Patents

Literature

2520 results about "Iodide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An iodide ion is the ion I⁻. Compounds with iodine in formal oxidation state −1 are called iodides. This page is for the iodide ion and its salts, not organoiodine compounds. In everyday life, iodide is most commonly encountered as a component of iodized salt, which many governments mandate. Worldwide, iodine deficiency affects two billion people and is the leading preventable cause of intellectual disability.

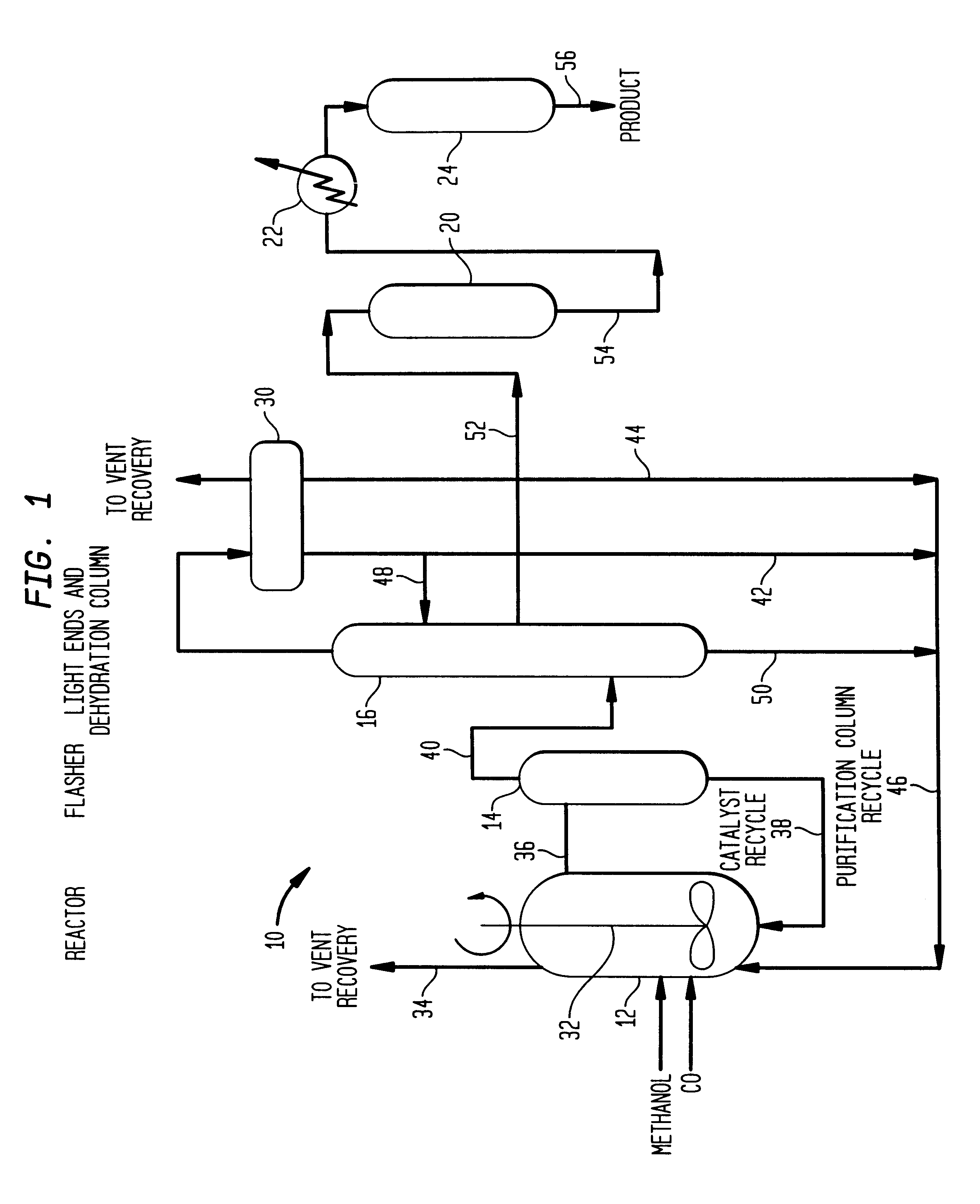

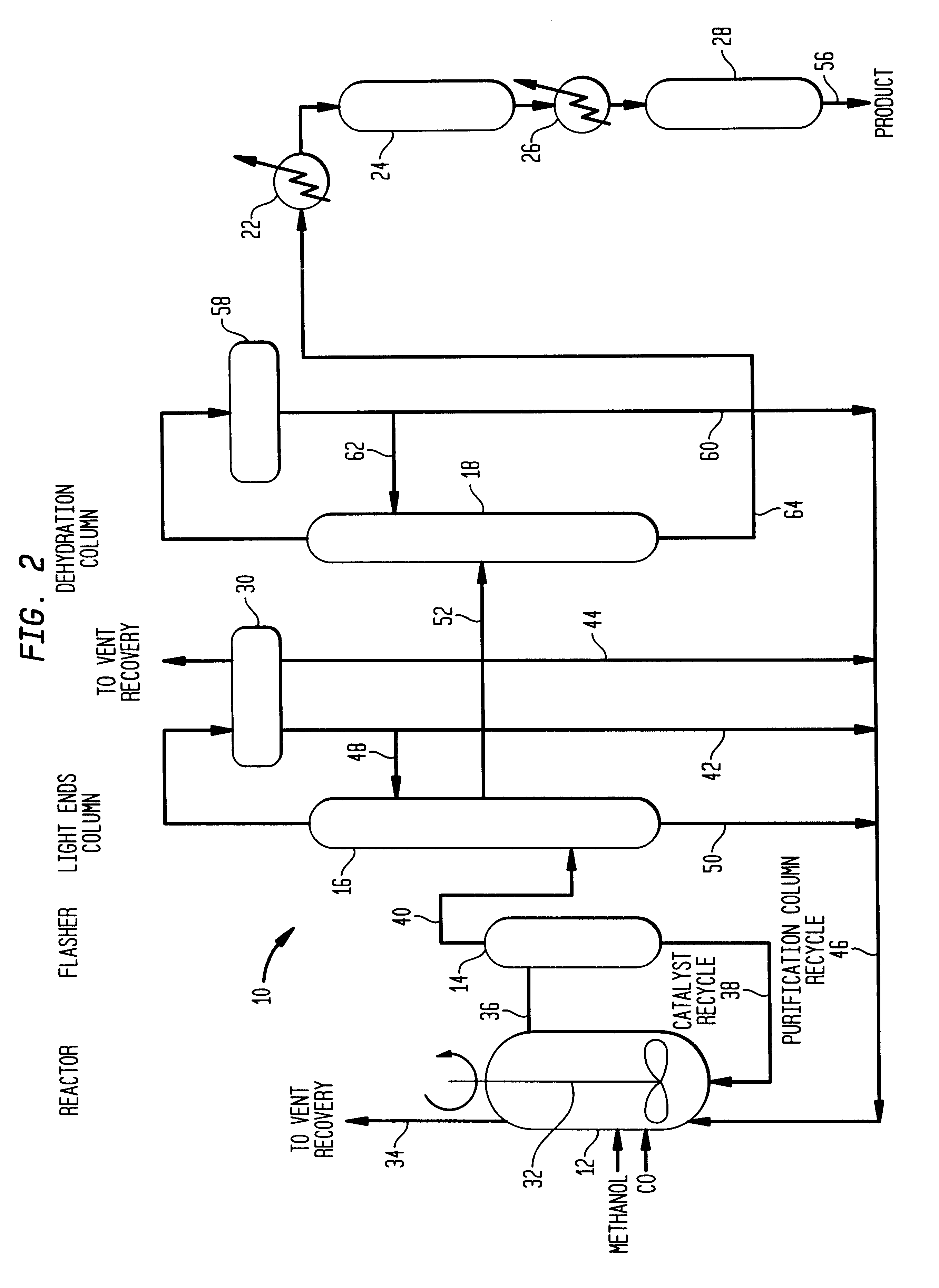

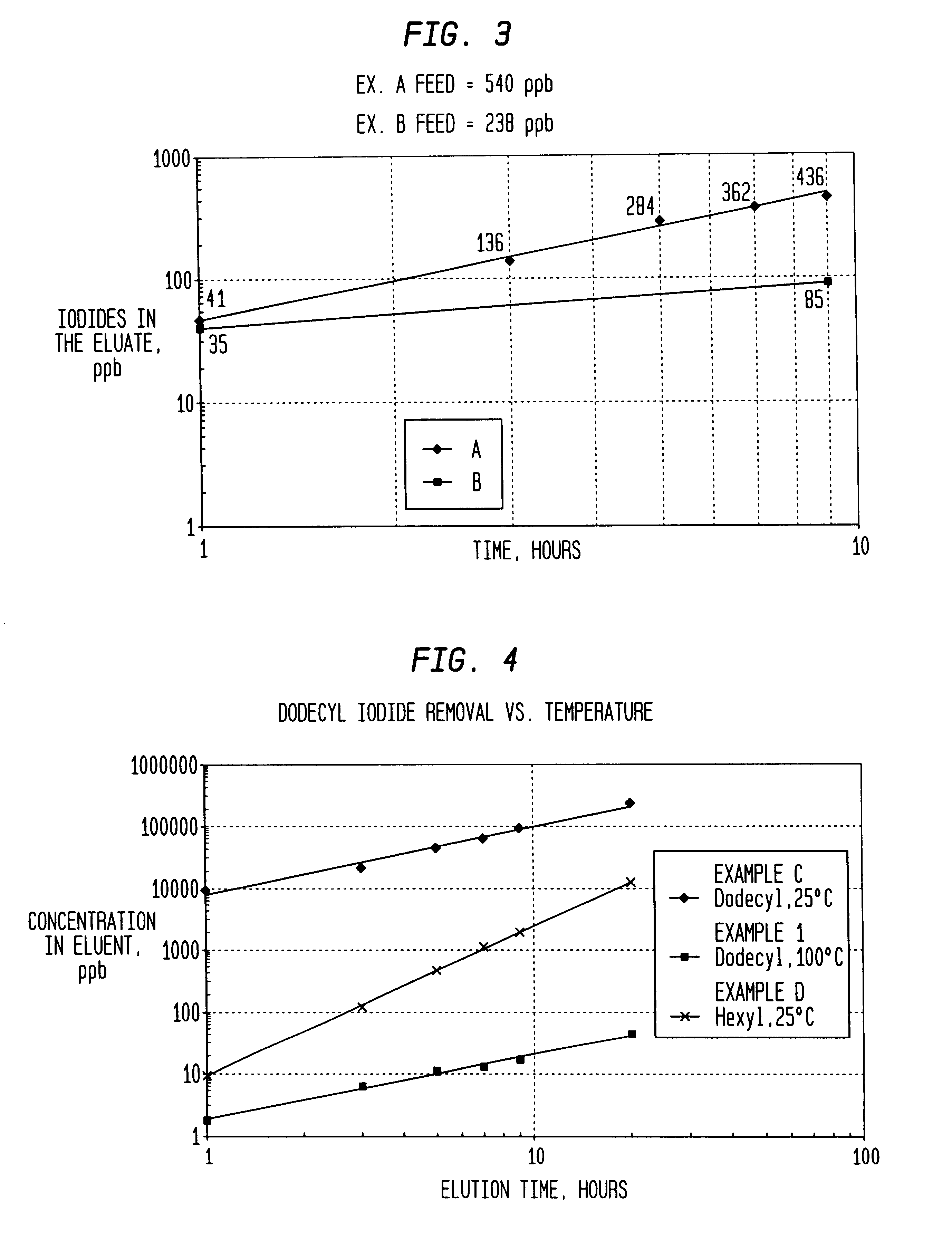

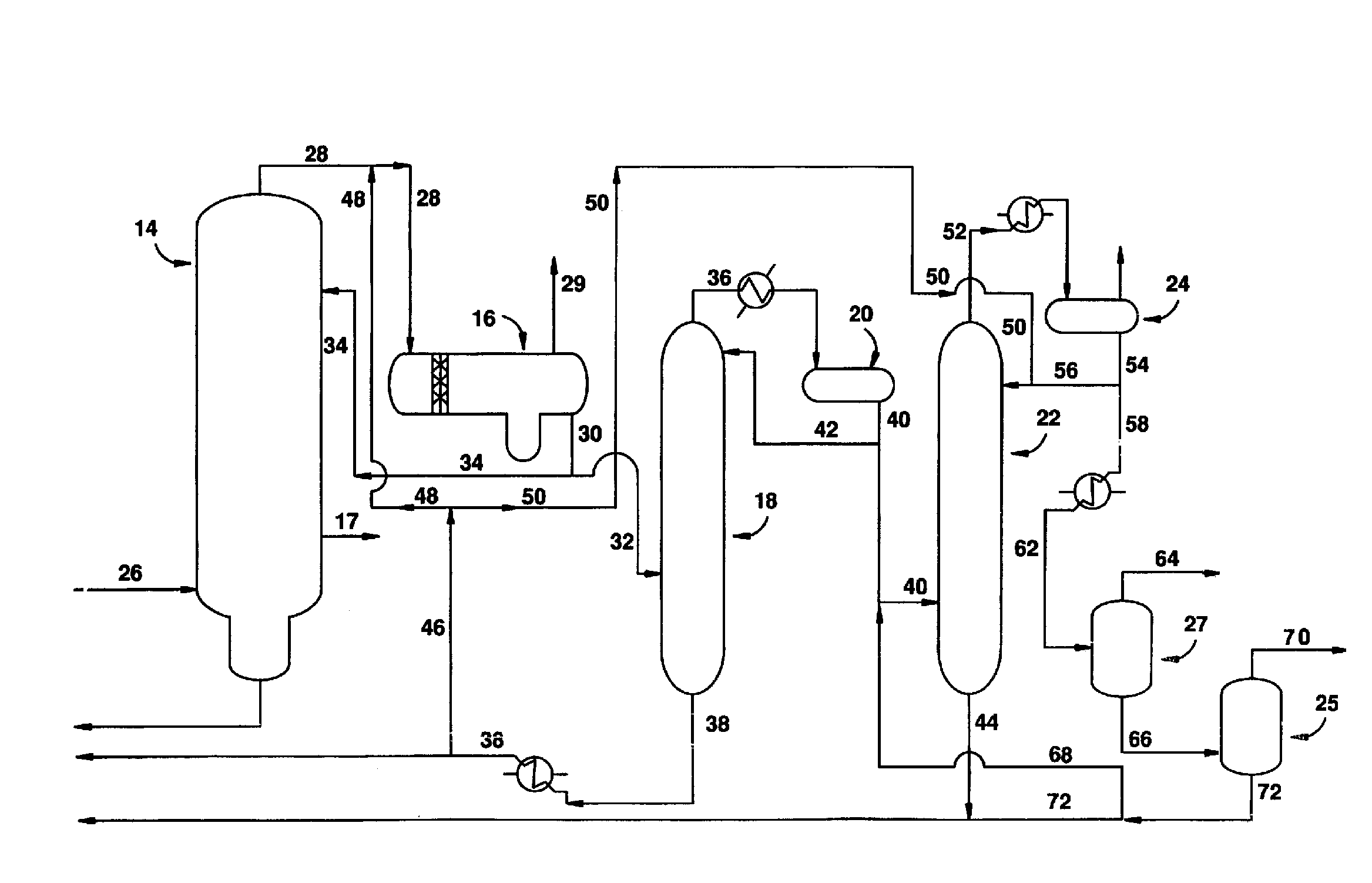

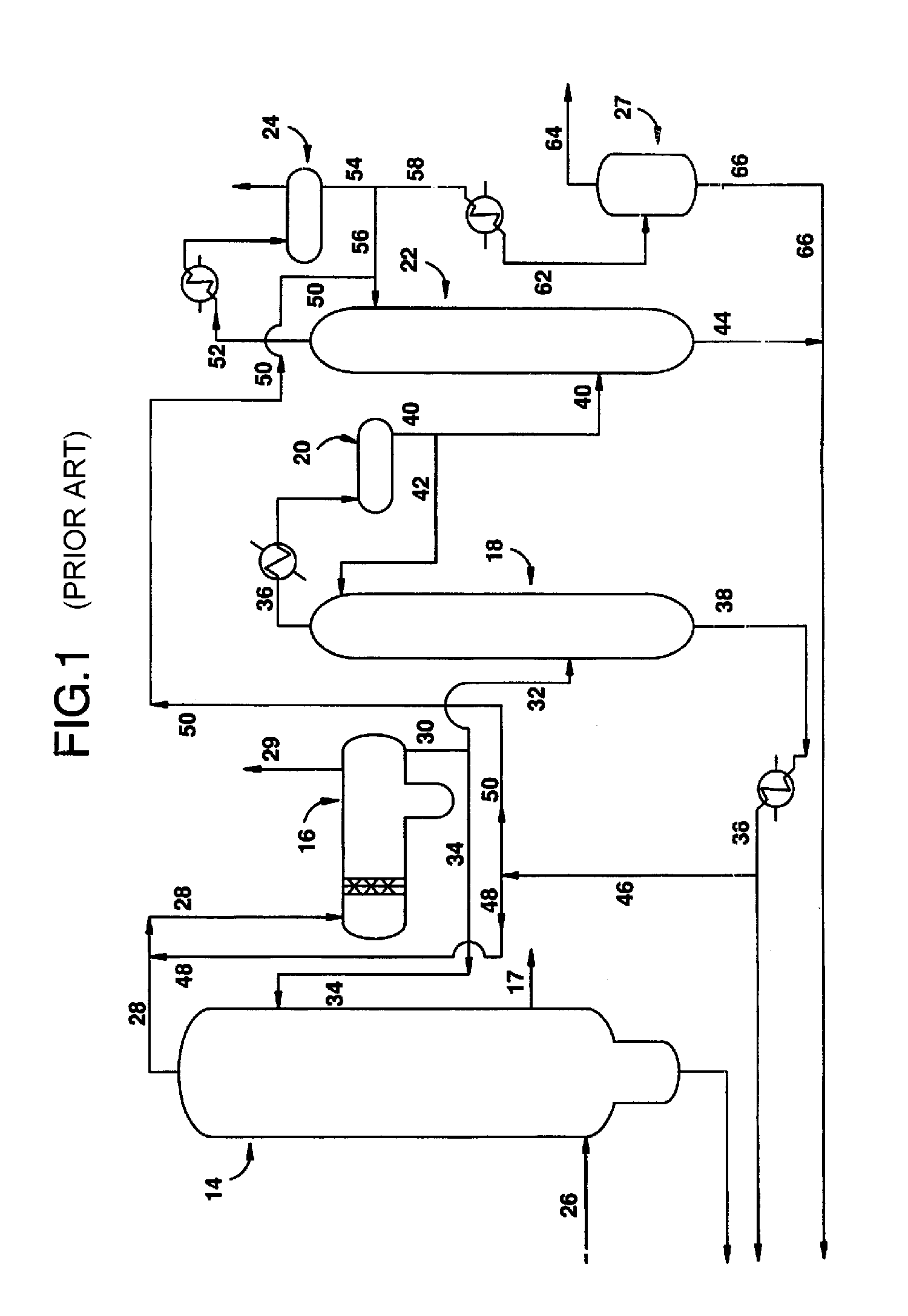

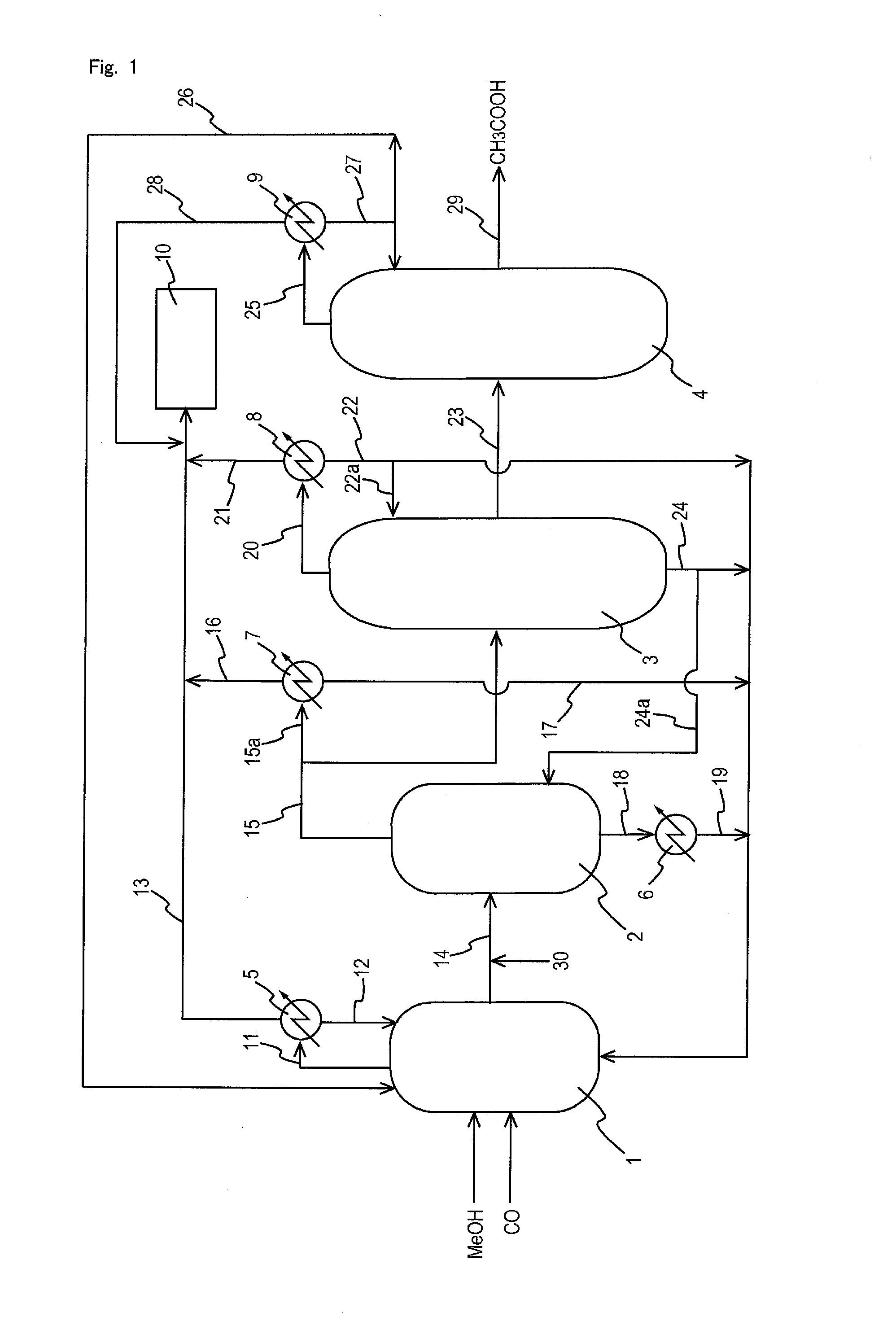

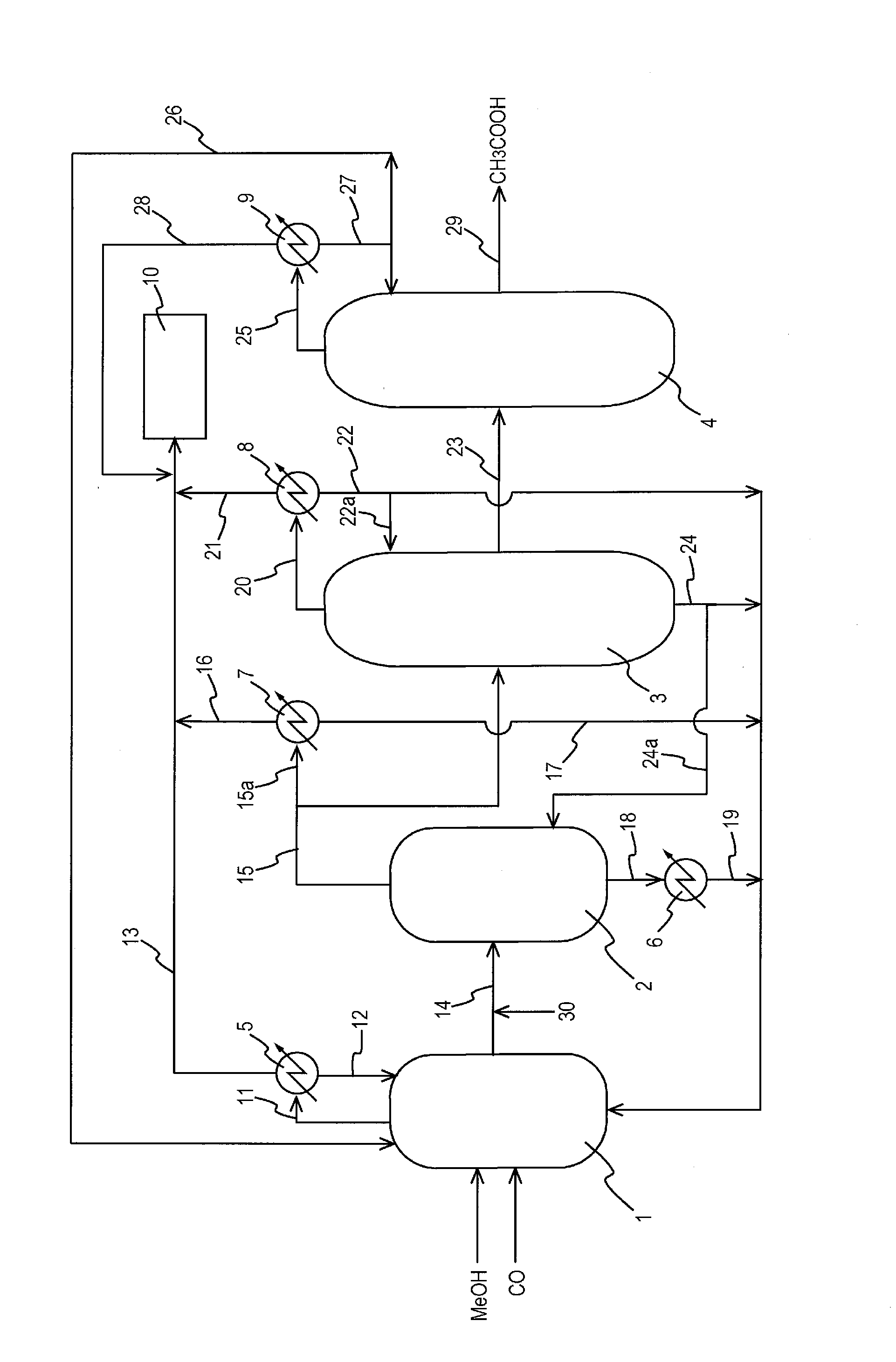

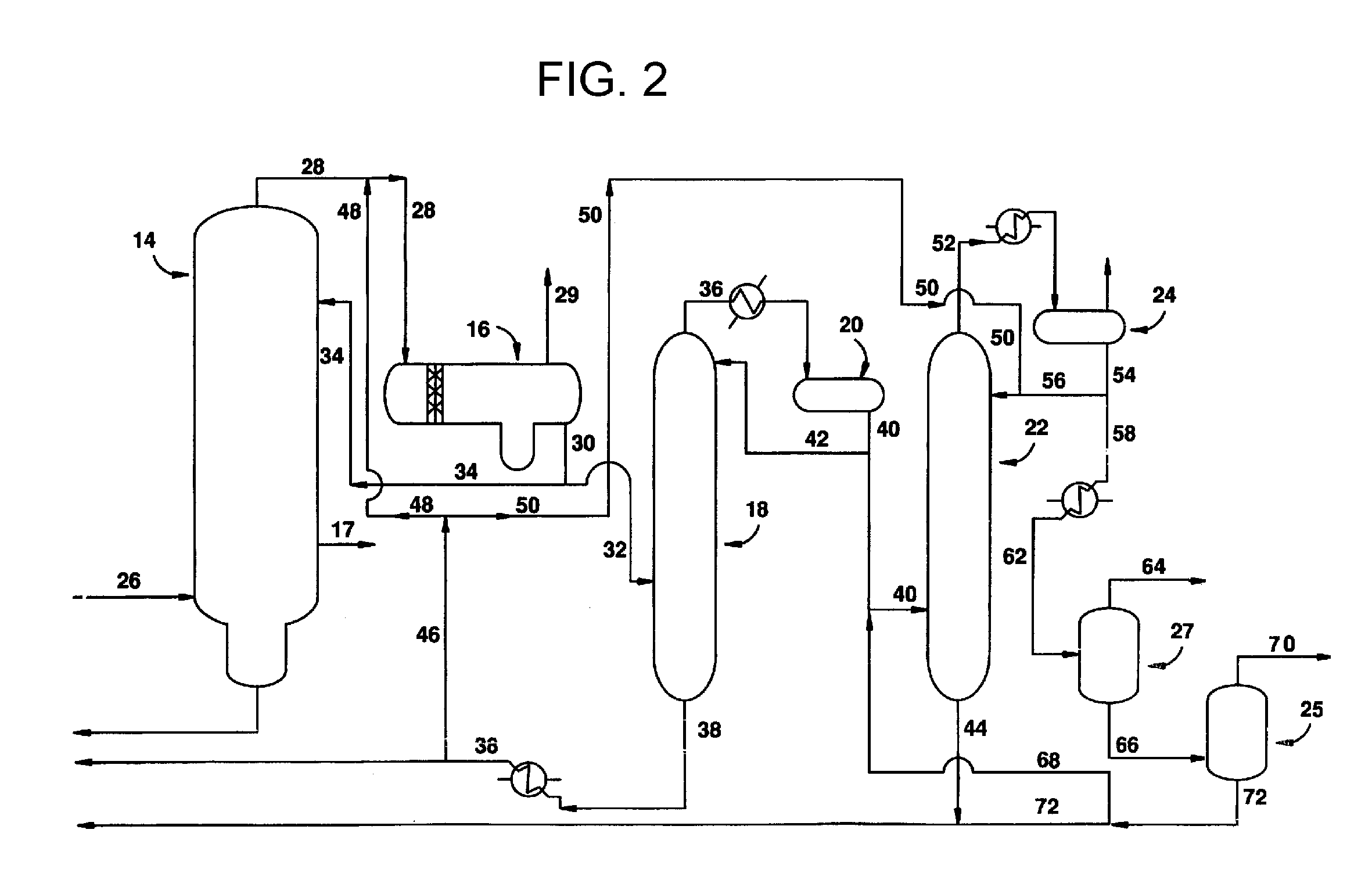

Low energy carbonylation process

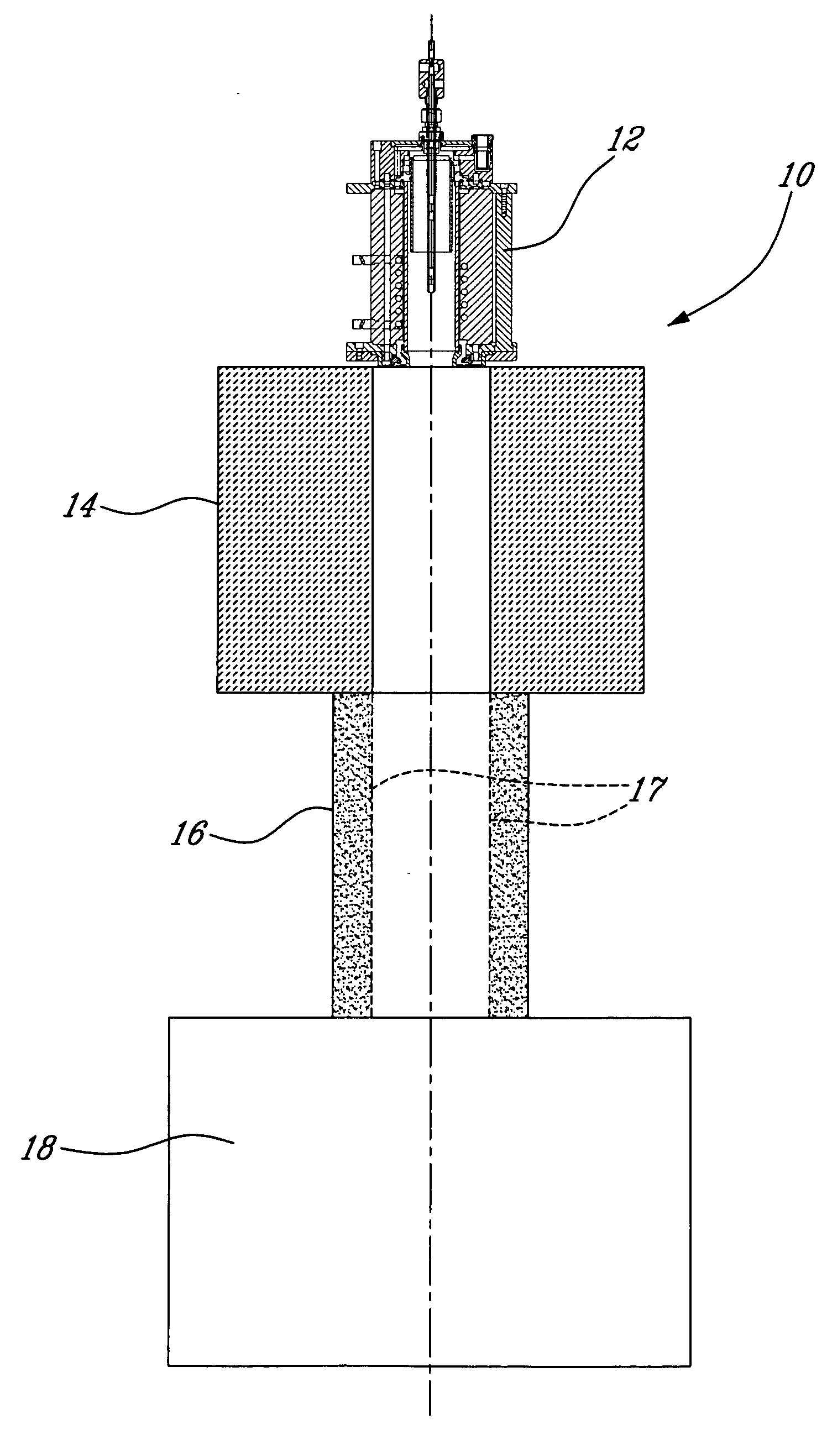

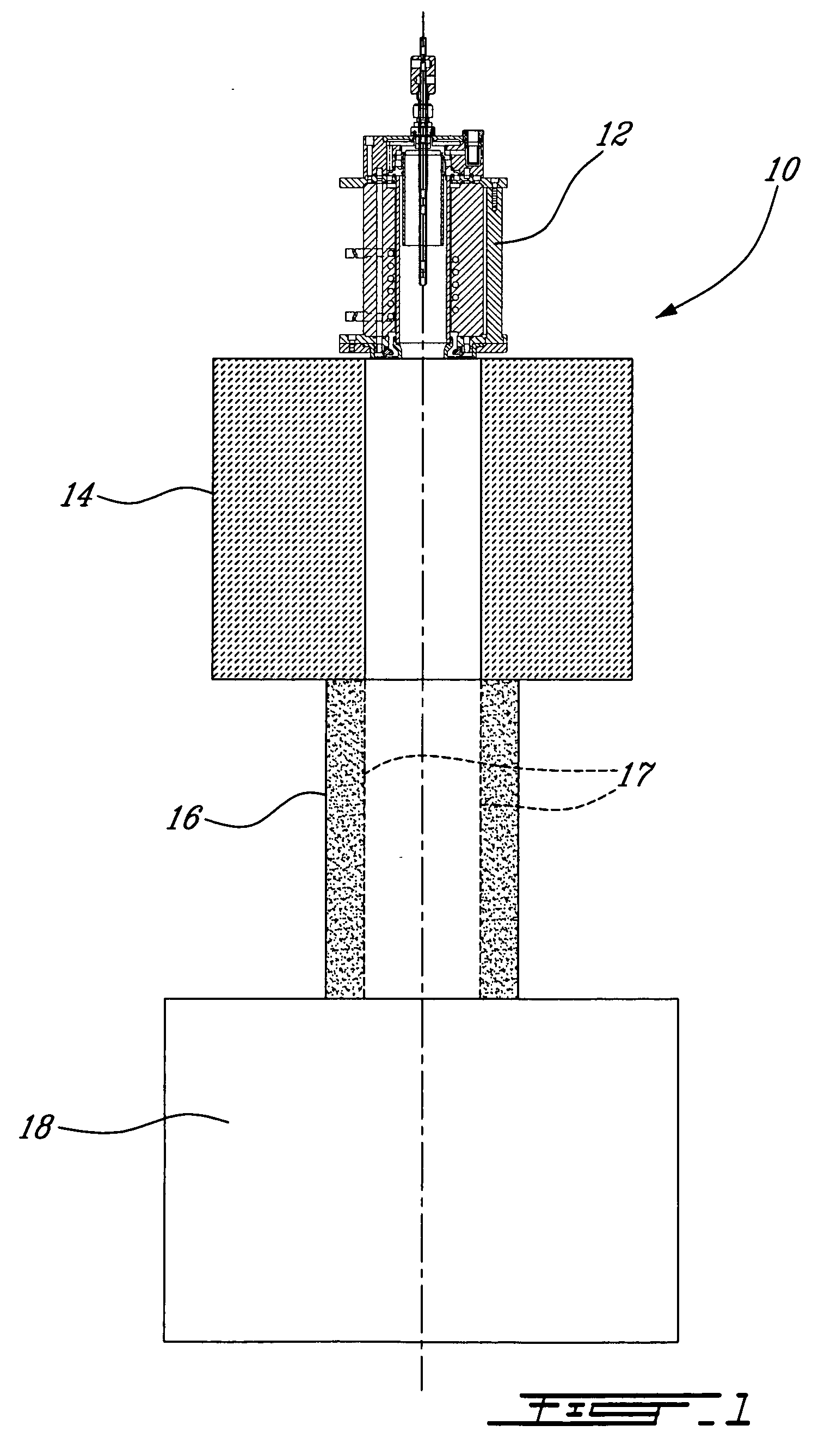

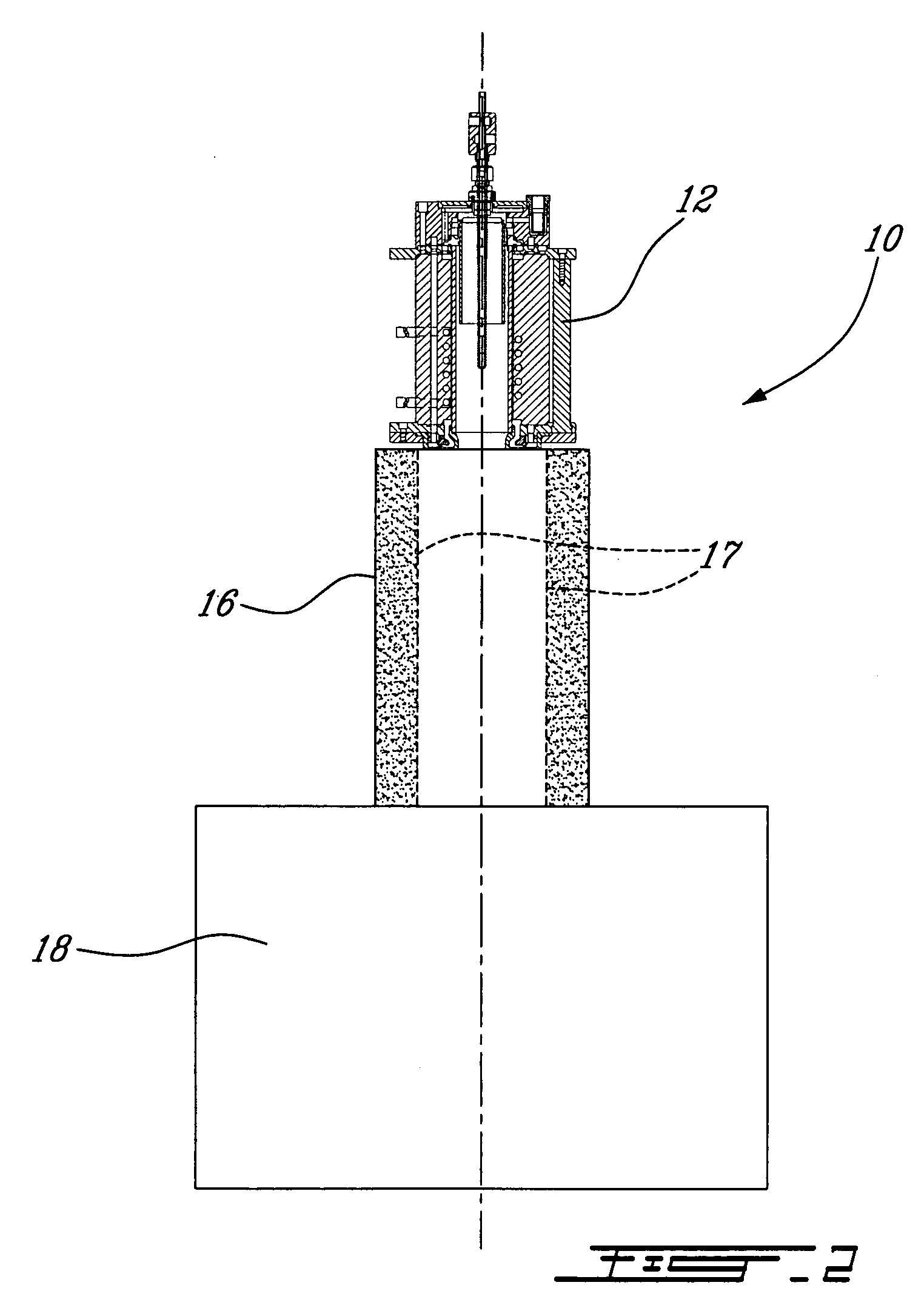

InactiveUS6657078B2Weaken energyHigh purityOrganic compound preparationOrganic chemistry methodsPropanoic acidIodide

A low energy process for producing acetic acid by the carbonylation of methanol is disclosed. The process involves a rhodium-catalyzed system operated at less than about 14% water utilizing up to 2 distillation columns. The process is preferably controlled such that the product stream has a low level of propionic acid impurity and the level of aldehyde impurities is minimized by way of aldehyde removal or minimizing aldehyde generation. The level of iodides is controlled by contacting the product, at elevated temperatures, with ion exchange resins. In preferred embodiments, at least one silver or mercury exchanged macroreticular strong acid ion exchange resin is used to purify the product. The high temperature treatment provides the added benefit of controlling the Color Value (Pt-Co units) of the product stream.

Owner:CELANESE INT CORP

Removal of permanganate reducing compounds from methanol carbonylation process stream

ActiveUS7223886B2Reduce solubilitySimple methodOrganic compound preparationPreparation by carbon monoxide or formate reactionAcetic acidIodide

