Patents

Literature

222results about How to "Improve thermal uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

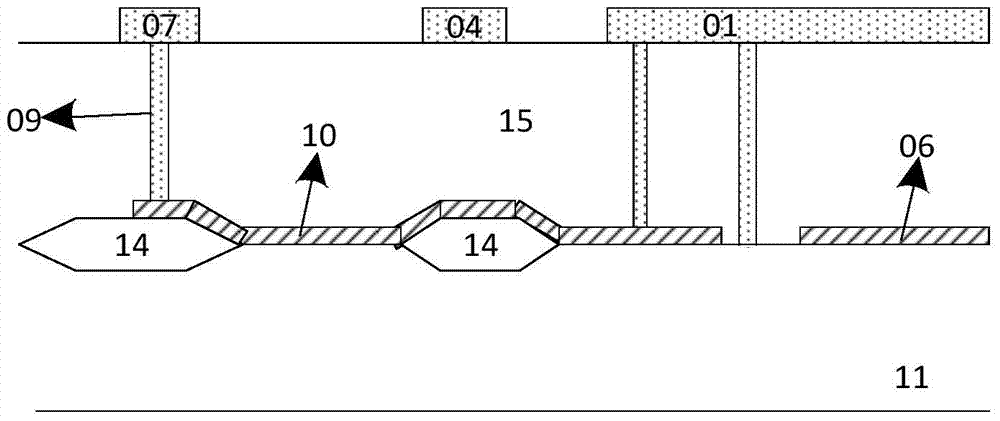

Wafer holder, and wafer prober provided therewith

InactiveUS20070205788A1Good effectIncrease speedSemiconductor/solid-state device manufacturingHot plates heating arrangementsYoung's modulusEngineering

A wafer holder is provided having high rigidity and an enhanced heat-insulating effect that allow positional accuracy and heating uniformity to be improved, a chip to be rapidly heated and cooled, and the manufacturing cost to be reduced, and a wafer prober apparatus on which the wafer holder is mounted. The wafer holder of the present invention includes a chuck top for mounting a wafer, a support member for supporting the chuck top, and a stand for supporting the support member. The chuck top has a thermal conductivity K1 and a Young's modulus Y1; the support member has a thermal conductivity K2 and a Young's modulus Y2; and the stand has a thermal conductivity K3 and a Young's modulus Y3. K1>K2 and K1>K3; and Y3>Y1 and Y3>Y2.

Owner:SUMITOMO ELECTRIC IND LTD

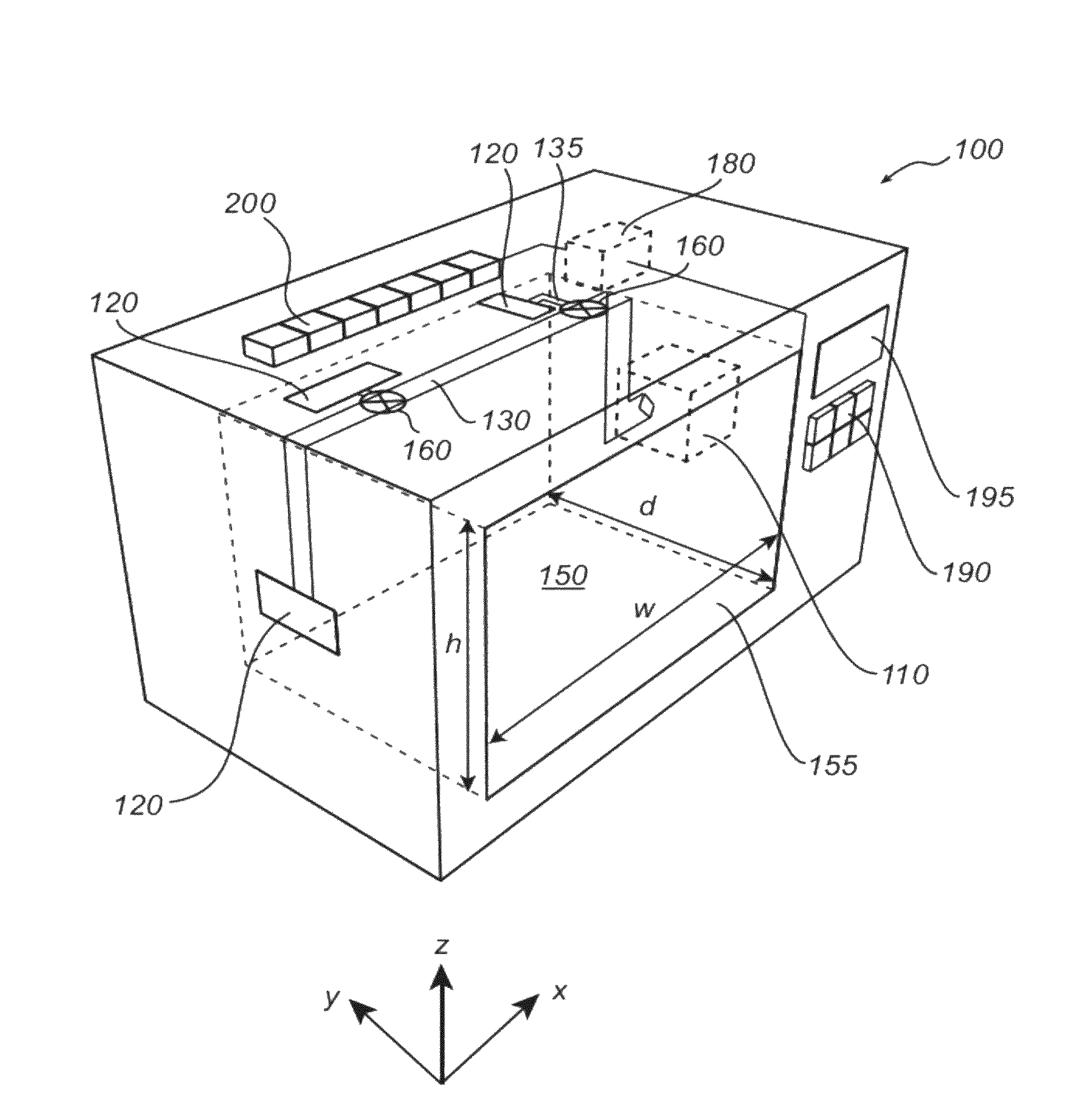

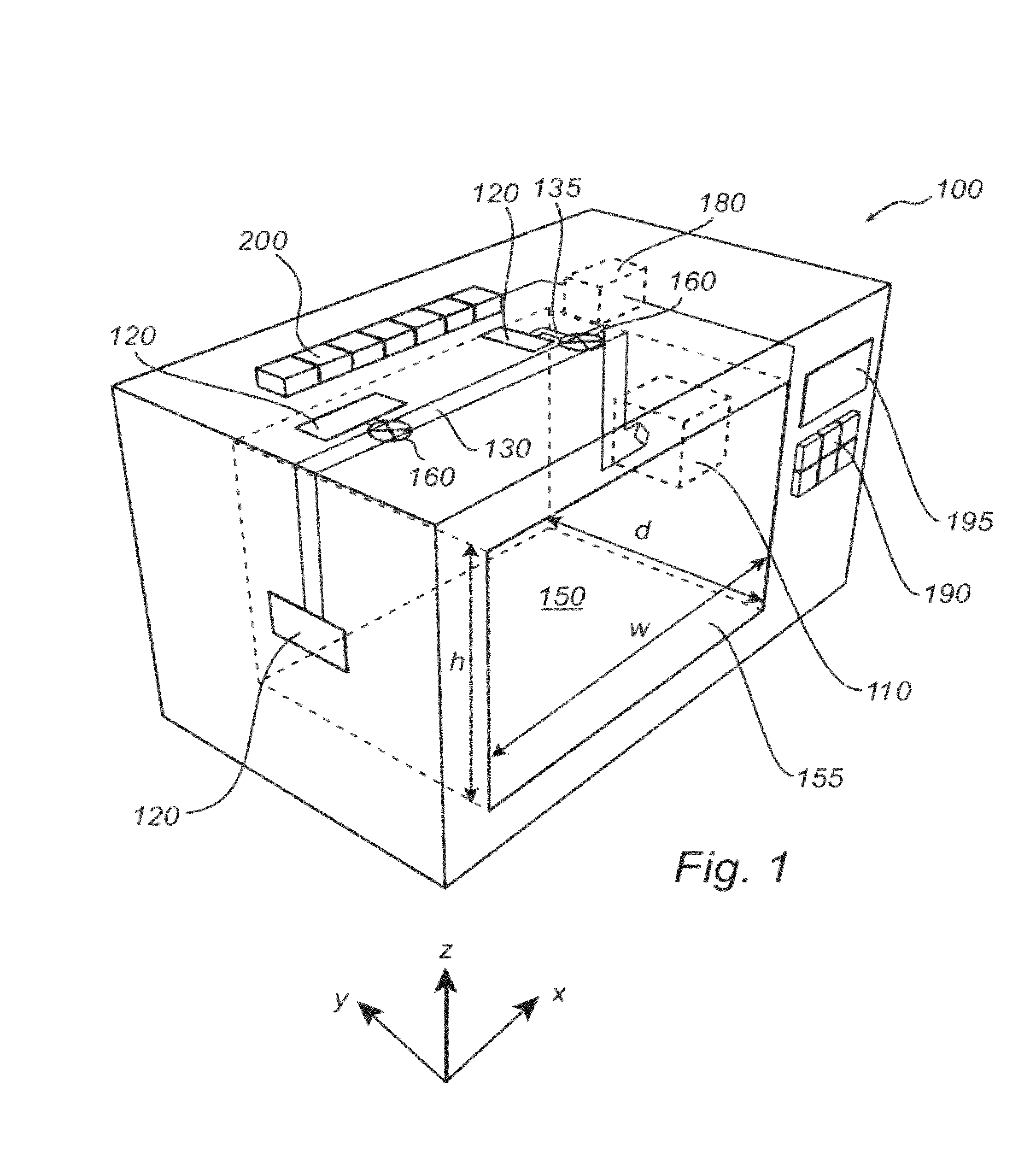

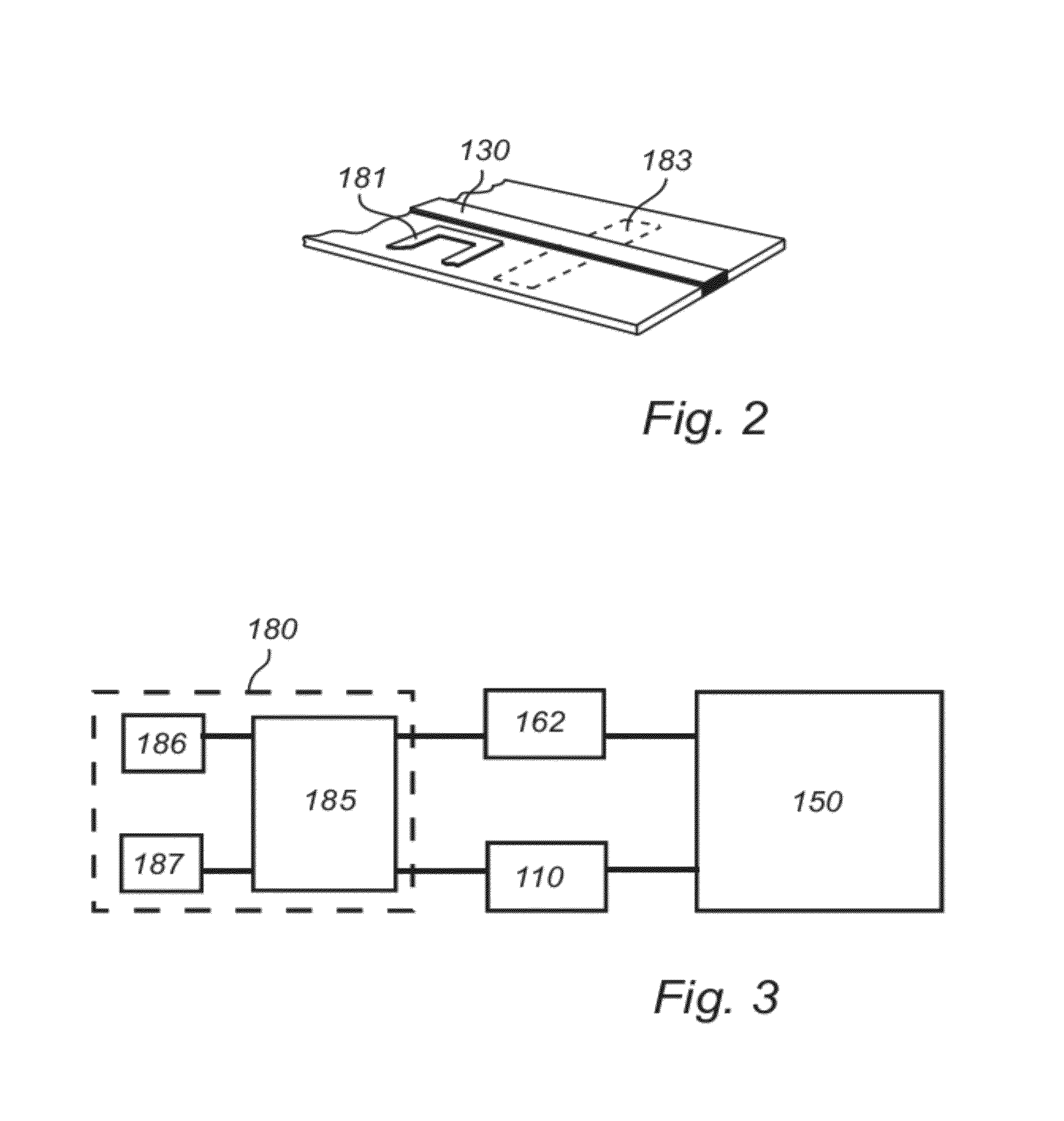

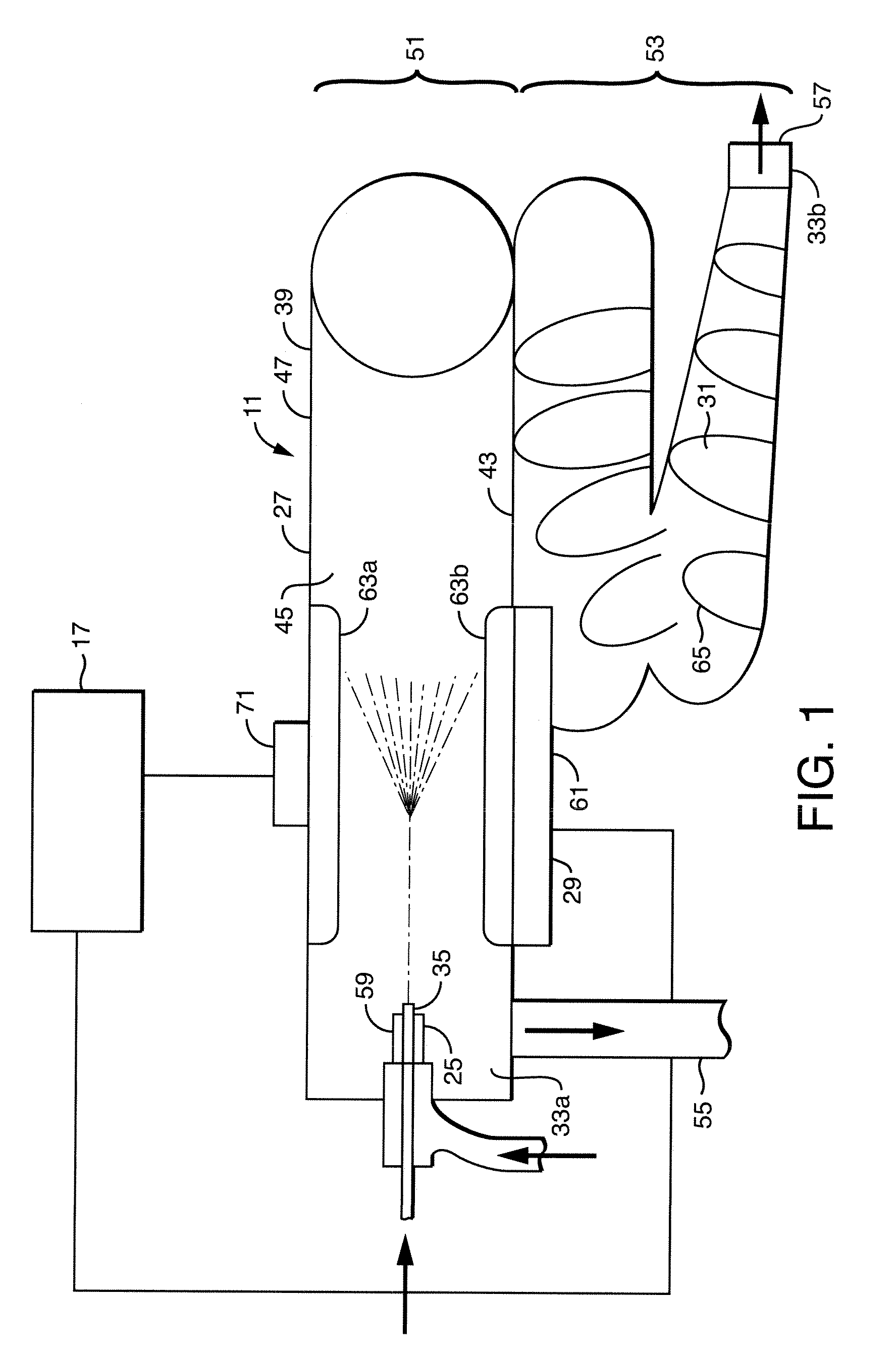

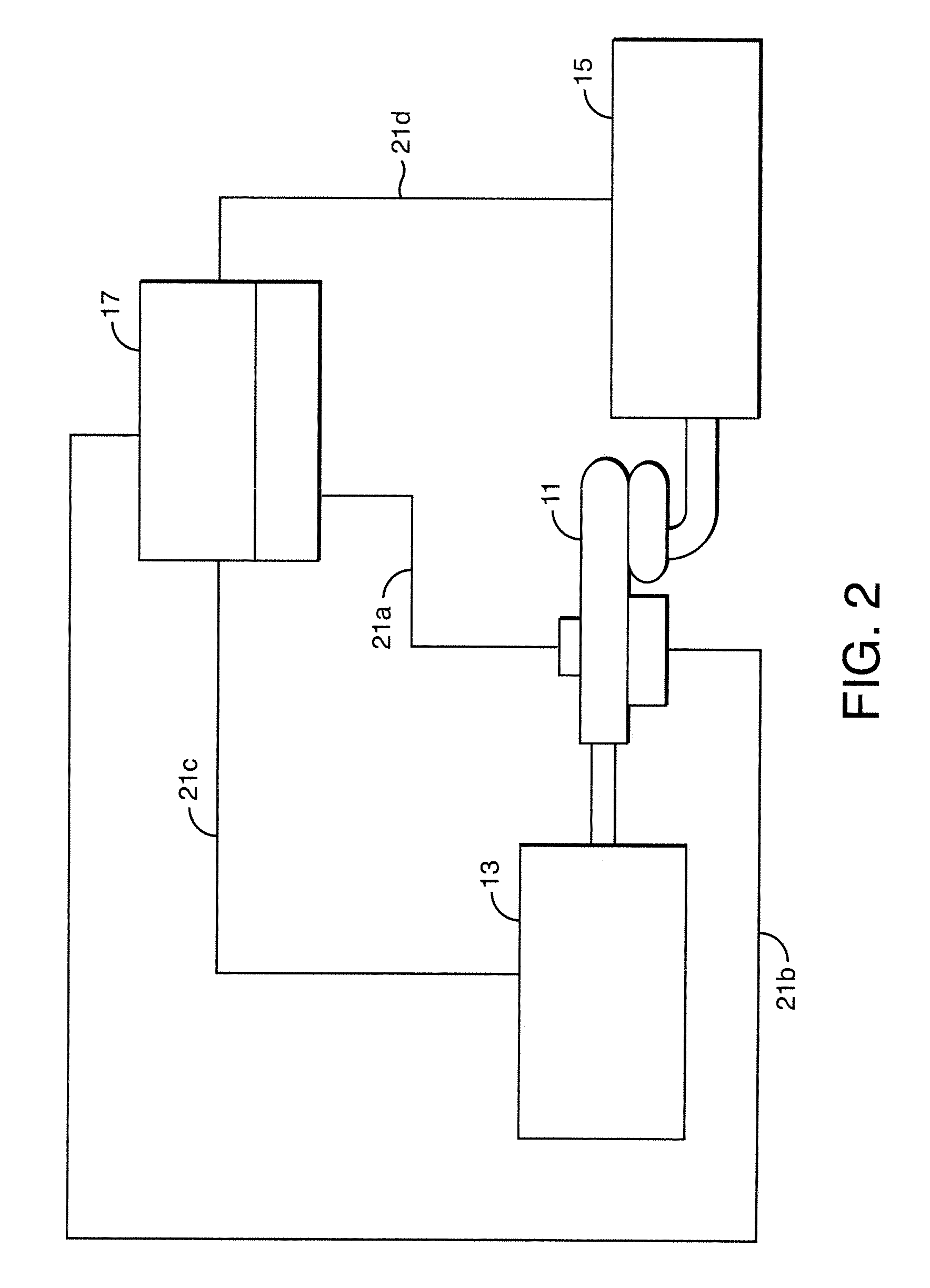

Microwave oven with a regulation system using field sensors

ActiveUS20100252551A1Improve energy efficiencyHigh sensitivityDielectric heating circuitsMicrowave heatingMicrowave ovenEngineering

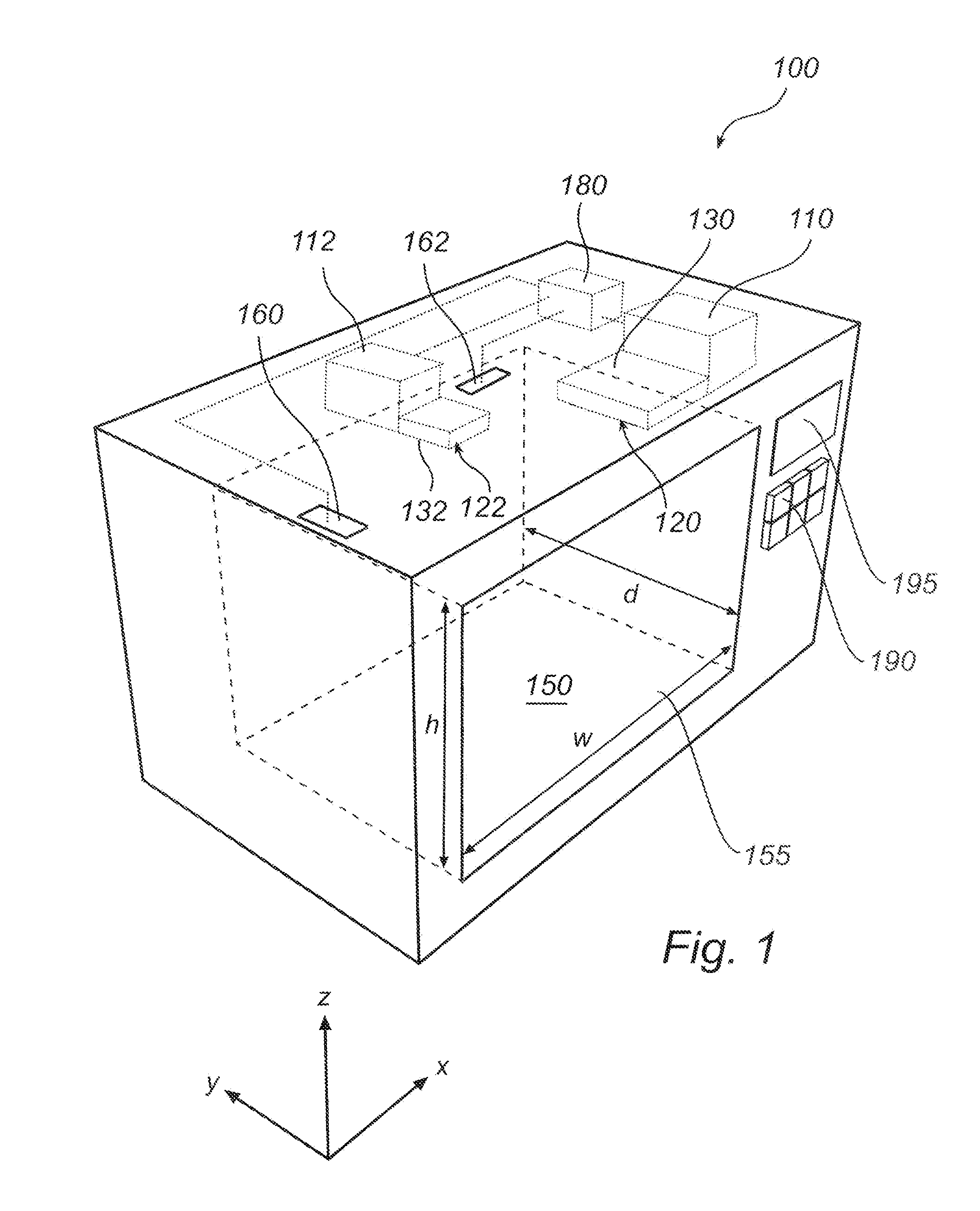

A microwave heating device and a method for heating a load using microwaves are provided. The microwave heating device comprises a cavity adapted to receive a load and at least two microwave sources for feeding microwave energy into the cavity through at least two feeding ports respectively. The microwave heating device further comprises at least two field sensors adapted to measure field strengths of the microwave energy in the cavity. A first field sensor is arranged at a first location for measuring the field strength representative of a mode fed from a first feeding port and a second field sensor is arranged at a second location for measuring the field strength representative of a mode fed from a second feeding port. The microwave heating device further comprises a control unit connected to the microwave sources and the field sensors for regulating the microwave sources based on the measured field strengths. The present invention is advantageous in that it enables uniform heating of the load in the cavity.

