Patents

Literature

464results about How to "Promote rupture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

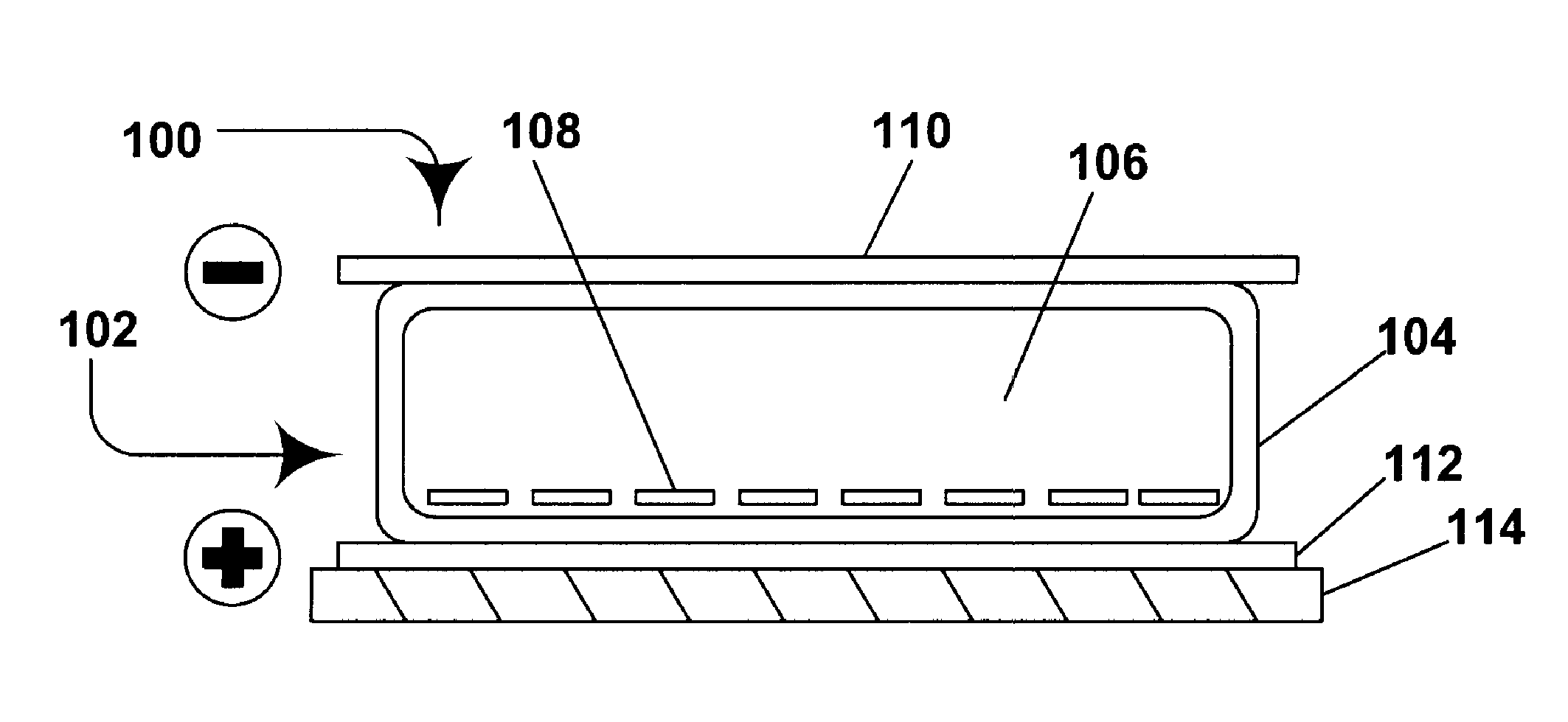

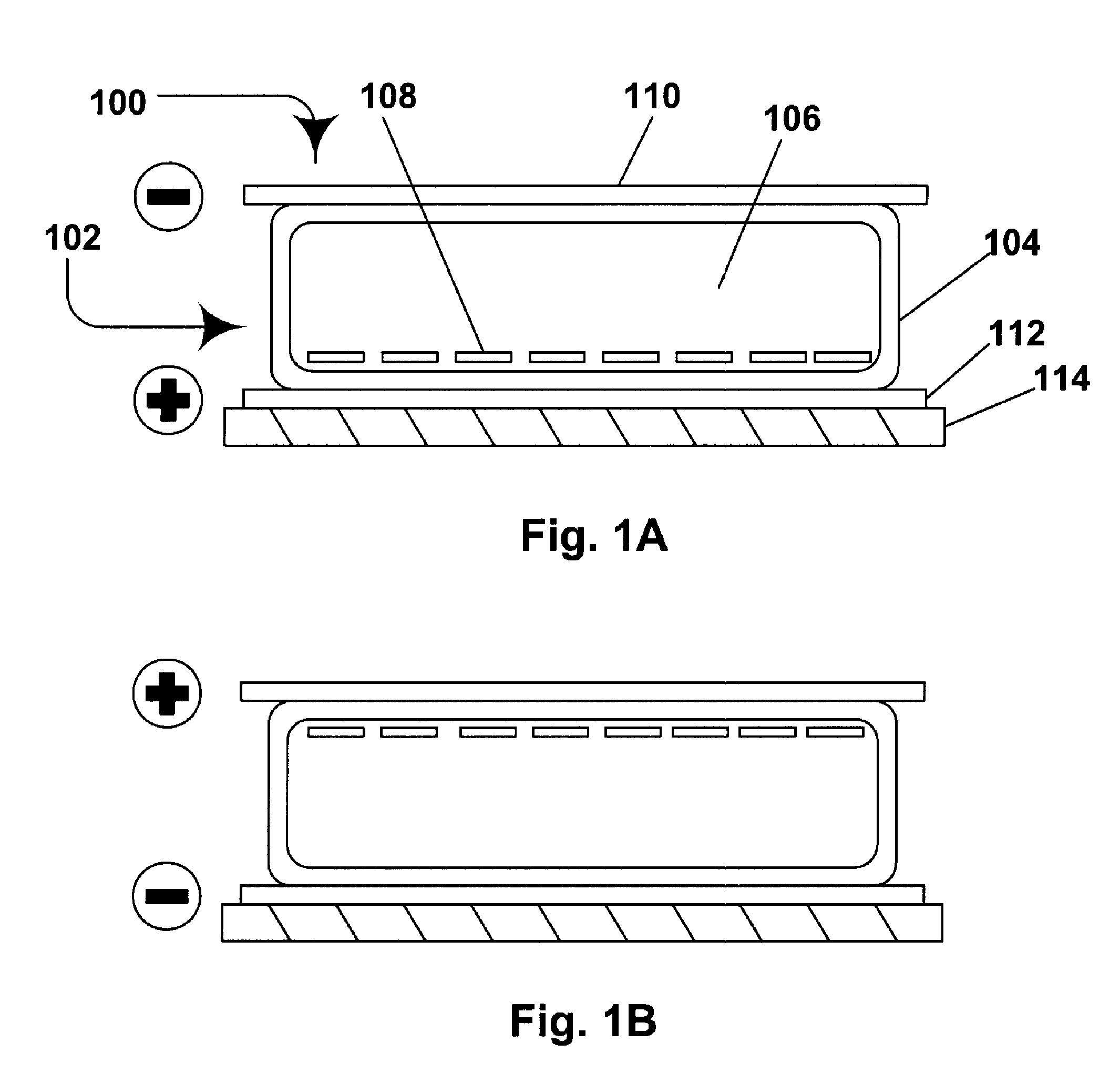

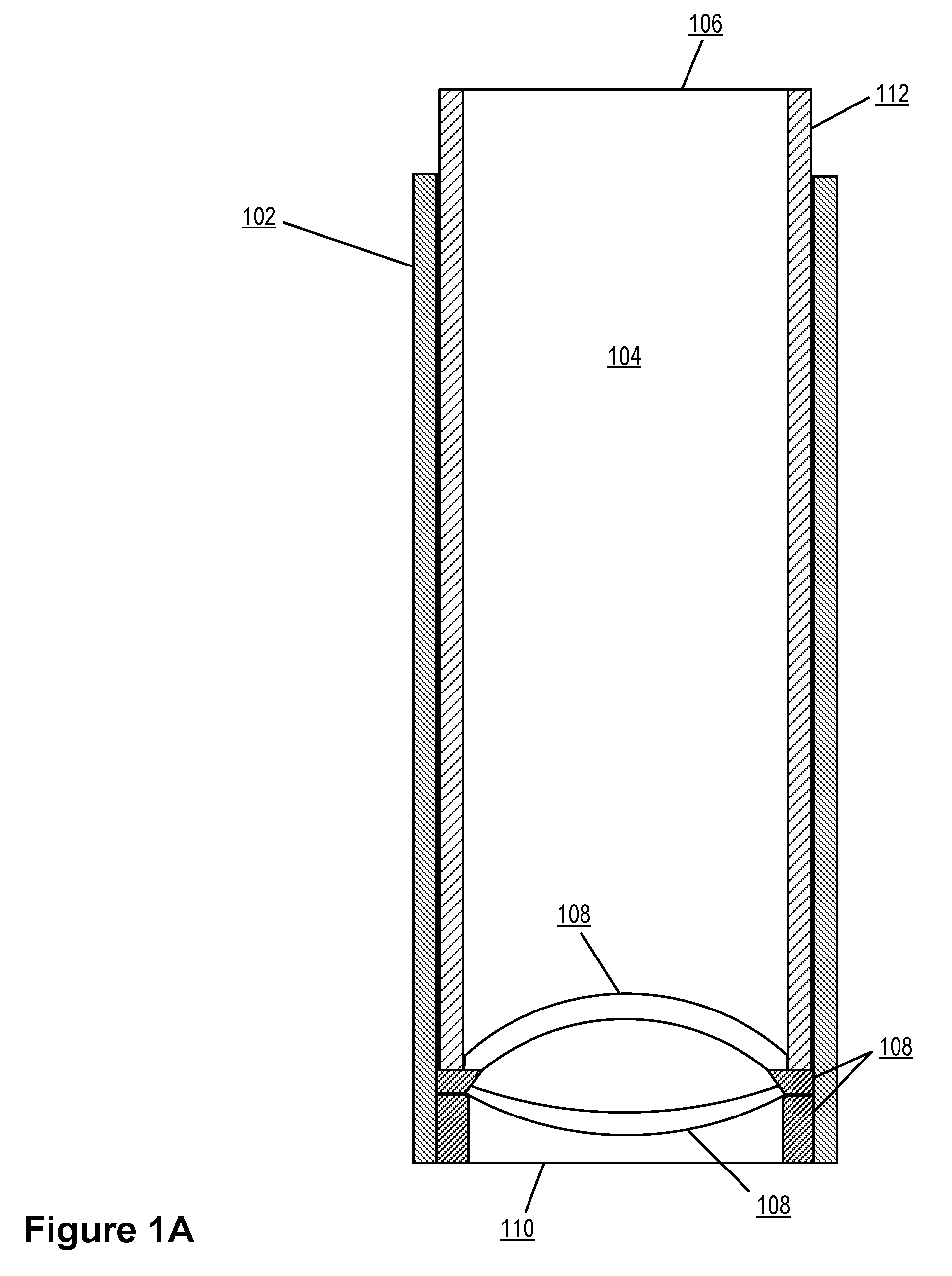

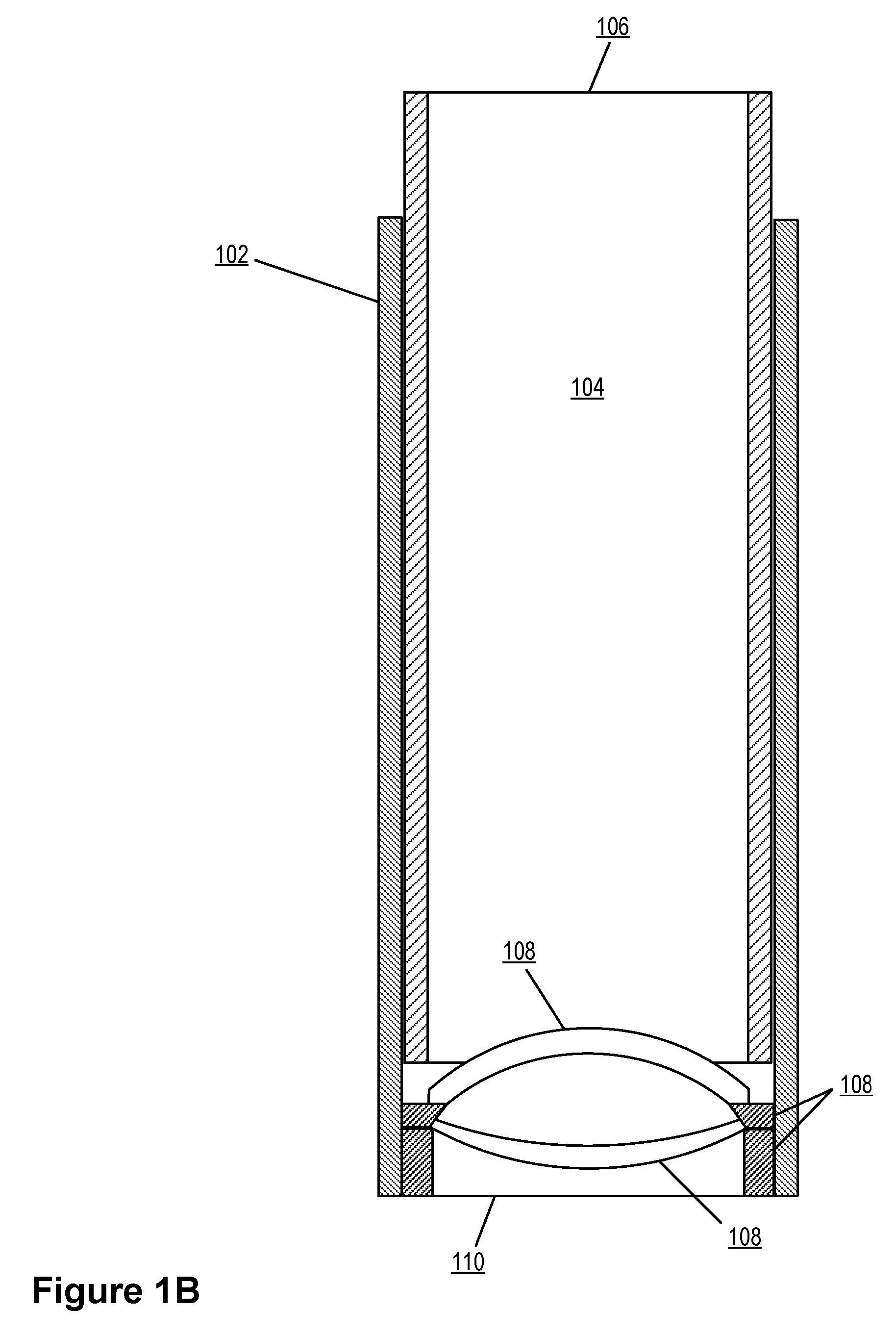

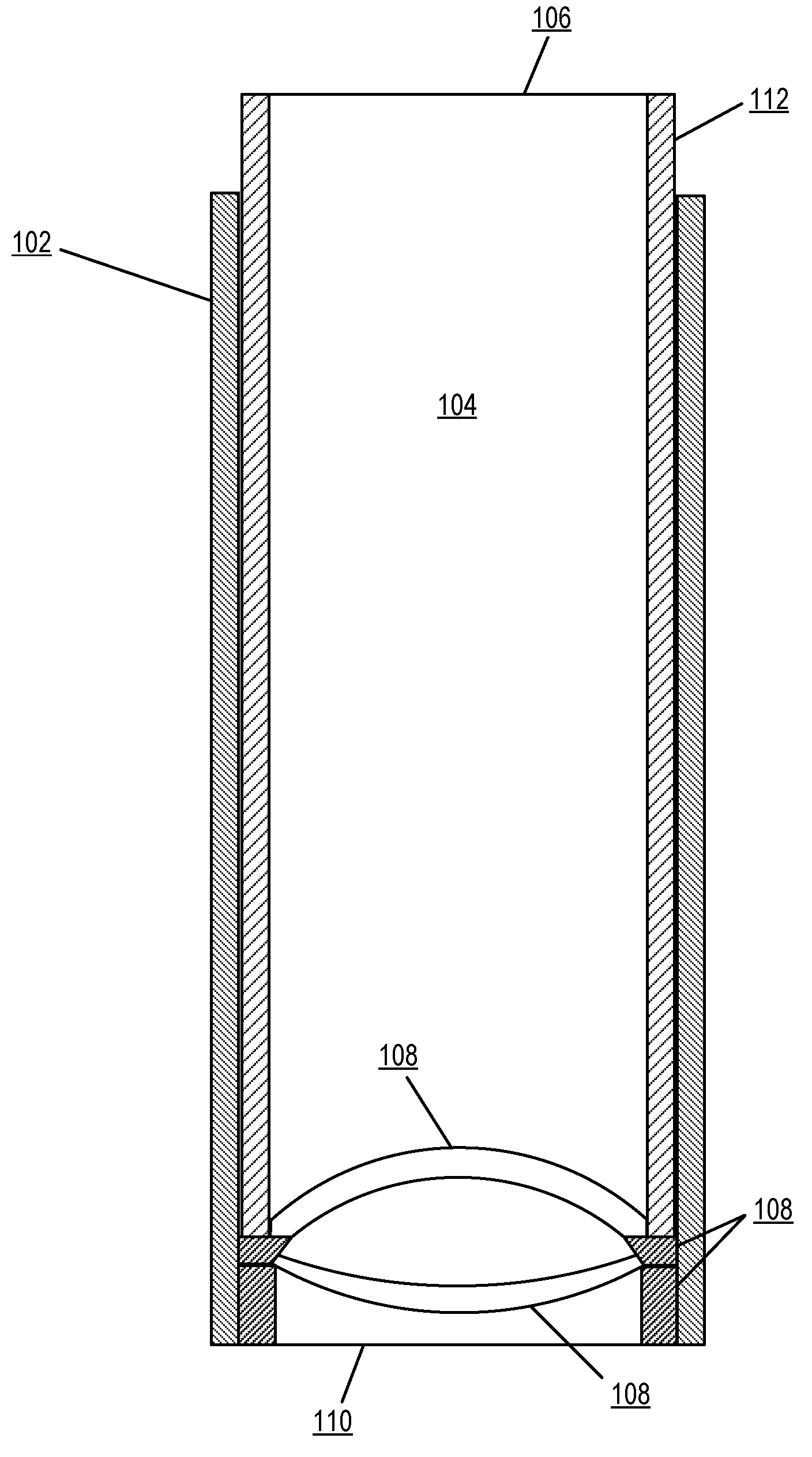

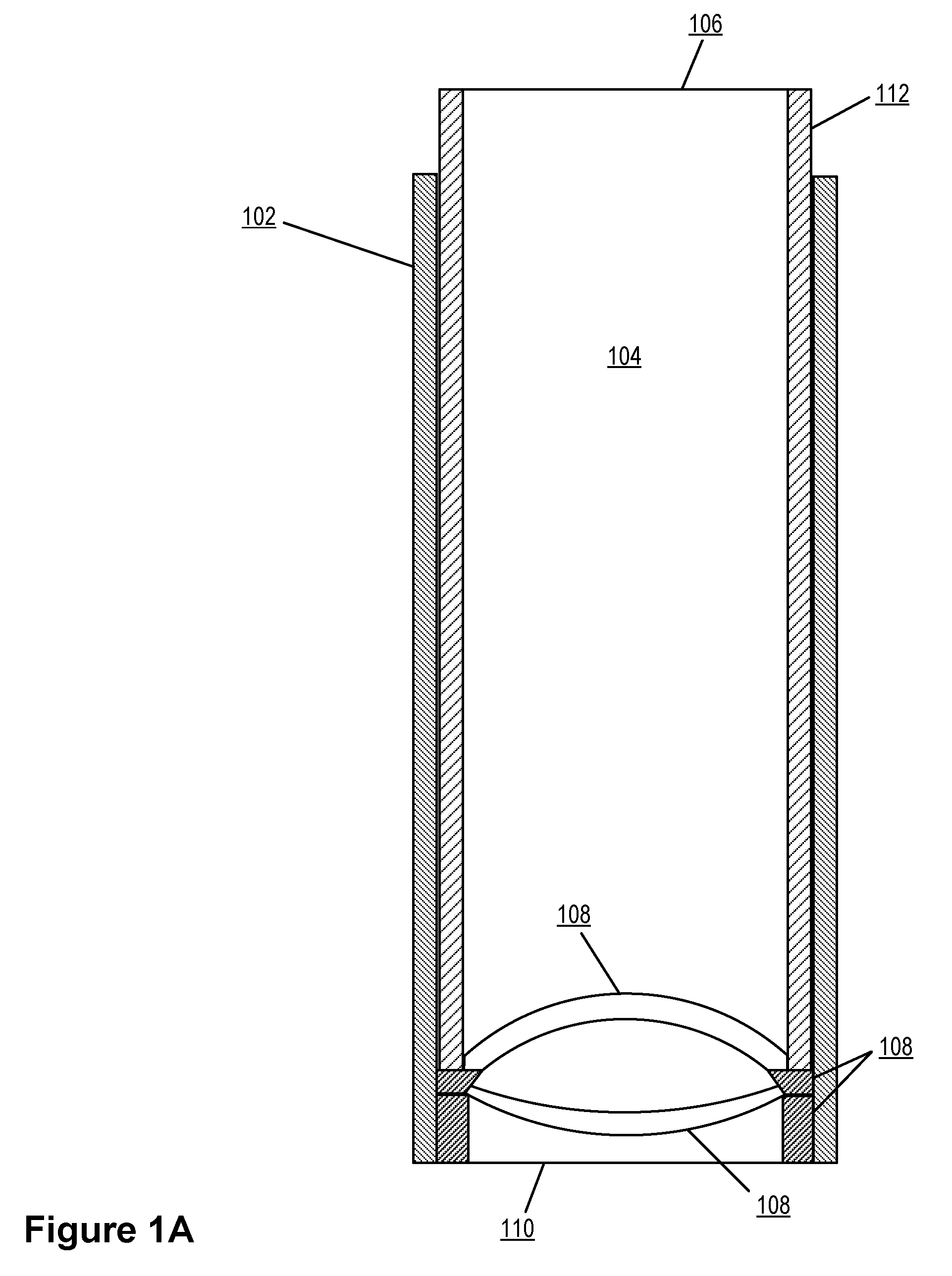

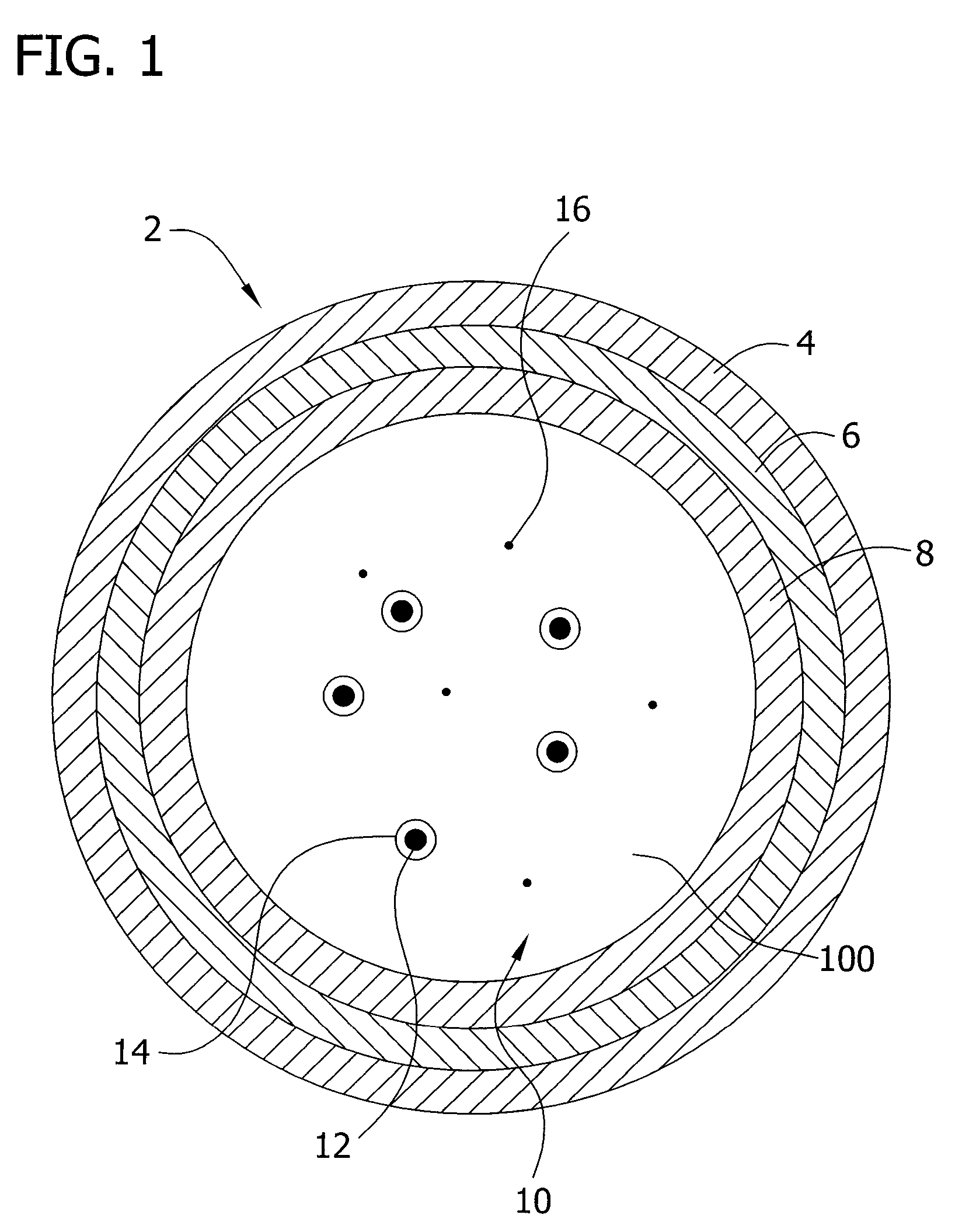

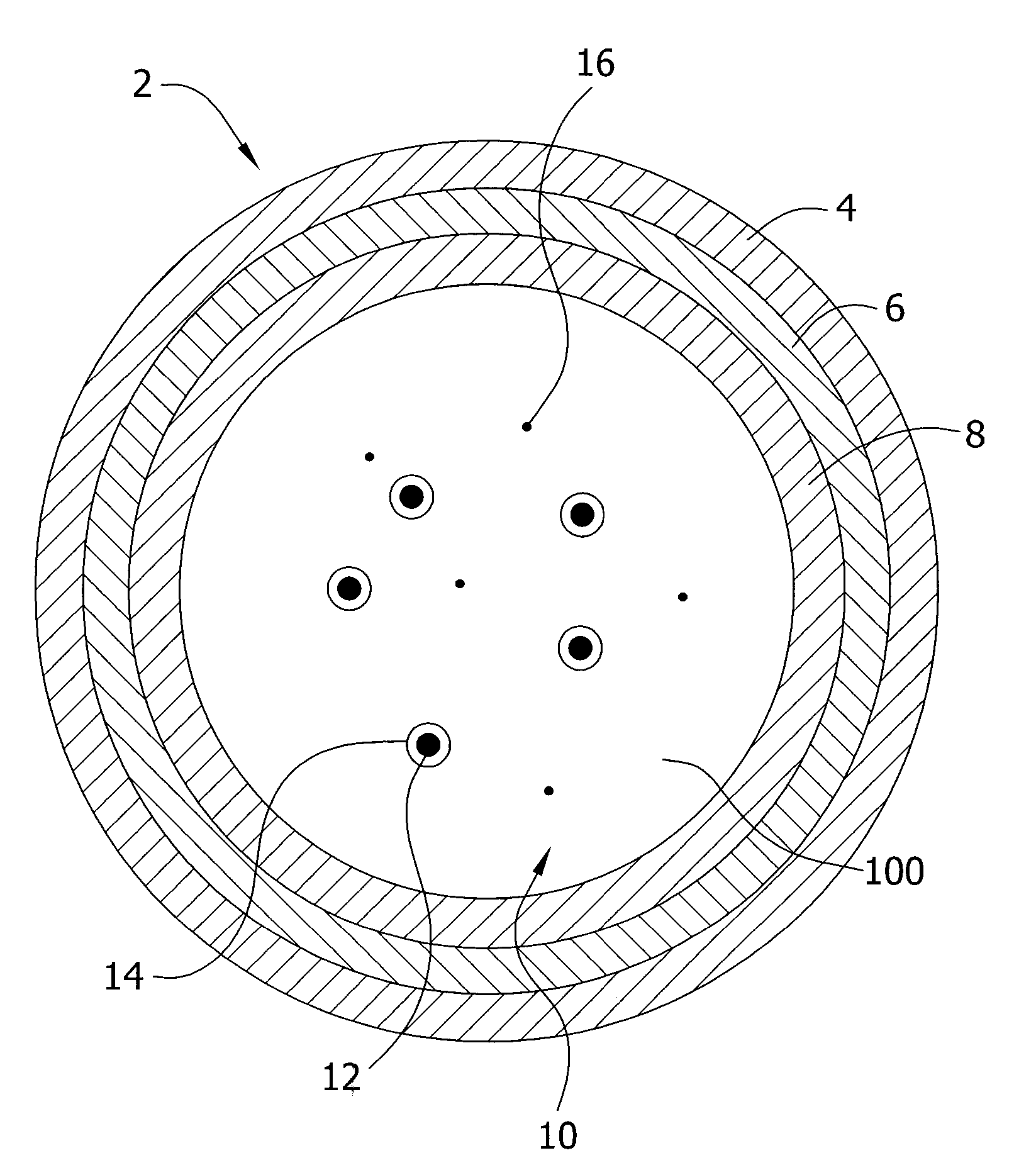

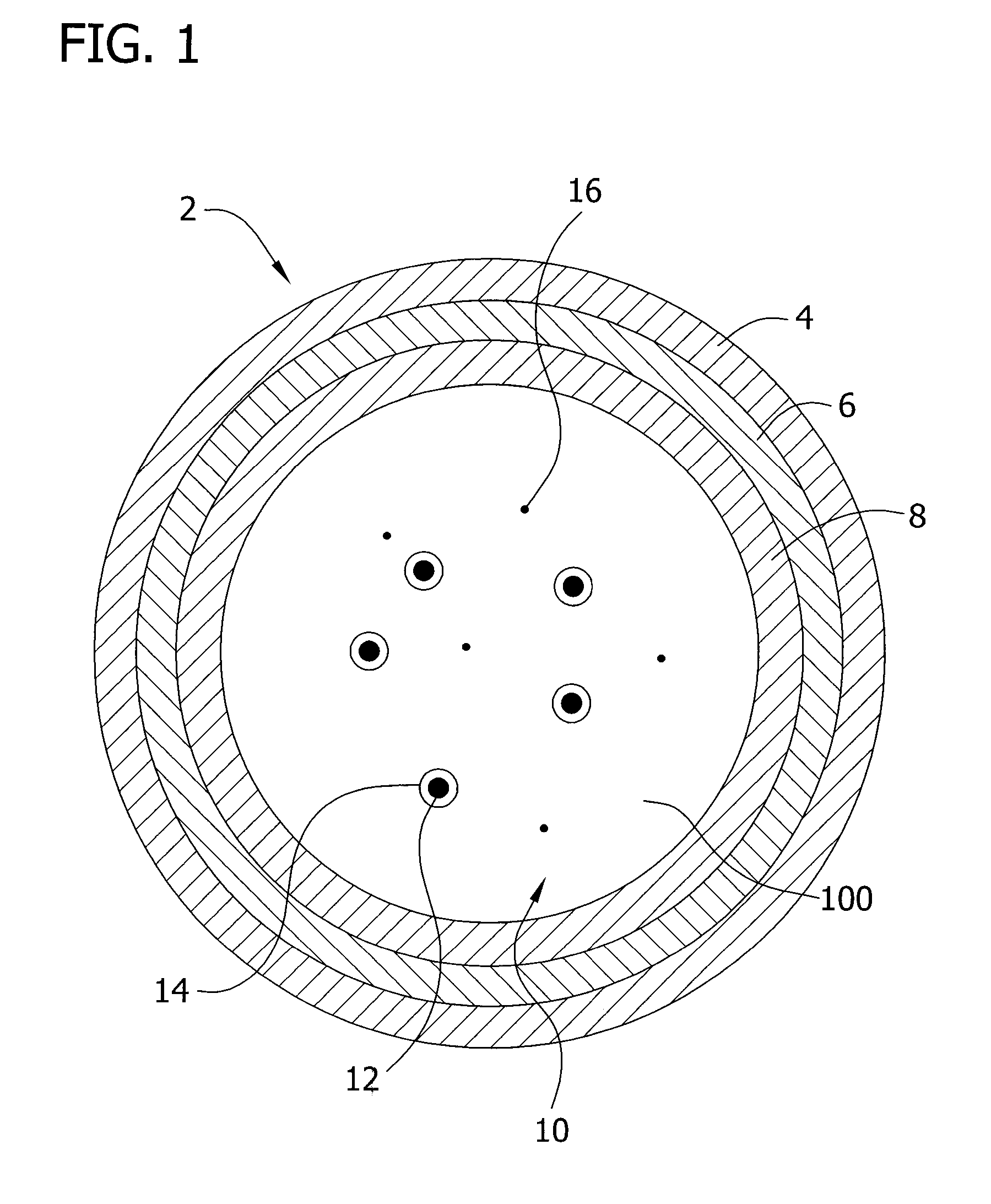

Electrophoretic media containing specularly reflective particles

ActiveUS20040094422A1Good flexibilityImprove uniformitySludge treatmentStatic indicating devicesElectrophoresisSpecular reflection

An electrophoretic medium (100) comprises at least one type of particle (108) suspended in a suspending fluid (106) and capable of moving therethrough on application of an electric field to the medium, the particles (108) including at least one electrophoretically mobile specularly reflective particle.

Owner:E INK CORPORATION

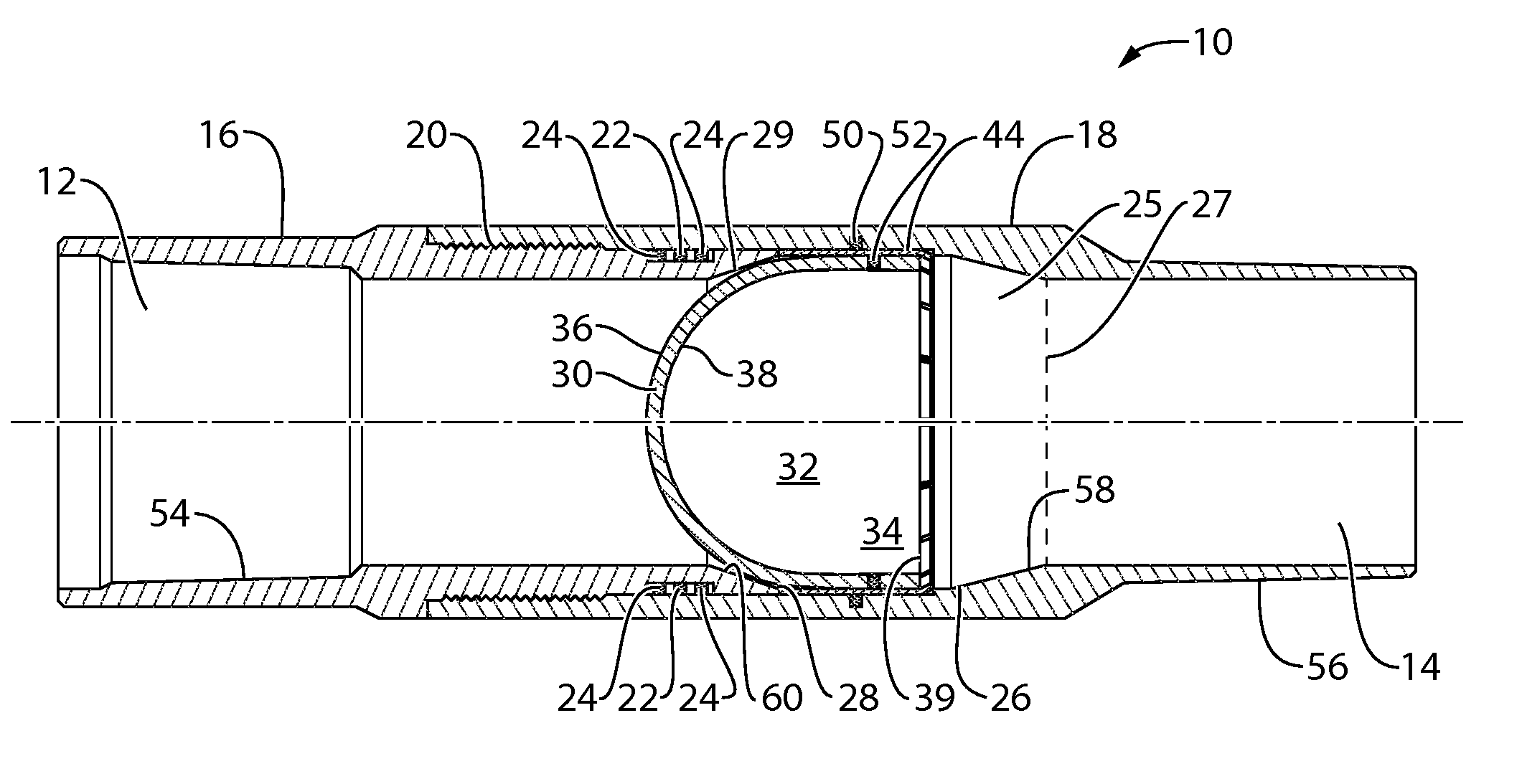

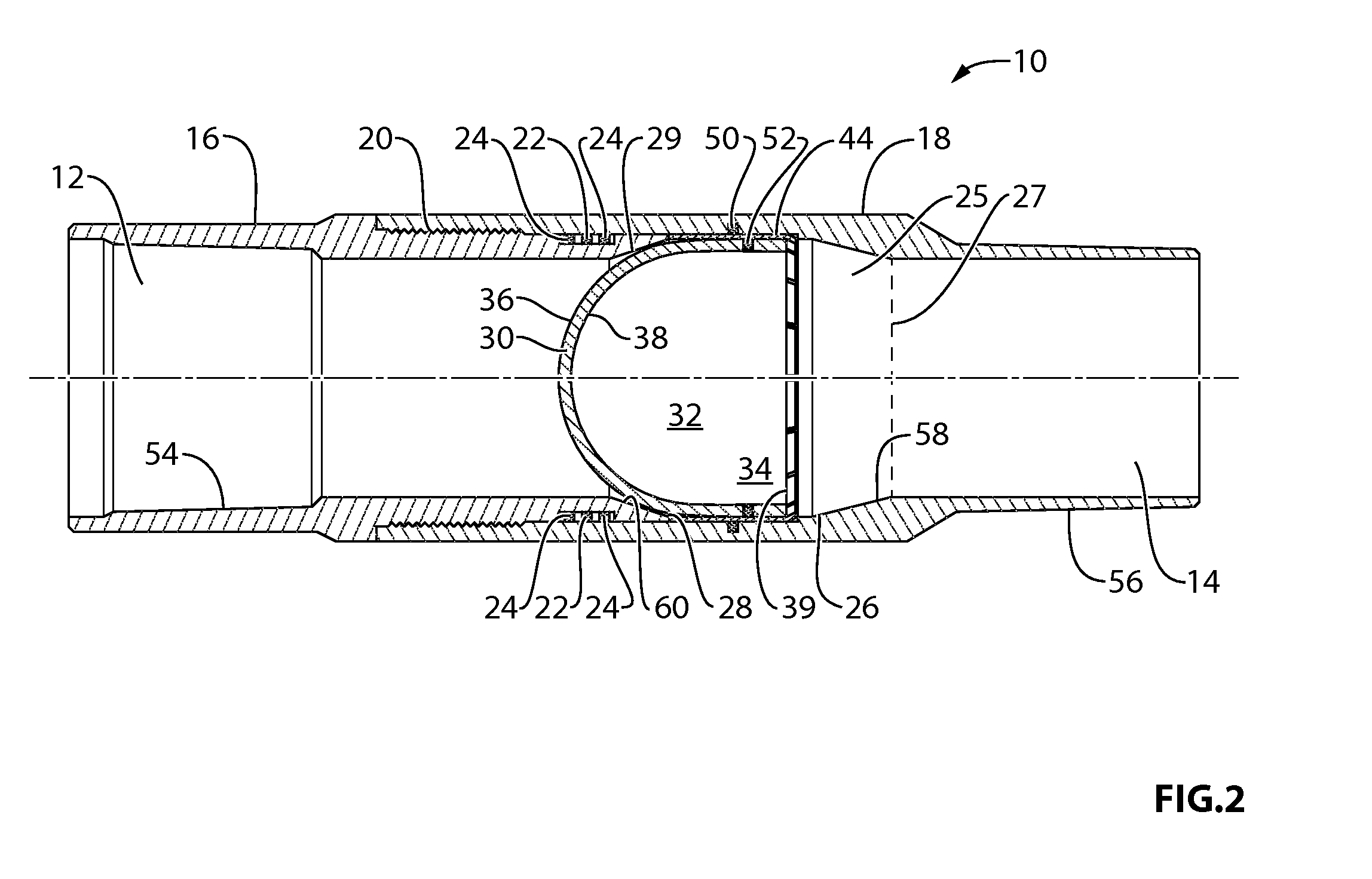

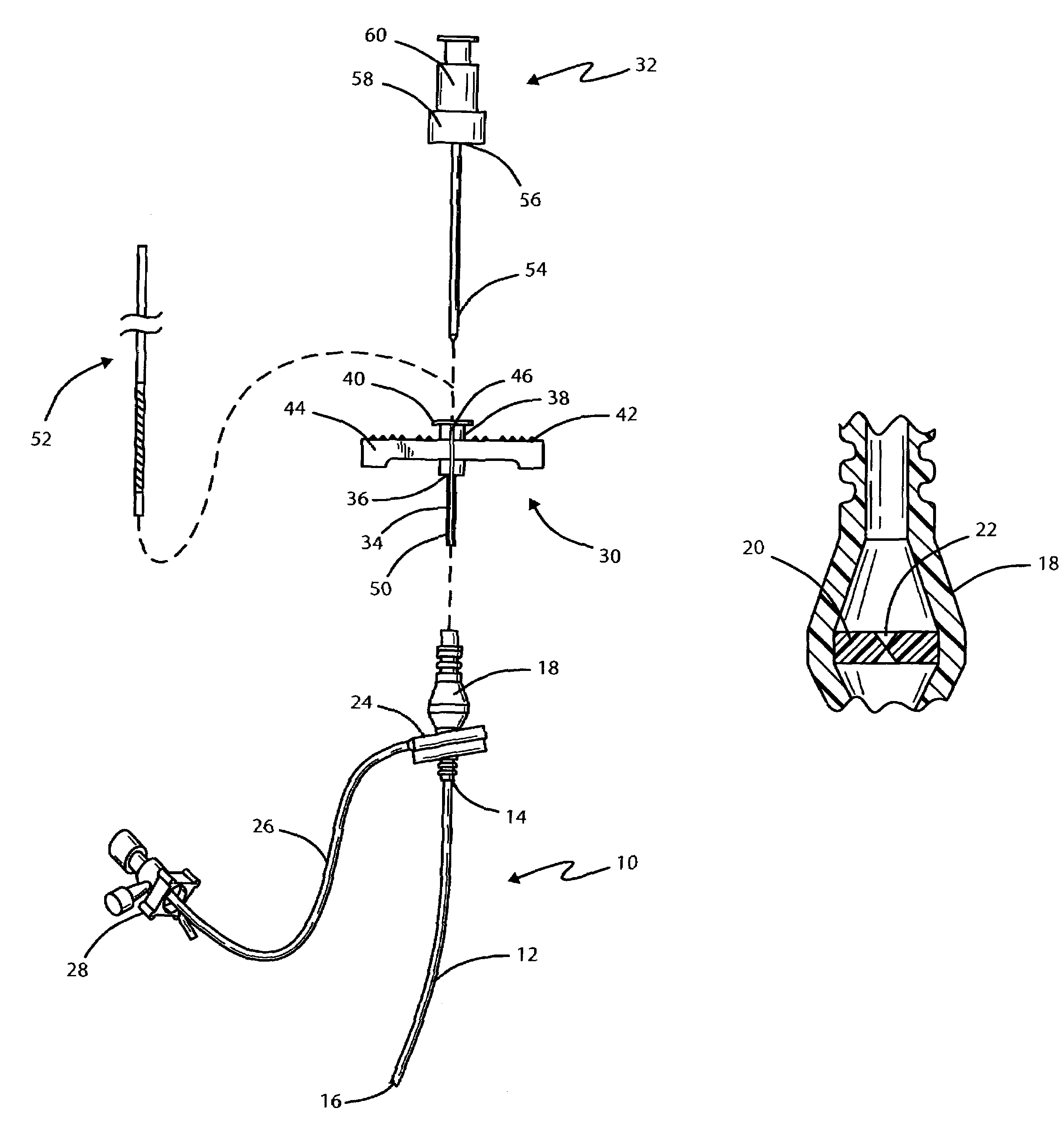

