Patents

Literature

1616results about "Hot plates heating arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

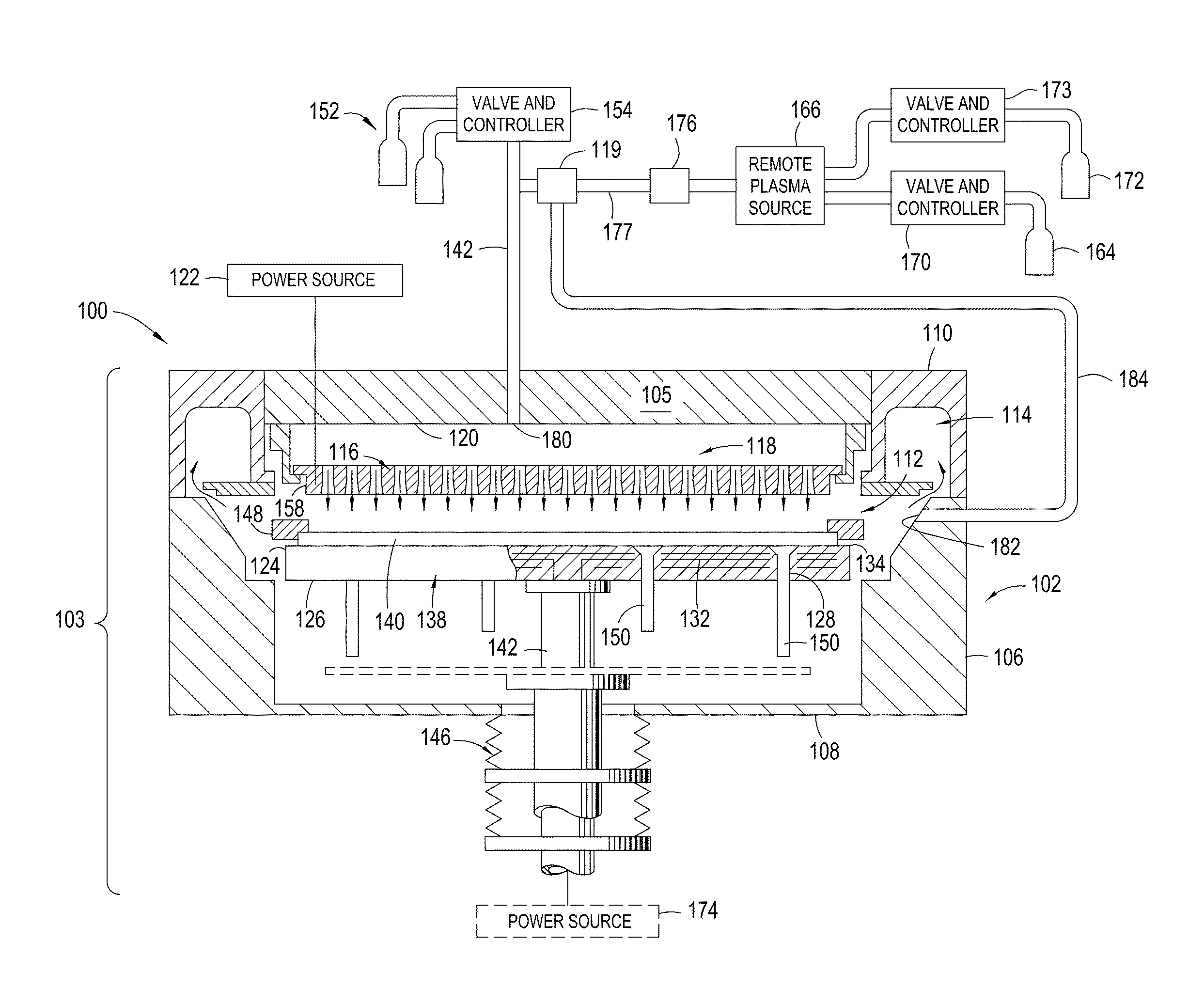

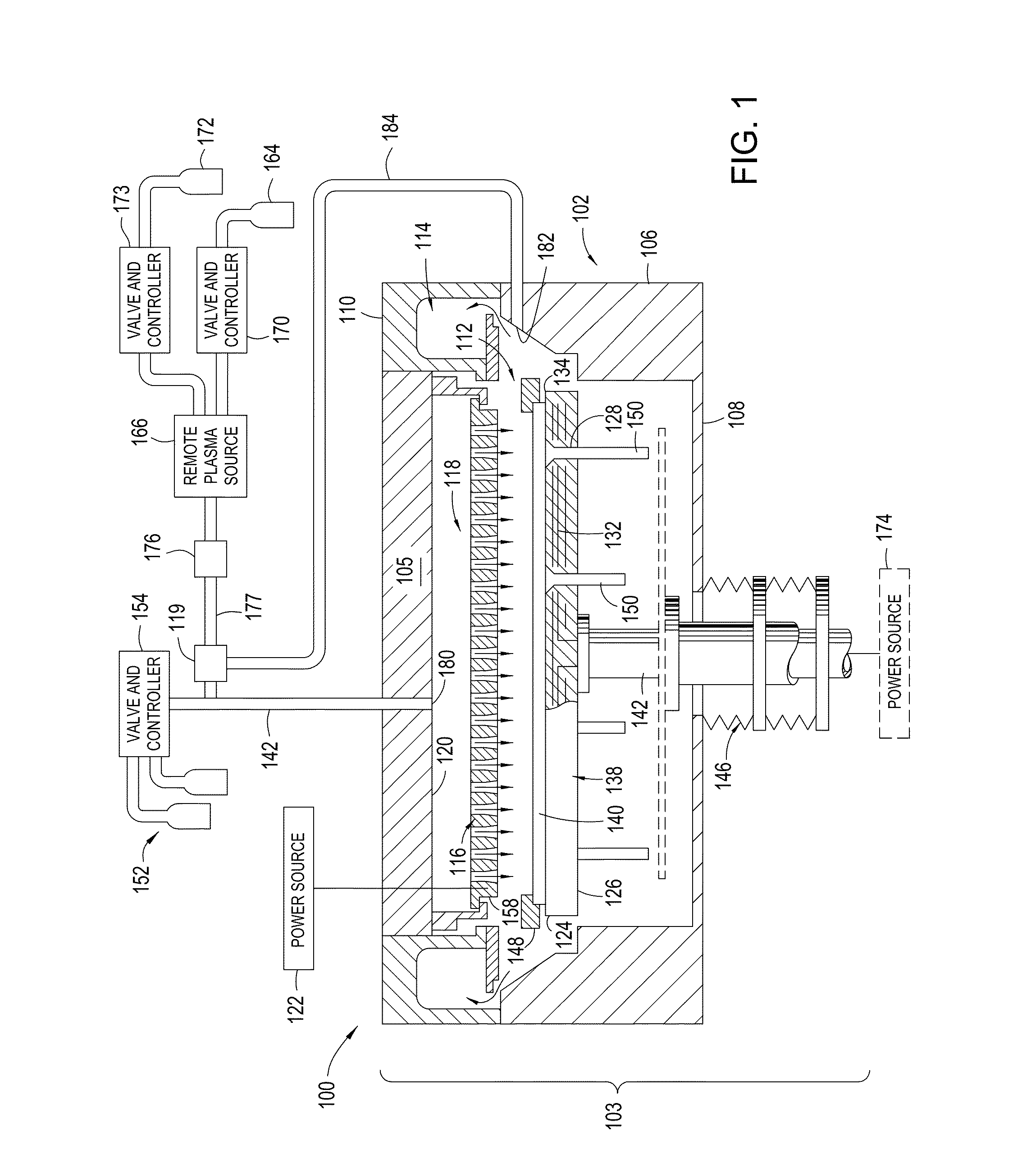

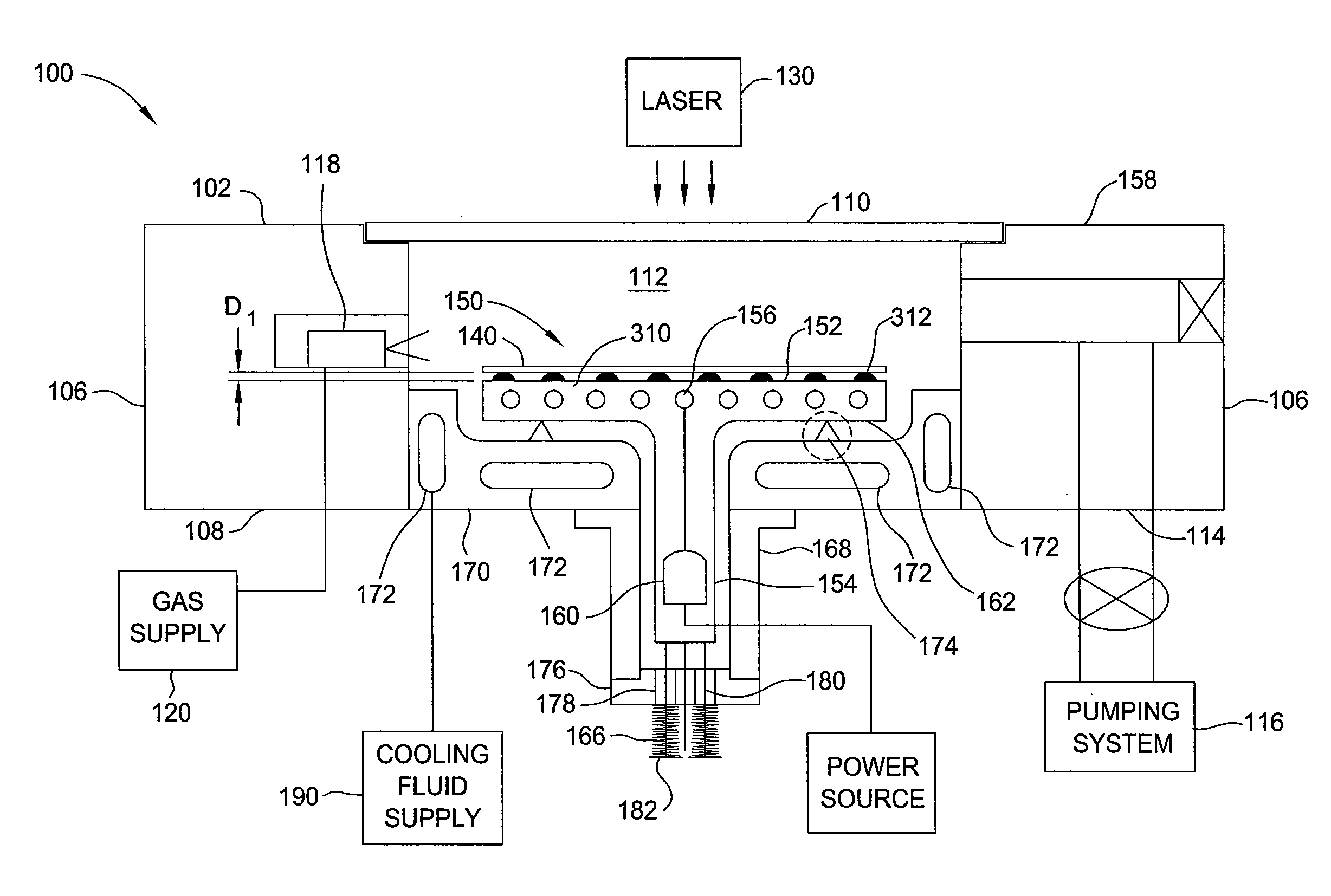

Method and apparatus for controlling the spatial temperature distribution across the surface of a workpiece support

InactiveUS6847014B1Electric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlEngineering

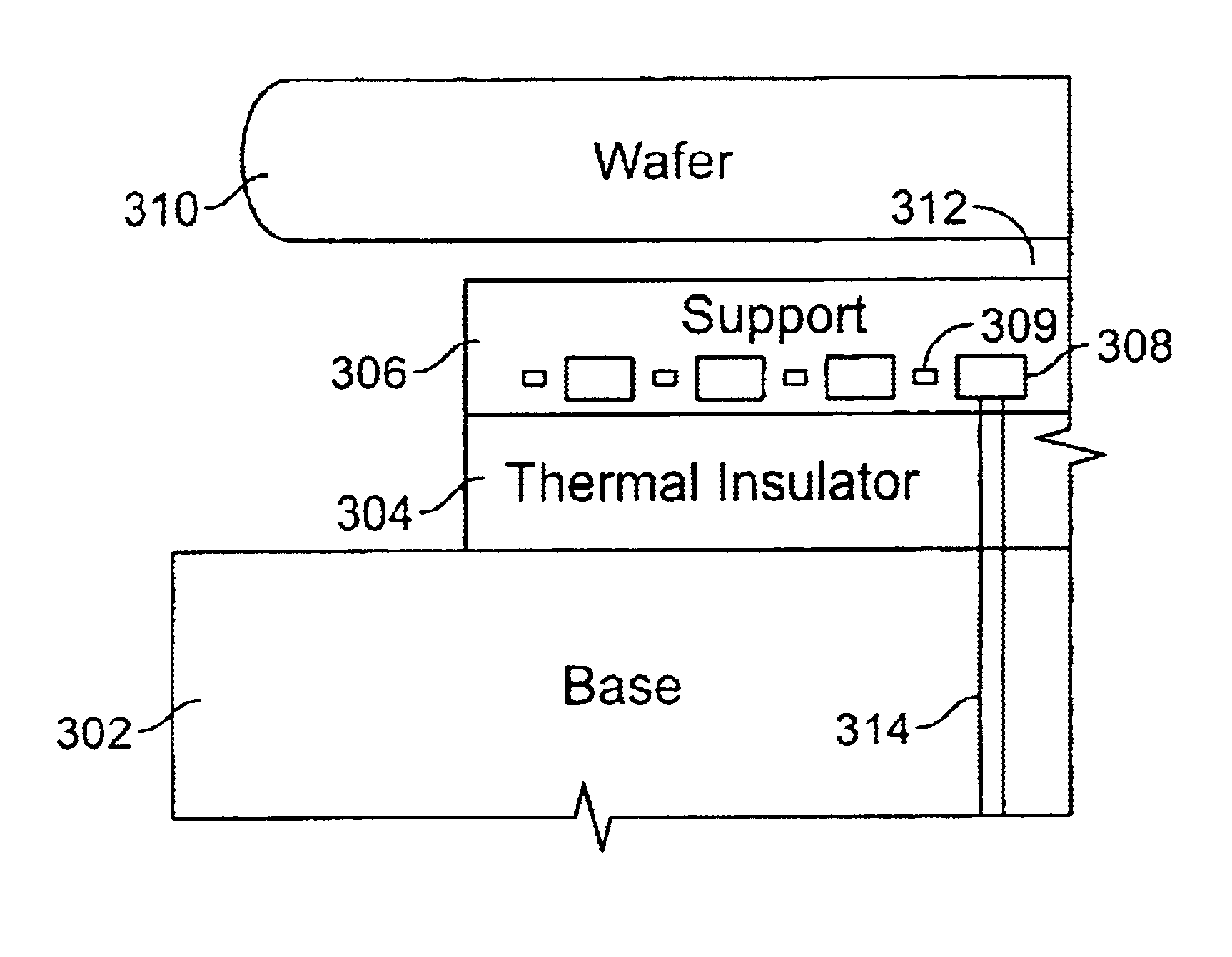

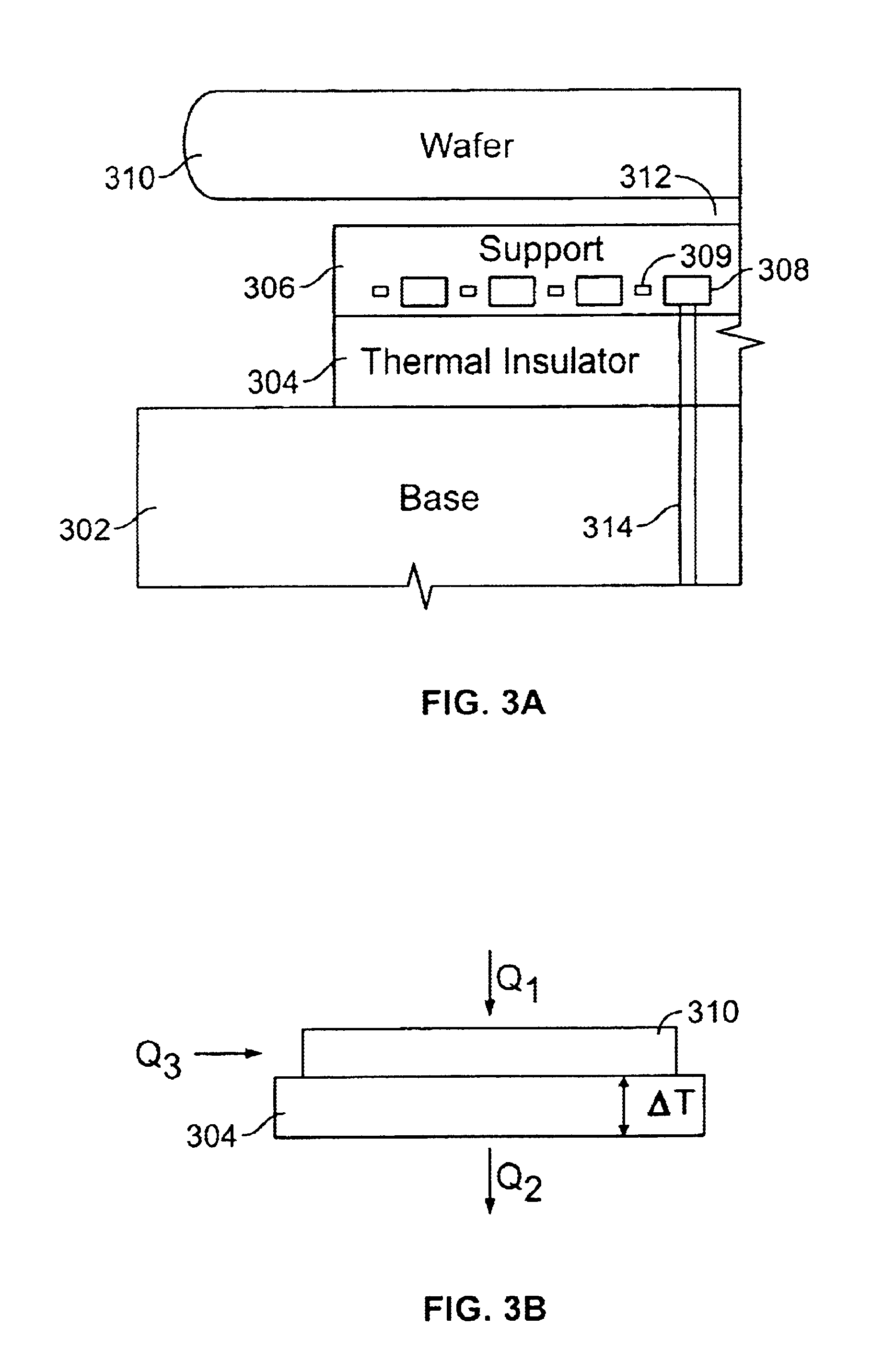

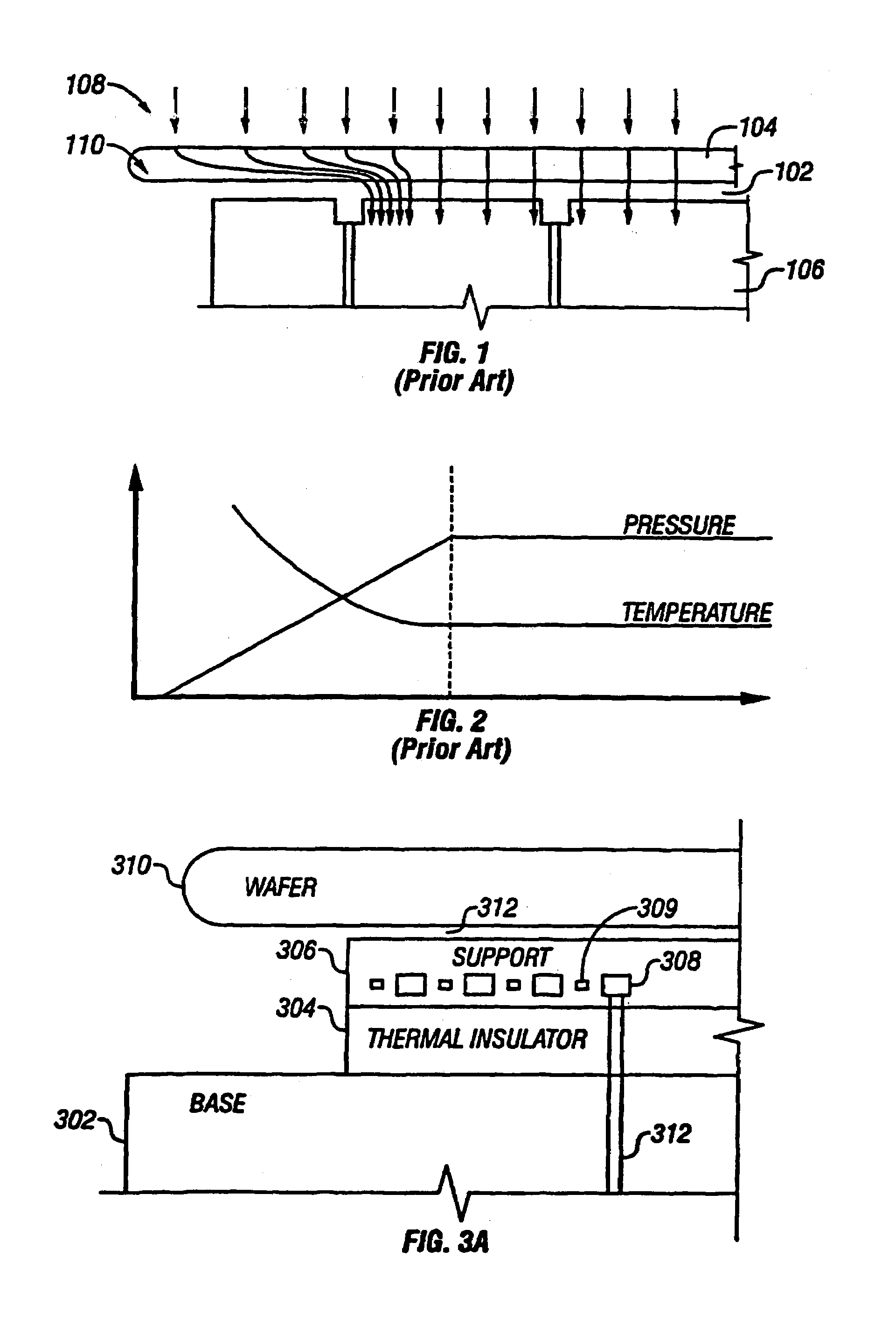

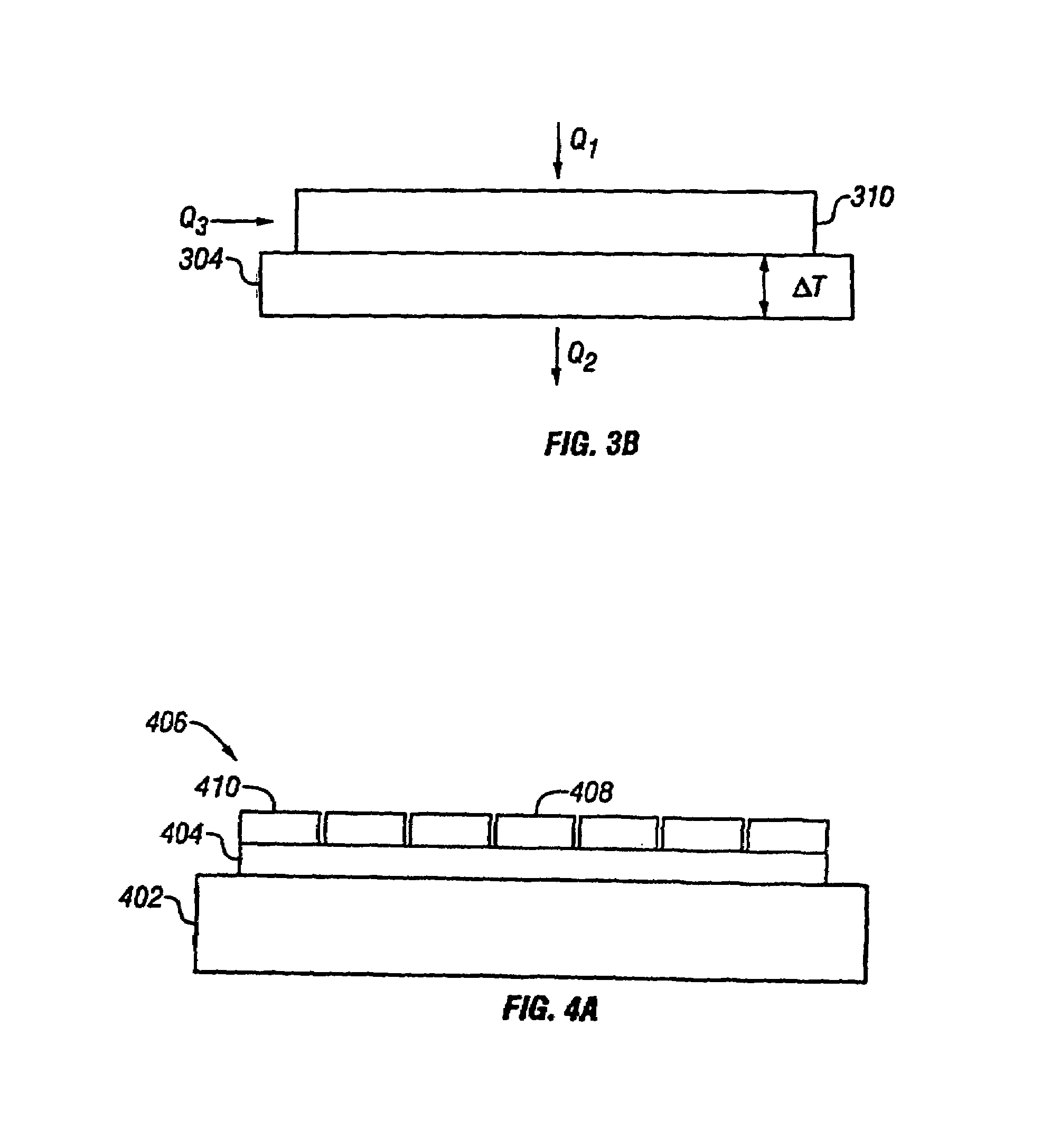

A chuck for a plasma processor comprises a temperature-controlled base, a thermal insulator, a flat support, and a heater. The temperature-controlled base has a temperature below the desired temperature of a workpiece. The thermal insulator is disposed over the temperature-controlled base. The flat support holds a workpiece and is disposed over the thermal insulator. A heater is embedded within the flat support and / or disposed on an underside of the flat support. The heater includes a plurality of heating elements that heat a plurality of corresponding heating zones. The power supplied and / or temperature of each heating element is controlled independently.

Owner:LAM RES CORP

Wafer heating apparatus

InactiveUS6753507B2Semiconductor/solid-state device manufacturingHot plates heating arrangementsMetallurgyHeat generation

