Patents

Literature

262results about How to "High salt content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for realizing zero emission of dyeing wastewater with high salinity in printing and dyeing enterprises

InactiveCN101955282AHigh salt contentReduce evaporationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentElectrochemical responseChemistry

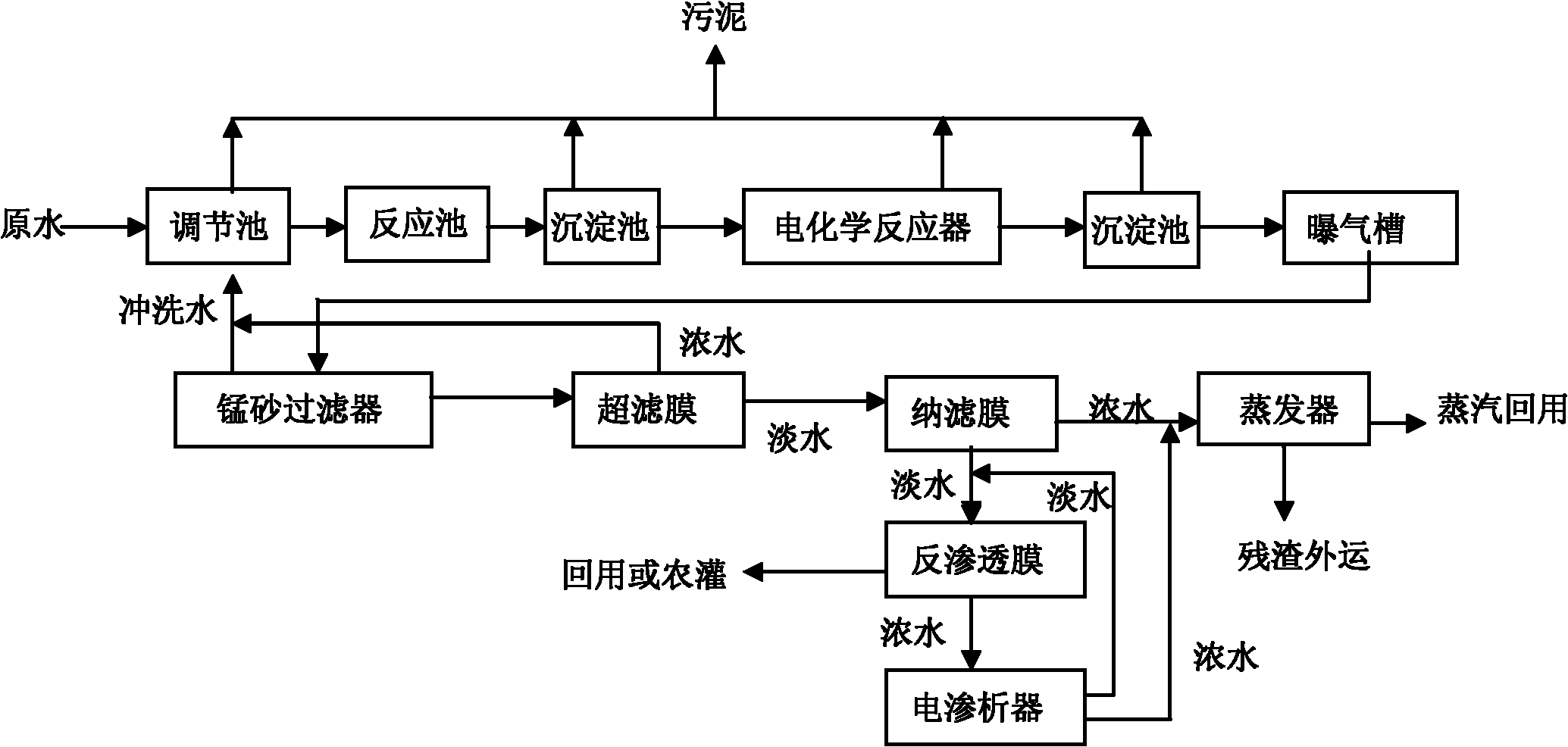

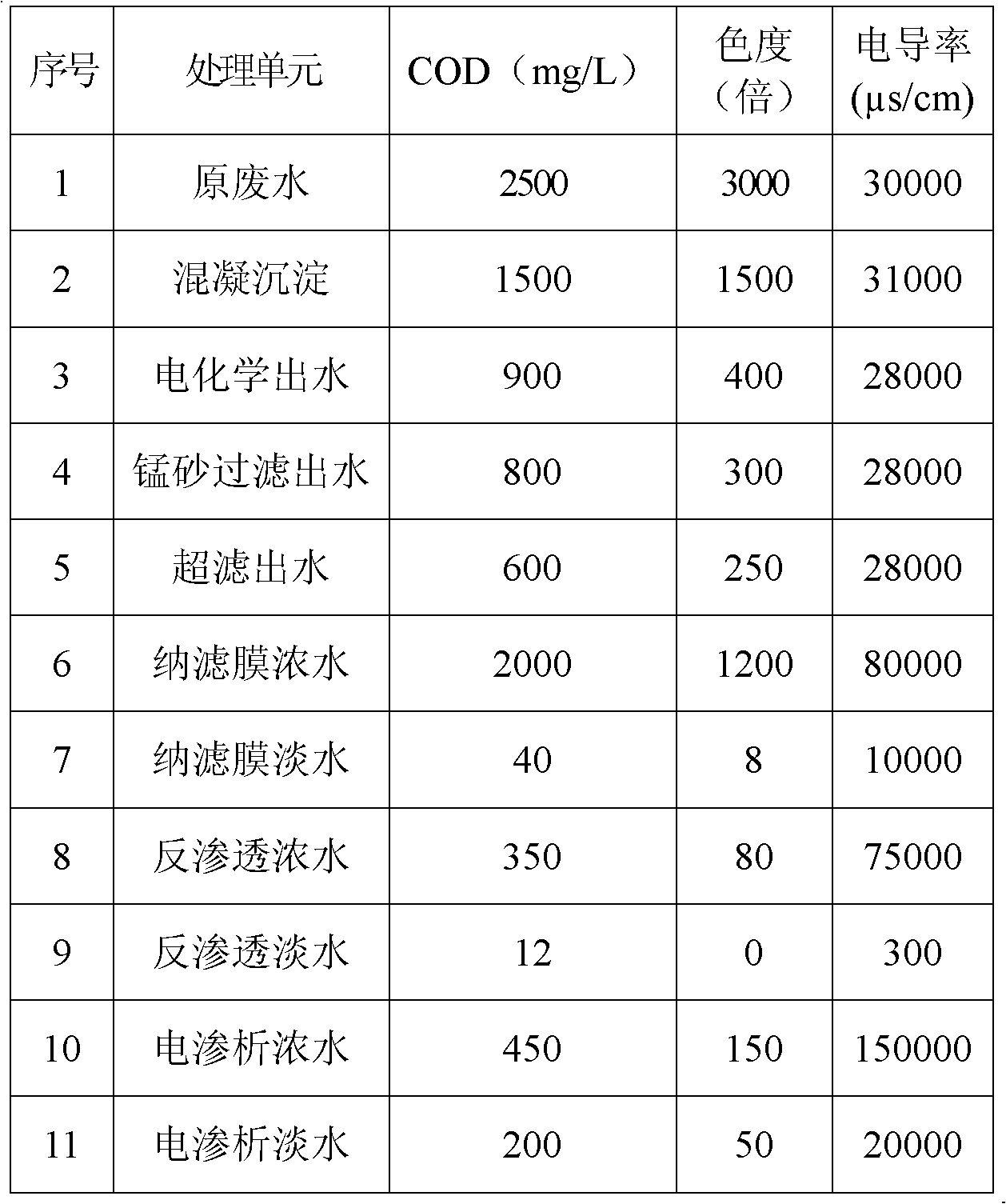

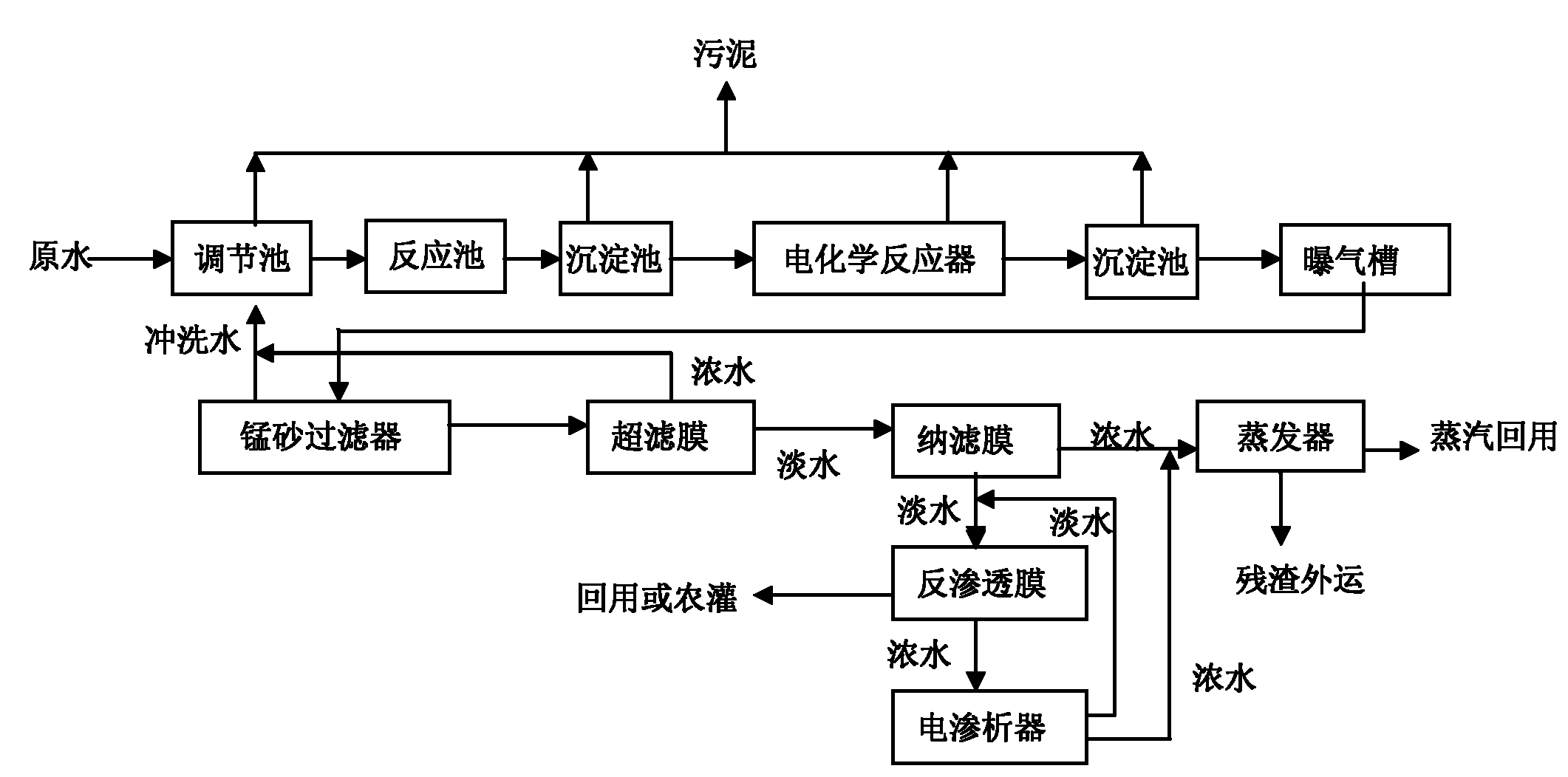

The invention discloses a method for realizing zero emission of dyeing wastewater with high salinity in printing and dyeing enterprises. The method comprises the following steps that: the wastewater enters a regulating reservoir first for homogenizing, and then enters a reaction tank, ferrous sulfate is added into the reaction tank to regulate the pH value and perform a coagulation reaction, effluent enters a sedimentation basin for precipitating after the reaction, supernate of the sedimentation basin is treated by an electrochemical reactor, enters a secondary sedimentation basin so as to remove scummings and dregs and enters an aeration tank for aerating, and the supernate is filtered by a manganese sand filter for deferrization after the aerating; the filtered effluent is treated by using an ultrafiltration membrane, concentrated water of the ultrafiltration membrane returns to the regulating reservoir, and fresh water enters a nanofilter membrane for treating; the fresh water outputted by the nanofilter membrane enters a reverse osmosis membrane, the outputted concentrated water returns to the regulating reservoir or is evaporated directly; and concentrated water of the reverse osmosis membrane enters an electrodialyzer, electrodialytic fresh water is refluxed to be used as inflow of the reverse osmosis membrane, and electrodialytic concentrated water enters an evaporator for evaporating. Vapor generated by evaporating can be used for printing and dyeing production, residues generated by the evaporating are used as solid wastes, and water pollutants are not discharged in the whole process.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +3

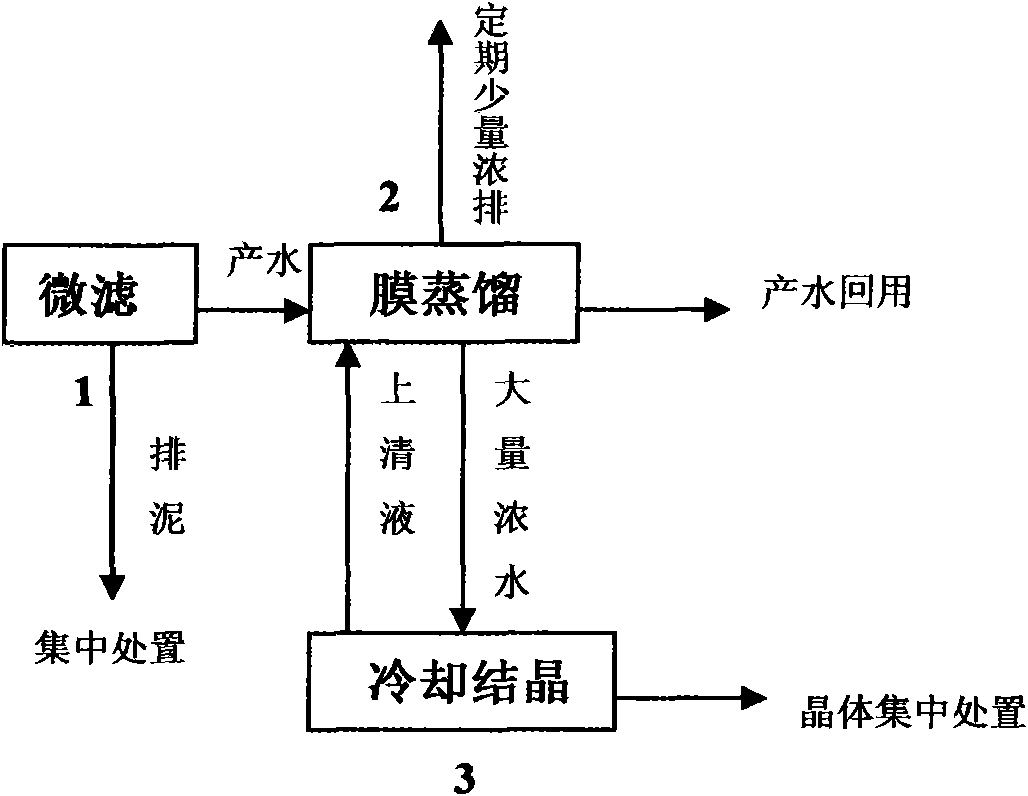

A method for the treatment and reuse of ammonia-nitrogen-containing high-salt catalyst wastewater

ActiveCN102295378ATake advantage of highly concentrated processingHigh salt contentWater contaminantsWater/sewage treatment bu osmosis/dialysisSocial benefitsSeparation technology

