Patents

Literature

36 results about "Hyper elastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

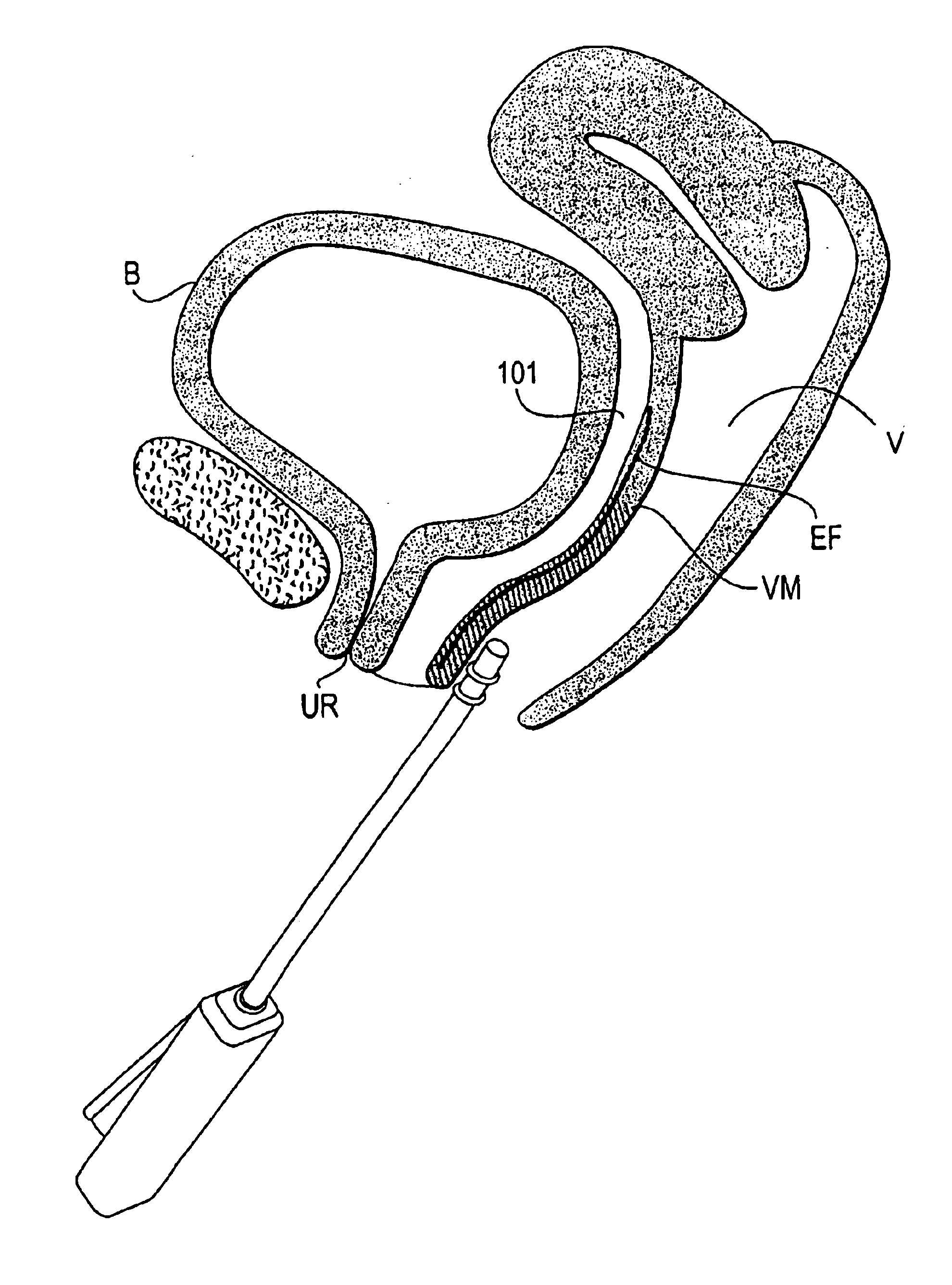

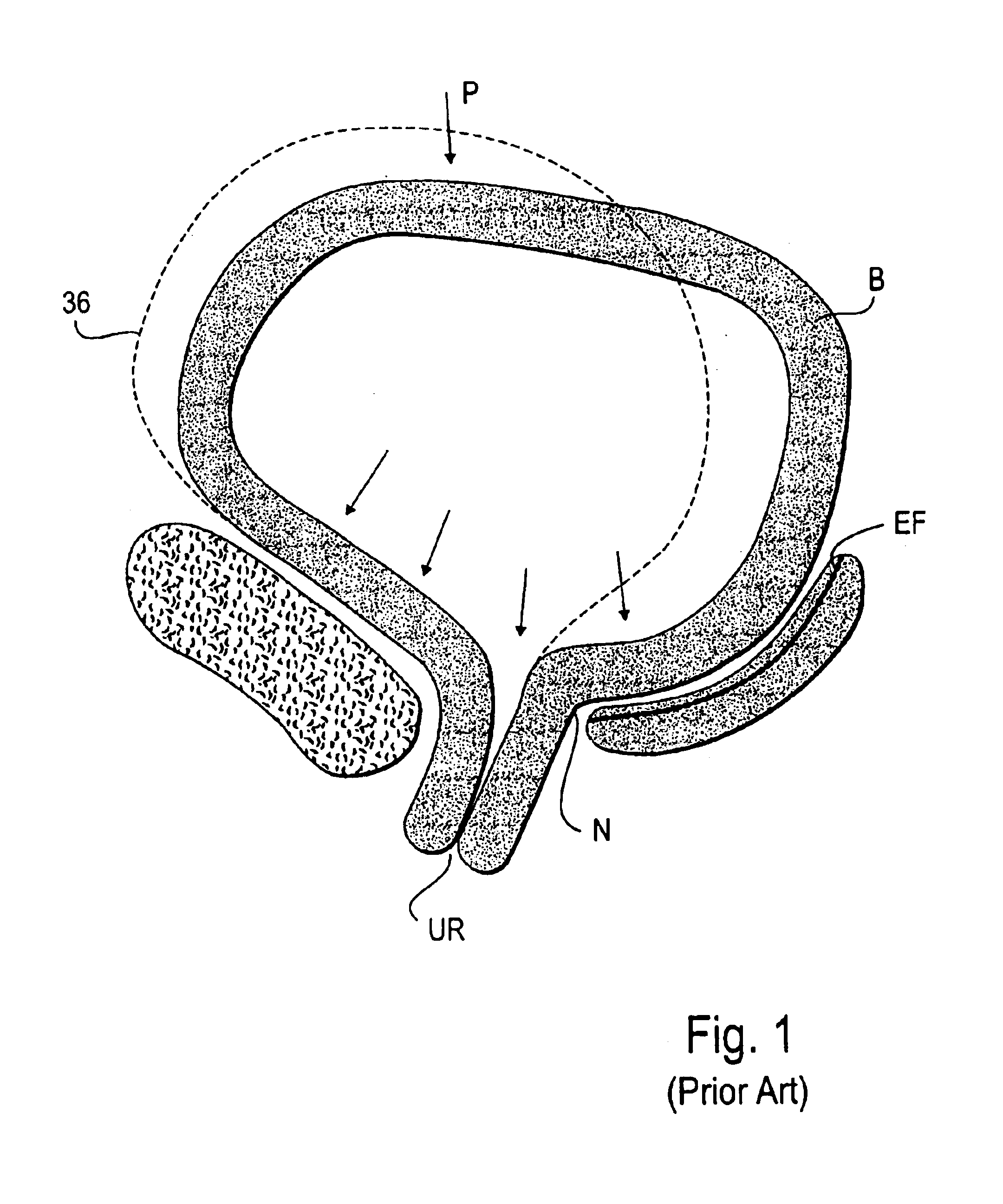

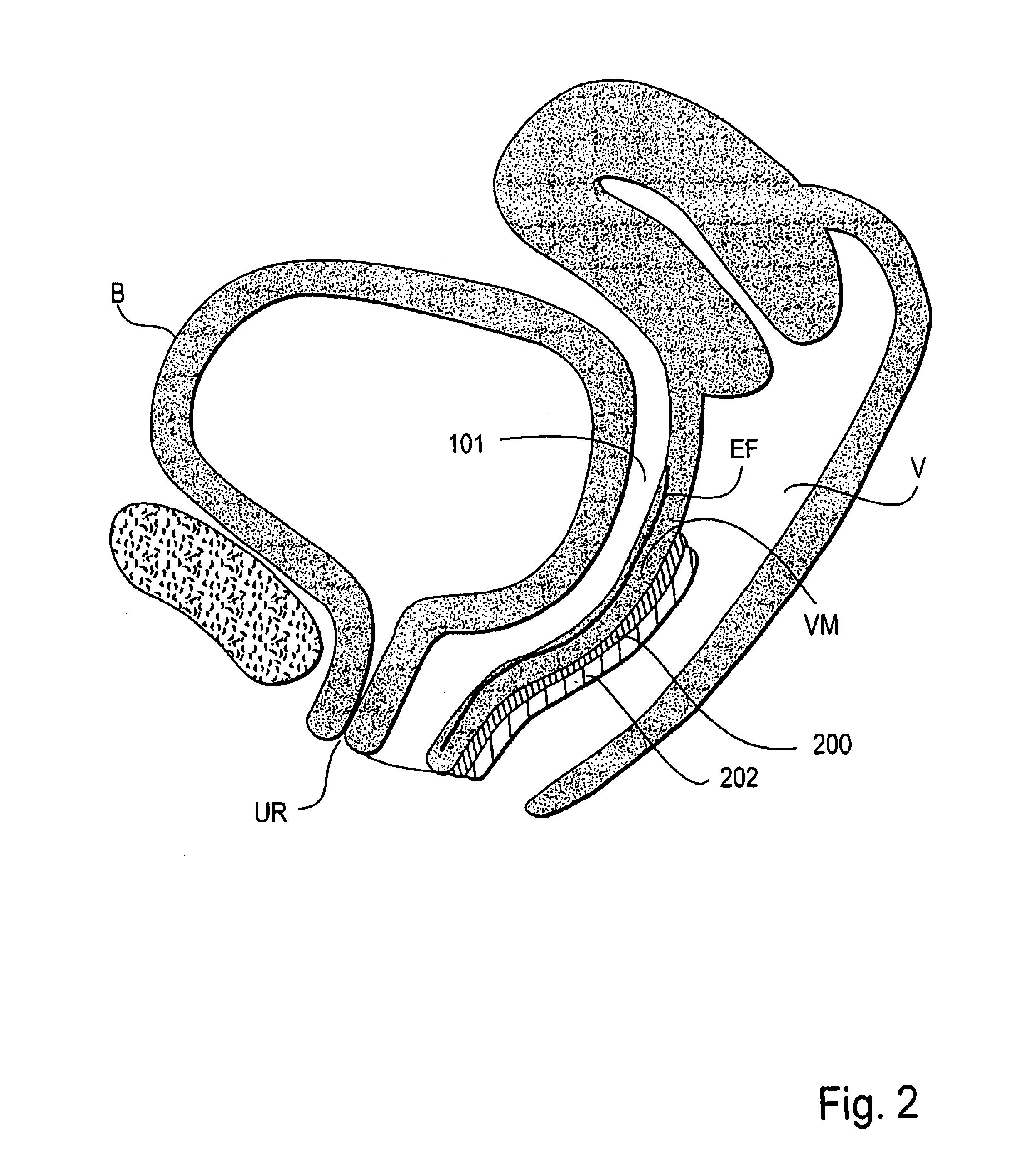

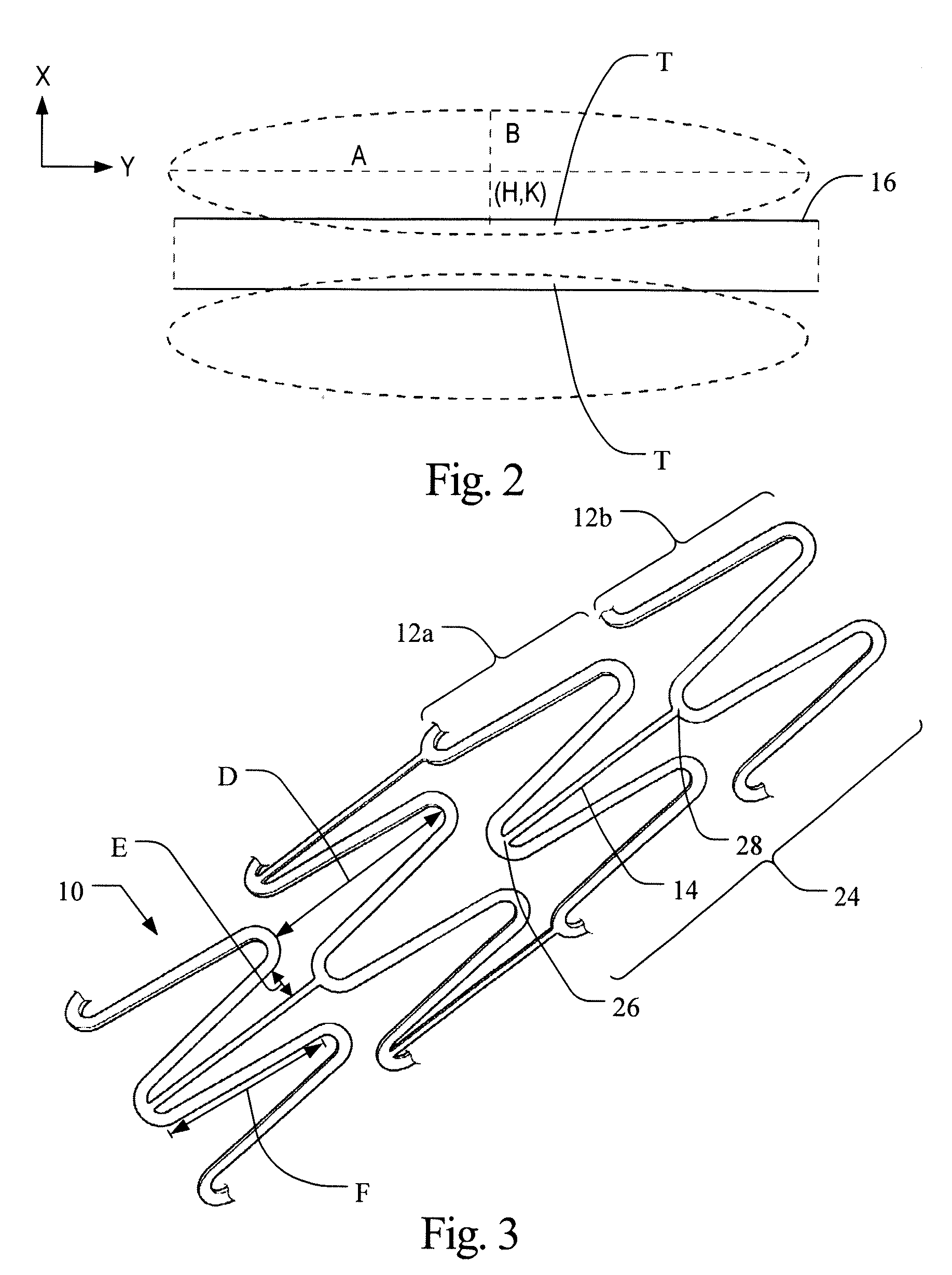

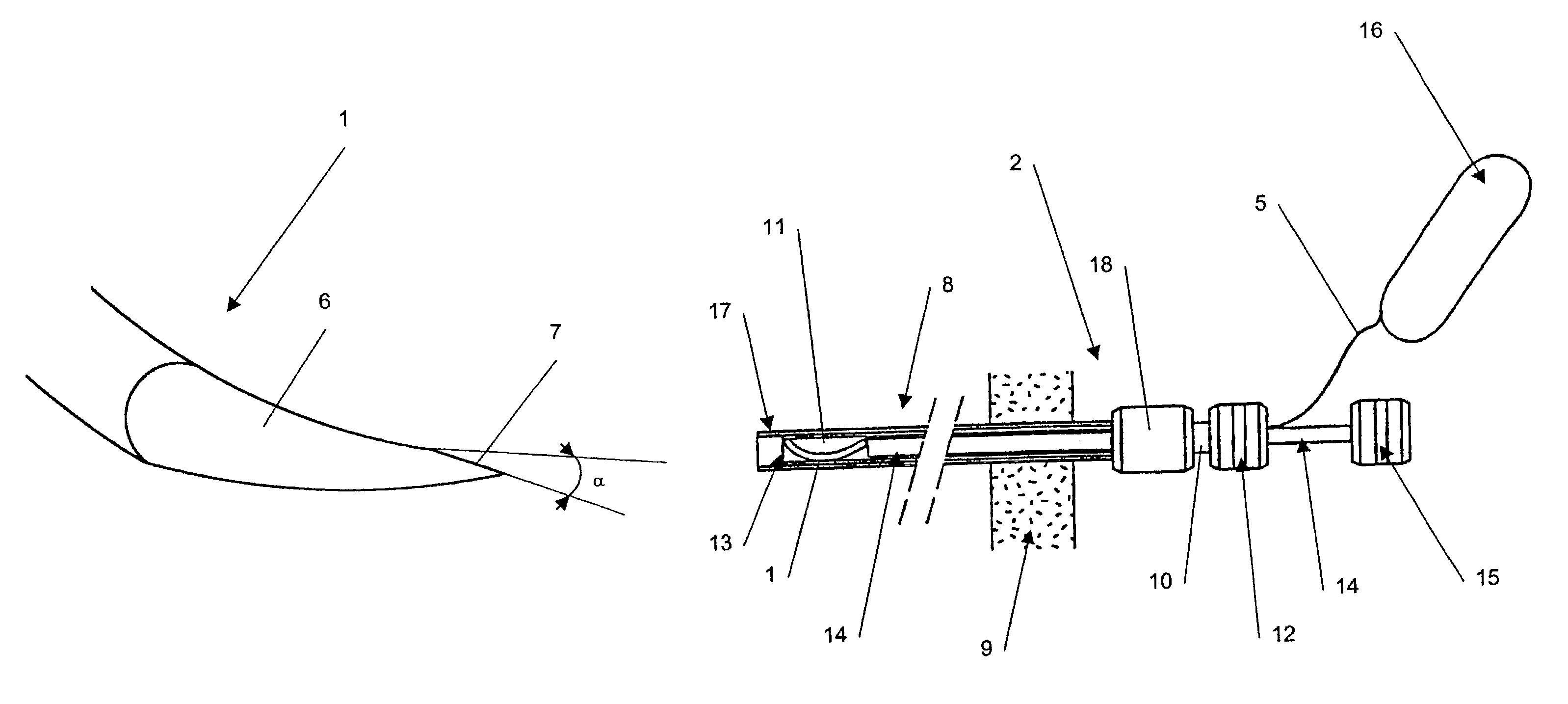

Systems and methods using vasoconstriction for improved thermal treatment of tissues

InactiveUS6840954B2Improve the effectiveness of treatmentEnhance such thermal treatmentAnti-incontinence devicesSurgical instruments for heatingArteriolar VasoconstrictionTreatment effect

The present invention enhances the effectiveness of treatment of support tissue structures. Generally, such tissue structures support organs and hold the organs in their proper position for appropriate functioning. When such tissue structures become weak, hyper-elastic, and / or excessively lengthy, the organs of are no longer supported in their proper position. This often leads to physical manifestations such as incontinence, hernias, and the like. Remedies often involve thermal treatment of the support tissue structures, such as thermally inducted controlled shrinkage, contraction, or stiffening of the support tissue structure. To enhance such thermal treatment and diminish the possibility of undesirable heating and damage to nearby tissue surfaces, vasoconstrictive agents are used.

