Manufacturing method for touch panel edge wire routing, touch panel and touch display device

A technology of edge routing and touch panel, applied in chemical/electrolytic methods to remove conductive materials, input/output process of data processing, instruments, etc., can solve problems affecting signal output results, signal errors, signal interference, etc. , to achieve the effect of large touch area and display area, good bad or wrong signal, and avoiding bad situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0055] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

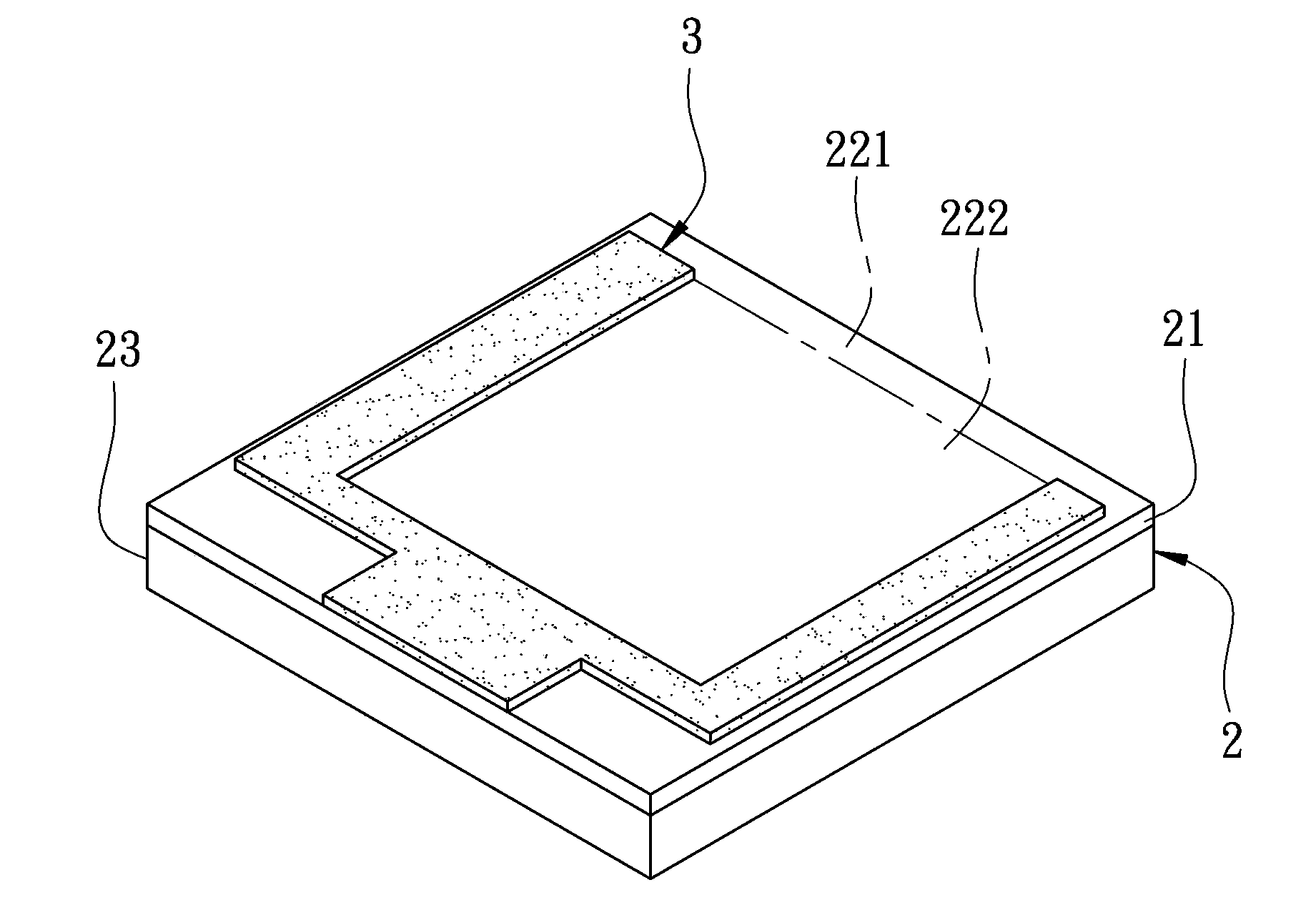

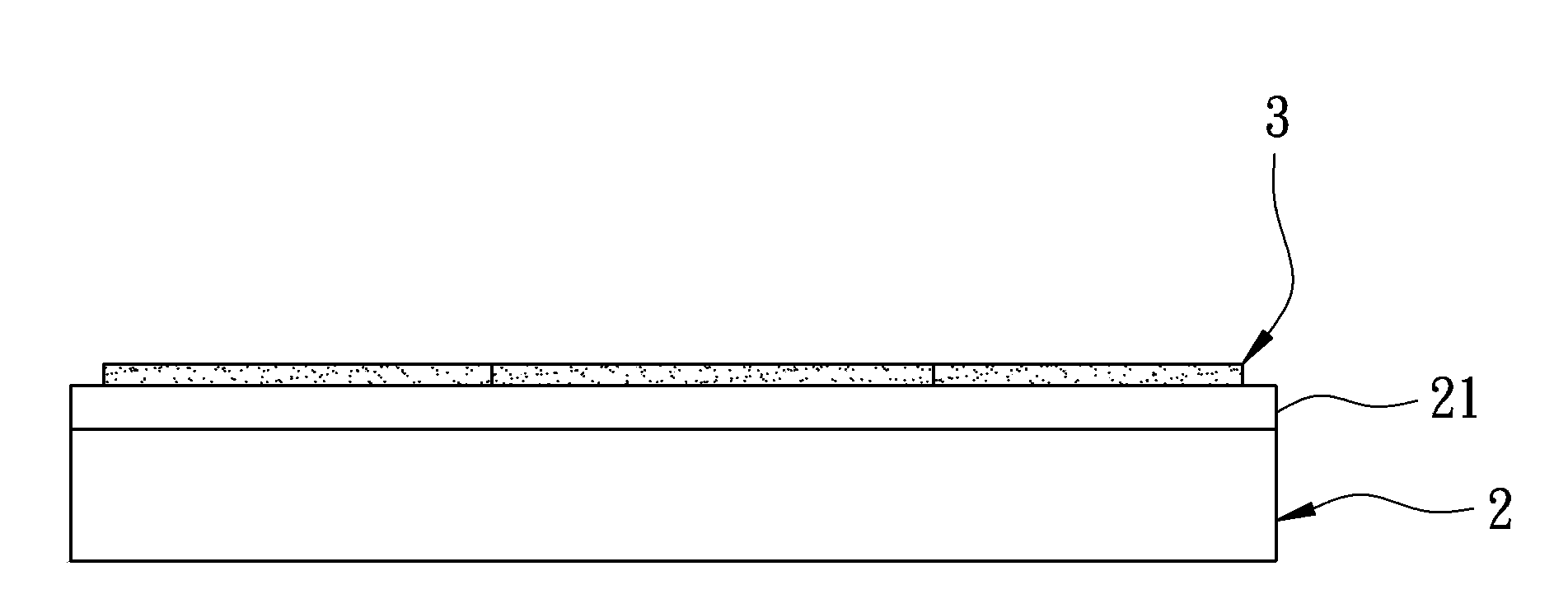

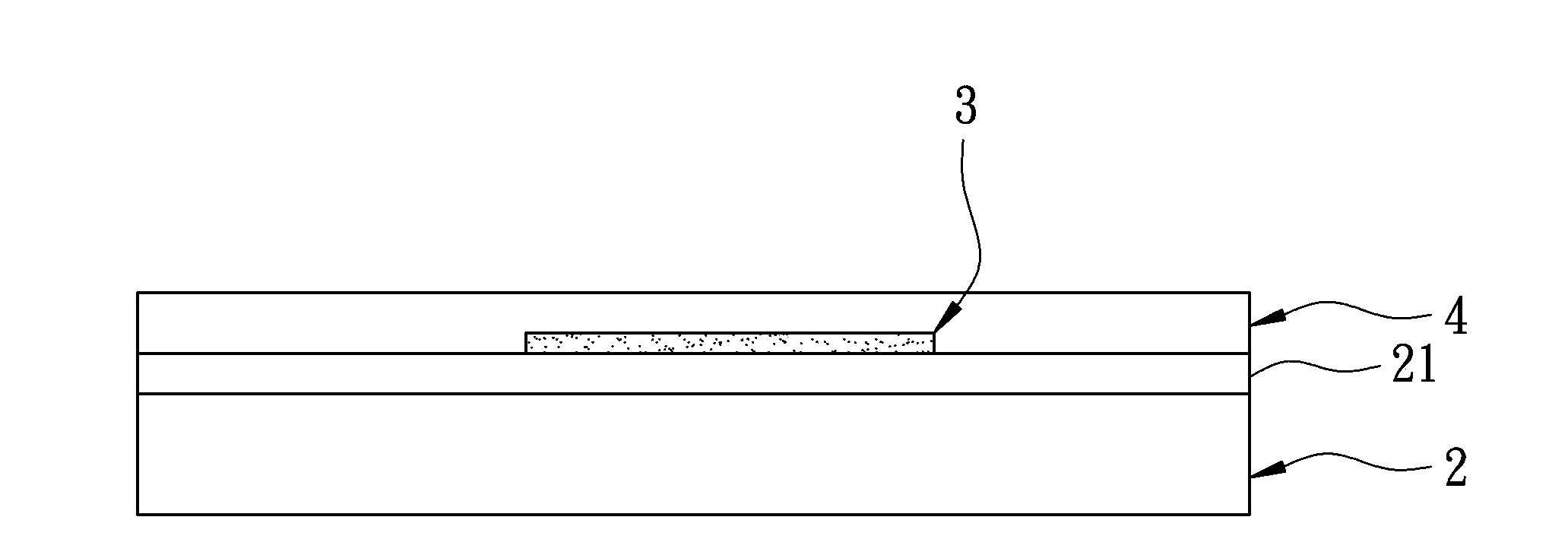

[0056] refer to Figure 1 to Figure 10 , illustrating the continuous steps of a first preferred embodiment of the method for manufacturing the edge traces of the touch panel of the present invention, wherein, figure 2 and image 3 are from figure 1 Schematic diagram of the side view taken from the front. The preparation method comprises the following steps:

[0057] refer to figure 1 , figure 2 and image 3 , the step (a) is to form a layer of photosensitive conductive paste layer 3 on an edge region 221 of a base material 2 with a layer of transparent conductive layer 21, and make the photosensitive conductive paste layer 3 at least in contact with the transparent conductive lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com