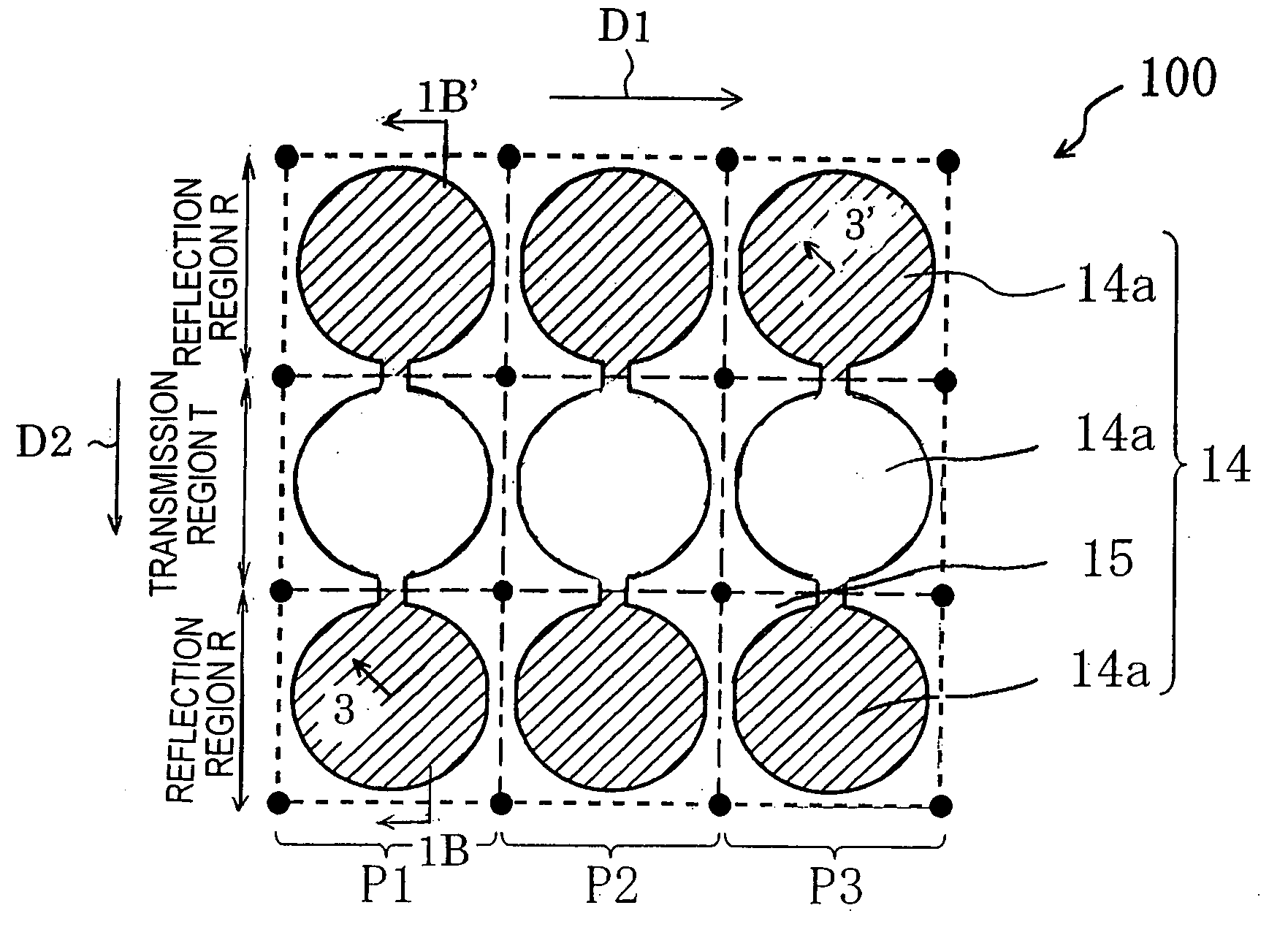

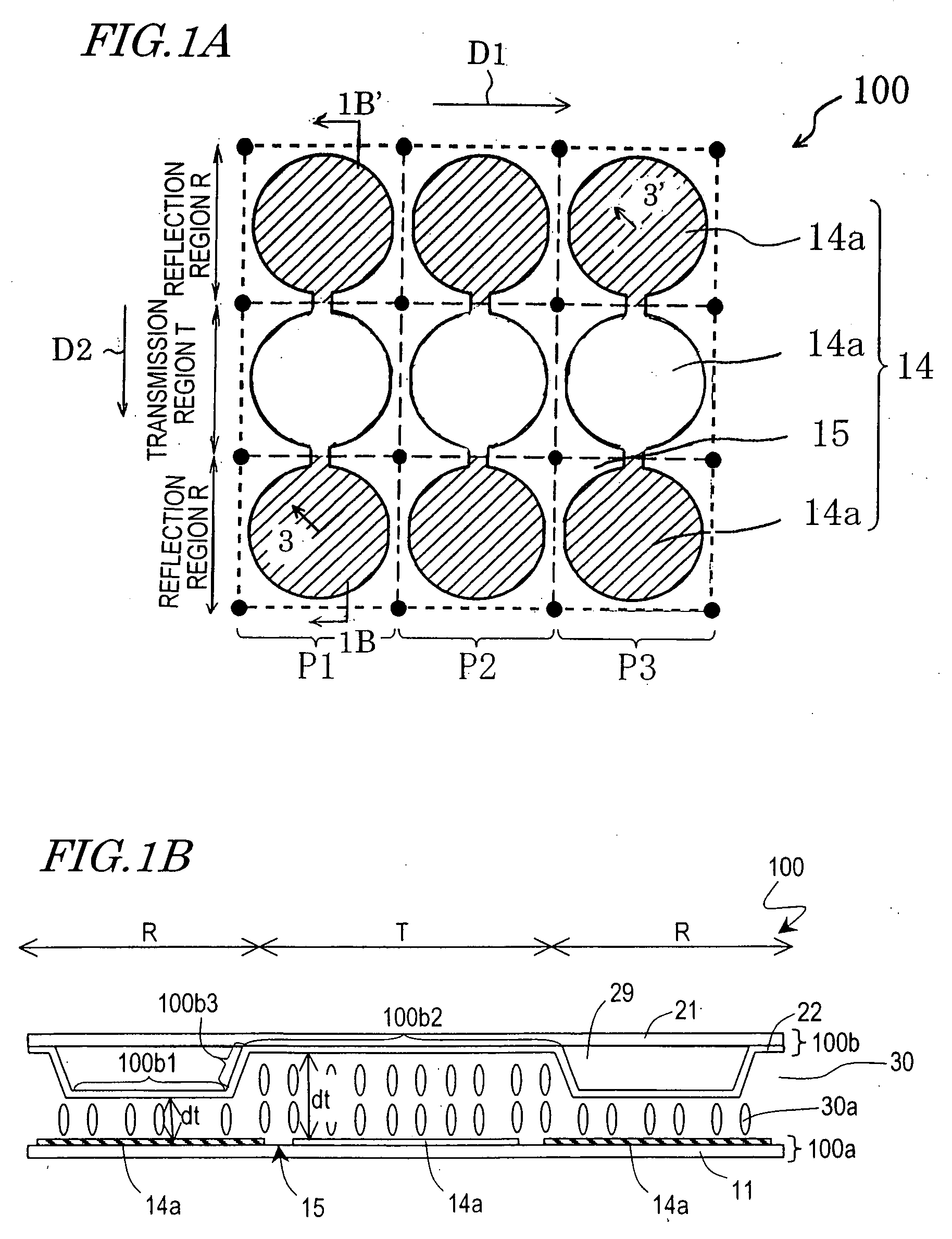

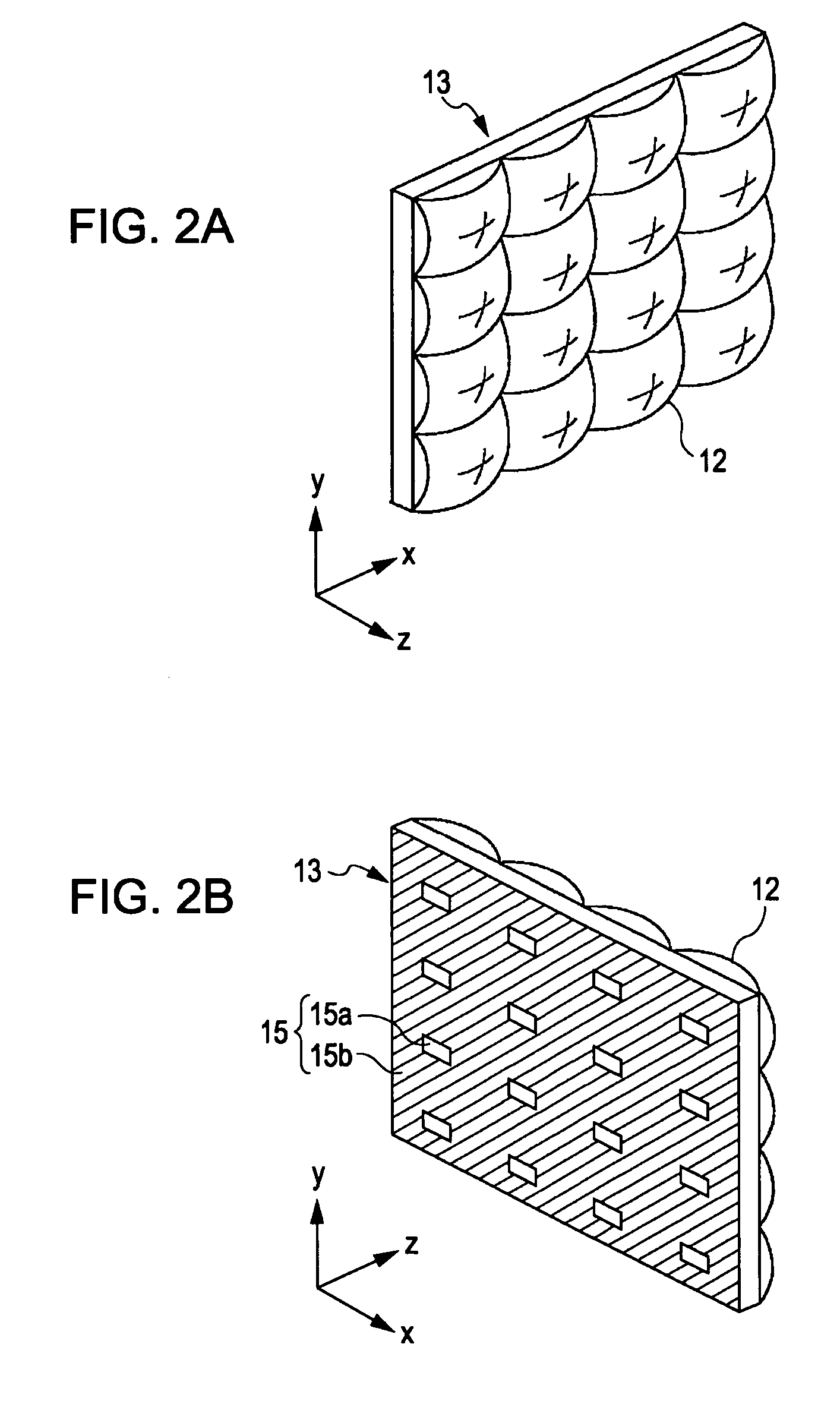

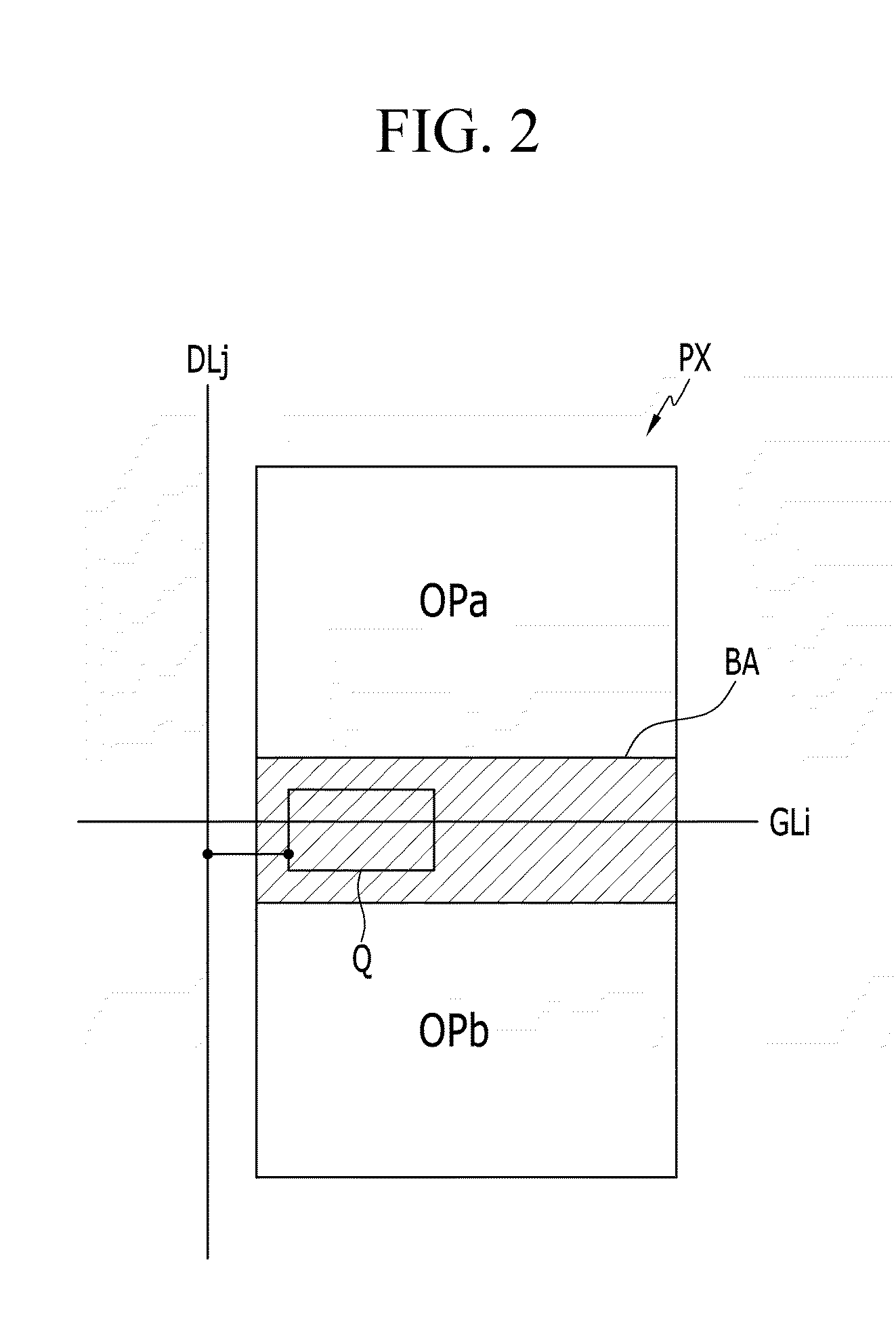

Liquid crystal display device

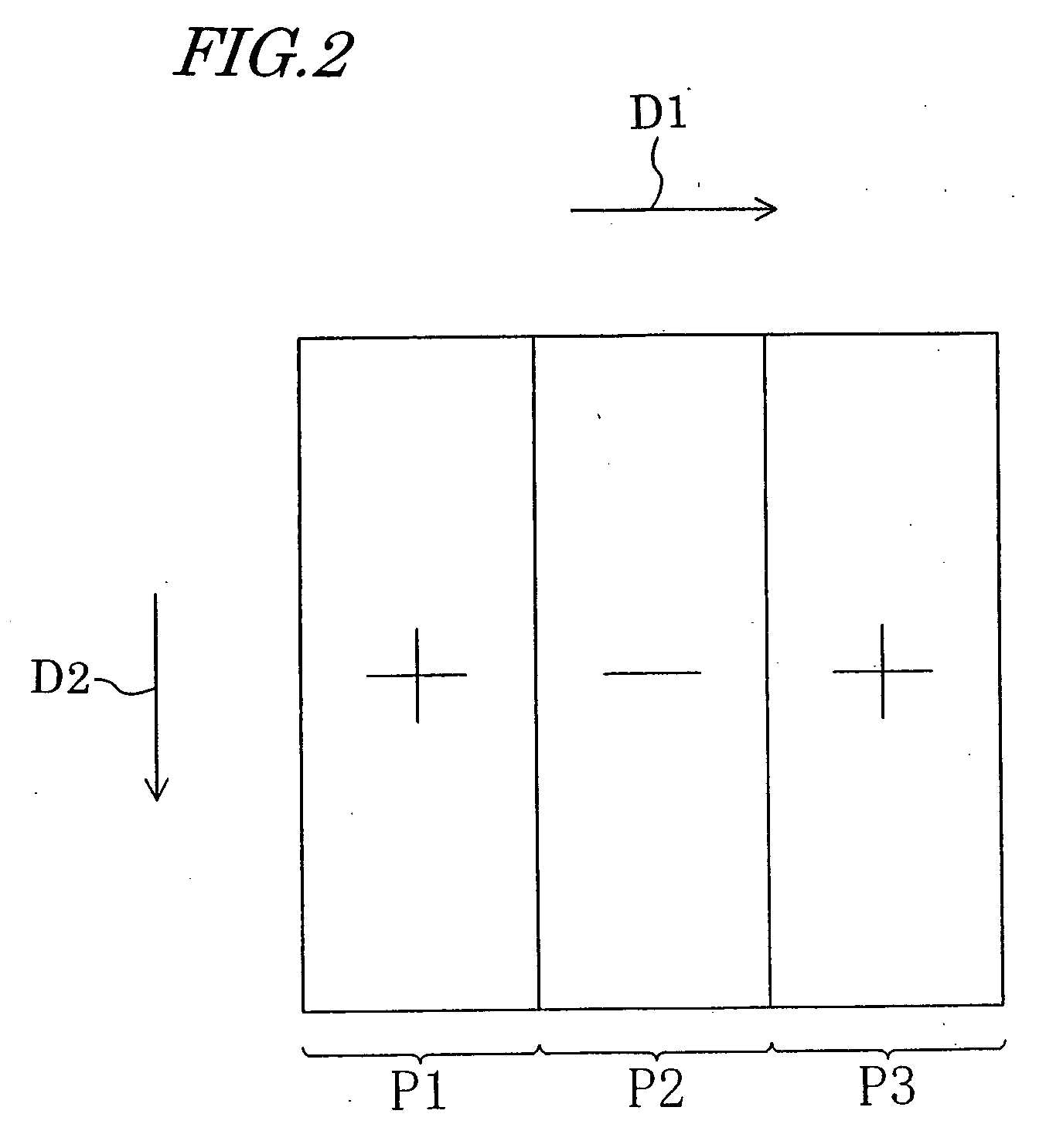

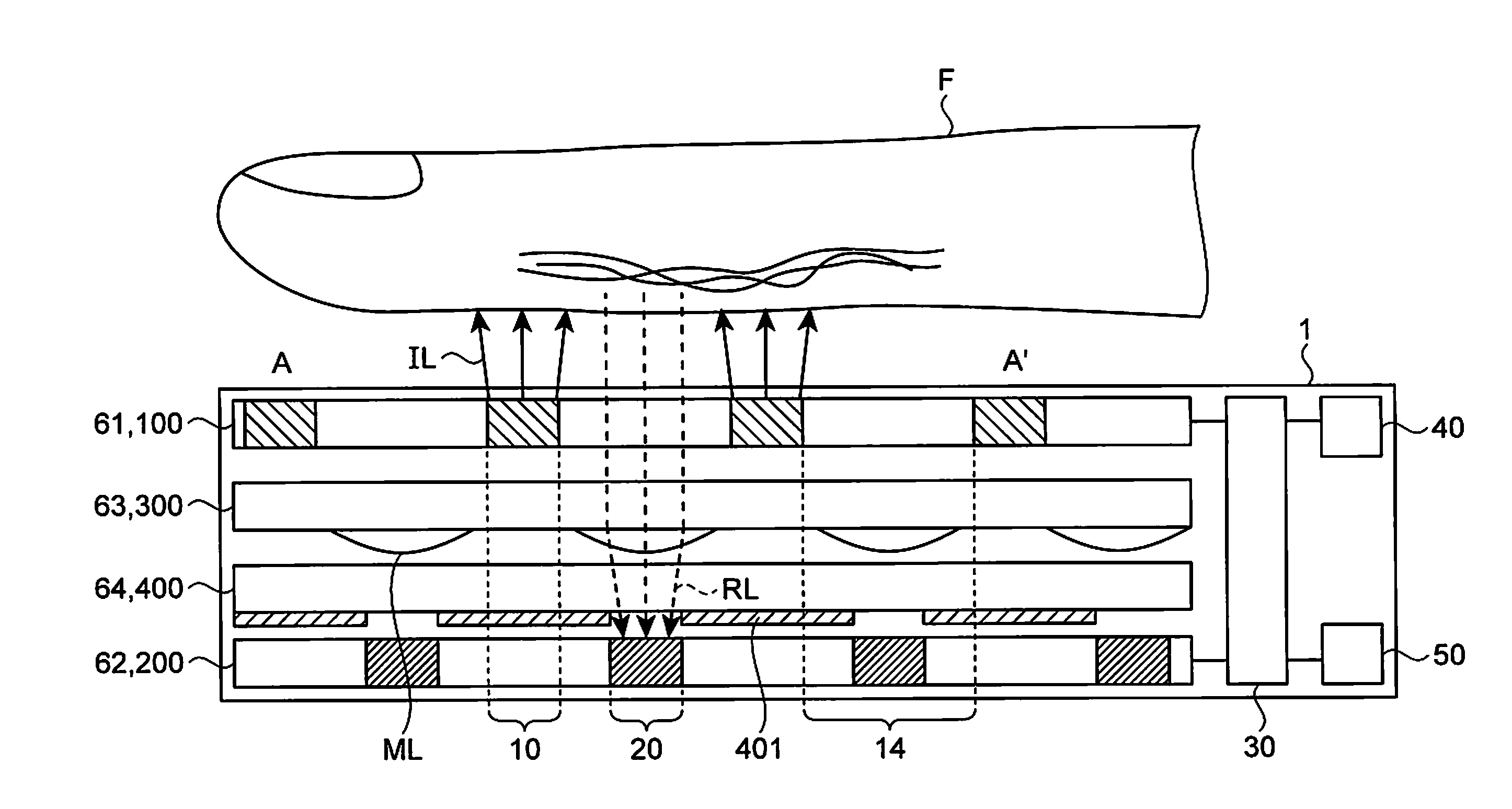

ActiveUS20050140876A1Improve continuityImprove display qualityStatic indicating devicesNon-linear opticsLiquid-crystal displayElectrical polarity

In each picture element region, a first electrode provided on one side of the first substrate that is closer to the liquid crystal layer includes a plurality of sub-electrodes, whereby the liquid crystal layer forms a liquid crystal domain taking a radially-inclined orientation above each sub-electrode by an inclined electric field produced around the sub-electrode. The second substrate includes a stepped portion including an upper tier located in the reflection region, a lower tier located in the transmission region and a side surface connecting the upper tier and the lower tier to each other, the side surface of the stepped portion being located in the reflection region and covered by the second electrode. The plurality of sub-electrodes are arranged in a line in a column direction D2, and picture elements that are adjacent to each other in a row direction D1 are driven with voltages of opposite polarities in each frame.

Owner:SHARP KK

Optical device

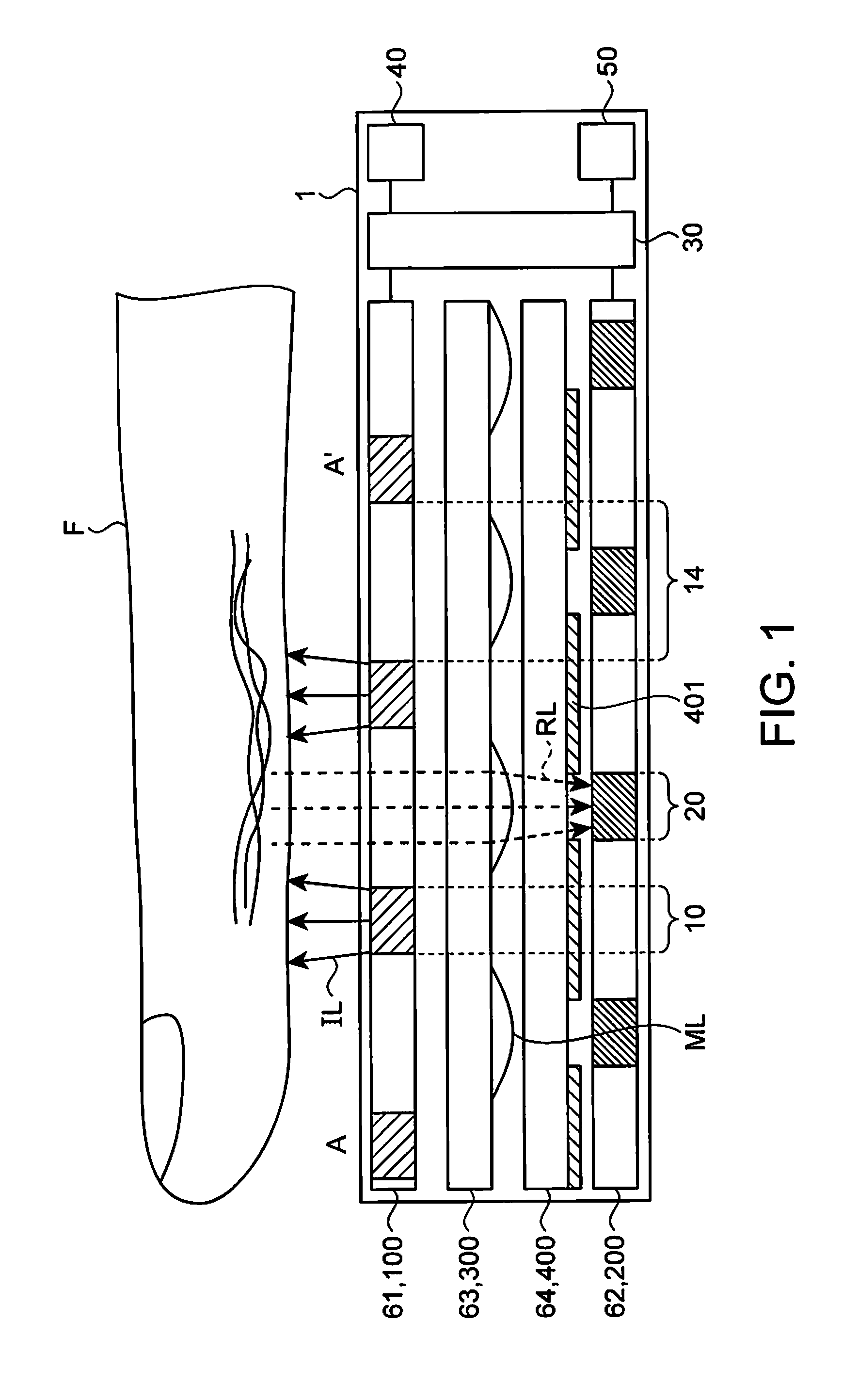

ActiveUS20150187980A1Power consumption be suppressReduce areaDigital data processing detailsElectroluminescent light sourcesEngineeringControl circuit

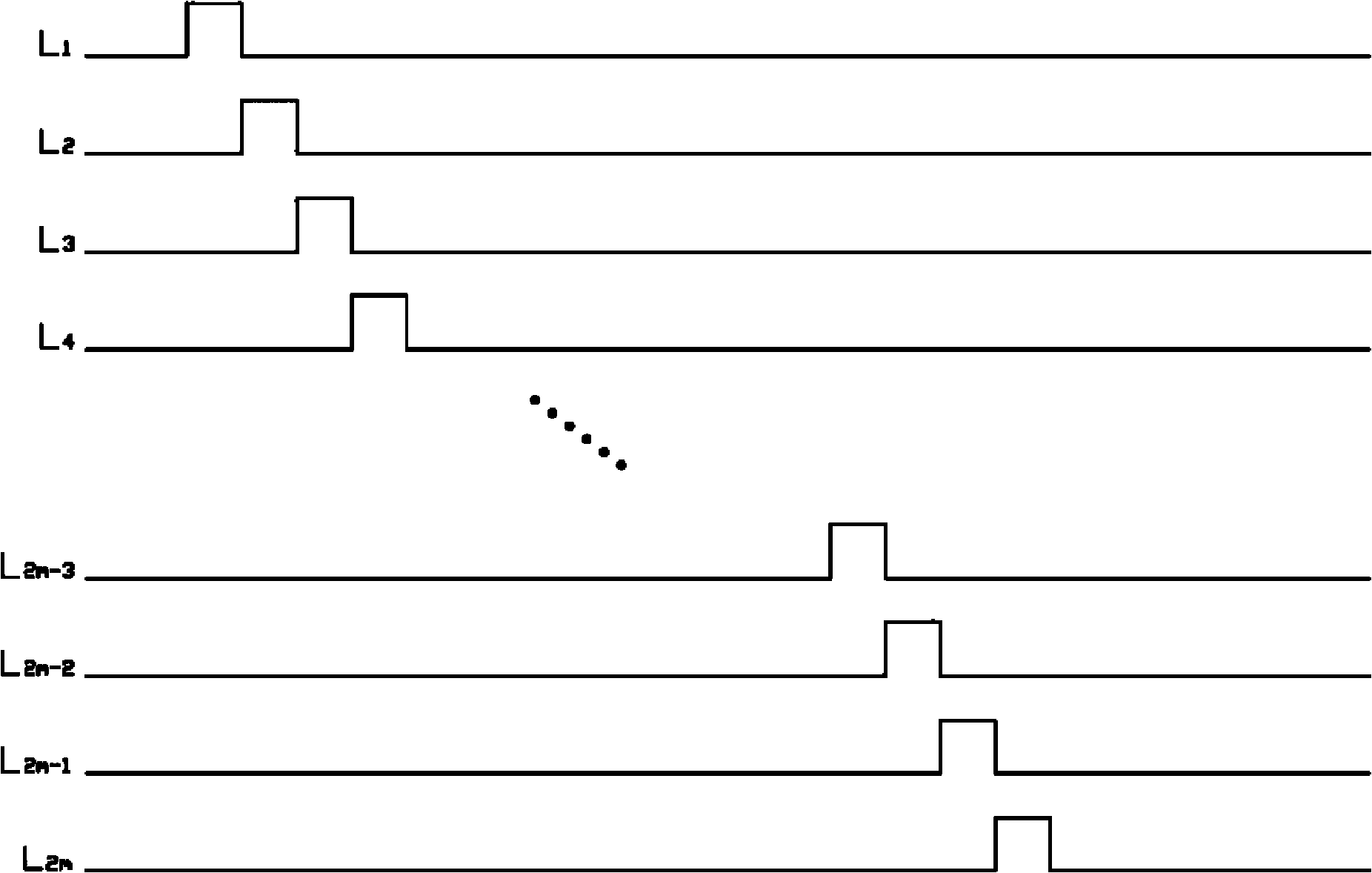

A high-performance optical device is provided. An optical device includes a first transmitting portion that is disposed at the center of a predetermined area in a first substrate, a light-receiving portion that receives light passing through the first transmitting portion, N light-emitting portions (N is an integer of 2 or more) that are disposed around the first transmitting portion in the predetermined area, and a control circuit that controls the light-emitting portions. The control circuit is functionally divided into N control portions, namely, first to N-th control portions. The N control portions are disposed in areas overlapping the N light-emitting portions, respectively, when viewed from above. The optical device can reduce noise light and achieve a high S / N ratio, and also the sensitivity of the optical device can be improved.

Owner:SEIKO EPSON CORP

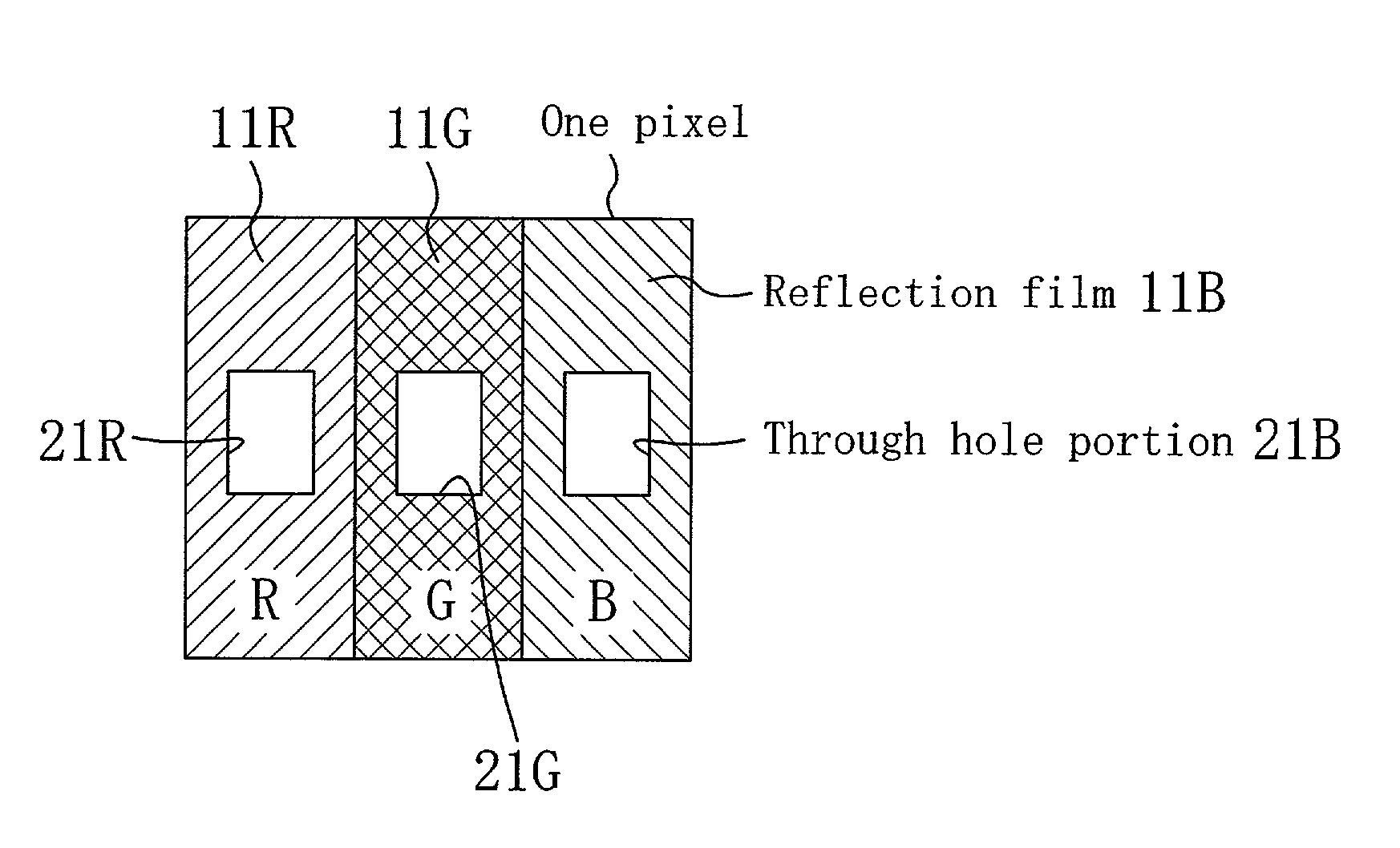

Transmission/reflection type color liquid crystal display device

InactiveUS20020126238A1Desirable color reproducibilityIncrease the area ratioNon-linear opticsLiquid-crystal displayMatrix pattern

A liquid crystal display device, including: a first substrate; a second substrate; opposing the first substrate; a liquid crystal layer interposed between the first substrate and the second substrate; a reflection film formed on one side of the second substrate that is closer to the liquid crystal layer; and a color filter formed on the reflection film, wherein: a plurality of pixel regions are arranged in a matrix pattern, each of the pixel regions including a reflection region where light coming from the first substrate side is reflected by the reflection film back to the first substrate side, and a transmission region where light coming from the second substrate side is transmitted to the first substrate side; and the color filter includes an opening in the reflection region.

