Patents

Literature

1255 results about "Metal chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This category is limited to inorganic chemical compounds which contain chlorine. These may be metal salts containing chloride ion such as sodium chloride, or more covalent chlorides of metals or nonmetals such as titanium(IV) chloride or carbon tetrachloride.

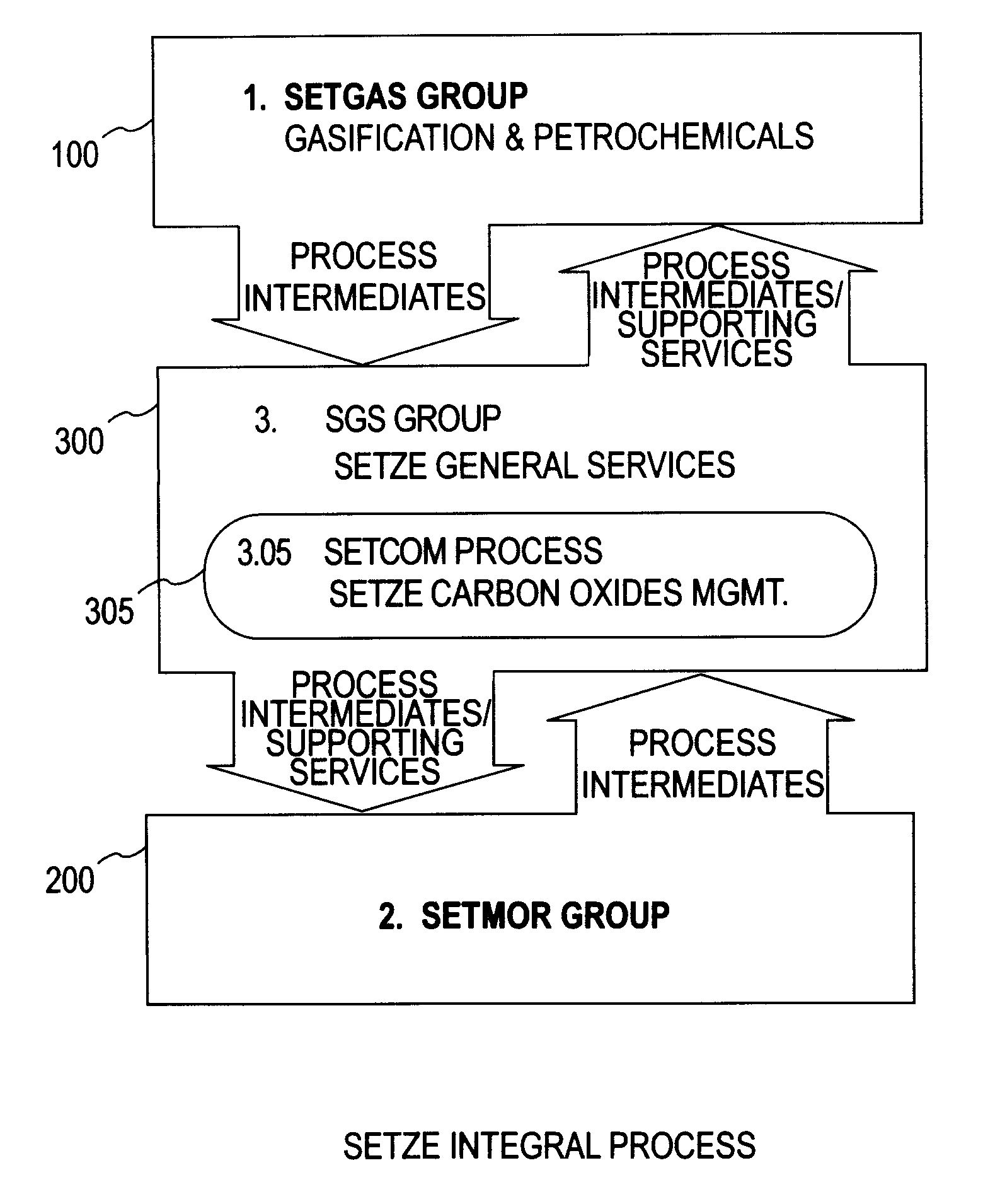

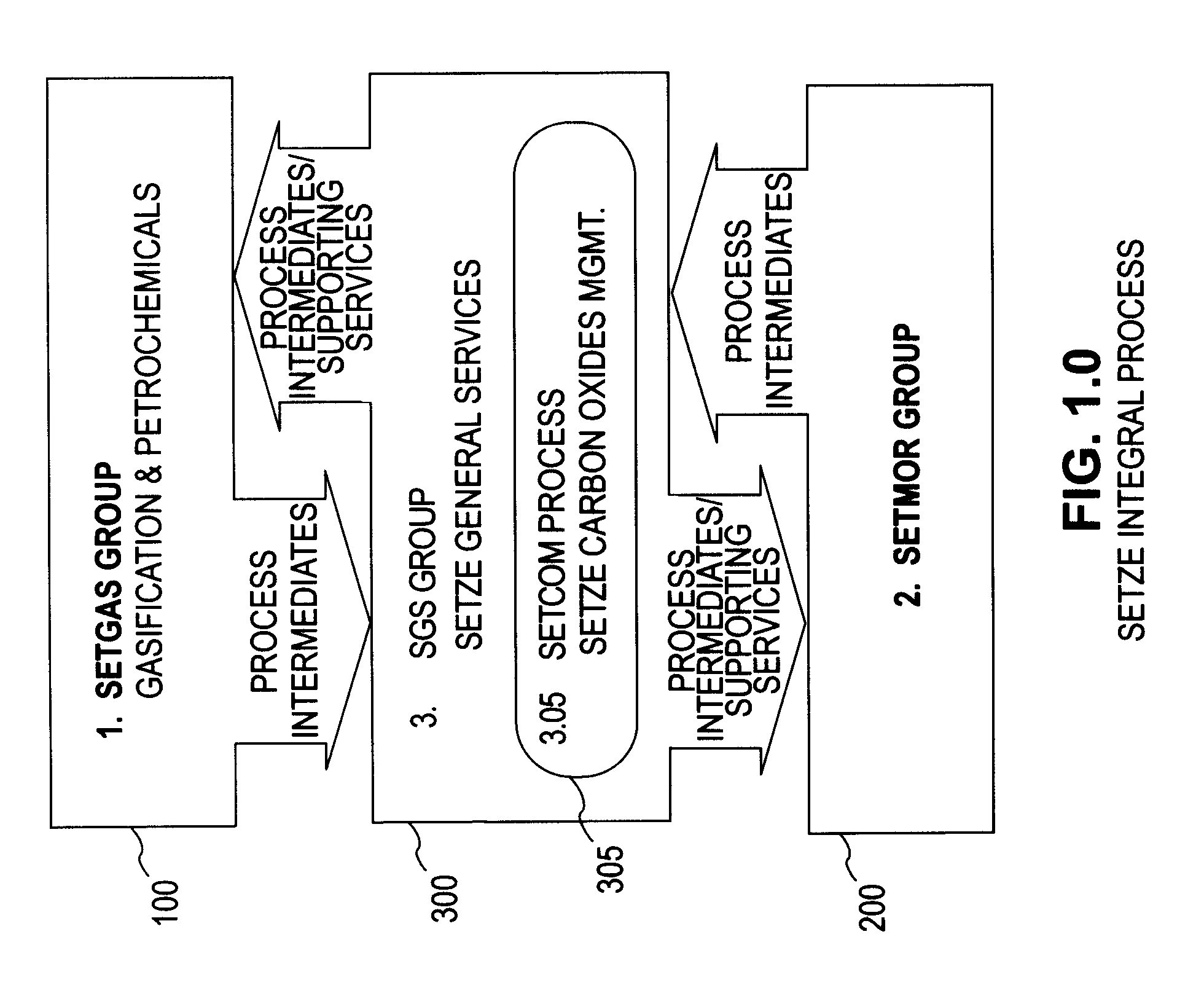

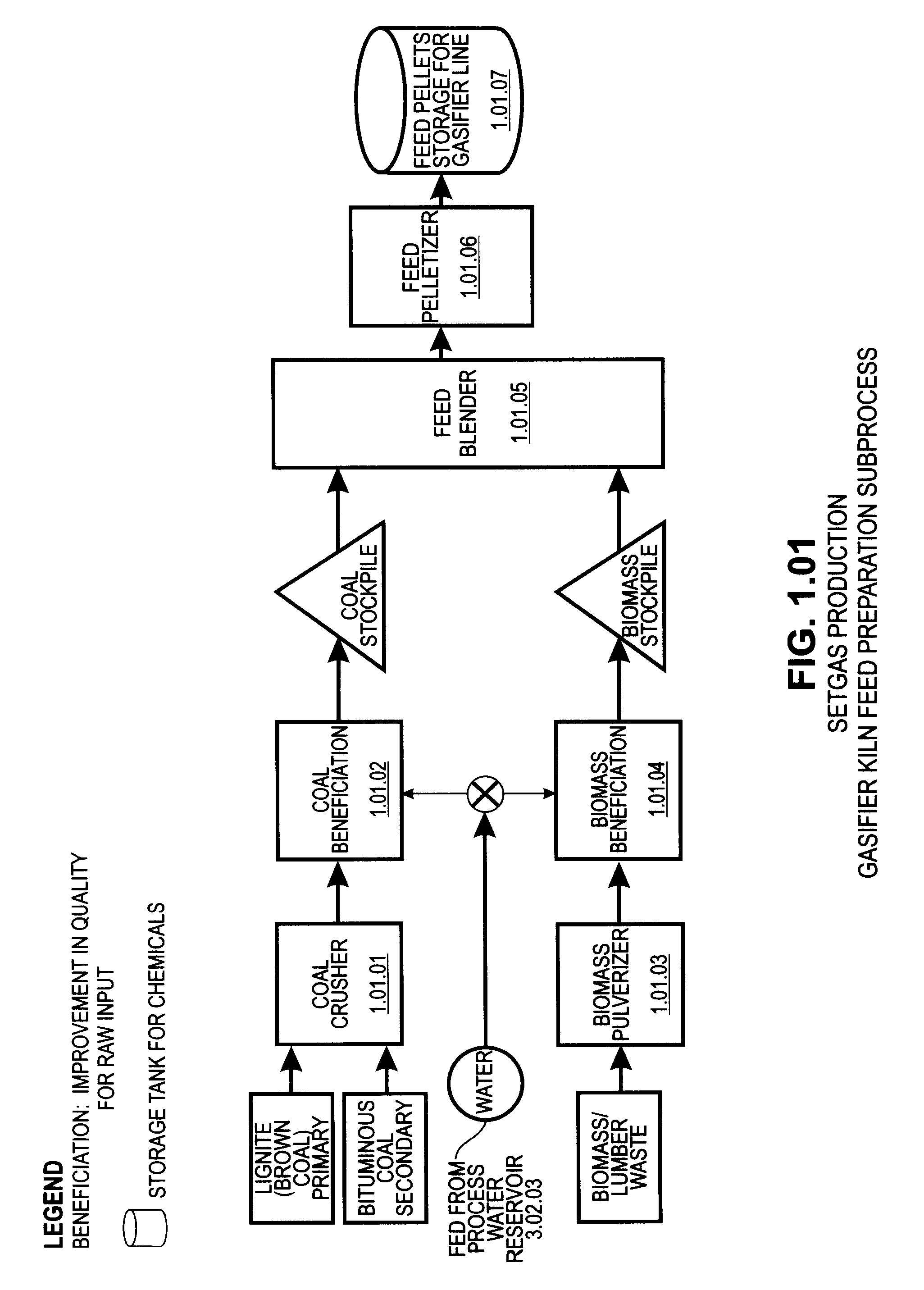

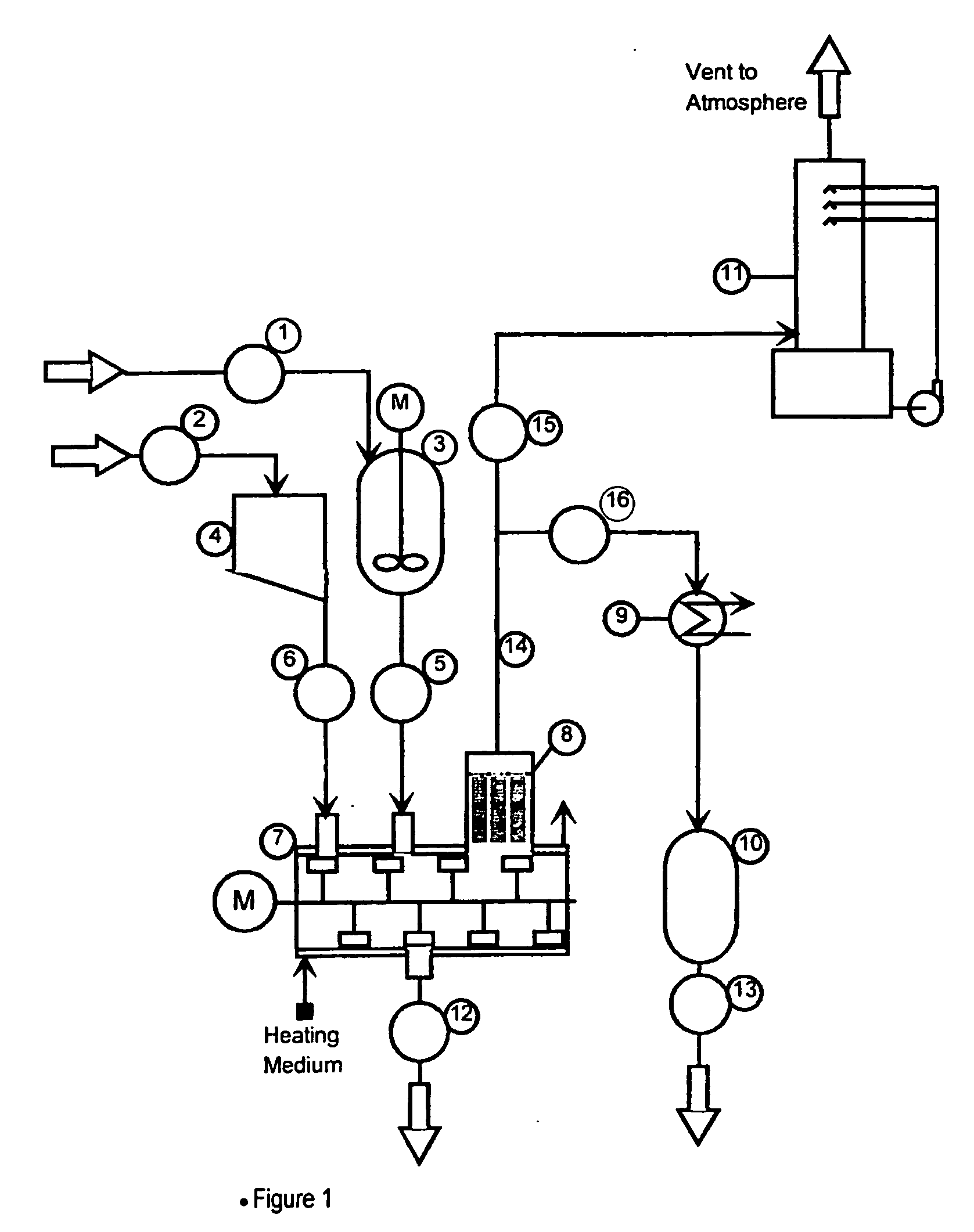

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

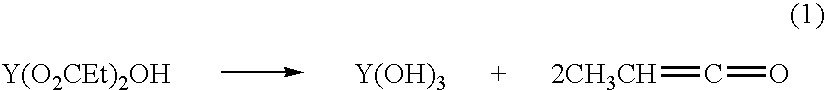

Mixed-metal oxide particles by liquid feed flame spray pyrolysis of oxide precursors in oxygenated solvents

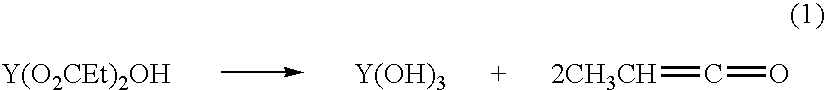

Liquid feed flame spray pyrolysis of solutions of a metal oxide precursor which is an alkoxide or C1-6 carboxylate and at least one second metal oxide precursor and / or second metal compound dissolved in oxygenated solvent by combustion with oxygen lead to the formation of sub-micron mixed-metal oxide powders not accessible by other processes or by the pyrolysis of metal chlorides or nitrates. The powders have numerous uses in advanced materials applications including particulate solid state lasers, advanced ceramic materials, and as catalysts in organic synthesis and automobile exhaust systems.

Owner:TAL MATERIALS +1

Mixed-metal oxide particles by liquid feed flame spray pyrolysis of oxide precursors in oxygenated solvents

Liquid feed flame spray pyrolysis of solutions of a metal oxide precursor which is an alkoxide or C1-6 carboxylate and at least one second metal oxide precursor and / or second metal compound dissolved in oxygenated solvent by combustion with oxygen lead to the formation of sub-micron mixed-metal oxide powders not accessible by other processes or by the pyrolysis of metal chlorides or nitrates. The powders have numerous uses in advanced materials applications including particulate solid state lasers, advanced ceramic materials, and as catalysts in organic synthesis and automobile exhaust systems.

Owner:TAL MATERIALS +1

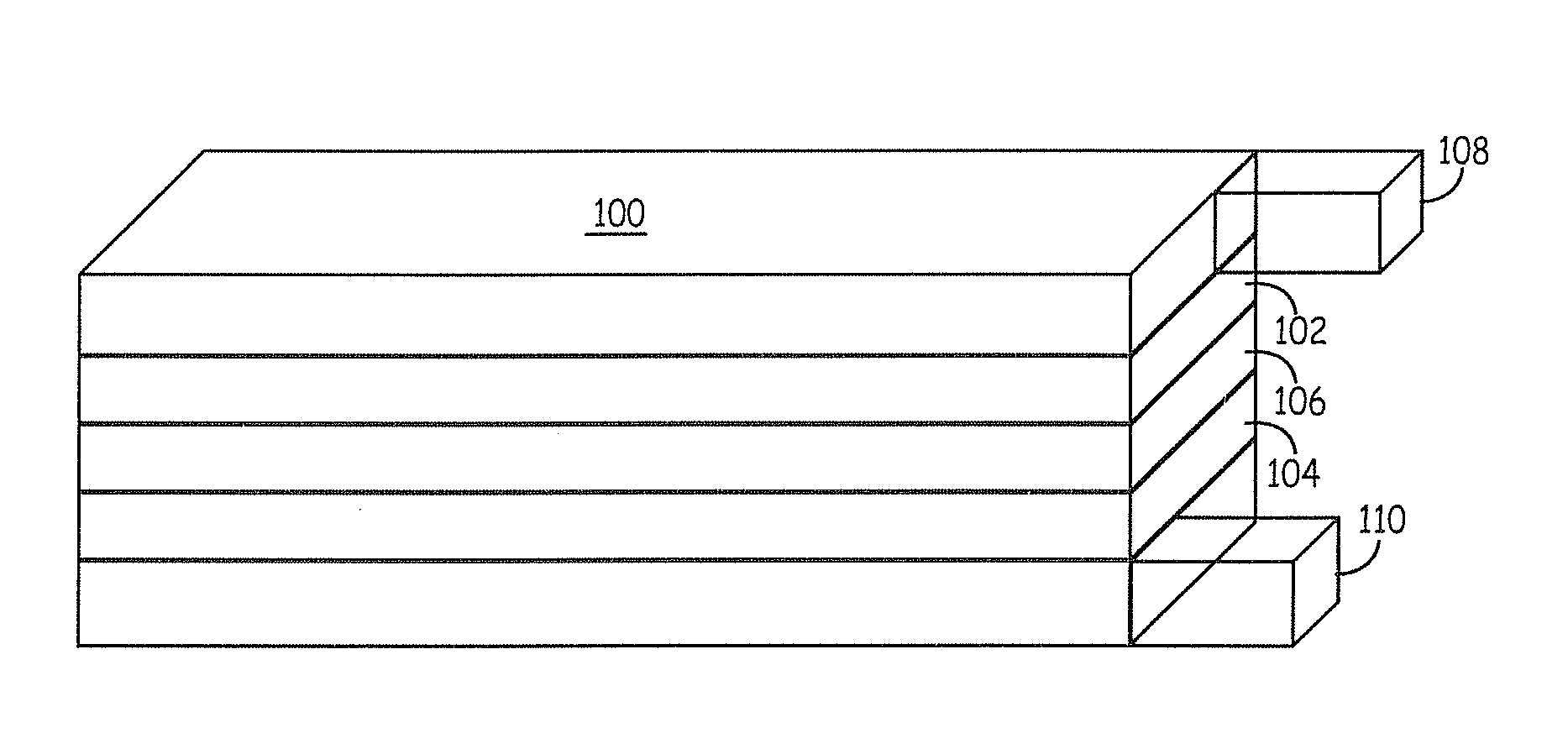

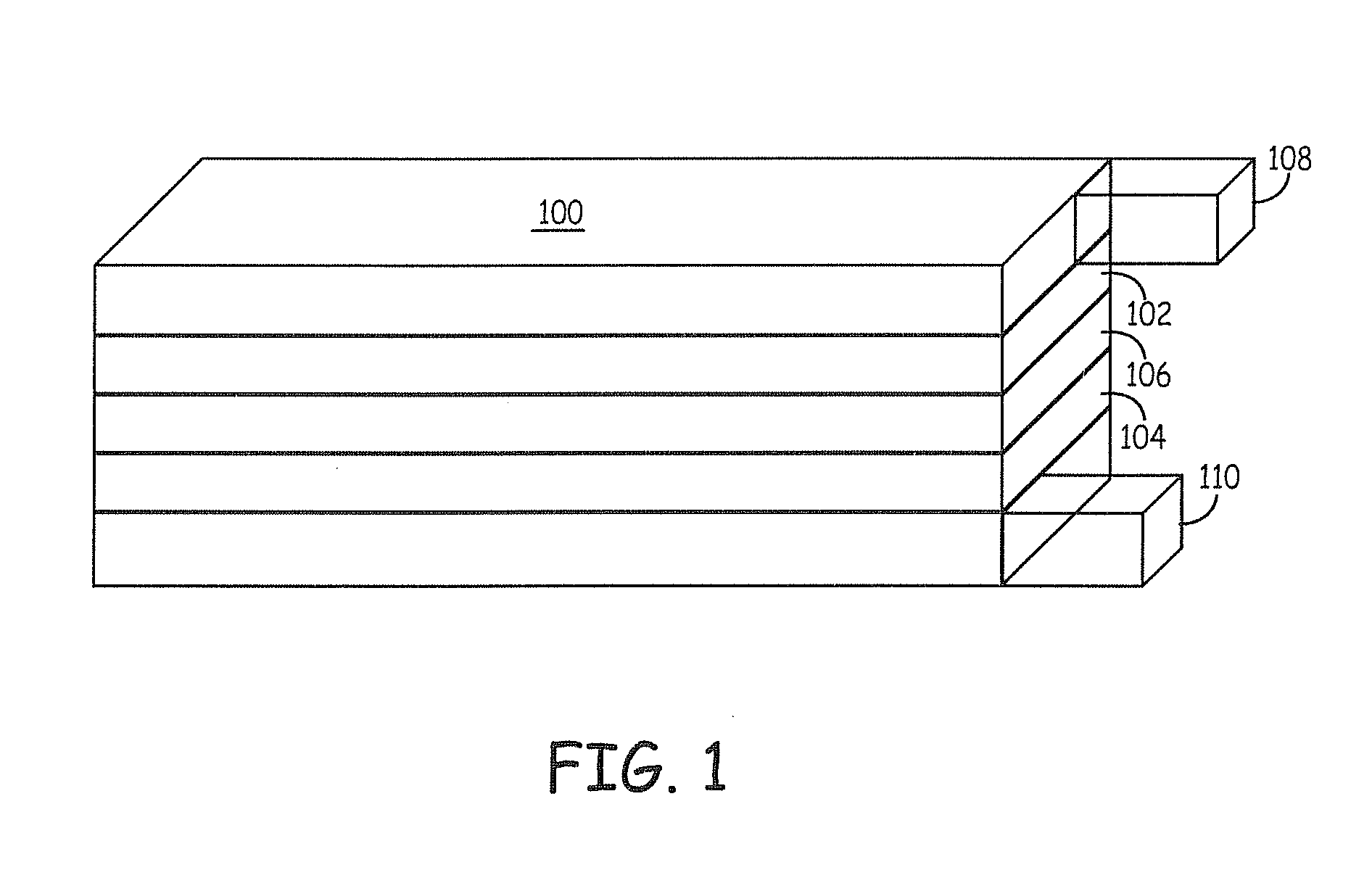

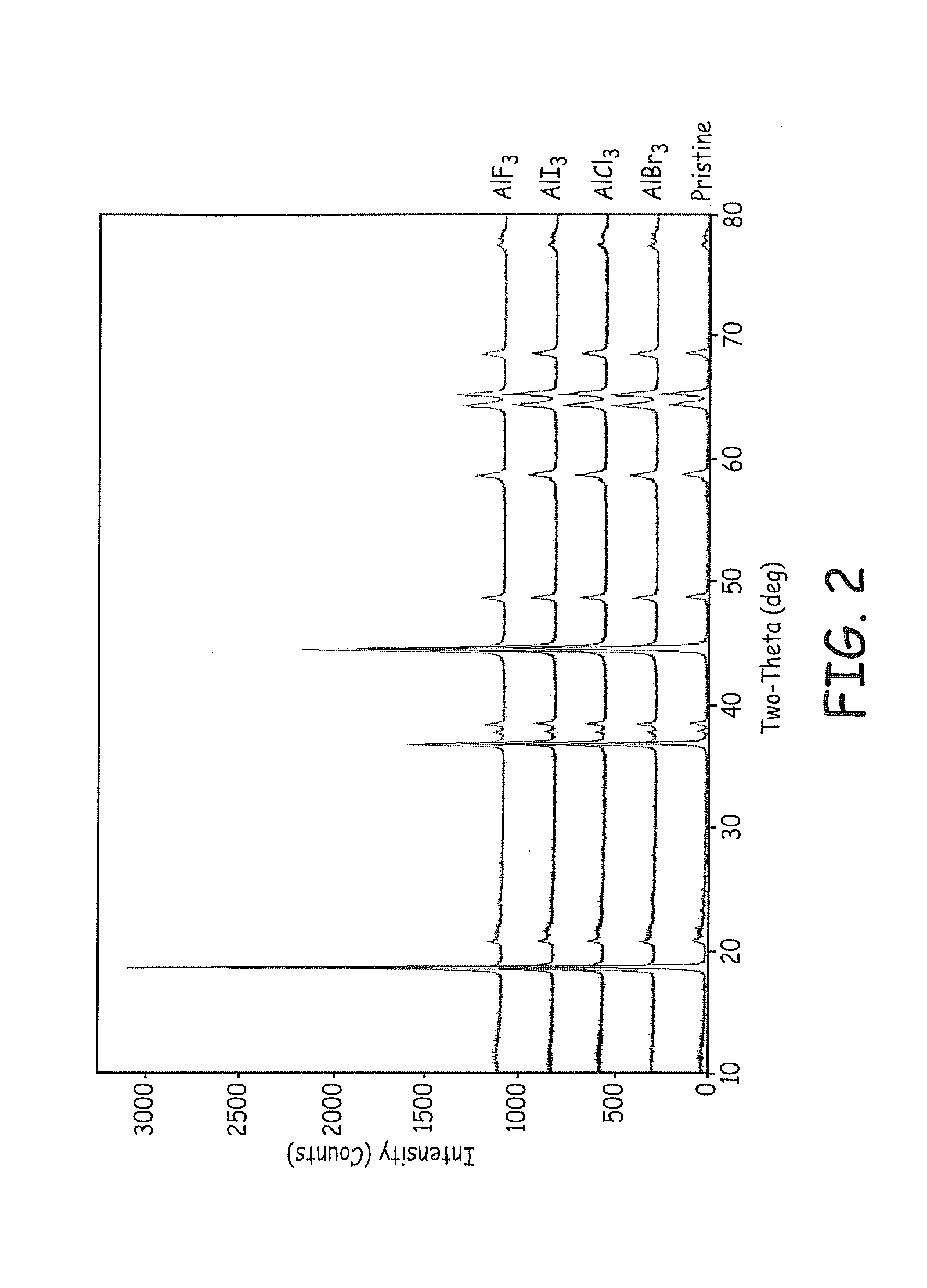

Metal halide coatings on lithium ion battery positive electrode materials and corresponding batteries

Lithium ion battery positive electrode material are described that comprise an active composition comprising lithium metal oxide coated with an inorganic coating composition wherein the coating composition comprises a metal chloride, metal bromide, metal iodide, or combinations thereof. Desirable performance is observed for these coated materials. In particular, the non-fluoride metal halide coatings are useful for stabilizing lithium rich metal oxides.

