A Ball Indentation Characterization Method for Mullins Effect Parameters

A technology of ball indentation and parameters, applied in the field of Mullins effect characterization of polymer materials, can solve the problems of apparent stress softening effect, rare and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below with reference to the accompanying drawings and examples.

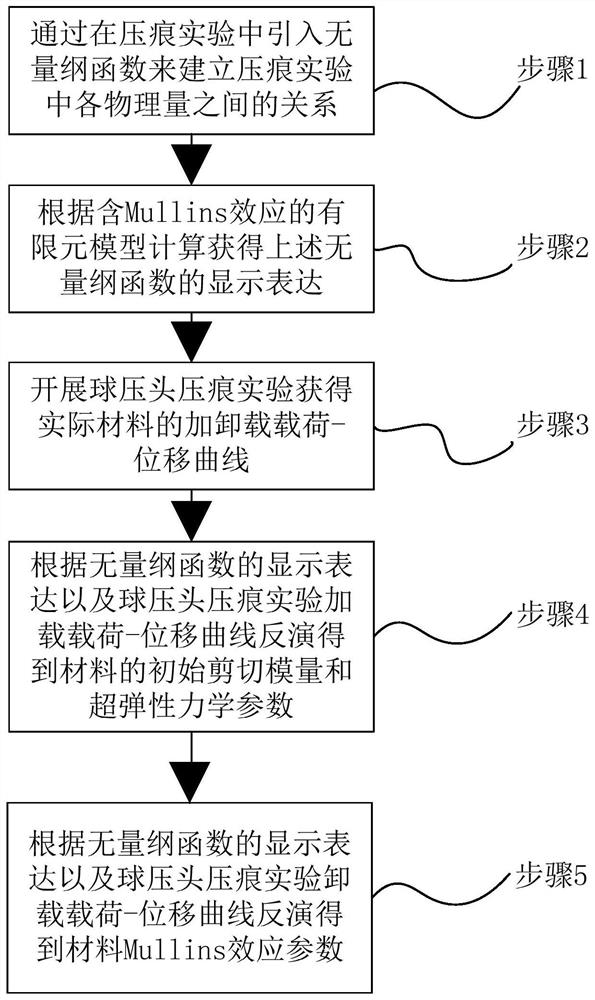

[0062] Such as figure 1 As shown, the ball indentation characterization method of the Mullins effect parameter provided by the present invention, the steps of its realization are as follows:

[0063] Step 1: Establish the relationship between the physical quantities in the indentation experiment by introducing a dimensionless function in the indentation experiment;

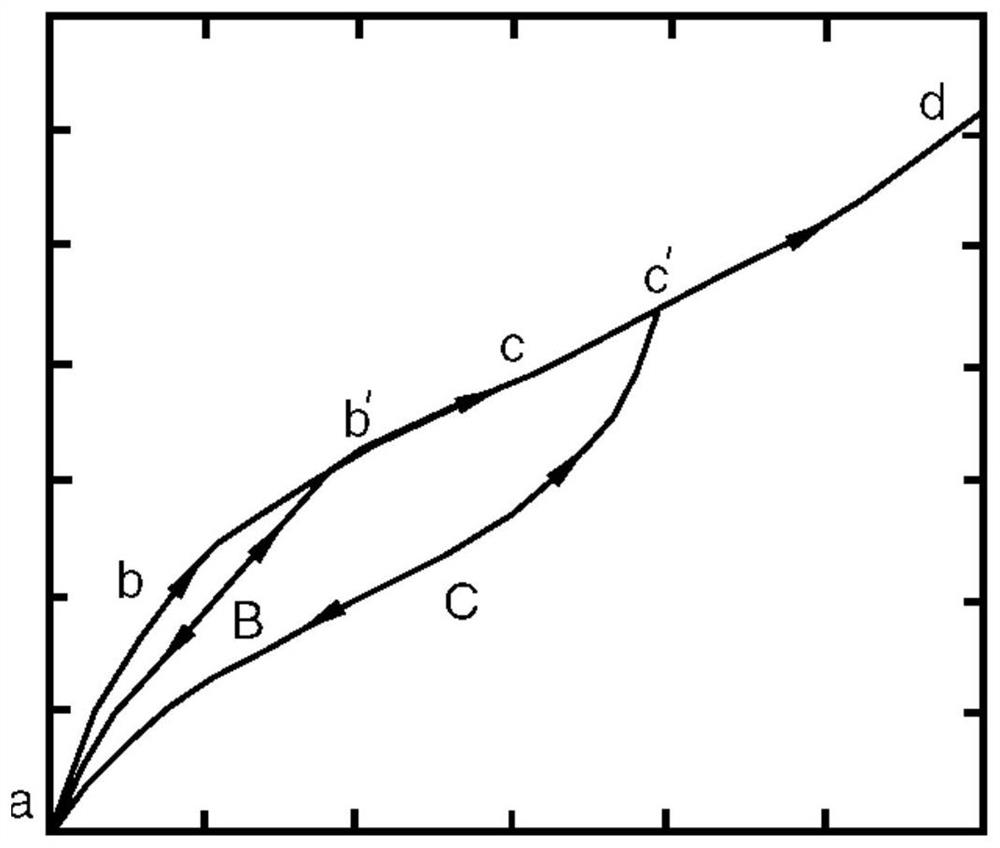

[0064] Step 2: Calculate and obtain the explicit expression of the above dimensionless function according to the finite element model including Mullins effect;

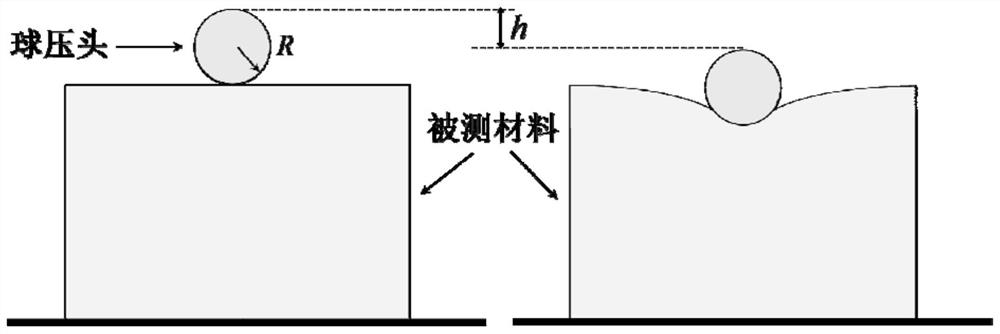

[0065] Step 3: Carry out the indentation test of the ball indenter to obtain the loading and unloading load-displacement curve of the actual material;

[0066] Step 4: Obtain the initial shear modulus and hyperelastic parameters of the material according to the explicit expression of the dimensionless function and the inversion of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com