Patents

Literature

48results about How to "Solve the three wastes problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

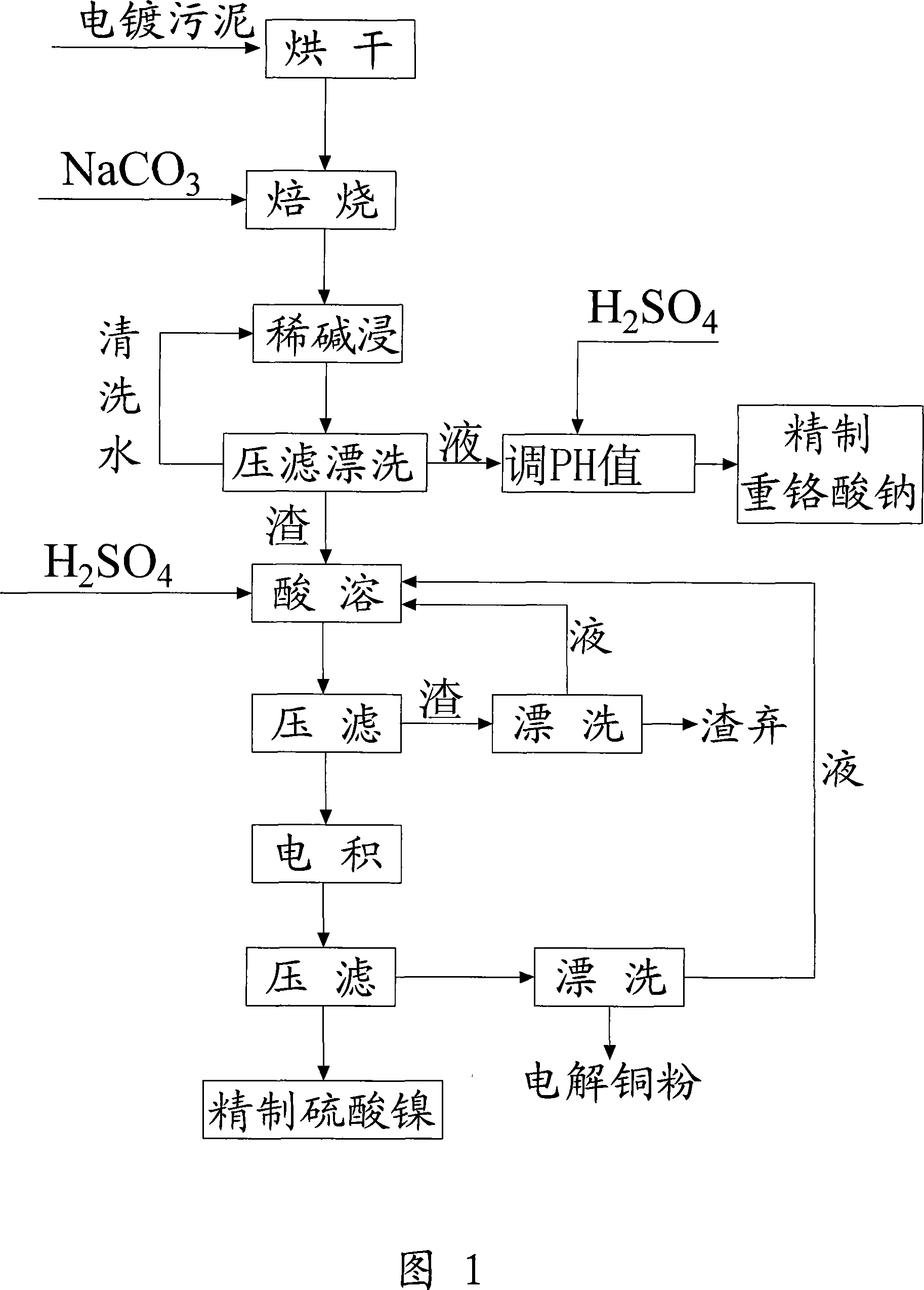

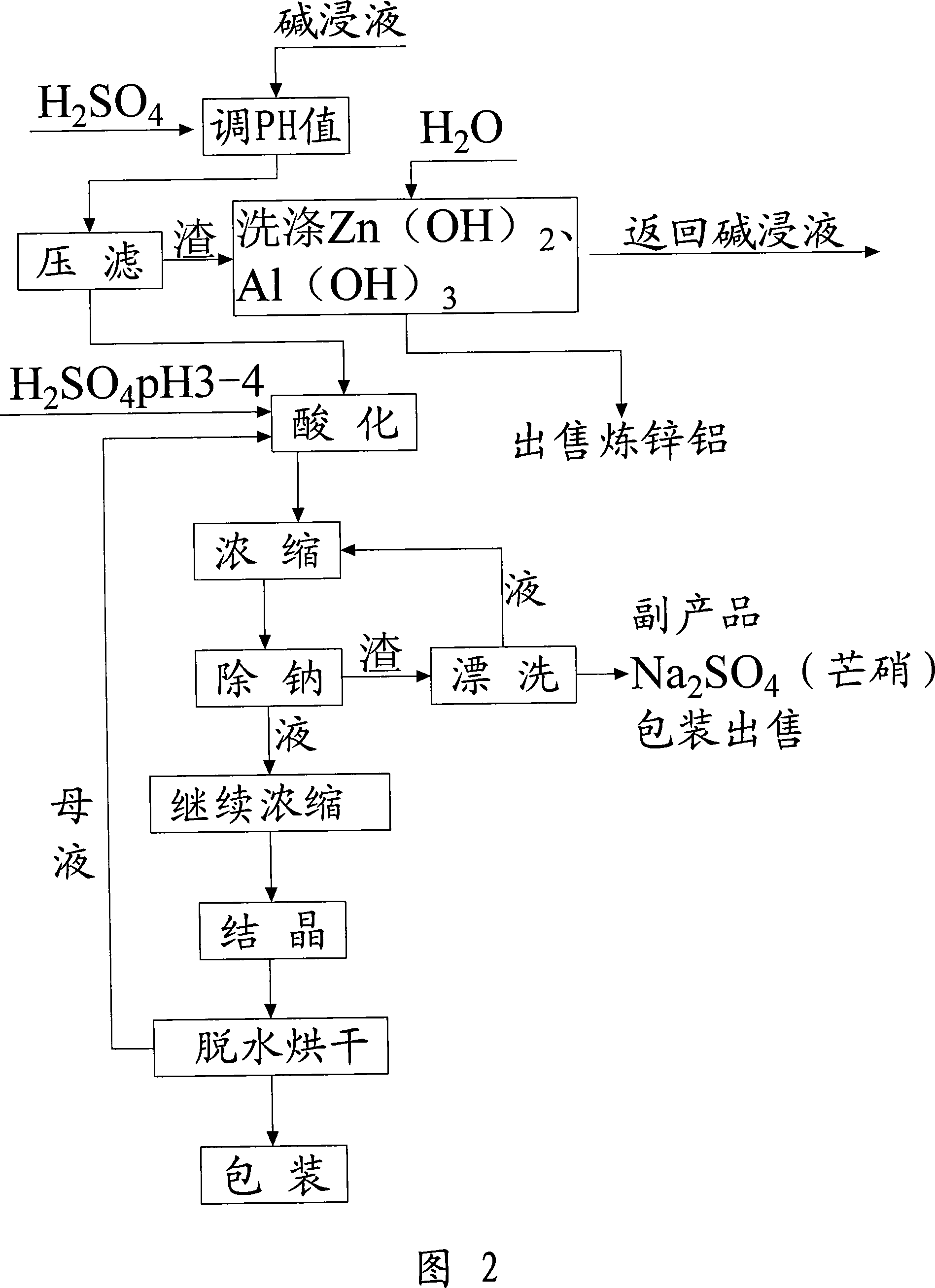

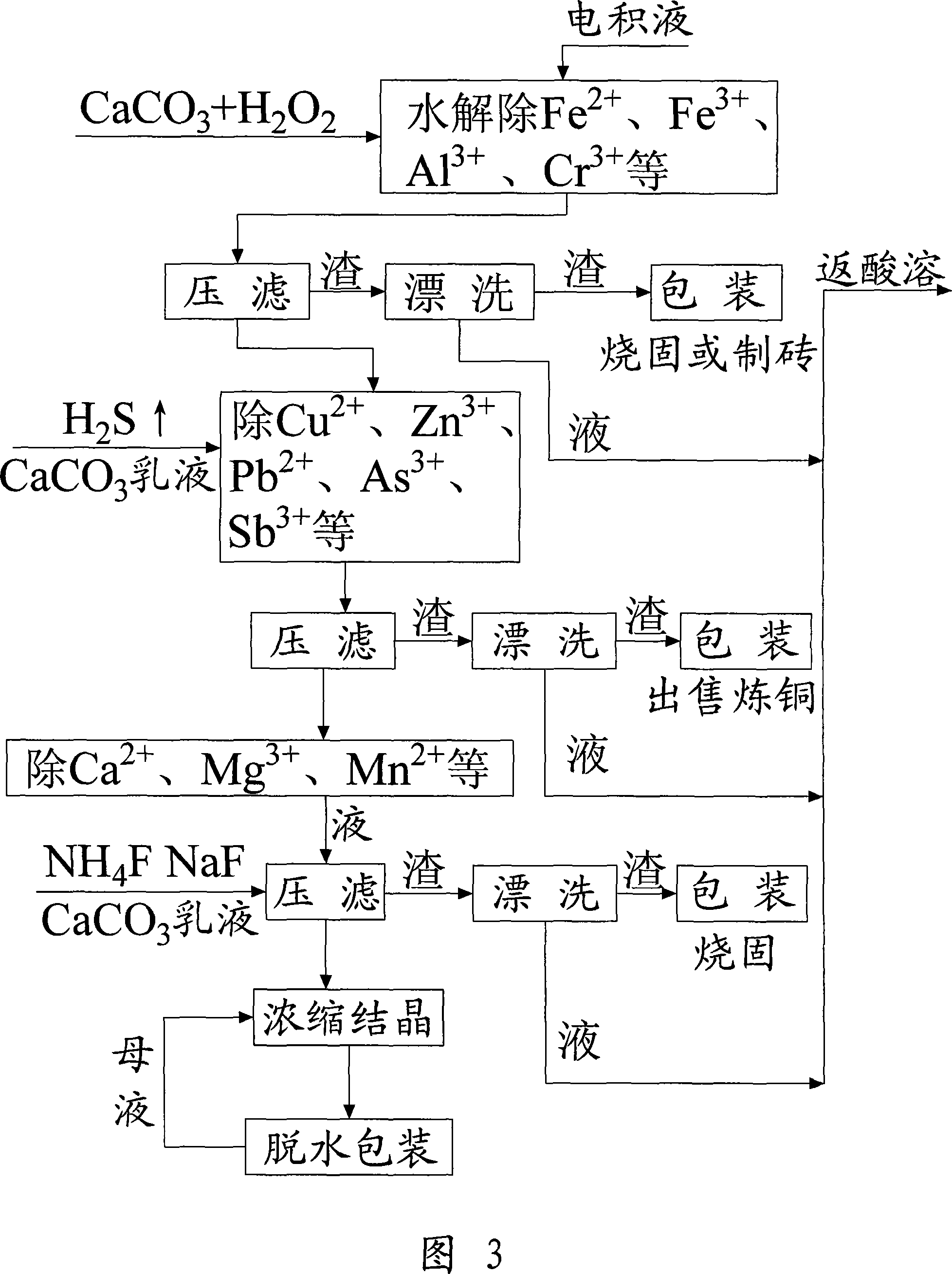

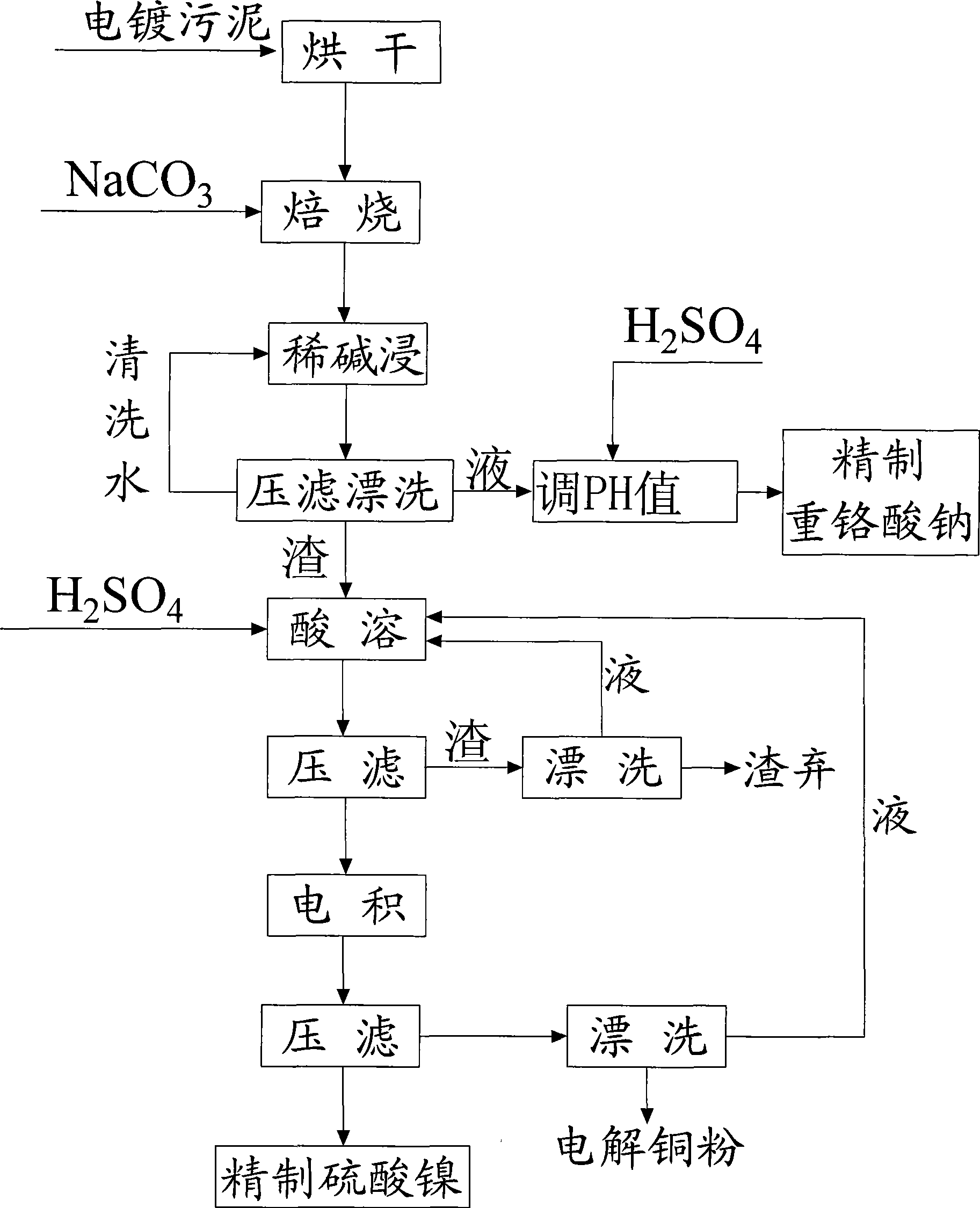

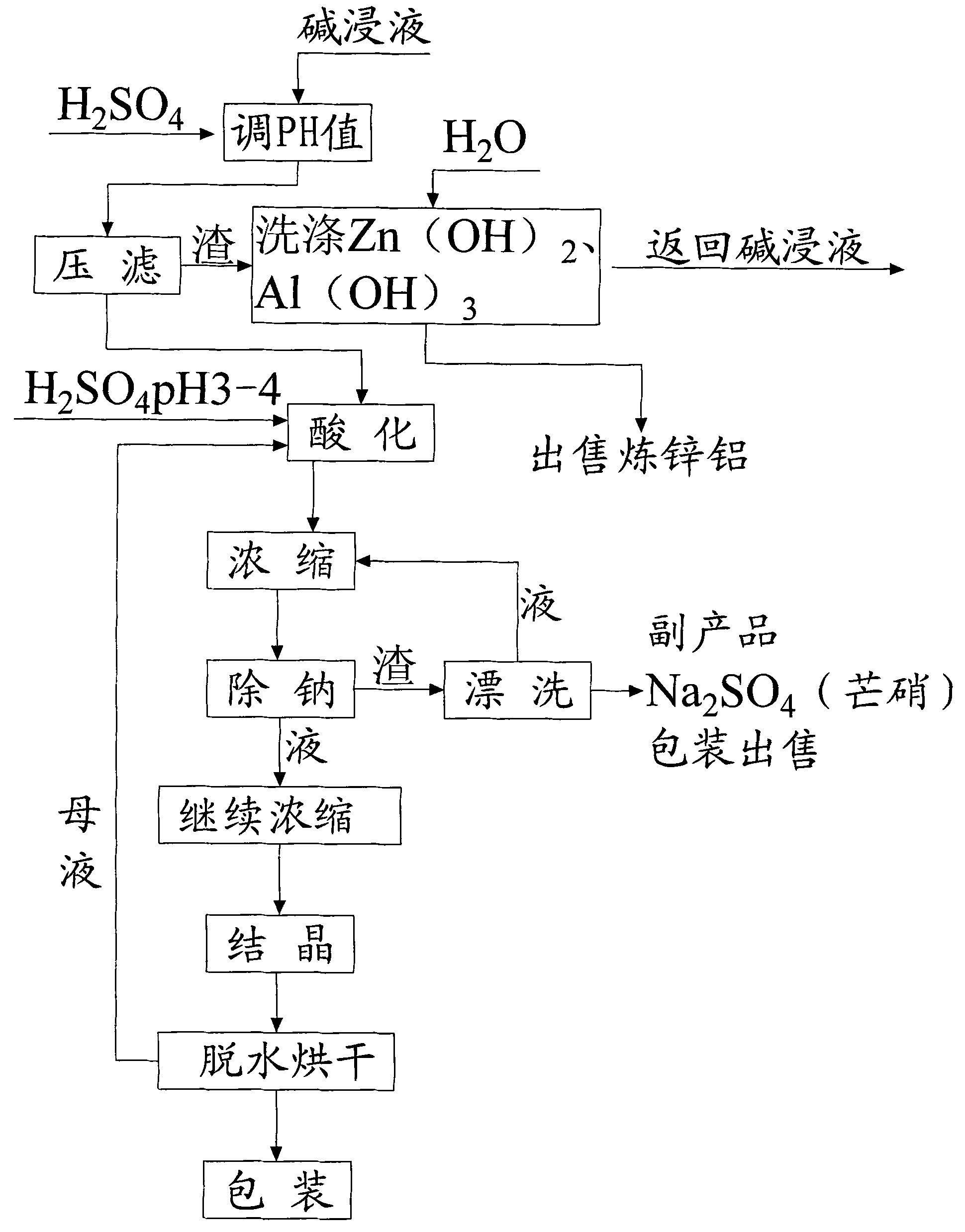

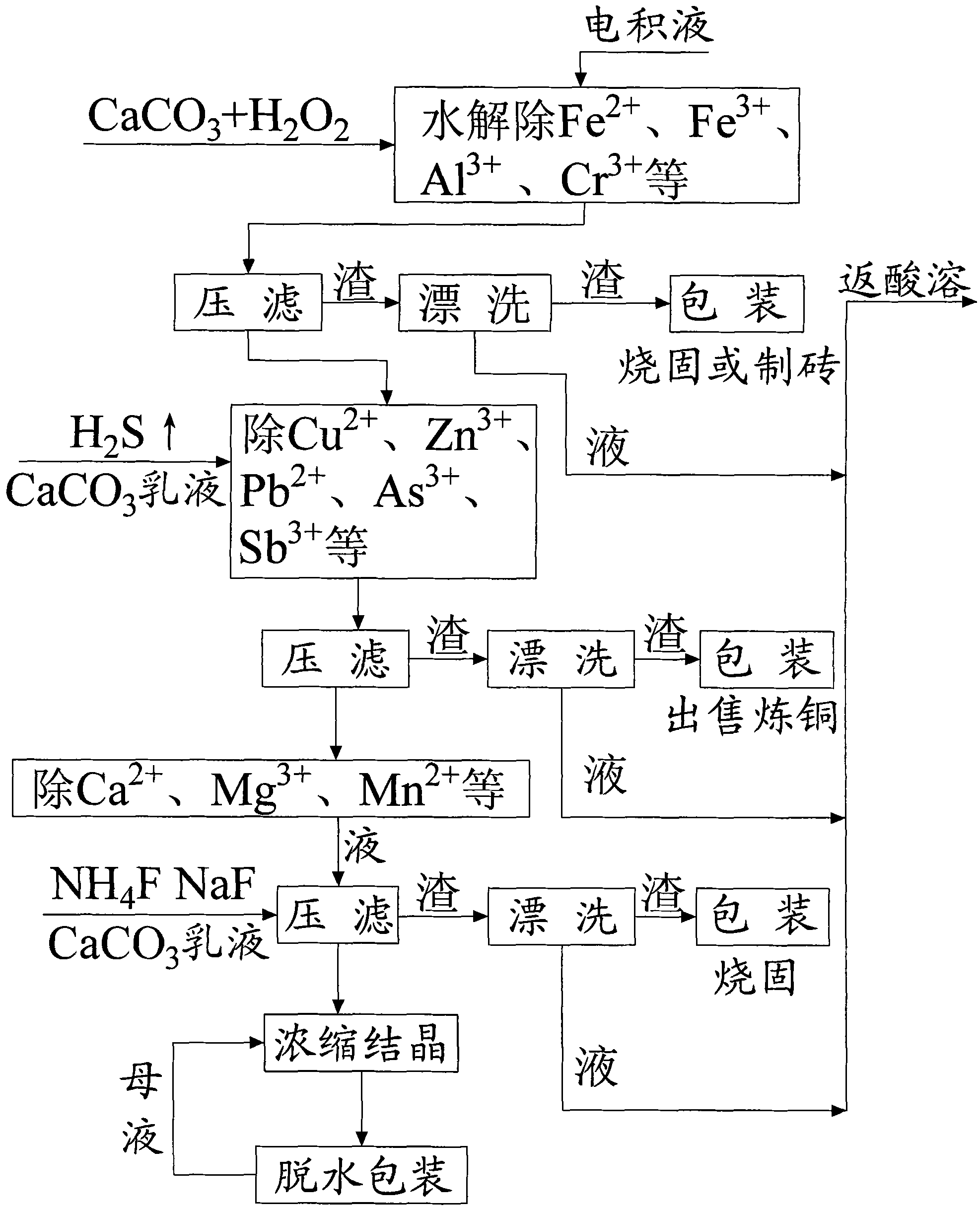

Electroplating sludge treating and utilizing process

InactiveCN101066827ASimple and easy to purifyEasy easy yieldSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processNickel saltSlag

The electroplating sludge treating and utilizing process includes the following steps: 1. adding alkali to stoved electroplating sludge, roasting, leaching out soluble metal in dilute alkali solution, and filtering to obtain alkali leached slag and alkali leached liquid; 2. adding acid to the alkali leached liquid, filtering to obtain hydrolyzed slag and hydrolyzed liquid, and preparing bichromate with the hydrolyzed liquid; and 3. dissolving the alkali leached slag in acid solution, filtering, electrodepositing the filtrate and filtering to obtain electrodeposited solution, depurating the electrodeposited solution and crystallizing to obtain nickel salt. The process has low power consumption and low cost, and can convert most of Cr, Cu and Ni in electroplating sludge into bichromate, nickel salt, copper powder and other side product.

Owner:台州盛世环境工程有限公司

Microbial fermentation agent for treating waste alkohol liquid and its preparing method

InactiveCN1377958ASolve the three wastes problemImprove protectionBacteriaClimate change adaptationLiquid wasteMicroorganism

The present invention relates to a microbial fermentation agent for treating waste alcohol liquid of sugar refinery and alcohol plant and it is a kind of bacillus and named WH colony. It is used to treat waste alcohol liquid and waste alcohol liquid and filtered mud is used as the second-stage culture medium, third-stage culture medium and carrier for WH colony. The fermented filtered mud is usedas material for producing organic fertilizer. The present invention has low cost and short technological process, and makes it possible to solve the problem of environment protection while increasingbenefit.

