Patents

Literature

200 results about "Organic chloride compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning of semiconductor processing systems

ActiveUS20100154835A1Improve stabilityElectric discharge tubesHollow article cleaningOrganic chloride compoundSufficient time

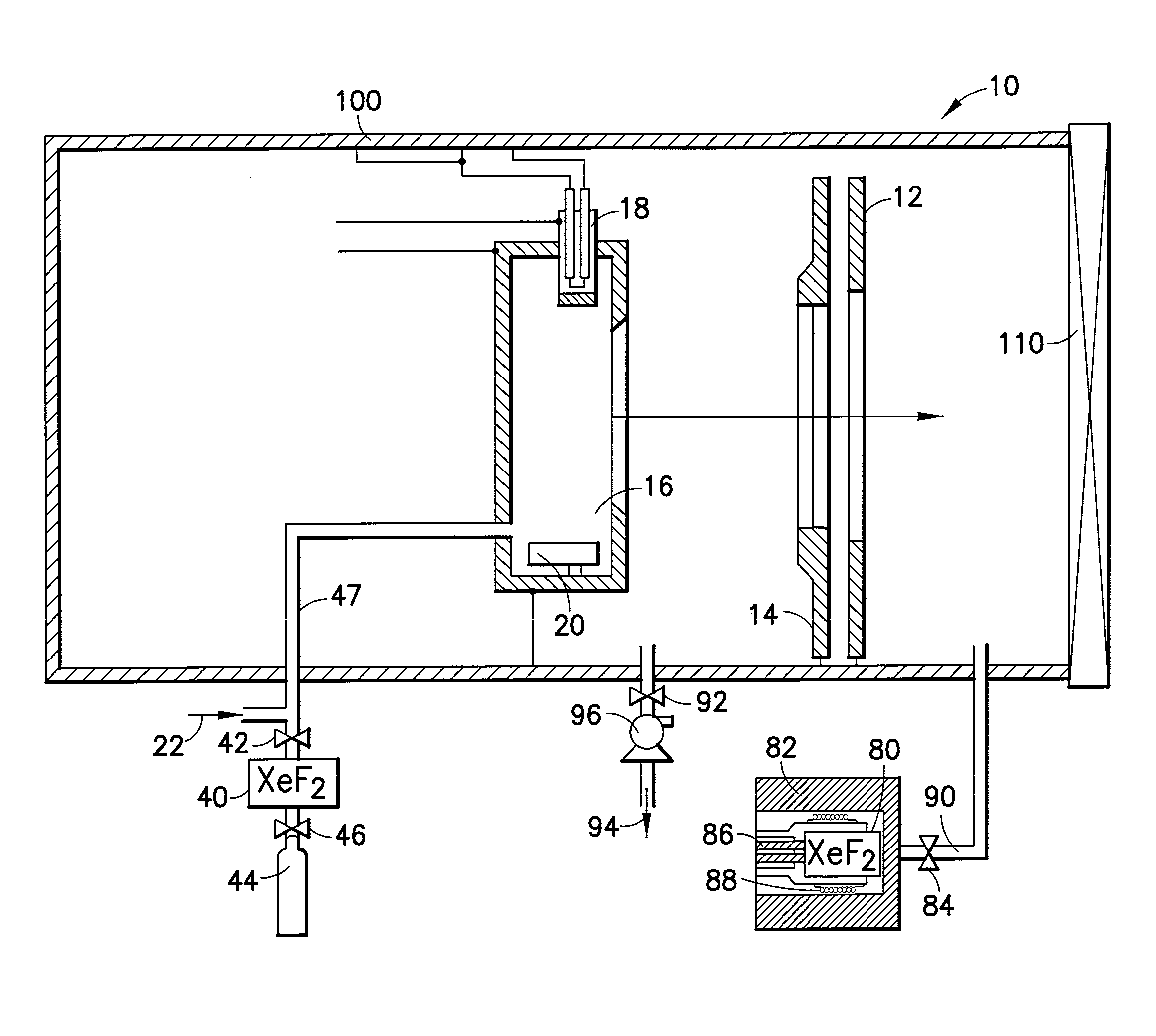

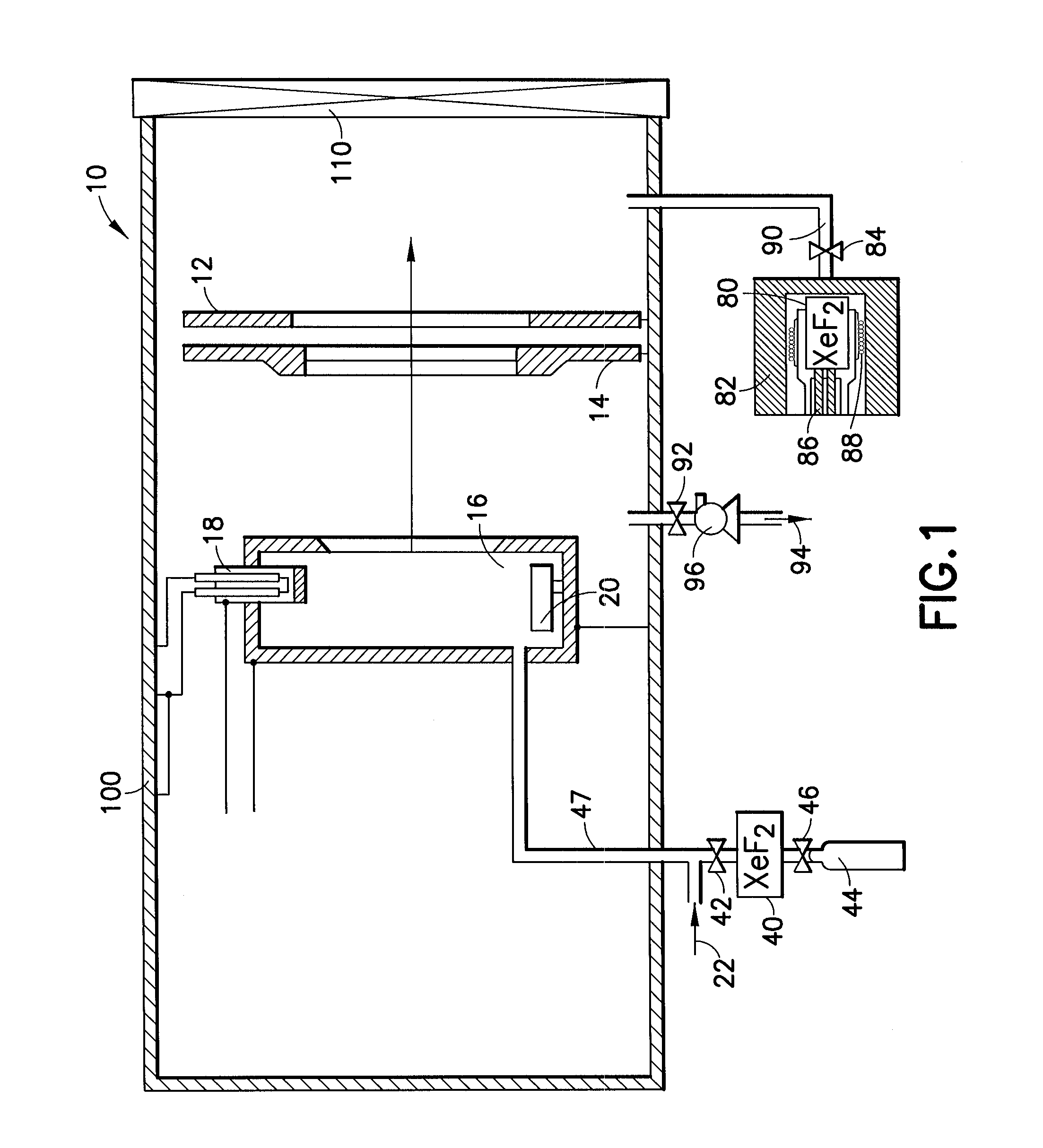

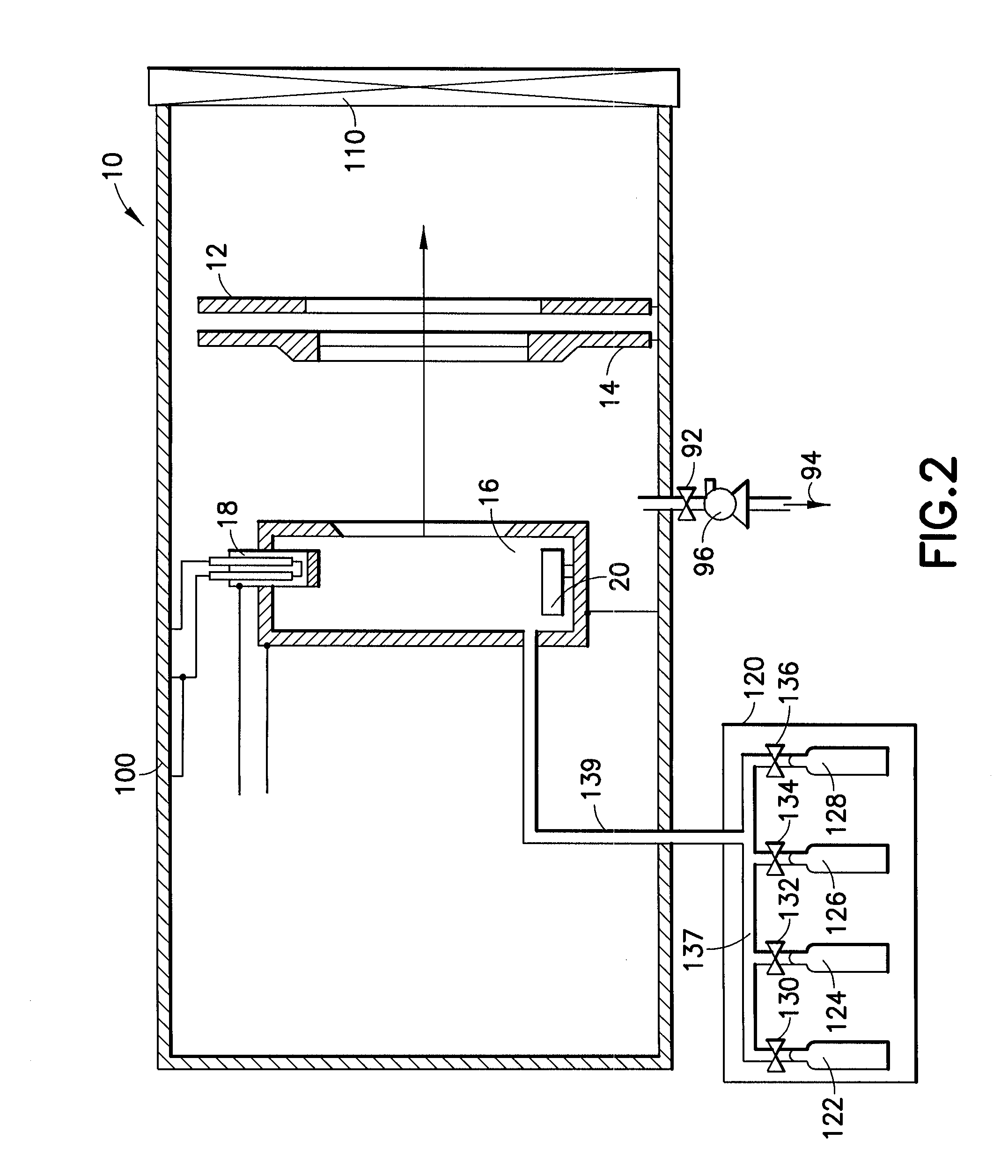

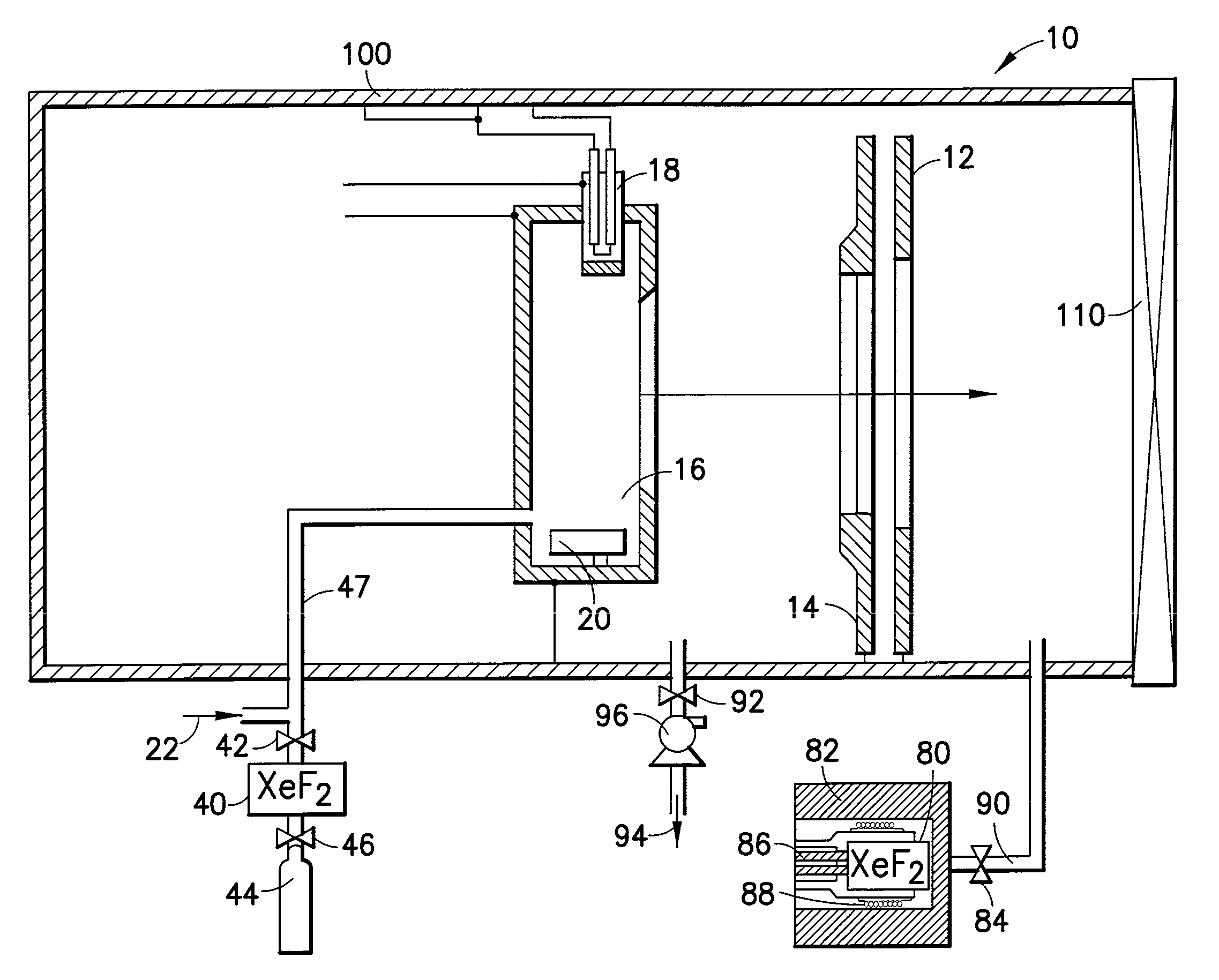

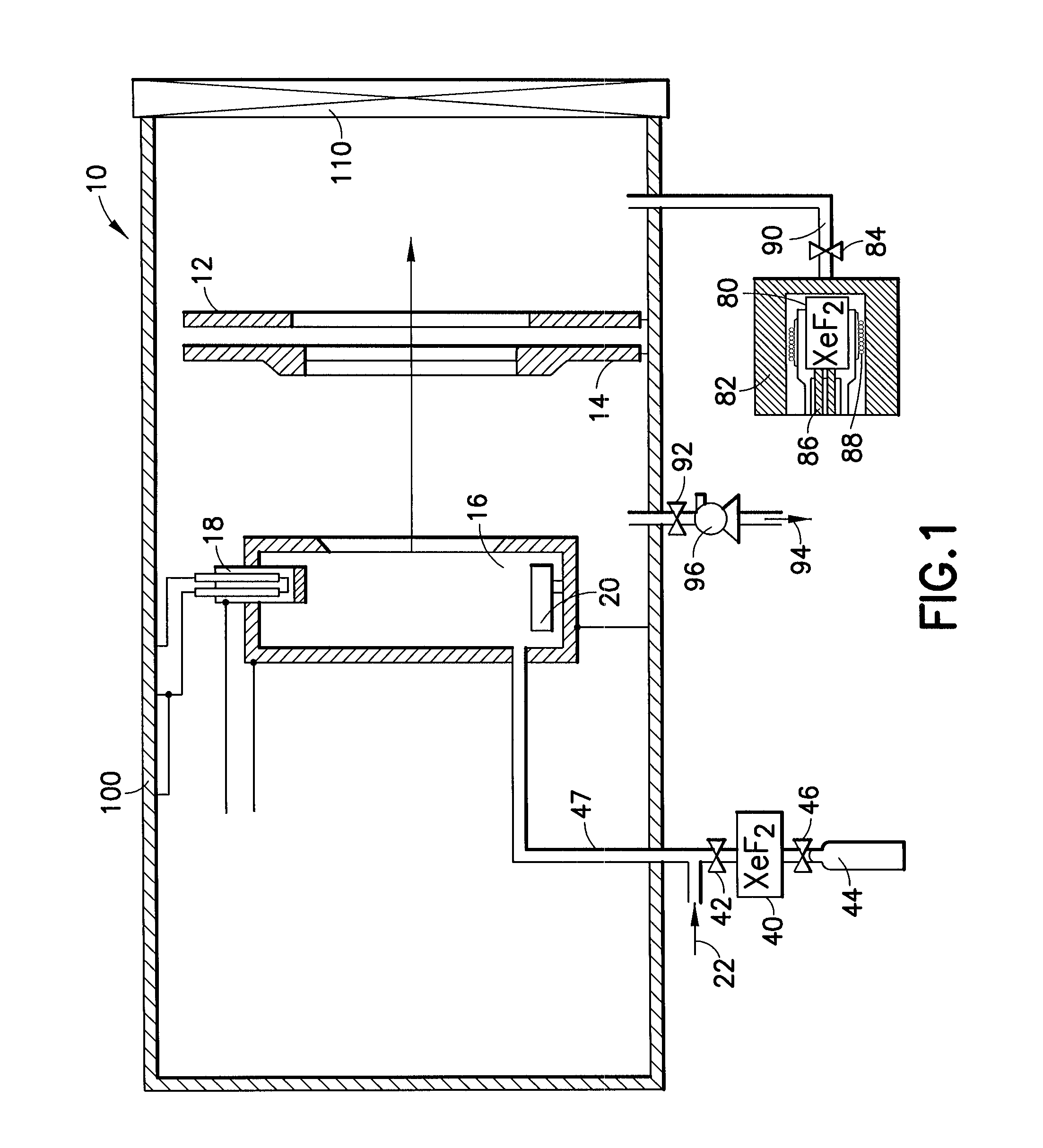

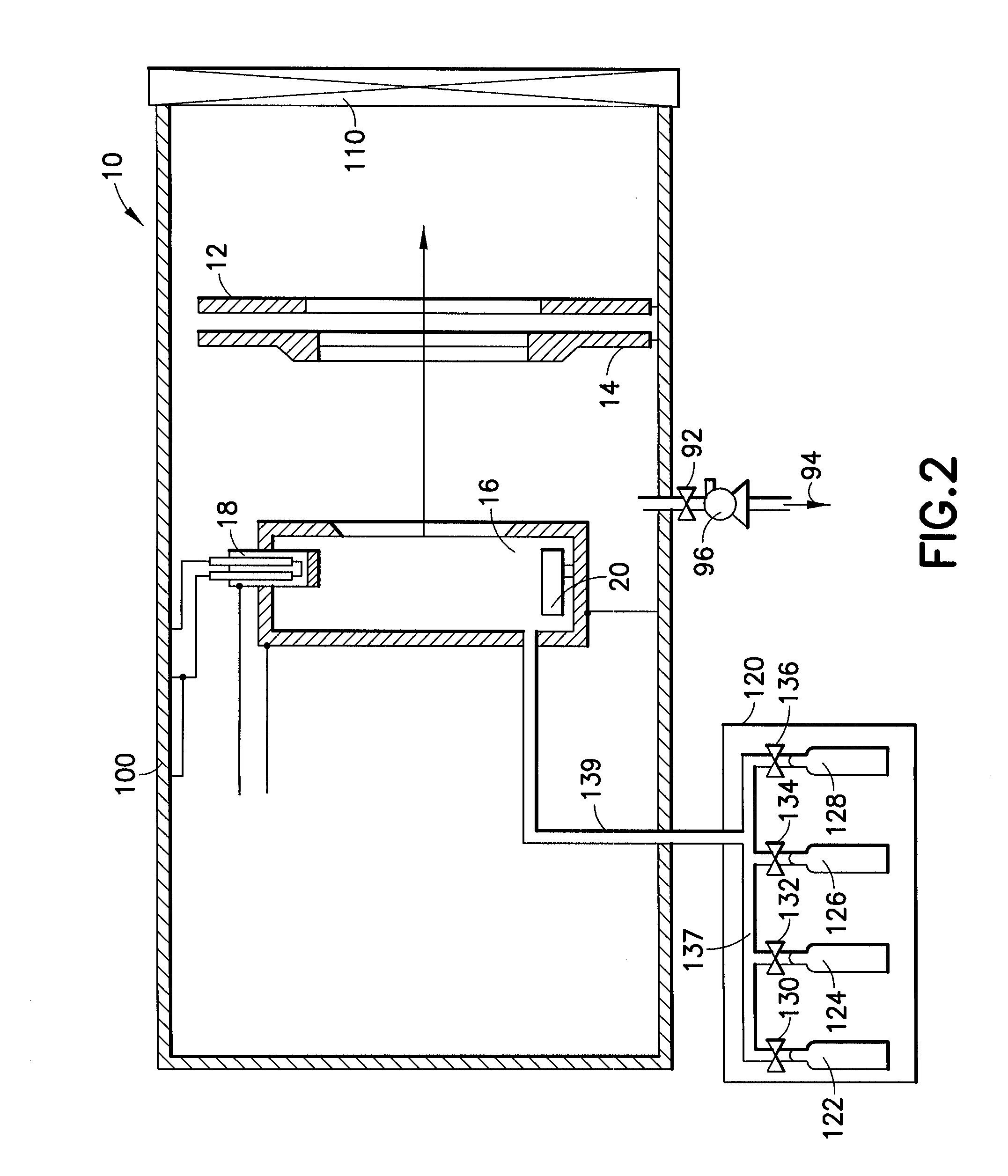

A method and apparatus for cleaning residue from components of semiconductor processing systems used in the fabrication of microelectronic devices. To effectively remove residue, the components are contacted with a gas-phase reactive material for sufficient time and under sufficient conditions to at least partially remove the residue. When the residue and the material from which the components are constructed are different, the gas-phase reactive material is selectively reactive with the residue and minimally reactive with the materials from which the components of the ion implanter are constructed. When the residue and the material from which the components are constructed is the same, then the gas-phase reactive material may be reactive with both the residue and the component part. Particularly preferred gas-phase