Ceramic heater for semiconductor manufacturing and inspecting equipment

a ceramic heater and semiconductor technology, applied in lighting and heating apparatus, muffler furnaces, furnaces, etc., to achieve the effect of preventing the drop of the temperature measurement element, preventing the generation of thermal stress, and high safety properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

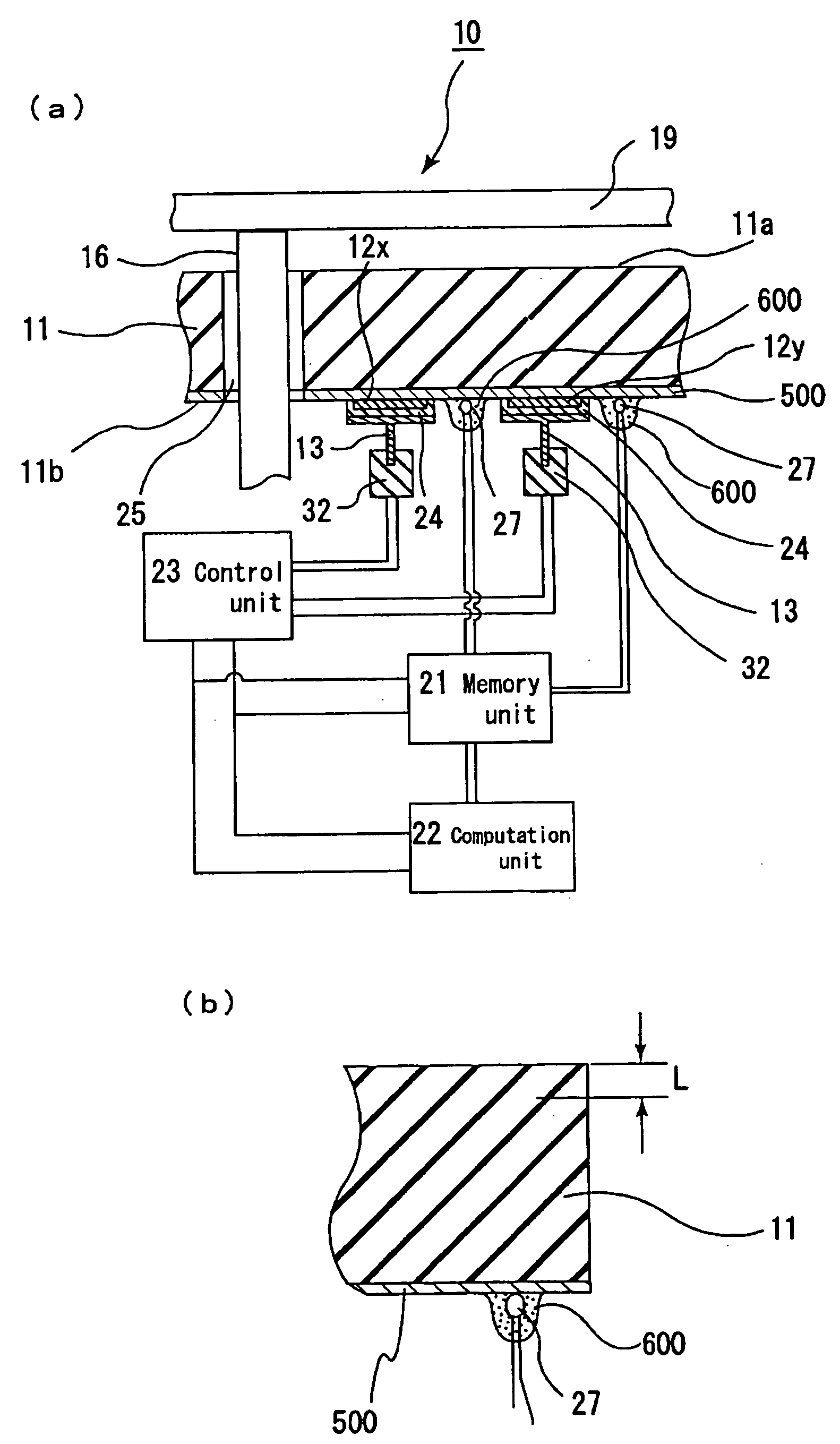

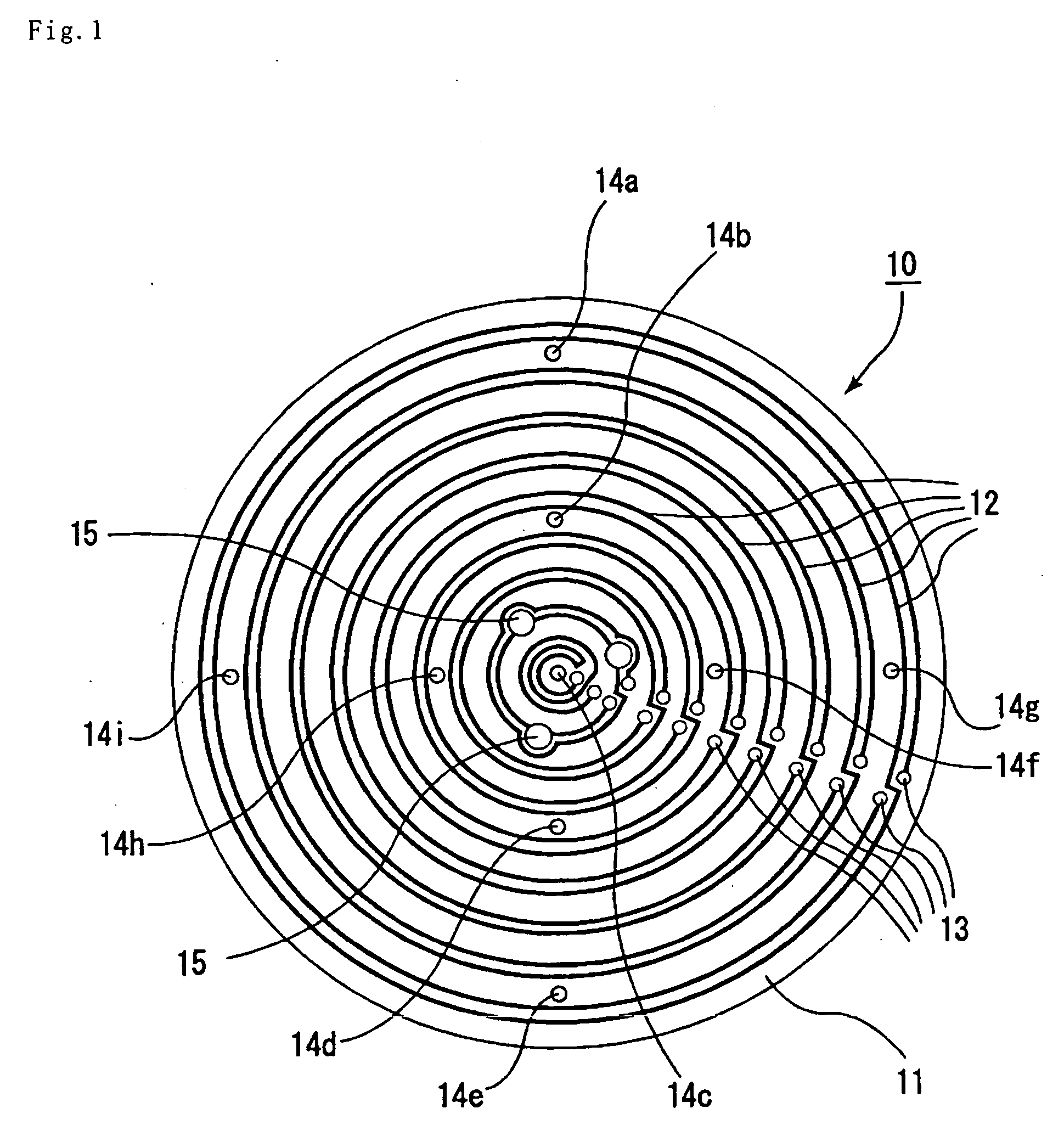

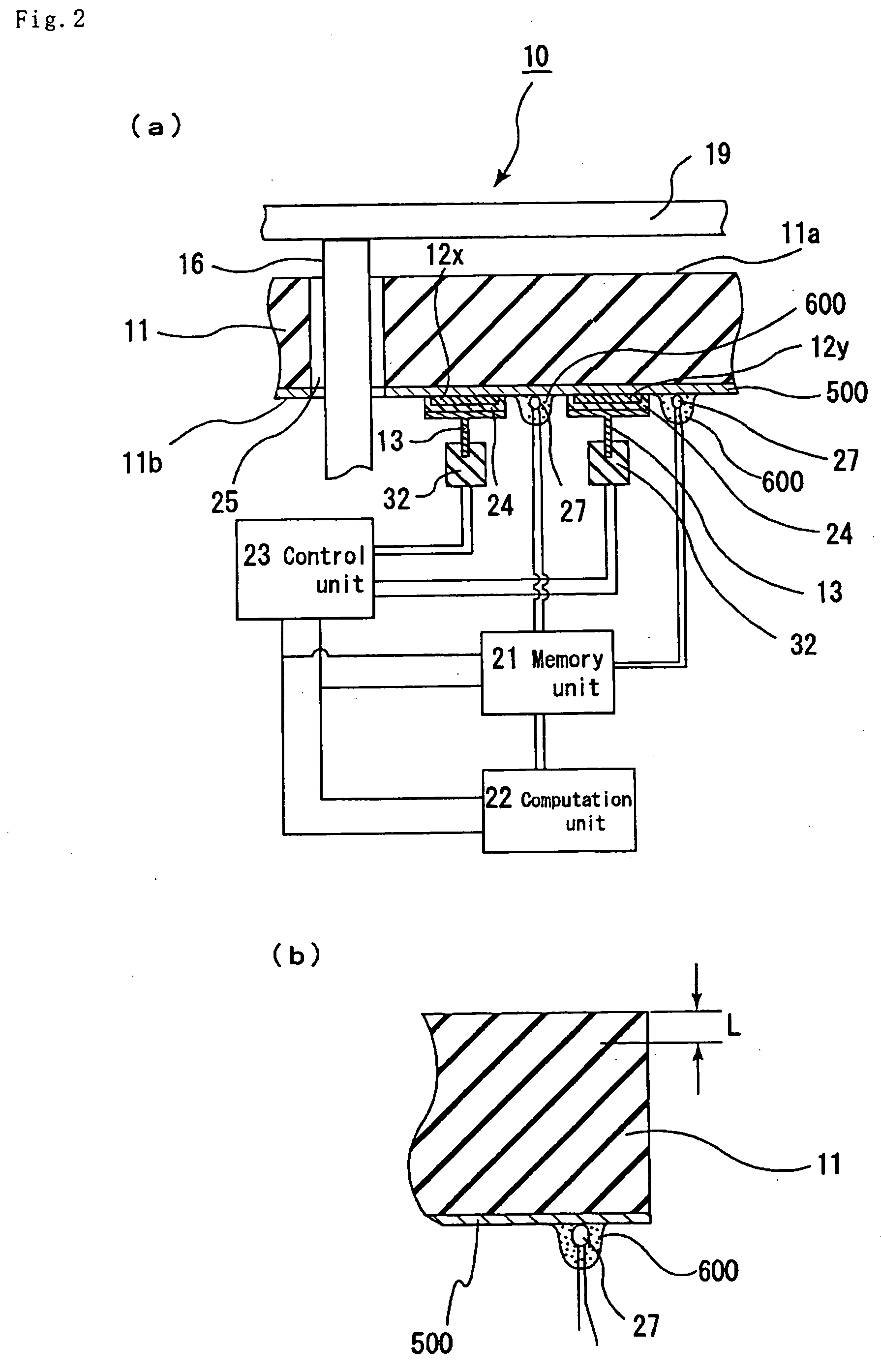

Manufacture of Ceramic Heater Made of Aluminum Nitride (Reference to FIG. 1)

[0205] (1) A composition containing 100 parts by weight of an aluminum nitride powder (the average particle diameter: 1.1 μm), 4 parts by weight of yttria (the average particle diameter: 0.4 μm), 12 parts by weight of an acrylic binder, and an alcohol was spray dried to produce a granular powder.

[0206] (2) Next, the obtained granular powder was filled in a die and molded to be a flat plate to obtain a raw formed body (a green sheet). The raw formed body was processed by drilling to form through holes 15 to insert lifter pins for a silicon wafer.

