Patents

Literature

821results about How to "Promote recombination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

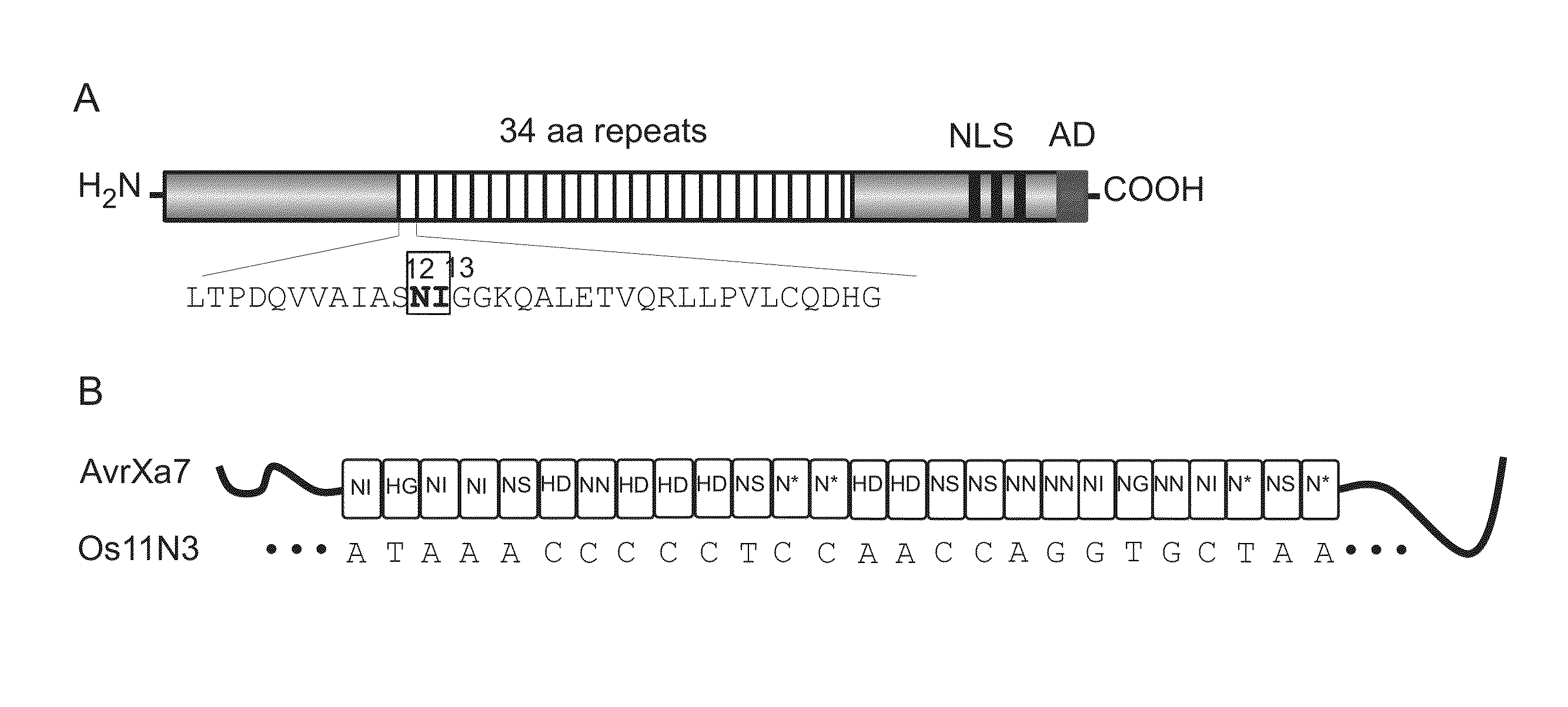

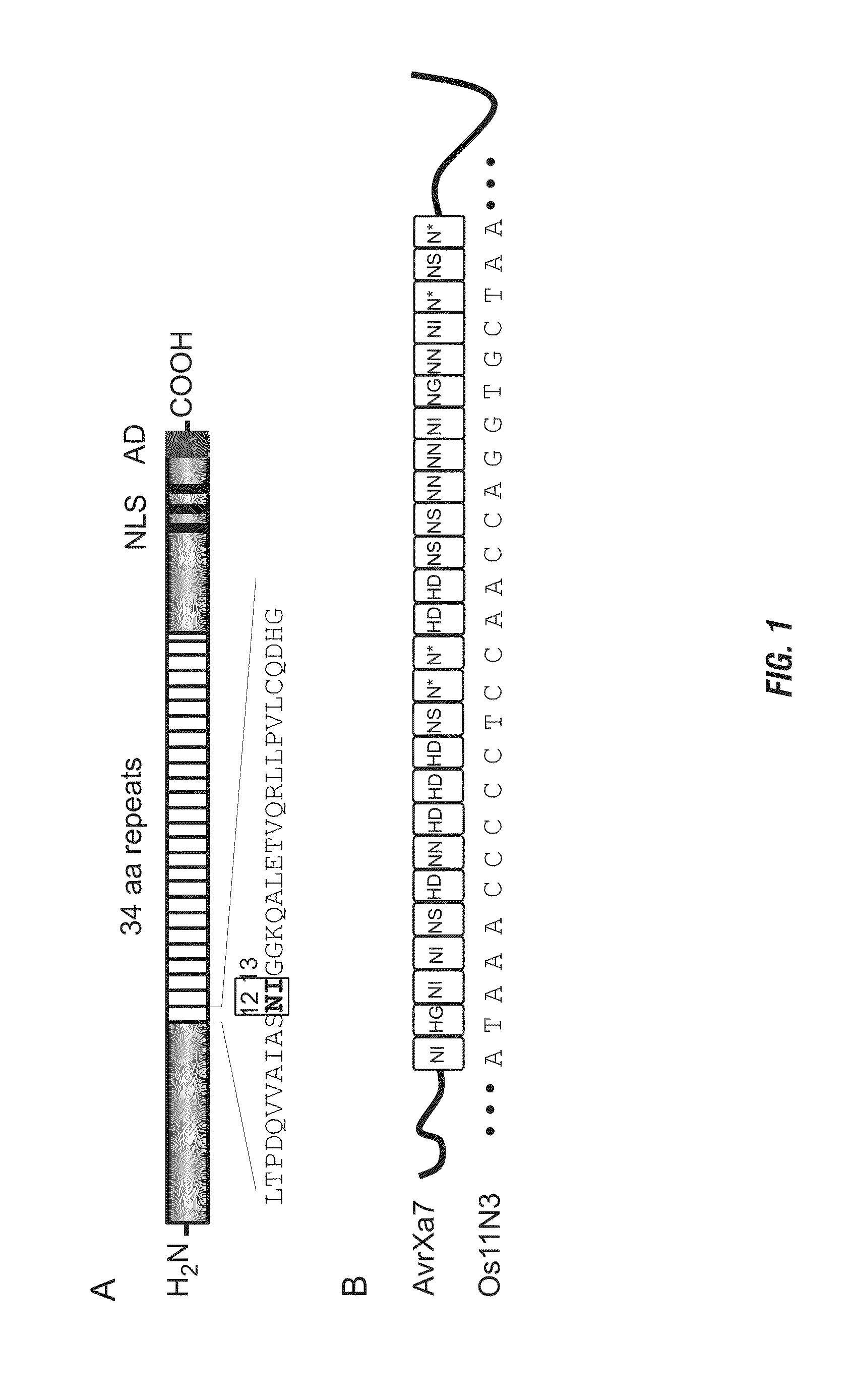

Nuclease activity of tal effector and foki fusion protein

The present invention provides compositions and methods for targeted cleavage of cellular chromatin in a region of interest and / or homologous recombination at a predetermined site in cells. Compositions include fusion polypeptides comprising a TAL effector binding domain and a cleavage domain. The cleavage domain can be from any endonuclease. In certain embodiments, the endonuclease is a Type IIS restriction endonuclease. In further embodiments, the Type IIS restriction endonuclease is FokI.

Owner:IOWA STATE UNIV RES FOUND

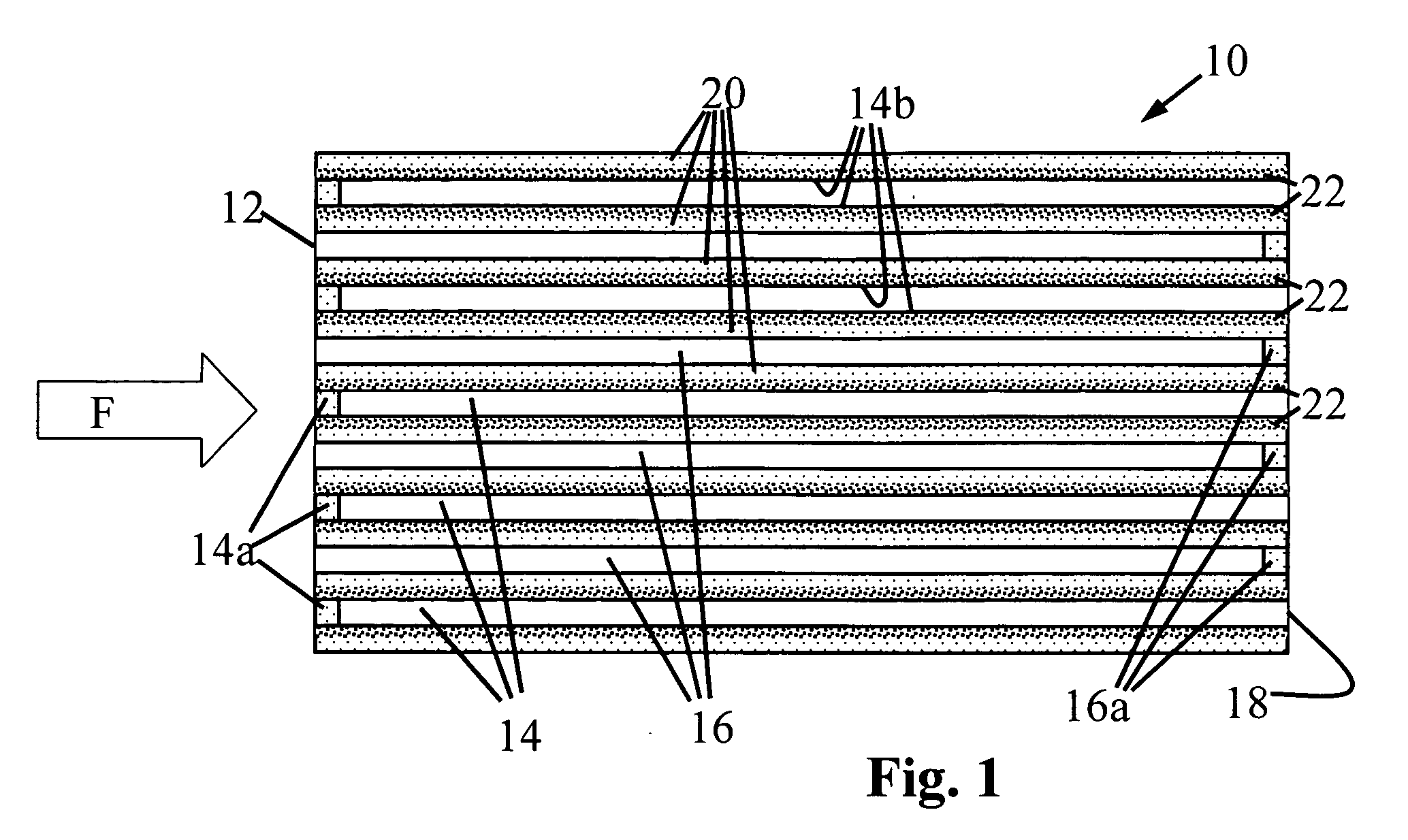

Low pressure drop coated diesel exhaust filter

InactiveUS20070140928A1Promote nitrogen oxide reductionReduce and avoid obstructionCombination devicesSilencing apparatusHigh concentrationNitrogen oxides

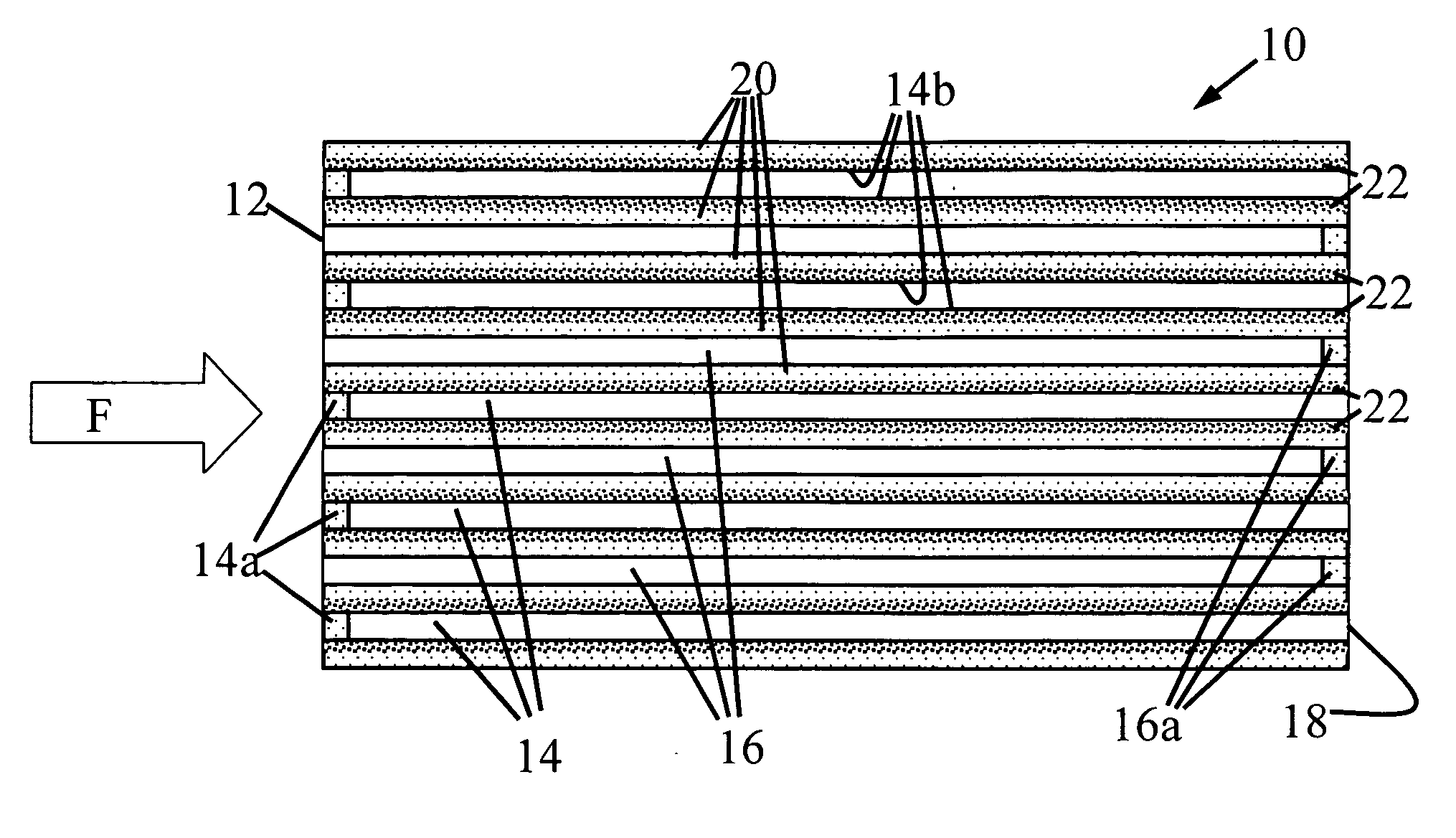

A coated diesel exhaust filter is provided that applies a relatively low pressure drop across the exhaust system despite the buildup of soot deposits. The filter includes a porous ceramic structure having an inlet end, an outlet end, and a plurality of gas inlet and gas outlet channels disposed between the inlet and outlet ends, the channels being separated by porous ceramic walls. A catalyst is distributed at least partly within the porous ceramic walls of the structure, and is distributed at a higher concentration within portions of the ceramic walls adjacent to the outlet surfaces than within portions of the ceramic walls adjacent the inlet surfaces. Both the inlet and outlet surfaces are substantially free of the catalyst in order to maintain a gas-conducting porosity in these surfaces. The resulting filter effectively treats nitrogen oxides, carbon monoxide and unburned hydrocarbons present in the exhaust gas stream while advantageously imposing a relatively low pressure drop across the exhaust system even when soot deposits accumulate on the inlet surfaces of the ceramic walls.

