Patents

Literature

154 results about "Thermal wind" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The thermal wind is the vector difference between the geostrophic wind at upper altitudes minus that at lower altitudes in the atmosphere. It is the hypothetical vertical wind shear that would exist if the winds obey geostrophic balance in the horizontal, while pressure obeys hydrostatic balance in the vertical. The combination of these two force balances is called thermal wind balance, a term generalizable also to more complicated horizontal flow balances such as gradient wind balance.

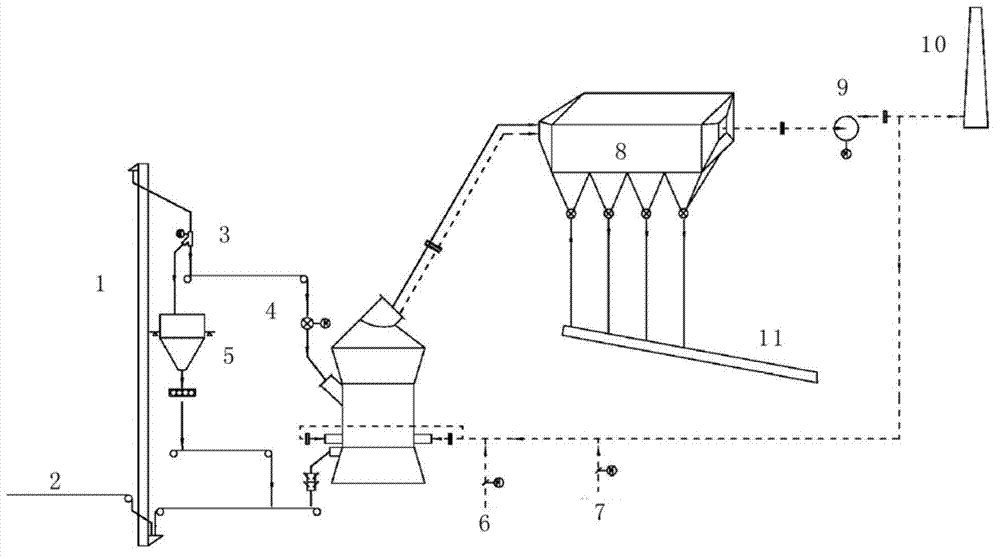

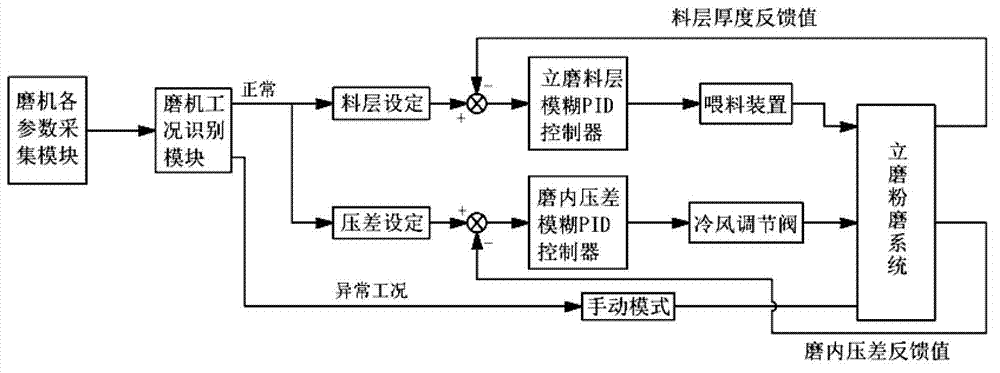

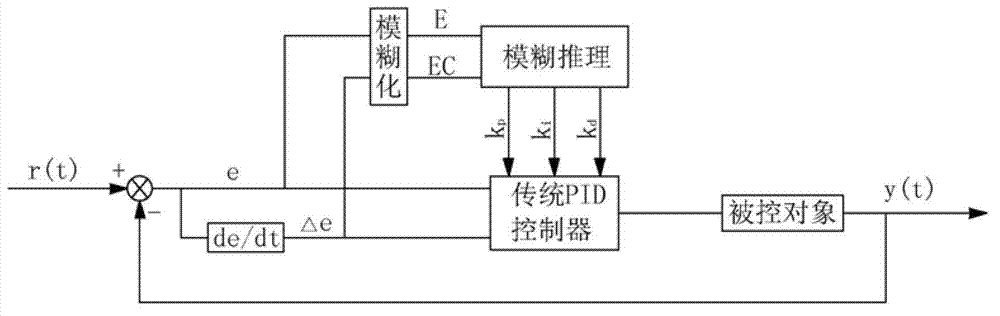

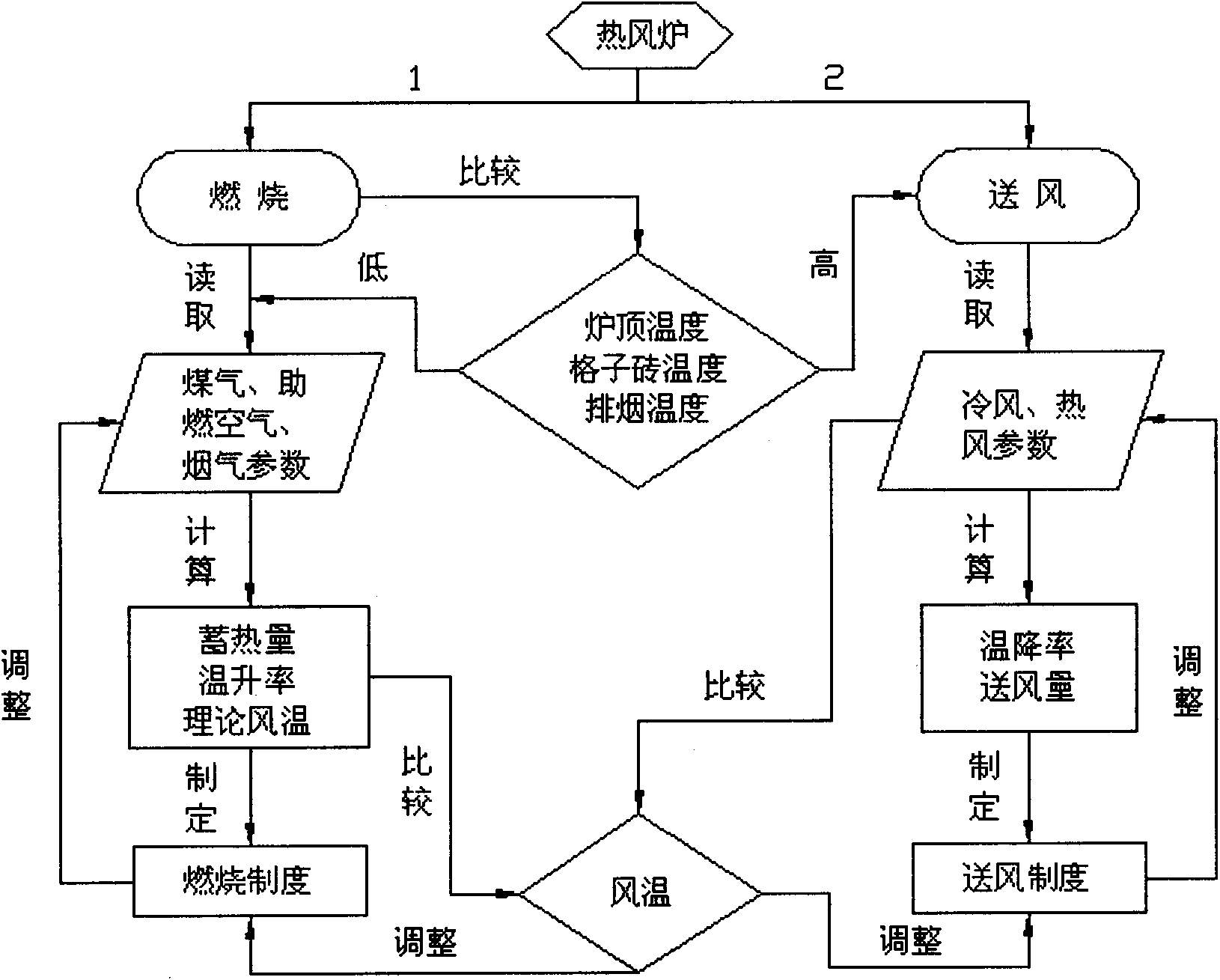

Intelligent control system for vertical mill based on fuzzy PID (proportion integration differentiation) algorithm

ActiveCN103028480AStable thicknessStable mill internal pressure differenceGrain treatmentsAdaptive controlCold airProportion integration differentiation

The invention relates to the technical field of control on production equipment, and particularly relates to an intelligent control system for a vertical mill based on a fuzzy PID (proportion integration differentiation) algorithm. The intelligent control system comprises the vertical mill, a dust remover and a feeding device, wherein the feeding device comprises an unloader, a bucket elevator and a storage bin; and the intelligent control system is characterized in that an air inlet in the bottom of the vertical mill is connected with a fan via a pipeline, a cold-air device and a hot-air stove are arranged on the pipeline between the air inlet and the fan, a cold-air adjusting valve and a hot-air adjusting valve are respectively arranged on the cold-air device and the hot-air stove, a vertical mill material layer PID controller is arranged on the feeding device, and an in-mill pressure difference fuzzy PID controller is arranged on the cold-air adjusting valve. According to the intelligent control system disclosed by the invention, mathematical models of the change of the vertical mill material layer thickness and an in-mill pressure difference along with parameters of a feeding amount, a mill inlet hot-air temperature and the like can be established only by inputting and outputting data without analyzing the complex grinding process of the vertical mill; and the intelligent control system is simple in process, high in adaptability, fast in the dynamic response time of a controller algorithm, high in robustness, high in control accuracy, and good in market prospect.

Owner:SHANGHAI TRIUMPH ENERGY CONSERVATION ENG TECH CO LTD

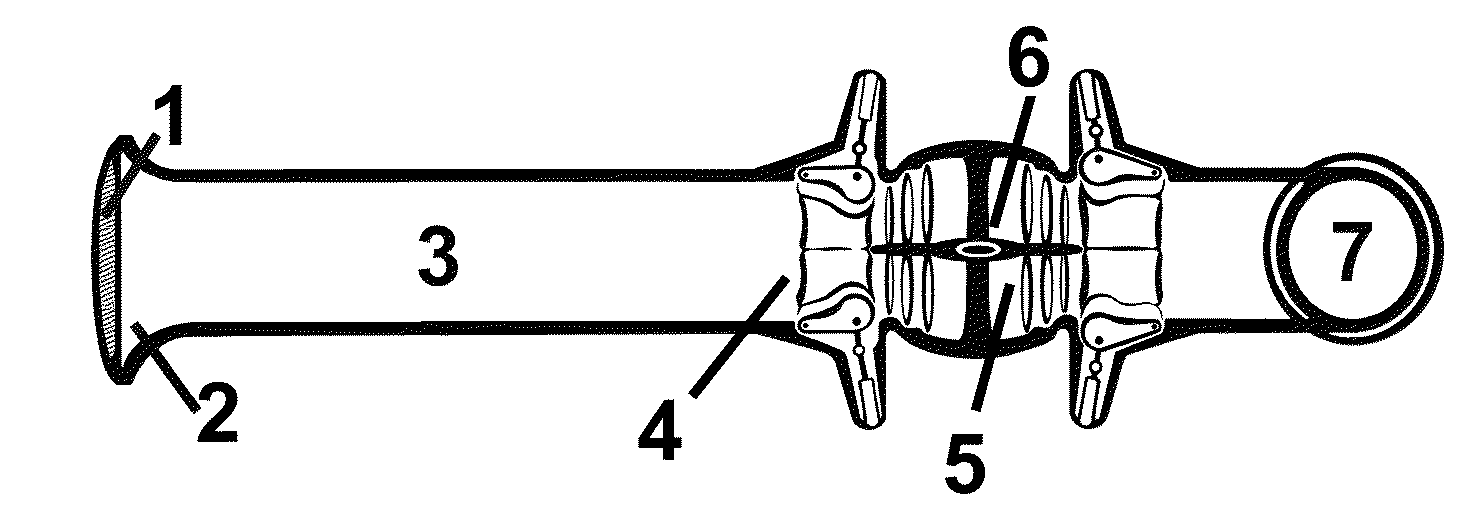

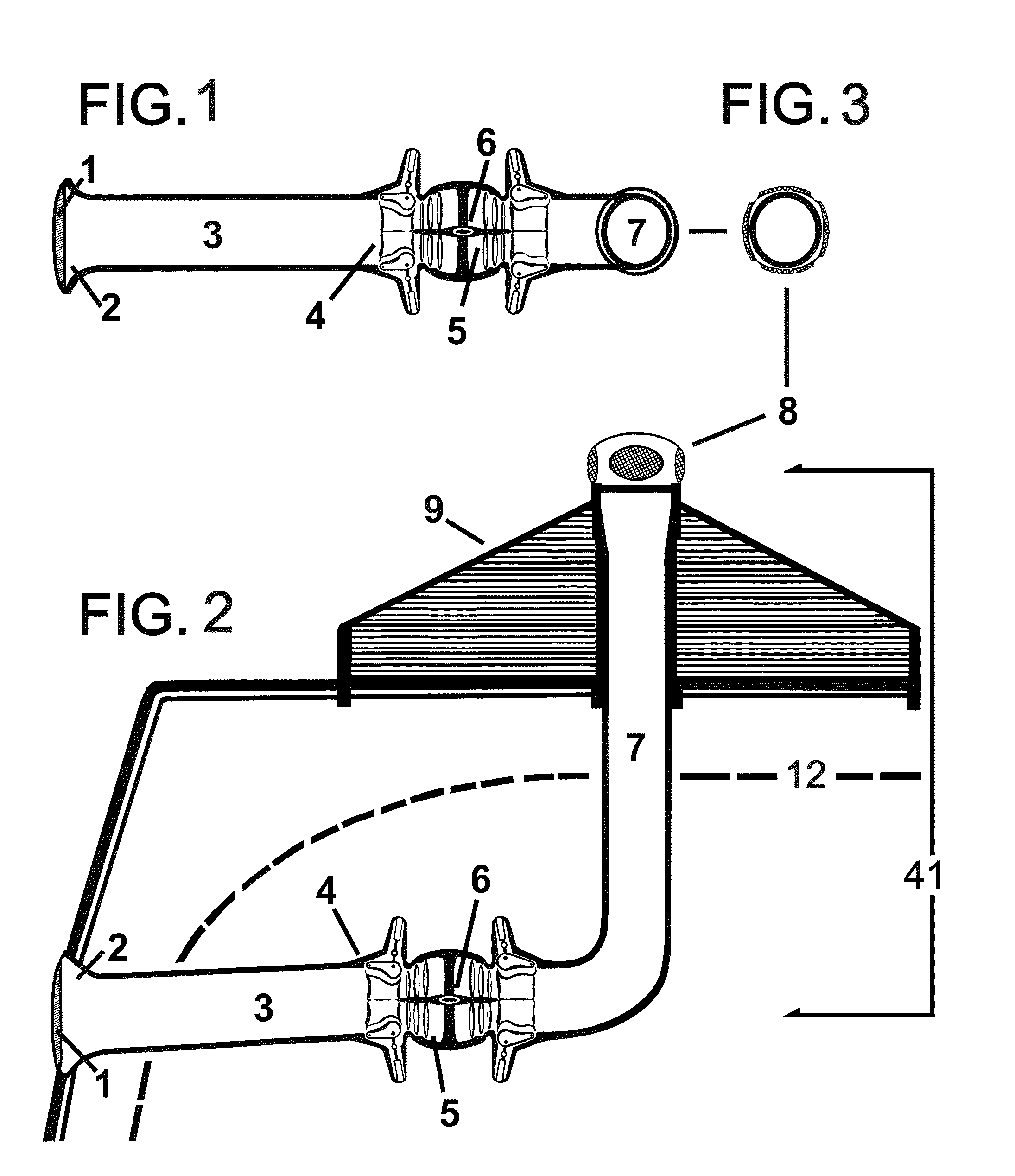

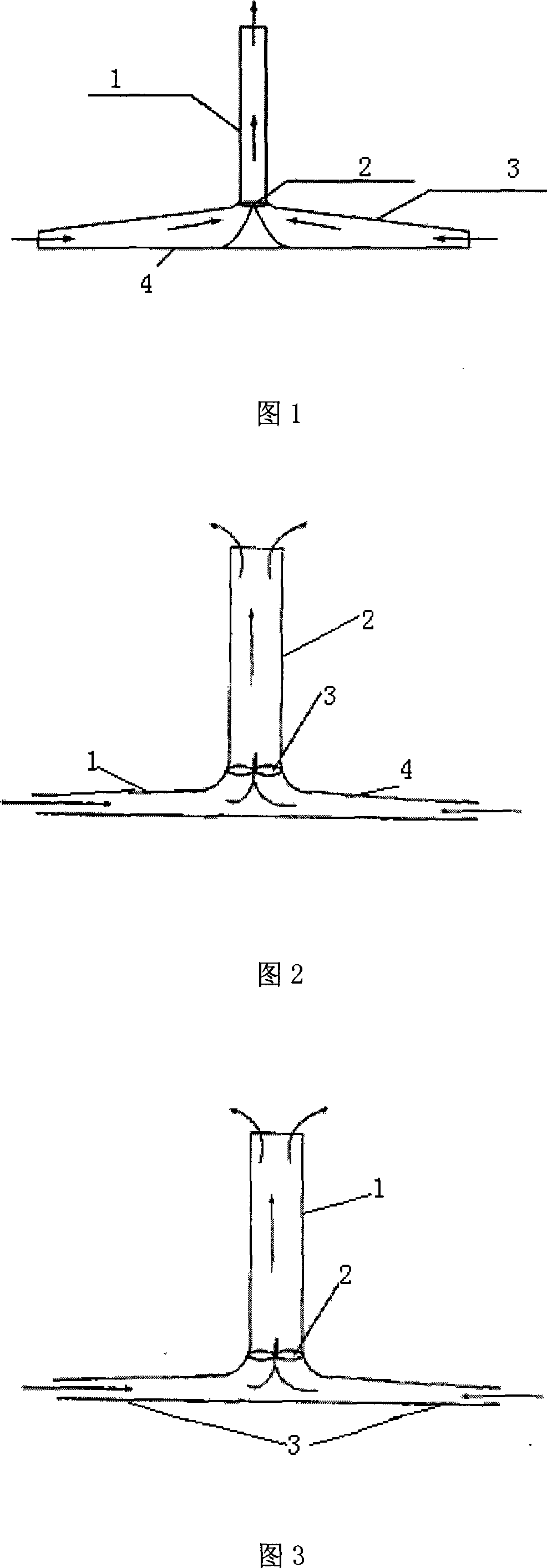

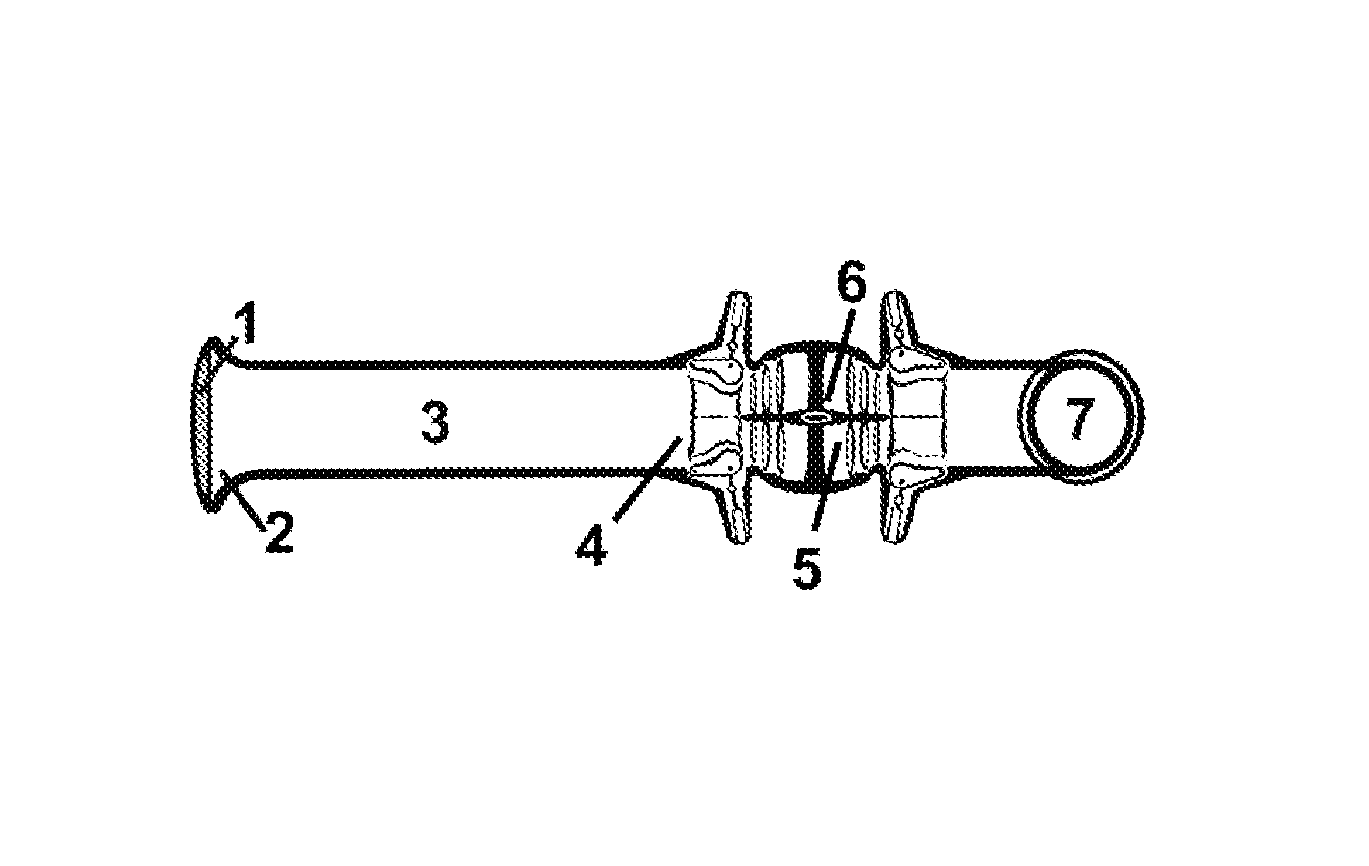

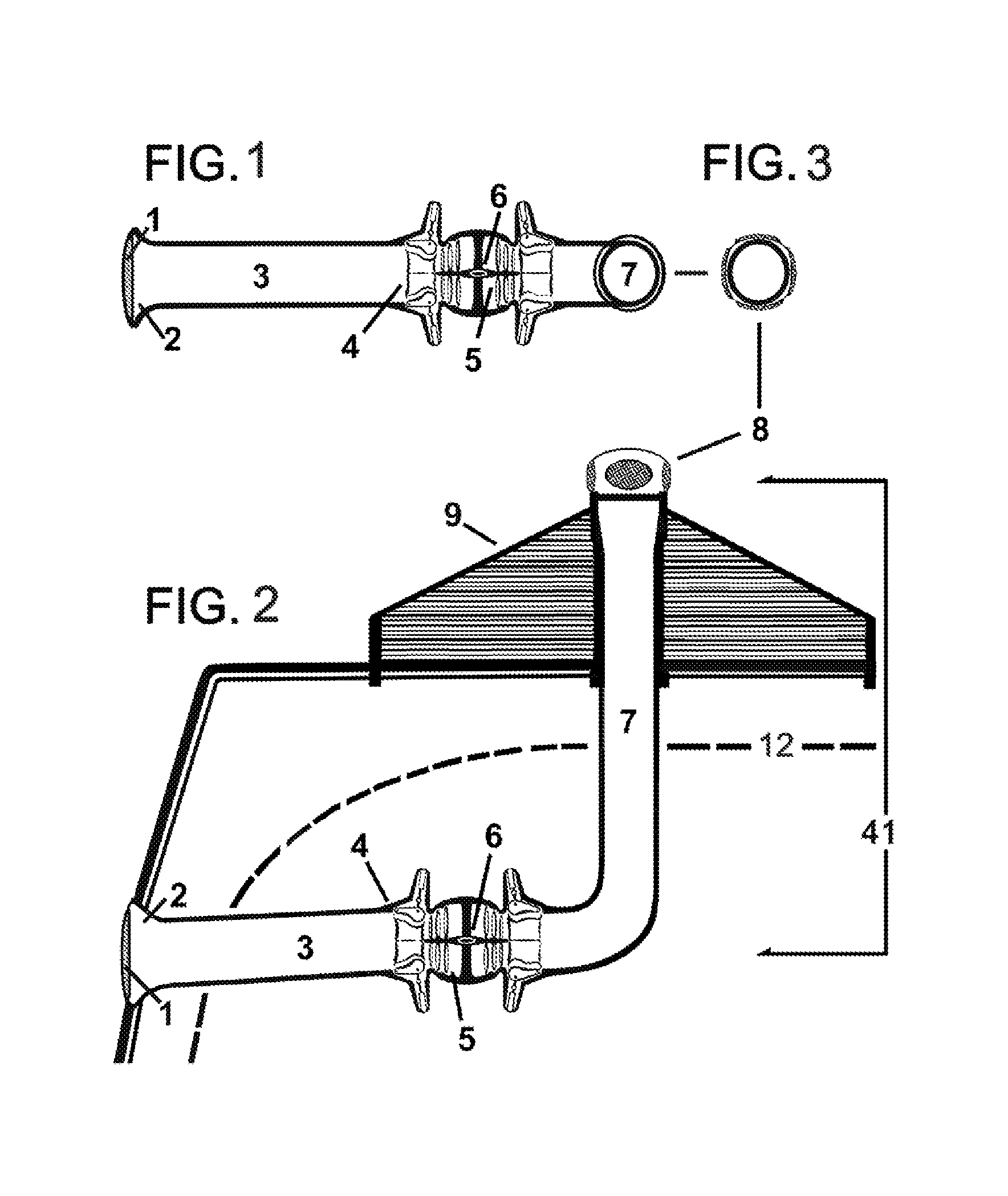

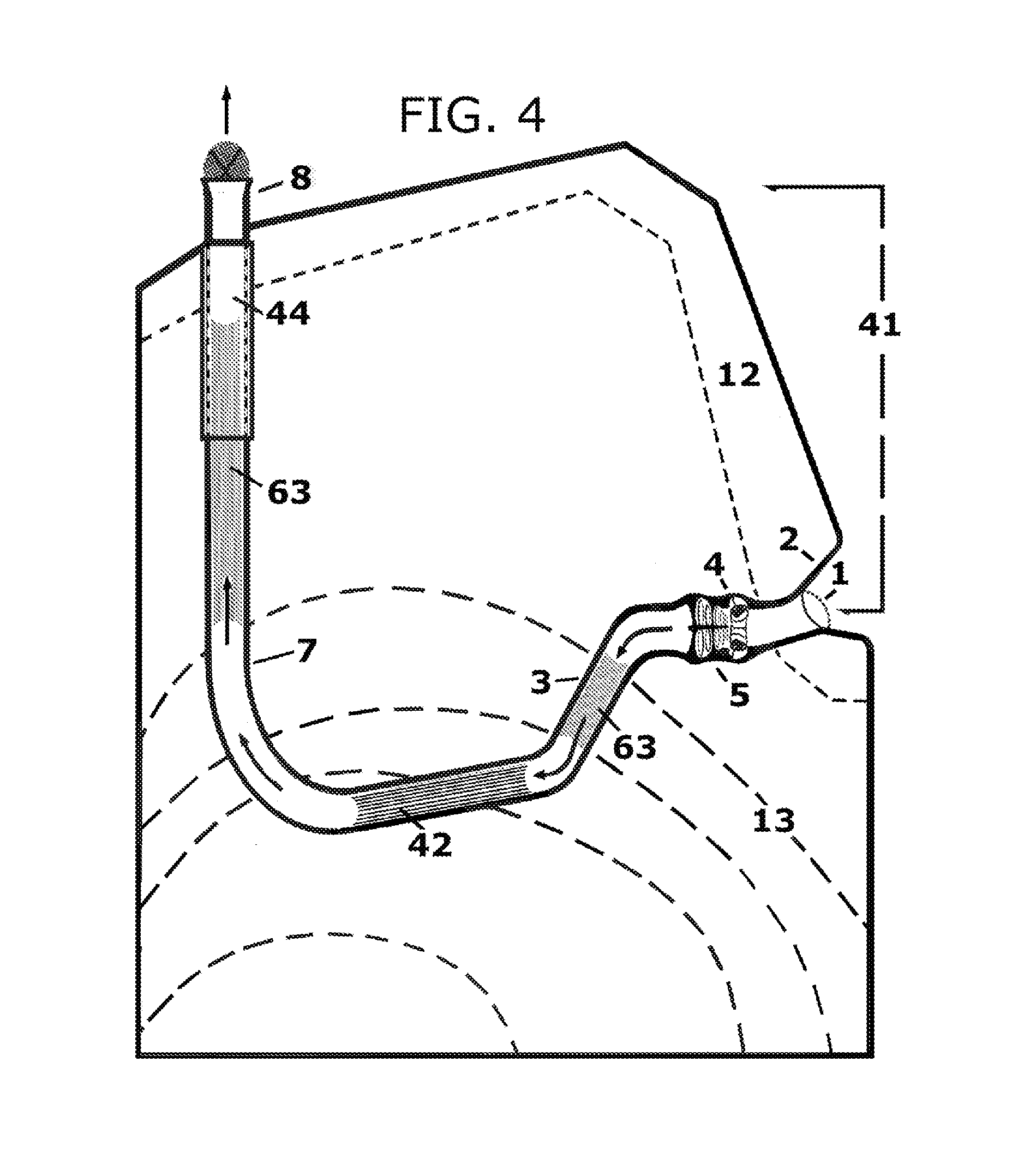

Geothermal Wind System

InactiveUS20130257055A1Reduce noiseSmall footprintOther heat production devicesGeothermal energy generationWind forceDynamo

The Geothermal Wind System is a hybrid power production system using geothermal transfer of heat between native rock and an air mass circulating between two or more portals of substantially different vertical elevations by use of the stack effect and the buoyancy of heated air or gravity pulling cooled air to turn one or more wind turbines which drive one or more generators. This wind speed can be improved by use of a venturi valve in close proximity to the turbine(s). A novel example of an aerodynamic, adjustable radial venturi is also herein incorporated. Two modes of the GWS are herein described, one used at shallow depths having geothermal temperatures approximating the average exterior climate, and the second used with geothermal temperatures found at greater depths at substantially higher than outside temperatures. The GWS is a non-polluting, non-carbon burning, non-water-dependent power production system easily implemented in third world countries.

