Rolling method for improving combination intensity of double-metal composite board

A technology of bonding strength and clad plate, applied in the direction of metal rolling, etc., can solve the problem of low bonding strength of bimetal clad plate, and achieve the effect of improving the area bonding rate, high interlaminar shear strength, and high mechanical interlocking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

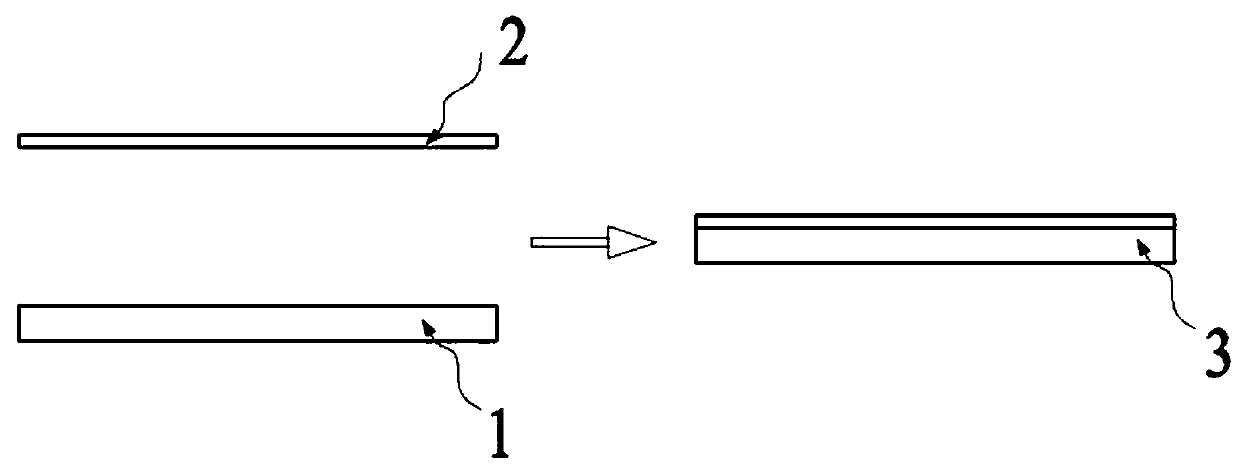

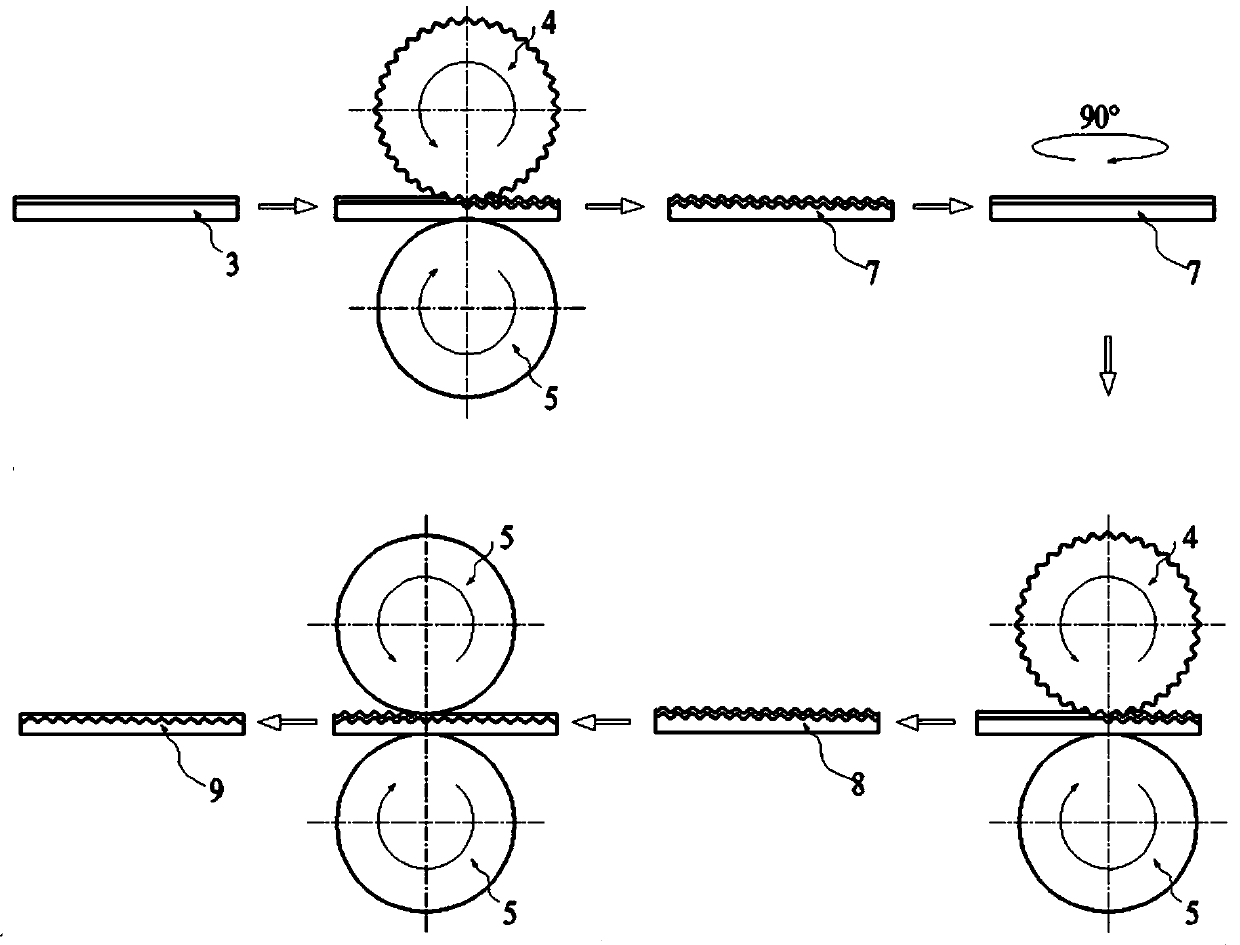

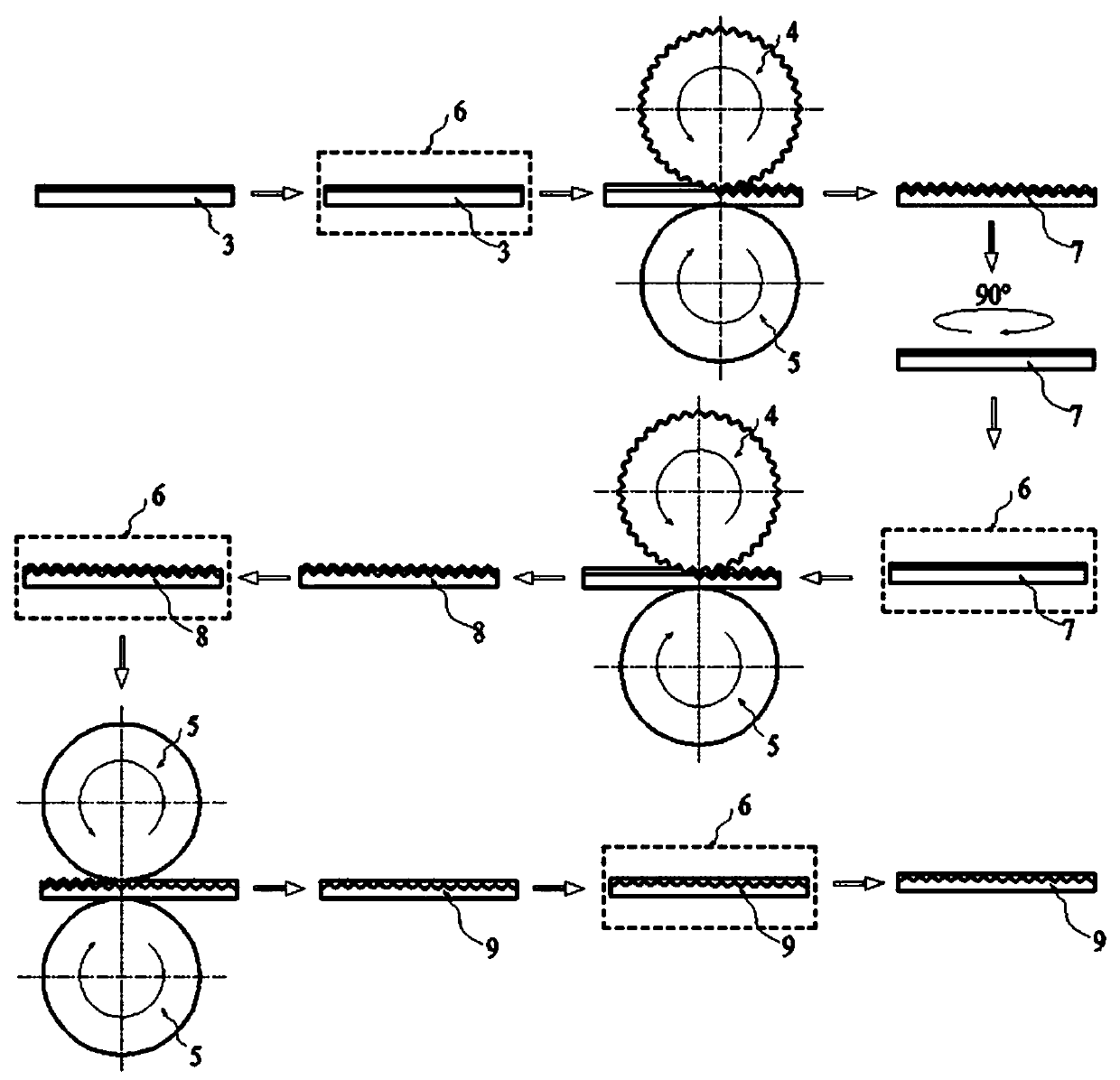

[0026] refer to figure 1 , 2 , 4-6, a kind of cold-rolling method of preparing Cu / Al bimetal clad plate, comprises the following steps:

[0027] S1. Billet making: select pure Al plate as substrate 1, with length, width, and height of 50, 50, and 3 mm respectively, and select pure Cu plate as double plate 2, with