Owner:SHARP KK

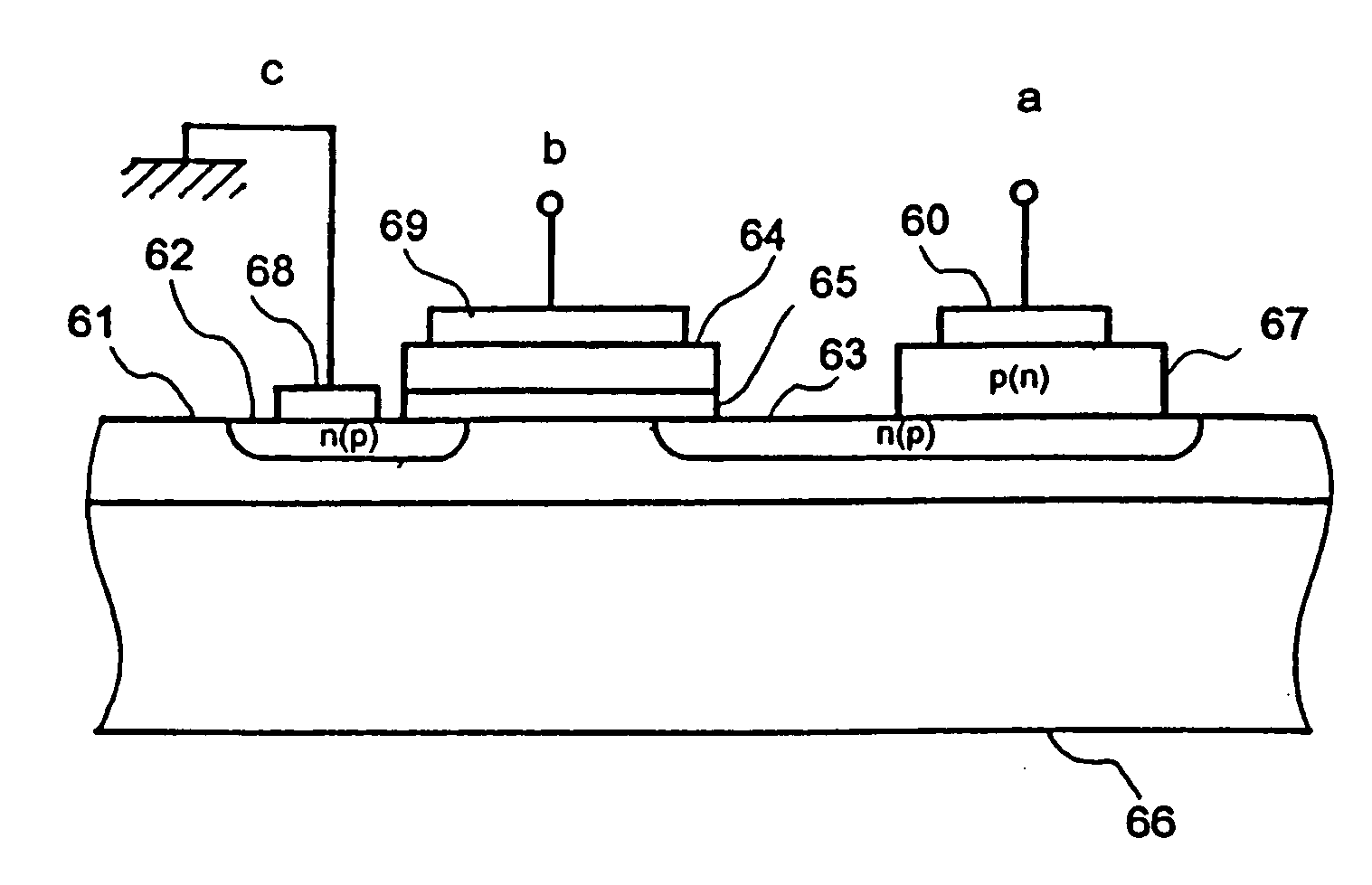

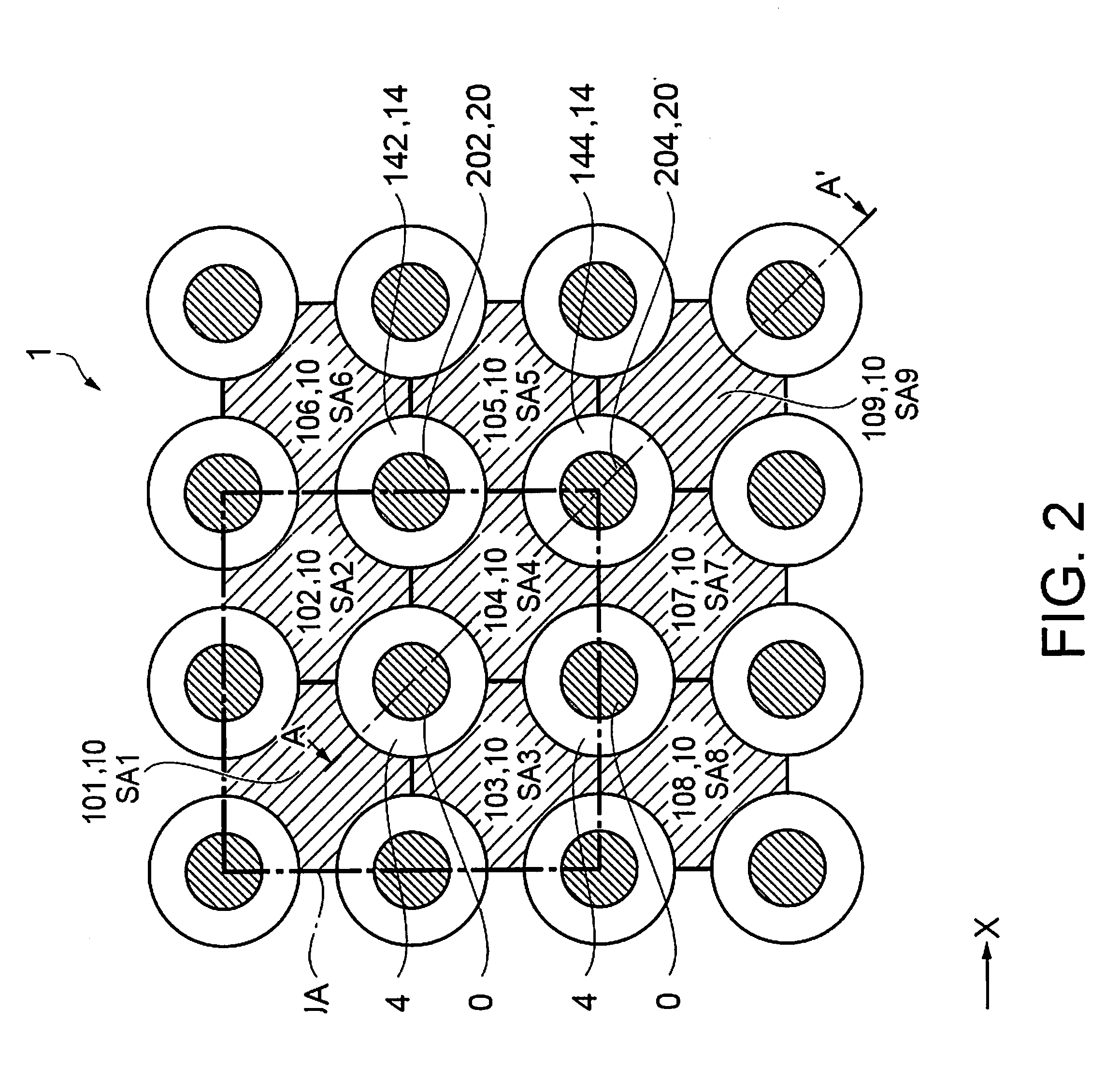

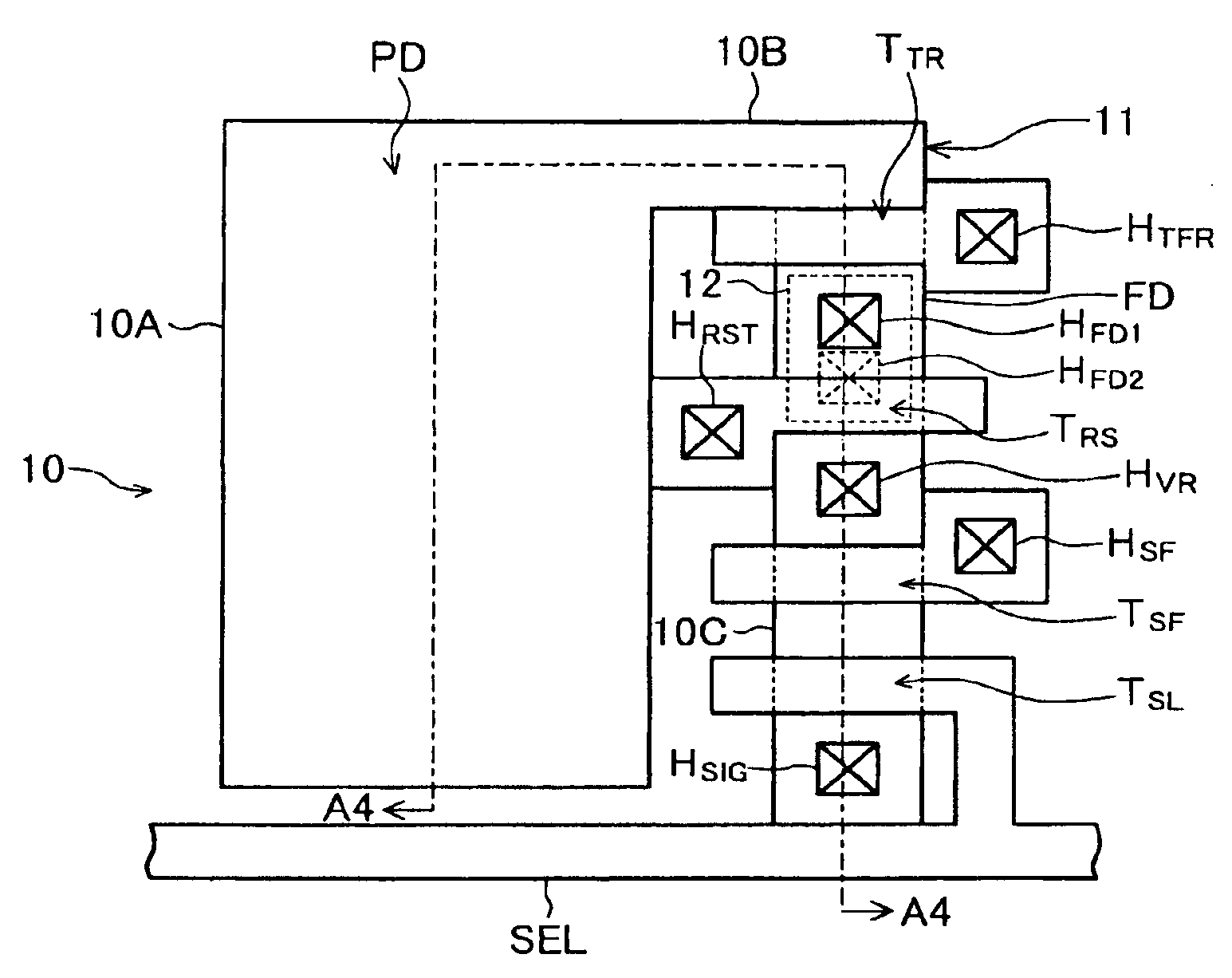

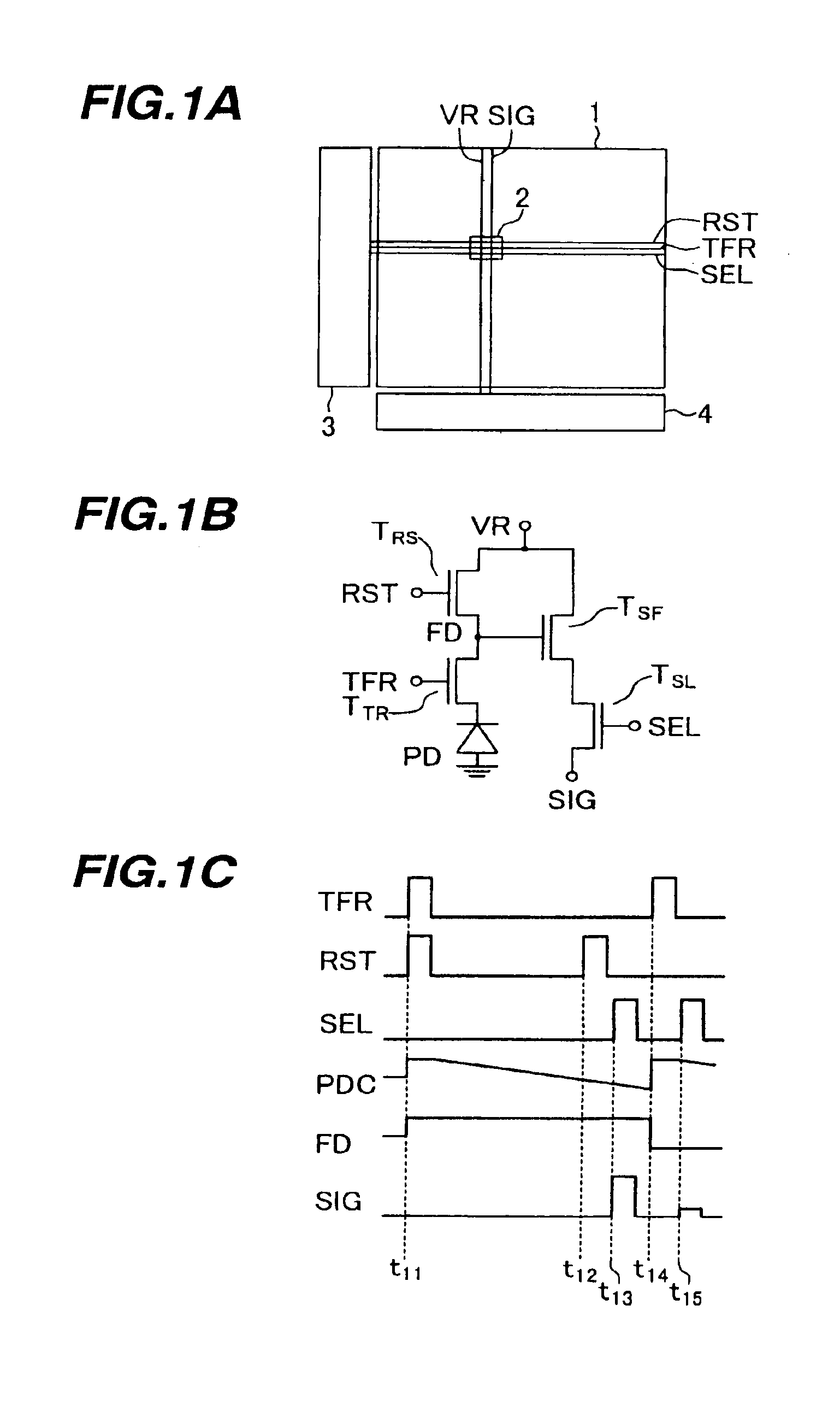

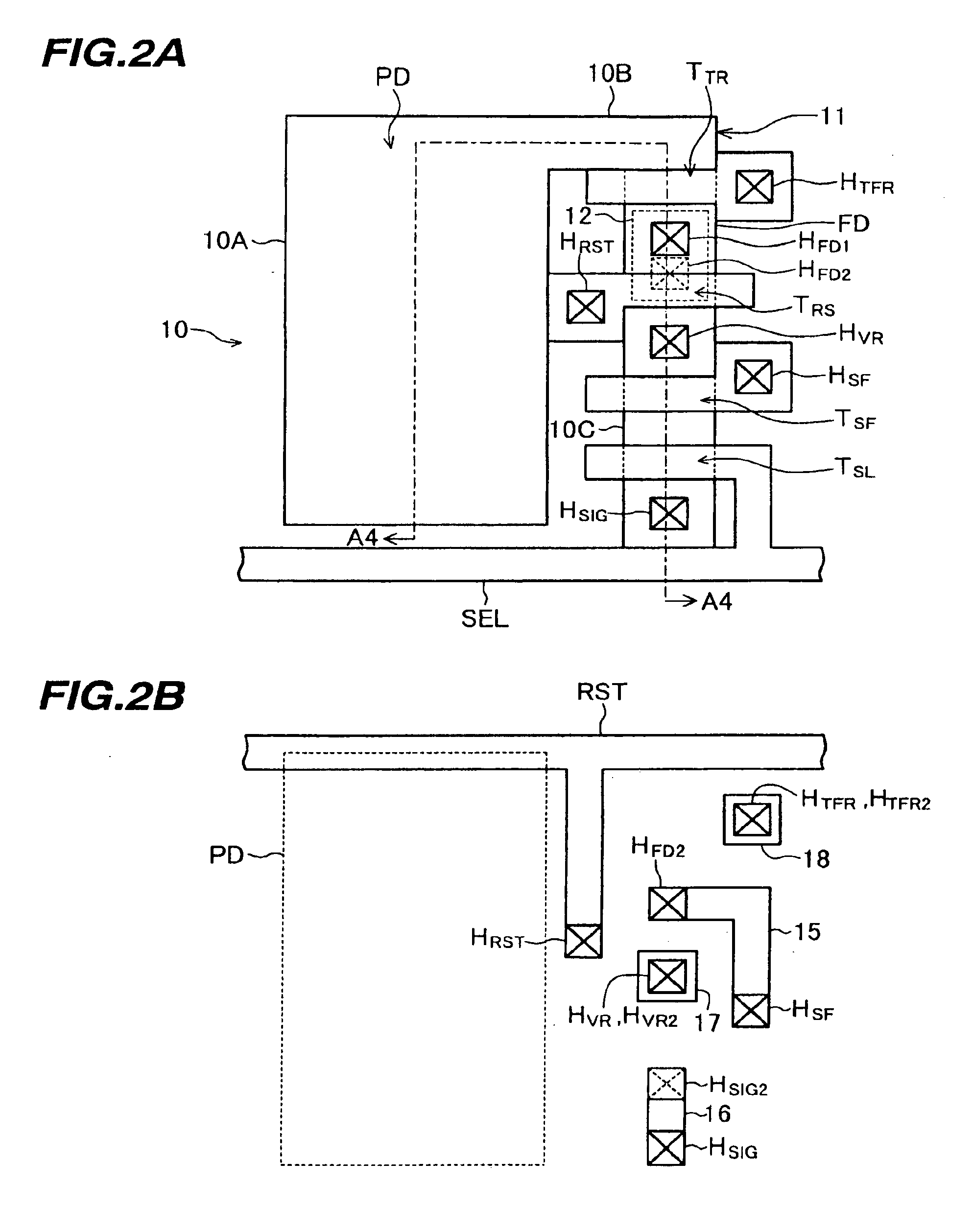

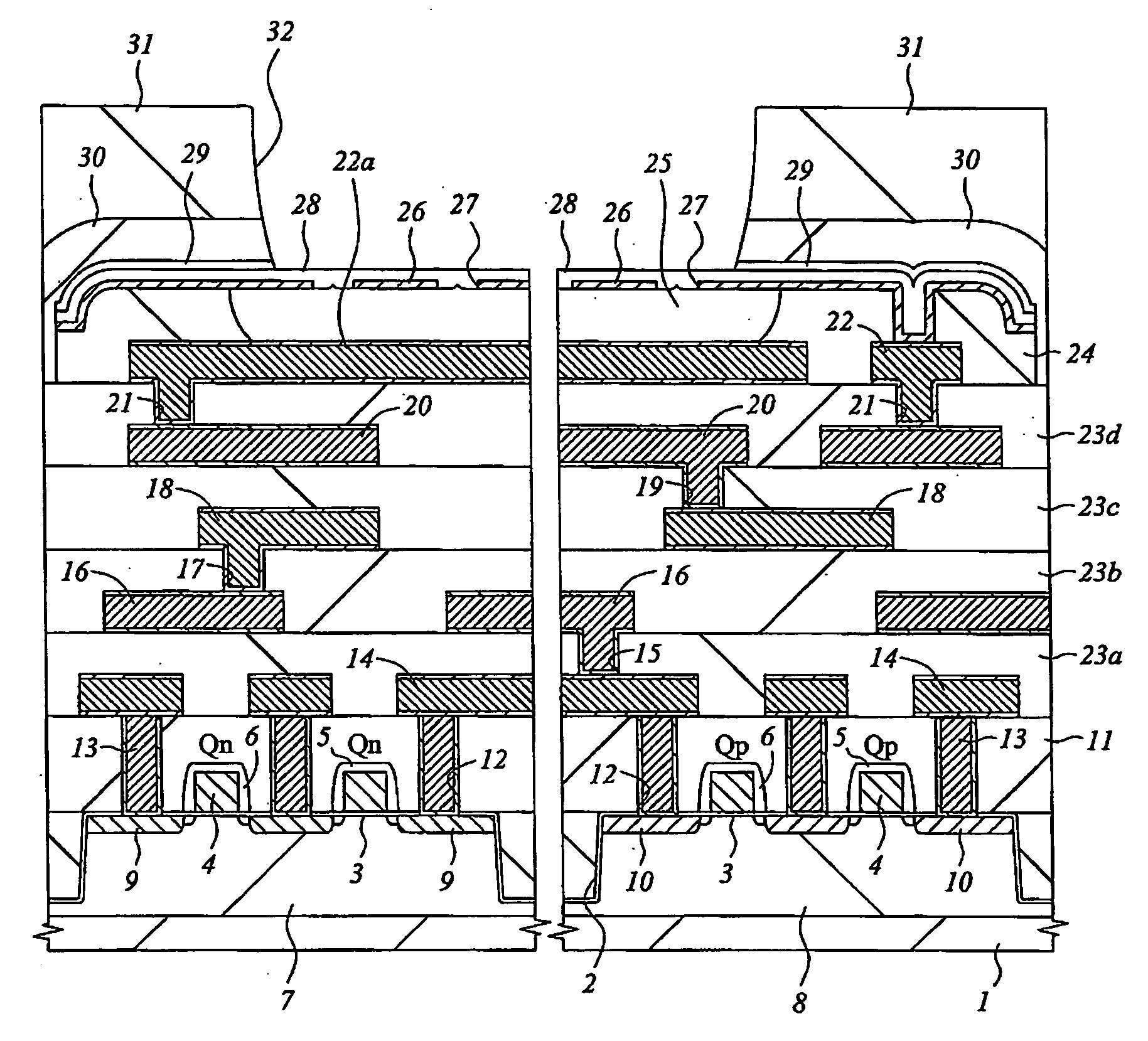

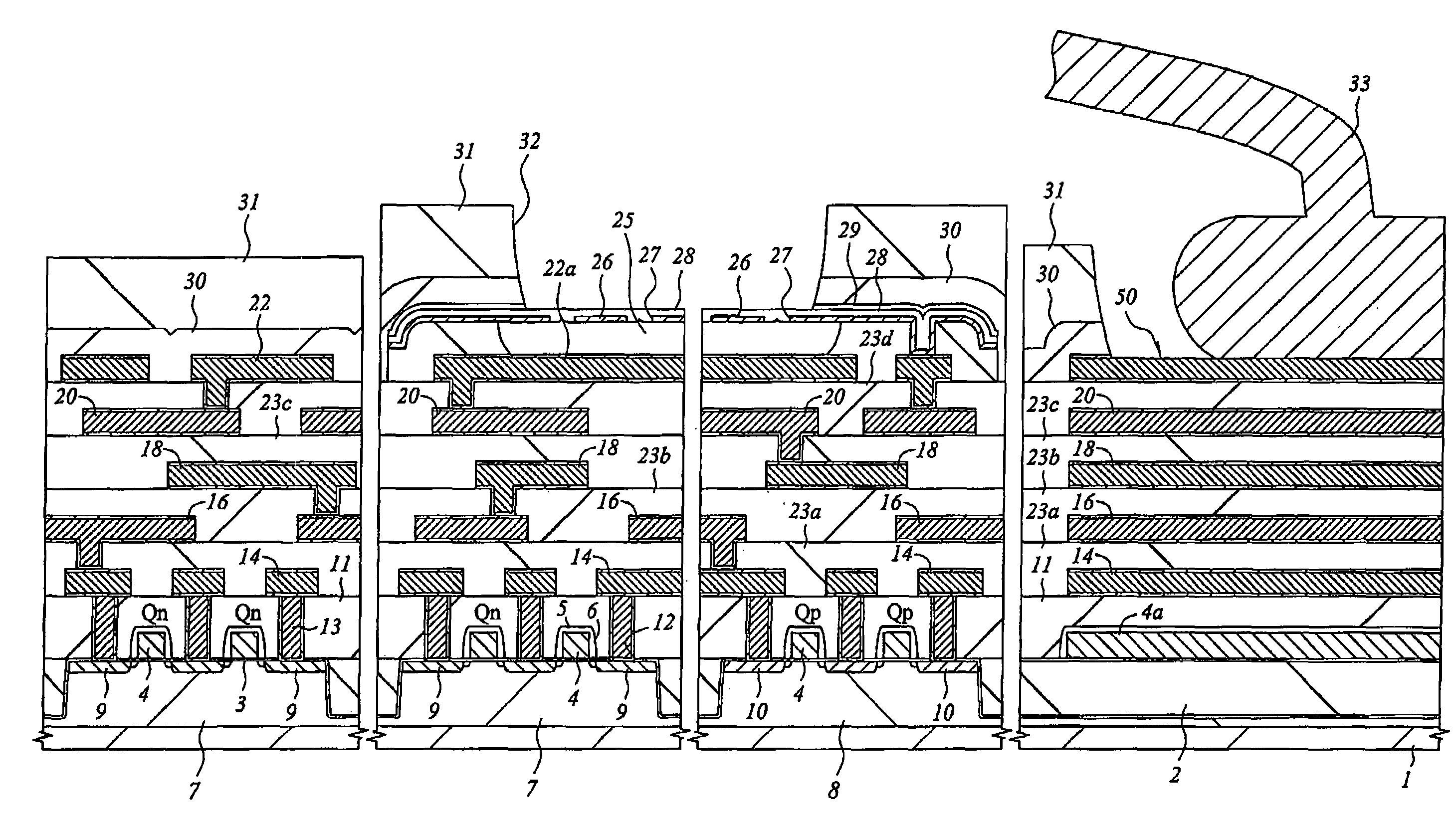

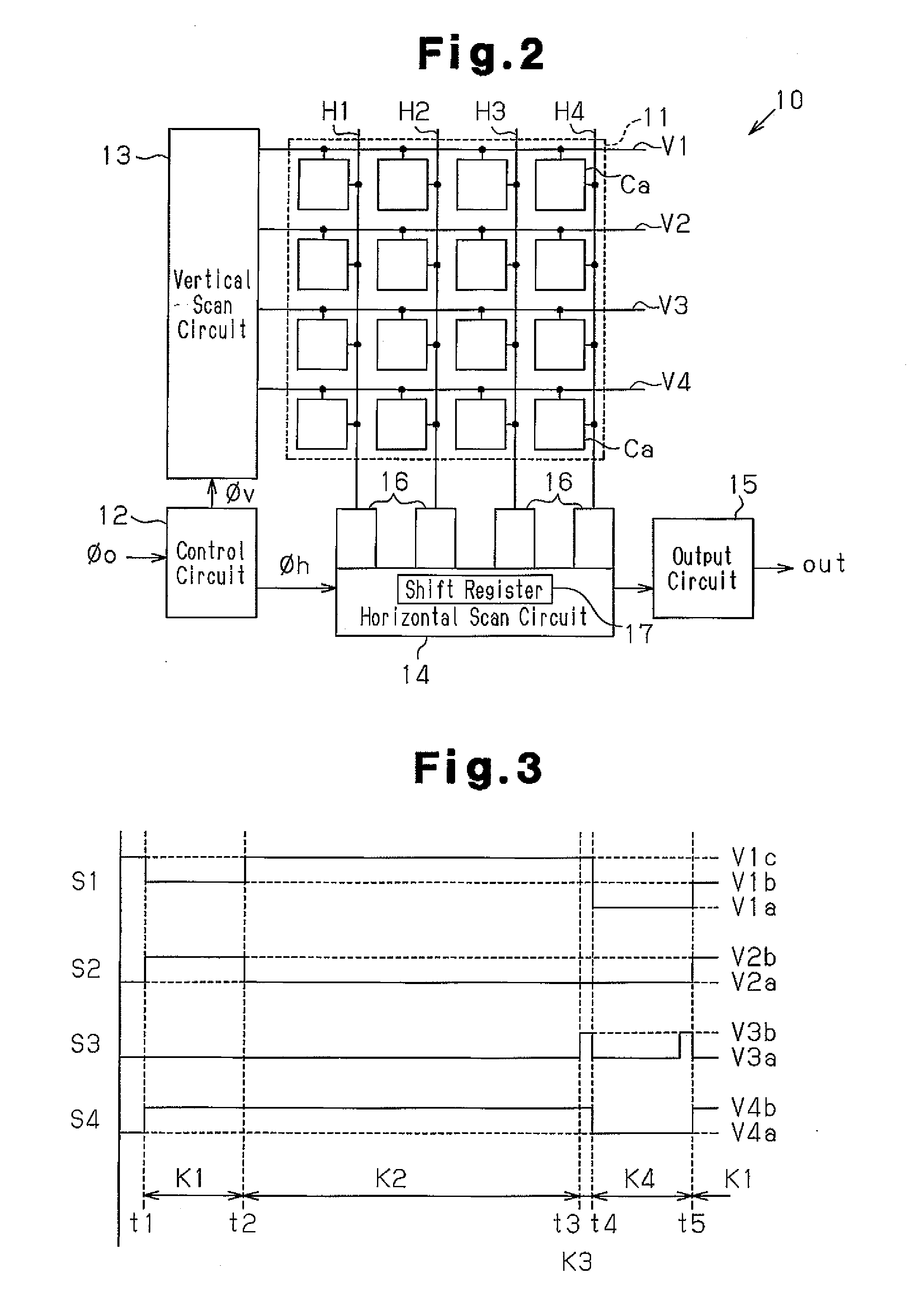

Semiconductor device for reading signal from photodiode via transistors

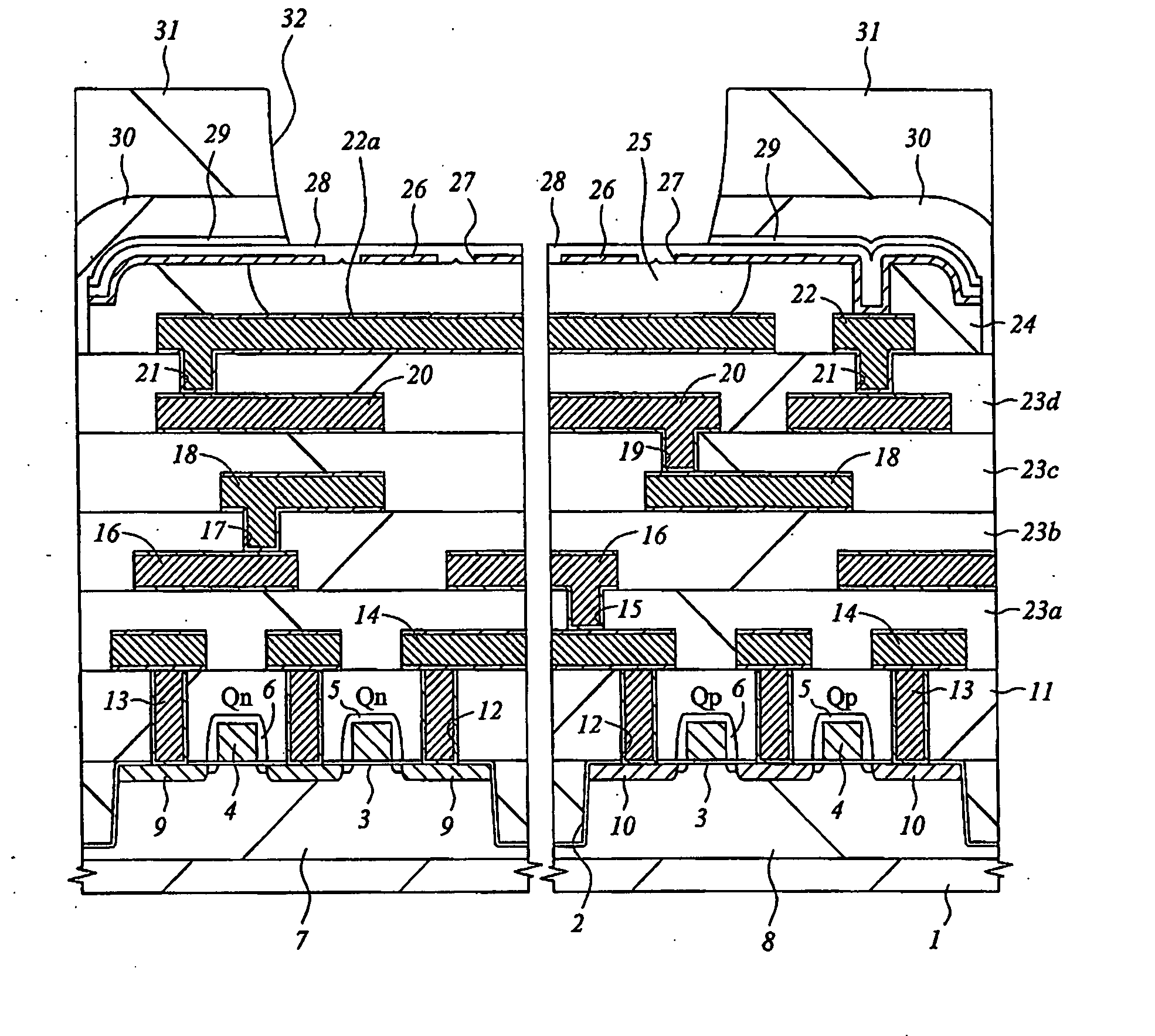

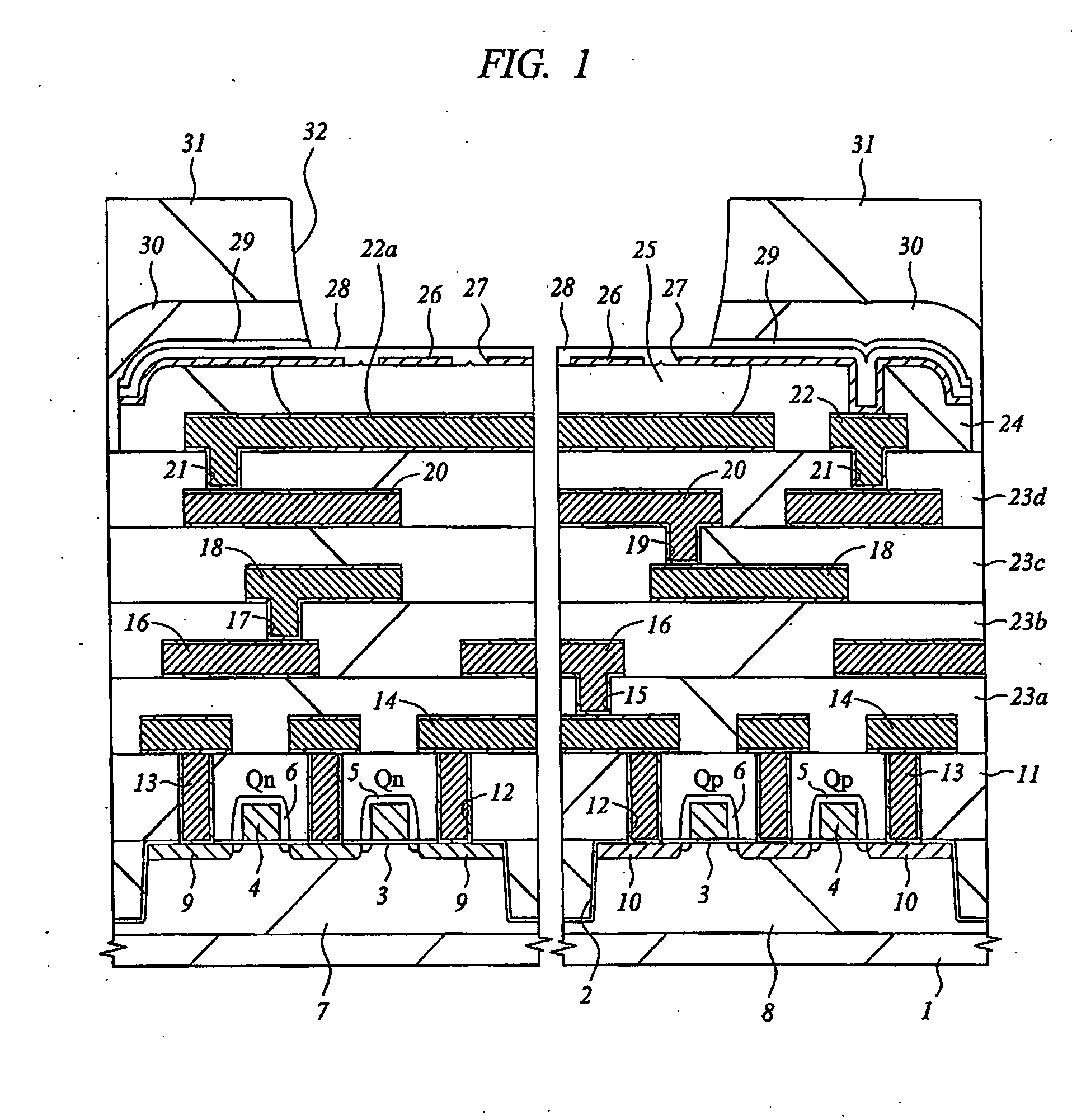

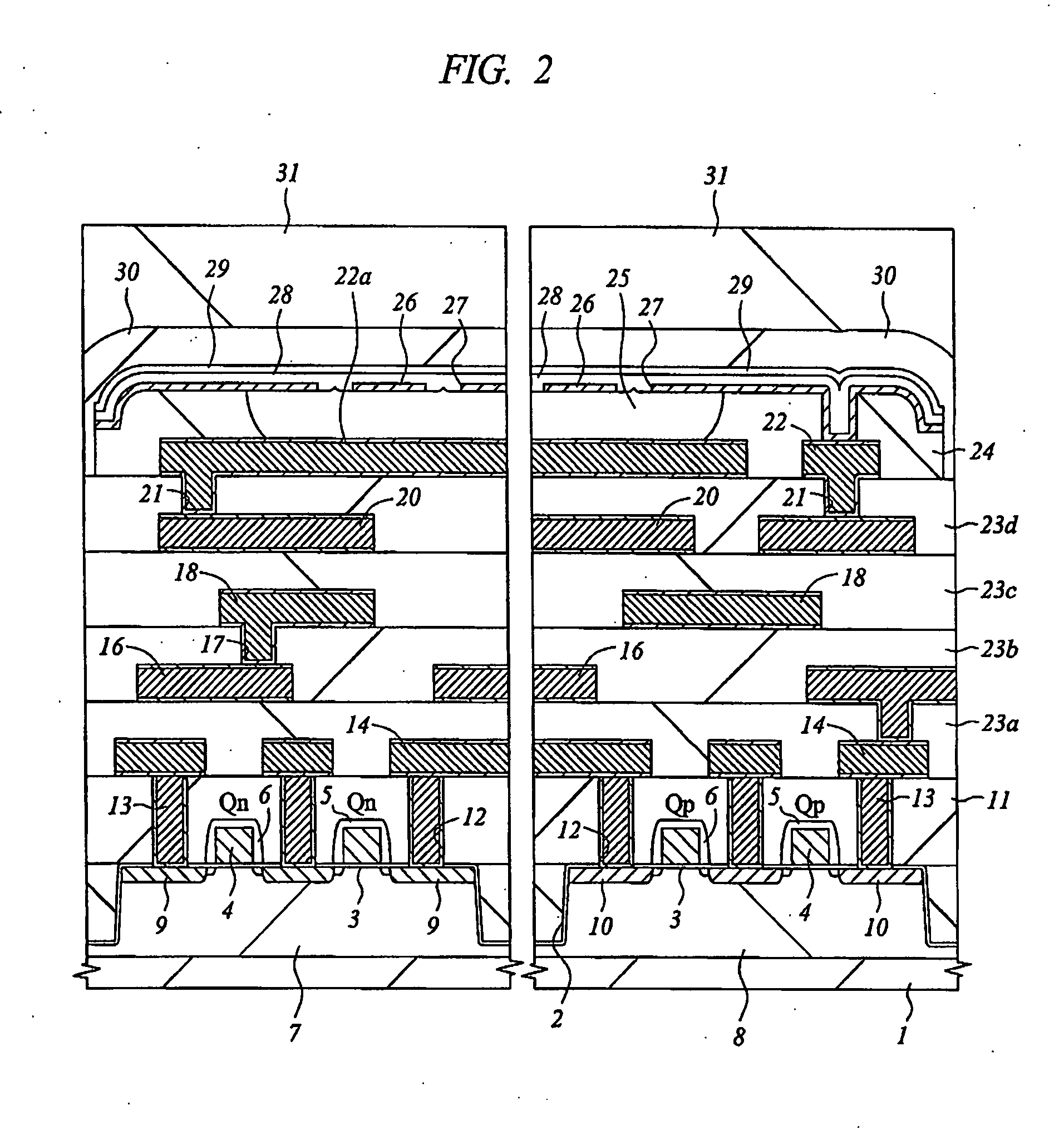

ActiveUS6930299B2Increase the area ratioReduced Junction Leakage CurrentTelevision system detailsTelevision system scanning detailsEngineeringPhotodiode

Pixels are disposed on a semiconductor substrate in a matrix shape. Each pixel includes a photodiode, a reset transistor, a source follower transistor and a select transistor. An active region in which the photodiode and transistors are disposed includes a first area in which the photodiode is disposed and a second area having an are elongated in a first direction. Each of the gate electrodes of the reset transistor, source follower transistor and select transistor crosses the area, elongated in the first direction, of the second area. An intra-pixel wiring line interconnects the drain region of the reset transistor and the gate electrode of the source follower transistor.

Owner:FUJITSU SEMICON LTD

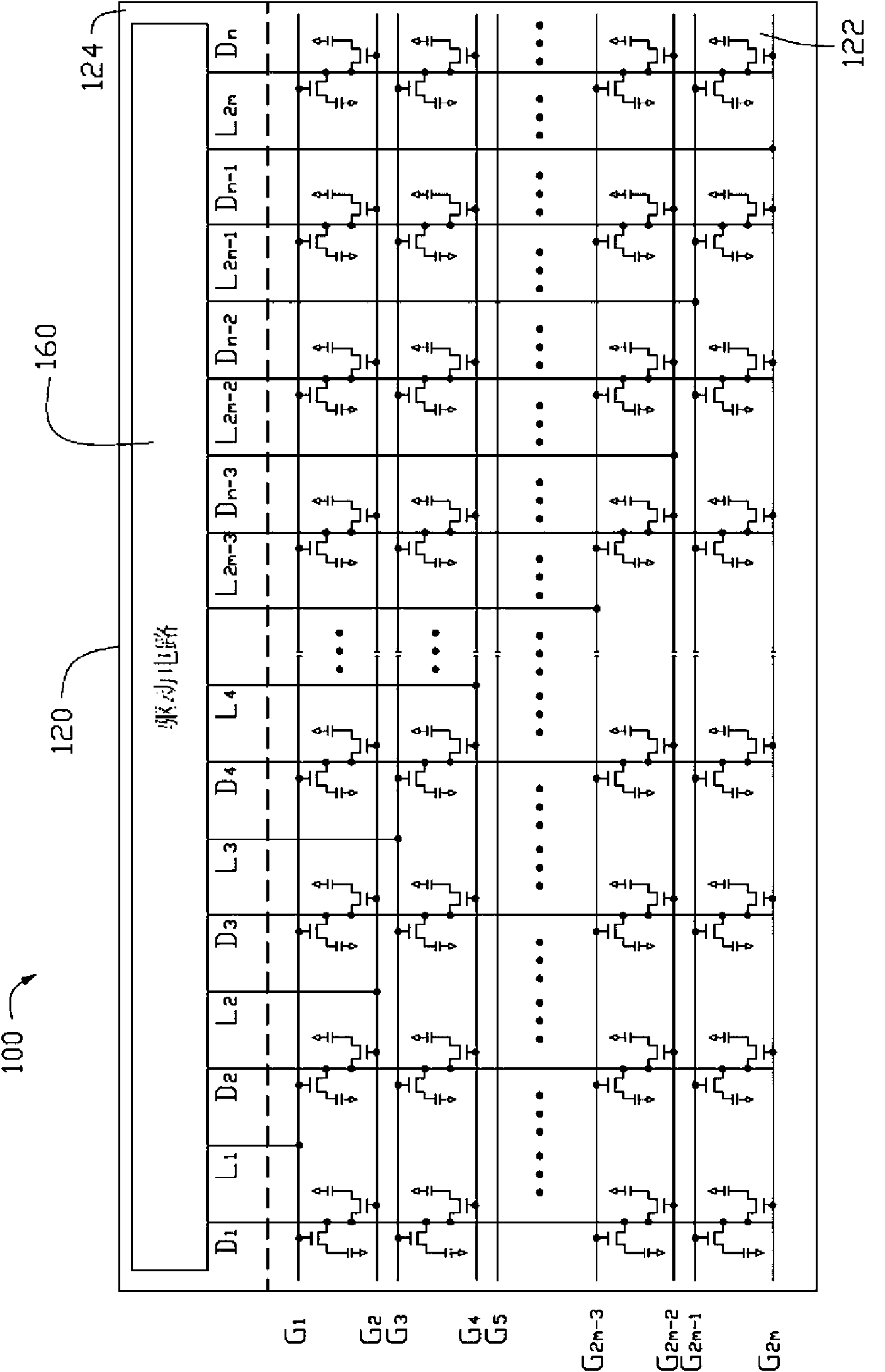

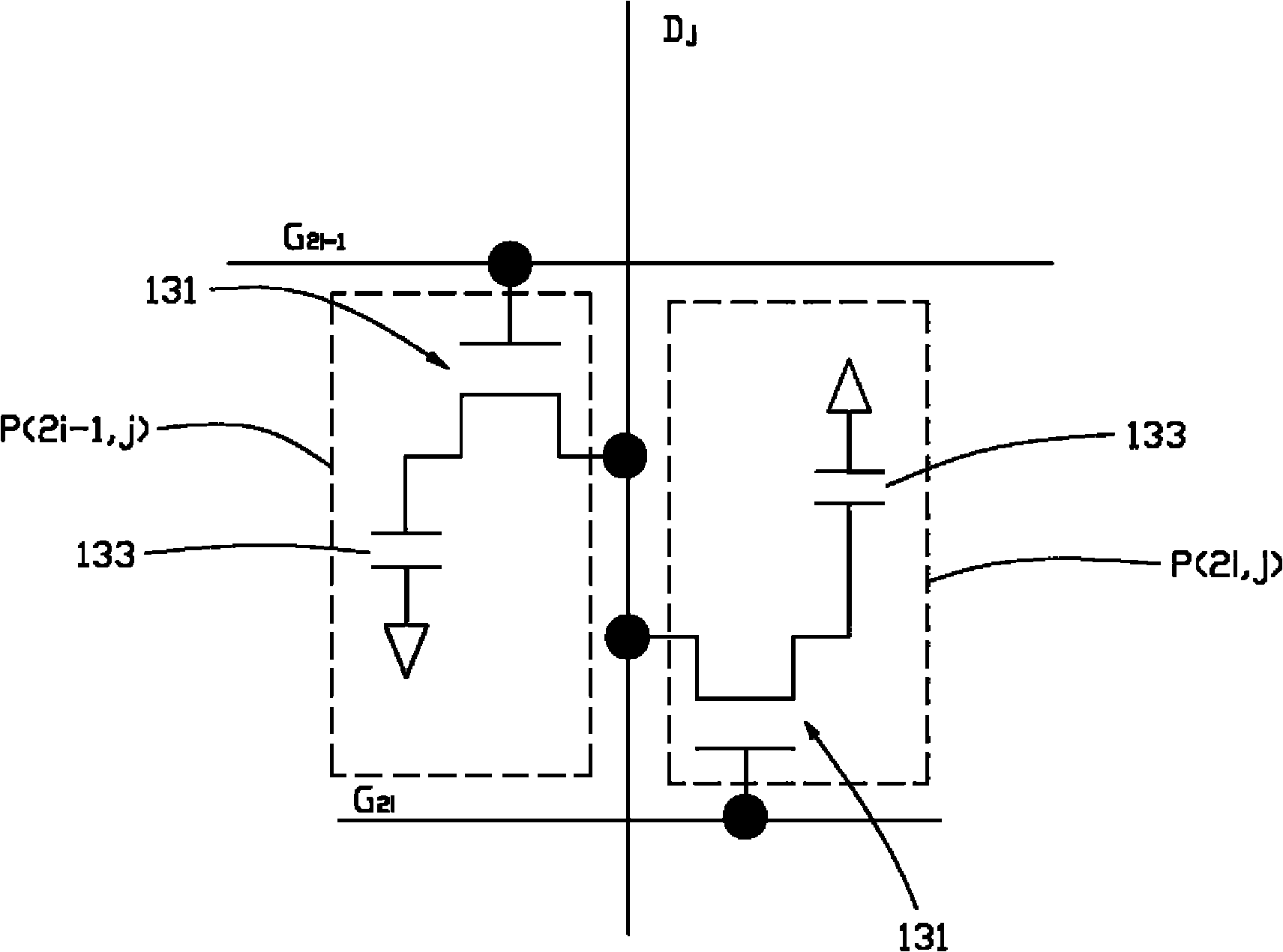

Liquid crystal display panel and liquid crystal display device

InactiveCN102081246AReduce areaIncrease the area ratioStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

Semiconductor device embedded with pressure sensor and manufacturing method thereof

ActiveUS20070262401A1High precision measurementReduced footprintFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsDevice materialSilicon oxide