Owner:ASTORA WOMENS HEALTH

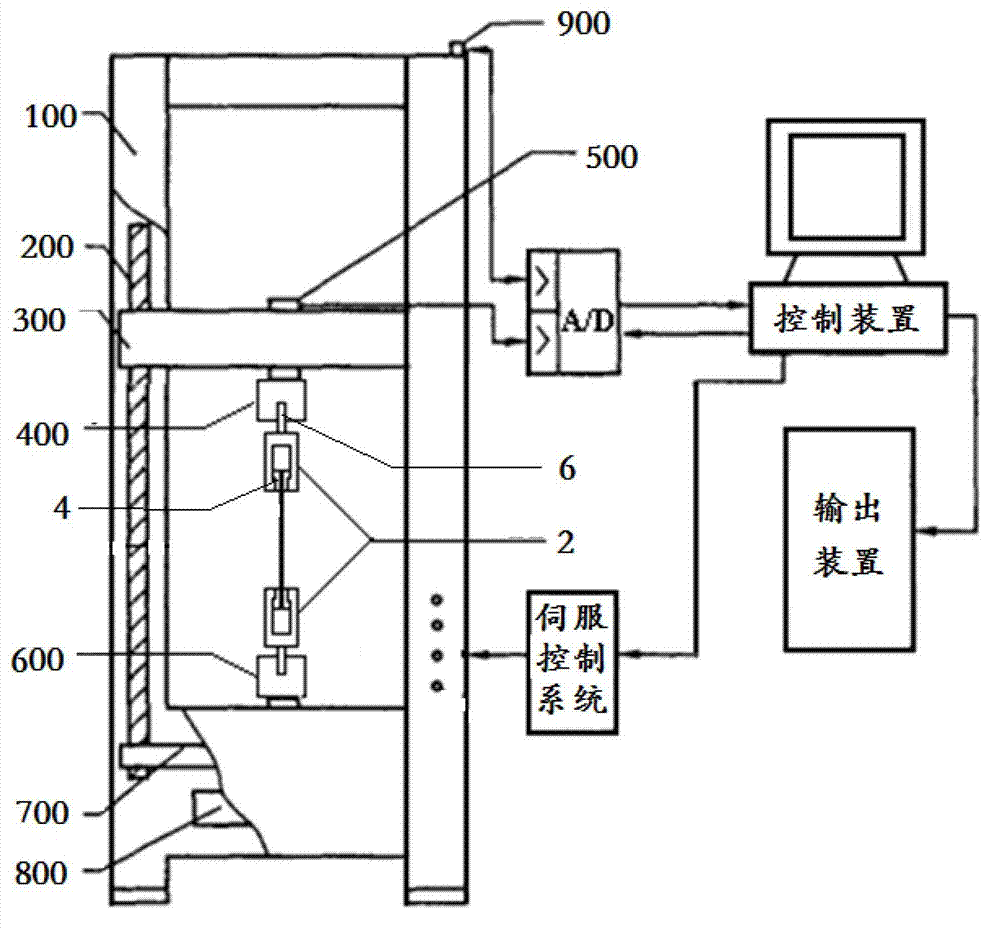

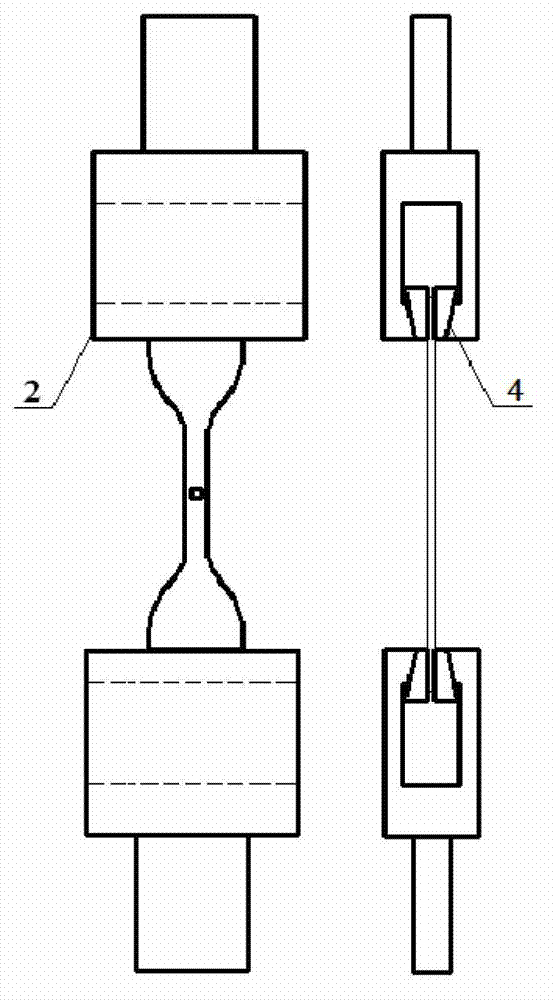

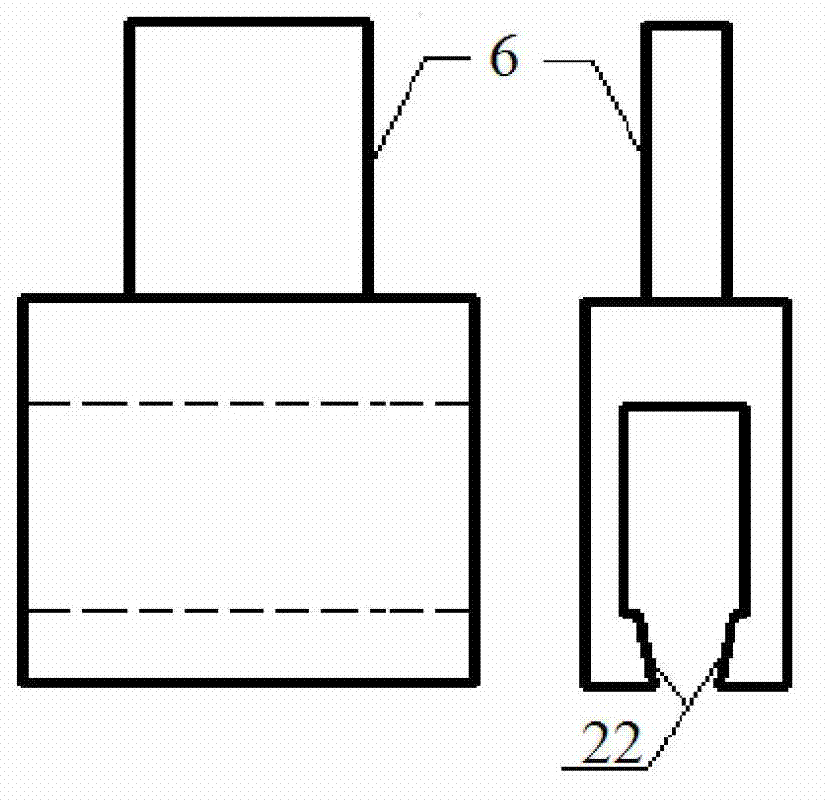

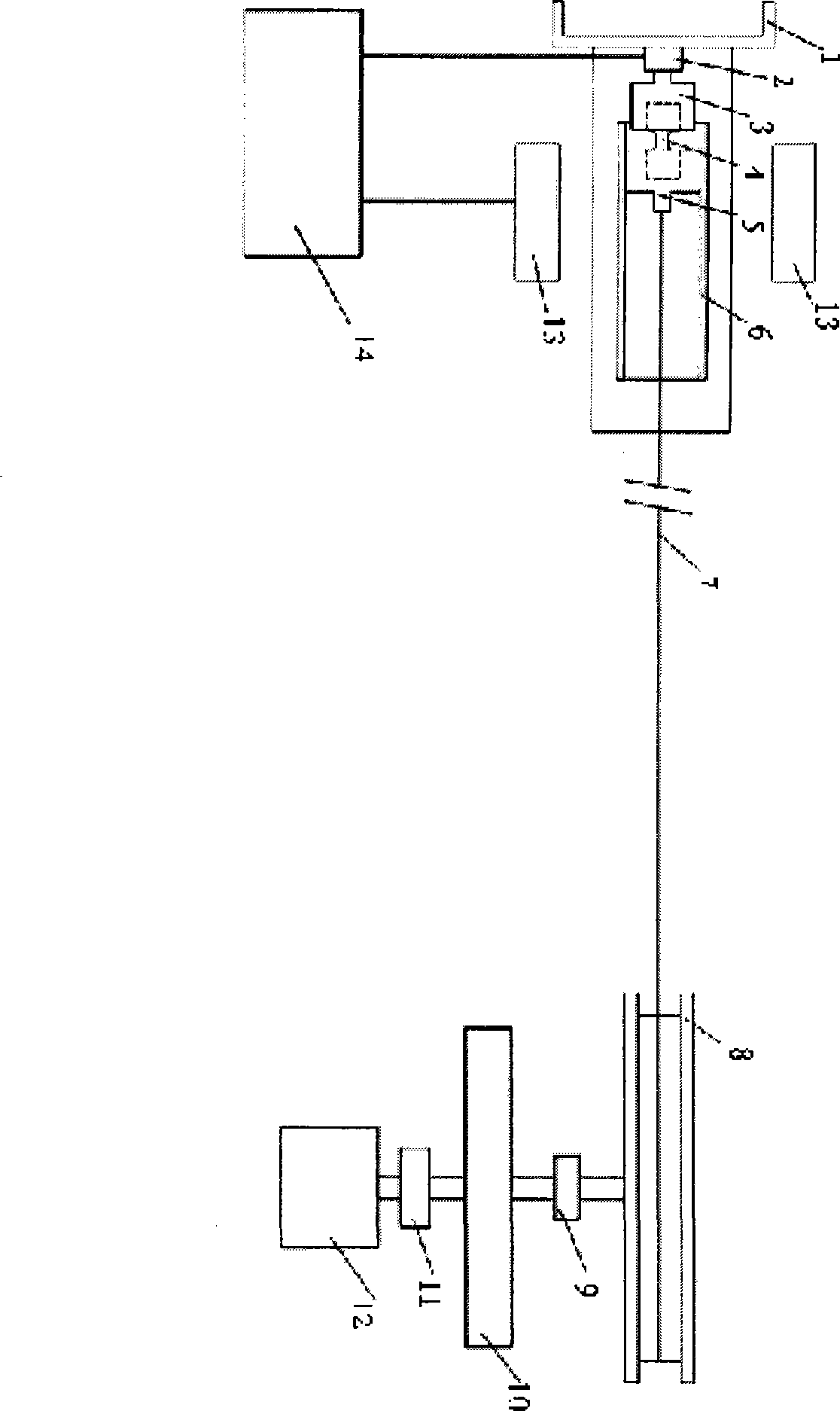

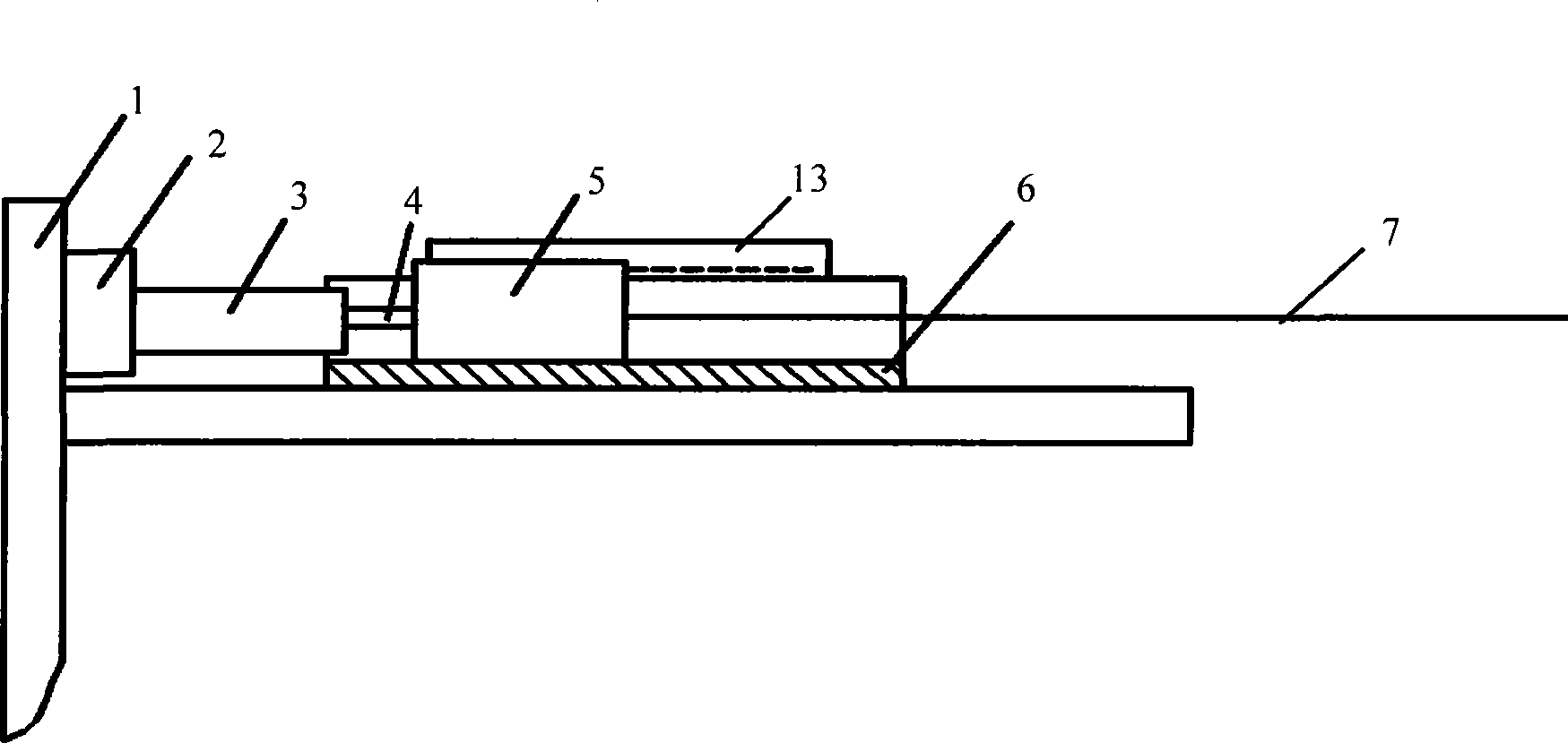

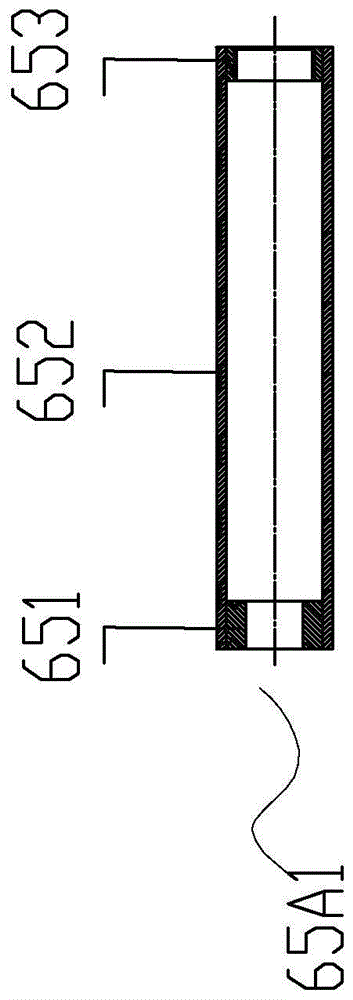

Clamp, device with clamp for testing mechanical property of hyper-elastic material and method

InactiveCN102768149AUniform deformationQuick disassemblyMaterial strength using tensile/compressive forcesData acquisitionHyper elastic

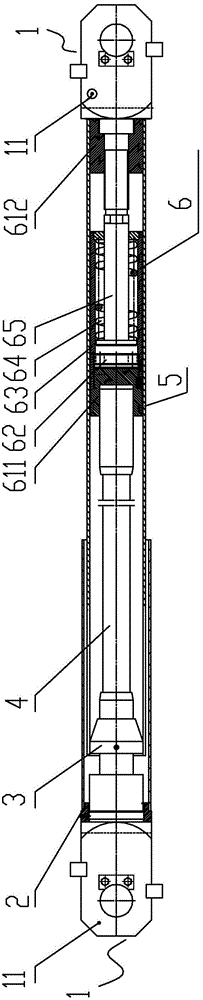

The invention relates to a device and a method for testing mechanical property of a hyper-elastic material. The device mainly comprises a reinforcing piece (4) at the end of a test piece and a test piece clamp, wherein the reinforcing piece (4) has a trapezoidal cross section; a clamping port of the clamp is an inclined surface; the reinforcing piece (4) is adhered to the end of the test piece and is arranged in the clamp, the inclined surface of the clamp tightly clamps the inclined surface of the reinforcing piece (4), and the clamp is self-locked in the tensioning process and is prevented from locally deforming. The device is applied to multiple stress-strain tests of the hyper-elastic material such as uniaxial tension, equally biaxial tension and planar tension (pure shear). Stress data is acquired by a data acquisition system of an electronic universal testing machine, and the strain data is acquired by a charge coupled device (CCD) image acquisition device. Due to the technical scheme, the clamping force is high when the tension is high in the process of tensioning the test piece, so that the test piece is uniformly stressed, more accurate testing data can be obtained, and the mechanical property parameters of the hyper-elastic material obtained accordingly are more reliable.

