Patents

Literature

572results about How to "Good surface smoothness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

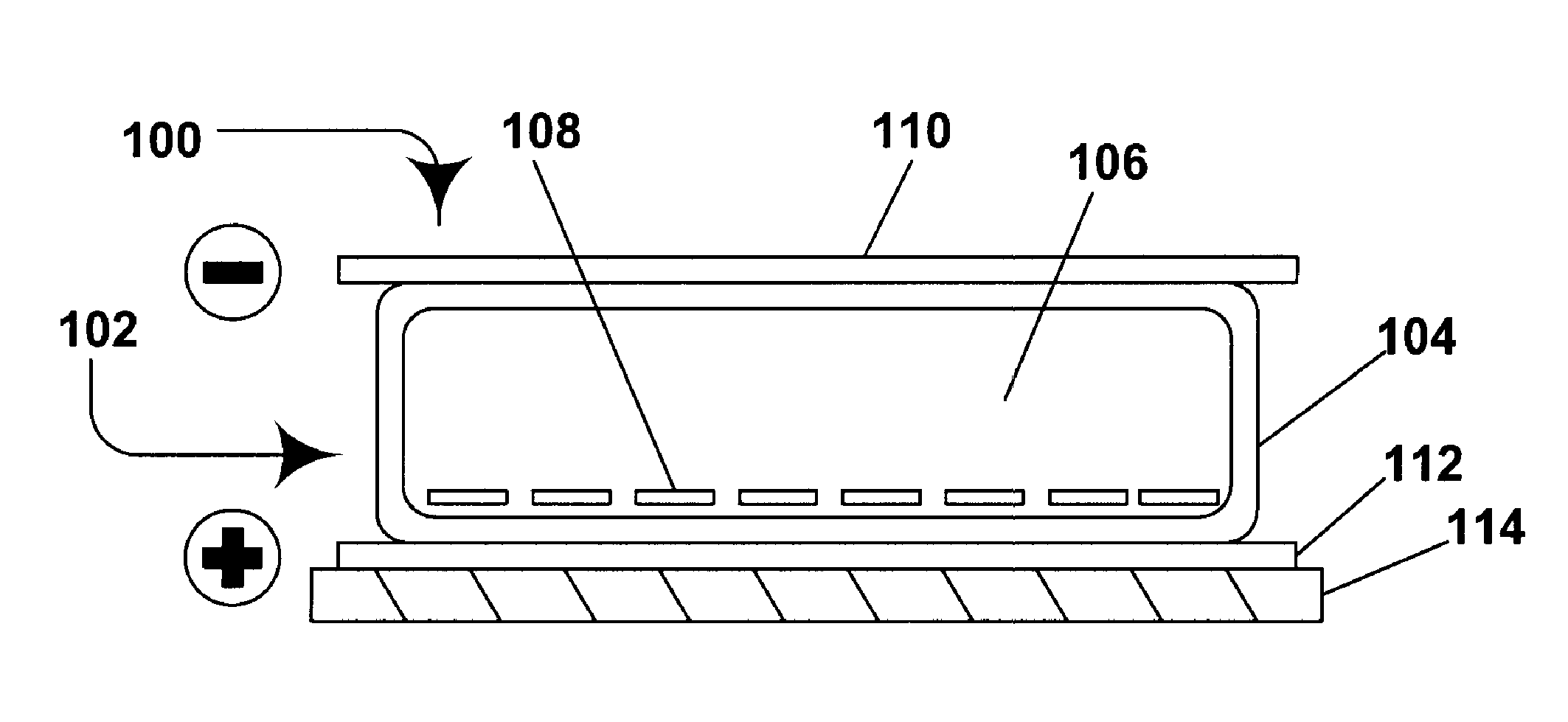

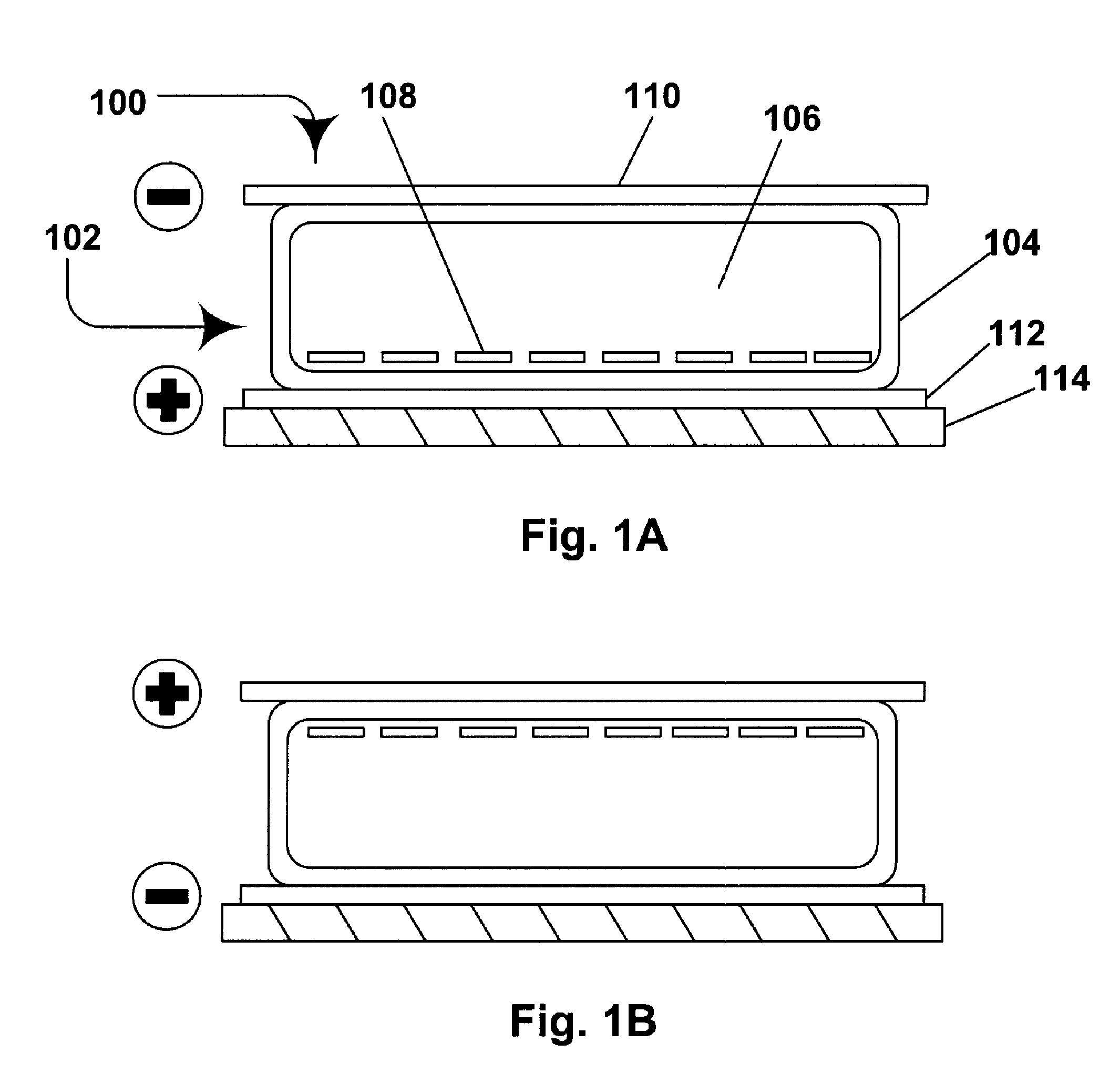

Electrophoretic media containing specularly reflective particles

ActiveUS20040094422A1Good flexibilityImprove uniformitySludge treatmentStatic indicating devicesElectrophoresisSpecular reflection

An electrophoretic medium (100) comprises at least one type of particle (108) suspended in a suspending fluid (106) and capable of moving therethrough on application of an electric field to the medium, the particles (108) including at least one electrophoretically mobile specularly reflective particle.

Owner:E INK CORPORATION

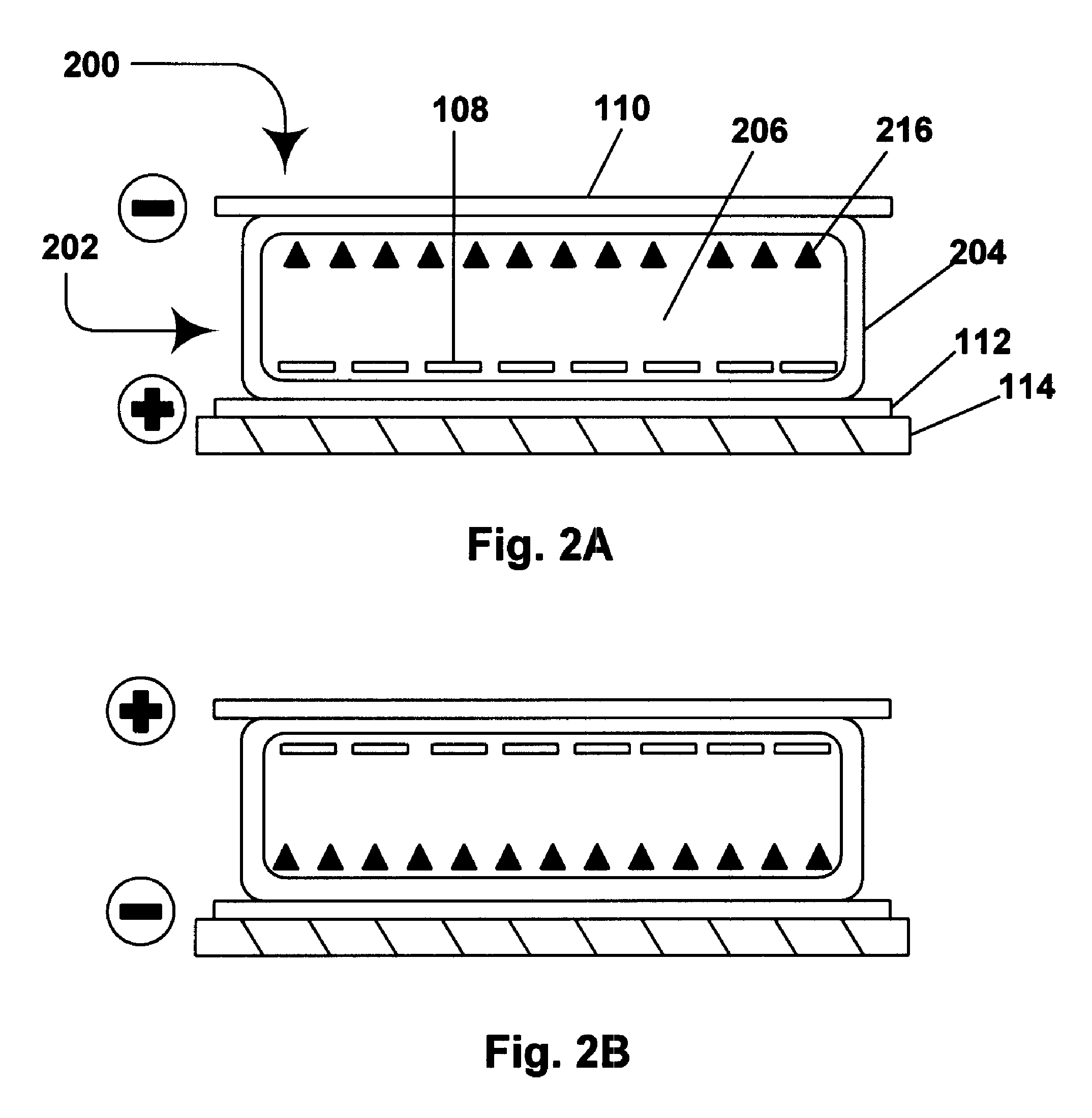

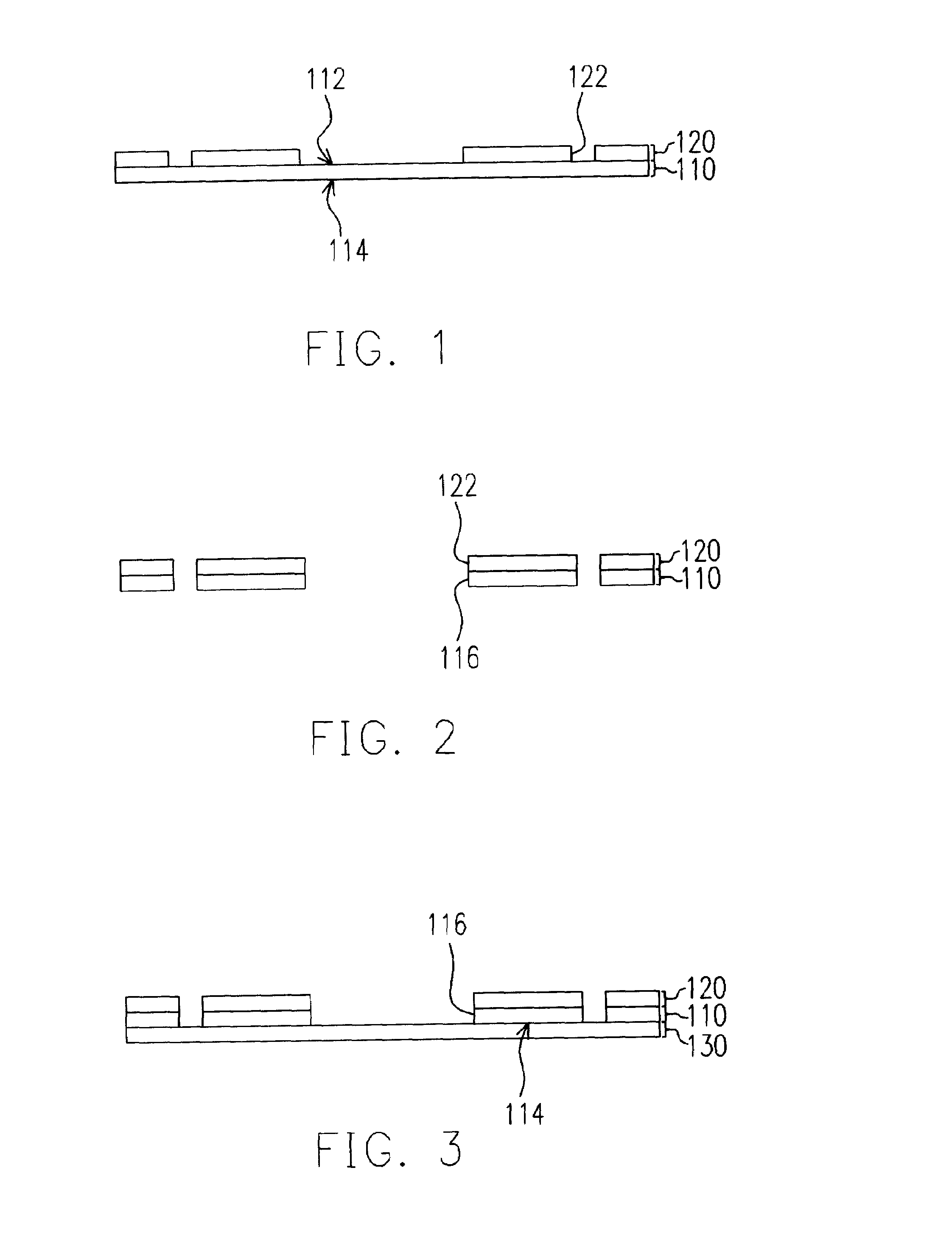

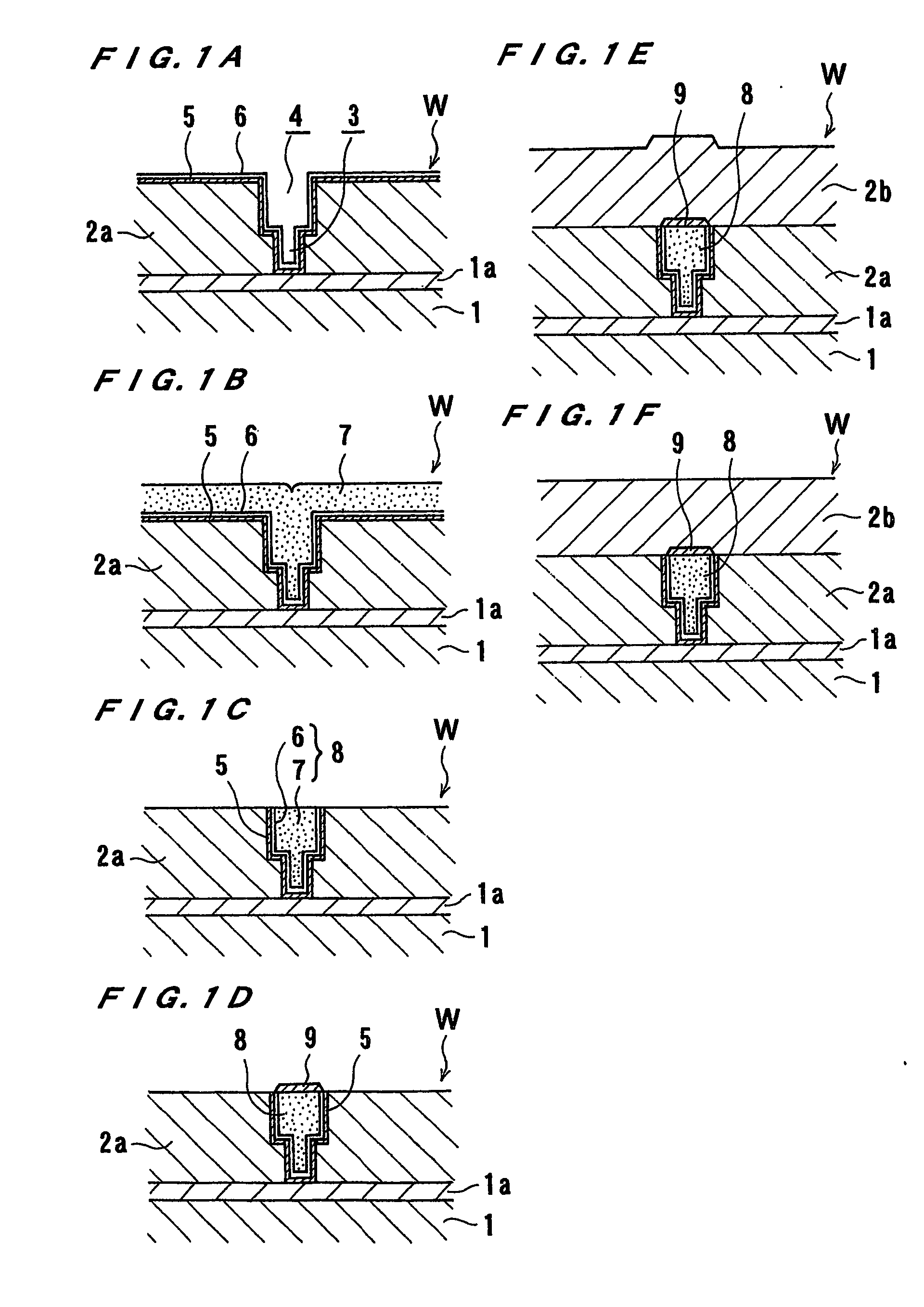

Process and structure for semiconductor package

ActiveUS7005327B2Reduce pollutionGood surface smoothnessSemiconductor/solid-state device detailsSolid-state devicesResistSemiconductor chip

A packaging process for a semiconductor chip that includes the following steps. A carrier having an upper surface and a corresponding lower surface is provided. A photoresist layer is formed on the upper surface of the carrier. A plurality of photoresist openings that expose the carrier is formed in the photoresist layer. A plurality of openings that connects with the photoresist openings are formed in the carrier. A tape is attached to the lower surface of the carrier. The body is filled into the openings of the carrier. A chip is mounted onto the upper surface of the carrier and electrically connected therewith. Finally, the tape is removed from the lower surface of the carrier.

