Patents

Literature

319 results about "Sugar refinery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

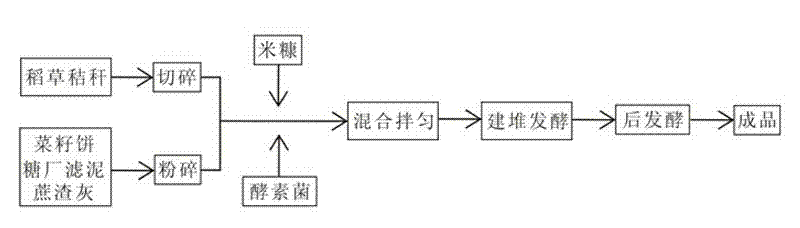

Organic fertilizer or bio-mixed organic fertilizer special for rice and preparing method thereof

ActiveCN102503611ARestore fertilityReduce manufacturing costBio-organic fraction processingOrganic fertiliser preparationChaffRapeseed

The invention discloses an organic fertilizer or a bio-mixed organic fertilizer special for rice and a preparing method thereof. The organic fertilizer or the bio-mixed organic fertilizer special for rice is prepared by composting and fermenting raw materials (dry basis) according to the following weight percentage: 10%-20% of straw stalks, 25%-30% of rice chaff (bran), 25%-35% of rapeseed cakes (dregs), 5%-20% of sugar refinery filtered mud, 5%-10% of bagasse ash and 0.1% of ferment bacterial fertilizer. The organic fertilizer or the bio-mixed organic fertilizer is good in fertilizer effect and environment-friendly, can lead nutritional components absorbed by rice, rape and sugarcanes from the soil to return to the land so as to restore soil fertility, leads circular economy to be developed, use quantity of fertilizers and pesticides are reduced, green and organic agricultural products are produced, production cost and environment cost are reduced, food safety is improved, environment is protected, and modern agriculture and green agriculture development are promoted.

Owner:广西宾阳县华彦新材料科技有限公司

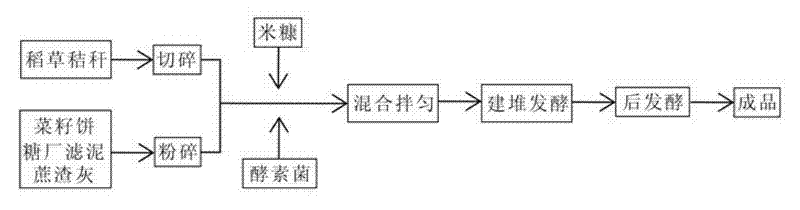

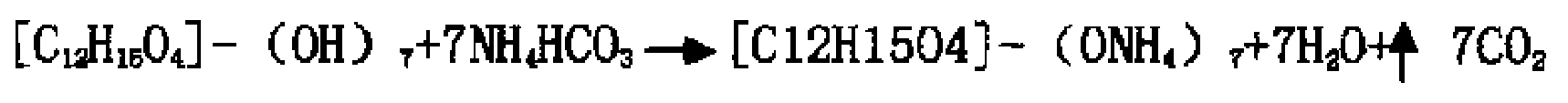

Technique for producing humic acid organic compound fertilizer from sugar refinery waste slag and wastewater

ActiveCN101462899ASolve pollutionHigh thermal efficiencyBio-organic fraction processingClimate change adaptationSocial benefitsEcological environment

The invention discloses a process for producing an organic humic complex fertilizer by the waste residue and waste water of sugar mills. The process comprises the following steps: condensing waste alcohol liquid; performing an alkalization reaction; mixing, reacting and composting for fermentation; crushing, screening, mixing, and disk balling; powdering, drying, screening and packaging. The process for producing the organic humic complex fertilizer by the waste residue and the waste water of the sugar mills helps thoroughly recovers and utilizes the waste residue and the waste water of the sugar mills, solve the problem of environmental pollution caused by waste discharge and increase the economic benefit and social benefit of enterprises. The novel organic humic complex fertilizer integrates yield increase benefit, quality benefit and ecological environment benefit, has stronger market competitiveness as a substitute product of imported complex fertilizers and represents the radical direction of fertilizer development in the future.

Owner:湛江中研科技开发有限公司

Activated calcium magnesium phosphate fertilizer and preparation method thereof

The invention belongs to the field of chemical production, and relates to an activated calcium magnesium phosphate fertilizer and a preparation method thereof. The activated calcium magnesium phosphate fertilizer is prepared from a calcium magnesium phosphate fertilizer and an organic activating agent. The organic activating agent is one or a mixture of more of lignin, acid lignin, sodium lignin, alcohol waste liquor, monosodium waste liquor, monosodium waste sludge, acid sludge, furfural sludge, beer filter mud, sugar-refinery filter mud and weathered coal. The activated calcium magnesium phosphate fertilizer is prepared by adding the organic activating agent into the calcium magnesium phosphate fertilizer according to a specified ratio, and grinding, placing and drying the mixture. Phosphorus in the activated calcium magnesium phosphate fertilizer is in an activated state, the activated calcium magnesium phosphate fertilizer can be fast and stably released when applied to the soil, can reduce fixation of the soil, and has fast and durable fertilizer effect, so that the utilization rate of the phosphorus is obviously improved. Meanwhile, the activated calcium magnesium phosphate fertilizer has the advantages of simple production process, low production cost, high and stable yield, and contribution to large-scale production and application. Compound fertilizer plants or newly-built phosphate fertilizer plants can produce the activated calcium magnesium phosphate fertilizer under the conditions of small equipment investment.

Owner:SOUTH CHINA AGRI UNIV

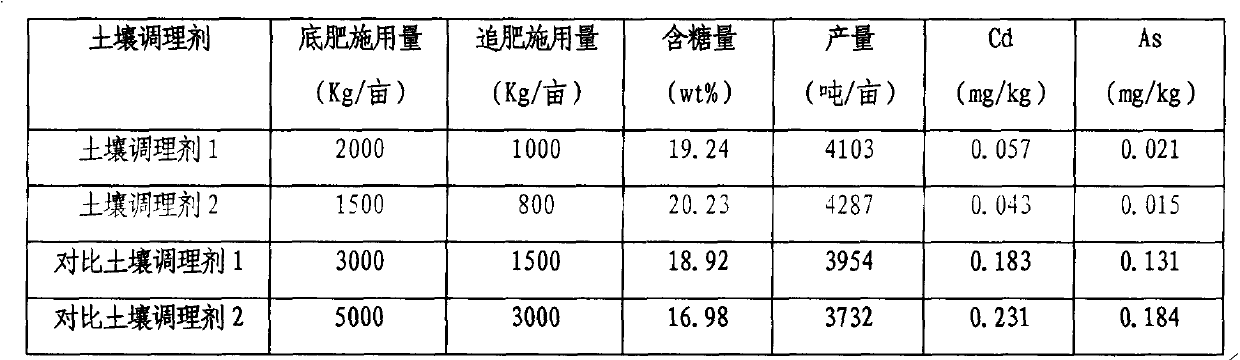

Soil conditioner containing sugar refinery alcohol waste liquor, filter mud and peat

ActiveCN103102226AReduce processing costsReduce pollutionFertilizer mixturesLiquid wasteStructural balance

The invention relates to soil conditioner containing sugar refinery alcohol waste liquor, filter mud and peat. The soil conditioner is characterized by being prepared from sugar refinery alcohol waste liquor, the sugar refinery filter mud and the peat at a ratio of (4000-6000):(300-500):(50-150) in parts by weight. The soil conditioner disclosed by the invention has the advantages of balanced influence can be provided for crops; the structural balance of soil is optimized; and the adequacy of the soil nutrient can be kept for a long time.

Owner:叶长东

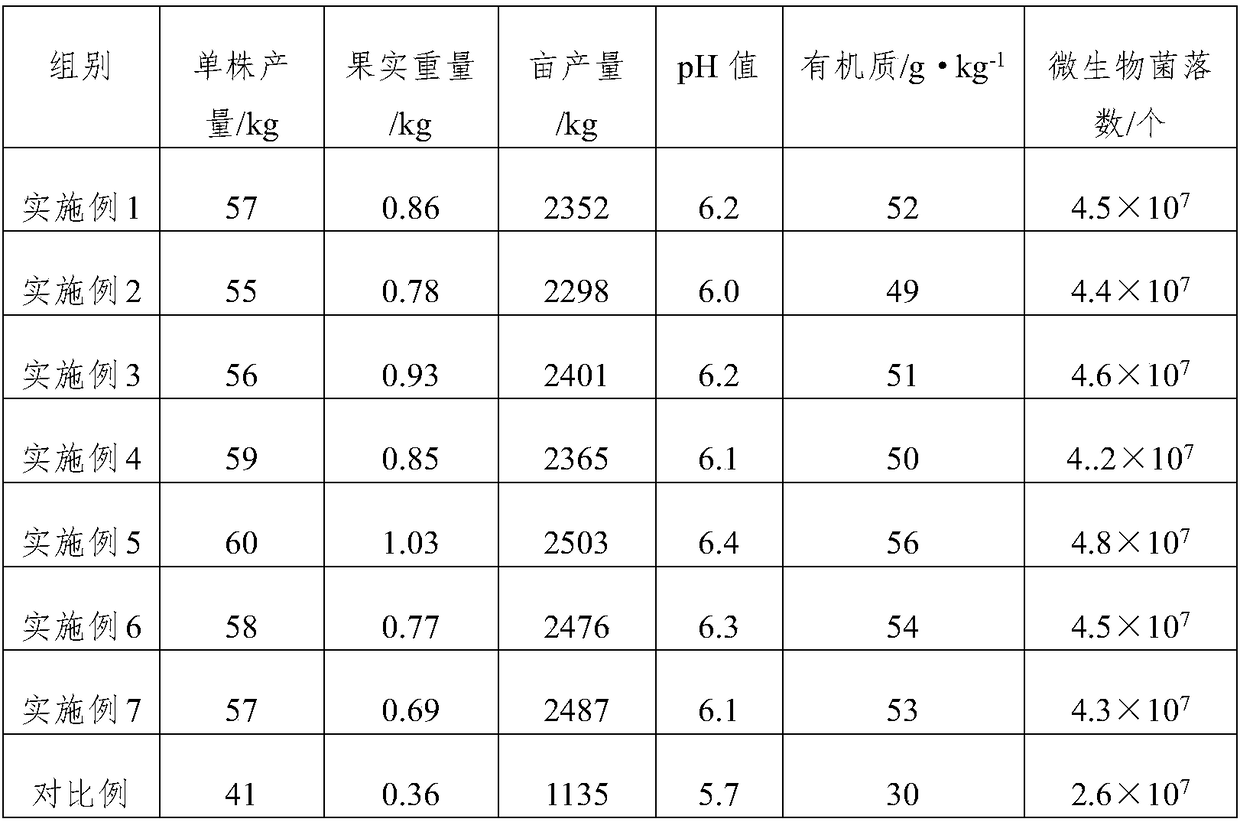

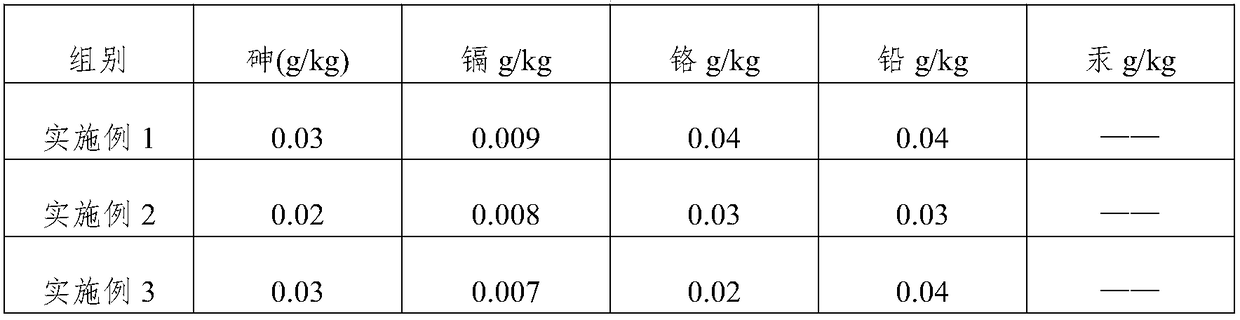

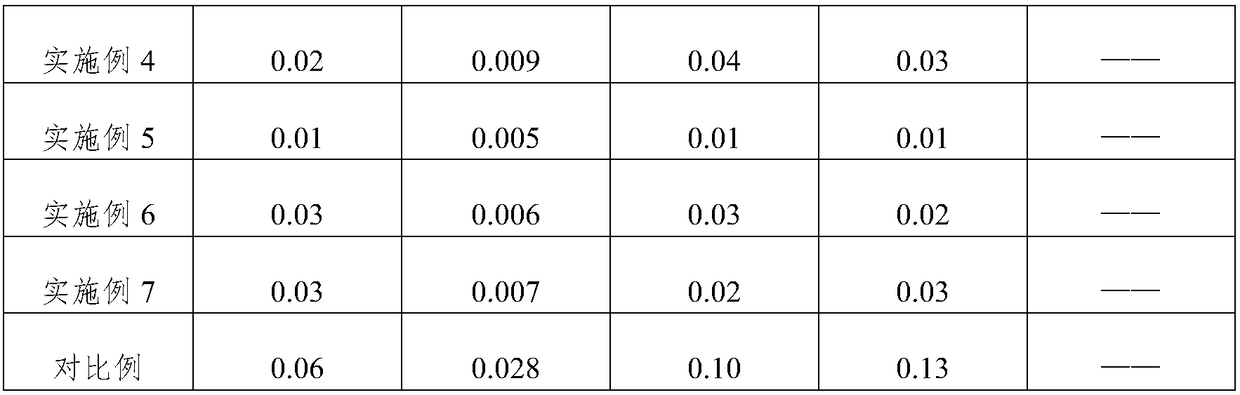

Efficient and environment-friendly microbial organic fertilizer and preparation method thereof

InactiveCN108840777AFull of nutritionReduce pests and diseasesBio-organic fraction processingAnimal corpse fertilisersPhosphateMicrobial agent

The invention discloses efficient and environment-friendly microbial organic fertilizer. The fertilizer is prepared from raw materials as follows: kitchen waste, agricultural waste, livestock and poultry manure, waste mushroom sticks, mud from sugar refineries and beer breweries, waste from slaughter houses, ground phosphate rock, plant ash, peanut shell, traditional Chinese medicine residues, leaves and weeds, mildewed feed, a microbial agent and a leavening agent. The invention also discloses a preparation method of the fertilizer. The efficient and environment-friendly microbial organic fertilizer contains rich nutrients, can reduce disease and pest damage in soil, prevent soil hardening, provide nutrients required for growth of crops and increase the pH value, organic matter content and microbial florae of the soil after being applied, has high utilization rate and can promote absorption and conversion of crops for fertilizer and promote growth and elongation of crops. The organicfertilizer can inhibit absorption of crops for heavy metals in soil, reduce the content of heavy metals in crop products and improve the quality of crops while protecting the soil.