The method for promoting the size reduction, the performance improvement and the reliability improvement of a semiconductor device embedded with pressure sensor is provided. In a semiconductor device embedded with pressure sensor, a part of an uppermost wiring is used as a lower electrode of a pressure detecting unit. A part of a silicon oxide film formed on the lower electrode is a cavity. On a tungsten silicide film formed on the silicon oxide film, a silicon nitride film is formed. The silicon nitride film has a function to fill a hole or holes and suppress immersion of moisture from outside to the semiconductor device embedded with pressure sensor. A laminated film of the silicon nitride film and the tungsten silicide film forms a diaphragm of the pressure sensor.

Owner:HITACHI LTD

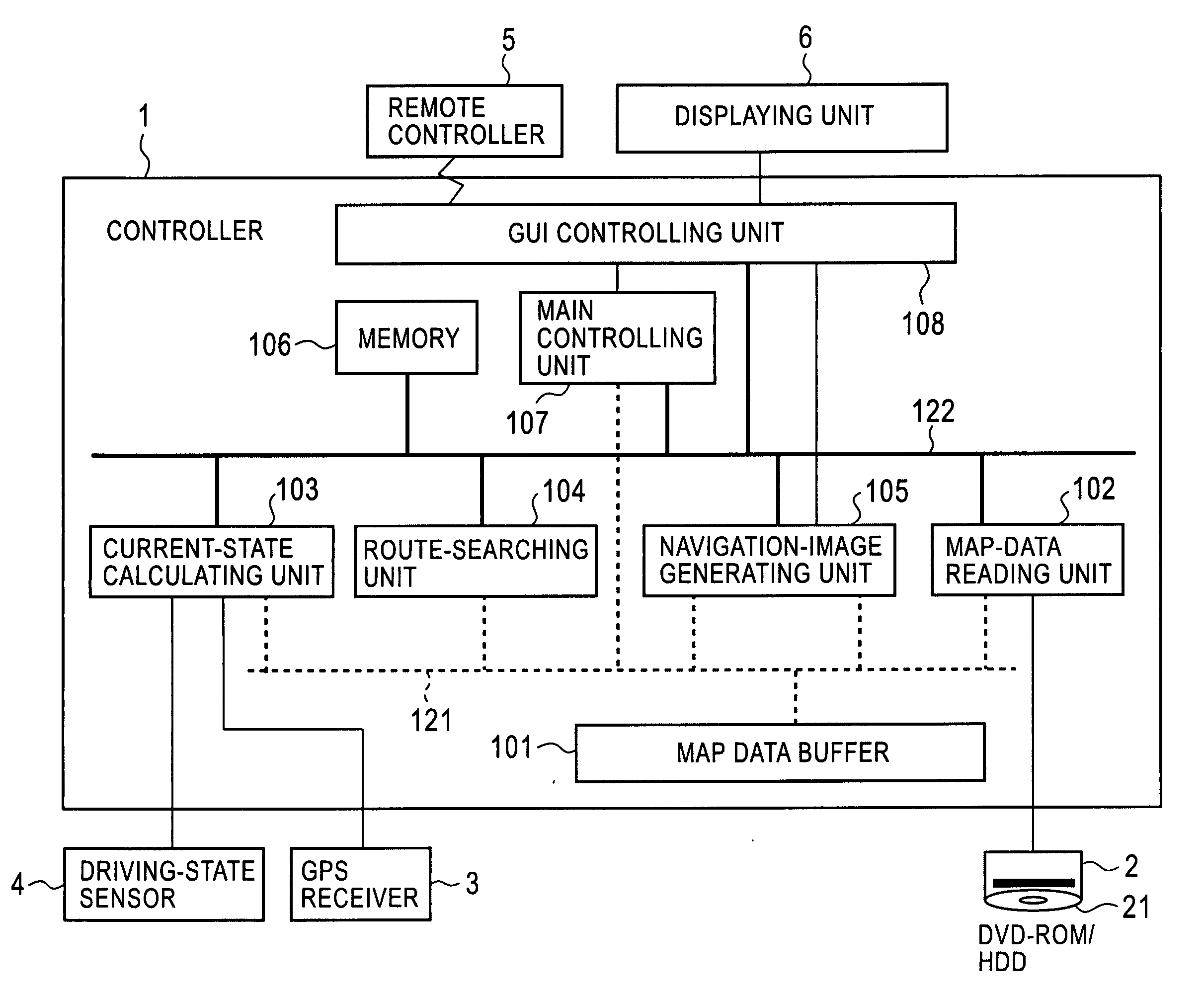

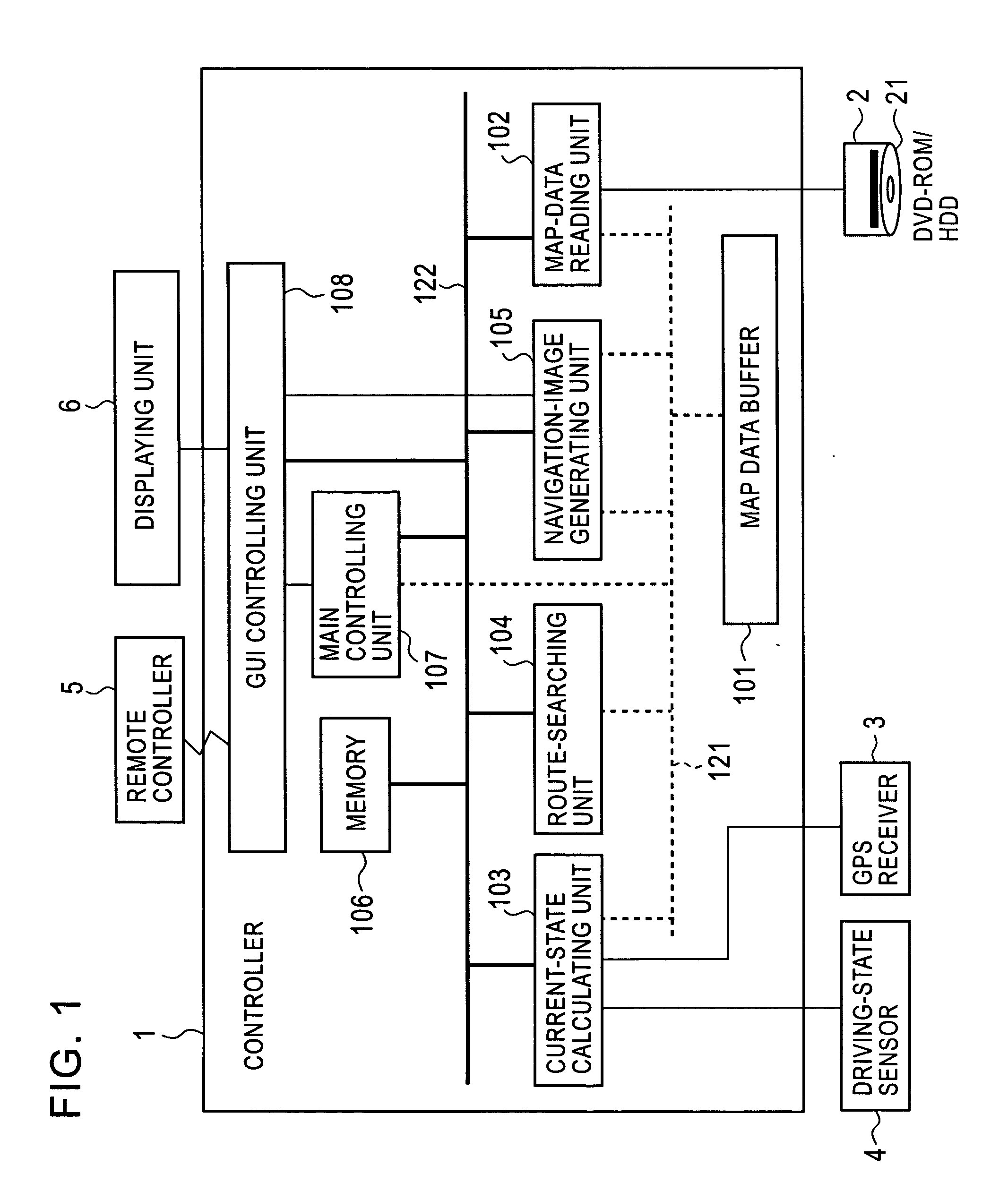

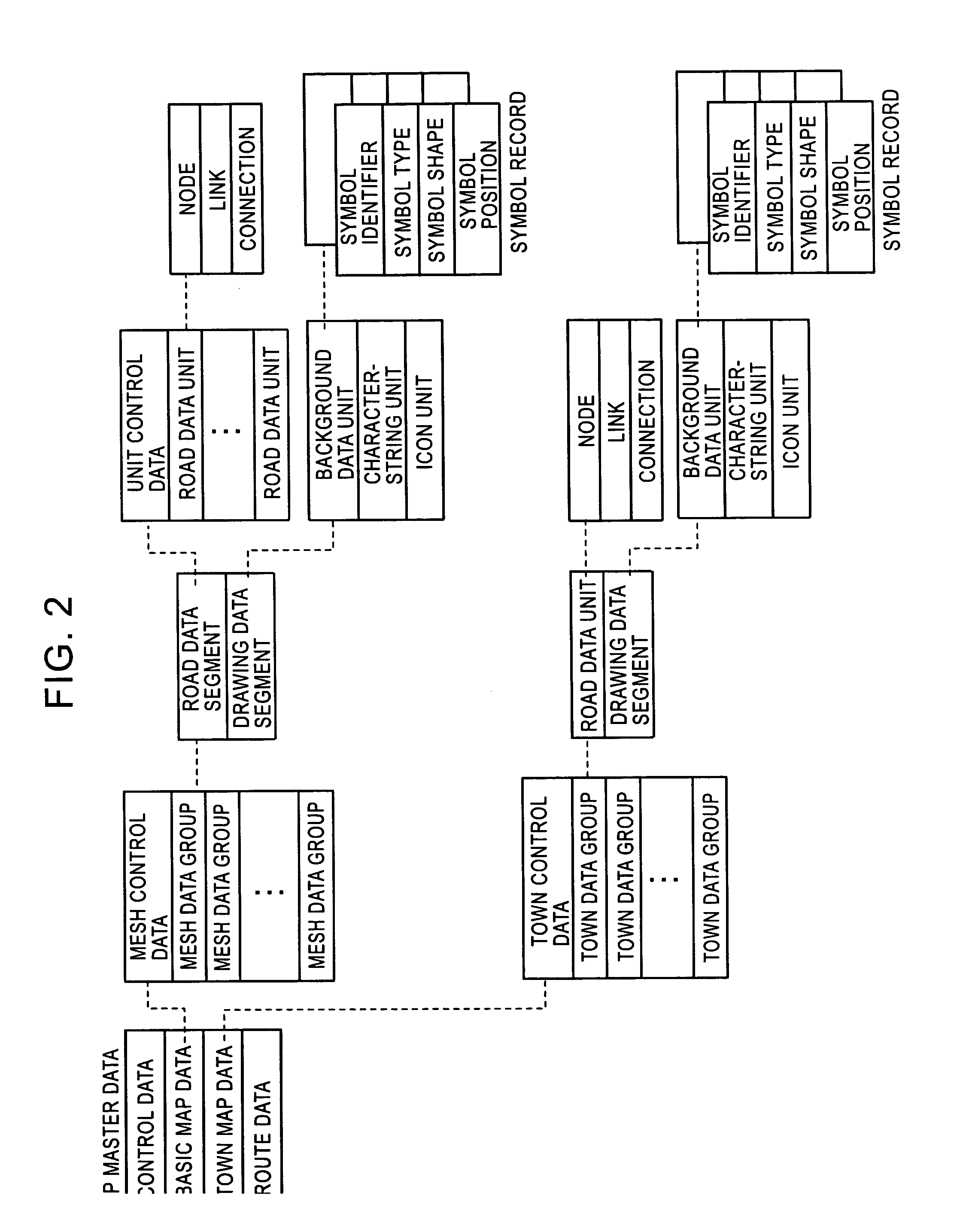

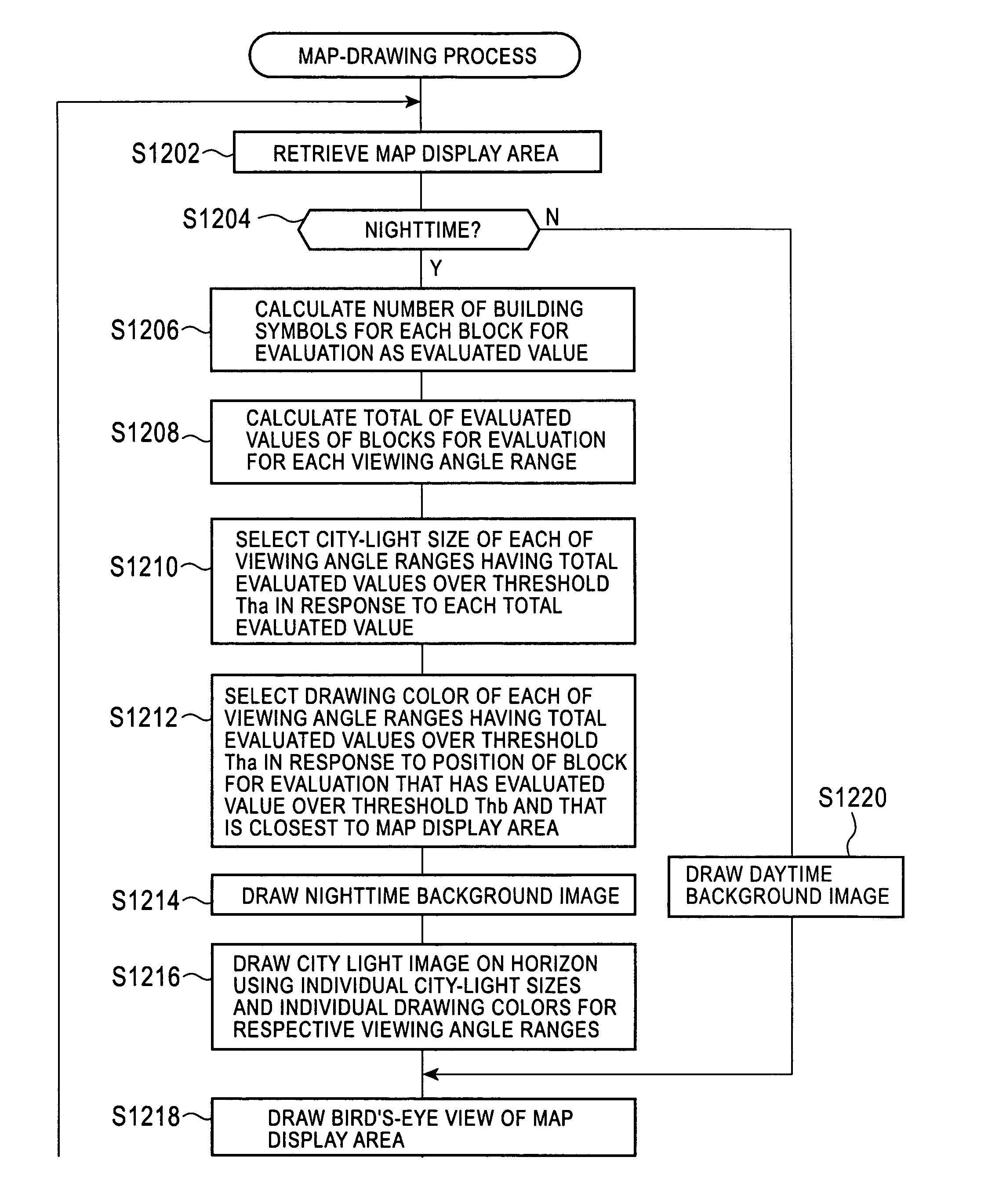

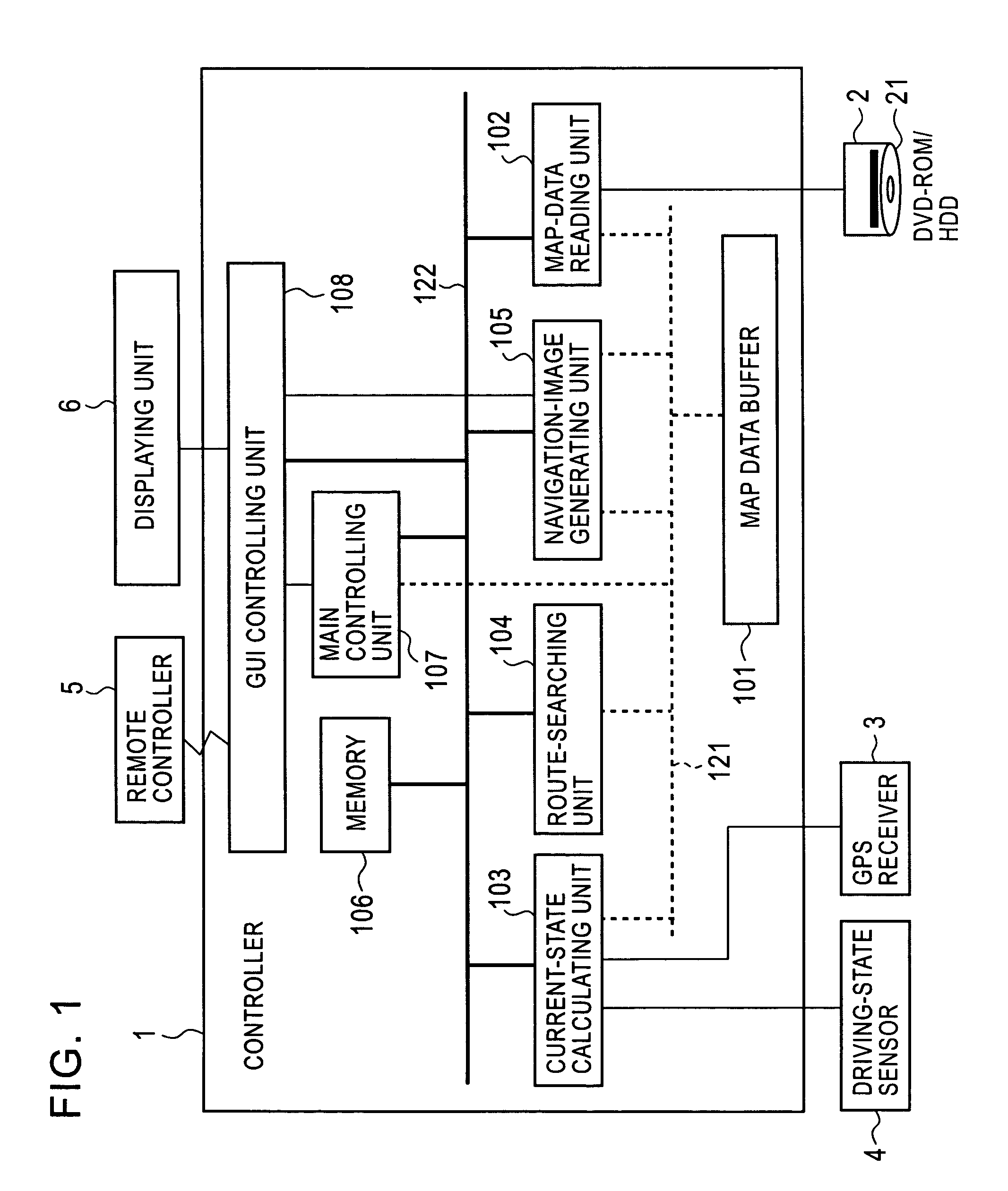

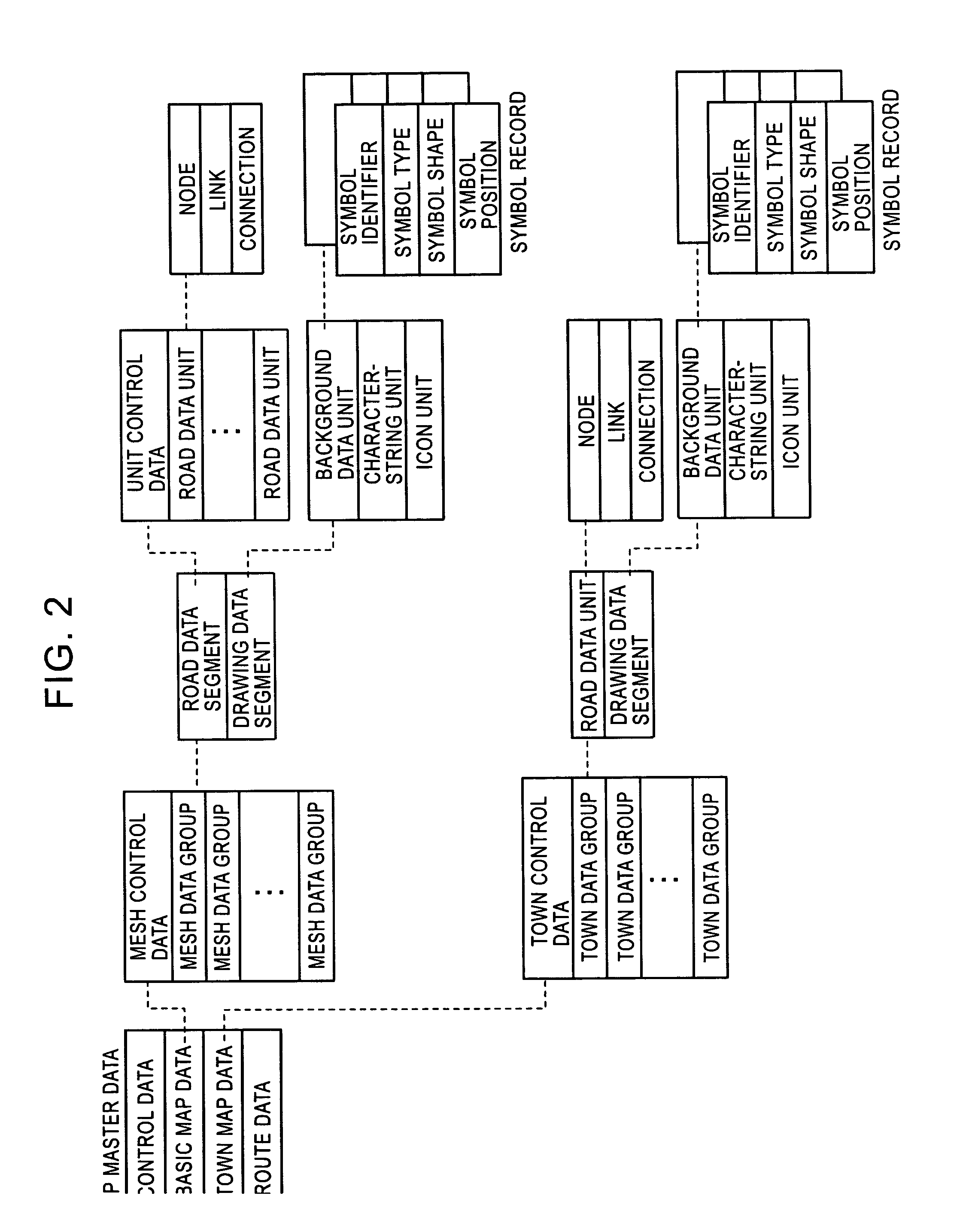

Method and apparatus for displaying a map

ActiveUS20050261826A1Improve clarityImprove the level ofInstruments for road network navigationRoad vehicles traffic controlComputer scienceMarine navigation

Owner:ALPINE ELECTRONICS INC

Semiconductor device embedded with pressure sensor and manufacturing method thereof

ActiveUS20060070449A1High precision measurementReduced footprintFluid pressure measurement by electric/magnetic elementsSolid-state devicesDevice materialSilicon oxide

The method for promoting the size reduction, the performance improvement and the reliability improvement of a semiconductor device embedded with pressure sensor is provided. In a semiconductor device embedded with pressure sensor, a part of an uppermost wiring is used as a lower electrode of a pressure detecting unit. A part of a silicon oxide film formed on the lower electrode is a cavity. On a tungsten silicide film formed on the silicon oxide film, a silicon nitride film is formed. The silicon nitride film has a function to fill a hole or holes and suppress immersion of moisture from outside to the semiconductor device embedded with pressure sensor. A laminated film of the silicon nitride film and the tungsten silicide film forms a diaphragm of the pressure sensor.