An improvement of the methanol carbonylation process for manufacturing acetic acid is disclosed. Specifically disclosed is a method for reducing the formation of alkyl iodides and C3-8 carboxylic acids by removing permanganate reducing compounds (“PRC's”) from the light phase of the condensed light ends overhead stream, including (a) distilling the light phase to yield a PRC enriched overhead stream; and (b) extracting the third overhead stream with water in at least two consecutive stages and separating therefrom one or more aqueous streams containing PRC's.

Owner:CELANESE INT CORP

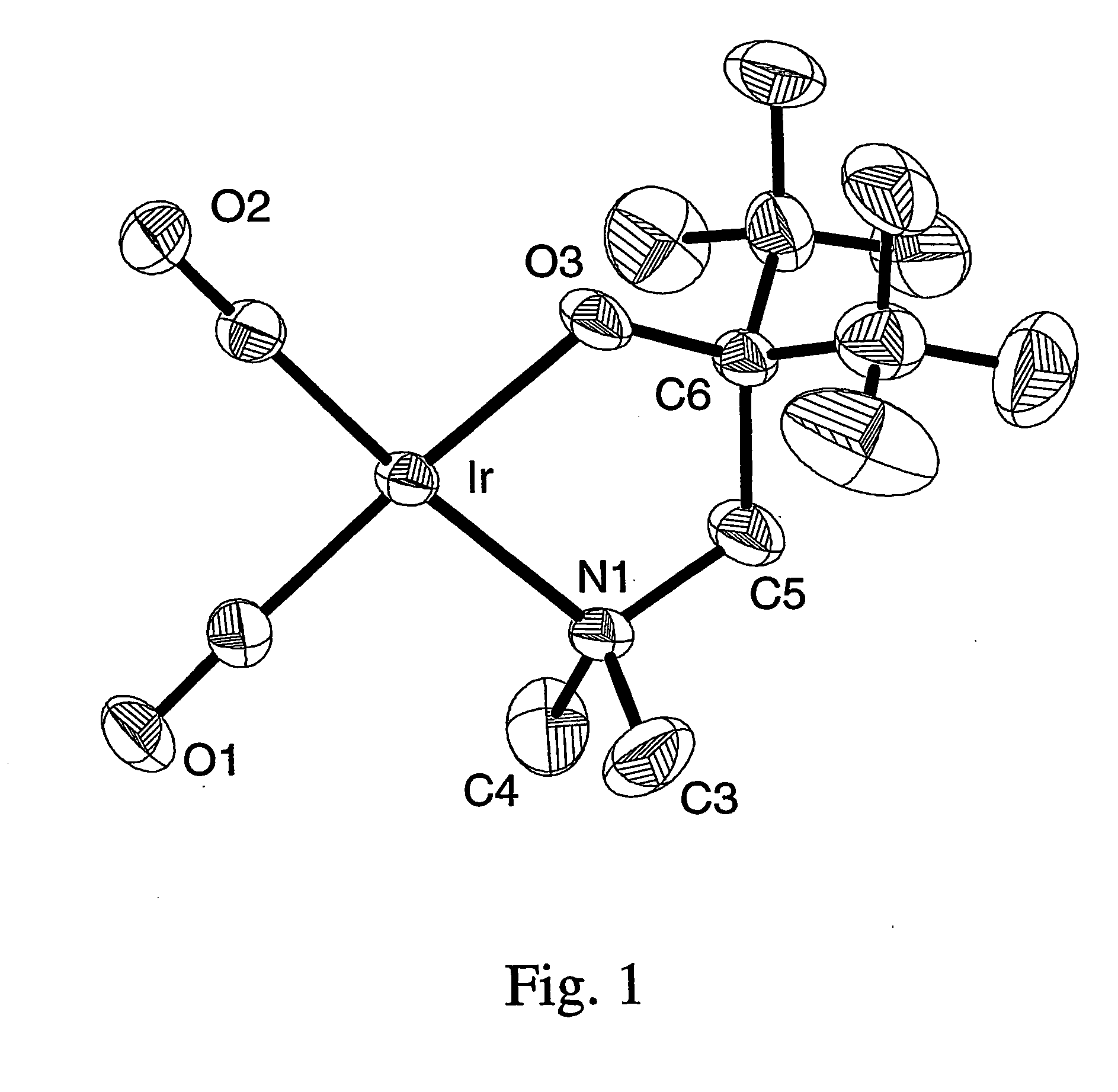

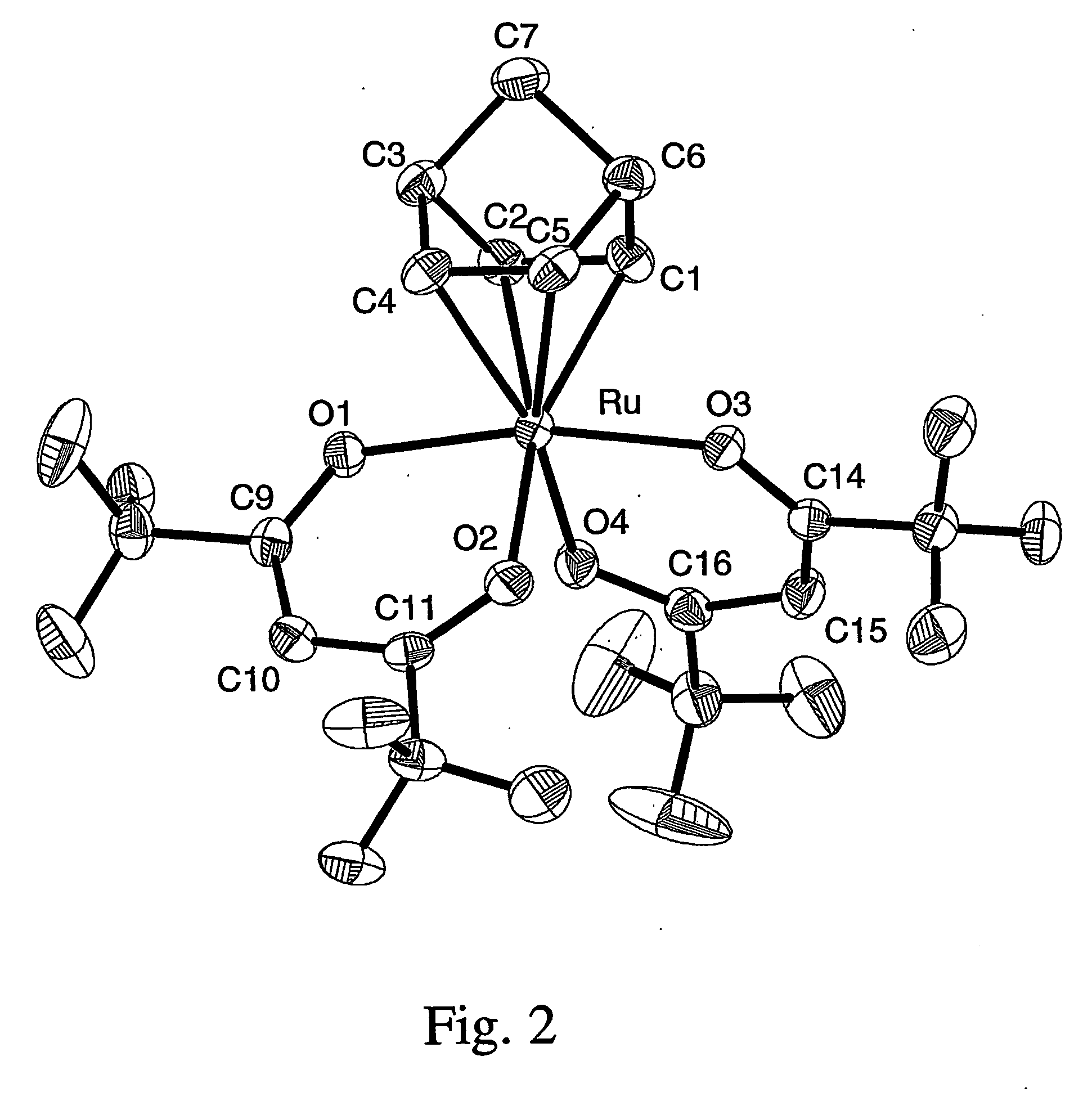

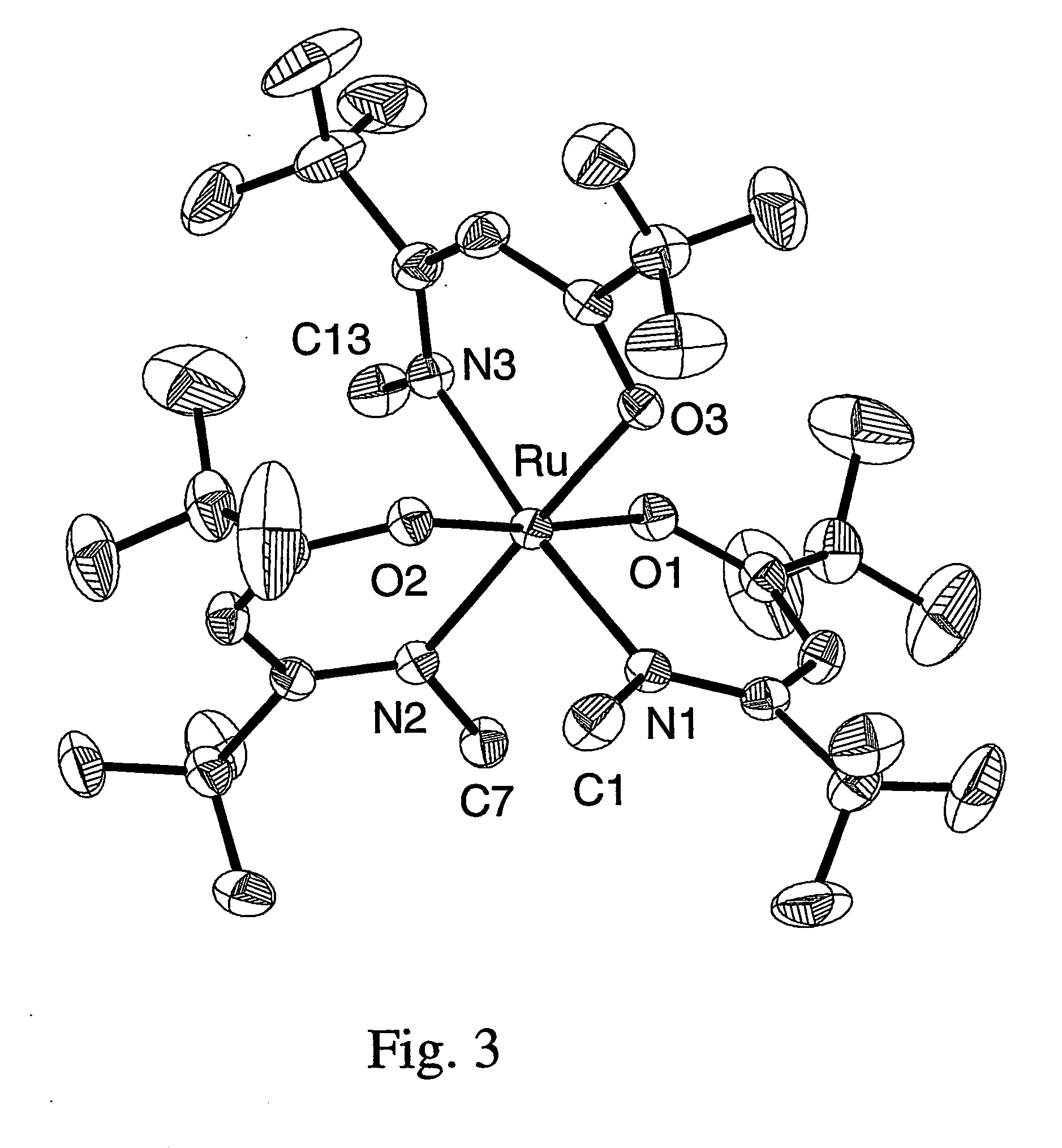

Volatile noble metal organometallic complexes

InactiveUS20050033075A1Reduce Van der Waals interactionBoiling and sublimation temperatureFurnaces without endless coreRuthenium organic compoundsIridiumIodide

A series of noble metal organometallic complexes of the general formula (I): MLaXb(FBC)c, wherein M is a noble metal such as iridium, ruthenium or osmium, and L is a neutral ligand such as carbonyl, alkene or diene; X is an anionic ligand such as chloride, bromide, iodide and trifluoroacetate group; and FBC is a fluorinated bidentate chelate ligand such as beta diketonate, beta-ketoiminate, amino-alcoholate and amino-alcoholate ligand, wherein a is an integer of from zero (0) to three (3), b is an integer of from zero (0) to one (1) and c is an 10 integer of from one (1) to three (3). The resulting noble metal complexes possess enhanced volatility and thermal stability characteristics, and are suitable for chemical vapor deposition(CVD) applications. The corresponding noble metal complex is formed by treatment of the FBC ligand with a less volatile metal halide. Also disclosed are CVD methods for using the noble metal complexes as source reagents for deposition of noble metal-containing films such as Ir, Ru and Os, or even metal oxide film materials IrO2, OsO2 and RuO2.

Owner:NATIONAL TSING HUA UNIVERSITY +1

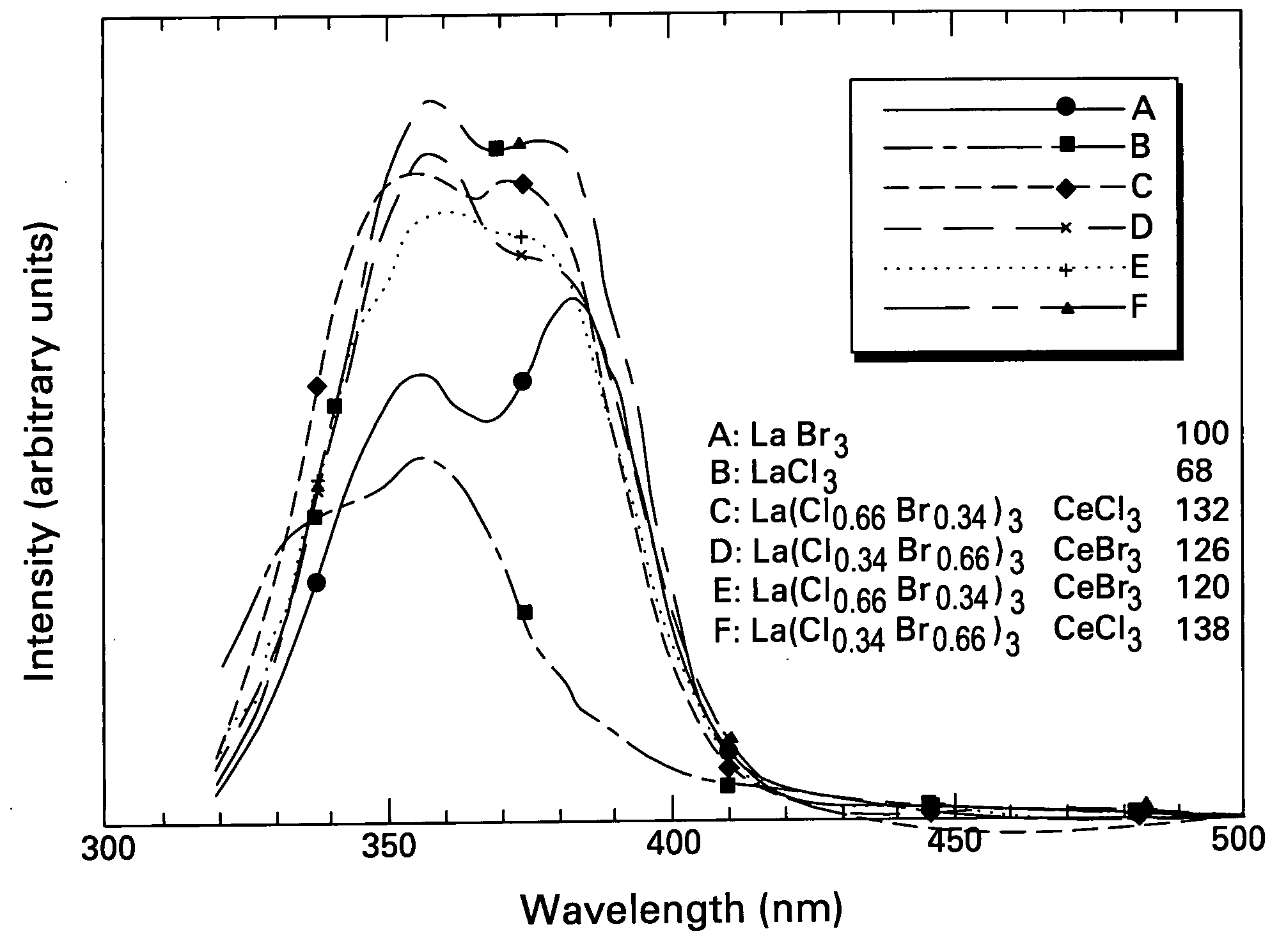

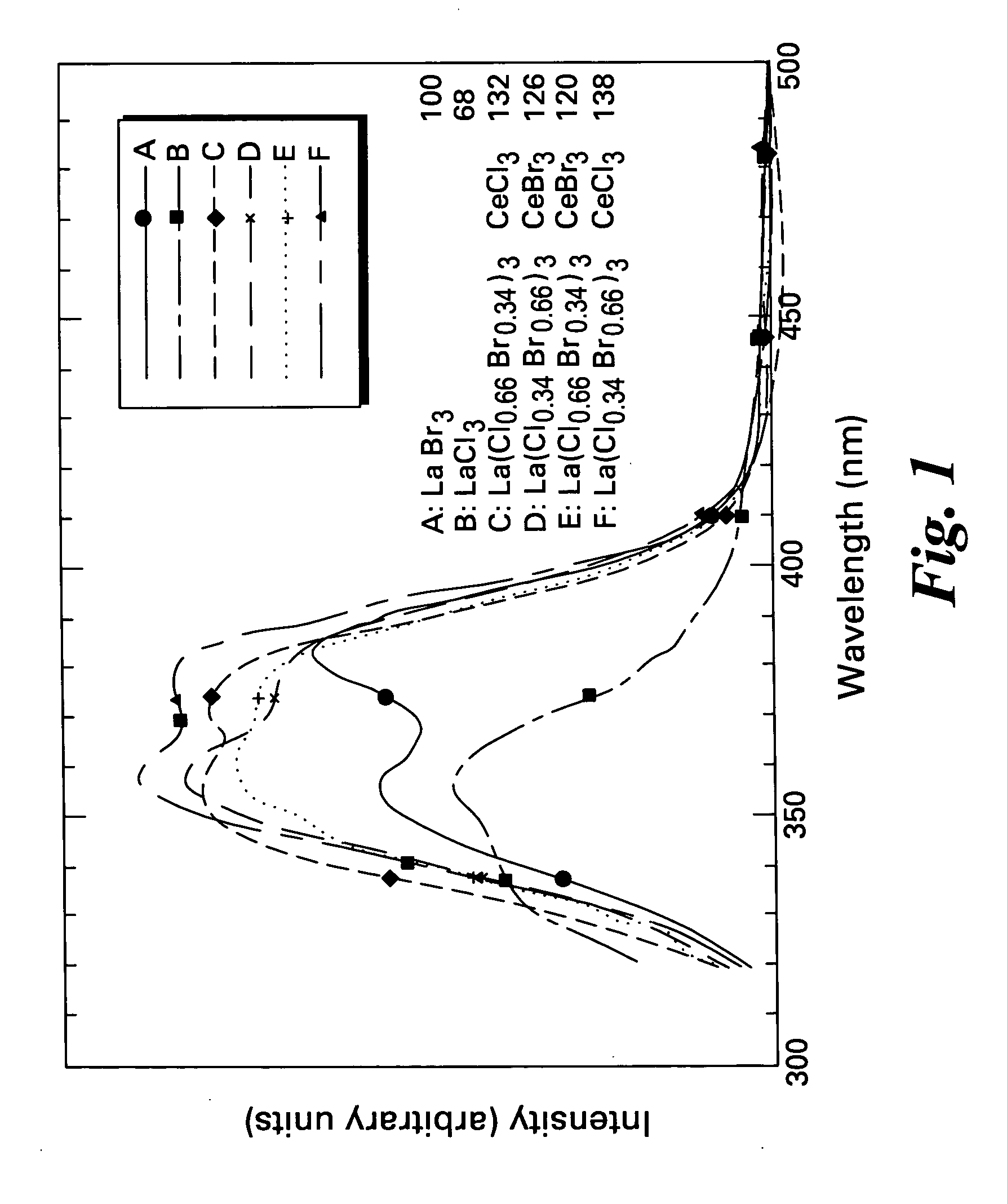

Scintillator compositions, and related processes and articles of manufacture

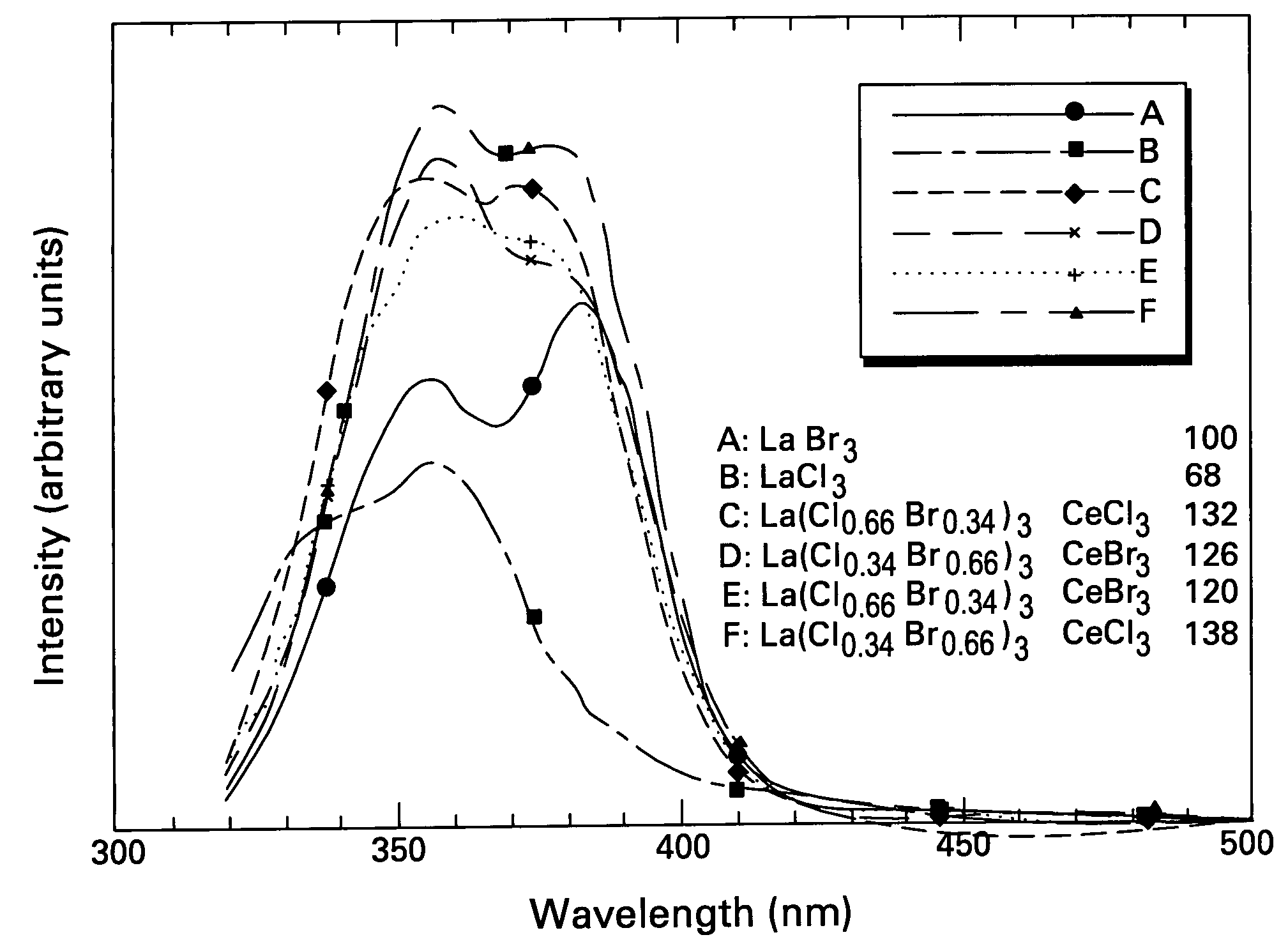

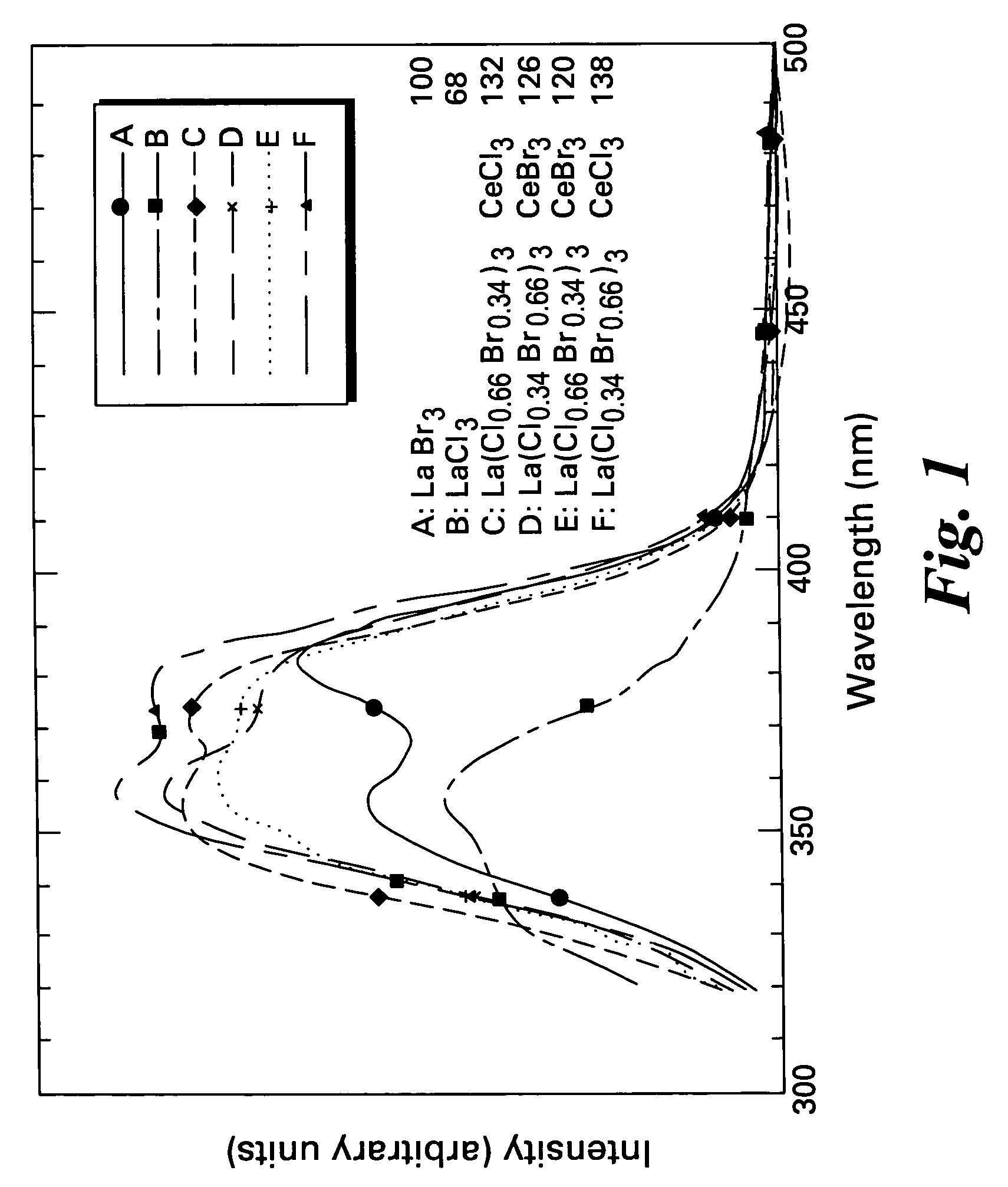

ActiveUS20050082484A1Improve performanceExcellent and reproducible scintillation responseMaterial analysis by optical meansLuminescent compositionsIodideHigh energy