Owner:TSINGHUA UNIV

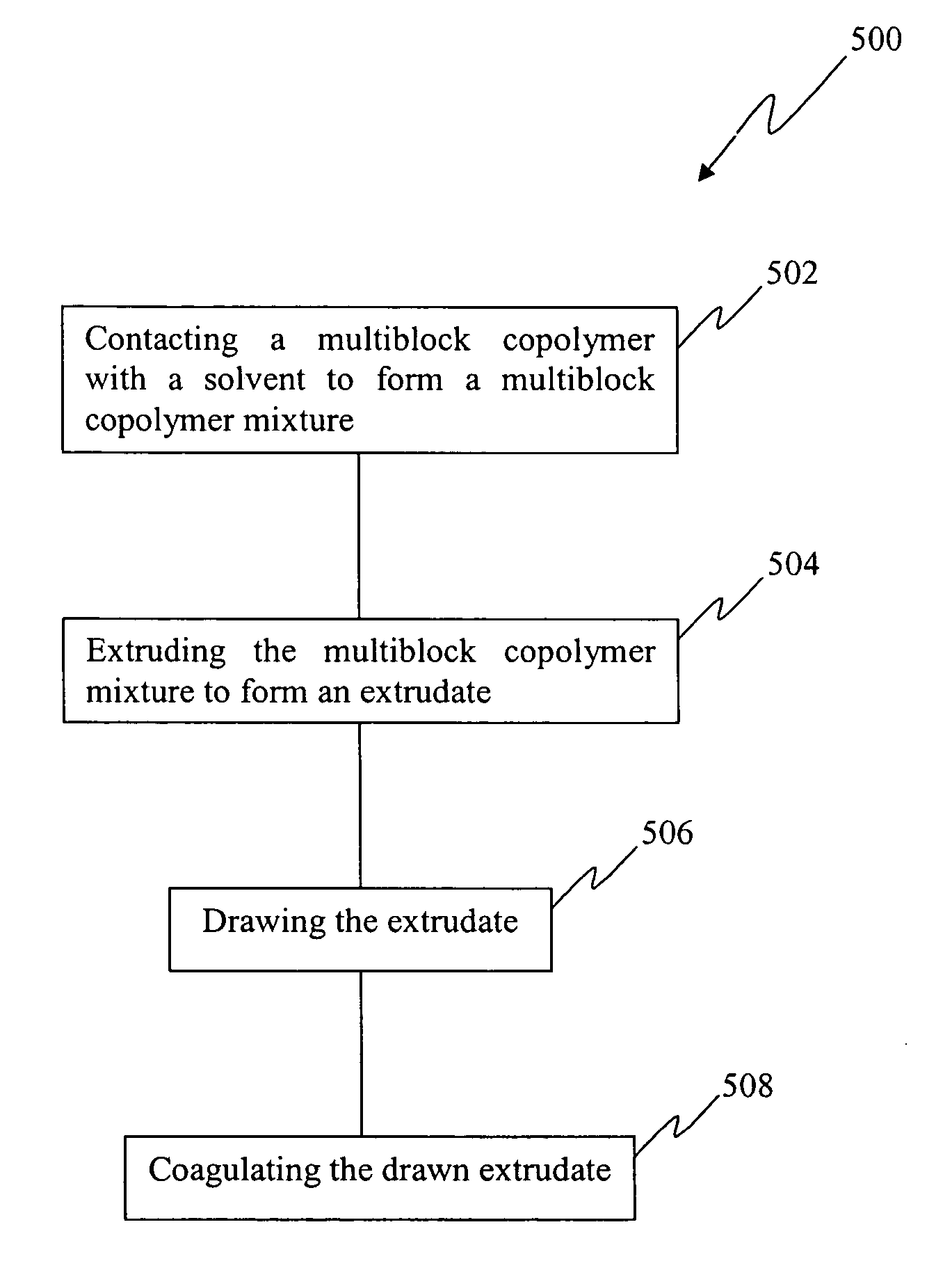

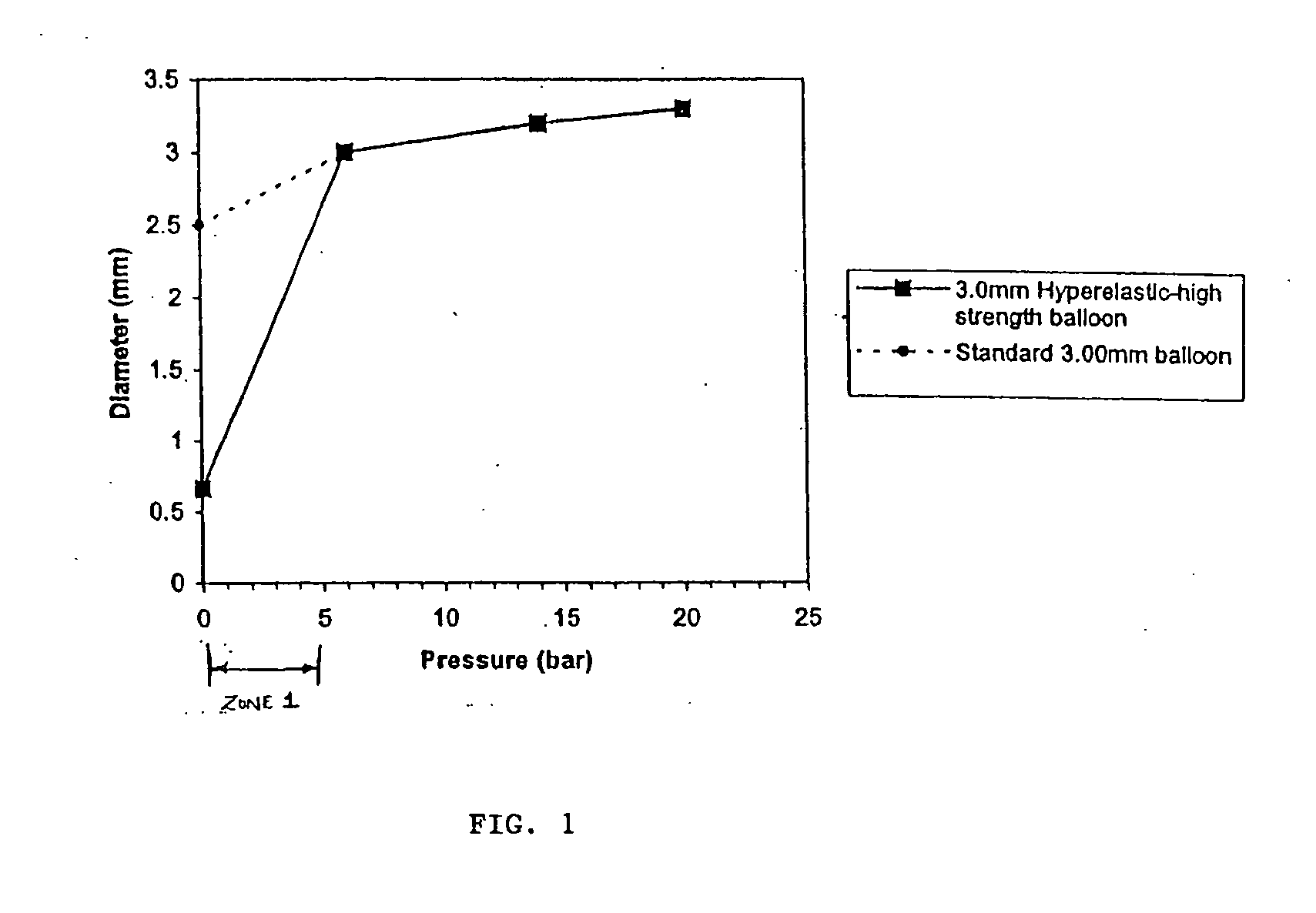

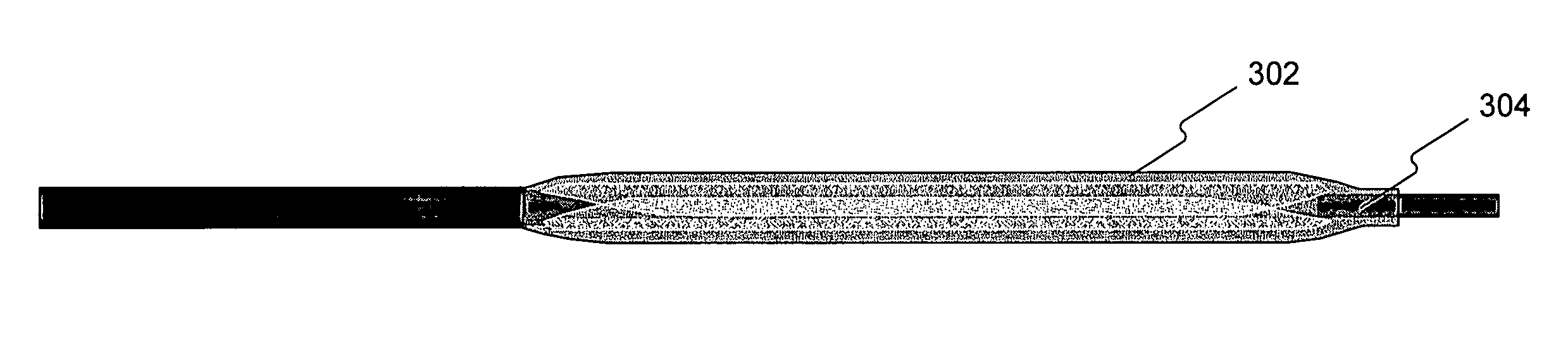

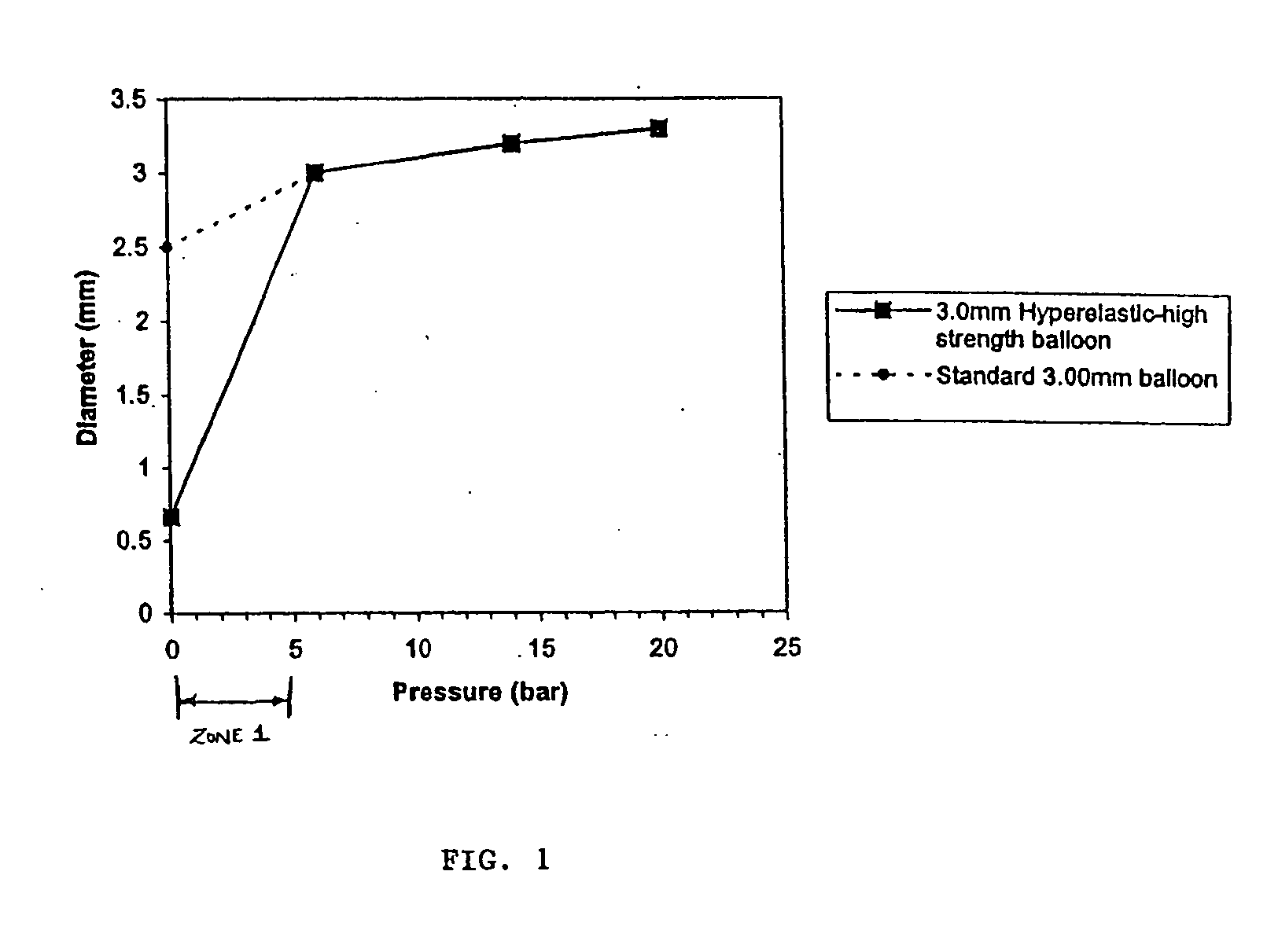

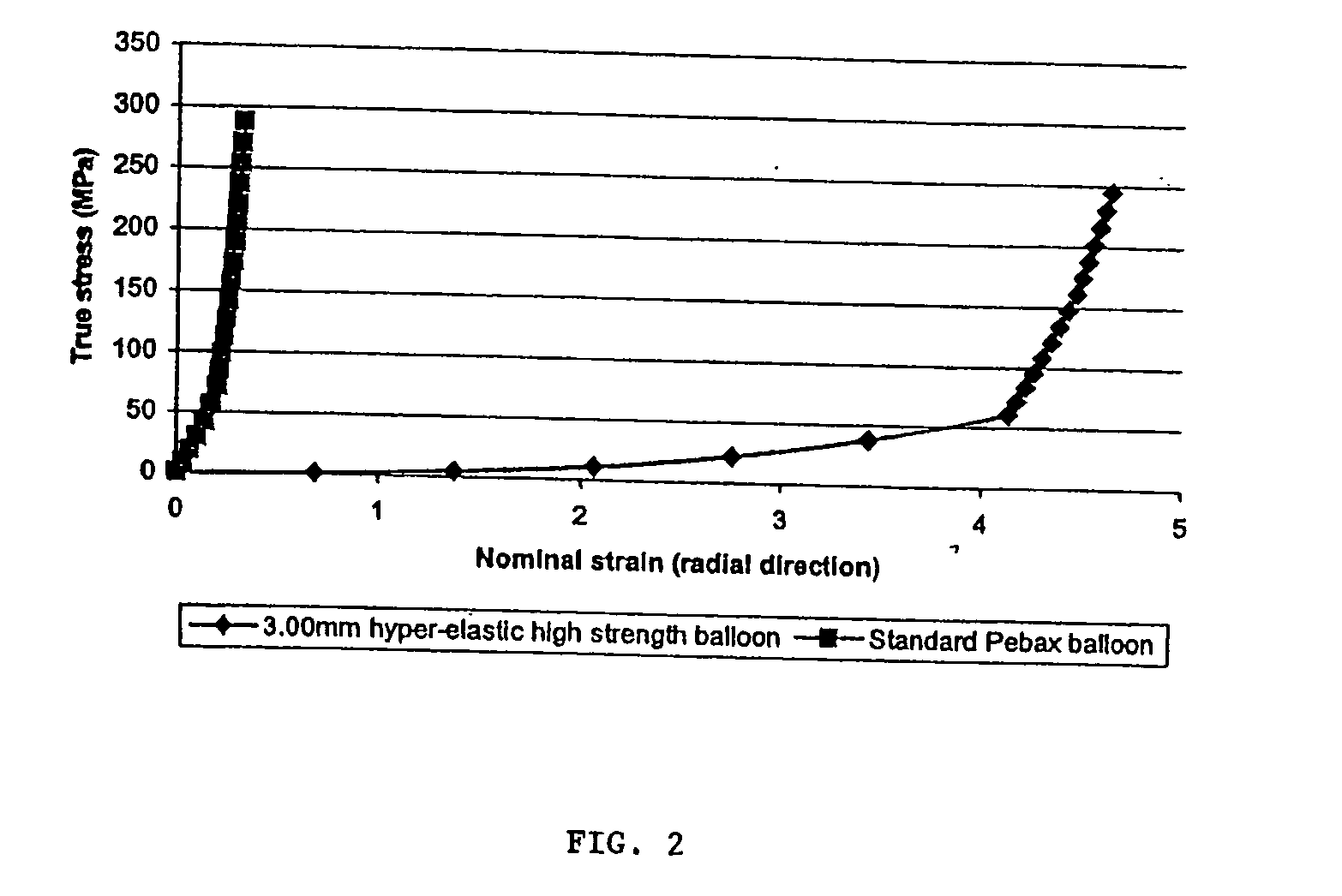

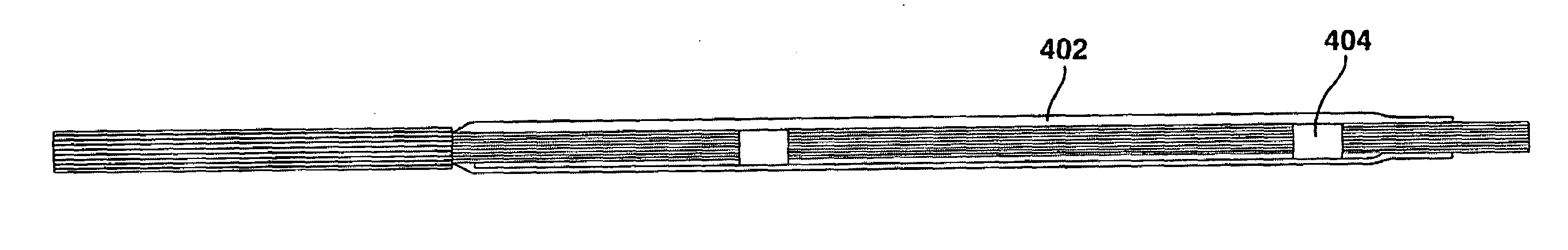

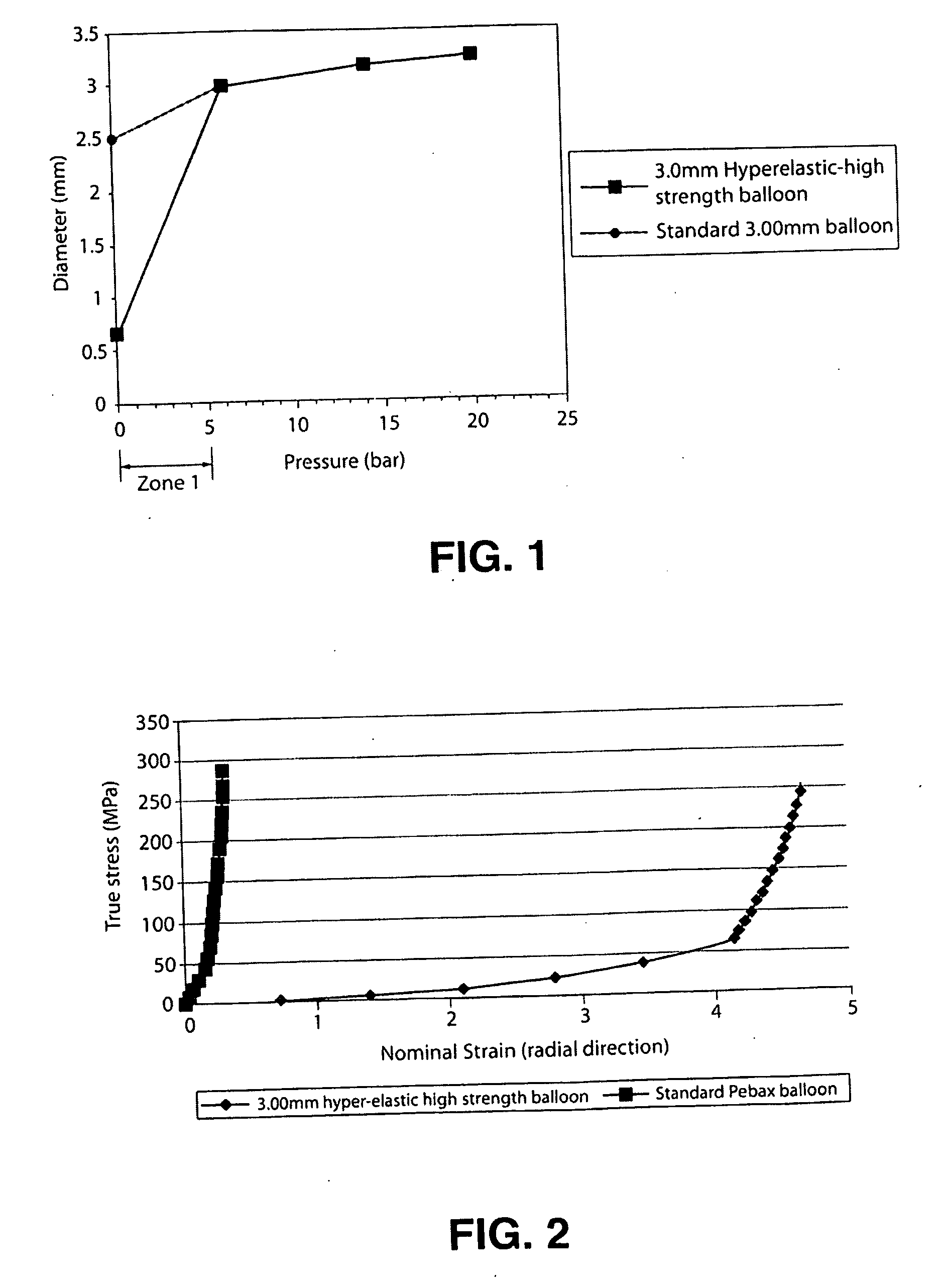

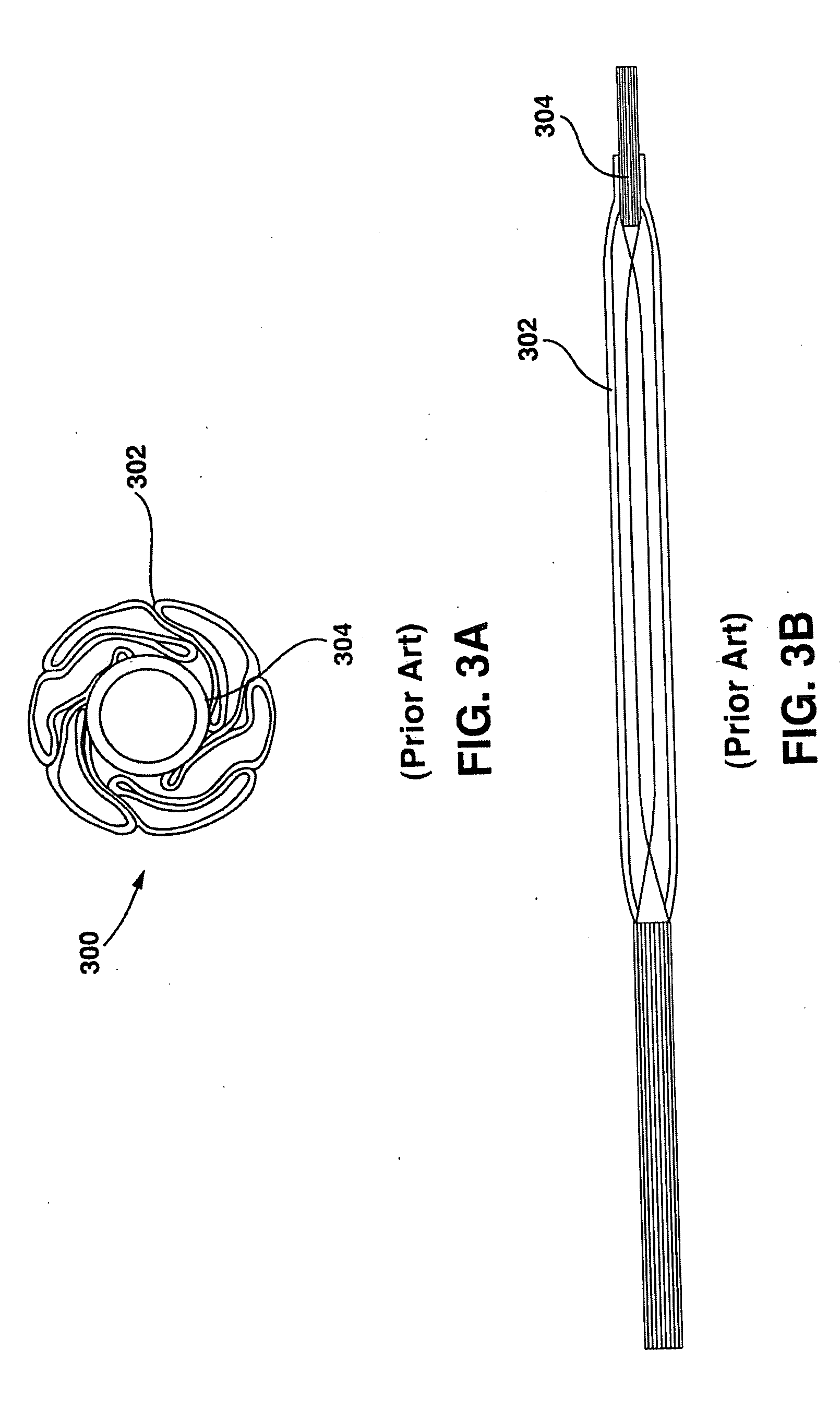

Process for producing a hyper-elastic, high strength dilatation balloon made from multi-block copolymers

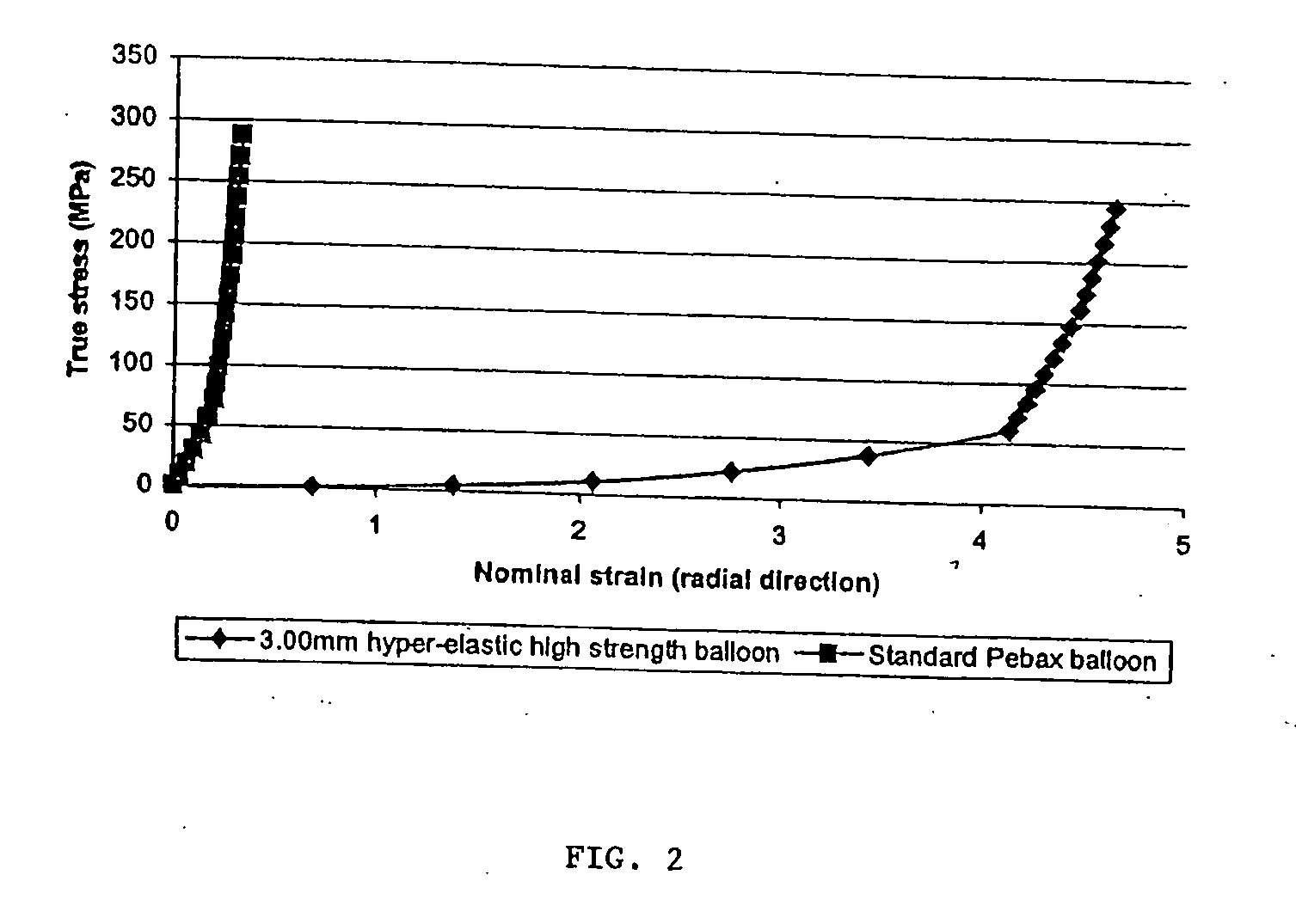

InactiveUS20050098914A1Increase elasticityLow profileCatheterThin material handlingHyper elasticUltimate tensile strength

A self-wrapping dilatation balloon comprising a multiblock copolymer having high elasticity and elastic recovery from nominal strains greater than about 30% is described. Also described herein, is a polymeric extrudate for making a dilatation balloon comprising a multiblock copolymer having tensile strength in the range of about 50 MPa to about 450 MPa, strain at break in the range of about 50% to about 600% and substantially complete elastic recovery from nominal strains of at least about 30%. The extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. Also described herein is a process for producing a polymeric extrudate for use as a dilatation balloon. The process comprises extruding a multiblock copolymer mixture or composition to form an extrudate. The extruding is done such that the extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. After extrusion, the process optionally comprises the steps of drawing and coagulating the extrudate.

Owner:VARMA ASHISH +5

A left auricle occluding device

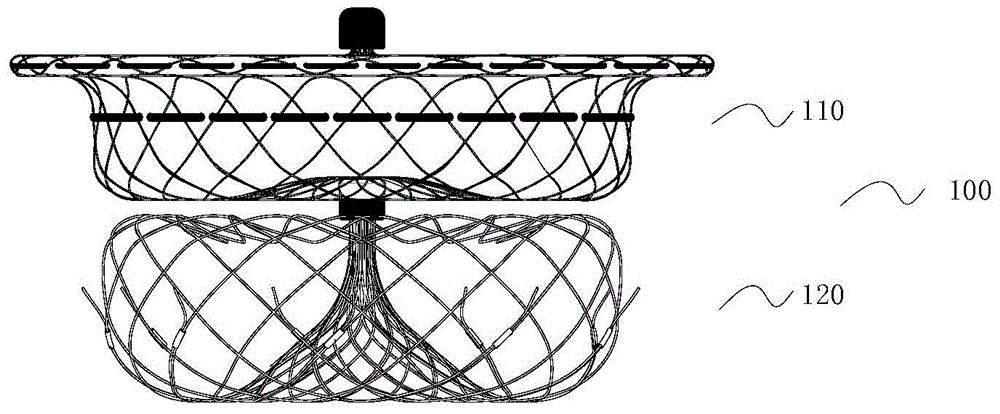

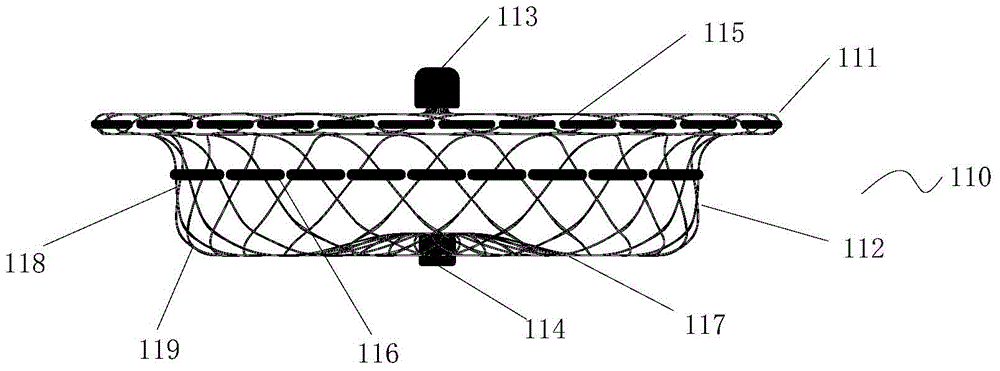

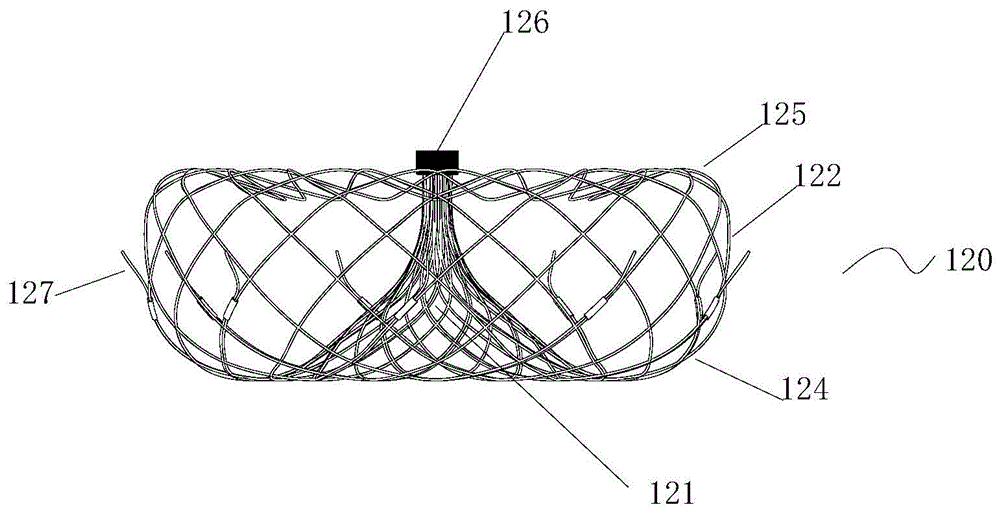

ActiveCN104958087AReduced risk of punctureEliminate local stress concentrationOcculdersHyper elasticBiomedical engineering

The invention discloses a left auricle occluding device. The left auricle occluding device comprises a sealing disc and an anchoring device, both of which are connected. The position where the anchoring device is matched with a left auricle is an anchoring net of a boneless structure. The overall anchoring device is of a boneless structure and formed by weaving of hyper-elastic metal wires or memory alloy metal wires. The far end of the anchoring device is in the shape of an opening. The near end of the anchoring device is collected and connected with the sealing disc to form a conical net. The far end of the anchoring device is opened and turned up towards the near end to form the anchoring net surrounding the conical net. The anchoring net is joined with the conical net by means of a circular transition area. The left auricle occluding device has following beneficial effects: force can be uniformly distributed to be anchored in the interior of the left auricle in order to eliminate concentration of local stress and can also be repeatedly released; and an opening part of the left auricle is effectively and reliably blocked.

Owner:HANGZHOU NUOMAO MEDTECH CO LTD

Hyper-elastic, high strength dilatation balloon made from multi-block copolymers

InactiveUS20050118370A1Increase elasticityLow profileSynthetic resin layered productsCatheterHyper elasticHigh intensity

A self-wrapping dilatation balloon comprising a multiblock copolymer having high elasticity and elastic recovery from nominal strains greater than about 30% is described. Also described herein, is a polymeric extrudate for making a dilatation balloon comprising a multiblock copolymer having tensile strength in the range of about 50 MPa to about 450 MPa, strain at break in the range of about 50% to about 600% and substantially complete elastic recovery from nominal strains of at least about 30%. The extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. Also described herein is a process for producing a polymeric extrudate for use as a dilatation balloon. The process comprises extruding a multiblock copolymer mixture or composition to form an extrudate. The extruding is done such that the extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. After extrusion, the process optionally comprises the steps of drawing and coagulating the extrudate.