Owner:GUIZHOU STANLEY FERTILIZER

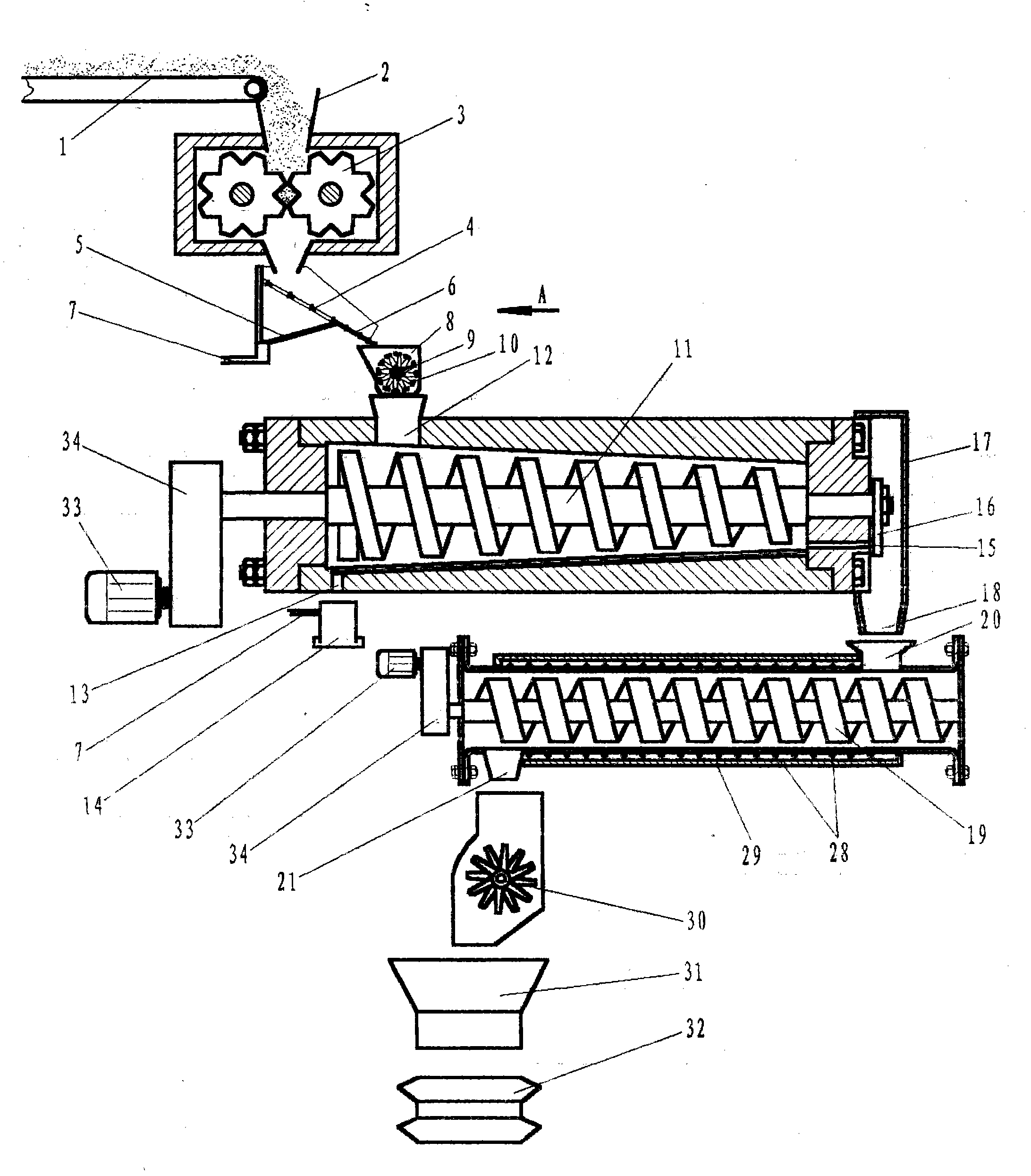

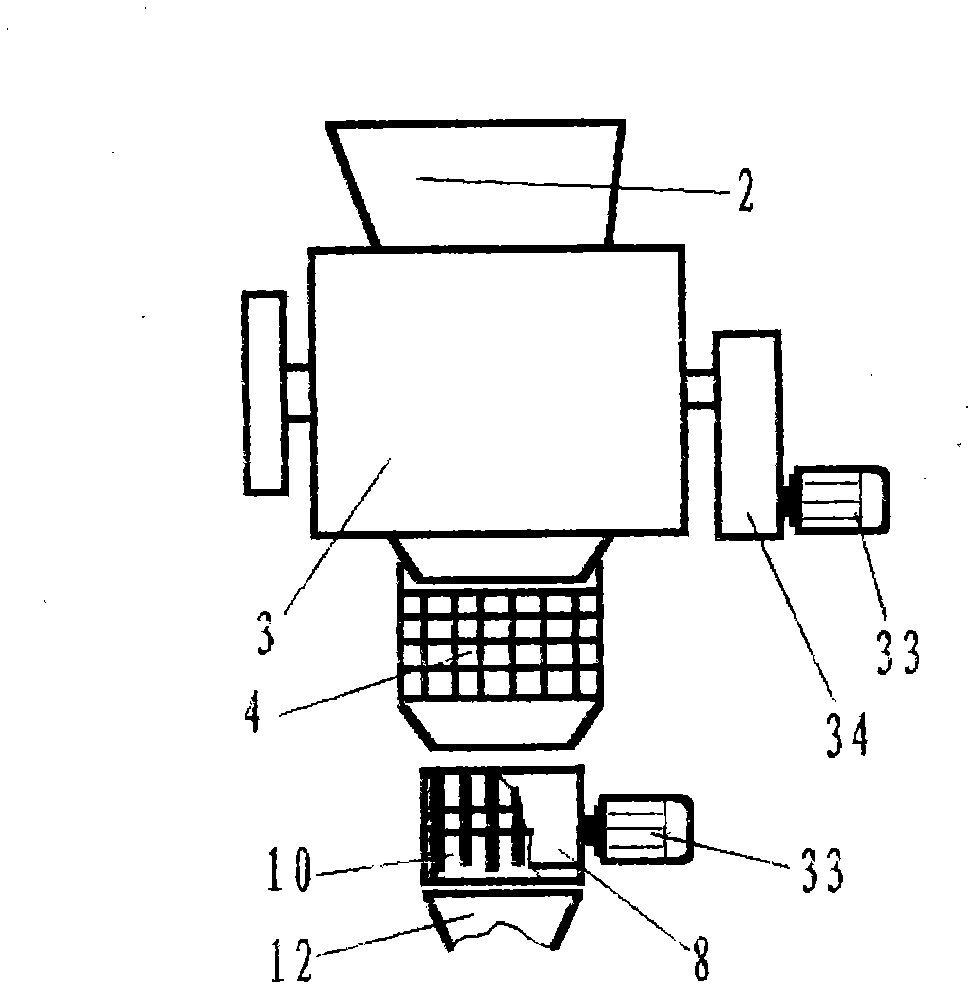

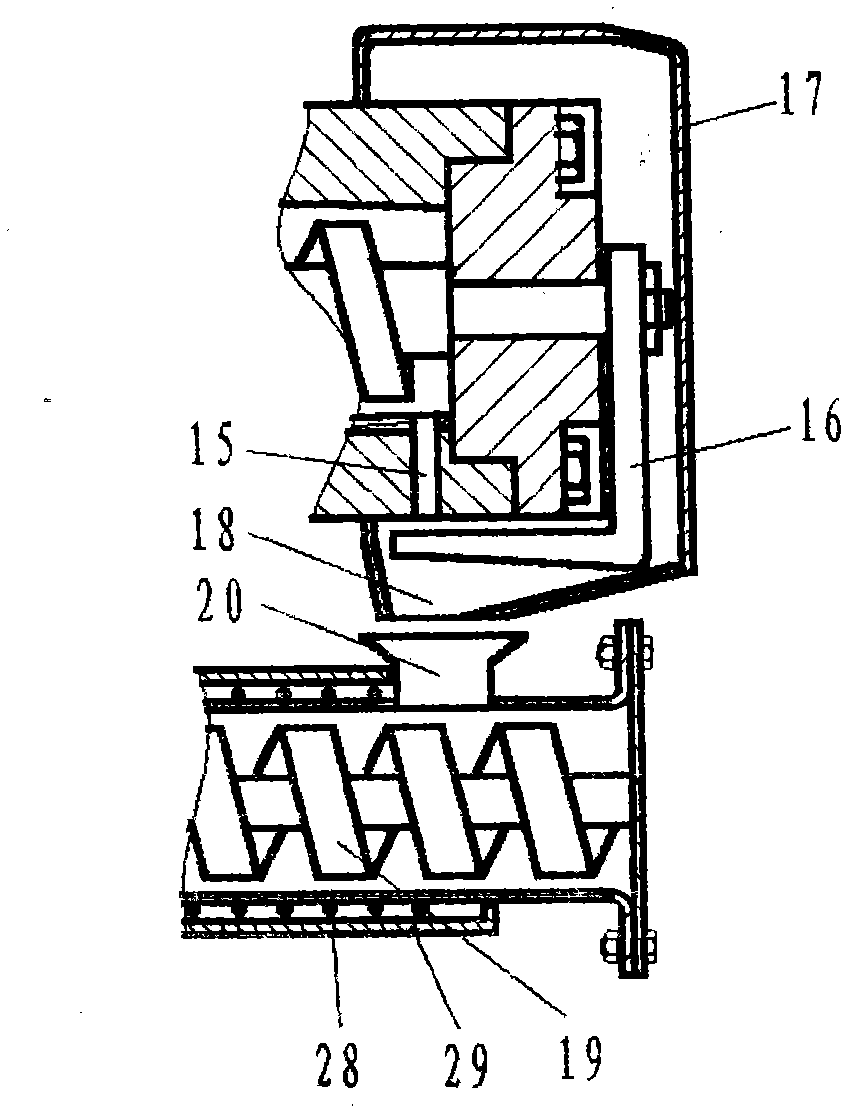

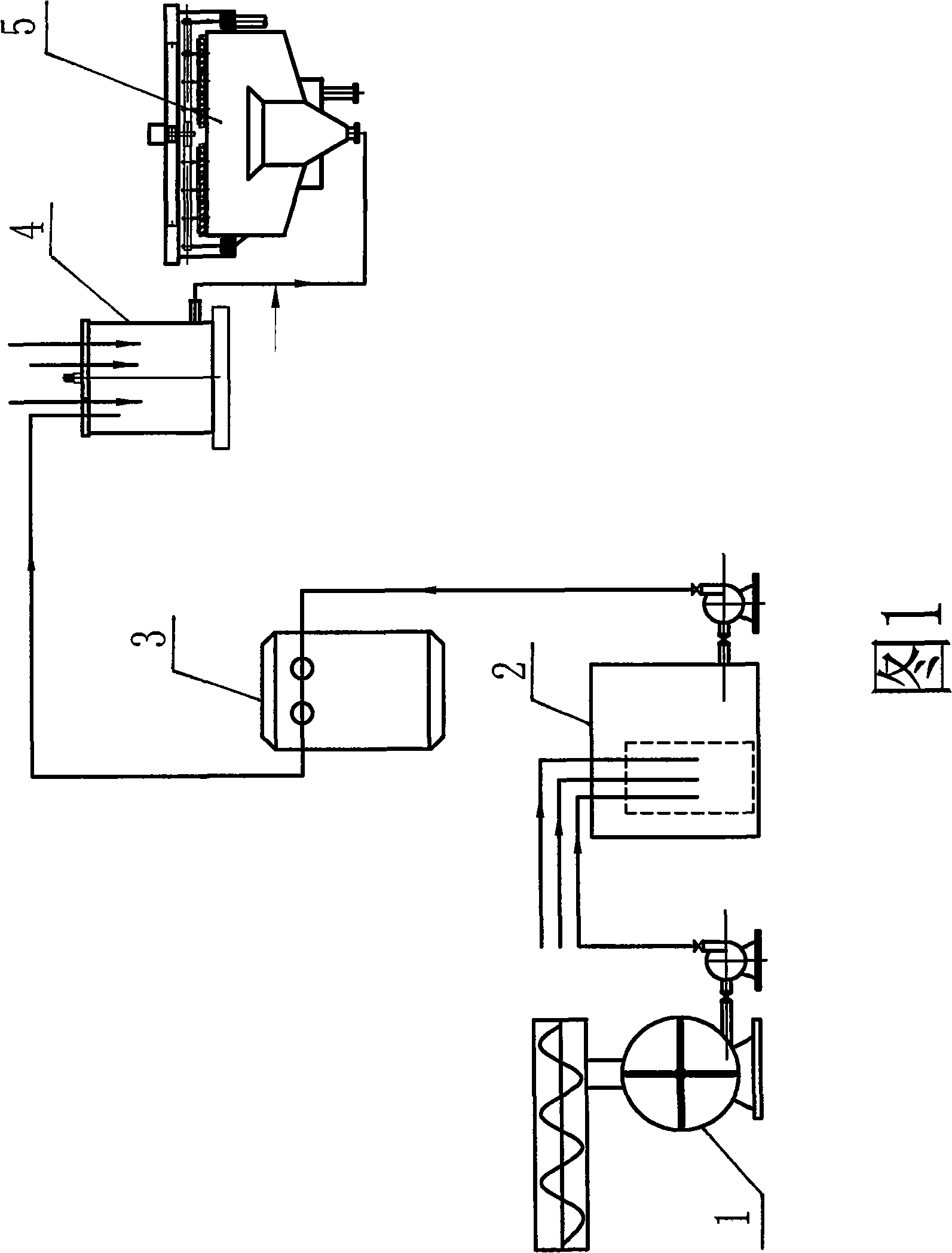

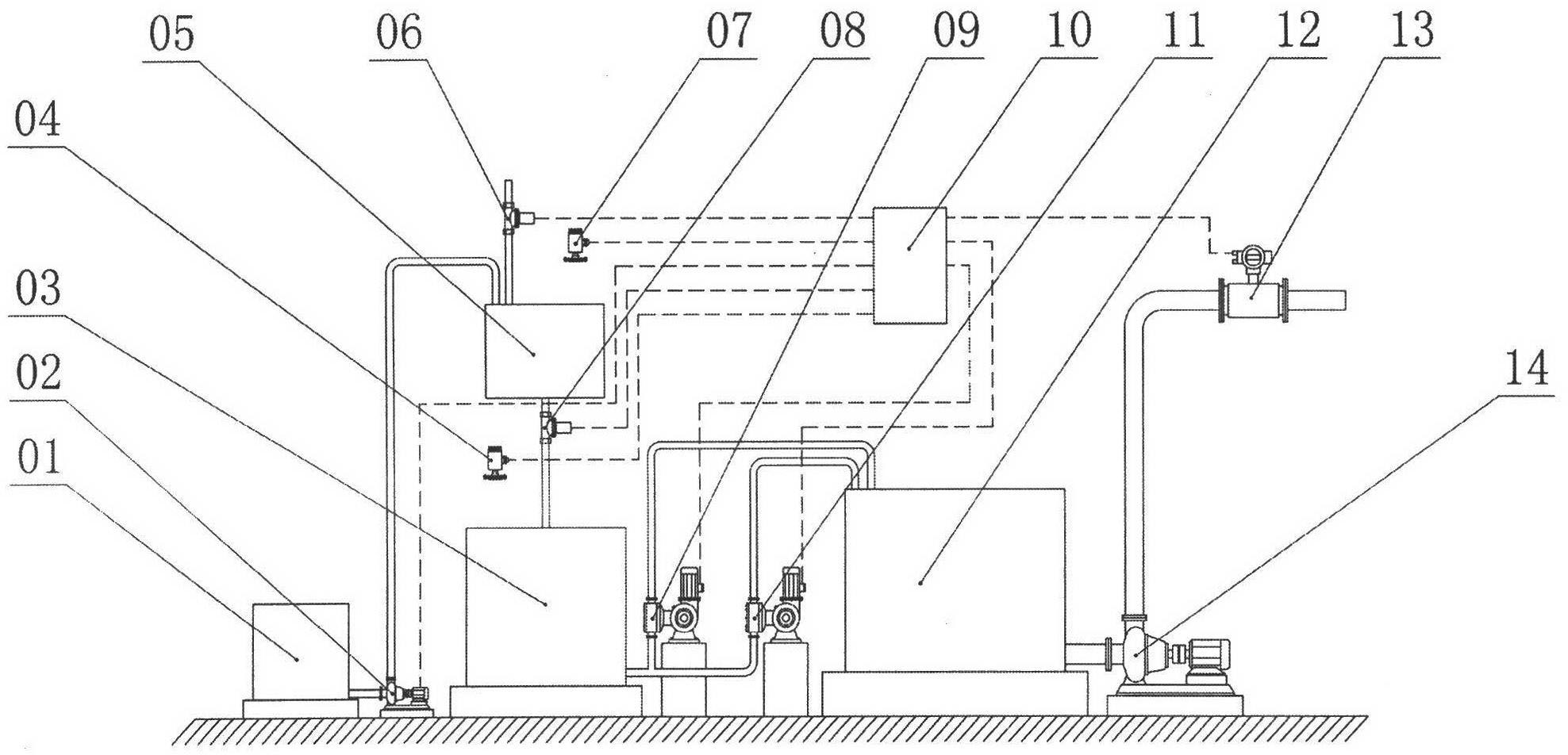

Solid liquid high-efficiency separation device for filter mud of sugar refinery

InactiveCN102583940AEnergy saving in dehydration and deodorizationWon't happenSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningCrusherSugar refinery

The invention relates to a solid liquid high-efficiency separation device for filter mud of a sugar refinery and belongs to a solid liquid separation device. The device comprises a conveying belt, a mud separating hopper, a double-wheel roller, a mud water separator, a mud block chopper, a screw extruder, a mud strip scraping device, a spiral conveyer with a heating component and a dry mud crusher which are driven to operate by a transmission device, wherein the conveying belt is arranged above the mud separating hopper; the mud separating hopper is arranged above the double-wheel roller; the mud water separator is arranged below the double-wheel roller; the mud block chopper is arranged between the mud water separator and the screw extruder; the mud strip scraping device is arranged at the outlet end of the screw extruder; the spiral conveyer is arranged below the screw extruder; the heating component is arranged on a shell; and the dry mud crusher and a bagging mechanism are arranged below the spiral conveyer. The device repeatedly extrudes wet filter mud, dries, crushes, separates sugar-containing water from the filter mud, prepares dry mud powder into fertilizer powder or building materials, and is energy-saving in dehydration and deodorization of the wet filter mud.

Owner:罗庆繁

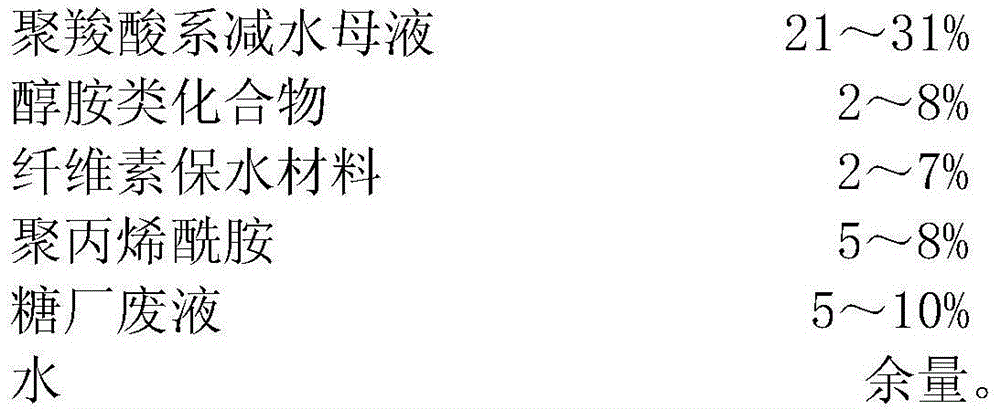

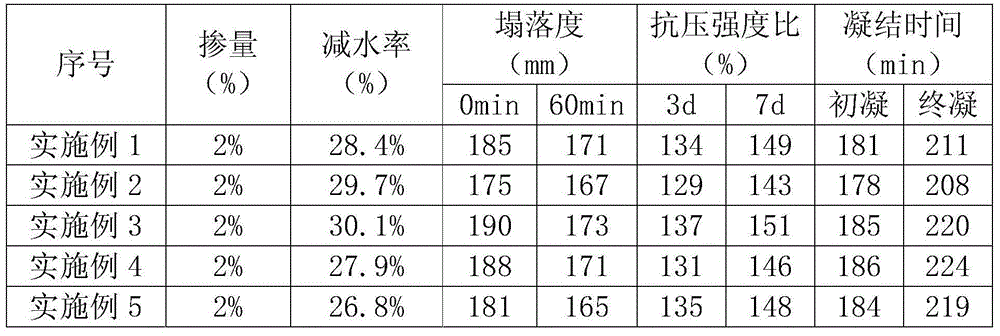

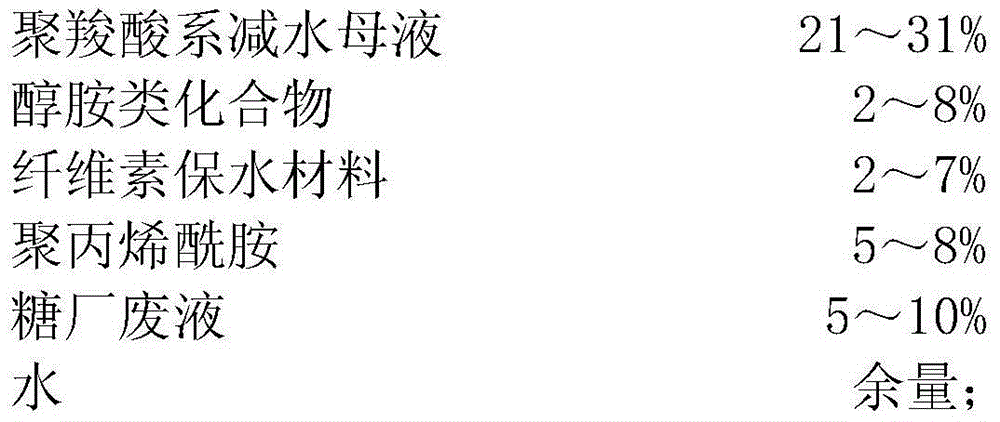

High-performance polycarboxylate water reducer

The invention relates to the technical field of concrete admixtures and particularly relates to a high-performance polycarboxylate water reducer prepared from the following raw materials in percentage by weight: 21-31% of a polycarboxylate water reducing mother solution, 2-8% of alcohol amine compounds, 2-7% of cellulose water retaining materials, 5-8% of polyacrylamide, 5-10% of waste liquid from a sugar refinery, and the balance being water. The water reducer disclosed by the invention is high in water reducing rate, small in slump loss and high in adaptability with cement and has a retarding effect.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Biochar fertilizer with soil heavy metal passivation and fertilizer efficiency functions

InactiveCN103755485AGood chemical inertnessHigh affinityFertilizer mixturesSoil heavy metalsSugar refinery