Owner:IONBLOX INC

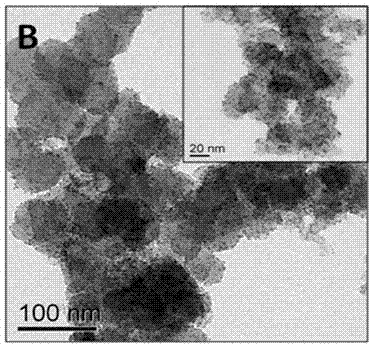

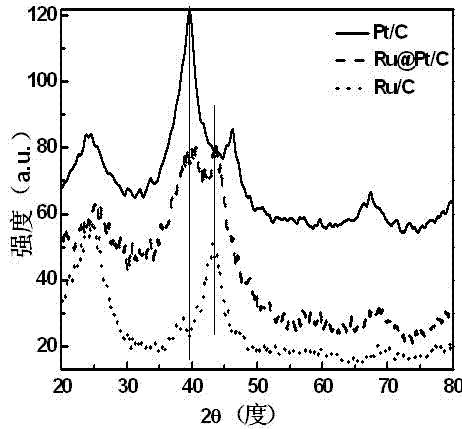

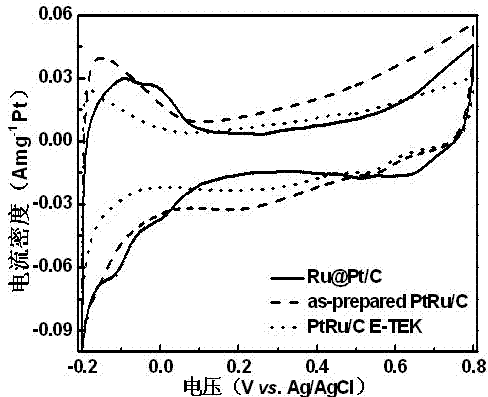

Preparation method of catalyst with core-shell structure for low-temperature fuel cell

InactiveCN102500365AHigh catalytic activitySolve the costCell electrodesCatalyst activation/preparationIridiumPtru catalyst

The invention discloses a preparation method of a catalyst with a core-shell structure for a low-temperature fuel cell, belonging to the technical field of fuel cells. In the catalyst with the core-shell structure prepared with the preparation method, platinum is taken as a shell, a metal alloy consisting of more than one of metals including ruthenium, platinum, iron, cobalt, nickel, copper, tin, iridium, gold and silver is taken as an inner core, and the shell and the inner core are loaded on a carbon carrier. The preparation method comprises the following preparation steps of: reducing a metal chloride or a metal nitrate with a reducing agent, and forming a core on the carbon carrier with a large specific surface area; stabilizing the core; and precipitating Pt on a core layer with a impregnation reduction method, a high-pressure organic sol method, a microwave method or an electrodeposition process to form the catalyst with the core-shell structure. Due to the adoption of the preparation method, the utilization ratio of noble metal platinum is increased, the cost of an electro-catalyst is reduced effectively, and the methanol oxidizing capability and oxygen reducing activity of the obtained catalyst are increased by 10.8 times and 8.7 times in maximum respectively in comparison to the mass ratio and activity of a commercial JM4100Pt / C catalyst.

Owner:SOUTH CHINA UNIV OF TECH

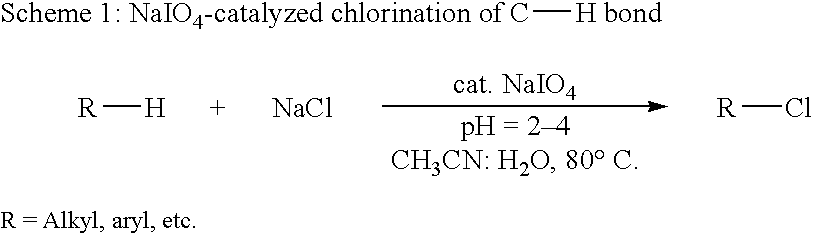

Catalytic process for regiospecific chlorination of alkanes, alkenes and arenes

InactiveUS6825383B1Save energyOrganic compound preparationPreparation by OH and halogen introductionMetal chlorideAlkene

The present invention provides a process for regiospecific chlorination of an aromatic or aliphatic compound with a chlorine source comprising a metal chloride and other than Cl2 and SO2Cl2 in presence of hypervalent iodine catalyst and in acidic medium.

Owner:COUNCIL OF SCI & IND RES

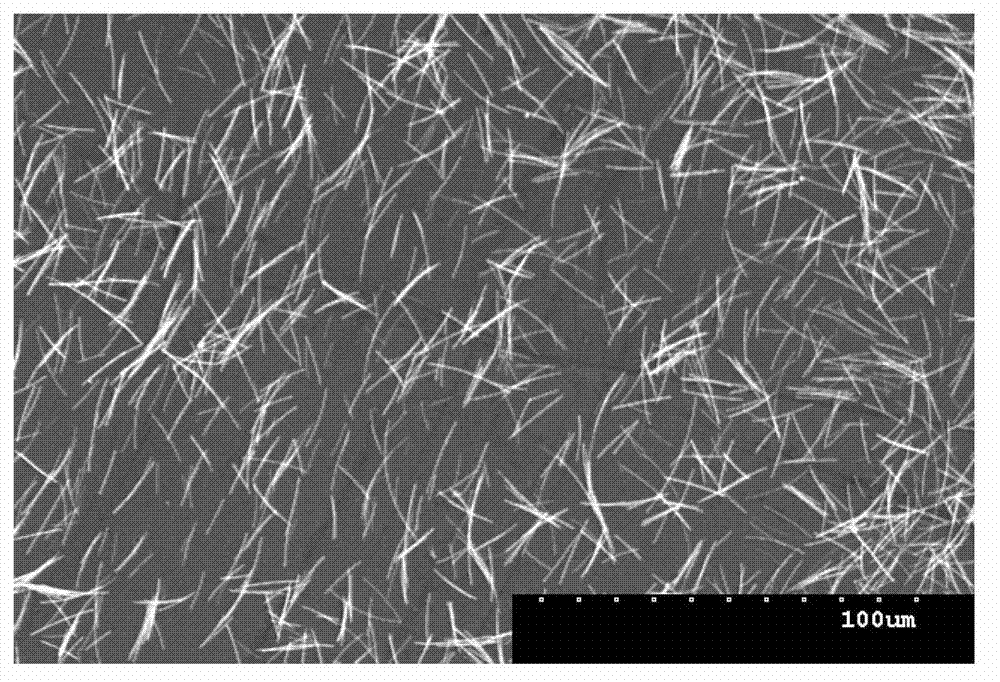

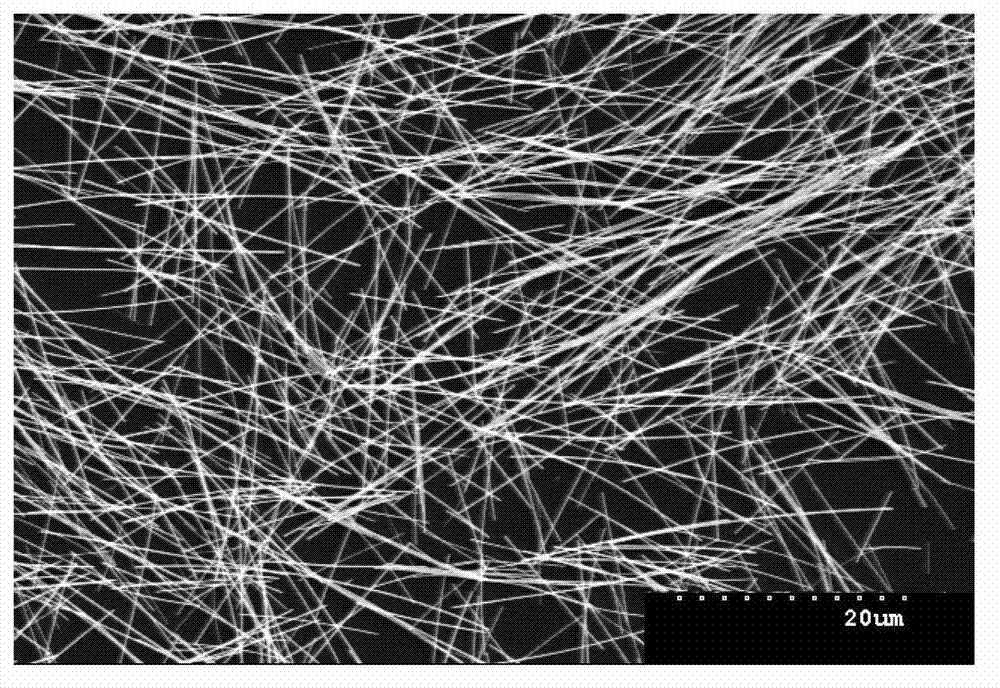

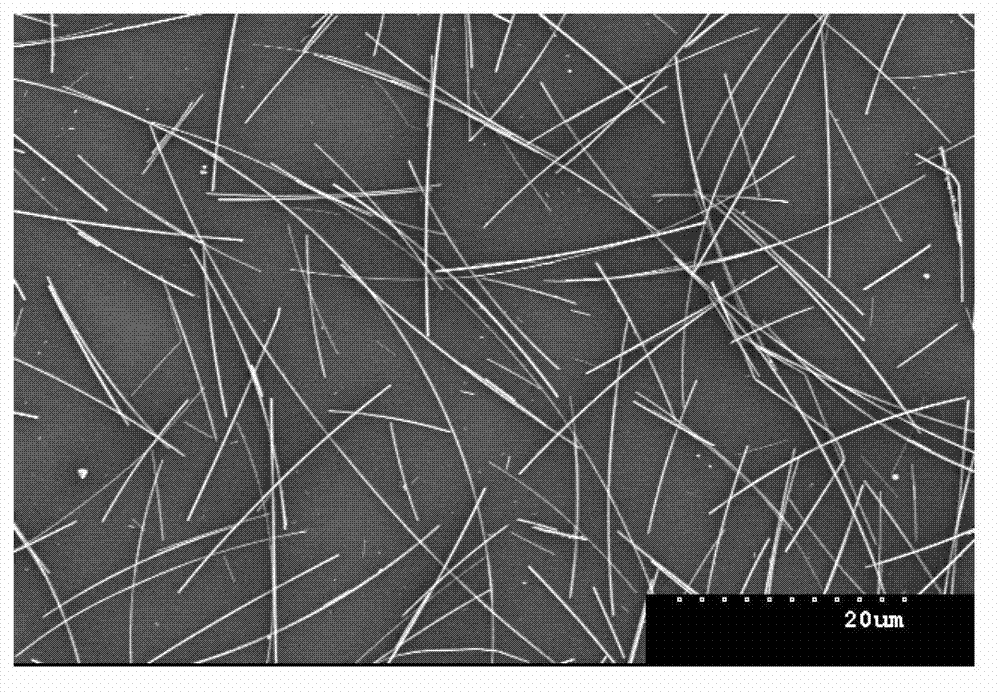

Method of preparing silver nanowire by utilization of hydrothermal method

InactiveCN103084584AImprove processing stabilityLow sensitivity to process parametersNanotechnologyMetal chlorideHigh volume manufacturing

The invention relates to a method of preparing silver nanowire by utilization of a hydrothermal method. The steps including: directly mixing ethylene glycol PVP solution which contains metal chloride with the concentration of 0.01M-2MPVP and the concentration of 1*10M-1*10-2M with ethylene glycol silver nitrate solution with the concentration of 0.01M-1M at normal temperature, stirring the mixed solution to be uniformed mixed, obtaining mixed reaction mother solution; the volume ratio of ethylene glycol silver nitrate solution to ethylene glycol PVP solution is 1:1-10:1; the molar ratio of silver nitrate to the PVP in the mixed reaction mother solution is 1:10-10:1, and the molar ration of silver nitrate to metal chloride is 10:1-104:1; putting the mixed reaction mother solution into an reaction kettle, warming the mixed reaction mother solution to 160 DEG C - 180 DEG C to carry out reduction reaction, the silver salt in the mother solution is restored, and silver nanowire is obtained. The method of preparing silver nanowire by utilization of the hydrothermal method has the advantage of being simple and high-efficient, no need of being preheated when the preliminary reaction is carried out at the normal temperature, easy to control of reaction conditions, and especially applicable to mass production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

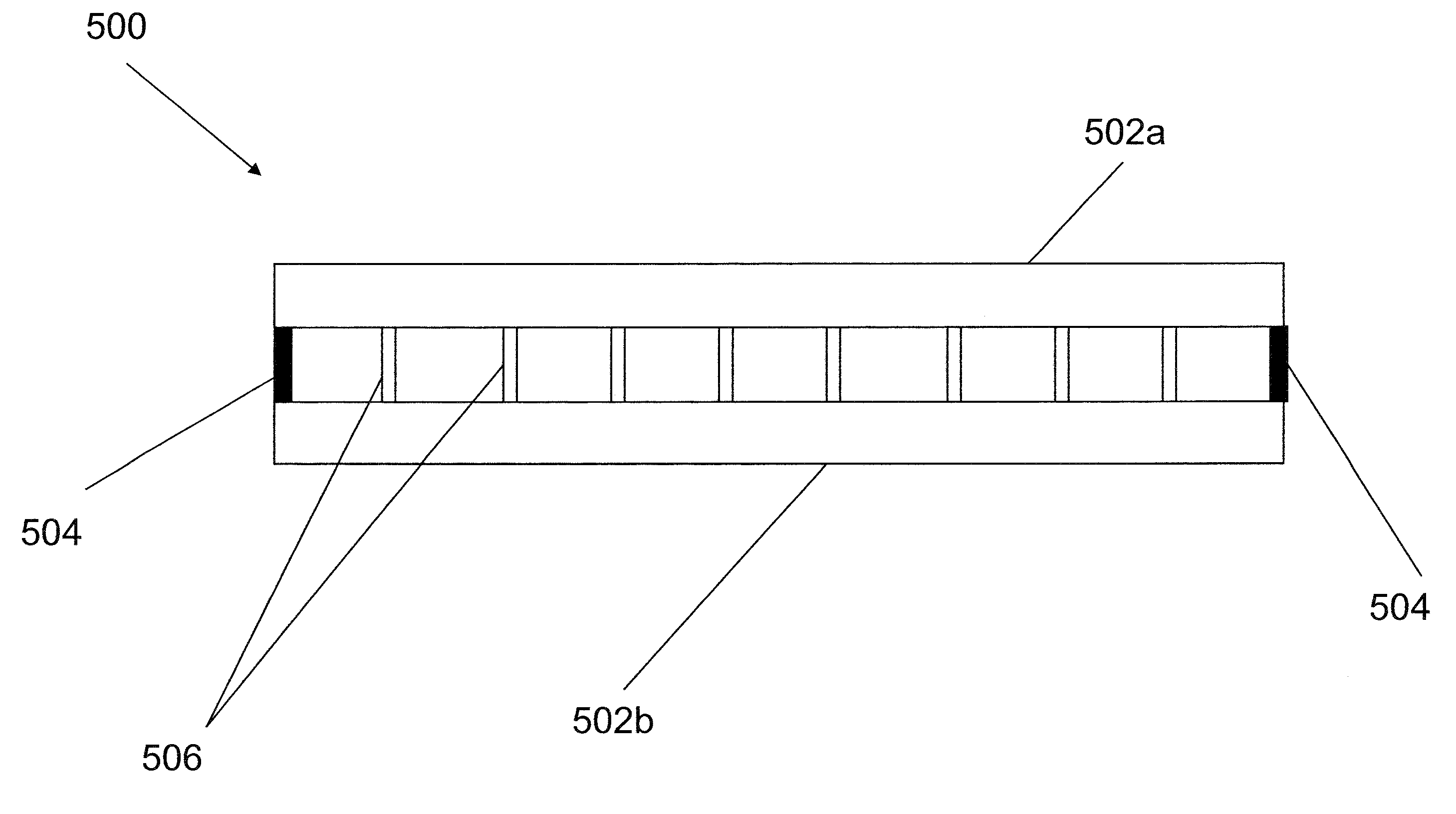

Coefficient of thermal expansion filler for vanadium-based frit materials and/or methods of making and/or using the same

ActiveUS20120213954A1Improve sealingReduce sealClimate change adaptationWindows/door improvementMetal chlorideFrit

Certain example embodiments relate to seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a composition may be combined with a binder solution that substantially or completely burns out by the time the composition is melted. In certain example embodiments, a CTE filler is included with a frit material. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

Vanadium-based frit materials, and/or methods of making the same

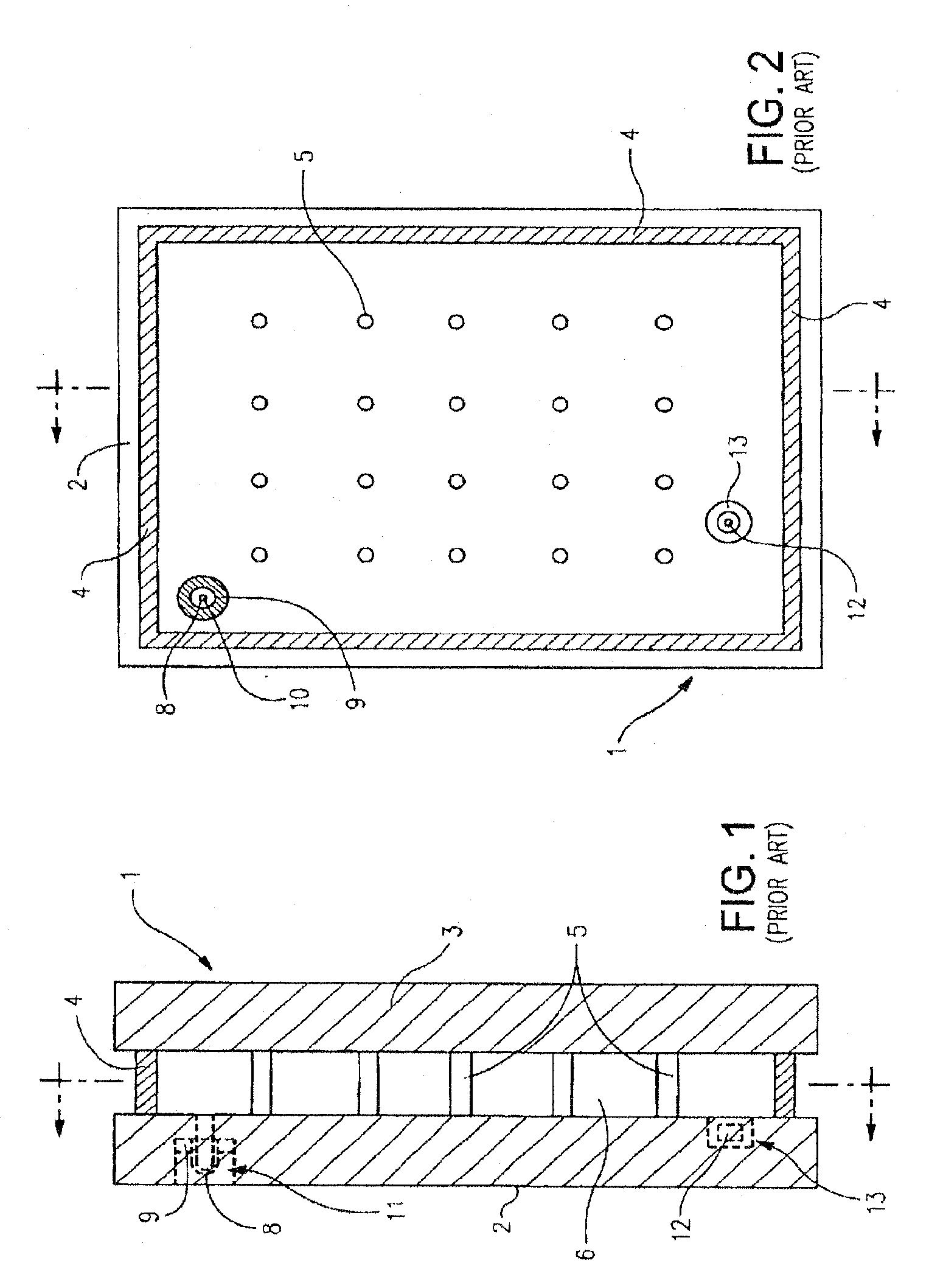

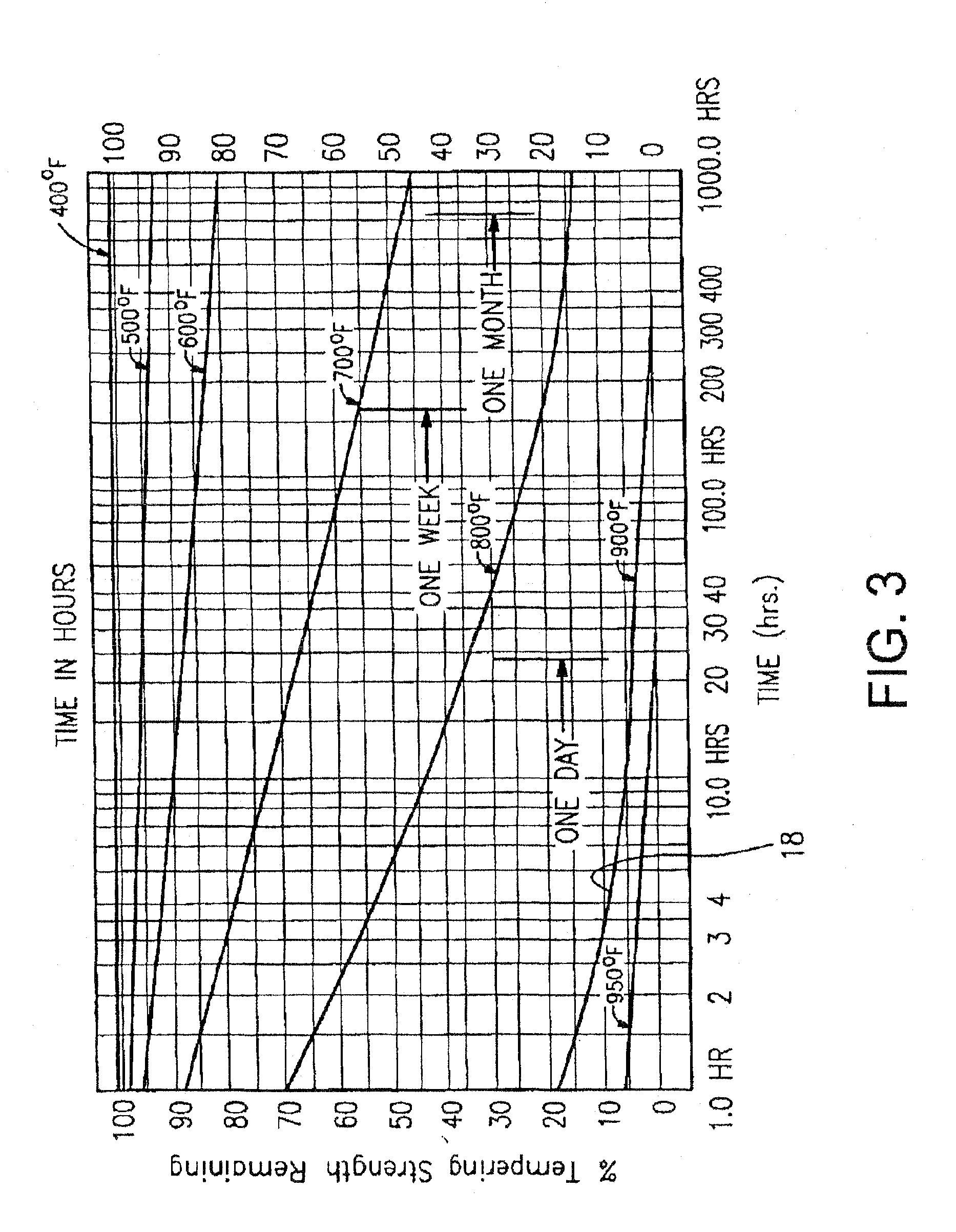

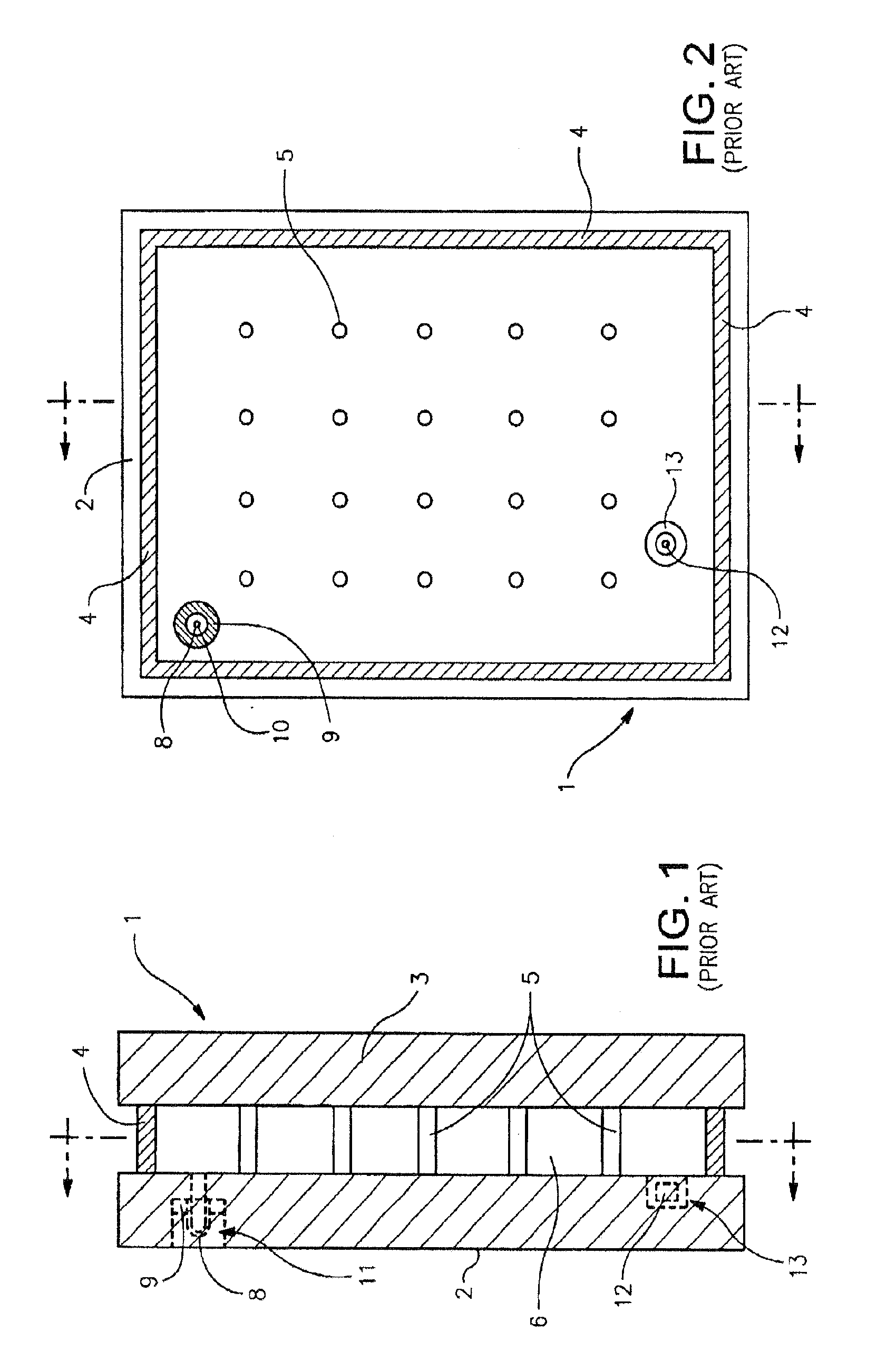

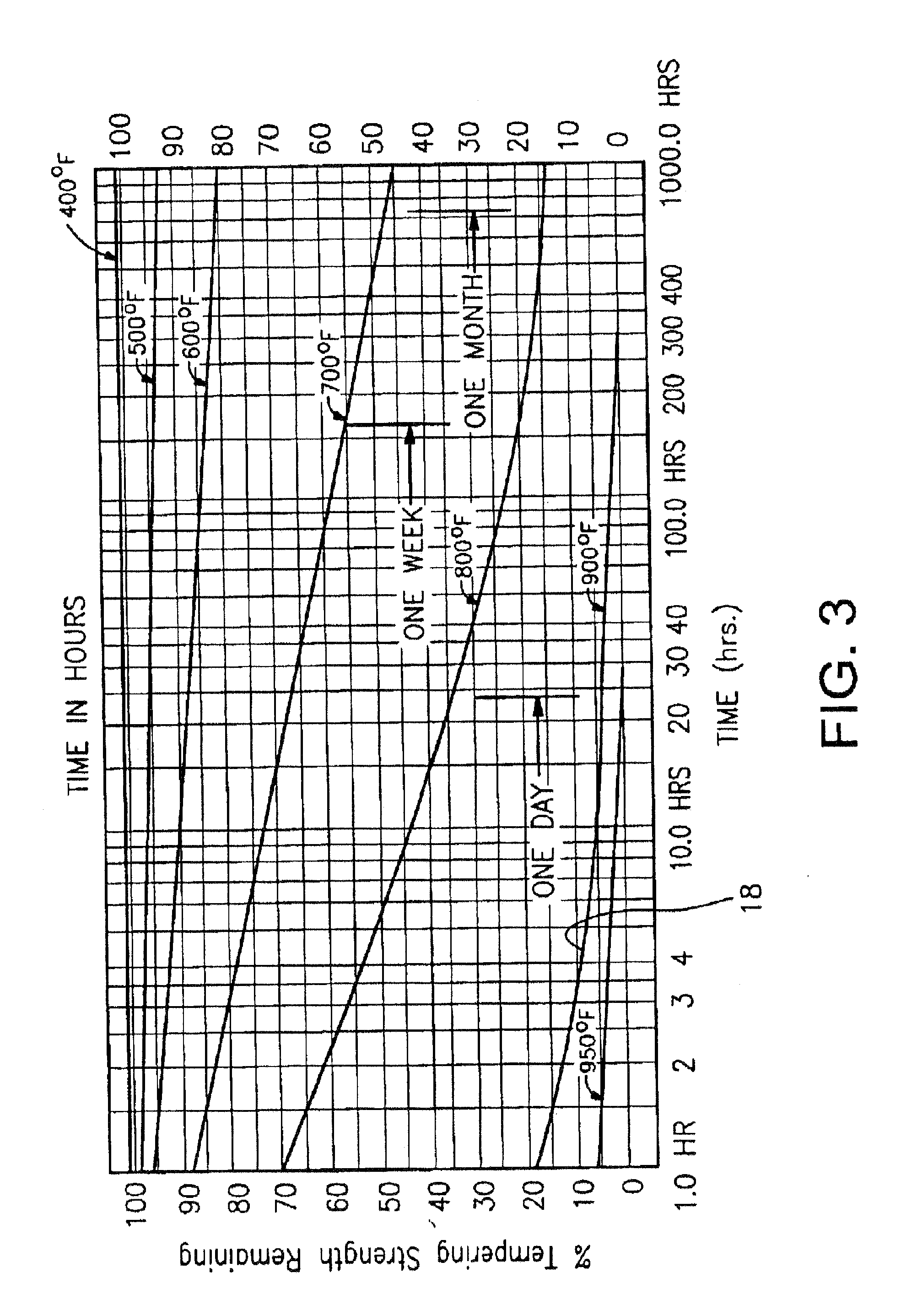

ActiveUS20120213952A1Little loss of strengthImprove sealingGlass blowing apparatusGlass reforming apparatusMetal chlorideFrit