Owner:KYOCERA CORP

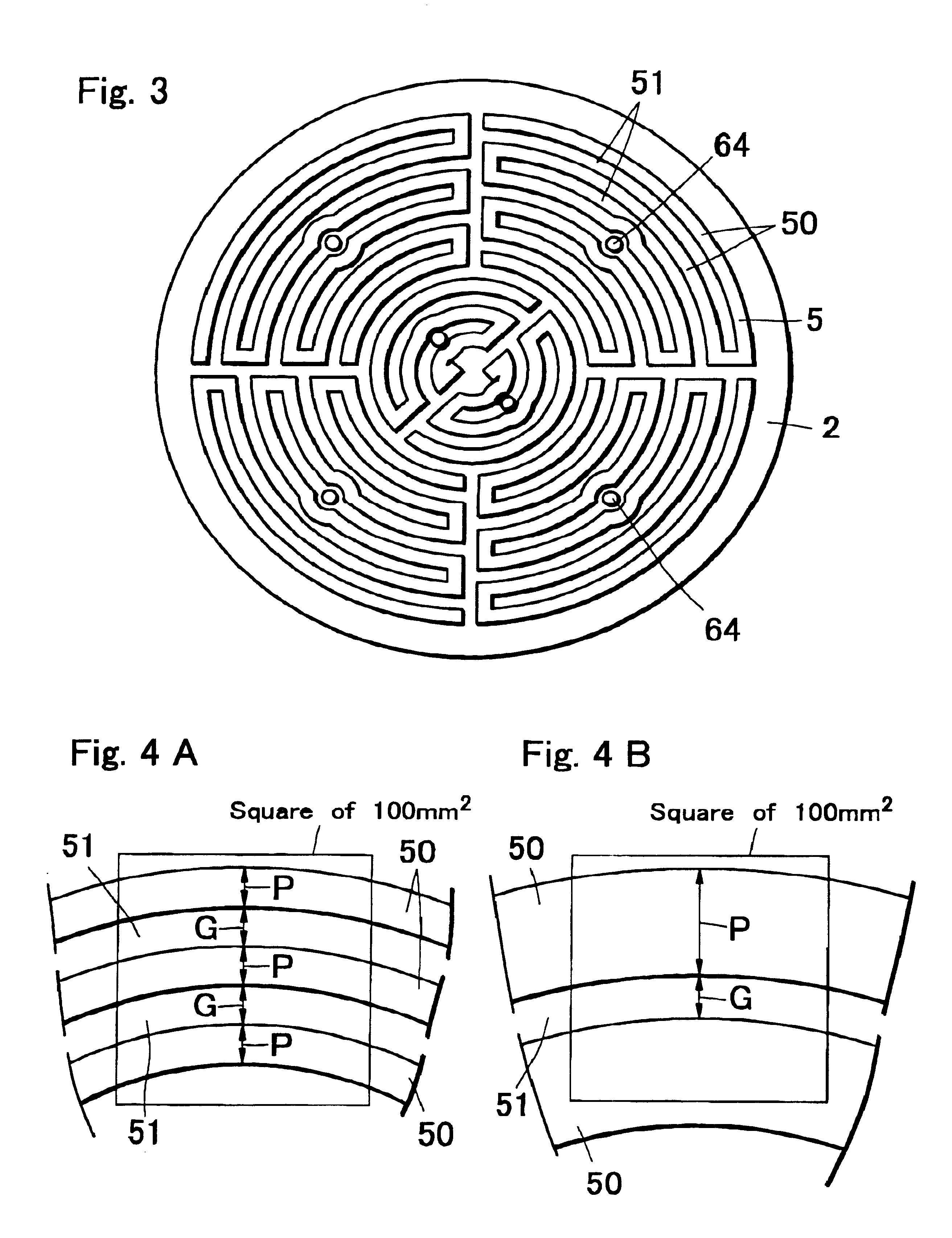

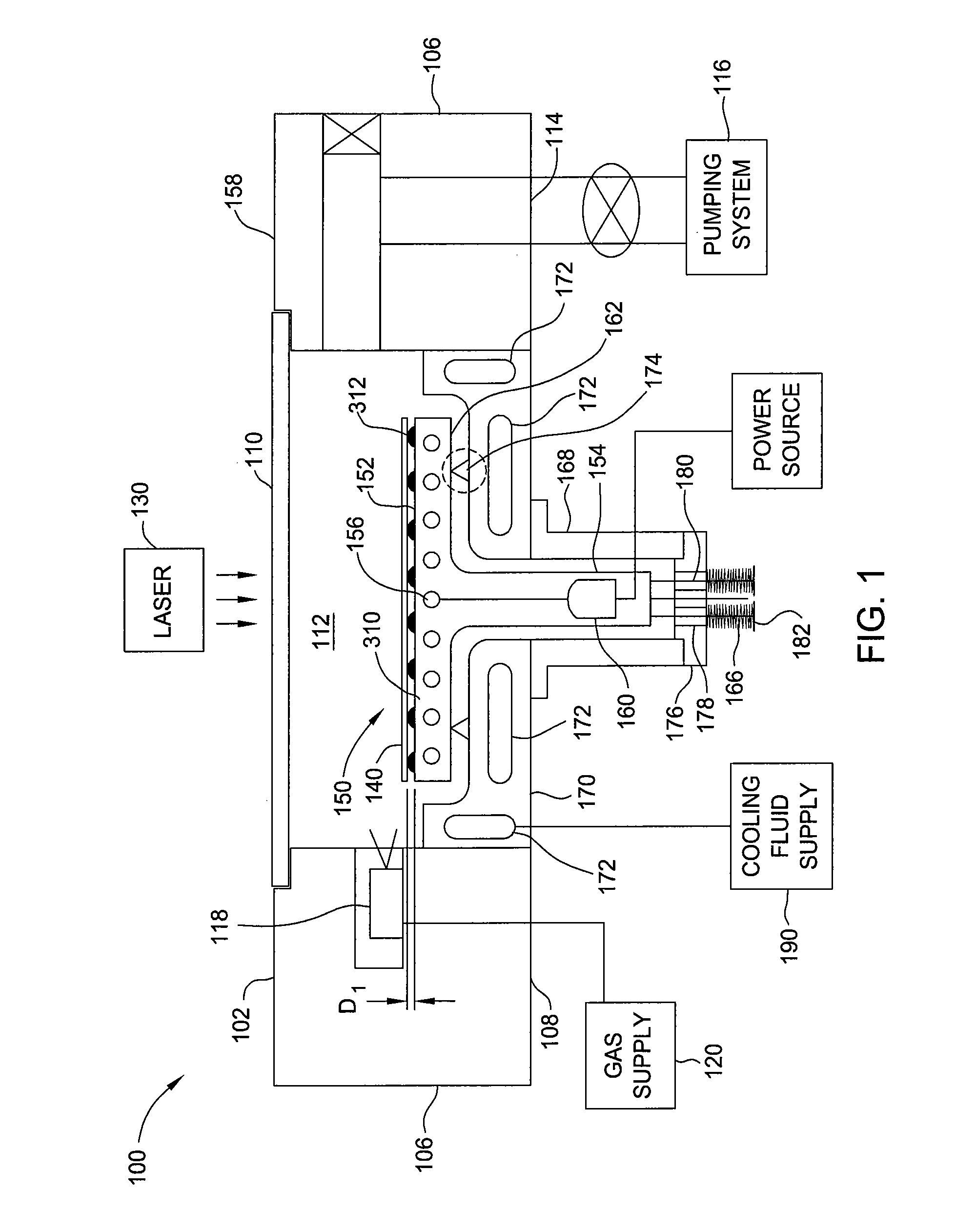

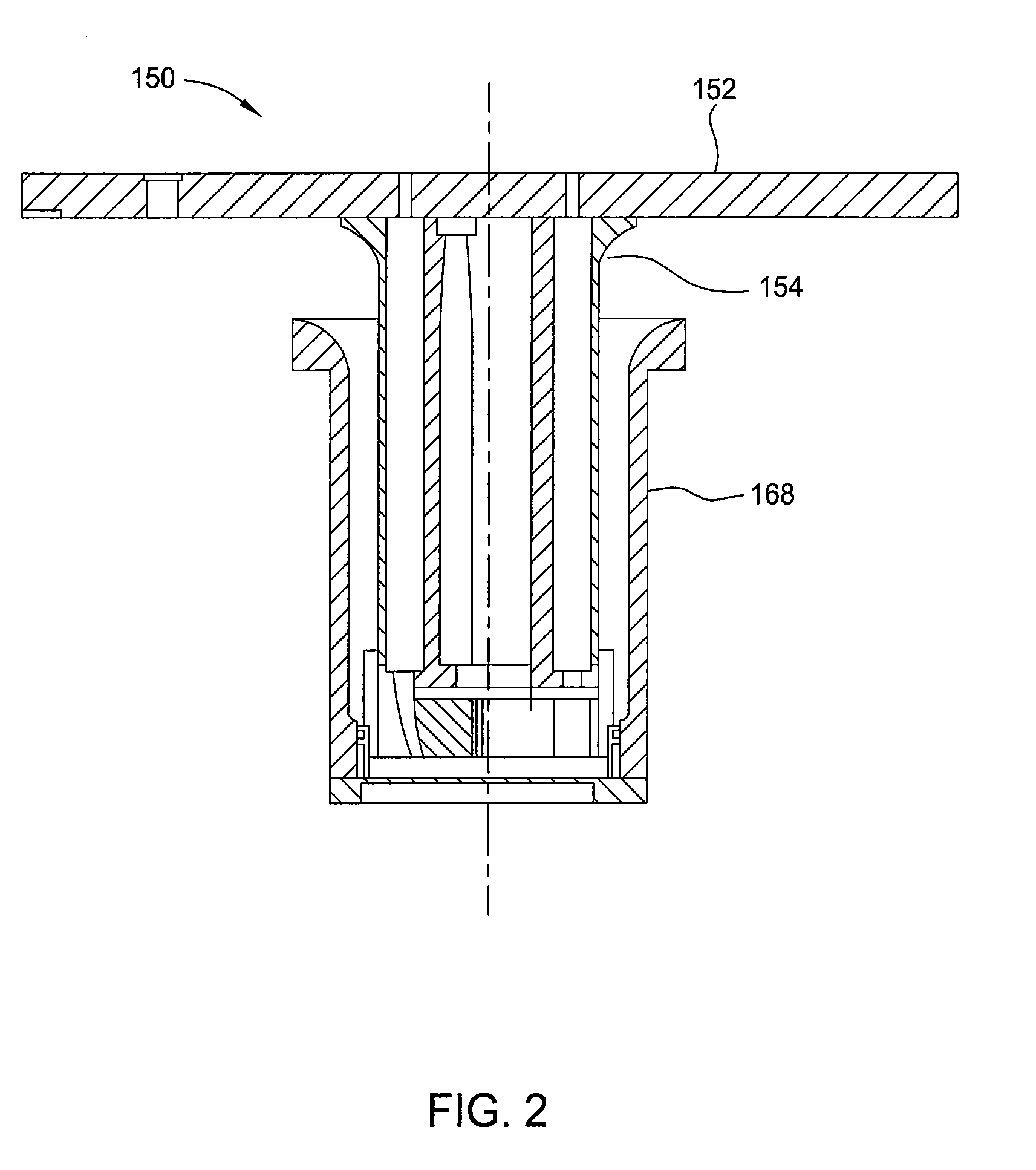

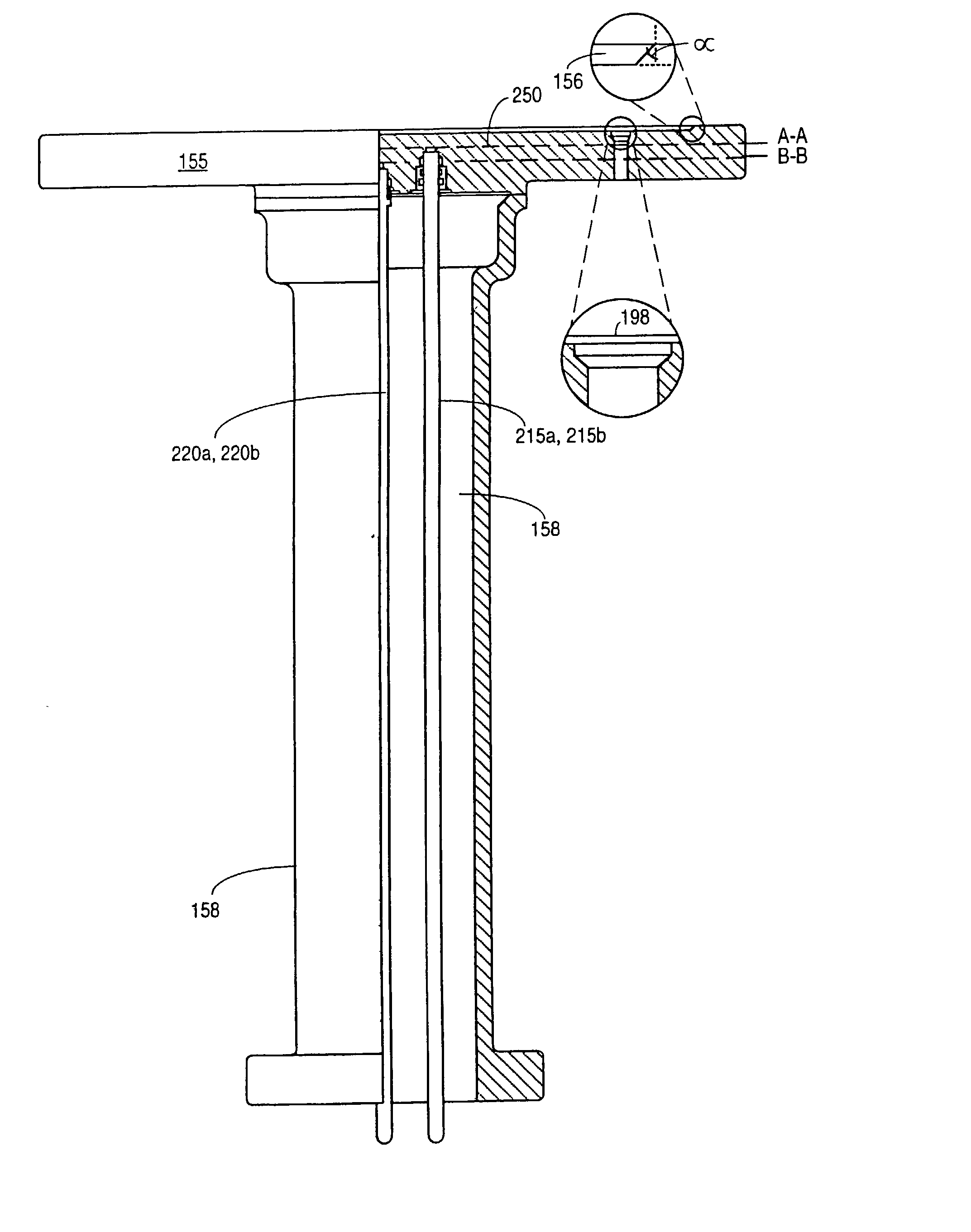

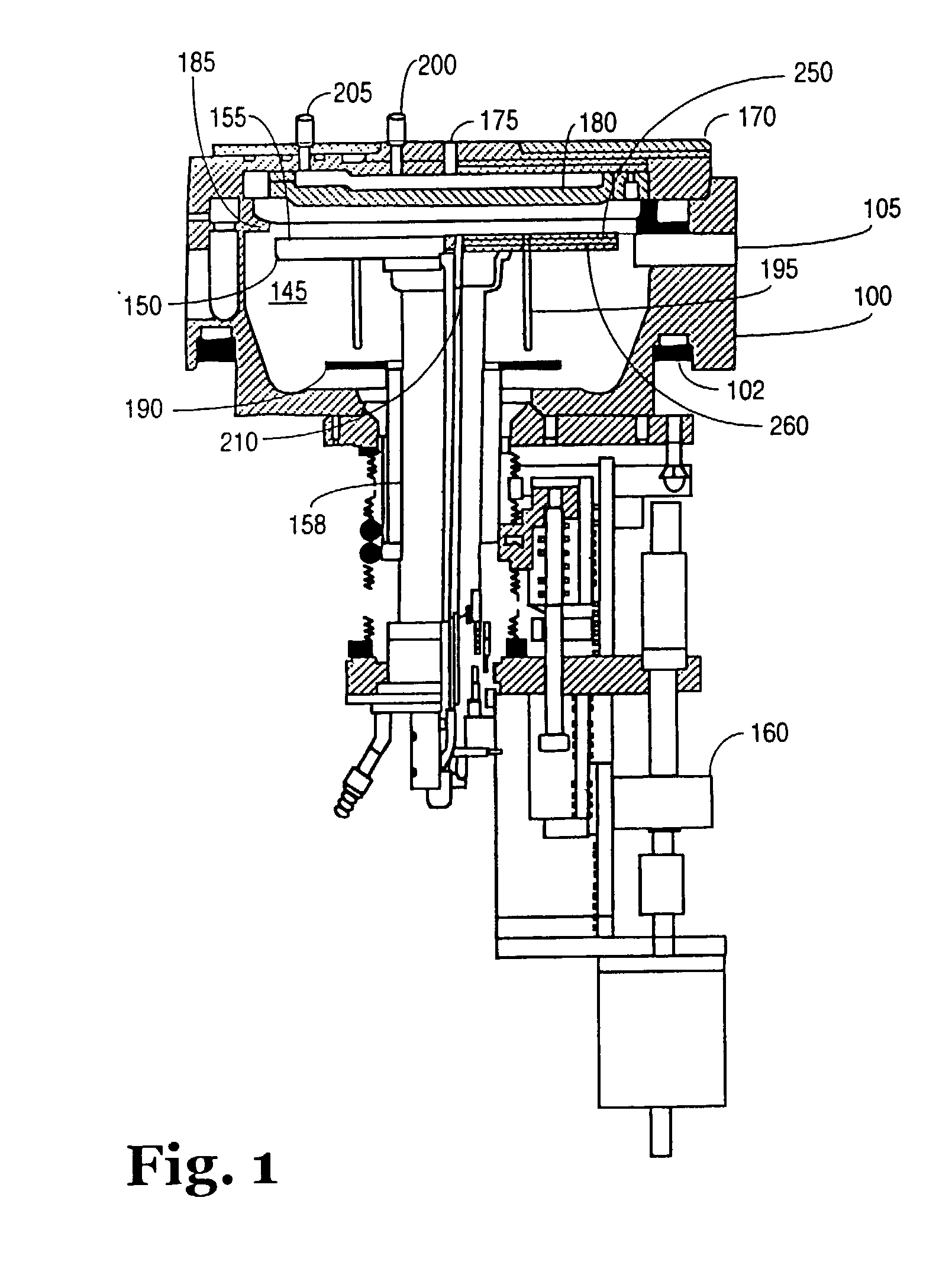

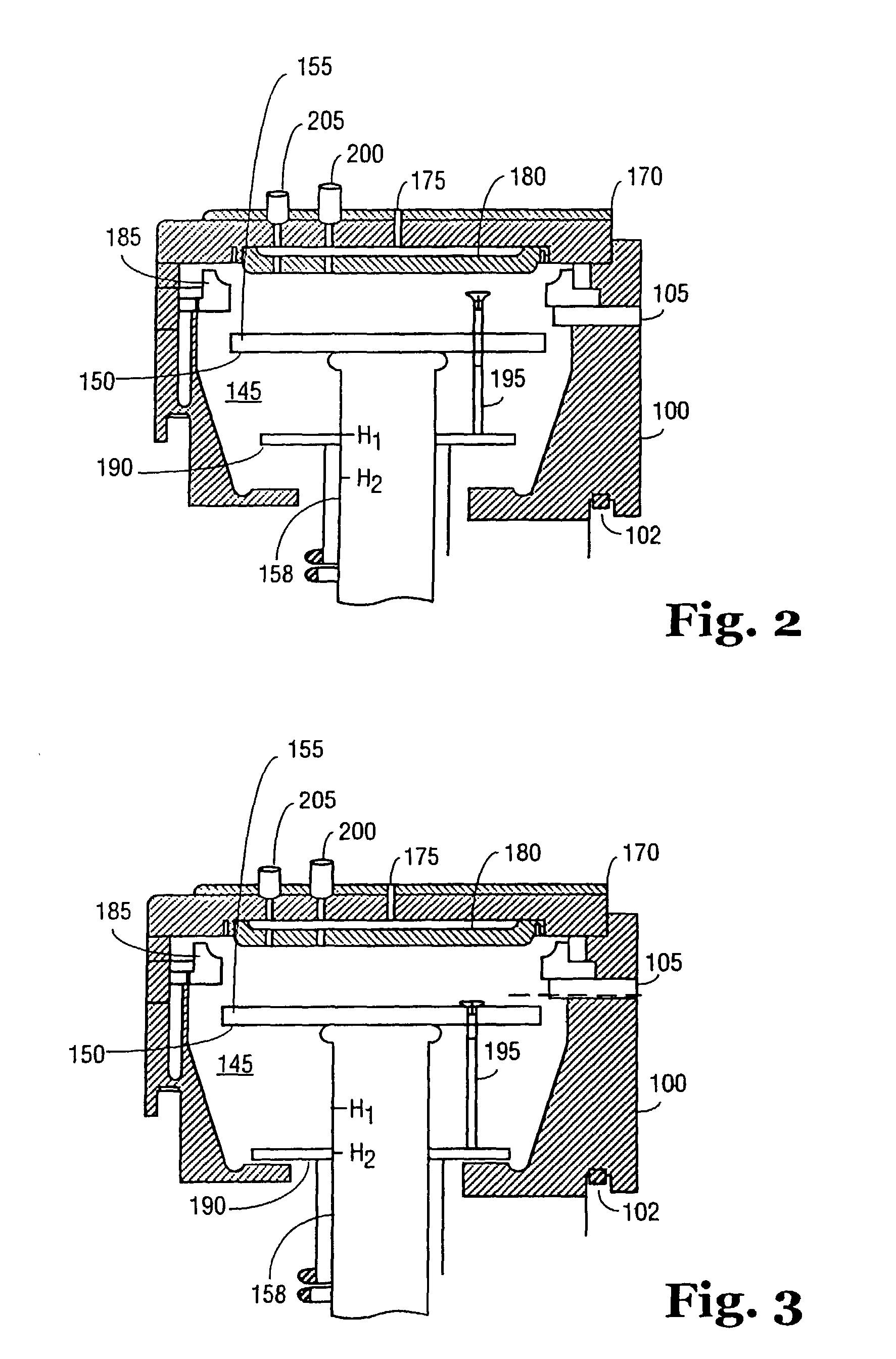

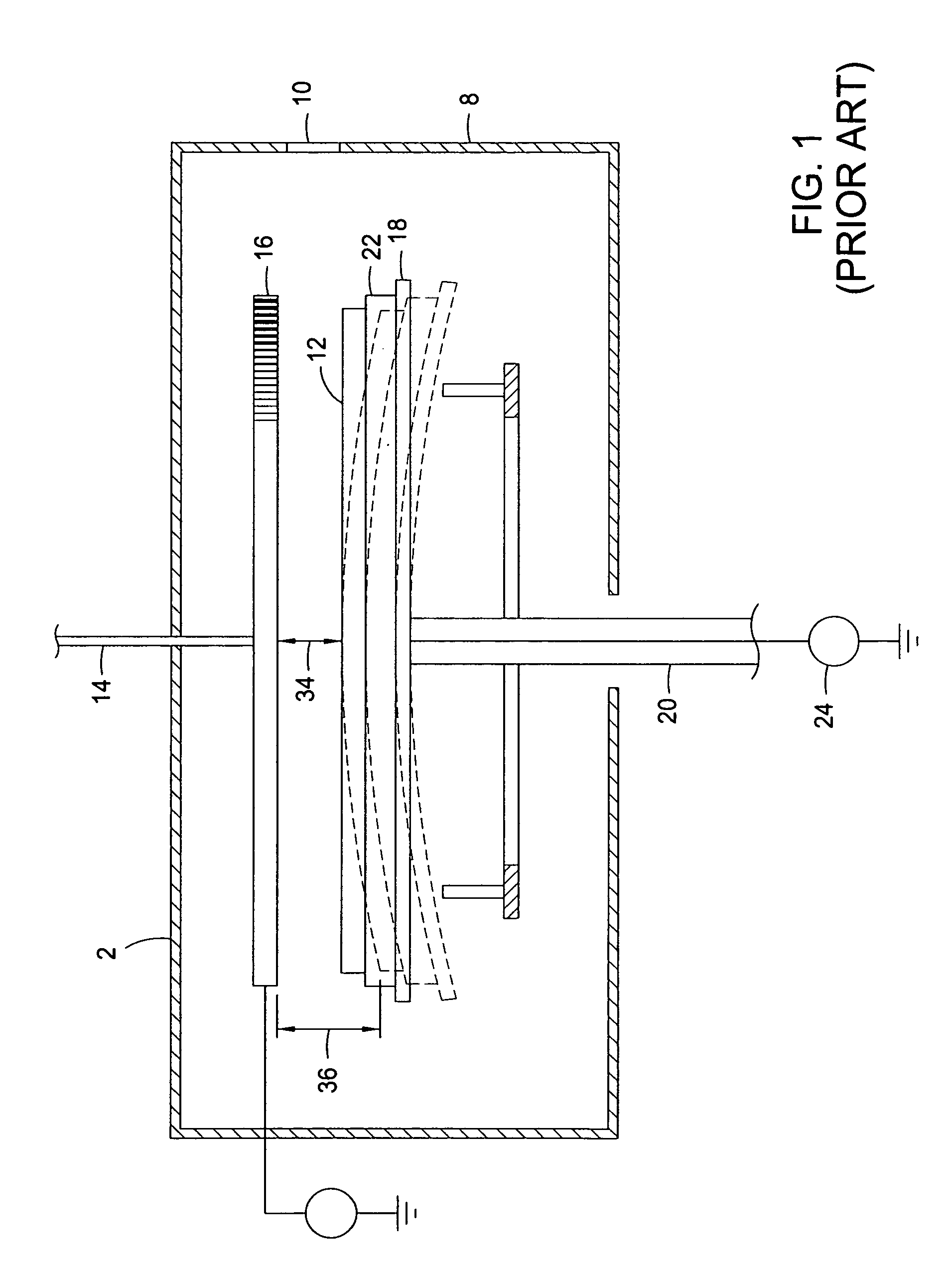

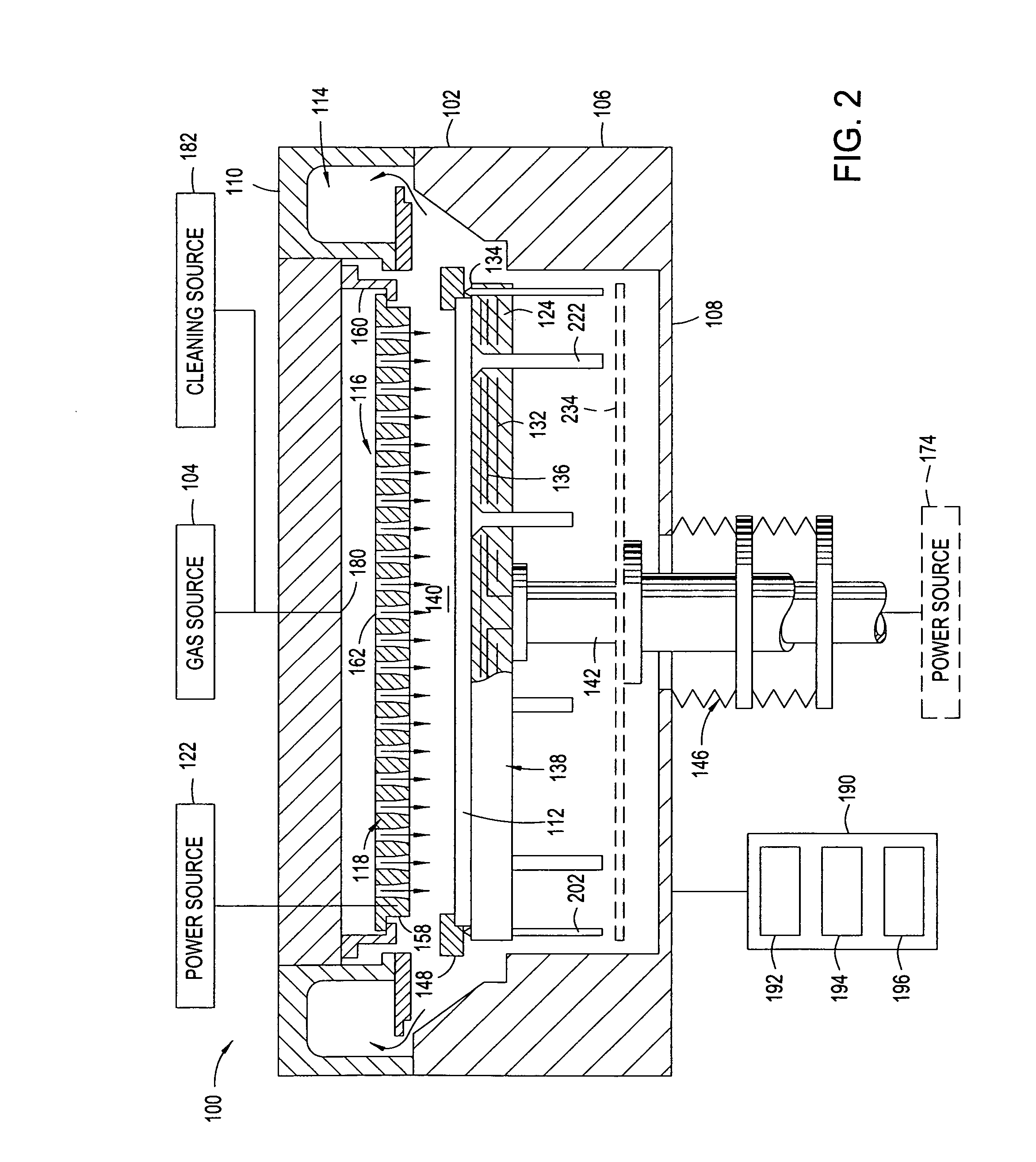

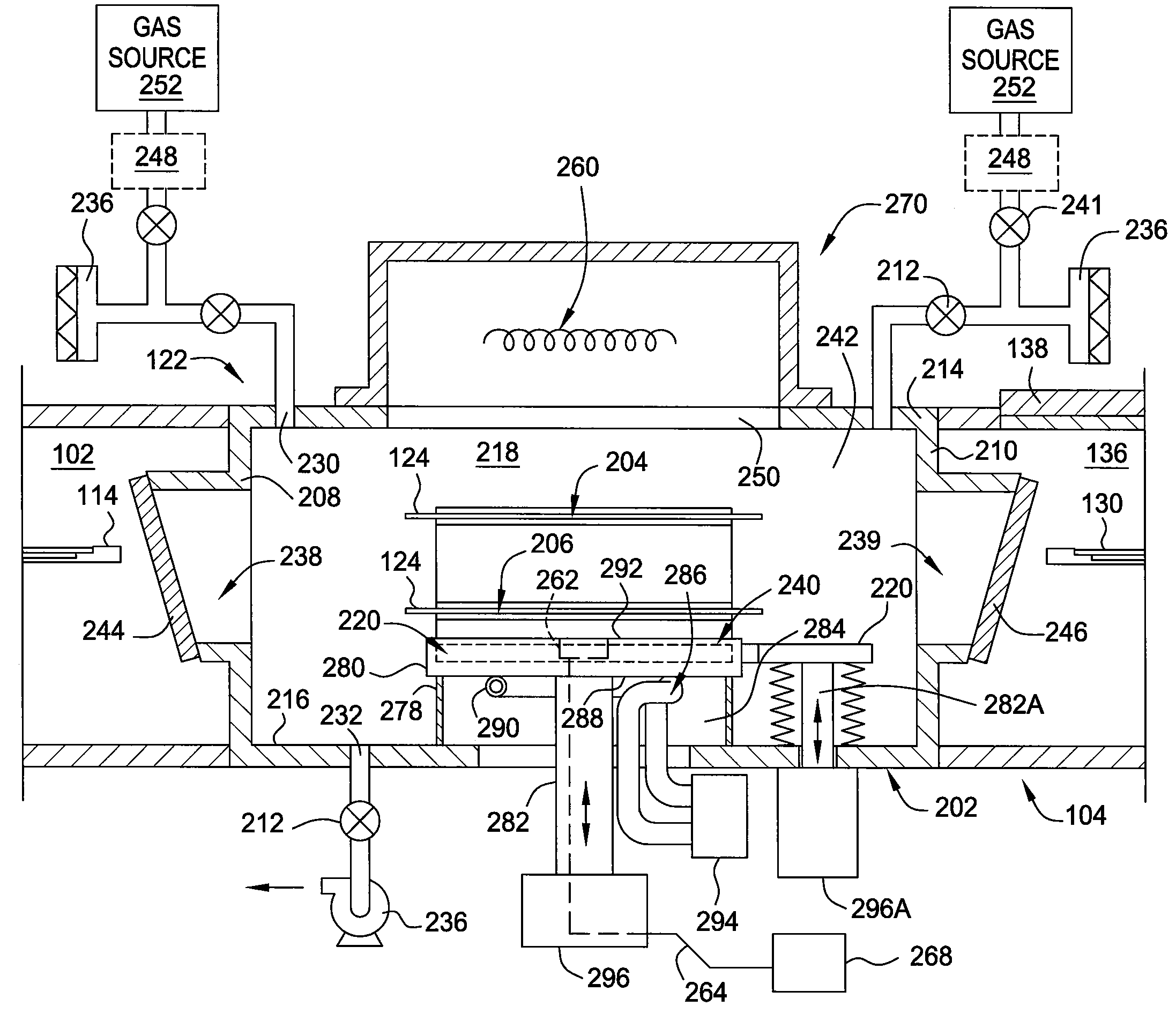

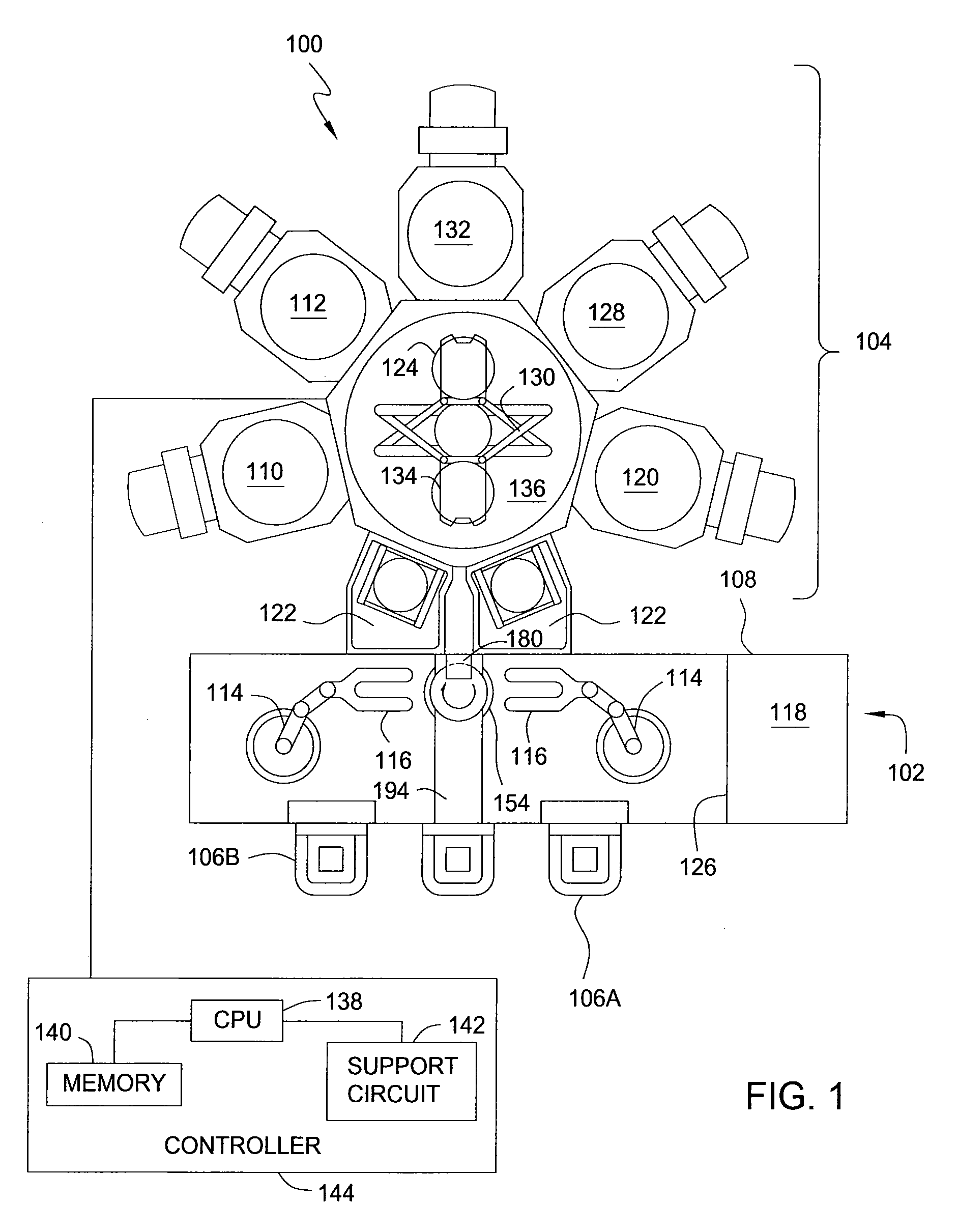

Apparatus for efficient removal of halogen residues from etched substrates

An apparatus for removing volatile residues from a substrate is provided. In one embodiment, an apparatus for removing halogen-containing residues from a substrate includes a chamber suitable for operating maintaining a vacuum therein and a heat module positioned to heat a substrate disposed in the chamber. The apparatus for removing halogen-containing residues from a substrate also includes at least one of A) a temperature controlled pedestal having a projection extending radially therefrom suitable for supporting the temperature control pedestal on a ledge of the chamber body, the projection thermally isolating the base from the chamber body; B) a pair of substrate holders that include two support flanges extending radially inward from an inner edge of an arc-shaped body, each support flange having a substrate support step that includes a sloped landing; or C) a domed window.

Owner:APPLIED MATERIALS INC

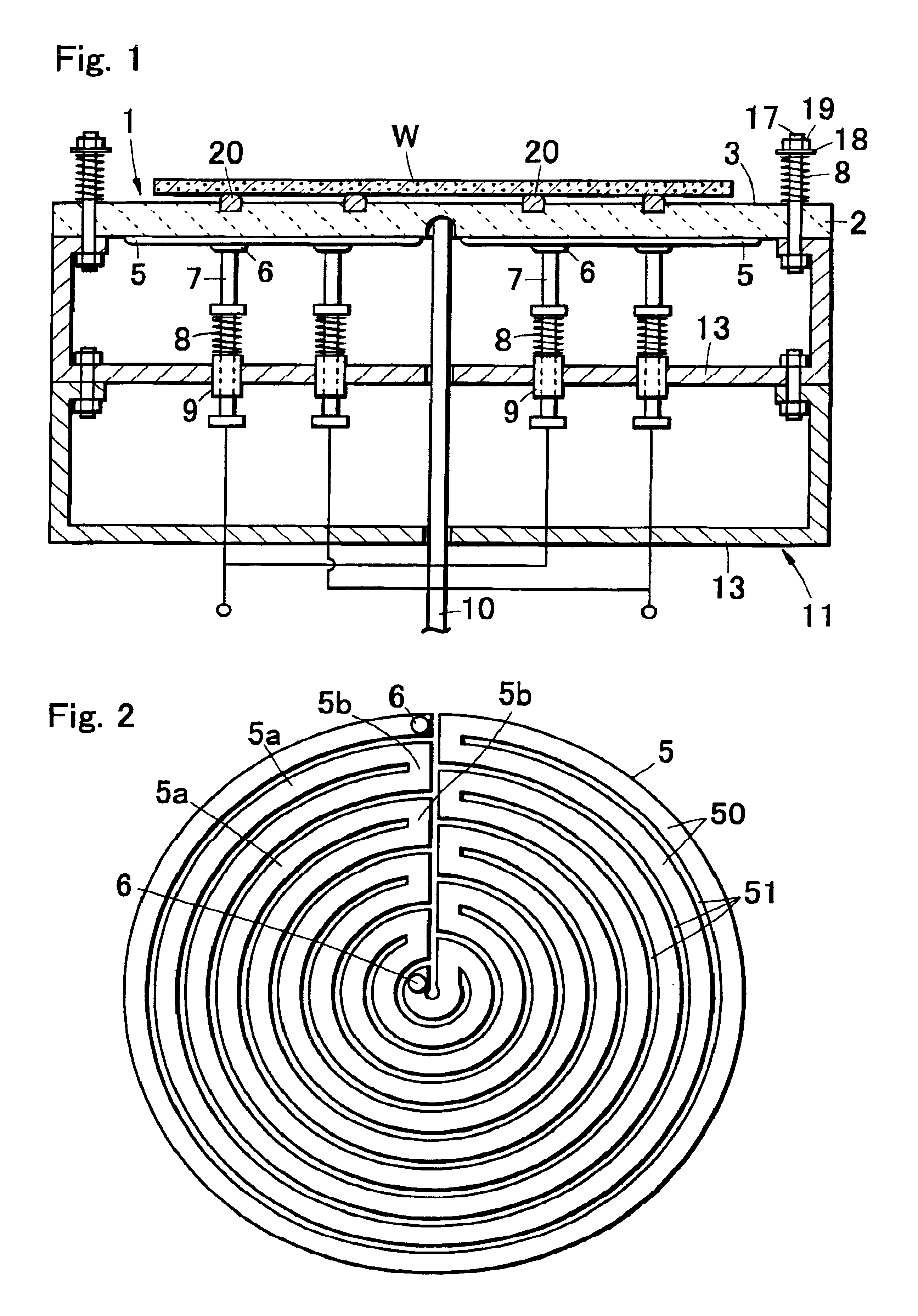

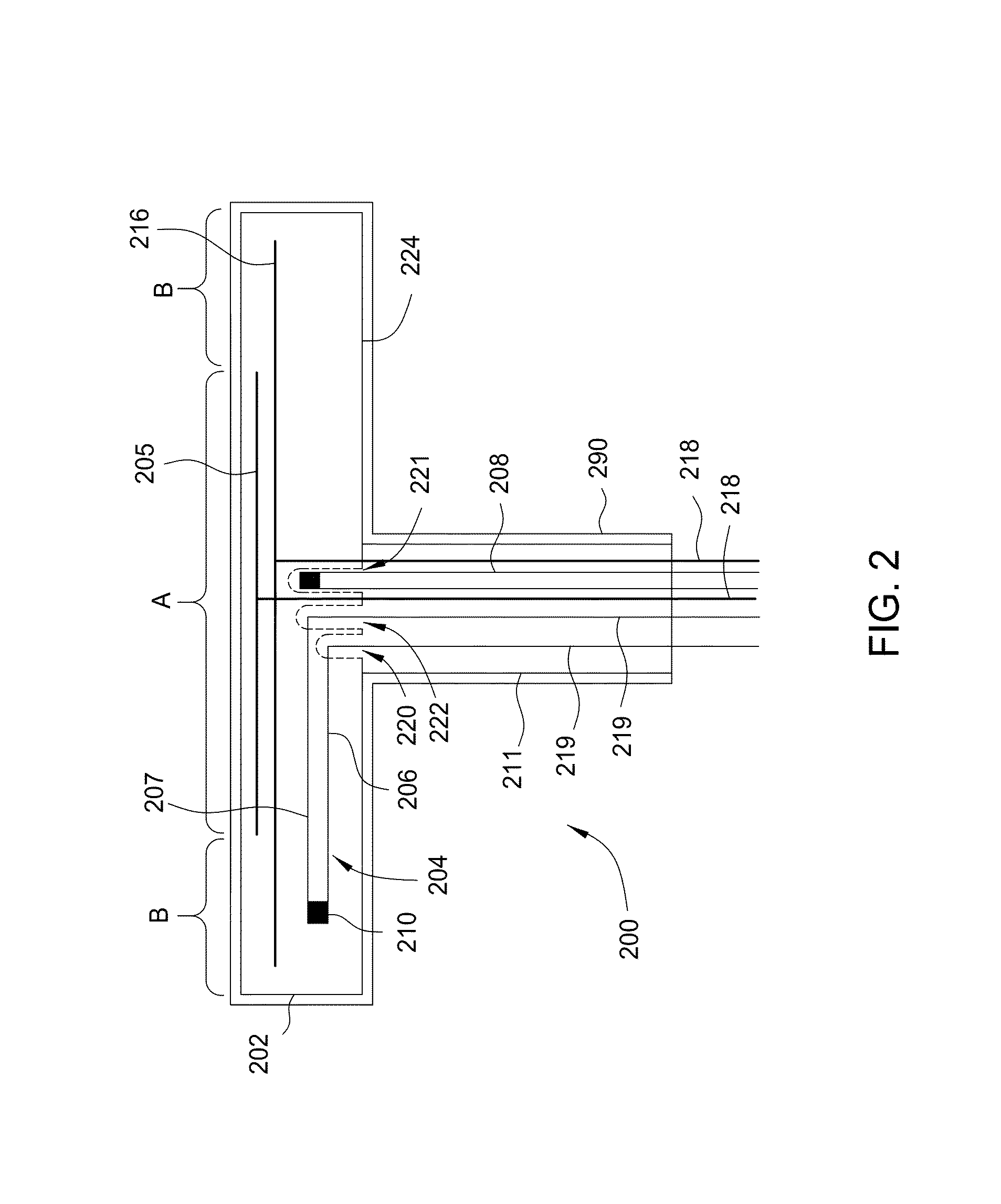

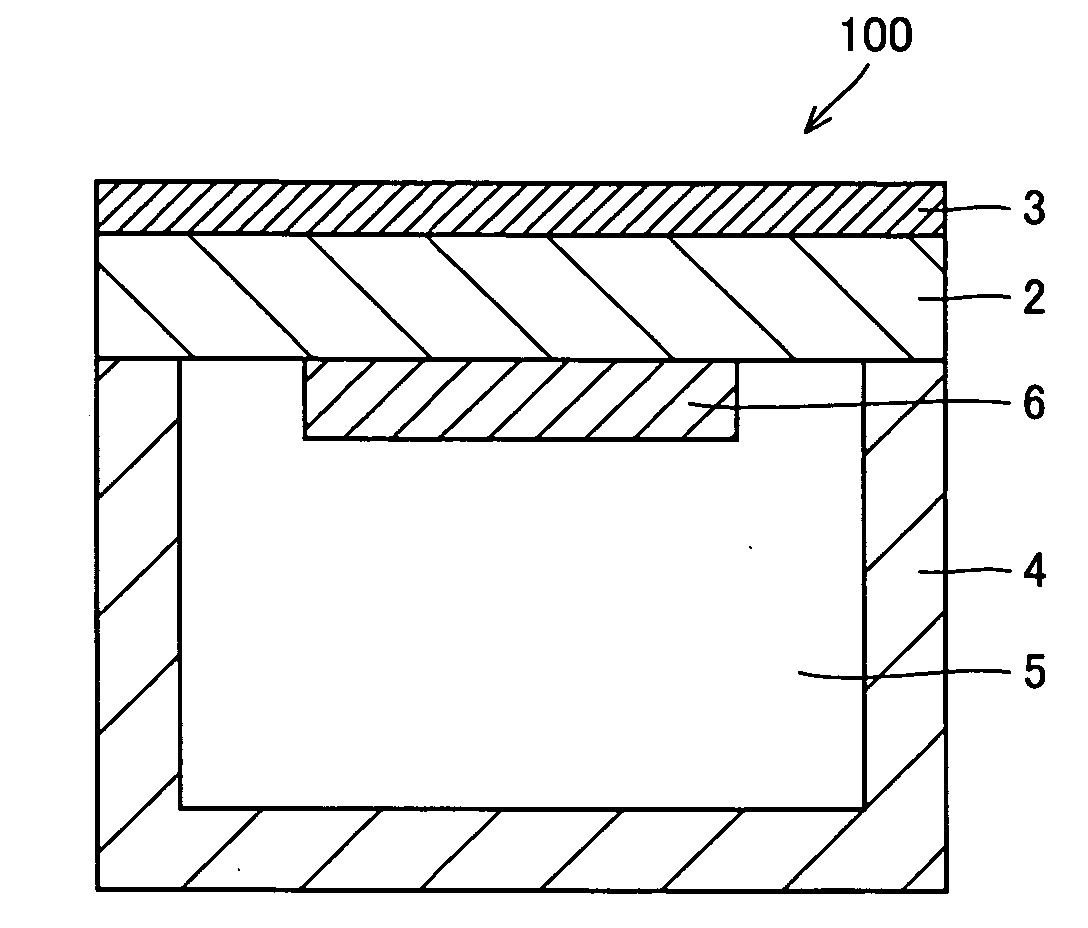

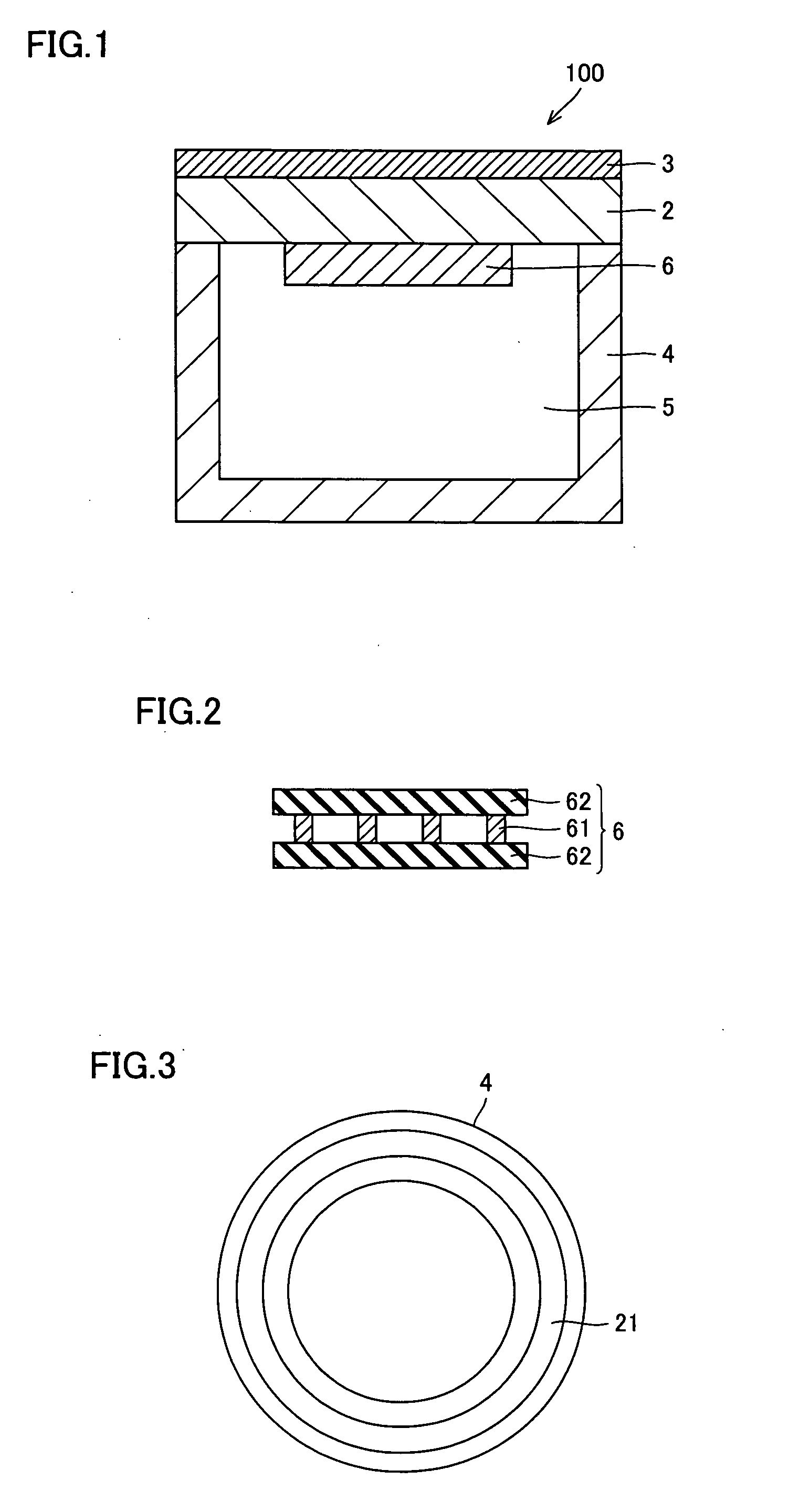

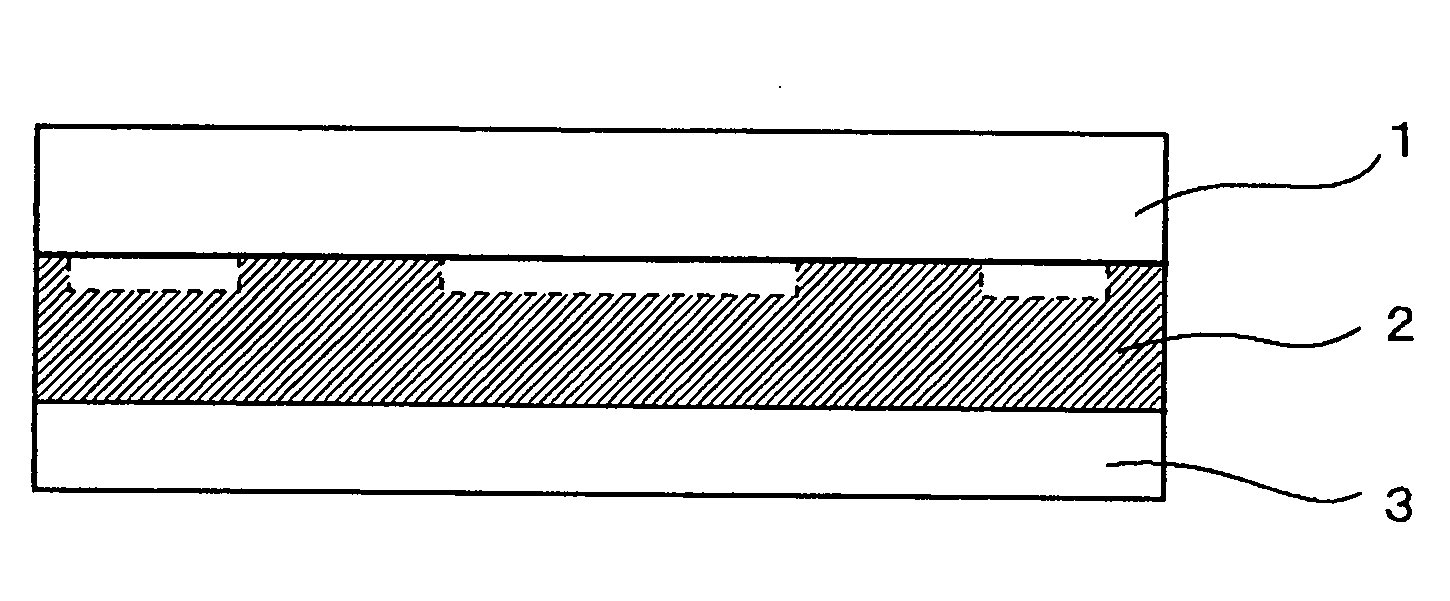

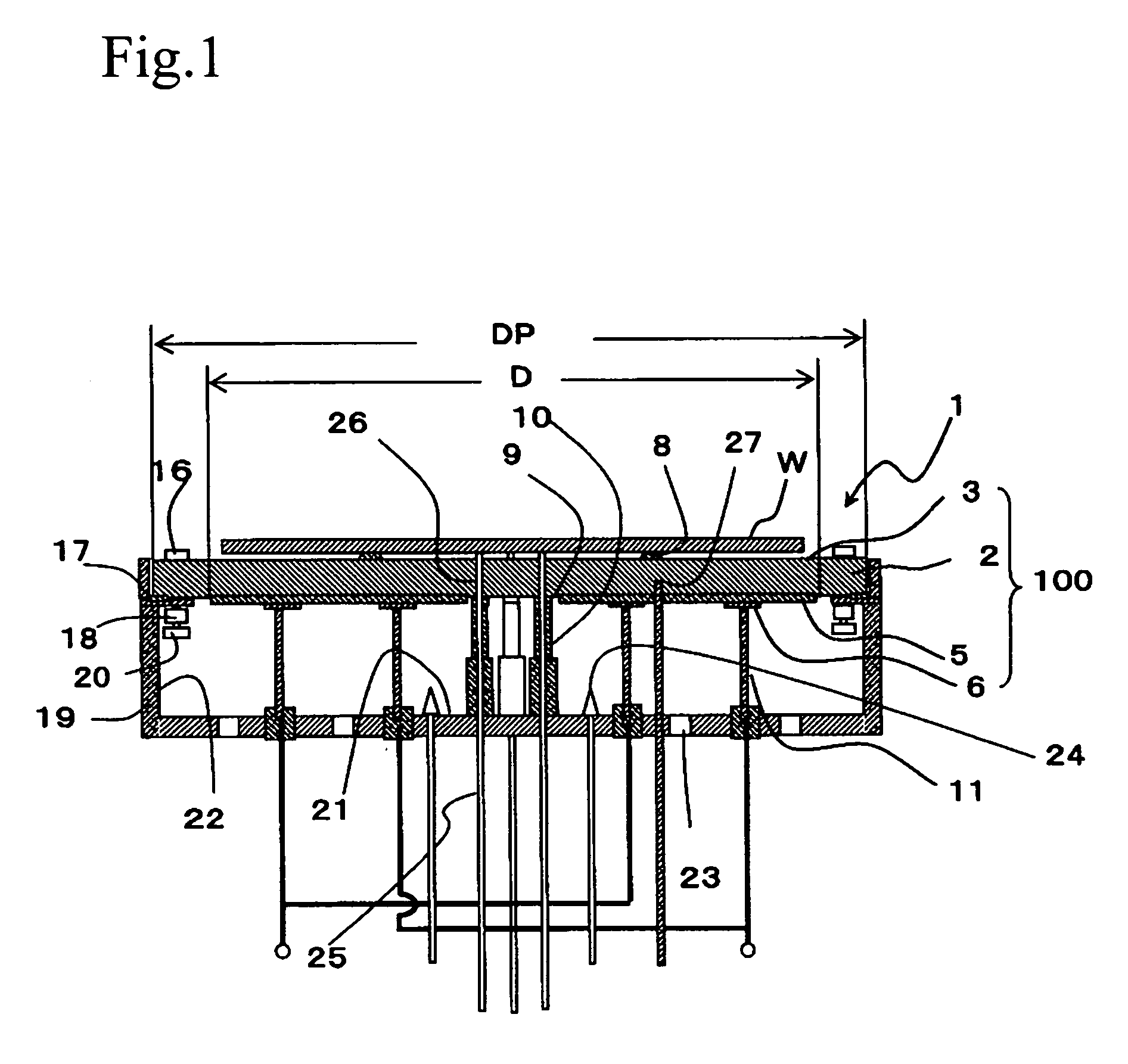

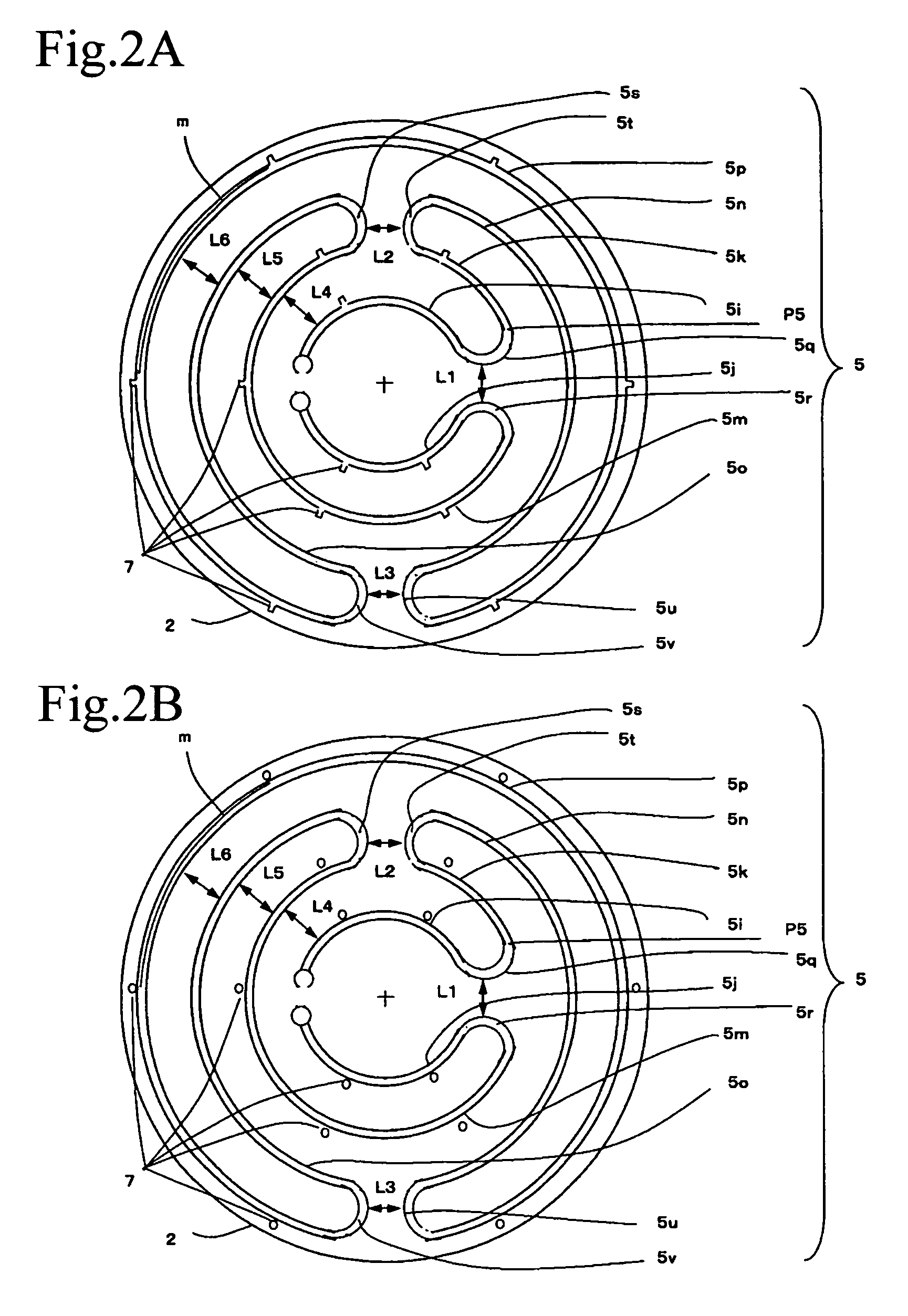

Substrate heat treatment apparatus

A substrate heat treatment apparatus includes a heat-treating plate having a flat upper surface, support devices formed of a heat-resistant resin for contacting and supporting a substrate, a seal device disposed annularly for rendering gastight a space formed between the substrate and heat-treating plate, and exhaust bores for exhausting gas from the space. The support devices are formed of resin, and the upper surface of the heat-treating plate is made flat, whereby a reduced difference in the rate of heat transfer occurs between contact parts and non-contact parts on the surface of the substrate. Consequently, the substrate is heat-treated effectively while suppressing variations in heat history over the surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