length, width, and height of 50, 50, and 1 mm, respectively. The deformation resistance of Al plate is relatively high. small, the deformation resistance of the Cu plate is relatively large, the ratio of the thickness of the base plate 1 to the double plate 2 is 3, and the double plate 2 is stacked on the top of the base plate 1, symmetrically at a distance of 15mm in the width direction of the rolled bite end. Drill two holes and rivet them with rivets, so as to ensure that the component plates of the bimetallic composite slab 3 can be bitten into the roll synchronously, and the other end is bound with a binding wire to ensure that the base plate 1 and the composite...

Embodiment 2

[0035] refer to figure 1 , 3 , 4-6, a kind of warm rolling method for preparing Mg / Al bimetal clad plate, comprises the following steps:

[0036]S1. Blank making: choose 5052 aluminum alloy as the base plate 1, the length, width and height are 300, 300, and 25mm respectively, and select the AZ31 magnesium alloy plate as the double board 2, and the length, width and height are 300, 300, 5mm respectively, and 5052 aluminum The deformation resistance of the alloy plate is small, and the deformation resistance of the AZ31 magnesium alloy plate is relatively large. The thickness ratio of the base plate 1 and the double plate 2 is 5. Two holes are symmetrically drilled at a distance of 200mm in the width direction of the end and riveted by rivets, so as to ensure that the component plates of the bimetallic composite slab 3 can be bitten into the roll synchronously, and the other end is bound with a binding wire to ensure rolling. During the process, there will be no deviation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com