reactive materials utilized comprise gaseous compounds such as XeF2, XeF4, XeF6, NF3, IF5, IF7, SF6, C2F6, F2, CF4, KrF2, Cl2, HCl, ClF3, ClO2, N2F4, N2F2, N3F, NFH2, NH2F, HOBr, Br2, C3F8, C4F8, C5F8, CHF3, CH2F2, CH3F, COF2, HF, C2HF5, C2H2F4, C2H3F3, C2H4F2, C2H5F, C3F6, and organochlorides such as COCl2, CCl4, CHCl3, CH2Cl2 and CH3Cl.

Owner:ENTEGRIS INC

Process for the start-up of an epoxidation process, a process for the production of ethylene oxide, a 1,2-diol, a 1,2-diol ether, a 1,2-carbonate, or an alkanolamine

InactiveUS20090281339A1Improve catalytic selectivityHigh selectivityProductsOrganic compound preparationOrganic chloride compoundOxygen

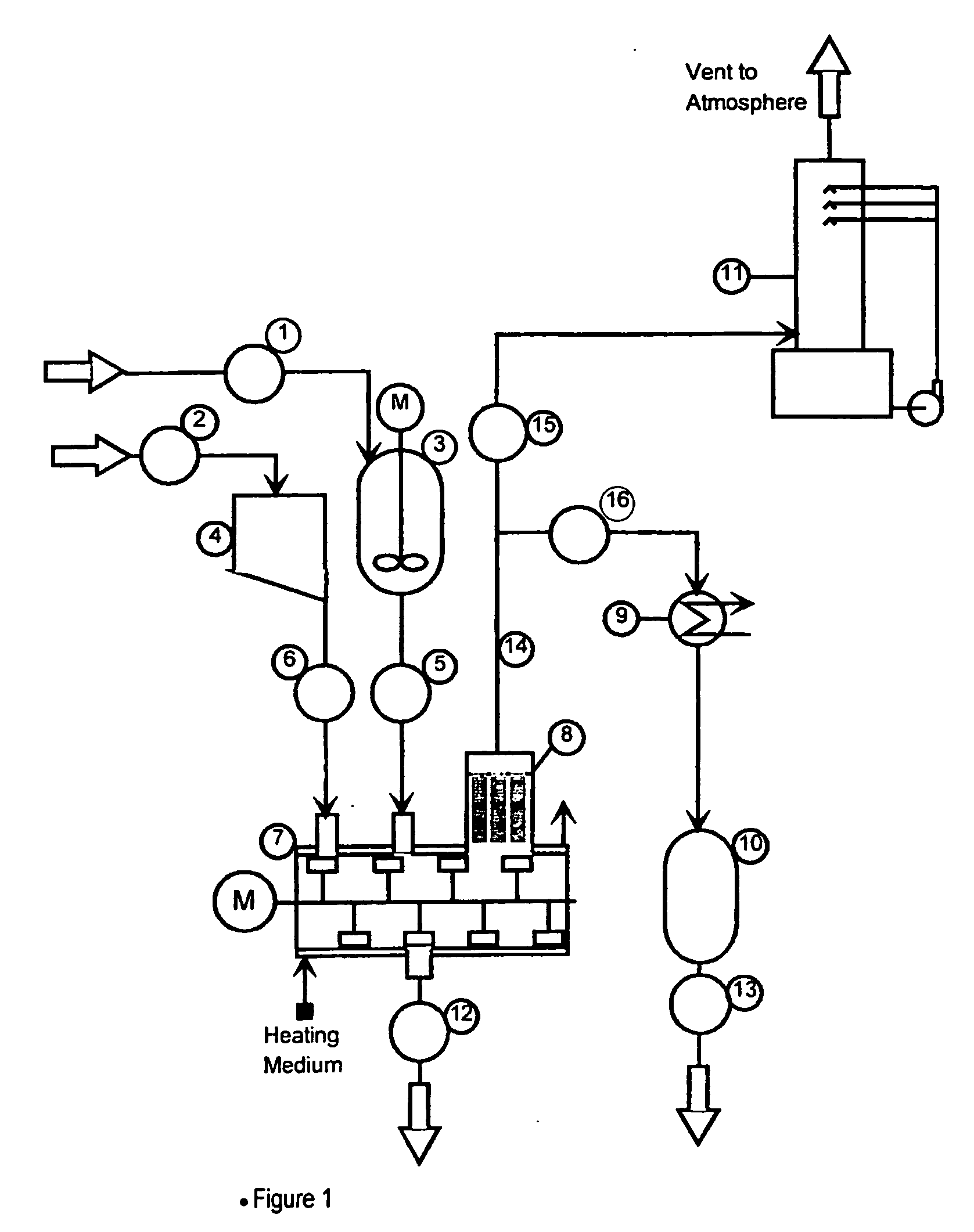

A process is provided for the start-up of an ethylene epoxidation process comprising: (a) contacting a catalyst bed comprising a high selectivity epoxidation catalyst with a feed comprising ethylene, oxygen and an organic chloride for a period of time until an increase of at least 1×10−5 mole-% of vinyl chloride (calculated as the moles of vinyl chloride relative to the total gas mixture), preferably 2×10−5 mole-% of vinyl chloride is detected in a reactor outlet gas or a recycle gas loop; and (b) subsequently adjusting the quantity of organic chloride in the feed to a value sufficient to produce ethylene oxide at a substantially optimum selectivity.

