Annealing and cooling treatment system for two-stage hot wind circulation of glass ceramic tunnel crystallization kiln

A technology of hot air circulation and glass-ceramics, which is applied in the field of annealing and cooling treatment systems of sintered glass-ceramic tunnel crystallization kilns, can solve problems such as thermal stress relief, product cracking, etc., to improve quality and strengthen hot air agitation , the effect of increasing the convective heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

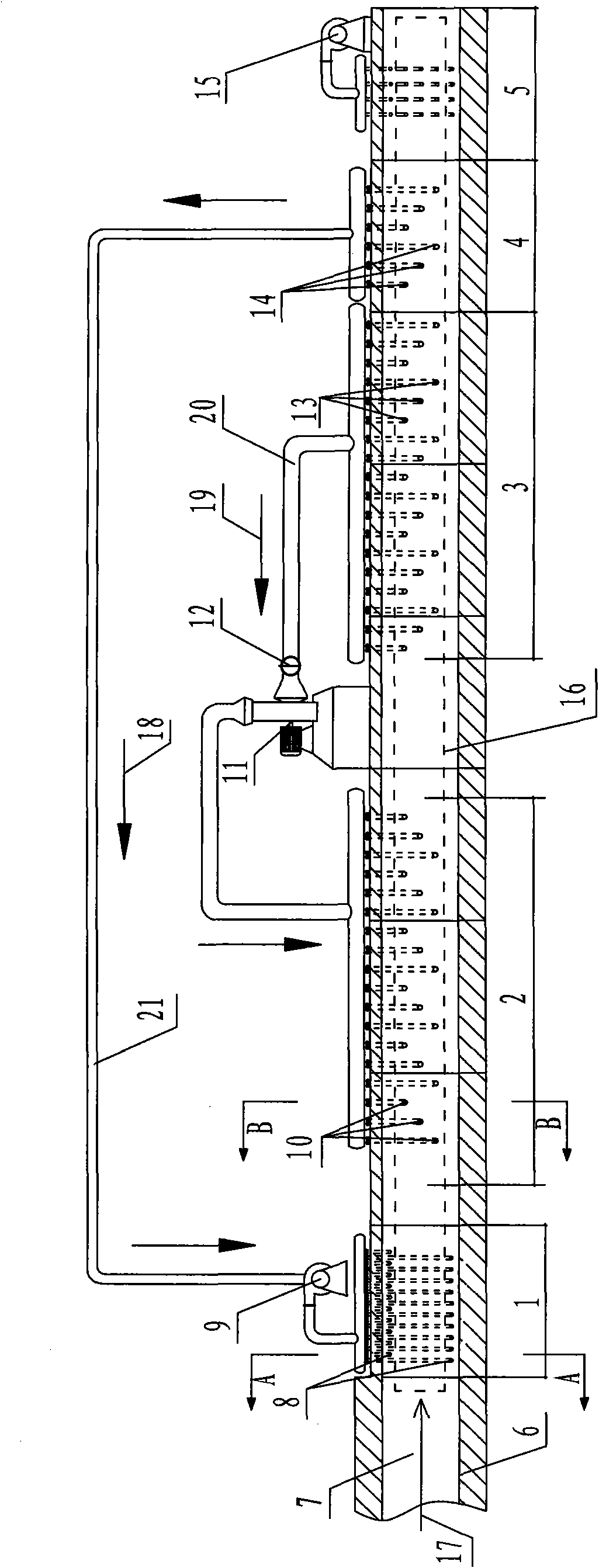

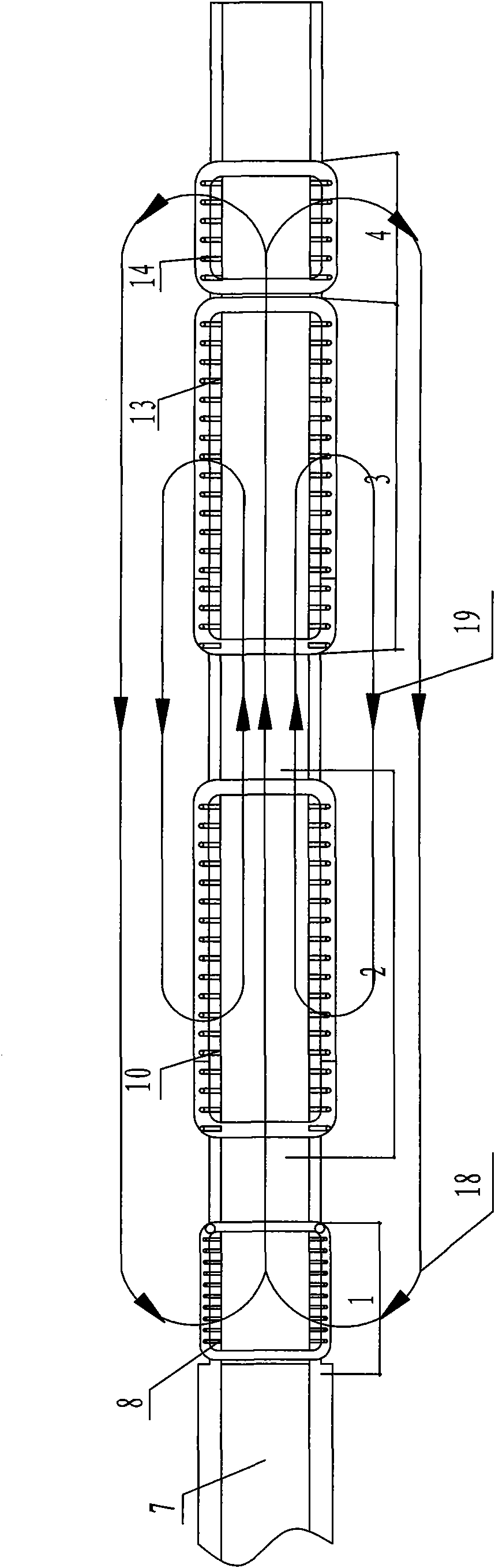

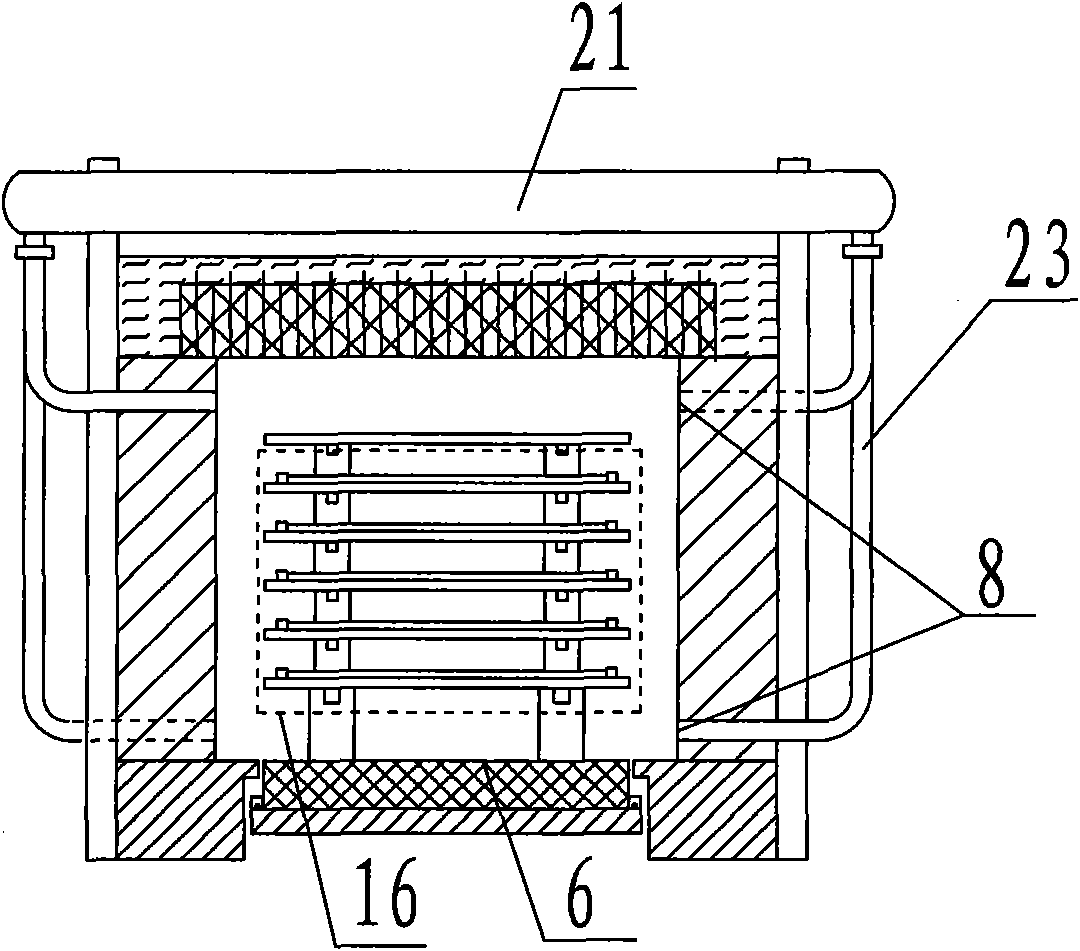

[0020] The present invention will be further described below with reference to the drawings and examples.

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the two-stage hot air circulation annealing and cooling treatment system of the tunnel crystallization kiln for glass-ceramics includes the kiln body 22 of the annealing and cooling treatment system of the tunnel crystallization kiln. The kiln body 22 is insulated from the firing zone Zone 7 to the kiln end outlet (ie according to the product forward direction 17) is divided into quenching section 1, cooling zone slow cooling section 2, first cooling zone 3, second cooling zone 4, kiln end cooling section 5, 1120℃ according to the temperature range The interval between ~950℃ is the quenching section 1, the interval between 850℃~550℃ is the slow cooling section of the cooling zone 2, the interval between 500℃~250℃ is the first cooling zone 3, and the interval between 250℃~150℃ is the second cooling zone 4,1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com