Plastic film granulator

A technology of plastic film and granulator, which is applied in the field of waste recycling and processing machinery, can solve the problems of secondary pollution and plastic aging, and achieve the effect of high utilization rate of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

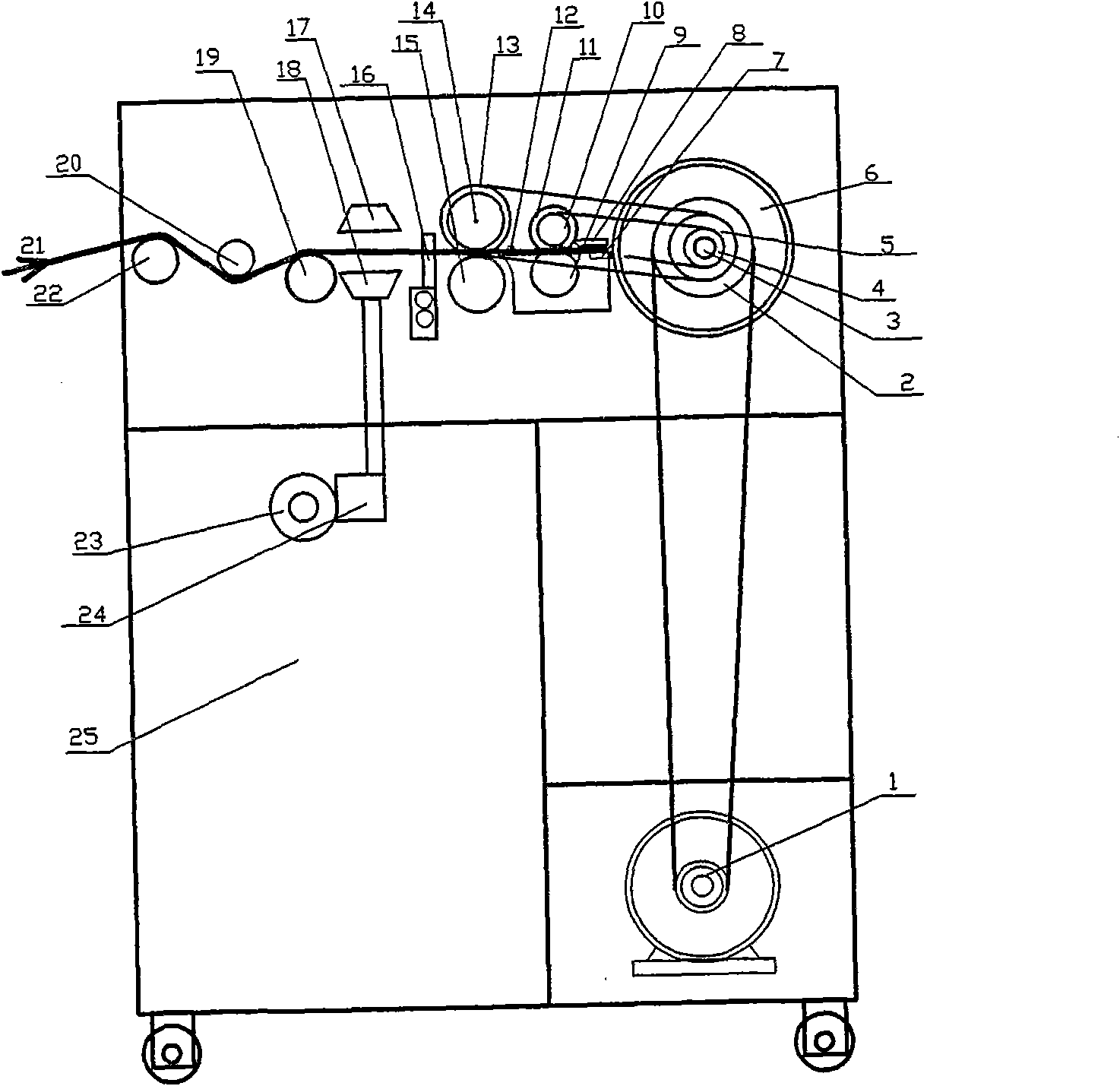

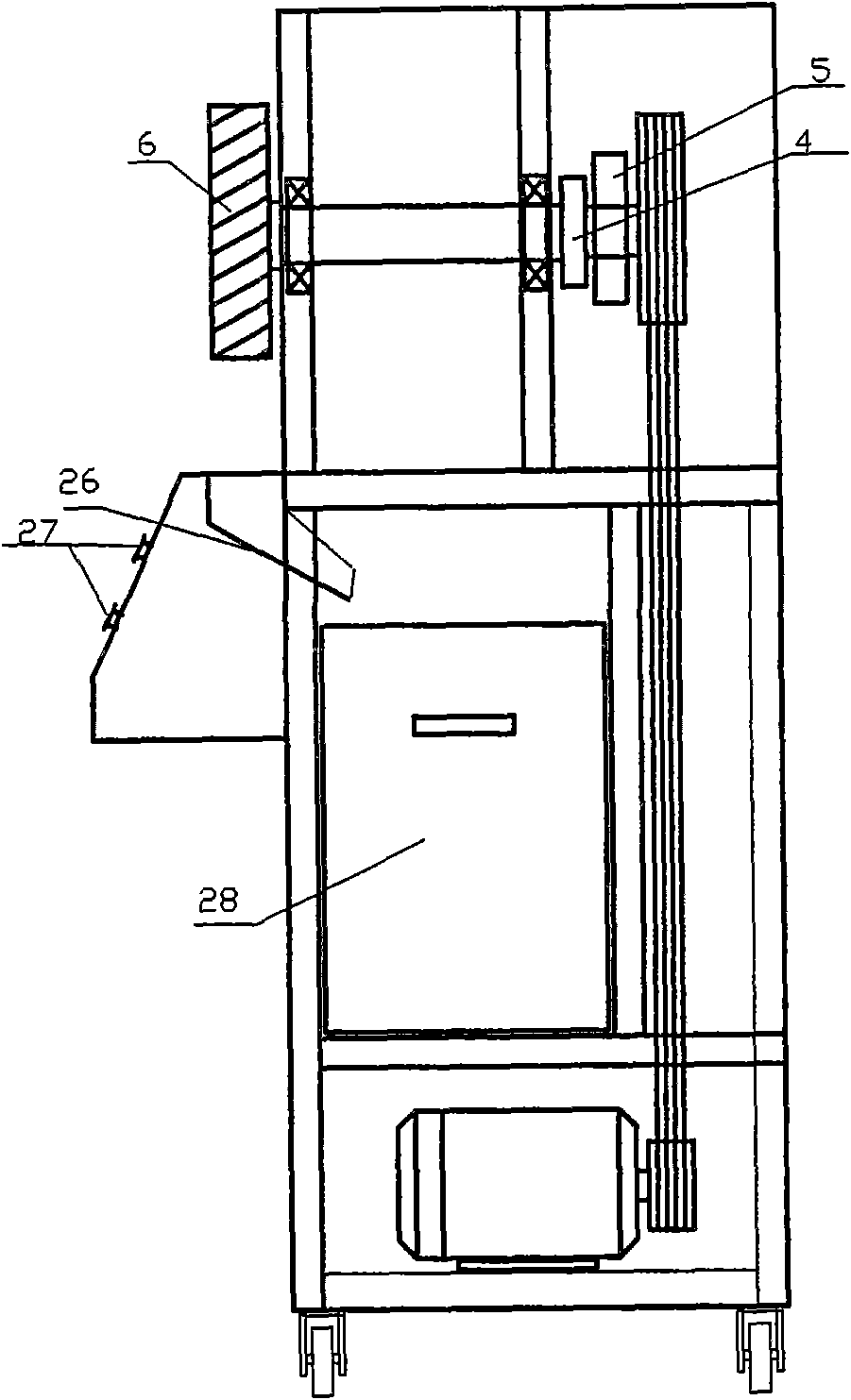

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] As shown in the figure, the main shaft 3 in the upper right part of the body 25 is equipped with a toothed slitting circular knife 6, a slitting knife roller active synchronous belt pulley 4, a flower-shaped pressing roller active synchronous belt pulley 5, and a passive synchronous belt wheel 5 on the main shaft 3 from front to back. The belt pulley 2, the left side of the tooth-shaped slitting round knife 6 is equipped with the slitting bottom knife 7, the left side of the slitting bottom knife 7 is equipped with the upper slitting knife roller 11, and the slitting knife roller 11 is left at the rear of the upper slitting knife roller 11 The passive synchronous pulley 10, the slitting knife roller active synchronous pulley 4 and the slitting knife roller passive synchronous pulley 10 are connected by a belt, the upper slitting knife roller 11 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com