Owner:ADVANCED SEMICON ENG INC

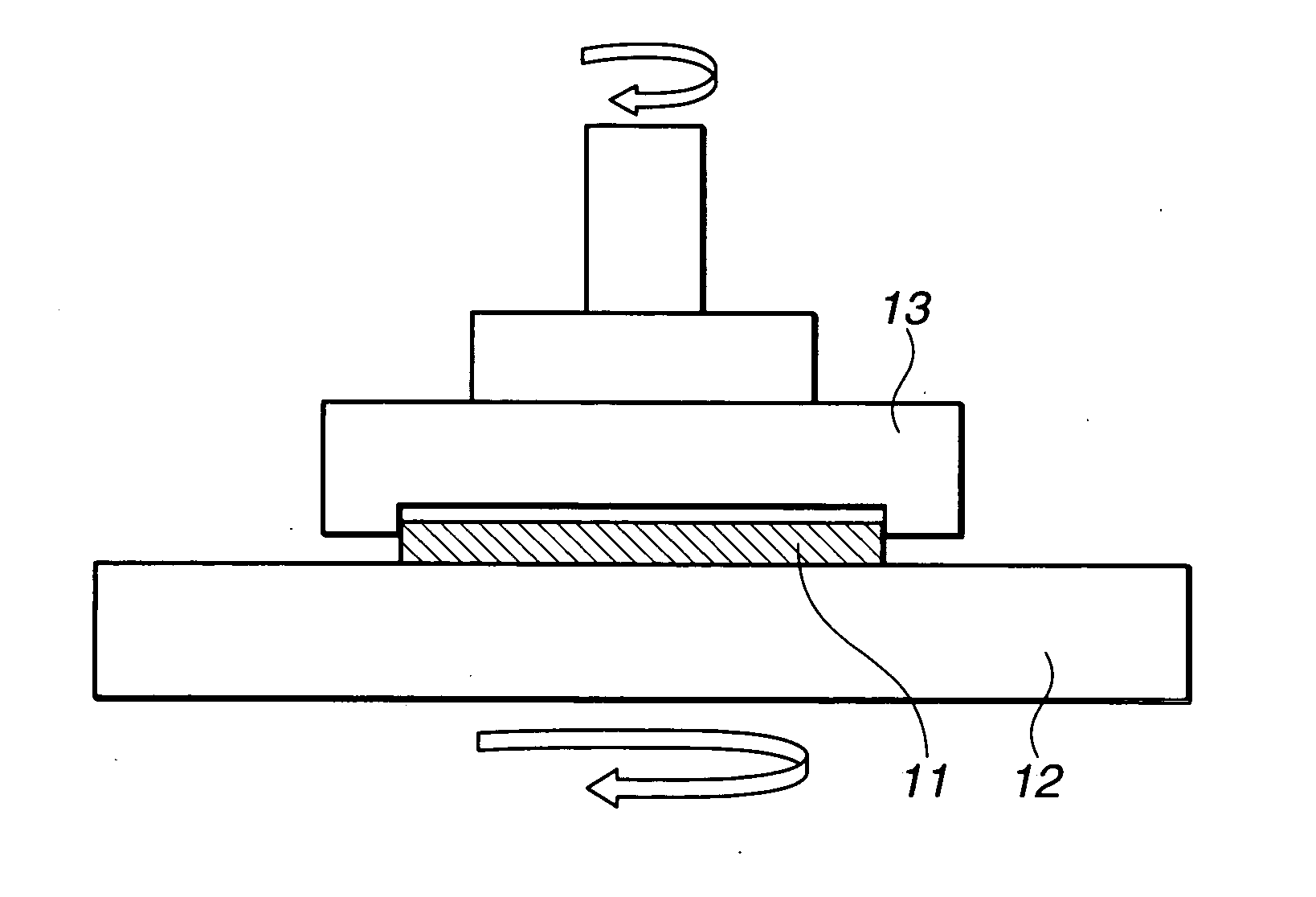

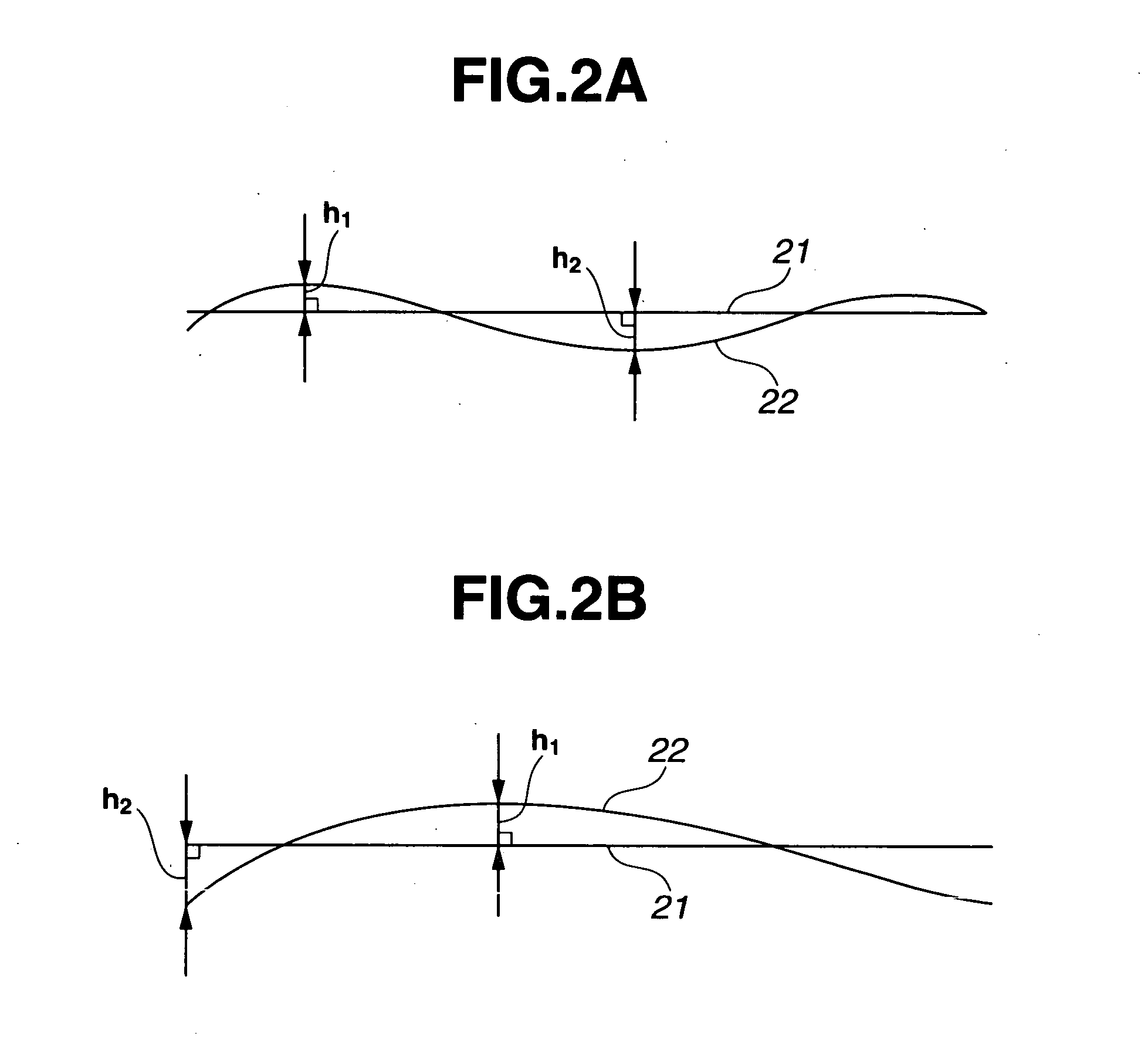

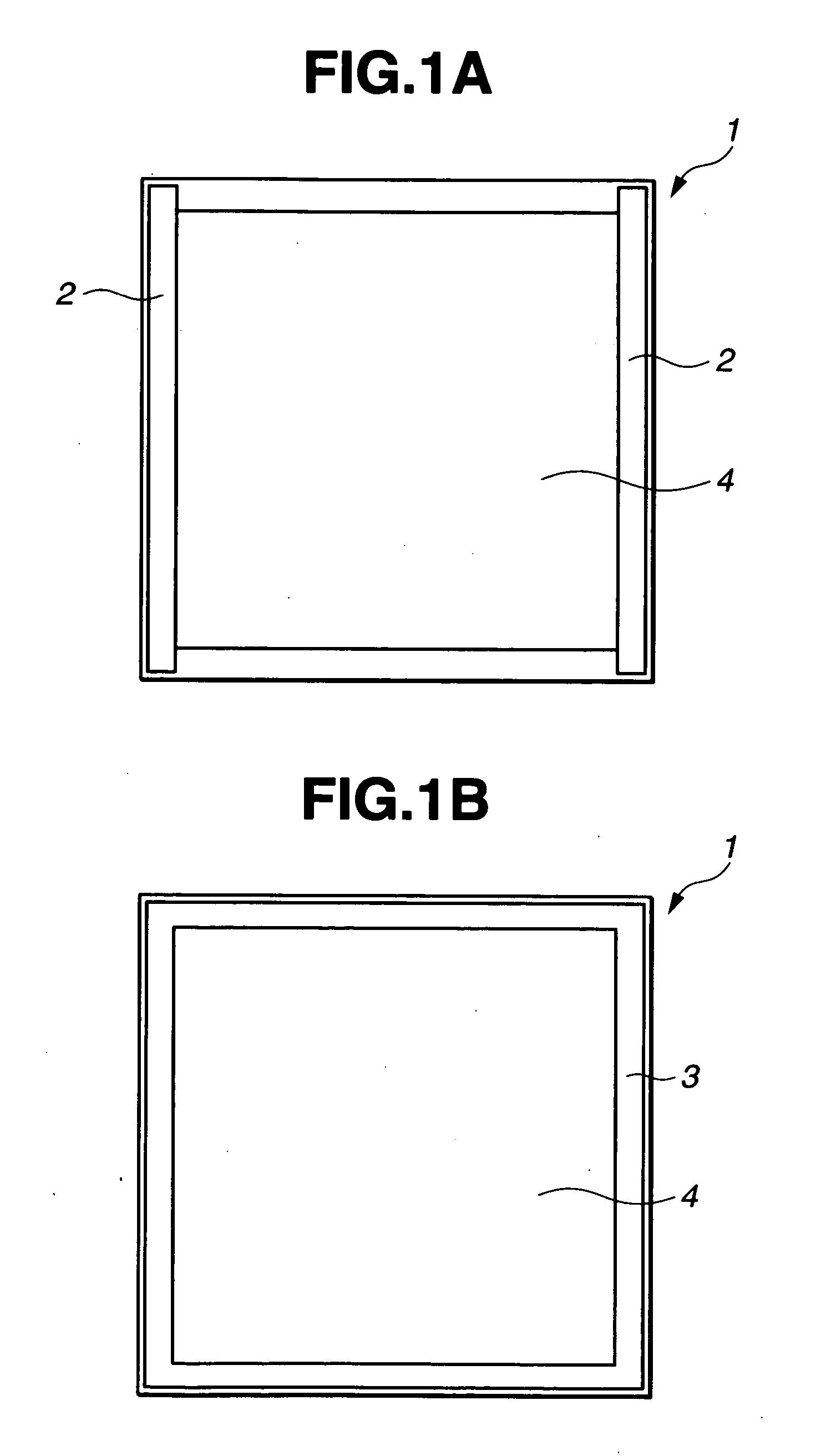

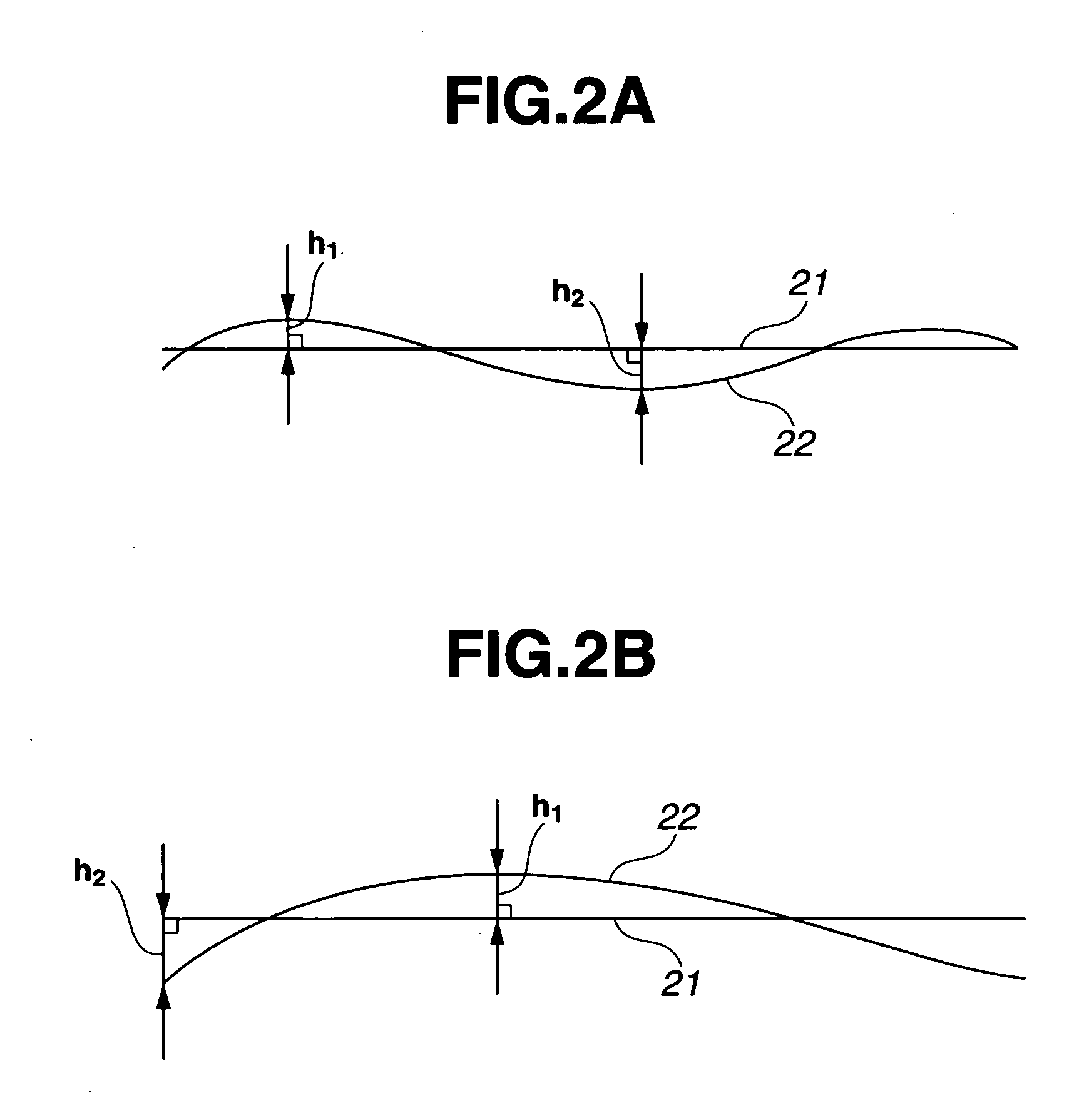

Photomask blank substrate, photomask blank and photomask

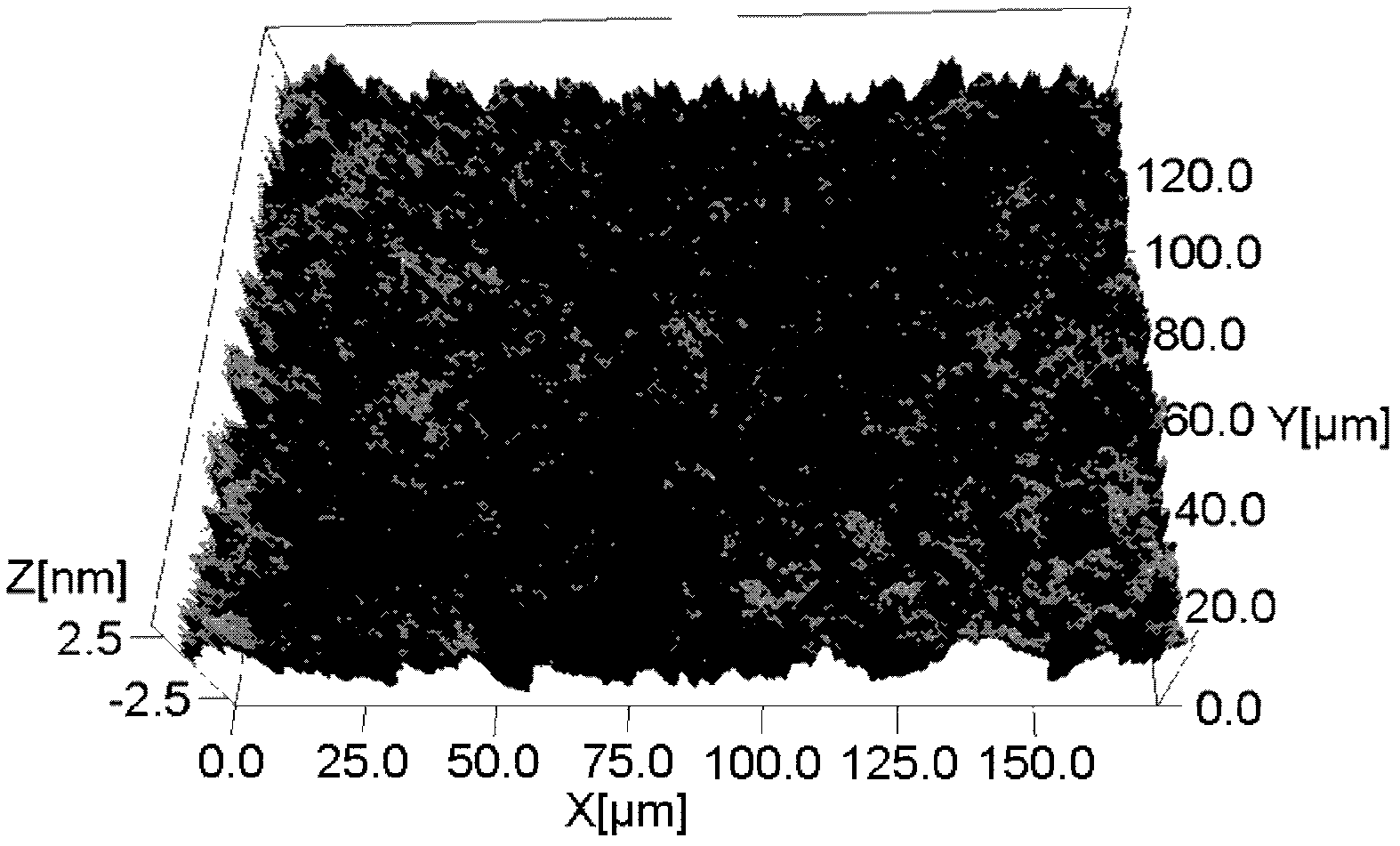

ActiveUS20050019677A1Good surface smoothnessImprove flatnessGlass/slag layered productsOriginals for photomechanical treatmentLeast squaresPhotomask

In a quadrangular photomask blank substrate with a length on each side of at least 6 inches, which has a pair of strip-like regions that extend from 2 to 10 mm inside each of a pair of opposing sides along an outer periphery of a substrate top surface, with a 2 mm edge portion excluded at each end, each strip-like region is inclined downward toward the outer periphery of the substrate, and a difference between maximum and minimum values for height from a least squares plane for the strip-like region to the strip-like region is at most 0.5 μm. The substrate exhibits a good surface flatness at the time of wafer exposure.

Owner:SHIN ETSU CHEM IND CO LTD +2

Reflective Ag alloy film for reflectors and reflector provided with the same

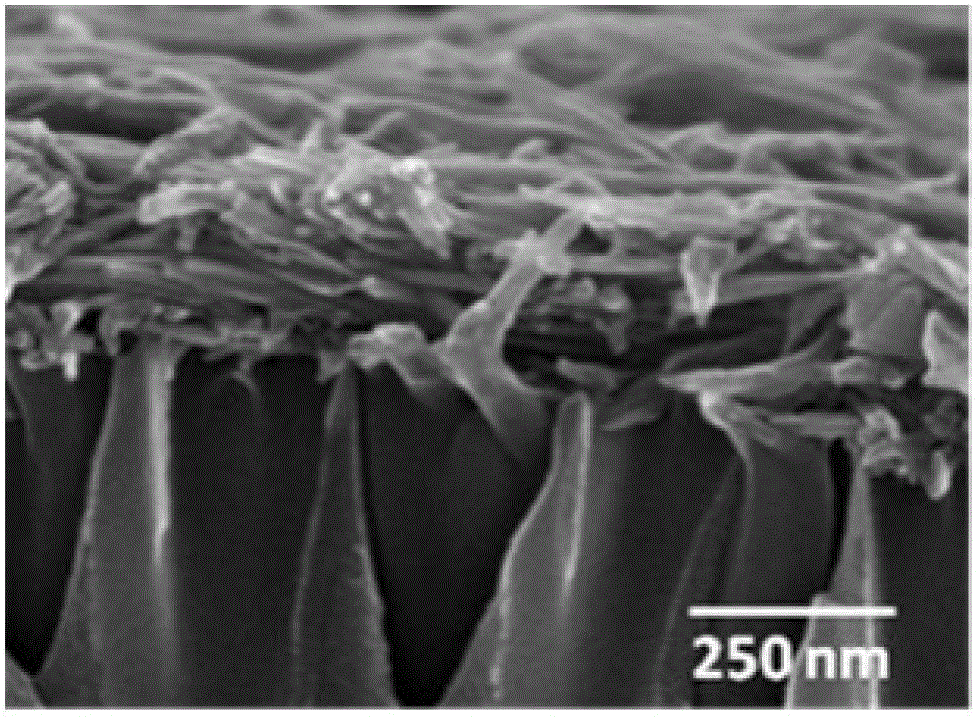

ActiveUS20050008883A1Improve reflectivityProductivity is deterioratedMirrorsVacuum evaporation coatingRare-earth elementSurface roughness

A reflective Ag alloy film for reflectors, which has excellent surface flatness and shows high reflectivity even under a heating environment and a reflector. The reflective Ag alloy film for reflectors has an average surface roughness of 2.0 nm or less and contains a rare earth element (such as Nd) in a content in the range of 0.1 to 3.0 at %, or further at least one selected from Au, Pd, Cu and Pt in a content in the range of 0.5 to 5.0 at %. The reflector comprises the above reflective Ag alloy film formed on a substrate.

Owner:KOBE STEEL LTD

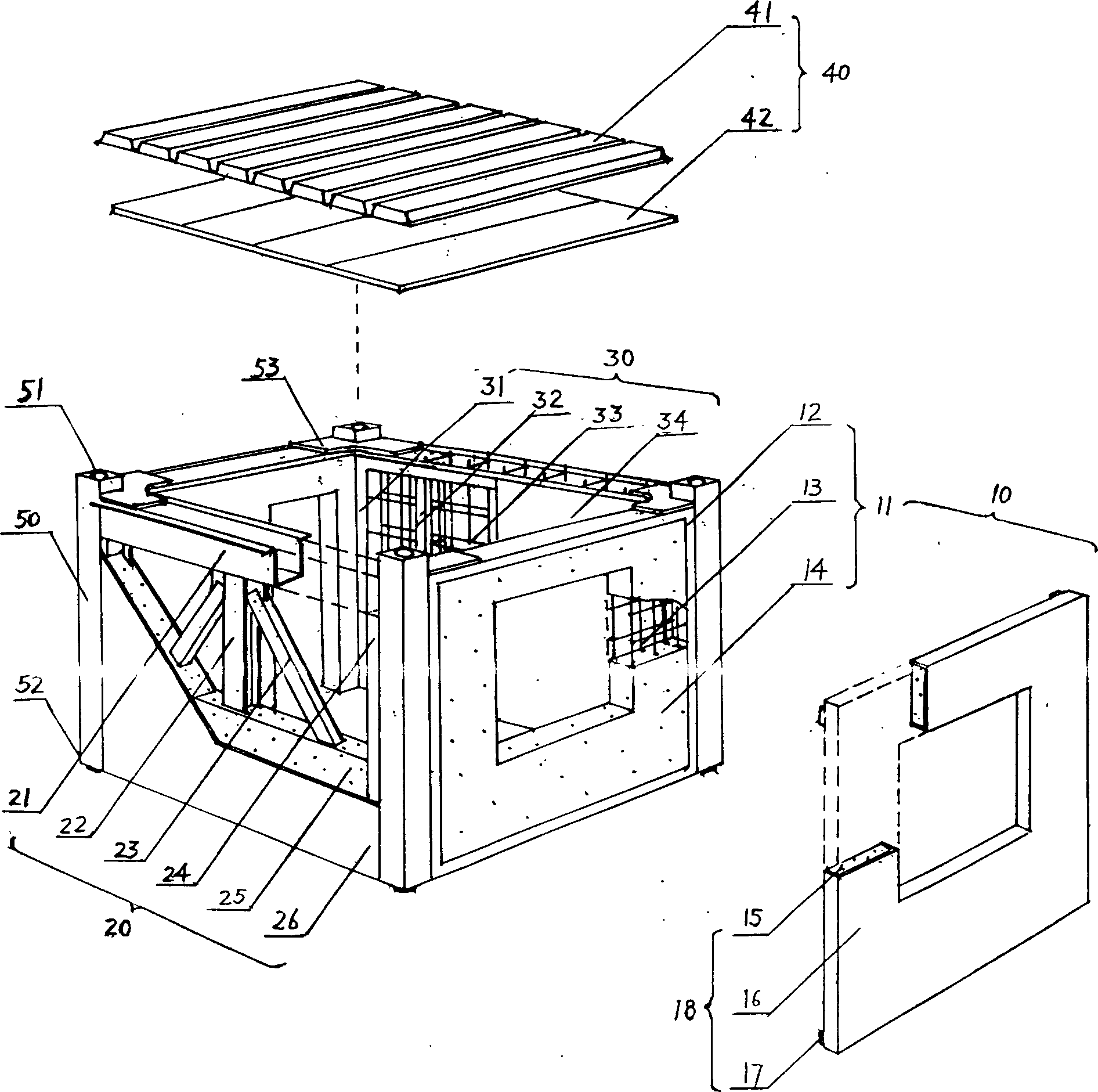

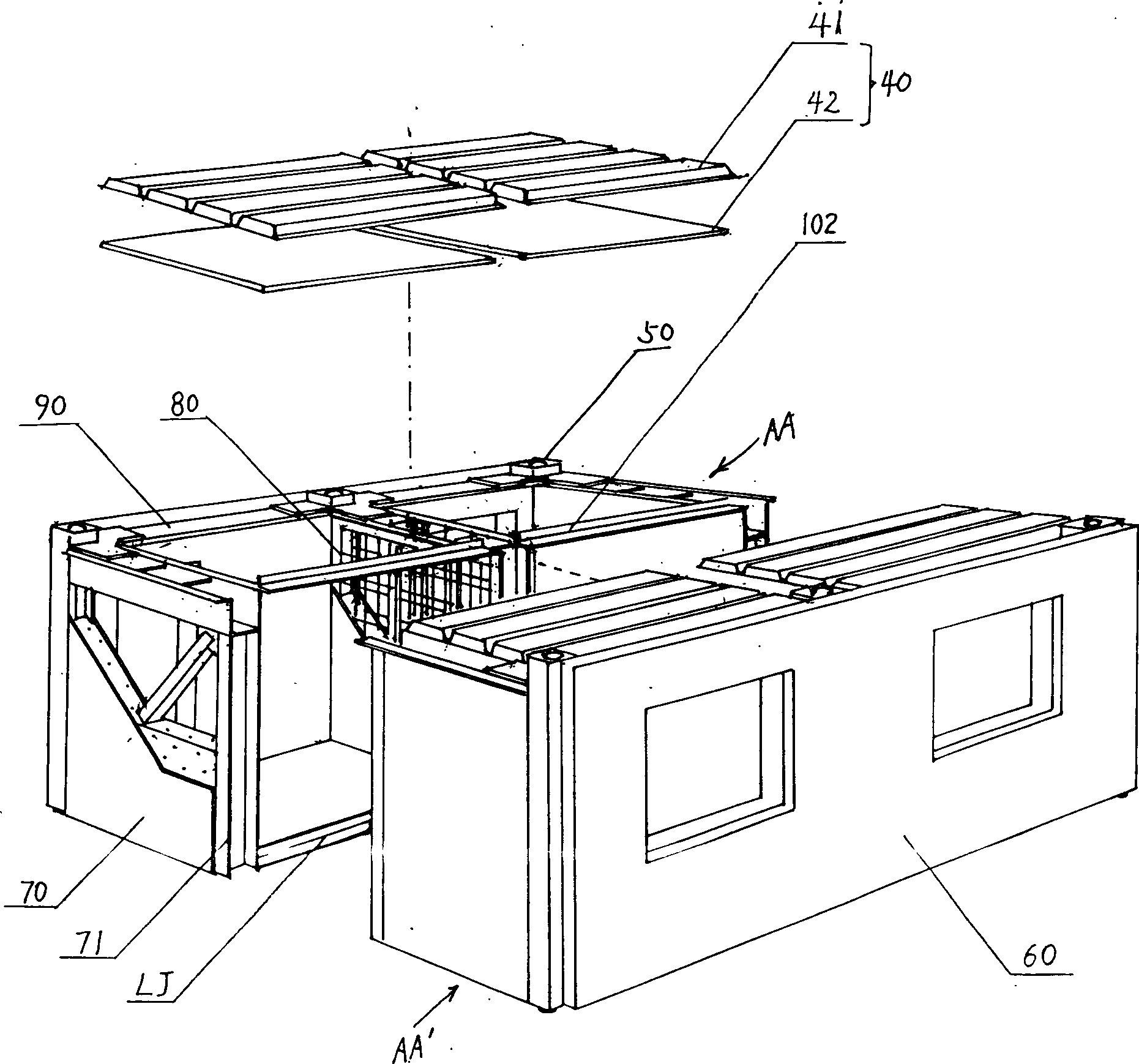

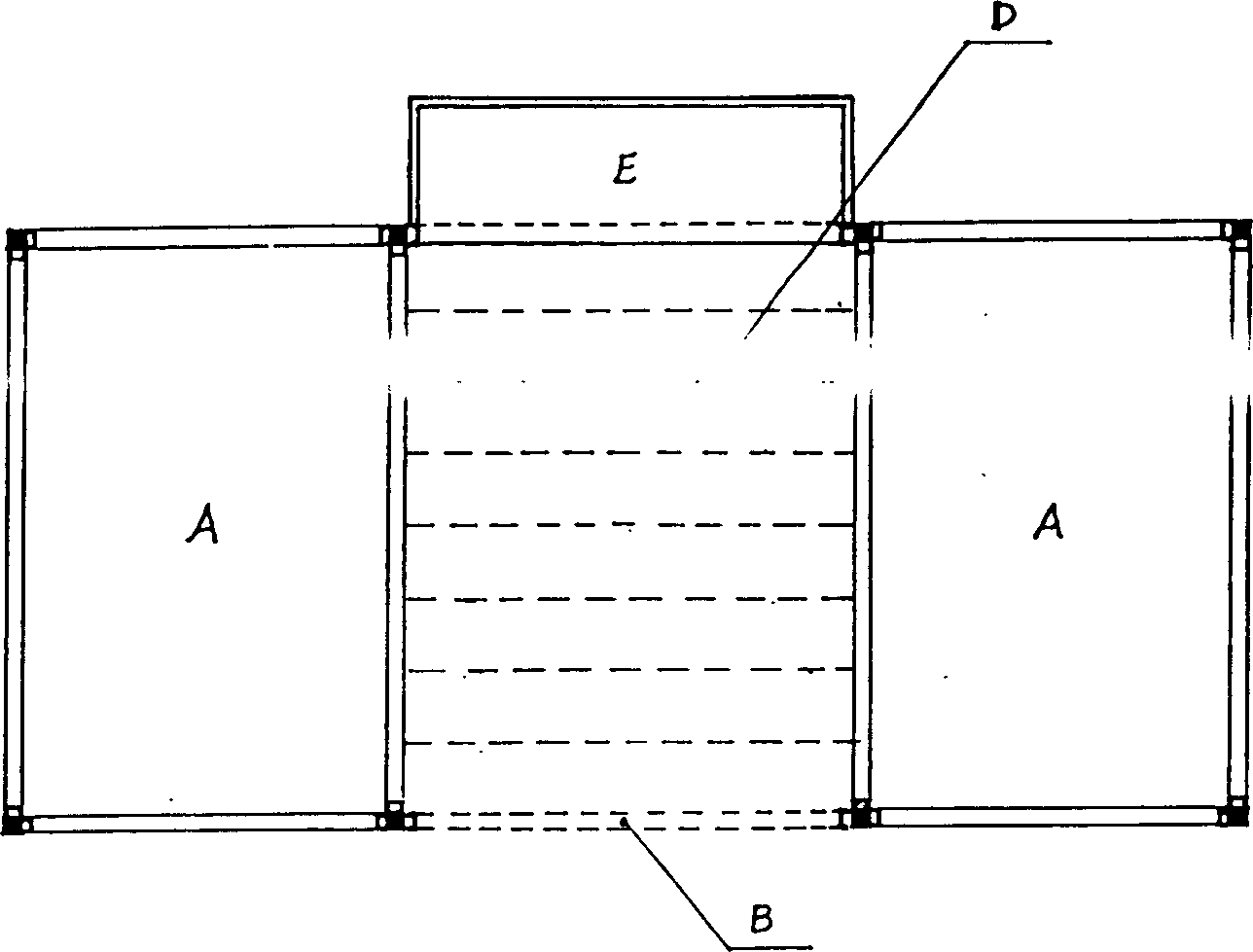

Box shaped house model of construction and fabricating method

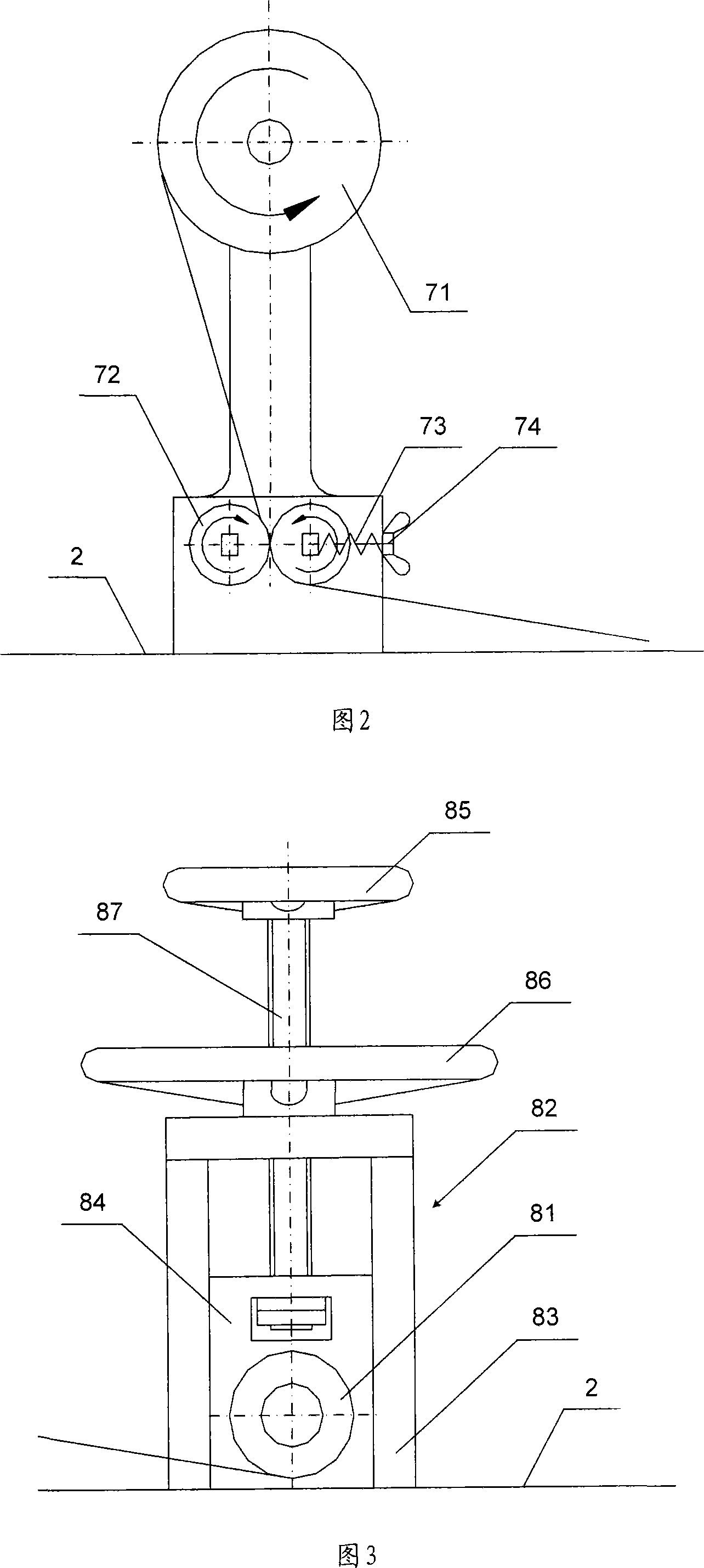

A box type of house mould used on building consists of outer wall formed by steel frame, steel screen frame and aero ¿C concrete plate; inner wall formed by hollow wall plate and composite frame wall plate; top plate mould formed by pressed steel bearing plate and light thin plate and steel tube. It is featured as enclosing box type of house mould by one outer wall and three inner walls and furthermore forming stereo structure house mould with five surfaces by welding said box type of house mould with top plate mould.

Owner:张东川

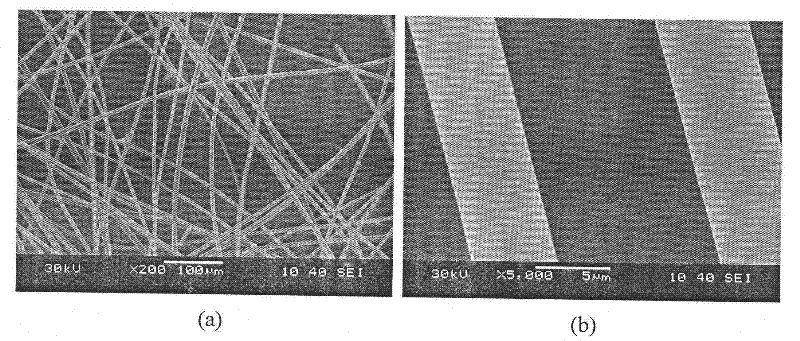

Method for preparing thin-diameter zirconium oxide fibers and fiber board thereof

ActiveCN102181962ALow costHigh purityFibreboardInorganic material artificial filamentsYttriumAdhesive

The invention relates to a method for preparing thin-diameter zirconium oxide fibers and a fiber board thereof. The method comprises the following steps of: preparing poly zirconium sol spinning solution by adopting basic zirconium carbonate, glacial acetic acid, water and yttrium nitrate as raw materials, obtaining thin-diameter poly zirconium sol fibers by ultrahigh-speed centrifugal swinging and high-speed hot airflow blowing and drafting, and performing thermal treatment and sintering on the thin-diameter poly zirconium sol fibers to obtain the thin-diameter zirconium oxide fibers; and performing vacuum suction molding and pressure leveling to prepare a wet fiber board blank by adopting the thin-diameter zirconium oxide fibers as a raw material and adopting poly zirconium sol spinningsolution diluted by adding water as adhesive, and drying and calcining the wet blank to obtain the zirconium oxide fiber board. The raw materials are easily obtained, the preparation of the adhesive is simple and convenient, and the method has low cost and no pollution and is suitable for large-batch industrialized production; the prepared thin-diameter zirconium oxide fibers have good bending flexibility; and the prepared zirconium oxide fiber board has uniform thickness, flat surface, accurate and controllable thickness, and good mechanical property and high-temperature bending resistance.