Owner:MEDTRONIC VASCULAR INC

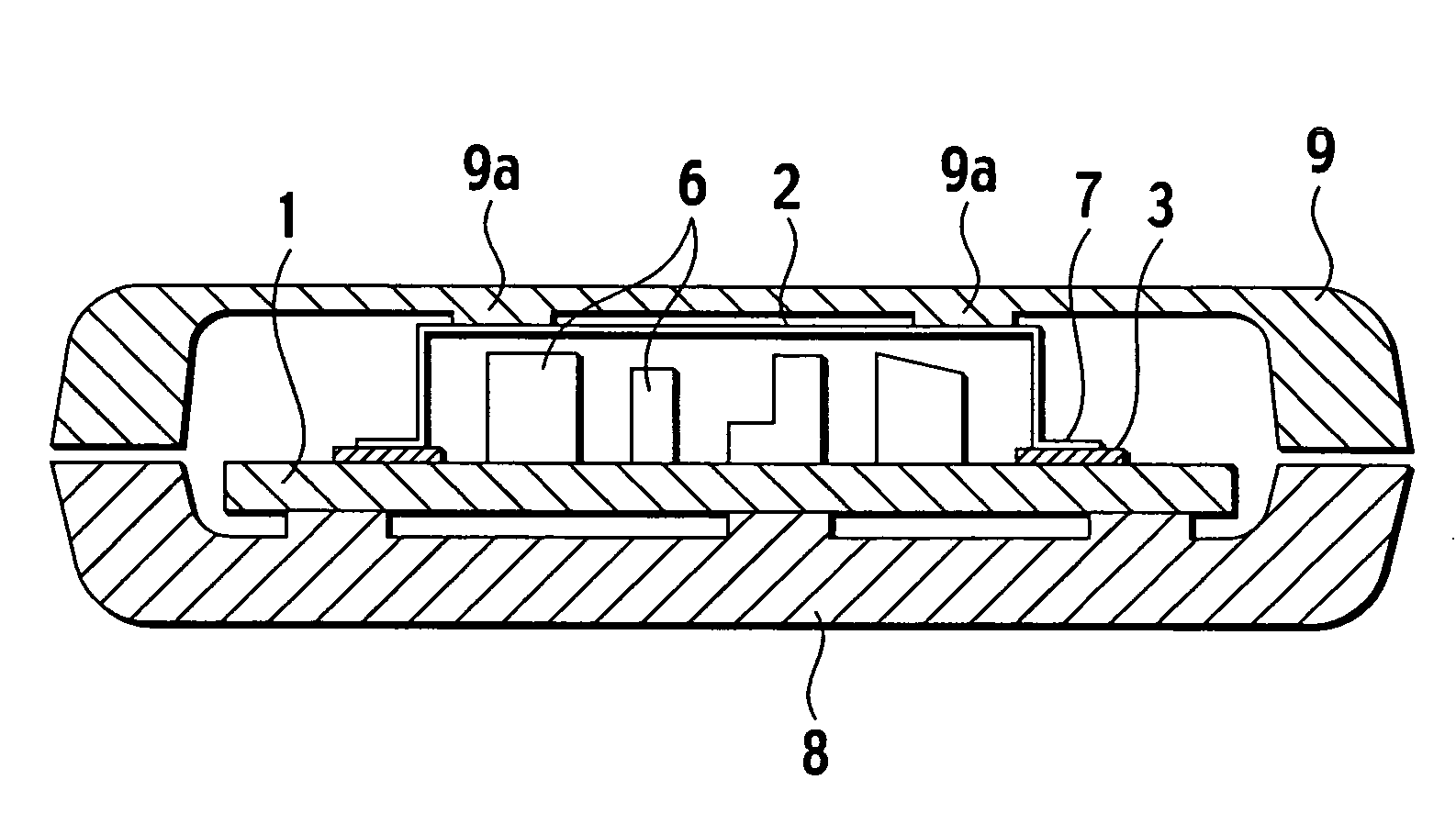

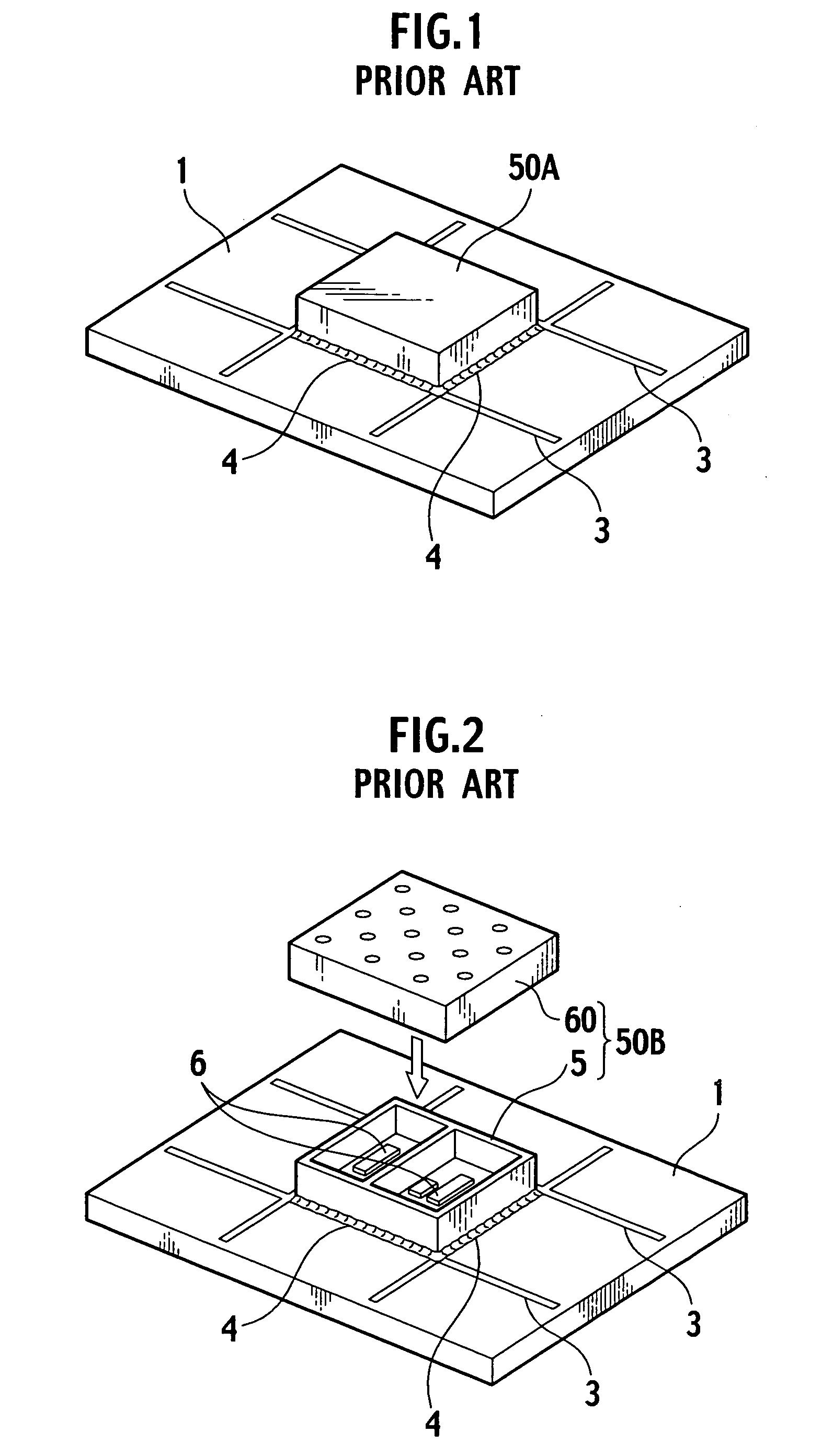

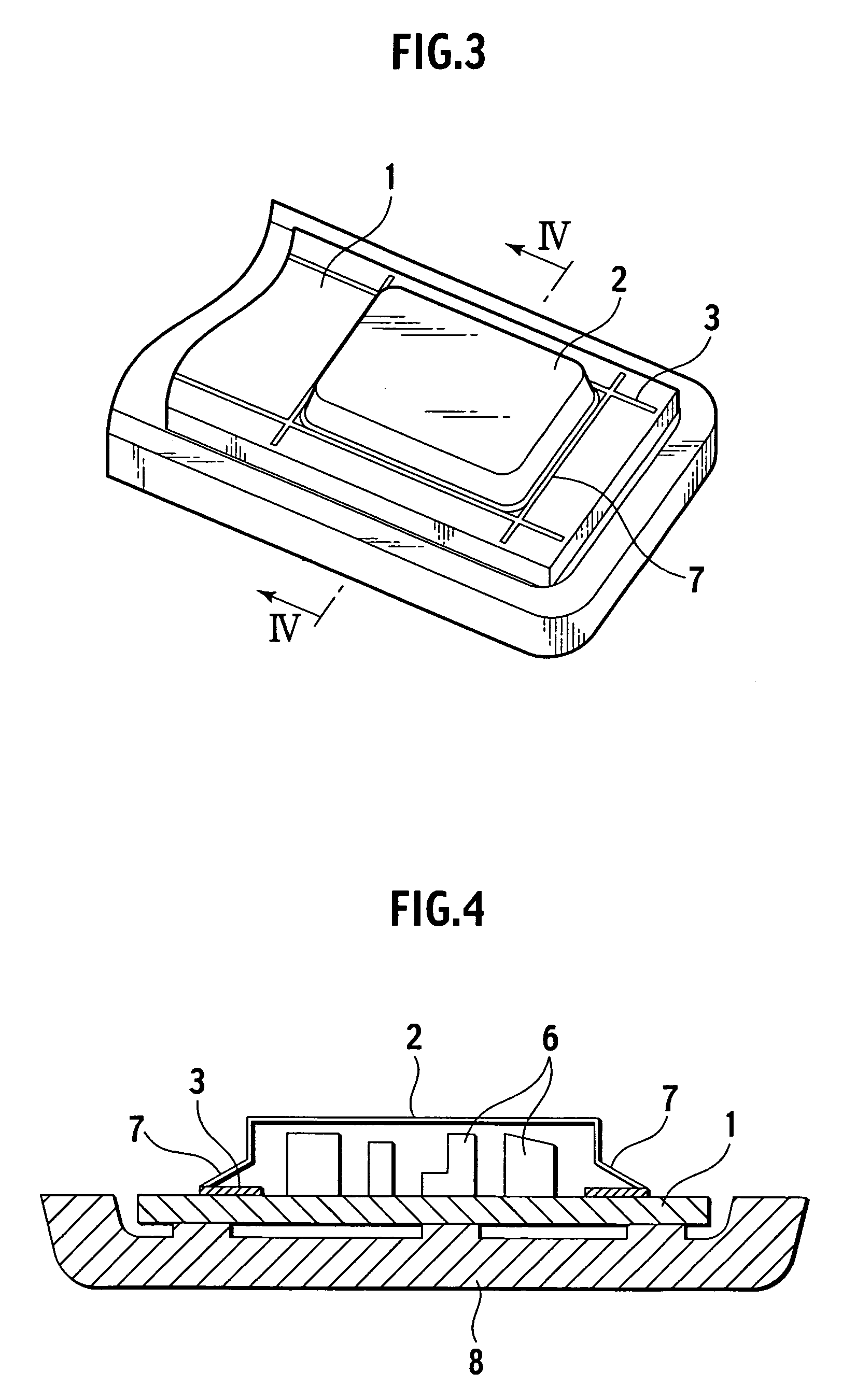

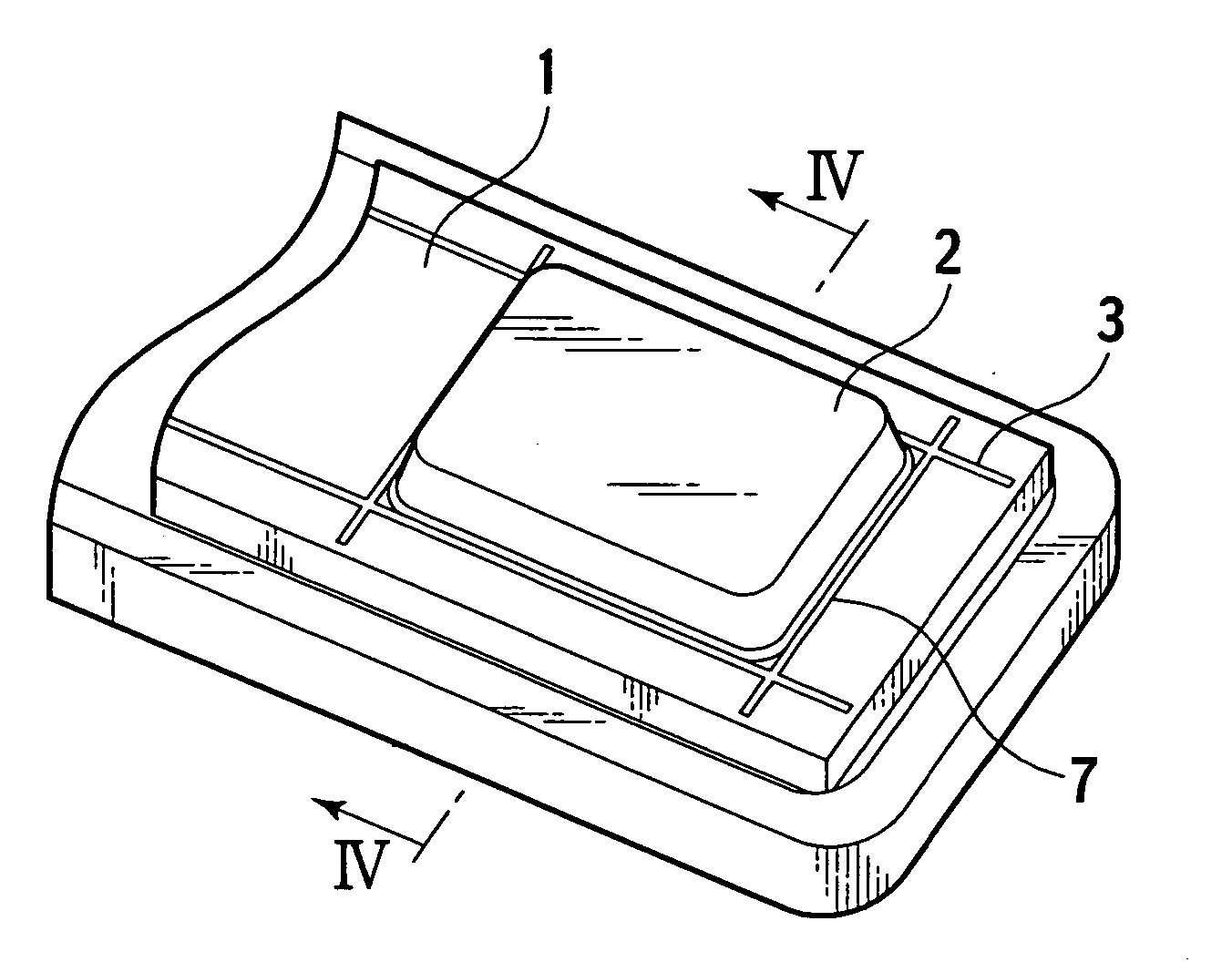

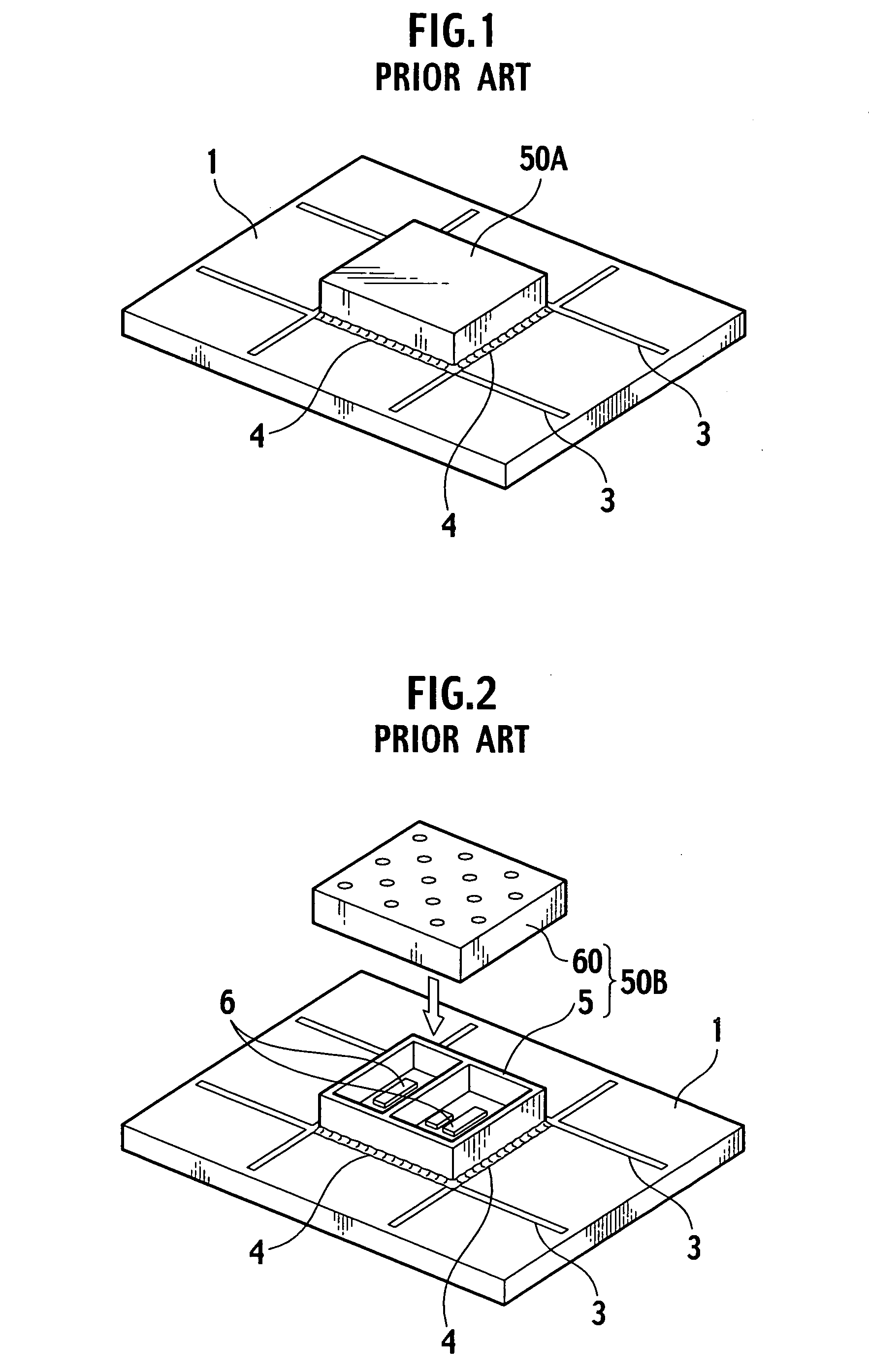

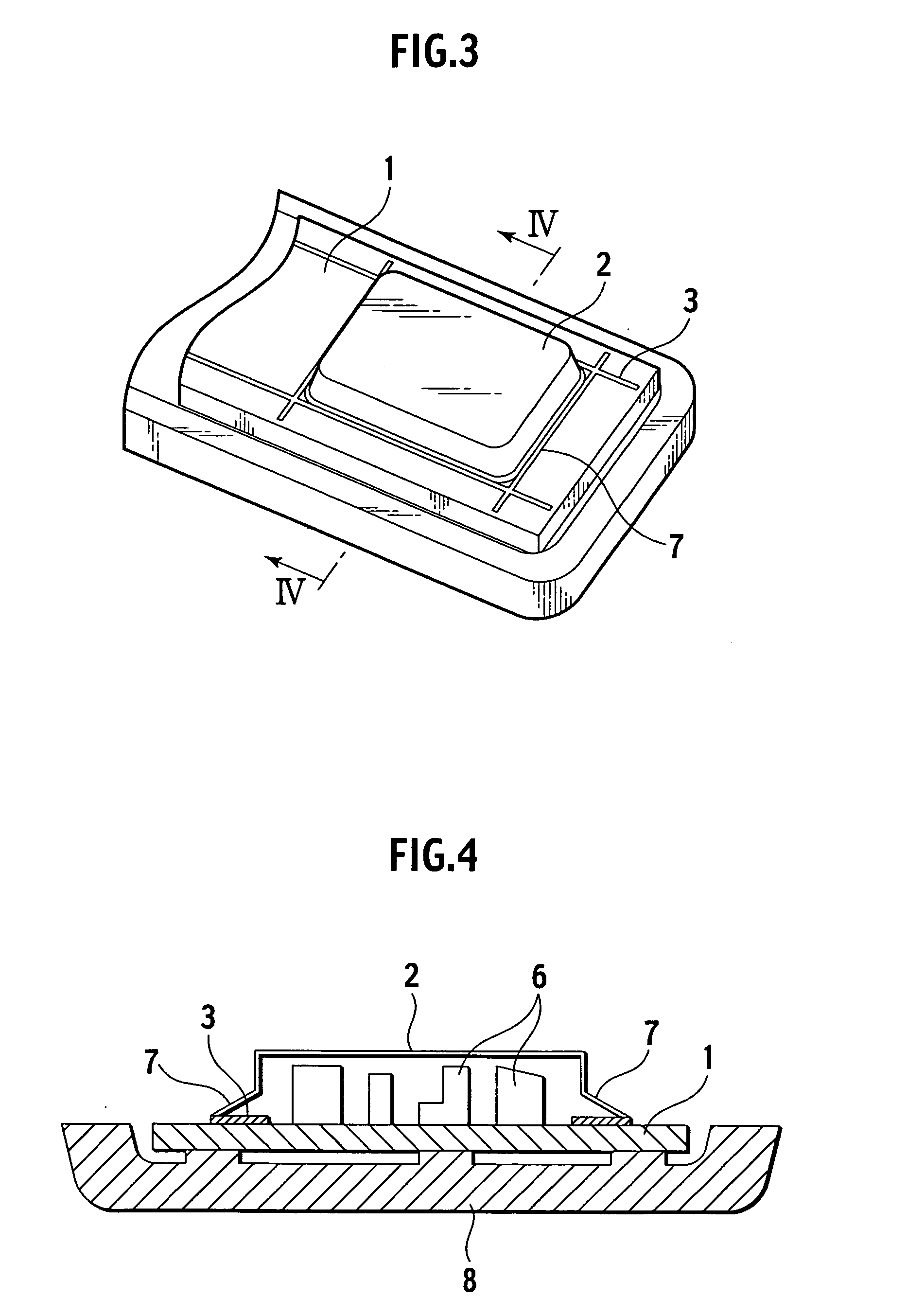

Electromagnetic wave shield case and a method for manufacturing electromagnetic wave shield case

InactiveUS7626832B2Reduce thicknessLow costMagnetic materialsShielding efficiency measurementHyper elasticViscous flow

An objective of the present invention is to form a hyper-elastic flange integrally within a shield case body around a periphery thereof while decreasing an occupied area for grounding. The shield case 2 according to the present invention is disposed to cover electronic parts 6 on a circuit board 1, and which has a flange 7 formed integrally therewith so as to contact with a metallic ground line 3 on the circuit board 1. The flange 7 is elastically deformed to be grounded, thus a leakage of electromagnetic waves to the outside of the shield case 2 is prevented. The flange 7 is made of metallic glass. By forming the flange 7 from metallic glass, a displacement due to viscous flowing on the atomic level, which is different from a plastic deformation, can be utilized, and thus a high precision flange can be formed without a spring-back.

Owner:NGK INSULATORS LTD +1

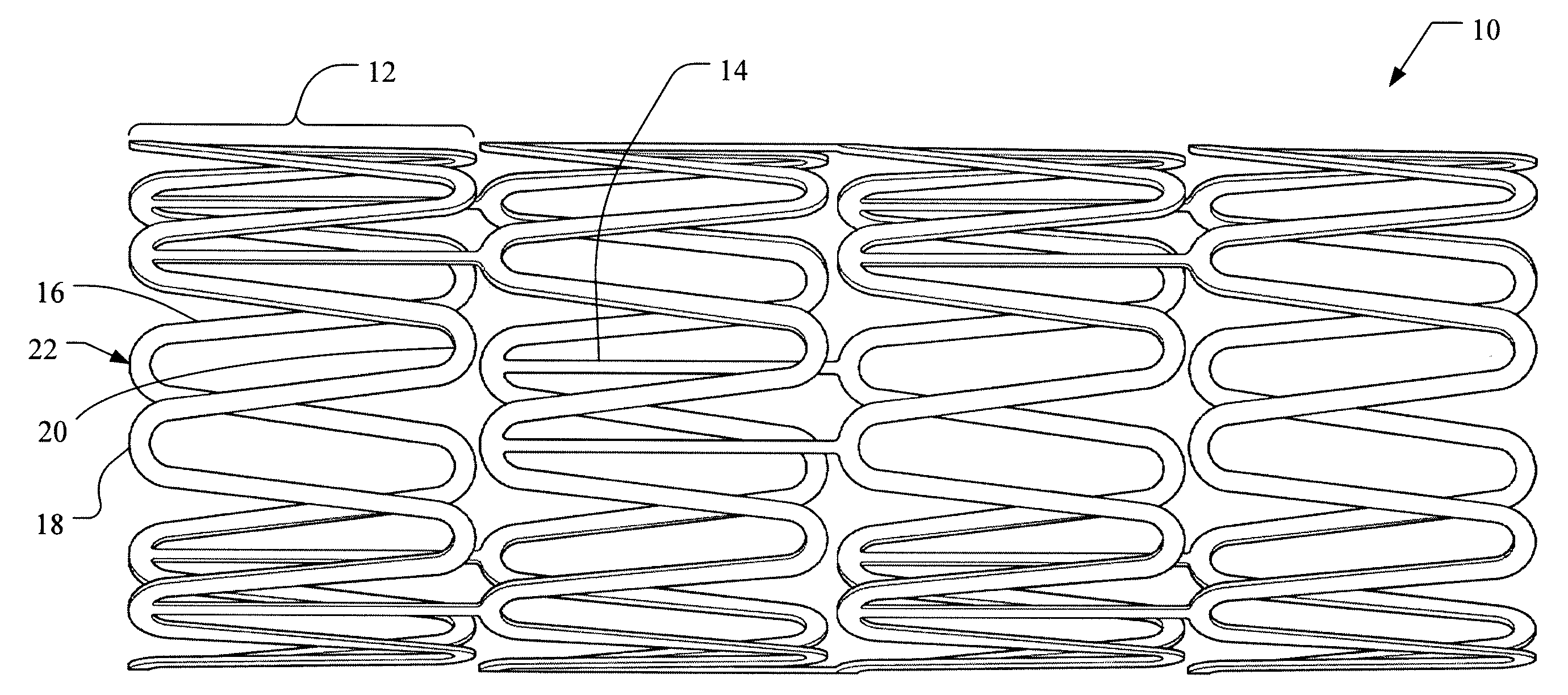

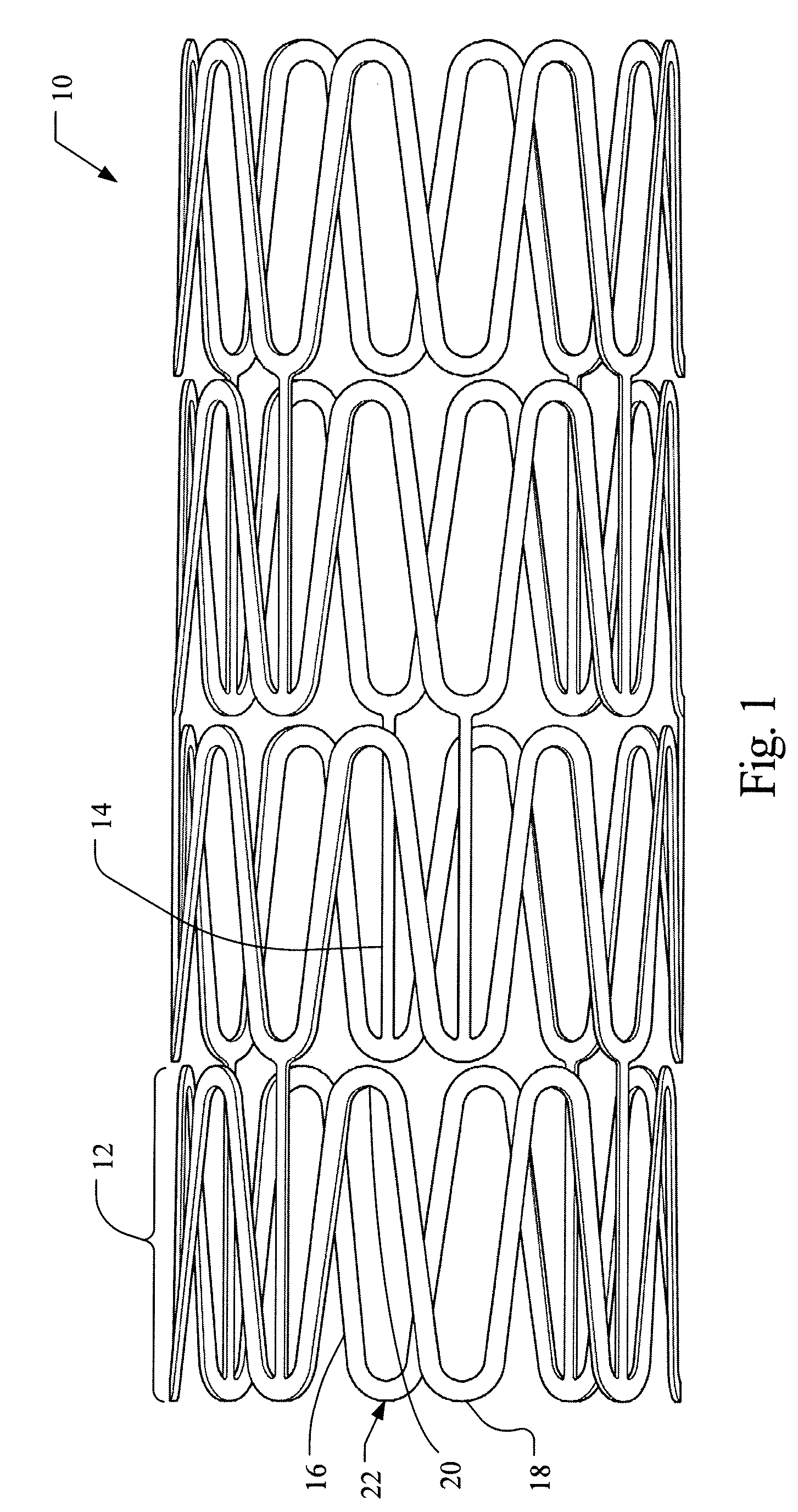

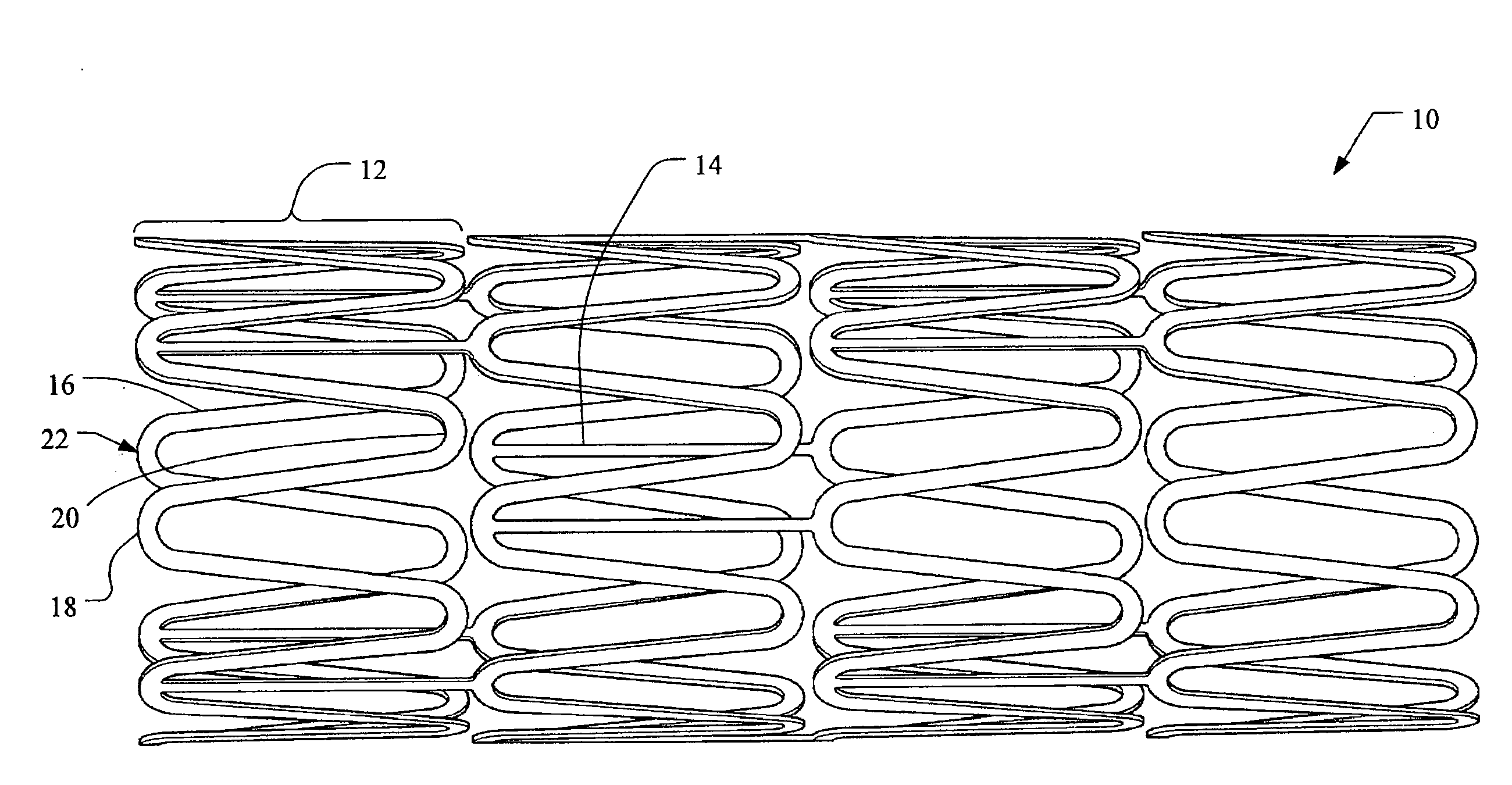

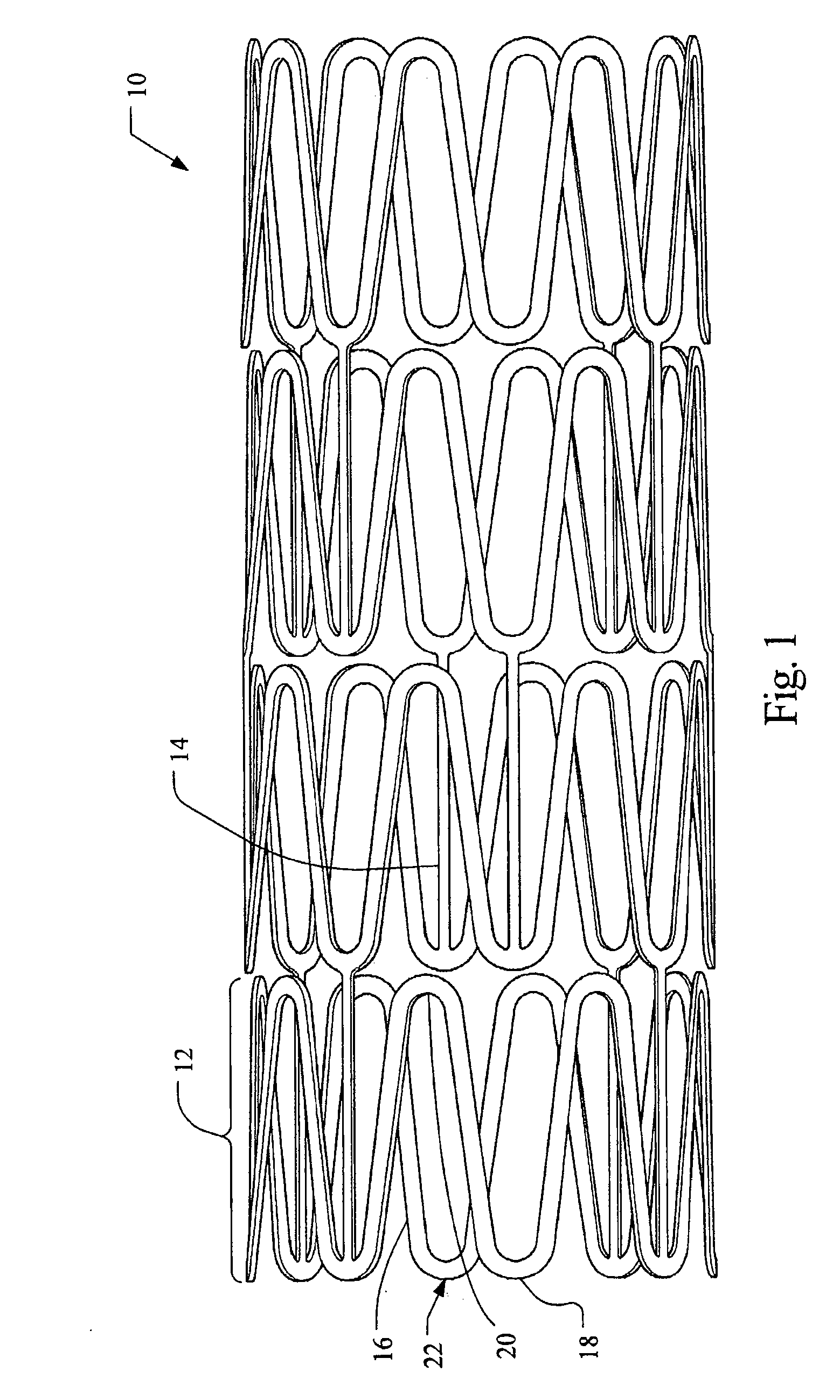

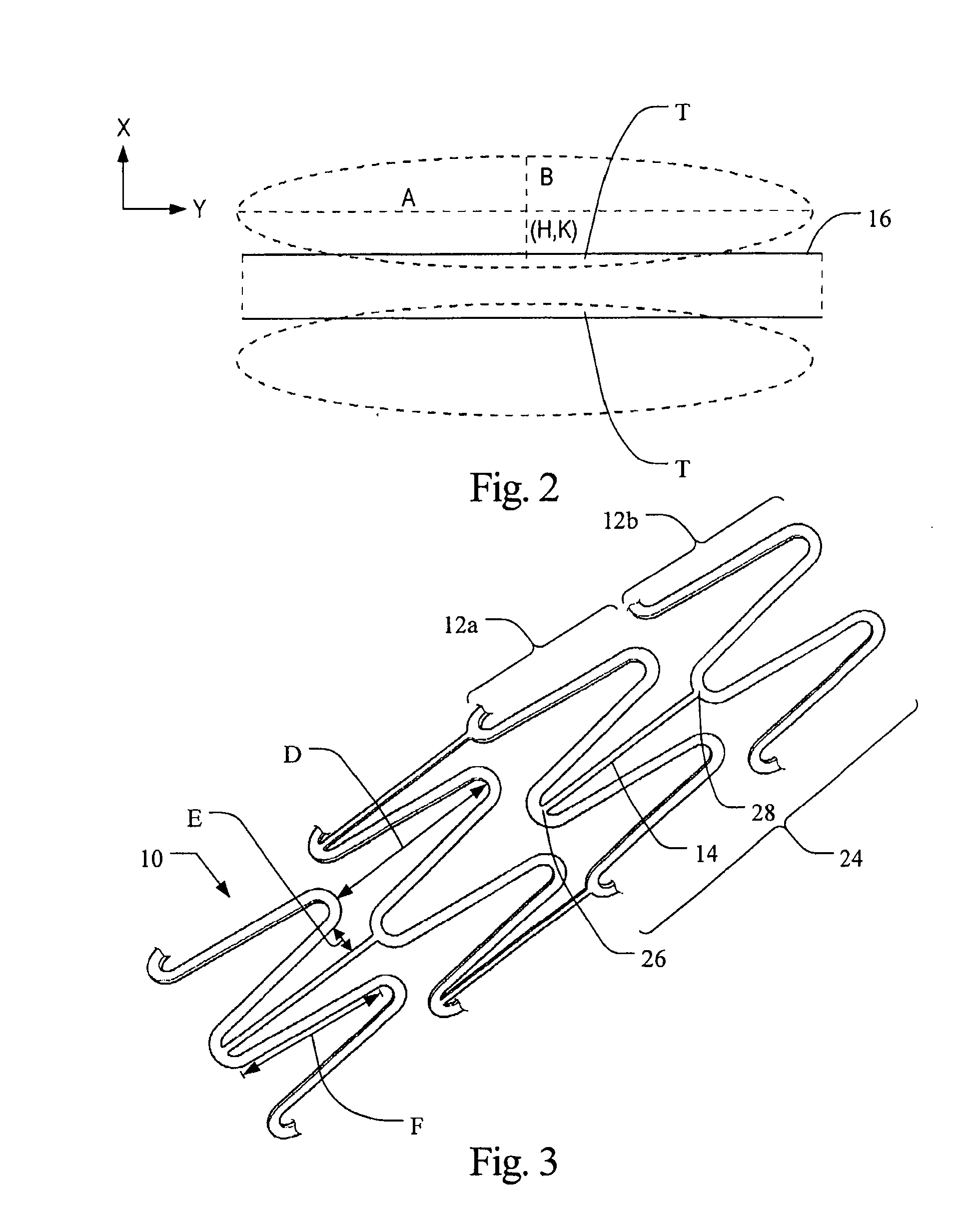

Covered balloon expandable stent design and method of covering

A balloon expandable covered stent consists of a plurality of primary stent units, each having an undulating shape defined by a series of primary strut members converging to form peaks and valleys. The primary stent units are assembled into a single cylindrical structure of the stent by connecting corresponding peaks with secondary strut members. Generally, surfaces of the stent may then coated with a polymeric, hyper-elastic material, preferably Thoralon®, by pre-expanding the stent prior to coating.