The invention relates to a fertilizer technology, a soil improvement technology and an environmental protection technology which solve the problems that the general soil heavy metal passivation treatment agent is very short of a fertilizer nutrient effect and a biological bacterium effect. A biochar fertilizer is prepared by pelleting and charring residues of a food product plant, obtaining biological carbon granules, mixing probiotics, urea and waste molasses of a sugar refinery, adding to the biological carbon granules, and performing final stirring and mixing, wherein the final stirring and mixing process is performed when the temperature of the biological carbon granules is 50-150 DEG C. The biochar fertilizer with soil heavy metal passivation and fertilizer functions can be obtained by the preparation process.

Owner:广东巴斯德环境科技有限公司

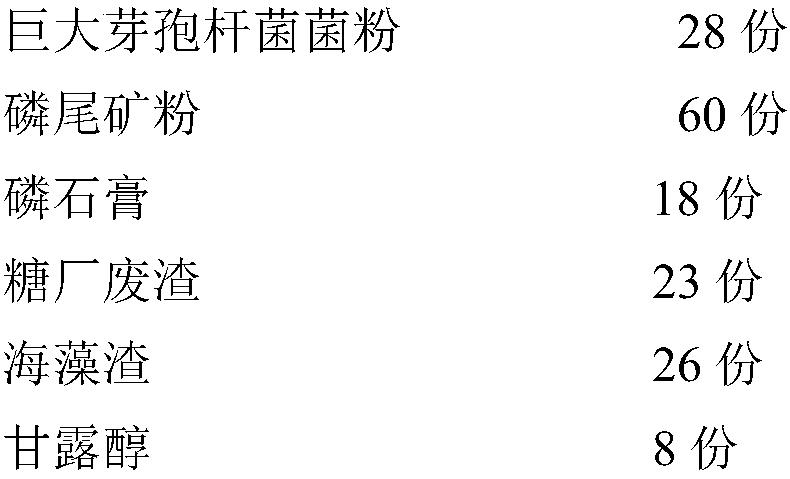

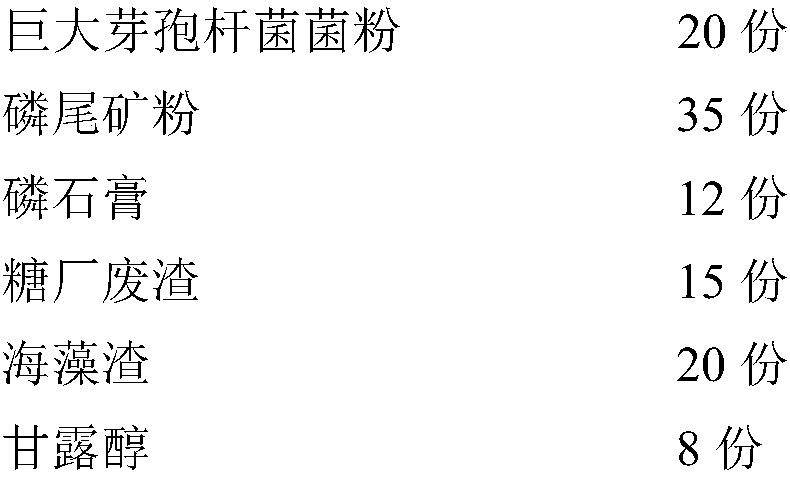

Saline-alkali soil modified microbial inoculum and preparation method thereof

InactiveCN108017445AOccupy living spaceEnhance colonization abilityCalcareous fertilisersBioloigcal waste fertilisersAgricultural scienceAlkali soil

The invention discloses a saline-alkali soil modified microbial inoculum and a preparation method thereof. The microbial inoculum comprises, by weight, 10-30 parts of bacillus megatherium HB bacteriapowder, 35-65 parts of phosphorus tailings powder, 12-18 parts of phosphogypsum, 8-25 parts of sugar refinery wastes, 6-26 parts of seaweed residue and 1-8 parts of mannitol. Components of the saline-alkali soil modified microbial inoculum have synergistic interactions with each other to enhance effects, if any one of the components lacks, expected effects cannot be reached, and only when the saline-alkali soil modified microbial inoculum with whole formulas is adopted and 30-80 kg of the microbial inoculum is used per mu, can the effects of increasing fertilizer utilization rate and crop yields, and improving quality and saline-alkali lands be achieved.

Owner:菏泽金正大生态工程有限公司 +2

Culture medium for straw mushroom

ActiveCN103467187AMeet training requirementsReduce manufacturing costFertilizer mixturesDrug biotransformationMushroom

The invention provides a culture medium for straw mushroom, which comprises the following raw and auxiliary materials in parts by weight: 300-600 parts by weight of cane trash, 100-400 parts by weight of dregs, 0-200 parts by weight of straw, 0-200 parts by weight of corncob, 0-10 parts by weight of peanut bran, 5-10 parts by weight of compound fertilizer, 5-10 parts by weight of plaster, 5-8 parts by weight of lime, and 4-8 parts by weight of urea. According to the invention, cane trash and dregs, two primary by-products of the sugar industry, are used for cultivate the straw mushroom; the recipe is reasonable; the physical and chemical properties are reliable and can meet the cultivation requirement of the straw mushroom; the culture medium has the advantages of increasing comprehensive utilization of sugar refinery by-product, reducing straw mushroom manufacturing cost, reducing environment pollution, and accelerating the development of domestic fungus industry; the biotransformation ratio of straw mushroom cultivated through the culture medium is higher than 40%.