Owner:南京理工宇龙新材料科技股份有限公司

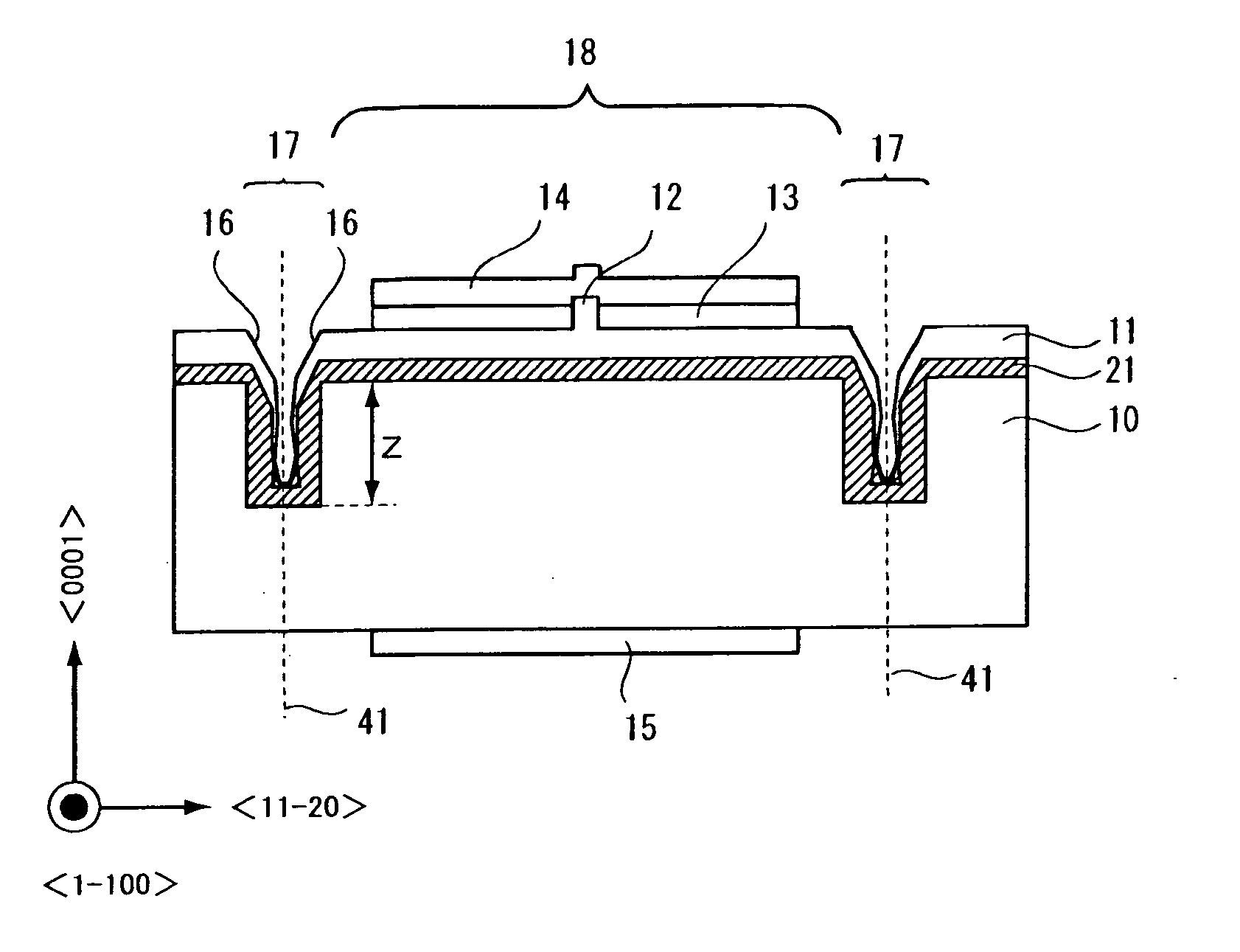

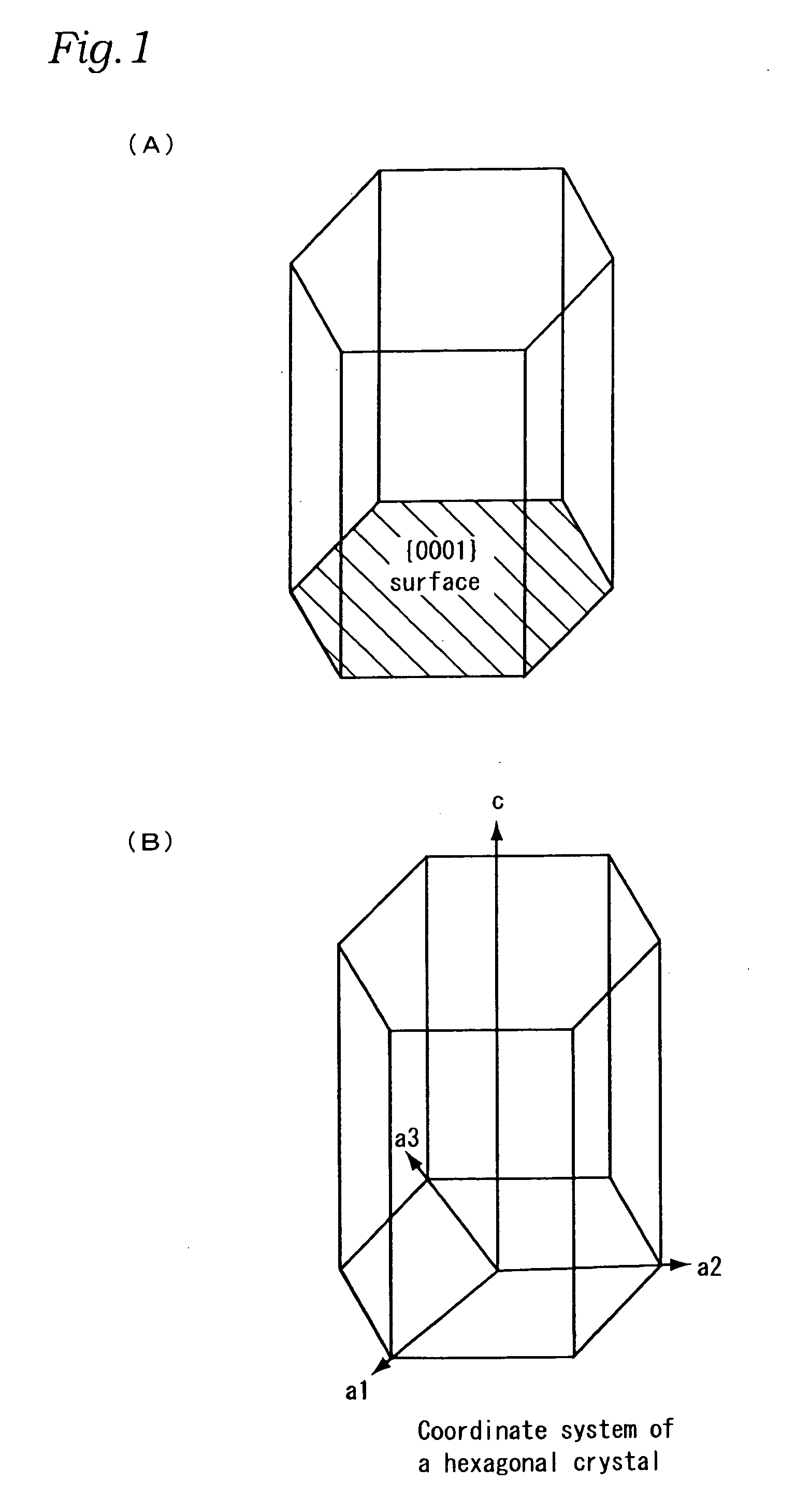

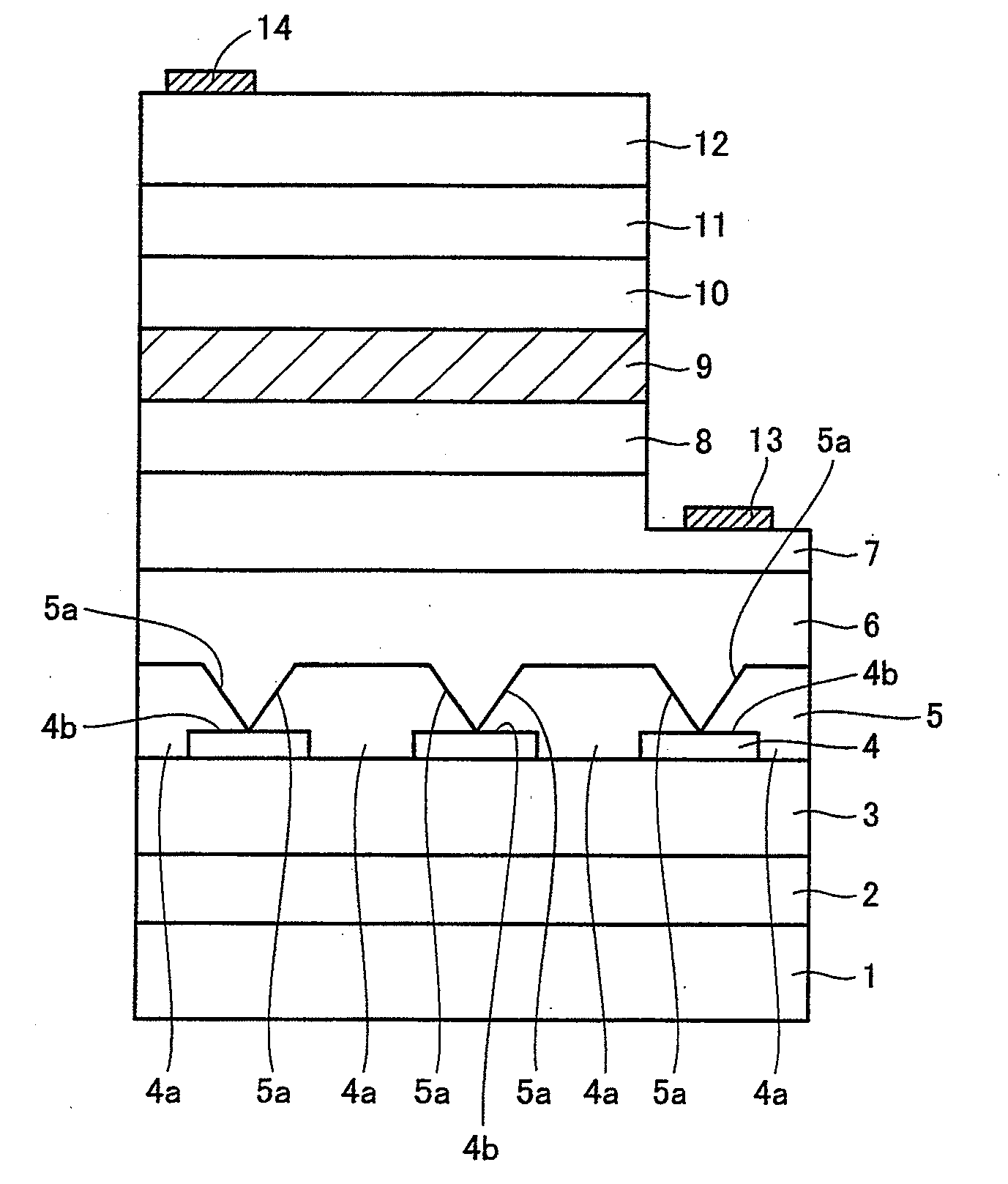

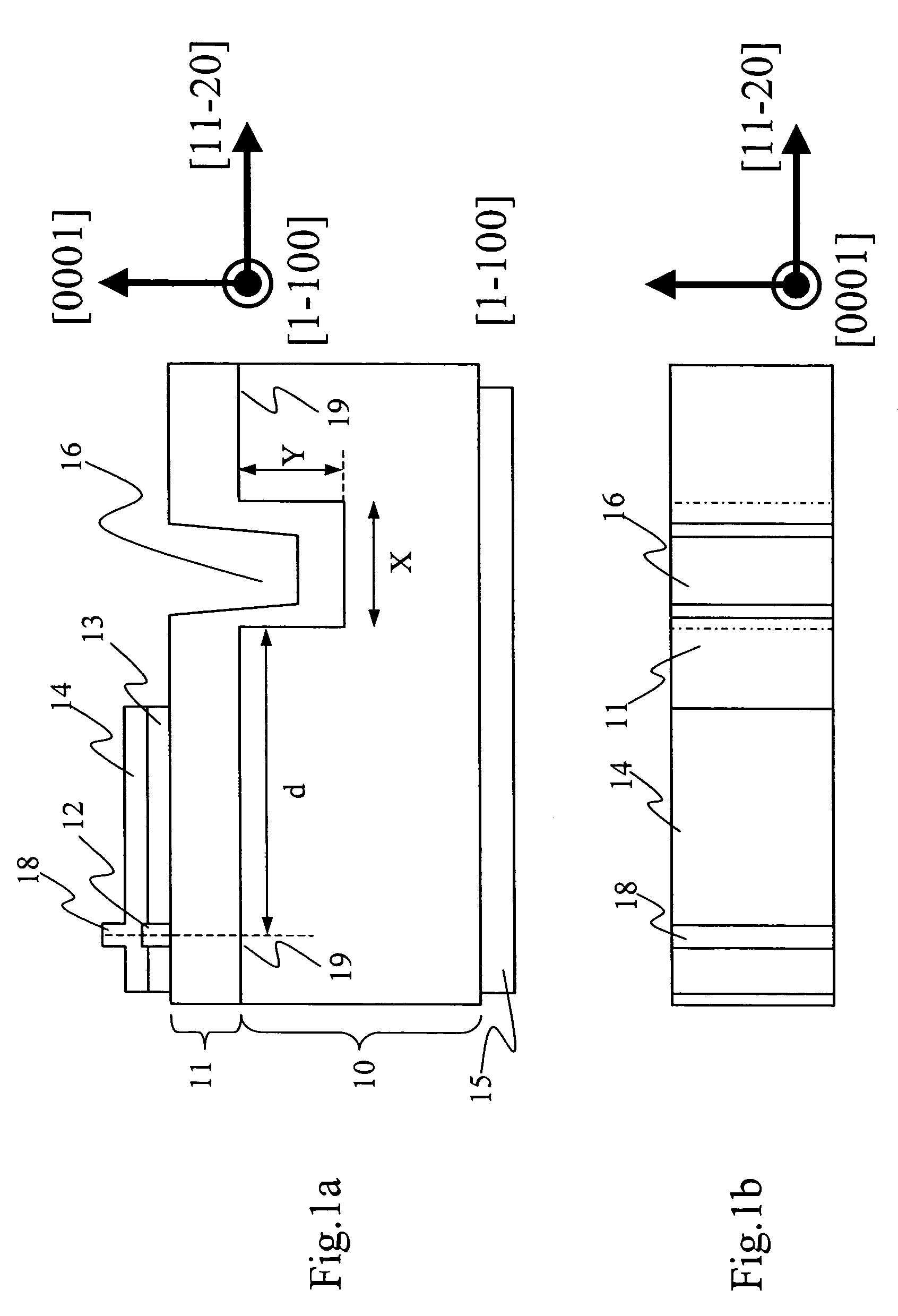

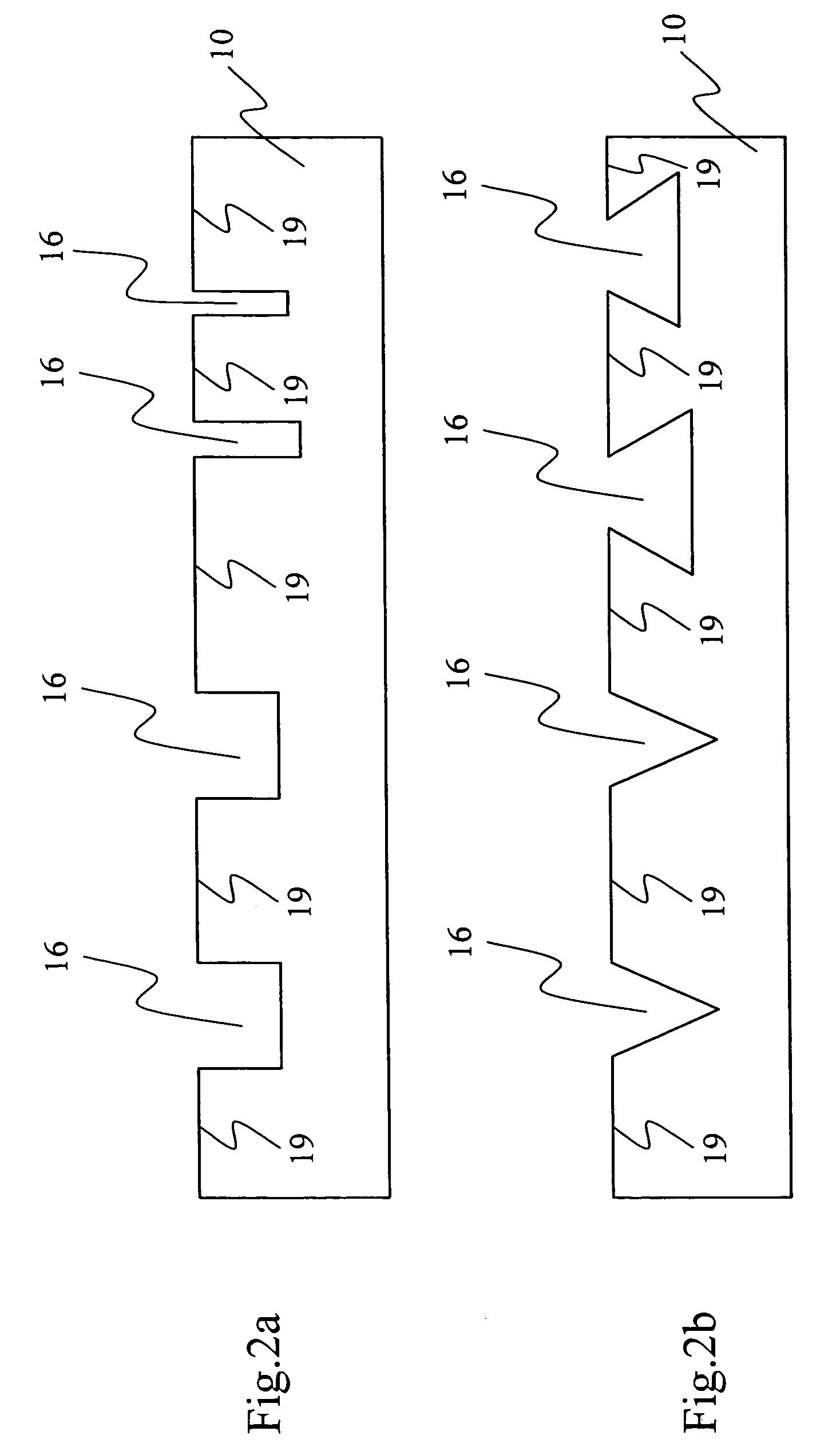

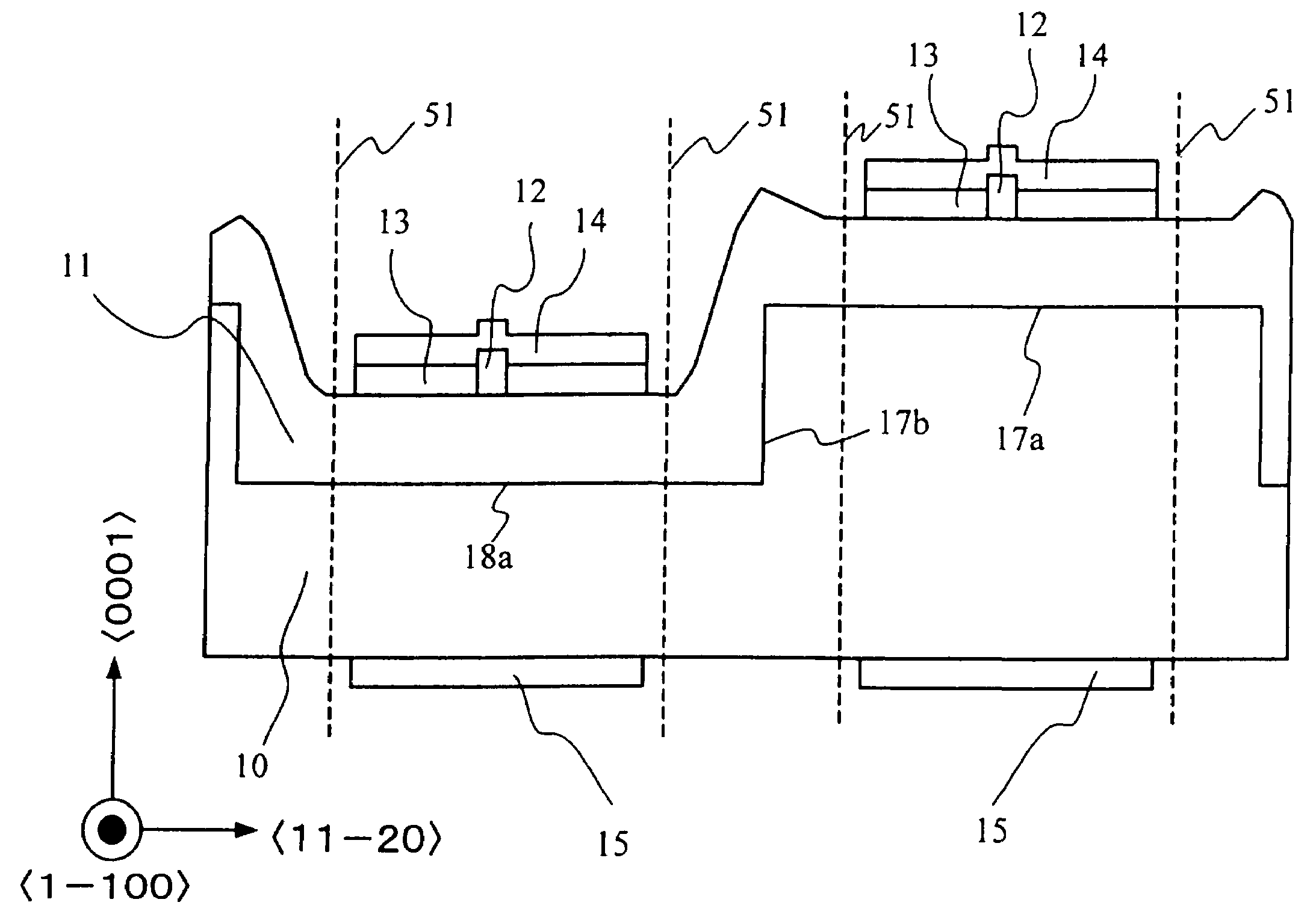

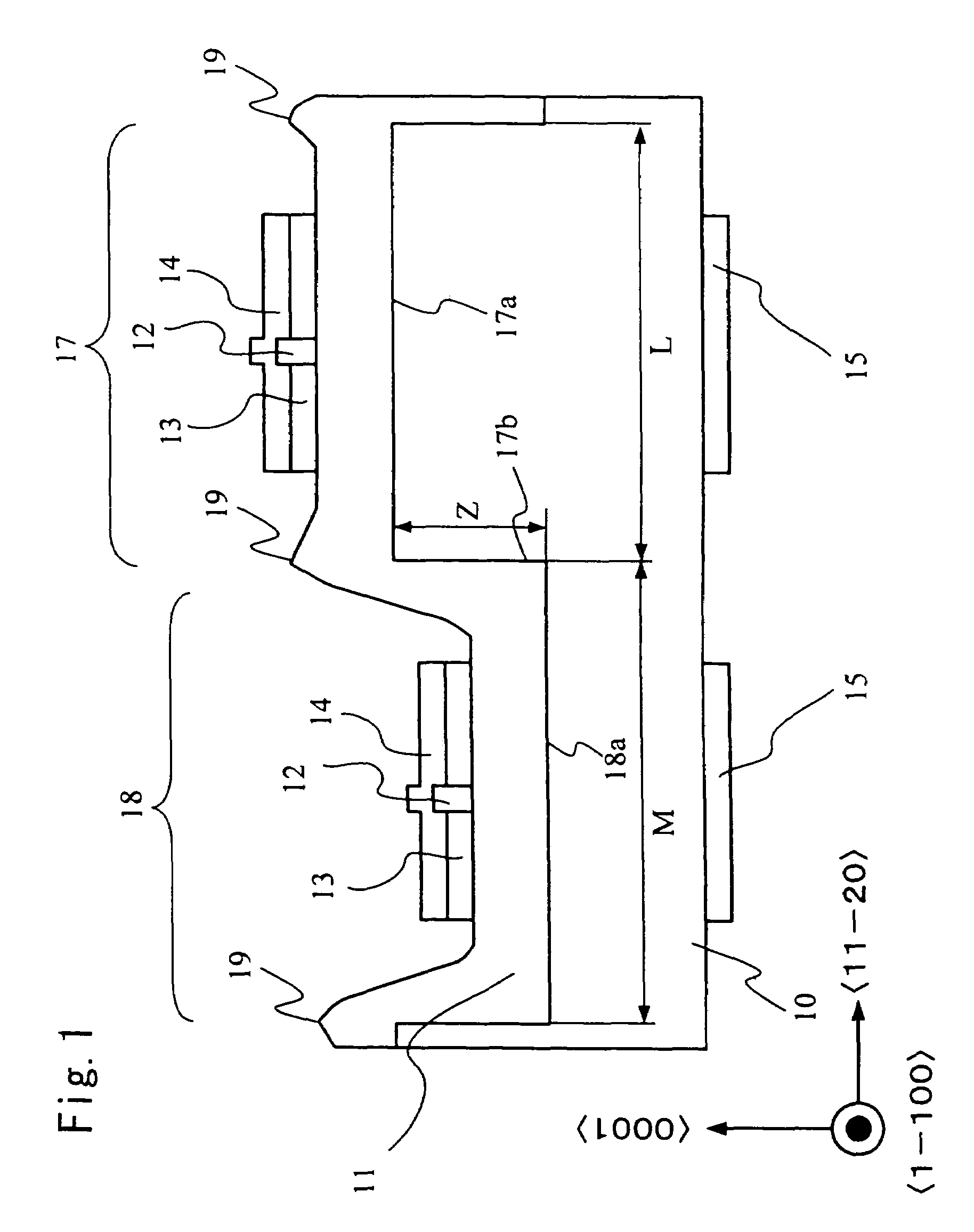

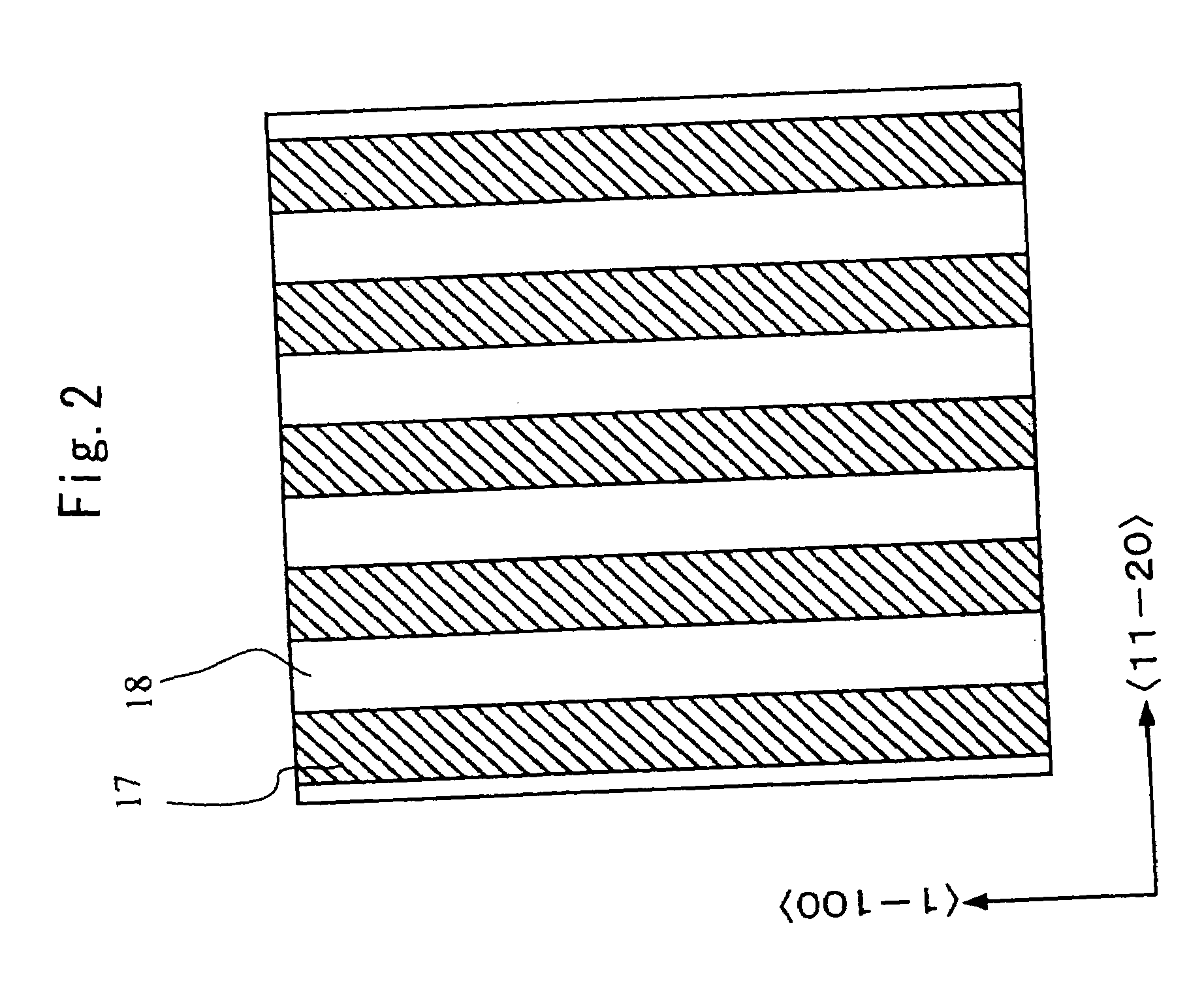

Nitride semiconductor light-emitting device and method for producing same

ActiveUS20060131590A1Good surface smoothnessAvoid crackingOptical wave guidanceLaser detailsActive layerLight emitting device

In a method for producing a nitride semiconductor light-emitting device according to the present invention, first, a nitride semiconductor substrate having groove portions formed is prepared. An underlying layer comprising nitride semiconductor is formed on the nitride semiconductor substrate including the side walls of the groove portions, in such a manner that the underlying layer has a crystal surface in each of the groove portions and the crystal surface is tilted at an angle of from 53.5° to 63.4° with respect to the surface of the substrate. Over the underlying layer, a light-emitting-device structure composed of a lower cladding layer containing Al, an active layer, and an upper cladding layer containing Al is formed. According to the present invention, thickness nonuniformity and lack of surface flatness, which occur when accumulating a layer with light-emitting-device structure of nitride semiconductor over the nitride semiconductor substrate, are alleviated while inhibiting occurrence of cracking.