Unit for varying a temperature of a test piece and testing instrument incorporating same

ActiveUS7115838B2Easy to control temperatureUniform temperature distributionDrying solid materials with heatDomestic cooling apparatusInstrumentationCoolant

Owner:ESPEC CORP

Yttria-based material coated chemical vapor deposition chamber heater

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

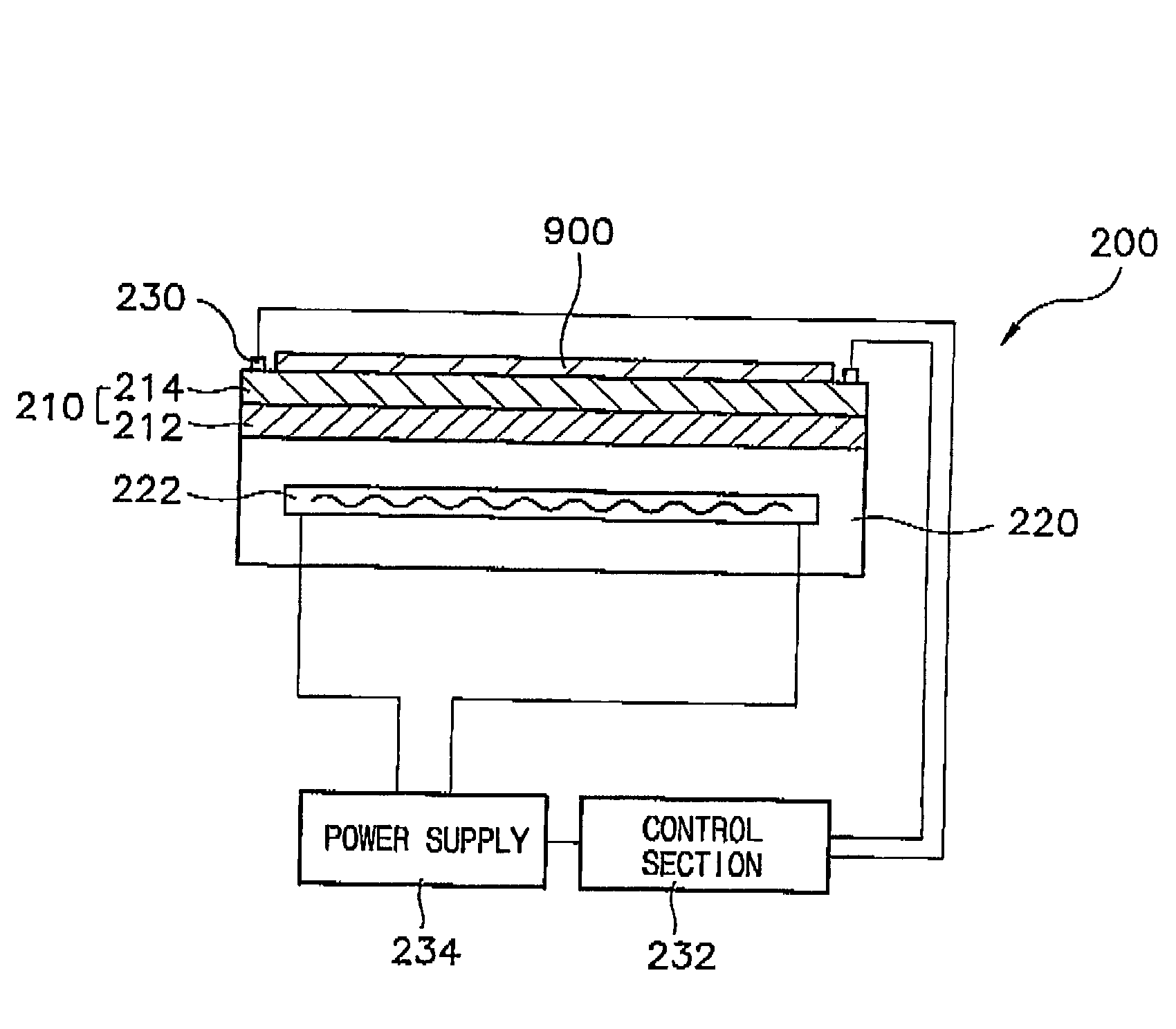

Apparatus for processing a substrate including a heating apparatus

InactiveUS20030066826A1Drying solid materials with heatMuffle furnacesProduction rateDevice material

An apparatus for heating a substrate of a semiconductor device includes a hot plate, on which a semiconductor substrate is placed, and a heater for heating the hot plate. The hot plate is preferably a composite plate including a plurality of plates having different thermal conductivities from each other. For example, a first plate adjacent to the heater can be made of aluminum, which has a relatively high thermal conductivity. A second plate, laminated on top of the first plate, can be made of titanium or stainless steel, which both have a thermal conductivity lower than aluminum. A composite hot plate as disclosed herein is better able to maintain a constant temperature and a uniform temperature distribution in order to more uniformly heat a substrate and to reduce an amount of energy required for the heating process. In addition, the reliability and productivity of the semiconductor device manufactured by the apparatus can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

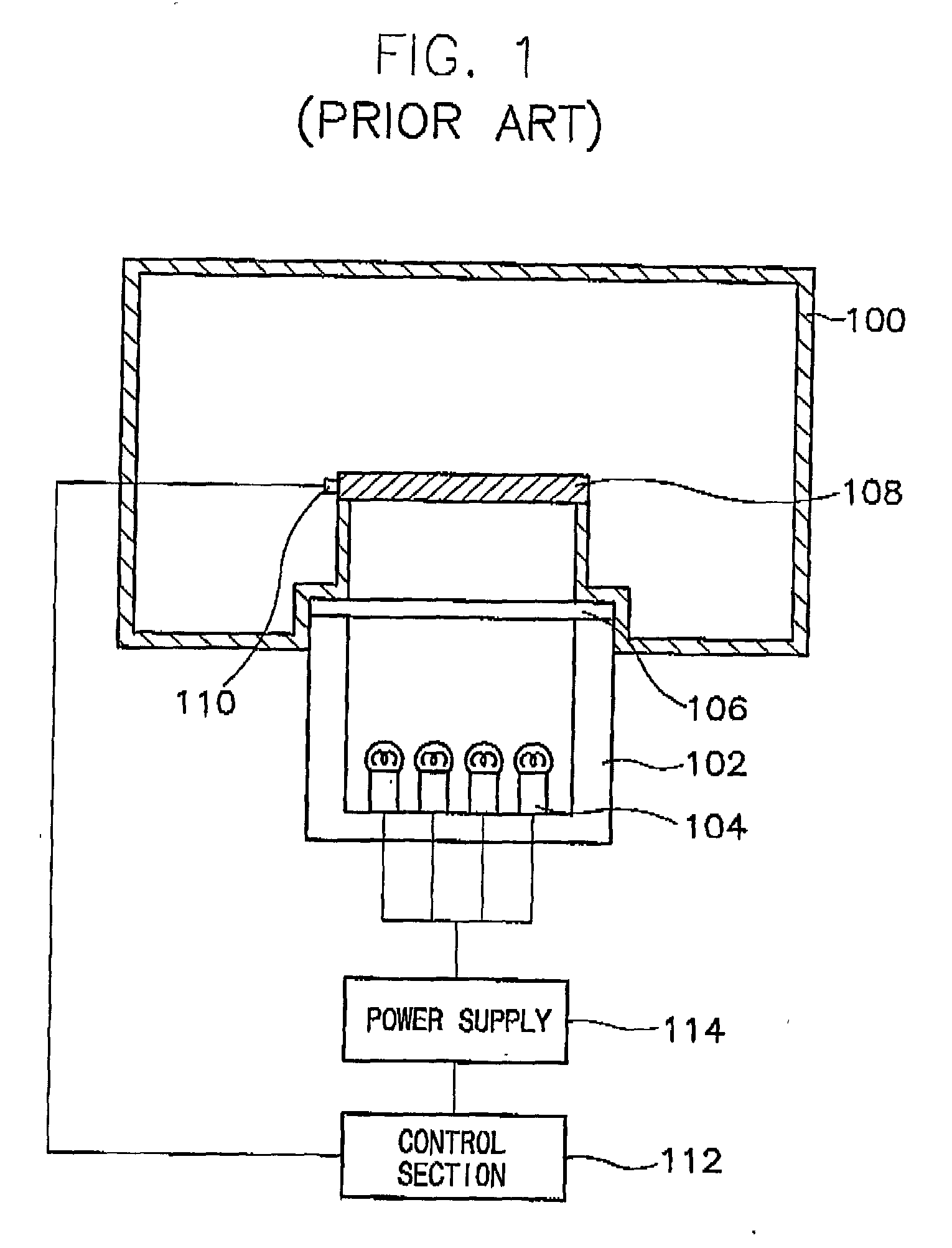

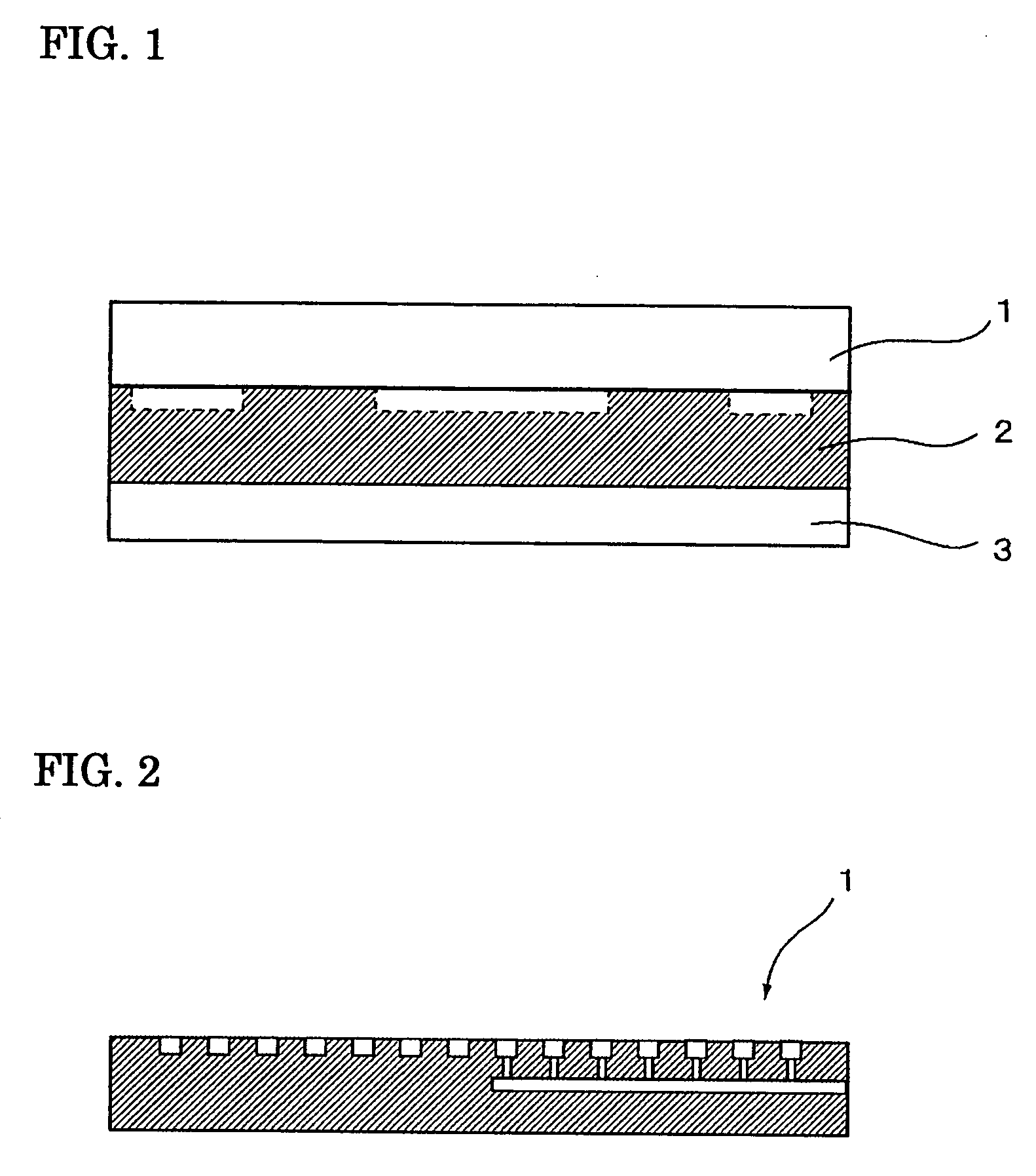

Method for manufacturing semiconductor device

InactiveUS20060240574A1Warpage suppressionPolycrystalline material growthSemiconductor/solid-state device manufacturingDevice materialManufactured apparatus

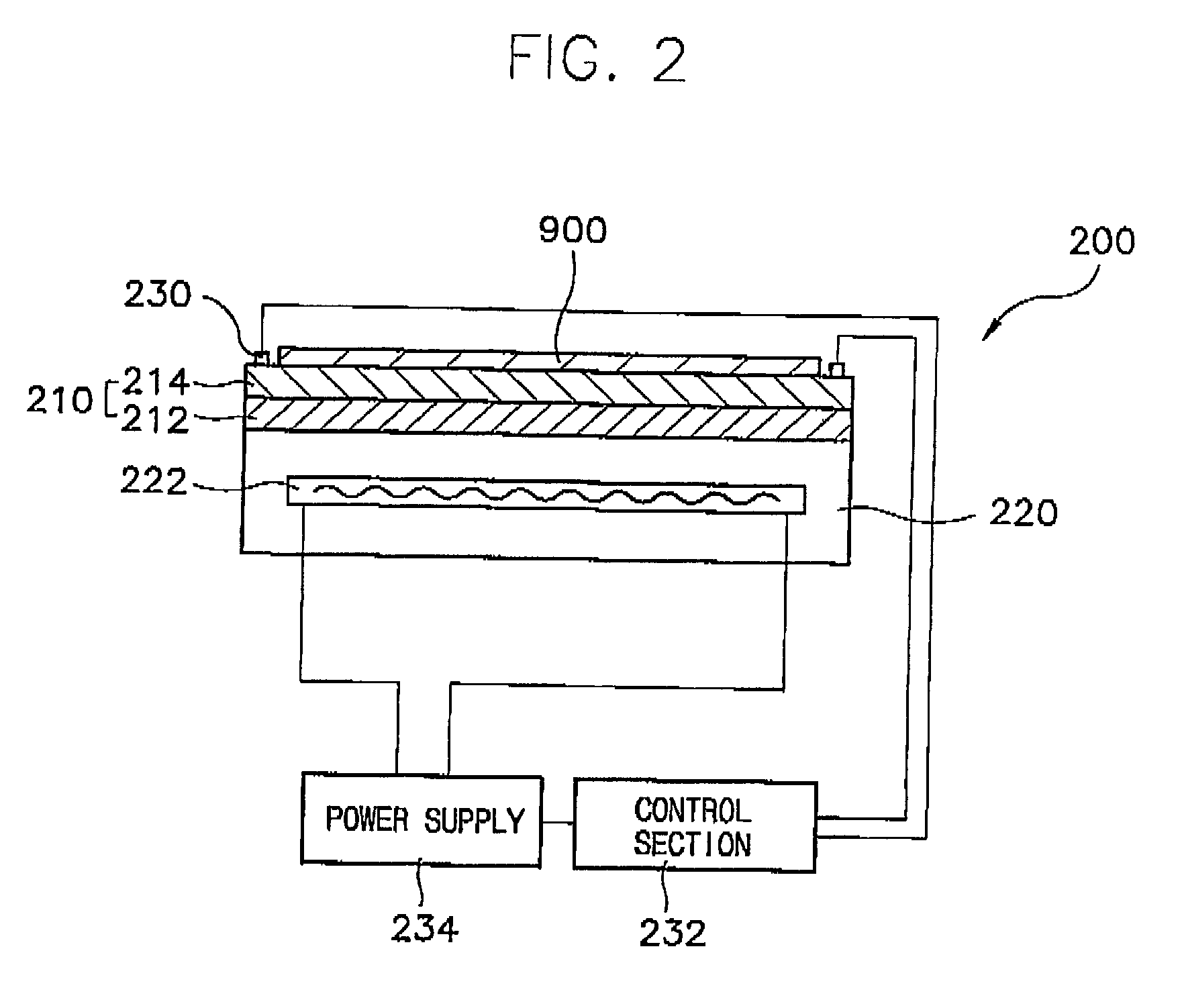

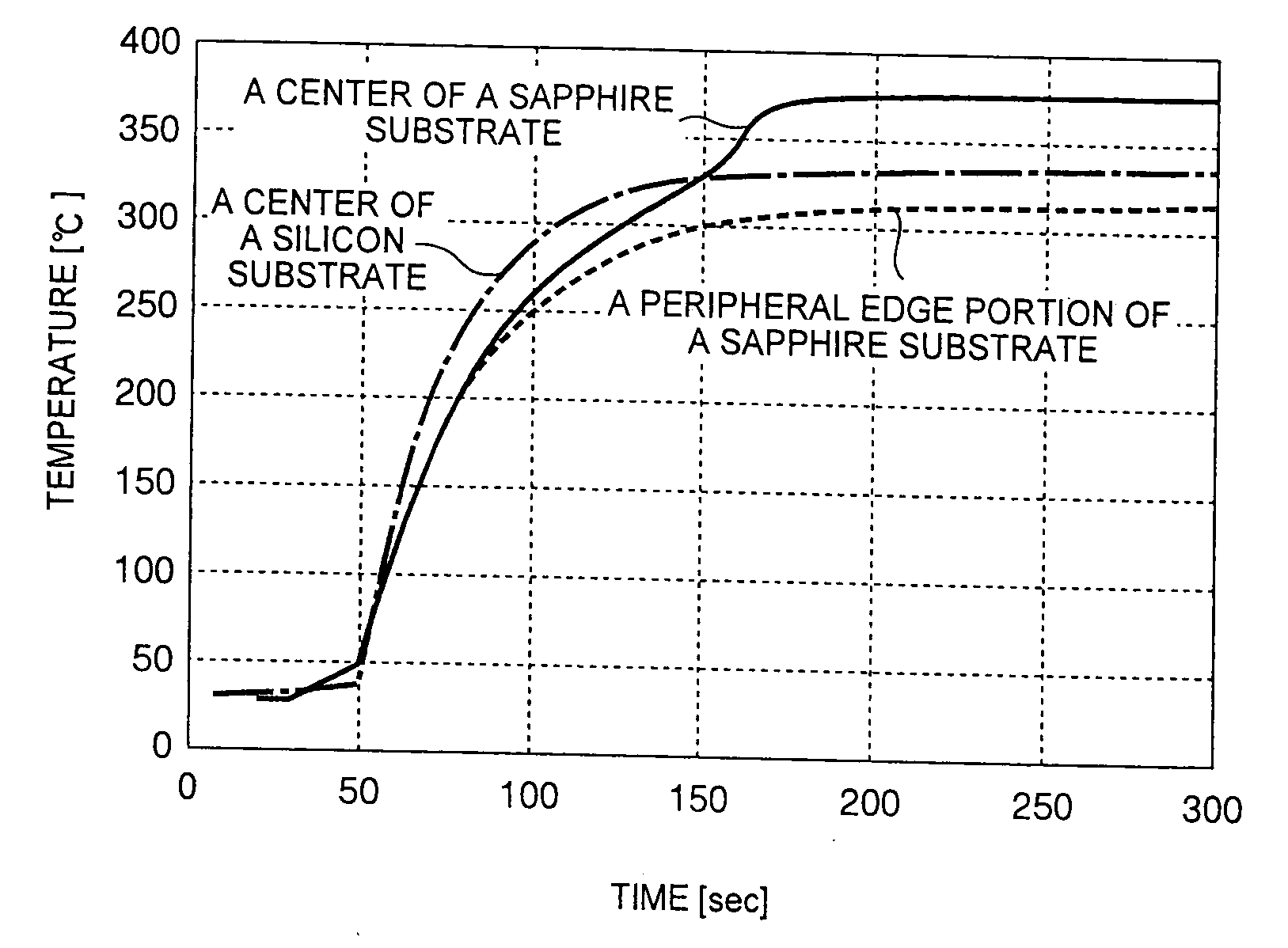

A semiconductor manufacturing apparatus A semiconductor manufacturing apparatus comprises a hot plate which heats a sapphire substrate; a support table having a support plate disposed with being spaced away from the hot plate by a predetermined interval, and support portions which respectively support the sapphire substrate with being spaced by a predetermined interval between the hot plate and the support plate and support the sapphire substrate in such a manner that back surfaces of the hot plate and the sapphire substrate are opposite to each other; an elevating device which moves the support table up and down; and a shielding cover which externally blocks off spacing defined between the hot plate and the sapphire substrate and spacing defined between the sapphire substrate and the support plate.

