Patents

Literature

306 results about "Ammonium iodide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium iodide is the chemical compound NH₄I. It is used in photographic chemicals and some medications. It can be prepared by the action of hydroiodic acid on ammonia. It is easily soluble in water, from which it crystallizes in cubes. It is also soluble in ethanol. It gradually turns yellow on standing in moist air, owing to decomposition with liberation of iodine.

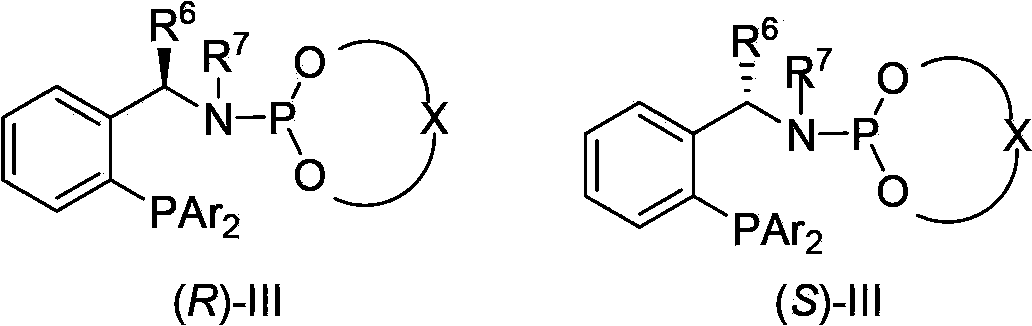

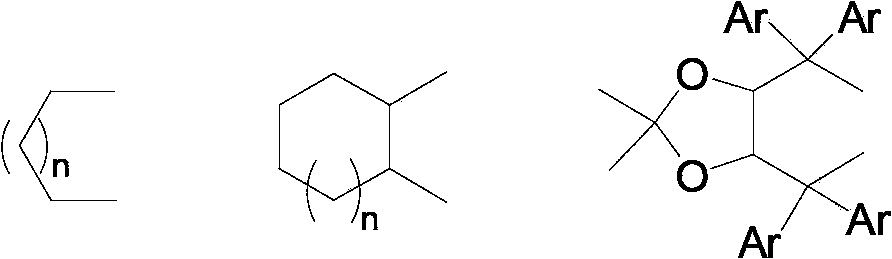

Chiral diphosphite ligand and iridium composite catalyst and preparation thereof method and application to asymmetrical hydrogenization synthesis (S)-metolachlor

ActiveCN101857612AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneDiphosphines

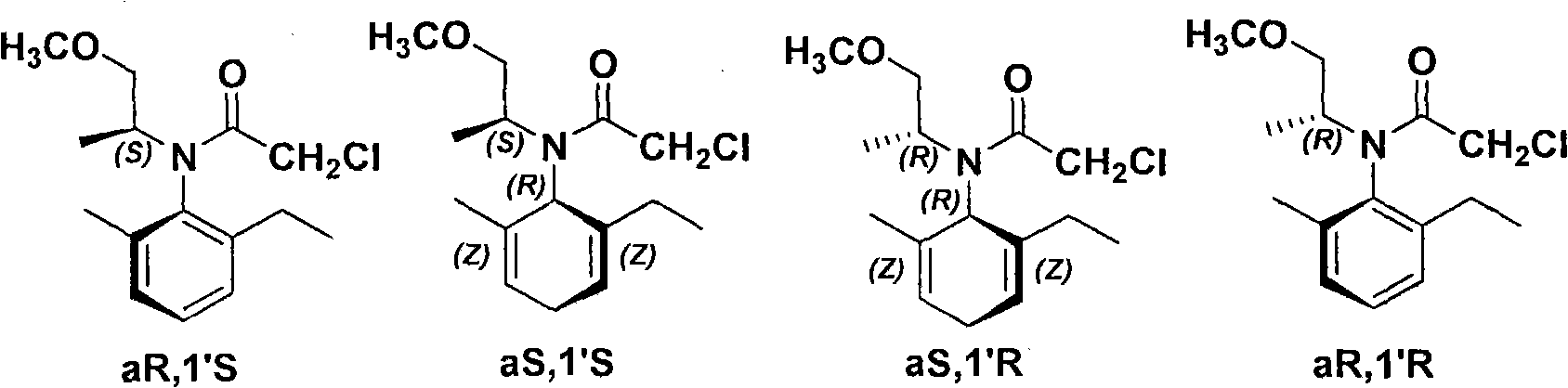

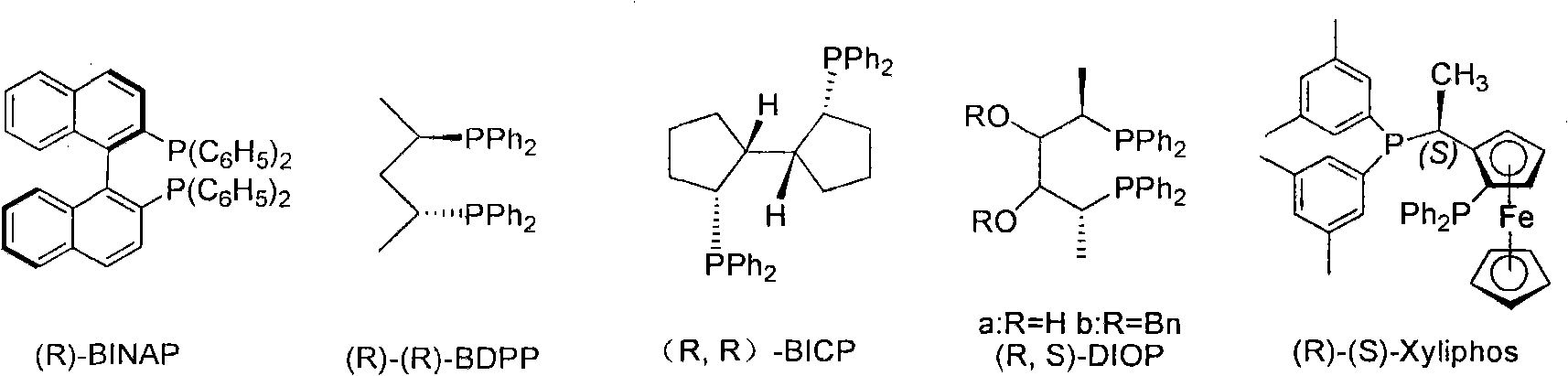

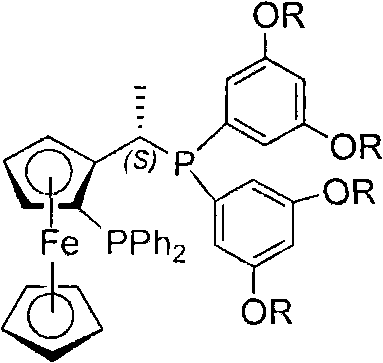

The invention relates to a kind of chiral diphosphite ligands, an iridium composite catalyst thereof, a preparation method and application thereof. The ligands are obtained through using chiral (R)-(S)-1-dimethylamino ethyiferroene as raw materials to react with diphenyl phosphonium chloride under the effect of butyl lithium and then to carry out displacement reaction with diaryl phosphine alkane. The chiral diphosphite ligands respectively act with homotropilidene compositions of iridous chloride, tetrabutyl ammonium iodide and glacial acetic acid, and imine asymmetrical hydrogenization catalysts can be obtained. When the iridium-diphosphine catalysts are used for catalyzing 2-methyl-6-ethyl-N-methylene aniline (EMA-imine) hydrogenization reaction, (S)-N-(1-anisyl-2-propyl)-2-methyl-6- ethylaniline ((S)-NNA) can be obtained, and the antimer excessive value (ee) can reach 86.5 percent. The (S)-NNA and chloracetyl chloride carry out acylation reaction to obtain (S)-metolachlor with the ee value of 86 percent. Thereby, the ligands provided by the invneiton can be used for synthesizing chiral herbicidal chemicals of (S)-metolachlor.

Owner:NANJING UNIV OF TECH +2

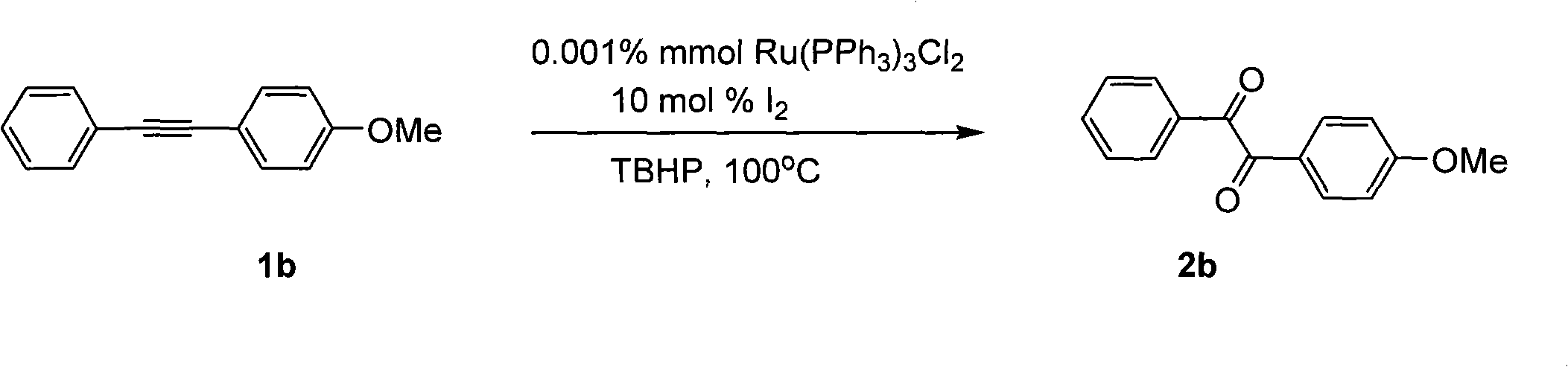

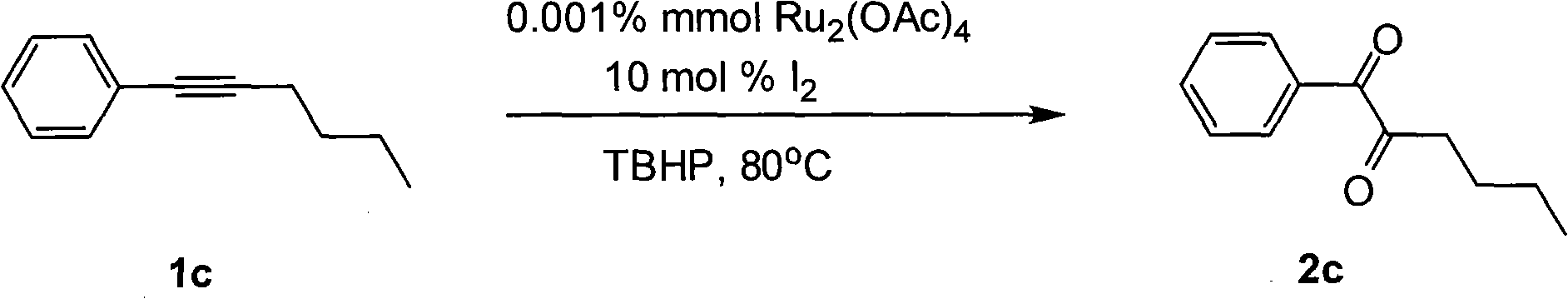

Method for preparing 1, 2-diketone by catalyzing and oxidizing alkynes

InactiveCN101624322AMild reaction conditionsMeet the requirementsCarboxylic acid nitrile preparationOrganic compound preparationCatalytic oxidationKetone

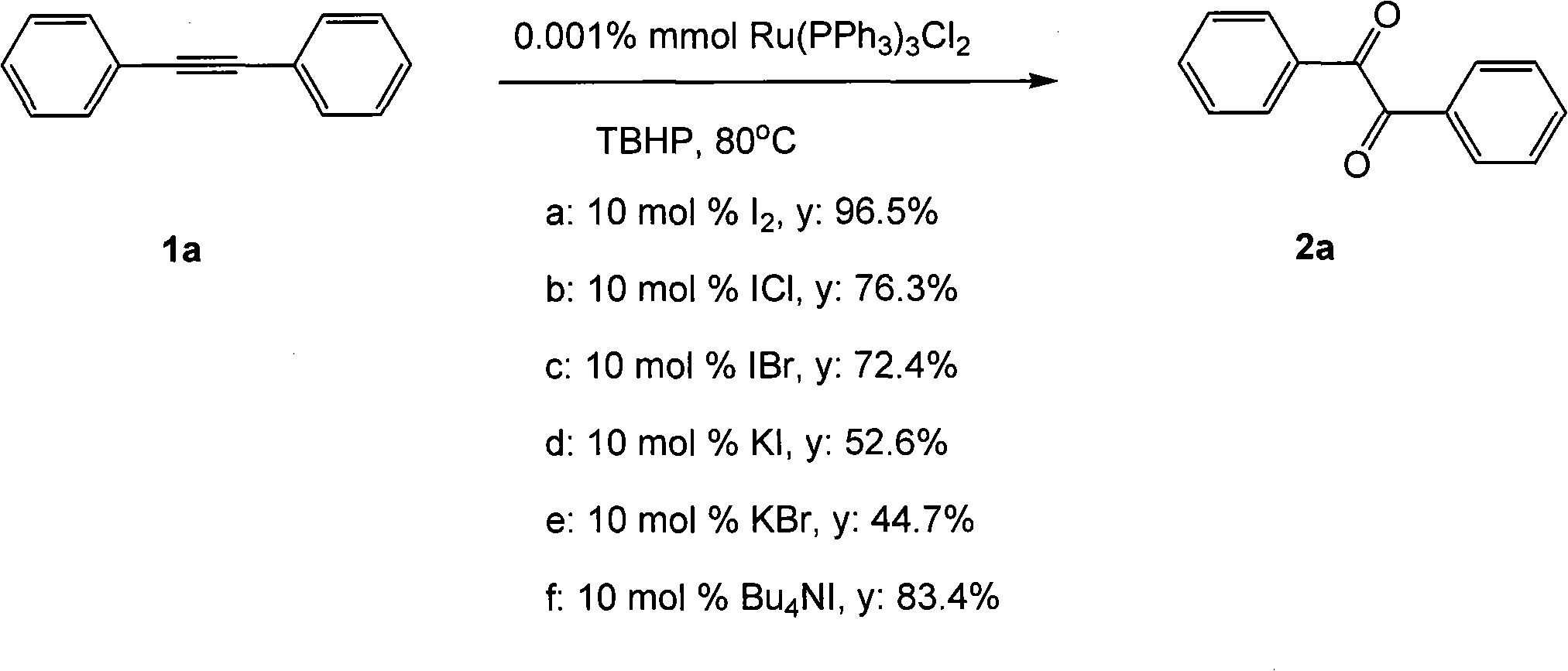

The invention belongs to the field of catalysis and oxidization, and particularly discloses a method for preparing 1, 2-diketone by catalyzing and oxidizing alkynes. The method comprises the following steps: taking alkynes R1-C-C-R2 (acetylenic link exists between C and C) as a reaction substrate, taking one of TBHP, m-chloroperoxybenzoic acid and p-benzoquinone as a oxidant, taking one of dichloro (p-cymene) ruthenium (II) dimer, tri (triphenylphosphine) ruthenous chloride, ruthenium acetate, ruthenium dichlorophenyl (II) dimer, ruthenium trichloride, BINAP ruthenous chloride, dodecacarbonyltriruthenium and tricarbonyldichlororuthenium (II) dimer as a catalyst, taking one of iodine, iodine chloride, iodine bromide, potassium iodide, tetrabutyl ammonium iodide and potassium bromide as a cocatalyst, and taking 1, 4-dioxane as a solvent to react under 40 DEG C to 100 DEG C for 4 to 24 h to prepare the 1, 2-diketone. The method is economic, environmental-friendly and mild.

Owner:SUZHOU UNIV

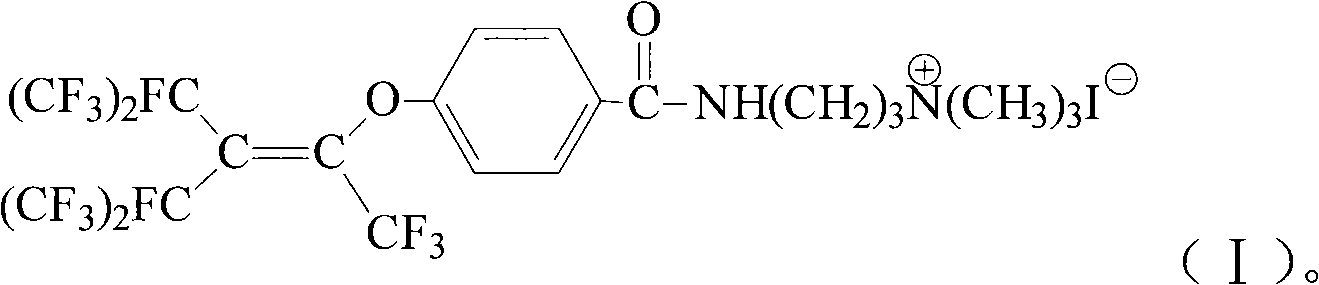

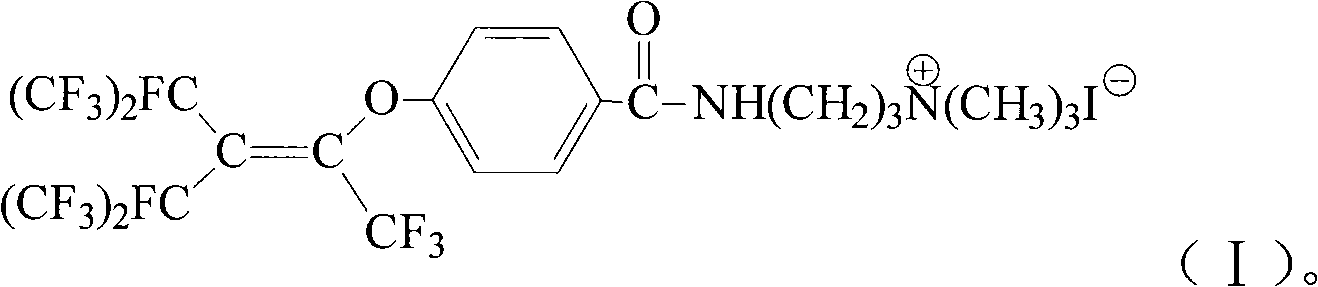

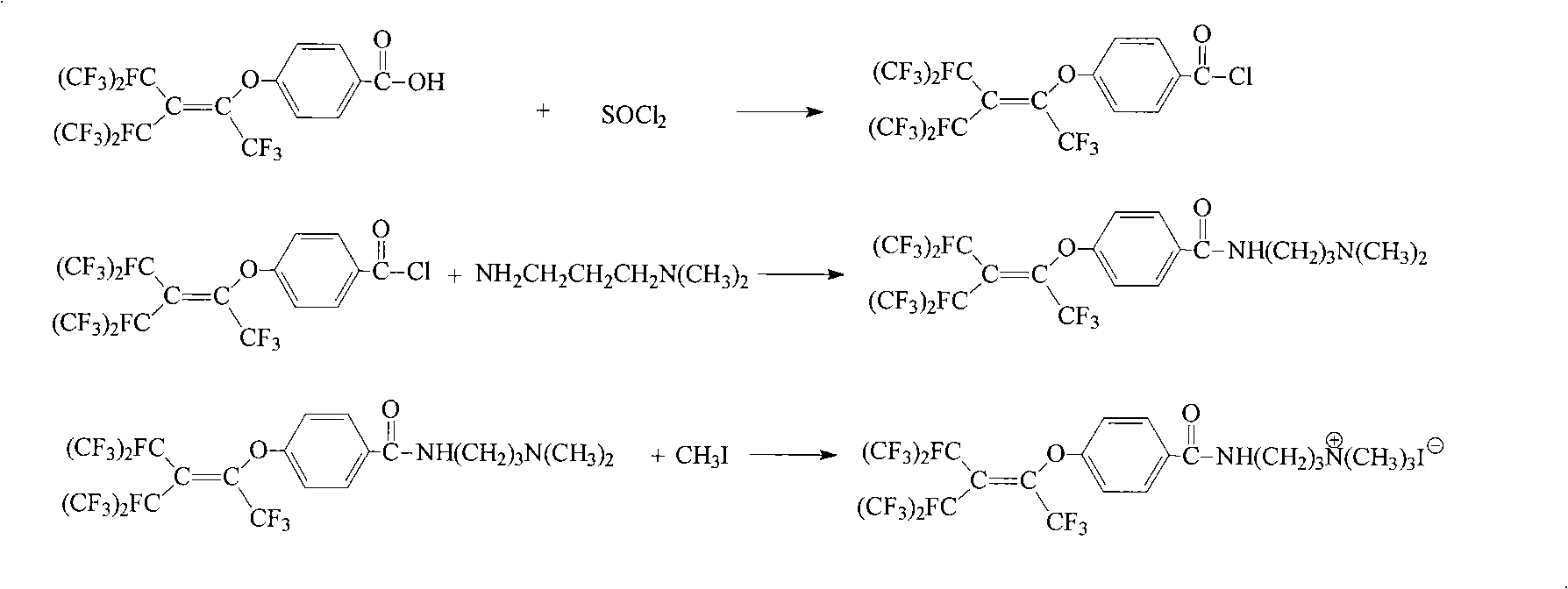

Cation fluorine surfactant and preparation method thereof

InactiveCN101293853AReduce surface tensionThe synthesis method is simpleOrganic compound preparationTransportation and packagingBenzoic acidSolvent