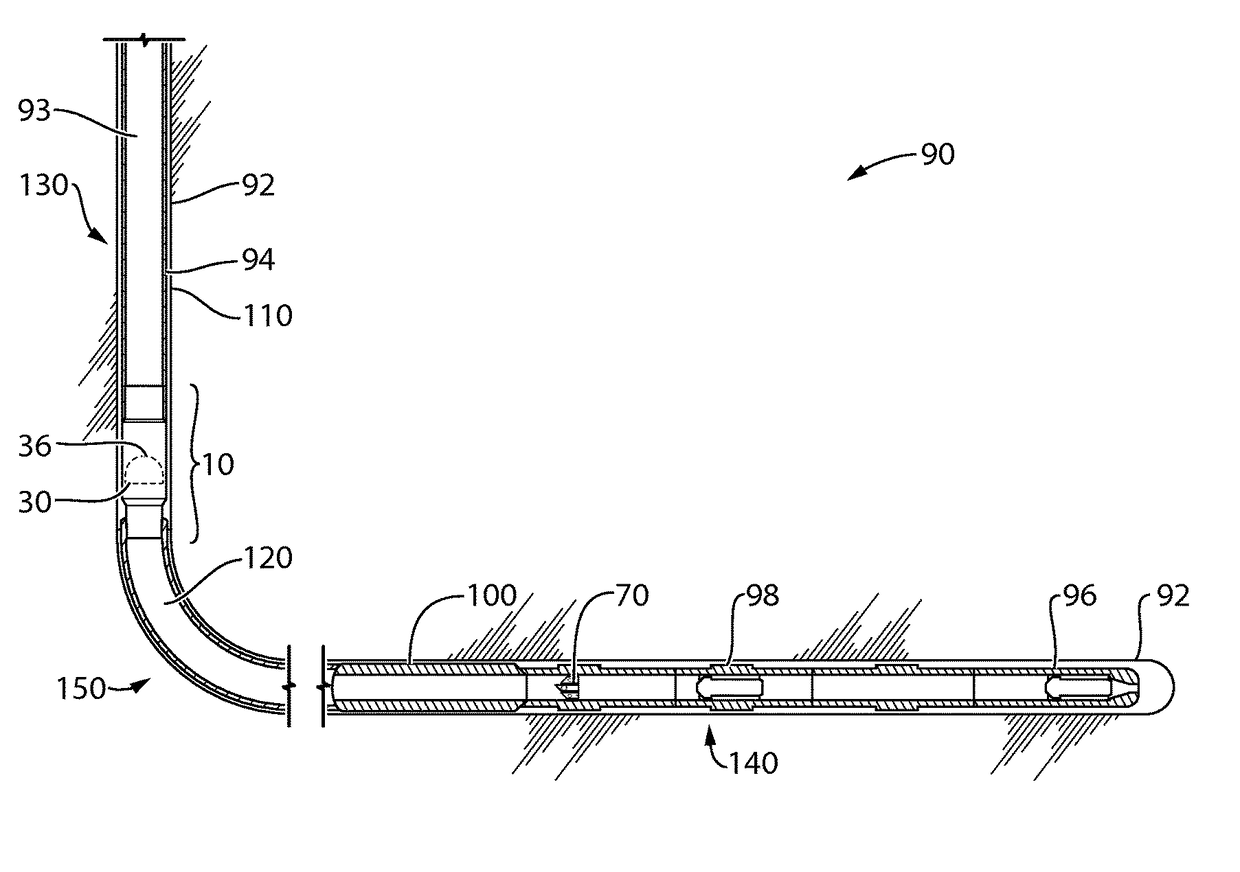

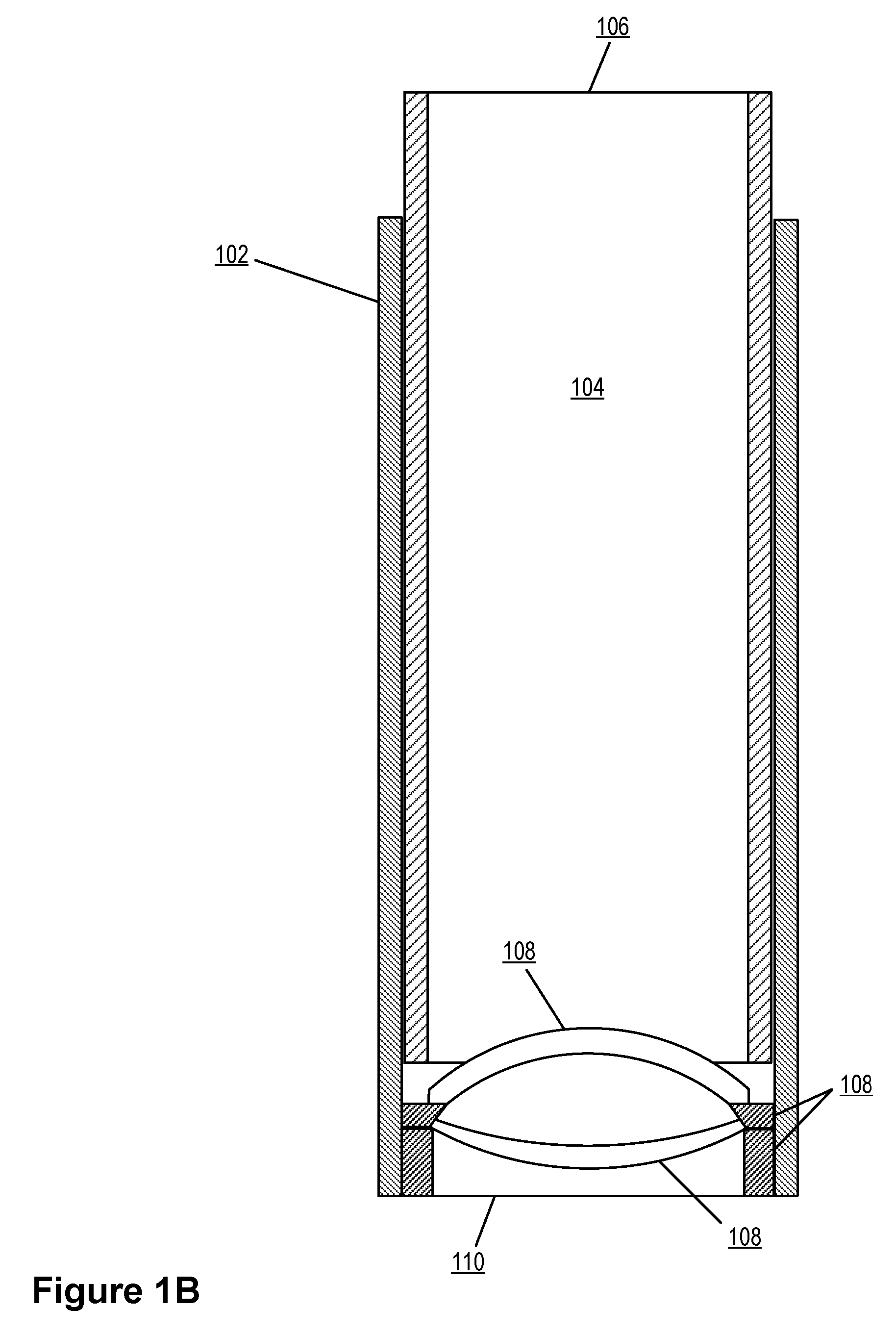

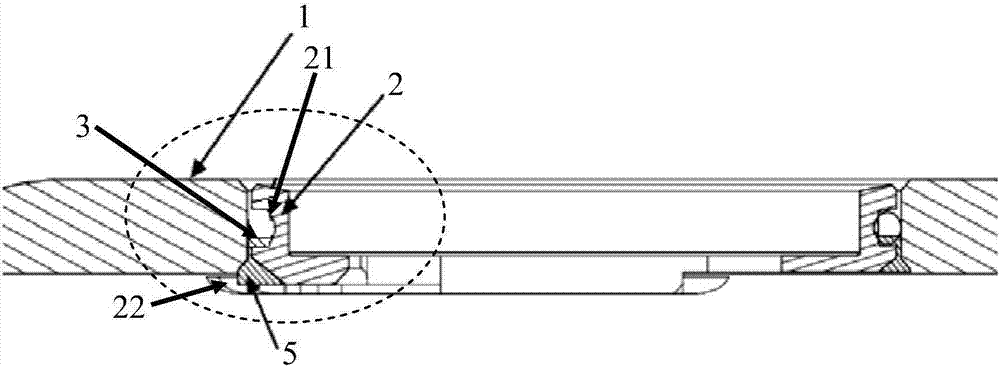

Temporary well zone isolation

InactiveUS7513311B2Avoid breakingPromote ruptureFluid removalWell/borehole valve arrangementsEngineeringFluid pressure

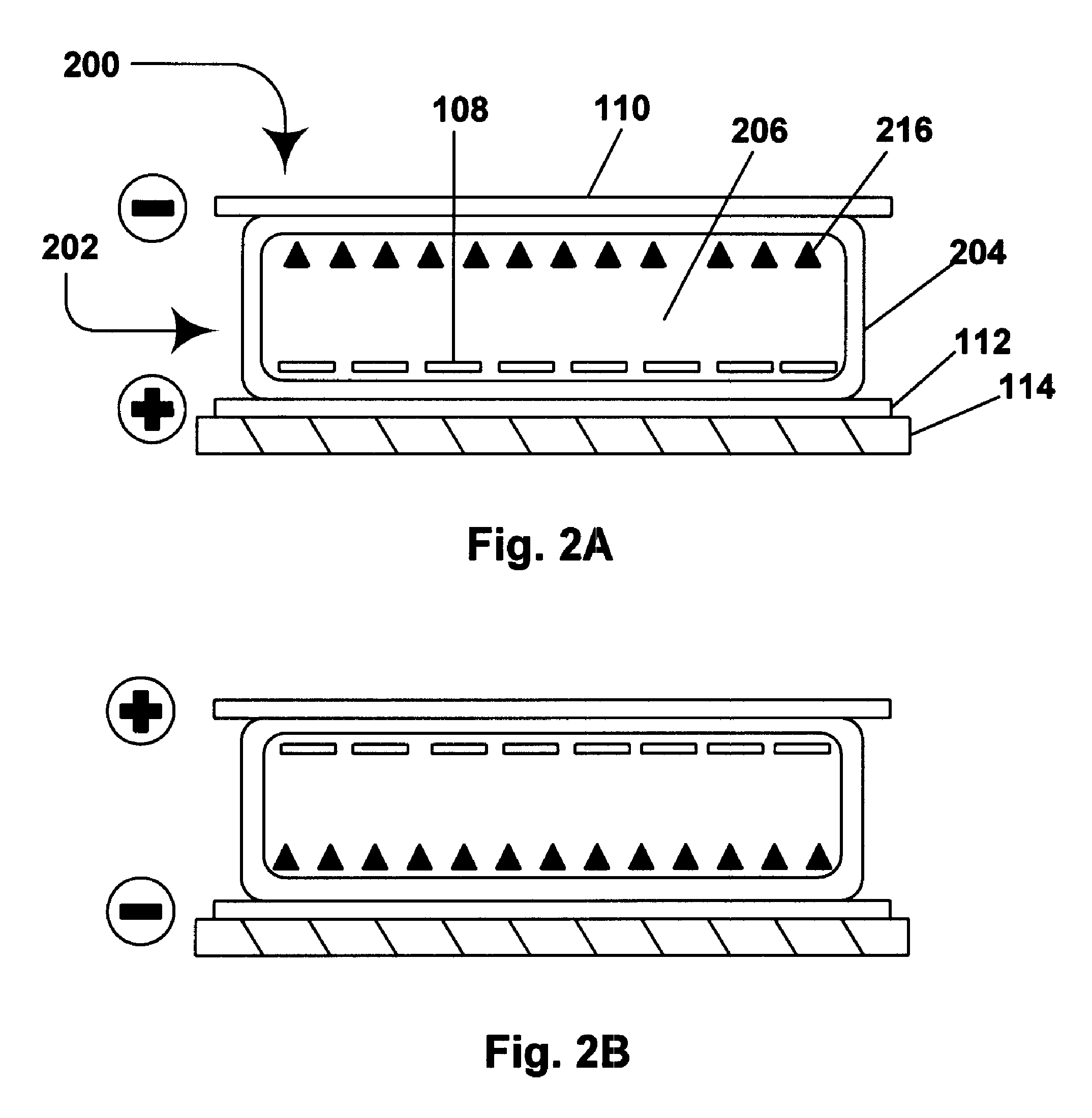

Disclosed herein is a temporary well isolation device, which is sealingly disposable in downhole tubing, and which has a housing with an axial passage. The temporary well isolation device also has frangible barrier element within the housing, where the frangible barrier element is sealingly engaged in the passage blocking fluid flow through the passage. The frangible barrier element bears a load from fluid pressure. The temporary well isolation device also has a disengagable constraint in contact with a frangible barrier element so as to redirect the load on the frangible barrier element from a first component of the load to a second component of the load, thereby preventing rupture of the frangible barrier element. Also disclosed herein is a method for disintegrating a frangible barrier element disposed in a passage of a temporary well isolation device.