Owner:CORNING INC

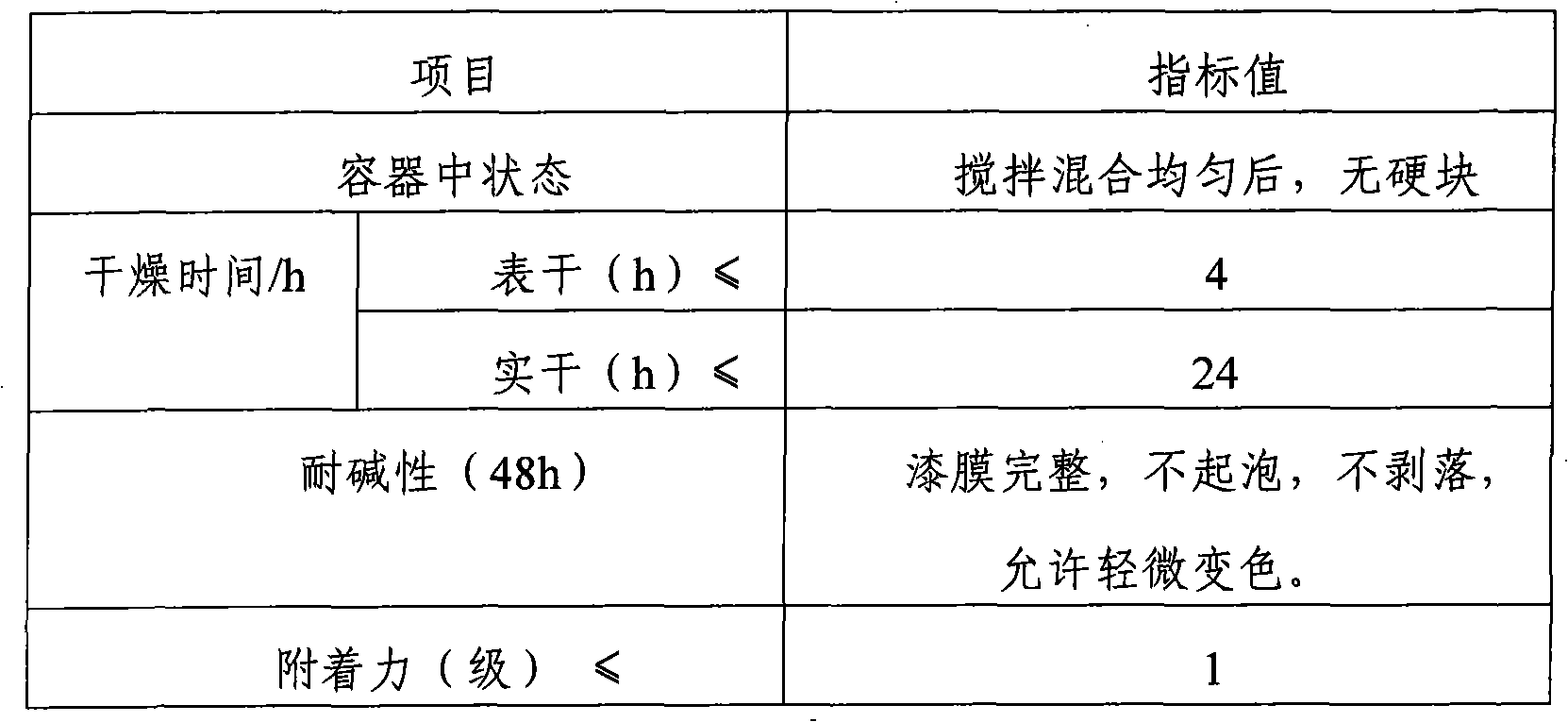

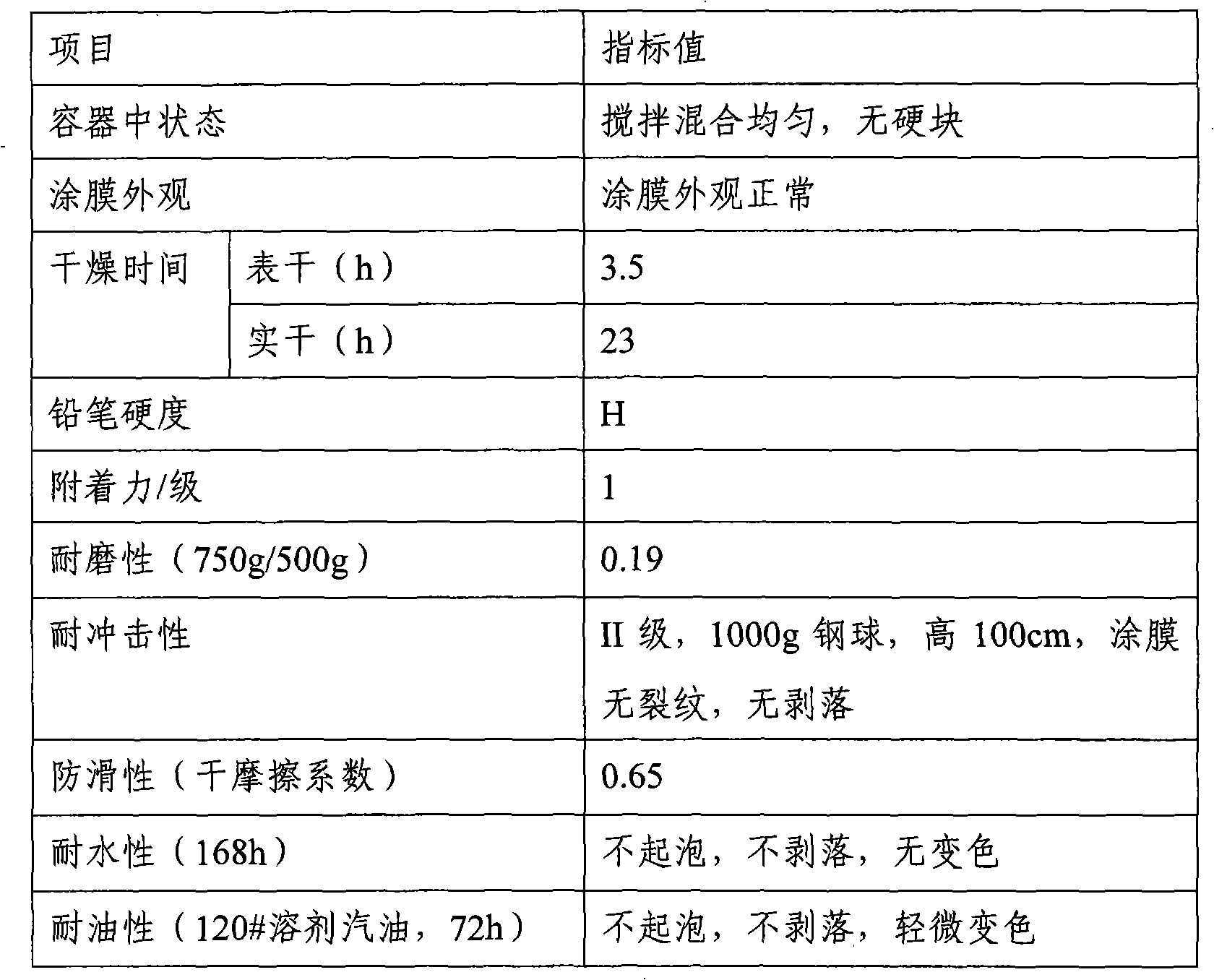

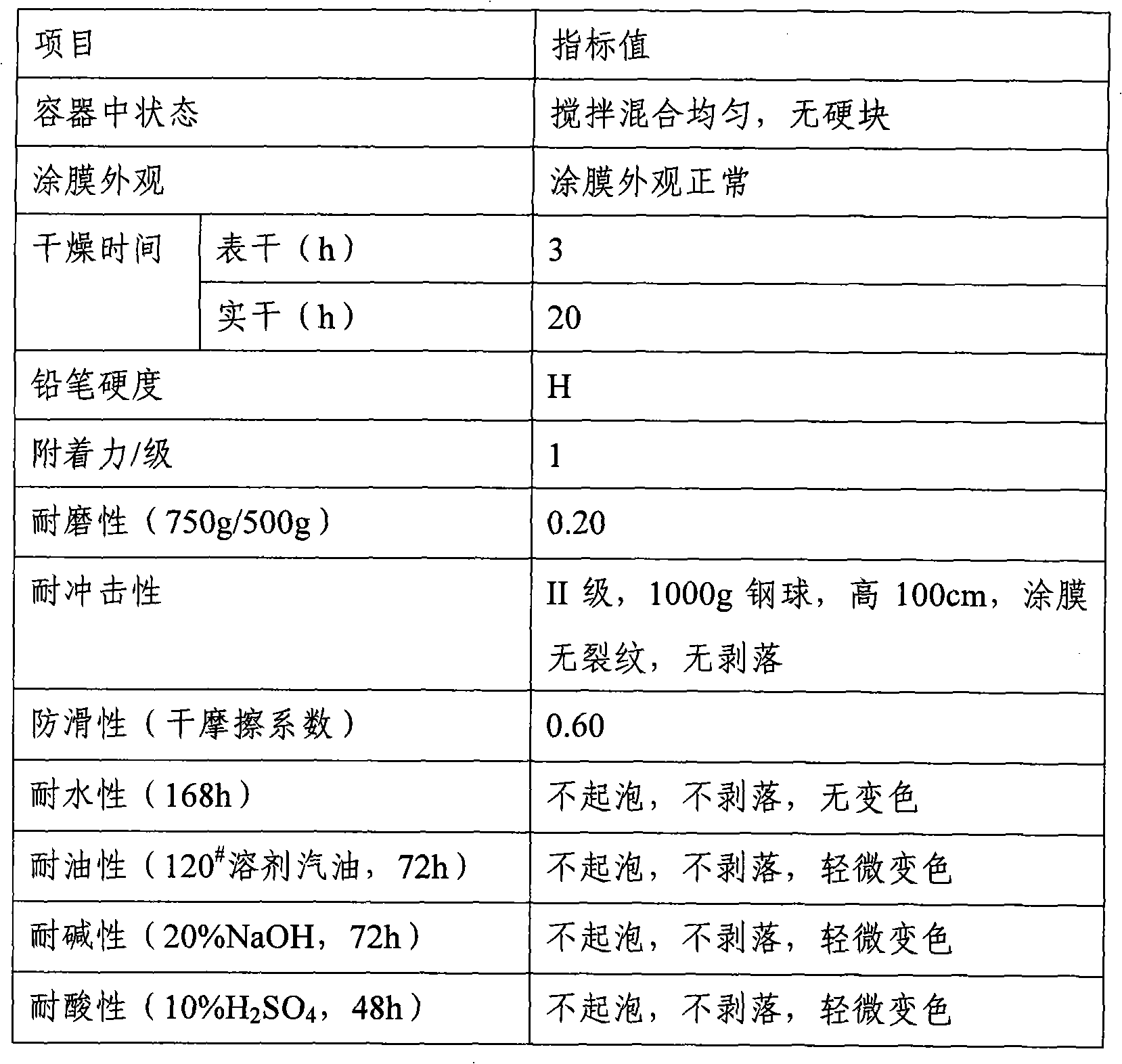

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

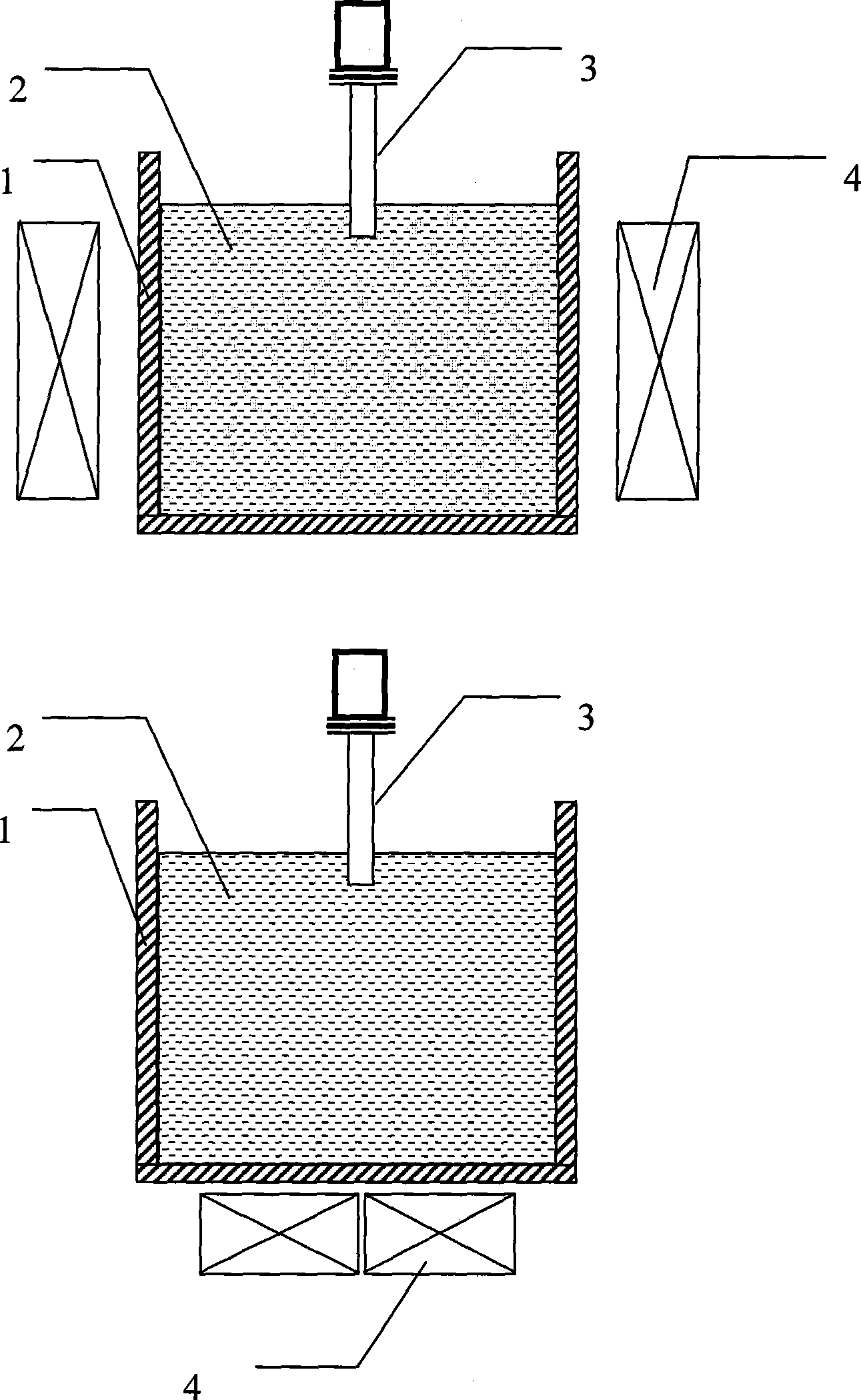

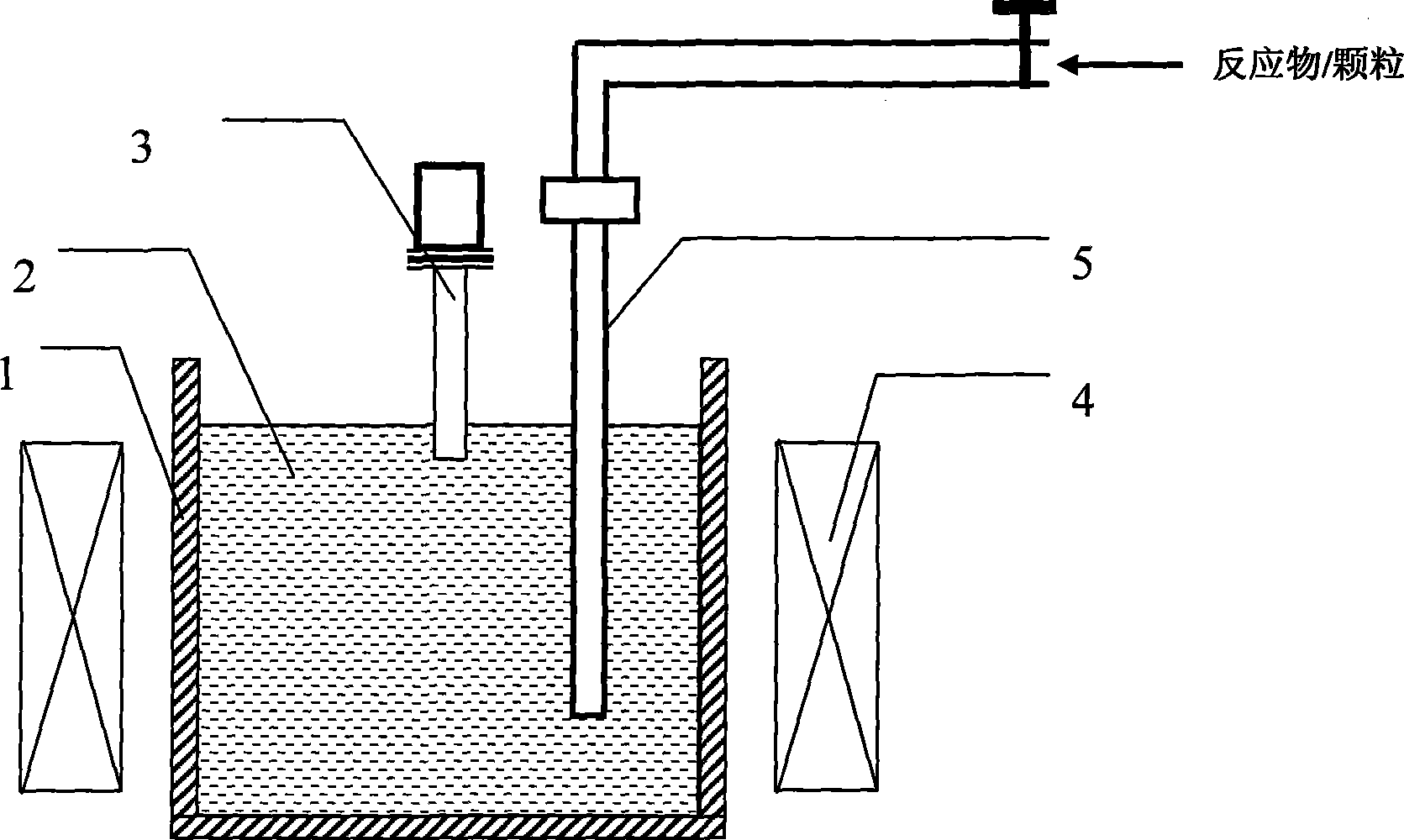

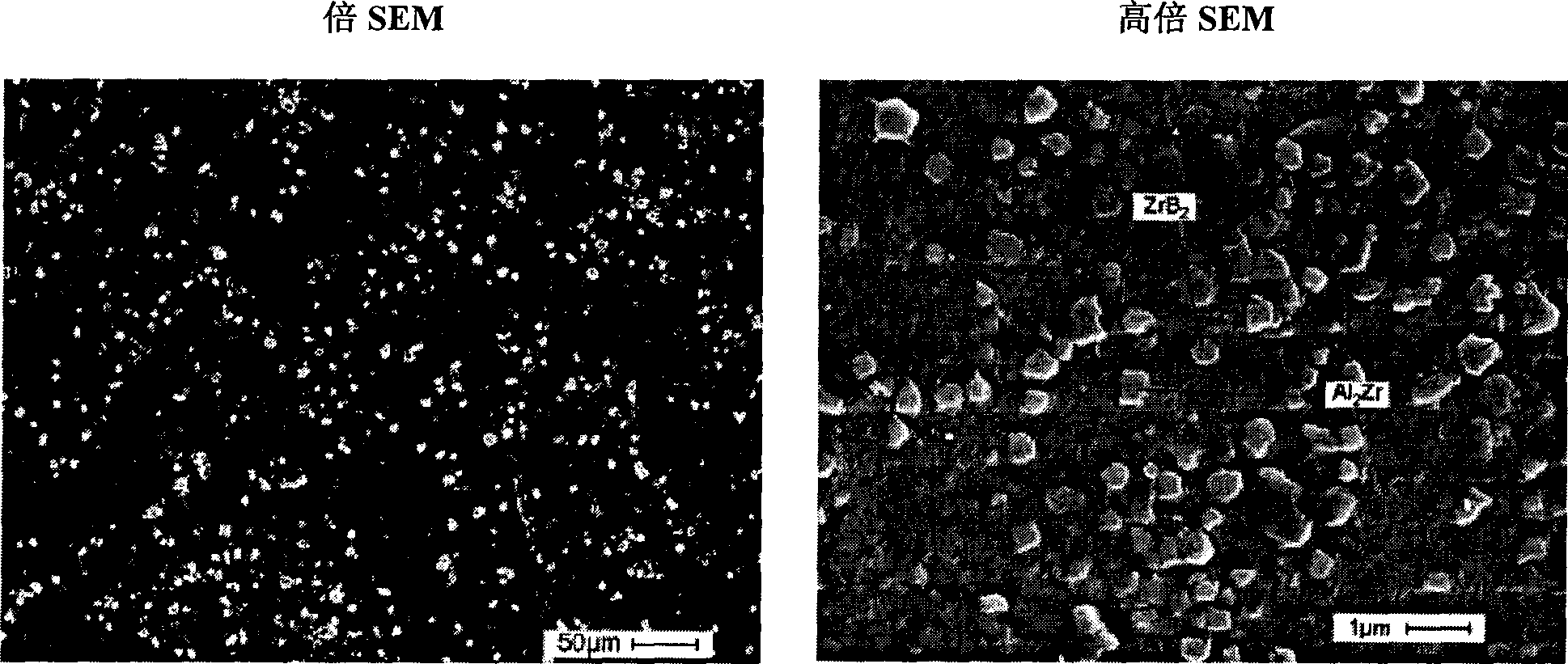

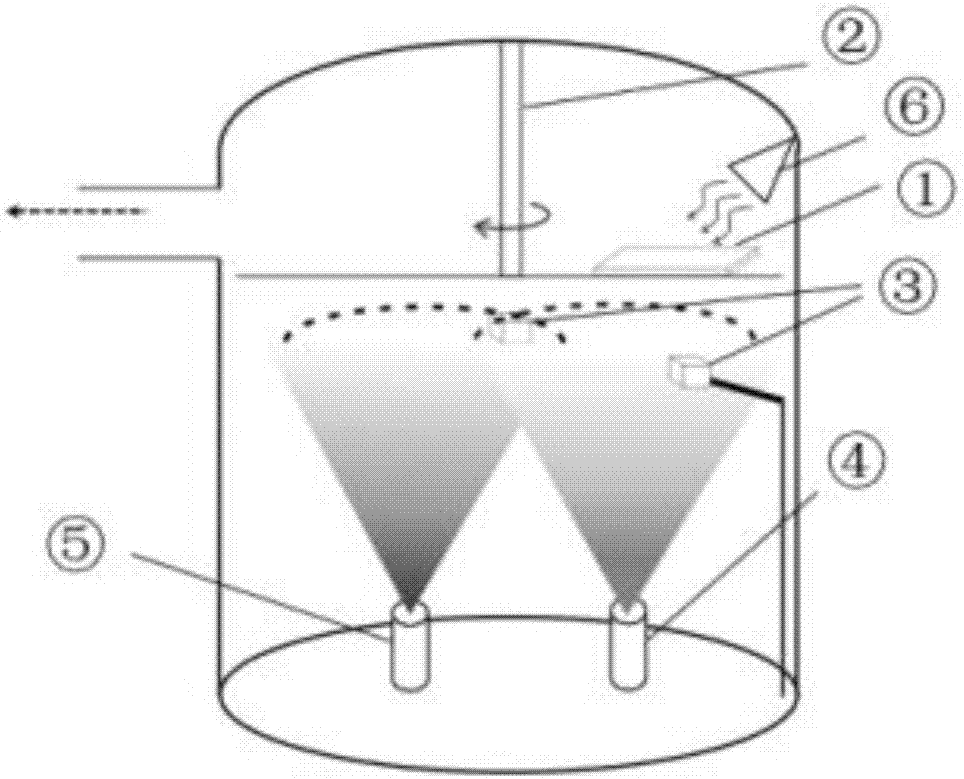

Method for synthesizing metal matrix composition using metal reaction under the coupling action of magnetic field and ultrasonic field

The invention relates to a method for preparing endogenetic particle reinforced metal matrix composites under the coupling effect of a magnetic field and supersonic waves. The method comprises: adjusting the temperature of a metal matrix fused mass to the reaction initial temperature after refining, adding a reactant which can generate a particle phase with the fused mass through the reaction in situ for implementing the synthesis reaction, standing the mixture after the reaction is over, and cooling the mixture to the pouring temperature for pouring; and the method is characterized in that: the magnetic field and the high-intensity ultrasonic field are simultaneously exerted in the reaction synthesis process to realize the synthesis of endogenetic particle reinforced metal matrix composites under the coupling effect of the magnetic field and the high-intensity ultrasonic field. The magnetic field can be an intense pulse magnetic field, a high frequency oscillation magnetic field or a low frequency alternating magnetic field. In the method, the coupling effect of the magnetic field and the ultrasonic field makes the particle sizes be thinned and dispersed evenly; the ultrasonic vibration agitation and electromagnetic stirring functions improve the composite dynamic condition, and the compounding of the particle phase and a base metal interface is better; and the co-action of magnetochemistry and sonochemistry improves the thermodynamic condition of the reaction in situ, as well as speeding up the reaction in situ and controlling the growth of the particle phase.

Owner:JIANGSU UNIV

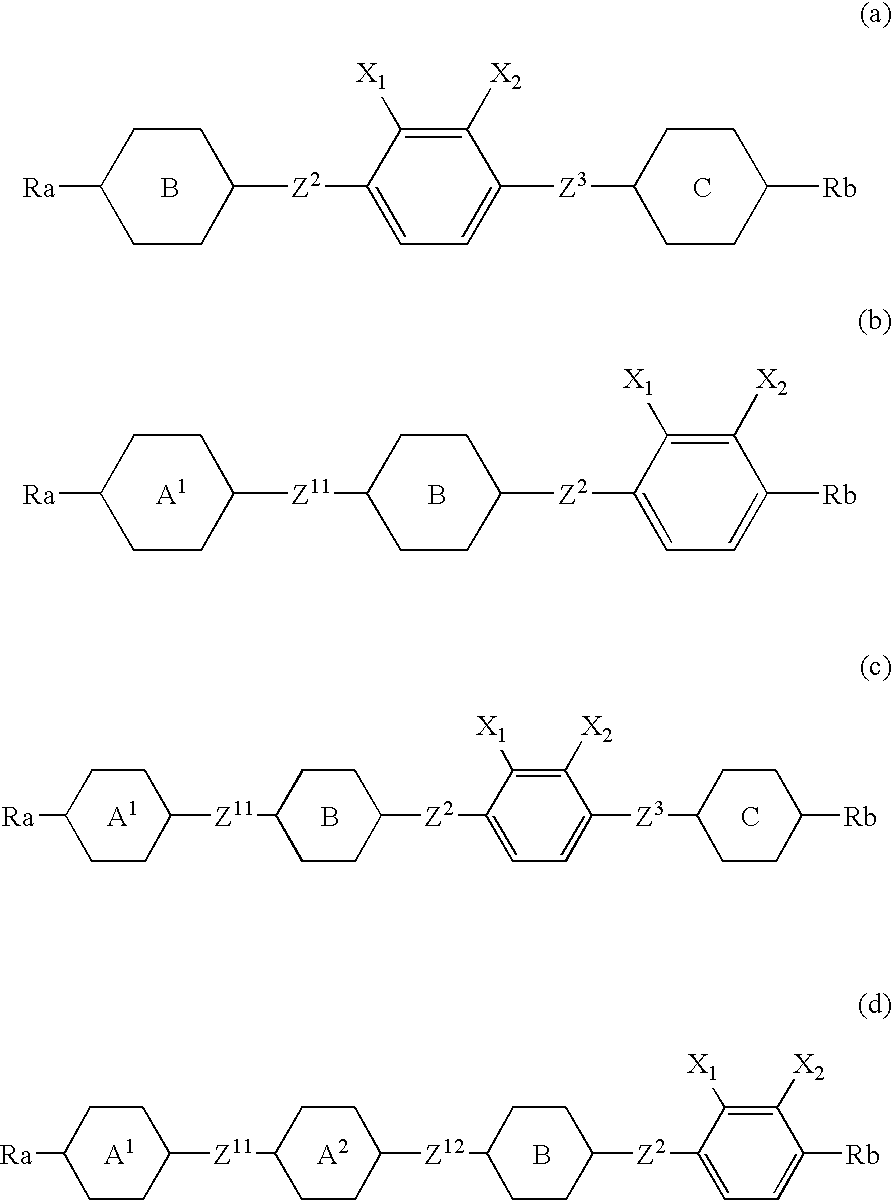

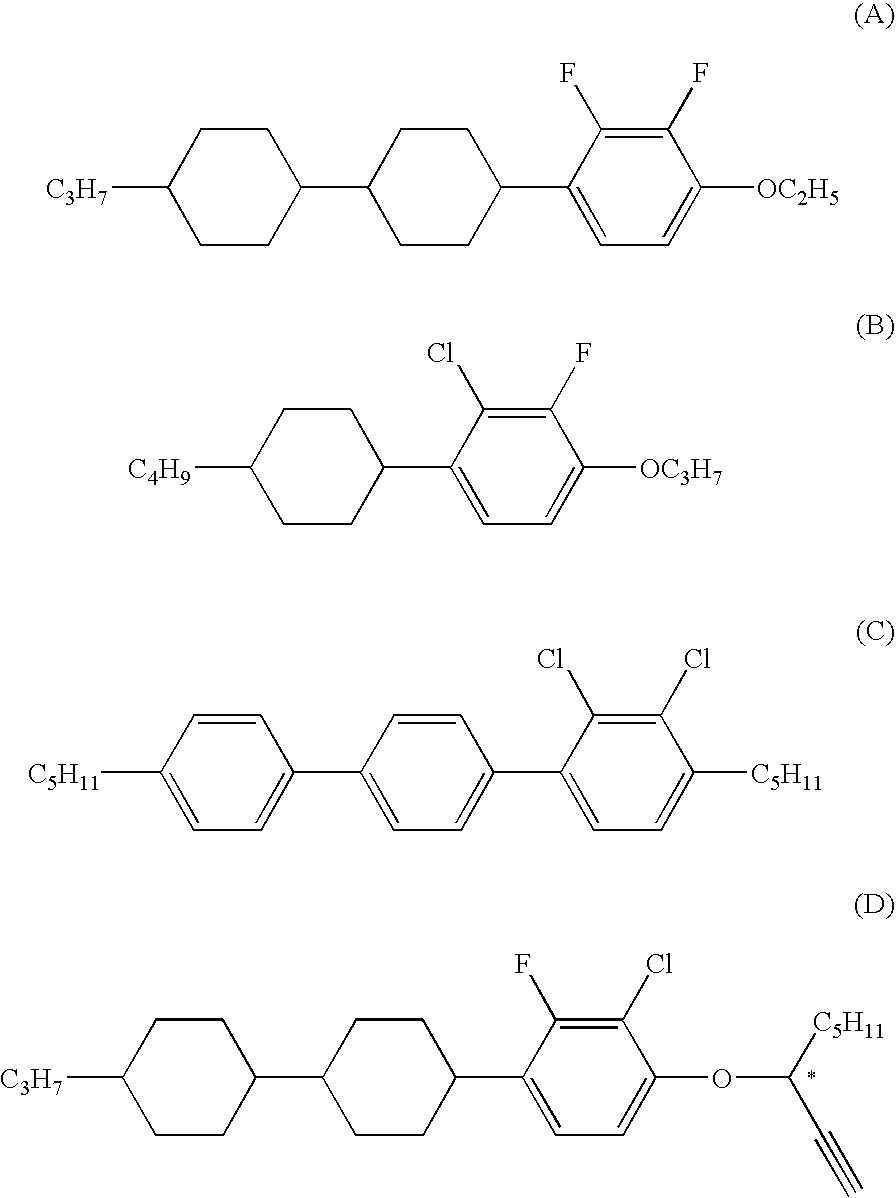

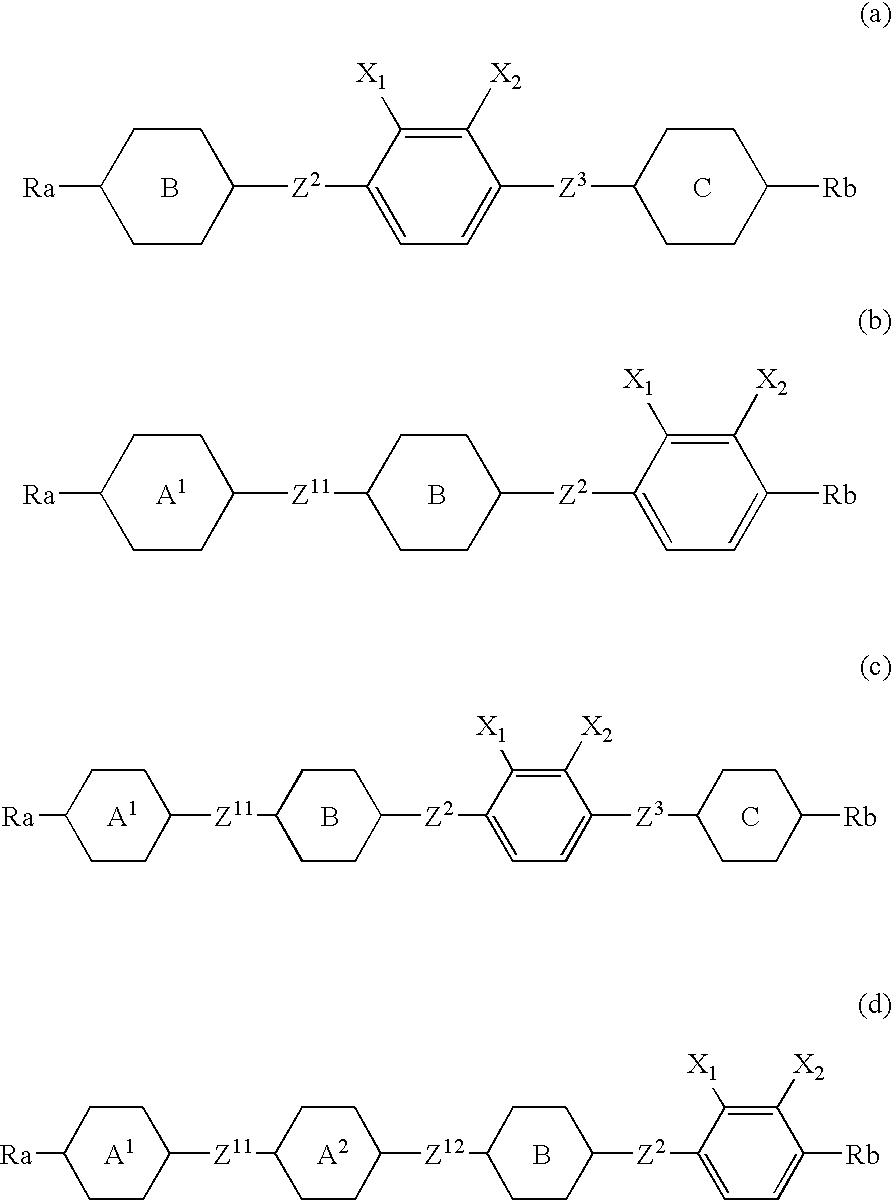

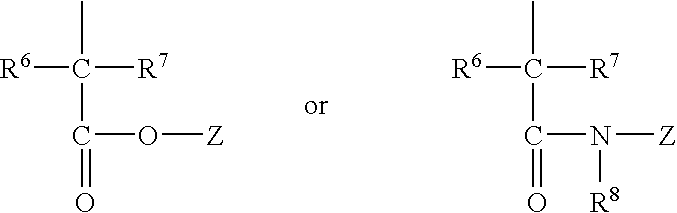

Chlorofluorobenzene liquid crystal compound, liquid crystal composition, and liquid crystal display device

ActiveUS20060198968A1Improve compatibilitySmall viscosityLiquid crystal compositionsHalogenated hydrocarbon preparationCrystallographyDielectric anisotropy

Such a liquid crystal compound is provided that has stability to heat, light and so forth, has a nematic phase in a wide temperature range, has a small viscosity, a suitable optical anisotropy, and suitable elastic constants K33 and K11 (K33: bend elastic constant, K11: splay elastic constant), and has suitable negative dielectric anisotropy and excellent compatibility with other liquid crystal compounds. A liquid crystal composition containing the liquid crystal compound, and a liquid crystal display device containing the liquid crystal composition are also provided. The liquid crystal compound is represented by one of formulas (a) to (d), the liquid crystal composition contains the liquid crystal compound, and the liquid crystal display device contains the liquid crystal composition: wherein Ra and Rb are independently linear alkyl or linear alkoxy, rings A1, A2, B and C are independently trans-1,4-cyclohexylene or 1,4-phenylene, Z11, Z12, Z2 and Z3 are independently a single bond or alkylene, and one of X1 and X2 is fluorine, and the other thereof is chlorine.

