Patents

Literature

487 results about "Viscous flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

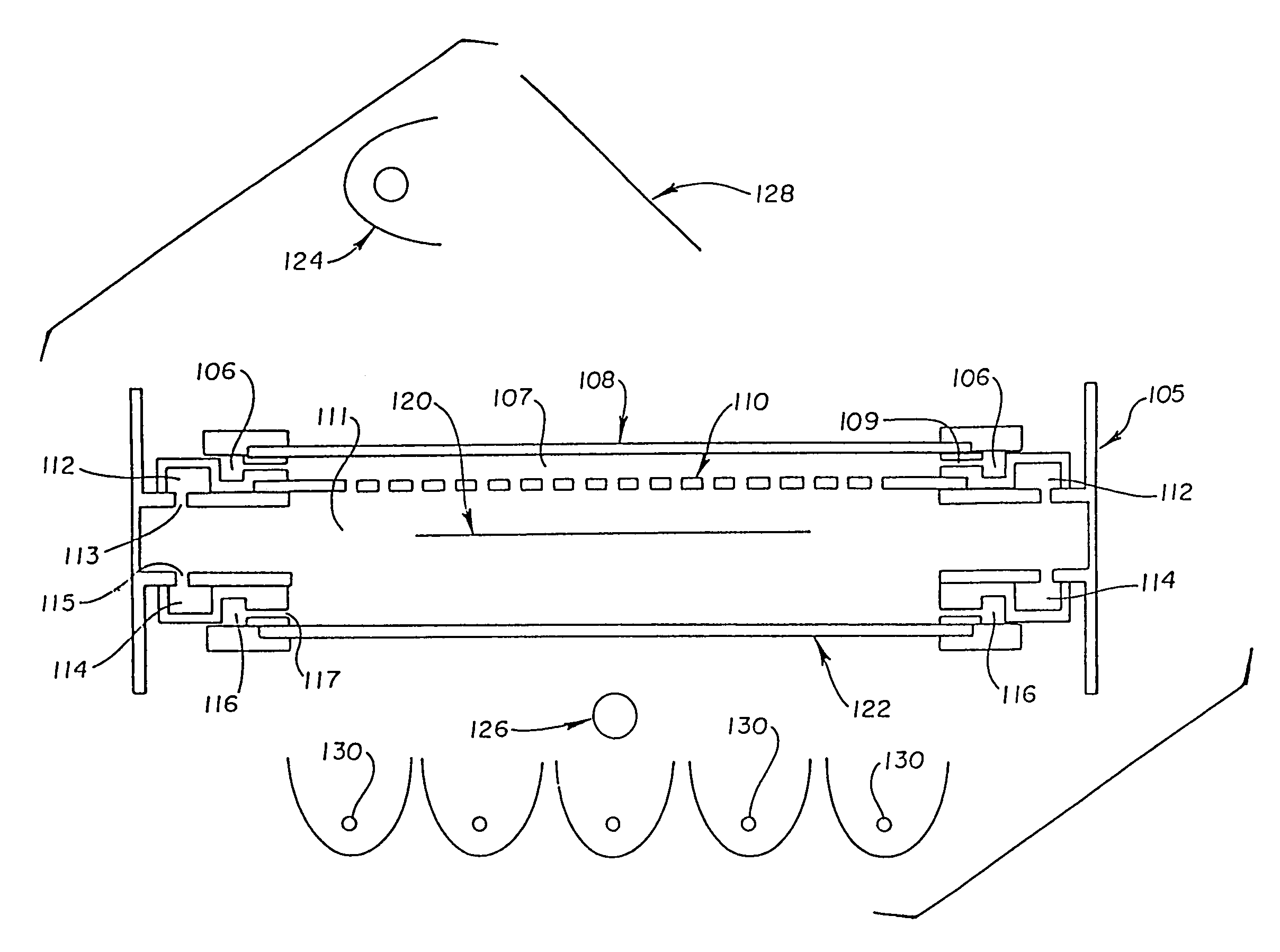

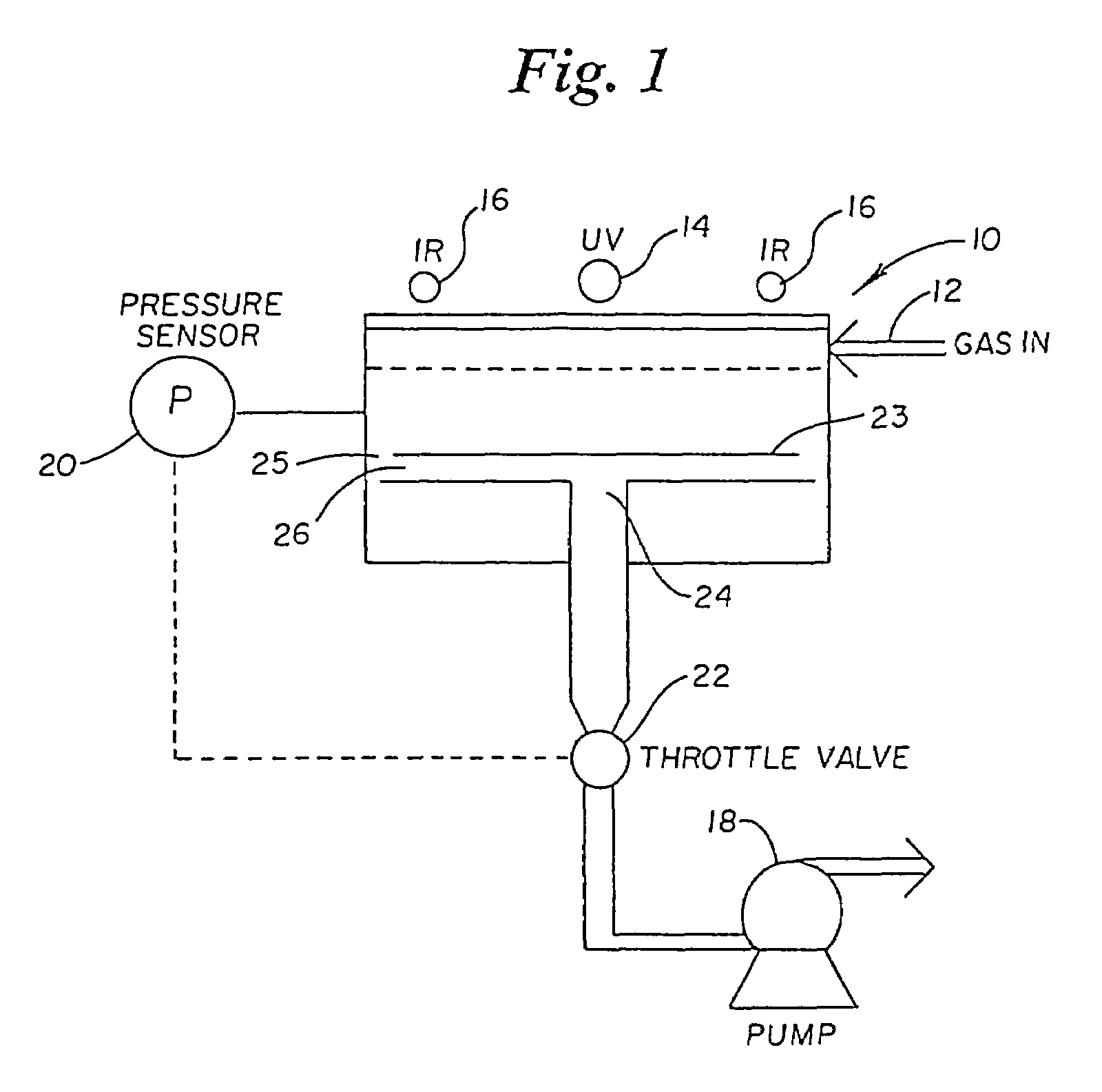

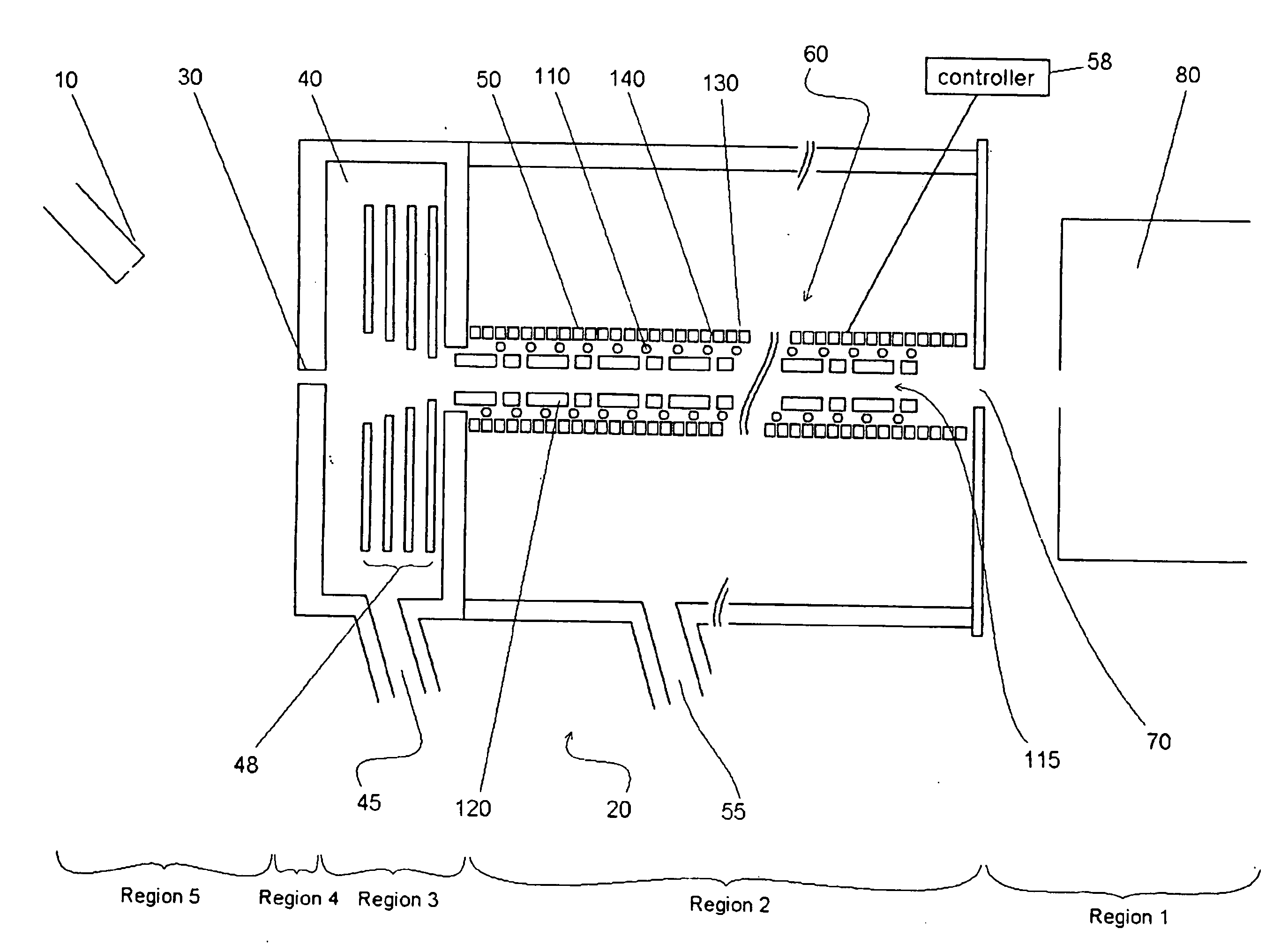

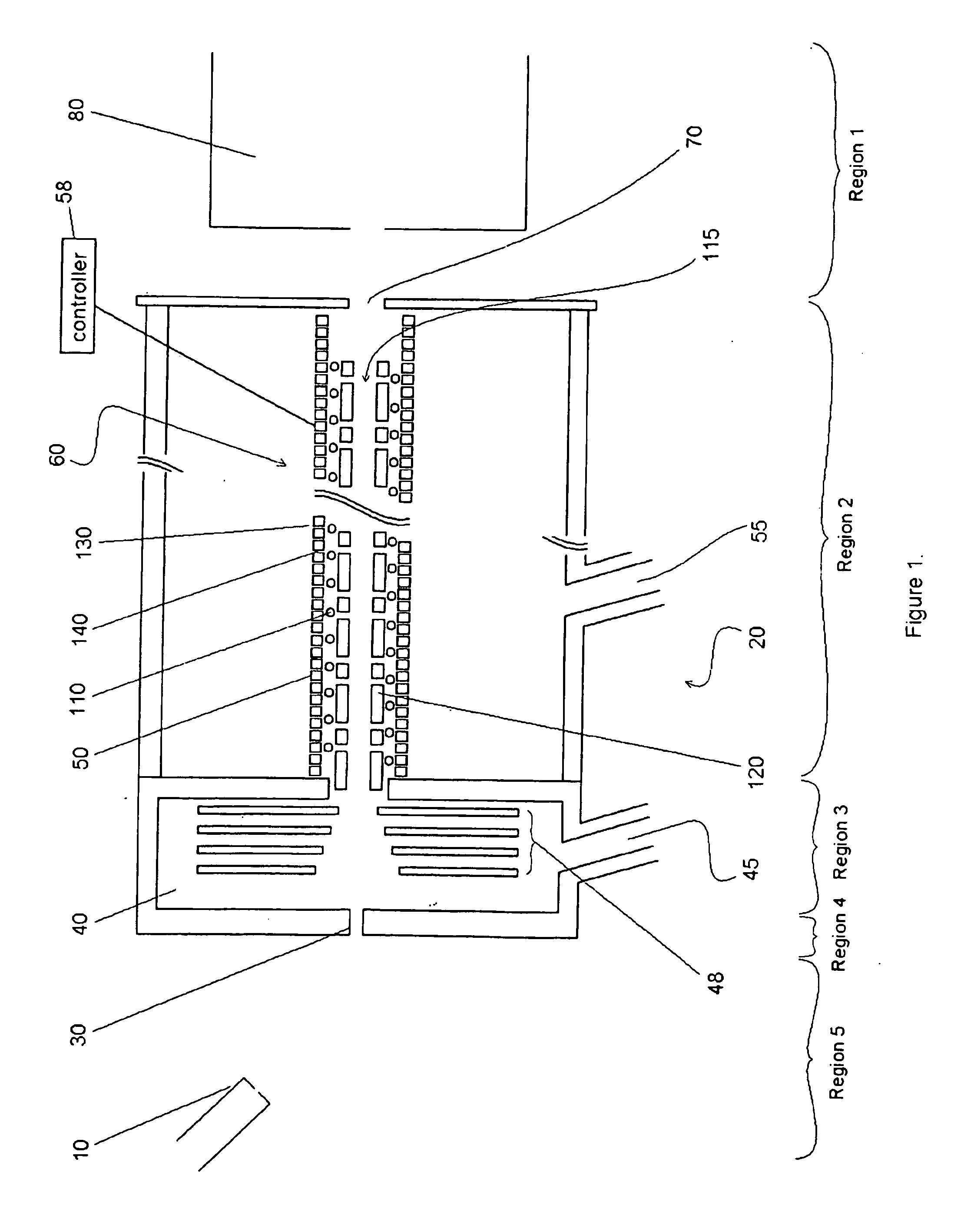

Method and apparatus for surface conditioning

InactiveUS6015503ADecorative surface effectsSemiconductor/solid-state device manufacturingLight activationChemical reaction