Owner:SHELL OIL CO

Process for the treatment of waste metal chlorides

InactiveUS20060183958A1Low costMaximize recoveryTitanium tetrachlorideSilicon oxidesMetal chlorideOrganic chloride compound

A process is described for treating the residues from metal chlorination processes wherein valuable volatile metal chlorides or metalorgano chlorides are recovered while low volatility metal chlorides and chloride complexes are reacted with a neutralizing humectant. The resulting neutral, dry solid is suitable for land fill disposal or for recovery of valuable metal constituents by extractive metallurgy techniques.

Owner:REC SILICON

Dechlorination agent and preparation method thereof

ActiveCN103386244AImprove adsorption efficiencyHigh dechlorination precisionDispersed particle separationHigh concentrationChemical reaction

Owner:康健科技(山东)有限公司

Method for removing organochlorine from hydrocarbon oil

ActiveCN102127464ADewatering/demulsification with chemical meansDewatering/demulsification with electric/magnetic meansDemulsifierOrganic chloride compound

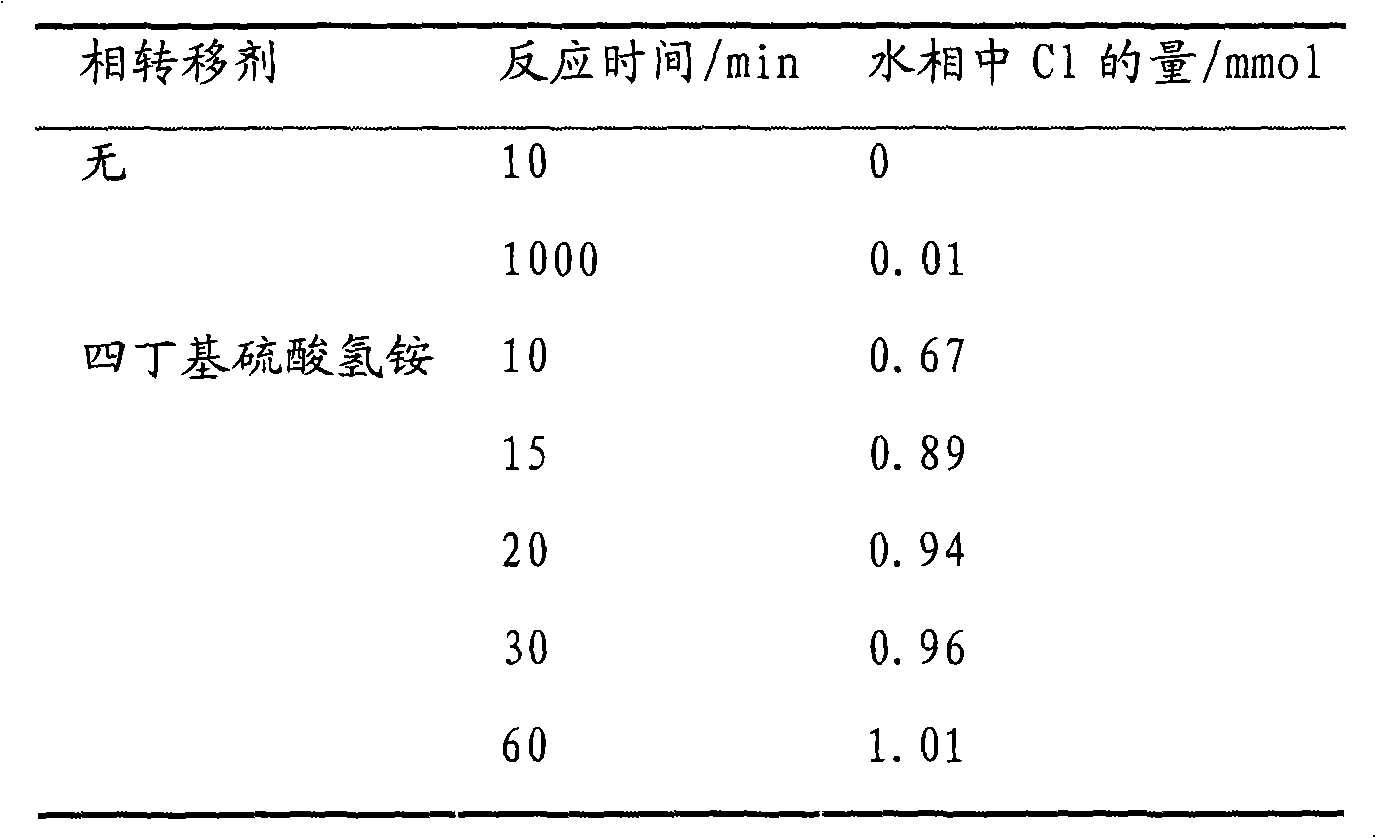

The invention relates to a method for removing organochlorine from hydrocarbon oil. A demulsifier, an alkaline compound, a phase transfer agent, injected water and the hydrocarbon oil are mixed, oil-water separation is performed under the action of a thermal field and / or an electric field, organic chloride is transformed into inorganic chloride and the inorganic chloride is removed with a water phase, so that the aim of dechlorination is fulfilled. The method is suitable for organochlorine-containing conventional crude oil, heavy crude oil and distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Adsorbent for removing organic chlorides in hydrocarbon-containing substance flow and preparation method thereof

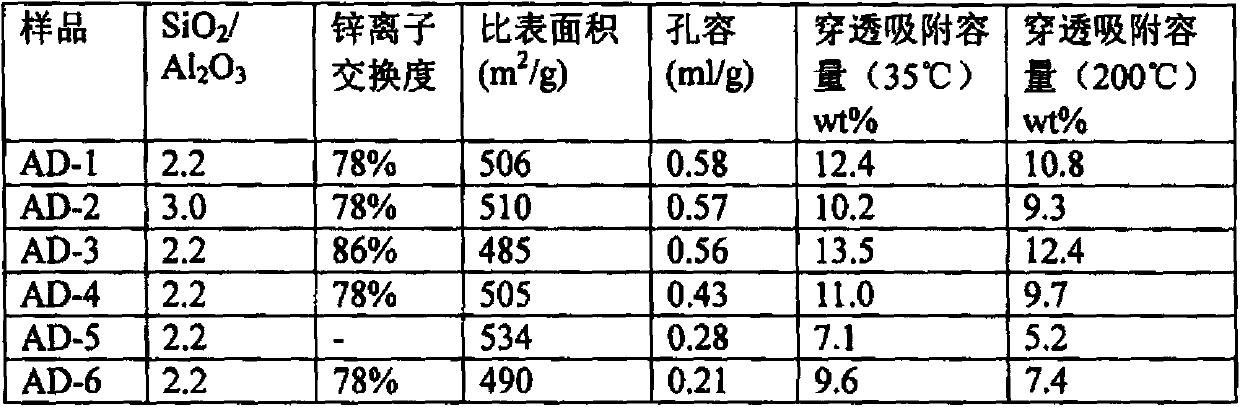

ActiveCN103611495AAchieve removalAdjust the pore size distributionOther chemical processesHydrocarbon oils refiningMolecular sieveCatalytic reforming

The invention relates to an adsorbent for removing organic chlorides in a hydrocarbon-containing substance flow and a preparation method thereof. The adsorbent comprises a modified zeolite molecular sieve, an inorganic macroporous material and a clay component. The zinc ion-modified zeolite molecular sieve contained in the adsorbent shows remarkably high reaction activity on organic chlorides; compared with the prior art, the adsorbent has relatively high selective adsorption capacity on organic chlorides; moreover, with wide temperature range and low reaction activity, the adsorbent is suitable for removing at least one organic chloride from a hydrocarbon-containing substance flow containing hydrogen, hydrocarbons and chlorides, and particularly suitable for deeply removing organic chlorides in the oil generated by a catalytic reforming reaction as well as the byproduct hydrogen.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Method for producing a Ti/V supported catalyst for ethylene polymerization and ethylene/alpha - olefin copolymerization

InactiveUS6214759B1High bulk densitySolve the lack of activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOrganic chloride compoundAlpha-olefin

The present invention relates to a method for producing a Ti / V supported catalyst useful in polymerization of ethylene and copolymerization of ethylene and alpha-olefin. The method includes a treatment, by a titanium compound and a vanadium compound, of the magnesium-containing carrier, which is obtained by reaction of an organomagnesium compound of the structure of MgPh2.nMgCl2.mR2O (n=0.37~0.7; m>=1; R2O=ether; Ph=phenyl) with an organic chloride compound in a mole ratio of organic chloride compound / Mg>=0.5, at -20~80° C. According to the method for producing the catalyst, it is possible to provide a catalyst which can control the distribution of molecular weight, and when polymerization is performed using this catalyst, it is possible to restrain the inactivation and to secure a sufficient activity. Moreover, the polymer produced by the use of this catalyst proves to have a high bulk density and an adjusted particle size distribution.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

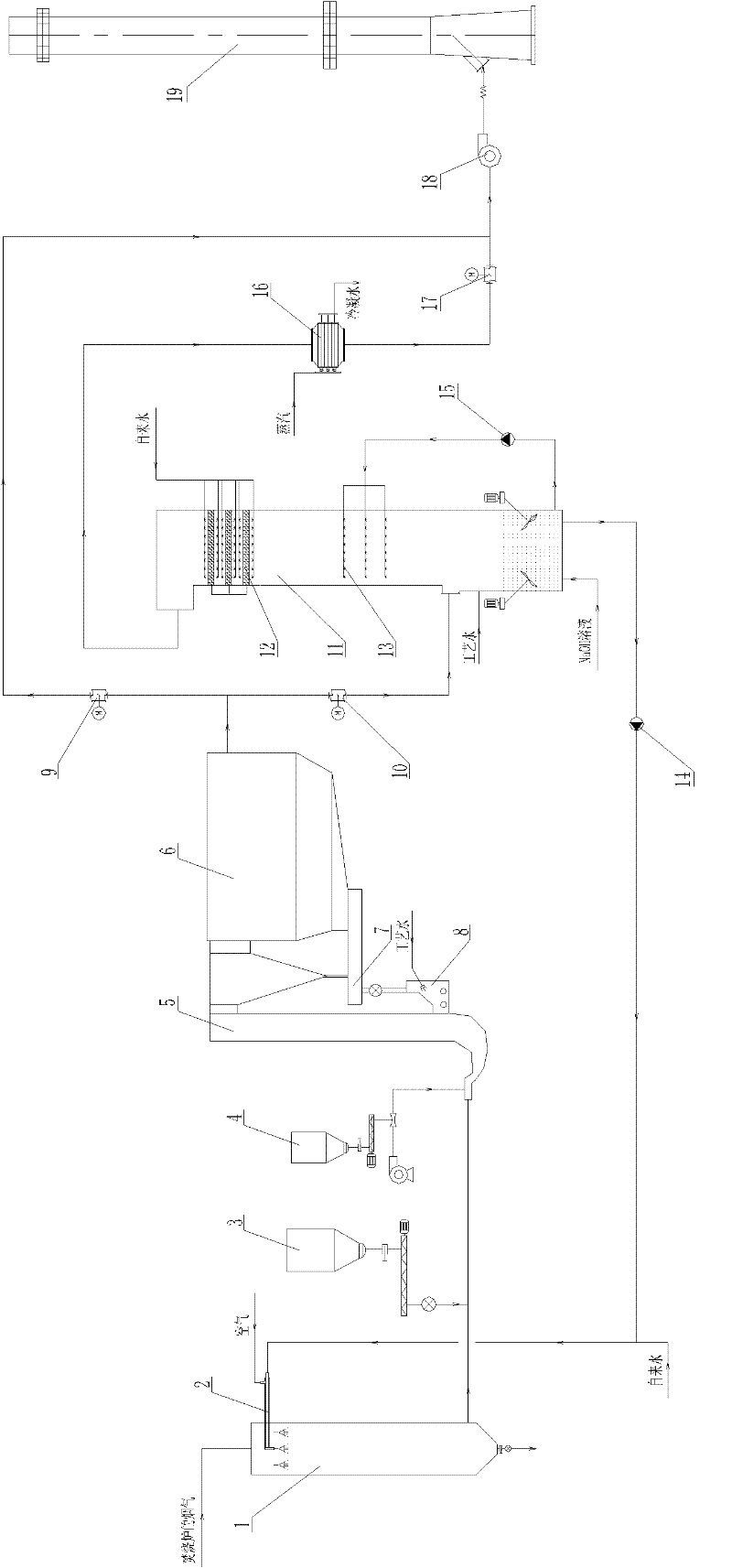

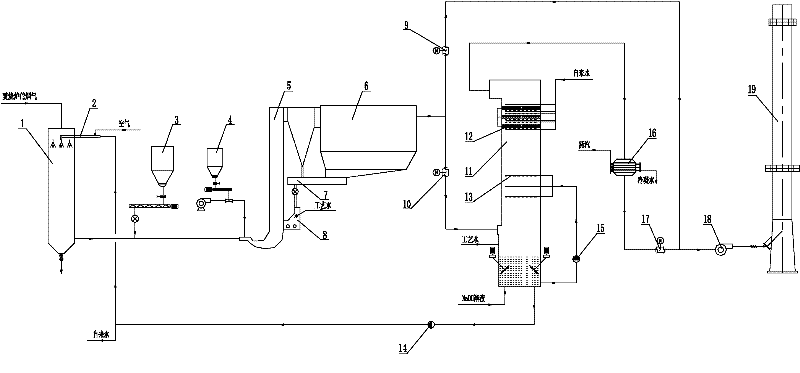

System and method for purifying tail gas of medical waste incineration

InactiveCN102225302AImprove purification efficiencySolve the problem of generating waste waterHuman health protectionDispersed particle filtrationOrganic chloride compoundPolyvinyl chloride