Owner:JNC PETROCHEM +1

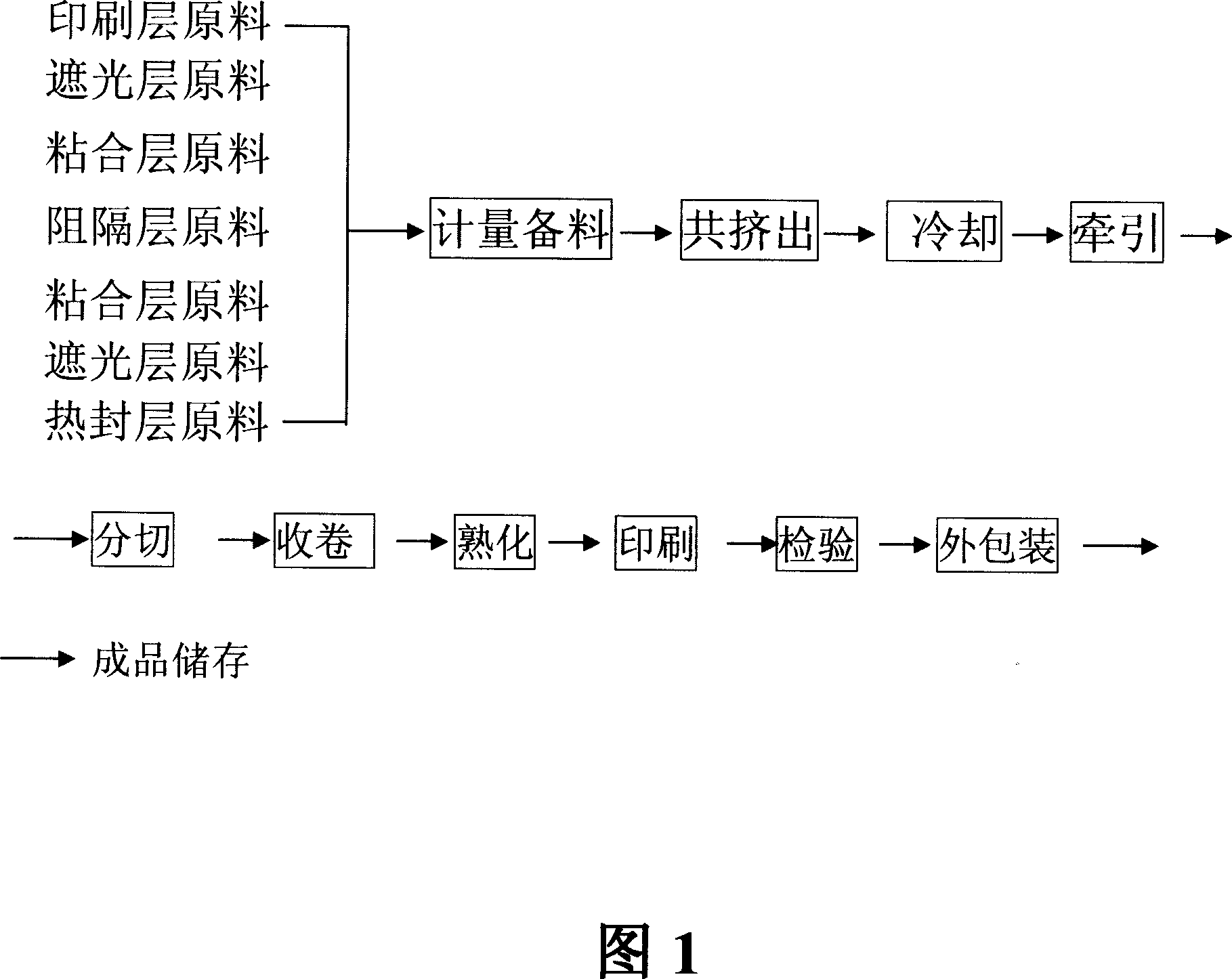

Seven-layer co-extrusion high-isolating packaging film

The seven layer high obstruct packing film includes the first printing layer made of LLDPE, LDPE and FSU; the second shading layer made of white color, LLDPE and LDPE; the third adhering layer of adhesive Tie; the fourth obstructing layer comprising EVOH; the fifth adhering layer of adhesive Tie; the sixth shading layer made of black color, LLDPE and LDPE; and the seventh thermal sealing layer made of LLDP, LDPE and FSU. The present invention possesses the advantages of non-toxicity, high humidity resistance, high oxygen resistance, high heat resistance, high flexibility, high cold resistance and high thermal sealing strength, and is used in packing milk without need of adding preservative and being cold stored.

Owner:郭瑞林

Preparation method of soft and durable anti-penetrating material

ActiveCN107815870AIncreased durabilityGood flexibilityUltrasonic/sonic fibre treatmentGrip property fibresFiberEngineering

The invention discloses a preparation method of a soft and durable anti-penetrating material. The preparation method is characterized by comprising the following steps: (1) preparing shearing thickening liquid; (2) preparing a high performance fiber fabric with a special tissue structure, namely preparing a fabric from high performance fibers by virtue of a special tissue structure weaving process, putting the fabric into a vacuum drying oven, and drying at 120-150 DEG C for 2-3 hours; and (3) preparing the anti-penetrating material. According to the method, by virtue of reasonable tissue structure configuration on the fabric and plasma treatment on the shearing thickening liquid and the fabric, the shearing thickening liquid and the fabric are adequately compounded, so that the durabilityand flexibility of the anti-penetrating material are improved, and the soft and durable anti-penetrating material suitable for multiple environments of daily protective clothes of military police, armored military equipment, civil and industrial protection and the like is prepared.

Owner:江苏威之盾安防科技有限公司

Methods of unidirectional, site-specific integration into a genome, compositions and kits for practicing the same

InactiveUS20060128020A1Facilitate site-specific recombinationReducing and avoiding secondary recombination eventSugar derivativesStable introduction of DNAIntegrasesSite-specific recombination

The subject invention provides a unidirectional site-specific integration system for integrating a nucleic acid into the genome of a target cell. The provided system includes a site-specific integrating expression cassette (INTEC) vector, consisting of (a) a polynucleotide of interest operably linked to a promoter, (b) a single recombination site, and (c) a hybrid recombination site. In using the subject systems for site-specific integration, the INTEC vector and integrase are introduced into the target cell and the cell is maintained under conditions sufficient to provide for site-specific integration of the nucleic acid into the target cell genome via a recombination event mediated by the site-specific recombinase. Also provided are kits that include the subject systems. The subjects systems, methods and kits find use in a variety of different applications, several representative ones of which are described in detail as well.

Owner:POETIC GENETICS +1

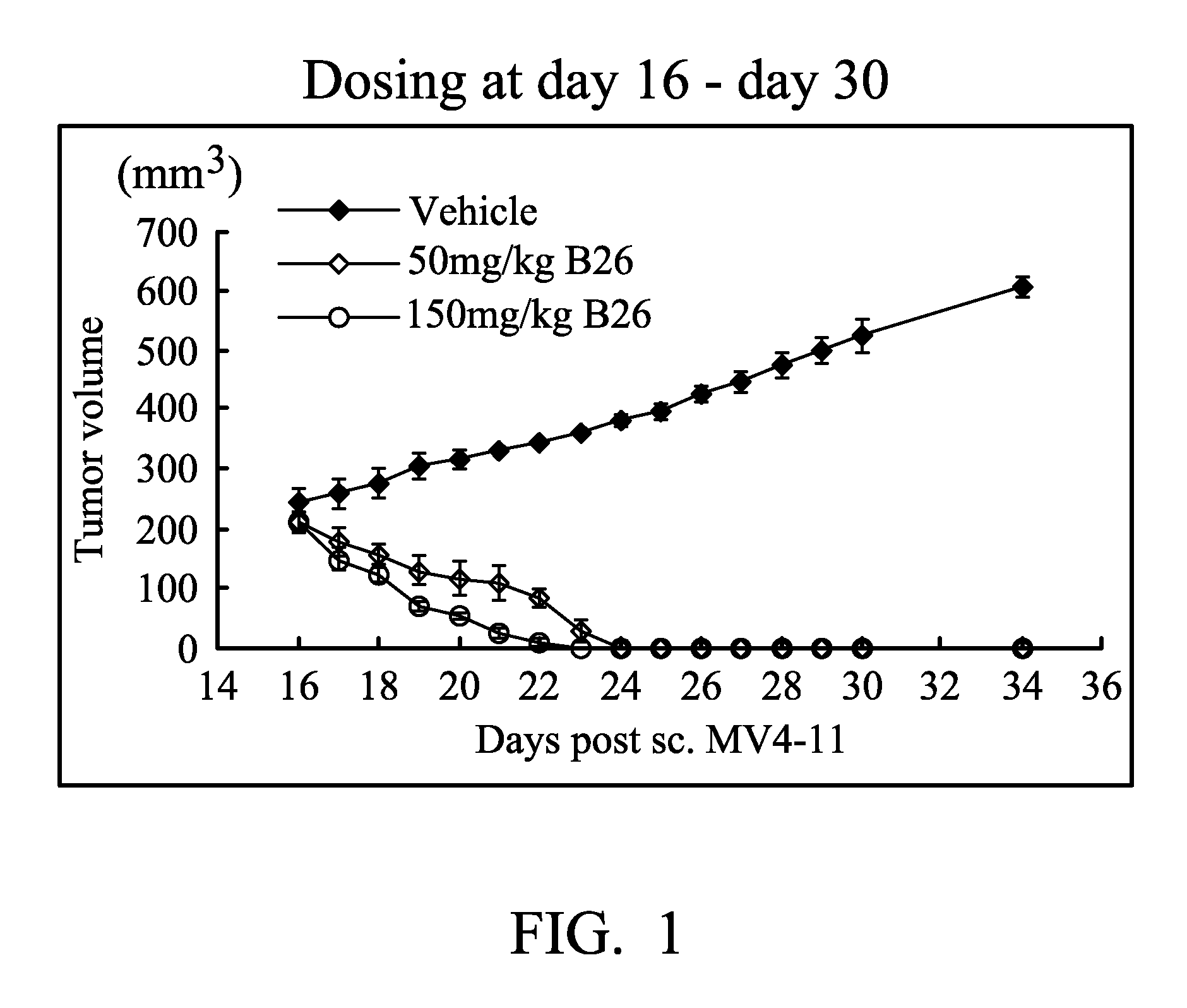

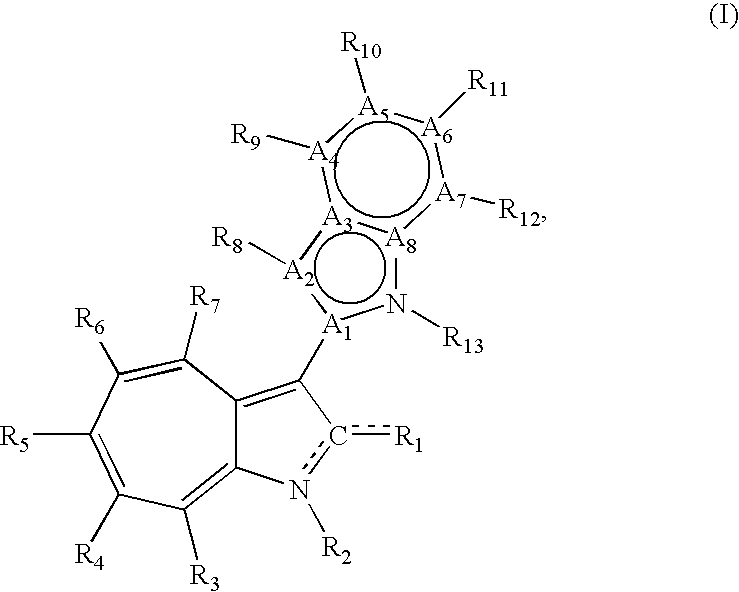

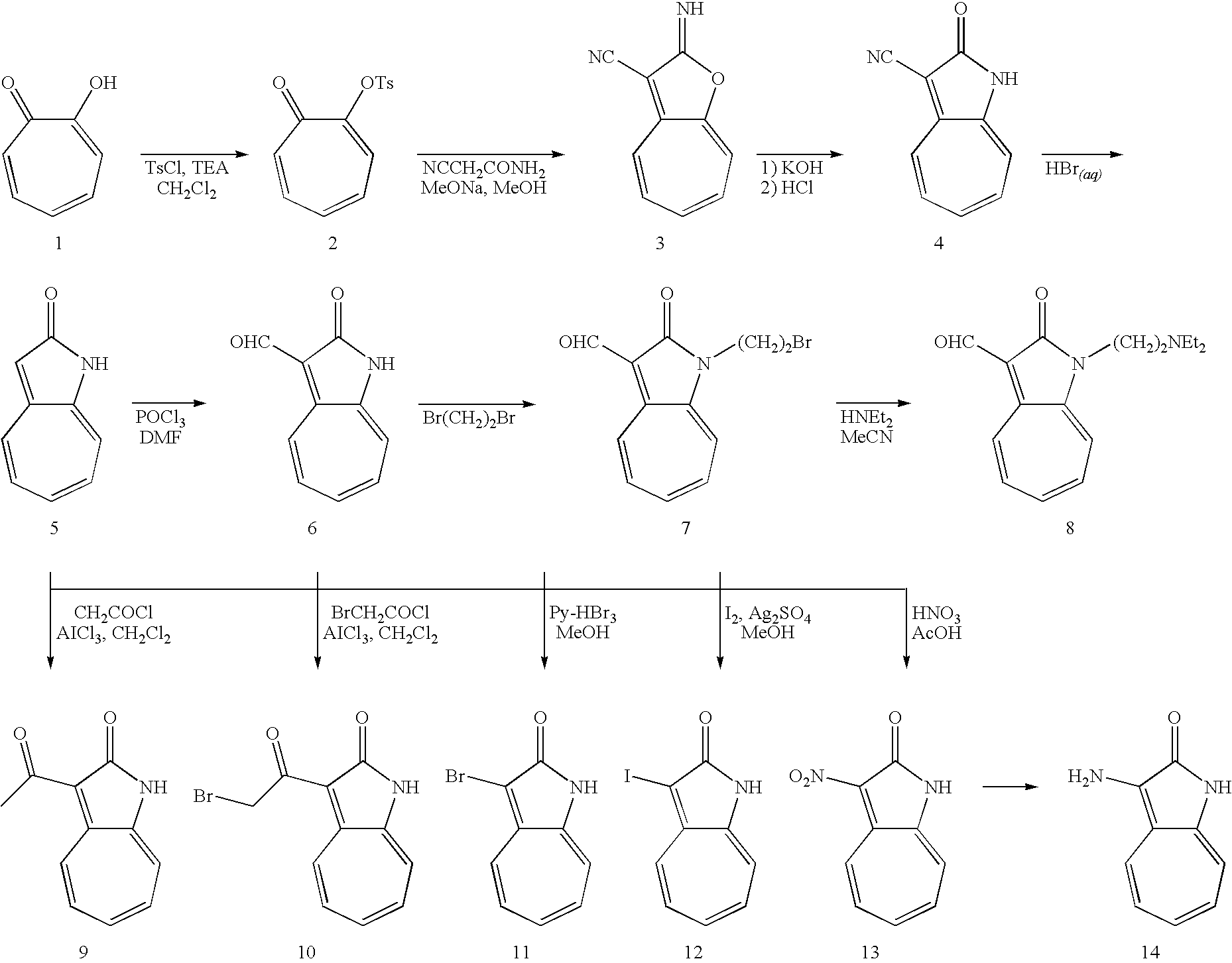

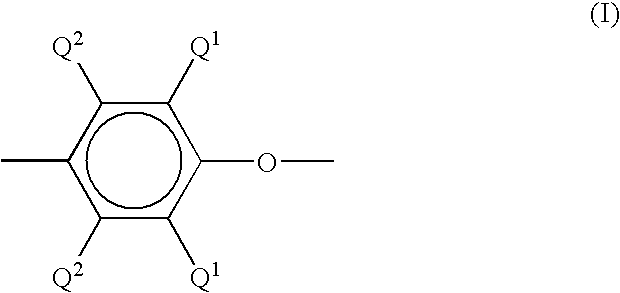

Azaazulene compounds

ActiveUS20100280012A1Inhibits protein kinase activityPromote recombinationBiocideOrganic chemistryCancer researchCancer

An azaazulene compound is provided. The azaazulene compound has formula (I) shown below. Each variable in formula (I) is defined in the specification. The compound can be used to treat cancer. The invention also provides a method for treating cancer. The method includes administering to a subject in need thereof an effective amount of one or more azaazulene compounds of formula (I).

Owner:IND TECH RES INST

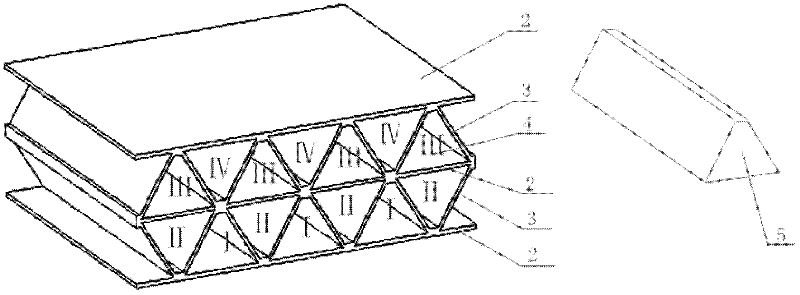

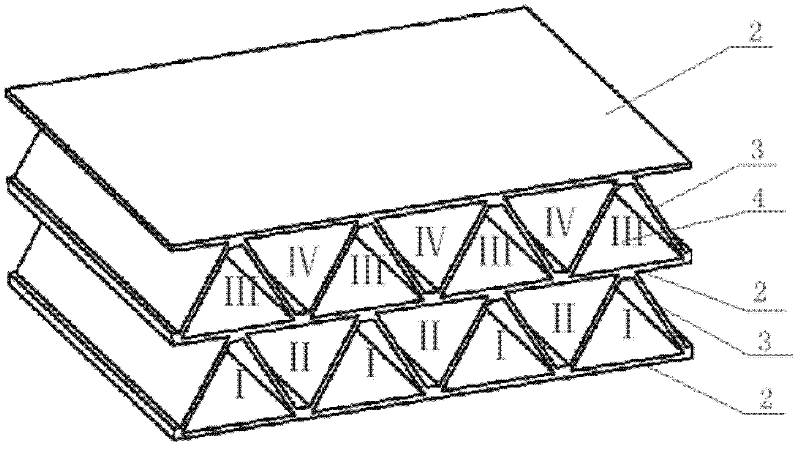

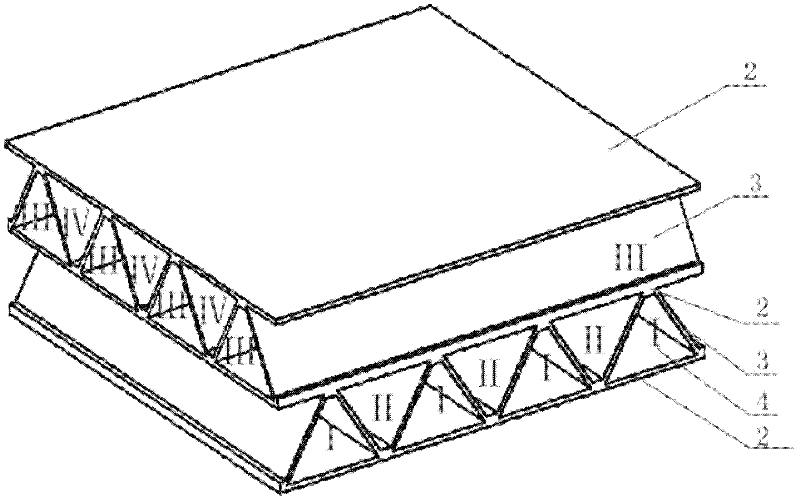

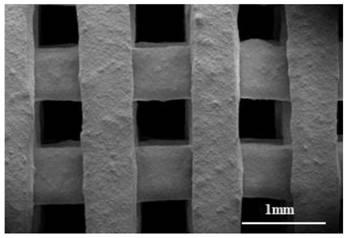

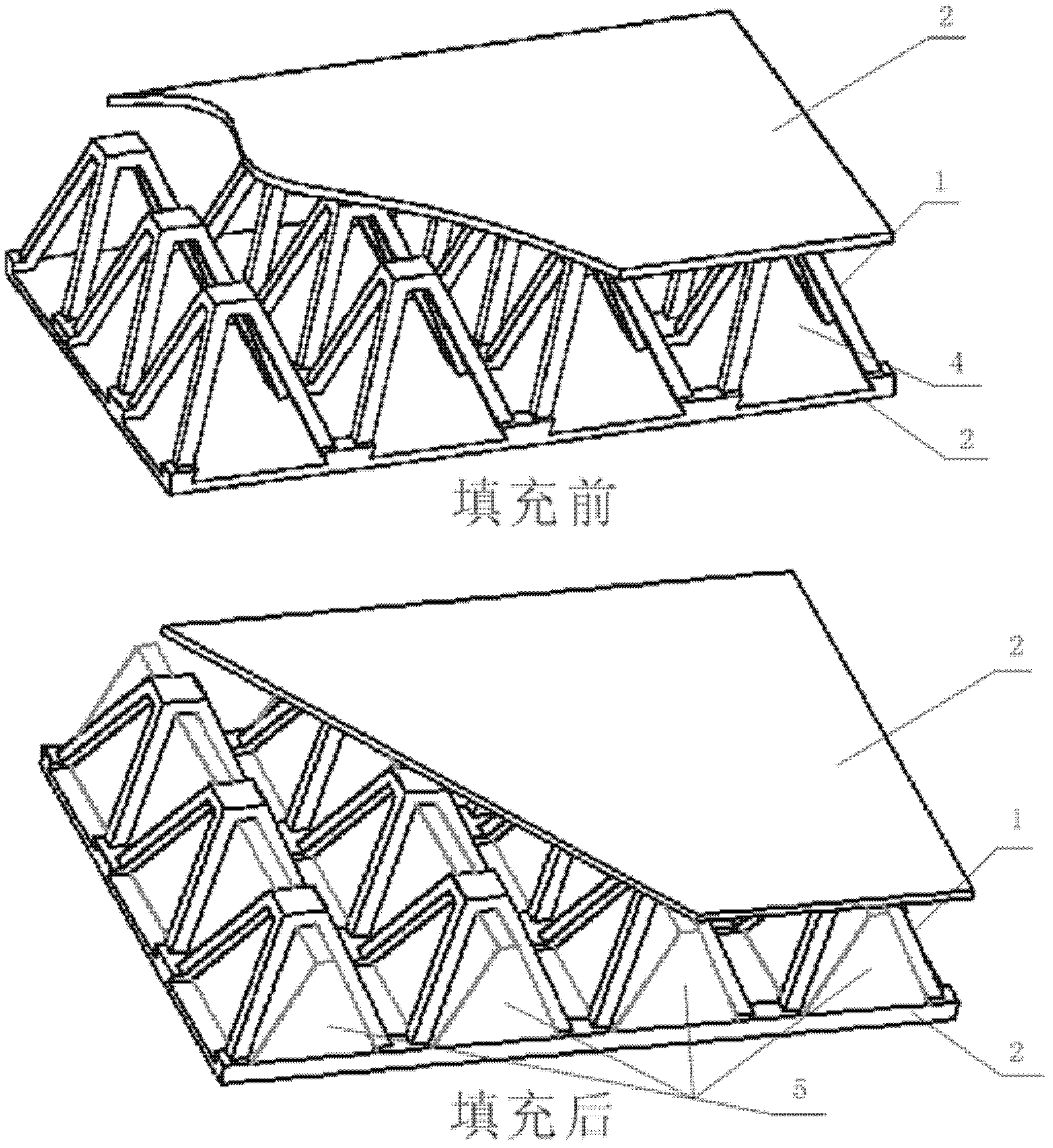

Method for preparing multilayered lattice metal and foamed aluminium composite material

InactiveCN102390136AGood mechanical propertiesImprove performanceMetal layered productsAluminum compositesLayer wise

A method for preparing multilayered lattice metal and foamed aluminium composite material comprises the steps of welding a lattice metal core body (comprising corrugated structures and pyramid structures) and a steel plates one layer after another to get the multilayered lattice metal interlayered plate, and getting the multilayered lattice metal and foamed aluminium composite material after compounding with cut foamed aluminium in a gluing manner. The invention realizes the preparation of the multilayered lattice metal material and the compounding of the multilayered lattice metal and the foamed aluminium, and can get the multilayered lattice metal and foamed aluminium composite material interlayered plate. The multilayered lattice metal and foamed aluminium composite material interlayered plate has a broad application prospect in security safeguard, military, and other fields, can effectively reduce construction weight, improves impact deformability, has excellent buffering energy-absorber effect and low intensity when being used in personnel and equipment security safeguard particularly, has obvious edges compared with solid material on specific strength and specific stiffness, and has a lower manufacturing cost.