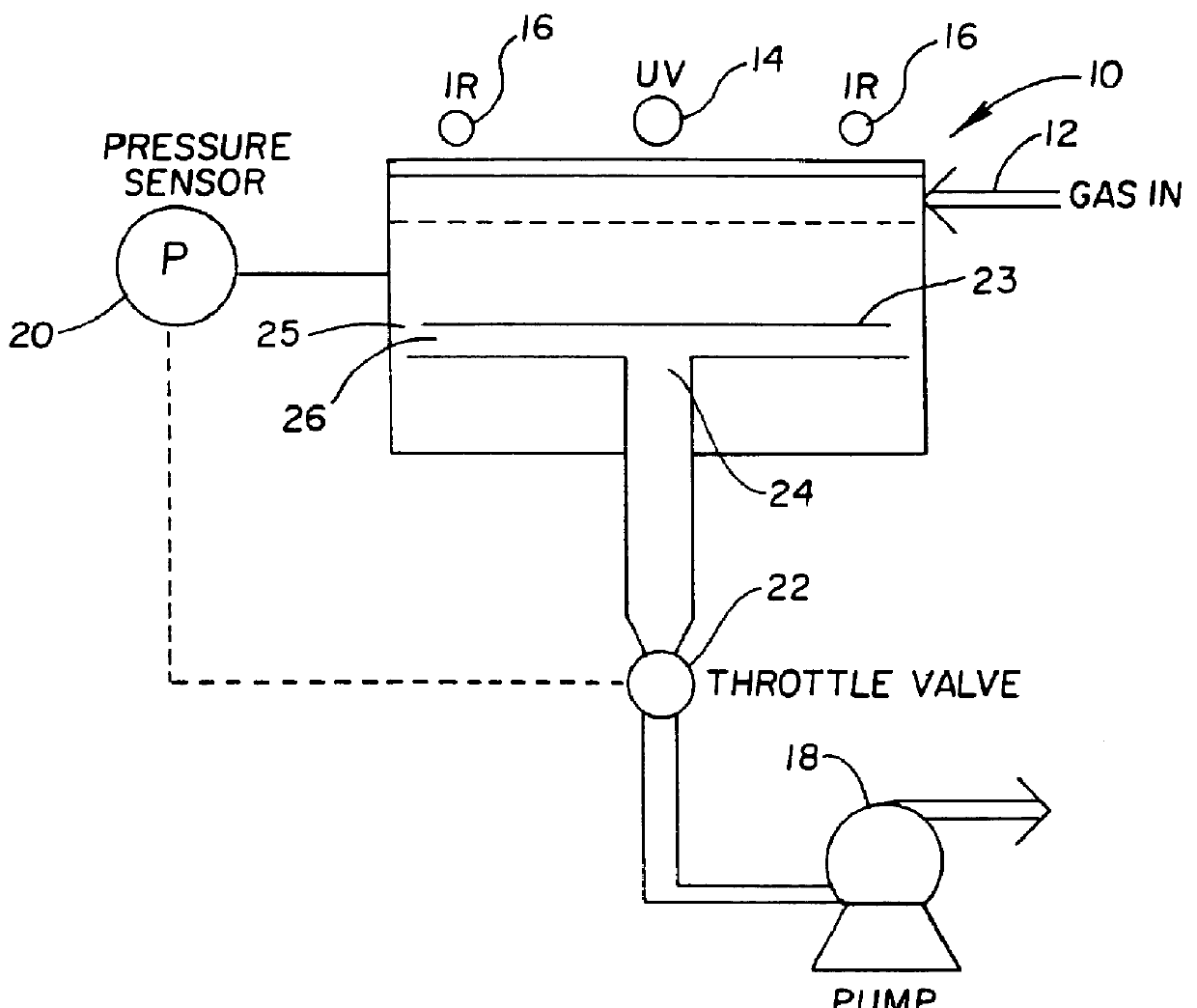

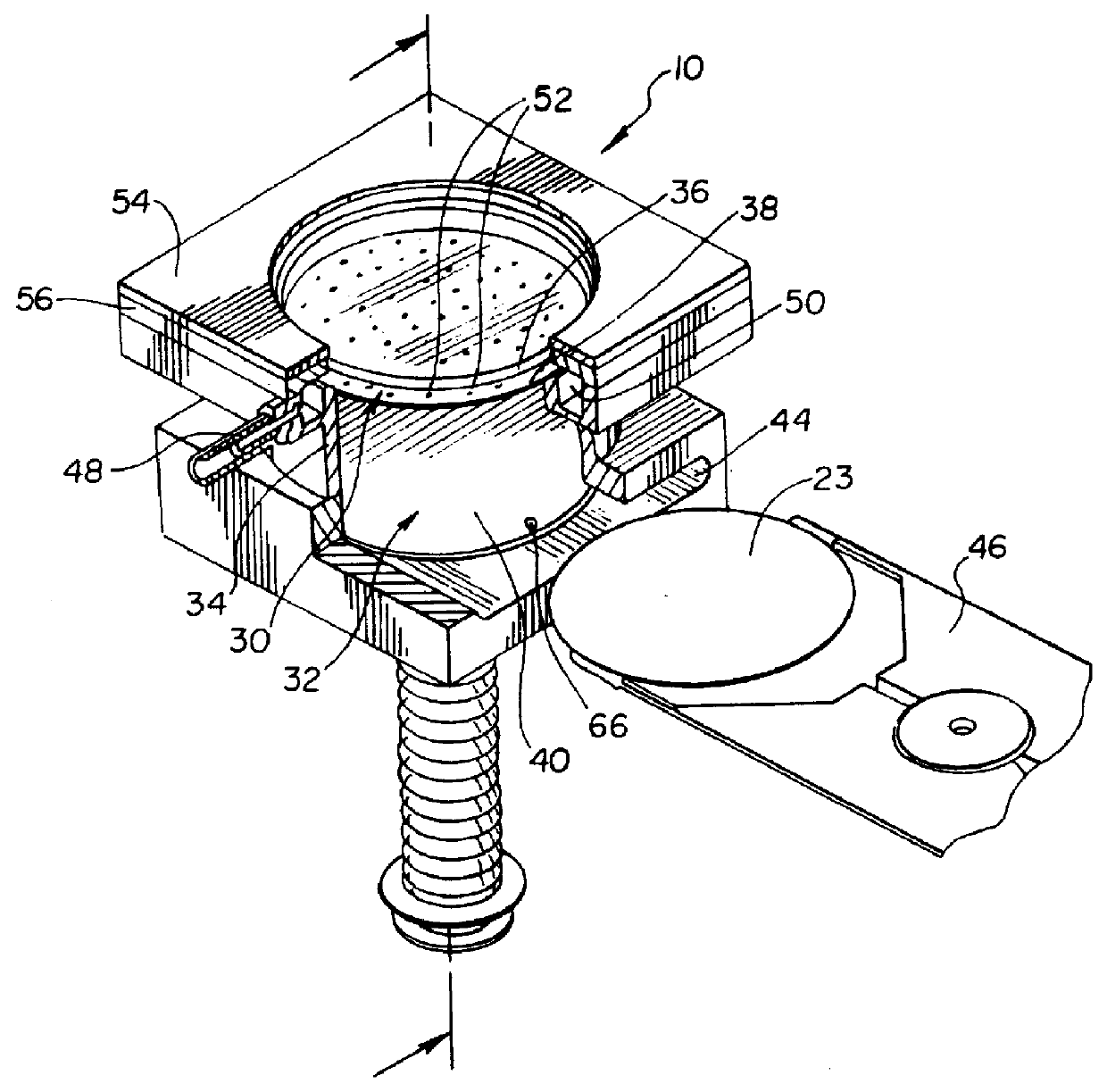

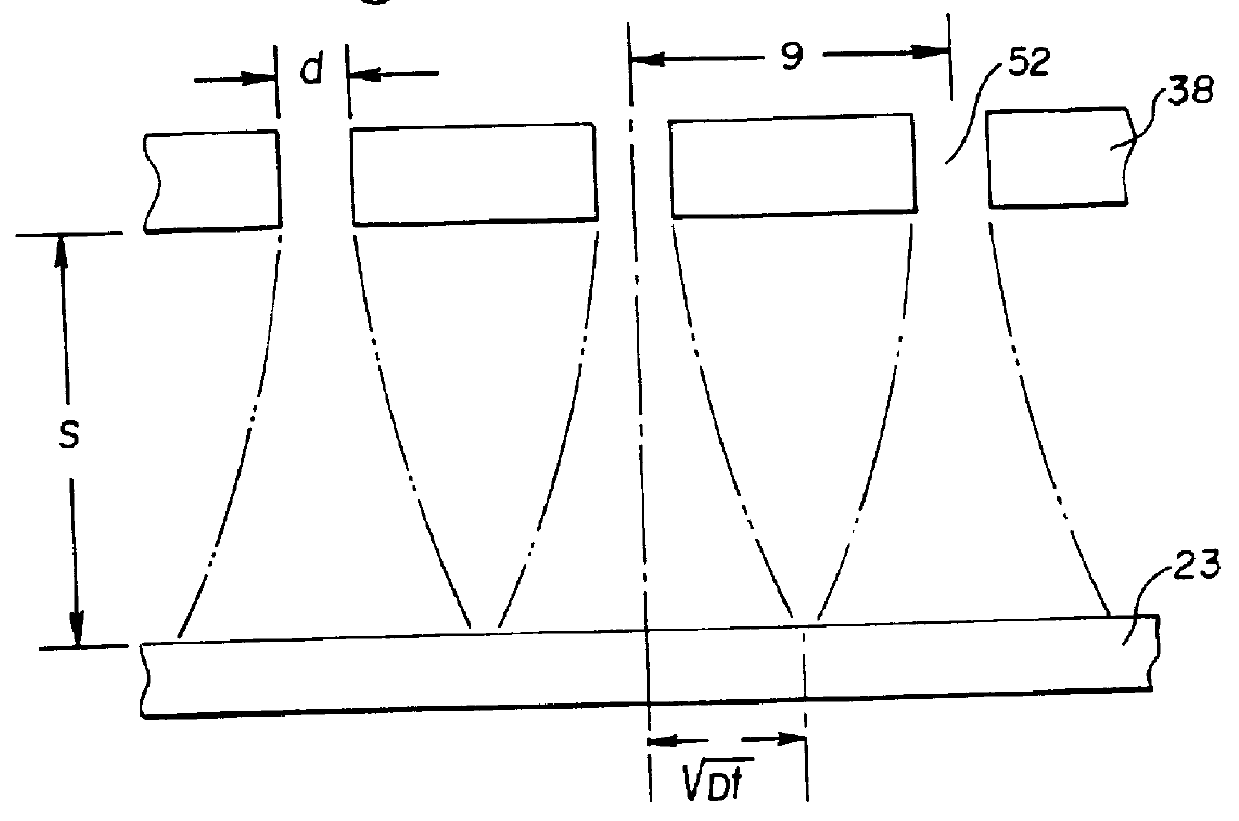

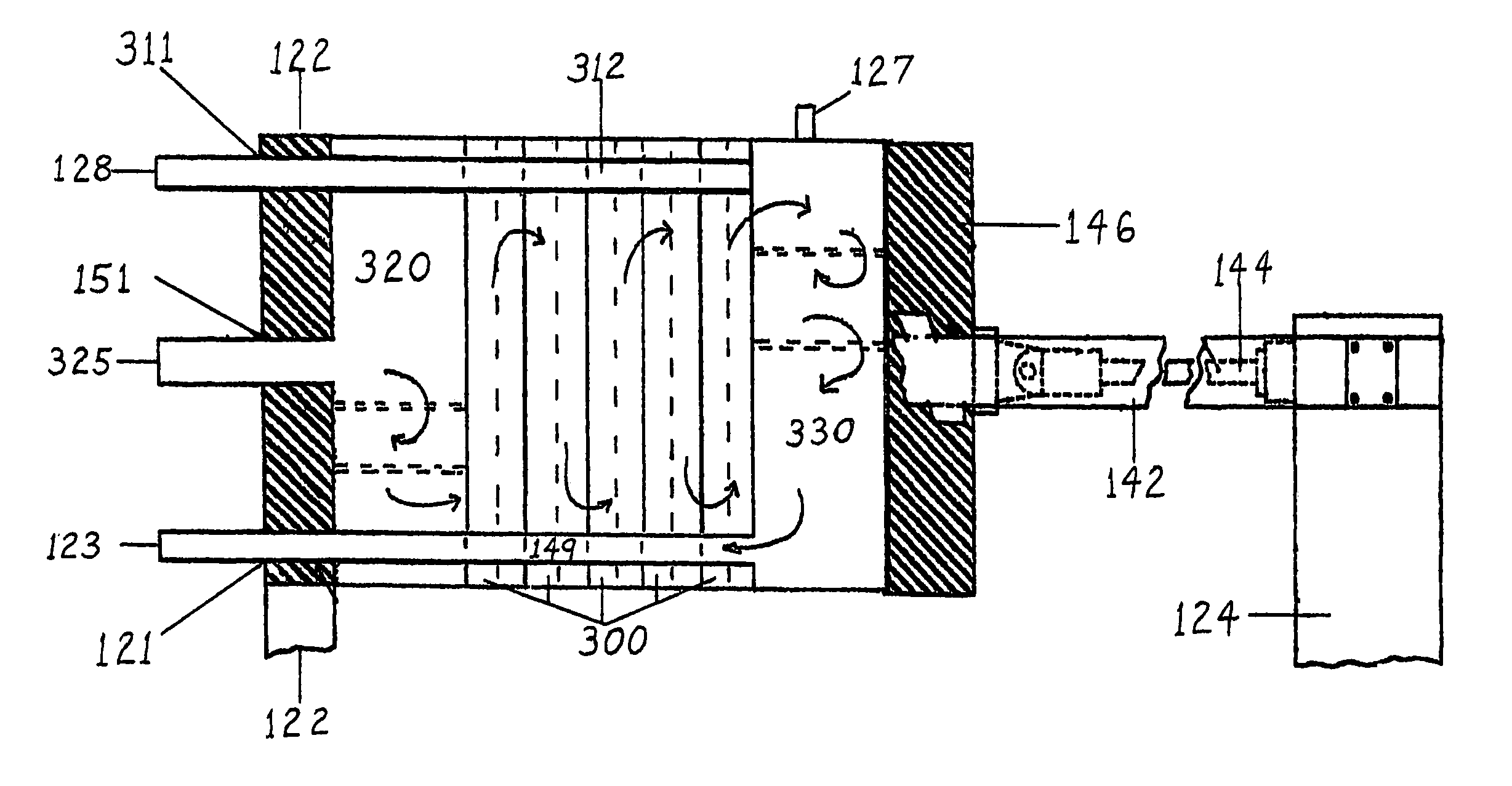

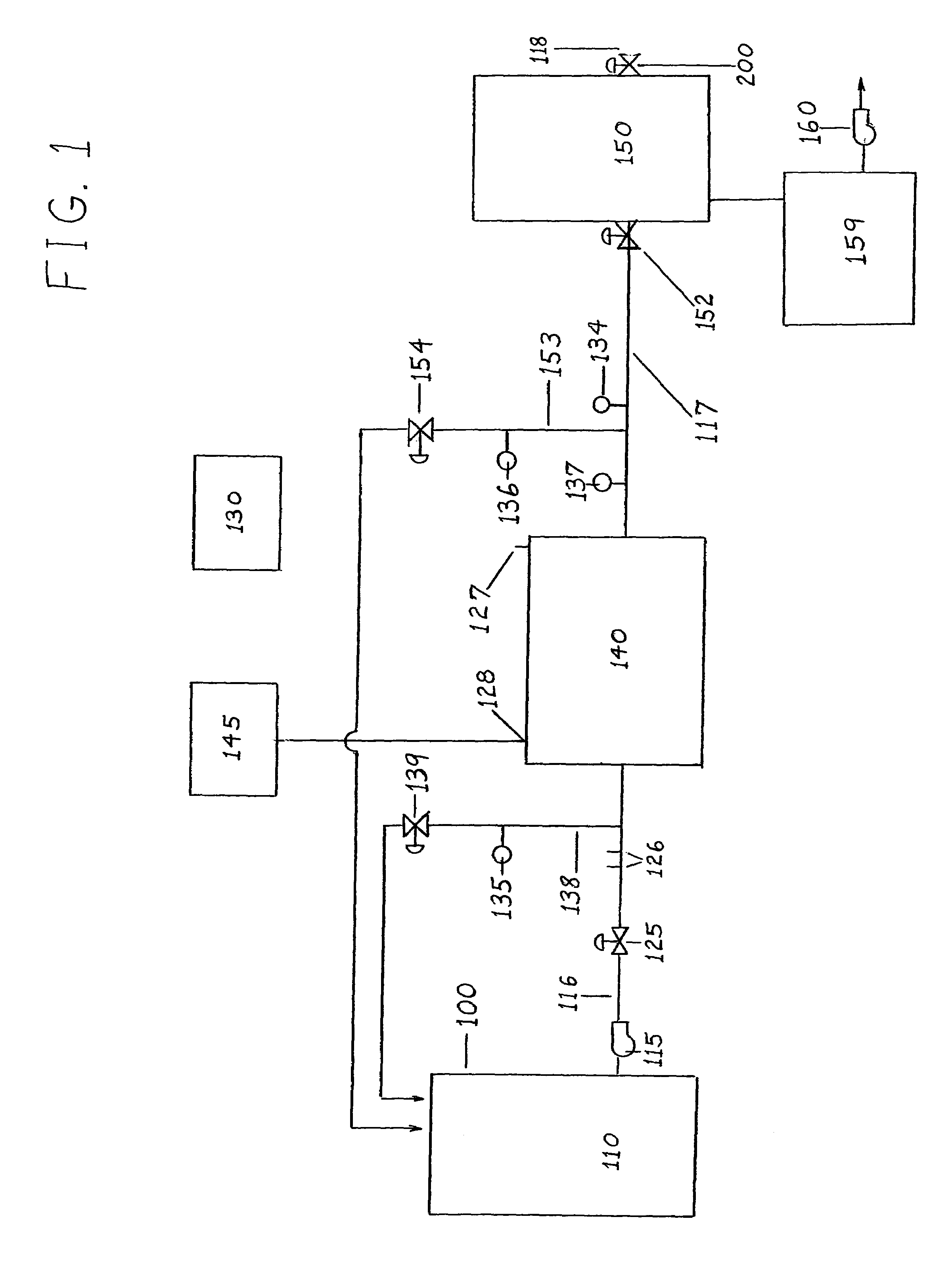

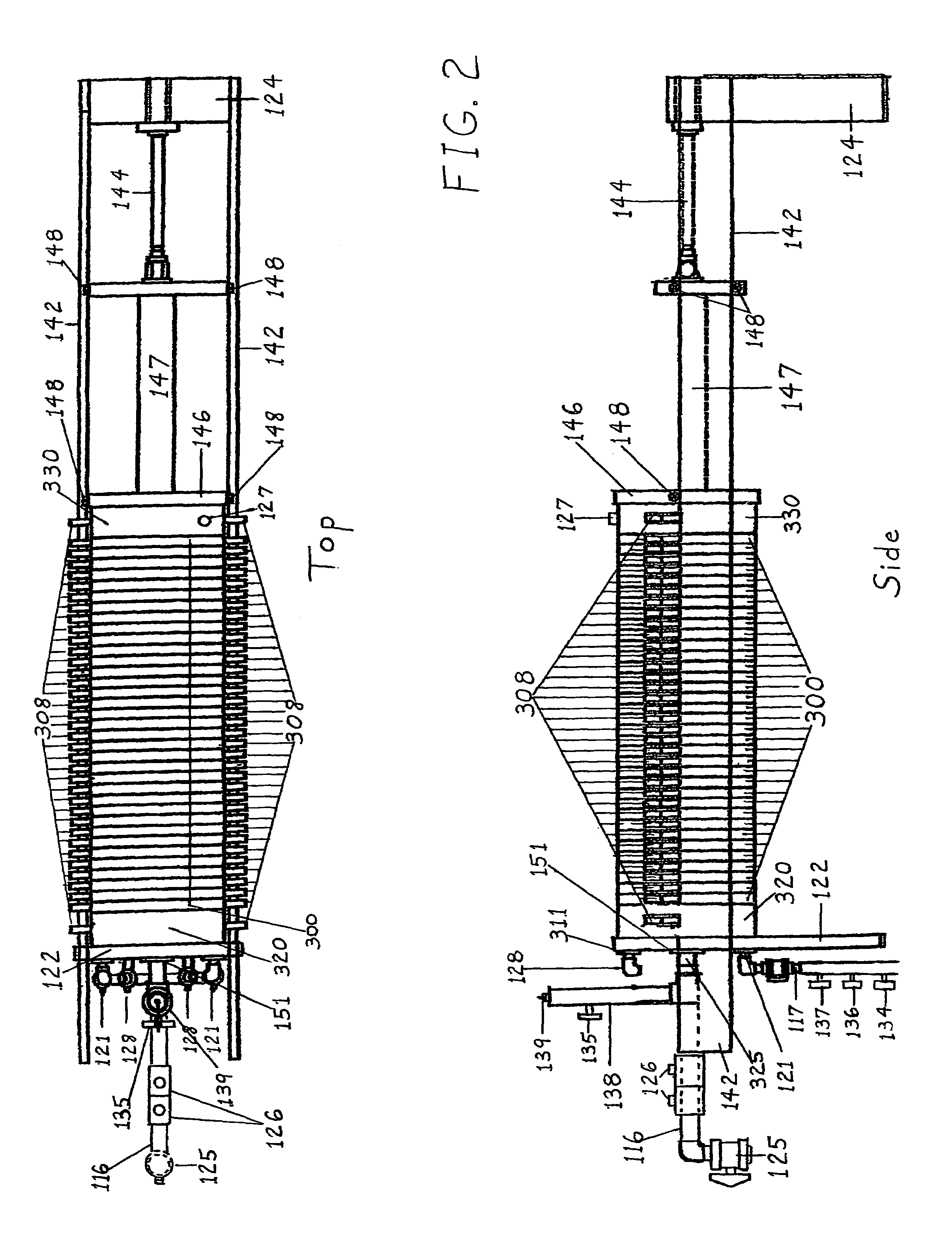

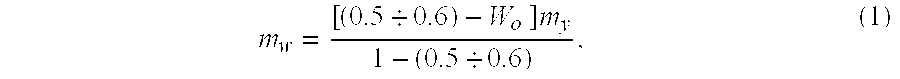

PCT No. PCT / US95 / 16649 Sec. 371 Date Sep. 2, 1997 Sec. 102(e) Date Sep. 2, 1997 PCT Filed Dec. 21, 1995 PCT Pub. No. WO96 / 19825 PCT Pub. Date Jun. 27, 1996Apparatus and process for conditioning a generally planar substrate, contained in a chamber isolatable from the ambient environment and fed with a conditioning gas which includes a reactive gas. The apparatus includes a support for supporting the substrate in the chamber, the substrate being in a lower pressure reaction region of the chamber. A gas inlet is provided for feeding conditioning gas into a gas inlet region of the chamber which is at a higher pressure than the lower pressure reaction region so that the pressure differential causes the conditioning gas to flow toward the surface of the substrate wherein the conditioning gas component will chemically react with and condition the substrate surface, both said higher and lower pressure regions operating in a viscous flow regime. The substrate is supported such that a pressure bias is created across the surface of the substrate so that the gas, after it has chemically reacted with the substrate surface, flows outward from where it has reacted, off the substrate toward the periphery of the chamber and out a peripheral or central underside exhaust outlet. Gas feed may be provided to one or both sides of the substrate and light activation of the substrate or conditioning gas may be provided on one or both sides.

Owner:FSI INTERNATIONAL INC

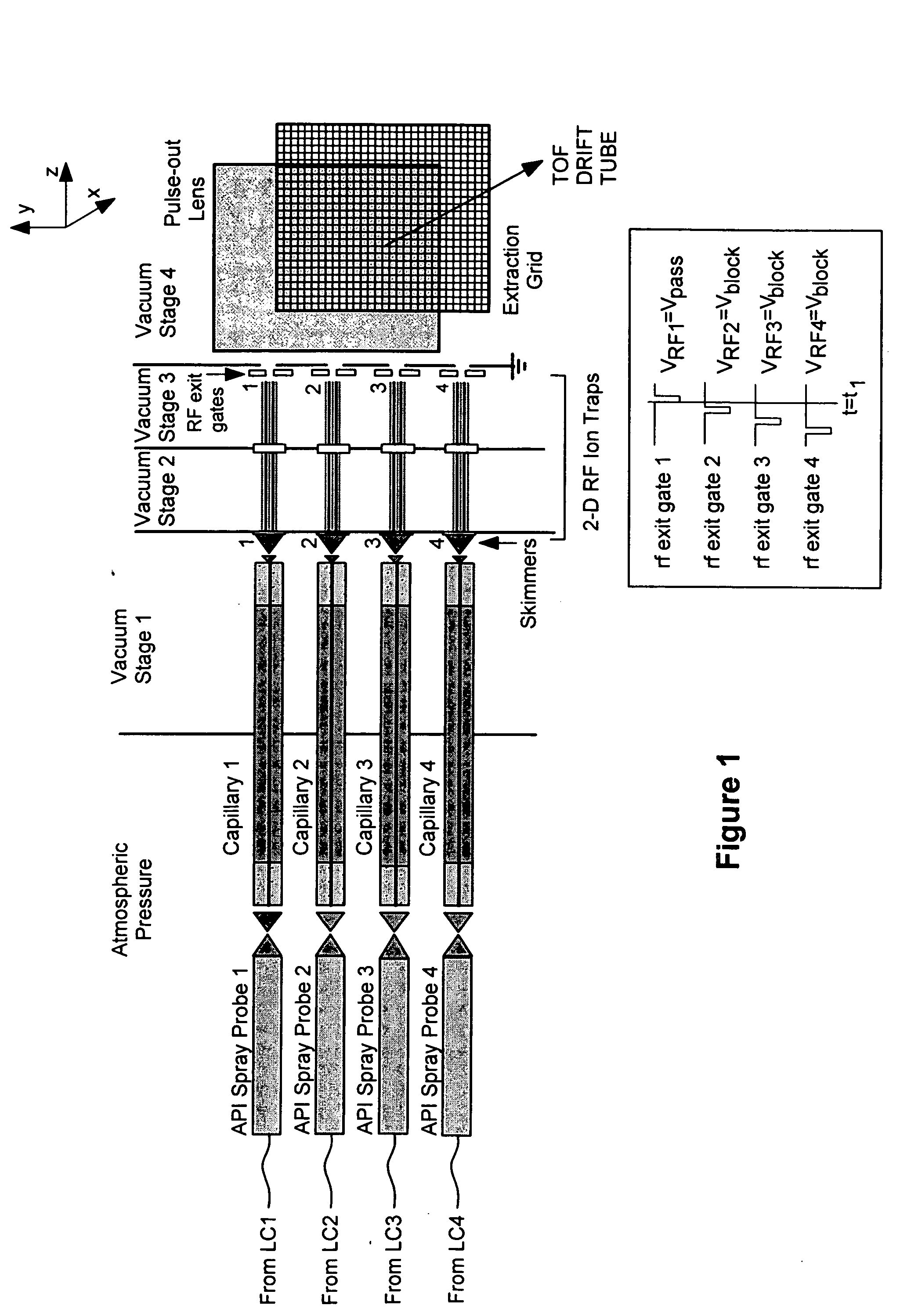

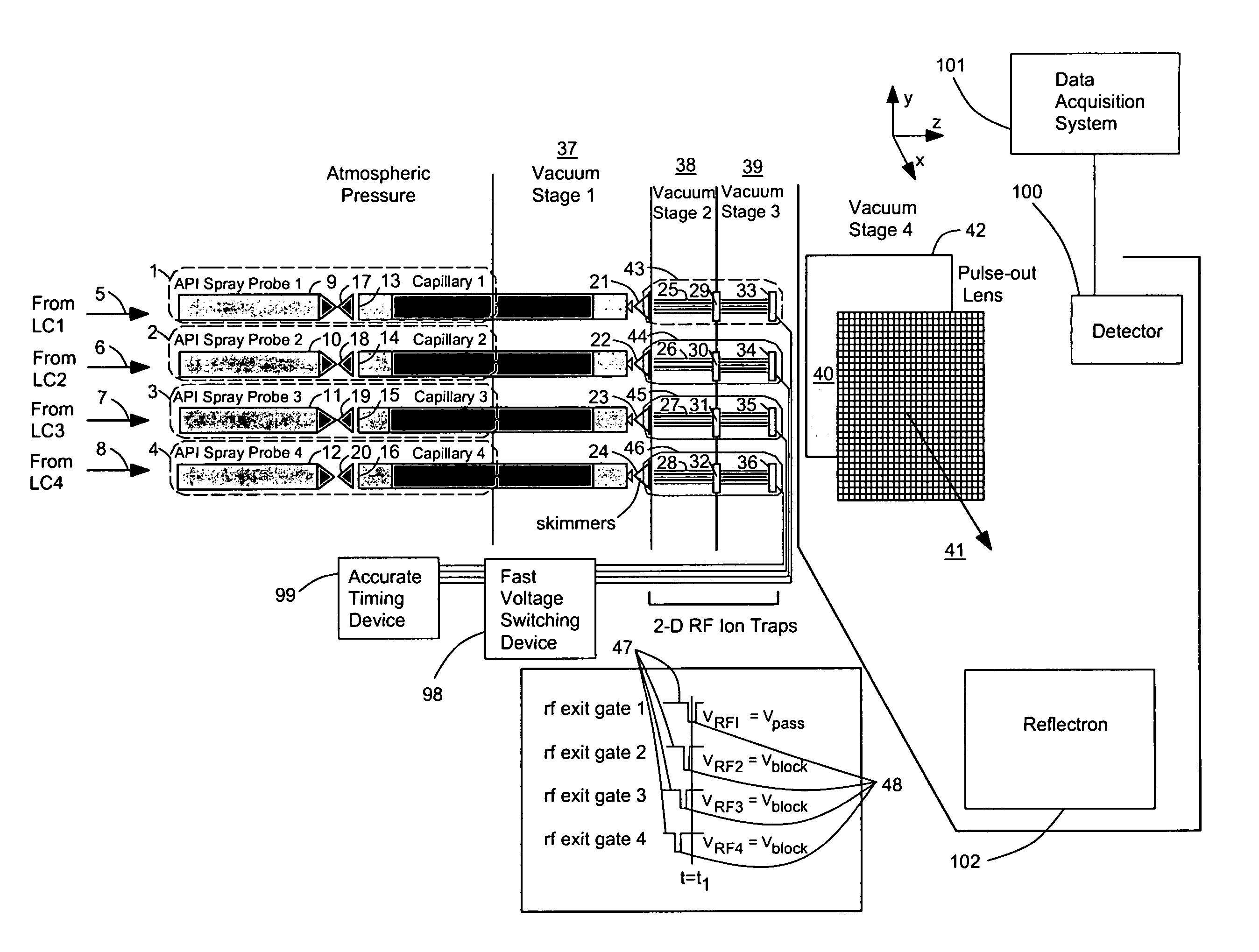

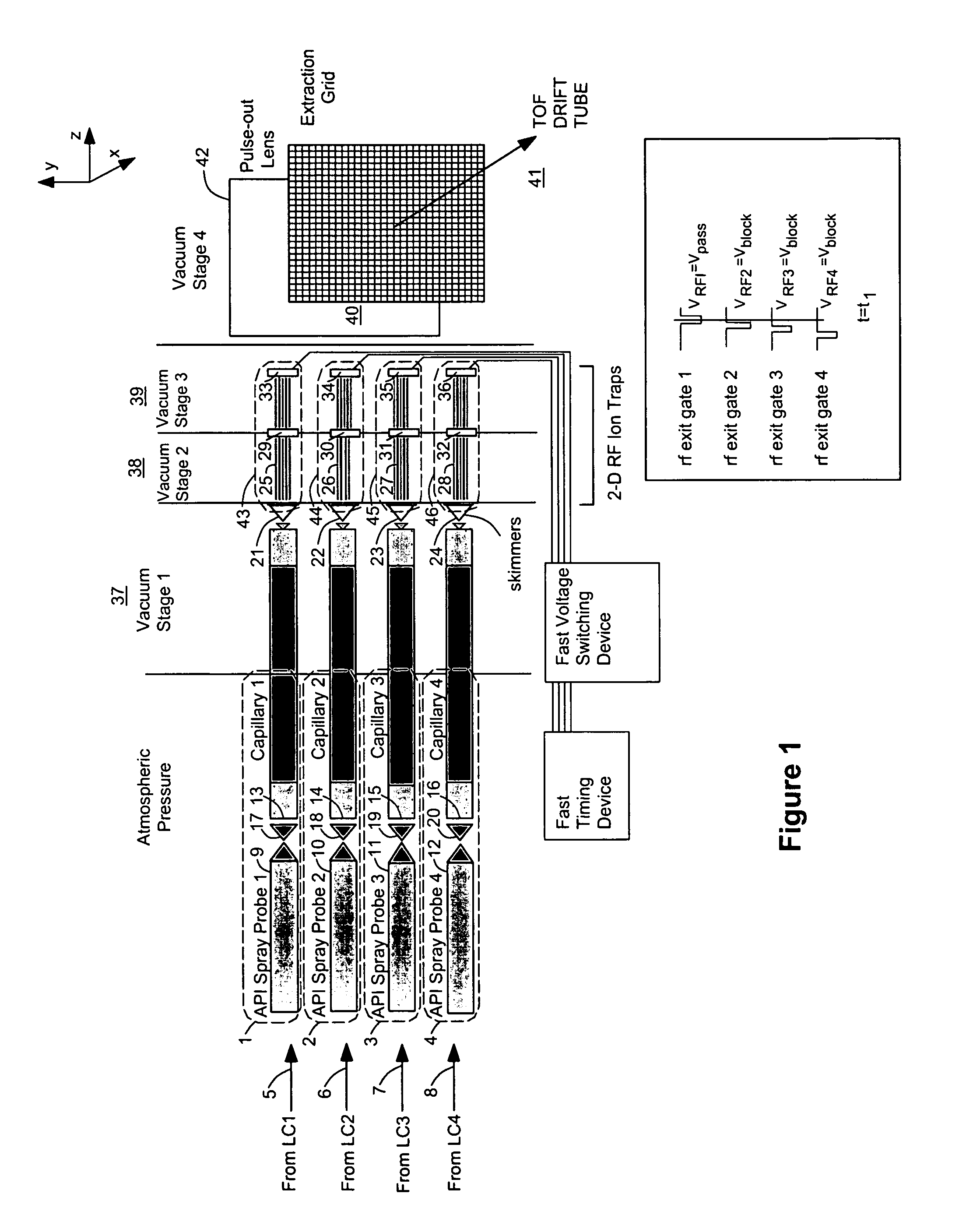

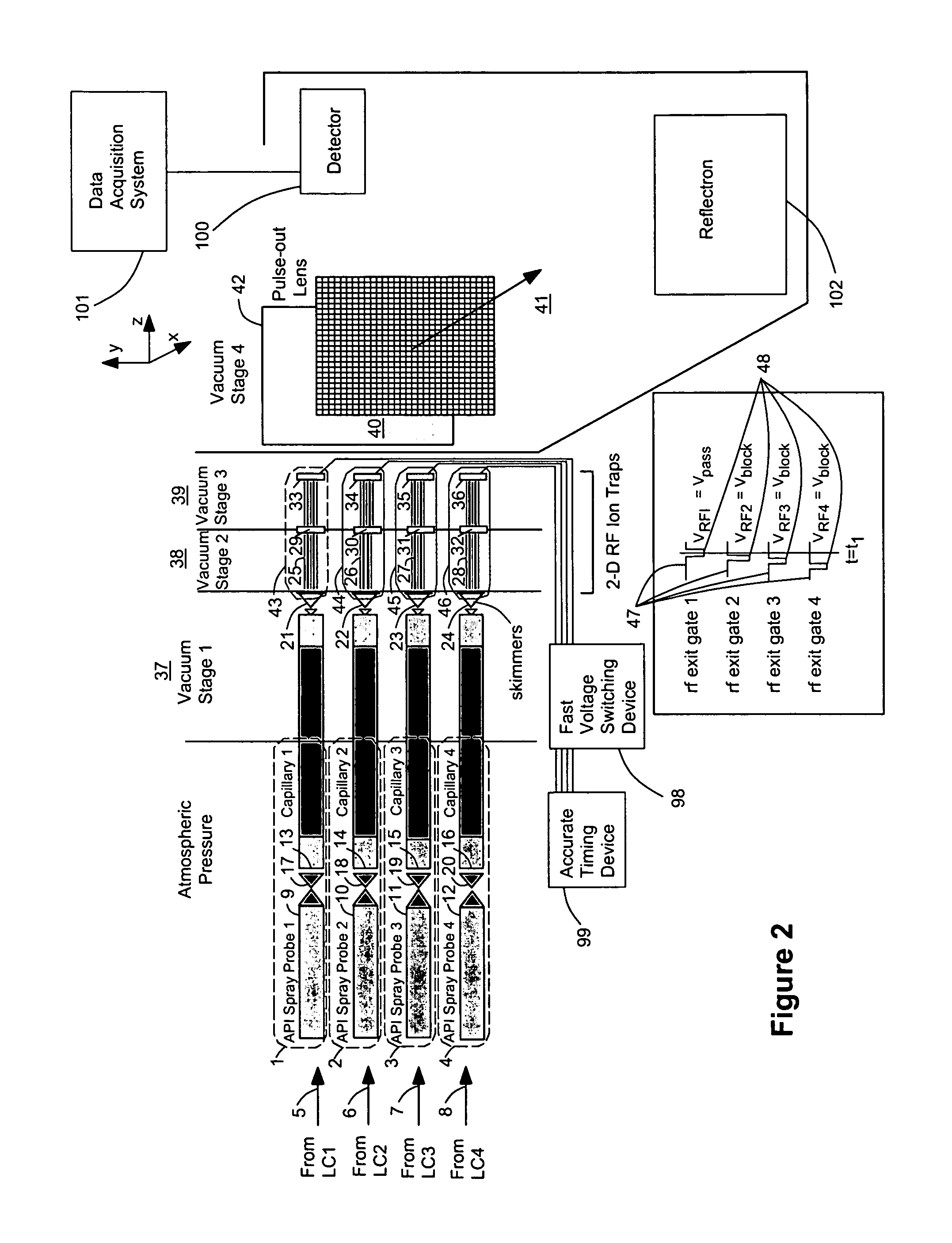

Method and apparatus for multiplexing plural ion beams to a mass spectrometer

ActiveUS20060091308A1Quick checkImprove throughputTime-of-flight spectrometersIsotope separationIon trap mass spectrometryIon beam

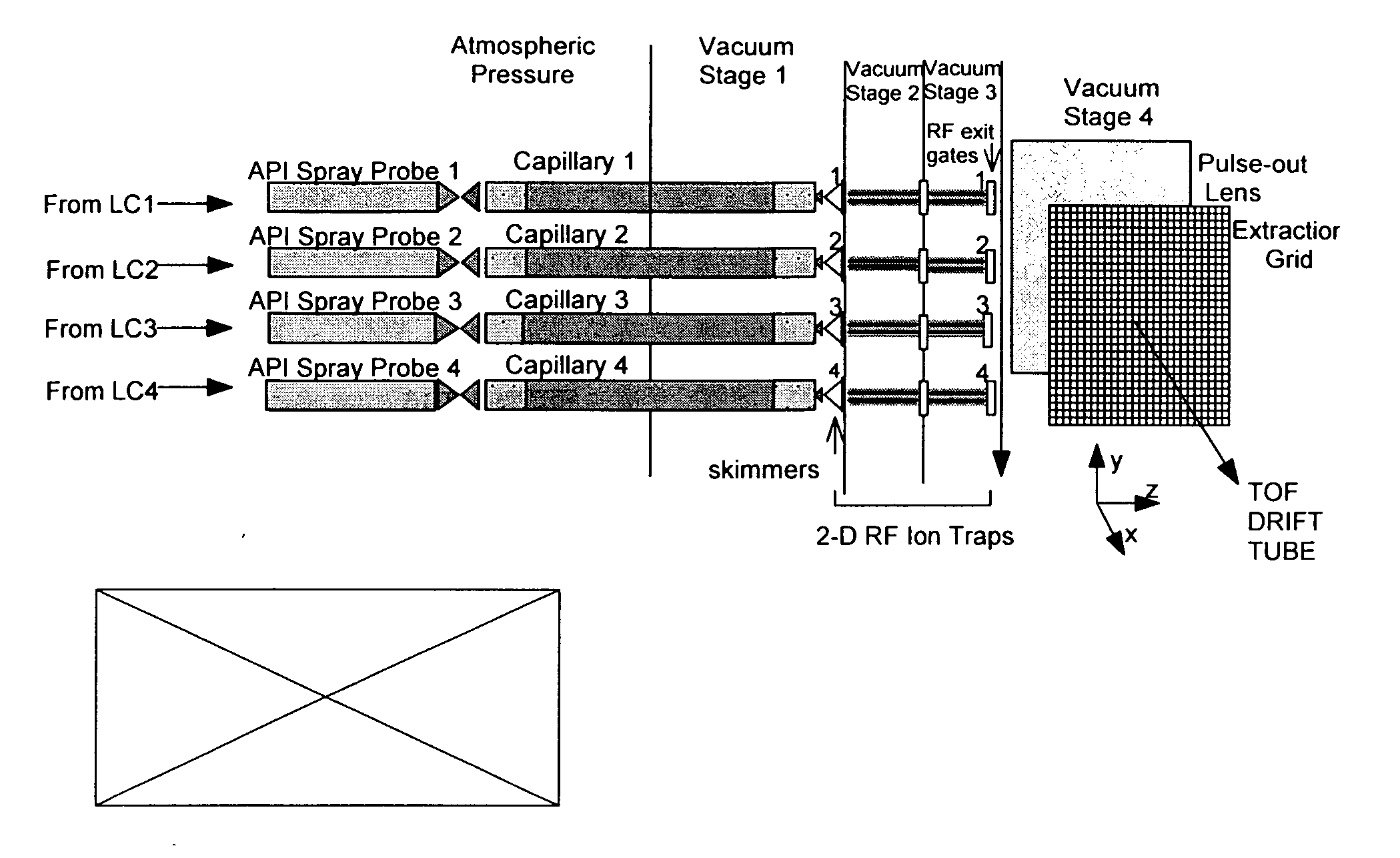

A method / apparatus for multiplexing plural ion beams to a mass spectrometer. At least two ion sources are provided with means of transporting the ions from the ion sources to separate two-dimensional ion traps. Each ion trap is used for storage and transmission of the ions and operates between the ion sources and the mass analyzer. Each ion trap has a set of equally spaced, parallel multipole rods, as well as entrance and exit sections into which and from which ions enter and exit the trap, respectively. For each ion trap, the entrance section is placed in a region where background gas pressure is at viscous flow. The pressure at the exit section drops to molecular flow pressure regimes without a break in the structure of the ion trap. Each trap alternately stores and transmits ions by way of a fast voltage switch applied to the ion trap exit lens.

Owner:PERKINELMER HEALTH SCIENCES INC

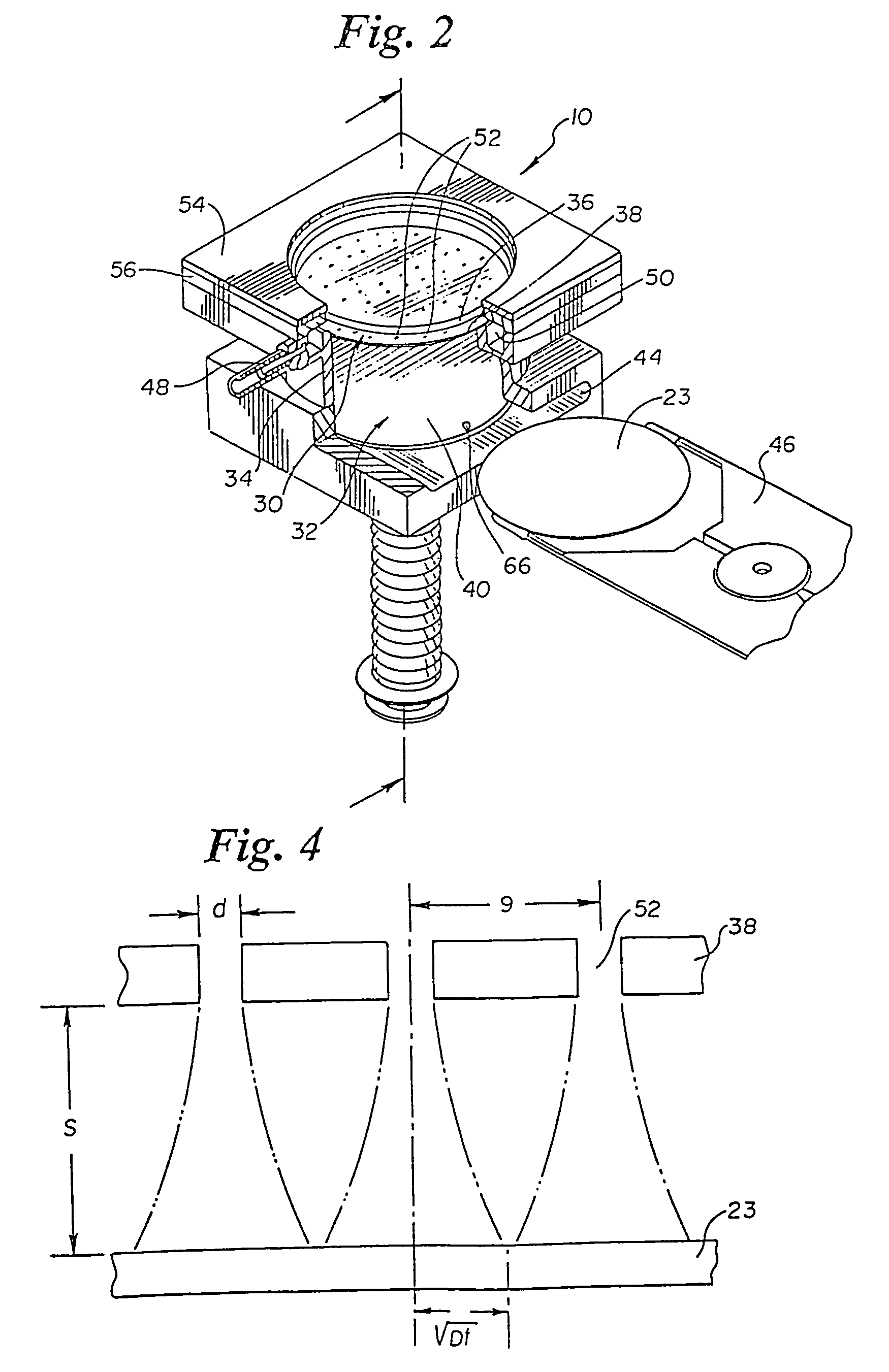

Apparatus for surface conditioning

InactiveUS7025831B1Promote resultsOvercome limitationsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical reactionLight activation

Apparatus and process for conditioning a generally planar substrate, contained in a chamber isolatable from the ambient environment and fed with a conditioning gas which includes reactive gas. The apparatus includes a support for supporting the substrate in the chamber, the substrate being in a lower pressure reaction region of the chamber. A gas inlet is provided for feeding conditioning gas into a gas inlet region of the chamber which is at a higher pressure than the lower pressure reaction region so that the pressure differential causes the conditioning gas to flow toward the surface of the substrate wherein the conditioning gas component will chemically react with and condition the substrate surface, both said higher and lower pressure regions operating in a viscous flow regime. The substrate is supported such that a pressure bias is created across the surface of this substrate so that the gas, after it has chemically reacted with the substrate surface, flows outward from where it has reacted, off the substrate toward the periphery of the chamber and out a peripheral or central underside exhaust outlet. Gas feed may be provided to one or both sides the substrate and light activation of the substrate or conditioning gas may be provided on one or both sides.