Scintillator materials based on certain types of halide-lanthanide matrix materials are described. In one embodiment, the matrix material contains a mixture of lanthanide halides, i.e., a solid solution of at least two of the halides, such as lanthanum chloride and lanthanum bromide. In another embodiment, the matrix material is based on lanthanum iodide alone, which must be substantially free of lanthanum oxyiodide. The scintillator materials, which can be in monocrystalline or polycrystalline form, also include an activator for the matrix material, e.g., cerium. Radiation detectors that use the scintillators are also described, as are related methods for detecting high-energy radiation.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

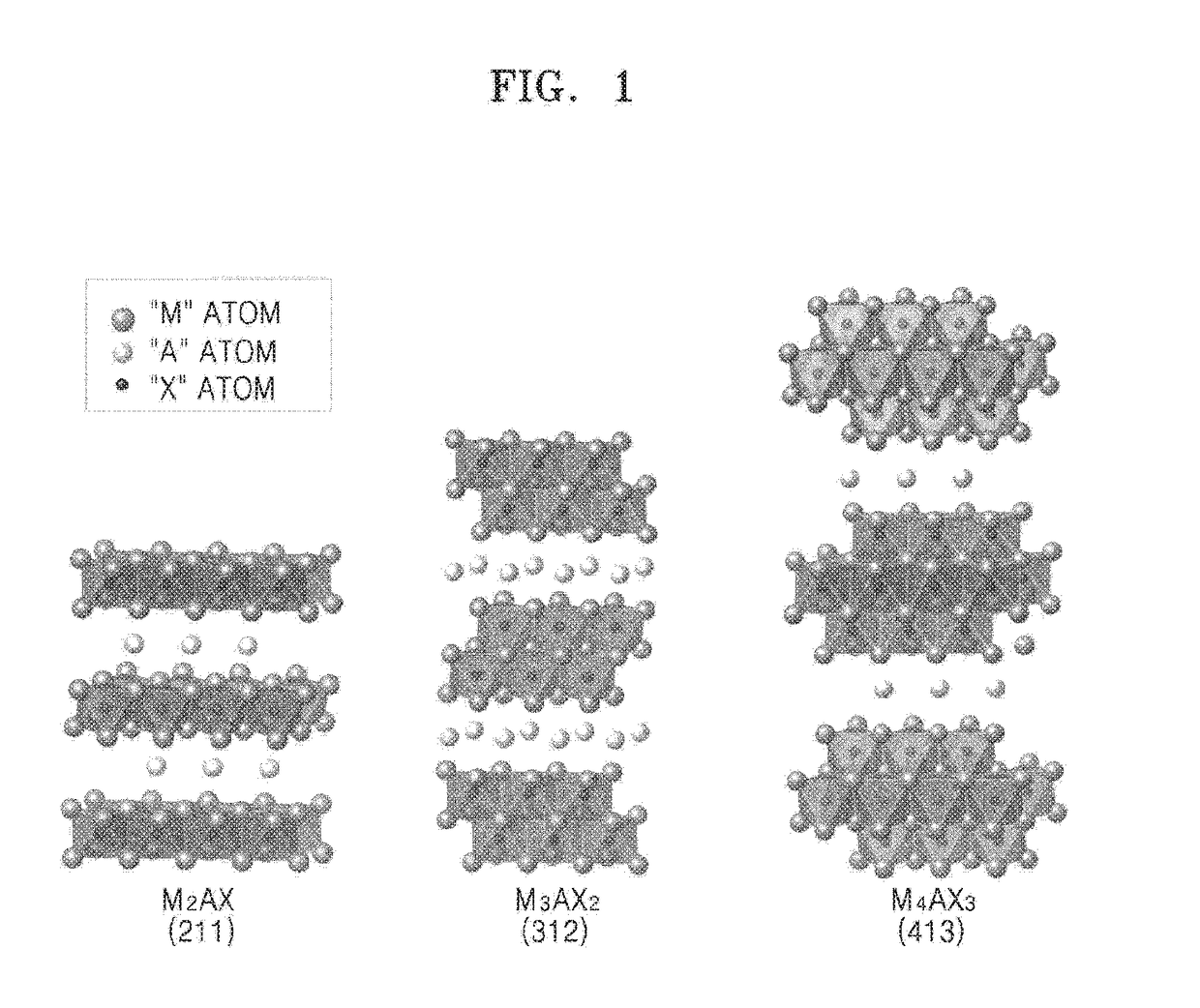

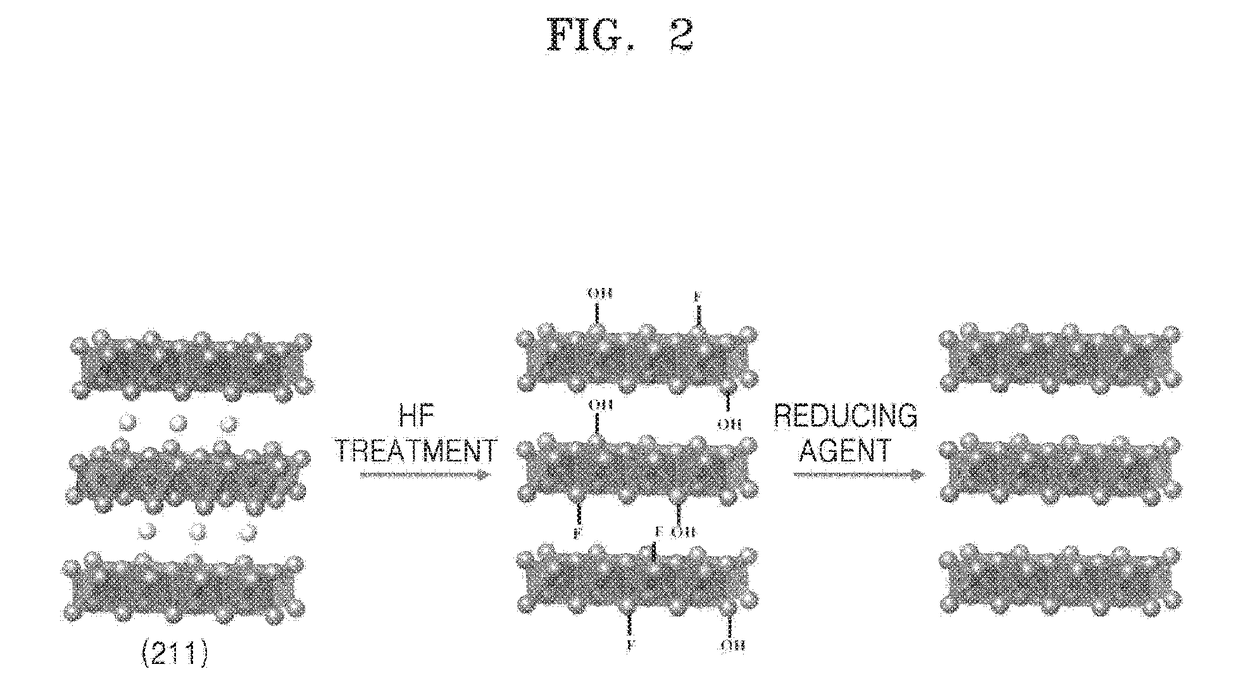

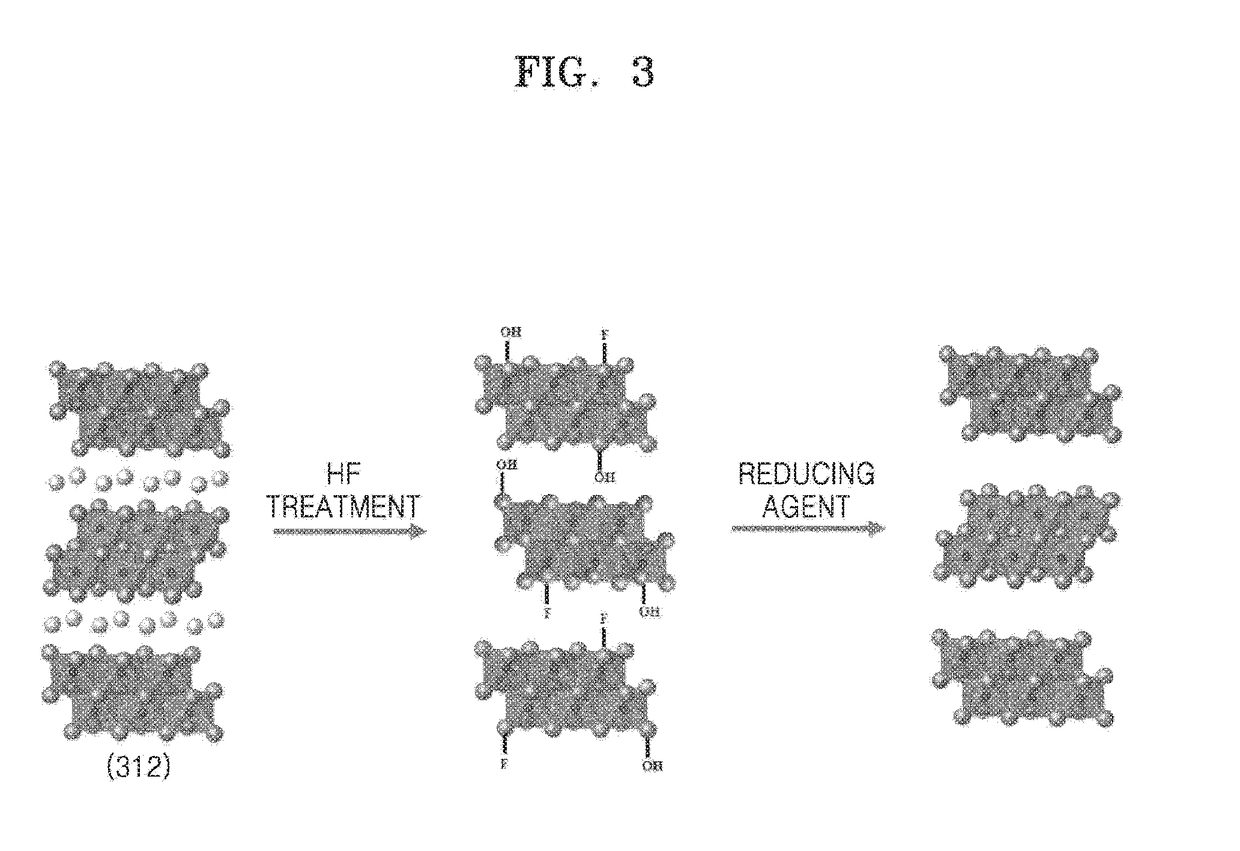

Mxene nanosheet and manufacturing method thereof

ActiveUS20170088429A1Material nanotechnologyNitrogen-metal/silicon/boron binary compoundsIodideInorganic compound

A method of manufacturing a MXene nanosheet includes removing an A atomic layer from an inorganic compound having a formula of Mn+1AXn to form a nanosheet, the nanosheet having a formula of Mn+1XnTs, and reducing the nanosheet having a formula of Mn+1XnTsto form an MXene nanosheet, the MXene nanosheet having a formula of Mn+1Xn, wherein M is at least one of Group 3 transition metal, Group 4 transition metal, Group 5 transition metal, and Group 6 transition metal, A is at least one of a Group 12 element, Group 13 element, Group 14 element, Group 15 element and Group 16 element, X is one of carbon (C), nitrogen (N) and a combination thereof, Ts is one of oxide (O), epoxide, hydroxide (OH), alkoxide having 1-5 carbon atoms, fluoride (F), chloride (Cl), bromide (Br), iodide (I), and a combination thereof, and n is one of 1, 2 and 3.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV +1

Physiologically balanced, ionized, acidic solution and methodology for use in wound healing

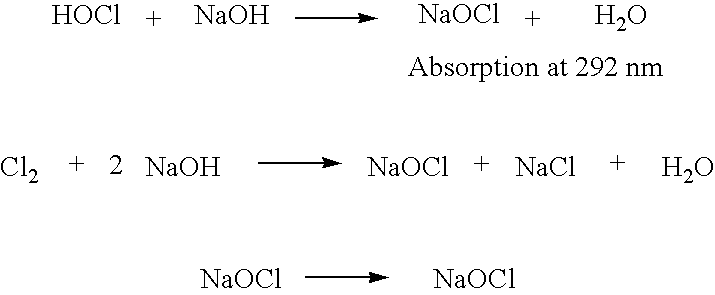

Described herein is a physiologically-balanced, acidic solution. Typically the solution is prepared by a chemical reactions or by the electrolysis of a solution comprising a mixture of an inorganic salt to form a physiologically balanced solution. This invention also relates to methods for use of the solutions, including a specialized bandage which may be used in combination with the solutions, or optionally with other topically applied materials. A mixture of inorganic salts and, optionally minerals, is used in order to mimic the electrolyte concentration and mixture of body fluid in an isotonic state. The solution typically comprises of one halide salt of lithium, sodium, potassium, calcium, and other cations. Typically the halide is fluoride, chloride, bromide, or iodide, and most typically chloride. A typical electrolyzed solution of the present invention has a pH within the range of about 2 to about 5, an oxidation reduction potential within the range of about +600 mV to about +1200 mV, and hypohalous acid concentration in the range of about 10 ppm to about 200 ppm. The solution has bactericidal, fungicidal, and sporicidal properties. The composition of the invention is nontoxic and has antibacterial properties, and is useful in any application in which antimicrobial properties are desirable.

Owner:NOVABAY PHARM INC

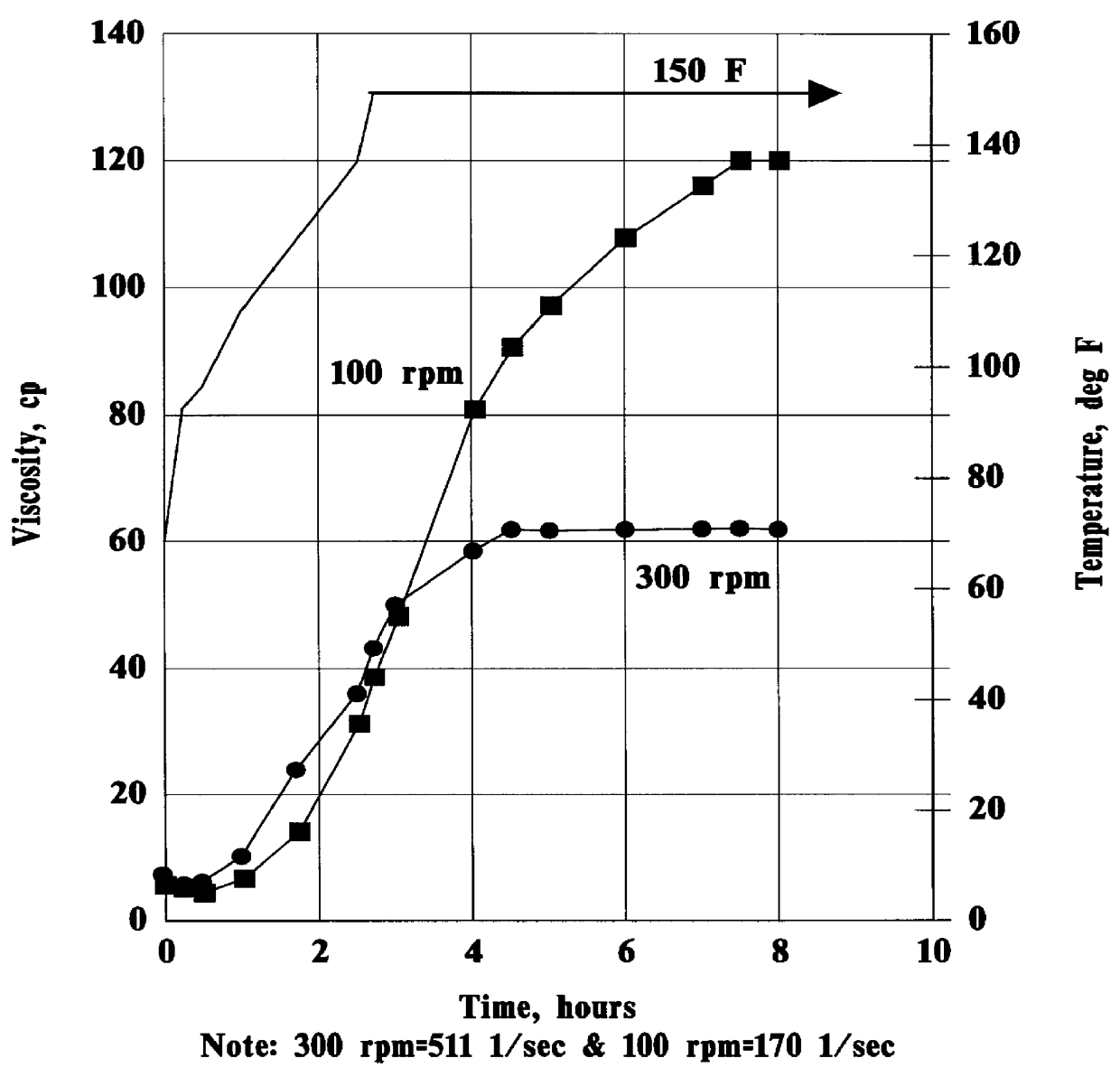

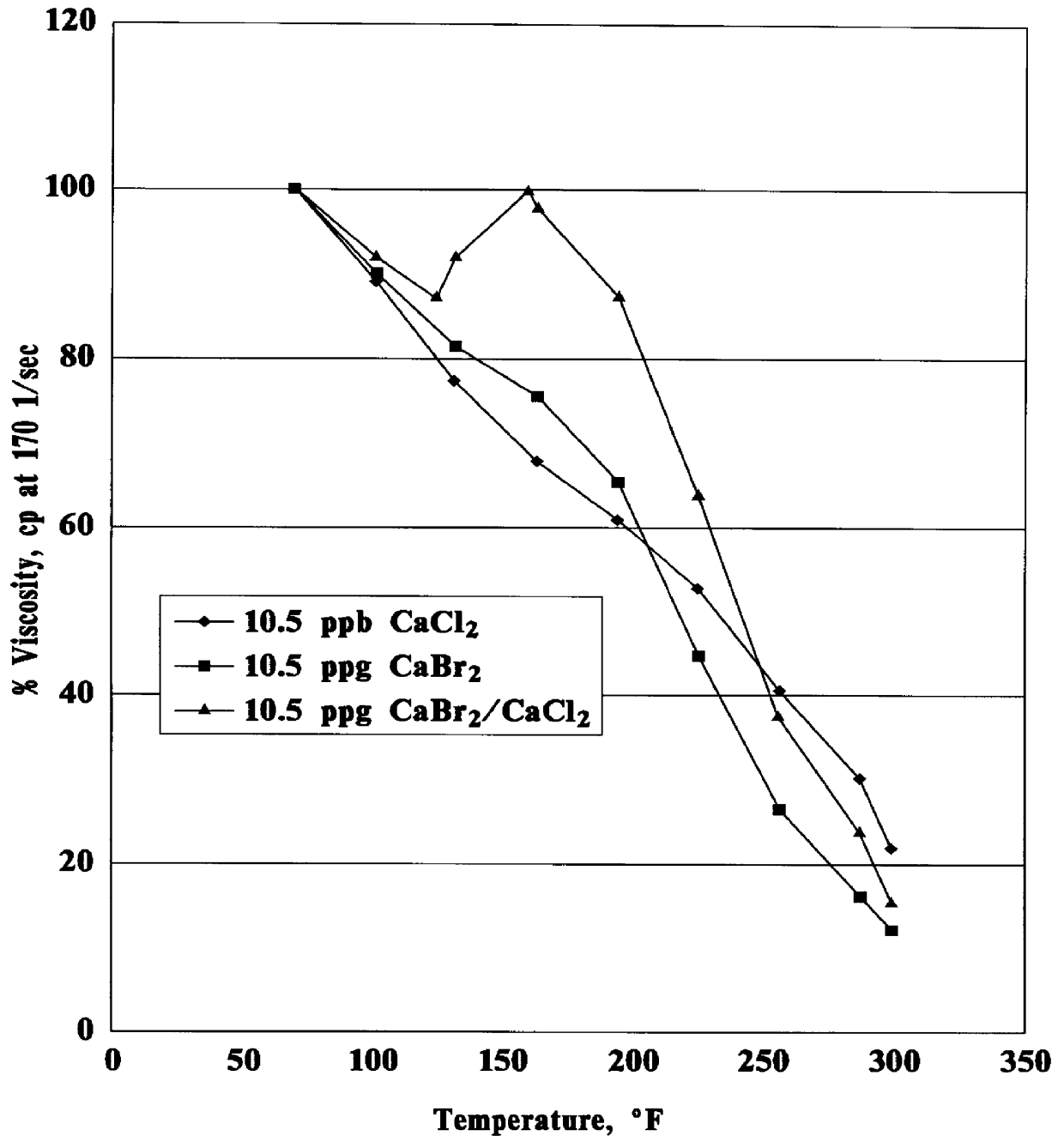

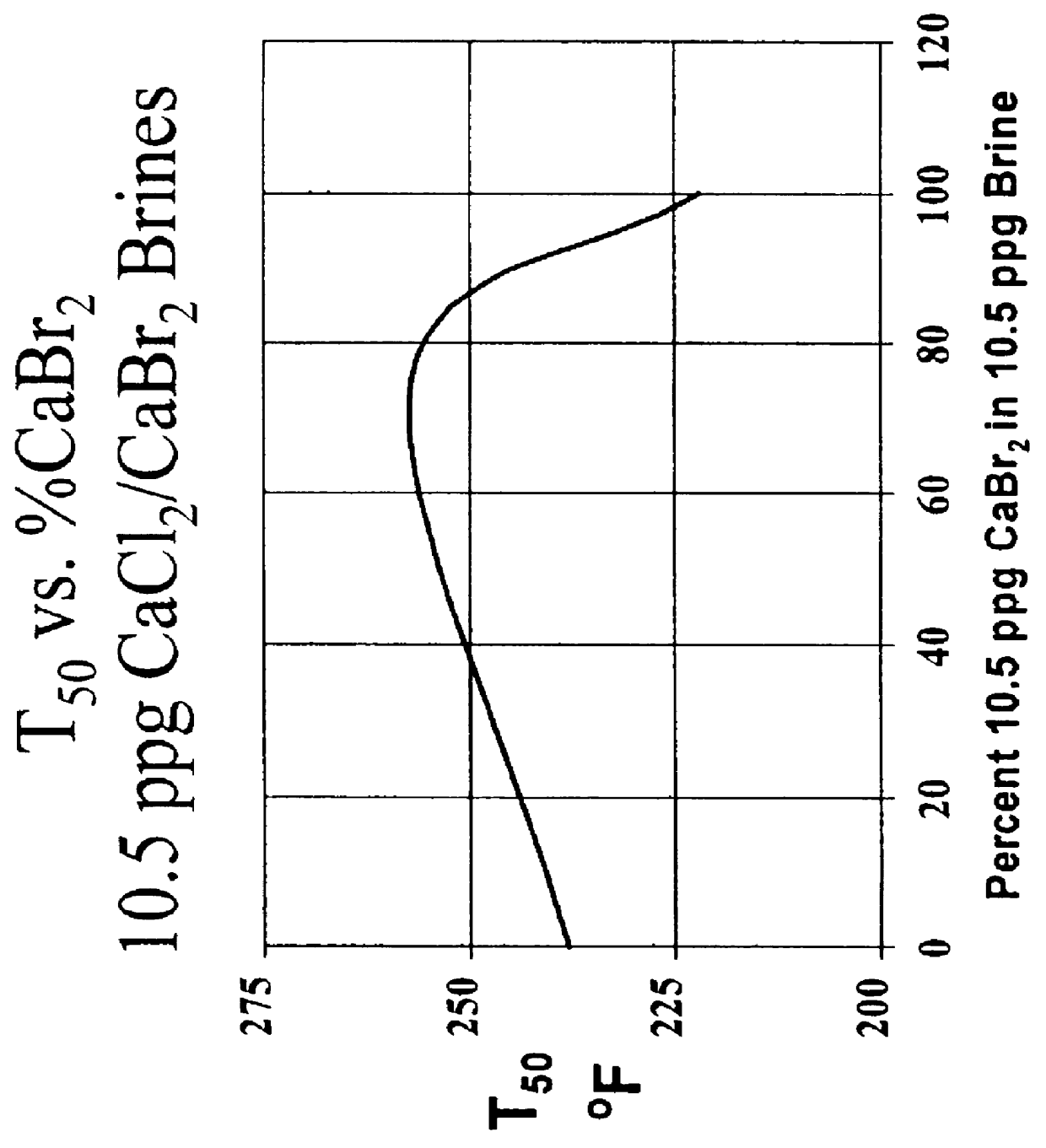

High density, viscosified, aqueous compositions having superior stability under stress conditions