Owner:SIMPSON LARRY C

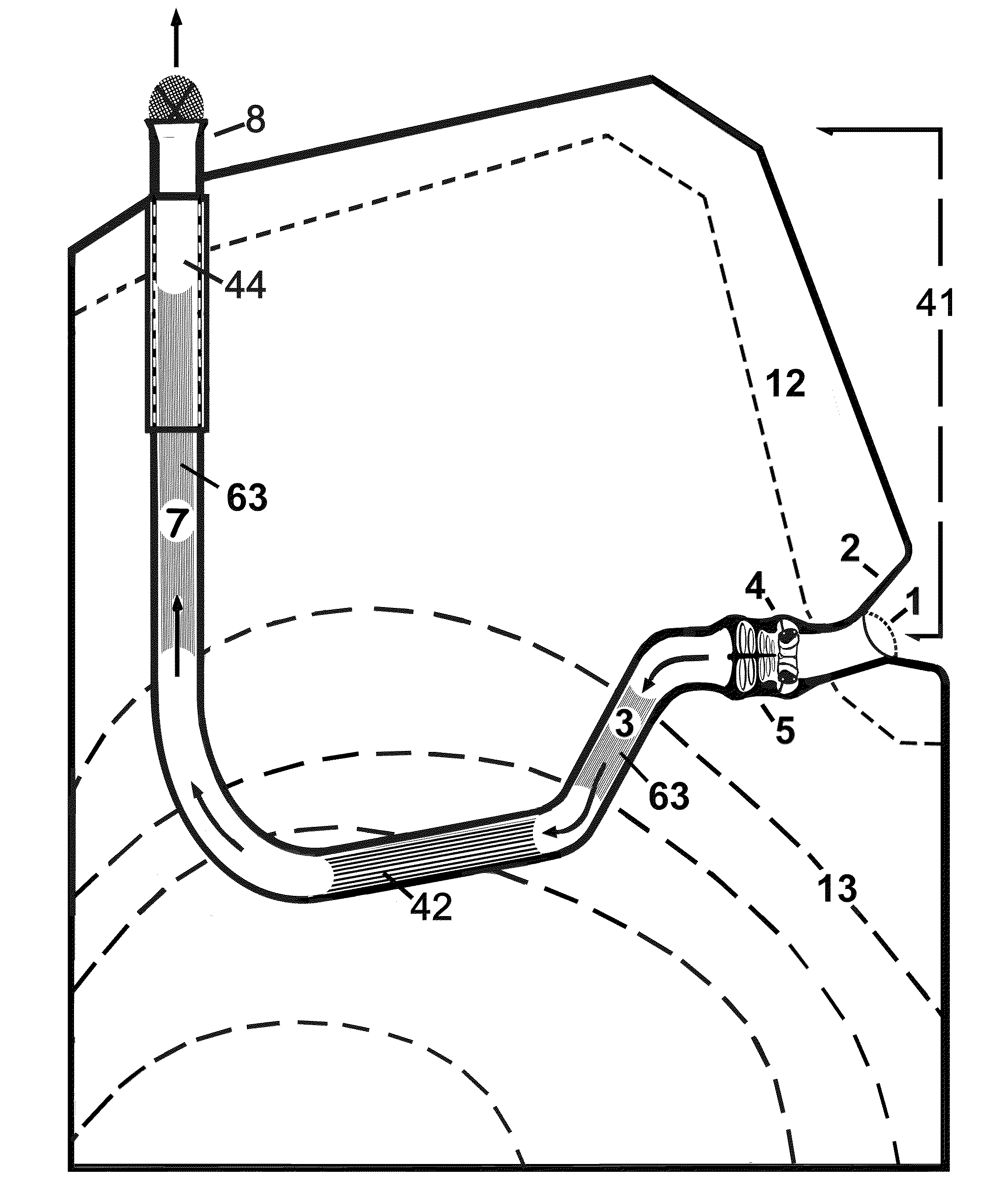

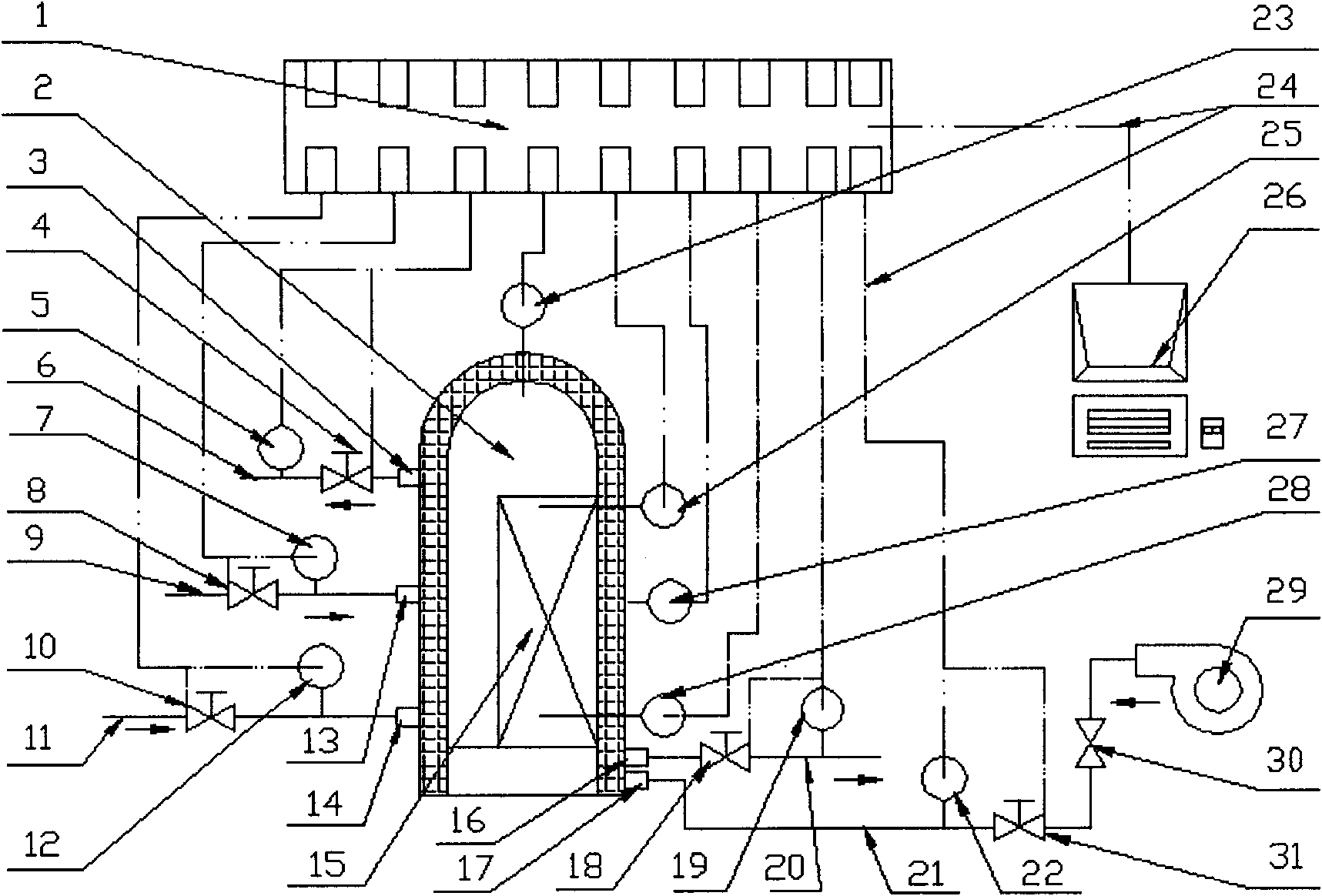

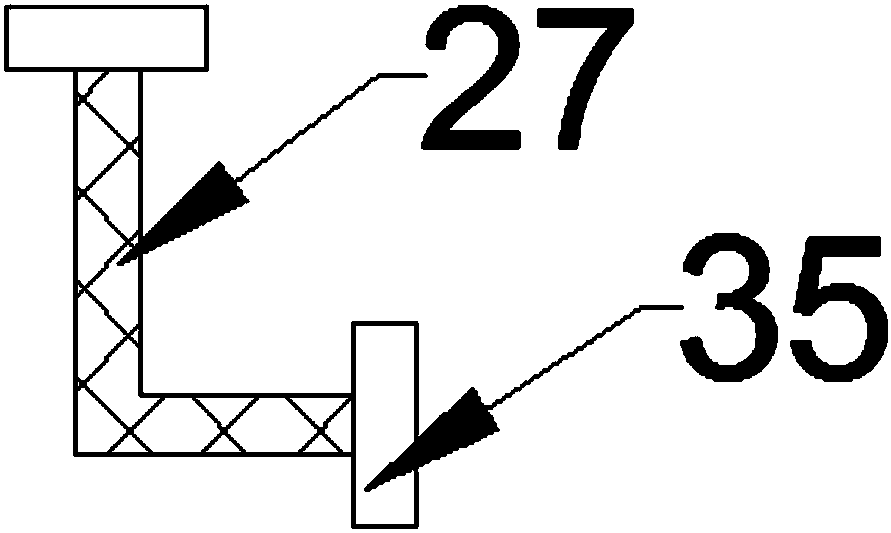

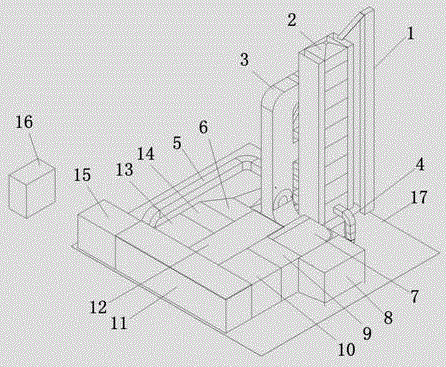

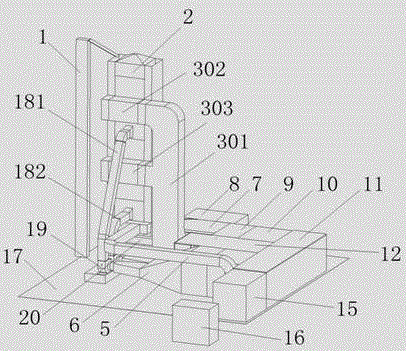

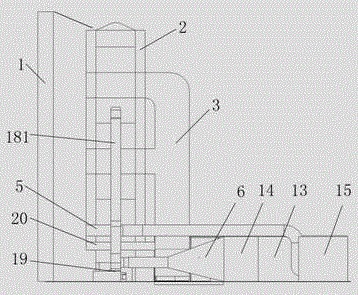

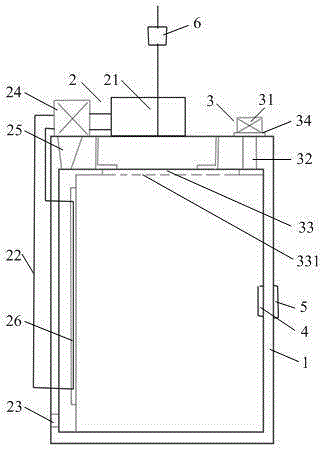

Constant wind temperature control system for hot blast stove

ActiveCN101892338ARegulating pressureAdjustable temperatureBlast furnace detailsHeating stovesBrickAir volume

The invention provides a constant wind temperature control system for a hot blast stove, comprising the hot blast stove (2), a detection element, a regulating valve, a data acquisition unit (1) and a computer (26). The control method of the control system comprises the following processes: detection of fluid parameters and valve location signals, data acquisition, data transmission, data comparison and data correction and control adjustment, wherein the detection element and the regulating valve are arranged in a pipeline, and temperature measuring equipment is arranged on the surface of a stove body. Specific steps are as follows: dynamically calculating parameters such as the heat storage capacity of checker bricks, temperature-rise ratio, theoretical wind temperature and the like during the combustion process, and carrying out on-line adjustment of parameters such as combustion air and gas flow, preheating temperature and the like; controlling direction change of the hot blast stove by the highest setting temperature of the checker bricks, a stove top and fume; and during the air supply period, taking hot blast temperature control as a target to determine an air supply curve and air supply time. The method based on calculation of dynamic balance of on-line energy of the hot blast stove effectively controls the heat storage capacity of the checker bricks of the hot blast stove, adjusts air supply quantity and air supply time, and ensures stable output of wind temperature of the hot blast stove.

Owner:SHOUGANG CORPORATION

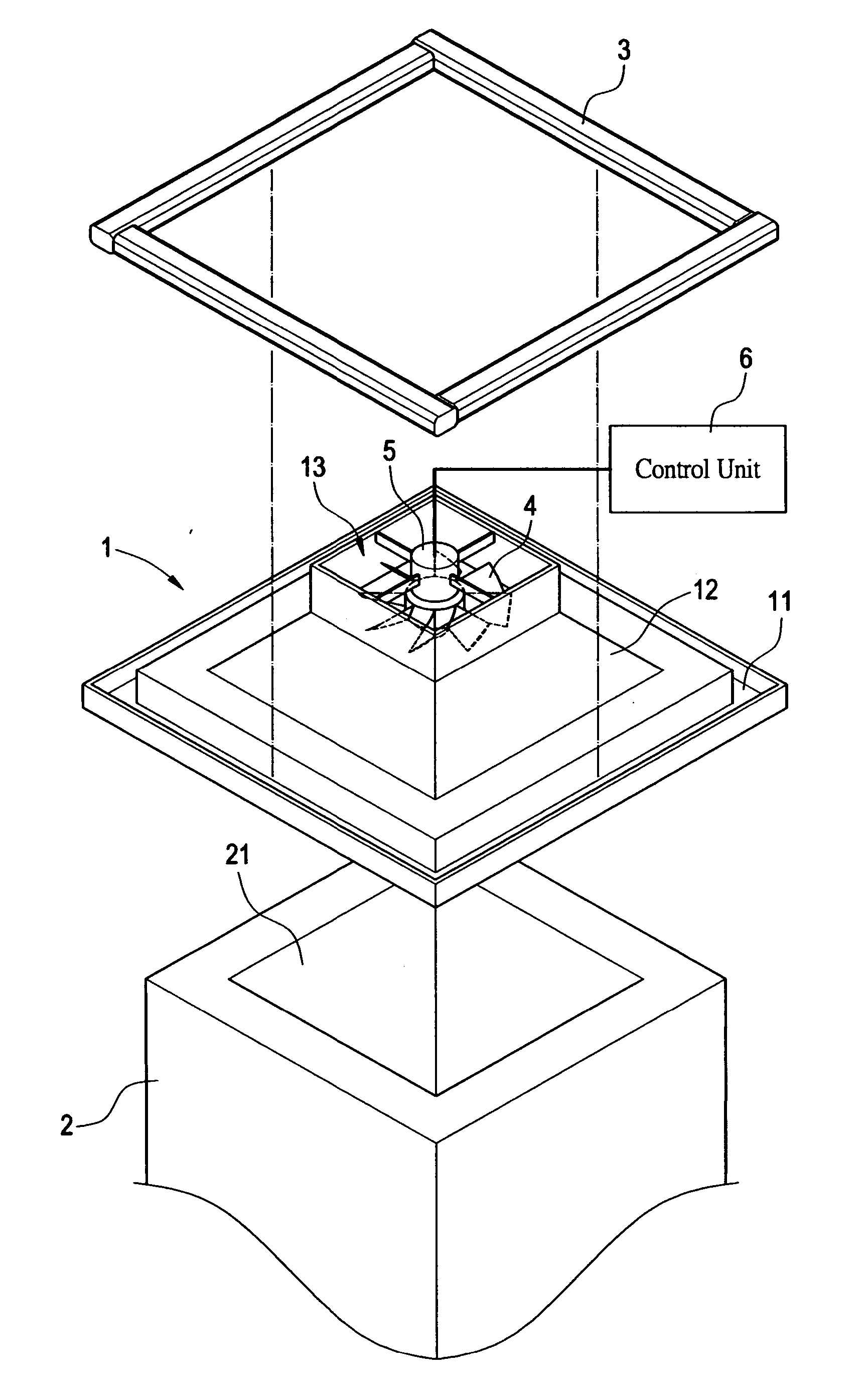

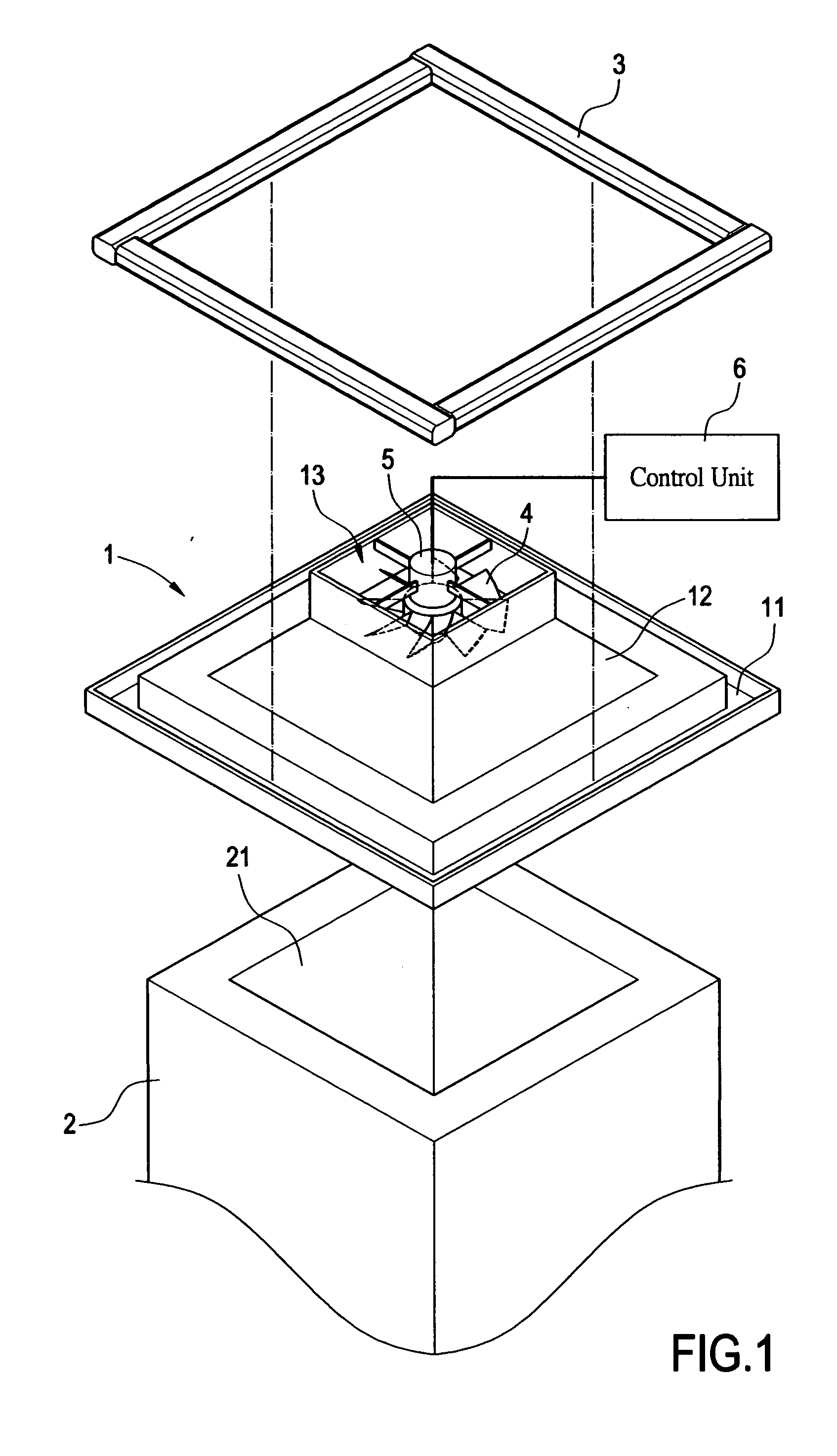

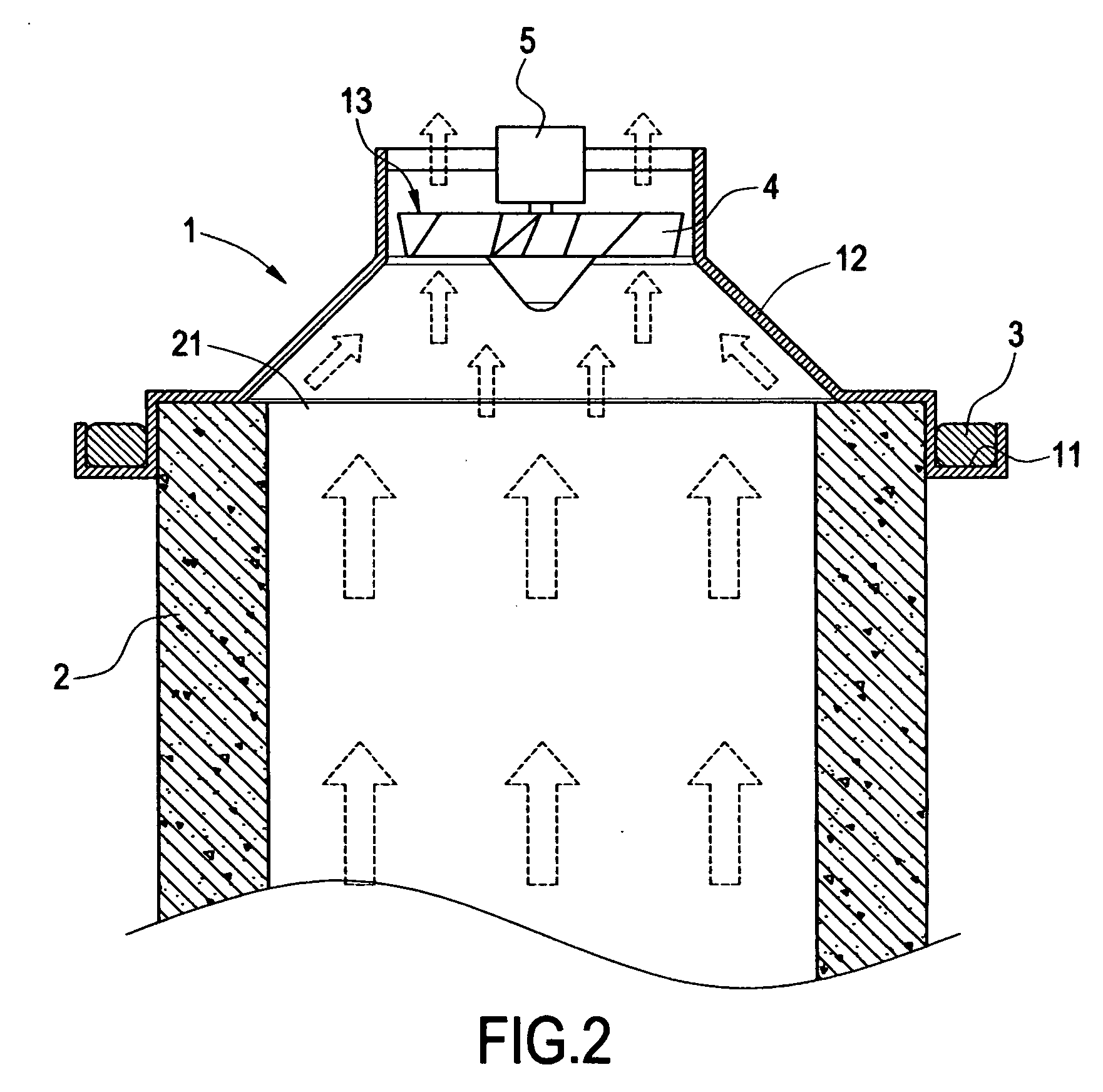

Thermal wind power generator

InactiveUS20070252391A1Safely generatedWind energy with electric storageEngine fuctionsElectricityEngineering

A thermal wind power generator uses thermal wind of household chimney to generate electrical power. The thermal wind power generator includes a rectangular hood as main body and is arranged on a smoke outlet of a chimney. The hood includes a projected space of inverse funnel shape to collect thermal wind in the chimney. A wind opening is defined at center of the projected space and a blade is arranged at the opening. The blade is electrically connected to a power generator. The hot air flows upward and is collected into the hood to drive the blade. The mechanical momentum of the blade is sent to the power generator.