[0207] (3) On completion of the processing, the raw formed body was hot pressed at 1800° C. and a pressure of 200 kg / cm2 to obtain a 3 mm thick aluminum nitride plate-like body. Next, a disk with a diameter of 12 inch (300 mm) was cut out of the plate-like body to obtain a plate-like body made of ceramic (a ceramic substrate) 11. Further, a glass paste (G-5177 prod...

example 2

Manufacture of Ceramic Heater Made of Silicon Carbide

[0215] A ceramic heater made of silicon carbide was manufactured in the same manner as Example 1, except that silicon carbide with an average particle diameter of 1.0 μm was used and the sintering temperature was 1900° C. and further, the obtained ceramic substrate surface was fired at 1500° C. for 2 hours to form a 1 μm-thick SiO2 layer on the surface.

[0216] The substrate was ground with a diamond grind stone of #220 at 1 kg / cm2 load and polished with a polishing cloth (Malto Co.) and a diamond paste (particle diameter of 0.25 μm) to adjust the surface roughness to Ra=0.008 μm.

[0217] To the substrate, sheaths S housing thermocouples 44 as shown in FIG. 4 were pushed with springs 45.

example 3

Manufacture of Ceramic Heater Containing Heating Element Inside (Reference to FIG. 3)

[0218] (1) Using a paste produced by mixing an aluminum nitride powder (the average particle diameter: 1.1 μm produced by Tokuyama), 4 parts by weight of yttria (the average particle diameter: 0.4 μm), 11.5 parts by weight of an acrylic binder, 0.5 parts by weight of a dispersant, and 53 parts by weight of alcohol consisting of 1-butanol and ethanol, forming was carried out by a doctor blade method to obtain a 0.47 mm green sheet.

[0219] (2) Successively, after the green sheet was dried at 80° C. for 5 hours, portions to be through holes 15 with diameters of 1.8 mm, 3.0 mm, and 5.0 mm to insert silicon wafer lifter pins into and portions to be conductor-filled through holes for connection with terminal pins were formed by punching.

[0220] (3) Next, a conductor containing paste A was produced by mixing 100 parts by weight of a tungsten carbide particle with an average particle diameter of 1 μm, 3.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness Ra | aaaaa | aaaaa |

| surface roughness Ra | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com