The invention provides a cationic fluorosurfactant (I) and a preparation method thereof. The method comprises adopting perfluorobutenyloxy benzoic acid and thionyl chloride as raw materials to perform a chloroacylation reaction at -30 DEC C to 70 DEC C in polar solvent, adding N,N-dimethyl propylene diamine and base catalyst, performing an amidation reaction at -20 DEC C to 120 DEC C, separating the reactant liquor to obtain N-[3-(p-perfluorobutenyloxybenzamido)propyl]-N, N-dimethyl amine, dissolving into non-proton polar solvent, adding iodomethane, performing a quaternization reaction at 0 DEC C to 100 DEC C, and filtering the reactant liquor to obtain N-[3-(p-butenyloxybenzamido)propyl]-N,N,N-trimethyl ammonium iodide. The method has simple synthetic method and high reaction yield. Aqueous solution prepared from the N-[3-(p-butenyloxybenzamido)propyl]-N,N,N-trimethyl ammonium iodide has low surface tension.

Owner:ZHEJIANG UNIV OF TECH

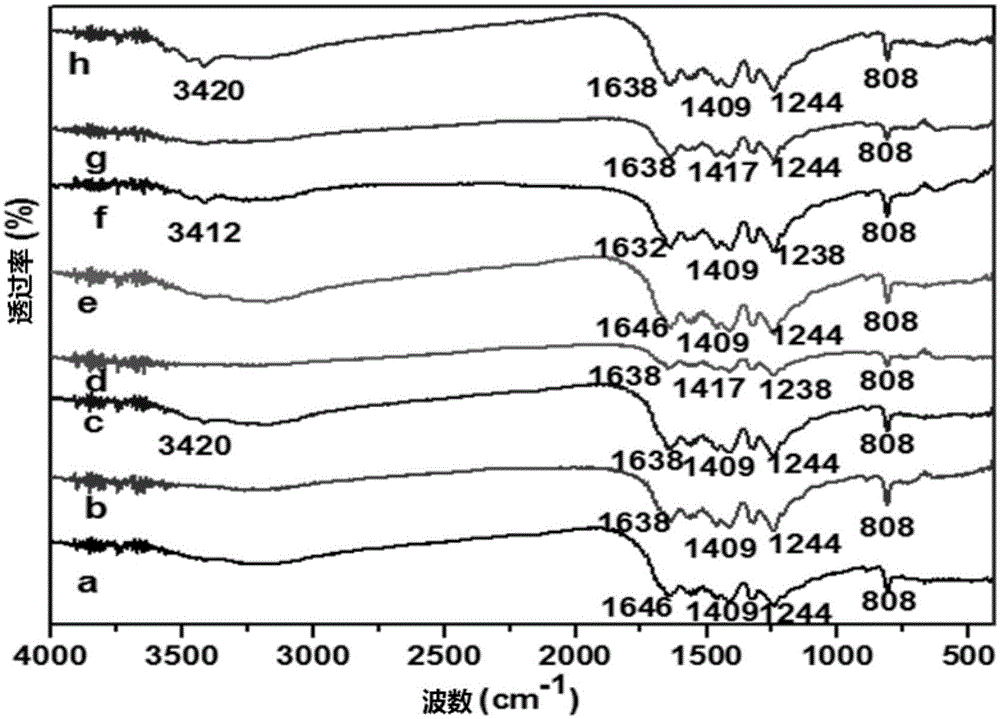

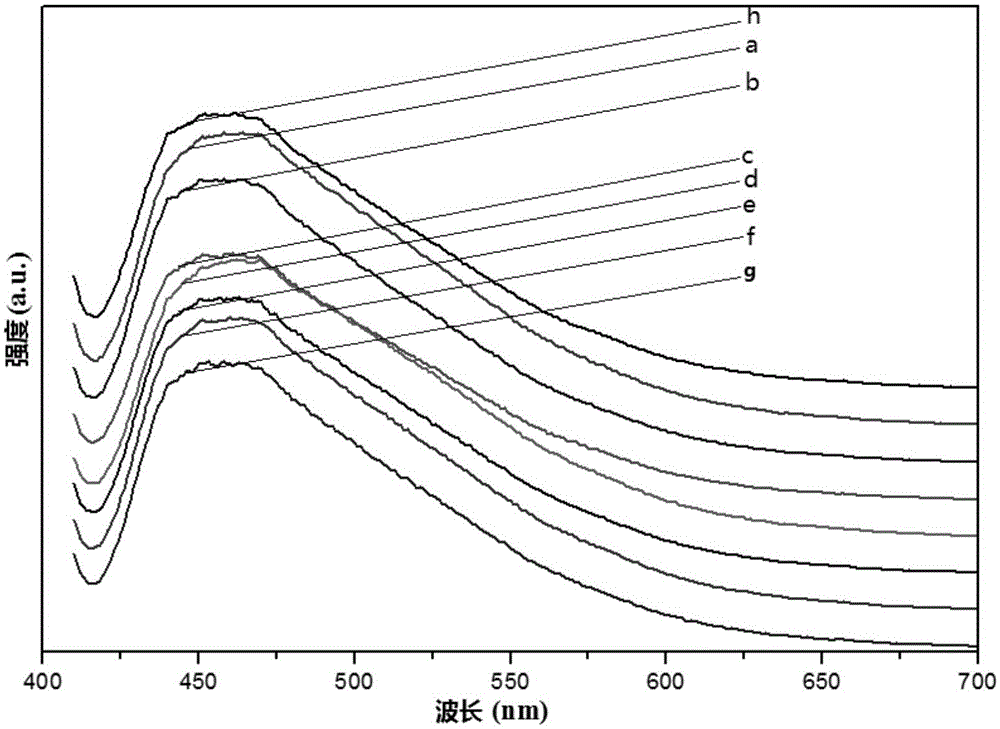

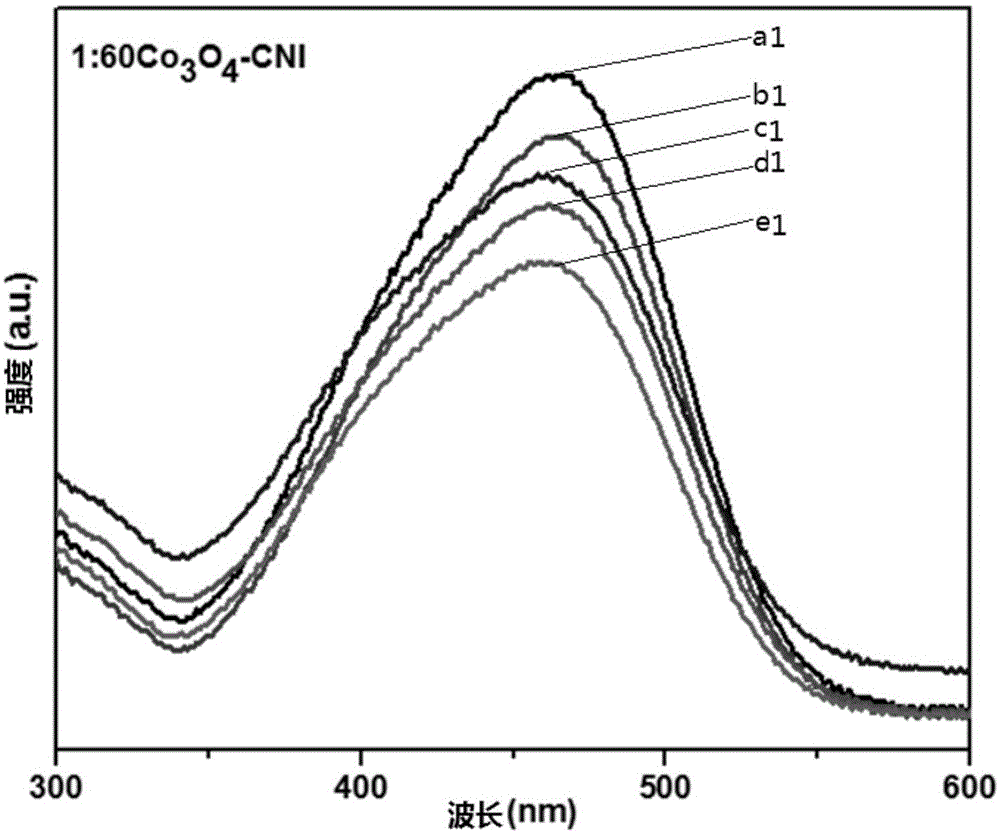

Photocatalyst Co3O4-CNI and preparation method and application thereof

InactiveCN105195196AImprove photocatalytic degradation performancePhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyePhotocatalytic degradation

The invention provides a photocatalyst Co3O4-CNI and a preparation method and application thereof. According to the photocatalyst Co3O4-CNI, nitrogen-containing organic matter and ammonium iodide serve as raw materials, iodine-doped graphite-phase carbon nitride (abbreviated as CNI) can be prepared through a hydrothermal method, then prepared CNI and a cobalt-containing compound react through a hydrothermal method, and optionally, cooling and smashing are performed so that the photocatalyst Co3O4-CNI can be prepared. The prepared photocatalyst has a good catalytic degradation effect on organic dye and particularly azo type organic dye under visible light.

Owner:FUYANG NORMAL UNIVERSITY

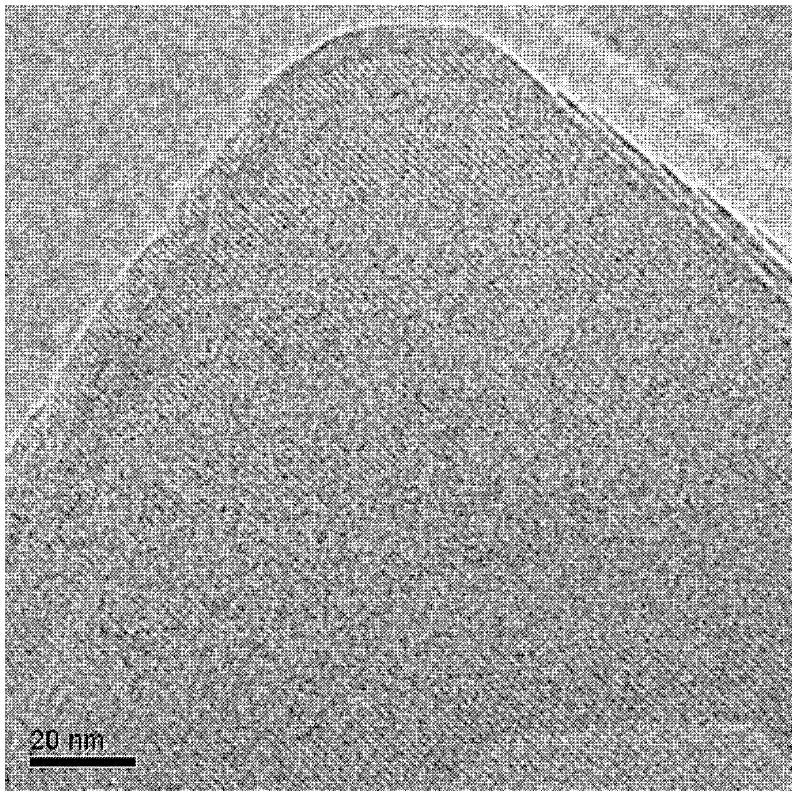

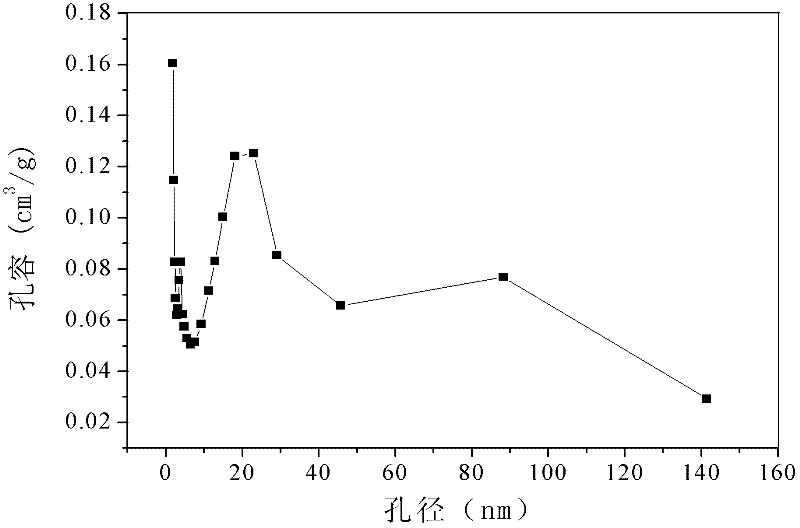

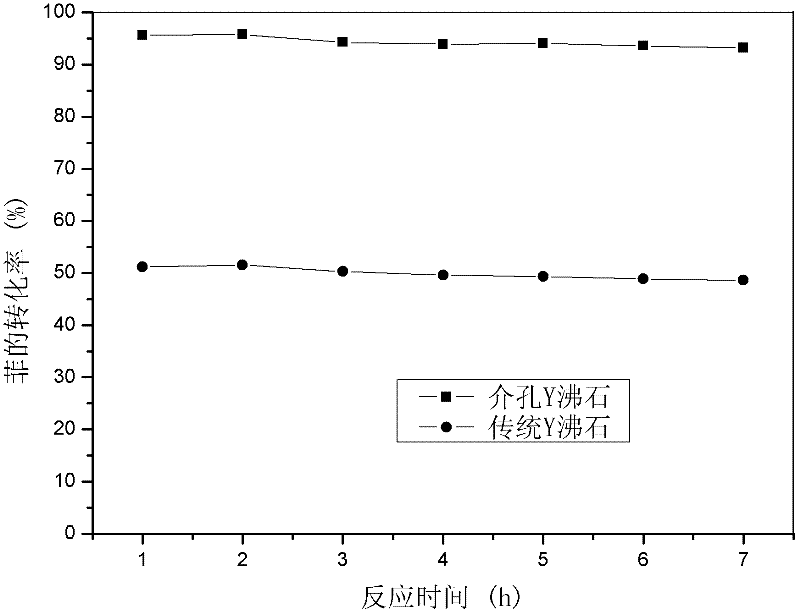

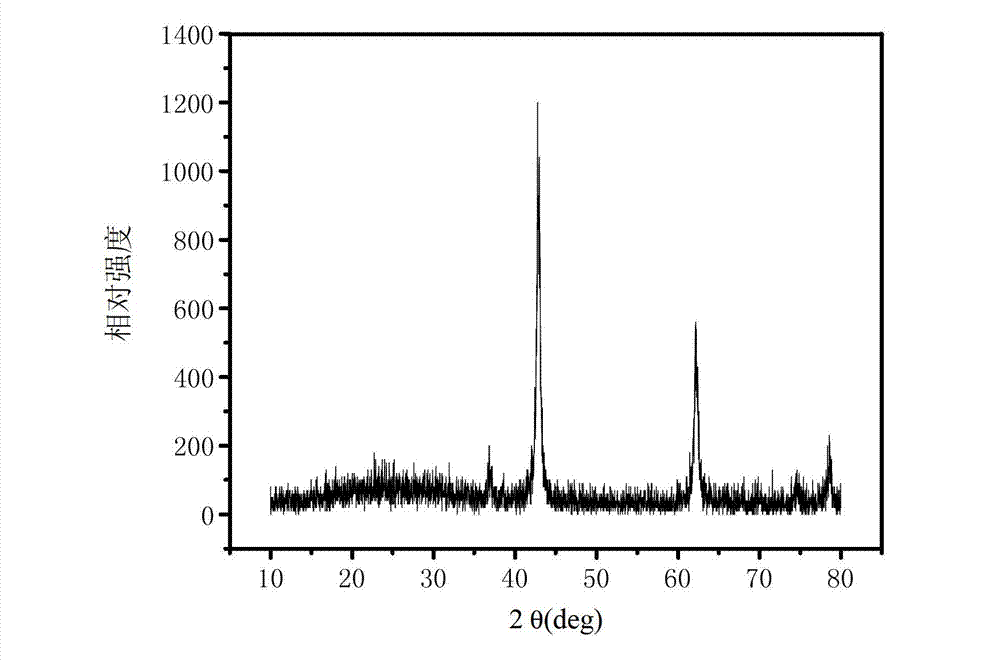

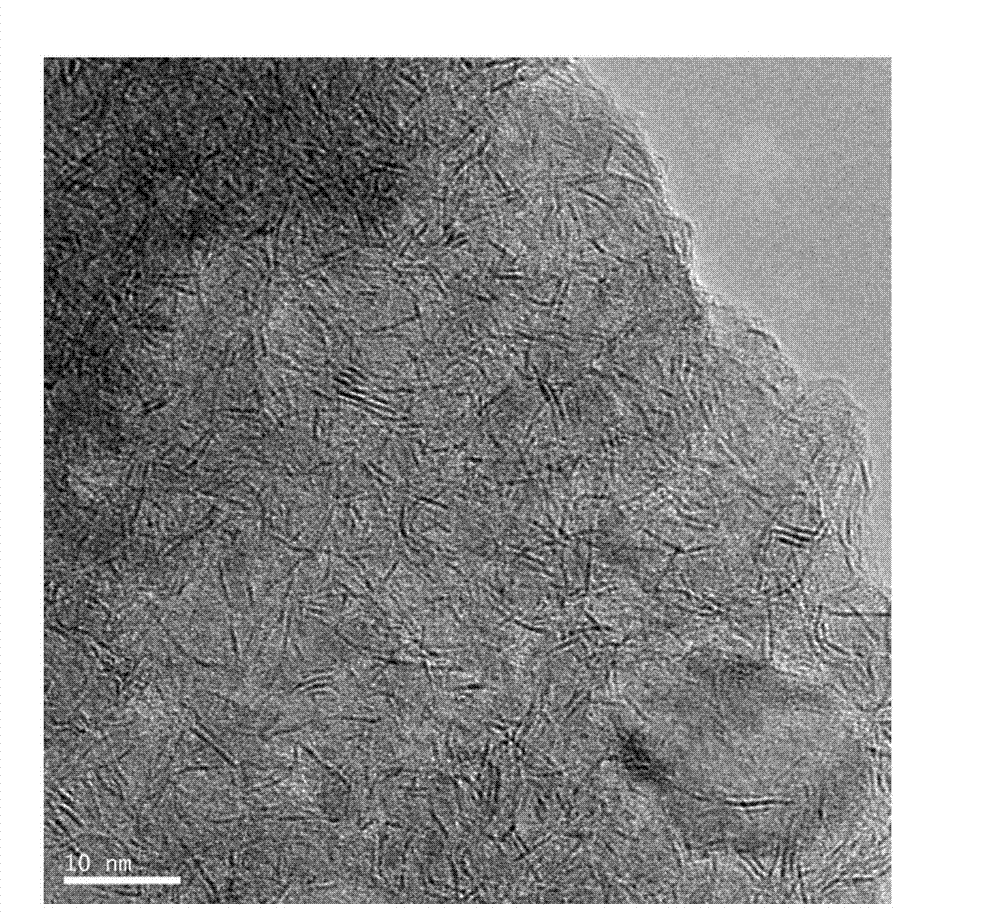

A kind of synthetic method of Y-type mesoporous zeolite

ActiveCN102259889AThe synthesis method is simpleLower requirementFaujasite aluminosilicate zeoliteSilanesSodium aluminate

The invention discloses a synthetic method of Y type mesoporous zeolite. In the synthetic method, water glass is used as a silicon source; aluminum sulphate and sodium aluminate are used as aluminum sources; macromolecular surface active agent N, N-diethyl-N-hexadecyl-N-(3-methyl silane and propane) ammonium iodide is used as a templete agent; and Y zeolite which contains a mesoporous structure is synthesized by a traditional water heating method. According to the invention, the synthetic method is simple; the synthetic Y zeolite material has the microporous structure of a traditional molecular sieve and also has a large amount of mesoporous structures; thereby, the mesoporous structures as catalysts and carriers in heavy oil refining industry and synthetic industry of macromolecular finechemical have a wide application prospect.