Owner:WEATHERFORD TECH HLDG LLC

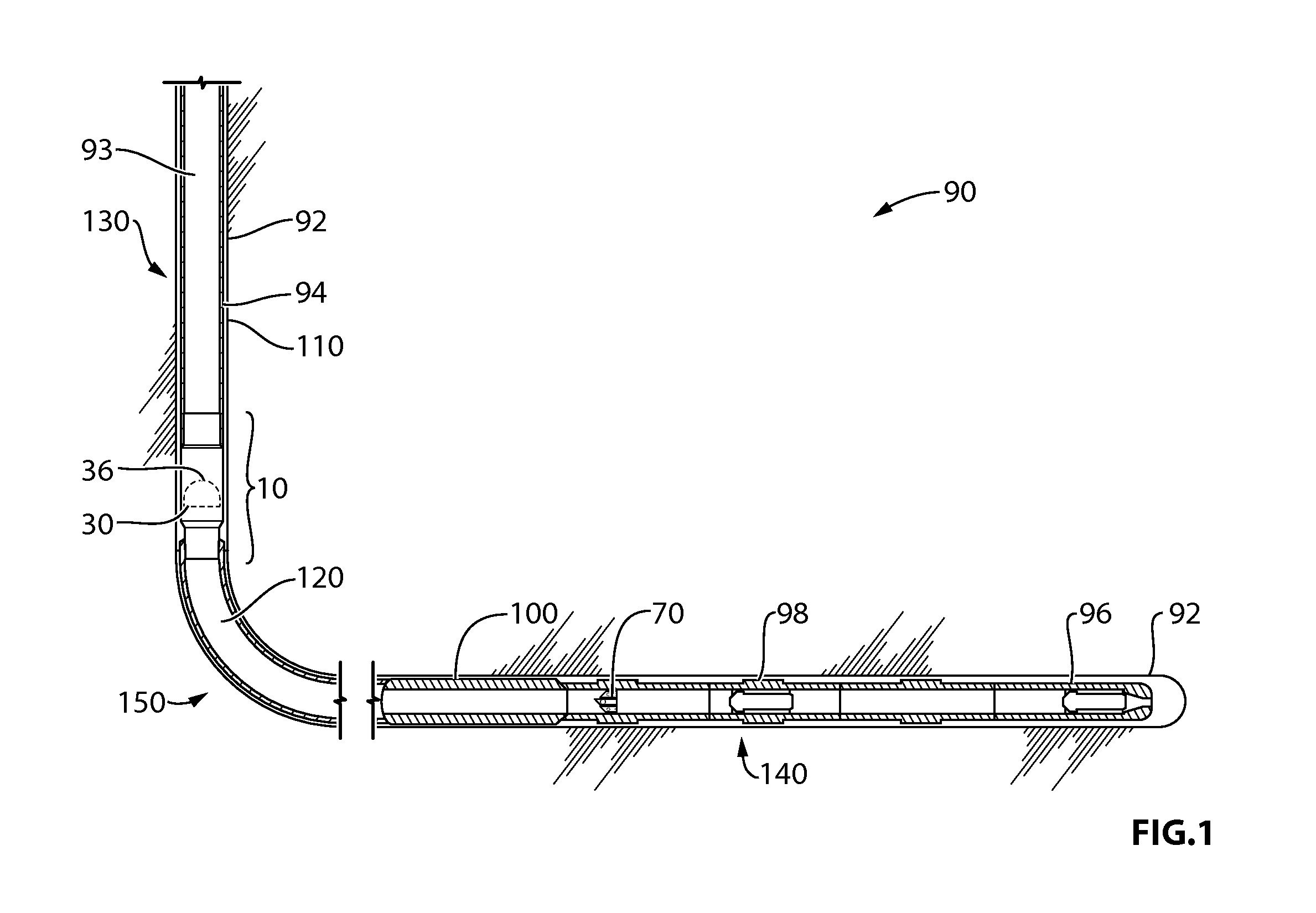

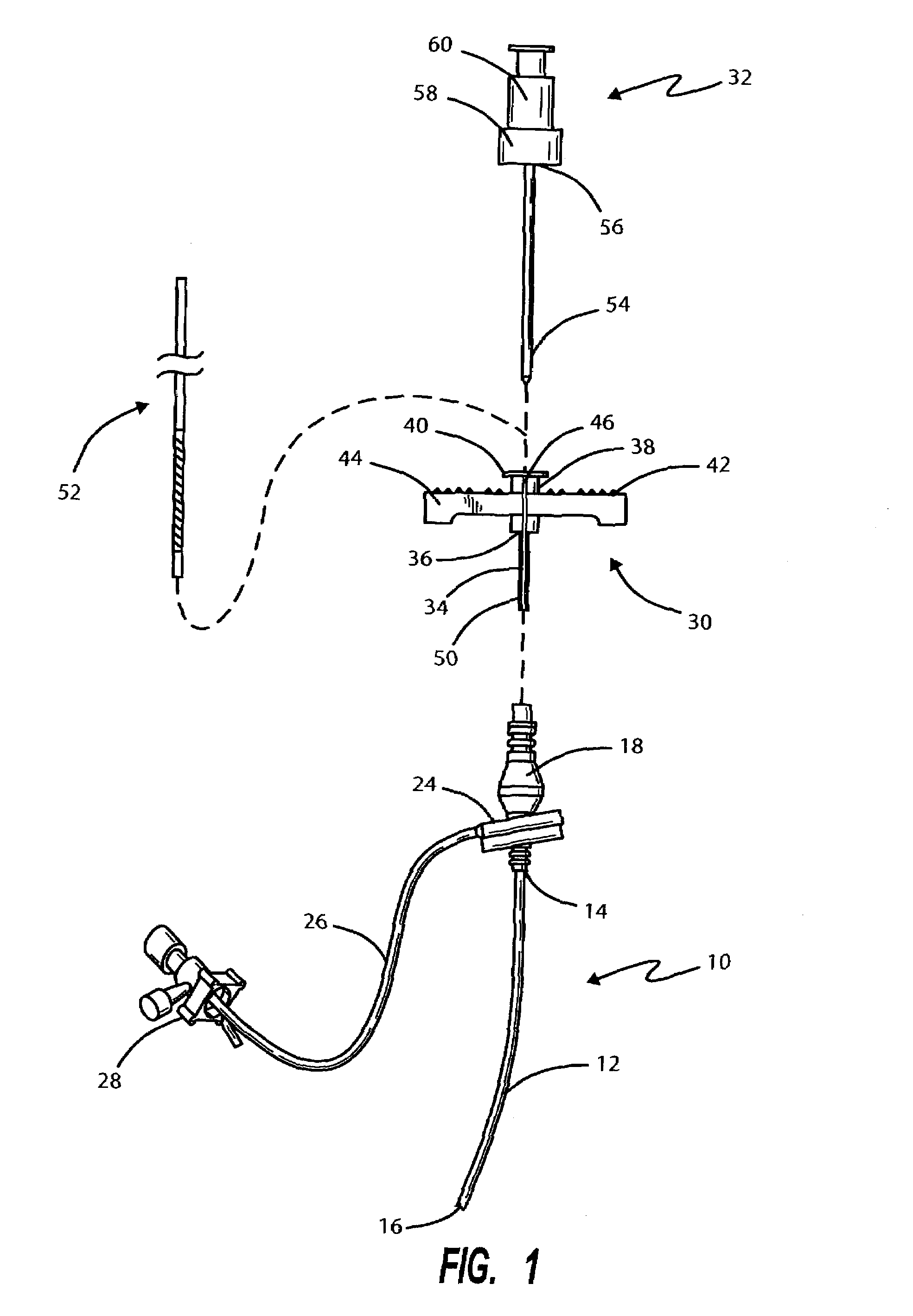

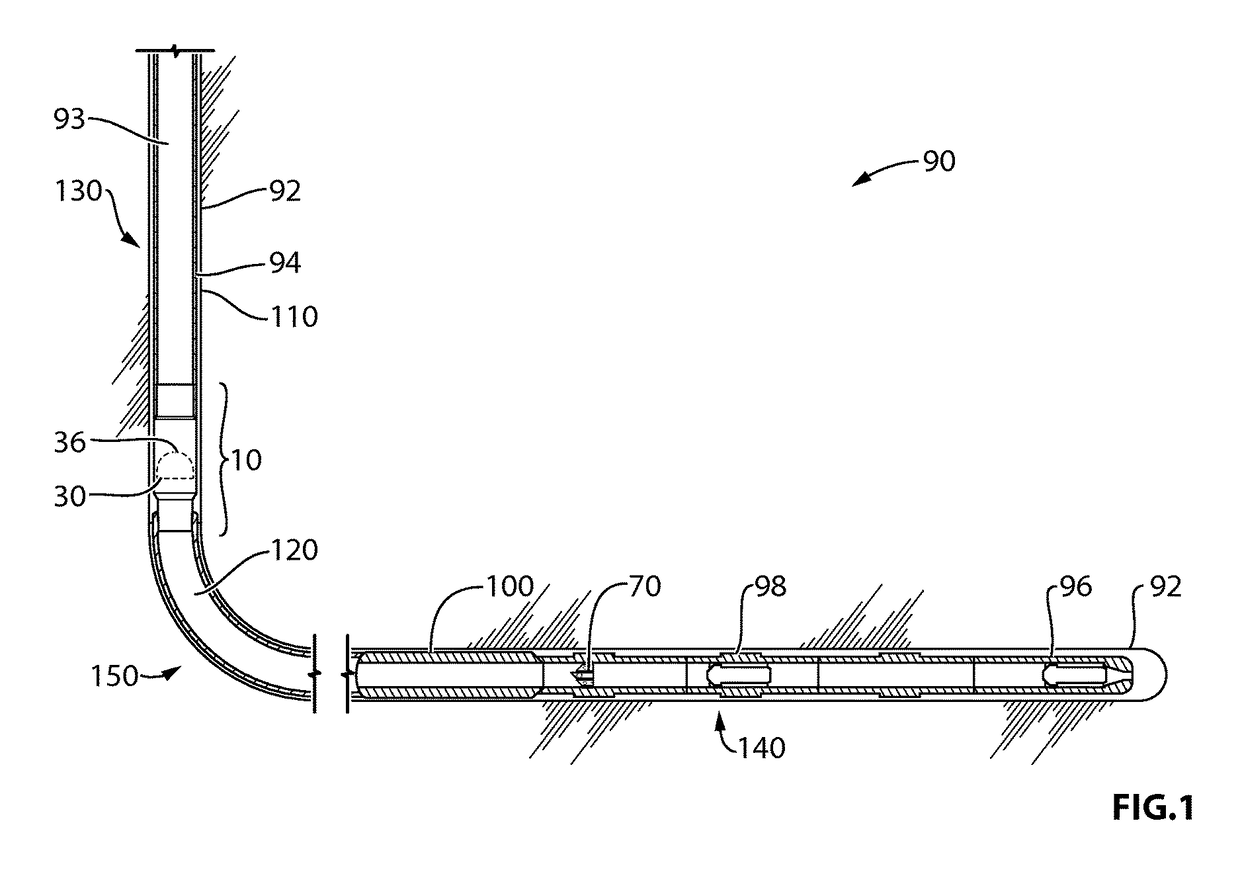

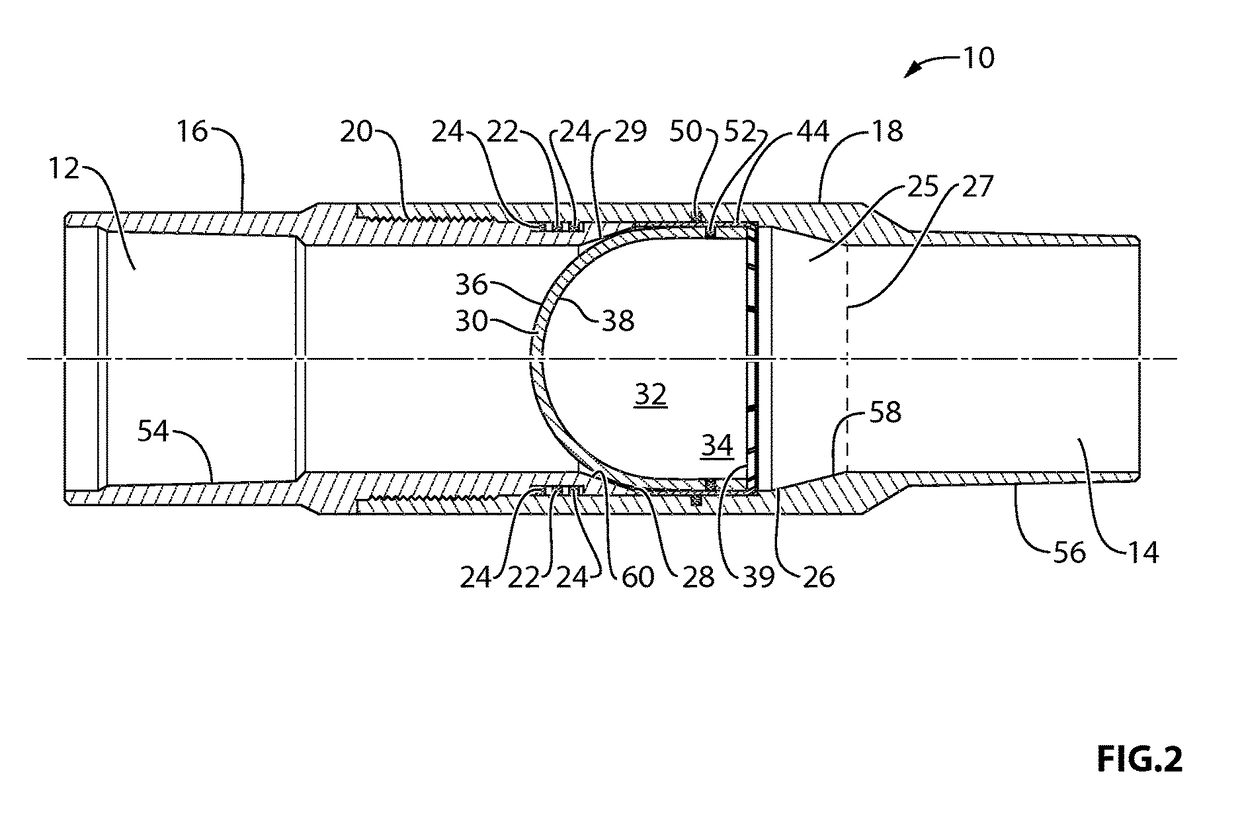

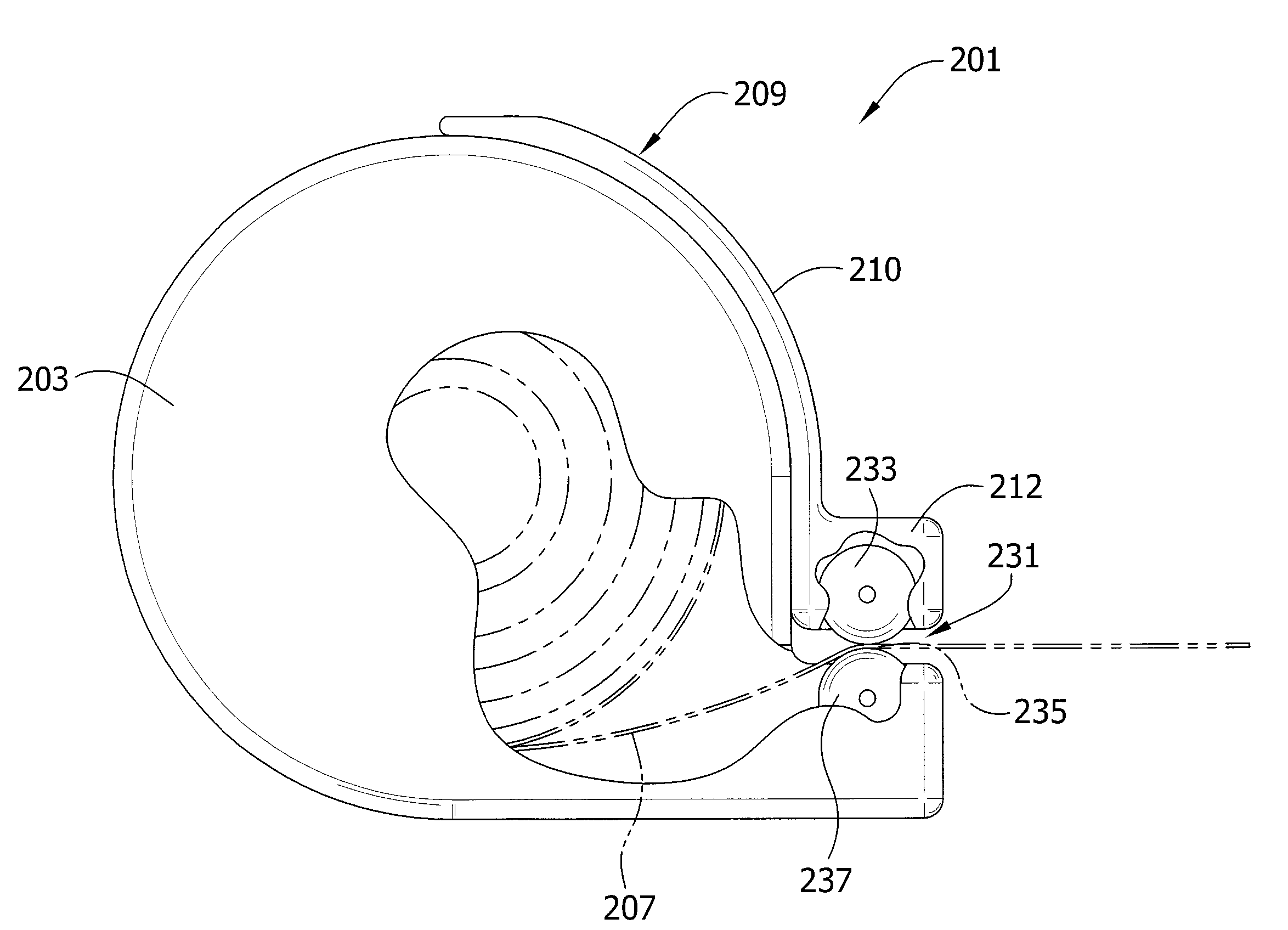

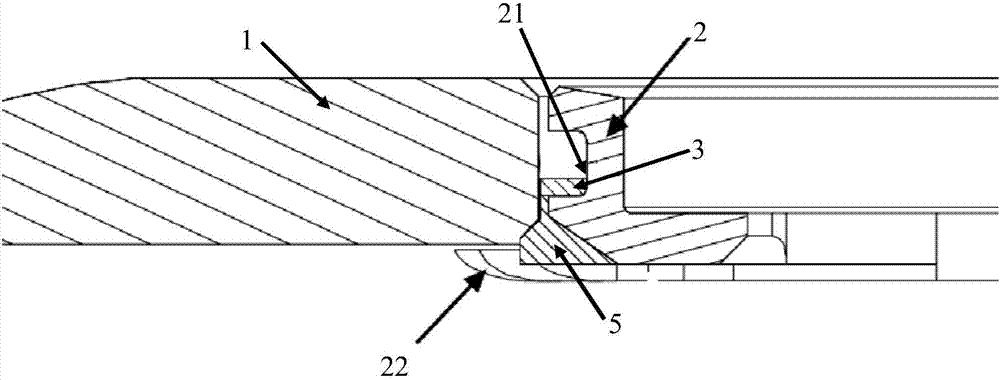

Casing float tool

ActiveUS20140216756A1Lower requirementReduce pressureDrilling rodsFluid removalCasing stringEngineering

A rupture disc assembly and a float tool incorporating the rupture disc assembly is disclosed. The rupture disc assembly may include a rupture disc assembly comprising a rupture disc, an upper tubular portion and a lower tubular portion, and a securing mechanism for holding the rupture disc between the upper and lower tubular portions. A float tool for creating a buoyant chamber in a casing string may include the rupture disc assembly and a sealing device for sealing the lower end of the casing string, the buoyant, sealed chamber may be created there between. In operation, applied fluid pressure causes the rupture disc to move downward. The rupture disc may be shattered by contact with a surface on the lower tubular portion. Full casing internal diameter may be restored in the region where the rupture disc formerly sealed the casing.

Owner:NCS MULTISTAGE

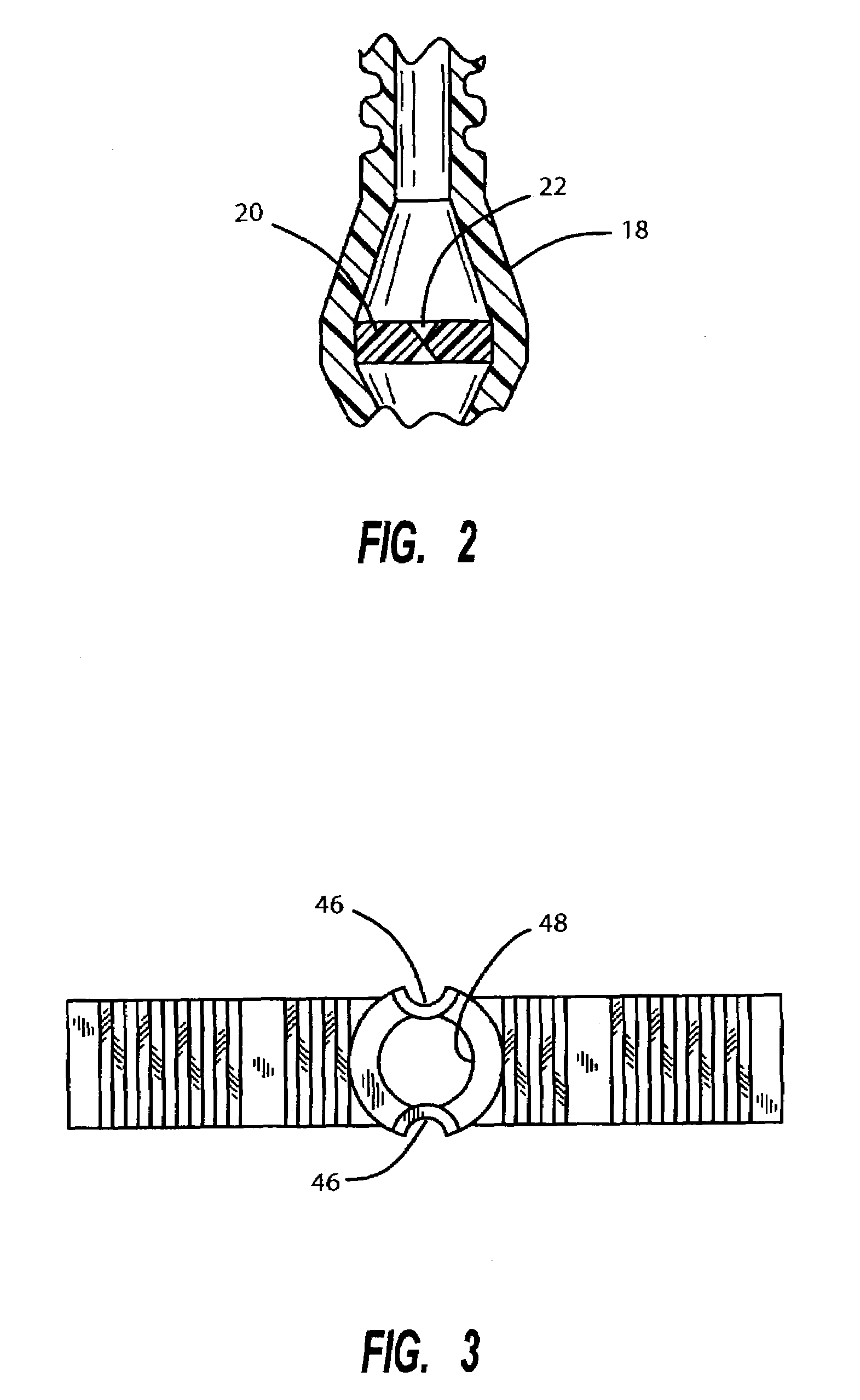

Lead insertion tool for hemostatic introducer system

A tool for protecting a cardiac stimulating lead from damage upon passing through a hemostasis valve of a vascular introducer in the course of an implantation procedure comprises a splittable, peal-away sheath that is rendered sufficiently rigid by a tool dilator or placement of the lead body within the sheath so that the combination can be forced through a self-closing aperture formed through the hemostatic valve member. The use of the tubular sheath in breaching the self-closing aperture shields the lead electrodes and any covering that may be present from becoming distorted as well as from contamination by silicon oil commonly found in vascular introducers having a hemostasis valve.

Owner:CARDIAC PACEMAKERS INC

Casing float tool

A rupture disc assembly and a float tool incorporating the rupture disc assembly is disclosed. The rupture disc assembly may include a rupture disc assembly comprising a rupture disc, an upper tubular portion and a lower tubular portion, and a securing mechanism for holding the rupture disc between the upper and lower tubular portions. A float tool for creating a buoyant chamber in a casing string may include the rupture disc assembly and a sealing device for sealing the lower end of the casing string, the buoyant, sealed chamber may be created there between. In operation, applied fluid pressure causes the rupture disc to move downward. The rupture disc may be shattered by contact with a surface on the lower tubular portion. Full casing internal diameter may be restored in the region where the rupture disc formerly sealed the casing.