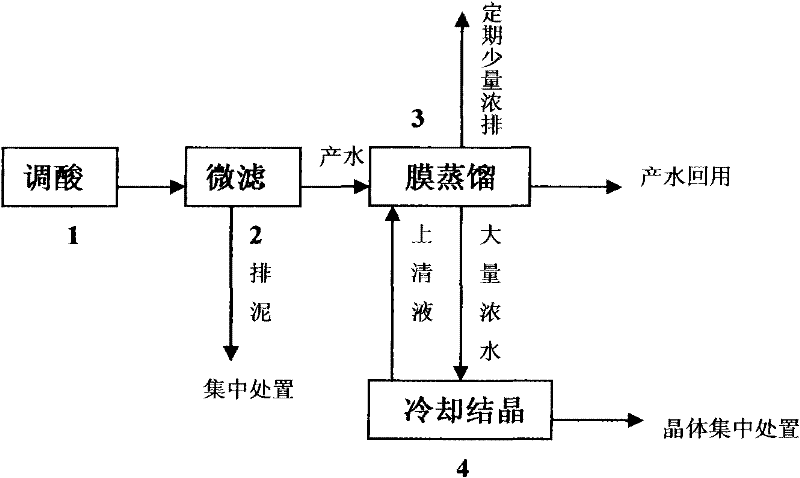

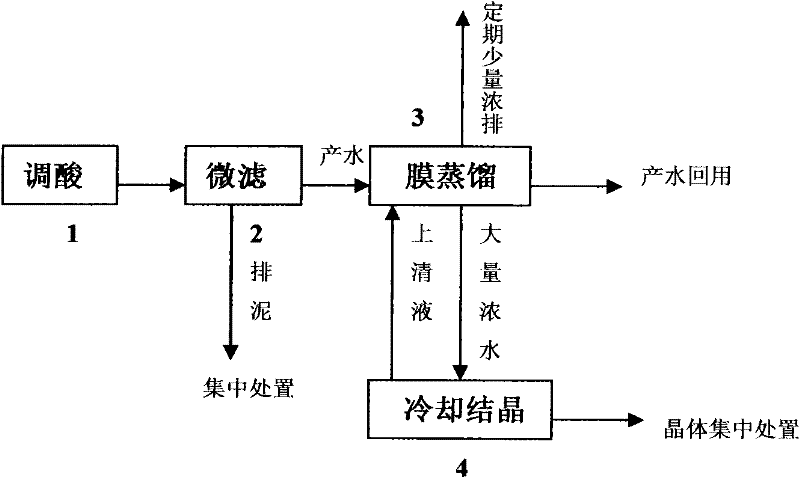

The invention relates to a recycling method for treating ammonia nitrogen containing high-salt catalyst wastewater by adopting a membrane separation technology. The process flow of 'acid regulation, micro-filtration, membrane distillation, cooling and crystallization' is adopted in the method. By adopting the process flow, salts, ammonia nitrogen and metal ions in the wastewater can be effectively removed, and deep treatment and recycle of the ammonia nitrogen containing high-salt catalyst wastewater are realized. The process flow makes full use of the technical advantages of membrane distillation, solves the problem that the discharge of high salts, ammonia nitrogen and metal ions of the ammonia nitrogen containing high-salt catalyst wastewater does not reach the standards, and realizes recycle of the produced water. After the ammonia nitrogen containing high-salt catalyst wastewater is treated by the process flow, the reclamation rate of the wastewater is more than 90 percent, and high recycle of the ammonia nitrogen containing high-salt catalyst wastewater is realized; and the method accords with the development strategies of energy conservation and emission reduction, and has remarkable social benefit and economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

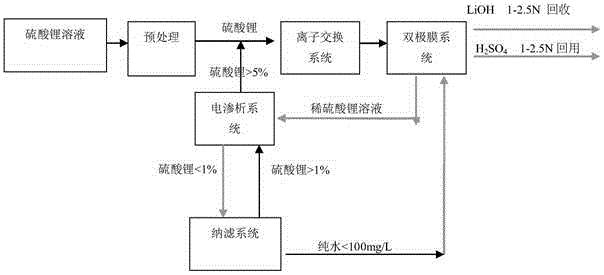

Method for preparing acid-base from rare-earth sodium saponification waste water

ActiveCN103086551AAvoid contamination and cloggingReduce material and energy consumptionSemi-permeable membranesFatty/oily/floating substances removal devicesUltrafiltrationChemistry

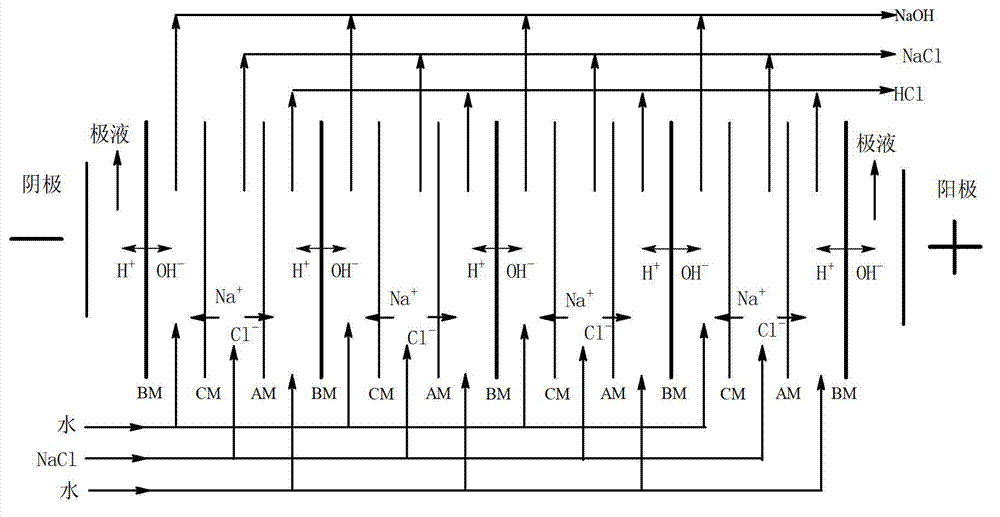

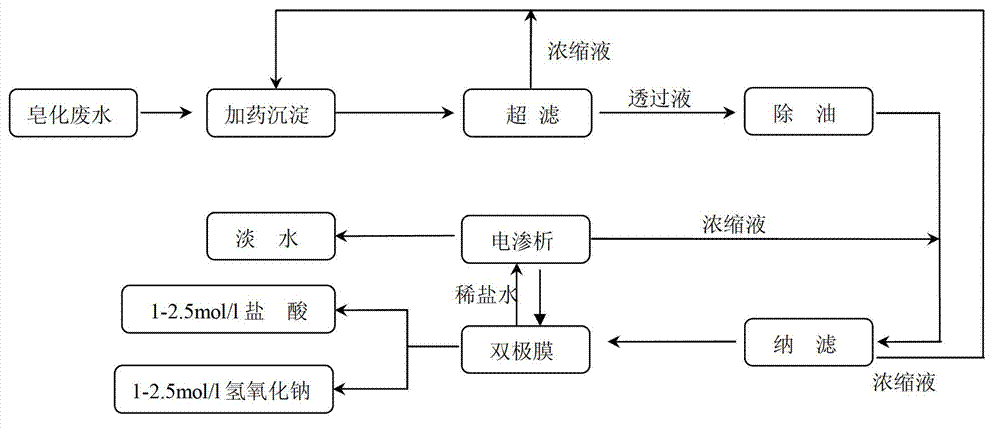

The invention provides a method for preparing acid-base from rare-earth sodium saponification waste water. The method comprises the steps that: firstly sodium saponification waste water is treated by a sedimentation basin and an ultrafiltration system; water produced by the ultrafiltration system enters an oil removal system to be treated, and concentrated water enters the sedimentation basin to be settled; water produced by the oil removal system enters a nanofiltration system to be treated; water produced by the nanofiltration system enters a bipolar membrane system to be treated, and concentrated water returns to the sedimentation basin; water treated by the bipolar membrane system is acid-base, and residual thin brine is conveyed to an electrodialysis system to be treated; concentrated water passing through the electrodialysis system returns to the bipolar membrane system for producing the acid-base, part of freshwater enters the bipolar membrane system to serve as make-up water, and part of freshwater serves as recycle water. According to the method, a pretreatment and membrane integration technology is adopted for treating rare earth metallurgy waste water, a final permeating liquid is used for production, concentration desalination treatment is carried out on smelting waste water by using the characteristics of ultrafiltration, electrodialysis, a nano-filtration membrane and a bipolar membrane, a concentrated liquid is used for preparing acid-base, and freshwater subjected to electrodialysis treatment is recycled; and the rare-earth sodium saponification waste water is comprehensively treated.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

Process for the co-manufacture of ingredients for use in foods and beverages using potatoes as starting material

InactiveUS20010041199A1Reduce the amount requiredPrevent enzymatic browningBeer fermentationAlcoholic beverage preparationBiotechnologyFruit juice

Disclosed is a process for the co-manufacture of ingredients having food and beverage applications, using potatoes as starting material. The process comprises six steps. The first step is a cutting and dipping of washed raw potatoes in an anti-oxidant solution. The second step is an extraction of undiluted juice free of starch and fibers from a purée made from the anti-oxidant-dipped raw potatoes. The third step is a concentration and enzymatic treatment of the juice. The fourth step is a heating of the juice to specific temperatures to cause precipitation of proteins and separation of precipitated protein therefrom. The fifth step is a thermal browning of the clear juice. The sixth step is an adjustment of the final pH of the juices of the fourth and fifth steps and a blending of these juices in ratios appropriate for intended use. These six steps yield products which may be used as the main flavor principle in malt-free beer, as a coffee substitute and as a flavor enhancer in savory mixes. They also yield dietary fibers, a concentrated edible protein and non-gelatinized granular starch, thereby increasing revenues derived from potato processing while minimizing liquid waste stream.

Owner:SENSICULTURE FY BIOTECH

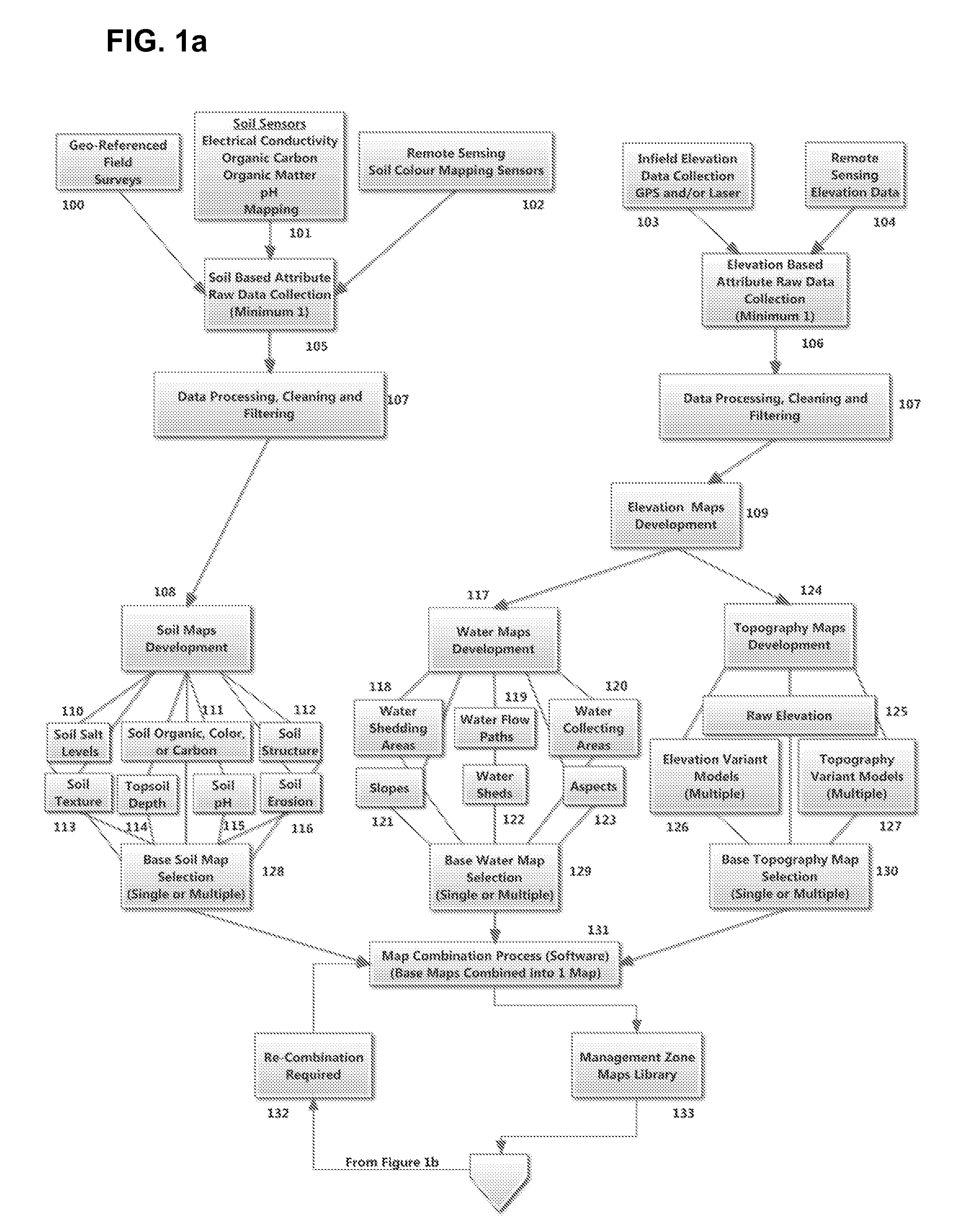

Method and System for Identifying Management Zones for Variable-Rate Crop Inputs

InactiveUS20130231968A1Increase productionLow yieldData processing applicationsSoil-working methodsEngineeringLandform

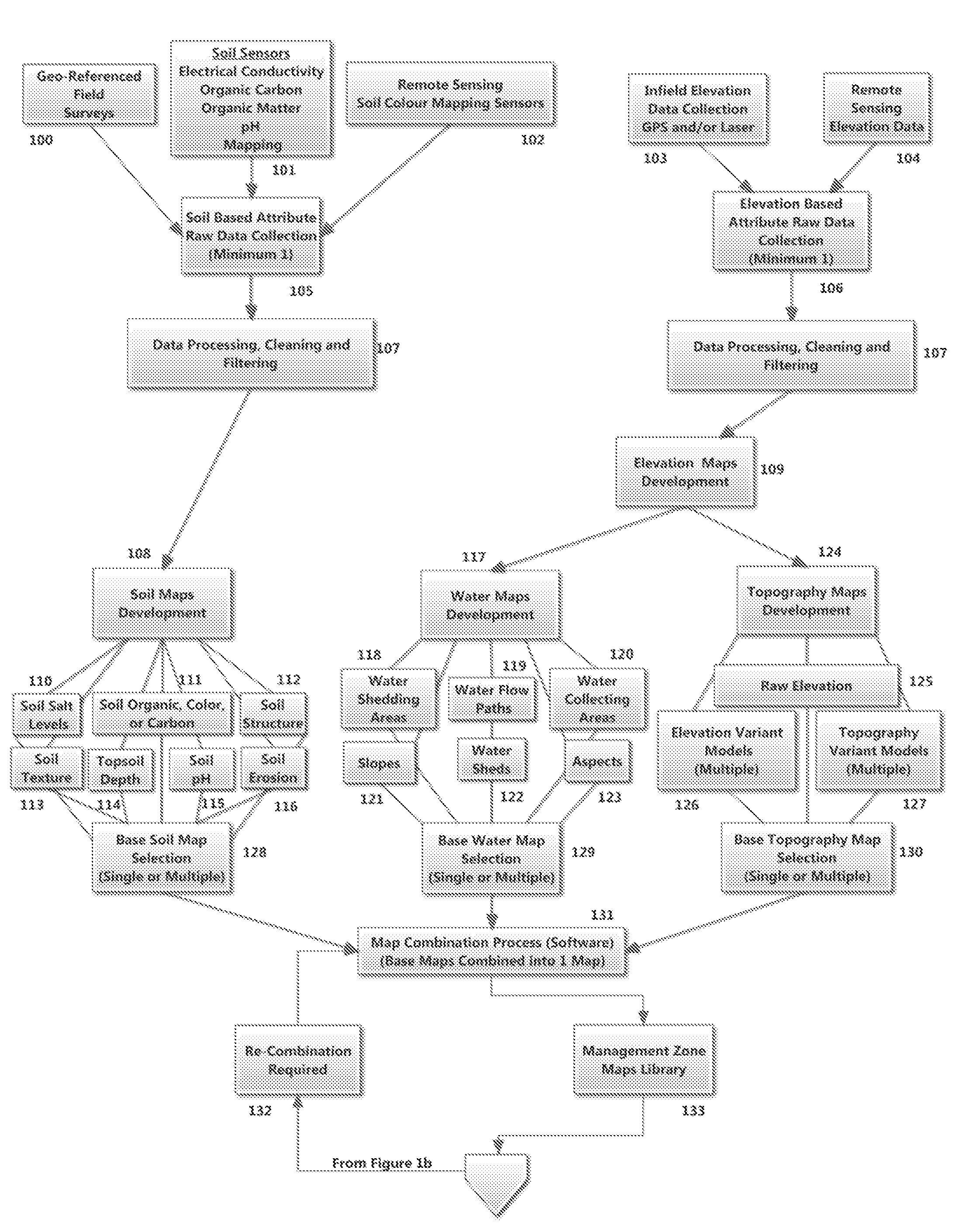

A method and system for identifying management zones for variable-rate crop inputs, wherein the zones are developed using soil, water and topography base maps. The base maps are combined into various different zone maps, and a final zone map is selected on the basis of observed field characteristics.