Owner:WHIRLPOOL CORP

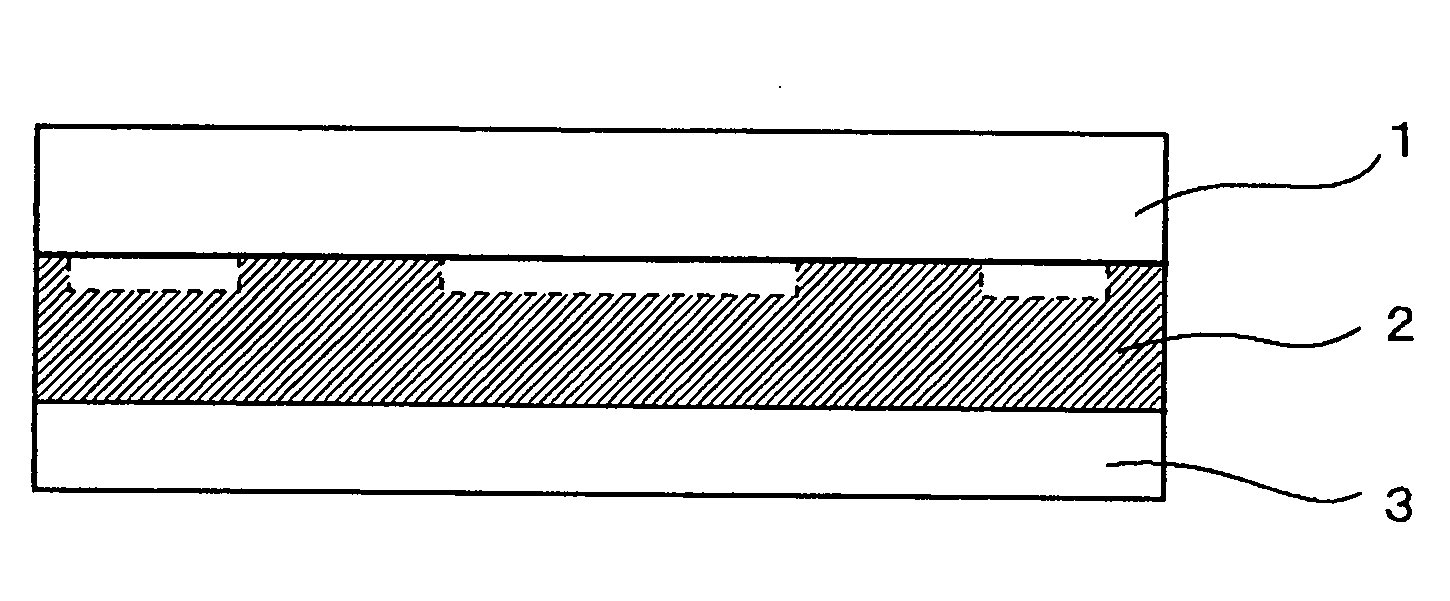

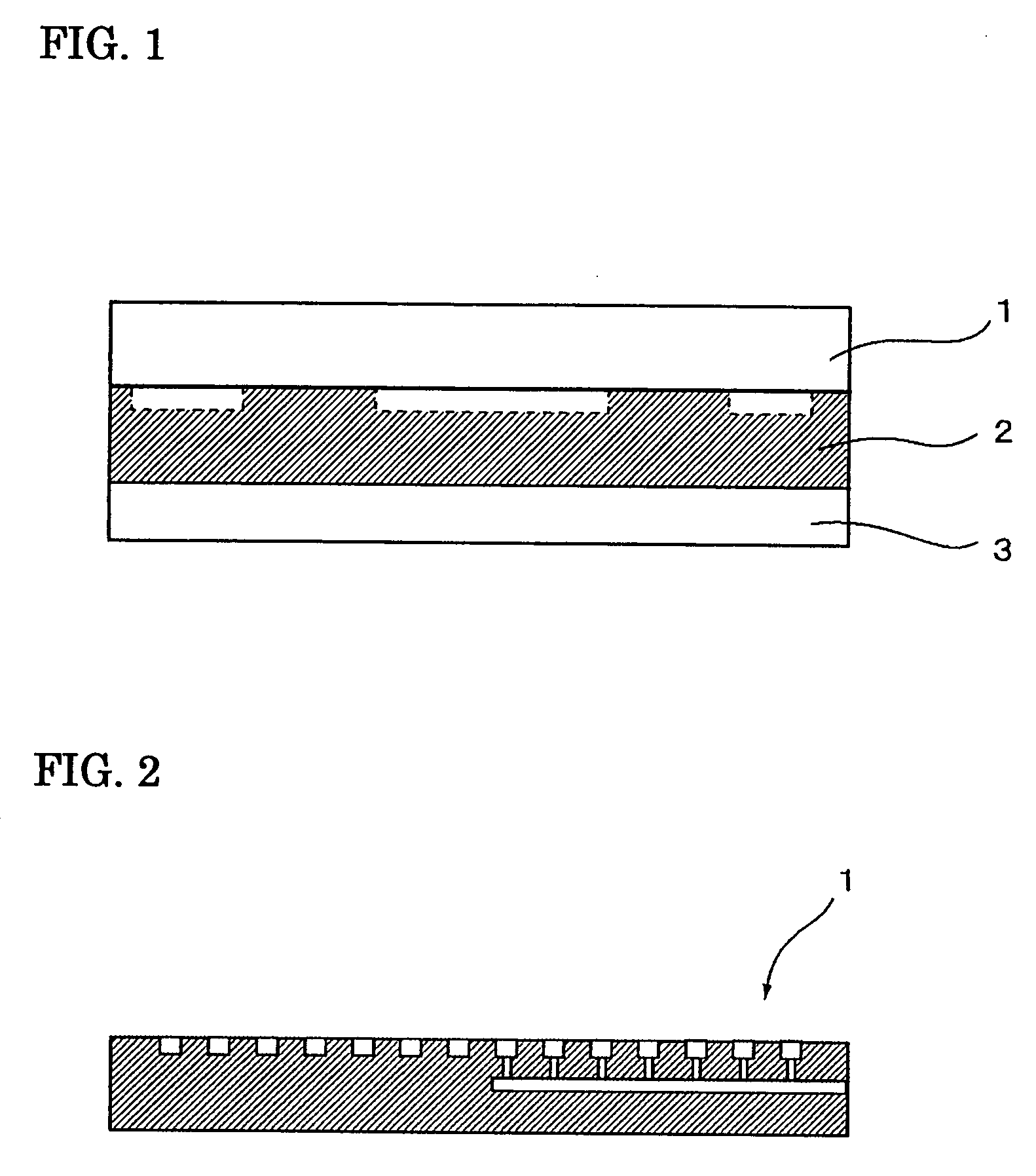

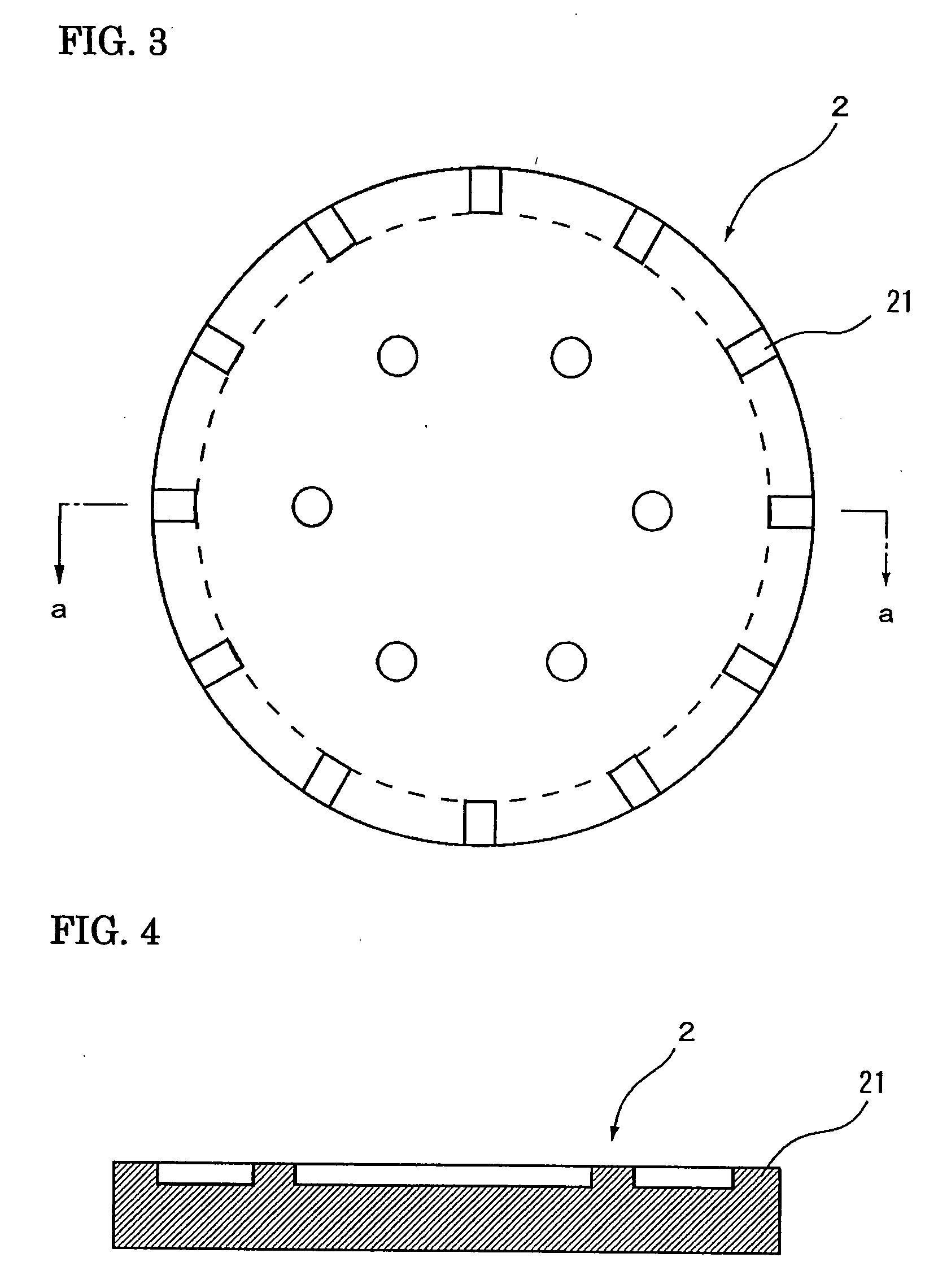

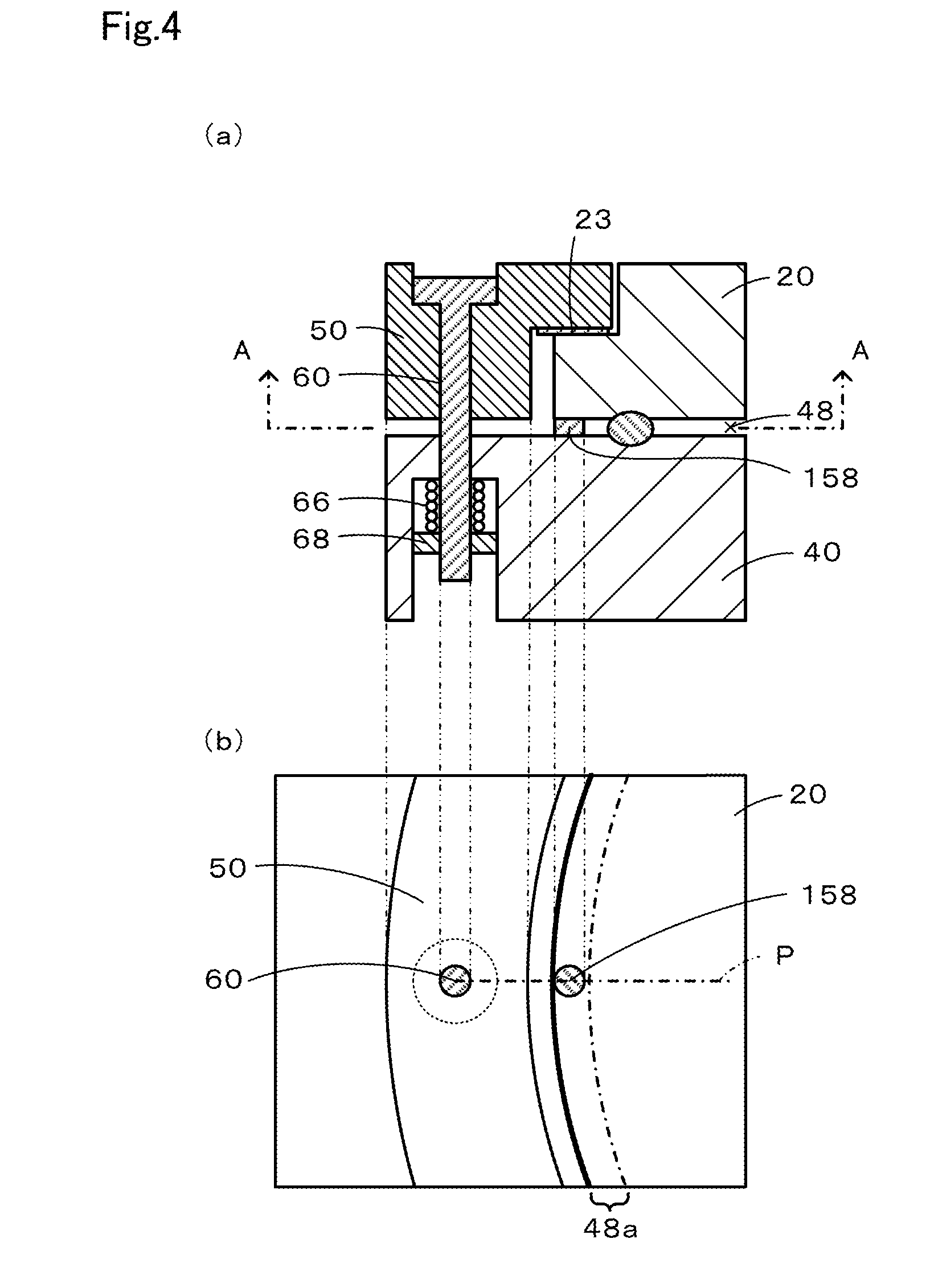

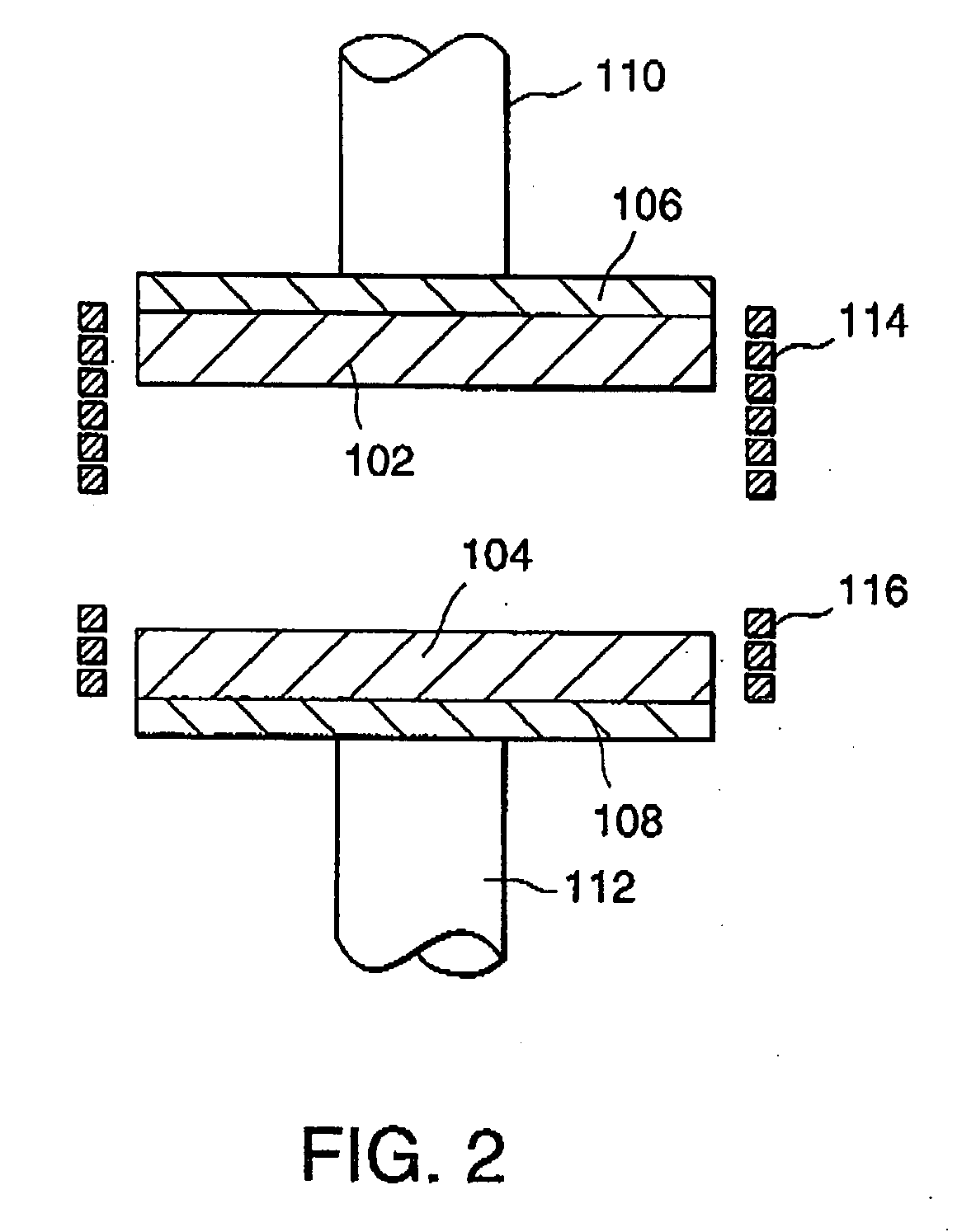

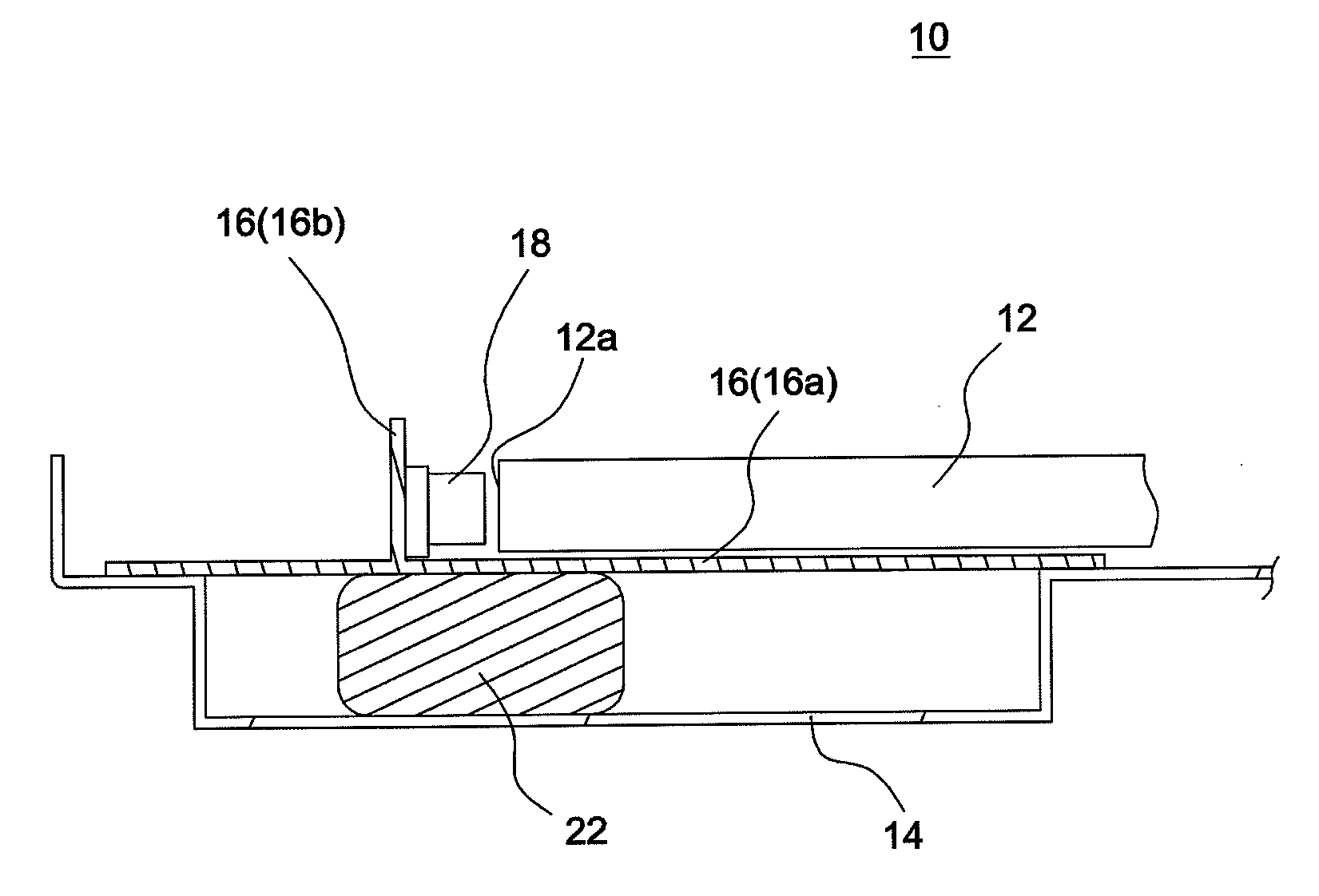

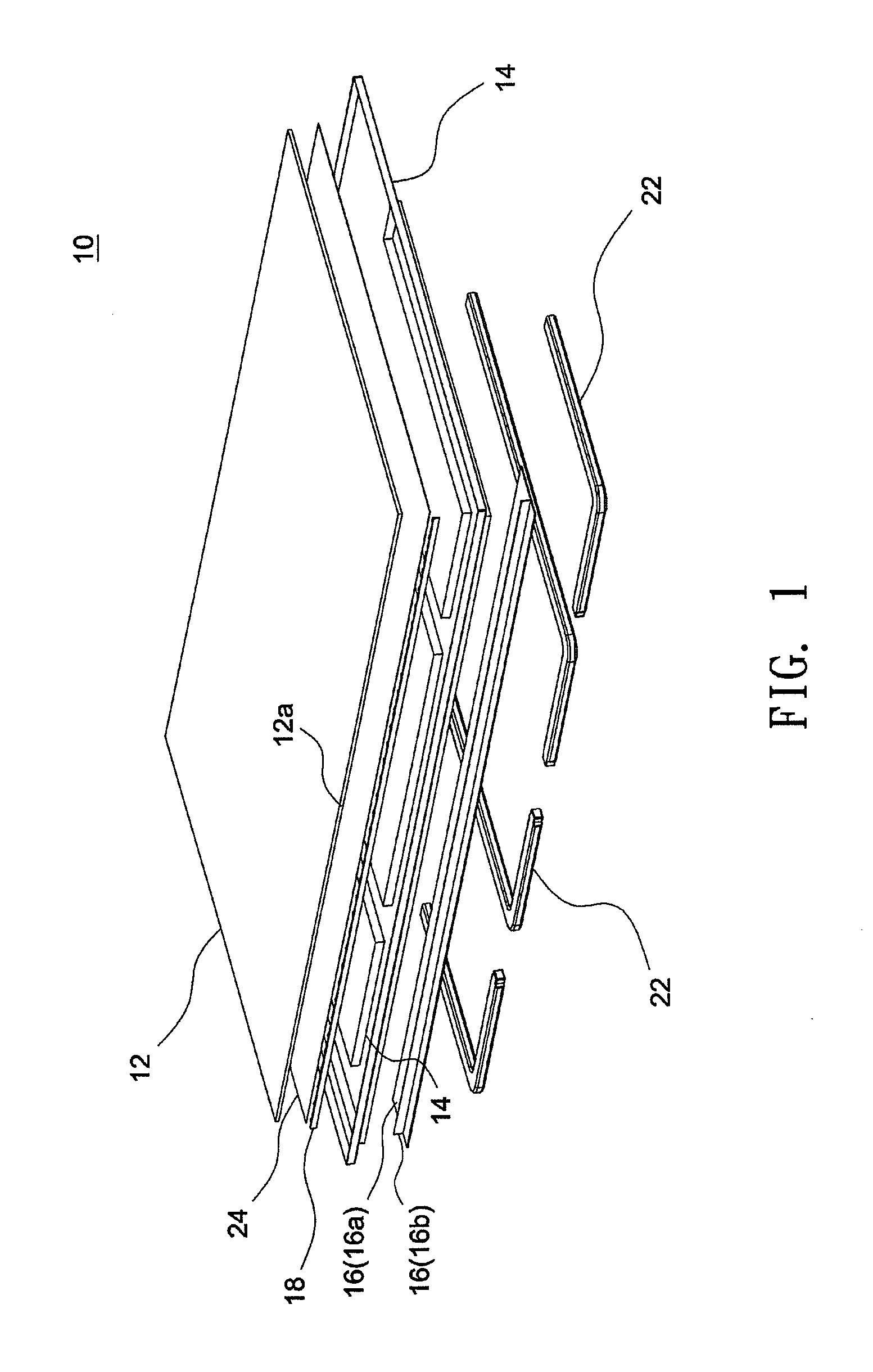

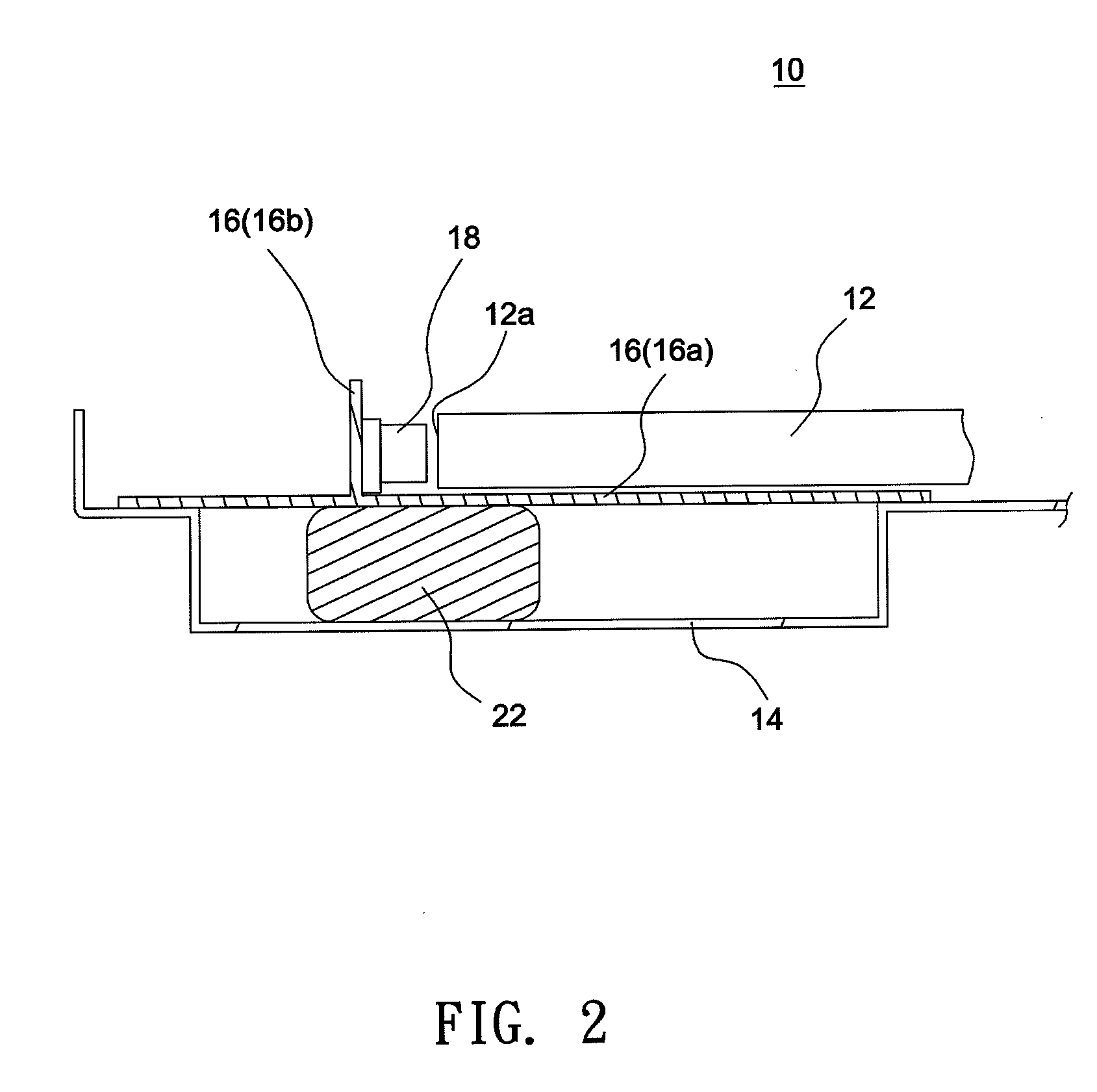

Member for semiconductor manufacturing apparatus

ActiveUS20130286533A1Improve thermal uniformityEasy constructionSemiconductor/solid-state device manufacturingElectrostatic holding devicesManufactured apparatusSemiconductor

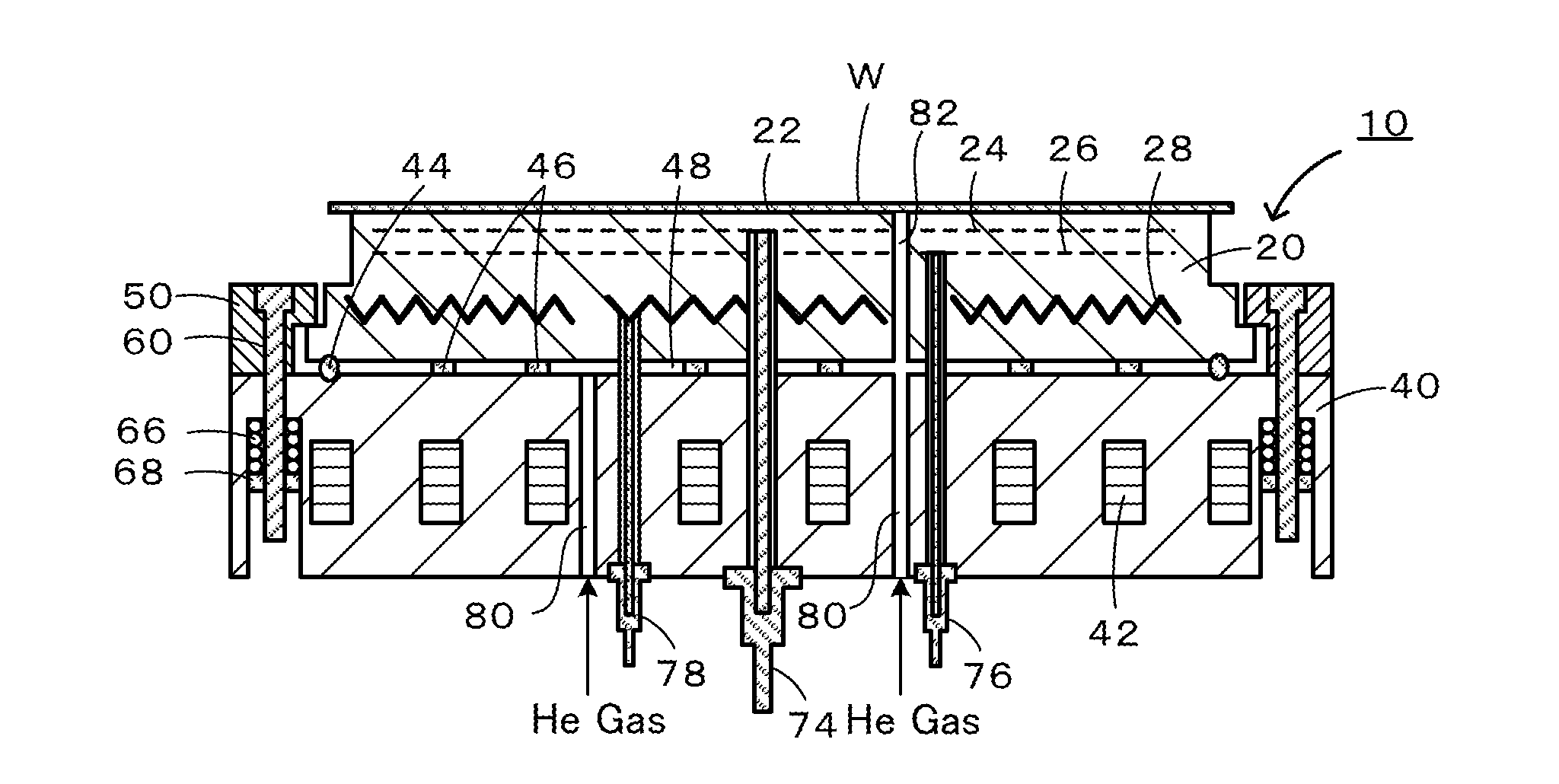

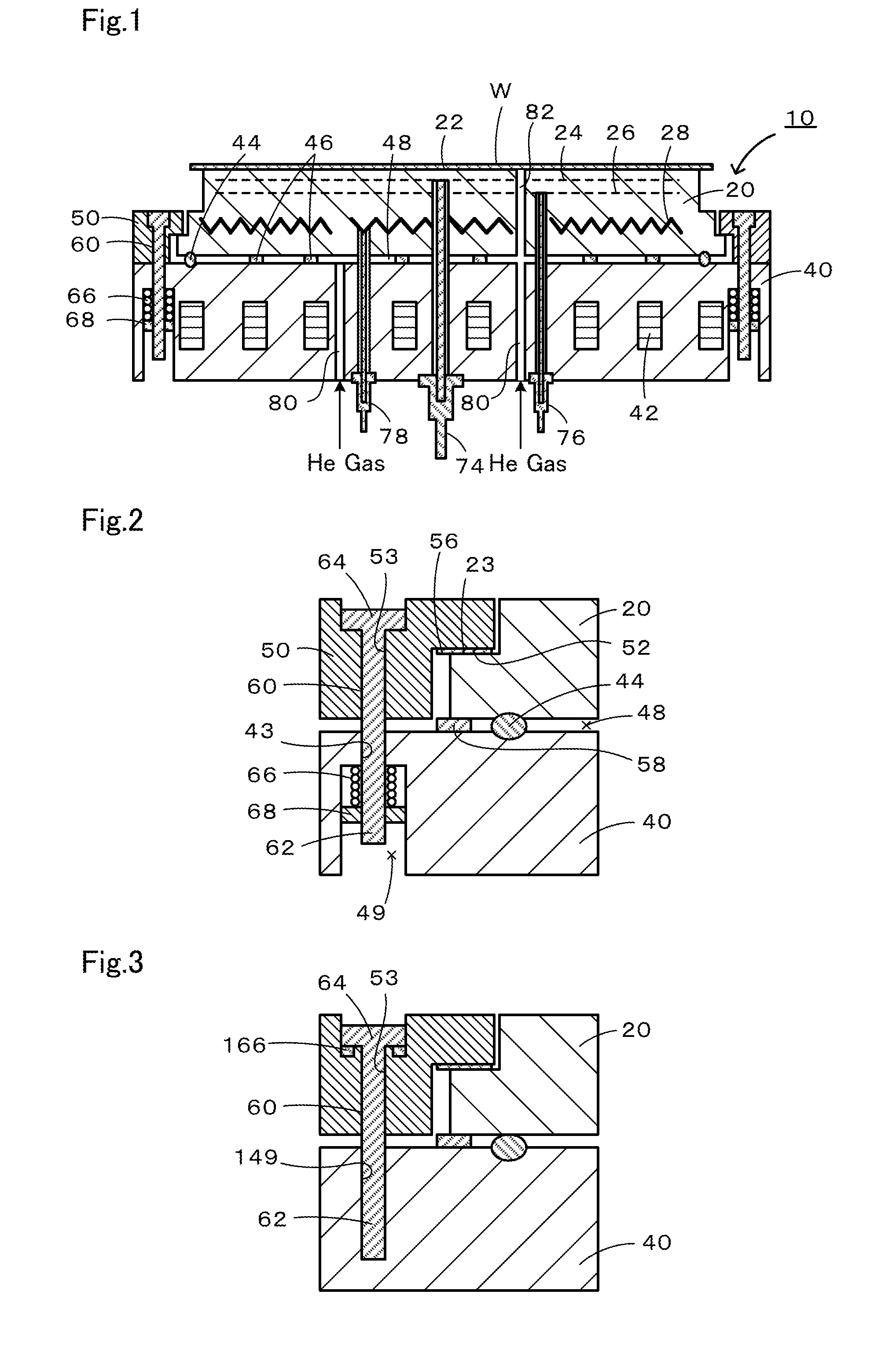

A member 10 for a semiconductor manufacturing apparatus includes an electrostatic chuck 20, a cooling unit 40, a spacer (an O-ring 44, an outer periphery spacer 58, or the like) for securing a gap 48 placed between the electrostatic chuck 20 and the cooling unit 40, and a clamp ring 50 placed on the upper surface of the outer periphery of the electrostatic chuck 20. The clamp ring 50 is fastened to the cooling unit 40 with screws 60. The screws 60 are inserted into coil springs 66 that prevent loosening, and are fastened to nuts 68. The coil springs 66 are attached not to the clamp ring side but to the cooling unit side.

Owner:NGK INSULATORS LTD

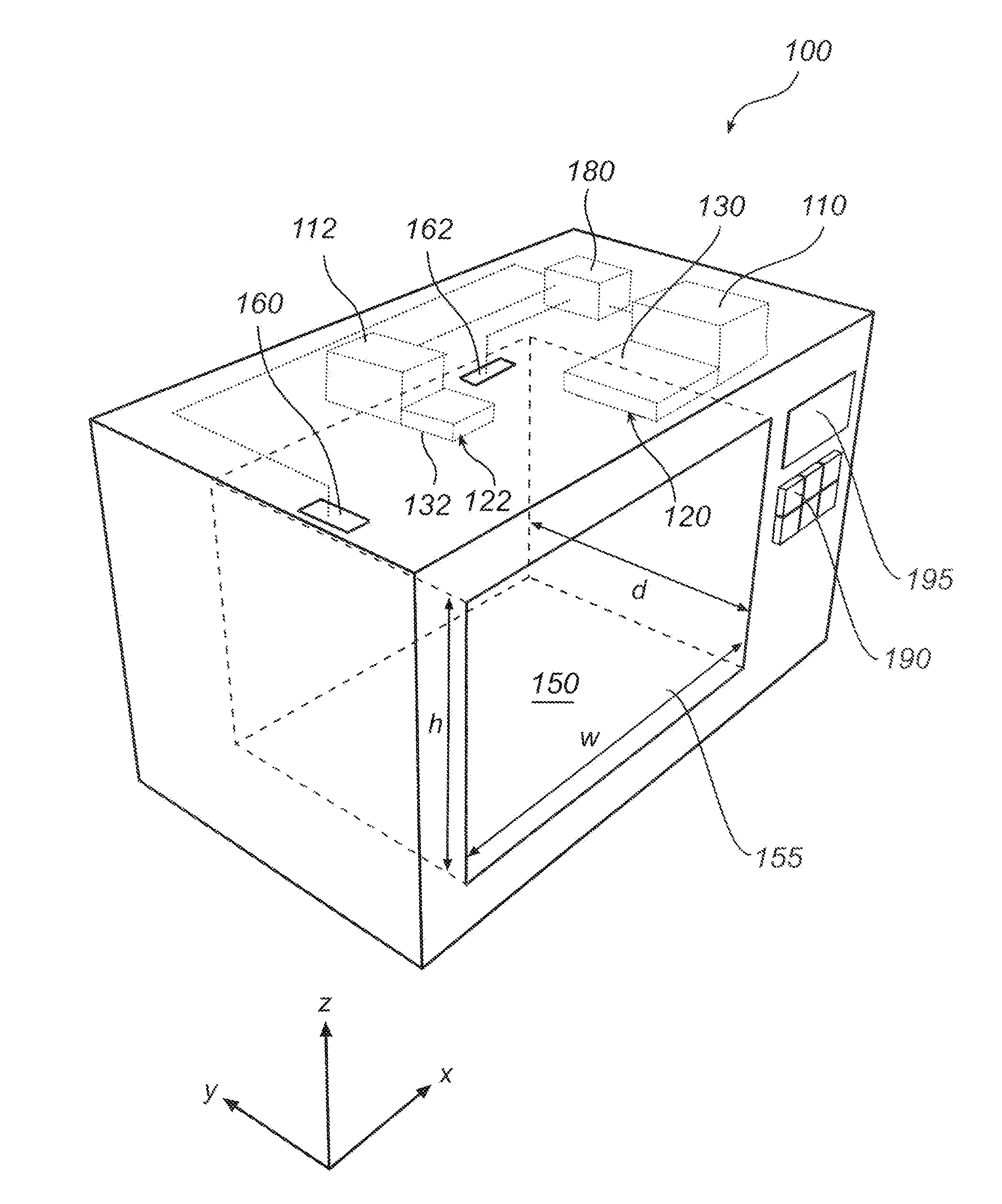

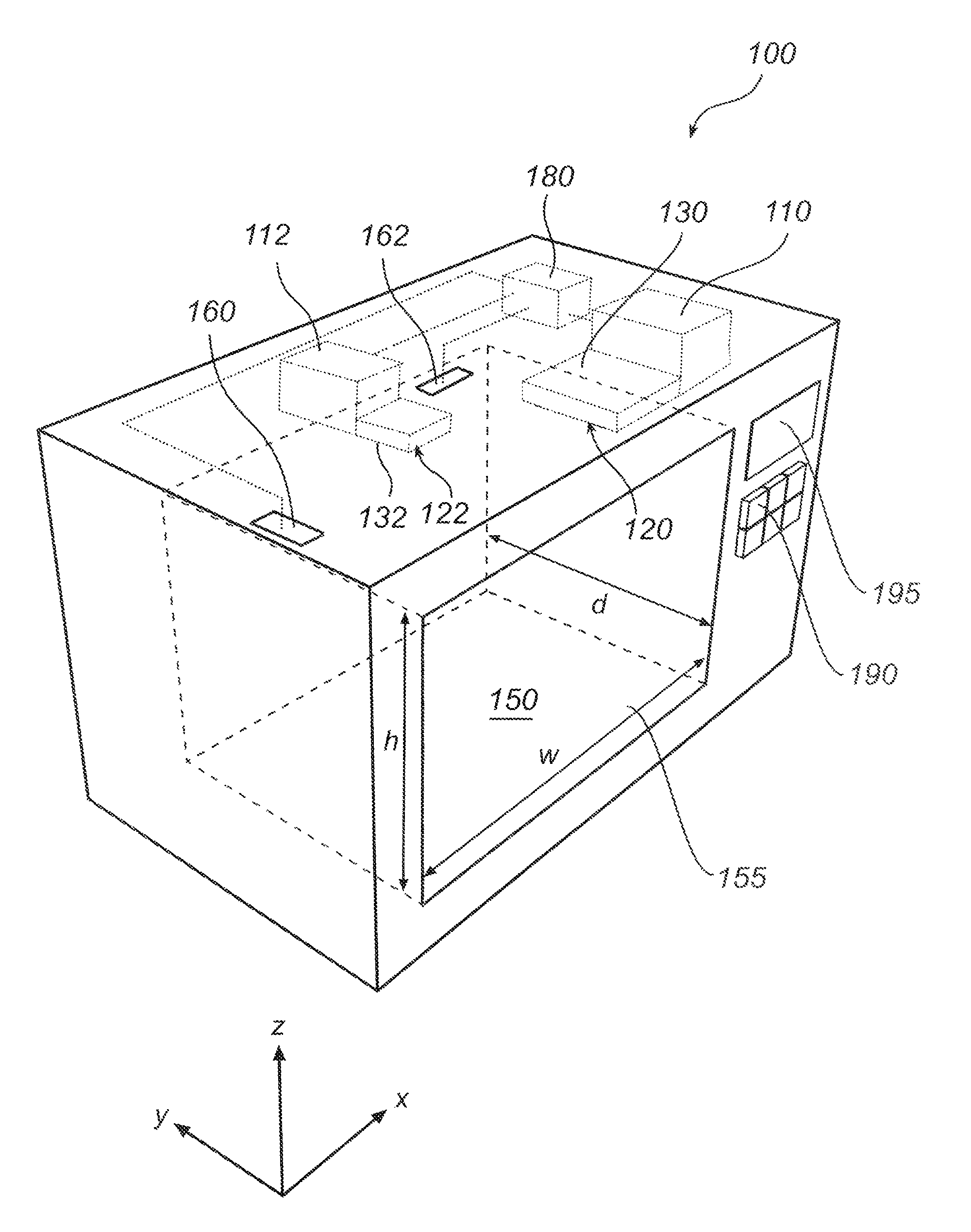

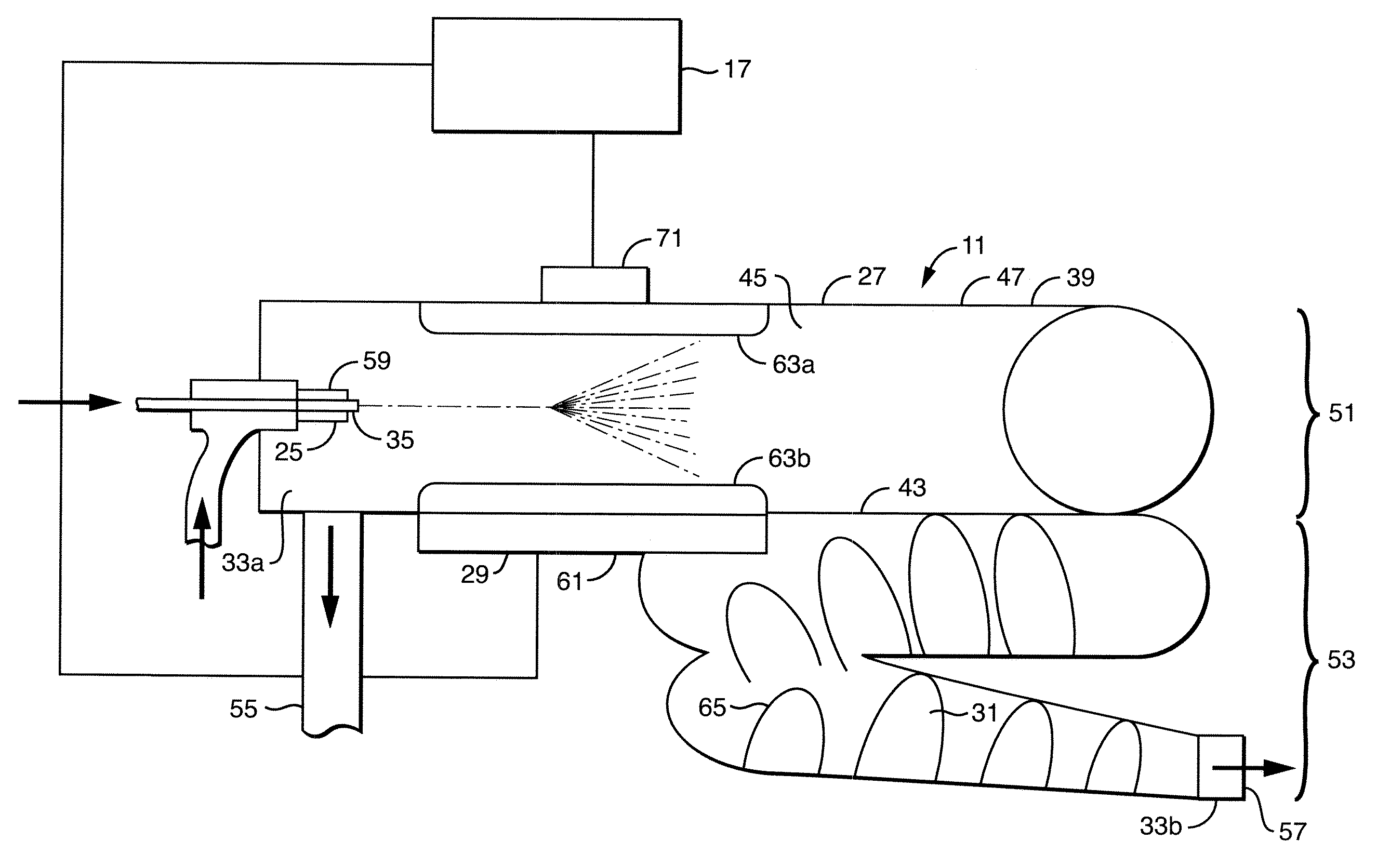

Microwave oven with a regulation system using field sensors

ActiveUS8338763B2Improve thermal uniformityHigh sensitivityDielectric heating circuitsMicrowave heatingMicrowave ovenField strength

A microwave heating device and a method for heating a load using microwaves are provided. The microwave heating device comprises a cavity adapted to receive a load and at least two microwave sources for feeding microwave energy into the cavity through at least two feeding ports respectively. The microwave heating device further comprises at least two field sensors adapted to measure field strengths of the microwave energy in the cavity. A first field sensor is arranged at a first location for measuring the field strength representative of a mode fed from a first feeding port and a second field sensor is arranged at a second location for measuring the field strength representative of a mode fed from a second feeding port. The microwave heating device further comprises a control unit connected to the microwave sources and the field sensors for regulating the microwave sources based on the measured field strengths. The present invention is advantageous in that it enables uniform heating of the load in the cavity.