The invention discloses a system and a method for purifying tail gas of medical waste incineration. The method is characterized in that a spray gun is used for quickly cooling tail gas at 400-600 DEG C to below 200 DEG C in a tail gas quenching tower; the cooled tail gas enters into a semi-dry type reactor; lime and activated carbon are added in front of the semi-dry type reactor, so as to de-acidify the tail gas and absorb dioxin and heavy metal; dust is removed from the de-acidified tail gas by a bag-type dust collector; the de-dusted tail gas is subjected to spraying alkali wash through a spraying layer in a spraying absorbing tower; liquid drop carried by the tail gas after being subjected to the spraying alkali wash is removed by a demister in the spraying absorbing tower; and then the tail gas is heated after entering into a steam-tail gas heat exchanger, and lastly the tail gas is discharged from a chimney by a draught fan. By using the system and method provided by the invention, the purifying efficiency for the tail gas of medical waste incineration can be obviously increased. Especially, when a large amount of organic chloride is burnt, such as waste plastics (for example, PVC (polyvinyl chloride), PVDc (polyvinyl dichloride)), rubbers, leathers, and the like, concentration of HCL (hydrogen chloride) generated by being burnt is higher, the wet alkali wash is automatically performed, and the deacidification demand is still met, thereby reducing environmental pollution, generating no waste water and solving the problem of generating waste water by performing wet treatment.

Owner:浙江菲达脱硫工程有限公司 +1

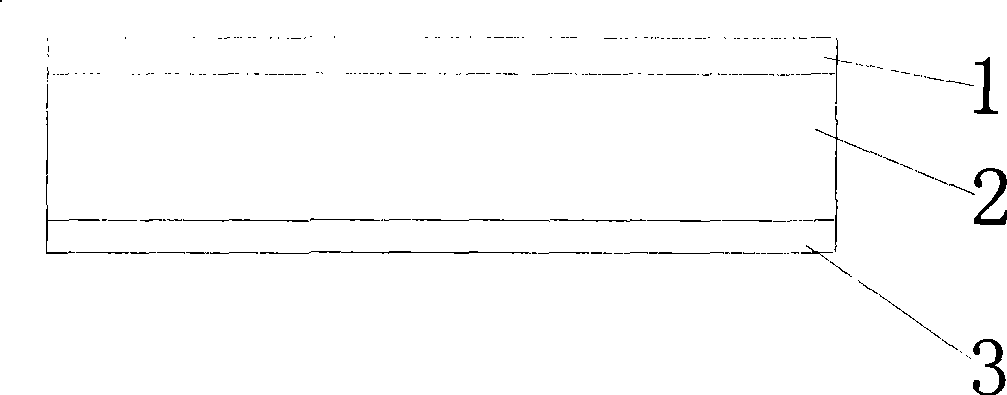

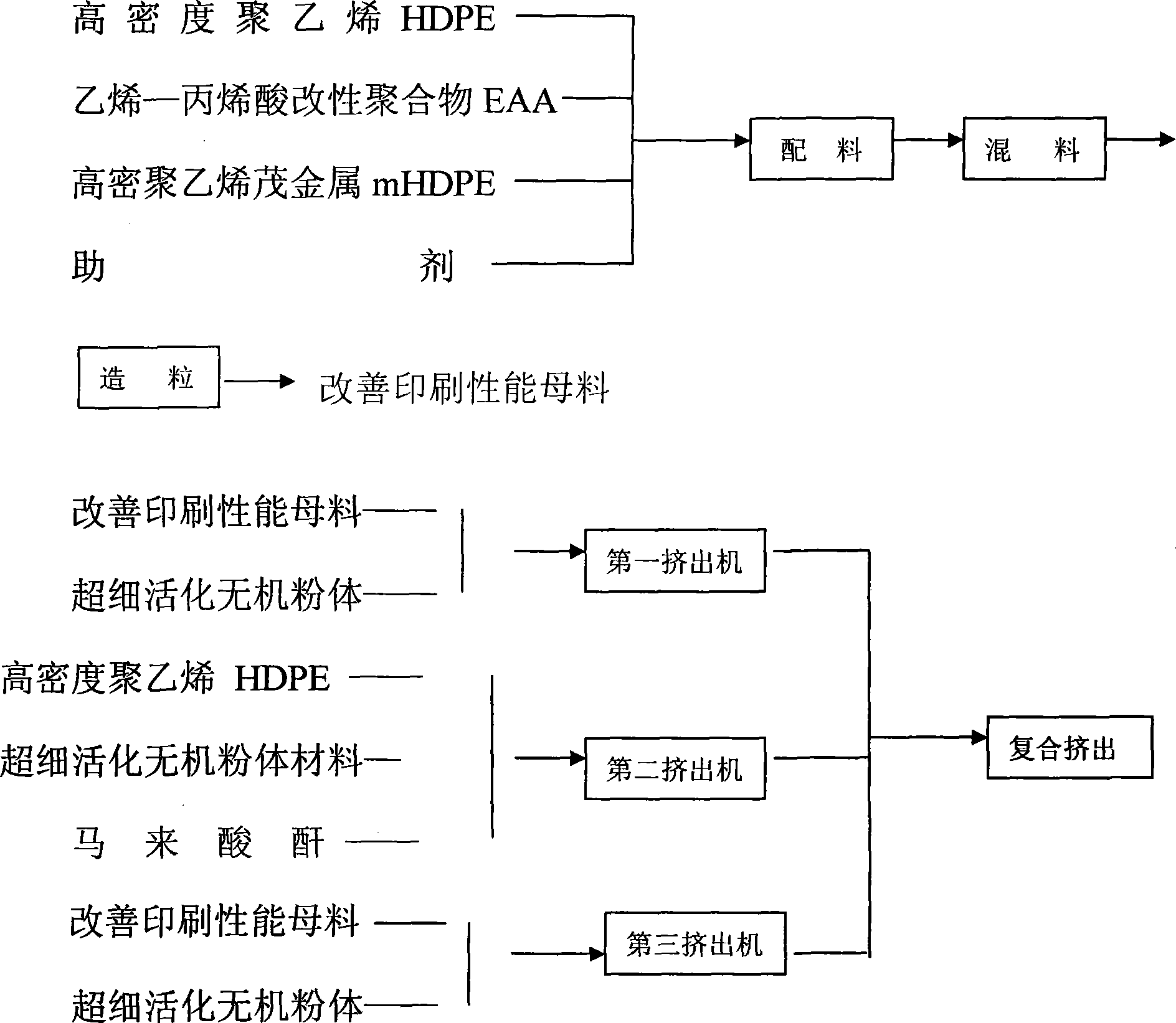

Modified polyolefins paper without plant fibre

InactiveCN101462387AImprove folding resistanceImprove rigiditySynthetic resin layered productsPolyolefinOrganic chloride compound

The invention discloses modified polyolefin paper without plant fiber. The modified polyolefin paper is formed by a matrix layer 1 without the plant fiber, a matrix layer 2 without the plant fiber and a matrix layer 3 without the plant fiber which are compounded into a whole, wherein the matrix layer 1 and the matrix layer 3 are prepared by 20 to 30 percent of ethylene-acrylic acid modified copolymer EAA, 45 to 60 percent of metallocene high-density polyethylene mHDPE, and 20 to 25 percent of activated ultrafine inorganic powder respectively, and the matrix layer 2 is prepared by 60 to 90 percent of activated ultrafine inorganic powder, 2 to 5 percent of maleic anhydride and 8 to 35 percent of high-density polyethylene. The modified polyolefin paper has the advantages of good ink receptivity and softness. Therefore, the modified polyolefin paper can be used as industrial paper, packing paper and household paper, can also be used as cultural paper, and enlarges the use range. The modified polyolefin paper has higher foldability and rigidity, has the longitudinal and transverse tearing strength which are superior to those of plant fiber paper, has good surface flattening, good handwriting, and clear printing performance, saves printing ink, has simple production technology, protects forest resources, saves energy sources and water, reduces the discharge of organic chlorides and harmful gas, has no waste, and protects the environment.

Owner:宋旭

Method for carbonizing active giantreed carbon and pore-forming

InactiveCN1944246ALow carbonization temperatureReduce energy consumptionOrganic chloride compoundSorbent

The present invention relates to adsorbent, and belongs to the field of technology of treating water and air with active carbon. The present invention prepares active carbon with giant reed root and stem and through crushing, stoving, carbonizing, forming pore and activating. The prepared active carbon may be applied widely in eliminating aromatic compound and organic chloride from waste water, eliminating heavy metal ions, treating atmosphere pollution, etc. The giant reed has low carbonizing temperature and low power consumption.

Owner:SHANDONG UNIV

Cleaning of semiconductor processing systems

ActiveUS8603252B2Improve stabilityElectric discharge tubesHollow article cleaningOrganochlorideSufficient time

A method and apparatus for cleaning residue from components of semiconductor processing systems used in the fabrication of microelectronic devices. To effectively remove residue, the components are contacted with a gas-phase reactive material for sufficient time and under sufficient conditions to at least partially remove the residue. When the residue and the material from which the components are constructed are different, the gas-phase reactive material is selectively reactive with the residue and minimally reactive with the materials from which the components of the ion implanter are constructed. When the residue and the material from which the components are constructed is the same, then the gas-phase reactive material may be reactive with both the residue and the component part. Particularly preferred gas-phase reactive materials utilized comprise gaseous compounds such as XeF2, XeF4, XeF6, NF3, IF5, IF7, SF6, C2F6, F2, CF4, KrF2, Cl2, HCl, ClF3, ClO2, N2F4, N2F2, N3F, NFH2, NH2F, HOBr, Br2, C3F8, C4F8, C5F8, CHF3, CH2F2, CH3F, COF2, HF, C2HF5, C2H2F4, C2H3F3, C2H4F2, C2H5F, C3F6, and organochlorides such as COCl2, CCl4, CHCl3, CH2Cl2 and CH3Cl.

Owner:ENTEGRIS INC

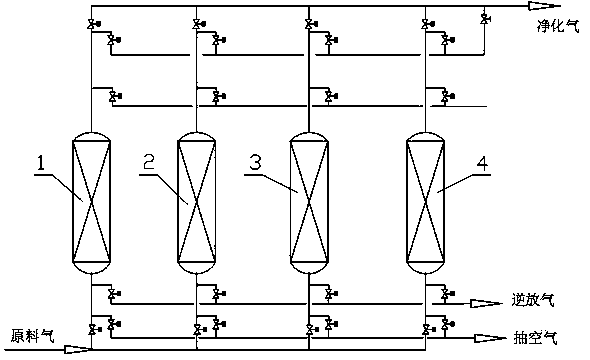

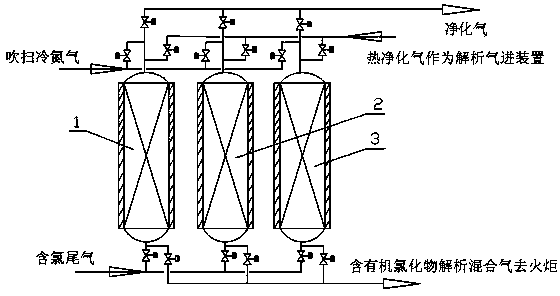

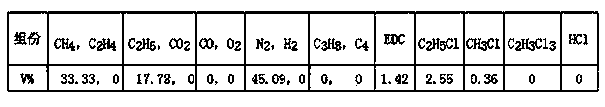

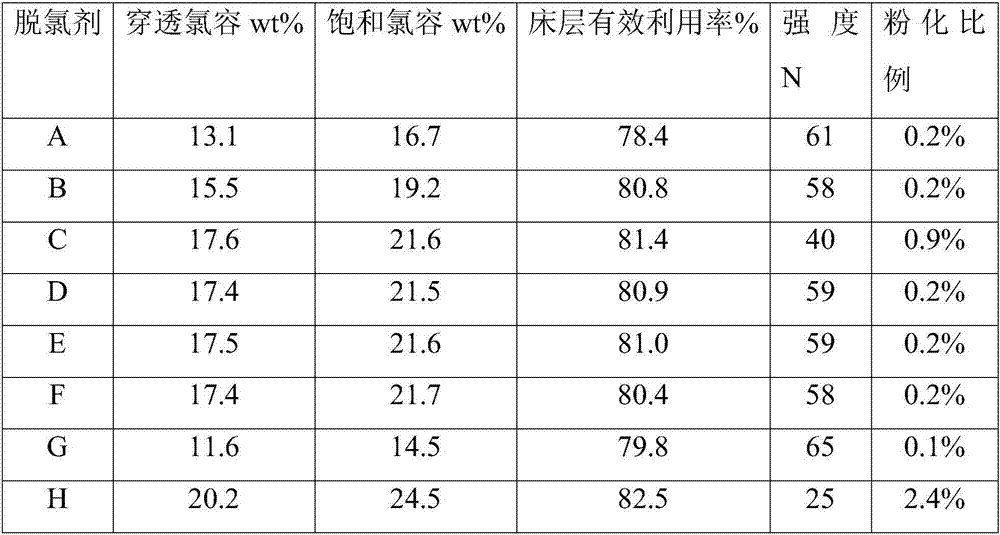

Method for purifying and removing chlorides contained in chlorine-containing industrial mixed gas and recovering light hydrocarbon