Owner:CHEN SHIH H

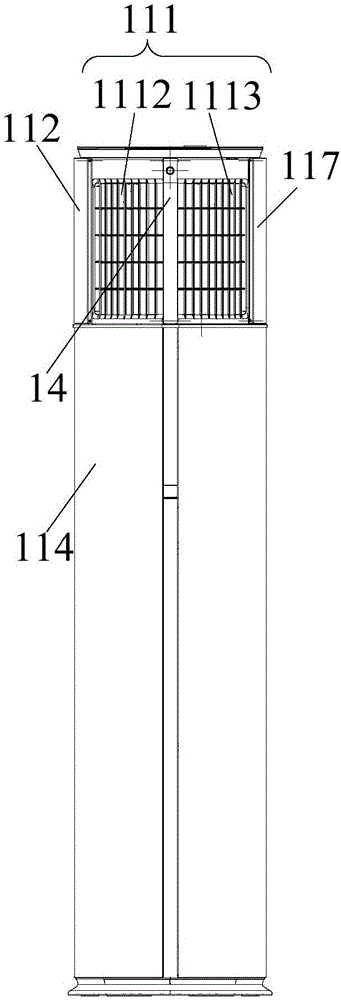

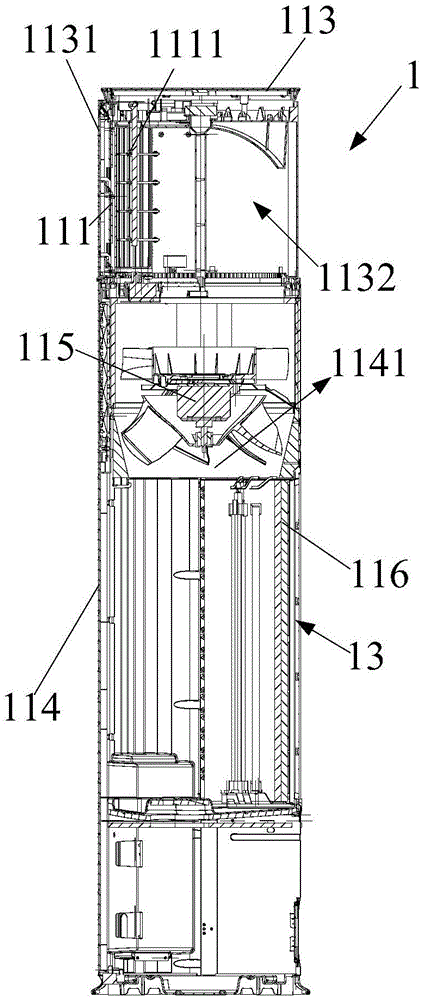

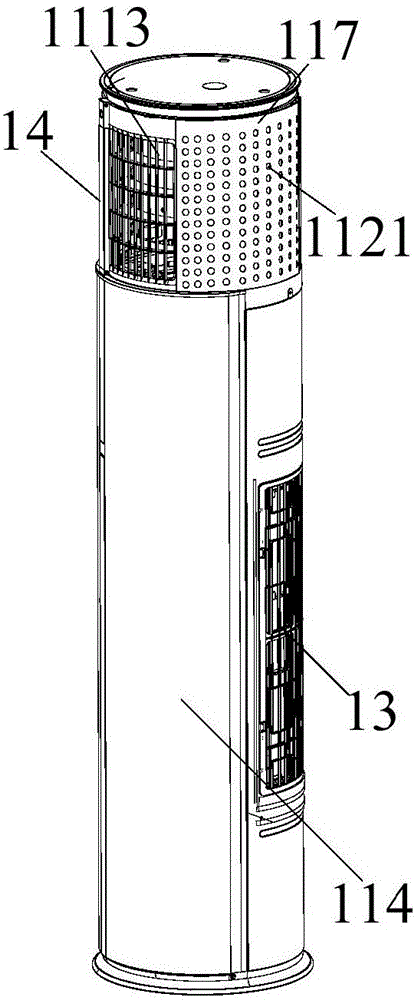

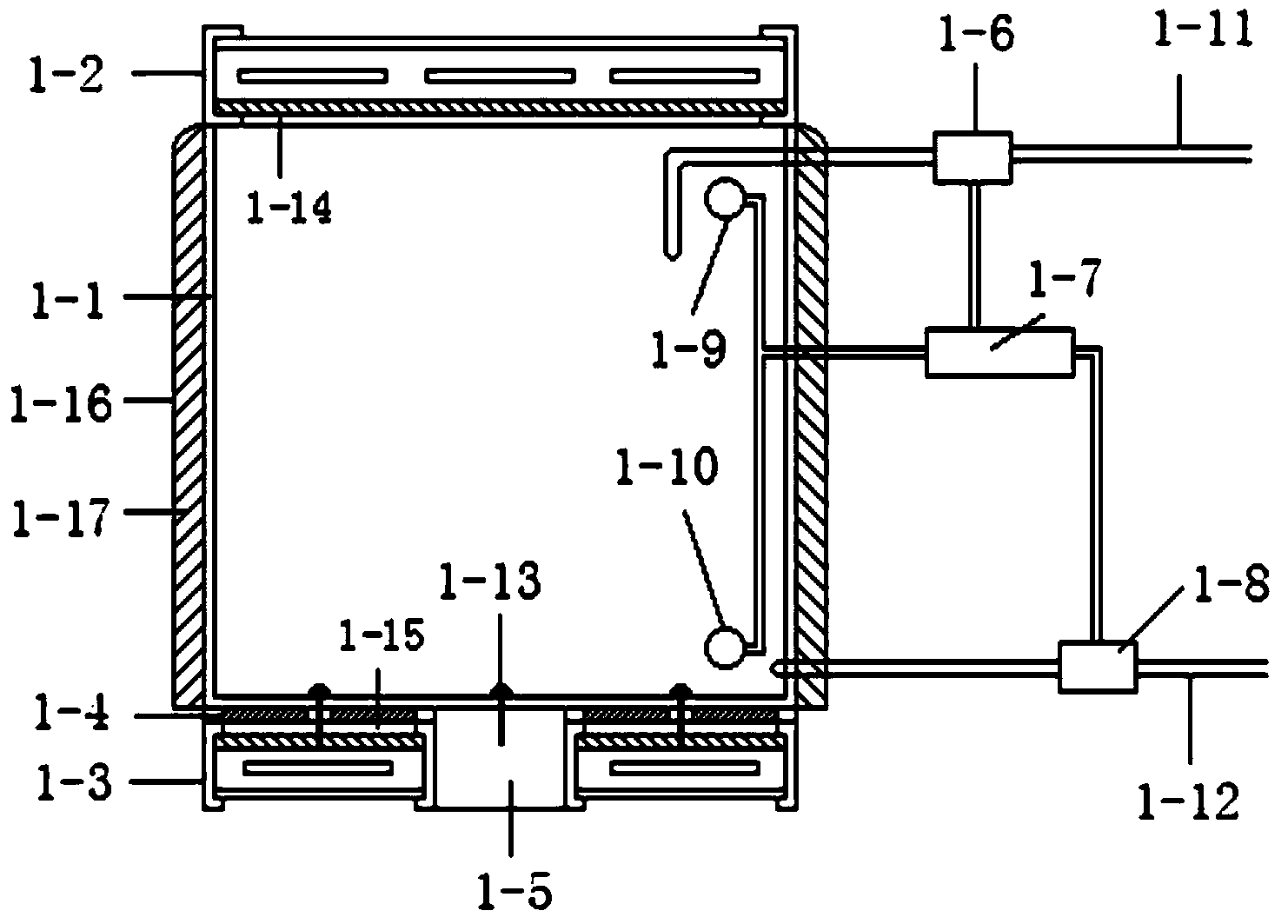

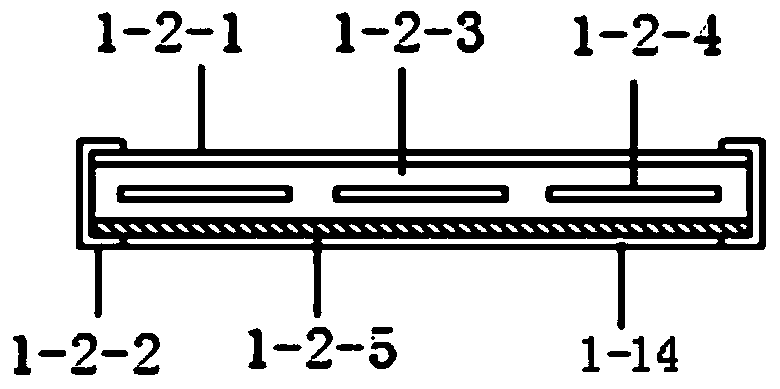

Vertical air conditioner indoor unit and control method thereof

ActiveCN106152290AFeel comfortableImprove user experienceDucting arrangementsSpace heating and ventilation safety systemsCold airHome appliance

The invention relates to the technical field of household appliances, in particular to a vertical air conditioner indoor unit and a control method of the indoor unit. The vertical air conditioner indoor unit comprises a unit machine shell, a head, a first wind scattering plate and a second wind scattering plate; therefore, when an air conditioner works, the first wind scattering plate and the second wind scattering plate are controlled to rotate through a drive device, and when the first wind scattering plate rotates to the first wind outlet end, and the second wind scattering plate rotates to the second wind outlet end, the first wind scattering plate and the second wind scattering plate jointly block a wind outlet; due to the fact that a plurality of wind scattering holes are formed in the first wind scattering plate and the second wind scattering plate, the airflow blown to the wind outlet through a wind way assembly can be blown out through the wind scattering holes in the first wind scattering plate and the second wind scattering plate; due to the small size of the wind scattering holes, when the airflow passes through the wind scattering holes, the airflow is dispersed into much tiny silky air to be spread indoors, a user does not need to be blown by cold air or hot air directly, and can feel the cold sense or hot sense in a room, and the user feels more comfortable.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

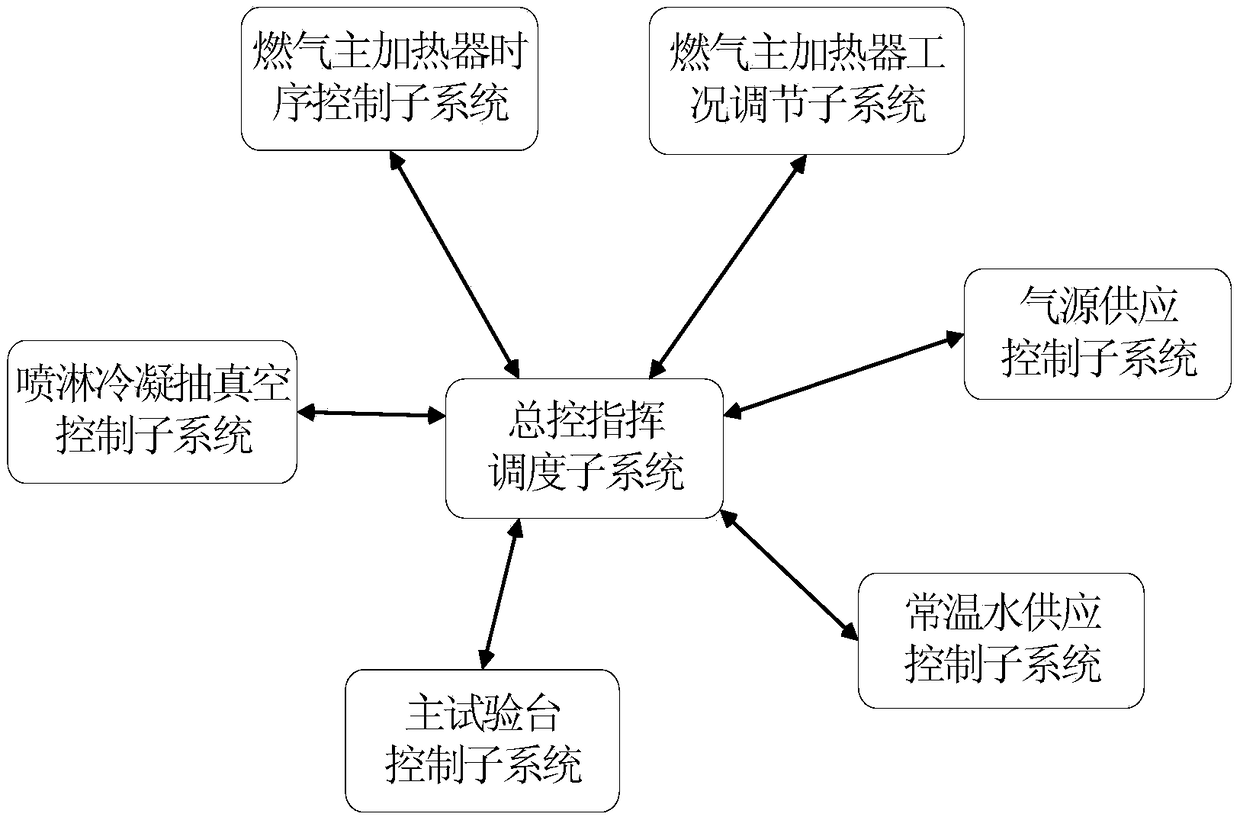

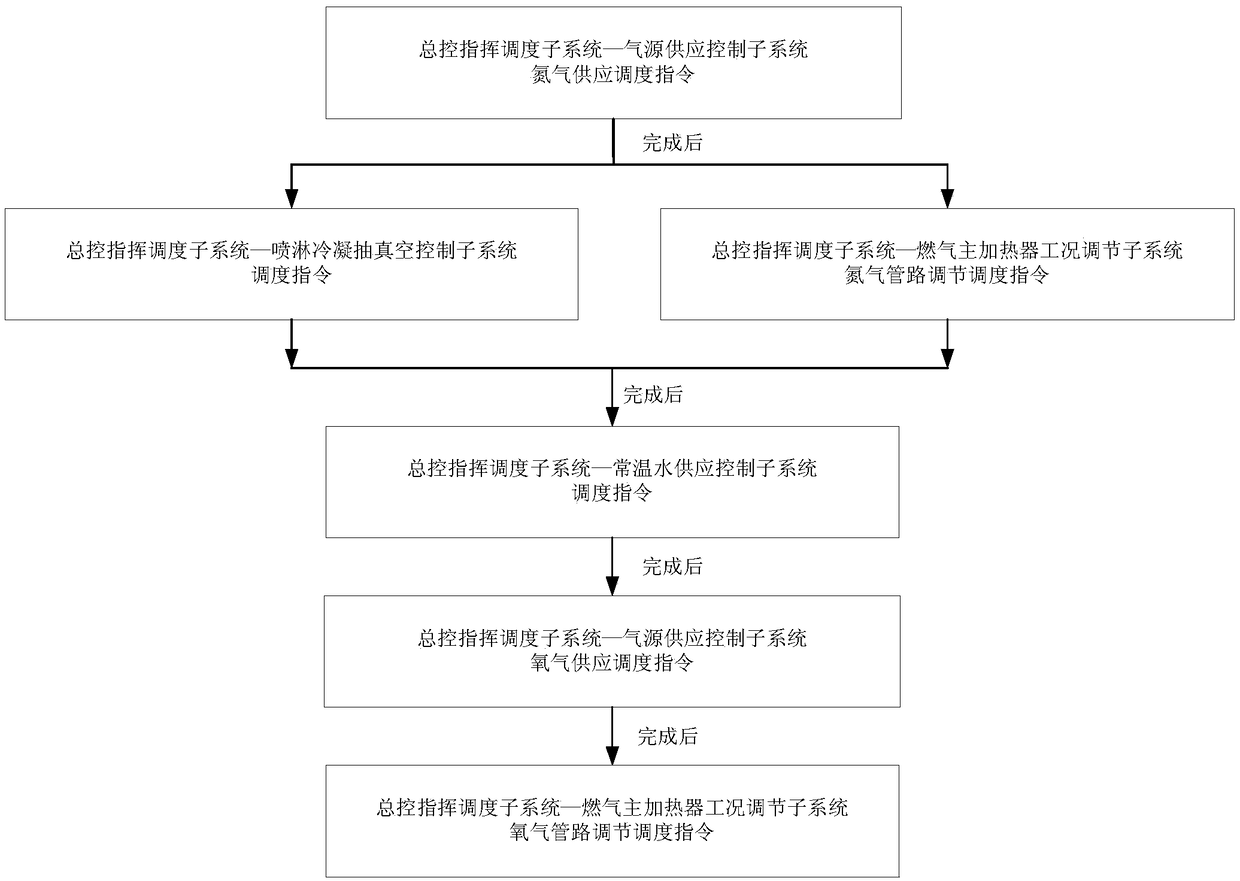

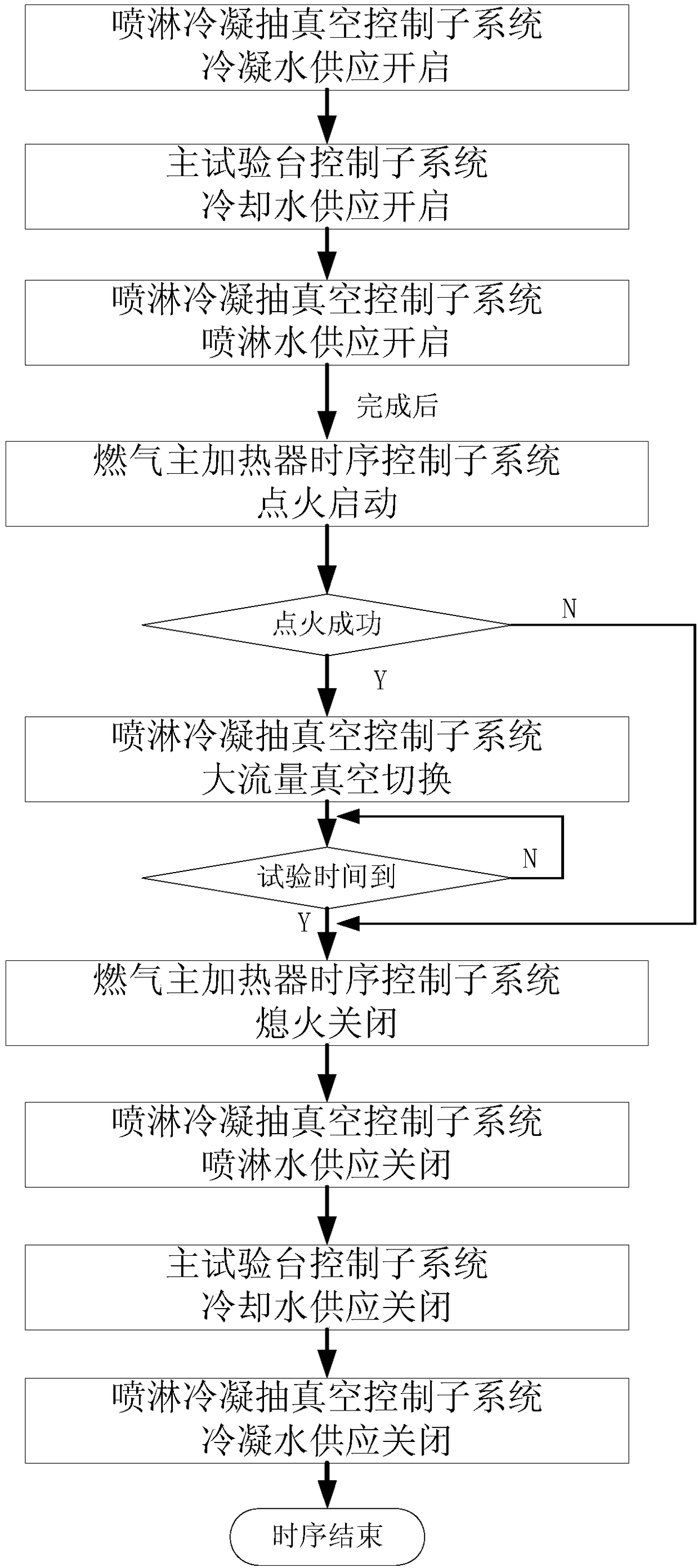

Wind tunnel operation control system based on distributed architecture

ActiveCN108760217ASolve complexitySolve coordination problemsAerodynamic testingSimultaneous control of multiple variablesCombustionThermal insulation

The invention discloses a wind tunnel operation control system based on a distributed architecture, which belongs to the technical field of aerospace ground thermal insulation tests, so as to controleach part in a combustion-gas flow thermal wind tunnel test system to realize thermal examination on a spacecraft thermal protection structure. The distributed control architecture is used, each control subsystem of the wind tunnel has an independent controller, operation control is carried out on a corresponding device, coordination of the whole action is realized through a top-layer master control command and dispatch subsystem, the whole wind tunnel system is ensured to act in a coordinated and orderly mode, software and hardware supports are provided for stable operation of the wind tunnelsystem, and a technical support is provided for condition monitoring and timing control on the equipment.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

Solar thermal wind power generation system combing light voltage technology

InactiveCN101237199AImprove cooling effectGuaranteed efficiencyPV power plantsWind motor combinationsThermal energyLight energy

The invention relates to a solar chimney power generation system combining the photovoltaic technology, comprising a solar chimney and a solar thermal collector, wherein, the ceiling of the solar thermal collector is stuck with a thin film solar PV panel; or the bottom surface of the solar thermal collector is paved with the solar panel. The thin film solar PV panel stuck on the ceiling of the solar thermal collector is non-light tight. The solar panel paved on the bottom surface of the solar thermal collector is an ordinary monocrystalline silicon solar PV panel. The system can take full advantage of the light energy and the heat energy of the solar energy, after the solar panel converts the light energy of the solar energy into the electrical energy, the remaining solar energy is used for heating the air entering the solar thermal collector in the form of heat energy; the PV panel can be cooled perfectly to guarantee the efficiency and the generated output of the PV power generation system; the system raises the rate of utilization of the solar chimney power generation system on the solar energy and raises the generating efficiency of the solar chimney power generation system by about 30 percents.

Owner:DONGHUA UNIV

Geothermal wind system

InactiveUS8875511B2InhibitionReduce skin frictionReciprocating combination enginesOther heat production devicesWind systemEngineering

Owner:SIMPSON LARRY C

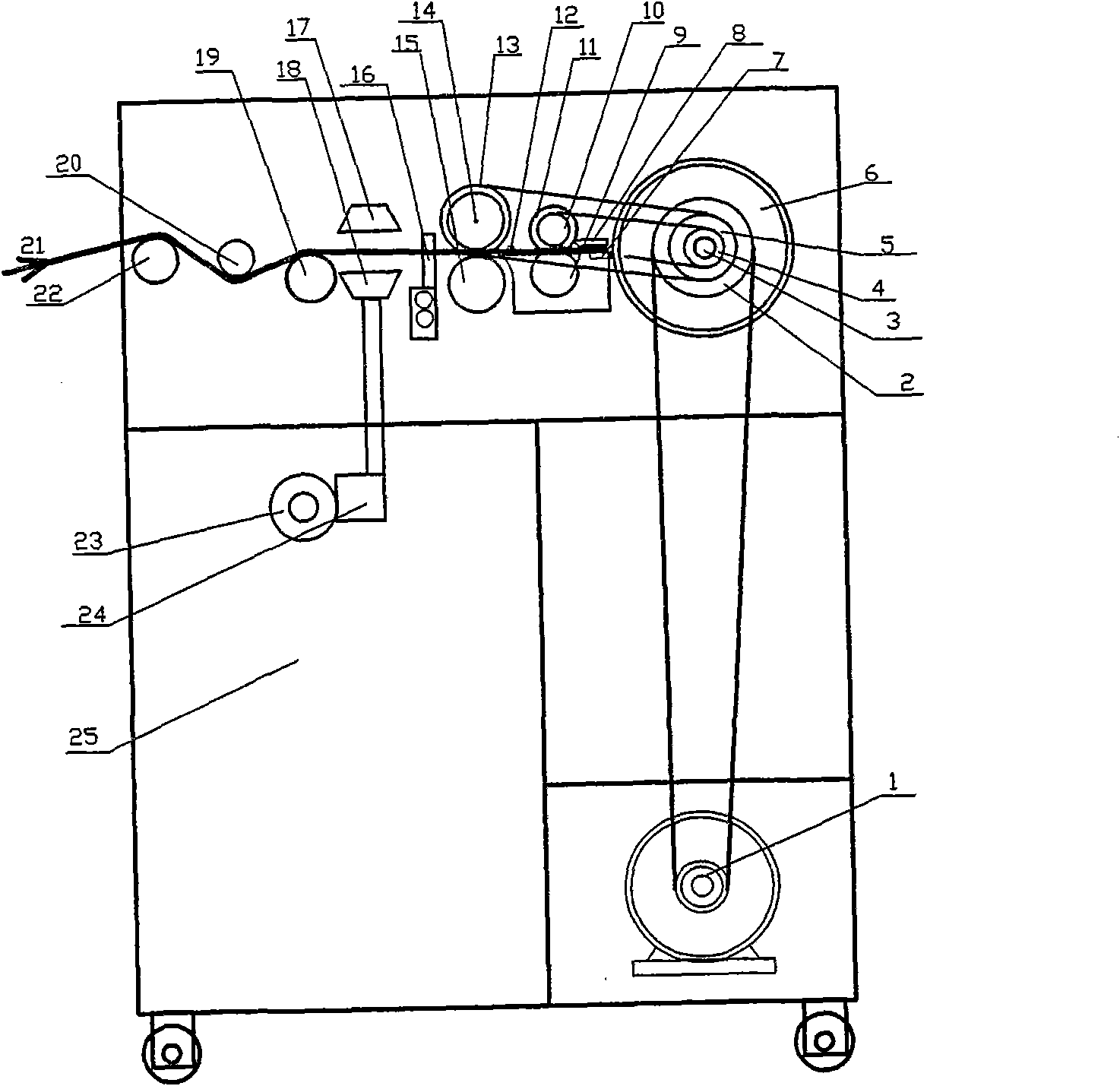

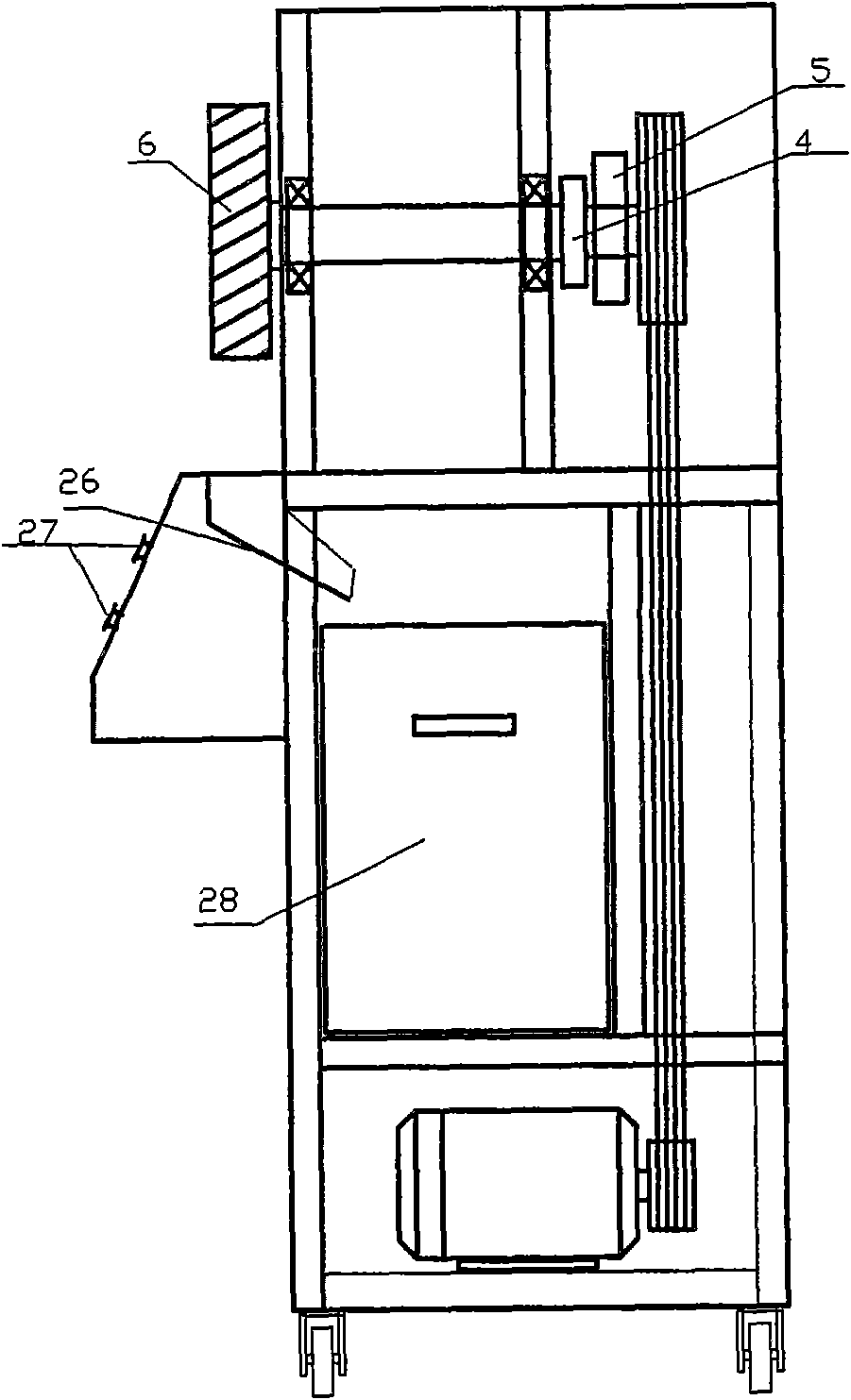

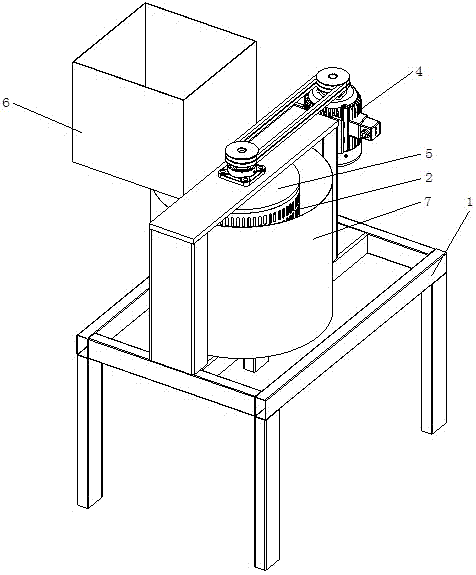

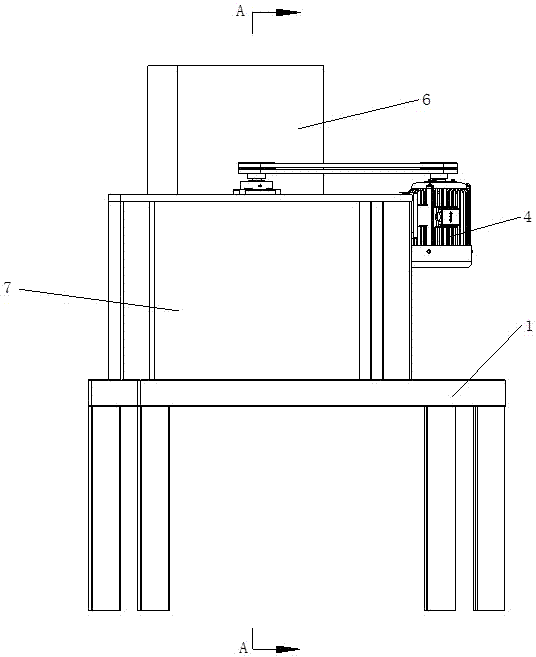

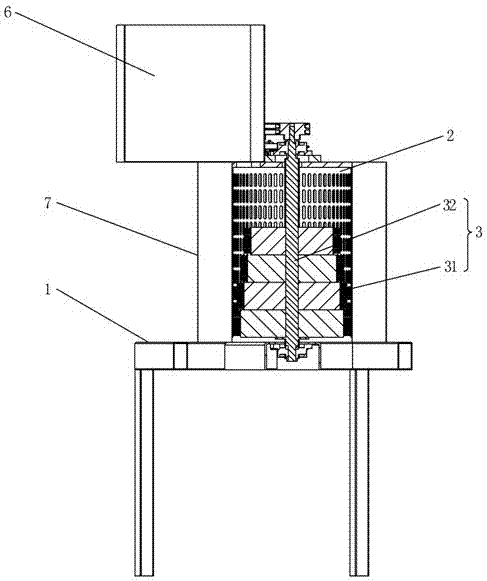

Plastic film granulator

The invention discloses a plastic film granulator, which comprises a granulator body, a main motor and a control switch. The plastic film granulator is characterized in that the upper right part of the granulator body is provided with a main shaft; the main shaft is provided with a tooth-shaped circular cutter, a striping knife roll driving synchronous belt pulley, a flower-shaped press roll driving synchronous belt pulley and a driven belt pulley in turn from the front to back; the underside of an upper striping knife roll is provided with a lower striping knife roll; the underside of an upper flower-shaped press roll is provided with a lower flower-shaped press roll; and the left side of the upper flower-shaped press roll is vertically provided with an upper thermal wind catcher and a lower thermal wind catcher side by side. The plastic film granulator solves the problems that the prior granulation equipment is easy to cause plastic ageing and cause secondary pollution and the like, and is suitable for regenerating and granulating reclaimed plastic films.