Owner:BJ SERVICES CO

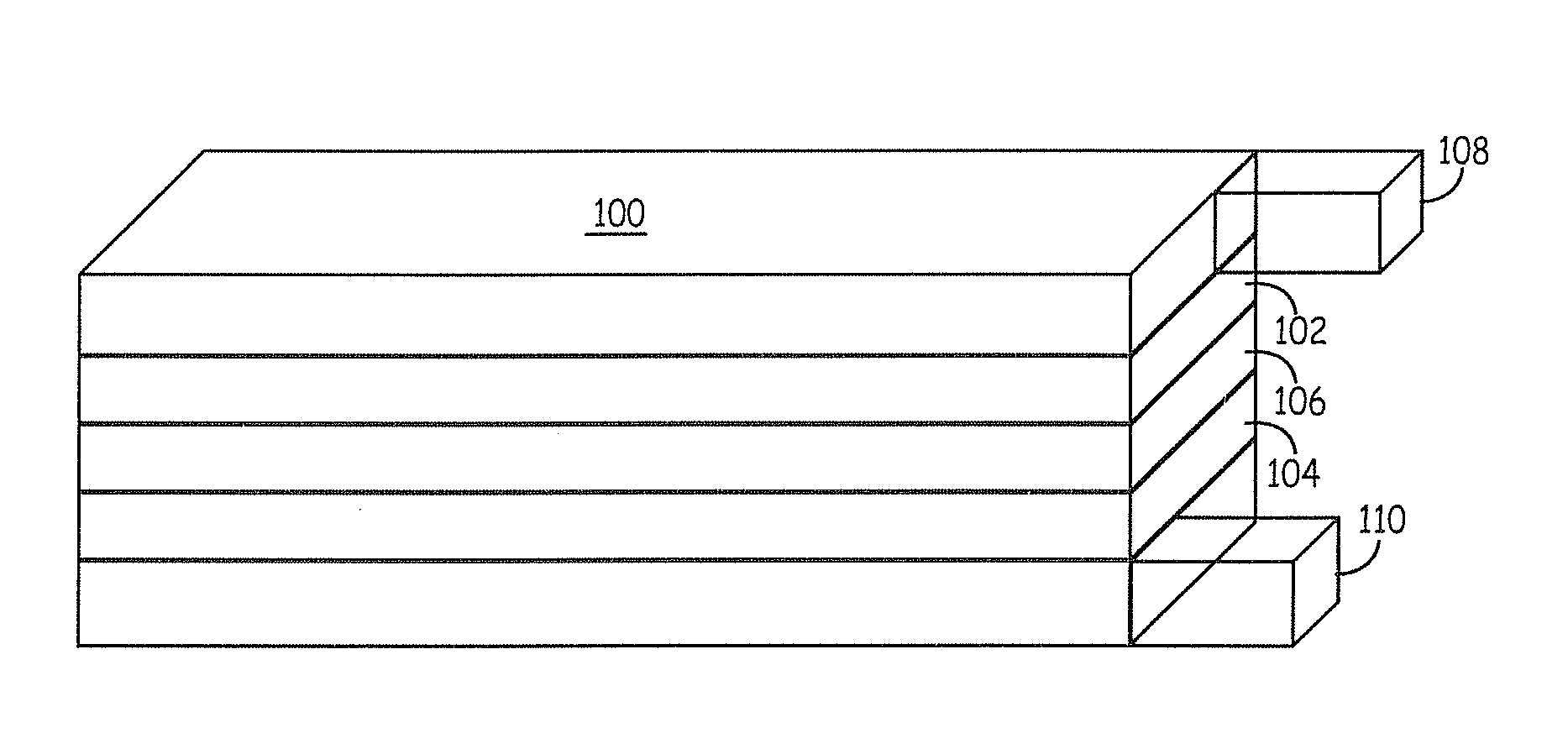

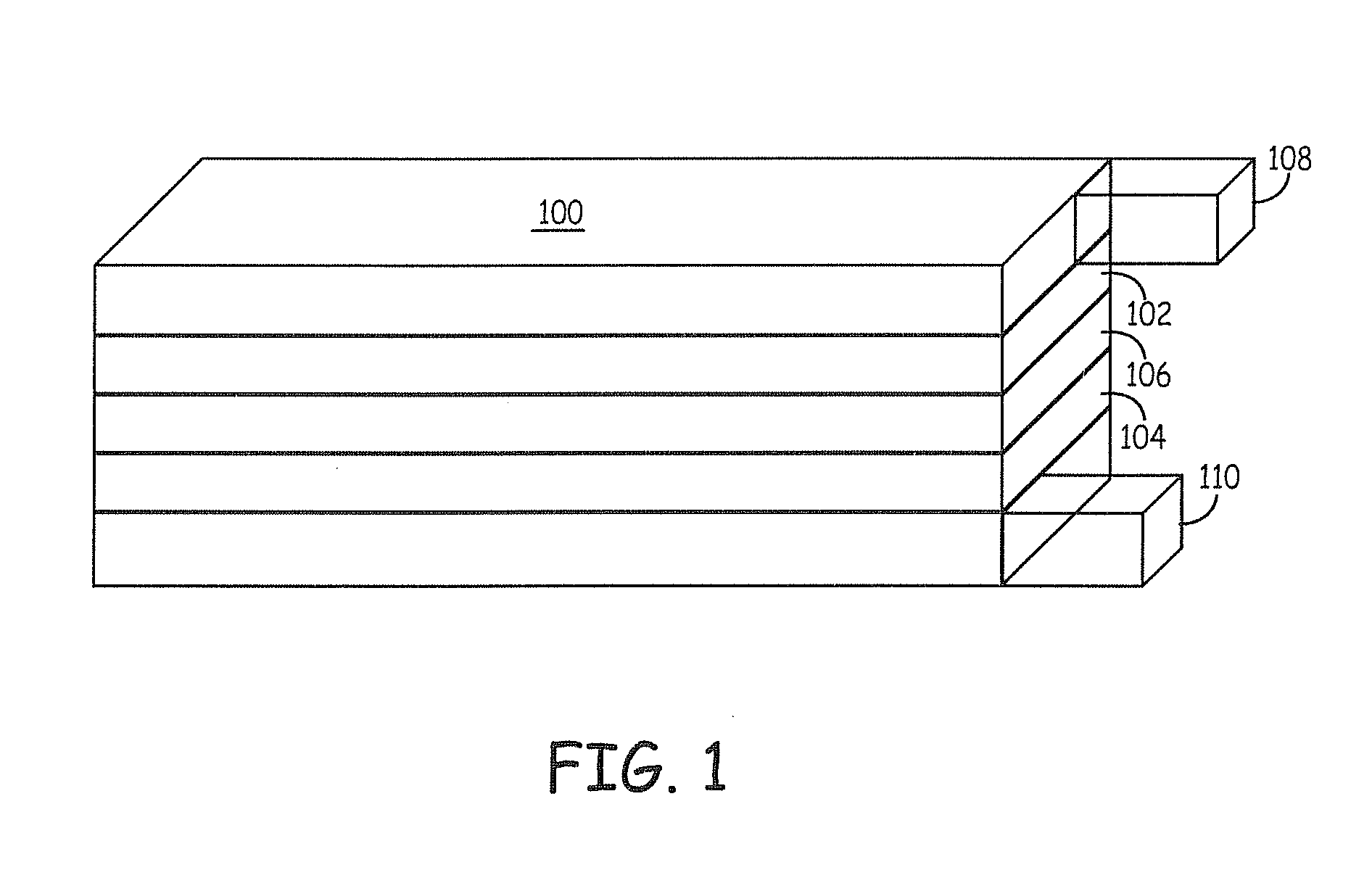

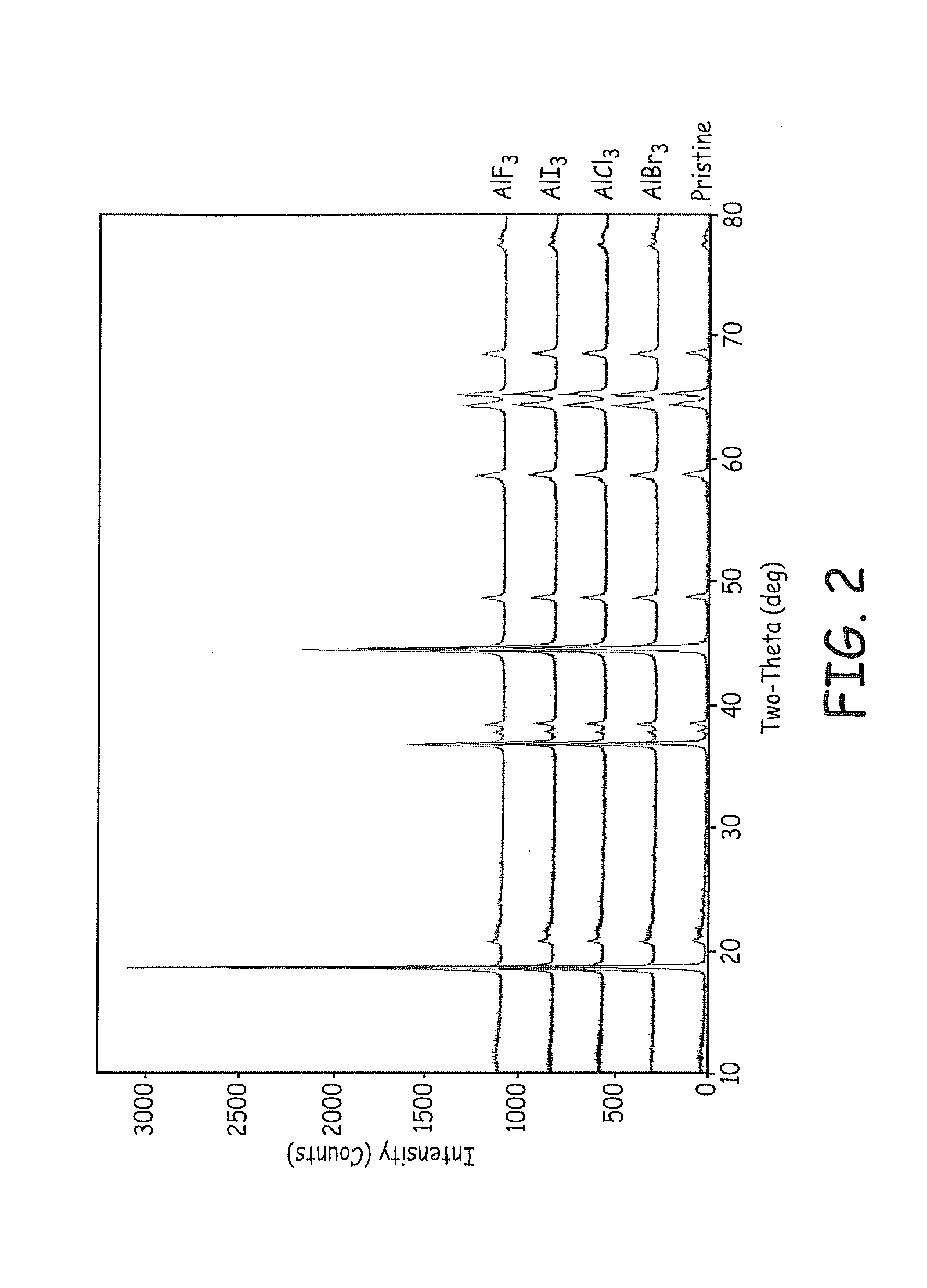

Metal halide coatings on lithium ion battery positive electrode materials and corresponding batteries

Lithium ion battery positive electrode material are described that comprise an active composition comprising lithium metal oxide coated with an inorganic coating composition wherein the coating composition comprises a metal chloride, metal bromide, metal iodide, or combinations thereof. Desirable performance is observed for these coated materials. In particular, the non-fluoride metal halide coatings are useful for stabilizing lithium rich metal oxides.

Owner:IONBLOX INC

Scintillator compositions, and related processes and articles of manufacture

ActiveUS7084403B2Excellent and reproducible scintillation responseImprove performanceMaterial analysis by optical meansLuminescent compositionsHigh energyIodide

Scintillator materials based on certain types of halide-lanthanide matrix materials are described. In one embodiment, the matrix material contains a mixture of lanthanide halides, i.e., a solid solution of at least two of the halides, such as lanthanum chloride and lanthanum bromide. In another embodiment, the matrix material is based on lanthanum iodide alone, which must be substantially free of lanthanum oxyiodide. The scintillator materials, which can be in monocrystalline or polycrystalline form, also include an activator for the matrix material, e.g., cerium. Radiation detectors that use the scintillators are also described, as are related methods for detecting high-energy radiation.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

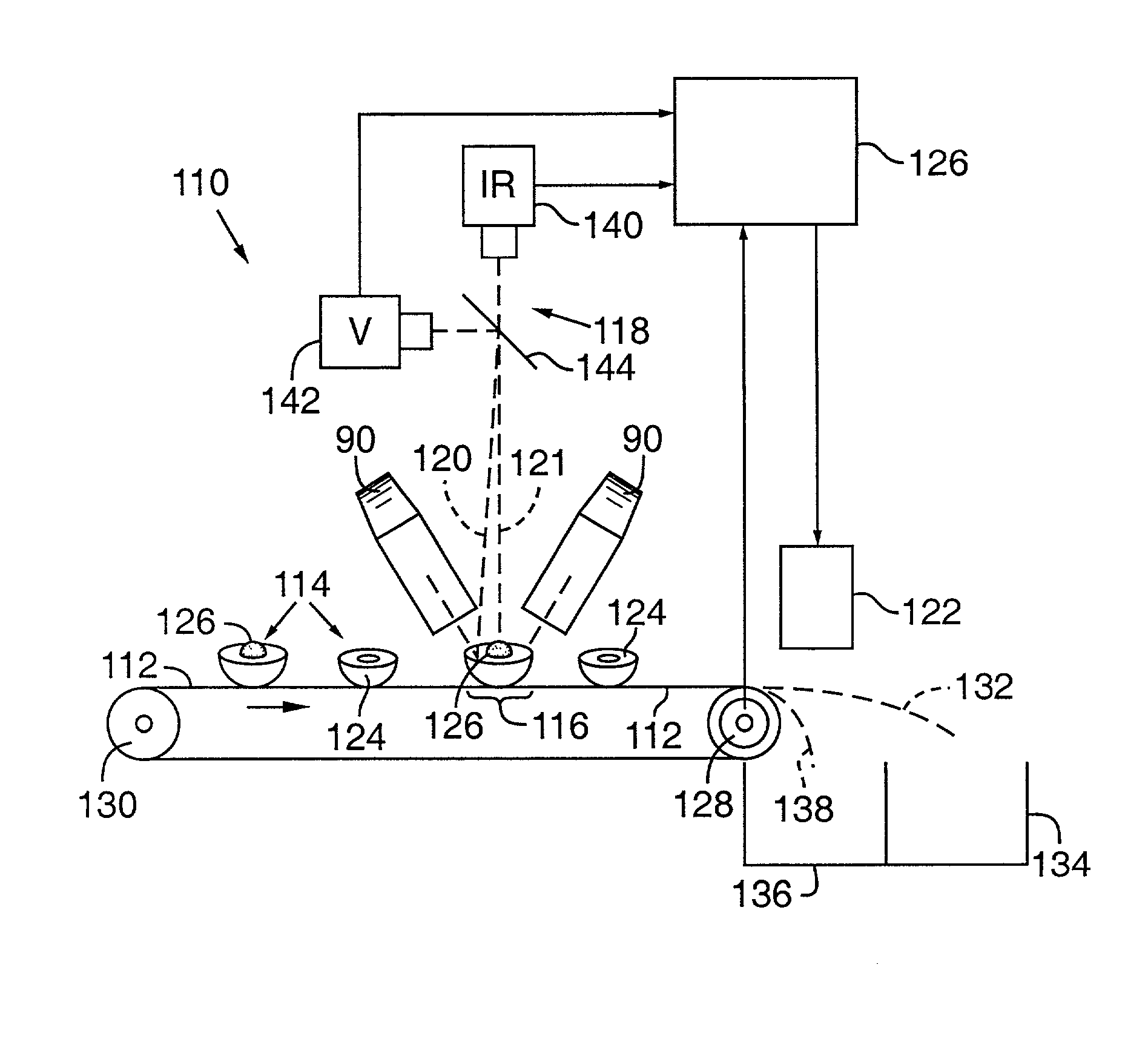

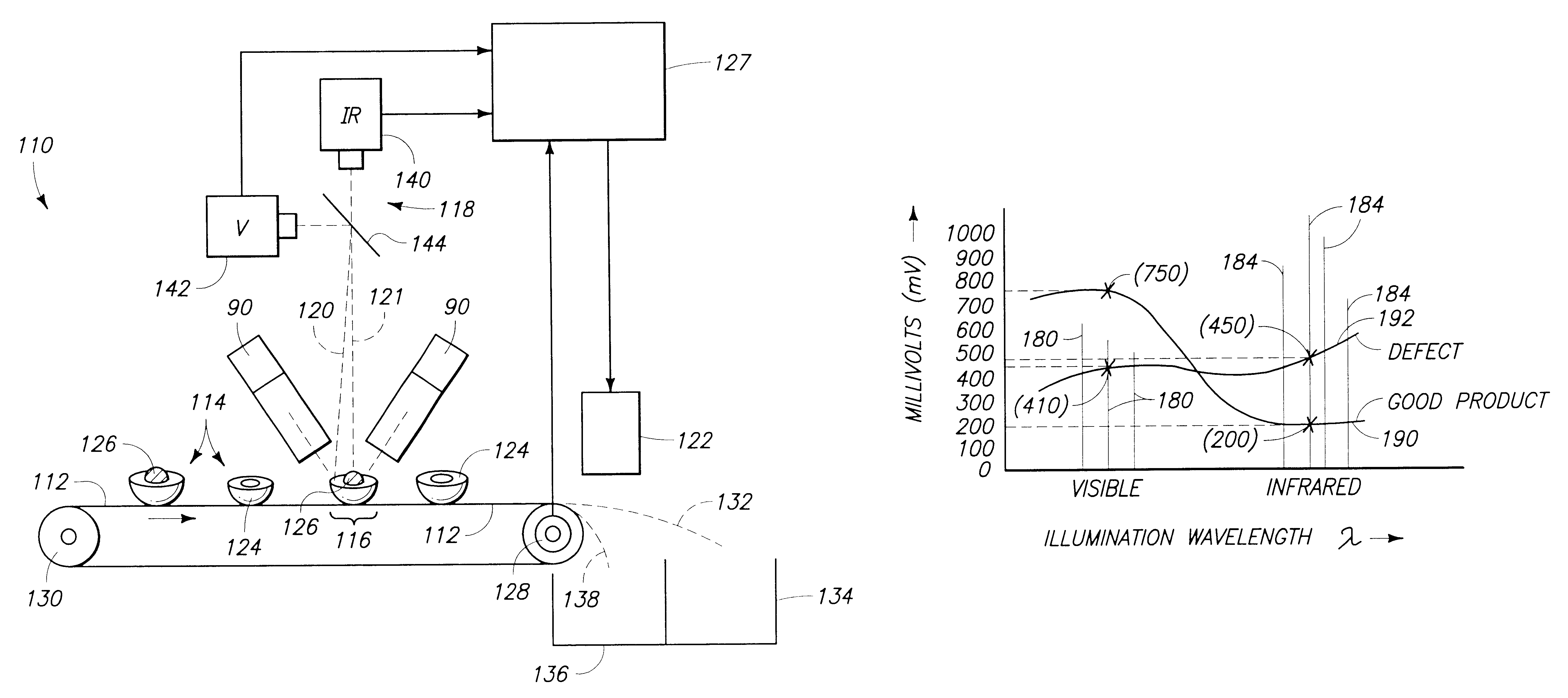

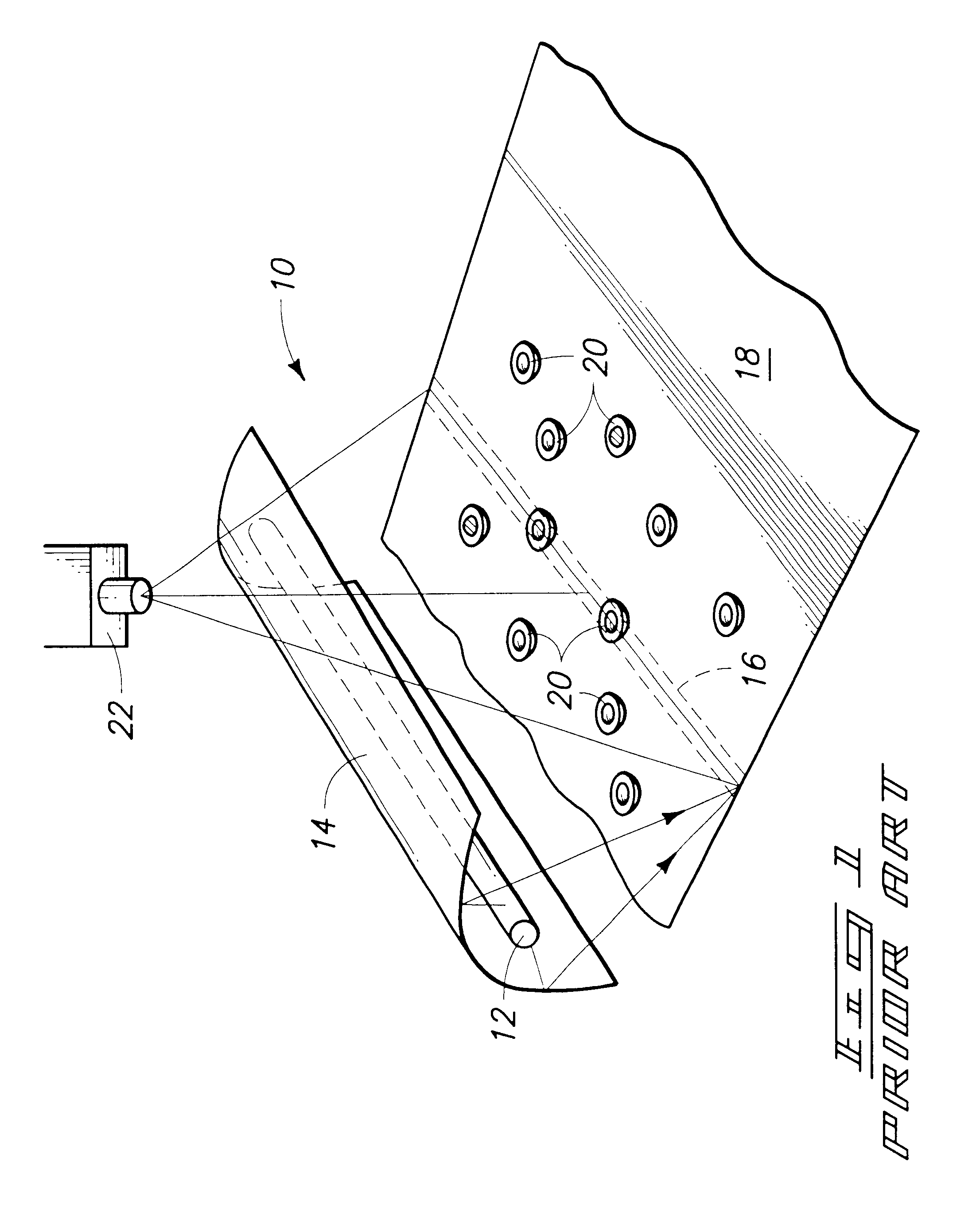

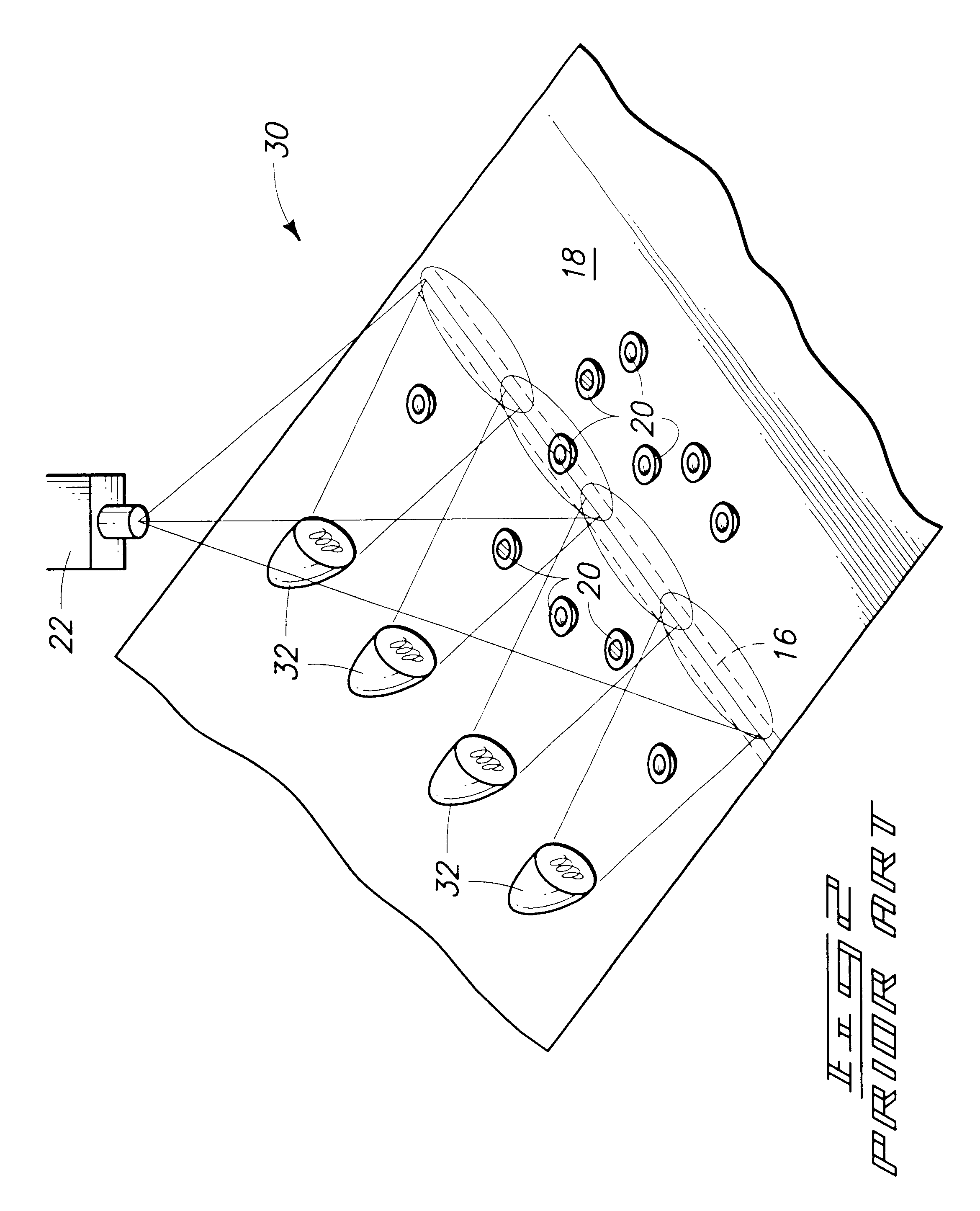

Agricultural article inspection apparatus and method employing spectral manipulation to enhance detection contrast ratio

InactiveUS20020008055A1Diminishes chlorophyll effect reflectanceImprove image contrastInvestigation of vegetal materialInvestigating moving fluids/granular solidsIodideImage contrast

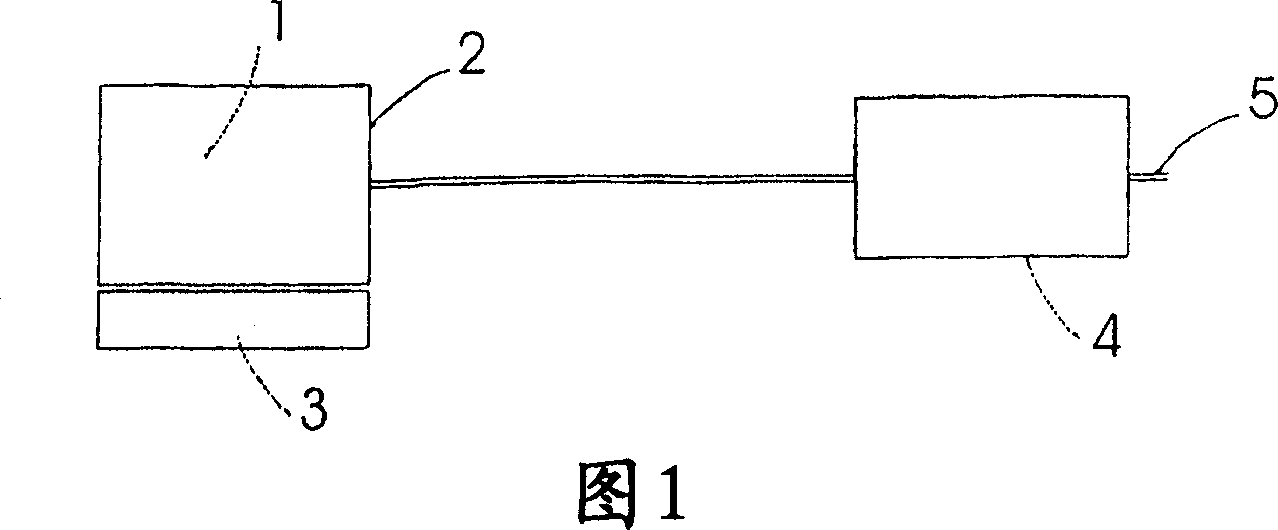

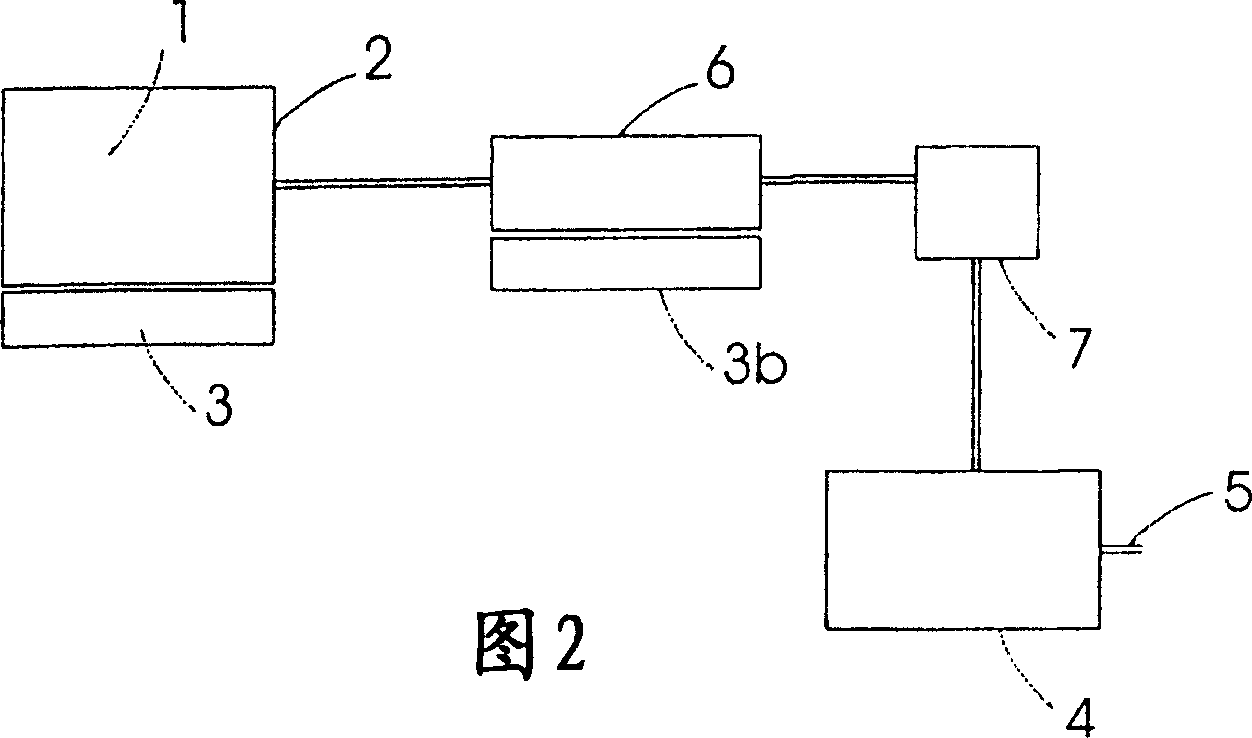

A sorting system (110) conveys articles, such as peaches (114) on a conveyor belt (112) past an inspection zone (126) that is lighted by an illumination source (90) radiating a number of emission peaks over visible and infrared portions of the spectrum. The illumination source generates the radiation from an Indium Iodide lamp (92) that is reflected off a parabolic reflector (94) and through a "soda straw" collimator (100) to illuminated the peaches. A detector system (118) employs line scanning visible and infrared cameras (142, 140) to sense visible and IR wavelength reflectance values for the peach meat (124) and peach pit or pit fragments (126). Various image processing and analysis methologies, such as subtraction, ratio, logarithmic, regression, combination, angle, distance, and shape may be employed to enhance the image contrast and classify the resulting data for sorting the peaches. Employing subtraction also cancels "glint" caused by specular reflections of the illumination source off the peaches and into the cameras.

