Method for lightening salt deposition of catalytic fractionating tower

A fractionation tower and salt formation technology, which is applied in the field of reducing salt formation in catalytic fractionation towers, can solve problems such as high salt content in residual oil, reduction of salt content in catalytic feed, and inability to remove organic chlorine in residual oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

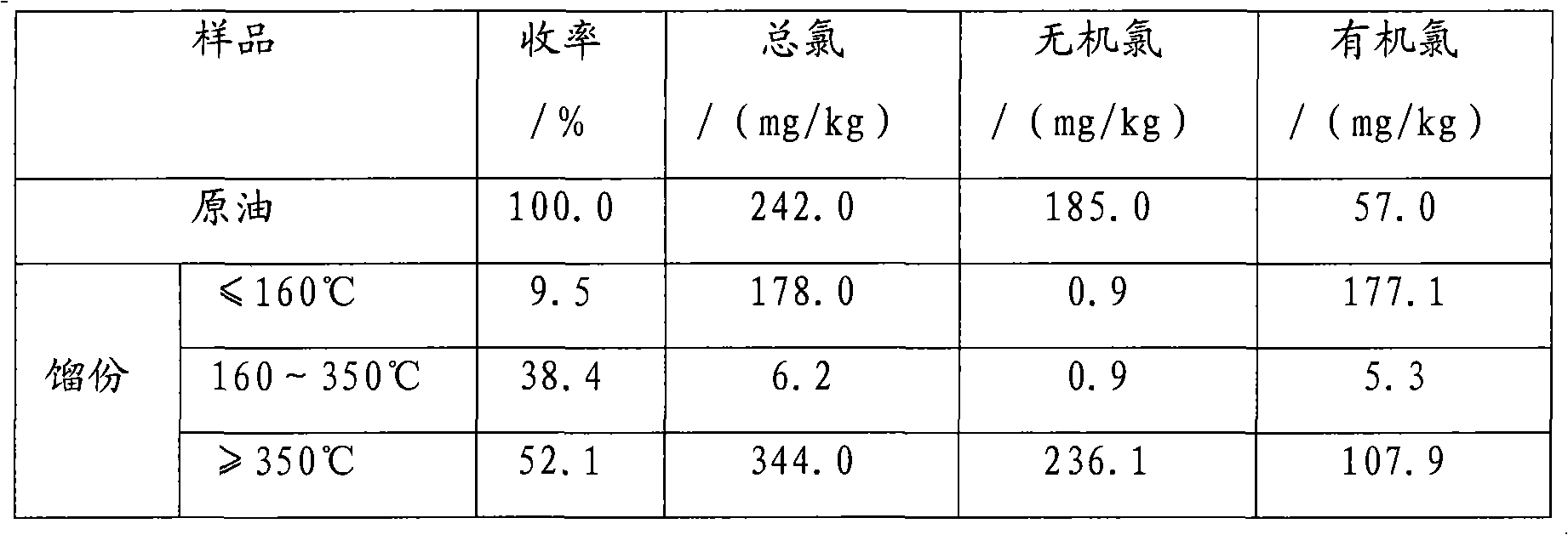

[0028] An actual distillation experiment was carried out on a certain crude oil in Zhongyuan Oilfield, and the distribution of organic chlorine in each fraction was analyzed. The results are shown in Table 1. It can be seen from the experimental results that the content of organic chlorine in naphtha is relatively high, as high as 177.1mg / kg. This part of organic chlorine is likely to come from wax removers added in the oil recovery process, such as dichloroethane, dichloropropane, chloroform, carbon tetrachloride, epichlorohydrin, etc., whose boiling point is 60-116 °C. Atmospheric distillation, most of it enters the naphtha fraction. The content of organic chlorine in the diesel fraction at 160-350°C is relatively low, 5.3mg / kg. The organic chlorine content in the atmospheric residue is also relatively high, reaching 107.9 mg / kg. This part of organic chlorine may come from the decomposition of chlorinated hydrocarbons in the atmospheric distillation process, which is the ma...