Owner:WHIRLPOOL CORP

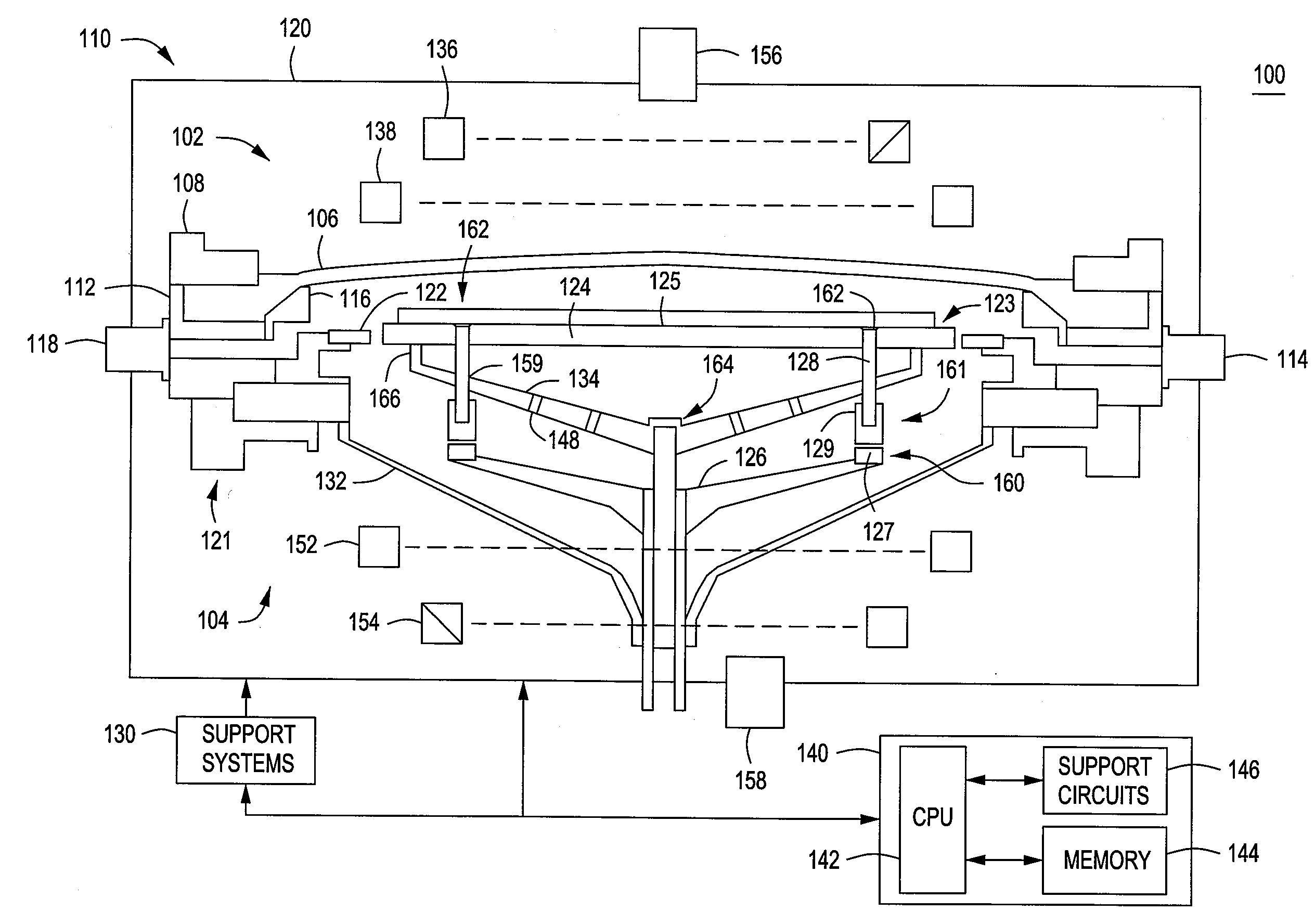

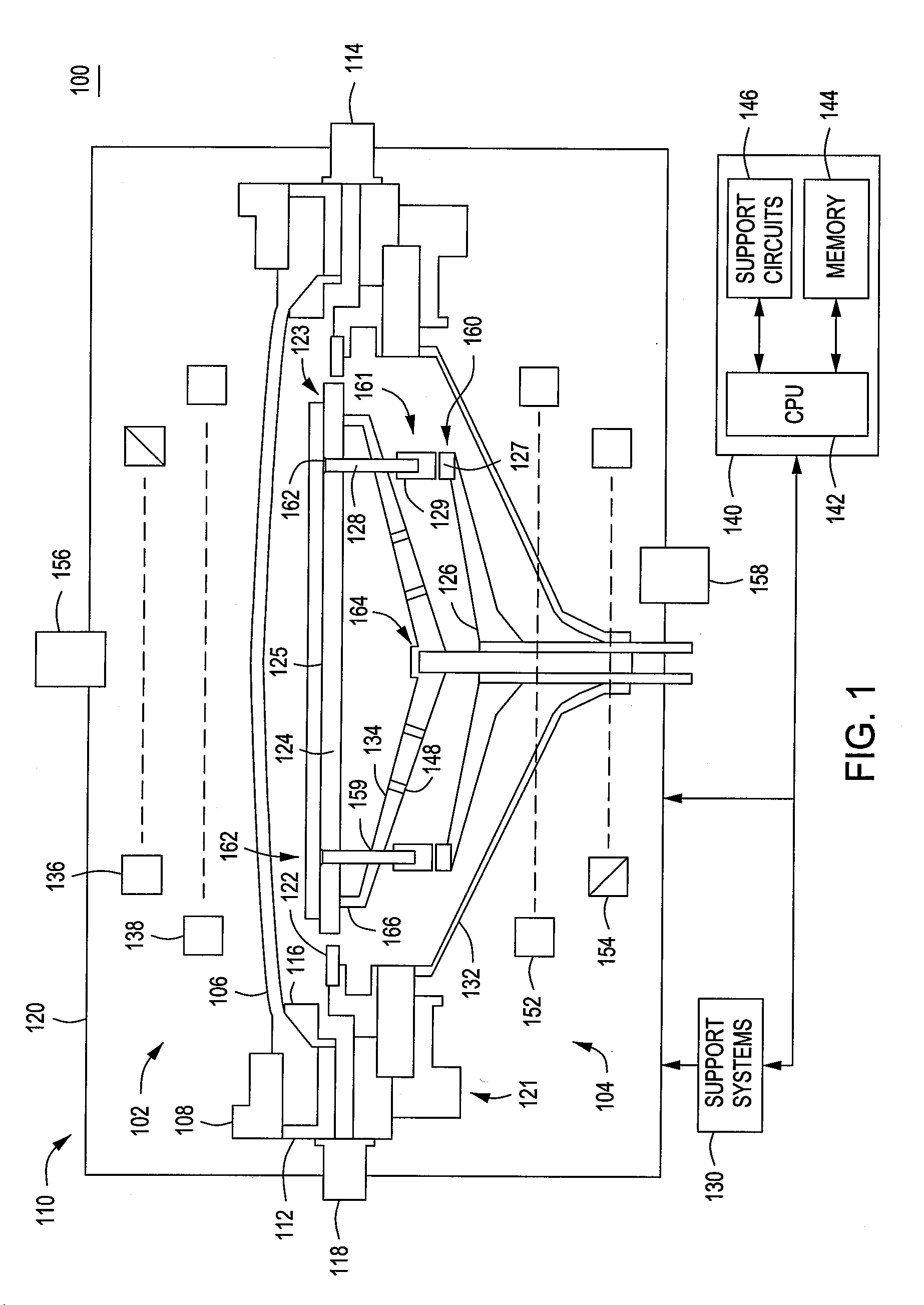

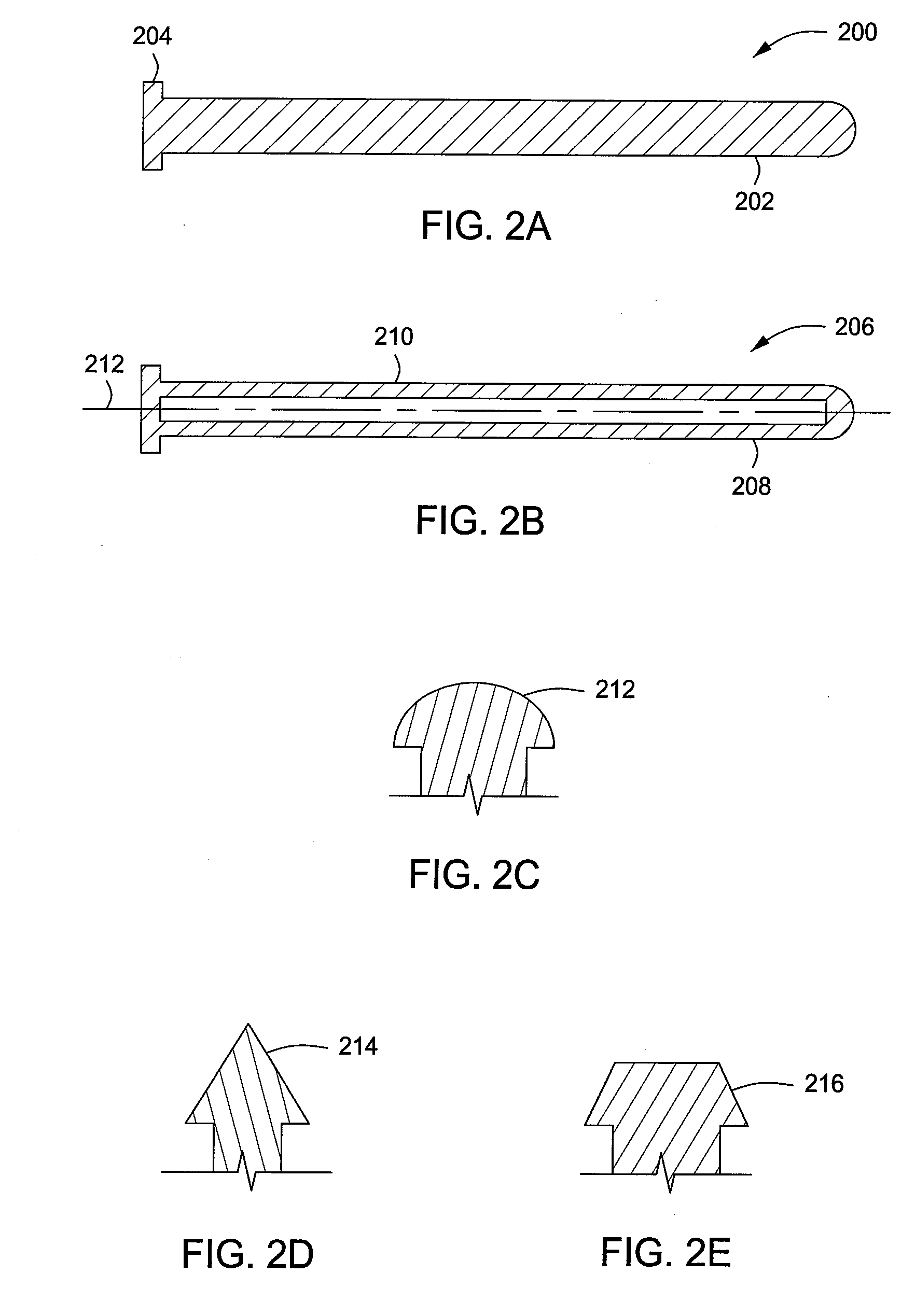

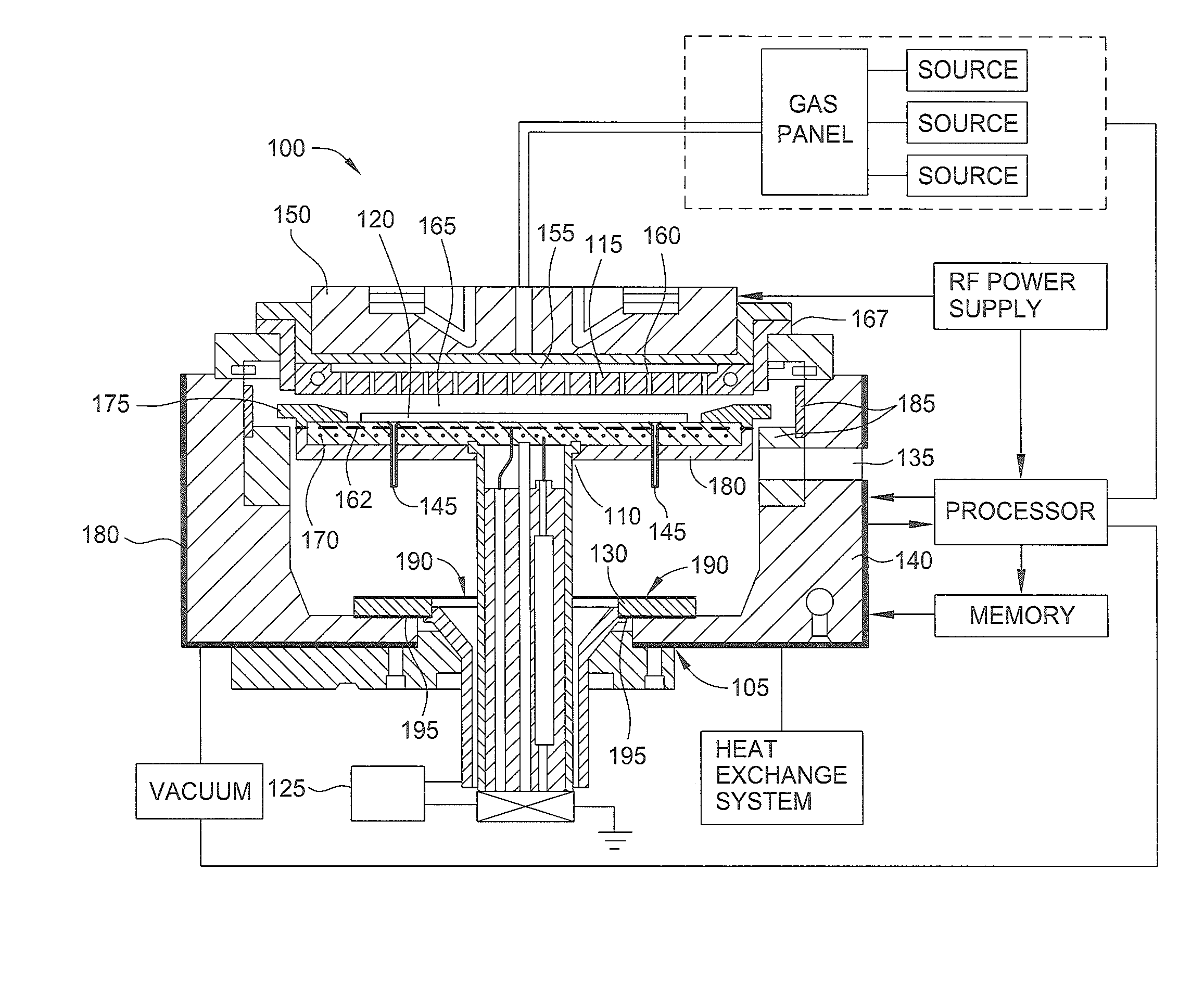

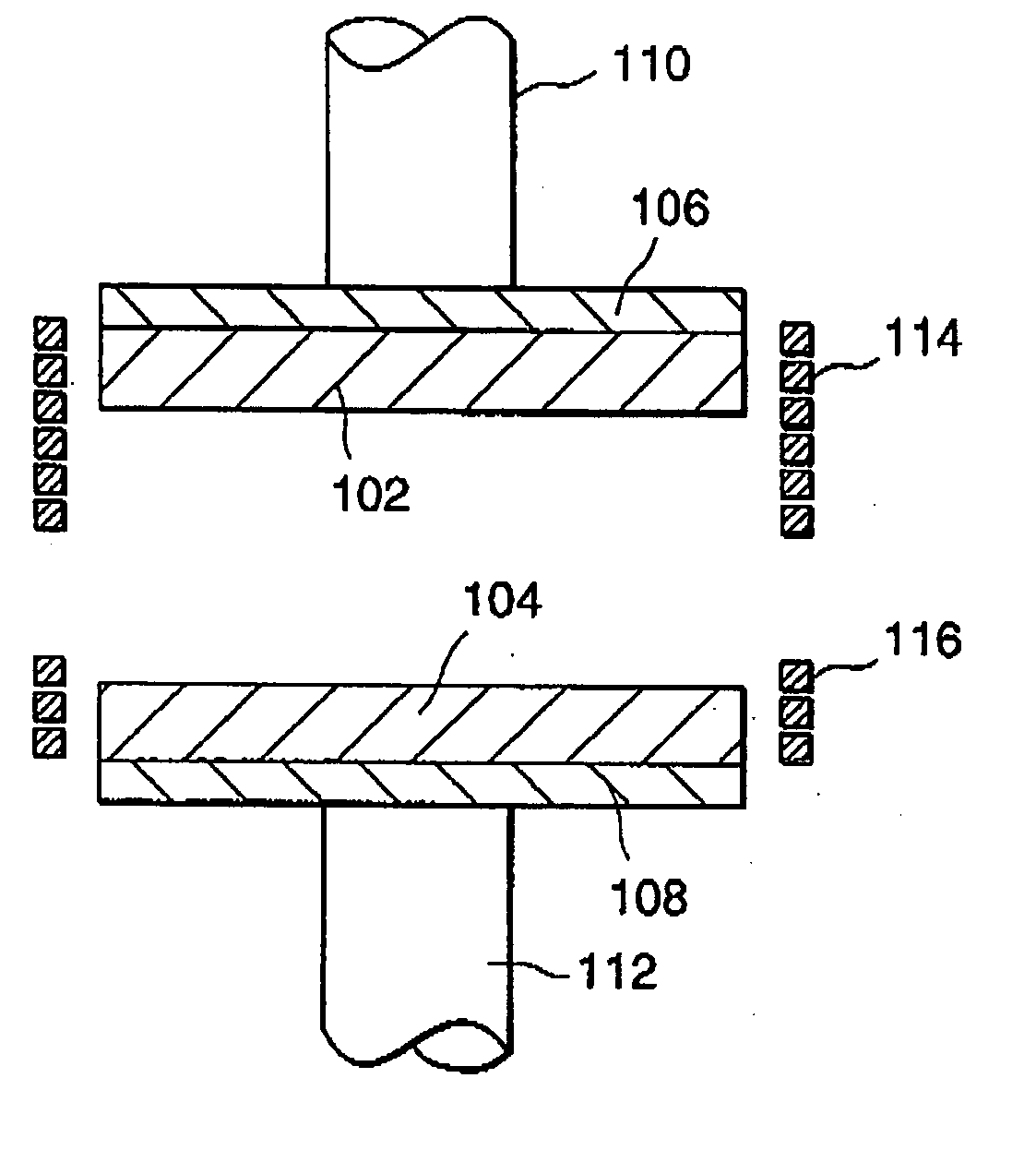

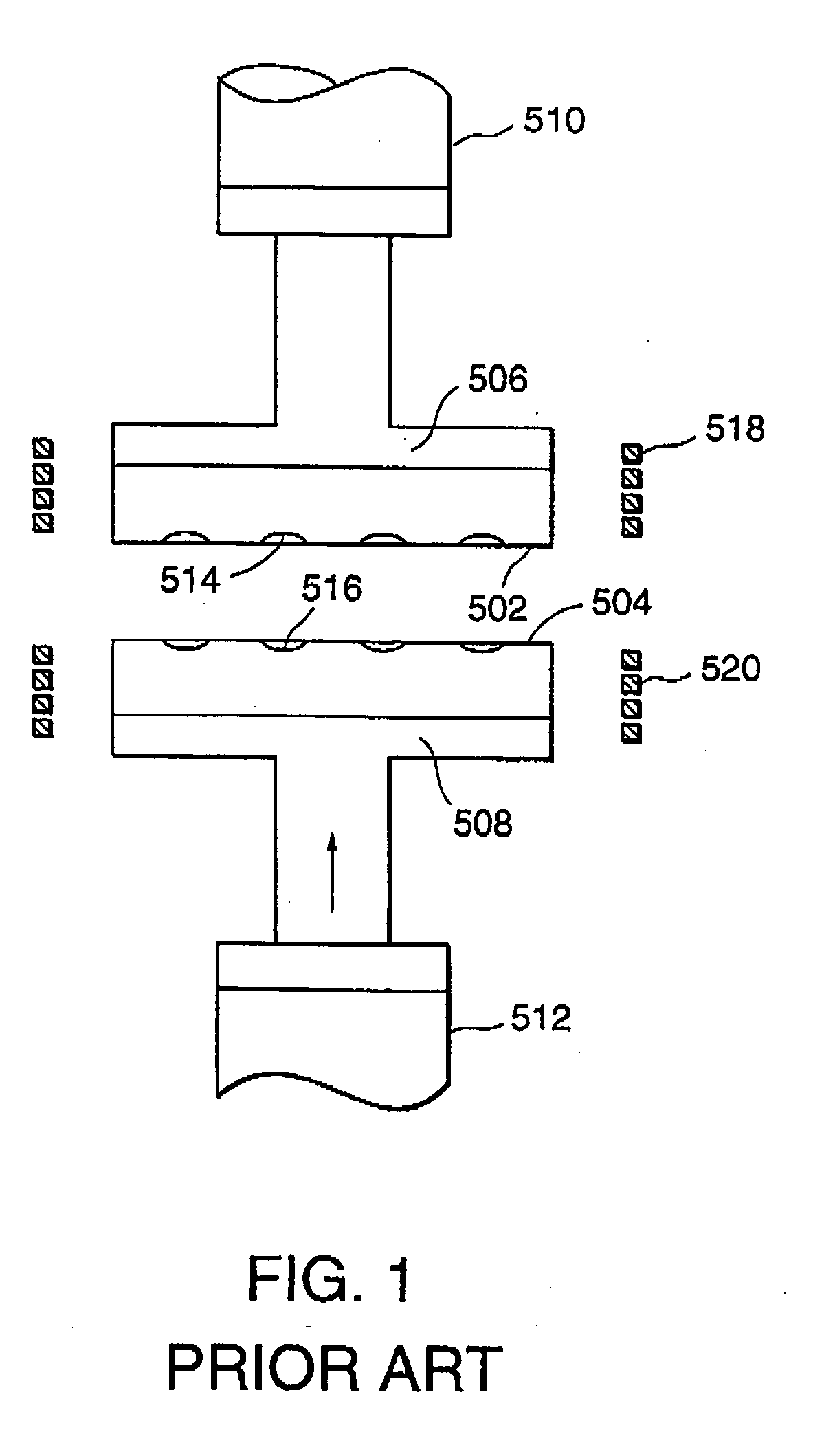

Methods and apparatus for improved azimuthal thermal uniformity of a substrate

InactiveUS20100086784A1Improve thermal uniformityLiquid surface applicatorsLayered productsSusceptorEngineering

Methods and apparatus for providing an improved azimuthal thermal uniformity of a substrate are provided herein. In some embodiments, a substrate support for use in a semiconductor process chamber includes a susceptor plate; and a supporting member to support a backside of the susceptor plate proximate an outer edge thereof, wherein the supporting member substantially covers the backside of the susceptor plate. In some embodiments, the substrate support is disposed in a process chamber having at least some lamps disposed below the supporting member and utilized for heating the back side of the susceptor plate.

Owner:APPLIED MATERIALS INC

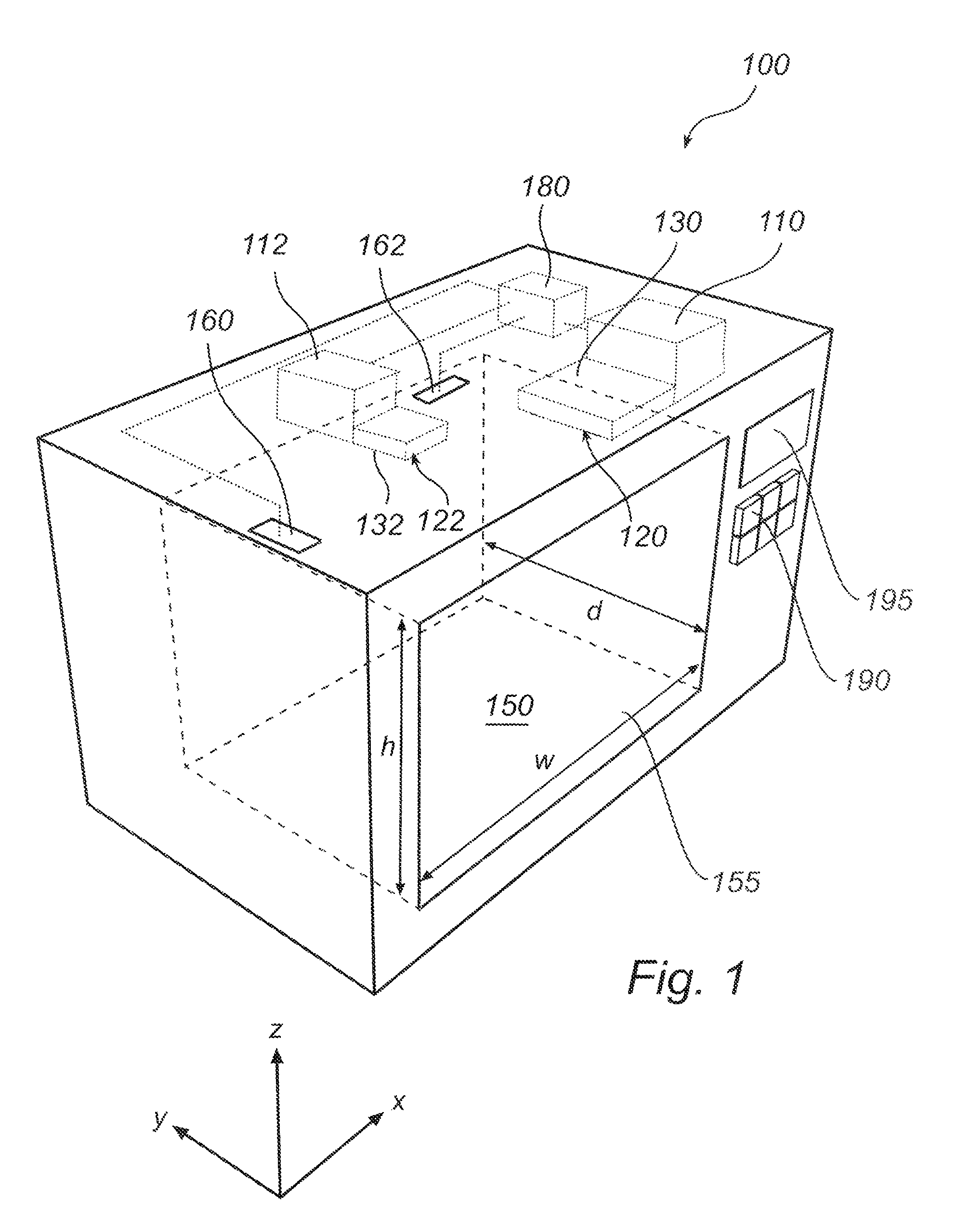

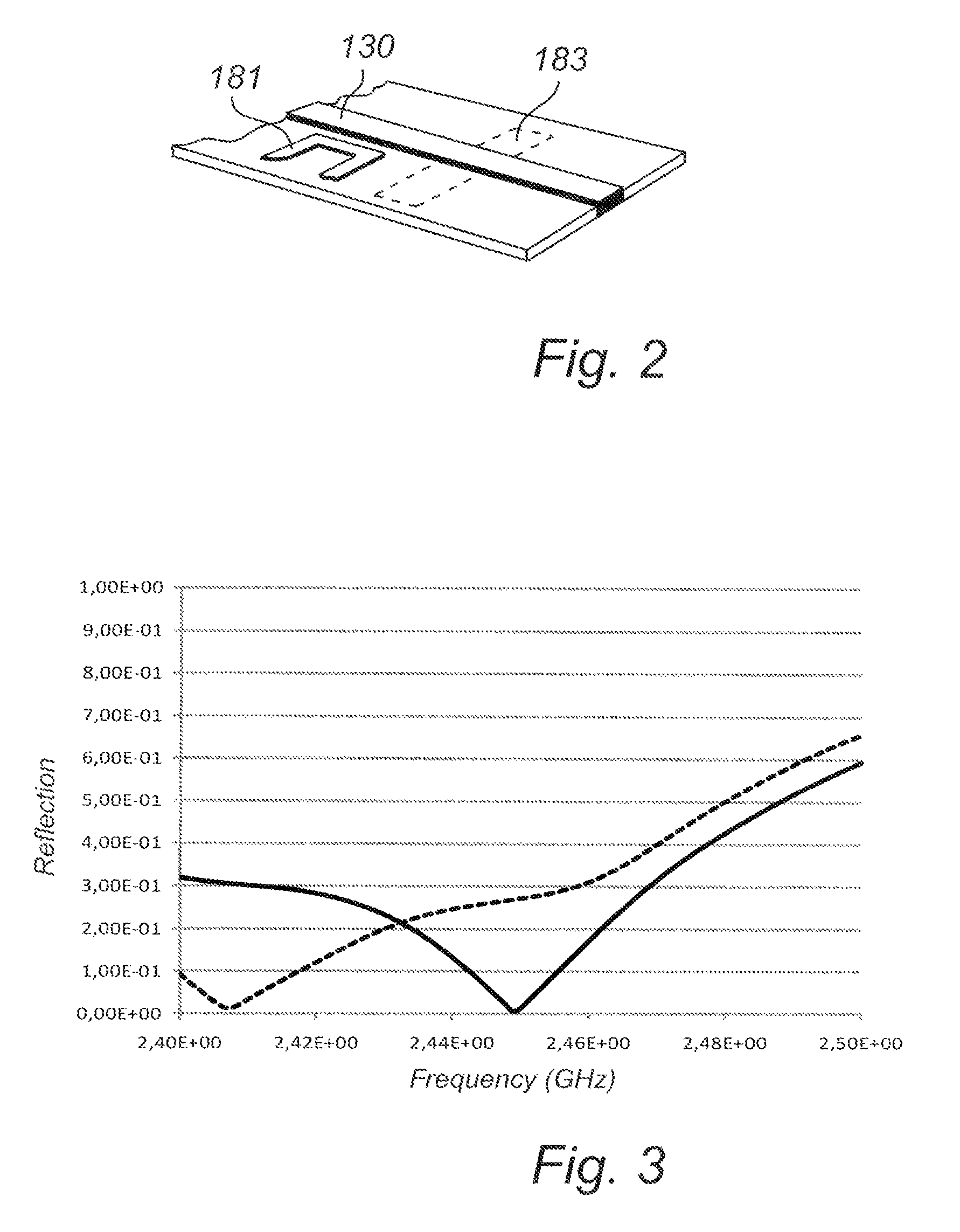

Microwave oven switching between predefined modes

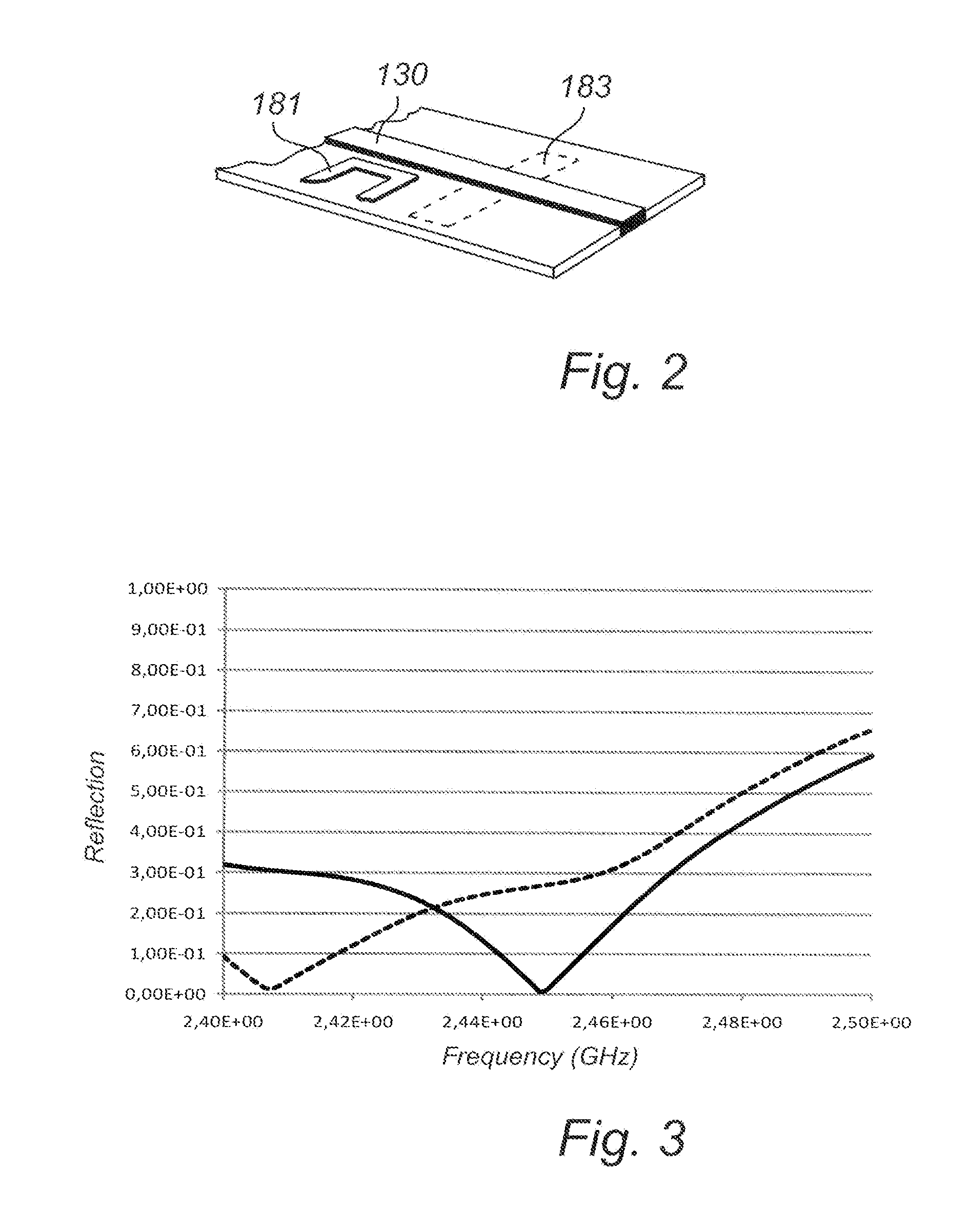

ActiveUS8324540B2Improve thermal uniformityHeating evenlyDielectric heating circuitsMicrowave heatingMicrowave ovenResonance

A microwave oven and method for heating a load using microwaves are provided. The microwave oven comprises a cavity adapted to receive a load. The cavity is designed to support at least two predefined mode fields. For each predefined mode field, a resonance frequency in the cavity is known. Further, the microwave oven comprises a frequency-controllable microwave source for feeding microwaves into the cavity via at least one feeding port. The method comprises the steps of measuring a signal reflected from the cavity as a function of the operating frequency of the microwave source and identifying resonance frequencies in the cavity based on the measured signal. Further, the method comprises the steps of selecting, for the predefined modes, at least two of the identified resonance frequencies based on the known resonance frequencies and switching the operating frequency of the microwave source using the selected frequencies. The present invention is advantageous in that it enables uniform heating of the load in the cavity.