Owner:HITACHI LTD

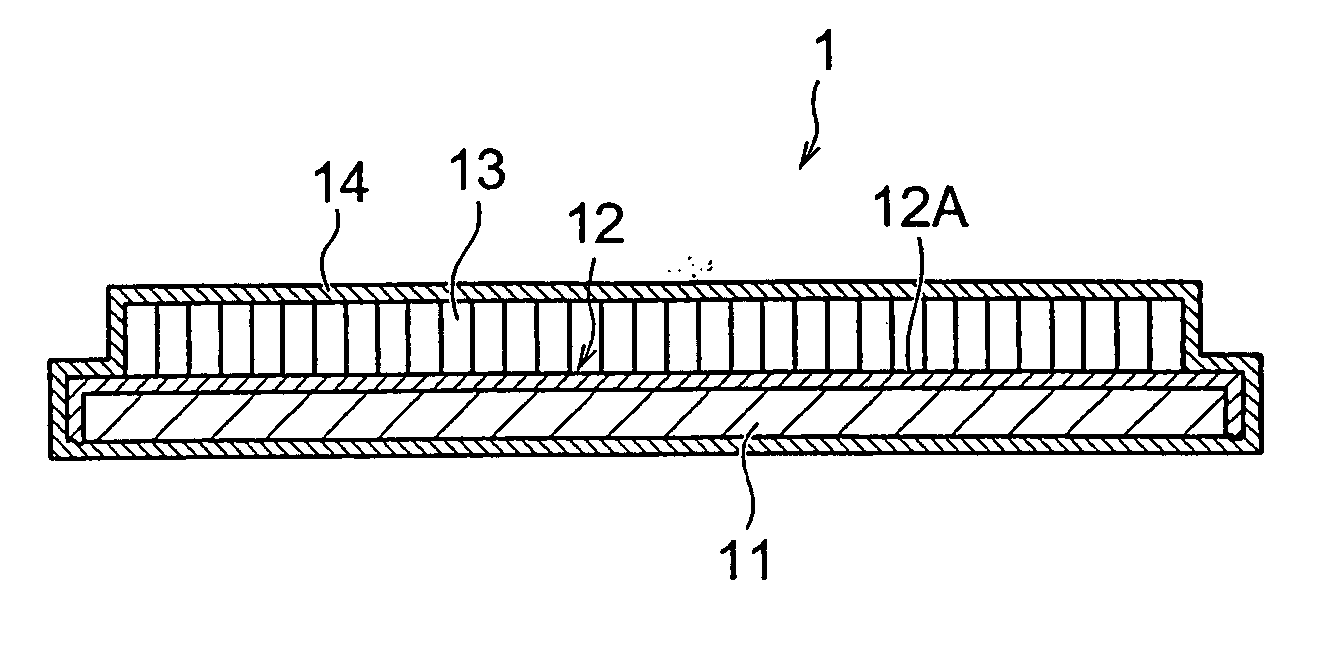

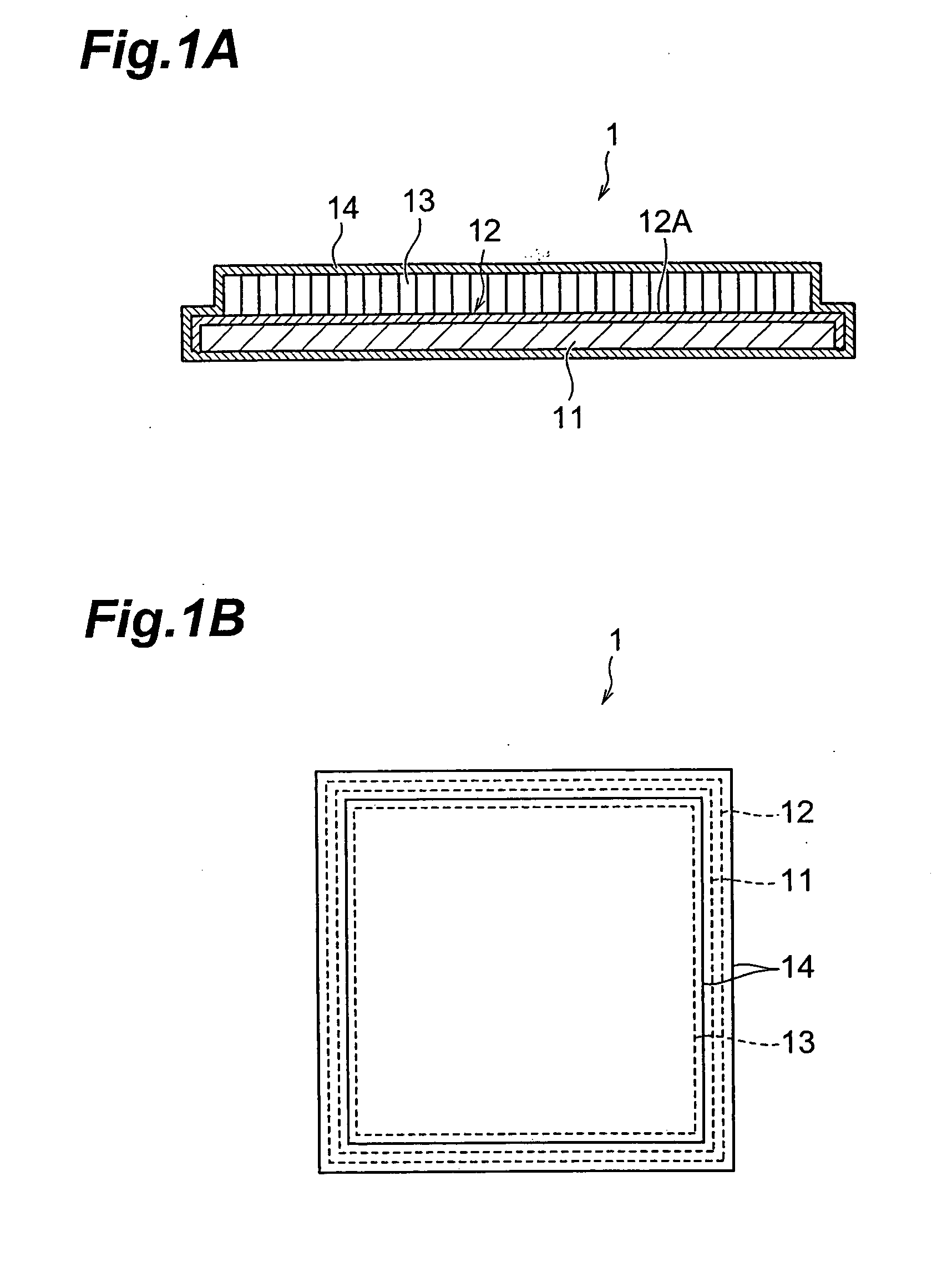

Scintillator panel and method of manufacturing radiation image sensor

InactiveUS20060263521A1Increase the area ratioSlimming down of the substrateAdhesivesChemical vapor deposition coatingOrganic filmOptoelectronics

An auxiliary substrate 20 is overlapped onto a thin substrate 11, and substrate 11 and auxiliary substrate 20 are covered with an organic film 12. Thereafter, a scintillator 13 is formed on a scintillator forming portion 12A of organic film 12 that corresponds to substrate 11. Here, since thickness is added to substrate 11 by auxiliary substrate 20, the warping of substrate 11 is prevented and scintillator 13 is formed uniformly.

Owner:HAMAMATSU PHOTONICS KK

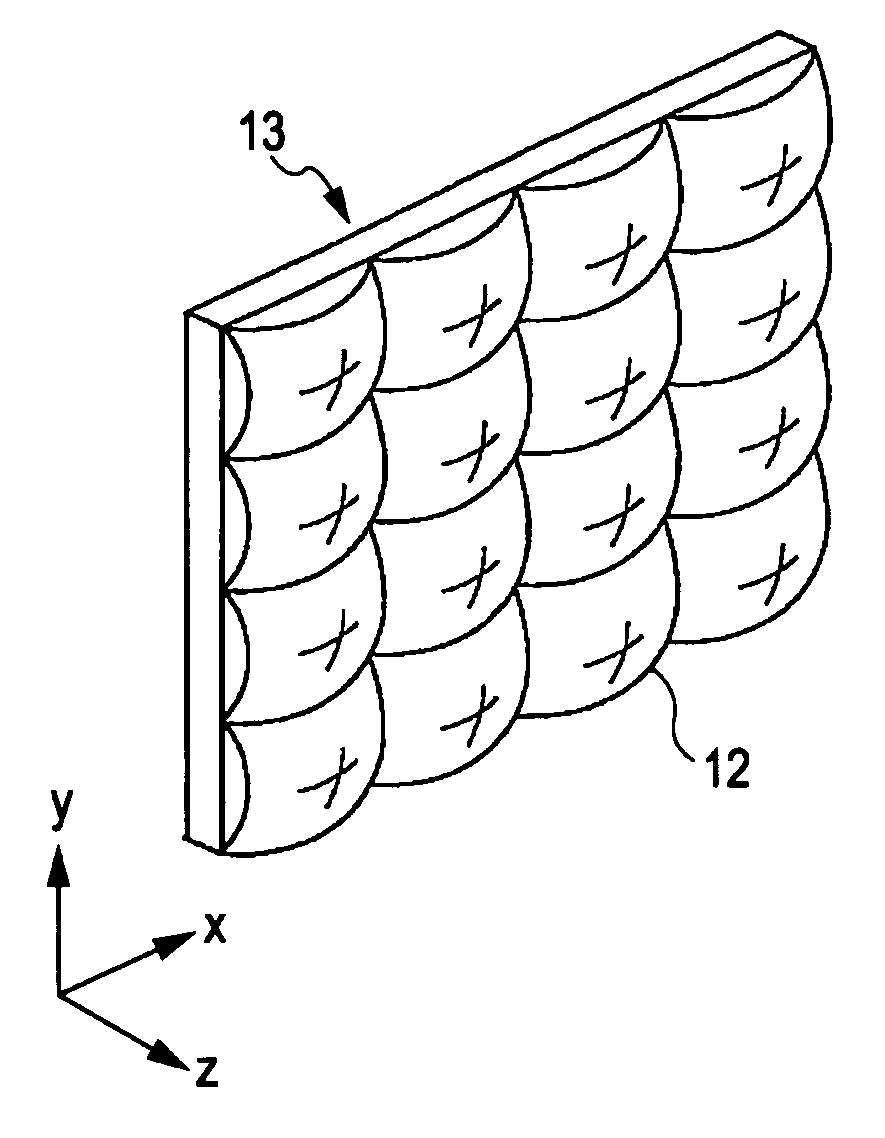

Fly's-eye lens sheet having light-shielding layer, method for fabricating the same, transmissive screen, and rear projection image display device

InactiveUS20060285214A1High light transmittanceIncrease contrastDiffusing elementsProjectorsProjection imageDisplay device

A fly's-eye lens sheet having a light-shielding layer includes a fly's-eye lens sheet body provided with fly's-eye lenses on one principal surface thereof, the light-shielding layer provided on the other principal surface of the fly's-eye lens sheet body, and a photosensitive adhesive layer disposed between the fly's-eye lens sheet body and the light-shielding layer, the photosensitive adhesive layer having adhesive and non-adhesive patterns, wherein the light-shielding layer includes a light-shielding portion disposed on the adhesive pattern and transmitting portions disposed on the non-adhesive pattern for transmitting light transmitted through the fly's-eye lenses, the transmitting portions are located at positions corresponding to light-collecting parts of the fly's-eye lenses, and the light-shielding portion contains carbon particles, the content of the carbon particles being 45% to 65% by weight.

Owner:SONY CORP

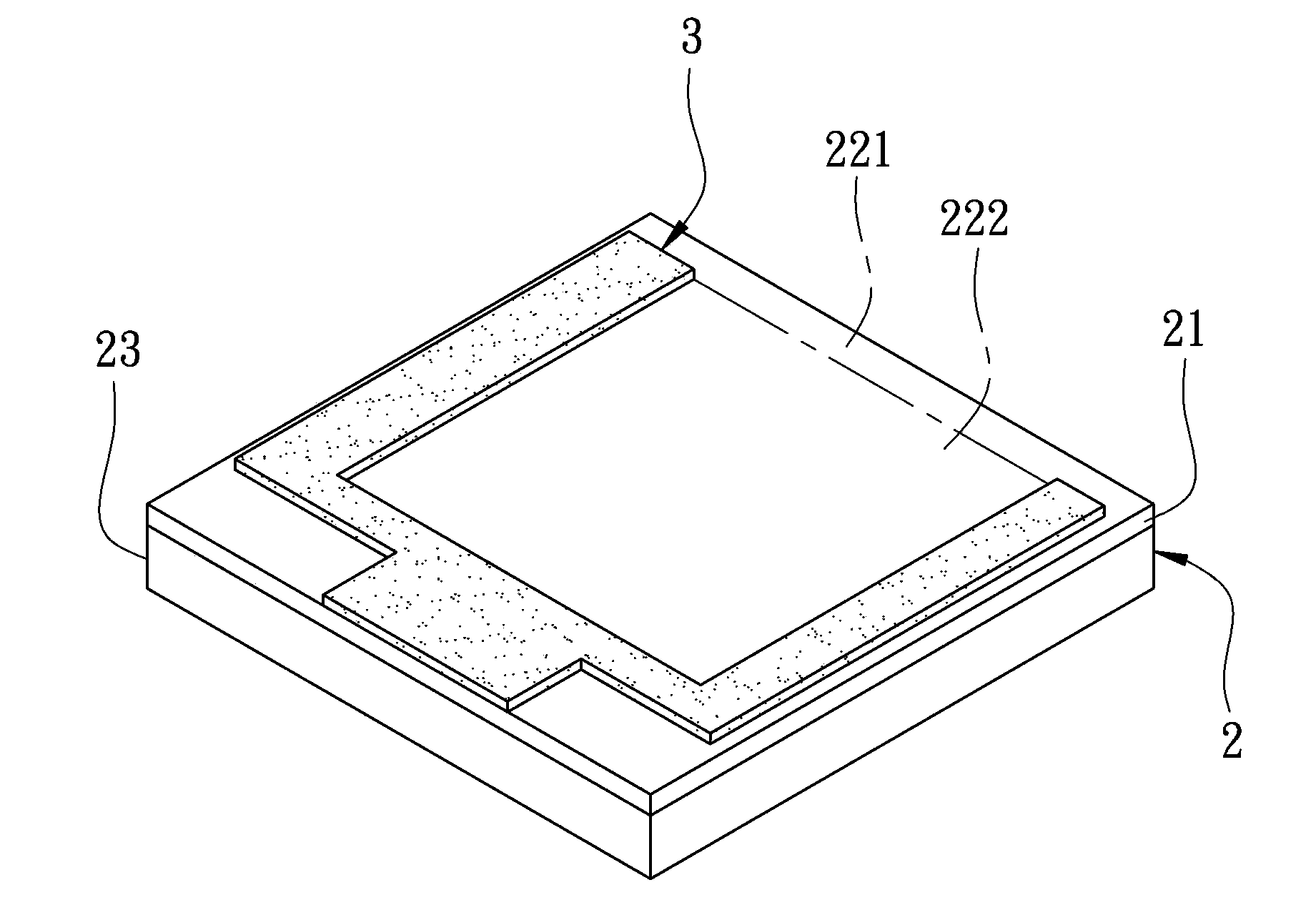

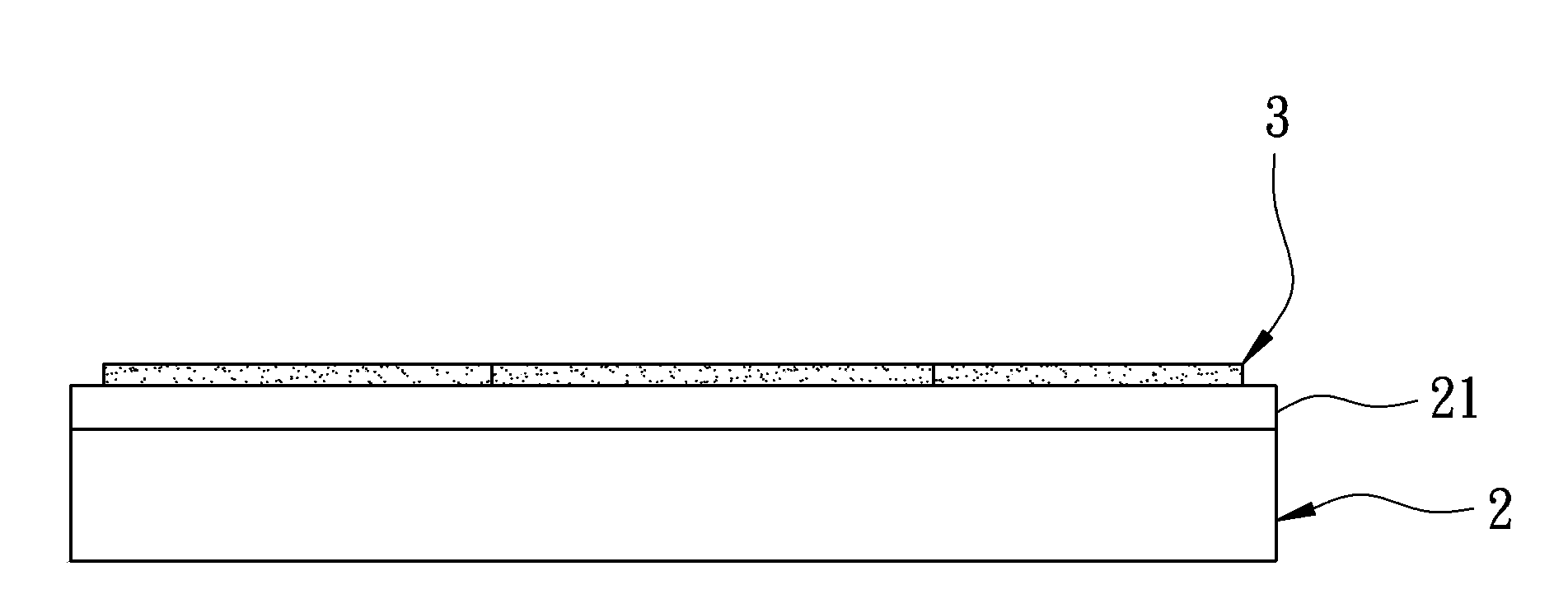

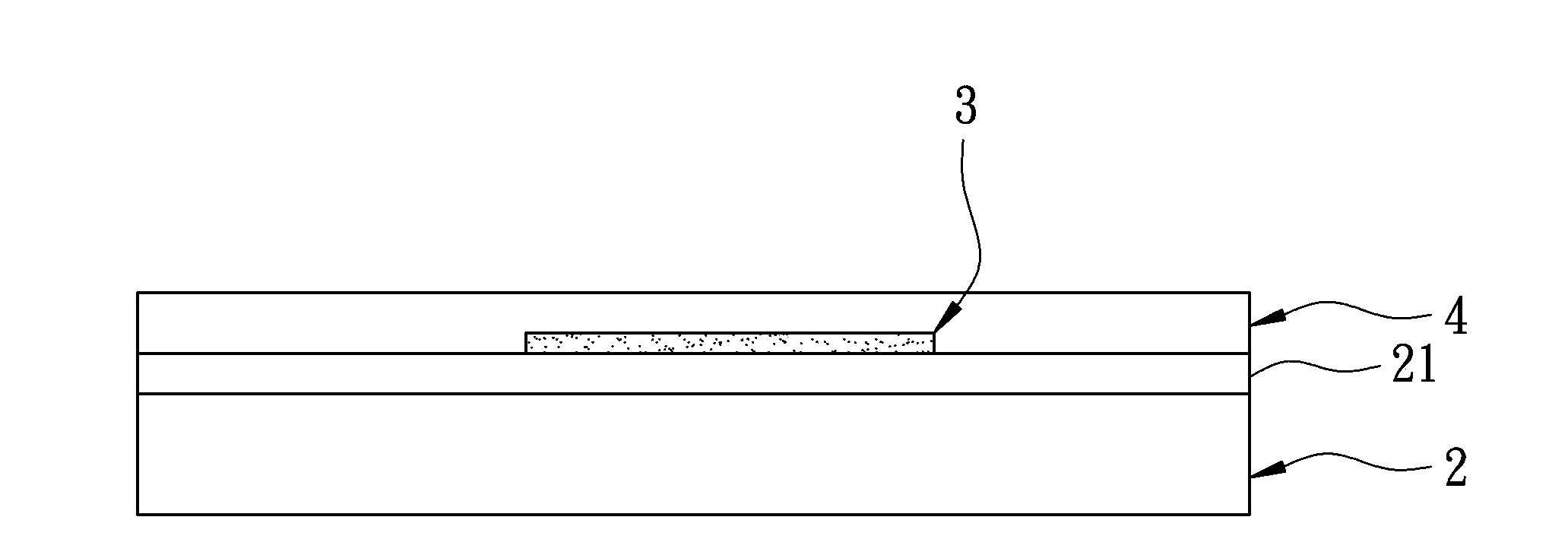

Manufacturing method for touch panel edge wire routing, touch panel and touch display device

InactiveCN103384451AAvoid bad situationsBad or error signal goodConductive material chemical/electrolytical removalInput/output processes for data processingTouch panelSurface smoothness

The invention provides a manufacturing method for touch panel edge wire routing, a control panel with the edge wire routing and a touch display device. The manufacturing method comprises the following steps of (a) forming a photosensitive conductive paste layer on an edge area of a substrate with a transparent conductive layer, enabling the photosensitive conductive paste layer to be at least in partial overlapping with the transparent conductive layer, (b) exposing the photosensitive conductive paste layer by using a mask, and (c) carrying out developing on the exposed photosensitive conductive paste layer to form a patterning edge wire routing unit on the edge area of the substrate. The manufacturing method is beneficial to improving the precision of a wire route under the situation that the wire width of the edge wire routing is narrowed, and can enable the wire route to have good surface smoothness.

Owner:INNOCOM TECH SHENZHEN +1

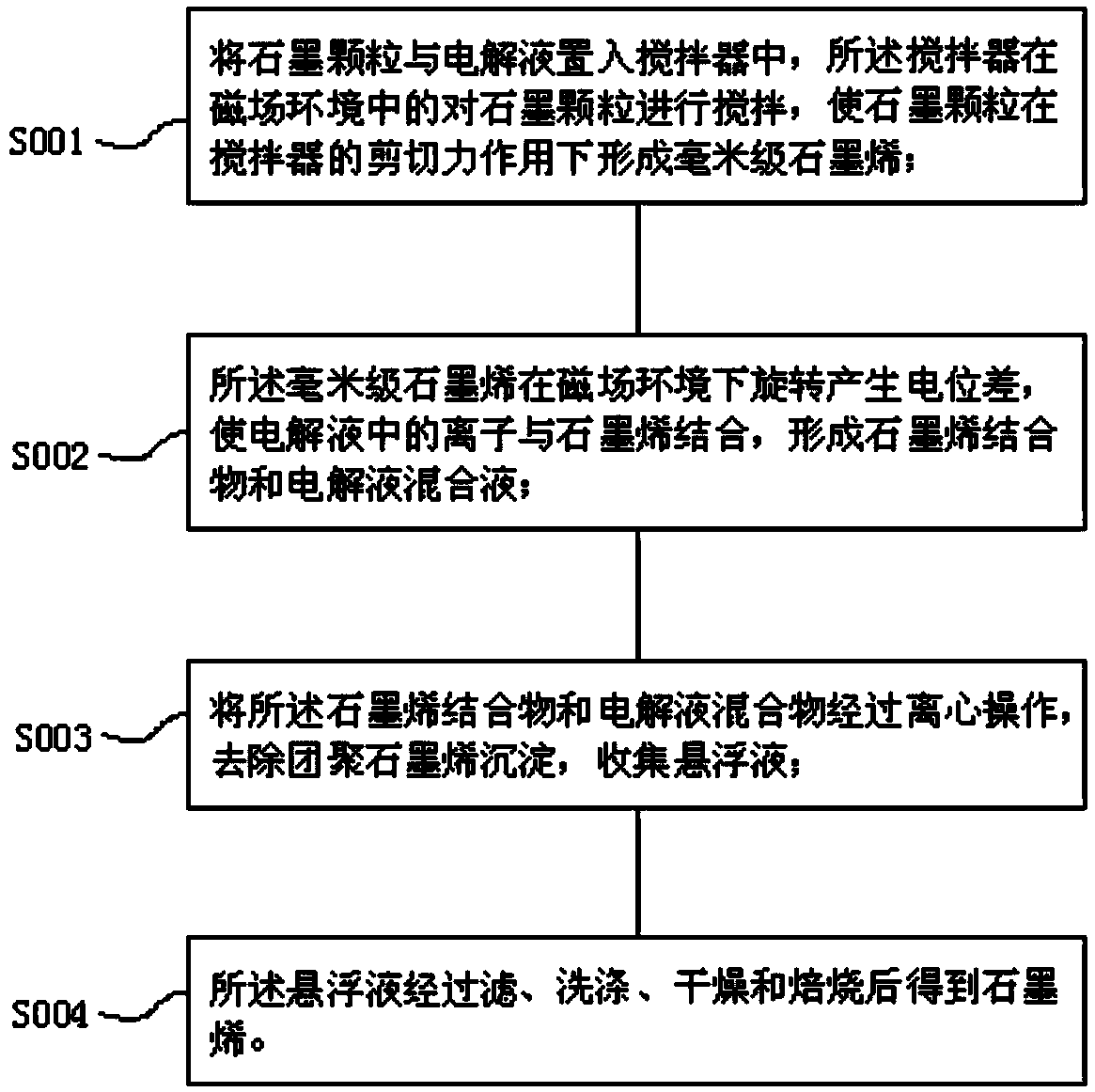

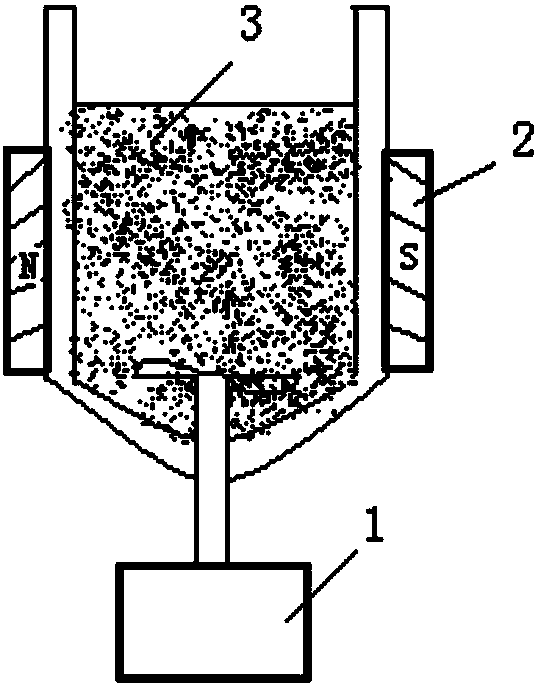

Novel graphene preparation technique

The invention relates to a novel graphene preparation technique which at least comprises the following steps: S001: adding graphite particles and an electrolyte into a stirrer, and stirring the graphite particles in a magnetic field environment by the stirrer so that the graphite particles form millimeter-grade graphene under the action of the shearing force of the stirrer; S002: rotating the millimeter-grade graphene in the magnetic field environment to generate potential difference so that the ions in the electrolyte are combined with the graphene to form a graphene conjugate-electrolyte mixture; S003: centrifuging the graphene conjugate-electrolyte mixture to remove the aggregated graphene precipitate, and collecting the suspension; and S004: filtering the suspension, washing, drying and roasting to obtain the graphene. The graphene preparation provided by the invention is simple, has high operability, is suitable for industrial production, improves the high area ratio and purity of the graphene, enhances the graphene production efficiency and lowers the production cost.