Owner:SHARP FUKUYAMA LASER CO LTD

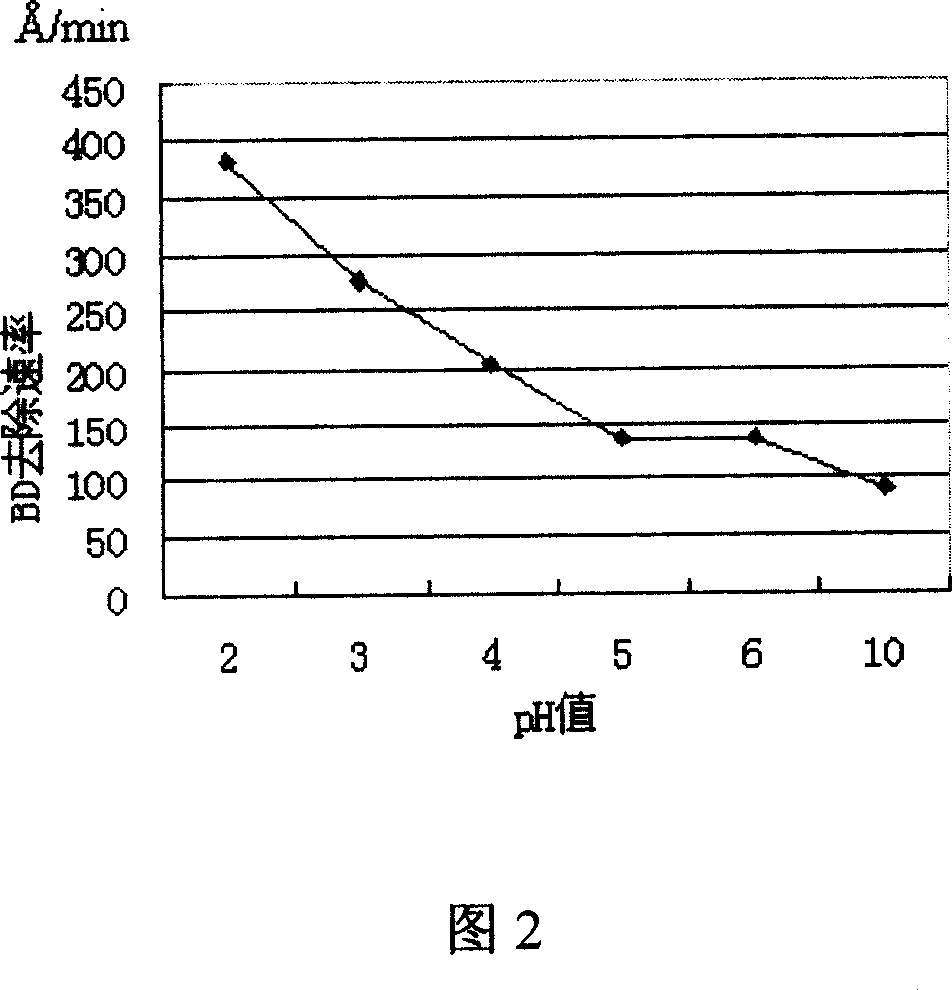

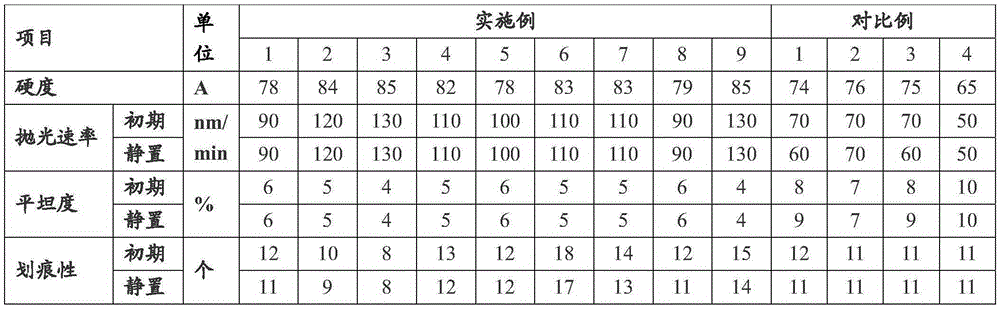

Acidic chemical and mechanical polishing composition

ActiveCN102585706AEasy to polishBoost rateOther chemical processesPolishing compositions with abrasivesColloidal silicaOrganic film

The invention provides an acidic chemical and mechanical polishing composition. The pH value of the acidic chemical and mechanical polishing composition is 2-7, and the acidic chemical and mechanical polishing composition comprises 1-20% by weight of abrasive material, 0.5-10% by weight of oxidant, 0.1-10% by weight of complexing agent, 0.001-1% by weight of corrosion inhibitor, 0.001-5% by weight of organic film-forming auxiliaries and the balance of pH regulator and deionized or distilled water, wherein the abrasive material is of colloidal silica sol after modification in the special step, and the average particle size is of 10-200nm. According to the chemical and mechanical polishing composition provided by the invention, the abrasive material is refined and modified; by using the method, the stability of the abrasive material in polishing slurry can be effectively upgraded, and polishing removal rate and surface roughness degree are respectively optimized to a certain extent; and the unique adding effect of the organic film-forming auxiliaries can well balance the strength of chemical corrosion action and the strength of mechanical grinding action, and achieve the effects of improving polishing removal efficiency and performing global planarization.

Owner:TSINGHUA UNIV

Preparation method and application of separation film with nano composite cortical layer

ActiveCN102908906AImprove throughputImprove interception effectSemi-permeable membranesDesalinationNanofiltration

The invention provides a preparation method and application of a separation film with a nano composite cortical layer. The separation film comprises a non-woven fabric layer, two porous support layers and a desalination layer, and is characterized in that the lower layer of the two porous support layers is a porous body layer containing polymers and / or nano particles, and the upper layer of the two porous support layers is a porous cortical containing polymers and nano particles. The preparation method includes coating the upper layer and the lower layer of the non-woven base material by means of a double-layer coating technology. An ultrafilter support layer of the composite separation film prepared by the preparation method is good in surface evenness, hight water flux is kept in the meantime of keeping higher cutoff rate, and the separation film can be directly used as an ultrafiltration film or can be used as a basic porous support layer to further prepare a composite forward osmosis, reverse osmosis and nanofiltration film. The preparation method can be applied to preparing the reverse osmosis film and the nanofiltration film which are good in performance, and a composite ultrafiltration film with low molecular weight cutoff.

Owner:VONTRON TECH CO LTD

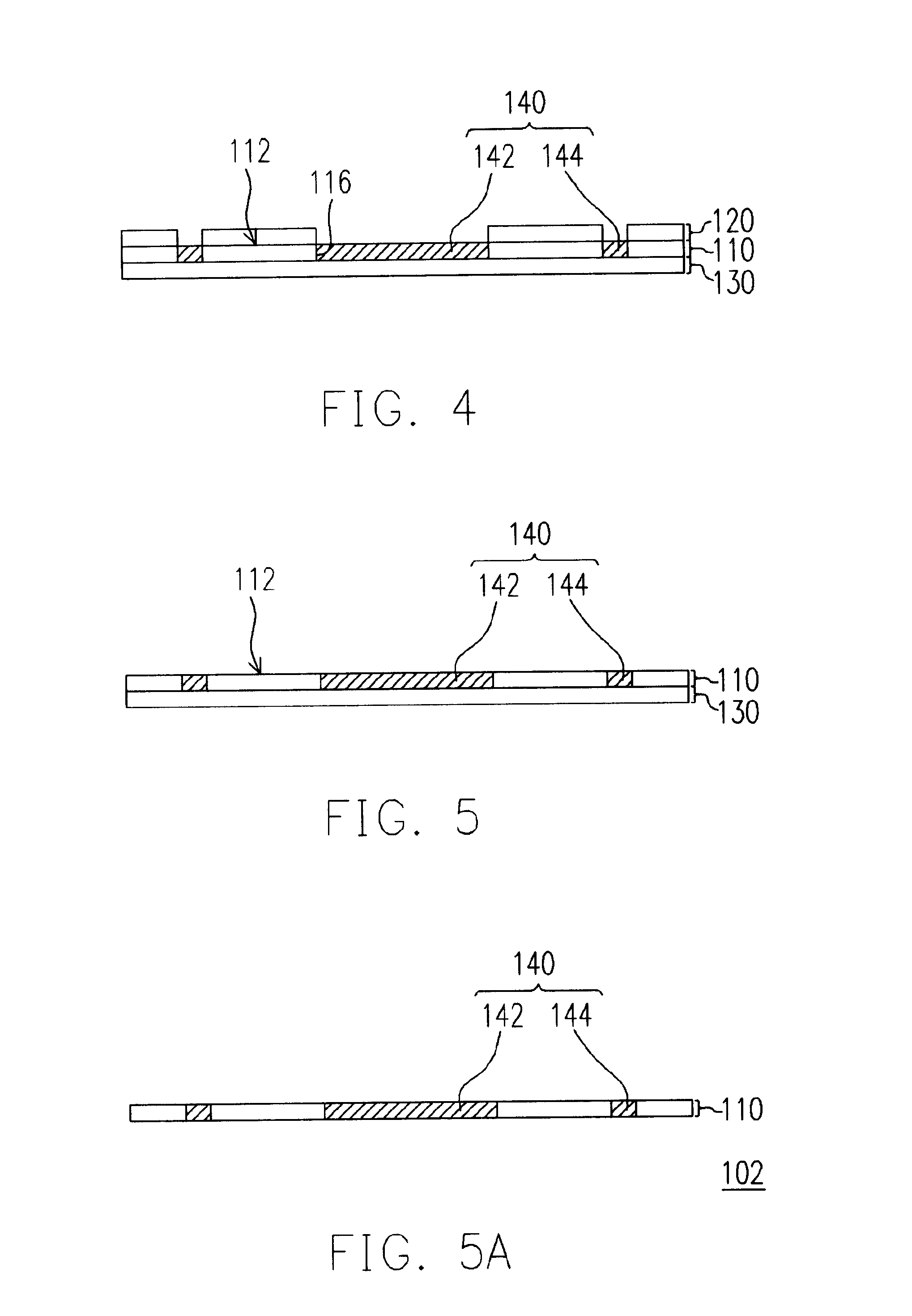

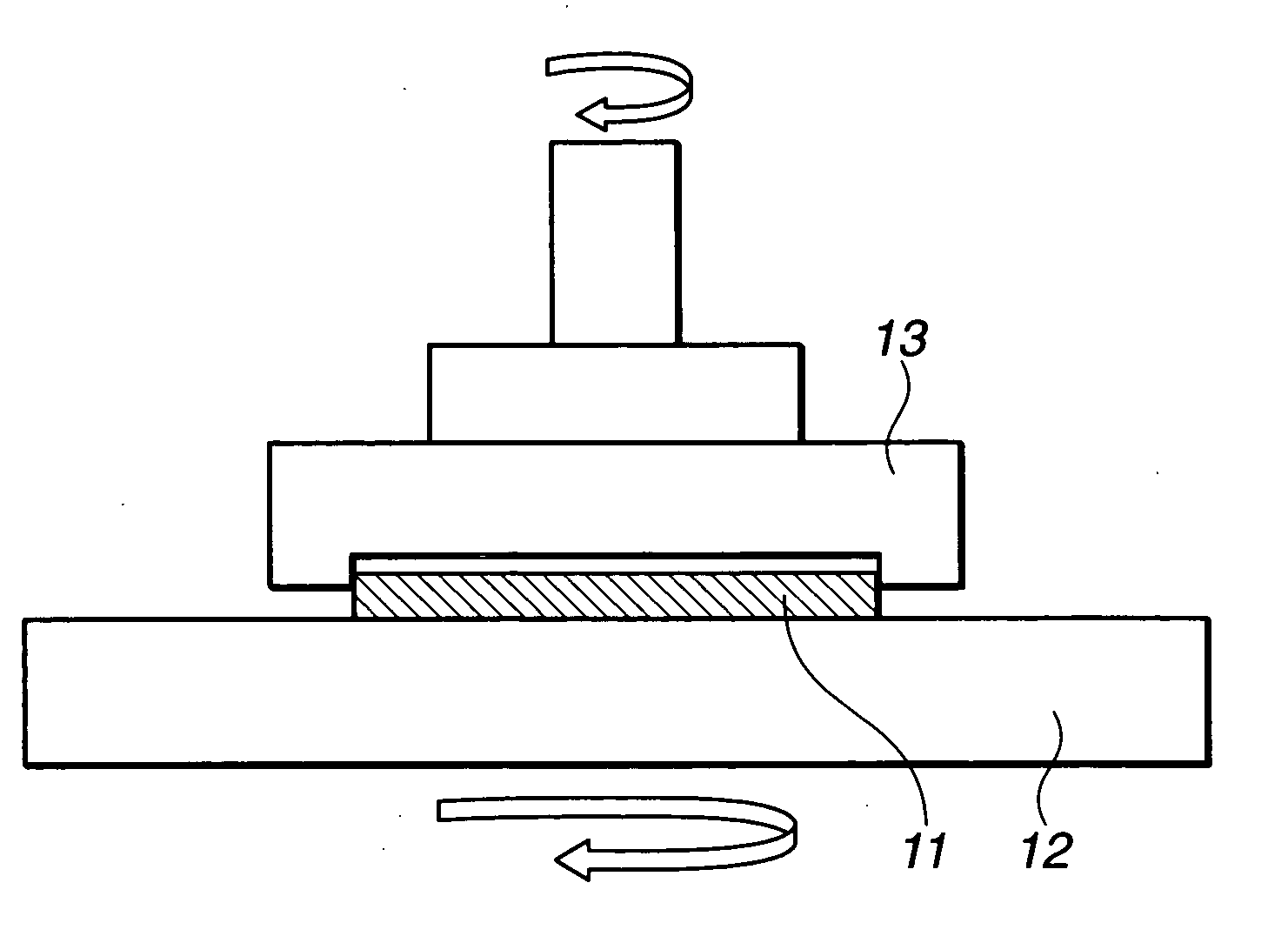

Substrate processing apparatus and substrate processing method

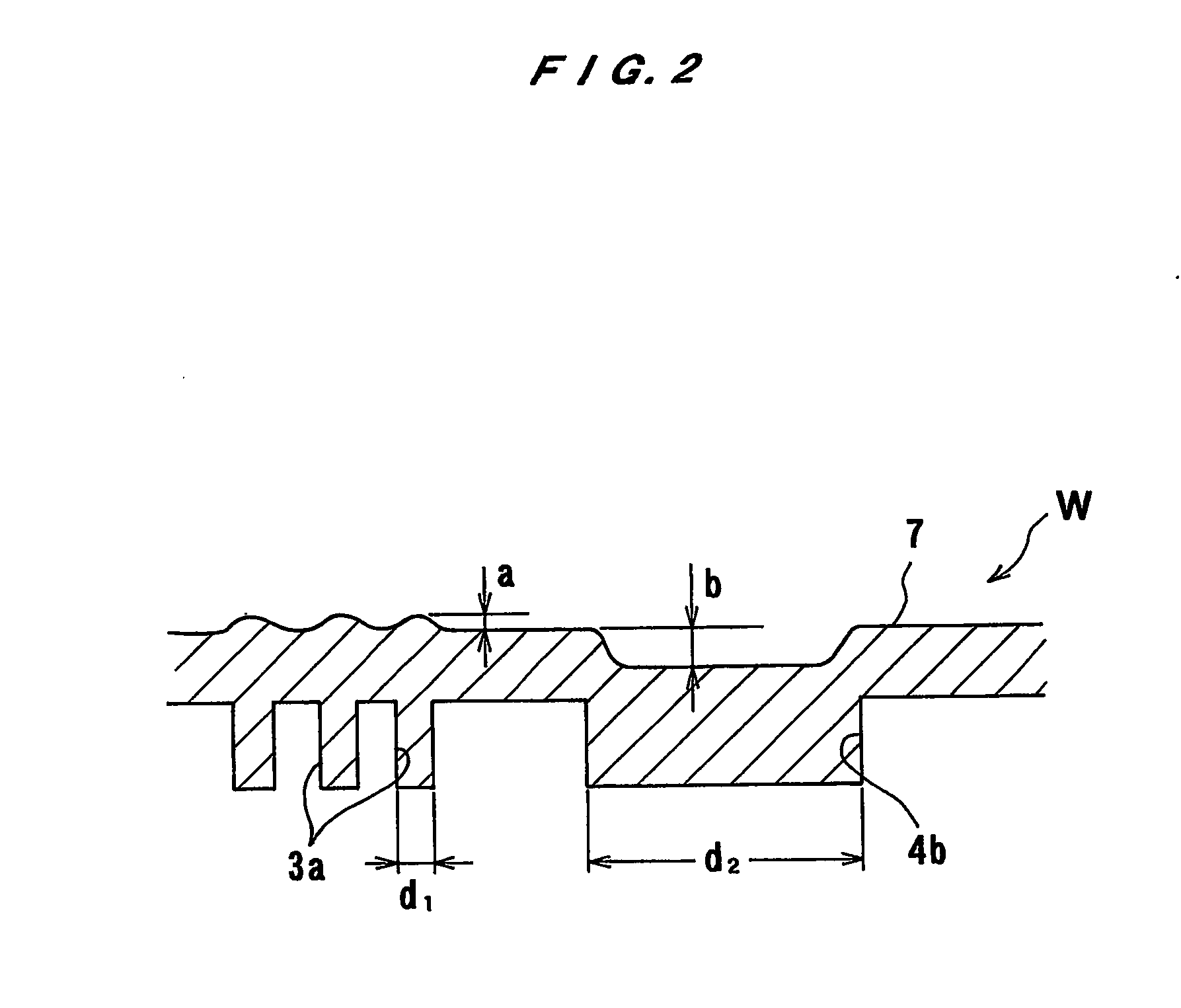

InactiveUS20060234508A1Reduce loadSufficient flatnessElectrolysis componentsSemiconductor/solid-state device manufacturingMaterials scienceElectrolysis

There is provided a substrate processing apparatus which can process a substrate by using an electrolytic processing method, while reducing a load upon a CMP processing to the least possible extent. The substrate processing apparatus of the present invention includes: an electrolytic processing unit (36) for electrolytically removing the surface of the substrate W having a to-be-processed film formed in said surface, said unit including a feeding section (373) that comes into contact with said surface of the substrate W; a bevel-etching unit (48) for etching away the to-be-processed film remaining unprocessed at the portion of the substrate that has been in contact with the feeding section (373) in the electrolytic processing unit (36); a chemical mechanical polishing unit (34) for chemically and mechanically polishing the surface of the substrate.

Owner:EBARA CORP

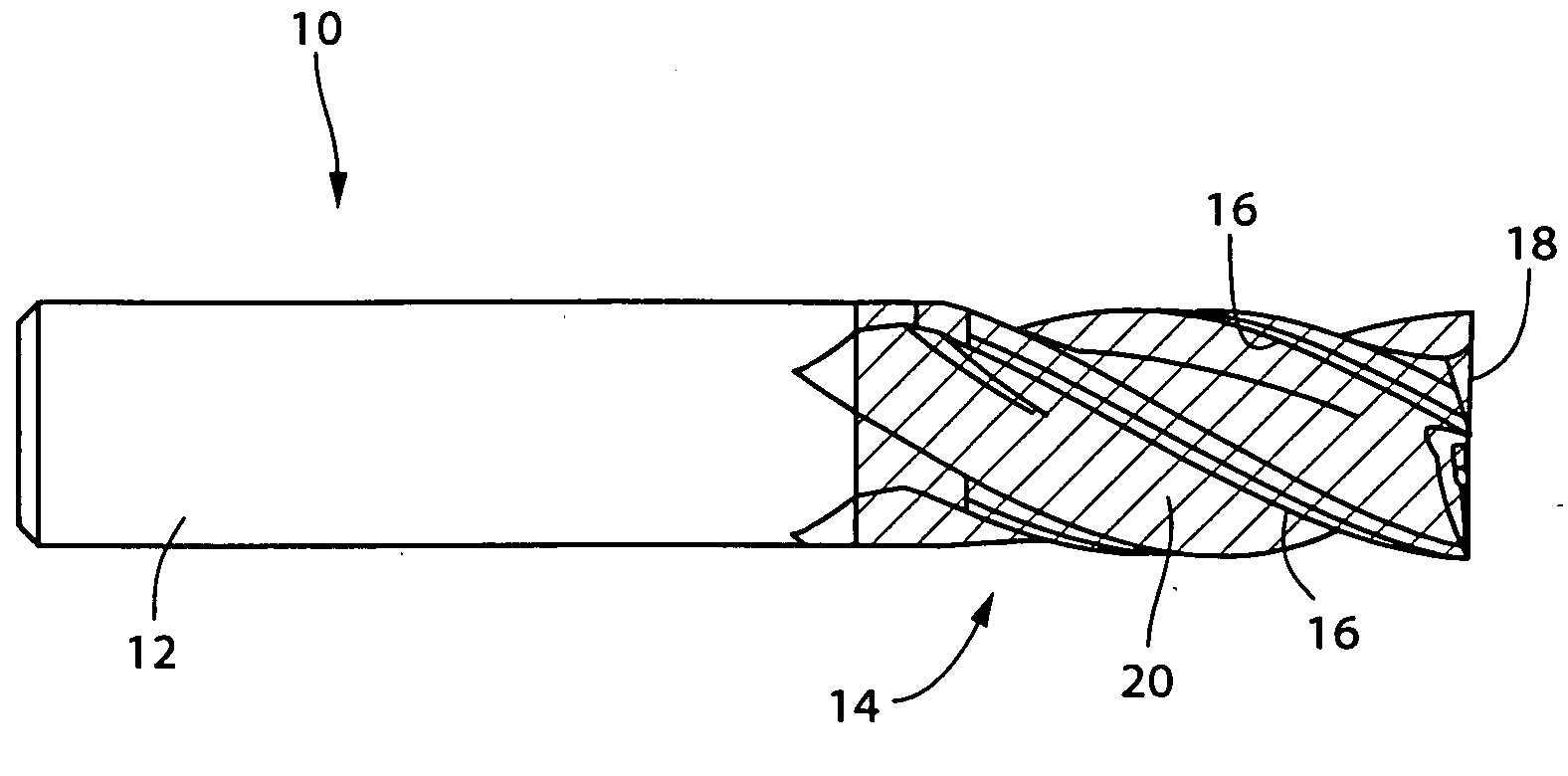

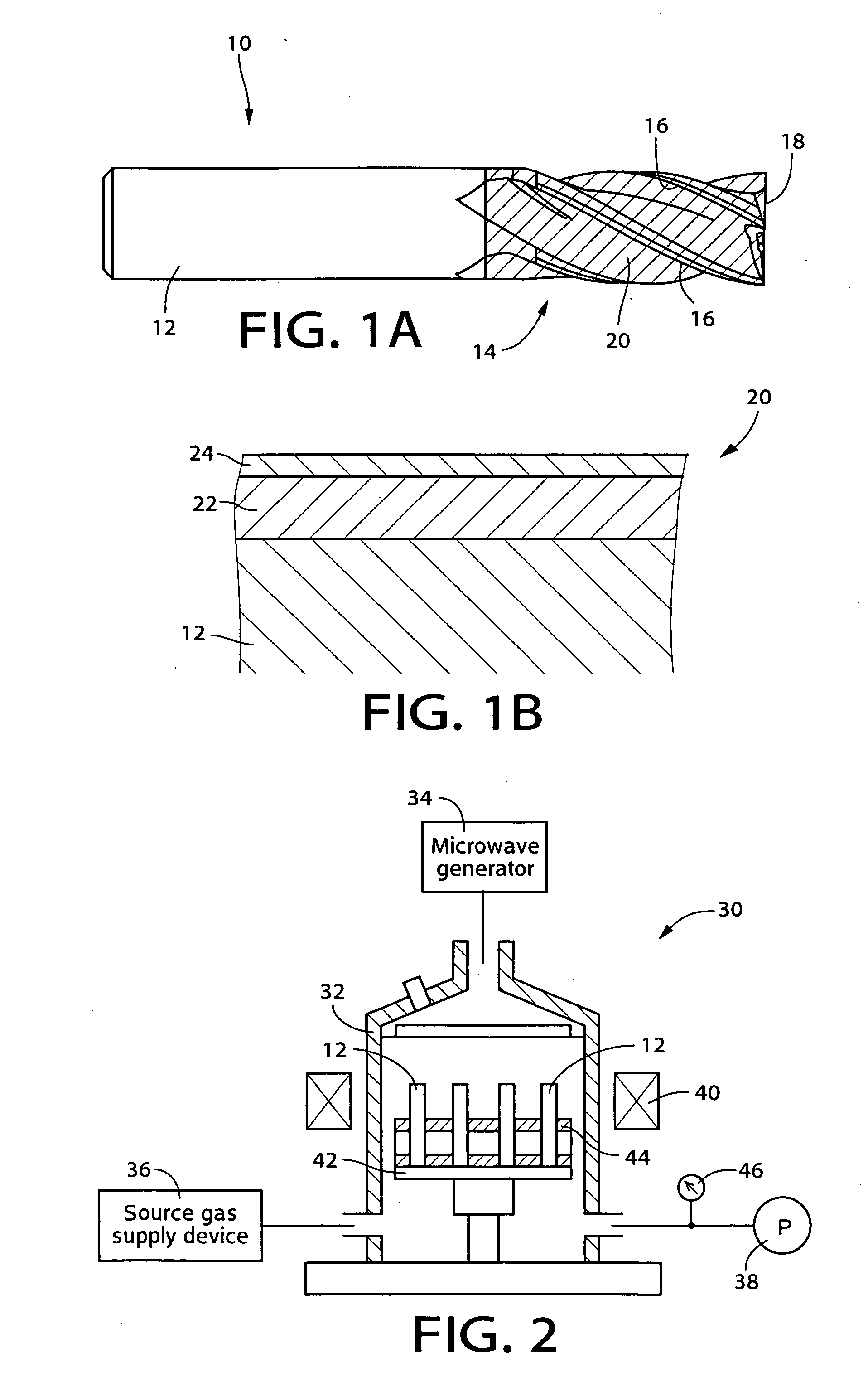

Hard coating and machining tool disposed with hard coating

ActiveUS20060115650A1Procures electrical conductivityImprove adhesionThread cutting toolsPigmenting treatmentBoronMachining

A hard coating that is to be disposed on a surface of a body includes a diamond layer which includes a plurality of diamond grains and is doped with boron, and an outer layer which includes an intermetallic compound and is disposed on the diamond layer by a physical vapor deposition method.

Owner:OSG

Thermoplastic polymer composition and sheet-like molded article therefrom

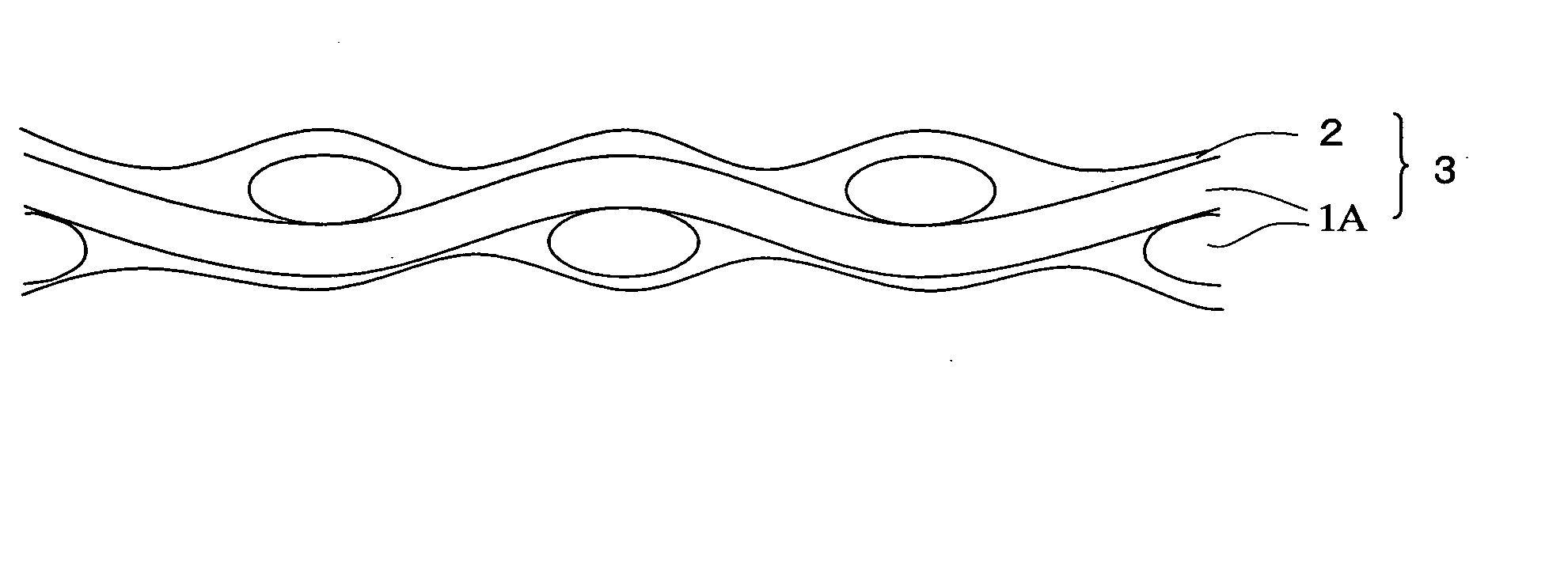

[Object] Provided are a sheet-like molded article having excellent surface smoothness, moldability, flexibility, and a high transmittance of short-wavelength light, and a thermoplastic polymer composition used to produce the sheet-like molded article.[Solution] A thermoplastic polymer composition containing an acrylic block copolymer (A) and an acrylic resin (B), in which the acrylic block copolymer (A) has, in its molecule, at least one structure where polymer blocks (a2) mainly composed of a methacrylic ester unit are bonded to both ends of a polymer block (a1) mainly composed of an acrylic ester unit, the acrylic block copolymer (A) having a specific weight-average molecular weight range, the acrylic block copolymer (A) contains an acrylic block copolymer (A1) having a polymer block (a2) content of 40% by mass or more and not less than 80% by mass and contains an acrylic block copolymer (A2) having a polymer block (a2) content of 10% by mass or more and less than 40% by mass, the acrylic resin (B) is mainly composed of a methacrylic ester unit, and the mass ratio [(A) / (B)] is in the range of 97 / 3 to 10 / 90.