Owner:LAPIS SEMICON CO LTD

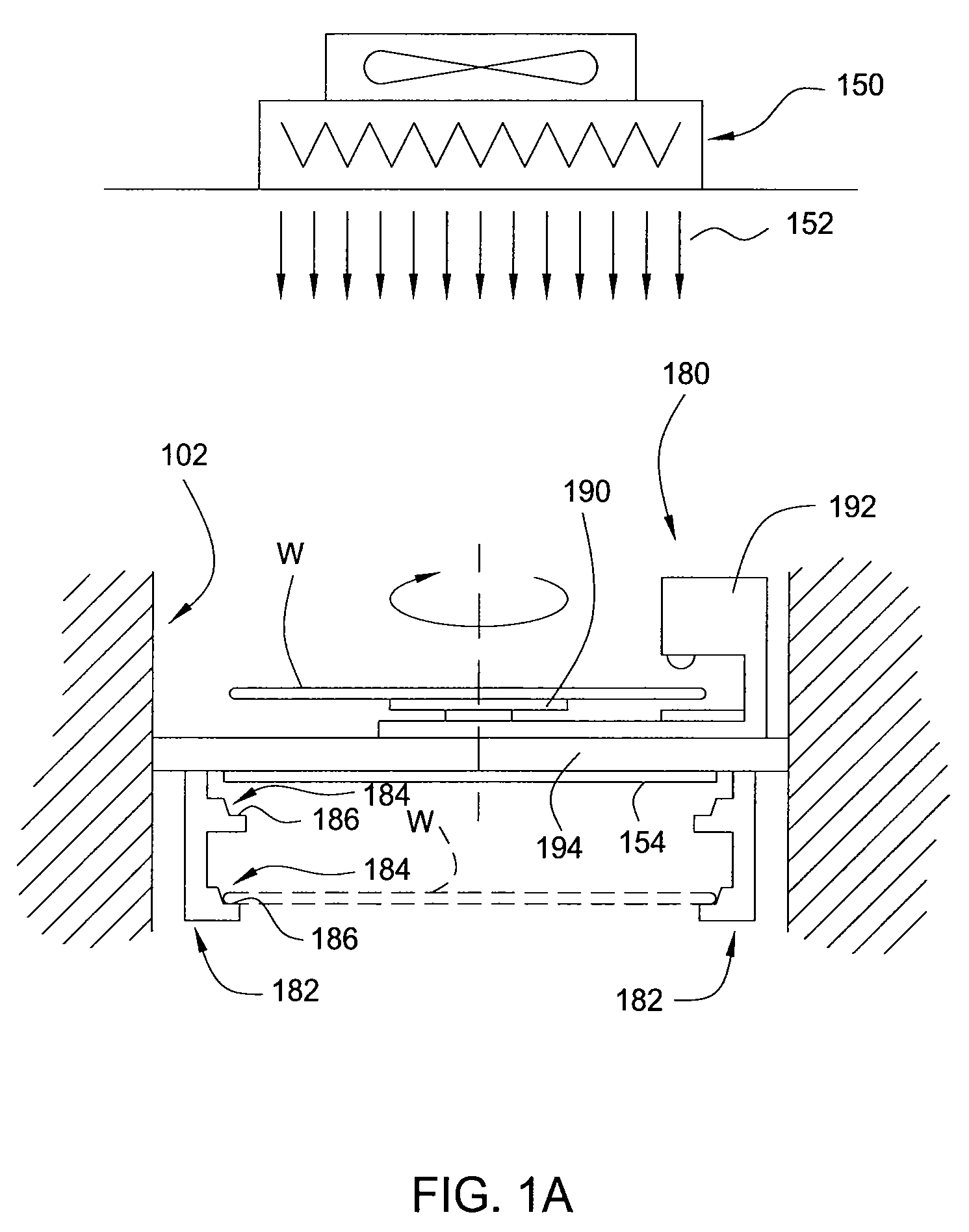

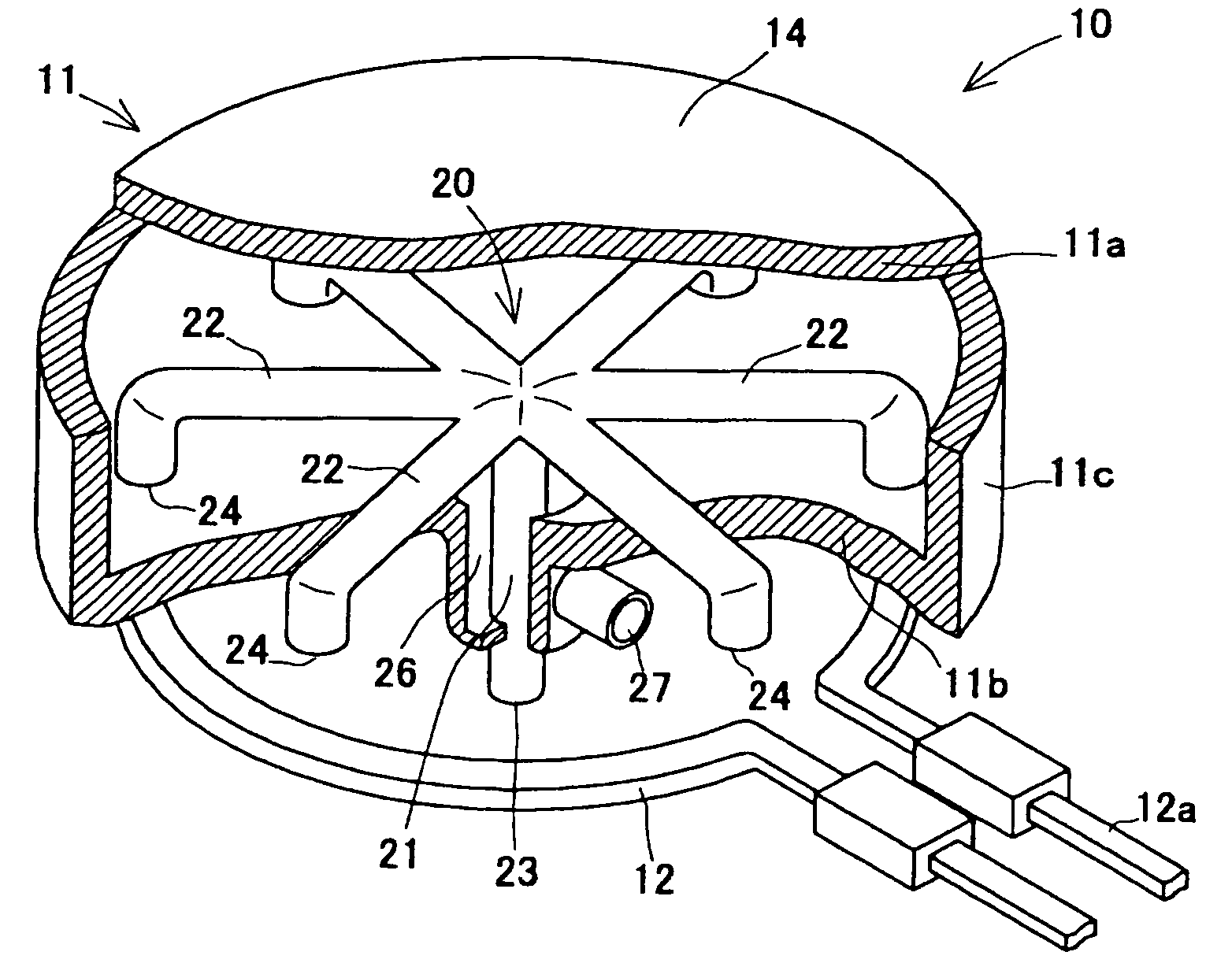

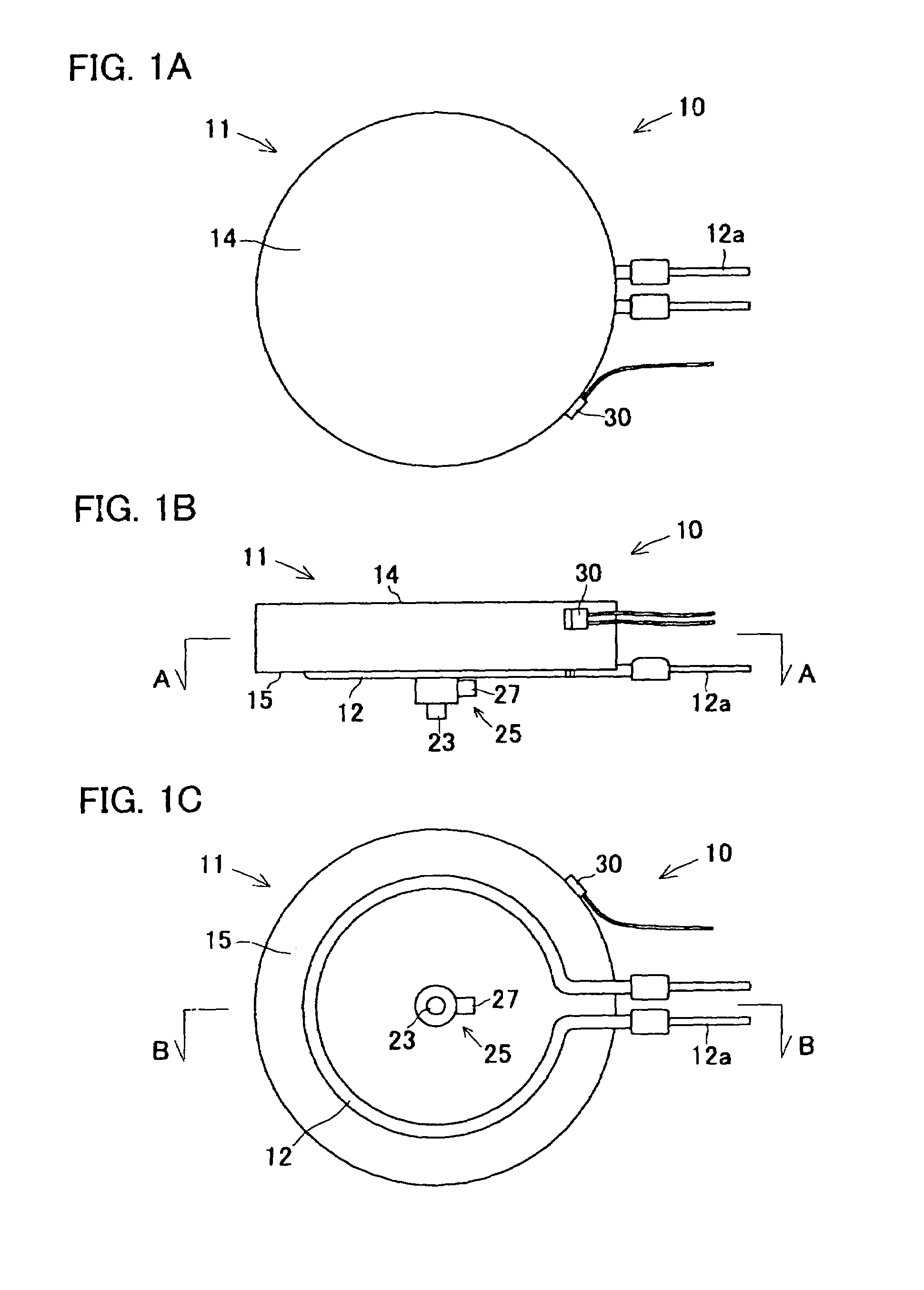

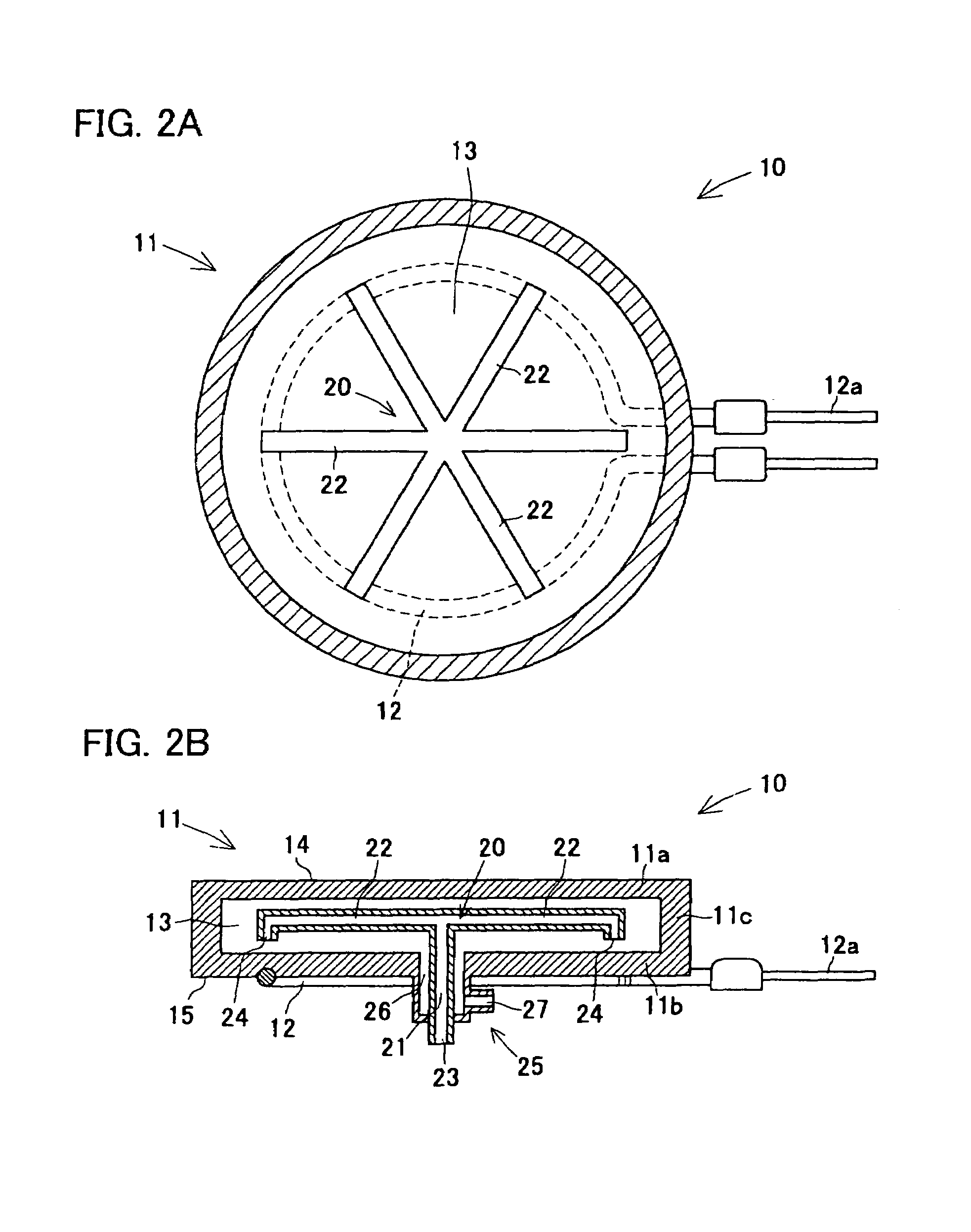

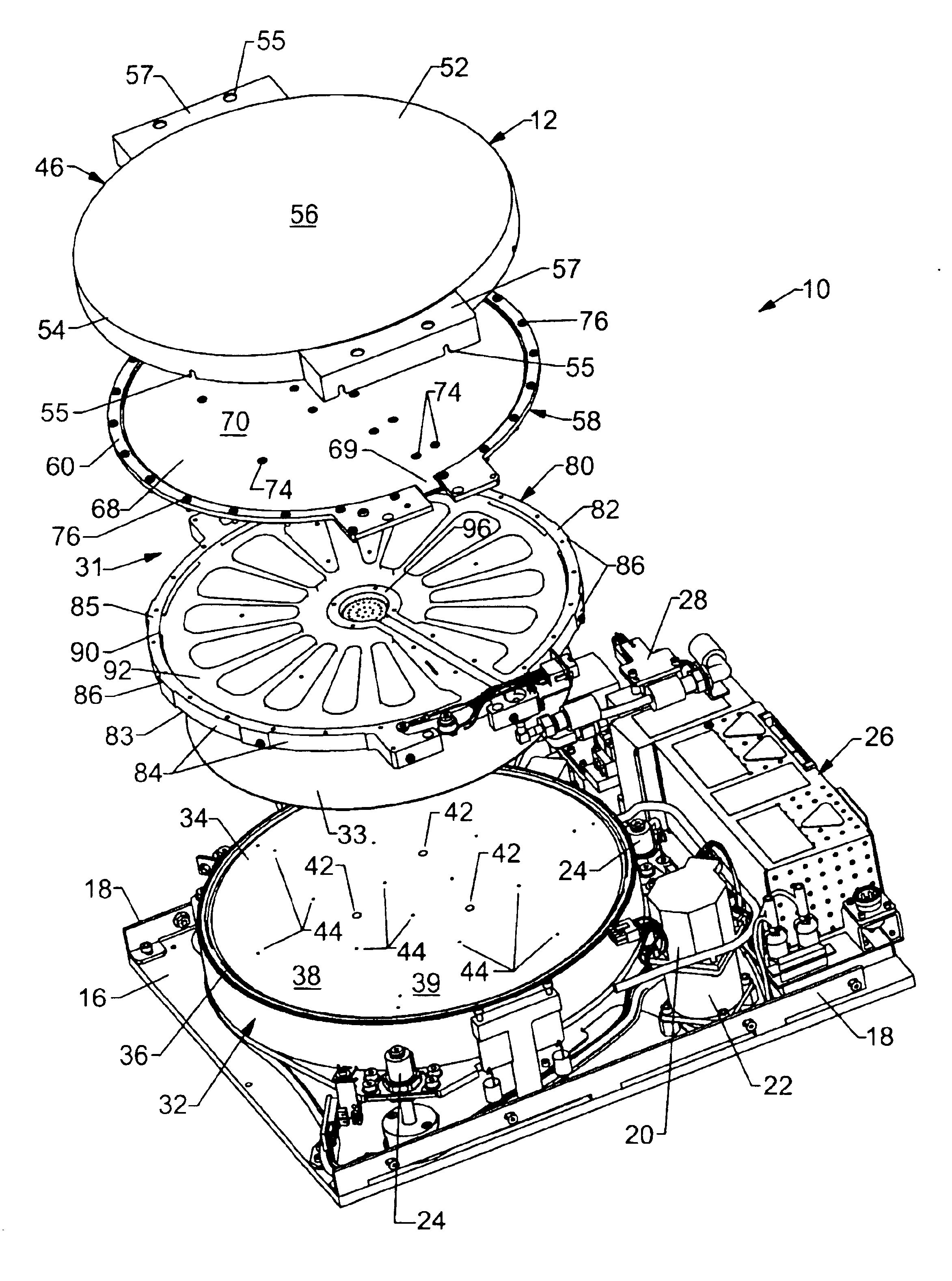

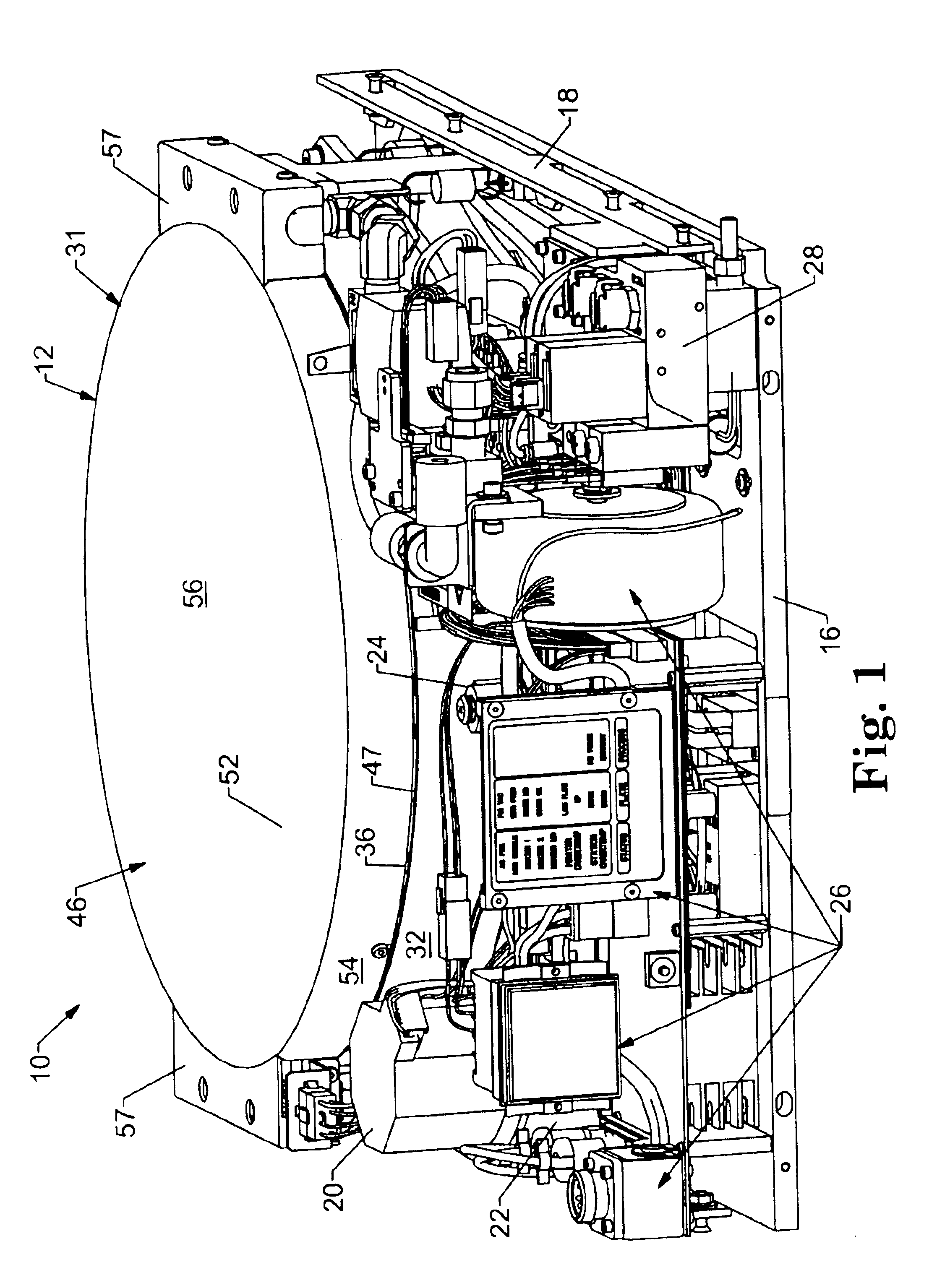

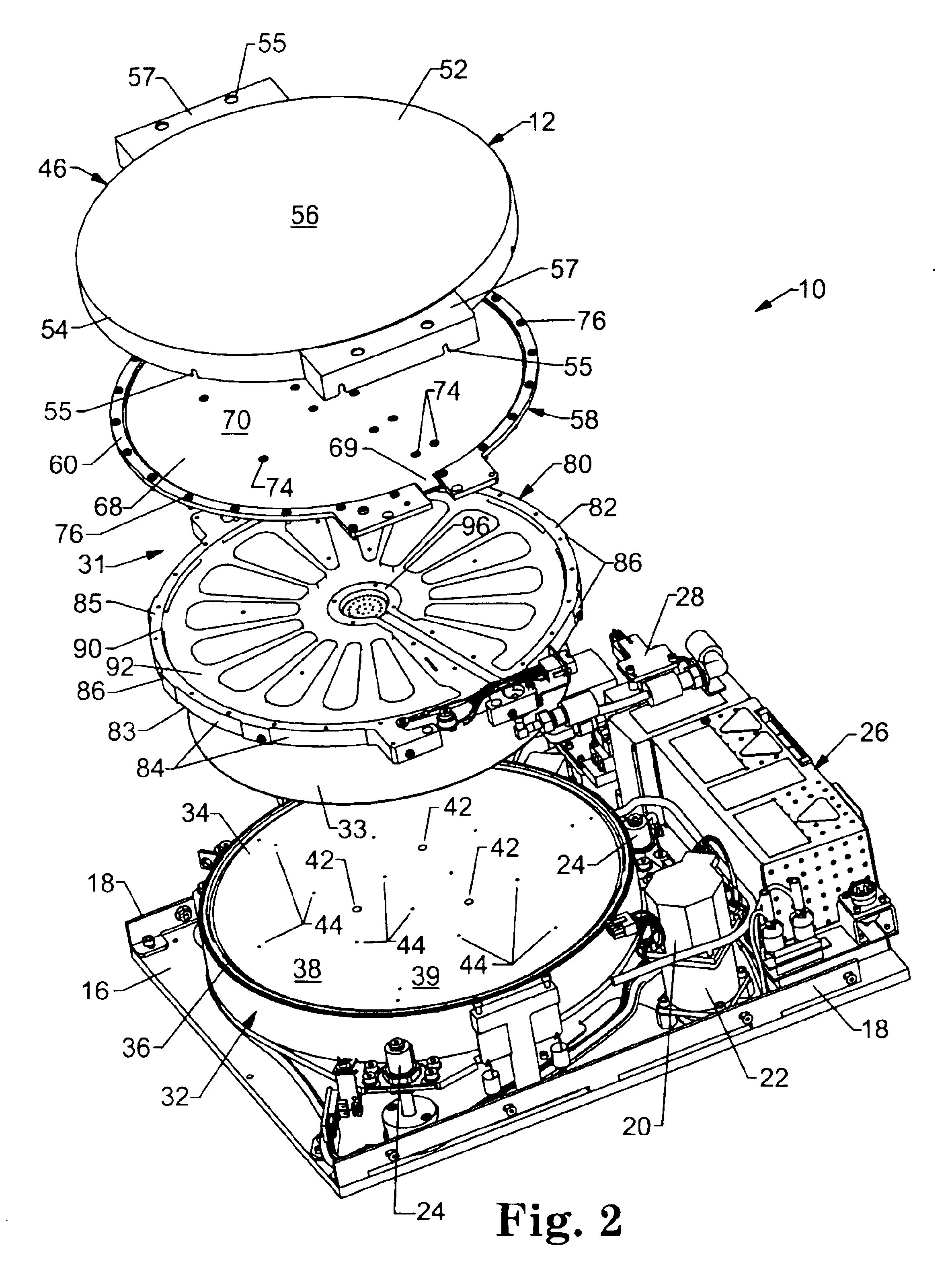

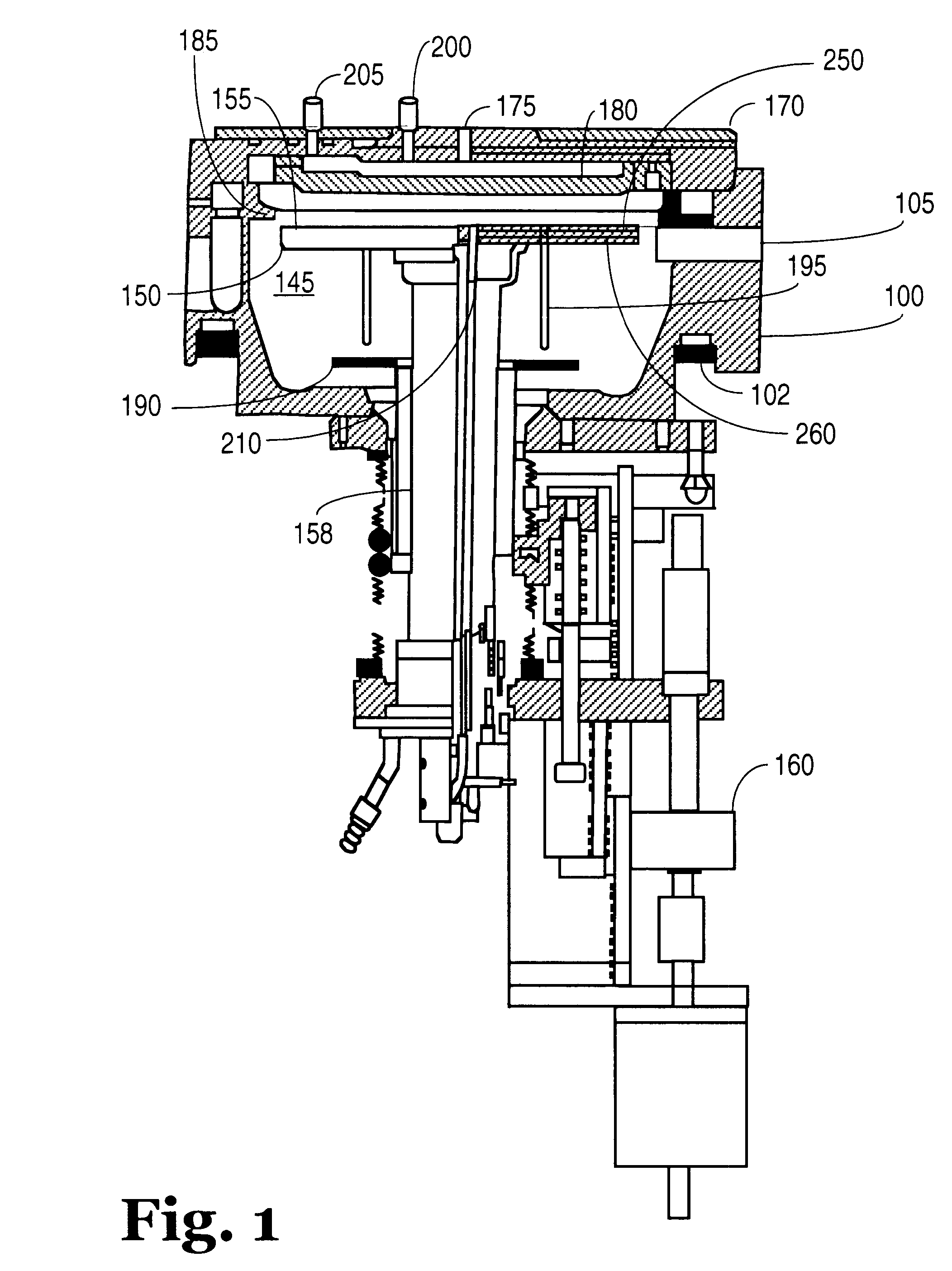

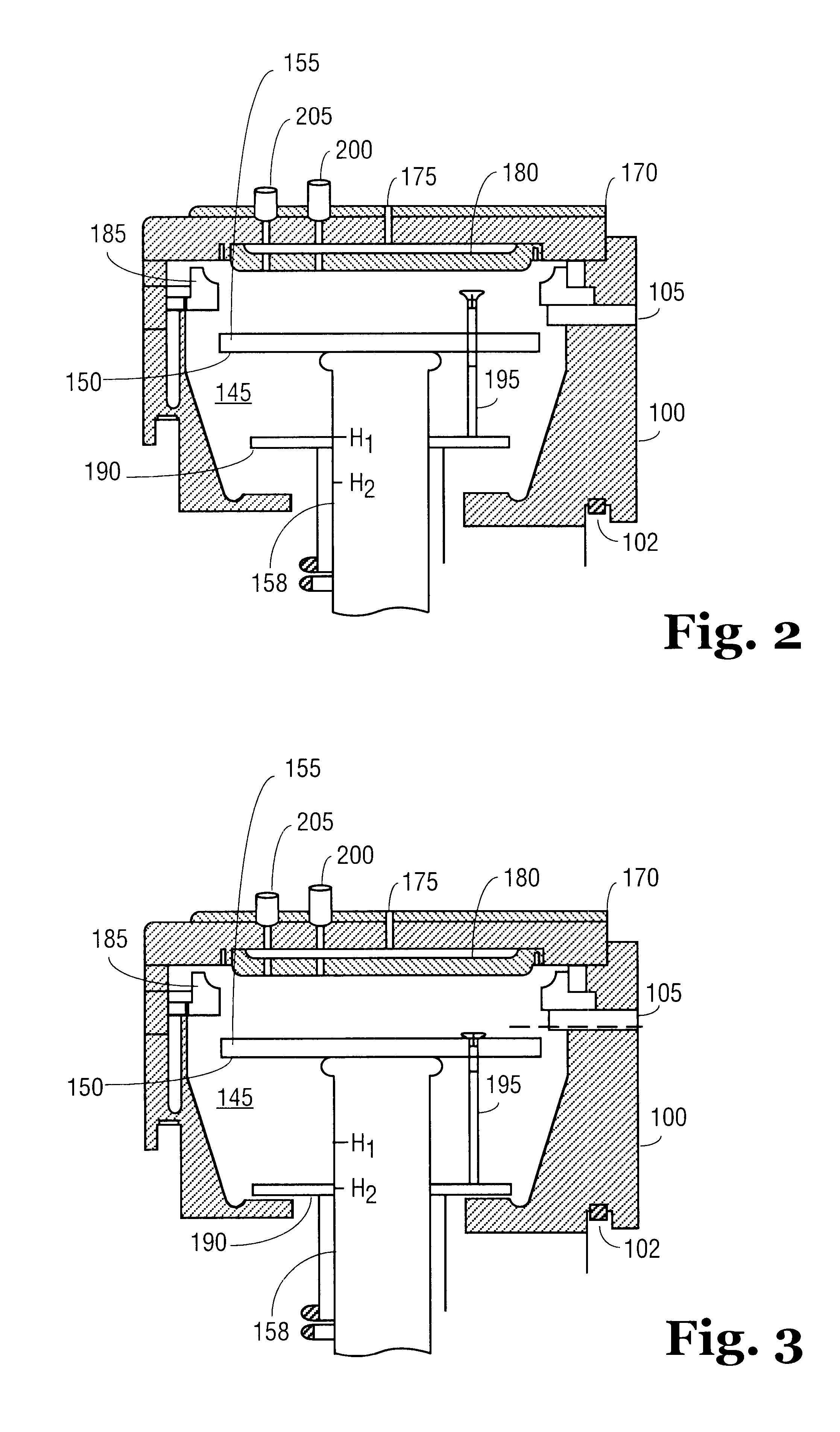

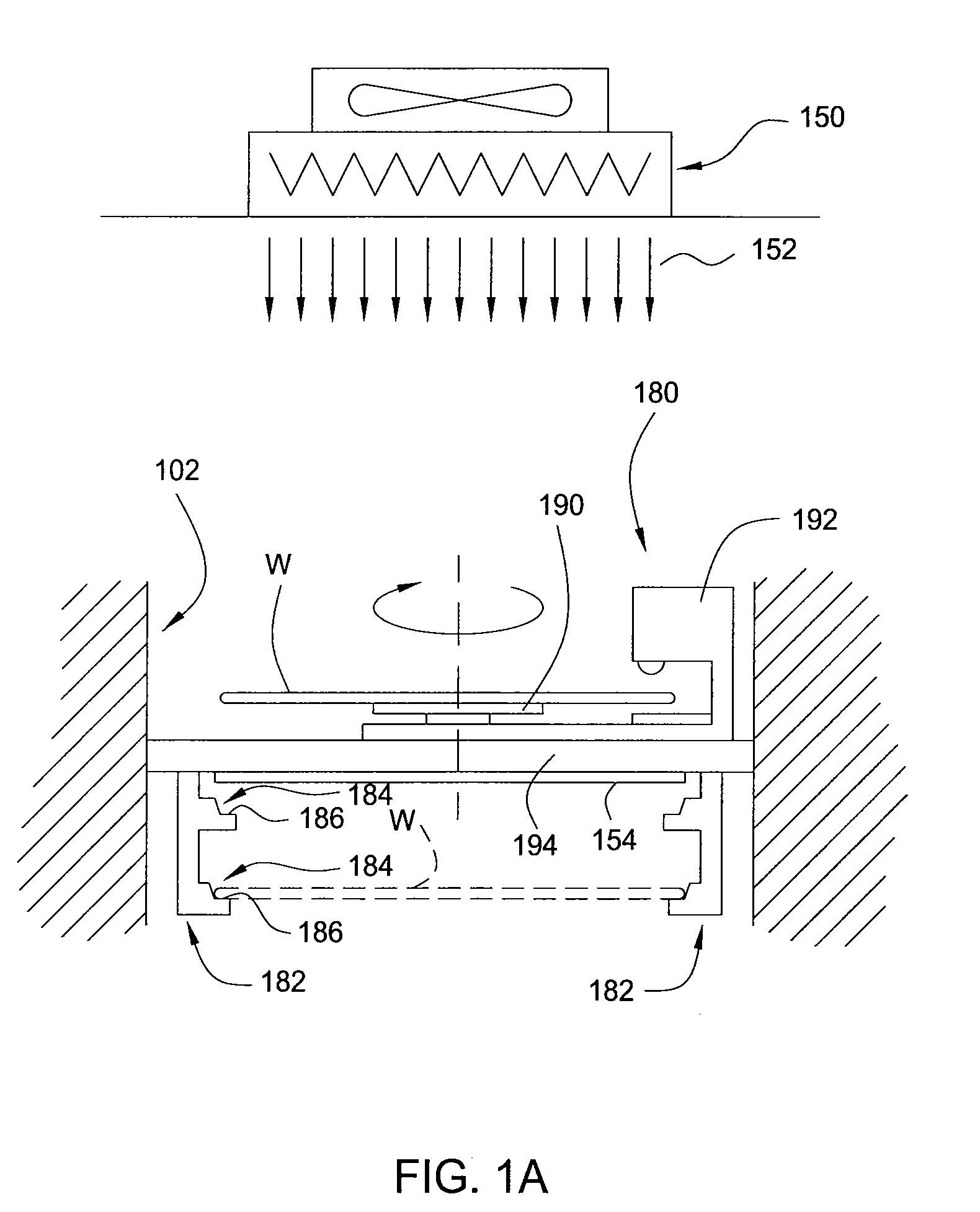

Thermal process station with heated lid

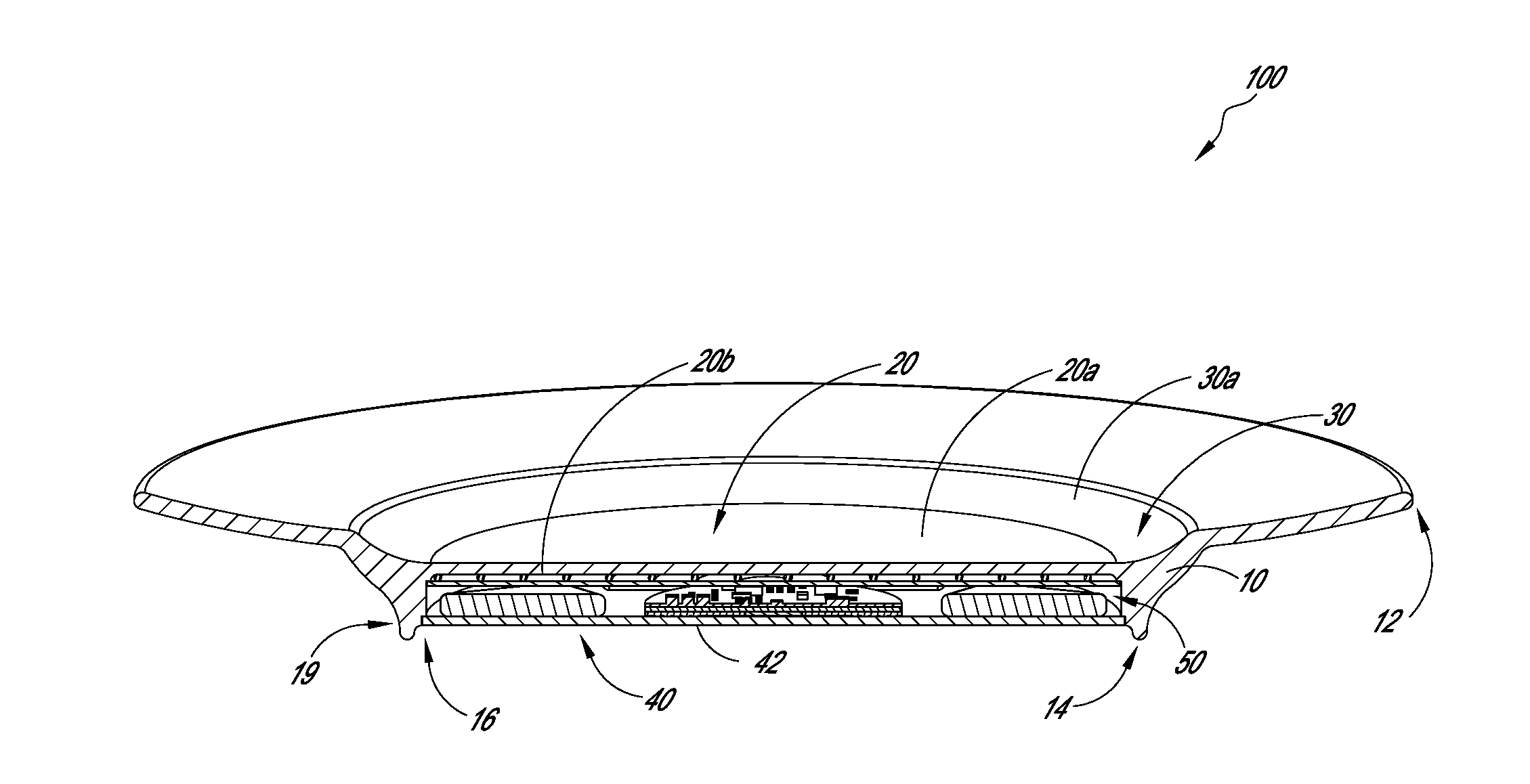

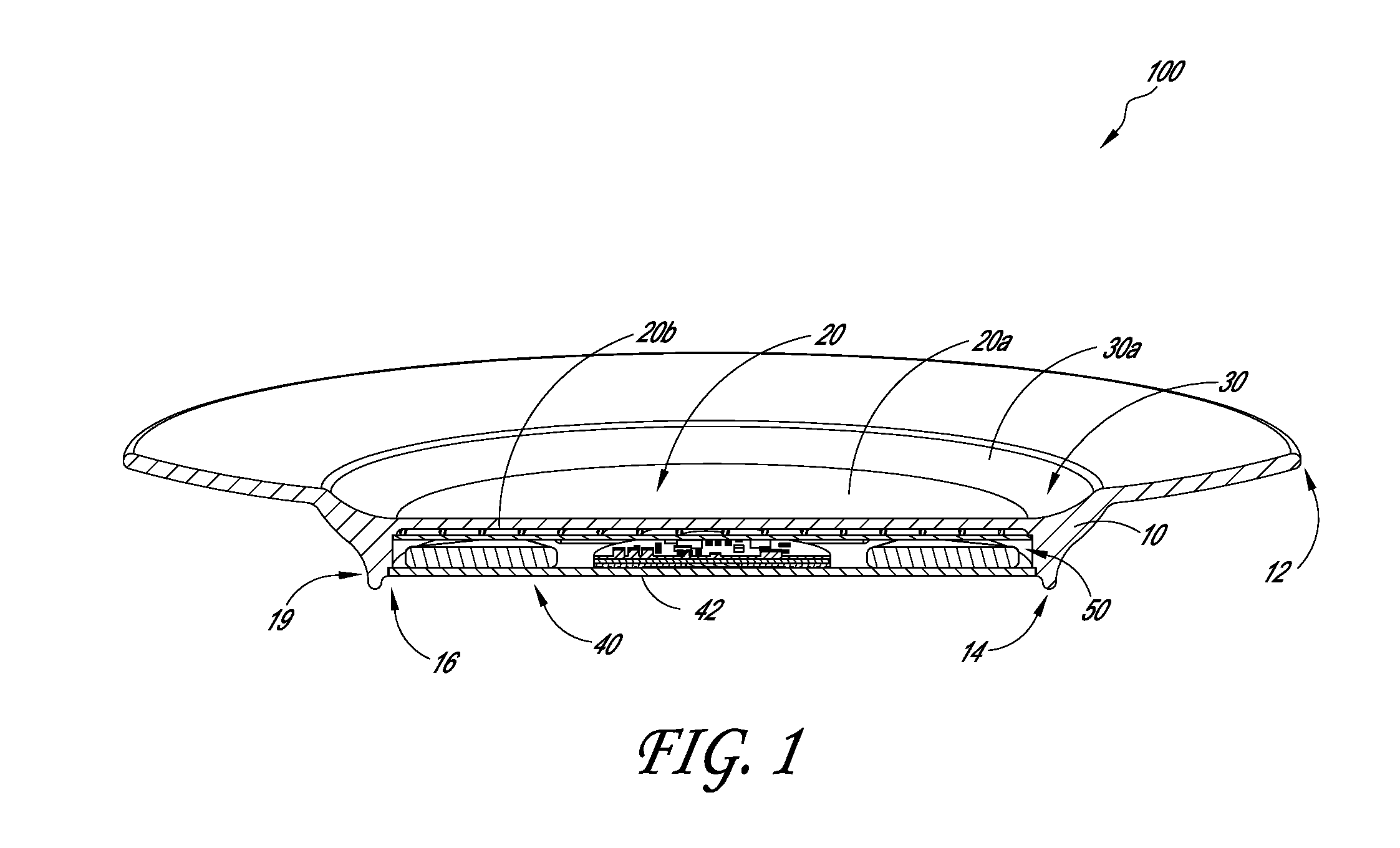

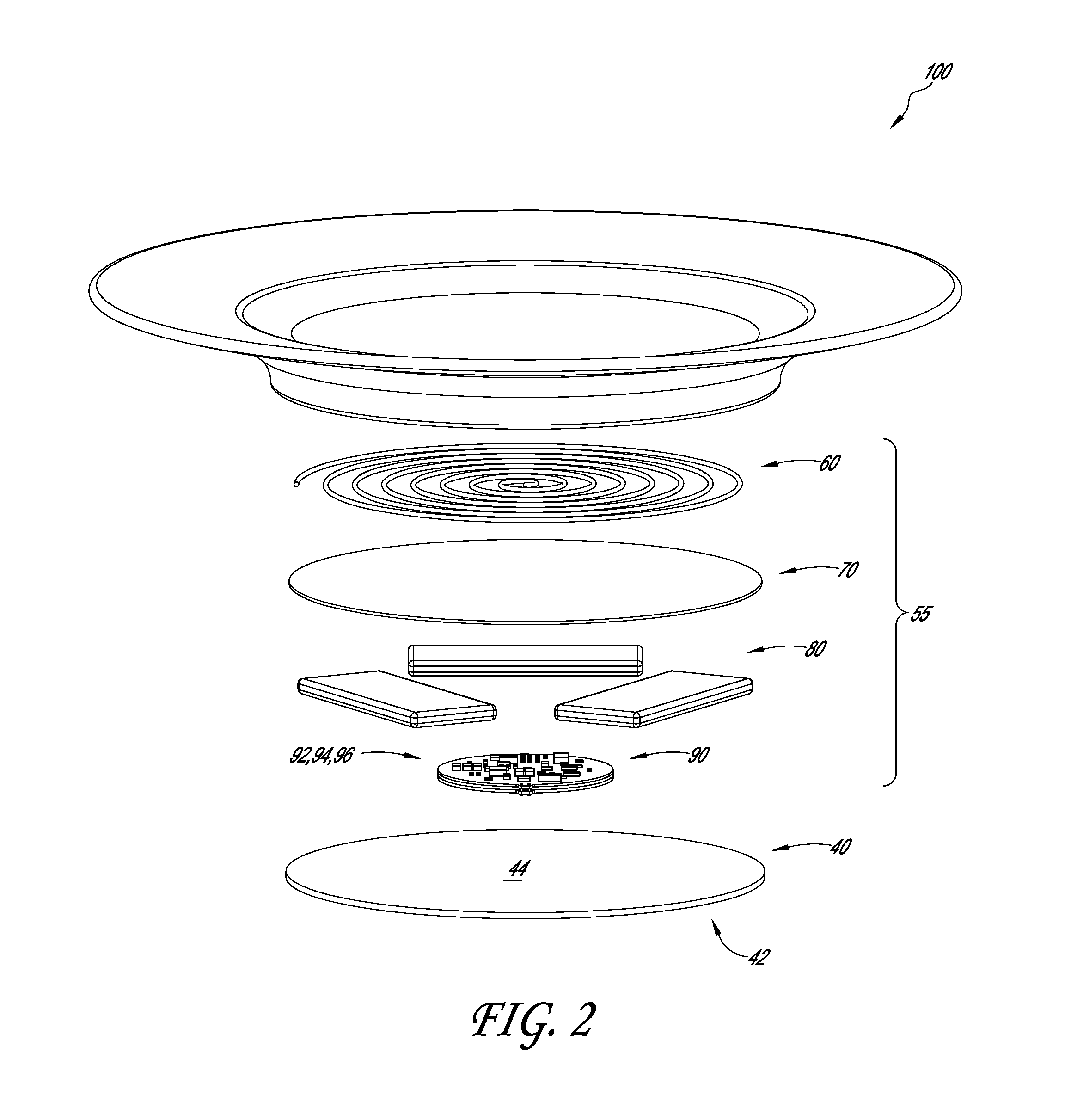

ActiveUS6884066B2Improve thermal uniformityImprove temperature uniformityCharge supportsSemiconductor/solid-state device manufacturingResistThermal energy

Methods and apparatuses to improve the temperature uniformity of a workpiece being processed on a heated platen of a thermal processing station. A heated platen is enclosed in a housing incorporating an additional heat source that uniformly outputs thermal energy into the process chamber in which the heated platen is positioned. In preferred embodiments, this heat source is positioned in the lid of the housing. It is additionally preferred that the heated lid includes features that provide a gas flow path to introduce to and / or purge gas from the process chamber. In terms of photoresist performance, the improved thermal uniformity provided by using such an additional heat source in the housing, e.g., in the lid, offers improved line width control and line uniformity across a wafer.

Owner:TEL EPION

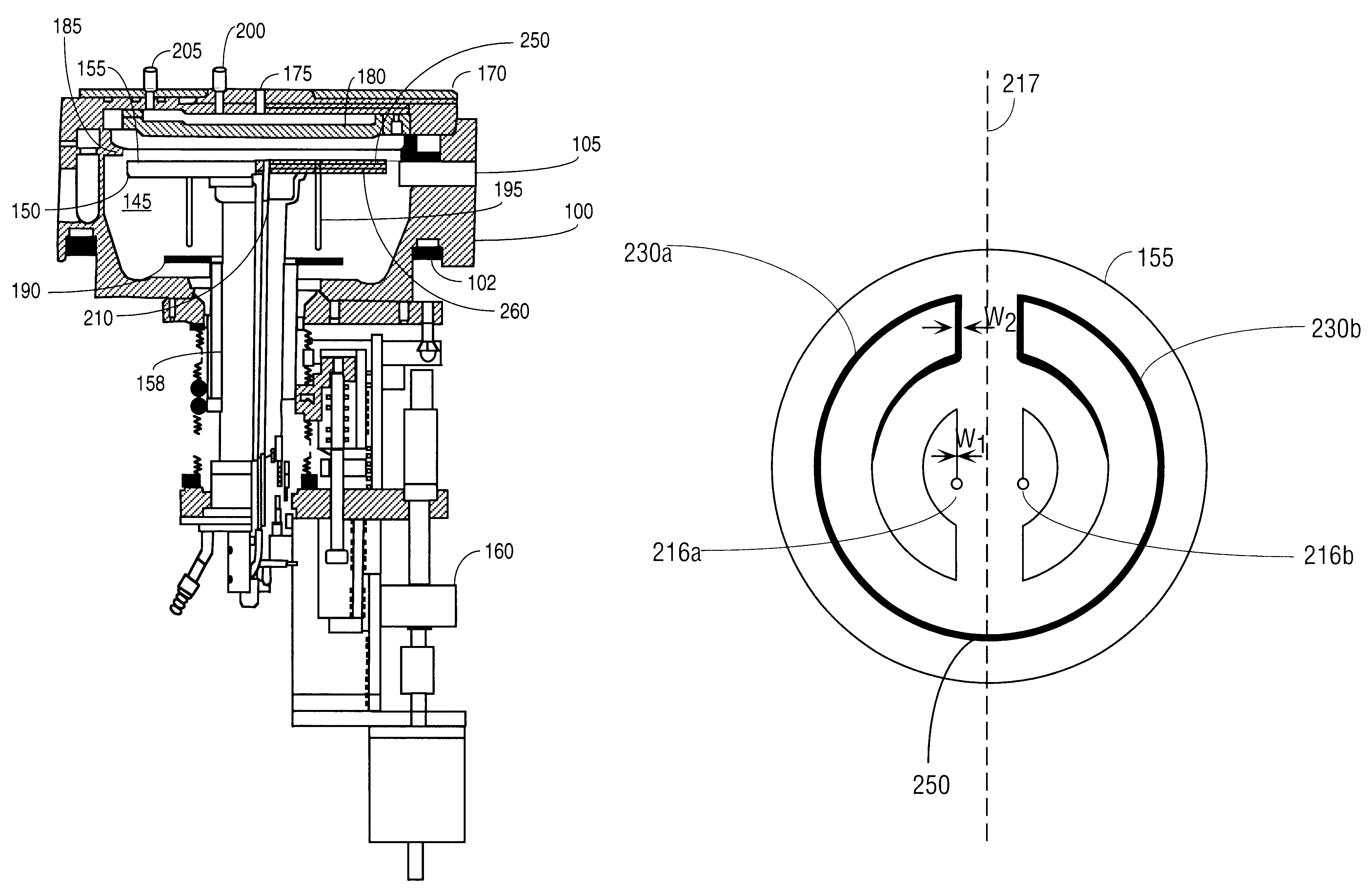

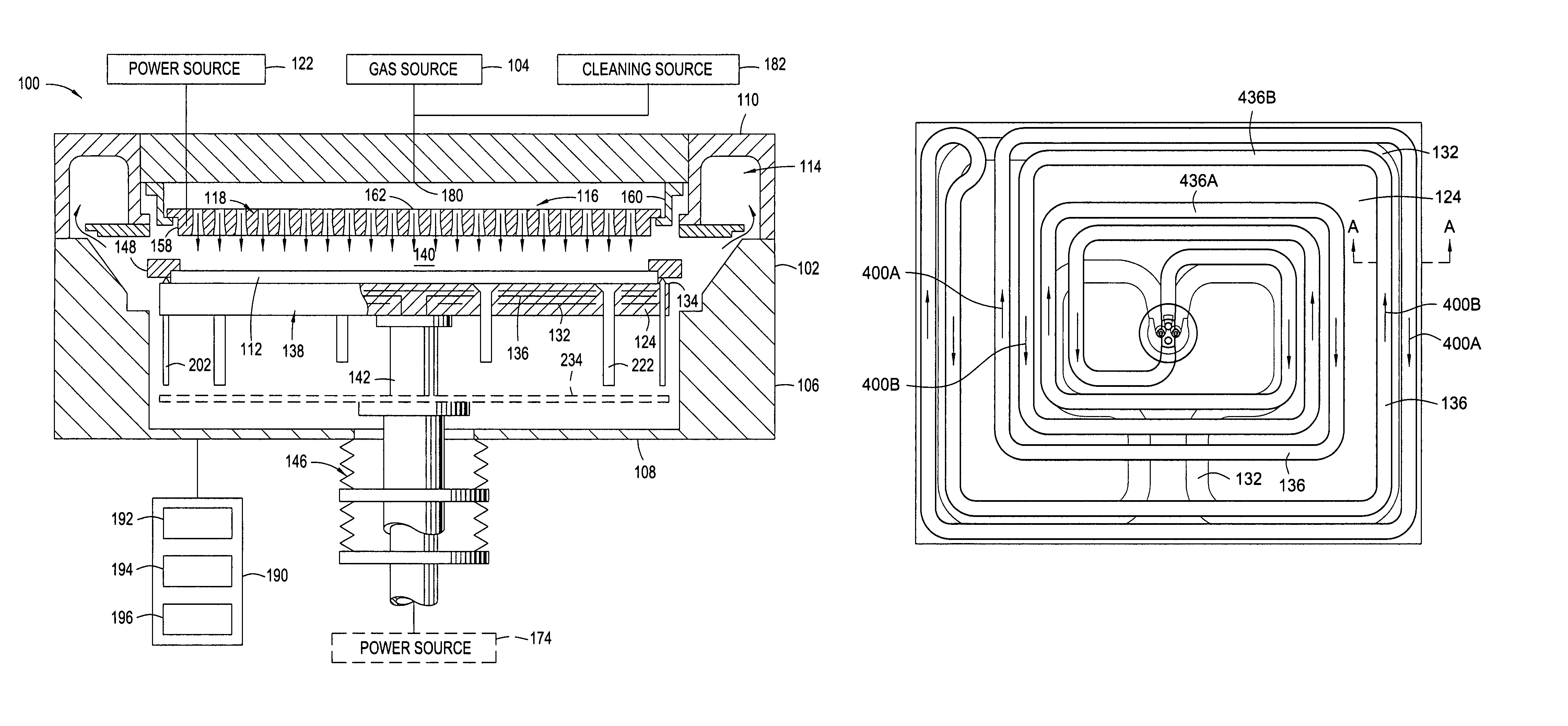

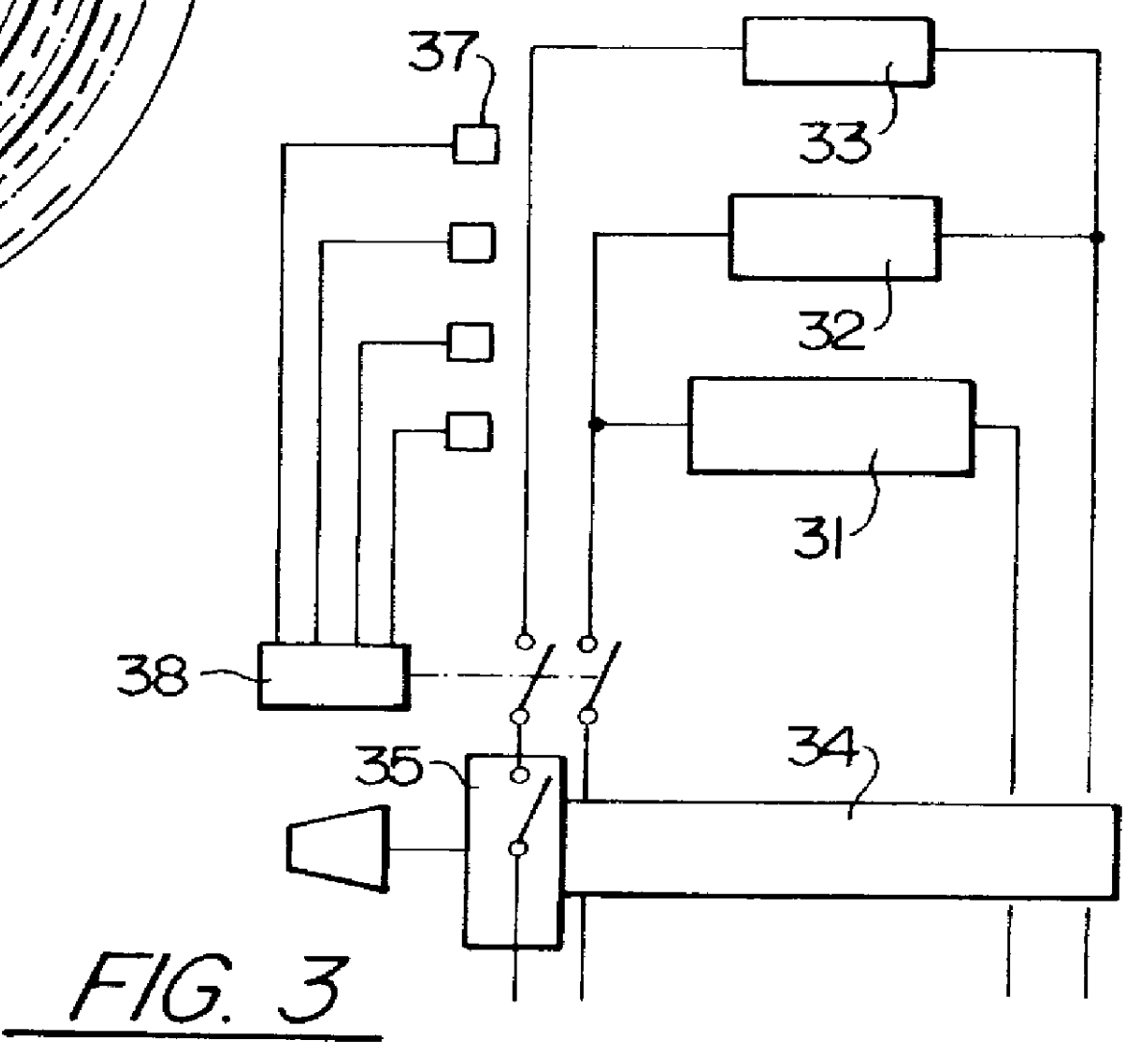

Multi-zone resistive heater

InactiveUS6423949B1Improve temperature uniformitySemiconductor/solid-state device manufacturingHot plates heating arrangementsTwo temperatureEngineering