Owner:GUANGXI UNIV

Molded coal made from garbage and process for preparing same

The invention provides a molded coal made from garbage and process for preparing same, wherein the molded coal comprises, (1) urban domestic refuse, (2) one or several flammable substances containing fixed carbon, including coal gangue, coal mud, stone coal, pulverized coke, bituminous shale, charcoal powder, coal, graphite powder, carbon black, (3) binder including loess, carclazyte, cement, soluble glass, industrial sewage, asphalt slag, coal tar, industrial maize starch and cellulose. The preparation process comprises the steps of sterilizing, artificial sorting, disintegrating, drying, charging binder, addition agent, mixing, magnetic separating, super fine crushing, modeling and drying.

Owner:CHANGCHUN HONGGUANG CLEAN ENERGY DEV

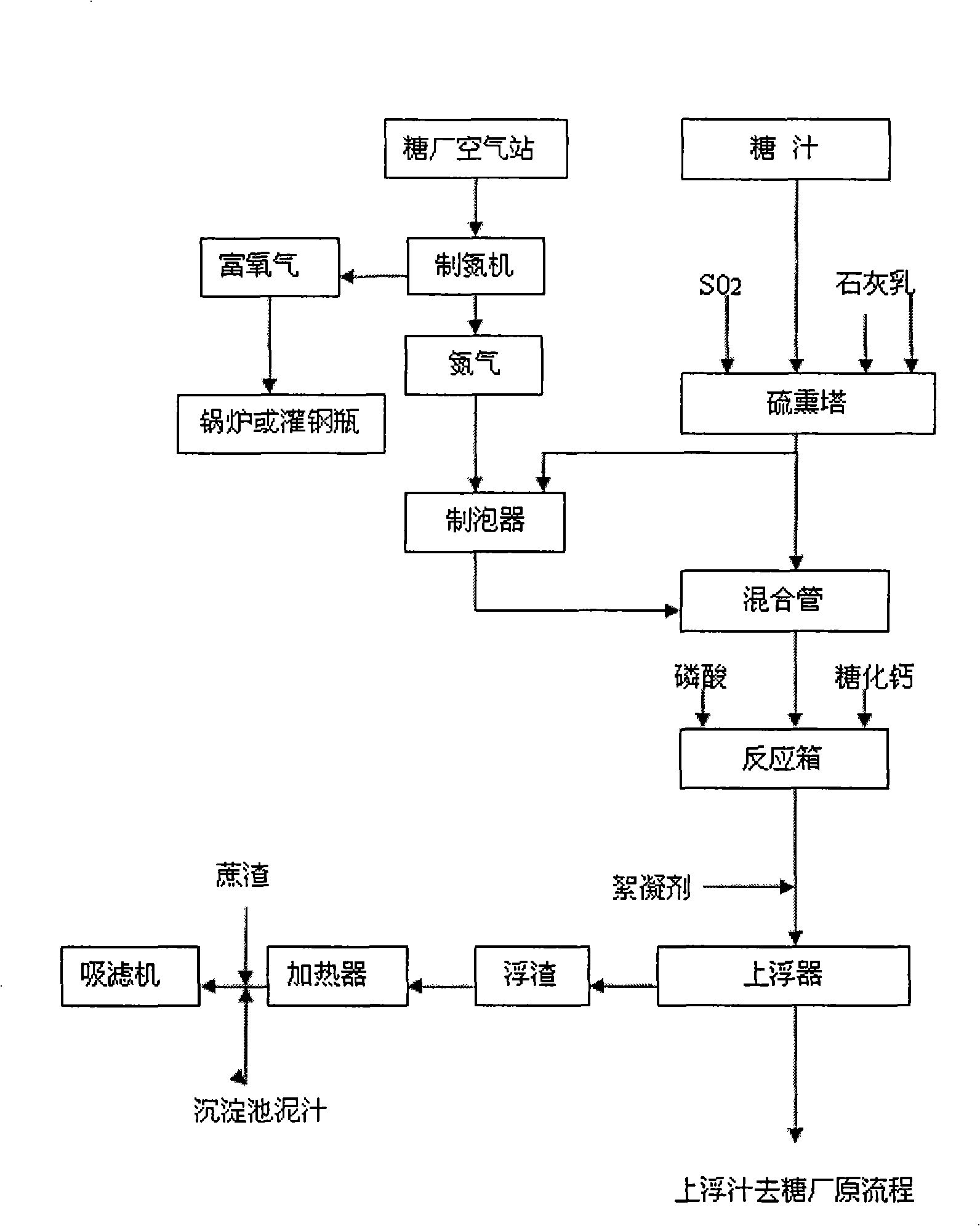

Sugar juice air-float clearing method

InactiveCN101294227AHighlight substantive featuresSignificant progressSugar juice purificationNitrogenNitrogen gas

The invention discloses an air floatation lustration method of sugar juice. Nitrogen is used as foaming air supply instead of air; thin juice (such as mixed juice, diffusion juice, neutral juice, clear juice and filtered juice) and concentrated sugar juice (such as syrup and molasses) in a sugar-refinery are processed through floatation lustration. The lustration method solves the problems that oxygen generated in the air floatation lustration method which takes the air as the foaming air supply has the oxidation encolouration side effects on the phenols in the sugar juice, the intensity of sulfitation is reduced, the sugar juice is fermented under the low temperature, etc., the sugar juice with better quality is obtained, and the product quality of the sugar-refinery is increased.

Owner:GUANGXI NANNING HUAXIN SUGAR IND TECH

Floating method of brown granulated sugar dissolved by a-wash

The invention discloses a floating method for A-wash remelting brown granulated sugar, in the method, A-wash is added while remelting brown granulated sugar to enable the purity of mixed syrup to reach or near the purity of rough syrup, and then the mixed syrup is treated by the syrup floating method. Not only the product quality is guaranteed, the color value is lowered and reducing sugar, color elements and impurities are removed, but also the back boiling amount of low purity materials is increased, the rearward shift of the materials is reduced, the yield and the purity of waste molasses are effectively lowered to achieve the purposes of improving the yield of white granulated sugar, increasing the product recovery and improving the economic benefits of the sugar factories.

Owner:GUANGXI YONGXINHUA SUGAR GROUP

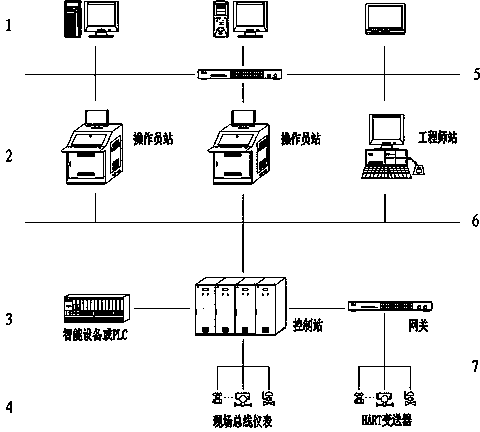

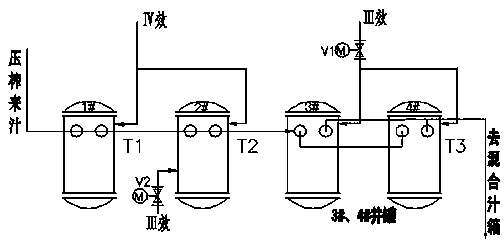

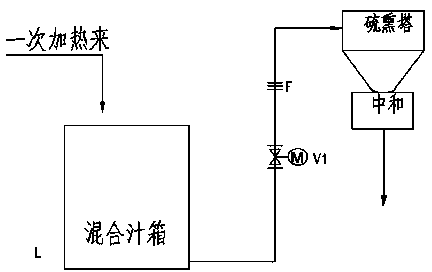

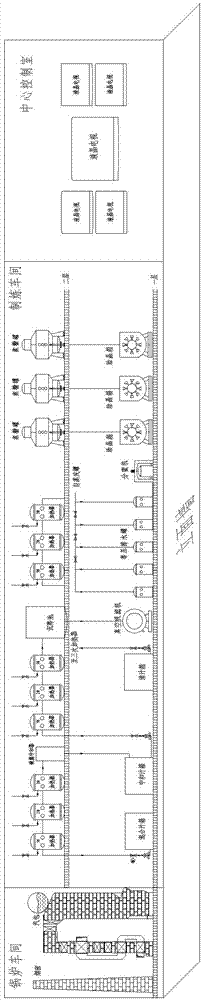

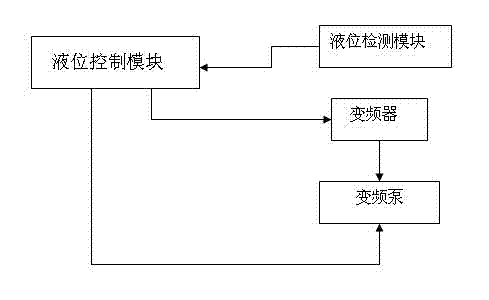

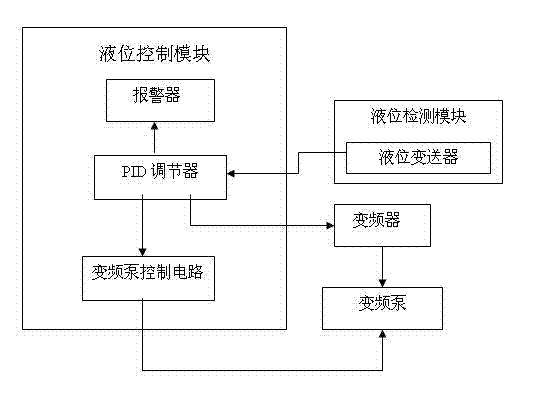

Automatic control system for clarification and evaporating process of sugar refinery

InactiveCN103365274ARealize fully automatic controlAvoid churnSugar juice boiling/evaporationTotal factory controlSteam pressureAutomatic control

The invention provides an automatic control system for a clarification and evaporating process of a sugar refinery. The automatic control system comprises six subsystems, namely a mixed juice heating and uniform-pumping automatic-control system, a neutralizing juice heating and uniform-pumping automatic-control system, a clear juice heating and uniform-pumping automatic-control system, waste steam and live steam pressure-reducing temperature-reducing automatic-control system, an I-V-effect evaporation tank syrup liquid level control and last-effect syrup brix control system and a production dispatching management system. The whole automatic control system structure is divided into four levels, namely a field instrument layer, a control station, an engineer station and an operator station, and an information management layer from bottom to top. The whole system forms the four-level structure through the six subsystems to automatically control the production process. According to the system, sugar enterprises can achieve the operating target of the production process, namely five stabilities, different levels of managers can master industrial site conditions any time and anywhere across the regions, and the fully-automatic control for the clarification and evaporating process of the sugar refinery and the cross-region real-time production management are realized.