ActiveCN103357242ATo achieve the purpose of removalDispersed particle separationOrganic chloride compoundSorbent

The invention discloses a method for purifying and removing chlorides contained in a chlorine-containing industrial mixed gas and recovering light hydrocarbon, and the method comprises a pressure-swing adsorption and / or temperature swing adsorption method. An adsorptive separation system which comprises two or more than two adsorption towers filled with adsorbents and a series of program control valves absorbs and fine removes the chlorine-containing industrial mixed gas; a tail gas is respectively subjected to the following steps of: adsorption, reverse release, normal-temperature evacuation or heating flushing and filling increase in the adsorption towers under the action of the program control valves; the adsorption towers is operated according to a sequence circulating and time sequence alternating mode; the outlets positioned on the upper ends of the adsorption towers control the total content of the chlorides to be less than 5 ppm, so that a purified gas or other target product gases are obtained after the chlorides are purified and removed. The method disclosed by the invention can be used for fine purifying and removing various organic chlorides, chlorine hydride and chlorine which are contained in a dichloroethane synthetic tail gas synthesized by directly chloridizing a refining and chemical dry gas and dilute ethylene or other chlorine-containing industrial mixed gases and recovering the light hydrocarbon or the other target product gases.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Straw pulp bleaching technique

InactiveCN101463573AReduce generationReduce pollutionPulp bleachingOrganic chloride compoundChlorine dioxide

The invention discloses a bleaching process with low pollution used for straw pulp by virtue of elemental chlorine-free bleaching agents such as oxygen, chlorine dioxide, hydrogen peroxide and the like. The invention is characterized in that the process comprises the steps as follows: (1) on oxygen delignification section, sealing, sifting and washing are carried out; (2) on chlorine dioxide delignification section, washing is carried out; (3) on alkaline extraction section, washing is carried out; (4) on chlorine dioxide whitening section, washing and papermaking are carried out. The process of the invention is simple and feasible, applicable for reed pulps and the mixed pulp thereof and anaphalis yedoensis, the final brightness of the pulp of the reed pulps (ISO) reaches 78-85%, the brightness stability and the strength are good, and tear index is more than or equal to 8.0mN.m<2> / g; as no elemental chlorine joins the bleaching process, the generation amount of organic chloride during the bleaching process is greatly lowered and the pollution to ecological environment is reduced, thus having obvious social and economic benefits.

Owner:YUANJIANG PAPER

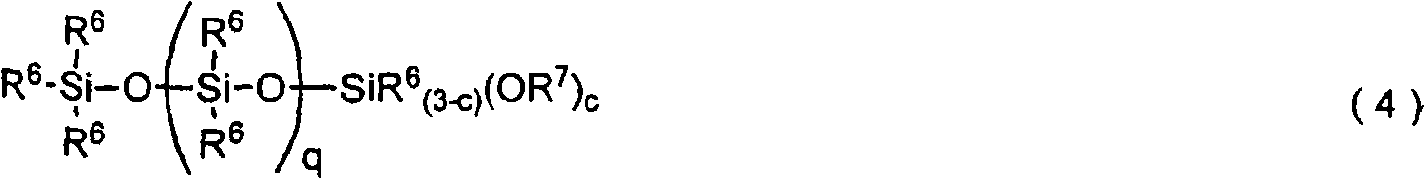

Organosilicon lubricating grease composition with heat conductivity

InactiveCN101525489AHigh thermal conductivityImprove discharge effectBase-materialsMetal/metal-oxides/metal-hydroxide catalystsOrganic chloride compoundOxime

The invention provides a liquid organosilicon lubricating grease composition, which is cast between a heating element and a heat radiation element and then solidified, thereby improving thermometric conductivity and simultaneously maintaining allocation performance of organosilicon lubricating grease composition with heat conductivity. The organosilicon lubricating grease composition with heat conductivity contains the following substances: 25 DEG C, viscosity 50-1000 Pa.s: (A) organopolysiloxane containing more than two alkenyl groups in one molecule; (B) organic hydrogen polysiloxane showed in general formula (1); (C) organic hydrogen polysiloxane showed in general formula (2); (D) bulking agent with heat conductivity, whose thermometric conductivity is more than 10W / m DEG C; (E) catalyst selected from platinum and platinum compound; (F) control agent selected from acetylenic compound, nitrogen compound, organic phosphorus compound, oxime compound and organic chloride compound; (G) volatile solvent for dispersing or dissolving ingredients mentioned above and the boiling point is 80-360 DEG C.

Owner:SHIN ETSU CHEM IND CO LTD

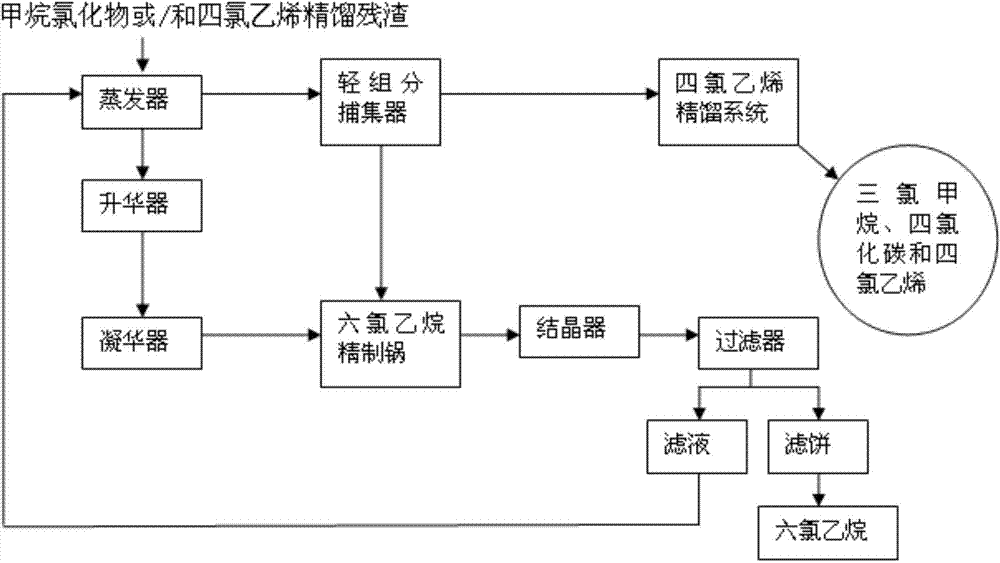

Method for recovering organic chloride from rectification residues of methane chloride or/and tetrachloroethylene

ActiveCN103787823AEfficient recyclingDisposal savingsHalogenated hydrocarbon separation/purificationOrganic chloride compoundEvaporation

Owner:山东中盛药化设备有限公司

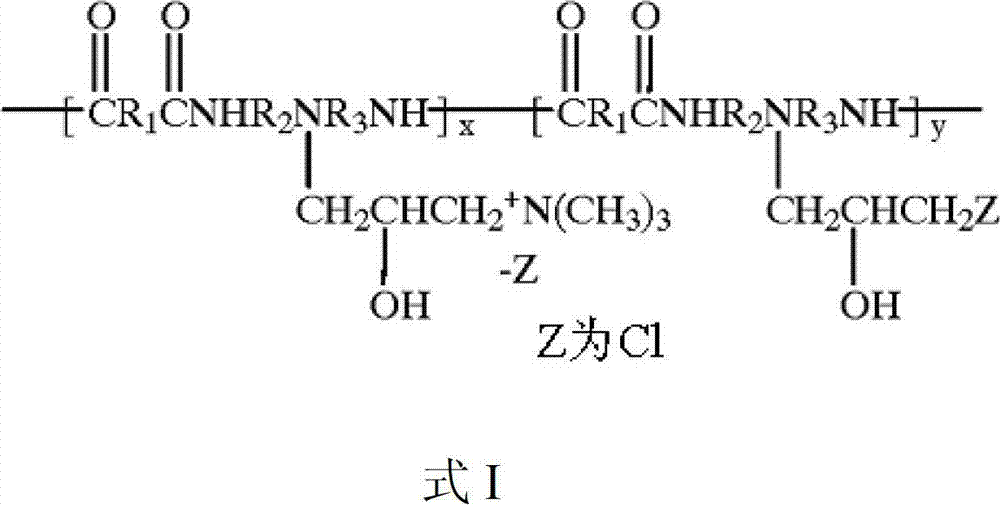

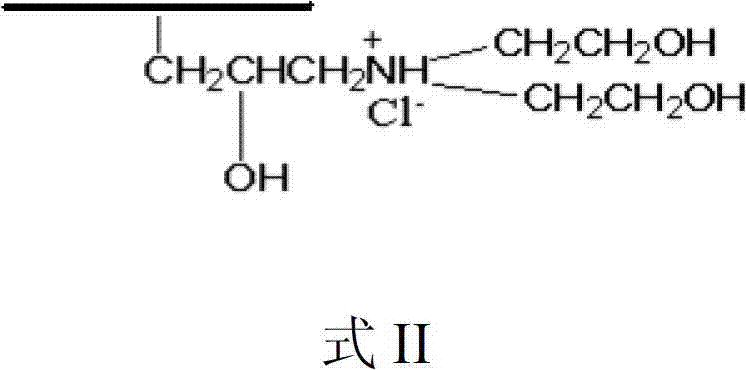

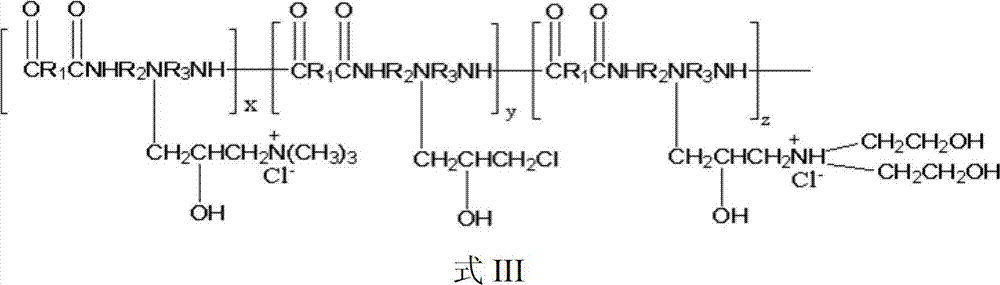

High-solid content polyamide polyamine epichlorohydrin wet strength agent, as well as preparation and application thereof

InactiveCN103030806AHigh solid contentHigh positive charge densityReinforcing agents additionPaper/cardboardOrganic chloride compoundPolyamide

The invention discloses a high-solid content polyamide polyamine epichlorohydrin wet strength agent, as well as a preparation method and an application thereof. The preparation method comprises the following steps: performing condensation on a dibasic acid and a diamine under the action of an acidic catalyst to get a polyamide polyamine intermediate; enabling the polyamide polyamine intermediate, an organic chloride and a cation active monomer or a mixture of the cation active monomer and sodium hydroxide to perform nucleophilic addition reaction to get a high-viscosity cation polymer; and further adding water-soluble hydroxy amine to react and regulating pH with an acid to get the high-solid content polyamide polyamine epichlorohydrin wet strength agent. The obtained wet strength agent has the advantages of high solid content above 40% (in percentage by weight), high charge density, stability in storage, great wet-strengthening performance and few chlorine-containing byproducts, and can be applied in papermaking wet-end chemistry process.