Owner:KURARAY CO LTD

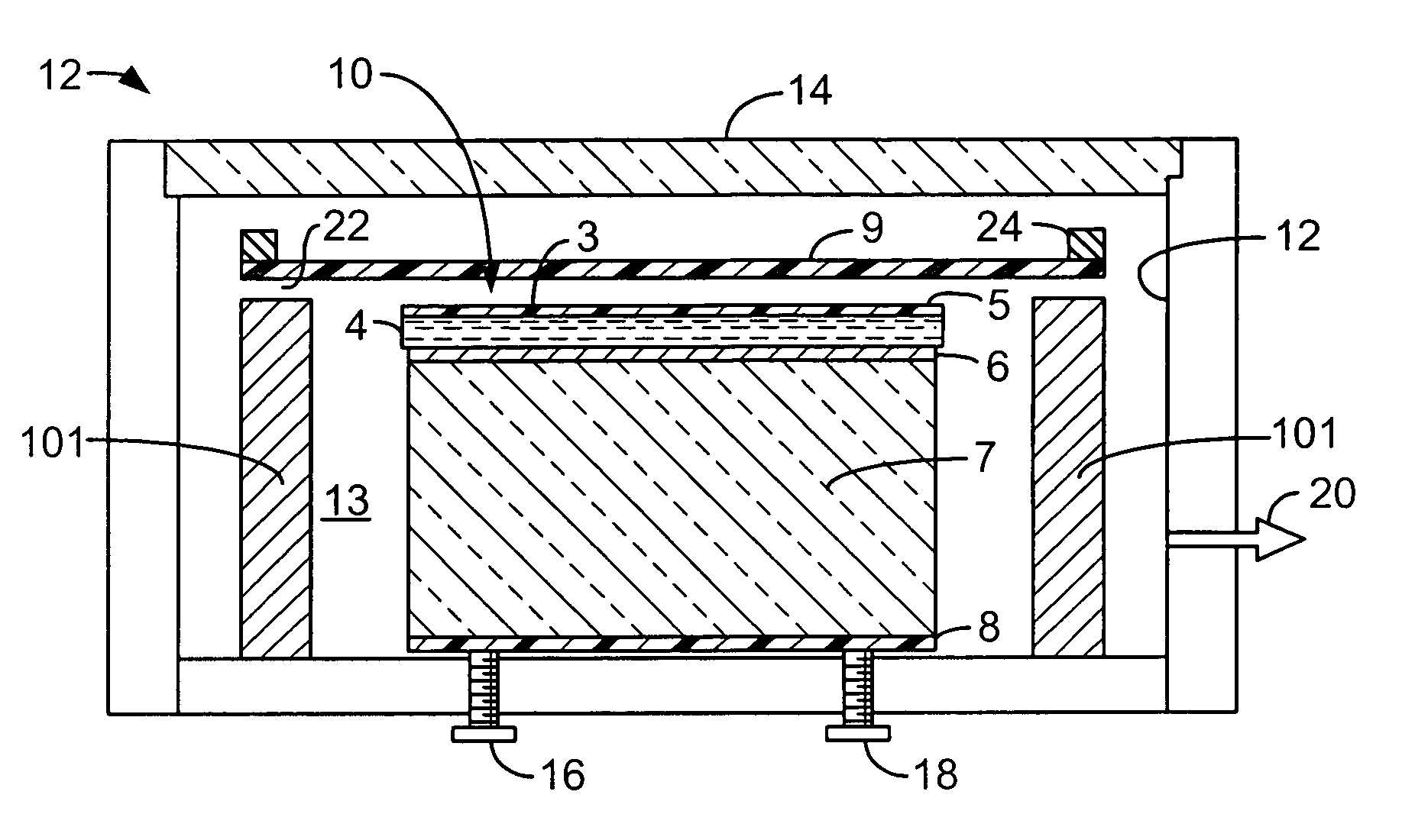

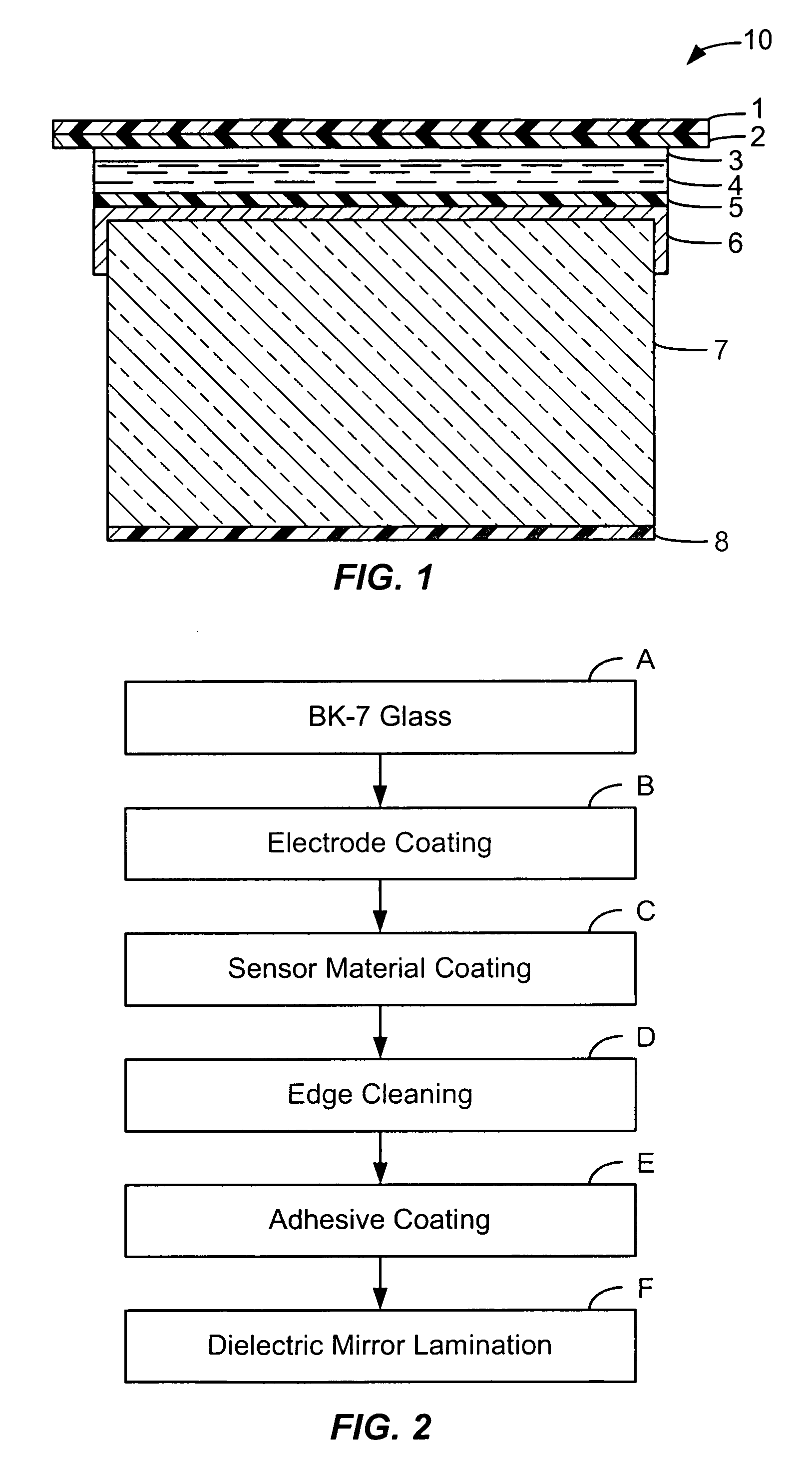

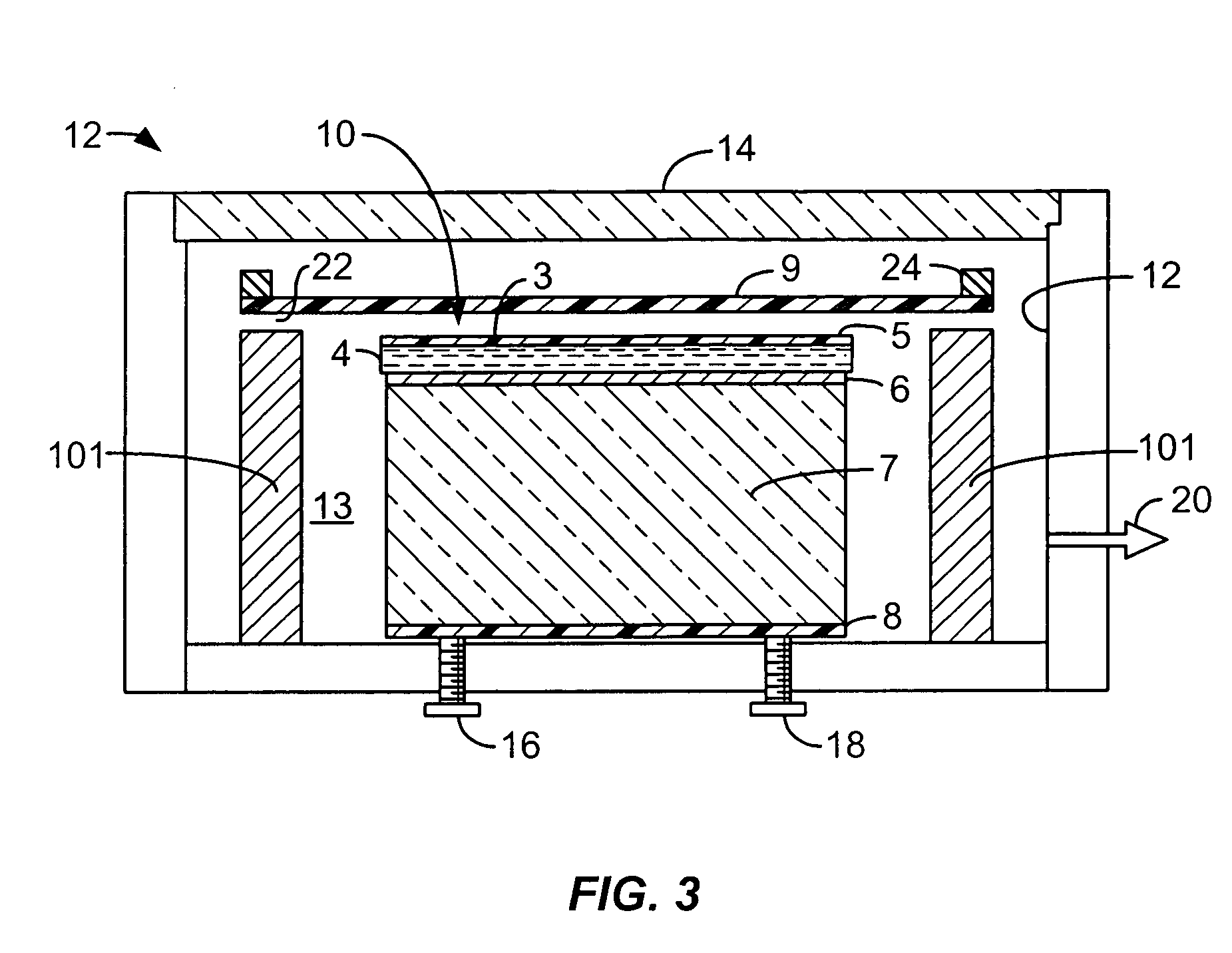

Method for fabricating electro-optic light modulator

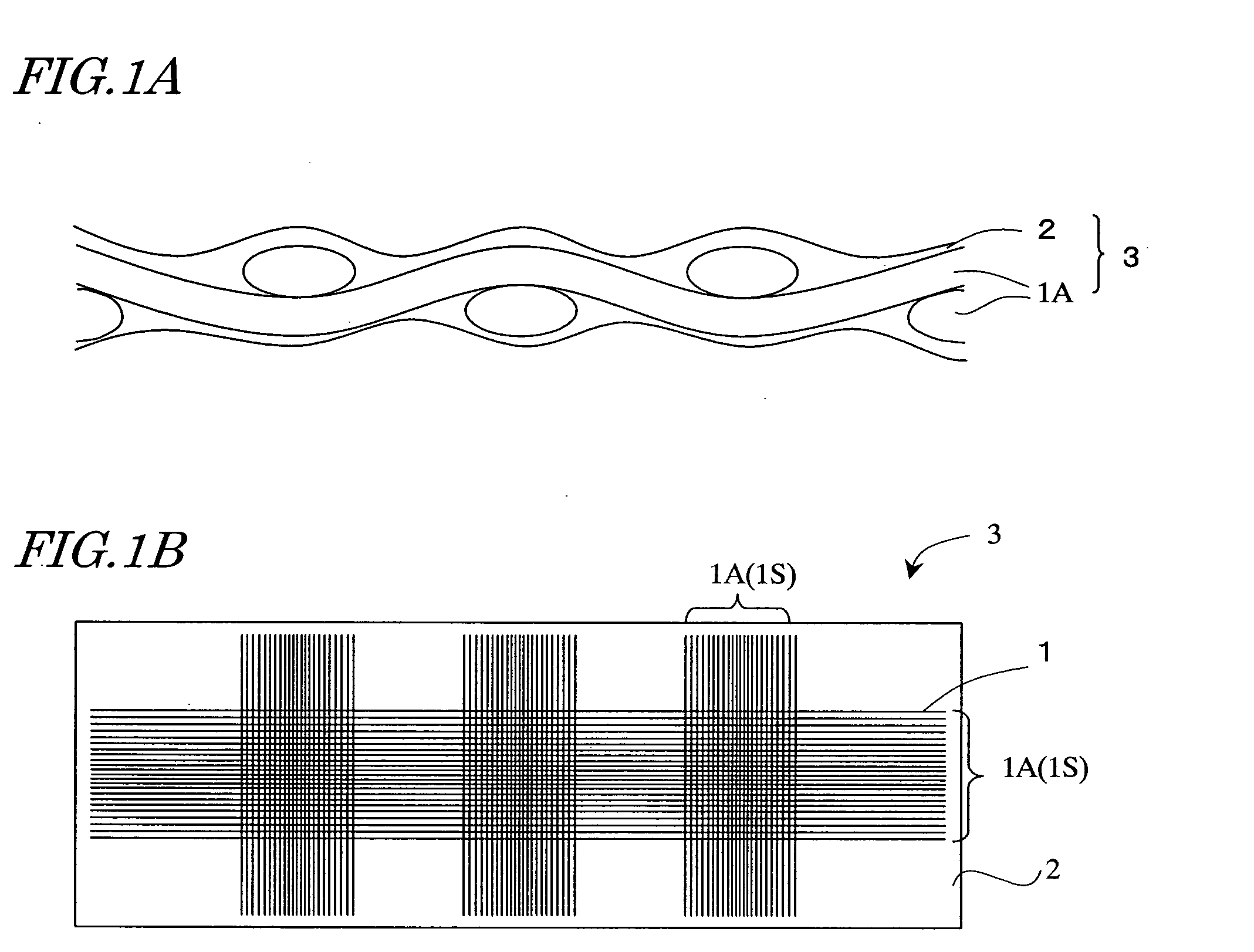

InactiveUS20050077005A1Improve mechanical stabilityImprove surface flatnessLayered product treatmentHollow inflatable ballsPolyesterAdhesive

In an electro-optic light modulator requiring an electro-optical sensor material such as polymer dispersed liquid crystal, or PDLC is directly coated on an optical glass substrate with a transparent electrode, such as indium tin oxide (ITO) and an optional layer of passivation coating such as silicon dioxide (SiO2) on its surface. A thin layer of polymeric adhesive is coated on top of PDLC layer and then this two-layer coating is laminated with a dielectric mirror on a polyester film (Mylar™) preferably with the assistance of a vacuum.

Owner:PHOTON DYNAMICS

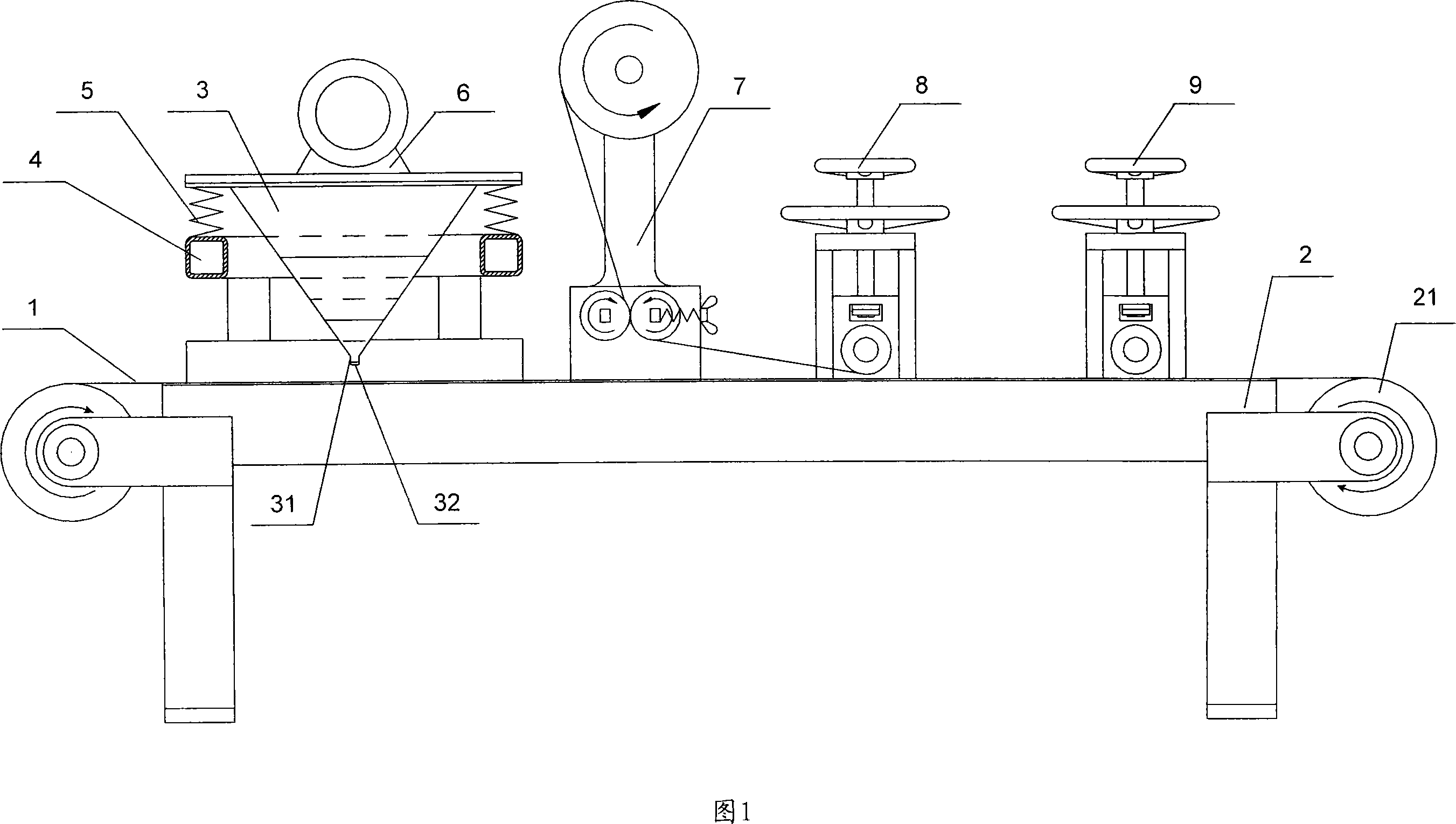

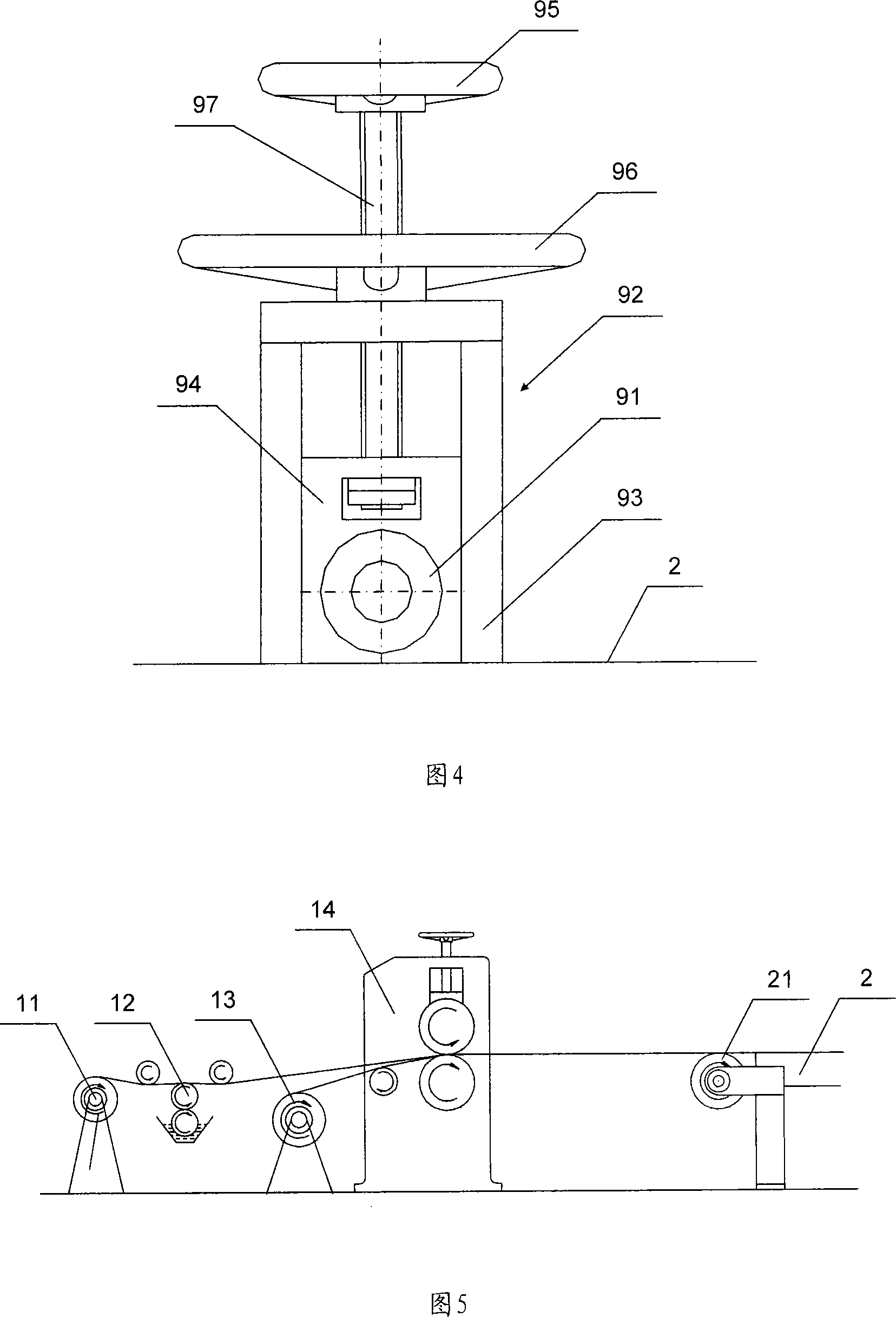

Nano-plate plane glue distributing device and method

InactiveCN101085563AConsistent thicknessImprove efficiencyLamination plant layoutLamination ancillary operationsFiberglass meshGlass fiber

The invention relates to the nanometer plate surface glue equipment and the cloth glue that comprises the working platform, cloth hopper distributing nanometer fluid on the compound extractor, vibrating device connected with the cloth hopper, cloth applying device setting the glass fiber net on the nanometer glue band, and the scraping device and compression device. The compound extraction band moving horizontally on the working platform and forming nanometer band, setting glass fiber net cloth with tension on the nanometer band, compressing the glass fiber net cloth and the nanometer band into nanometer compound band, compressing the compound band tightly. It is heat and sound insulation, radiation resistant, and improved in product feature and reduced in production cost.

Owner:KEDA INDUSTRIAL GROUP CO LTD

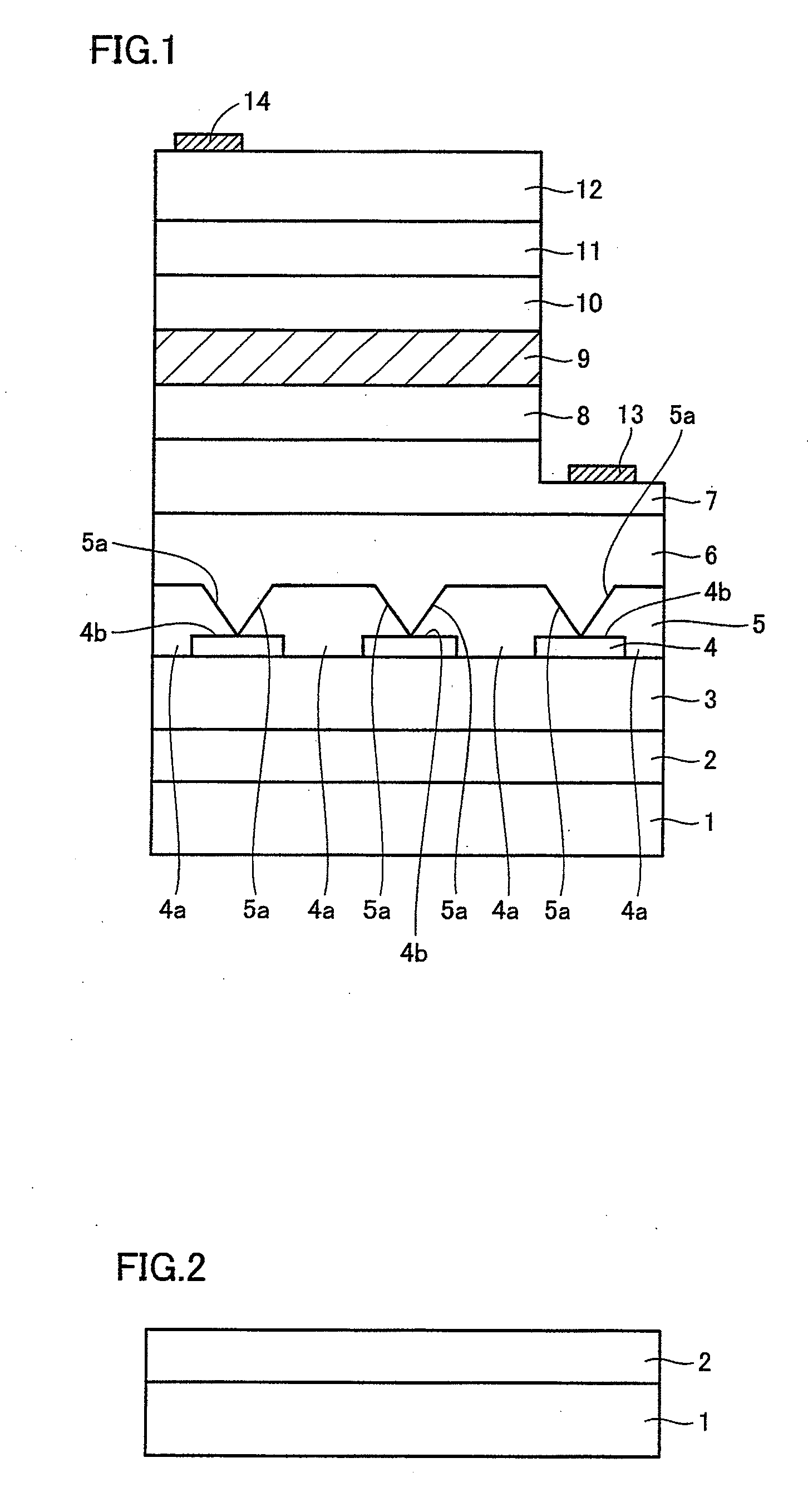

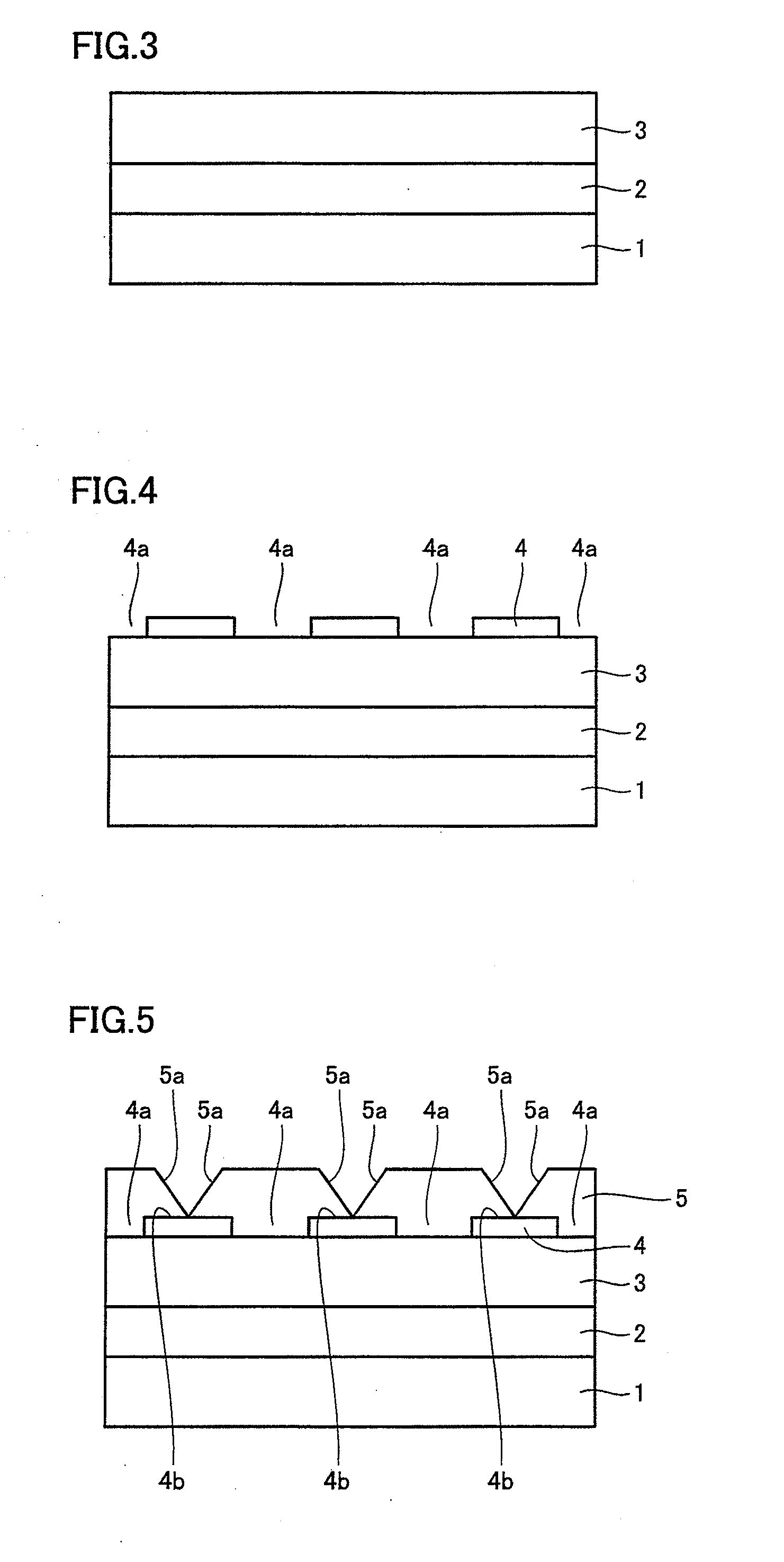

Nitride semiconductor element, methods for manufacturing nitride semiconductor element and nitride semiconductor layer, and nitride semiconductor light-emitting element

ActiveUS20110049544A1Good surface smoothnessHigh crystallinitySemiconductor/solid-state device manufacturingSemiconductor devicesNitride semiconductorsSilicon nitride

Described herein is a method for manufacturing a nitride semiconductor layer by stacking, on a silicon nitride layer, the first nitride semiconductor layer having a surface inclined with respect to the surface of the silicon nitride layer and then stacking the second nitride semiconductor layer on the first nitride semiconductor layer, a nitride semiconductor element and a nitride semiconductor light-emitting element each including the nitride semiconductor layer; and a method for manufacturing the nitride semiconductor element.

Owner:SHARP FUKUYAMA LASER CO LTD

Method of making photomask blank substrates

ActiveUS20050020083A1Improve accuracySmall sizeSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentOptoelectronicsSubstrate surface

A photomask blank substrate is made by polishing a starting substrate to a specific flatness in a principal surface region on a top surface of the substrate so as to form a polished intermediate product, then additionally polishing the intermediate product. Substrates made in this way exhibit a good surface flatness at the time of wafer exposure. When a photomask fabricated from a blank obtained from such a substrate is held on the mask stage of a wafer exposure system with a vacuum chuck, the substrate surface undergoes minimal warping, enabling exposure patterns of small geometry to be written onto wafers to good position and linewidth accuracies.