Owner:MED INST INC

Electromagnetic wave shield case and a method for manufacturing electromagnetic wave shield case

InactiveUS20050162842A1Simple moldingReduce thicknessMagnetic materialsShielding efficiency measurementViscous flowHyper elastic

An objective of the present invention is to form a hyper-elastic flange integrally within a shield case body around a periphery thereof while decreasing an occupied area for grounding. The shield case 2 according to the present invention is disposed to cover electronic parts 6 on a circuit board 1, and which has a flange 7 formed integrally therewith so as to contact with a metallic ground line 3 on the circuit board 1. The flange 7 is elastically deformed to be grounded, thus a leakage of electromagnetic waves to the outside of the shield case 2 is prevented. The flange 7 is made of metallic glass. By forming the flange 7 from metallic glass, a displacement due to viscous flowing on the atomic level, which is different from a plastic deformation, can be utilized, and thus a high precision flange can be formed without a spring-back.

Owner:NGK INSULATORS LTD +1

Covered balloon expandable stent design and methodof covering

A balloon expandable covered stent consists of a plurality of primary stent units, each having an undulating shape defined by a series of primary strut members converging to form peaks and valleys. The primary stent units are assembled into a single cylindrical structure of the stent by connecting corresponding peaks with secondary strut members. Generally, surfaces of the stent may then coated with a polymeric, hyper-elastic material, preferably Thoralon®, by pre-expanding the stent prior to coating.

Owner:MED INST INC

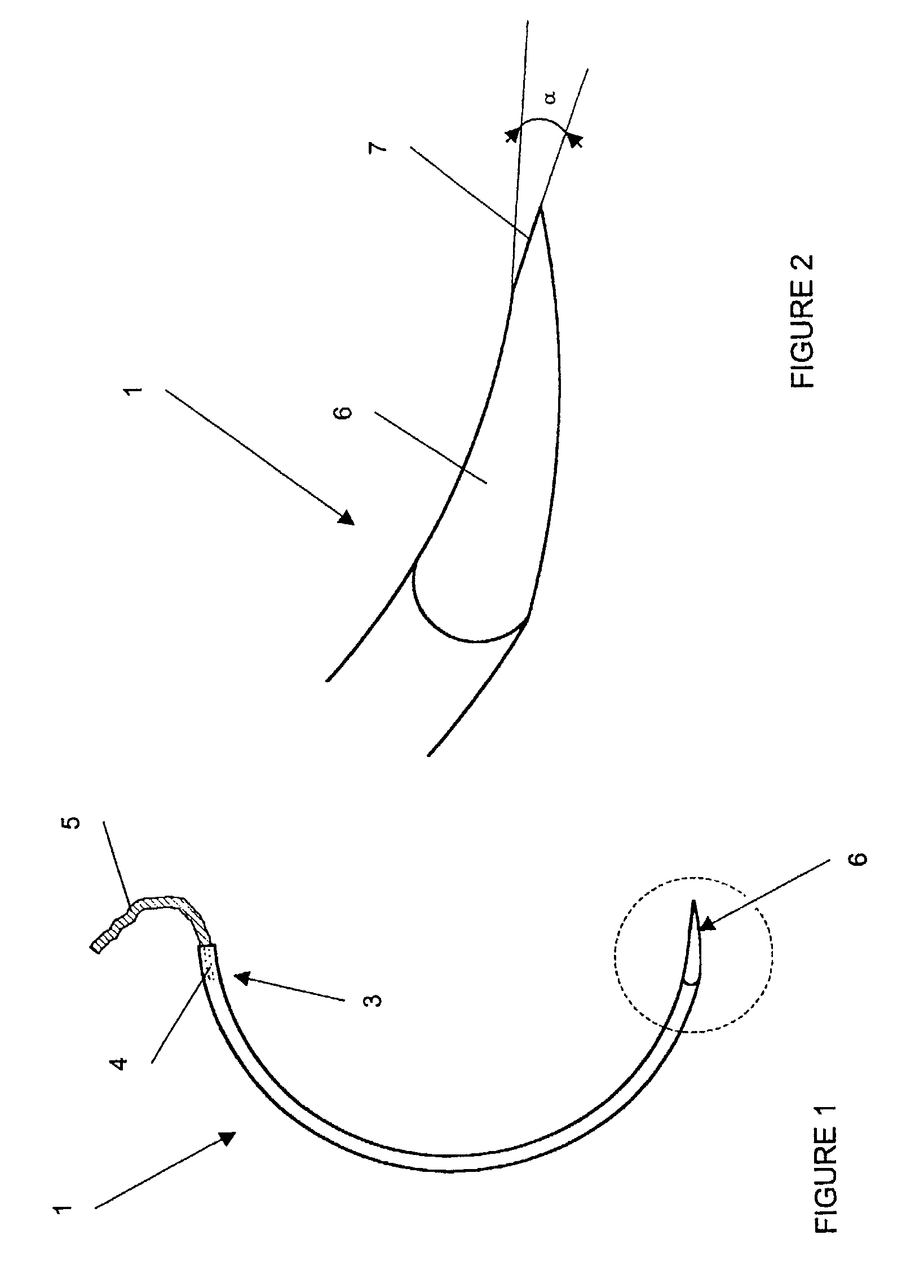

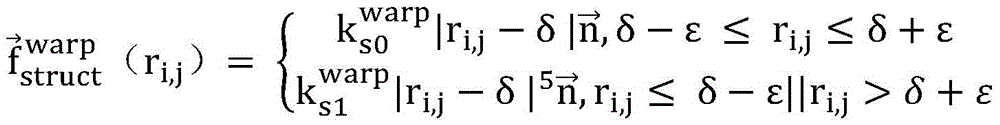

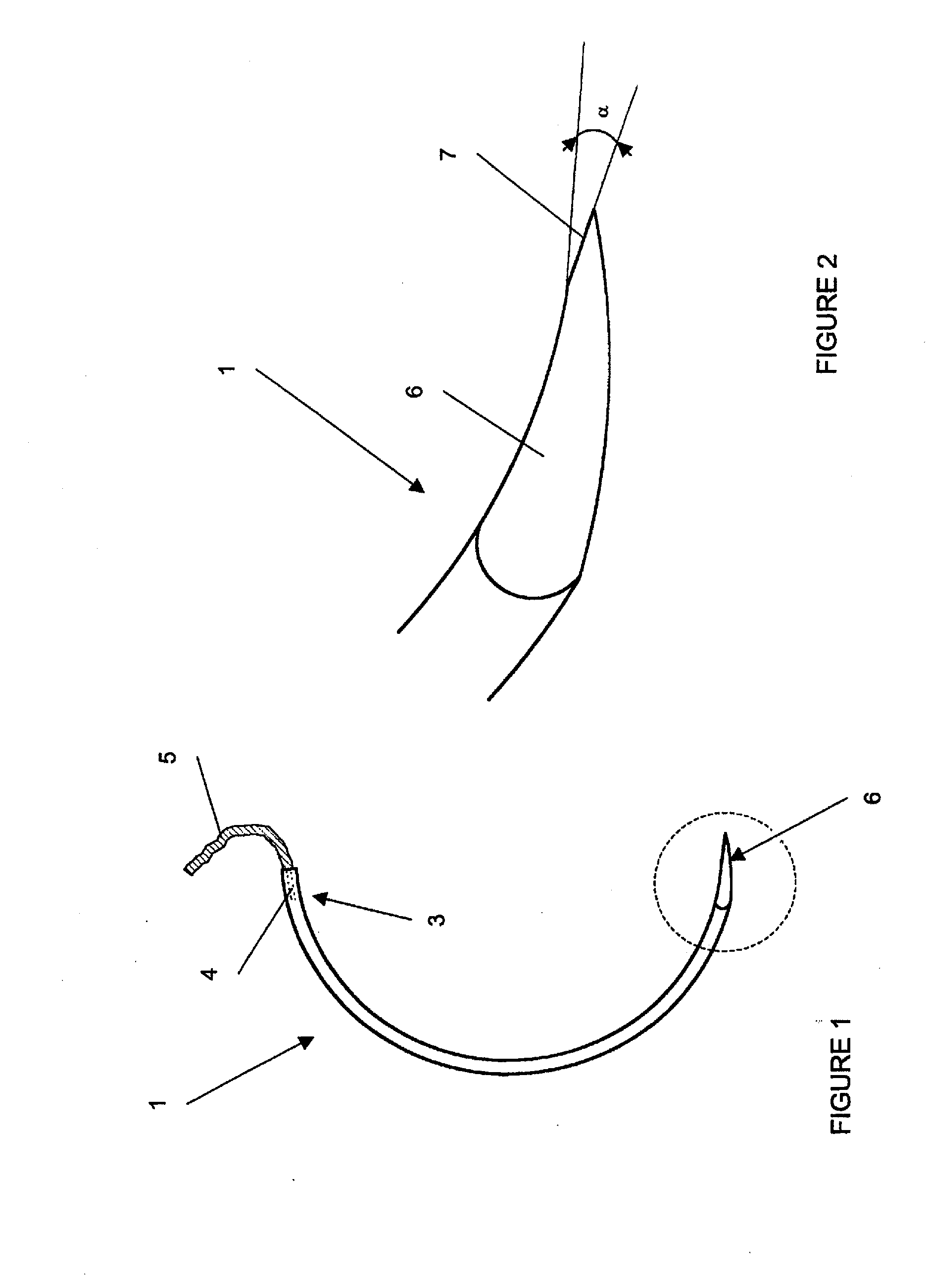

Hyper-elastic needle

Surgical needle including a crimping zone for securing a suture to the needle. The needle is made of a hyper-elastic alloy which, after treatment, has two distinct states. One of the two distinct states allows the needle to be forced into a roughly elongated position when the needle is housed in an internal bore. Another of the two distinct states allows the needle to adopt a curved profile as a result of superelasticity or hyper-elasticity of the needle. The needle has a free end which has a tapered point which includes an inclined heel portion. The inclined heel portion is arranged on an inside portion of the curved profile.

Owner:SOPRANE

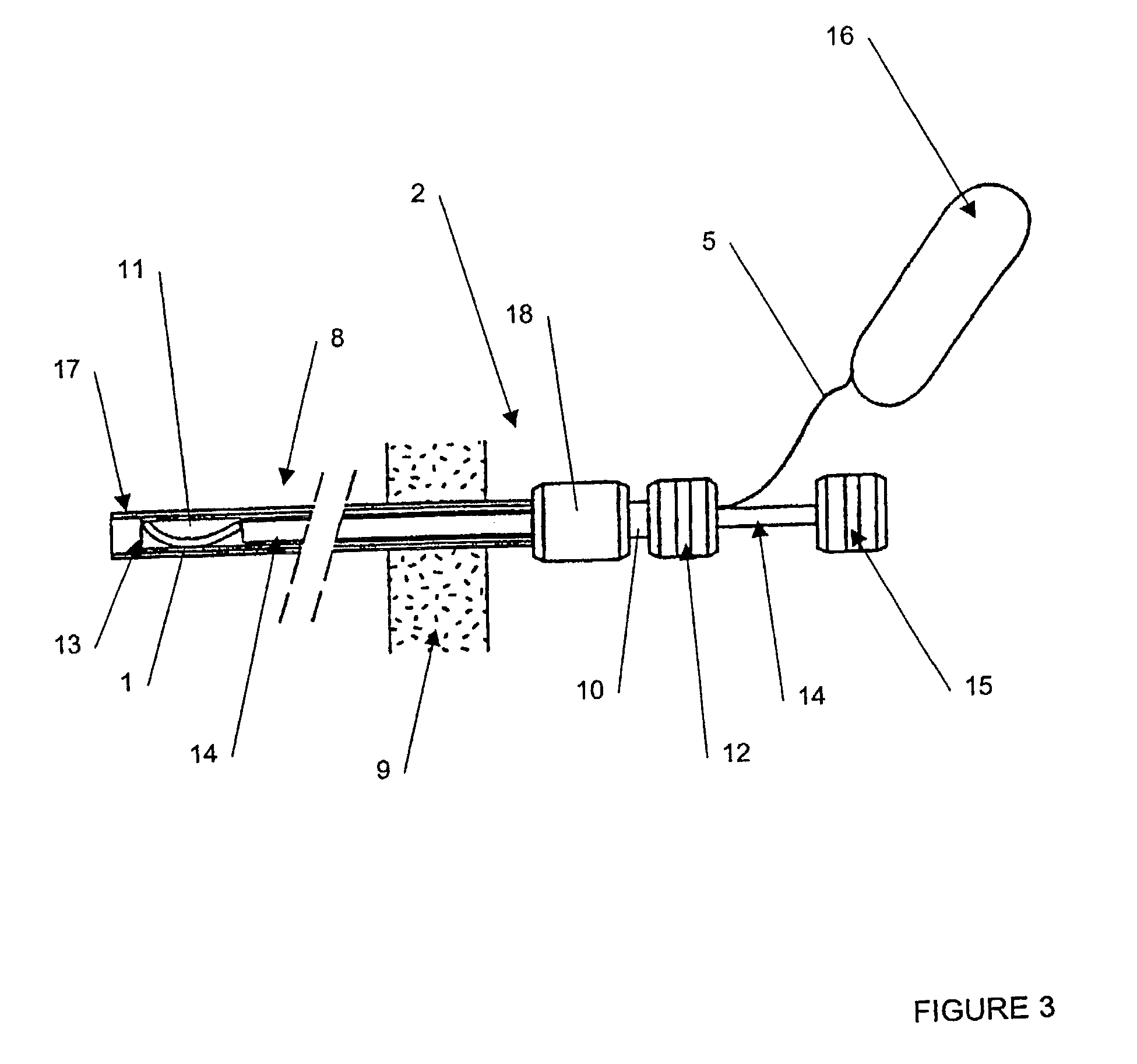

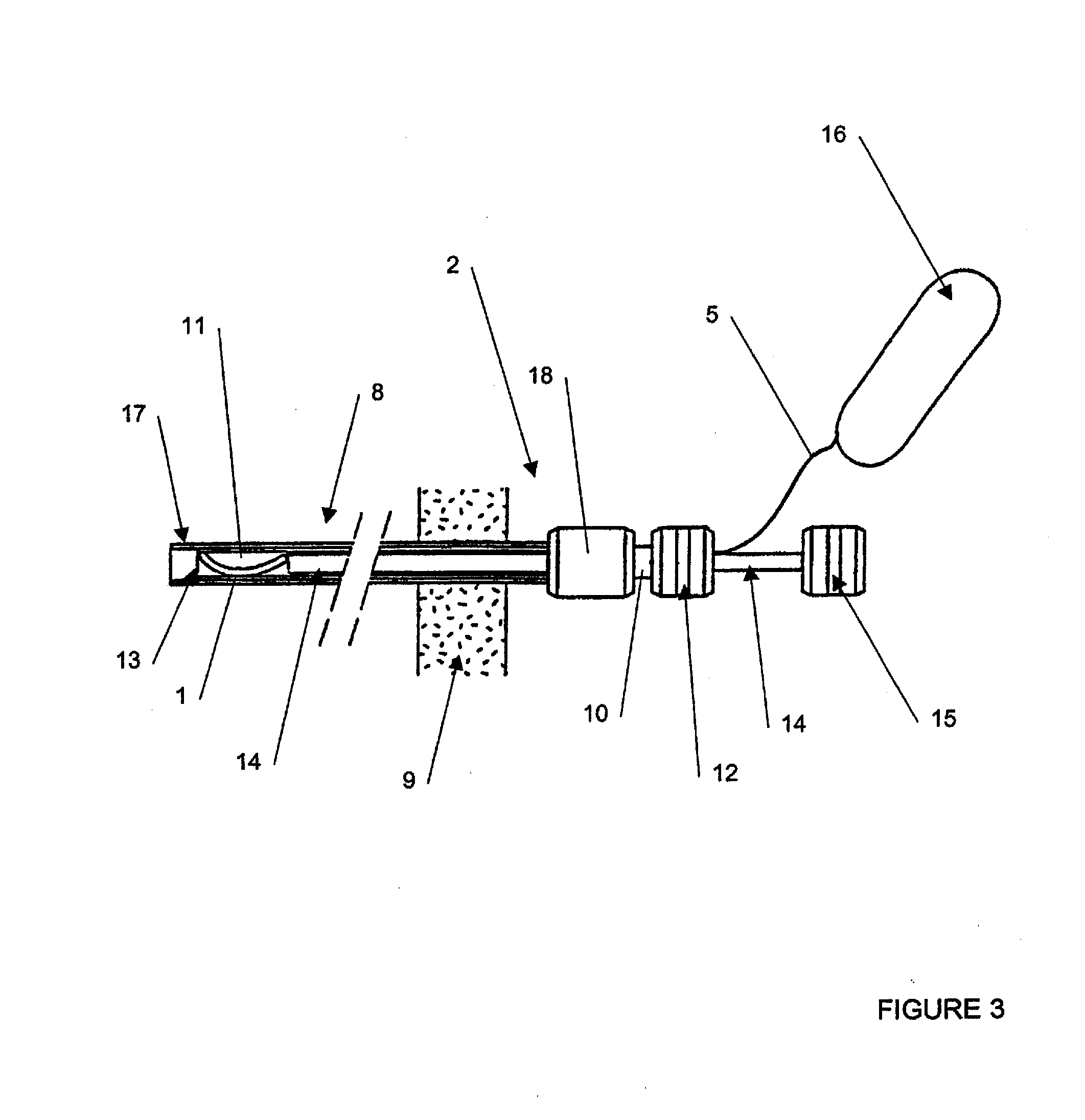

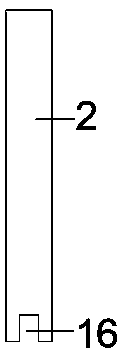

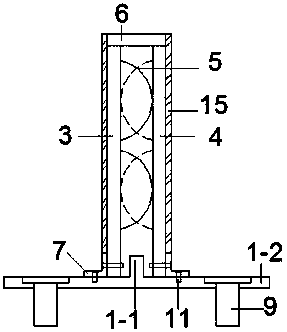

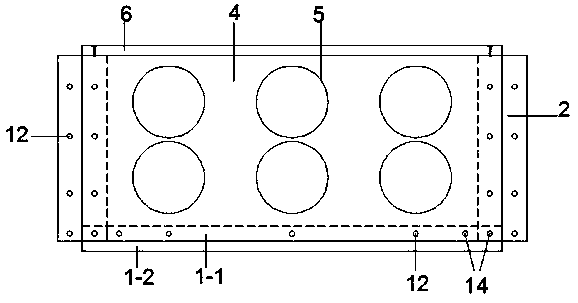

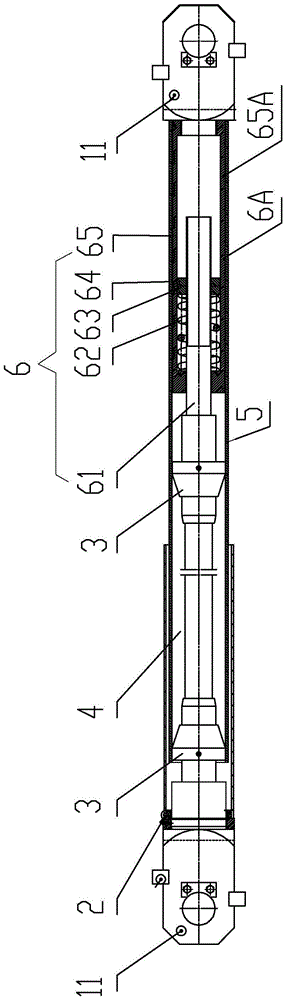

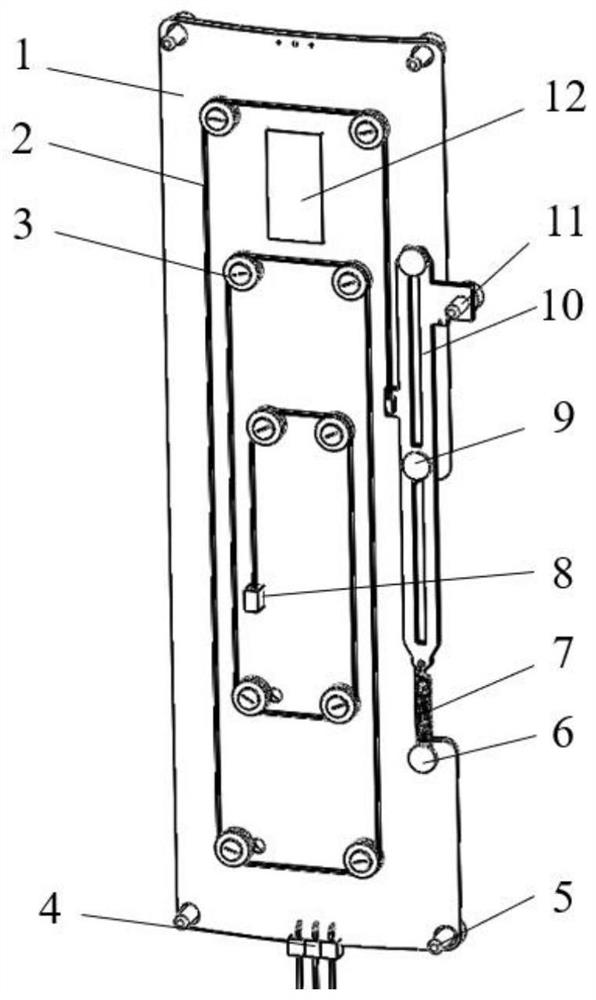

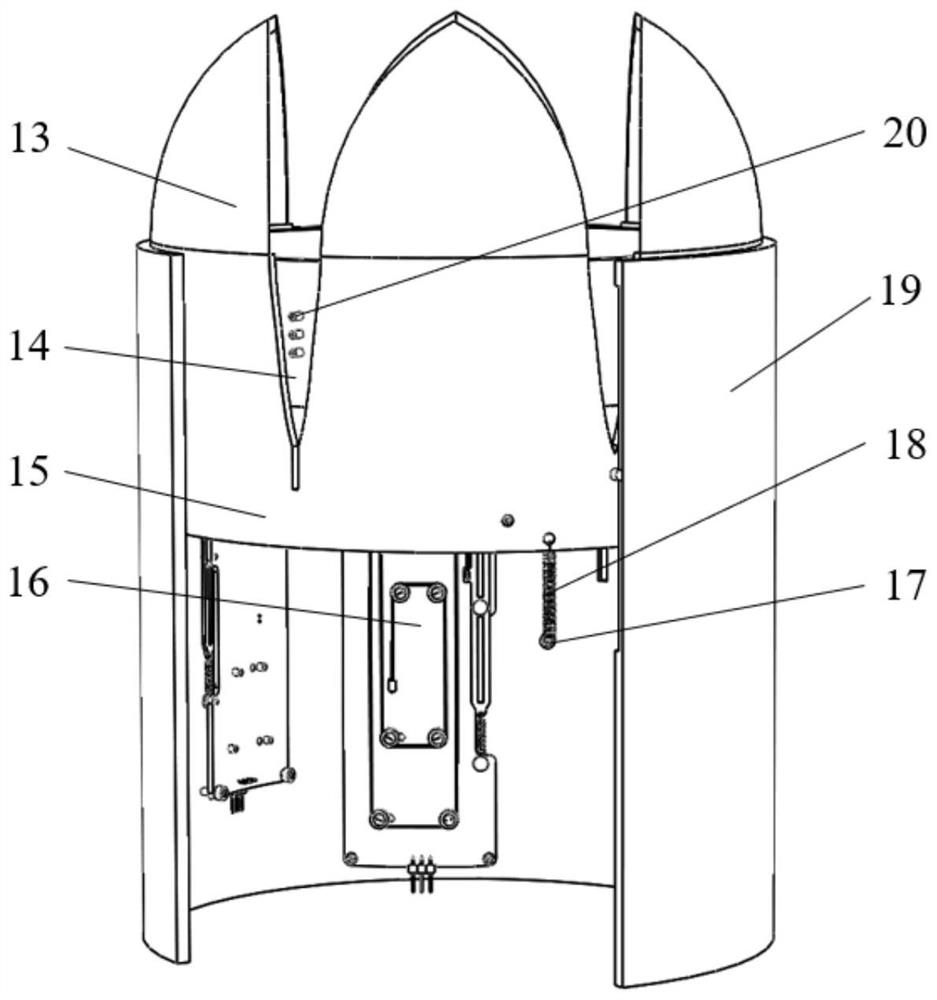

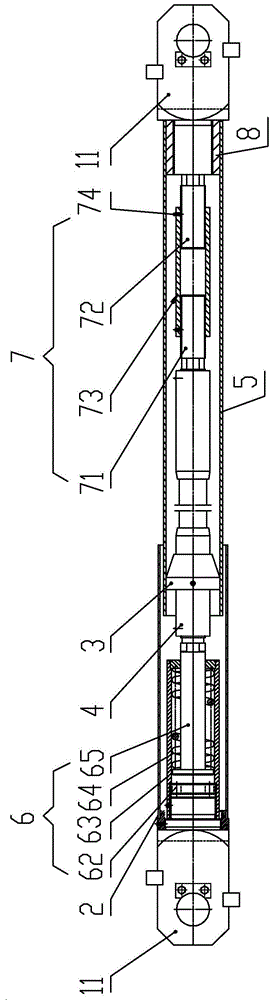

Hyper-elastic material high-speed stretching tester and experiment method

InactiveCN101504348AThe principle is simpleSolved the problem of not being able to apply a large amount of stretch to the specimenMaterial strength using single impulsive forceExperimental methodsCoupling

The invention relates to a high-speed stretching tester for a hyperelastic material and an experimental method. A speed regulation motor (12) is connected with a mass disc (10) through a coupler (11); the mass disc is connected with a turnplate (8) through a clutch (9); and two ends of a haulage rope (7) are fixedly connected with the turnplate (8) and a front stretching clamp (5) respectively. A test sample (4) is arranged between the front stretching clamp (5) and a rear stretching clamp (3). The centerlines of the haulage rope (7), the front stretching clamp (5), the test sample (4), the rear stretching clamp (3) and a load sensor (2) are in the same plane. When the speed regulation motor (12) rotates at high rotational speed, the outer edge of the turnplate (8) coaxially connected with the speed regulation motor (12) has high linear velocity and drives the haulage rope (7) to be wound on the turnplate (8) at a high speed and simultaneously drives the test sample (4) to move along the direction of the haulage rope (7) to allow the test sample (4) to have deformation; and the high-speed stretching tester solves the problem that a Hopkinson pull rod and other loading devices are adopted and cannot apply large elongation on the test sample and has the characteristics of simple operation and reliable testing data.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

