Preparation method of cross-linked fullerene bulk heterojunction perovskite solar cell

A solar cell and perovskite-type technology, applied in the field of solar cells, can solve the problems of limiting the energy conversion efficiency of battery devices, etc., and achieve the effects of improving low coverage, increasing coverage, and increasing optional space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

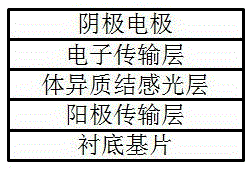

Image

Examples

Embodiment 1

[0025] A method for preparing a cross-linked fullerene heterojunction perovskite solar cell, the preparation steps of the preparation method are as follows:

[0026] (1) Dissolve 256mg of methylammonium iodide, 149mg of lead chloride, and 6mg of [6,6]-phenyl-C61-butyricstyryldendronester in dimethylformamide, stir for 5 hours, and prepare 30wt% perovskite Mine dimethylformamide solution;

[0027] (2) Spin-coat the PEDOT:PSS solution on the ITO glass substrate at a speed of 4500rpm for 40s, and then anneal in air at 100°C for 20min to form a cured anode modification layer with a thickness of 45nm;

[0028] (3) Spin-coat the perovskite dimethylformamide solution obtained in (1) on the anode modification layer obtained in (2) at a rotation speed of 4000rpm for 40s, and then anneal at 100°C to obtain a uniform A cured bulk heterojunction photosensitive layer with a thickness of 250nm;

[0029] (4) Spin-coat [6,6]-phenyl-C61-butyric acid methyl ester on the bulk heterojunction ph...

Embodiment 2

[0032] A method for preparing a cross-linked fullerene heterojunction perovskite solar cell, the preparation steps of the preparation method are as follows:

[0033] (1) Dissolve 256mg of methylammonium iodide, 149mg of lead chloride, and 6mg of [6,6]-phenyl-C61-butyricstyryldendronester in dimethylformamide, stir for 5 hours, and prepare 30wt% perovskite Mine dimethylformamide solution;

[0034] (2) Spin-coat the PEDOT:PSS solution on the ITO flexible substrate at a rotation speed of 4500rpm for 40s, and then anneal in air at 100°C for 20min to form a cured anode modification layer with a thickness of 45nm;

[0035] (3) Spin-coat the perovskite dimethylformamide solution obtained in (1) on the anode modification layer obtained in (2) at a rotation speed of 4000rpm for 40s, and then anneal at 100°C to obtain a uniform A cured bulk heterojunction photosensitive layer with a thickness of 250nm;

[0036] (4) Spin-coat [6,6]-phenyl-C61-butyric acid methyl ester on the bulk heter...

Embodiment 3

[0039] A method for preparing a cross-linked fullerene heterojunction perovskite solar cell, the preparation steps of the preparation method are as follows:

[0040] (1) Dissolve 256mg of methylammonium iodide, 149mg of lead chloride, and 1mg of [6,6]-phenyl-C61-butyricstyryldendronester in dimethylformamide, stir for 2 hours, and prepare 30wt% perovskite Mine dimethylformamide solution;

[0041] (2) Spin-coat the PEDOT:PSS solution on the ITO glass substrate at a speed of 4500rpm for 40s, and then anneal in air at 95°C for 40min to form a cured anode modification layer with a thickness of 45nm;

[0042] (3) Spin-coat the perovskite dimethylformamide solution obtained in (1) on the anode modification layer obtained in (2) at a rotation speed of 4000rpm for 40s, and then anneal at 100°C to obtain a uniform A cured bulk heterojunction photosensitive layer with a thickness of 250nm;

[0043] (4) Spin-coat [6,6]-phenyl-C61-butyric acid methyl ester on the bulk heterojunction pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com