Owner:NCS MULTISTAGE

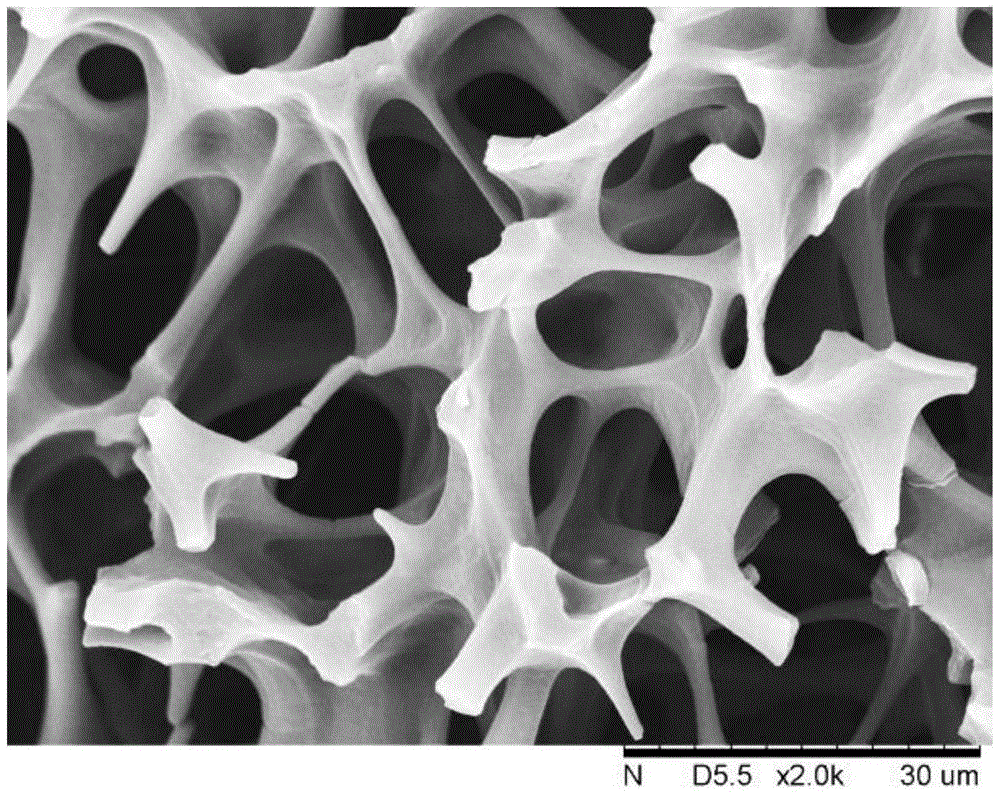

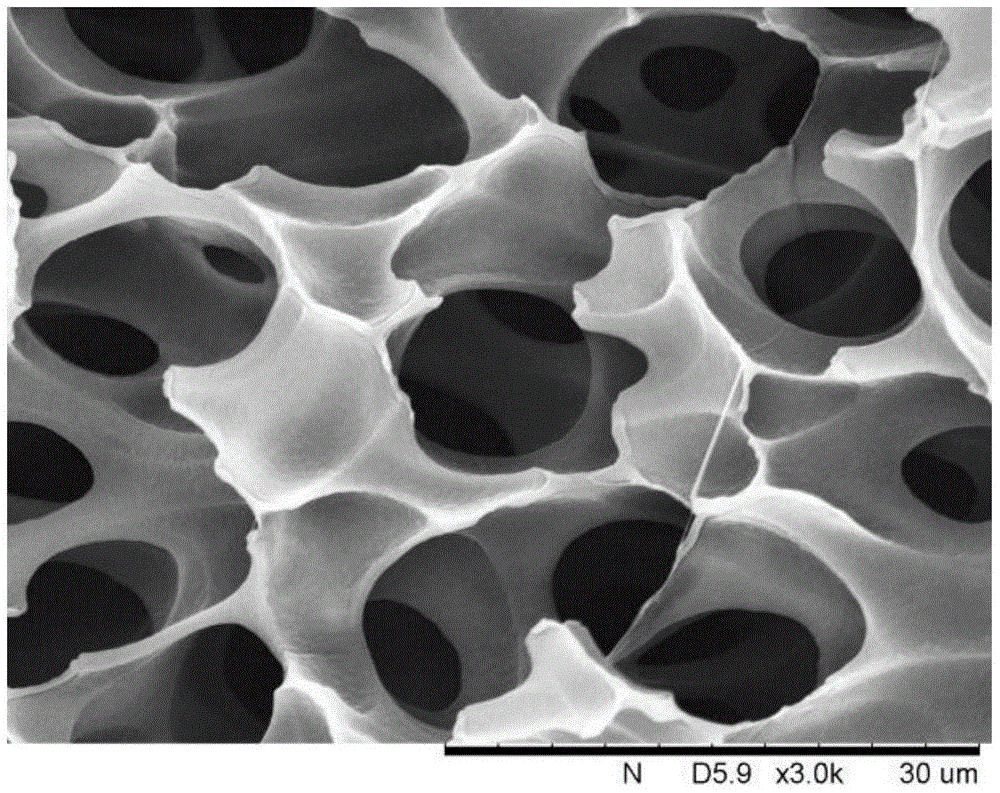

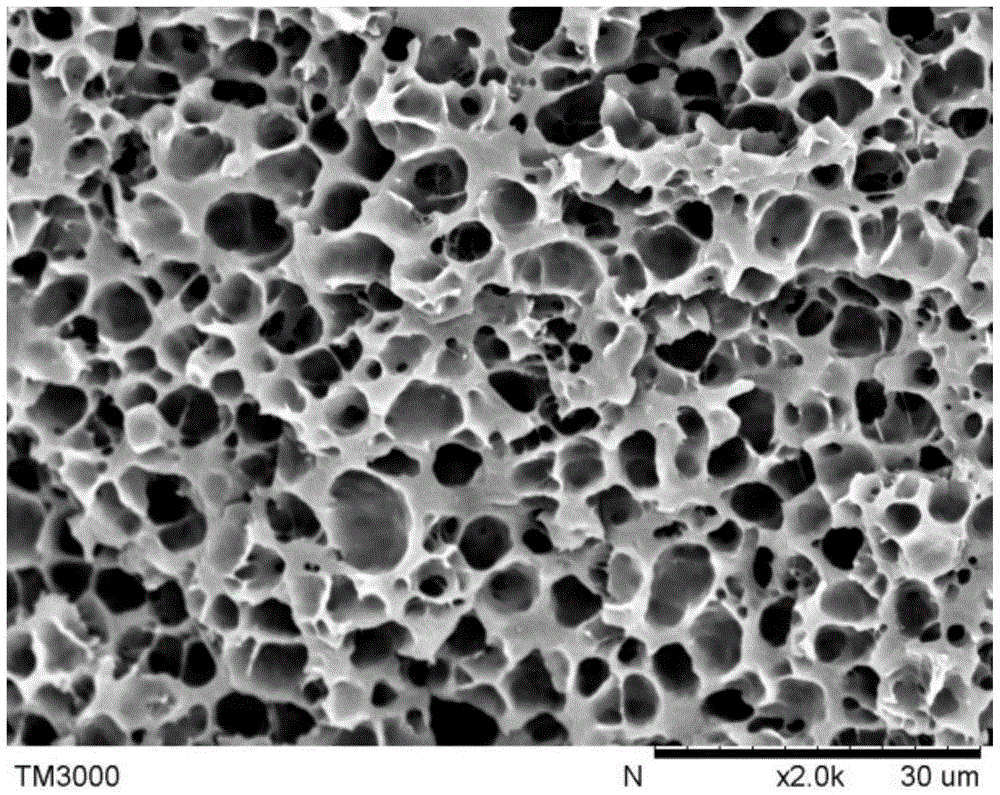

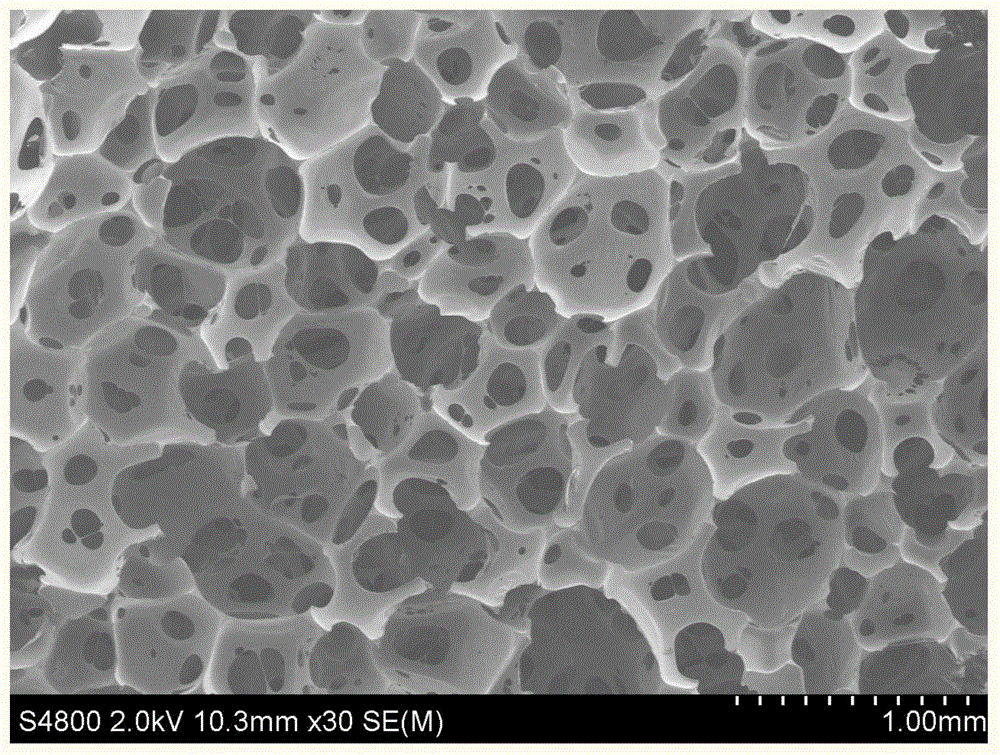

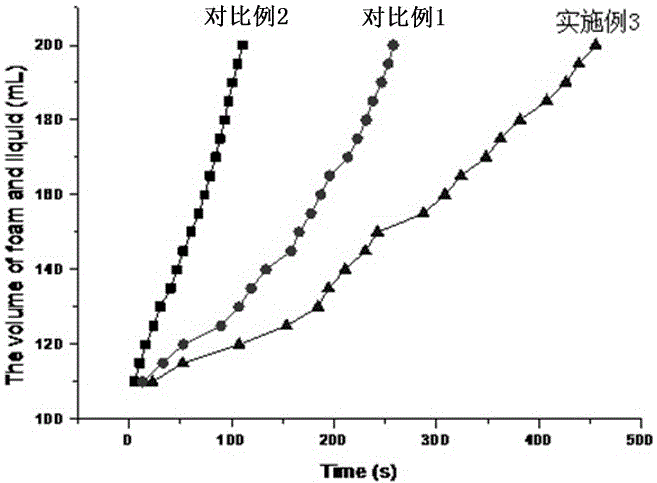

Method for preparing polymeric open cell foam material

The invention relates to a method for preparing a polymeric open cell foam material. By virtue of a supercritical fluid foaming technology, by way of mould foaming, under the premise that other performances of a polymer are not affected, nanoparticles with double effects of a nucleating agent and a cell-opening agent are added, so that the nucleation density and the aperture ratio of the polymer are remarkably improved. By adding a cell-opening auxiliary agent, on the one hand, an effect of a heterogeneous nucleating agent can be exerted to accelerate cells to be nucleated and to increase the cell density; on the other hand, the cell-opening auxiliary agent is a good cell-opening agent which promotes cell walls to break and increases the aperture ratio. The whole process provided by the invention is green and environmental-friendly and free of chemical residues; moreover, the pressure and temperature in a swelling treatment process can be adjusted to prepare the open cell foam material with different cell sizes. The polymer provided by the invention has a lot of open cells and is adjustable in cell size.

Owner:NINGBO UNIV

Temporary well zone isolation

InactiveUS20070251698A1Promote ruptureAvoid flowFluid removalWell/borehole valve arrangementsEngineeringFluid pressure

Disclosed herein is a temporary well isolation device, which is sealingly disposable in downhole tubing, and which has a housing with an axial passage. The temporary well isolation device also has frangible barrier element within the housing, where the frangible barrier element is sealingly engaged in the passage blocking fluid flow through the passage. The frangible barrier element bears a load from fluid pressure. The temporary well isolation device also has a disengagable constraint in contact with a frangible barrier element so as to redirect the load on the frangible barrier element from a first component of the load to a second component of the load, thereby preventing rupture of the frangible barrier element. Also disclosed herein is a method for disintegrating a frangible barrier element disposed in a passage of a temporary well isolation device.