Owner:WHIRLPOOL CORP

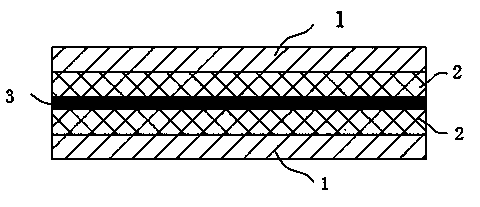

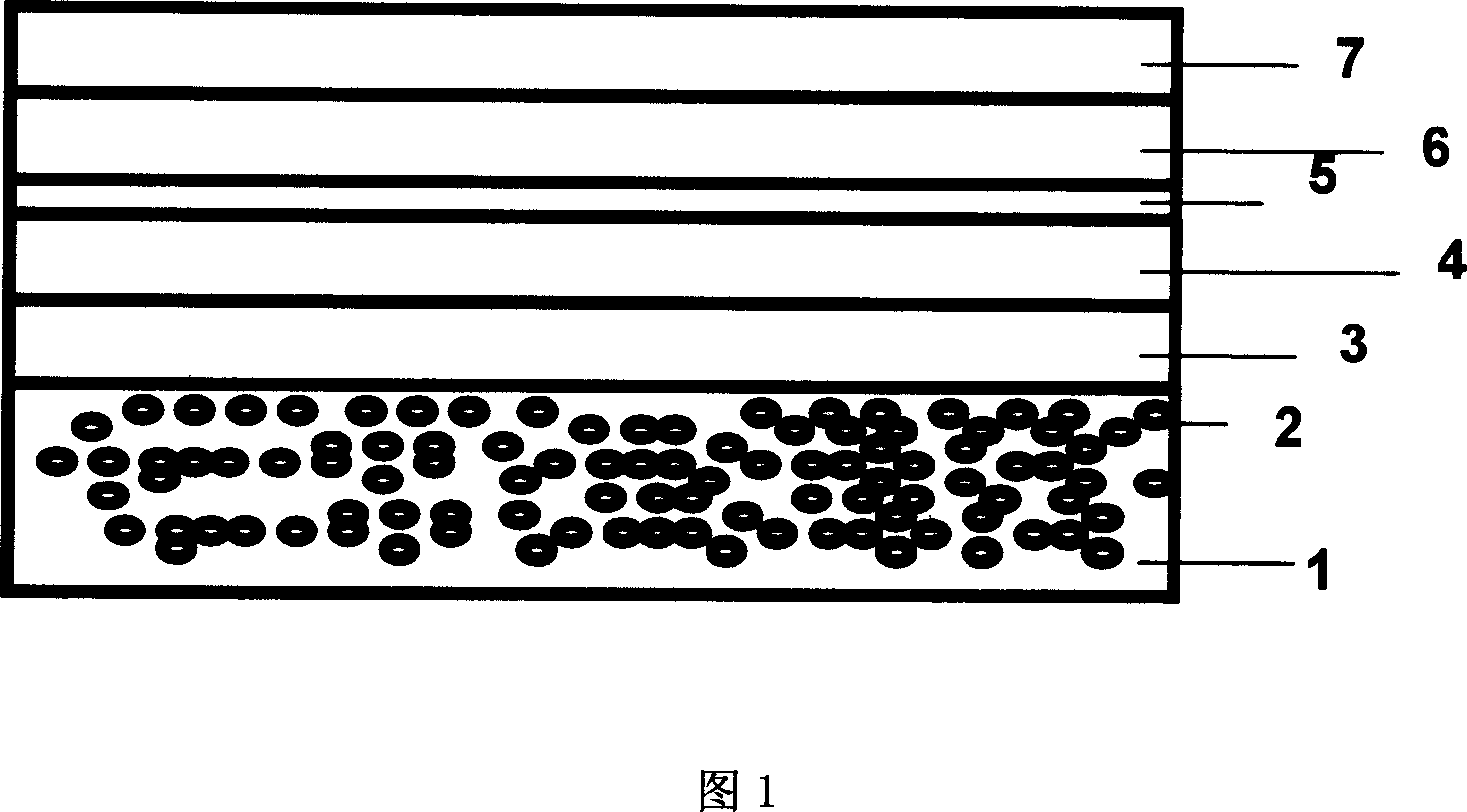

Heat conducting adhesive tape and preparation method thereof

InactiveCN104087186AImprove uniformityImprove thermal conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceMetal foil

The invention discloses a heat conducting adhesive tape and a preparation method thereof. The heat conducting adhesive tape adopts a metal foil as the substrate, the upper surface and the lower surface of the substrate are coated with a high performance heat conducting glue, and the outer layer of the heat conducting glue is release paper. The high performance heat conducting glue is composed of the following substances by weight part: 100 of an acrylic pressure-sensitive adhesive, 50-200 of a heat conducting filler, 0.1-1.5 of a coupling agent, 0.1-1.5 of a cross-linking agent, and 4-10 of a solvent. The preparation method includes the steps of pretreatment, glue preparation, coating, drying and the like. The heat conducting adhesive tape provided by the invention has the characteristics of good heat conducting uniformity, high heat conducting coefficient, high bonding strength, high temperature resistance and insulation, etc., and can be widely applied in bonding of LED, flexible circuit boards, microprocessors, printed circuit boards and the like with heat radiating devices.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

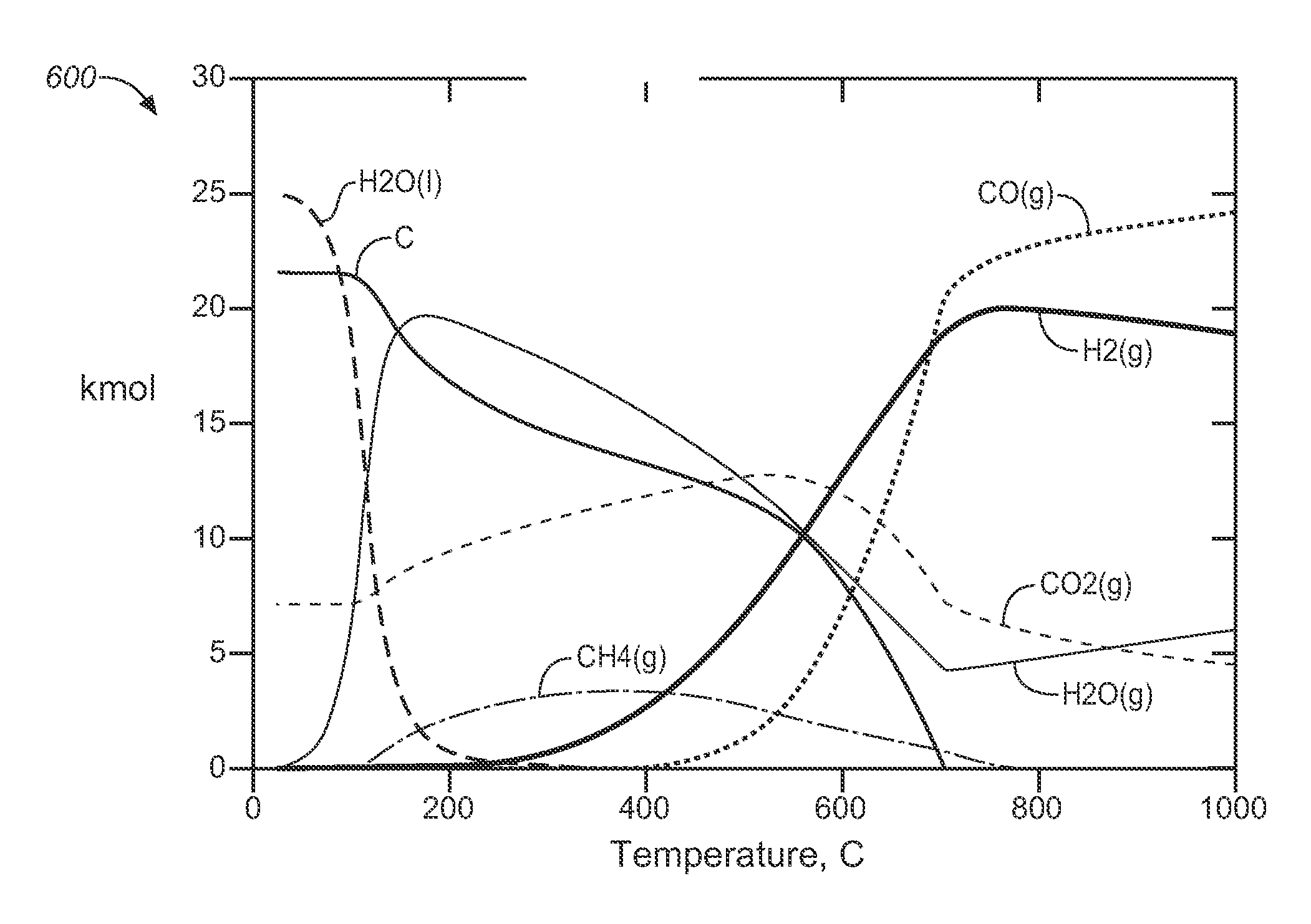

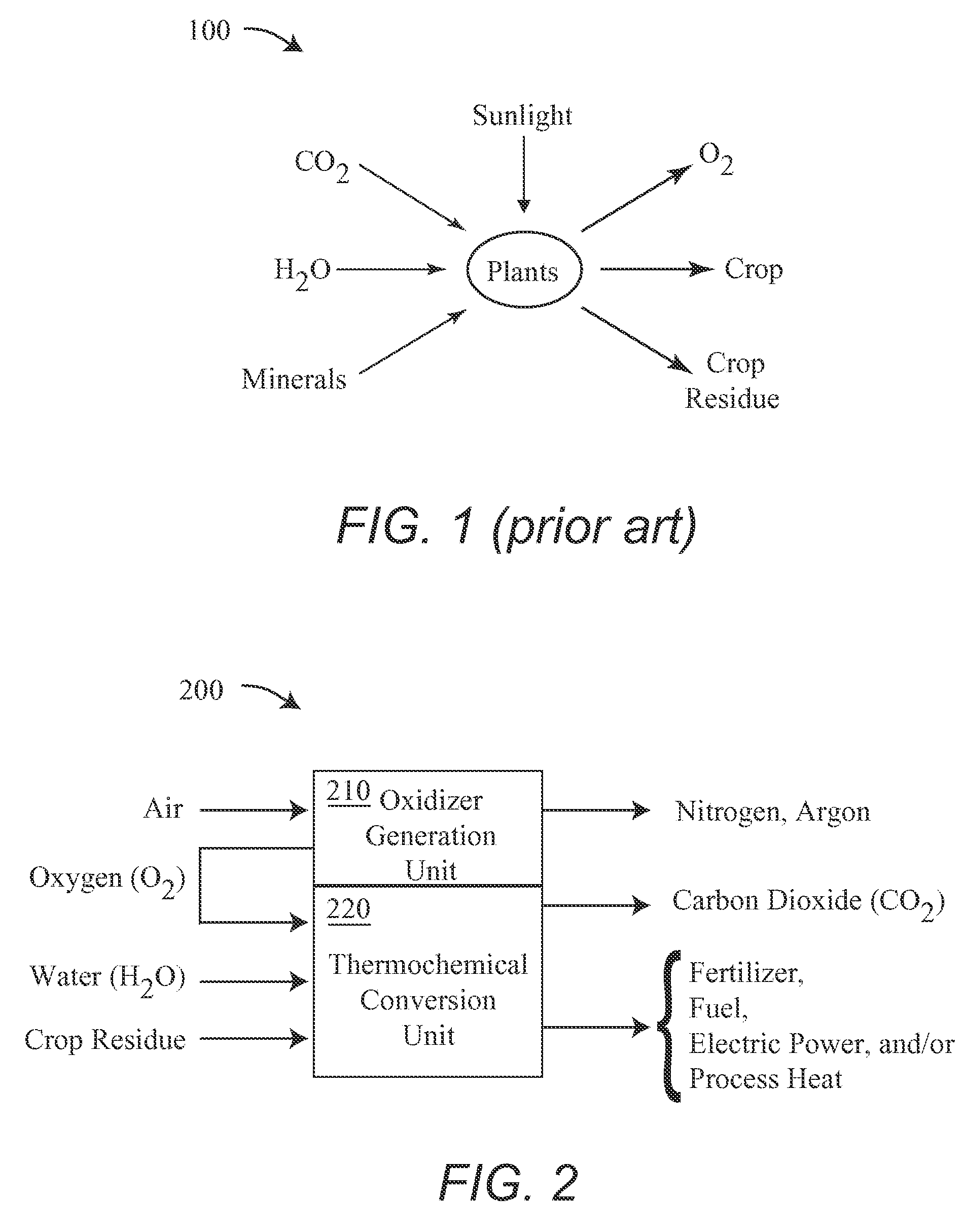

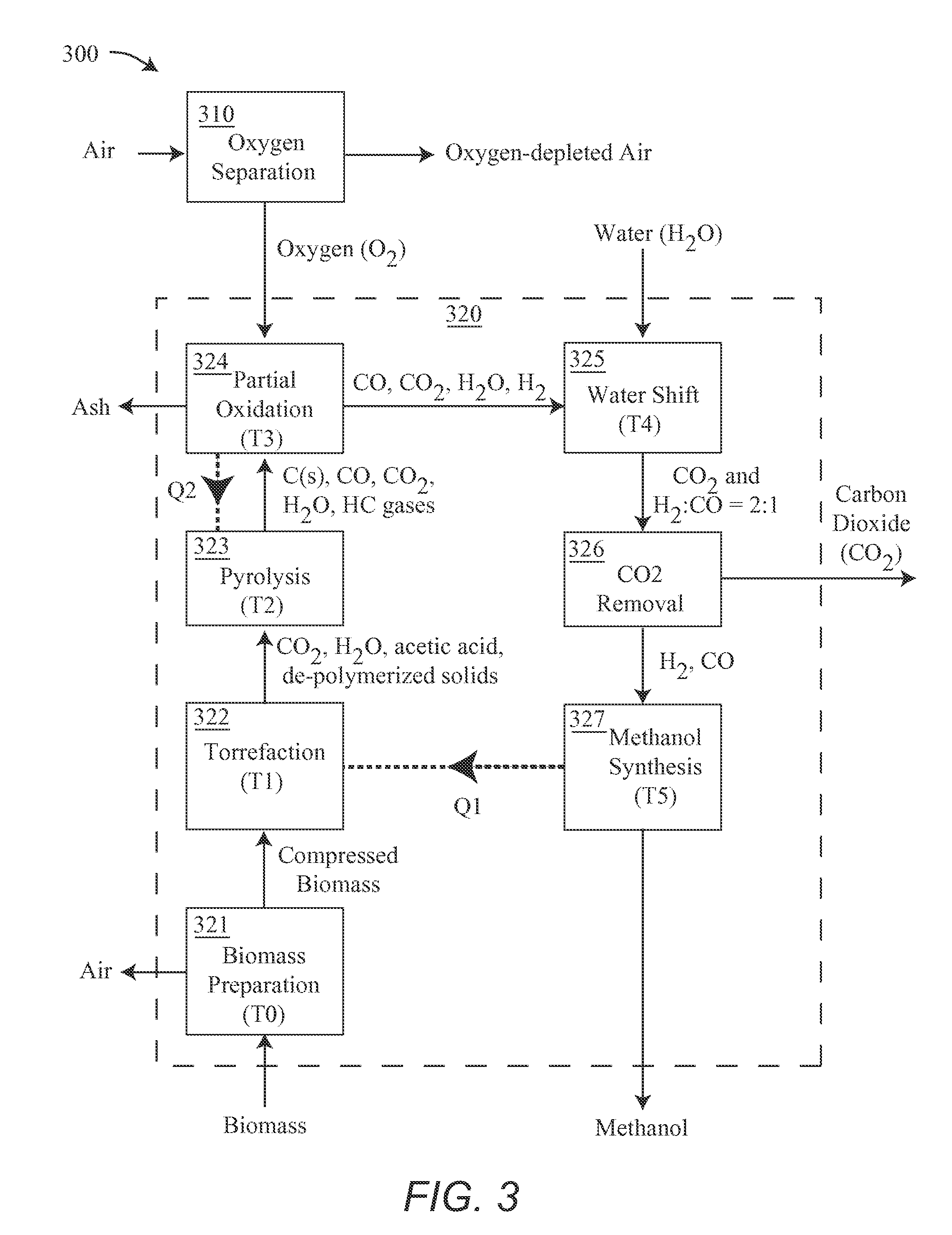

Biomass energy conversion apparatus and method

InactiveUS20090077892A1Efficient and cost-effective methodRaise the ratioHydrogenBiofuelsElectricityExternal energy

Method and apparatus are disclosed to utilize the energy in biomass (waste agricultural products). The inventive method and apparatus utilized heat and mass flow to efficiently generate a variety of products from biomass. In various embodiment, the invention may generate a liquid fuel (such as methanol or dimethyl ether), pure liquid CO2 (intended for CO2 sequestration), a soil enhancement product (intended to return to the agricultural site), process heat, and / or electricity. In one embodiment, the process requires no external energy inputs, and preserves a large percentage (ie. >50%) of the energy contained in the biomass. In another embodiment, the inventive method and apparatus can selectively be operated to produce electricity and or liquid fuels.

Owner:RENEWABLE FUEL TECH

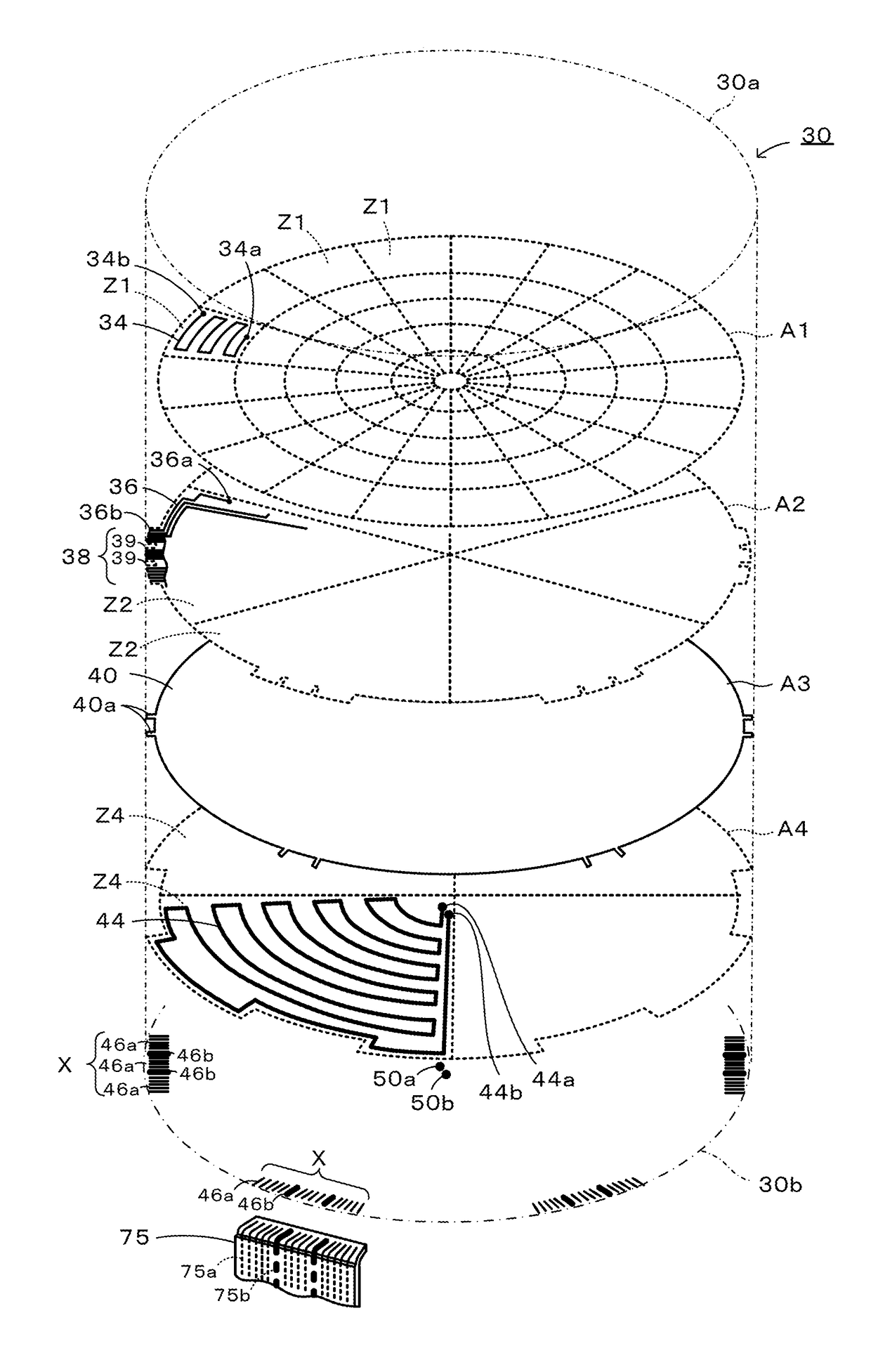

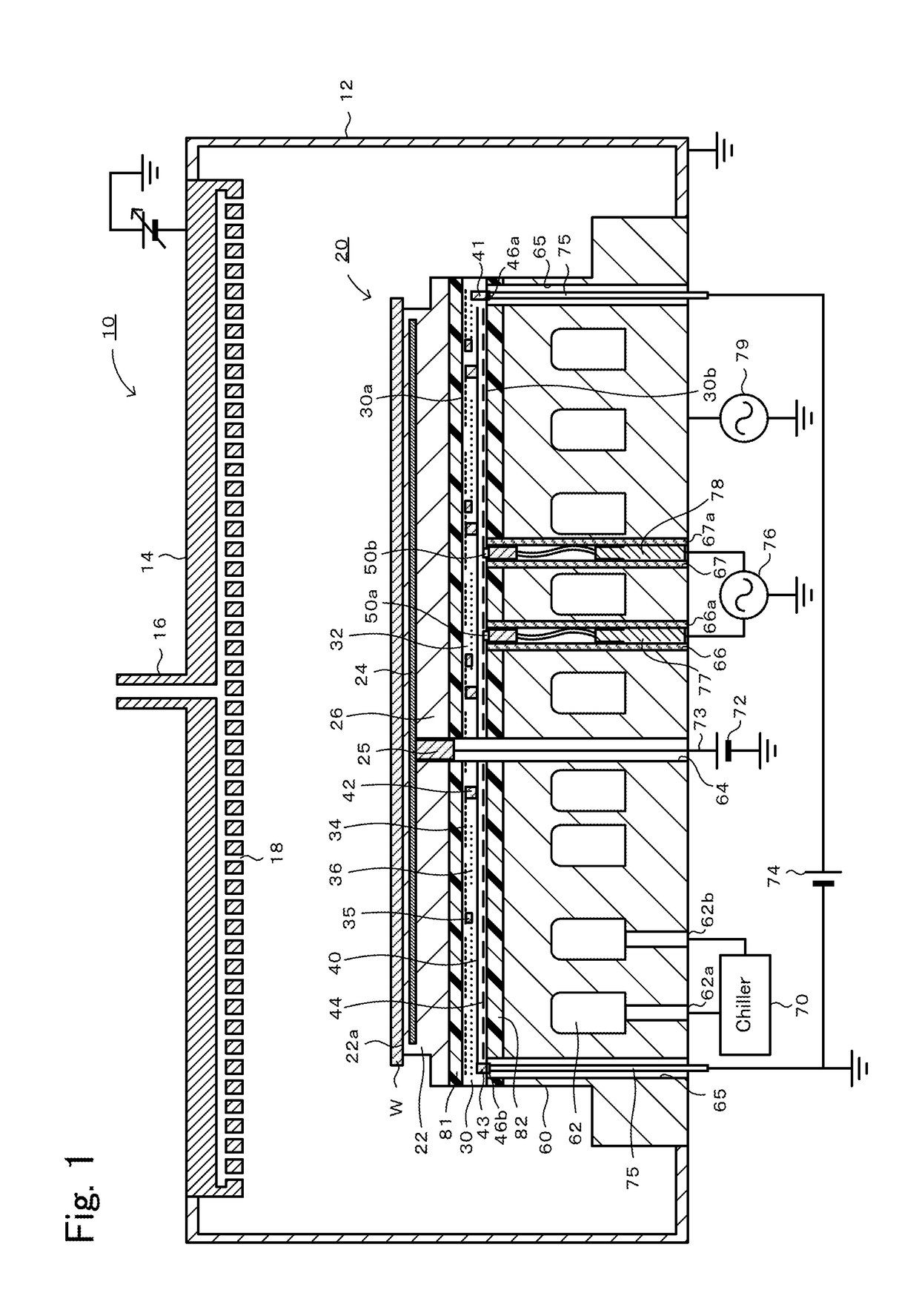

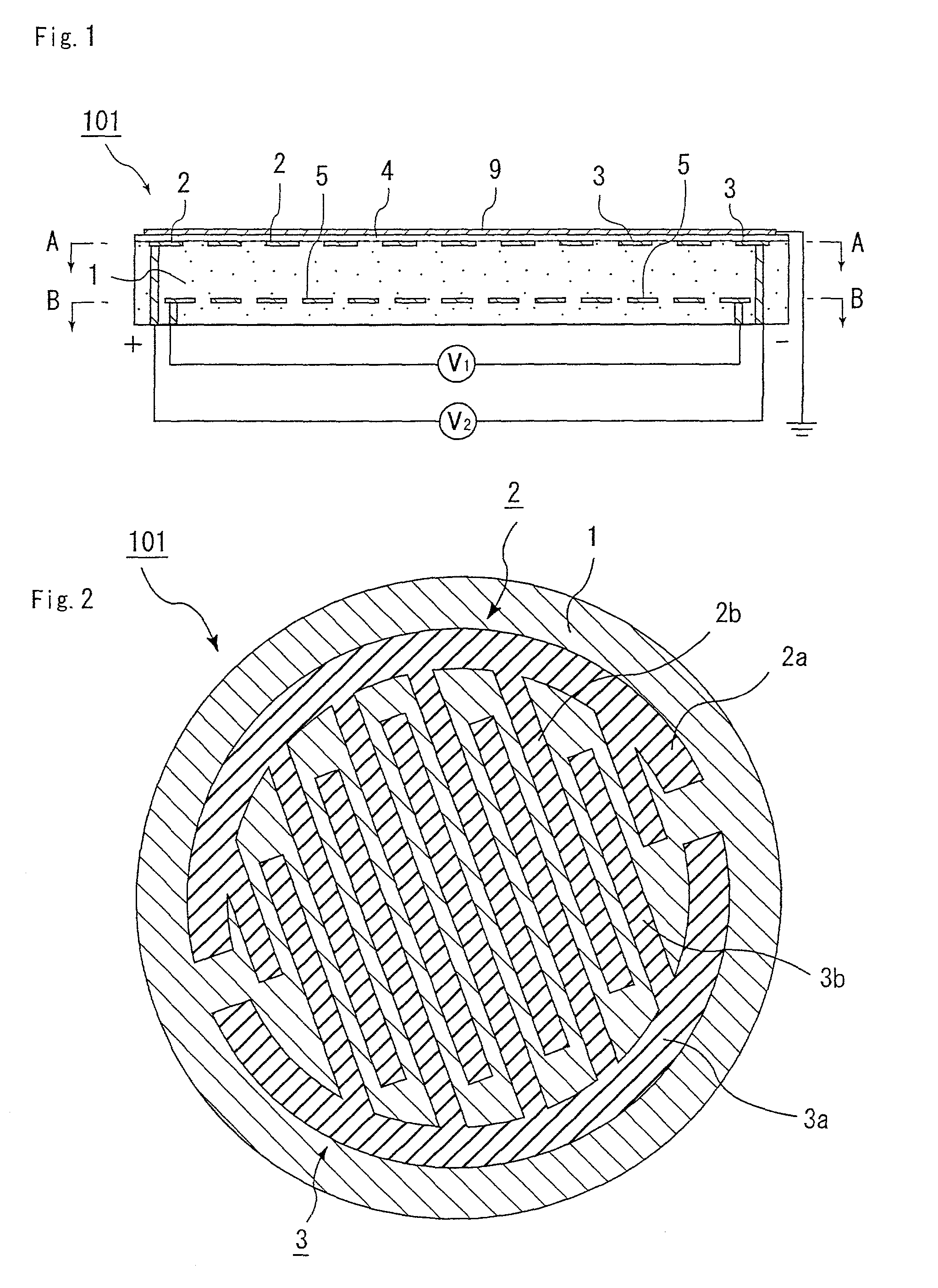

Electrostatic chuck heater

ActiveUS20170280509A1Improve thermal uniformityHigh resolutionSemiconductor/solid-state device manufacturingOhmic-resistance heating detailsEngineering

An electrostatic chuck heater 20 includes an electrostatic chuck 22, a sheet heater 30, and a support pedestal 60. The electrostatic chuck 22 is obtained by embedding an electrostatic electrode 24 in a ceramic sintered body 26. The sheet heater 30 is a resin sheet 32 having a plurality of correction heater electrodes 34 and a plurality of base heater electrodes 44. A first surface of the sheet heater 30 is resin-bonded to the electrostatic chuck 22, and a second surface of the sheet heater 30 is resin-bonded to the support pedestal 60 made of metal.