Certain example embodiments relate to improved seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

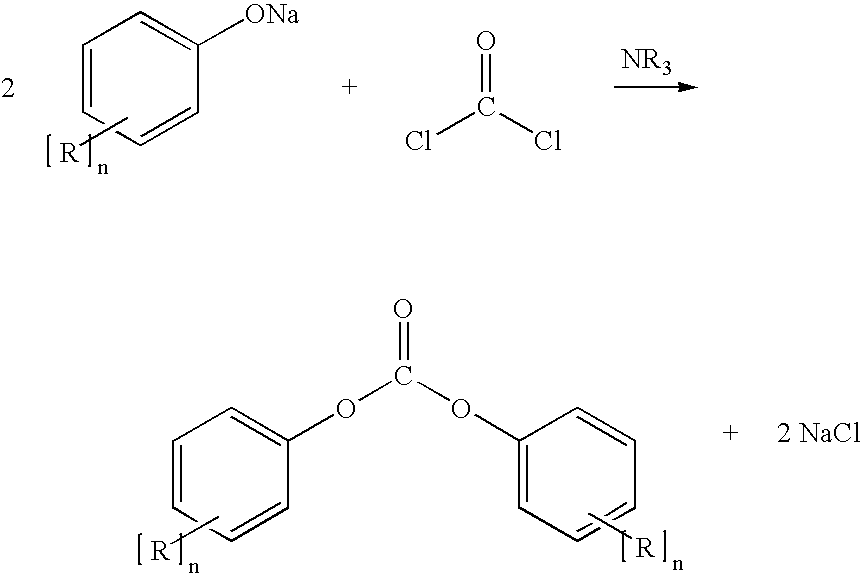

Process for the production of diaryl carbonates and treatment of alkalichloride solutions resulting therefrom

Processes comprising: (a) reacting phosgene and a monohydroxyl aryl compound in the presence of a suitable catalyst to form a diaryl carbonate and a solution comprising an alkali chloride; (b) separating the diaryl carbonate from the solution; (c) adjusting the pH of the solution to a value of less than or equal to 8 to form a pH-adjusted solution; (d) treating the pH-adjusted solution with an adsorbent to form a treated solution; (e) subjecting at least a portion of the treated solution to electrochemical oxidation to form chlorine and an alkali hydroxide solution; and (f) recycling at least a portion of one or both of the chlorine and the alkali hydroxide solution.

Owner:BAYER MATERIALSCIENCE AG

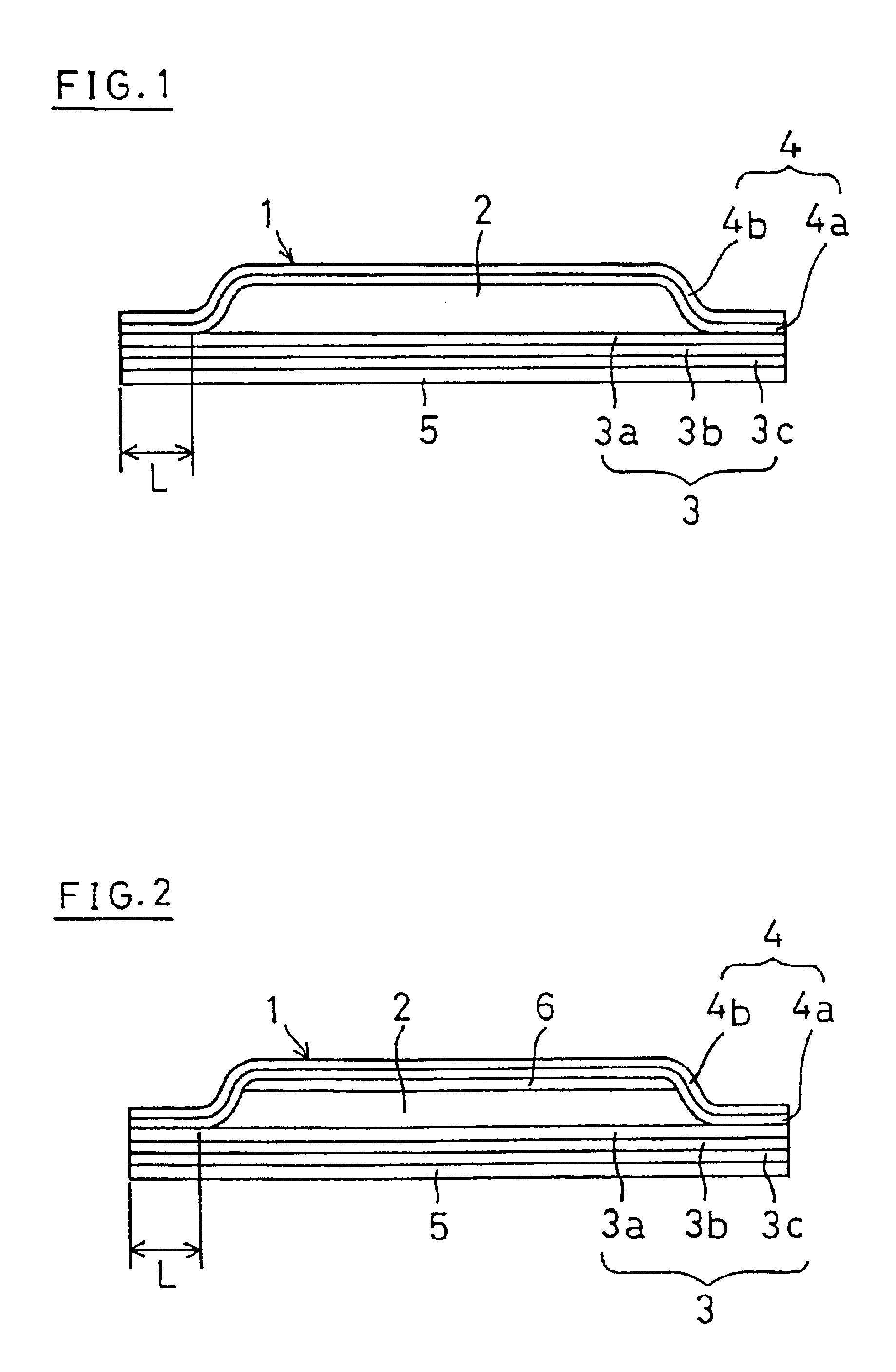

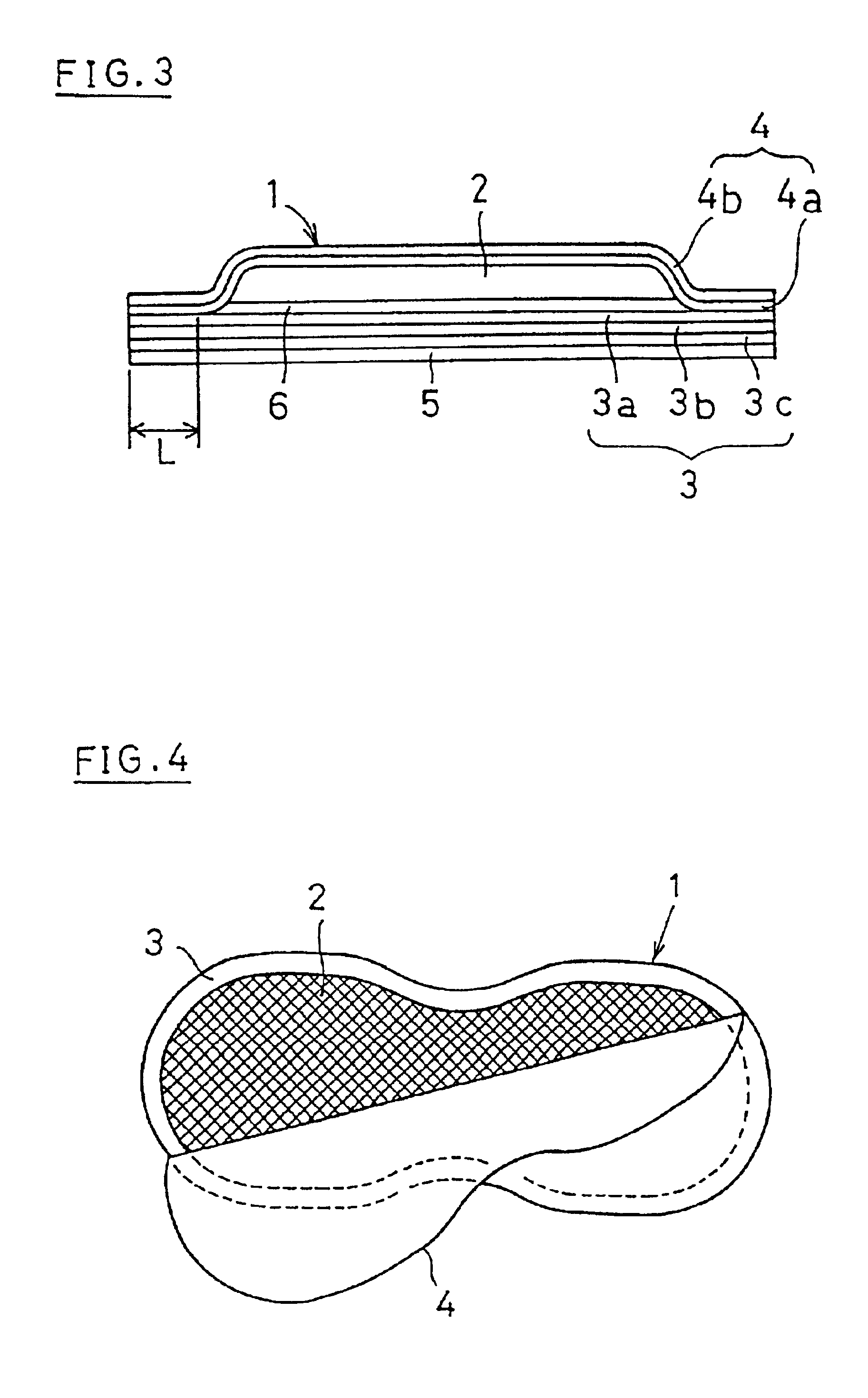

Method for manufacturing thin body warming devices

InactiveUS6863682B2Avoid exothermic reactionsSmall film thicknessExothermal chemical reaction heat productionMechanical working/deformationMetal chlorideTackifier

The present invention relates to the use of an exothermic composition having, as essential components, a water absorptive polymer and / or tackifier, carbon component and / or metal chloride and features that the product is as a whole ink-like or cream-like in a method of manufacturing an exothermic device.