Owner:XI AN JIAOTONG UNIV

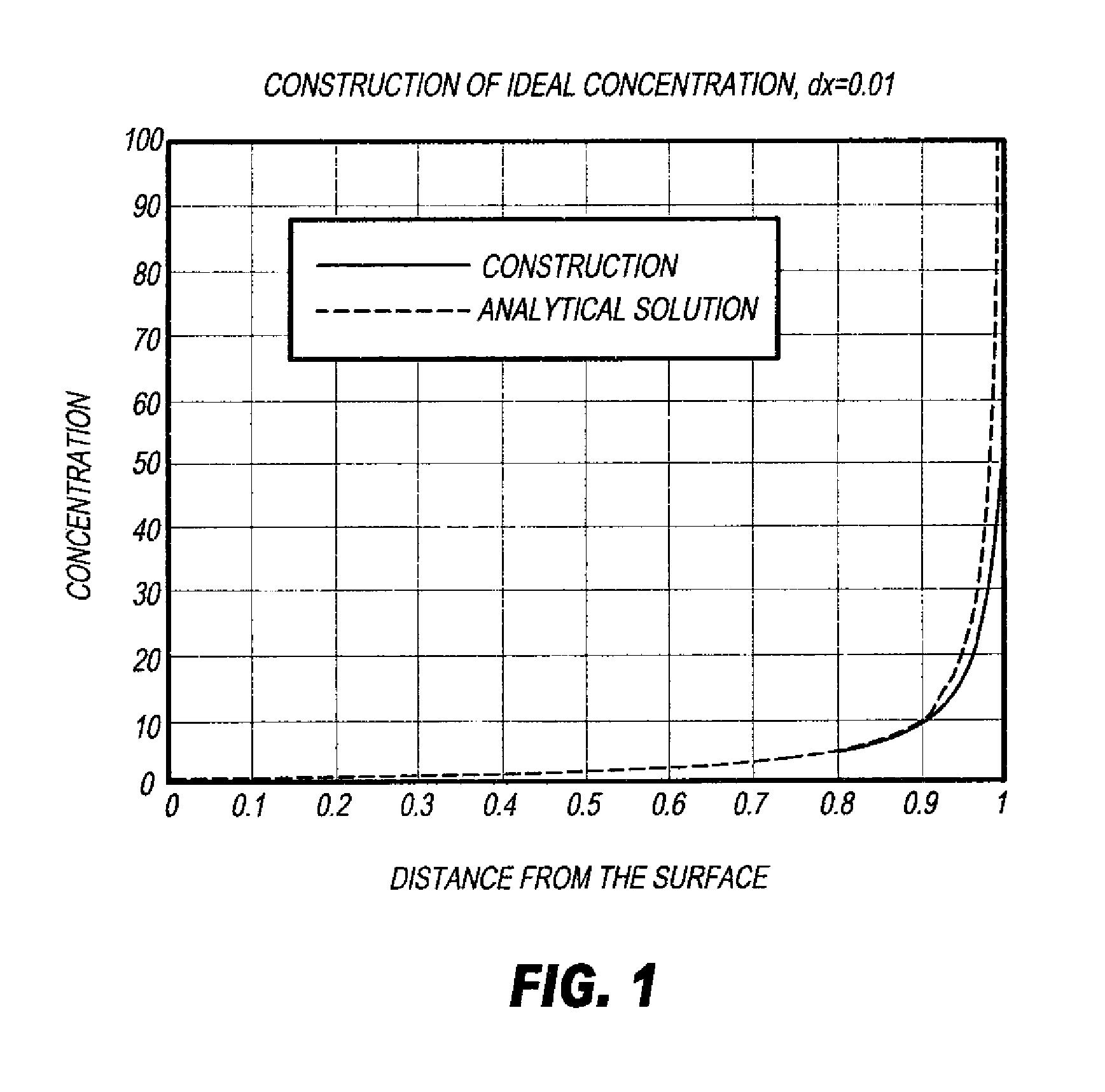

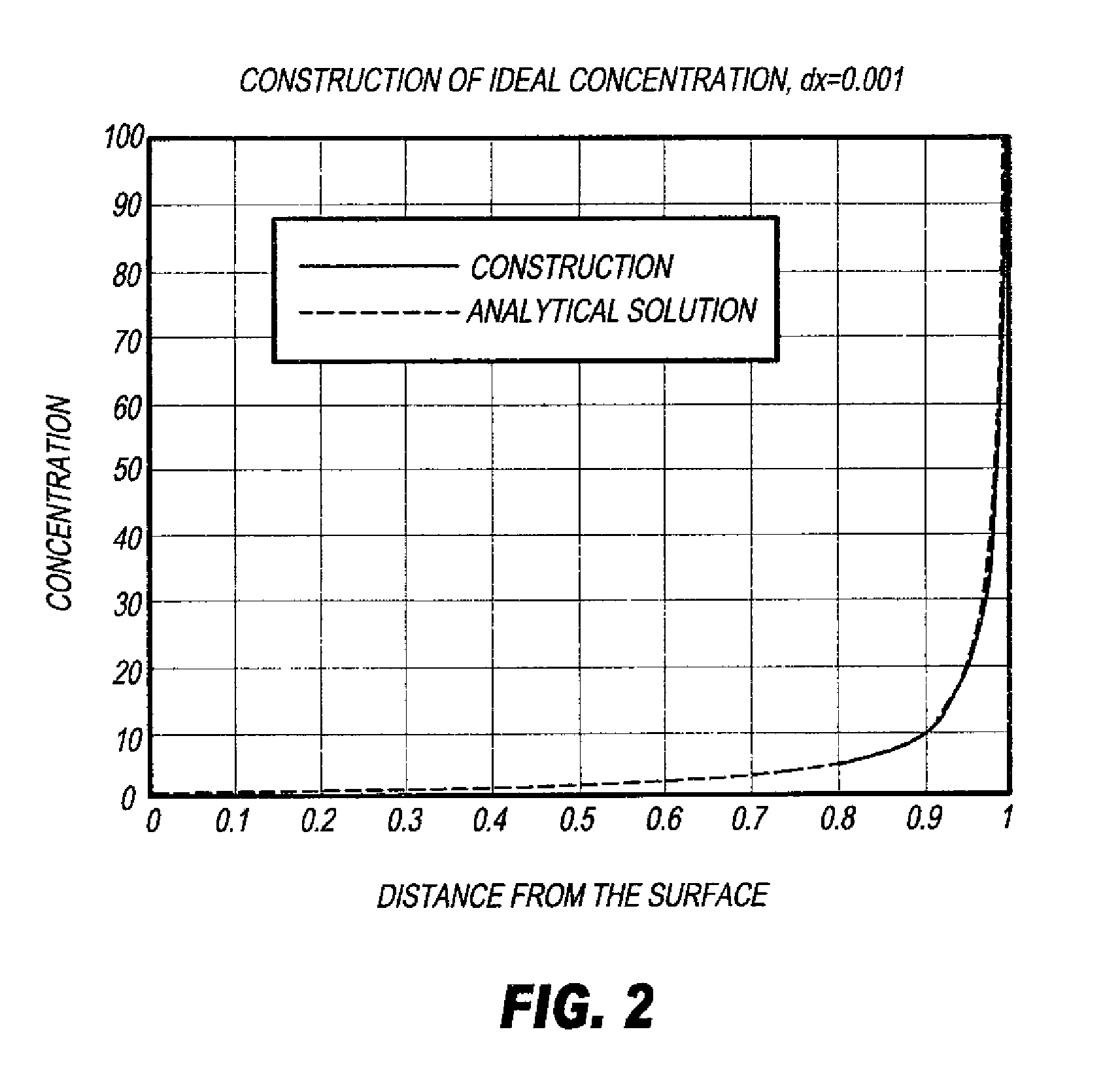

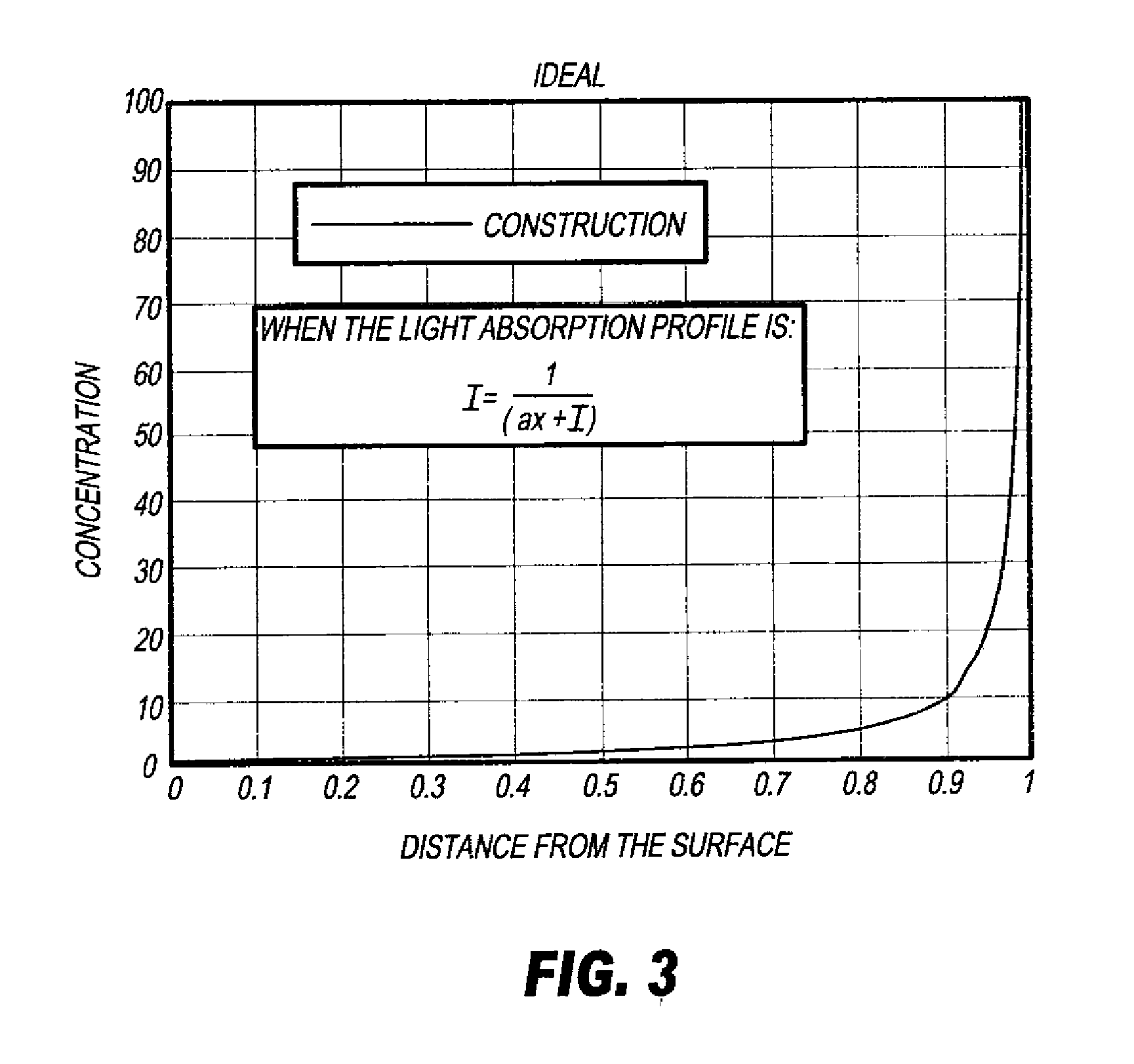

Laser-ablatable elements and methods of use

ActiveUS20110089609A1Improve ablation efficiencyPromote recombinationPhotosensitive materialsRadiation applicationsLaser engravingLaser exposure

A laser-ablatable element for direct laser engraving has a laser-ablatable, relief-forming layer that has a relief-image forming surface and a bottom surface. This relief-forming layer includes a laser-ablatable polymeric binder and an infrared radiation absorbing compound that is present at a concentration profile such that its concentration is greater near the bottom surface than the image-forming surface. This arrangement of the infrared radiation absorbing compound provides improved ablation efficiency, particularly when laser exposure is carried out adiabatically.

Owner:MIRACLON CORP

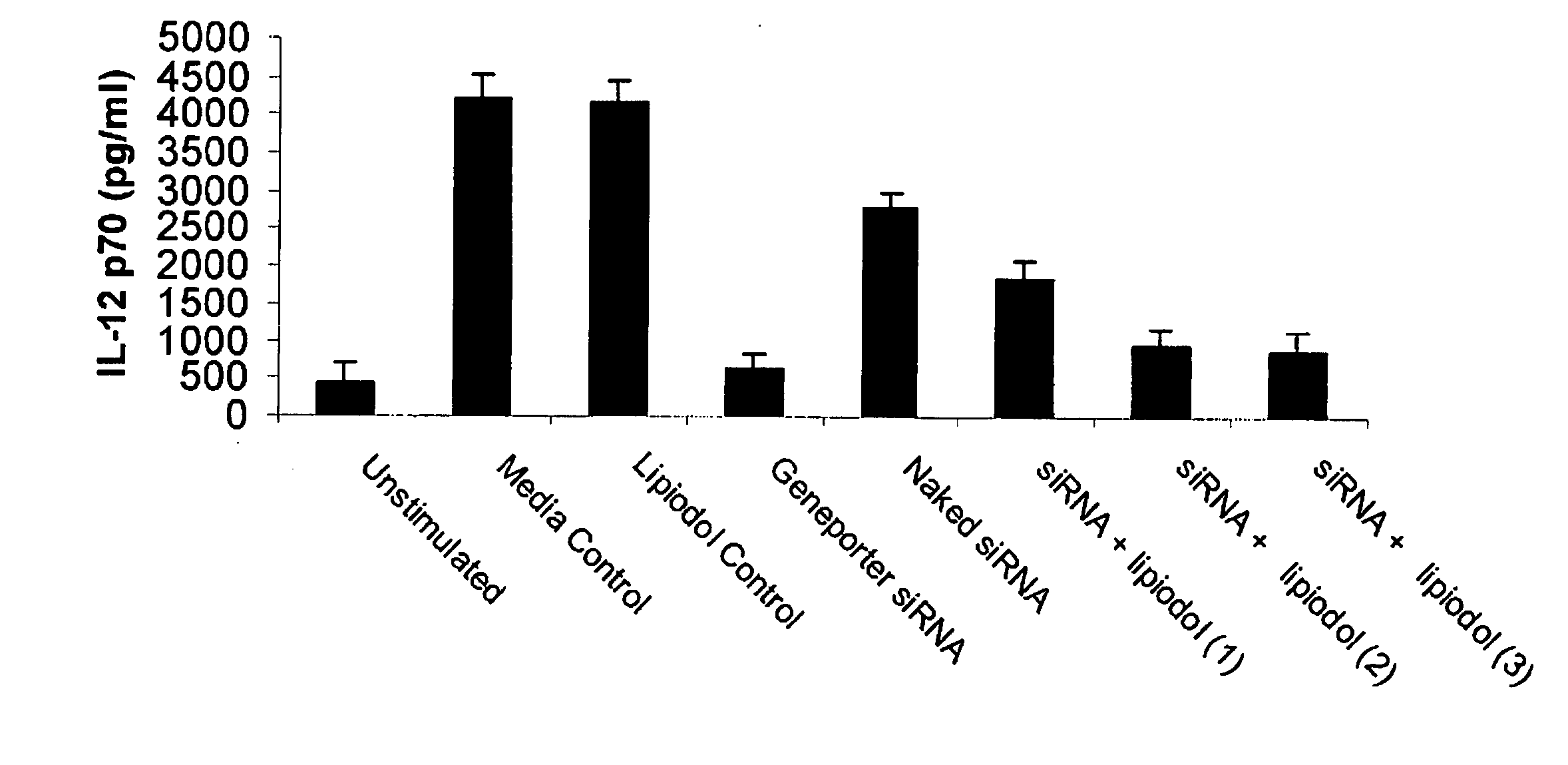

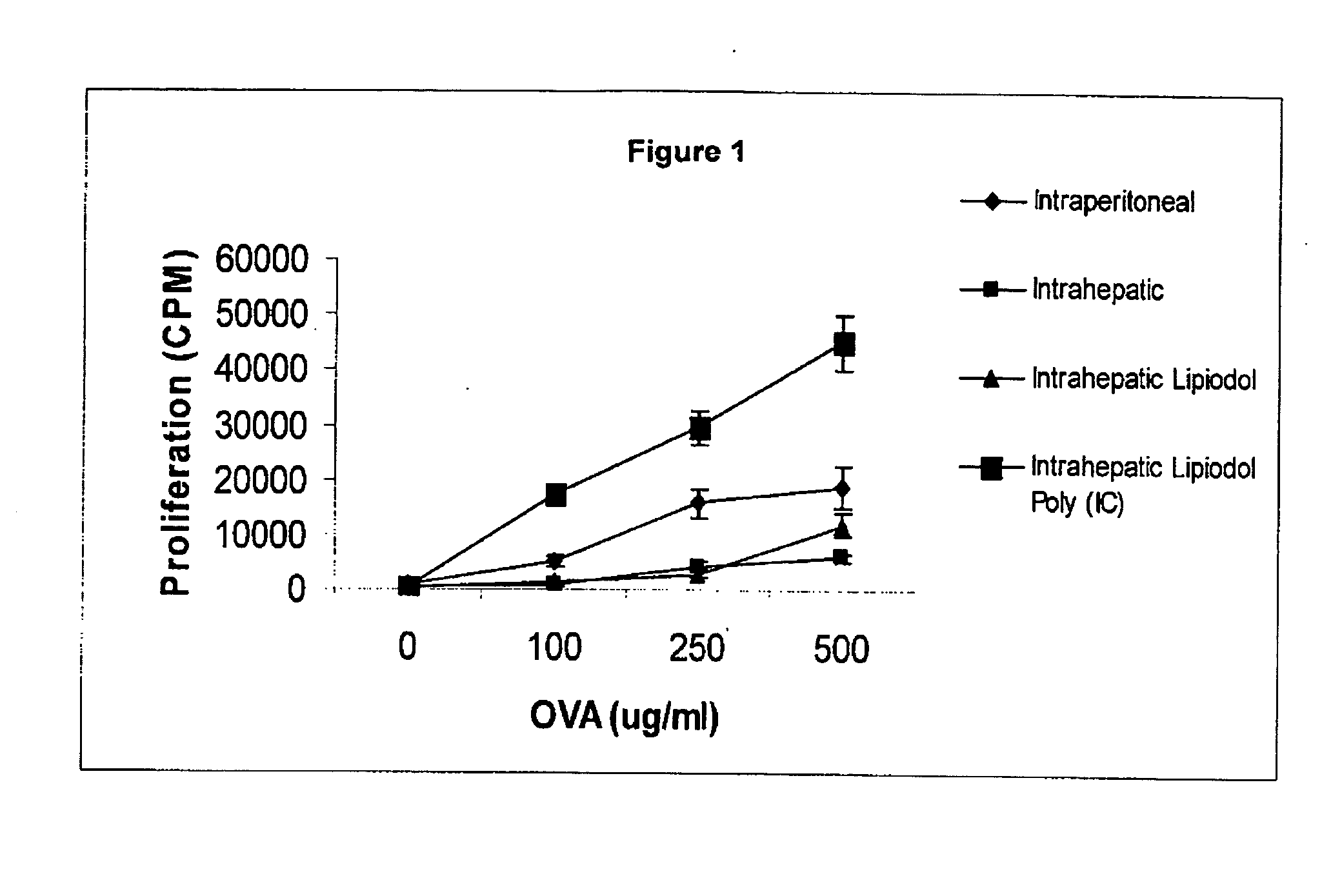

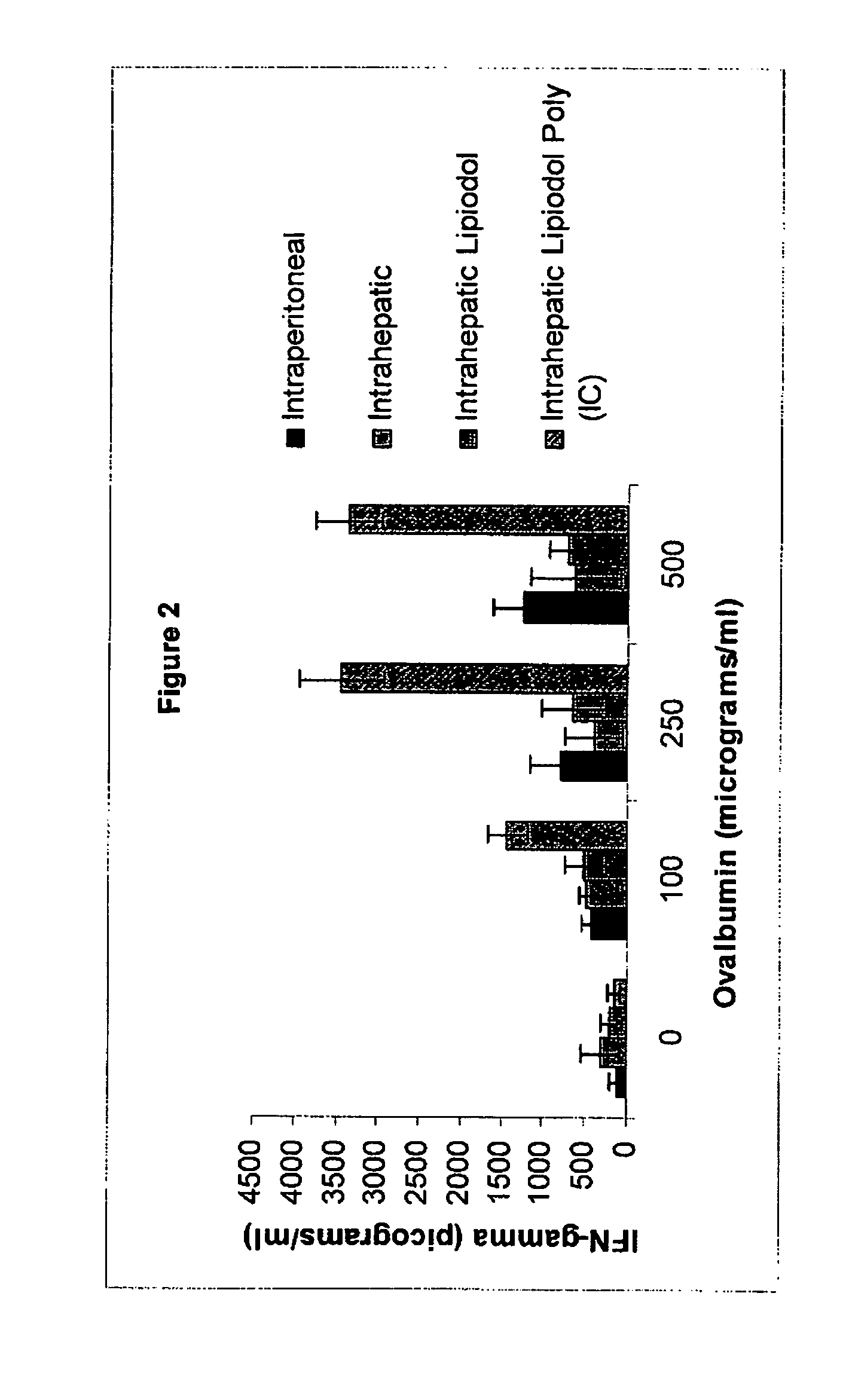

Transcatheter tumor immunoembolization

InactiveUS20070269406A1Providing therapyPrevent implantationSpecial deliveryPeptide/protein ingredientsAbnormal tissue growthIMMUNE STIMULANTS

Methods of inducing a cancer-specific immune response are disclosed through administration of an immune stimulant in the context of tumor cell death induction. Currently used clinical methods of inducing localized tumor cell death are modified to optimize immune response induction. One embodiment of the invention discloses pharmaceutical compositions and kits for modifying the palliative procedure of transarterial chemoembolization so as to promote uptake and presentation of tumor antigens in an immunostimulatory microenvironment, thereby allowing for induction of T cell, B cell and NK responses, which control not only local, but also systemic tumor growth and metastasis.