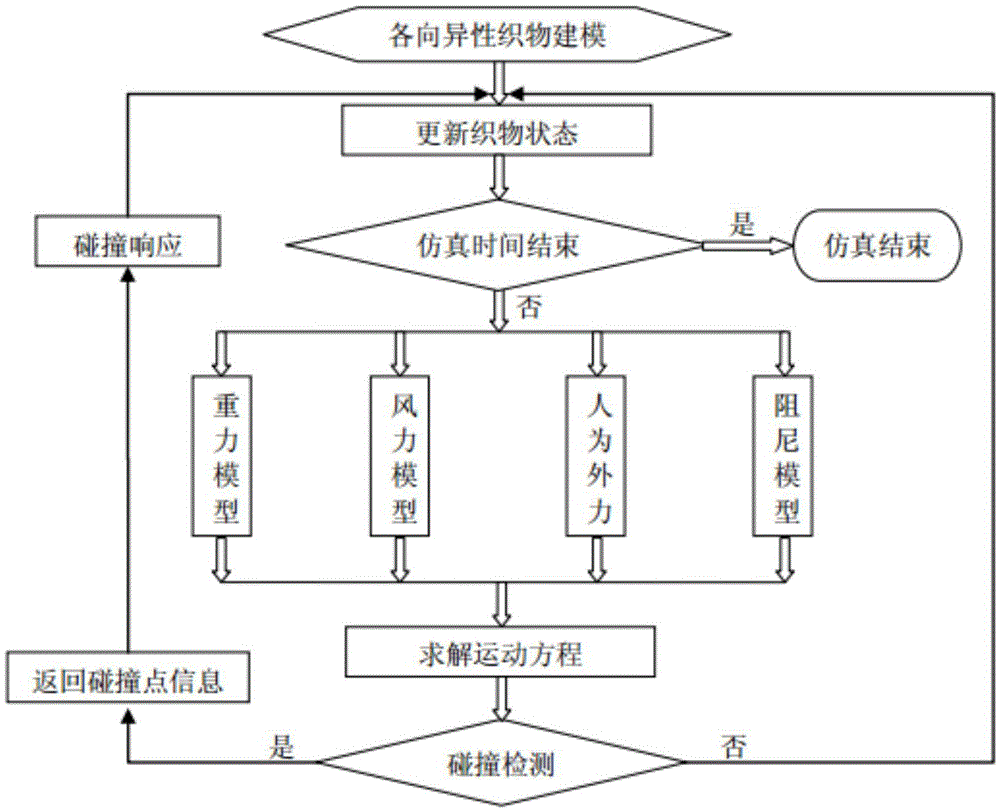

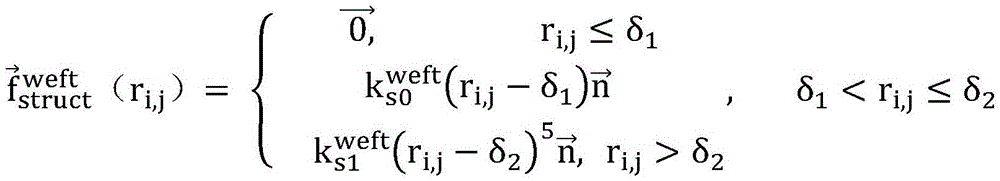

Fabric deformation simulation method

InactiveCN105677950AFully consider stretchabilityFully consider compressibilityComputer aided designSpecial data processing applicationsSurface roughnessEngineering

The invention discloses a fabric deformation simulation method which, based on the classic spring-mass model, introduces the concept of a semi-rigid spline, and takes into full consideration of stretching property, compressing property, cutting property, bending property and surface roughness of the fabric, and effectively addresses the problem of anisotropy and superelasticity in fabric deformation simulation, and increases real sense of fabric deformation simulation. In aspect of numerical integration, compared with traditional explicit euler method and implicit euler method which have defects of slow solution speed, the method of the invention Verlet integration method which has substantial increase in velocity and computing stability. In aspect of collision treatment, the method further simplifies a collision model, and only considers collisions of "top pint-triangle" type and "edge-edge" type that occur in large amount in fabric simulation, which effectively reduces times for collision treatment and accelerates computing velocity.

Owner:ZHEJIANG BABEI NECKTIE +1

Hyper-Elastic Needle

A method of arranging a surgical needle in an applicator. The needle is made of a hyper-elastic alloy which, after treatment, has two distinct states and includes a crimping zone for securing a suture to the needle, a free end having a tapered point which includes an inclined heel portion arranged on an inside portion of a curved profile. The method includes forcing the needle into a roughly elongated position when the needle is housed in an internal bore of the applicator. When the needle is not housed in an internal bore of the applicator, the needle adopts a curved profile as a result of superelasticity or hyper-elasticity of the needle.

Owner:SOPRANE

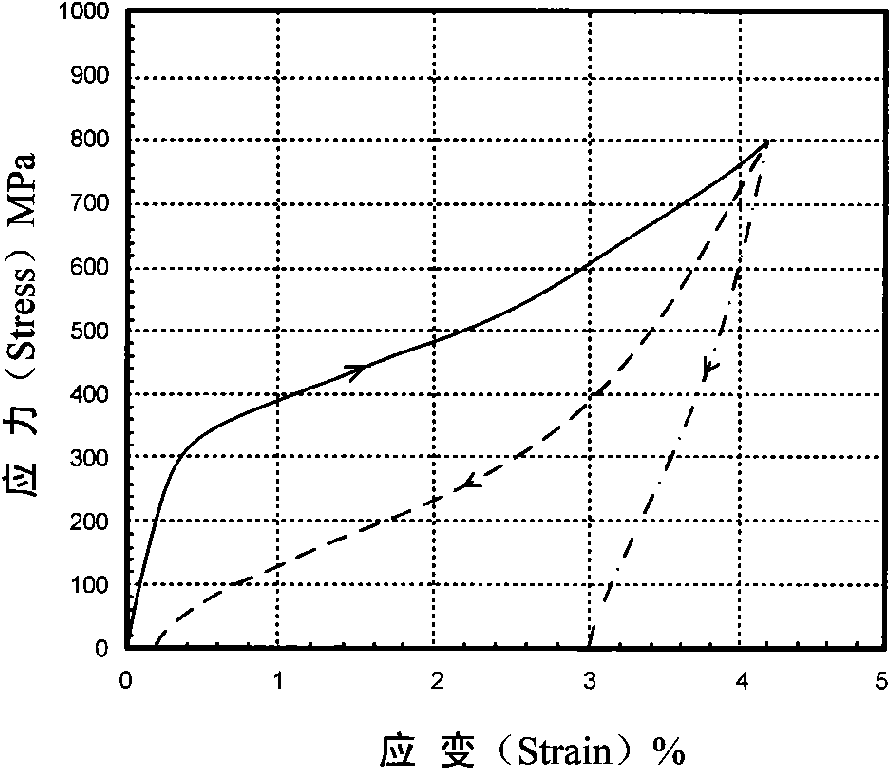

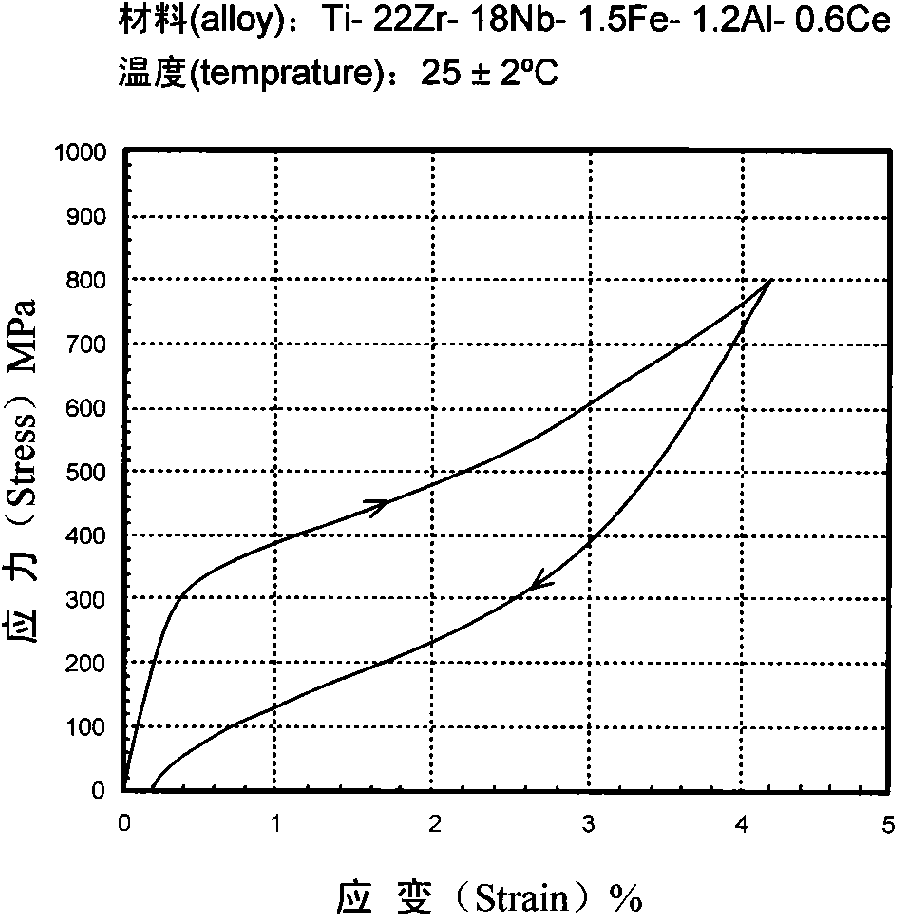

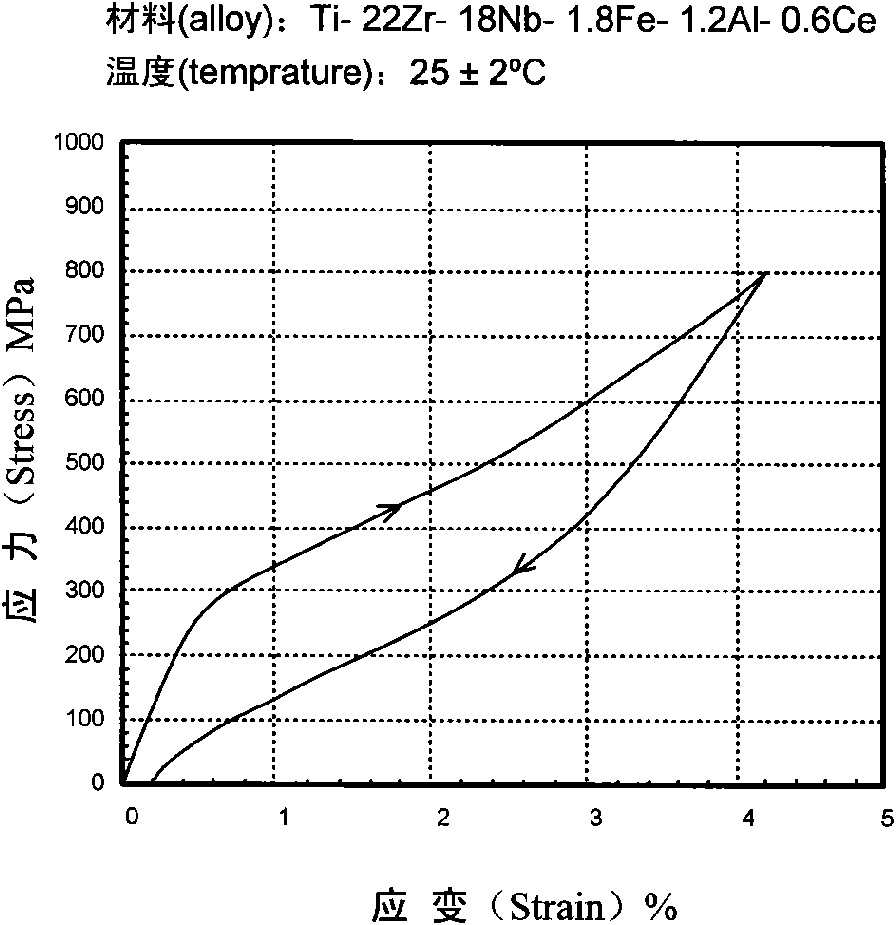

Ti-Zr-Nb-Fe-Al-Ce super elastic alloy and products thereof

InactiveCN101580906AImprove corrosion resistanceImprove high temperature oxidation resistanceImpression capsSurgeryBiocompatibility TestingShape-memory alloy

The invention relates to Ti-Zr-Nb-Fe-Al-Ce super elastic alloy and products thereof. Because of adding appropriate amount of Fe, Al and Ce elements, the super elastic alloy has high erosion resistance and oxidation resistance as well as excellent welding performance, cold workability, phase-changing super elasticity, shape memory property and biocompatibility. The welding performance, the cold workability and the biocompatibility of the alloy are better than those of TiNi shape memory alloy, while the super elasticity and the shape memory property are equivalent to those of the TiNi shape memory alloy. The Ti-Zr-Nb-Fe-Al-Ce super elastic alloy not only can be used as biomaterial capable of being implanted in a human body for a long time, but also can be used as industrial products made from the alloy such as spectacle frame, bra support, golf club head, pipe joint, spring and drive element; moreover, the alloy has the advantages of easy processing, low cost and wide application range.

Owner:深圳市星河泉新材料有限公司

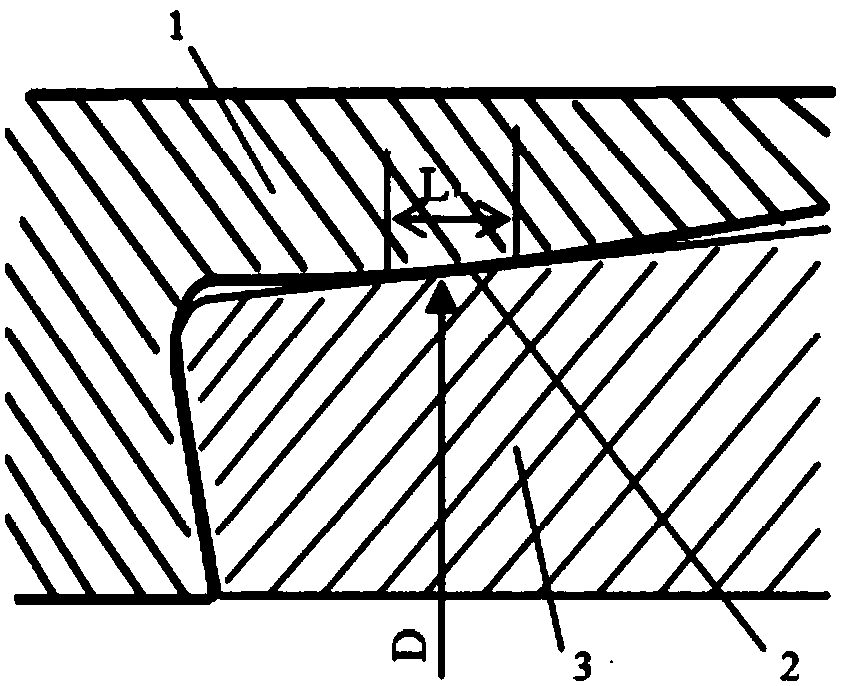

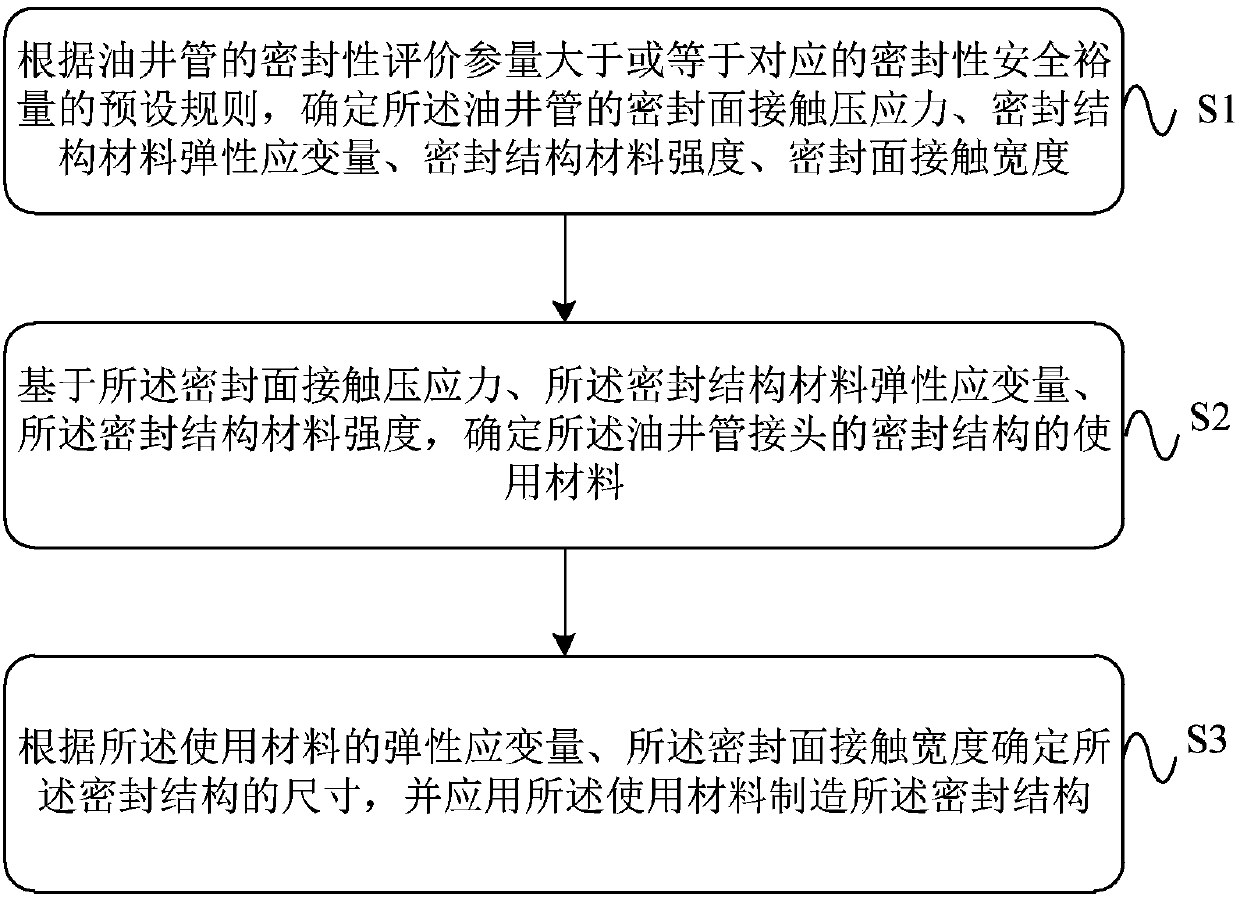

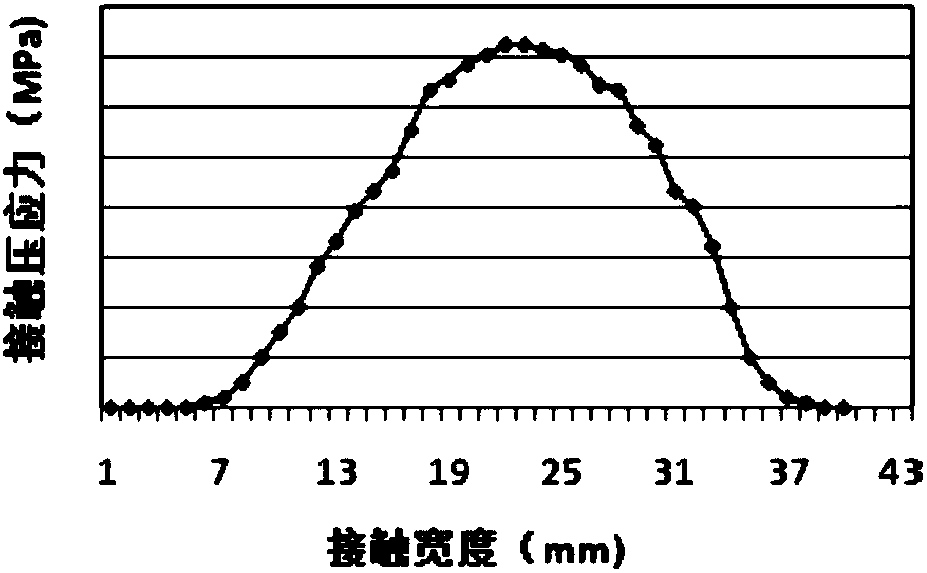

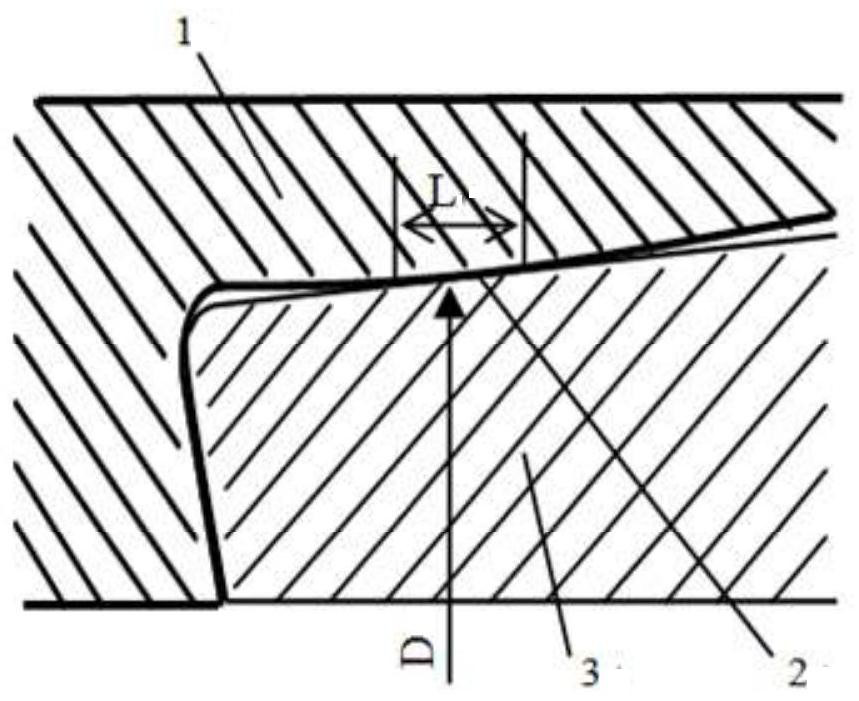

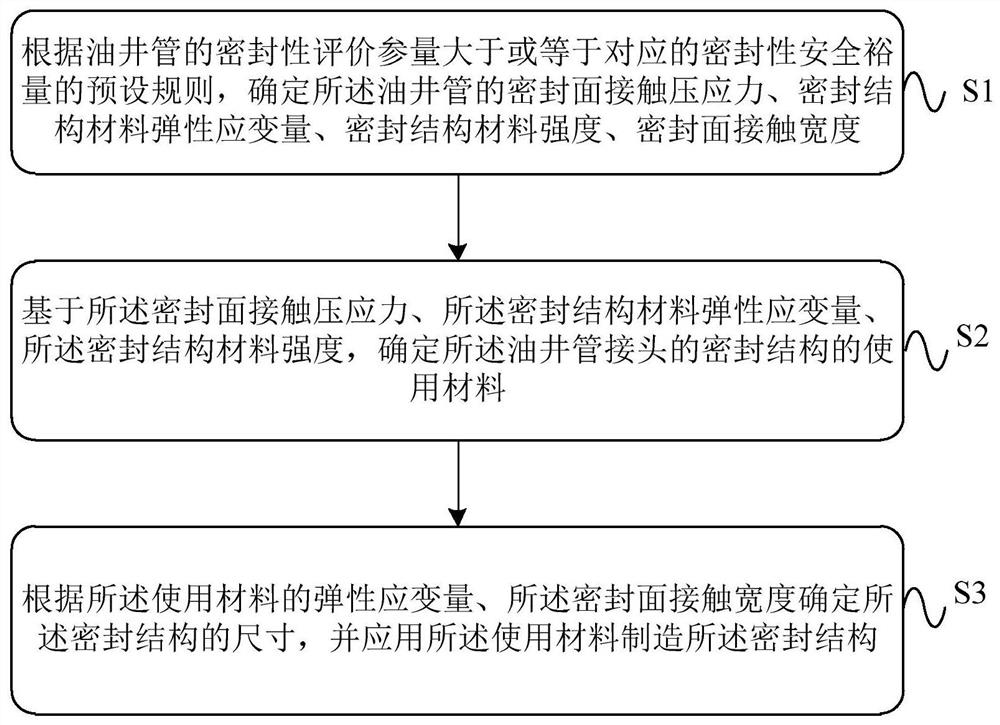

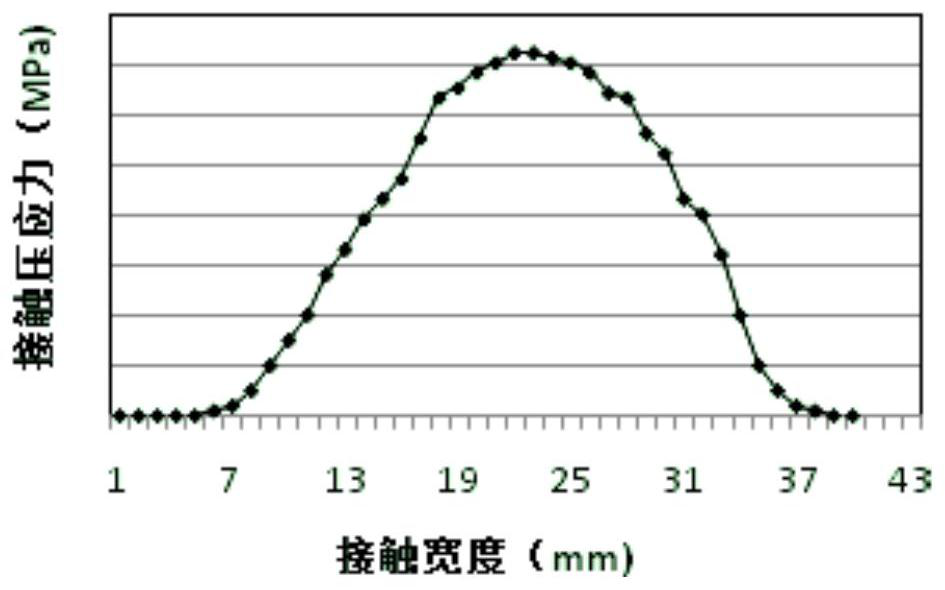

Designing and manufacturing method and sealing method of sealing structure of oil well pipe joint

ActiveCN110359858AImproves sealing reliabilityIncrease the amount of interferenceDrilling rodsDesign optimisation/simulationContact pressureAlloy

The invention provides a designing and manufacturing method and a sealing method of a sealing structure of an oil well pipe joint. The manufacturing method comprises the steps of according to a presetrule that a sealing performance evaluation parameter is larger than or equal to a corresponding sealing performance safety allowance of an oil well pipe, determining a sealing surface contact pressure stress, a sealing structure material elasticity strain capacity, sealing structure material strength and a sealing surface contact width of the oil well pipe; according to the sealing performance safety allowance of the oil well pipe, enabling the sealing structure material elasticity strain capacity to be larger than 0.5%; according to the sealing surface contact pressure stress, the sealing structure material elasticity strain capacity and the sealing structure material strength, determining a used material of the sealing structure; according to the determined sealing structure material elasticity strain capacity, determining the used material of the sealing structure as a hyperelastic alloy material with the elasticity strain capacity being larger than 0.5%; and manufacturing the sealing structure according to the used material and the elasticity strain capacity thereof. By utilizing the designing and manufacturing and the sealing method of the sealing structure of the oil well pipe joint provided by the embodiment of the invention, the reliability of a sealing performance of the oil well pipe joint is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Novel production method of copper-aluminum-manganses-beryllium memory hyperelastic alloy

InactiveCN101306500AImprove plasticityHigh Memory Super ElasticityMetal rolling arrangementsHyper elasticHigh memory

The invention relates to a method for the heated mold continuous casting production of a novel Cu-Al-Mn-Be memory hyper-elastic alloy. The invention is characterized in that the alloy is composed of the following alloying elements by the weight percentages as follows: Al 8-14%, Mn 3-11%, Be 0.2-0.6% and Cu in balancing amount. The method mainly includes the following technical steps: a Cu-Al-Mn-Be memory hyper-elastic mother alloy is ingoted in a smelter and smelted in the presence of argon gas under the pressure of -0.04Mpa to -0.1Mpa, so as to obtain a Phi 120 round ingot; the ingot is subjected to uniform heat treatment at 840 DEG C-860 DEG C for 9.5h-10.5h, hot-rolled into wire material, sheet material or belt material at 740 DEG C-760 DEG C, then hot-drawn into thread material semi-finished products at 645 DEG C-655 DEG C; and the thread material semi-finished products is subjected to heat treatment for obtaining the finished product thread material. The Cu-Al-Mn-Be memory hyper-elastic alloy produced by the method has good plasticity and high memory hyper-elastic capability.