Owner:FSI INTERNATIONAL INC

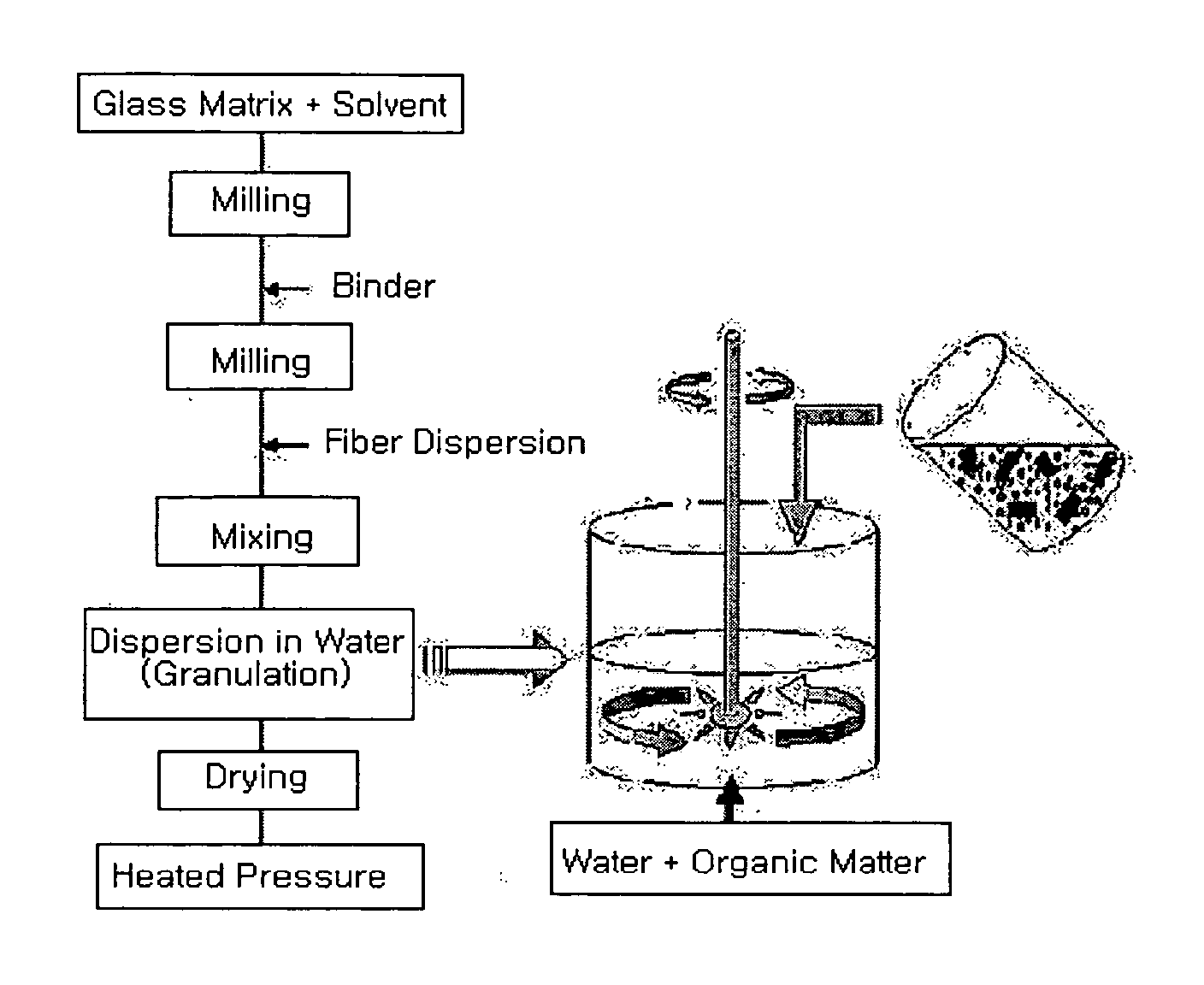

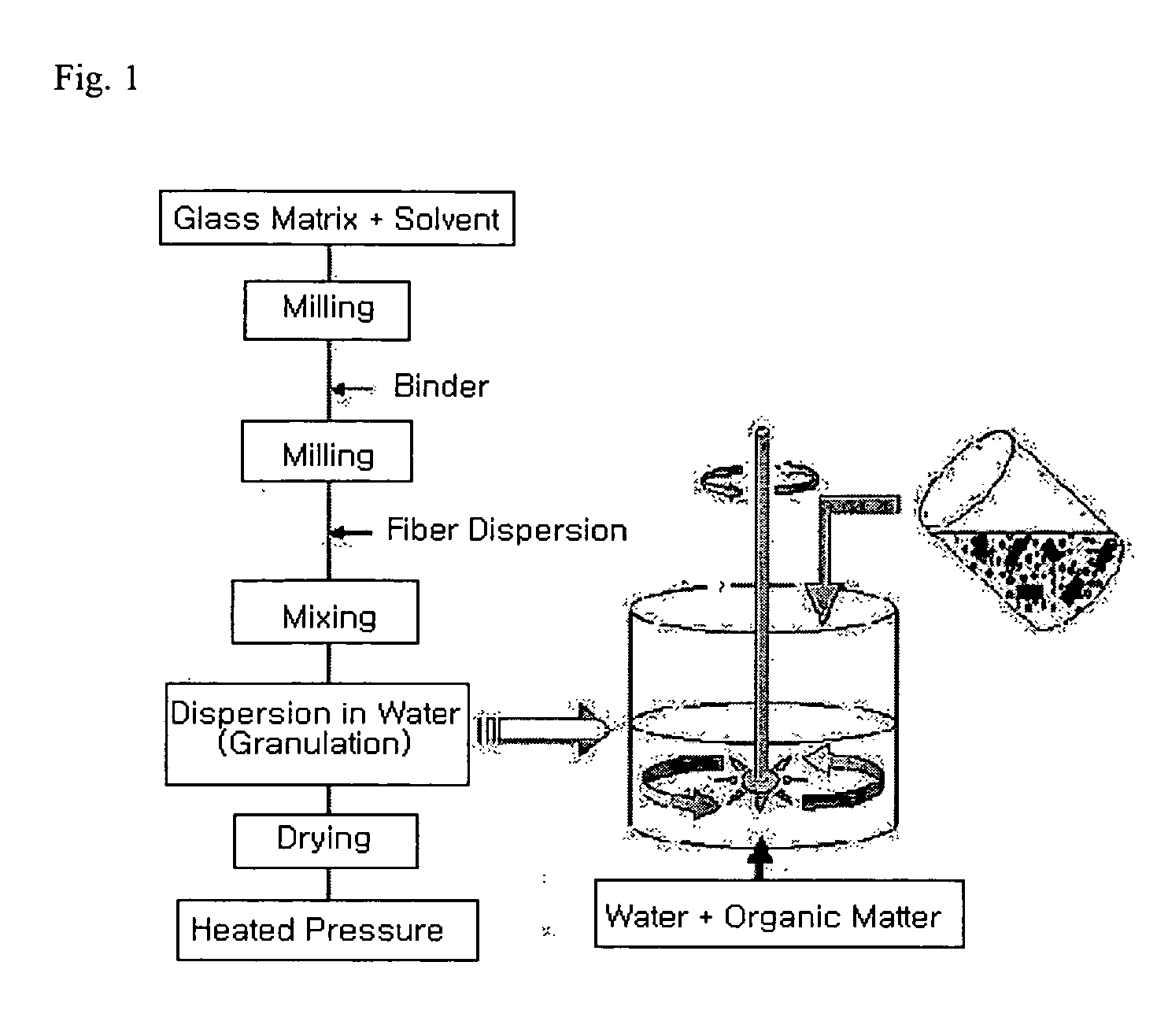

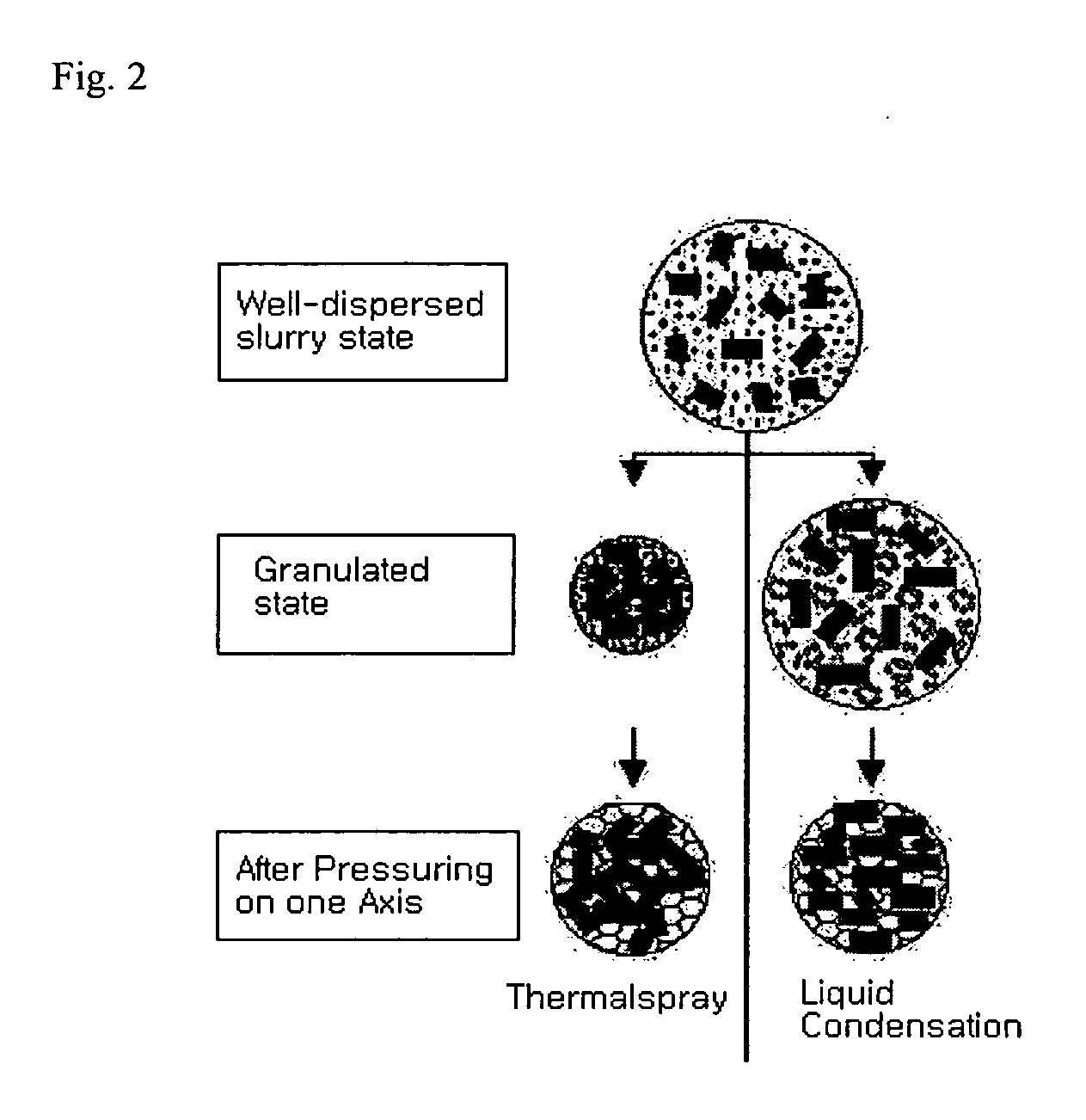

Solid oxide fuel cell sealant comprising glass matrix and ceramic fiber and method of manufacturing the same

InactiveUS20050147866A1Efficiently prevent and minimize viscous flowAccurate locationTime-programme switchesFinal product manufactureFiberFuel cells

Sealant compositions particularly suitable for solid oxide fuel cell sealant are provided and preferably comprise glass matrix and ceramic fiber, wherein glass matrix and ceramic fiber are mixed in an volume ratio of 25:75-75:25 in the sealant, and the ceramic fibers are preferably uniformly dispersed in the sealant to exhibit an orientation. Methods to manufacture the sealant compositions also are provided. Particularly preferred sealant compositions of the invention can efficiently avoid undesired viscous flow of glass matrix, precisely locate the stack of fuel cell on the region to be sealed, and maintain uniform sealing ability under various changes in size of the fuel cell stack.

Owner:HYUNDAI MOTOR CO LTD +1

Method for preparing low density polypropylene foam section or beads by two-step extrusion molding

The invention discloses a method for a preparing low density polypropylene foam section or beads by two-step extrusion molding, which comprises the following steps that: expandable master batch is prepared from 30 to 80 portions of polypropylene, 10 to 40 portions of foaming agent, 0 to 15 portions of foaming accelerant, 0 to15 portions of dispersant and 0 to 10 portions of nucleating agent at a temperature below the decomposition temperature of the foaming agent and above a viscous flow temperature of the polypropylene; 20 to 99 portions of polypropylene with high melt strength, 0 to 70 portions of common polypropylene and 1 to 10 portions of expandable master batch are plasticizated and extruded together; supercritical gas is added to perform the blending of the plasticizated and extruded mixture; and the product obtained is made to generate foamcores in a foaming nucleation apparatus to form the section or beads finally. A chemical foaming agent is partially decomposed and foamed during the plasticization and extrusion, so that the viscosity of fused mass is reduced, the dissolution and dispersion of the supercritical gas are facilitated, and a problem that a foam imploding is likely to happen in a secondary forming process so as to influence the quality and appearance of secondarily formed product is solved as the chemical foaming agent retained in molding beads can be decomposed and foamed again during the secondary processing.

Owner:SICHUAN UNIV

Composite stacked and coated lithium ion battery diaphragm and preparation method thereof

ActiveCN104393217AHigh strengthImprove heat resistanceCell seperators/membranes/diaphragms/spacersViscous flowLithium-ion battery

The invention relates to a composite stacked and coated lithium ion battery diaphragm and a preparation method thereof. The diaphragm is a porous diaphragm which is prepared by mixing one or many kinds of coating sizing agents and is provided with a layer or multiple layers of structures; the porous diaphragm comprises the following components in parts by weight: 30-100 parts of a polymeric material, 0-70 parts of inorganic powder bodies and a surface treating agent thereof, and 0-50 parts of a compatibilizer; the polymeric material at least selects and uses two kinds of polymeric materials, one kind of the polymeric materials is a thermoplastic material of which the melting point or the viscous flow temperature is 100-150 DEG C, and the other kind of the polymeric materials is a thermoplastic material or a thermosetting material of which the melting point or the viscous flow temperature is higher than or equivalent to that of the thermoplastic material of which the melting point or the viscous flow temperature is 100-150 DEG C. The composite stacked and coated lithium ion battery diaphragm provided by the invention is uniform in bore diameter, good in wettability, favorable in heat resistance and good in hot melting and closing function, and the preparation method for the composite stacked and coated lithium ion battery diaphragm is simple in technology, wide in the material selecting range, and controllable in the micropore forming condition.

Owner:HORIZON SPECIALTY MATERIAL

Method and apparatus for multiplexing plural ion beams to a mass spectrometer

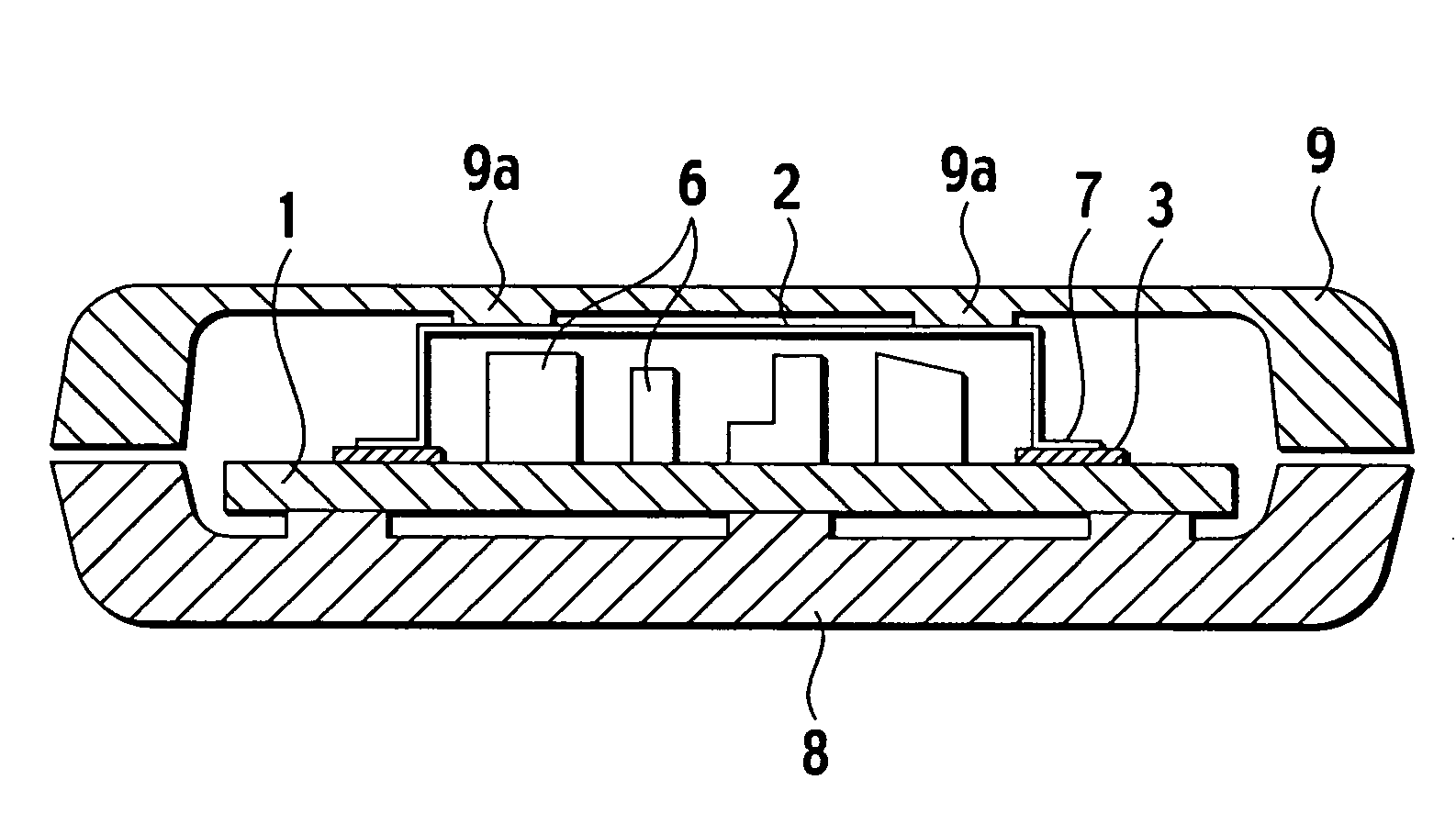

ActiveUS7217919B2High sample throughputCompromise sensitivityTime-of-flight spectrometersIsotope separationIon trap mass spectrometryIon beam

A method / apparatus for multiplexing plural ion beams to a mass spectrometer. At least two ion sources are provided with means of transporting the ions from the ion sources to separate two-dimensional ion traps. Each ion trap is used for storage and transmission of the ions and operates between the ion sources and the mass analyzer. Each ion trap has a set of equally spaced, parallel multipole rods, as well as entrance and exit sections into which and from which ions enter and exit the trap, respectively. For each ion trap, the entrance section is placed in a region where background gas pressure is at viscous flow. The pressure at the exit section drops to molecular flow pressure regimes without a break in the structure of the ion trap. Each trap alternately stores and transmits ions by way of a fast voltage switch applied to the ion trap exit lens.

Owner:PERKINELMER HEALTH SCIENCES INC

High temperature anti-oxidation coating and slurry for same of Cf/SiC composite material and preparation method thereof

InactiveCN101613209AThe coefficient of thermal expansion is close toSmall coefficient of thermal expansionCeramic layered productsMass ratioViscous flow

The invention discloses a slurry for high temperature anti-oxidation coating of Cf / SiC composite material and a preparation method thereof; the slurry is suspension liquid containing solid-phase components and organic carrier in a mass ratio of (1-4):1, the solid-phase components comprise BaO-Al2O3-SiO2 glass powder and oxide mixed powder in a mass ratio of (0-1):1 and the oxide mixed powder comprises Y2O3 powder and SiO2 powder in a molar ratio of 1:2. The invention also discloses a high temperature anti-oxidation coating of Cf / SiC composite material which is prepared from the slurry and a specific preparation method thereof. The coating is yttrium silicate composite coating or multilayer composite coating which is superimposed with various yttrium silicate composite coatings. The coating prepared by the method of the invention has low expansion coefficient and sufficient consistency, suitable high temperature viscous flow property and strong chemical bond with the protected composite material.