Owner:PHANTOM AG LTD

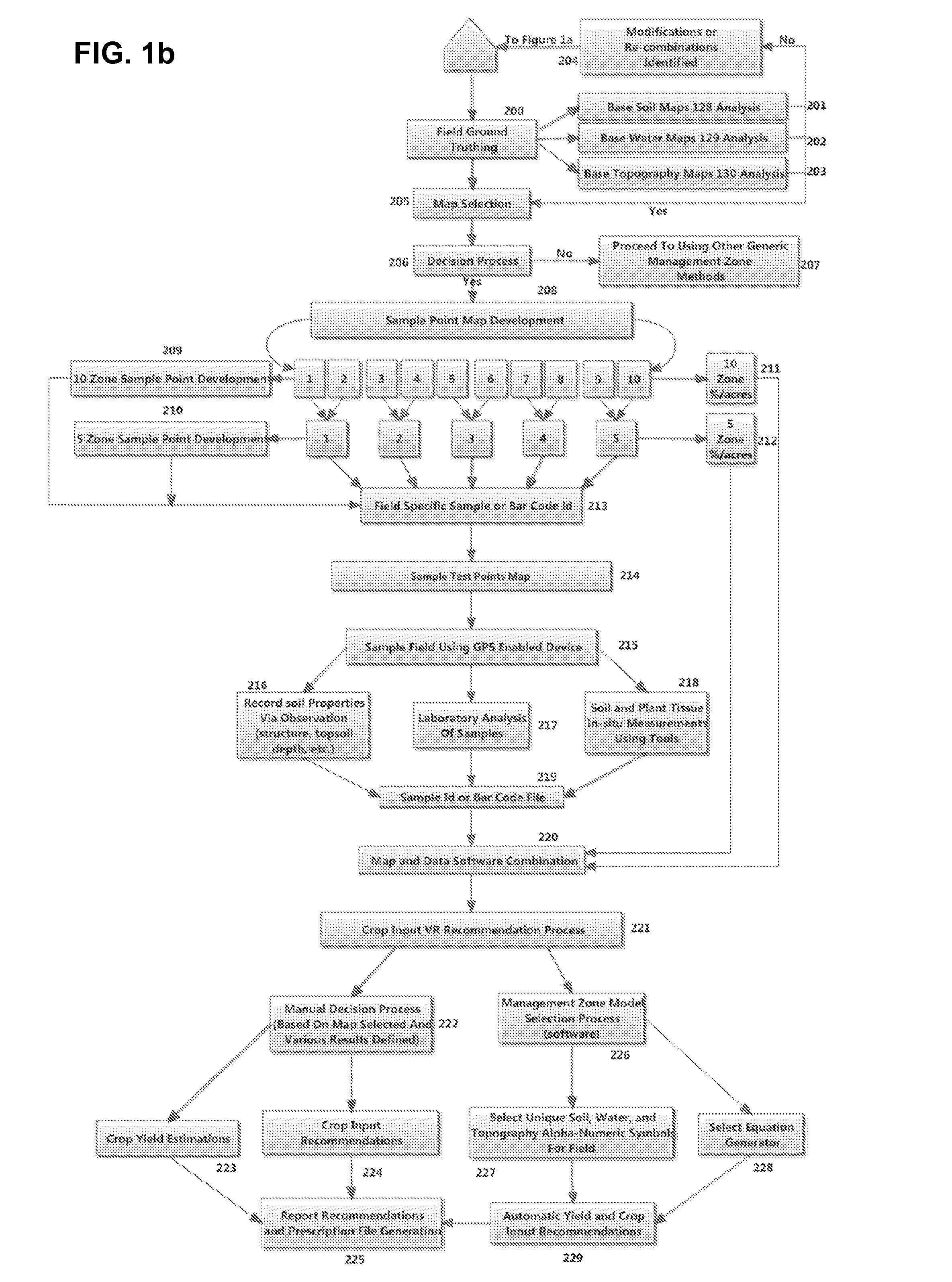

Advanced treatment process for paper-making waste water

ActiveCN101337752AHigh salt contentImprove conductivitySludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentIron reductionWater pipe

The invention discloses an advanced treatment process of paper-making wastewater. The process comprises the following steps: introducing the paper-making wastewater after being subjected to secondary biochemical treatment into a micro-aeration iron reduction bed, backfilling iron chips in the micro-aeration iron reduction bed, and carrying out reducing reaction to the paper-making wastewater in the micro-aeration iron reduction bed; introducing effluent water after being processed according to step one into a coagulation basin, and adding a coagulating agent and a coagulant aid to the coagulation basin, so as to promote grains in the water to be agglomerated; introducing effluent water after being processed according to step two to a sedimentation tank for sludge separation; introducing the effluent water in the sedimentation tank into a filter basin for being filtered; introducing the effluent water filtered after being sterilized and disinfected into a reusing water pipe network; introducing sludge in the sedimentation tank and back washing blow-off water in the filter basin into a sewage thicker, and outwardly transporting the sludge and the back washing blow-off water after being dehydrated for disposal; and meanwhile, introducing dehydrate filtrate solution and overflowing liquid in the sewage thicker into the coagulation basin for re-treatment. The process has the advantages of simple process, good decoloration effect and cheap cost.

Owner:HUATIAN ENG & TECH CORP MCC

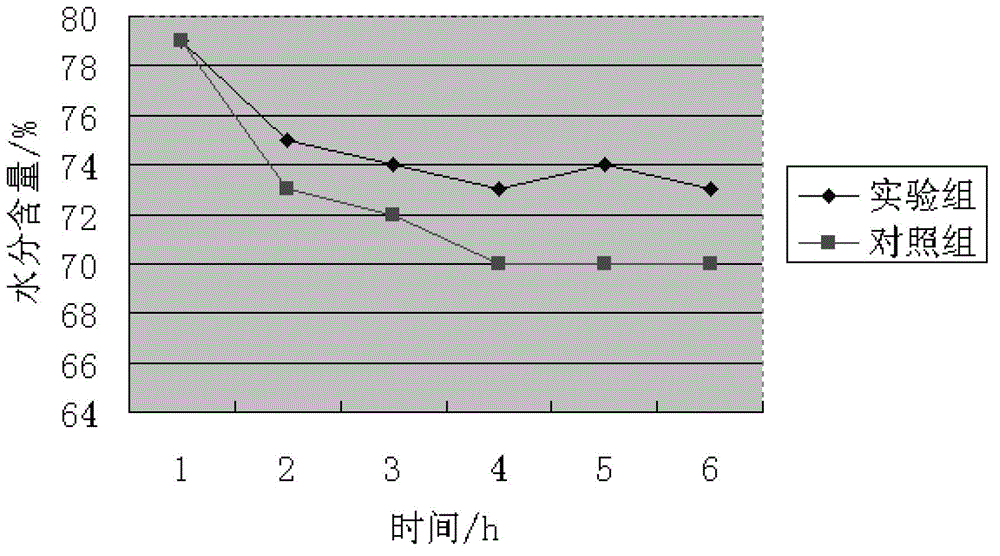

Salted goose processing method

ActiveCN103330230APromote absorptionIncrease moisture contentFood preparationSaline waterSalt content

The invention discloses a salted goose processing method. The salted goose processing method comprises the following steps: (1) slaughtering and cleaning a goose; (2) covering the goose carcass with a mixture formed by grinding geranium, xanthoxyli fructus and star anise and then frying the obtained powder with salt; (3) evenly injecting marinade into the goose body, placing the goose into a vacuum tumbling machine after injection to achieve pickling at a low temperature in an intermittent circulatory vacuum mode; (4) placing the processed goose into marinade for pickling, and then taking out the goose, air-drying, disinfecting and vacuum-packing. As the intermittent circulatory vacuum node is adopted for pickling, salt absorption of goose is promoted, water loss is reduced, and salt and water can be distributed on the surface and in the goose more evenly. The salted goose processing method can save about 4 hours (more than 200%) when used for one-step pickling to achieve the same pickling effect as a traditional pickling method; compared with the control group of the traditional pickling method, the moisture content, salt content and mass of goose are all remarkably higher than those of the control group.

Owner:ANHUI SHUXIANG FOOD CO LTD

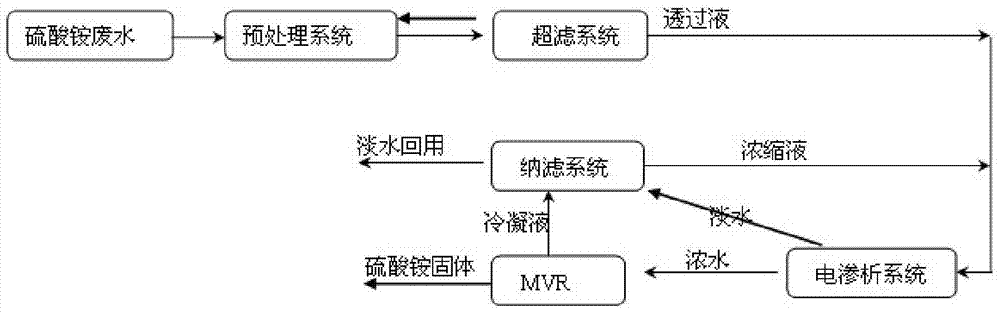

Recycling method for saponified ammonium-sulfate wastewater in rare soil

InactiveCN103771642AReduce manufacturing costHigh salt contentMultistage water/sewage treatmentUltrafiltrationRare earth

The invention provides a recycling method for saponified ammonium-sulfate wastewater in rare soil. The recycling method comprises the following steps: (1) pretreatment of coagu-flocculation reaction and a precipitation tank is carried out on the ammonium-sulfate wastewater; (2) an ultrafiltration system is adopted; (3) an electrodialysis system is adopted, concentrated water treated by the electrodialysis system enters the step (4), and fresh water enters the step (5) for treatment; (4) an MVR (Mechanical Vapor Recompression) system is adopted, concentrated salt water treated by the MVR system is crystallized and then becomes solid salt which is used as a composite fertilizer material or is sold to outside as a side product, and evaporated and condensed water is directly reused as process water for sulfuric-acid extraction in a rare-soil saponifying process; and (5) the fresh water electrodialyzed in the step (3) is treated by using a nanofiltration system, the permeated liquid of the nanofiltration system is used as the process water, and the concentrated liquid returns to the step (3) and is added into electrodialyzed water. The recycling method provided by the invention has the advantages that comprehensive treatment can be carried out on the ammonium-sulfate wastewater in the rare soil, so that not only can the environmental burden be caused, but also the ammonium-sulfate wastewater can be recycled.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

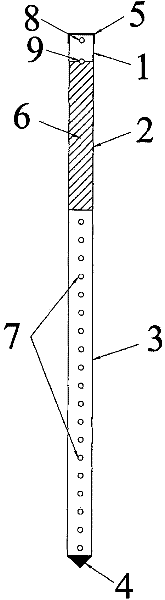

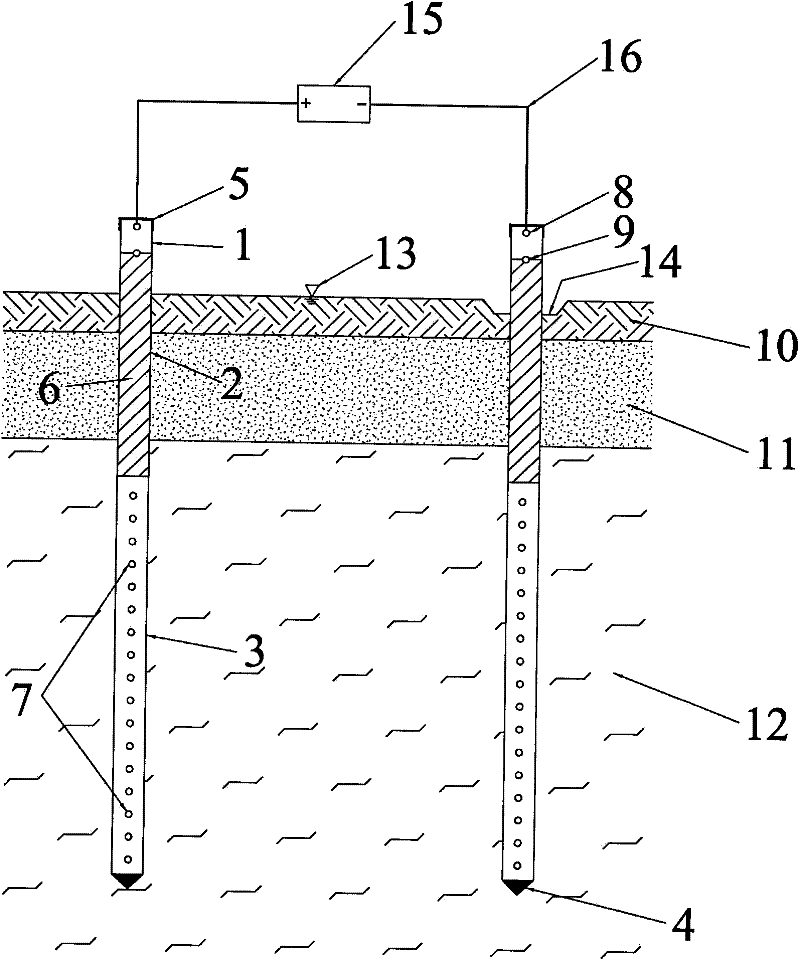

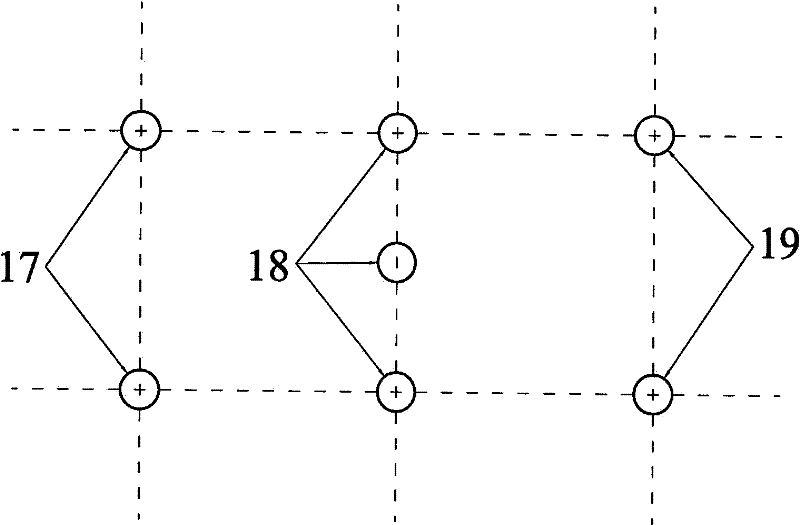

Electroosmosis electrode and mounting mode

InactiveCN101748724AGood water permeabilityLower resistanceSoil preservationWater dischargeElectrical polarity

The invention discloses an electroosmosis electrode and a mounting mode. The electroosmosis electrode on the same metal pipe is divided into a connecting exhausting section, an insulating section and an open pore processing section from up down in sequence; wire connecting pores and water and air discharging pores are distributed on the connecting exhausting section; the outside of the insulating section is coated with insulating varnish; water discharging pores are distributed on the open pore processing section densely; the top of the connecting exhausting section is provided with a plastic cap and the bottom thereof is provided with metal shoes. When mounting, the top end of the insulating section is required to be higher than the ground, the bottom end thereof is required to be deeper than the bottom of soil layer good in water permeability; adjacent four electroosmosis electrodes are mounted in rectangle shape, and the distance between electrodes with similar polarities is shorter than that between electrodes with opposite polarities; intermediate water discharging electroosmosis electrodes are inserted between the adjacent four electroosmosis electrodes; anode electroosmosis electrodes and cathode electroosmosis electrodes are respectively connected with the anode and cathode of DC power source. The invention can cause electroosmosis processing efficiency to be enhanced and the effect to be uniform, and is economic and efficient under condition of complicated stratum.