Owner:GENCHI KENKYUSHO

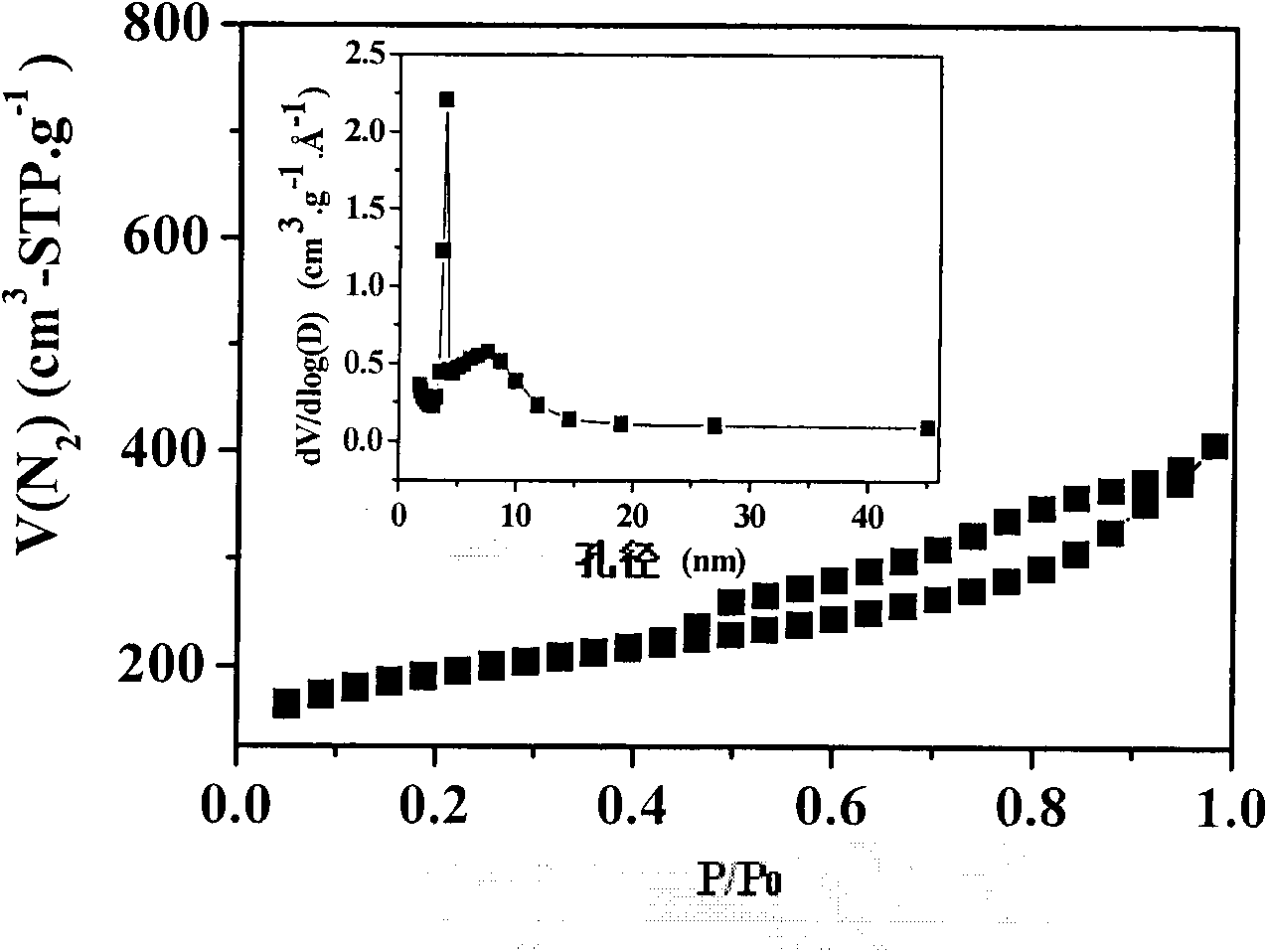

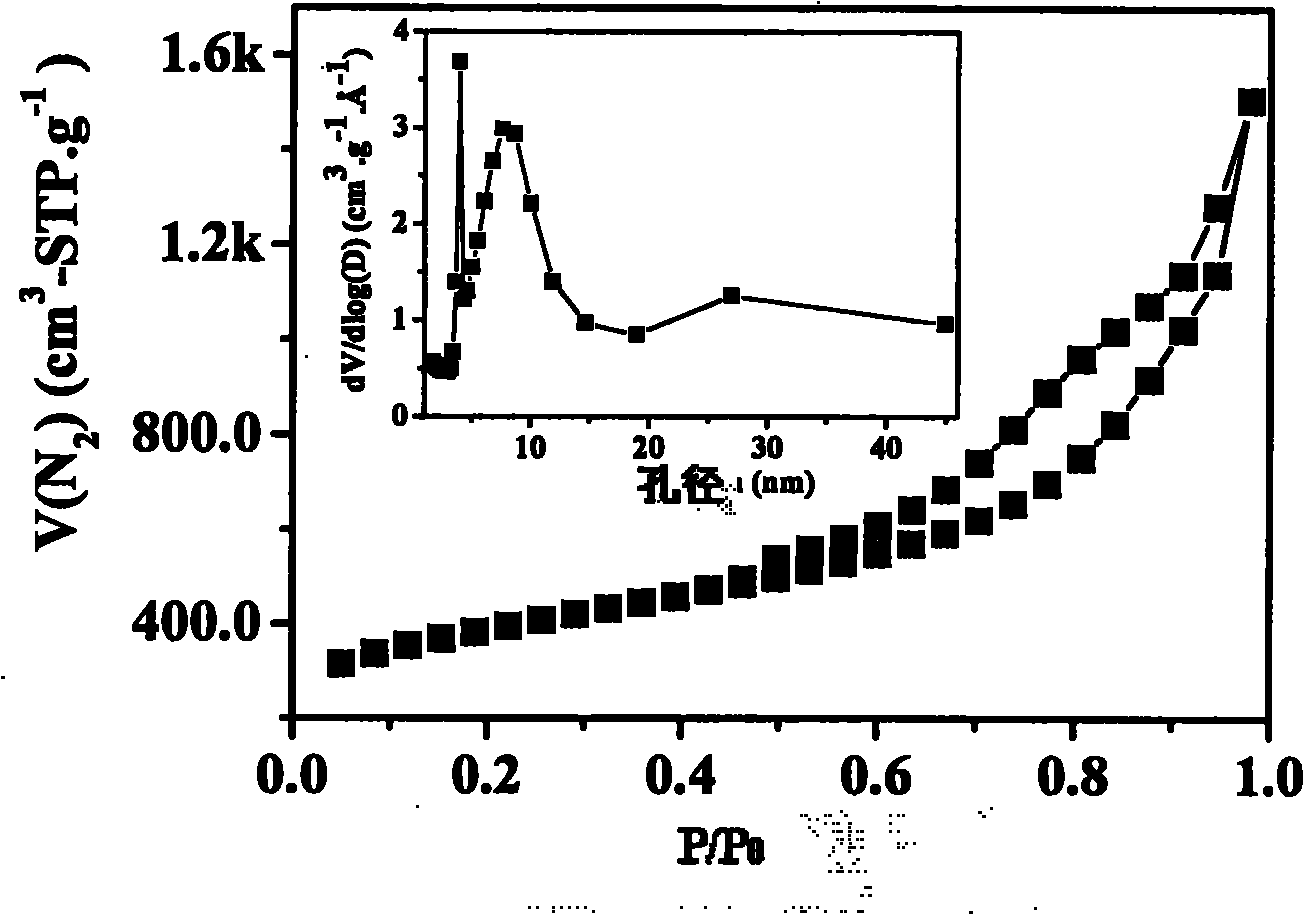

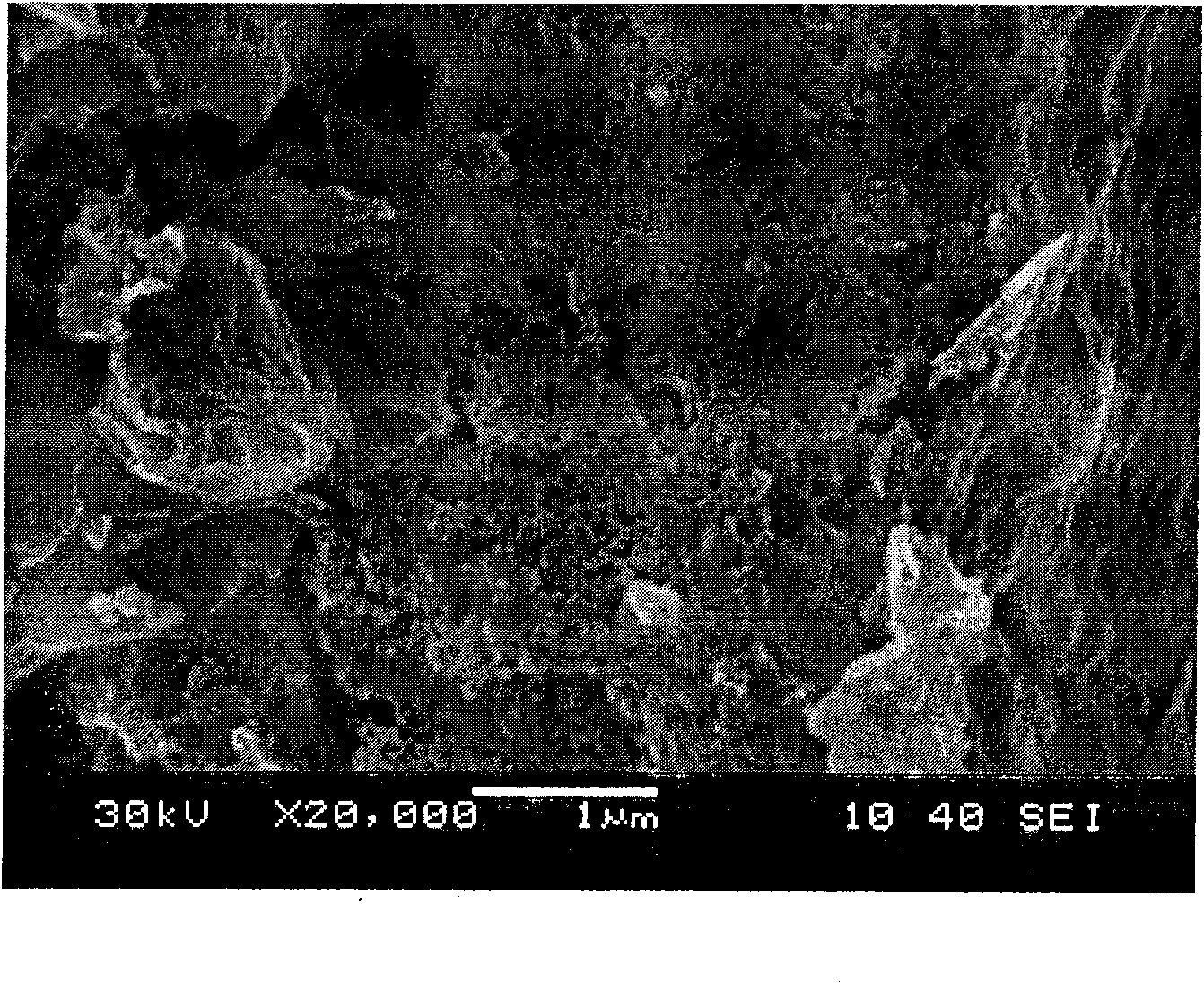

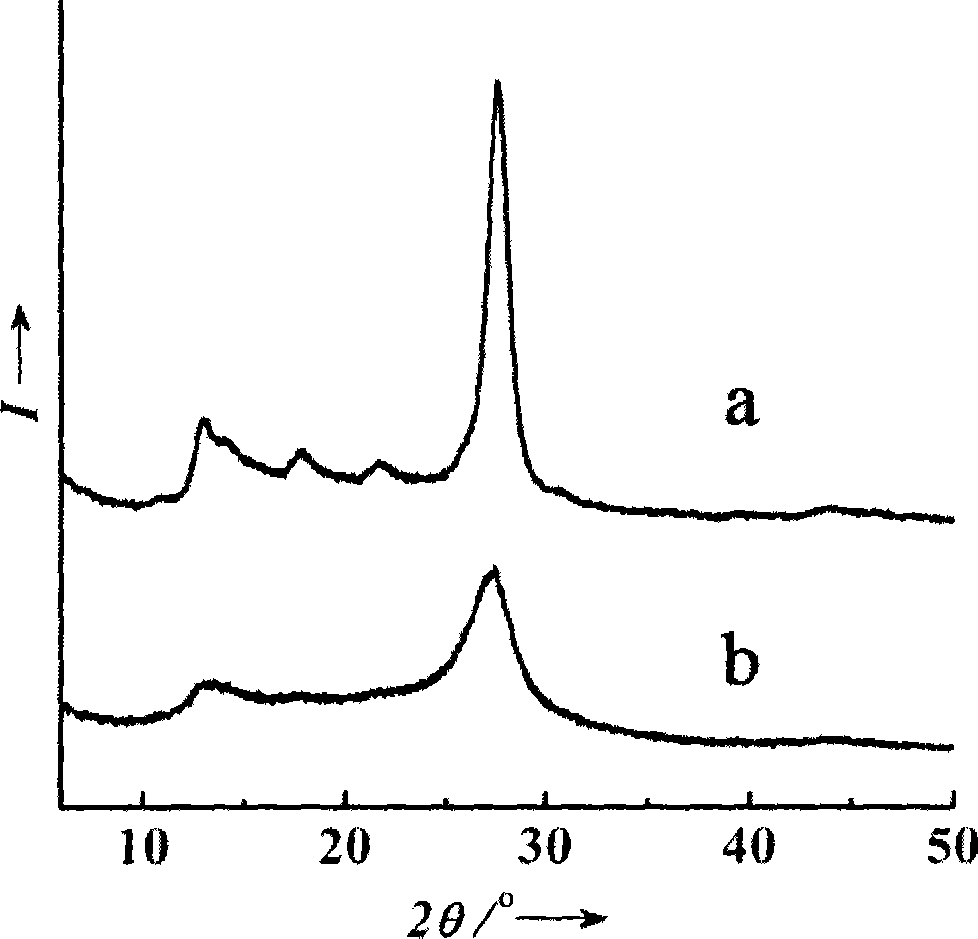

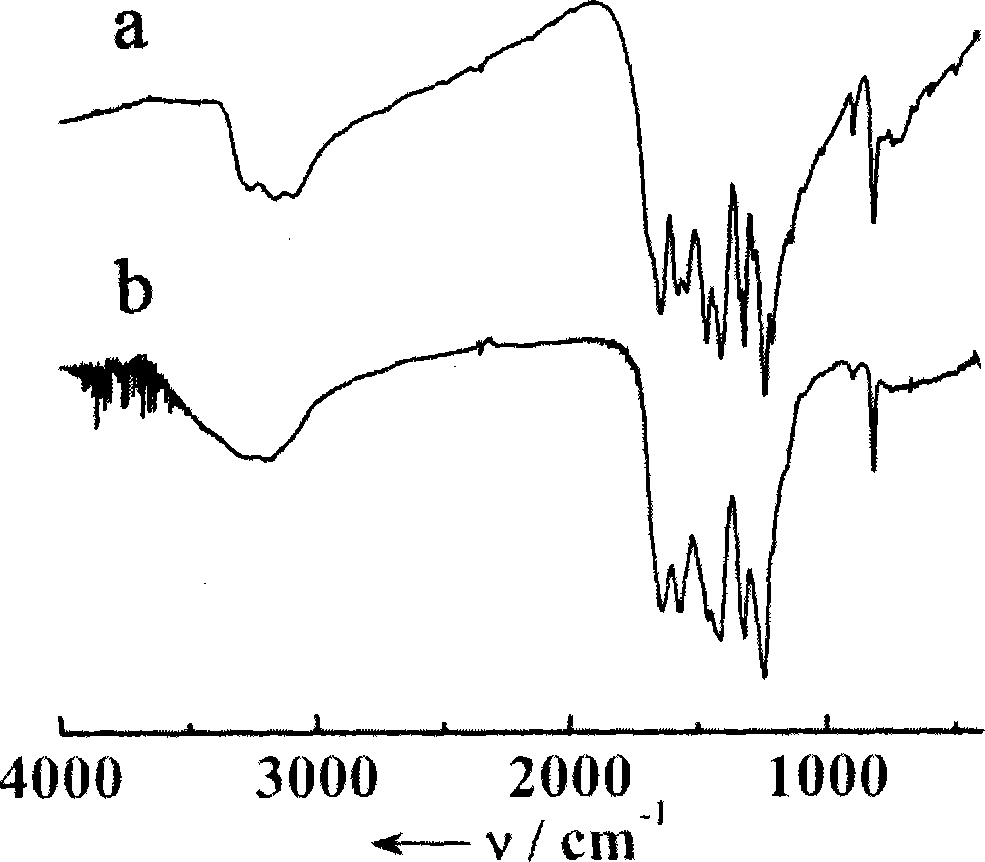

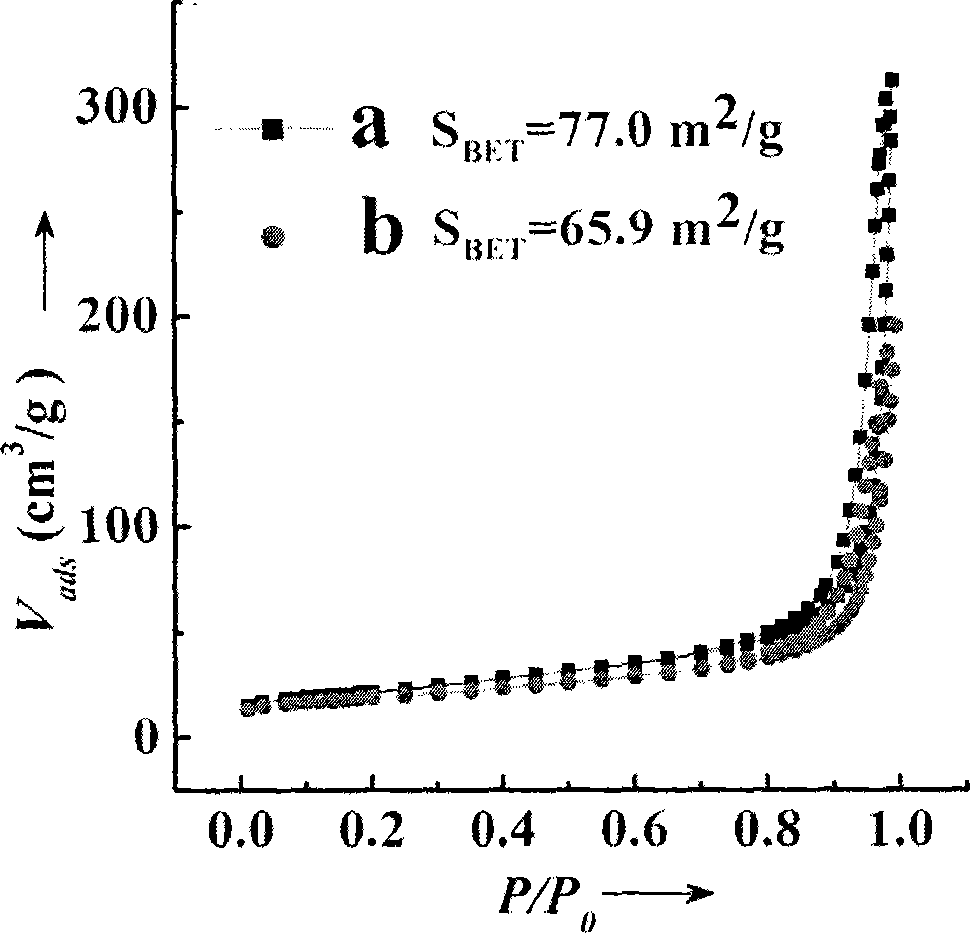

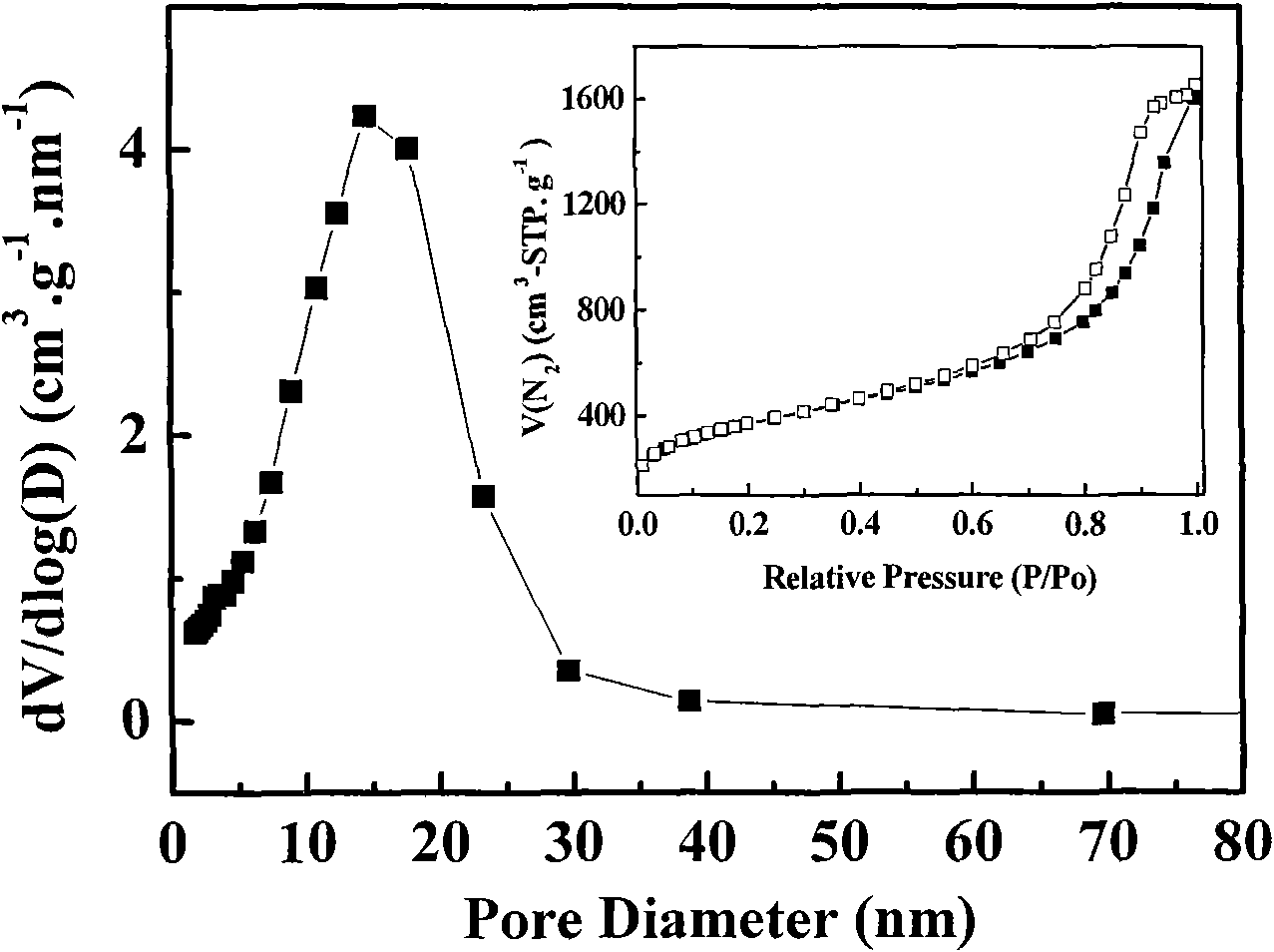

Method for preparing high-surface-area nitrogenous mesoporous carbon material

The invention discloses a method for preparing a high-surface-area nitrogenous mesoporous carbon material. The method prepares the nitrogenous mesoporous carbon material by using melamine, urea and formaldehyde as raw materials, using metal chloride as a template agent and an active agent, and performing the steps of dissolution, polymerization, solidification, carbonization, washing, drying and the like. The raw materials are rich in sources and have low prices; the metal chloride used as the template agent and the active agent has a low price and can be recycled; the whole preparation method is simple and feasible; and the prepared nitrogenous mesoporous carbon material has a specific area of 500 to 1,500 m<2> / g, a total pore volume of 1.0 to 3.0 cm<3> / g, a mesoporous ratio of 80 to 92 percent, an adjustable pore diameter of between 2.5 nm to a plurality of microns and the nitrogen content (atomic percent) of 5 to 28 percent at, and is expected to be widely applied in the fields of adsorbents, catalyst carriers, electrode materials and the like.

Owner:NANJING UNIV

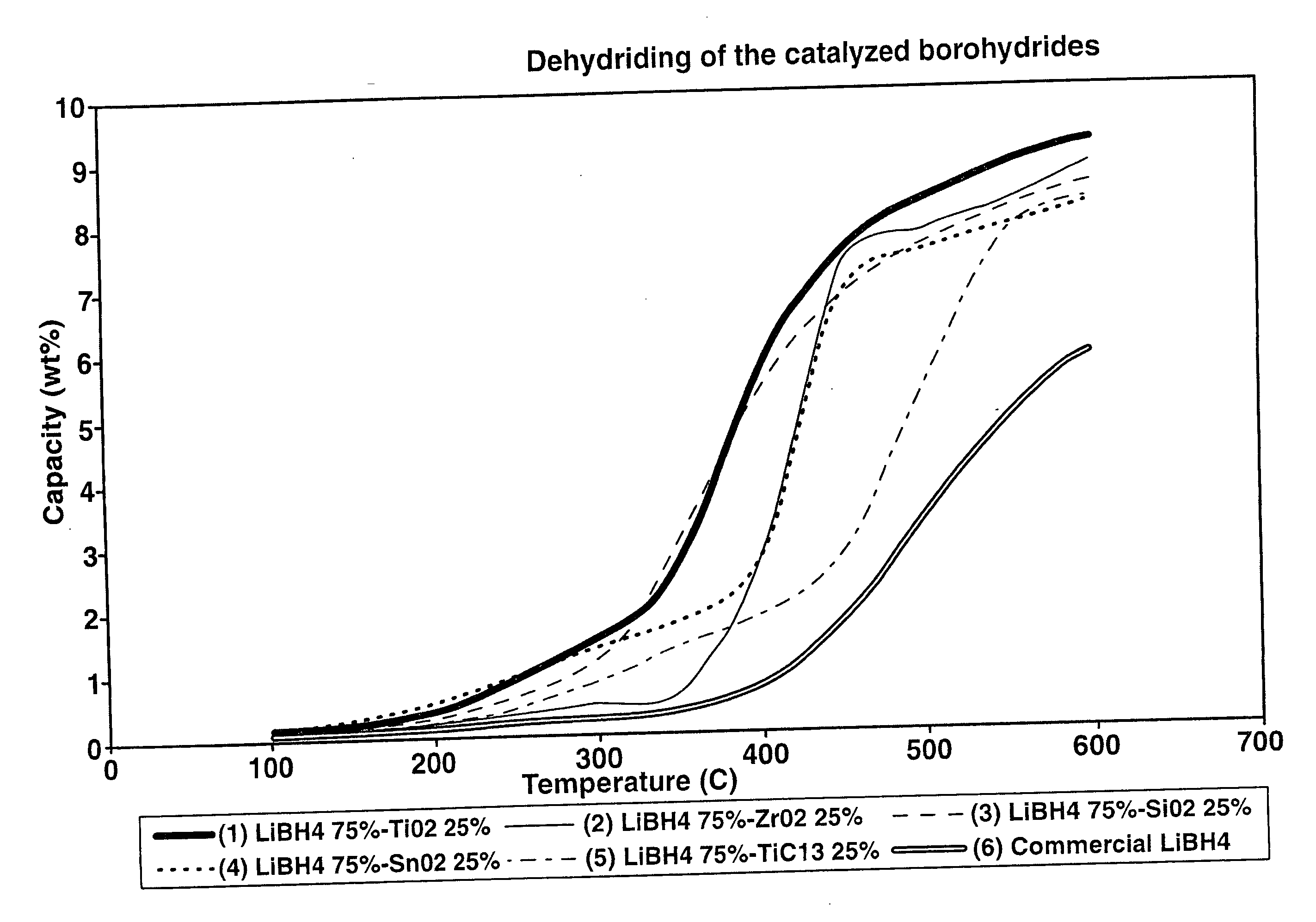

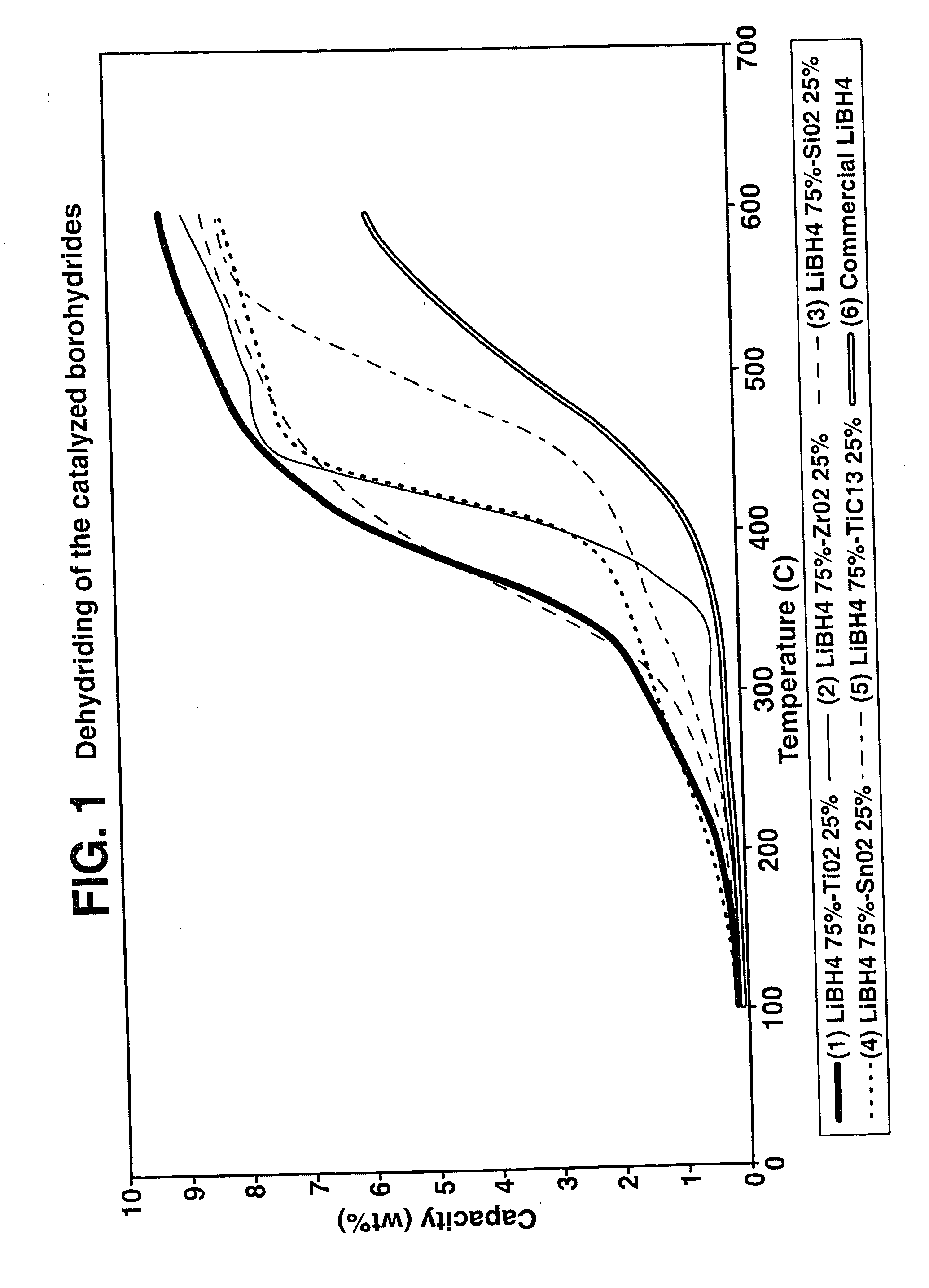

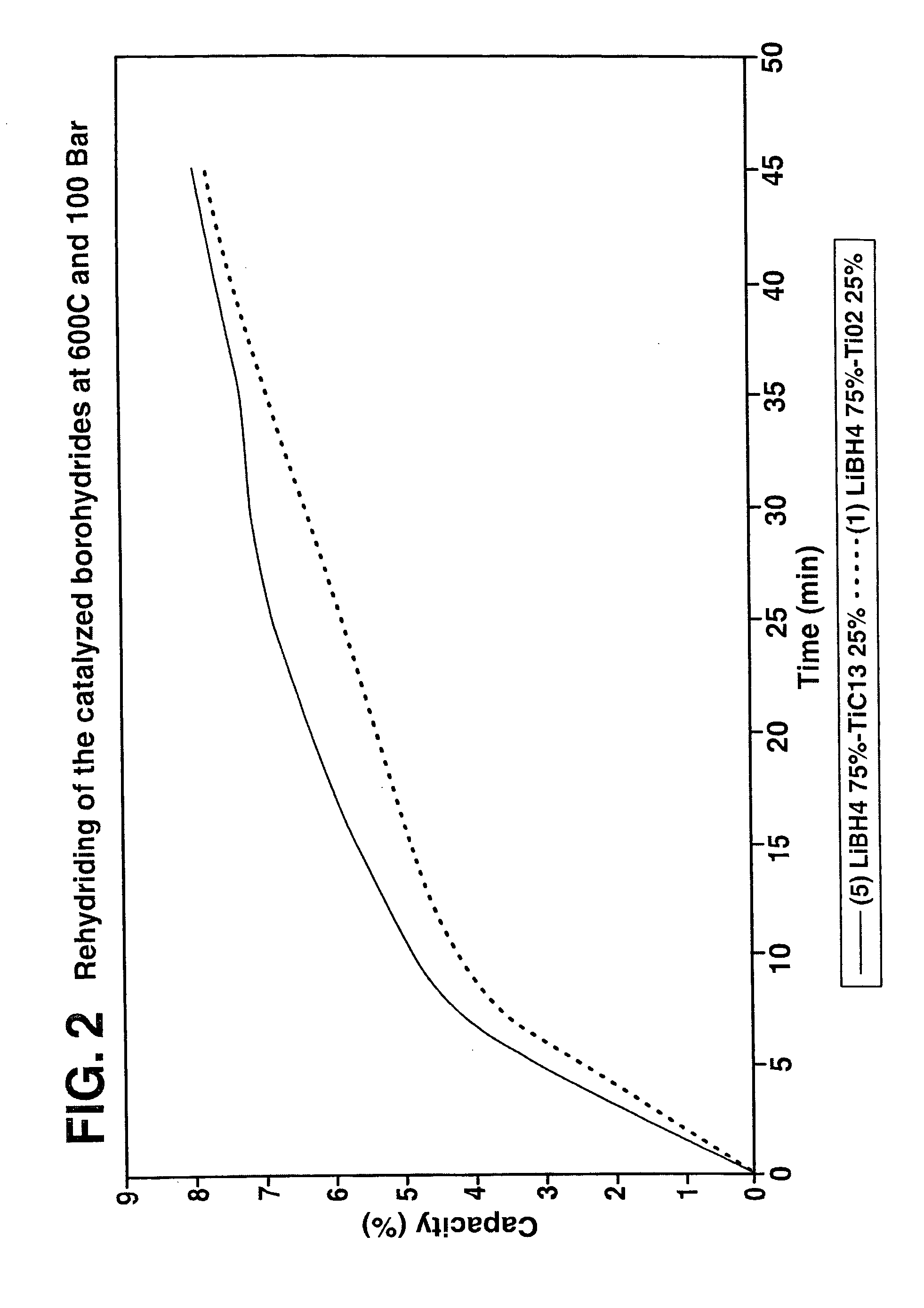

Destabilized and catalyzed borohydrided for reversible hydrogen storage

InactiveUS20060194695A1Reduce the temperatureImproved hydrogen binding/release kineticsHydrogenPhysical/chemical process catalystsIndiumCobalt

A hydrogen storage material and process is provided in which catalyzed alkali borohydride materials and partially substituted borohydride materials are created and which may contain effective amounts of catalyst(s) which include transition metal oxides, halides, and chlorides of titanium, zirconium, tin, vanadium, iron, cobalt and combinations of the various catalysts and the destabilization agents which include metals, metal hydrides, metal chlorides and complex hydrides of magnesium, calcium, strontium, barium, aluminum, gallium, indium, thallium and combinations of the various destabilization agents. When the catalysts and destabilization agents are added to an alkali borodydride such as a lithium borohydride, the initial hydrogen release point of the resulting mixture is substantially lowered. Additionally, the hydrogen storage material may be rehydrided with weight percent values of hydrogen of at least about nine percent.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