Owner:NAT UNIV OF DEFENSE TECH

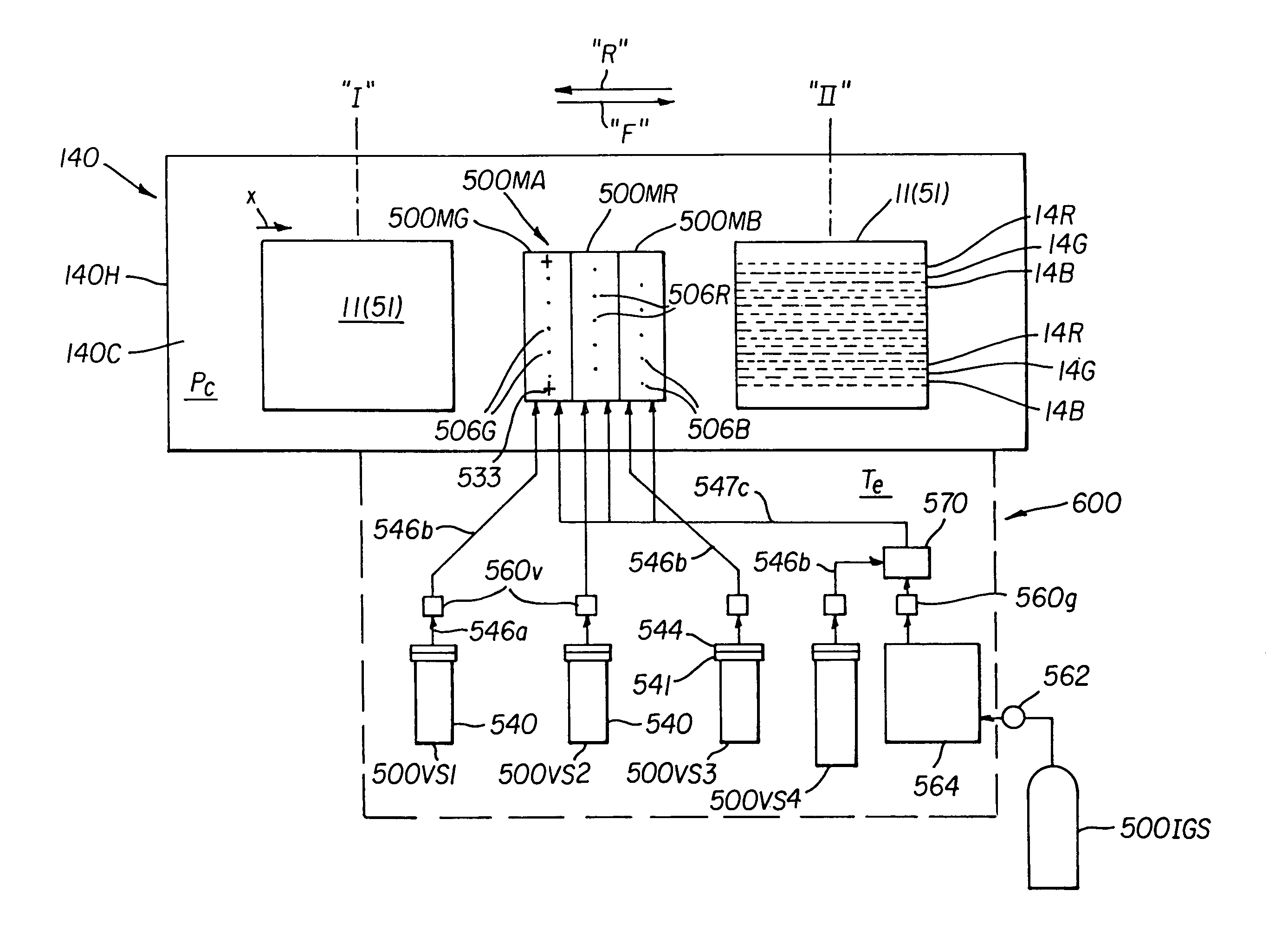

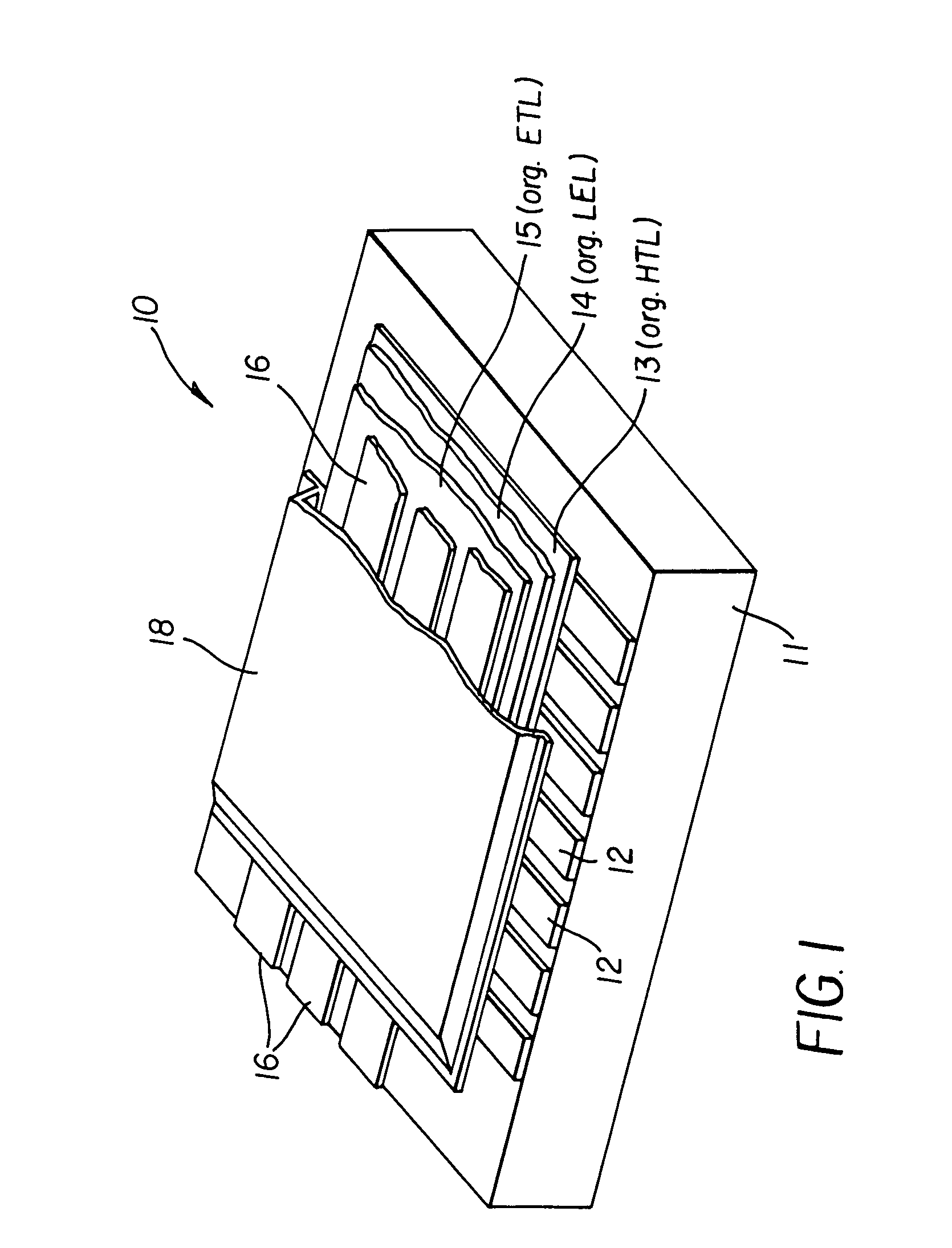

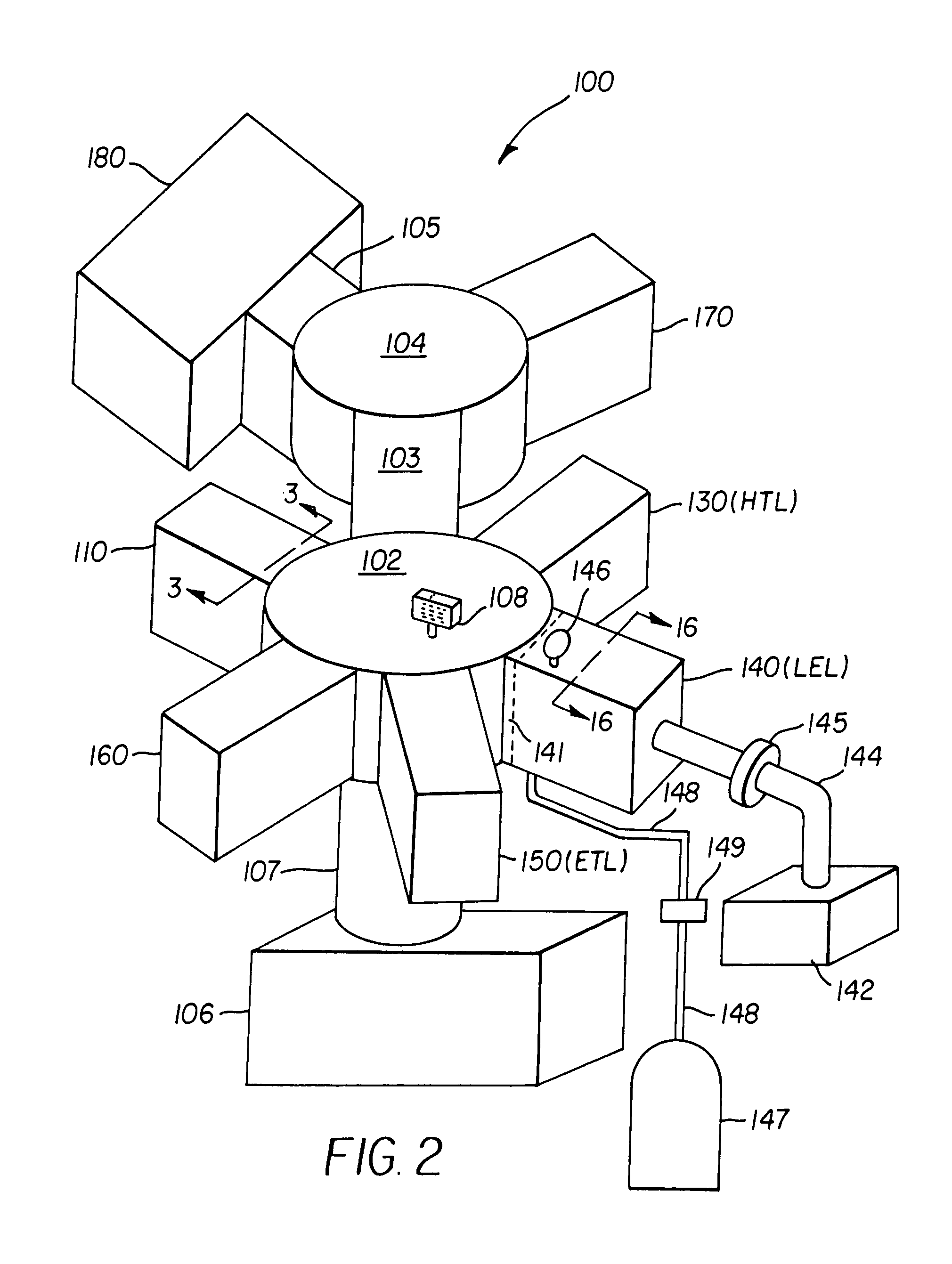

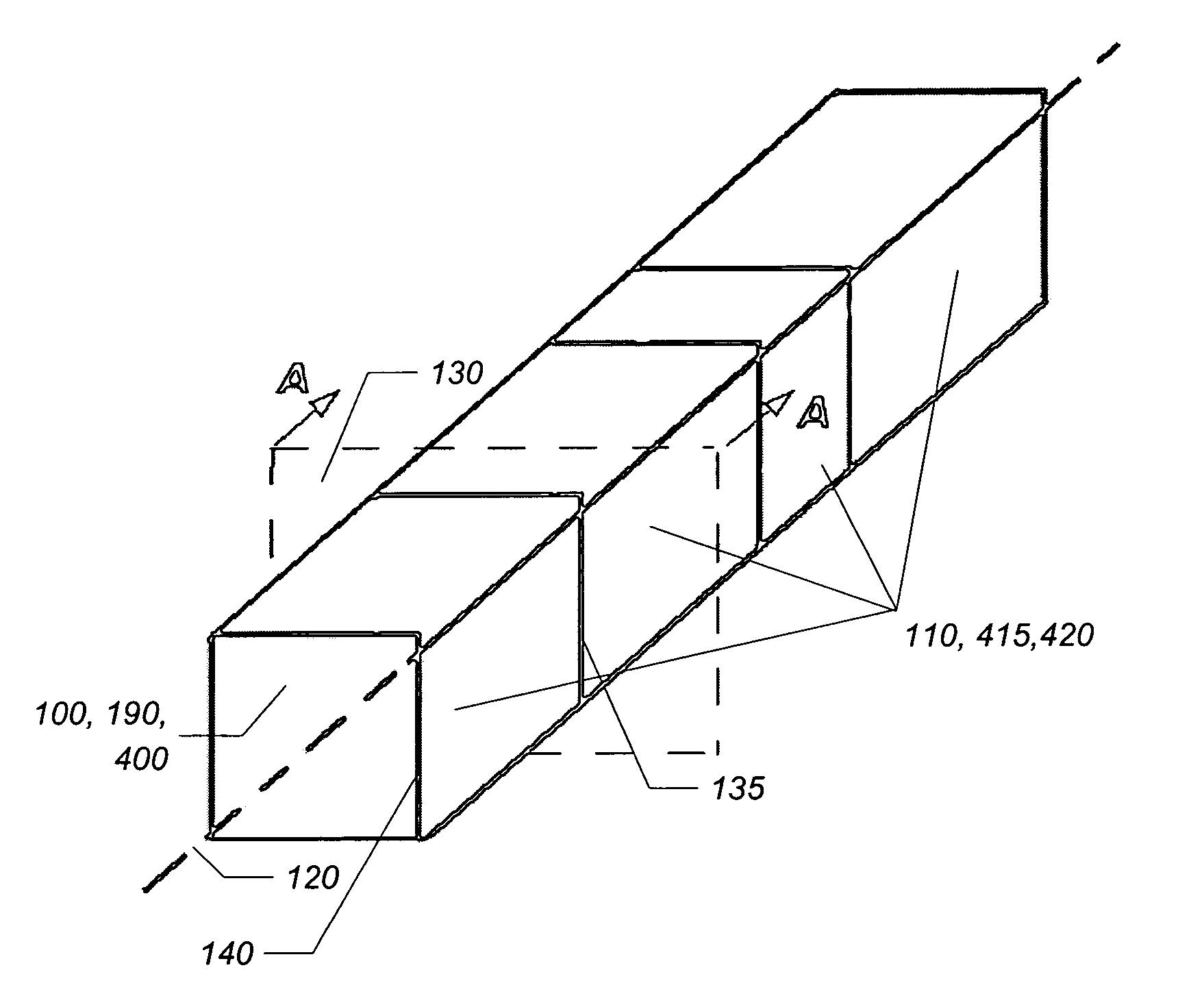

Depositing layers in OLED devices using viscous flow

InactiveUS7067170B2Reduce pressureOvercome limitationsElectroluminescent light sourcesSolid-state devicesViscous flowOrganic layer

A method of depositing a patterned organic layer includes providing a manifold and an OLED display substrate in a chamber at reduced pressure and spaced relative to each other; providing a structure sealingly covering at least one surface of the manifold, the structure including a plurality of nozzles extending through the structure into the manifold. The method also includes delivering vaporized organic materials into the manifold, and applying an inert gas under pressure into the manifold so that the inert gas provides a viscous gas flow through each of the nozzles, such viscous gas flow transporting at least portions of the vaporized organic materials from the manifold through the nozzles to provide directed beams of the inert gas and of the vaporized organic materials and projecting the directed beams onto the OLED display substrate for depositing a pattern of an organic layer on the substrate.

Owner:GLOBAL OLED TECH

Automated generation of lean models for injection molding simulation

ActiveUS7574339B2Preserve efficiencyPreserve spiritComputer aided designSpecial data processing applicationsComputer resourcesKey innovation

The present invention is a method and system for simulating fluid flow in a cavity, having relevance to the modeling of viscous flows within thin cavities of complex shapes in which heat exchange with the cavity walls may be a governing factor, as in injection molding of plastic parts. Its automated discretization scheme, in which the model cavity is partitioned into macrocells, each macrocell having substantial contact areas with the model cavity walls, eliminates the need for time consuming and expensive manual model configuration required by some modeling methods. Because of the simplicity of the discretization, models based on the invention are less demanding on computer resources then conventional finite element methods, and execute more quickly. A key innovation of the method is a function characterizing the shape of a macrocell that appears in a coefficient in equations governing the flow. As a consequence of the improvements offered by the invention, molds for complex parts can be fabricated more rapidly, with the resulting parts having high quality.

Owner:PROTOMOLD CO THE

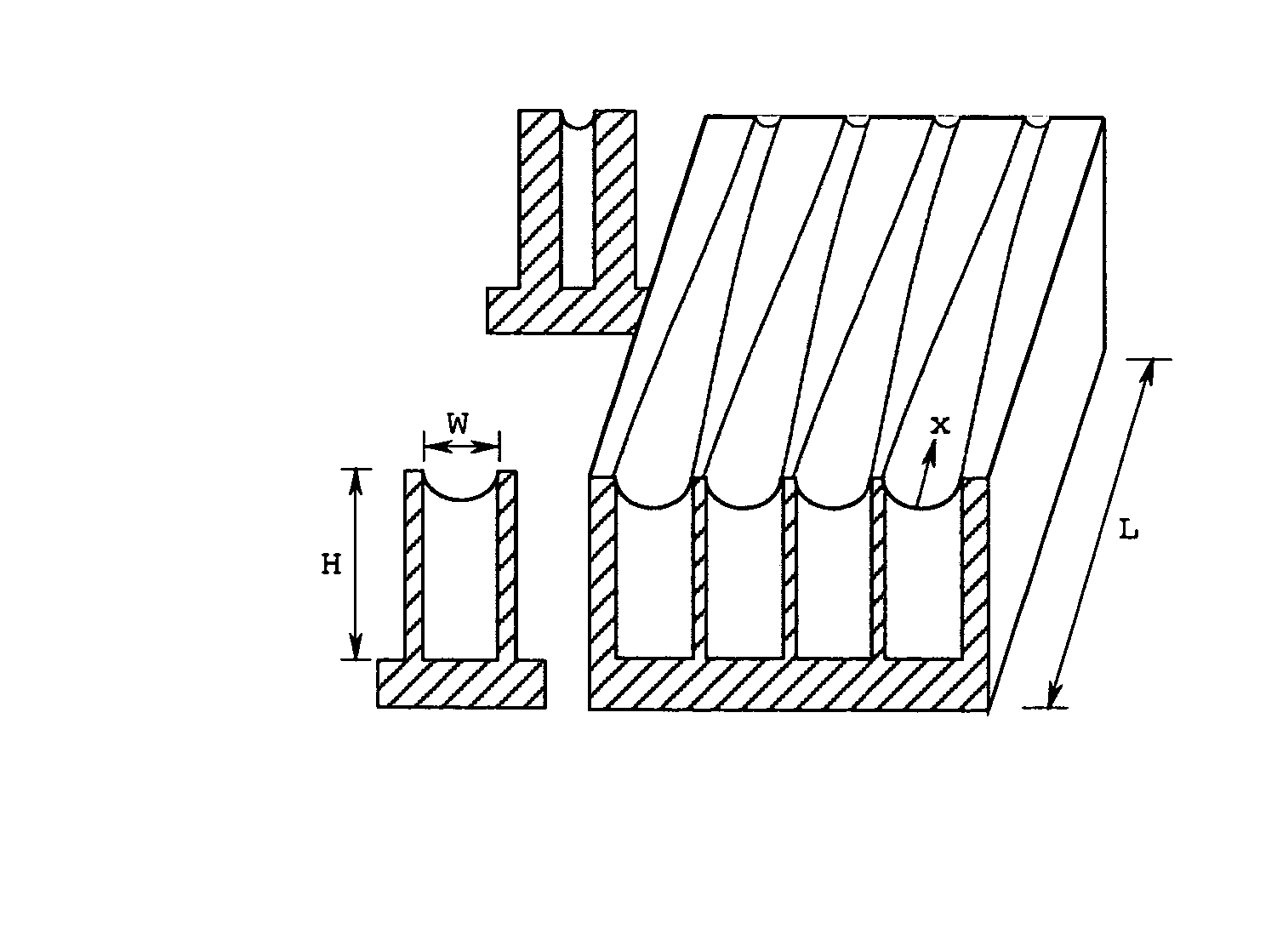

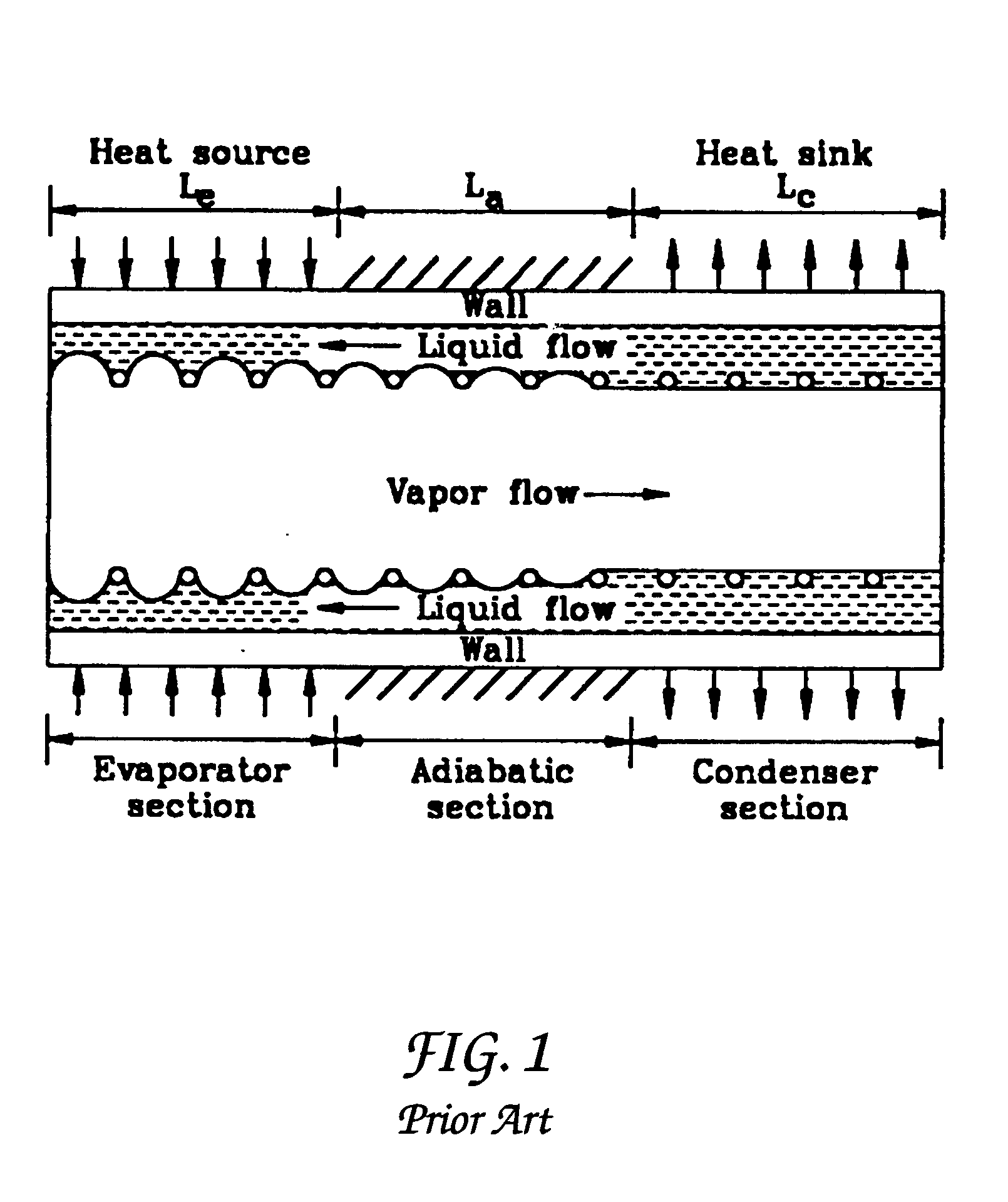

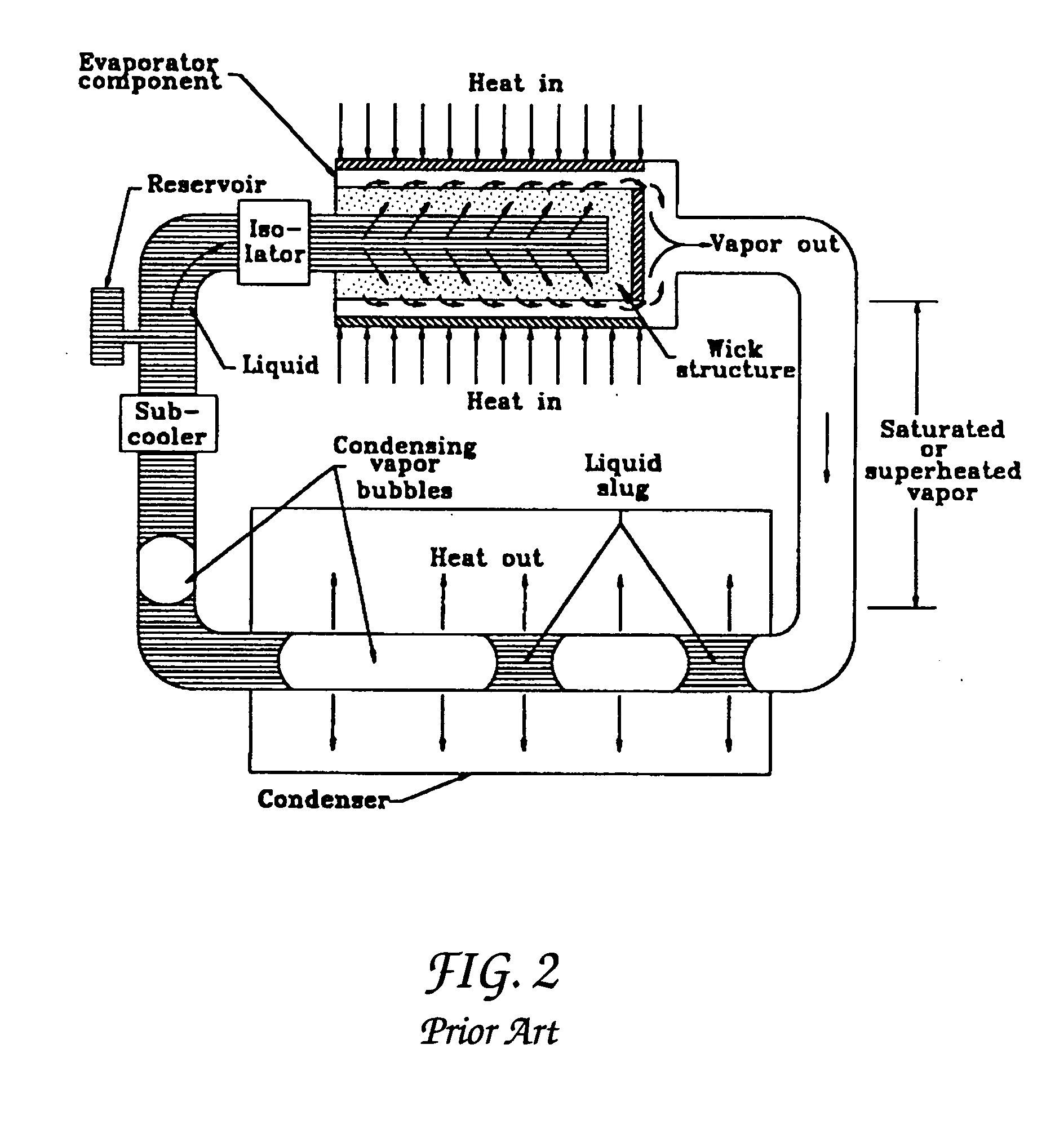

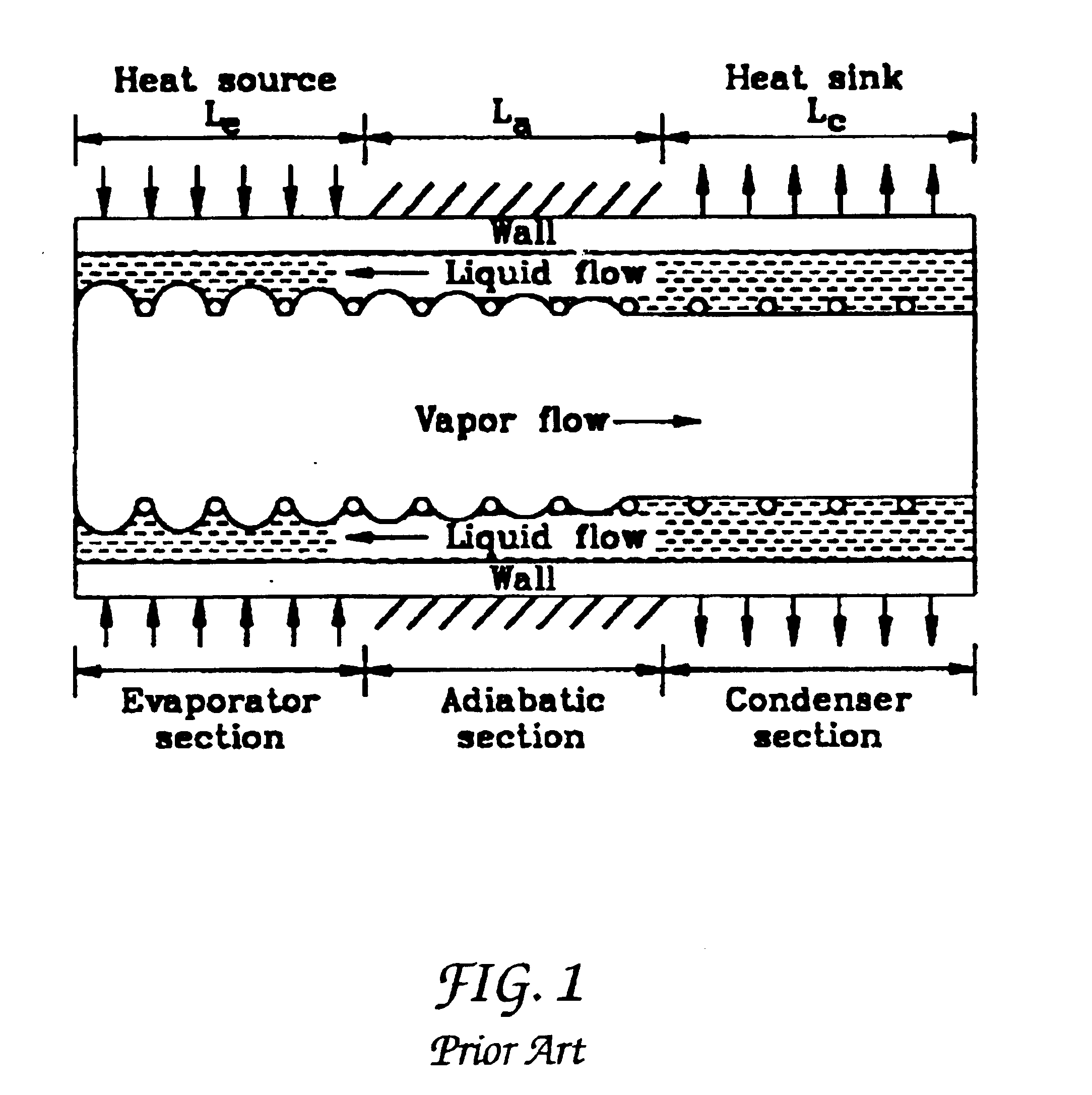

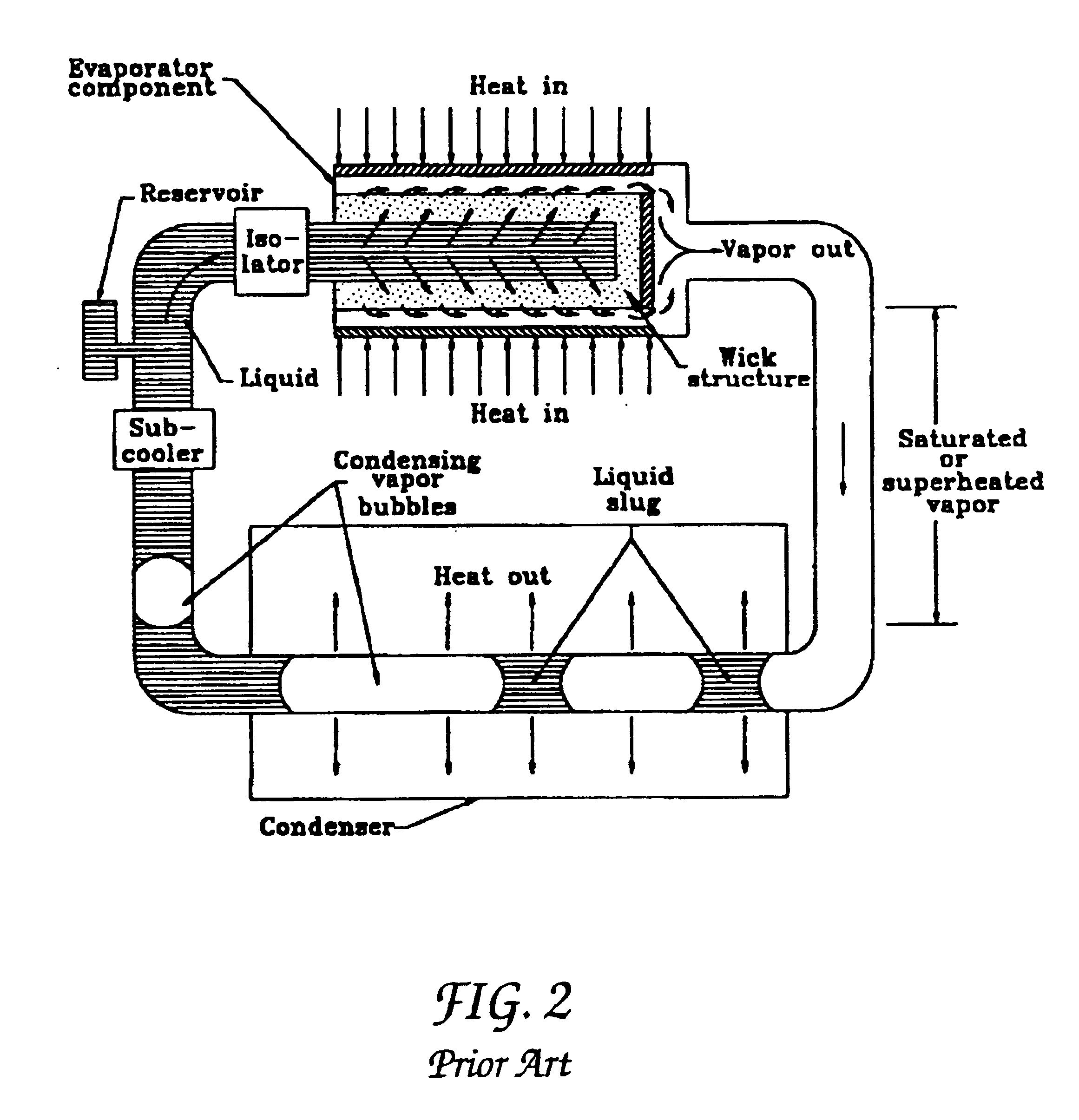

Axially tapered and bilayer microchannels for evaporative coolling devices

The invention consists of an evaporative cooling device comprising one or more microchannels whose cross section is axially reduced to control the maximum capillary pressure differential between liquid and vapor phases. In one embodiment, the evaporation channels have a rectangular cross section that is reduced in width along a flow path. In another embodiment, channels of fixed width are patterned with an array of microfabricated post-like features such that the feature size and spacing are gradually reduced along the flow path. Other embodiments incorporate bilayer channels consisting of an upper cover plate having a pattern of slots or holes of axially decreasing size and a lower fluid flow layer having channel widths substantially greater than the characteristic microscale dimensions of the patterned cover plate. The small dimensions of the cover plate holes afford large capillary pressure differentials while the larger dimensions of the lower region reduce viscous flow resistance.

Owner:SANDIA NAT LAB

A kind of production method of superfine high-strength high-modulus viscose fiber

InactiveCN102296373AIncrease contact areaIncreasing the thicknessSpinnerette packsArtificial filaments from viscoseCellulosePolymer science

The invention discloses a production method of ultra-fine, high-strength and high-modulus viscose fibers. The cellulose xanthate polymer spinning viscose which is still in a viscous flow state is provided with viscose ejection holes and coagulation baths respectively. The composite spinneret of the spray hole is sprayed out, and is solidified and formed by a low-acid, high-zinc, low-salt and low-temperature coagulation bath, and then combined with bath stretching and air stretching, and drawn by nozzles with different ratios , inter-disk drafting and plasticizing drafting, and then post-treatment to obtain a fineness of 0.44~0.78dtex, dry strength ≥ 3.1cN / dtex, wet strength ≥ 2.1cN / dtex, wet modulus ≥ 0.5cN / dtex, whiteness ≥82.0% ultra-fine high-strength high-modulus viscose fiber. The invention realizes the effective coordination of the ultrafine denier fiber spinning forming process and drafting, and the normal implementation of the spinning process, and the produced ultrafine high-strength high-modulus viscose fiber has a uniform structure, and the fiber strength and modulus are 50% higher than conventional varieties. %above.

Owner:CHTC HELON

Industrial automation paint line

An industrial automation paint line comprises a conveying chain, an ultrasonic pretreatment production line, a drying room, a spraying room and a curing room; wherein, the conveying chain is hinged with a suspension bracket; the lower part of the suspension bracket is hinged with a C-shaped rack; the lower part of the C-shaped rack is hinged with a suspension balance beam which is provided with a suspension workpiece hole and a hinge hole; a flow equalization tube is fixed on the upper part of the spraying room; a flow equalization filter layer is fixed on the lower part of the flow equalization tube and a viscous flow device is arranged on the lower part of a worktable of the spraying room. A flow equalizing device ensures the spray painting effect free from the influence of uneven wind force; the viscous flow device can effectively treat the waste gas generated in the process of spray painting; the C-shaped rack can effectively prevent the viscous flow from generating. The industrial automation paint line has high degree of automation and shortens the running-in period in use of the system.

Owner:ZHEJIANG MINGQUAN INDAL COATING

Super-soft SS (spunbond and spunbond) nonwoven fabric and production process thereof

ActiveCN103132241AAppropriately meet the requirements of tender skinSoft and smoothNon-woven fabricsElastomerMasterbatch

The invention discloses super-soft SS (spunbond and spunbond) nonwoven fabric. The super-soft SS nonwoven fabric is mainly made from, by weight, 55-90 parts of polypropylene, 5-40 parts of elastomer, 1-4 parts of softener and 0.5-1 part of cooling masterbatch. The invention further discloses a production process of the super-soft SS nonwoven fabric. The production process includes the steps of preparing raw materials and auxiliary materials according to the proportion, mixing well, melt-compressing by a screw extruder to obtain viscous flow melt, sending the melt into a melt filter for filtration, allowing the melt to enter a spinning die head, allowing trickle of the melt to be extruded out of spinneret orifices, allowing a drafting air channel to draft and shape the trickle of the melt under the action of process cooling air so as to obtain fiber of certain strength, allowing the fiber to be evenly adsorbed to a forming conveyor belt by a diffusion air channel to form a continuous mesh fiber layer, and rolling the fiber mesh into the nonwoven fabric of certain longitudinal and transverse tension by a hot rolling mill. The SS nonwoven fabric produced according to the formula by the process is smaller than 1.5g in softness, and is as soft and smooth as silk to touch and highly suitable for shell fabrics of baby diapers.