Owner:FOSHAN JINKUIZI PLANT NUTRIMENT CO LTD

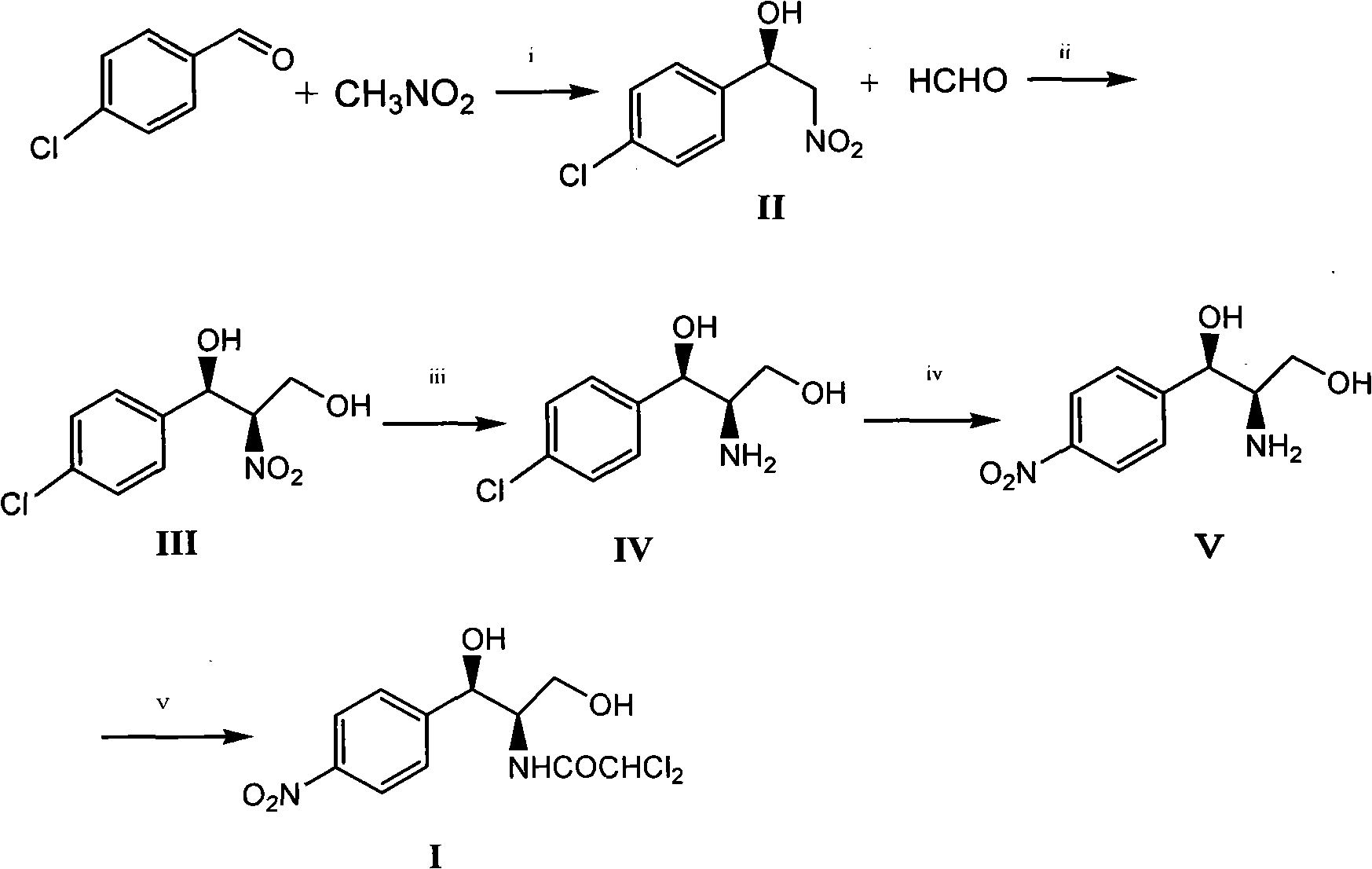

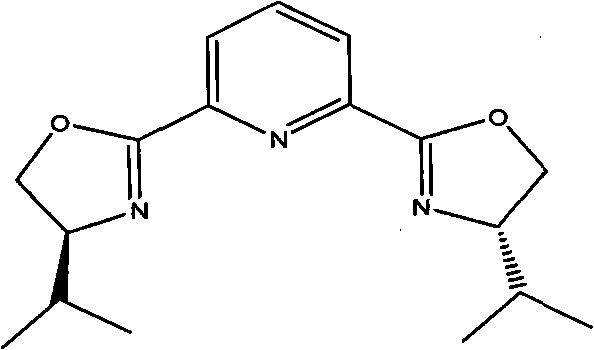

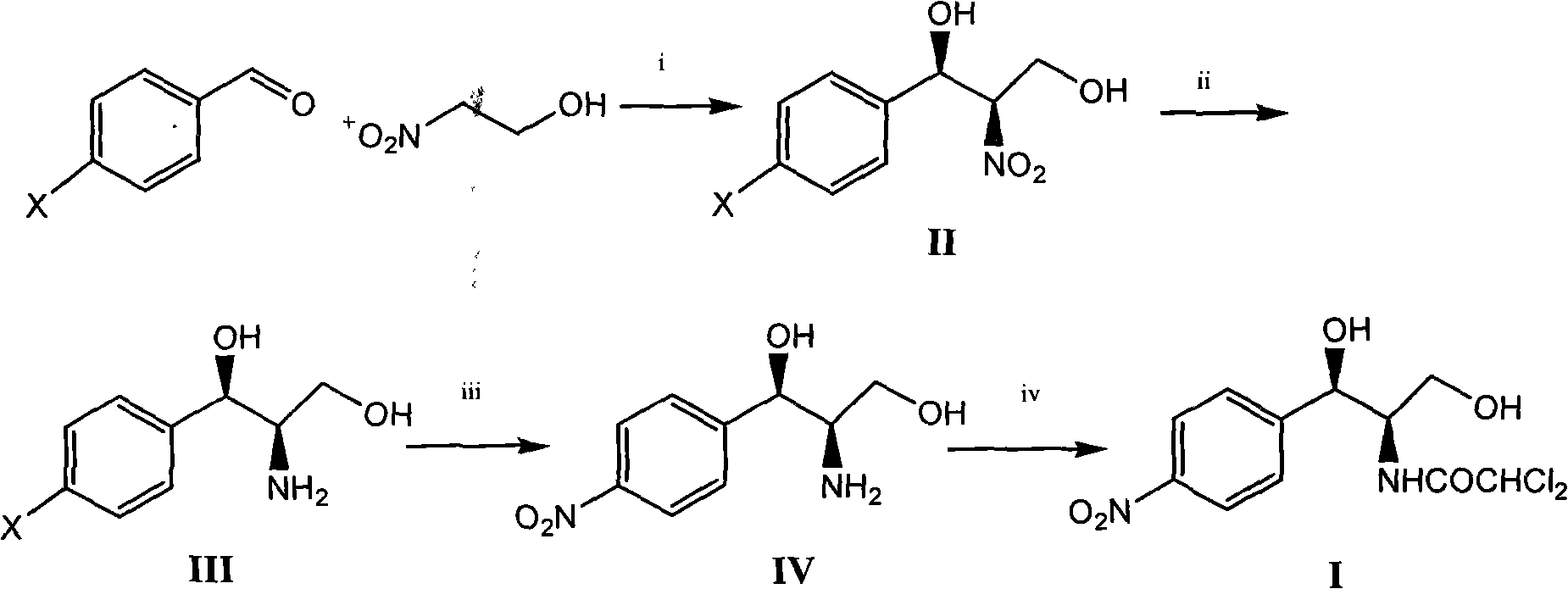

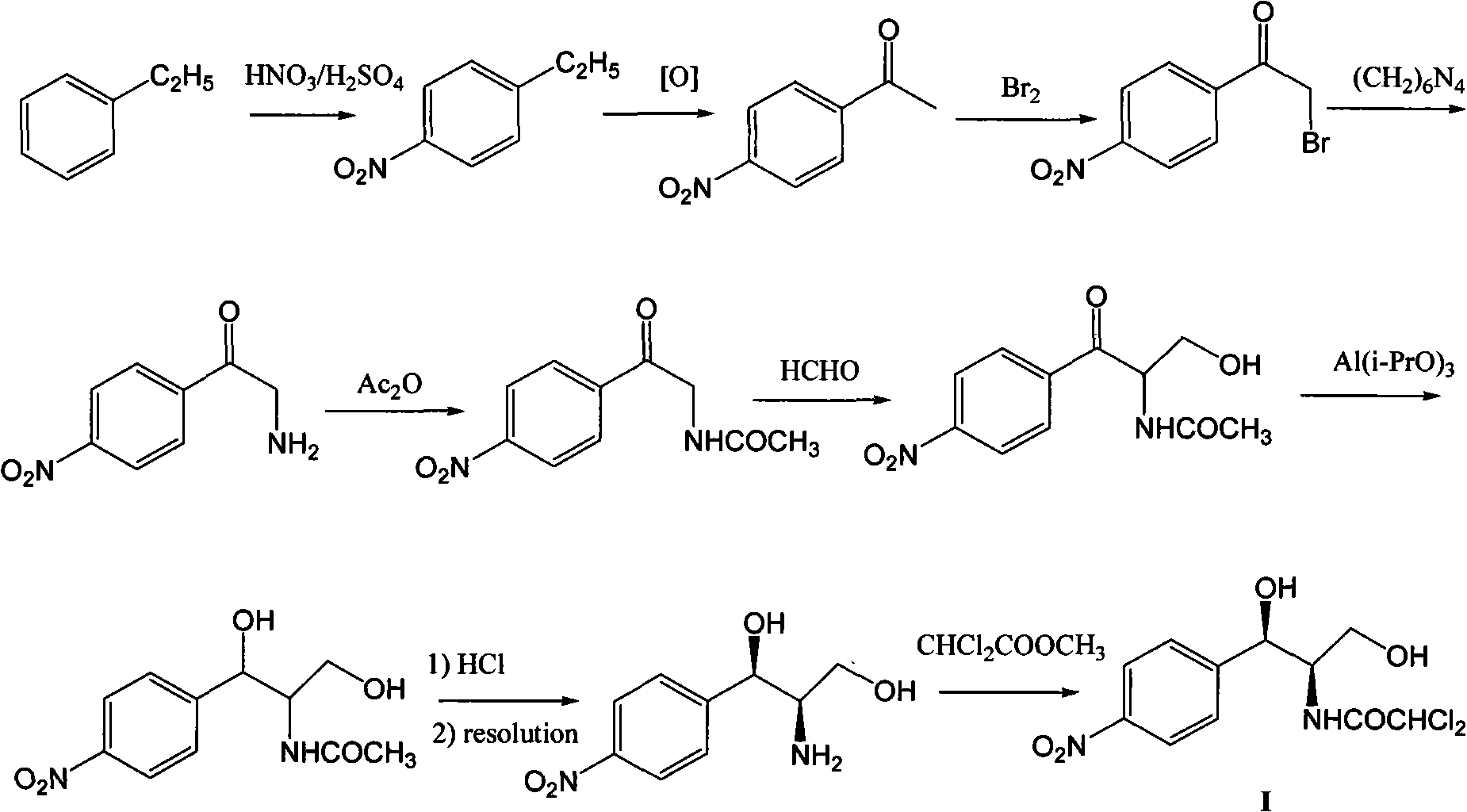

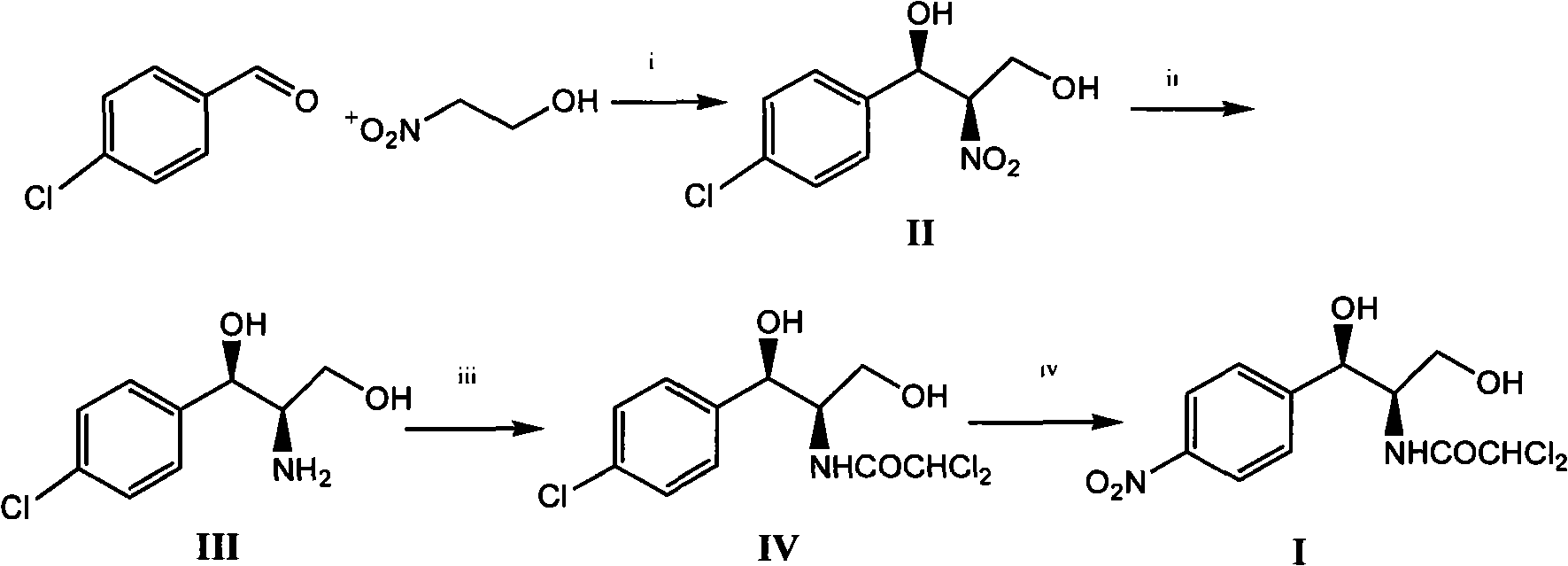

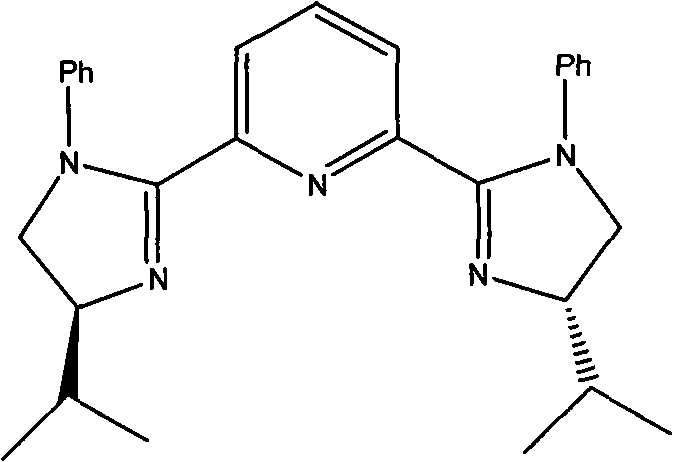

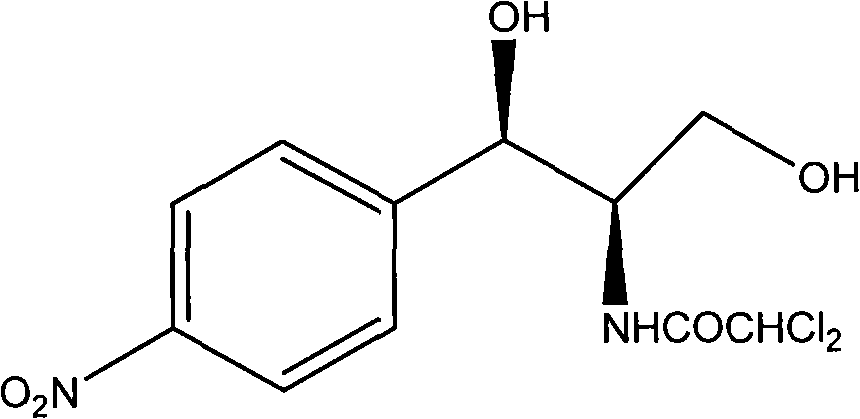

Method for synthesizing chloramphenicol from nitromethane

ActiveCN102399164ARaw materials are cheap and easy to getAvoid splittingOrganic compound preparationCarboxylic acid amides preparationP-chlorobenzaldehydeNitromethane