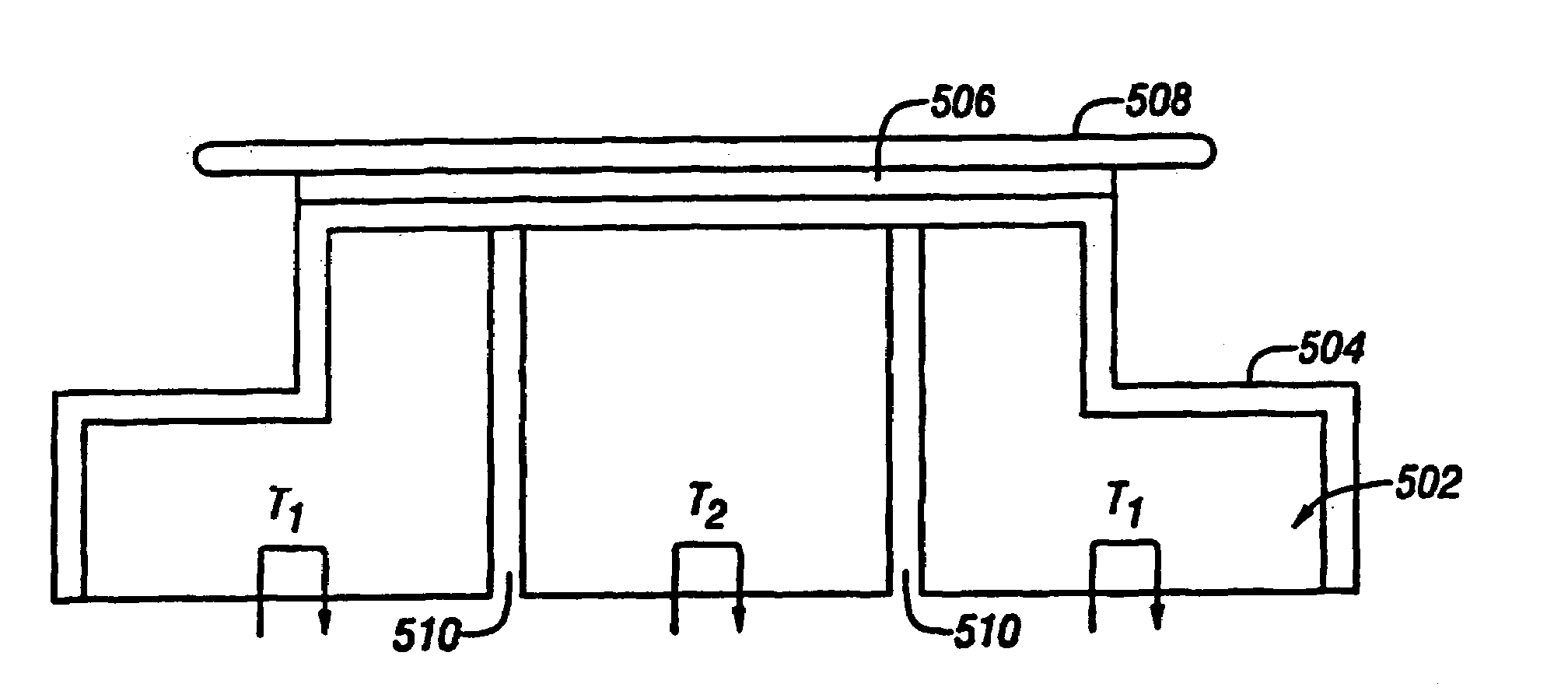

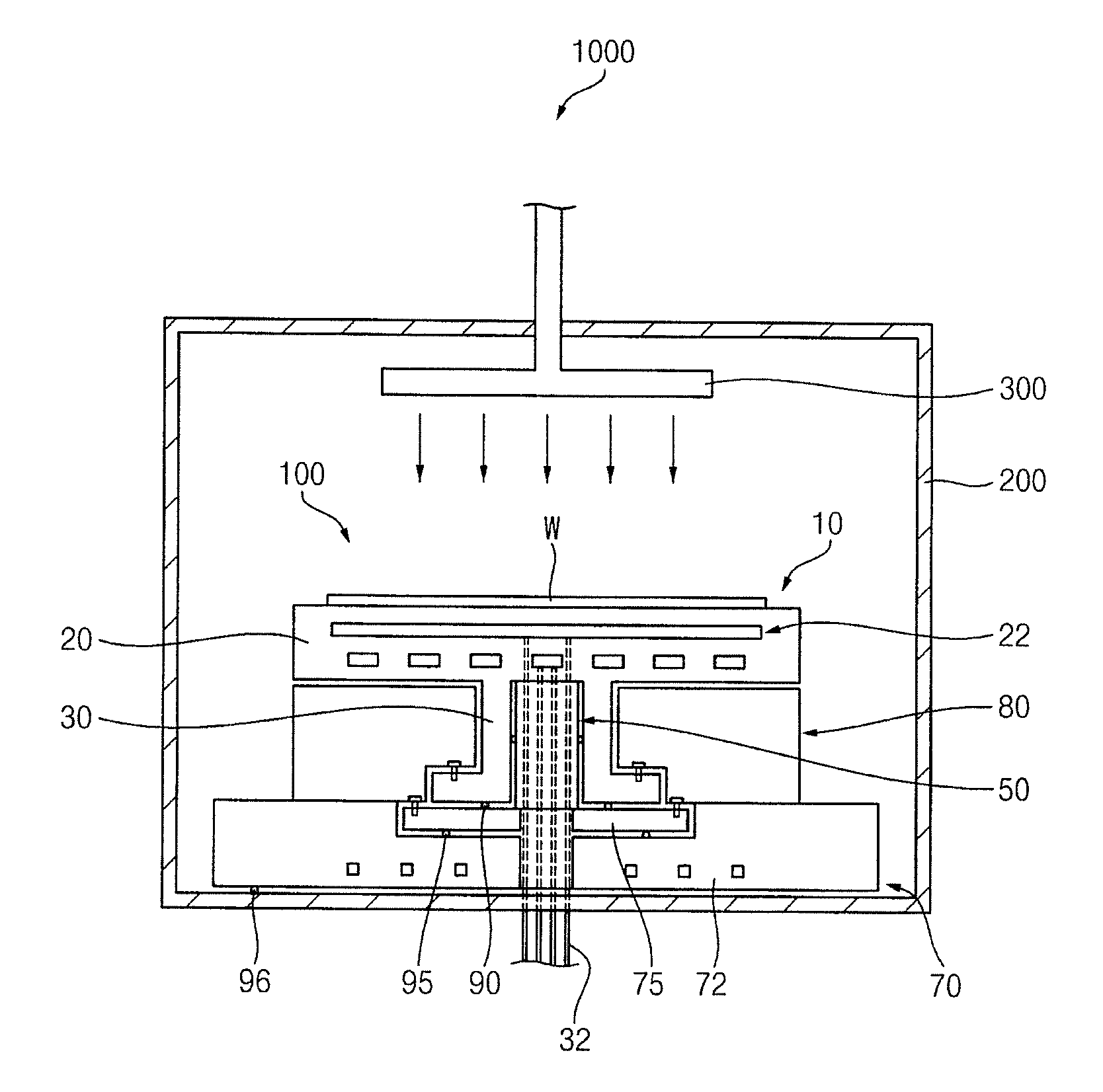

A heating apparatus including a stage comprising a surface having an area to support a wafer and a body, a shaft coupled to the stage, and a first and a second heating element. The first heating element is disposed within a first plane of the body of the stage. The second heating element is disposed within a second plane of the body of the stage at a greater distance from the surface of the stage than the first heating element. A reactor comprising a chamber, a resistive heater, a first temperature sensor, and a second temperature sensor. A resistive heating system for a chemical vapor deposition apparatus comprising a resistive heater. A method of controlling the temperature in a reactor comprising providing a resistive heater in a chamber of a reactor, measuring the temperature with at least two temperature sensors, and controlling the temperature in the reactor by regulating a power supply to the first heating element and the second heating element according to the temperature measured by the first temperature sensor and the second temperature sensor.

Owner:APPLIED MATERIALS INC

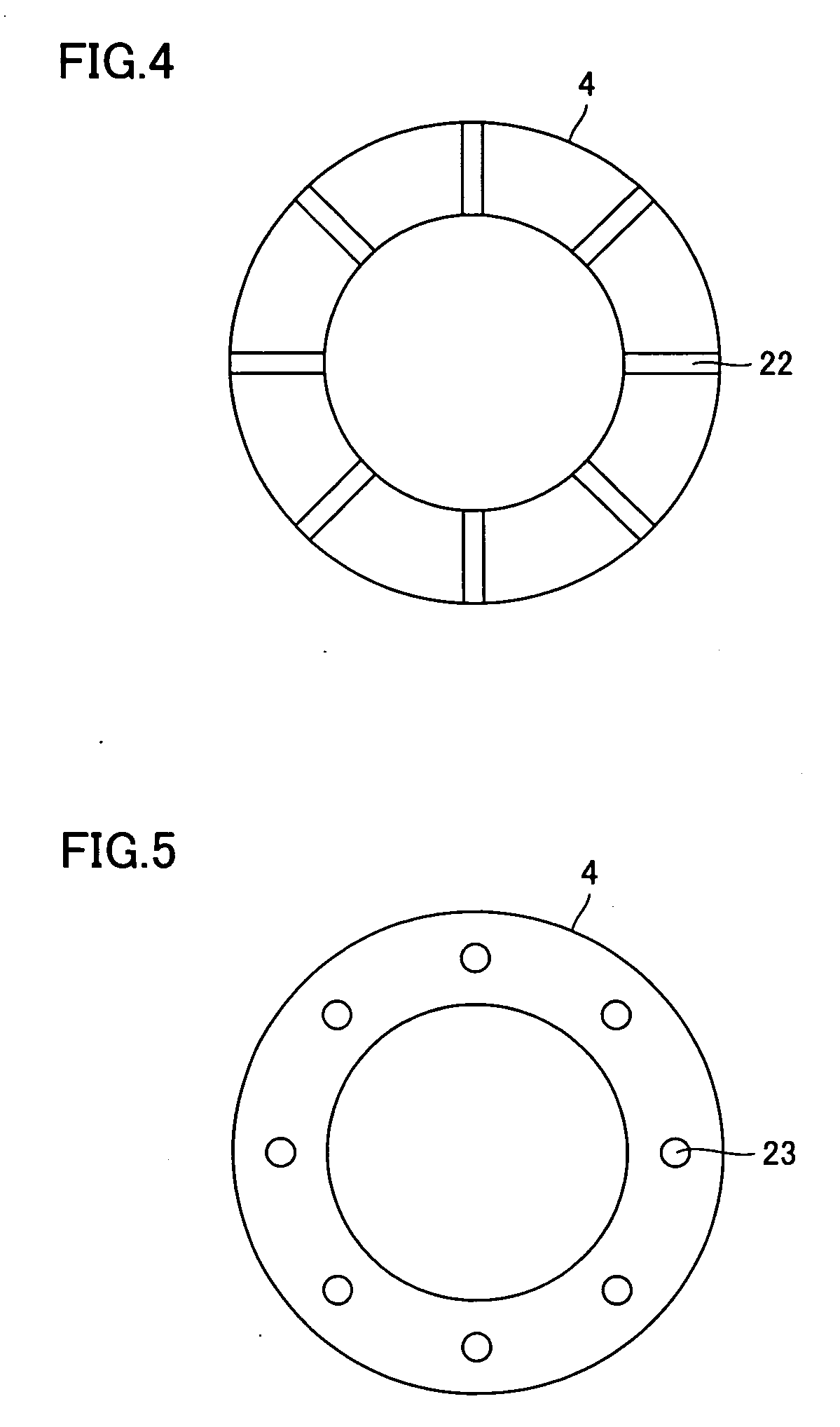

Wafer holder, heater unit used for wafer prober having the wafer holder, and wafer prober having the heater unit

InactiveUS20090050621A1Improve thermal uniformityAvoid measuringSemiconductor/solid-state device manufacturingHot plates heating arrangementsEngineeringSilicon

A wafer holder that prevents positional deviation of the wafer mounted on the wafer-mounting surface of a chuck top and enables better thermal uniformity of the wafer, as well as a heater unit including the wafer holder and a wafer prober mounting these are provided. The wafer holder has a chuck top mounting and fixing the wafer and a supporter supporting the chuck top, and the chuck top has water absorption of at least 0.01% and preferably at least 0.1%. Preferable material of the chuck top is a composite of metal and ceramics, and particularly, a composite of aluminum and silicon carbide, or a composite of silicon and silicon carbide.

Owner:SUMITOMO ELECTRIC IND LTD

Wafer holder for wafer prober and wafer prober equipped with same

InactiveUS20090045829A1Improve rigidityGood effectHot plates heating arrangementsIndividual semiconductor device testingRoom temperatureEngineering

It is an object of the present invention to provide a wafer prober wafer holder that is highly rigid and increases the heat insulating effect, thereby improving positional accuracy, thermal uniformity, and chip temperature ramp-up and cooling rates, as well as a wafer prober device equipped therewith.A wafer holder of the present invention includes a chuck top that mounts a wafer, and a support member that supports the chuck top, wherein, a restricting member is provided that covers an interface between the chuck top and the support member. By covering the gap between the chuck top and the support member with the restricting member, the heat insulating effect can be increased by preventing the flow of outside air through the gap into the support member, and the cooling rate can be particularly improved if cooling to a temperature below room temperature.

Owner:SUMITOMO ELECTRIC IND LTD

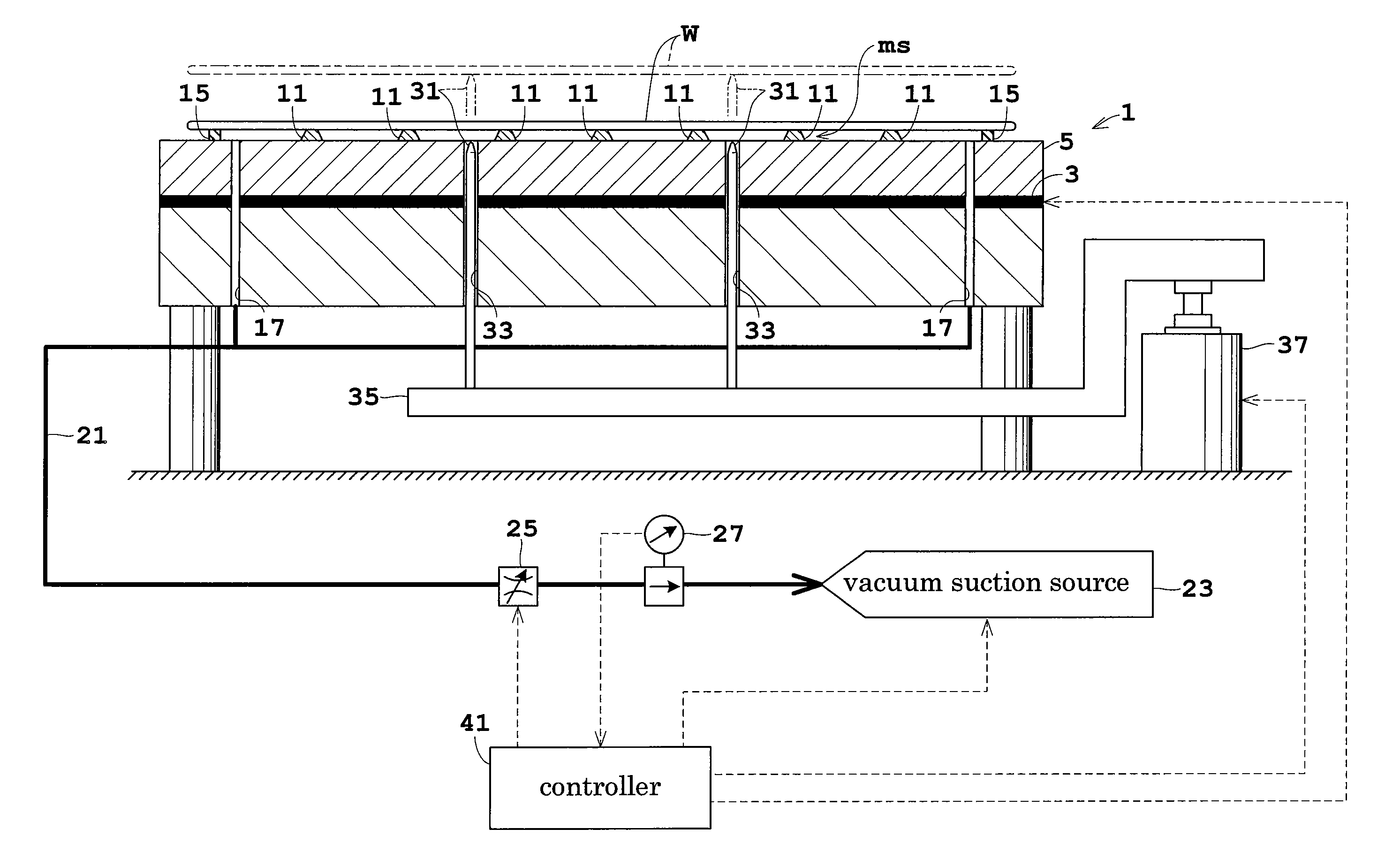

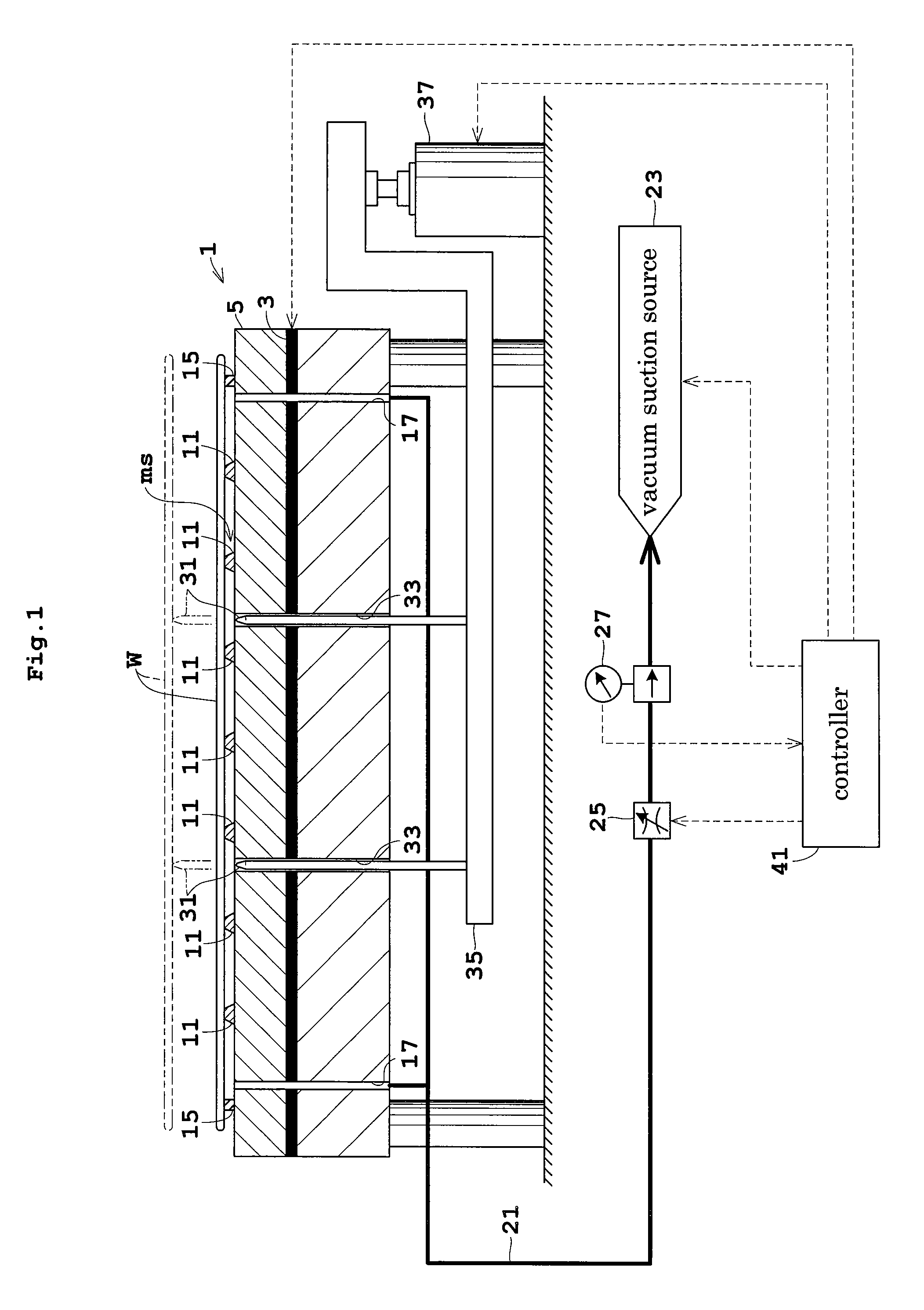

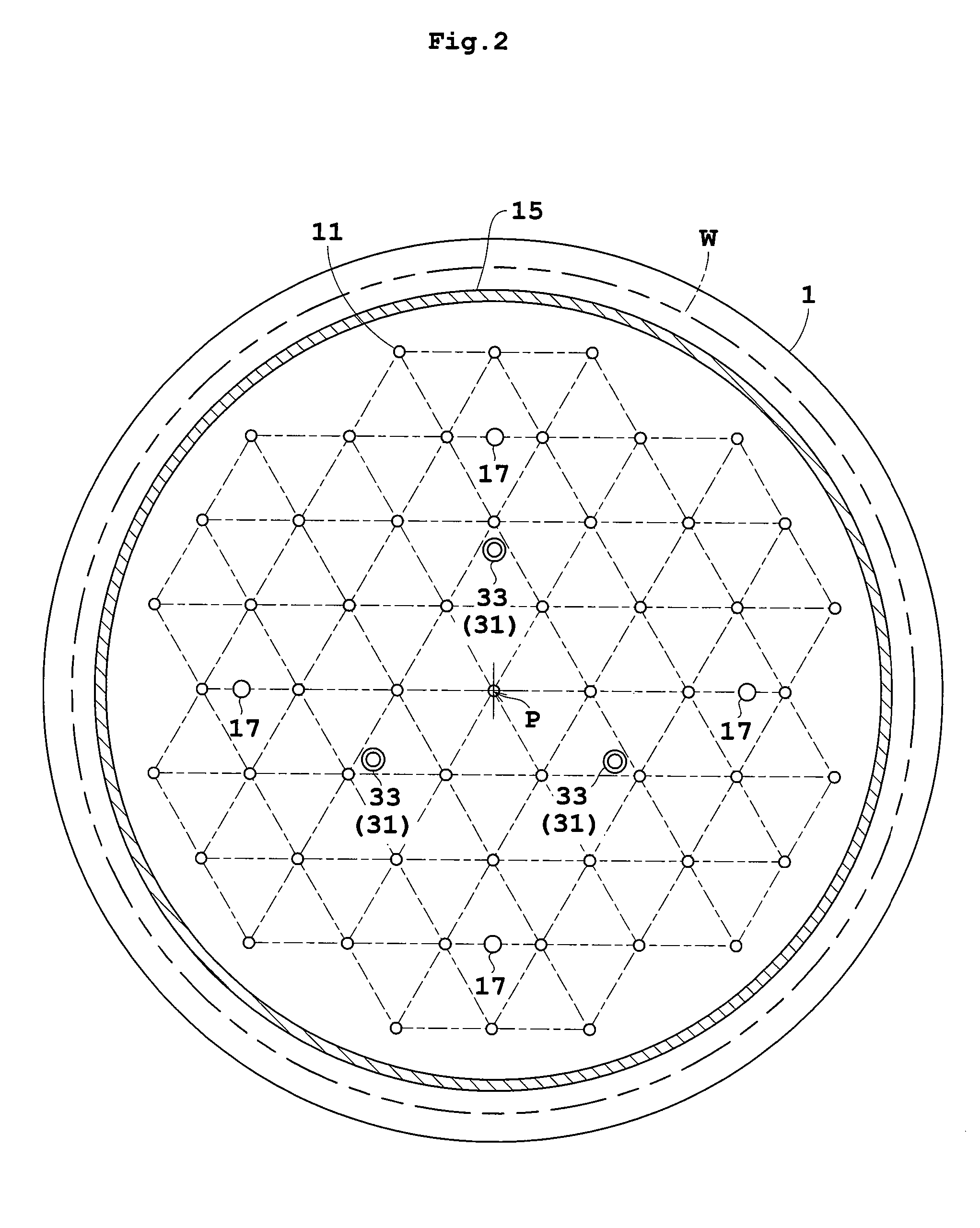

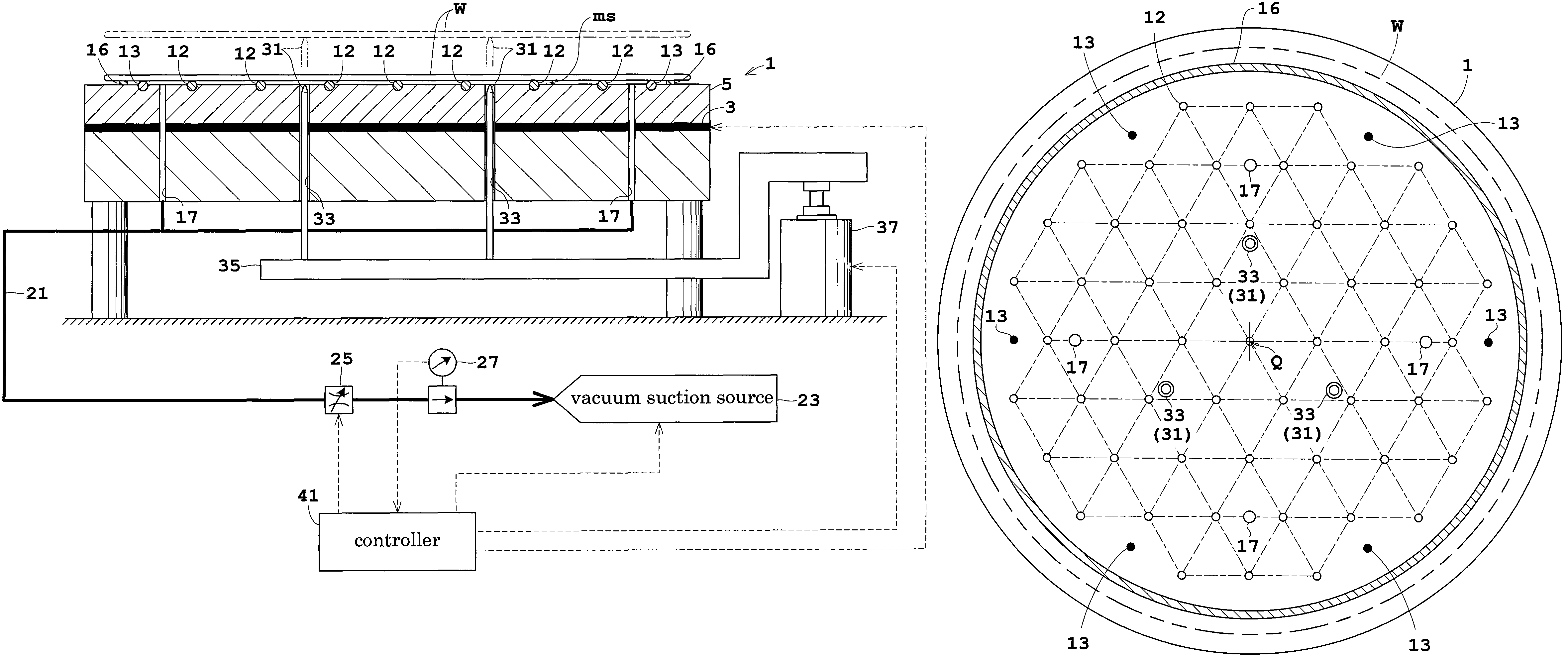

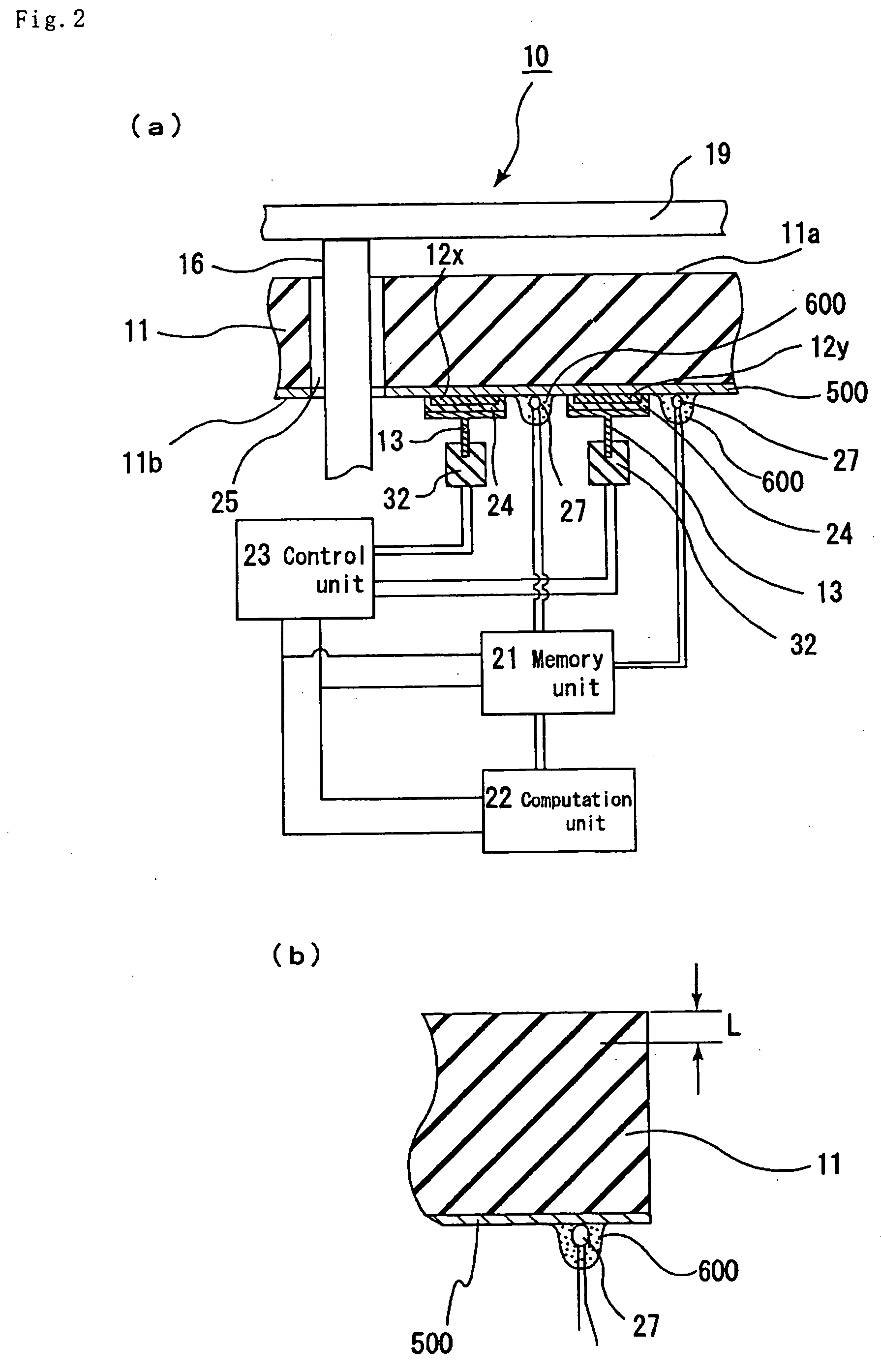

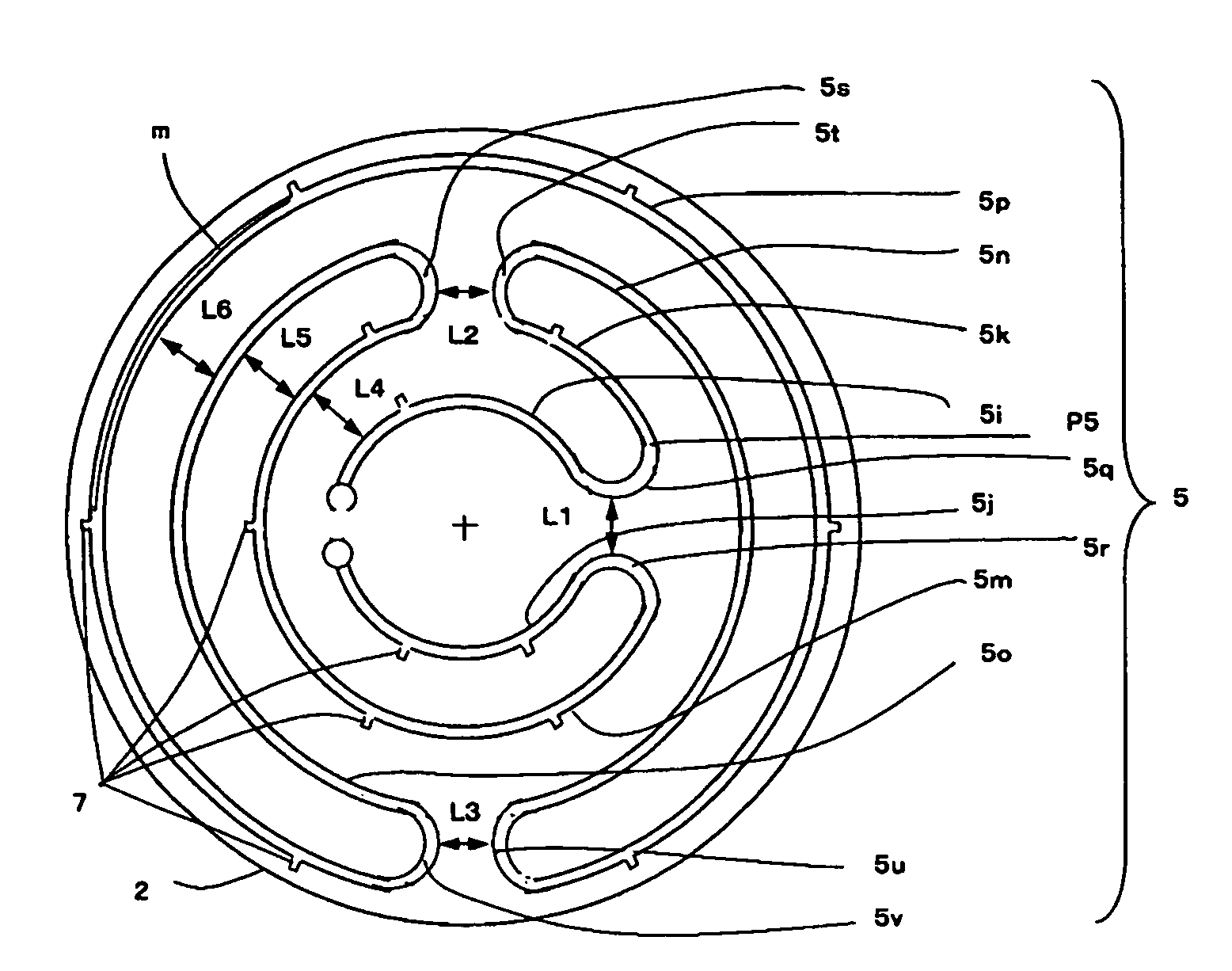

Substrate heat treatment apparatus

ActiveUS7432476B2Efficient actionEfficient use ofMuffle furnacesSemiconductor/solid-state device manufacturingMechanical engineeringHeat treated

Owner:DAINIPPON SCREEN MTG CO LTD

Substrate heat treatment apparatus

ActiveUS8003919B2Efficient heat treatmentEfficiently inhibiting sagging of a substrateMuffle furnacesCharge supportsIsoetes triquetraEngineering

Owner:DAINIPPON SCREEN MTG CO LTD

Ceramic heater for semiconductor manufacturing and inspecting equipment

InactiveUS20050092733A1Improve responseCausing temperature distributionMuffle furnacesSemiconductor/solid-state device manufacturingMetallurgySemiconductor

A ceramic heater for a semiconductor producing / examining device including a ceramic substrate having a heating surface for receiving a semiconductor wafer, a heating device for generating heat sufficient for producing / examining the semiconductor wafer and formed on the heating surface or inside the ceramic substrate, and a temperature measuring device for measuring a temperature of the heating surface and pressed against the ceramic substrate.