Owner:QINGDAO JUTAI MACHINERY

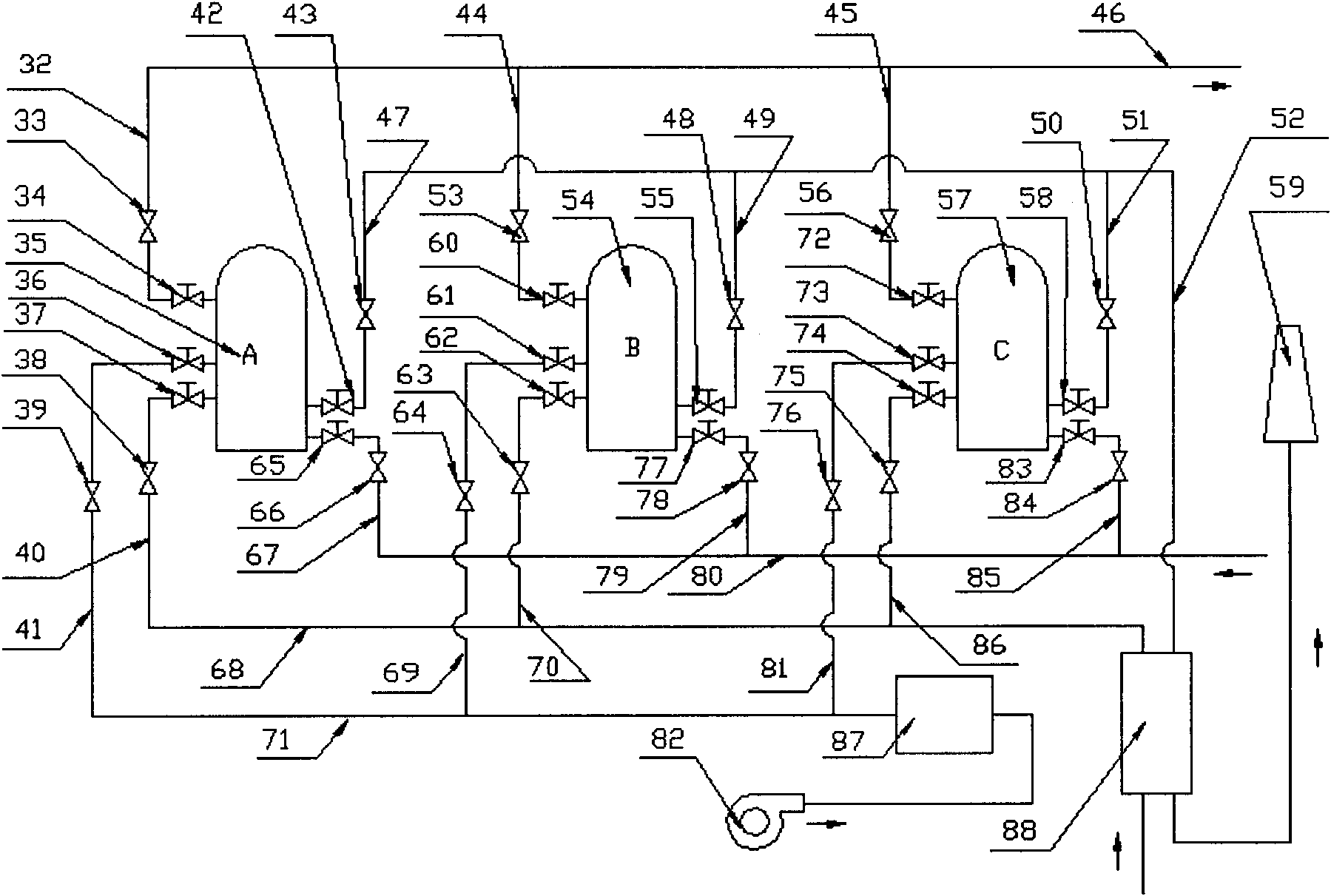

Annealing and cooling treatment system for two-stage hot wind circulation of glass ceramic tunnel crystallization kiln

The invention belongs to the technical filed of glass ceramic annealing by a sintering method, and discloses an annealing and cooling treatment system for two-stage hot wind circulation of a glass ceramic tunnel crystallization kiln. The treatment system is characterized in that the upper part and the lower part of kiln walls at two sides of a quench zone are respectively installed with a row of fast cold wind blowing openings which are communicated with fast cold wind blowing opening branch pipes, the fast cold wind blowing openings are all communicated with the output ports of second hot wind circulation pipes; the kiln walls at two sides of the slow cooling segment of a cooling zone are respectively provided with three rows of hot circulation wind blowing openings which are communicated with the hot circulation wind blowing opening branch pipes, all hot circulation wind blowing opening branch pipes are communicated with the output ports of first hot wind circulation pipes; the first hot circulation wind suction opening blowing branch pipes are all communicated with the input ports of the first hot wind circulation pipes; and the second hot circulation wind suction opening blowing branch pipes are all communicated with the input ports of the second hot wind circulation pipes. The annealing and cooling treatment system can improve product quality, and reduce deformation, burst and other defects of the products.

Owner:WUHAN UNIV OF TECH

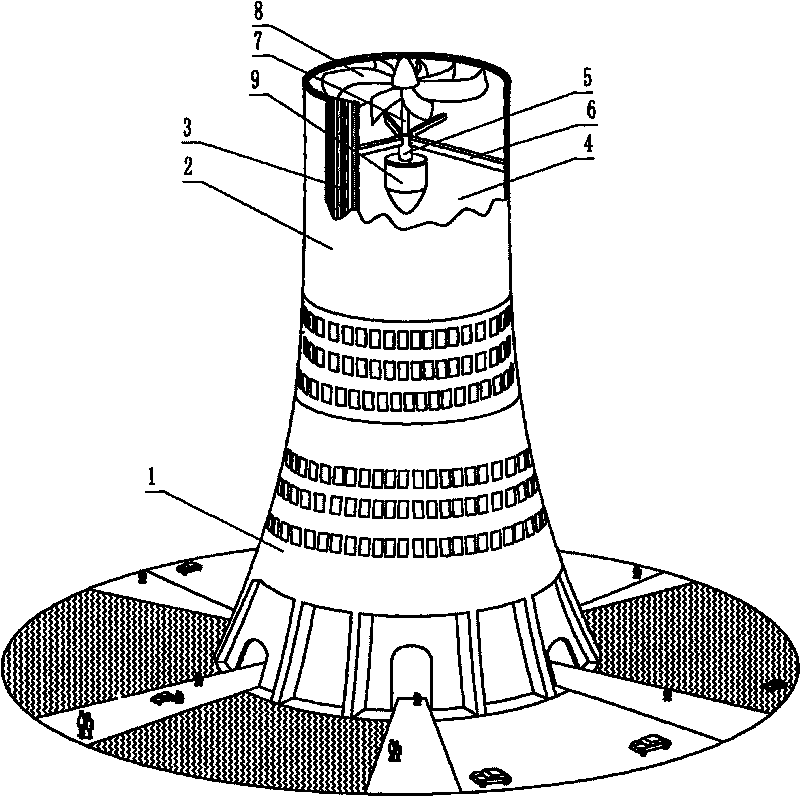

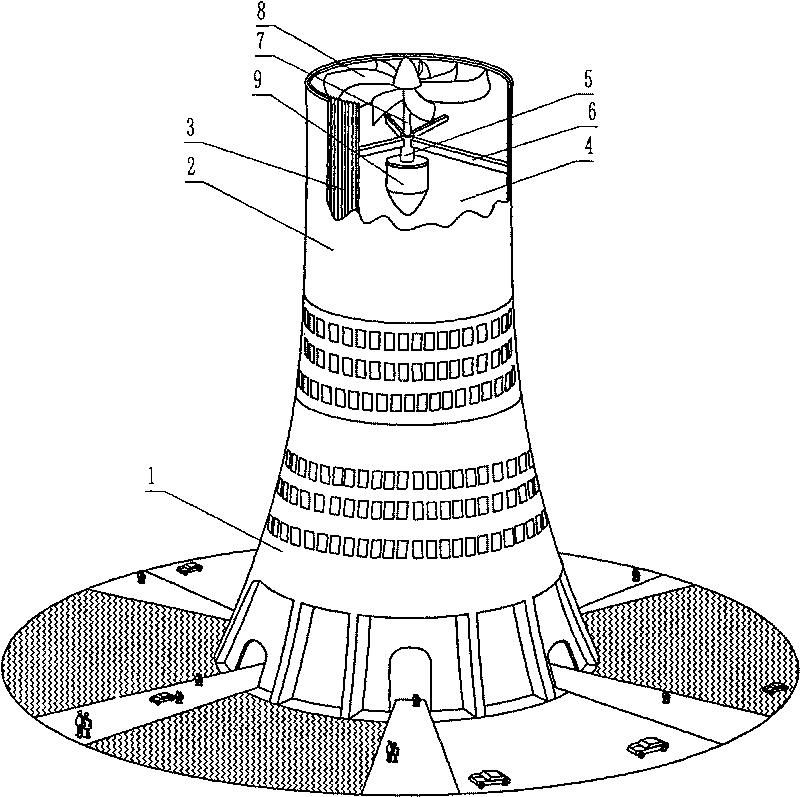

Energy-saving building for generating electricity by utilizing solar thermal wind

InactiveCN101691820AReasonable designSimple structureFinal product manufactureSpecial buildingElectricityInfrared

The invention relates to an energy-saving building for generating electricity by utilizing solar thermal wind, and belongs to the technical field of the manufacture of novel energy-saving buildings. The energy-saving building consists of a cylindrical building main body, a transparent layer, a heat absorption layer, a hot airflow channel, a worm-wheel shaft sleeve, a shaft sleeve support, a worm-wheel shaft, a worm wheel and a generator, wherein the transparent layer is connected with the cylindrical building main body; the heat absorption layer is arranged on the inner wall of the transparent layer; the heat absorption layer rolled into a cylindrical shape forms the hot airflow channel; the worm-wheel shaft sleeve is connected with the shaft sleeve support which is connected with the heat absorption layer; and the inside of the worm-wheel shaft sleeve is provided with the worm-wheel shaft of which one end is connected with the worm wheel and the other end is connected with the generator. When the energy-saving building is used, after the transparent layer is radiated by sunlight, infrared rays in the sunlight pass through the transparent layer and reach the heat absorption layer, air in the hot airflow channel is heated to become light and is raised in the hot airflow channel, cold air enters the channel for supplementation through a gate on the bottom layer of the building, and the raising hot airflow pushes the worm wheel to rotate so as to drive the generator on the worm-wheel shaft to rotate for generating the electricity. The energy-saving building has the advantages of reasonable design, simple structure, convenient use and the like.

Owner:赵姝珅

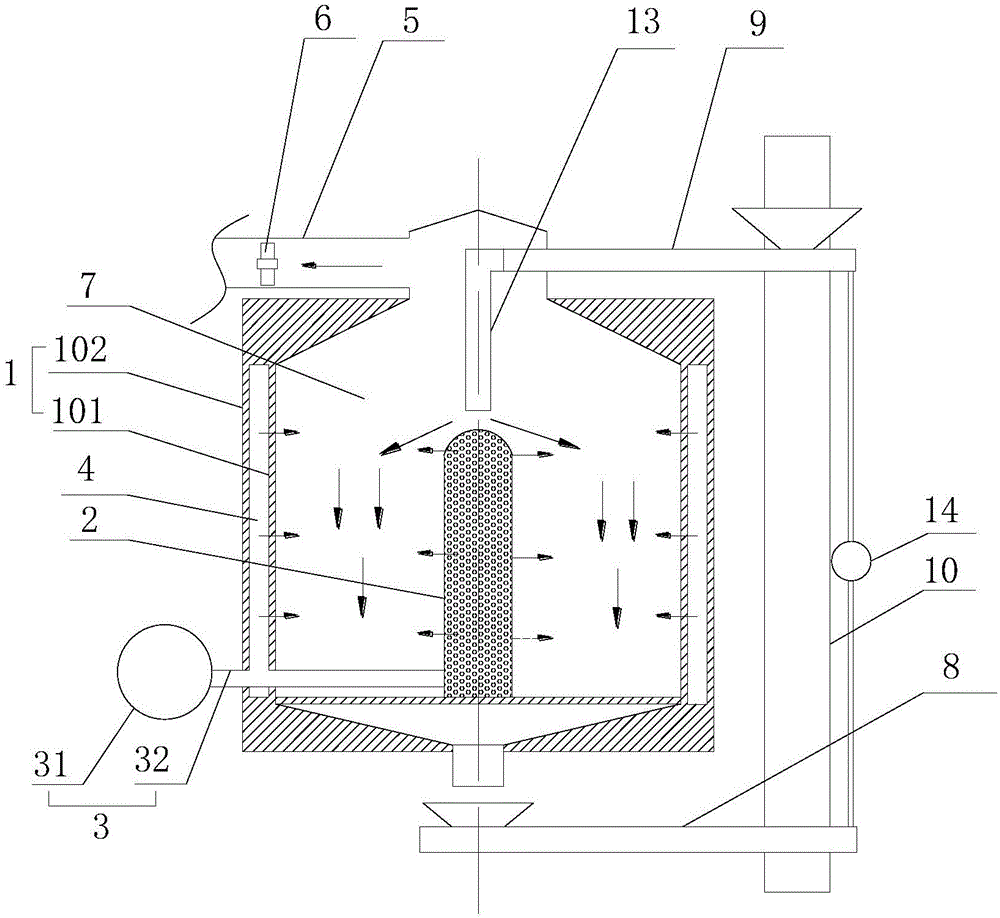

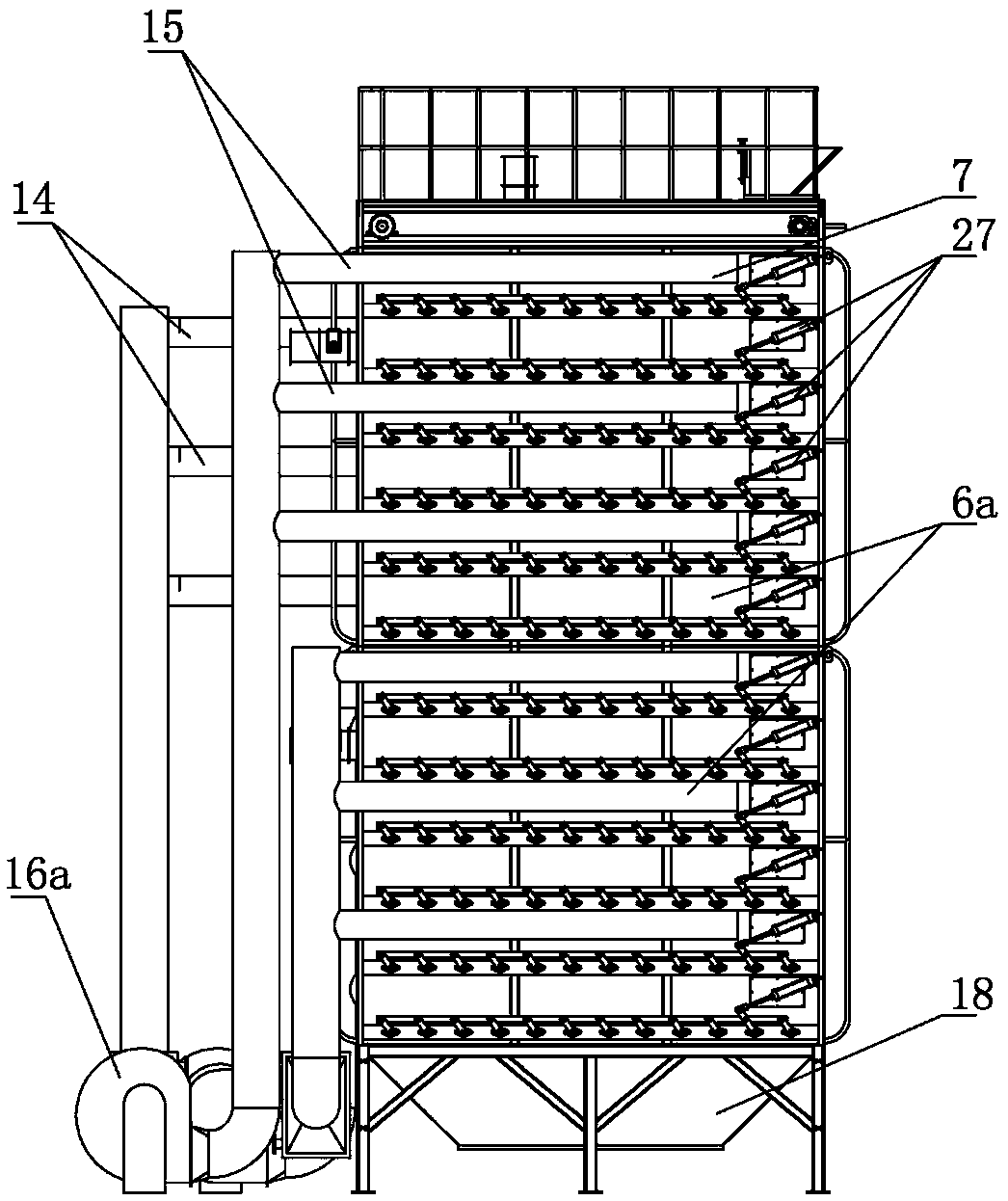

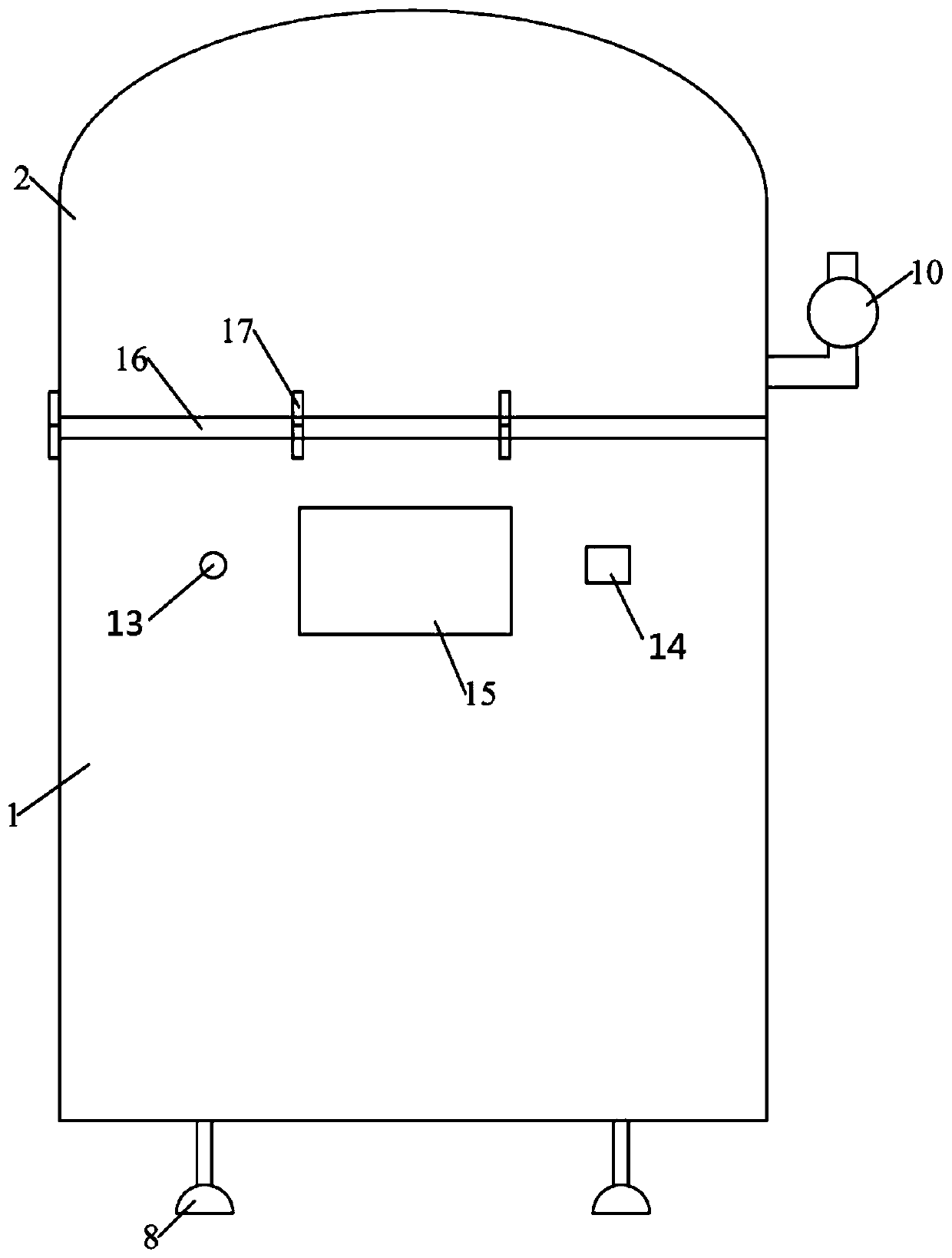

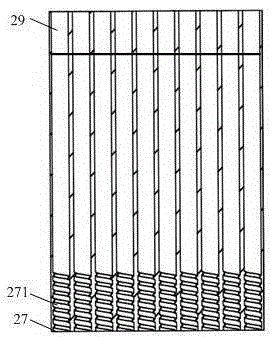

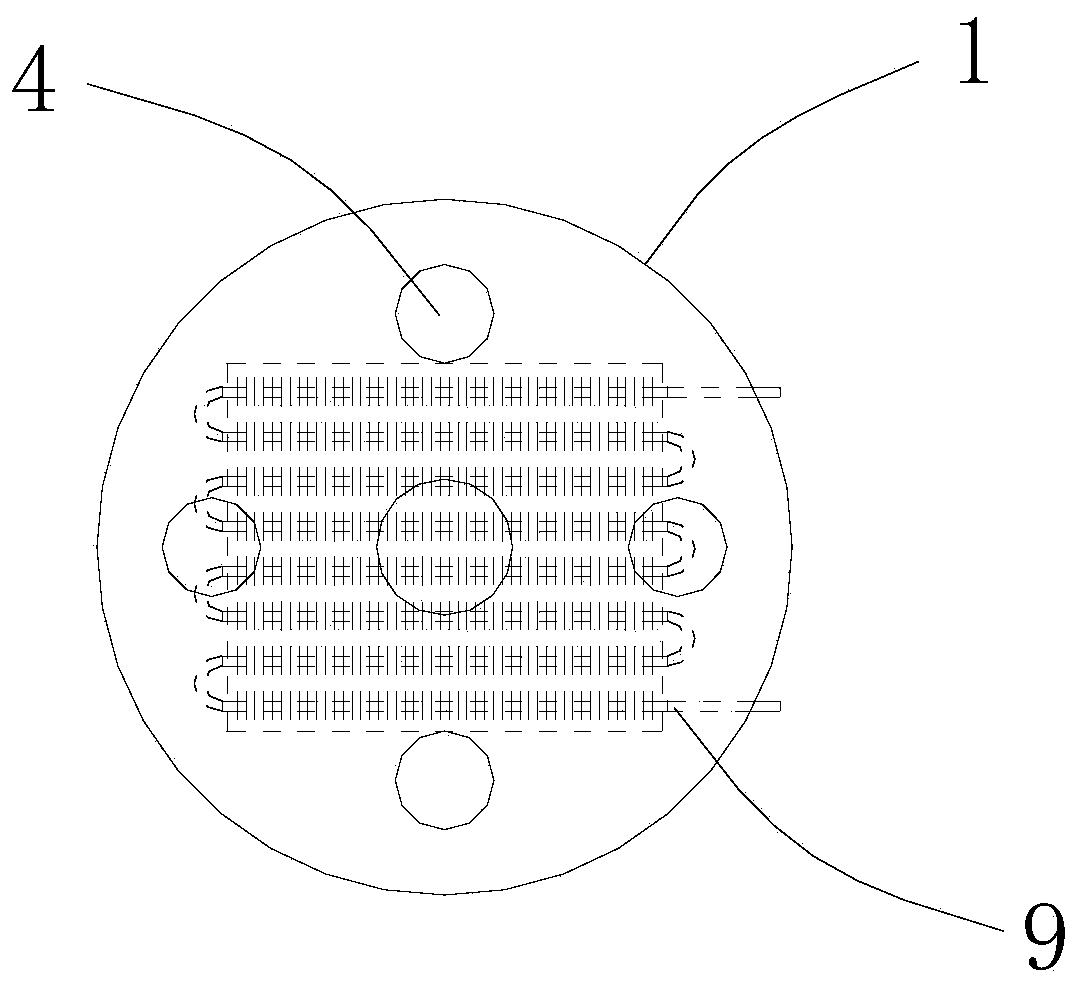

Round bin type cereal drying equipment

InactiveCN106035643AIncrease contact surfaceEasy dischargeSeed preservation by dryingFood dryingPulp and paper industryTower

The invention discloses round bin type cereal drying equipment. The round bin type cereal drying equipment comprises a drying bin, a wind supplying cylinder, a thermal wind generating device and a conveying device, wherein a feed opening and a discharge opening are formed in the drying bin; the drying bin is a round bin, the side wall of the drying bin comprises an inner wall and an outer wall, a ventilating cavity is formed between the inner wall and the outer wall, and wind supplying holes are formed in the inner wall; the drying bin is provided with a dampness removing passage, and a dampness removing fan is arranged in the dampness removing passage; the wind supplying cylinder is vertically arranged in the drying bin and is positioned below a discharge end of the feed opening, and a tower-shaped dome is arranged at the top of the wind supplying cylinder; a drying chamber is formed between the wind supplying cylinder and the inner wall, and wind supplying holes are formed in the side wall of the wind supplying cylinder; the thermal wind generating device is respectively connected with the ventilating cavity and the wind supplying cylinder for delivering thermal wind to the ventilating cavity and the wind supplying cylinder; and the conveying device is respectively connected with the discharge opening and the feed opening of the drying bin, so that cereals flowing out of the drying bin are newly transported into the drying bin. The round bin type cereal drying equipment disclosed by the invention is high in drying speed and good in uniformity, and besides, the problems that the dried cereals are charred, the dried cereals have cracks, and the dried cereals are crushed are solved.