Owner:KII TEKU INC

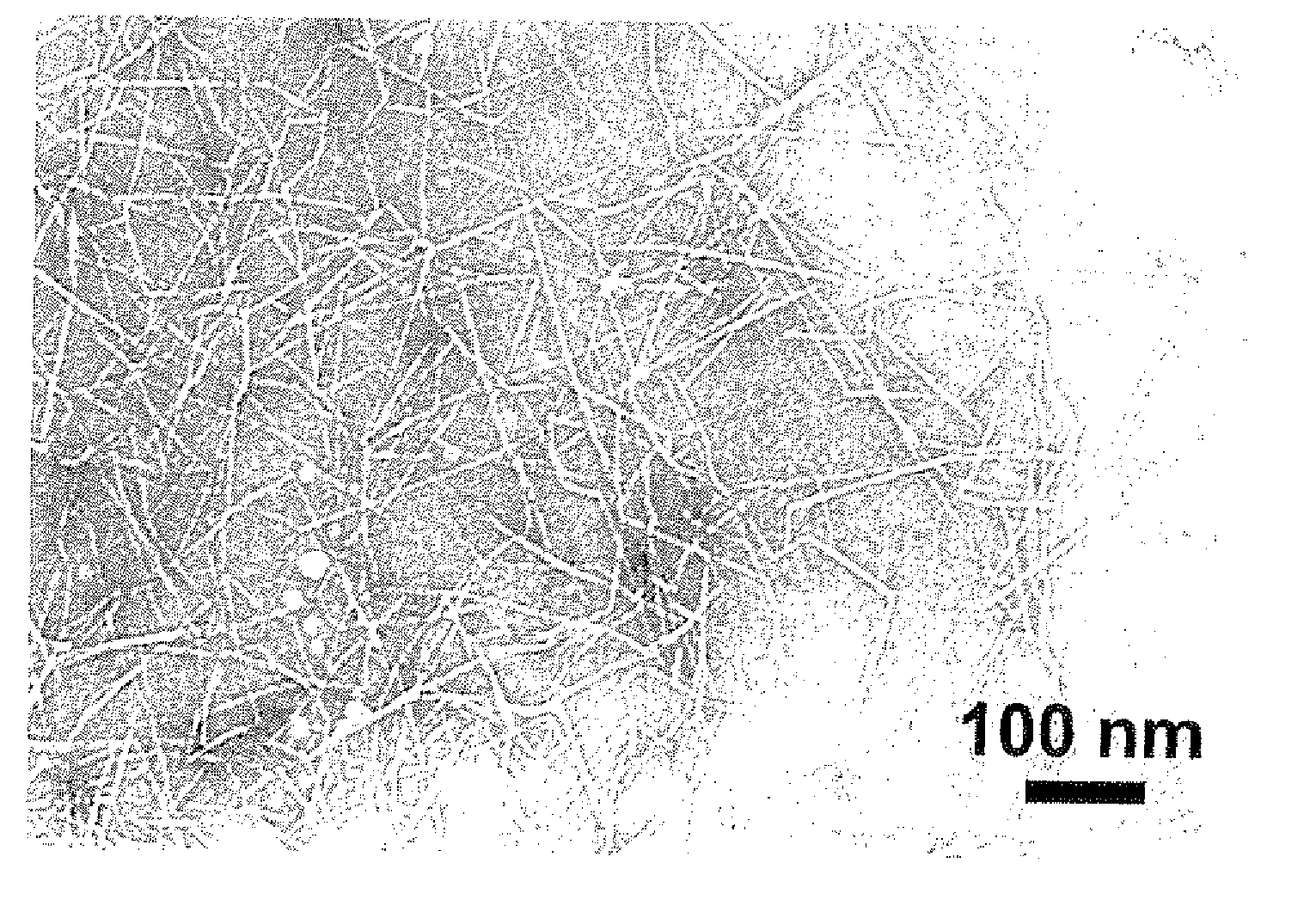

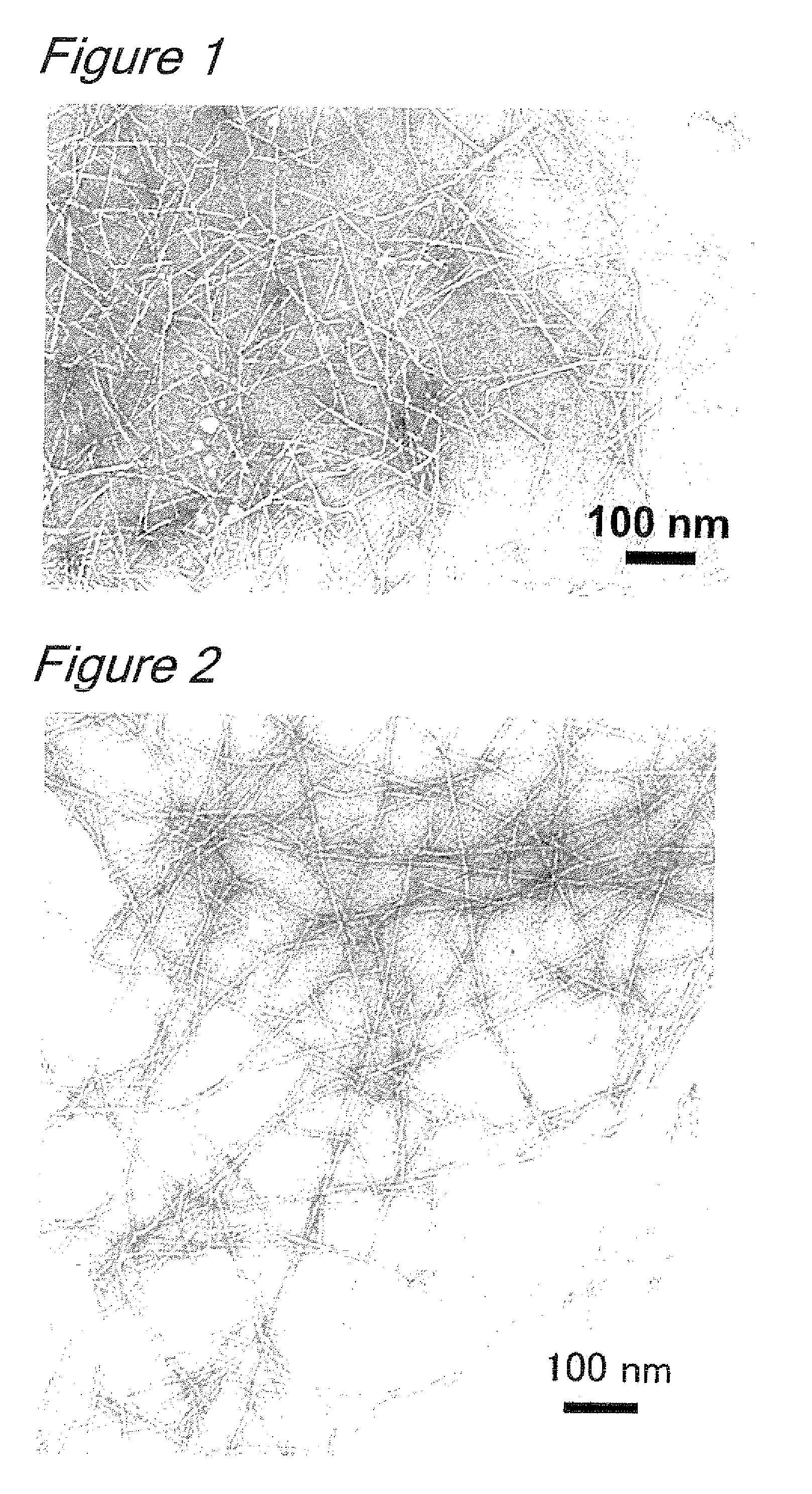

Processes for producing cellulose nanofibers, cellulose oxidation catalysts and methods for oxidizing cellulose

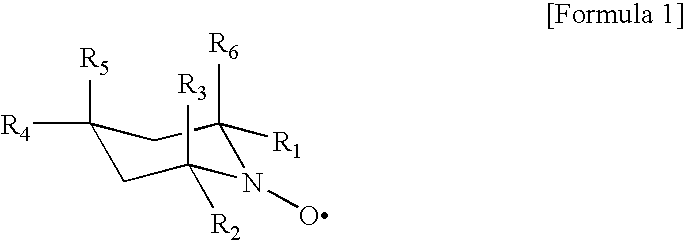

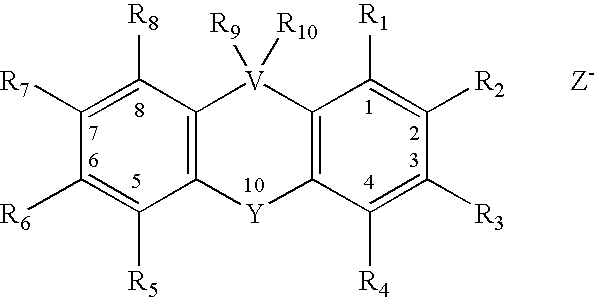

The present invention aims to provide a process for producing cellulose nanofibers using a 4-hydroxy TEMPO derivative less expensive than TEMPO and a process capable of rapidly producing homogeneous cellulose nanofibers. Wood cellulose can be efficiently converted into nanofibers by a process for producing cellulose nanofibers comprising treating a cellulosic material with an oxidizing agent in water in the presence of a cellulose oxidation catalyst comprising an N-oxyl compound represented by formula 1 below:wherein R1 and R2 are each independently hydrogen or a C1-C6 straight or branched alkyl group; and(i) one of R4 or R5 is —OR, —OCOR or —OSO2R wherein R is a straight or branched carbon chain having 4 or less carbon atoms, and the other of R4 or R5 is hydrogen, and R3 and R6 are methyl, or(ii) R4 is hydrogen, and R5, R3 and R6 are taken together with a piperidine ring to form an aza-adamantane compound having formula 2 below:or a mixture thereof, and a compound selected from the group consisting of bromides, iodides and mixtures thereof to prepare oxidized cellulose, and microfibrillating the oxidized cellulose to convert it into nanofibers.

Owner:NIPPON PAPER IND CO LTD

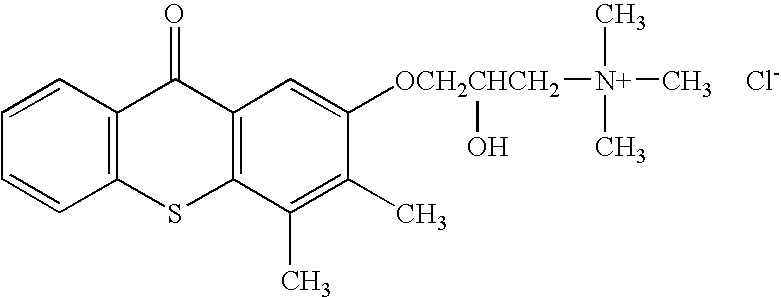

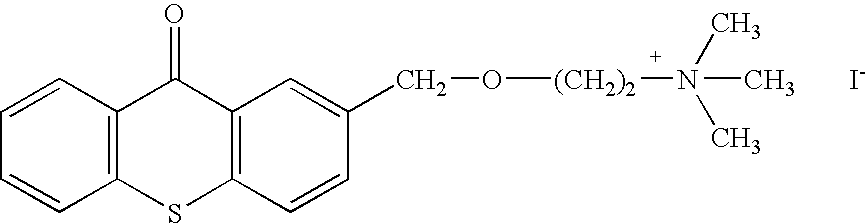

Small molecules for the reduction of high blood glucose level

InactiveUS20090317372A1Lower blood sugar levelsAntibacterial agentsBiocideDiseaseAcute hyperglycaemia

Embodiments of the present invention include the in vivo use of a family of heterocyclic compounds containing a quaternary ammonium group as exemplified by the thioxanthone and thioxanthene compounds [3-(3,4-dimethyl-9-oxo-9H-thioxanthen-2-yloxy)-2-hydroxypropyl]trimethylammonium chloride, or CCcompound1, N,N,-diethyl-N-methyl-2-[9-oxo-9H-thioxanthen-2-yl)methoxy]ethanaminium iodide, or CCcompound3, and N,N,N-trimethyl-3-(9H-thioxanthen-9-ylidene)-propane-1-aminium iodide, or CCcompound19 to reduce higher than normal blood glucose level within or close to the normal range in subjects with insulin resistance, hyperglycemia, and diabetes thereby also reducing or preventing associated diseases, complications, and pathological states.

Owner:KISS ZOLTAN

Agricultural article inspection apparatus and method employing spectral manipulation to enhance detection contrast ratio

InactiveUS6410872B2Improve image contrastCancels "glInvestigation of vegetal materialInvestigating moving fluids/granular solidsIodideConveyor belt

A sorting system (110) conveys articles, such as peaches (114) on a conveyor belt (112) past an inspection zone (126) that is lighted by an illumination source (90) radiating a number of emission peaks over visible and infrared portions of the spectrum. The illumination source generates the radiation from an Indium Iodide lamp (92) that is reflected off a parabolic reflector (94) and through a "soda straw" collimator (100) to illuminated the peaches. A detector system (118) employs line scanning visible and infrared cameras (142, 140) to sense visible and IR wavelength reflectance values for the peach meat (124) and peach pit or pit fragments (126). Various image processing and analysis methologies, such as subtraction, ratio, logarithmic, regression, combination, angle, distance, and shape may be employed to enhance the image contrast and classify the resulting data for sorting the peaches. Employing subtraction also cancels "glint" caused by specular reflections of the illumination source off the peaches and into the cameras.

Owner:KII TEKU INC

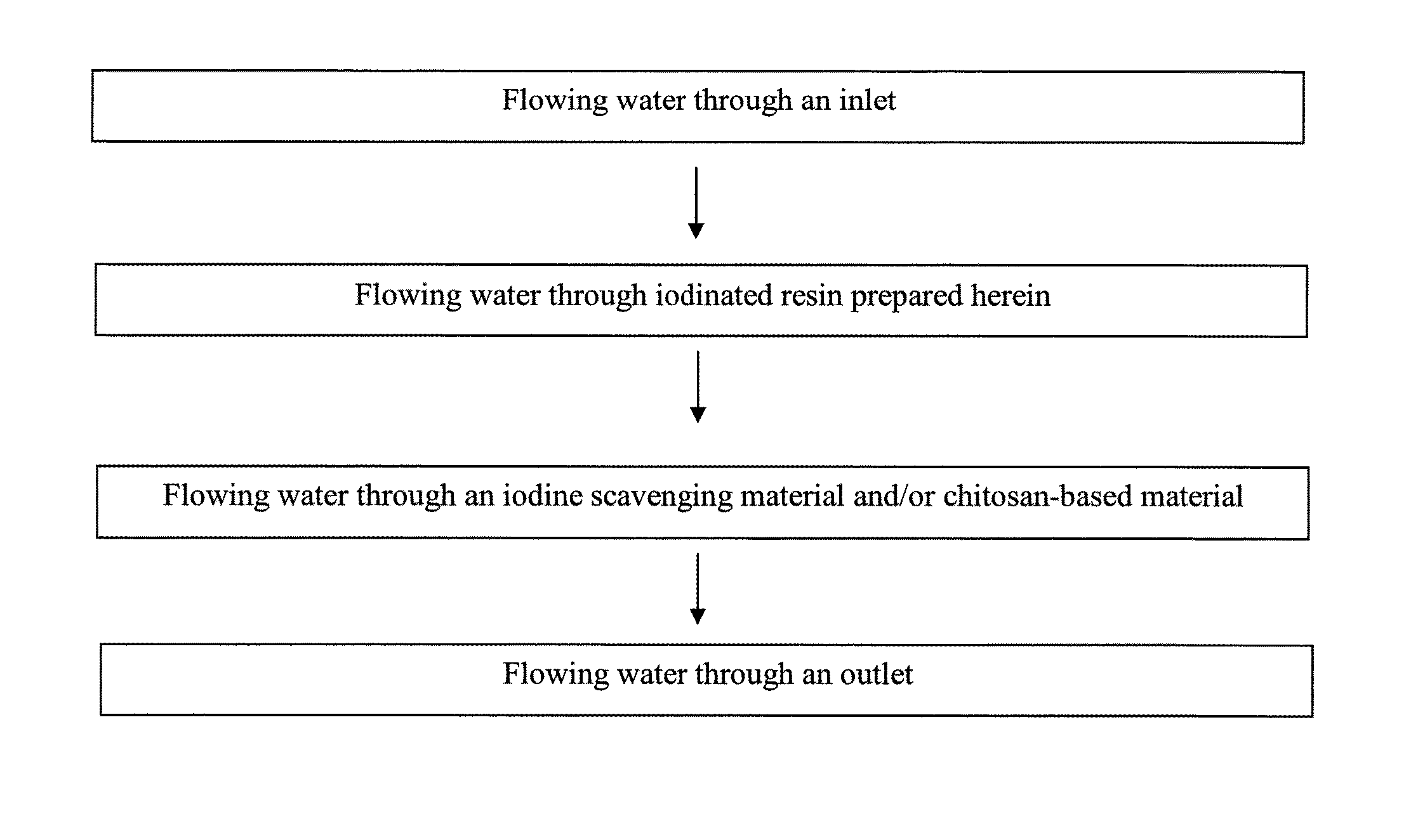

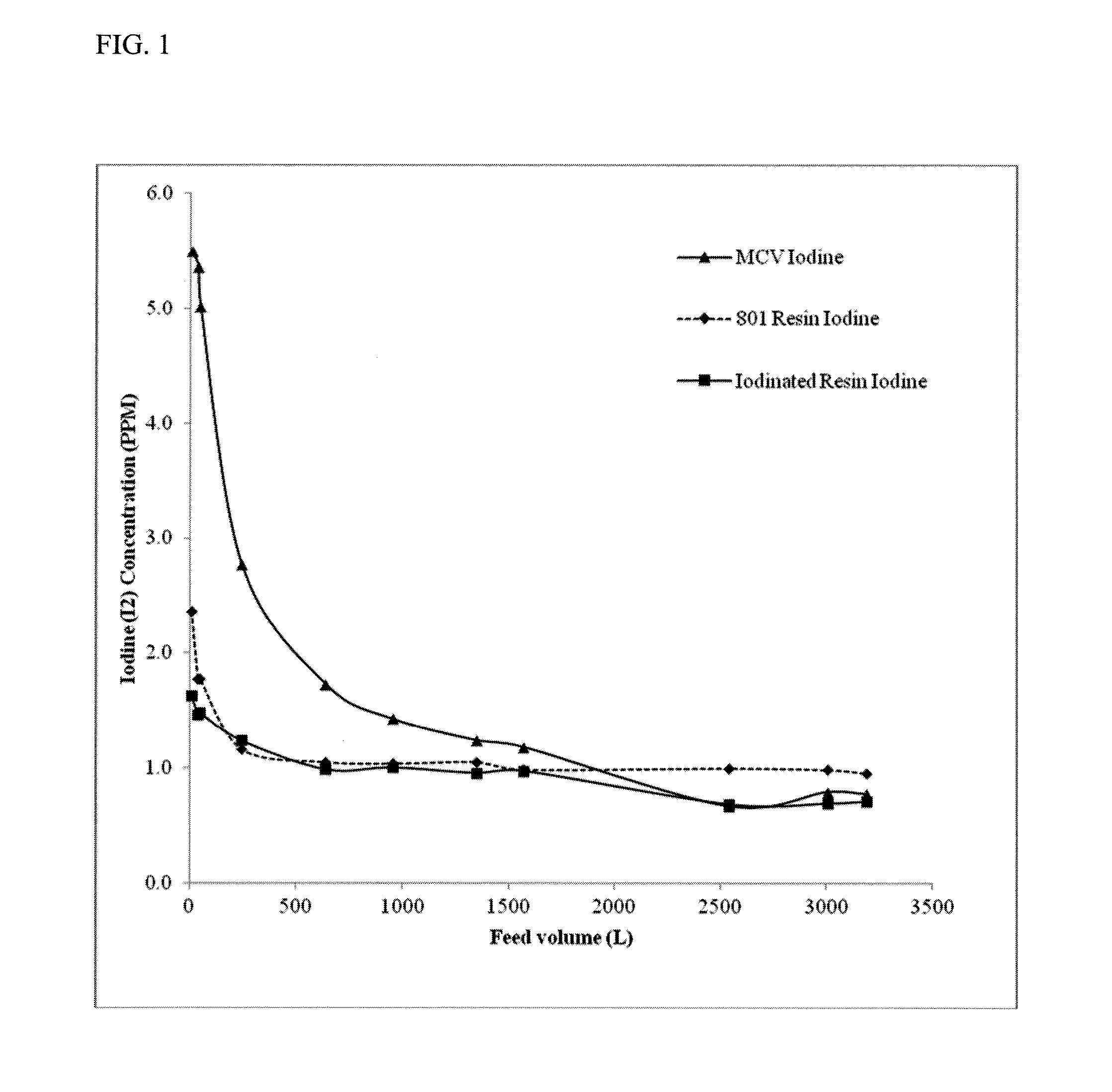

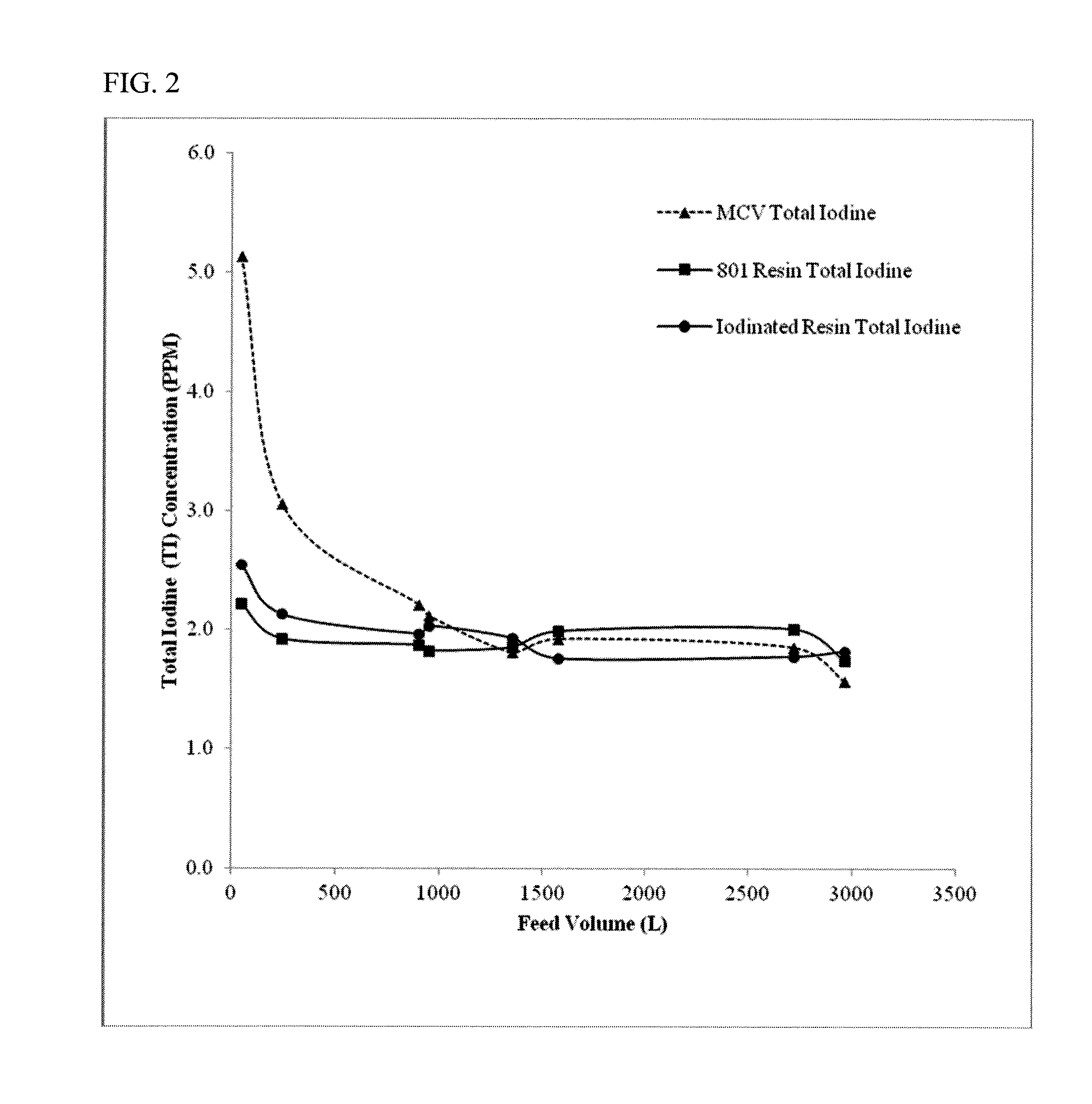

Methods of producing iodinated resins

Methods for producing or regenerating an iodinated resin are presented. The methods include converting iodide residues on a surface of and in pores of an iodide loaded anion exchange resin to iodine and iodine intermediates using a source of active halogen to form an iodinated resin having iodine and iodine intermediate residues on the surface of and in the pores of the iodinated resin. The iodinated resins show reduced and stable levels of iodine elution compared to conventional iodinated anion exchange resins and may utilizes less iodine raw materials during the manufacturing process. The iodinated resin can also act as an end-of life indicator in a water purification system that incorporates the iodinated resin to reduce microbial, including bacterial and viral, contamination in drinking water sources. Methods and systems for purifying water are also presented.

Owner:WATER SECURITY CORP

Induction plasma synthesis of nanopowders

ActiveUS20070029291A1Tight controlEasy to controlMaterial nanotechnologyOxygen/ozone/oxide/hydroxideIodideInduction plasma technology

A process and apparatus for synthesizing a nanopowder is presented. In particular, a process for the synthesis of nanopowders of various materials such as metals, alloys, ceramics and composites by induction plasma technology, using organometallic compounds, chlorides, bromides, fluorides, iodides, nitrites, nitrates, oxalates and carbonates as precursors is disclosed. The process comprises feeding a reactant material into a plasma torch in which is generated a plasma flow having a temperature sufficiently high to yield a superheated vapour of the material; transporting said vapour by means of the plasma flow into a quenching zone; injecting a cold quench gas into the plasma flow in the quenching zone to form a renewable gaseous cold front; and forming a nanopowder at the interface between the renewable gaseous cold front and the plasma flow.

Owner:TEKNA PLASMA SYST INC

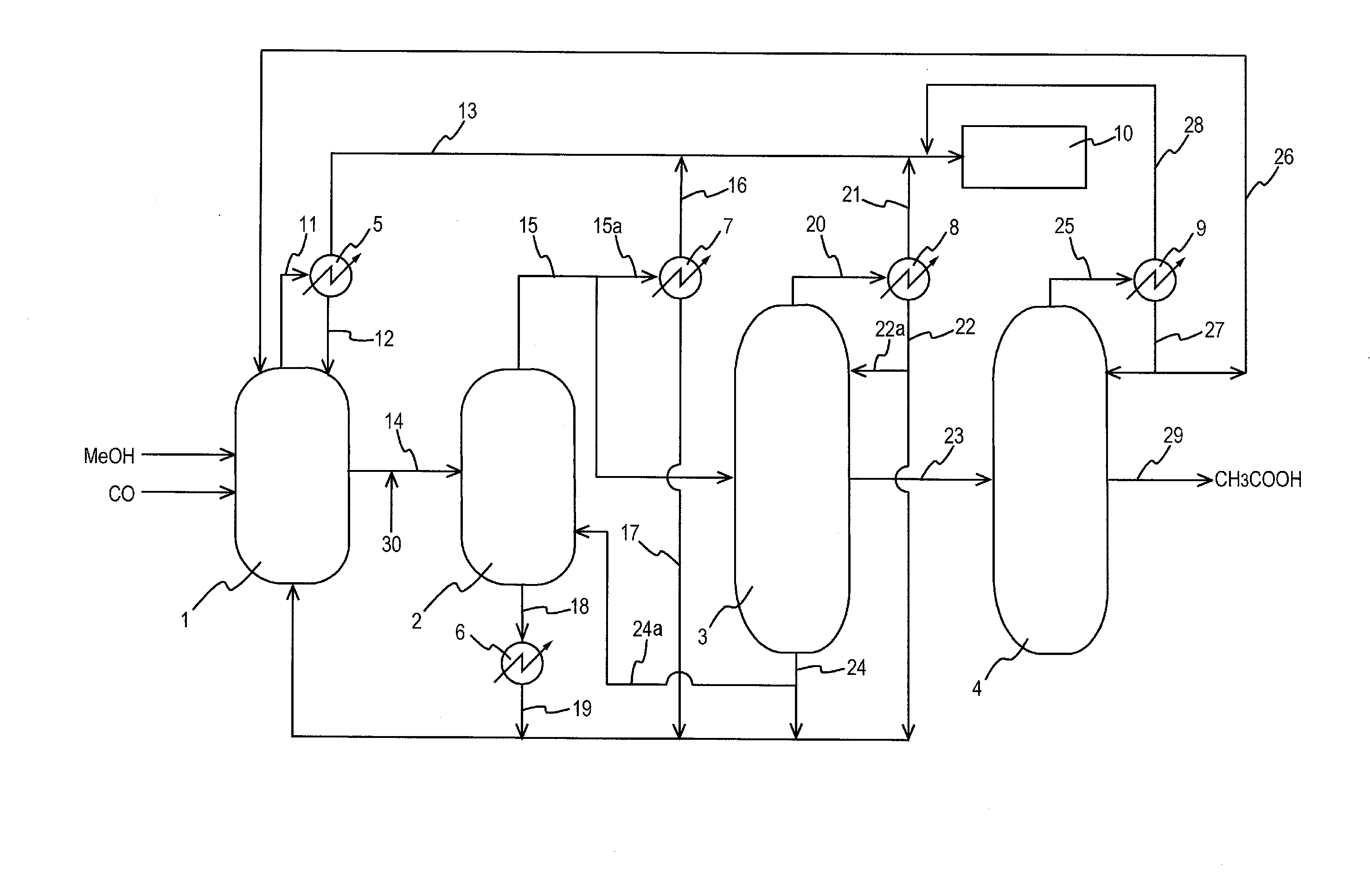

Process for producing acetic acid

ActiveUS20130310603A1Efficient productionEasy to save energyOrganic compound preparationOrganic chemistry methodsIodideReaction step

Acetic acid is produced while inhibiting an increased concentration or production of hydrogen iodide in a carbonylation reactor or corrosion of the carbonylation reactor.A production process of acetic acid comprises a reaction step for continuously allowing methanol to react with carbon monoxide in the presence of a catalyst system comprising a metal catalyst (e.g., a rhodium catalyst), an ionic iodide (e.g., lithium iodide), and methyl iodide in a carbonylation reactor; and in the process, (i) the concentration of the metal catalyst is maintained at not less than 860 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 15% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor, and / or (ii) the concentration of the metal catalyst is maintained at not less than 660 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 3.9% by weight, the concentration of the ionic iodide is maintained at not more than 13% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor.