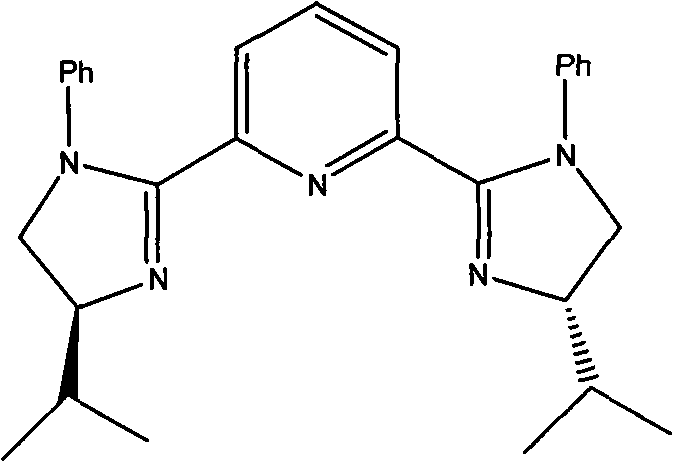

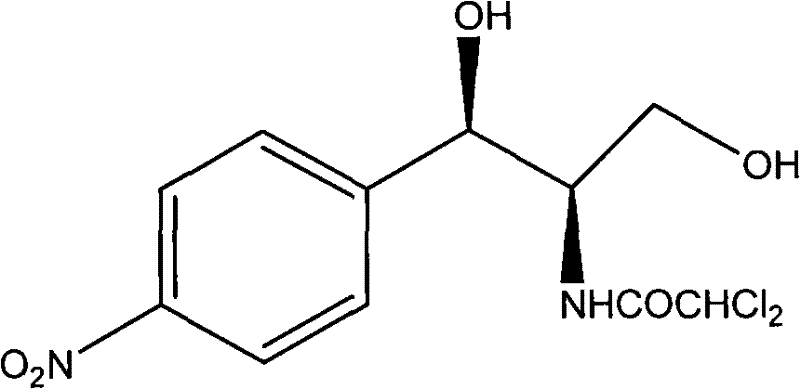

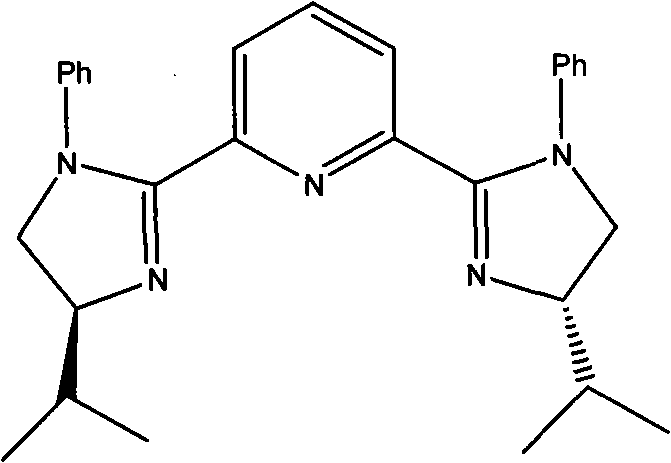

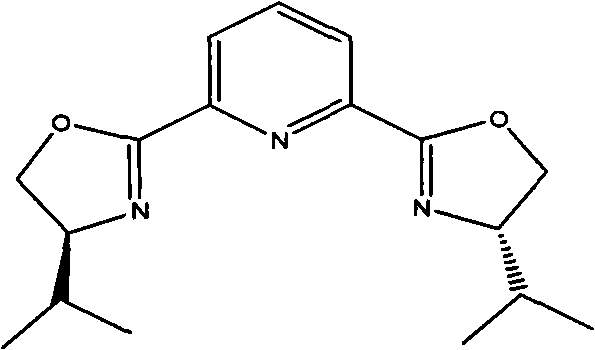

The invention relates to a method for synthesizing a broad spectrum antibiotic of chloramphenicol. The method comprises the following steps of: synthesizing (R)-2-nitro-1-(4-chlorophenyl)ethanol by using p-chlorobenzaldehyde and nitromethane as raw materials in the presence of a chiral catalyst; reacting with formaldehyde to obtain (1R,2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol, and performing catalytic hydrogenation to obtain (1R,2R)-2-amino-1-(4-chlorophenyl)-1,3-propanediol; and performing nitro substitution and dichloro acetylization on the intermediate to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, the raw materials and reagents are cheap and readily available, the method comprises a few synthesizing steps, the yield is high, and the method is more suitable for industrial production.

Owner:WUHAN WUYAO SCI & TECH

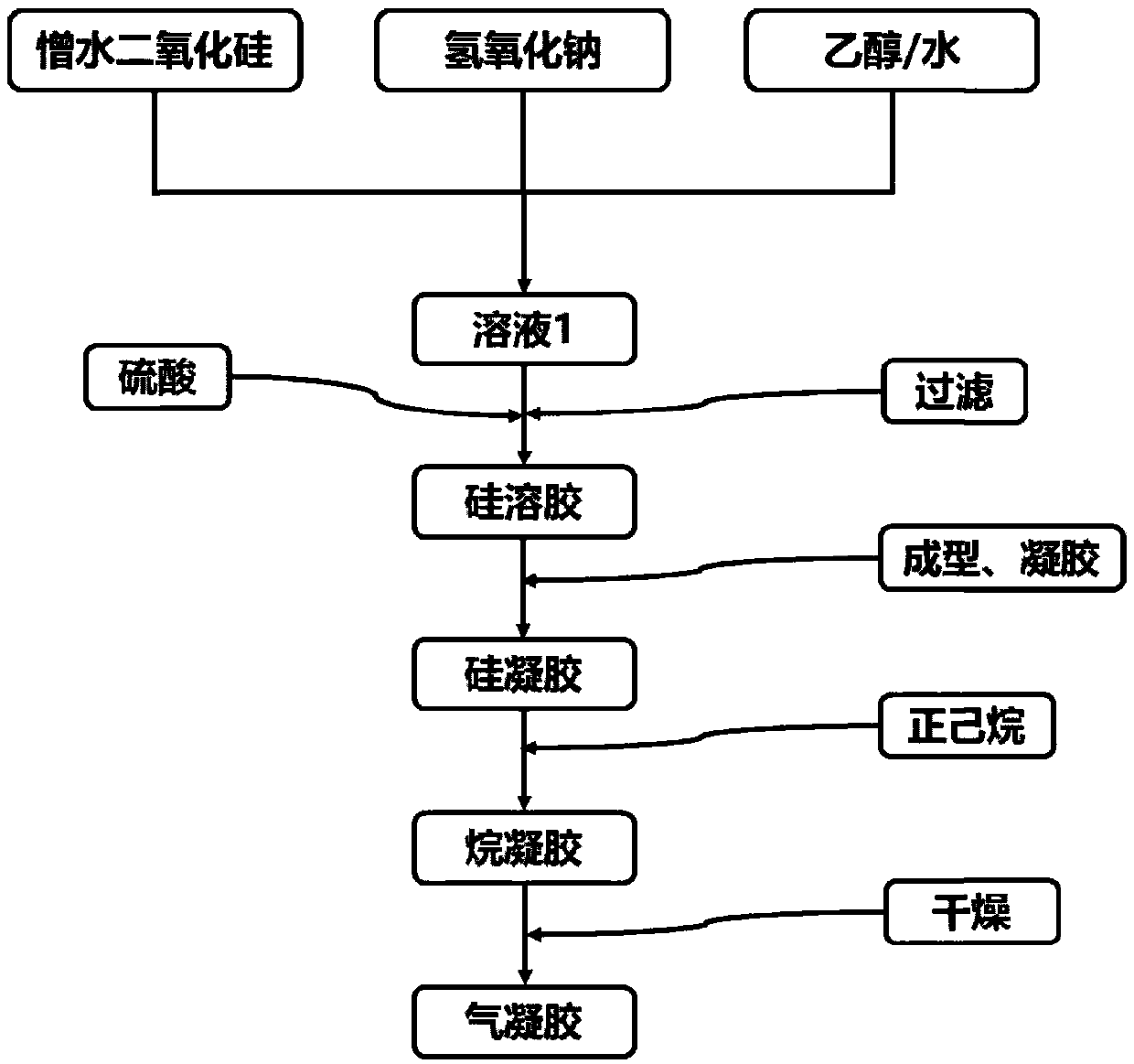

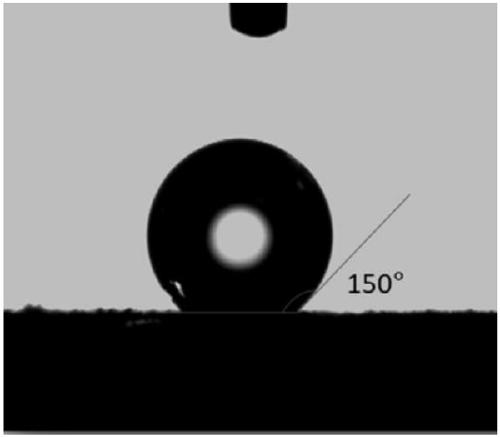

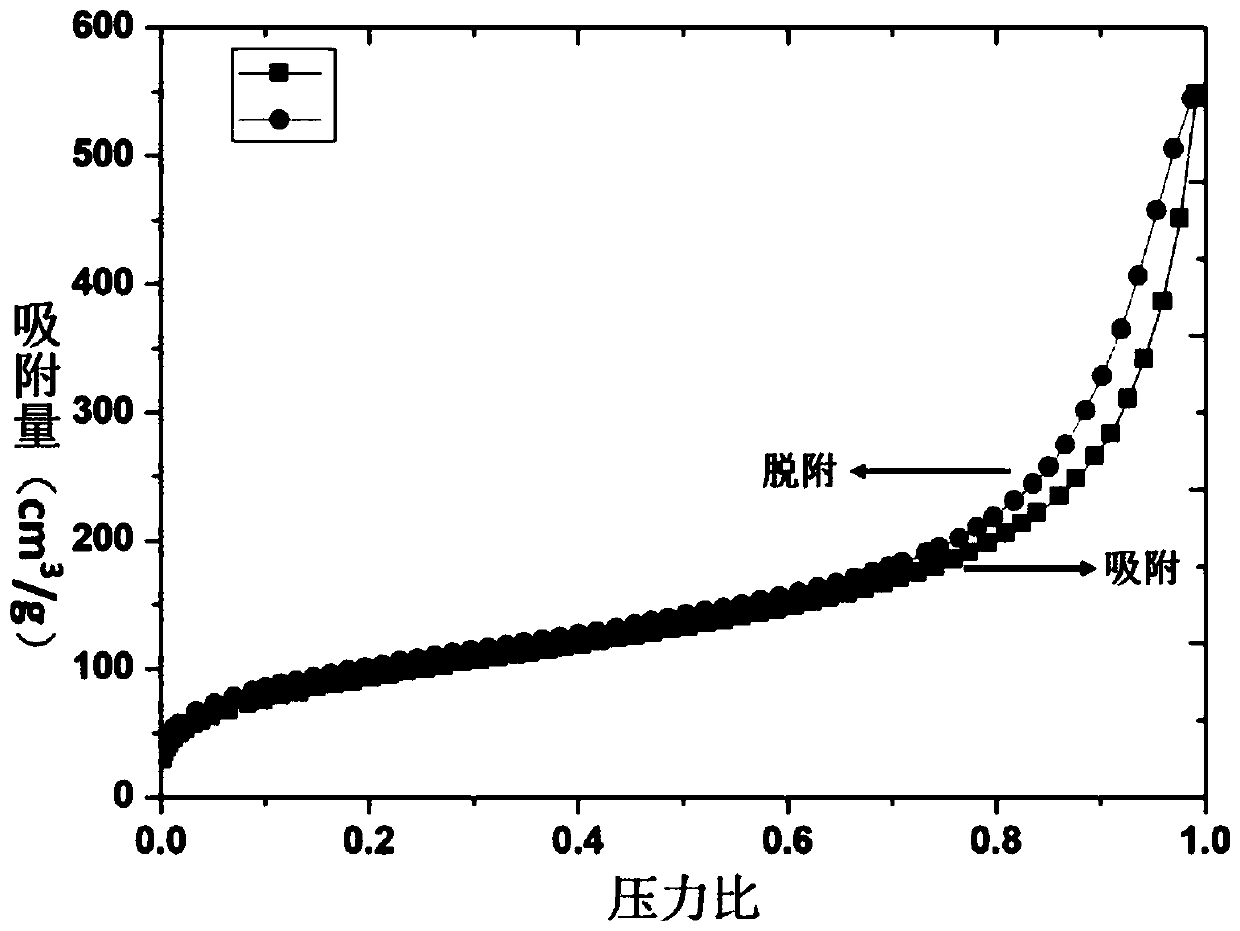

Preparation method of silicon dioxide aerogel and prepared silicon dioxide aerogel