Owner:WENZHOU UNIVERSITY

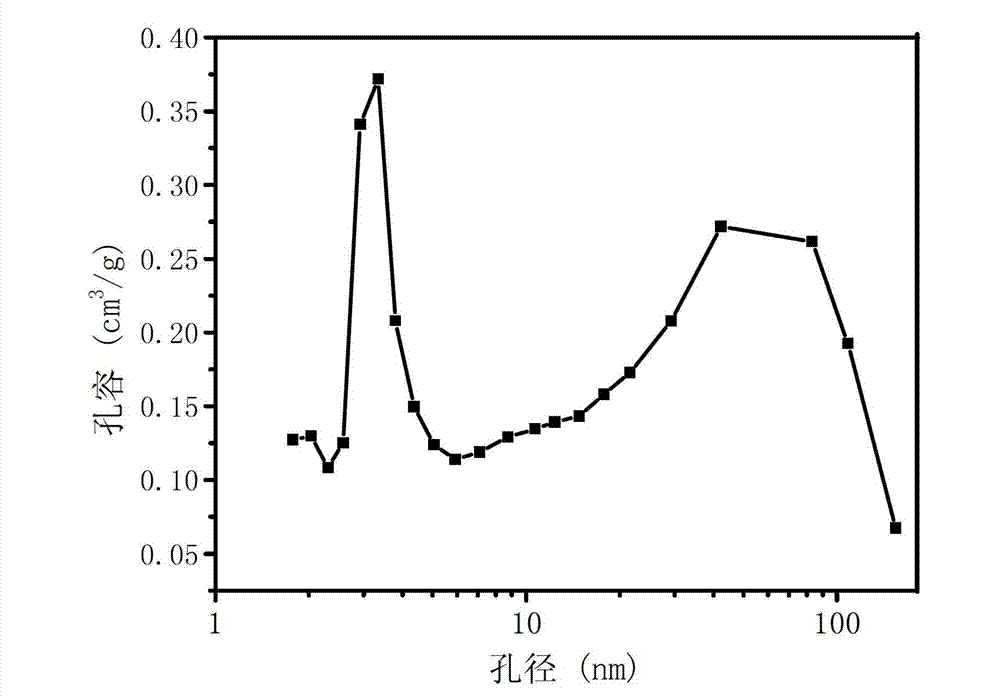

Mesoporous magnesium oxide, hydrodesulfurization catalyst loading CoMo metal sulfide and application thereof

ActiveCN103157518ALarge specific surface areaHigh activityCatalyst carriersMagnesiaSilanesHydrodesulfurization

The invention discloses a mesoporous magnesium oxide, a hydrodesulfurization catalyst loading CoMo metal sulfide and an application thereof. The mesoporous magnesium oxide is prepared through the following steps that (1) water is used as reaction medium, magnesium hydroxide fully reacts with carbon dioxide under room temperature in an airtight reaction still, then reaction liquid in the reaction still is filtered, and filtrate which contains Mg (HCO3)2 is obtained; (2) macromolecule surfactant N, N-Diethyl-N-Cetyl-N- (3-methoxy silane propane) ammonium iodide are added into the filtrate which contains the Mg (HCO3)2, mixture is heated to 80 DEG C-95 DEG C and maintained to 0.5h-2h under stirring, the mixture is calcinated for 3h-4h after the mixture is filtered and dried, and the mesoporous magnesium oxide is obtained. The hydrodesulfurization catalyst loading CoMo metal sulfide is prepared by that the mesoporous magnesium oxide is used as carriers, is suitable for hydrodesulfurization reactions of dibenzothiophene, and exerts high catalytic activity.

Owner:WENZHOU UNIVERSITY

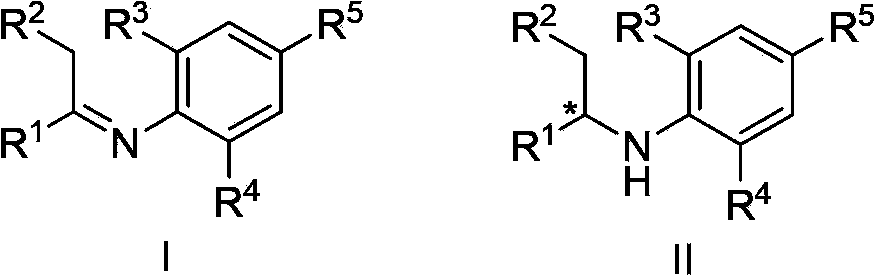

Iridium catalyzed enantiotropic hydrosubstituting process of aromatic pyridine ring and pyrazine ring

InactiveCN1468852AHigh enantiomeric excessMild reaction conditionsOrganic chemistry methodsOrganic-compounds/hydrides/coordination-complexes catalystsIridiumQuinoxaline

The iridium catalyzed enantiotropic hydrosubstituting process of aromatic pyridine ring and pyrazine ring uses catalyst system comprising chiral coordination compound of iridium and additive compound. The reaction conditions includes temperature of 0-80 deg.c; solvent of dichloromethane, toluene, tetrahydrofuaran, 1, 2-dichloro ethane, isopropanol, etc.; additive compound of tetrabutyl ammonium iodide, iodine, amine, etc.; pressure of 1-100 atm; substrate / catalyst ratio up to 5000; and chiral coordination compound of diphosphine, N-P compound, S-P compound, etc. The catalyst system is prepared through reaction of iridium precursor and chiral compound in the said solvent and the addition of the additive compound while stirring; and can produce asymmetrical induction up to 96 %. The process of the present invention is environment friendly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

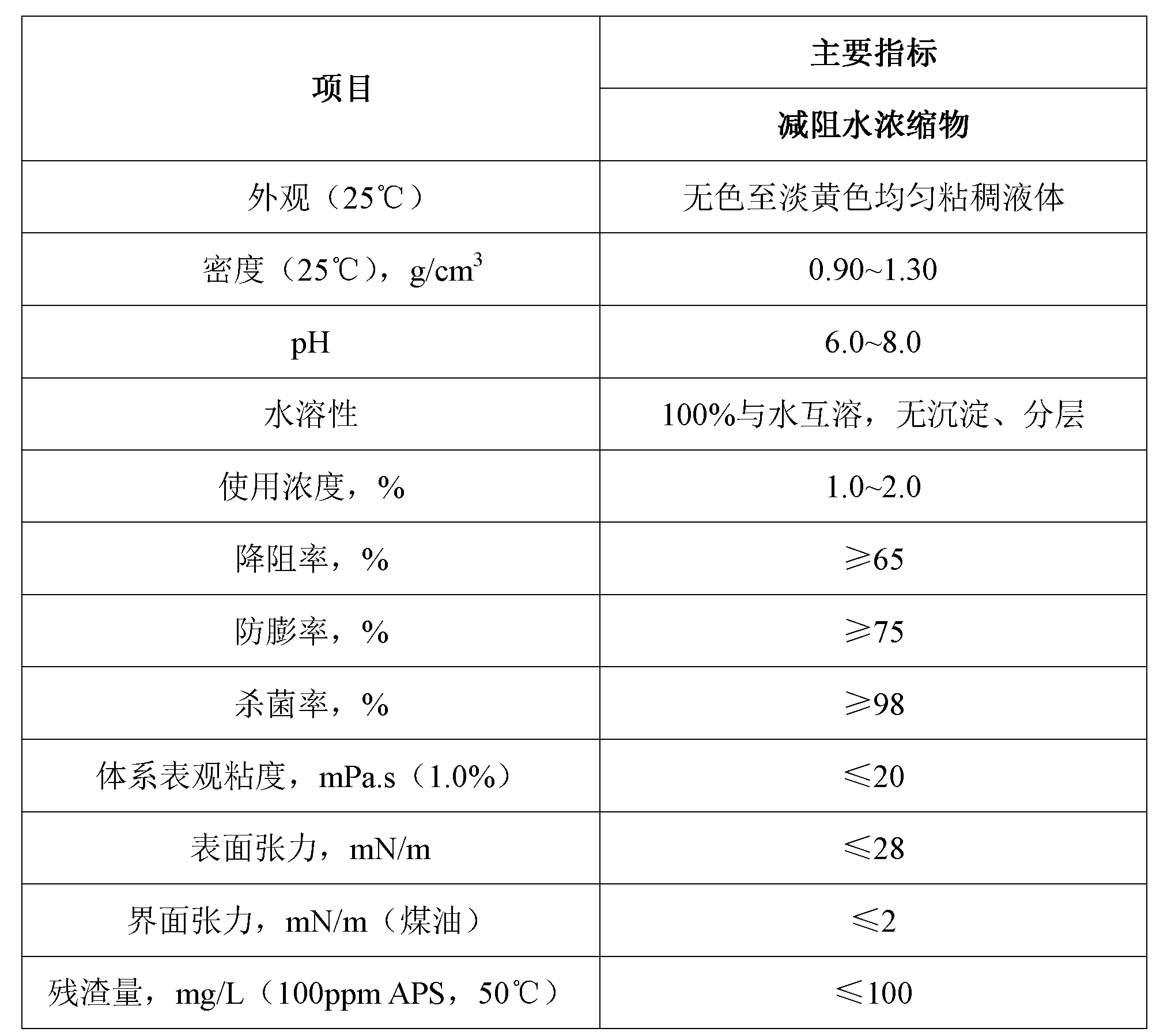

Anti-drag aqueous fracturing fluid preparation

InactiveCN103254887AGuarantee the demand for large displacement pumping in constructionMeet the needs of efficient developmentDrilling compositionSolubilityPolyethylene glycol

The invention aims at providing an anti-drag aqueous fracturing fluid preparation, and provides a single-dosage anti-drag aqueous fracturing fluid preparation in order to overcome defects during preparation of anti-drag aqueous fracturing fluid and construction. The preparation can be compounded with water in any proportions, is good in solubility, meets the requirement on continuous mixing during on-site construction of shale gas, and has an important application value in shale gas exploration. The anti-drag aqueous fracturing fluid preparation comprises the following components by weight percentage: 4-6% of anti-drag agent, 8-12% of clay stabilizing agent, 1-3% of cleanup additive, and the balance of water, wherein the anti-drag agent is a bipolymer of acrylamide and polyethylene glycol oxide ether acrylate; the clay stabilizing agent is polydimethyl propylenediene ammonium chloride; and the cleanup additive comprises the following components by mass percentage: 9-11% of perfluorooctanoyl ethylene amino methyl diethyl ammonium iodide, 20-30% of polyoxyethylene 2,5-dimethyl stearyl alcohol ether, and 20-30% of isopropanol.

Owner:郑建立

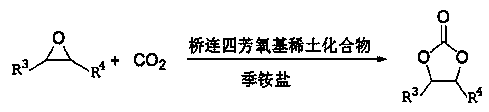

Method for preparing cyclic carbonate

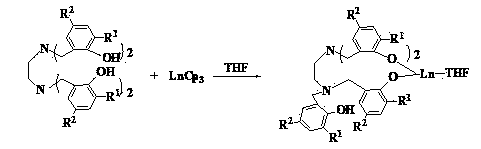

InactiveCN103641811AClear structureThe synthesis method is simpleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsQuaternary ammonium cationRare earth metal compounds

The invention discloses a method for preparing cyclic carbonate. The method specifically comprises the following step: with a quadri-aryloxy bridged rare earth metal compound as a catalyst, catalyzing carbon dioxide and alkylene oxide to react in the present of quaternary ammonium salt, wherein the general formula of the quadriaryloxy bridged rare earth metal compound is LLn(THF), wherein L refers to ethanediamine group bridged quadri-aryloxy, Ln refers to rare earth metal ions, and the quaternary ammonium salt is one of tetrabutylammonium iodide, tetrabutylammonium bromide, tetrabutylammonium chloride, tetraoctyl ammonium bromide, bis(triphenylphosphine) ammonium chloride and benzyl butyl ammonium bromide. The rare earth catalyst in the catalysis system is clear in structure, easy to synthesize, high in catalysis activity, less in using amount, mild in reaction conditions and wide in universality to alkylene oxide. According to the preparation method disclosed by the invention, raw materials are easily available, the reaction conditions are wild, a reaction substrate is wide in universality, the reaction time is short, the yield of the target product, namely the cyclic carbonate is high, and the reaction operation and the posttreatment process are simple.

Owner:SUZHOU UNIV

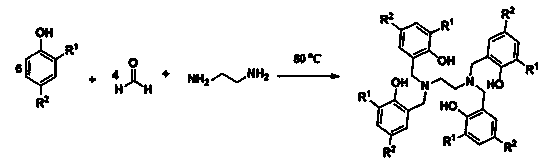

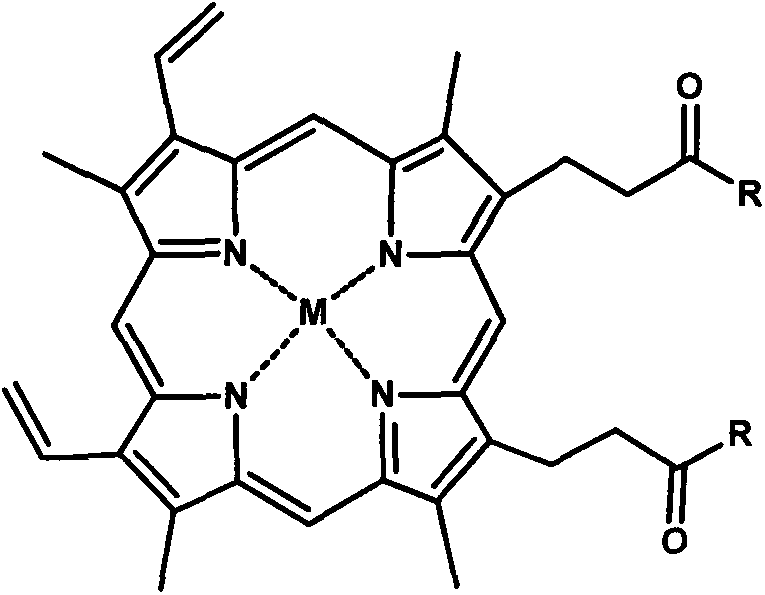

Use of novel amine compound modified protoporphyrin

InactiveCN103601727AEnhanced inhibitory effectGood killing effectAntibacterial agentsOrganic active ingredientsChemical compoundTherapeutic effect

The present invention discloses a use of N,N-dimethylethylenediamine or N,N-diethylethylenediamine or N-(2-aminoethyl)-trimethyl ammonium iodide or N-(2-aminoethyl)-triethyl ammonium iodide modified protoporphyrin. The N,N-dimethylethylenediamine or N,N-diethylethylenediamine or N-(2-aminoethyl)-trimethyl ammonium iodide or N-(2-aminoethyl)-triethyl ammonium iodide modified protoporphyrin has the following structure. Experiment results show that: the N,N-dimethylethylenediamine or N,N-diethylethylenediamine or N-(2-aminoethyl)-trimethyl ammonium iodide or N-(2-aminoethyl)-triethyl ammonium iodide modified protoporphyrin has a good in vitro photodynamic antibacterial performance, and provides good treatment effects for photodynamic treatments of mice infections caused by bacteria, fungi and the like.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

