Preparation method of soft and durable anti-penetrating material

A durable and soft technology, applied in fiber type, improved handle fiber, textile, etc., can solve the problems of overall thickness, protection effect cannot be guaranteed for a long time, and is not suitable for daily protection, etc., to achieve the effect of fluffy fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method (abbreviation method) of soft and durable anti-stab material, it is characterized in that the method comprises the following steps:

[0032] The first step, preparation of shear thickening liquid:

[0033] (1) Slowly add nanoparticles in small quantities to the dispersion medium while stirring; the particle diameter of the nanoparticles is 12nm-800nm, and the nanoparticles account for 10-60% of the total mass of the dispersion medium and the nanoparticles;

[0034] Preferably, when adding nanoparticles, supplementary materials are added, and supplementary materials account for 0-2% of the total mass of the dispersion medium and nanoparticles; the supplementary materials are single-wall carbon nanotubes, multi-wall carbon nanotubes or graphene. At least one, the particle size of the supplementary material is 8-20nm;

[0035] The dispersion medium is at least one of water, ethanol, vinyl alcohol, polyethylene glycol or ...

Embodiment 1

[0050] The first step, preparation of shear thickening liquid:

[0051] (1) While stirring at 100rpm, slowly add silicon dioxide powder (average particle diameter 800 nanometers) in small portions to polyethylene glycol, the mass fraction of silicon dioxide powder is 15%;

[0052] (2) After adding the nanoparticles, adjust the speed of the agitator to 600rpm, and continue to stir for 2-3h until the dispersion is uniform;

[0053] (3) After the dispersion is completed, put it into an ultrasonic oscillator, and ultrasonically oscillate at a frequency of 40KHz for 30min;

[0054] (4) Repeat steps (2) and (3) three times, then put it into a vacuum drying oven after standing at room temperature for 24 hours, and dry it in vacuum at 30°C for 8 hours to obtain a uniformly dispersed and stable shear thickening liquid;

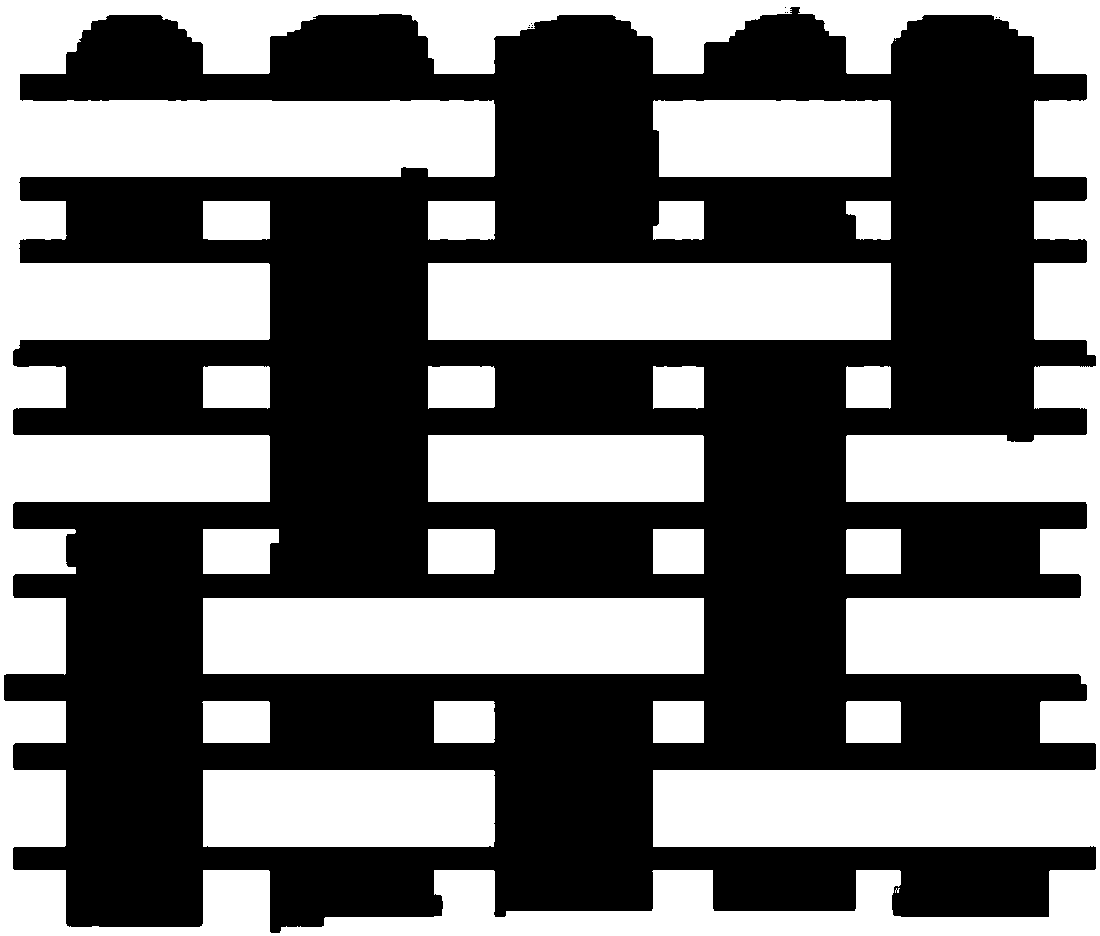

[0055] The second step, preparation of high-performance fiber fabric with special structure:

[0056] (1) Use aramid 1414 filaments with a fineness of 112tex / 500f, a...

Embodiment 2

[0064] The first step, preparation of shear thickening liquid:

[0065] The first step, preparation of shear thickening liquid:

[0066] (1) Put fumed silica particles with an average particle diameter of 12nm into a plasma processor for plasma treatment, set the parameters as a vacuum degree of 120Pa, a power of 75W, and a treatment time of 5 minutes;

[0067] (2) While stirring at 100rpm, slowly add silicon dioxide powder (average particle diameter 12nm) in small portions to polyethylene glycol, the mass fraction of silicon dioxide powder is 14.8%;

[0068] (3) After adding the nanoparticles, adjust the speed of the agitator to 600rpm, and continue to stir for 2h until the dispersion is uniform;

[0069] (4) disperse the multi-walled carbon nanotubes of 8-15nm with dehydrated alcohol, pour in the solution prepared in step (3) then, wherein the volume ratio of liquid and dehydrated alcohol is 1:1, multi-walled carbon nanotubes and The mass ratio of silicon dioxide powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com