The invention discloses a preparation method of silicon dioxide aerogel. The problems need to be solved that for an existing normal-pressure drying method, multi-time solvent replacement is needed, the preparation period is long, and operation is complex. According to the method, silicon dioxide and sodium hydroxide react to generate modified sodium silicate, and ethyl alcohol / water is used as a solvent; inorganic acid is added for neutralizing a modified sodium silicate solution, then a modified silica solution is generated, an inorganic salt by-product is removed, and modified silica gel isgenerated through the modified silica solution at certain temperature and pressure; a nonpolar solvent is used for conducting solvent exchange on the modified silica gel and drying the modified silicagel to obtain a hydrophobic aerogel material. The preparation method of the silicon dioxide aerogel has the advantages that the time of preparing the aerogel is short, the cost is low, and wastewater, waste gas and solid waste are not generated.

Owner:安徽科昂纳米科技有限公司

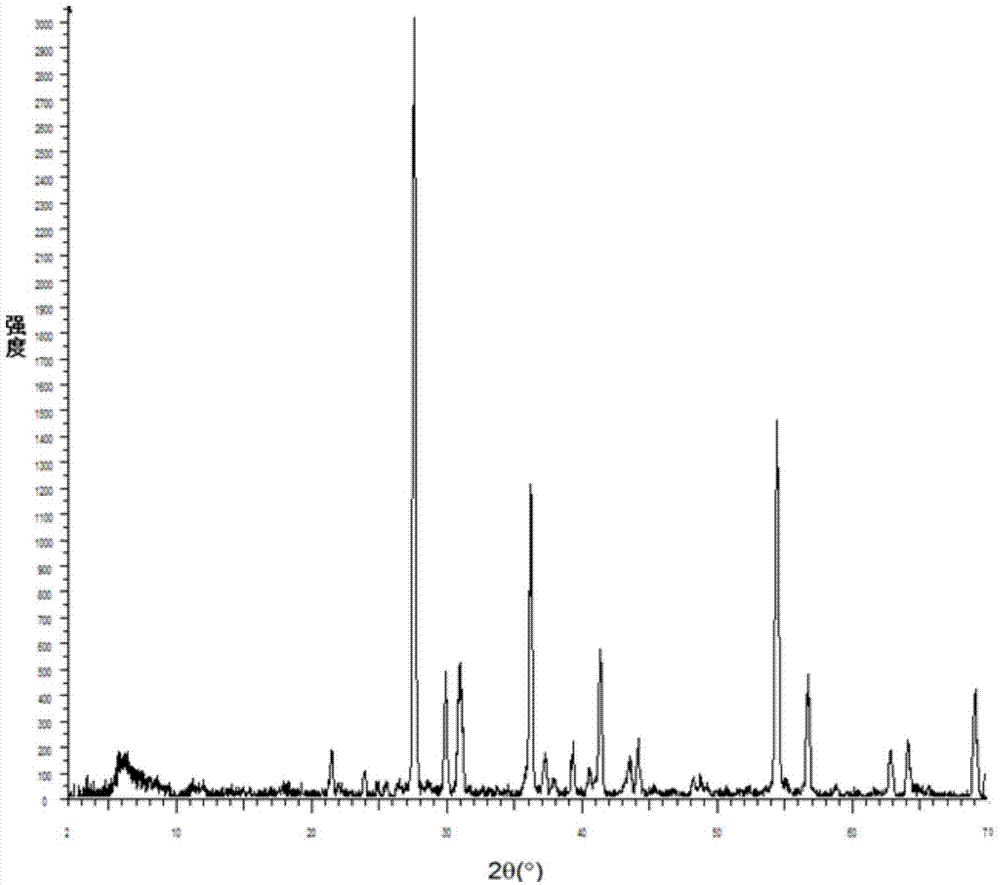

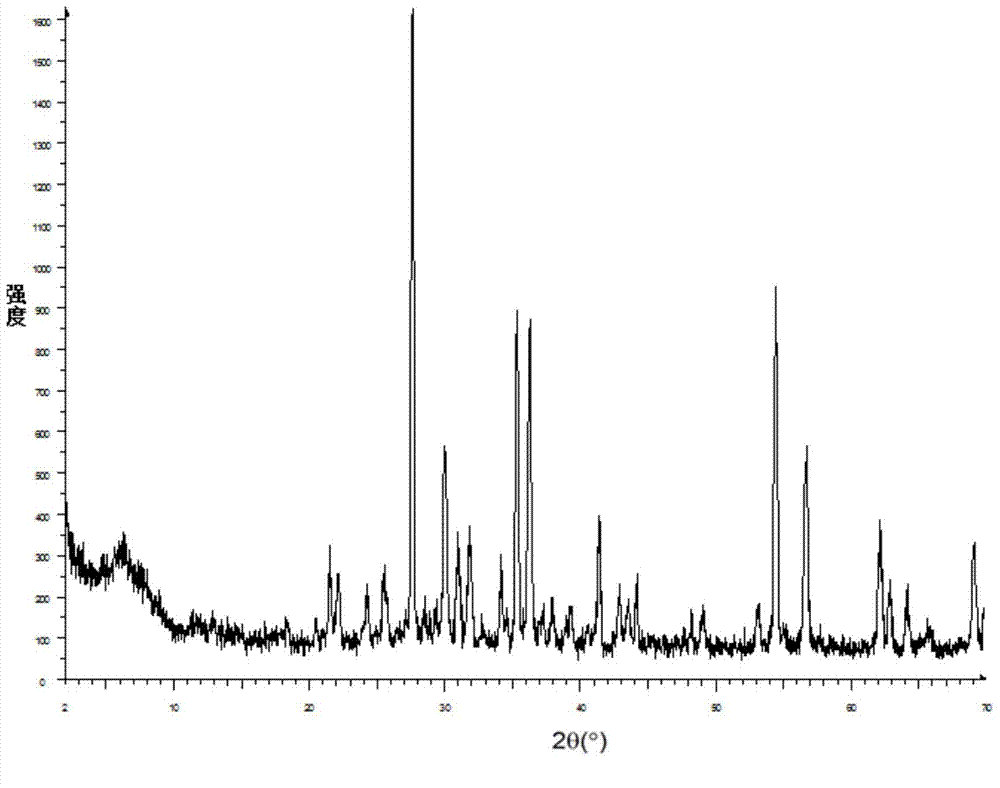

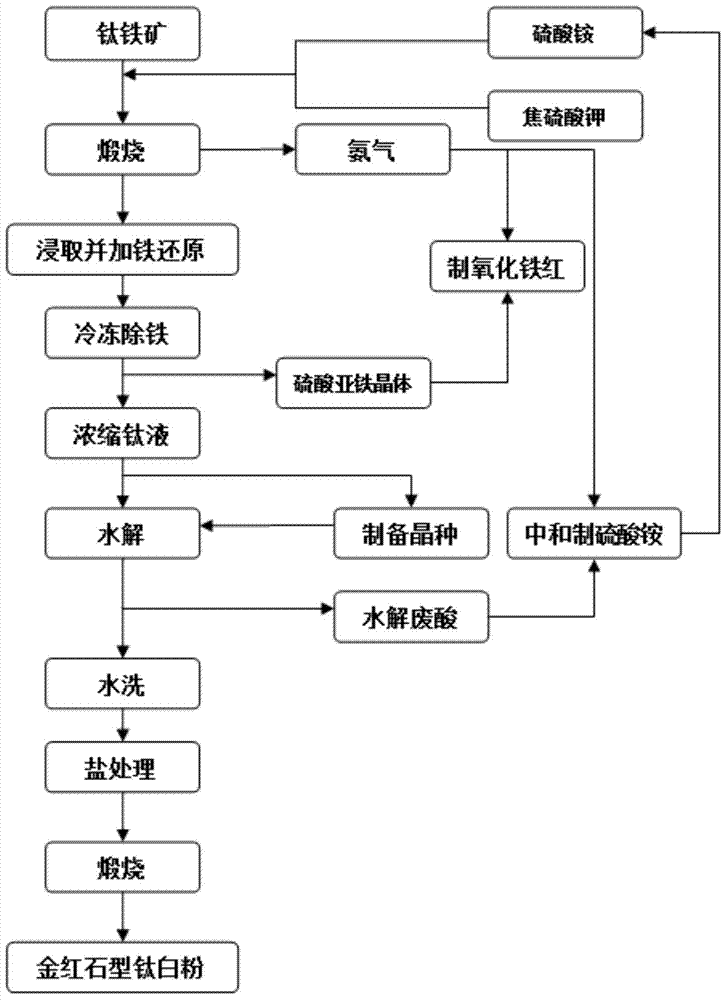

Method for preparing rutile type titanium dioxide by using ilmenite as raw material

The invention discloses a method for preparing rutile type titanium dioxide by using ilmenite as a raw material. The method comprises the steps of grinding ilmenite, calcining, extracting, freezing to remove iron, concentrating titaniferous solution, hydrolyzing titaniferous solution, rinsing, treating with salt and calcining. The method has the beneficial effects that: (1) high equipment cost generated by using high-concentration sulfuric acid is reduced by means of the process; (2) temperature for calcining is reduced by adding potassium pyrosulfate, and the extraction rate of titanium dioxide is greatly improved; (3) ammonium sulfate is generated from ammonia generated in calcining and waste acid generated in hydrolyzing and is recycled, the important problem of 'three wastes' is solved, and environmental friendliness is achieved; (4) a proper amount of rutile seed crystal is added under a certain condition in the hydrolyzing process, the yield of rutile type titanium dioxide is greatly increased; and (5) the temperature of crystal form transformation is reduced, rutile type crystal phase transformation can be obtained at 110 DEG C, and the calcining time is shortened to 2 hours.