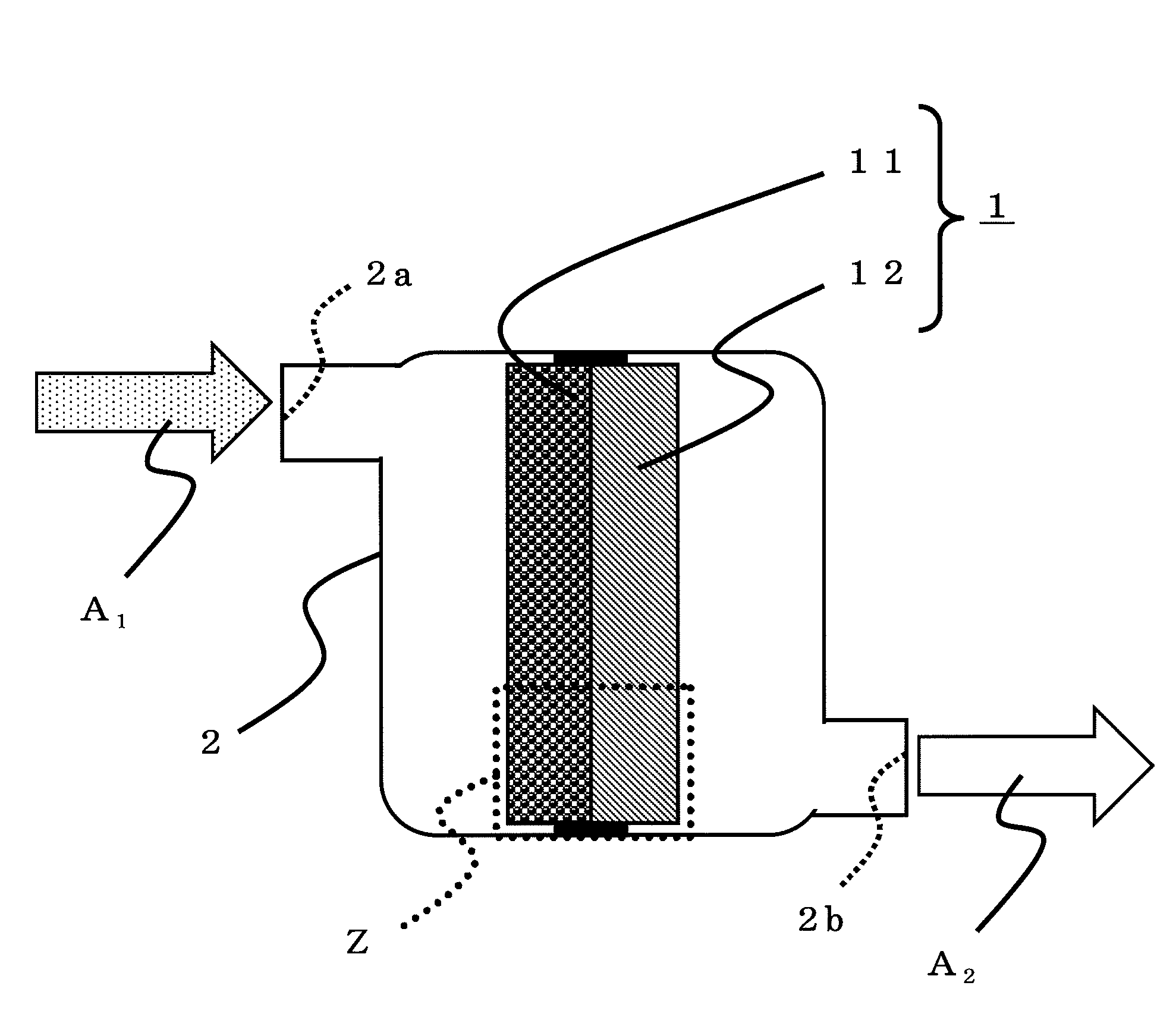

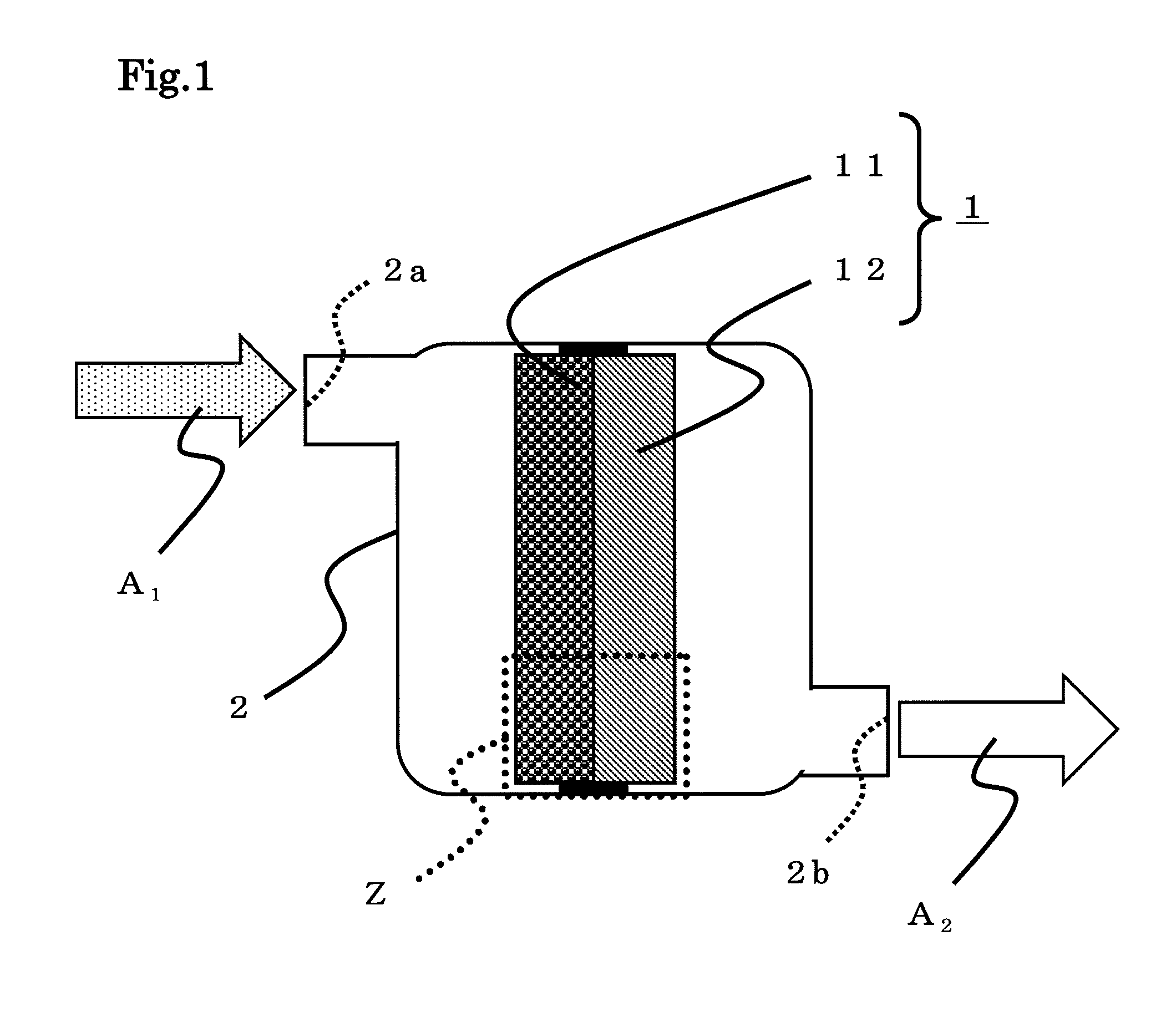

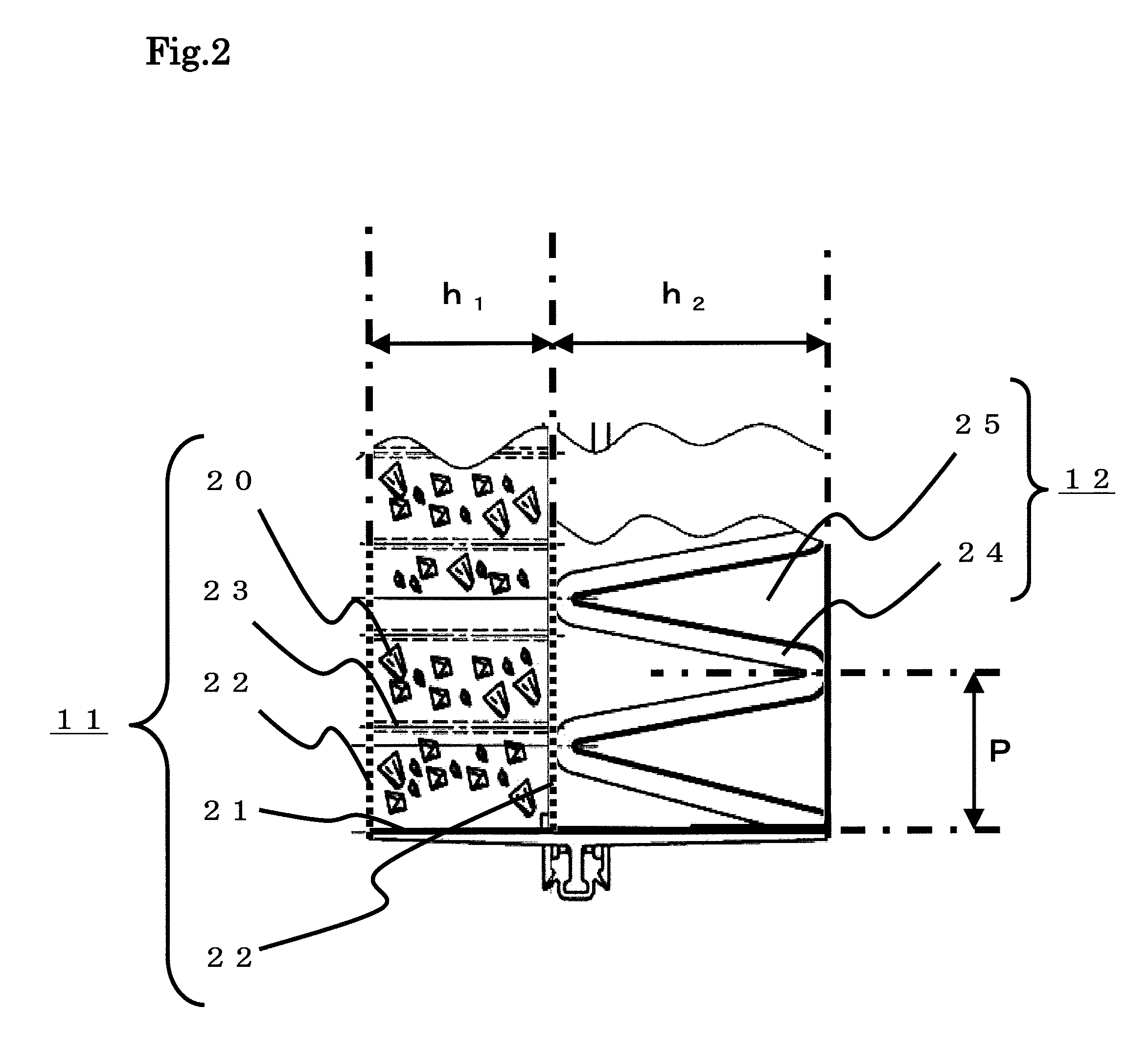

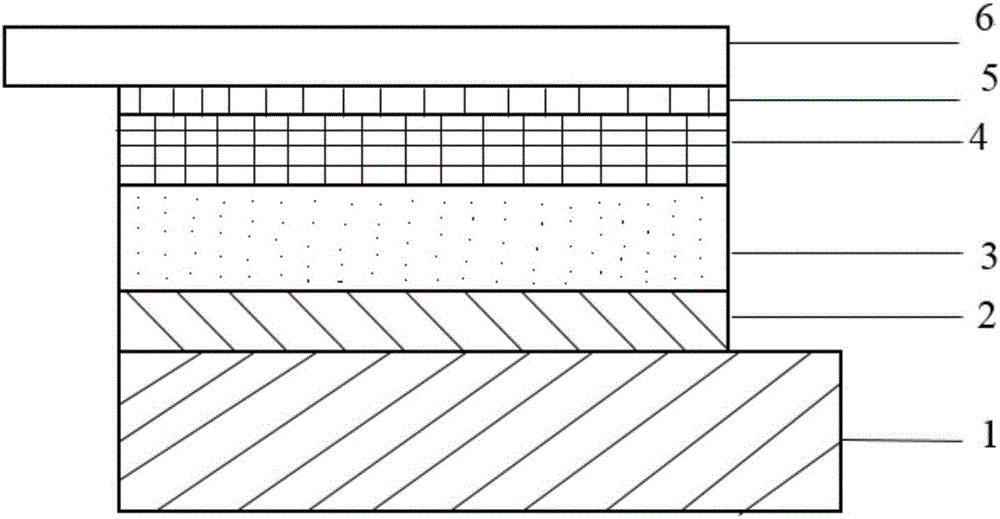

Filter for removing a sulfur-containing-gas and method for removing a sulfur-containing-gas using the same

InactiveUS20100024642A1High sulfur-containing-gas removal performanceFast adsorptionCombination devicesIsotope separationCatalytic pyrolysisFiber

Provided is a filter for removing a sulfur-containing-gas (1), which removes the sulfur-containing-gas by being brought into contact with the sulfur-containing-gas in a gas flow path, the filter comprising a former filter (11) disposed on an upstream side of the gas flow path, and a latter filter (12) disposed on a downstream side of the gas flow path, whereinthe former filter (11) comprises a first material for removing a sulfur-containing-gas, the first material comprising a porous support, and iodine which is supported on the porous support, and is produced by catalytic pyrolysis of ammonium iodide at a thermal decomposition ratio of 80% or more by use of the porous support as a catalyst, andthe latter filter (12) comprises a second material for removing a sulfur-containing-gas, the second material comprising an activated carbon fiber, and an alkali component which is supported on the activated carbon fiber.

Owner:TOYOTA BOSHOKU KK

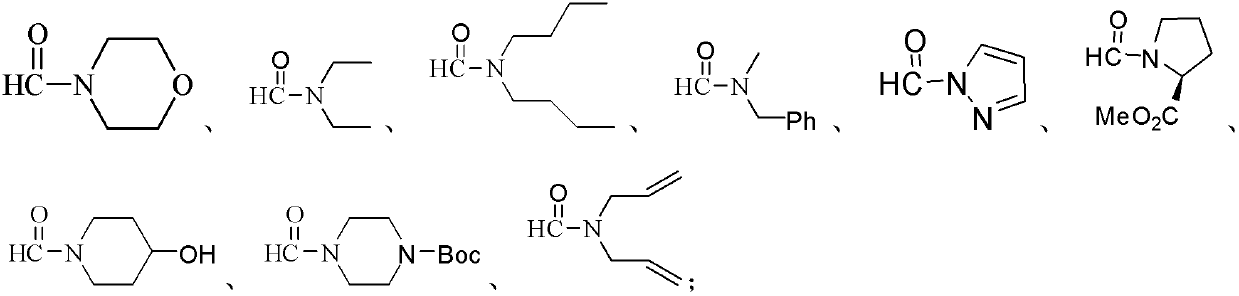

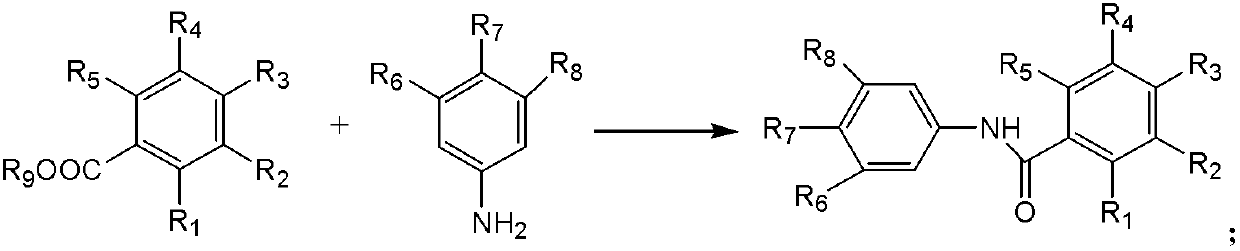

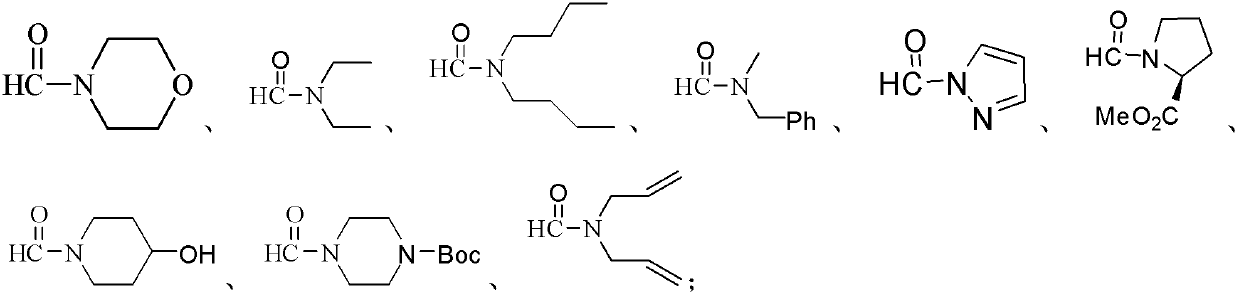

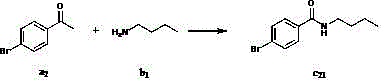

Preparation method of amide

ActiveCN102584509AReact SafeMild reaction conditionsCarboxylic acid nitrile preparationOrganic compound preparationTetramethylammonium iodideSodium iodide

The invention discloses a preparation method of amide. With an aldehyde derivative and a formamide derivative as a reaction substrate, iodide as catalyst and tert-butanol hydrogen peroxide as an oxidizing agent, the amide is prepared through decarbonylation double free radical cross-coupling reaction, wherein the chemical structural formula of the aldehyde derivative is shown in the description, R1 is selected from a naphthyl, a heterlcyclic ring, an alkylene or a mono-substituted aryl; and the iodide is one selected from sodium iodide, potassium iodide, cuprous iodide, lithium iodate, an iodine elementary substance, tetrabutyl ammonium iodide, tetraheptylammonium iodide, tetramethylammonium iodide and benzyltrimethylammonium iodide. According to the invention, because the amide is prepared by using the iodide as the catalyst and using the double free radical cross-coupling method, the use of the traditional metal catalyst with expensive price and larger toxicity as well as a complicated experiment method is avoided so that the reaction is simpler, more convenient, easier, safer, greener and more economic; moreover, the preparation method of the amide disclosed by the invention has the advantages of quite moderate reaction condition, simpler post-treatment and potential industrial application value.

Owner:铜陵市官作文化有限公司

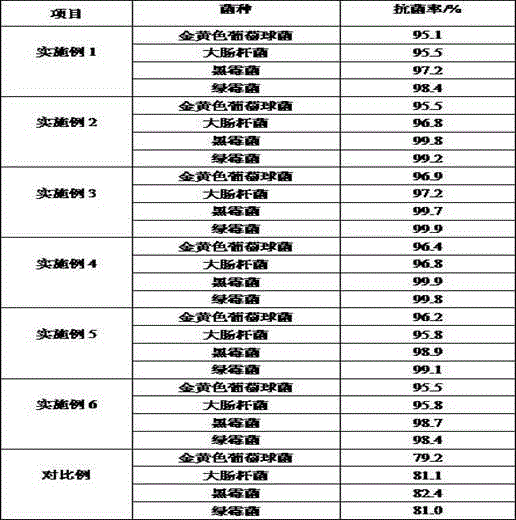

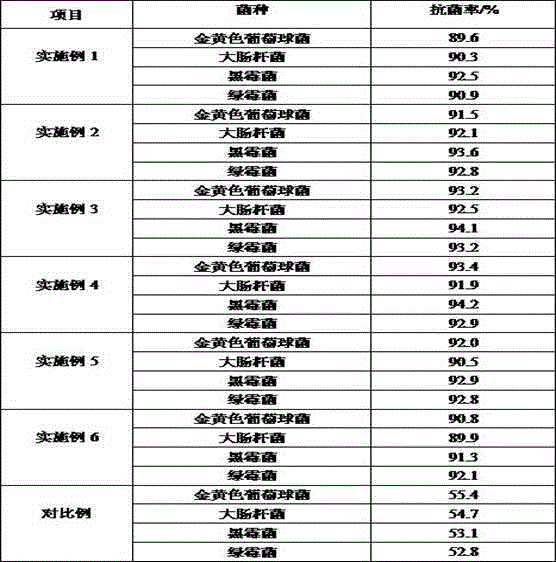

Antibacterial powder coating for pipeline

ActiveCN104804558AReasonable ratioImprove anti-corrosion performanceAntifouling/underwater paintsPaints with biocidesTetramethylammonium iodideCleaning product

The invention discloses an antibacterial powder coating for pipeline. The antibacterial powder coating comprises the following raw materials in parts by weight: 60-90 parts of resin powder, 20-30 parts of filler, 0.5-1.5 parts of tetramethyl ammonium iodide, 3-5 parts of enhancer, 2-4 parts of corrosion inhibitor, 1-8 parts of antibacterial agent and 0.2-0.7 parts of paint. The proportion of each raw material of the antibacterial powder coating for pipeline is reasonable, the corrosion resistance of the material is enhanced, and the antibacterial powder coating has excellent inhibiting and killing effects on microorganisms like fungi, bacteria and mould, is healthy and environment-friendly, and is especially applicable to pipelines for storing and transporting healthy and clean products; after being sprayed with the paint, the surface gloss is good and products are attractive and practical; the preparation method is convenient, the materials are easy to get, the process is simple, the production cost is saved, the effect is significant, and so the antibacterial powder coating has wide application prospect.