Owner:NGK INSULATORS LTD

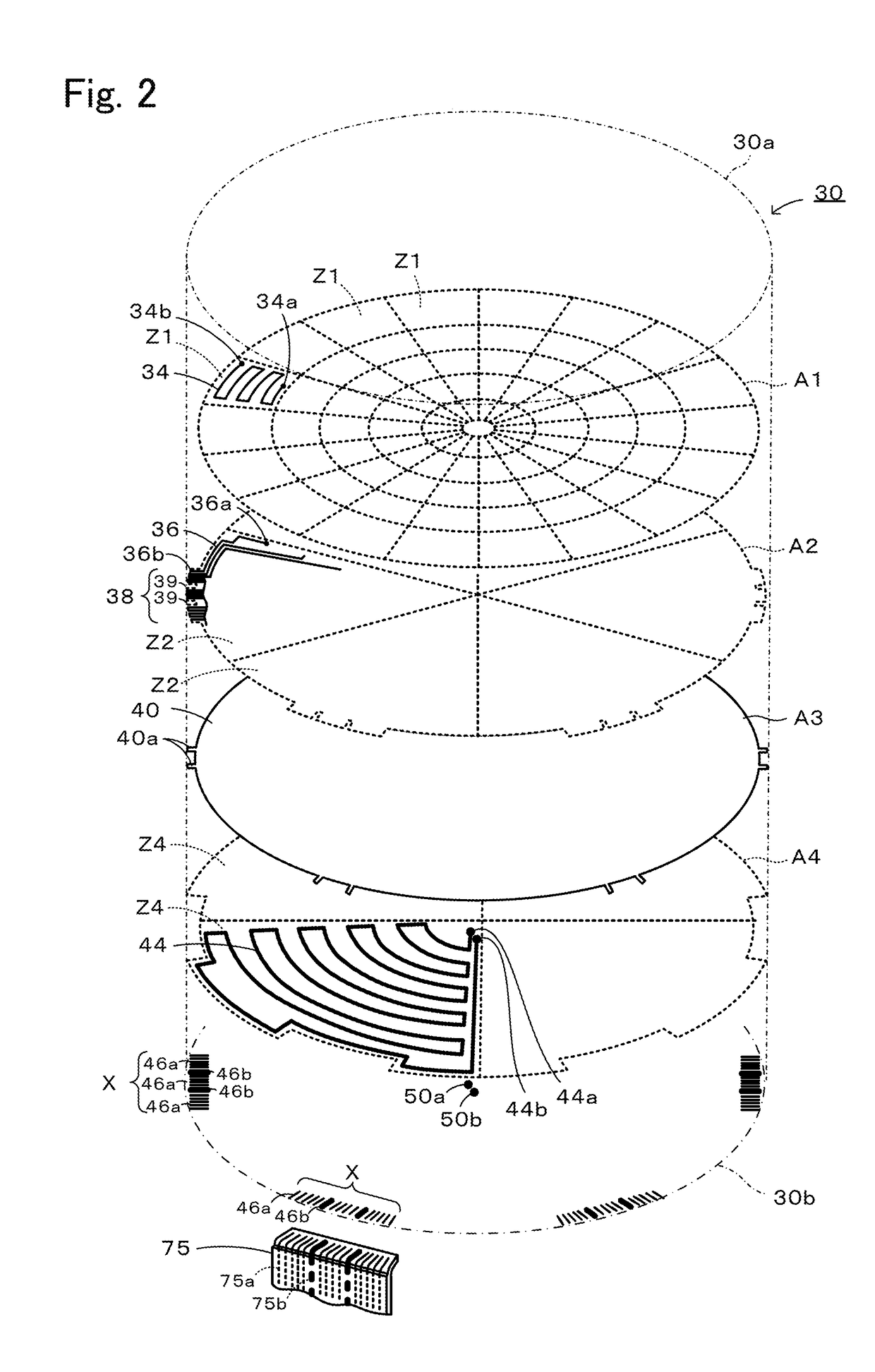

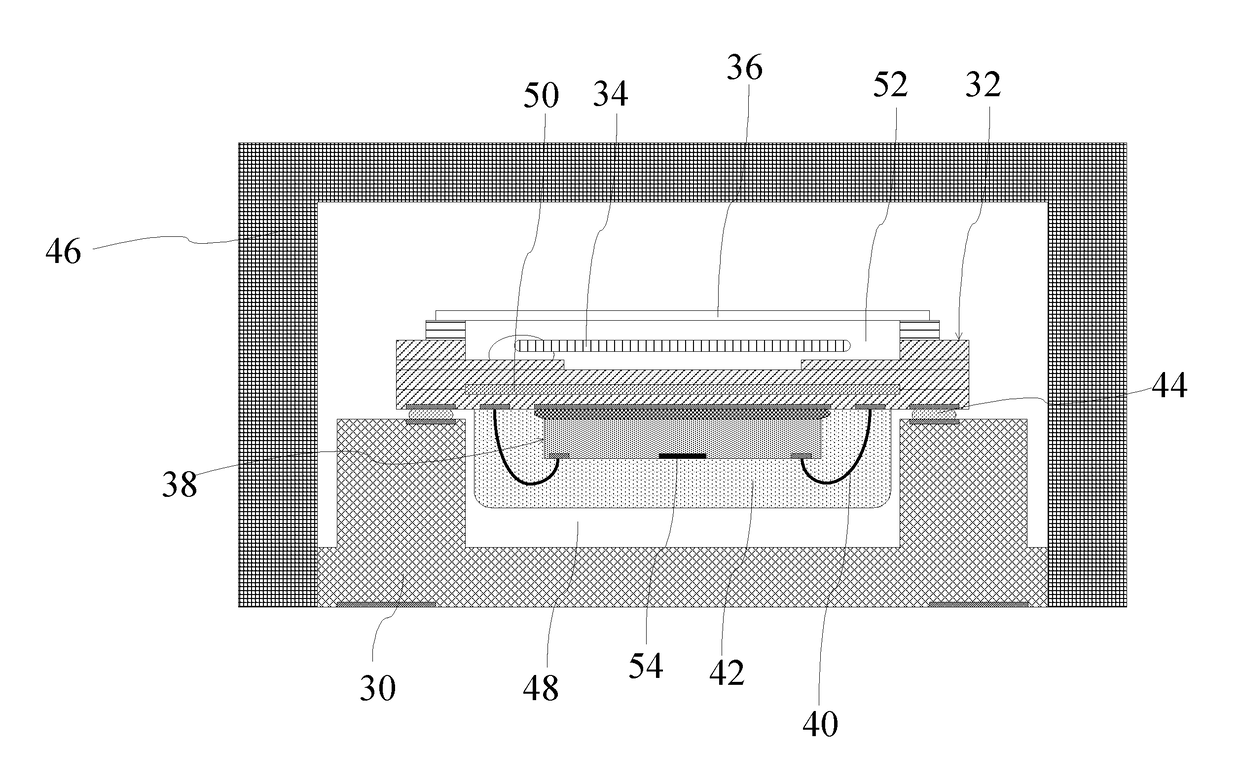

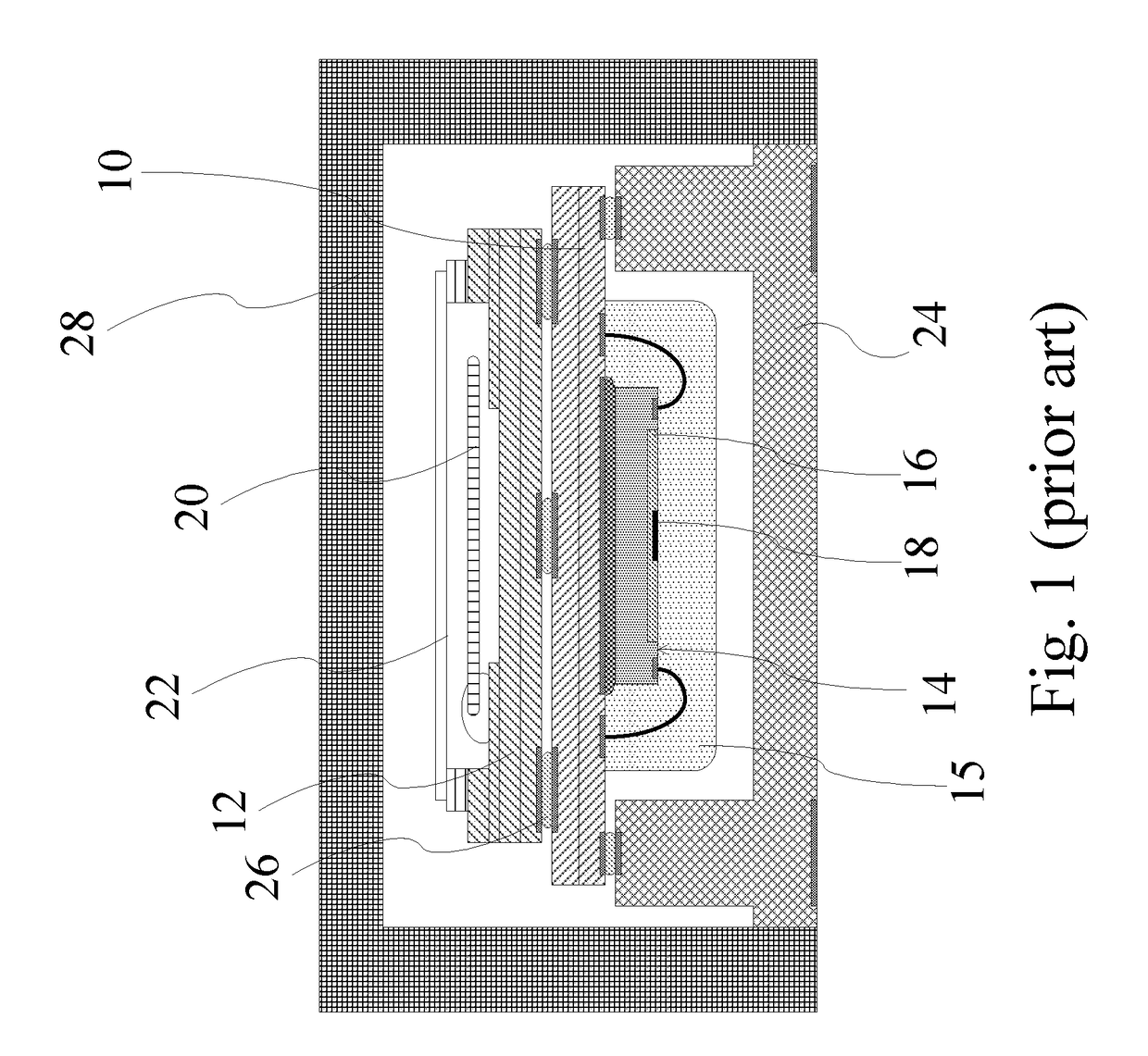

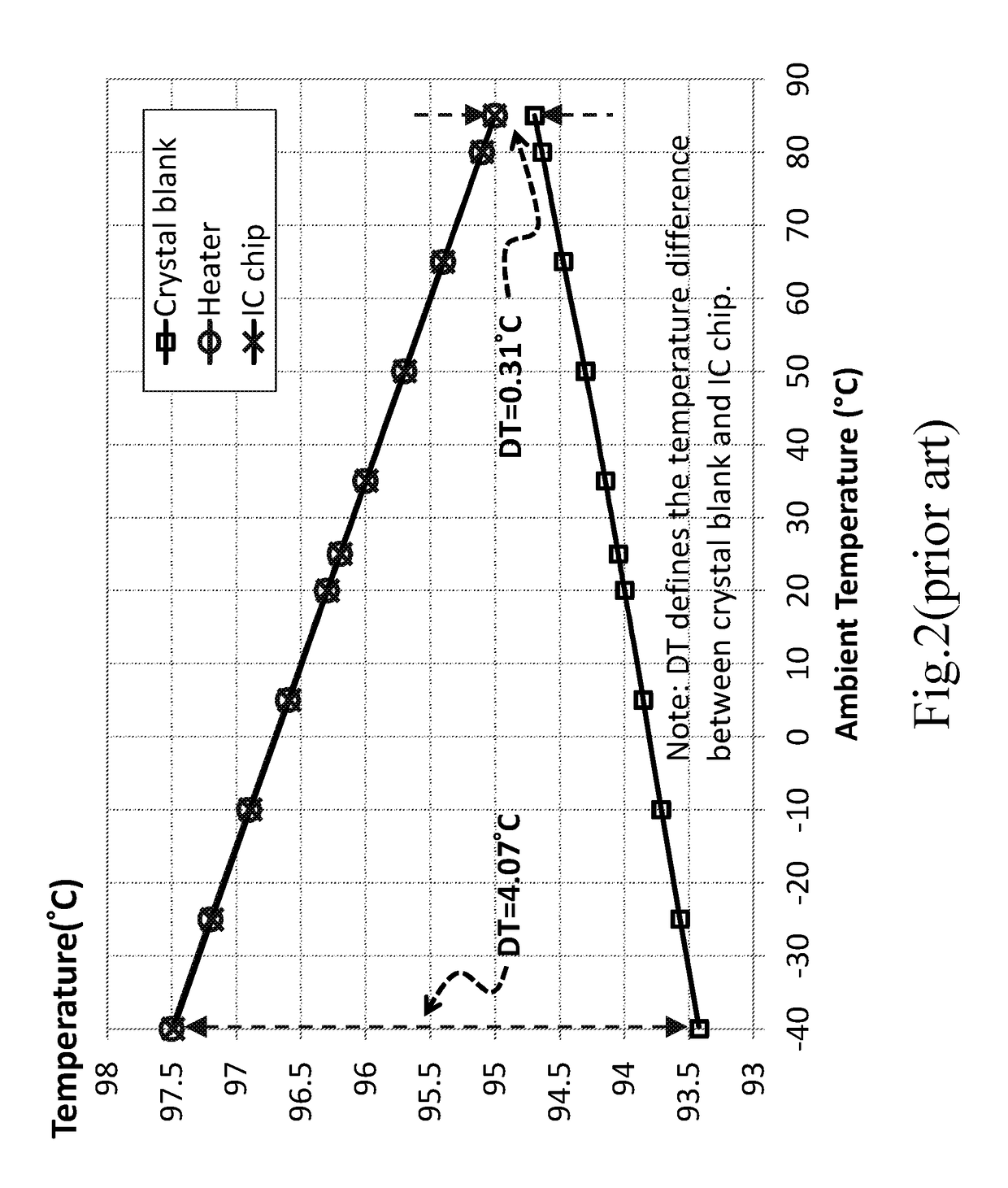

Oven controlled crystal oscillator consisting of heater-embedded ceramic package

ActiveUS20170272081A1Good thermal uniformityMaintain oven stabilitySemiconductor/solid-state device detailsPrinted circuit aspectsMaterials scienceCrystal

Owner:TXC CORP

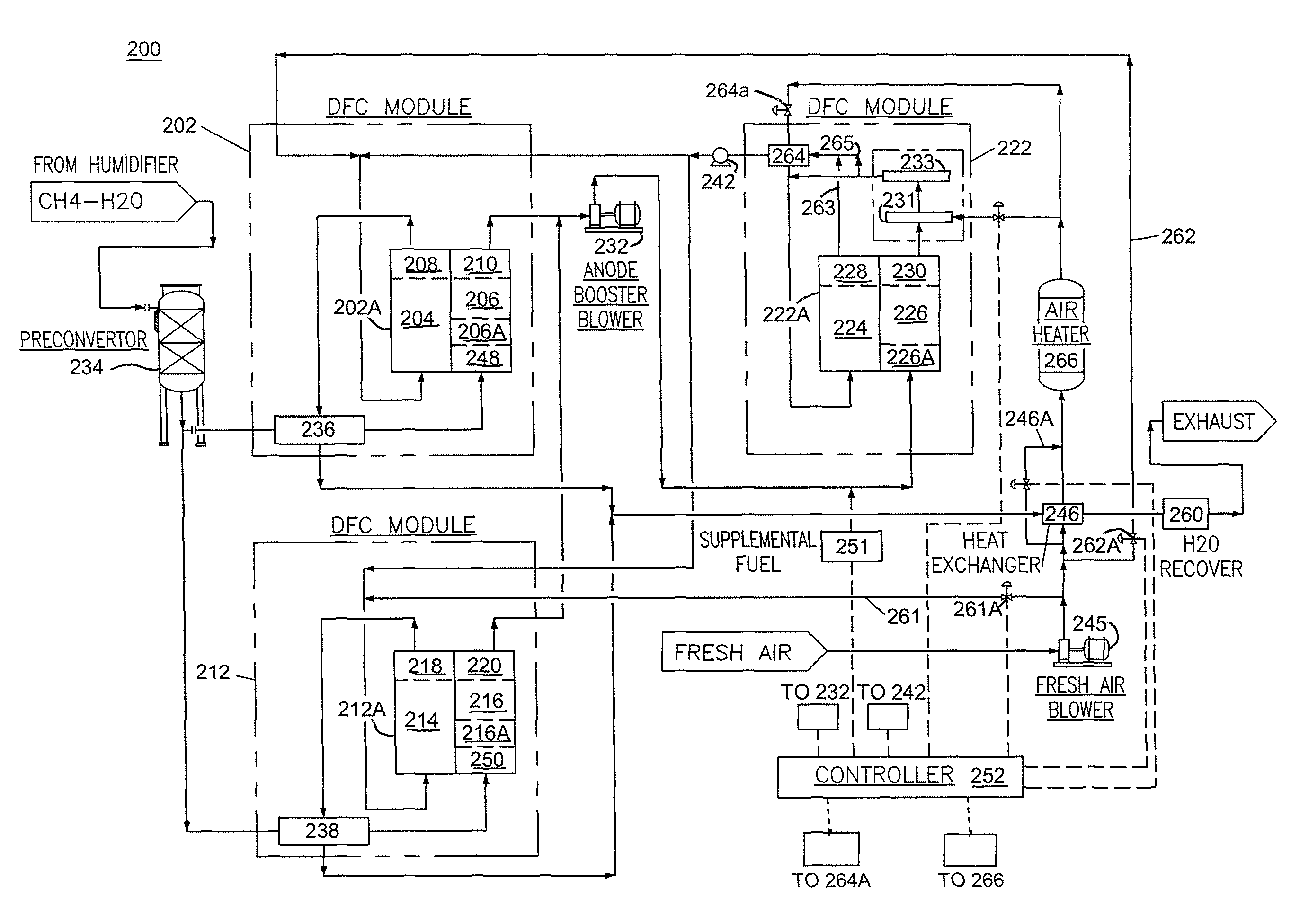

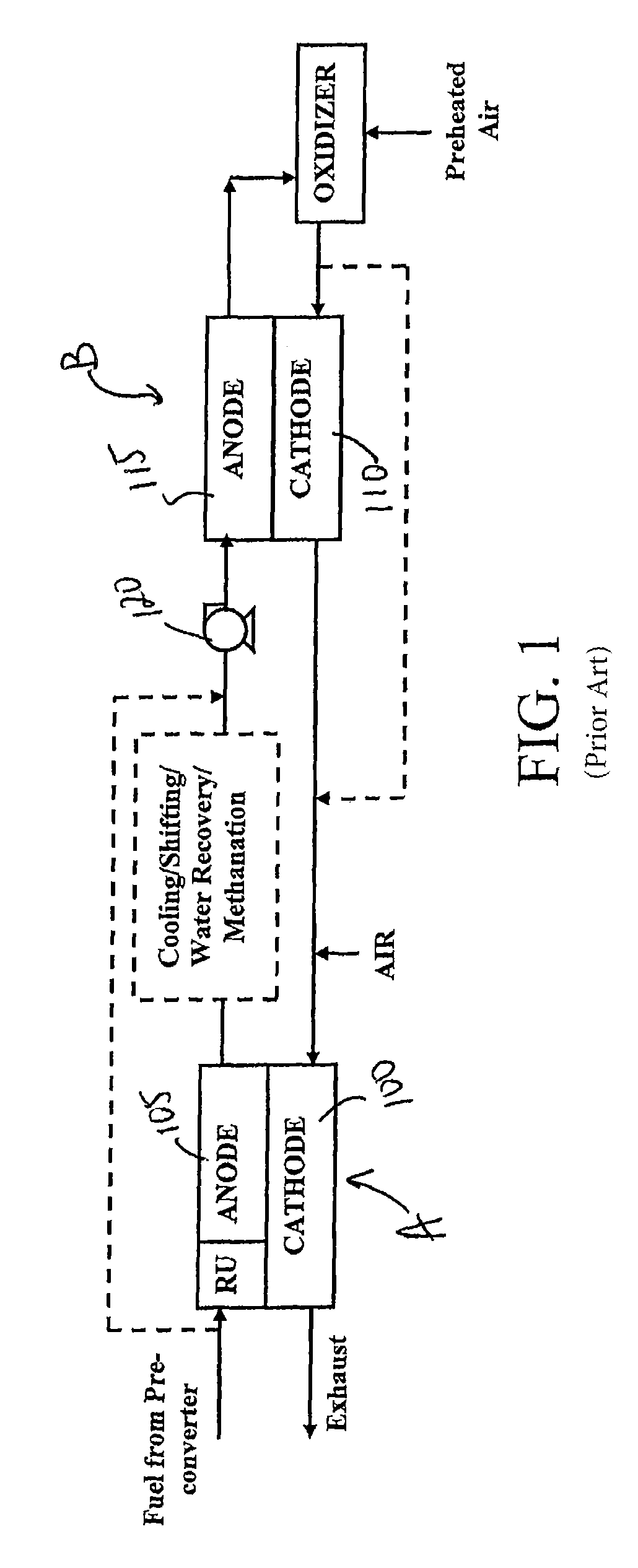

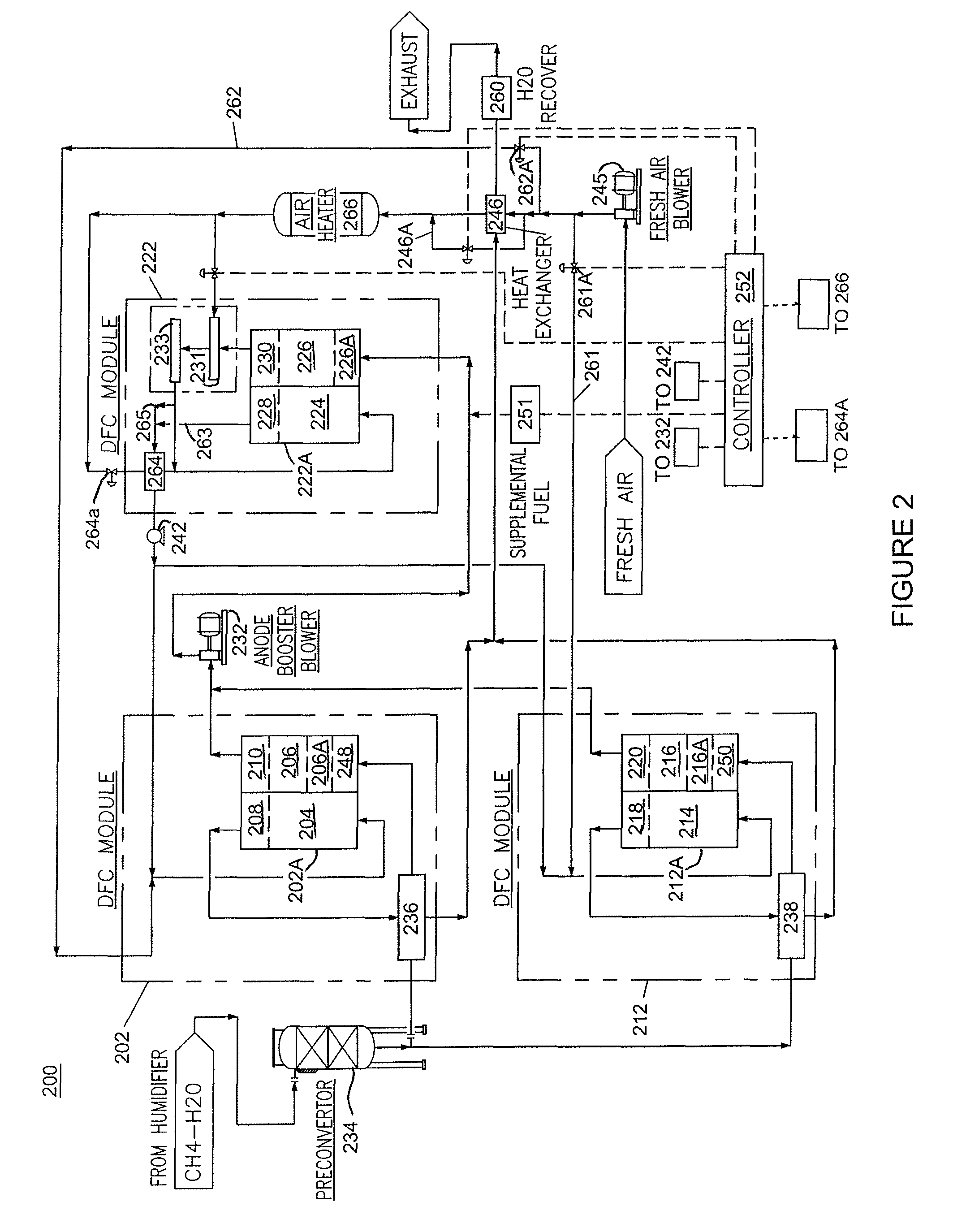

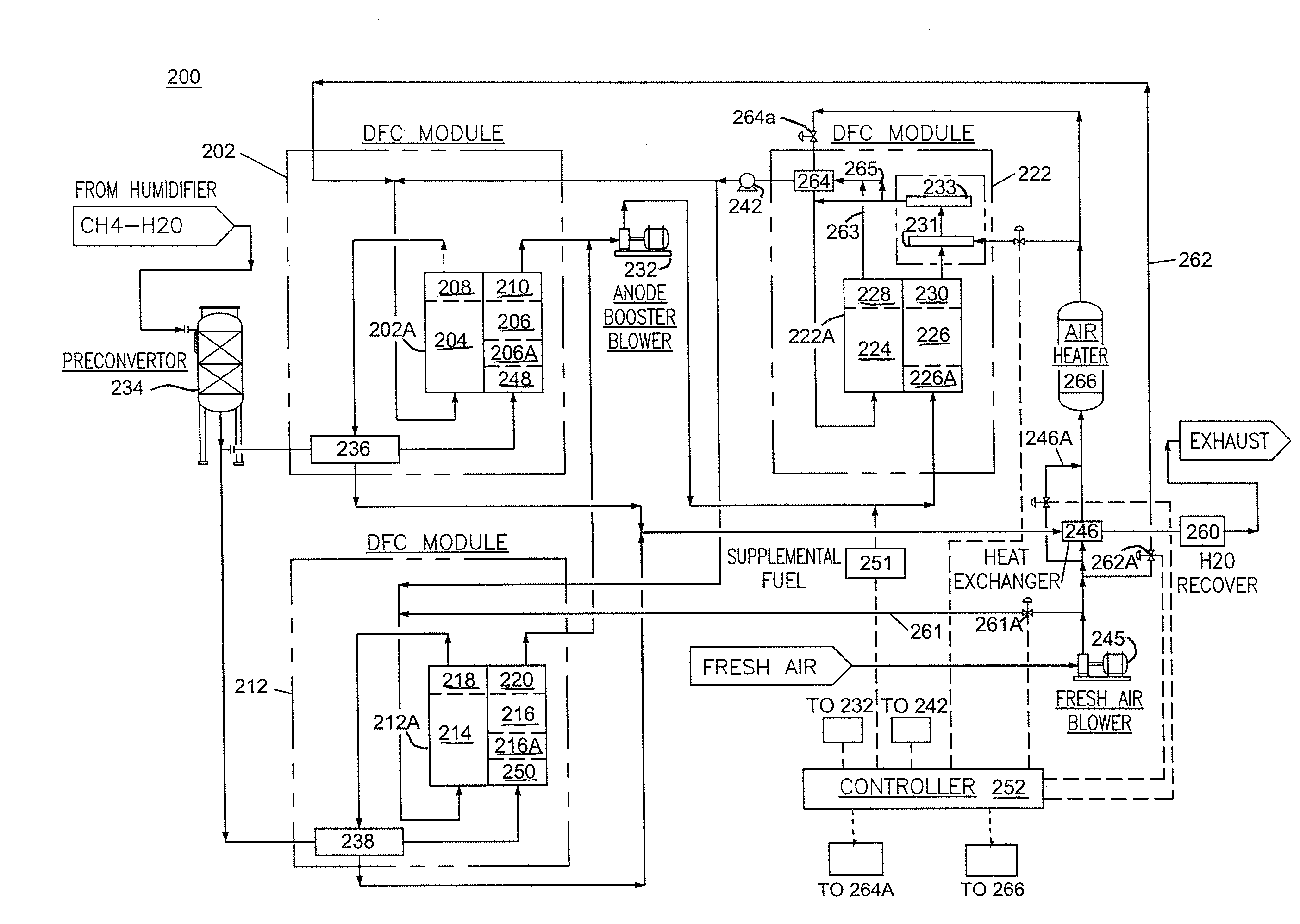

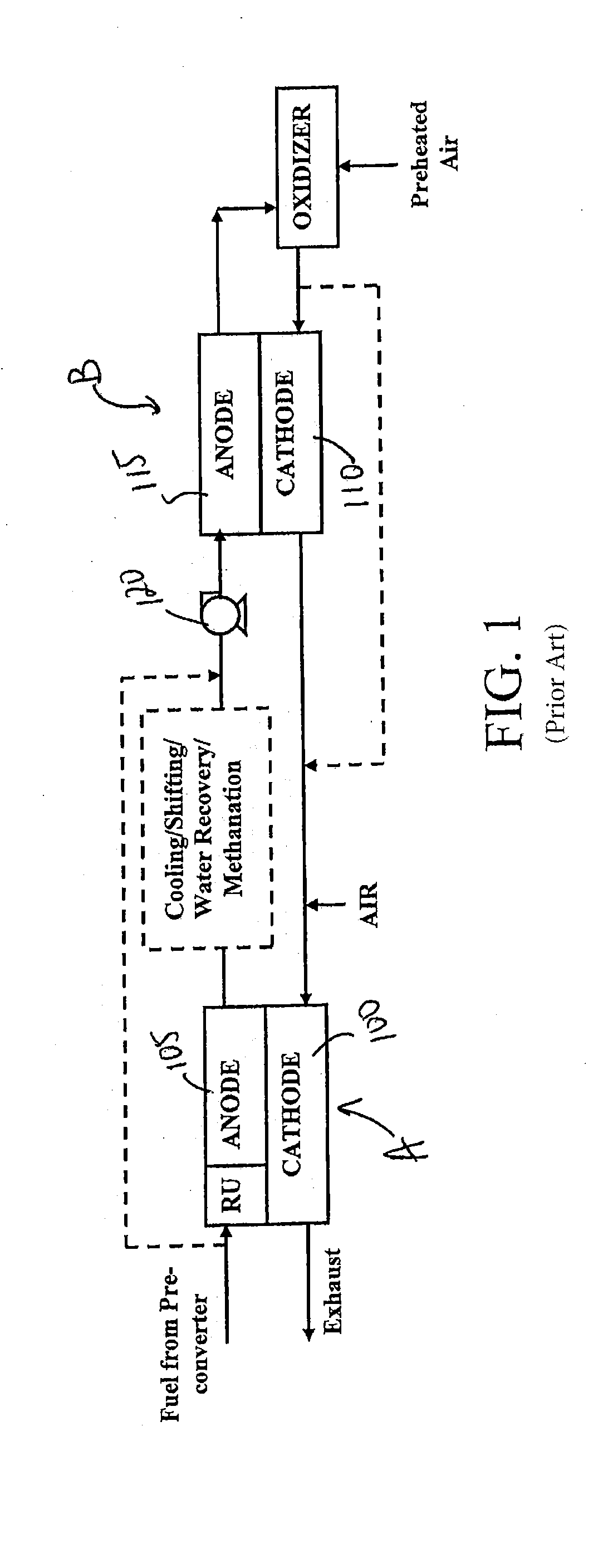

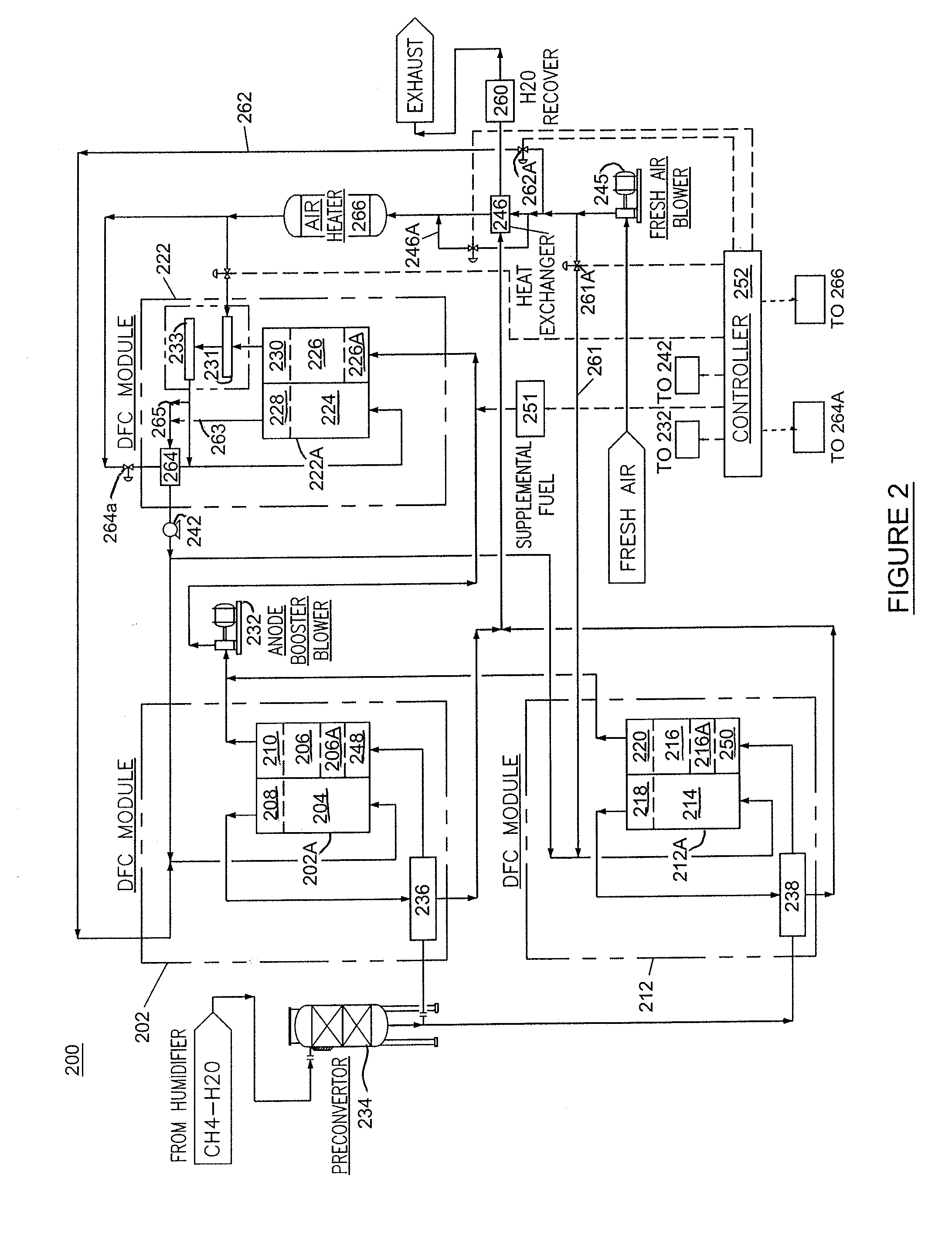

High-efficiency molten carbonate fuel cell system and method

ActiveUS9478819B2Maintain thermal balanceCost-effectiveFuel cells groupingFuel cell auxillariesFuel cellsMolten carbonate fuel cell

A high efficiency fuel cell system comprising a topping fuel cell assembly comprising a topping cathode portion and a topping anode portion; and a bottoming fuel cell assembly comprising a bottoming cathode portion and a bottoming anode portion, wherein the bottoming anode portion receives anode exhaust output from the topping anode portion and the topping cathode portion receives cathode exhaust from the bottoming cathode portion, and wherein the topping fuel cell assembly has a greater number of fuel cells than the bottoming fuel cell assembly so that the topping fuel cell assembly utilizes more fuel than the bottoming fuel cell assembly.

Owner:FUELCELL ENERGY INC

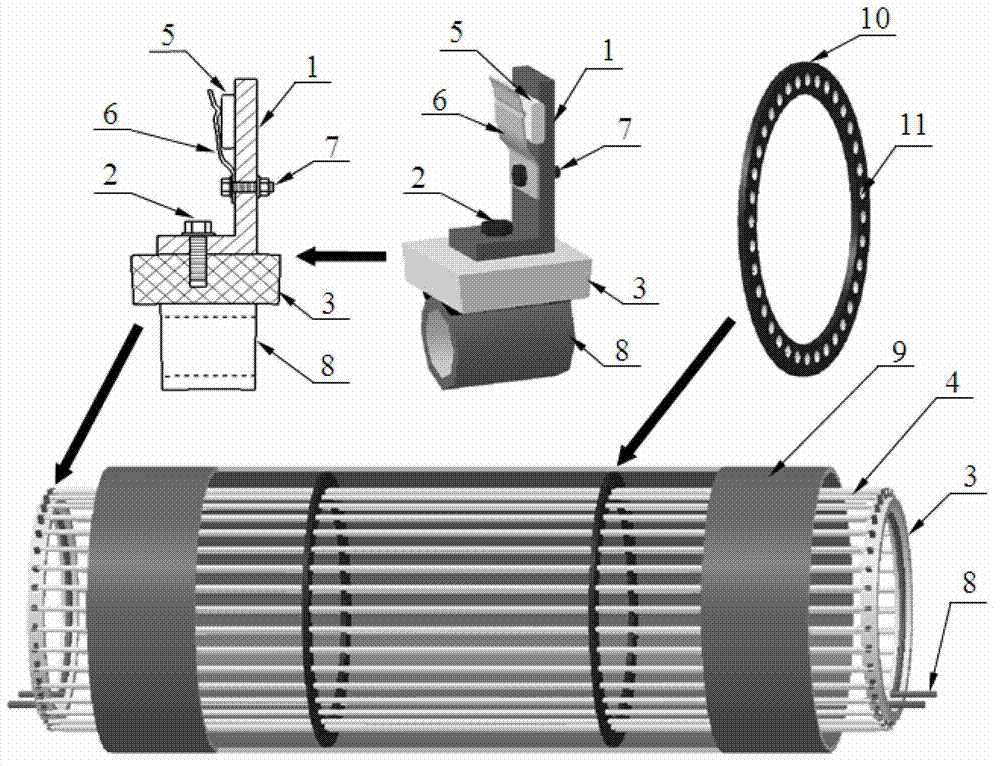

Inner-wall non-sectional type high-temperature thermal test device of large high-speed aircraft round-shell structure

InactiveCN103163173AAvoid Vacuum Seal DamageImprove reliabilityMachine part testingMaterial thermal analysisElastomerWave shape

The invention provides an inner-wall non-sectional type high-temperature thermal test device of a large high-speed aircraft round-shell structure. The device comprises an L-shaped electrode support, an annular flat copper bracket, a quartz burner, an electrode, a metal pressing piece, a water-cooling copper tube, a large high-speed aircraft round-shell structure, an annular ceramic locating rack and a round locating hole. The device can achieve a non-sectional type high-temperature thermal test for a 2-m large high-speed aircraft inner cabin structure, prevents wave-shaped peak-valley variation of a large elastomer temperature field caused by a sectional splicing heating mode, improves the temperature uniformity, reality and safe reliability of the large elastomer temperature test, and provides an important means for researching high-temperature characteristic and heat-insulation performance of the large high-speed aircraft inner cabin structure.