Owner:ICHIM THOMAS E

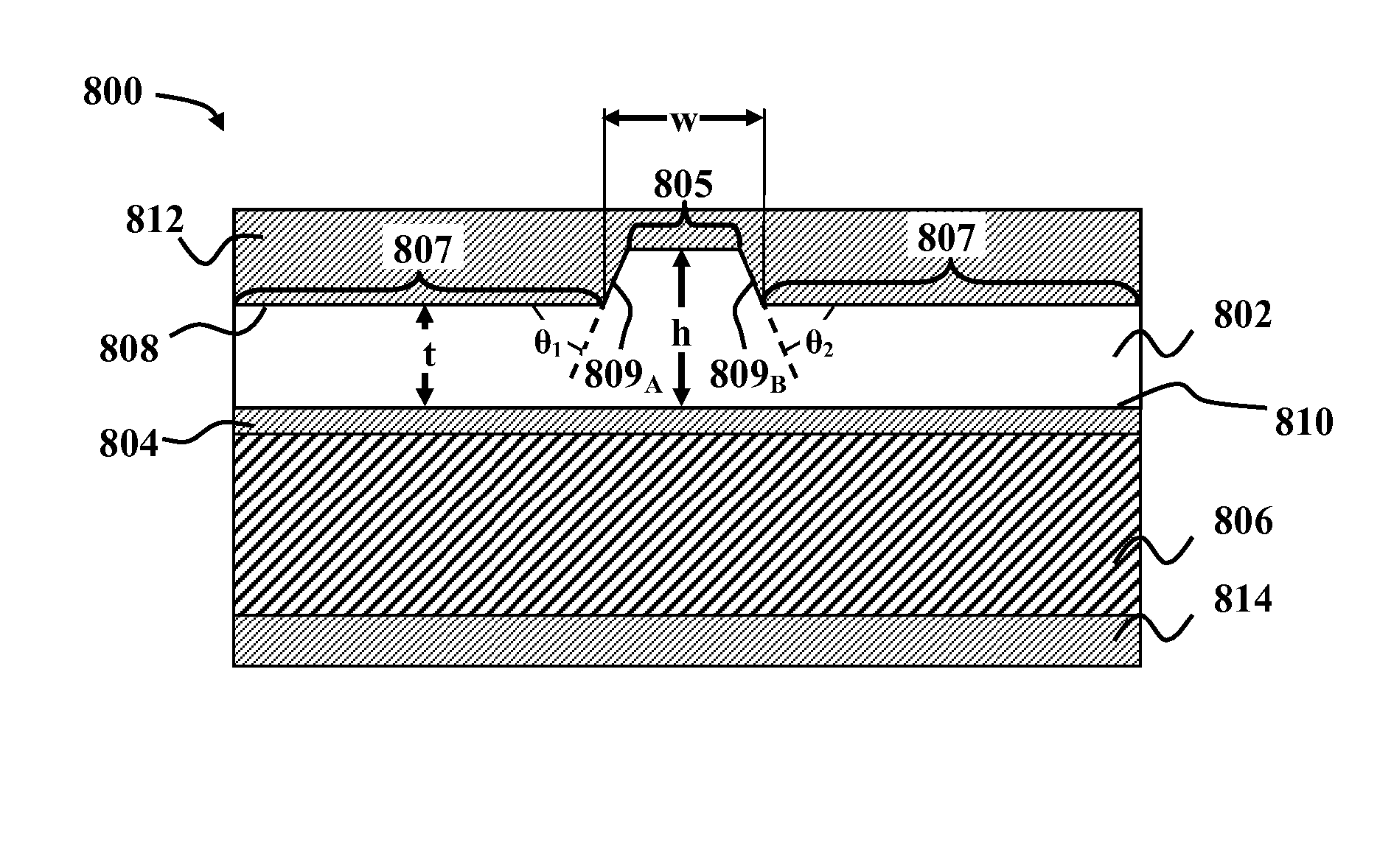

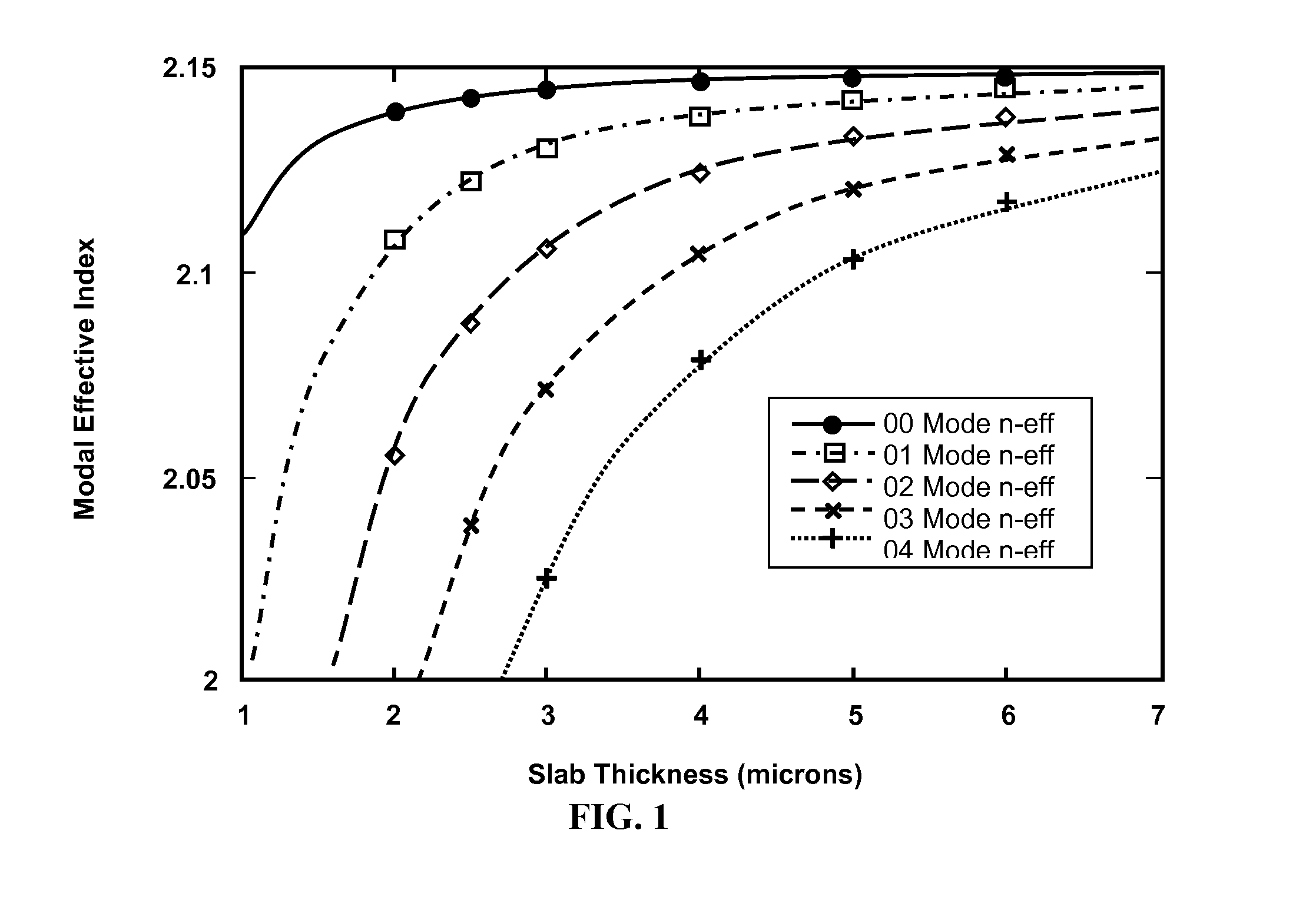

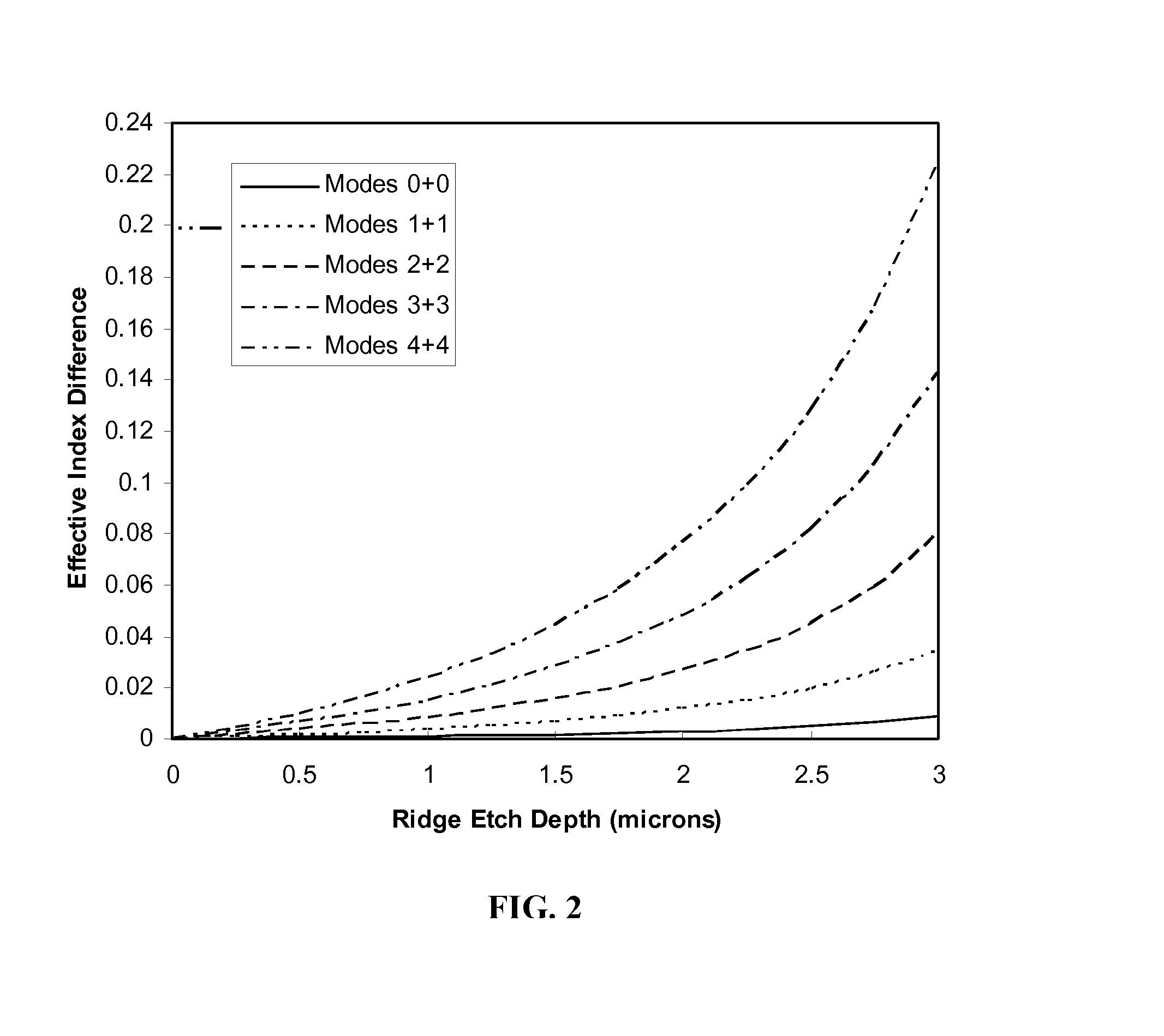

Efficient nonlinear optical waveguide using single-mode, high v-number structure

InactiveUS20070297732A1Increase the number ofIntuitive presentationOptical light guidesNon-linear opticsBasic modeWaveguide

Owner:CARR & FERRELL

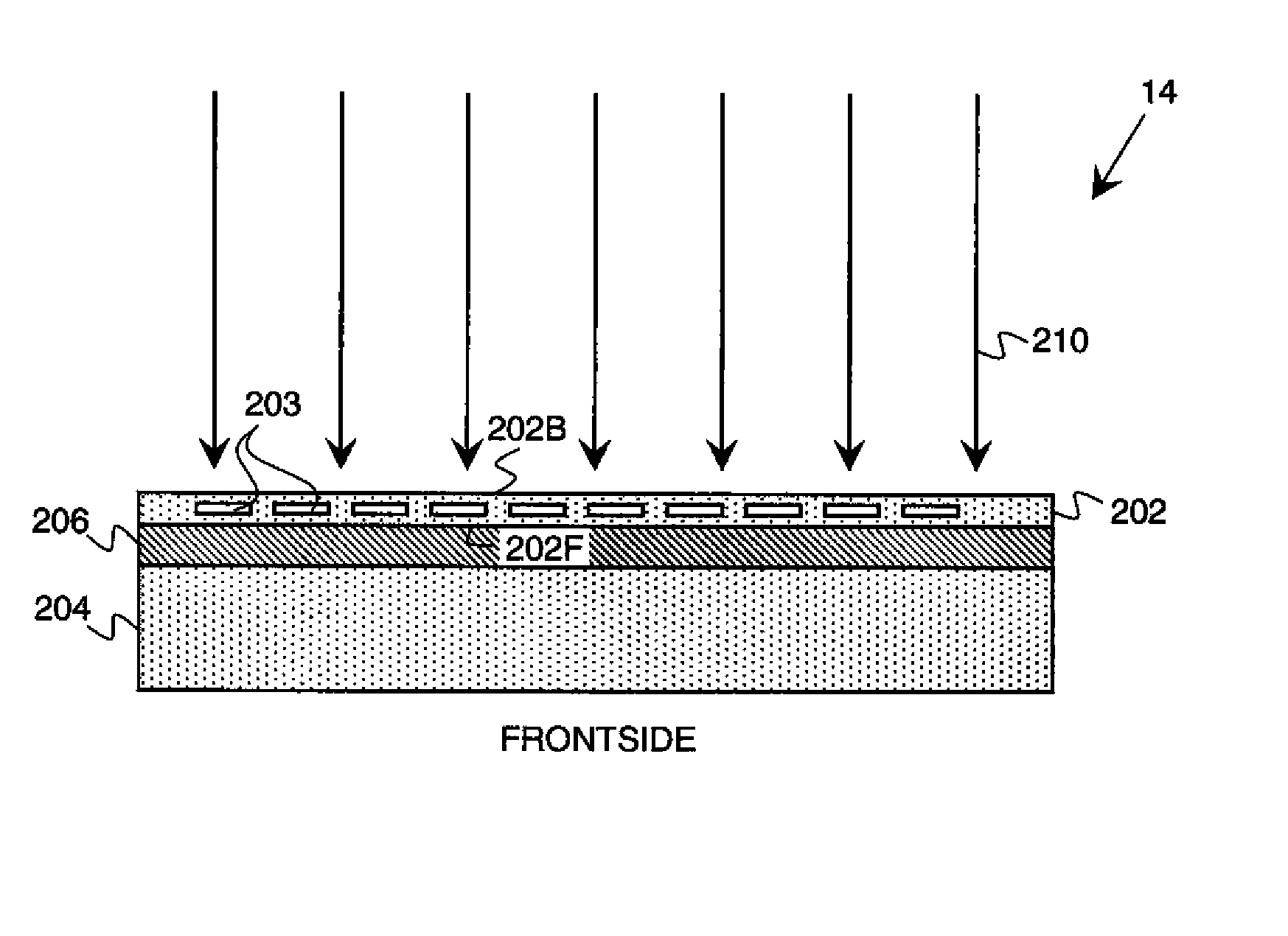

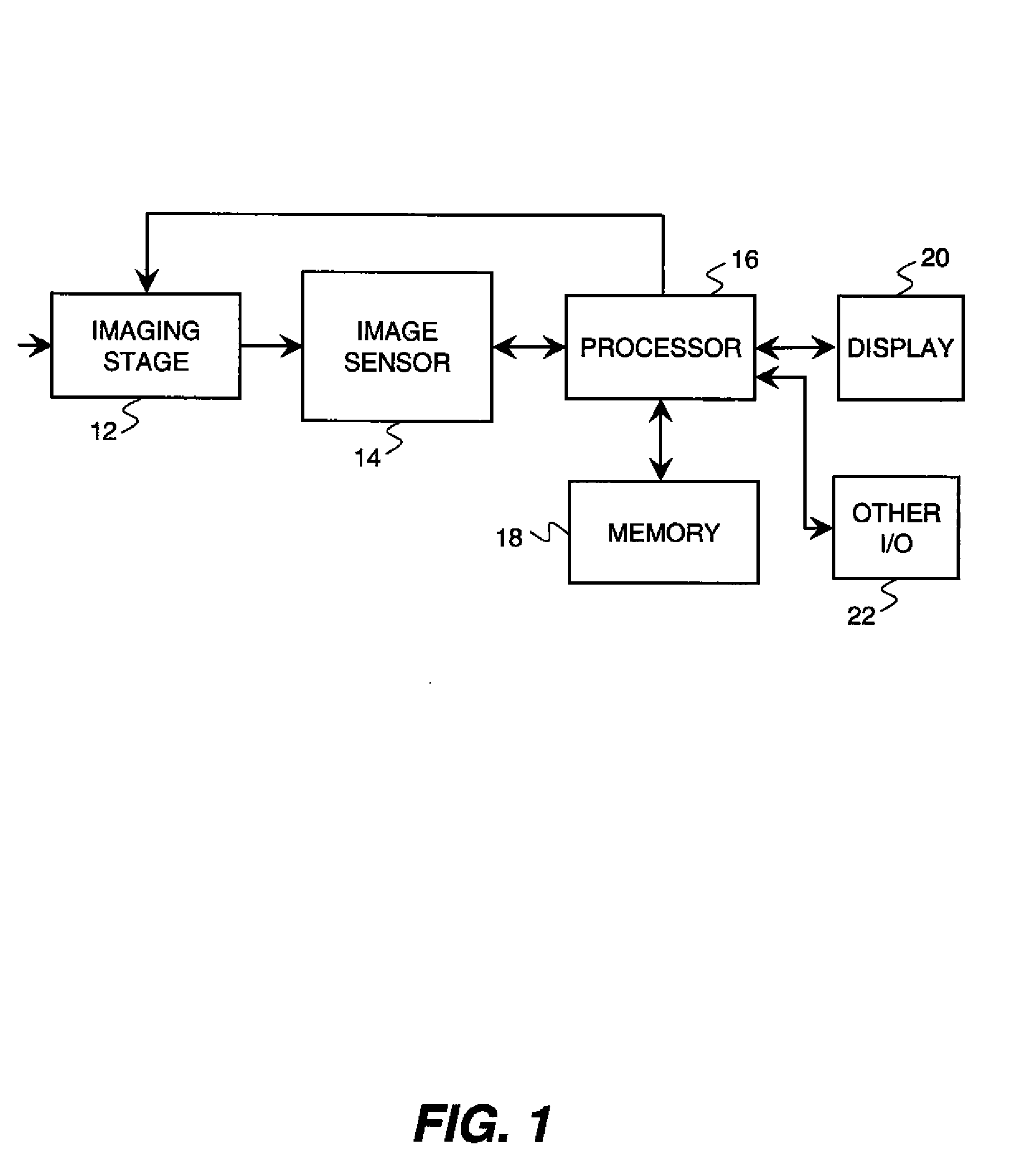

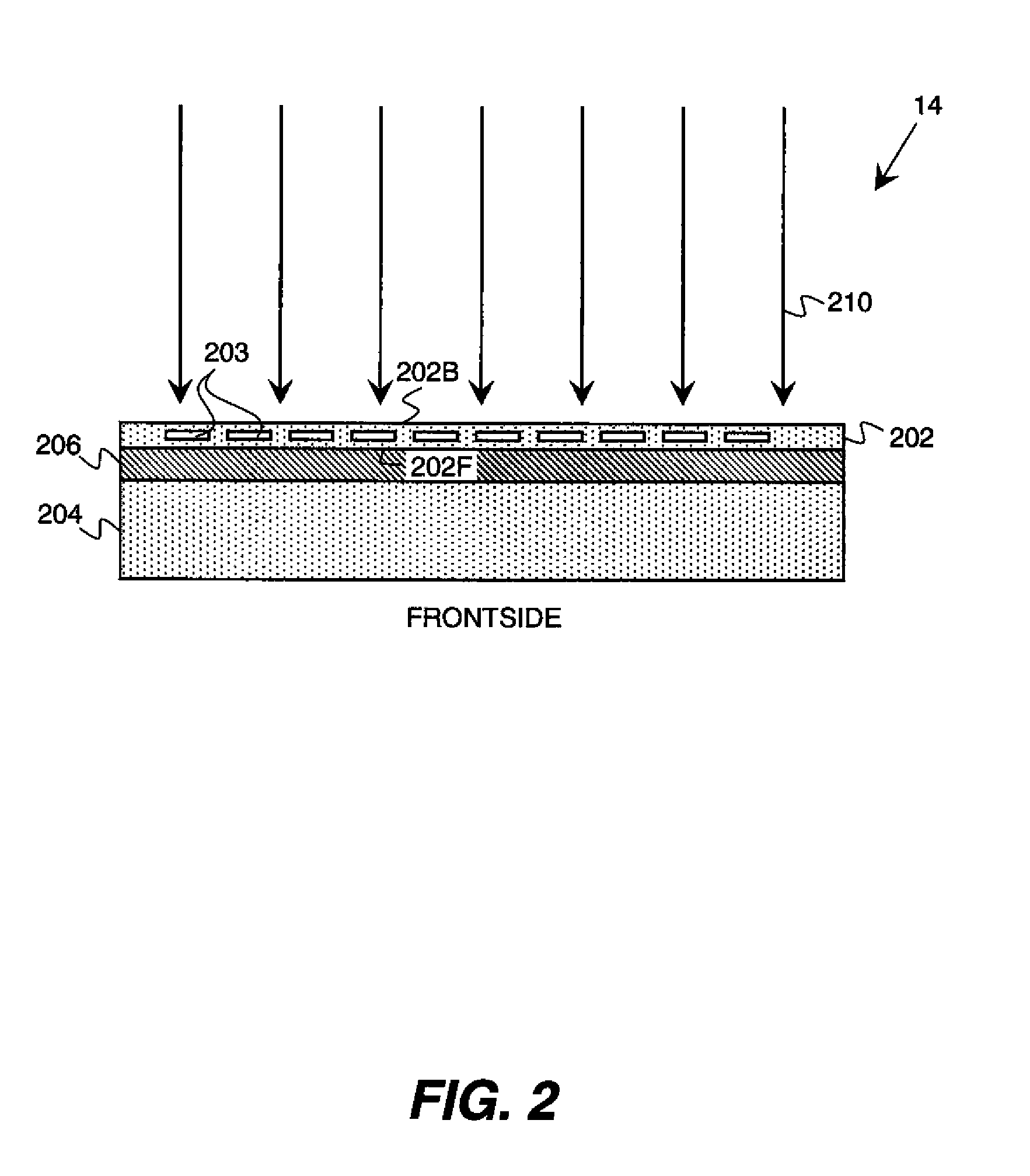

Image sensor with reduced red light crosstalk

InactiveUS20100026824A1Improve performanceReduce red light crosstalkTelevision system detailsSolid-state devicesPixel arrayRed light

An image sensor having a pixel array includes a sensor layer comprising a plurality of photosensitive elements of the pixel array, a circuit layer comprising circuitry associated with the pixel array, and a crosstalk reduction layer arranged between the sensor layer and the circuit layer and configured to reduce crosstalk between adjacent ones of the photosensitive elements. The crosstalk reduction layer may comprise, for example, an amorphous silicon germanium (a-SiGe) layer specifically configured to reduce red light crosstalk in the image sensor. The image sensor may be implemented in a digital camera or other type of digital imaging device.

Owner:EASTMAN KODAK CO

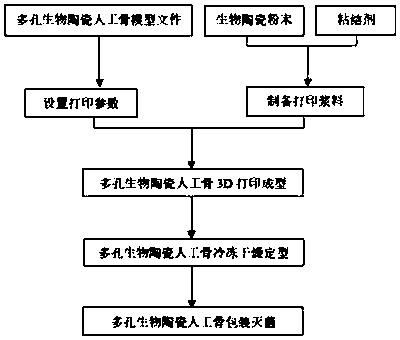

3D printing bionic porous biological ceramic artificial bone and preparation method thereof

ActiveCN111070376APrecise porosity controlGood molding propertiesAdditive manufacturing apparatusBone implantHuman bodyTissue fluid

The invention discloses a 3D printing bionic porous biological ceramic artificial bone and a preparation method thereof. A porous biological ceramic artificial bone model is designed through a TPMS and CSG combined method, slurry capable of being used for printing is prepared through biological ceramic powder and a binding agent, macropores and micropores are distributed in the porous biological ceramic artificial bone prepared through the combination with the 3D filament-free printing process, the pore diameter of the micropores is smaller than 100 micrometers, the pore diameter of the macropores is 200-800 micrometers, the total porosity is 20% to 80%, the communicating rate between the macropores is not lower than 99%, precise design of porosity, communication and homogeneity in the artificial bone is achieved, and meanwhile good pore communication is ensured. Adopted raw materials have good biocompatibility, entry passageways of cells and tissue fluid are provided by the macropores, the micropores can better adsorb tissue fluid nearby for cell growth, the cell growth speed and the new bone generation speed can be increased by combining the micropores with the marcropores, and application of the porous biological ceramic artificial bone in human body large bone defect repair clinic treatment is facilitated.

Owner:西安点云生物科技有限公司

Method for making a conductive thermoplastic composition

InactiveUS20040238793A1Promote recombinationImprove conductivityConductive materialSpecial tyresPolyamideEther

PROBLEM TO BE SOLVED: To provide a production method for a thermoplastic resin composition, composed of a polyphenylene ether and a polyamide, having an electric conductivity, and excellent in balance of fluidity and impact strength, by producing with a specific process, and to provide the thermoplastic resin composition obtained thereby. SOLUTION: The thermoplastic resin composition is composed of the following component (A)-(E), wherein a weight ratio of (A) / (B) is 5 / 95-70 / 30, an amount of (C) is effective to phase-solvate (A) and (B), the amount of (D) is 0.8-10 pts.wt. per the total 100 pts.wt. of (A) and (B), and the amount of component (E) is 5-40 pts.wt. per the total 100 pts.wt. of (A) and (B). The production method for the thermoplastic resin composition is provided. (A): a polyphenylene ether, (B): a polyamide. (C): a phase-solvating agent, (D): an electrically conductive carbon black and / or a fine fibrous carbon, and (E) an improving agent for shock resistance.