Owner:GUANGSHA CONSTR GROUP +1

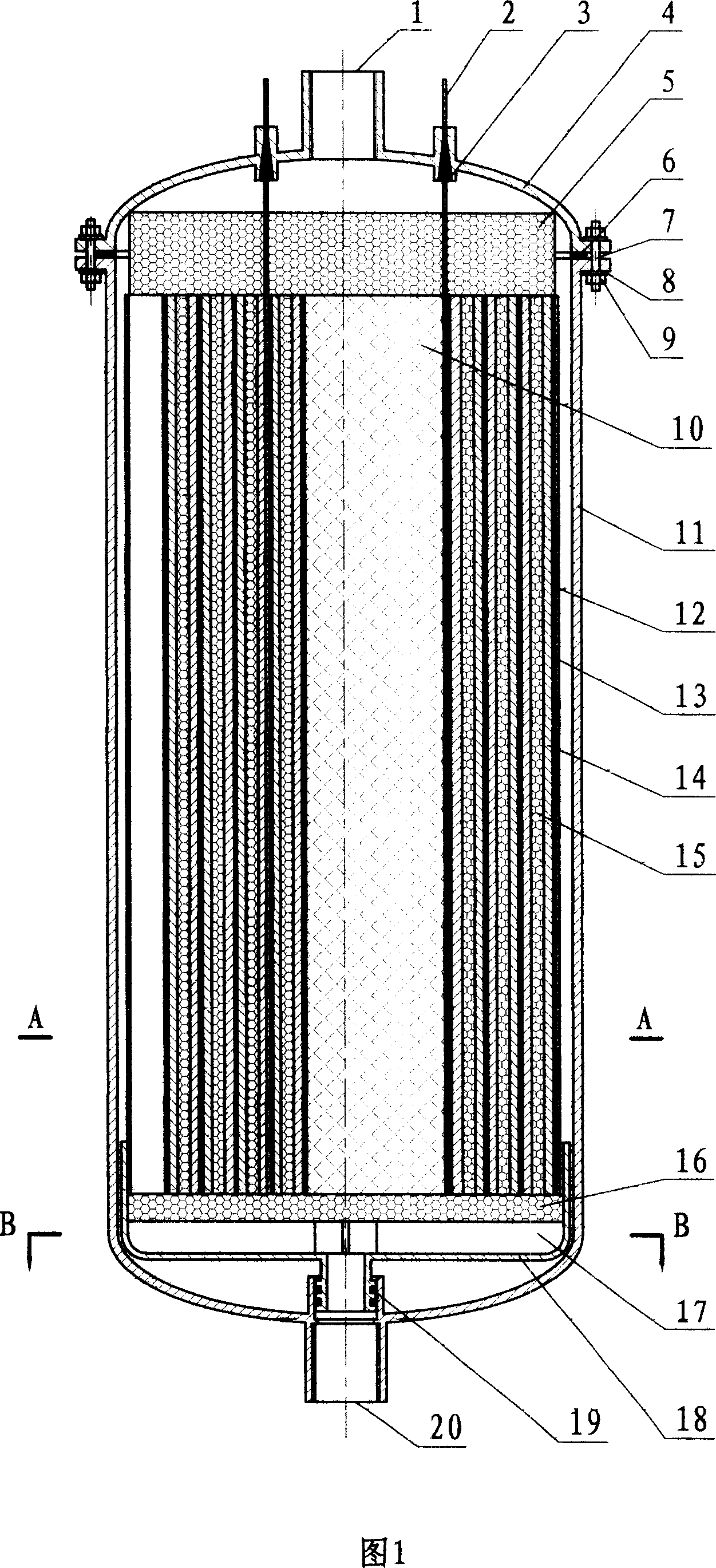

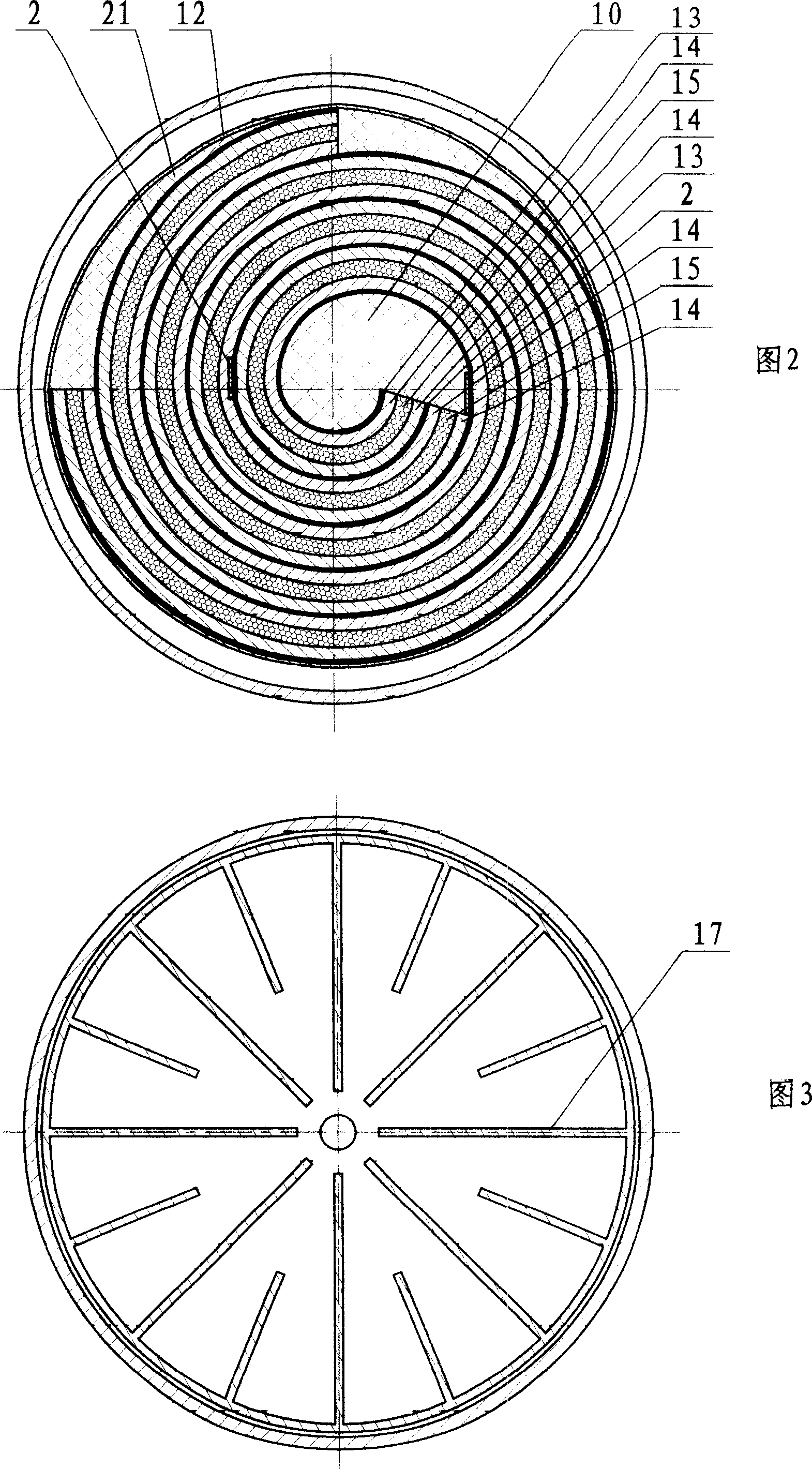

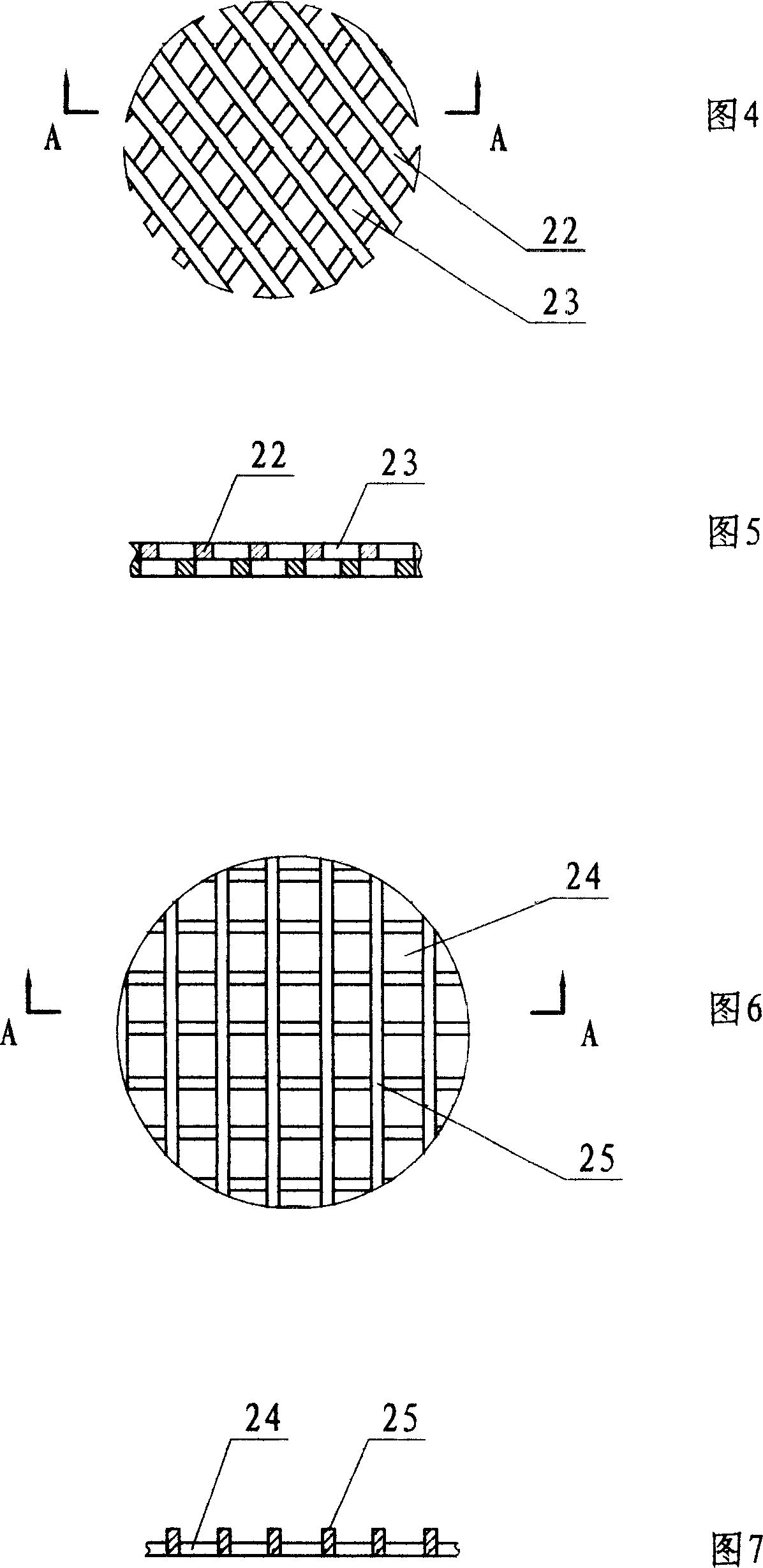

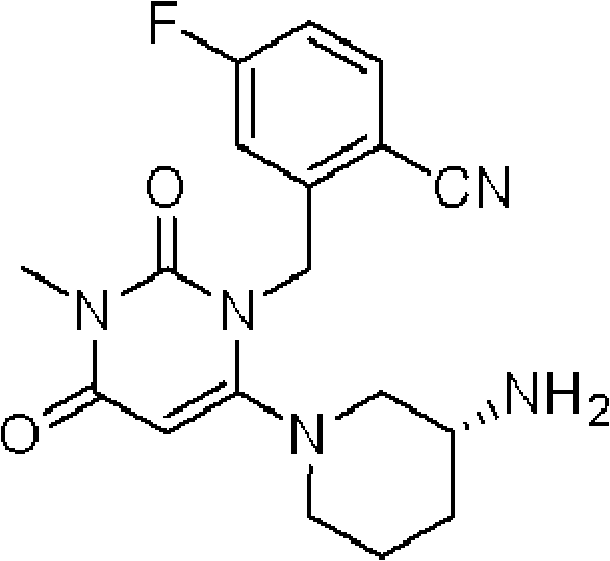

Rolling type electric adsorption filter element

InactiveCN101143271AHigh salt contentEvenly distributedIon-exchange column/bed processesWater/sewage treatment by electrochemical methodsEngineeringCadmium Cation

The invention relates to a roll typed electric adsorption filter core. The invention has the structure that a roll typed electric adsorption component part is arranged inside a casing, and a liquid inlet, a liquid outlet and an electrode are arranged in the casing. A composite layer, which is composed of a conductive layer, a adsorption layer, a supporting layer, a adsorption layer, a conductive layer, a adsorption layer, a supporting layer and a adsorption layer (totally eight layers), winds on the core shaft, and the fixing layer on the lateral side tightens the composite layer to make the composite layer fixed on the core shaft. When original liquid enters into the filter core through the liquid inlet, and while passing the supporting layer of the roll typed electric adsorption component parts, the charged particles (like metal ions: calcium, magnesium, sodium, lead, mercury, cadmium and so on, and acid radical, etc) are absorbed in the electric double layer on the surface of adsorption layer under the effect of direct current electric field force, and then are effectively removed, and so the liquid is purified. The fluid flow of the roll typed electric adsorption filter core distributes evenly and has strong adaptability to original liquid. The invention has good purification effect, low operation energy consumption, simple structure, low manufacture cost and long useful life, and can purify water, wine, beverage and other liquids.

Owner:黄樟焱

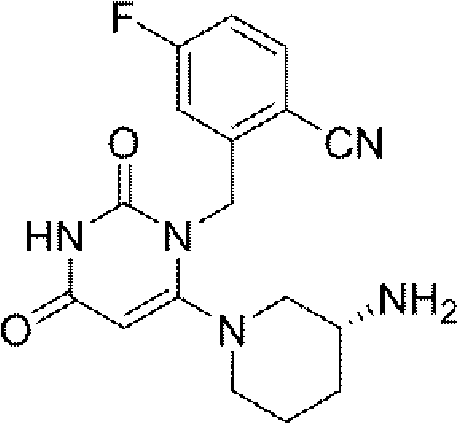

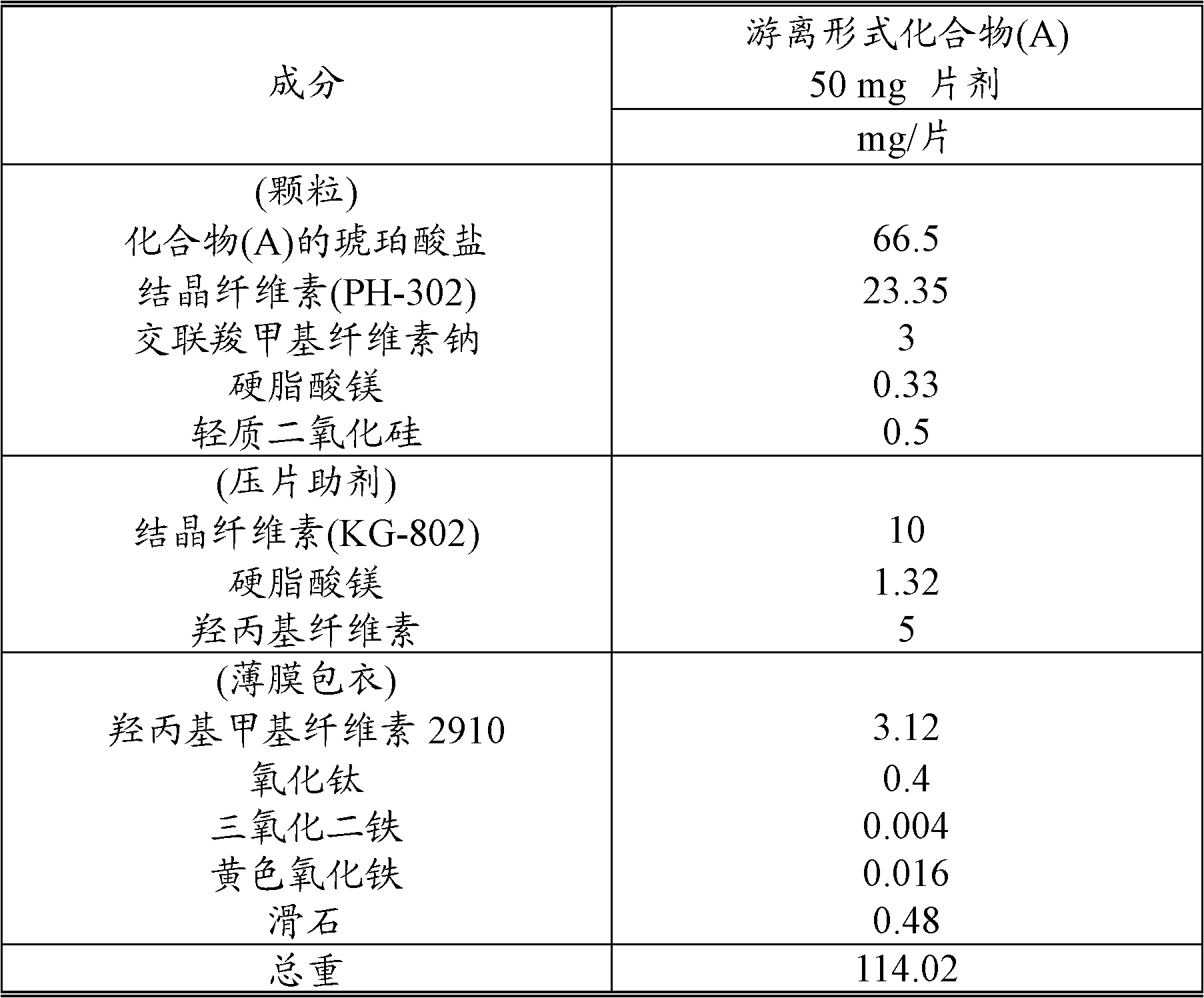

Tablet

InactiveCN102548556AHigh salt contentSmall sizeOrganic active ingredientsSenses disorderCombinatorial chemistryDrug activity

Disclosed is a high-dose tablet which contains 2-[[6-[(3R)-3-amino-1-piperidinyl]-3,4-dihydro-3-methyl-2,4-dioxo-1(2H)- pyrimidinyl]methyl]-4-fluorobenzonitrile (compound (A)) or a salt thereof as a pharmaceutically active ingredient. Specifically disclosed is a tablet which contains the compound (A) or a salt thereof, and a fluidizer, with the content of the compound (A) being 35-50% by weight.