Owner:广西宏智科技有限公司

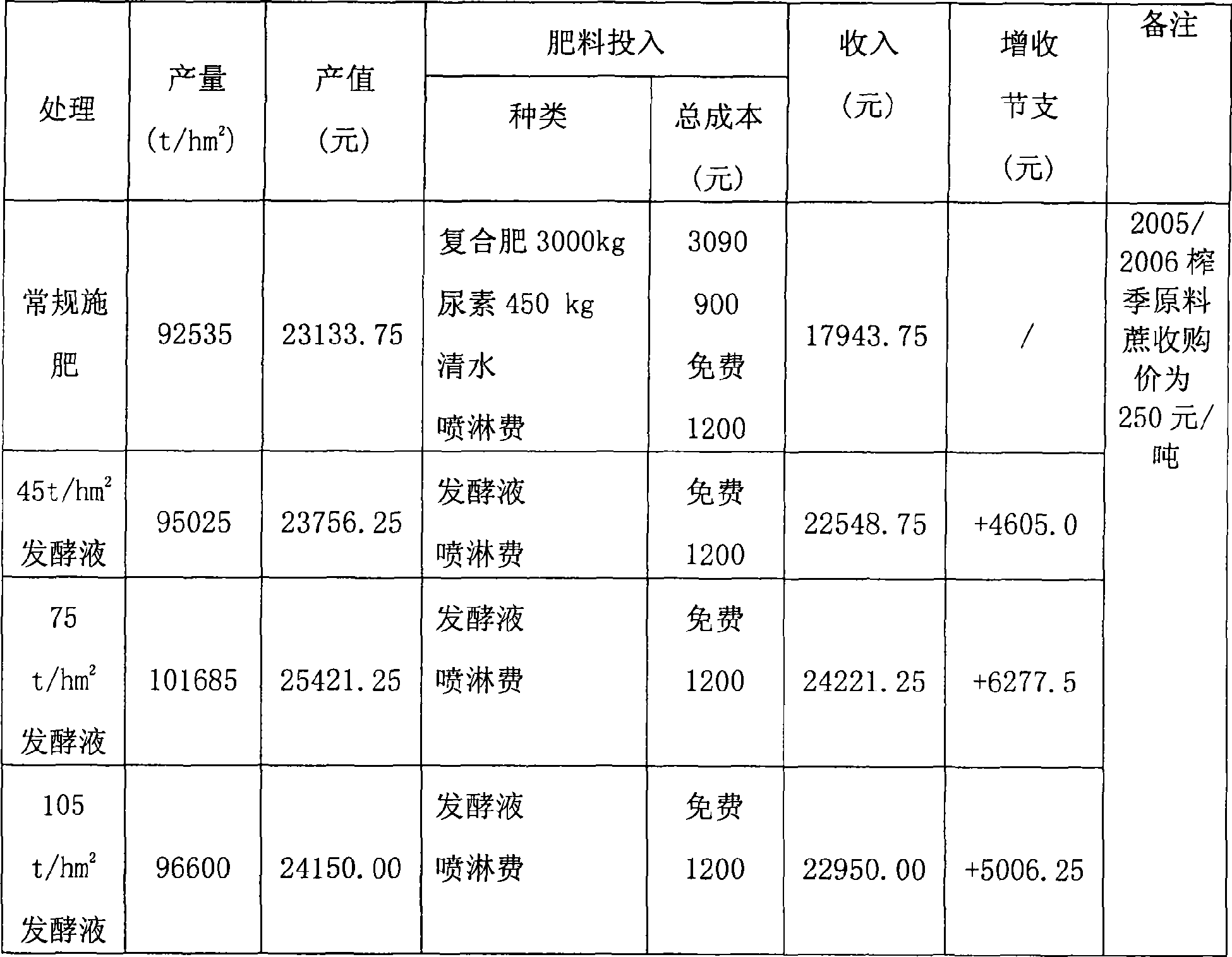

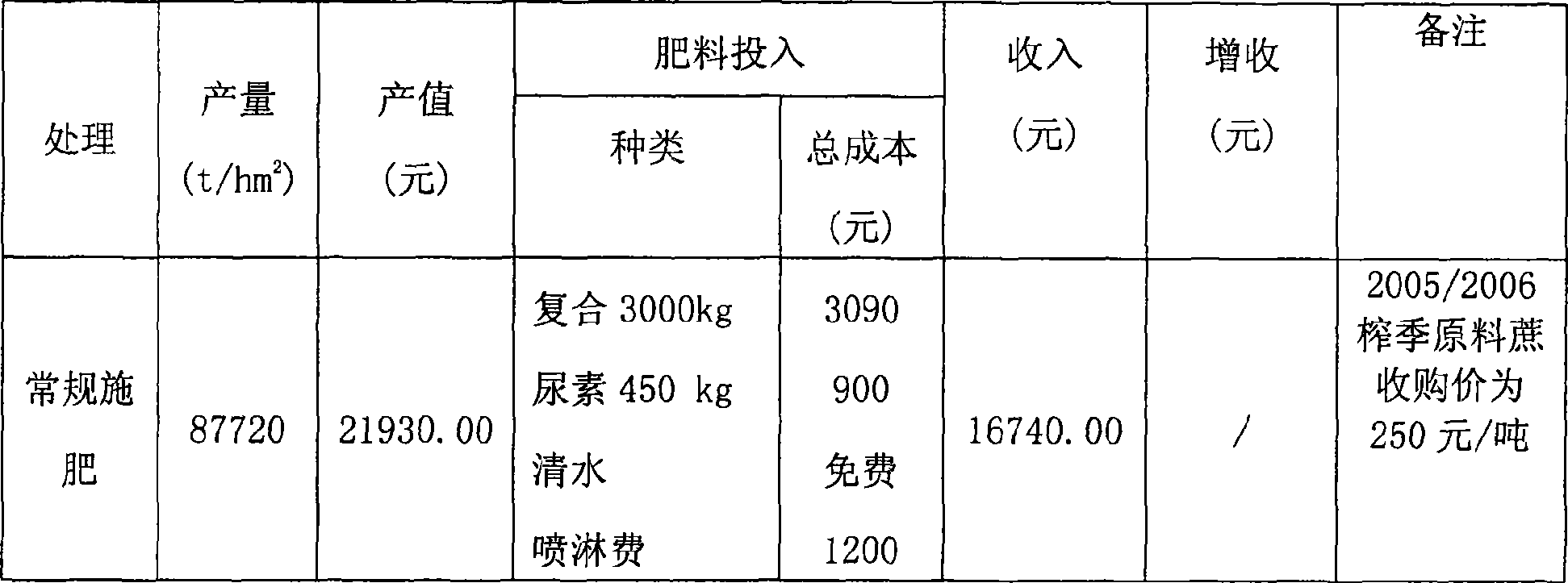

Method for using molasses alcohol fermentation liquid as sugarcane liquid fertilizer

InactiveCN101439994ASolve the problem of water and fertilizerSolve pollutionClimate change adaptationBioloigcal waste fertilisersHectarePlastic mulch

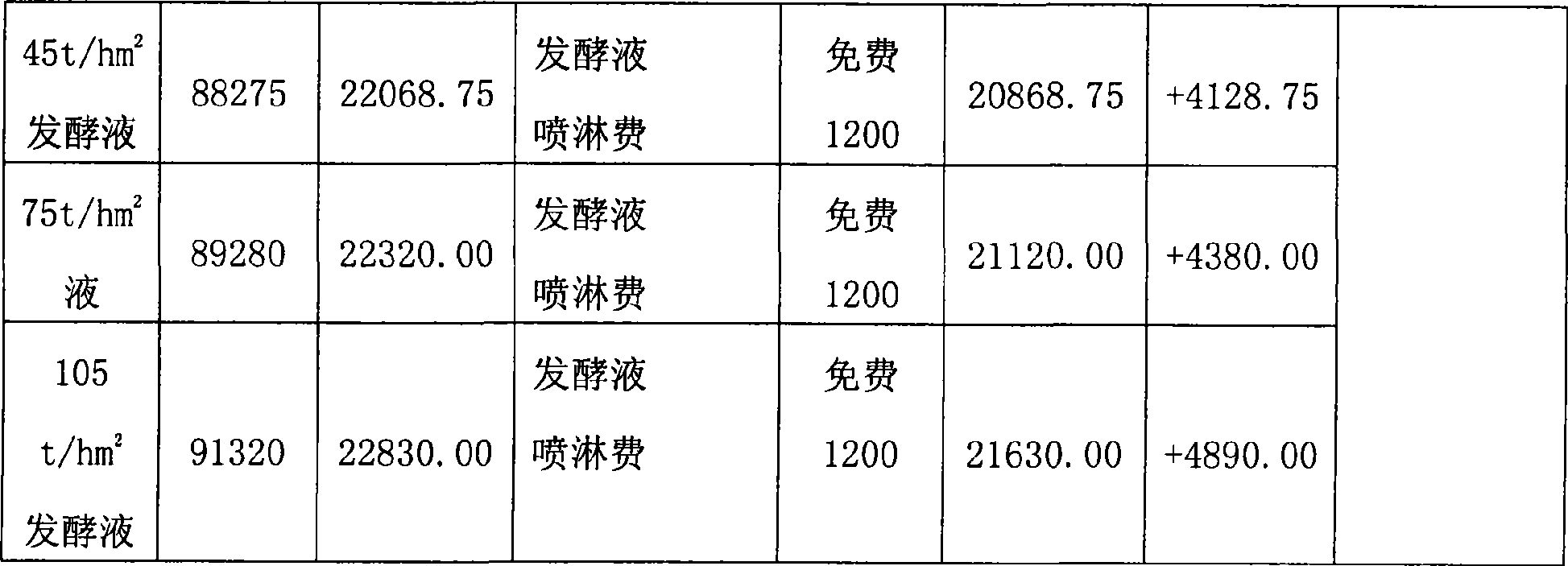

The invention discloses a method for using sugar-syrup alcohol fermentation liquid as a sugarcane liquid fertilizer. To apply the sugarcane liquid fertilizer to newly planted cane plants, the method comprises the following steps: diluting the fermentation liquid till the Baume degree reaches 6 to 8 and spraying the sugarcane liquid fertilizer in furrows for planting cane at a rate of 90 to 110 tons per hectare after the cane seeds are planted; covering a film on the next day after spraying operation and spraying pre-emergence herbicide; and removing the film after the stem pushing of cane seedlings and carrying out cultivating and hilling without applying any chemical fertilizer. To apply the sugarcane liquid fertilizer to stubble cane, the method comprises a step of diluting the fermentation liquid till the Baume degree reaches 8 to 10 and other steps which are the same as those used for newly planted cane plants. Using sugar-syrup alcohol fermentation liquid as a sugarcane fertilizer, the method solves the problem of pollution caused by sugar-syrup alcohol fermentation liquid of a sugar refinery and the problem of sugar liquid manure, recycles waste materials, increases soil fertility and improves production and yield of sugar. When applied at a rate of 45 to 105 t / hm<2>, a stock solution of the fermentation liquid can increase yield of sugar by 10 to 30 percent compared with the prior chemical fertilizer applied.

Owner:李杨瑞

Method for producing drinking water by utilizing steam condensation water of sugar refinery

InactiveCN101798148AEasy accessEmission reductionWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisSteam condensationPotable water

The invention discloses a method for producing drinking water by utilizing steam condensation water of a sugar refinery. In the method, the steam condensation water of the sugar refinery is subjected to one, two or more devices of a sand leach device, an active carbon device, an ion exchange resin device, a reverse osmosis device and a nanofiltration device in order to reach the standard of the drinking water. The invention can effectively recycle the steam condensation water, increase the comprehensive utilization approaches for the sugar refinery, improve the economic benefit and can reduce the exhaust of the waste water of the sugar refinery.

Owner:GUANGXI UNIV

Humid acid type organic water-retaining agent containing wastes in sugar refinery and alcohol plant

ActiveCN103664384APromote rootingIncrease root to shoot ratioFertilizer mixturesAlcoholSugar refinery

The invention relates to a humid acid type organic water-retaining agent containing wastes in sugar refinery and alcohol plant. The humid acid type organic water-retaining agent contains active humic acid, a water-retaining agent and bactericide; the composition can effectively promote crop rooting.

Owner:广西勤德科技股份有限公司

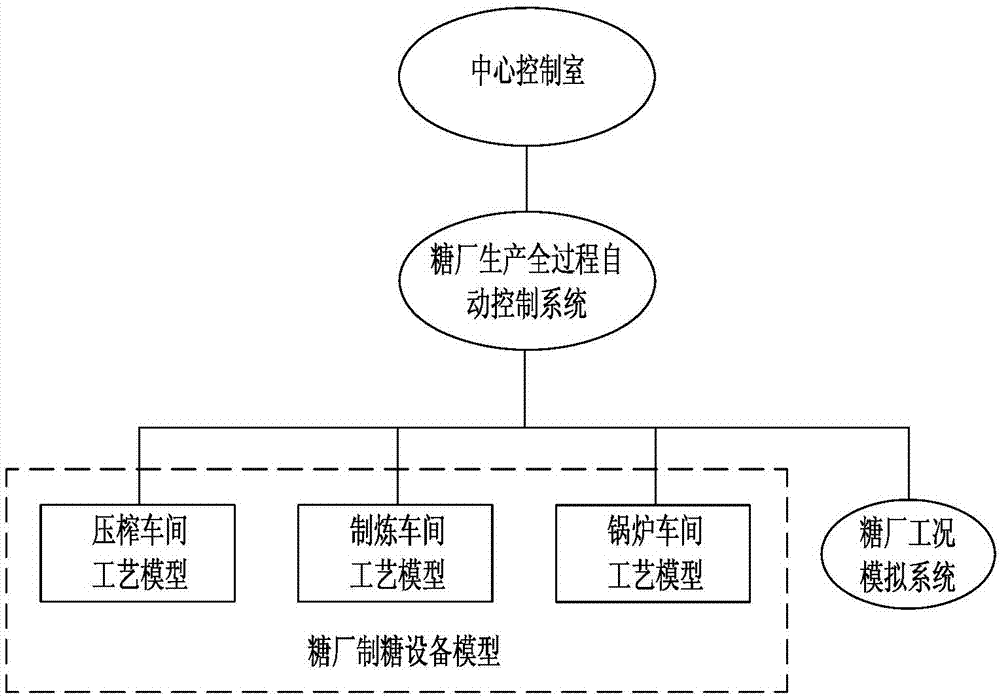

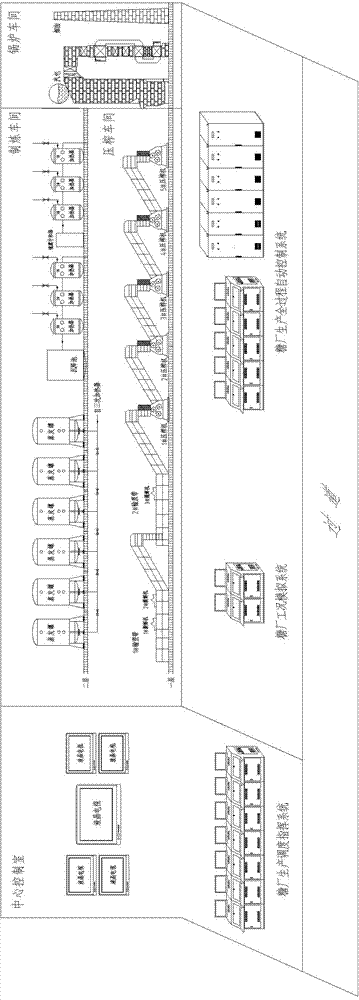

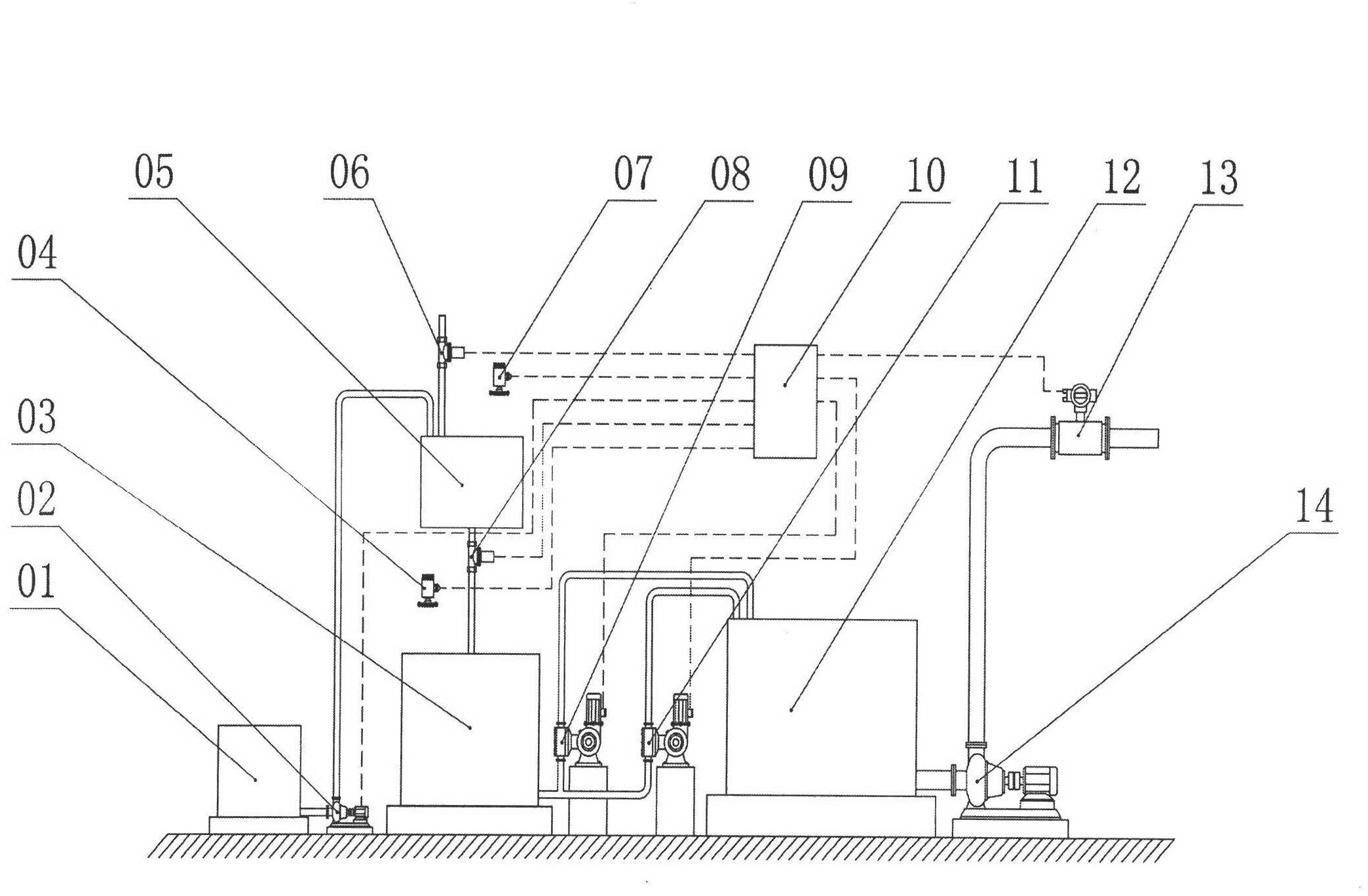

Practical training centre for sugar manufacturing process control technology

ActiveCN104122875AAchieve wiredReal-timeEducational modelsTotal factory controlAutomatic controlAutomated control system