Owner:WEATHERFORD TECH HLDG LLC

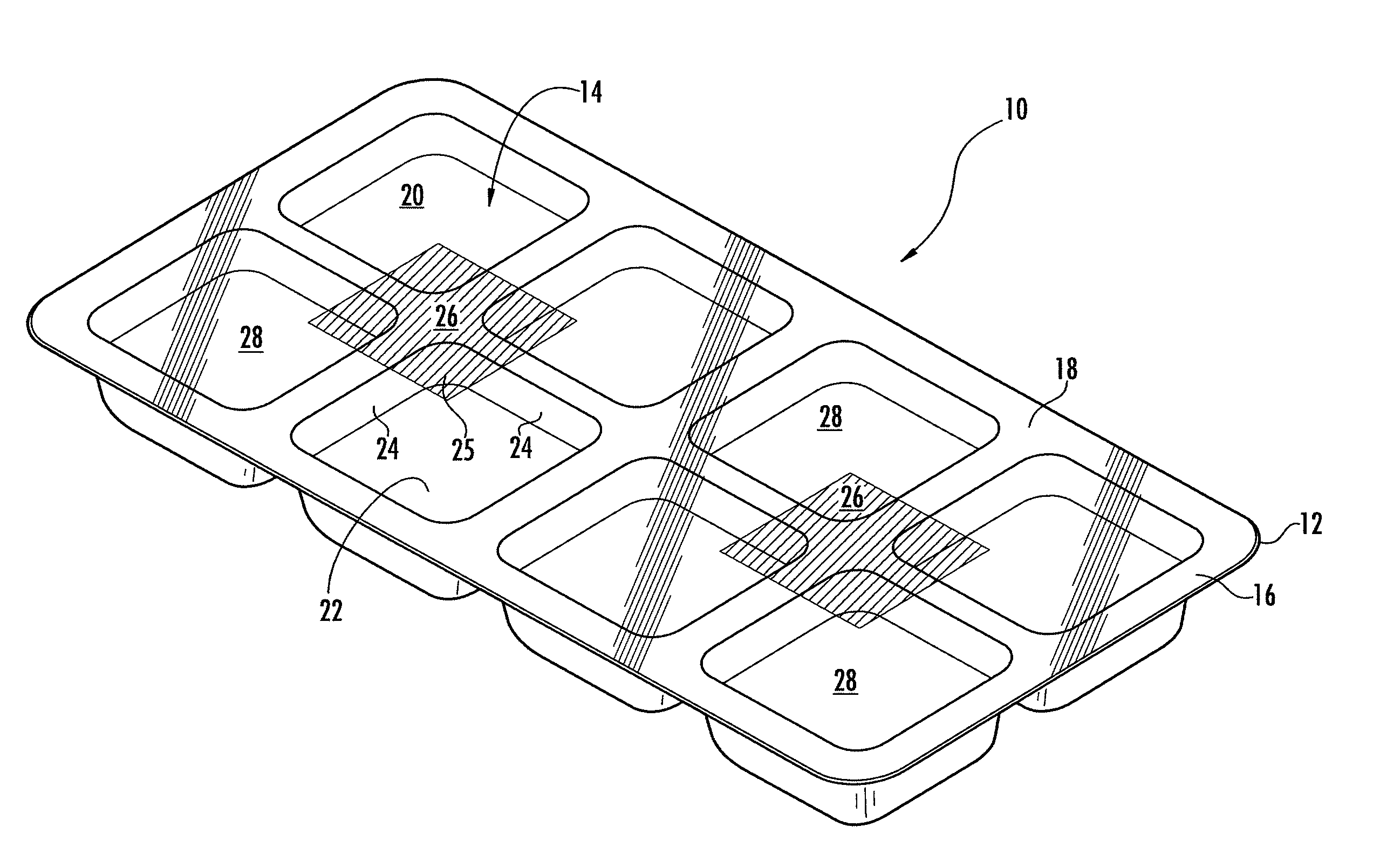

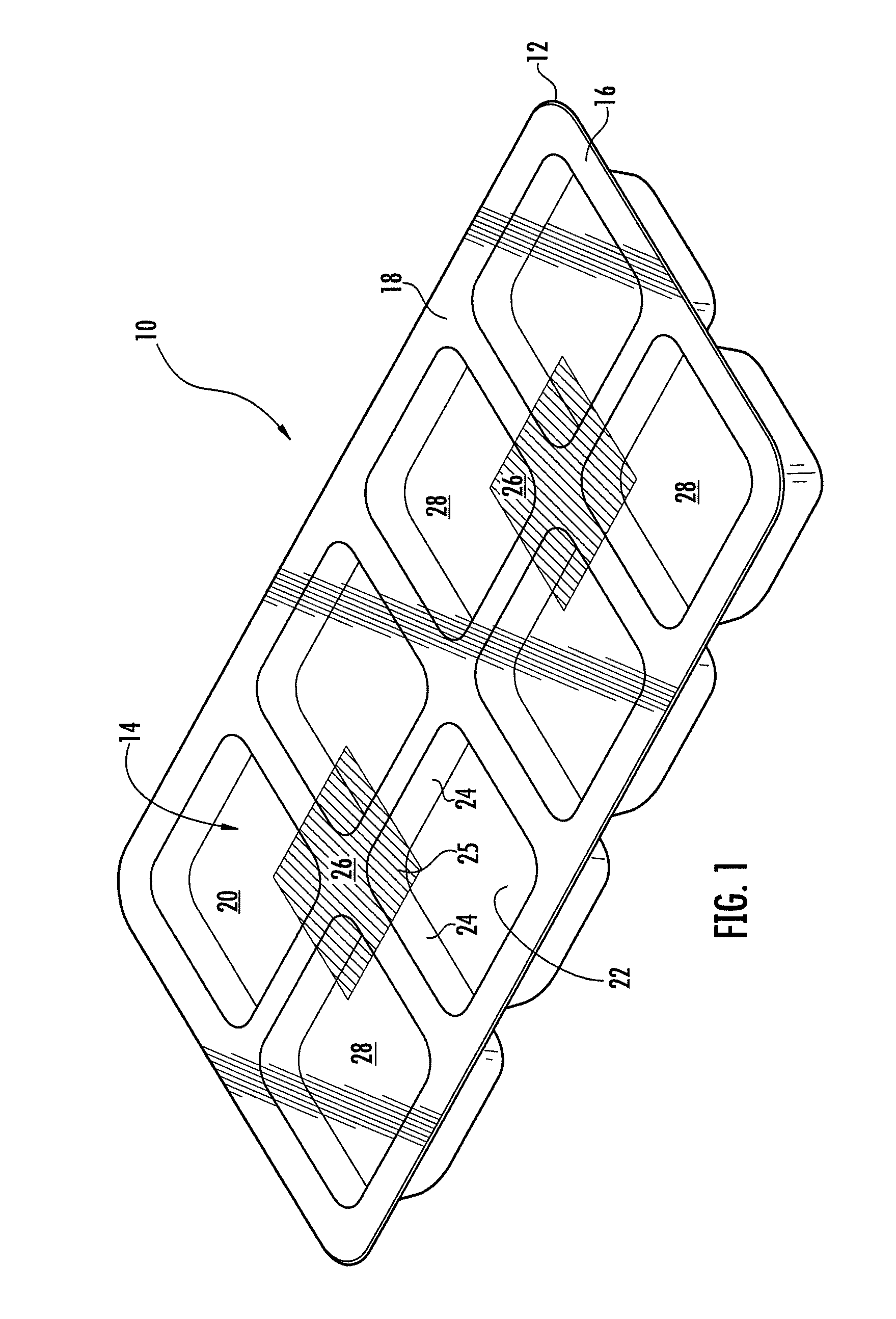

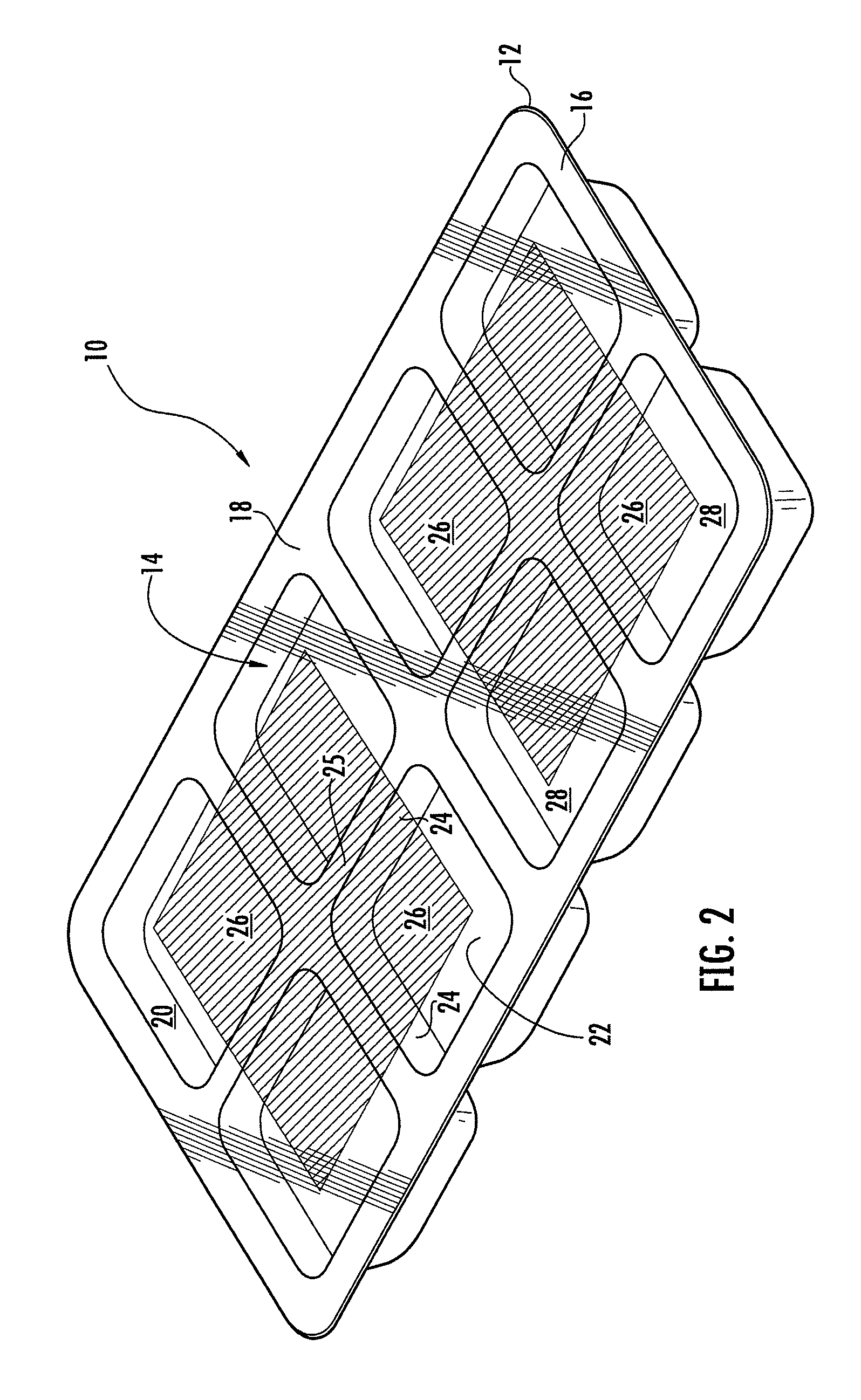

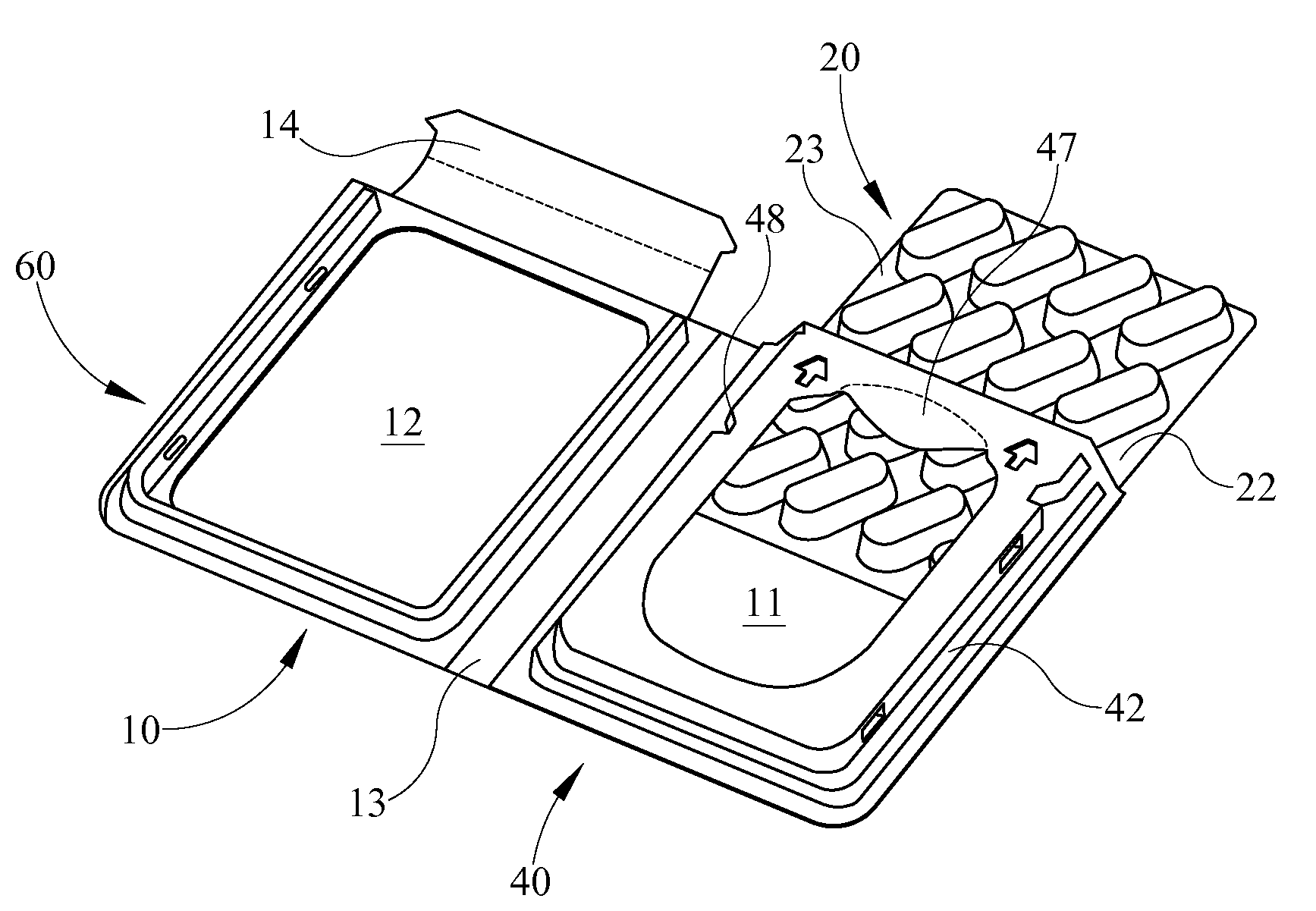

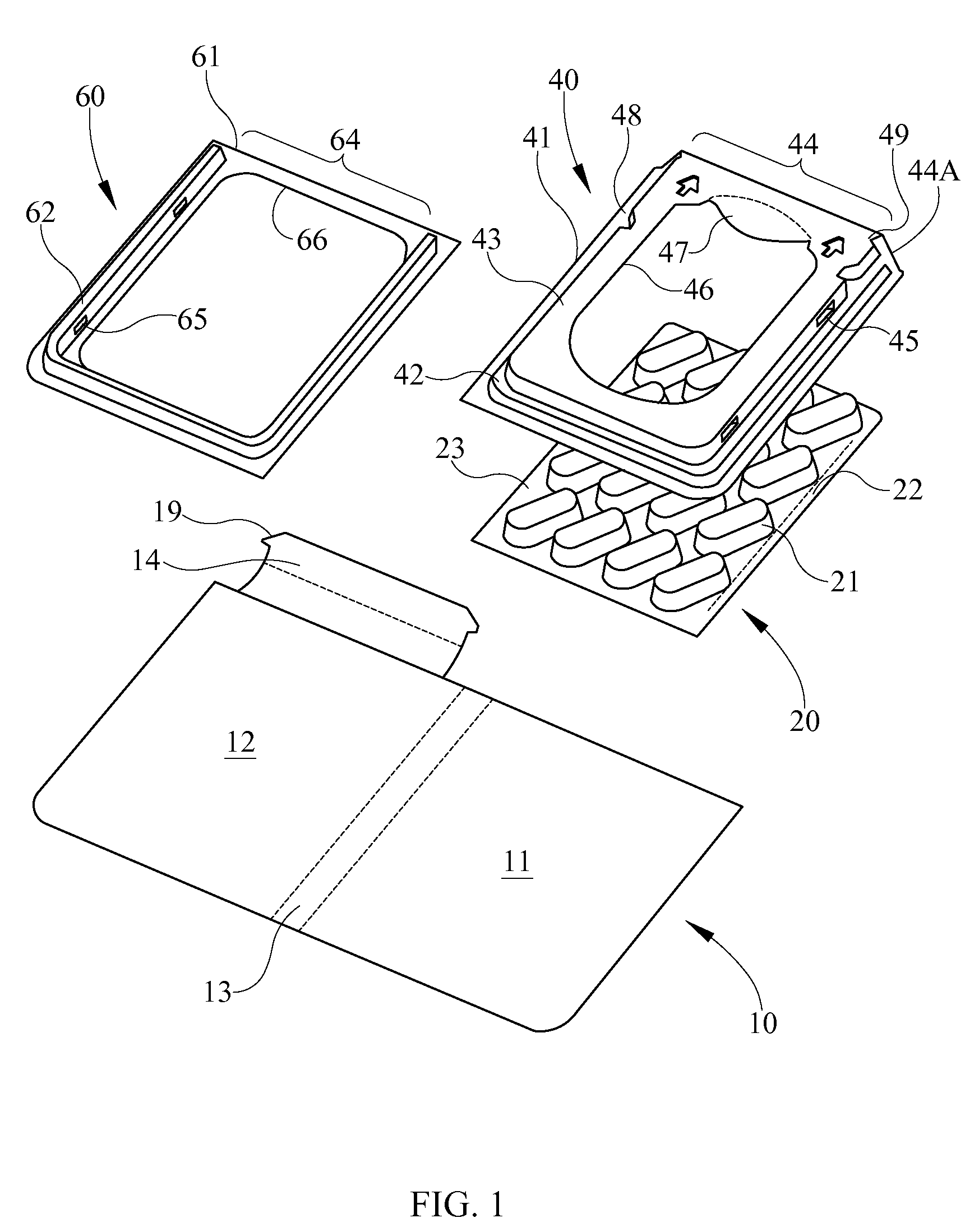

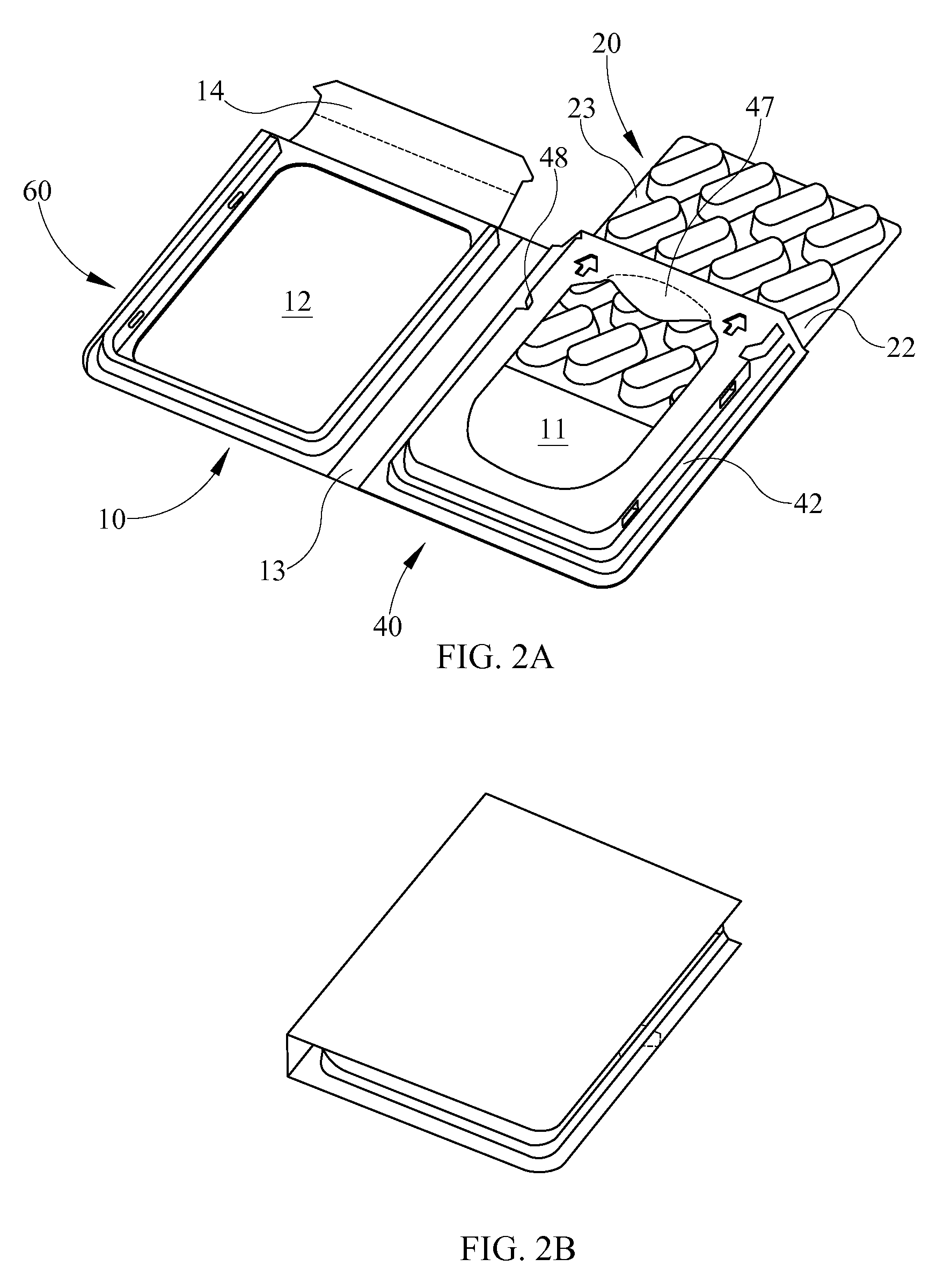

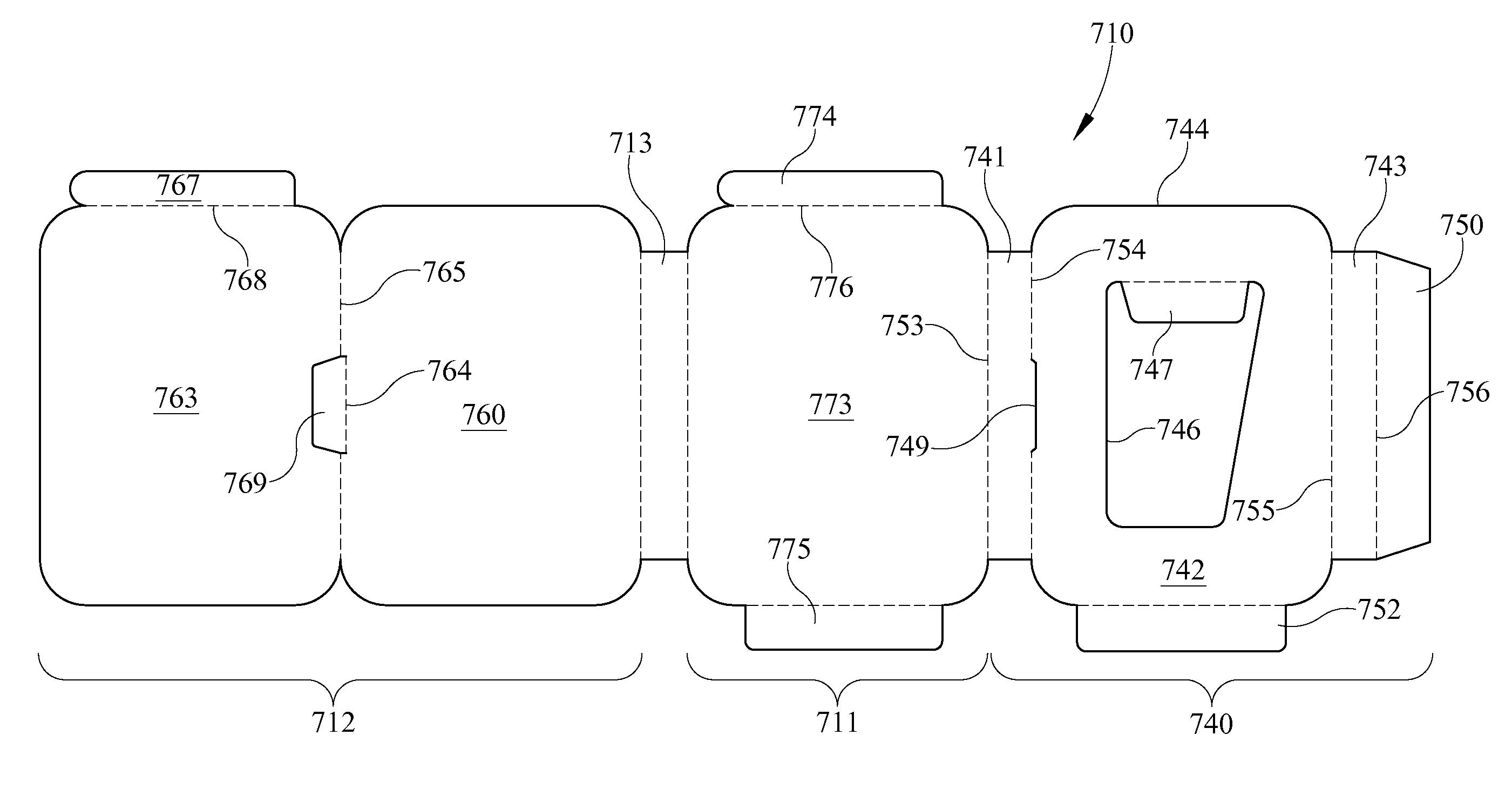

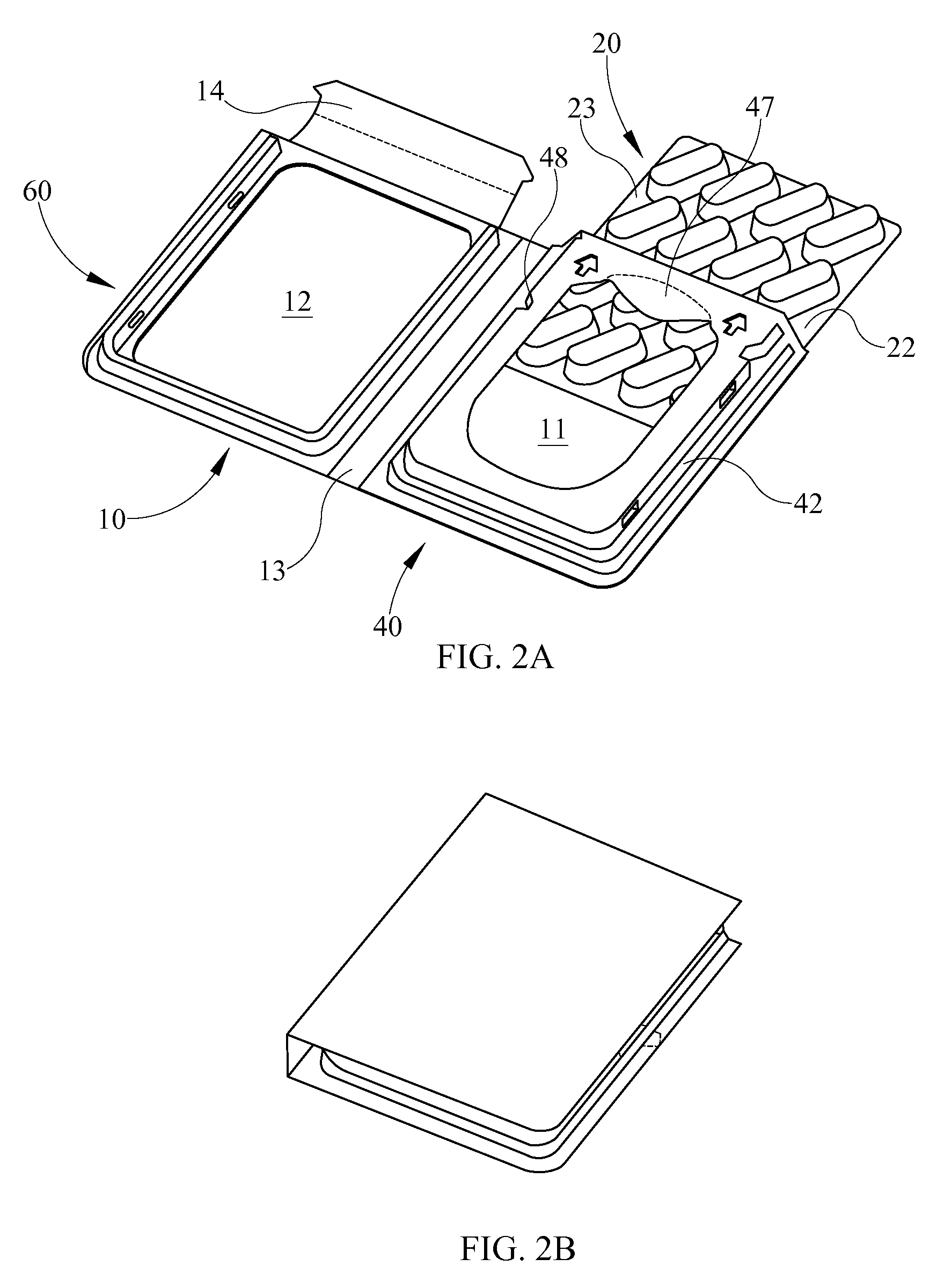

Child resistant blister package

ActiveUS8479921B2Easy to openPromote ruptureSmall article dispensingPharmaceutical containersBlistersBiomedical engineering

Owner:AMCOR FLEXIBLES INC

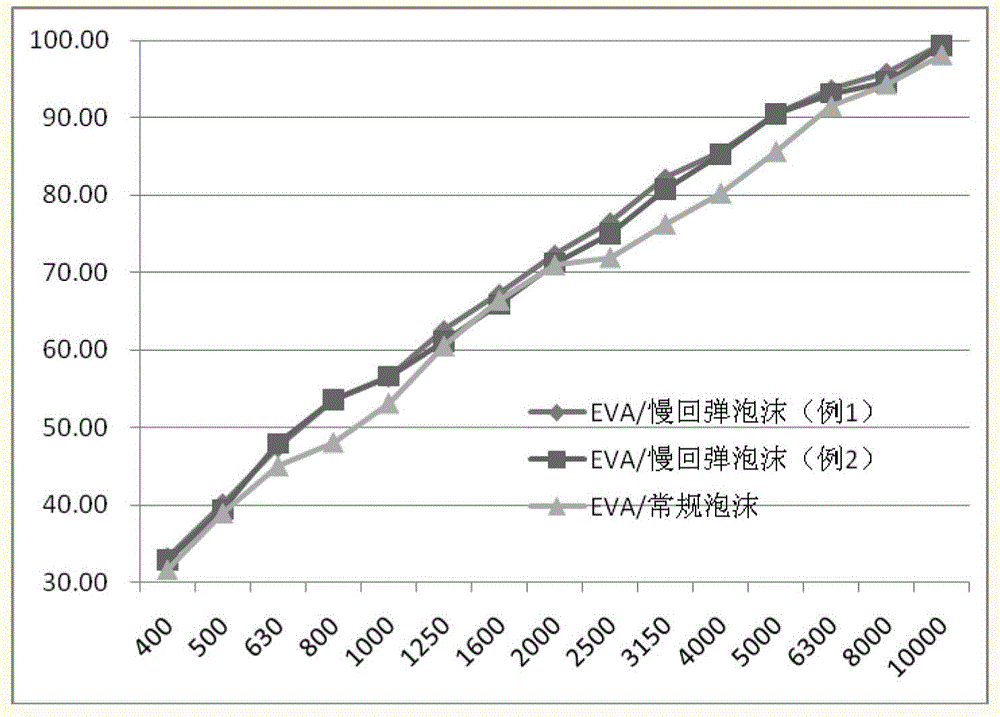

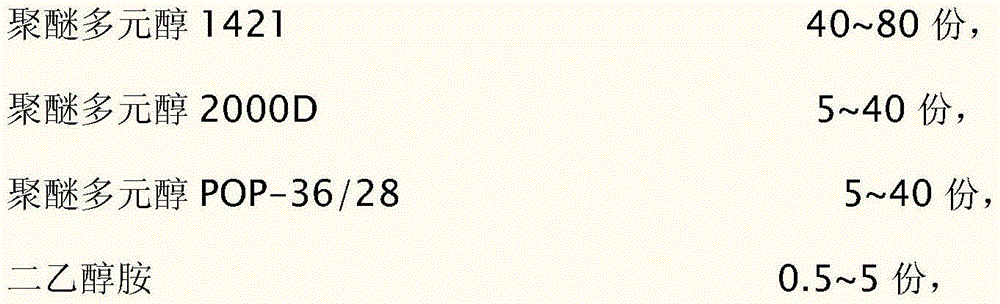

Vehicle-used slowly-springback polyurethane foam composite material

ActiveCN104149455AHigh reactivityGood physical propertiesSynthetic resin layered productsEnvironmental resistanceSilicone oil

The invention discloses a vehicle-used slowly-springback polyurethane foam composite material which is compounded from slowly-springback polyurethane foam and an ethylene-vinyl acetate copolymer. The slowly-springback polyurethane foam is prepared from following components including, by weight, an A material: 40-80 parts of a polyether polyol 1421, 5-40 parts of a polyether polyol 2000D, 5-40 parts of a polyether polyol POP-36 / 28, 0.5-5 parts of diethanolamine, 1-6 parts of water, 0.1-1.5 parts of a catalyst EF-600, 0.1-0.5 parts of a catalyst ZF-10 and 1-6 parts of a silicone oil L-580; a B material: 40-80 parts of a modified MDI. During preparation of the slowly-springback polyurethane foam, a weight usage amount ratio of the A material to the B material is 100:40-80. The vehicle-used slowly-springback polyurethane foam is high in reaction activity, is low in toxicity, is environmental-protective, is high in damp loss factor, is high in sound-insulation performance and is free of addition of a foam-forming agent.

Owner:NINGBO TUOPU GROUP CO LTD

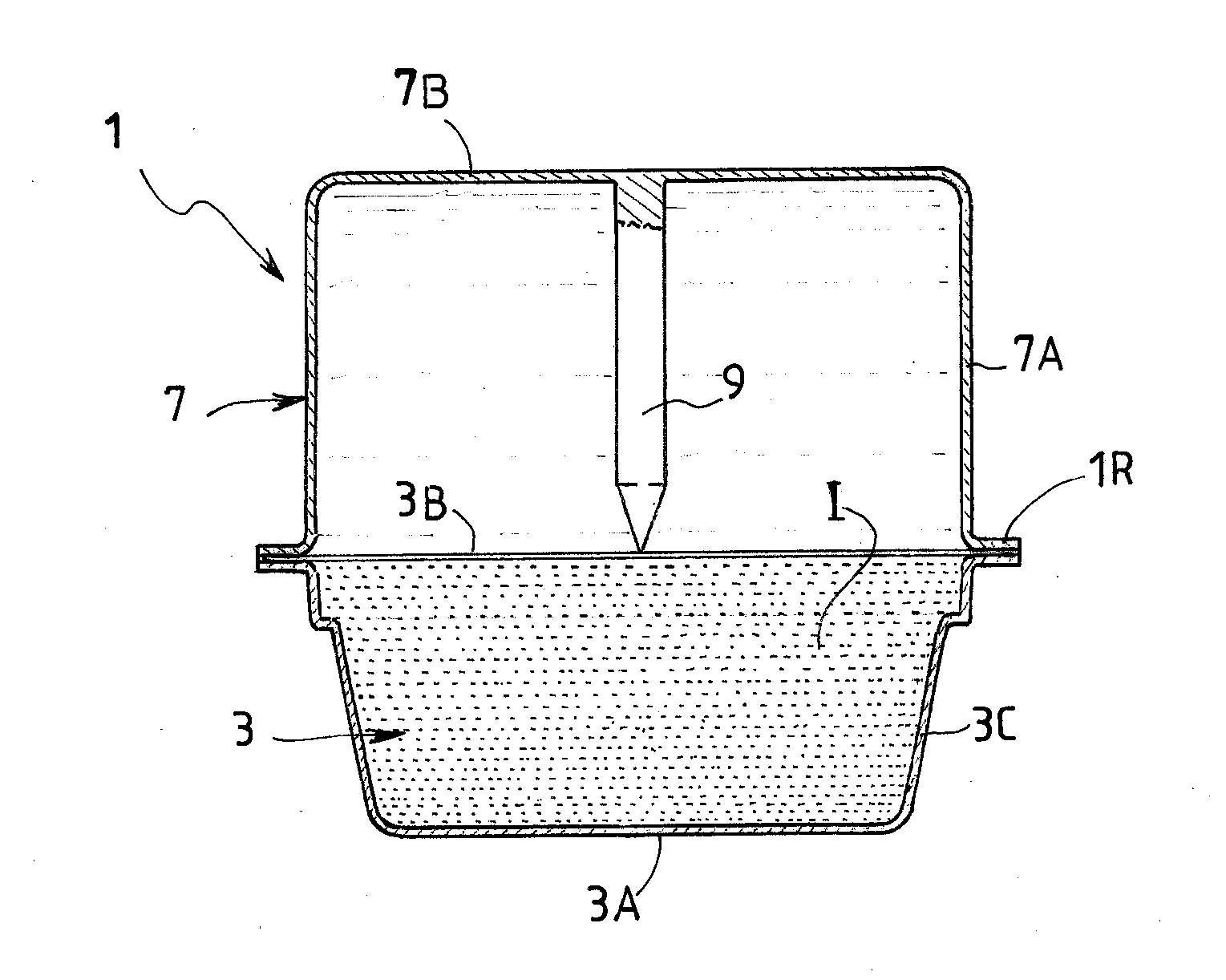

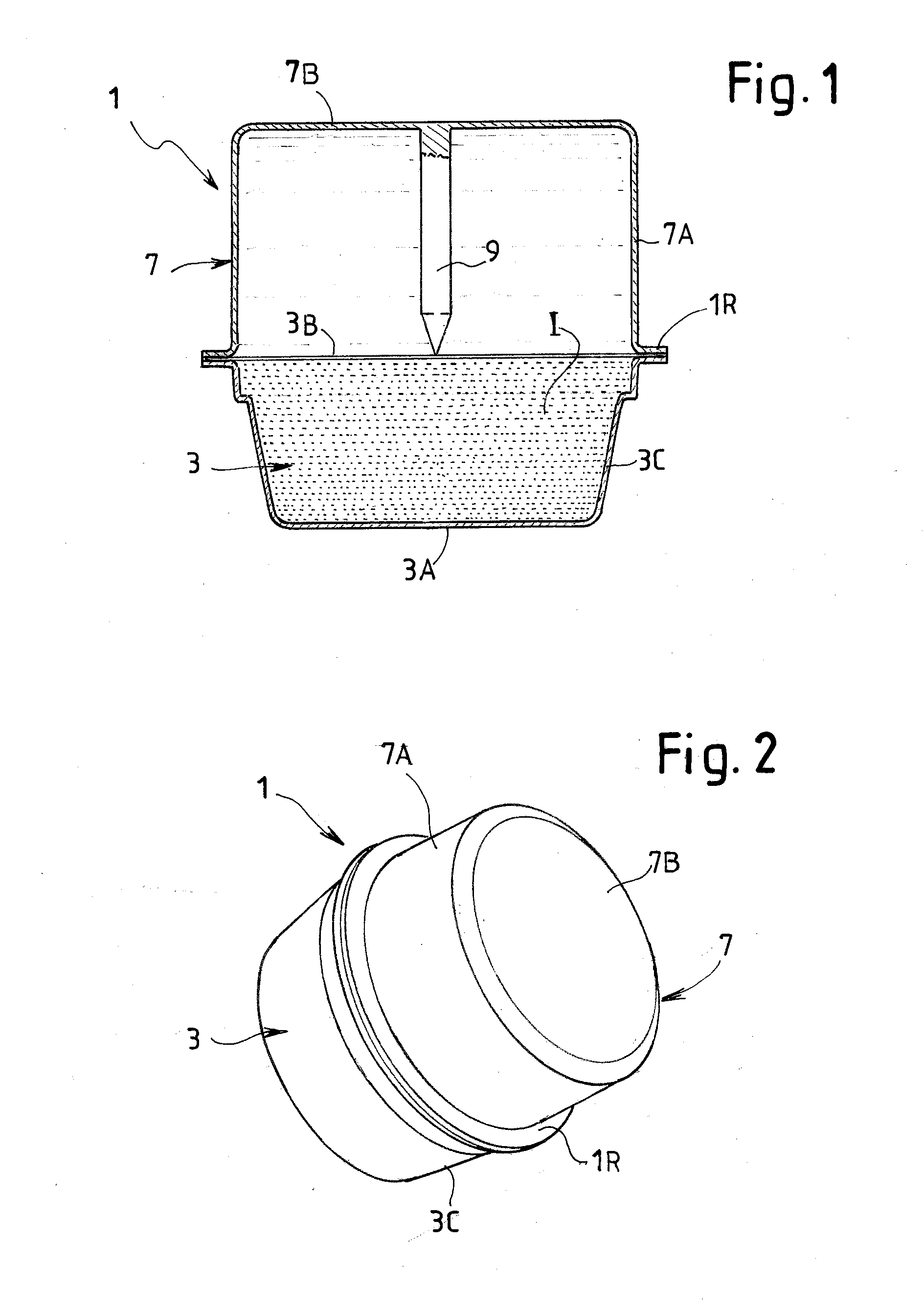

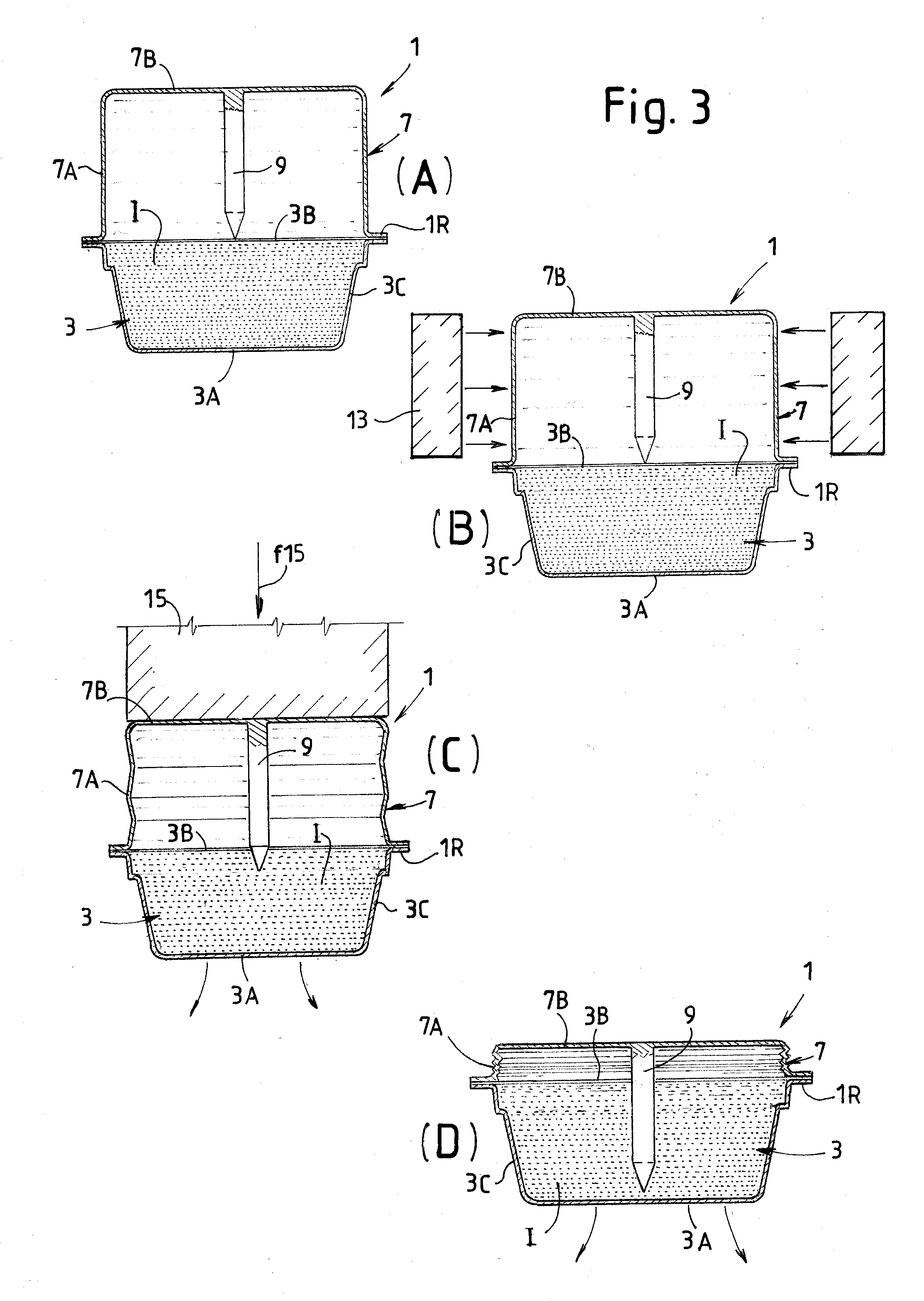

Capsule for the preparation of beverages, device and method

InactiveUS20150203285A1Reduce thicknessLower the volumeReady-for-oven doughsBeverage vesselsAdditive ingredientBiomedical engineering

A capsule (1) for preparing a beverage is disclosed. The capsule comprises: an ingredient receptacle (3), which contains at least one ingredient (I) for the preparation of a beverage, and a sealed liquid container (7) containing an amount of liquid sufficient for preparing a beverage by means of said at least one ingredient (I). A liquid-tight separating wall (3B) is arranged between the liquid container (7) and the ingredient receptacle (3). The separating wall (3B) is arranged to be ruptured to cause the liquid to contact the at least one ingredient and produce a beverage.