Owner:BEIHANG UNIV

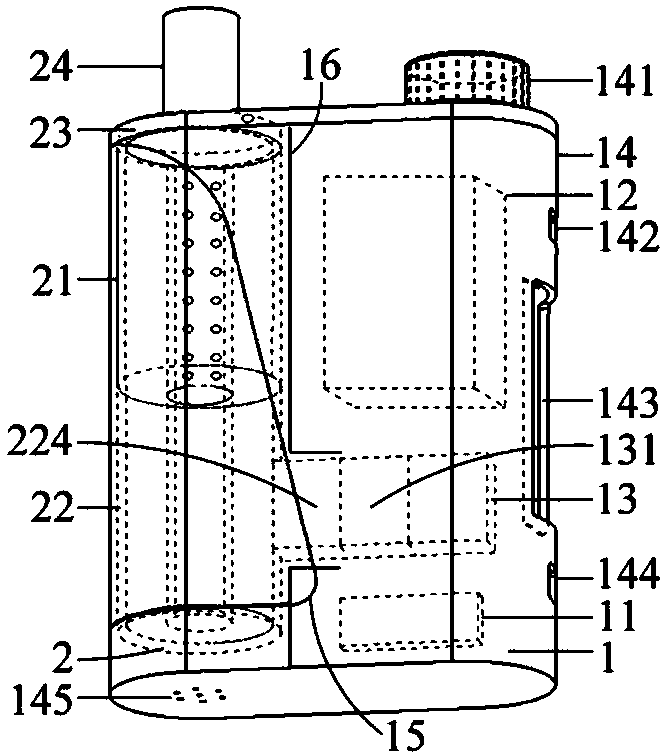

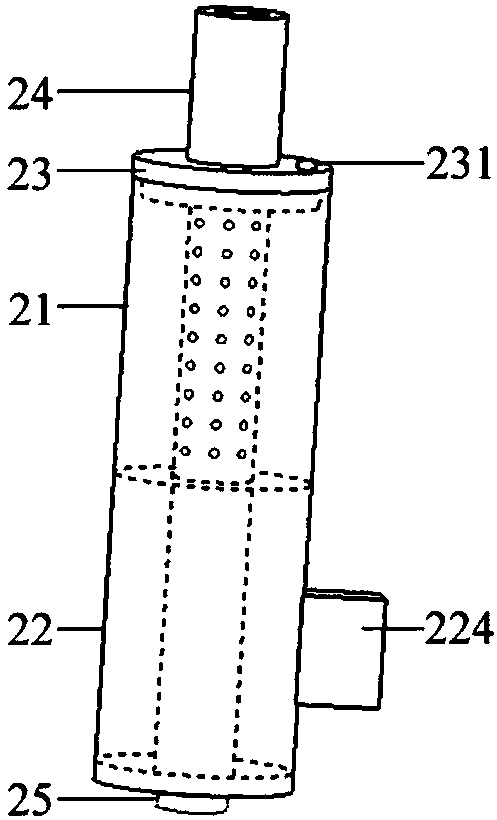

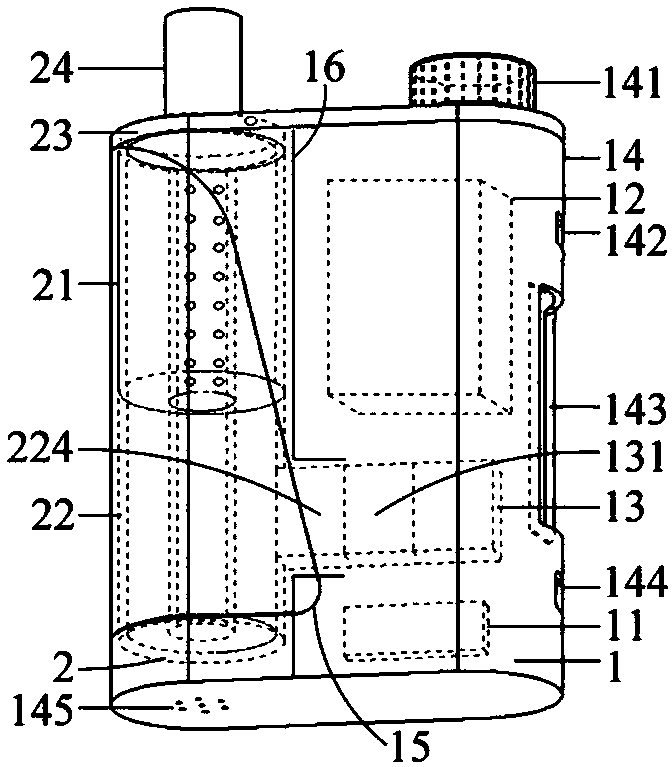

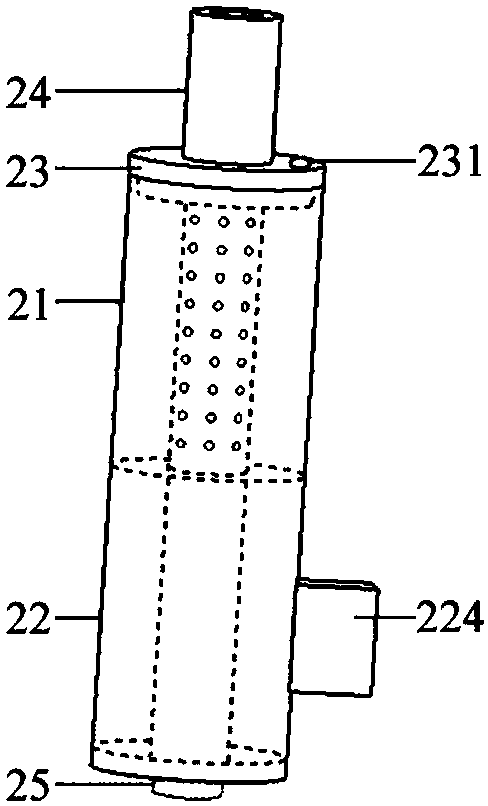

Microwave resonant atomizer for electronic cigarette

InactiveCN108552614AAvoiding patent infringementIncrease energy densityTobacco devicesTarInterior space

The invention discloses a microwave resonant atomizer (2) for an electronic cigarette. The microwave resonant atomizer comprises an oil storage unit (21), an atomizing unit (22), an upper cover plate(23) and a suction nozzle (24), wherein a microwave resonant cavity (221) is formed in the internal space of the atomizing unit (22); and a coupling hole (225) is formed in the side wall of the microwave resonant cavity (221), and the outer side wall of the microwave resonant cavity (221) with the coupling hole (225) can be covered with an energy coupling (224). When being applied to the electronic cigarette, the microwave resonant atomizer has the advantages that instant heating is realized, the efficiency is high, heat uniformity is good, non-contact atomization is realized, the low temperature sterilization of tobacco tar can be realized, and the like.

Owner:CHINA TOBACCO YUNNAN IND

Structure of low temperature solid oxide fuel cell supported by porous metal

InactiveCN1960048AHigh mechanical strengthImprove stabilityCell electrodesFuel cell auxillariesFuel cellsKey issues

Structure of the disclosed fuel cell includes porous anodal thin film, compact solid electrolyte film, reaction barrier layer, active layer of cathode, contact layer of cathode, supporter of porous stainless steel, reforming catalyst. Porous anodal thin film, compact solid electrolyte, reaction barrier layer, active layer of cathode, and contact layer of cathode are tight connected in sequence from bottom-up so as to constitute single cell. Supporter of porous stainless steel of carrying reforming catalyst is located at underside porous anodal thin film. The invention raises performances of structural stability, electrocatalysis capability of anode, heat evenness of fuel cell so as to increase service life. Structure of system is more compact and possesses higher efficiency. The invention possesses very important meaning for solving key issue faced by solid oxide fuel cell for applying to power generation system.

Owner:SHANGHAI JIAO TONG UNIV

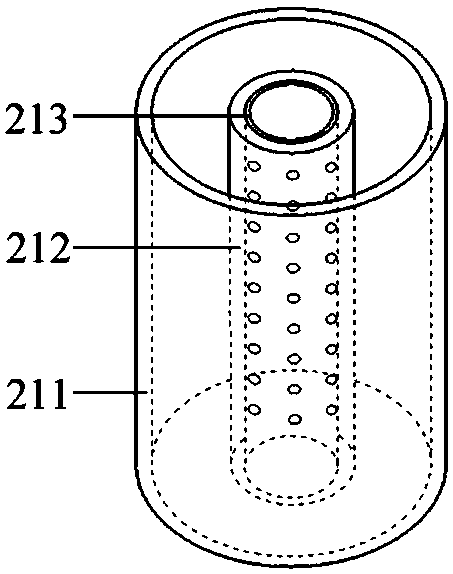

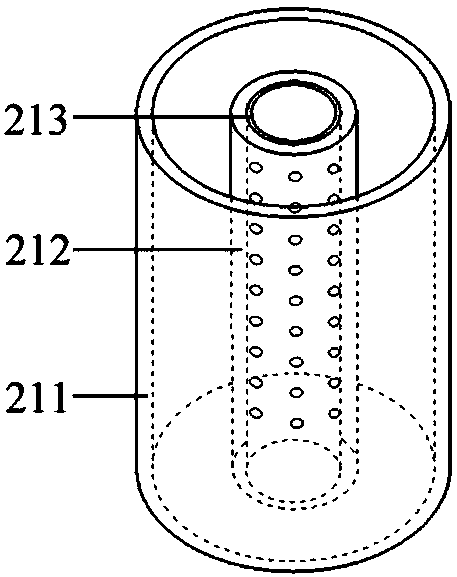

Microwave resonant cavity for electronic cigarette

InactiveCN108552612AAvoiding the Risk of Patent InfringementIncrease energy densityTobacco devicesResonant cavityMicrowave

The invention discloses a microwave resonant cavity (221) for an electronic cigarette. The microwave resonant cavity is of a cylinder shape, wherein a second oil guiding component (223) is arranged inthe microwave resonant cavity (221) along the axial direction; and a coupling hole (225) is formed in the side wall of the microwave resonant cavity (221). When being applied to the electronic cigarette, the microwave resonant cavity has the advantages that instant heating is realized, the efficiency is high, heat uniformity is good, non-contact atomization is realized, the low temperature sterilization of tobacco tar can be realized, and the like.

Owner:CHINA TOBACCO YUNNAN IND

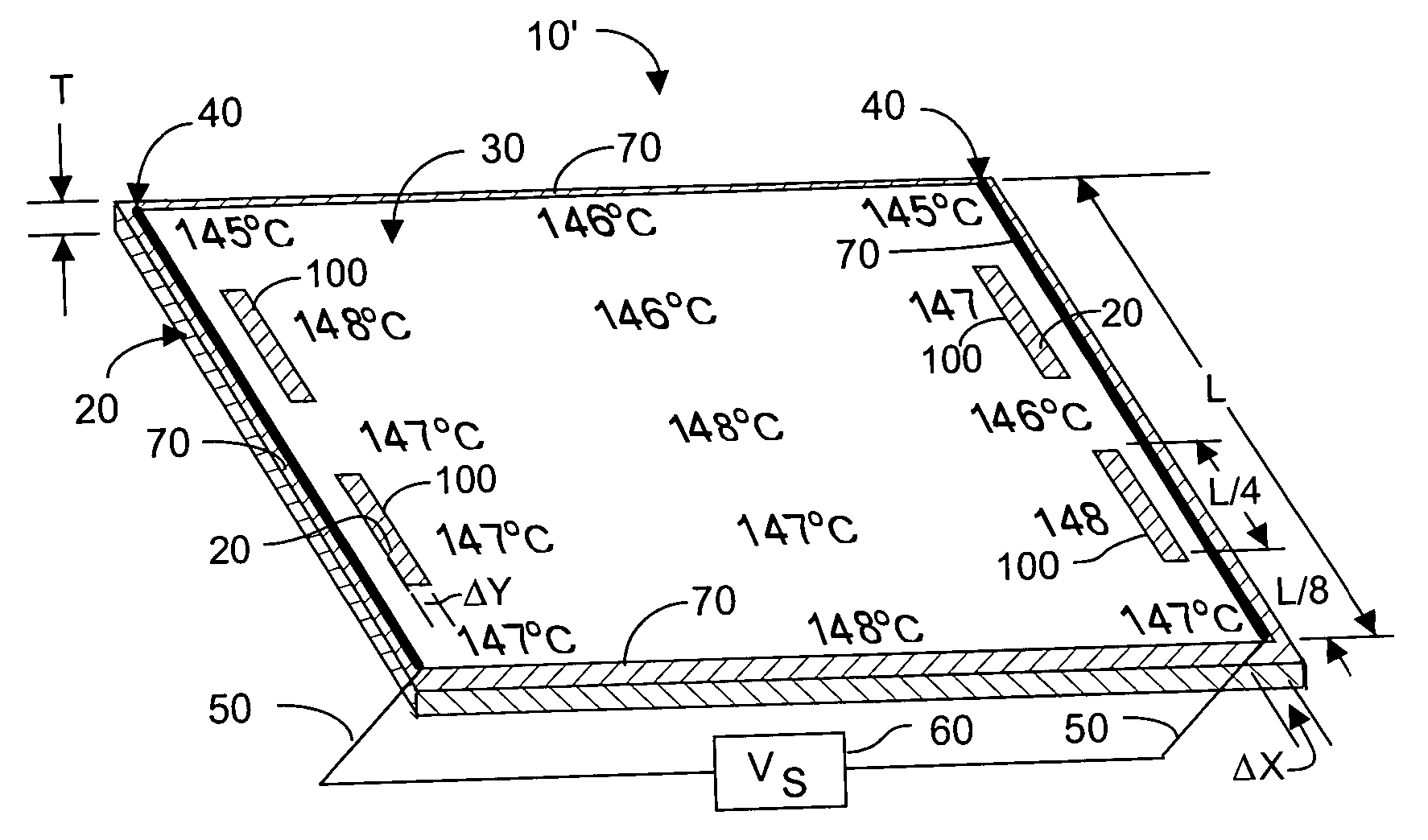

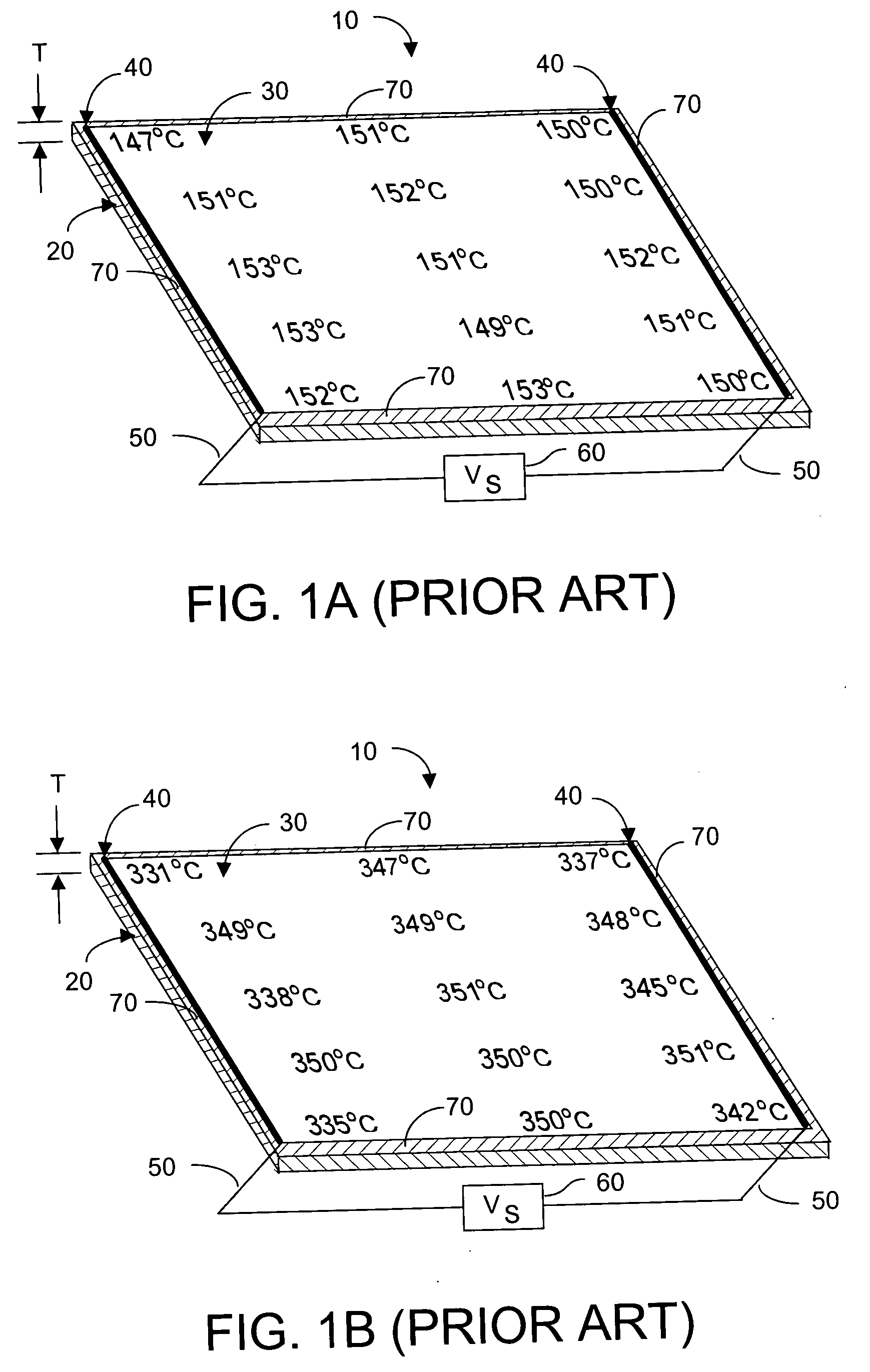

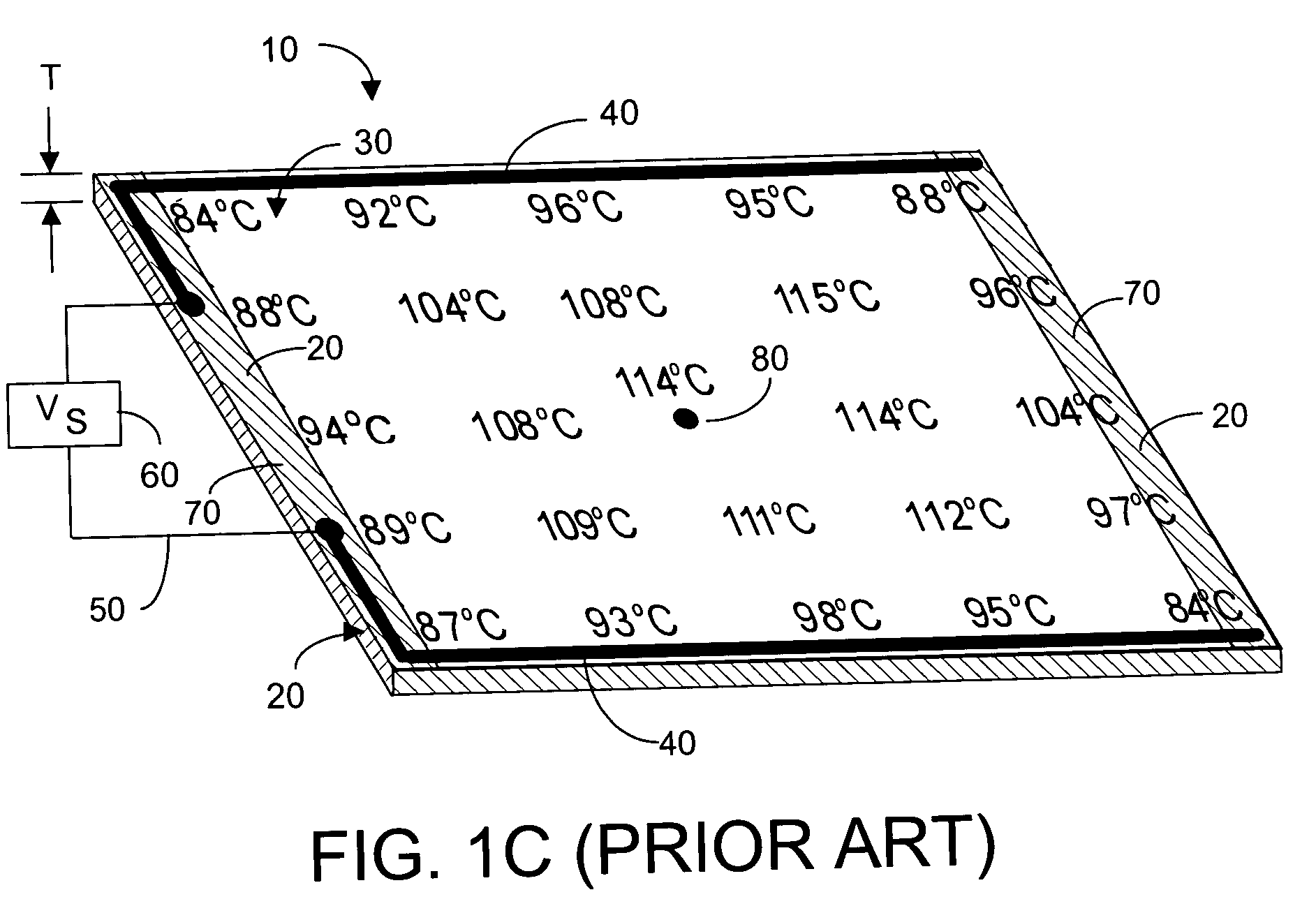

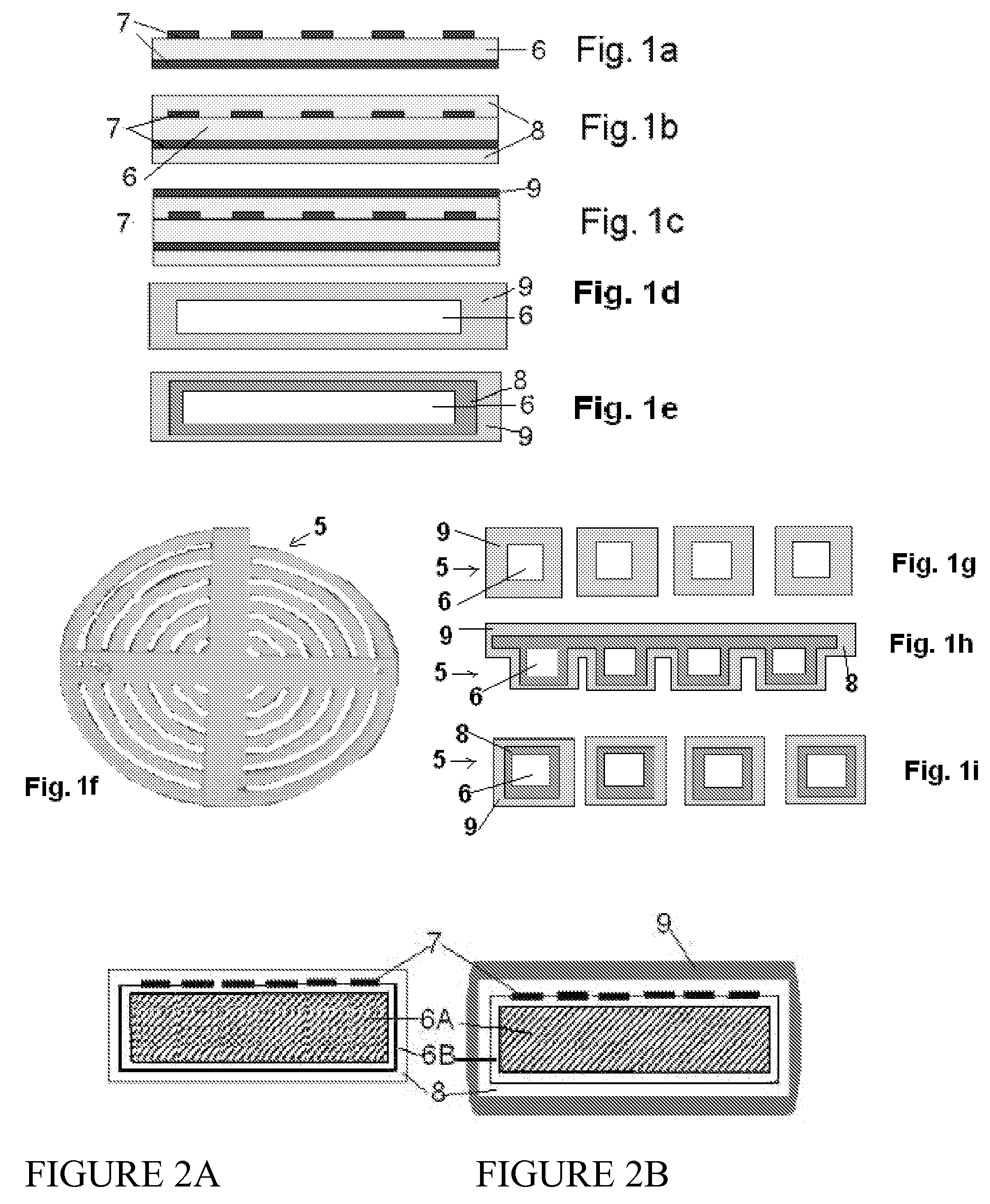

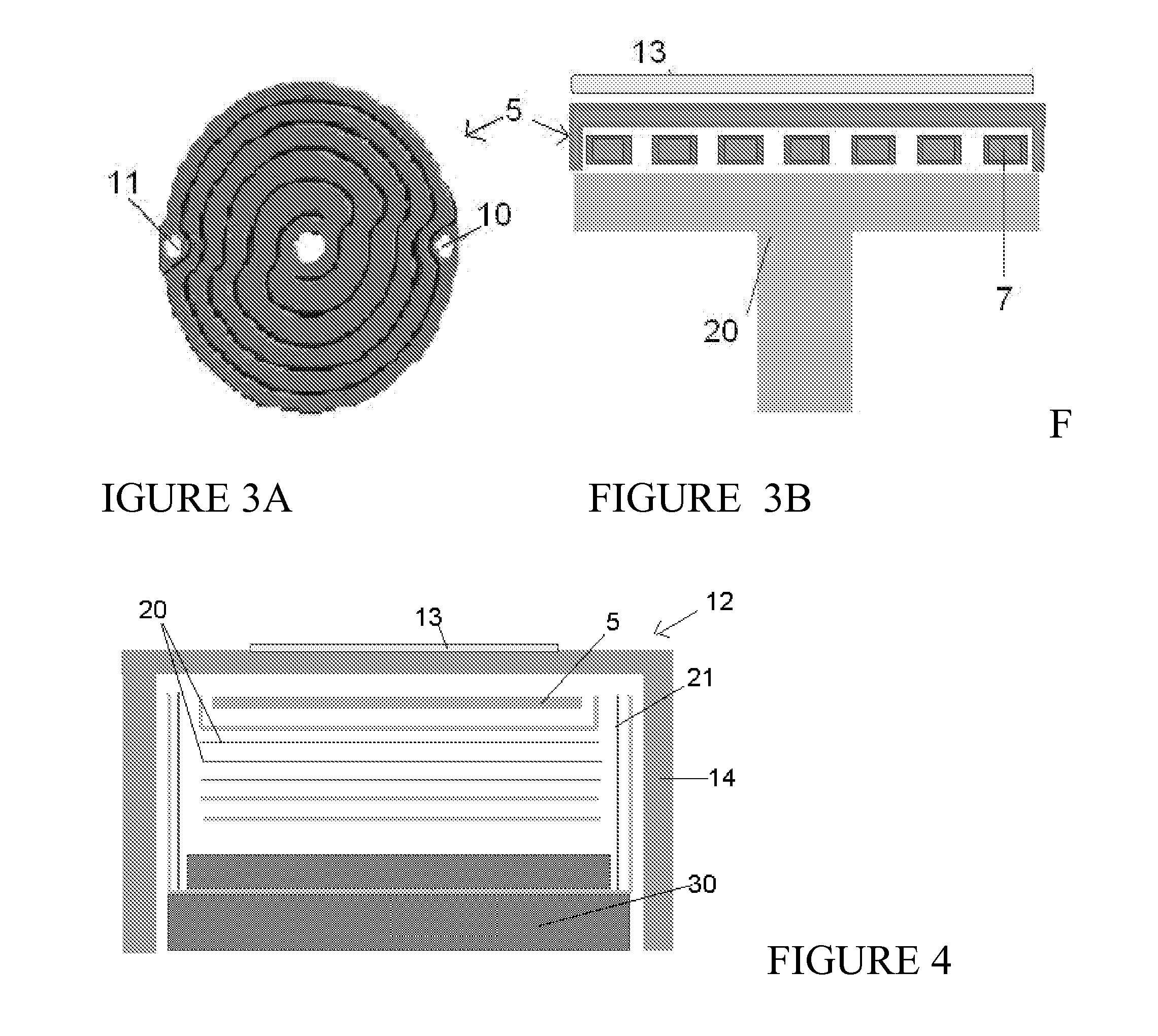

Structure and method to compensate for thermal edge loss in thin film heaters

ActiveUS20050035111A1Avoid depositionImprove temperature uniformityDecorative surface effectsOhmic-resistance heating detailsElectric forceEngineering

A thin film heater includes at least two open regions formed along each of two spaced-apart edges of the thin film material, which edges are parallel to two spaced-apart edges of the underlying substrate. The open regions expose areas of underlying substrate. When electrical power is coupled to the two spaced-apart edges of the thin film material, uniformity of the heat generated across the thin film material is enhanced. The substrate may be planar or curved, and the open regions in the thin film material may be removed from deposited thin film material, or may be formed by preventing deposition of thin film material in such regions.