Owner:SABIC GLOBAL TECH BV

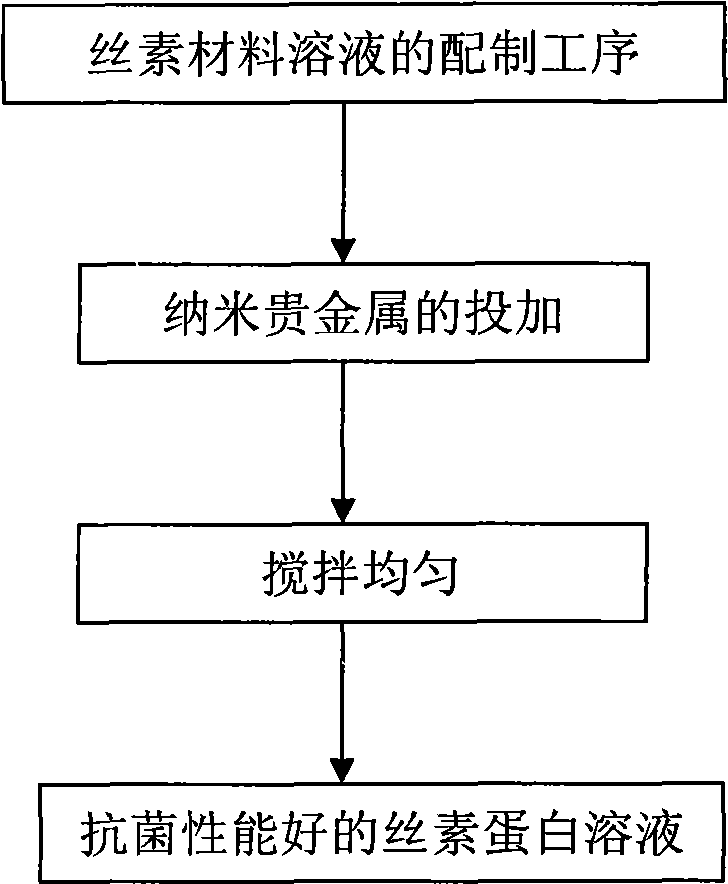

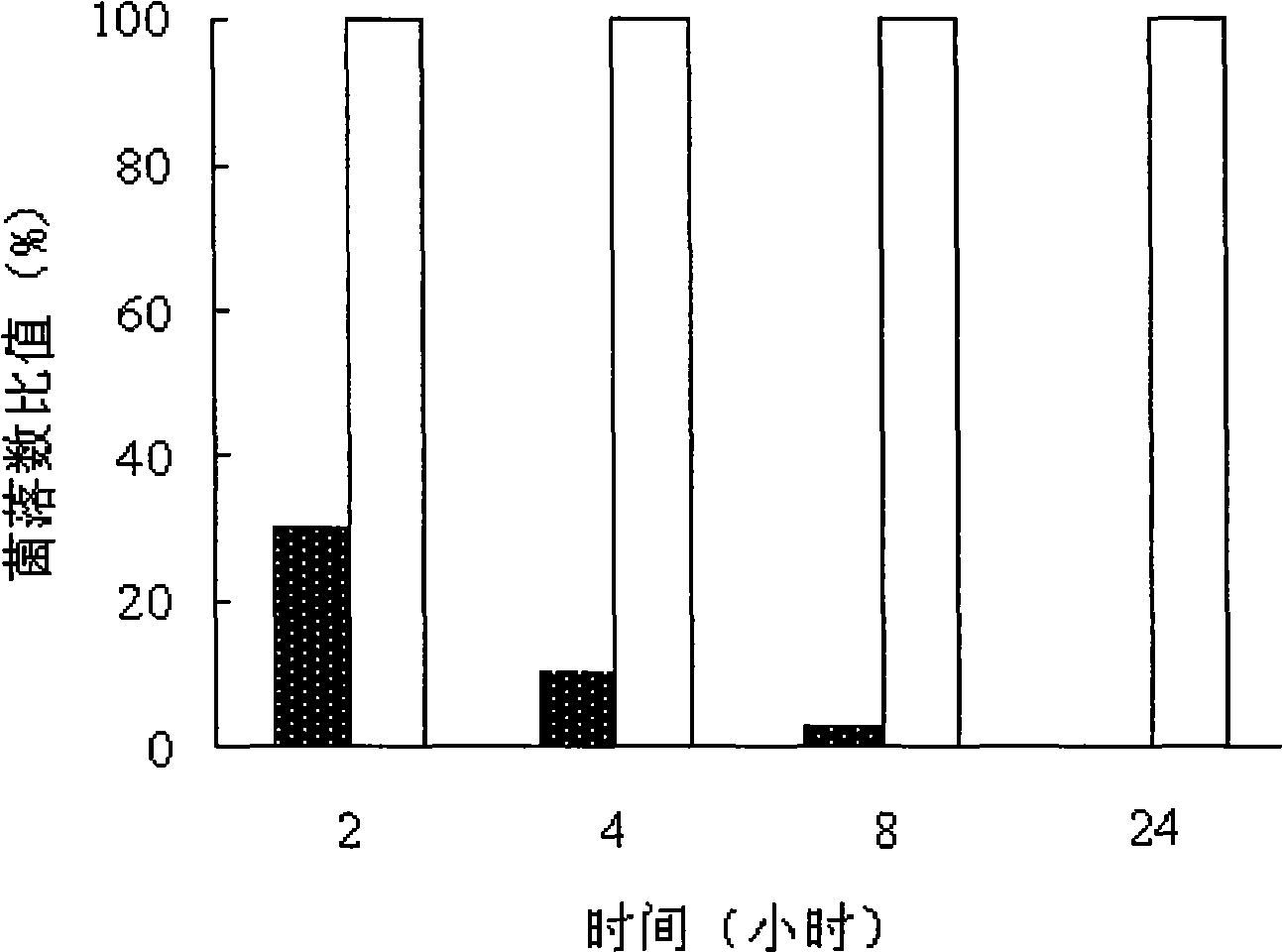

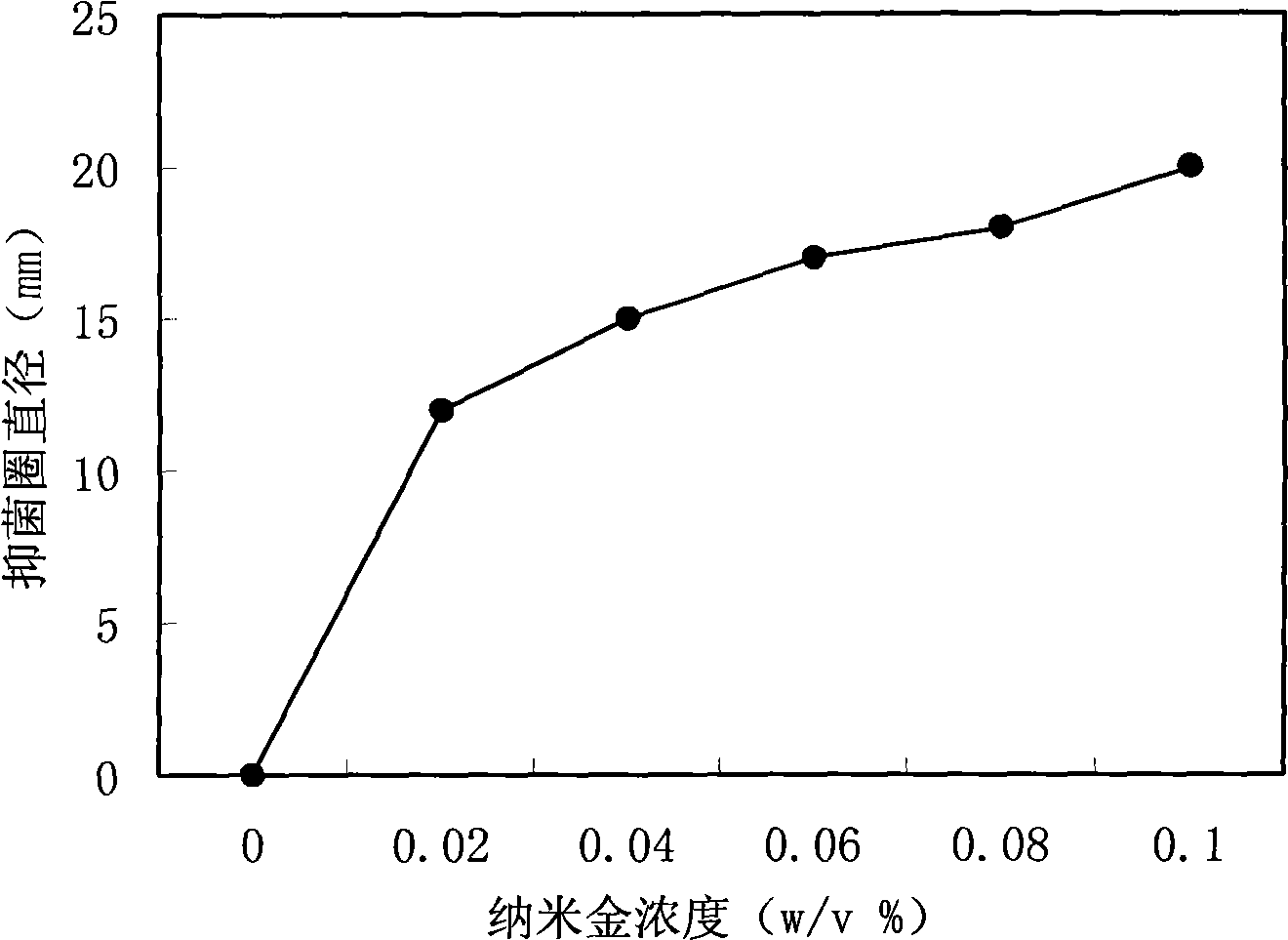

Method for improving antibiosis of silk fibroin material

InactiveCN101498061AEasy to get materialsUniform and effective releaseMonocomponent fibroin artificial filamentArtifical filament manufactureAntibiosisEngineering

The invention relates to a method of improving the bacterinertness of a silk fibroin solution. Silk fibroin material has favorable prospects when applied in biomedicine aspect, and thus the search of a method of improving the bacterinertness of silk material is meaningful. The invention comprises a silk fibroin solution preparing working procedure which adopts silk fibroin to prepare the silk fibroin solution and is characterized by also comprising a nanometer noble metal feeding working procedure by selecting nanometer noble metal with the grain diameter between 5 nanometers to 100 nanometers. When a temperature is between 0 DEG C to 50 DEG C, the nanometer noble metal is fed to a stand-by silk fibroin solution and is stirred at a rotating speed of 100-400 round / min to obtain the silk fibroin solution comprising the nanometer noble metal; the concentration of the silk fibroin is 0.5-15w / v percent, and the concentration of the nanometer noble metal is 0.005-0.2w / v percent. The invention can favorably improve the antibiotic performance of the silk fibroin solution so that the silk fibroin can be more widely applied to biological material.

Owner:ZHEJIANG UNIV

Preparation method of organic-chain-segment-modified graphene oxide

InactiveCN102745672APreparation helpsPromote recombinationCarbon compoundsOrganosolvPotassium manganate

The invention discloses a preparation method of organic-chain-segment-modified graphene oxide. According to the invention, graphite is oxidized under the effects of strong oxidizing agents such as concentrated sulfuric acid, sodium nitrate and potassium permanganate; the oxidized graphite is subjected to ultrasonic dispersion in an organic solvent, such that a graphene oxide dispersion system is prepared; diisocyanate and dihydric alcohol are subjected to a reaction; hydroxyacrylate is used for sealing one end; and an NCO group in the organic chain segment is subjected to a reaction with the prepared graphene oxide, such that the organic-chain-segment-modified graphene oxide is prepared. The organic chain segment contains polymerizable double bonds, such that cross-linking polymerization of the modified graphene oxide and other organic materials can be promoted, and composite materials with special properties can be obtained.

Owner:SHENZHEN POLYTECHNIC

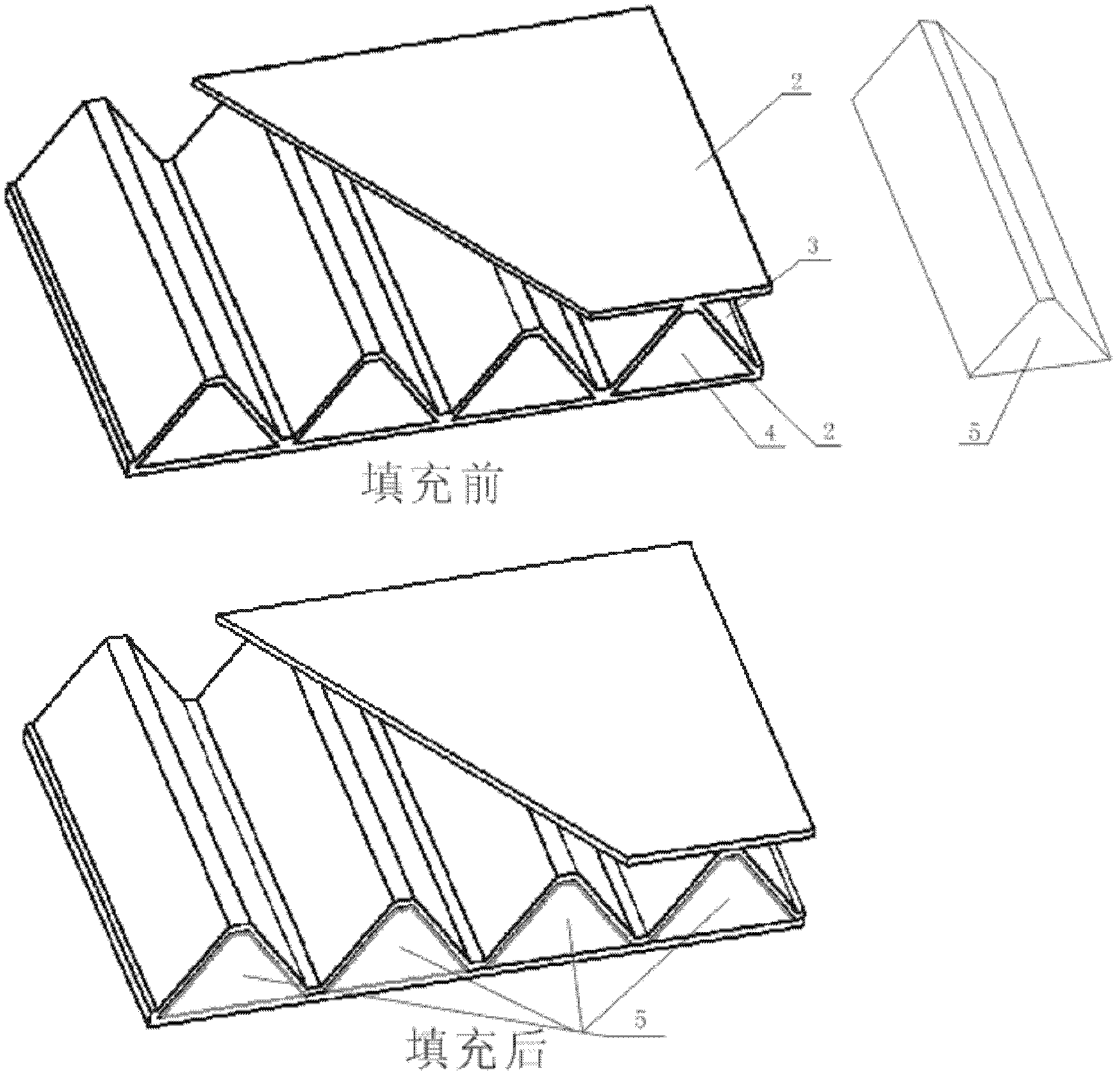

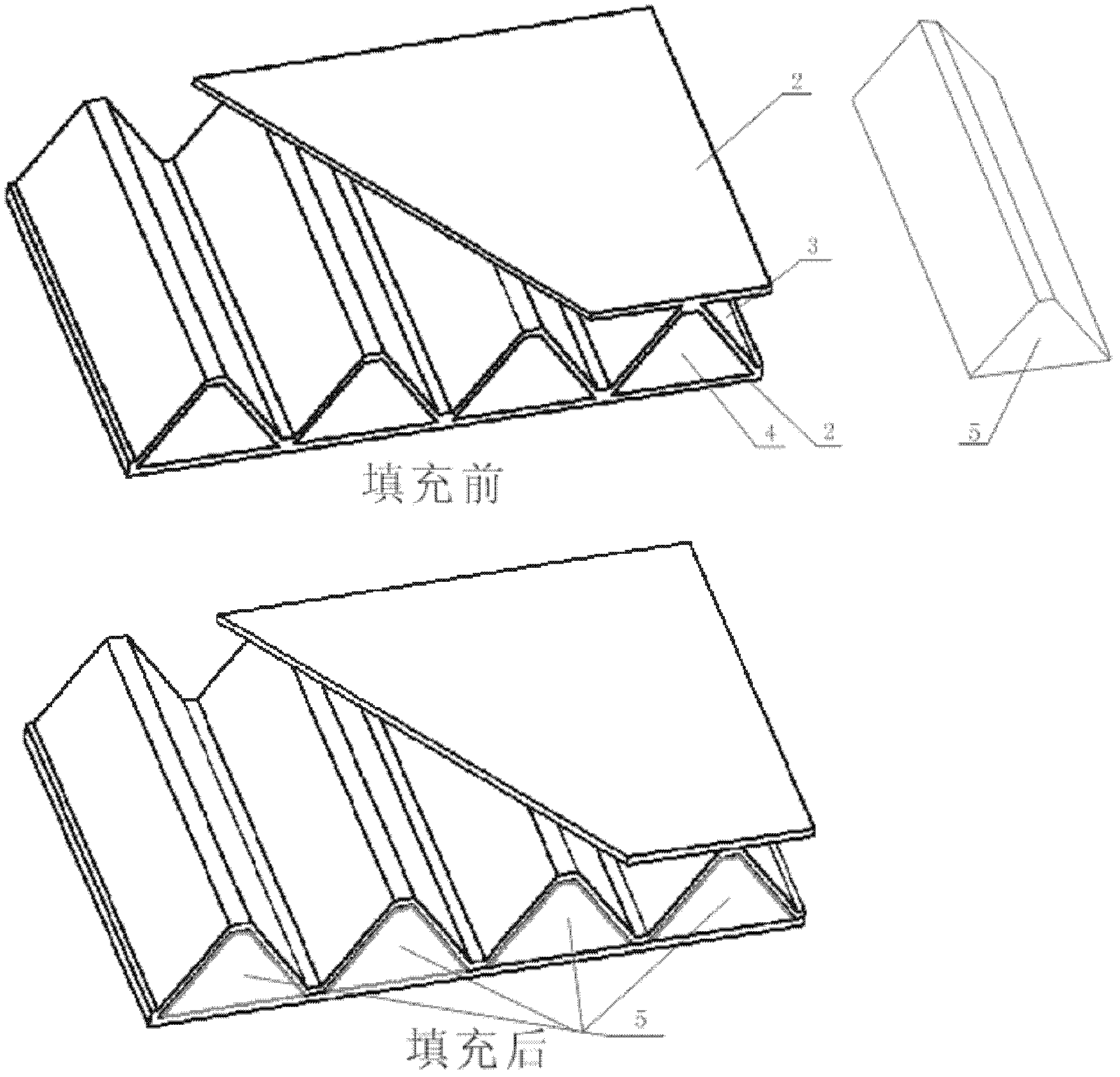

Lattice-gradient foamed aluminum composite material and preparation method thereof

InactiveCN102416713AImprove performanceGood mechanical propertiesMetal layered productsMetallic materialsHigh intensity

A preparation method of a lattice-gradient foamed aluminium composite material comprises the adhesive bonding and combination of a lattice metal material (including a ripple structure and a pyramid structure) and a cut foamed aluminium to obtain a multifunctional gradient composite porous material. The invention realizes the combination of a lattice metal material and foamed aluminium, and obtains a lattice-gradient foamed aluminium composite structural material sandwich plate with a geometric gradient. The lattice metal-gradient foamed aluminium composite material sandwich plate has wide application prospects in fields of safety protection, traffic transportation, mechanical manufacturing, and military affairs, has very effective performance with respect to structure weight reduction, impact deformation improvement, magnetic shielding and the like, can bring into play its high strength, high rigidity and excellent damping performance especially in mechanical manufacturing industry, and also has low manufacturing cost.

Owner:XI AN JIAOTONG UNIV

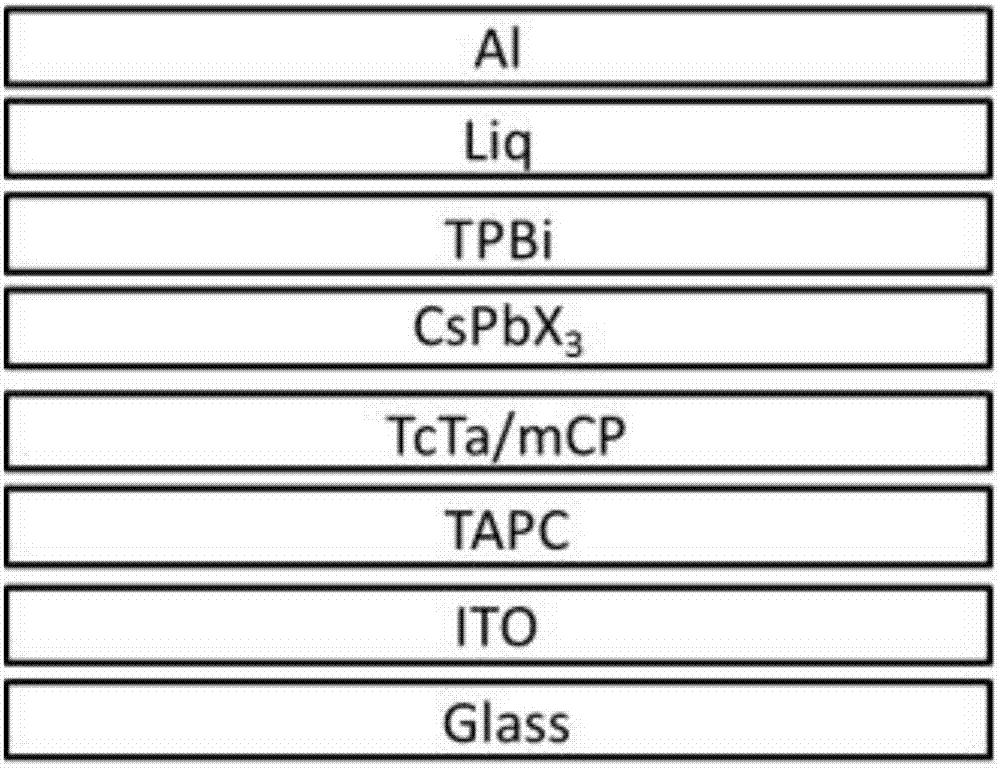

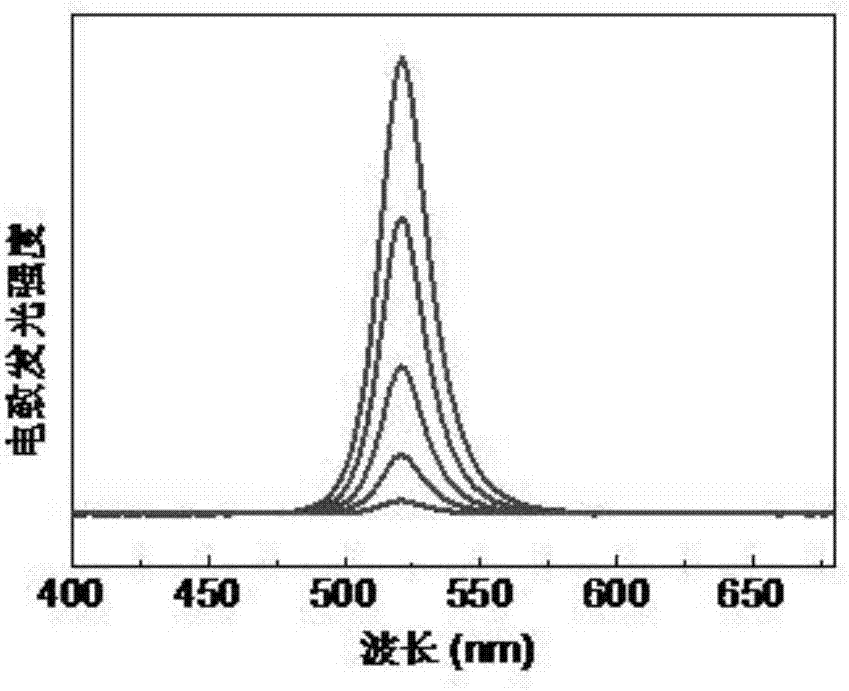

Pure inorganic perovskite light emitting diode device manufacturing method

InactiveCN107275523AImprove performanceReduce leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeVacuum evaporation

The invention provides a pure inorganic perovskite light emitting diode device manufacturing method. The method comprises the following steps: (1) an ITO transparent conductive glass substrate is subjected to standardized cleaning and drying and then pretreatment; (2) the ITO is transferred to a vacuum cavity, and evaporation on a hole injection layer and a transport layer is carried out; (3) a dual source co-evaporation method is adopted, and a pure inorganic CsPbX3 perovskite light emitting layer thin film is formed through evaporation; (4) an infrared thermal radiation device is used to carry out thermal treatment on the CsPbX3 perovskite film; and (5) an electron transport layer, an electron injection layer and a metal cathode are formed through thermal evaporation. The manufacturing process is simple and convenient, the manufacturing difficulty is low, the full vacuum evaporation method is adopted to manufacture the device, the manufacturing is easy, the repeatability is good, and the device performance is stable; and through the dual source co-evaporation manufacturing method, the smoothness and the uniformity of the thin film are improved, replacement of a subject material and an object material is facilitated, the ratio of the two can be changed, and regulation on the position of a light emitting peak is realized.