Owner:张泽宇

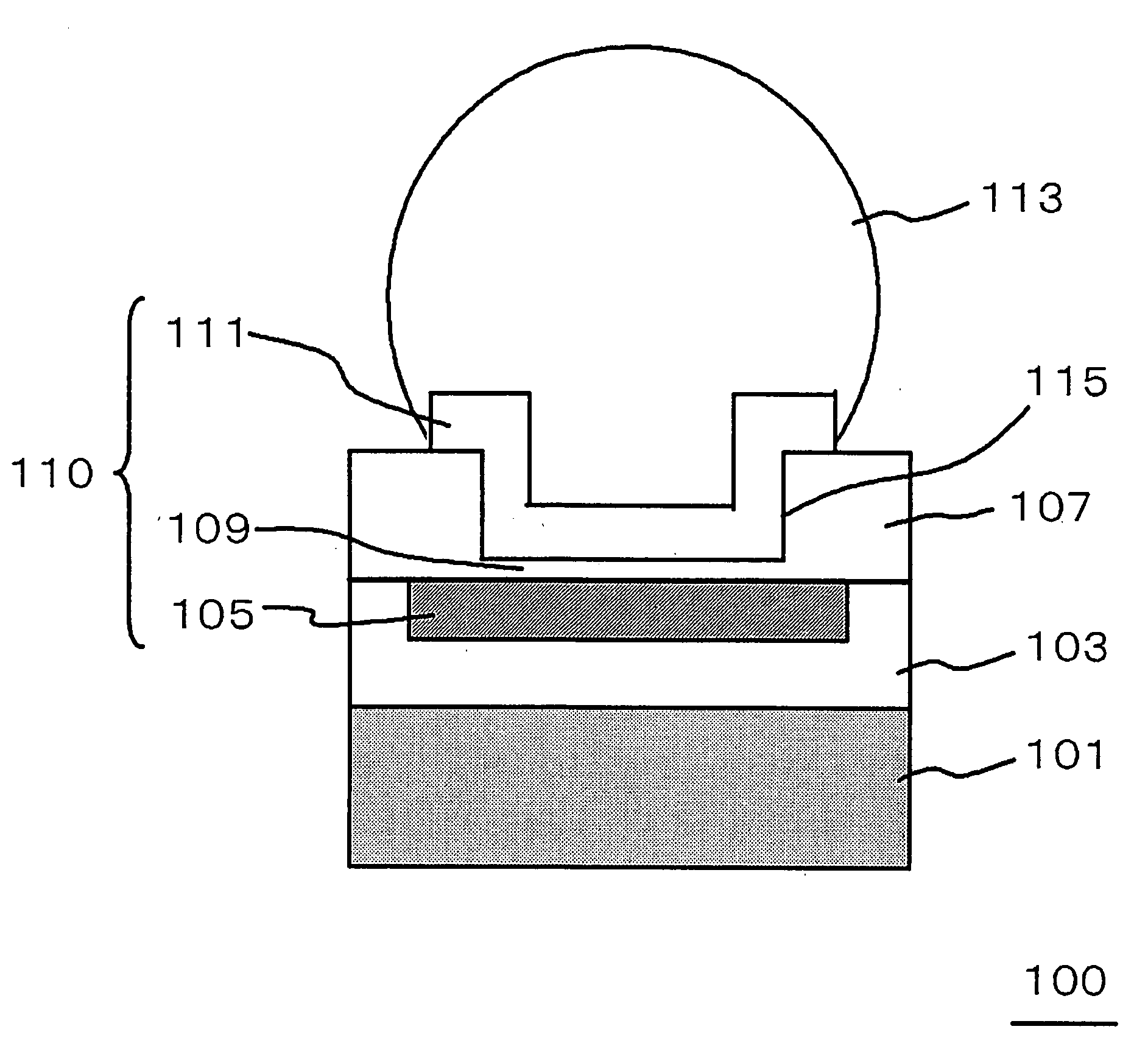

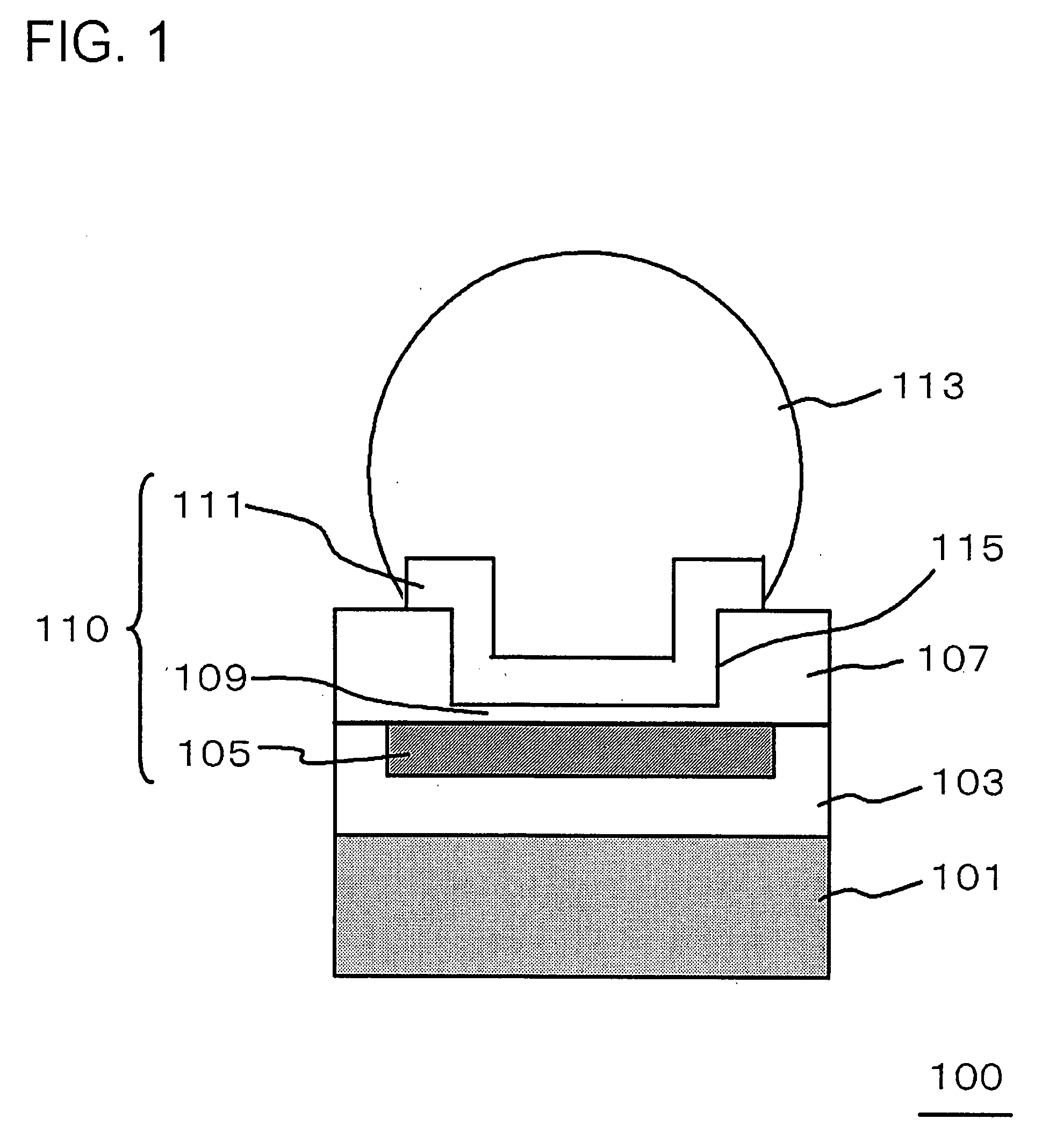

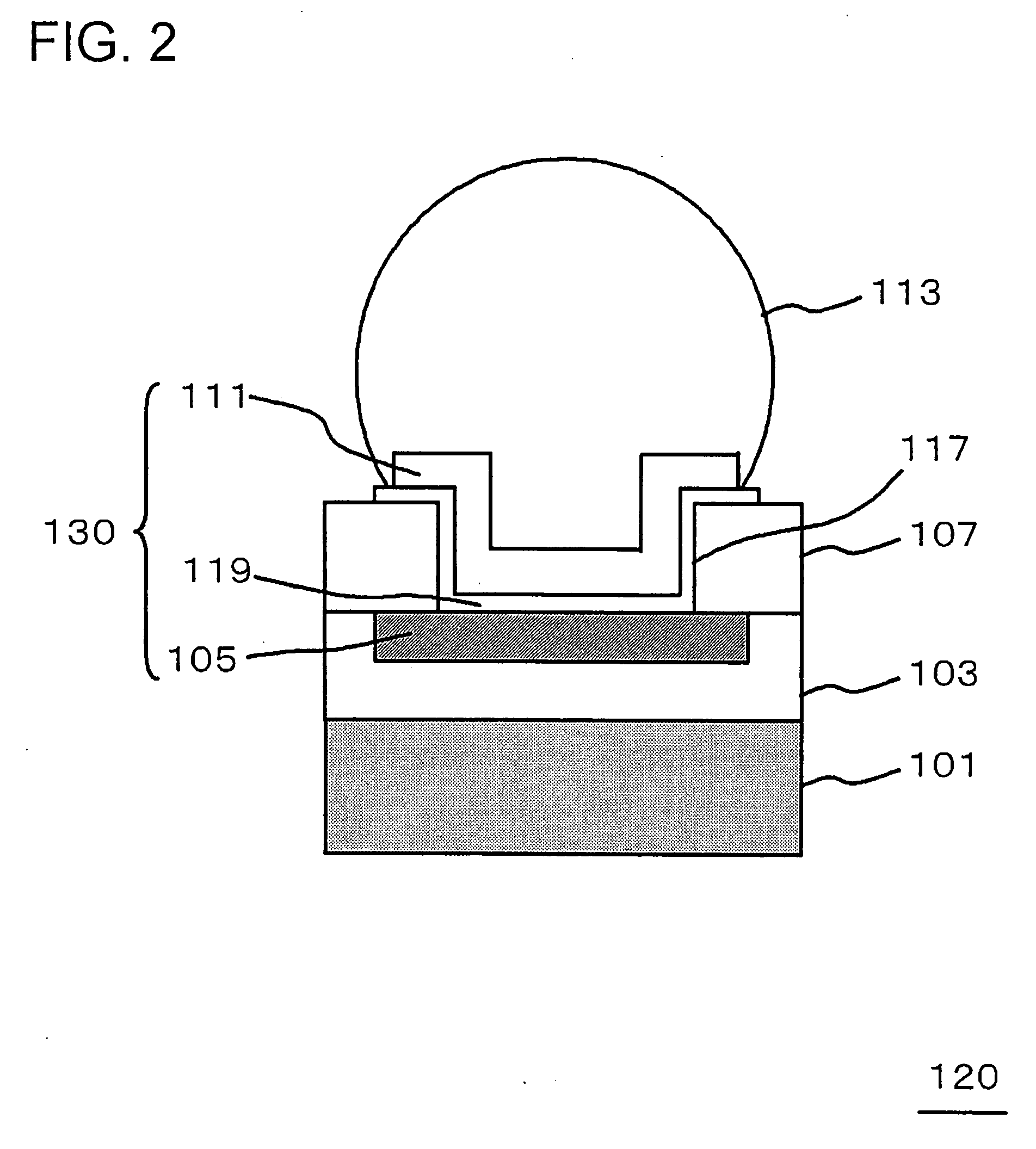

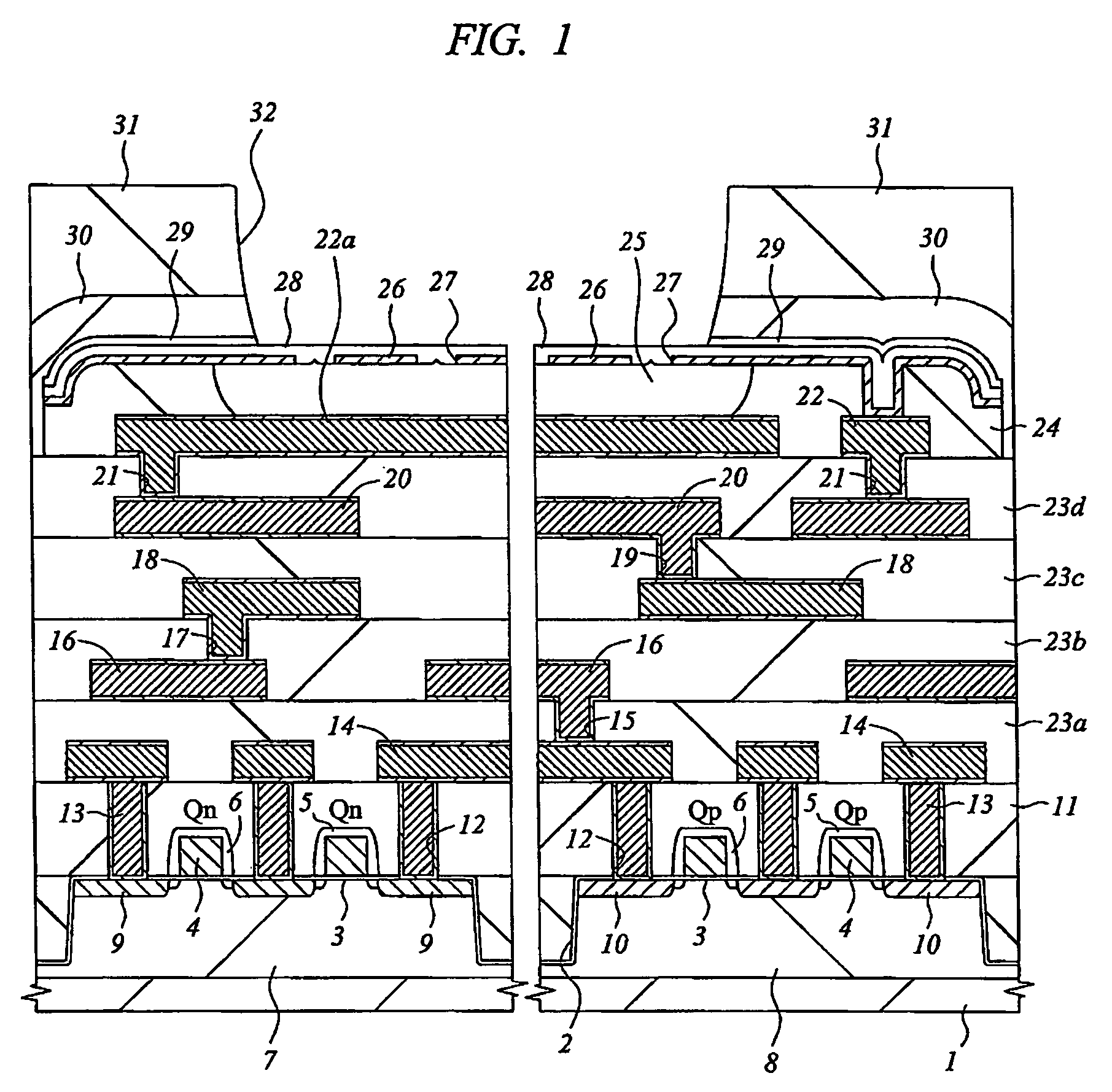

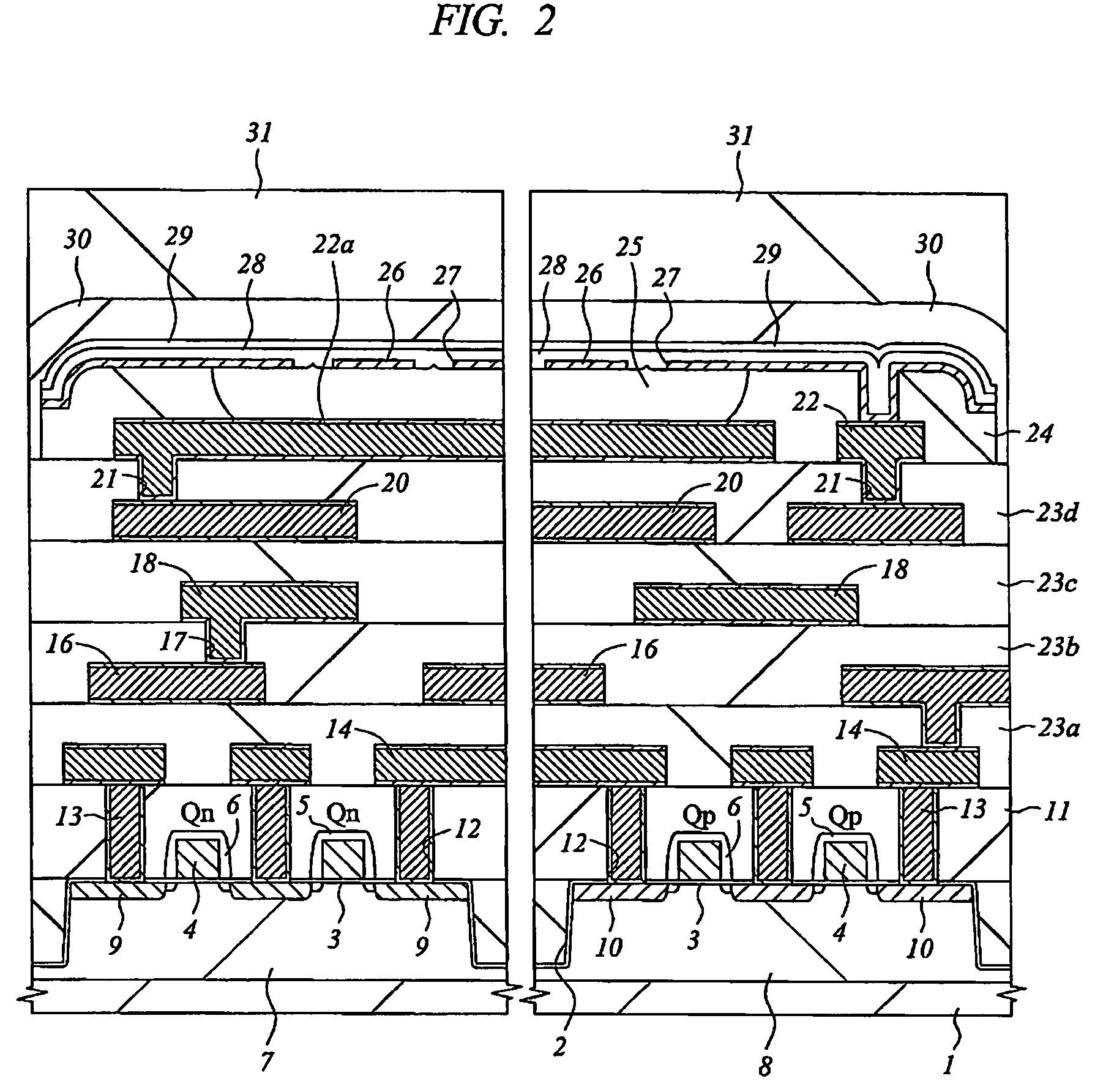

Semiconductor device

InactiveUS20070216027A1Reduced flexibilityIncrease capacitySemiconductor/solid-state device detailsSolid-state devicesCapacitanceCoupling

A semiconductor device, which exhibits an increased design flexibility for a capacitor element, and can be manufactured with simple method, is provided. A semiconductor device 100 includes: a silicon substrate 101; an interlayer film 103 provided on the silicon substrate 101; a multiple-layered interconnect embedded in the interlayer film 103; a flip-chip pad 111, provided so as to be opposite to an upper surface of an uppermost layer interconnect 105 in the multiple-layered interconnect and having a solder ball 113 for an external coupling mounted thereon; and a capacitance film 109 provided between said uppermost layer interconnect 105 and the flip-chip pad 111. Such semiconductor device 100 includes the flip-chip pad 111 composed of an uppermost layer interconnect 105, a capacitive film 109 and a capacitor element 110.

Owner:RENESAS ELECTRONICS CORP

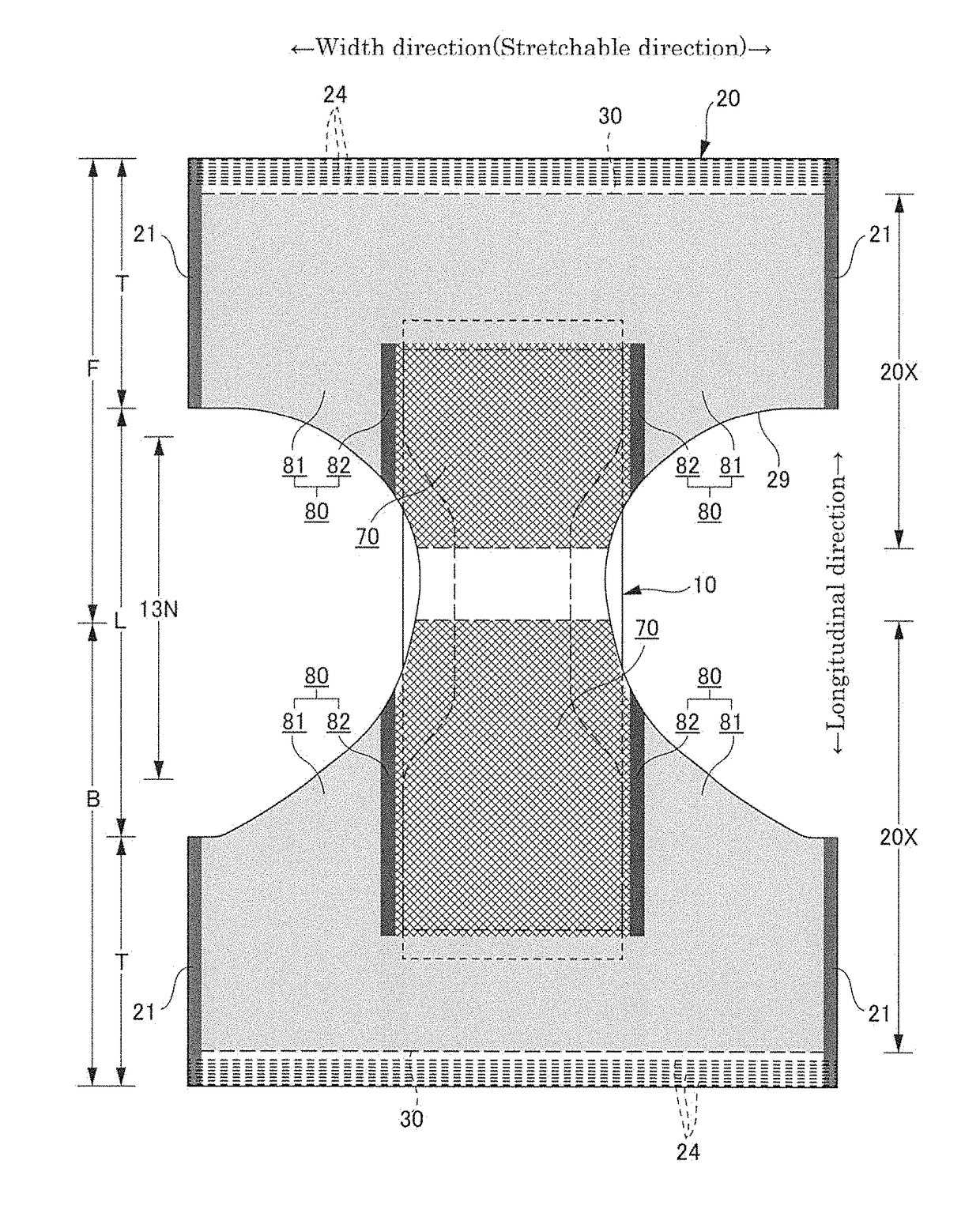

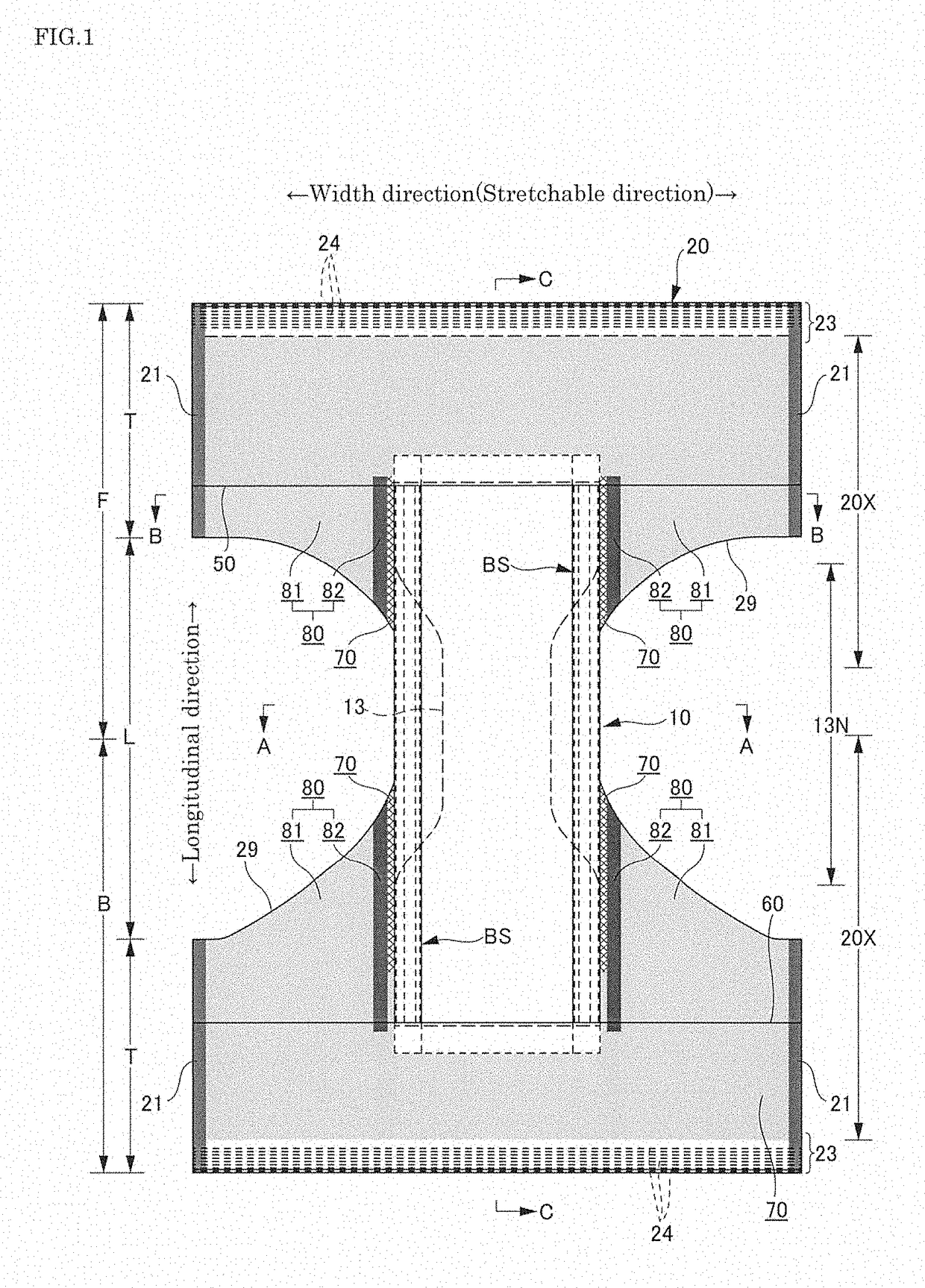

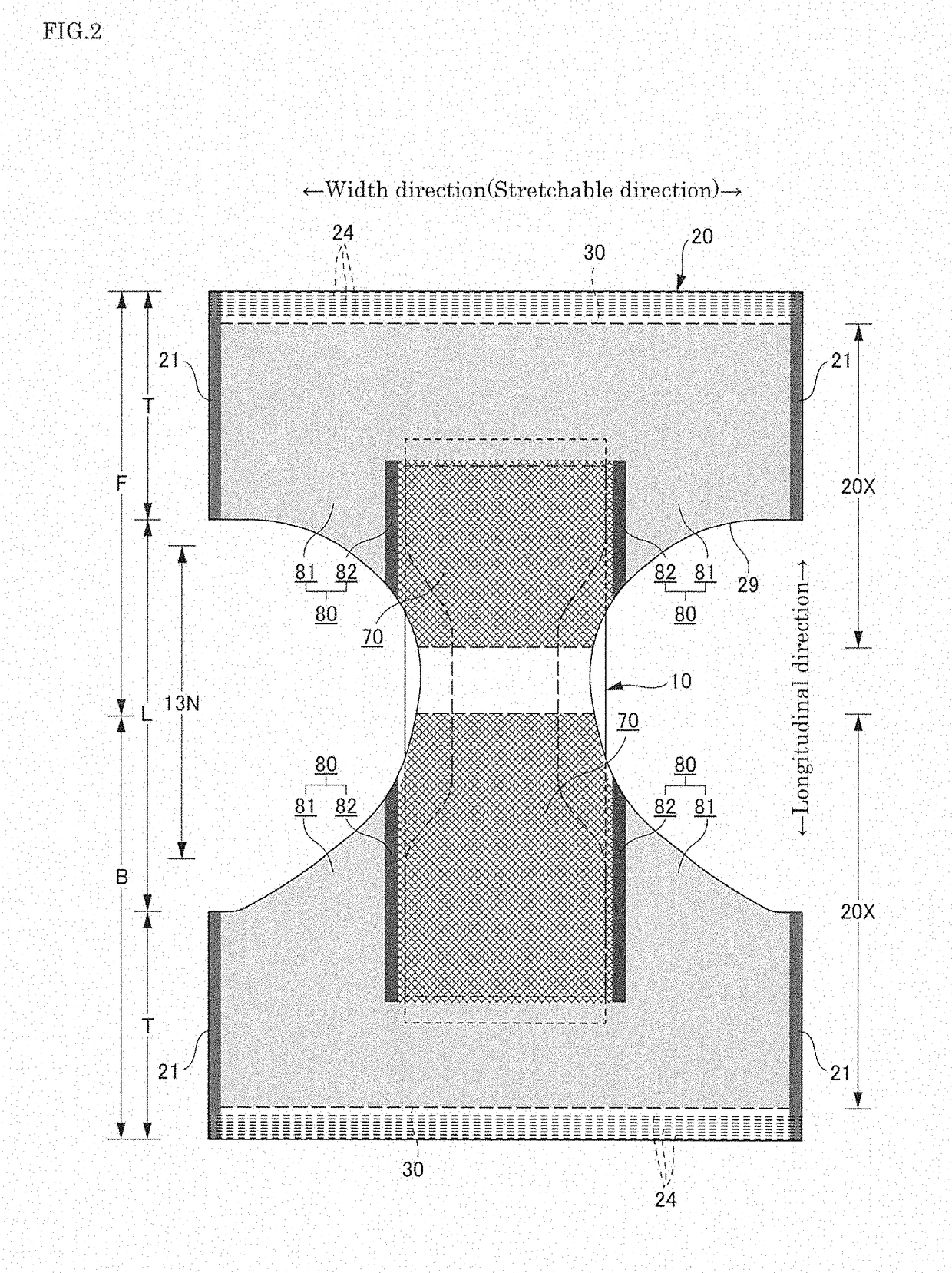

Stretch structure for absorbent article, and underpants-type disposable diaper using same

ActiveUS20180028371A1Increase the area ratioIncreased riskAbsorbent padsBandagesSacroiliac jointElectrical and Electronics engineering

A stretchable structure of an absorbent article includes a stretchable region and a non-stretchable region. A laminate of a first sheet layer, second sheet layer, and elastic film between the first and second sheet layers extends over the stretchable and non-stretchable regions. The first and second sheet layers are bonded to each other at a large number of dot-like joints via through holes formed in the elastic film stretched along the surfaces of the first and second sheet layers in a stretchable direction. The dot-like joints are arrayed at intervals in the stretchable direction and a direction perpendicular to the stretchable direction. An end of the stretchable region adjacent to the non-stretchable region is a buffer stretchable section. The area rate of dot-like joints in the buffer stretchable section is larger than the area rate of dot-like joints in the main section not including the buffer stretchable section.

Owner:DAIO PAPER CORP

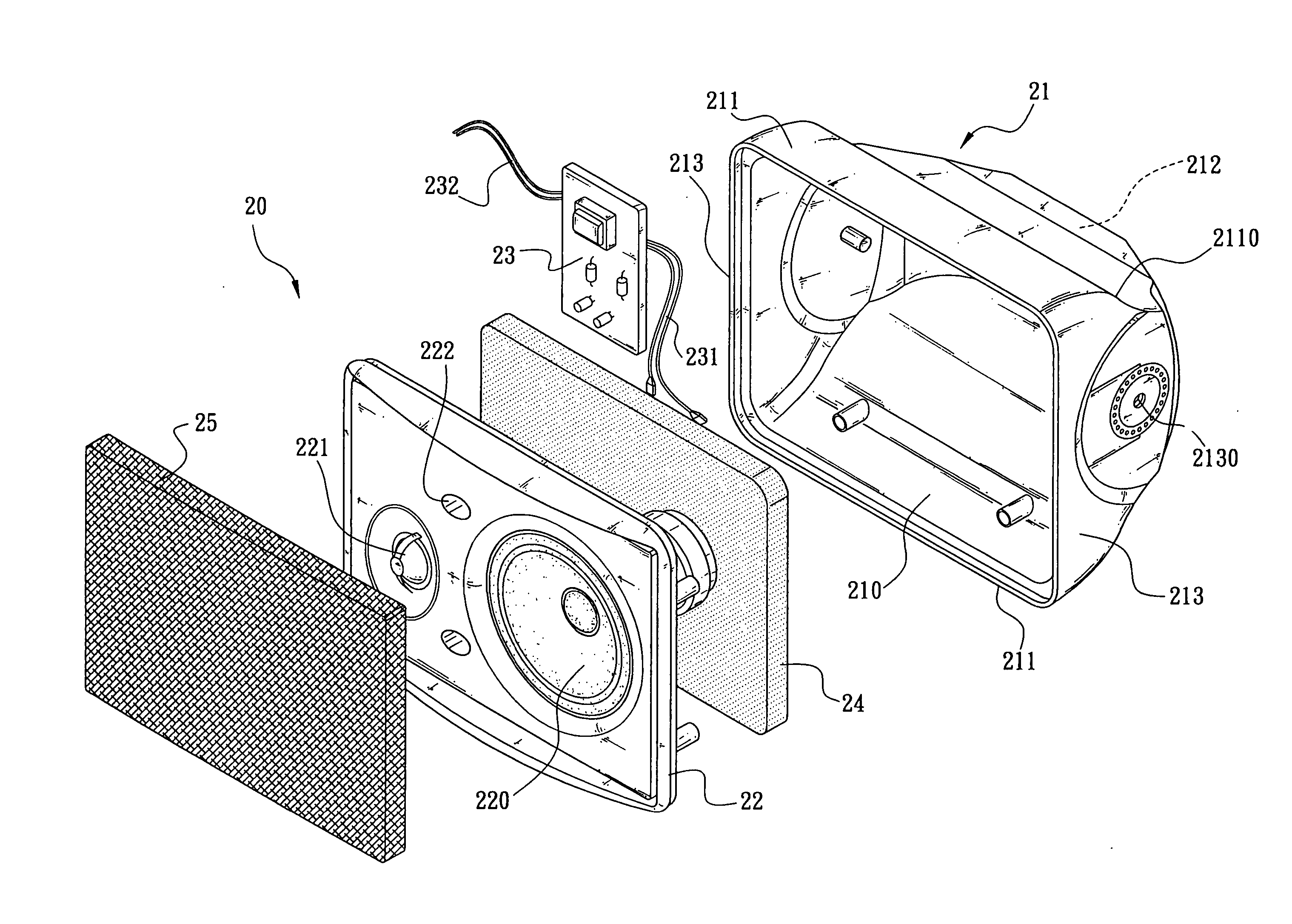

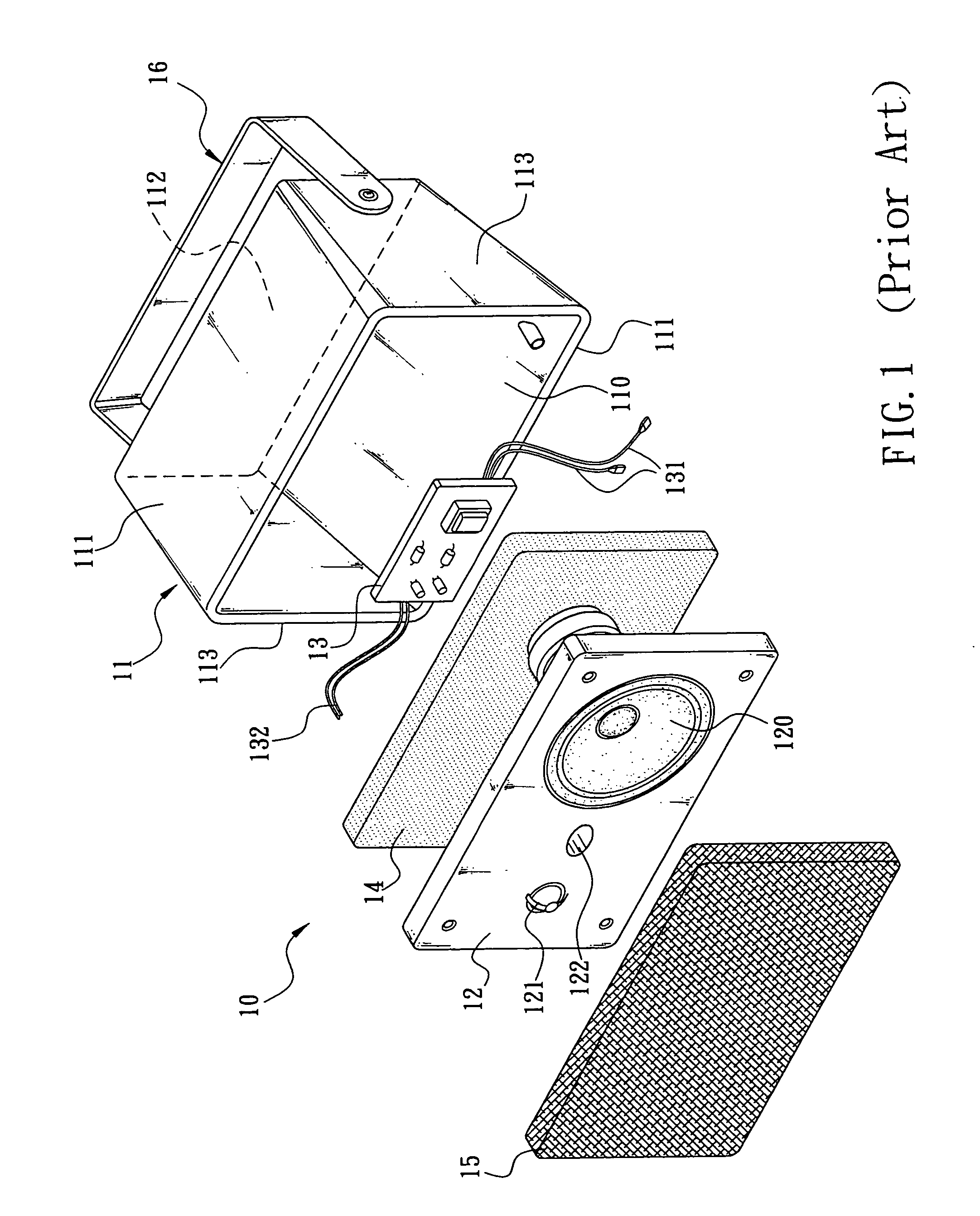

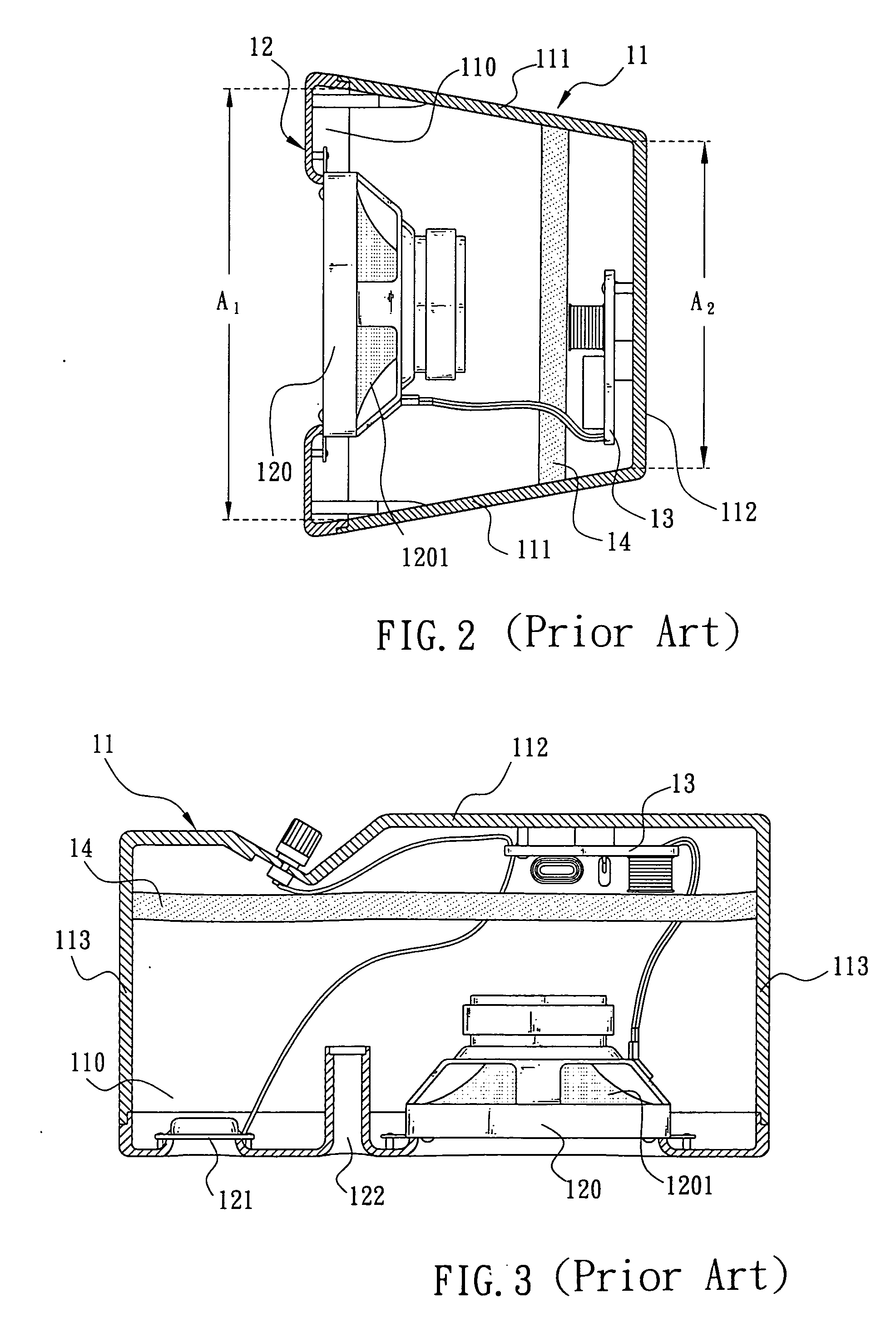

Speaker cabinet with increased air circulation efficiency

ActiveUS20050089184A1Strong low-frequency resonanceReduce probabilityFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsAir cycleResonance

The present invention is to provide a speaker cabinet comprising a hollow case in which a top and a bottom thereof both are wavily tapered from a pair of opposite edges of a front opening to a rear thereof. By utilizing the wavy, rearward taper design of the top and the bottom, a ratio of an area of the opening to an area of the rear is increased. Thus, air inside the case will be compressed rearward when a diaphragm of a woofer vibrates. Next, the compressed air will quickly flow toward the rear along the wavy, rearward taper inner surfaces of the top and the bottom. As a result, air dynamic at the rear is higher and stronger low-frequency resonance of the cabinet can be generated.