Owner:SHANDONG XIANDAI CHENGXIN IND CO LTD

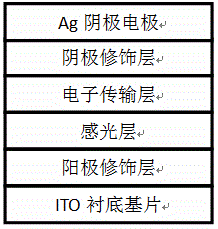

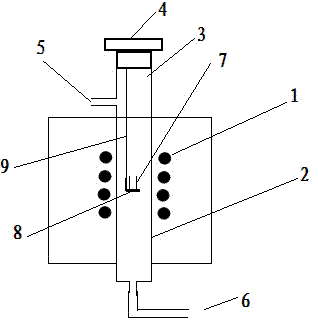

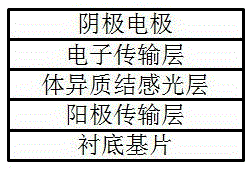

Preparation method of cathode and anode-modified perovskite solar cell

InactiveCN105489769ASpeed up extractionIncrease currentSolid-state devicesSemiconductor/solid-state device manufacturingMaterials processingChemistry

The invention provides a preparation method of a cathode and anode-modified perovskite solar cell. The method comprises the following preparation steps: dissolving methyl ammonium iodide and lead chloride into dimethyl formamide to prepare a perovskite precursor solution; dissolving metal nano-particles into ethanol, mutually dissolving with PEDOT:PSS, carrying out processing on a substrate and then carrying out annealing to obtain a cured anode modifying layer; processing the perovskite precursor solution on the anode modifying layer, and then carrying out annealing to obtain a curved photosensitive layer; processing [6,6]-phenyl-C61-methyl butyrate on the photosensitive layer to obtain an electron transport layer; processing an organic material on the electron transport layer to obtain a cathode modifying layer; and processing a cathode electrode on the cathode modifying layer to obtain the cathode and anode-modified perovskite solar cell. The prepared cathode and anode-modified perovskite solar cell is high in energy conversion efficiency and good in photovoltaic characteristics.

Owner:SUZHOU UNIV

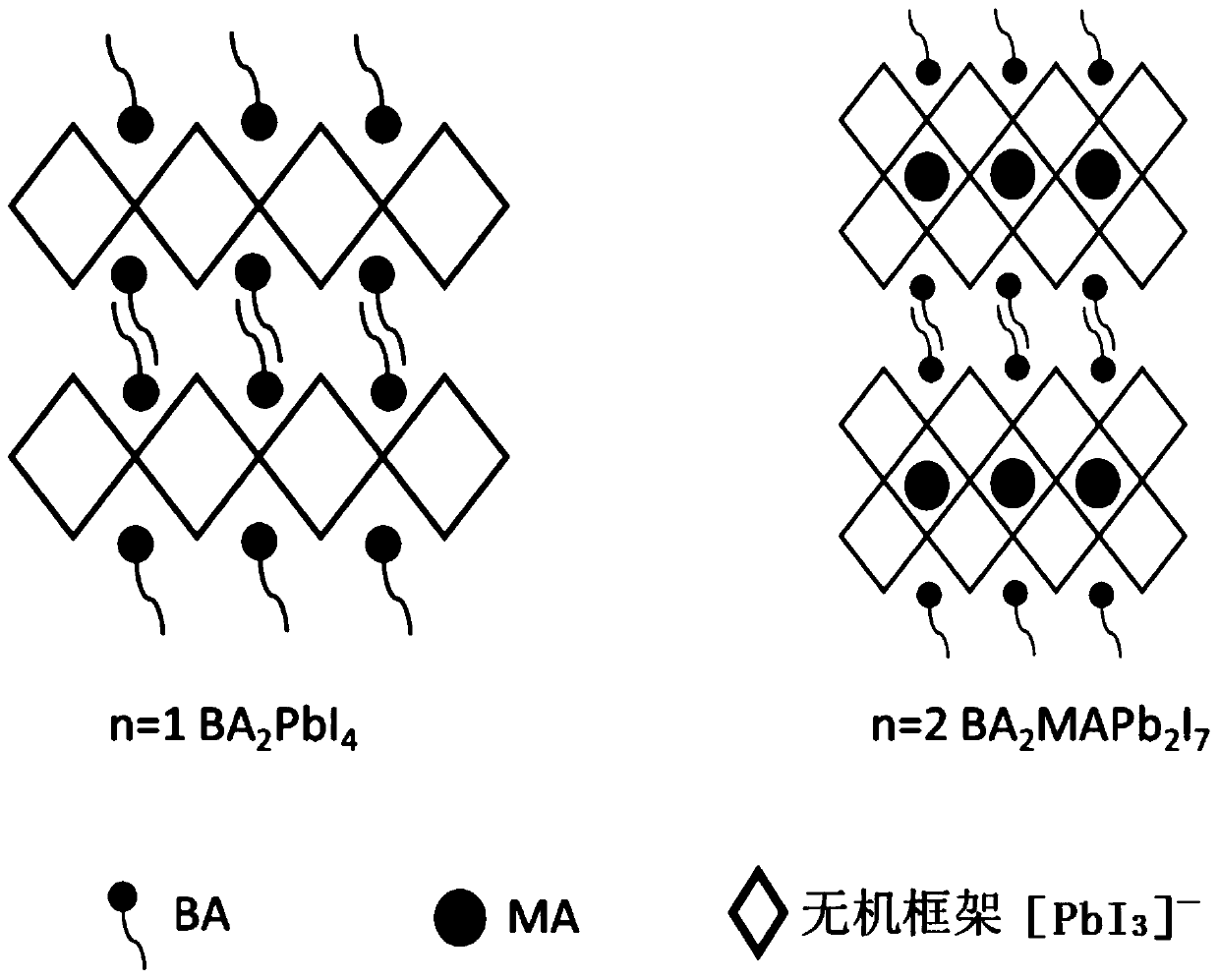

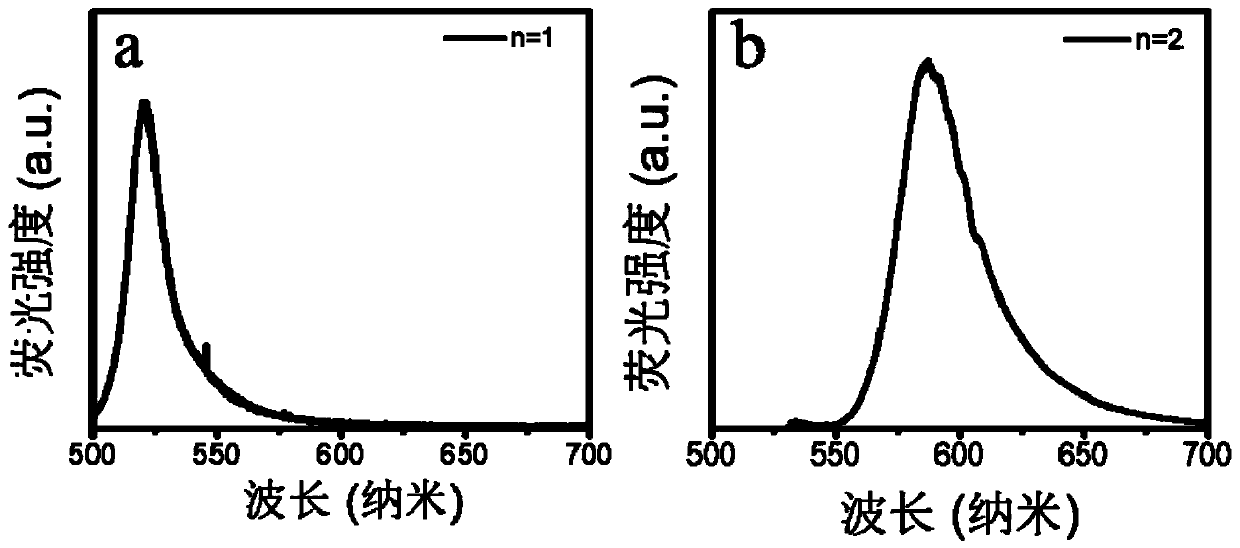

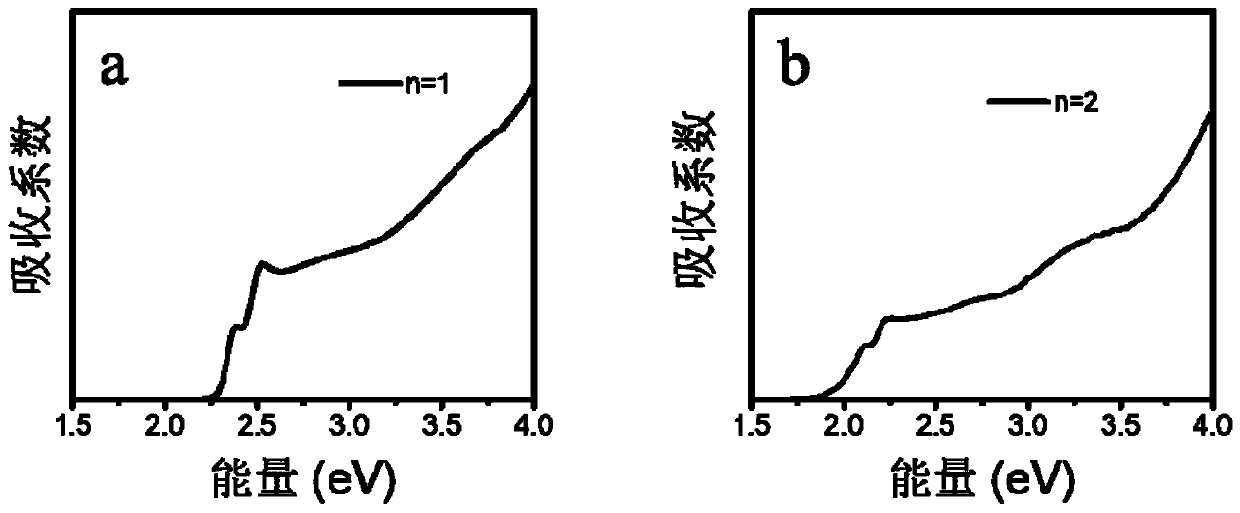

Two-dimensional layered perovskite layer and preparation method thereof

ActiveCN110305019AImprove intrinsic stabilityExpandableOrganic compound preparationOrganic chemistry methodsAmmonium iodidePolytetrafluoroethylene

The invention relates to a two-dimensional layered perovskite layer and a preparation method thereof. The preparation method mainly comprises the following steps: uniformly mixing a certain amount ofbutylamine hydroiodate or butylamine hydroiodate and methyl ammonium iodide with a certain amount of lead iodide so as to obtain mixed powder; transferring the mixed powder into a polytetrafluoroethylene liner, and performing sealing; putting the sealed polytetrafluoroethylene liner into a reaction kettle, and performing heating for 24-48 hours at 160-200 DEG C, so as to obtain the two-dimensionallayered perovskite crystal (BA)2(CH3NH3)n-1PbnI3n+1, wherein n is a positive integer. By adopting the method, a toxic solution is not adopted for the reaction, so that the method is green and environment-friendly. In addition, the two-dimensional layered perovskite crystal prepared by using the method is good in stability.

Owner:JINAN UNIVERSITY

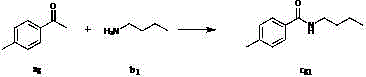

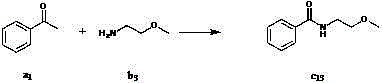

Method for preparing amide compound

InactiveCN102746077AMild reaction conditionsMeet the requirementsOrganic compound preparationSulfonic acid esters preparationSodium iodidePotassium iodine

The invention discloses a method for preparing an amide compound, which comprises the steps of configuration of reaction system. Methyl ketone, amine, catalyst, an oxidizing agent and solvent are use, wherein the general formula of the methyl ketone is RCOCH3, and R is selected from one kind of C6-C14 aryl group, C2-C8 alkenyl group, and five-or six-membered heterocyclic group; the amine is primary amine; the catalyst is selected from one kind of potassium iodide, iodine, tetramethyl ammonium iodide, tetrabutyl ammonium iodide, tetrahexyl ammonium iodide, bismuth iodide, lithium iodide, phenyl trimethyl ammonium iodide, benzyl trimethyl ammonium iodide or sodium iodide; the oxidizing agent is tert-butyl hydroperoxide; the solvent is selected from one kind of water, dichloromethane, ethyl acetate, toluene, 1,2-dichloroethane, 1,1,1-trichloroethane, acetonitrile, and isopropanol. The methyl ketone, the catalyst and the amine are added into the reaction system under the temperature of 0 DEG C and stirred for 5 minutes, and then the oxidizing agent is added to react for 2-48 hours to obtain the amide compound. The method provided by the invention is green, moderate, high in selectivity and wide in application range.

Owner:云梦星联物流有限公司

Asymmetric hydrogenation synthetic method of chiral aromatic amine compound with high steric hindrance

InactiveCN103570484AThe hydrogenation reaction conditions are mildSmooth responseOrganic compound preparationCarboxylic acid amides preparationIridiumPotassium iodine

The invention relates to an asymmetric hydrogenation synthetic method of a chiral aromatic amine compound of iridium-catalyzed imine with high steric hindrance. The catalyst adopted is a catalyst generated by in-situ reaction of a 1, 5-cyclooctadiene iridium chloride dimer and a chiral phosphine-phosphoramidite ligand. The reaction can be carried out under the following condition: the additives comprise iodine, potassium iodide and tetrabutyl ammonium iodide; the temperature is 0-200 DEG C; the solvent is dichloromethane, 1, 2-dichloroethane to the like; the pressure is 10-100 barometric pressures; the time is 12-48 hours; and the proportion of a primer and the catalyst can reach 100000 / 1. The method provided by the invention has the characteristics of mild reaction condition, high activity, high stereoselectivity, wide application range of the primer and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