Owner:KONINKLJIJKE PHILIPS NV

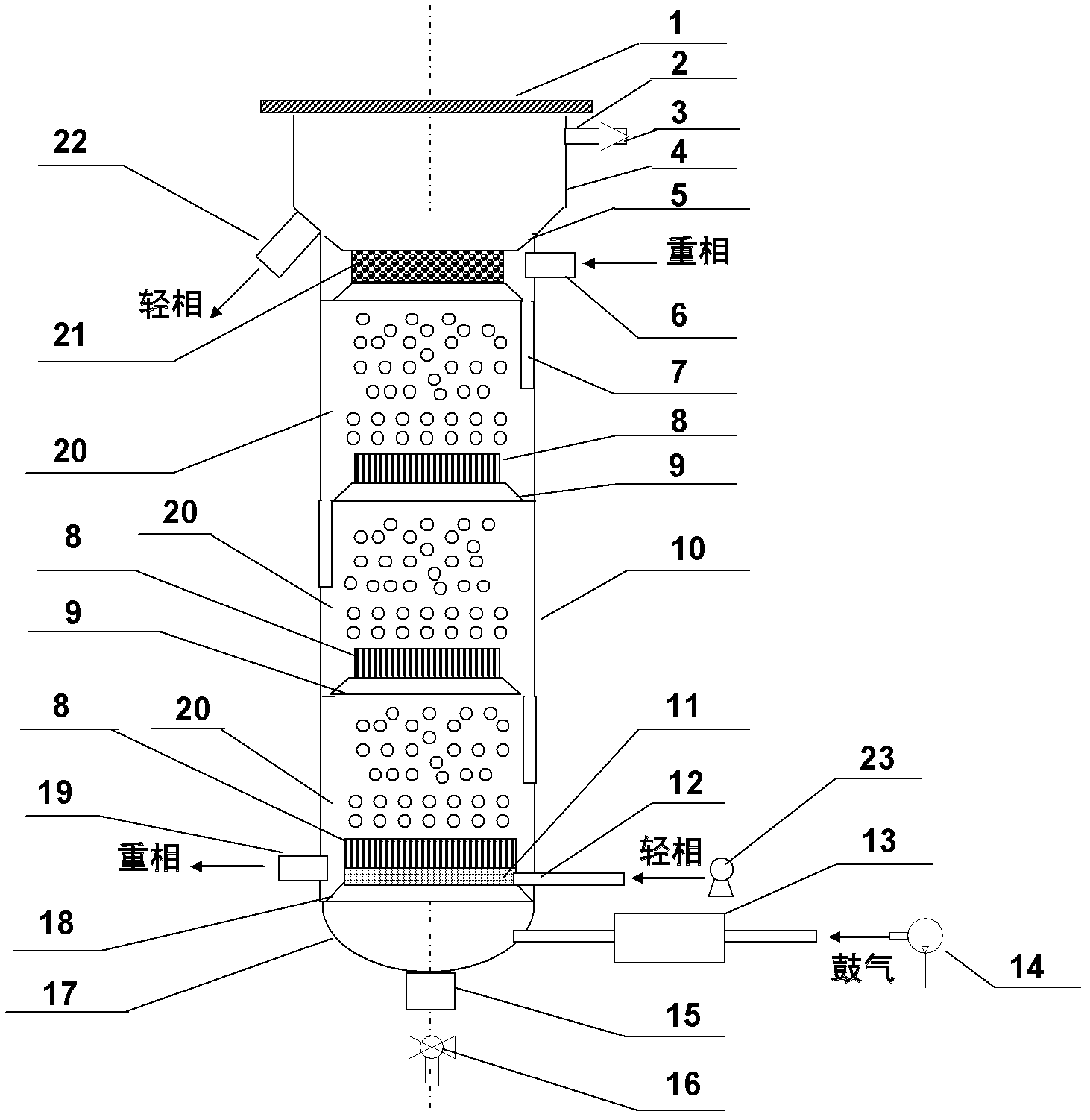

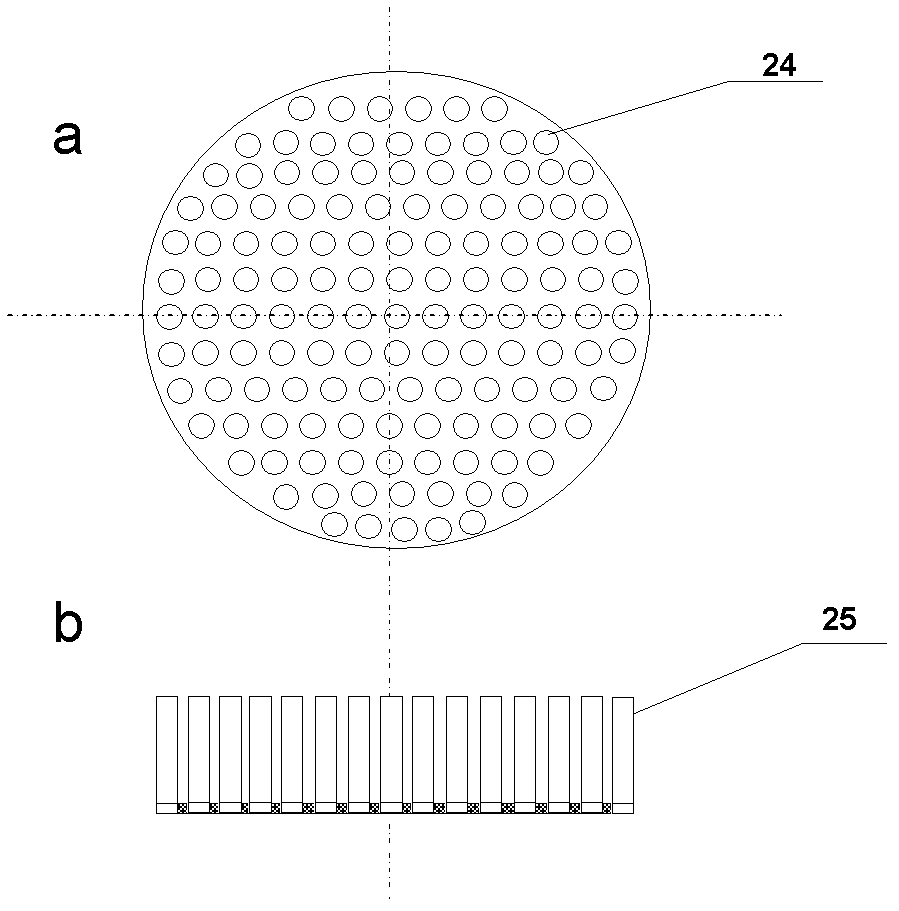

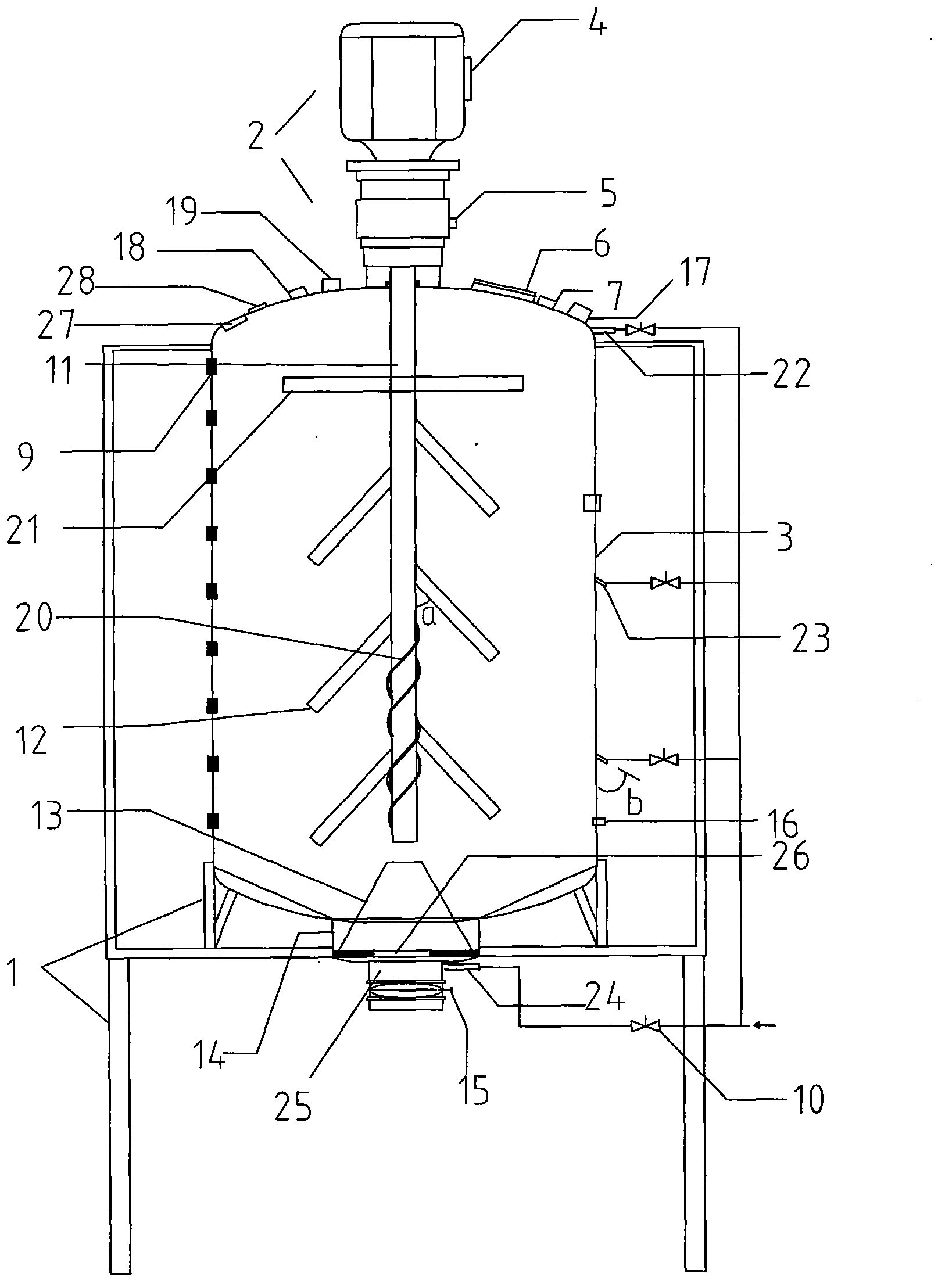

Large phase ratio liquid-liquid two-phase continuous extraction apparatus

ActiveCN102512848APrevent backmixingImproved stage efficiency for unit mass transfer heightsLiquid solutions solvent extractionPhase ratioEngineering

A large phase ratio liquid-liquid two-phase continuous extraction apparatus belongs to the field of liquid-liquid extraction and separation. The apparatus contains a tower body, a gas buffer chamber, a liquid film aggregation device, liquid film dispersers, a liquid film distributor, an air-pressure chamber and the like. The liquid film dispersers and the liquid film distributor can be combined together to realize dispersion of small-volume organic phase by the use of tiny bubbles, thus solving the problem that it is not easy to fully disperse small-volume organic phase by a traditional stirring mode. The phase ratio of a light phase to a heavy phase flowing upstream in the tower body can be adjusted by the interlayer gap of the liquid film distributor. The light phase and the heavy phase can be operated by counter current under the condition of super-large phase ratio. A liquid film disperser and a bubble connection cap are arranged at intervals in the tower body, so as to realize repeated coagulation and dispersion of rising bubbles and achieve high stage efficiency of height of mass transfer unit. A liquid film aggregation device on the top of the tower can be used for bubble coagulation and demulsification and is suitable for extraction operation of an easily-emulsified system. The apparatus provided by the invention is applicable to continuous countercurrent operation under the condition of multi-stage series connection.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

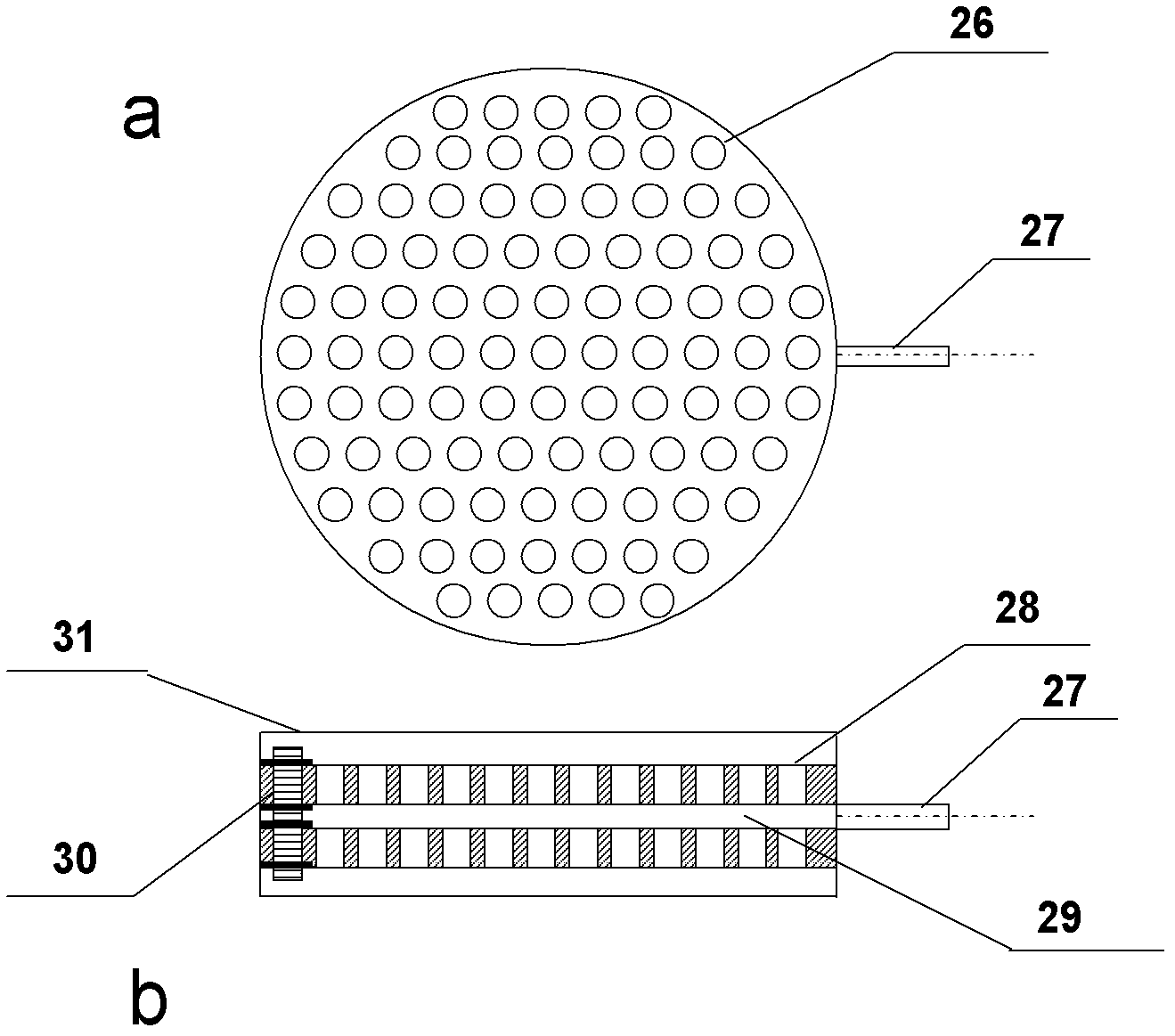

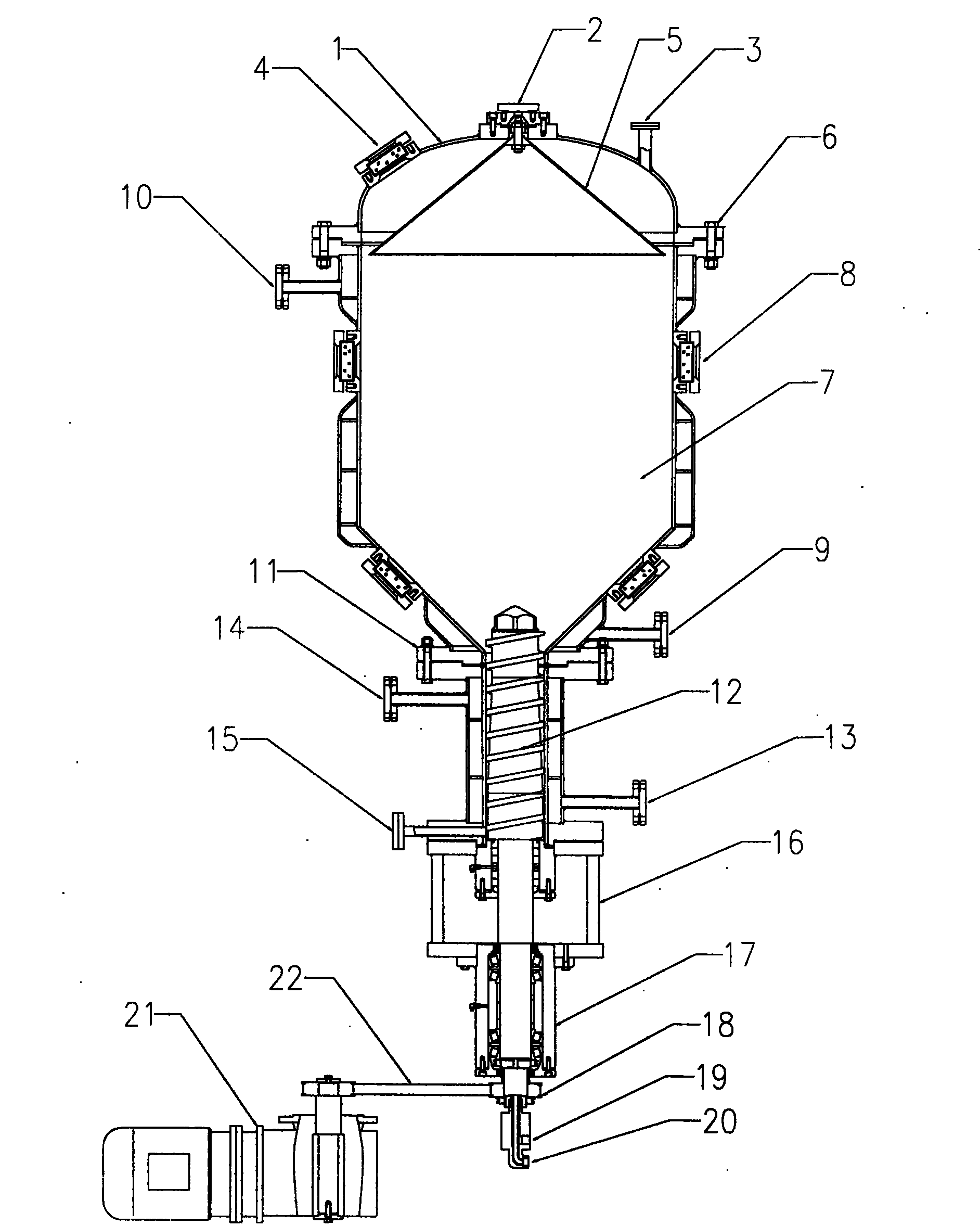

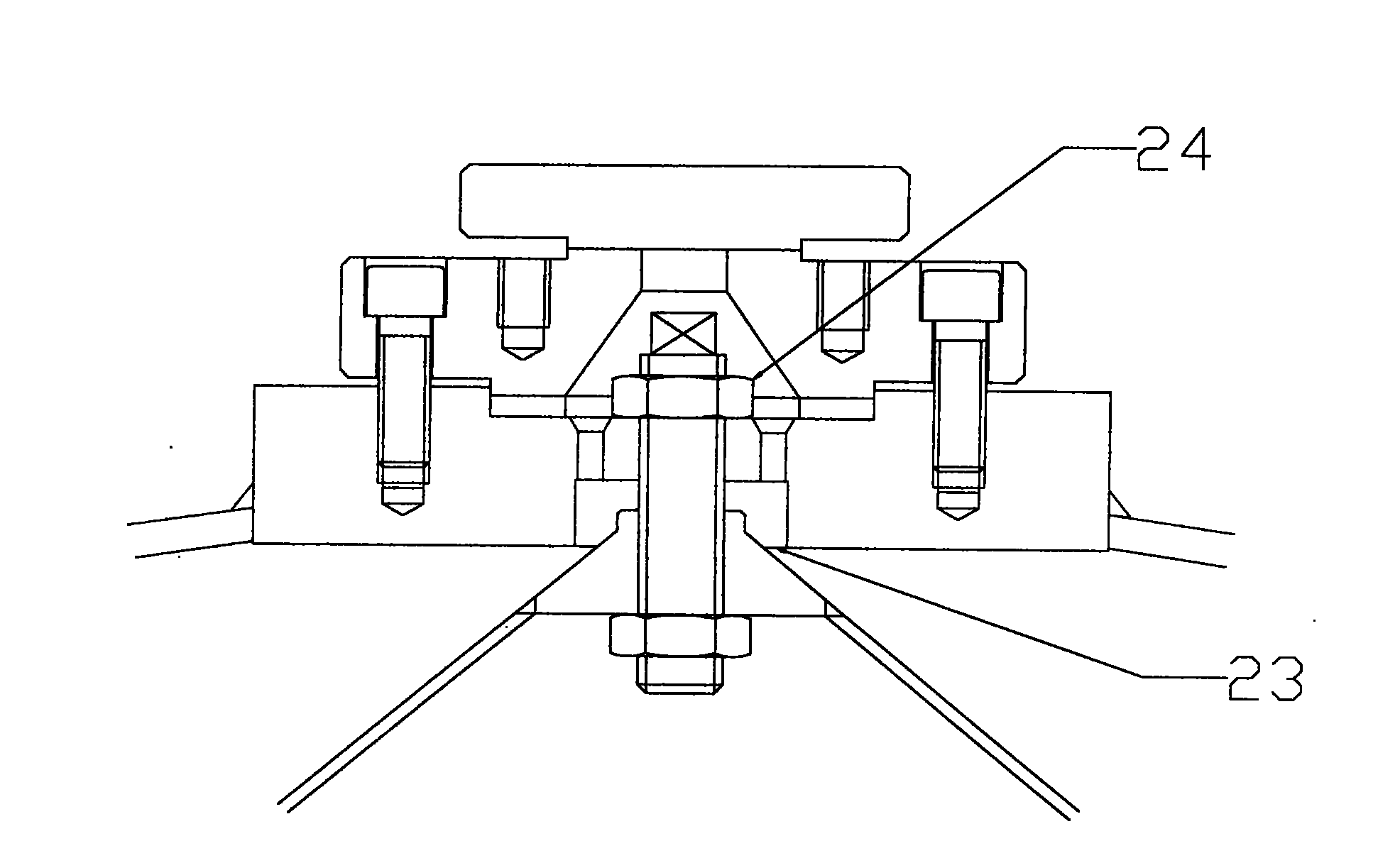

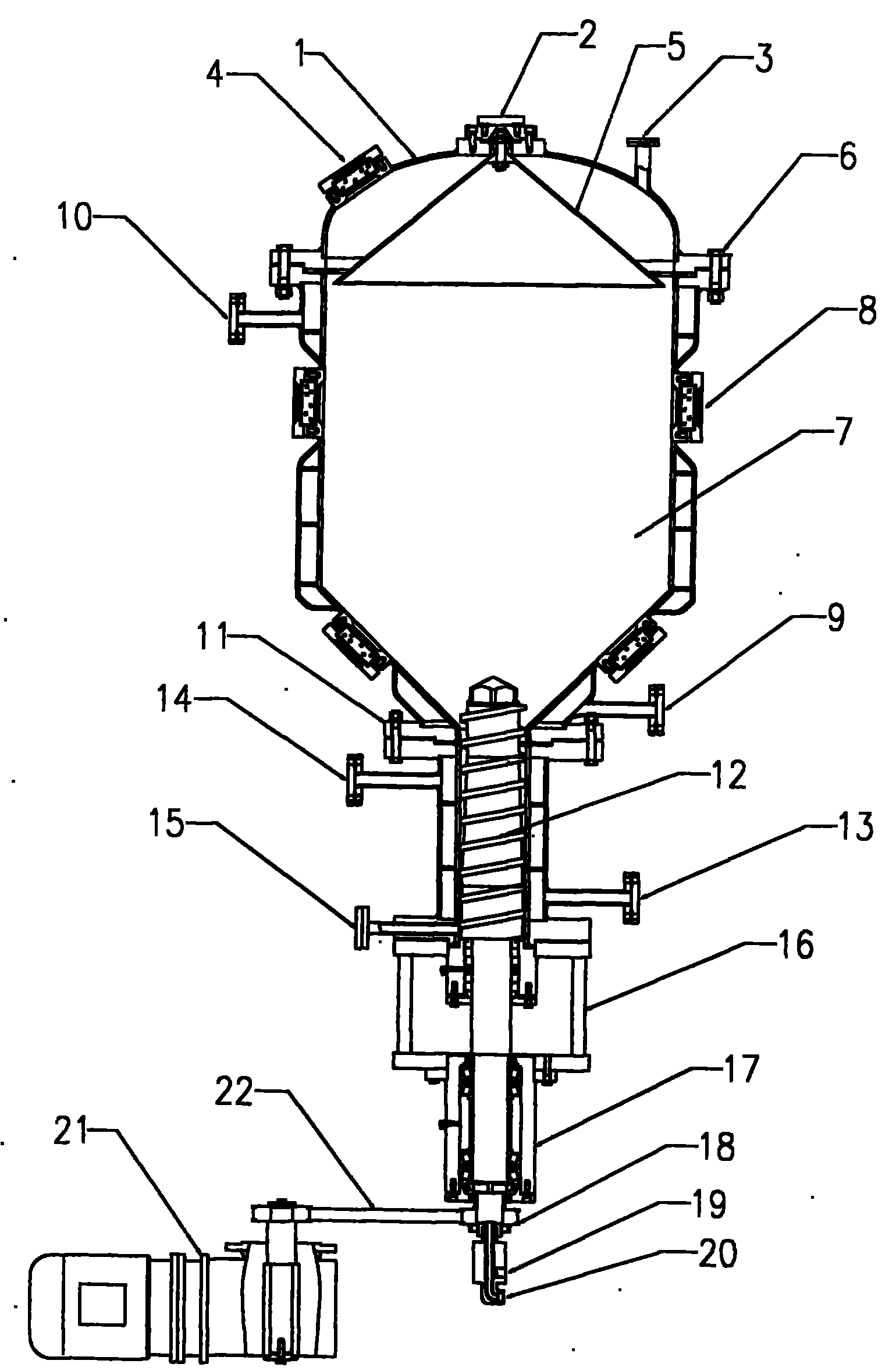

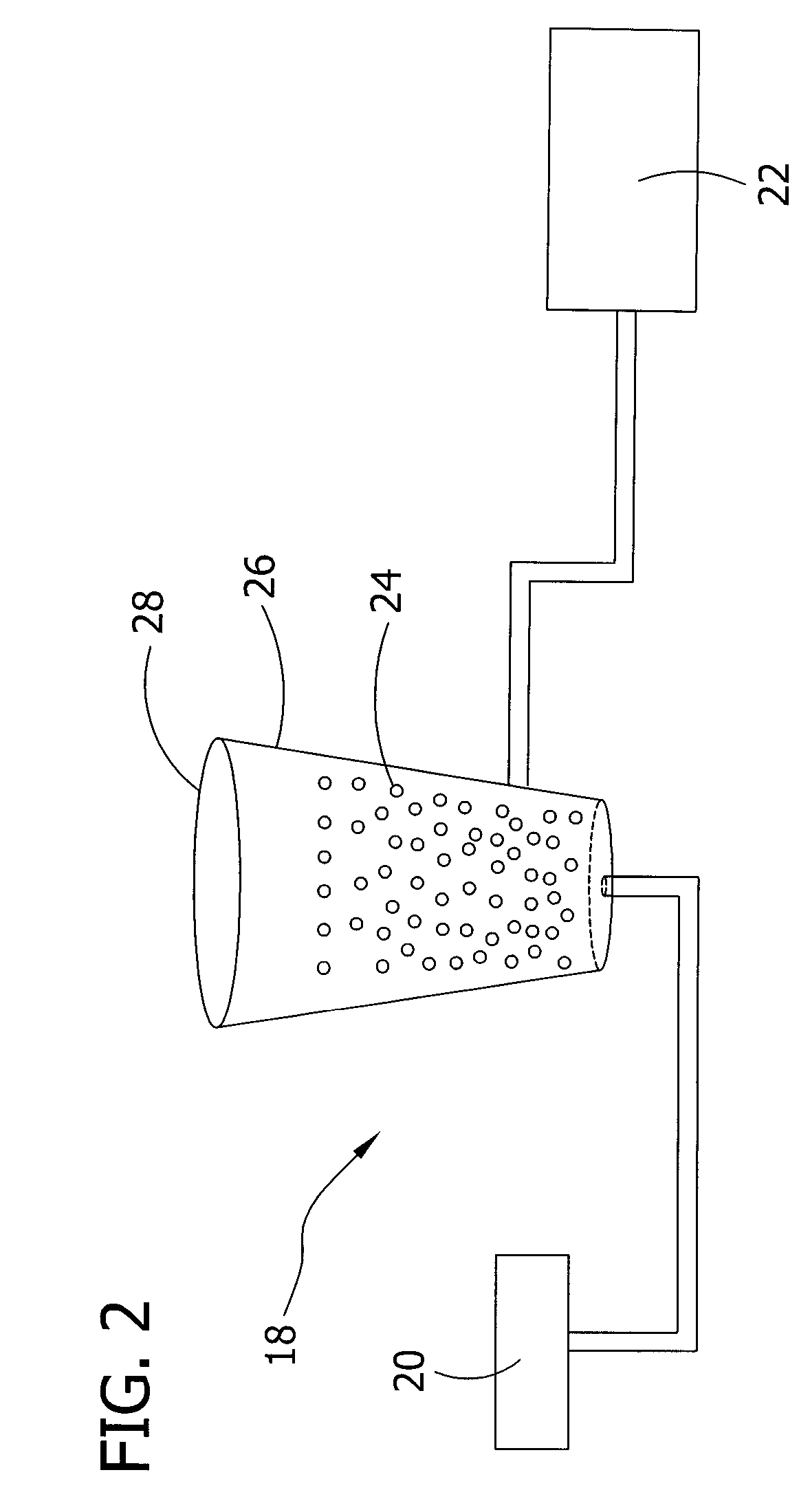

Multiple-magnetron type large-capacity microwave-assisted extraction machine and microwave-assisted extraction method thereof

InactiveCN103505902AHeating evenlyHigh extraction rateEnergy based chemical/physical/physico-chemical processesSolid solvent extractionEngineeringElectromagnetic field

The invention discloses a multiple-magnetron type large-capacity microwave-assisted extraction machine and a microwave-assisted extraction method thereof, belonging to the field of biological raw material extraction equipment and an extraction method. The multiple-magnetron type large-capacity microwave-assisted extraction machine comprises a rack, a transmission device, a microwave tank, a microwave device, an air-entrapping device, a rotor device, a discharging device and a control device, wherein a plurality of magnetron installing holes uniformly and equidistantly distributed are formed in the wall of the microwave tank; the microwave device comprises a plurality of high-frequency magnetrons which are uniformly and equidistantly arranged on the wall of the microwave tank, and the high-frequency magnetrons are connected with an external power source; the air-entrapping device comprises a plurality of compressed air inlets formed in the wall of the microwave tank, a compressed air input pipeline and a plurality of electromagnetic valves; the rotor device comprises a rotating shaft and a plurality of stirring wings which are fixed on the rotating shaft and form certain crossing angles with the rotating shaft. The multiple-magnetron type large-capacity microwave-assisted extraction machine has the advantages that feed liquid in the microwave tank continuously runs and interchanges, an extractive is uniformly subjected to the action of an electromagnetic field to be heated, the extraction rate is increased, and the extraction time is shortened.