The invention provides a practical training centre for a sugar manufacturing process control technology. The practical training centre comprises a sugar refinery sugar manufacturing equipment model, a sugar refinery working condition simulation system, a sugar refinery production whole-process automatic control system and a central control room, wherein the sugar refinery sugar manufacturing equipment model is produced by scaling down according to the ratio of the appearance and the like of actual production equipment, arranged and connected according to an actual process flow, and further used as a field instrument installation carrier; the sugar refinery working condition simulation system is used for simulating the actual working condition of a sugar refinery; the sugar refinery production whole-process automatic control system is used for implementing automatic control on the whole process of sugar refinery production according to a working condition simulation signal and the signal of a field instrument in each production workshop; the central control room is used for carrying out centralized management and monitoring on the control system data of each working section of each workshop of the sugar refinery, and realizing remote production management and dispatching conduction. The high actual operational abilities of students can be trained through the training of the practical training centre, thus laying a solid foundation for working on the sugar industry or the related work in other automation fields in the future.

Owner:广西龙河门科技有限公司

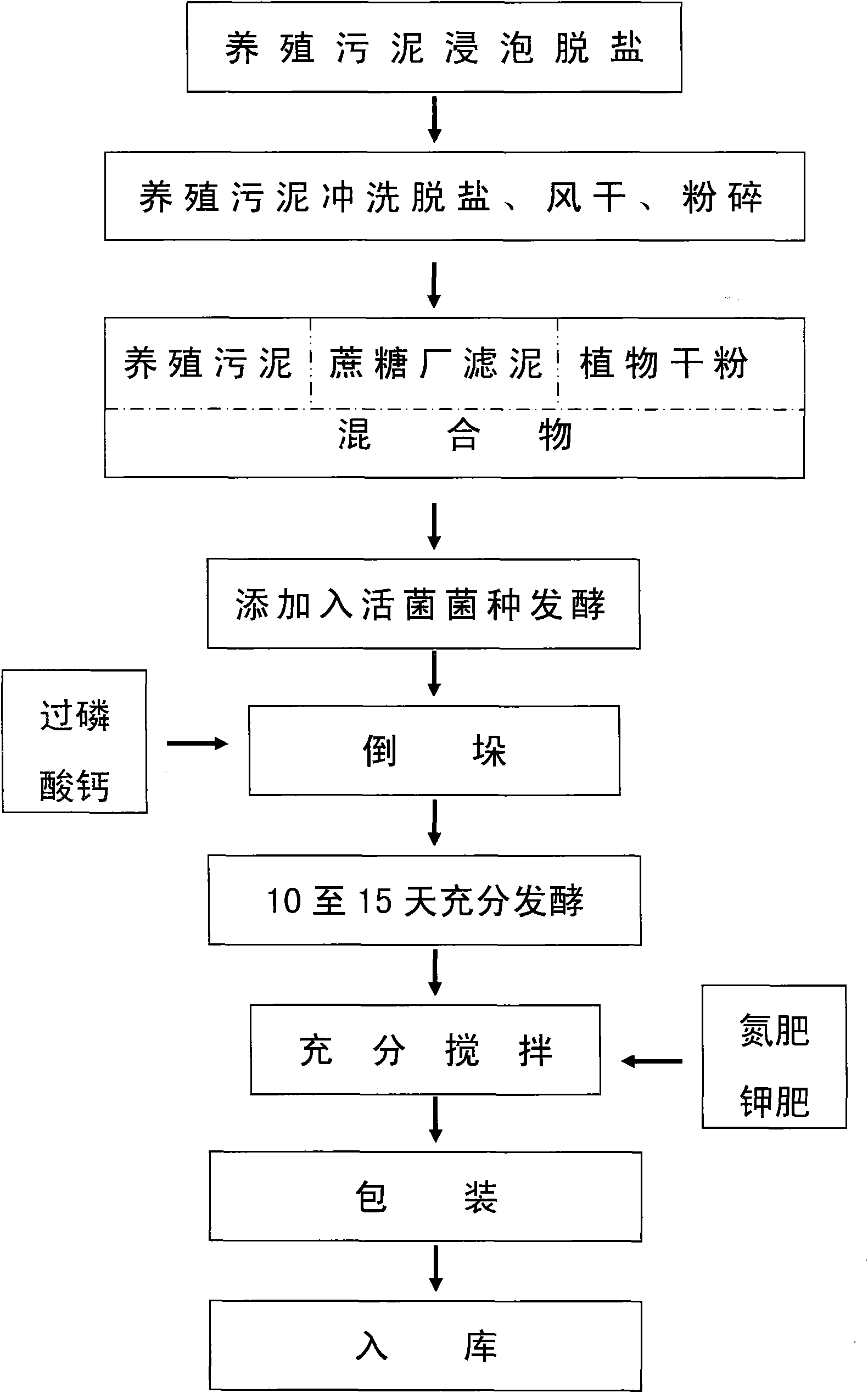

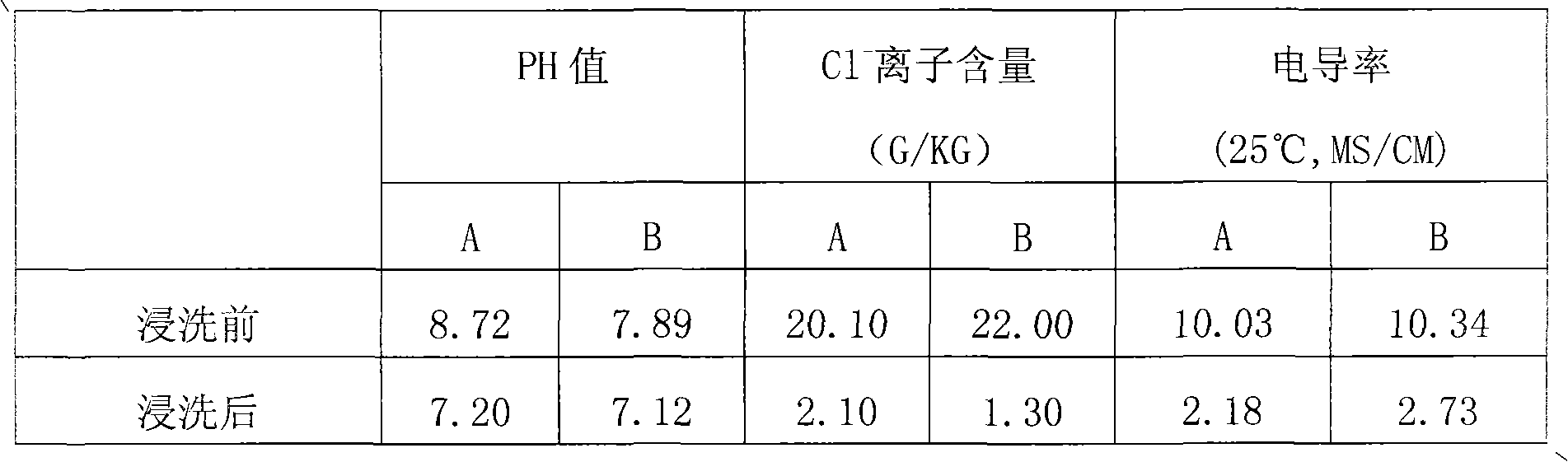

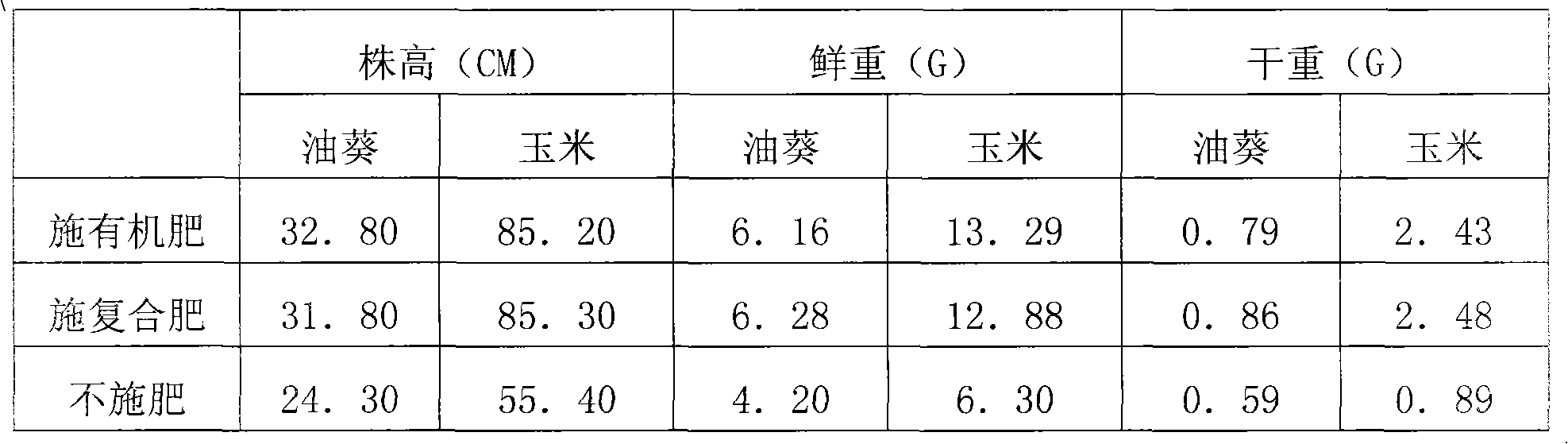

Method for producing micro organic matters by marine culture sludge and sugar refinery filtration sludge

InactiveCN101555171AHigh salt contentBio-organic fraction processingSludge treatmentHalophyteSucrose

The invention relates to a method for producing micro organic matters by marine culture sludge and sugar refinery filtration sludge, belonging to the comprehensive utilization of marine animal utilization technology and sugar refinery filtration sludge drogs and being dedicated in preparing micro organic matter fertilizer by marine culture sludge and sugar refinery filtration sludge. The method comprises the following steps: wind drying the marine culture sludge and sugar refinery pond sludge and desalting by leaching the culture sludge; mixing the leached wind-dried sludge and the sugar refinery wind-dried pond sludge with fresh plant dry power, adding viable bacteria for anaerobic fermentation with the proportion of 2kg of viable bacteria per ton and the moisture is controlled at 30-35%, fermenting for about 10 days at the temperature of 50-60 DEG C, adding 4% of sodium humate, 7% of nitrogenous fertilizer, 12% of phosphate fertilizer and 6% of potassium fertilizer into composts after fermentation to obtain the halophilous plant highly efficient organic fertilizer. The water-soil proportion of the organic fertilizer is controlled at 5:1 to be proper, and the sum nutrient of N+P+K is more than or equal to 48%. The leaching, fermenting and composting technologies of the invention have simple and convenient process, strong operation, high production efficiency and high fertilizer effect with rich nutrient.