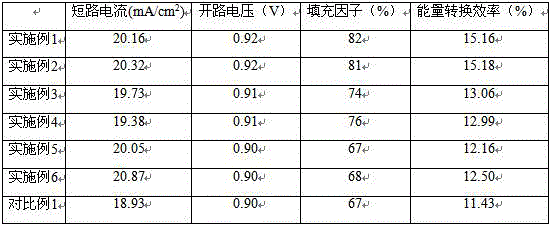

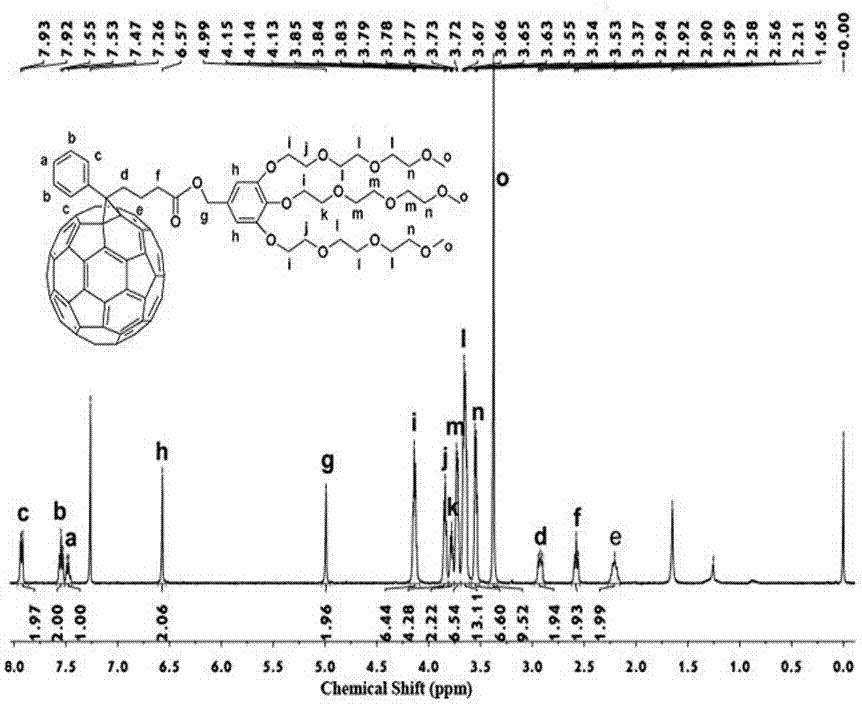

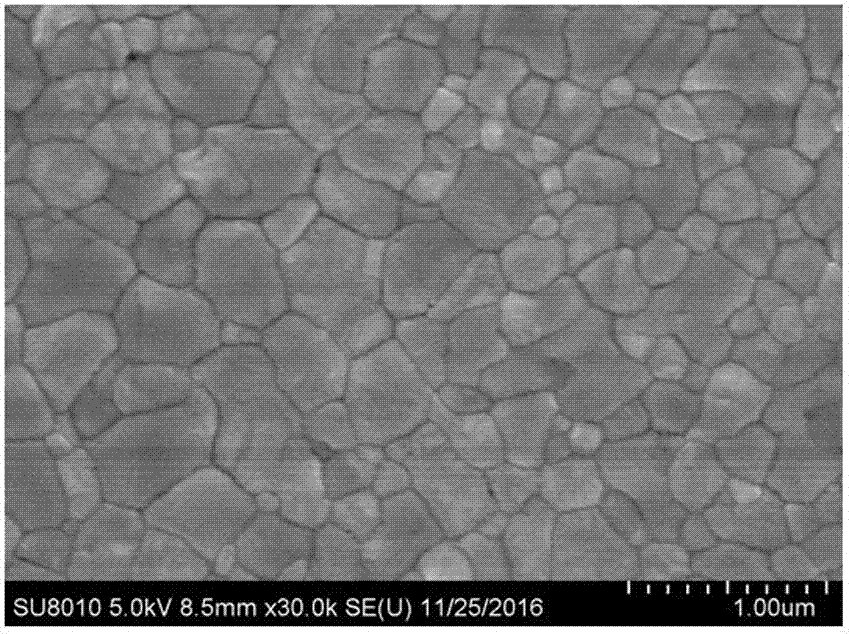

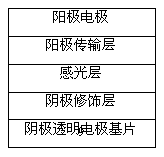

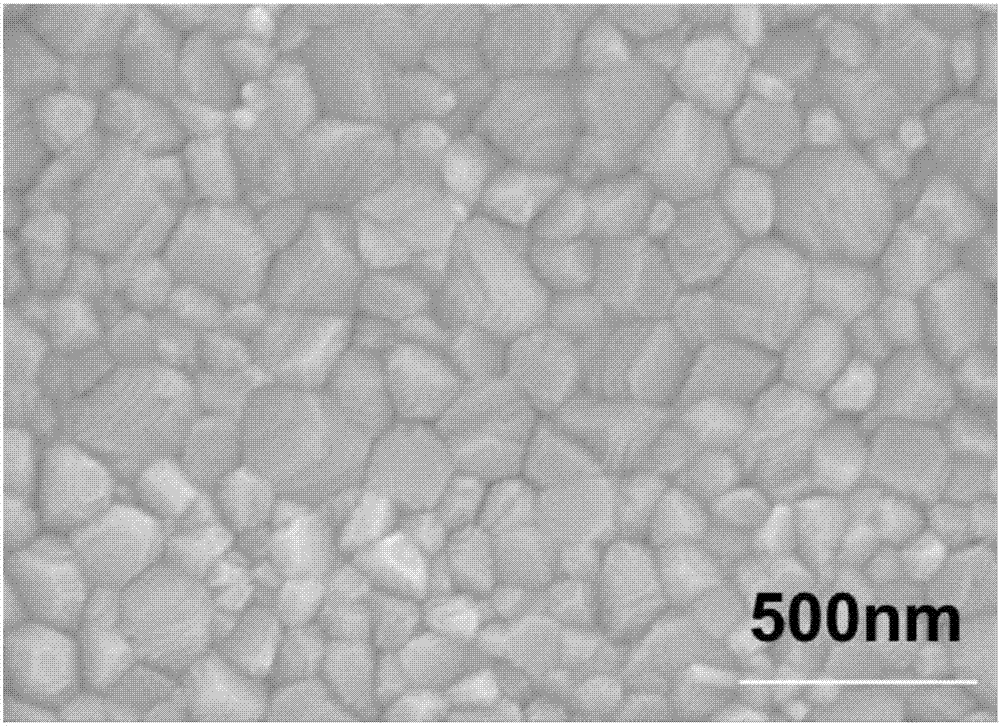

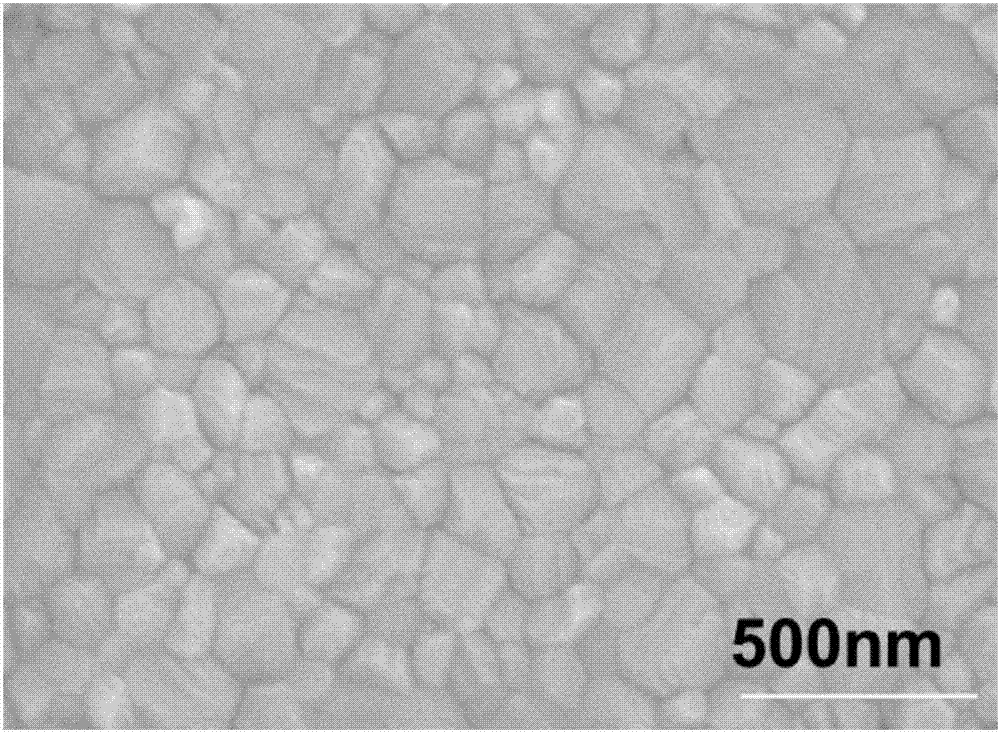

Application of alcohol soluble fullerene derivative in perovskite solar cell

ActiveCN107394047ALarge grainDense grainOrganic compound preparationOrganic chemistry methodsHole transport layerSpin coating

The invention discloses an application of an alcohol soluble fullerene derivative in a perovskite solar cell. The preparation process of a cell includes the following steps: preparing a cavity transmission layer on a piece of clean electro-conductive glass; spin-coating the cavity transmission layer with DMF solution of PbI2, spin-coating methyl ammonium iodide (MAI) isopropanol solution doped with the alcohol soluble fullerene derivative, and then obtaining a perovskite layer through annealing; and preparing an electronic modification layer and electrodes on the perovskite layer, and obtaining a perovskite solar cell. The application of an alcohol soluble fullerene derivative in a perovskite solar cell enables the fullerene to be distributed in a perovskite film from top to bottom in a graded manner by means of a simple doping method, thus maximally improving the electron mobility so as to improve the current and fill factors of devices. Therefore, the application of an alcohol soluble fullerene derivative in a perovskite solar cell can obtain a perovskite solar cell with high performance and simplify the process of device preparation, and can obtain better device performance at the same time.

Owner:SUZHOU UNIV +1

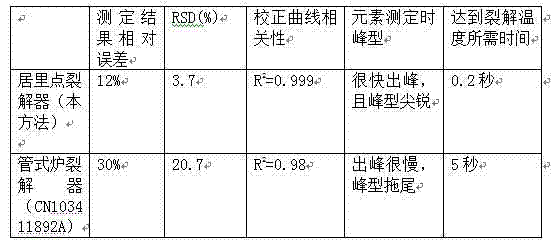

Elemental analysis determination method and device

InactiveCN103792223AReduce distractionsSlow heating ratePreparing sample for investigationAnalysis by thermal excitationSodium hydrosulfideElemental analysis

The invention discloses an elemental analysis determination method and device. The elemental analysis determination method comprises the following steps: adding an inorganic compound capable of releasing hydrogen in pyrolysis into a to-be-detected sample and mixing the inorganic compound with the sample uniformly; carrying out pyrolysis on the mixture at a certain temperature, enabling an element to form a volatile matter, and determining the volatile matter by an atom spectrogram, wherein the inorganic compound for releasing hydrogen in pyrolysis is sodium bisulfide, potassium hydrogen sulfide, ammonium sulfide, ammonia hydrogen sulfide, ammonium iodide, hydrogen sulfide or hydrogen iodide, and the weight of the added inorganic compound is 0.2-100 times the weight of the sample. According to the invention, an inorganic hydrogen release reagent and a curie point pyrolyser are used, and the advantages of low analysis cost, less interference, high element volatile matter formation speed, high sampling efficiency of to-be-detected elements and the like are realized, and the method is a rapid and accurate analysis method.

Owner:TIANJIN NORMAL UNIVERSITY

Polishing composition

The polishing composition contains an abrasive, a microwaviness reducing agent, an oxidizing agent, a polishing accelerator, and water. The microwaviness reducing agent is a reducing agent and contains at least one kind selected from phosphonic acid, phosphinic acid, ammonium hypophosphite, ammonium sulfite, sodium sulfite, hydroquinone, pyrogallol, erysorbic acid, sodium erysorbate acid, L-ascorbic acid, formic acid, sodium formate, amumonium formate, oxalic acid, ammonium oxalate, ammonium iodide, and gallic acid. The abrasive can contain silicon dioxide, and the oxidizing agent can contain hydrogen peroxide. The accelerator can contain e.g. phosphoric acid, glycolic acid, maleic acid or succinic acid as well as diammonium hydrogen phosphate or ammonium dilhydrogen phosphate. The polishing composition can be used in polishing a substrate for a magnetic disk.

Owner:FUJIMI INCORPORATED

Preparation method of cross-linked fullerene bulk heterojunction perovskite solar cell

ActiveCN105470403AImprove performanceReduce performanceSolid-state devicesSemiconductor/solid-state device manufacturingCross-linkHeterojunction

The invention provides a preparation method of a cross-linked fullerene bulk heterojunction perovskite solar cell. The method comprises the following preparation steps: dissolving methyl ammonium iodide, lead chloride and [6,6]-phenyl-C61-butyric styryl dendron ester into dimethyl formamide to prepare 30wt% of perovskite dimethyl formamide solution; processing a PEDOT:PSS solution on a substrate to form cured anode modifying layer; processing the perovskite dimethyl formamide solution on the anode modifying layer to obtain a uniformly cured bulk heterojunction photosensitive layer; processing [6,6]-phenyl-C61-methyl butyrate on the bulk heterojunction photosensitive layer to obtain a uniform electron transport layer; and processing a cathode electrode on the electron transport layer, so as to obtain the cross-linked fullerene bulk heterojunction perovskite solar cell. The perovskite solar cell prepared by the method has the advantages of high energy conversion efficiency and good photovoltaic characteristic.

Owner:SUZHOU UNIV

Perovskite material, application thereof on solar cell and preparation method of solar cell

ActiveCN108183170AReduce pollutionOvercome the shortcomings of small grains and large defectsSolid-state devicesSemiconductor/solid-state device manufacturingEnvironmental resistanceIodide

The invention provides a perovskite material, an application thereof on a solar cell and a preparation method of the solar cell. The preparation method comprises the steps of dissolving a precursor material of methyl ammonium iodide, lead iodide, tin iodide or copper bromide or a precursor material of methyl ammonium iodide, lead iodide and copper bromide into a mixed solvent of gamma-butyrolactone and dimethyl sulfoxide to prepare a perovskite solution; using TiO2 prepared at a low temperature to serve as a cathode transmission layer; processing the ternary lead-tin-copper perovskite solutionto the cathode transmission layer, and then processing 2,2',7,7'-tetra[N,N-di(4-methoxyphenyl)amino]-9,9'-spirobifluorene to a junction light sensing layer to obtain a hole transport layer; and thendepositing an anode electrode so as to obtain an efficient and environment-friendly perovskite solar cell. The obtained perovskite solar cell is high in energy conversion efficiency, environment-friendly, simple in process and good in perovskite crystal characteristic.

Owner:SUZHOU UNIV

Synthetic method of glycerol carbonate

InactiveCN102383142AEfficient conversionReduce pollutionElectrolysis componentsElectrolytic organic productionN dimethylformamideGlycerol

The invention discloses a synthetic method of glycerol carbonate. The synthetic method is characterized in that: N,N-dimethylformamide is mixed with tetraethyl ammonium iodide and glycerol to obtain an electrolyte, the electrolyte is saturated with CO2 at normal pressure and is electrolyzed under conditions of a constant current, and the electrolyte is esterified and distillated to prepare glycerol carbonate. Compared with the prior art, the synthetic method of the invention, which has the advantages of simple technology, convenient operation, safety, cheap and easily available raw material, effective utilization of a greenhouse effect gas carbon dioxide, substantial reduction of atmospheric pollution, realization of the high efficiency conversion of glycerol, and alleviation of the increasingly exhausted energy problem and has a very significant meaning to the environment protection, is a technical route with a good industrial synthetic value.

Owner:EAST CHINA NORMAL UNIV

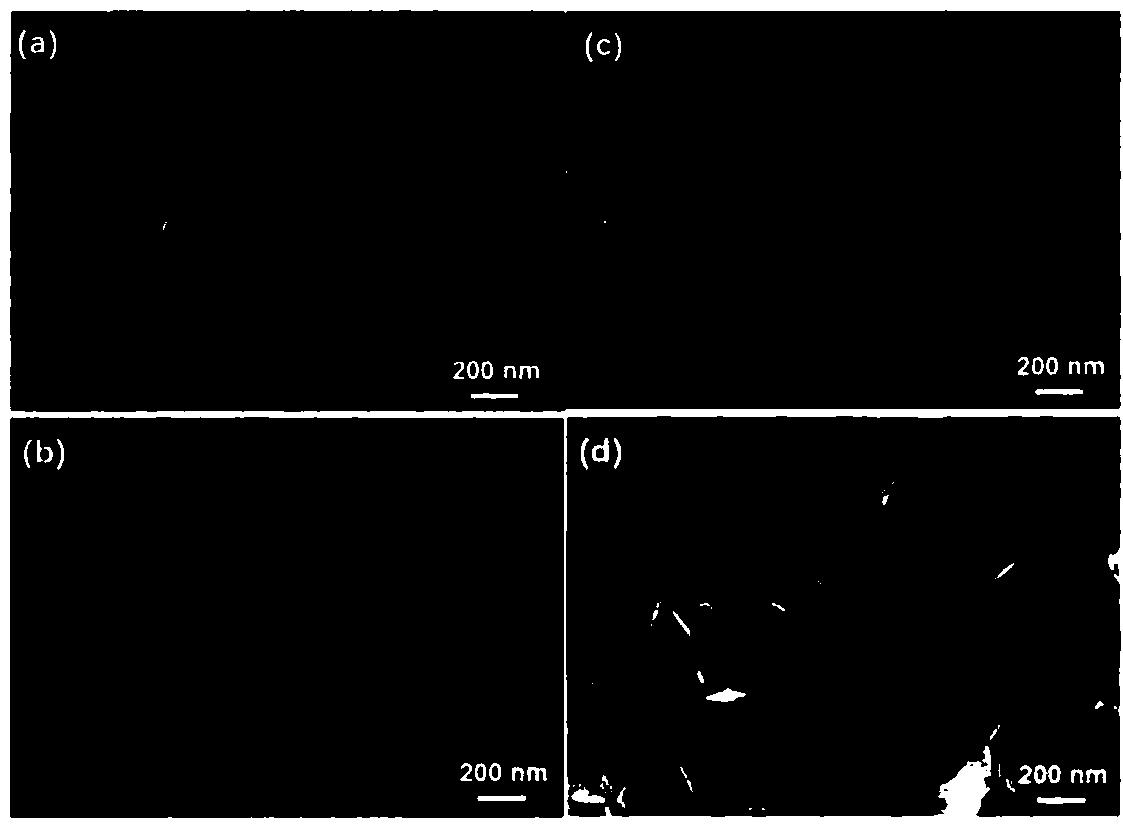

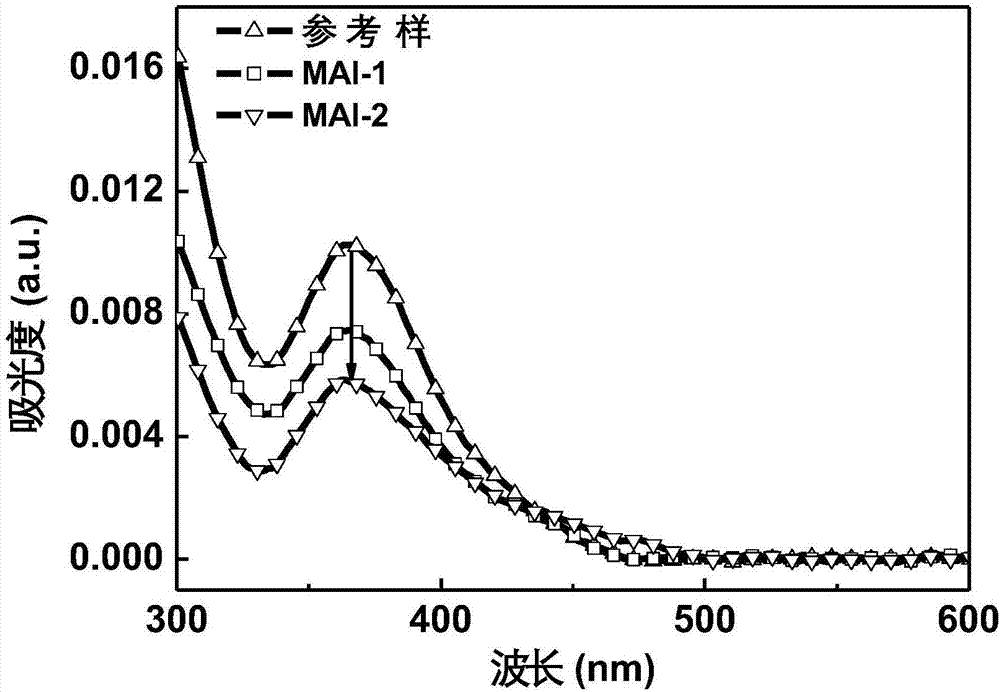

Preparation method for methylammonium iodide

ActiveCN107337607APromote generationSuppress generationAmino compound purification/separationOrganic compound preparationNitrogen gasState density

The invention relates to a preparation method for methylammonium iodide, belonging to the technical fields of organic-inorganic hybrid materials and photoelectric materials. According to the method in the invention, under the protection of nitrogen, a crude product is purified by using an alcoholic solution of organic amine capable of providing an alkaline environment; the alcoholic solution of organic amine facilitates disproportionation of I2 to produce iodide ions and effectively inhibits generation of I2, so the content of elemental iodine in the prepared methyl ammonium iodide is greatly reduced; a perovskite film prepared by using the methyl ammonium iodide as a precursor has large crystal size, low defect state density and long carrier life; and a solar cell prepared from the perovskite film has photoelectric conversion efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

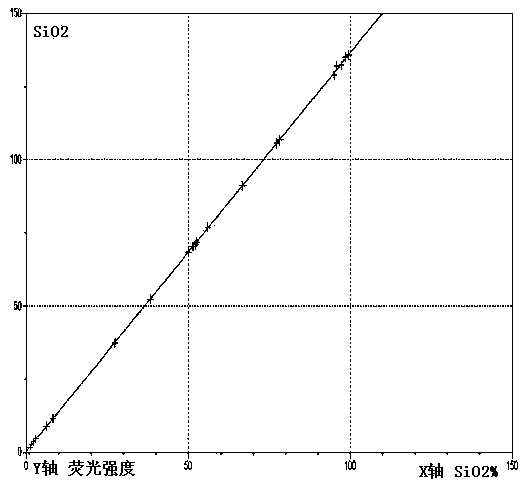

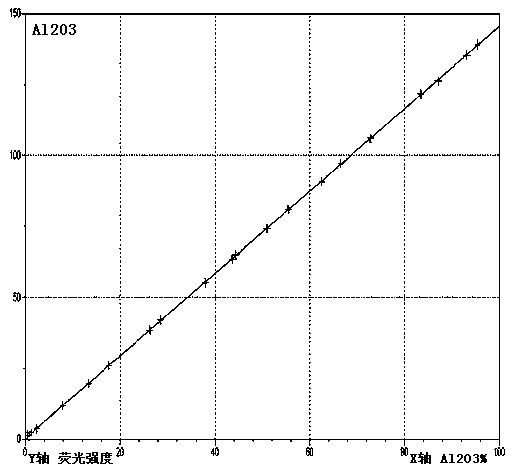

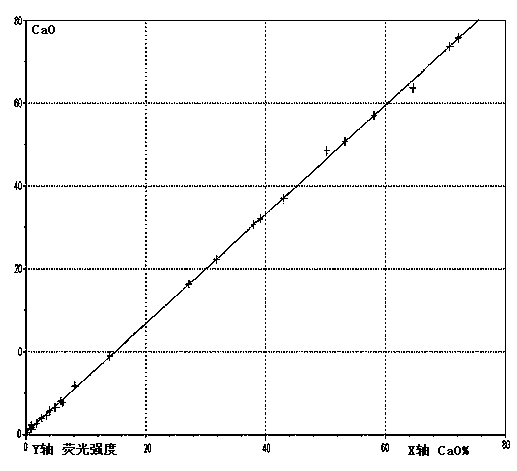

Metallurgy miscellaneous material fast spectral analysis method

InactiveCN103512911AAvoid pollutionQuick analysisMaterial analysis using wave/particle radiationPreparing sample for investigationBurn treatmentFluorescence spectrometry