Owner:IBIDEN CO LTD

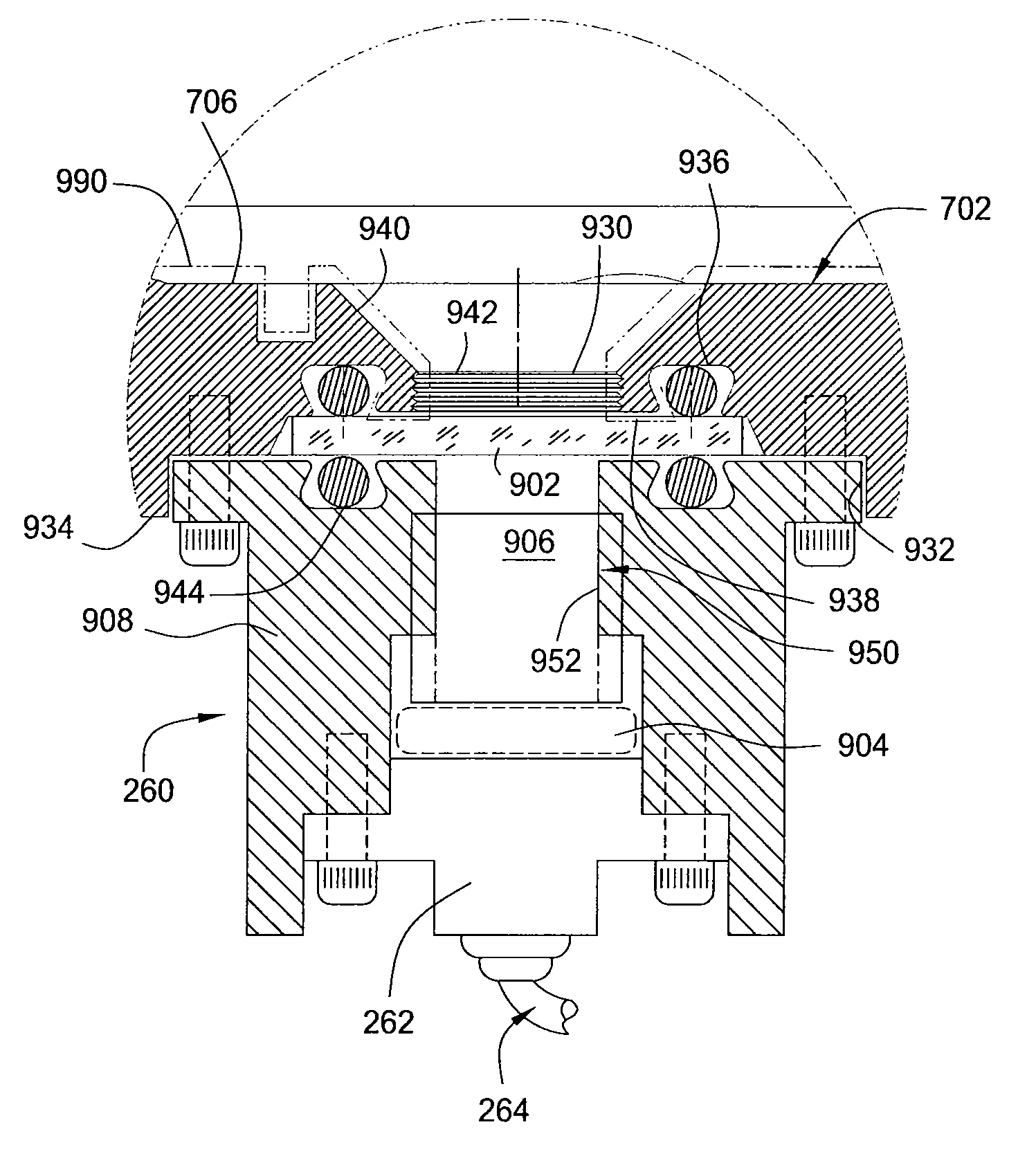

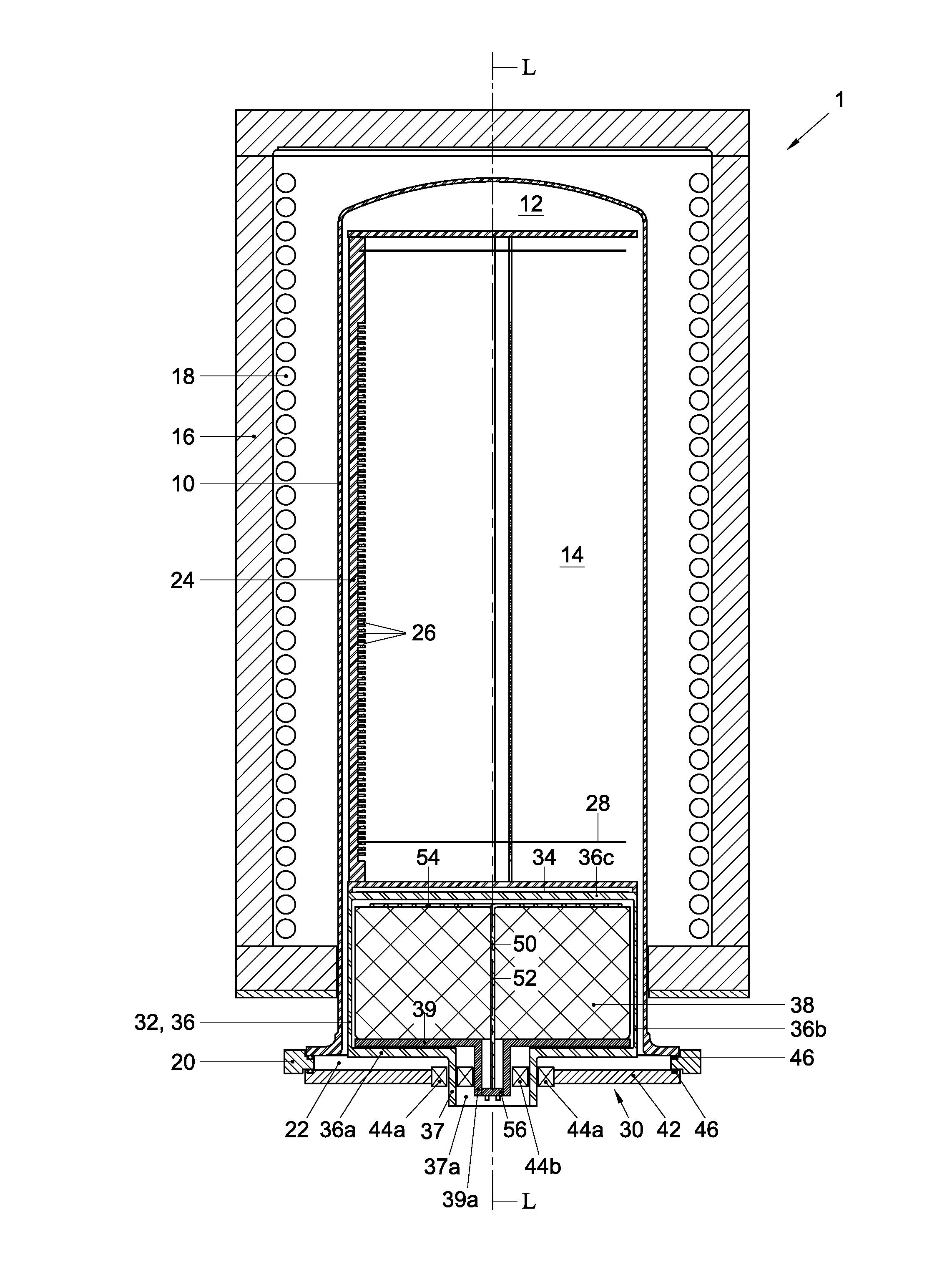

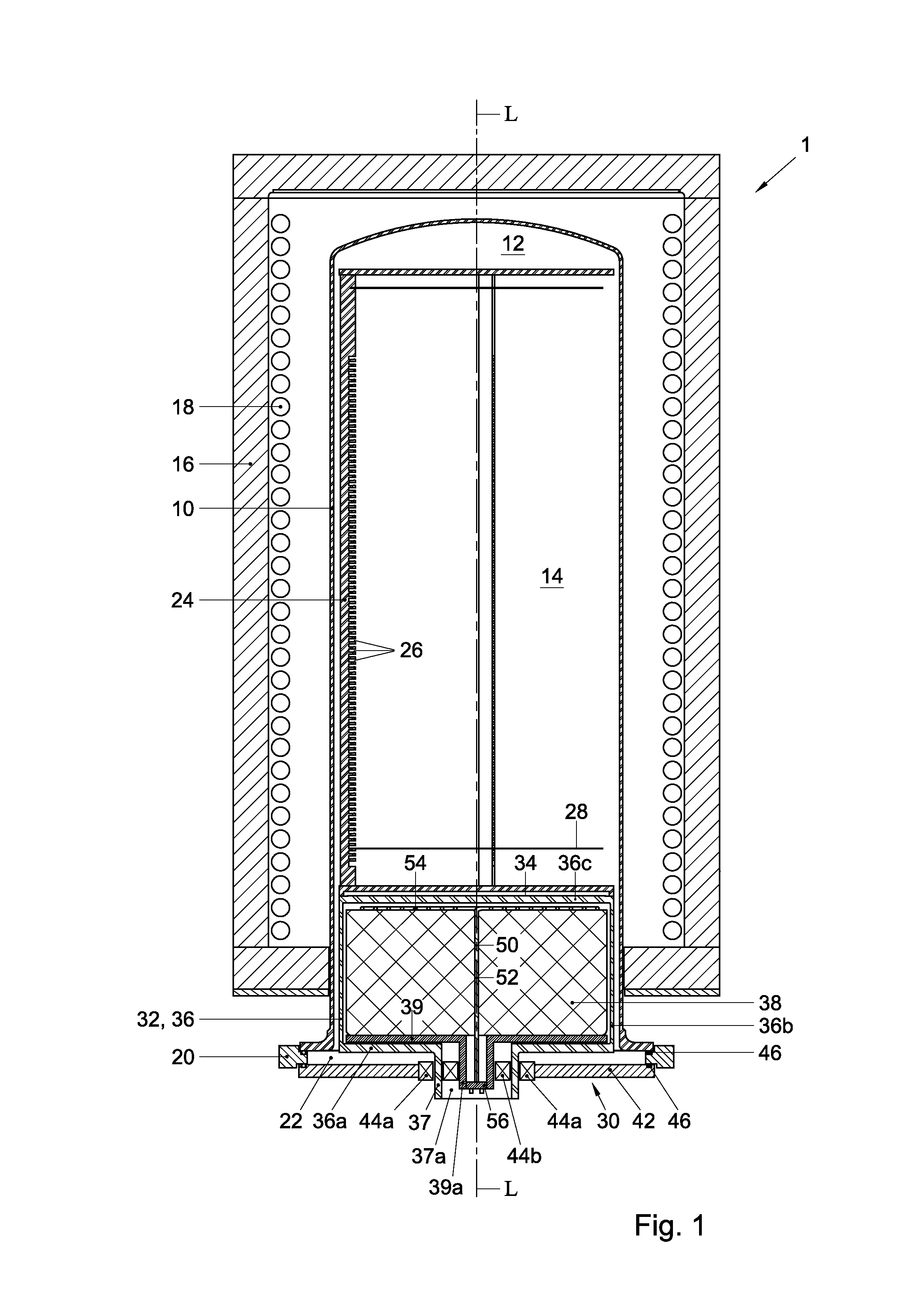

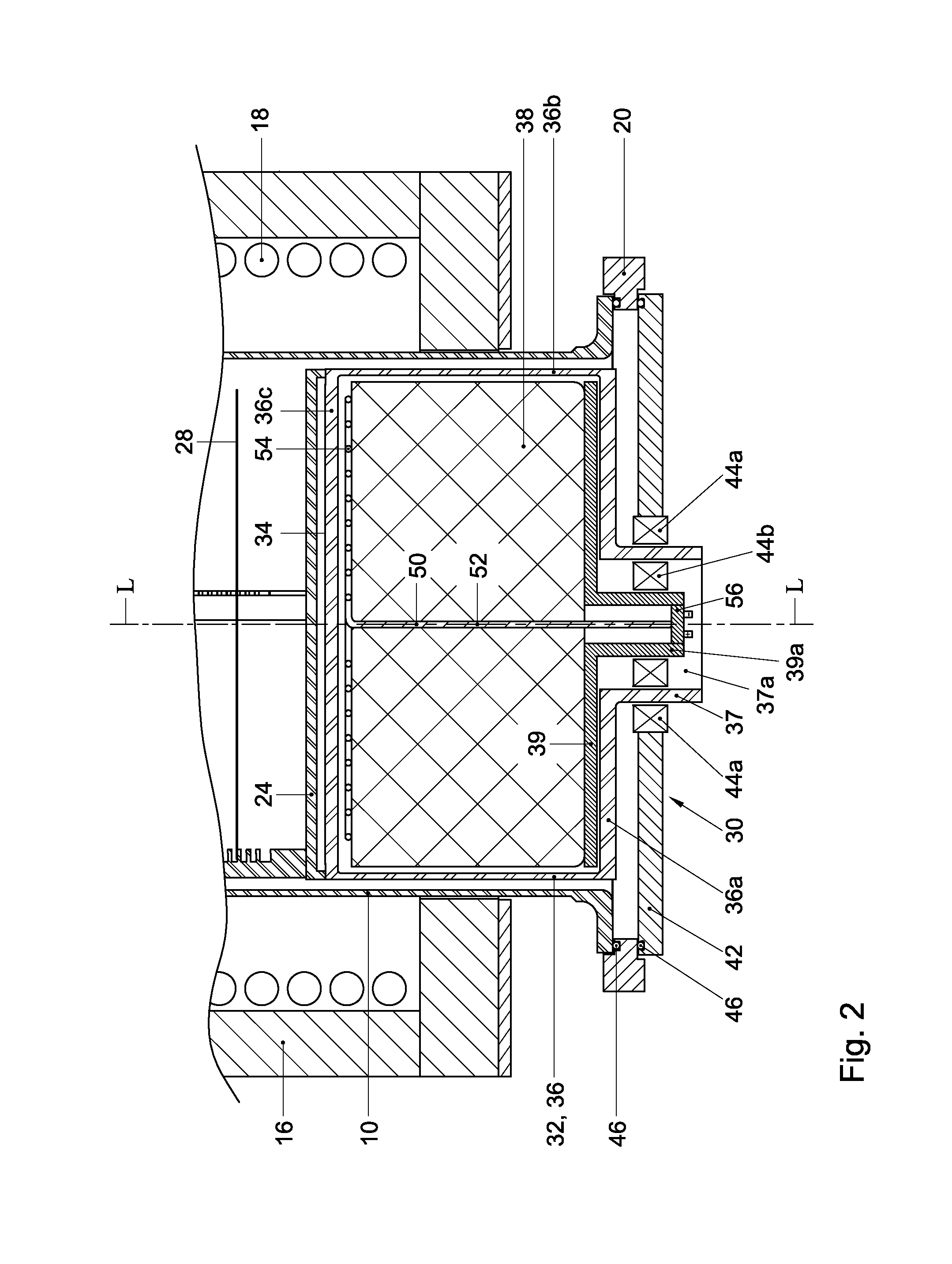

Wafer processing apparatus with heated, rotating substrate support

ActiveUS9018567B2Easy constructionEasy and economical to constructMuffle furnacesCharge supportsEngineeringSemiconductor

A semiconductor substrate processing apparatus (1), comprising a substrate support assembly (30), including a substrate support (32) defining an outer support surface (34) for supporting a substrate or substrate carrier (24) thereon, and a heater (50) comprising a heat dissipating portion (54) that is disposed within the substrate support (32) and that extends underneath and substantially parallel to the support surface (34), said substrate support (32) being rotatably mounted around a rotation axis (L) that extends through said support surface (34), such that the support surface (34) is rotatable relative to the heat dissipating portion (54) of the heater (50).

Owner:ASM IP HLDG BV

High temperature vacuum chuck assembly

ActiveUS20090179365A1Avoid overall overheatingSleeve/socket jointsMuffle furnacesEngineeringElectrical connector

A vacuum chuck and a process chamber equipped with the same are provided. The vacuum chuck assembly comprises a support body, a plurality of protrusions, a plurality of channels, at least one support member supporting the support body, at least one resilient member coupled with the support member, a hollow shaft supporting the support body, at least one electrical connector disposed through the hollow shaft, and an air-cooling apparatus. The support body has a support surface for holding a substrate (such as a wafer) thereon. The protrusions are formed on and project from the support surface for creating a gap between the substrate and the support surface. The channels are formed on the support surface for generating reduced pressure in the gap. The air-cooling apparatus is used for providing air cooling in the vicinity of the electrical connector.

Owner:APPLIED MATERIALS INC

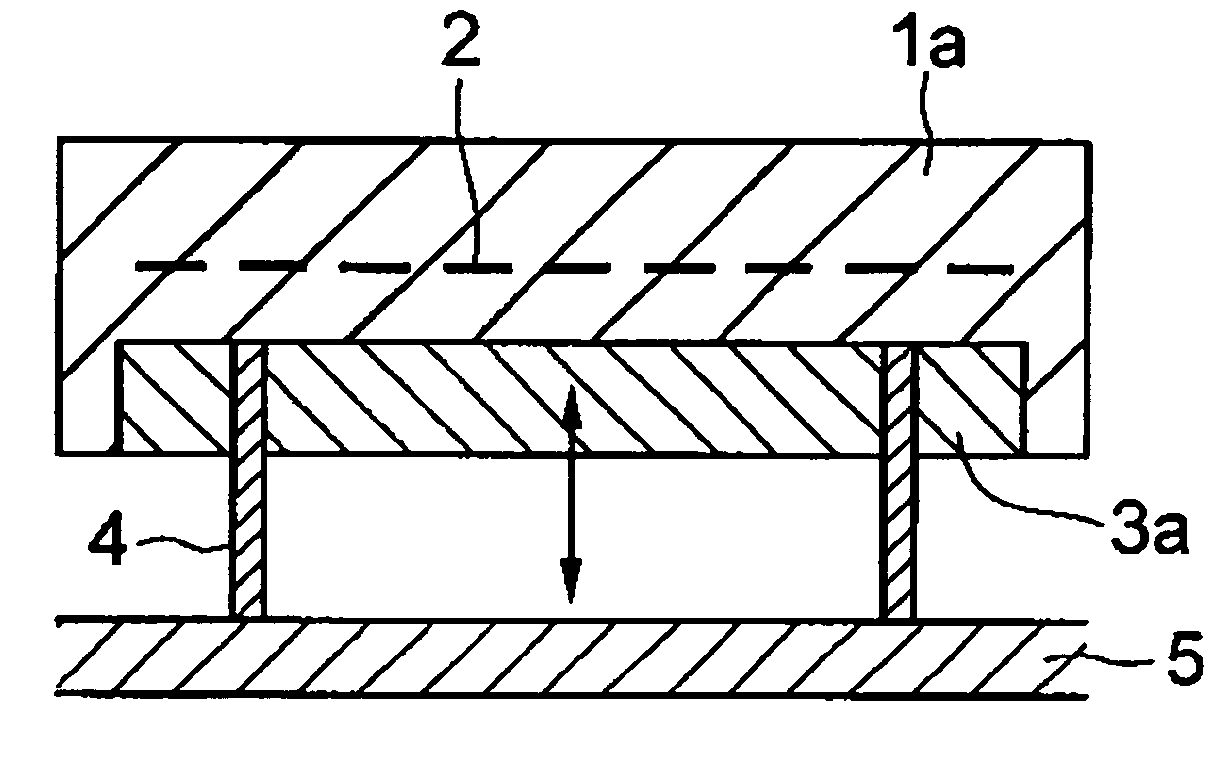

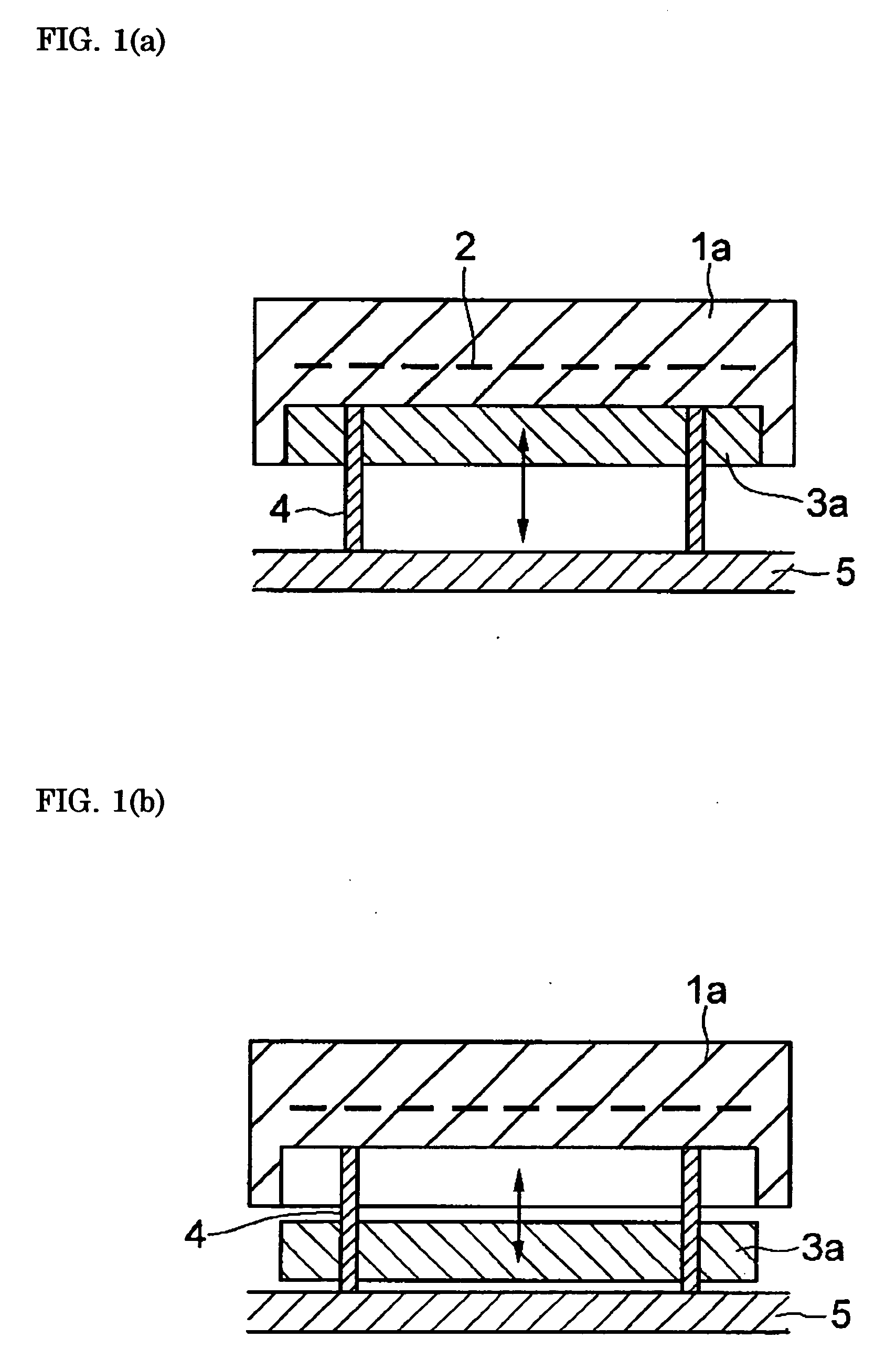

Heater module for semiconductor production system

InactiveUS20040238523A1Speed up coolingHigh bonding strengthSemiconductor/solid-state device manufacturingHot plates heating arrangementsProduction rateComputer module

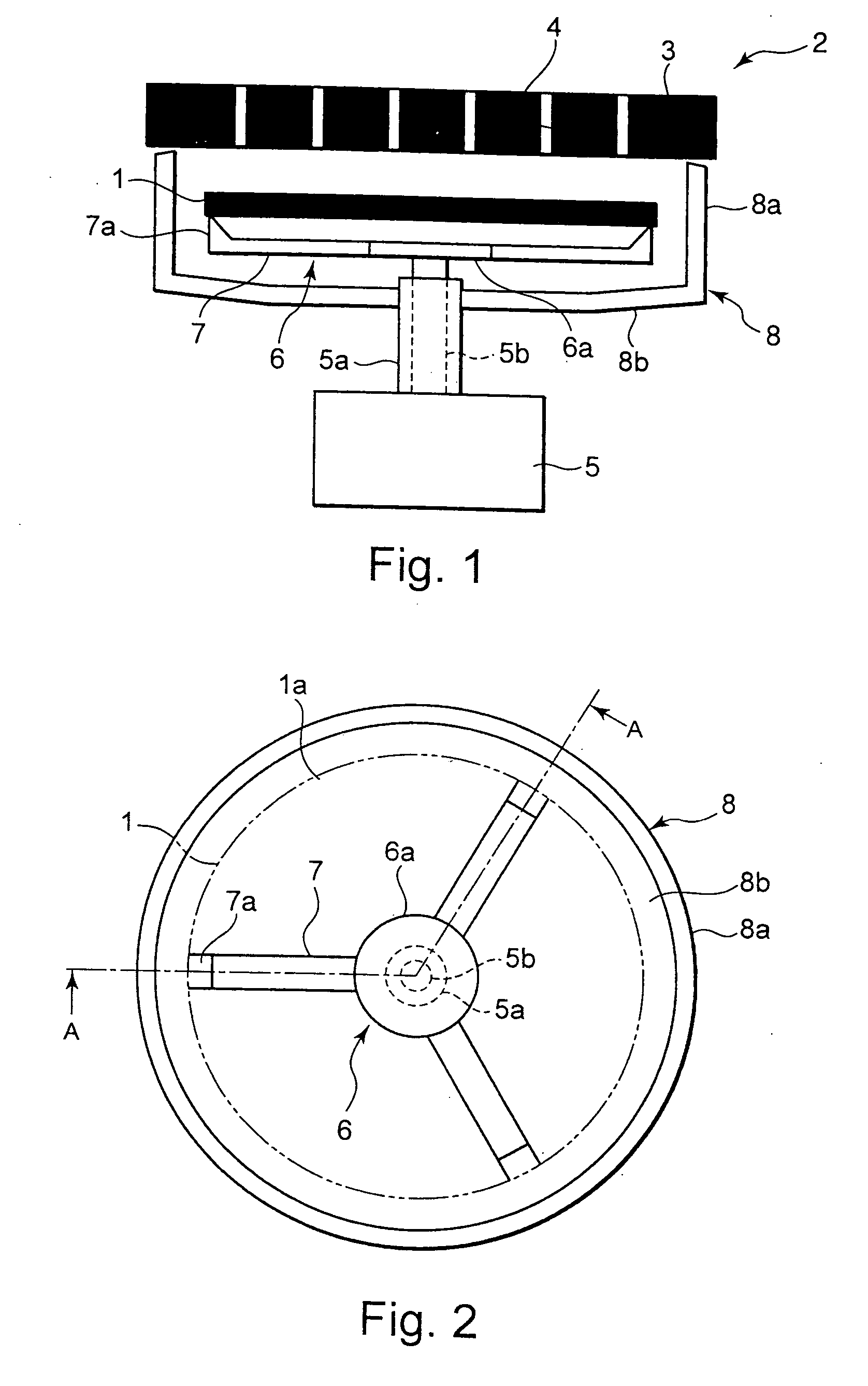

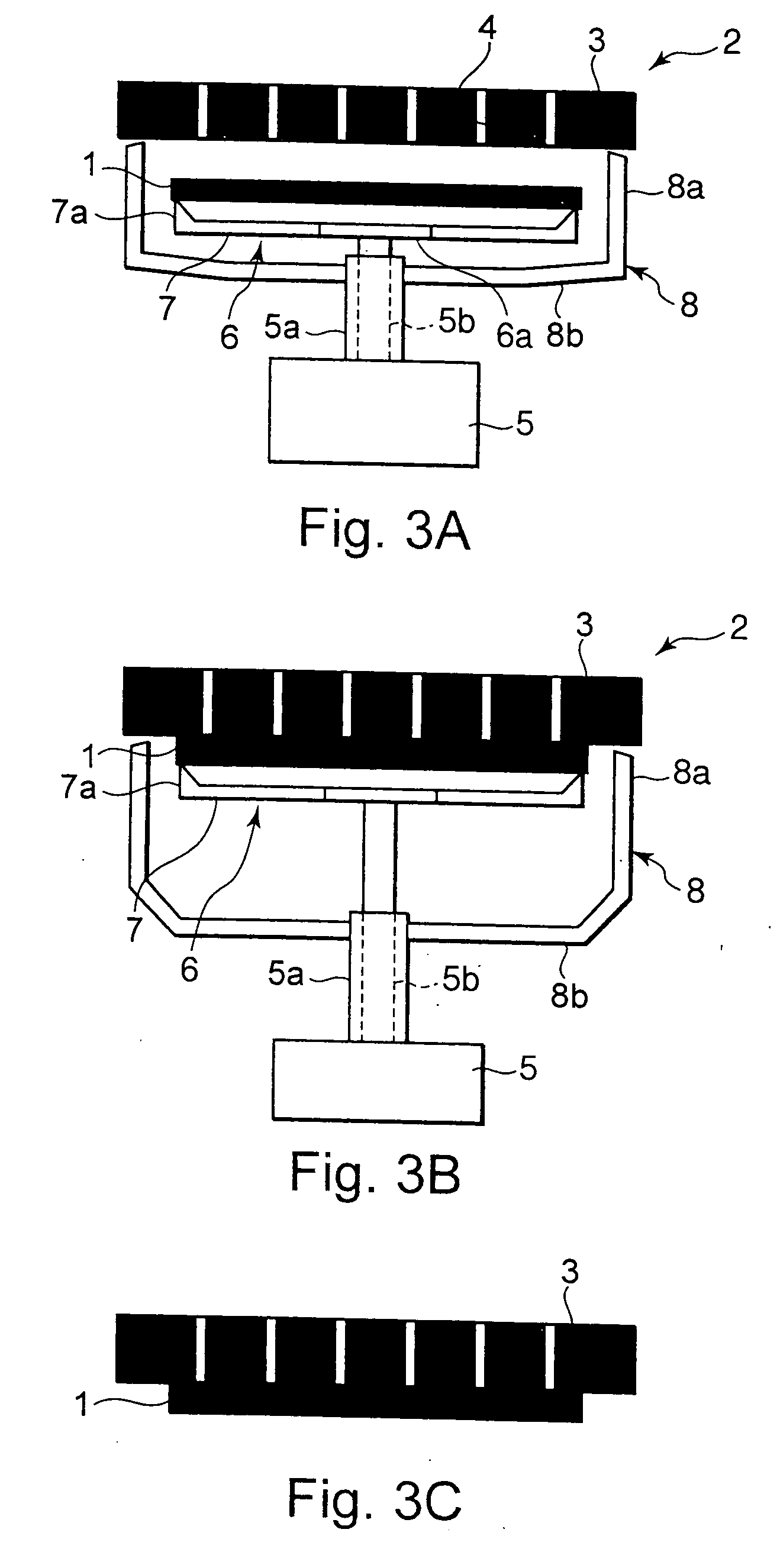

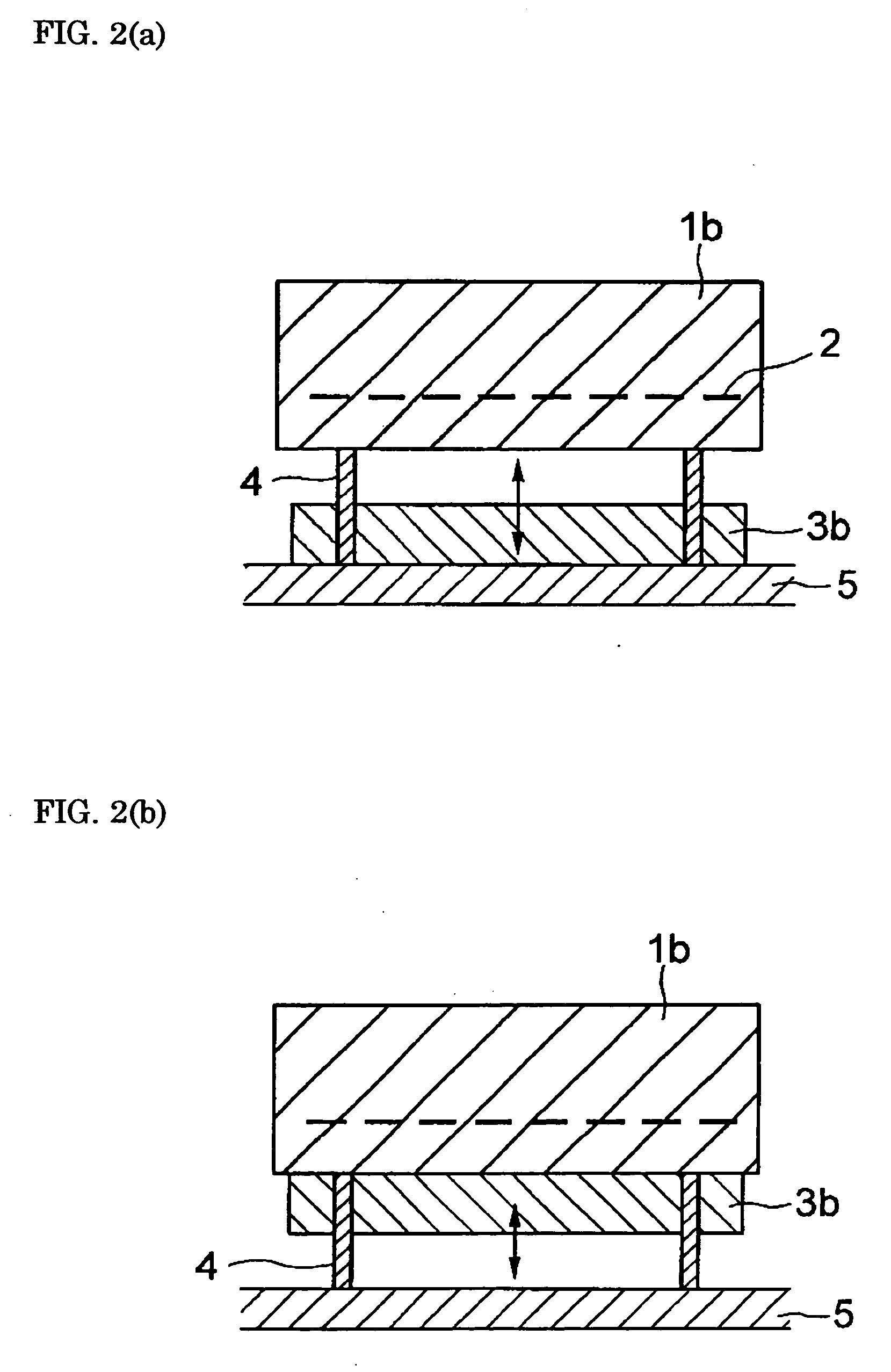

Heater module, and semiconductor manufacturing equipment in which the heater module is utilized, for raising the cooling speed of a post-heating heater markedly more than conventional, and that can contribute toward bettering and improving productivity, without accompanying scaling-up of and cost increases in the semiconductor manufacturing equipment. The heater module is furnished with heater part 1a for controlled heating of a wafer placed on its top face, and block part 3a provided to be shiftable relative to said heater part, for varying heat capacity in total with heater part 1a by abutting on or separating from the reverse surface of heater part 1a. By having the heat capacity of block part 3a be 20% or more of the total heat capacity of heater part 1a and block part 3a, the heater cooling speed can be made 10° C. / min or more.

Owner:SUMITOMO ELECTRIC IND LTD

Multi-zone resistive heater

InactiveUS20030062359A1Semiconductor/solid-state device manufacturingHot plates heating arrangementsHeating elementWafering

A heating apparatus including a stage comprising a surface having an area to support a wafer and a body, a shaft coupled to the stage, and a first and a second heating element. The first heating element is disposed within a first plane of the body of the stage. The second heating element is disposed within a second plane of the body of the stage at a greater distance from the surface of the stage than the first heating element, and the second heating element is offset from the first heating element in a plane substantially parallel to at least one of the first plane and the second plane.

