Energy-saving building for generating electricity by utilizing solar thermal wind

A construction and hot air technology, applied in wind power generation, buildings, building types, etc., can solve the problems of less than 20%, blockage of upper and lower water pipes, and high cost of photovoltaic cell manufacturing and use, and achieves reasonable design, convenient use, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

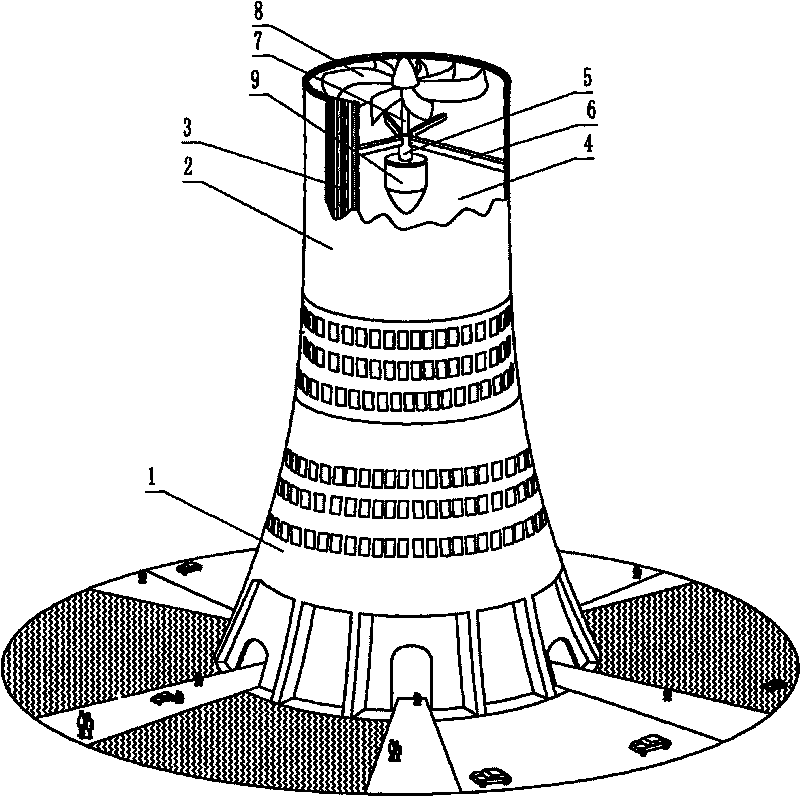

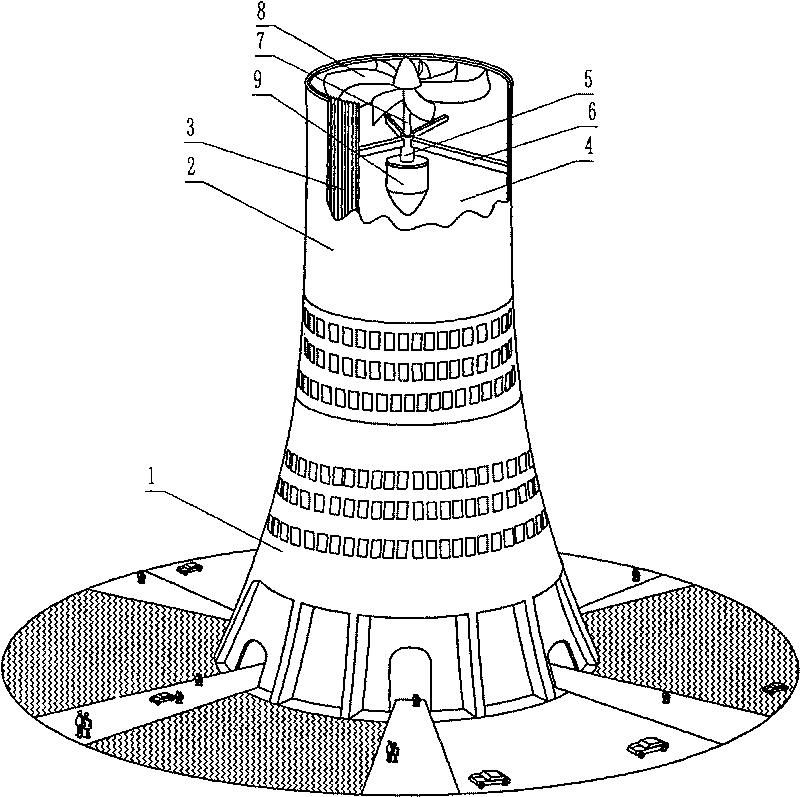

[0015] Embodiment: The structure is as shown in the accompanying drawings, consisting of a barrel-shaped building body 1, a transparent layer 2, a heat-absorbing layer 3, a hot air flow channel 4, a worm gear bushing 5, a bushing bracket 6, a worm gear shaft 7, a worm gear 8 and power generation machine 9, wherein the transparent layer 2 is connected to the barrel-shaped building body 1, the heat-absorbing layer 3 is arranged on the inner wall of the transparent layer 2, and the heat-absorbing layer 3 rolled into a barrel shape forms a hot air flow channel 4, and the worm gear sleeve 5 is connected with the shaft sleeve bracket 6, and the shaft sleeve bracket 6 is connected with the heat absorbing layer 3. The worm gear shaft sleeve 5 is provided with a worm gear shaft 7, and one end of the worm gear shaft 7 is connected with the worm gear 8, and the other end is connected with the generator 9. When in use, after the transparent layer on the upper part of the barrel-shaped buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com