Owner:江阴鑫裕装潢材料有限公司

Highway double-way anti-collision energy consuming plate

InactiveCN110144839AProtection securityProtectiveRoadway safety arrangementsHyper elasticEngineering

The invention relates to a highway double-way anti-collision energy consuming plate and belongs to the technical field of road construction. The highway double-way anti-collision energy consuming plate comprises an embedded concrete base, a rectangular solid body and a bottom plate; the embedded concrete base is embedded underground and connected with the ground through a bolt by using a concreteconnecting piece to form a highway anti-collision plate basic structural body; after connection, an elastic energy consuming plate I and an elastic energy consuming plate II are placed on the two sides of the rectangular solid body and the two sides of the concrete connecting piece on the embedded concrete base; a hyper-elastic memory alloy hemisphere is placed between the elastic energy consumingplate I and the elastic energy consuming plate II and connected to the rectangular solid body and the concrete connecting piece through a bolt; a concrete cover plate is placed on the hyper-elastic memory alloy hemisphere and connected with the hyper-elastic memory alloy hemisphere through a bolt; and anti-collision cushion layers are placed on the external side of the elastic energy consuming plate I and the external side of the elastic energy consuming plate II. The highway double-way anti-collision energy consuming plate has the beneficial effects that the mounting is simple, the materialis cheap, the transportation is convenient, the repairing is simple, and the efficient anti-collision effect can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

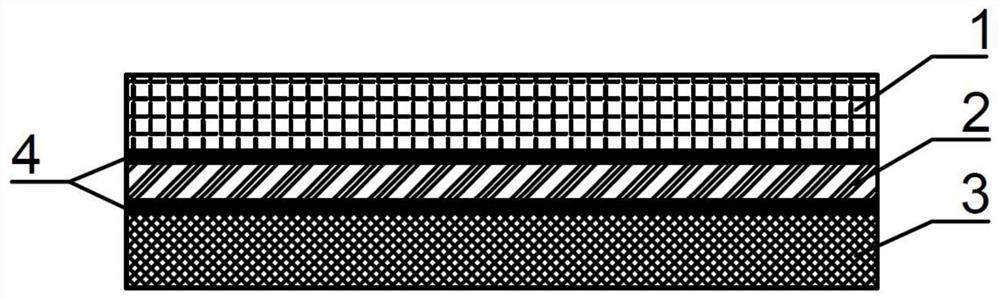

Lightweight functionally graded composite bulletproof armor plate and preparation method thereof

PendingCN112140654AImprove the protective effectReduce weightLamination ancillary operationsProtective equipmentShape-memory alloyHyper elastic

The invention discloses a lightweight functionally graded composite bulletproof armor plate and a preparation method thereof. The lightweight functionally graded composite bulletproof armor plate comprises a bulletproof ceramic plate, a shape memory alloy layer and an ultrahigh molecular weight polyethylene plate, and the shape memory alloy layer is arranged between the bulletproof ceramic plate and the ultrahigh molecular weight polyethylene plate; the shape memory alloy layer serves as the sandwich plate, the hyper-elastic effect of the shape memory alloy layer is exerted, the composite plate with a sandwich structure is formed, the defects of an existing bulletproof armor material are overcome, the weight is greatly reduced compared with bulletproof steel under the condition of the sameprotective capacity, and then the high practical value of the bulletproof composite armor plate is achieved. The bulletproof composite armor plate can be used as a preparation material of armor equipment, and is applied to the fields of armor equipment including armored vehicles, naval vessels, bulletproof clothes, bulletproof helmets and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Process for Producing a Hyper-Elastic, High Strength Dilatation Balloon made from Multi-Block Copolymers

InactiveUS20090140449A1Increase elasticityLow profileCatheterCeramic shaping apparatusHyper elasticHigh intensity

A self-wrapping dilatation balloon comprising a multiblock copolymer having high elasticity and elastic recovery from nominal strains greater than about 30% is described. Also described herein, is a polymeric extrudate for making a dilatation balloon comprising a multiblock copolymer having tensile strength in the range of about 50 MPa to about 450 MPa, strain at break in the range of about 50% to about 600% and substantially complete elastic recovery from nominal strains of at least about 30%. The extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. Also described herein is a process for producing a polymeric extrudate for use as a dilatation balloon. The process comprises extruding a multiblock copolymer mixture or composition to form an extrudate. The extruding is done such that the extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. After extrusion, the process optionally comprises the steps of drawing and coagulating the extrudate.

Owner:VARMA ASHISH +5

Spinal fusion cage

InactiveCN106109064AHigh mechanical strengthSuper elasticSpinal implantsSpinal columnMetallic materials

The invention discloses a spinal fusion cage, and belongs to the technical field of bio-medical metal materials, in particular a homogeneous hyper-elastic porous interbody fusion cage. The spinal fusion cage provided by the invention has a novel structure. The spinal fusion cage, through special structural design, not only guarantees braking, fixing and durable supporting performances but also greatly improves a fusion rate between an implant and surrounding tissues, so that the problems that the spinal fusion cage is easily loosened and is poor in new bone formation capacity are thoroughly solved. The spinal fusion cage disclosed by the invention is integrally represented as a three-dimensional interlinked porous structure and is made by weaving and sintering metal wires; and the metal wires are made from pure titanium, titanium alloy, pure tantalum or tantalum alloy.

Owner:NORTHEASTERN UNIV

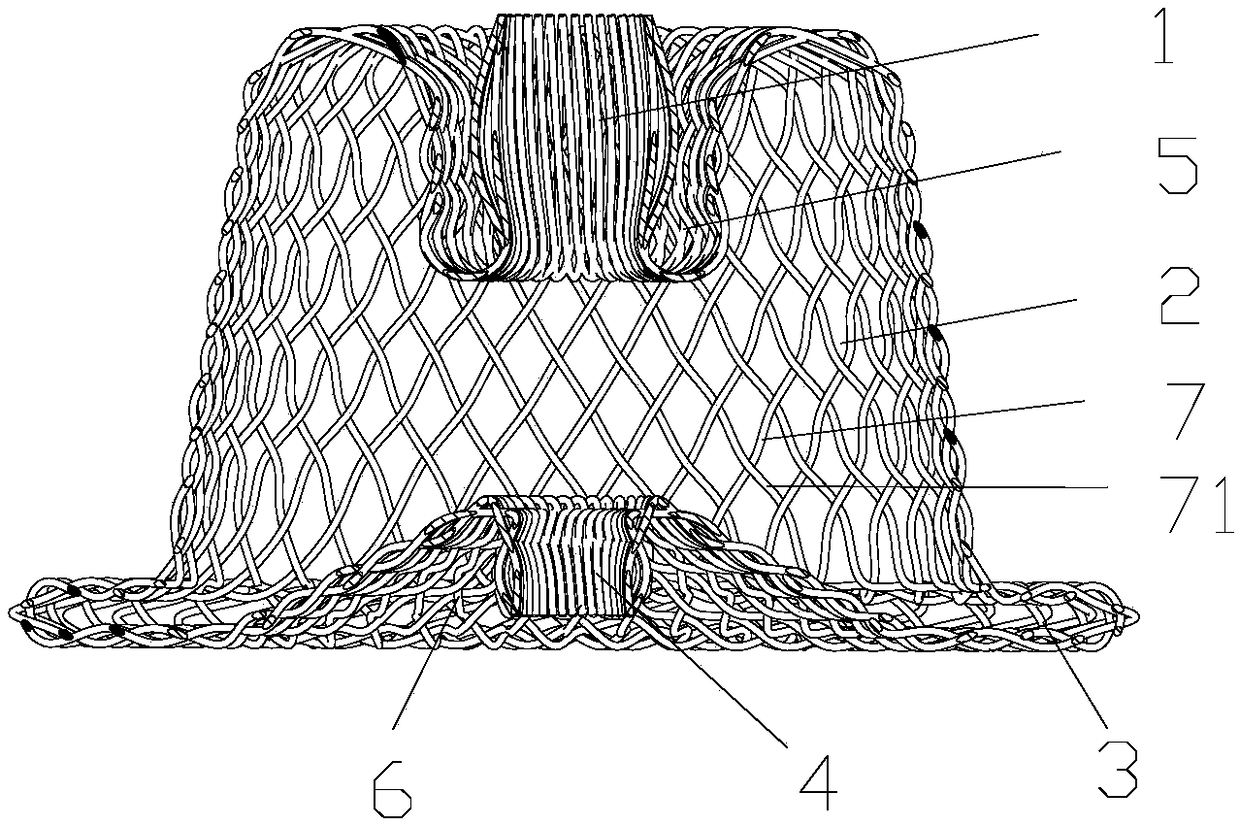

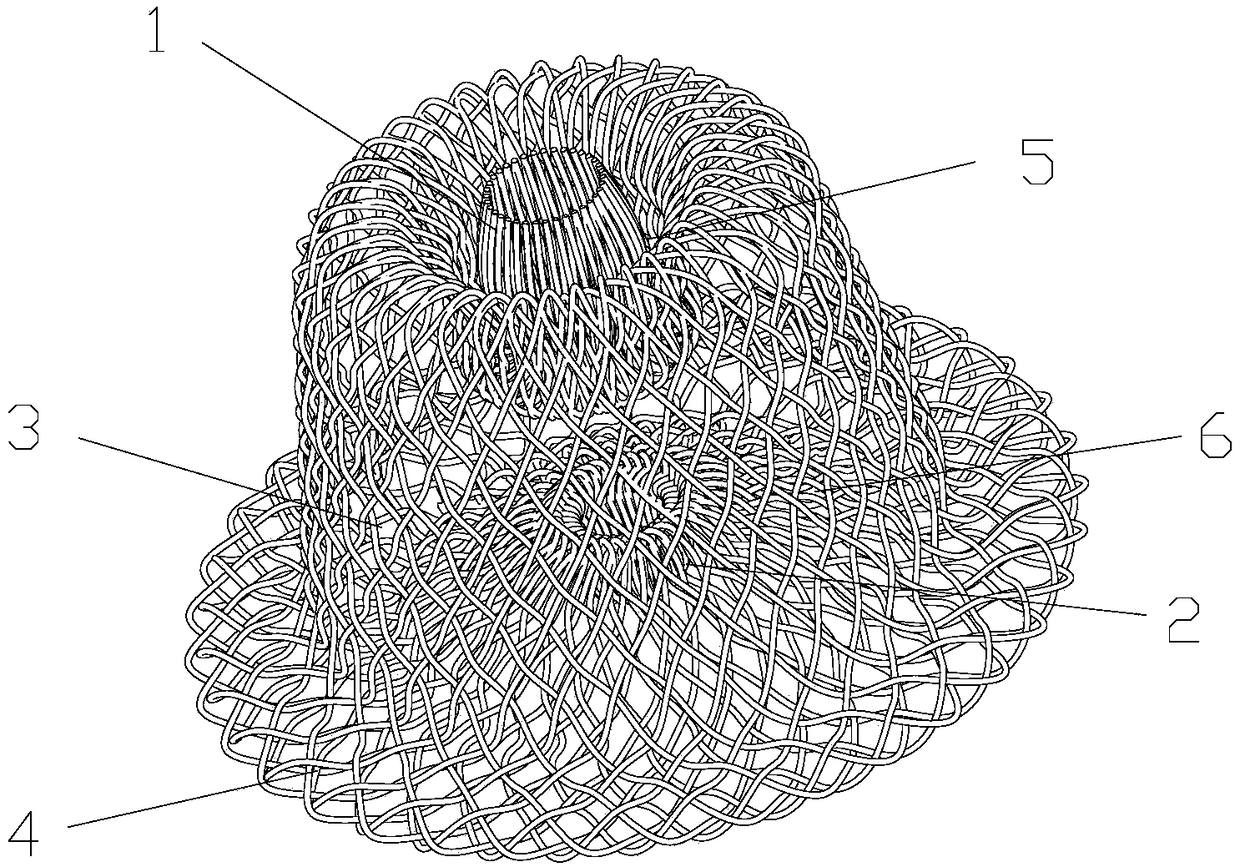

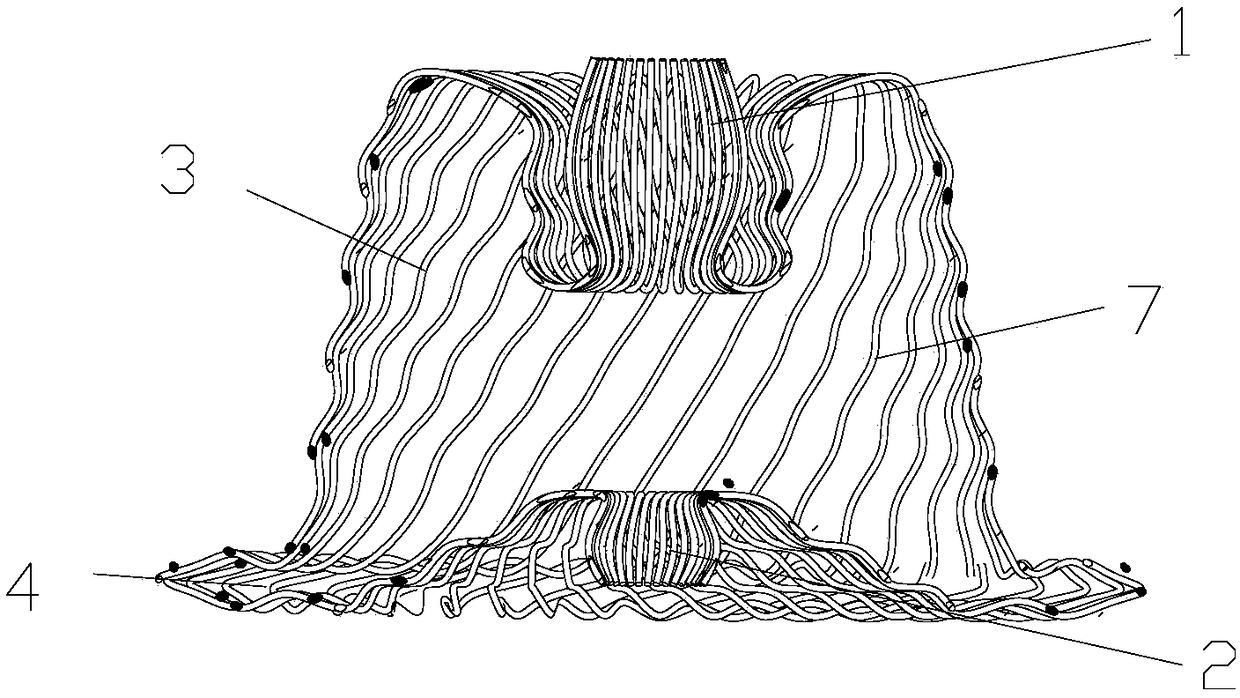

Arterial duct open plug

The invention relates to the technical field of medical apparatuses, in particular to an arterial duct open plug. The arterial duct open plug is a rotating body formed by weaving and twining a plurality of hyper-elastic metal alloy wires in an open state. The rotating body comprises a first connecting part, a second connecting part, a circular truncated cone-shaped body and a disk-shaped body. A first concave opening is downwards indented in the middle of the top face of the circular truncated cone-shaped body. The first connecting part is formed in the first concave opening. The upper portionand the lower portion of the first connecting part are closed up, and the middle of the first connecting part protrudes towards the outside. The disk-shaped body is arranged at the bottom of the circular truncated cone-shaped body. The upper surface of the disk-shaped body is connected with the bottom side of the circular truncated cone-shaped body. A second concave opening is upwards indented inthe middle of the lower surface of the disk-shaped body. The second connecting part is formed in the second concave opening. The upper portion and the lower portion of the second connecting part areclosed up, and the middle of the second connecting part protrudes towards the outside. The arterial duct open plug is convenient to unfold completely, effective in fixing and capable of preventing disengagement.

Owner:陈金凤

A superelastic decorative cable

ActiveCN104963287BReasonable structureMeet the appearance and size requirementsBridge structural detailsHyper elasticMechanical engineering

Owner:LIUZHOU OVM MASCH CO LTD

Design and manufacturing method and sealing method of sealing structure of oil well pipe joint

ActiveCN110359858BImproves sealing reliabilityIncrease the amount of interferenceDrilling rodsDesign optimisation/simulationContact pressureHyper elastic

The present application provides a design and manufacturing method of a sealing structure of an oil well pipe joint, and a sealing method. The manufacturing method includes: determining the contact pressure stress of the sealing surface of the oil well pipe, the elastic strain amount of the sealing structure material, the strength of the sealing structure material, The contact width of the sealing surface; according to the sealing safety margin of the oil well pipe, the material elastic strain of the sealing structure is greater than 0.5%; according to the contact compressive stress of the sealing surface, the material elastic strain of the sealing structure, and the strength of the sealing structure material, determine the sealing structure. Use material; according to the determined elastic strain amount of the sealing structure material, determine the used material of the sealing structure to be a superelastic alloy material with an elastic strain amount greater than 0.5%; manufacture the sealing structure according to the used material and its elastic strain amount. By using the various embodiments of the present application, the reliability of the joint sealing performance of the oil country tubular goods is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

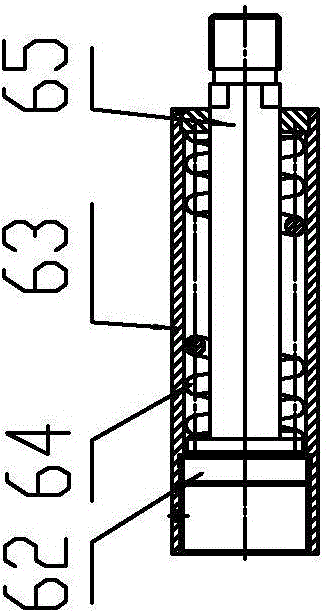

A Direct-Push Mechanical 3D Iris Device Based on Superelastic Shape Memory Alloy Blades

ActiveCN110928106BRealize opening and closingLarge caliberCamera diaphragmsShape-memory alloyHyper elastic

The present invention proposes a direct-push mechanical 3D iris device based on superelastic shape memory alloy blades, including an iris mechanism module and a drive module; the iris mechanism module includes blades, an outer shell and an inner shell; the blades are superelastic shape memory alloy blades; The bottom of each superelastic shape memory alloy blade is fixed on the same blade ring, and the free shape of all superelastic shape memory alloy blades is the hemispherical shape when the blade is closed; the driving module can drive the blade ring to move in the axial direction; when the driving module drives the blade When the ring retracts in the axial direction, the blades of the superelastic shape memory alloy are opened, deformed by the action of the outer shell and the inner shell, and retracted between the outer shell and the inner shell; when the driving module drives the blade ring to extend axially, the superelastic shape Memory alloy blades protrude from between the outer shell and the inner shell and restore the free shape. The invention overcomes the disadvantage that the traditional 3D spherical iris shell needs to be designed as a spherical surface, so the iris device can be designed as a straight cylinder, and the head diameter is increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

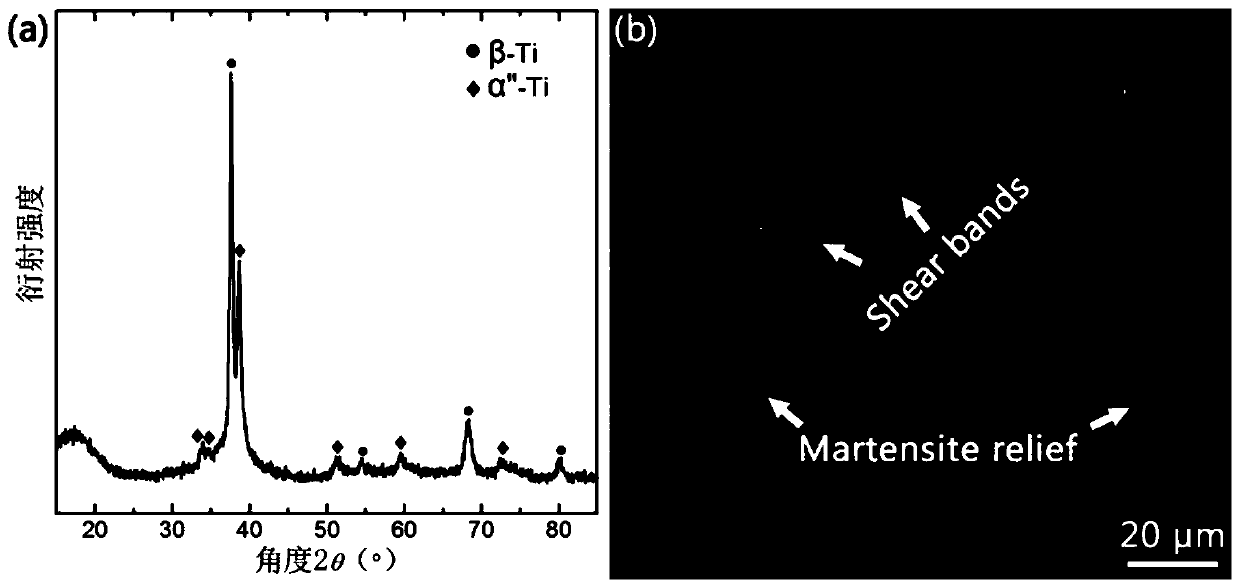

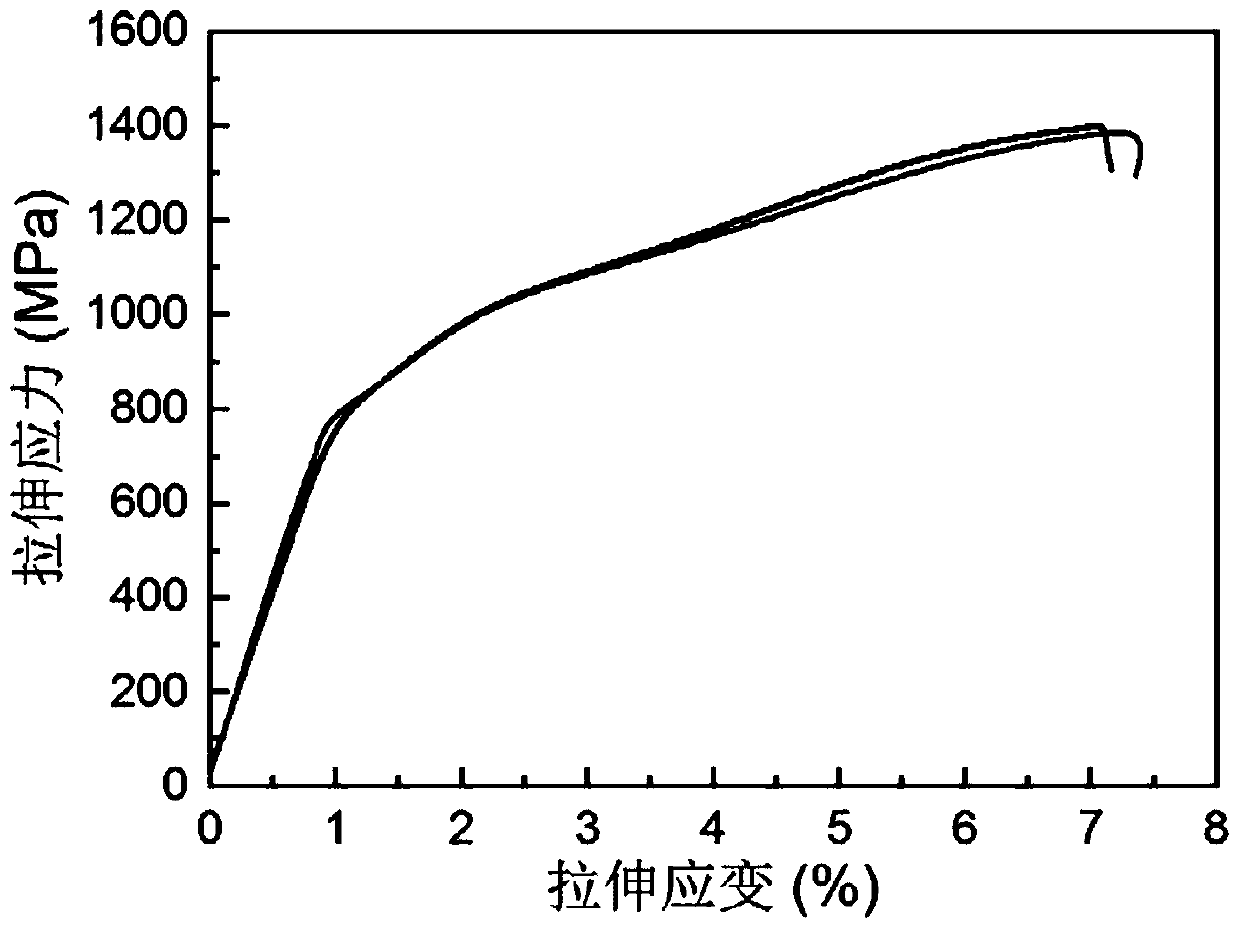

Method for improving mechanical properties of amorphous endogenous composite materials through amorphous matrix structural recovery

The invention relates to a method for improving mechanical properties of amorphous endogenous composite materials through amorphous matrix structural recovery, and belongs to the field of amorphous alloys and endogenous composite materials thereof. The amorphous endogenous composite materials have the microstructure characteristics that reversible phase change endogenous crystalline-state phases are distributed in an amorphous matrix. Under the action of a tensile load, the amorphous endogenous composite materials show super-elasticity, and that is shapes completely recover after small strainunloading. Tensile circulation loading is carried out at small strains, the structural recovery driven by ''shape memory effect'' happens to amorphous matrix phases in the amorphous endogenous composite materials. The amorphous matrix of the structural recovery can enable the mechanical properties of the amorphous endogenous composite materials to be improved, for example, the tensile plasticity is improved, and a work hardening stage is prolonged. According to the method, the mechanical properties of the amorphous endogenous composite materials can be improved, so that the practical application of the amorphous endogenous composite materials being used as the structural materials is expanded, and important socioeconomic benefits are achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