Owner:WANG CHAO LANG

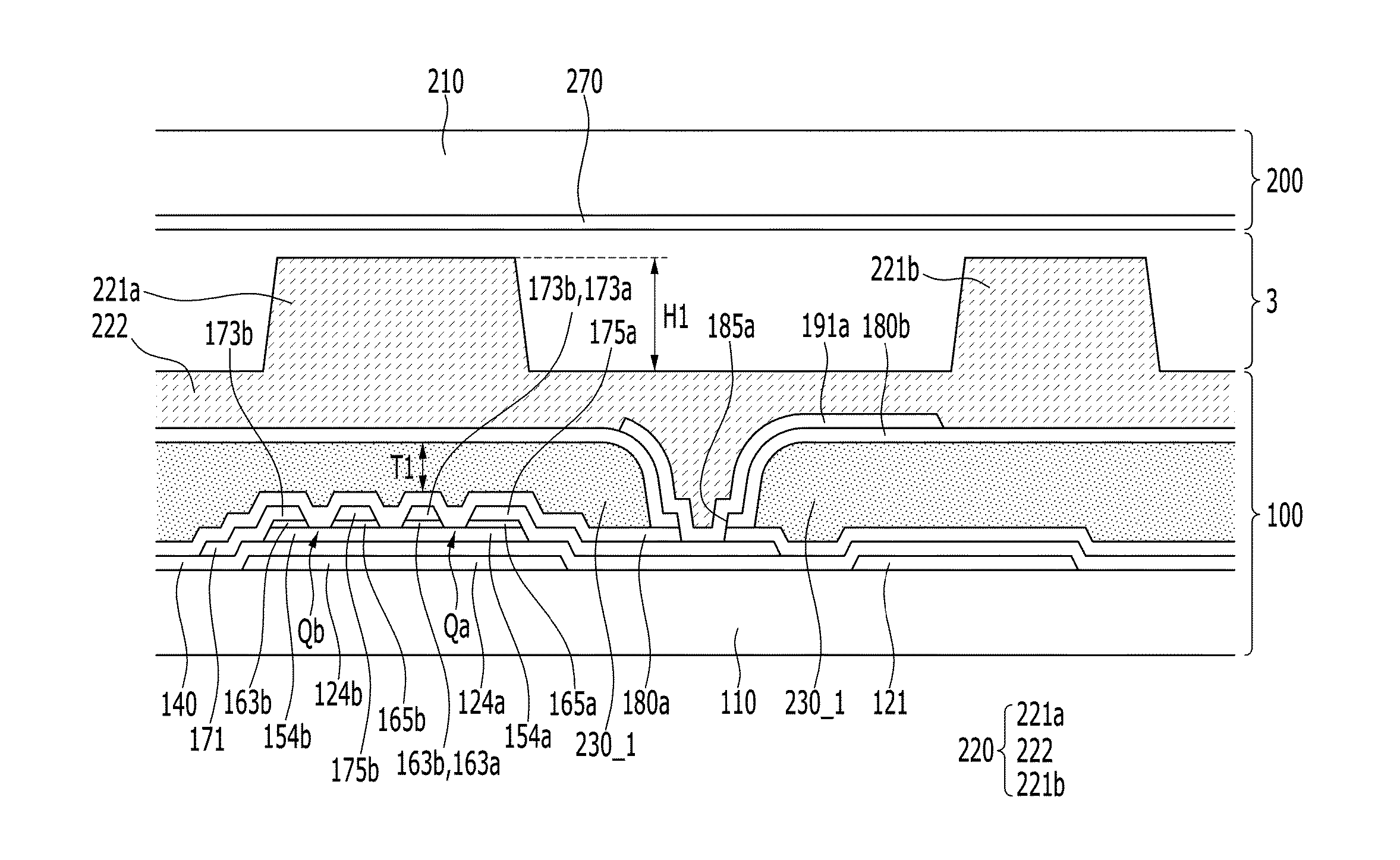

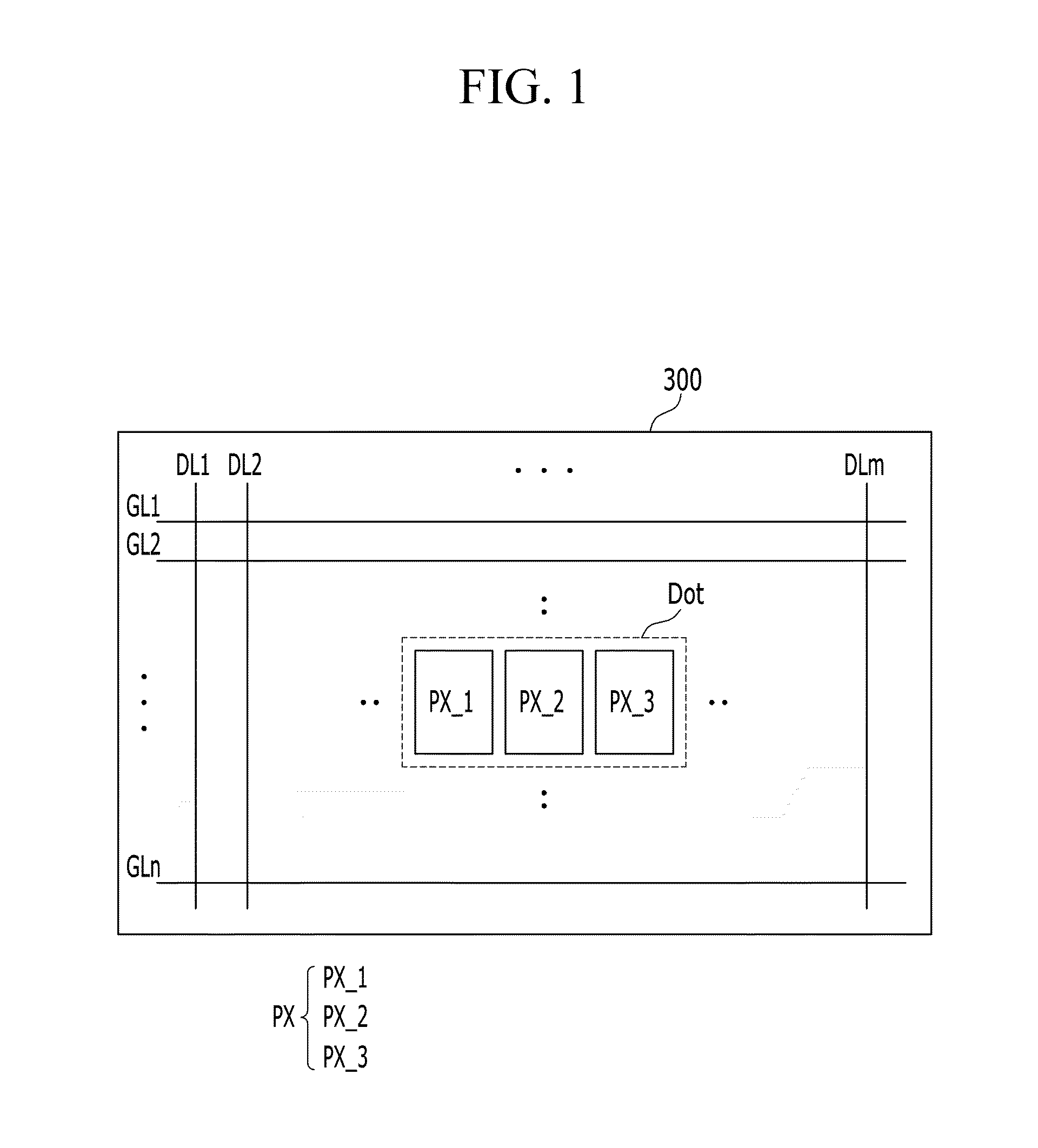

Display device and manufacturing method thereof

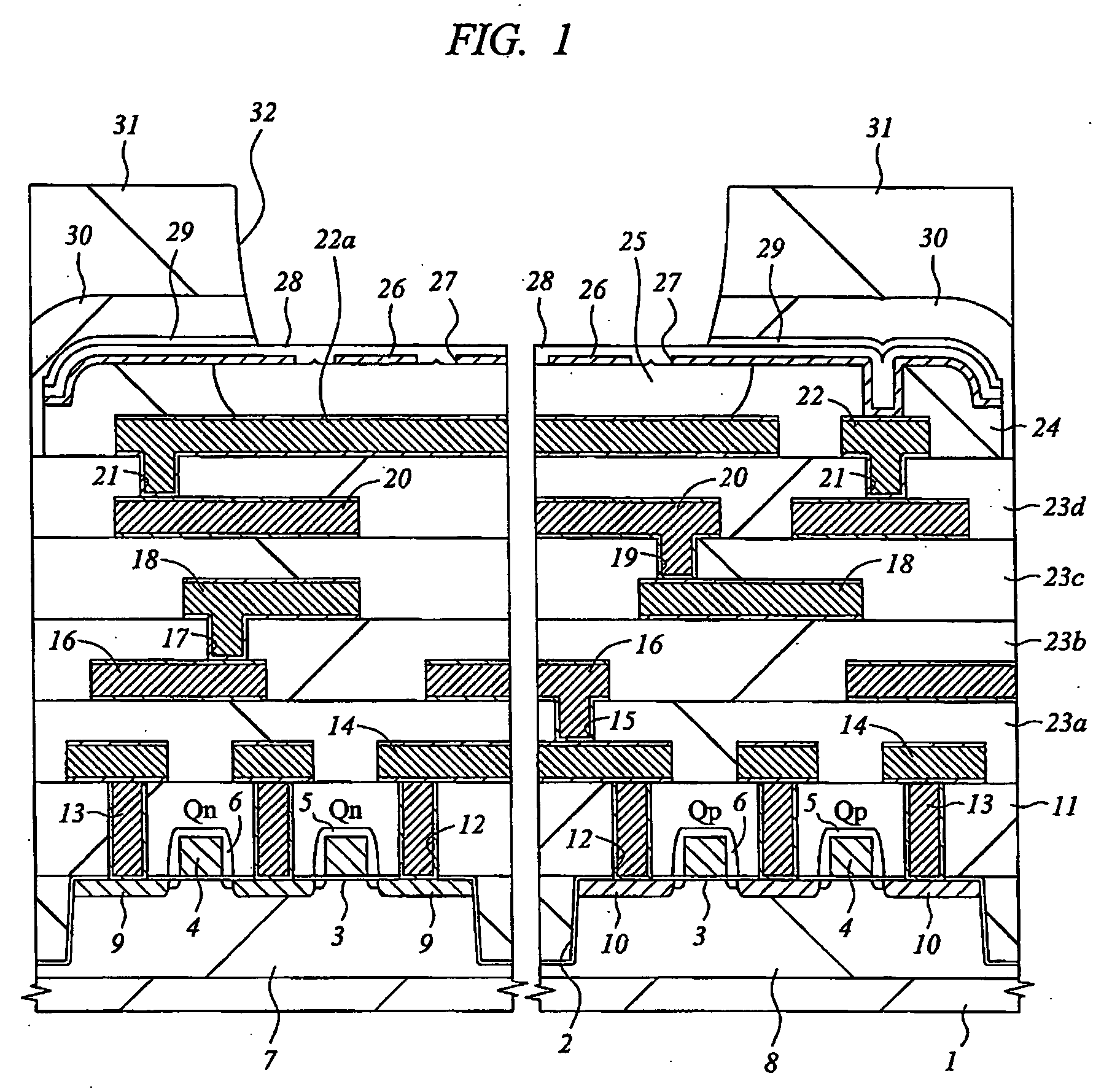

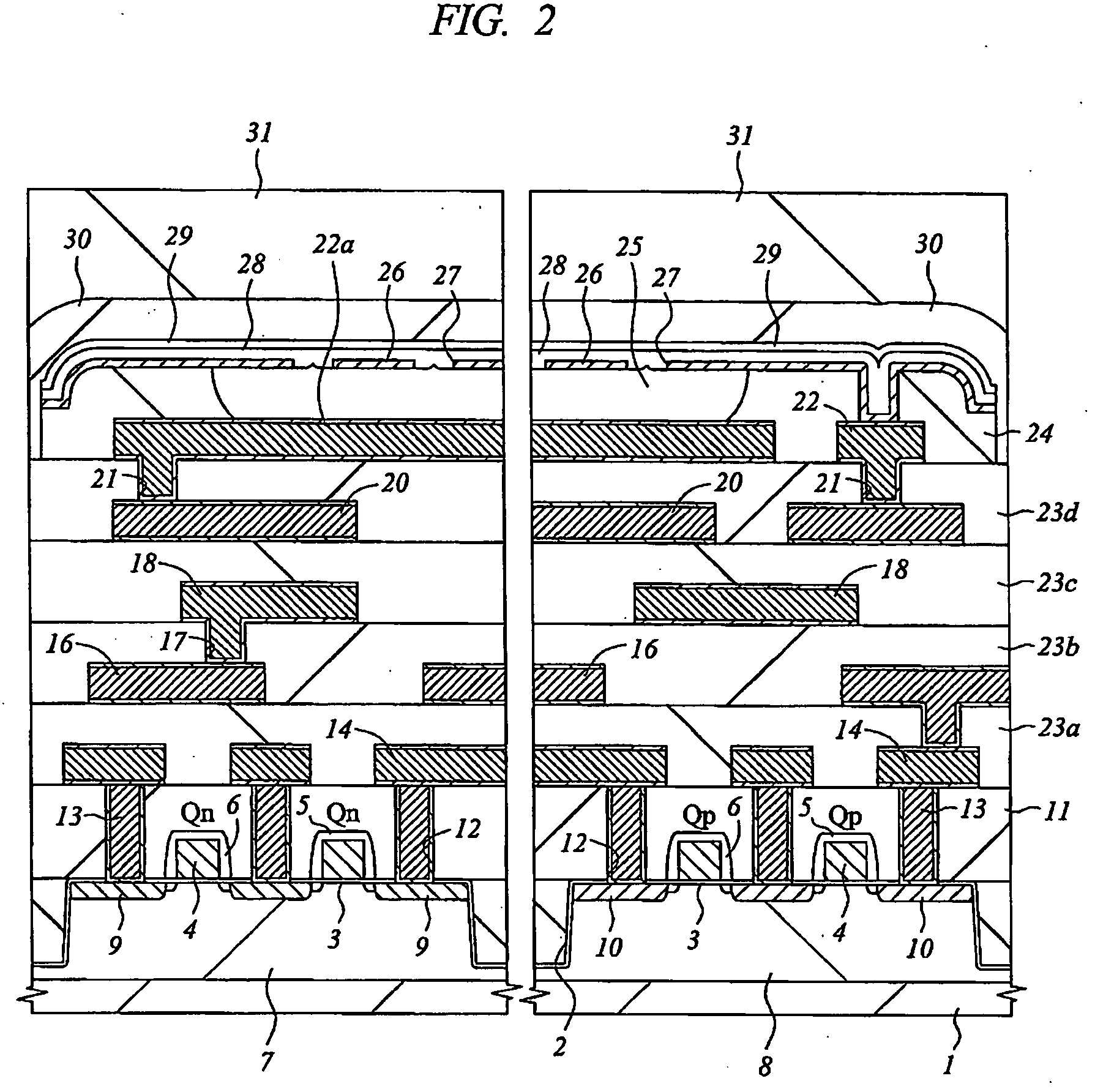

ActiveUS20160178950A1Increase area ratioReduce smudgeTransistorSolid-state devicesEngineeringDisplay device

A display device includes a first substrate and a second substrate facing each other, a first thin film transistor (“TFT”) disposed on the first substrate, a second TFT disposed on the first substrate, a first color filter disposed on the first TFT and a periphery thereof, a second color filter disposed on the second TFT and a periphery thereof and representing a different color from the first color filter, and a light blocking member disposed on the first and second color filters where the light blocking member includes a first spacer disposed on the first TFT and the first color filter, a second spacer disposed on the second TFT and the second color filter, a main light blocking portion disposed in peripheries of the first and second spacers, and a furrow disposed between the second spacer and the main light blocking portion.

Owner:SAMSUNG DISPLAY CO LTD

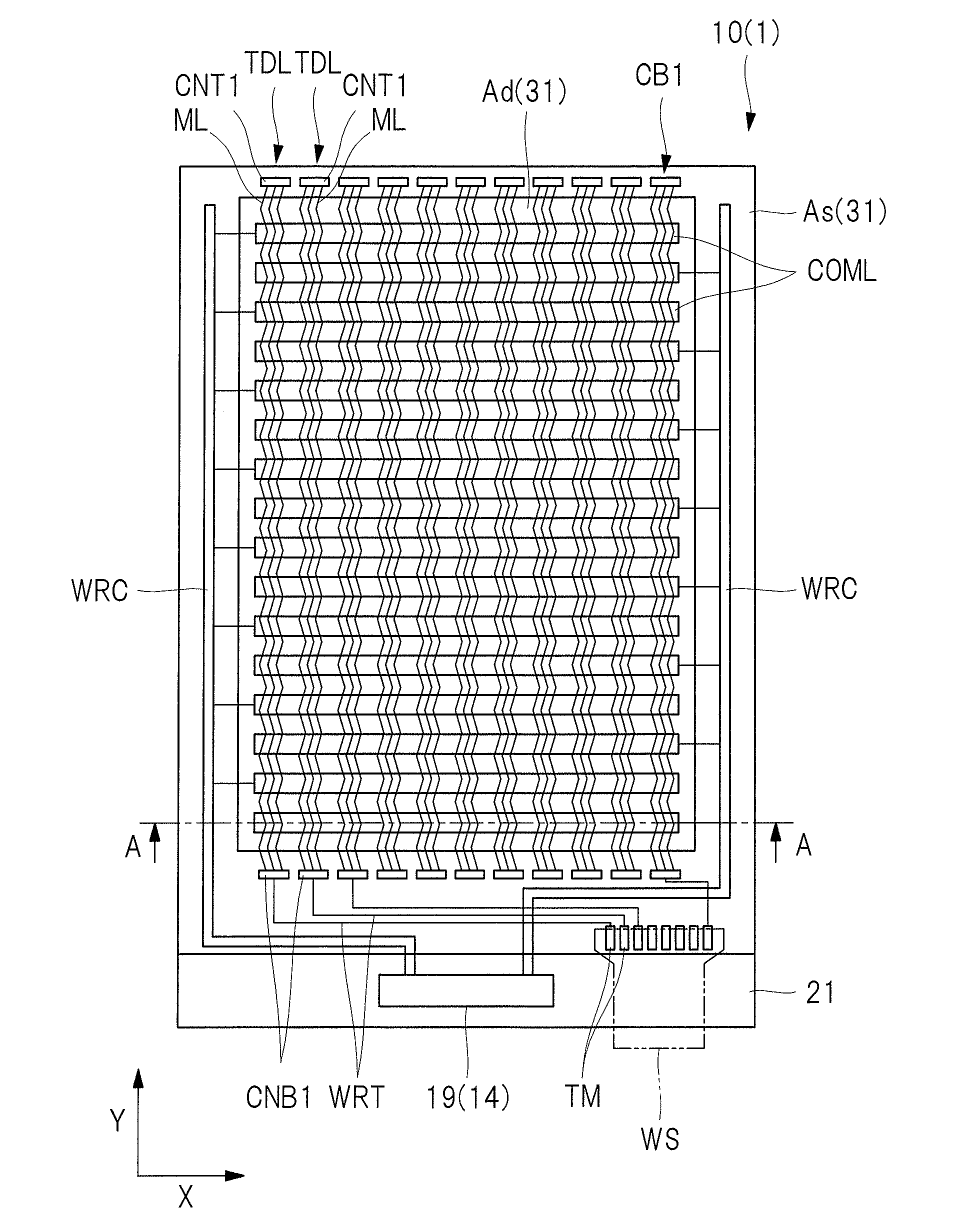

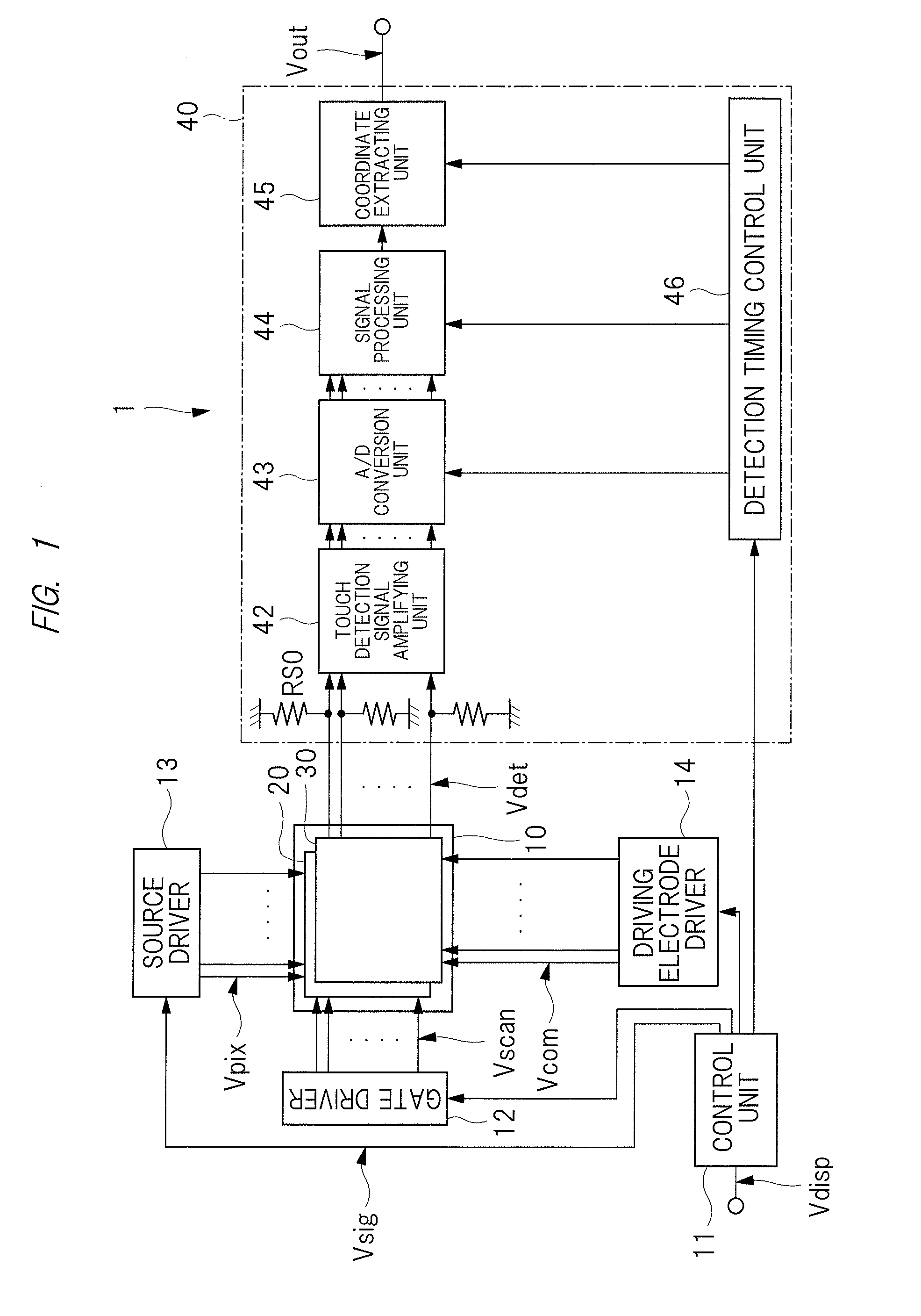

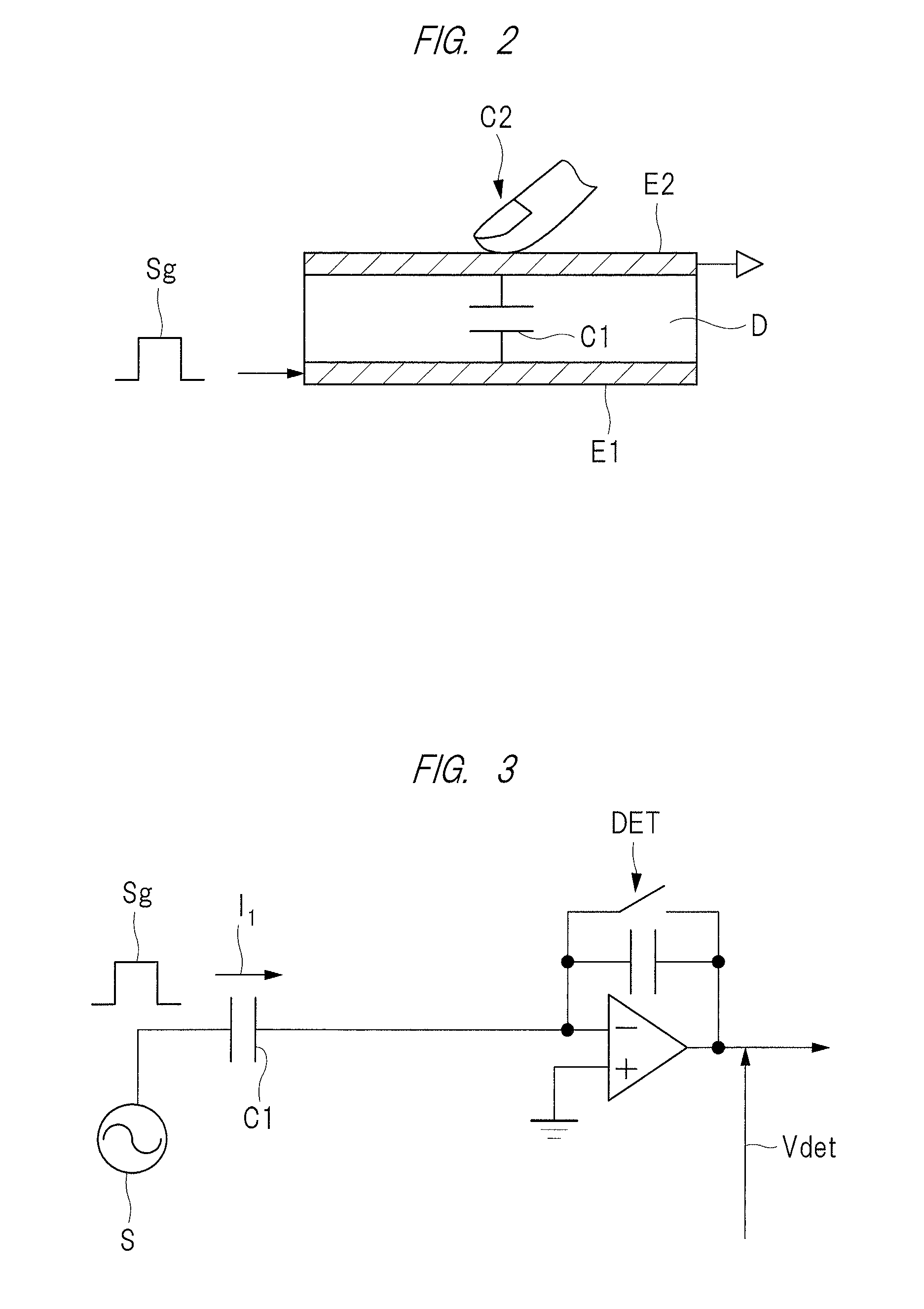

Display

ActiveUS20150370370A1Reduce sheet resistanceEasily static electricityNon-linear opticsInput/output processes for data processingOptical propertyDisplay device

To reduce disturbances in display of images due to static electricity without deteriorating optical properties in a display. The display includes a conductive pattern provided on the upper surface of the substrate, a protection layer provided on the upper surface of the substrate to cover the conductive pattern, and a conductive layer provided on the protection layer. The sheet resistance of the conductive pattern is not more than 8Ω / square. A ratio of the total sum of areas of portions of the plurality of sub-pixels that overlap the conductive pattern in a plan view to the total sum of the areas of the plurality of sub-pixels is 1 to 22%. A sheet resistance of the conductive layer is higher than the sheet resistance of the conductive pattern.