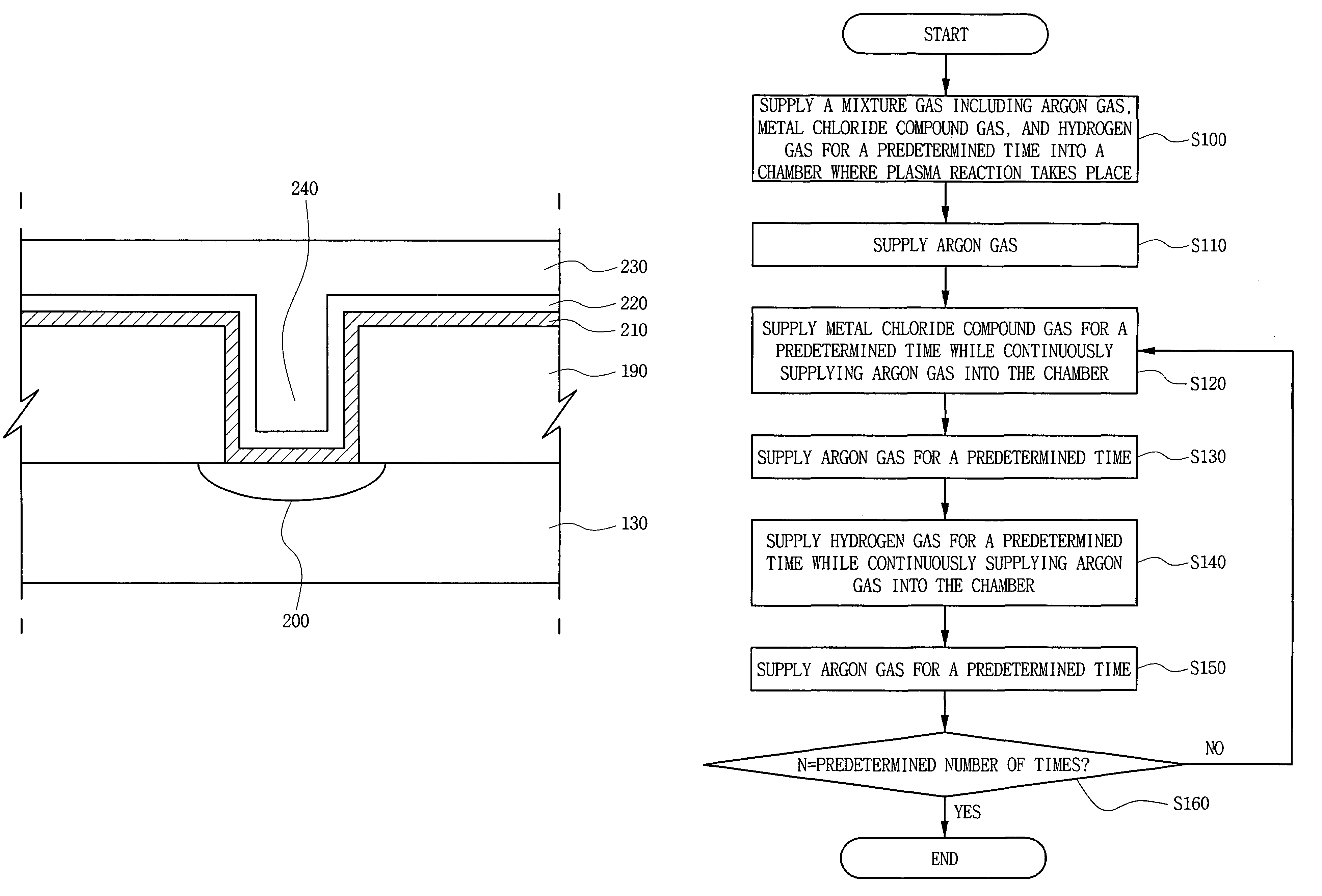

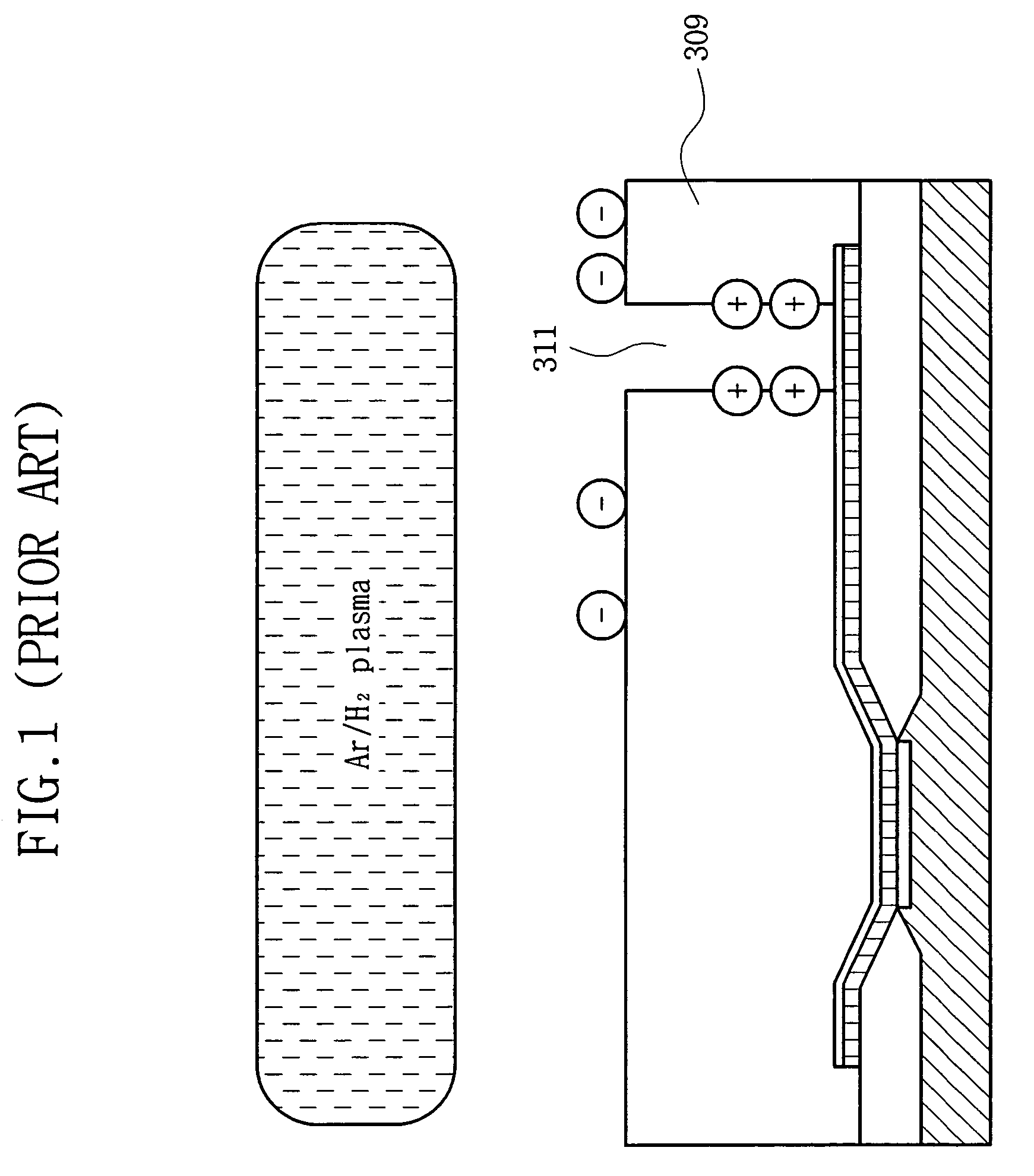

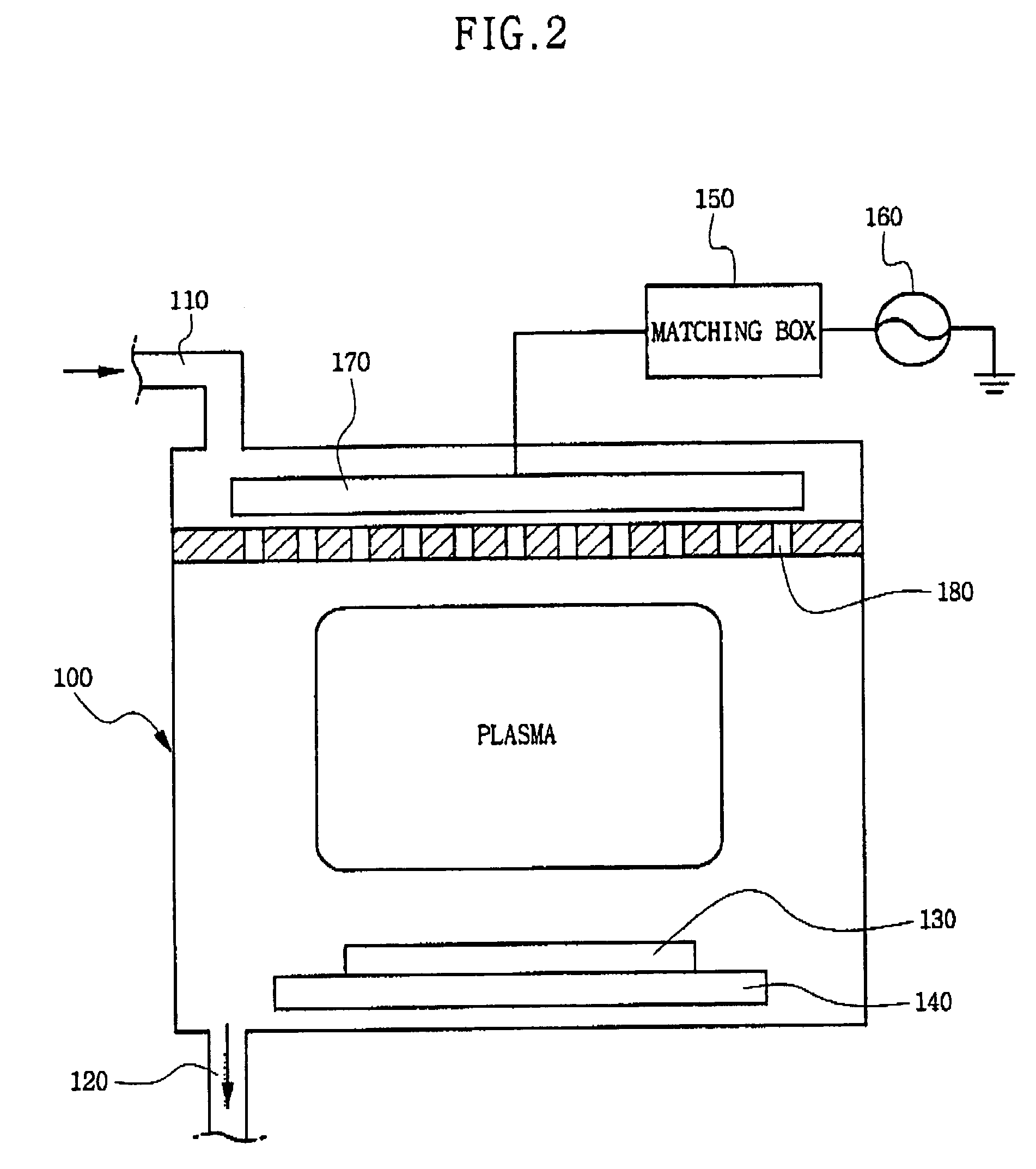

Method of forming metal layer used in the fabrication of semiconductor device

ActiveUS7416981B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMetal chlorideHydrogen

A method of forming a metal layer on the conductive region of a semiconductor device includes concurrently supplying a mixture gas including a hydrogen gas and a metal chloride compound gas, and a purge gas into a chamber having a sealed space for a predetermined time, thereby forming a first metal layer on the semiconductor substrate, using a plasma enhanced chemical vapor deposition (PECVD) method. The hydrogen gas and metal chloride gases are thereafter alternately supplied for a predetermined time while the purge gas is continuously supplied into the chamber, thereby forming a second metal layer on the first metal layer, using a PECVD method. Deterioration of semiconductor devices due to high heat by a conventional CVD method can be prevented using a PECVD method as a low temperature process, thereby improving a production yield.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for quickly preparing quasi-graphite-structure carbon nitride material by adopting microwave heating

InactiveCN104415786AOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationThioureaMetallic sulfide

The invention relates to a quick, energy-saving and high-yield preparation method of quasi-graphite-structure carbon nitride catalysis materials and application of the materials, belonging to the field of preparation and application of catalysis materials. According to the preparation process, one or multiple nitrogen-rich small organic molecules of urea, melamine, thiourea, cyanamide, dicyanamide, cyanuric chloride and cyanuric acid is / are taken as raw materials, a simple metal substance, a metallic oxide, a metal sulfide and a metal chloride are taken as microwave absorbers, microwave is taken as a heating source, and under the condition of radiation of microwave, the quasi-graphite-structure carbon nitride material can be quickly prepared. The prepared carbon nitride material has a large specific area and crystallinity and has high photocatalytic water decomposition hydrogen production performance and organic pollutant degradation performance. The preparation method provided by the invention is short in time, small in energy consumption, high in production efficiency and simple in process, does not have harsh preparation conditions, is easy to operate and has wide application prospect.

Owner:ANHUI UNIVERSITY

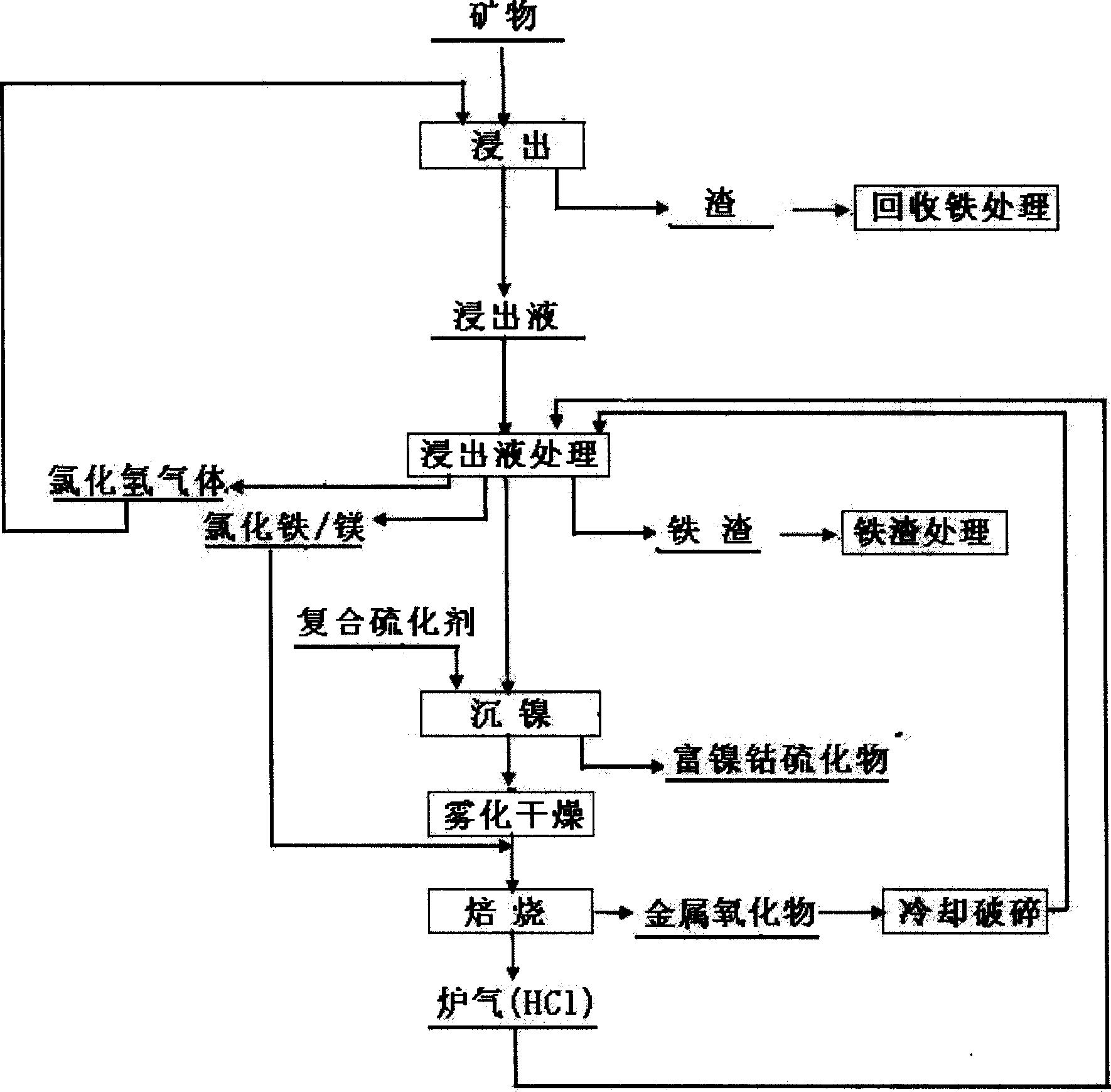

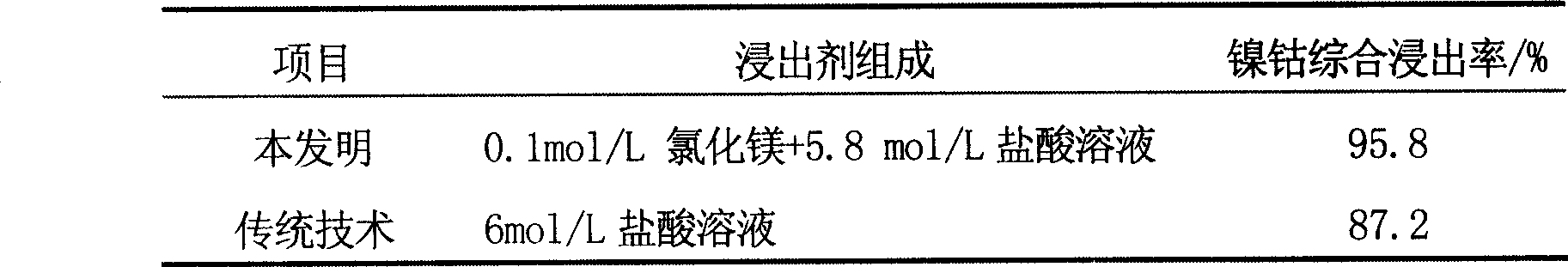

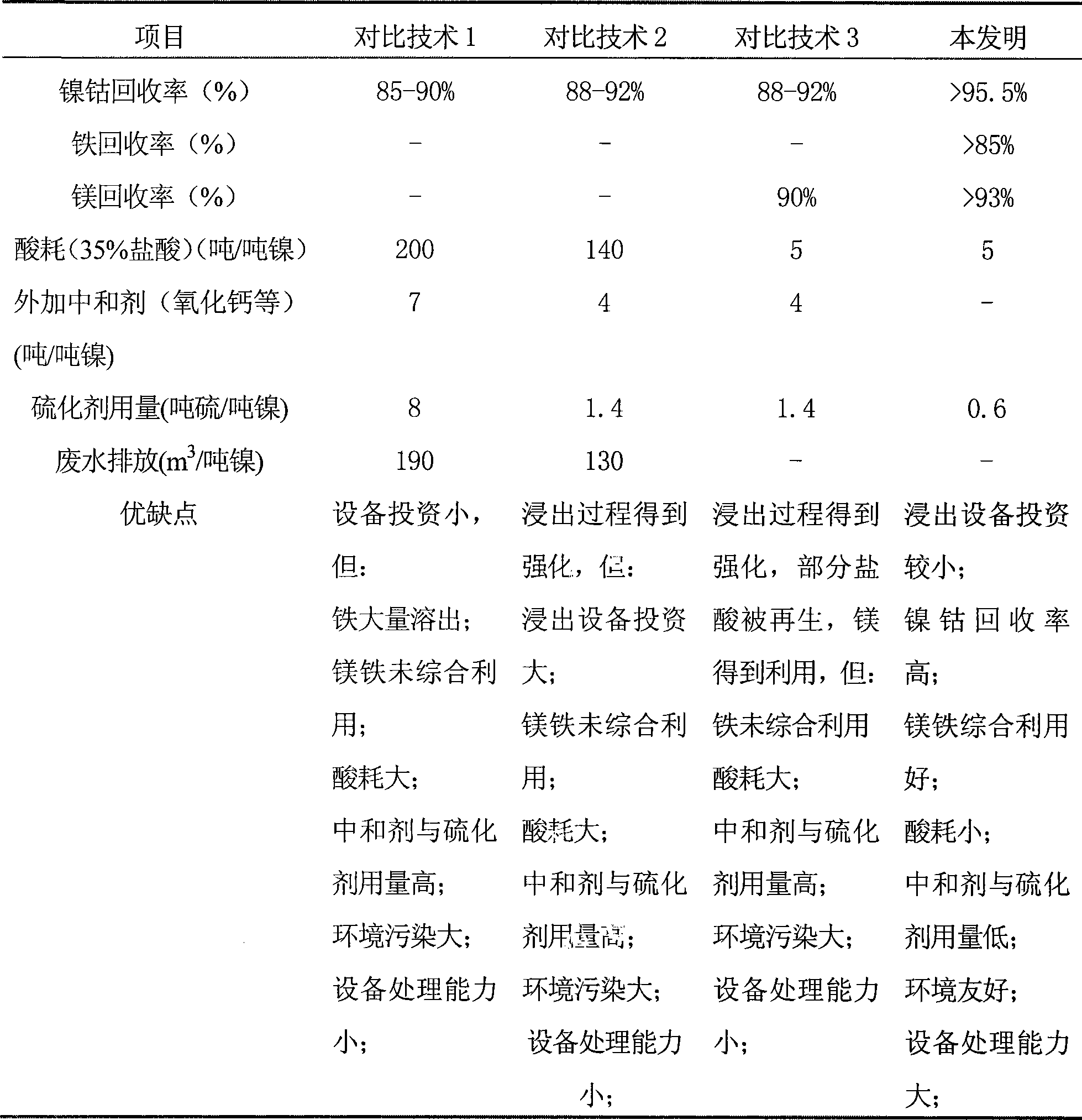

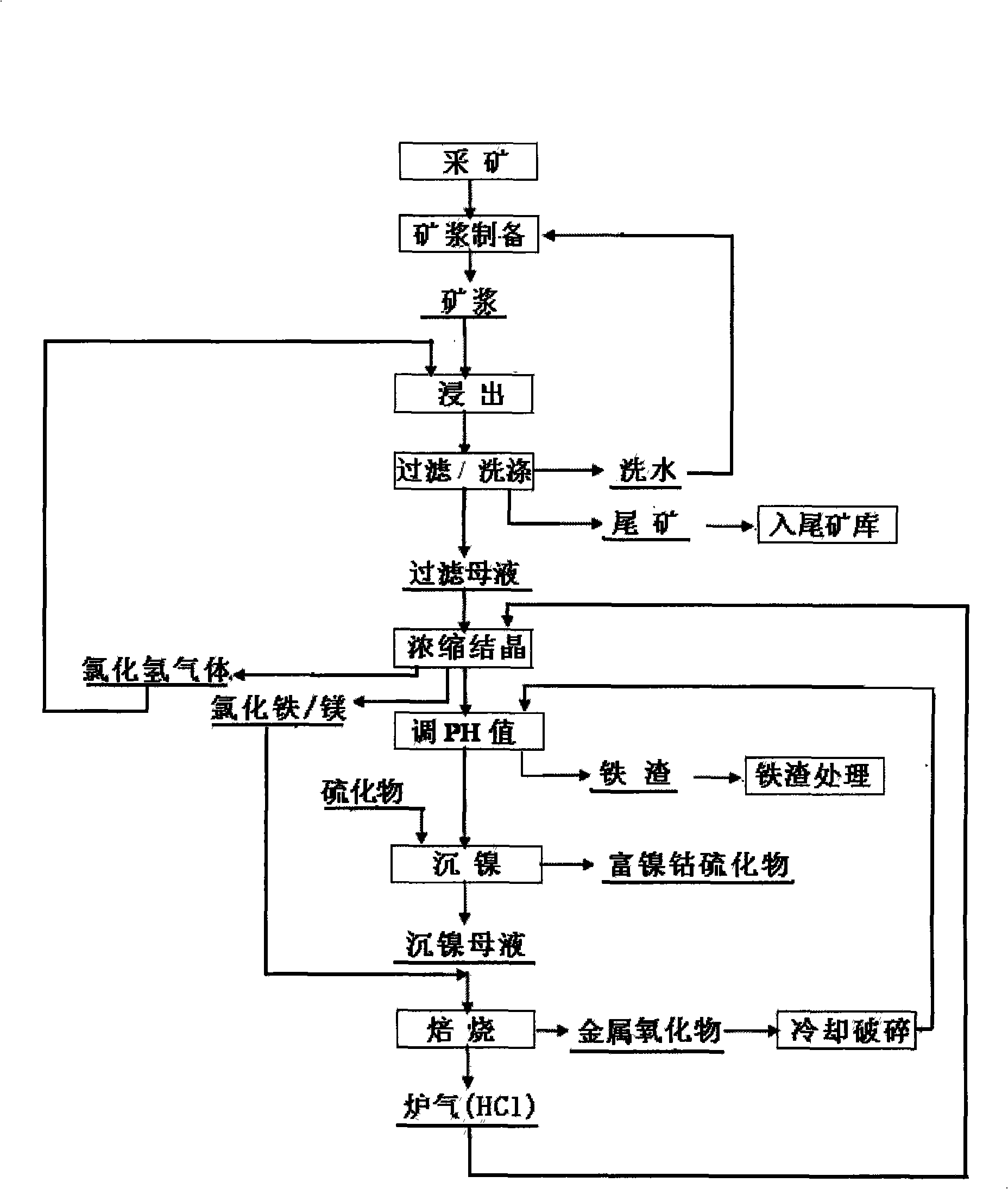

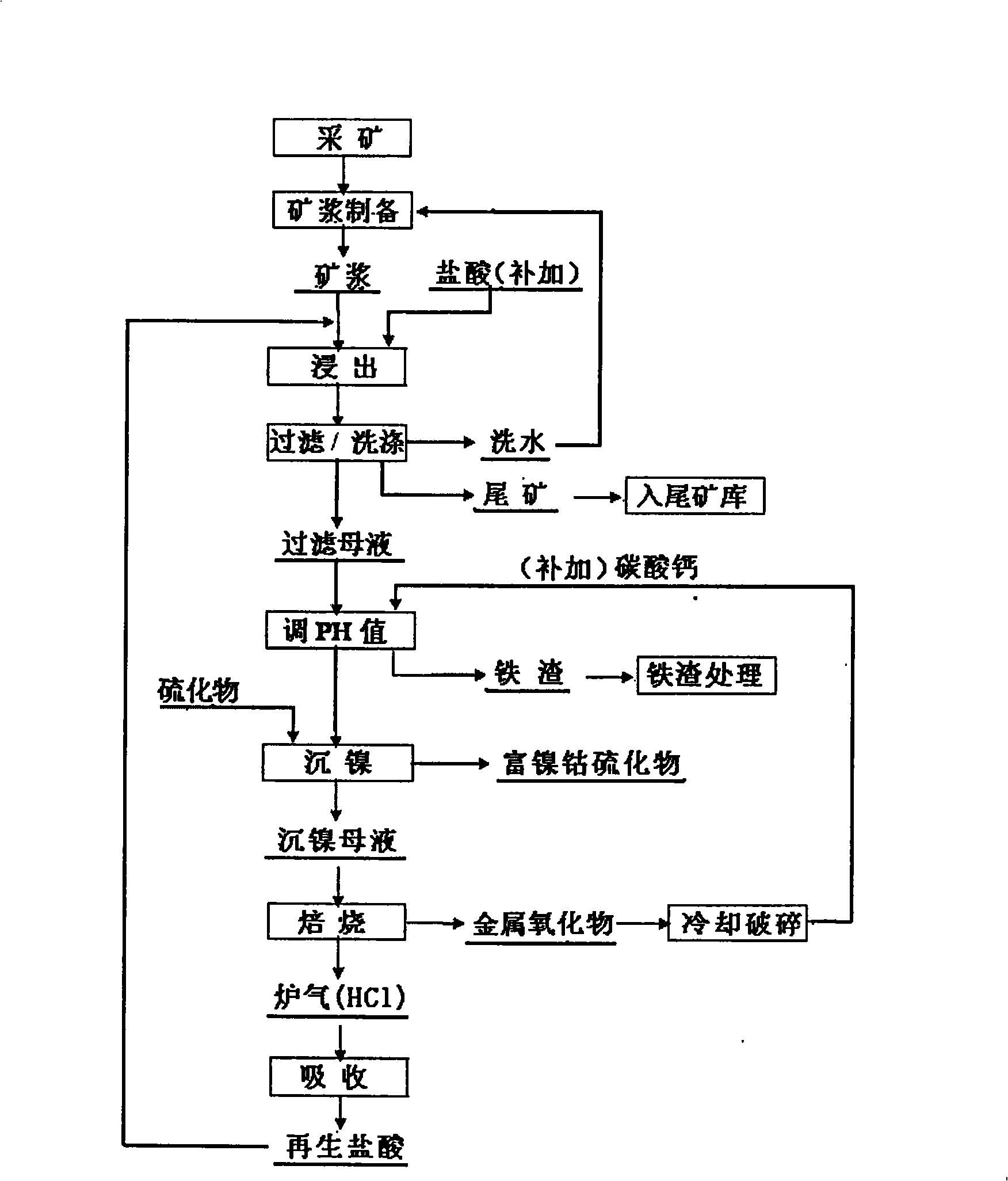

Method for extracting valuable metals from laterite nickel mine with hydrochloric acid full-closed circulation method

ActiveCN101509072AImprove leaching efficiencyIncrease profitMagnetic separationProcess efficiency improvementMetal chlorideWastewater

A method for extracting valuable metals from laterite nickel ore on the basis of the hydrochloric acid fully-closed circulation method belongs to the field of non-ferrous metallurgy. Crushed laterite nickel minerals are taken as raw material and the technique comprises the following technological steps: chlorination-leaching; recovering iron (Fe) from leaching residue; extracting nickel (Ni) and cobalt (Co); spray-drying the mother liquor; and calcining. By leaching the laterite nickel minerals with a mixed solution of hydrochloric acid and metal chlorides as a leaching agent under the proper conditions of heating and pressurizing and further precipitating nickel and cobalt with a compound vulcanizing agent, the overall recovery rate of nickel and cobalt is high; the closed circulation of hydrochloric acid is realized while processing the laterite nickel minerals with water and hydrochloric acid, therefore, the method is environment-friendly by realizing the zero discharge of waste water; comprehensive utilization of the resources, such as Ni, Co, Fe and Mg, in the laterite nickel ore can be realized; and the resources can be efficiently utilized and the clean production can be realized by recovering and reutilizing the waste heat and the residue acid during the production.