Owner:DAICEL CHEM IND LTD

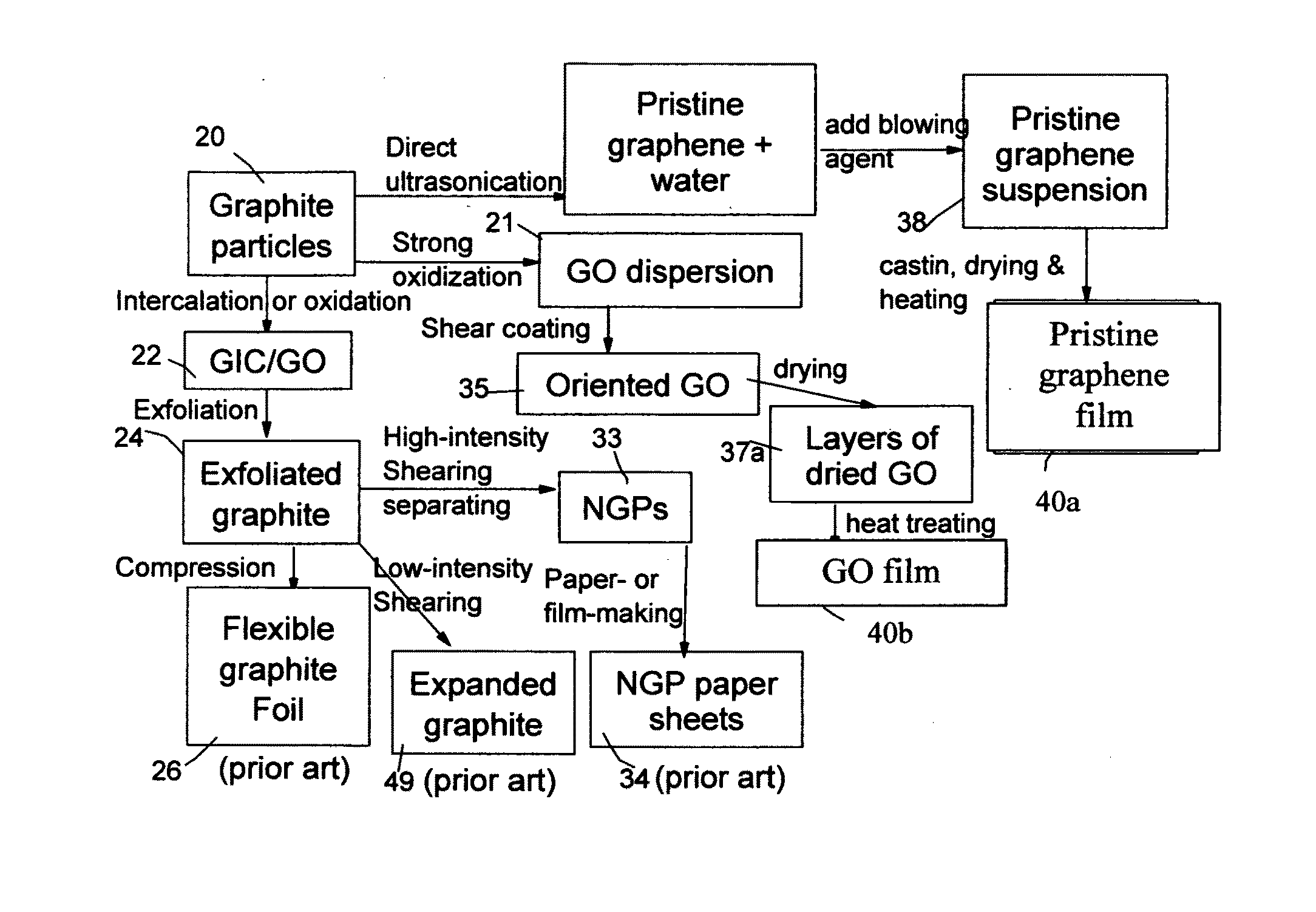

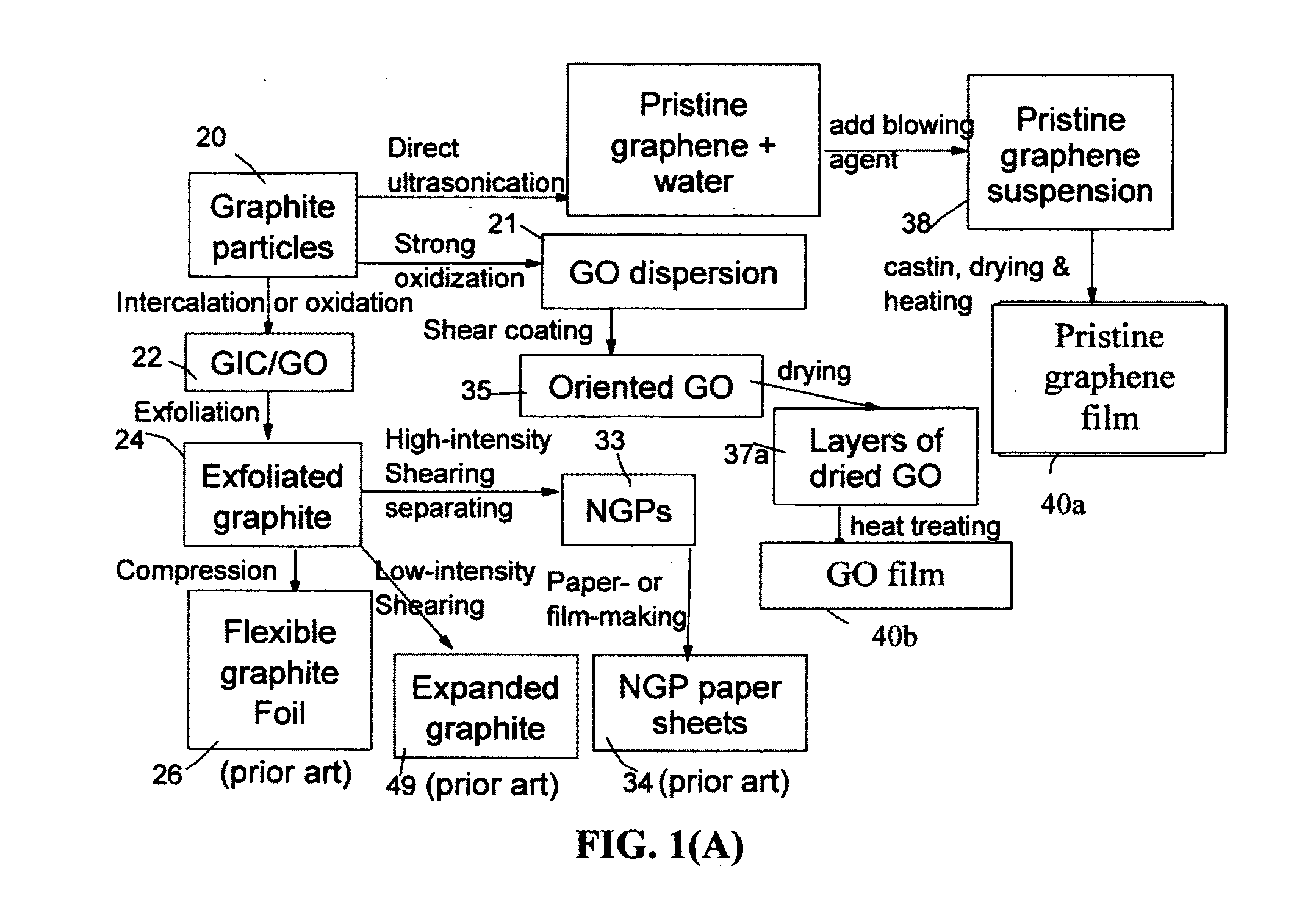

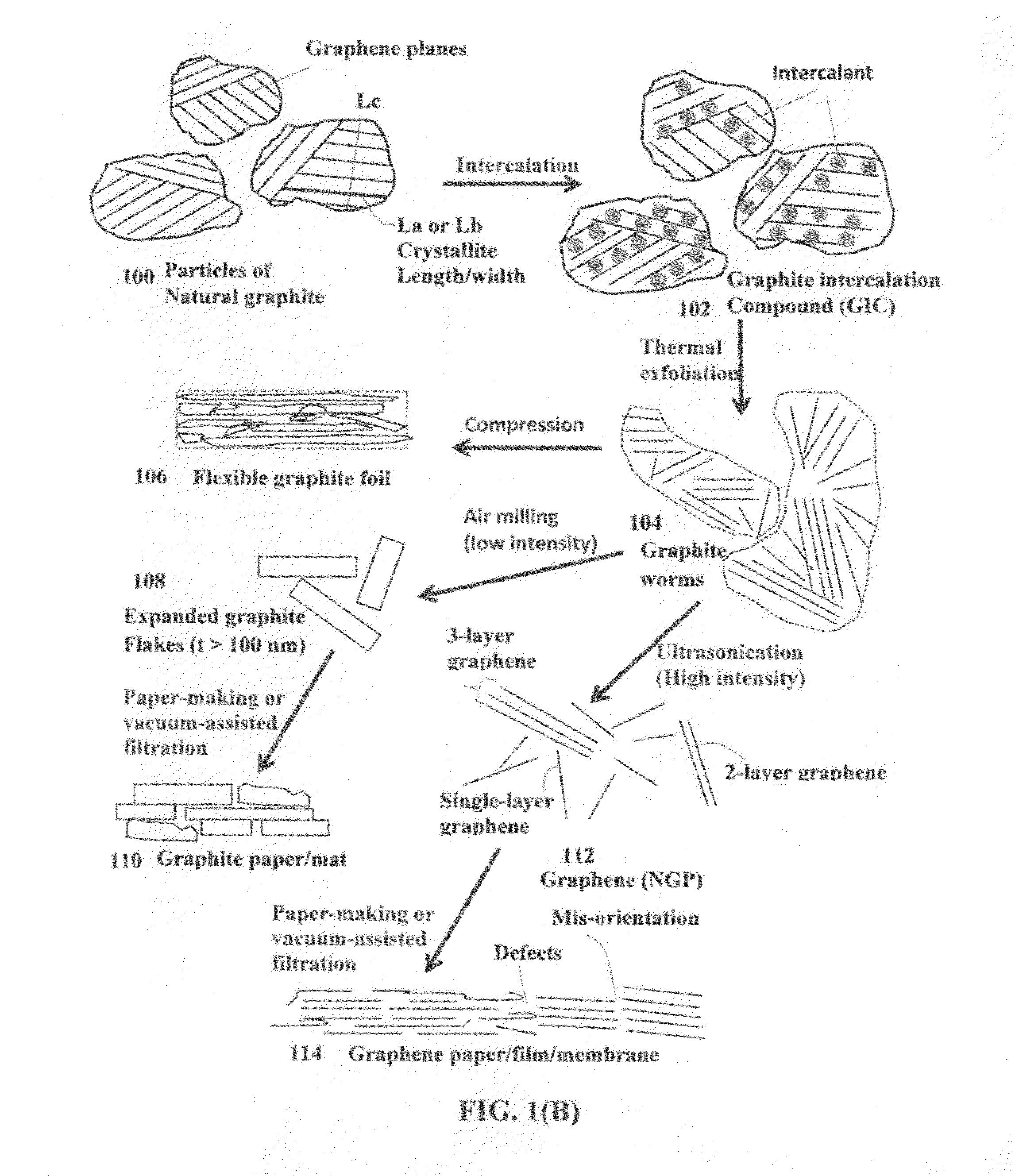

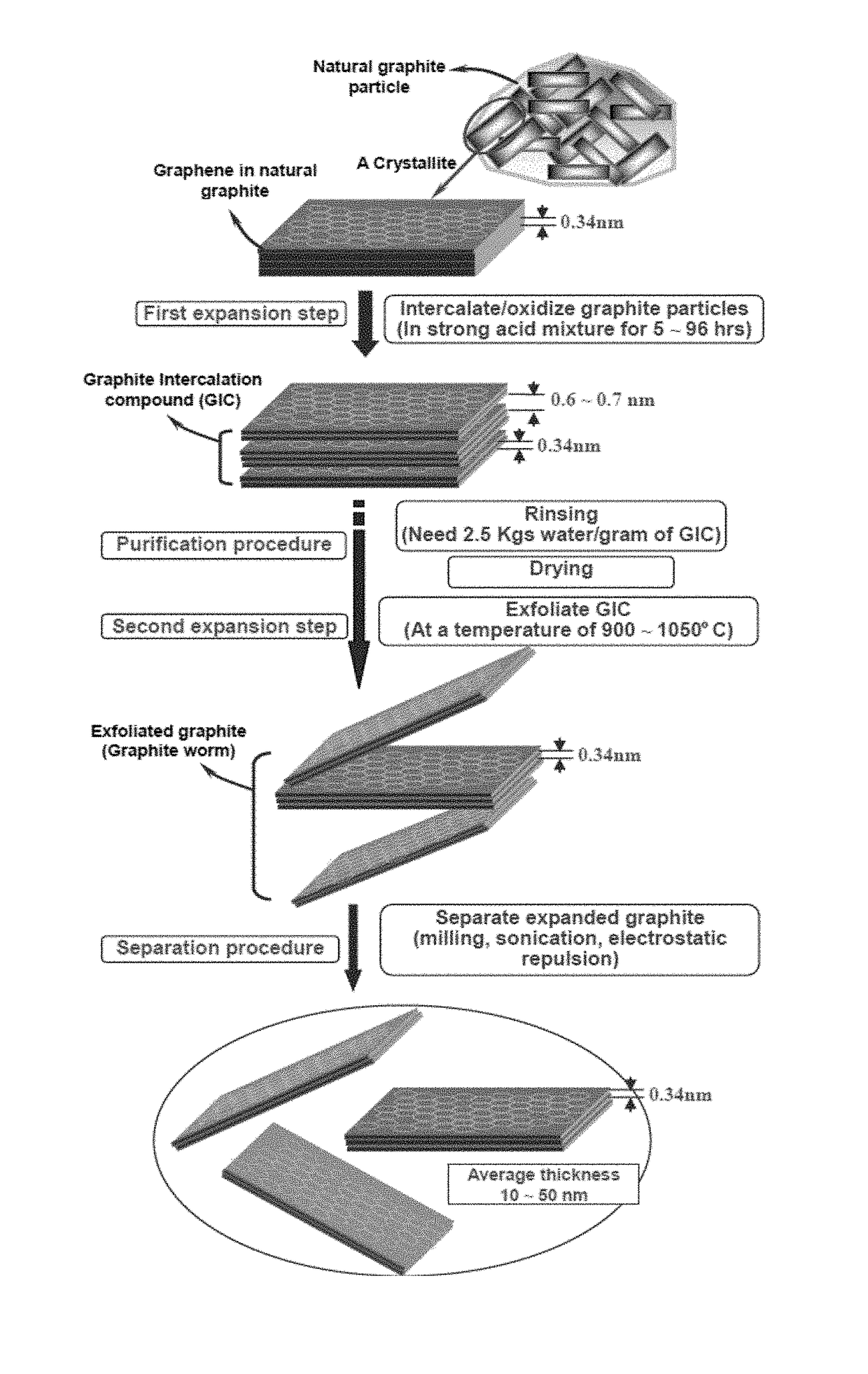

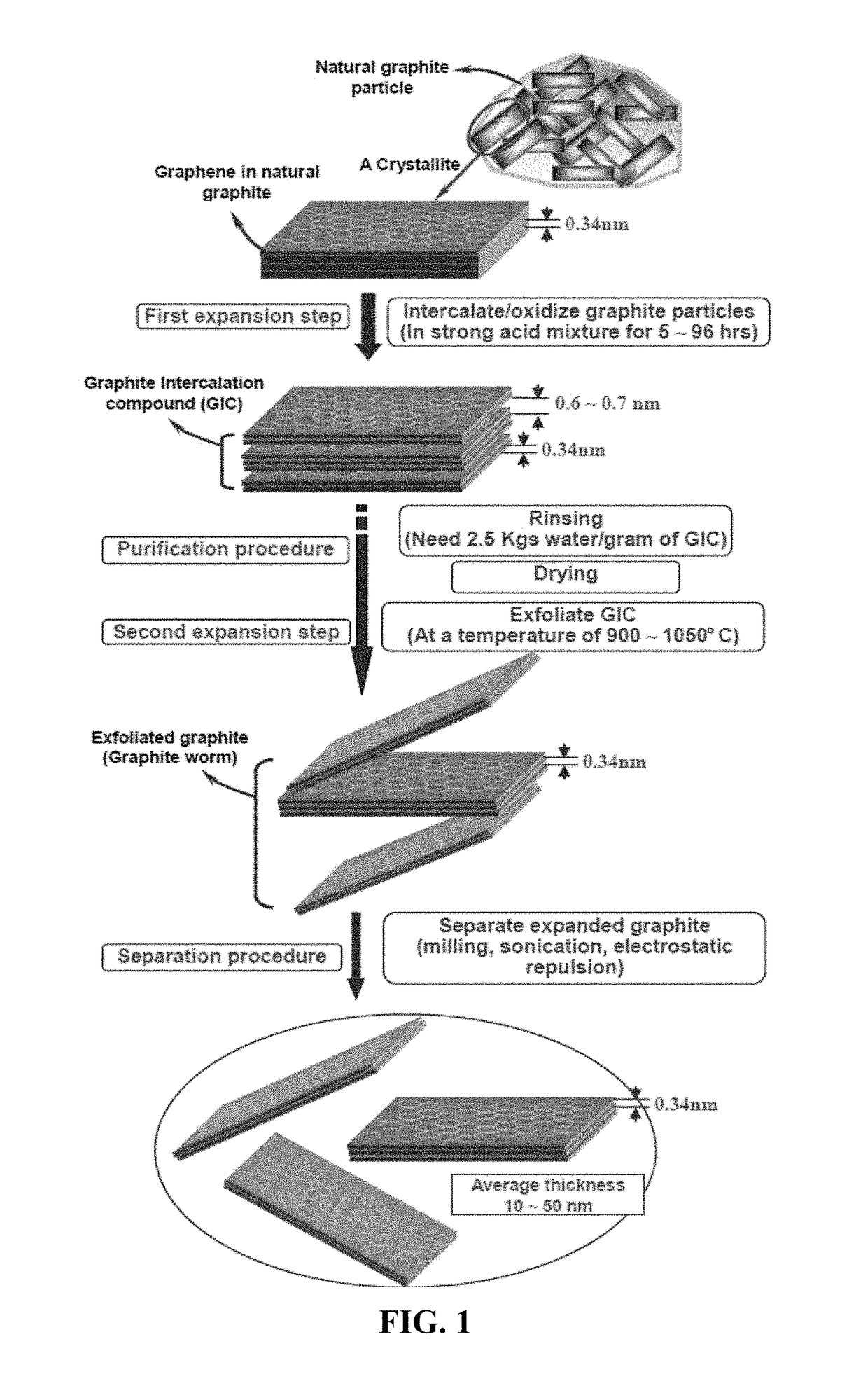

Graphene Electrode Based Ceramic Capacitor

ActiveUS20160079001A1Improve crystal structureGood physical propertiesFixed capacitor electrodesFixed capacitor dielectricDoped grapheneIodide

A ceramic capacitor comprising at least a dielectric ceramic layer and at least a graphene electrode layer deposited on the ceramic layer, wherein the graphene electrode layer has a thickness no less than 2 nm and consists of a graphene material or a graphene composite material containing at least 0.1% by weight of a graphene material dispersed in a matrix material or bonded by a binder material, wherein the graphene material is selected from (a) a plurality of single-layer or multi-layer pristine graphene sheets having less than 0.01% by weight of non-carbon elements, or (b) one or a plurality of a non-pristine graphene material having at least 0.01% by weight of non-carbon elements, wherein the non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

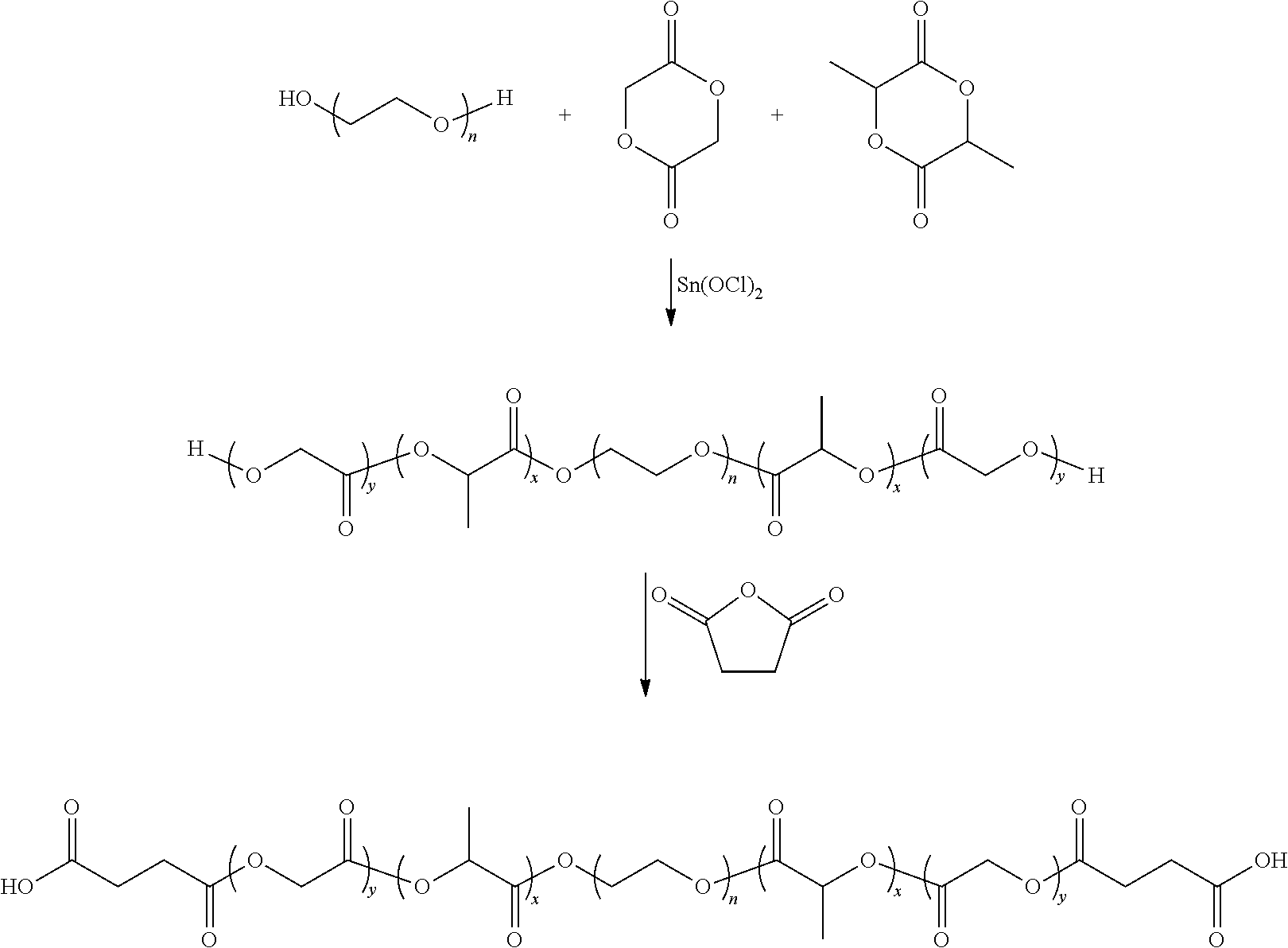

Microparticles and nanoparticles having negative surface charges

This invention provides methods for producing a polymer particle which contains unusually high negative charges on the surface of the particle. Preferably, the polymer is pharmaceutically acceptable. The negative charges can be conferred by chemical groups such as carboxyl, sulfonate, nitrate, fluorate, chloride, iodide, persulfate, and many others, with carboxyl group being preferred. The invention also provides polymer particle produced by the methods of the invention.

Owner:CYTODIGM INC

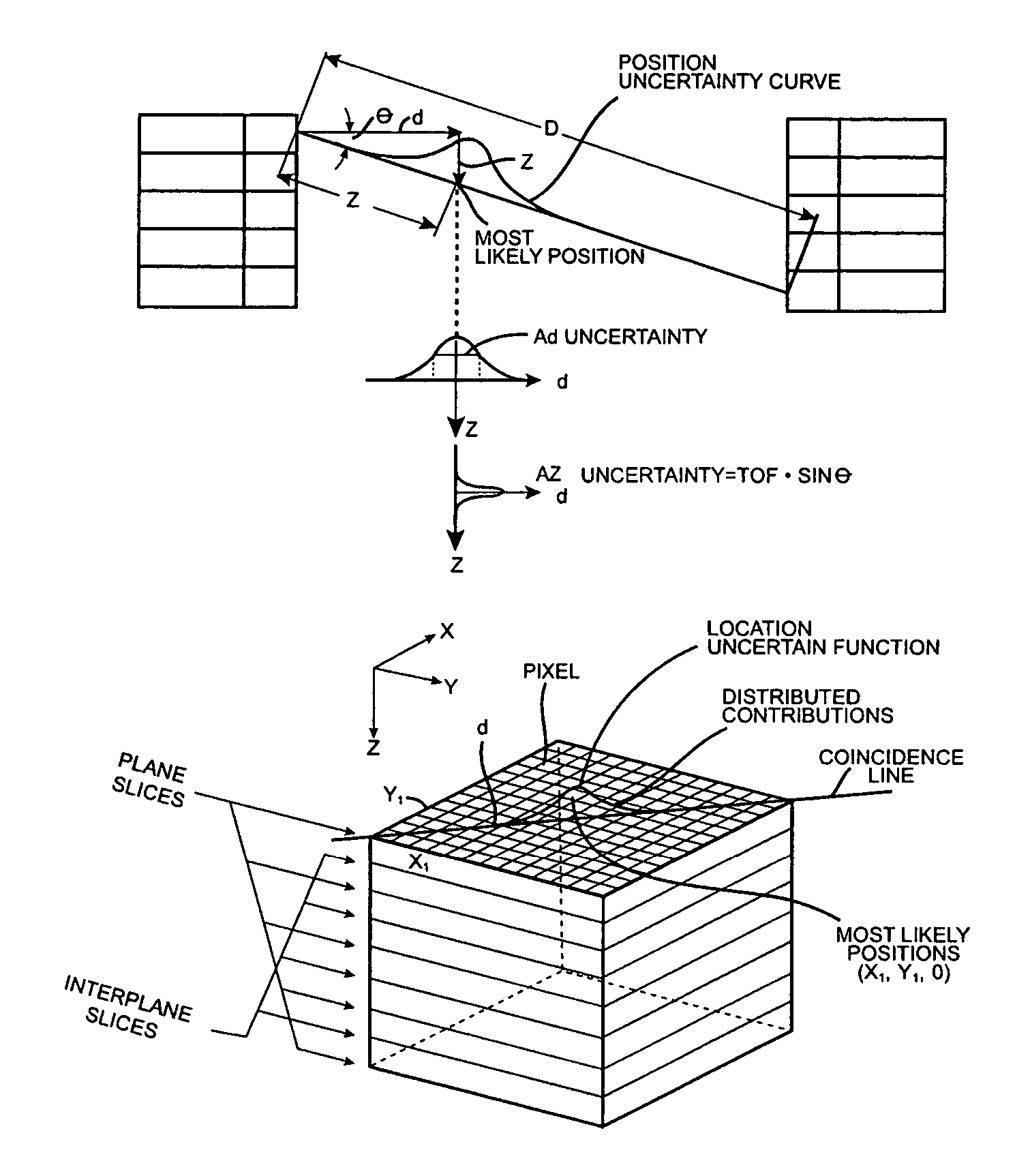

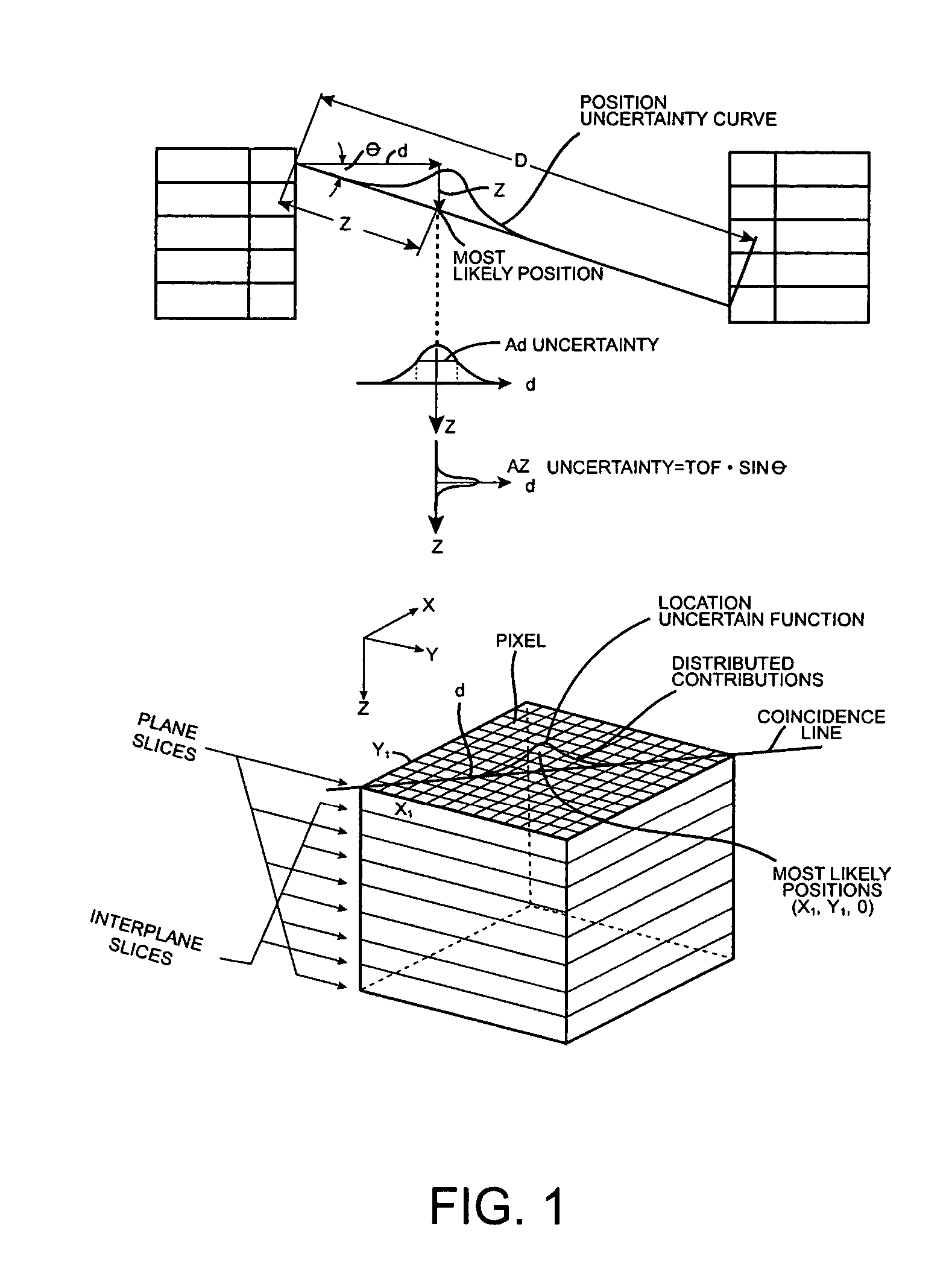

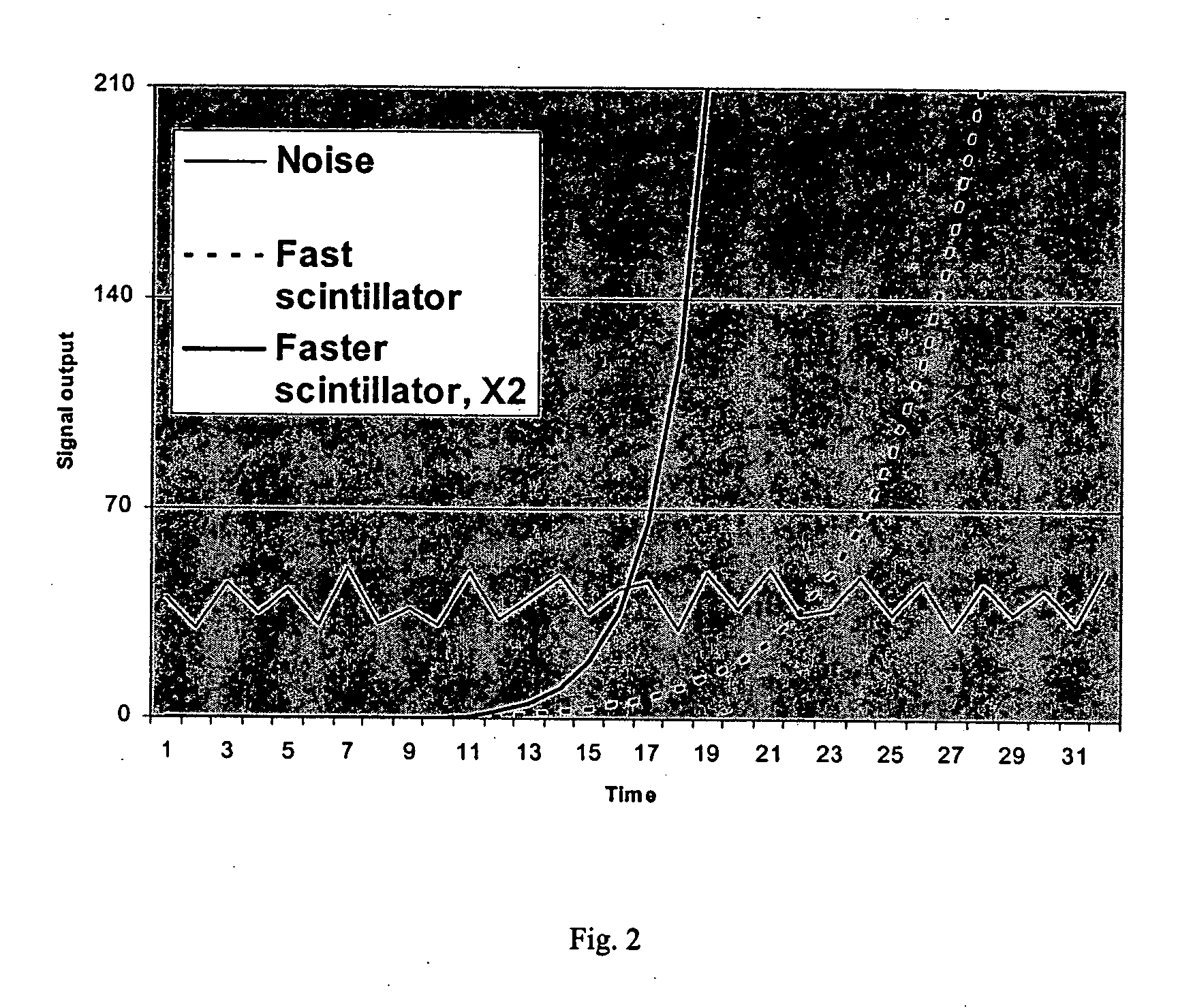

Lu1-xI3:Cex - a scintillator for gamma ray spectroscopy and time-of-flight PET

ActiveUS20050104002A1Improve light outputRapid responsePolycrystalline material growthMaterial analysis by optical meansLutetiumIodide

The present invention concerns very fast scintillator materials comprising lutetium iodide doped with Cerium (Lu1-xI3:Cex; LuI3:Ce). The LuI3 scintillator material has surprisingly good characteristics including high light output, high gamma ray stopping efficiency, fast response, low cost, good proportionality, and minimal afterglow that the material is useful for gamma ray spectroscopy, medical imaging, nuclear and high energy physics research, diffraction, non-destructive testing, nuclear treaty verification and safeguards, and geological exploration. The timing resolution of the scintillators of the present invention provide compositions capable of resolving the position of an annihilation event within a portion of a human body cross-section.