Owner:望江县乡缘农业有限责任公司

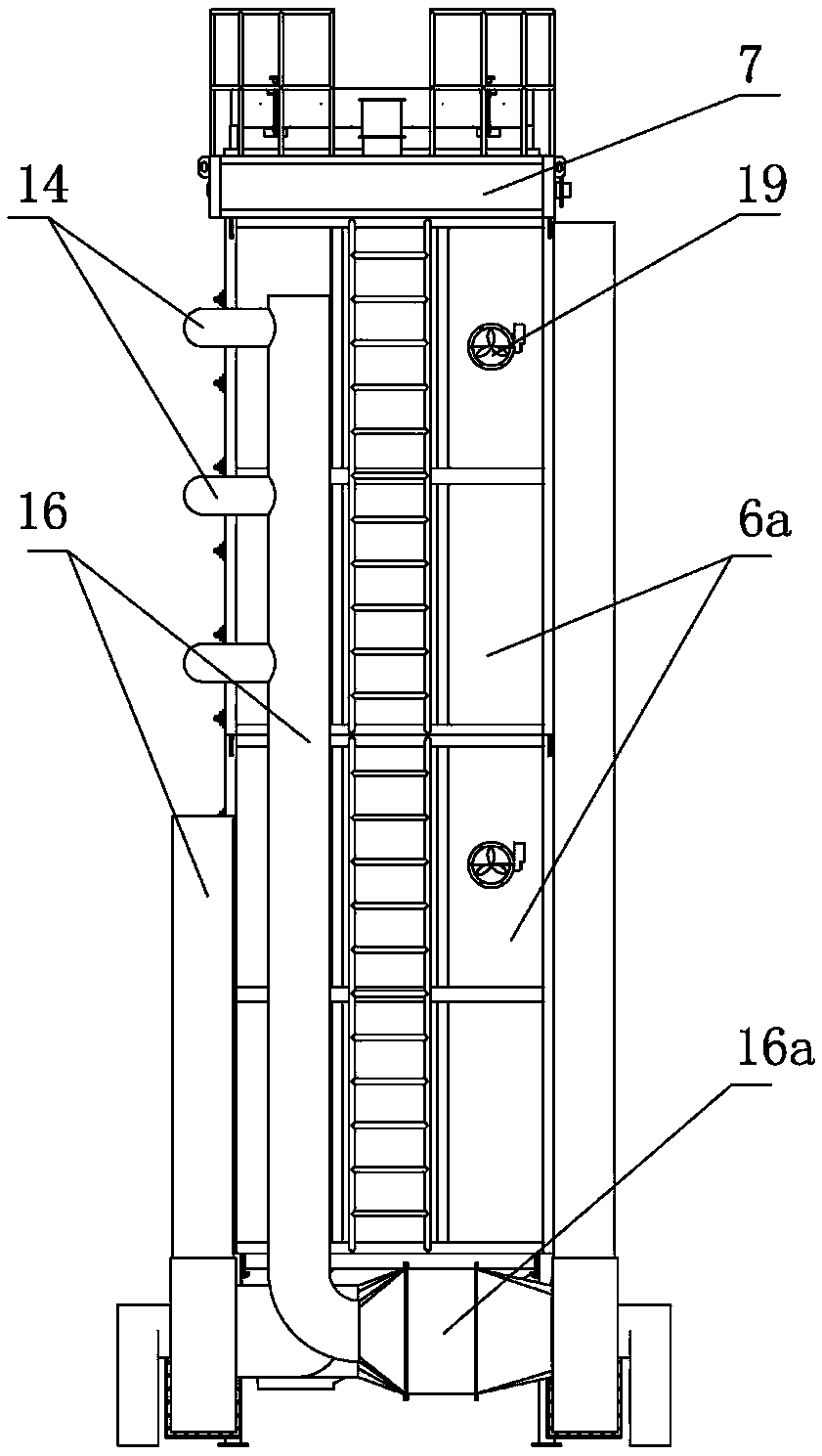

Fruit and vegetable drying machine

The invention discloses a fruit and vegetable drying machine, and belongs to the field of drying of agriculture products. The fruit and vegetable drying machine comprises a drying chamber, wherein a feeding opening is formed in the top of the drying chamber; a distributing device is arranged at the upper part of the inner part of the drying chamber, corresponding to the feeding opening, and can beused for uniformly tiling materials on a plurality of feeding turning plates which are sequentially arrayed; a lifting supporting mechanism is arranged on the lower side of each feeding turning plate, and is in transmission connection with a lifting driving device; a discharging channel allowing the materials to fall is reserved on each lifting supporting mechanism; at least one layer of drying supporting layers which are vertically arrayed at intervals are arranged under the distributing device, in the drying chamber; each drying supporting layer comprises a plurality of drying turning plates which are sequentially arrayed; each drying turning plate is rotatably connected to the drying chamber by the corresponding drying rotating shafts; each set of the drying rotating shafts are in transmission connection with the corresponding overturning driving device; and a discharging mechanism is arranged at the bottom of the drying chamber. According to the fruit and vegetable drying machinedisclosed by the invention, the overall length of the turning plates can be opened, and materials on each layer are safely transmitted level by level, so that the situation that the materials are sufficiently in contact with thermal wind is guaranteed, and the materials are sufficiently dried.

Owner:扬州福尔喜果蔬汁机械有限公司

Energy-saving type poultry feed drying processing device

InactiveCN107594596AEasy to recycleSimple preparation processFeeding-stuffPulp and paper industryThermal wind

The invention provides an energy-saving type poultry feed drying processing device, and belongs to the technical field of processing of poultry feeds. The energy-saving type poultry feed drying processing device comprises a supporting device and a drying processing device, wherein two feeding hoppers are arranged on the left side of the upper surface of a material transporting cylinder; a materialtransporting device is arranged at the right end of a left bearing; a blowing machine is fixedly arranged on the right side on the supporting frame; a baffle is arranged on the lower side of an innercavity of a box body in a penetrating manner through a fixing sleeve ring arranged at the right end of the box body; and a collecting vessel is arranged at the bottom of the inner cavity of the box body. According to the energy-saving type poultry feed drying processing device disclosed by the invention, the material transporting device is arranged in the inner cavity of the material transportingcylinder, so that the energy-saving type poultry feed drying processing device has the functions of performing preliminary crushing on caked feed and feed transporting; the left end of the blowing machine is connected with a heater through an air inlet pipe, and the right end of the heater is connected with a filter through the air inlet pipe, so that the energy-saving type poultry feed drying processing device has functions of blowing fresh thermal wind to the box body for drying the feed; and the energy-saving type poultry feed drying processing device has the characteristics of being simple in manufacturing process, high in practicality and good in drying effect.

Owner:温子墨

Tea perfume oil extraction technique

InactiveCN101121911AUnimpeded escapeHigh yieldEssential-oils/perfumesNatural ventilationDistillation

The invention relates to a technique to extract effective constituents form tea leaves. The process is capable to achieve high extraction rate and the quality of extracted aromatic oil is high, the processing technique is simple, the cost is low, and can be applied to massive production easily. In terms of the technical proposal, the aromatic oil is extracted from tea leaves through the following process: A. fresh tea leaves are evenly spread in the sun and dried to green; B. the fresh leaves dried to green are moved into a curing room equipped with natural ventilating facilities and maintained for 6-15 hours under normal temperature; C. the leaves are put into a steamer for distillation. Tea greenness deleting machine is adopted to delete greenness for 2-3 passes during the curing process. The fresh tea leaves undergone curing under normal temperature are processed into dry tea leaves after nzyme deactivation and drying, and then put into the steamer for distillation again; D. the nzyme deactivation process adopts traditional technique; E. intermediate thermal-wind is adopted for drying; F. the distillation duration increases 30-60 minutes compared with distillation of fresh leaves. When the dried tea leaves are distilled in the steamer, the tea dusts, tea stalks and pruned leaves are mixed and distilled.

Owner:唐妙火 +1

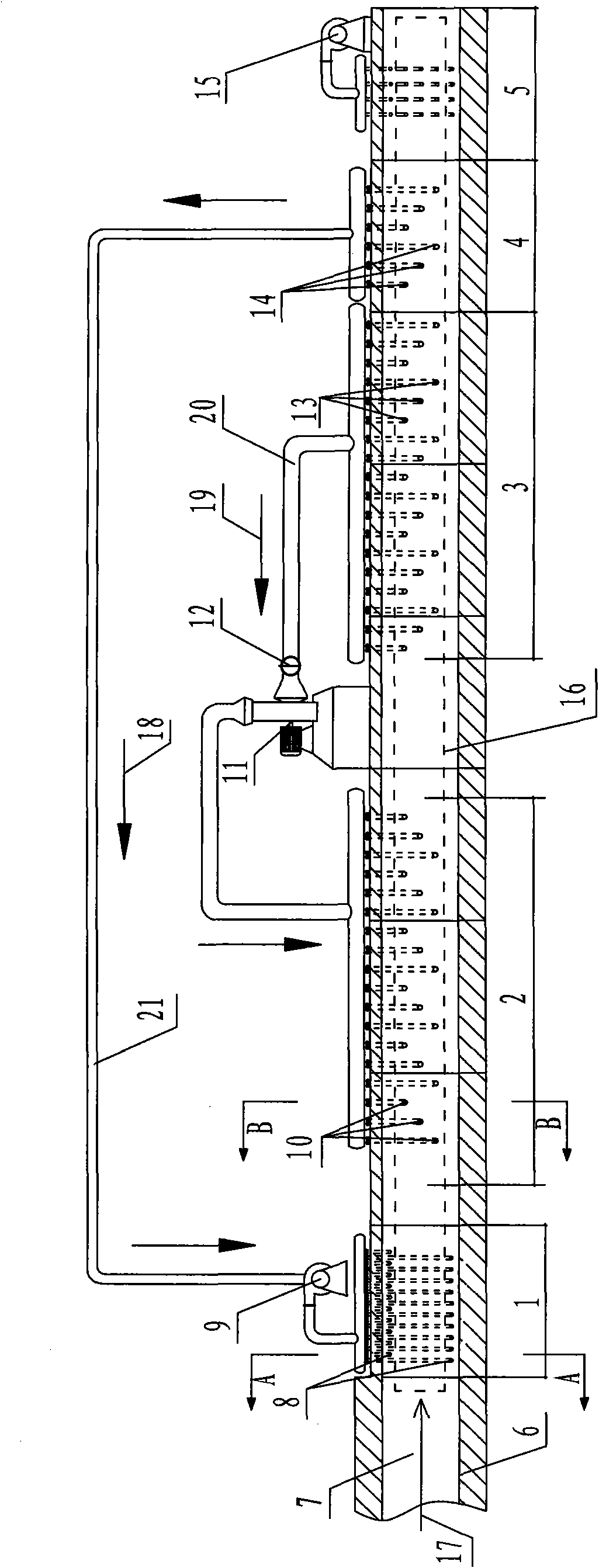

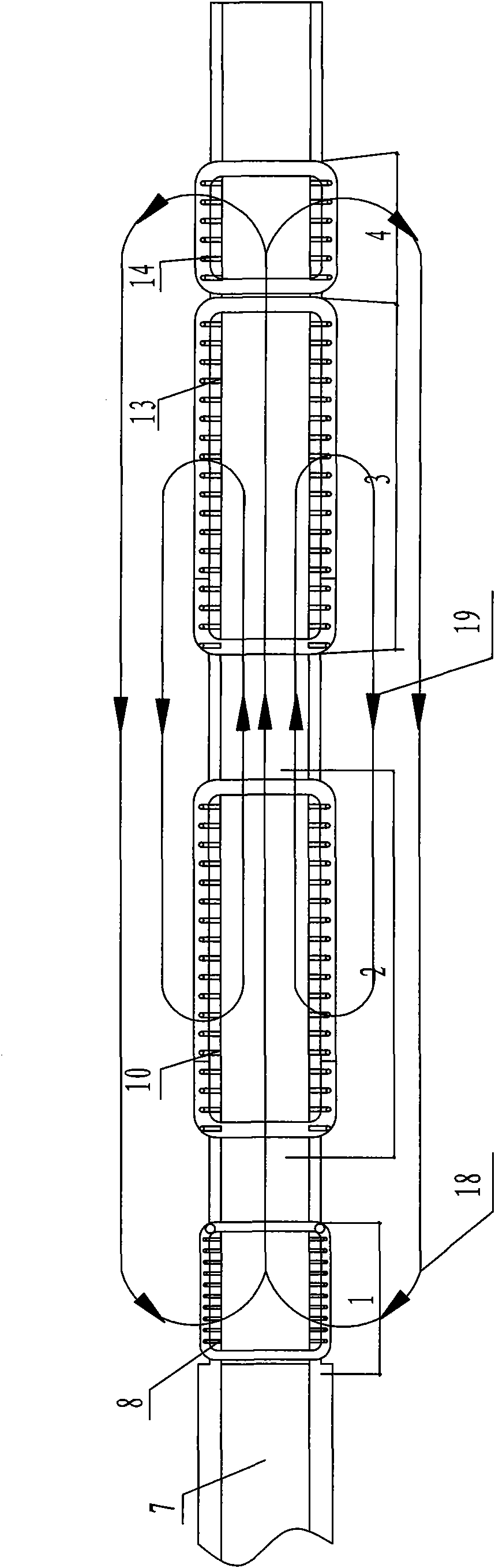

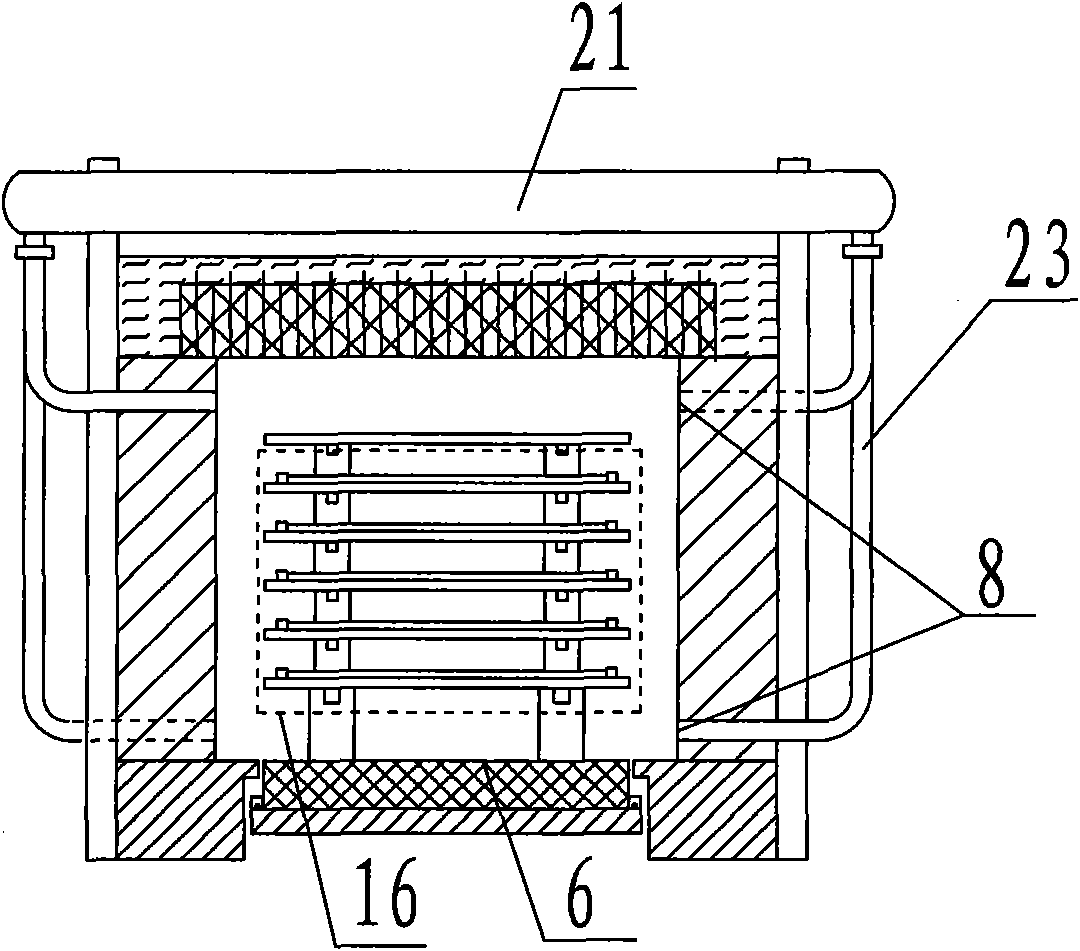

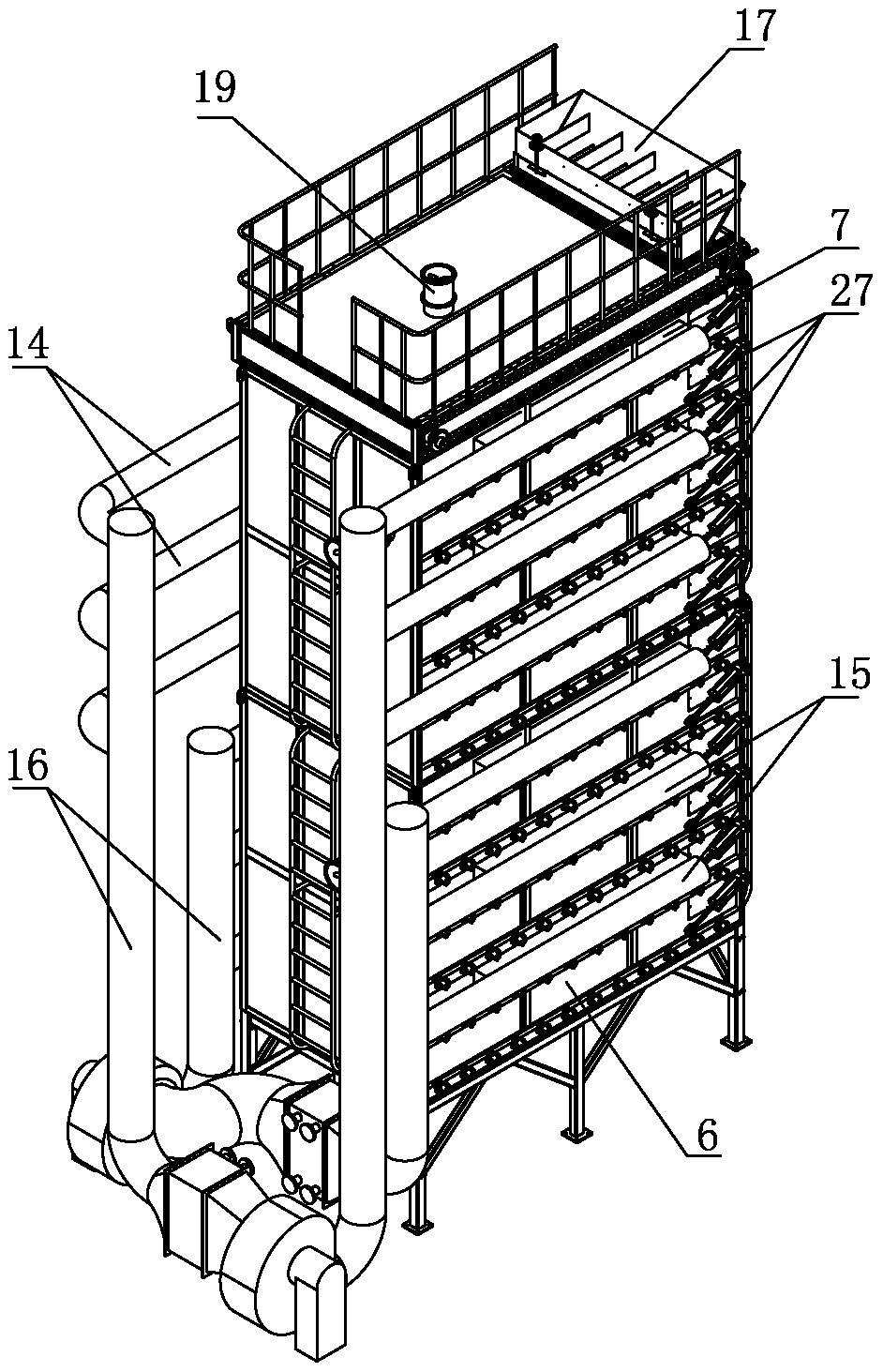

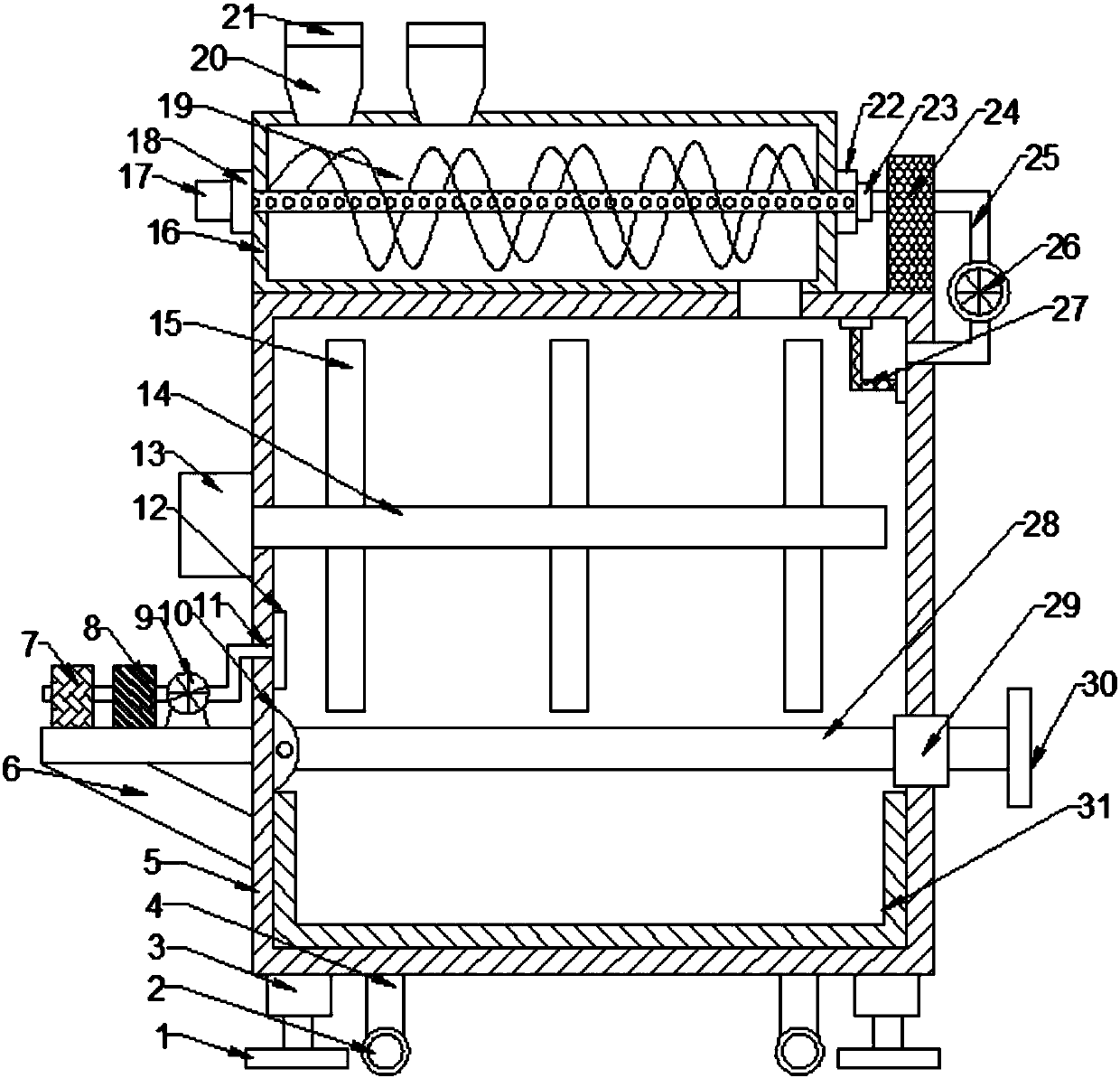

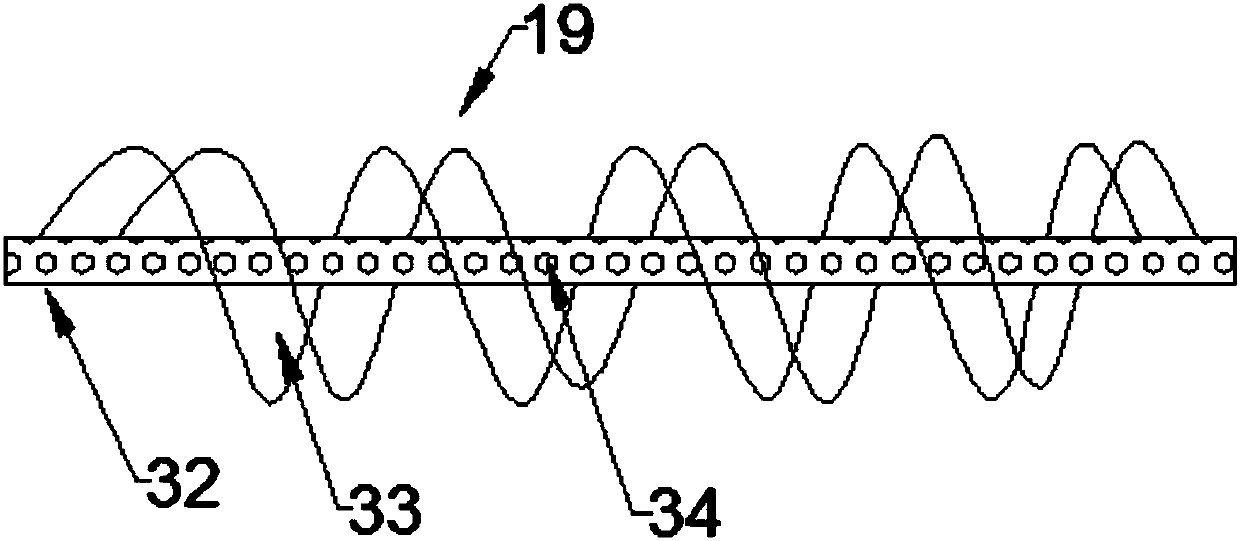

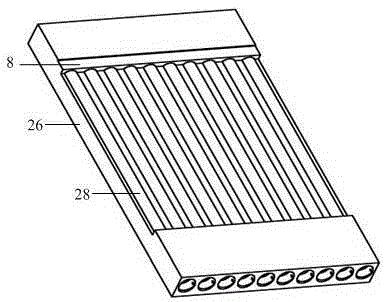

Food grain drying system through heat pump

ActiveCN105961582AEfficient dryingEnvironmentally friendly dryingFood processingClimate change adaptationOutput deviceEngineering