Owner:CENT SOUTH UNIV

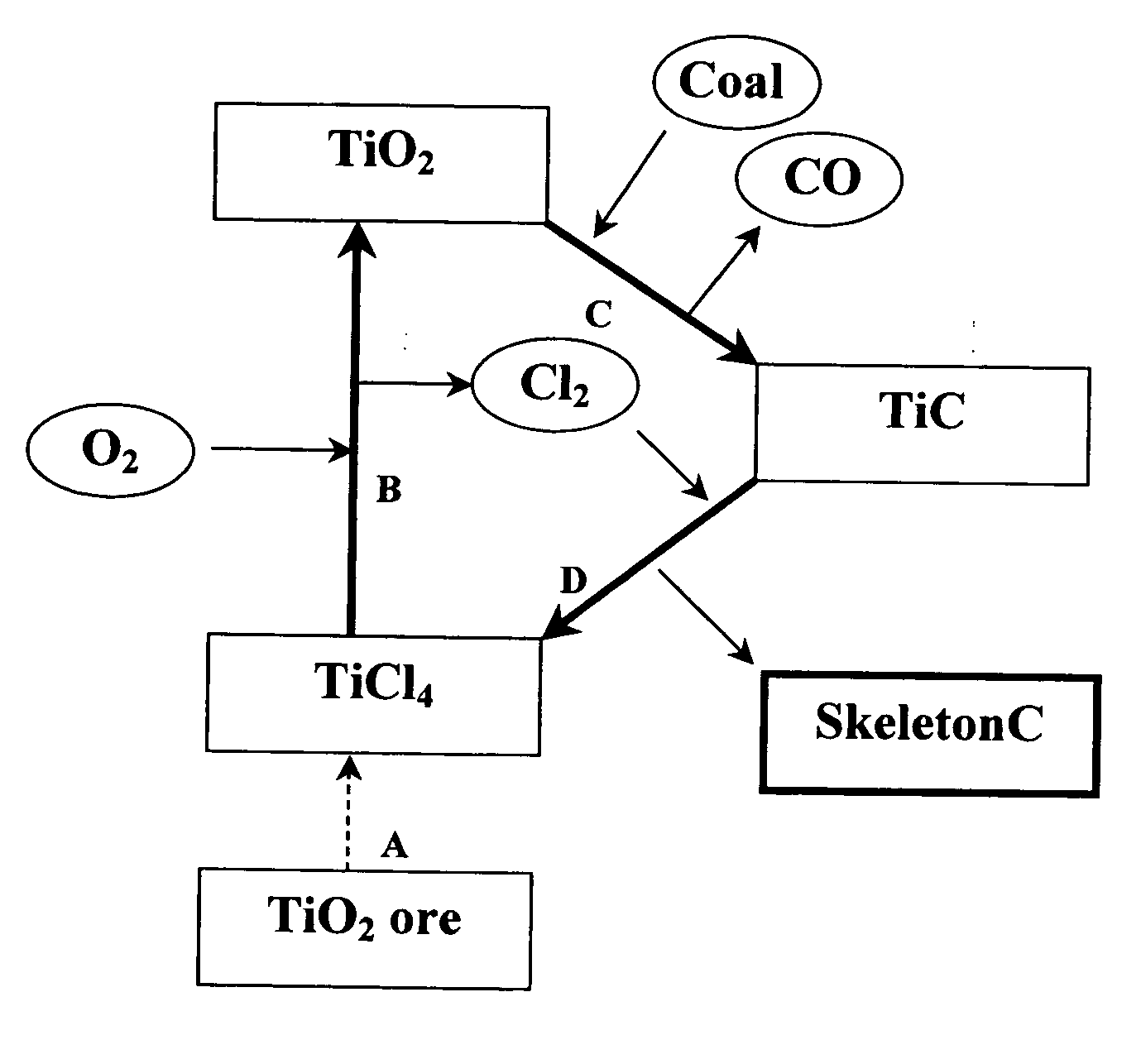

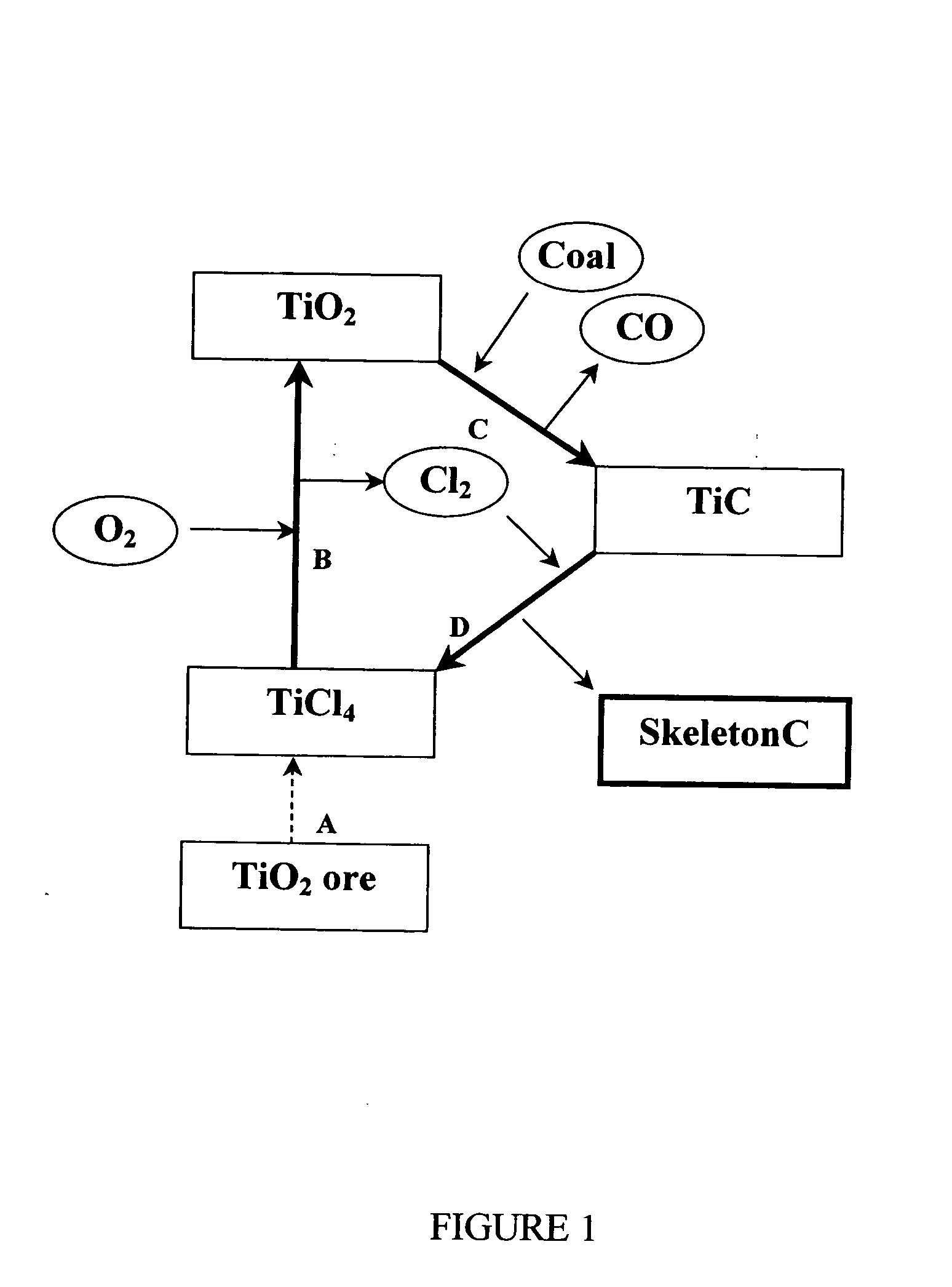

Method for manufacturing the nanoporous skeletonC material

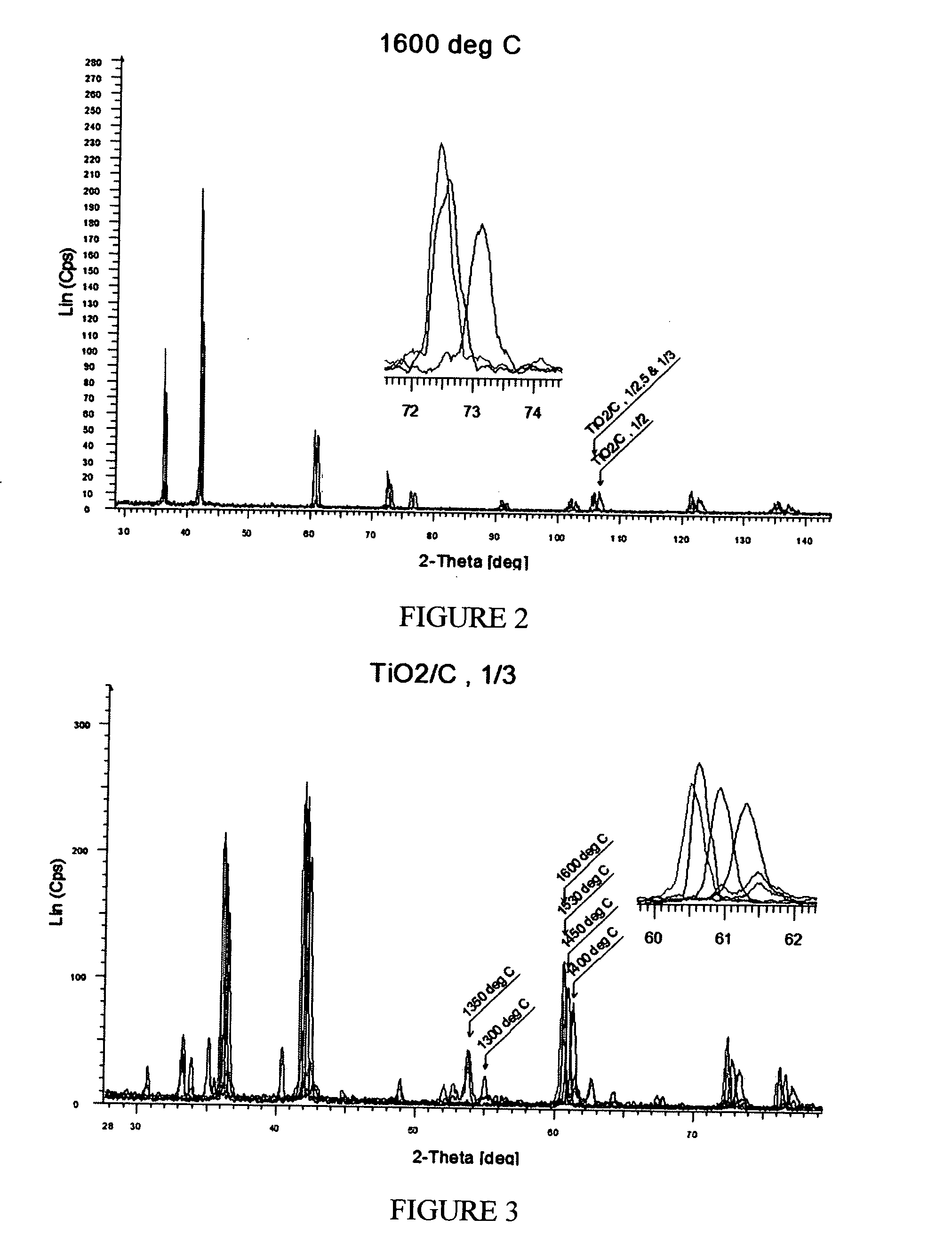

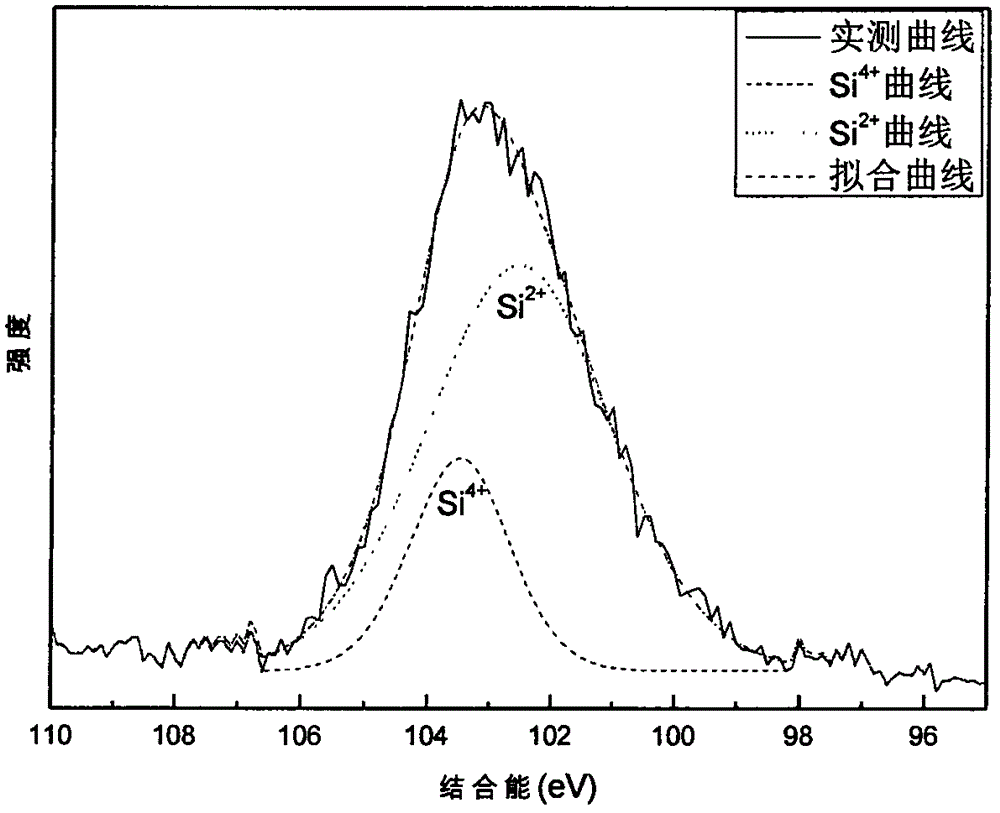

InactiveUS20060251565A1Noticeable economic benefit in productionWaste minimizationTitanium carbideCarbon preparation/purificationMetal chlorideCarbide

A method to produce the nanostructured carbon material comprising the steps of synthesis of metal or metalloid oxide (STAGE B) from respective metal or metalloid chloride, synthesis of metal or metalloid carbide (STAGE C) from respective metal or metalloid oxide and synthesis of metal or metalloid chloride (STAGE D) from the solid product wherein the metal or metalloid carbide in STAGE C is synthesized from the respective metal or metalloid oxide produced in STAGE B.

Owner:CARBON EE OU

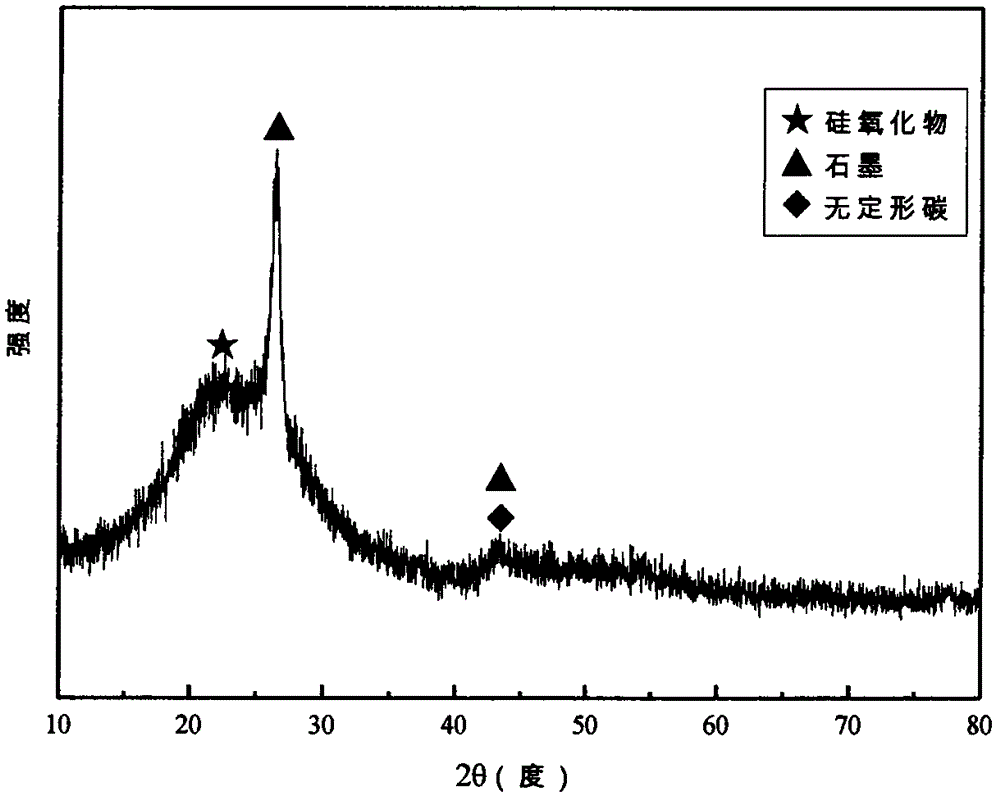

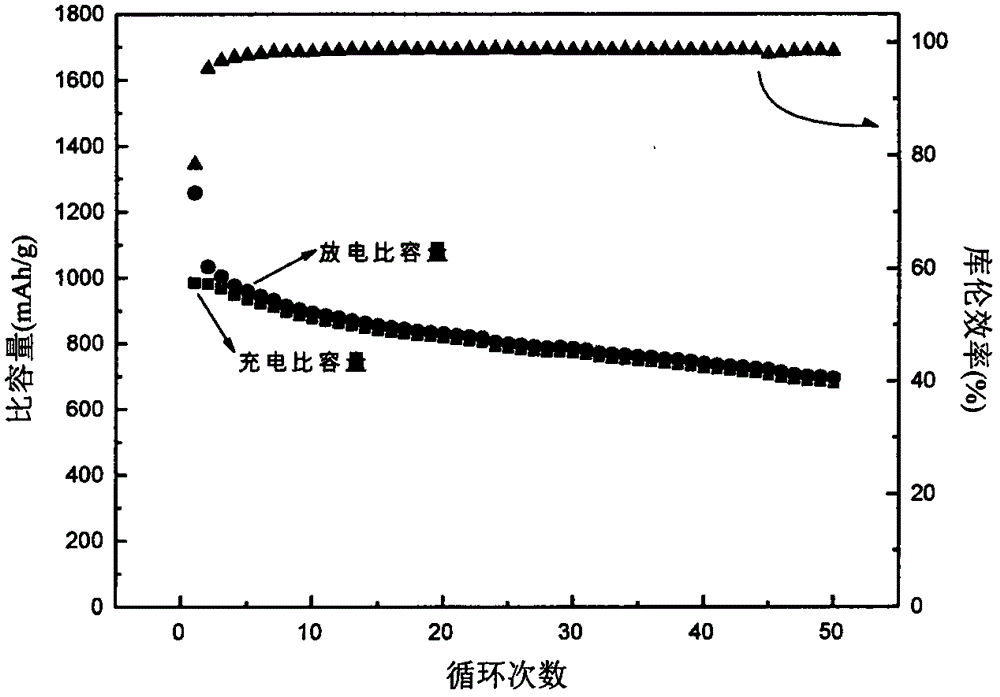

Silicon oxide composite negative pole material for lithium ion secondary battery and preparation method thereof

ActiveCN104577066AReduce manufacturing costImprove the first Coulombic efficiencyCell electrodesFiltrationSilicon oxide

The invention relates to a silicon oxide composite negative pole material for a lithium ion secondary battery and a preparation method thereof. The composite material consists of silicon oxide, graphite type carbon materials and amorphous carbon materials. The preparation method comprises the following steps: performing magnesiothermic reduction on silicon dioxide so as to generate the silicon oxide by using alkaline(soil) metal chloride as a heat absorbent; after performing acid corrosion, sucking filtration, washing and vacuum drying on the silicon oxide, performing pre-ball milling on the dried silicon oxide and graphite; then complementing an organic carbon source, performing secondary ball milling, and then performing high-temperature heat treatment so as to obtain the silicon oxide composite negative pole material. The oxygen content of the silicon oxide is controlled by regulating the proportion of the silicon dioxide to magnesium, and then the silicon oxide is uniformly mixed with the graphite type carbon materials and the organic carbon source. The silicon oxide composite negative pole material disclosed by the invention has the characteristics of a higher first-time Kulun efficiency, a high specific capacity, a better cycle performance and the like; the preparation method adopted by the invention is easy in operation, simple in technology, low in cost and suitable for the industrial mass production.

Owner:NANKAI UNIV

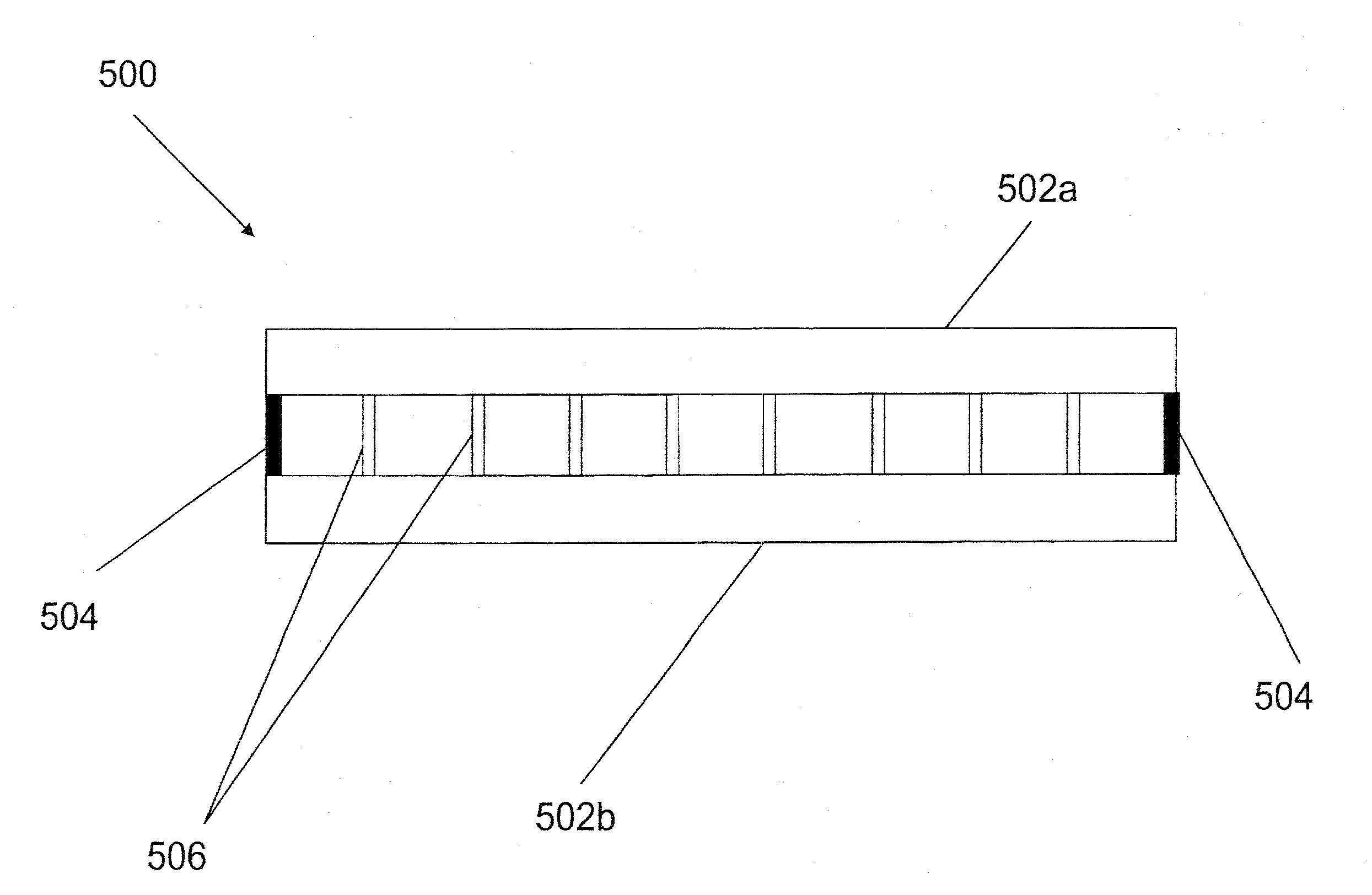

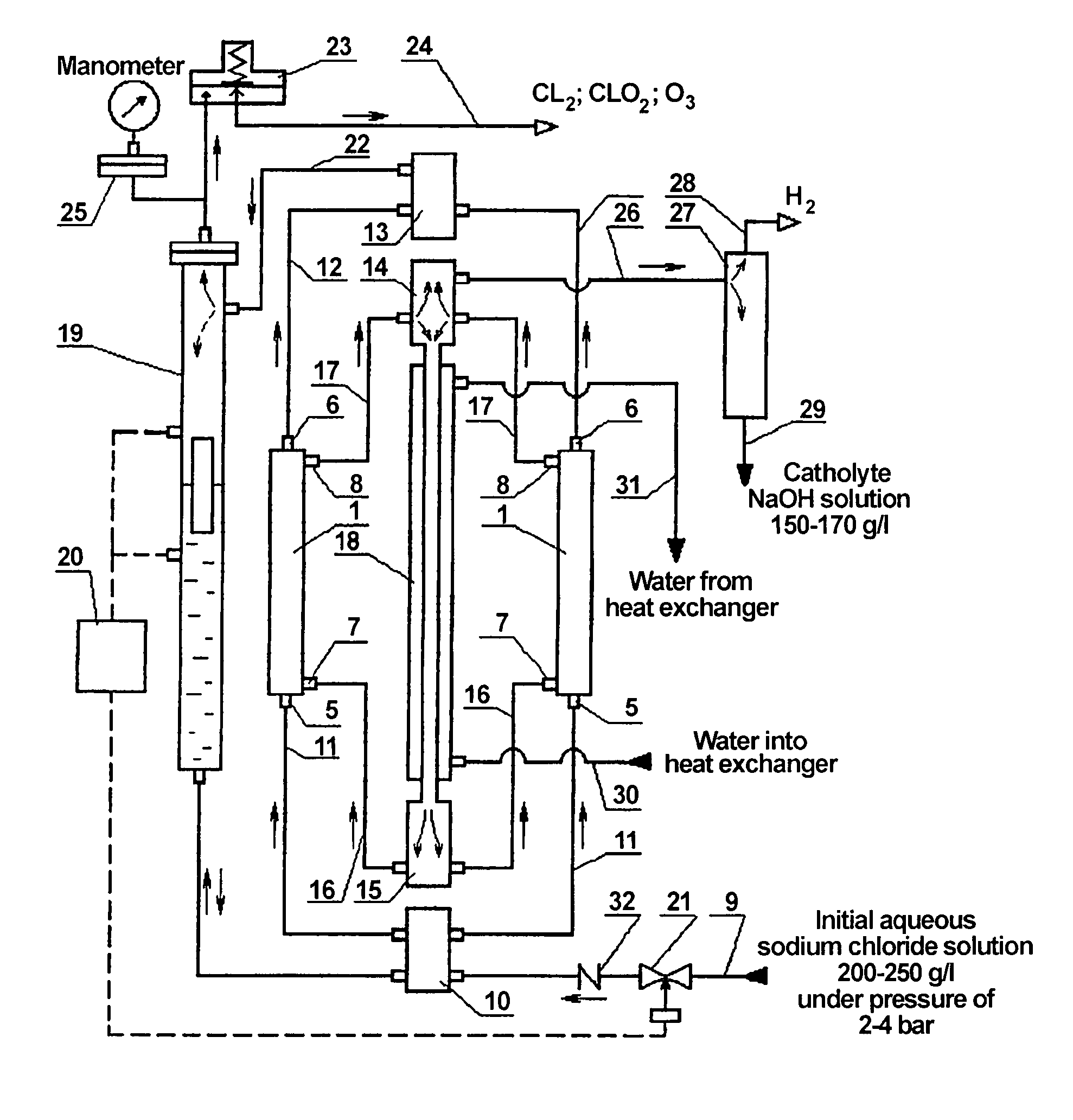

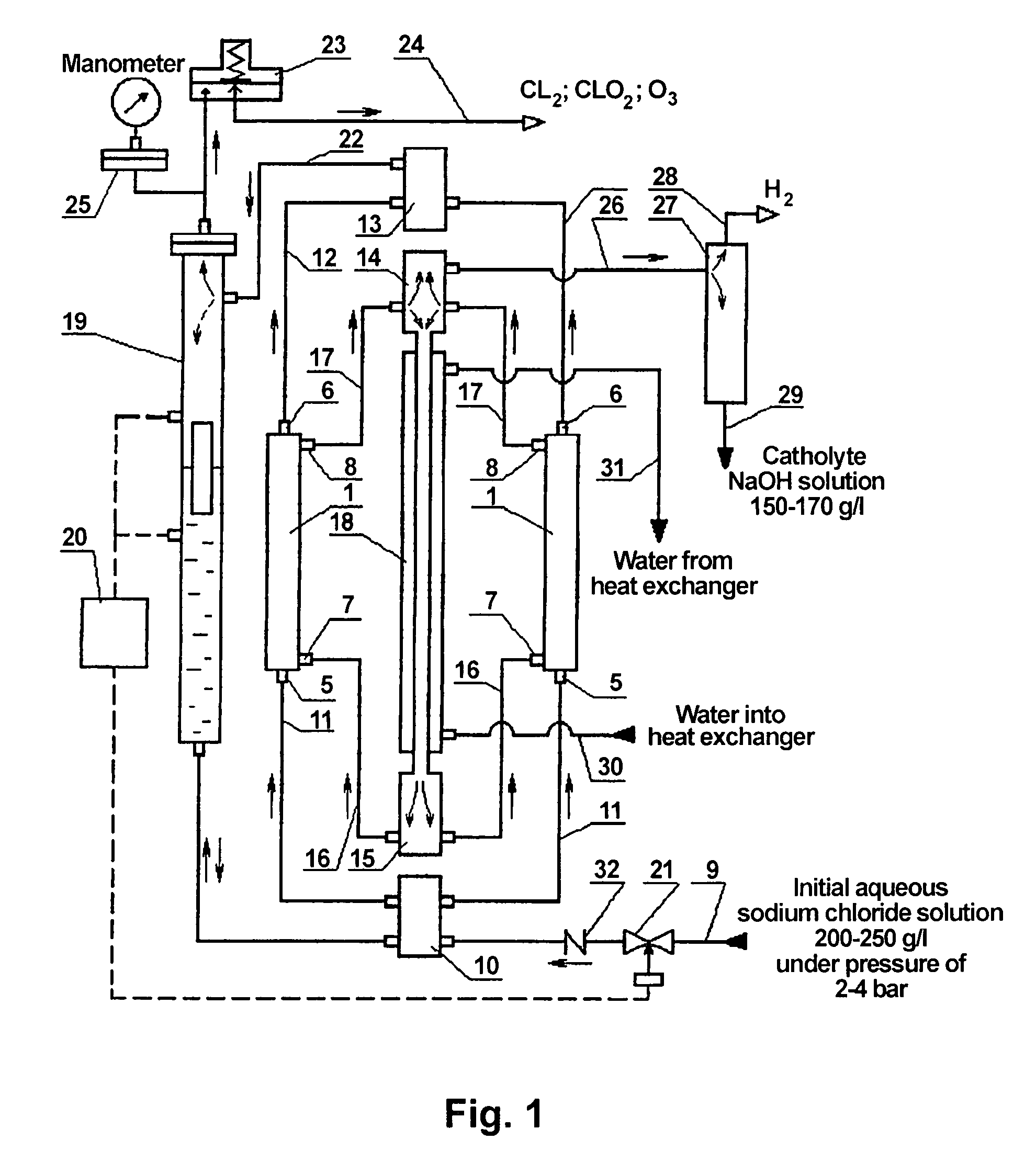

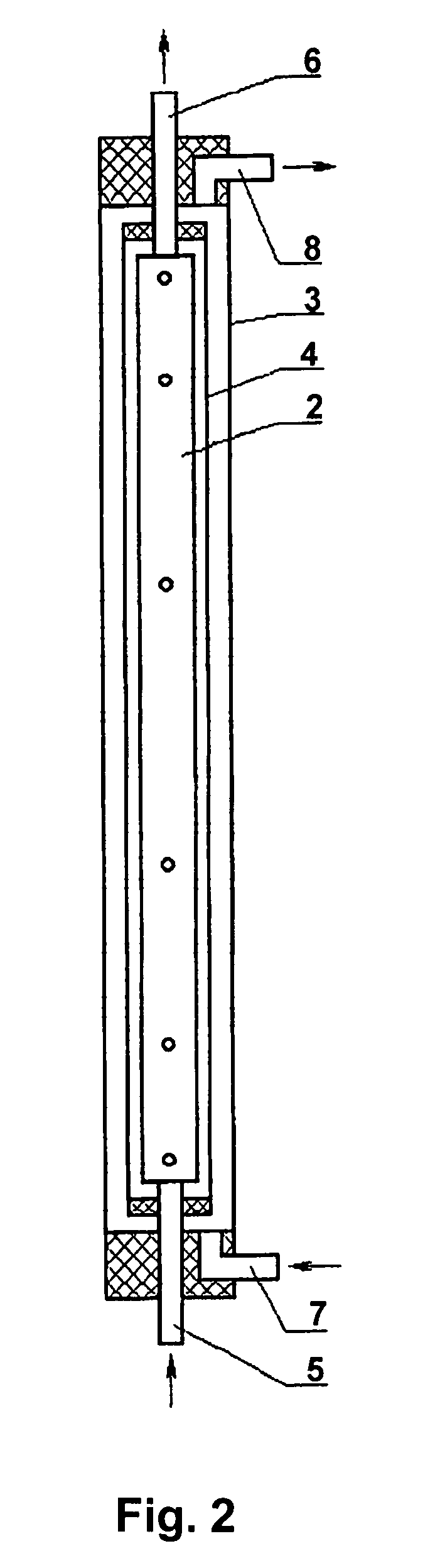

Device for producing anodic oxidaton products of an alkali or alkali-earth metal chloride solution

ActiveUS7897023B2Improve productivityReduce power consumptionCellsWater/sewage treatment apparatusElectrochemical responseElectrolysis

The invention relates to chemical engineering, in particular to devices for electrolyzing aqueous solutions of alkali or alkali-earth metal chlorides and for obtaining gaseous electrolytic products such as chlorine and oxygen. It can be used for water purifying and disinfecting processes and for electrochemically producing some chemical products. The inventive device includes at least one electrochemical reactor (1) comprising from 2 to 16 electrochemical cells. Lines for supplying and discharging cathode and anode chambers are embodied in the form of pipelines having an inner diameter equal to or less than 0.5 of the interelectrode distance and lengths which are equal to or greater than 2 Ld, wherein the interelectrode distance is an anode-to-cathode distance and Ld is the cathode length. A manifold for supplying an initial solution (10), a lower manifold of the cathode circulation circuit (15), a heat exchanger (18), an upper manifold of the cathode circulation circuit (14) and a manifold for collecting gaseous products of the anodic chamber cells (13) are arranged along the same vertical axis. The upper manifold of the cathode circulating circuit (14) is mounted at a height not less than then the distance equal to Ld from the cathode chamber output. The number of the inputs and outputs of the manifolds corresponds to the number of cells in the reactor, and said inputs and outputs are arranged symmetrically with respect to the vertical axis of symmetry of the manifold.