Owner:许绪满

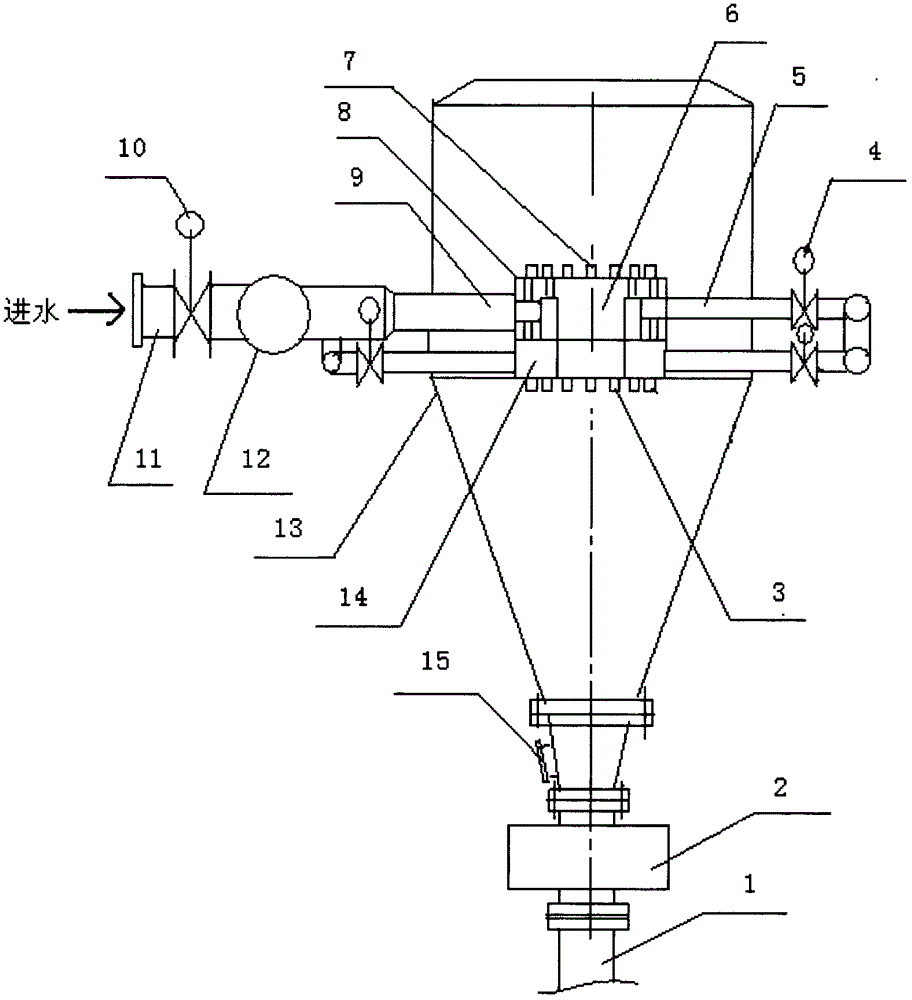

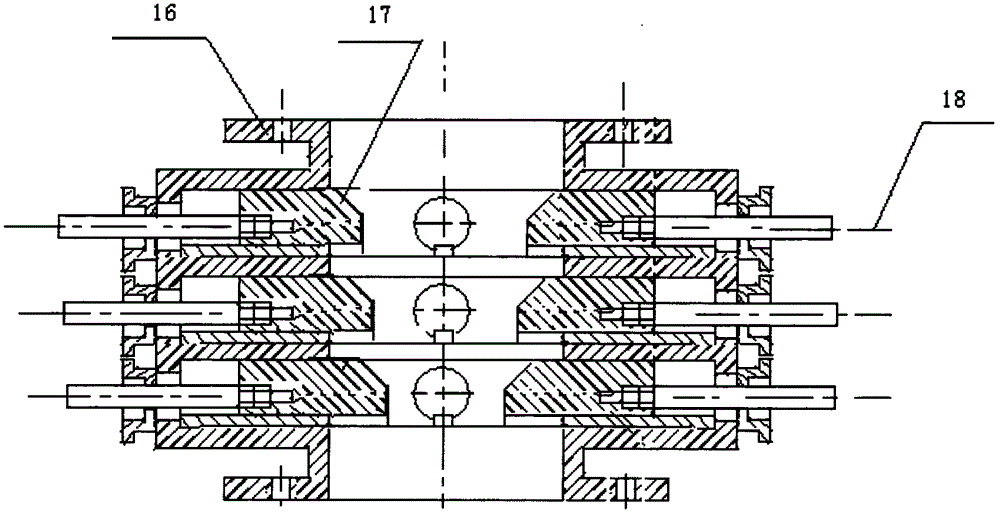

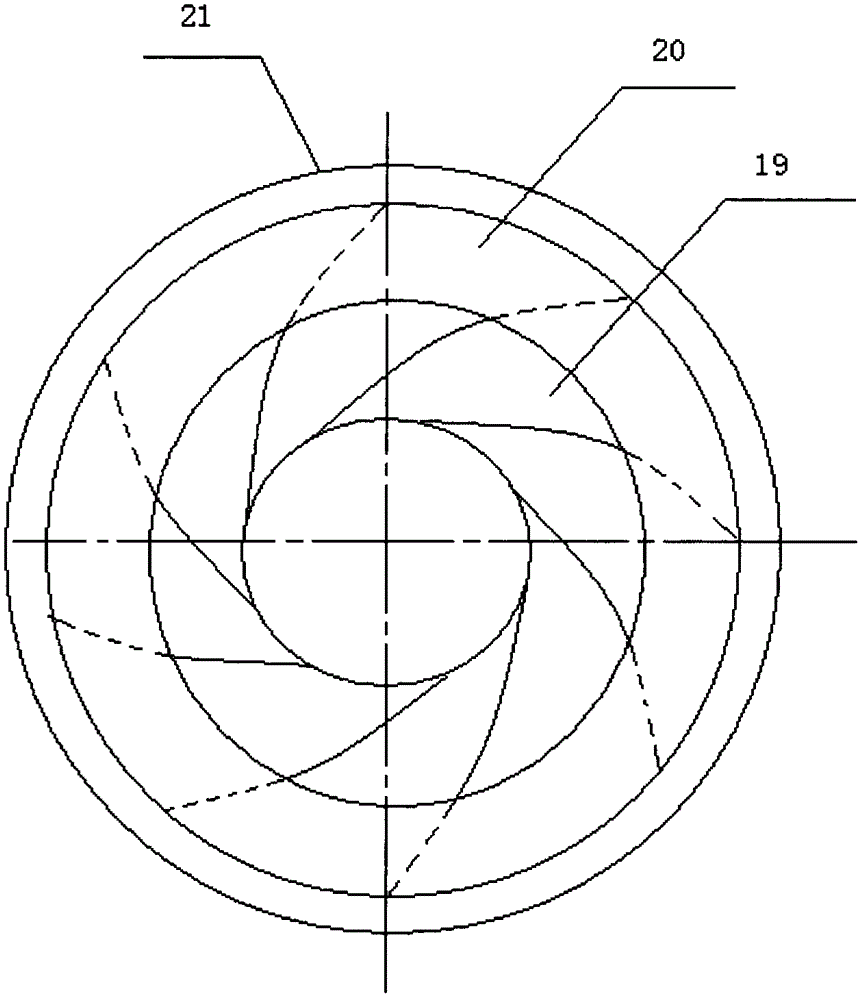

Novel water jet condenser with multiple closed water chambers and jet flow control valve

The invention discloses a novel water jet condenser with multiple closed water chambers and a jet flow control valve used in a sugar refinery. The water jet condenser is characterized in that a water chamber of the condenser is divided into an opened big water chamber and a plurality of closed small water chambers; each water chamber is respectively provided with a jet nozzle and a spray nozzle; a plurality of closed small water chambers are respectively controlled by a plurality of pneumatic or electric butterfly valves installed on the outside of the condenser; the lower part of the condenser is provided with a monolayer or multilayer jet flow control valve for making the size of the central round aperture of a jet flow passage keep a coaxial change; the jet nozzle and the spray nozzle in each water chamber are respectively cooperated with the monolayer or multilayer jet flow control valve to control the water supply amount of the condenser, so that a high vacuum degree of the condenser can be always kept in the production.

Owner:NANNING MAST SUGAR MACHINE EQUIP MFG CO LTD

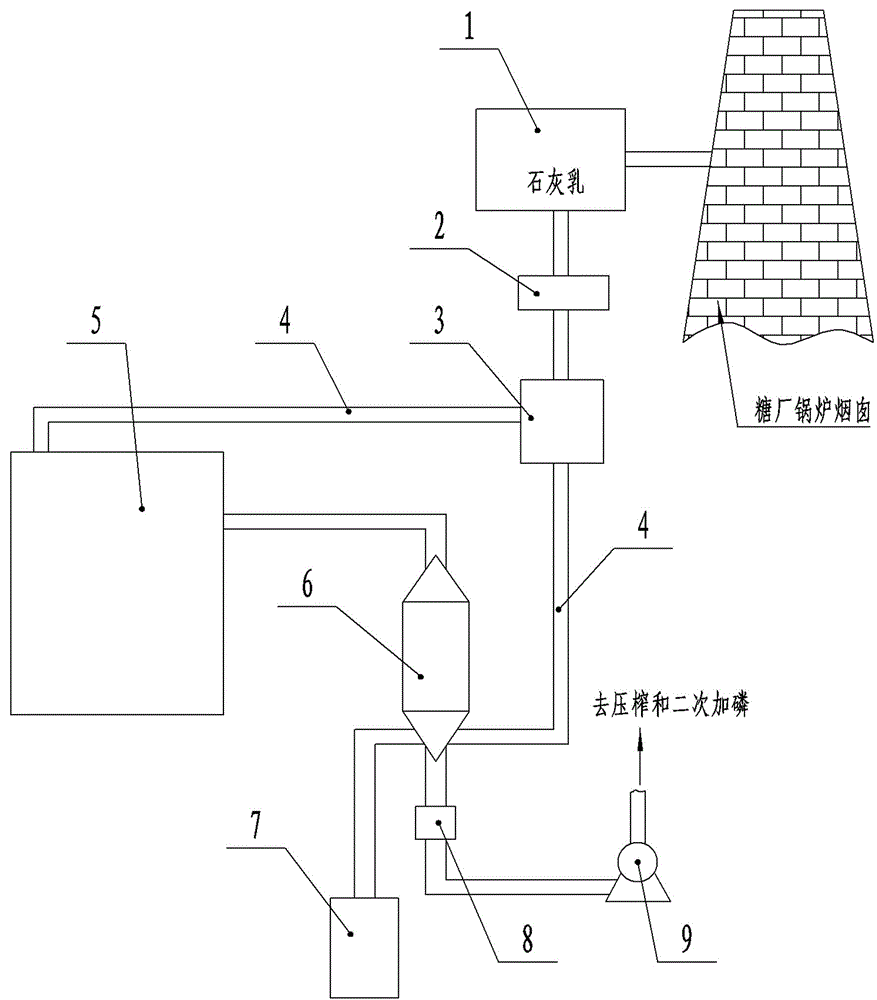

Method and equipment for recovering, activating and utilizing carbon dioxide from sugar refinery

InactiveCN104437060AIncrease profitEmission reductionPurification using alkaline earth metal compoundsDispersed particle separationCalcium bicarbonateJuice clarification

The invention discloses method and equipment for recovering, activating and utilizing carbon dioxide from a sugar refinery. The method comprises the following steps: introducing low-content carbon dioxide contained in flue gas of a boiler of the sugar refinery into a carbon dioxide adsorption tower, and reacting the carbon dioxide with lime cream inside the carbon dioxide adsorption tower to form a calcium carbonate solution; introducing a part of the calcium carbonate solution into phosphoric acid to generate calcium dihydrogen phosphate and the carbon dioxide, wherein the calcium dihydrogen phosphate is used for squeezing and secondary phosphorus addition; reacting the other part of the other part of the calcium carbonate solution with the carbon dioxide to generate calcium hydrogen carbonate, and pumping to mixed juice preliming, a floating device overflow pipe and a filtered juice quick-sinking reactor by using a calcium hydrogen carbonate pump. The method disclosed by the invention can be used for generating the calcium carbonate by reacting the low-concentration carbon dioxide contained in the flue gas of the boiler with the lime cream and preparing the calcium hydrogen carbonate and the calcium dihydrogen phosphate as clarifying agents used for the sugar refinery by utilizing the calcium carbonate and the phosphoric acid, thereby achieving the purpose of cane juice clarification by removing a part of colloid and non-sugar components in an adsorbing way, enhancing the CO2 utilization rate and reducing the discharge amount of the carbon dioxide from a chimney of the sugar refinery.

Owner:GUANGXI DAXIN COUNTY LEIPING YONGXIN SUGAR

Microbial fermentation agent for treating waste alkohol liquid and its preparing method

InactiveCN1377958ASolve the three wastes problemImprove protectionBacteriaClimate change adaptationLiquid wasteMicroorganism

The present invention relates to a microbial fermentation agent for treating waste alcohol liquid of sugar refinery and alcohol plant and it is a kind of bacillus and named WH colony. It is used to treat waste alcohol liquid and waste alcohol liquid and filtered mud is used as the second-stage culture medium, third-stage culture medium and carrier for WH colony. The fermented filtered mud is usedas material for producing organic fertilizer. The present invention has low cost and short technological process, and makes it possible to solve the problem of environment protection while increasingbenefit.

Owner:FOSHAN JINKUIZI PLANT NUTRIMENT CO LTD

Biomass nanometer gasoline liquid fuel

InactiveCN101955807AFull combustion, non-toxic and smoke-freeNo pollutionLiquid carbonaceous fuelsFertilizer plantNew energy

The invention belongs to the technical field of new energy, in particular relates to a biomass nanometer gasoline liquid fuel which comprises the following raw materials by weight percent: 20-94% of biomass alcohol, 0-50% of gasoline, and 6-35% of combustion-supporting additive. The main raw material, i.e. biomass alcohol used in the invention is leftovers or a secondary product of a chemical plant, a fertilizer plant, a winery, a pharmaceutical factory and a sugar refinery. The invention has advantages that the liquid fuel can not blow up, is relatively safe for storing and transportation, can fully burn, is non-poisonous and smokeless, does not pollute the environment, and can replace the national-standard gasline of 90#, 93#, 97# to be used for motor vehicles.

Owner:东莞市智造生物科技有限公司

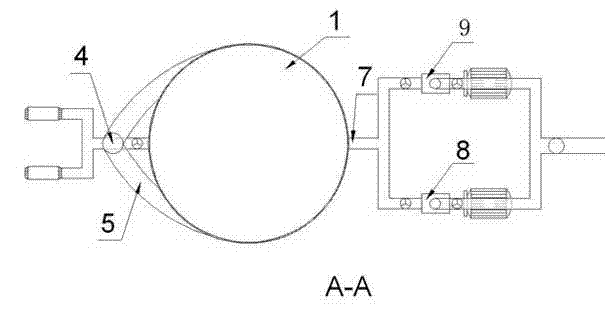

Stoving neutralizing auxiliary reaction tower

InactiveCN103173579AControl dwell timeControl unit controls dwell timePurification by oxidation/reductionPurification using alkaline earth metal compoundsChemical reactionSulfur

The invention aims to provide a stoving neutralizing auxiliary reaction tower. The stoving neutralizing auxiliary reaction tower comprises a cylindrical tank body, a stoving neutralizing reactor, a tube diffuser, a juice outlet pipe, a variable frequency juice outlet pump and a liquid level control device. By using the stoving neutralizing auxiliary reaction tower, the defects of the conventional neutralizing reaction device in a sugar refinery are overcome, and the problem of incomplete chemical reaction of the cane juice subjected to stoving liming is solved. The invention also provides a method for carrying out stoving neutralizing reaction by using the stoving neutralizing auxiliary reaction tower. According to the method, the stoving neutralizing auxiliary reaction tower is reasonably utilized, so that the standing time of the cane juice subjected to stoving liming is greatly increased, the uniformity of the cane juice is improved, the reaction of neutralized juice is more complete, and remarkable effects of improving the syrup purity, reducing the color value of white sugar and turbidity and lowering the sulfur dioxide residues are achieved.