Owner:THERMO STONE USA

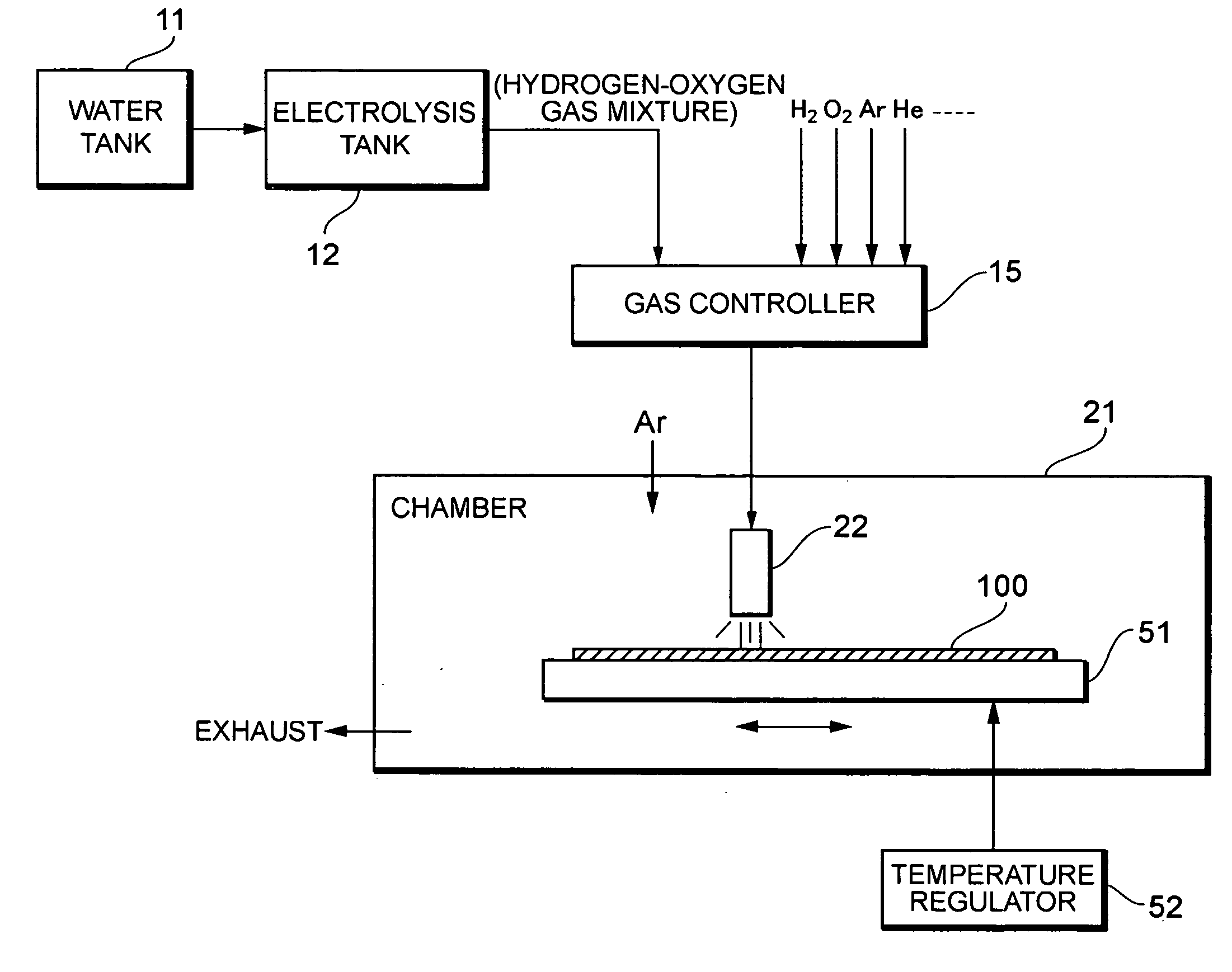

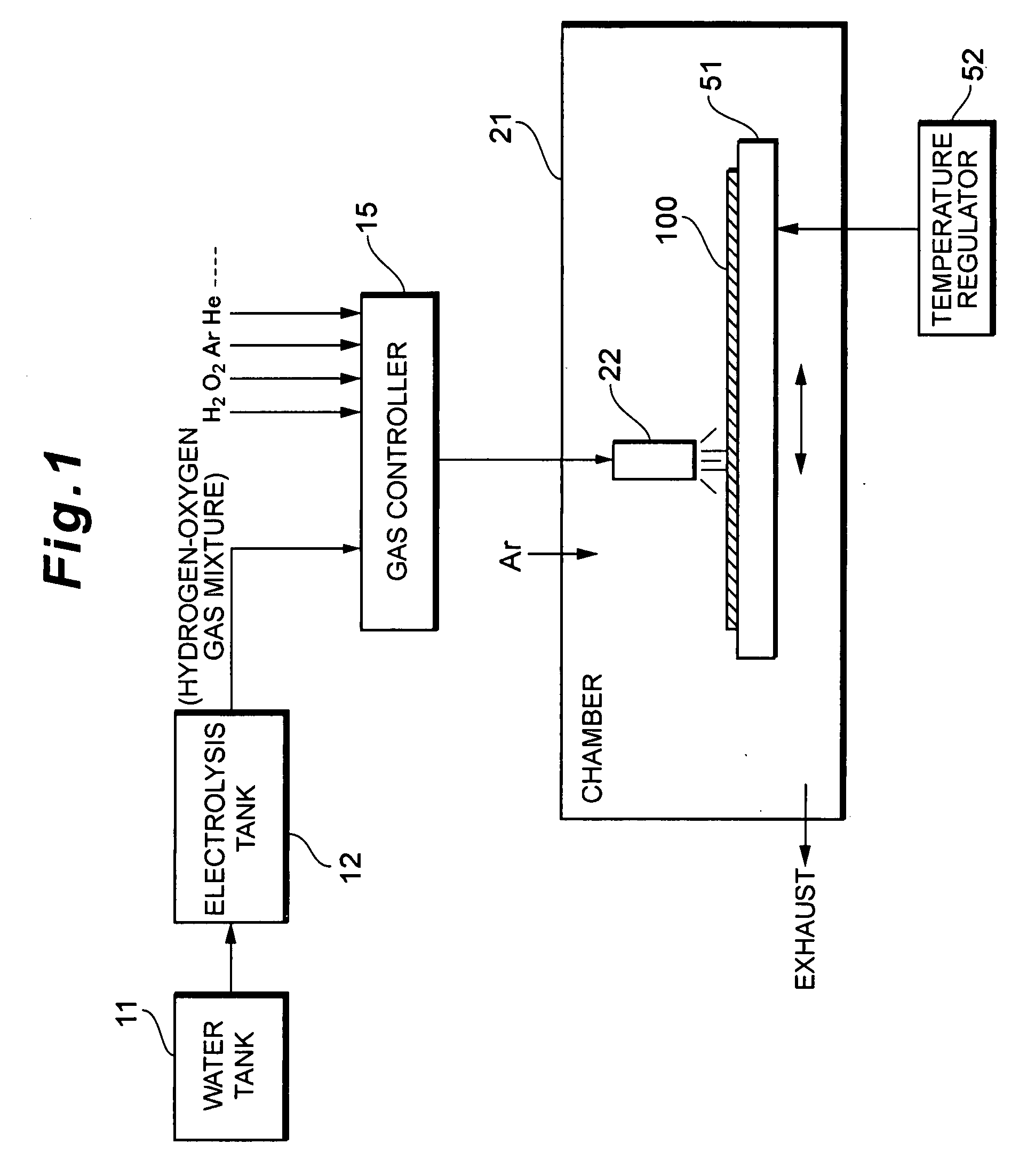

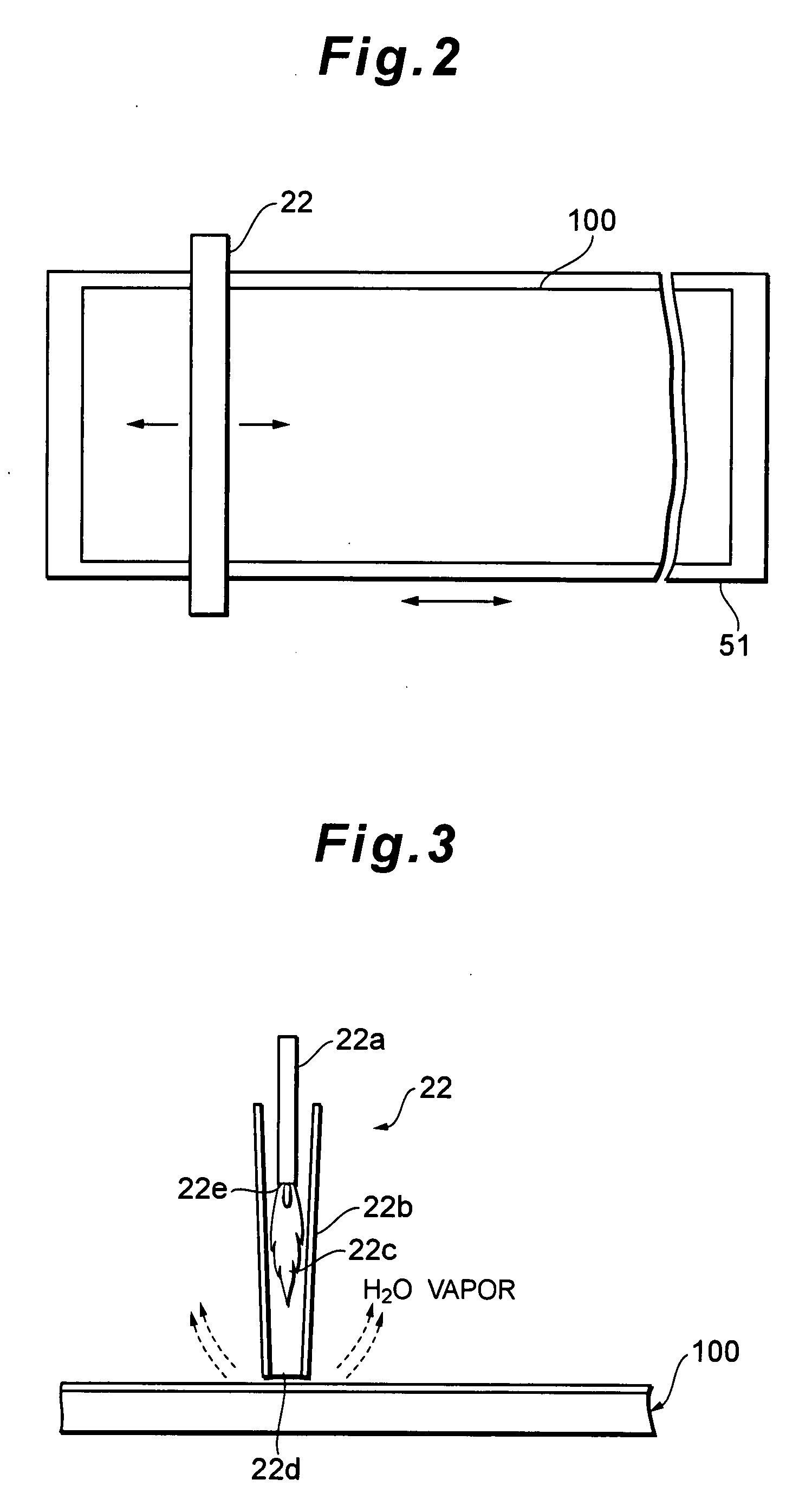

Method for fabricating a semiconductor device, method for fabricating an electronic device, and semiconductor fabricating apparatus

InactiveUS20080087213A1Improve uniformityReduce heat loadLiquid surface applicatorsSemiconductor/solid-state device manufacturingHydrogenEngineering

A method for fabricating a semiconductor device including: a step of forming a first film on a substrate; and a step of performing a thermal process by scanning the first film with a flame of a gas burner using a hydrogen and oxygen gas mixture as a fuel, wherein the flame of the gas burner is approximately linear.

Owner:SEIKO EPSON CORP

Constant temperature metal bath

ActiveCN102211047AImprove heat preservation functionIncrease the number ofHeating or cooling apparatusThermal insulationHeat conducting

The invention relates to a biochemical instrument, and provides a constant temperature metal bath, which comprises a base, a warming and cooling part and a radiating part, and also comprises a heat-conducting fin used for heat exchange, wherein the upper and lower surfaces of the heat-conducting fin are attached to the base and the warming and cooling part; and the coefficient of heat conduction K of the heat-conducting fin is more than 237W / m.K. A layer of heat-conducting fin is arranged between the base and the warming and cooling part, and thermal interface materials are coated on contact surfaces among the base, the heat-conducing fin, the warming and cooling part and the radiating part, and the heat conducting uniformity is enhanced; a thermal insulation gasket is arranged between the base and the heat-conducing fin, and the thermal insulation function of the base is enhanced; an exhaust fan is moved to the bottom, and the number of the exhaust fans is increased, so that the warming and cooling efficiency is improved; and an anti-condensation device and a gasket are arranged above the base, and a lantern ring is arranged at the periphery of the base, so that the usability of the constant temperature metal bath is improved.

Owner:盛司潼

Thermal wind speed sensor encapsulated based on carbon nanotube array

InactiveCN102967725AHigh sensitivityGood axial heat transfer performanceIndication/recording movementFluid speed measurement using thermal variablesNanometreCarbon nanotube

The invention discloses a thermal wind speed sensor encapsulated based on a carbon nanotube array, comprising a silicon substrate, four temperature measurers, a heating element, a copper film layer, a carbon nanotube layer, a nickel film layer and a thermal insulating medium layer. The top surface of the silicon substrate is connected with the bottom surface of the copper film layer, the top surface of the copper film layer is connected with the bottom surface of the carbon nanotube layer, and the top surface of the carbon nanotube layer is connected with the bottom surface of the nickel film layer; the heating element and the four temperature measurers are embedded on the bottom surface of the silicon substrate respectively, the four temperature measurers are uniformly distributed at the periphery of the heating element, and an annular thermal isolation groove is arranged between the heating element and the temperature measurers, and the distance from the top surface of the thermal isolation groove to the top surface of the silicon substrate is smaller than 50 nanometers; and the thermal insulating medium layer is covered on the outer surface of the silicon substrate, the carbon nanotube layer is formed by carbon nanotubes which are arranged in arrays, and each carbon nanotube is vertically arranged. The thermal wind speed sensor of the structure can reduce the influence of the transverse heat conduction of the silicon substrate, and the flexibility of the sensor is improved.

Owner:SOUTHEAST UNIV

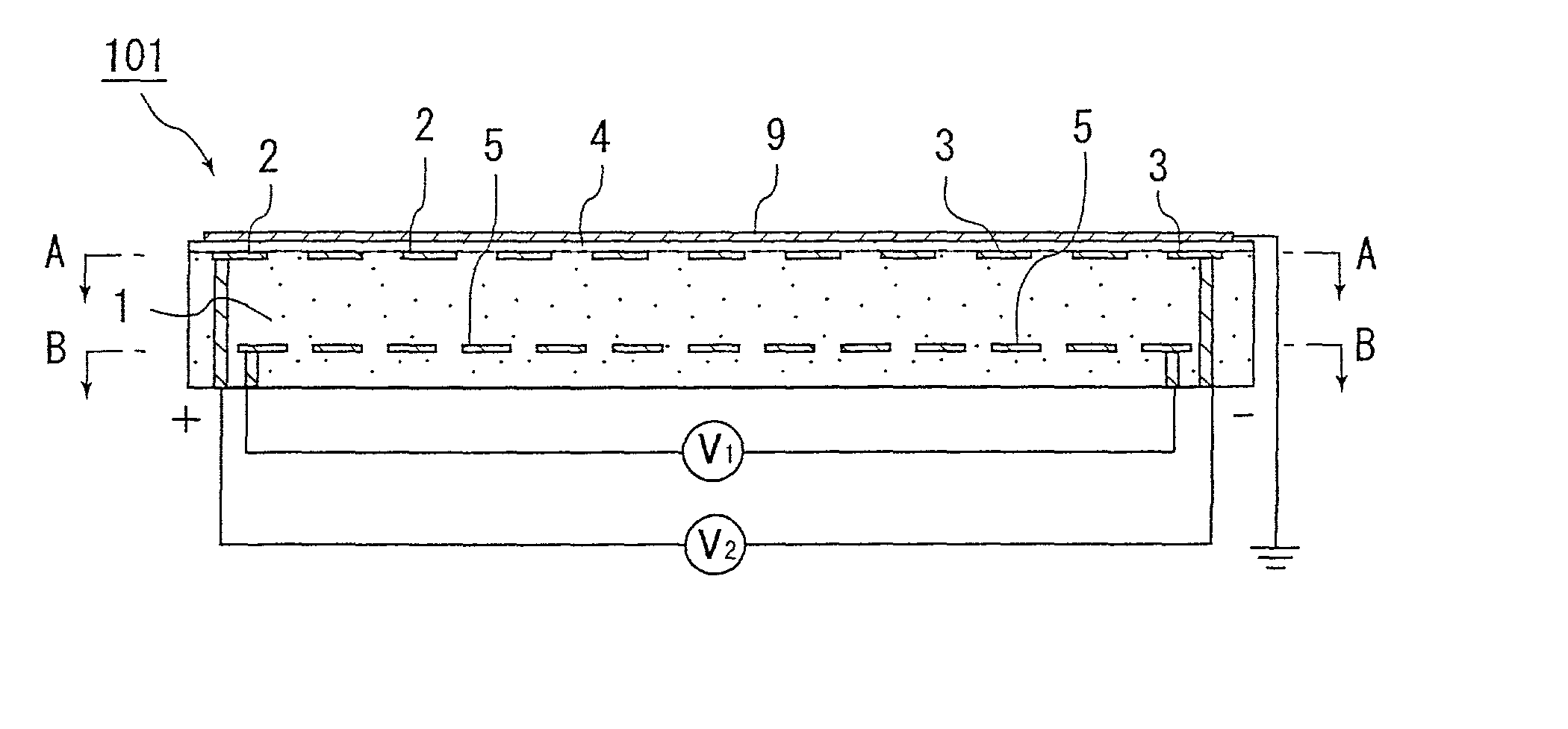

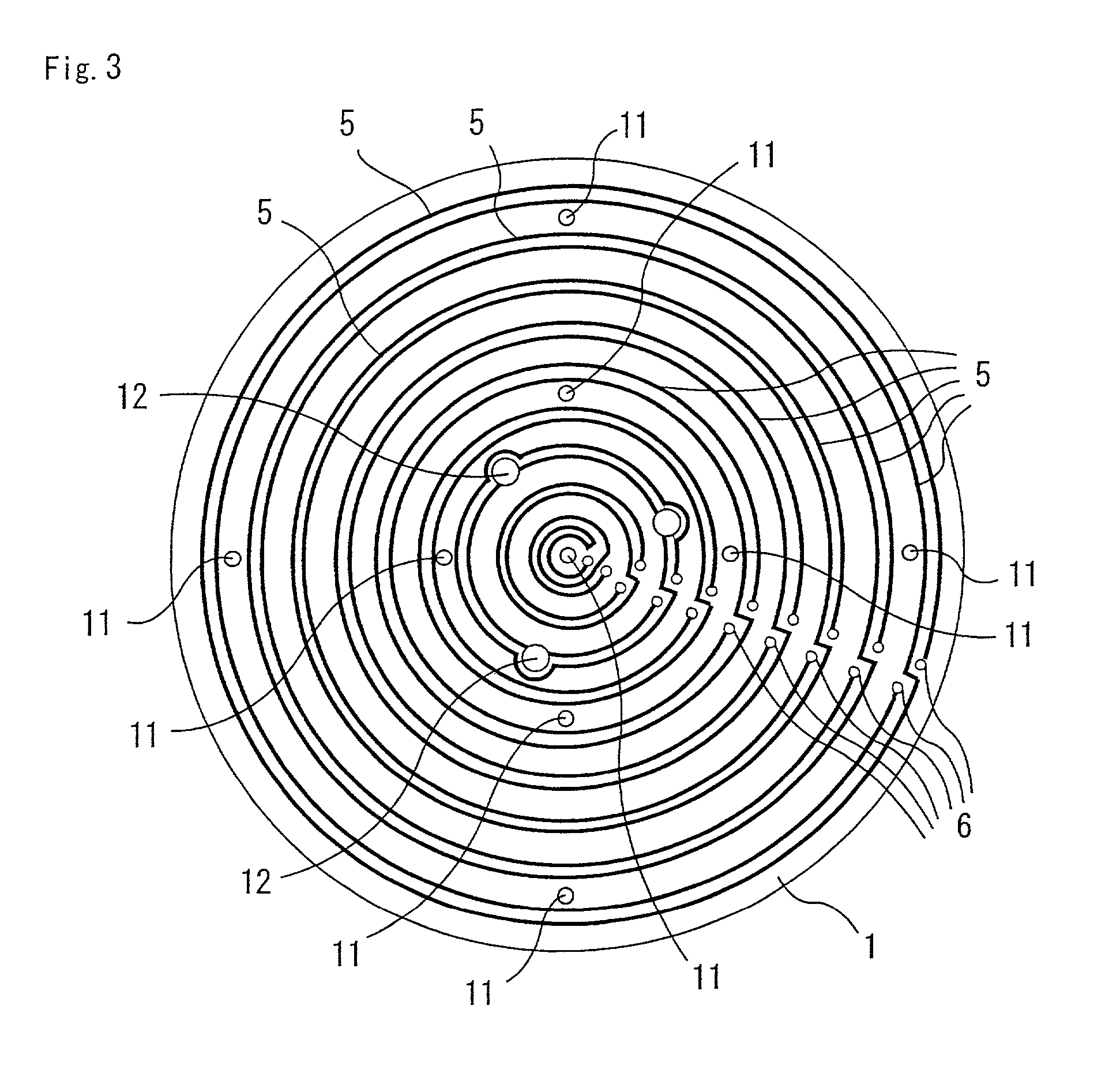

Ceramic substrate for semiconductor production and inspection devices

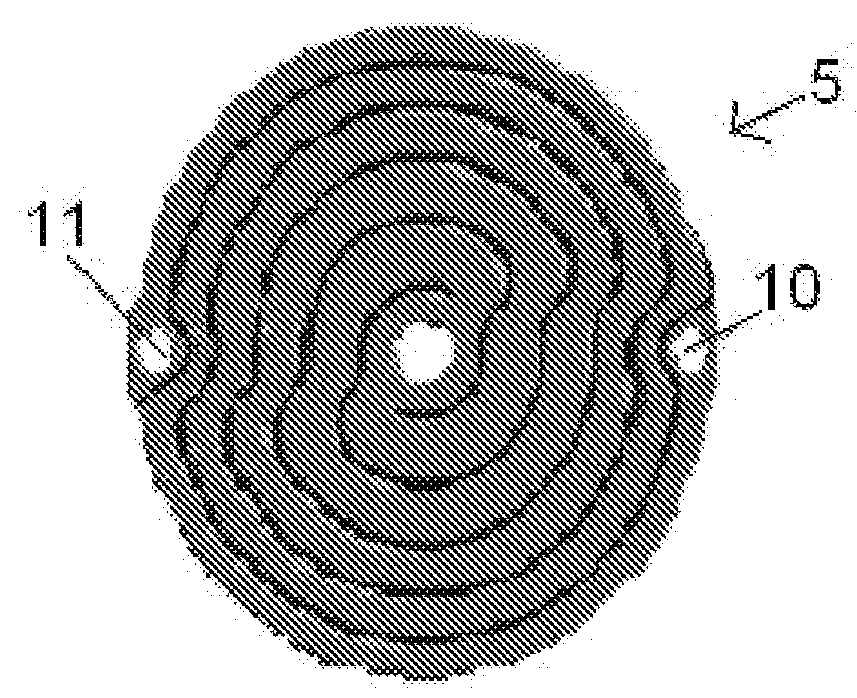

InactiveUS7011874B2Improve thermal uniformityReduce heat transferFurnaces without endless coreLiquid surface applicatorsElectrical conductorMetallurgy

The object of the present invention is to provide a ceramic substrate that can provide a substantially uniform temperature distribution to a surface of the ceramic substrate where a semiconductor wafer is treated. A ceramic substrate for a semiconductor-producing / examining device according to the present invention is a ceramic substrate having a conductor formed on a surface of the ceramic substrate or inside the ceramic substrate, wherein said substrate is containing oxygen and having a disc form, the diameter thereof exceeding 250 mm and a thickness thereof being 25 mm or less.

Owner:IBIDEN CO LTD

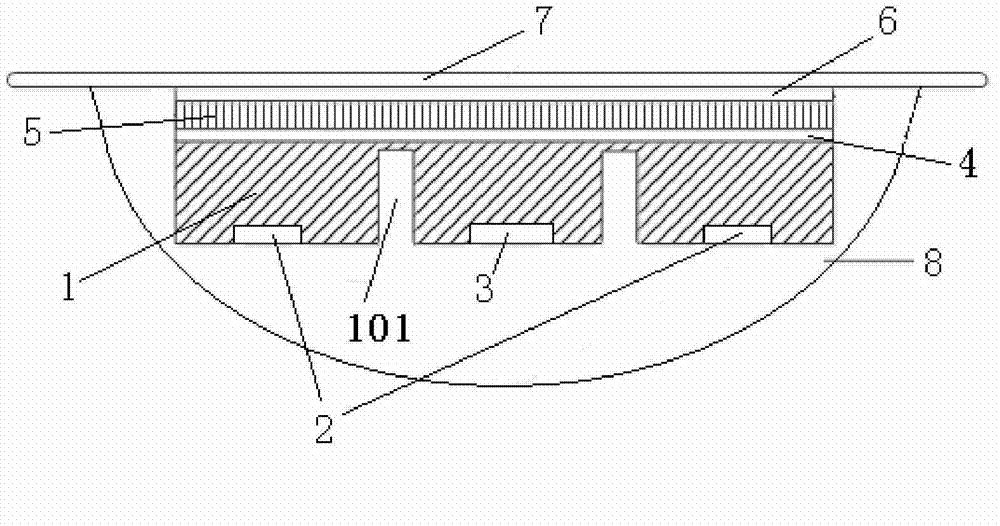

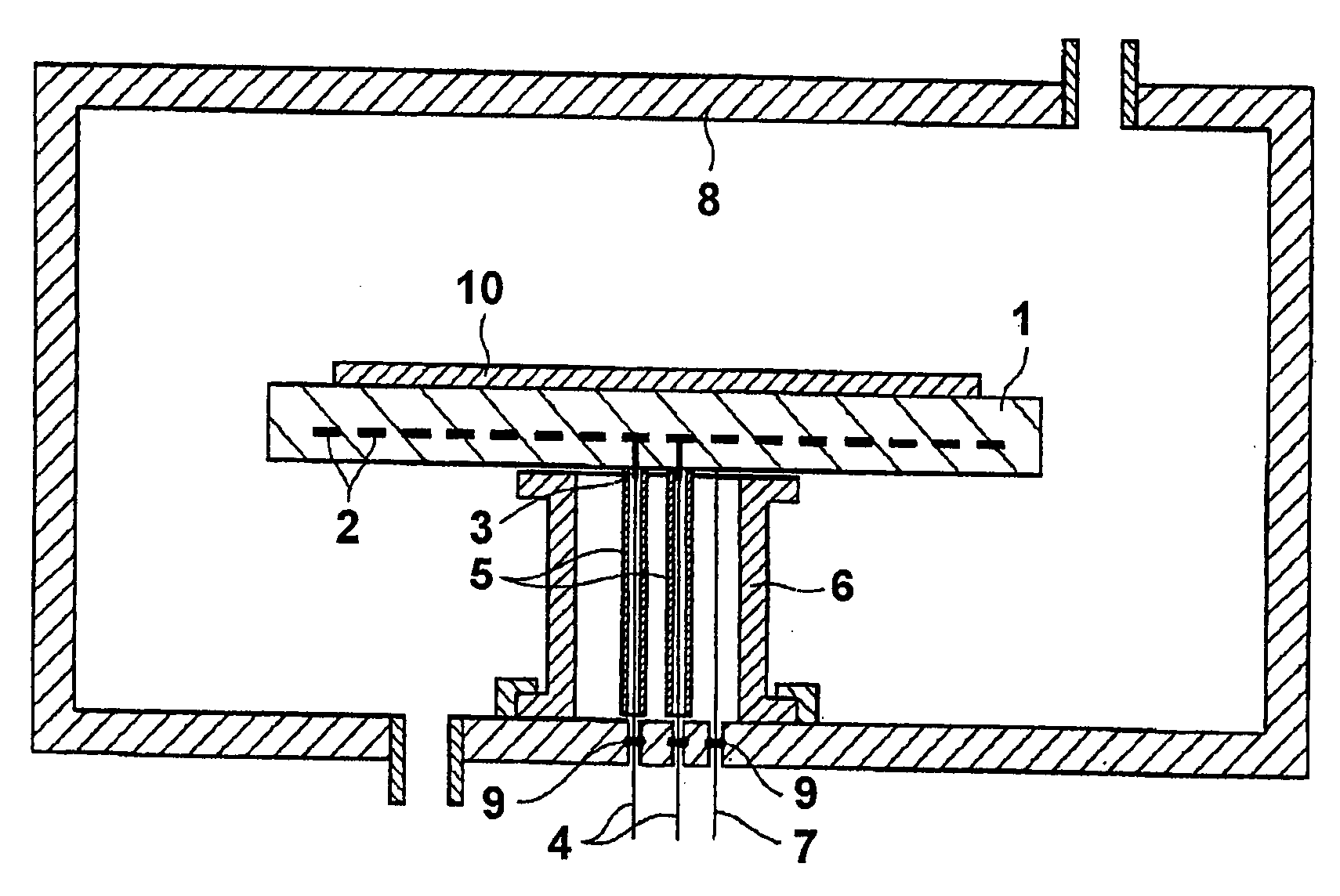

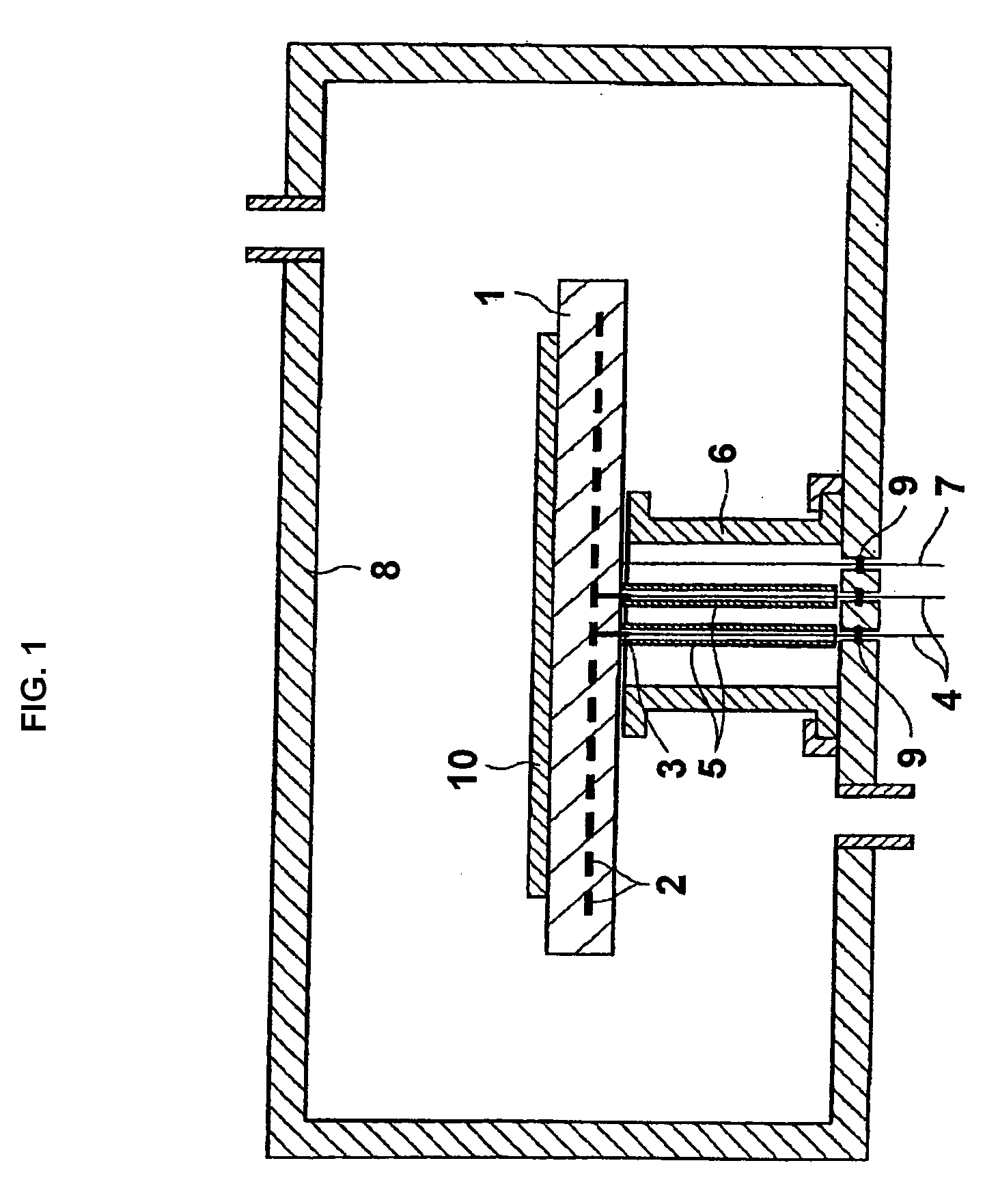

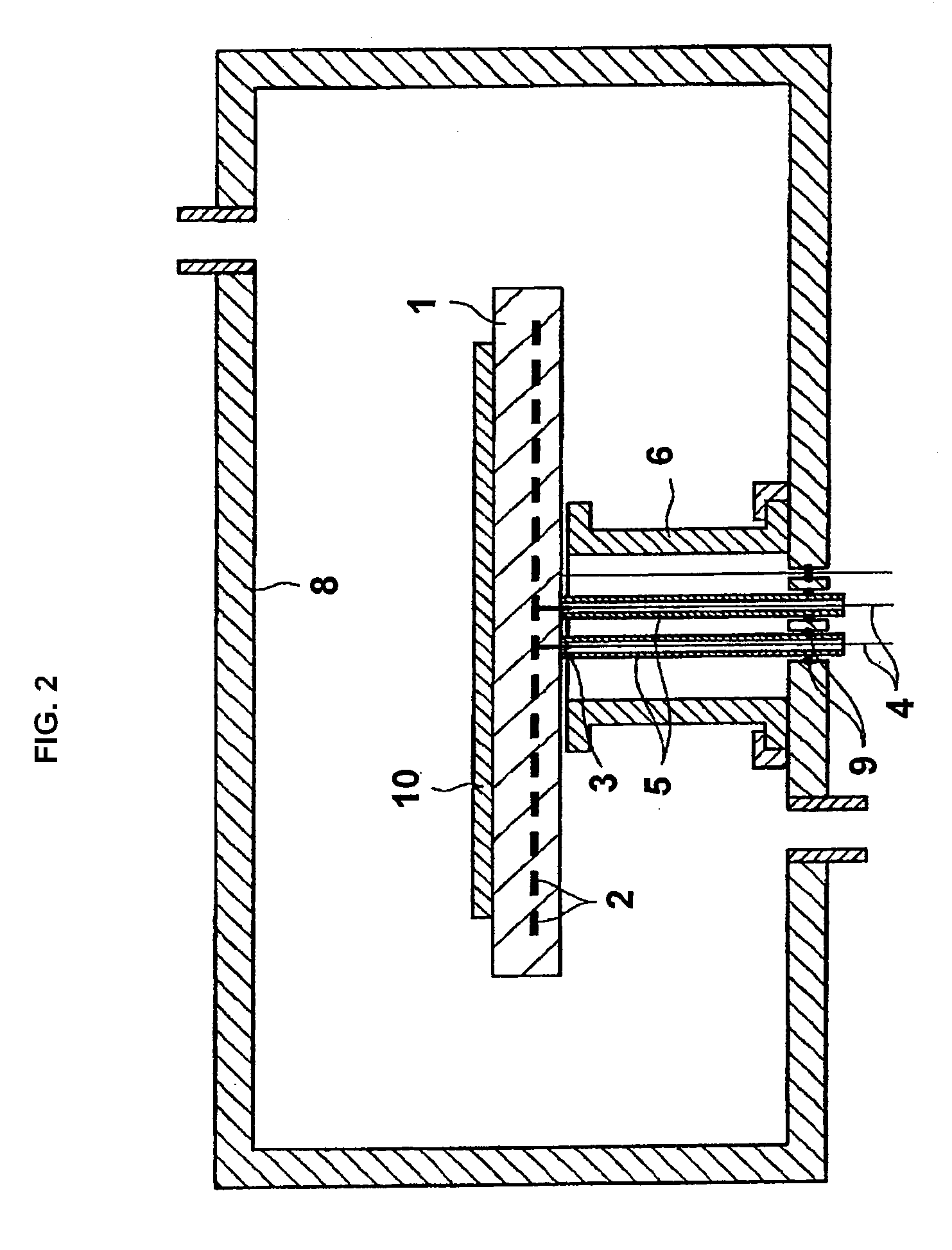

Holder for semiconductor manufacturing equipment

InactiveUS20100242844A1Prevent leakageReduce uniformitySemiconductor/solid-state device manufacturingOhmic-resistance heating detailsReactive gasEngineering

A holder for semiconductor manufacturing equipment is provided, in which electrical leakage and sparks do not occur across the electrode terminals and lead wires to supply power to a resistive heating element embedded in a holder, and the thermal uniformity in the holder is within ±1.0%.The holder for semiconductor manufacturing equipment, that is provided in a chamber to which reactive gas is supplied, comprises a ceramic holder 1 which holds a treated material 10 on a surface thereof and is provided with a resistive heating element 2 for heating the material to be treated, and a support member 6 one end of which supports the ceramic holder 1 at a position other than the surface holding the material to be treated, and the other end of which is fixed to the chamber. Electrode terminals 3 and lead wires 4 of the resistive heating element 2 provided at a portion other than the surface of the ceramic holder 1 holding the material to be treated are housed within an insulating tube 5 in the holder 1 for the semiconductor manufacturing equipment.