Owner:SHIN ETSU CHEM IND CO LTD +1

Organic electroluminescence type display apparatus

InactiveUS20060192481A1Brighter imageHigh light efficiencyDischarge tube luminescnet screensRoad vehicles traffic controlOrganic electroluminescenceImpurity

An organic electroluminescence type display apparatus of top emission type, in which a thin film transistor (TFT), a flattening film made of organic resin and an organic EL element, in which at least an anode, an electroluminescence layer and a cathode are laminated on the flattening film in this order, are formed in each picture element in a display region on a substrate. The anode is composed of at least two layer film including an aluminum (Al) alloy film containing as a impurity at least one of transition metals of the eighth group of 3d into Al and including a light transmitting conductive oxide film laminated on the Al alloy film.

Owner:MITSUBISHI ELECTRIC CORP

Method of modifying surface of powder, magnetic recording medium, and coating material

InactiveUS20090087684A1Good dispersionGood running durabilityNanomagnetismLiquid surface applicatorsCarboxylic groupCoating

An aspect of the present invention relates to a method of modifying a surface of a powder, comprising mixing a powder with a heterocyclic compound comprising at least one hydroxylic group and / or carboxylic group. The present invention further relates to a magnetic recording medium and a coating material.

Owner:FUJIFILM CORP

Reflective Ag alloy film for reflectors and reflector provided with the same

ActiveUS7452604B2Improve reflectivityProductivity is deterioratedMirrorsVacuum evaporation coatingRare-earth elementSurface roughness

A reflective Ag alloy film for reflectors, which has excellent surface flatness and shows high reflectivity even under a heating environment and a reflector.The reflective Ag alloy film for reflectors has an average surface roughness of 2.0 nm or less and contains a rare earth element (such as Nd) in a content in the range of 0.1 to 3.0 at %, or further at least one selected from Au, Pd, Cu and Pt in a content in the range of 0.5 to 5.0 at %. The reflector comprises the above reflective Ag alloy film formed on a substrate.

Owner:KOBE STEEL LTD

Environment-friendly flame-retardant polyurethane wood-imitation material

The invention belongs to the field of chemical synthesis, and in particular relates to an environment-friendly flame-retardant polyurethane wood-imitation material, which is characterized by comprising a component A and a component B, wherein the component A consists of polyether polyalcohol, a foam stabilizer, a catalyst, a foaming agent and a flame retardant; and the component B is polymethylene polyphenyl polyisocyanate. A method for preparing the environment-friendly flame-retardant polyurethane wood-imitation material comprises the following steps of: mixing and stirring the component A and the component B, injecting the components into a constant-temperature die at the temperature of between 40 and 50 DEG C, reacting and curing for 10 to 13 minutes to obtain the environment-friendly flame-retardant polyurethane wood-imitation material. The invention has the advantages that due to the adoption of the reaction type catalyst, the generation of volatile gas is prevented, and the harm to the health of human bodies is reduced greatly; water is used as the single foaming agent instead of the conventional hydrochlorofluorocarbon (HCFC)-141B foaming agent, so that the consumption of an ozone layer is reduced effectively; and demolding can be performed after 10 to 13 minutes during production, so that the production efficiency is improved greatly.

Owner:SHANGHAI DONGDA POLYURETHANE

Method for fabrication of semiconductor device

InactiveUS7157297B2Avoid developmentGood surface smoothnessOptical wave guidanceLaser detailsNitride semiconductorsSemiconductor device

On a processed substrate having an engraved region as a depressed portion formed thereon, a nitride semiconductor thin film is laid. The sectional area occupied by the nitride semiconductor thin film filling the depressed portion is 0.8 times the sectional area of the depressed portion or less.

Owner:SHARP KK

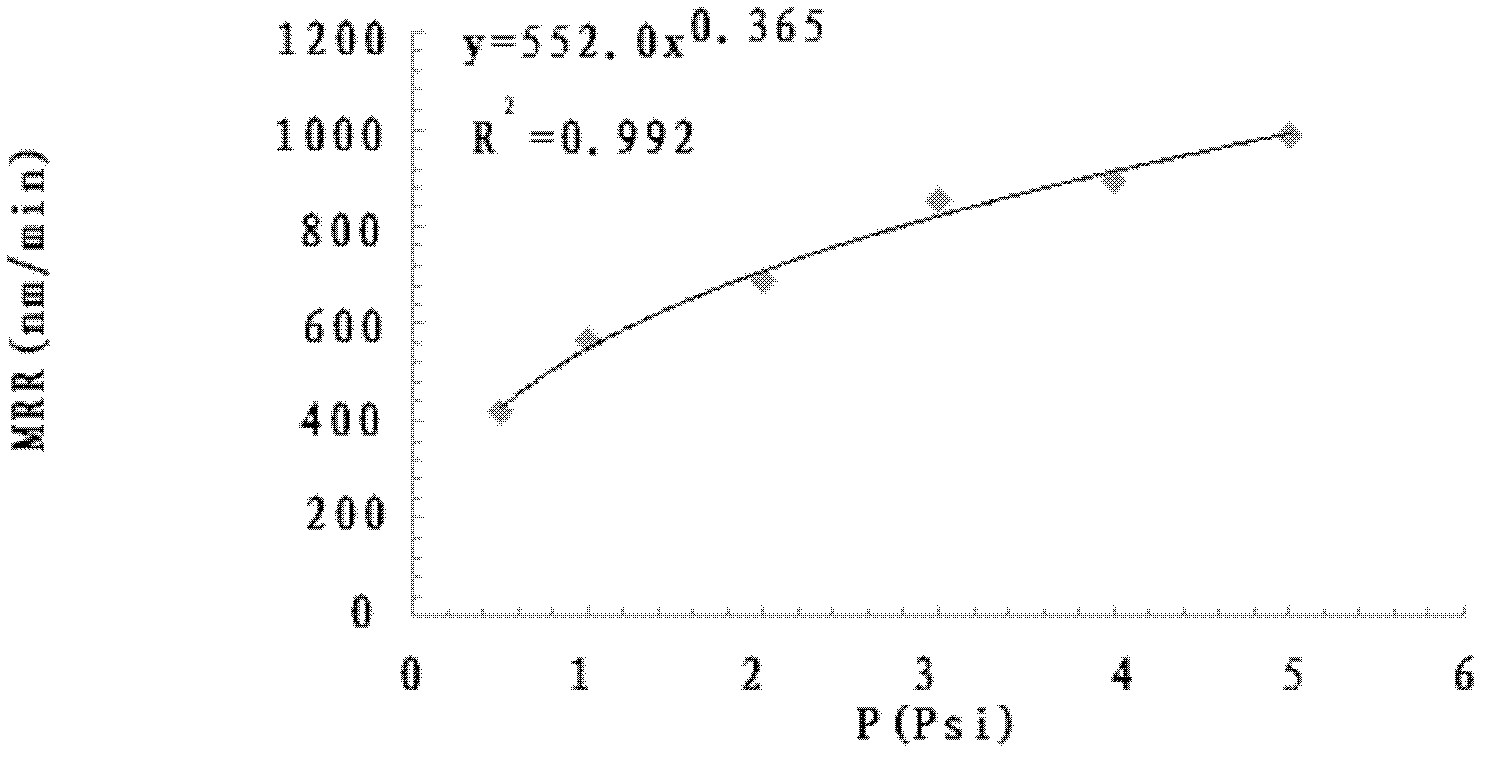

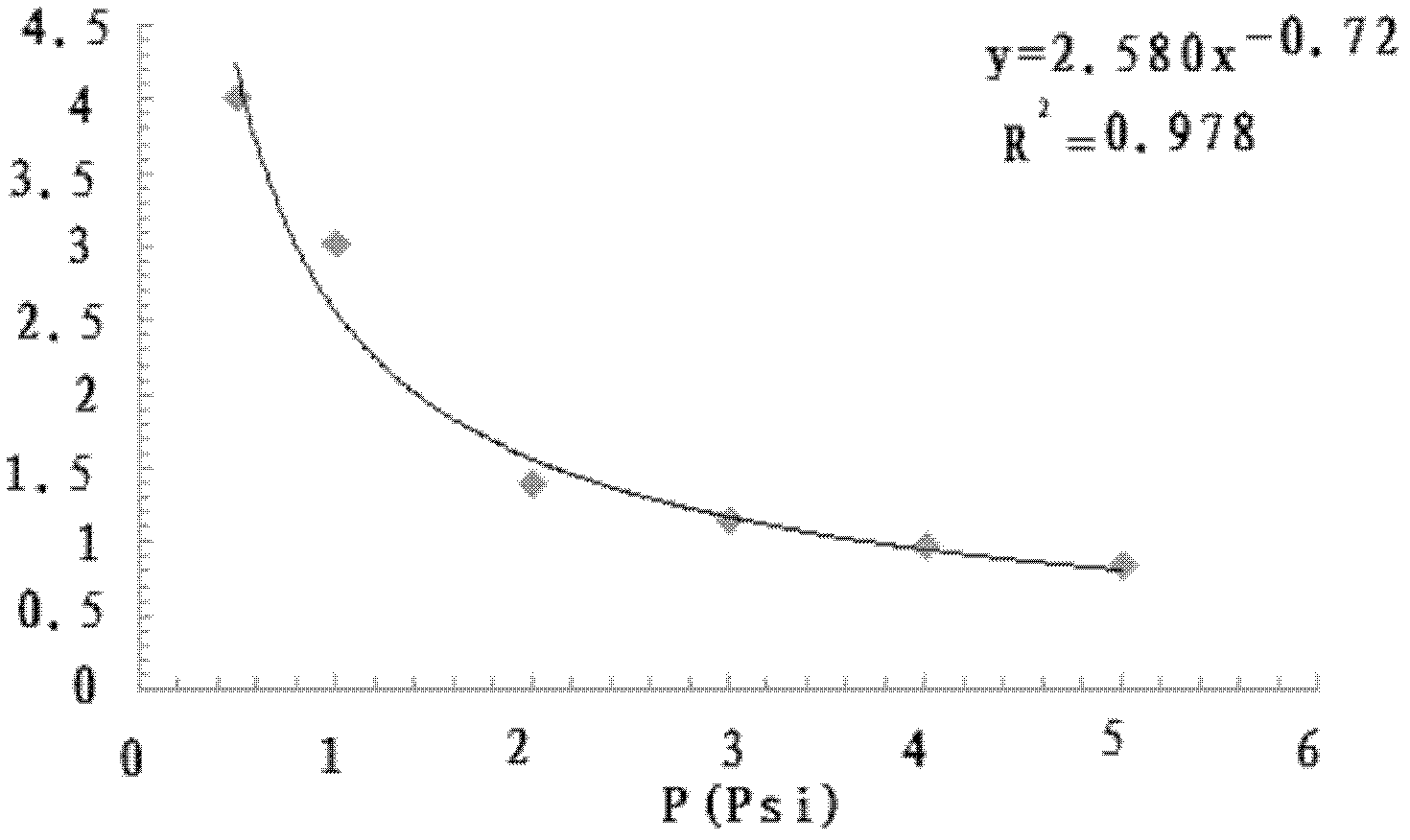

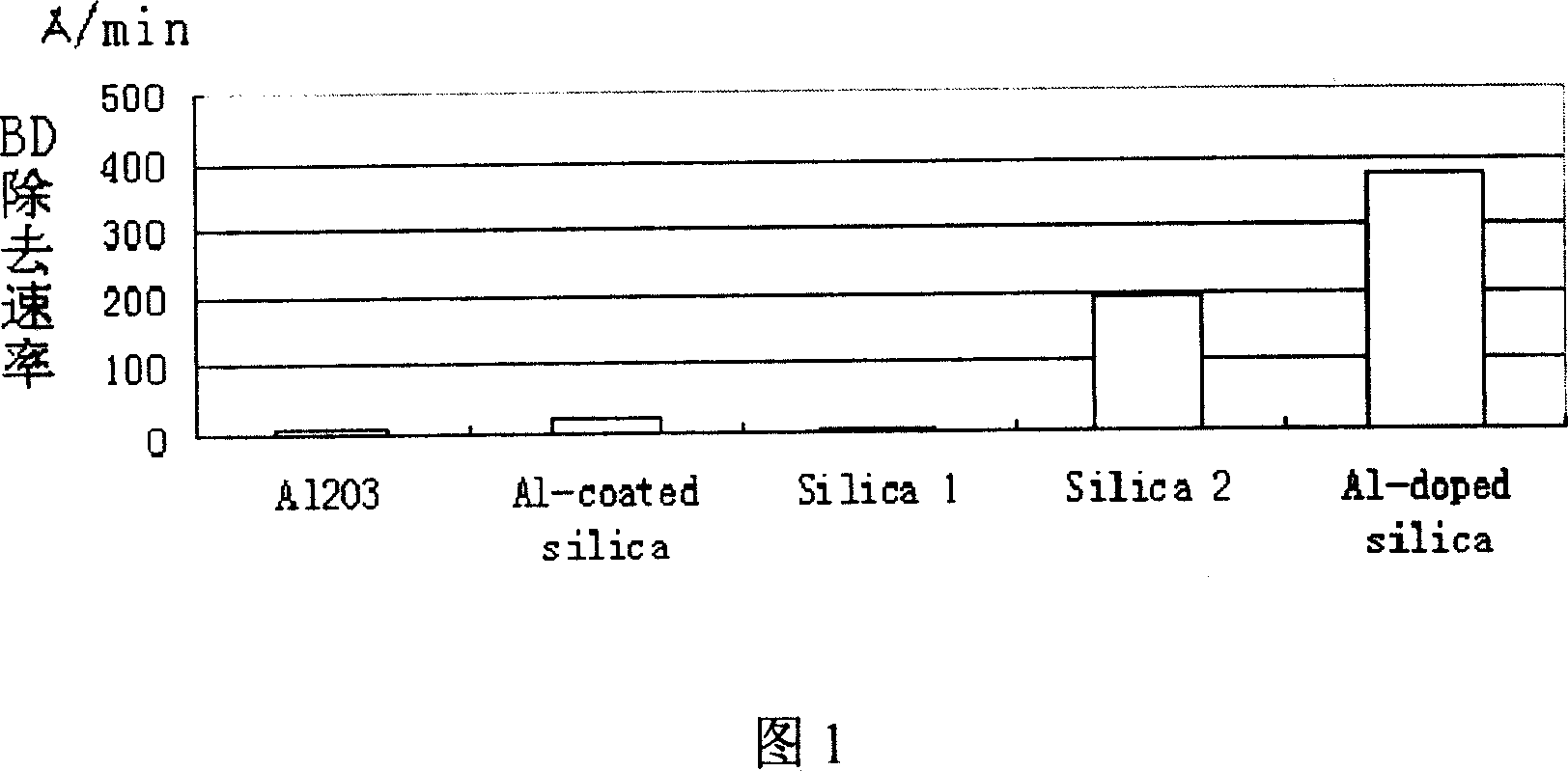

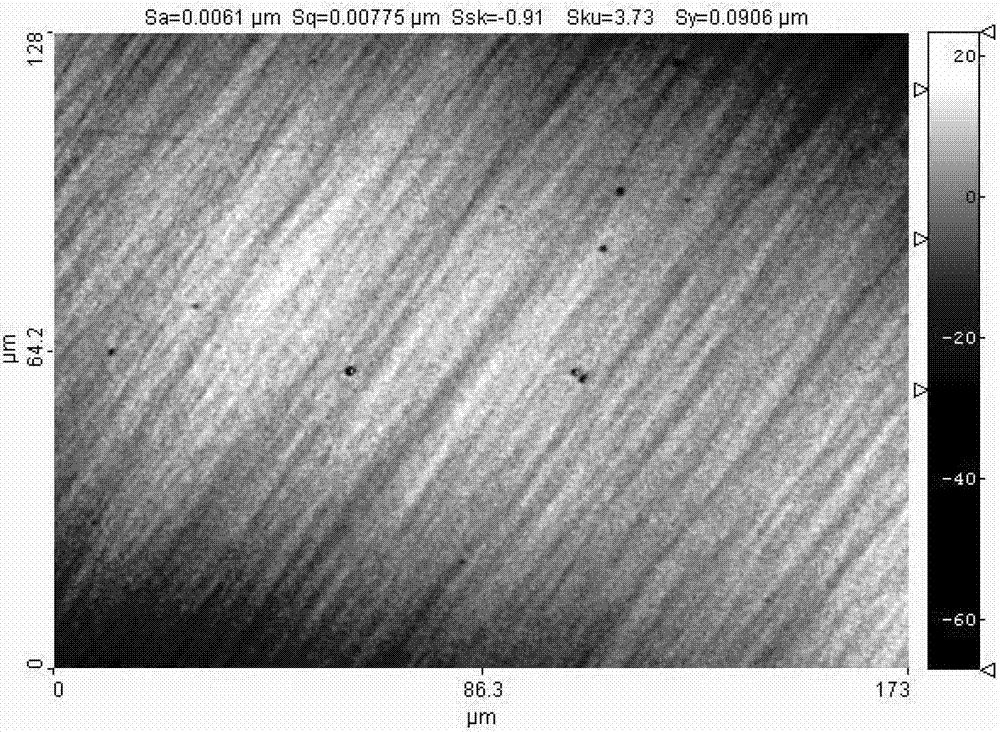

Polishing fluid for smoothing treatment of refined surface and use method thereof

ActiveCN101077961AImprove removal rateEfficient removalOther chemical processesSemiconductor/solid-state device manufacturingSilicon dioxideMaterials science

The present invention discloses one kind of polishing fluid for fine surfacing and its usage. The polishing fluid includes abradant and water, and the abradant is water dispersed sol type aluminum mixing silica abradant. When the polishing fluid is used in chemomechanical polishing, the downward pressure is 0.5-3 psi. The polishing fluid may be used to eliminate Ta, TaN, TEOS, FSG, BD and other low dielectric constant material effectively, and has especially high low dielectric constant material eliminating efficiency.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

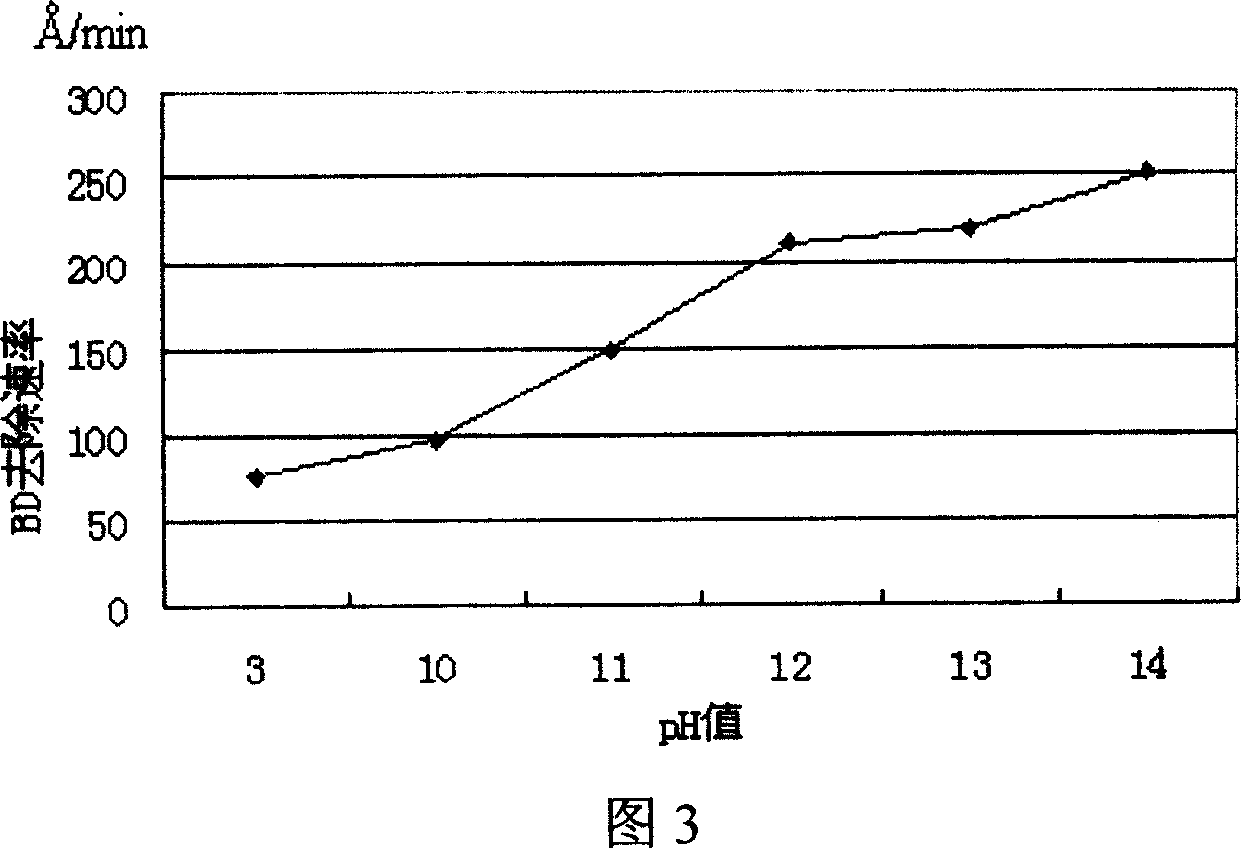

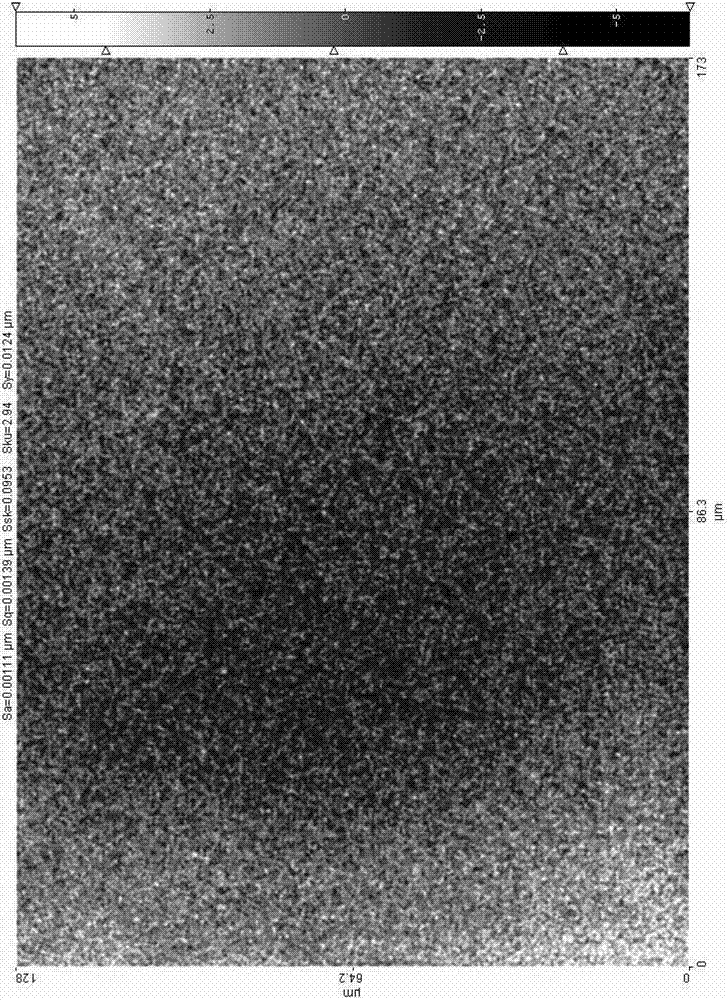

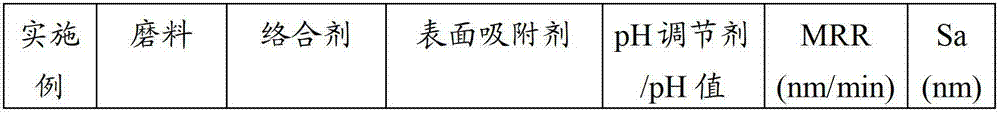

Barium titanate chemico-mechanical polishing aqueous composition and its application

ActiveCN102786879AImprove removal rateReduce concentrationPolishing machinesPolishing compositions with abrasivesBarium titanateSorbent

The invention relates to a barium titanate chemico-mechanical polishing aqueous composition and its application. Specifically, the barium titanate chemico-mechanical polishing aqueous composition comprises: 1-20 wt%, preferably 8-15 wt% of an abrasive; 0.5-10 wt%, preferably 1-3 wt% of a complexing agent; and 0.01-5 wt%, preferably 0.1-1 wt% of a surface adsorbent, wherein the barium titanate chemico-mechanical polishing aqueous composition has a pH value of 8.0-12.0, preferably 10.0-11.5. The barium titanate chemico-mechanical polishing aqueous composition provided in the invention can be effectively applied to a barium titanate substrate chemico-mechanical polishing process, thereby being able to effectively obtain a polished barium titanate layer with a high polishing rate and high surface quality.

Owner:TSINGHUA UNIV

Acrylic resin composition, acrylic premix, process for producing acrylic artificial marble and thickening agent

InactiveUS6323259B1Improve productivityExcellent in molding-processabilityOther chemical processesMulticolor effect coatingsMethyl methacrylatePolymer chemistry

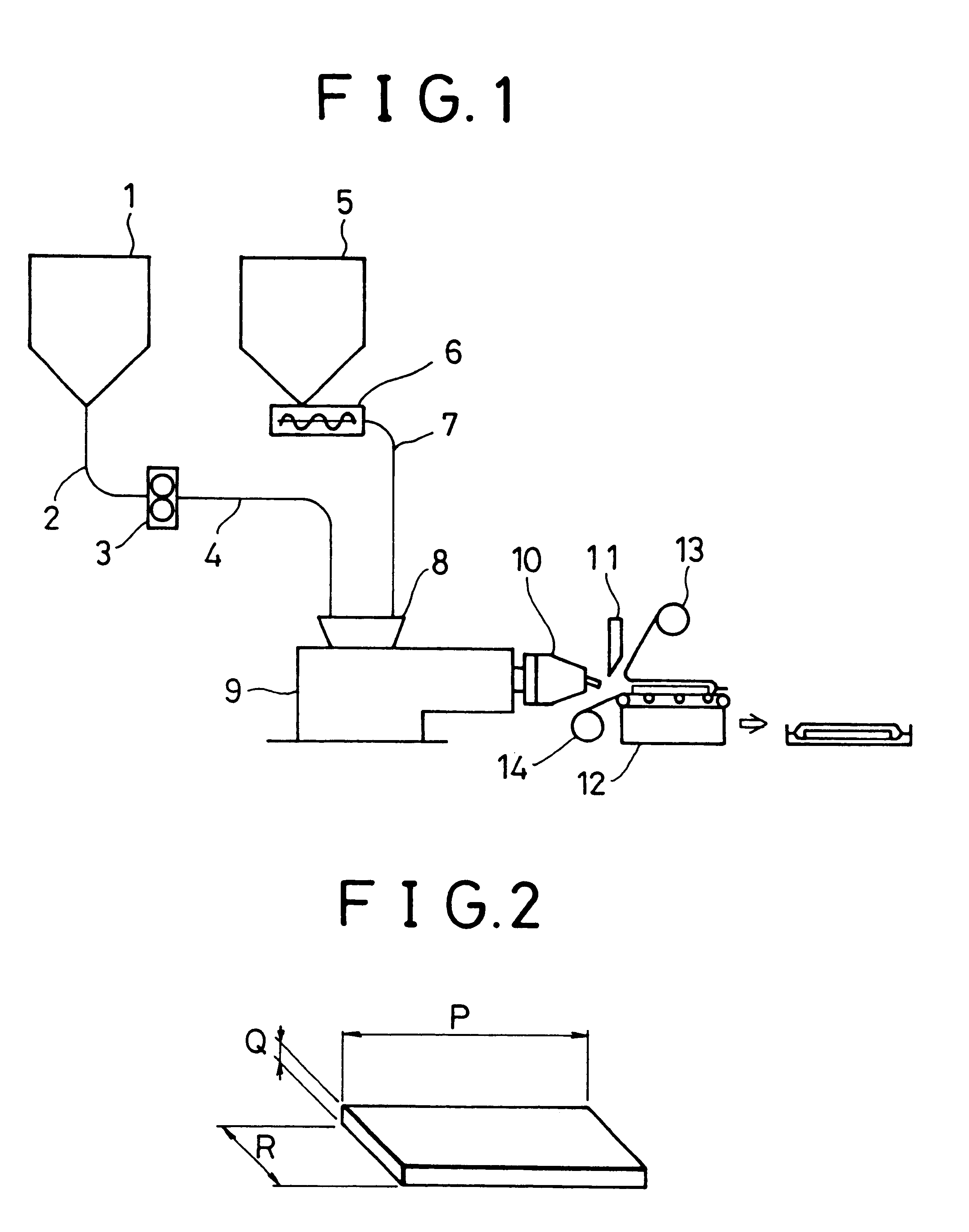

The present invention is directed to an acrylic resin composition obtained by adding a non-crosslinked polymer powder having a bulk density within the range from 0.1 to 0.7 g / ml, an oil absorption based on linseed oil within the range from 60 to 200 ml / 100 g and a degree of swelling by methyl methacrylate of 16-fold or more as a thickening agent to acrylic syrup; and acrylic premix obtained by mixing an inorganic filler with this composition; and acrylic premix obtained by extruding constituent components by a kneading extruder to continuously form the mixture; and a method for producing an acrylic artificial marble in which these acrylic premixes are cured.