Owner:BAKHIR VITOLD MICHAILOVI +1

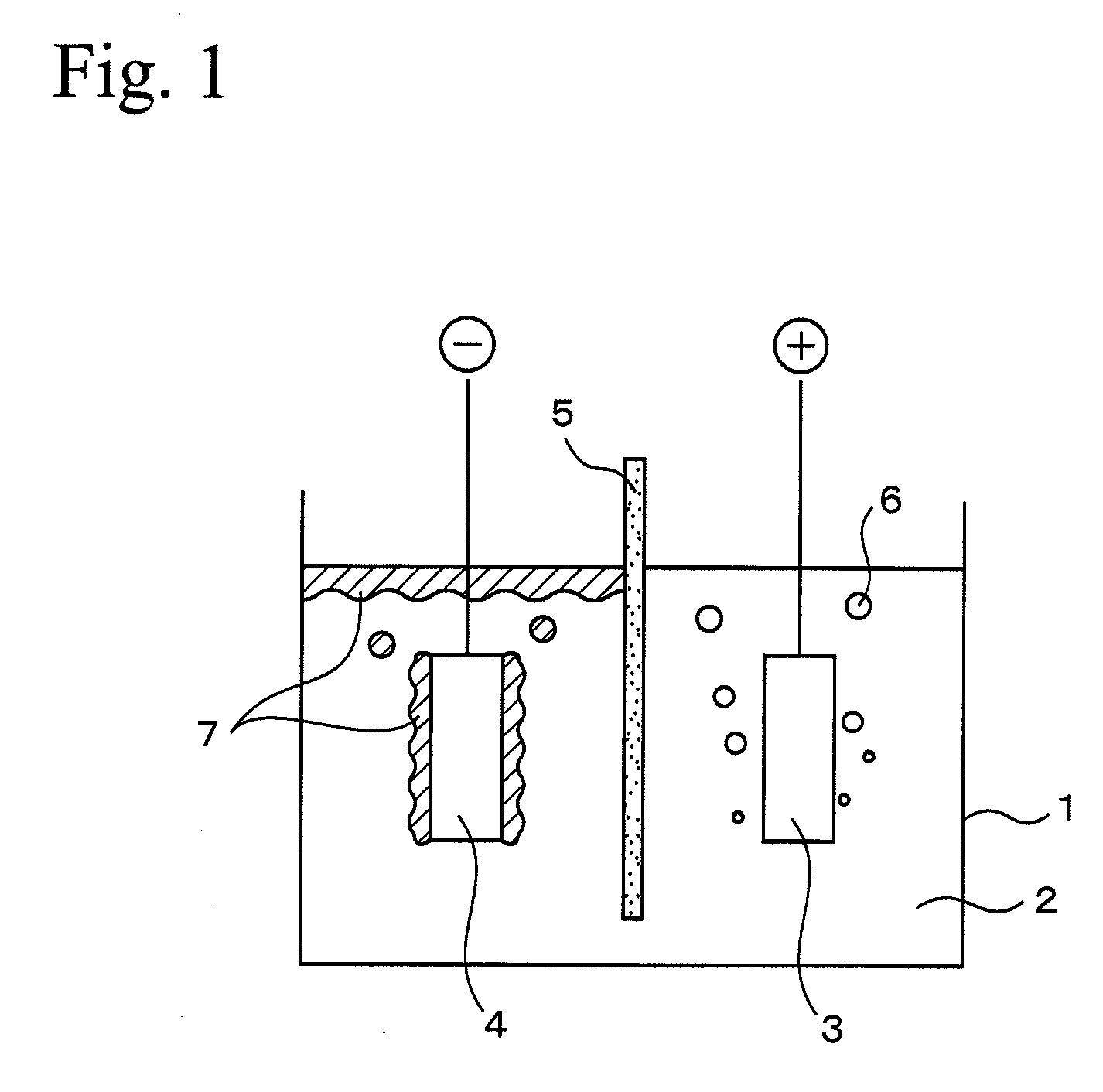

Method for Production of Metal by Molten-Salt Electrolysis and Method for Production of Titanium Metal

InactiveUS20080053838A1Effective recoveryReduce solubilityElectrolysis componentsMetal chlorideElectrolysis

A method for production of metal by molten-salt electrolysis is a method for production of metal by molten-salt electrolysis which is performed by filling molten salt of a metal chloride in an electrolysis vessel having an anode and a cathode, and a molten salt which reduces solubility of the metal in the molten salt is used.

Owner:TOHO TITANIUM CO LTD +1

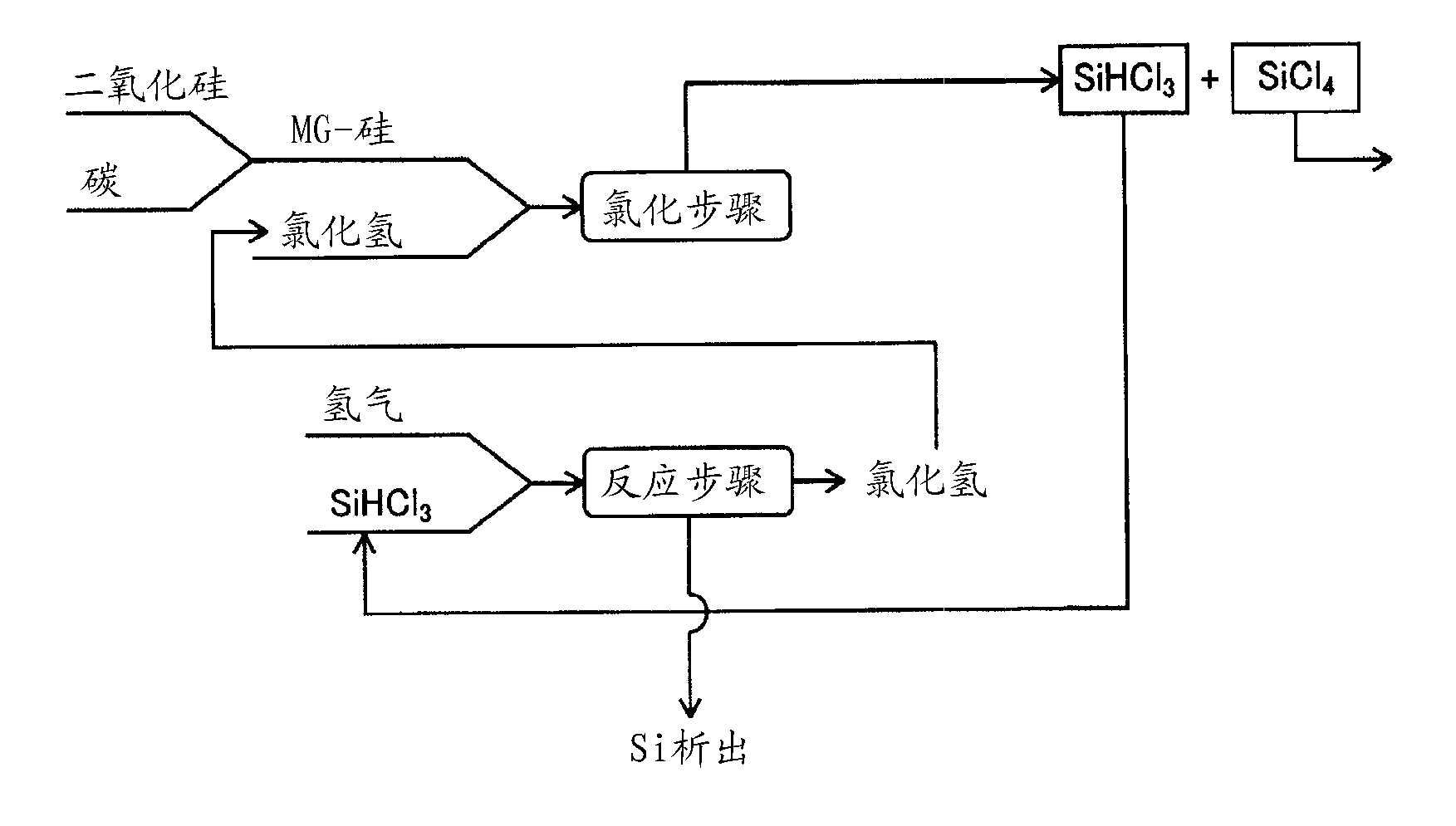

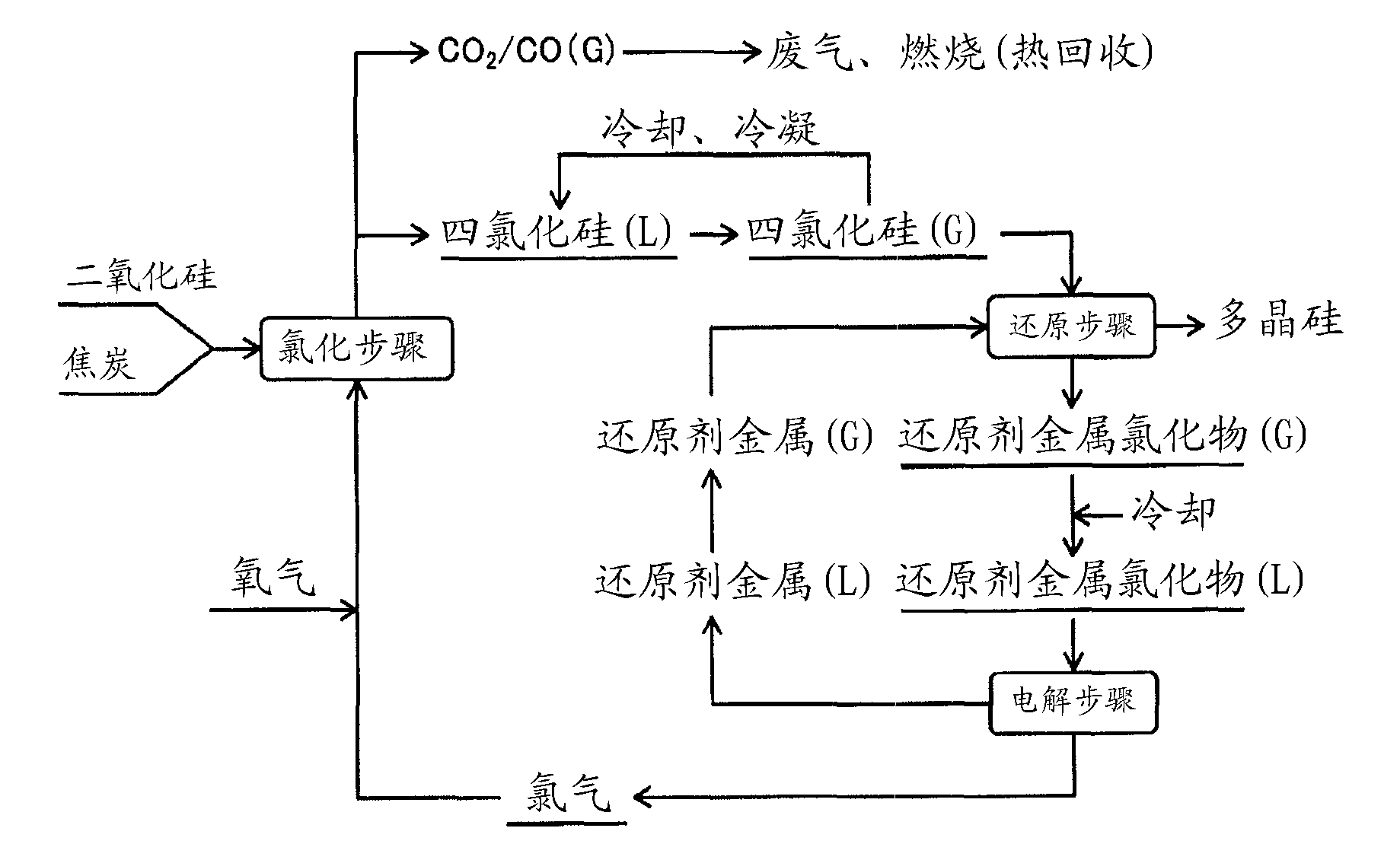

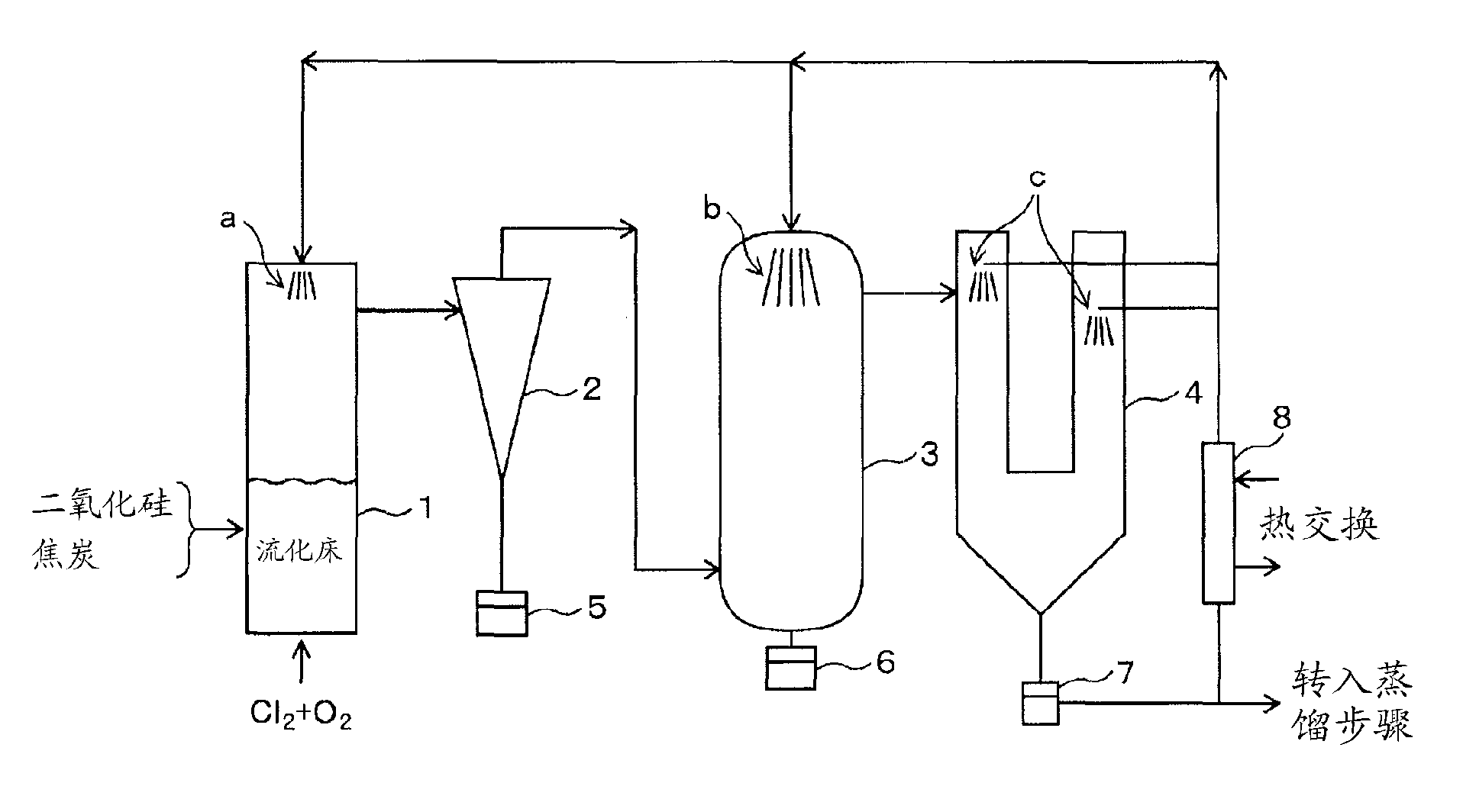

Method for manufacturing polysilicon and method for manufacturing silicon tetrachloride

InactiveCN102686514AEfficient use ofCheap manufacturingSiliconHalogenated silanesElectrolysisSilicon dioxide

Provided is a method for manufacturing polysilicon and silicon tetrachloride. The polysilicon manufacturing process used in said method is energy-efficient and can use an inexpensive raw material, the supply of which is stable. The chlorination reaction in said process proceeds smoothly and post-chlorination impurities are minimized. The provided method comprises: a chlorination step which generates silicon tetrachloride by chlorinating granules comprising silicon dioxide and a carbon-containing substance; a reduction step which generates polysilicon by using a reducing metal to reduce the silicon tetrachloride; and an electrolysis step which generates chlorine gas and a reducing metal by performing molten-salt electrolysis on a reducing metal chloride generated as a by-product from the reduction step. In the chlorination step, chlorine gas is supplied to the silicon dioxide and the carbon-containing substance in the presence of oxygen gas in order to react said substances. The reducing metal generated in the electrolysis step is reused as the reductant for the silicon tetrachloride in the reduction step, and the chlorine gas generated in the electrolysis step is reused in the chlorination step.

Owner:JNC CORP +2

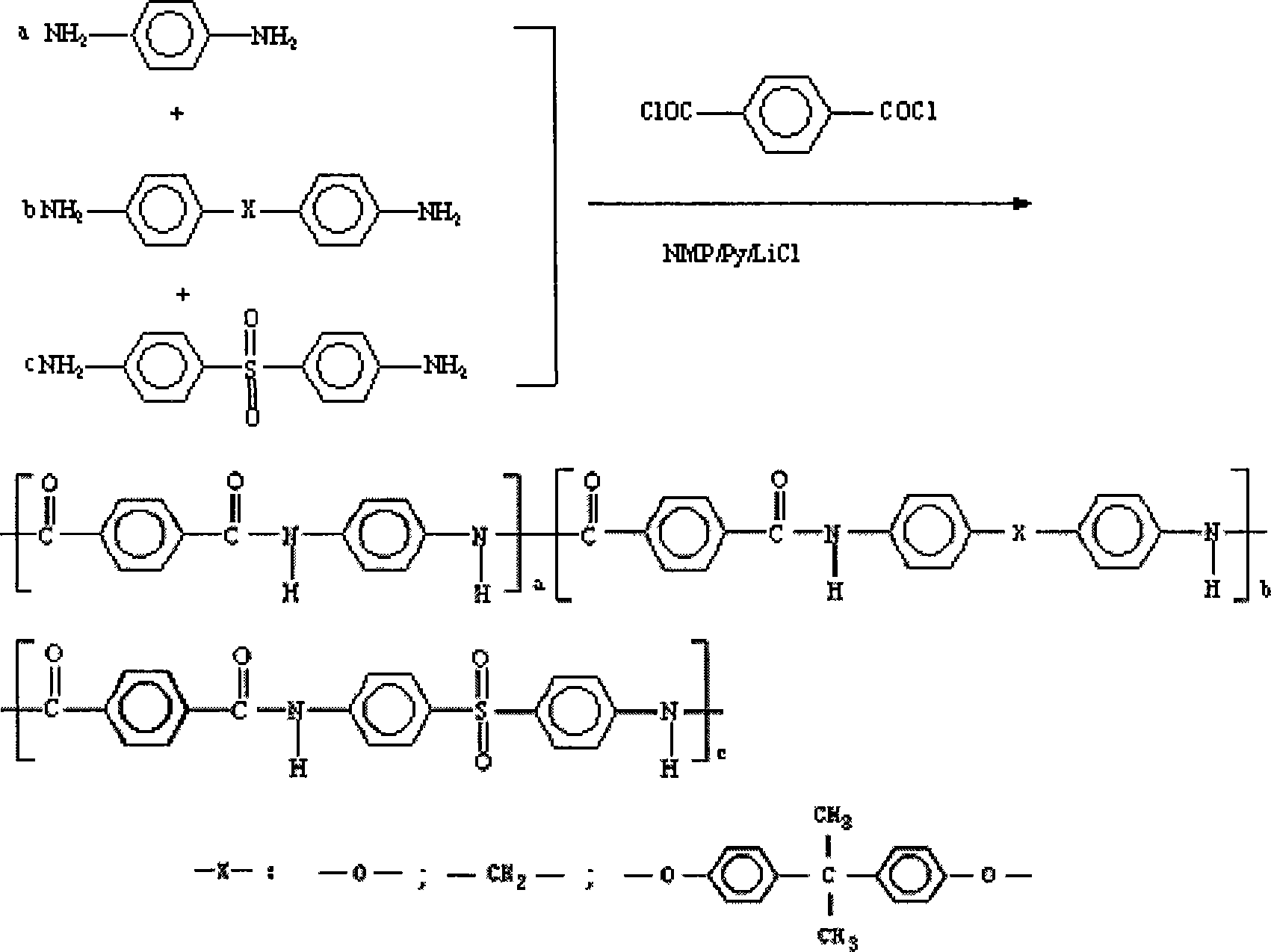

Random copolymerization polysulfonamide spinning liquid and preparation method thereof

InactiveCN101235552ADisruption of regularityImprove flexibilityMonocomponent copolyamides artificial filamentSpinning solutions preparationMetal chlorideMechanical property

The invention relates to random copolymerization poly-sulfone amide spinning fluid which is composited by three species aromatic diamine and terephthaloyl chloride and a method for preparing the random copolymerization poly-sulfone amide spinning fluid, wherein the spinning fluid takes the N-methyl-2pyrrolidone NMP as the dissolvent, monomer and the mole percent which are adopted by the method are as following: the aromatic diamine 40%-60%, the terephthaloyl chloride 60%-40%, taking the above total monomer 100% as a benchmark, further adding 1.0%-4.0% alkali chloride as the solvent. Since the method takes the manifold aromatic diamine as the monomer of the poly-reaction, which properly damages the regularity of the main chain, however, which has no effect to arrange the original crystal lattice, increasing the flexibility of the chain at various degree, the method is beneficial for orienting and crystallizing of the entire molecular chain and for improving the mechanical property of the material. The method has the advantages of simple technology, condition optimized, high operability, convenient manufacture and low cost.