Owner:SUZHOU UNIV

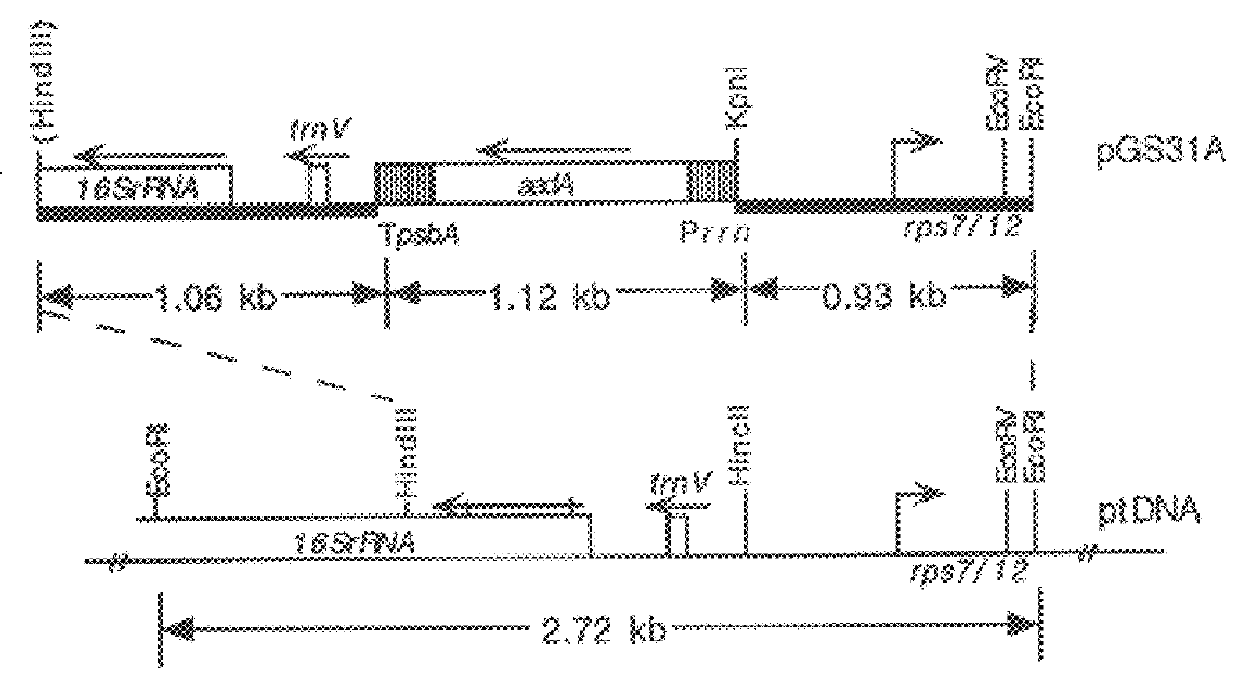

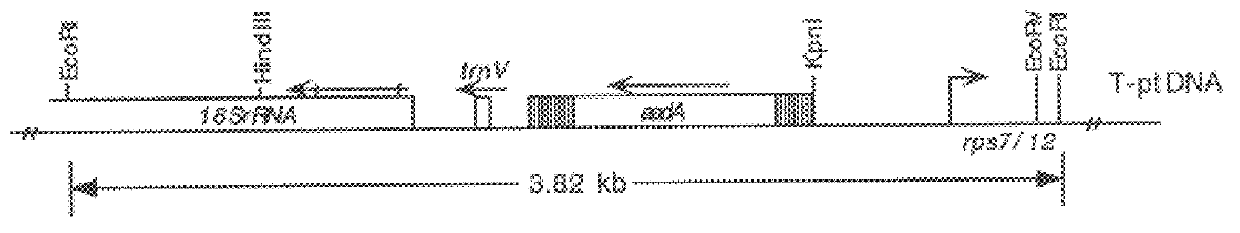

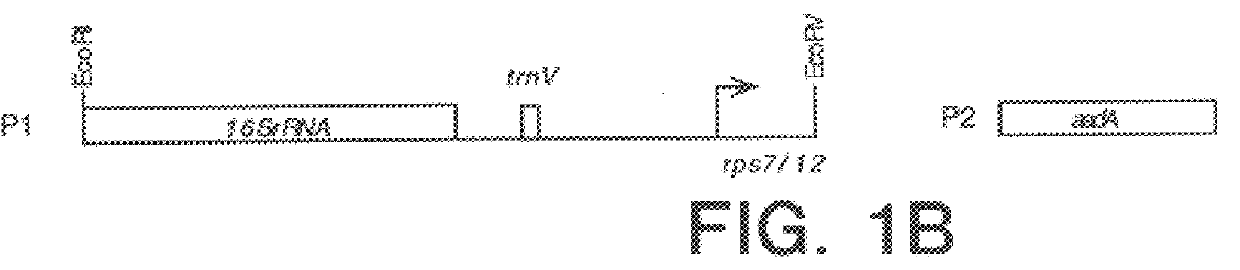

Plastid transformation in Arabidopsis thaliana

InactiveUS6376744B1High expressionImprove stabilityOther foreign material introduction processesFermentationBiotechnologyEtioplasts

The invention provides methods and compositions for obtaining transplastomic Arabidopsis plants. Specifically, the method provides culturing protocols and compositions that facilitate the regeneration of transformed plants following delivery of exogenous DNA molecules.

Owner:RUTGERS THE STATE UNIV

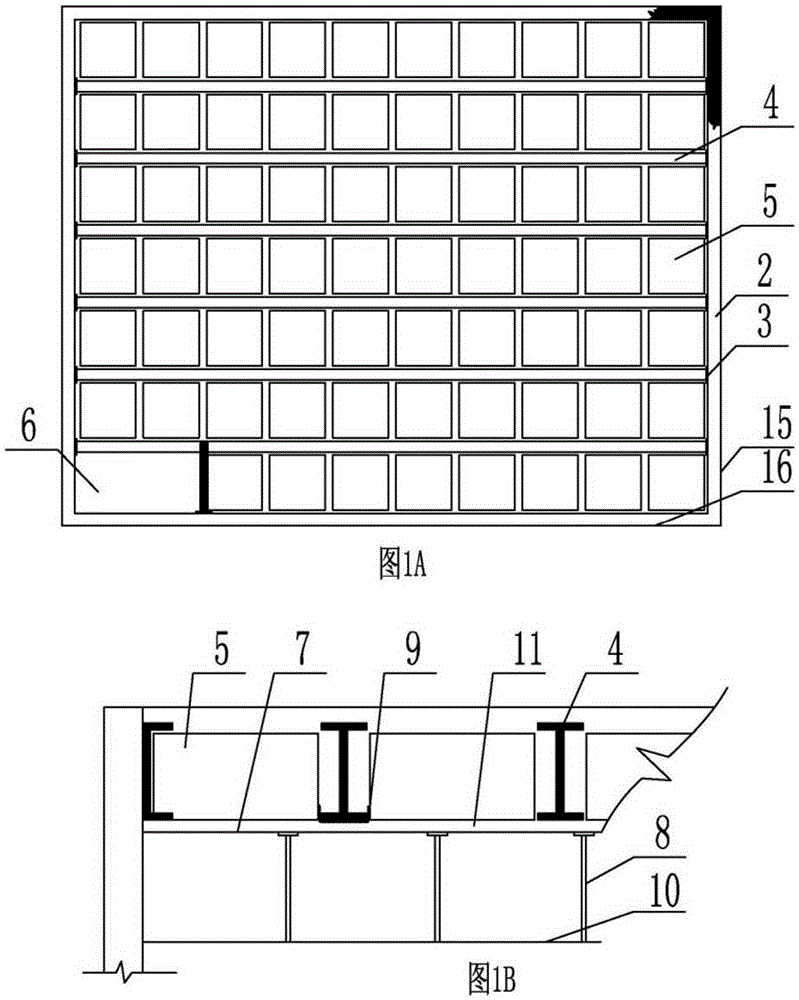

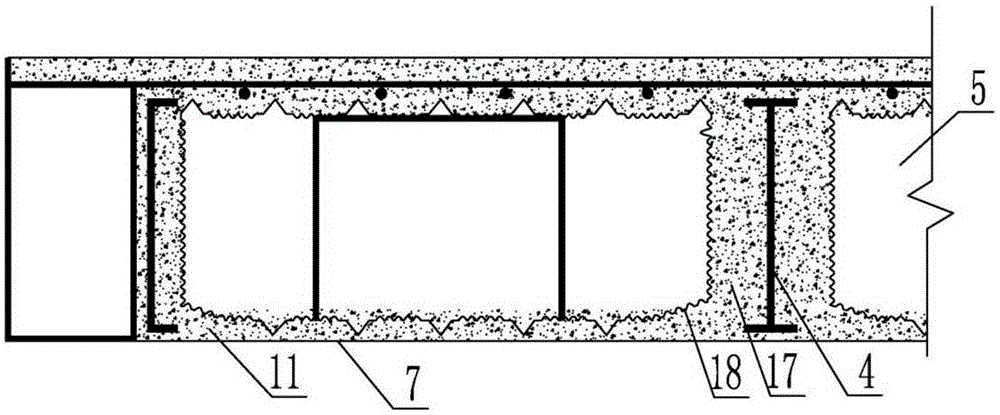

House interlayer cast-in-situ cavity floor

The invention provides a house interlayer cast-in-situ cavity floor. The house interlayer cast-in-situ cavity floor comprises interlayer space height reserved in a main body house building, light steel beams, a light steel beam and wall slab combined member, a reinforced concrete upper flange slab, a hollow ribbed steel mesh and a lower flange thin slab compounded with concrete mortar at the bottom of the hollow ribbed steel mesh, wherein a house interlayer cast-in-situ cavity floor is arranged in the reserved space height of the main body building; the house interlayer cast-in-situ cavity floor adopts light steel beams; the compounded lower flange thin slab is directly compounded by cement mortar and the bottom surface of the hollow ribbed steel mesh; the thickness of the lower flange thin slab is smaller than or equal to 30mm; the hollow ribbed steel mesh comprises a hollow mesh, a floor end mesh and a support mesh; the thickness of the interlayer cast-in-situ cavity floor is smaller than or equal to 250mm. Through the house interlayer cast-in-situ cavity floor, the defect that any filling body cannot act and stress with the floor of the existing cavity floor hole formation technique is overcome; the potential safety hazard of the quality caused by non-uniform house interlayer standard is reduced; the interlayer durability co-exists with the building main body.

Owner:王本淼 +2

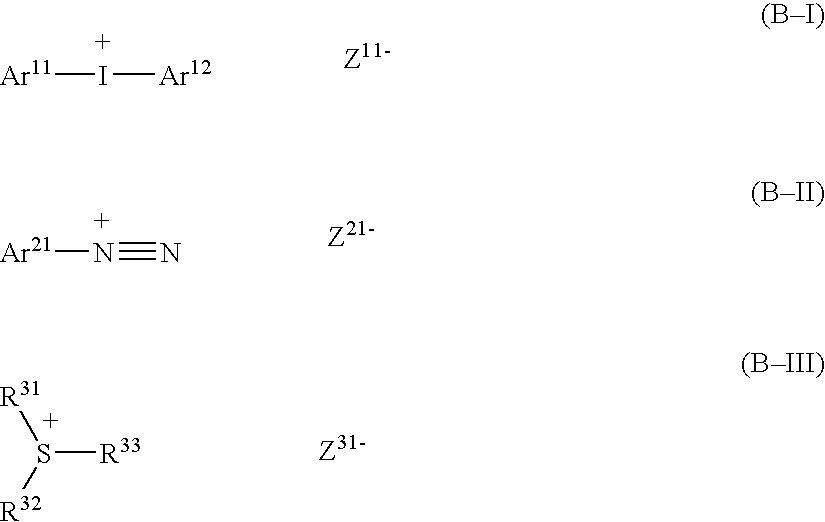

Lithographic printing plate precursor and lithographic printing method

InactiveUS20050037282A1Good storage stabilityImprove propertiesPhotosensitive materialsSemiconductor/solid-state device manufacturingChemical compoundImage recording

Owner:FUJIFILM CORP

Alcohol-free transdermal insulin composition

InactiveUS7291591B2Promote recombinationPromote absorptionPeptide/protein ingredientsDepsipeptidesAlcohol freeMedicine

The instant invention is directed toward a dermal delivery system composition comprising an aqueous base vehicle including Emu oil, at least one fatty acid alkyl ester, polyethylene glycol, and a gelling agent, in combination with a therapeutically effective amount of at least one species of insulin, and to processes for the manufacture and use thereof.

Owner:ALL NATURAL FMG

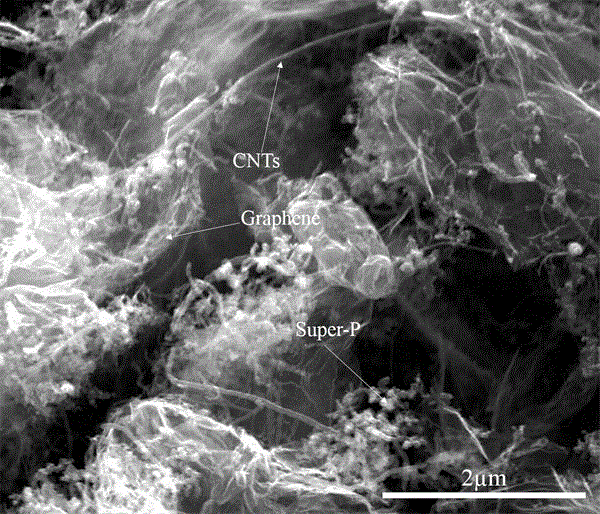

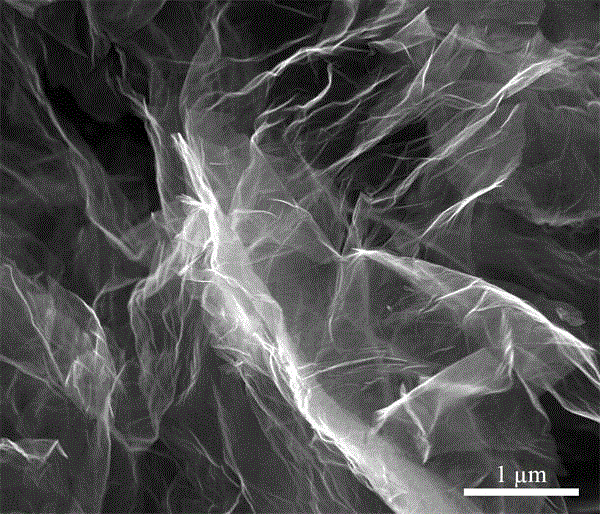

Graphene/CNTs/Super-P composite electric conduction agent, composite electric conduction agent slurry, and preparation methods of graphene/CNTs/Super-P composite electric conduction agent and composite electric conduction agent slurry

ActiveCN105336958AAchieve fast charge and discharge performanceGood dispersionCell electrodesActive agentSurface-active agents

The present invention discloses a graphene / CNTs / Super-P composite electric conduction agent, a composite electric conduction agent slurry, and preparation methods of the graphene / CNTs / Super-P composite electric conduction agent and the composite electric conduction agent slurry, wherein the composite electric conduction agent comprises graphene, CNTs (carbon nano-tubes) and Super-P (electric conduction carbon black). The preparation method comprises: adding a graphene oxide slurry, carbon nano-tubes, electric conduction carbon black and a surfactant to a reaction kettle, uniformly stirring, carrying out complete ultrasonic dispersion, drying, crushing, adding the crushed mixture to a muffle furnace, puffing in air, carrying out a reduction treatment in an inert atmosphere, and cooling to a room temperature to obtain the composite electric conduction agent powder, wherein the composite electric conduction powder can further be mixed with a solvent, and stirring and ultrasonic dispersion are performed to prepare the composite electric conduction agent slurry. According to the present invention, the composite electric conduction agent has excellent performances, and is suitable for being used as the electric conduction agent of power ion batteries; and the used preparation process has characteristics of simpleness and low energy consumption, and is suitable for large-scale industrial production.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

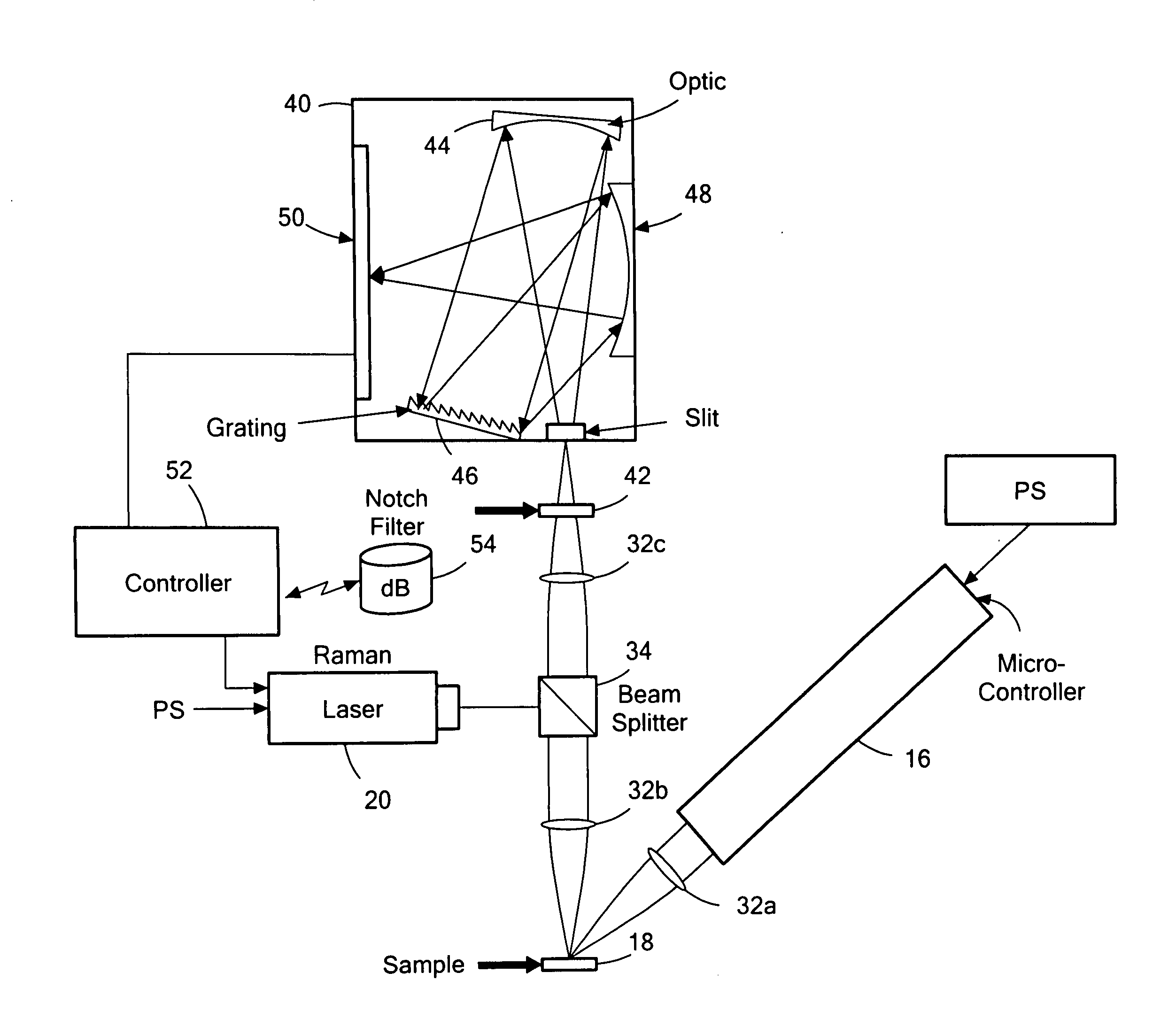

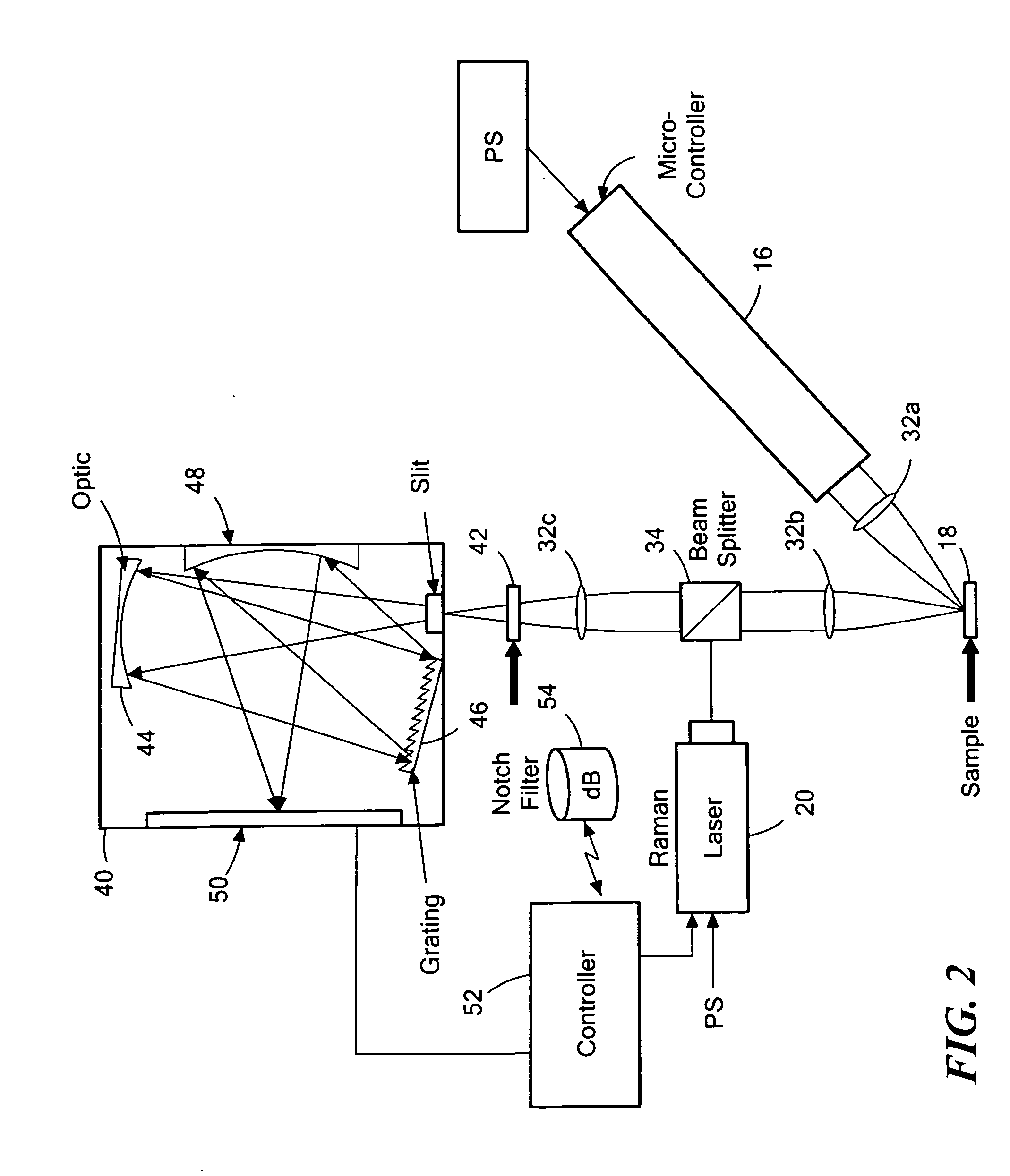

Dual source system and method

ActiveUS20140022531A1Promote recombinationEasy to quantifyEmission spectroscopyRadiation pyrometryHigh power lasersLaser

A dual source system and method includes a high power laser used to determine elemental concentrations in a sample and a lower power device used to determine compounds present in the sample. A detector subsystem receives photons from the sample after laser energy from the high power laser strikes the sample and provides a first signal. The detector subsystem then receives photons from the sample after energy from the lower power device strikes the sample and provides a second signal. The high power laser is pulsed and the first signal is processed to determine elemental concentrations present in the sample. The lower power device is energized and the second signal is processed to determine compounds present in the signal. Based on the elemental concentrations and the compounds present, the compounds present in the sample are quantified.