Owner:SOUTH CHINA UNIV OF TECH

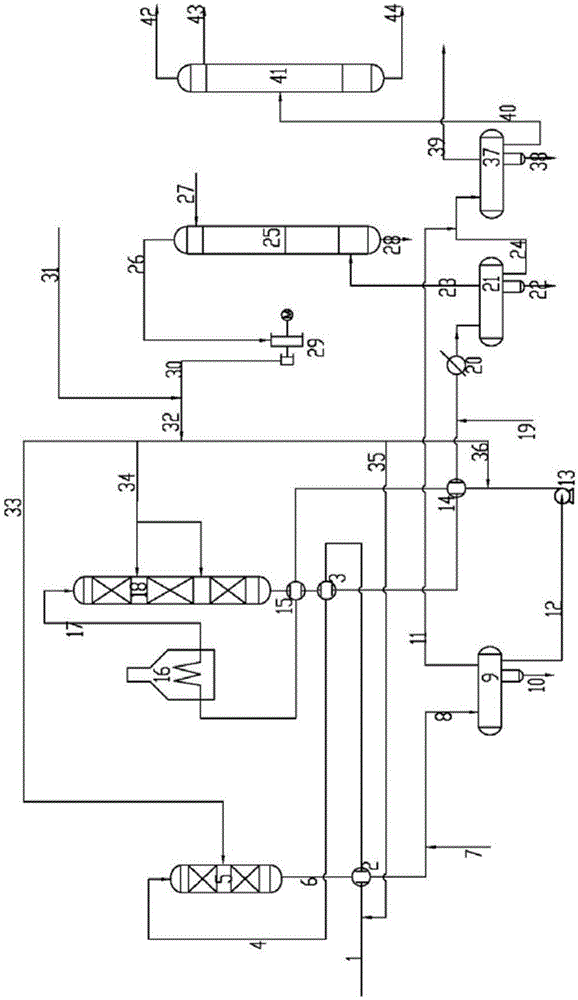

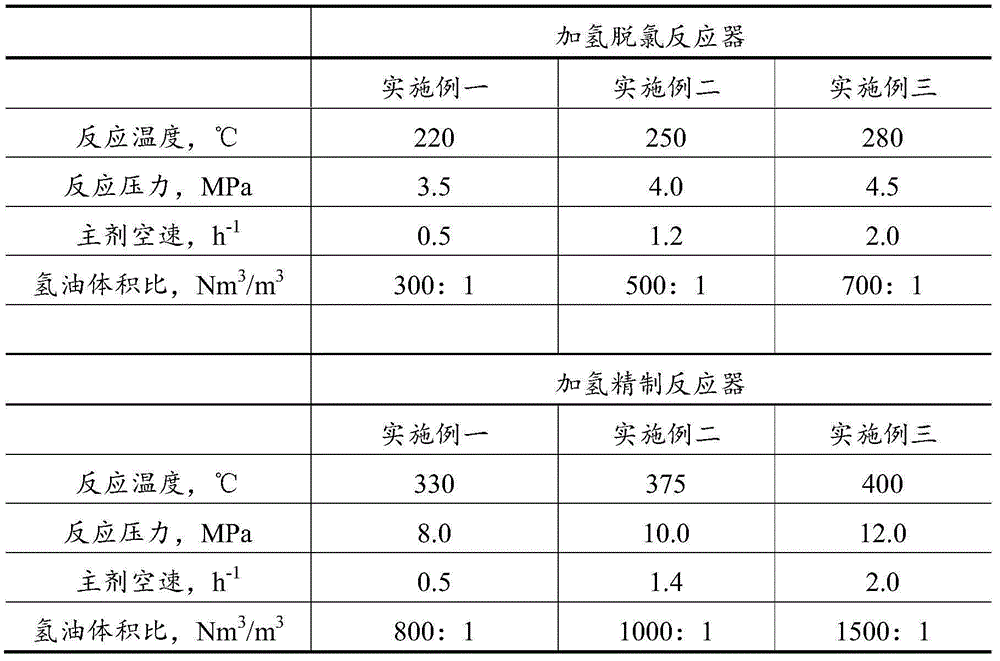

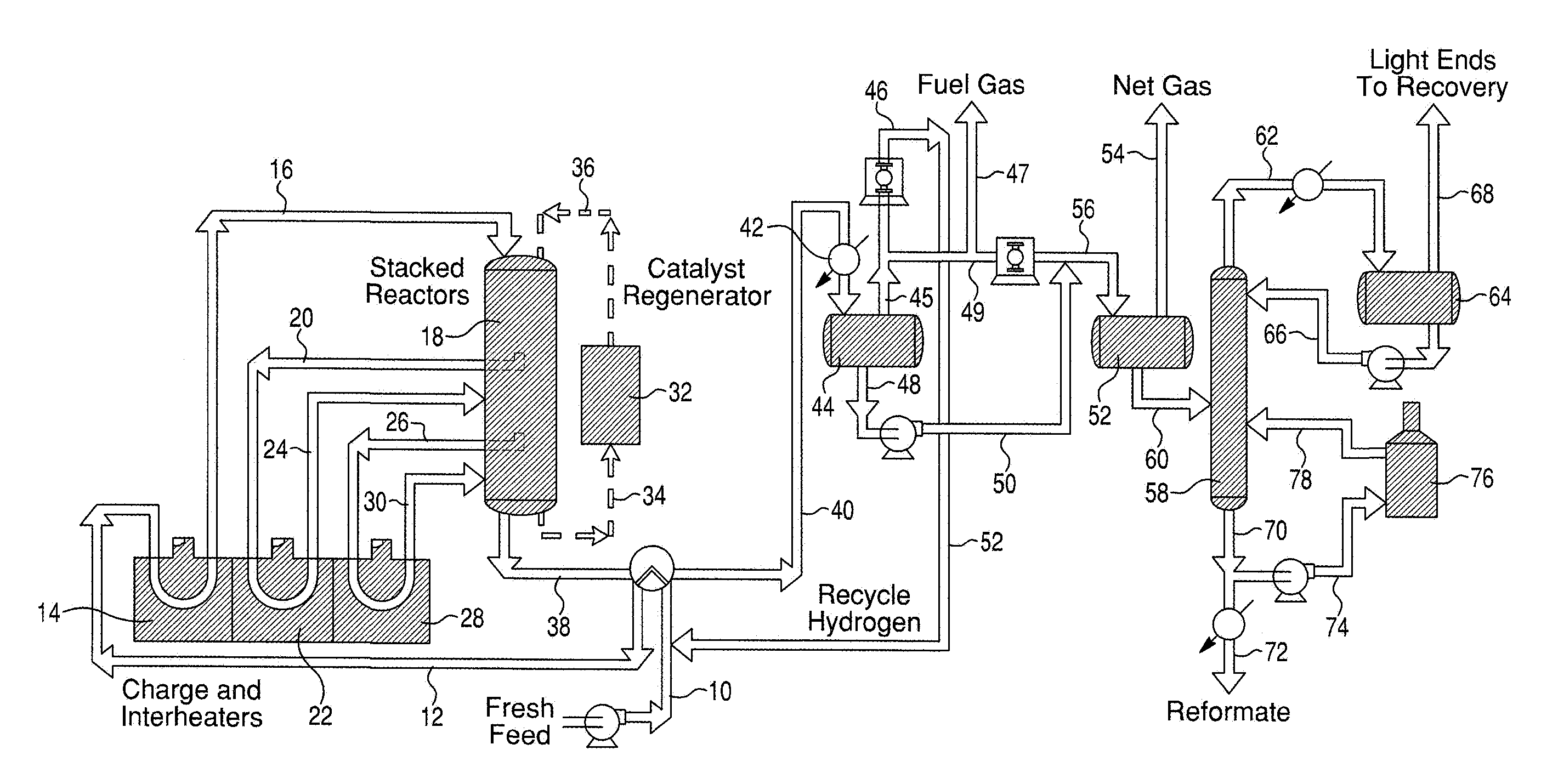

Combined-type hydrogenation treatment method of tire pyrolysis oil

The invention discloses a combined-type hydrogenation treatment method of tire pyrolysis oil. According to the combined-type hydrogenation treatment method, gasoline and diesel oil ingredients in tire pyrolysis oil are subjected to treatment; tire pyrolysis oil is delivered through a hydrogenation dechlorination reactor, a thermal low pressure separator, and a hydrotreating reactor successively; an obtained reaction effluent is delivered into a hydrogenation high pressure separator; hydrogen-rich gas obtained via separation is subjected to desulfuration, and is mixed with a part of new hydrogen, and obtained mixed gas is taken as mixed hydrogen and cold hydrogen for cycling; a liquid phase obtained from the bottom of the hydrogenation high pressure separator is subjected to further separation so as to obtain dissolved gas; and an product is subjected to separation via a fractionation unit. According to the combined-type hydrogenation treatment method, organic chloride in waste tire pyrolysis oil, especially organic chloride in the gasoline and diesel oil ingredients, is reduced effectively in the dechlorination reactor, so that the downstream hydrotreating reactor is protected from influences of chlorine ions, and equipment investment on hydrogenation equipment is reduced effectively; heat energy utilization ratio of refined products is increased, fuel gas consumption amount is reduced, equipment operation cost is reduced, modification using of tire pyrolysis oil is realized, and economic benefits and environmental benefits are maximized.

Owner:LUOYANG RUIZE PETROCHEM ENG

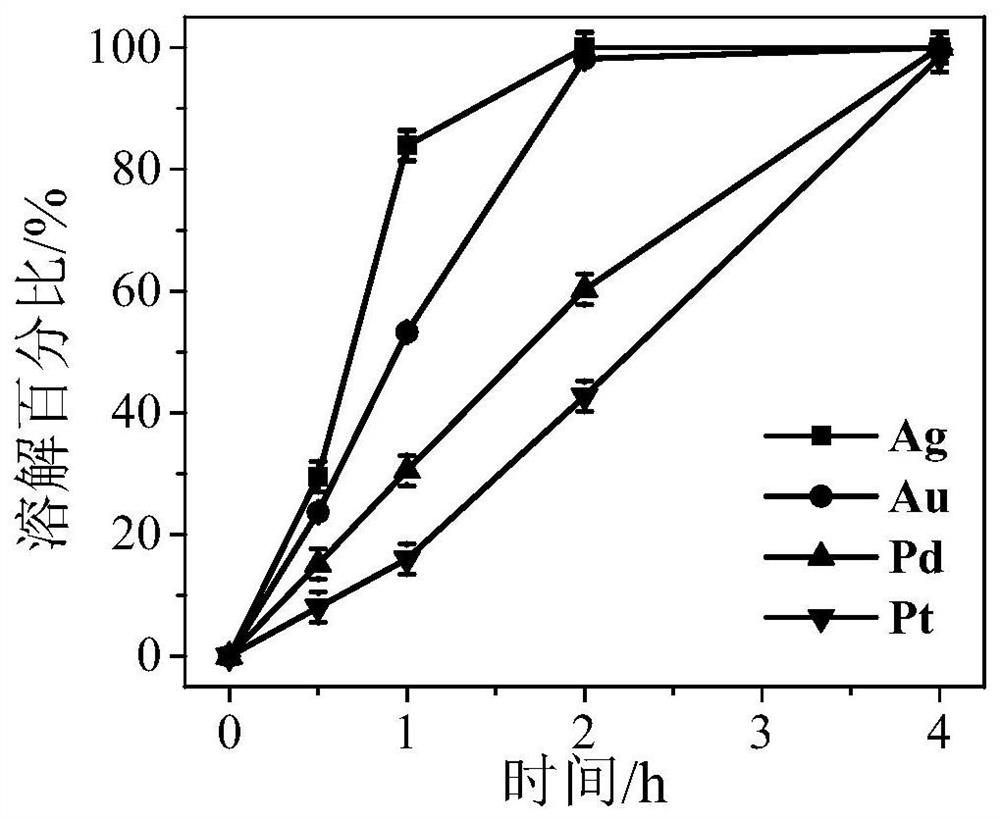

Photocatalytic metal dissolution method

ActiveCN111809063ALow toxicityMild photocatalytic reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsProcess efficiency improvementCyanide compoundOrganic chloride compound

The invention relates to a photocatalytic metal dissolution method. The method comprises the steps that a metal-containing material to be dissolved is dispersed into a mixed solution of a cyanide compound and organic chloride, then photocatalyst is added, oxygen-containing gas is introduced or a substance capable of generating oxygen is added, and metal can be dissolved through light irradiation for a certain period of time. Compared with the prior art, the method has the advantages of being mild in process, energy-saving, green, environmentally-friendly, low in costs and convenient to operate, and is suitable for large-scale industrialized metal dissolution treatment.