Owner:MITSUBISHI RAYON CO LTD +1

Display device

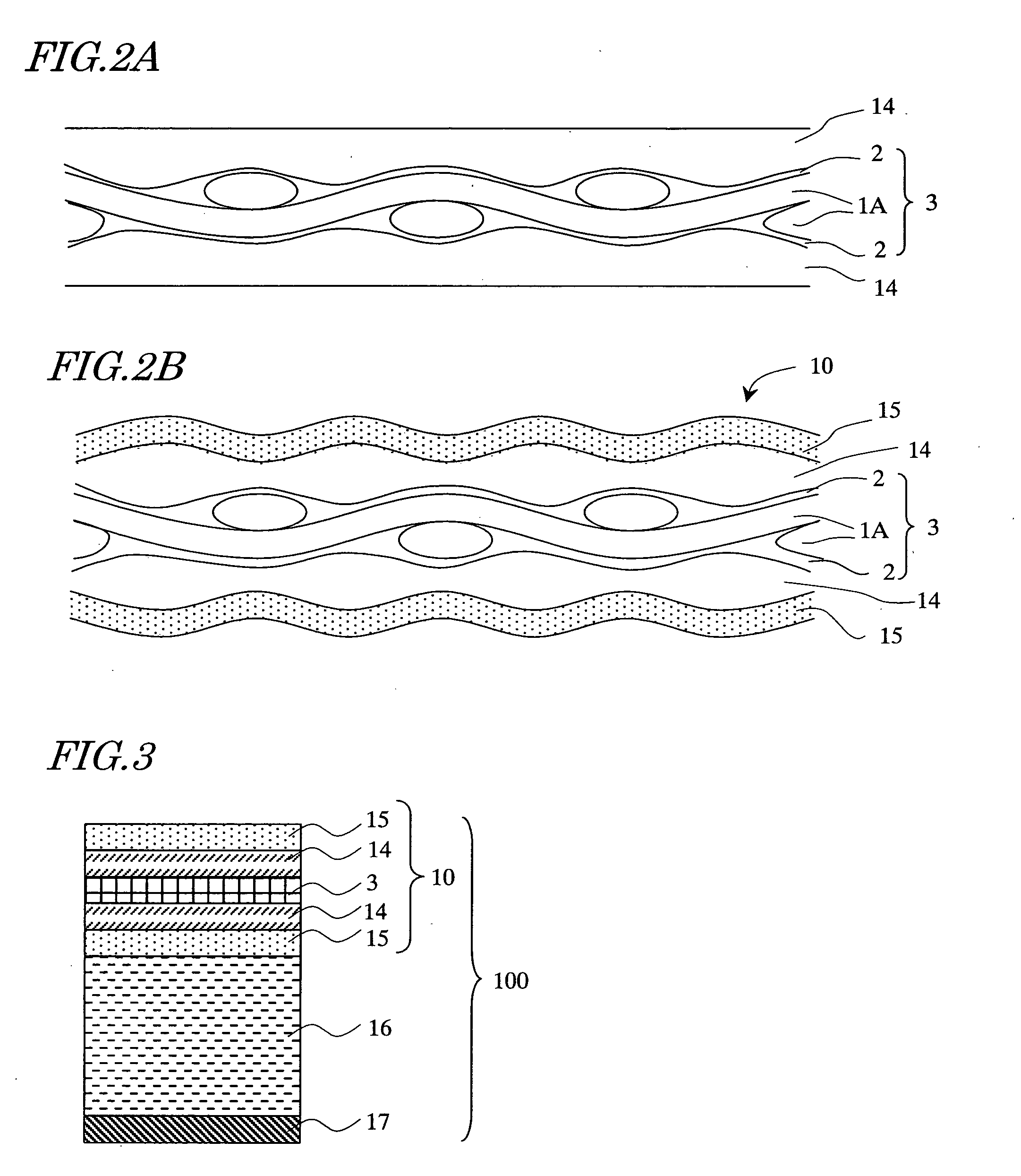

InactiveUS20050140861A1High quality displayAvoid it happening againFinal product manufactureElectroluminescent light sourcesFiberDisplay device

The display device of the invention includes: a first plastic substrate including a composite layer having a resin-impregnated fiber fabric, an inorganic barrier layer 25 formed on the composite layer, and a planarizing resin layer formed on the inorganic barrier layer; and a display medium layer formed on the planarizing resin layer-side of the first plastic substrate.

Owner:SHARP KK

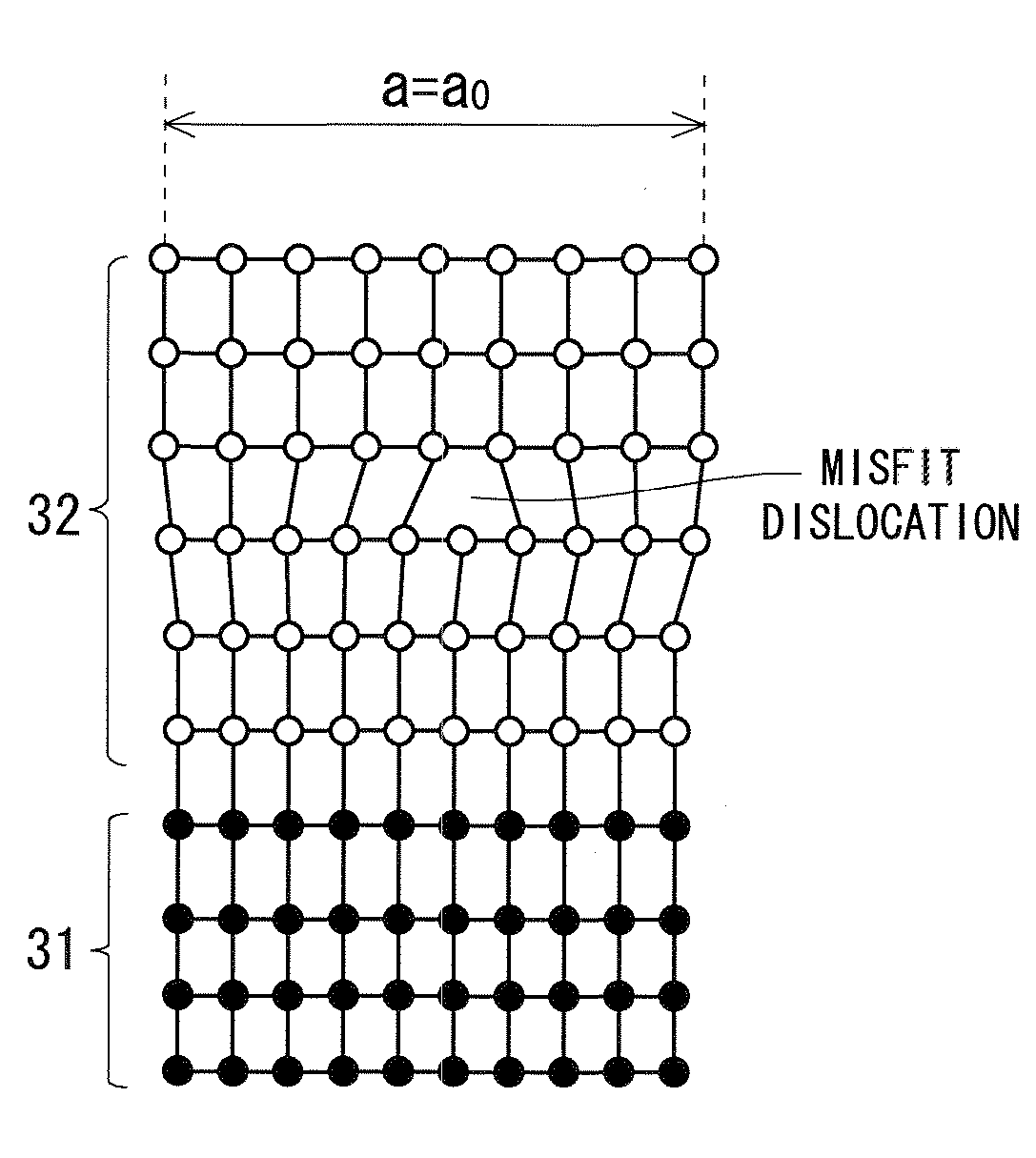

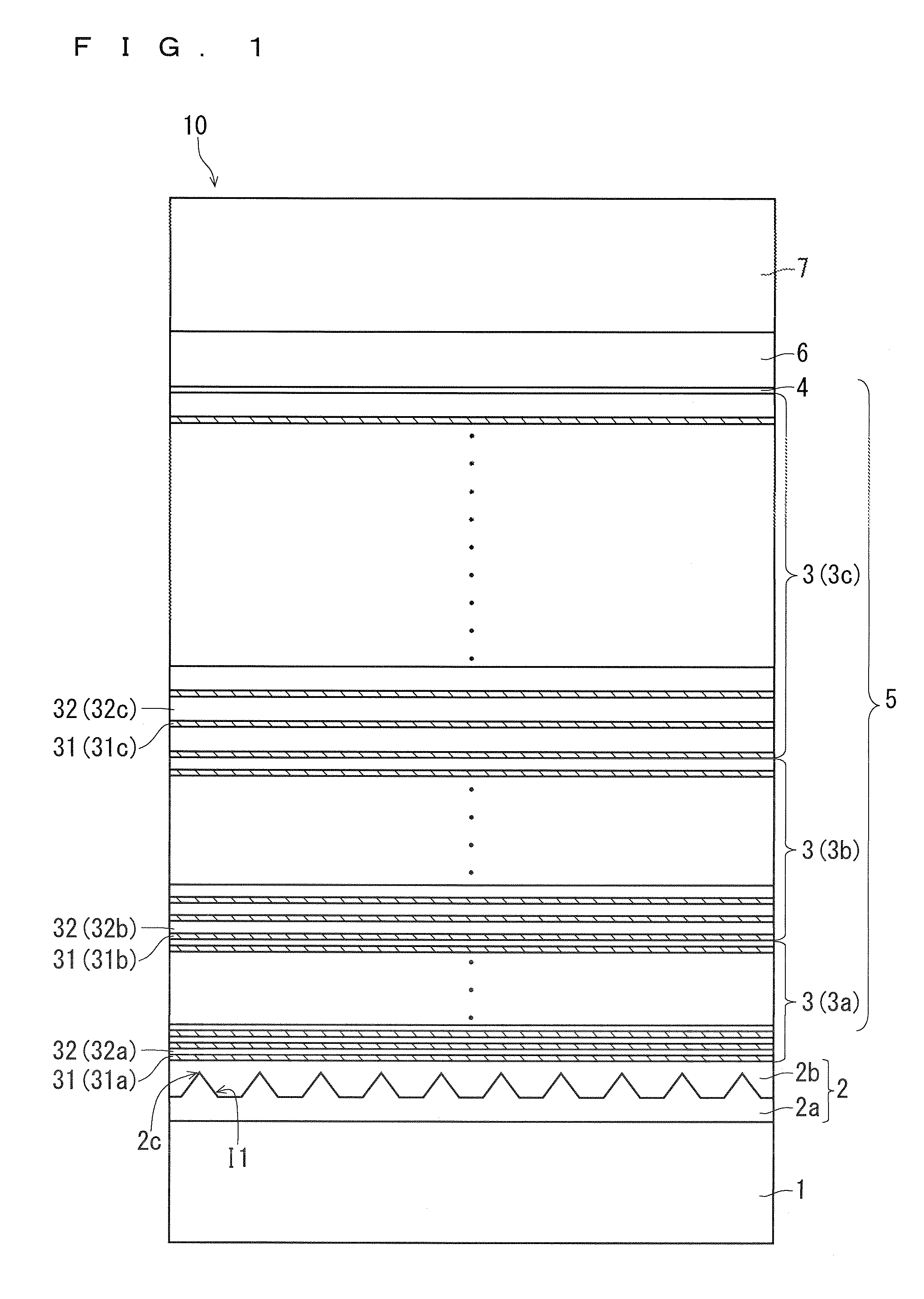

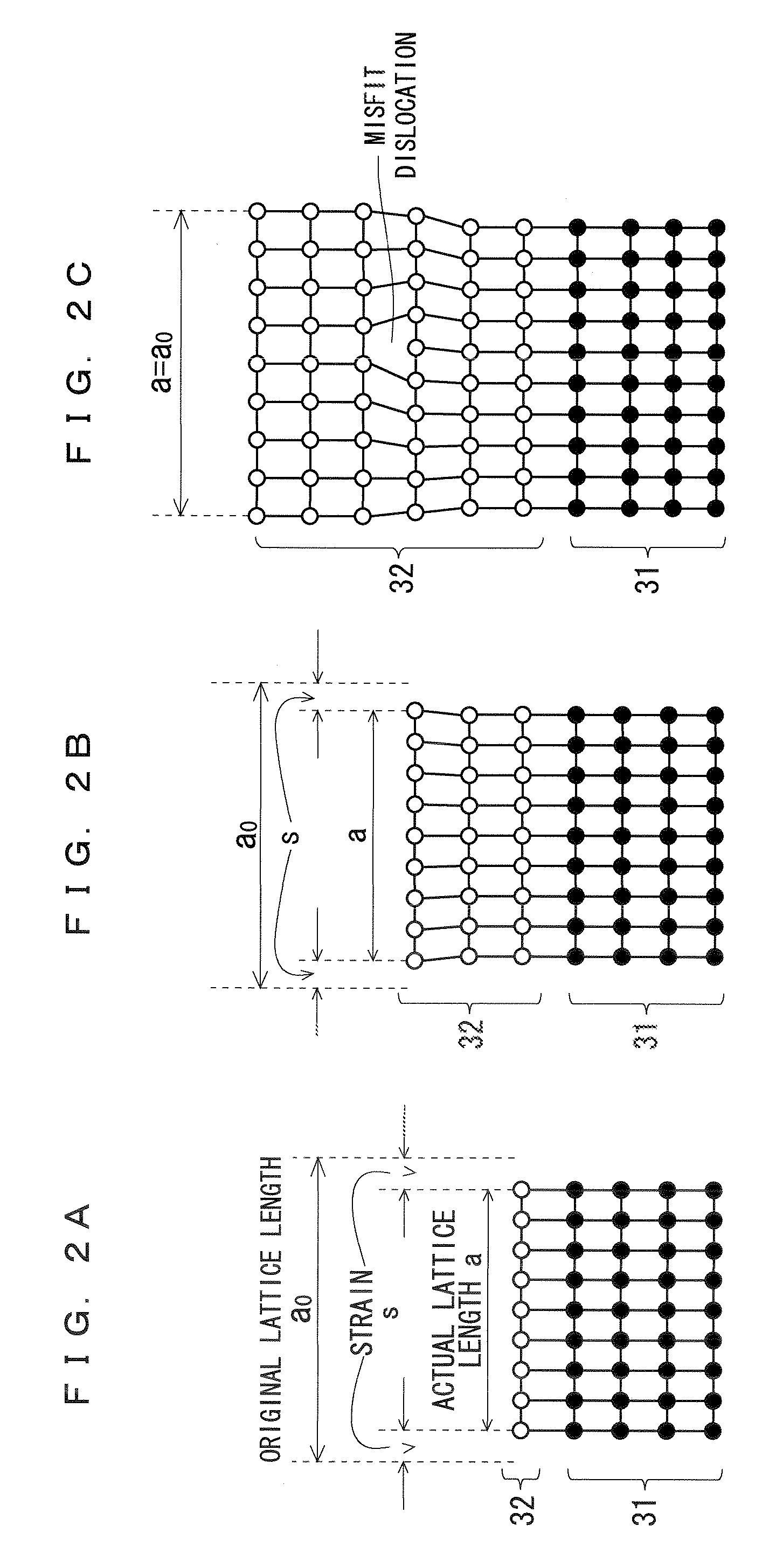

Epitaxial substrate and method for manufacturing epitaxial substrate

ActiveUS20130032781A1Reduce warpageImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingCrack freeSingle crystal

Provided is a crack-free epitaxial substrate with reduced warping, in which a silicon substrate is used as a base substrate. The epitaxial substrate includes a (111) single crystal Si substrate, a superlattice layer group in which a plurality of superlattice layers are laminated, and a crystal layer. The superlattice layer is formed of a first unit layer and a second unit layer made of group-III nitrides having different compositions being alternately and repeatedly laminated. The crystal layer is made of a group-III nitride and formed above the base substrate so as to be positioned at an upper side of the superlattice layer group relative to the base substrate. The superlattice layer group has a compressive strain contained therein. In the superlattice layer group, the more distant the superlattice layer is from the base substrate, the greater the compressive strain becomes.

Owner:NGK INSULATORS LTD

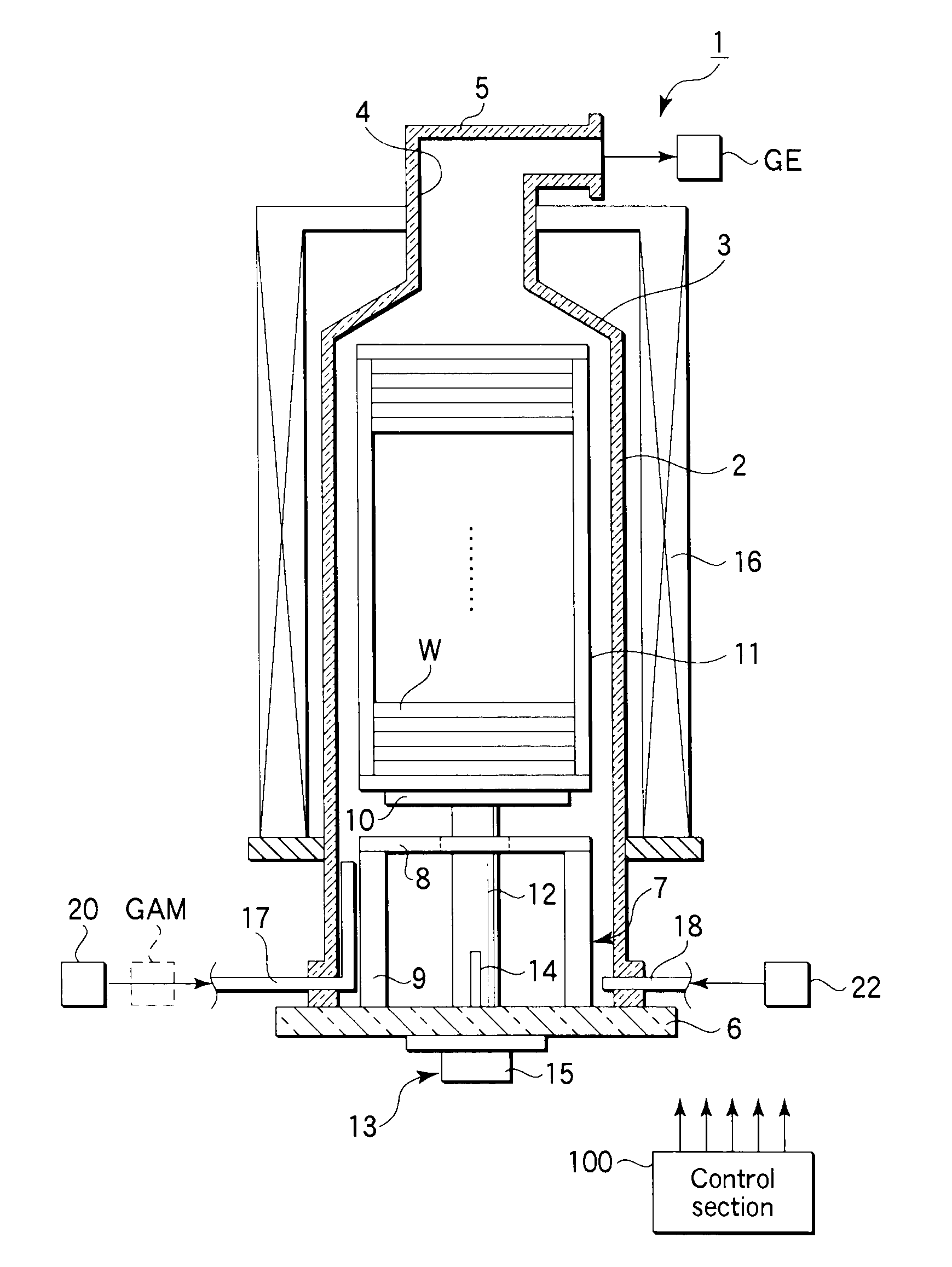

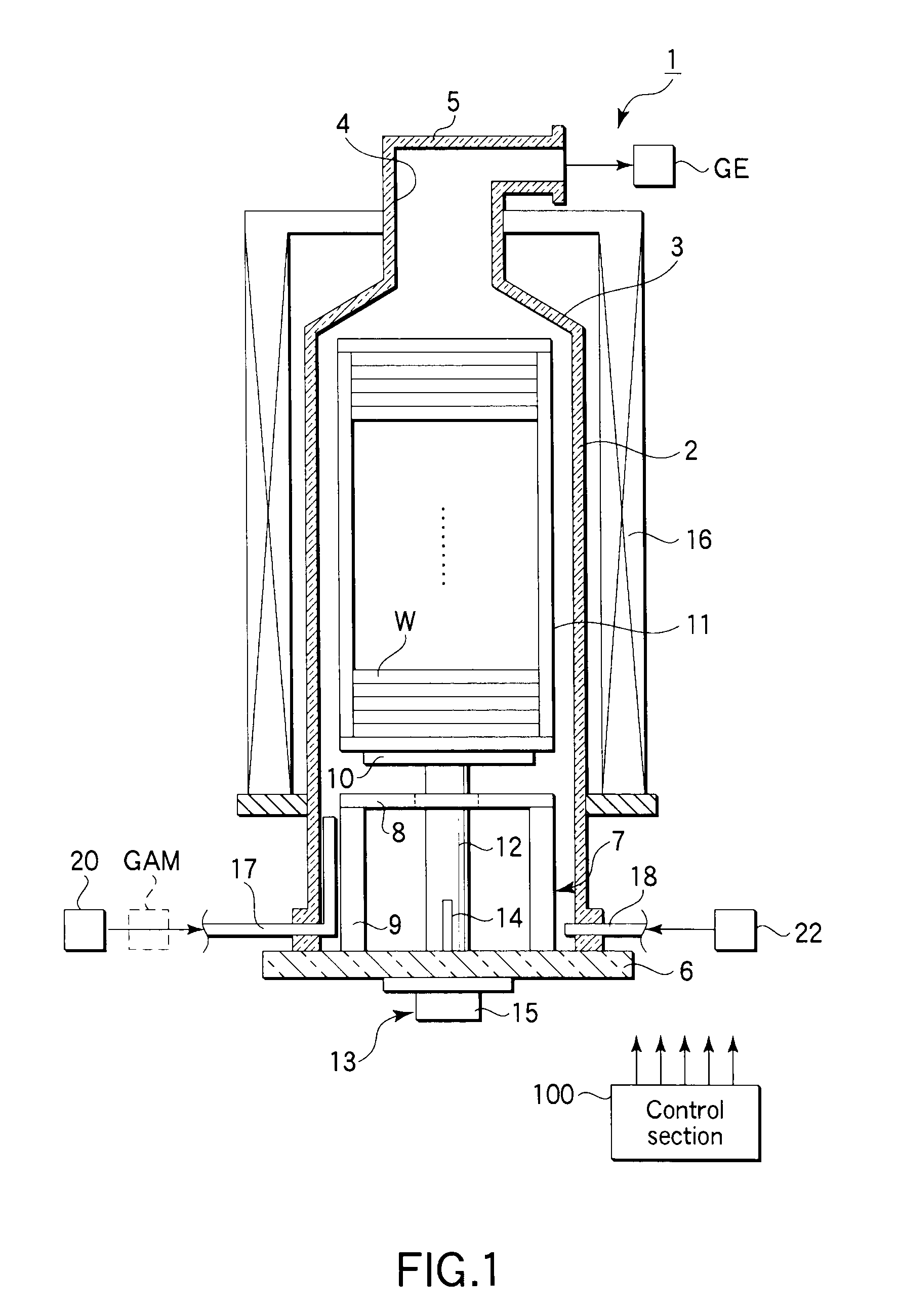

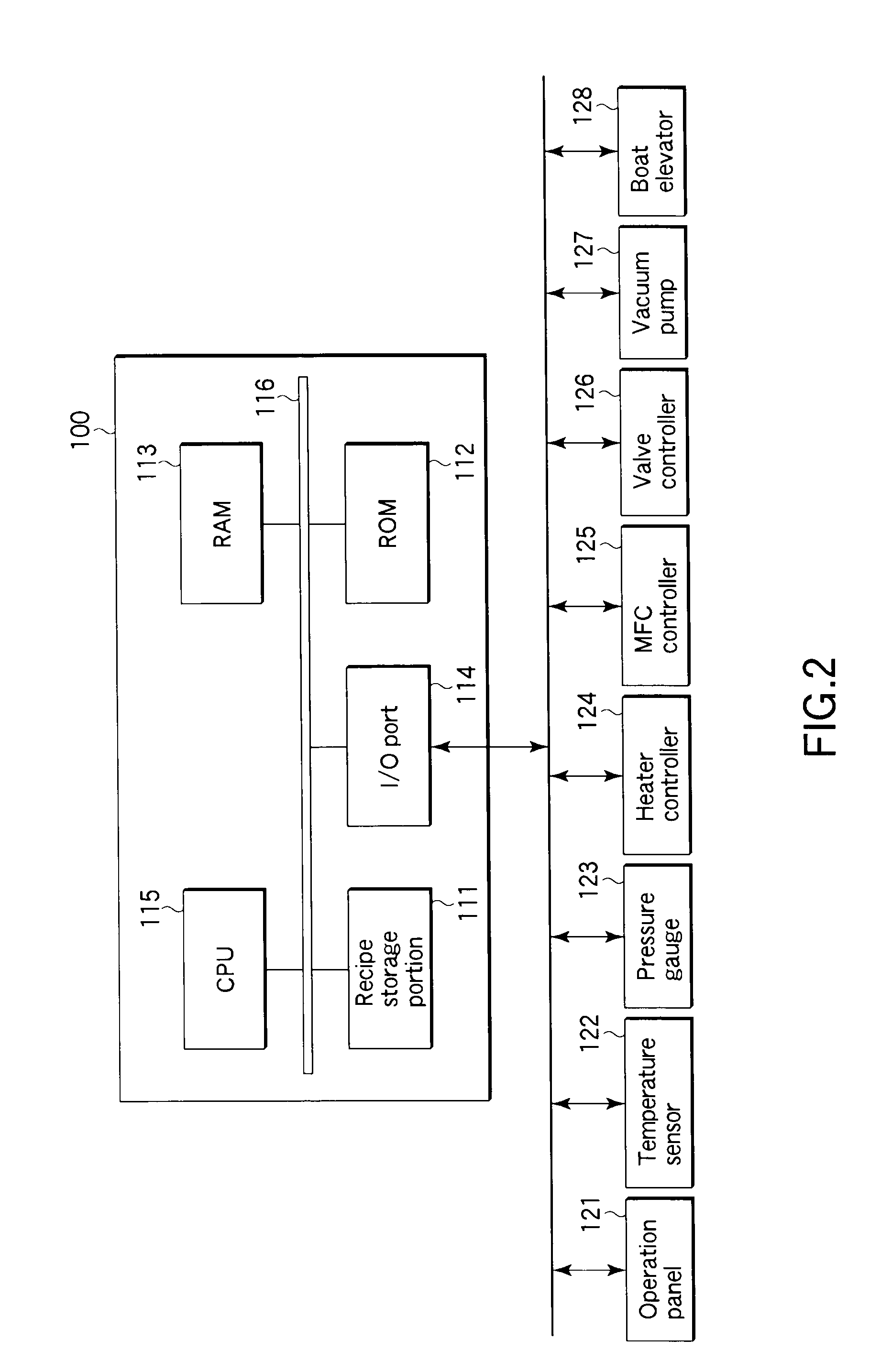

Batch processing method for forming structure including amorphous carbon film

ActiveUS20100311251A1Good surface flatnessGood surface smoothnessSampled-variable control systemsSemiconductor/solid-state device manufacturingExhaust gasPre treatment

A batch processing method for forming a structure including an amorphous carbon film includes performing a preliminary treatment of removing water from a surface of the underlying layer by heating the inside of the reaction chamber at a preliminary treatment temperature of 800 to 950° C. and supplying a preliminary treatment gas selected from the group consisting of nitrogen gas and ammonia gas into the reaction chamber while exhausting gas from inside the reaction chamber; and, then performing main CVD of forming an amorphous carbon film on the underlying layer by heating the inside of the reaction chamber at a main process temperature and supplying a hydrocarbon gas into the reaction chamber while exhausting gas from inside the reaction chamber.

