A method for realizing high-efficiency liquid encapsulation

A technology for liquid and liquid encapsulation, which is used in measurement devices, preparation of test samples, discharge tubes, etc., and can solve the problems of limited strength of silicon nitride, reduced imaging resolution, reduced liquid sealing efficiency and repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1. High-efficiency packaging of high-quality graphene transmission grids in aqueous solution of gold nanoparticles

[0081] 1) Take out the grown isolated large single-crystal graphene sample, and bake it on a hot table at 150°C for 3-5 minutes to develop the graphene and visualize its position.

[0082] The graphene on the side of the copper foil that does not need to be transferred is removed by bombardment through an air plasma cleaning machine. The air flow is 15 sccm, the power is 90W, and the time is 3 minutes.

[0083] The graphene on the side to be transferred is facing upwards, and the target transmission substrate is facing down, and placed directly above the graphene sample to be transferred. Since the transmission substrate target is a disc with a diameter of 3mm, drop 5-10 microliters of chromatographic purity Propanol, to make isopropanol volatilize naturally, and then heat to 60°C for 10 minutes to ensure the close contact between the substrate an...

Embodiment 2

[0109] Example 2: An aqueous solution of ammonium persulfate encapsulated with high-quality graphene large single-crystal support film with high efficiency

[0110] According to embodiment 1 step 1) the graphene large single crystal thin film sample that has grown is transferred to transmission electron microscope substrate by growth substrate; Step 2)-5) is the same as embodiment 1, only embodiment 1 step 2) is used 20 microliters of the aqueous solution of gold nanoparticles was replaced by 5-8 microliters of ammonium persulfate aqueous solution; the ethanol used in Step 5) of Example 1 was replaced with isopropanol.

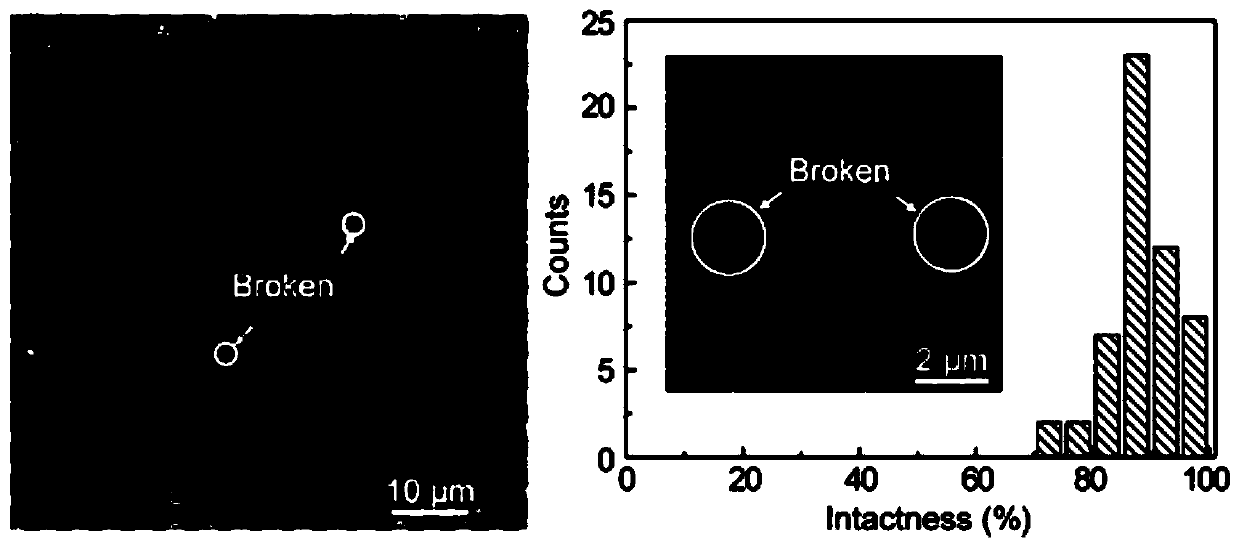

[0111] Figure 7 It shows that the metal ribs of the two graphene large single crystal support film grids can be completely stacked after the fixed-point liquid seal, which ensures the maximum area of the liquid-sealed sample. It can be seen that since the light absorption rate of single-layer graphene is only 2.3%, the graphene liquid-sealed area can still...

Embodiment 3

[0116] Embodiment 3: High-efficiency encapsulation of potassium iodide-based lead ammonium (CH 3 NH 3 PB 3 ) butyrolactone solution

[0117] According to embodiment 1 step 1) the graphene large single crystal thin film sample that has grown is transferred to the transmission substrate (that is, the commercial transmission electron microscope microgrid net) from the growth substrate; steps 2)-5) are the same as embodiment 1, only The 1-20 μl aqueous solution of gold nanoparticles used in step 2) of Example 1 was replaced by the butyrolactone solution of lead ammonium iodide; the ethanol used in step 5) of Example 1 was replaced by isopropanol.

[0118] Figure 7 It shows that the metal ribs of the two graphene large single crystal support film grids can be completely stacked after the fixed-point liquid seal, which ensures the maximum area of the liquid-sealed sample. It can be seen that since the light absorption rate of single-layer graphene is only 2.3%, the graphene l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com