Owner:APPLIED MATERIALS INC

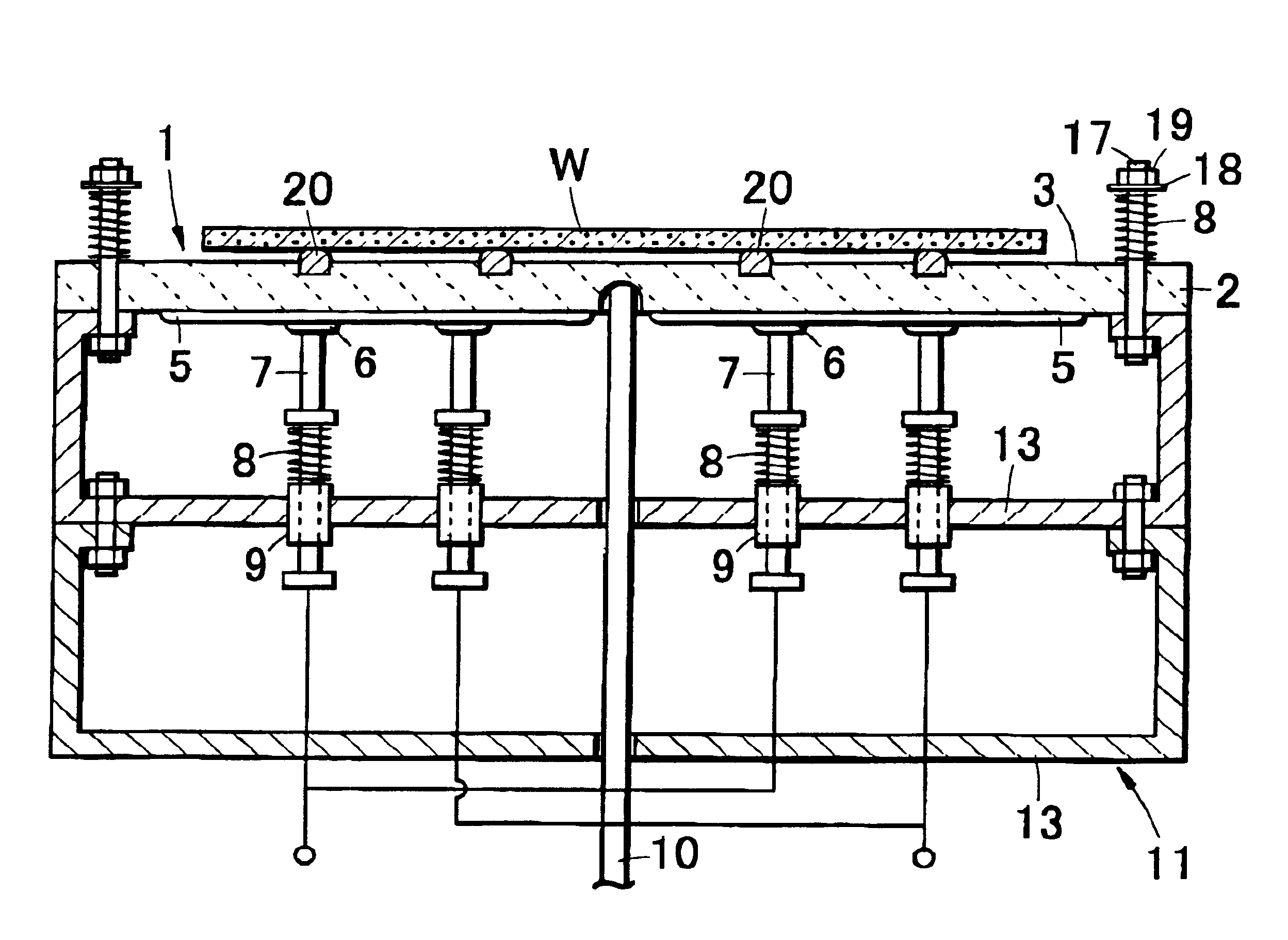

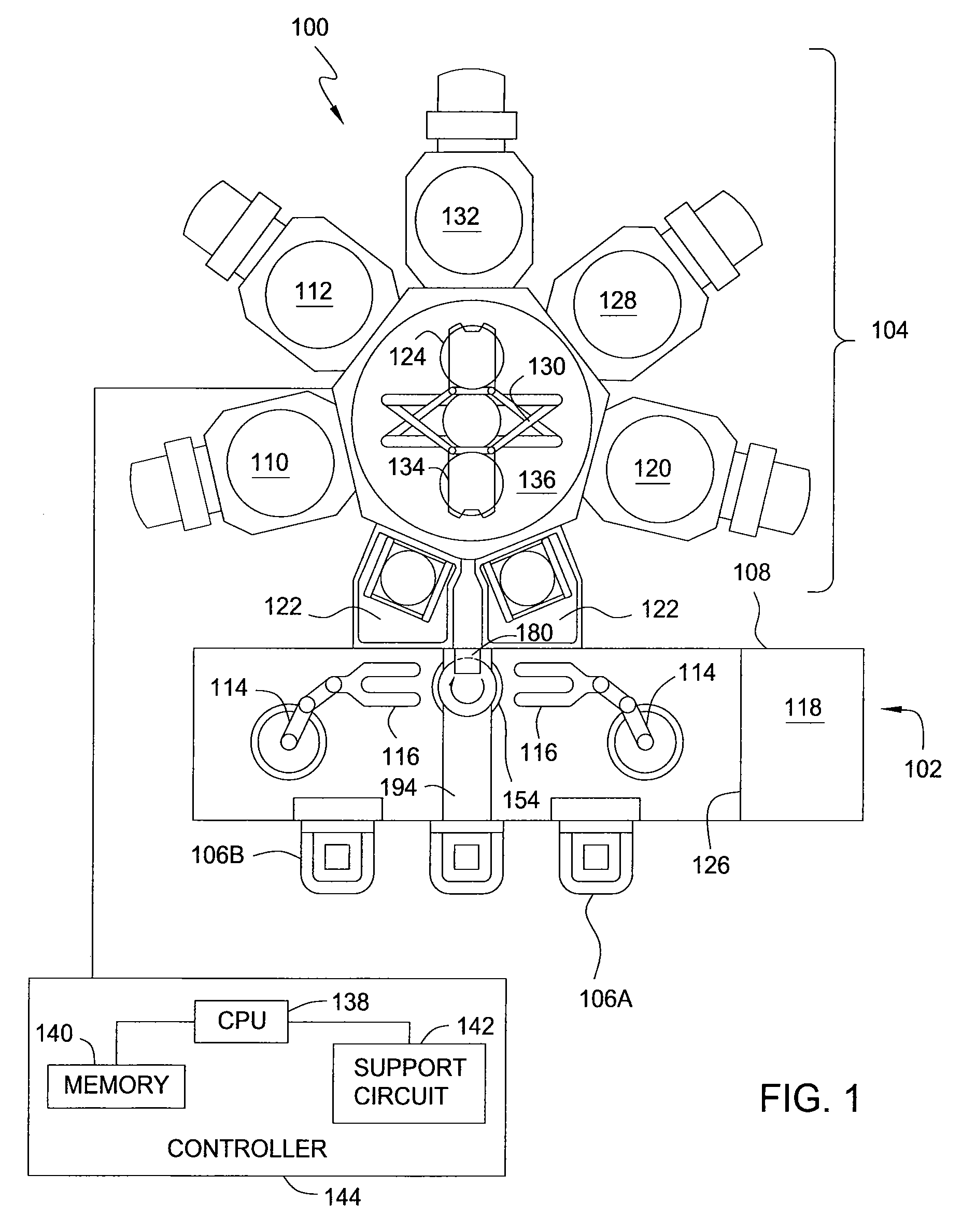

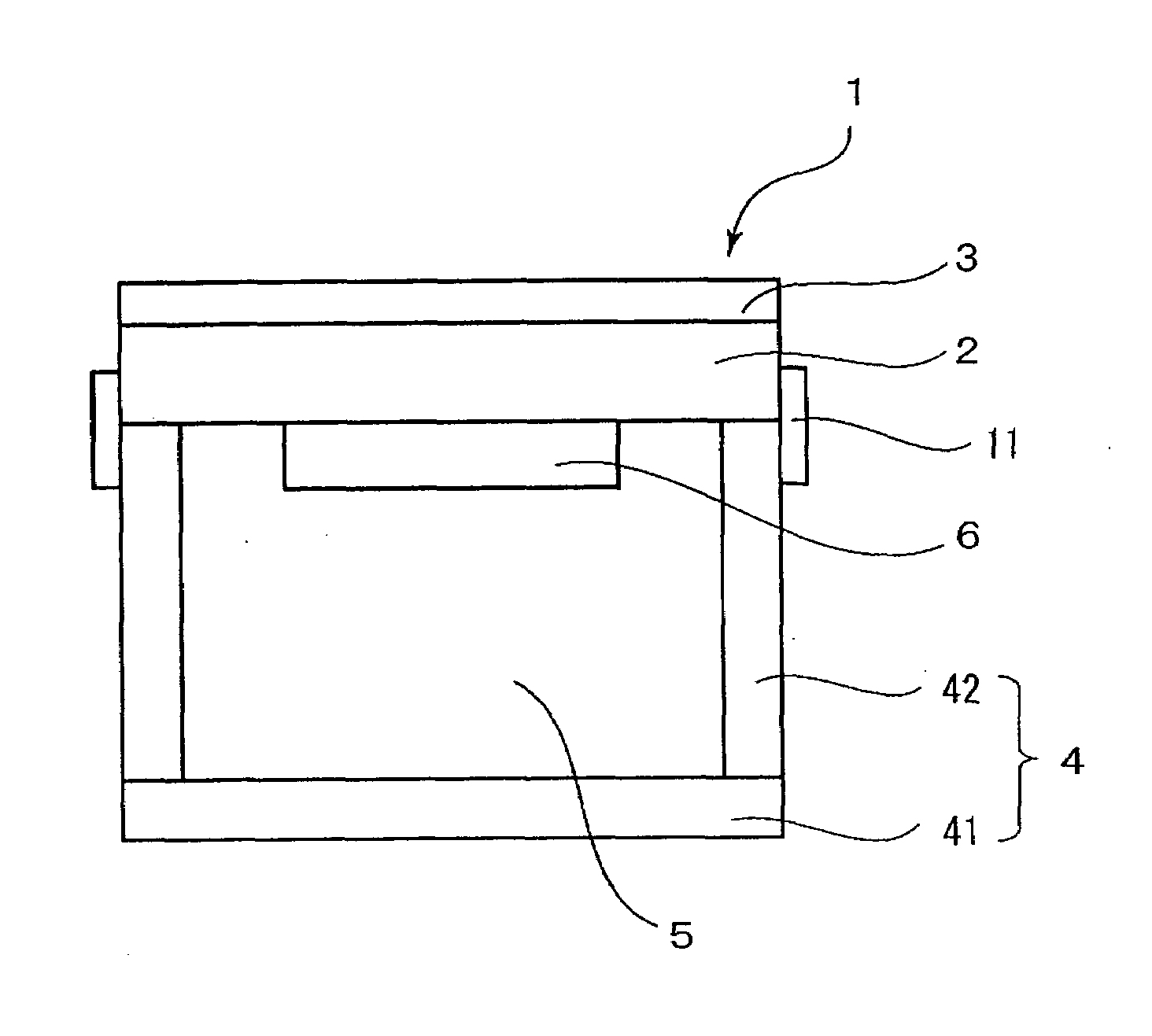

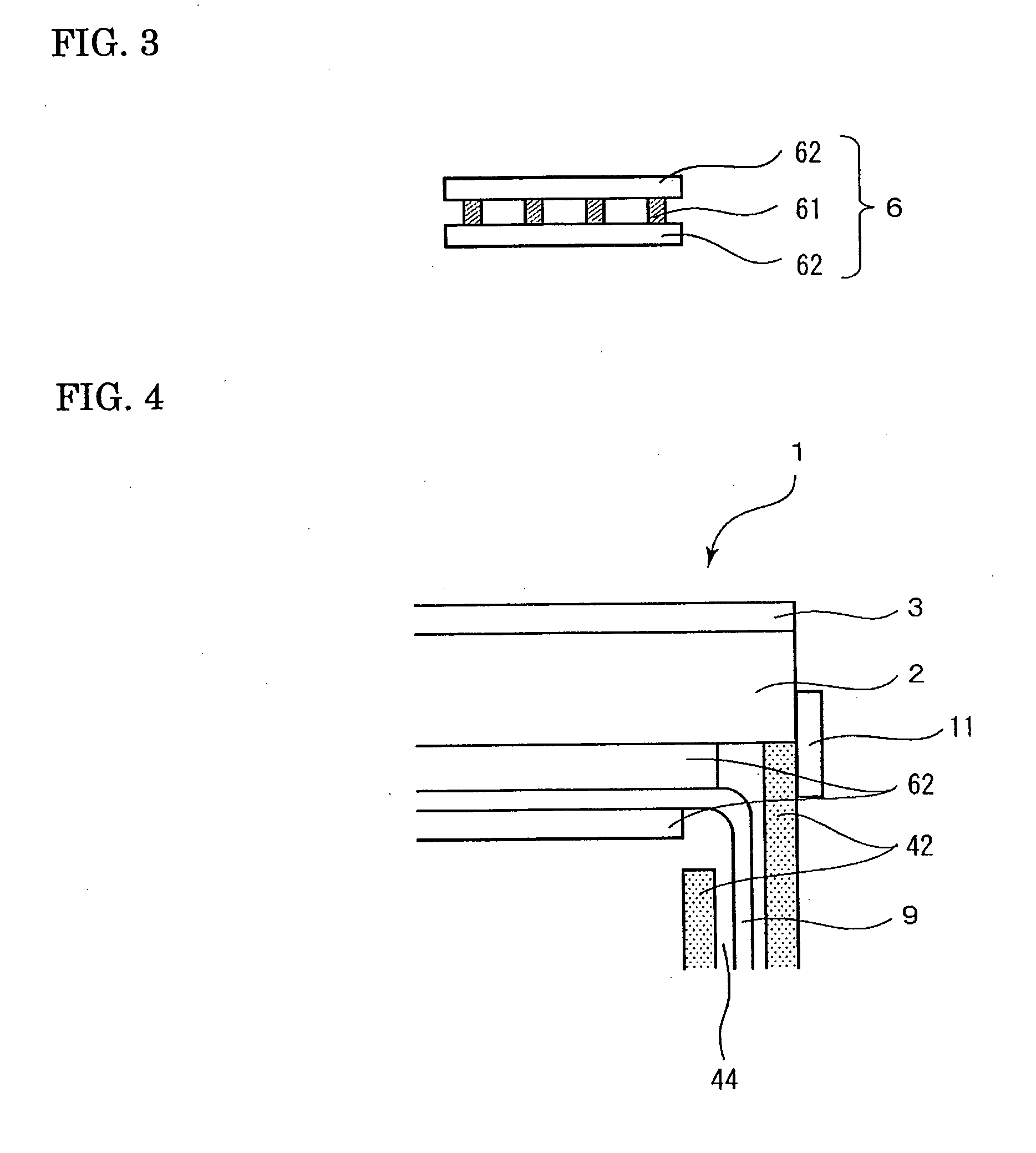

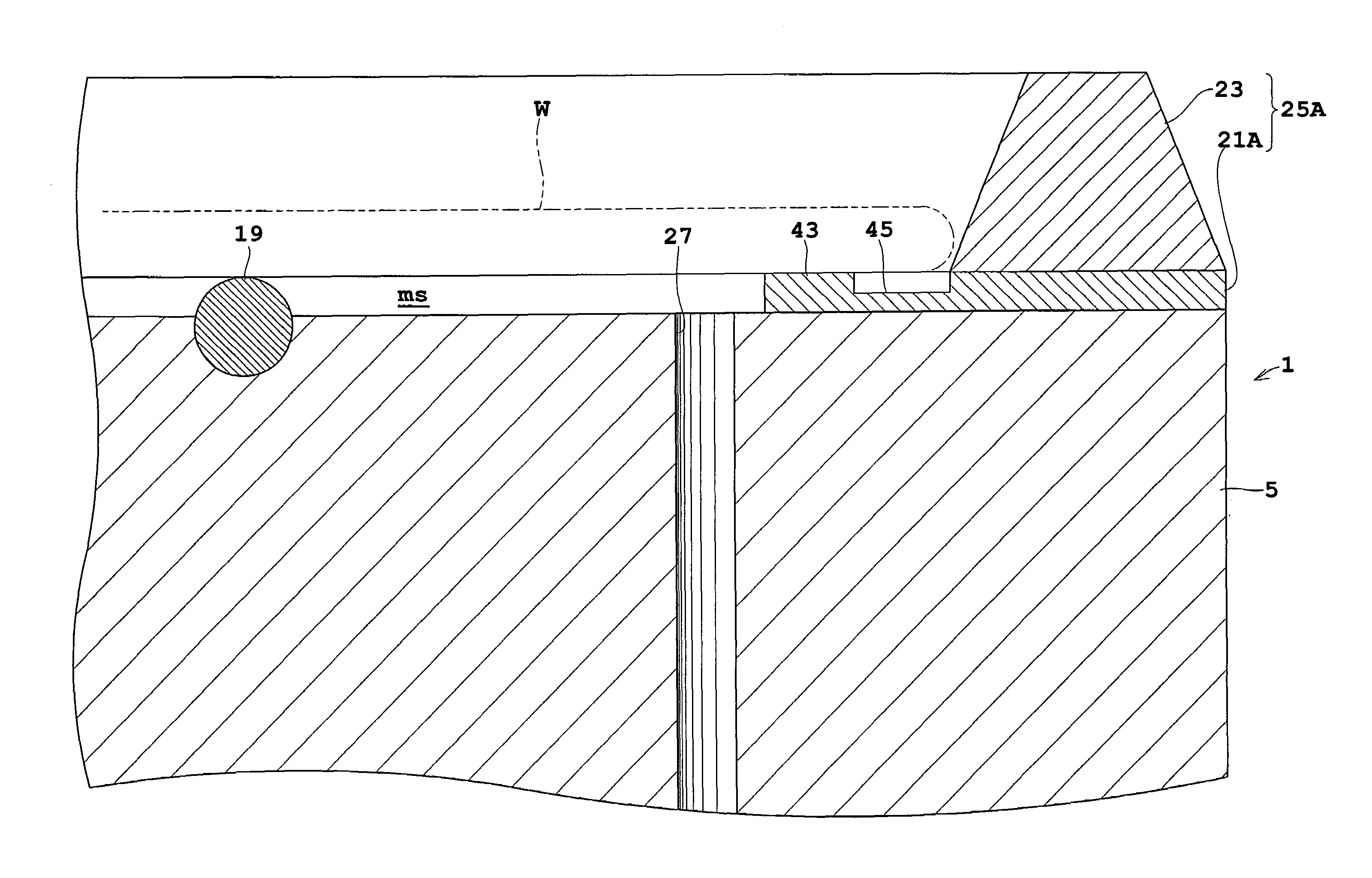

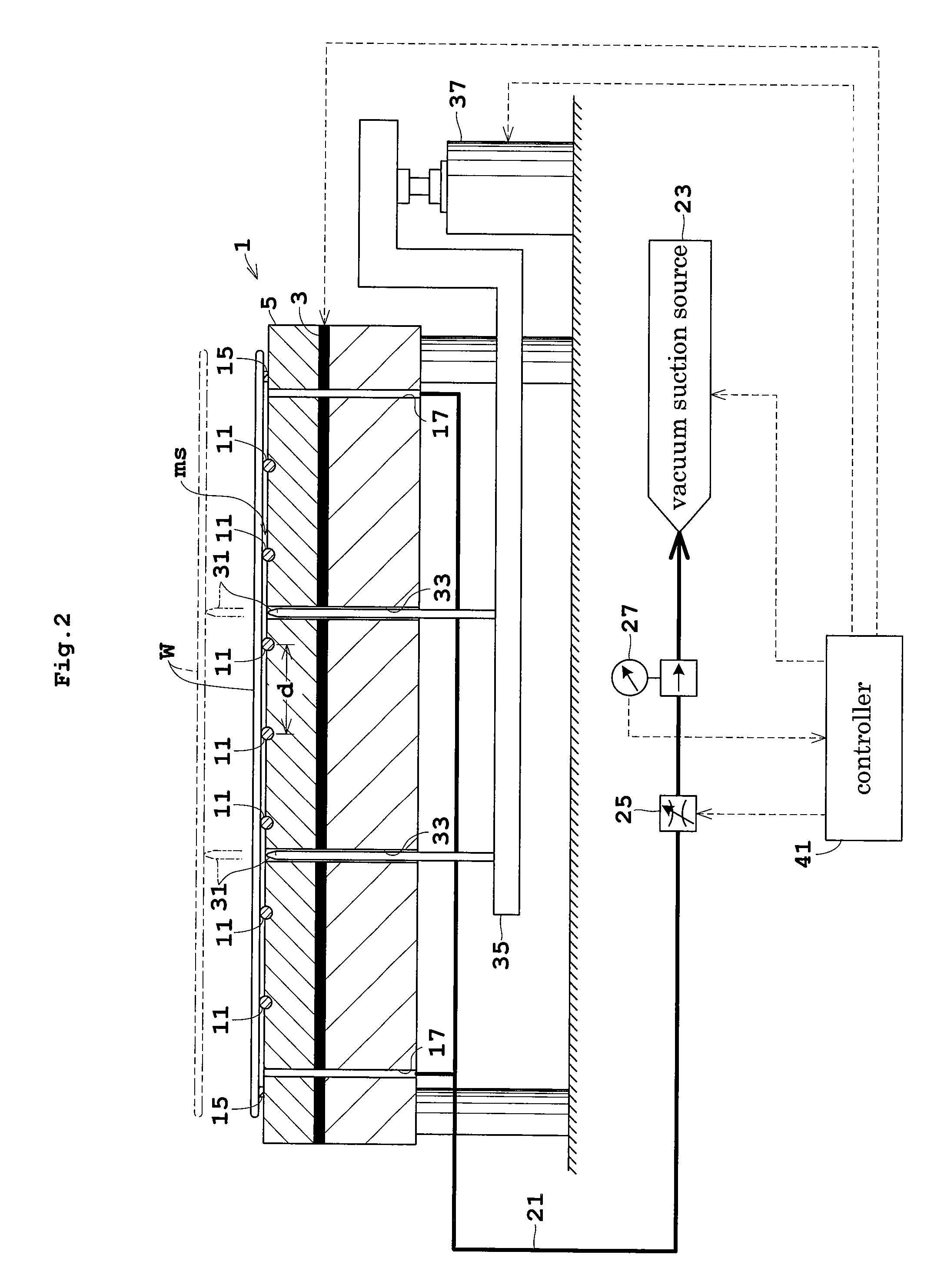

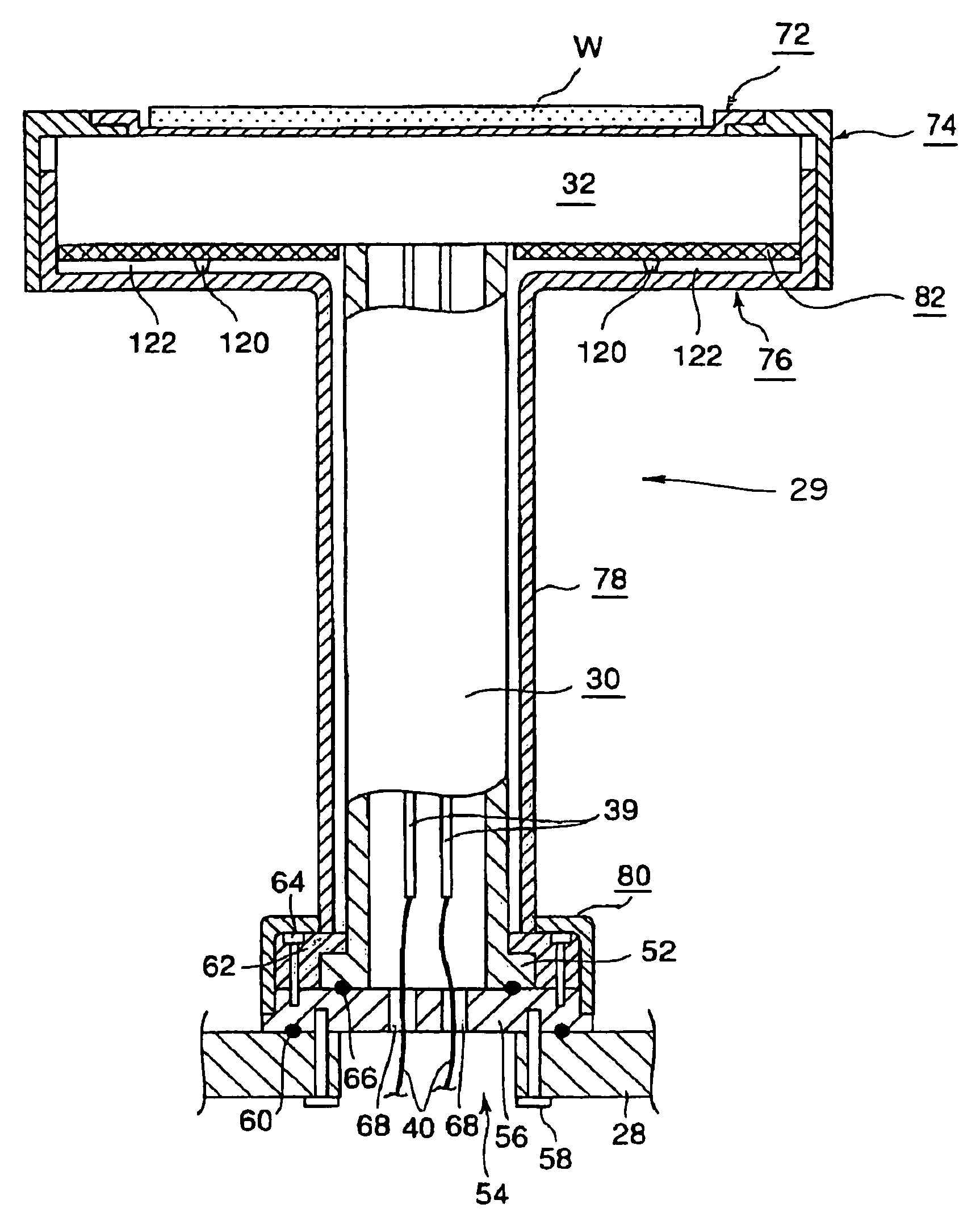

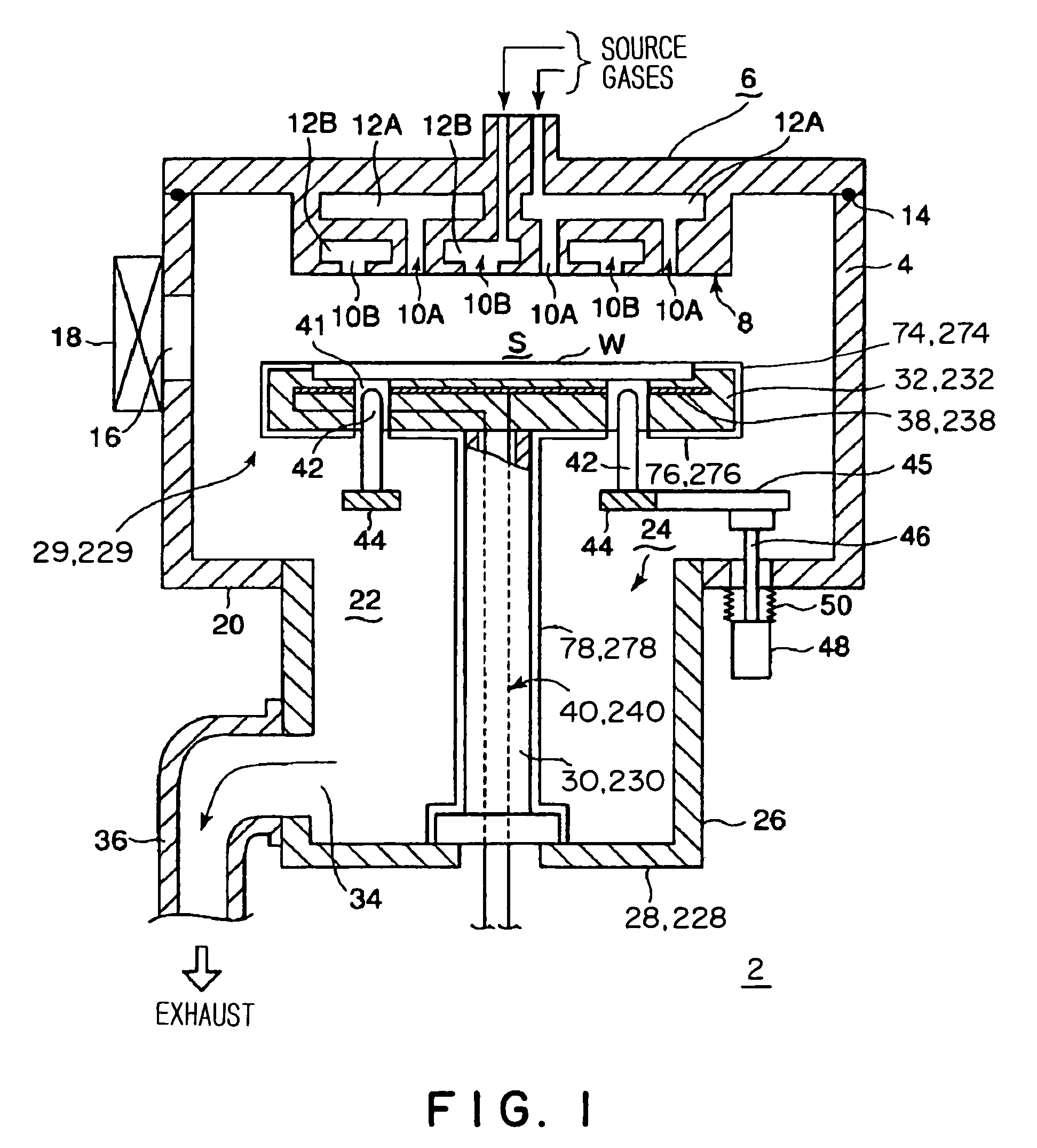

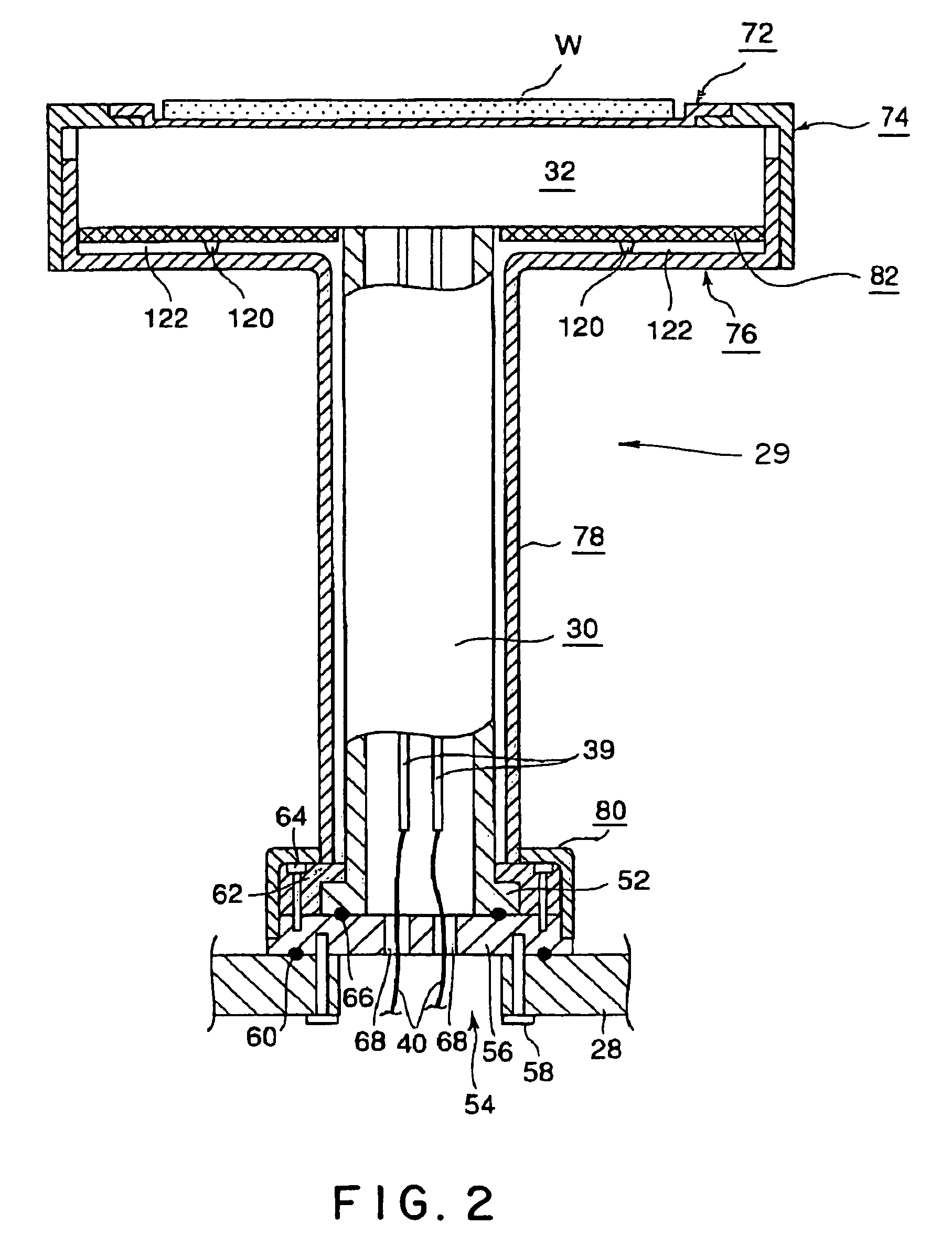

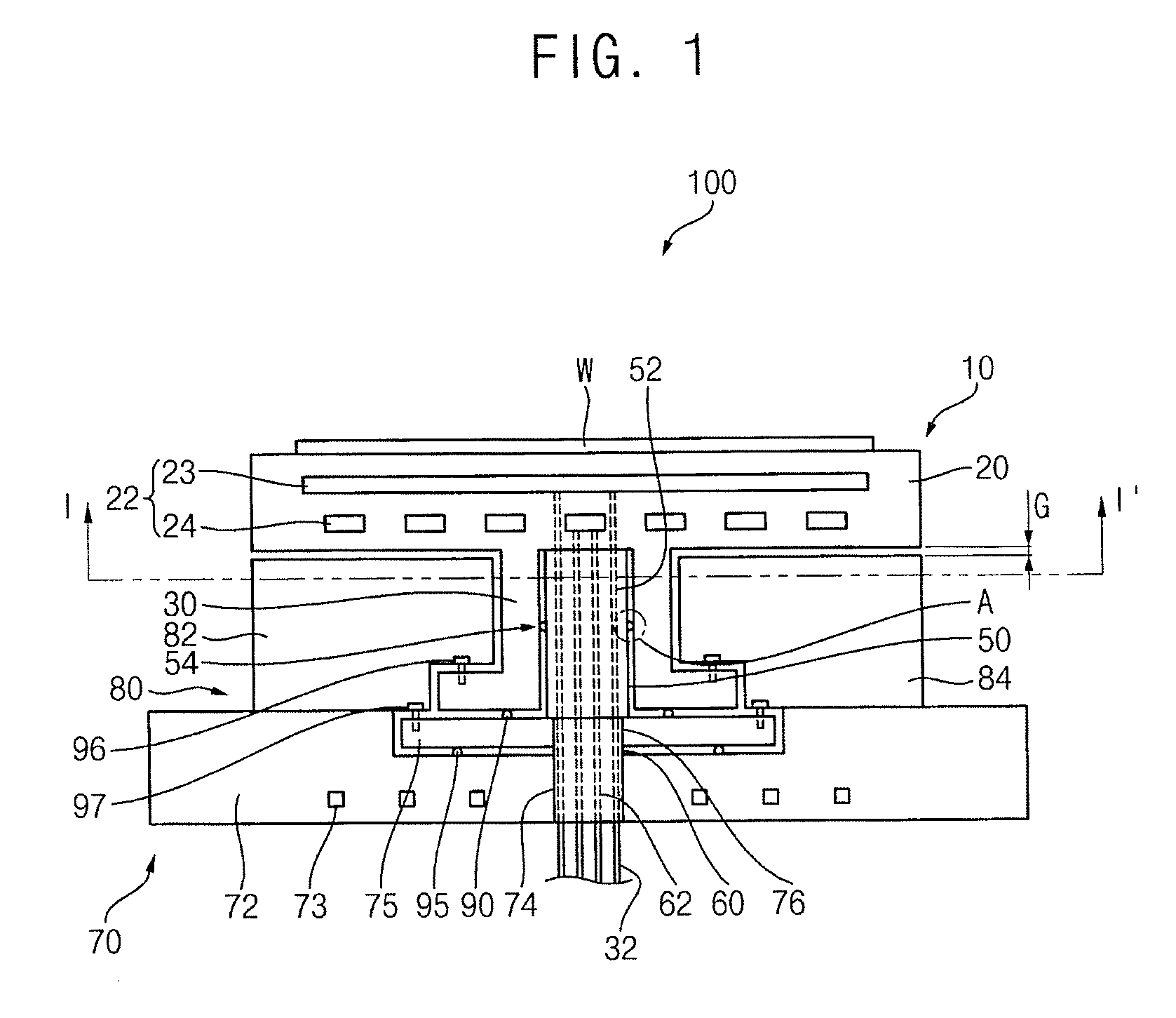

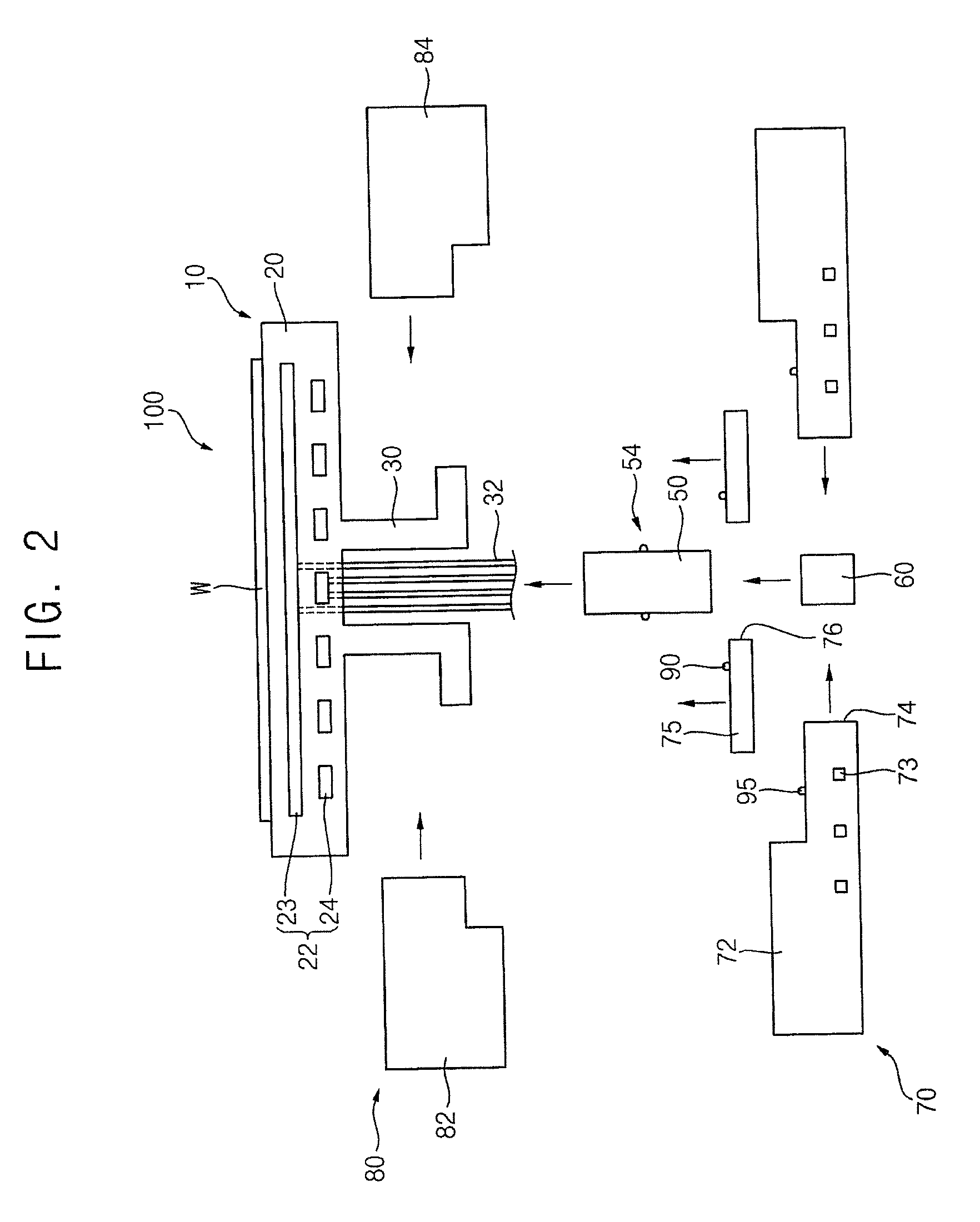

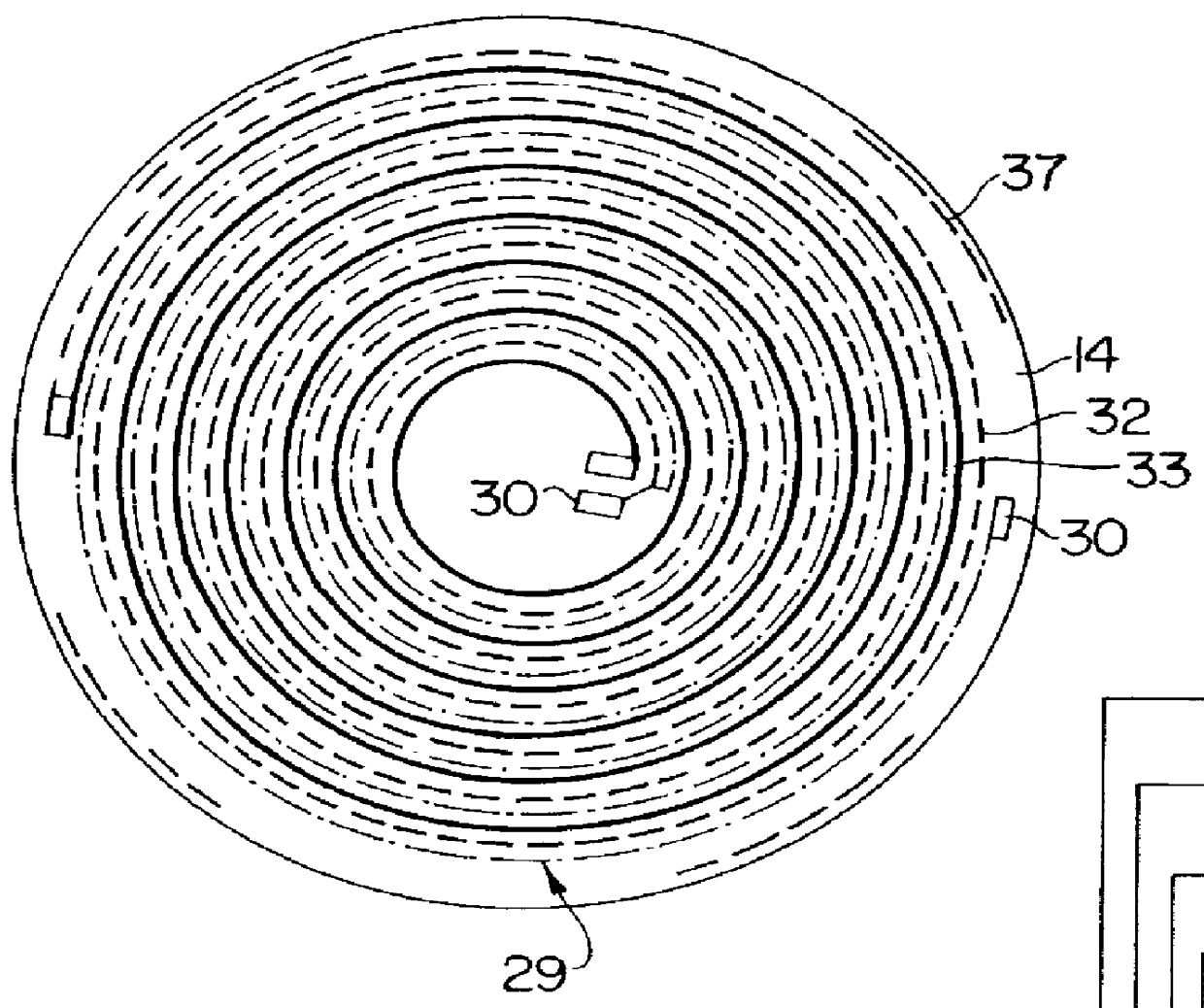

Loading table and heat treating apparatus having the loading table

ActiveUS7718930B2Thermal diffusionPrevent heat from spreadingDrying solid materials with heatMuffle furnacesEngineeringContamination

A thermal processing system has a processing vessel 4, a support post 30 stood on the bottom wall of the processing vessel 4, and a support table 32 internally provided with a heating means 38 and supported on the support post 30. A workpiece W is placed on the upper surface of the support table 32 and is subjected to a predetermined thermal process. The upper, the side and the lower surface of the support table 32 are covered with heat-resistant covering members 72, 74 and 76 to prevent the thermal diffusion of metal atoms causative of contamination from the support table 32. thus, various types of contamination, such as metal and organic contamination, can be prevented.

Owner:TOKYO ELECTRON LTD

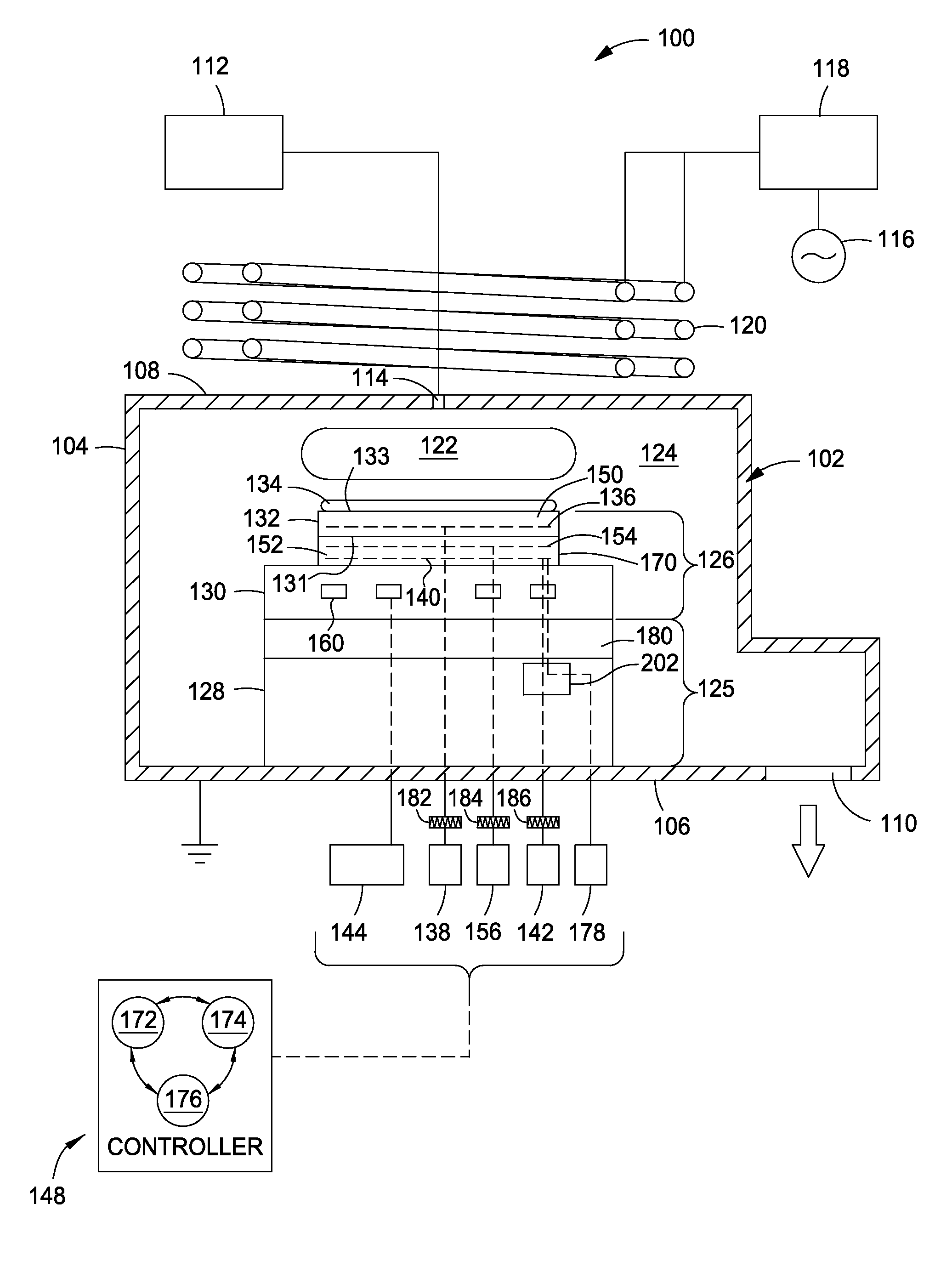

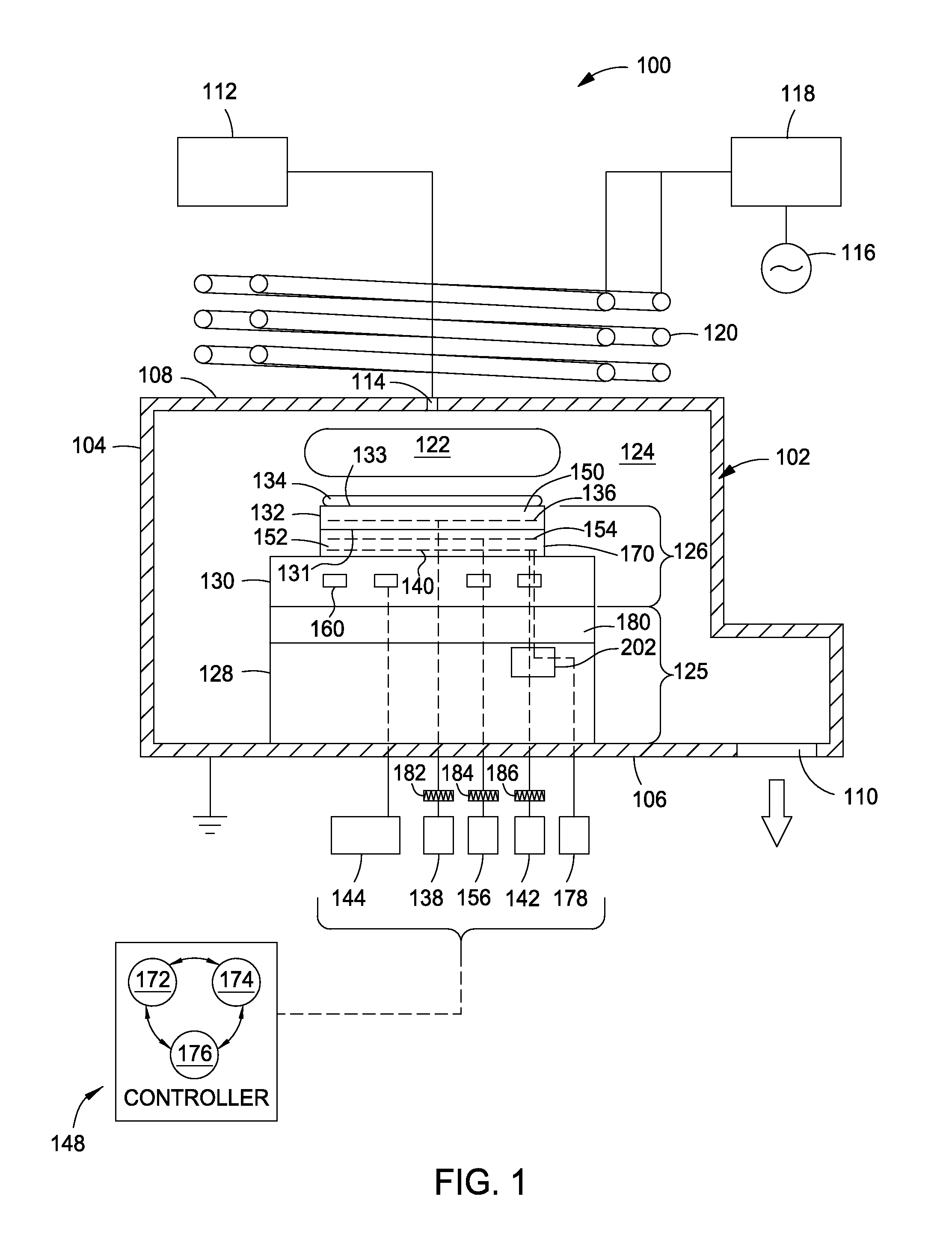

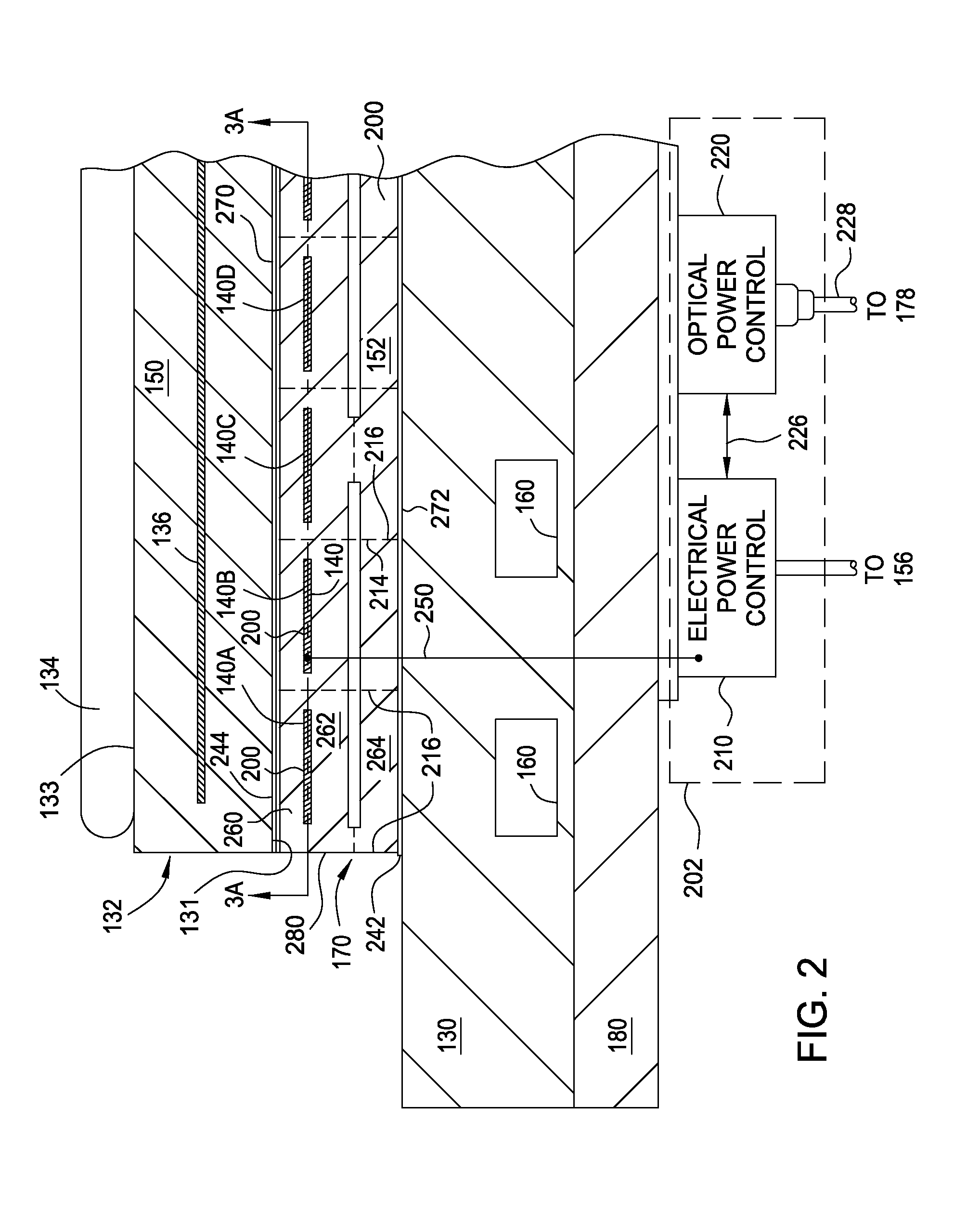

Pixilated temperature controlled substrate support assembly

ActiveUS20150228513A1Charge supportsBaking ovenElectrical resistance and conductanceTemperature control

Implementations described herein provide a pixilated substrate support assembly which enables both lateral and azimuthal tuning of the heat transfer between an electrostatic chuck and a heating assembly. The pixilated substrate support assembly comprises an upper surface and a lower surface; one or more main resistive heaters disposed in the pixilated substrate support; and a plurality of pixel heaters in column with the main resistive heaters and disposed in the substrate support. A quantity of the pixel heaters is an order of magnitude greater than a quantity of the main resistive heaters and the pixel heaters are independently controllable relative to each other as well as the main resistive heater.