Owner:JAPAN DISPLAY INC

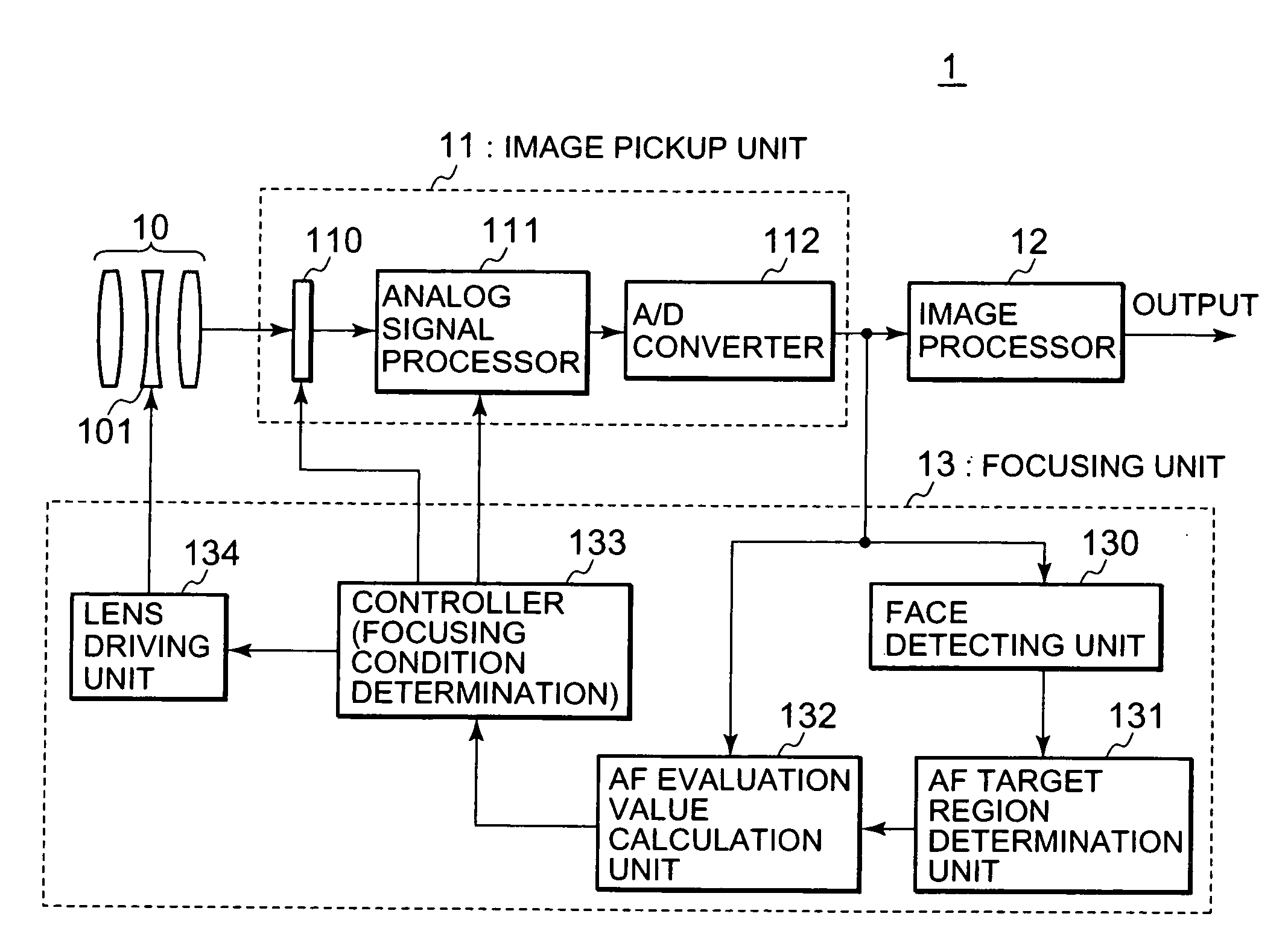

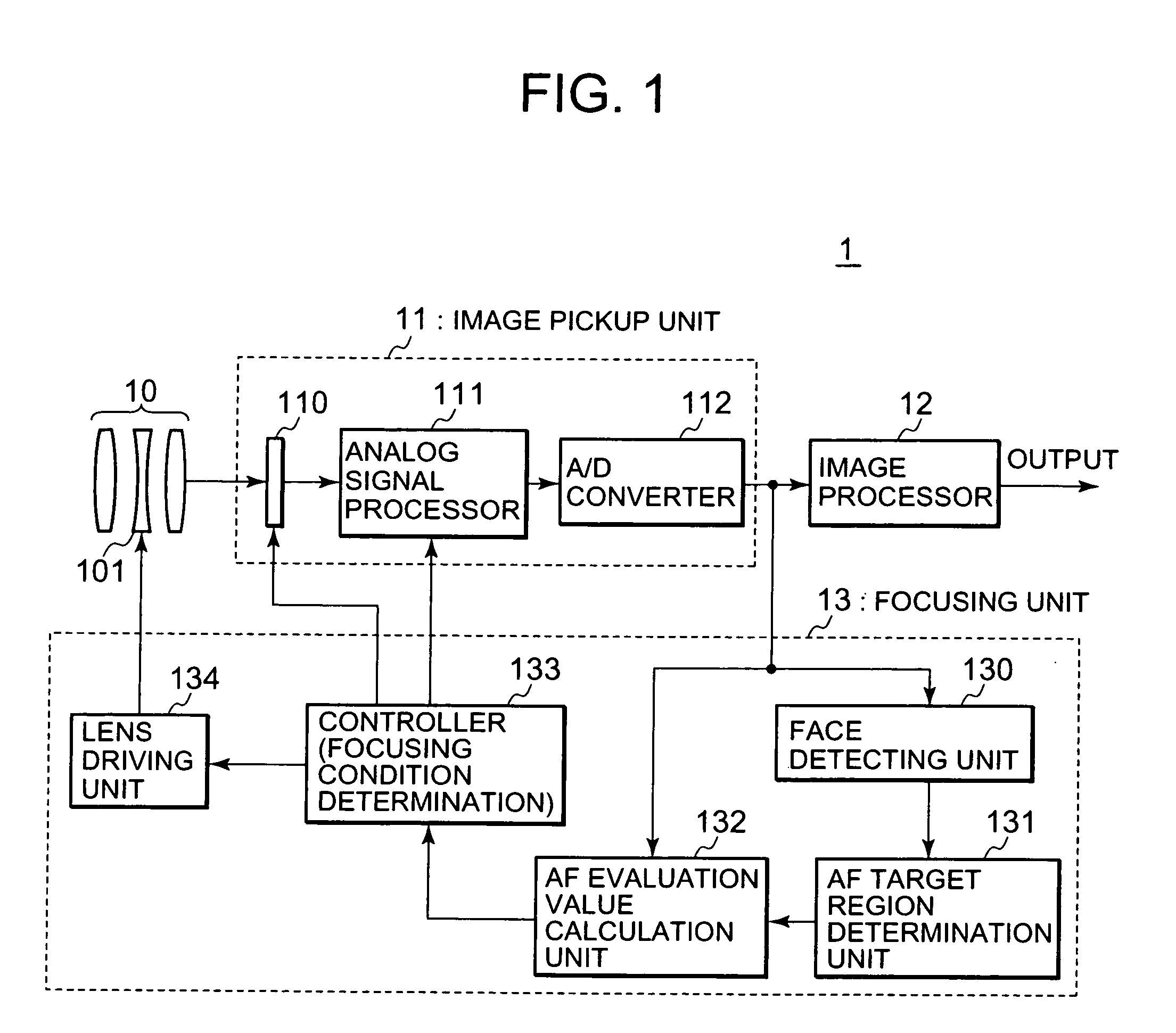

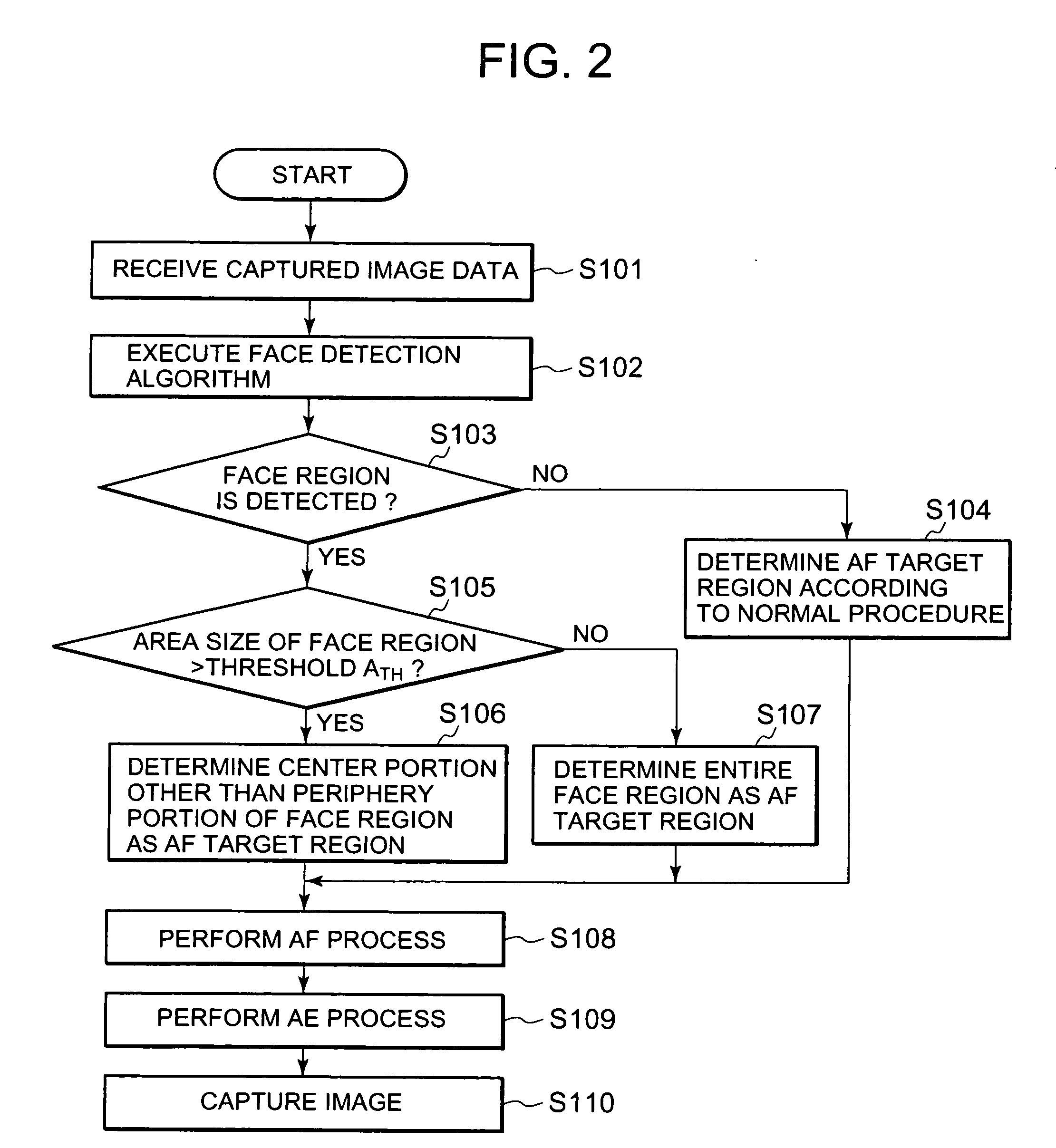

Autofocus control circuit, autofocus control method and image pickup apparatus

InactiveUS20090095880A1High computational complexityArea ratioMaterial analysis by optical meansMountingsCamera lensFace detection

The invention aims to reduce, in performing autofocusing on an autofocus target region determined within a face region obtained by face detection, the risk of misfocusing attributable to a background image included in the autofocus target region. To this end, a face detecting unit firstly performs face detection to determine a face region including a human face image. Then, an AF target region determination unit determines an AF target region within the face region. In this event, the AF target region determination unit can change the area ratio of the AF target region to the face region. Thereafter, based on contrast of a region, corresponding to the AF target region determined by the AF target region determination unit, of captured image data, an AF evaluation value calculation unit, a controller and a lens driving unit adjust a location where a subject image is formed by a shooting optical system.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device embedded with pressure sensor and manufacturing method thereof

ActiveUS7270012B2High precision measurementReduced footprintFluid pressure measurement by electric/magnetic elementsSolid-state devicesSilicon oxideMoisture

The method for promoting the size reduction, the performance improvement and the reliability improvement of a semiconductor device embedded with pressure sensor is provided. In a semiconductor device embedded with pressure sensor, a part of an uppermost wiring is used as a lower electrode of a pressure detecting unit. A part of a silicon oxide film formed on the lower electrode is a cavity. On a tungsten silicide film formed on the silicon oxide film, a silicon nitride film is formed. The silicon nitride film has a function to fill a hole or holes and suppress immersion of moisture from outside to the semiconductor device embedded with pressure sensor. A laminated film of the silicon nitride film and the tungsten silicide film forms a diaphragm of the pressure sensor.

Owner:HITACHI LTD

Method and apparatus for displaying a map

ActiveUS7801676B2Improve visibilityImprove clarityInstruments for road network navigationRoad vehicles traffic controlComputer scienceMarine navigation

Owner:ALPINE ELECTRONICS INC

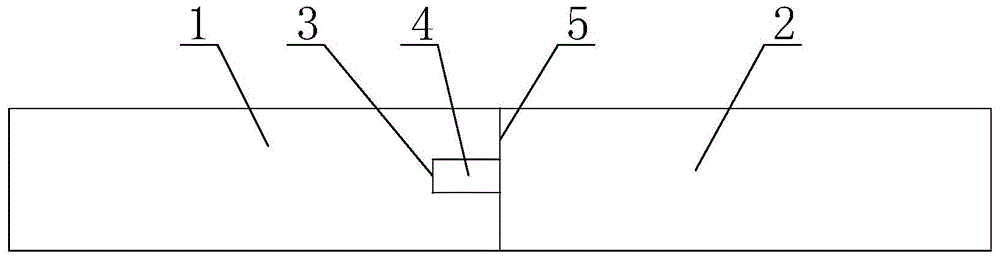

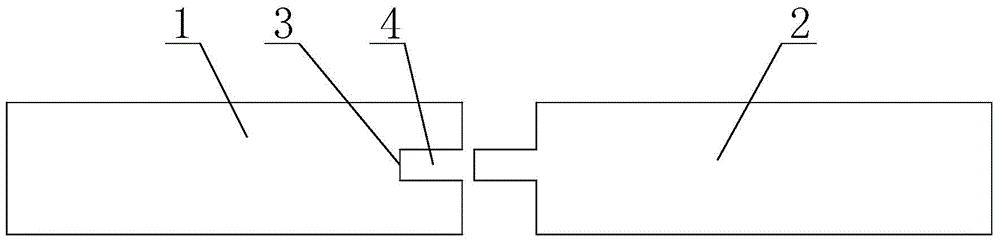

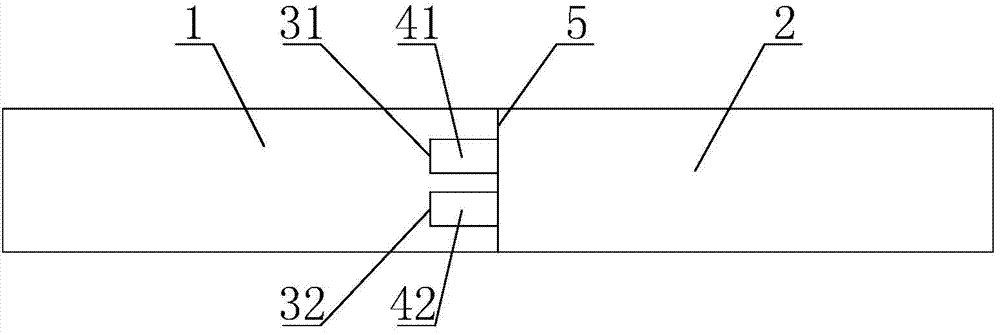

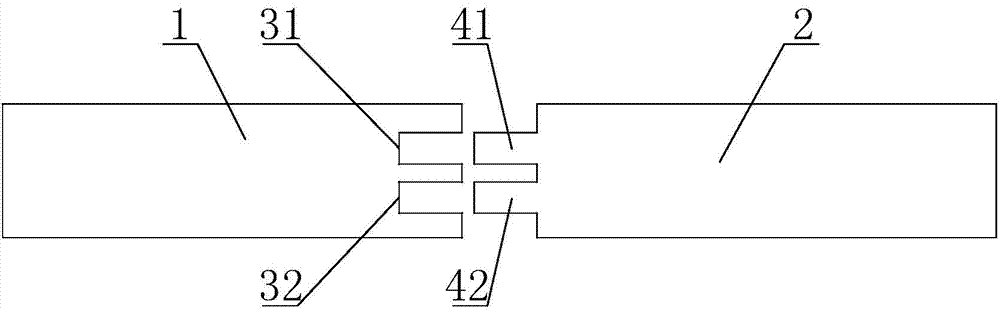

Seed crystal splicing structure for ingot casting

InactiveCN104831343AImprove fitIncrease the area ratioPolycrystalline material growthFrom frozen solutionsMortise and tenonIngot casting

The invention relates to a seed crystal splicing structure for ingot casting. The structure comprises mutually spliced seed crystal blocks, a splicing surface between adjacent seed crystal blocks is a plane vertical to the bottom of a crucible, the seed crystal blocks at one side of the splicing surface are provided with an elongated rectangular slot, the seed crystal blocks at the other side of the splicing surface are provided with an elongated rectangular projection suitable for being insert to the rectangular slot, and after the adjacent seed crystal blocks are spliced, the rectangular projection is insert to the rectangular slot, and a gap between splicing surfaces is lower than 0.5mm. The splicing surface of the seed crystal blocks are provided with the rectangular projection and the rectangular slot cooperating with each other to form a mortise and tenon joint structure to improve the lamination degree of the seed crystal splicing surface, and seed crystals at edges are expanded in the heating process, so the mortise and tenon joint structure is compact, the gap is small, the lamination of the adjacent seed crystal blocks is close, and the enlargement of the gap induced by cocking of edges of the seed crystal blocks is prevented, thereby the crystal dislocation defect is maximally reduced, and the monocrystalline area proportion is improved.

Owner:NANTONG UNIVERSITY

Seed crystal splicing method for monocrystalline-like silicon cast ingot

InactiveCN104775148AImprove fitIncrease the area ratioPolycrystalline material growthFrom frozen solutionsMortise and tenonCrucible

The invention relates to a seed crystal splicing method for a monocrystalline-like silicon cast ingot. The monocrystalline-like silicon cast ingot comprises seed crystal blocks which are mutually spliced, wherein a splicing surface between adjacent seed crystal blocks is a plane perpendicular to the bottom of a crucible, two long-strip-shaped rectangular grooves are formed in each seed crystal block on one side of the splicing surface from top to bottom, two long-strip-shaped rectangular bumps which are suitable for being inserted into the rectangular grooves are arranged on each seed crystal block on the other side of the splicing surface, and after the adjacent seed crystal blocks are spliced, the rectangular bumps are inserted into corresponding rectangular grooves, and gaps among the splicing surfaces are less than 0.5mm. According to the monocrystalline-like silicon cast ingot disclosed by the invention, the rectangular bumps and the rectangular grooves which are matched mutually are arranged on the splicing surfaces of the seed crystal blocks to form mortise and tenon structures so as to ensure that the adhering degree of the seed crystal splicing surfaces can be improved; in a heating process, seed crystals on edges are heated to be expanded, the mortise and tenon structures are closer, the gaps become smaller, and the adjacent seed crystal blocks can be adhered more closely so as to prevent gap expansion caused by edge up-warping of the seed crystal blocks, so that crystal dislocation defects can be reduced to a highest extent, and the single crystal area proportion can be increased.

Owner:NANTONG UNIVERSITY +1

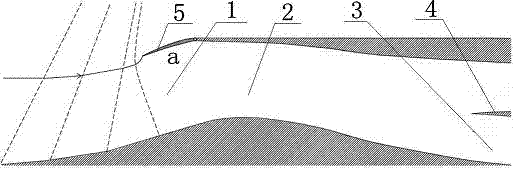

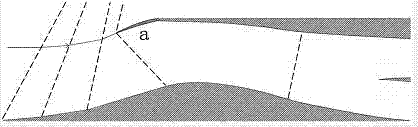

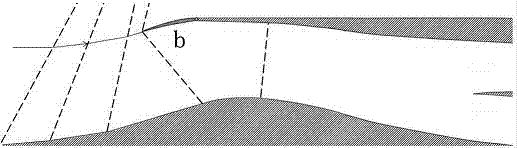

Supersonic aircraft air inlet channel with adjustable throat area and adjusting method

InactiveCN107023395AGuaranteed angle of attackIncrease the area ratioGas turbine plantsJet propulsion plantsInlet channelArea ratio

The invention relates to the field of supersonic propulsion and discloses a supersonic aircraft air inlet channel with an adjustable throat area and an adjusting method. The air inlet channel comprises a lip, a throat and an expansion section, a displacement mechanism is arranged in the air inlet channel, blades are arranged in the air inlet channel through the displacement mechanism, and the displacement mechanism can control the blades to move forwards and backwards and rotate in the air inlet channel. According to the supersonic aircraft air inlet channel and the adjusting method, large-scale and continuous adjustment of the throat area ratio can be realized, so that the air inlet channel always works in a low-loss state, and the adjusting process is simple and convenient.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

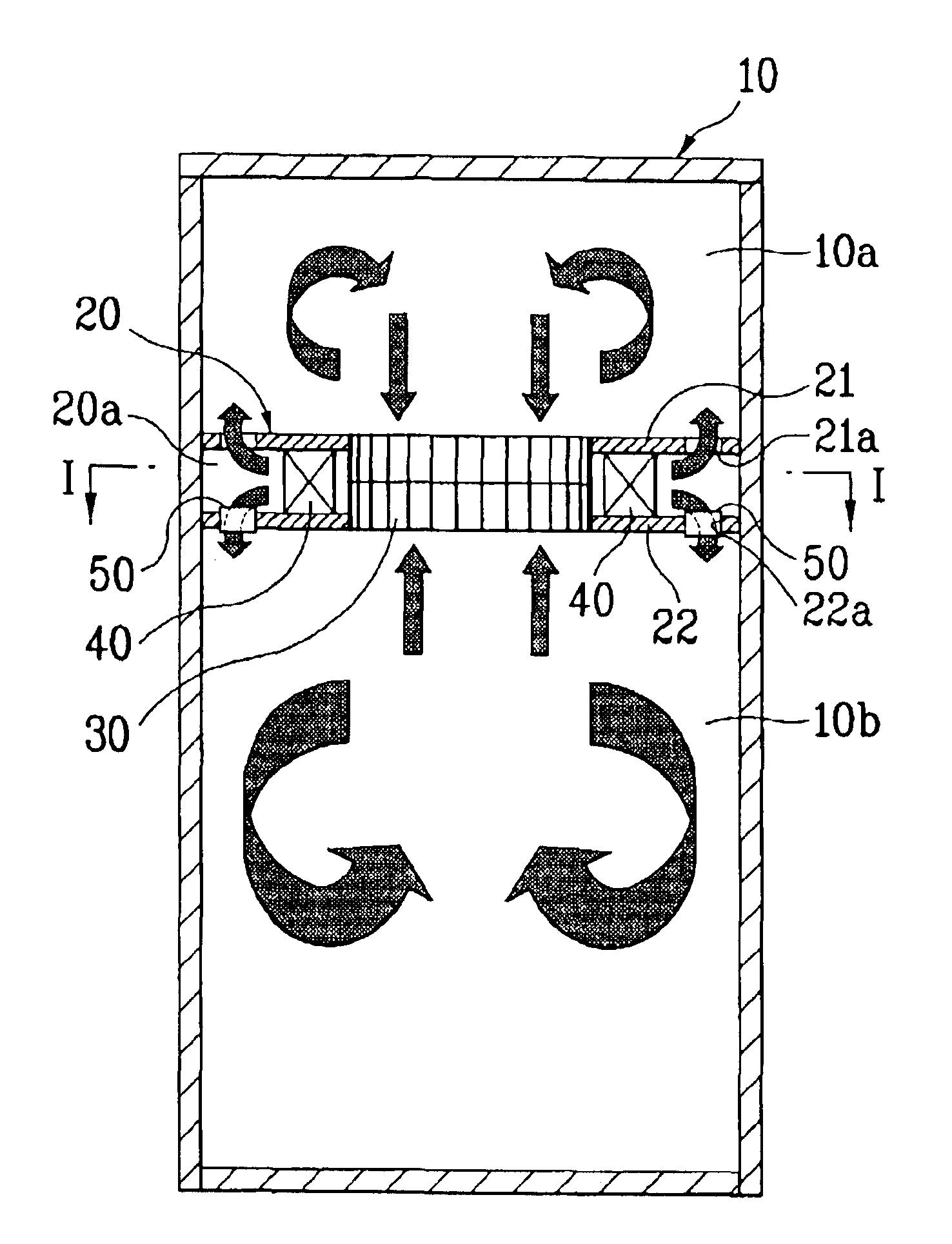

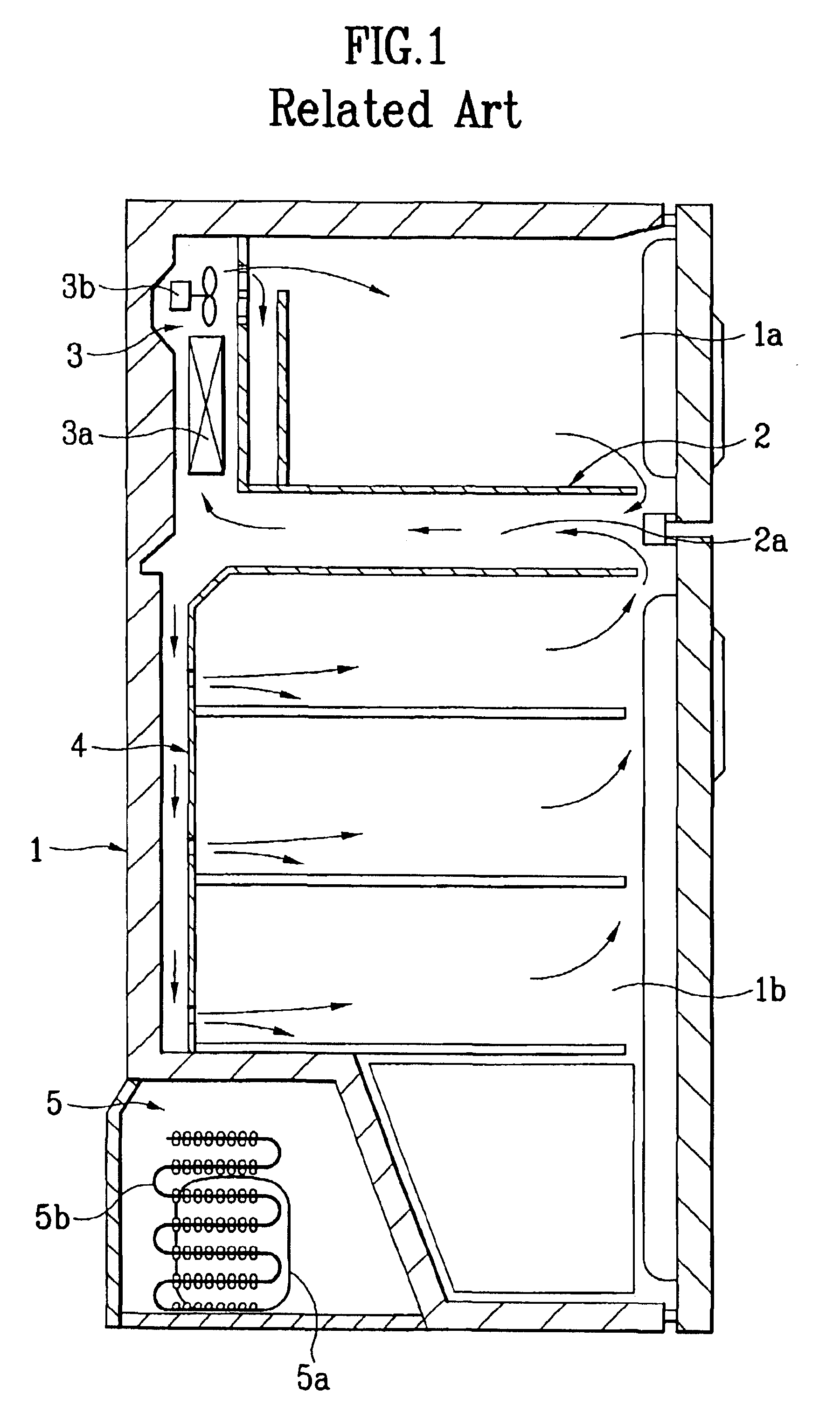

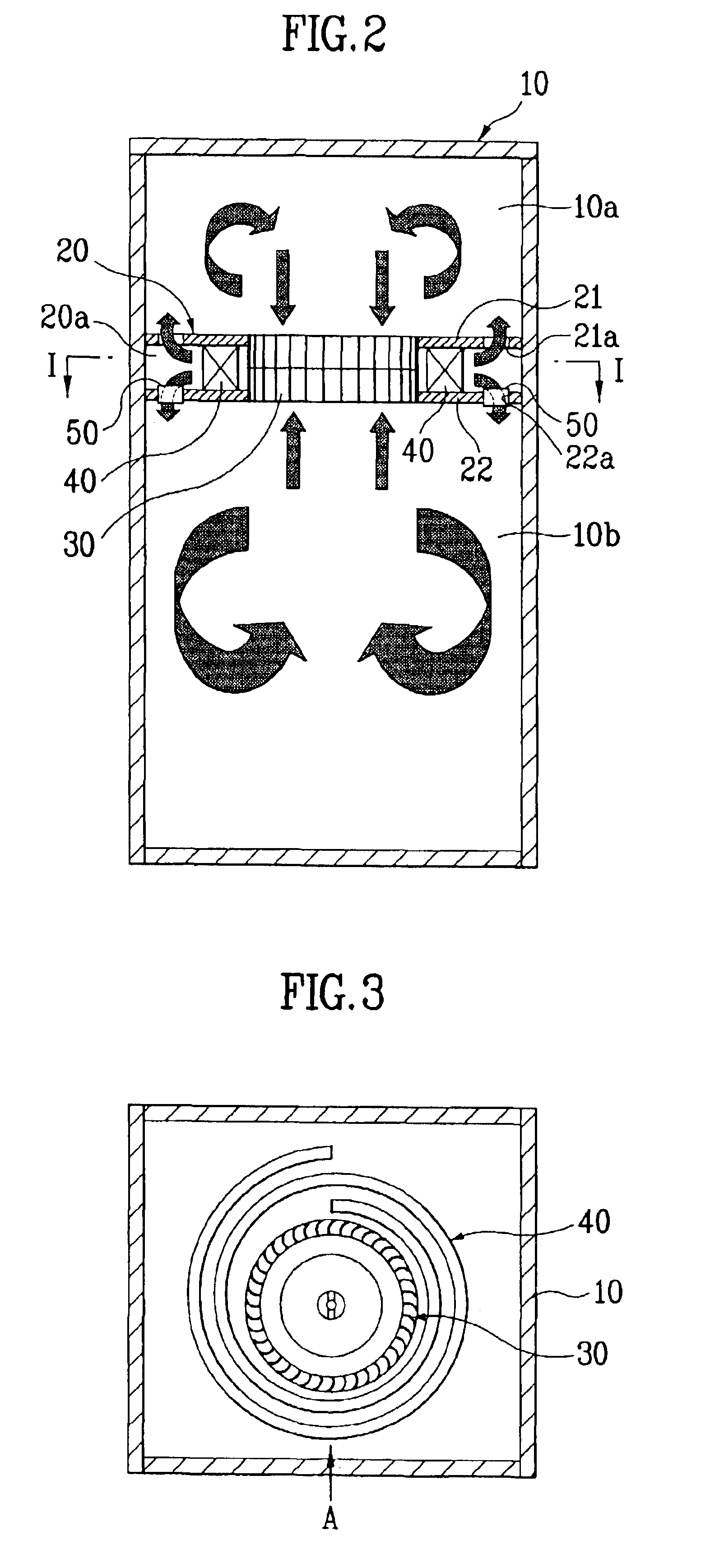

Refrigerator using double suction type centrifugal blower

ActiveUS6837067B2Increase the area ratioIncrease profitLighting and heating apparatusDomestic refrigeratorsFreezing chamberAirflow

This invention is to increase a floor area ratio of a freezing chamber and a utilization rate of heat transfer. A refrigerator is disclosed, which includes a cabinet having a storage space, a mullion provided in the cabinet to divide the storage space into a freezing chamber and a refrigerator chamber, the mullion having a cold airflow passage provided therein that is communicated with the freezing chamber and the refrigerator chamber, a double suction centrifugal blower provided in a middle space of the mullion and sucking air from the freezing chamber and the refrigerator chamber and exhausting to the cold airflow passage, an evaporator provided in the cold airflow passage for exchanging heat with the air exhausted from the double suction centrifugal blower, a top outlet and a bottom outlet exhausting air being passed through the evaporator to the freezing chamber and the refrigerator chamber.

Owner:LG ELECTRONICS INC

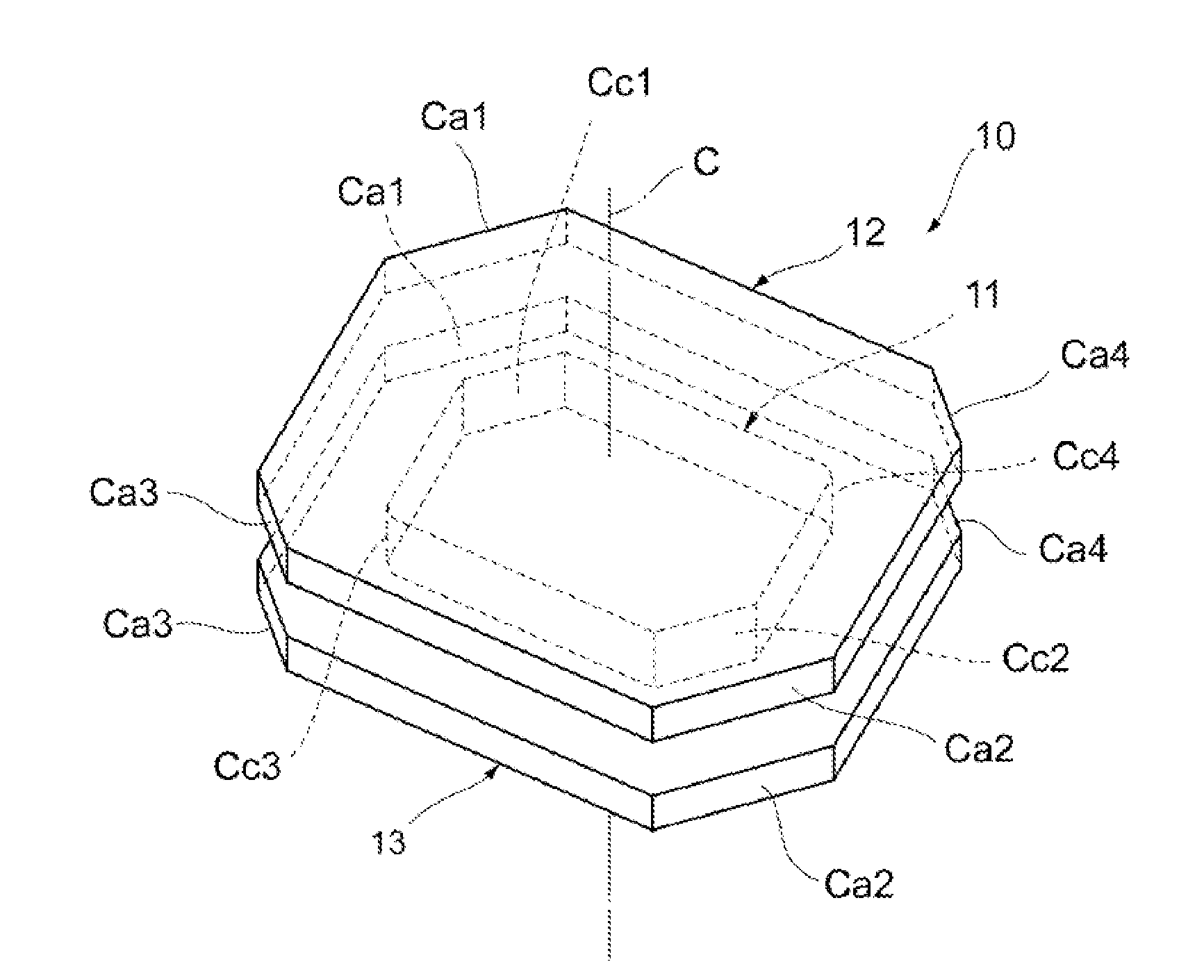

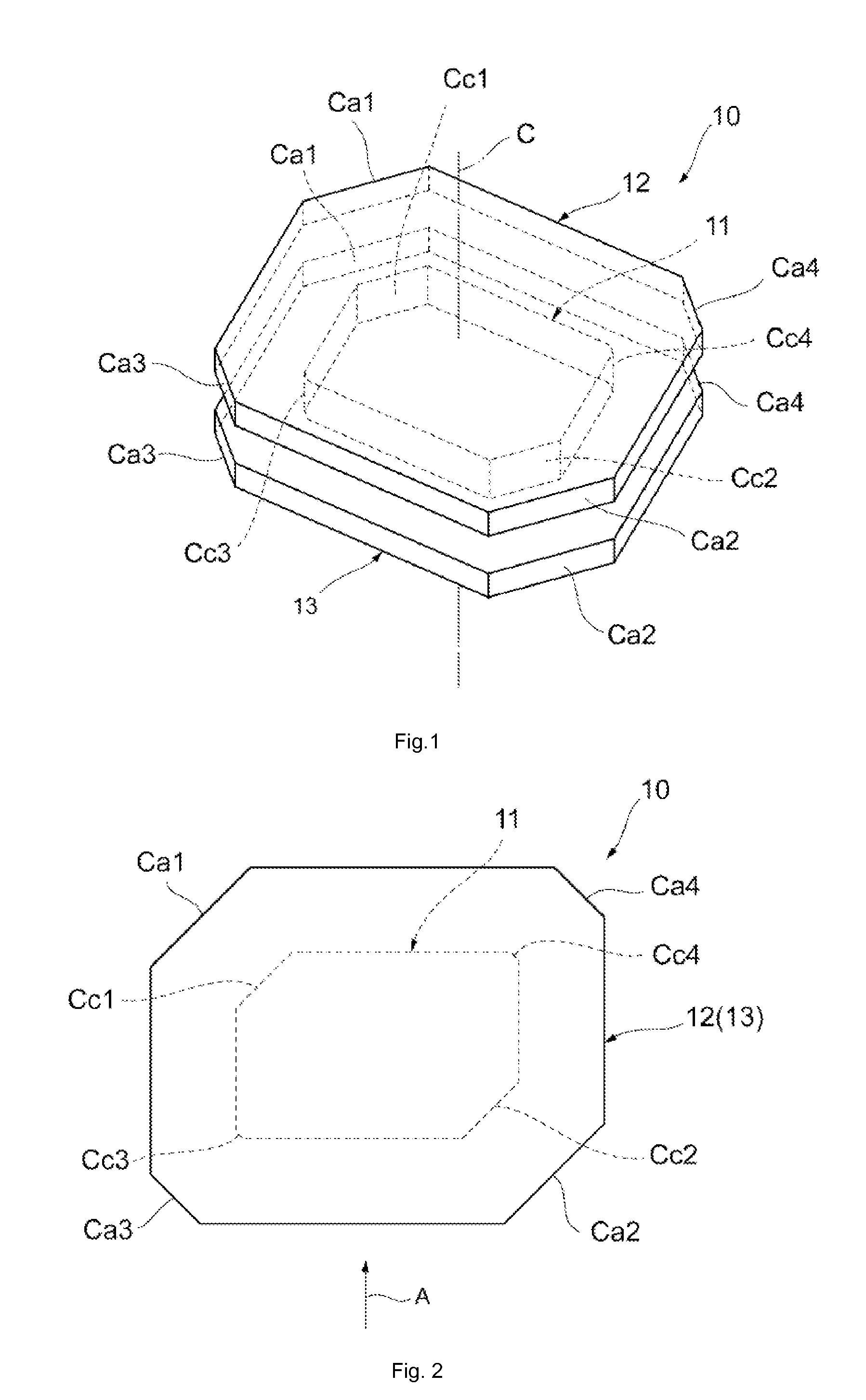

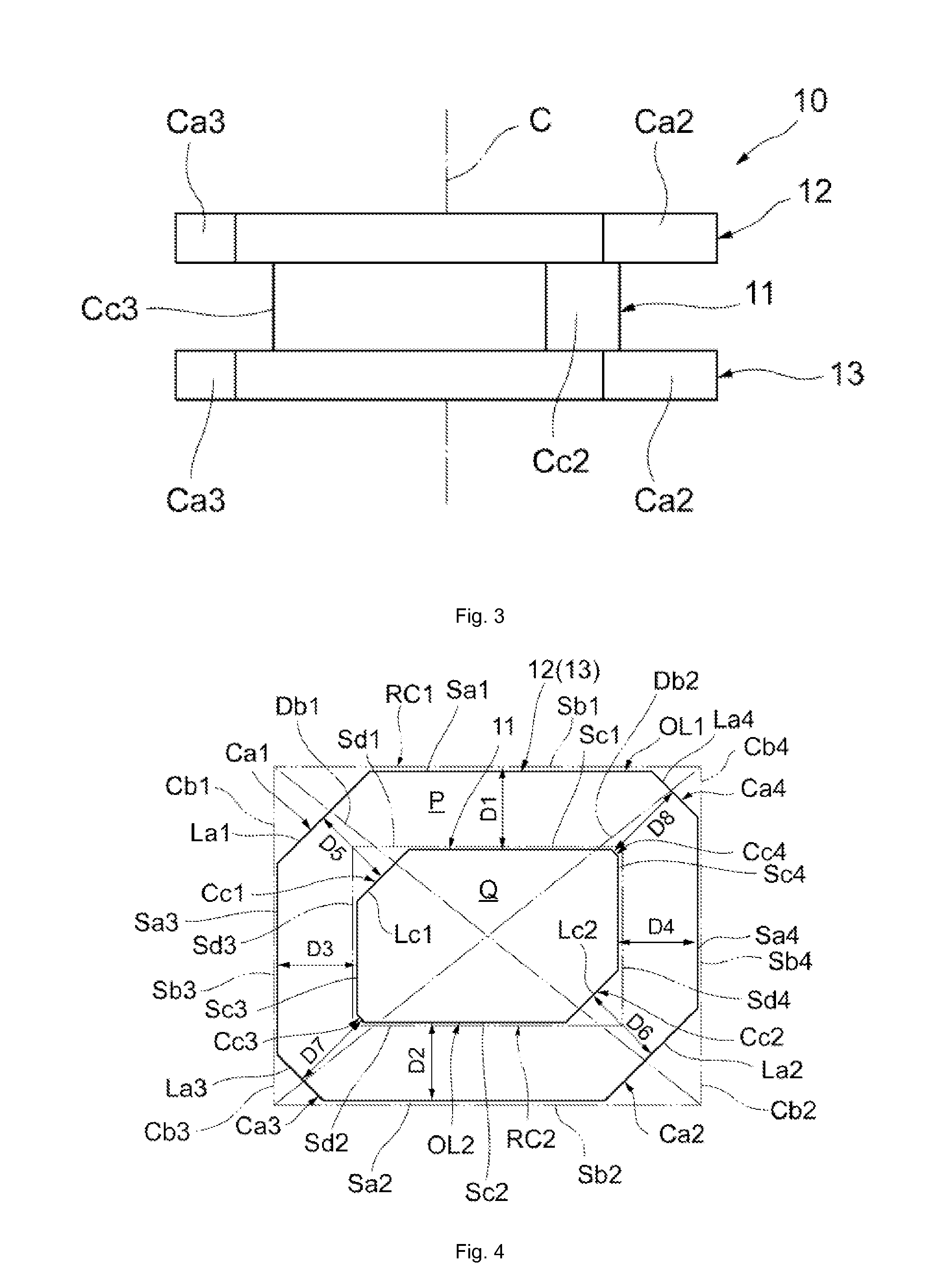

Magnetic core, magnetic component and design method of magnetic core

ActiveUS20140070914A1Increase the area ratioMounting region on the circuit board is more narrowed and decreasedTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresDesign methodsFlange

A magnetic core including a winding core portion; and a flange portion provided on the axial end side of at least one of the winding core portion, wherein the flange portion is formed such that contour line OL1 of cross-section P, of the flange portion, which becomes perpendicular with respect to the axis line of the winding core portion forms a shape of a first irregular convex polygon which is substantially a non-regular polygon and also a convex polygon, and the contour line OL1 contacts with respect to all of sides Sb1, Sb2, Sb3 and Sb4 which are the four sides of a first circumscribed rectangle which becomes minimum within imaginary rectangles circumscribed with the contour line OL1 and also, the contour line OL1 includes side Sa1 and side Sat which respectively overlap with portions of respective ones of the side Sb1 and the side Sb2.

