Agricultural article inspection apparatus and method employing spectral manipulation to enhance detection contrast ratio

a technology of spectral manipulation and inspection apparatus, applied in the direction of counting objects on conveyors, investigating moving fluids/granular solids, instruments, etc., can solve the problems of difficult detection of pit fragments, a considerable agricultural processing challenge, and the inability of blades to always adequately secure the pits, etc., to achieve the effect of reducing the reflectance of chlorophyll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

In the foregoing experimental results, subtraction can be used to increase the detection contrast because the pit reflectivity is higher than the meat reflectivity in the SWIR wavelengths and lower in the visible wavelengths. Subtraction is not the only image processing technique useful for increasing the detection contrast. For example, image processing employing division (ratio) may improve image contrast for certain illumination and product combinations.

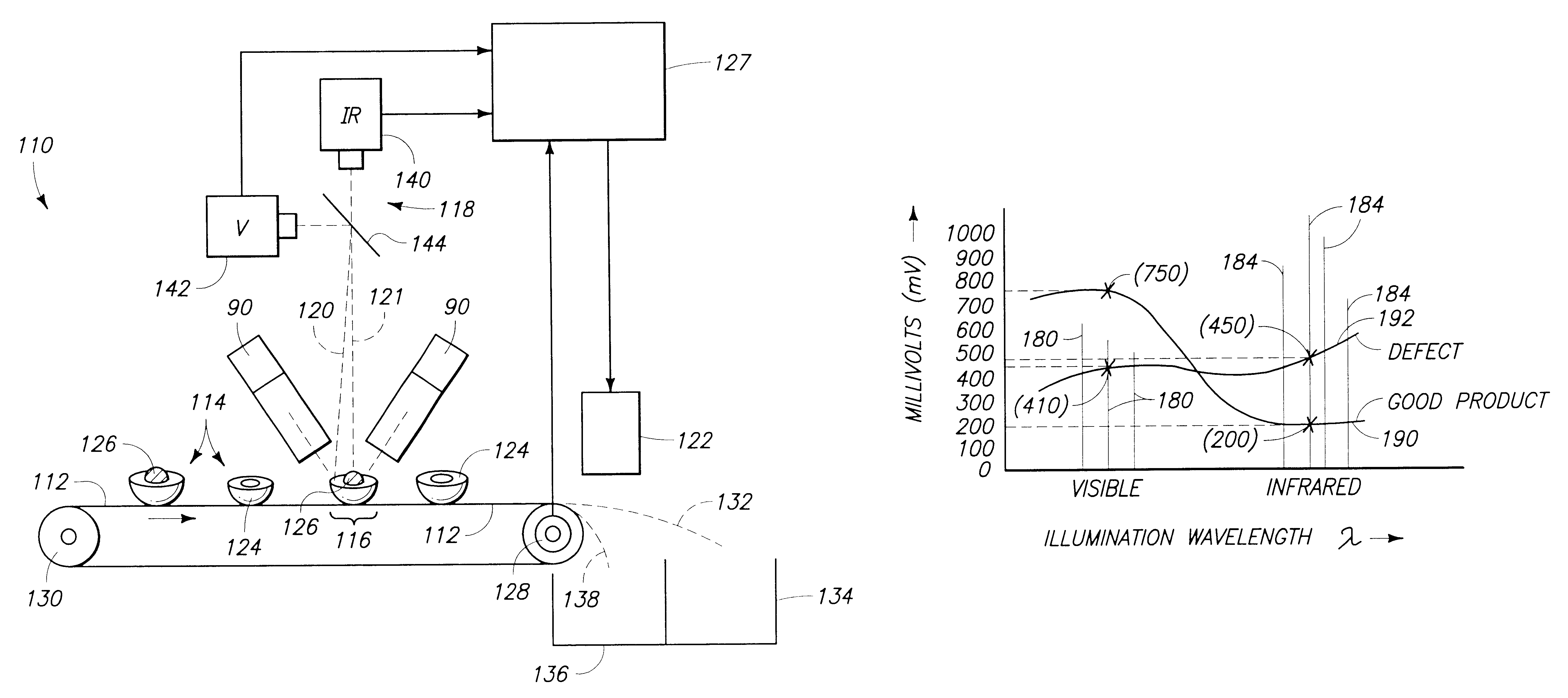

FIGS. 18 and 19, show simplified reflectance versus illumination wavelength graphs for peaches and a generic agricultural product. In particular, illumination is shown by spectral lines representing visible wavelengths 180, SWIR wavelengths 182, and IR wavelengths 184.

In particular, FIG. 18 shows curves representing detected reflectance versus illumination wavelength for peach meat 186 and a peach pit 188. Detected reflectance is shown as milliVolts of detected signal, with peach meat 186 producing a 300 mV signal at visible wavel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| IR wavelengths | aaaaa | aaaaa |

| visible wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com