Owner:TAKEDA PHARMA CO LTD

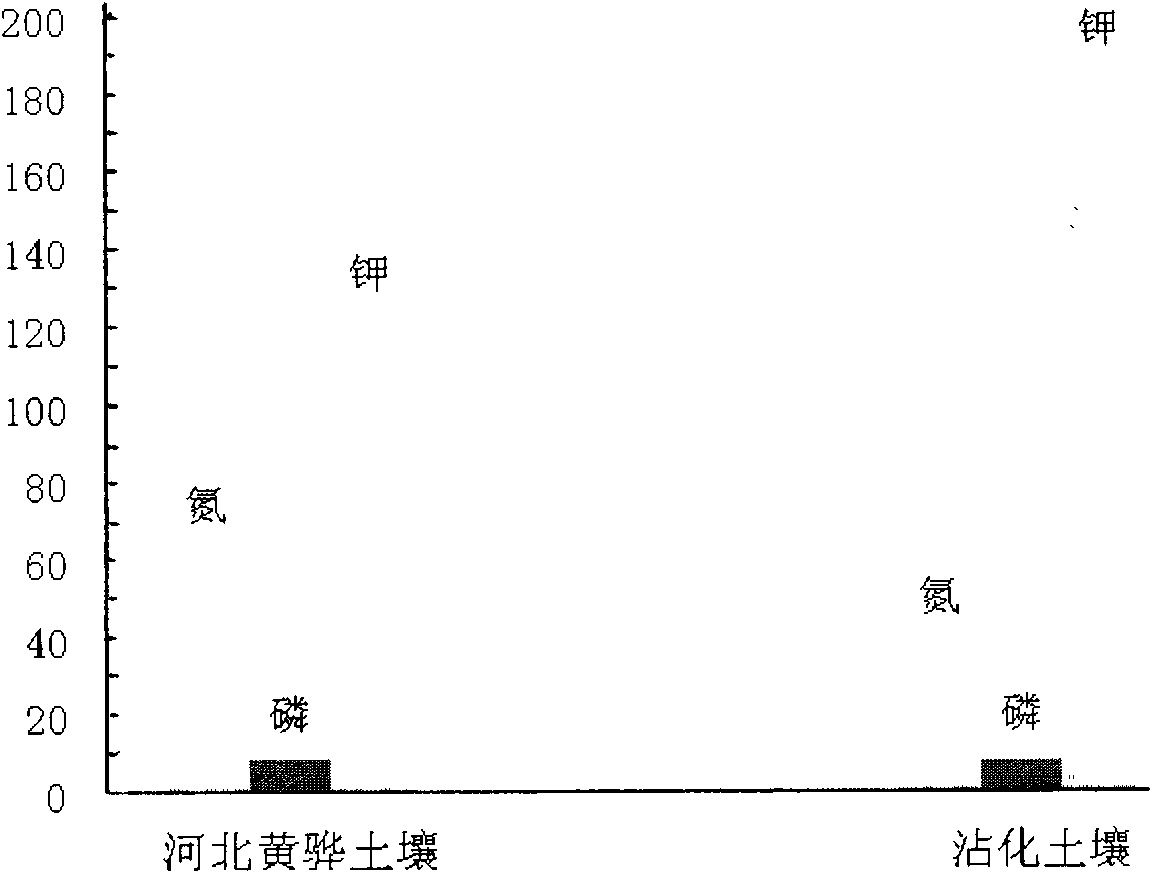

Special fertilizer for Zhanhua winter jujubes, preparation method and application thereof

InactiveCN101955390AReasonable ratio of nutrientsHigh yieldFertilising methodsFertilizer mixturesGeotrichumNutrient absorption

The invention relates to a special fertilizer for Zhanhua winter jujubes, a preparation method and the application thereof. The special fertilizer for Zhanhua winter jujubes comprises the following raw materials in parts by mass: 50 to 70 parts of zymolysing oil residues, 10 to 20 parts of urea, 5 to 15 parts of DAP (diammonium phosphate), 10 to 18 parts of potassium sulfate, 0.5 to 1 part of ferrous sulphate, 0.3 to 0.7 part of zinc sulfate and 0.2 to 0.4 part of boric acid, wherein the zymolysing oil residue is a product produced by carrying out biodegradation on the oil residues by using lipases in bacillus subtilis fermentation broth and yarrowia lipolytica fermentation broth and proteases in geotrichum candidum fermentation broth and lactobacillus plantarum fermentation broth. The special fertilizer of the invention is prepared especially according to the nutrient status of soils in the main producing areas of Zhanhua winter jujubes and the regulation of nutrient absorption of the jujubes, and has the advantages of reasonable nutrient ratio and strong pertinence. The special fertilizer can reduce the salt damages caused by fertilizing and the organic and inorganic combination can improve the soil fertility.

Owner:SHANDONG GUANGDA FERTILIZER INDAL TECHCO

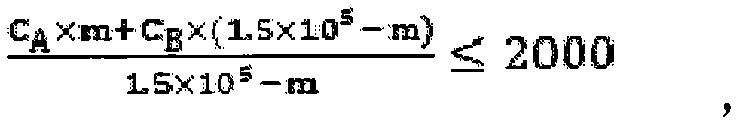

Ectopic-in-situ combined bioremediation method of high-concentration petroleum contaminated soil

ActiveCN104759459AImprove in situ repair efficiencyReduce concentrationContaminated soil reclamationHigh concentrationIn situ remediation

The invention relates to an ectopic-in-situ combined bioremediation method of high-concentration petroleum contaminated soil, and belongs to the technical field of contaminated soil remediation. The ectopic-in-situ combined bioremediation method comprises the following steps: firstly, high-concentration petroleum contaminated soil is subjected to ectopic biological piling, so that the concentration of petroleum hydrocarbon in soil is reduced greatly; then a certain amount of the piled materials are returned to the field, so that the concentration of petroleum hydrocarbon in soil after field return is less than 2000mg.kg<1-> to meet the in-situ remediation requirement; finally, the remediation requirement is achieved after in-situ remediation. The ectopic-in-situ combined bioremediation method is combined skillfully so as to achieve the economical and efficient remediation effect.

Owner:SHANDONG NORMAL UNIV

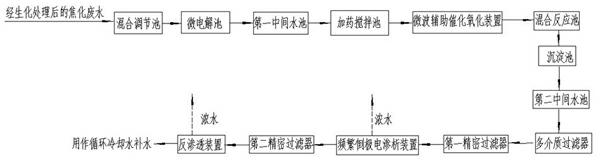

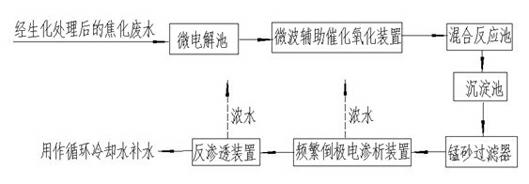

Efficient and stable coking wastewater advanced treatment process and treatment system

InactiveCN102659269AImprove efficiencyFresh water low in saltGeneral water supply conservationDispersed particle separationChemical oxygen demandFiltration

Disclosed are an efficient and stable coking wastewater advanced treatment process and a treatment system. The coking wastewater advanced treatment system comprises a microelectrolysis cell, a microwave auxiliary catalytic oxidation device, a mixed reaction pond, a settling pond, a filter, a frequent reverse electrode electro-osmosis device and a reverse osmosis device, the microwave auxiliary catalytic oxidation device is connected with the microelectrolysis cell, the mixed reaction pond is connected with the microwave auxiliary catalytic oxidation device, the settling pond is connected with the mixed reaction pond, the filter is connected with the settling pond, the frequent reverse electrode electro-osmosis device is connected with the filter, and the reverse osmosis device is connected with a fresh water outlet of the frequent reverse electrode elctro-osmosis device. The COD (chemical oxygen demand) content and the saltness of outflow water after treatment of the microelectrolysis cell and follow-up microwave catalytic oxidation, coagulation sedimentation, filtration and electro-osmosis treatment are low, so that the previous devices can be matched with the electro-osmosis device and the reverse osmosis desalting device, and the system can run stably while efficient desalting is realized. In addition, a concentrate circulation mode of the desalting system is optimized, and the quality of the outflow water is greatly improved under the condition that water use efficiency is not decreased.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

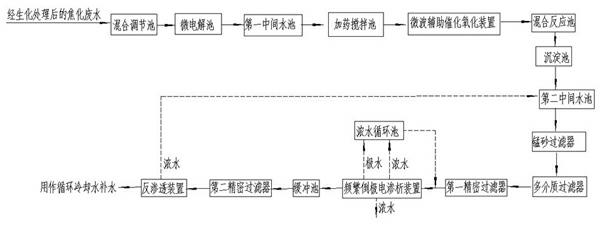

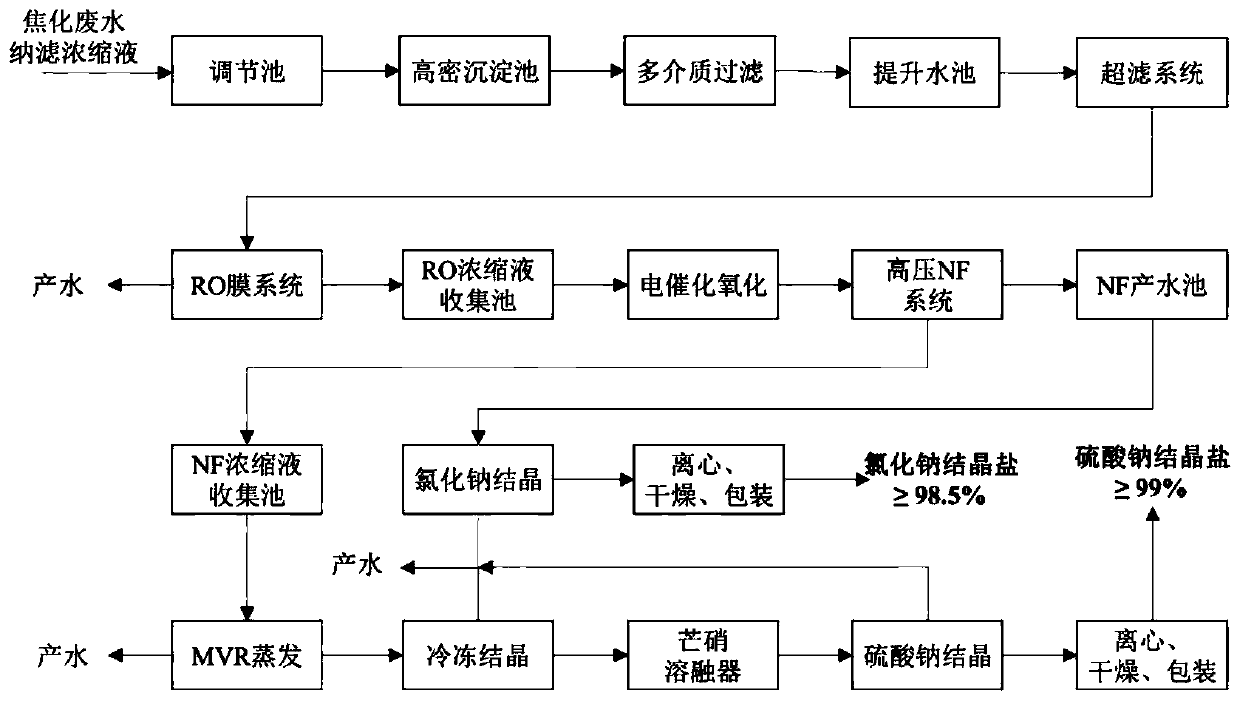

Salt splitting resource utilization method of coking wastewater nanofiltration concentrated solution

InactiveCN109809592AAchieve outputRealize resourcesMultistage water/sewage treatmentNature of treatment waterHigh concentrationFiltration

The invention discloses a salt splitting resource utilization method of a coking wastewater nanofiltration concentrated solution. The salt splitting resource utilization method of the coking wastewater nanofiltration concentrated solution comprises the steps that the coking wastewater nanofiltration concentrated solution enters an adjusting pool for adjustment with uniform mass and quantities, outlet water enters a high-density settling pond through a lifting water pump for realizing the removal of the hardness of the coking wastewater nanofiltration concentrated solution, the outlet water realizes most removal of residual suspended matters through a multi-media filter, and the outlet water enters a lifting pool and enters an ultrafiltration membrane filtration system through the lifting water pump and a booster water pump; ultrafiltration membrane produced water enters an ultrafiltration membrane produced water pool, then, the ultrafiltration membrane produced water enters a RO membrane system for concentration through a RO membrane raw water pump and a high-pressure pump, after RO concentrated water is removed organic matters through an electrocatalytic oxidation system, the outlet water enters a high-pressure nanofiltration salt splitting system; the high-pressure nanofiltration concentrated solution containing higher concentration SO4<2-> realizes output of sodium sulfate crystal salt separately through an MVR evaporated crystallization and freezing crystallization unit; and high-pressure ultrafiltration produced water containing higher concentration Cl<-> realizes output of sodium chloride crystal salt through a sodium chloride crystallizer.