Owner:南宁苏格尔科技有限公司

Automatic acid preparation method and device for phosphoric acid in sugar refinery

InactiveCN102553489AGuaranteed timelinessGuarantee stabilityMixer accessoriesSugar juice purificationSolenoid valvePhosphoric acid

The invention relates to an automatic acid preparation method and an automatic acid preparation device for phosphoric acid in a sugar refinery. The method comprises the following steps of: firstly, pumping concentrated phosphoric acid into a dilute phosphoric acid proportioning tank by starting a concentrated phosphoric acid pump through a control host, controlling the liquid level of the concentrated phosphoric acid in the dilute phosphoric acid proportioning tank, adding proportioning water, utilizing the control host to open an acid discharge solenoid valve so as to discharge proportioned dilute phosphoric acid into a dilute phosphoric acid storage tank for production standby, adopting a liquid indicator for the dilute phosphoric acid storage tank for continuously measuring the liquid level in the dilute phosphoric acid storage tank in real time, and utilizing the control host to accurately control the amount of phosphoric acid added to sugarcane juice according to the flow of the sugarcane juice, the dilution value of the phosphoric acid and the phosphoric acid added to the sugarcane juice, thereby solving the problem of inaccuracy resulted from artificial phosphoric acid proportioning of sugar refinery in the prior art, realizing the automatic phosphoric acid proportioning of the sugar refinery, ensuring the accuracy, timeliness and stability of adding of the phosphoric acid, and improving the efficiency of enterprises.

Owner:钦州华成自控设备有限公司

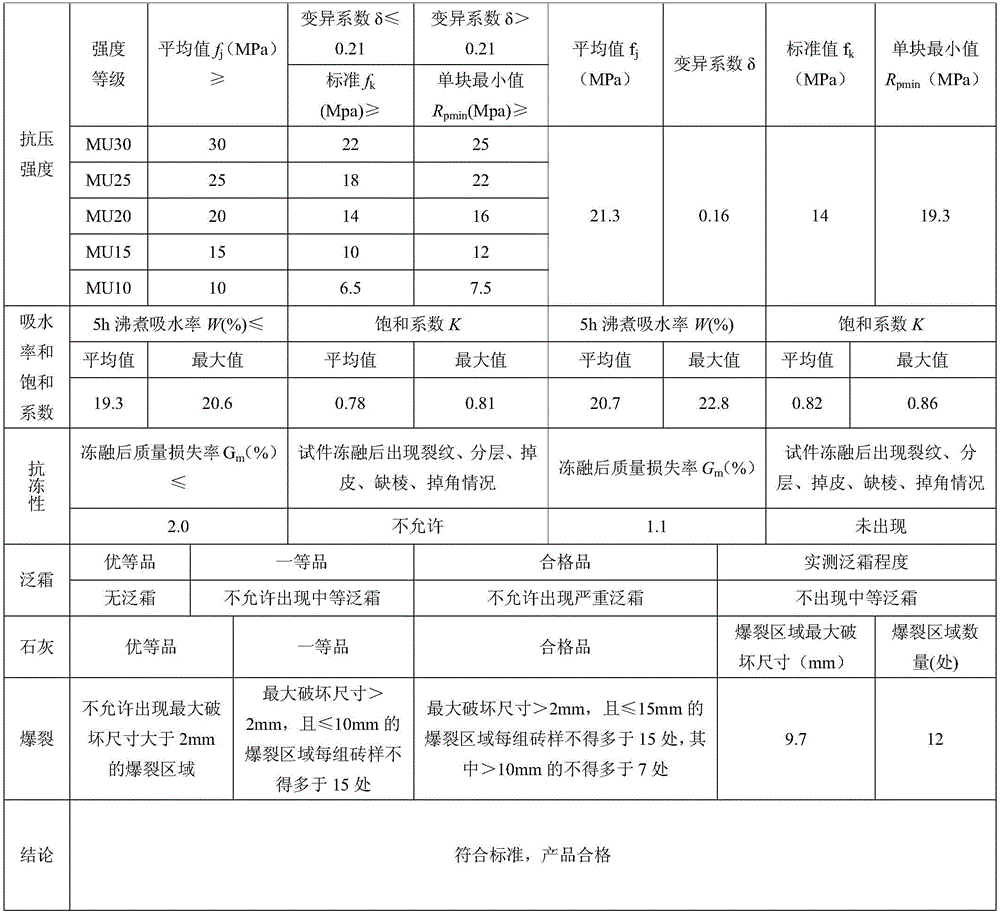

Electrolytic manganese residue fired perforated brick and preparation method thereof

InactiveCN105924223AAvoid damageAvoid harmfulCeramic materials productionCeramicwareBrickElectrolysis

The invention relates to the technical field of fired perforated brick preparation and concretely relates to an electrolytic manganese residue fired perforated brick and a preparation method thereof. The electrolytic manganese residue fired perforated brick is prepared from 45-65 parts by weight of modified electrolytic manganese residues, 15-25 parts by weight of clay, 10-15 parts by weight of fly ash, 15-25 parts by weight of coal, 10-20 parts by weight of sugar refinery residues, 15-25 parts by weight of black talc, 3-8 parts by weight of polyvinyl alcohol, 3-8 parts by weight of sodium carboxymethylcellulose, 2-5 parts by weight of crosslinked polyacrylic acid resin and a proper amount of water. The invention provides a preparation method of the electrolytic manganese residue fired perforated brick. The brick solves the problem of environmental pollution-caused by electrolytic manganese residue accumulation. The perforated brick has the characteristics of high finished product qualification rate, good air permeability and low water absorbency.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

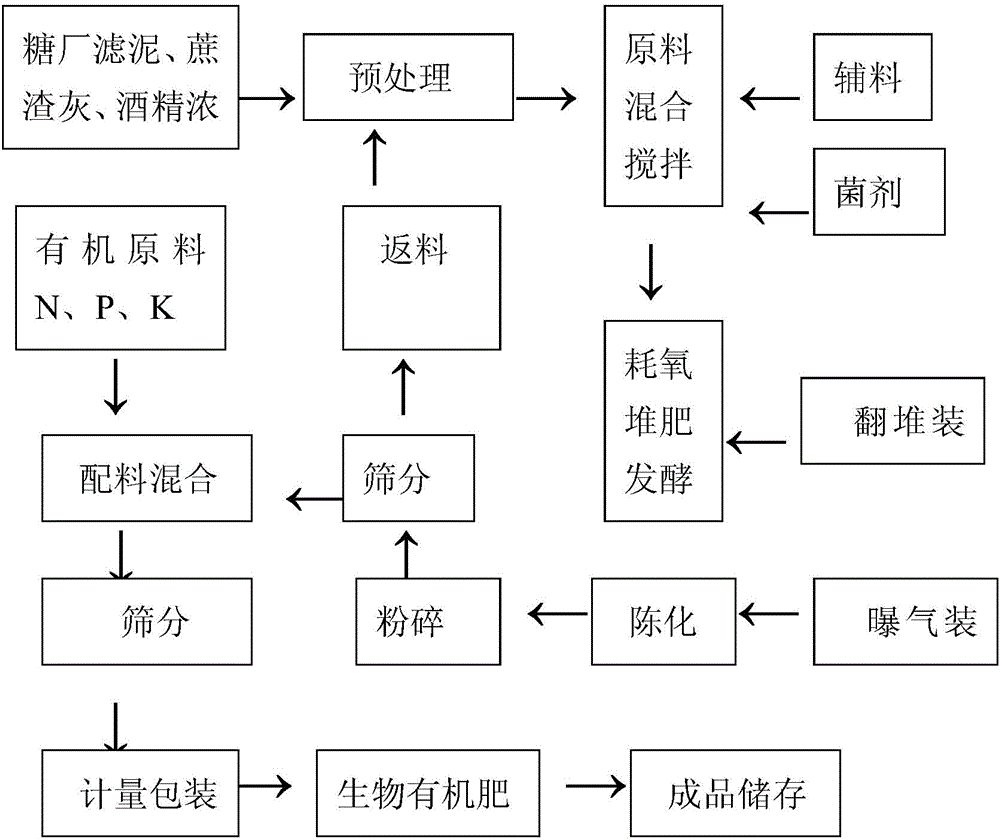

Bio-organic fertilizer and production method thereof

ActiveCN104045385AAccelerate the lossEasy to sieveBio-organic fraction processingOrganic fertiliser preparationFiltrationMoisture

The invention discloses bio-organic fertilizer. Through fermentation, the bio-organic fertilizer is prepared from 6-26wt% of filter mud produced by a sugar refinery, 55-75wt% of bagasse ash and 10-30wt% of ethanol concentrate. The production method comprises the following steps of 1, carrying out mixing stacking on filter mud produced by a sugar refinery, bagasse ash and ethanol concentrate, 2, removing moisture by filtration, 3, stacking the raw material mixture in a strip-shaped stack way, adding bifidobacterium, lactic acid bacteria, bacillus, saccharomycetes, actinomycetes and acetic bacteria into the stacked mixture, and carrying out fermentation, 4, keeping the primary fermented stack temperature above 60 DEG C and keeping material moisture content in a range of 40-45%, 5, increasing the height of the primary fermented stack, and carrying out secondary fermentation for aging until material moisture content is in a range of 30-35%, 6, adding the aged material into organic raw materials of N, P and K and carrying out mixing and 7, packaging the mixture to obtain the product. The bio-organic fertilizer has good fertilizer efficiency and is conducive to absorption by crops. The production method utilizes simple production equipment, has simple production processes and can be operated easily. The production method reduces a cost and has high income.

Owner:广西凭祥桂商现代农业投资有限公司

Biological fertilizer with camellia oleifera shells as raw materials and preparation method of biological fertilizer

InactiveCN109796289AHigh lignin contentHigh hardnessBio-organic fraction processingOrganic fertiliser preparationAnti stressCamellia oleifera

The invention discloses a biological fertilizer with camellia oleifera shells as raw materials and a preparation method of the biological fertilizer. The biological fertilizer comprises 60-70% of thecamellia oleifera shells, 15-25% of filter mud of a sugar refinery, 5-10% of tea seed cakes and 3-5% of peanut residues. The raw materials are evenly mixed, then fermentation microfloras are added forfermentation, then the mixture is subjected secondary fermentation by using acid producing floras and nitrogen-fixing bacteria, and the biological fertilizer can be obtained. According to the biological fertilizer, the camellia oleifera shells serve as the raw materials, the characteristics that the camellia oleifera shells are high in lignin content and high in hardness are utilized, the soil porosity is increased, soil is loosened, and soil hardening is effectively avoided; different strains are added and subjected to secondary fermentation to obtain the biological fertilizer. The biological fertilizer is rich in nutrient and good in fertilizer efficiency, and has certain disease resistance and anti-stress capability; the PH value is reduced, and the biological fertilizer is suitable for geographical conditions of plantation of camellia oleifera in the mountain area in Guangxi; cyclic utilization of resources is realized by recovering the camellia oleifera shells, application of compound fertilizers is reduced, the planting cost is reduced, and the industrial chain of camellia oleifera is expanded.

Owner:GUANGXI FORESTRY RES INST

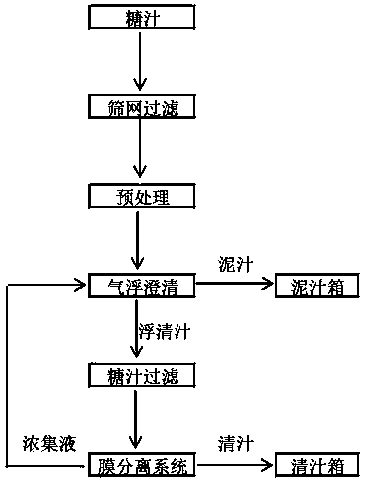

Syrup clarification method

The invention relates to a syrup clarification method, belonging to the technical field of syrup clarification of the sugar industry. The syrup clarification method is used for clarifying the syrup by use of a syrup air flotation clarification and membrane separation coupling technology and comprises major processes of treating in a syrup air flotation clarification pretreatment system, a syrup air flotation clarification system and a syrup membrane separation system, and specifically comprises the following steps: performing air flotation clarification pretreatment on the syrup first, namely filtering the syrup with a filter screen, adding lime and phosphoric acid to adjust the pH value, and performing primary heating treatment; after the treatment, treating the syrup in the air flotation clarification system, and removing the non-sugar components of the network in the syrup; treating the syrup obtained by the air flotation clarification with a syrup filtering system; and clarifying in the efficient syrup membrane separation system to obtain clear syrup of which the clarification quality is not lower than that of the traditional sugar production technology to finish the syrup clarification process. The process provided by the invention mainly adopts the air flotation clarification and membrane separation coupling technology; the method is simple and advanced, the retention time of the syrup is short, the sucrose loss is little, the clarification is stable and controllable, the clarification efficiency is high, and the method is an effective measure of a sugar refinery for realizing energy-saving and clean production and implementing sustainable development and has a relatively good application prospect.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for producing wormcast culture medium through sugar refinery waste

InactiveCN106431566AImprove absorption rateIncrease profitBio-organic fraction processingExcrement fertilisersResource utilizationSugar refinery

The invention discloses a manufacturing method for producing a wormcast culture medium through sugar refinery waste. The method comprises the steps that after broken bagasse and sugarcane filter mud are fermented and composted, 10-100 kg of waste molasses is added into per cubic meter of materials, 0.5-0.9 mg / L of sodium selenite is added, larger than 2.0*10<7> cfu / g of bacillus subtilis is added, uniform stirring is performed, the water content is adjusted to be 40-75%, then, earthworm seeds are inoculated, and earthworms and wormcast are separated after reproduction is performed for a period of time. According to the prepared culture medium, the element absorptivity, the utilization rate and the safety of crops are greatly improved, the culture medium is environmentally friendly, the emergence rate and the survival rate are higher than those of a common culture medium, and the method is suitable for most crops, even flowers with the strict requirement for the culture medium. The method is easy to implement, high in resource utilization rate and relatively low in environment pollution.

Owner:绿凰(茂名)酶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com