The invention relates to a metallurgy miscellaneous material spectral analysis method. With an existing metallurgy miscellaneous material fluorescent spectral analysis method, one working curve is only aimed at one material. With the method provided by the invention, the technical problem is solved. The invention provides a technical scheme that according to the metallurgy miscellaneous material fast spectral analysis method, a sample preparation method comprises the steps that a, a sample is subjected to a burning treatment in a high-temperature furnace, and burning reduction and increment are calculated; b, sample treatment is carried out; c, ammonium iodide is added as a de-molding agent, and a standard glass sheet is prepared. Working curve drawing comprises the steps that a, with a sample preparation method, a pure substance or a standard substance is prepared into a standard sample sheet of element to be tested; b, 2 pure mixed flux blank sheets are prepared with the sample preparation method; c, the sample weight of major elements is reduced, such that standard sheets with different contents can be obtained; d, the prepared standard substance sheet is subjected to fluorescent scanning; regression and counting are carried out with density as abscissa and fluorescence intensity as ordinate, such that regression curves of the elements can be obtained; e, similarly, the blank sheet is subjected to spectral scanning, and is deducted as a standard blank; f, unknown sample test is carried out; g, the unknown sample burning reduction and increment are introduced into calculation, and a total amount is normalized.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

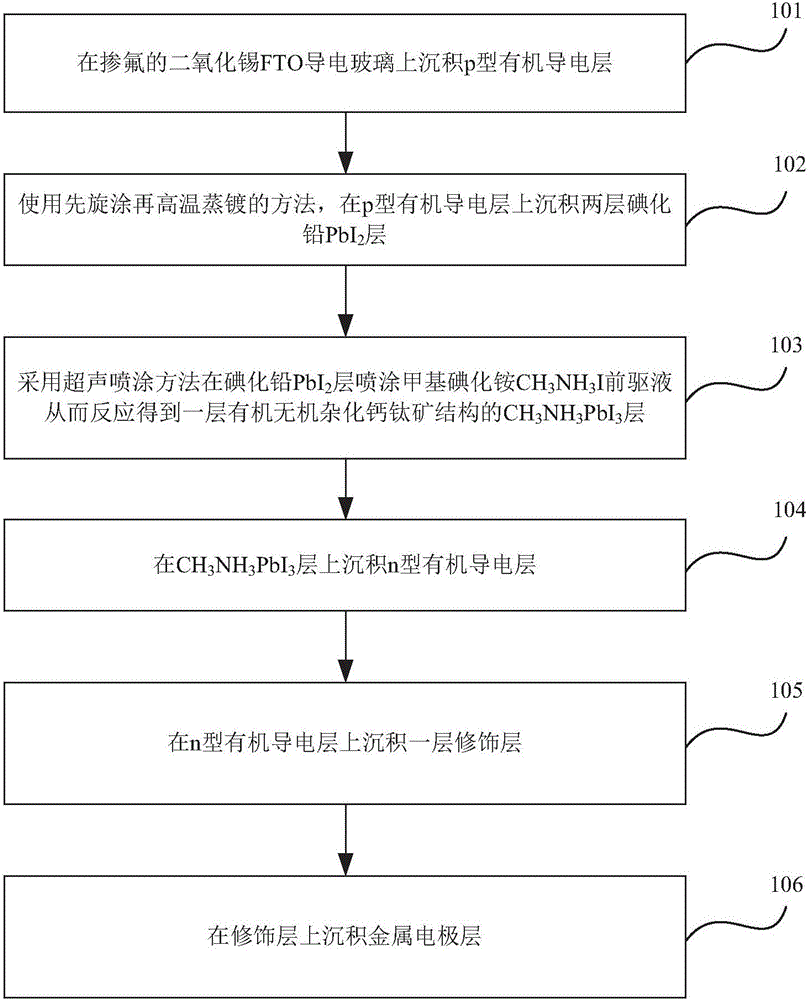

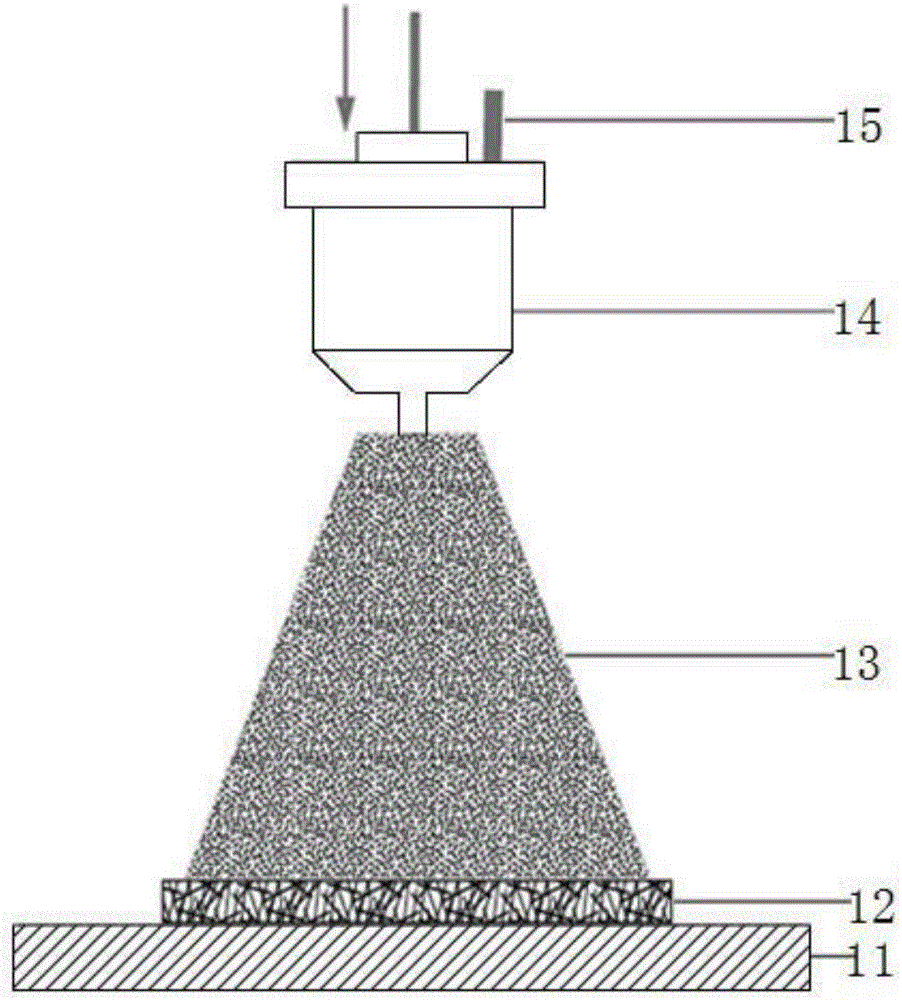

Preparing method of perovskite solar cell and perovskite solar cell

InactiveCN106159095AImprove reaction efficiencyIncrease usageFinal product manufactureSolid-state devicesPerovskite solar cellEvaporation

The embodiment of the invention provides a preparing method of a perovskite solar cell and the perovskite solar cell. The method comprises the steps that a p-type organic conductive layer is deposited on fluorine-doped stannic oxide FTO conductive glass; two lead iodide PbI2 layers are deposited on the p-type organic conductive layer with the method of carrying out spin coating first and then carrying out high-temperature evaporation; a methyl ammonium iodide CH3NH3I precursor solution is sprayed to the lead iodide PbI2 layers with an ultrasonic spraying method, and thus a Ch3NH3PbI3 layer of an organic and inorganic hybrid perovskite structure is obtained through a reaction; an n-type organic conductive layer is deposited on the Ch3NH3PbI3 layer; a modification layer is deposited on the n-type organic conductive layer; a metal electrode layer is deposited on the modification layer. According to the technical scheme, the preparing method of the perovskite solar cell and the perovskite solar cell have the advantages that preparation is carried out with the method of carrying out spin coating first and then carrying out high-temperature evaporation, the reaction efficiency can be improved, and the PbI2 layers and the CH3NH3I layer can react more sufficiently; preparation is carried out with the ultrasonic spraying method, the utilization rate of raw materials can be increased, the production cost can be reduced, and large-area industrialized production can be achieved.

Owner:深圳市先进清洁电力技术研究有限公司

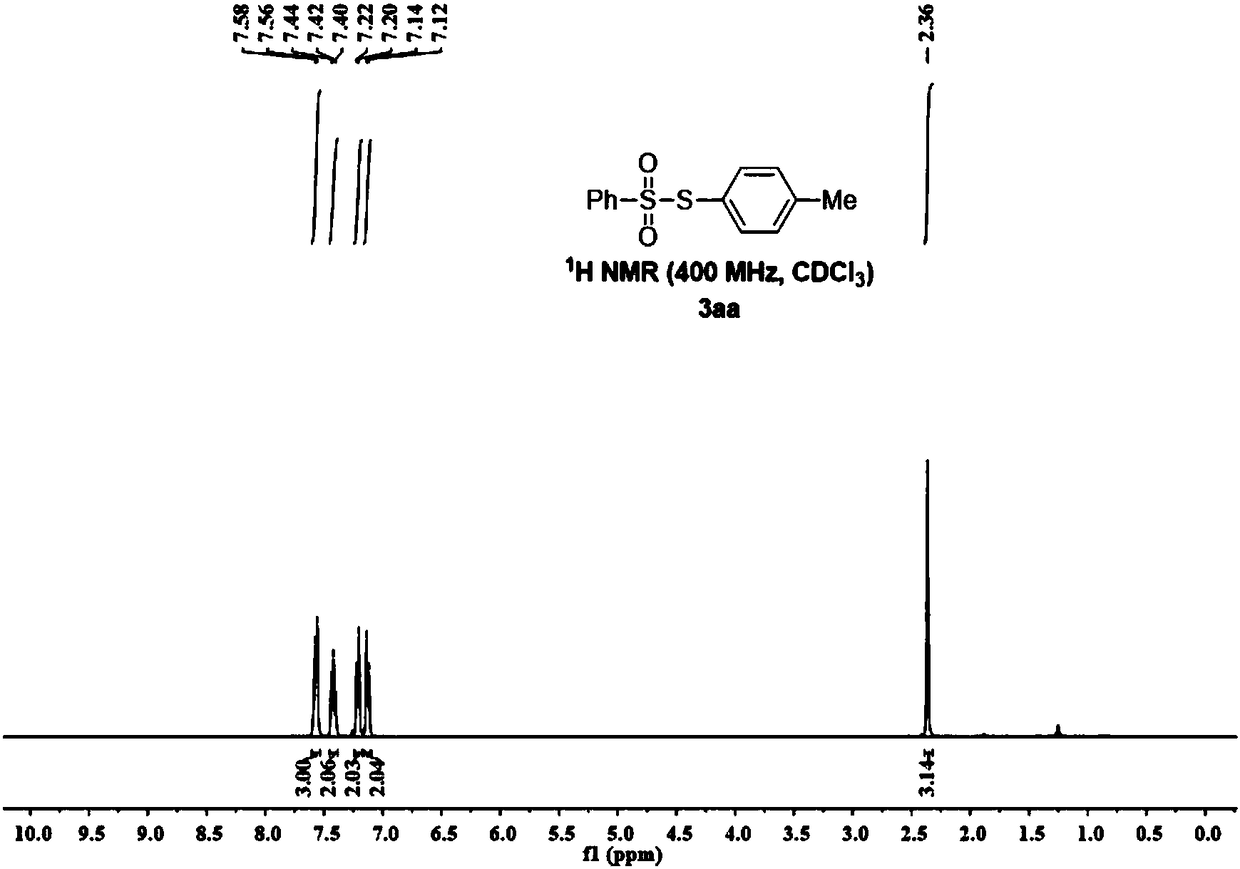

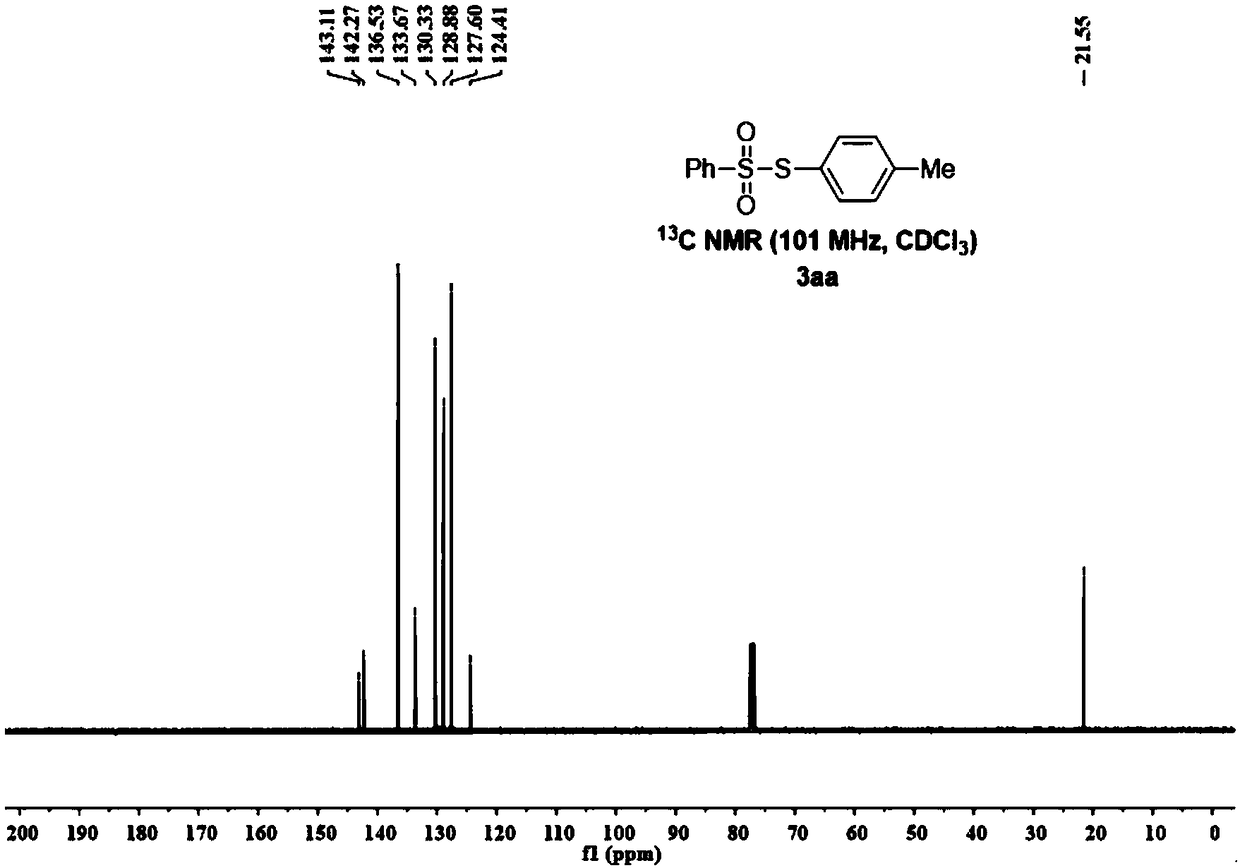

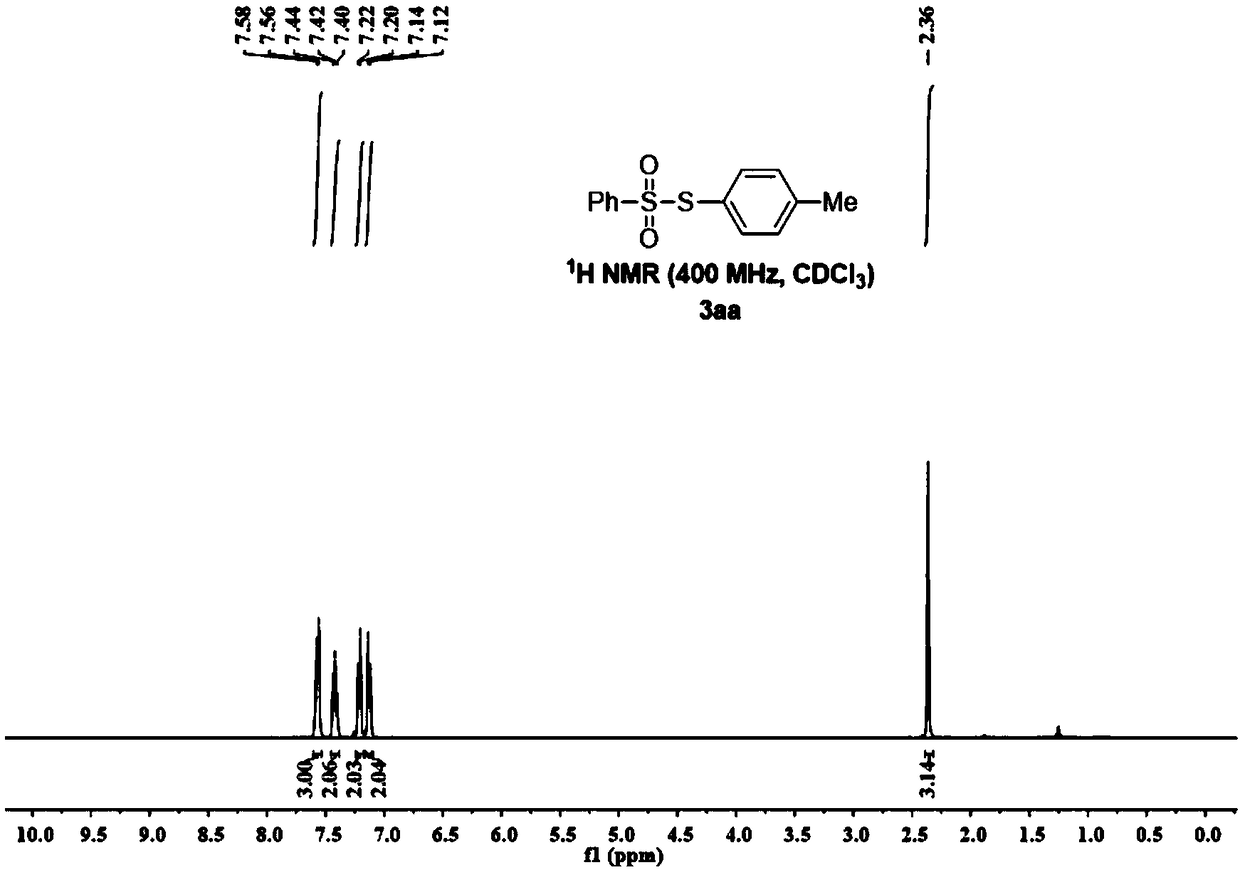

Synthesis method of thiosulfonate compound

ActiveCN108191729AImprove conversion rateNo pollutionOrganic chemistryOrganic synthesisThiosulfonic Acids

The invention belongs to the field of organic synthesis, and particularly relates to a synthesis method of a thiosulfonate compound. The invention provides the synthesis method of the thiosulfonate compound. The method comprises the following steps that methanesulfonohydrazide compounds, thiophenol compounds, oxidizing agents and catalysts are dissolved into a solvent for reaction; purification isperformed to obtain the thiosulfonate compound; oxidizing agents are any one kind or several kinds of materials from tertiary butanol peroxide and catalysts are sodium iodide, potassium iodide, ammonium iodide, iodine element and tetrabutylammonium iodide. Through experiment testing, the thiosulfonate compound prepared by the technical scheme provided by the invention has the advantages that no side reaction occurs; the yield can reach 84 to 100 percent; the conversion rate is high; meanwhile, the used catalysts and catalysts are environment-friendly compounds; the environment pollution cannot be caused; the reaction temperature is low; the method is suitable for industrial mass popularization. The defects that in the prior art, the damage to the environment in the asymmetric thiosulfonates synthesis process is great, and the application to industrial production cannot be realized are overcome.