Owner:SHANGHAI NORMAL UNIVERSITY

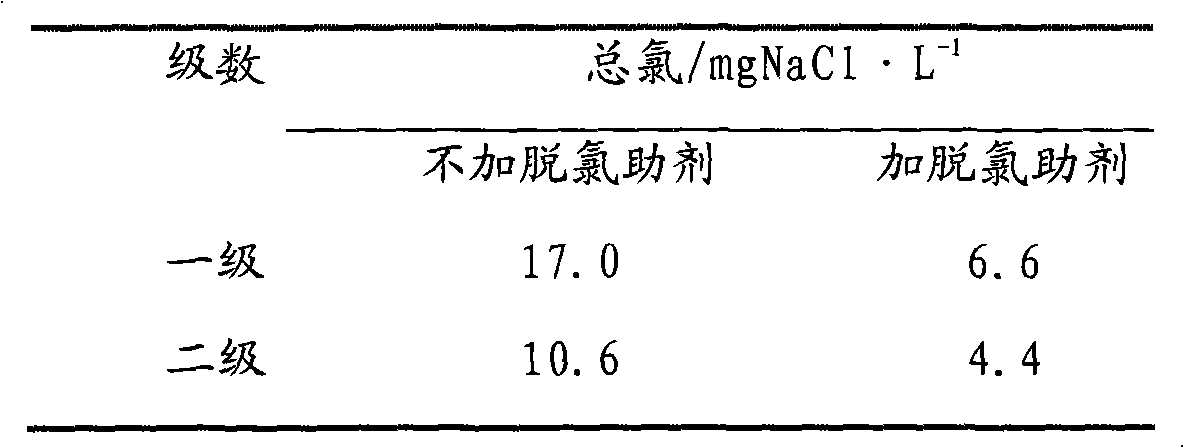

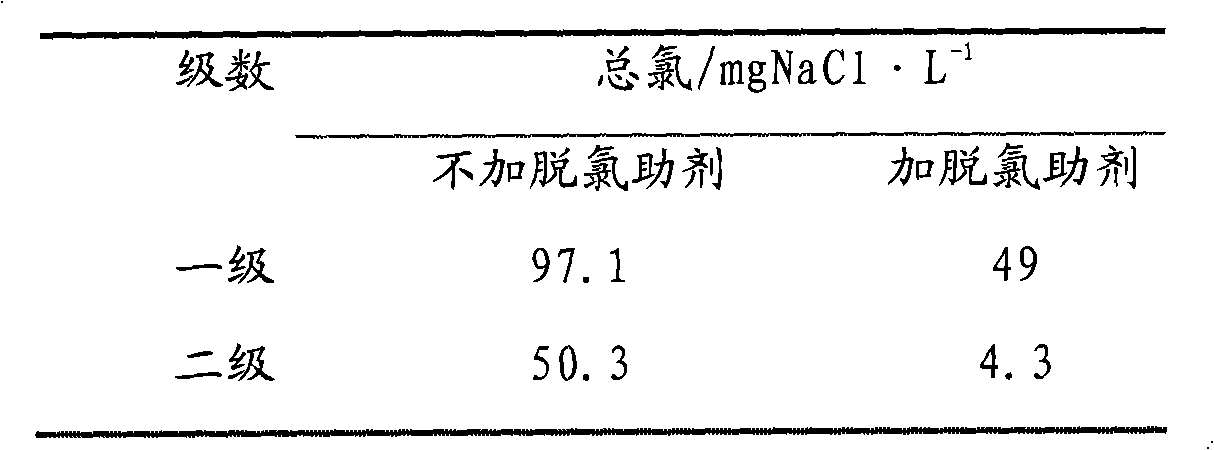

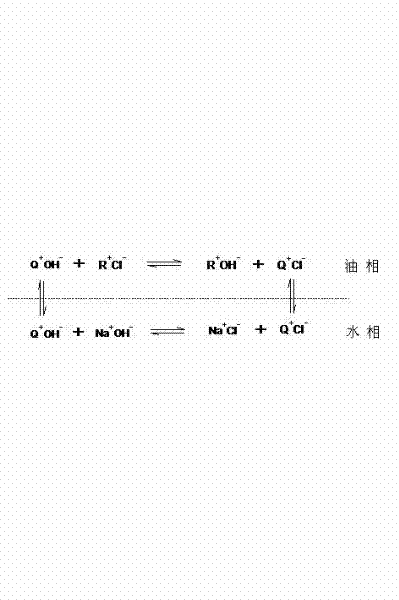

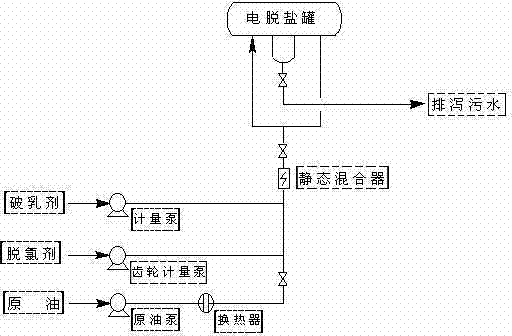

Additive for removing organochlorine from crude oil and removal technology thereof

InactiveCN102492458AEfficient removalReduce Chloride ContentHydrocarbon oils refiningDemulsifierOrganic chloride compound

The invention provides an additive for removing organochlorine from crude oil. The additive is characterized by being prepared through compounding of 2%-10% of a phase-transfer catalyst, 10%-30% of alkali and 60-88% of a solvent by mass. During electrical desalting and dewatering, the additive of the invention is added together with a demulsifier, thus being able to effectively remove an organic chloride from crude oil, reduce the content of chloride ions in condensed water at the top of a distillation tower, alleviate corrosion of tower top distillate pipelines and cooling-heat transfer equipment, as well as having no side effect on subsequent processes.

Owner:SHENYANG POLYTECHNIC UNIV

High-chlorine-content oil hydrogenation dechloridation catalyst and preparation method thereof

ActiveCN103611566AHigh low temperature activityStrong acid resistanceMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveOrganic chloride compound

The invention relates to high-chlorine-content oil hydrogenation dechloridation catalyst and a preparation method thereof. The method comprises the steps of first preparing a molecule sieve-MgAl2O4-Al2O3 composite carrier containing an assistant P, impregnating the carrier with the water-soluble compound of an active component Ni or Co and Mo, W and the assistant Ce, drying and roasting the carrier, and preparing the hydrogenation dechloridation catalyst. The content of each component of the catalyst is as follows in percentage by weight: 2 to 5 percent of NiO or CoO, 5 to 10 percent of MoO3, 4 to 10 percent of WO3, 2 to 4 percent of assistant P2O5, 1 to 2 percent of CeO2, and the balance of composite carrier. The catalyst is good in activity and stability, the organic chloride in the oil can be removed under a mild condition, and the removing rate is more than 99 percent.

Owner:WUHAN KELIN FINE CHEM

Method for lightening salt deposition of catalytic fractionating tower

ActiveCN102433155AHigh salt contentDesalination mitigationDistillation corrosion inhibitionTreatment with plural serial stages onlyInorganic saltsOrganic chloride compound

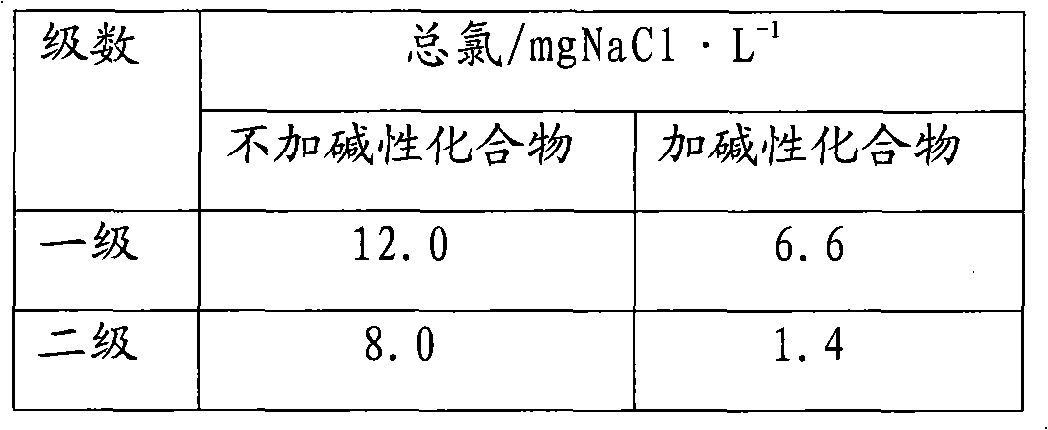

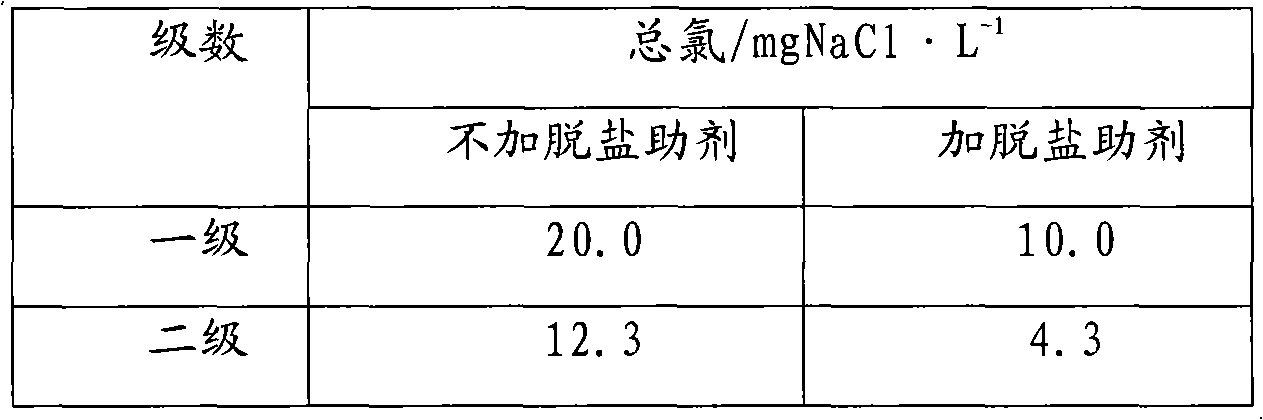

The invention relates to a method for lightening the salt deposition of a catalytic fractionating tower, wherein residual oil is pre-treated by an electro-desalting technique before entering in a catalytic cracking device; an alkaline compound is added during the electro-desalting process; and the alkaline compound is water-soluble organic amine and / or inorganic alkali. Utilizing the method disclosed by the invention, inorganic salts and organic chlorides in residual oil can be efficiently removed before the residual oil enters in a catalytic cracking device, thereby lighting the salt deposition of a catalytic fractionating tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for dechlorination of organic chloride through metal reduction assisted and strengthened by ultrasonic wave

InactiveCN1837106ASubsequent processing impactMaterials are cheap and readily availableWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentOrganic chloride compoundSupersonic waves

The invention discloses a hyperacoustic assisting and strengthening metal deacidizing organochloride antichloration method, which comprises the following steps: (1) choosing nulvalent metal or metal alloy as reducer to form powder, granule or clastic; (2) adujsting the organochloride waste water to acidic property or neutral; (3) filling or adding (1) reducer in reaction unit to react with (2) organochloride waste water; (4) installing supersonic generator in reaction unit to send supersonic wave to water body; strengthening the course of organic chlorine deacidizing and antichlorating by reducer; (5) discharging waste water which strengthened antichloration treatment by supersonic wave. The invention simplifies the handing, which possesses steady operation.

Owner:ZHEJIANG UNIV

Method for processing organic chloride and heavy metal polluted bed mud

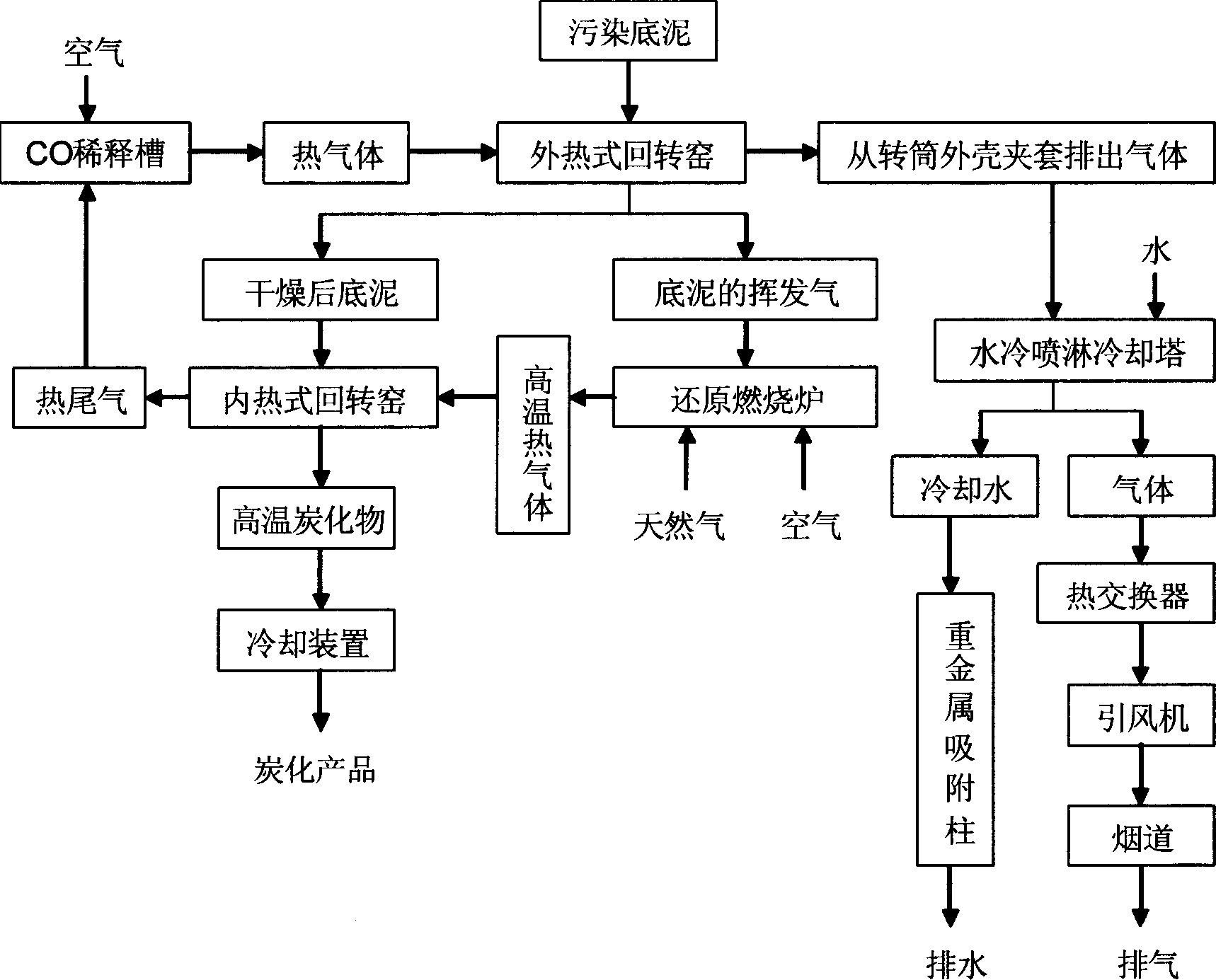

InactiveCN1884153ASimple processLow investment costSludge treatment by thermal conditioningSludge treatment by pyrolysisHeavy metal chelationCooling tower

The invention discloses a disposing method of organic chloride and heavy metal polluted sludge, which is characterized by the following: adopting anoxybiotic heat disposal method to heat through two rotary kilns; drying organic chlorinate in the external-heat rotary kiln indirectly; transmitting the volatilized gas in the reduced combustion furnace to decompose; heating the dried sludge through inner-heat typed swiveling kiln directly to carbonize common organic pollutant in the sludge; sealing heavy metal in the sludge or gasifying the tail gas; cooling the carbonized solid phase product to drain; transmitting heavy metal through spraying cooling tower in the cool water; recycling heavy metal through heavy metal chelant adsorbing column; discharging tail gas from flue through heat exchanging.