The invention relates to the technical field of drying of food grains, in particular to a food grain drying system through a heat pump. The system comprises a drying tower, a heat pump device, a thermal wind input device and a wet wind output device, wherein the heat pump device comprises a heat pump evaporator, a heat pump cycle wind chamber, a heat pump condenser and a heat pump compressor; the heat pump evaporator, the heat pump cycle wind chamber and the heat pump condenser are sequentially connected; the heat pump cycle wind chamber communicates with the heat pump compressor; the thermal wind input device comprises a thermal wind mixing chamber and a thermal wind transfer pipeline which are sequentially connected with the heat pump condenser; the wet wind output device comprises a wet wind output pipe, a dust removal collecting chamber and a wet wind mixing chamber which are sequentially connected with the drying tower. According to the food grain drying system through the heat pump, provided by the invention, the drying tower, the heat pump device, the thermal wind input device and the wet wind output device form a closed cycle energy recovering structure of dried cycle wind, and the purpose of drying food grains in an environmentally-friendly, energy-saving and efficient manner is achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

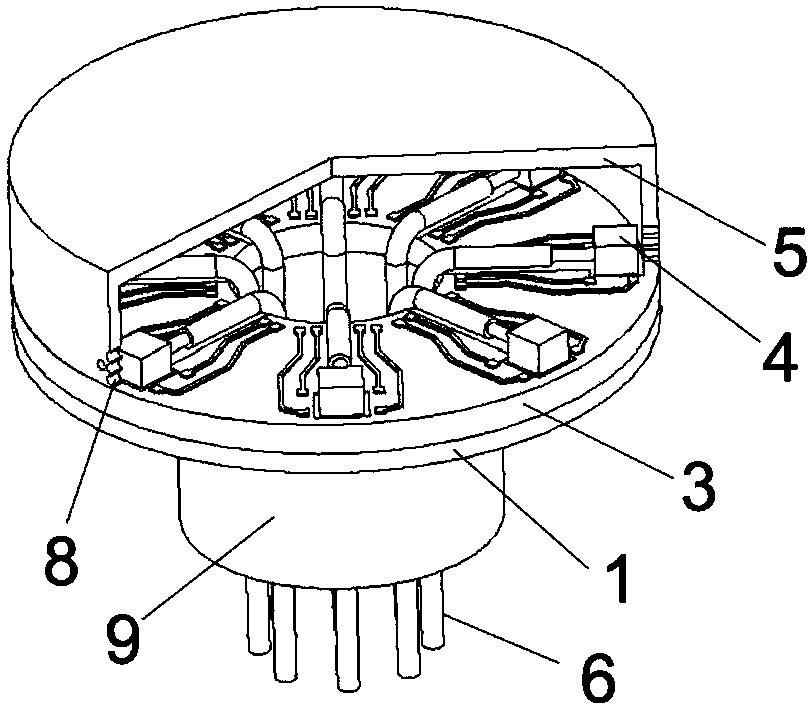

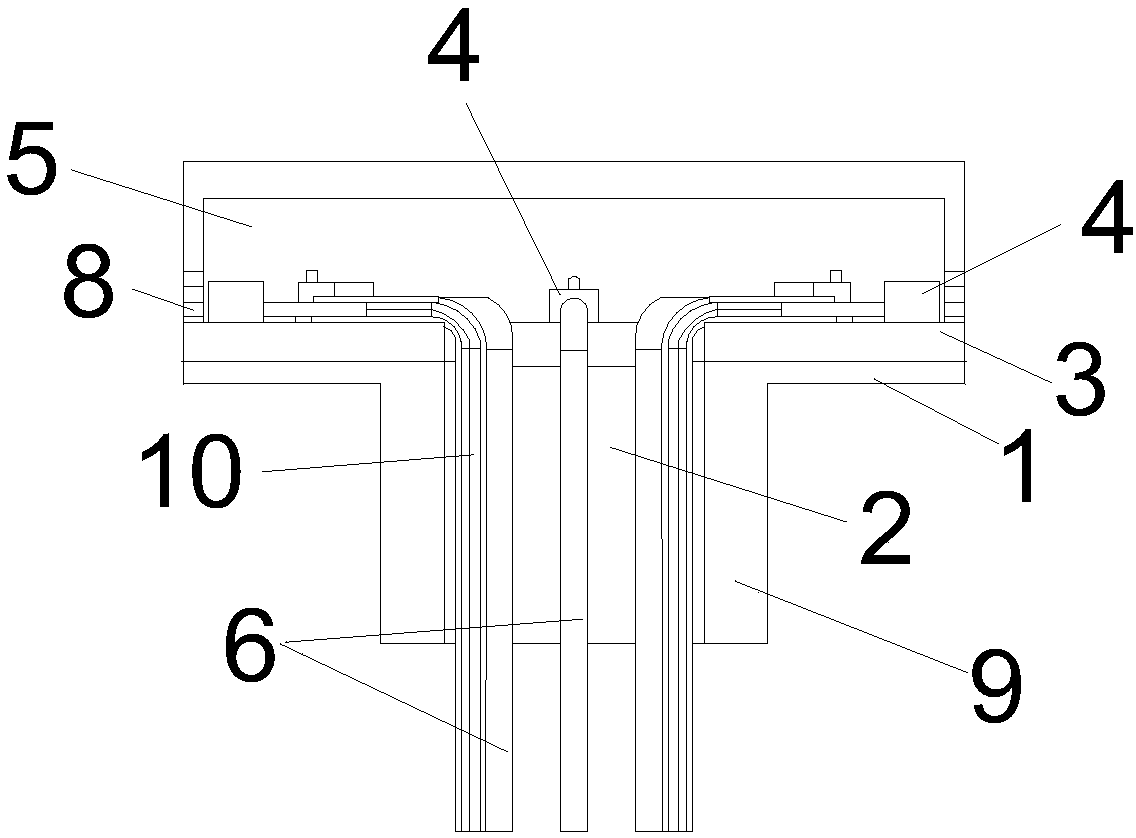

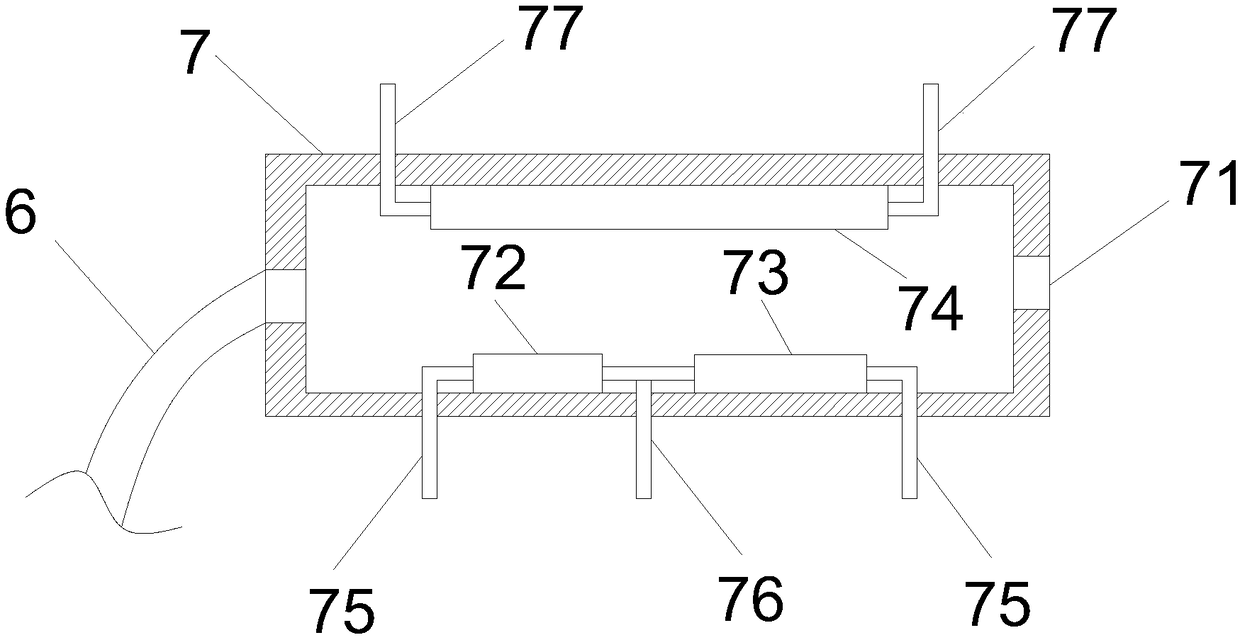

Thermal wind speed sensing device capable of performing zero compensation automatically and method for measuring wind speeds

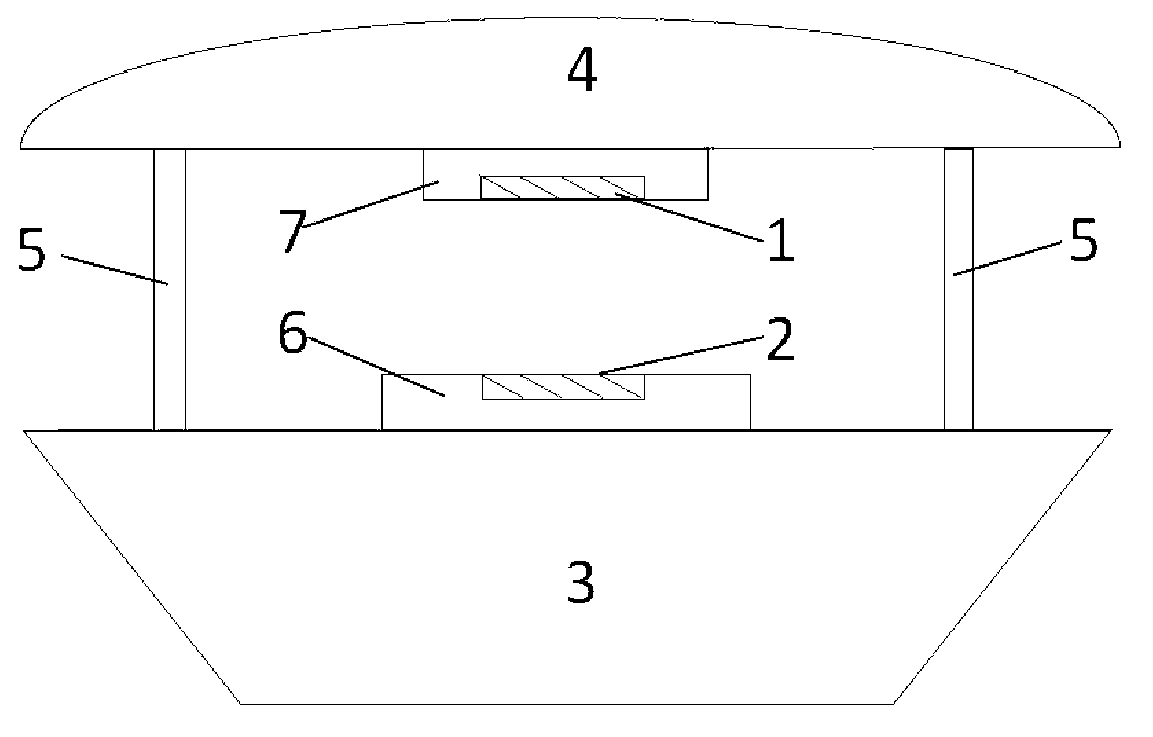

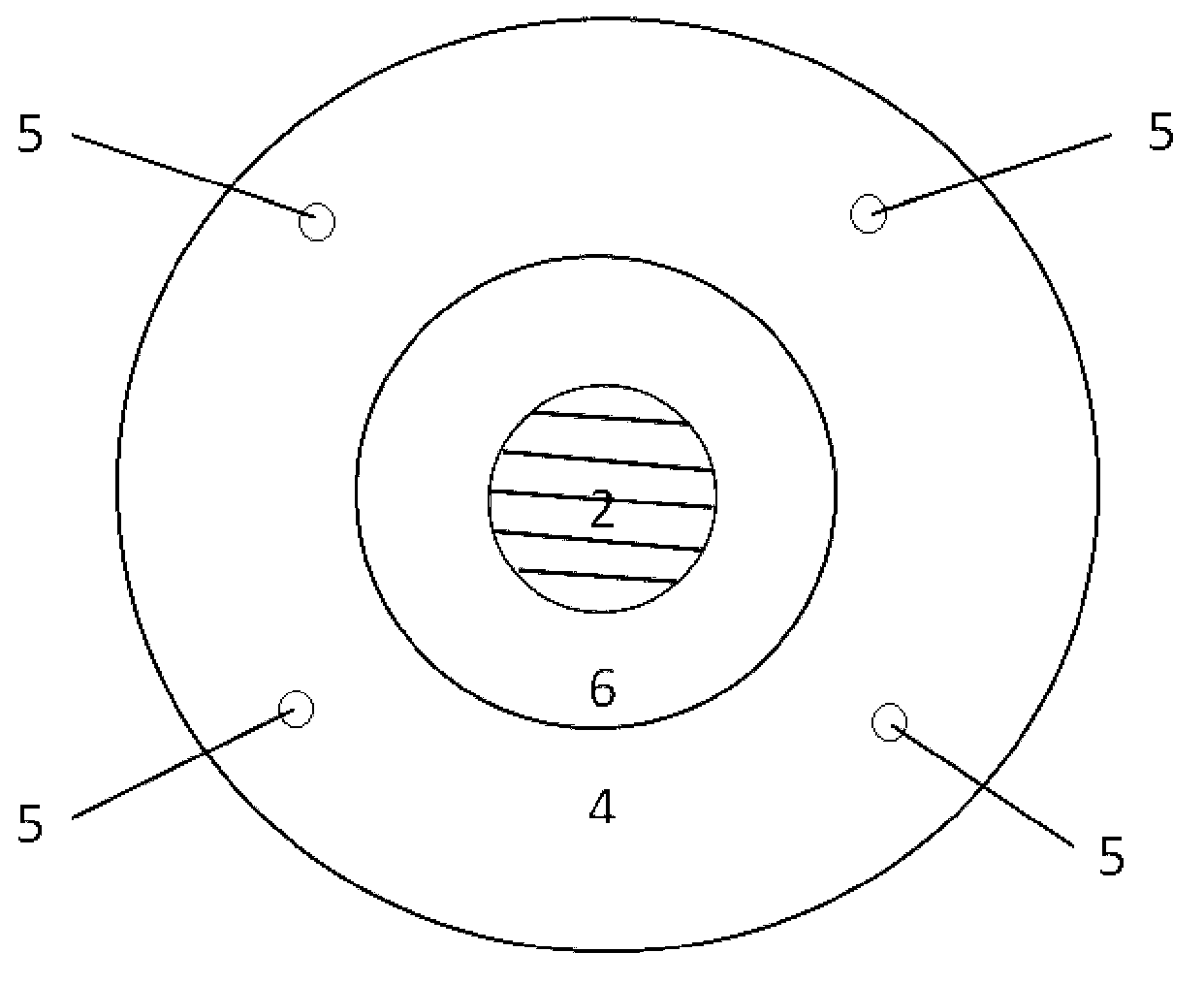

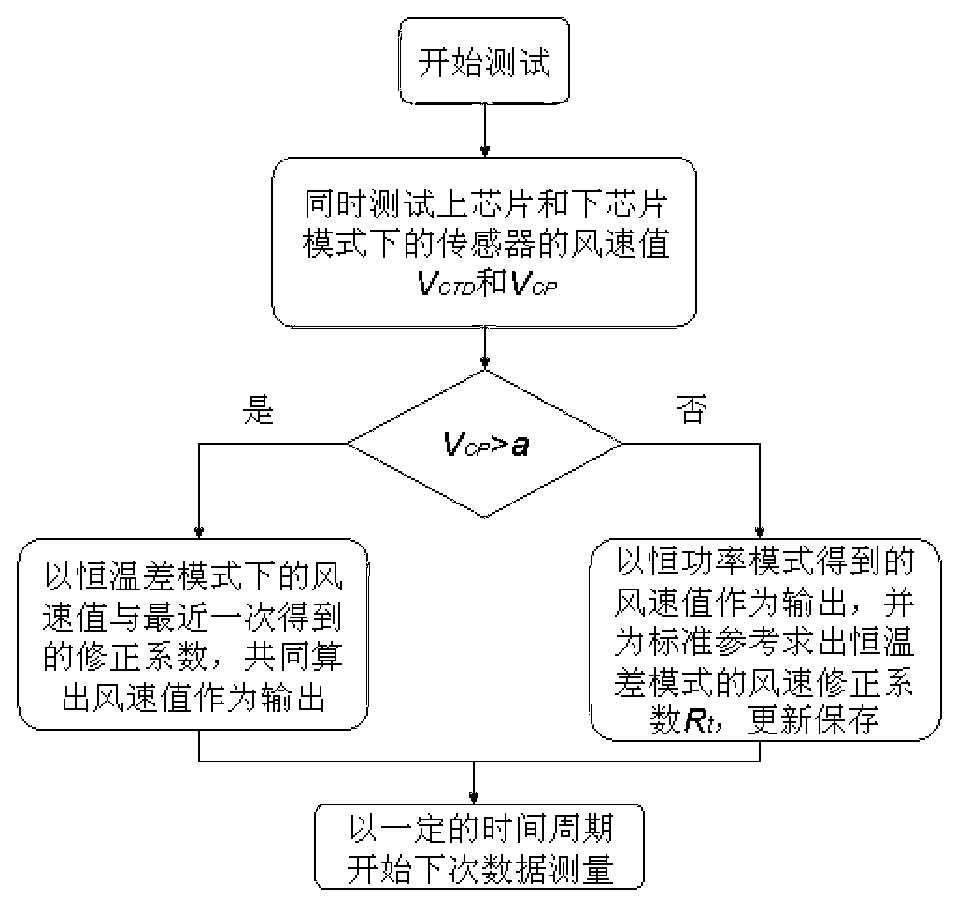

InactiveCN103018478AWide measurement rangeAccurate measurementFluid speed measurement using thermal variablesMicrocontrollerConstant power

The invention discloses a thermal wind speed sensing device capable of performing zero compensation automatically. The device comprises an upper sensor chip, a lower sensor chip, a top casing, a bottom casing, support column bodies, a lower support platform and an upper support platform. The upper sensor chip is embedded at the bottom of the upper support platform, and the lower sensor chip is embedded at the top of the lower support platform; and the upper sensor chip is a wind speed sensor chip in a constant-temperature-difference mode, and the lower sensor chip is a wind speed sensor chip in a constant-power mode. A method for measuring wind speeds through the thermal wind speed sensing device comprises placing a thermal wind speed sensing device at a place of a wind speed to be tested; performing measurement, wherein the upper sensor chip works in a constant temperature difference working mode, the lower sensor chip works in a constant temperature working mode, and a single-chip microcomputer system measures and calculates wind speeds; and performing next measurement. The thermal wind speed sensing device can perform zero compensation automatically when used for measuring the wind speeds and has the advantages of being accurate in measurement and wide in wind speed measurement range.

Owner:SOUTHEAST UNIV

Concentrating photovoltaic-photo-thermal-wind power-thermoelectricity integrated system

ActiveCN103929117AIncrease profitEfficient collectionPV power plantsWater heatersThermal insulationAlloy

The invention discloses a concentrating photovoltaic-photo-thermal-wind power-thermoelectricity integrated system and belongs to the technical field of solar comprehensive utilization. The integrated system comprises a photovoltaic photo-thermal temperature difference power generation boiler, a concentrating type solar cooker, a solar cooker and boiler support, a ventilation duct, a wind power generating set, solar battery assemblies and a thermal insulation water bin. Solar cell pieces are arranged at the top and the bottom of the photovoltaic-photo-thermal temperature difference power generation boiler for photovoltaic power generation, the concentrating type solar cooker is used for collecting solar energy and reflecting the solar energy to a heat transfer alloy block in the center of the bottom of the photovoltaic-photo-thermal temperature difference power generation boiler, so that water in the boiler is heated, and the heated water automatically enters the thermal insulation water bin for thermal insulation. Meanwhile, the wind power generating set collects wind energy for power generation, the collected wind further cools the solar cell assemblies, and the solar battery assemblies also performs photovoltaic power generation. Solar energy and the wind energy are efficiently collected for power generation, so that comprehensive utilization of clean natural resources is greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

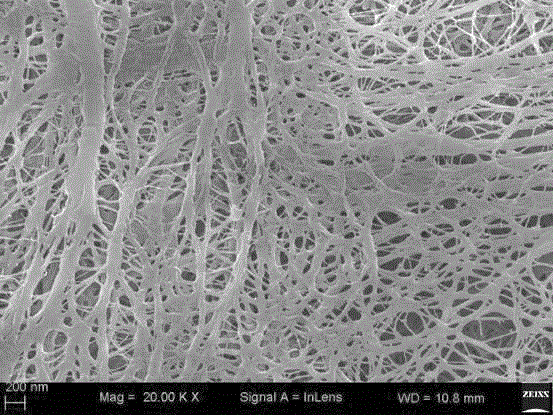

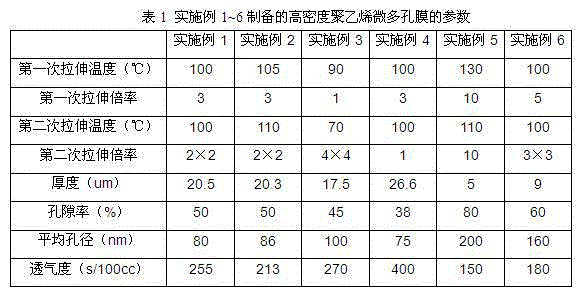

High-density polyethene micro porous membrane and preparation method therefor

The invention discloses a high-density polyethene micro porous membrane and a preparation method therefor, and belongs to the field of a film material. The method comprises the steps of: mixing raw materials, melting the mixed raw materials to form thick sheets, and then stretching the thick sheets twice: (1) stretching the thick sheets for the first time: preheating the thick sheets at the temperature of 40-130 DEG C, performing longitudinal stretching under the effect of thermal wind at 90-130 DEG C, wherein the stretching multiple rate is 1-10, and then performing heat shaping so as to obtain the films; (2) performing stretching for the second time: performing lateral uniaxial stretching or vertical and lateral bisynchronous stretching on the films prepared in the step (1) under the effect of thermal wind at 70-110 DEG C, maintaining stretching state for 2-4 minutes, wherein the multiple rate of lateral uniaxial stretching is 1-10, and the total multiple rate of vertical and lateral bisynchronous stretching is 4-16; and then, performing heat shaping so as to obtain finished products. According to the preparation method, in the stretching process, under the effect of thermal wind, a hole forming agent is rapidly volatilized from the films so as to form a micropore structure in mutual penetration, so that an extraction technology is omitted, the consumption of an extracting solvent is further reduced, the cost is reduced and the technological process is simplified.

Owner:XINXIANG ZHONGKE SCI&TECH

Camellia oleifera fruit hulling treatment method through flotation separation

InactiveCN107259591AThe method flow is simpleLow requirements for process conditionsFatty-oils/fats productionHuskingSurface moistureCamellia oleifera

The invention relates to a camellia oleifera fruit hulling treatment method through flotation separation. The camellia oleifera fruit hulling treatment method comprises the following steps of (1) throwing fruits: throwing fresh picked camellia oleifera fruits into a fruit throwing machine, thoroughly polishing camellia oleifera fruit shells, and performing extrusion and dispersion so as to obtain a camellia oleifera seed and camellia oleifera fruit shell mixture; (2) performing conditioning: performing air-drying transportation on the camellia oleifera seed and camellia oleifera fruit shell mixture obtained in the step (1) at thermal wind of 40-100 DEG C for a transportation period being within 30min, or performing microwave transportation at low frequency being 300MHz-915MHz for a transportation period being within 2min, so that the moisture of fruit shells is maintained to be 30-60%; (3) performing flotation: putting the camellia oleifera seed and camellia oleifera fruit shell mixture obtained in the step (2) into flotation fluid, wherein the density of the flotation fluid is 1-1.1g / cm<3>, enabling camellia oleifera seeds to sink, enabling fruit shells to float upwards, and separately fishing out the camellia oleifera seeds and the fruit shells so as to realize separation; and (4) performing baking: putting the camellia oleifera seeds obtained in the step (3) into a baking machine of 40-100 DEG C, performing thermal wind drying for the time of 30-90min, and removing surface moisture. The method is simple in technological processes, low in requirements for technological conditions, simple in equipment, and small in flour space, and continuous unrestricted mass production can be realized.