Owner:HAINAN UNIVERSITY

A traditional Chinese medicine capable of decreasing blood sugar and benefiting kidney

InactiveCN101007036AAvoid damageAvoid bringing inOrganic active ingredientsMetabolism disorderAcute hyperglycaemiaArctiin

The invention relates to a kind of Chinese traditional medicine that can decrease the saccharide content and tonify kidney with the total lignanoid extracts from arctii. The content of the total lignanoid extracts from the arctii is 50-89%, the content of the main active ingredient (arctiin) is more than 30%. Using the valid total lignanoid as the material, the producers can prepare different per oral preparations. The advantages of the invention includes: 1. the invention can decrease the blood sugar substantially, it can prevent the damage to kidney because of hyperglycemia, it can even treat the early kidney damage; 2. the preparing method is safe and simple.

Owner:TIANJIN DANXI TCM INST

Microchannel reactor, and method for preparing N-alkoxyoxalyl alaninate by using microchannel reactor

The invention discloses a microchannel reactor, and a method for preparing N-alkoxyoxalyl alaninate by using the microchannel reactor. The method comprises the following steps: a mixed solution of alanine, oxalic acid, C1-C8 alcohol and oxalic acid diester are introduced into the microchannel reactor and are reacted under a heating condition, water is removed by a permeable membrane during the reaction, and the obtained reaction solution is post-treated to obtain the N-alkoxyoxalyl alaninate. The method utilizes the internal microstructure and the excellent mass transfer and heat transfer capability of the microchannel reactor to realize efficient mass transfer of reaction materials and timely remove water generated by the reaction in order to promote the reaction, so the method has the advantage of high yield, low energy consumption, short cycle, good safety, environmental protection, and continuousness in operation.