Owner:河北能源职业技术学院

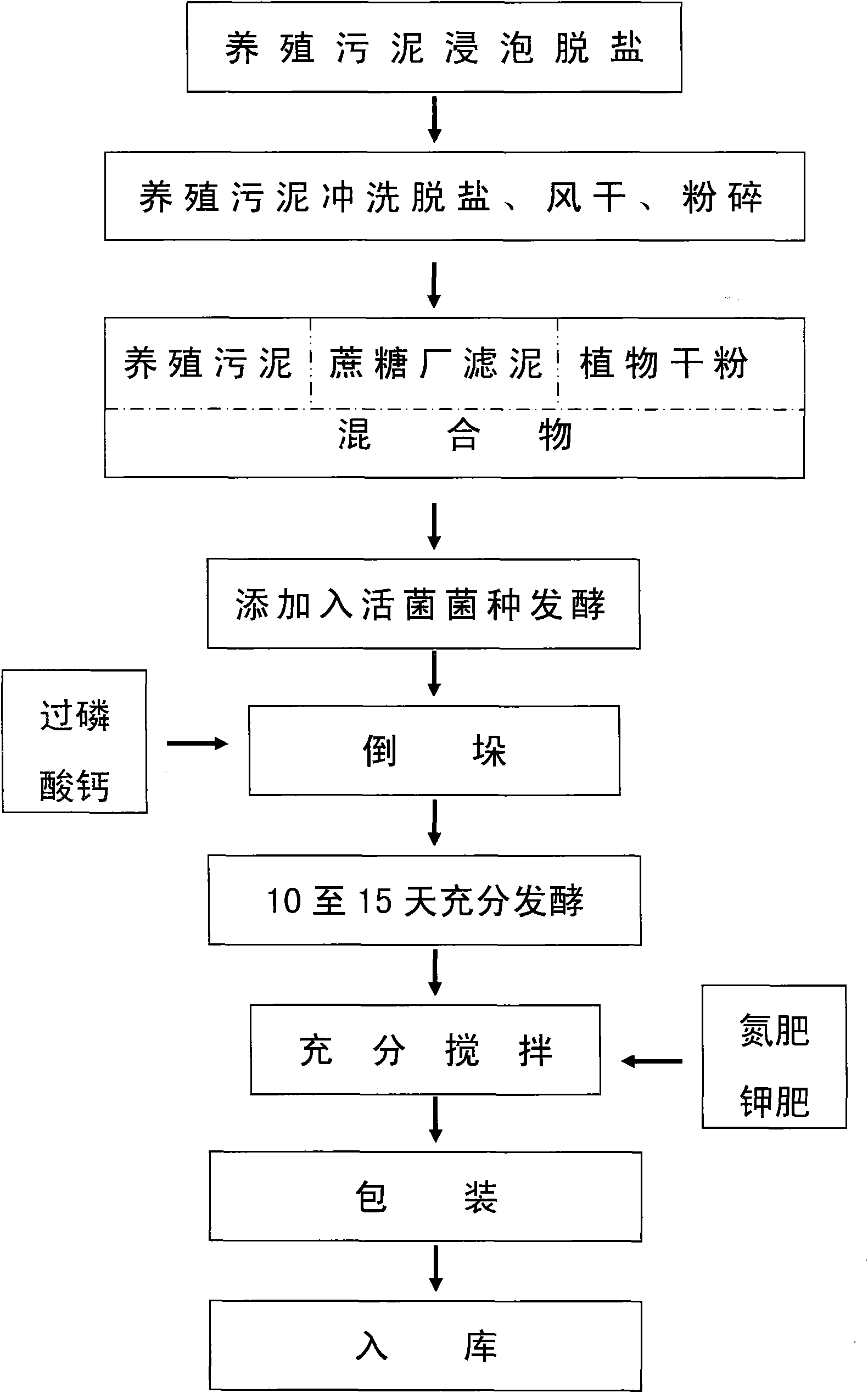

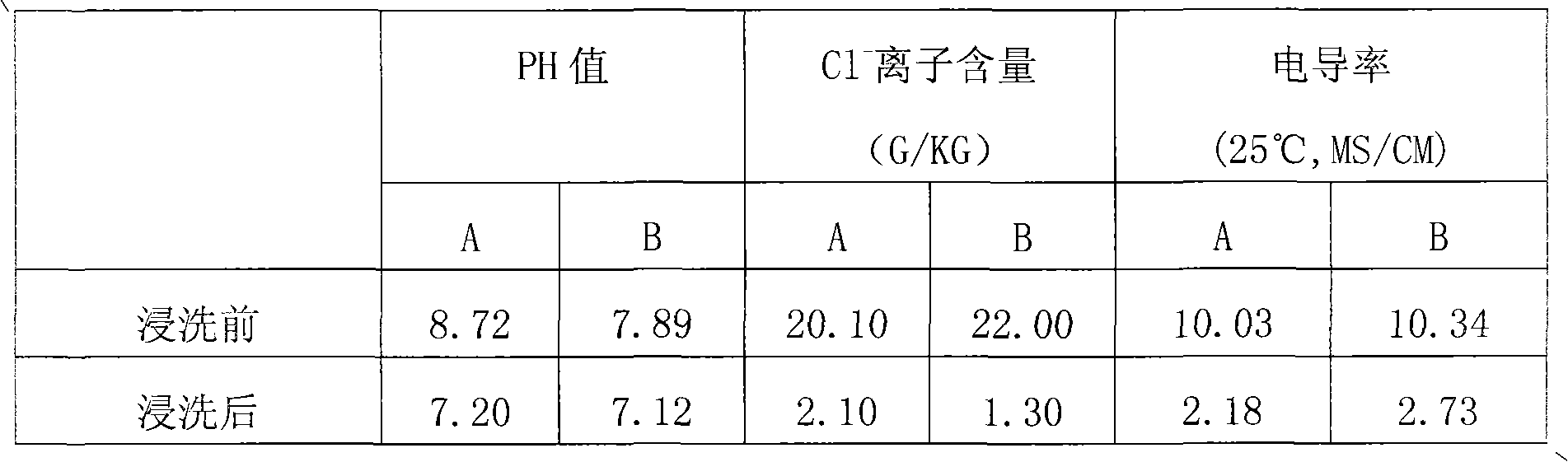

Method for producing micro organic matters by marine culture sludge and sugar refinery filtration sludge

InactiveCN101555171AHigh salt contentBio-organic fraction processingSludge treatmentHalophyteSucrose

The invention relates to a method for producing micro organic matters by marine culture sludge and sugar refinery filtration sludge, belonging to the comprehensive utilization of marine animal utilization technology and sugar refinery filtration sludge drogs and being dedicated in preparing micro organic matter fertilizer by marine culture sludge and sugar refinery filtration sludge. The method comprises the following steps: wind drying the marine culture sludge and sugar refinery pond sludge and desalting by leaching the culture sludge; mixing the leached wind-dried sludge and the sugar refinery wind-dried pond sludge with fresh plant dry power, adding viable bacteria for anaerobic fermentation with the proportion of 2kg of viable bacteria per ton and the moisture is controlled at 30-35%, fermenting for about 10 days at the temperature of 50-60 DEG C, adding 4% of sodium humate, 7% of nitrogenous fertilizer, 12% of phosphate fertilizer and 6% of potassium fertilizer into composts after fermentation to obtain the halophilous plant highly efficient organic fertilizer. The water-soil proportion of the organic fertilizer is controlled at 5:1 to be proper, and the sum nutrient of N+P+K is more than or equal to 48%. The leaching, fermenting and composting technologies of the invention have simple and convenient process, strong operation, high production efficiency and high fertilizer effect with rich nutrient.

Owner:许绪满

Rapid high-efficient fermentation production method of health fermented soya bean

InactiveCN103621913AHigh quality fermentationPollution controlFood preparationBiotechnologyNutrition

The invention relates to a rapid high-efficient fermentation production method of a health fermented soya bean. The rapid high-efficient fermentation production method comprises following steps: soybean is immersed, and is mixed with wheat bran, and the mixture is disinfected at a temperature of 121 DEG C for 30min; the cooked mixture is cooled to a temperature about 40 DEG C, is inoculated with triangular flask mold starter, and is cultured at a temperature of 30 DEG C until the surface of the cooked mixture becomes white so as to obtain fermented soya bean mold; salt solution with a concentration of 10% is added into the obtained fermented soya bean mold so as to get water content of a fermented soya bean mash reaching 80 to 100%, and the fermented soya bean mash is subjected to high temperature fermentation at a temperature of 50 DEG C for 7 days so as to obtain a matured fermented soya bean mash; hot water with a temperature of 90 DEG C is added into the fermented soya bean mash, the fermented soya bean mash is subjected to heat preservation for 2 to 4h, and then is filtered so as to obtain crude soybean sauce, wherein a left solid material is linyou fermented soya bean; 0.1 to 1% of a fermented bacillus natto solution (more than 2000IU / mL) is added into the linyou fermented soya bean so as to obtain a basic fermented soya bean; and different spices such as rice wine, capsicum and Chinese prickly ash are added into the basic fermented soya bean so as to obtain the health fermented soya bean. Compared with traditional production methods, advantages of the rapid high-efficient fermentation production method are that: microbial contamination is less, fermentation period is short, product salt content is low, and contained nattokinase is stable. In addition, one-step fermentation is adopted, the obtained soybean source and the health fermented soya bean are rich in nutrients, are varied, and are suitable for large scaled fermentation production.

Owner:河南省南街村(集团)有限公司

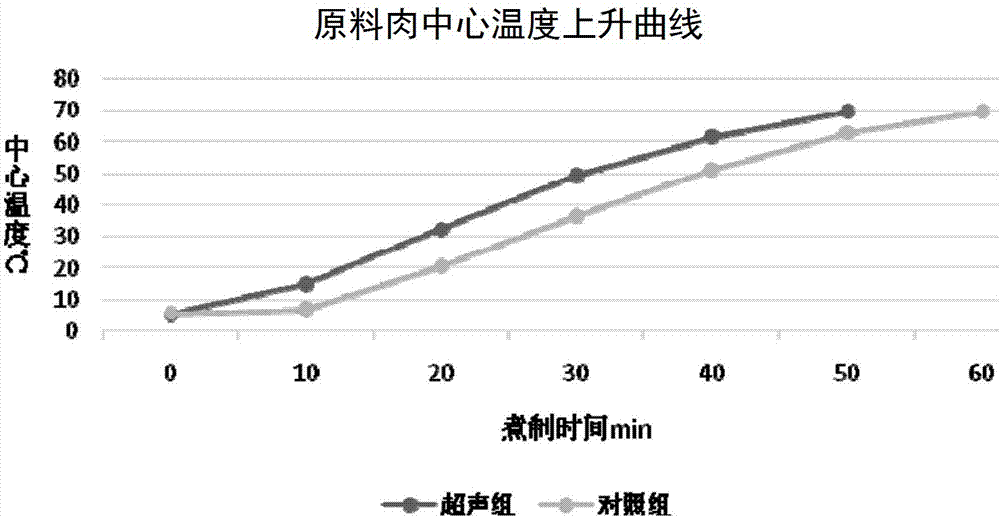

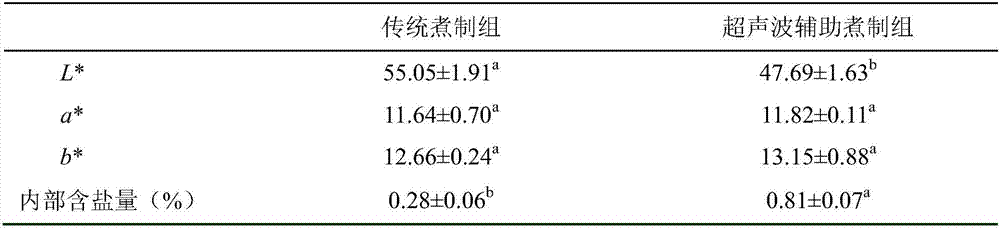

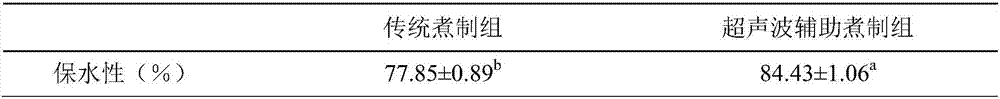

Method for processing soy sauce stewed beef by ultrasonic assisted boiling

InactiveCN106858365AImprove qualityColor deepeningFood ultrasonic treatmentUltrasonic assistedCavitation

The invention discloses a method for processing soy sauce stewed beef by ultrasonic assisted boiling. In a heating and boiling process, heating is assisted by ultrasonic waves and rapid boiling is carried out. According to the method disclosed by the invention, mechanical effect, cavitation effect and heat effect of the ultrasonic waves are applied, so that the boiling time of the soy sauce stewed beef is shortened, energy sources are saved and the production cost is reduced; the penetration efficiency of stewing soup is remarkably improved and the salt content at a central part of a large piece of the soy sauce stewed beef is increased; the water-retaining property of a meat product is improved, so that the production efficiency is improved; the rigidity of the product is reduced, the tenderizing effect is realized and the quality of the product is improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

Technology for recycling lithium hydroxide from solution through bipolar membrane method

ActiveCN105154908AReduce consumptionSolve environmental problemsElectrolysis componentsLithium hydroxidePhysical chemistry

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

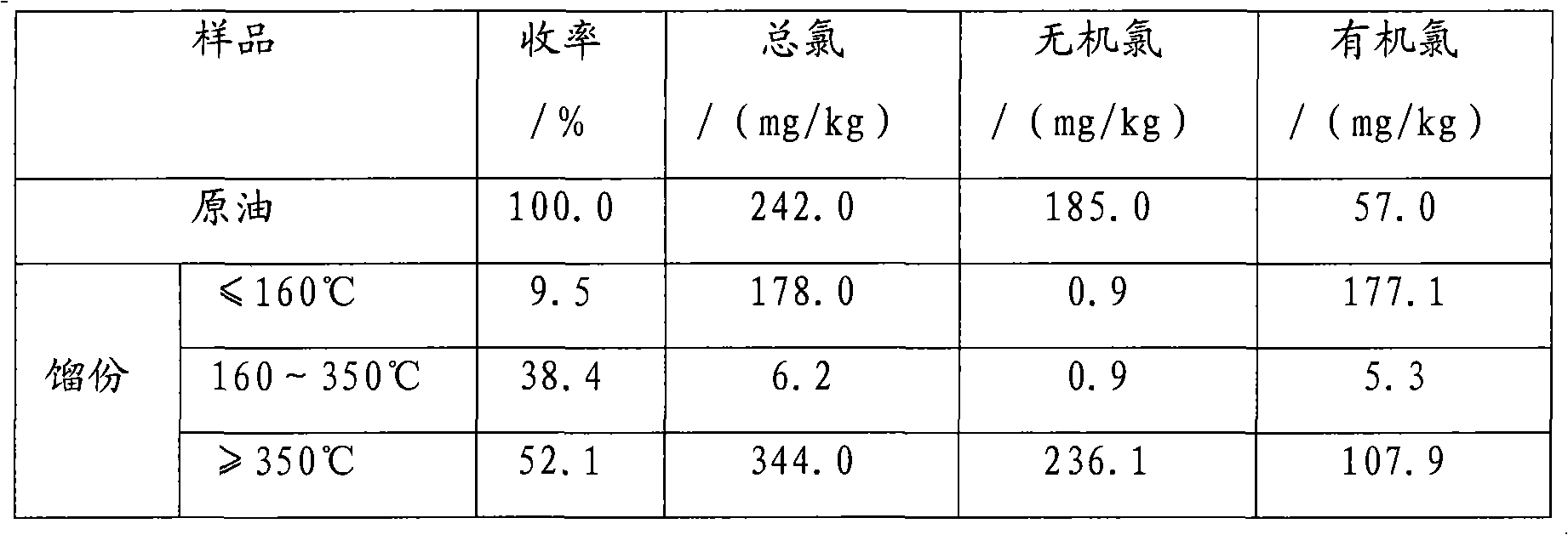

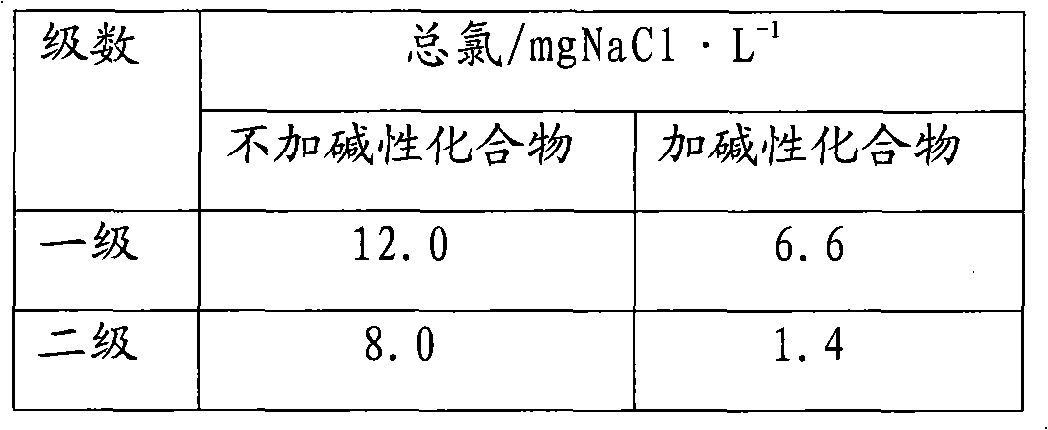

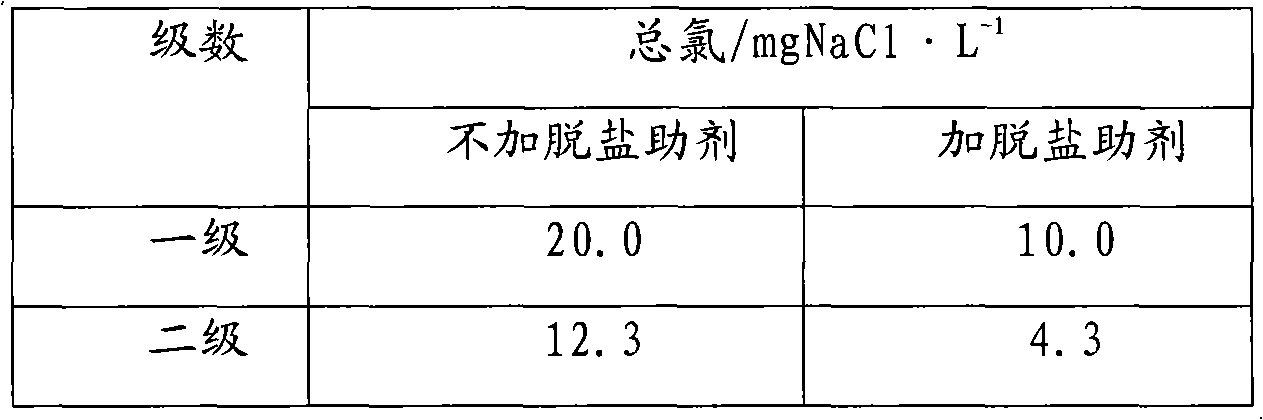

Method for lightening salt deposition of catalytic fractionating tower

ActiveCN102433155AHigh salt contentDesalination mitigationDistillation corrosion inhibitionTreatment with plural serial stages onlyInorganic saltsOrganic chloride compound

The invention relates to a method for lightening the salt deposition of a catalytic fractionating tower, wherein residual oil is pre-treated by an electro-desalting technique before entering in a catalytic cracking device; an alkaline compound is added during the electro-desalting process; and the alkaline compound is water-soluble organic amine and / or inorganic alkali. Utilizing the method disclosed by the invention, inorganic salts and organic chlorides in residual oil can be efficiently removed before the residual oil enters in a catalytic cracking device, thereby lighting the salt deposition of a catalytic fractionating tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fish hydrolysates as salt replacement