Owner:湖南大三湘油茶生态产业有限公司

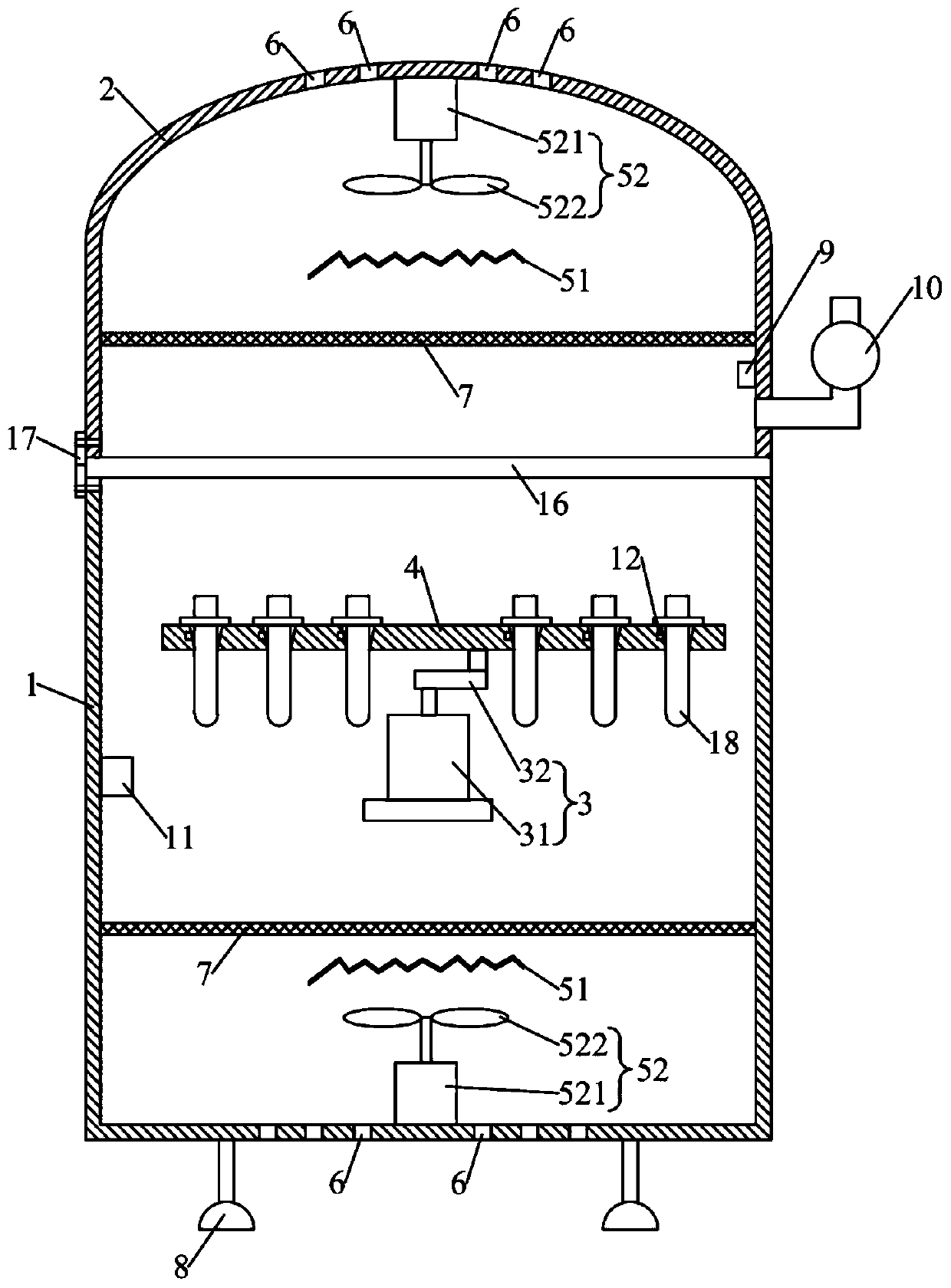

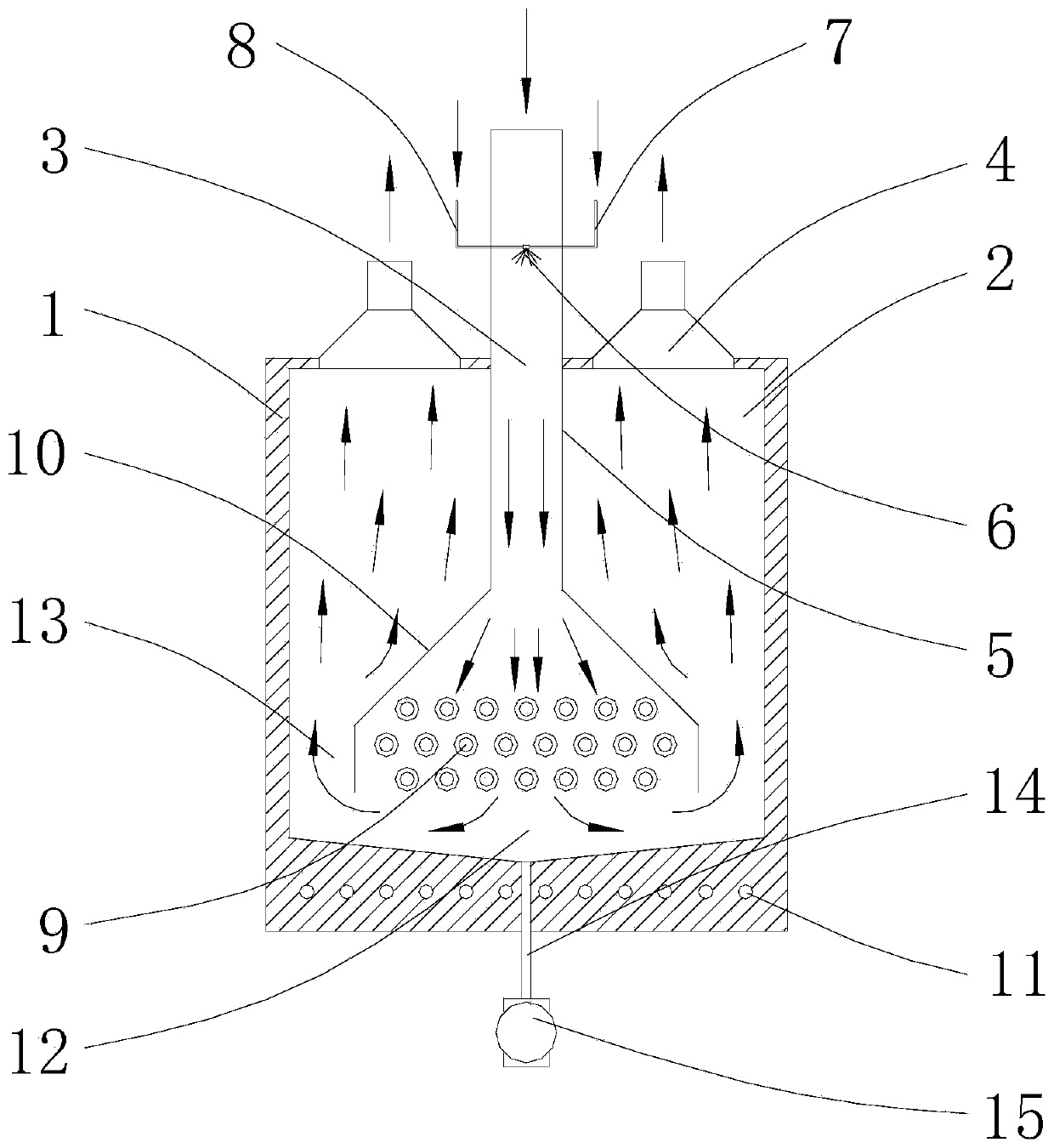

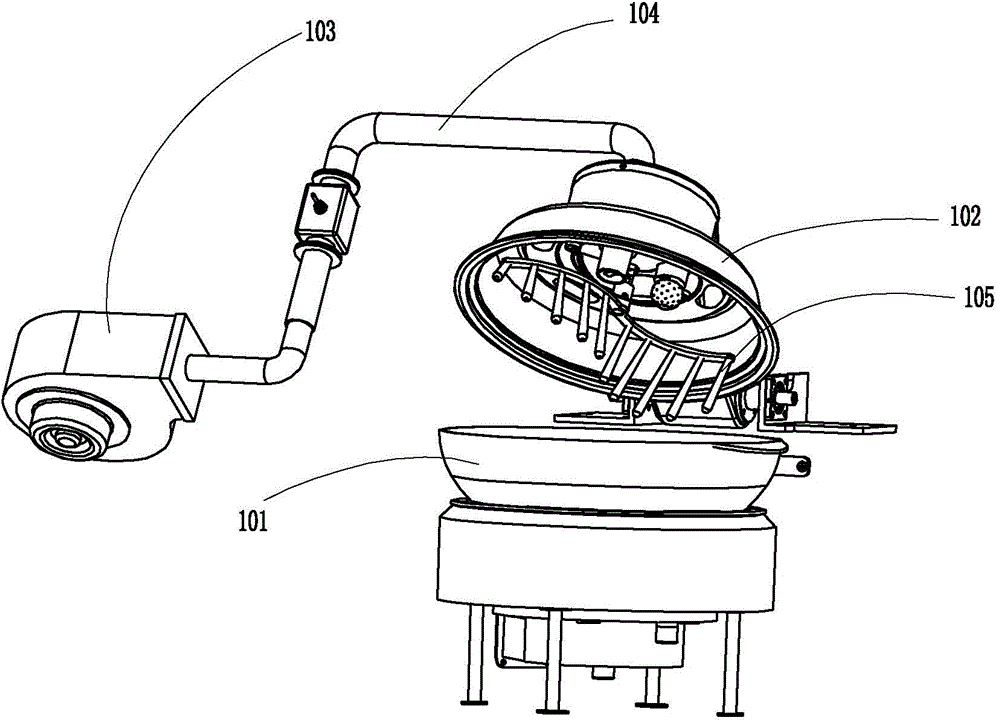

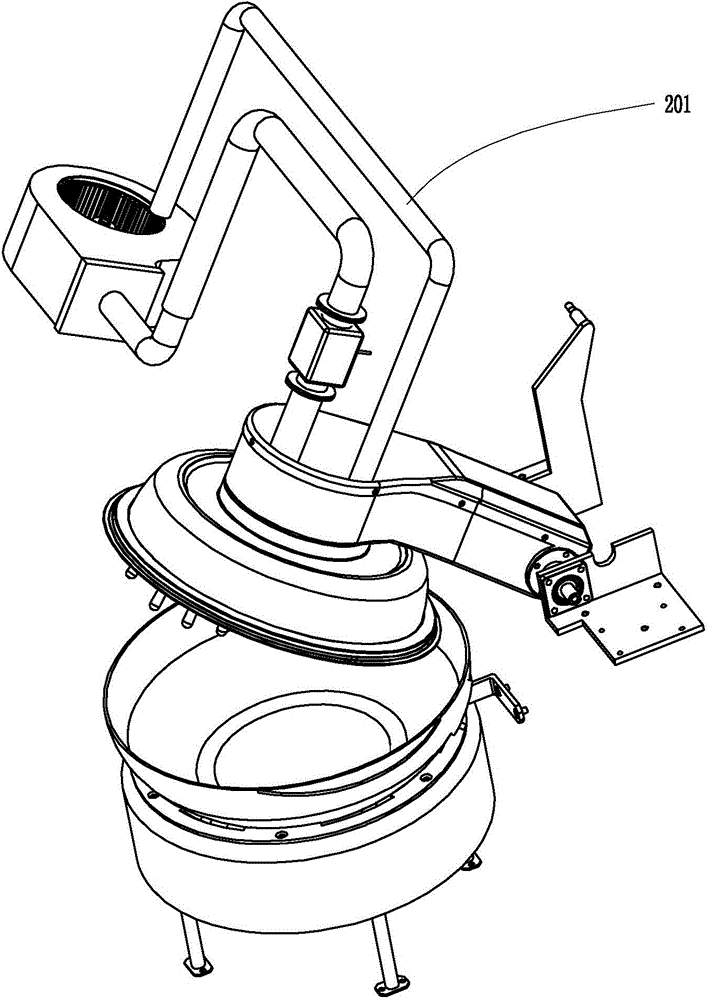

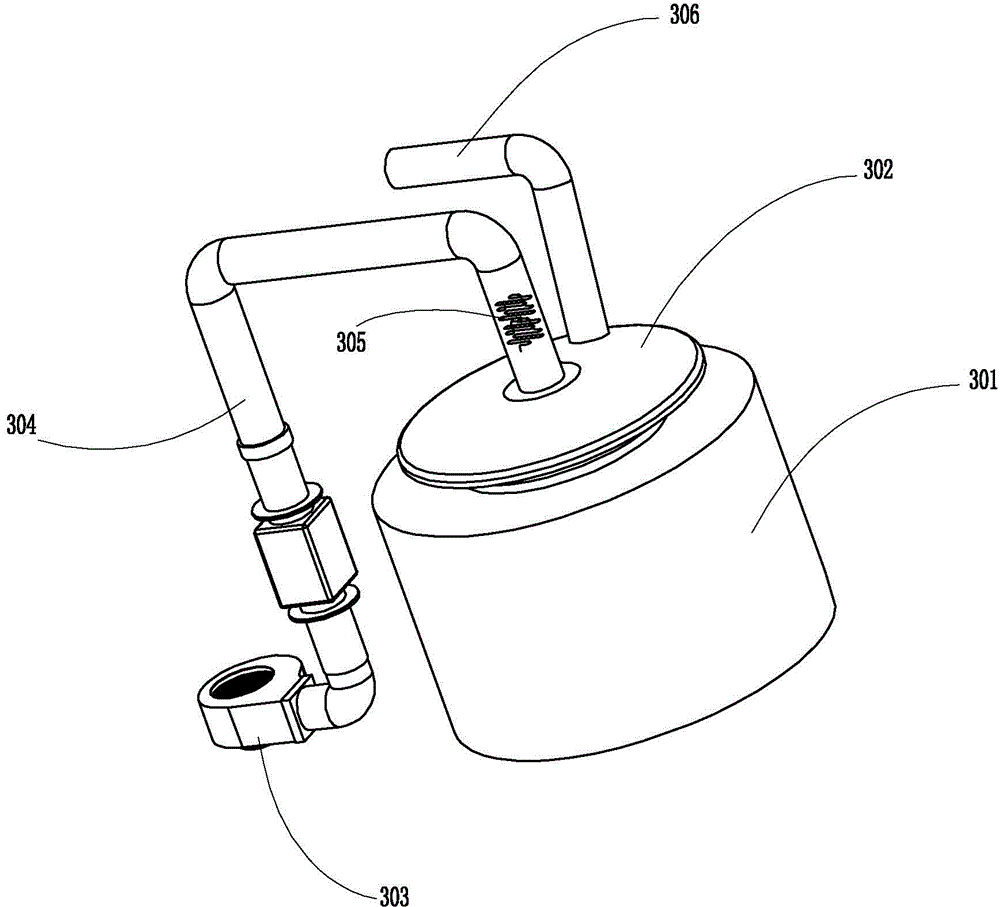

Cell resuscitation instrument

PendingCN110093267AAchieve recoveryImprove resuscitation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsFrozen storageEngineering

The invention belongs to the technical field of cell resuscitation, and discloses a cell resuscitation instrument. The cell resuscitation instrument comprises a body, an upper cover, a vibrating mechanism, a heated tray and a thermal wind heating device, wherein a working cavity is formed in the body; the upper cover is connected to the body to open or close the working cavity; the vibrating mechanism is arranged in the working cavity; the heated tray is connected to the vibrating mechanism; a plurality of placing grooves for placing cell frozen storage containers are formed in the heated tray; and the thermal wind heating device is arranged in the working cavity, and is used for blowing thermal wind to the heated tray and the cell frozen storage containers. According to the cell resuscitation instrument disclosed by the invention, through the vibrating mechanism, the heated tray is driven to sway, so that cells in the cell frozen storage containers are uniformly heated, and quick thawing is realized; a plurality of cell frozen storage containers can be borne by the heated tray in one time, so that the resuscitation efficiency of the cells is improved; and through the thermal windheating device, thermal wind is blown to the heated tray and the cell frozen storage containers, so that the cell frozen storage containers are heated, heat quantity is conducted to the inner cells, quick warming can be realized, and cell resuscitation can be efficiently realized.

Owner:JIANGSU PURECELL BIOMEDICAL TECH CO LTD

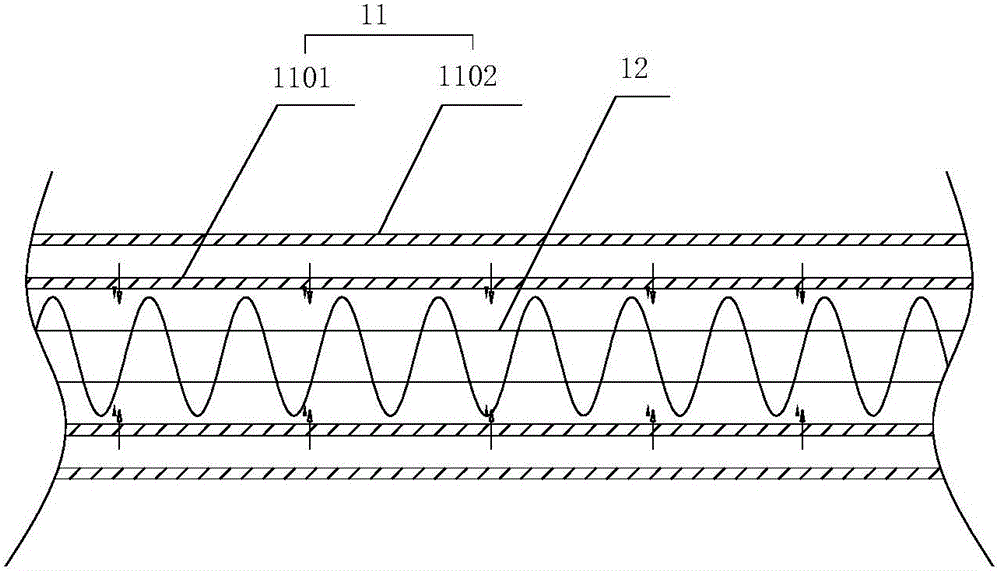

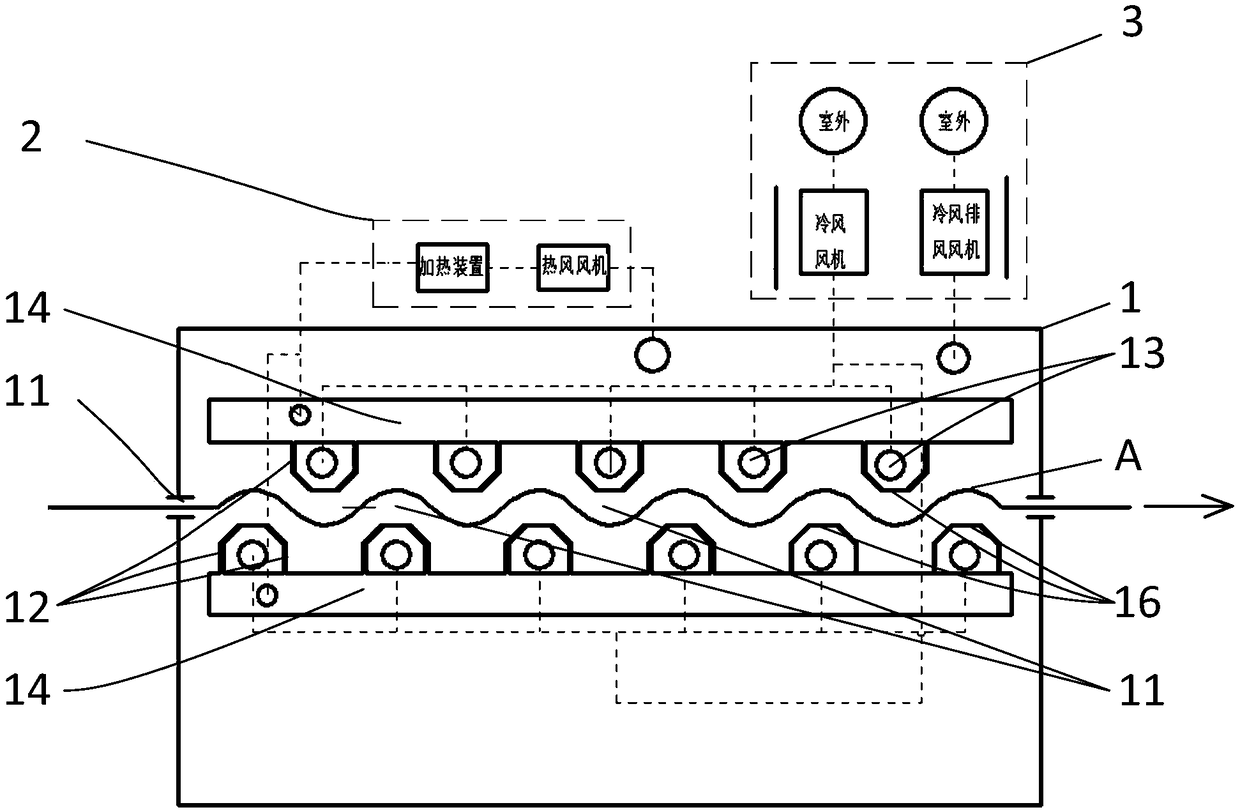

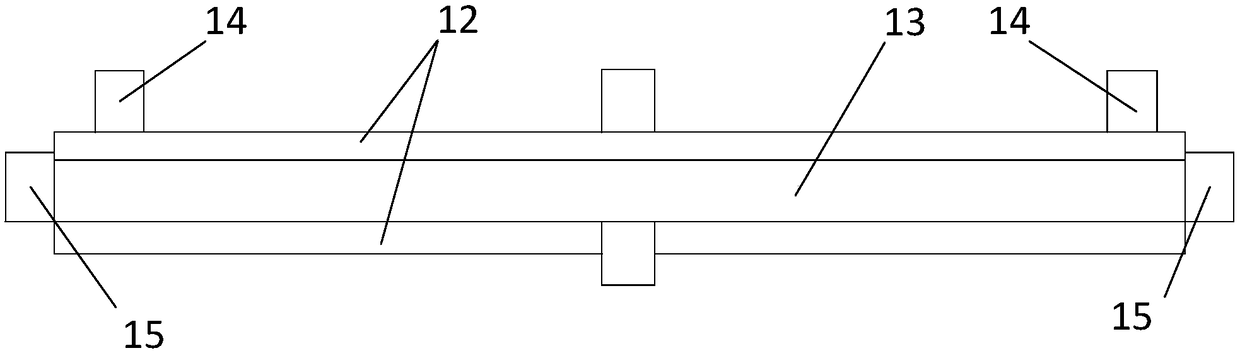

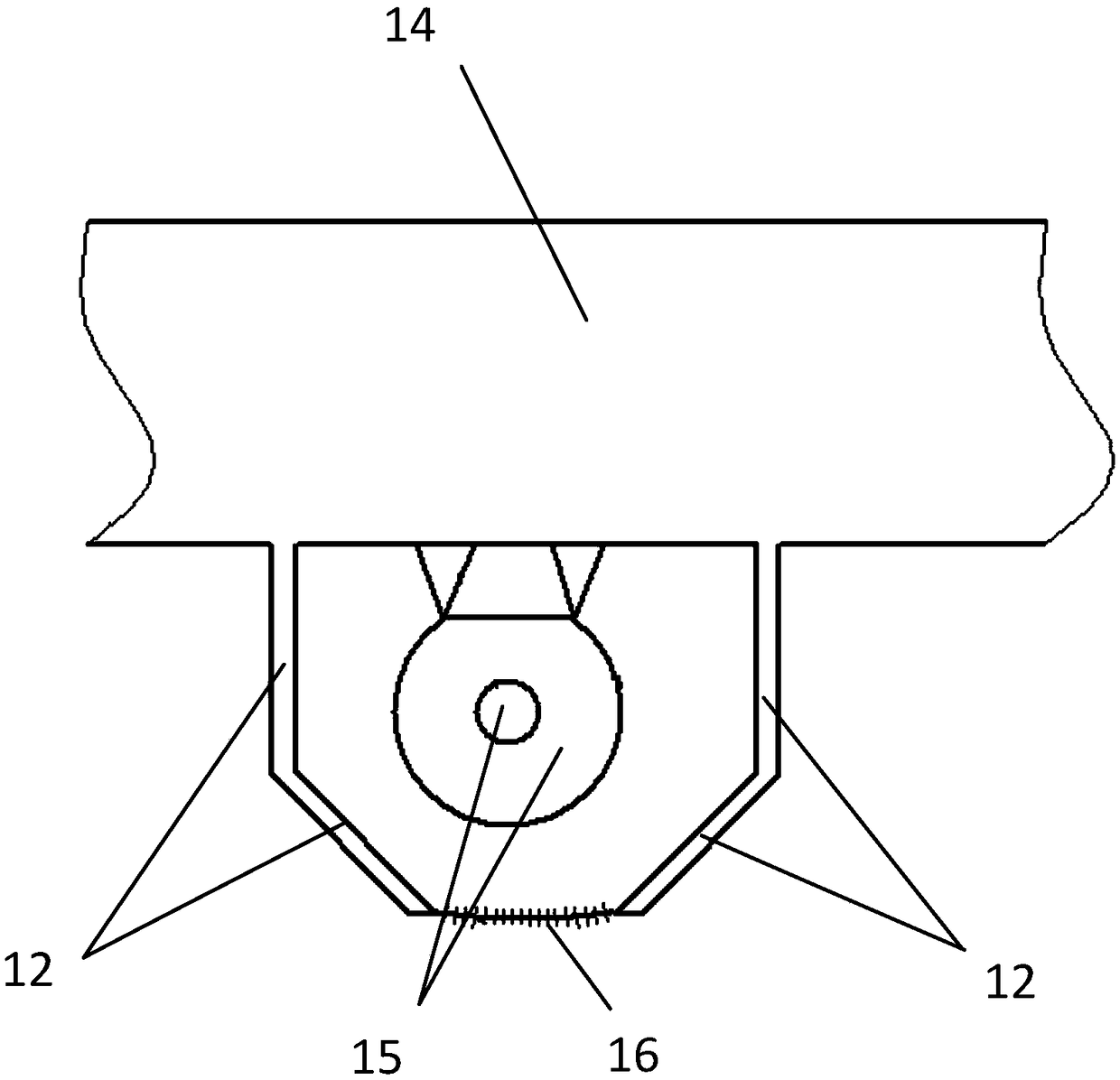

Air floating type oven of battery pole pieces

ActiveCN109365245ADry as soon as possibleAvoid accumulationPretreated surfacesCoatingsStopped workCold air

The invention discloses an air floating type oven of battery pole pieces. Thermal wind channels relatively located on the upper side and the lower side are arranged in a staggered manner; cold wind channels relatively located on the upper side and the lower side are arranged in a staggered manner; a thermal wind circulating device is used for transporting thermal air to the thermal wind channels and jetting the thermal air to base materials through thermal wind outlets; a cold wind circulating device is used for transporting cold air to the cold wind channels, and jetting cold air to the basematerials through cold wind outlets; in the normal belt conveying process of the base materials, thermal air is jetted to the base materials through the thermal wind channels, so that the base materials are dried as soon as possible; once the belt conveying of the base materials is stopped, the thermal wind circulating device stops working, and the cold air is jetted by the cold wind circulating device through the cold wind channels; the cold wind channels are arranged in a staggered manner, so that the base materials are still kept suspending, and do not need physical support; and the cold wind is jetted to the base materials, so that the situation that heat quantity is continuously accumulated to the same positions of the base materials can be avoided, and damaging the base materials andthe surface pulp is prevented.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