Owner:APPLIED MATERIALS INC

Active cooling substrate support

ActiveUS8709162B2Electric discharge tubesSemiconductor/solid-state device manufacturingActive coolingEngineering

A substrate support assembly and method for controlling the temperature of a substrate within a process chamber with a temperature uniformity of + / −5° C. are provided. A substrate support assembly includes a thermally conductive body comprising an aluminum material, a substrate support surface on the surface of the thermally conductive body and adapted to support the large area glass substrate thereon, one or more heating elements embedded within the thermally conductive body, and one or more cooling channels embedded within the thermally conductive body and positioned around the one or more heating elements. A process chamber comprising the substrate support assembly of the invention is also provided.

Owner:APPLIED MATERIALS INC

Wafer holder, and wafer prober provided therewith

InactiveUS20070205788A1Good effectIncrease speedSemiconductor/solid-state device manufacturingHot plates heating arrangementsYoung's modulusEngineering

A wafer holder is provided having high rigidity and an enhanced heat-insulating effect that allow positional accuracy and heating uniformity to be improved, a chip to be rapidly heated and cooled, and the manufacturing cost to be reduced, and a wafer prober apparatus on which the wafer holder is mounted. The wafer holder of the present invention includes a chuck top for mounting a wafer, a support member for supporting the chuck top, and a stand for supporting the support member. The chuck top has a thermal conductivity K1 and a Young's modulus Y1; the support member has a thermal conductivity K2 and a Young's modulus Y2; and the stand has a thermal conductivity K3 and a Young's modulus Y3. K1>K2 and K1>K3; and Y3>Y1 and Y3>Y2.

Owner:SUMITOMO ELECTRIC IND LTD

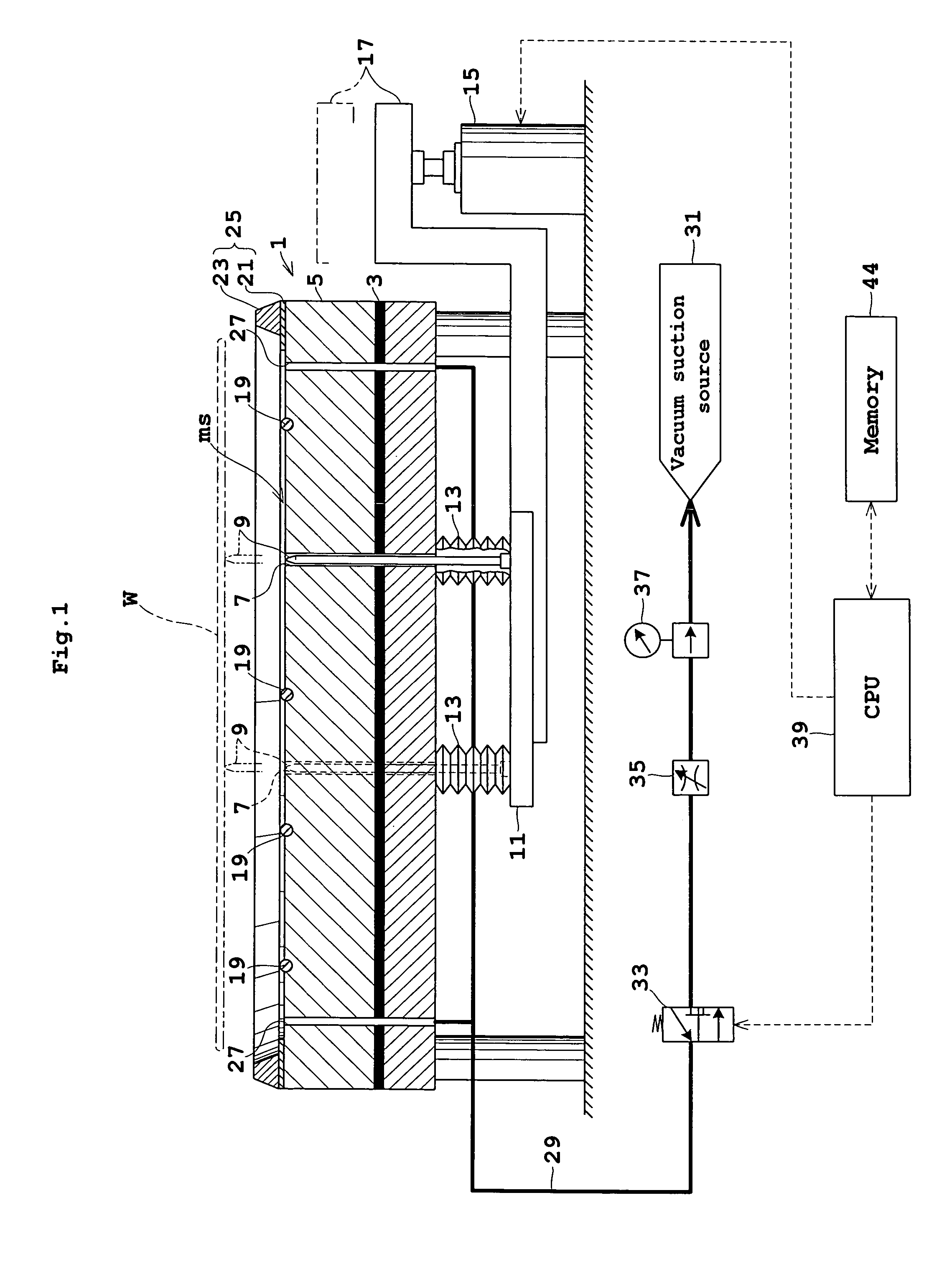

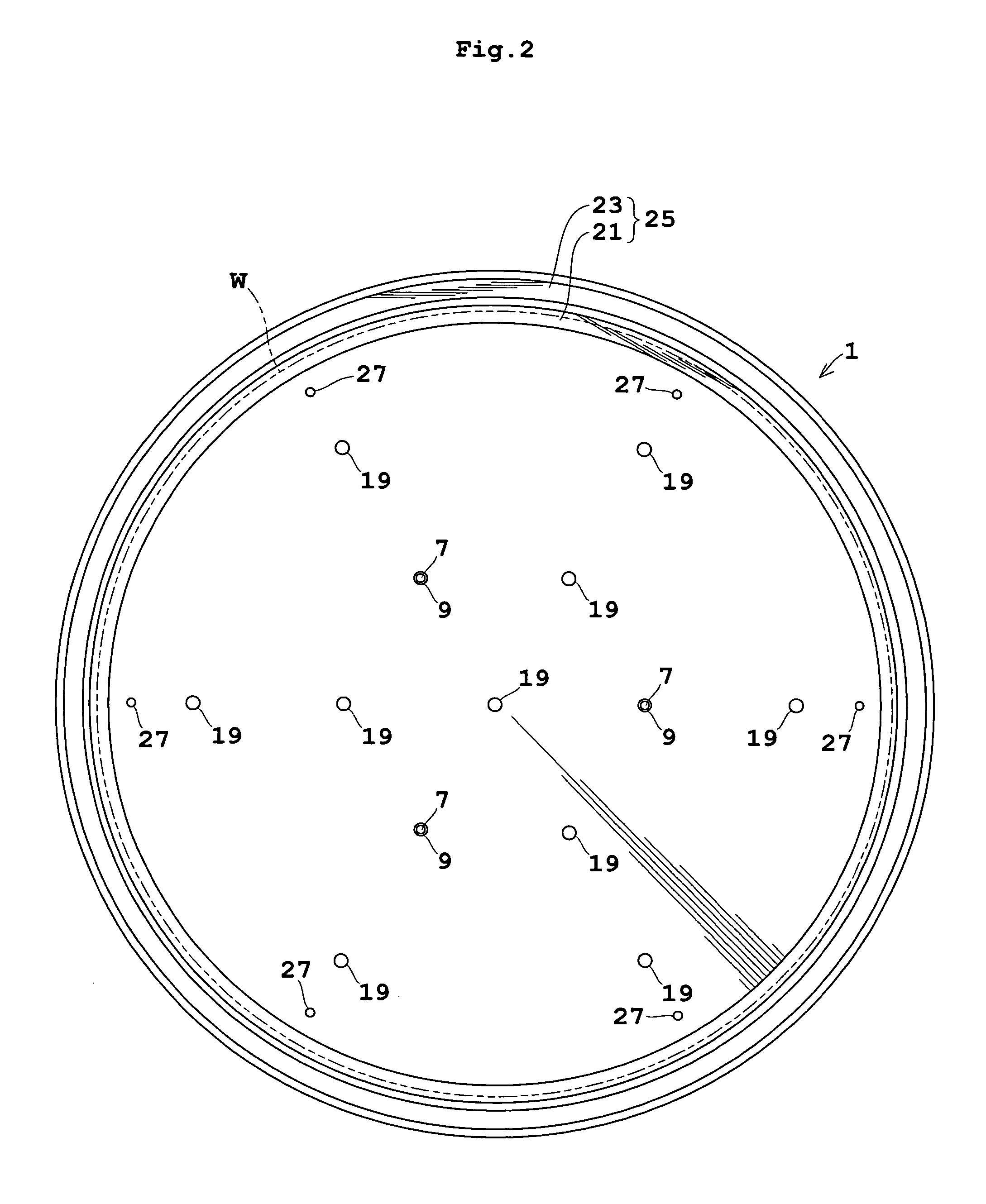

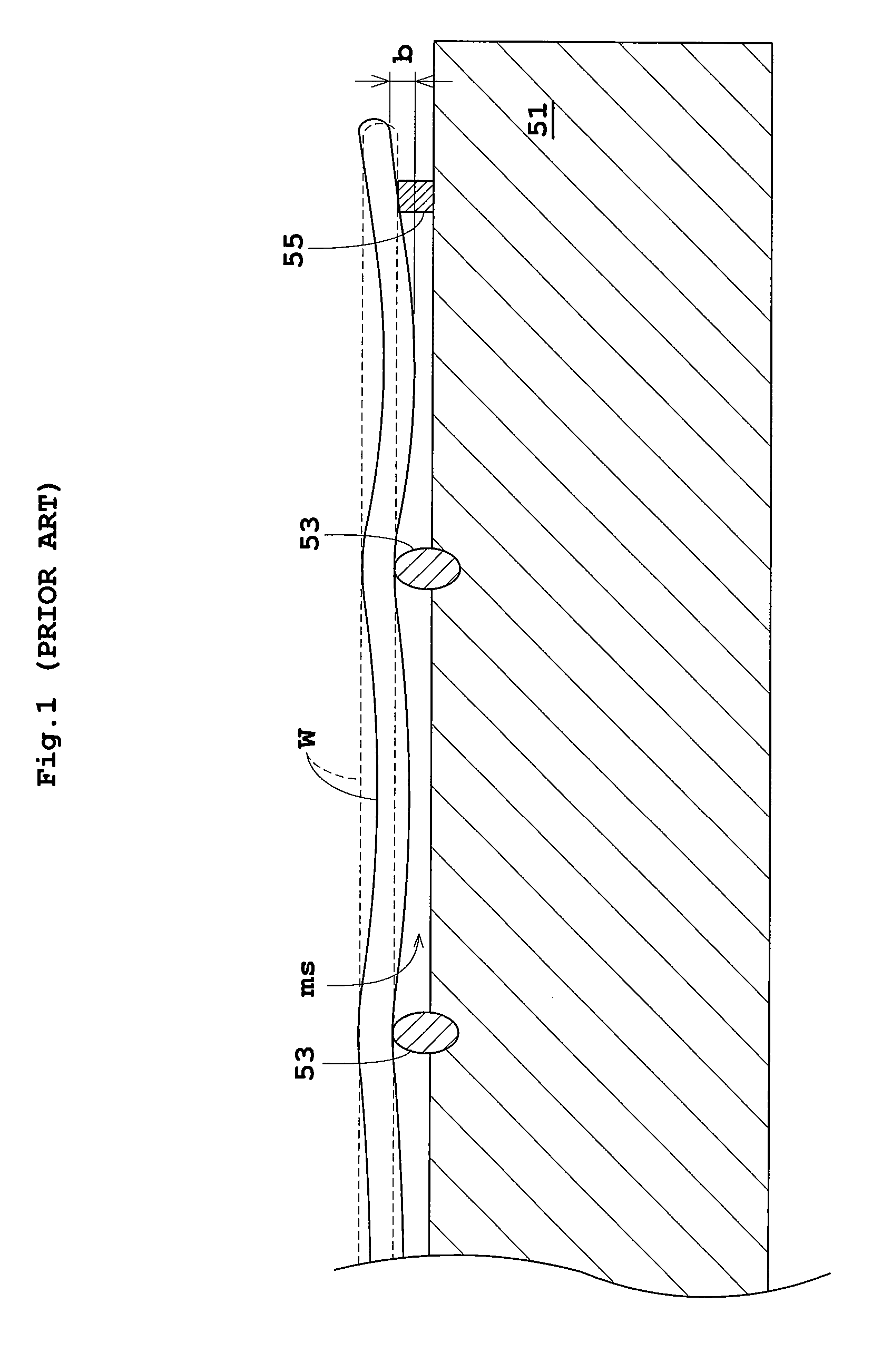

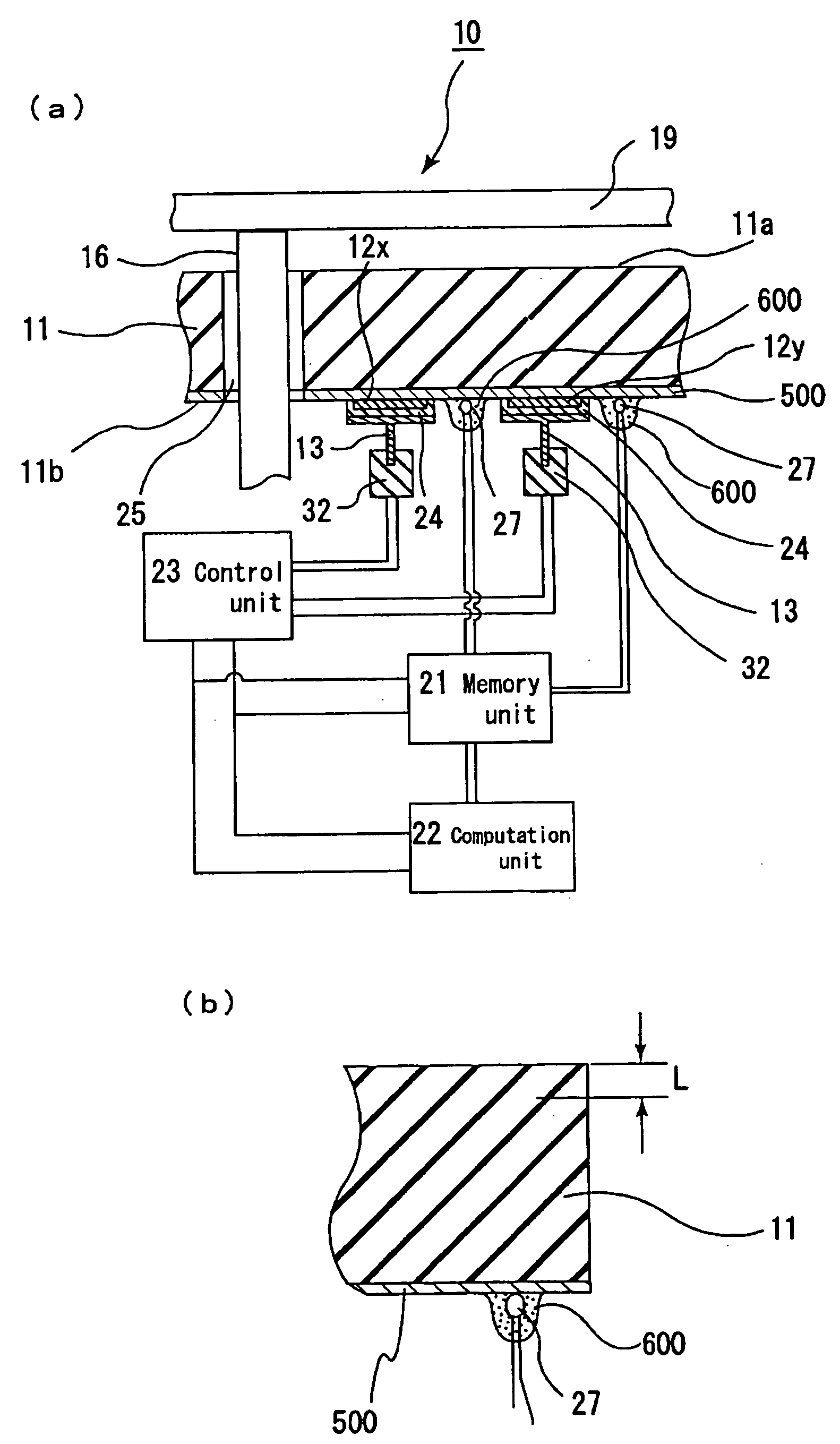

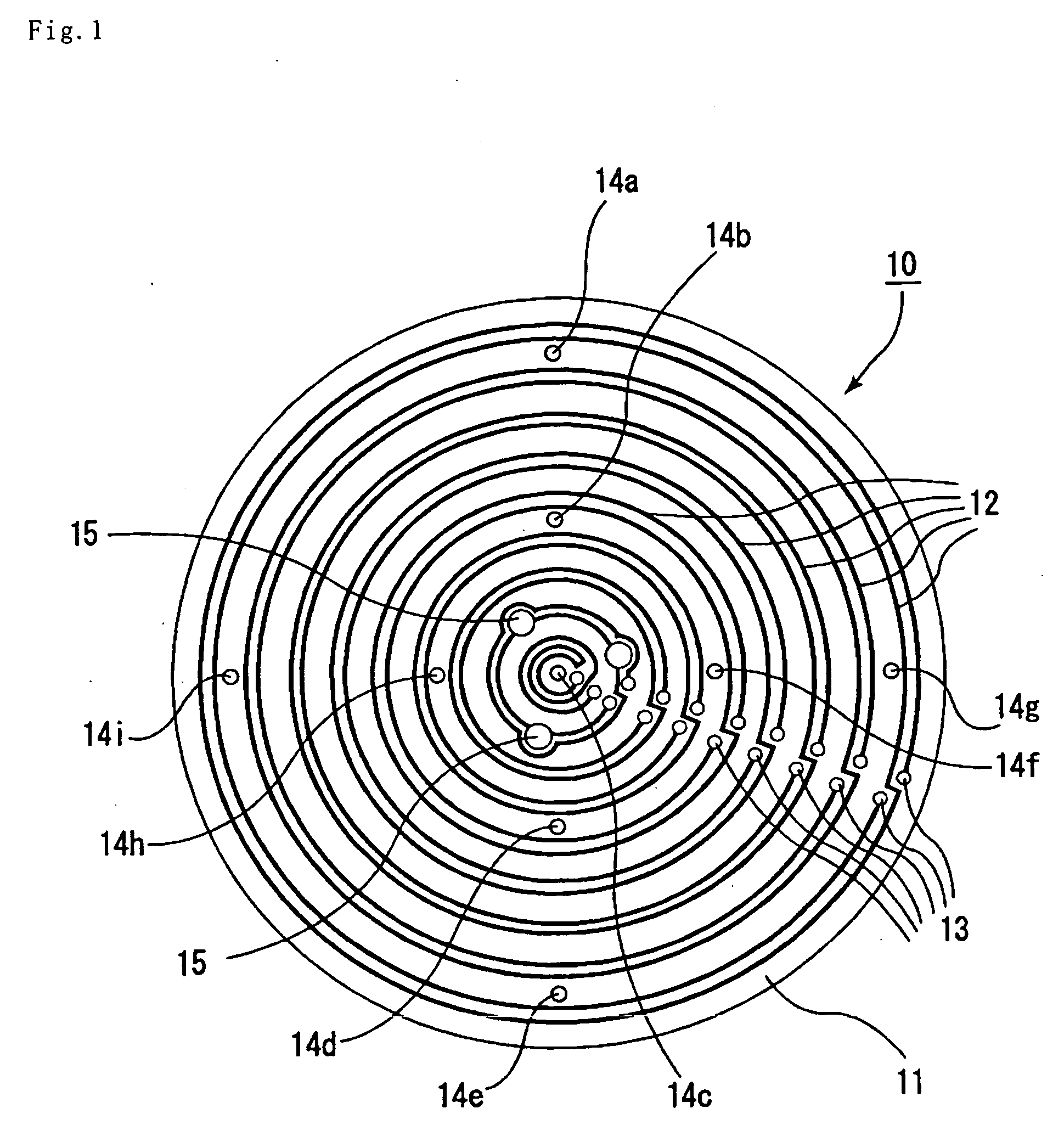

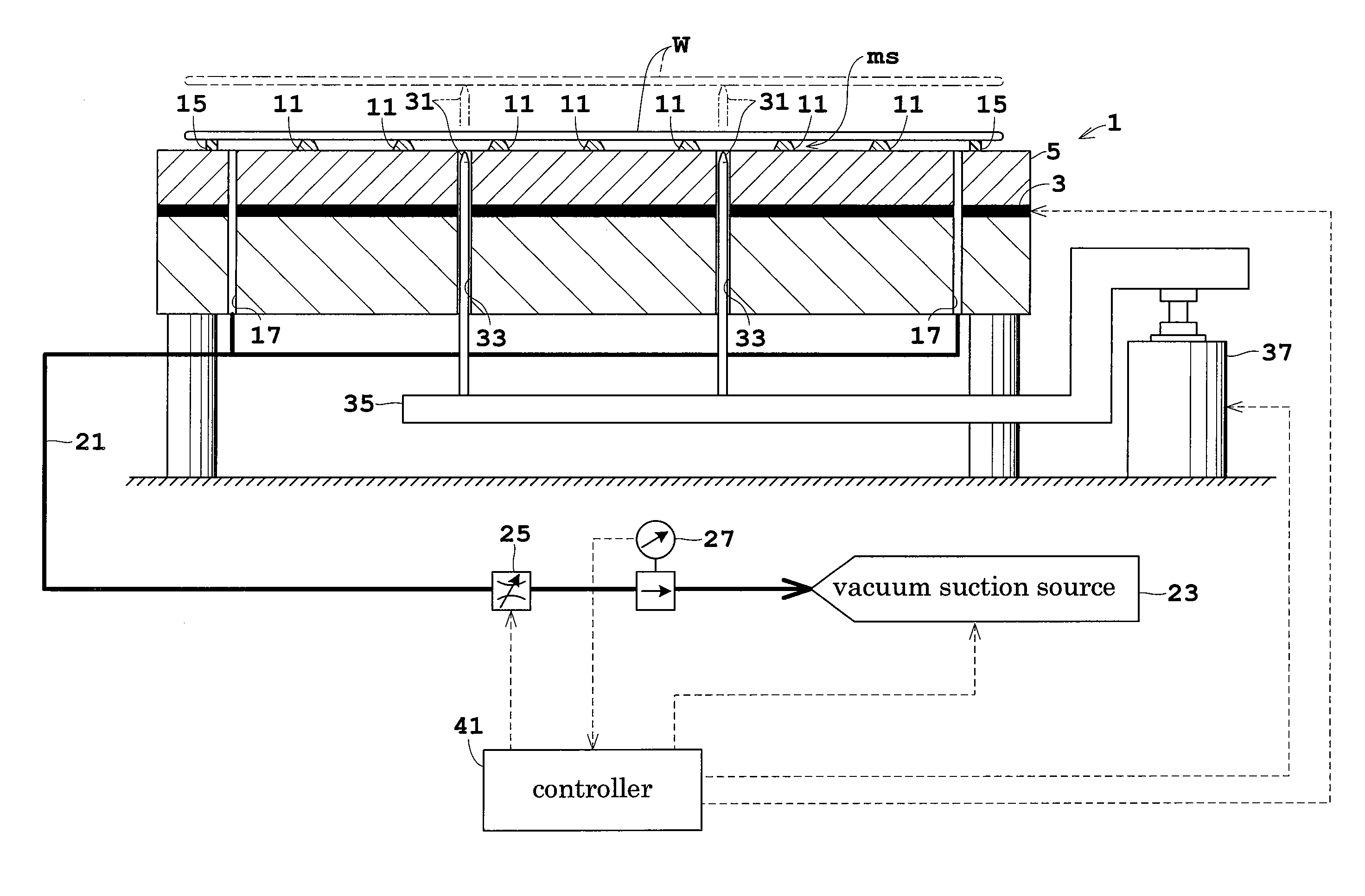

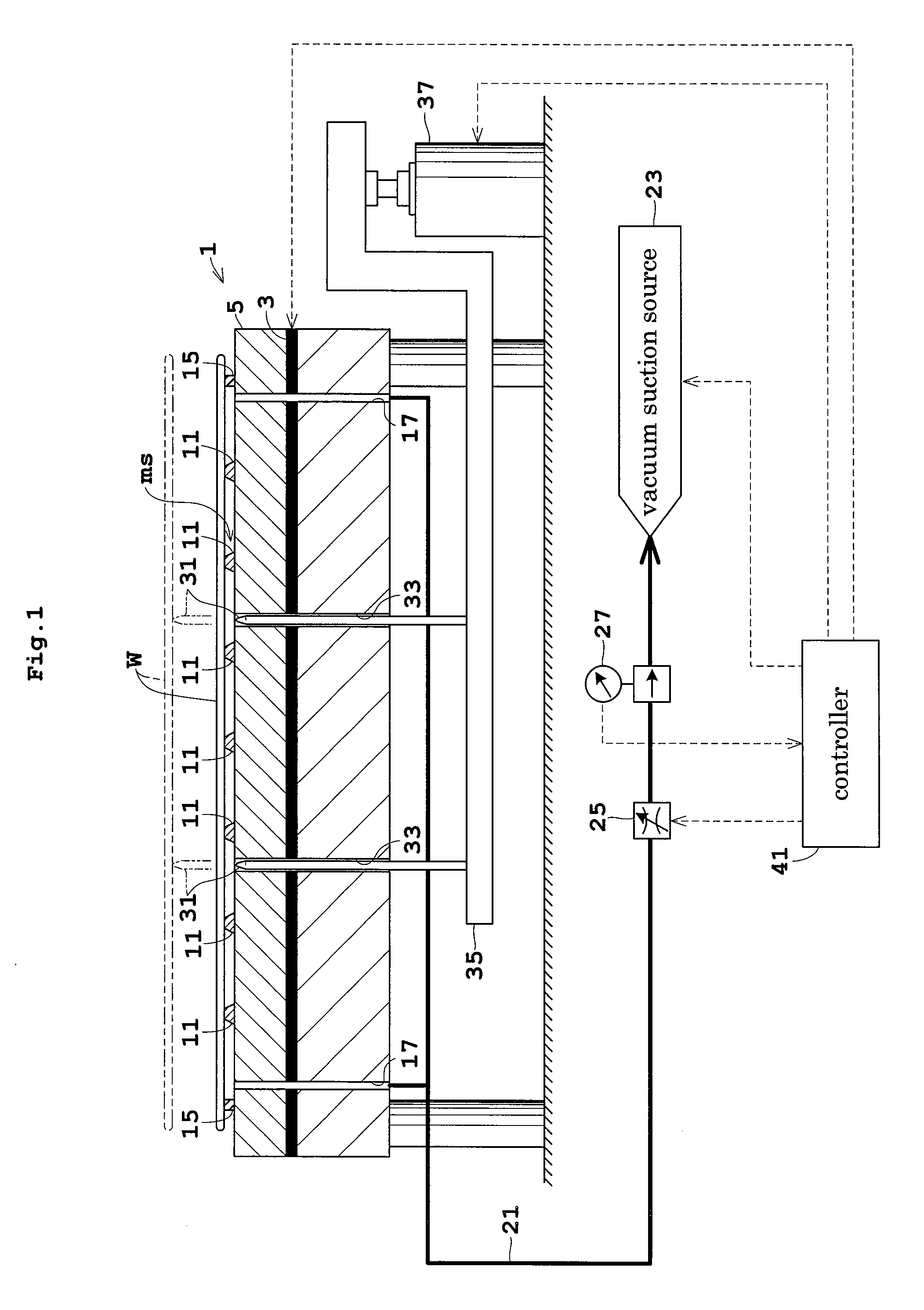

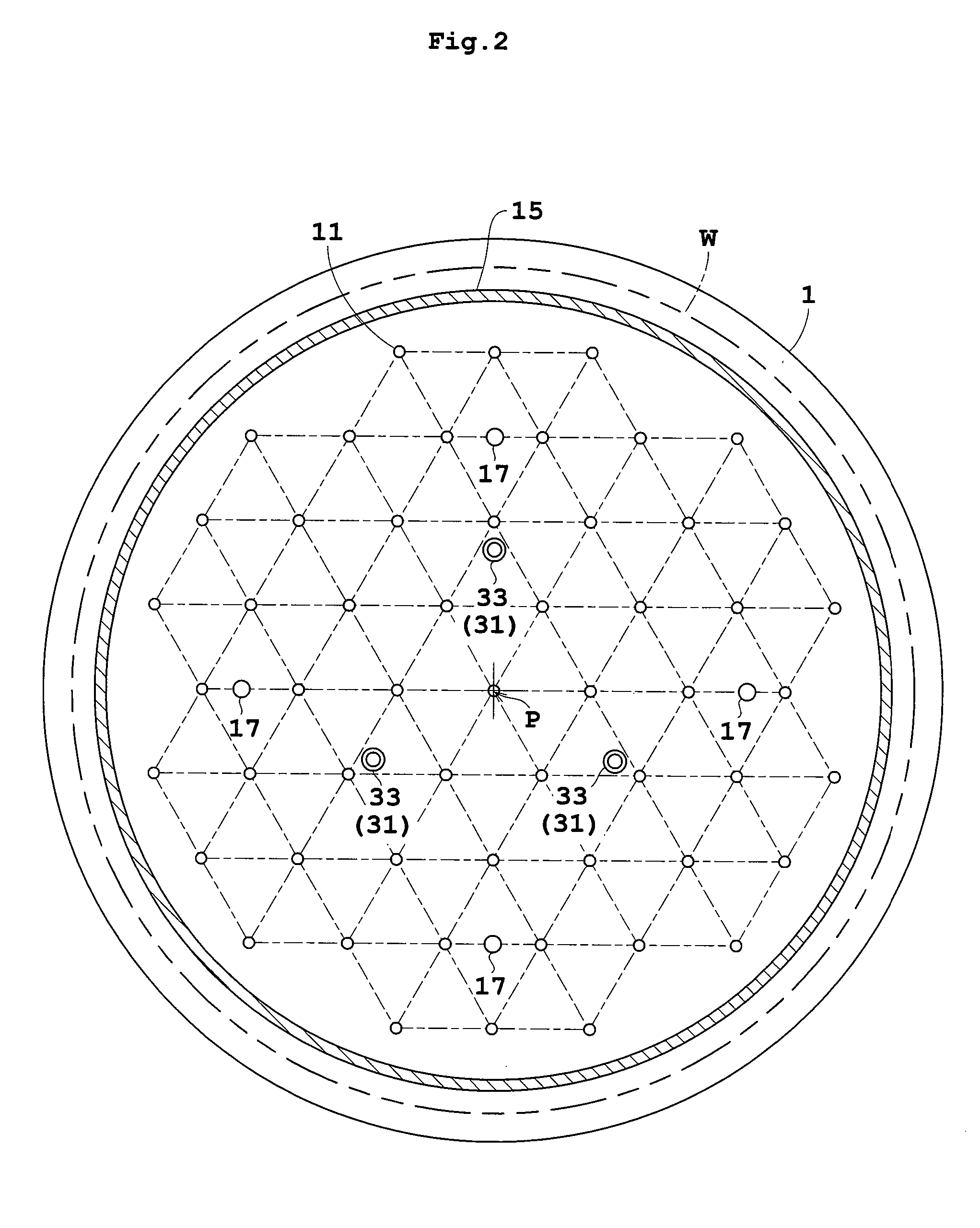

Substrate heat treatment apparatus

ActiveUS20070128570A1Stable separationEfficiently suckedCharge supportsSemiconductor/solid-state device manufacturingDevice formHeat treated

A substrate heat treatment apparatus includes a heat-treating plate having a flat upper surface, support devices formed of a heat-resistant resin for contacting and supporting a substrate, a seal device disposed annularly for rendering gastight a space formed between the substrate and heat-treating plate, and exhaust bores for exhausting gas from the space. The support devices are formed of resin, and the upper surface of the heat-treating plate is made flat, whereby a reduced difference in the rate of heat transfer occurs between contact parts and non-contact parts on the surface of the substrate. Consequently, the substrate is heat-treated effectively while suppressing variations in heat history over the surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

Method and apparatus for controlling the spatial temperature distribution across the surface of a workpiece support

InactiveUS7274004B2Electric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlEngineering

Owner:YOKOWO CO LTD +1

Apparatus for efficient removal of halogen residues from etched substrates

An apparatus for removing volatile residues from a substrate is provided. In one embodiment, an apparatus for removing halogen-containing residues from a substrate includes a chamber suitable for operating maintaining a vacuum therein and a heat module positioned to heat a substrate disposed in the chamber. The apparatus for removing halogen-containing residues from a substrate also includes at least one of A) a temperature controlled pedestal having a projection extending radially therefrom suitable for supporting the temperature control pedestal on a ledge of the chamber body, the projection thermally isolating the base from the chamber body; B) a pair of substrate holders that include two support flanges extending radially inward from an inner edge of an arc-shaped body, each support flange having a substrate support step that includes a sloped landing; or C) a domed window.

Owner:APPLIED MATERIALS INC

Heater for heating a wafer and method for fabricating the same

ActiveUS7361865B2Improve temperature distributionIncandescent ignitionSemiconductor/solid-state device manufacturingHeating element

Owner:KYOCERA CORP

Heated or cooled dishware and drinkware

ActiveUS20150245723A1Uniform liquid temperatureBaking ovenMachines using electric/magnetic effectsElectricityControl circuit

An actively heated mug, travel mug, baby bottle, water bottle or liquid container is provided. The mug, travel mug, baby bottle, water bottle or liquid container can include a body that receives a liquid therein and a heating or cooling system at least partially disposed in the body. The heating or cooling system can include one or more heating or cooling elements that heat a surface of the receiving portion of the body and one or more energy storage devices. The mug, travel mug, baby bottle, water bottle or liquid container can include a wireless power receiver that wirelessly receives power from a power source and control circuitry configured to charge one or more power storage elements and to control the delivery of electricity from the one or more power storage elements to the one or more heating or cooling elements. The mug, travel mug, baby bottle, water bottle or liquid container also can have one or more sensors that sense a parameter of the liquid or sense a parameter of the heating or cooling system and communicates the sensed information to the control circuitry. The control circuitry can turn on, turn off, and / or operate the heating or cooling element to actively heat or cool at least a portion of the body to maintain the liquid in a heated or cooled state generally at a user selected temperature setting based at least in part on the sensed parameter information. The mug, travel mug, baby bottle, water bottle or liquid container can also be paired with a remote device or mobile electronic device to send or receive communications or commands.

Owner:EMBER TECH INC

Stage unit for supporting a substrate and apparatus for processing a substrate including the same

InactiveUS20090293809A1No longer be movedAvoid damageSemiconductor/solid-state device manufacturingHot plates heating arrangementsDirect effectsThermal expansion

In a stage for supporting a substrate, a body, a base plate and a buffer are provided in the stage. The body on which the substrate is positioned includes a plate having a heating electrode for generating heat therein and a tube protruded from a bottom surface of the plate. The body is mounted on the base plate. The buffer is interposed between the base plate and the tube and has a thermal expansion ratio higher than that of the tube of the body and lower than that of the base plate. Accordingly, thermal expansion of the base plate may be absorbed by the buffer and may not have direct effect on the body. Therefore, the body may be prevented from being damaged due to the thermal expansion of the base plate.

Owner:KOMICO

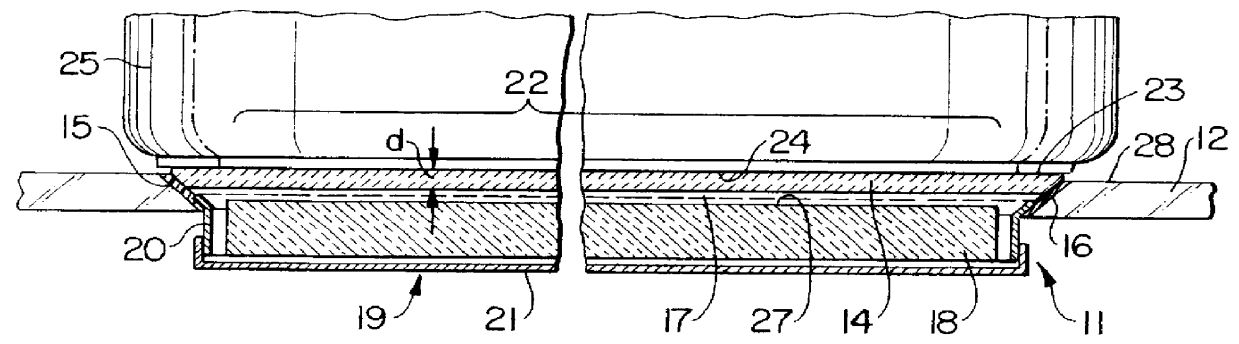

Contact heat-transferring cooking system with an electric hotplate

InactiveUS6150636AImprove heat transfer performanceIncrease temperature differenceCooking-vessel materialsDomestic stoves or rangesCouplingVolumetric Mass Density

A contact heat-transferring electric hotplate (11) is provided, which is made from nonoxidic ceramic, particularly silicon nitride. Its very thin hotplate body (14) in the form of a disk is installed in self-supporting manner in a hob plate, e.g. by bonding, and has an extremely flat surface or which is adapted to the cooking vessel shape, which creates such a small gap with respect to said vessel that a coupling is possible even with higher power densities with only a temperature difference of a few degrees. The heating means (17) is also in contact with or directly connected to the underside of the hotplate body (14).

Owner:E G O ELEKTRO GERAETEBAU GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com