Embodiment 2

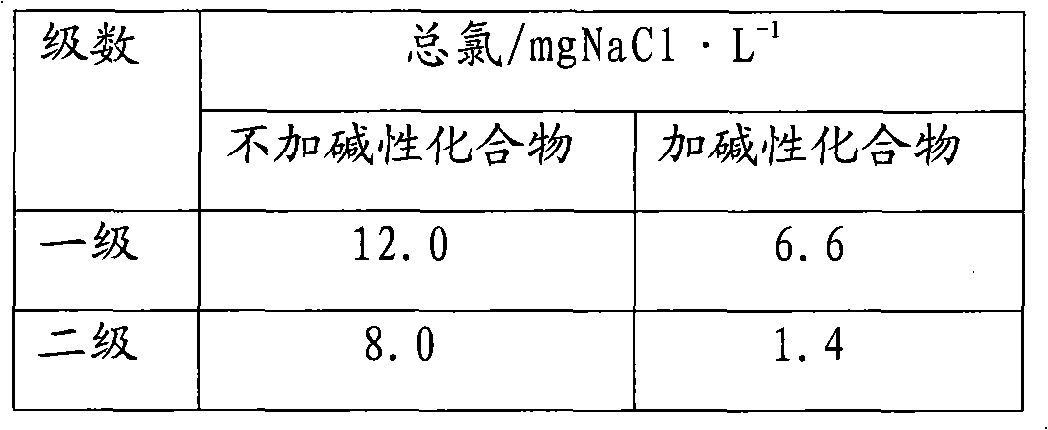

[0032] The experiment simulates the determination method of salt content in crude oil, and the dechlorination experiment is carried out on the atmospheric residual oil respectively. Add 1g of oil sample, 1.5ml of xylene, 2.0ml of ethanol-water (1:3) solution, and 200μg / g of basic compound (see Table 2) into the test tube, mix thoroughly on the shaker, and draw out the water after centrifugation Phase, analysis of Cl - Concentration, the experimental results are shown in Table 2. It can be seen from Table 2 that after the atmospheric residual oil is washed with water, the water phase Cl - The concentration is 316.0 mg / kg. After adding basic compound for treatment, the aqueous phase Cl - The concentration increased from 316.0mg / Kg to 505.0mg / Kg, indicating that the basic compound has a removal effect on the organic chloride in the residual oil.

[0033] Table 2

[0034] Dechlorination agent

Embodiment 3

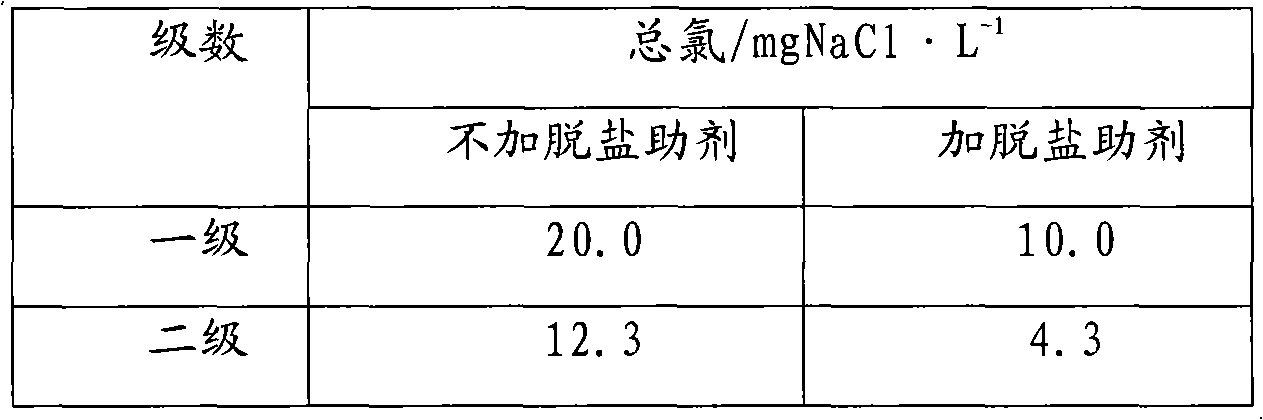

[0036] The atmospheric residue of Zhongyuan crude oil has a salt content of 15mgNaCl / L and a total chlorine content of 22mgNaCl / L. The difference between total chlorine and salt content is 7mgNaCl / L of organic chlorine.

[0037] The brand name of the demulsifier used is FC9301, and the basic compound consists of ethylenediamine and NH3 ·H 2 O is composed in a weight ratio of 1:7. The added amount of the demulsifier is 50 μg / g, and the added amount of the basic compound is 200 μg / g.

[0038] Mix the demulsifier and basic compound with water in a certain proportion to form a solution, the water injection rate is 10%, mix the aqueous solution with crude oil preheated to 90-100°C on a commercially available juicer for 20 seconds, and use DP-2C The demulsifier selection instrument is used for oil-water separation, the electric field strength is 300V / cm, and the temperature is 95°C. After the oil-water separation, the oil sample is added with demulsifier and washed with water twice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com