Owner:GUANGDONG UNIV OF TECH

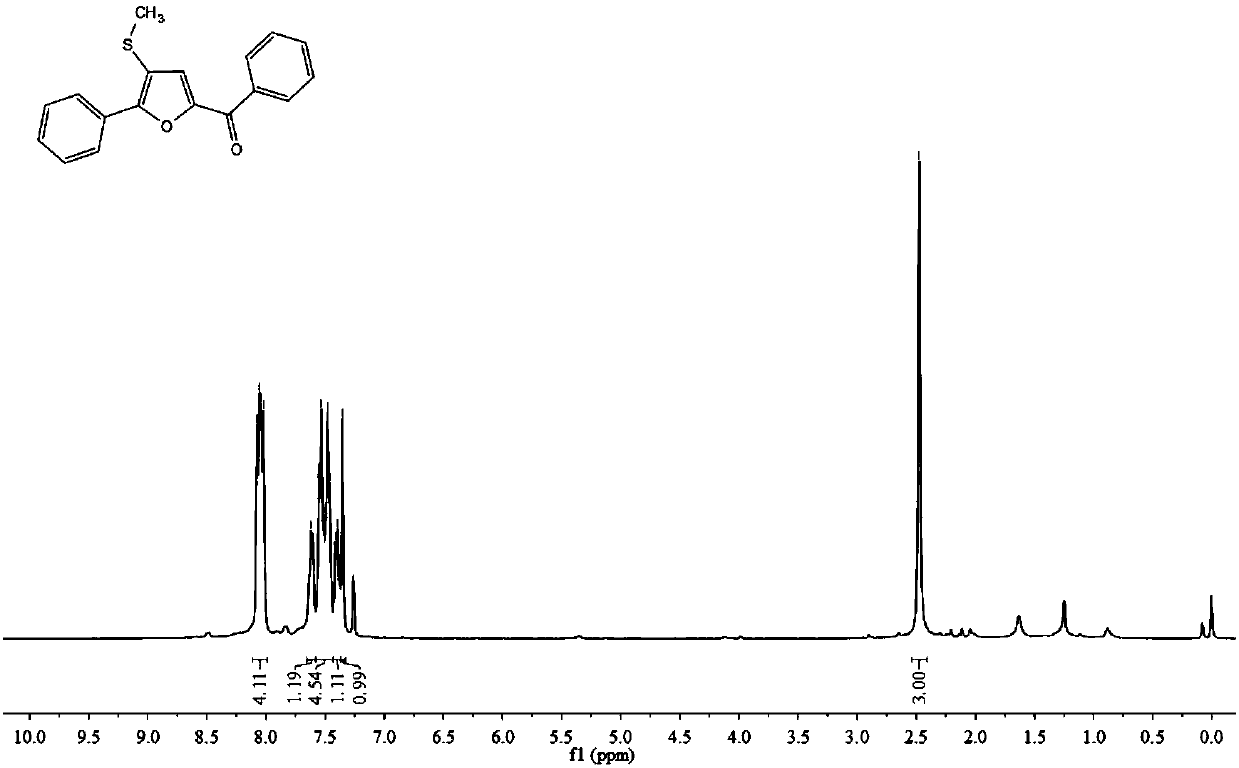

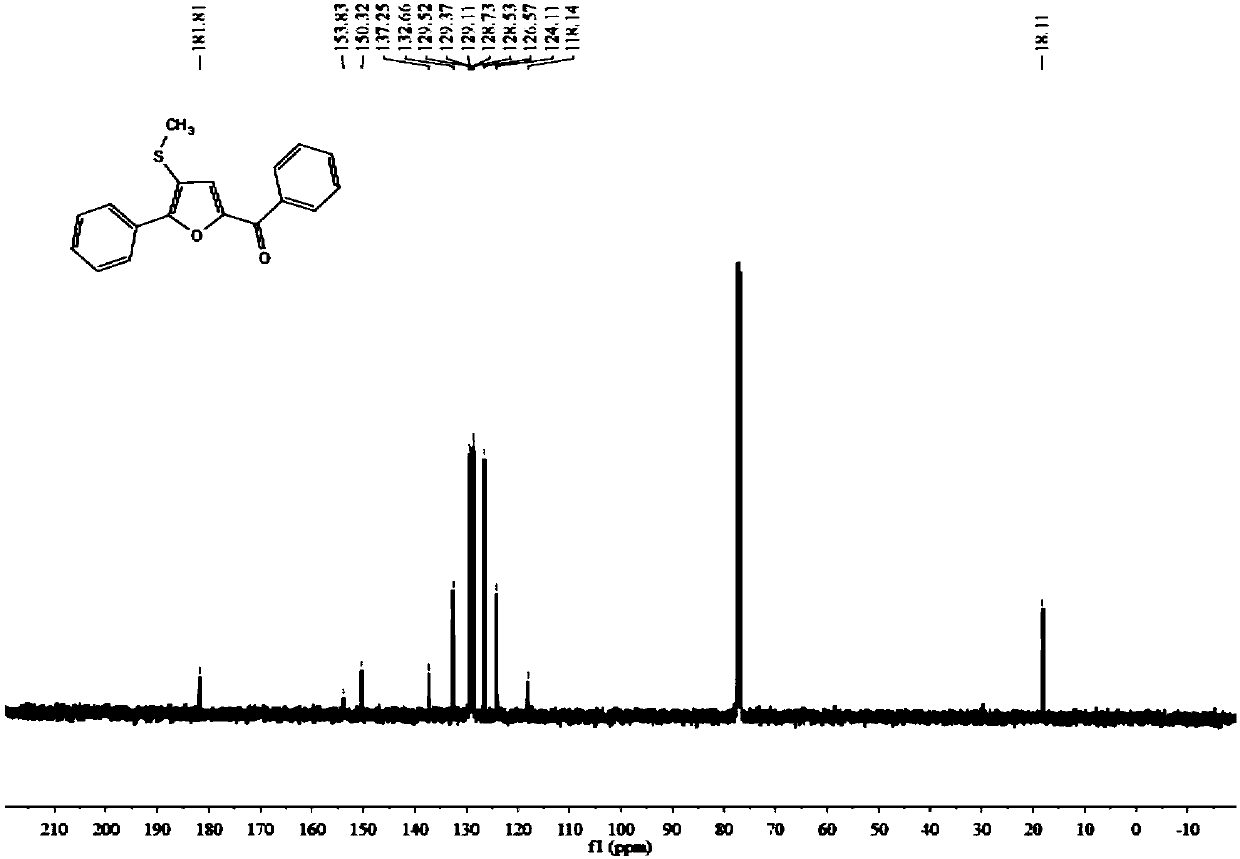

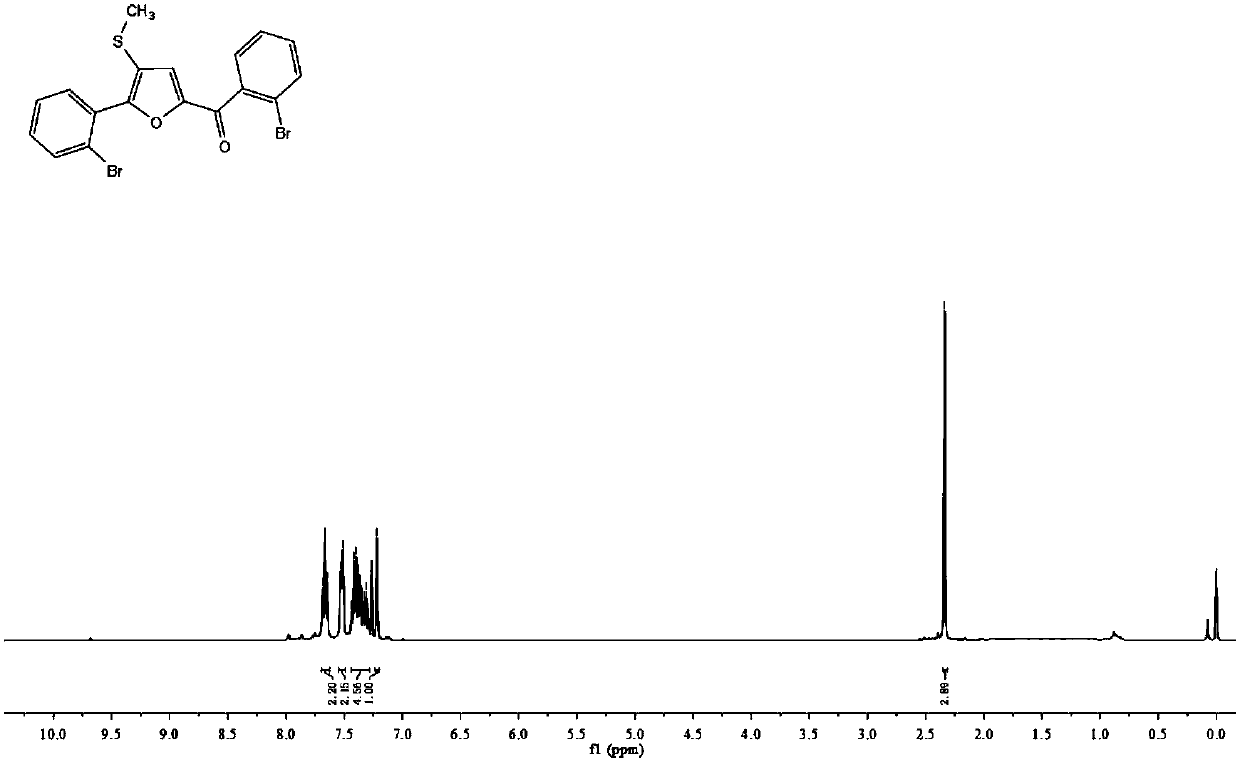

Method for synthesizing furan derivatives on basis of intermolecular ring-closure reaction

The invention discloses a method for synthesizing furan derivatives on the basis of an intermolecular ring-closure reaction. According to the method, the furan derivatives are prepared from acetophenone compounds and dimethyl sulfoxide through a one-pot reaction in the presence of tetra-alkyl ammonium iodide catalyst and a potassium persulfate oxidizing agent. Varieties of the furan derivatives are enriched, more intermediates are provided for drug synthesis, raw materials are widely sourced, and the method adopts simple step and mild reaction conditions and is high in yield and beneficial toindustrial production.

Owner:江西亚太科技发展有限公司

Method for preparing organic perovskite methyl amino lead iodide film through lead oxide film

ActiveCN105777800AUniform and dense formationEasy to manufactureVacuum evaporation coatingSputtering coatingTemperature controlPerovskite solar cell

The invention discloses a method for preparing an organic perovskite methyl amino lead iodide film based on a lead oxide film.The method specifically comprises the steps that with lead oxide as a target material, the lead oxide film is prepared on a base in a sedimentation mode through the film preparation technology, the film thickness is controlled through the number of laser pulses, laser energy or sputtering power and time, the lead oxide film growing well and methyl ammonium iodide powder are put into a temperature controlling furnace and heated at the constant temperature of 160-260 DEG C for 5 minutes to 3 hours, and the formed methyl ammonium iodide gas and the lead oxide film on the base react successively to produce the methyl amino lead iodide film.The preparing technology is simple, and large films can be prepared; by means of high-temperature crystal, a uniform and compact entirety is formed by the produced methyl amino lead iodide film, crystalline grains penetrate through the whole film, crystal boundaries, cracks and defects are reduced, and therefore the methyl amino lead iodide film helps efficiency improvement and actual application and production of organic perovskite solar cells.

Owner:SOUTHEAST UNIV

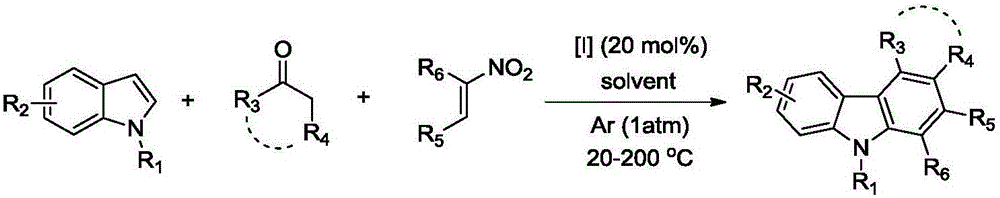

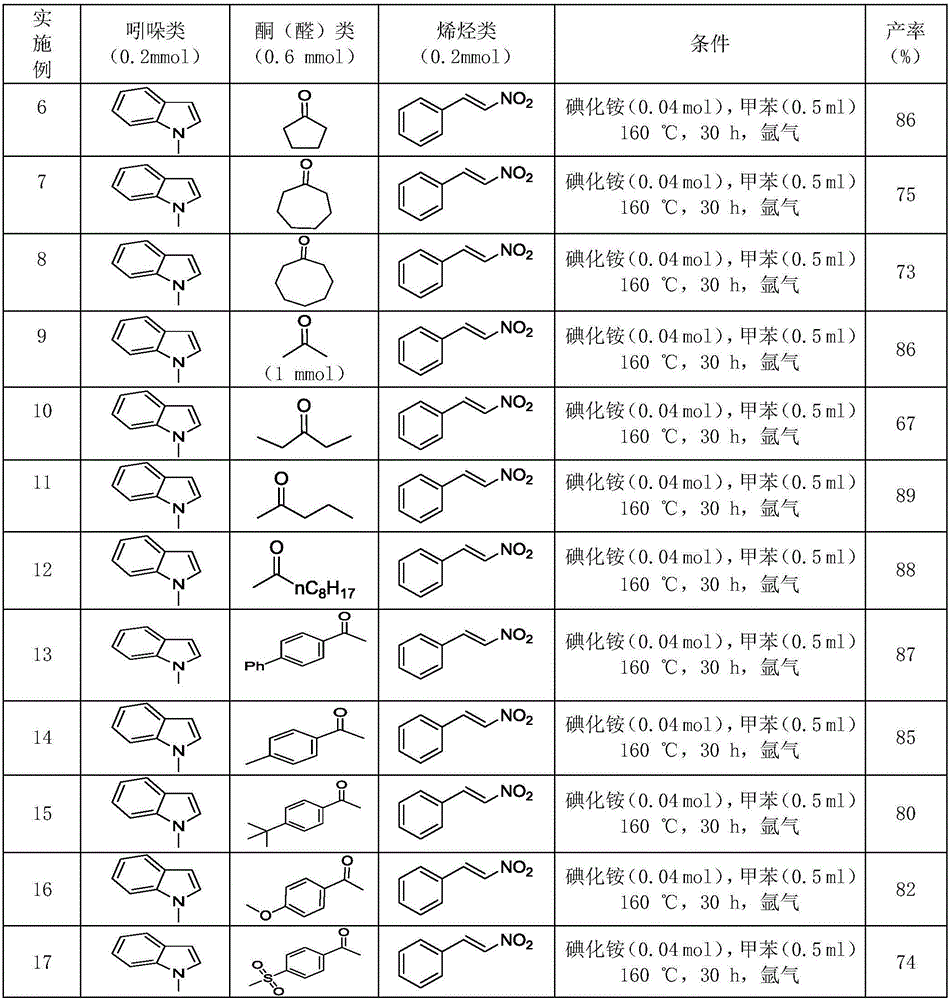

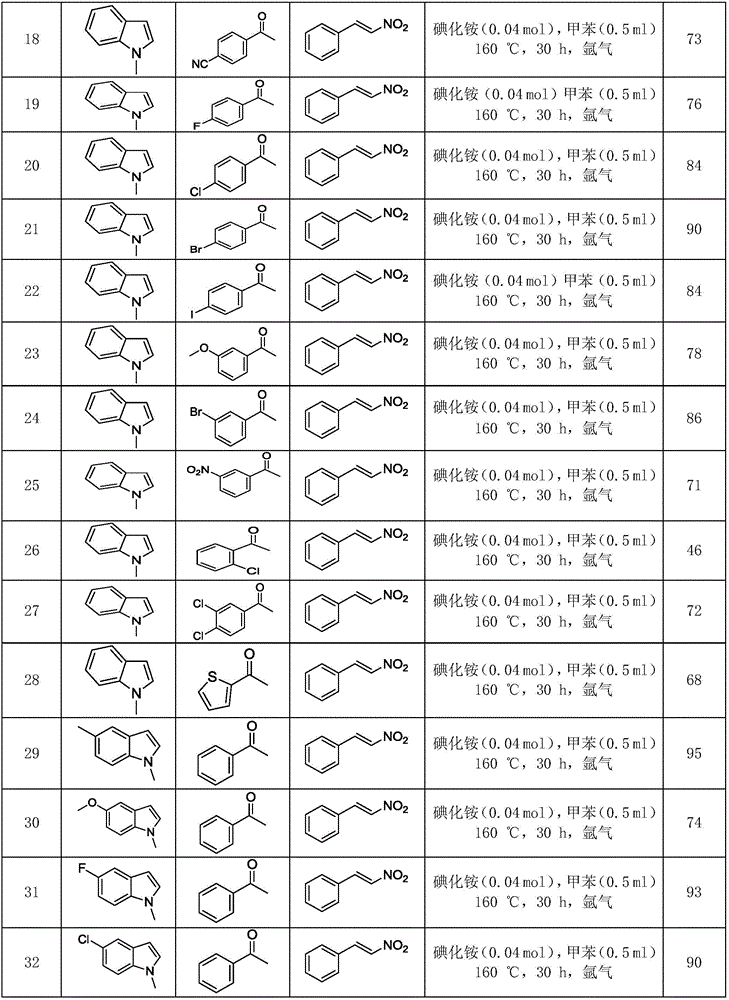

Polysubstituted carbazole, derivative and synthesis method thereof

ActiveCN106117113AReduce pollutionStable molecular structureOrganic chemistryKetoneMolecular recognition

The invention discloses polysubstituted carbazole, a derivative and a synthesis method thereof. The technical scheme includes that under inert gas shielding, three simple components including indole, alkene, and ketone (aldehyde) are adopted for selective synthesis of the polysubstituted carbazole and the derivative for the first time by adoption of ammonium iodide as a catalyst for the first time and adoption of acetonitrile, dichloroethane, tetrahydrofuran, N,N-dimethyl acetyl, benzene, chlorobenzene, orthodichlorobenzene, cyclohexane, 1,4-dioxane, anisole, benzonitrile, dimethylbenzene, trifluorotoluene, methylbenzene, trimethylbenzene and the like as organic solvents. The defect that an existing synthesis method is complex in synthesis steps and requires multi-step synthesis, tradition metal catalysts, chemical equivalent metal oxidizing agents and the like is overcome. The polysubstituted carbazole, the derivative and the synthesis method are widely applicable to various fields of photoelectricity, printing and dyeing, medicines, molecular recognition and the like and is especially suitable for research and development of metal-catalysis-free multi-component one-pot selective synthesis of polysubstituted carbazole compounds.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com