Owner:JINJIANG XINGTAI NON WOVEN PRODS

High pressure process and apparatus for the electrocoagulative treatment of aqueous and viscous fluids

ActiveUS7087176B2Easy maintenanceEasy to closeElectrostatic separatorsLiquid separation by electricityElectrocoagulationSludge

A method and apparatus for the high-pressure electrocoagulative treatment of aqueous and viscous fluids and sludge is provided. The apparatus includes a plate and frame design utilizing mechanical closure on a plurality of recessed, gasketed, non-electrically conductive electrocoagulation spacer plates that completely enclose and isolate all fluids, electrical contacts, and electrodes within the confines of the apparatus. The spacer plates include intergral supports that position and support said plates with enclosed electrodes on top of the side rails of the supporting frame of the apparatus allowing said plates to be separated for electrode replacement and maintenance and conversly closed, pressured and put into service. The apparatus includes a baffled influent and effluent chamber at both ends for the addition and flash mixing of chemical reagents and / or flocculants and to provide a means of fluid communication between fluid conduits and chambers formed within the apparatus.

Owner:GAVREL TOM GUS +1

Humic mineral reagent and method for the production thereof, method for rehabilitating polluted soils, method for detoxification of wastes of extracted and processed mineral products and recultivating rock dumps and tailing storages, method for sewage water treatment and method for sludge utilisation

InactiveUS20060058566A1Significant to useAvoid problemsSludge treatment by de-watering/drying/thickeningContaminated soil reclamationSludgeMoisture

The humic-mineral agent from naturally occurring carbon-series humites and caustobioliths comprises humic acids and salts thereof, naturally hydrated humic acids, hydrolyzed humic acids, hydrated and hydrolyzed humic-mineral and mineral complexes of parent carbon-series humites and caustobioliths chemically bound to the naturally hydrated humic acids. The method for preparing a humic-mineral agent comprises crushing and disintegrating of carbon-series humites and caustobioliths and mixing them with an alkali. The carbon-series humites and caustobioliths are crushed and disintegrated when their moisture content is close to the natural level at which humic acids are in a naturally hydrated state, hot water is added to the. Next an alkali is added thereto and the mixture is hydrolyzed till obtaining the end product having consistency from viscous-flow to plastic and the pH value of from 6.5 to 8. The method for detoxication of polluted soil. The method for detoxication of waste products of mining and processing useful minerals and for reclaiming waste piles and tailing pits, the method for sewage water treatment and the method for salvaging sewage sediment are carried into effect by using the humic-mineral agent mentioned before.

Owner:SHULGIN ALEXANDER IVANOVICH +1

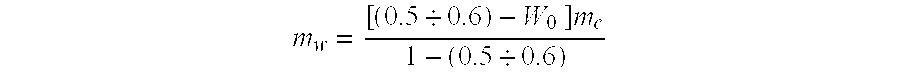

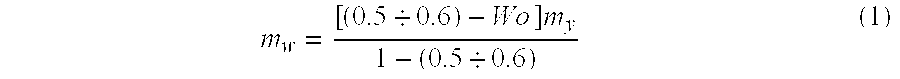

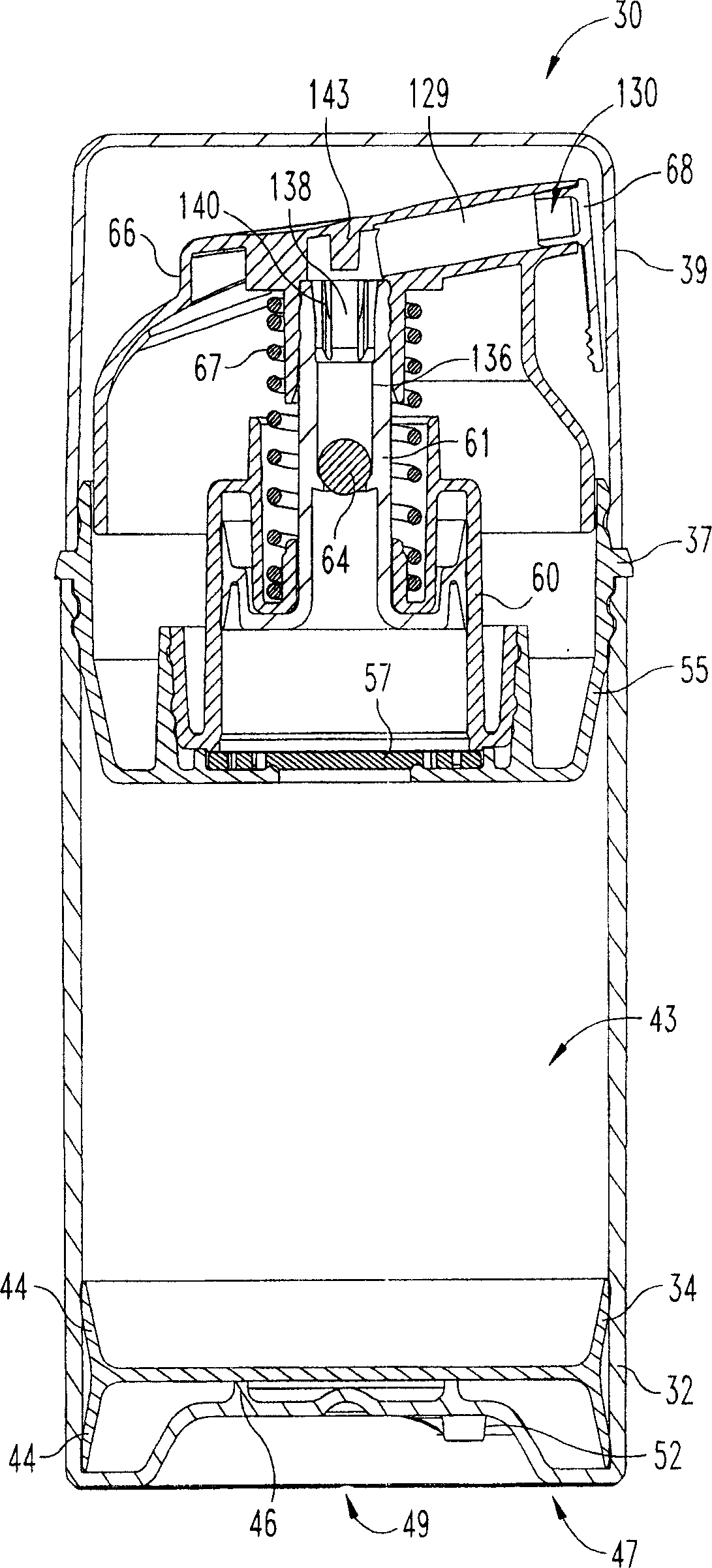

Airless dispensing pump with tamper evidence features

An airless dispenser pump assembly (30) includes a pump mechanism with an inlet valve (57) that is configured to efficiency pump viscous fluids and that is able to be pre-primed when the pump mechanism is attached to a container. In one form, the inlet valve includes a seal member that seals an inlet port of the pump and an outer support member that secures the inlet valve to the rest of the pump mechanism. Two or more legs (88) generally extend in a circumferential direction between the support member and the seal member in order to create a large flow opening for fluid flow through the inlet valve when opened and to rapidly dose the inlet valve. The pump mechanism further includes an outlet valve (64) that is configured to draw fluid back from a nozzle of the pump after dispensing in order to minimize build up around the nozzle.

Owner:RIEKE

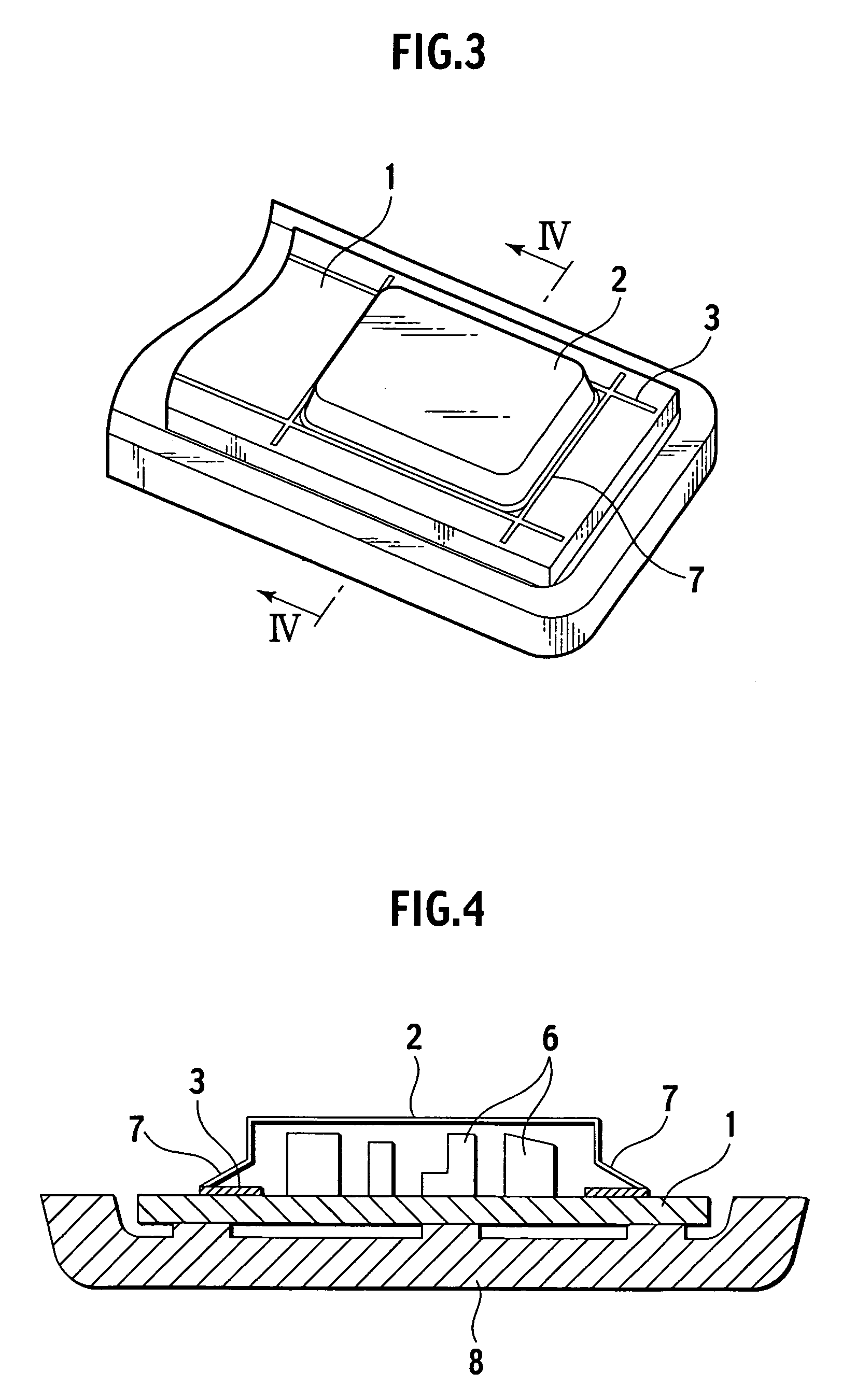

Electromagnetic wave shield case and a method for manufacturing electromagnetic wave shield case

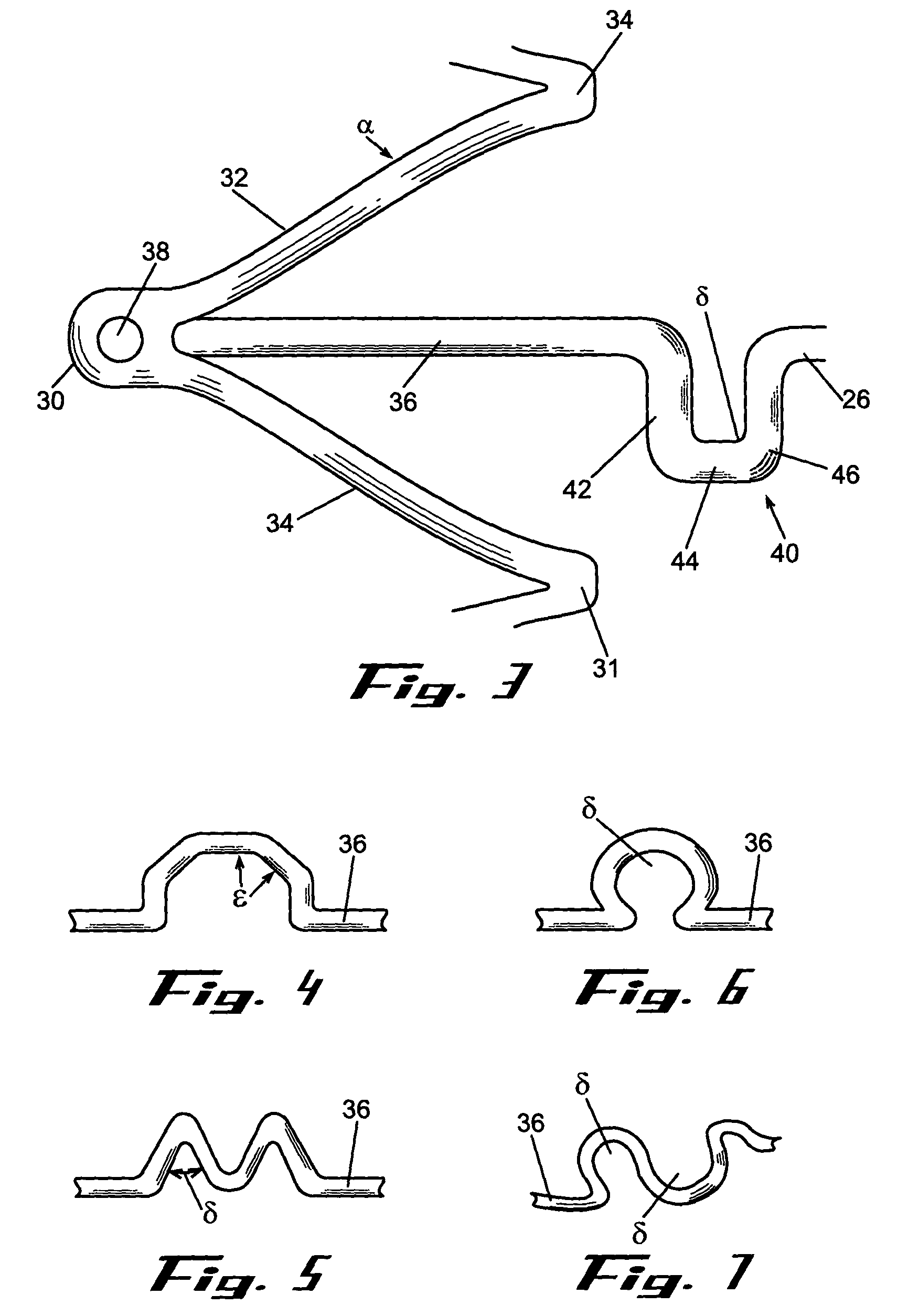

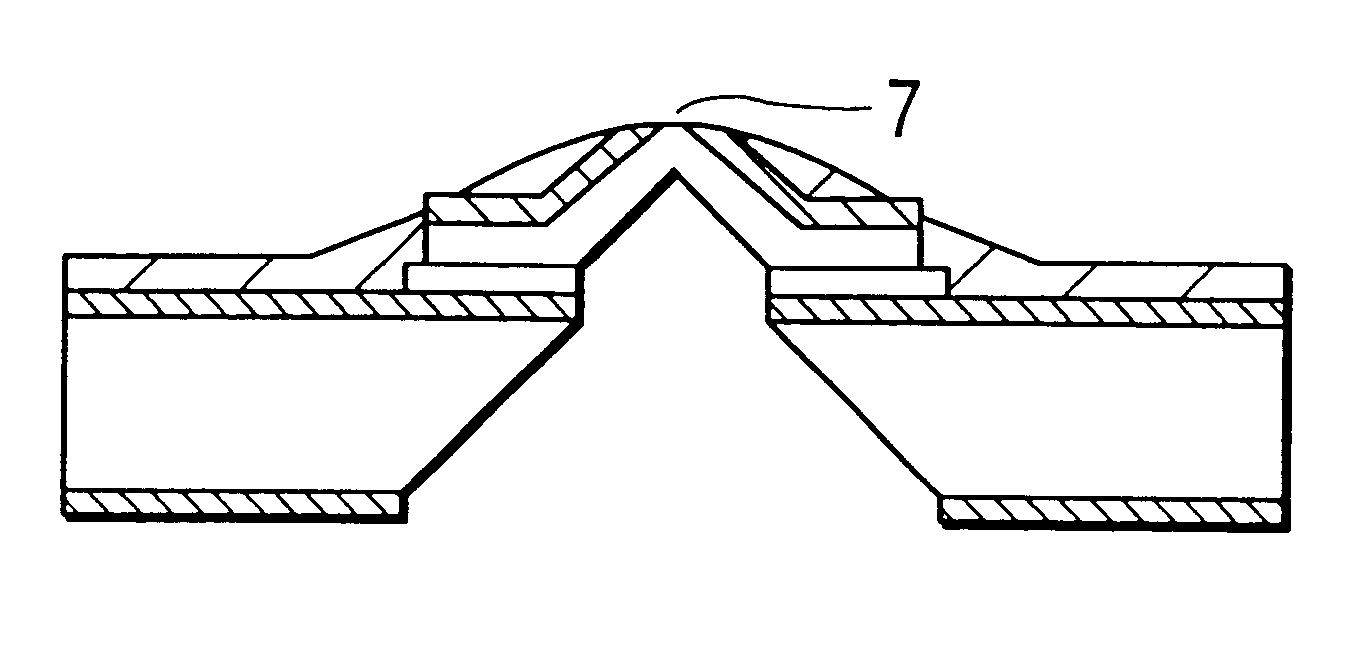

InactiveUS7626832B2Reduce thicknessLow costMagnetic materialsShielding efficiency measurementHyper elasticViscous flow

An objective of the present invention is to form a hyper-elastic flange integrally within a shield case body around a periphery thereof while decreasing an occupied area for grounding. The shield case 2 according to the present invention is disposed to cover electronic parts 6 on a circuit board 1, and which has a flange 7 formed integrally therewith so as to contact with a metallic ground line 3 on the circuit board 1. The flange 7 is elastically deformed to be grounded, thus a leakage of electromagnetic waves to the outside of the shield case 2 is prevented. The flange 7 is made of metallic glass. By forming the flange 7 from metallic glass, a displacement due to viscous flowing on the atomic level, which is different from a plastic deformation, can be utilized, and thus a high precision flange can be formed without a spring-back.

Owner:NGK INSULATORS LTD +1

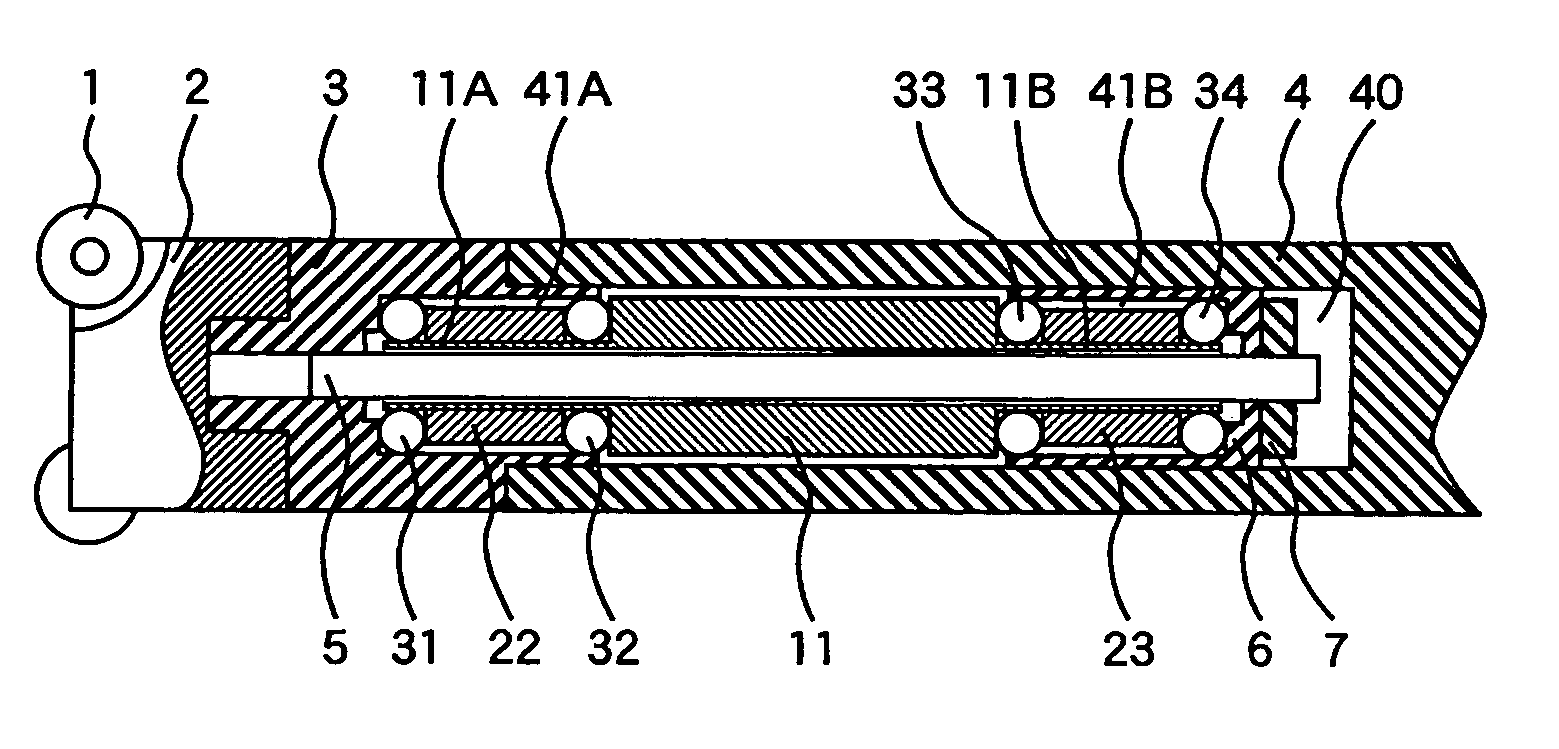

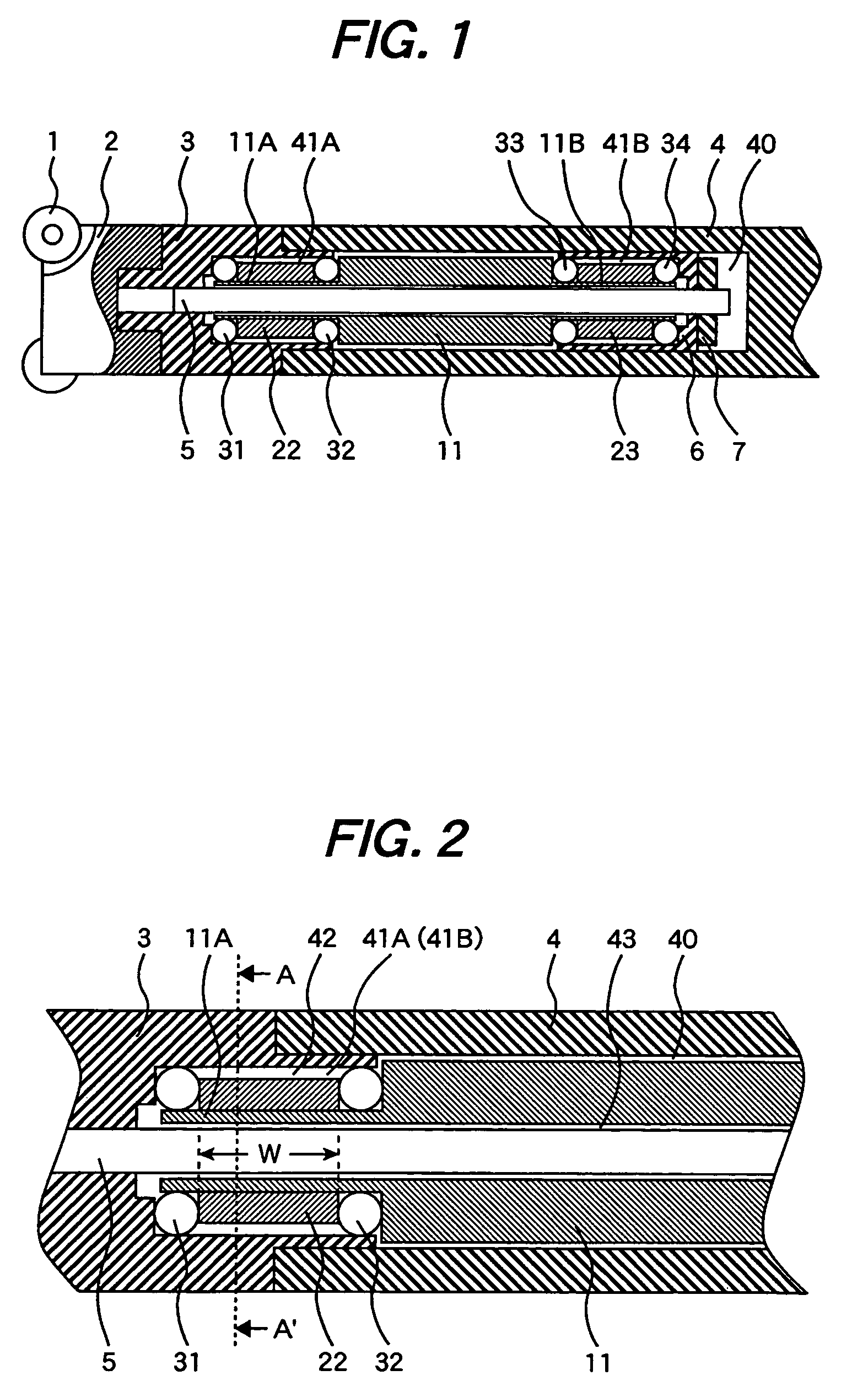

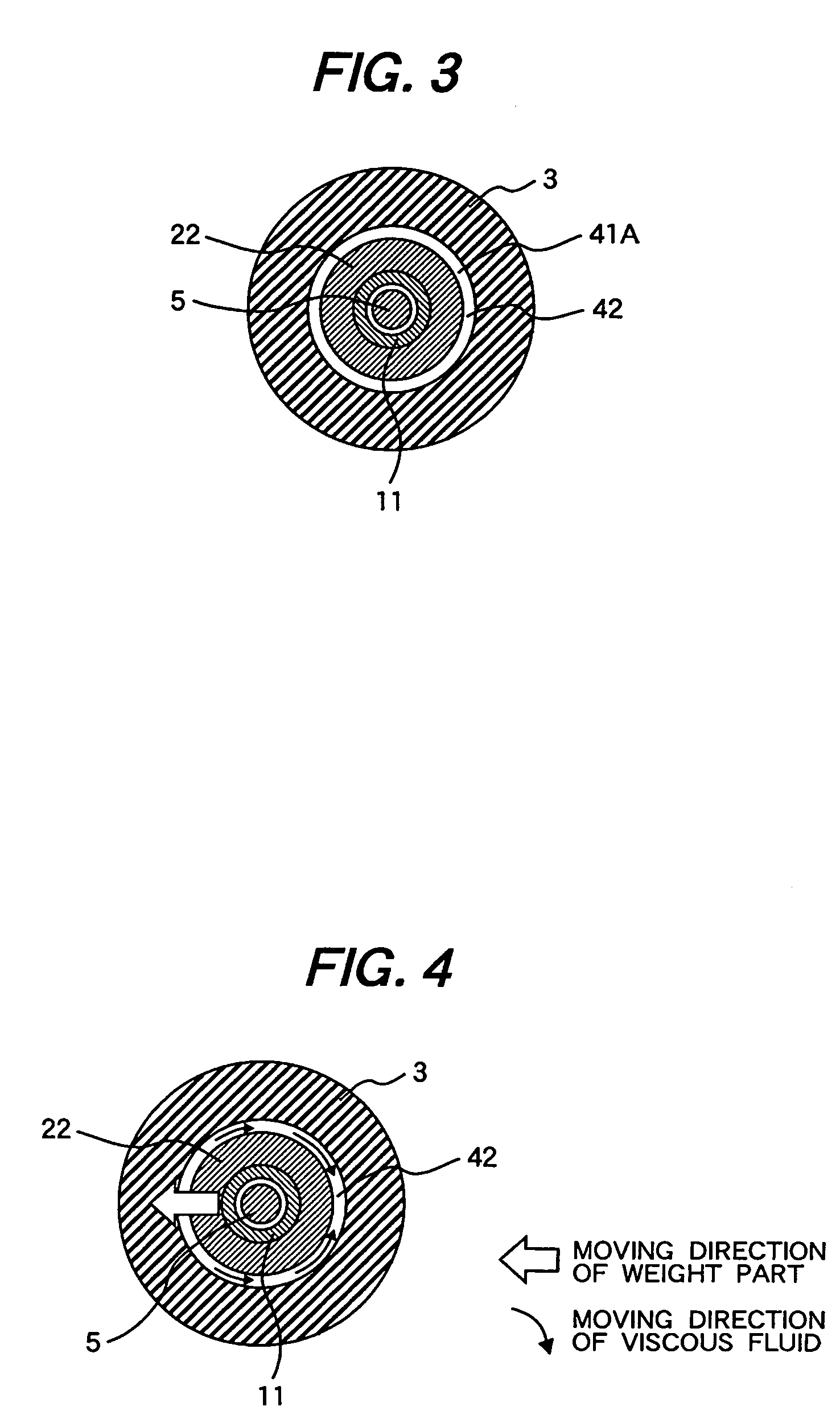

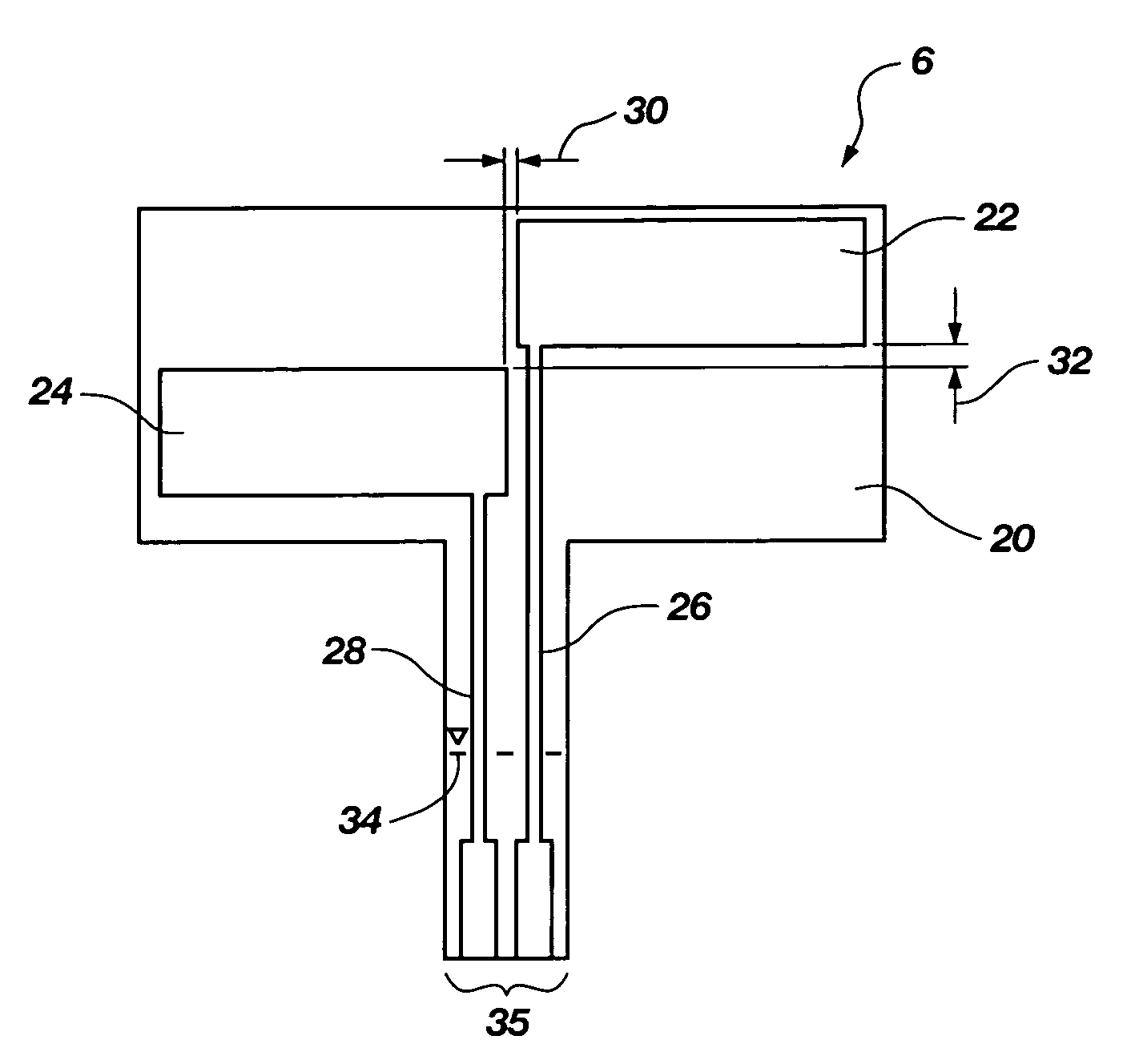

Tool having damper

InactiveUS7661912B2Improve featuresIncrease freedomMilling cuttersBoring barsDynamic stiffnessViscous flow