Owner:SHANDONG NHU FINE CHEM SCI & TECH CO LTD +1

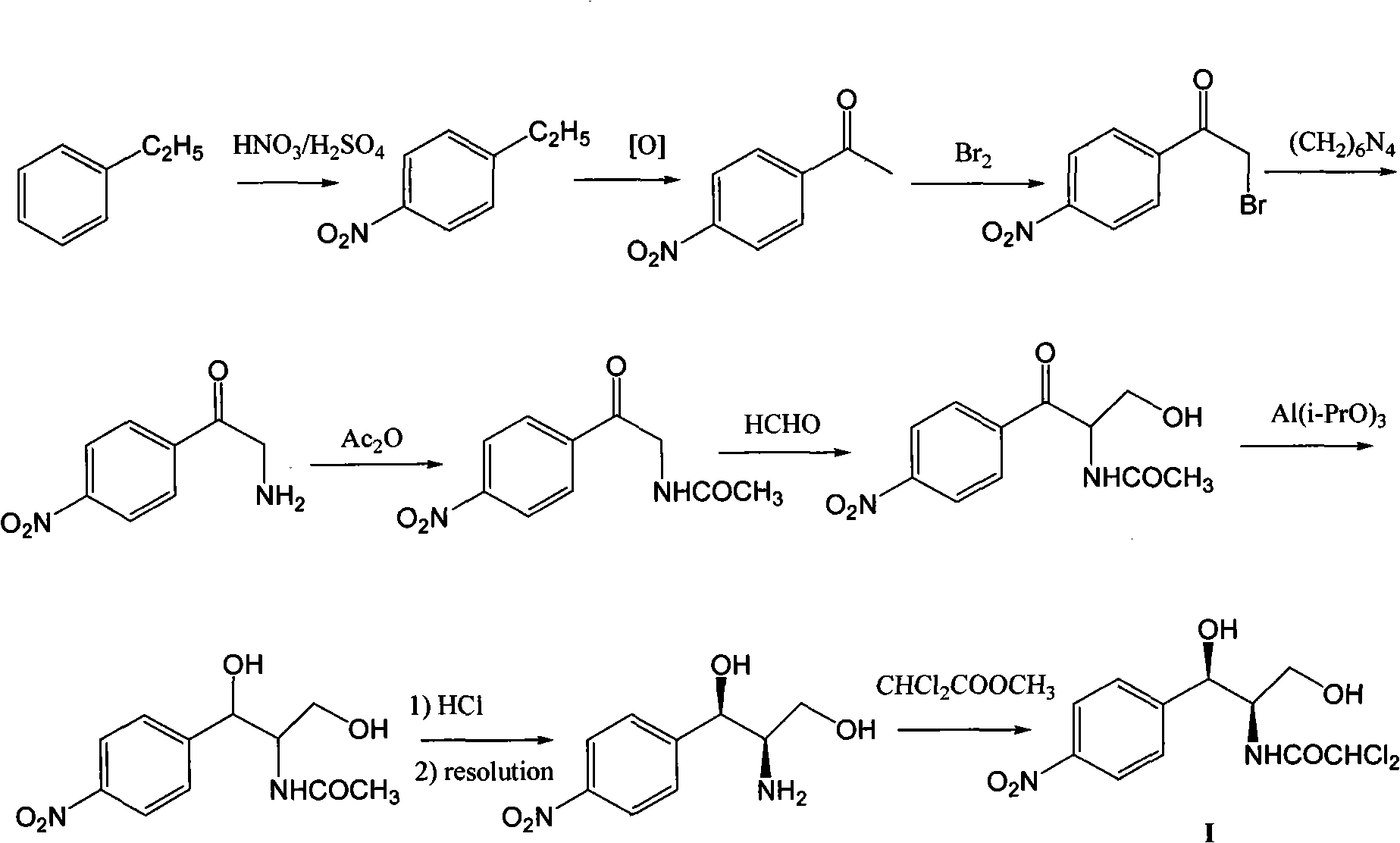

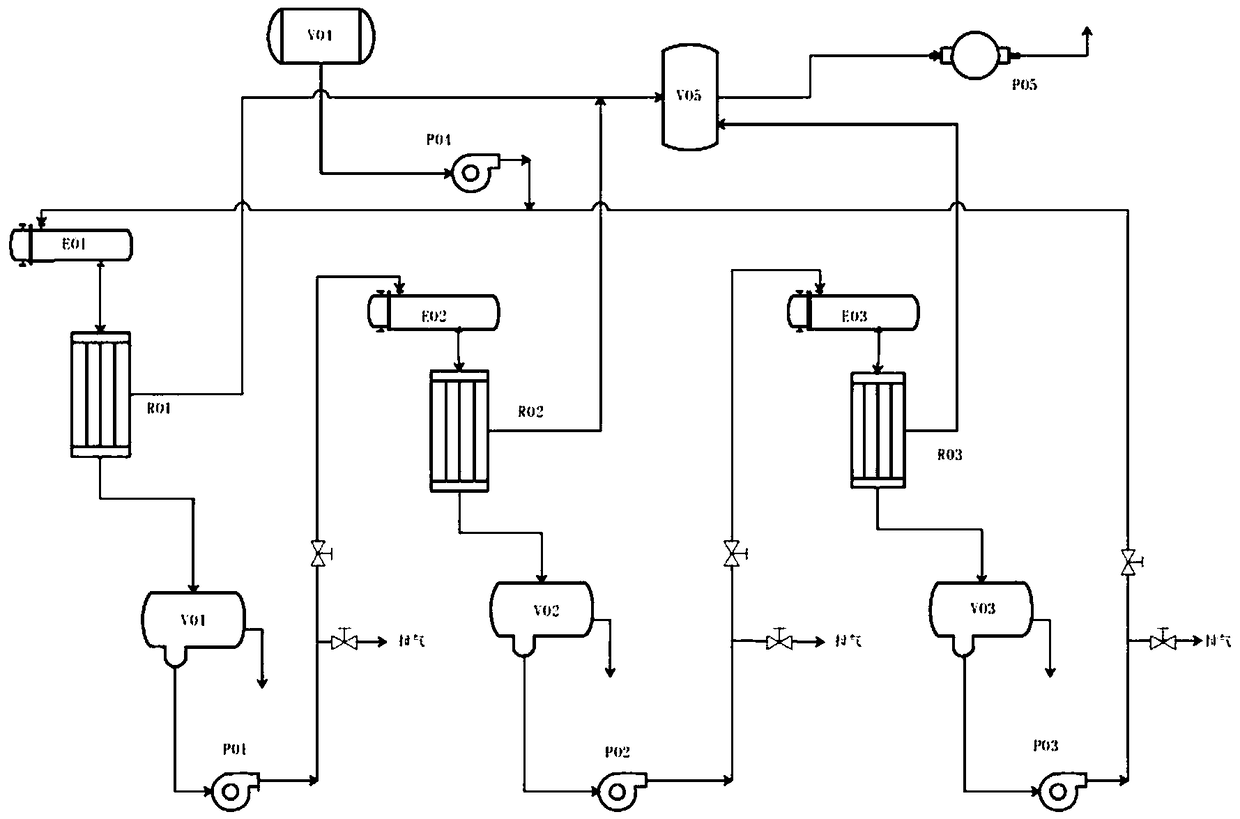

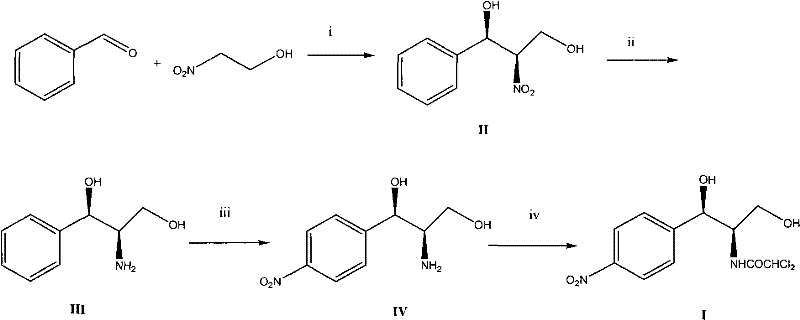

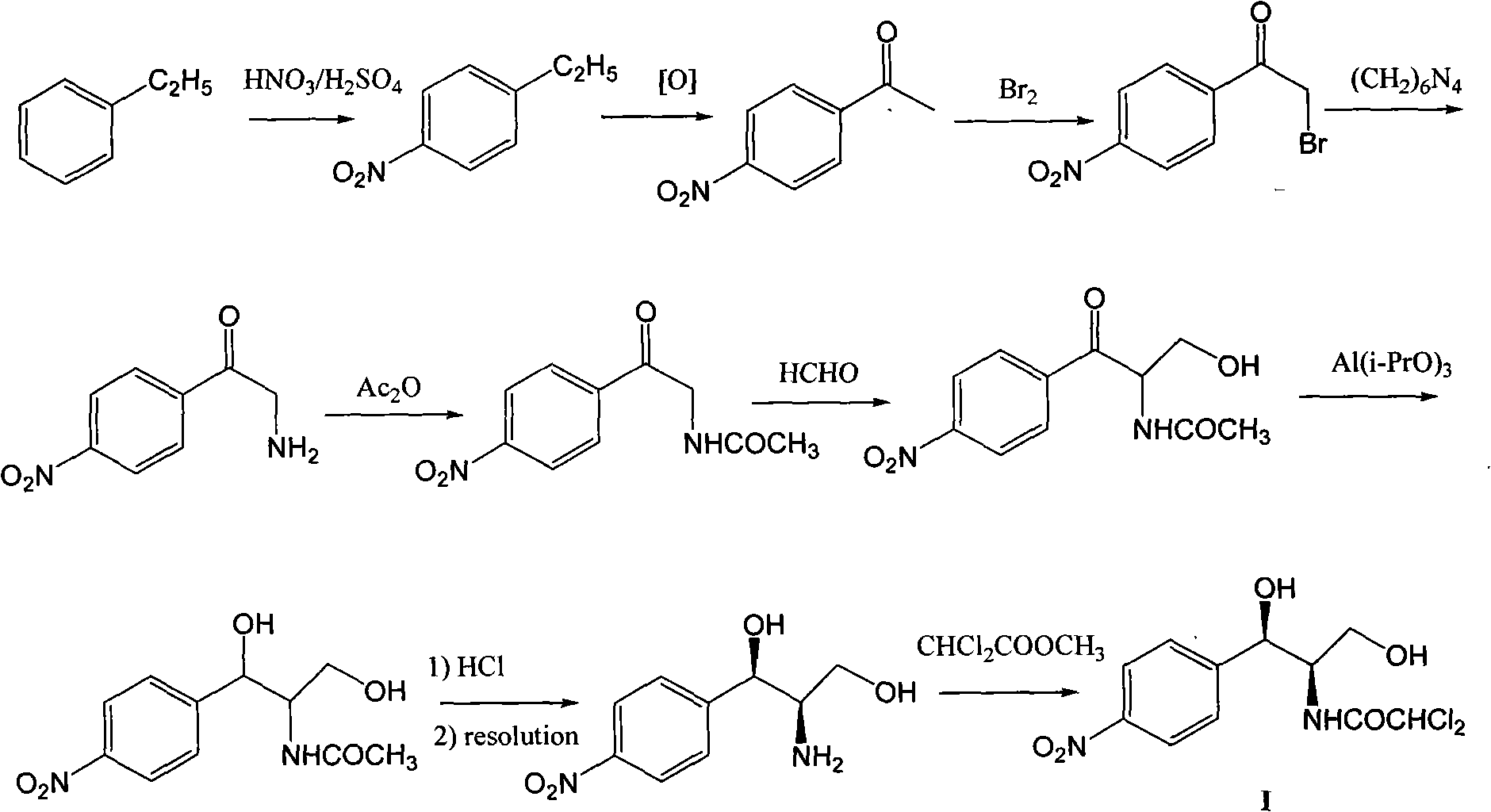