Owner:RADIATION MONITORING DEVICES

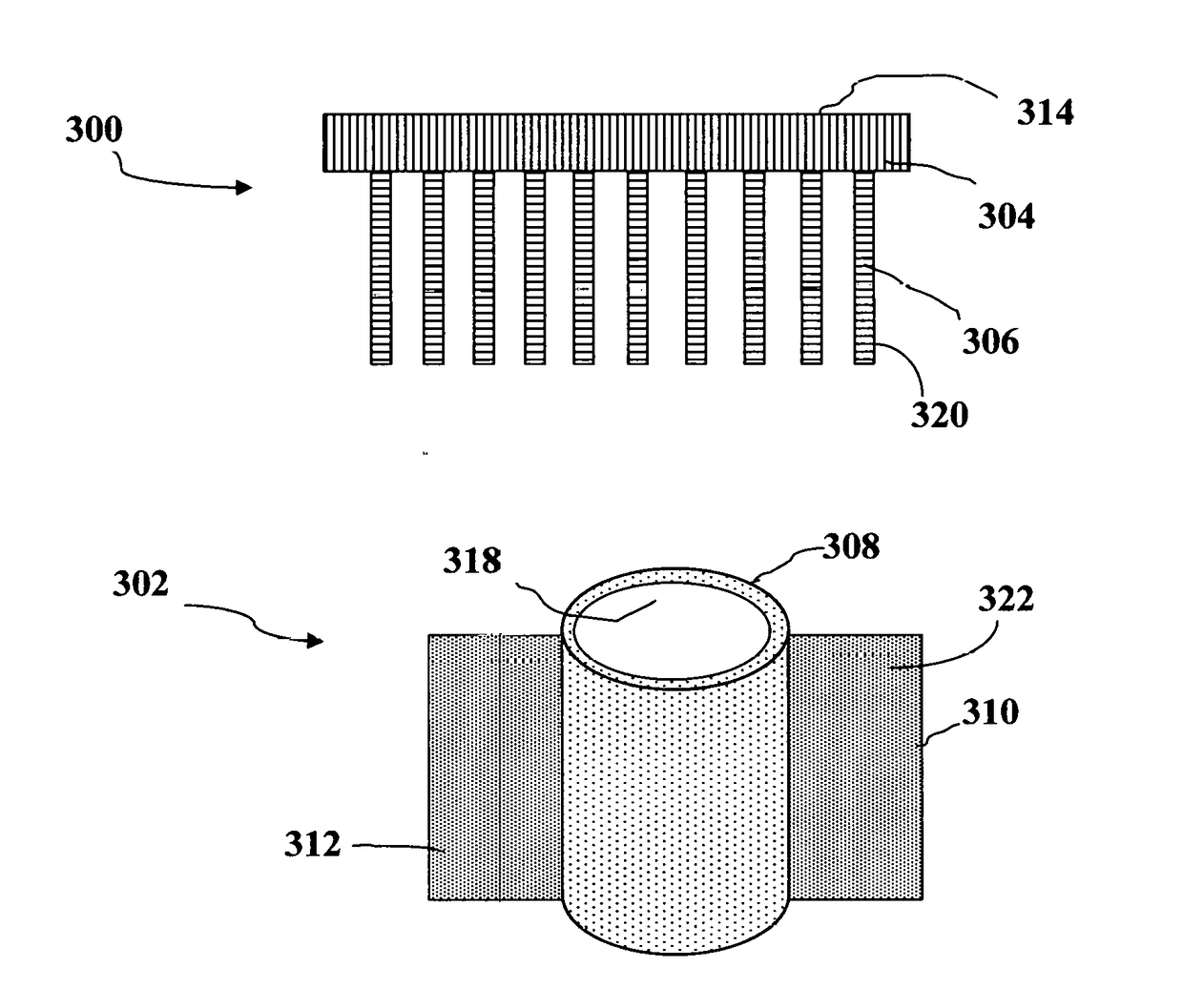

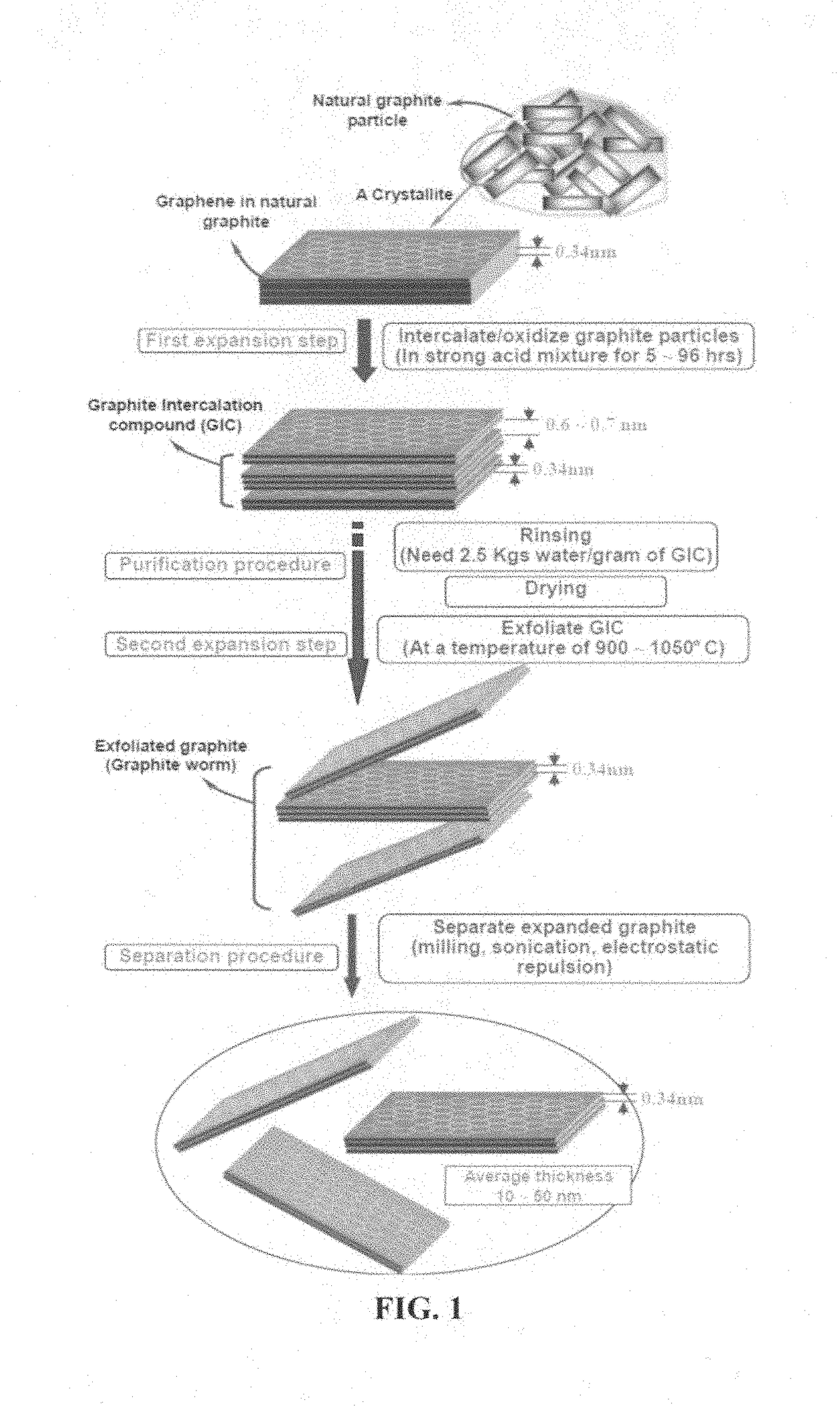

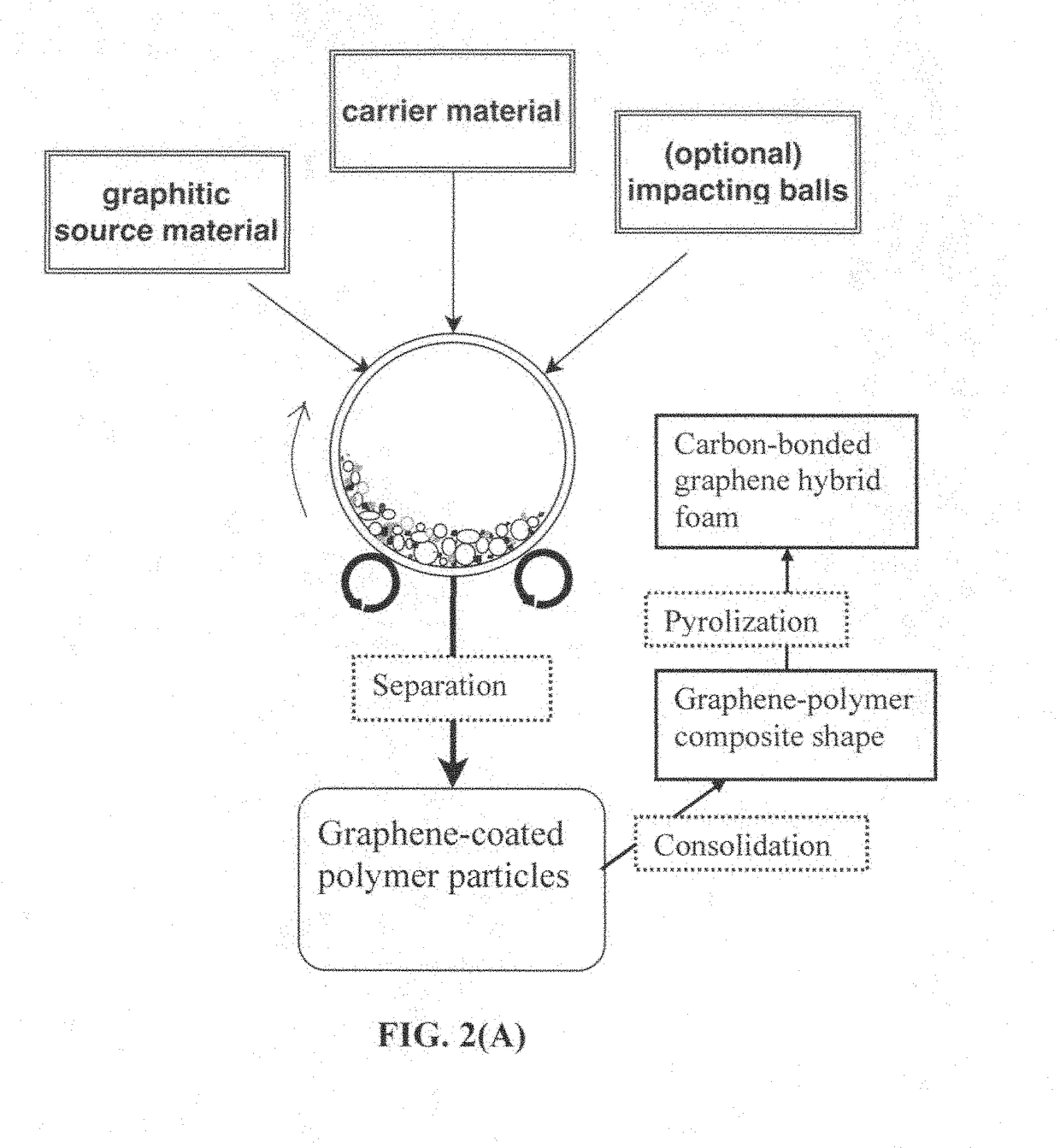

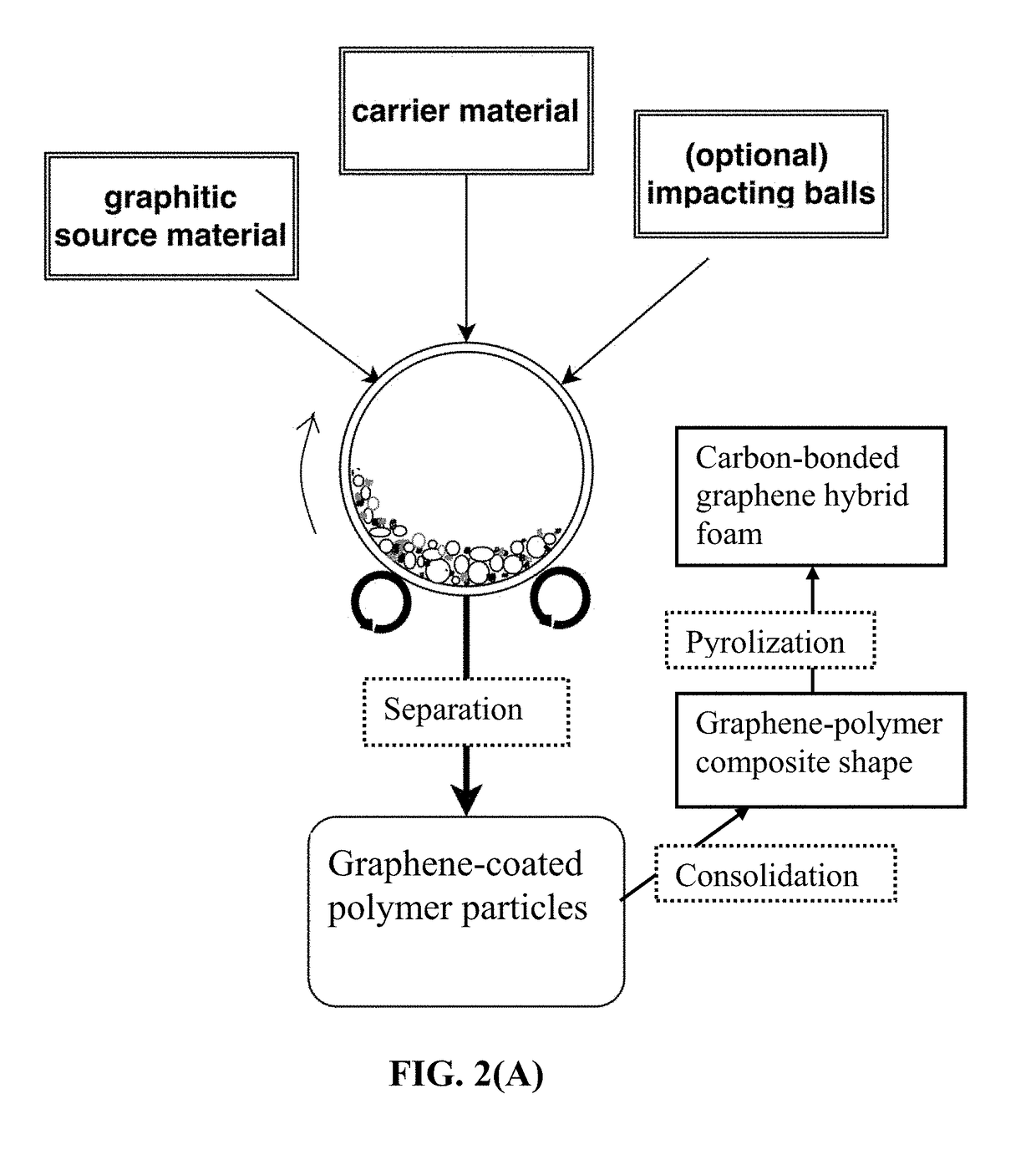

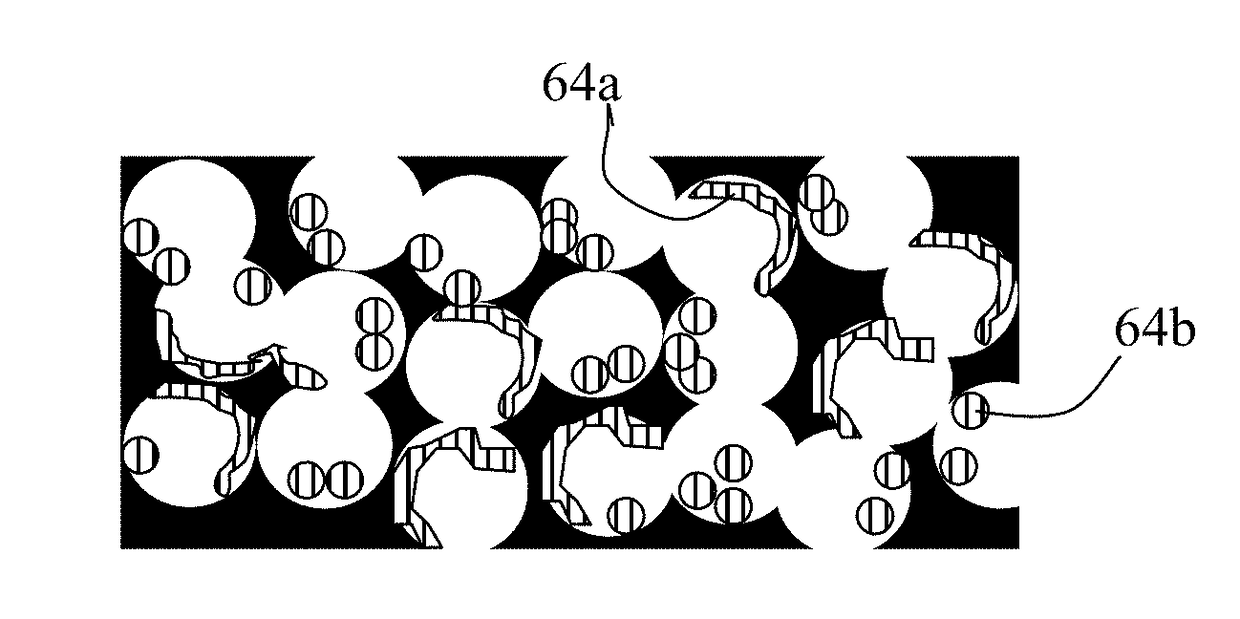

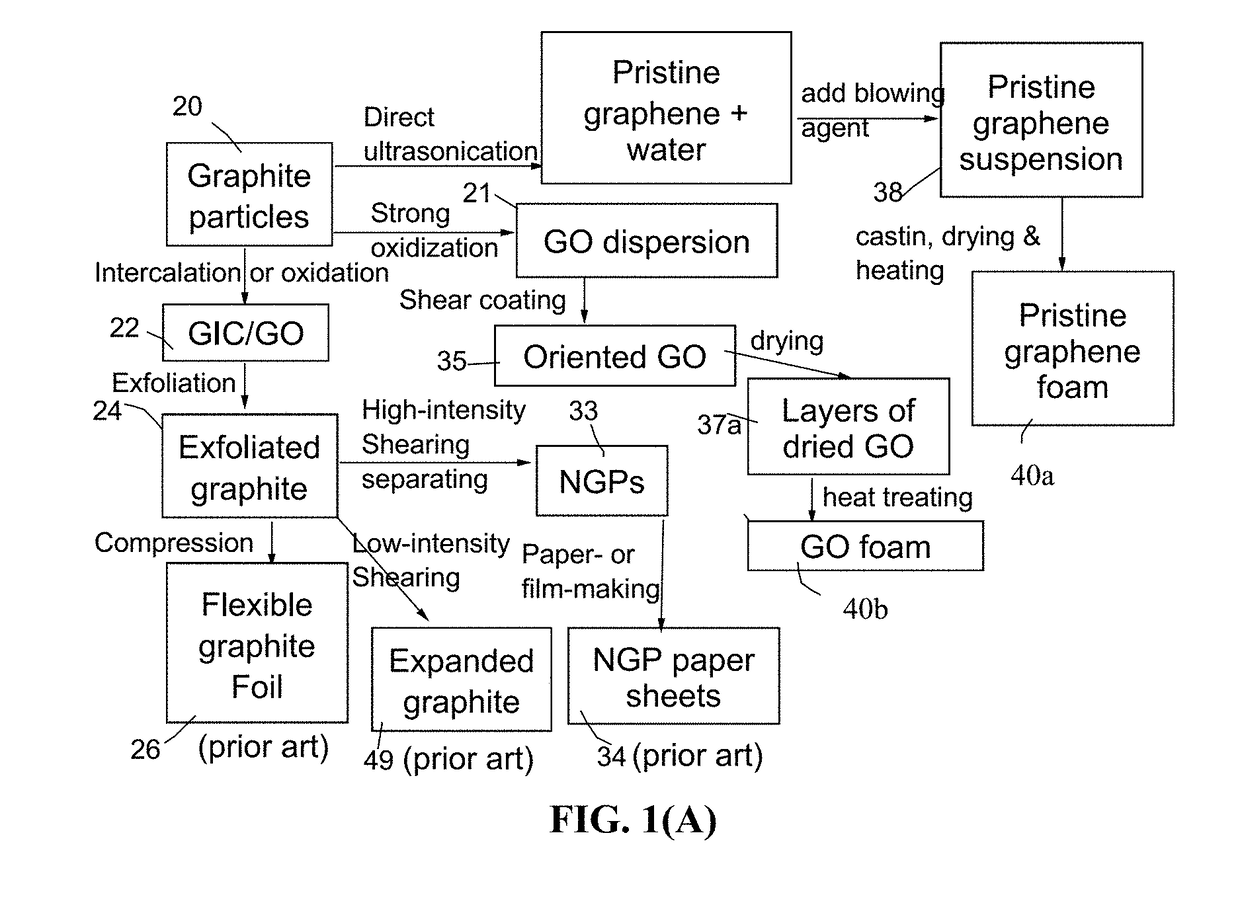

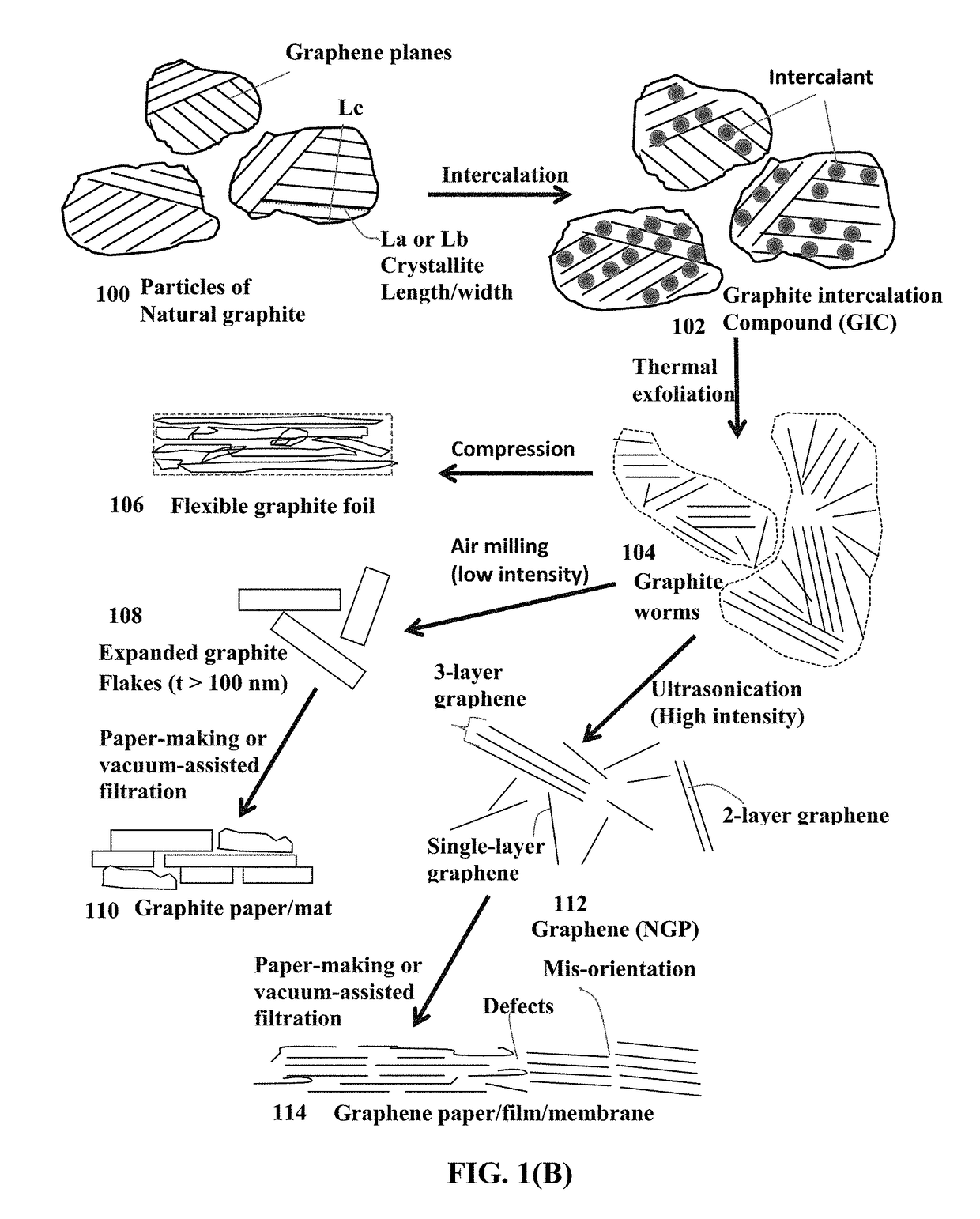

Integral 3D graphene-carbon hybrid foam and devices containing same

ActiveUS20170182474A1Increase heightReduce yieldIon-exchange process apparatusOther chemical processesDoped grapheneIodide

Provided is an integral 3D graphene-carbon hybrid foam composed of multiple pores and pore walls, wherein the pore walls contain single-layer or few-layer graphene sheets chemically bonded by a carbon material having a carbon material-to-graphene weight ratio from 1 / 100 to 1 / 2, wherein the few-layer graphene sheets have 2-10 layers of stacked graphene planes having an inter-plane spacing d002 from 0.3354 nm to 0.40 nm and the graphene sheets contain a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.01% to 25% by weight of non-carbon elements wherein said non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof. Also provided are a process for producing the hybrid form, products containing the hybrid foam, and its applications.

Owner:GLOBAL GRAPHENE GRP INC

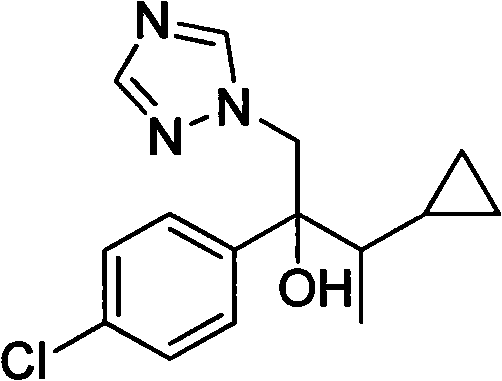

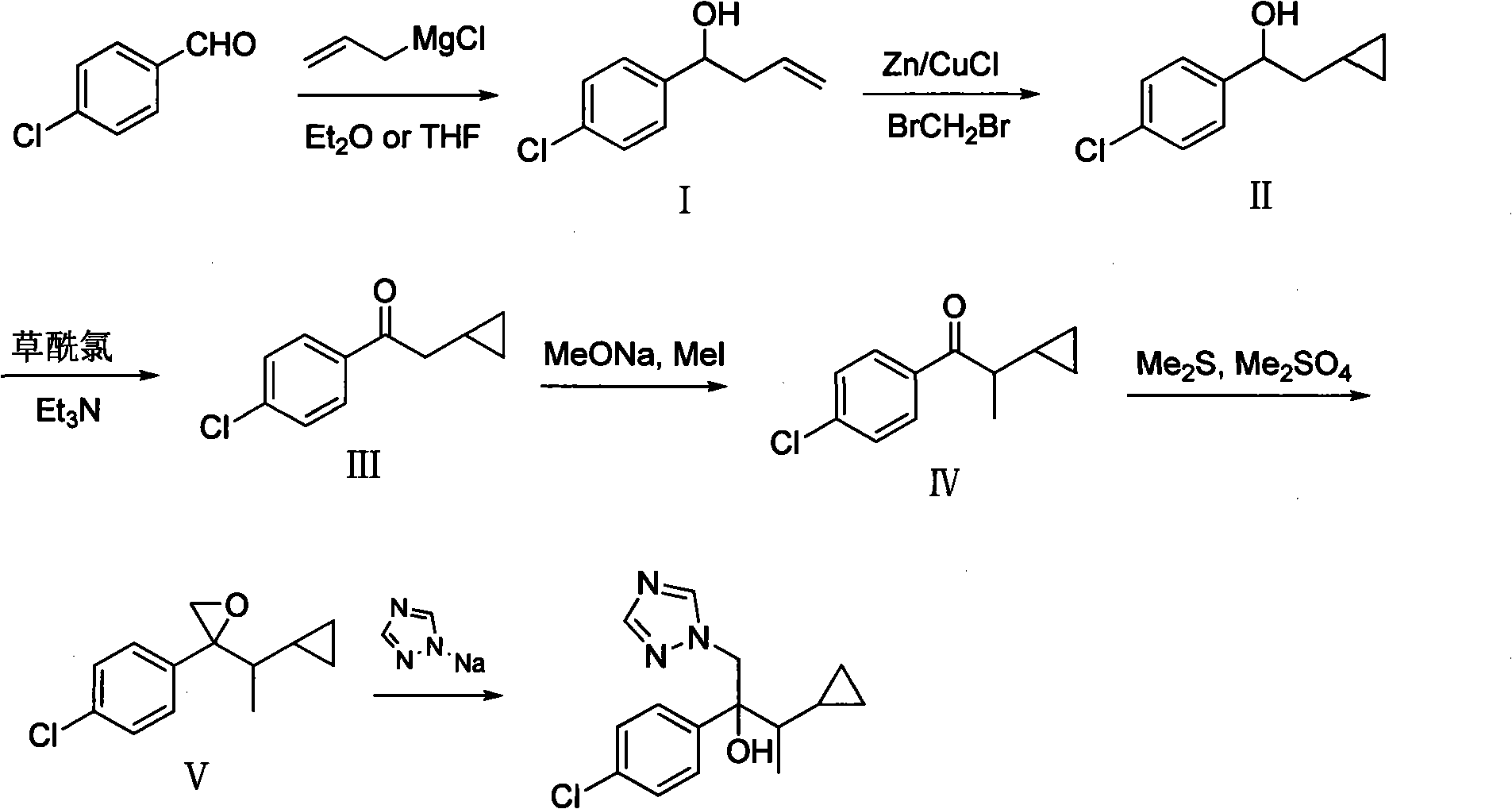

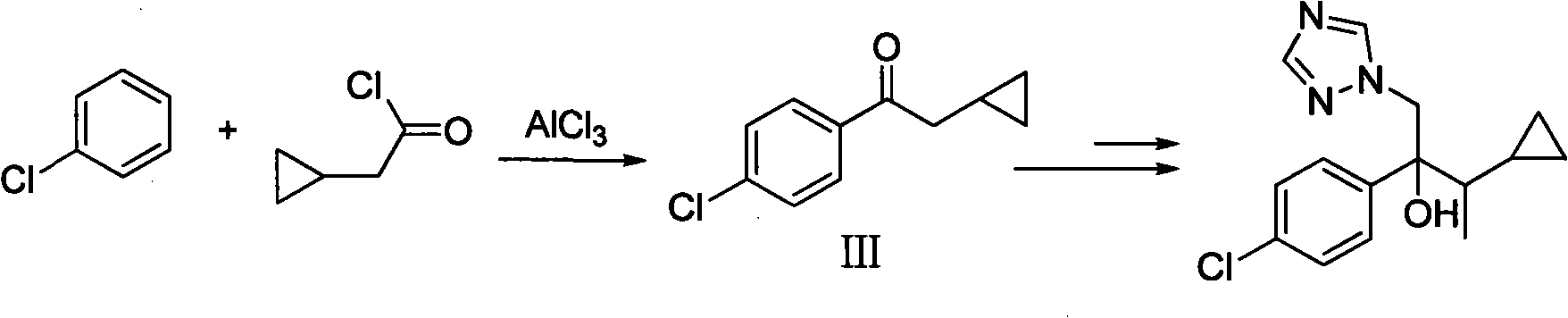

Simple method for preparing cyproconazole by cyclopropyl methyl ketone

The invention relates to a simple method for synthesizing cyproconazole through cyclopropyl methyl ketone. P-chlorobenzyl choride VI is taken as a starting raw material to prepare into a Grignard reagent which performs nucleophile substitution reaction with the cyclopropyl methyl ketone to generate alcohol VII; the alcohol VII is dehydrated in the presence of ortho-position benzene ring and oxygen phosphorus chloride to form conjugated alkene VIII; hydroxyl is introduced at benzyl position through hydroboration oxidation reaction to obtain alcohol IX; Dess-Martin oxidation is carried out on the obtained alcohol to obtain ketone IV; Darzens condensation is performed on the ketone IV and sulfonium iodide at alkalescence condition to further obtain cyproconazole through ring opening of triazole. The invention is a cyproconazole synthesizing method with simple operation, good safety, environmentally friendliness and high yield, can realize industrialized production, and satisfy heavy demands of agricultural production to cyproconazole.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

