Straw characterization method for Mullines effect parameters

A parameter and effect technology, applied in the field of straw experiments, can solve the problem of apparent stress softening effect, rare and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below with reference to the accompanying drawings and examples.

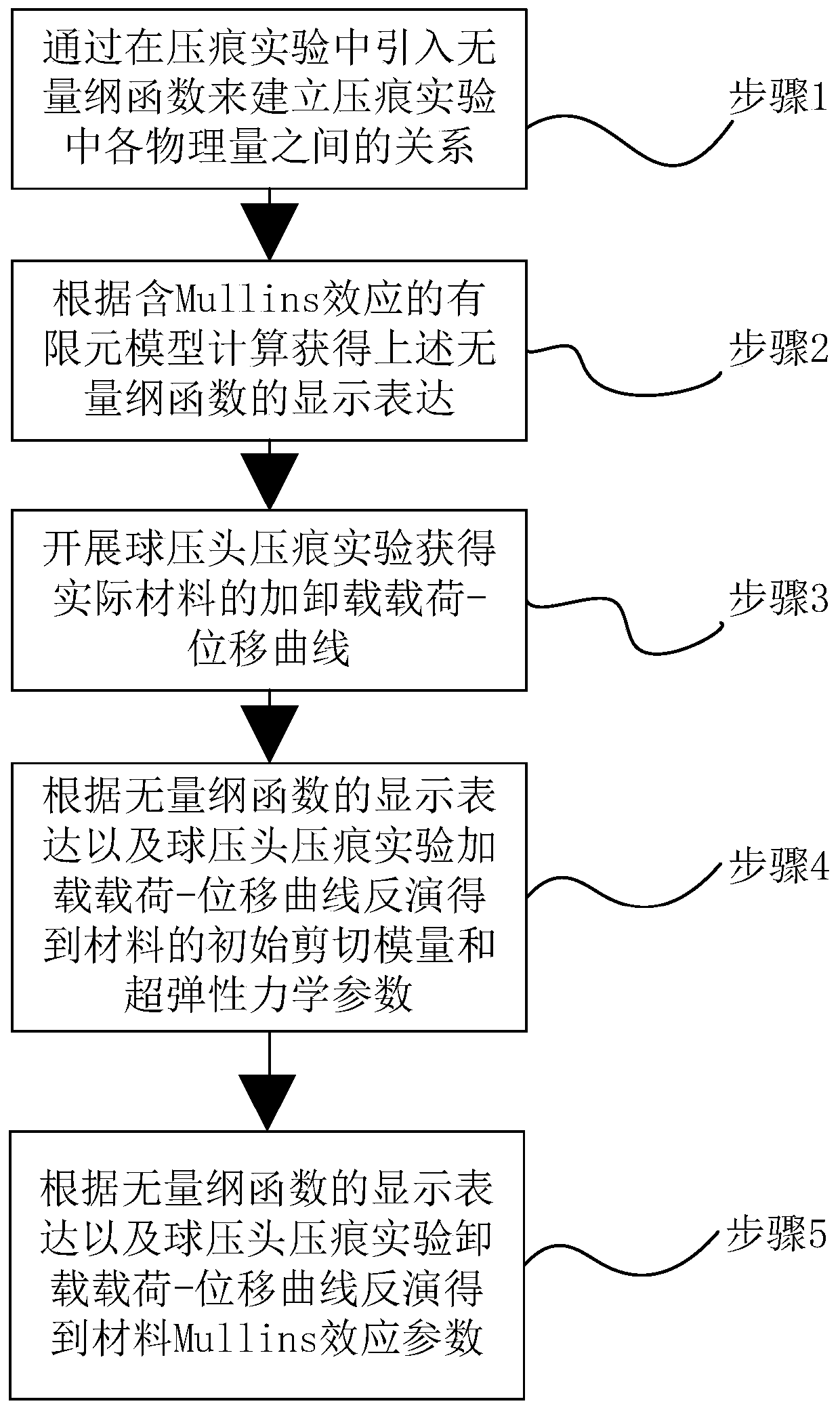

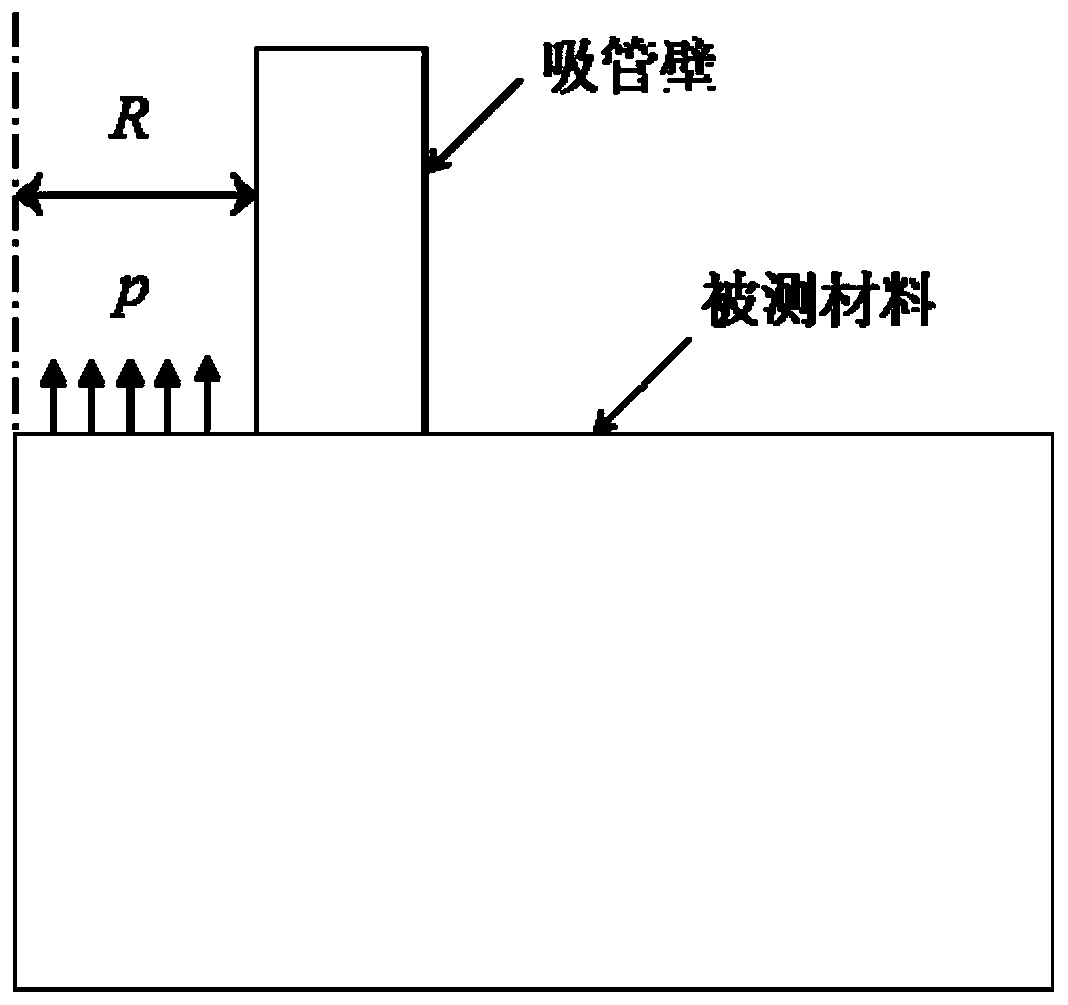

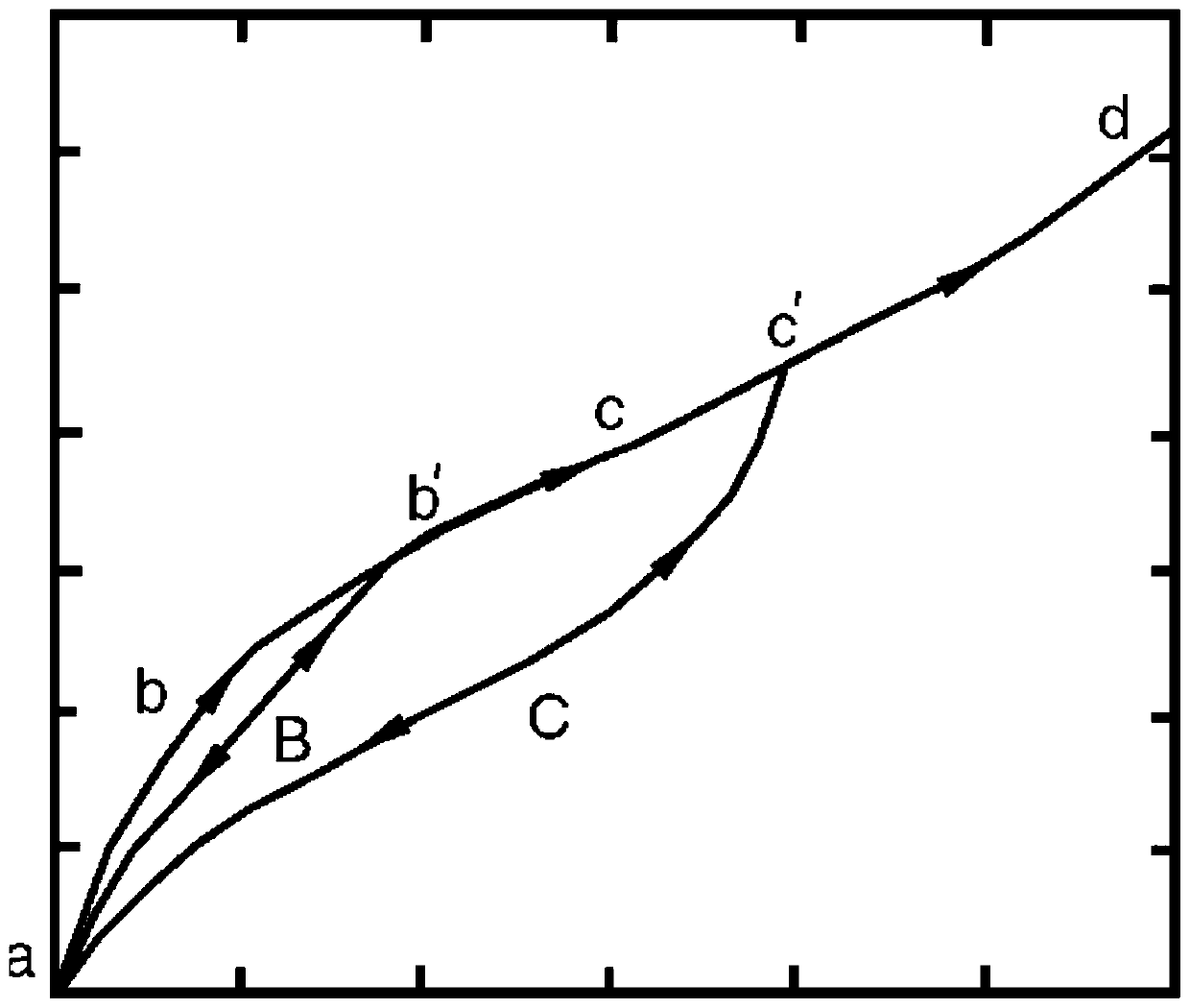

[0060] The invention provides a straw characterization method aimed at Mullins effect parameters, figure 2 is a schematic diagram of the pipette experiment, image 3 It is a schematic diagram of the loading and unloading load-displacement curve of the suction pipe experiment containing the Mullins effect, and the steps of this method are as attached figure 1 Shown:

[0061] Step 1: Establish the relationship between the physical quantities in the straw experiment by introducing dimensionless functions in the straw experiment;

[0062] Step 2: Calculate and obtain the display expression of the above dimensionless function according to the finite element model including Mullins effect;

[0063] Step 3: Carry out the straw experiment to obtain the loading and unloading load-displacement curve of the actual material;

[0064] Step 4: Obtain the initial sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com