Owner:永州中农银杏开发有限责任公司

Production method for preparing bamboo dissolving pulp by utilizing natural-color unbleached bamboo pulp in a modifying way

ActiveCN101736637AShort processShorten the production cyclePulp de-wateringPulp beating/refining methodsDissolving pulpAlpha-Cellulose

The invention discloses a production method for preparing bamboo dissolving pulp by utilizing natural-color unbleached bamboo pulp in a modifying way, overcoming the defect of poor reaction property of products prepared by an alkali refining method. The production method comprises the following steps of: concentrating and dewatering dredged natural-color unbleached bamboo pulp, and delivering to a double-helix roller type pulp grinder; continuously dewatering in the pulp grinder, and adding liquid medicine; continuously concentrating and kneading the pulp and mixing the pulp with the liquid medicine in the pulp grinder; then delivering the pulp to a stewing machine; and after stewing is completed, conducting subsequent procedures including washing and bleaching till paper making. The invention reduces the preparation cost, enhances the quality of products and increases resource supplying sources; in addition, the bamboo pulp prepared by the production method not only has higher content of alpha-celluloses, but also has good reaction property, and is suitable for filament and staple fibers.

Owner:YIBIN GRACE GROUP CO LTD

Method for extracting bamboo polysaccharides

The invention relates to methods for efficiently extracting and separating bamboo polysaccharides, belonging to the technical field of plant effective ingredient separated preparation. The invention discloses a method for extracting bamboo polysaccharides. The method comprises the following sequential steps: (1) pretreating bamboos, which serve as raw materials, by adopting a steam explosion method, so as to obtain a bamboo material subjected to steam explosion treatment; (2) carrying out water extraction on the bamboo material subjected to steam explosion treatment, so as to obtain a bamboo water extract; (3) carrying out concentrating refinement on the bamboo water extract by adopting any way as follows: a way I, namely carrying out vacuum concentration on the bamboo water extract, and then, carrying out alcohol precipitation treatment, thereby obtaining a bamboo polysaccharide product; a way II, namely carrying out concentrating refinement on the bamboo water extract by directly adopting a membrane separation method, thereby obtaining the bamboo polysaccharide product. According to the steam explosion method in the step (1), the bamboos are subjected to instantaneous explosion after the bamboos are subjected to pressure maintaining for 30-240 seconds under the pressure of 1.4-3.0MPa, and the explosion time T is not shorter than 0.005075 second and not longer than 0.008752 second.

Owner:ZHEJIANG UNIV

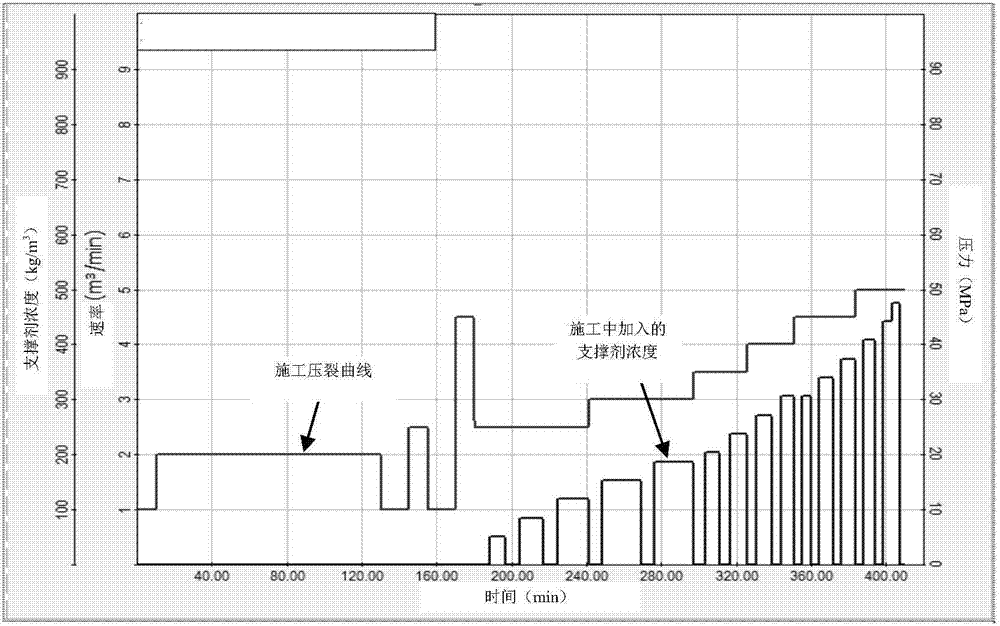

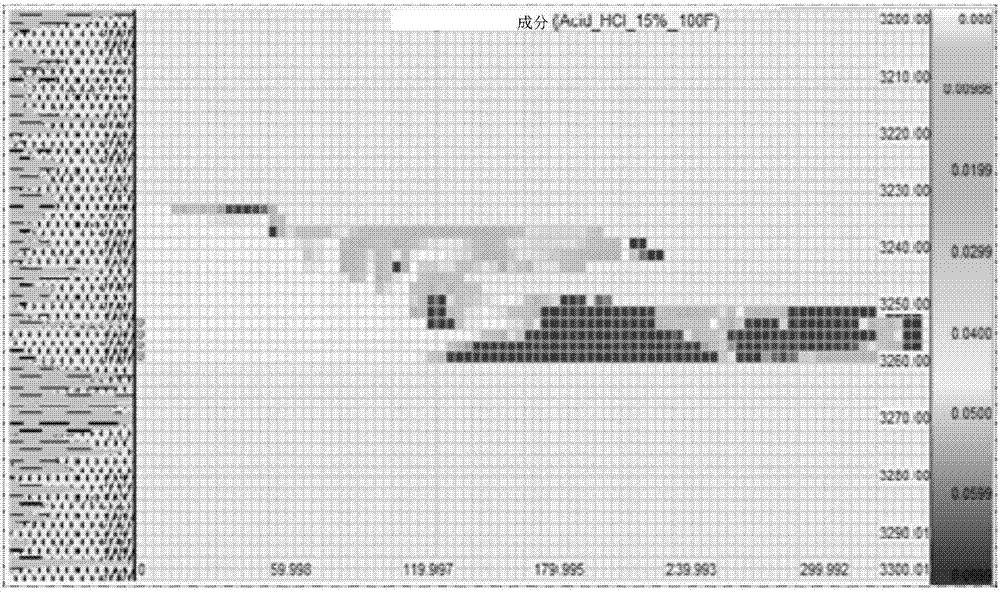

Acid injection fracturing method

The invention provides an acid injection fracturing method. The method comprises the steps that at the front liquid fissure forming stage, an alternative acid injection mode is adopted for fissure fracturing transformation, the alternative acid injection mode comprises the step that 1-5 levels of slugs are alternatively injected into fissures, and each level of slugs are composed of acid liquid and displacing liquid which are injected in sequence. According to the acid injection fracturing method, by combining with technical advantages of fracturing and acidification, through optimization of an alternative injection technology, the relation range of the acid liquid in a fissure fracturing system is enlarged to the greatest extent, and the porosity and permeability of fissure wall rock areimproved; a micro-fissure and branch fissure extension system is expanded and extended, increase of fissure complexity degree and transformation volume is promoted, and the duration time of keeping the flow diversion capacity of the fracturing system is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for continuously and rapidly defoaming high-viscosity fluid

The invention relates to a device for continuously and rapidly defoaming high-viscosity fluid. The upper part of the device is a vacuum defoaming tank; a vacuum suction opening is arranged on the vacuum defoaming tank, and an umbrella-shaped piece is arranged in the vacuum defoaming tank; the upper part of the umbrella-shaped piece is narrower than the lower part and is connected with a feeding inlet; the position where the upper part of the umbrella-shaped piece is connected with the feeding inlet is provided with a slit and a slit adjusting device; the fluid of different viscosity and flow rate, which enters the vacuum defoaming tank, can form continuous films of uniform thickness on the umbrella-shaped piece by adjusting the width of the slit; the lower part of the device is a screw extruder which is provided with a motor and a driving device; the motor rotates to drive a screw to rotate so as to continuously output the material in the vacuum defoaming tank; in addition, a stirring device can be arranged in the vacuum defoaming tank according to the need, and the stirring device can be driven by the screw at the bottom or other driving force on the top of the vacuum defoaming tank. The device can be used for continuously and rapidly defoaming the high-viscosity fluid, particularly the high-viscosity fluid whose characteristic can change along with time, temperature and other factors.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

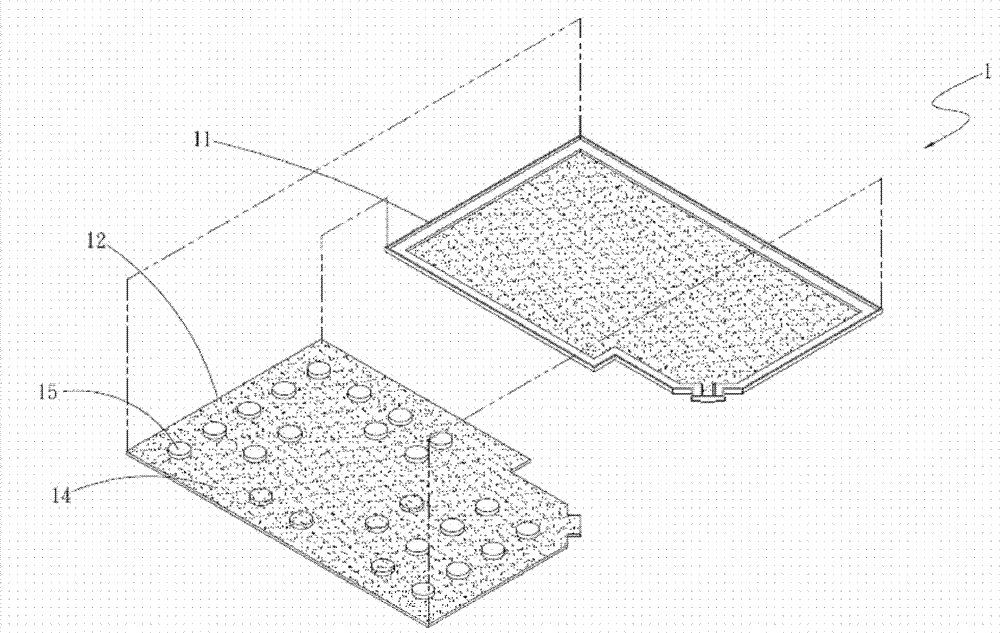

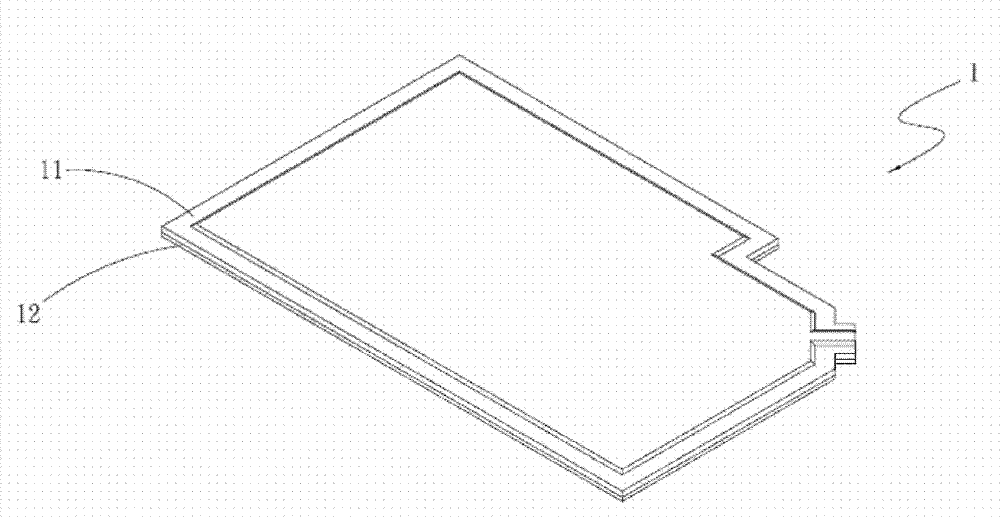

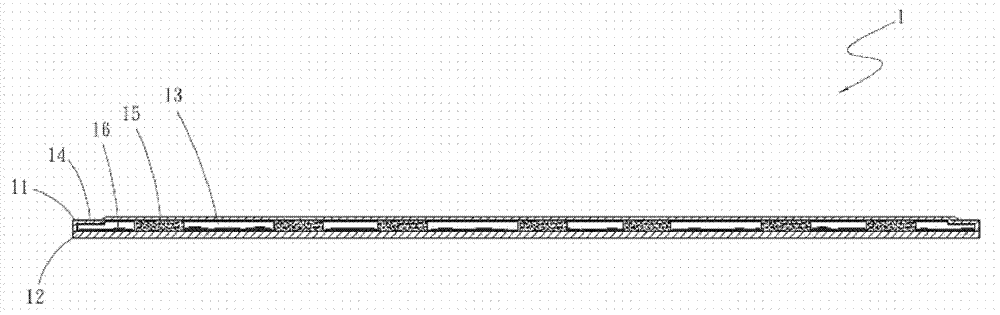

Temperature equalization plate structure and manufacturing method thereof

ActiveCN102956583AImprove heat fatigueImprove the problem of cracking at the joint boundary caused by thermal fatigueSemiconductor/solid-state device detailsSolid-state devicesThermal fatigueEqualization

The invention relates to a temperature equalization plate structure and a manufacturing method o temperature equalization plate structure. The temperature equalization plate structure comprises a body with a metal plate body and a ceramic plate body, the metal plate body and the ceramic plate body are covered together correspondingly to jointly define a chamber, the chamber is provided with a capillary structure as well as a support structure and an operating fluid, the metal plate body and the ceramic plate body are combined and then jointly combined with the capillary structure and the support structure through a welding or directly copper-cladding method, and the temperature equalization plate and the manufacturing method provided by the invention are used for solving the problem of cracking of a jointing interface between a temperature equalization plate and a heating source due to thermal fatigue.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Method for extracting allicin by using microwave-ultrasonic wave

InactiveCN103436564AImprove dissolution efficiencyImprove the extraction effectOrganic chemistryOrganic compound preparationFreeze-dryingAllium sativum

The invention relates to a method for extracting allicin by using microwave-ultrasonic wave. The method comprises the following steps of: pretreating garlic to obtain serous fluid; adding an ethanol solution, adjusting pH, and carrying out enzymatic method conversion; extracting by using a microwave-ultrasonic wave assisted exactor; carrying out membrane separation; freeze-drying to obtain the allicin. According to the method, the garlic is used as a raw material, and the superposition effect of the microwave and the ultrasonic wave is fully utilized, so that the method has the advantages of simple process, low energy consumption, high extraction rate and high purity and is easy for industrial production.

Owner:NANJING ZELANG AGRI DEV

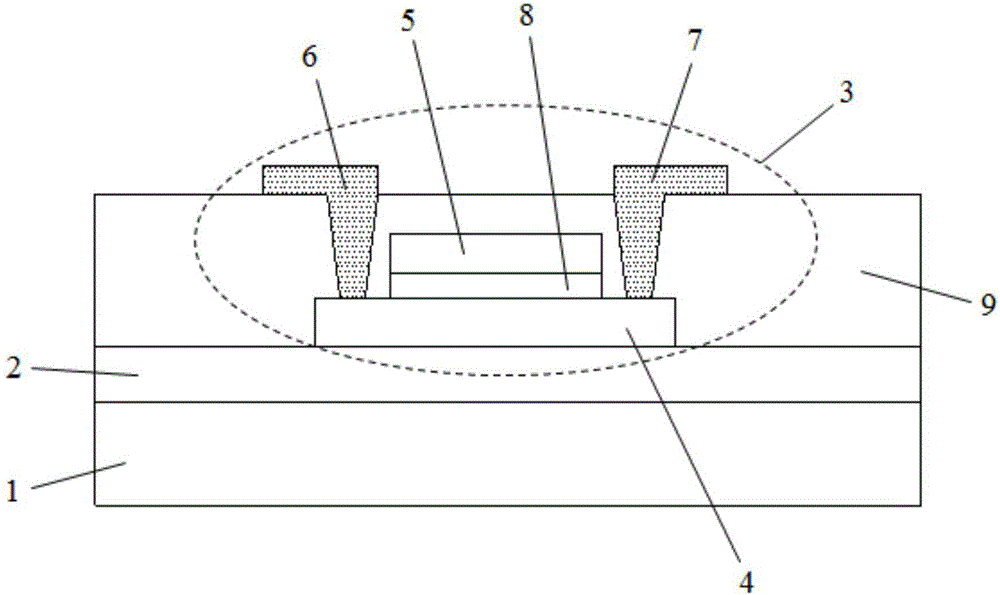

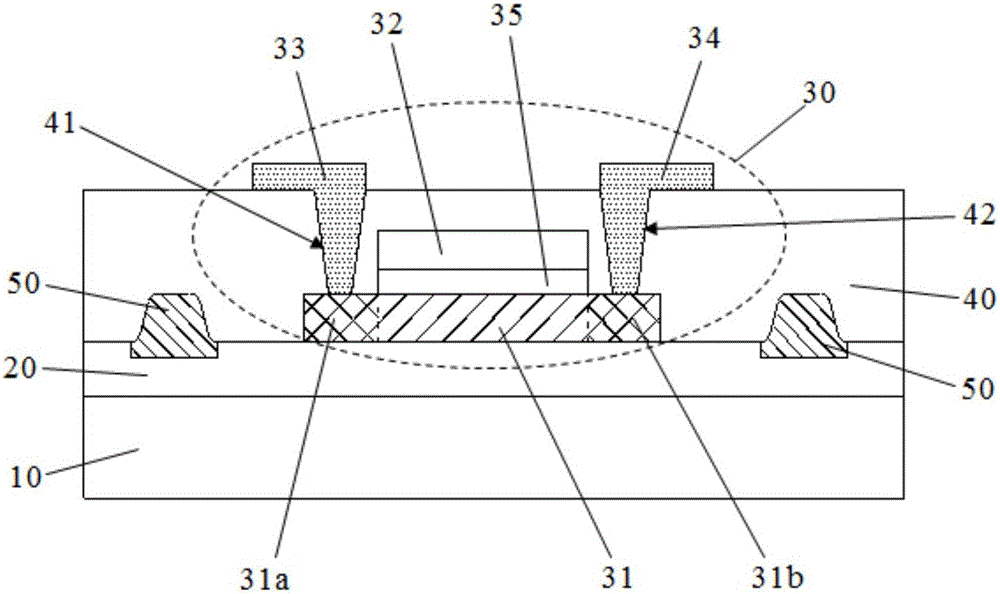

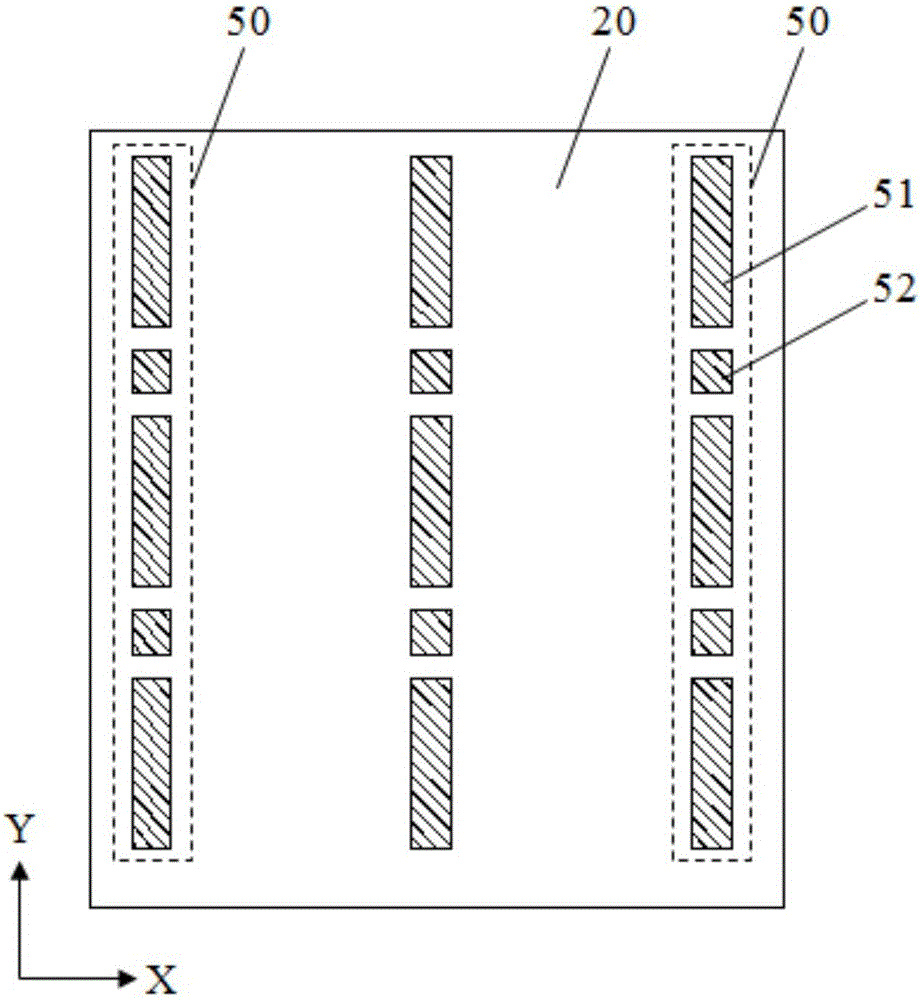

Flexible array substrate and preparation method thereof, and flexible display device

ActiveCN106169481AImprove qualityGood flexibilityFinal product manufactureSolid-state devicesDielectricInter layer

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

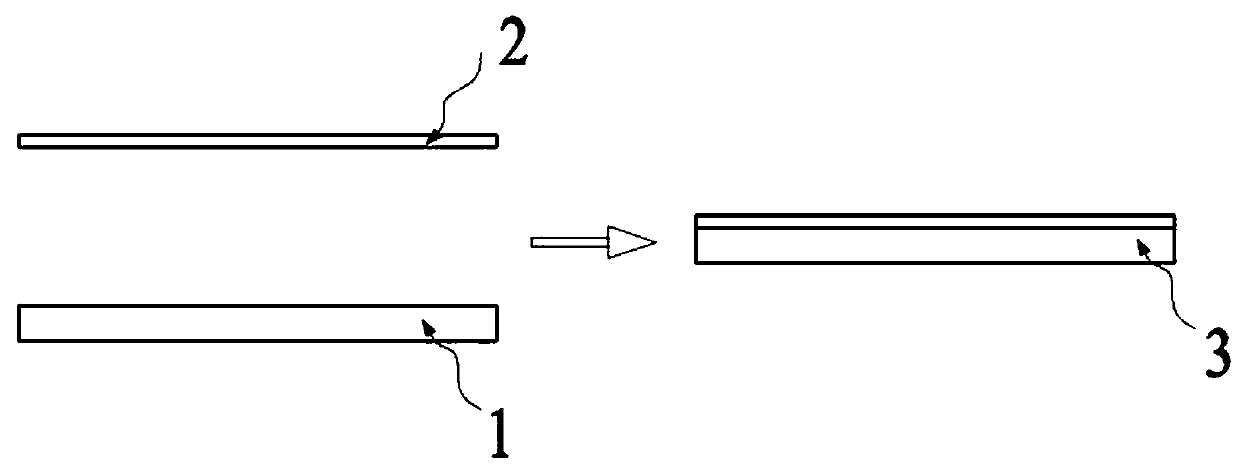

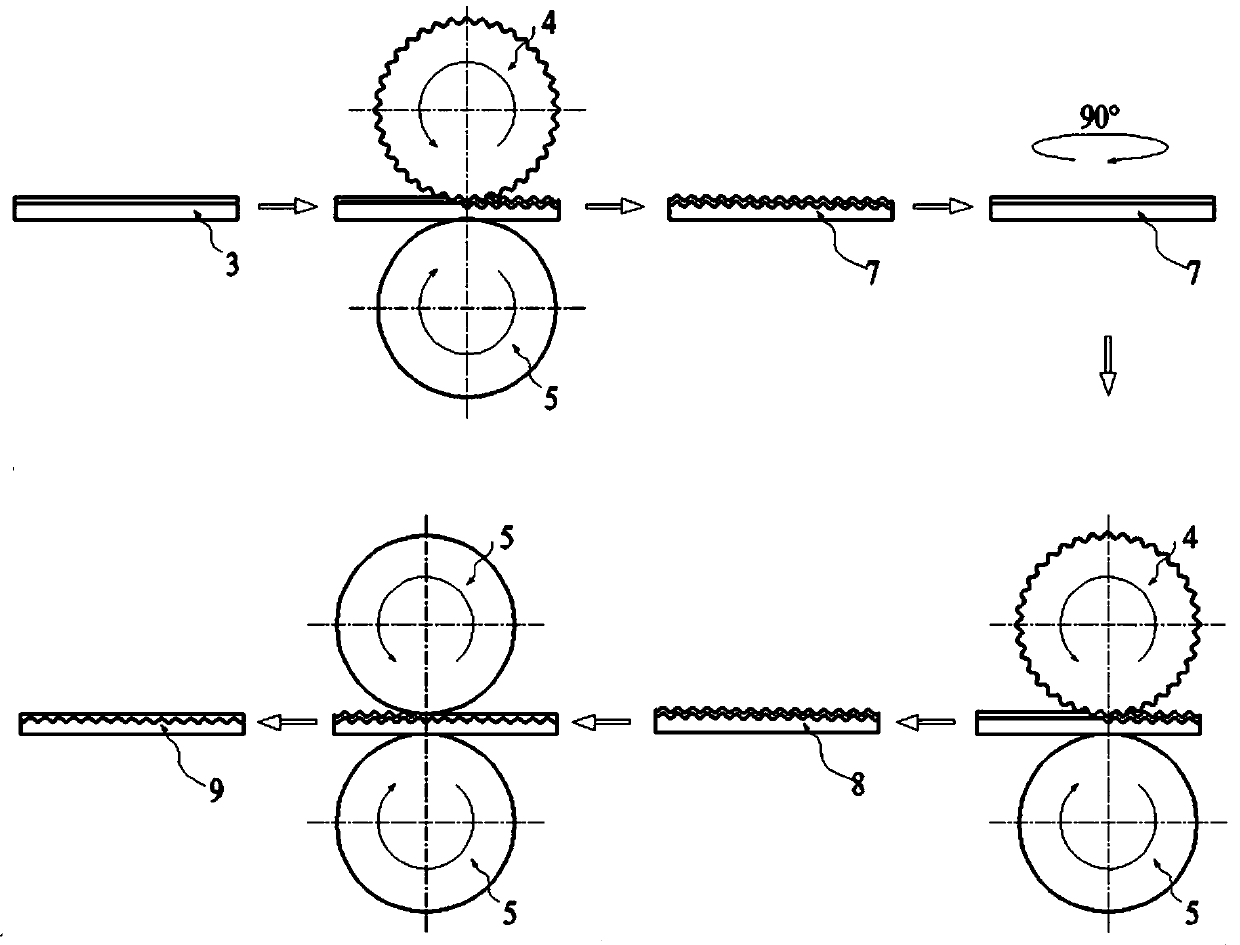

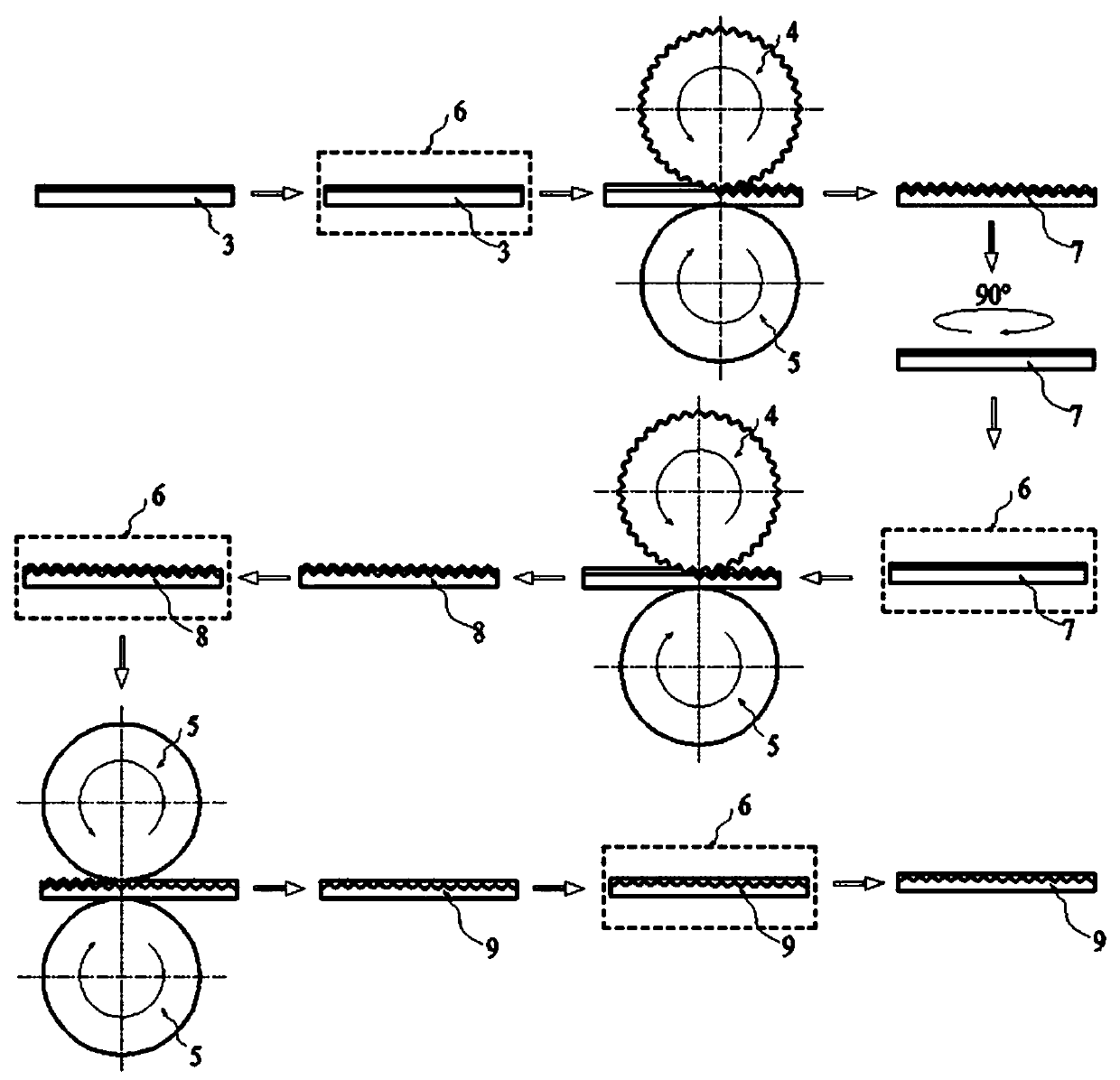

Rolling method for improving combination intensity of double-metal composite board

InactiveCN110252806AHigh bonding strengthLarge diffusion probabilityMetal rolling arrangementsComposite plateUltimate tensile strength

The invention relates to the technical field of preparation of double-metal composite boards, and specifically relates to a rolling method for improving combination intensity of a double-metal composite boards. The rolling method for improving the combination intensity of the double-metal composite board aims at solving the technical problem of low combination intensity of a double-metal composition board prepared by an existing rolling method. According to the technical scheme, the method is characterized in that a base plate and the composite board are vertically subjected to wave flat rolling and then are subjected to flat rolling. Compared with a traditional rolling method, the method has the advantages that two double-metal sheets of different types are subjected to non-uniform local intensity deformation in three times in the abovementioned manner, thus broken, fresh and activated metal atoms in an oxidizing layer of a combination interface are extremely promoted to be extruded out, and as a result, the diffusion probability of two metal atoms is increased; the metallurgical bonding scope of the two metals is expanded; and the combination intensity is effectively improved.