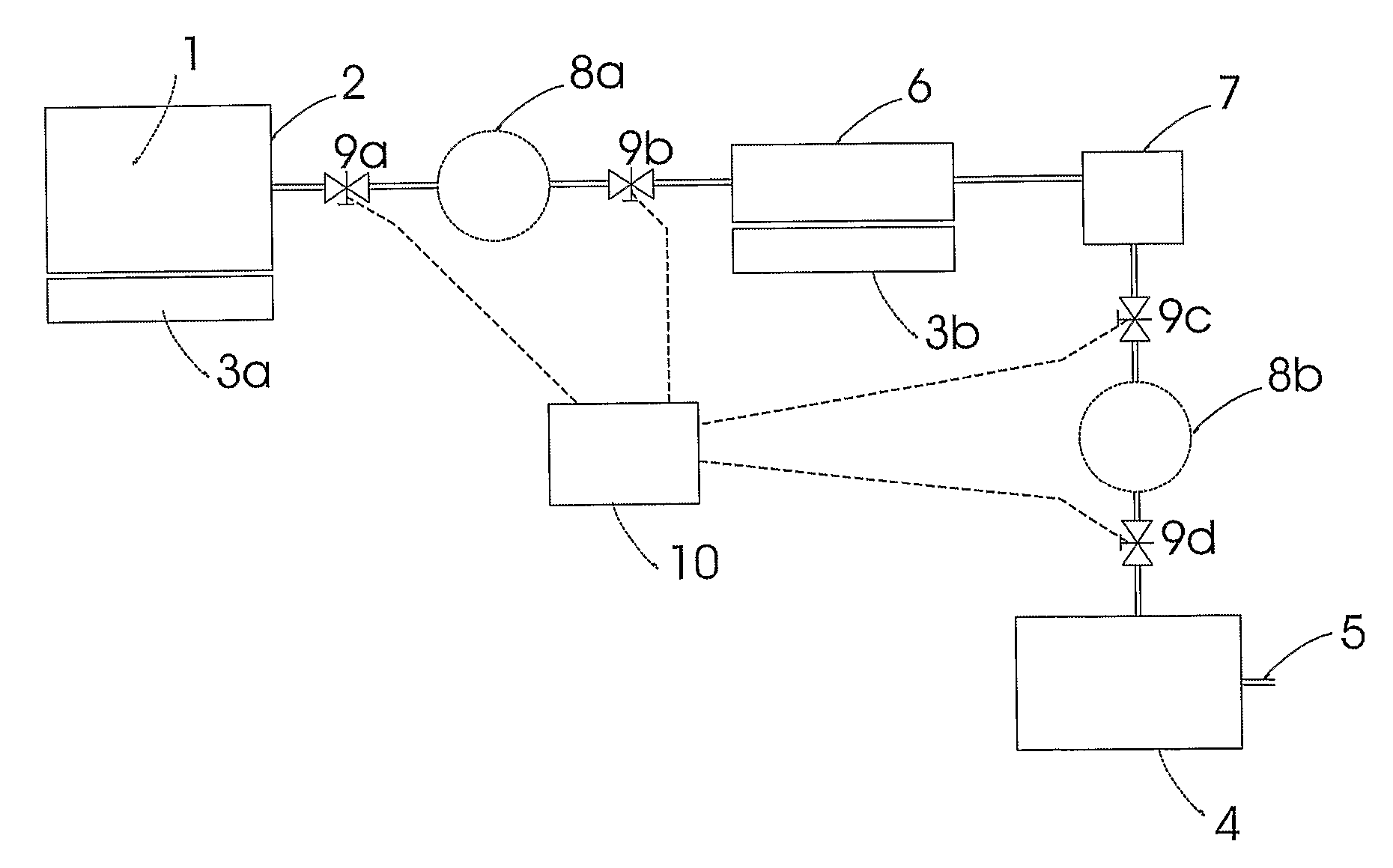

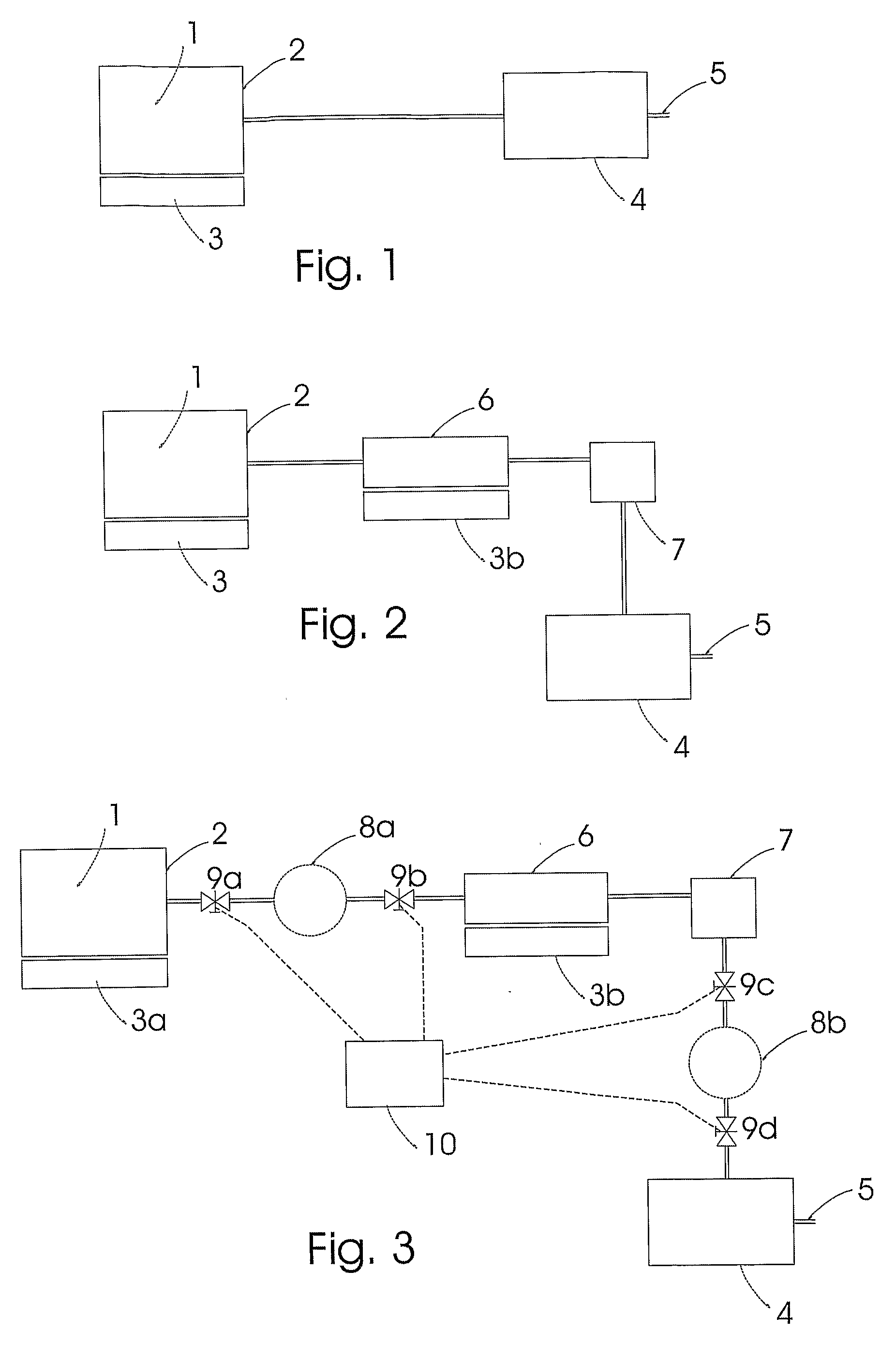

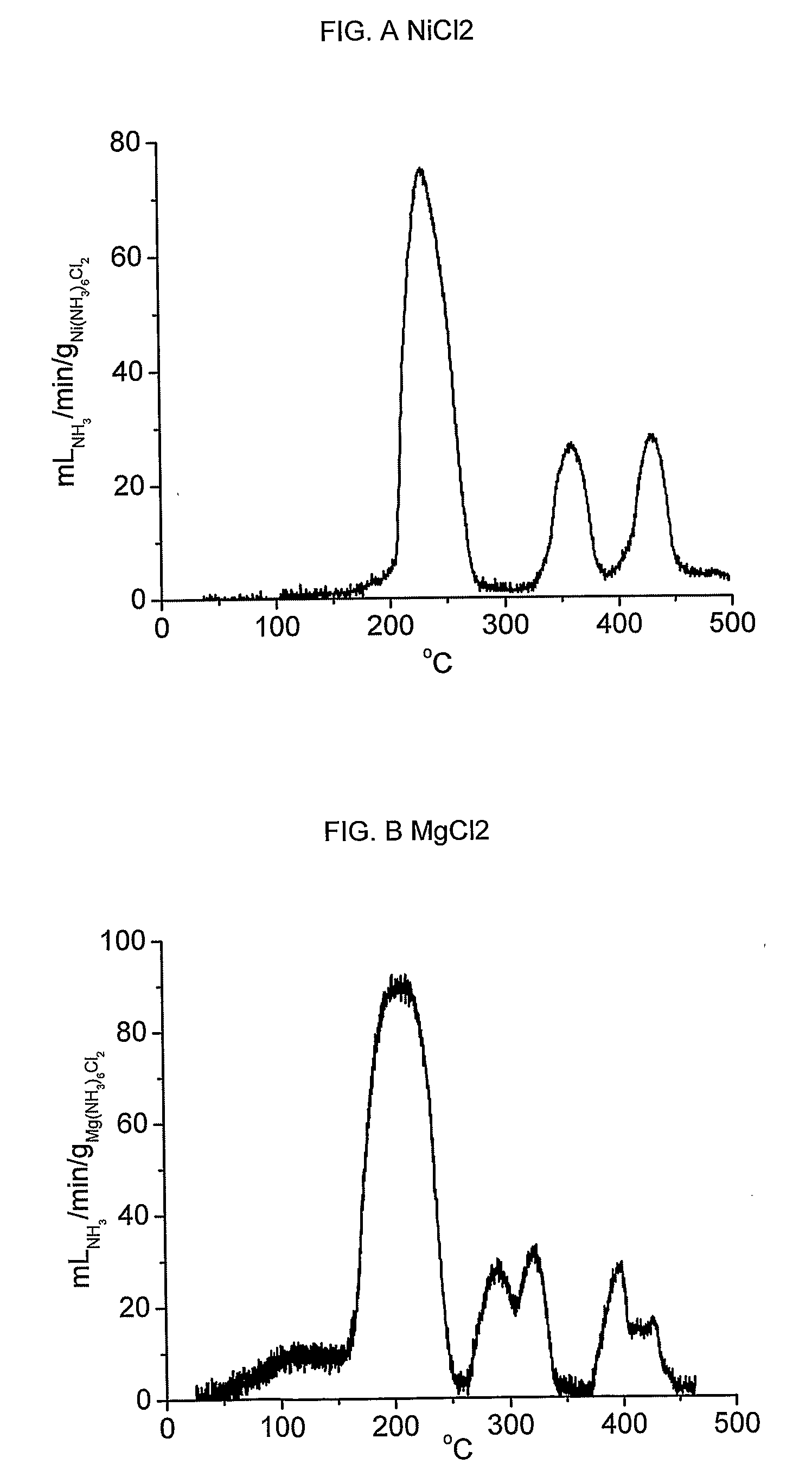

Use of an ammonia storage device in production of energy

An electric power generating unit comprising (i) an ammonia storage device in the form of a container comprising an ammonia absorbing and releasing salt of the general formula: Ma(NH3)nXz, wherein M is one or more cations selected from alkali metals, alkaline earth metals, and transition metals such as Li, K, Mg, Ca, V, Cr, Mn, Fe, Co, Ni, Cu or Zn, X is one or more anions selected from fluoride, chloride, bromide, iodide, nitrate, thiocyanate, sulphate, molybdate, phosphate, and chlorate ions, a is the number of cations per salt molecule, Z is the number of anions per salt molecule, and n is the coordination number of 2 to 12. (ii) means for heating said container and ammonia absorbing and releasing salt for releasing ammonia gas and (iiia) a fuel cell for converting ammonia directly into electric power; or (iiib1) a reactor for dissociating ammonia into hydrogen and nitrogen and (iiib2) a fuel cell for converting hydrogen into electric power.

Owner:AMMINEX

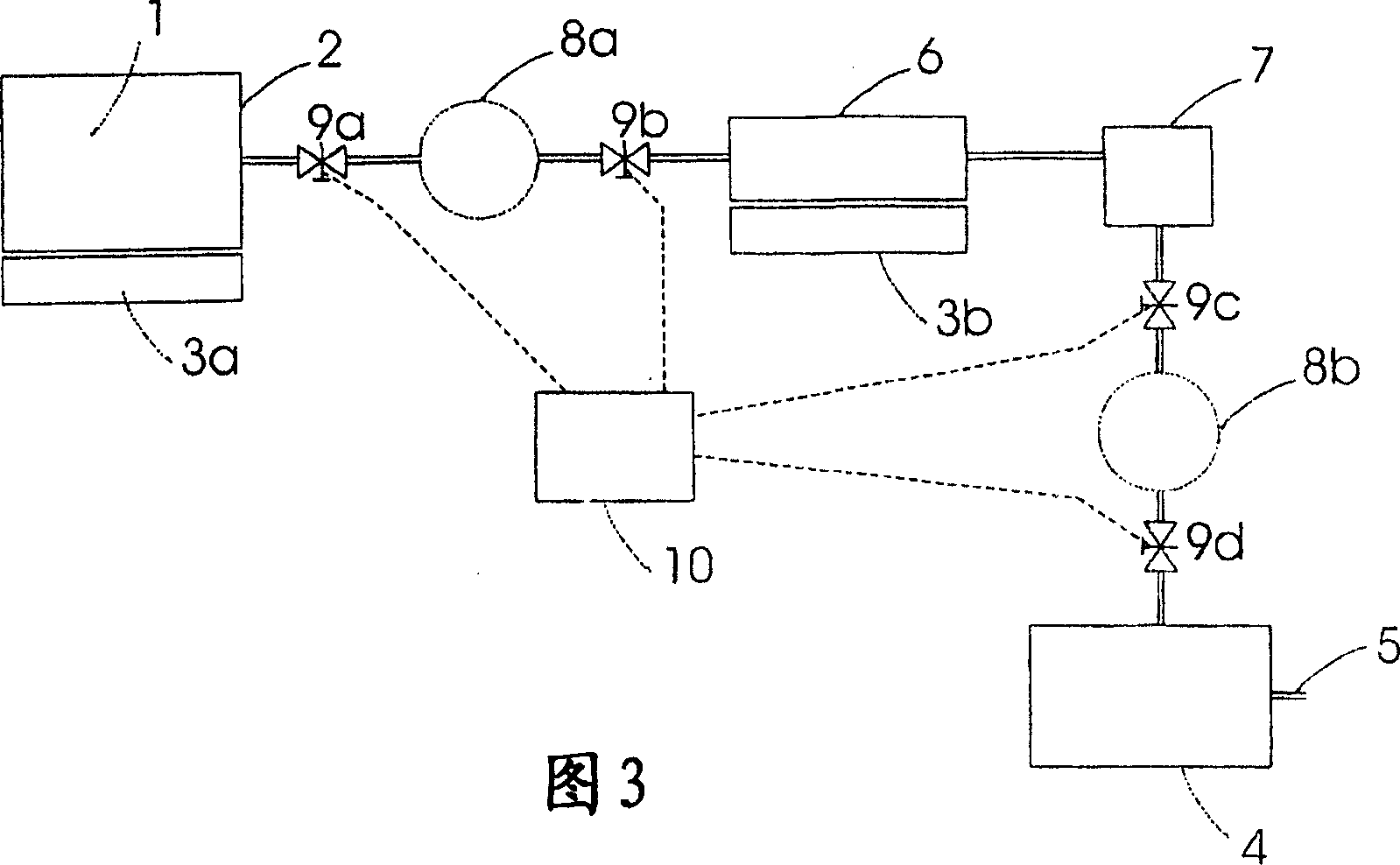

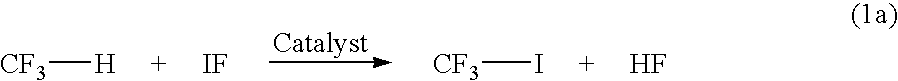

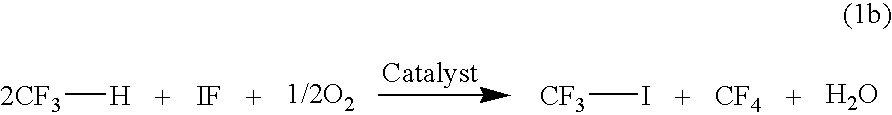

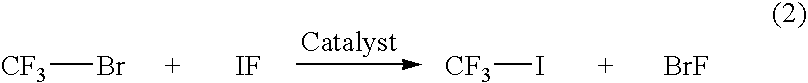

One-step synthesis of CF3-1

ActiveUS7132578B1High yieldHigh purity trifluoromethyl iodideHalogenated hydrocarbon preparationIodidePhotochemistry

A process for the preparation of trifluoromethyl iodide is provided. The process includes the step of contacting in a reactor a compound represented by the formula:CF3—Wand a compound represented by the formula:IFn wherein W can be H, Br, Cl, COOH, COCl, COOCH3, COOC2H5, COCH3, COPh, CF3, Si(CH3)3, SPh, SCH3, SSCF3, SSPh, SSCH3, or SO2Cl, wherein n is 1, 3, 5, or 7, and wherein the step of contacting is carried out, at a temperature, pressure and for a length of time sufficient to produce trifluoromethyl iodide. The contacting step can be carried out in the presence or absence of a catalyst and the contacting step can be carried out in the presence or absence of air.

Owner:HONEYWELL INT INC

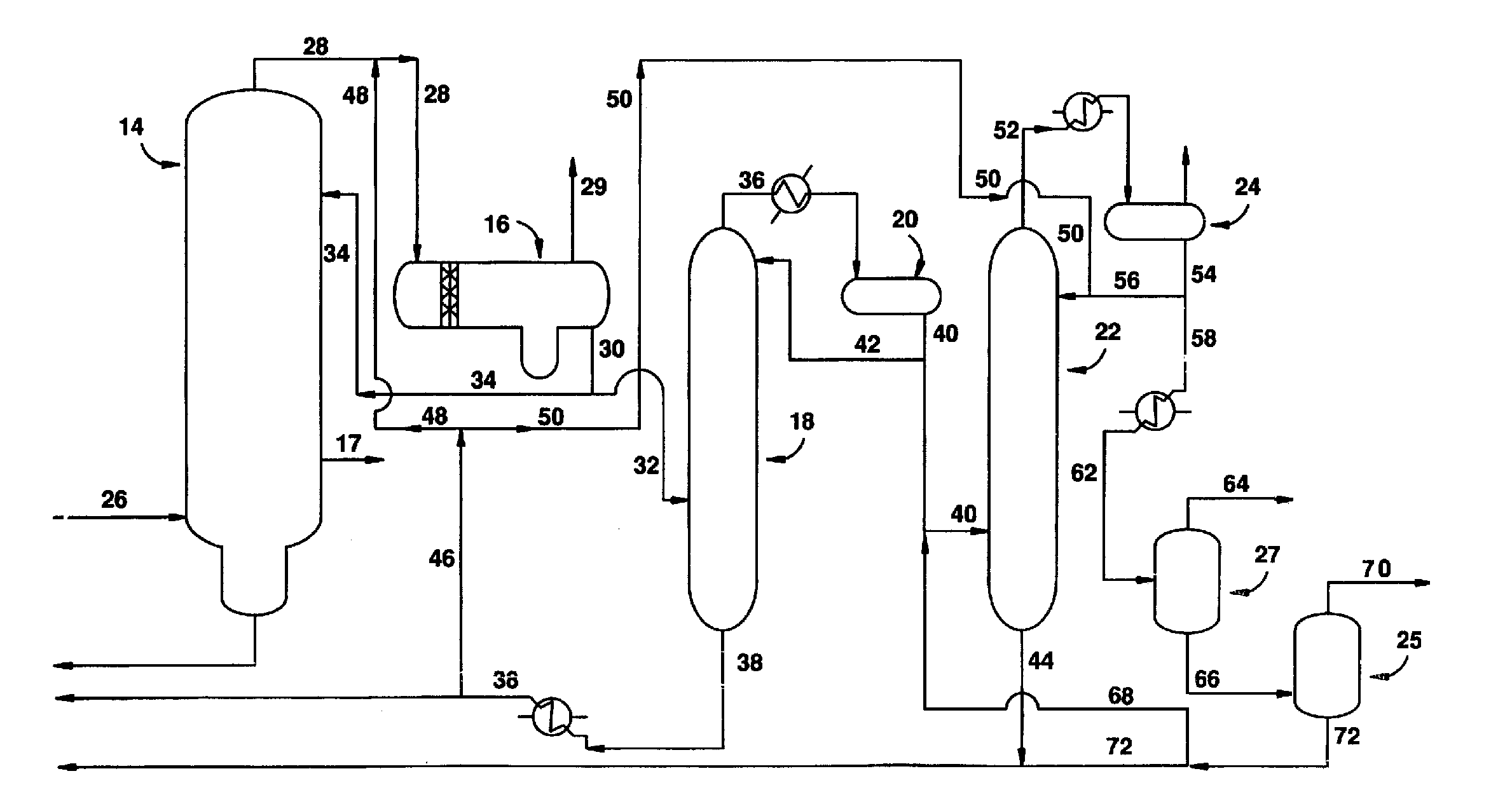

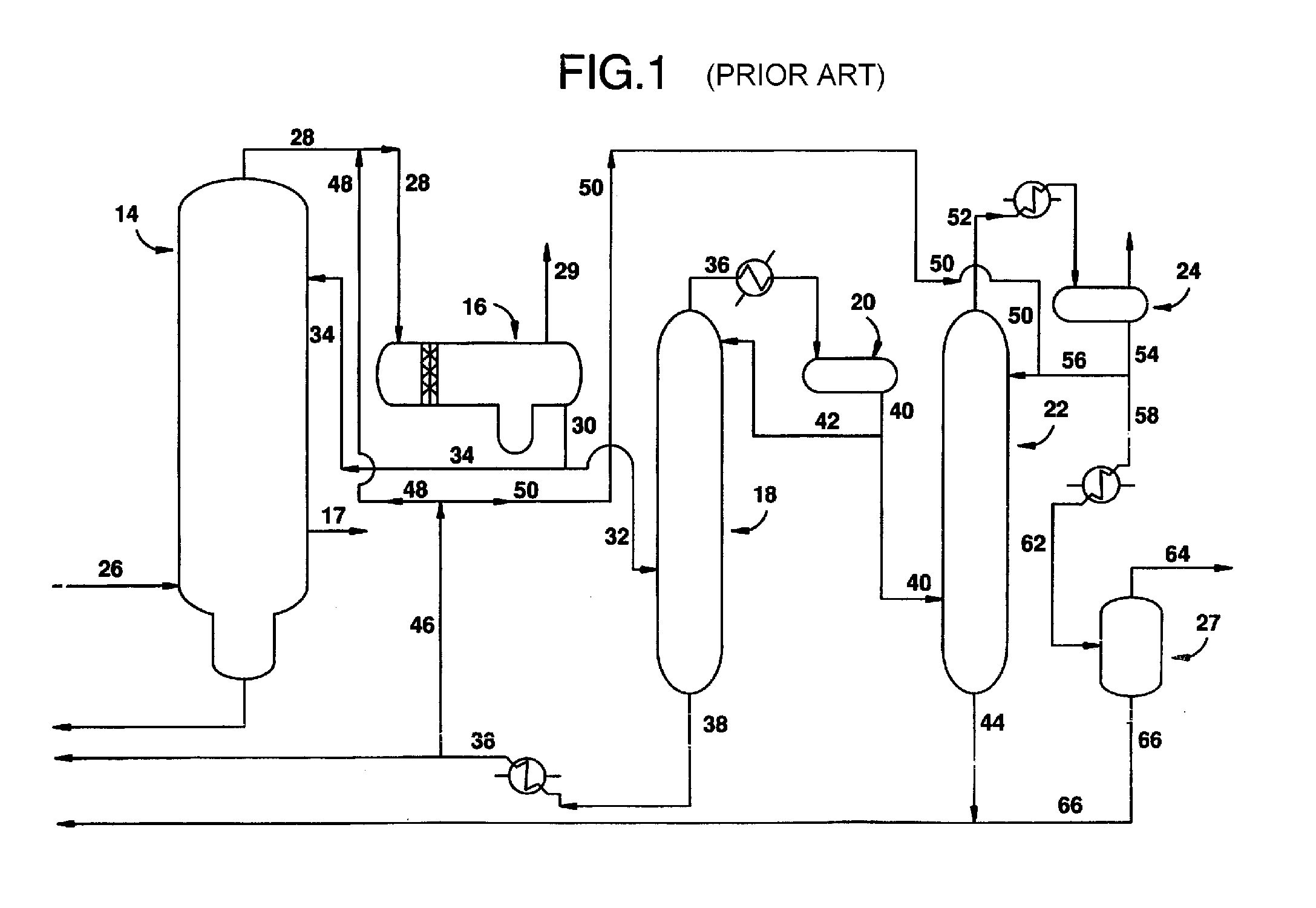

Process for producing acetic acid

ActiveUS20130261334A1Increase concentrationEfficient executionOrganic compound preparationOrganic chemistry methodsIodideDistillation

A process for producing acetic acid by: a reaction step for continuously allowing methanol to react with carbon monoxide in the presence of a catalyst system comprising a metal catalyst, an ionic iodide, and methyl iodide in a carbonylation reactor, a flash distillation step for continuously feeding a flasher with a reaction mixture from the reactor and evaporating a volatile component at least containing product acetic acid, methyl acetate, and methyl iodide by flash distillation to separate the volatile component and a liquid catalyst mixture at least containing the metal catalyst and the ionic iodide, and an acetic acid collection step for separating a stream containing acetic acid from the volatile component to collect acetic acid; wherein, in the flash distillation step, the flash distillation is conducted under the condition that the concentration of methyl acetate in the liquid catalyst mixture is not less than 0.6% by weight.

Owner:DAICEL CHEM IND LTD

Alkali Metal Battery Having an Integral 3D Graphene-Carbon-Metal Hybrid Foam-Based Electrode

ActiveUS20170352868A1Long and stable charge-discharge cycle lifeIncrease surface areaFuel and secondary cellsElectrochemical processing of electrodesDoped grapheneIodide

Provided is a lithium or sodium metal battery having an anode, a cathode, and a porous separator and / or an electrolyte, wherein the anode contains an integral 3D graphene-carbon hybrid foam composed of multiple pores, pore walls, and a lithium-attracting metal residing in the pores; wherein the metal is selected from Au, Ag, Mg, Zn, Ti, Na, K, Al, Fe, Mn, Co, Ni, Sn, V, Cr, or an alloy thereof and is in an amount of 0.1% to 50% of the total hybrid foam weight or volume, and the pore walls contain single-layer or few-layer graphene sheets chemically bonded by a carbon material having a carbon material-to-graphene weight ratio from 1 / 200 to 1 / 2, wherein graphene sheets contain a pristine graphene or non-pristine graphene selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

Graphene-Metal Hybrid Foam-Based Electrode for an Alkali Metal Battery

ActiveUS20170352869A1Increase surface areaHigh densityGrapheneNegative electrodesDoped grapheneIodide

Provided is a lithium or sodium metal battery having an anode, a cathode, and a porous separator and / or an electrolyte, wherein the anode contains a graphene-metal hybrid foam composed of multiple pores, pore walls, and a lithium- or sodium-attracting metal residing in the pores; wherein the metal is selected from Au, Ag, Mg, Zn, Ti, Na (or Li), K, Al, Fe, Mn, Co, Ni, Sn, V, Cr, or an alloy thereof and is in an amount of 0.1% to 90% of the total hybrid foam weight or volume, and the pore walls contain single-layer or few-layer graphene sheets, wherein graphene sheets contain a pristine graphene or non-pristine graphene selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

Use Of An Ammonia Storage Device In Production Of Energy

InactiveUS20070207351A1Reactant parameters controlMagnesium halidesAlkaline earth metalAmmonia storage

An electric power generating unit comprising (i) an ammonia storage device in the form of a container comprising an ammonia absorbing and releasing salt of the general formula: Ma(NH3)nXz, wherein M is one or more cations selected from alkali metals, alkaline earth metals, and transition metals such as Li, K, Mg, Ca, V, Cr, Mn, Fe, Co, Ni, Cu or Zn, X is one or more anions selected from fluoride, chloride, bromide, iodide, nitrate, thiocyanate, sulphate, molybdate, phosphate, and chlorate ions, a is the number of cations per salt molecule, Z is the number of anions per salt molecule, and n is the coordination number of 2 to 12. (ii) means for heating said container and ammonia absorbing and releasing salt for releasing ammonia gas and (iiia) a fuel cell for converting ammonia directly into electric power; or (iiib1) a reactor for dissociating ammonia into hydrogen and nitrogen and (iiib2) a fuel cell for converting hydrogen into electric power is useful for large stationary energy producing facilities, but also for use for is useful for large stationary energy producing facilities, but also for use for small rechargeable and / or replaceable power supply units for micro-fabricated or miniaturized ammonia decomposition reactors for use in mobile units and portable devices may be used for large energy producing facilities, and by use of small rechargeable and / or replaceable ammonia storage decomposition reactors, it is also possible to provide energy for mobile units and portable devices.

Owner:AMMINEX

Method for extracting gold from waste printed circuit board

InactiveCN101392325AAchieve separationEliminate pollutionPhotography auxillary processesProcess efficiency improvementIodideIodine solutions

The invention provides a method for leaching gold from a deserted printed circuit board. The method comprises the specified steps: Step 1: the deserted printed circuit board is crushed and smashed to separate metals and plastics; Step 2: the metals obtained from the Step 1 are mixed with nitric acid solution, stirring and reaction are carried out for 1h to 6h at the constant temperature of 10 DEG C to 80 DEG C, products are filtered, copper is leached from the filtrate, and the filter residue is washed and dried; Step 3: the filter residue obtained from the Step 2 is added into the blended solution of first iodine solution and a pro-oxidant, a reaction pH value is controlled at 3 to 9 by an inorganic acid and alkaline solution, reaction is carried out for 2h to 5h in a constant temperature oscillator at the temperature of 10 DEG C to 60 DEG C; and Step 4: products obtained from the Step 3 are filtered, with the filtrate fed into the cathode region of an electrobath, second iodine solution composed of iodine, water-soluble iodide and water is used as the electrolyte and fed into the anode region of the electrobath, electrolysis is carried out, the solution at the cathode region is filtered, then the filter residue obtained is gold mud, and the second iodine solution at the anode region is recovered. The method has high gold leaching ratio, low cost and less environmental pollution.

Owner:DONGHUA UNIV

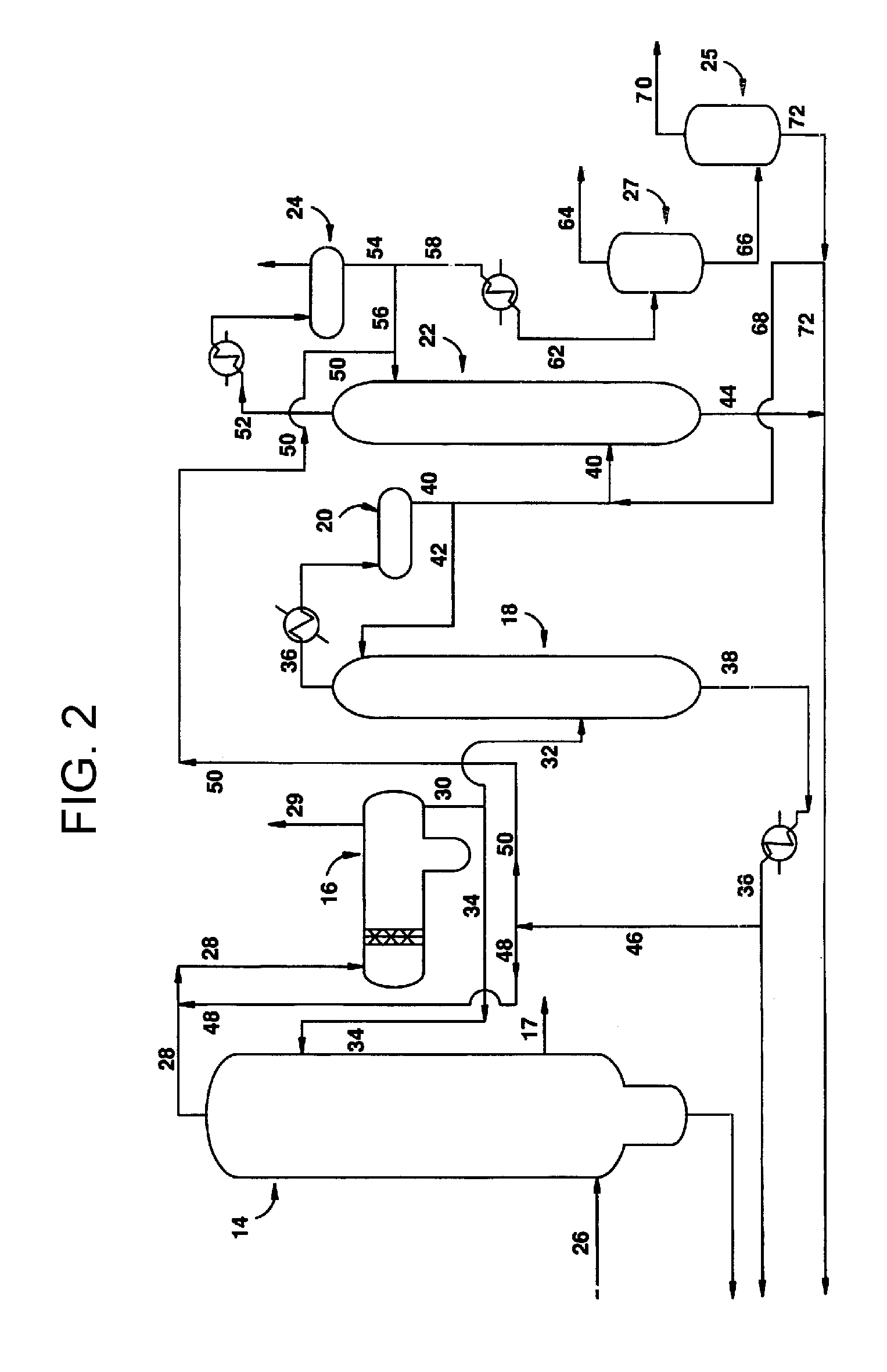

Removal of permanganate reducing compounds from methanol carbonylation process stream

ActiveUS20050197508A1Reduce solubilitySimple methodOrganic compound preparationPreparation by carbon monoxide or formate reactionAcetic acidIodide

An improvement of the methanol carbonylation process for manufacturing acetic acid is disclosed. Specifically disclosed is a method for reducing the formation of alkyl iodides and C3-8 carboxylic acids by removing permanganate reducing compounds (“PRC's”) from the light phase of the condensed light ends overhead stream, including (a) distilling the light phase to yield a PRC enriched overhead stream; and (b) extracting the third overhead stream with water in at least two consecutive stages and separating therefrom one or more aqueous streams containing PRC's.

Owner:CELANESE INT CORP

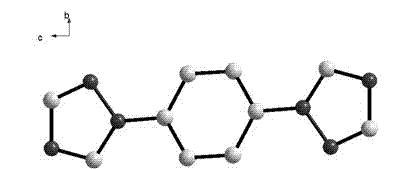

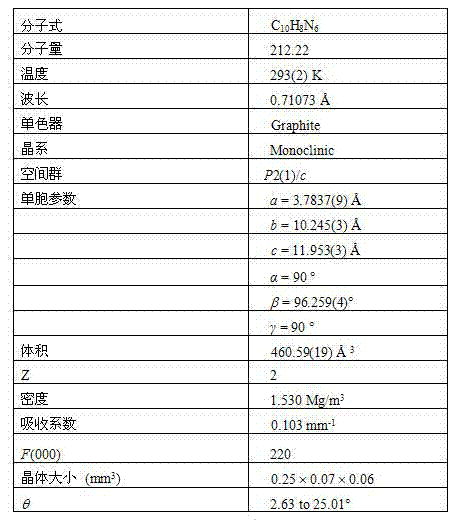

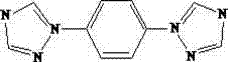

Phenyl bistriazole compound, and preparation method and application thereof

InactiveCN103086988AThe reaction is easy to operateHigh reaction yieldPolycrystalline material growthOrganic chemistrySimple Organic CompoundsBis triazole

The invention discloses a phenyl bistriazole compound, and a preparation method and application thereof, and particularly relates to a 1-[4-(1H-1,2,4-triazole-1-yl)phenyl]-1H-1,2,4-triazole single crystal and a preparation method of 1-[4-(1H-1,2,4-triazole-1-yl)phenyl]-1H-1,2,4-triazole. The organic compound is prepared by heating ethylenediamine, 1H-1,2,4-triazole, potassium carbonate, 1,4-diiodobenzene and cuprous iodide through a one-pot method. The preparation method disclosed by the invention has the characteristics simple process operation, low production cost and less environmental pollution, and is suitable for large-scale industrial production. The 1-[4-(1H-1,2,4-triazole-1-yl)phenyl]-1H-1,2,4-triazole single crystal prepared by the invention can be used in the aspect of photoelectric materials, especially dye and luminescent agents.

Owner:TIANJIN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com