Owner:SUMITOMO ELECTRIC IND LTD

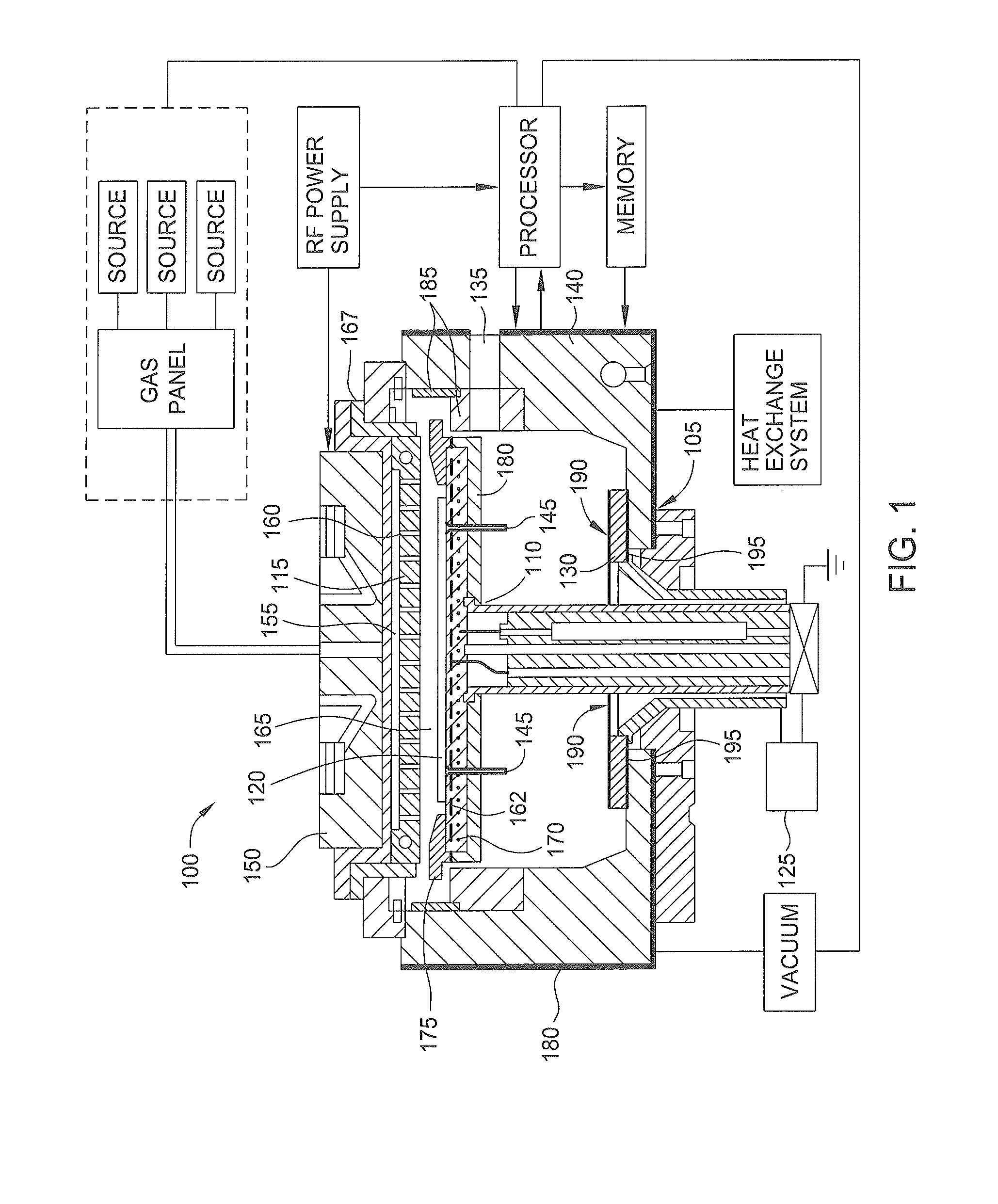

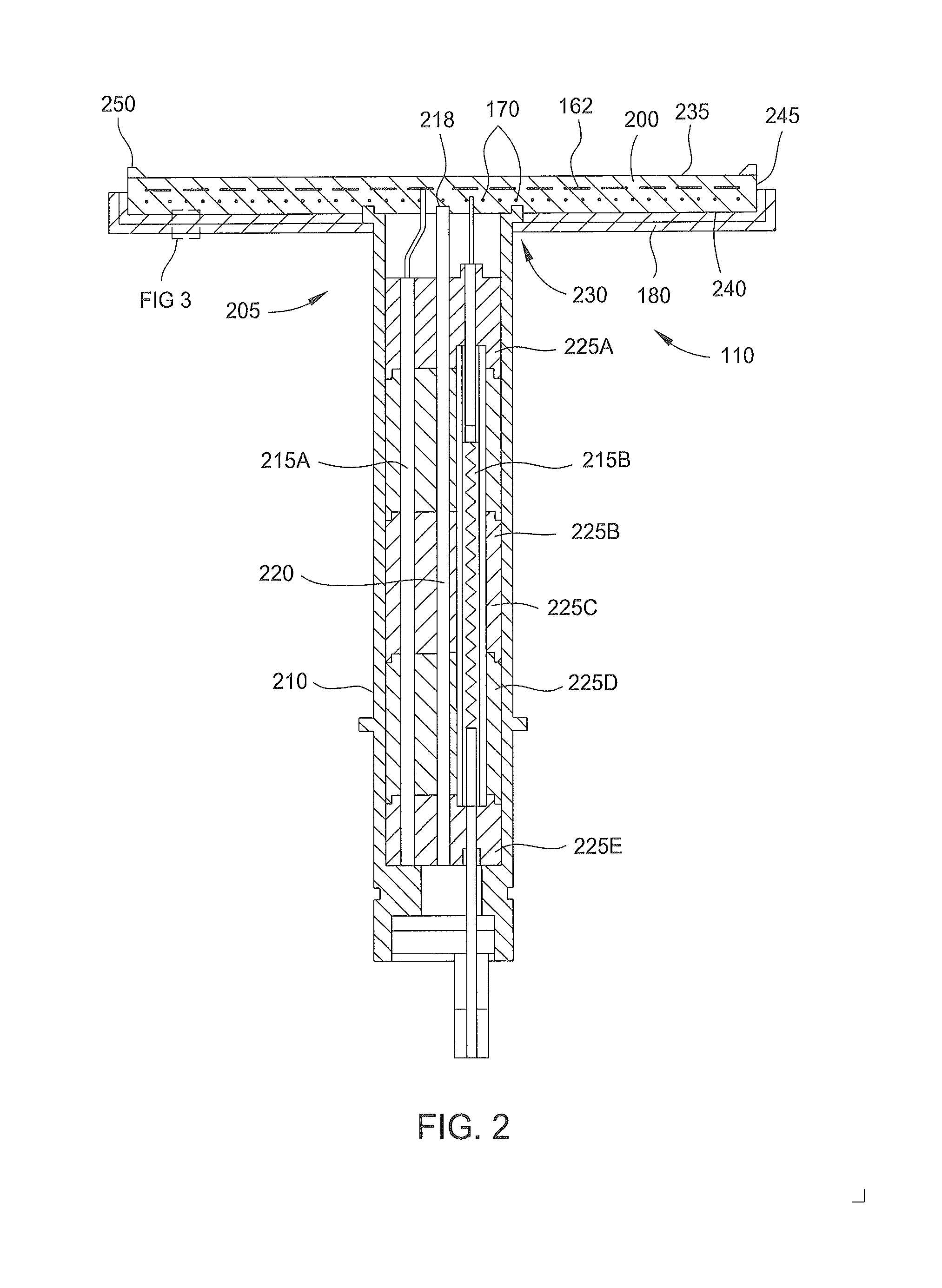

Thermal radiation barrier for substrate processing chamber components

ActiveUS20140165915A1Minimize heat transferImprove thermal uniformitySemiconductor/solid-state device manufacturingHeating element shapesSecondary layerEnergy loss

An apparatus for a substrate support heater and associated chamber components having reduced energy losses are provided. In one embodiment, a substrate support heater is provided. The substrate support heater includes a heater body having a first surface to receive a substrate and a second surface opposing the first surface, a heating element disposed in the heater body between the first surface and the second surface, and a thermal barrier disposed on the second surface of the heater body, wherein the thermal barrier comprises a first layer and a second layer disposed on the first layer.

Owner:APPLIED MATERIALS INC

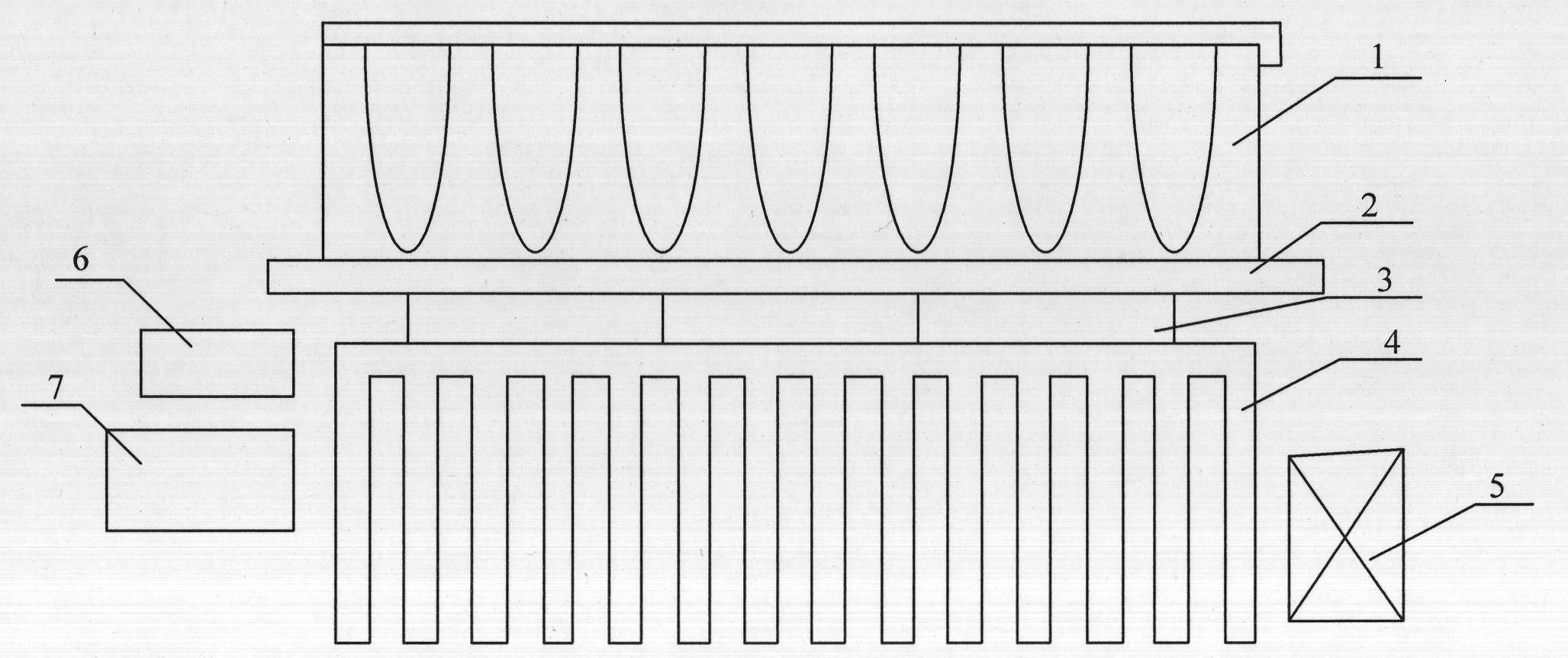

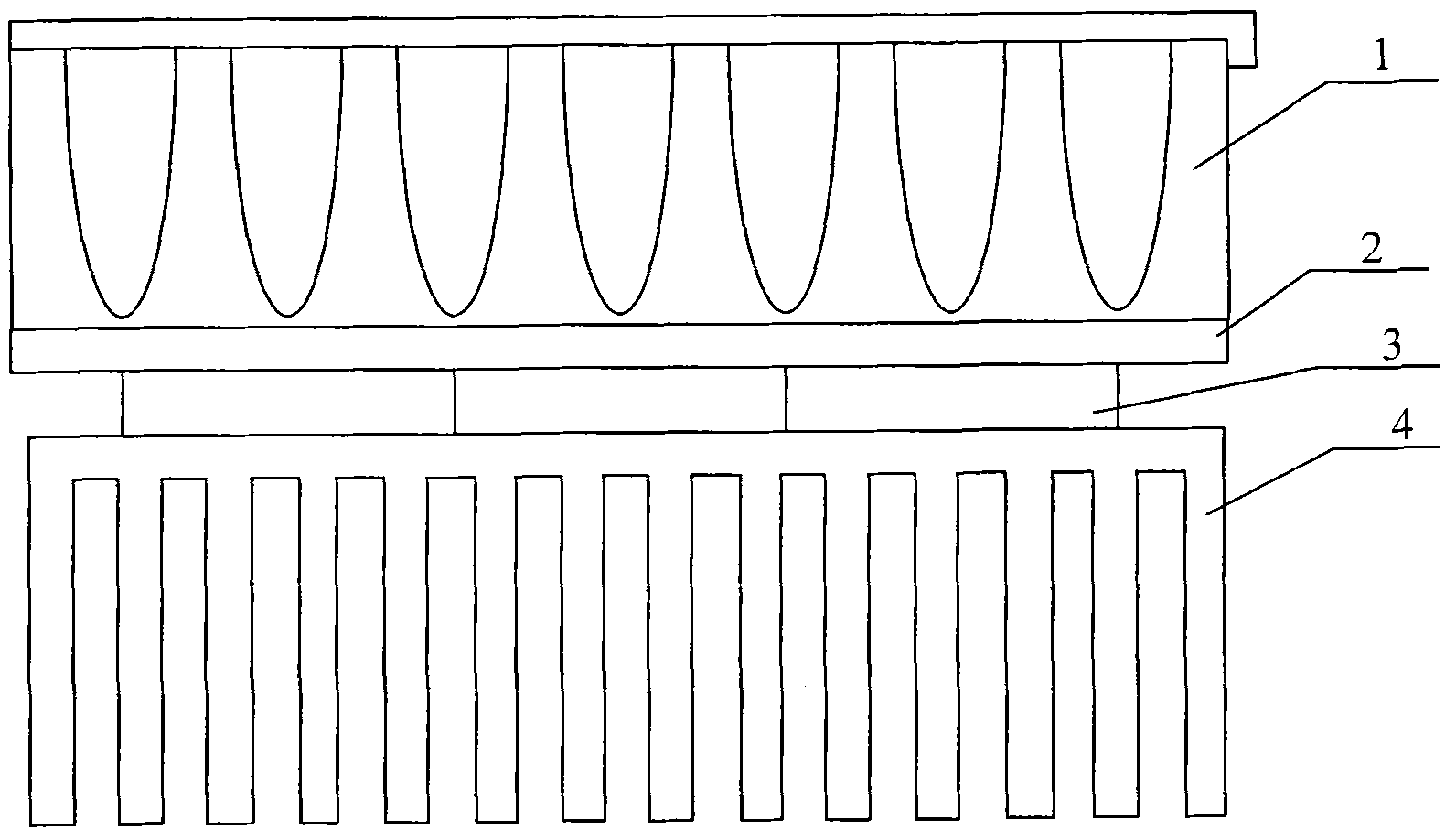

Press molding apparatus and method of producing a glass optical element using the apparatus

InactiveUS20060090512A1Increase ratingsImprove thermal uniformityGlass furnace apparatusGlass pressing apparatusMaterials scienceHigh frequency

In a press molding apparatus for press molding a plurality of glass materials into a plurality of glass optical elements by the use of a pressing mold including upper and lower molds each of which has a plurality of molding surfaces, at least one of the upper and the lower molds is a heat generator within which heat is generated when the heat generator is subjected to a high-frequency induction heating by an induction heating coil. The heat generator having a plurality of shape-processed portions (130) produced by partially processing a shape of the heat generator in order that a temperature distribution of the heat generator is adjusted. The apparatus simultaneously press forms, into the glass optical elements, the glass materials supplied between the molding surfaces of the upper and the lower molds which are subjected to the high-frequency induction heating.

Owner:HOYA CORP

High-efficiency molten carbonate fuel cell system and method

ActiveUS20160181647A1Increase power generationGuaranteed uptimeFuel cells groupingFuel cell auxillariesFuel cellsMolten carbonate fuel cell

A high efficiency fuel cell system comprising a topping fuel cell assembly comprising a topping cathode portion and a topping anode portion; and a bottoming fuel cell assembly comprising a bottoming cathode portion and a bottoming anode portion, wherein the bottoming anode portion receives anode exhaust output from the topping anode portion and the topping cathode portion receives cathode exhaust from the bottoming cathode portion, and wherein the topping fuel cell assembly has a greater number of fuel cells than the bottoming fuel cell assembly so that the topping fuel cell assembly utilizes more fuel than the bottoming fuel cell assembly.

Owner:FUELCELL ENERGY INC

Etch resistant heater and assembly thereof

InactiveUS20070181065A1Improve temperature uniformityImprove thermal uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEtching rateRadiation

An etch resistant heater for use in a wafer processing assembly with an excellent ramp rate of at least 20° C. per minute. The heater is coated with a protective overcoating layer allowing the heater to have a radiation efficiency above 70% at elevated heater temperatures of >1500° C., and an etch rate in NF3 at 600° C. of less than 100 A / min.

Owner:GENERAL ELECTRIC CO

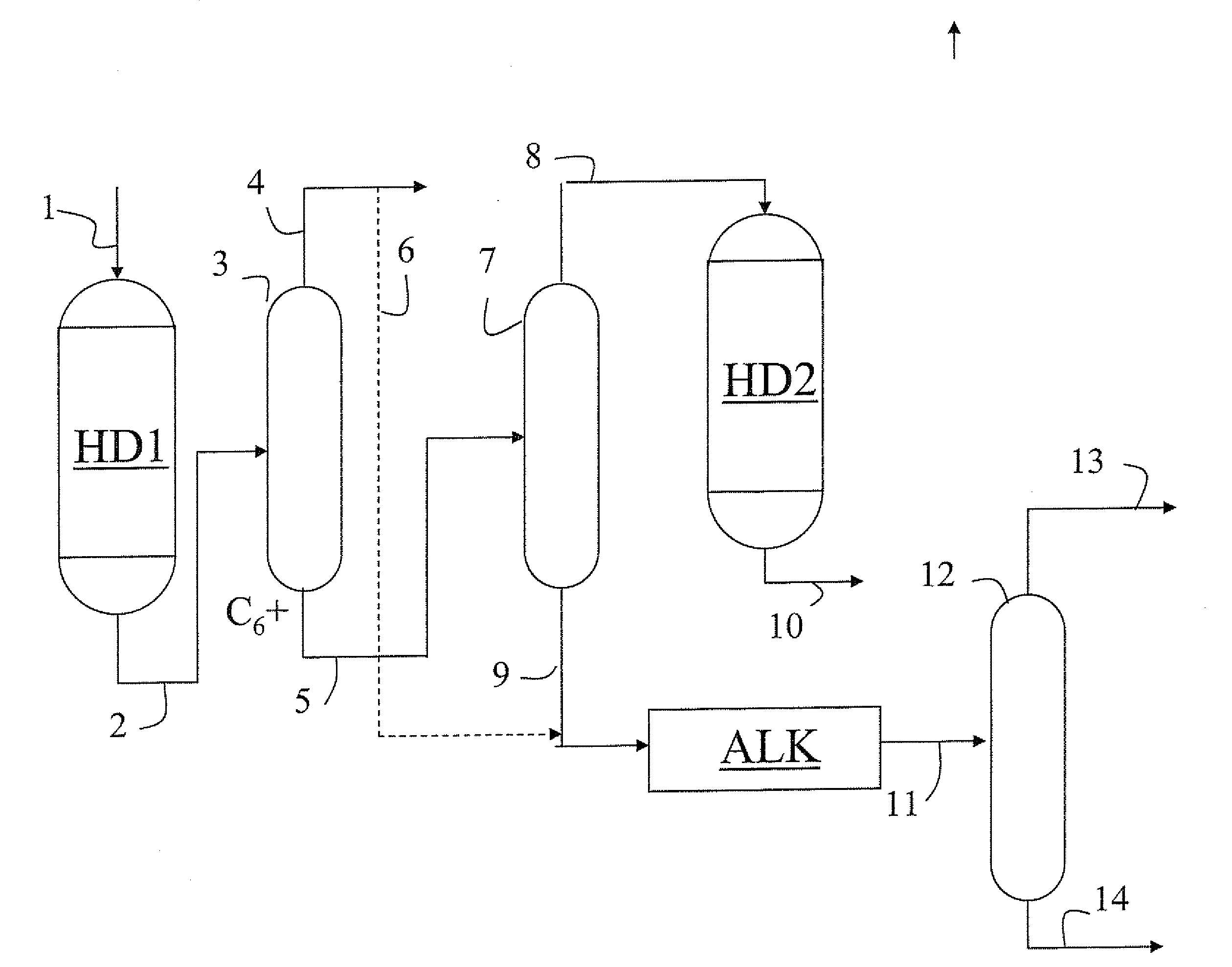

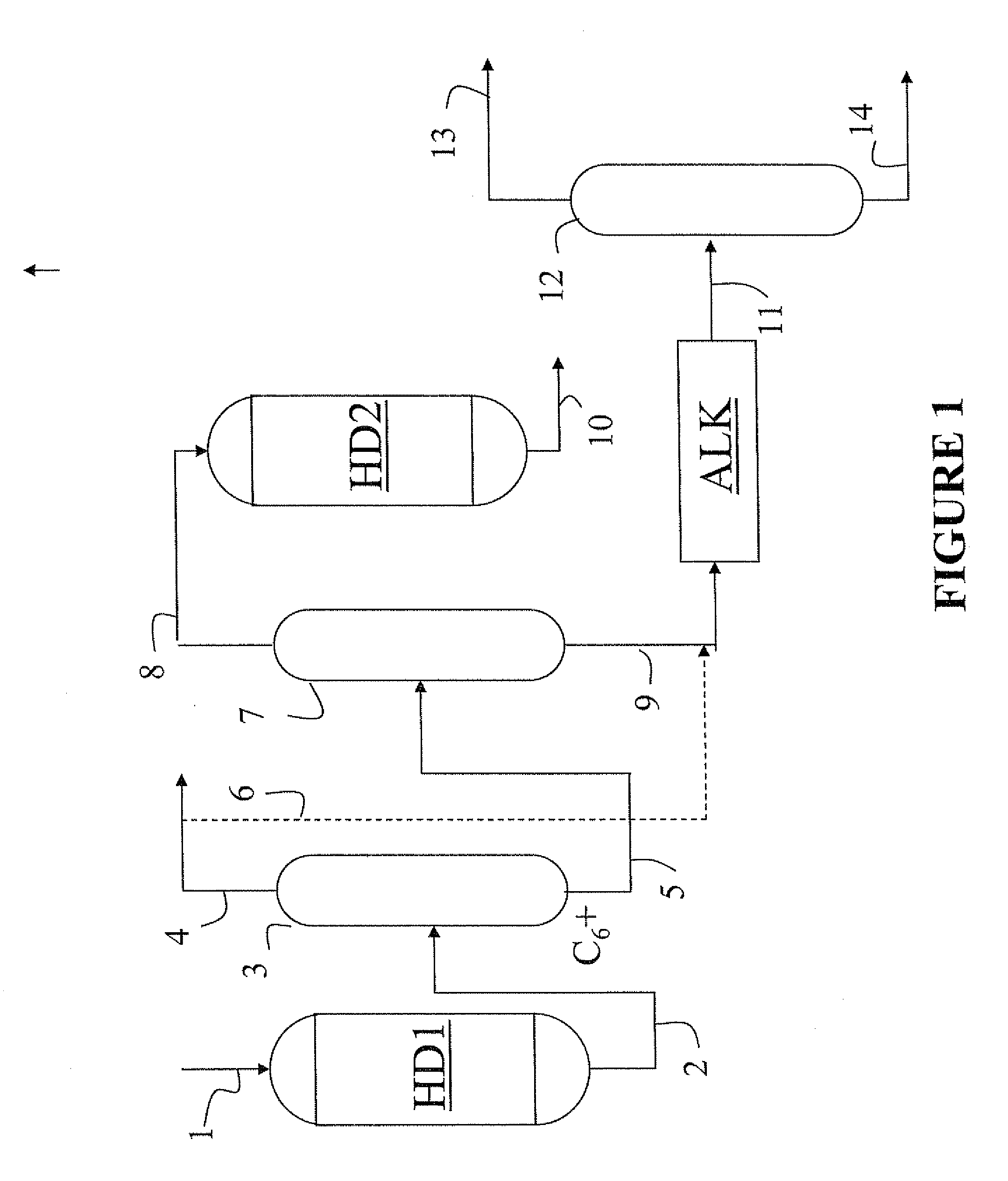

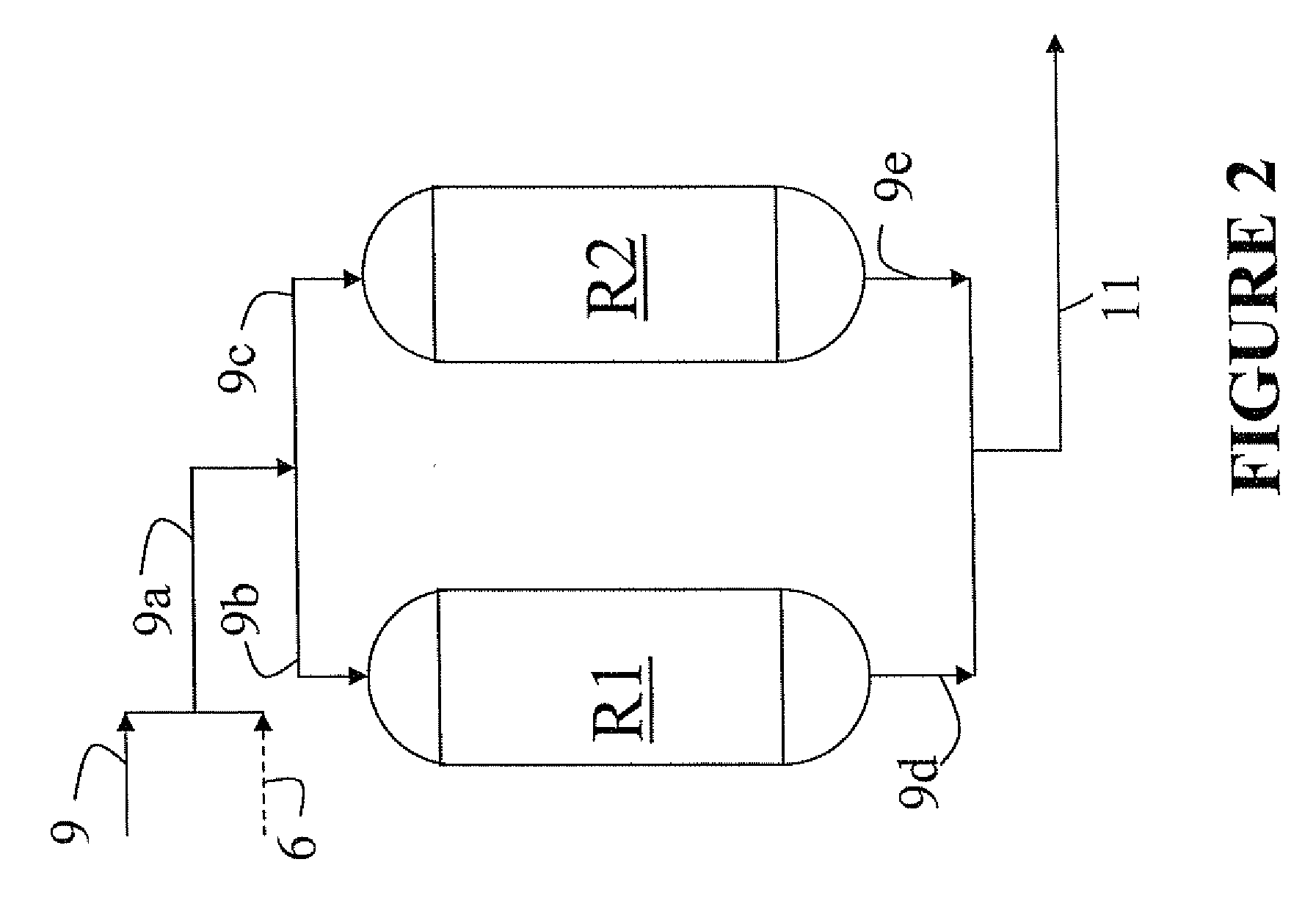

Method for desulfurizing hydrocarbon fractions from steam cracking effluents

ActiveUS20080223753A1Inhibit exothermNot to reachRefining with acid-containing liquidsTreatment with hydrotreatment processesAlkyl transferDistillation

The present invention relates to a method for treating a feed corresponding to a pyrolysis gasoline, comprising:a) at least one stage of selective hydrogenation of the feed, referred to as HD1,b) fractionating in one or more distillation columns the effluent from stage a) in order to produce at least one light C5 cut, an intermediate C6 or C6-C7 or C6-C8 cut intended for aromatics production, a heavy C7+ or C8+ or C9+ cut intended for gasoline production,c) at least one stage of hydrodesulfurization and deep hydrogenation of the intermediate cut, referred to as HD2,d) at least one stage of alkylation of the heavy C7+, C8+ or C9+ cut consisting of a treatment on an acid catalyst allowing weighting of the sulfur compounds,e) at least one stage of distillation of the effluent from stage d), intended to produce a light fraction that can be directly used as a low-sulfur gasoline base, and a heavy C11+ or C12+ fraction rich in sulfur compounds, used as middle distillate or fuel oil.

Owner:INST FR DU PETROLE

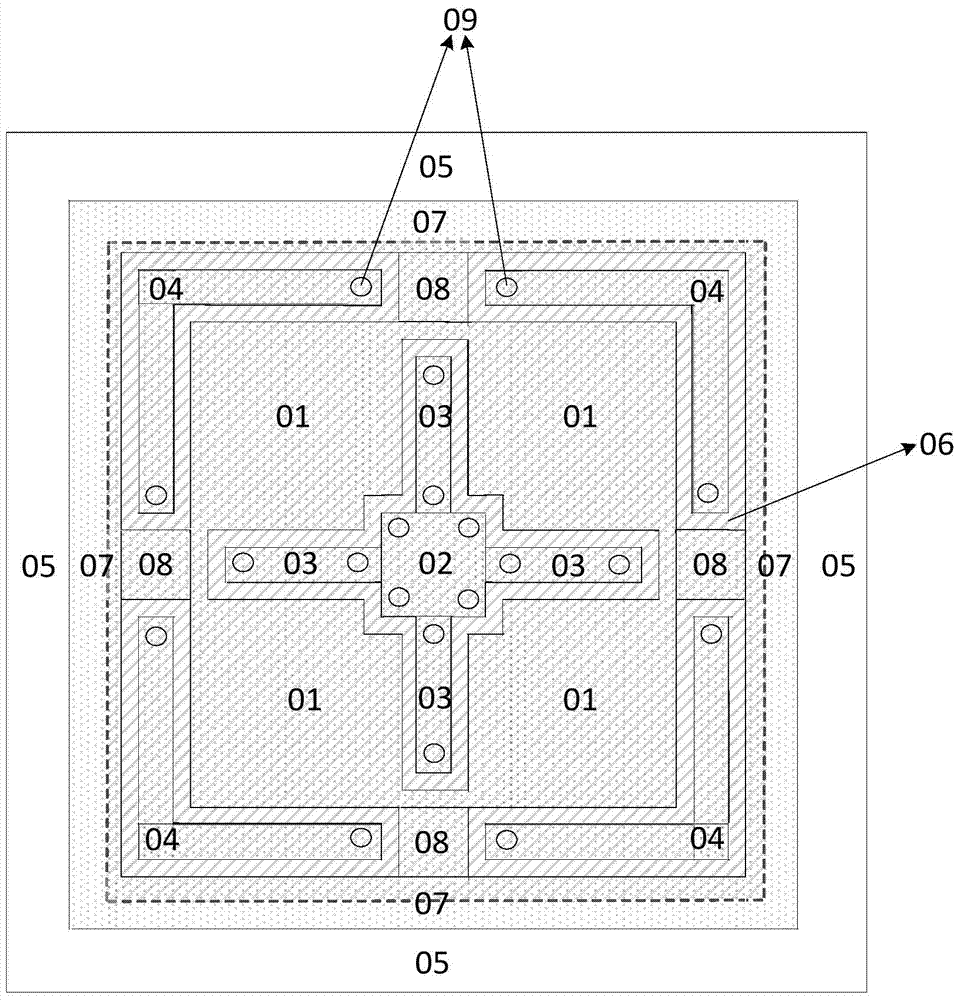

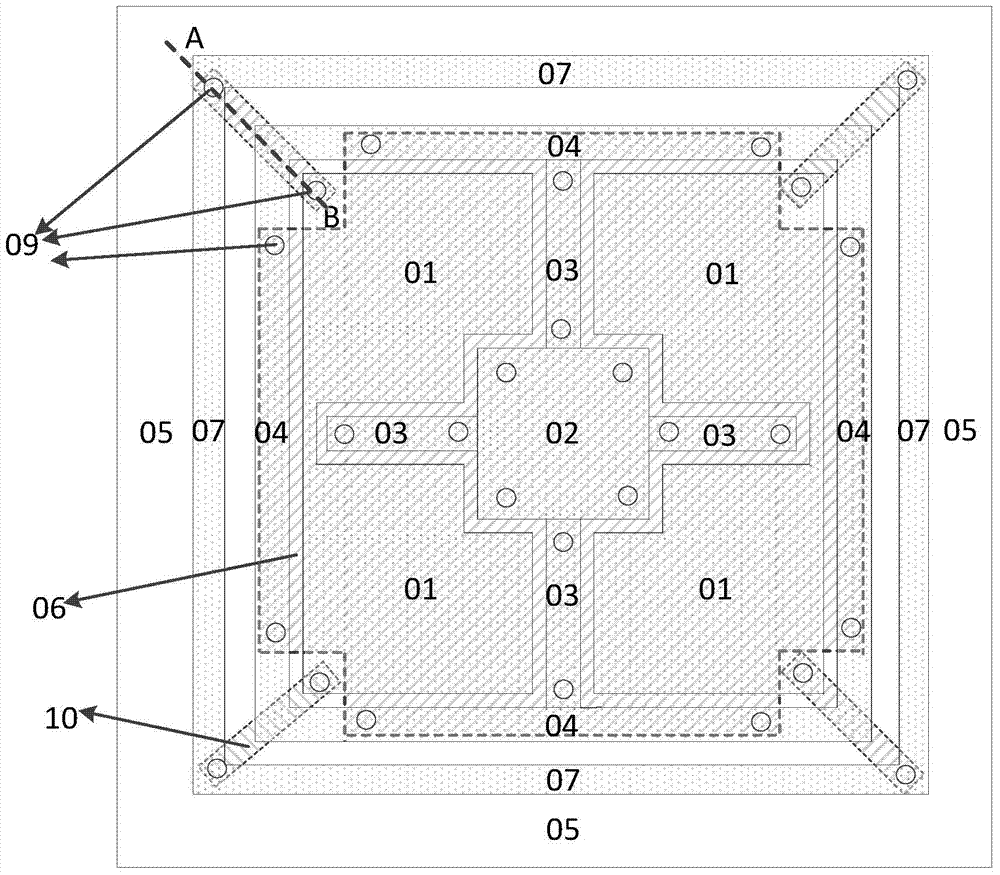

IGBT device capable of improving switch-on and switch-off speed and switch-on and switch-off uniformity and manufacturing method thereof

ActiveCN103579322AFast transmissionReduce opening timeSemiconductor/solid-state device detailsSolid-state devicesCharge and dischargePolycrystalline silicon

The invention relates to a power device and a manufacturing method of the power device, in particular to an IGBT device capable of improving the switch-on and switch-off speed and switch-on and switch-off uniformity and a manufacturing method of the IGBT device. The IGBT device comprises emitting electrode PAD regions, a grid PAD region, grid Finger regions, a grid Bus region and a terminal region. The grid PAD region is located at the center of the device, the emitting electrode PAD regions are distributed around the grid PAD region and separated by the grid Finger regions, the grid Bus region surrounds the emitting electrode PAD regions, and the terminal region is located on the periphery of the grid Bus region. By improving the traditional structural design of a polycrystalline silicon layer and a metal layer, the speed of charging and discharging cellular grids is improved when the IGBT device is switched on or switched off, and accordingly the overall switch-on and switch-off speed of the IGBT device is improved. Compared with a traditional IGBT device structure, the IGBT device has the advantages that the switch-on and switch-off speed of the IGBT device is improved, and the switch-on and switch-off uniformity of IGBT cells is improved at the same time.

Owner:STATE GRID CORP OF CHINA +2

Apparatus And Methods For Making Analyte Particles

InactiveUS20110121093A1Rapidly and efficiently removeEasy to disassembleLiquid surface applicatorsComponent separationParticulatesNebulizer

A device for making particulate analyte molecules comprising a nebulizer producing a plume of liquid droplets, a vessel having a chamber to receive the plume in which the chamber has a nebulization section, a desolvation section. The nebulization section is cooled to form a condensed waste from a portion of said plume. The desolvation section is heated to form solvent gas molecules and particulate analyte molecules.

Owner:WATERS TECH CORP

Heating bottom plate of 3D printer

InactiveCN106393681AAvoid damageUniform and stable temperatureManufacturing platforms/substratesManufacturing heating elementsAdhesion forceMetallurgy

The invention provides a multifunctional heating plate used at the bottom of a 3D printer. The heating plate comprises a metal support plate, an insulating plate, a metal ceramic heating plate, a high-temperature resisting heat conducting film and a high-temperature glass plate. According to the heating bottom plate of the 3D printer, the metal ceramic heating plate serves as a heating material, edge warping of a printed object can be effectively prevented, the printing quality is improved, and damage of the heating bottom plate when the 3D printer breaks down can be effectively avoided. A temperature sensor can accurately feed back the actual temperature of the heating bottom plate of the 3D printer to a control circuit of the 3D printer in time. Due to the insulating plate, heat losses can be effectively reduced, and the temperature of the heating bottom plate is more stable and uniform. Due to the high-temperature resisting heat conducting film, heat on the metal ceramic plate can be transmitted to the high-temperature glass plate more effectively and evenly. The adhesion force of the high-temperature glass plate to plastic materials is high, the trouble of replacing high-temperature double-sided adhesive tape is saved, and the printed object can be easily separated from the 3D printer.

Owner:WUHU CHUNYUAN PHOTOELECTRIC EQUIP TECH CO LTD

Backlight module

InactiveUS20110249470A1Improve thermal uniformitySolve the low heat dissipation efficiencyLighting heating/cooling arrangementsOptical signallingLight guideEngineering

A backlight module includes a light guide plate, a back plate, a heat-dissipating element, a light-emitting element, and at least one high-performance heat sink. The heat-dissipating element is disposed adjacent to a light incident surface of the light guide plate, and the heat-dissipating element has a bottom portion and a side portion forming an angle with the bottom portion. The light-emitting element is disposed on one side of the heat-dissipating element facing the light guide plate. The high-performance heat sink is disposed on the back plate, one end of the high-performance heat sink overlaps the heat-dissipating element, and another end of the high-performance heat sink extends away from the light-emitting element.

Owner:CORETRONIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com