Owner:SHANGHAI UNIV

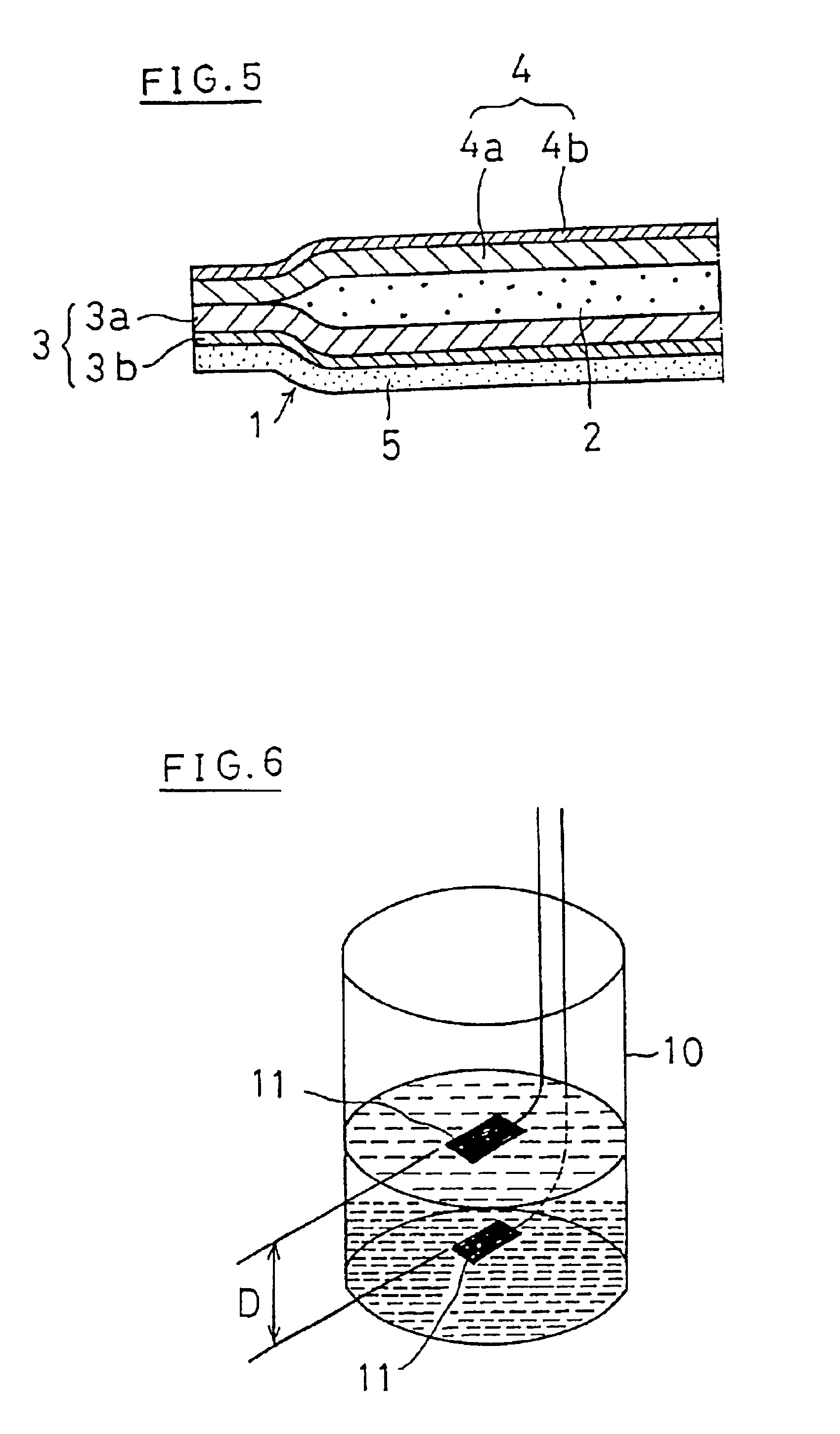

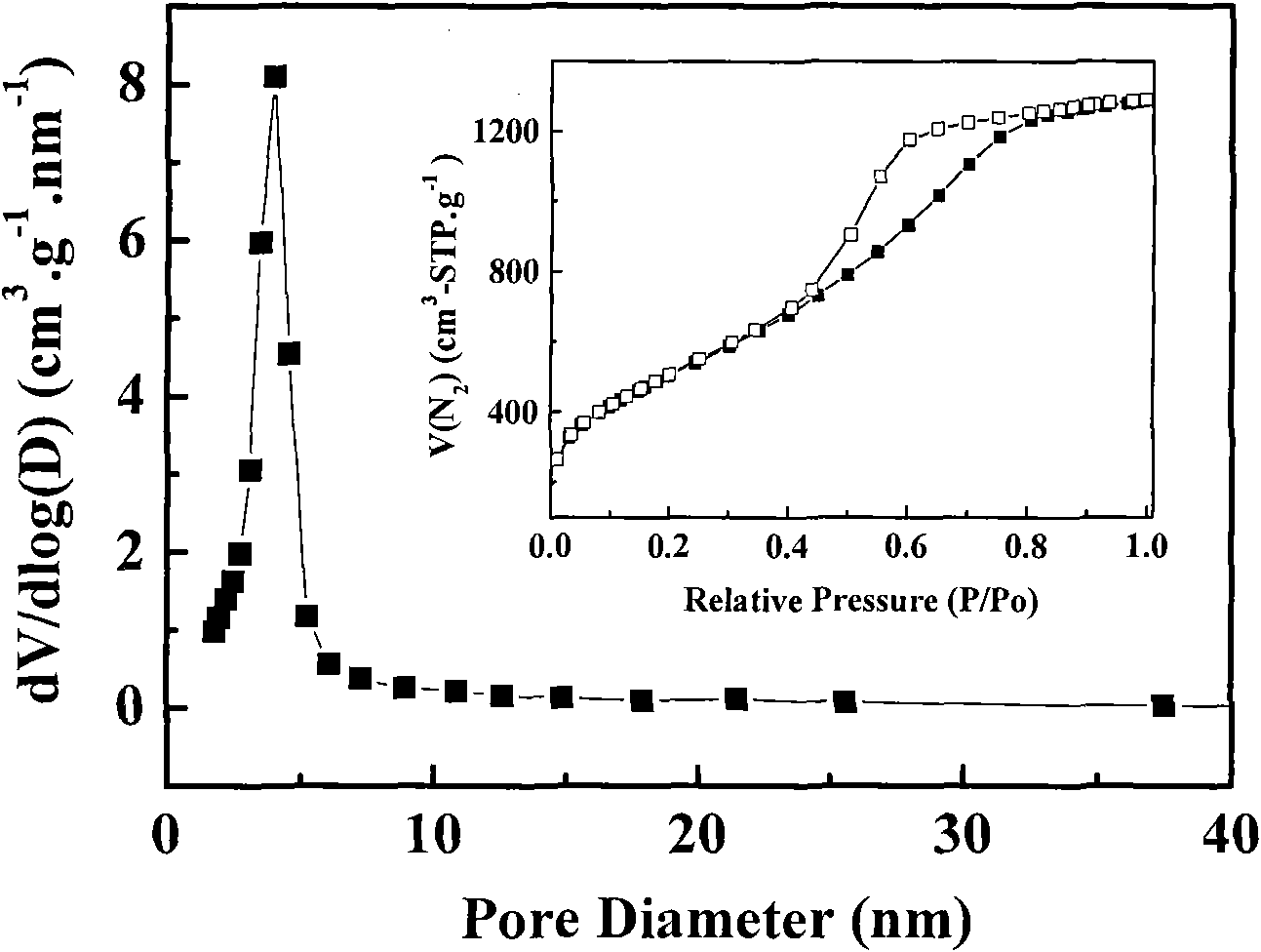

Preparation method of mesoporous carbon material with high specific surface area

The invention relates to a preparation method of a mesoporous carbon material with a high specific surface area, which comprises the following steps: using carbohydrates, phenolic compounds and metalchlorides as raw materials for hydrolysis and polymerization reaction, and then, carrying out the steps of drying, curing, carbonizing, washing, baking and the like to prepare the mesoporous carbon material. The invention has rich raw material sources, low cost and simple and easy preparation method. The prepared mesoporous carbon material has the characteristics that the specific surface area is500-2500m<2> / g, the total pore volume is 1.0-3.0cm<3> / g, and the mesoporous ratio is 80-100%. The invention can be probably applied to the fields of adsorbents, catalyst carriers, electrode materials,and the like.

Owner:NANJING UNIV

Process for the treatment of waste metal chlorides

InactiveUS20060183958A1Low costMaximize recoveryTitanium tetrachlorideSilicon oxidesMetal chlorideOrganic chloride compound

A process is described for treating the residues from metal chlorination processes wherein valuable volatile metal chlorides or metalorgano chlorides are recovered while low volatility metal chlorides and chloride complexes are reacted with a neutralizing humectant. The resulting neutral, dry solid is suitable for land fill disposal or for recovery of valuable metal constituents by extractive metallurgy techniques.

Owner:REC SILICON

Submicron transparent crystal alumina ceramic possessing high linear transmittance

The present invention belongs to the field of transparent ceramic material technology, and is especially preparation process of submicron transparent crystal alumina ceramic possessing high linear transmittance. The transparent alumina ceramic is prepared with high purity alumina and nanometer zirconia additive, and through drying pressing and cold isostatic pressing or gel injecting to form, low temperature pre-sintering and hot isostatic pressing sintering. It has ceramic body relative density greater than 99.95 %, average crystal size not greater than 0.5 micron, Vickers hardness of 2200, bending strength of 650-800 MPa and linear transmittance at 600 nm greater than 60 %. It is suitable for use in making transparent bulletproof armoring, high temperature observation window, false teeth, etc.

Owner:韩敏芳 +1

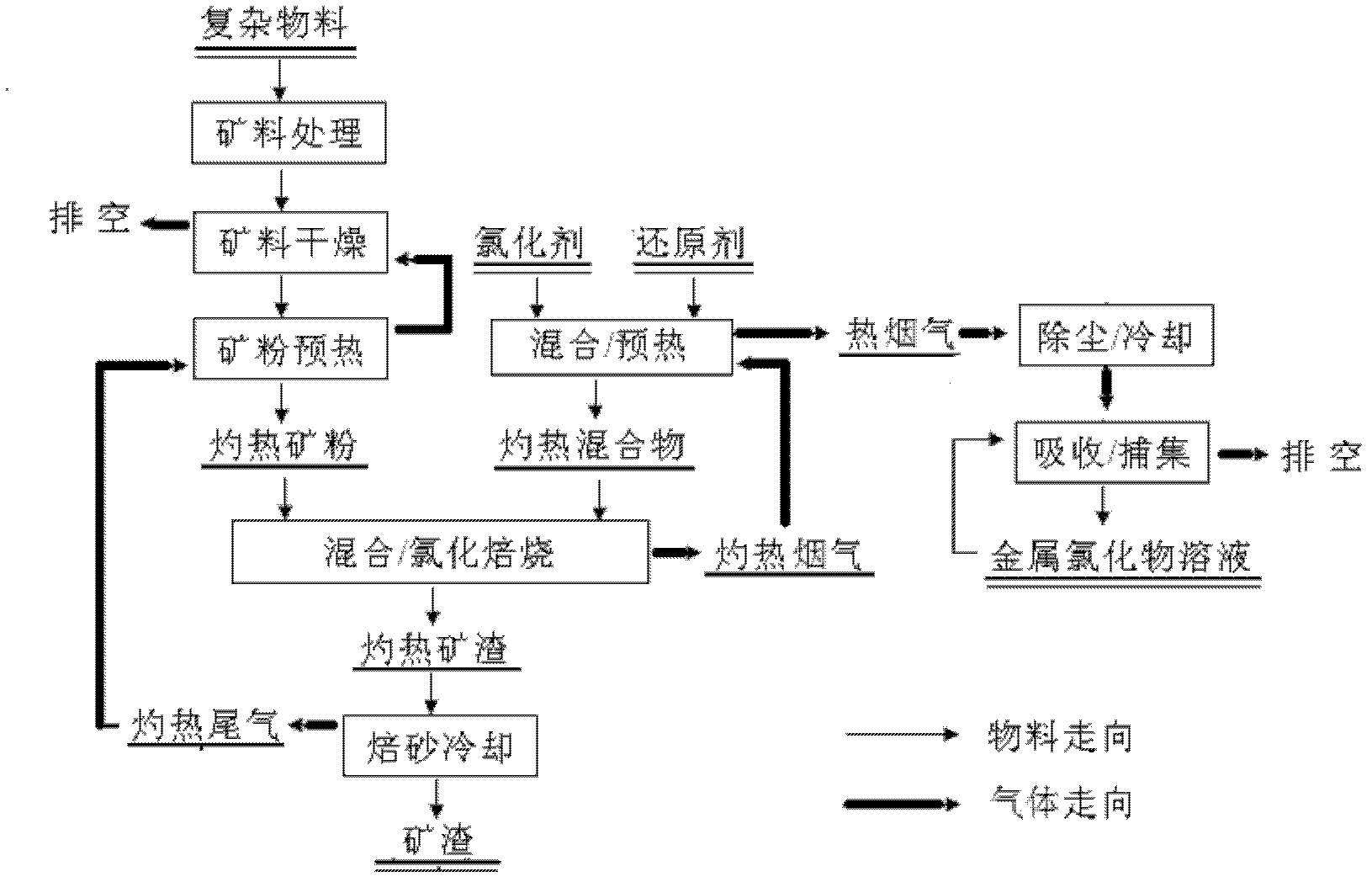

Process for abstracting nickel and cobalt by using wet method to chloridize laterite-nickel ore

InactiveCN101285127AImprove leaching efficiencyIncrease profitProcess efficiency improvementMetallic sulfideLaterite

The invention relates to a method for extracting nickel and cobalt from a laterite-nickel ore, comprising the following steps of mineral preparation, chloride leaching, solid-liquid separation, leaching liquid concentration, sulfide precipitation, solid-liquid separation and hydrochloric acid recovery of the laterite-nickel ore. A chloride leaching agent is mixing solution of metal chloride and hydrochloric acid; the leaching liquid is concentrated by heating; ferric chloride and magnesium chloride are crystallized and separated out so that Fe / Ni ratio is reduced below 1 / 5 of Fe / Ni ratio before the concentration; the magnesium oxide or the ferric oxide generated in the hydrochloric acid recovery process is used as neutralizer; polysulfide, just precipitated metal sulfide and metal sulfide are used as sulfuration precipitator; mother liquor with precipitated nickel is roasted with the ferric chloride and the magnesium chloride which are obtained by concentrating the leaching liquid; the metal chloride in the mother liquor and the metal chloride obtained from the concentration are hydrolyzed into chlorine hydride and metal oxide; and the obtained acid is recycled to use. The method for extracting nickel and cobalt from the laterite-nickel ore improves the leaching rate of valuable metals such as nickel, cobalt and so on in the leaching process of the laterite-nickel ore, reduces the energy consumption and is environment friendly.

Owner:CENT SOUTH UNIV

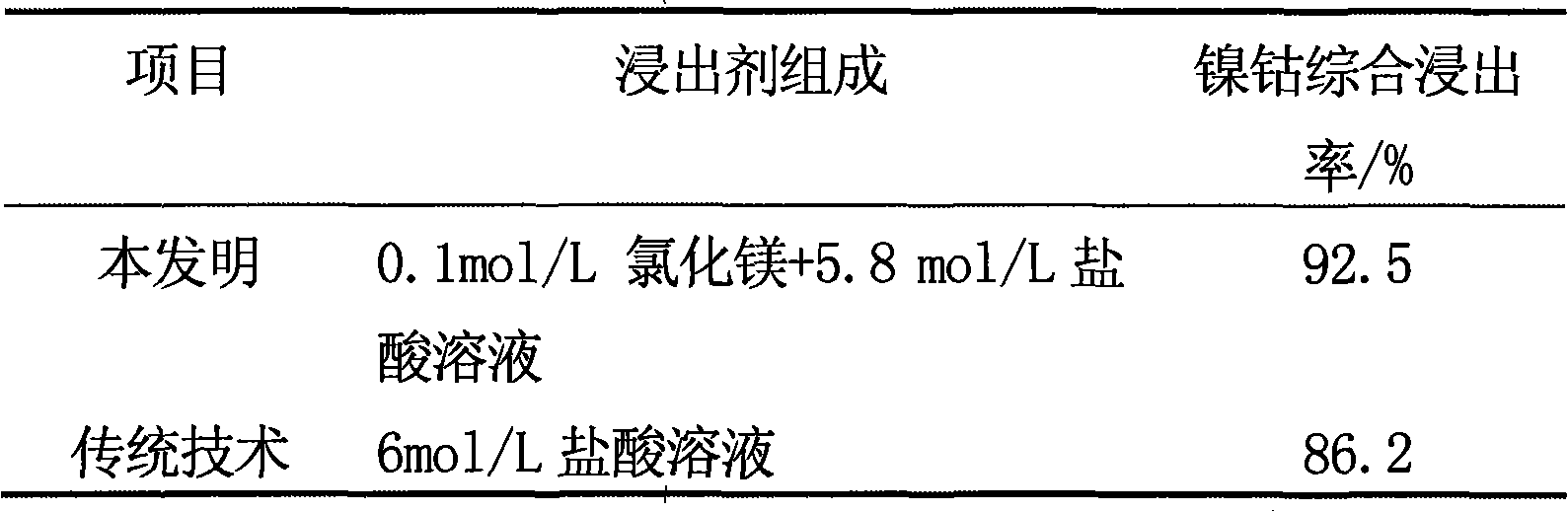

A method for processing low-content non-ferrous metal materials to extract non-ferrous metals

InactiveCN102277485ALow melting pointIncrease relative volatilityProcess efficiency improvementMetal chlorideFlue gas

The invention discloses a method for processing low-content non-ferrous metal materials to extract non-ferrous metals: (1) pretreatment: processing the low-content non-ferrous metal materials into powder materials with a water content not higher than 10% and a particle size of -60 mesh; ( 2) Preheating: Preheat the mixture of reducing agent and chlorinating agent and low-content non-ferrous metal materials to 500-800°C respectively; (3) High-temperature chlorination roasting: add to the preheated low-content non-ferrous metal materials 0~6wt% reducing agent and 4~10wt% chlorinating agent, carry out the chlorination roasting of valuable metals; roasting temperature 800~1100 ℃, roasting time 30~60min; (4) Valuable metal chloride capture recovery: chlorine After the high-temperature flue gas from chemical roasting is collected to remove mineral dust, it is cooled and wet-type collected to recover valuable metal chlorides. The economical and efficient extraction of valuable metals in low-content nonferrous metal materials is realized.

Owner:CENT SOUTH UNIV

Composite metal chloride catalyst and its production process

ActiveCN1814345AReduce dosageThe dosage can be greatly reduced when theCatalyst activation/preparationMetal chlorideActivated carbon

This invention is a complex metal chloride catalyst. Its carrier is active carbon with void ratio>=0.56cm3 / g, specific surface area>= 1000m2 / g, mechanical strength>=90%, and it is made by absorbing mercuric chloride and zinc chloride under condition of 92-96 degree centigrade. Computing as weight percentage, the mercuric chloride is 2-8%, zinc chloride 1-15%. Its advantage is that 1. Mercuric chloride content is low, but activity and stability is boosted 5-20% and 10-20% comparing to existing mercuric chloride catalyst. 2. Mercuric chloride using level can be reduced according to the boost of activity and stability and the catalyst activity is not reduced, and catalyst producing cost is reduced, mercury resource consumption is reduced. Otherwise, catalyst useful life can be prolonged, its dosage can be reduced, and catalyst replacing time is economized, so vinyl chloride producing cost is reduced. 3. Catalyst consumption is few, mercury drain is few. So the damage of drained mercury to environment and product is lightened.

Owner:那风换 +1

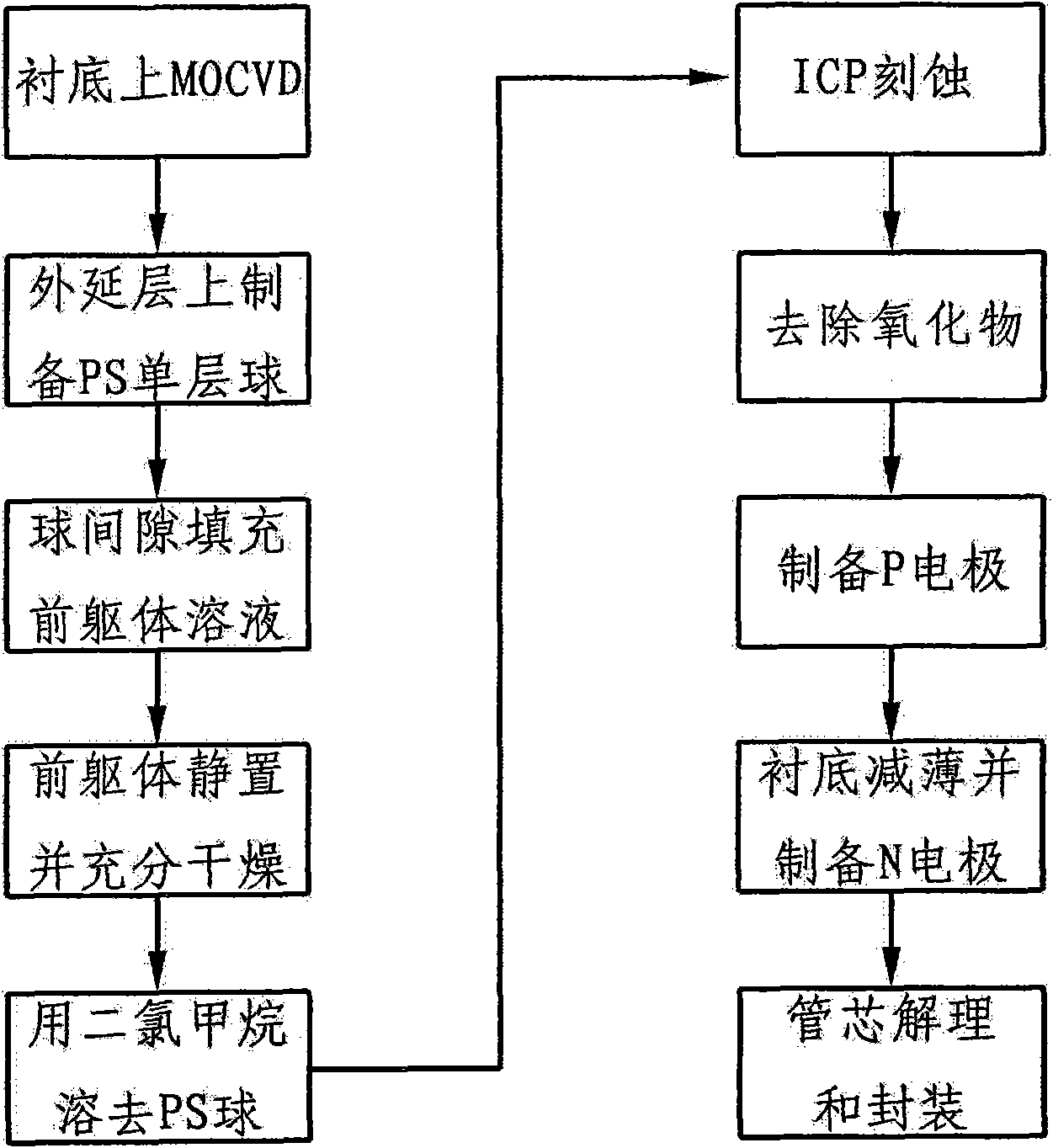

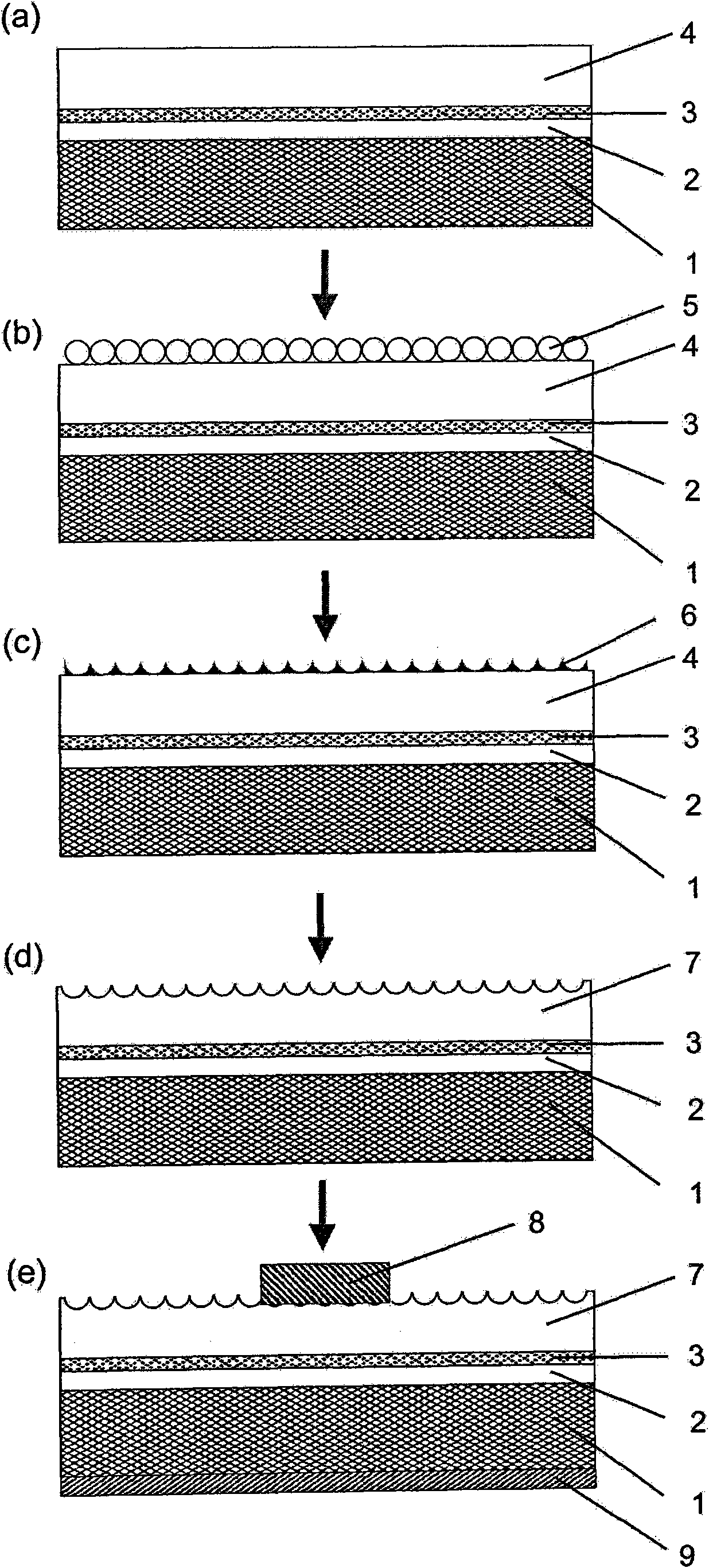

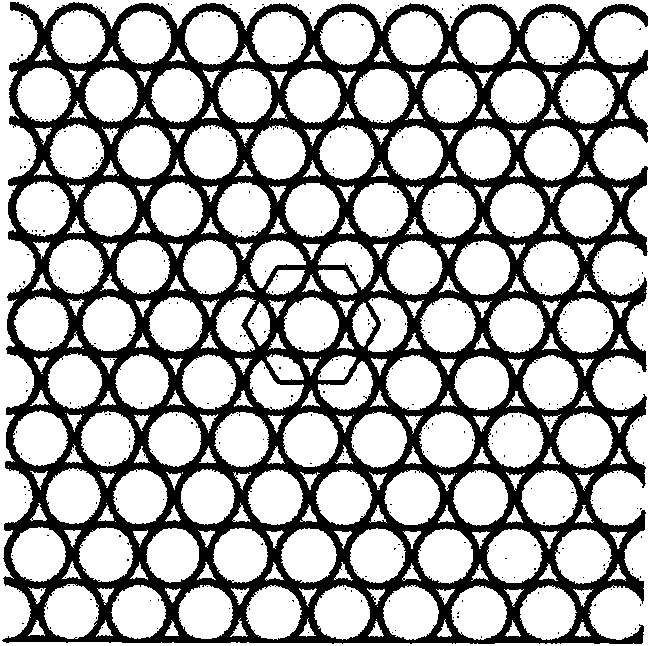

Method for preparing alligatored surface of light-emitting diode by using PS spheres as template

The invention provides a method for preparing an alligatored surface of a light-emitting diode by using PS spheres as template. The method comprises the following steps: (1) performing epitaxial growth according to the conventional method to prepare an epitaxial wafer; (2) paving a layer of one-layer film which comprises closely packed PS spheres on the P-type contact layer obtained through epitaxial growth; (3) mixing precursor which is tetraethyl silicate, metal chloride or metal nitrate with ethanol and water to fill in the gap of the PS spheres of the one-layer film and the P-type contactlayer, standing at room temperature, heating to decompose the mixture and obtain the related oxides; (4) placing the epitaxial wafer in dichloromethane to dissolve the PS spheres, preserving the formed oxides in the gap of the PS spheres and the P-type contact layer on the P-type contact layer according to bowl-shaped periodic arrangement structure; (5) using the formed oxides as mask to perform dry etching on the P-type contact layer and obtain the alligatored surface; and (6) corroding and removing the residual oxides. The invention can be used to prepare the alligatored surface of the light-emitting diode with controllable etching period and depth.

Owner:SHANDONG UNIV

Process for extracting nickel and cobalt from laterite-nickel ore

InactiveCN101338374ARealize closed loop recyclingImprove leaching rateProcess efficiency improvementMetal chlorideSlurry

The invention discloses a method for extracting nickel and cobalt from a lateritic nickel ore which includes the steps of: (1) preparing the slurry of the ore: cracking the ores and preparing the slurry; (2) dipping the ores with muriatic acid: adding the muriatic acid in the slurry of the ore to carry out stirring and extraction under a normal pressure; (3) separating the solid and liquid; (4) neutralizing an extraction liquid; (4) sulfurizing and depositing the nickel; (6) regenerating the muriatic acid: the mother deposition liquid after nickel depositing is concentrated and roasted, the metal chloride in the mother liquid is hydrolyzed into chlorine hydride and metal oxide; the chlorine hydride after being absorbed by water obtains the regenerated muriatic acid and return to the working procedure of ore extraction; the metal oxide after being cracked and grinded returns to the working procedure of neutralizing. The method of the invention has a simple flow and an environment protective technique; the application range to resources is large; besides, the extraction speed is fast; the impurity removing capacity is high; the extraction rate of the nickel and cobalt is high; the method realizes the closed circulation of HCl and the comprehensive utilization of the resources.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com