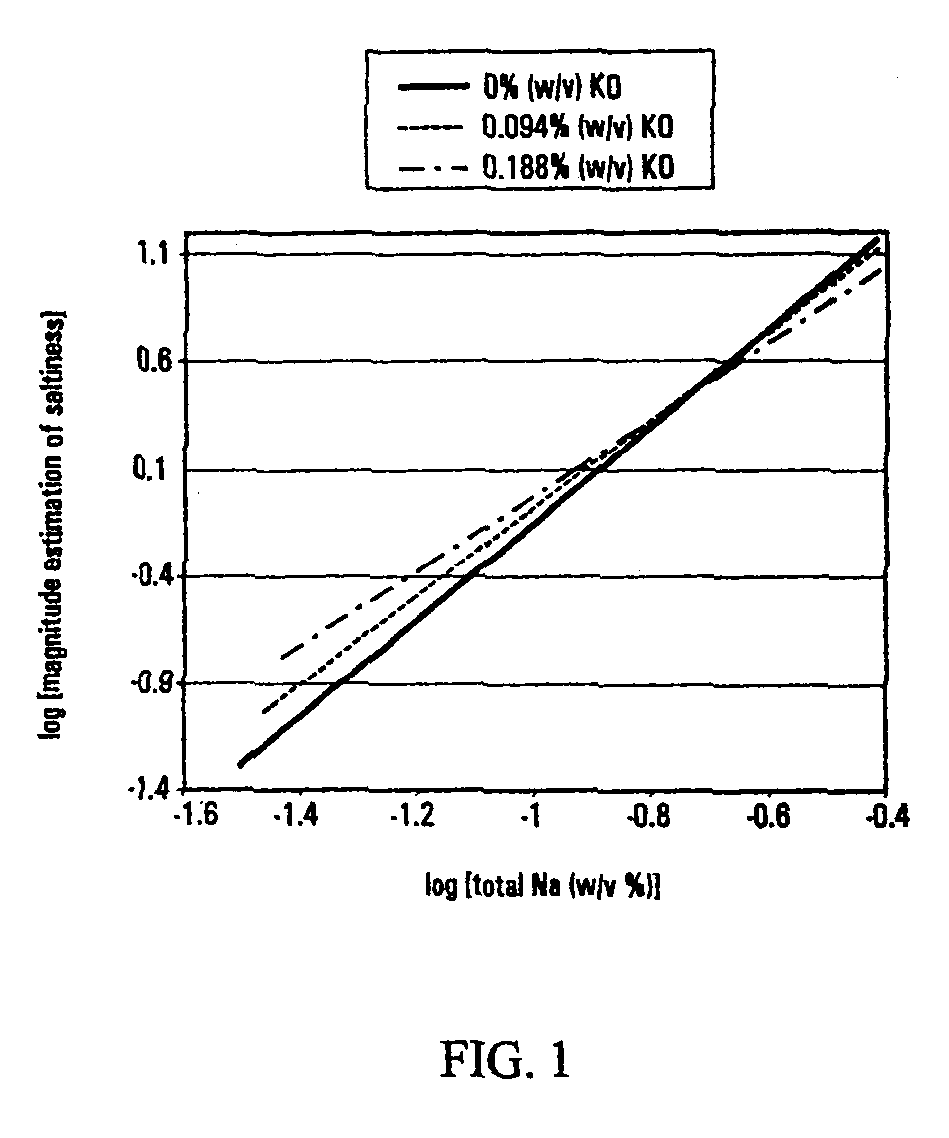

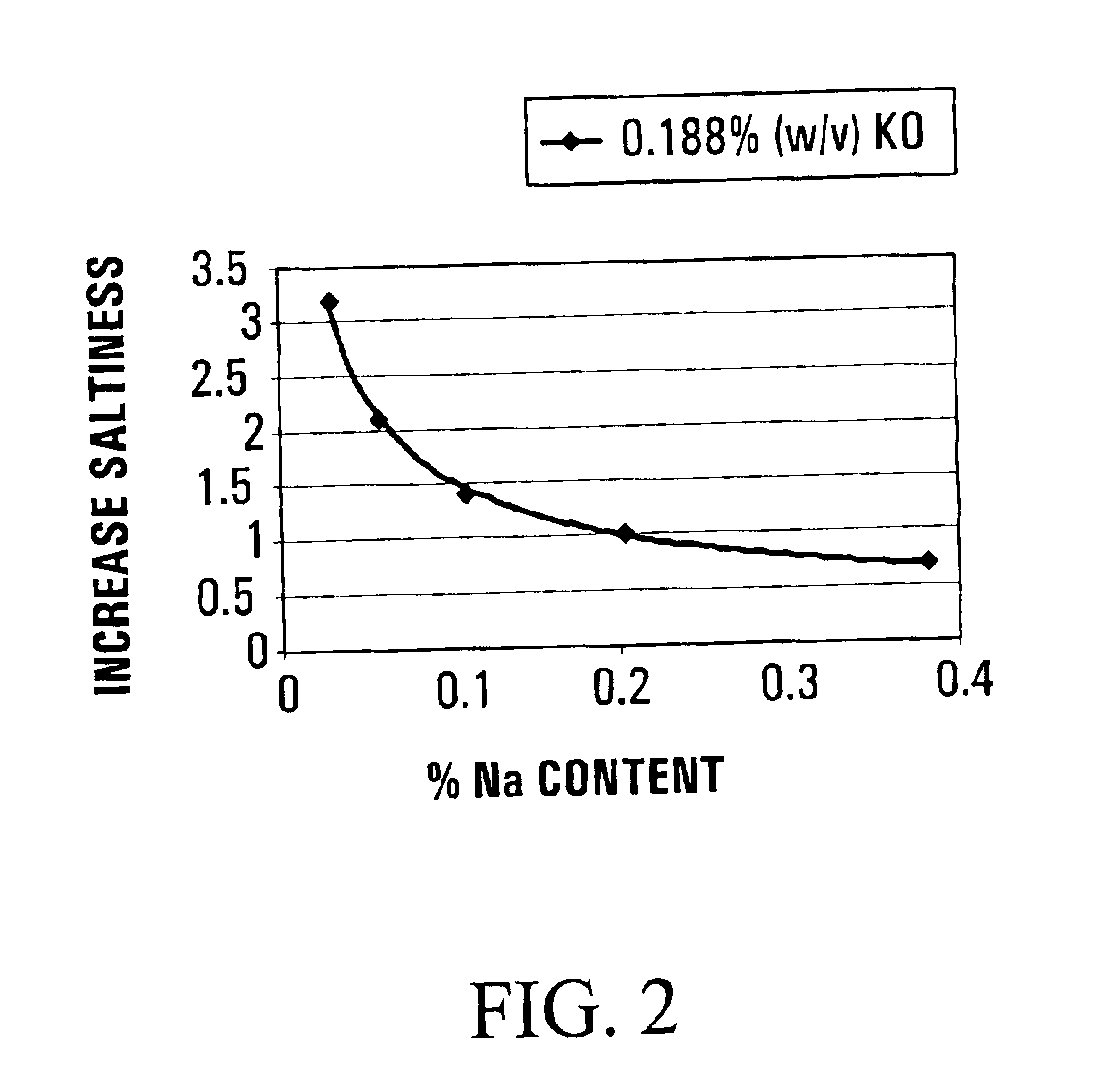

InactiveUS6926918B2Pleasant tasteGreat tasteFood preparationProtein foodstuffs working-upBonitoFish hydrolysate

Bonito hydrolysate (e.g. katsuobushi oligopeptide (KO)) enhances the flavour of salt and may be used to replace salt in foods and beverages.

Owner:OCEAN NUTRITION CANADA

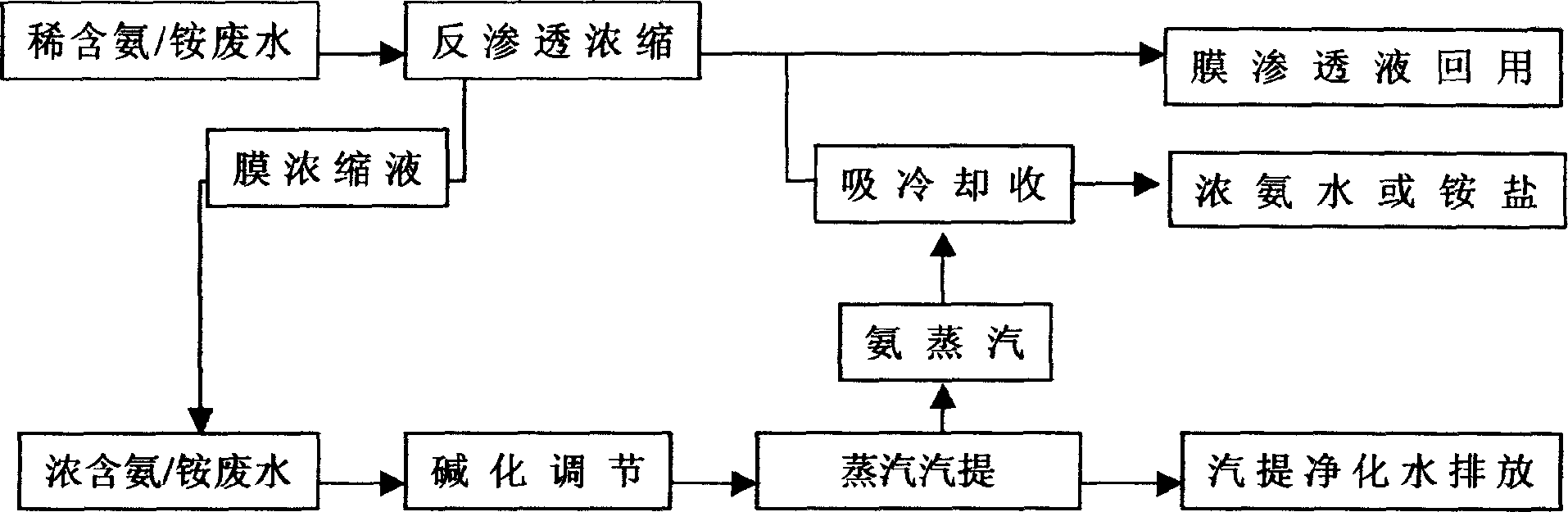

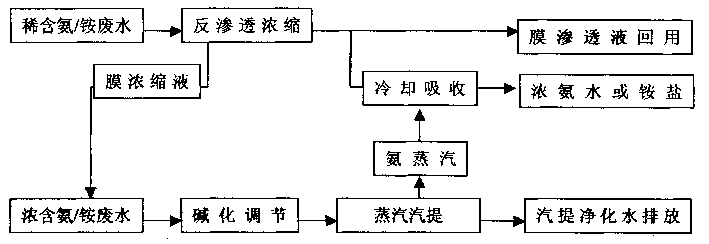

Process for reclaiming ammonia-contained sewage

InactiveCN1123543CHigh salt contentReduce dosageMultistage water/sewage treatmentHigh concentrationWastewater

A process for treating and recovering the ammonia / ammonium contained waste water generated in preparing catalyst includes reverse-osmosis concentration of the said waste with low ammonia content, direct use of the resultant liquid or partial use of it as the ammonia vapour absorbing liquid in stripping tower, mixing the concentrated liquid with the high-concentration the said waste water, adding alkali to regulate pH value, loading in stripping tower to recover ammonia from tower top and discharging the clean water. Its advantages include low energy and chemical consumption, and high recovery rate.

Owner:CHINA PETROCHEMICAL CORP +1

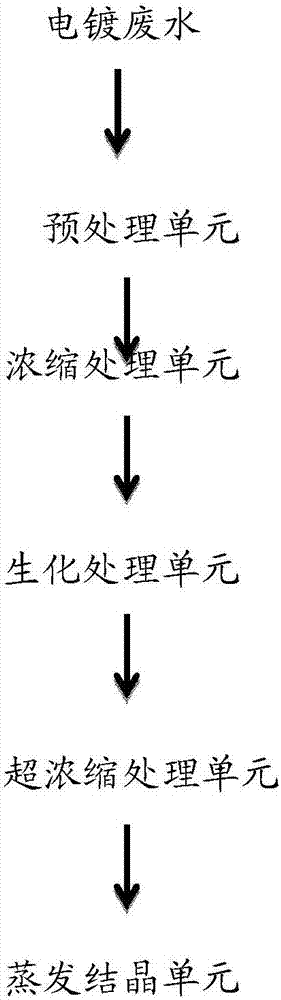

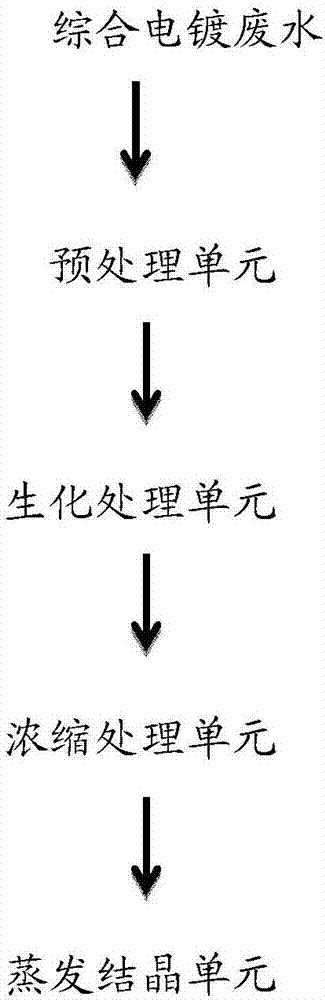

Electroplating wastewater treatment method, treatment system and application

ActiveCN107235600AImprove removal efficiencyImprove denitrification effectWater treatment parameter controlTreatment using aerobic processesTreatments waterTreatment system

The invention provides an electroplating wastewater treatment method which is characterized by sequentially including the steps: (1) pre-treating metal wastewater, organic wastewater, complex wastewater, cyanide-containing wastewater, nickel-containing wastewater, zinc-containing wastewater and chromium-containing wastewater to obtain pretreated water; (2) mixing and concentrating the pretreated water obtained in the step (1) to obtain high-salinity concentrated water and reused water; (3) mixing the high-salinity concentrated water obtained in the step (2) with the pretreated water obtained in the step (1), and performing biochemical treatment; (4) performing hyper-concentration on biochemical treatment water obtained in the step (3) to obtain ultra-high-salinity concentrated water; (5) evaporating and crystallizing the ultra-high-salinity concentrated water obtained in the step (4) to obtain reused water and a crystal substance. The method is simple in operation and stable in running, zero emission or low emission of comprehensive electroplating wastewater in electroplating production is achieved, and metal ions in the wastewater are recycled in a high-purity manner.

Owner:GUANGDONG YEANOVO ENVIRONMENTAL PROTECTION CO LTD

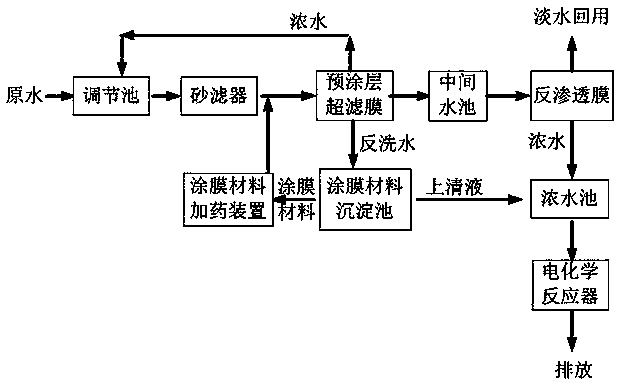

Advanced treatment and reuse method of pre-coated membrane of tail water of sewage plant

ActiveCN103964619AReduce direct contactRealize resource utilizationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationElectrochemical response

The invention discloses an advanced treatment and reuse method of a pre-coated membrane of tail water of a sewage plant. The method comprises the following steps: firstly, feeding tail water into an adjusting pool so as to be homogenized, and then passing through a sand filter; passing through an ultrafiltration membrane by a solution containing a pre-coated membrane material and sand filtered effluent and effectively forming a dynamic membrane on the surface of the ultrafiltration membrane, wherein concentrated water of the ultrafiltration membrane returns to the adjusting pool while the effluent enters into a middle water tank; backwashing the ultrafiltration membrane through a pump by part of water in the middle water tank periodically, wherein the pre-coated membrane automatically falls and the sediment of the coating material is recycled to a pre-coated membrane material dosing device repeatedly, so that the operating cost is lowered; entering into reverse osmosis membrane treatment by water in the middle water tank, fresh reverse osmosis membrane is used as industrial water in the park to be returned, and the concentrated water is treated by an electrochemical reactor, and the effluent reaches the standard to be discharged. By adopting the pre-coated membrane method, the ultrafiltration backwashing frequency is low, and the water yield of the ultrafiltration membrane is improved. Loose filter cake layers with great holes can be formed to effectively relieve the rate of descent of membrane flux, improve the anti-pollution capacity of the membrane and improve the removal effect of the membrane on the water quality index at the same time.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Highly concentrated plant protein preparation and method for producing the same

InactiveUS20090291189A1Reduction of water bindingFeel softProtein composition from vegetable seedsConfectioneryProtein moleculesIncreased saliva

The invention relates to a protein preparation and a method for the production thereof. The protein preparation includes protein particles. A protein particle includes several plant protein molecules with at least one hydrophilic and at least one hydrophobic moiety each. The protein molecules are bound to each other in such a manner that the protein particle has a mainly hydrophobic surface. The preparation allows production of foodstuffs that are rich in protein, that have a pleasant taste, that do not appear to be dry, solid, hard or crumbly, that do not cause increased saliva production and that are easy to swallow.