Owner:SHANGHAI JIAO TONG UNIV

Catalyst for removing organic chloride contained in hydrocarbon and preparing method thereof

InactiveCN101229516ARaw materials are cheap and easy to getEasy to preparePhysical/chemical process catalystsRefining to eliminate hetero atomsOrganic chloride compoundRoom temperature

The invention relates to a catalyst used for removing organic chloride in hydrocarbons. The catalyst is composed of 5-40 percent of active compositions and 95 percent-60 percent of carriers, which are calculated according to total weight of the total catalyst. The catalyst is prepared through the following three steps: 1) the catalyst carriers are dipped into aqueous solution with the active compositions for 2-20 hours; 2) the catalyst dipped in the step 1) is dried for 1-24 hours at 20-150 DEG C; 3) the catalyst dried in the step 2) is roasted for 1-24 hours at 300-600 DEG C, and then the temperature thereof is cooled to room temperature. By adopting the catalyst, the removal rate of the organic chloride in oil products is more than 90 percent.

Owner:CHINA PETROCHEMICAL CORP +1

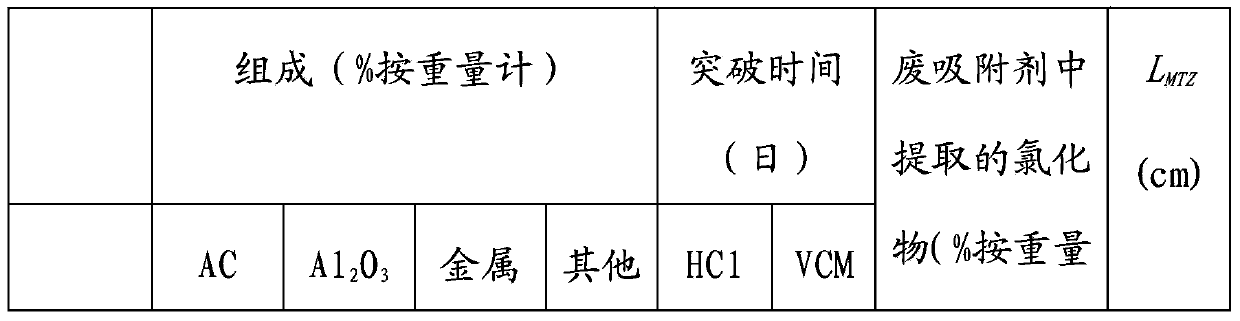

Absorbent for chloride removal

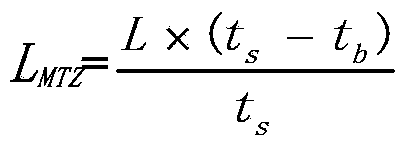

InactiveCN104209090AImprove adsorption capacityEfficient removalOther chemical processesDispersed particle separationCatalytic reformingActivated carbon

The invention provides an absorbent removing organic and inorganic chloride from hydrogen flows produced by catalytic reforming of heavy naphtha. The absorbent comprises 1% to 50% weight of activated carbon component, 40% to 90% weight of aluminum oxide component and 5% to 55% weight of metallic oxide component as well as 0.5% to 3% weight of binder. The invention further provides a method of manufacturing and using the absorbent.

Owner:PTT PUBLIC CO LTD

Method for removing chlorine included in hydrogen chloride gas

InactiveCN102849681AEasy to removeThe removal method is reliableChlorine/hydrogen-chloride purificationChemical industryOrganic chloride compound

Owner:HAOHUA HONGHE CHEM

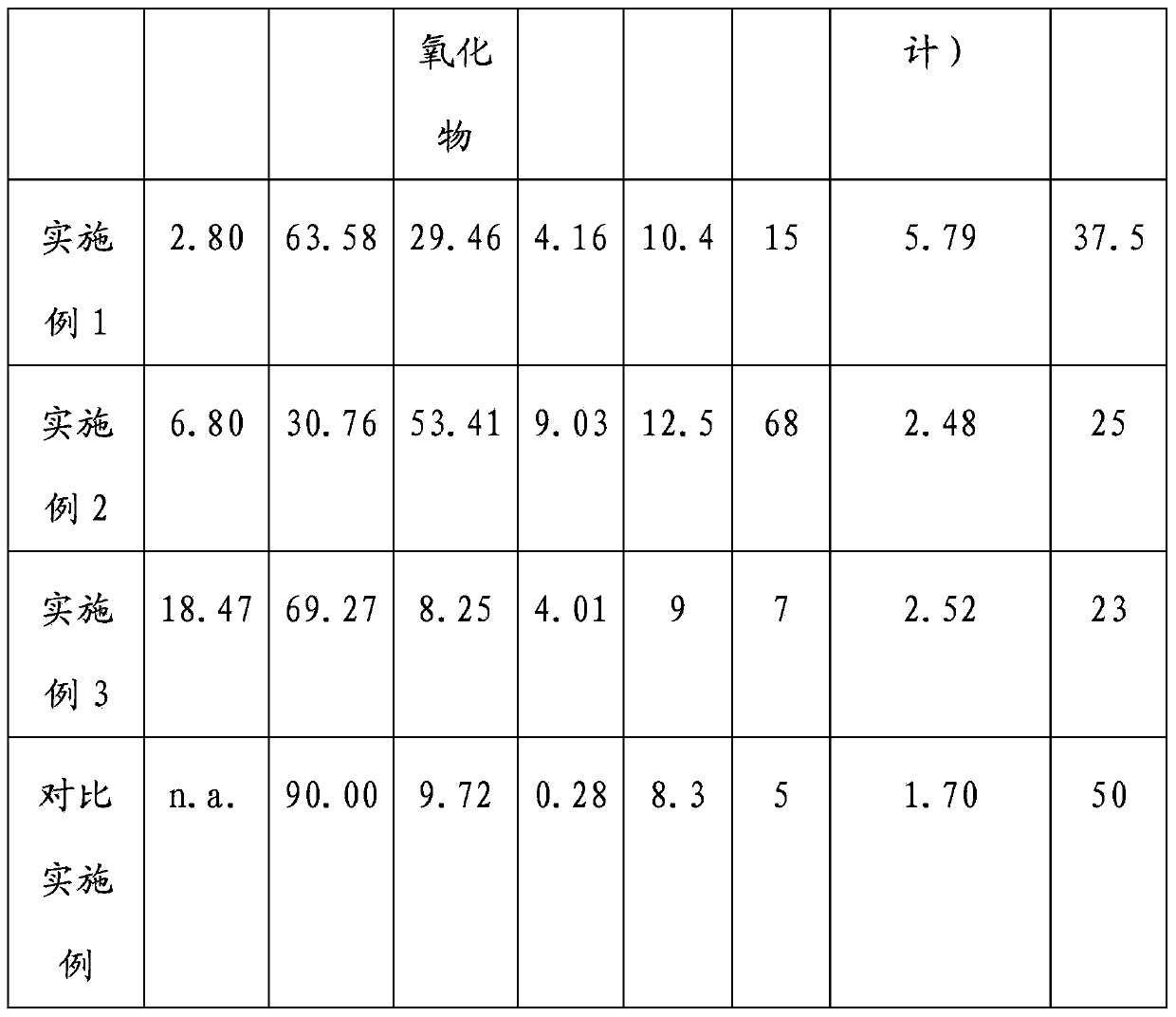

Antichlor and preparation method thereof

ActiveCN106861386ARaise the ratioEvenly dispersedGas treatmentDispersed particle separationAlkaline earth metalOrganic chloride compound

The invention discloses an antichlor and a preparation method thereof. The antichlor uses a composite oxide as a carrier to be loaded with oxides of alkali metal and / or alkaline earth; the composite oxide carrier contains theta aluminum oxide and calcium oxide. The composite oxide carrier is prepared by a coprecipitation method; calcium oxide is introduced into a carrier framework structure; the breakthrough chlorine content can reach 17.6 percent at the normal temperature. Through high-temperature roasting, the prepared aluminum oxide with the theta material phase structure reduces the surface hydroxyl quantity; the physical adsorption of HCl on the antichlor is reduced to the maximum degree; the phenomenon of antichlor surface acidity enhancement due to HCl physical adsorption concentration is reduced, so that the phenomenon of green oil generation through olefin polymerization due to acid catalysis is reduced; the phenomenon of organic chloride generation through reaction of olefin and HCl due to acid catalysis can be avoided. In addition, through the prepared composite oxide carrier, the intensity of the antichlor is obviously improved; the agglomeration or pulverization phenomenon under the water-containing steam work condition can be eliminated.

Owner:WANHUA CHEM GRP CO LTD

Organic chloride adsorbent

Owner:BASF CORP

Hybrid membrane capable of degrading organic chloride and preparation method of hybrid membrane

InactiveCN103611435AAdjustable sizeEasily adjustable in sizeSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chloride compoundMicrosphere

The invention relates to a hybrid membrane capable of degrading organic chloride and a preparation method of the hybrid memrbane, belonging to the scientific and technical field of polymers. The preparation method comprises the steps of dispersing polyvinylidene fluoride powder, polyacrylic acid microgel or microspheres in N,N-dimethylfomamide, and preparing a flat base membrane by adopting a phase inversion method; then soaking the base membrane in an aqueous solution containing FeCl2 to react for a certain period of time, then soaking the base membrane in an aqueous solution containing sodium borohydride to prepare a hybrid membrane containing Fe<0> nanoparticles, and then soaking the hybrid membrane in an anhydrous ethanol solution containing noble metal salt to prepare a hybrid membrane capable of degrading organic chloride and containing iron-noble metal nanoparticles. The hybrid membrane can degrade chlorinated organic compounds including monochloroacetic acid, chlorophenesic acid, trichloroethylene, tetrachlormethane, polychlorinated biphenyl and the like, and has the advantages of high catalytic reaction activity, convenience in operation, good reuse effect and the like. Besides, the hybrid membrane also has the advantages of simple preparation method, low cost, suitability for large-scale production and the like.

Owner:TIANJIN POLYTECHNIC UNIV

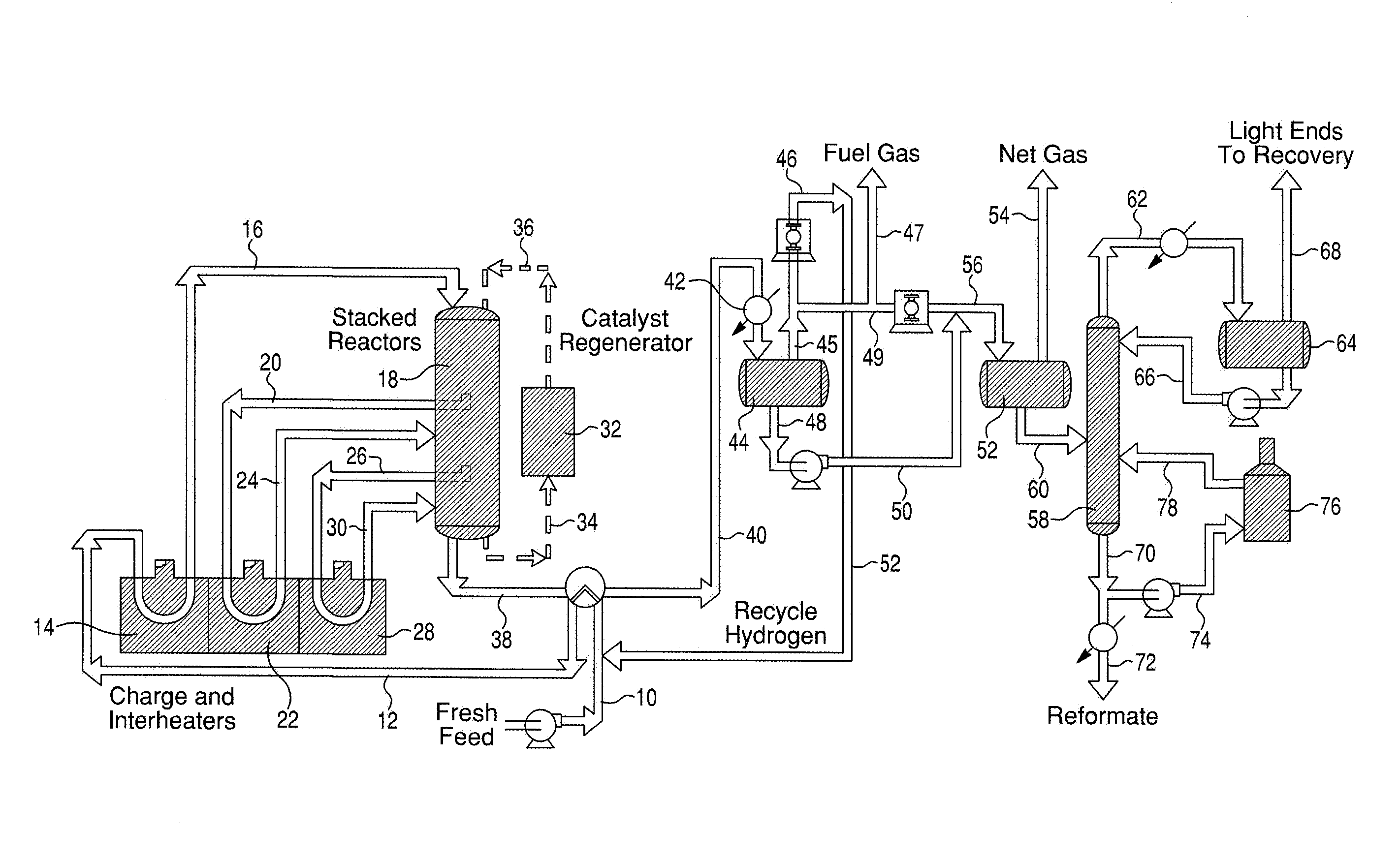

Organic Chloride Adsorbent

ActiveUS20120190906A1Gas treatmentCatalyst regeneration/reactivationOrganic chloride compoundHydrocarbon

Chemically combined chlorides are removed from intermediate and product streams of a hydrocarbon reforming process by contacting the streams with zeolite 13X, having a Si / Al ratio of less than 1.25.

Owner:BASF CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com