Owner:HITACHI TOOL ENG LTD

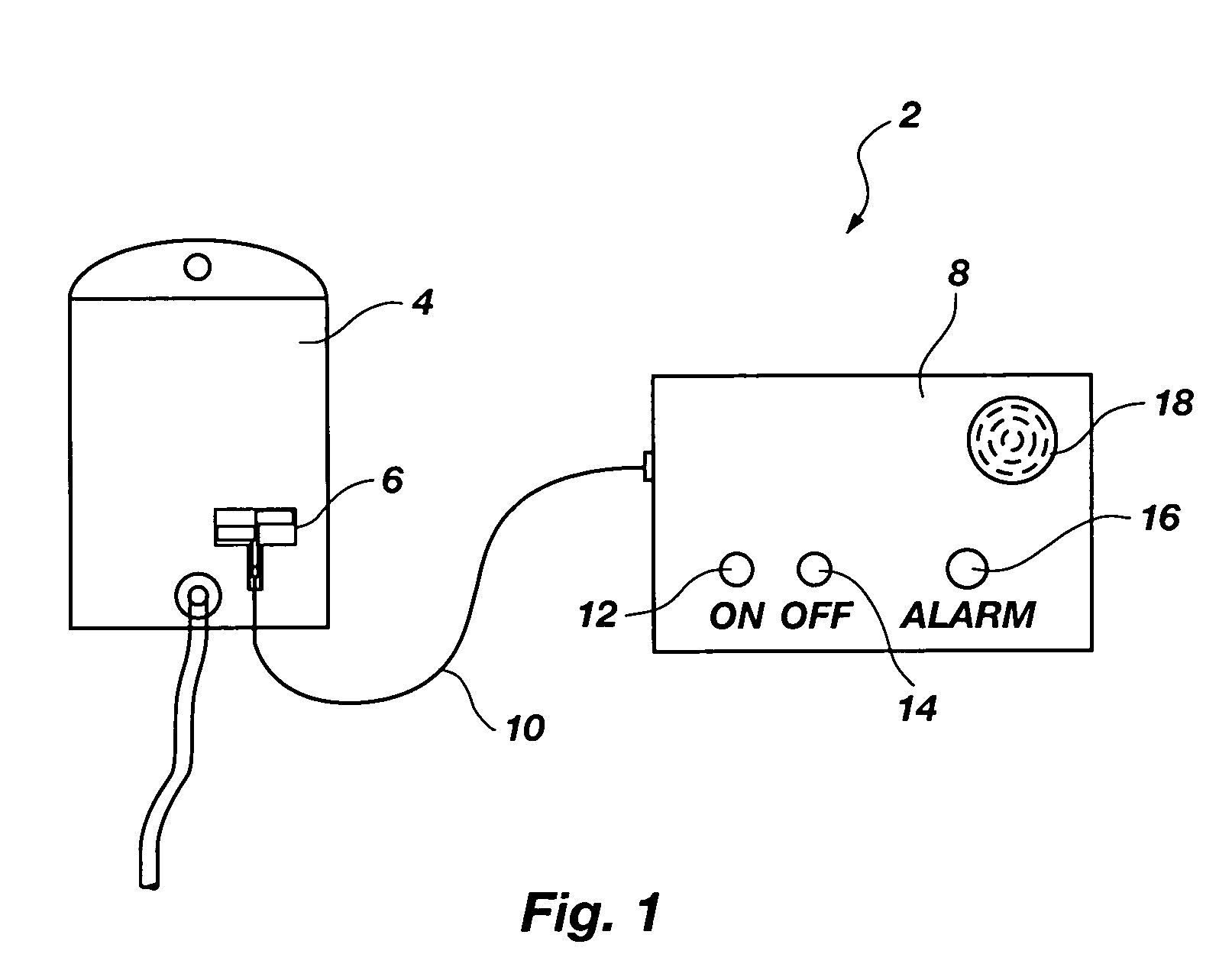

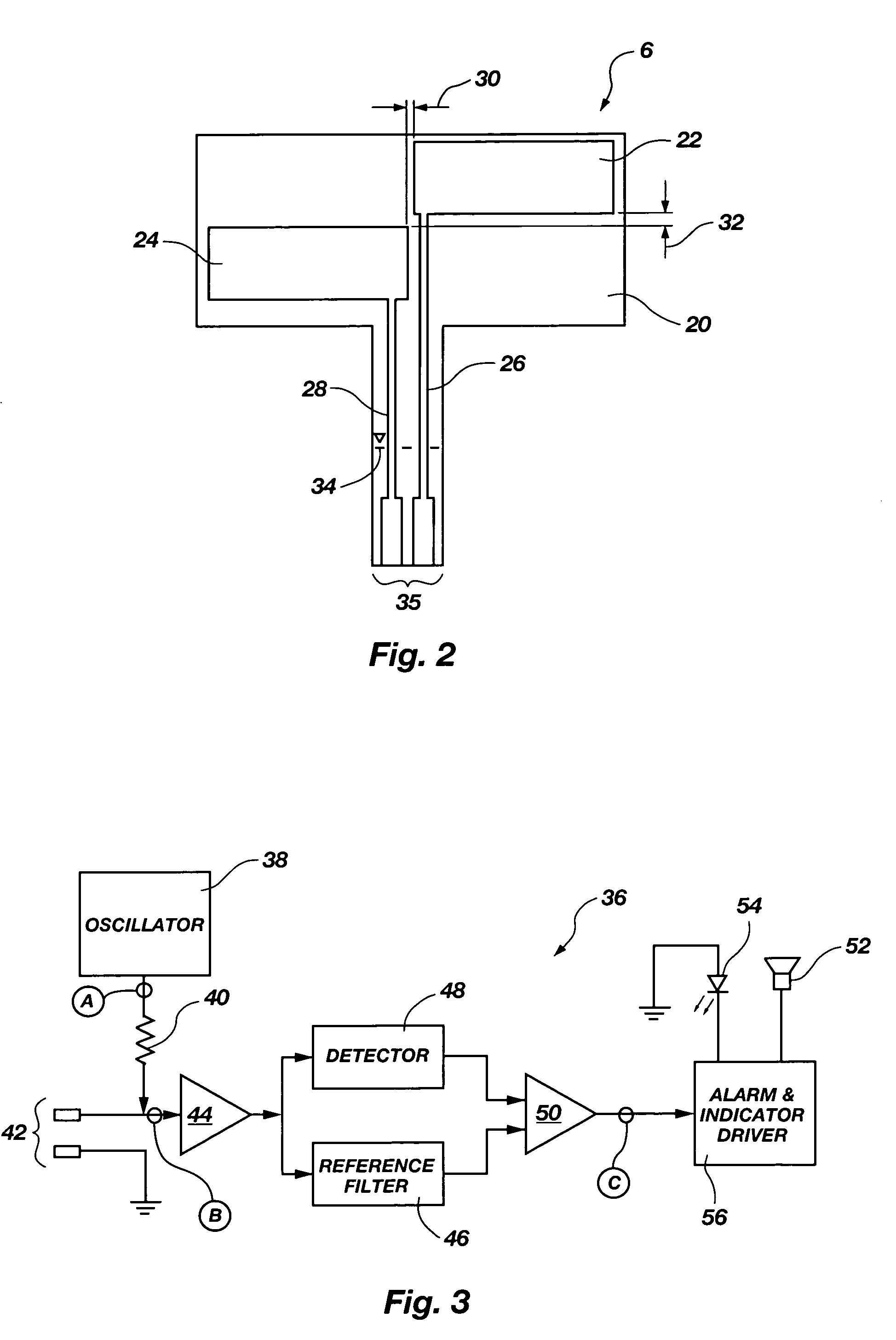

Method and apparatus for detection of fluid level in a container

InactiveUS7127943B1Accurately detect rapidly changing fluid levelReduce the effect of capacitanceMachines/enginesLubrication indication devicesCritical levelLiquid level sensor

A fluid level sensor is disclosed having first and second vertically and horizontally nonoverlapping electrode plates for placing on a wall of a fluid container. Most preferably, the plates are also vertically spaced from each other. The capacitor plates are driven by a high frequency square wave. By forming nonoverlapping plates and driving them using a high frequency, the level of a fluid within the container, particularly viscous fluid, is more accurately detected. Control and detection circuitry is also disclosed to trigger an alarm if the fluid level drops below a critical level within the container.

Owner:ROCKY MOUNTAIN COMPOSITES

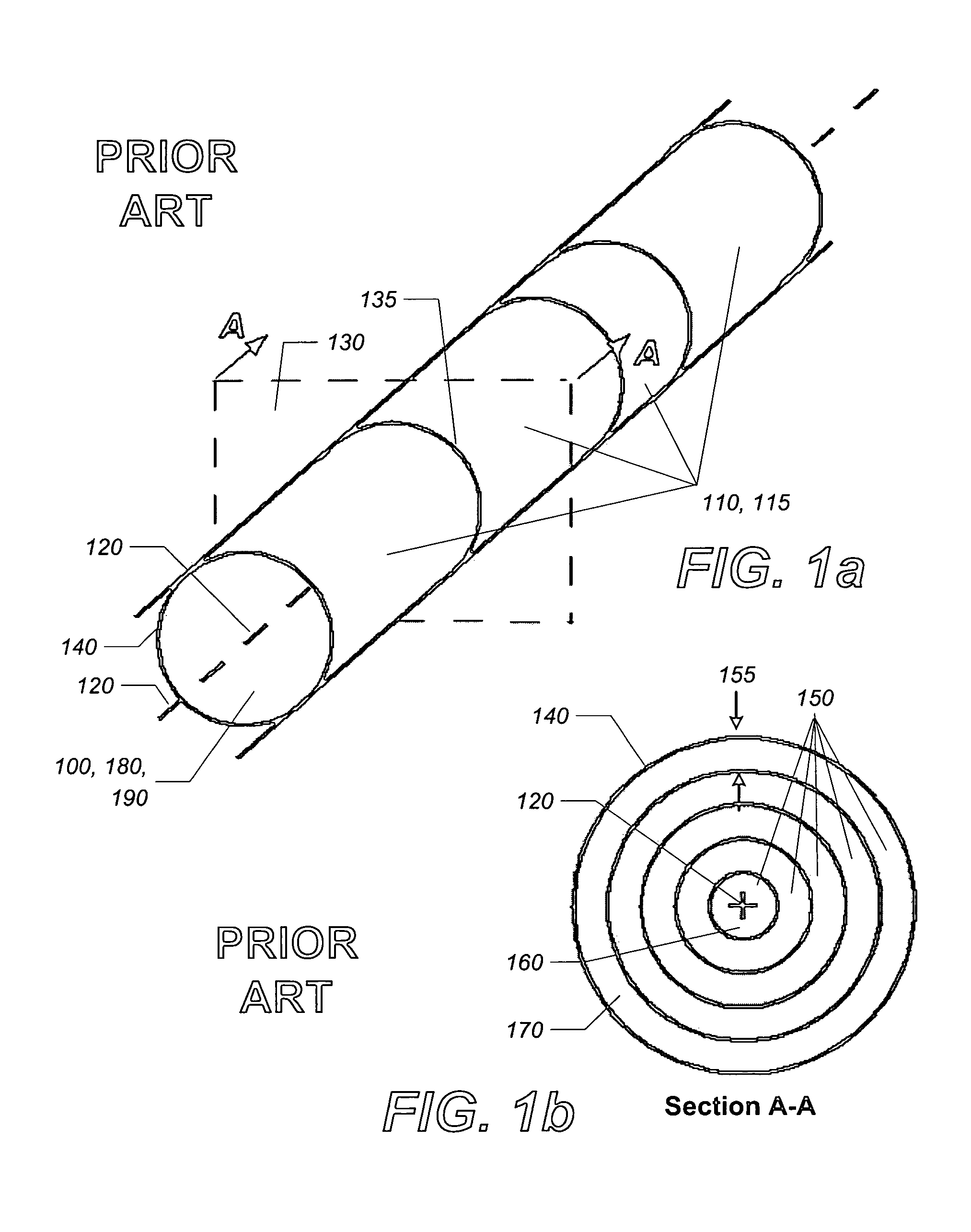

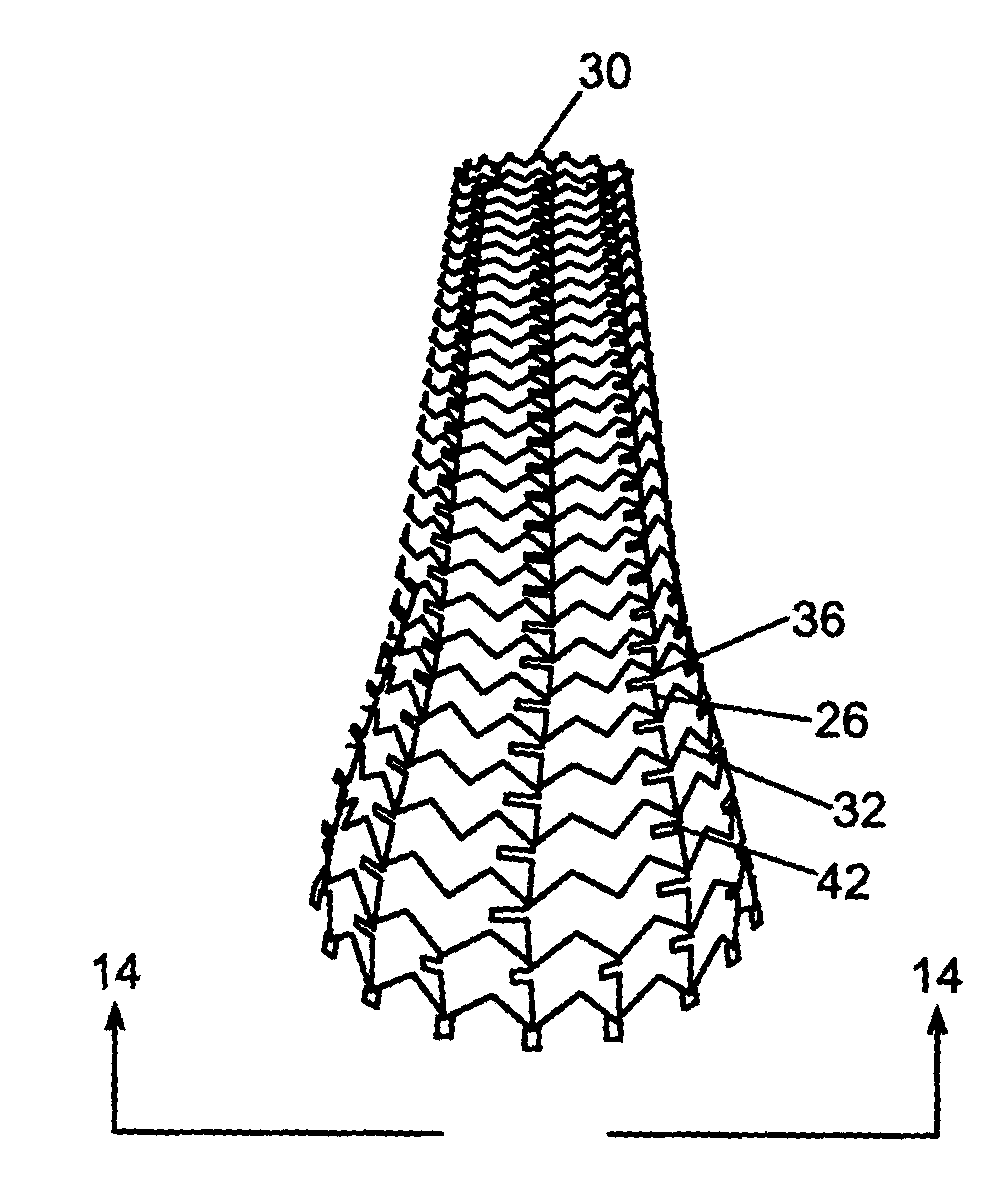

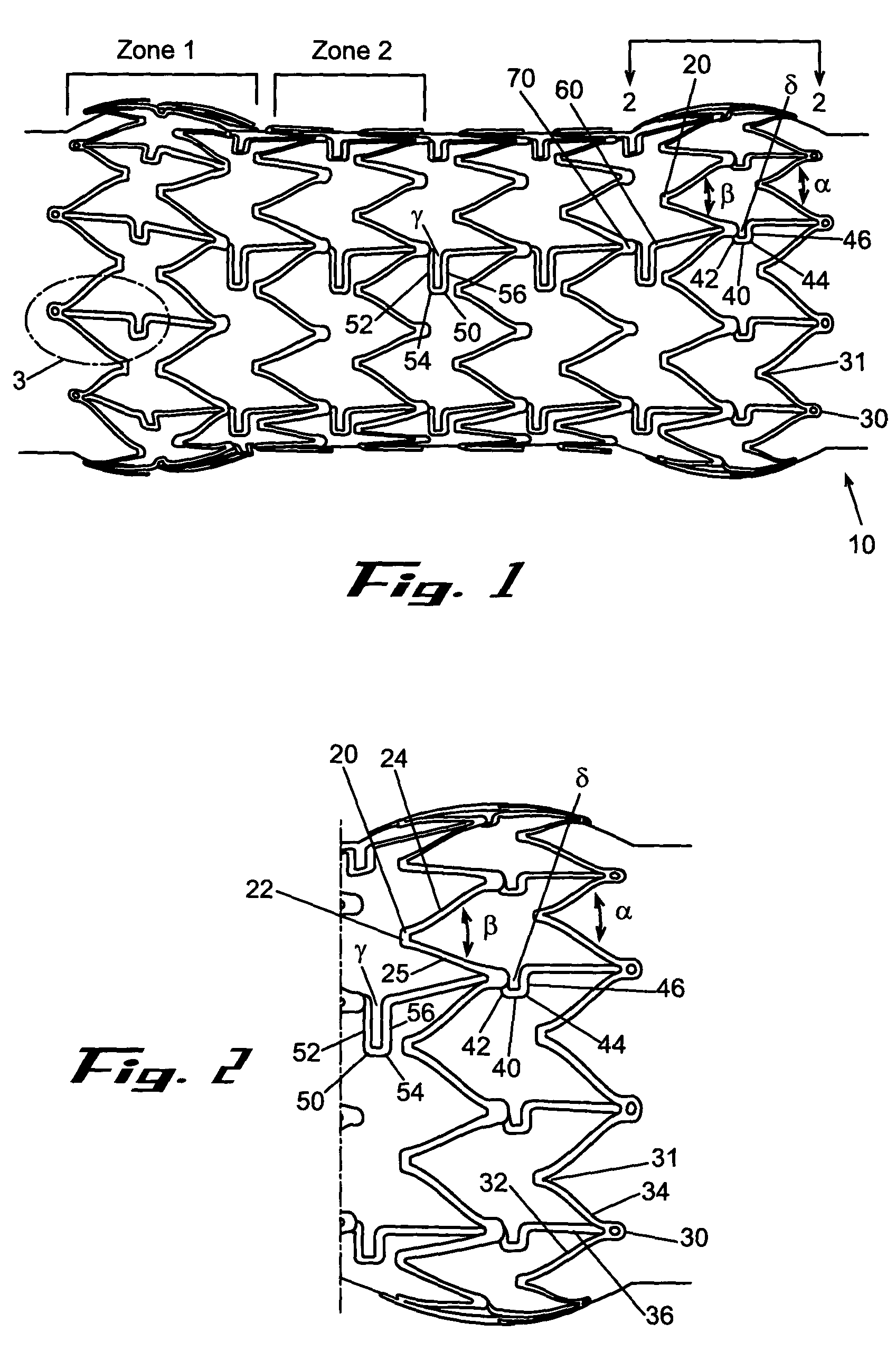

Removable biliary stent

The present invention, in an exemplary embodiment, provides a stent, which combines many of the excellent characteristics of both silicone and metal stents while eliminating the undesirable ones. In particular, a principal objective in accordance with the present invention is to provide a family of stents generally and a biliary stent in particular where the relative hardness / softness of regions of the stent can differ from other regions of the stent to provide additional patient comfort and resistance to radial forces. An exemplary embodiment also provides a family of stents with novel interstice configurations that facilitate flexibility, durability and / or proper installation. Additionally, the biliary stent in accordance with the present invention provides enhanced flow mechanics to ensure the adequate clearance of viscid fluids such as bile.

Owner:MERIT MEDICAL SYST INC

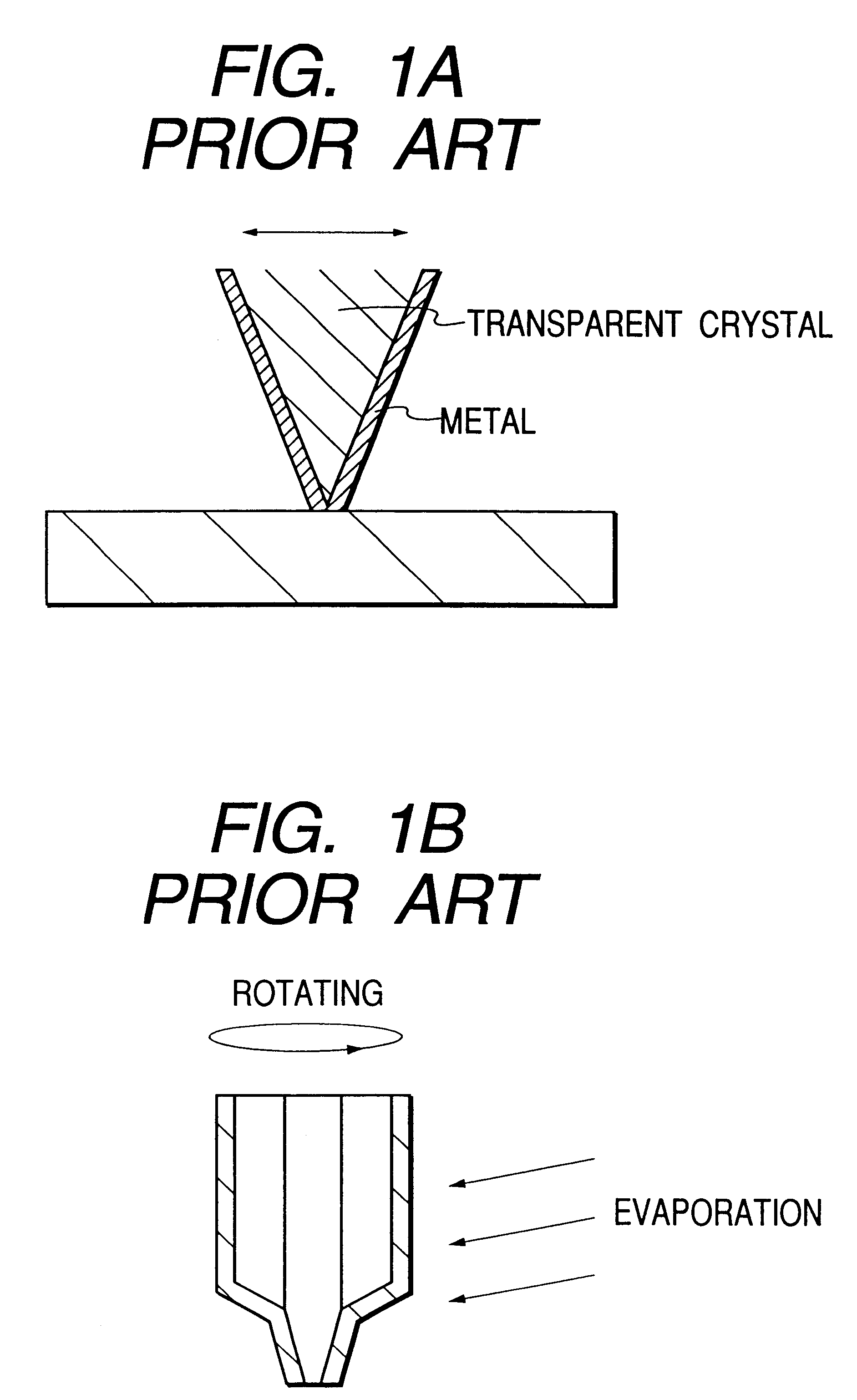

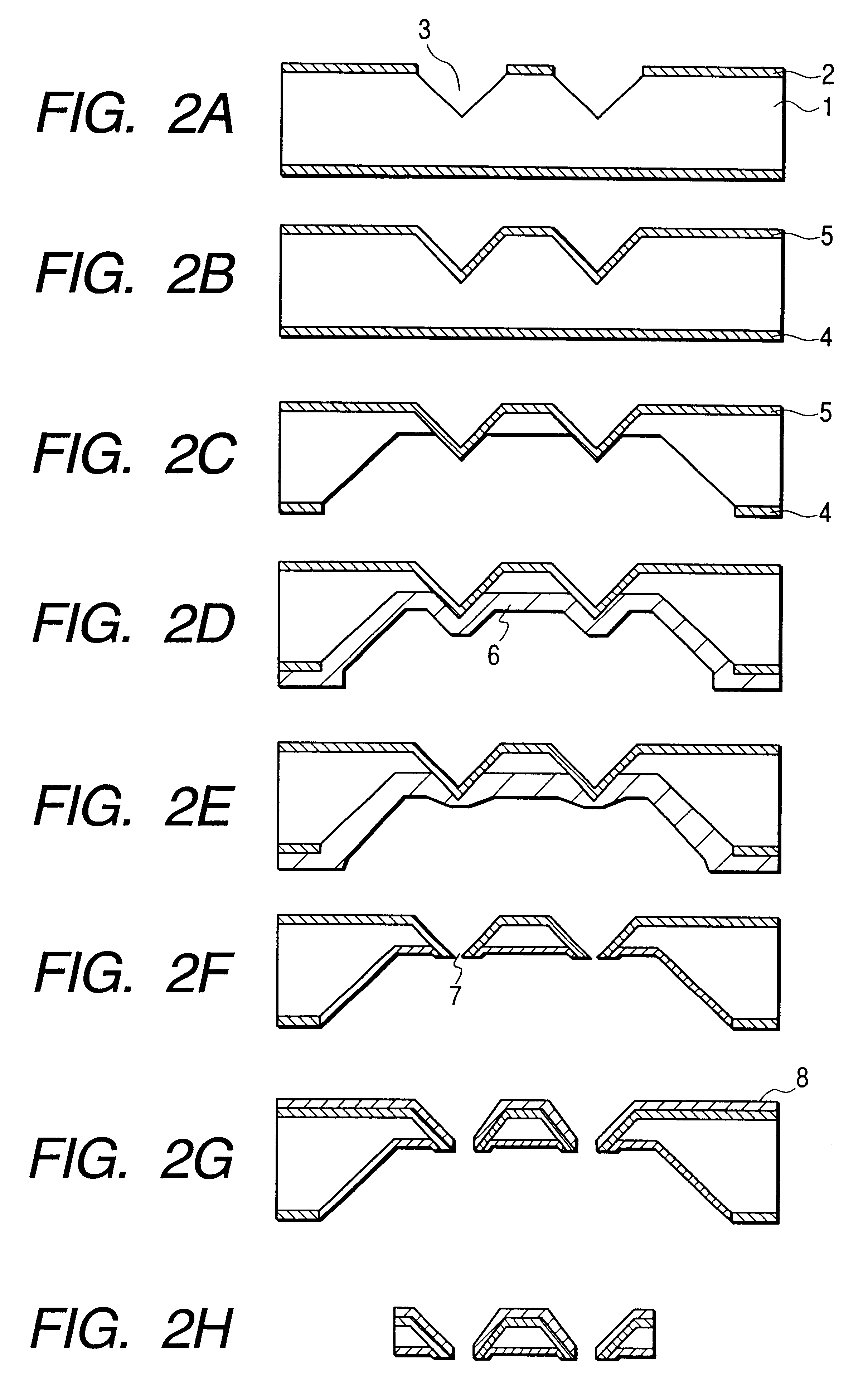

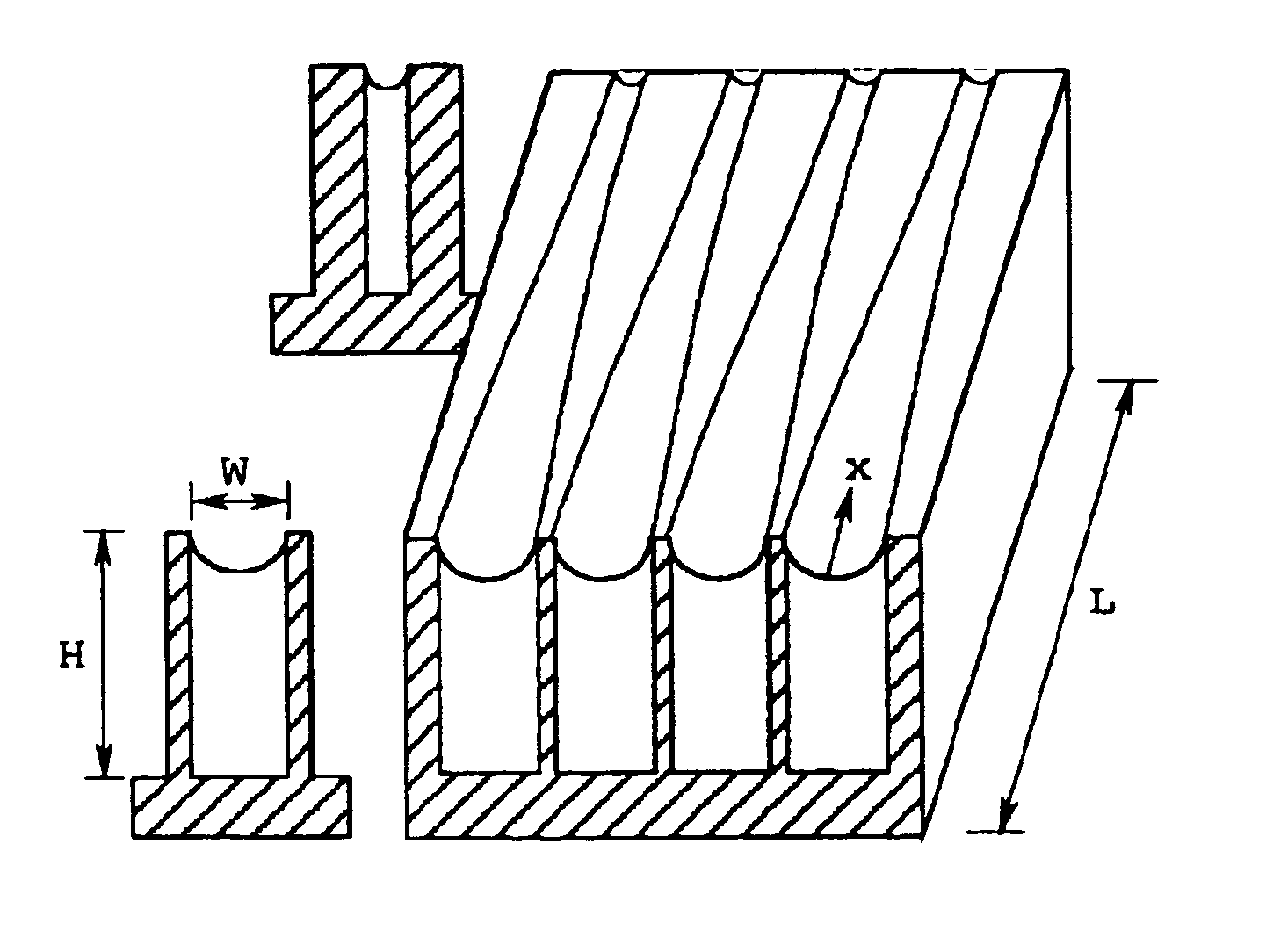

Projection having a micro-aperture, probe or multi-probe having such a projection and surface scanner, aligner or information processor comprising such a probe