Owner:SCIAPS

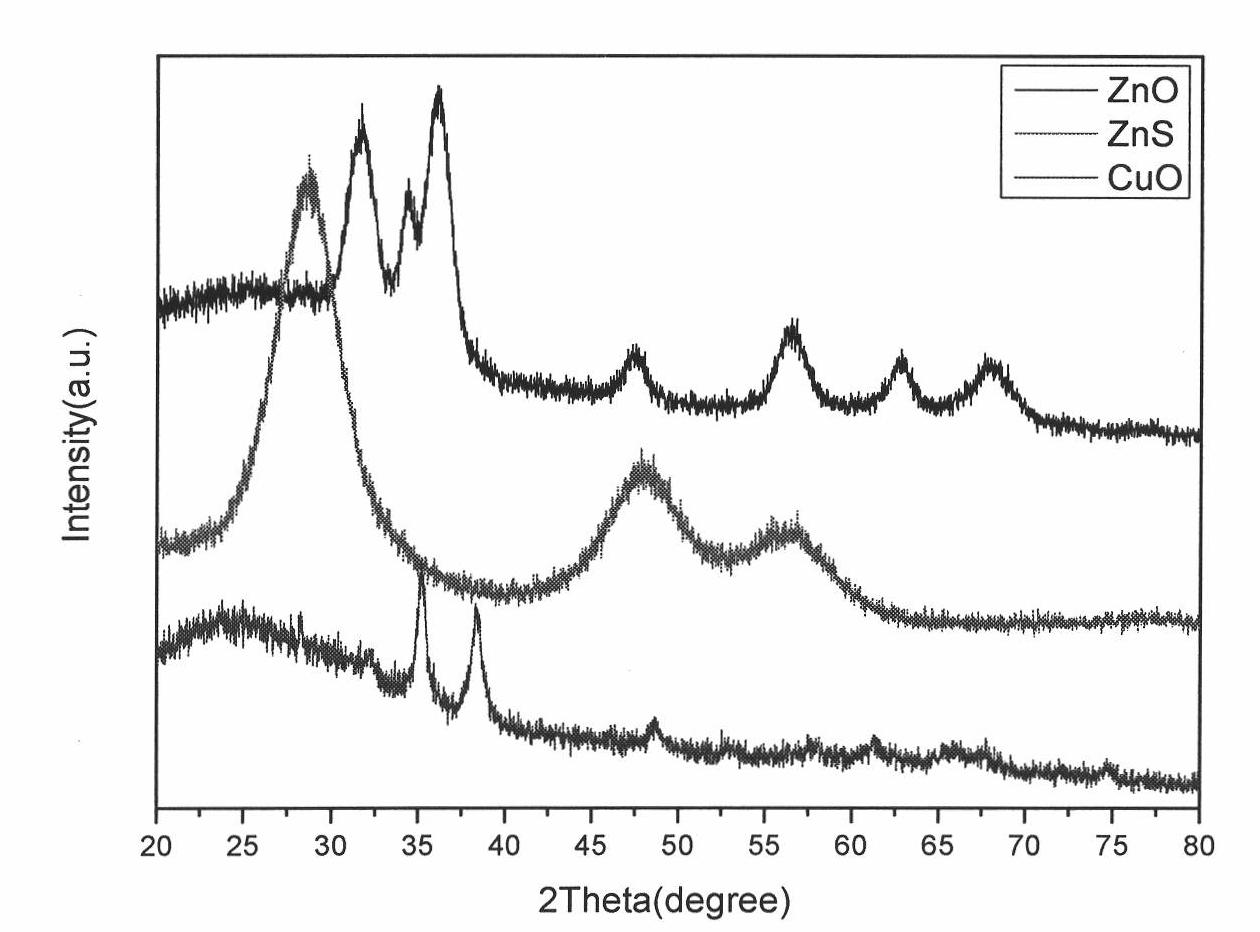

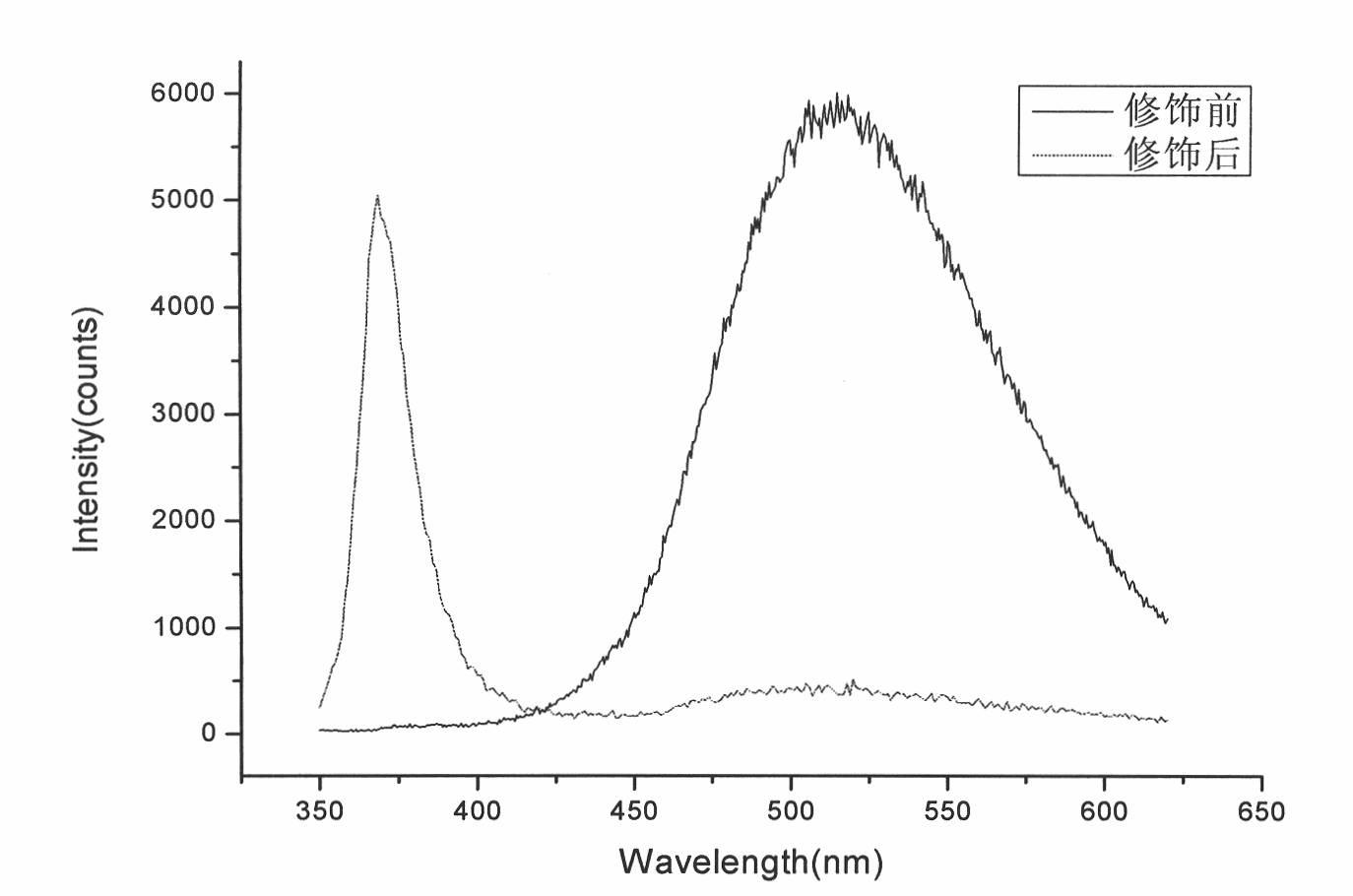

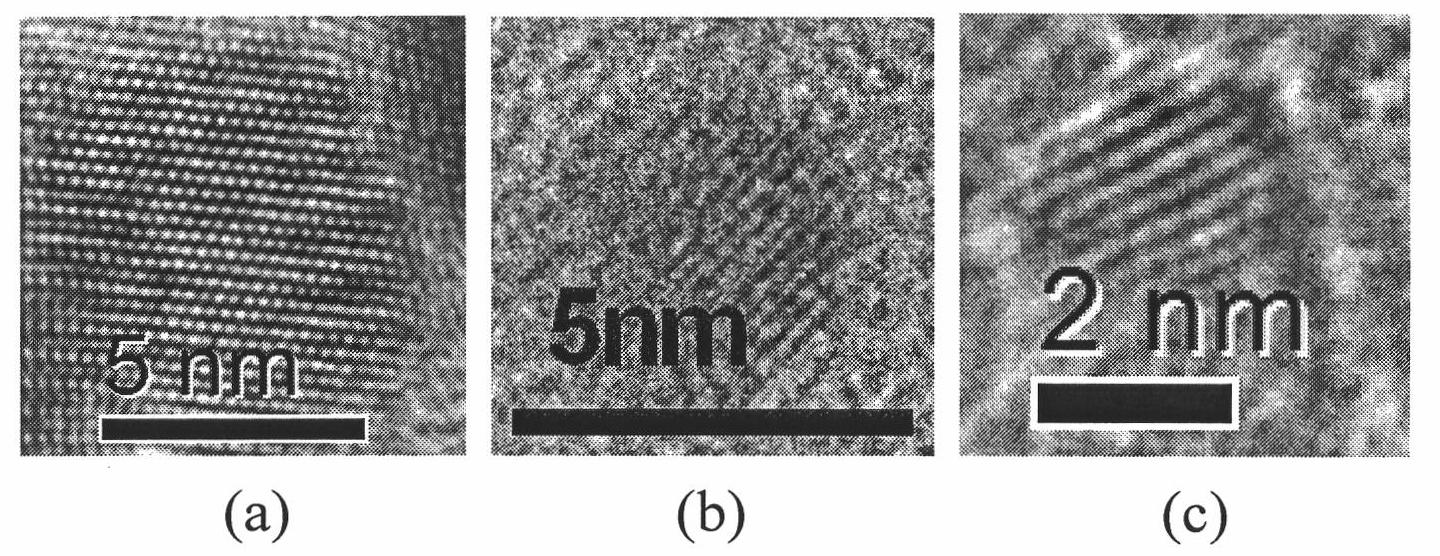

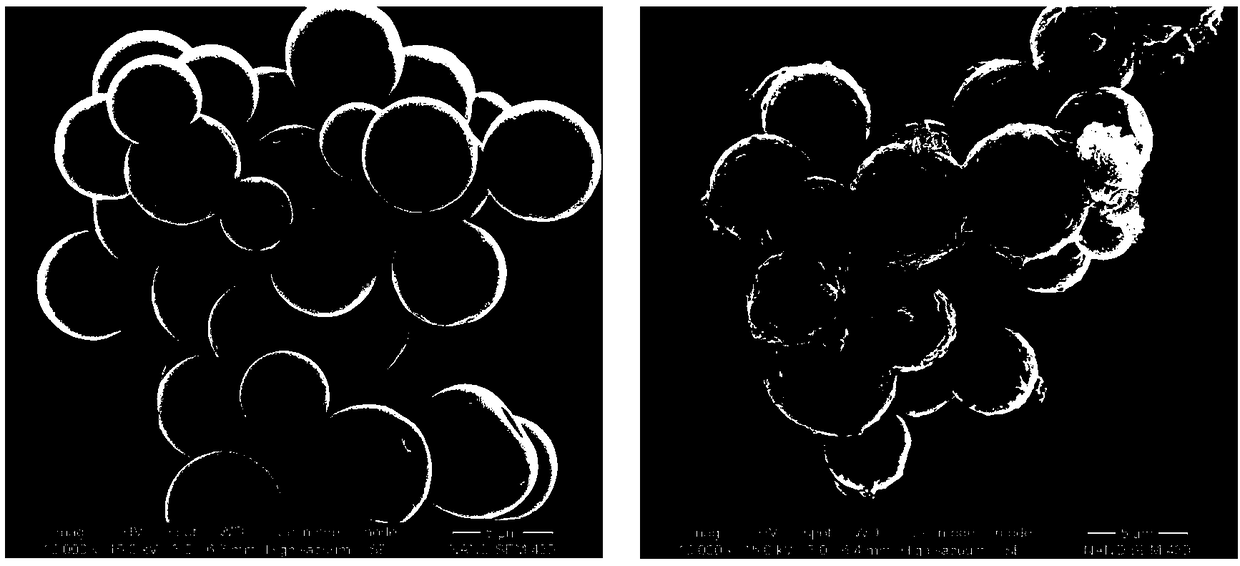

Preparation method of ZnO, CuO and ZnS quantum dot film

InactiveCN102086393ASimple processLow costFinal product manufactureLuminescent compositionsIndium tin oxideMaterials science

The invention relates to a preparation method of a ZnO, CuO and ZnS quantum dot film. The preparation method comprises the following steps: preparing Cu ion modified ZnO quantum dot precipitate, CuO quantum dot precipitate and ZnS quantum dot precipitate; adding trichloromethane in the prepared quantum dot precipitates respectively to fully dissolve, then adding n-octylamine dispersant to obtain Cu ion modified ZnO colloidal quantum dot solution, CuO colloidal quantum dot solution and ZnS colloidal quantum dot solution; diluting the three kinds of colloidal quantum dot solutions with the sameamount of trichloromethane, filtering with a polytetrafluoroethylene (PTFE) filter, coating one or more of the colloidal quantum dot solutions on an indium-tin oxide (ITO) substrate through the spin-coating method, prebaking, and annealing in the air to obtain the quantum dot single-layer or multi-layer film. The preparation process of the invention is simple; the coated quantum dot film is compact and smooth and has good adhesion performance and controllable film thickness; and the quantum dot multi-layer structure is easy to realize and the quantum dot film is suitable for the multi-layer quantum dot film element.

Owner:ZHEJIANG UNIV

Method for preparing pigment printing binder from oxidized graphene modified polyacrylate

ActiveCN103554346AImprove mechanical propertiesImprove performanceNon-macromolecular adhesive additivesEster polymer adhesivesEmulsionGraphene

A method for preparing a pigment printing binder from oxidized graphene modified polyacrylate comprises the following steps: dissolving ammonium persulfate in deionized water and placing the mixture in a reactor of 75-80 DEG C; adding an emulsion A and an initiator aqueous solution A, adding an emulsion B and an initiator aqueous solution B, keeping warm at 75-80 DEG C and reacting for 2 hours after dripping, cooling, adjusting pH to 4.0-6.5 by the use of an ammoniacal liquor, and discharging to prepare a polyacrylate emulsion; stirring an oxidized graphene aqueous solution and adding the oxidized graphene aqueous solution into the polyacrylate emulsion so as to obtain the pigment printing binder. The pigment printing binder is prepared by introducing oxidized graphene in modification of the polyacrylate emulsion. Under the condition of the same dosage of the binder, oxidized graphene is added to raise dry and wet rub fastness of a printed fabric, and softness and washing fastness of the fabric are basically unchanged.

Owner:威海联桥新材料科技股份有限公司

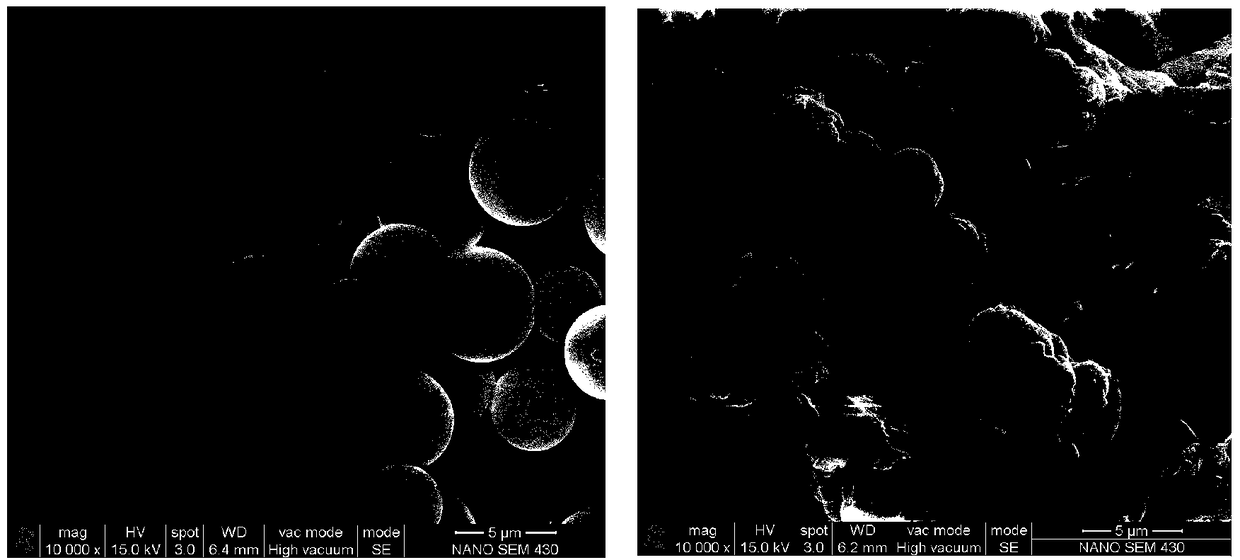

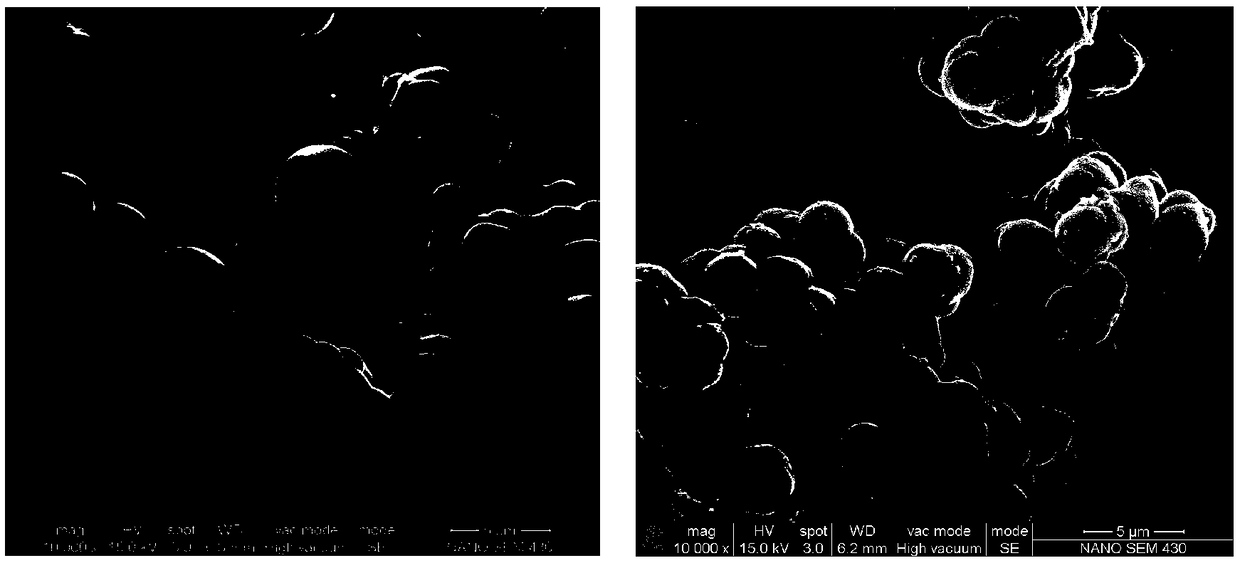

Double-shell epoxy resin microcapsule self-repair material and preparation method thereof

ActiveCN108892407AExcellent Mechanics and AcousticsChemically activeMicroballoon preparationMicrocapsule preparationEpoxyIn situ polymerization

The invention belongs to the technical field of microcapsule self-repair materials and particularly relates to a double-shell epoxy resin microcapsule self-repair material and a preparation method thereof. Epoxy resin serves as a repairing agent core material of the microcapsule self-repair material. Firstly, a single-shell microcapsule self-repair material with melamine-urea-formaldehyde resin asan inner wall material is prepared according to an in-situ polymerization method; then, a sol-gel method is adopted for preparing the double-layer microcapsule self-repair material with an inorganicSiO2 polymer as an outer wall material. Compared with a traditional emulsifying agent, graphene oxide serving as an epoxy resin emulsifying agent has advantages of nontoxicity and environmental friendliness. The inorganic SiO2 polymer with excellent biocompatibility and resistance to acids and alkalis serves as the outer wall material to improve compatibility of the microcapsule self-repair material to cement concrete materials, and the microcapsule self-repair material is enabled to give a full play to the self-repair performance in the cement concrete materials.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

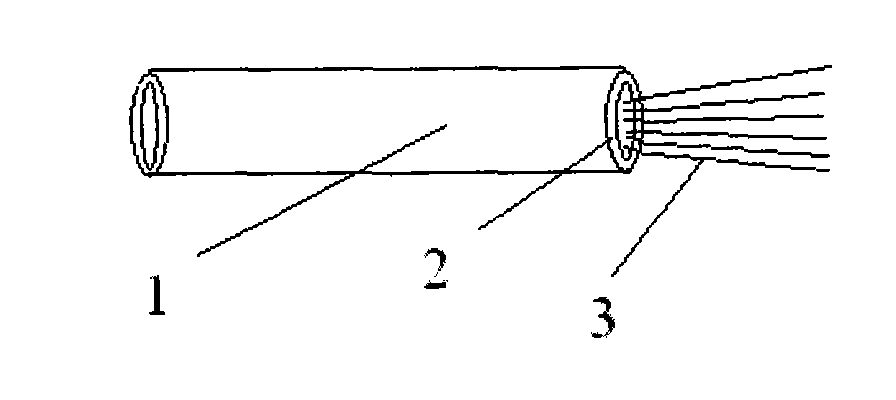

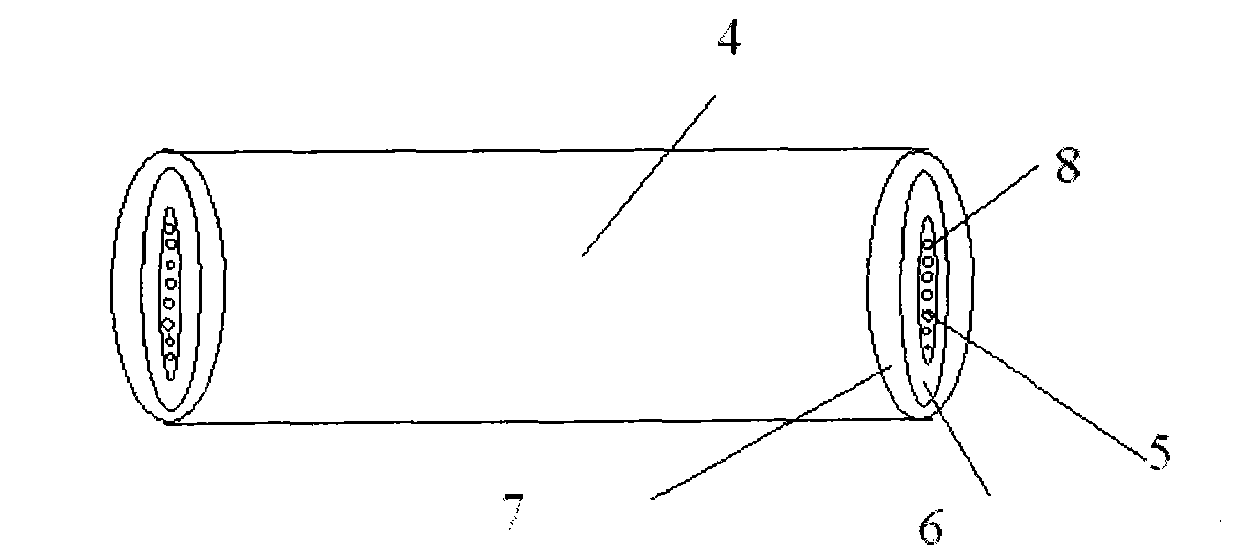

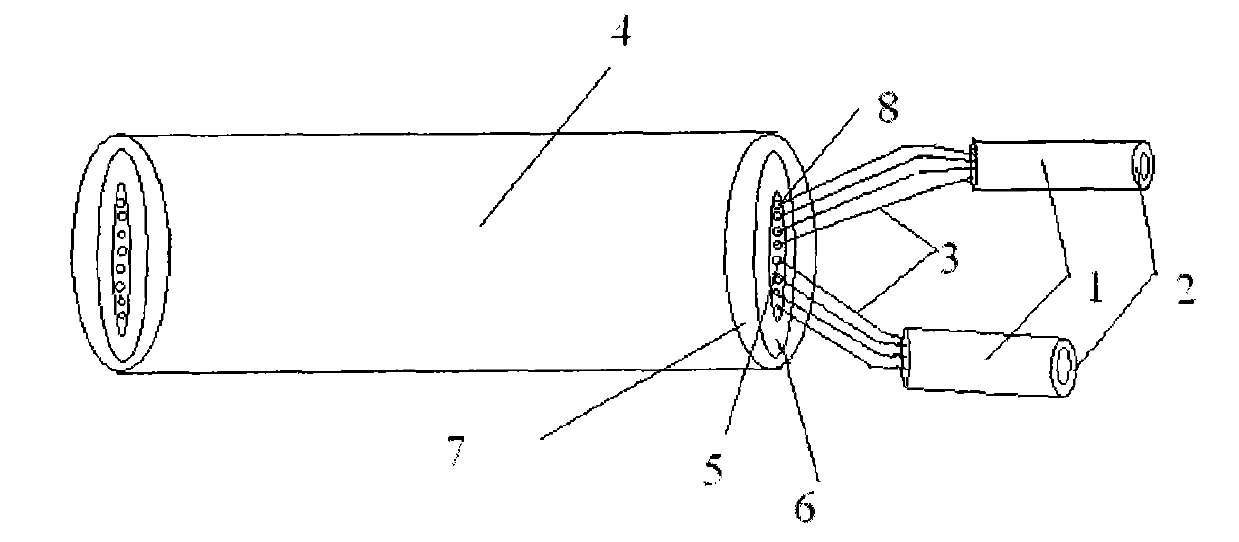

Method for manufacturing low-resistance superconducting joint with high shielding characteristic

ActiveCN101794655APromote recombinationImprove shielding effectSuperconductors/hyperconductorsSuperconductor detailsEngineeringNiobium

The invention relates to a low-resistance superconducting joint with a high shielding characteristic, which is manufactured by a method comprising the following steps of: corroding copper (2) on the outer surfaces of the end parts of NbTi / Cu superconducting lines (1) to form NbTi superconducting lines (3); inserting the same amount of the NbTi superconducting lines (3) into each through hole (8) of a niobium layer (5) of a Nb / NbTi / Cu multilayer composite rod (4) respectively; exerting certain pressure to the outside of the Nb / NbTi / Cu multilayer composite rod (4) to ensure that the Nb / NbTi / Cu multilayer composite rod (4) is combined together with the NbTi superconducting lines (3) by pressure to form a joint; inserting the joint into a YBCO tube (9); and filling a molten woods metal solder (10) into the YBCO tube (9) to obtain the high-shielding low-resistance superconducting joint.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com