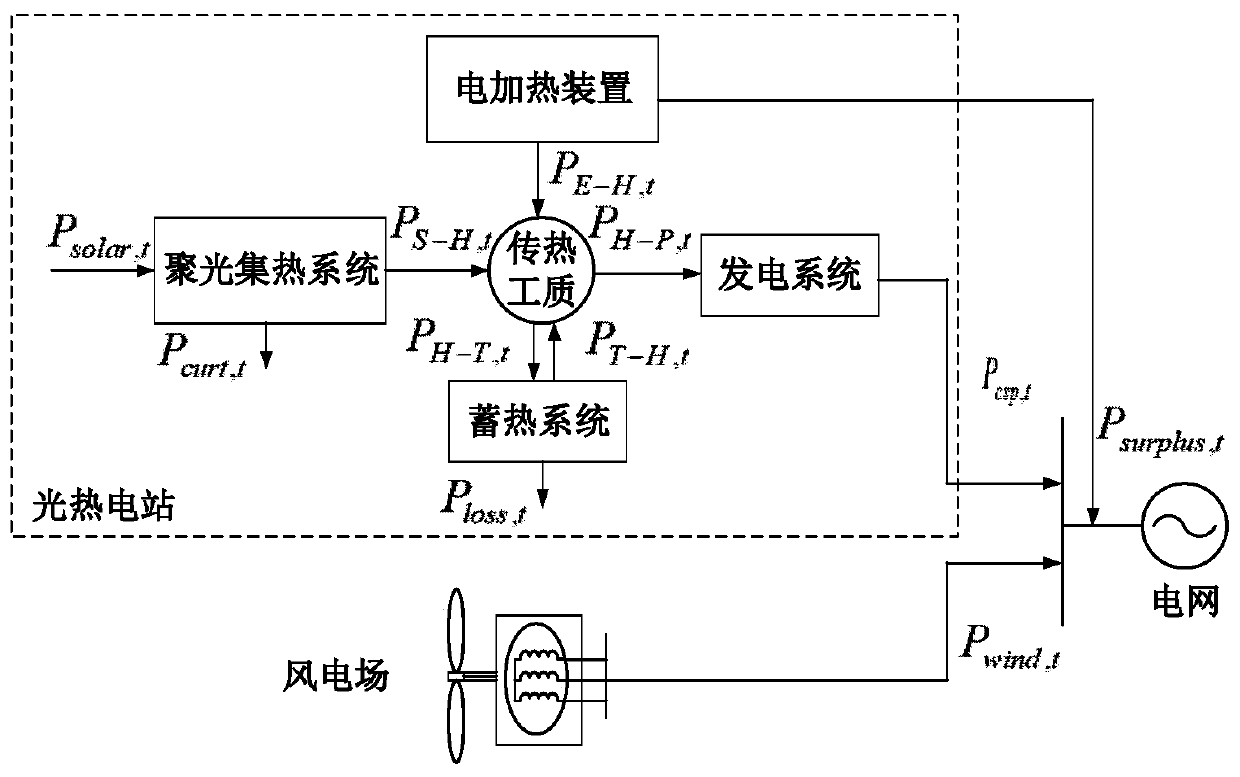

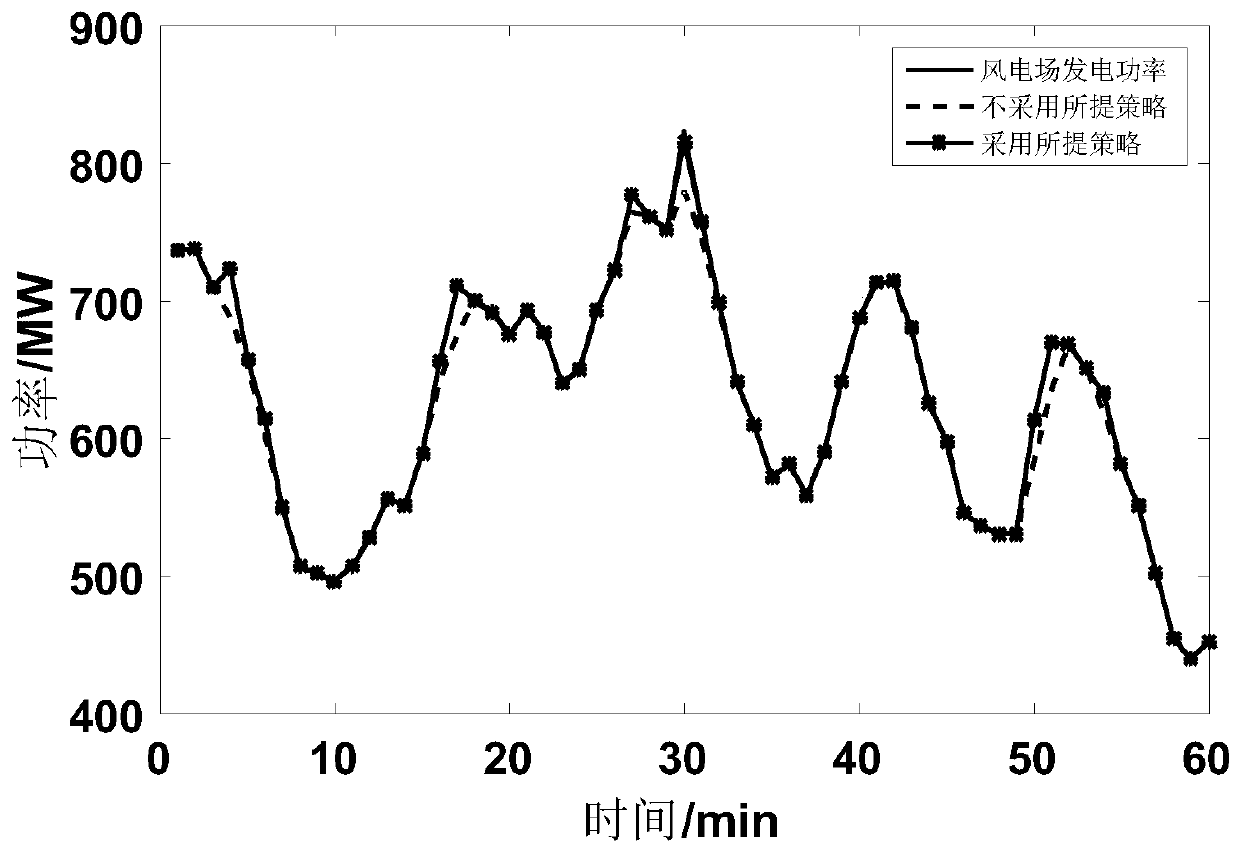

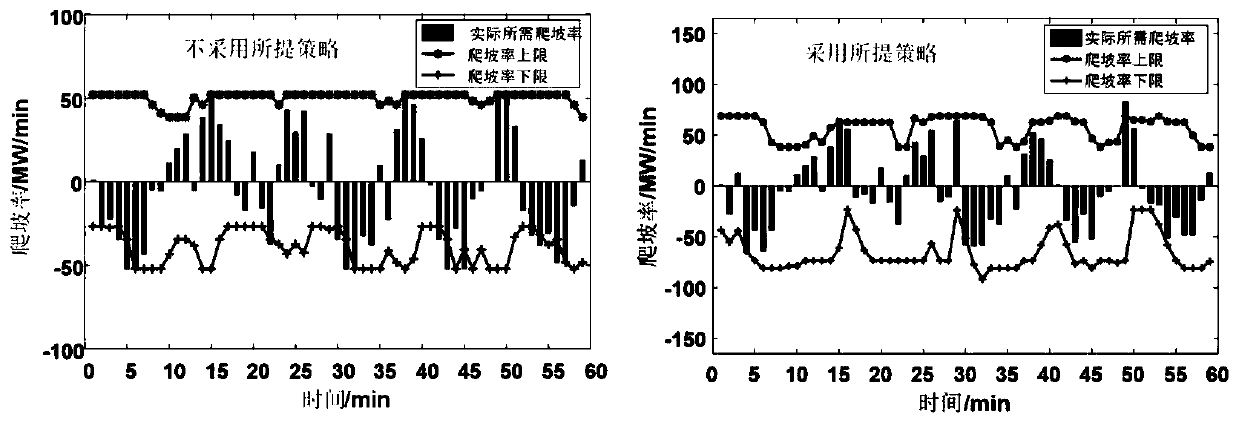

Optimal scheduling method for promoting wind power consumption by utilizing photo-thermal power station

ActiveCN110048469AImprove consumption levelRelieve Regulatory StressSingle network parallel feeding arrangementsWind energy generationElectricityElectric power system

The invention discloses an optimal scheduling method for promoting wind power consumption by utilizing a photo-thermal power station. The method comprises the following steps: firstly, a photo-thermal-wind power system structure containing a thermal storage system and an electric heating device is in combined grid-connected operation with a wind power plant; secondly, with the lowest system comprehensive cost as an objective function, through constructing a mathematical model of the photo-thermal power station in detail, utilizing the schedulability of a thermal storage system, the absorptivecapacity of an electric heating device and the good adjusting characteristic of a photo-thermal unit, a wind power optimization model is established; and finally, on the premise that the system cost is not increased, optimal scheduling is performed on the power system by using the model. According to the technical method, the adjusting capability of the system can be improved, the wind power consumption is promoted, the occurrence of wind power climbing events is reduced, and the safety stability and the operation economy of the power system are improved.

Owner:LIYANG RES INST OF SOUTHEAST UNIV +1

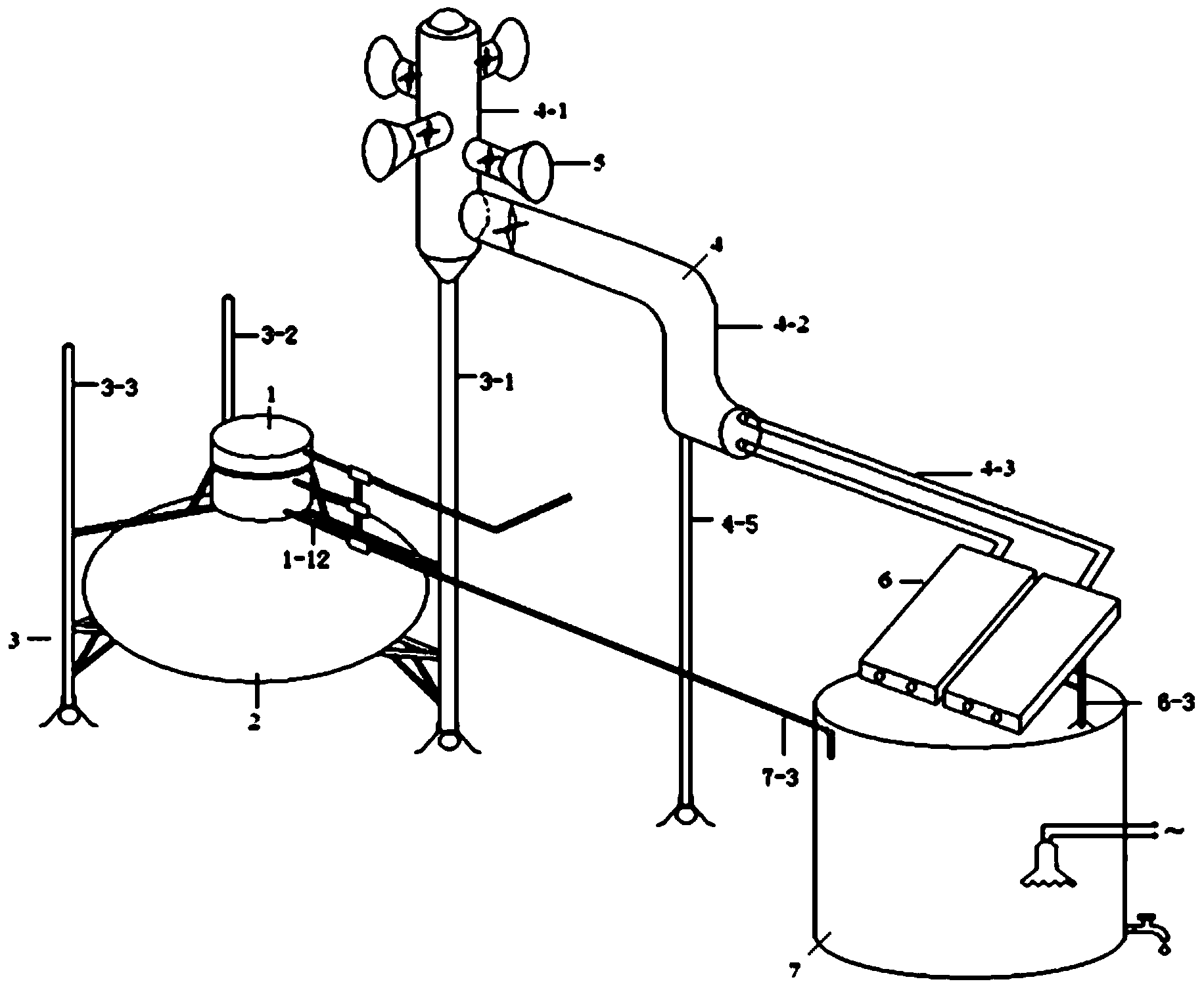

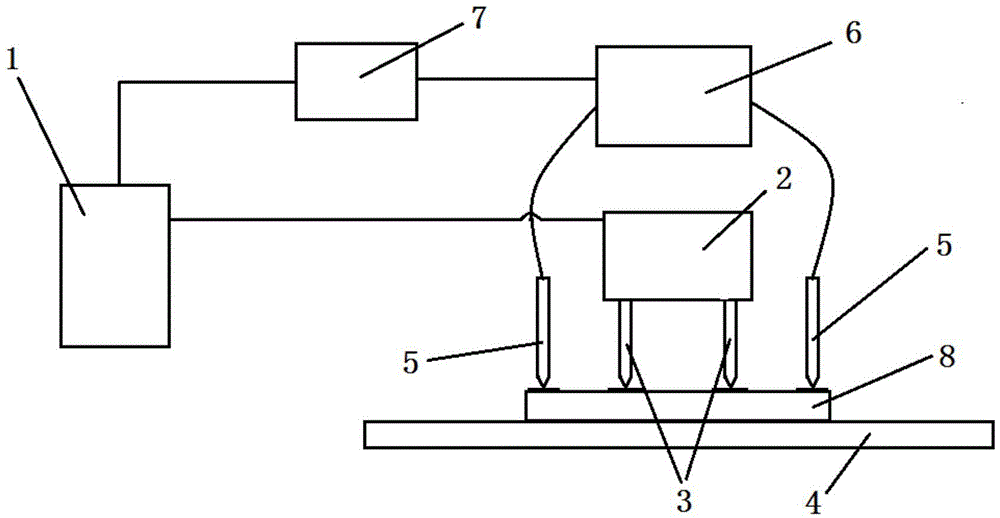

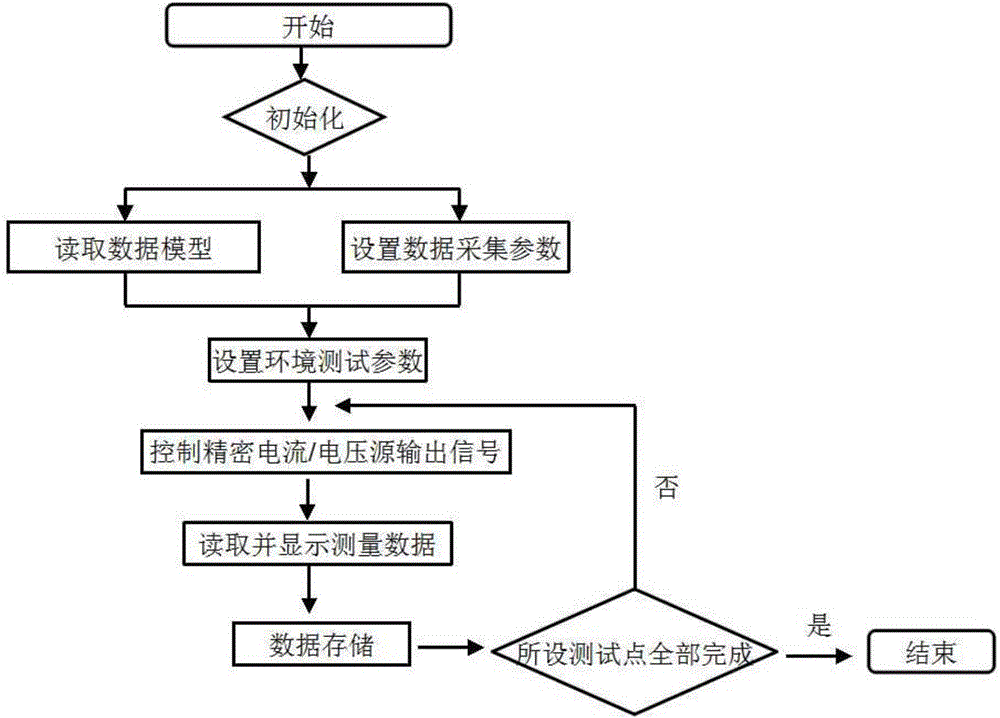

Virtual test apparatus for thermal wind speed sensor in absence of wind tunnel

ActiveCN104977430AHigh speedImprove operational reliabilityTesting/calibration of speed/acceleration/shock measurement devicesWhole bodyData acquisition

The invention discloses a virtual test apparatus for a thermal wind speed sensor in absence of a wind tunnel. Thermal probes for precise temperature control are adopted to apply temperature difference signals directly to the surface of a sensor, thereby simulating the influence of actual wind speed. The apparatus can conveniently collect, analyze, process, display and store a lot of test data of a thermal wind speed sensor, thus providing a basis for automatic test and calibration of the thermal wind speed sensor. The advantage and technical effects of the apparatus are that: computer software and hardware resources and apparatus hardware are combined as a whole body, the great calculating processing capability of a computer and the measuring and control capability of the apparatus hardware are combined to be a system, parameter setting and data collection of test software are simple and feasible, and analysis and processing functions are flexible, so the test efficiency for the thermal wind speed sensor is greatly improved, and the test cost is reduced.

Owner:SOUTHEAST UNIV

Array wind speed and direction sensor and manufacturing method thereof

PendingCN108562761ASolve the problem of insufficient wind direction measurementReduce the deviation of the measured wind speedIndication/recording movementFluid speed measurement using thermal variablesVentilation tubeArray data structure

Owner:北京天创金农科技有限公司

Product cleaning detection method based on machine vision

InactiveCN109663771ASimple structureEasy to operateDrying gas arrangementsOptically investigating flaws/contaminationProduction lineMachine vision

The invention discloses a product cleaning detection method based on machine vision. The product cleaning detection method comprises the following steps of receiving and transmitting products out of aproduction line through a conveying roller way, and during entering each region, performing overturning movement on the products through clamping by mechanical arms on two sides; rinsing dirt on thesurfaces of the products through rinsing nozzles, and performing drying on the surfaces of the products through thermal wind blowing from a drying top hood, then performing image collection on weldingworkpieces on the conveyor belt through an image collector, and feeding the collected images back to an industrial control computer for analysis treatment; and performing contrast analysis on detection parameters and standard parameters through the industrial control computer, determining an error range, finally storing the error range in the industrial control computer, and performing feedback to personnel through a displayer. The product cleaning detection method disclosed by the invention has the characteristics of being simple in structure, convenient to operate, low in cost and the like,automatic cleaning detection of a large quantity of products can be realized, the detection efficiency and the detection precision are effectively improved, and the product cleaning detection methodis used for providing strong guarantee for modernized industrial production.

Owner:南京敏光视觉智能科技有限公司

Constant temperature elevator lift car

ActiveCN105253745AStable temperature regulationReduce direct impactElevatorsBuilding liftsCold airPull force

The invention discloses a constant temperature elevator lift car. The constant temperature elevator lift car comprises a lift car body, an air conditioning system and a ventilation system, wherein the air conditioning system comprises an air conditioner principal machine, an air inlet, an exhaust fan, a heat exchange mechanism, a first temperature sensor and a second temperature sensor; the start and stop and operating power of the air conditioner principal machine are controlled by itself according to the temperature difference fed back by the first temperature sensor and the second temperature sensor and a preset target temperature; the ventilation system comprises an air intake fan and an air exchange mechanism; a pulling force sensor is arranged on a lifting steel rope of an elevator; and when the pulling force sensor reaches a preset numerical valve, the air intake fan is started. The constant temperature elevator lift car has the beneficial effects that the interior of the lift car is ventilated and cooled by the heat exchange mechanism provided with refrigerant pipes, the temperature in the lift car can be stably adjusted, the direct impact of cold air / hot air on people taking the elevator is reduced, and the taking experience is improved.

Vaporization device

PendingCN110755660AImprove disinfection effectReduce energy consumptionChemicalsAtomizer nozzleEngineering

The invention discloses a vaporization device. The vaporization device comprises a housing with a hollow cavity, a feeding opening formed in the top of the housing, a plurality of discharging openingsformed in the top of the housing, a thermal wind pipe which extends into the hollow cavity through the feeding opening, an atomizing nozzle located in the thermal wind pipe, a compressed air pipelineand a hydrogen peroxide solution pipeline which communicate with the atomizing nozzle, a fin pipe which is located below the thermal wind pipe, in the hollow inner cavity, a first heating mechanism enabling high-temperature steam to penetrate in and out of the fin pipe, and a fan cover of which the upper end is connected to the lower end of the thermal wind pipe, and which is used for covering the fin pipe, wherein a gap allowing hydrogen peroxide solution steam to flow upwards to the discharging openings is formed between the fan cover and the inner surface of the housing. According to the vaporization device disclosed by the invention, after being atomized, hydrogen peroxide is reheated to obtain hydrogen peroxide steam, so that energy consumption is relatively low; the hydrogen peroxide steam firstly is in contact with the inner bottom surface of the housing, and then flows upwards to the discharging openings, so that the condensation water carried when the hydrogen peroxide steamflows upwards is greatly reduced, the hydrogen peroxide steam is dry, and the disinfection effect is relatively good.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

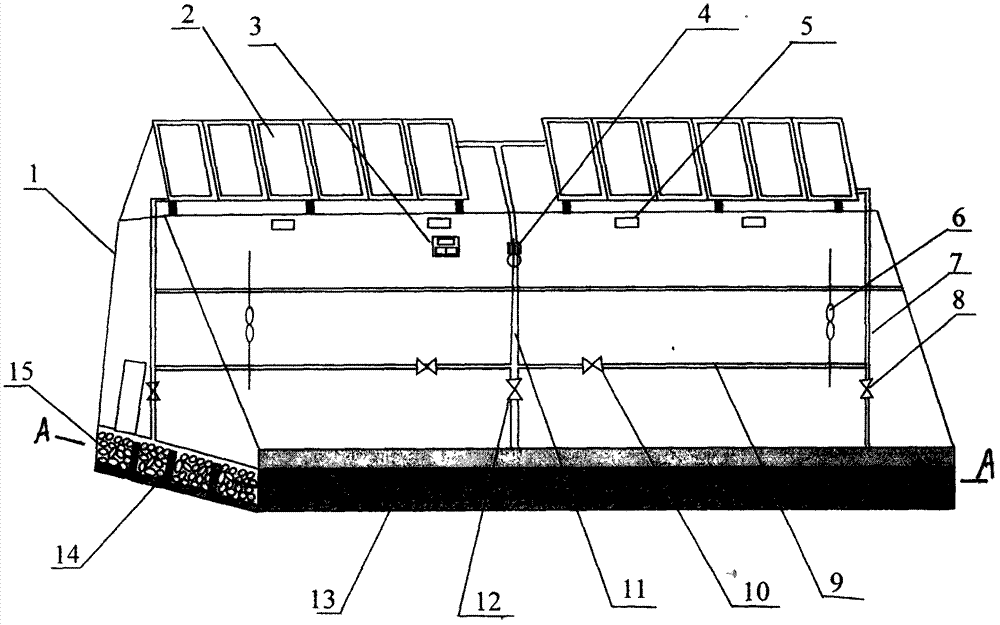

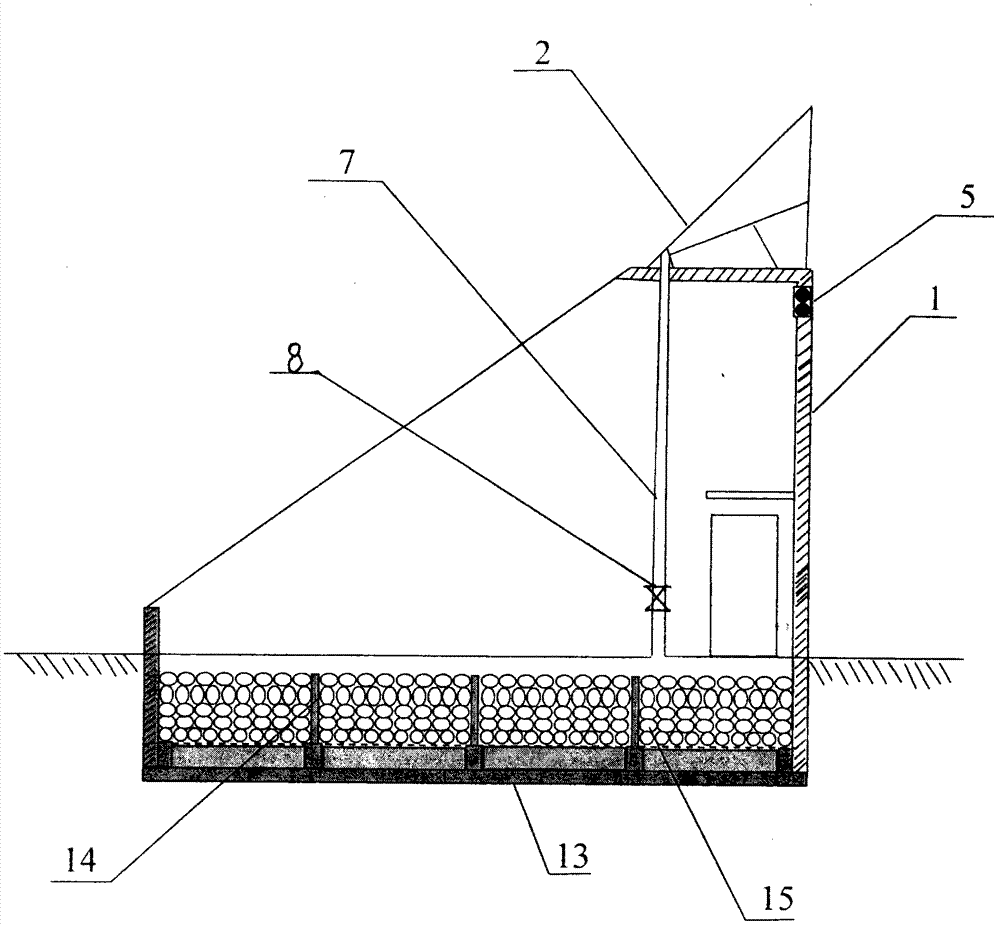

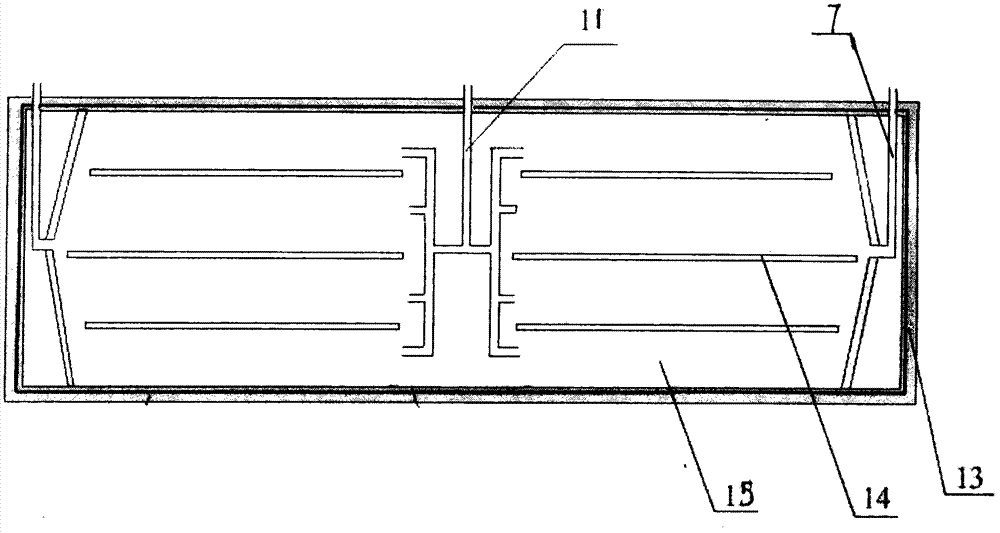

Greenhouse heat-storage type solar hot-wind drying device for grains

InactiveCN102177964BAchieve dryingIncrease temperatureFood processingClimate change adaptationCold airGreenhouse

A greenhouse heat-storage type solar hot-wind drying device for grains belongs to a utilization technology of renewable energy. An underground heat storage tank is arranged under the ground surface inside a greenhouse drying room; a solar-air heat collector is arranged at the upper part outside the greenhouse drying room; an automatic controller, a blower, a hot wind discharge pipe, a hot wind delivery pipe and a cold air returning pipe are arranged in the greenhouse drying room; two ends of the hot wind delivery pipe with a suction fan and a third valve are respectively communicated with the solar-air heat collector and the underground heat storage tank; two ends of the cold air returning pipe with a first valve are respectively connected on the solar-air heat collector and the underground heat storage tank; two ends of the hot wind discharge pipe with a second valve are respectively communicated with the hot wind delivery pipe and the cold air returning pipe; an exhaust outlet is arranged on the wall of the greenhouse drying room; and the automatic controller is connected with the suction fan, the blower, the first valve, the second valve and the third valve respectively by leads. The greenhouse heat-storage type solar hot-wind drying device fully utilizes solar energy as drying energy and has the characteristics of being simple in structure, low in operation cost and excellent in environment-friendly effect.

Owner:HARBIN SUNSHINE ENERGY ENG

Cooking method by using hot wind in heating assistance

The present invention provides a cooking method by utilizing hot wind in heating assistance. The cooking method herein employs a combination of a main heater and an auxiliary heater, wherein the main heater and the auxiliary heater have different heat sources, and the auxiliary heater includes a hot wind heater. The cooking method of the invention comprises the following steps: (1) start a cooking utensil and call in a cooking program; (2) start the main heater which supplies heat to the cooking utensil body from below;(3)put cooking objects to the cooking utensil; (4) periodically employ the hot air heater once or more than once during cooking process so as to lead the hot air flow into the cooking utensil and supply direct heat to the cooking objects inside the cooking utensil; (4) after periodical heating, close the hot wind heater or decrease heating power of the hot wind heater. The cooking method makes good use of the advantages of hot wind direct heating, and makes up the defects of traditional cooking methods. The cooking method has effects like stero, rapid and even heating, rapid maturing, rapid water locking, excellent surface process and moisture removal, etc.

Owner:PANSUM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com