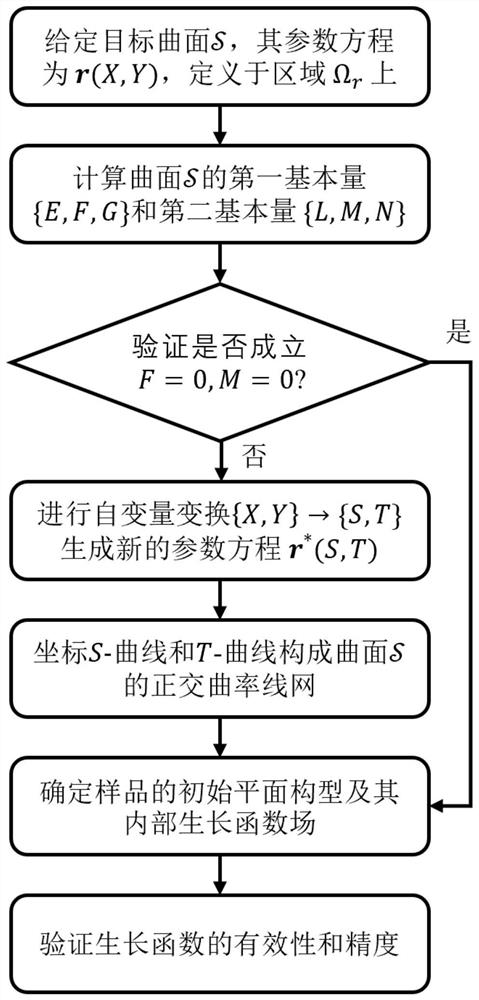

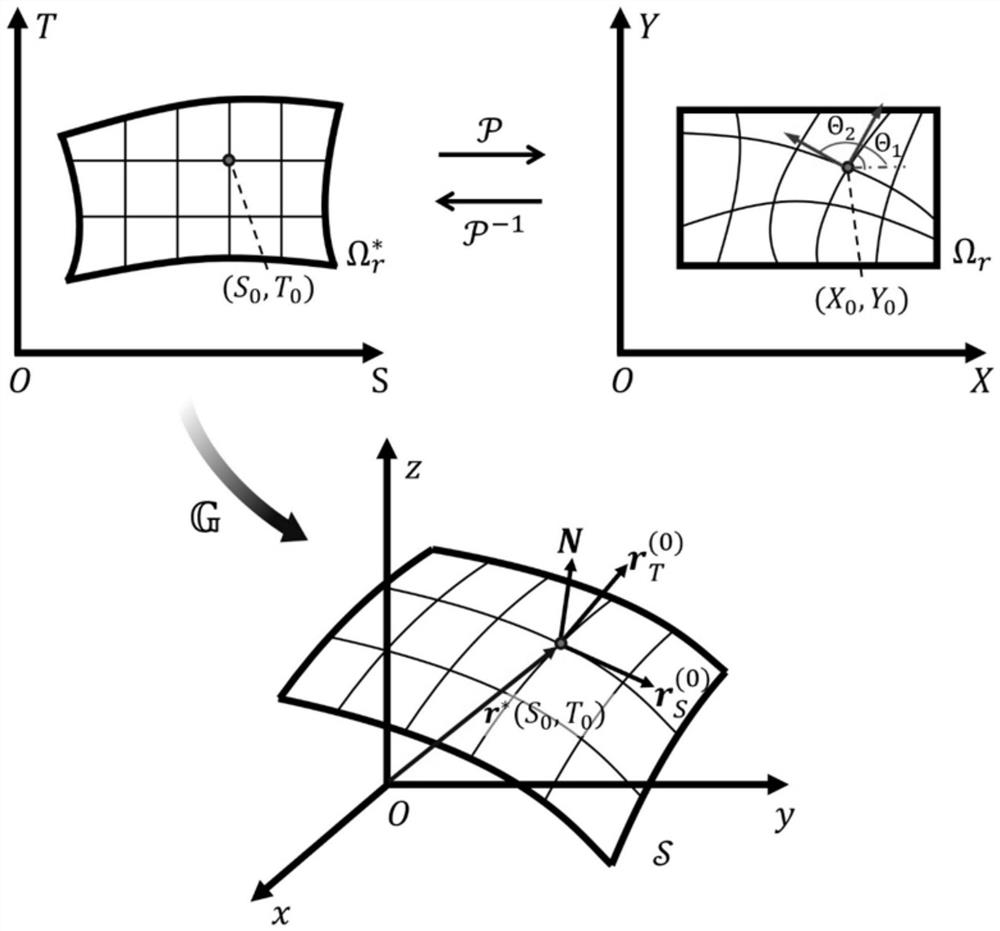

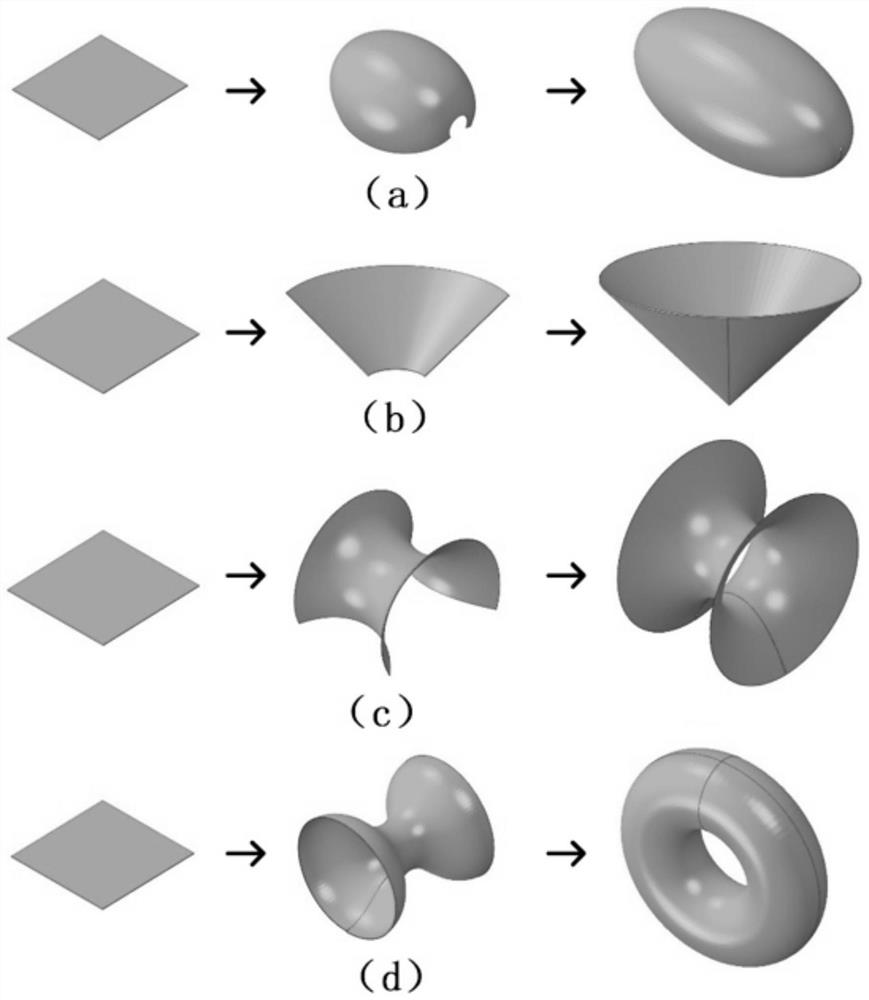

Hyperelastic thin plate configuration evolution control method and system based on growth deformation and medium

PendingCN114239334ADesign optimisation/simulationSpecial data processing applicationsClassical mechanicsHyper elastic

The invention discloses a hyperelastic thin plate configuration evolution control method and system based on growth deformation and a medium, and the method comprises the steps: S1, calculating a first class basic quantity and a second class basic quantity of a target curved surface according to a parameter equation of the target curved surface; s2, judging whether the coordinate curve forms an orthogonal curvature line net or not according to the first type of basic quantity and the second type of basic quantity, and if so, executing the step S4; if not, executing the step S3; s3, performing independent variable transformation on the parameter equation of the target curved surface to enable the new coordinate curve to form an orthogonal curvature line net on the curved surface; and S4, determining the initial plane configuration of the plate-shaped sample and the distribution of the growth function in the plate-shaped sample according to the first basic quantity and the second basic quantity. According to the method, whether a parametric curved surface coordinate net is an orthogonal curvature line net or not is considered, and the growth function of any parametric curved surface can be calculated. The method can be widely applied to the technical field of software intelligent device design and development.

Owner:SOUTH CHINA UNIV OF TECH

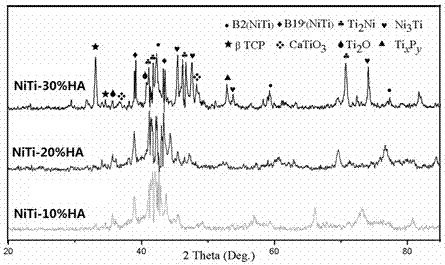

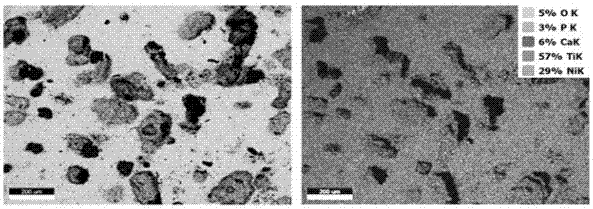

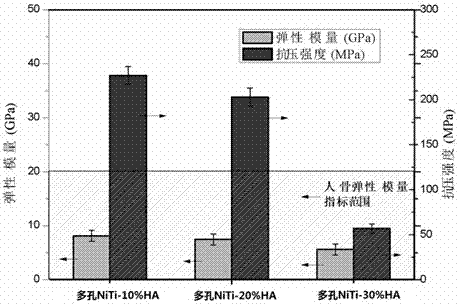

A kind of preparation method of porous nickel-titanium/hydroxyapatite composite material

Owner:KUNMING UNIV OF SCI & TECH

Hyper-elastic decorative stay cable as well as making and mounting method thereof

ActiveCN104963288AReasonable structureMeet the appearance and size requirementsBridge structural detailsBridge erection/assemblyHyper elasticEngineering

Owner:LIUZHOU OVM MASCH CO LTD

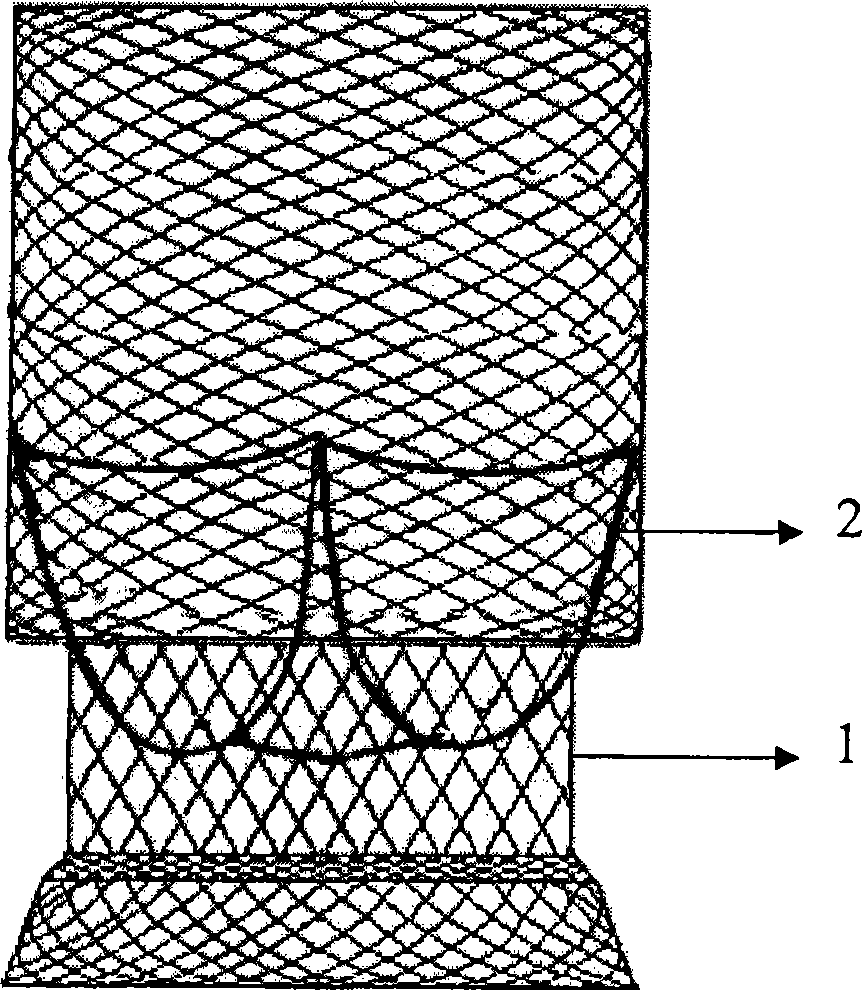

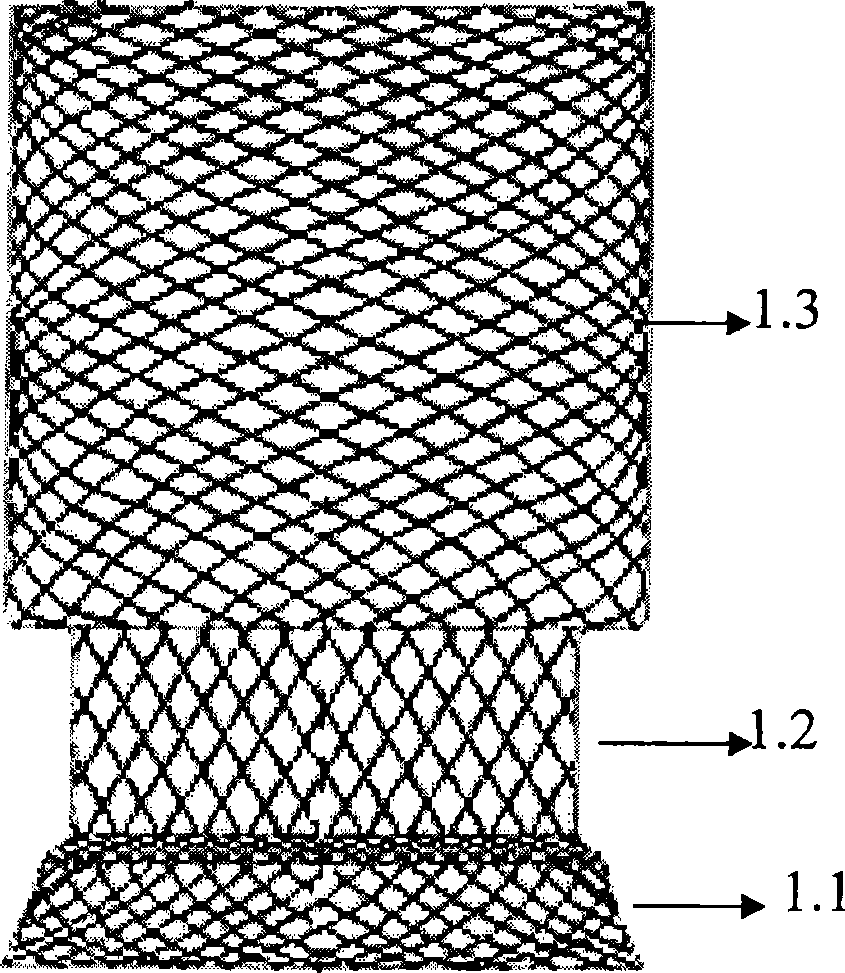

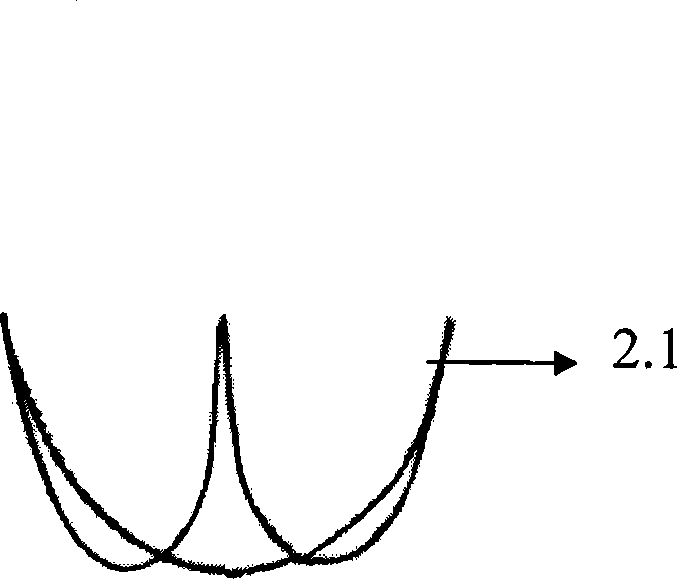

Lung arterial support with valve

The invention relates to the field of medical apparatus technique, which in detail is a cradle with valve pulmonary artery, comprising tubular cradle (1) and valve (2) inside it. The tubular cradle is braided with hyper-elastic shape memory alloy silk, and comprises head (1. 1), neck (1. 2) and body (1. 3). The head is near to heart and in horn shape, which matches to shape of pulmonary artery opening; the neck is a little narrower and connects head and body; the body is straight tube shape, the outer diameter is a little bigger than that of internal diameter of pulmonary artery. The valve comprises valve mount (2. 1) and valve leaf (2. 2), and the valve mount is made from hyper-elastic shape memory alloy silk. The wall of cradle is thin and soft, easy to compress, and it is convenient to put it into tube, thin conveying tube can be used to reduce injury. Because the valve leaf is fixed on valve mount, the sewing of tubular cradle is convenient and it will not move, and the curative effect is ensured.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

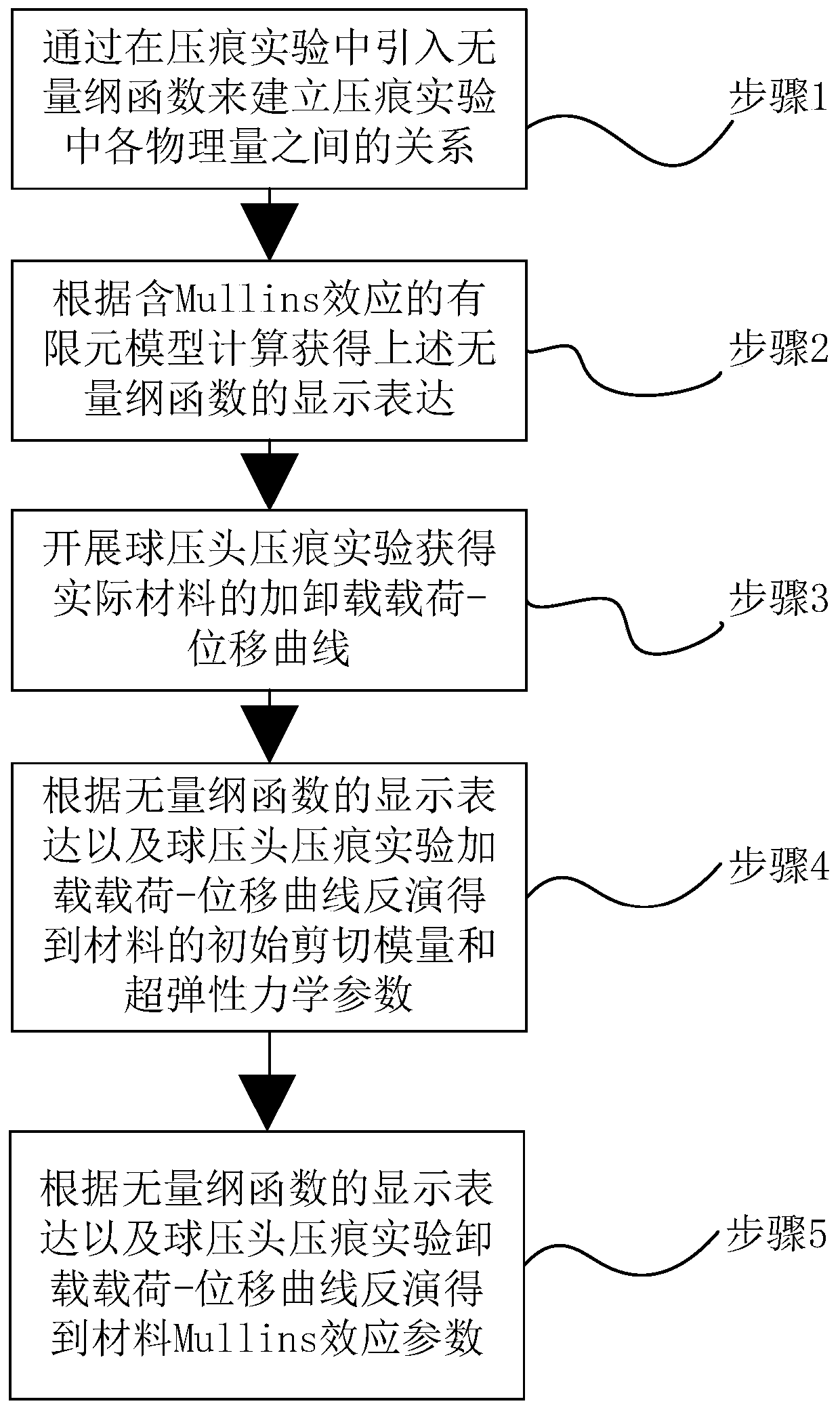

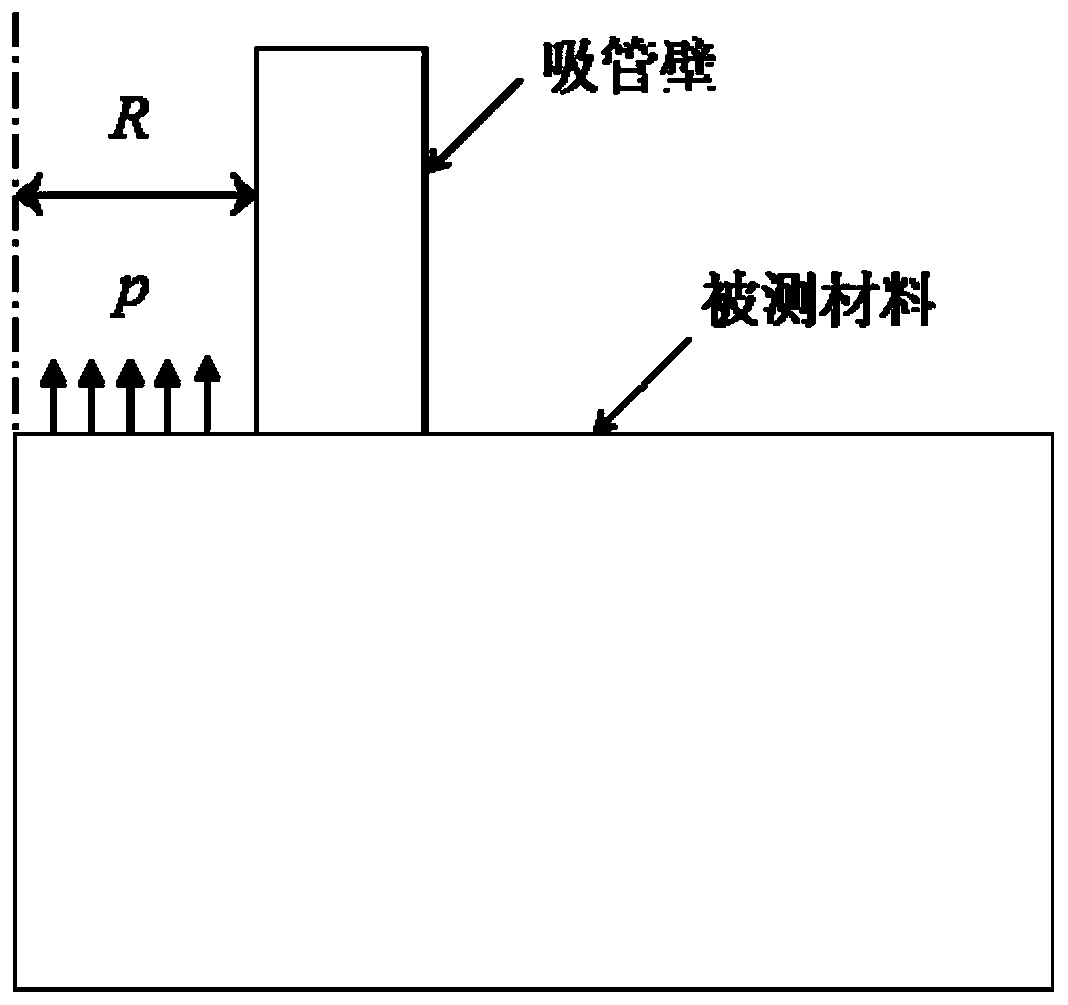

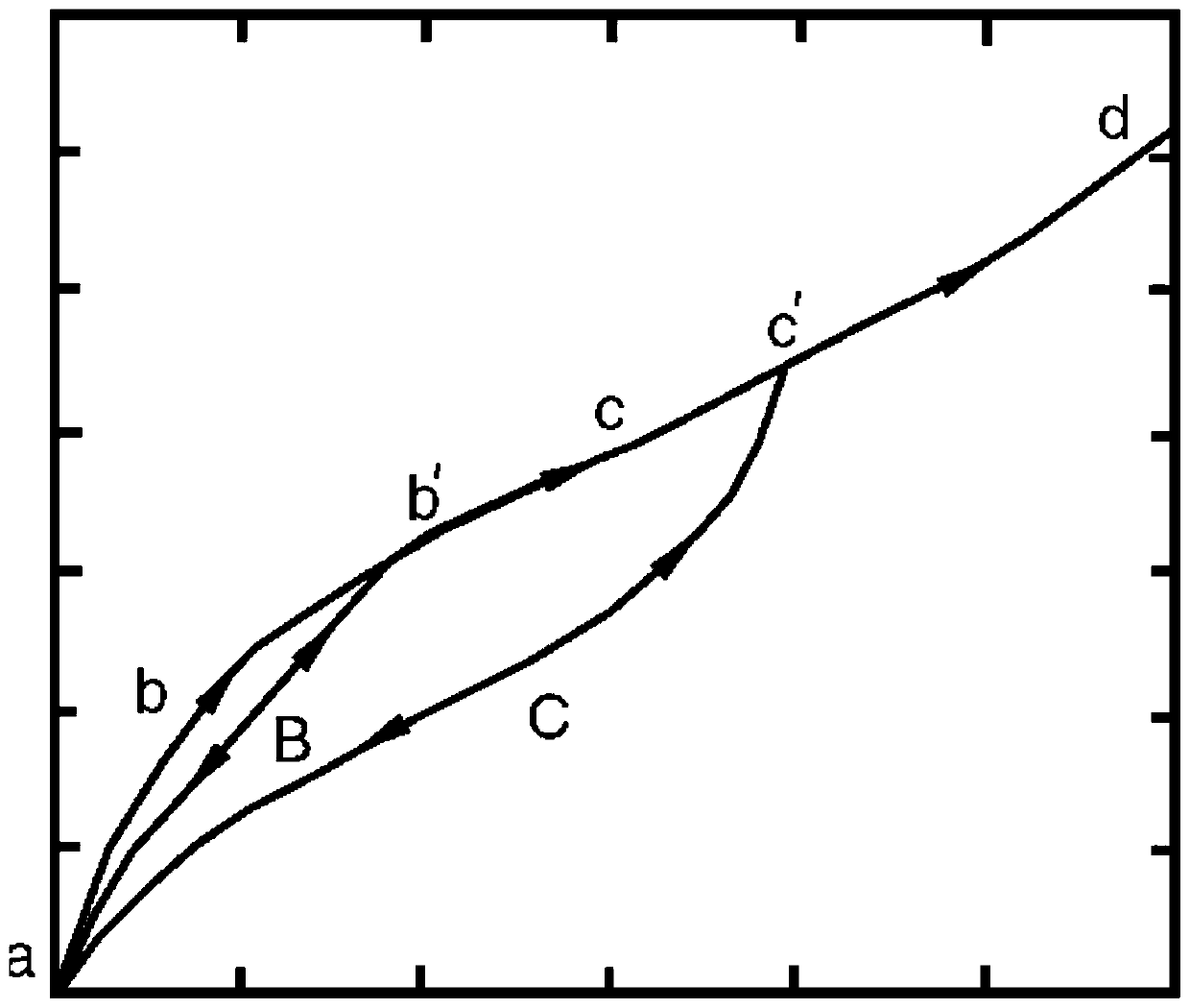

Straw characterization method for Mullines effect parameters

ActiveCN111103188AComplete mechanical property characterization methodStrength propertiesRubber materialShear modulus

The invention discloses a straw characterization method for Mullines effect parameters. The method comprises the following steps: firstly, a dimensionless function is introduced into a straw experiment to establish the relation between physical quantities in the straw experiment, then display expression of the dimensionless function is obtained through calculation according to a finite element model containing the Mullines effect, and then the straw experiment is carried out to obtain a loading and unloading load-displacement curve of an actual material; and then the initial shear modulus andthe hyperelastic mechanical parameters of the material are obtained according to the display expression of the dimensionless function and the loading load-displacement curve inversion of the straw experiment, and finally the Mullines effect parameters of the material are obtained according to the display expression of the dimensionless function and the unloading load-displacement curve inversion of the straw experiment. The stress softening mechanical property of the rubber material can be rapidly and locally characterized in situ in a multi-scale mode, the complexity of a traditional tensilecompression experiment is reduced and the accuracy of the obtained Mullines effect parameters is improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com