InactiveUS6376833B2Decorative surface effectsMaterial analysis by optical meansSilicate glassPlastic materials

Owner:CANON KK

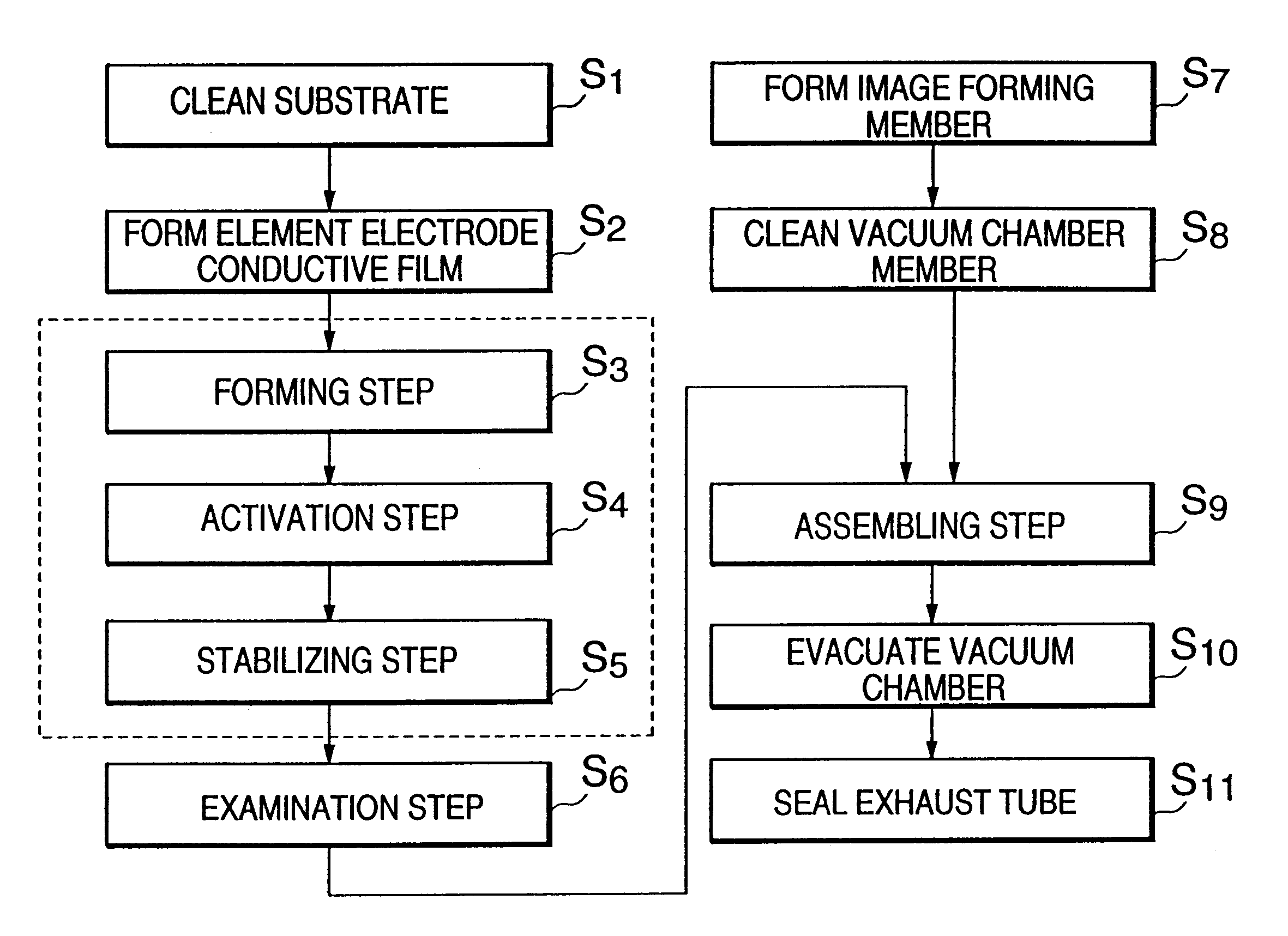

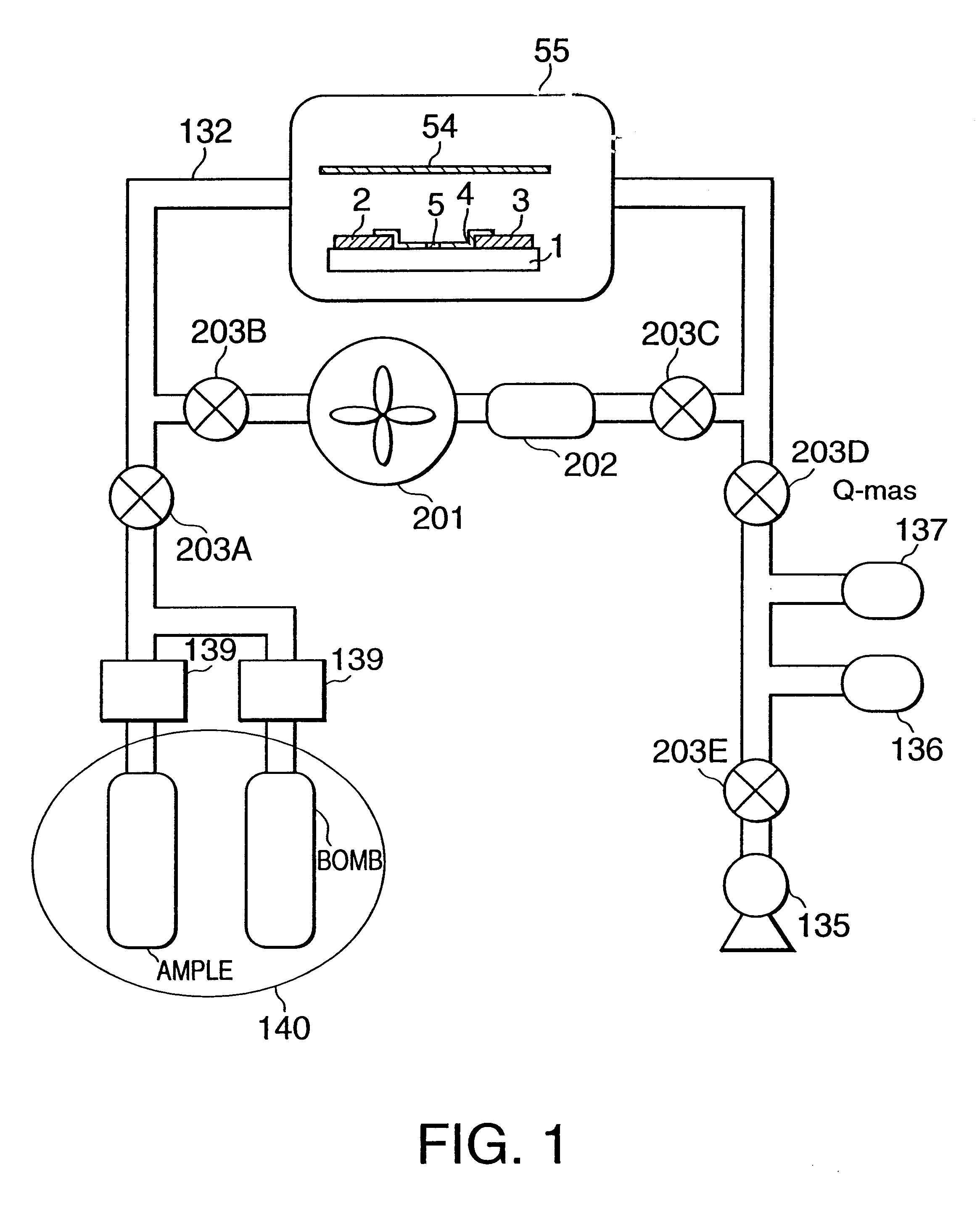

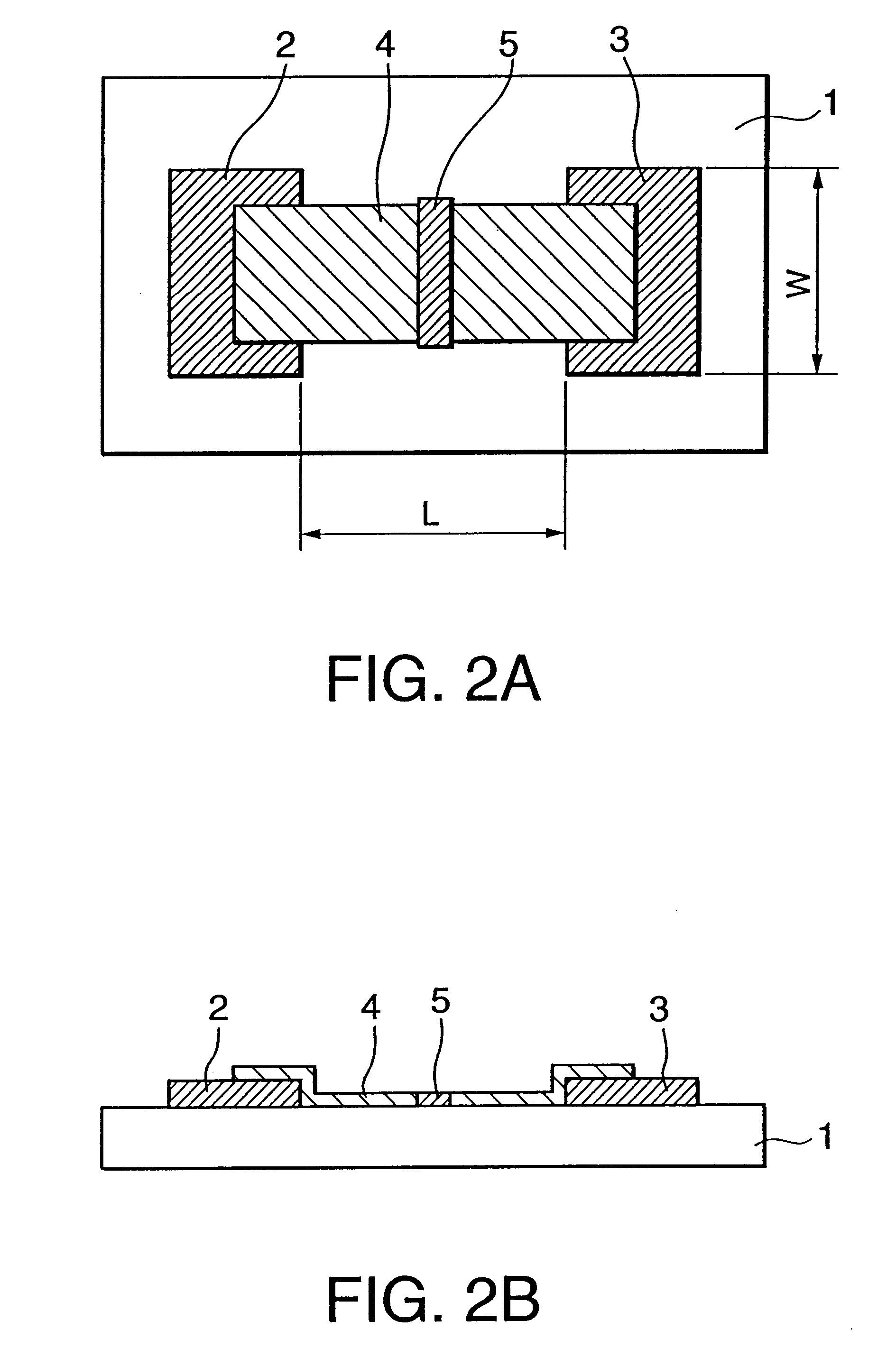

Electron source manufacturing method, and image forming apparatus method

A method of manufacturing an electron source with electron emitting elements is provided. The method has a process of depositing a deposit substance in an area including at least an area of the electron emitting element from which area electrons are emitted. The depositing process is performed in an atmosphere of a gas containing at least a source material of the deposit substance, the gas having a mean free path allowing the gas to take a viscous flow state.

Owner:CANON KK

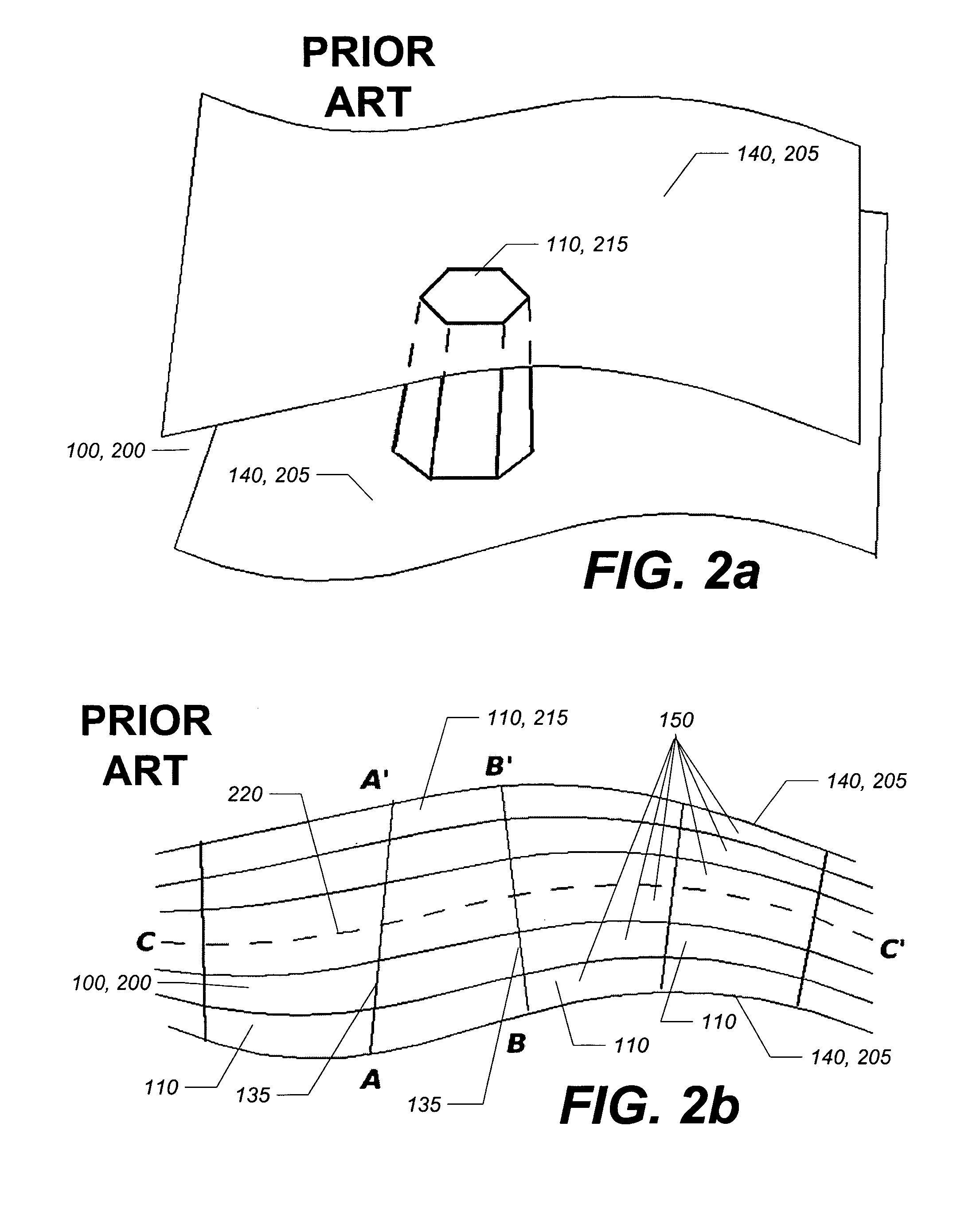

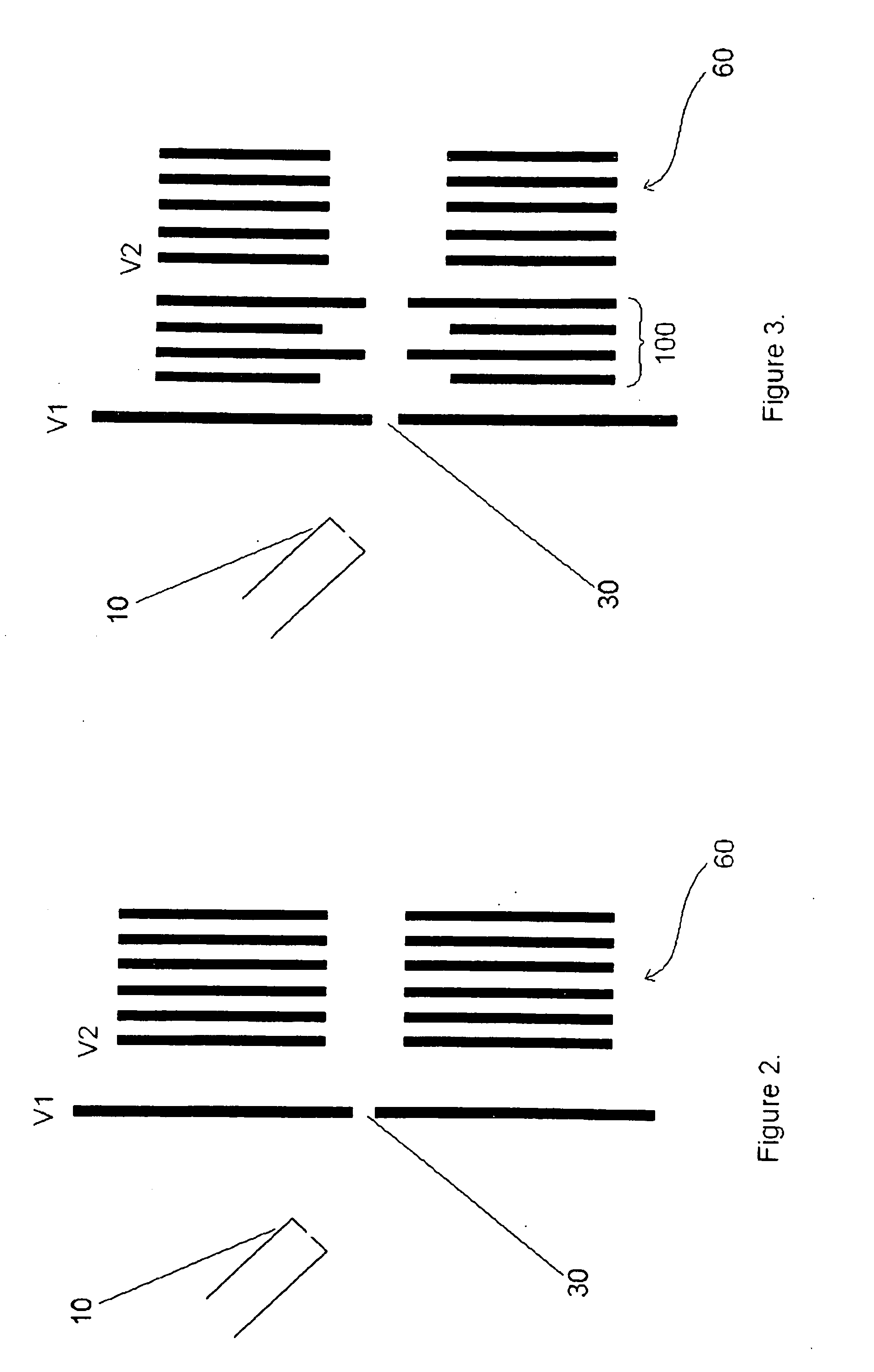

Axially tapered and bilayer microchannels for evaporative coolling devices

The invention consists of an evaporative cooling device comprising one or more microchannels whose cross section is axially reduced to control the maximum capillary pressure differential between liquid and vapor phases. In one embodiment, the evaporation channels have a rectangular cross section that is reduced in width along a flow path. In another embodiment, channels of fixed width are patterned with an array of microfabricated post-like features such that the feature size and spacing are gradually reduced along the flow path. Other embodiments incorporate bilayer channels consisting of an upper cover plate having a pattern of slots or holes of axially decreasing size and a lower fluid flow layer having channel widths substantially greater than the characteristic microscale dimensions of the patterned cover plate. The small dimensions of the cover plate holes afford large capillary pressure differentials while the larger dimensions of the lower region reduce viscous flow resistance.

Owner:SANDIA NAT LAB

Humic mineral reagent and method for the production thereof, method for rehabilitating polluted soils, method for detoxification of wastes of extracted and processed mineral products and recultivating rock dumps and tailing storages, method for sewage water treatment and method for sludge utilisation

InactiveUS7204660B2Significant to useAvoid problemsSludge treatment by de-watering/drying/thickeningOrganic chemistrySludgeMoisture

The humic-mineral agent from naturally occurring carbon-series humites and caustobioliths comprises humic acids and salts thereof, naturally hydrated humic acids, hydrolyzed humic acids, hydrated and hydrolyzed humic-mineral and mineral complexes of parent carbon-series humites and caustobioliths chemically bound to the naturally hydrated humic acids. The method for preparing a humic-mineral agent comprises crushing and disintegrating of carbon-series humites and caustobioliths and mixing them with an alkali. The carbon-series humites and caustobioliths are crushed and disintegrated when their moisture content is close to the natural level at which humic acids are in a naturally hydrated state, hot water is added to the. Next an alkali is added thereto and the mixture is hydrolyzed till obtaining the end product having consistency from viscous-flow to plastic and the pH value of from 6.5 to 8. The method for detoxication of polluted soil. The method for detoxication of waste products of mining and processing useful minerals and for reclaiming waste piles and tailing pits, the method for sewage water treatment and the method for salvaging sewage sediment are carried into effect by using the humic-mineral agent mentioned before.

Owner:SHULGIN ALEXANDER IVANOVICH +1

Method for preparing flexible biodegradable polytrimethylene carbonate composite film

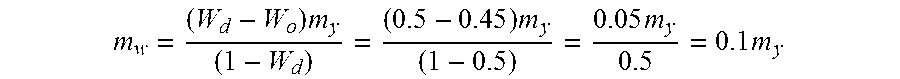

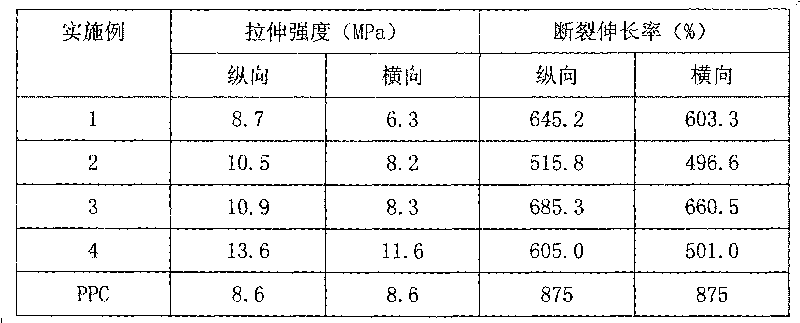

ActiveCN101717567AImprove brittlenessImprove low temperature viscous flow problemComposite filmPolymer science

The invention discloses a flexible biodegradable polytrimethylene carbonate composite film and a preparation method thereof. The composite film is formed by blowing a film after melting and mixing polytrimethylene carbonate, thermoplastic polyurethane elastomers, a bulking agent, antioxygen, a heat resistant stabilizing agent, a slipping agent, an antiblocking agent, a filling agent, a biodegradation accelerating agent and a light decomposition agent. In the invention, PPC and elastomers TPU are effectively compounded, thereby solving the problems of brittleness and low-temperature viscous flow of materials; the processing temperature of unsealed PPC is expanded to 170 DEG C, and the thermal degradation temperature is improved to 210 DEG C. Meanwhile, the composite film has good mechanical property and film blowing stability, can be applied to the fields of soft film materials, such as disposable shopping bags, land films, preservative films, and the like, and opens a new approach for the popularization and the application of PPC.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Ion Transfer Arrangement with Spatially Alternating DC and Viscous Ion Flow

ActiveUS20100038533A1Reduce gas flowWeaken energyBeam/ray focussing/reflecting arrangementsElectron/ion optical arrangementsViscous flowElectrical polarity

A method of transporting gas and entrained ions between higher and lower pressure regions of a mass spectrometer comprises providing an ion transfer conduit 60 between the higher and lower pressure regions. The ion transfer conduit 60 includes an electrode assembly 300 which defines an ion transfer channel. The electrode assembly 300 has a first set of ring electrodes 305 of a first width D1, and a second set of ring electrodes of a second width D2 (≧D1) and interleaved with the first ring electrodes 305. A DC voltage of magnitude V1 and a first polarity is supplied to the first ring electrodes 205 and a DC voltage of magnitude V2 which may be less than or equal to the magnitude of V1 but with an opposed polarity is applied to the second ring electrodes 310. The pressure of the ion transfer conduit 60 is controlled so as to maintain viscous flow of gas and ions within the ion transfer channel.