Owner:SUMIDA CORP

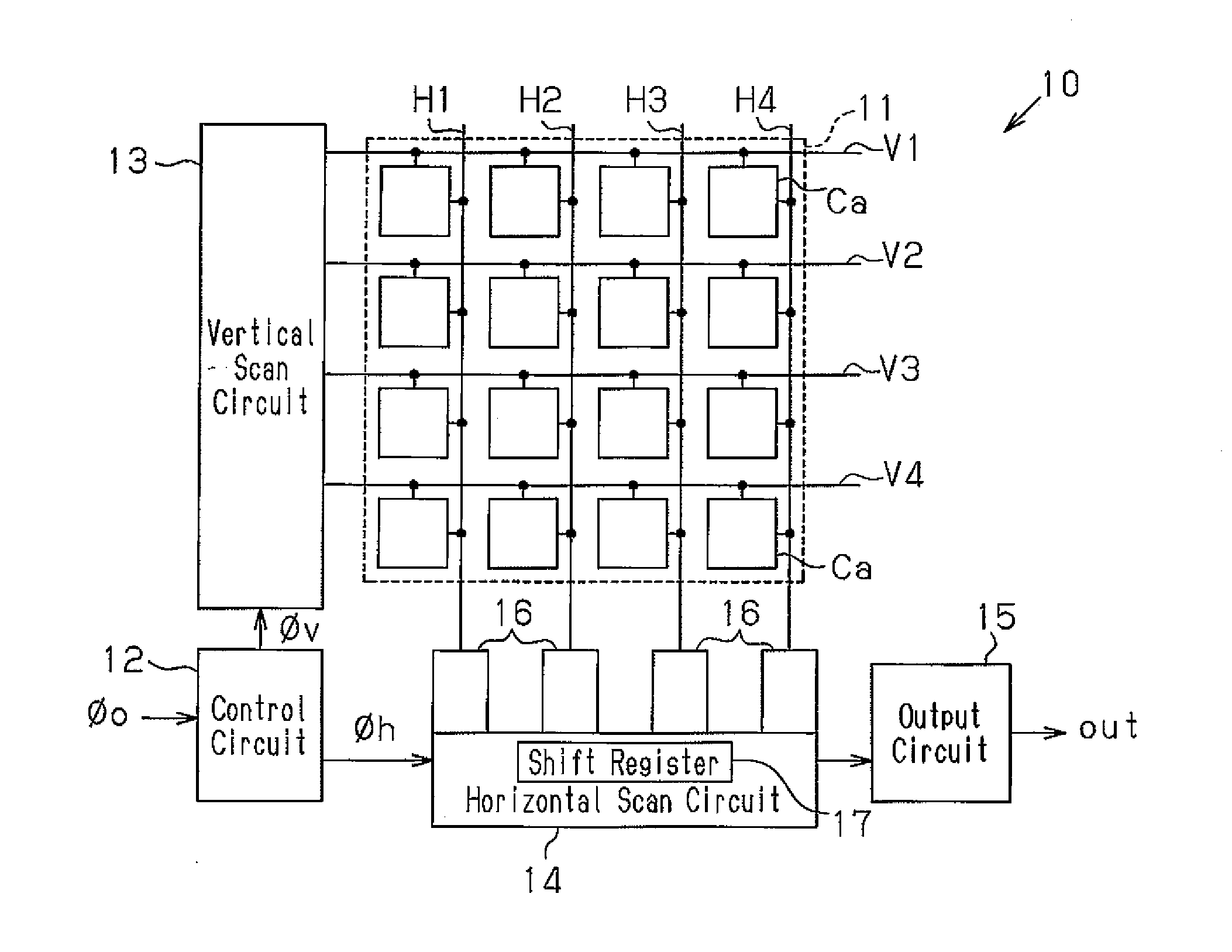

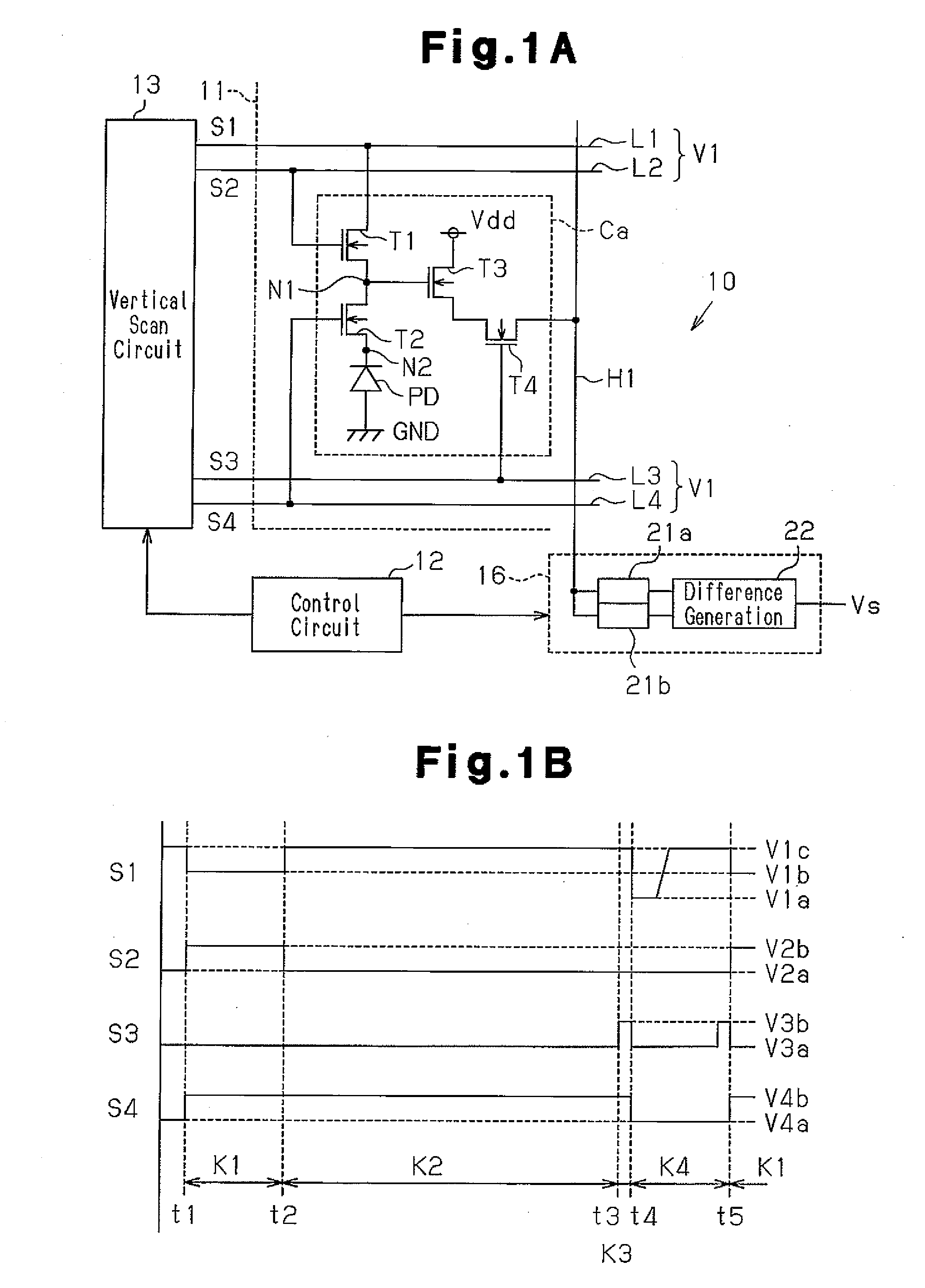

Solid-state imaging device

InactiveUS20100289932A1Increase the areaReduce pattern noiseTelevision system detailsTelevision system scanning detailsEngineeringPhotoelectric conversion

Suppressing increases in the area of an image cell while reducing fixed pattern noise (FPN). A photoelectric conversion signal is generated from photocurrent flowing through a photodiode (PD) in a pixel (Ca). A first transistor functioning as a load transistor is driven to operate in a strong inversion state and then operate in a subthreshold range. When the first transistor (T1) is operating in a subthreshold range, the potential at a sense node (N1) is read as a reset signal. Further, the difference between the photoelectric conversion signal and the reset signal is calculated to generate an image signal (Vs).

Owner:ORMON CORP

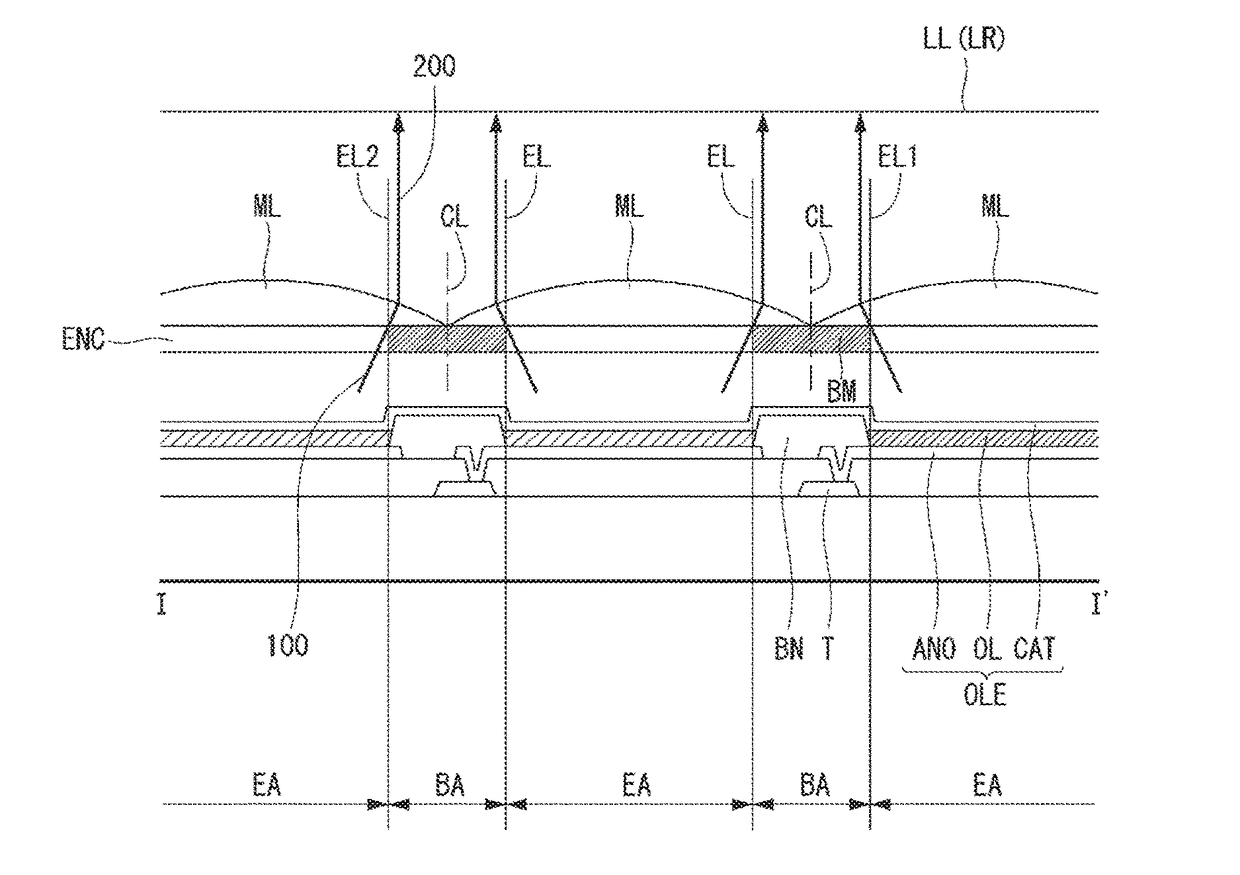

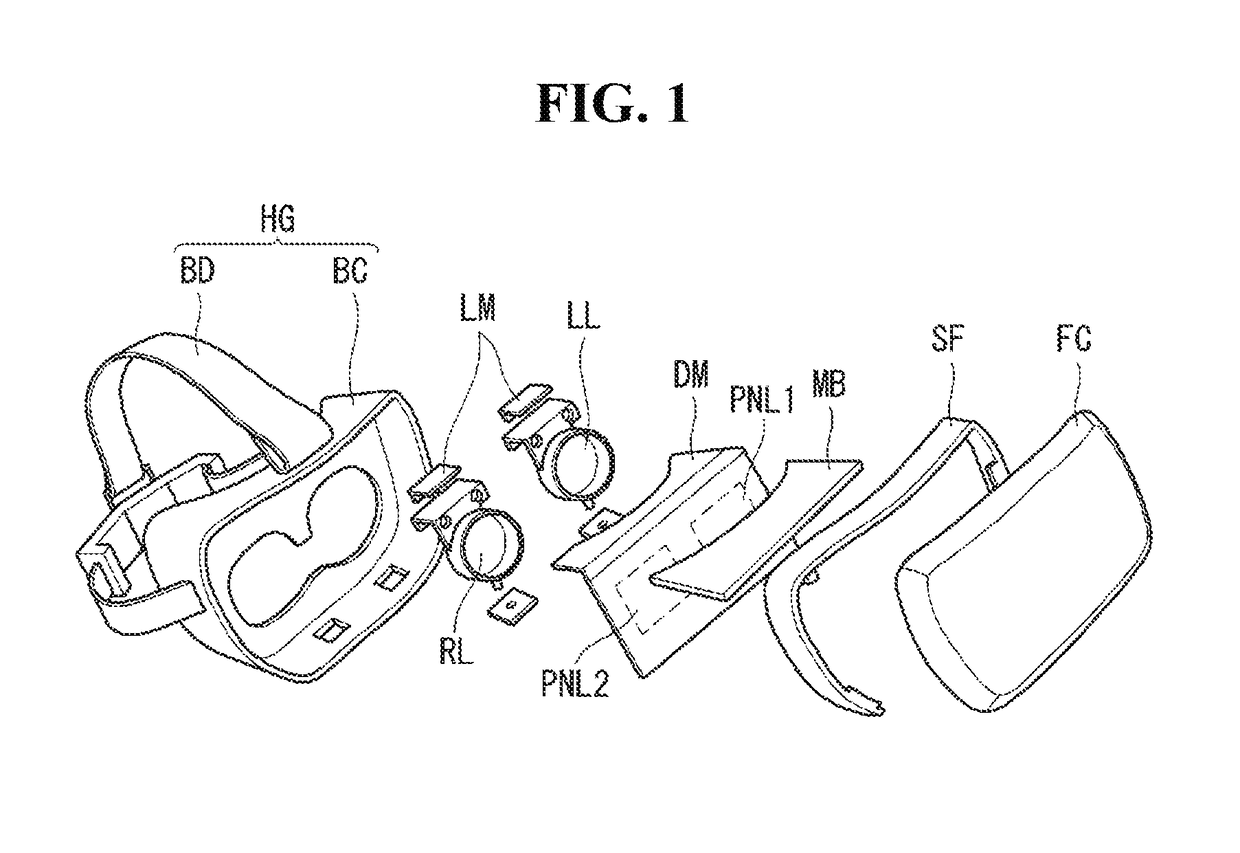

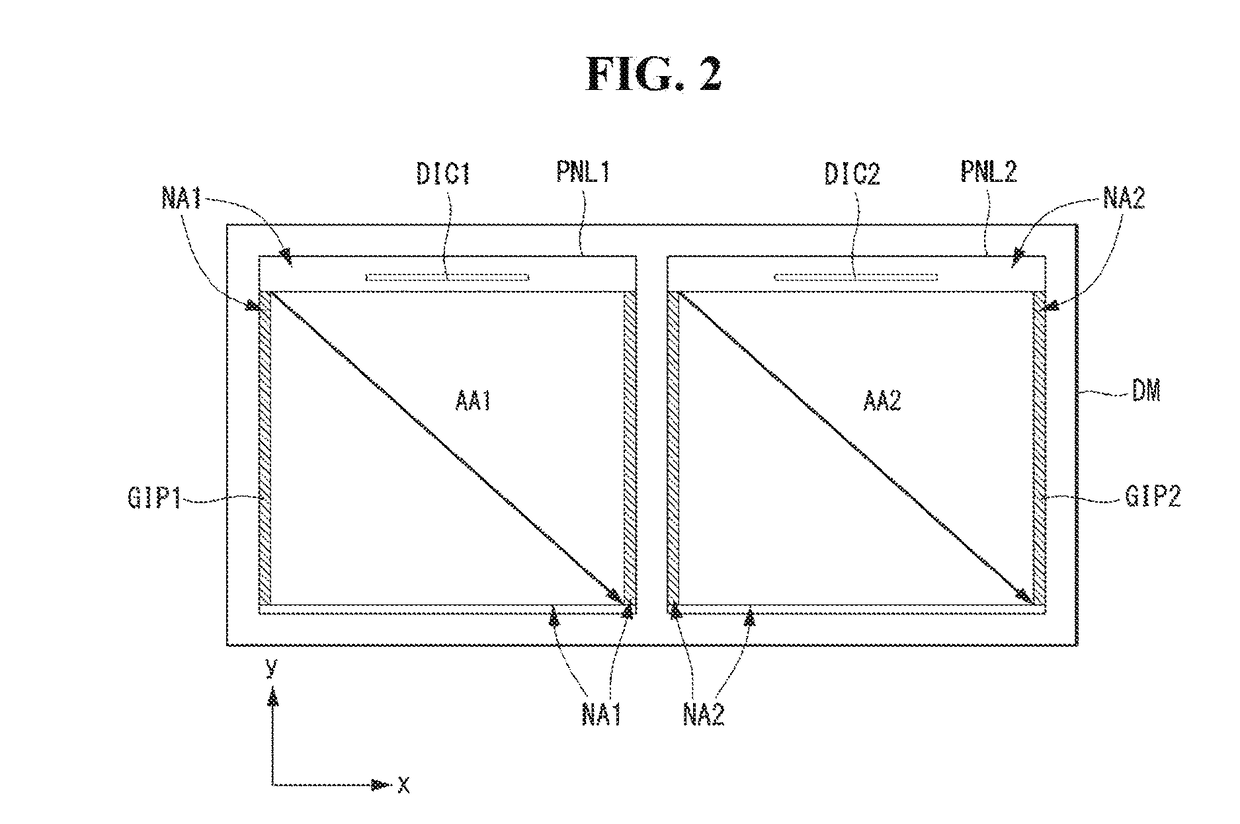

Display for personal immersion apparatus

ActiveUS20170315372A1Reduce fatigueEnhances stereoscope and reality and immersion propertyStatic indicating devicesSolid-state devicesCamera lensDisplay device

The present disclosure relates to a display for a personal immersion apparatus for embodying the virtual reality or the augmented reality. The present disclosure suggests a display for a personal immersion apparatus comprising: a display panel; and an imaging lens; wherein the display panel includes: a plurality of pixel areas disposed on a substrate; an emission area defined in the each pixel area; a non-emission area surrounding the emission area in the each pixel area; and a micro deflector configured to deflect lights scattered over the non-emission area from the emission area to a normal direction with respect to a surface of the substrate, and to provide the deflected lights to the imaging lens, and wherein the imaging lens is disposed apart from the display panel with a focal length of the imaging lens.

Owner:LG DISPLAY CO LTD

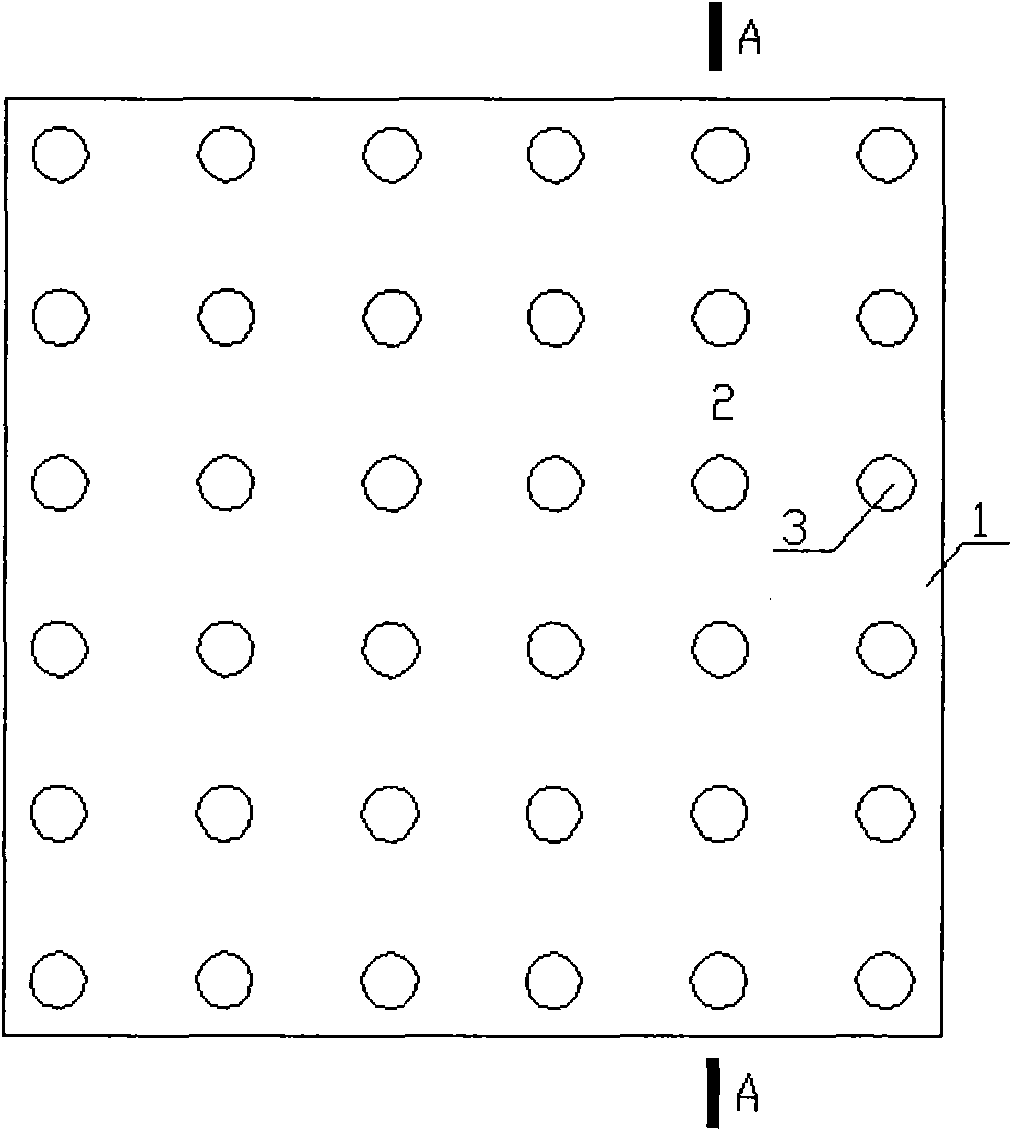

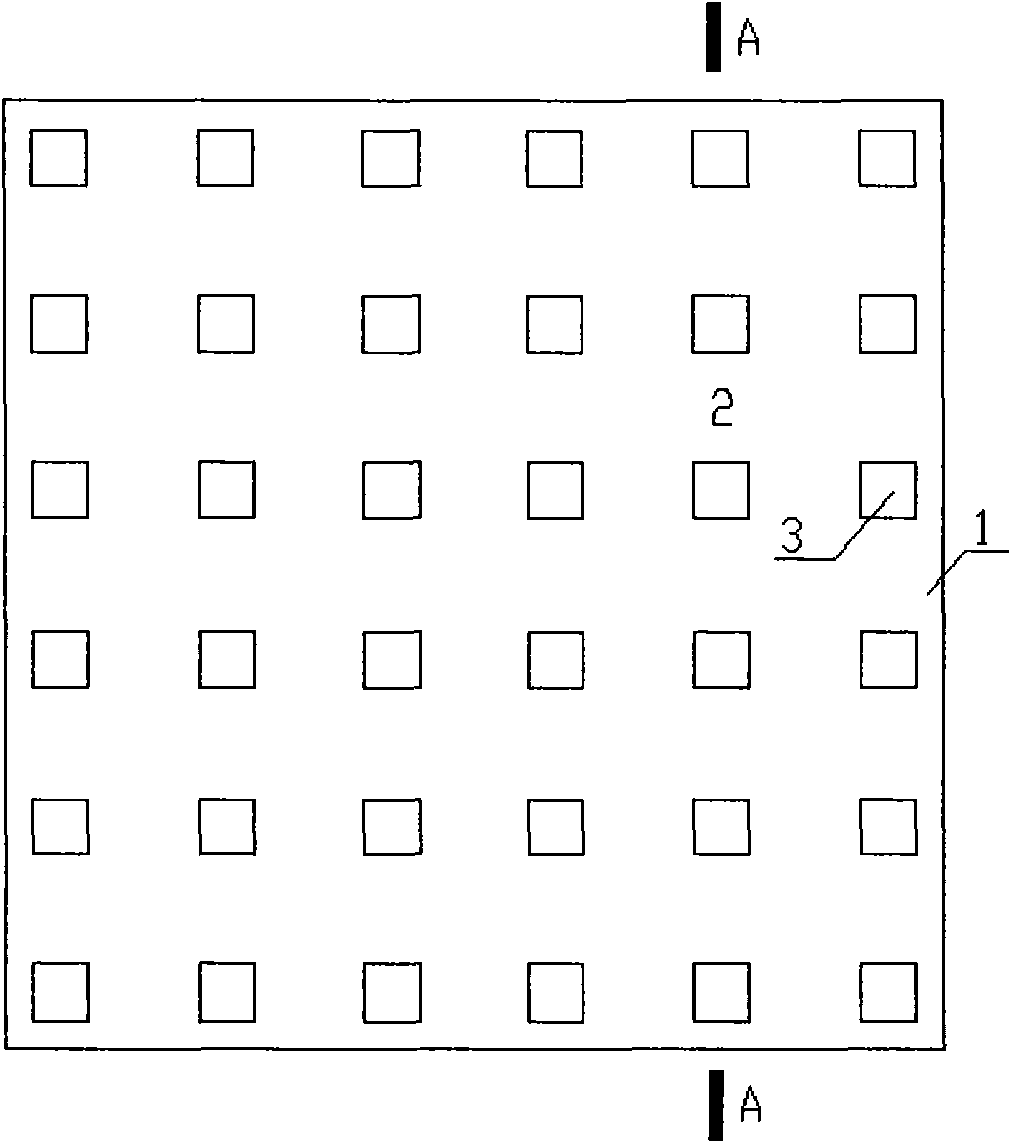

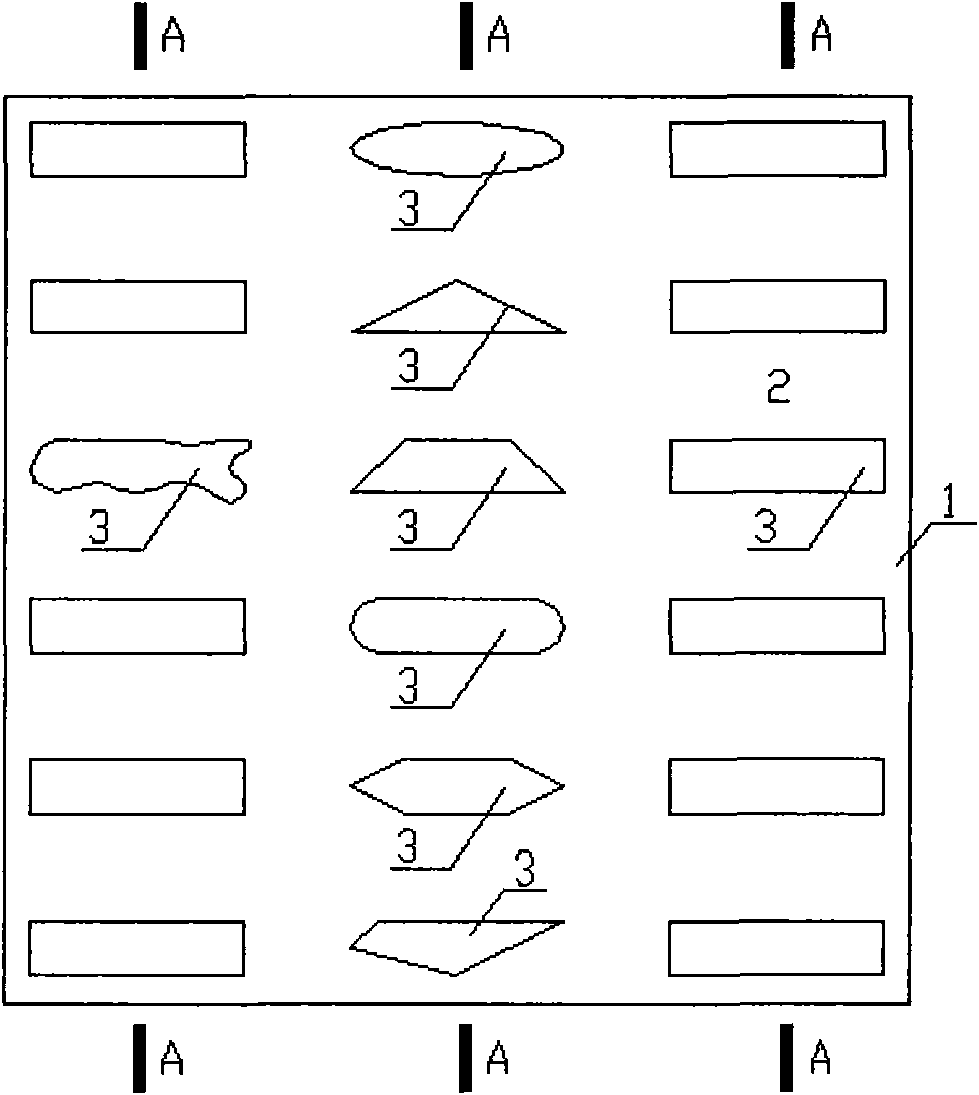

Porous glass plate and structures adopting porous glass plate

InactiveCN101654995AWith transparencyBreathableWallsNoise reduction constructionSound barrierGlass sheet

The invention discloses a porous glass plate and structures adopting the porous glass plate, which adopt the technical scheme that: the porous glass plate is provided with pores, the pores are perforated in a thickness direction and are in regular or irregular distribution in a plane direction, the opening ratio is more than or equal to 0.5 percent and is less than or equal to 60 percent, and thepores are circular or in any shape; and the structures adopting the porous glass plate comprise building and structure windows adopting the porous glass plate, vehicle windows adopting the porous glass plate, enclosures adopting the porous glass plate, sound barriers adopting the porous glass plate, totally enclosed structures of traffic passages adopting the porous glass plate, and paravents adopting the porous glass plate. The porous glass plate has the advantages of having air permeability and being favorable for the ventilation, having the sound-absorbing effect of a perforated plate and amicroperforated plate and certain sound insulation effect, having the effects of keeping out the wind and reducing the wind pressure, and having the rainproof and antitheft effects. The porous glassplate is applicable to windows or glass curtain walls of buildings and structures, vehicle windows, enclosures, sound barriers, enclosed structures of traffic passages and paravents.

Owner:马兴华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com