Owner:TOKYO ELECTRON LTD

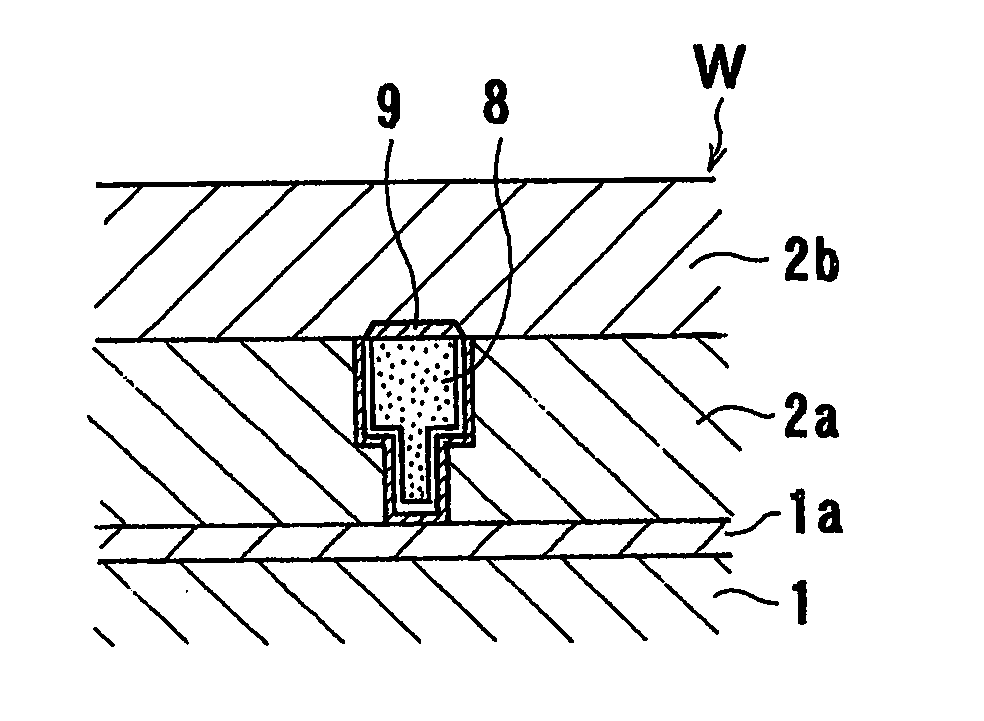

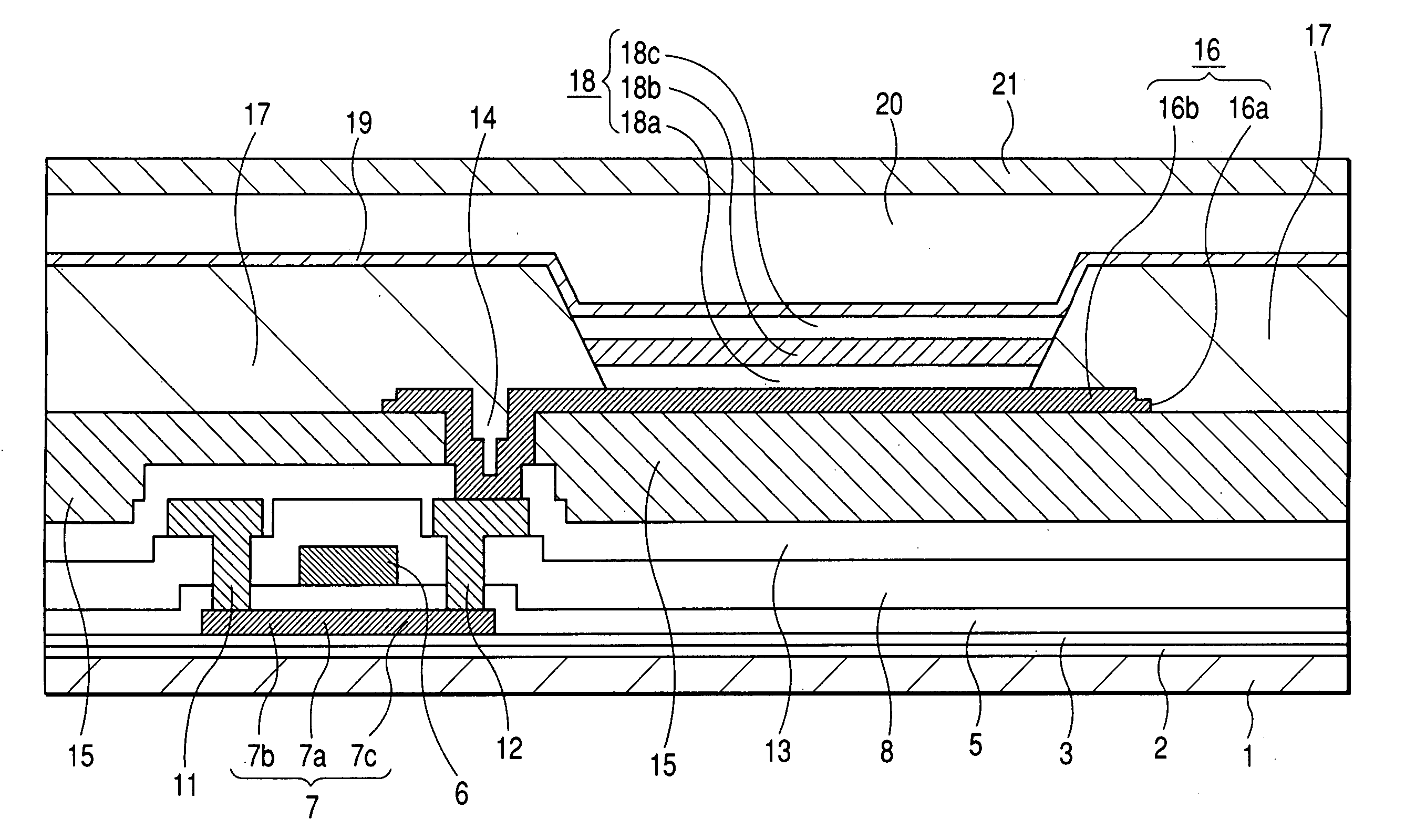

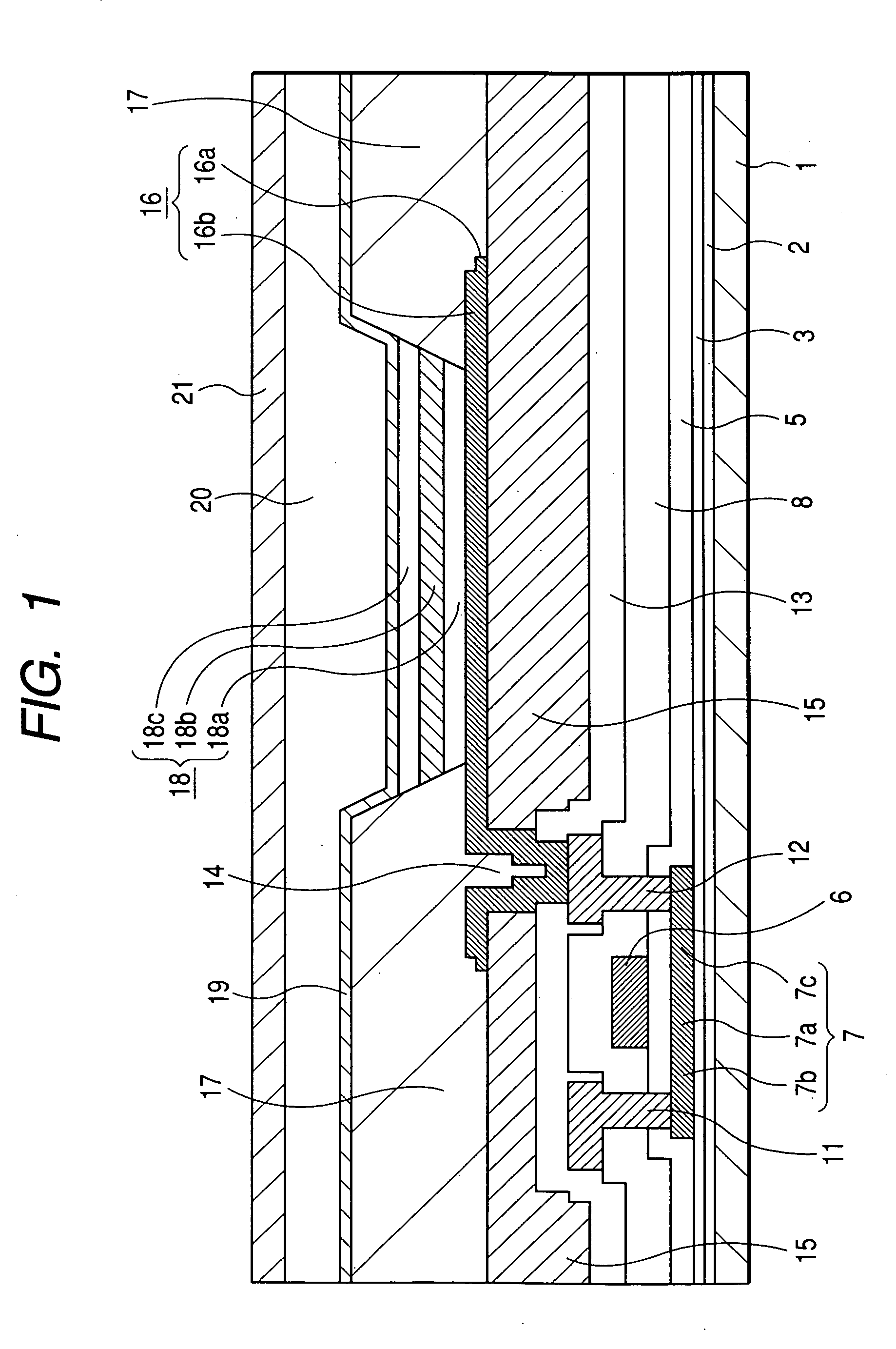

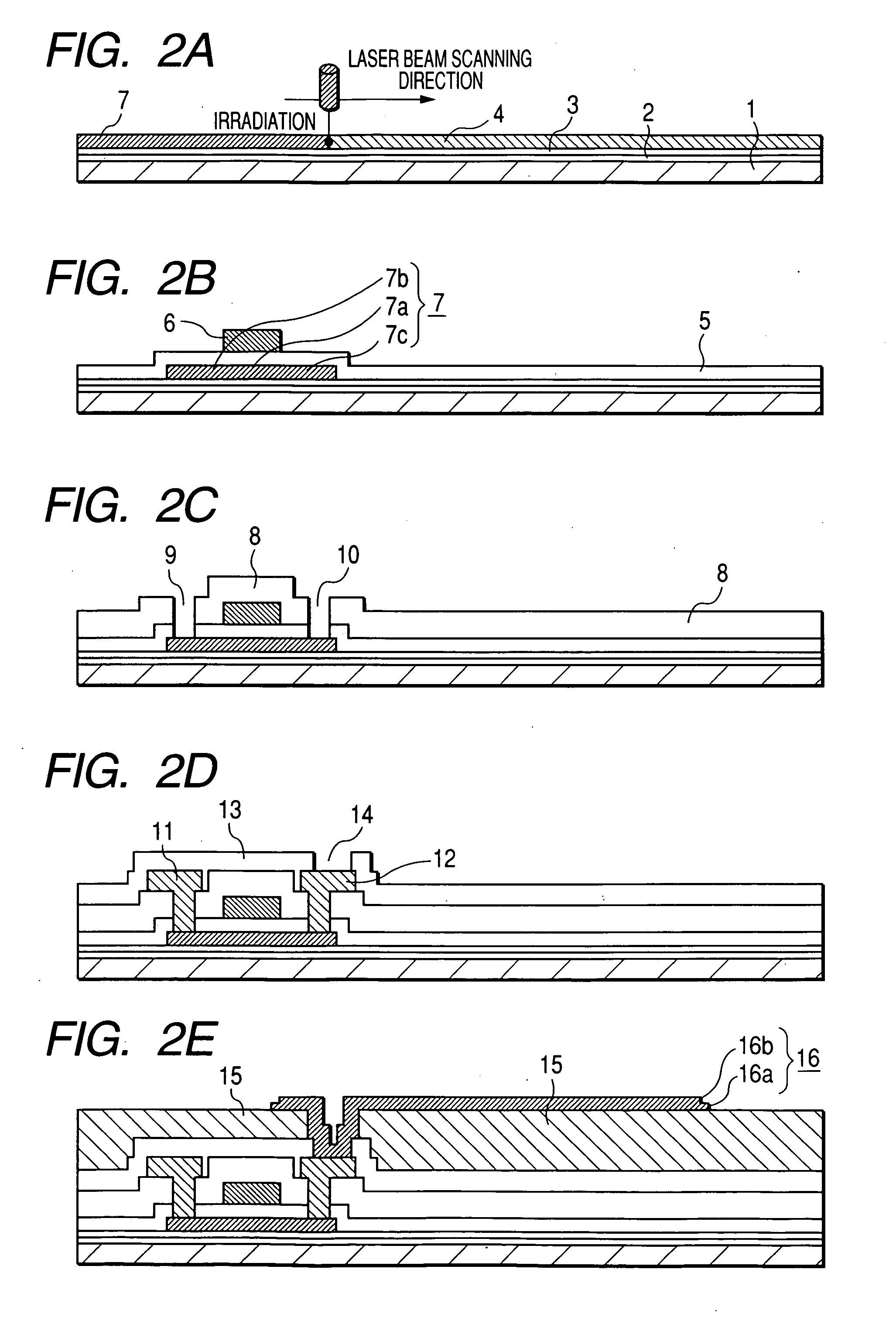

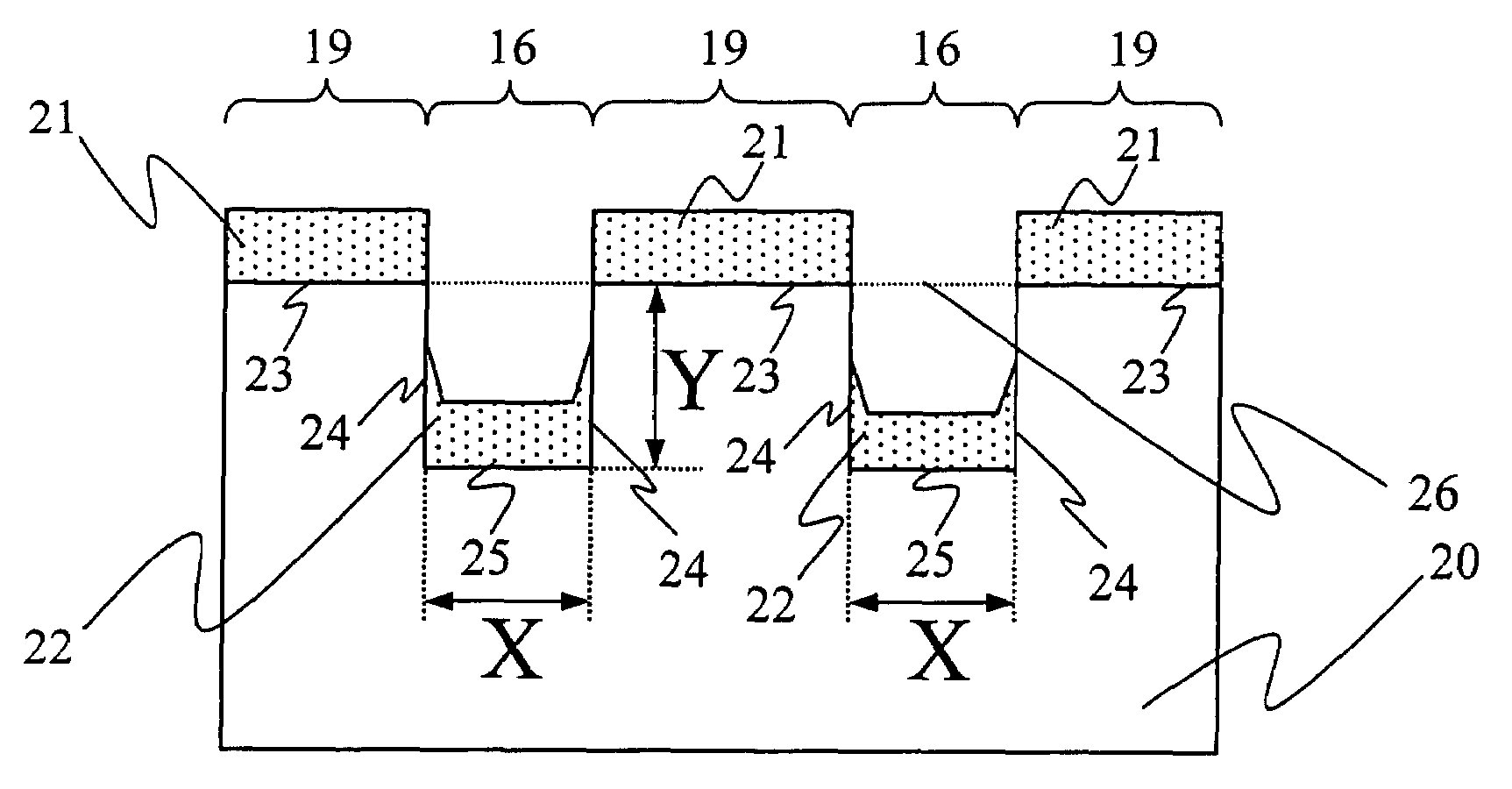

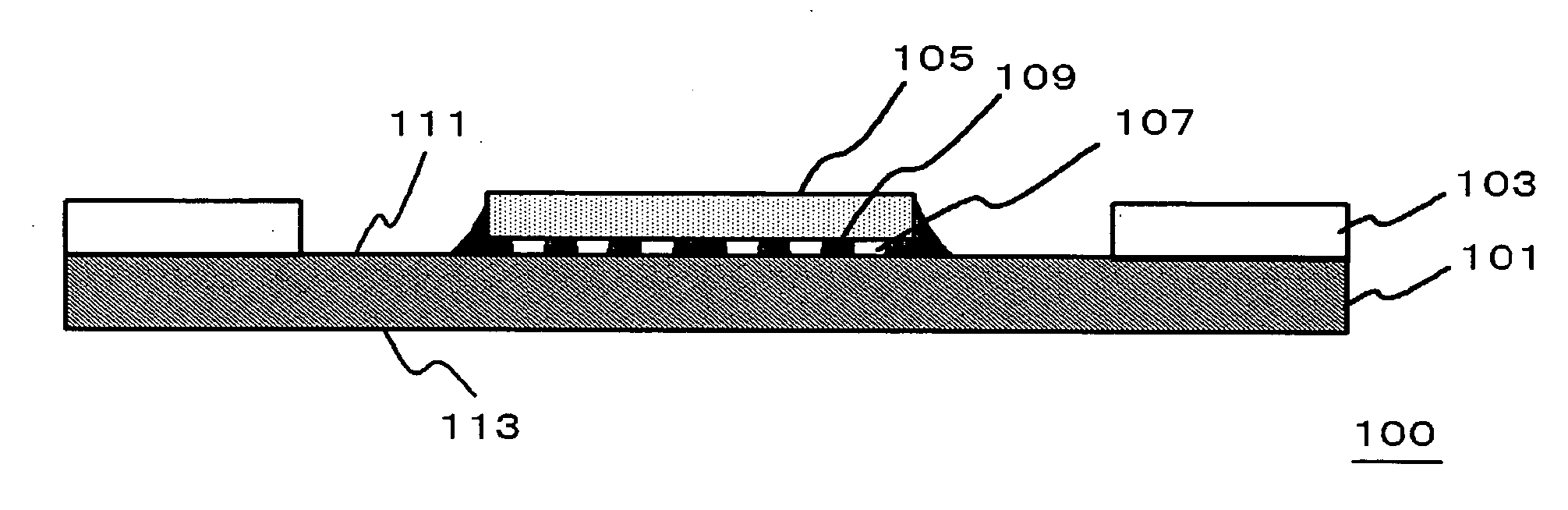

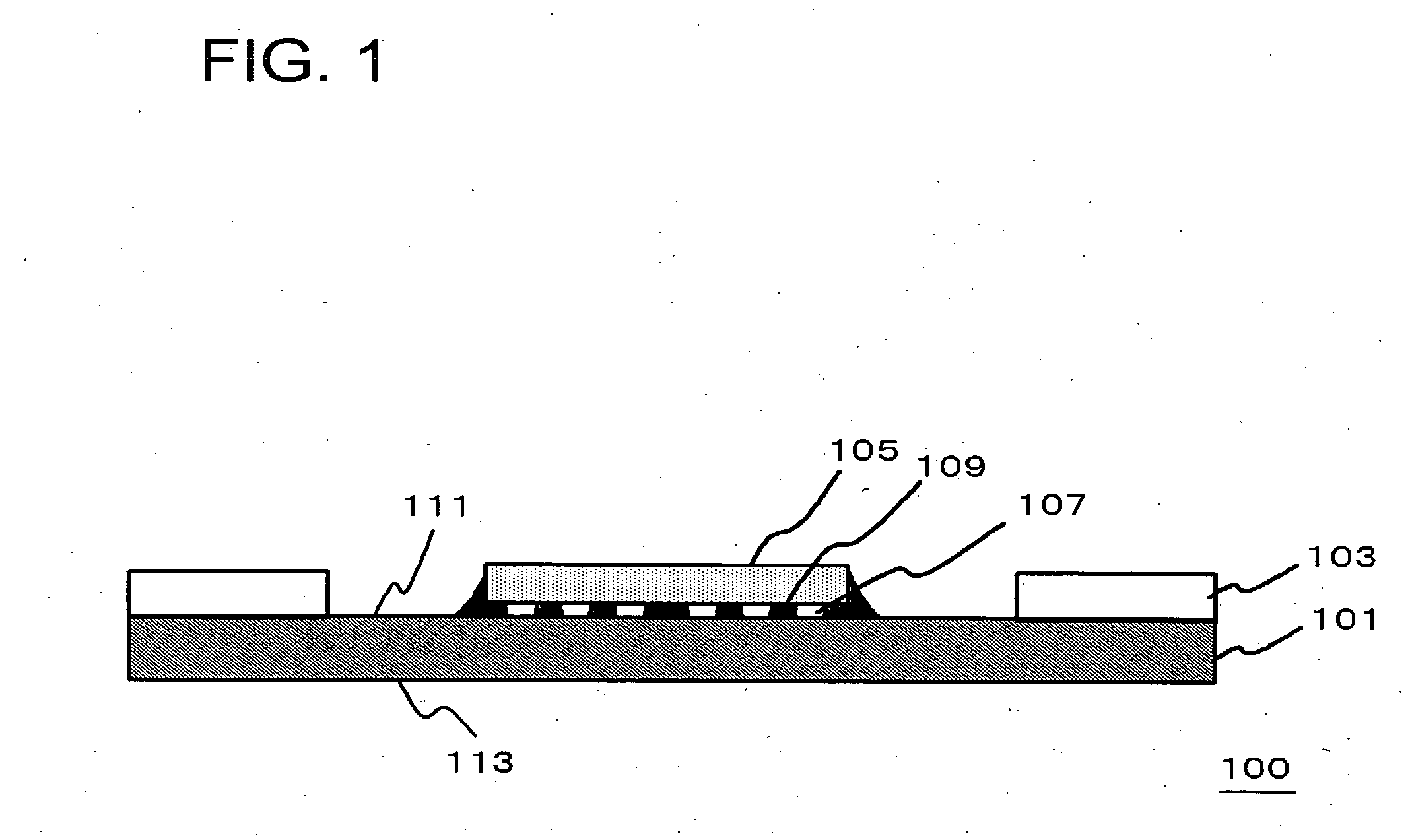

Interposer and semiconductor device employing same, and method for manufacturing semiconductor device

InactiveUS20060226538A1Good surface smoothnessImprove production yieldSemiconductor/solid-state device detailsSolid-state devicesInterposerSemiconductor chip

Bending generated in a side of a device mounting surface of an organic resin substrate after an assembly process for a semiconductor device is inhibited, thereby providing an improved production yield. A semiconductor device 100 is formed by solder-joining a semiconductor chip 105 onto a device mounting surface 111 of an interposer that is composed of an organic resin substrate 101. The interposer is an interposer, which is composed of an organic resin substrate 101, and on one surface of which a semiconductor chip 105 is to be mounted, and has a convex curvature in a side of a back surface 113 opposite to the device mounting surface 111, in a condition before an assembling process for the semiconductor device 100.

Owner:RENESAS ELECTRONICS CORP

Composite polishing pad and preparation method thereof

ActiveCN105415168AReduce hair sheddingGood surface smoothnessGrinding devicesLapping toolsElastomerPolymer science

The invention discloses a preparation method of a composite polishing pad. The preparation method comprises the following steps that (1) non-woven fabric is preprocessed, specifically, (a) the non-woven fabric is put into a drying oven for flattening, (b) the flattened non-woven fabric is immersed into a glue solution and then is taken out after being infiltrated sufficiently, and a non-woven fabric substrate material is obtained; (2) a polymer solution is prepared, specifically, (I) a macromolecular elastomer is dissolved into a solvent, and a macromolecular elastomer solution is prepared; (II) polymer particles are added into the macromolecular elastomer solution, and the polymer solution is obtained; (3) the non-woven fabric is made into a pad, specifically, the non-woven fabric substrate material is infiltrated into the polymer solution and then is taken out after being infiltrated sufficiently, and unnecessary solutions on the surface of the non-woven fabric substrate material are scraped off; the non-woven fabric substrate material is immersed into coagulating bath for consolidation forming and then put into pure water for rinsing and finally dried to the constant weight, and an original polishing pad is obtained; and (4) the polishing pad is formed, specifically, after the surface of the original polishing pad is polished, cut and rubberized, and the finished polishing pad is obtained. By means of the preparation method, the composite polishing pad has a large polishing rate, and moreover the flatness of a polished object is good.

Owner:河南惠强新能源材料科技股份有限公司

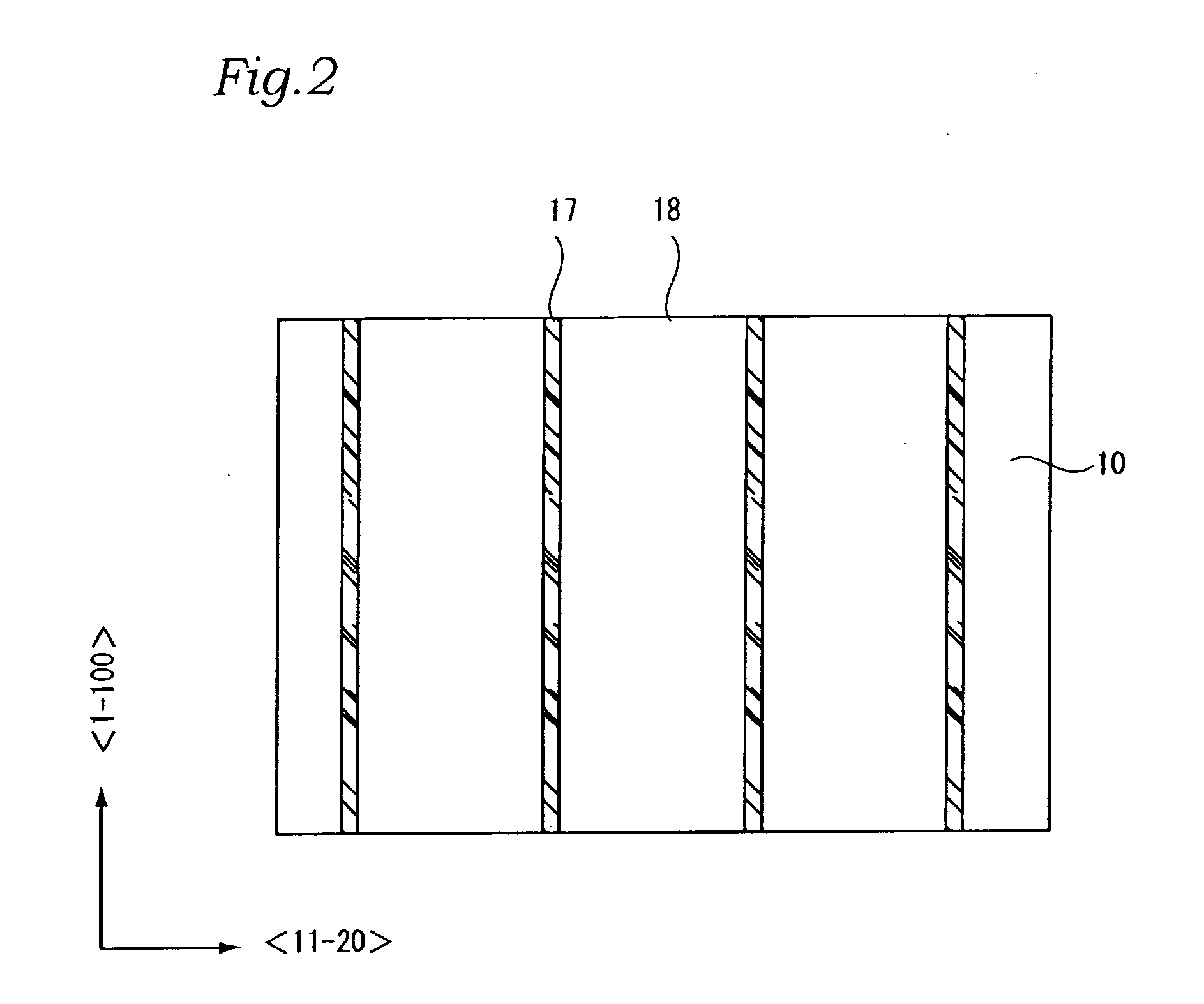

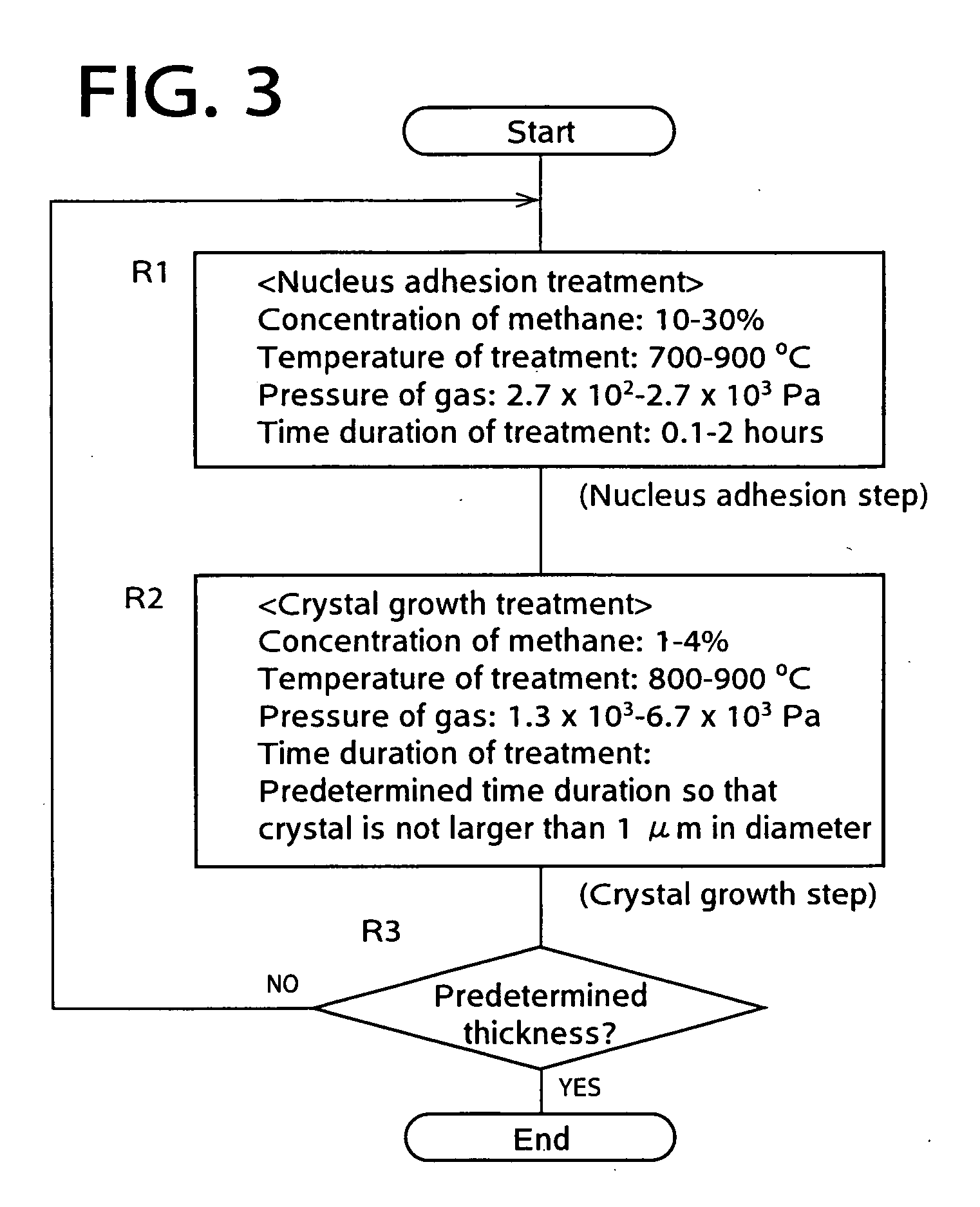

Method for fabricating a nitride semiconductor light-emitting device

ActiveUS7109049B2Reduce crackingGood surface smoothnessOptical wave guidanceLaser detailsLight emitting deviceNitride semiconductors

Provided is a method for fabricating a nitride semiconductor light-emitting device including a nitride semiconductor substrate having a groove and a ridge formed on the top surface thereof so as to extend in the shape of stripes and a nitride semiconductor growth layer consisting of a plurality of nitride semiconductor layers laid on top of the nitride semiconductor substrate. The method involves a step of forming a 10 μm or more wide flat region above at least either of the groove and ridge by forming the nitride semiconductor growth layer on top of the nitride semiconductor substrate so that the height of the nitride semiconductor growth layer laid above the groove is smaller than the height of the nitride semiconductor growth layer laid above the ridge.

Owner:SHARP FUKUYAMA LASER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com