Owner:潍坊林地源经贸有限公司

Method for preparing wood dissolving pulp by modifying true color unbleached wood pulp

InactiveCN101818460AShort processShorten the production cyclePulp de-wateringInorganic compound additionDissolving pulpSilk fiber

The invention discloses a production method for preparing wood dissolving pulp by modifying true color unbleached wood pulp, overcoming the defects of poor reaction property of a product prepared by using an alkali refining method. The method comprises the following steps of: concentrating and dewatering defibered unbleached true color wood pulp and then sending the pulp into a double-helix roll type refiner; continuing to dewatering in the refiner and adding liquid medicine; finishing continued concentrating, kneading and liquid medicine mixing working procedures on the pulp in the refiner, and then conveying the pulp into a digester; and entering subsequent working procedures comprising washing and bleaching after steaming and boiling until manufacturing paper with pulp. The invention reduces the preparation cost, improves the product quality and enlarges the resource supply source. The wood pulp dregs prepared by the method has higher alpha-cellulose content and good reaction property and is suitable for long and short silk fibers.

Owner:YIBIN GRACE GROUP CO LTD

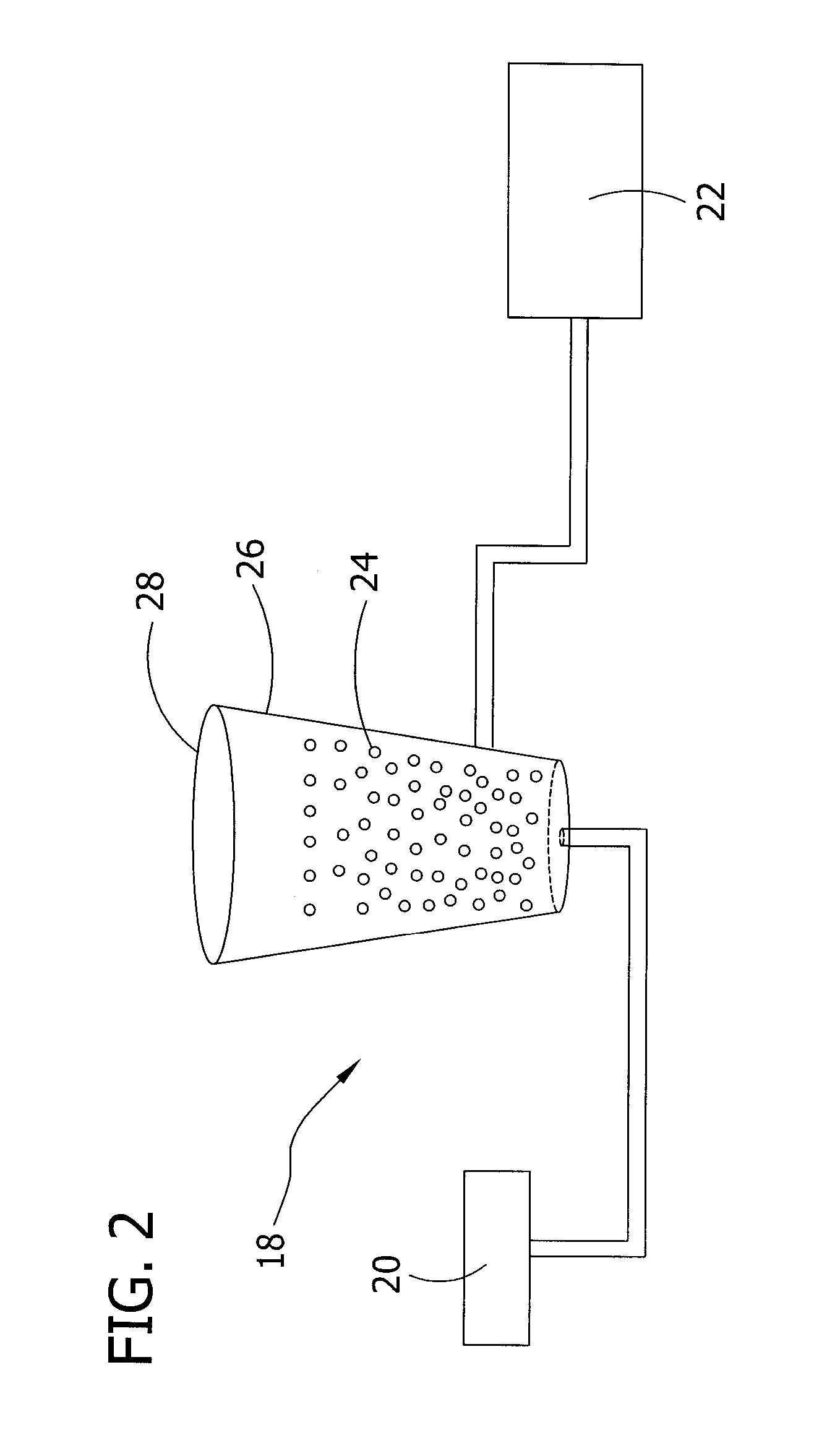

Wet wipe dispensing system for dispensing warm wet wipes

InactiveUS7654412B2Promote ruptureImprove responseRacksLighting and heating apparatusDelivery vehicleWet wipe

In a dispensing system and process for dispensing a warm wet wipe, a wet has an aqueous solution and microencapsulated delivery vehicles including a temperature change agent capable of generating a temperature change upon contact with the aqueous solution. An activating device facilitates rupturing of the microencapsulated delivery vehicles as the wet wipe is removed from a wet wipe container to allow contact between the temperature change agent and the aqueous solution of the wet wipe to thereby dispense a warm wet wipe. In another embodiment the wet wipe in the container has an aqueous solution. A lotion having the microencapsulated delivery vehicles is disposed in a lotion container free from contact with the wet wipe. An applicator in communication with the lotion is operable to apply the lotion to the wet wipe while the wet wipe is disposed at least in part within the wet wipe container.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Extraction method of gardenia jasminoides volatile oil

InactiveCN104164302APromote ruptureImprove dissolution efficiencyEssential-oils/perfumesOrganic solventPhysical chemistry

The invention relates to an extraction method of gardenia jasminoides volatile oil, and particularly relates to a method for extracting gardenia jasminoides volatile oil by adopting ultrasonic-microwave synergic technology. The extraction method comprises the following steps: putting gardenia jasminoides powder into a container, adding distilled water the weight of which is five to eight times that of the gardenia jasminoides powder, extracting by adopting ultrasonic-microwave technology, controlling the ultrasonic power to 500W, microwave power to 400-600 so as to perform continuous extraction for 2-3 hours, filtering, extracting the filtrate for two to three times with an organic solvent, combining extracting liquor, drying with anhydrous sodium sulfate, and conducting pressure-reduced concentration, to obtain gardenia jasminoides volatile oil. By fully utilizing the ultrasonic-microwave superposition effect, the extraction method has the advantages of being simple in technology, low in energy consumption, high in yield and the like, and is an environment-friendly extraction method of gardenia jasminoides volatile oil, thus being applicable to industrial production.

Owner:NANJING BIAOKE BIO TECH

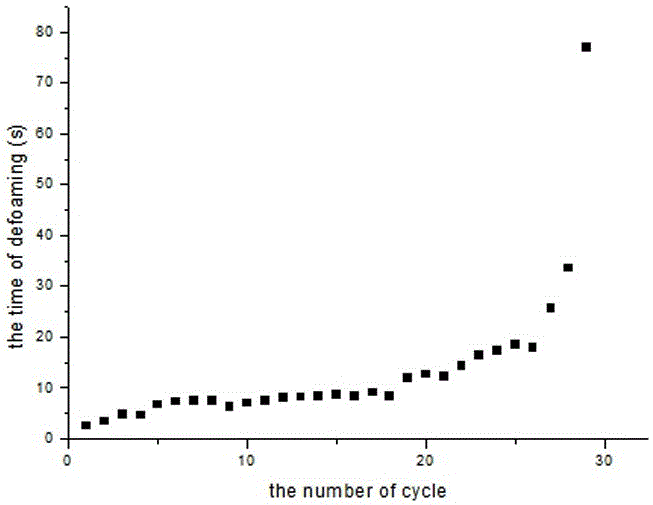

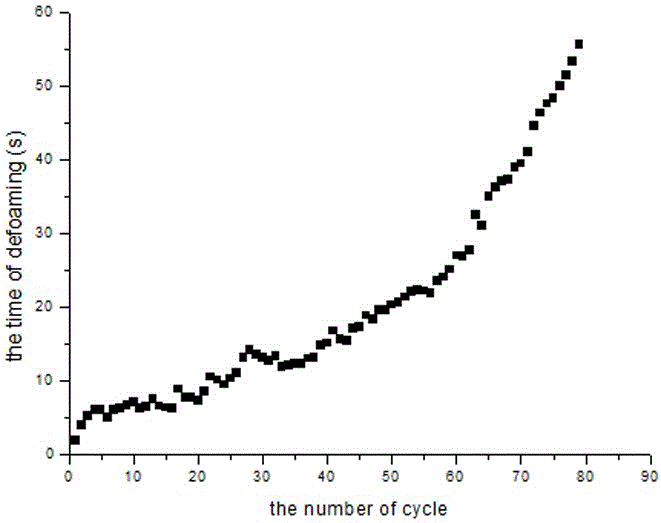

Emulsion-type organosilicone defoamer and preparation method thereof

ActiveCN105688452AImprove bindingLong-lasting defoaming effectFoam dispersion/preventionEmulsionSodium phosphates

The invention discloses an emulsion-type organosilicone defoamer and a preparation method thereof. The preparation method includes: at 90-100 DEG C, using a hydrophobic treatment agent and ammonium dihydrogen phosphate to pre-treat hydrophobic gas-phase white carbon black; bending obtained gas-phase white carbon black with dimethicone at 170-200 DEG C to obtain silicone cream; under action of a compound emulsifier, compounding the silicone cream, fatty alcohol and sodium phosphate to obtain the emulsion-type organosilicone defoamer. The defect that existing emulsion-type organosilicone defoamers are prone to inactivation and poor in foam inhibiting performance is overcome, the organosilicone defoamer obtained has excellent alkali resistance and good continuous application performance, and is high in defoaming speed, foam inhibiting performance and emulsion stability and long in defoaming activity time, and the preparation process is clean and environment-friendly, free of emission of 'three wastes' and suitable for industrial production.

Owner:FUZHOU UNIV

Container for housing a tray or blister pack

ActiveUS20110127320A1Smooth sliding actionSecure retentionSmall article dispensingPharmaceutical containersEngineeringBlister pack

Owner:WESTROCK MWV LLC

Dispensing system for dispensing warm wet wipes

In a dispensing system for dispensing wet wipes, a wet wipe has an aqueous solution and microencapsulated delivery vehicles including a temperature agent, and is disposed in a wet wipe container. A cartridge is held in assembly with the wet wipe container and has an activating device that facilitates rupturing of the microencapsulated delivery vehicles as the wet wipe is removed from the dispensing system to allow contact between the temperature change agent and the aqueous solution of the wet wipe to thereby dispense a warm or cooled wet wipe. In another embodiment, the wet wipe has an aqueous solution and a lotion having the microencapsulated heat delivery vehicles disposed in the cartridge free from contact with the wet wipe. The cartridge also has an applicator that is operable to apply the lotion to the wet wipe as the wet wipe is removed from the wet wipe container.

Owner:KIMBERLY-CLARK WORLDWIDE INC

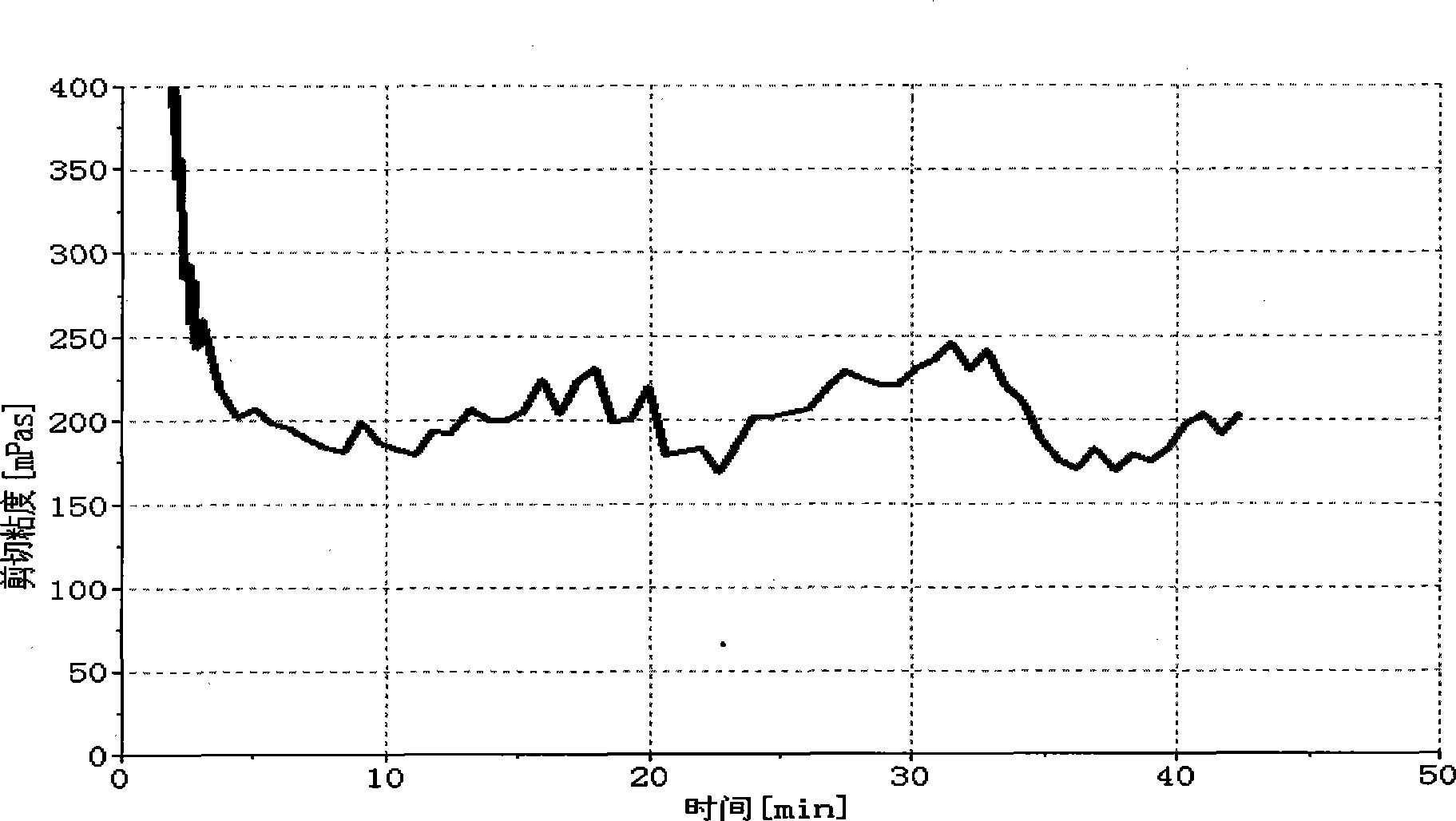

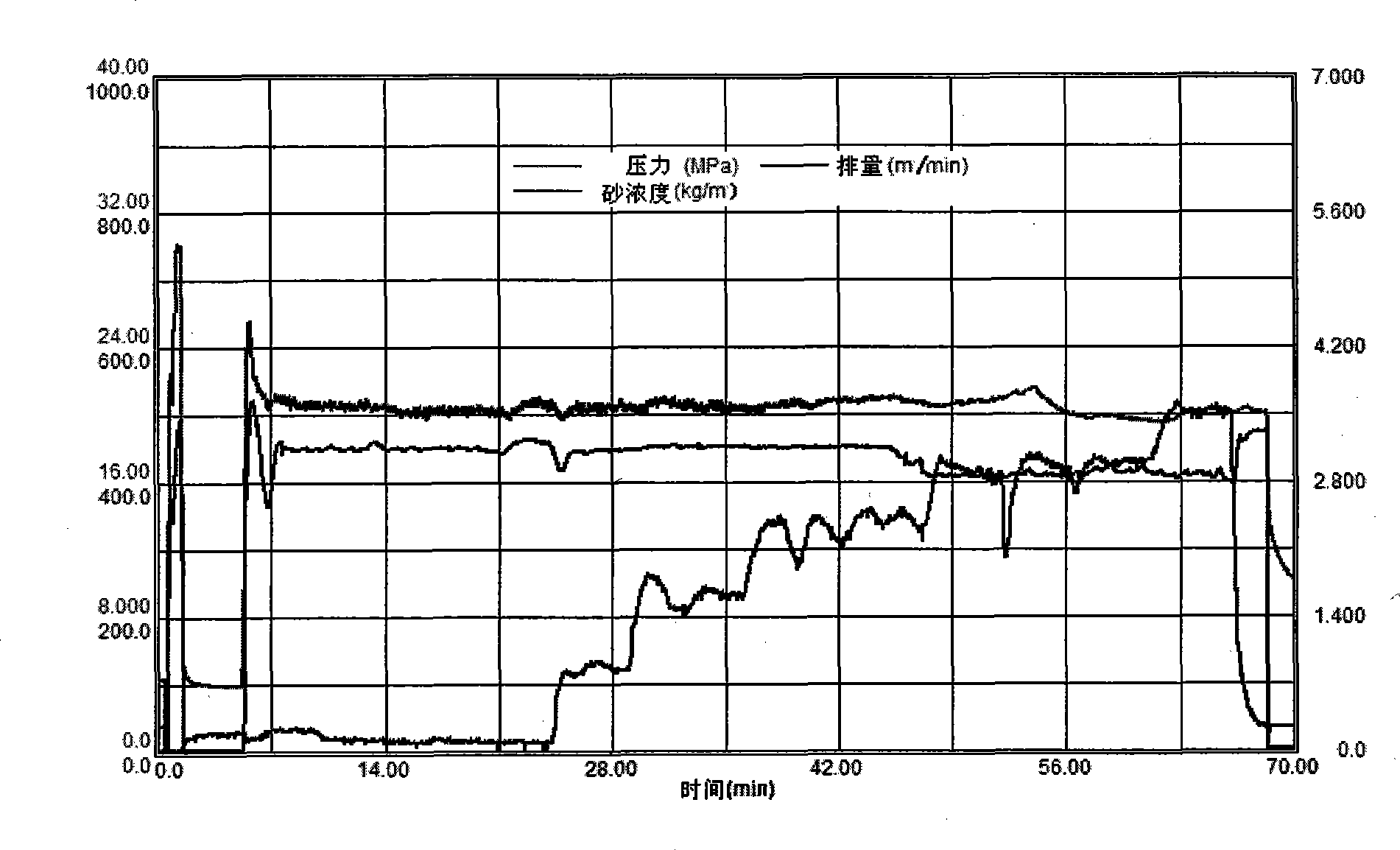

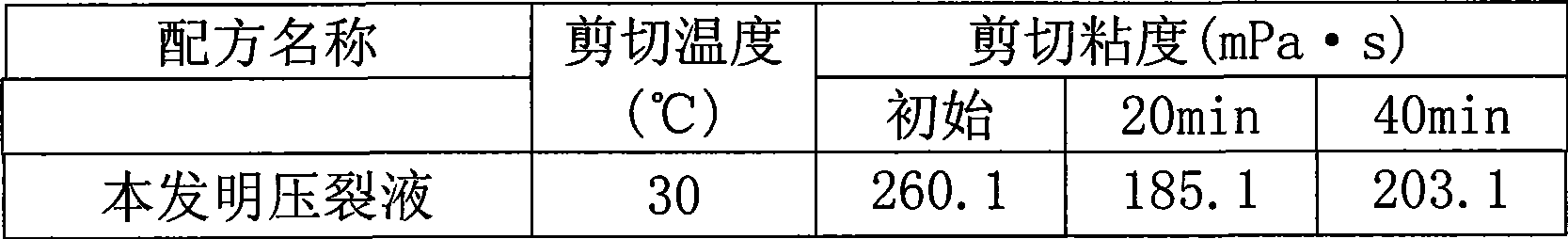

Ultra low temperature super guanidine gum fracturing fluid

ActiveCN101531892AFast swellingGuaranteed gel-forming propertiesDrilling compositionOrganosiliconEther

The invention relates to ultra low temperature super guanidine gum fracturing fluid, comprising the ingredients with mass percents as follows: 0.20% of super guanidine gum, 0.12% of organopolysiloxane, 0.07% of polyoxypropylene polyoxyethylene polyoxypropylene octadeyl alcohol ether, 0.32% of cationic organic amino, 0.09% of cationic long chain polymer, 0.03% of organic silicone oil, 0.0003% of borax, 0.00027% of persulfate, 0.00009% of hyper-valent oxysalt, 0.00014% of peroxide and balance of water. The fracturing fluid has good anti-shearing property and breaks gum completely.

Owner:PETROCHINA CO LTD +1

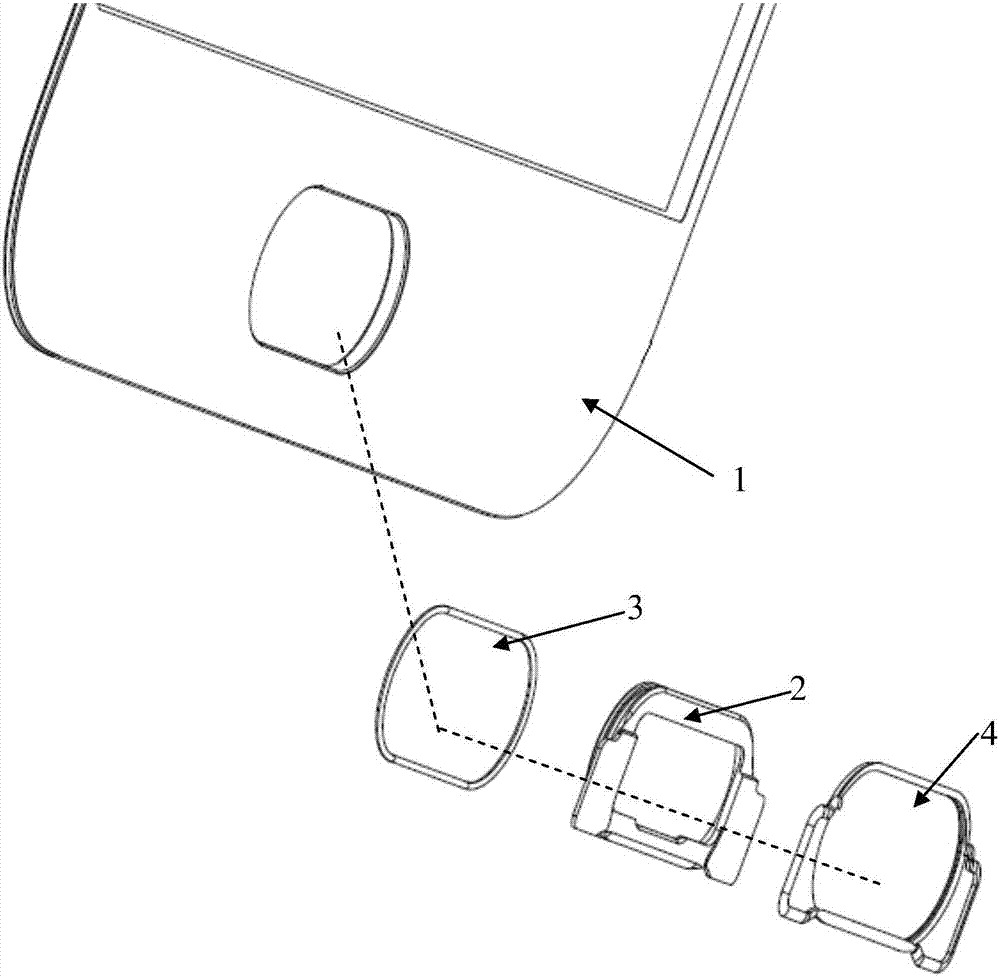

Assembling structure of fingerprint module and mobile terminal

ActiveCN106909200AImprove sturdinessSolve poor appearanceDigital data processing detailsCharacter and pattern recognitionGlass coverAdhesive

The invention provides an assembling structure of a fingerprint module and a mobile terminal. The assembling structure comprises a glass cover plate and the fingerprint module, wherein the fingerprint module comprises a fingerprint identification assembly, a decorating part and a flexible part; the decorating part sleeves the fingerprint identification assembly, and the outer wall of the decorating part is provided with a glue overflow groove and a projection structure; the flexible part is embedded in the glue overflowing groove; the fingerprint module is fixed on the glass cover plate by virtue of an adhesion manner of adhesive, and the adhesive is disposed in an accommodating space defined by the projection structure, the glass cover plate and the flexible part. The assembling structure provided by embodiments of the invention solves the problem of unfavorable appearance caused by overflowing glue after glue dispensing, and improves the appearance fineness; and meanwhile, by controlling the glue overflowing amount, the glass cracking problem caused by the non-uniform inner stress of the adhesive on the glass cover plate due to the temperature variation can be solved, and the firmness of the glass cover plate can be improved.

Owner:VIVO MOBILE COMM CO LTD

Method for extracting toosendanin from cortex meliae

The invention relates to a method for extracting toosendanin from cortex meliae. The method comprises the following processing steps: cleaning dry mature cortex meliae and then crushing the mature cortex meliae by a pulverizer, grinding the mature cortex meliae into powder, drying the powder and adding a 60% ethanol solvent; adjusting the pH value of the solution to 4-6, and adding cellulase for enzymolysis; putting the extracting solution into a double-frequency ultrasonic extractor to obtain an enzymatic hydrolysate; carrying out high-temperature inactivation on the enzymatic hydrolysate to obtain an extracting solution; centrifuging, taking supernate, extracting by use of chloroform, and drying by use of anhydrous sodium sulfate; carrying out suction filtration, concentrating, adding ethanol and heating for dissolving; dropping petroleum ether until the mixture becomes a turbid matter; stewing for separating out a flavescent solid, namely the toosendanin. According to the method, the cortex meliae is taken as the raw material; the stacking effect of enzymolysis and a double-frequency ultrasonic wave is fully utilized; the toosendanin in the cortex meliae is dissolved to the greatest extent; the high-purity toosendanin can be obtained by virtue of extraction and crystallization. The method has the advantages of being simple in equipment, low in extraction cost, high in extraction efficiency, mild in reaction condition, less in solvent consumption, free of pollution and the like.

Owner:NANJING TONGZE AGRI SCI & TECH

Container for housing a tray or blister pack

ActiveUS8701889B2Promote ruptureSecure retentionSmall article dispensingPharmaceutical containersBlister pack

Owner:WESTROCK MWV LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com