Owner:ZACHERL CHRISTIAN +3

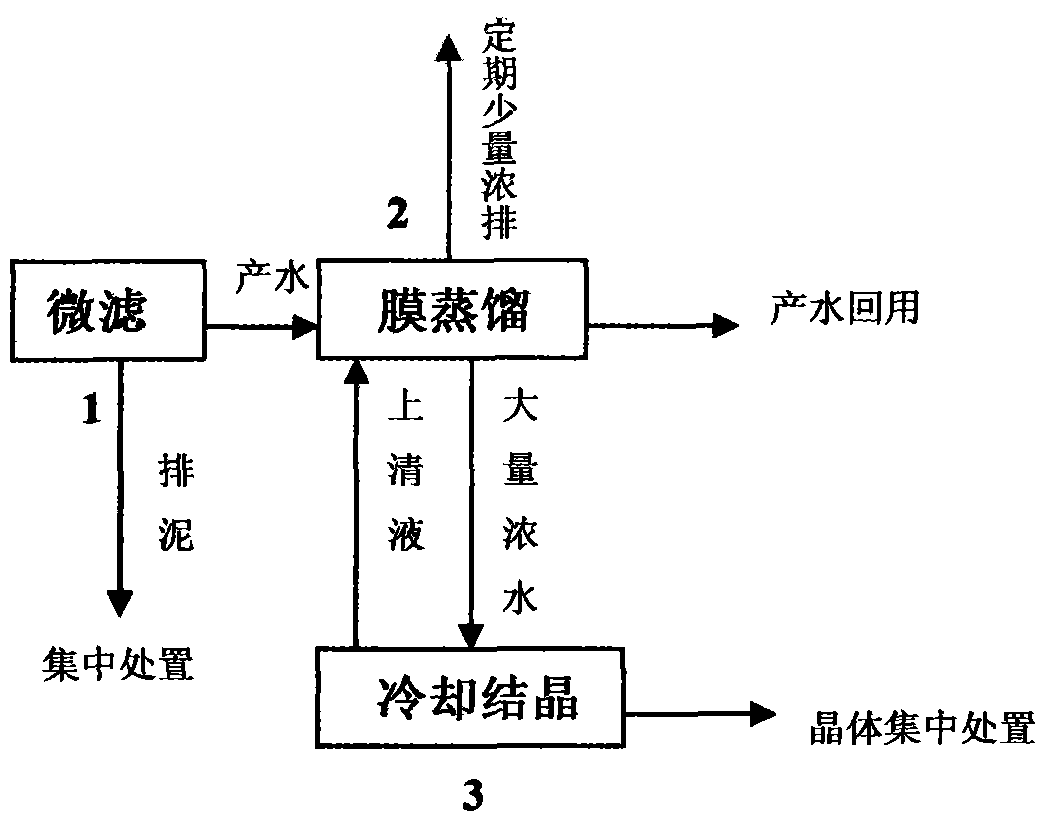

Method for treating filter cake filter-press filtrate in polyolefin catalyst production

ActiveCN102311193AHigh salt contentHigh desalination rateMultistage water/sewage treatmentChemical oxygen demandPolyolefin

The invention relates to the field of industrial wastewater treatment, in particular to a method for treating filter cake filter-press filtrate in polyolefin catalyst production. Process flows of microfiltration, membrane distillation and cooling crystallization are adopted in the method. By utilizing the process flows, a mass of salinity, TDS (Total Dissolved Solids) and COD (Chemical Oxygen Demand) are effectively separated and removed to ensure that the advanced treatment and recycling of the filter cake filter-press filtrate are realized. In the process flows, the technical advantages of the membrane distillation are fully utilized, the problem of discharging the filter cake filter-press filtrate is solved and the recycling of product water is realized. After the filter cake filter-press filtrate is subjected to process flow treatment, the wastewater recovery rate is up to 30-60%; the partial recycling of the filter cake filter-press filtrate is realized; the development strategy of energy saving and emission reduction of enterprises is achieved; and remarkable social benefit and economic benefit are provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

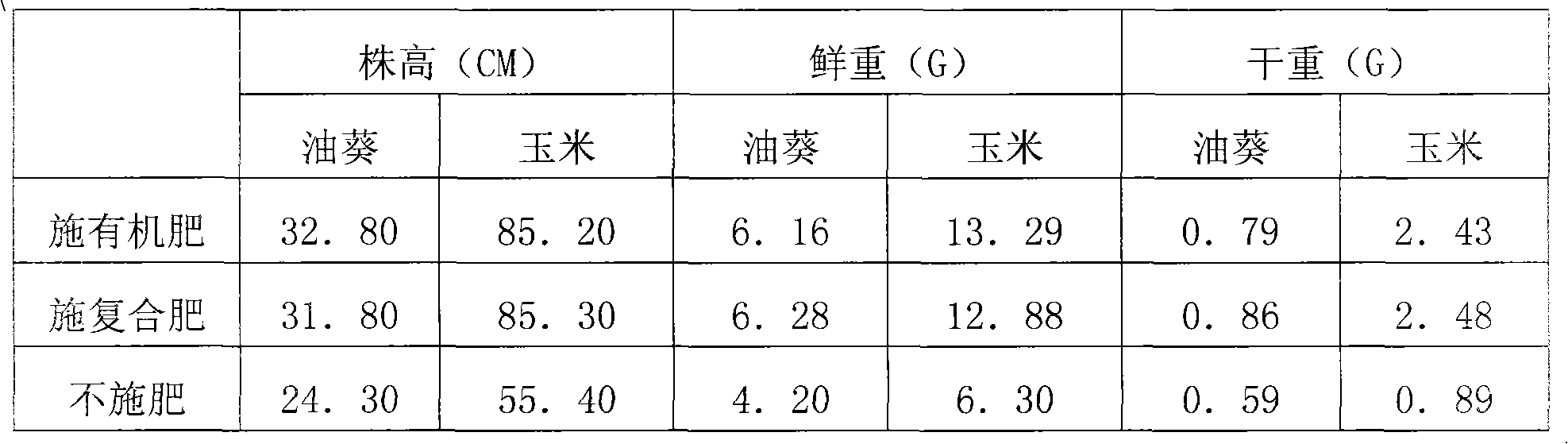

Fertilizing method capable of improving lodging resistance of alfalfa plants

ActiveCN108450109ASolve coordination problemsImprove lodging resistanceFabaceae cultivationExcrement fertilisersAdditive ingredientOrganic fertilizer

The invention discloses a fertilizing method capable of improving the lodging resistance of alfalfa plants. The fertilizing method comprises the following steps: step one, mixing a first soil layer with the depth of above 15 cm with a first organic fertilizer and vermiculite to obtain first soil before sowing; step two, mixing a second soil layer with the depth of 15 to 30 cm with mixed powder anda second organic fertilizer to obtain second soil; step three, after mixing and stirring a third soil layer with the depth of below 30 cm with a third organic fertilizer uniformly, paving the mixturein a room of 25 to 28 DEG C for 12 to 18 h so as to obtain third soil; and step four, paving liquid storage layers between the third soil and the second soil and between the second soil and the firstsoil respectively so as to obtain an alfalfa planting land. Fertilization is carried out on the soil of the planting land in batches, the fertilizer with the ingredients in proportion is applied at different periods so as to improve the lodging resistance of alfalfa, so that the purpose of improving the alfalfa yield and product quality is reached.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Comprehensive electroplating wastewater treatment method and system and application thereof

ActiveCN107235601AImprove removal efficiencyImprove denitrification effectWater treatment parameter controlTreatment using aerobic processesChemical oxygen demandTurbidity

The invention provides a comprehensive electroplating wastewater treatment method. The comprehensive electroplating wastewater treatment method is characterized by including the steps of 1), pretreating comprehensive electroplating wastewater to obtain pretreated water; 2), subjecting the pretreated water obtained in the step 1) to biochemical treatment to obtain biochemically treated water; 3), subjecting the biochemically treated water obtained in the step 2) to concentration treatment to obtain concentration treated high-salt water and reuse water; 4), subjecting the concentrated treated high-salt water obtained in the step 3) to evaporation crystallization treatment to obtain the reuse water and crystal substances, wherein the standard of the reuse water is that the pH value is 6-8, the conductivity is smaller than or equal to 50, COD (chemical oxygen demand) is smaller than or equal to 30, and the turbidity is smaller than or equal to 1. The method is simple in operation, stable in running, low in cost and high in treatment efficiency; zero emission or low emission of the comprehensive electroplating wastewater in electroplating production is achieved, and meanwhile, metal ions in the wastewater are recovered in high purity.

Owner:广东尚宸环境科技有限公司

Method for cultivating cotton in saline-alkali soil

The invention discloses a method for cultivating cotton in saline-alkali soil, and relates to the field of technologies for cultivating crops. The method is characterized by comprising steps of plowing the soil to press salt; pressing the salt by the aid of water; additionally applying organic fertilizers to the saline-alkali soil; sowing seeds in due time; covering the soil by mulching films; placing seedlings in the soil in due time; reducing branches of cotton and pruning the cotton; uncovering the mulching films timely, watering the cotton and applying additional fertilizers to the cotton; performing reasonable chemical control; timely performing insect disease prevention on the cotton. The method has the advantages of simplicity, clear steps and good cultivation effect.

Owner:固镇县淮鸿灰天鹅养殖专业合作社

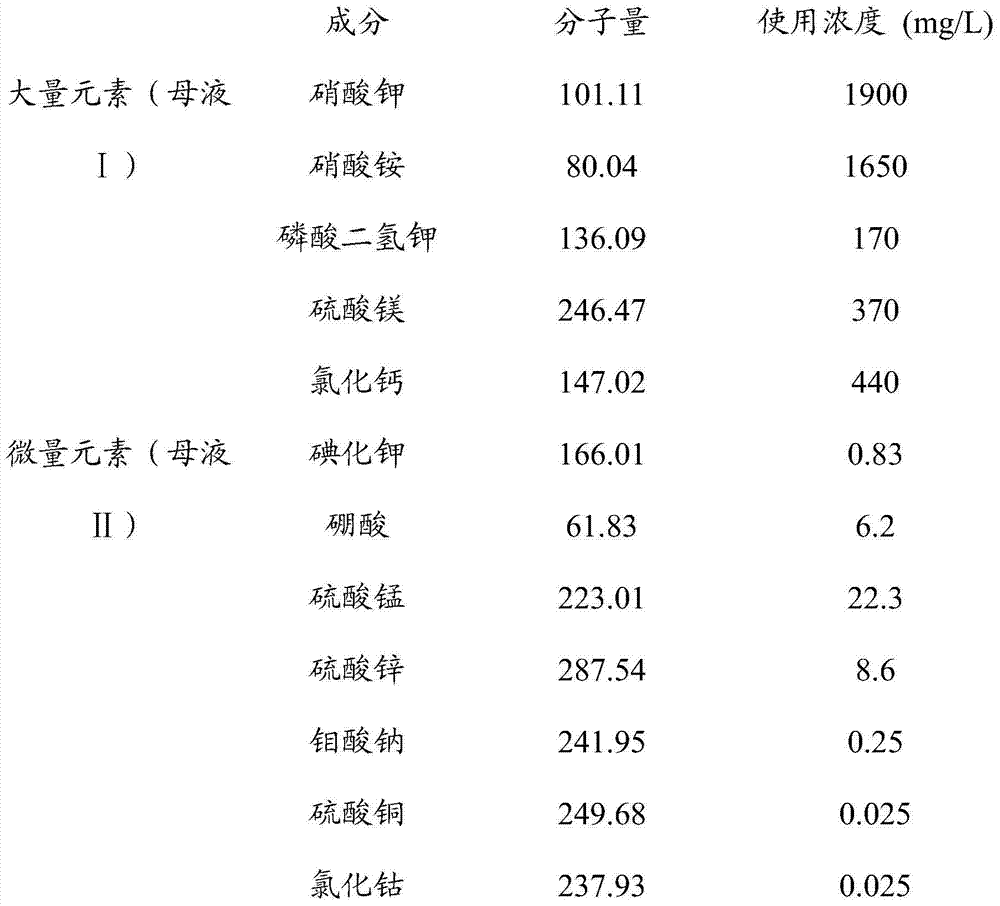

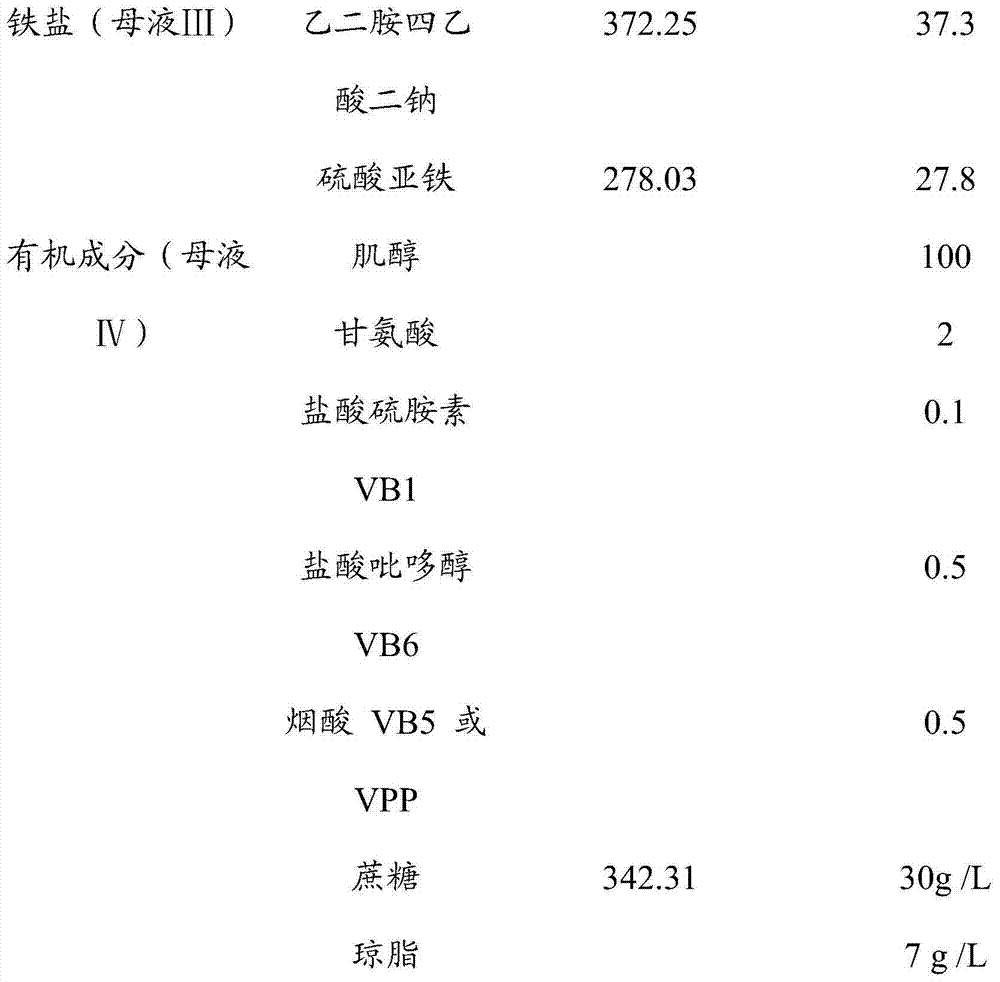

Method for improving Abelia seedling salt tolerance by oriented induction

ActiveCN103583360AImprove salt toleranceNormal growthCultivating equipmentsHorticulture methodsSalt resistanceAlkali soil

The invention discloses a method for improving Abelia seedling salt tolerance by oriented induction. The method comprises the steps of: (1) material sterilization, (2) induction of adventitious buds, (3) bud differentiation and subculture, (4) rooting culture, (5) seedling hardening, (6) seedling transplanting, and (7) seedling management. The method provided by the invention makes use of tissue culture and container seedling raising to add NaCl with different concentrations into a differentiation proliferation medium, a rooting medium and a culture matrix for transplanted seedlings gradually, so that the seedling salt tolerance can be enhanced from about 0.2% to about 0.6% (normal growth can be realized when the NaCl content of an annual seedling matrix is 0.4-0.5%, and normal growth can be realized when the NaCl content of a biennial seedling matrix is 0.5-0.6%), and the fixed planting survival rate in saline-alkali soil can be over doubled.

Owner:ZHEJIANG WANLI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com