Owner:THERMO FISHER SCI BREMEN

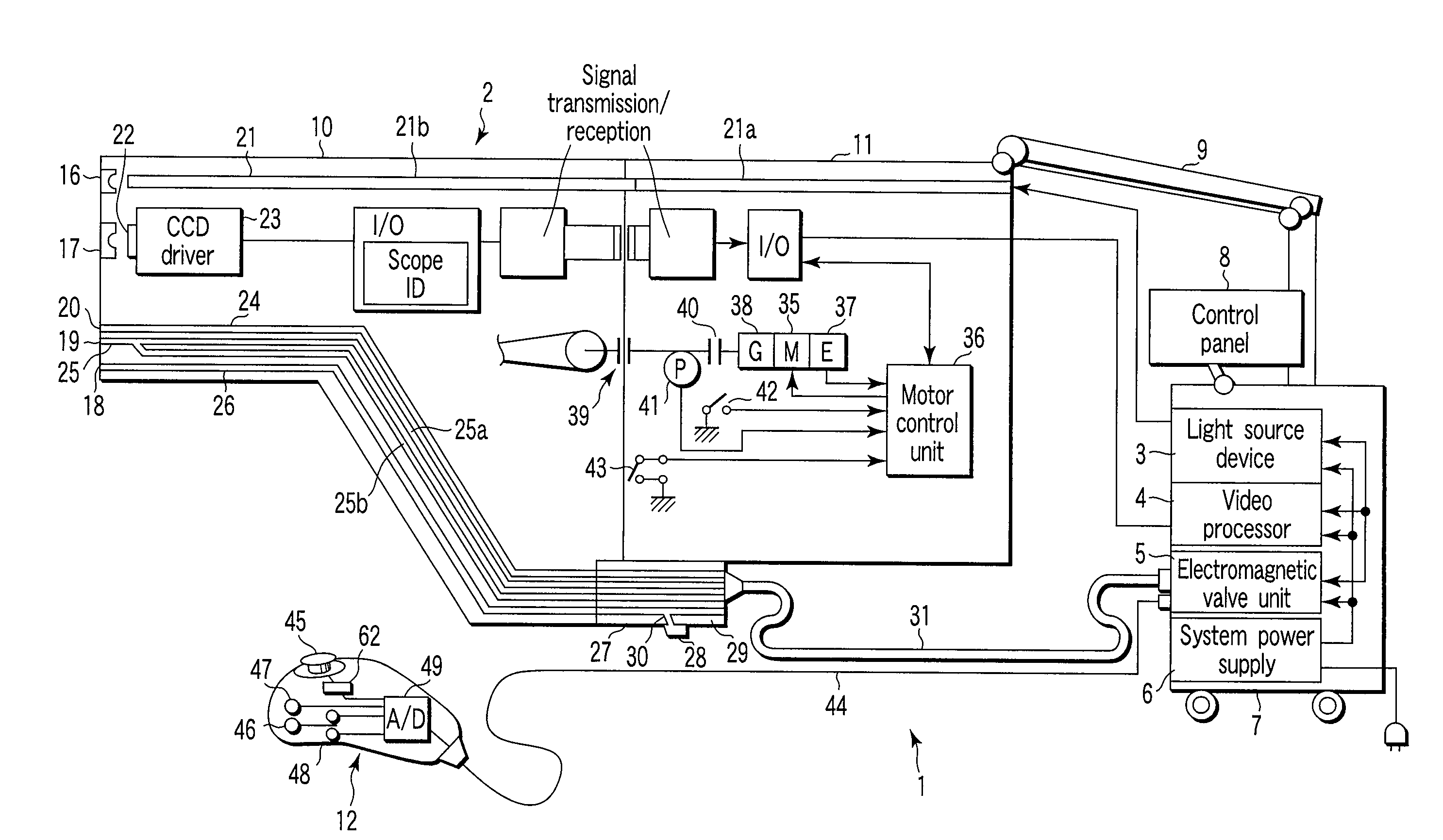

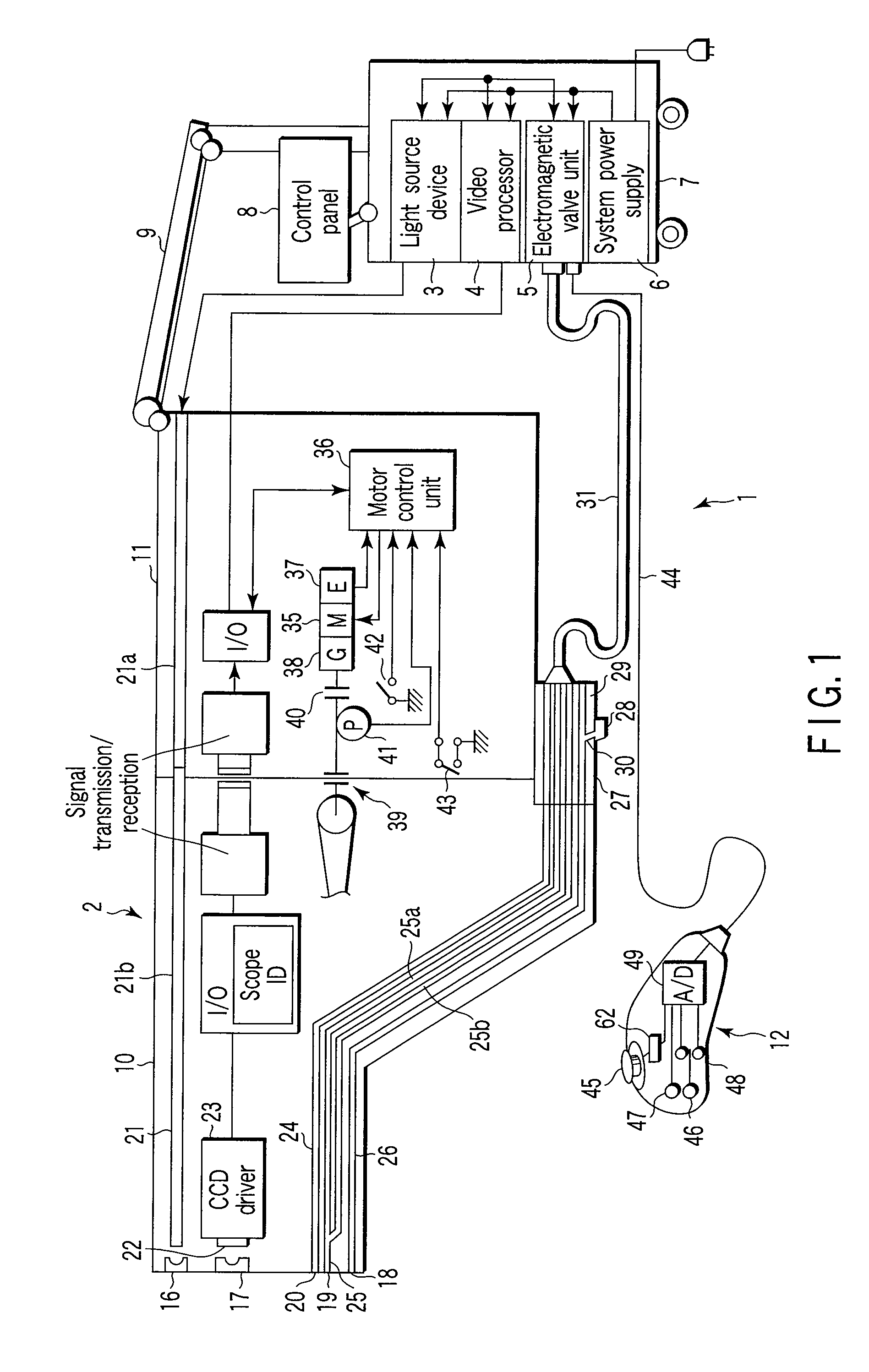

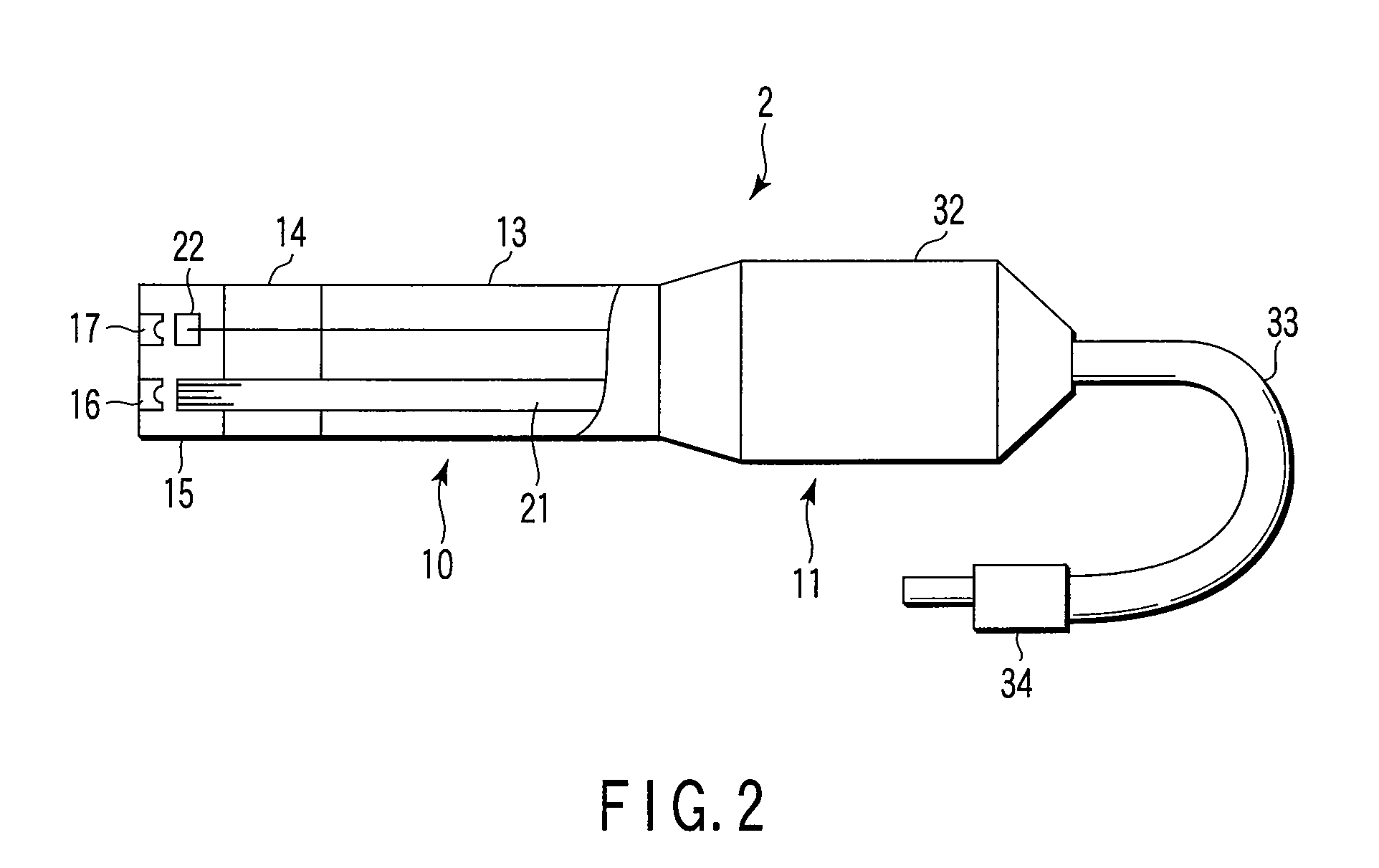

Operation device and bending operation device of endoscope

ActiveUS20080275303A1Avoid it happening againManual control with multiple controlled membersMechanical apparatusEndoscopic operationsControl engineering

In the present invention, there are provided a movement member which includes an engaging section, which is engaged with an intermediate part of an operation shaft of a joystick device, and operates as one body with the operation shaft at a time of performing an inclining operation of the operation shaft, and a damper case in which the movement member is movably inserted, and which holds a viscous fluid which increases a sliding resistance of the movement member when the movement member is moved. Thereby, a desired operational sensation can be always obtained, and a stable bending operation can be performed.

Owner:OLYMPUS CORP

Sound absorbent

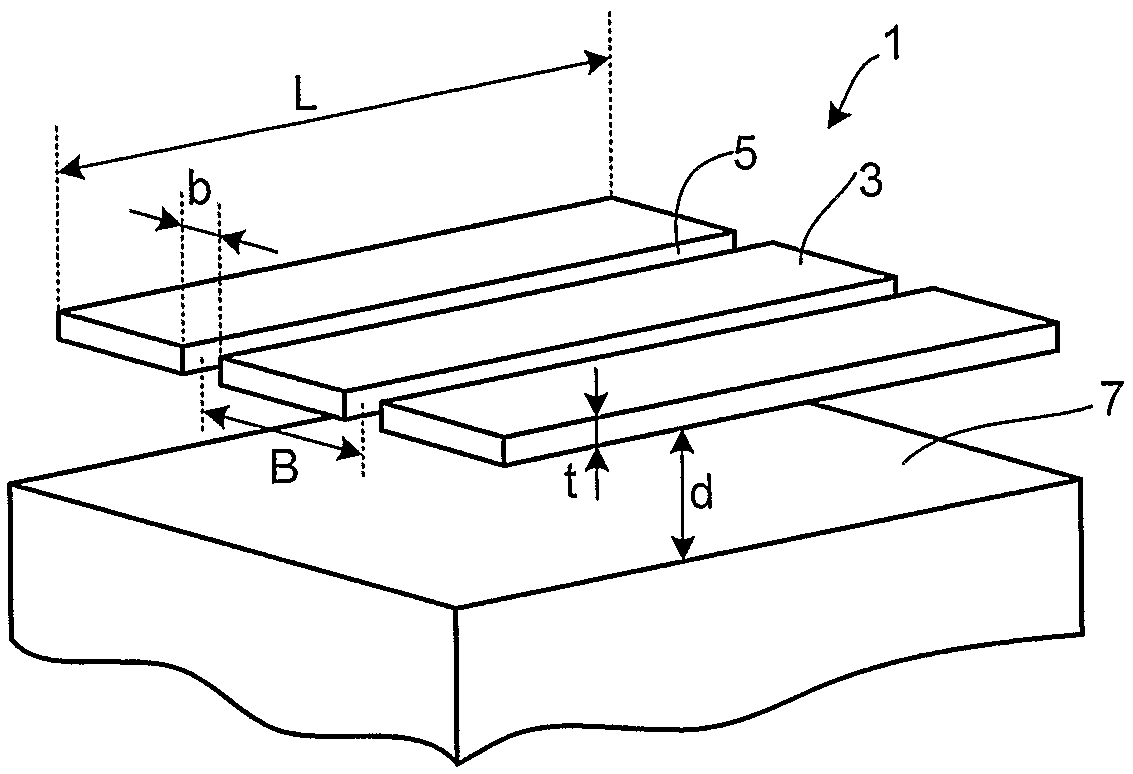

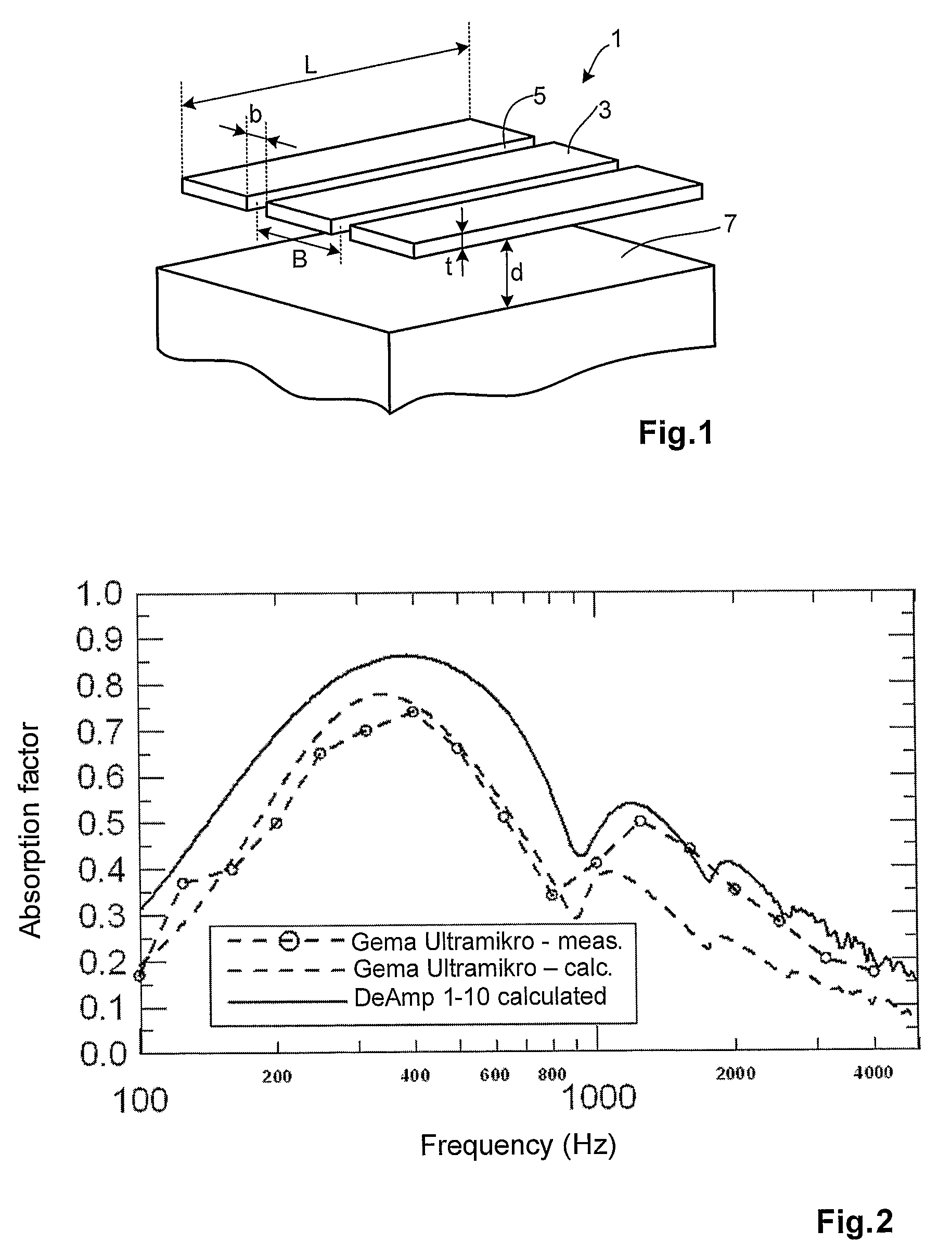

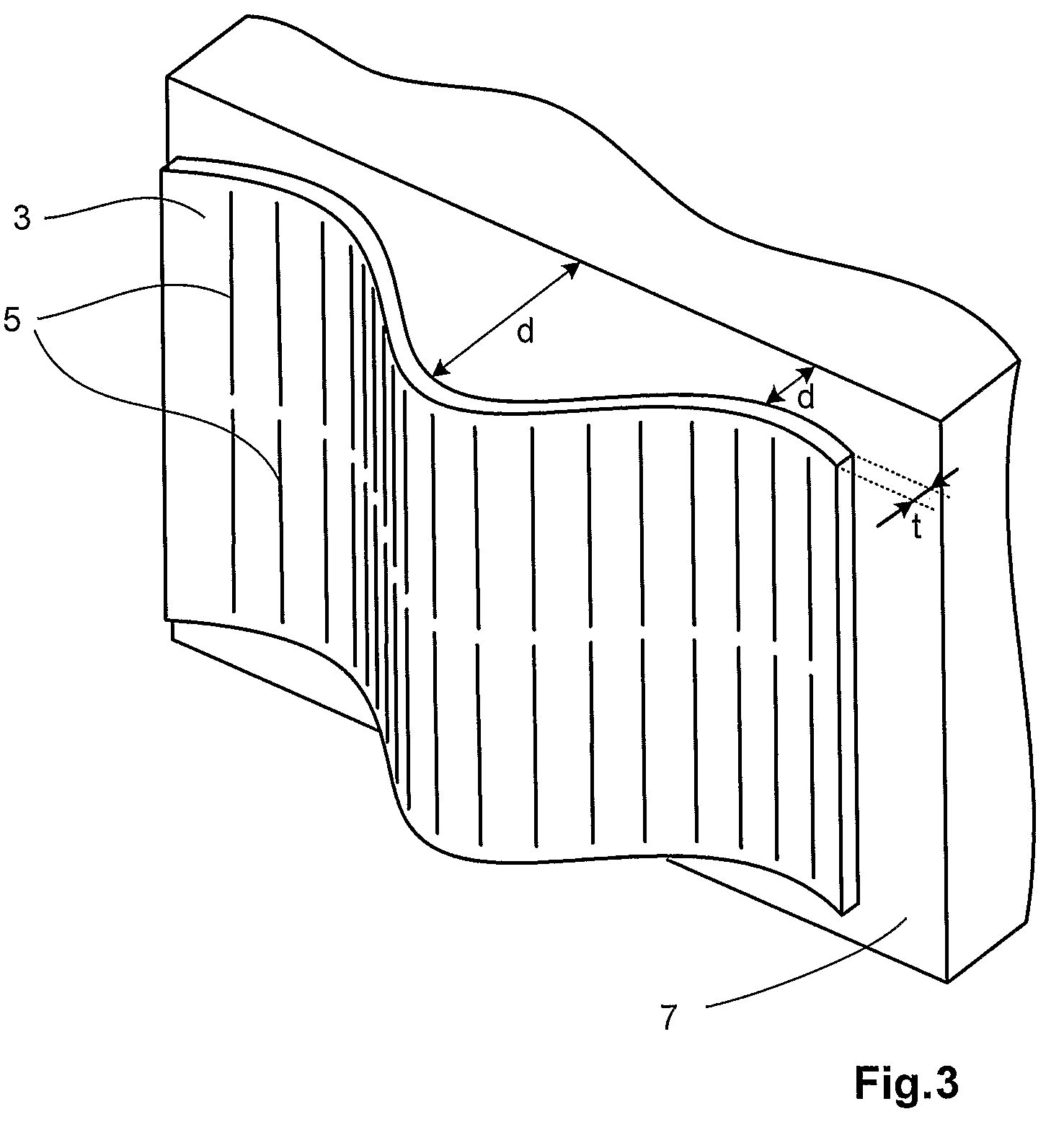

ActiveUS7677359B2Less-costly to produceImprove featuresCovering/liningsSound proofingViscous flowEngineering

Sound absorbent (1) of a hard material, such as metal, glass, hard plastic or composites thereof, for absorption of acoustic waves by friction of viscous flow, essentially in the frequency range between 100 and 4000 Hz. The sound absorbent (1) comprises a panel element (3) with microslits (5) therethrough, said microslits (5) having a minimum slit width (b) of less than 0.45 mm. When in use, the panel element (3) is arranged with a distance to a rear surface.

Owner:DEAMP AS

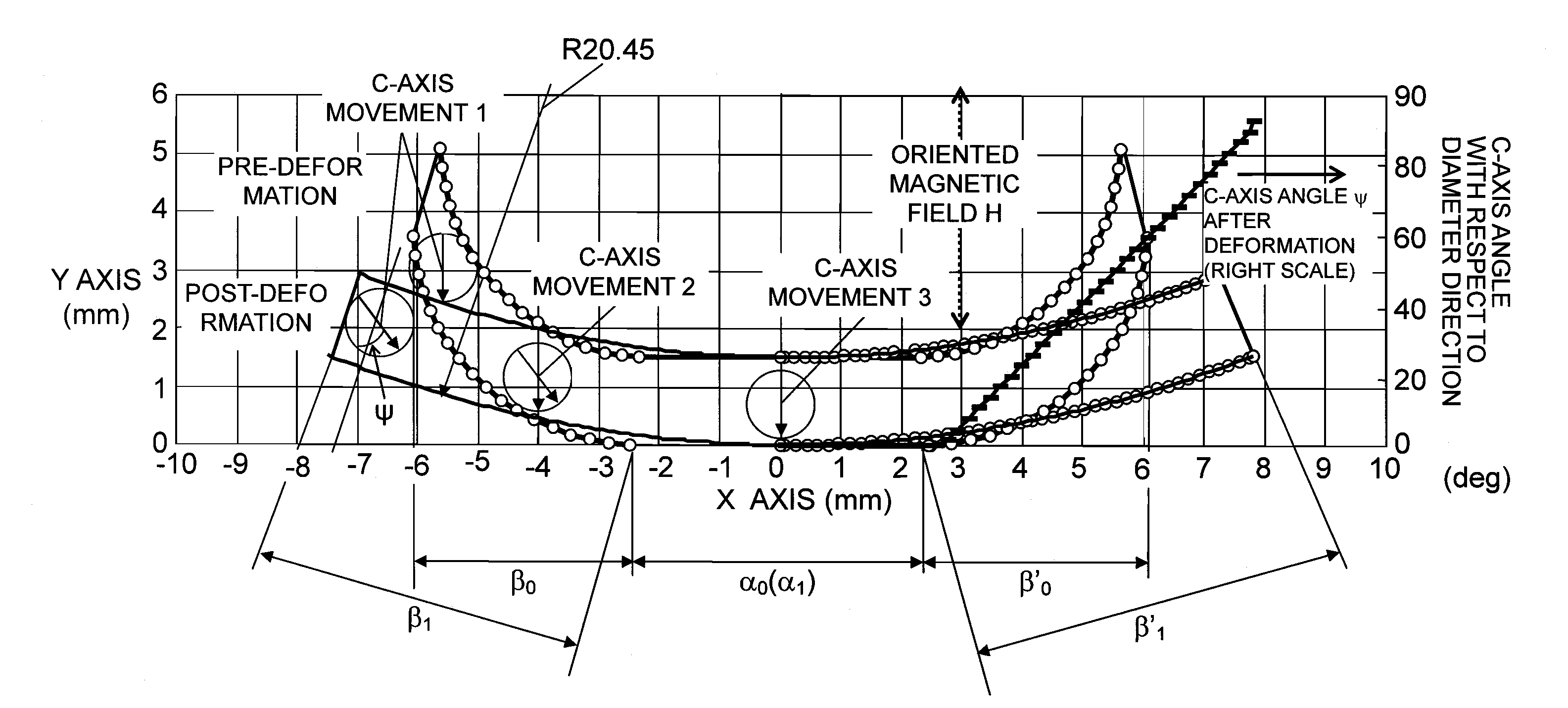

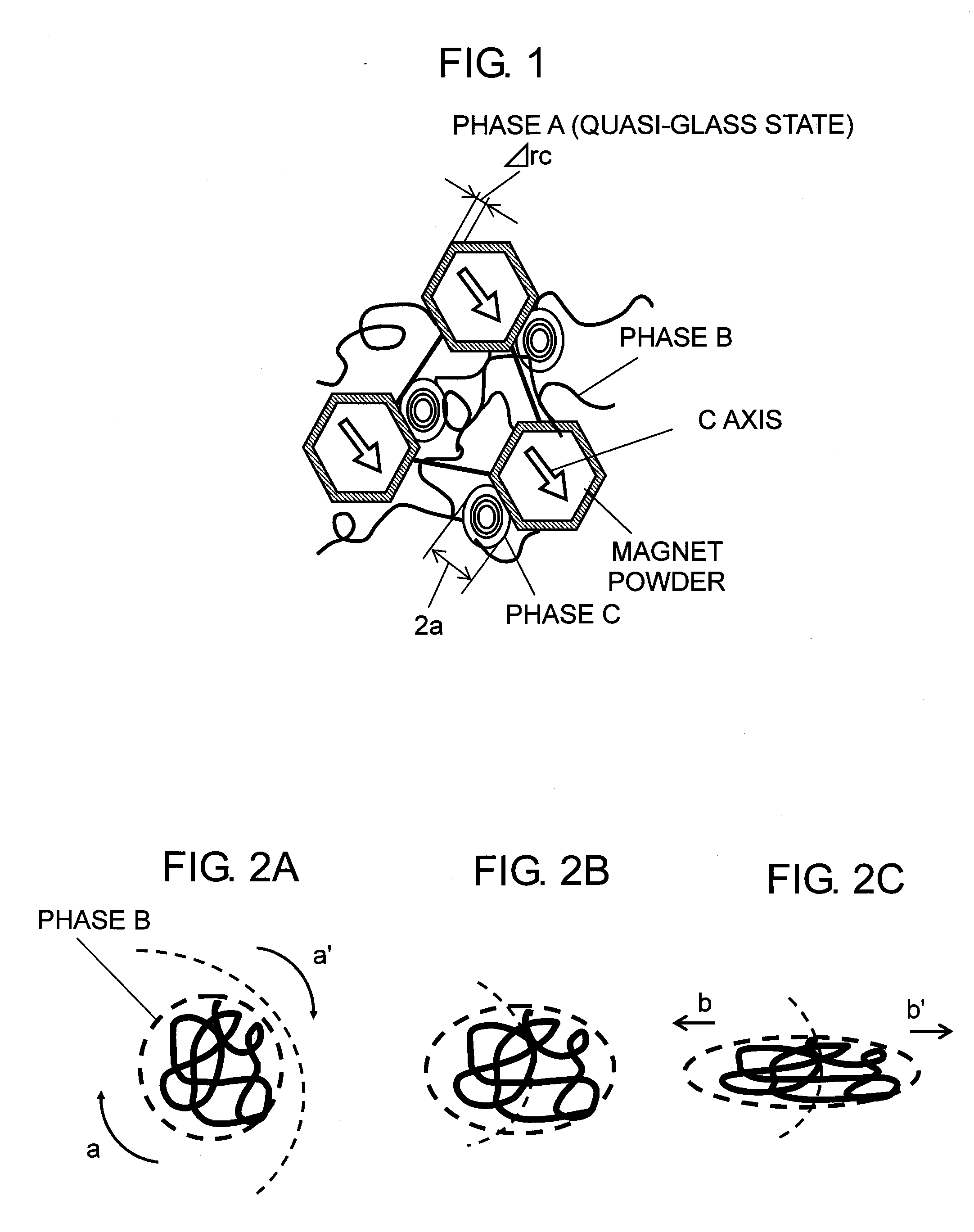

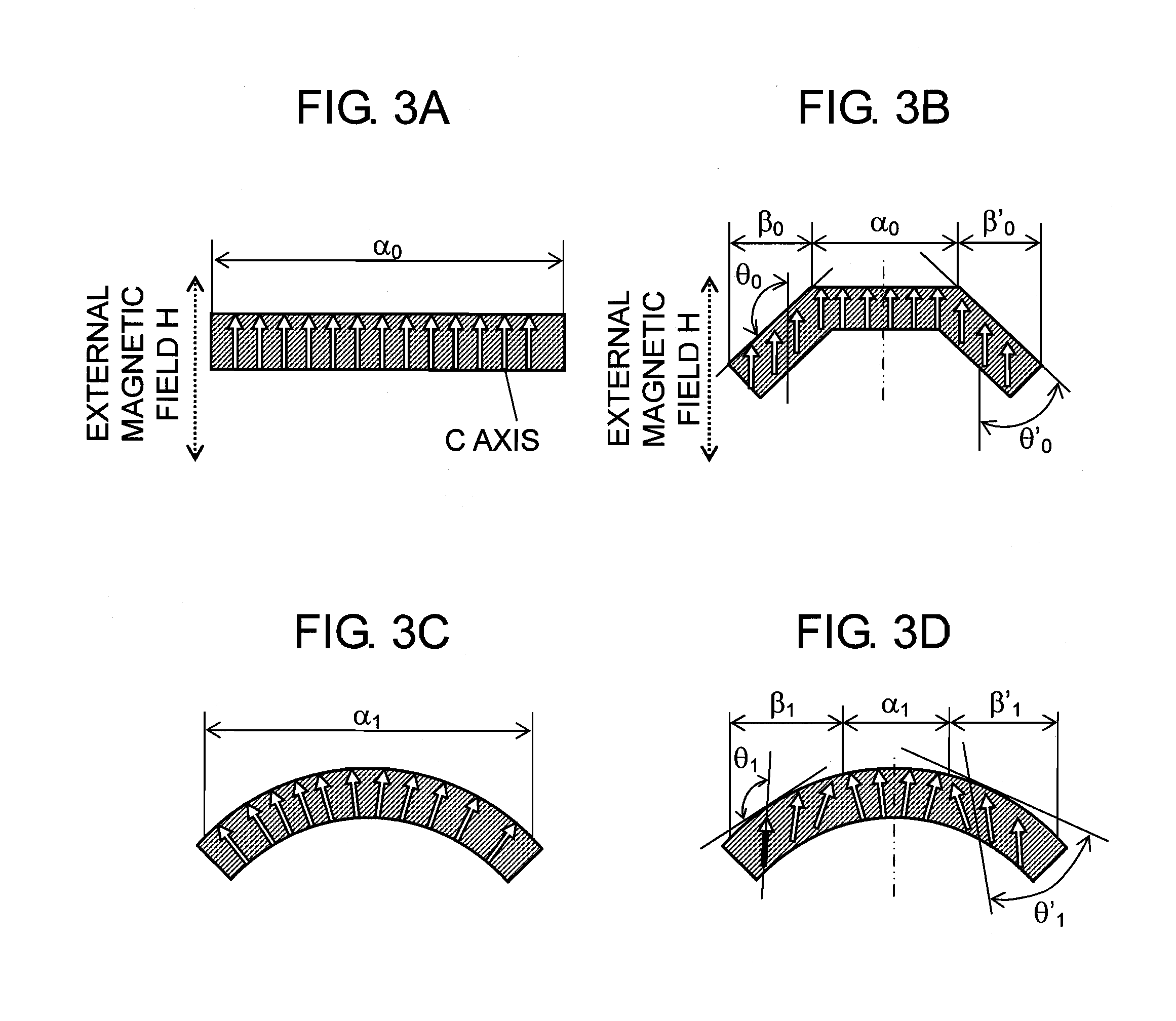

Radial Anisotropic Magnet Manufacturing Method, Permanent Magnet Motor Using Radial Anisotropic Magnet, and Iron Core-Equipped Permanent Magnet Motor

ActiveUS20090007417A1Small sizeIncrease productionMagnetic circuit rotating partsPermanent magnetsMagnetic anisotropyMagnetic poles

In order to improve tranquility and controllability of an iron core-equipped permanent magnet motor with an improvement of a maximum energy product (BH)max by improving a shape compatibility of a radial anisotropic magnet, there is provided a radial anisotropic magnet manufacturing method of fixing magnet powder in a net shape so as to maintain a magnetic anisotropic (C-axis) angle of a magnet with respect to a tangential line and for performing a deformation with a flow so as to have a predetermined circular arc shape or a predetermined annular shape. Particularly, by performing a deformation with a viscous flow or an extension flow, a deformability of the magnet is improved, and thus a shape compatibility with respect to a thickness is improved. AC-axis angle θ with respect to a tangential direction is controlled at an arbitrary position and an arbitrary angle so as to reduce cogging torque without separating a magnetic pole into segments.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com