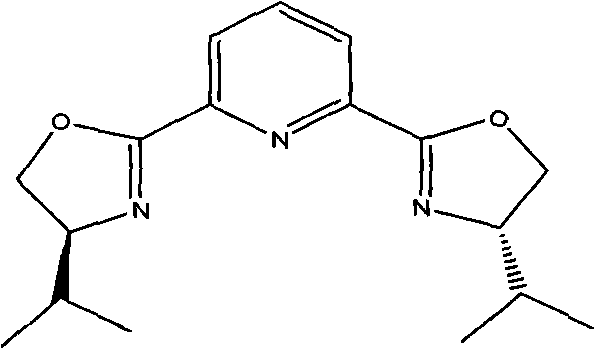

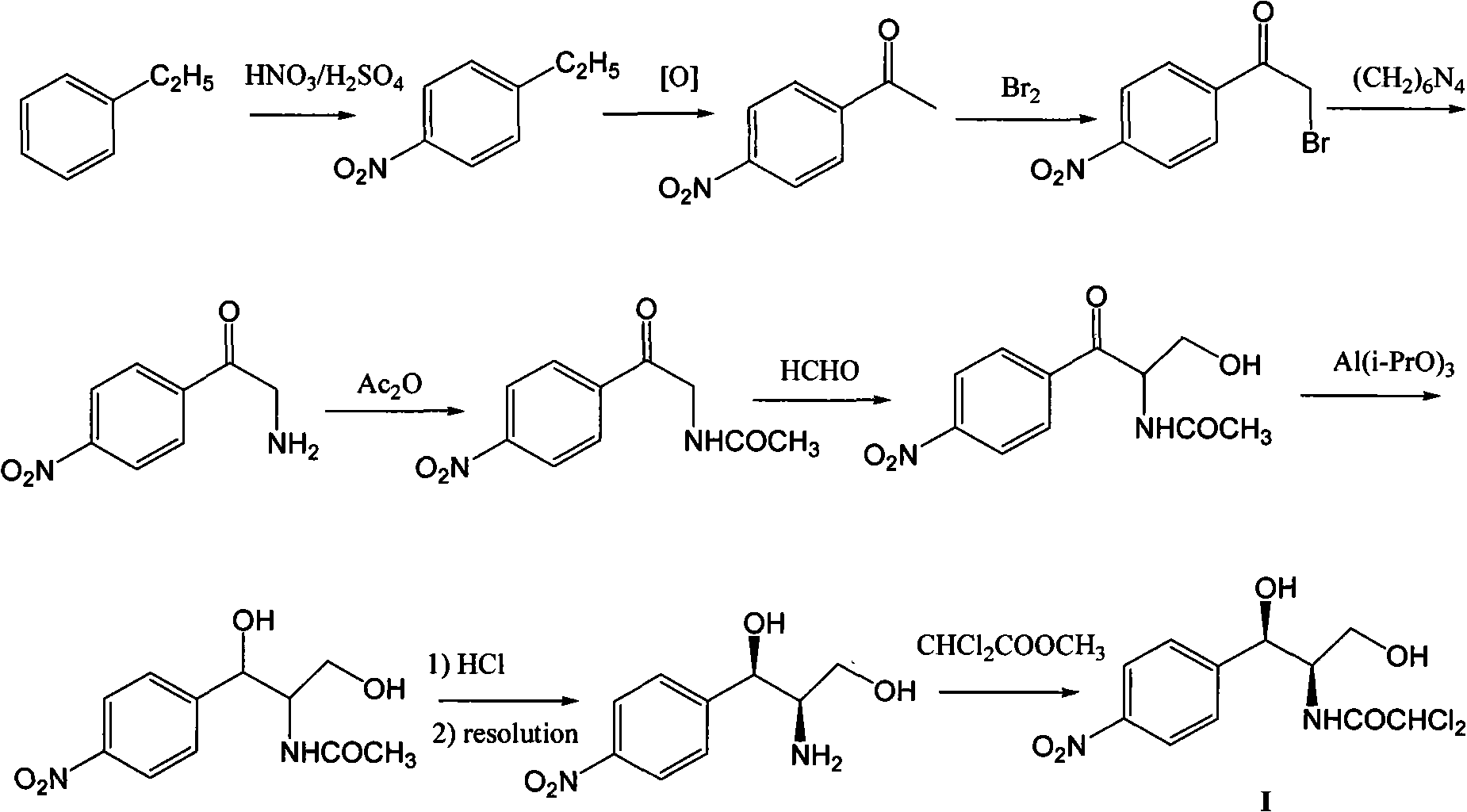

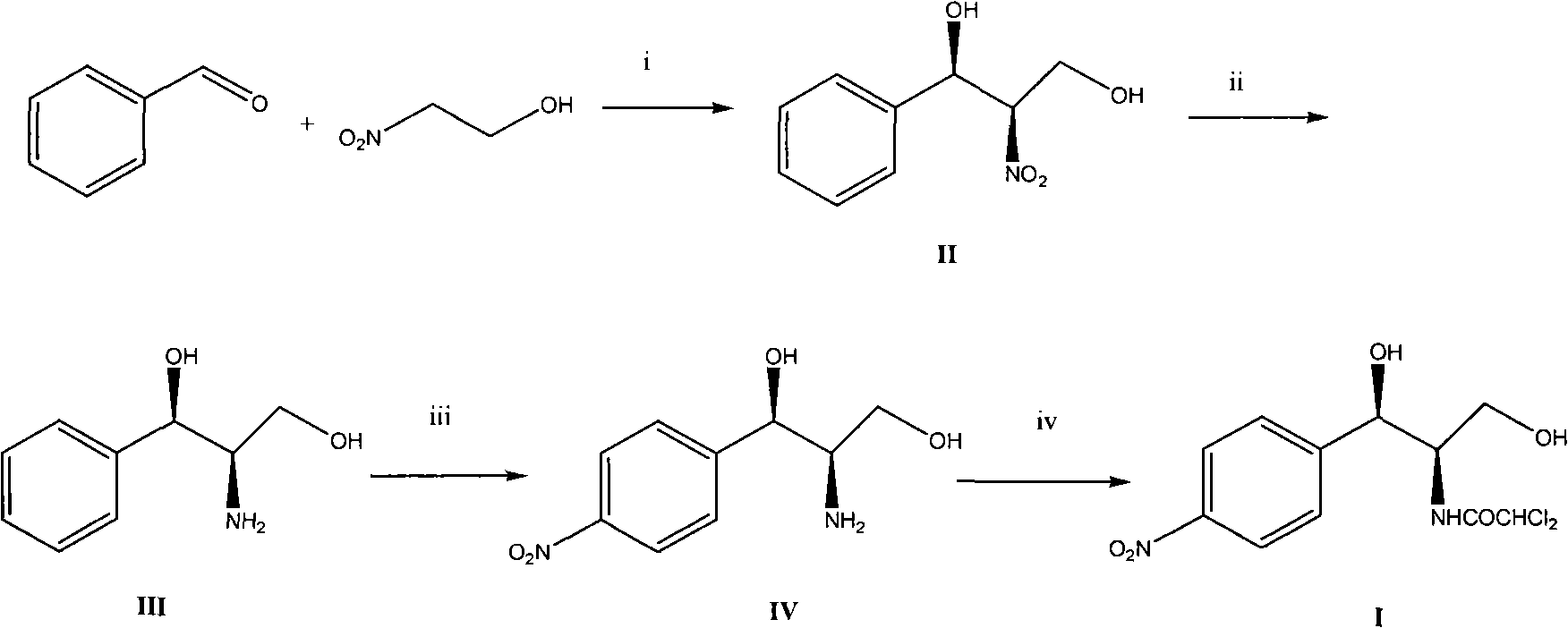

Method for preparing broad-spectrum antibiotic chloramphenicol

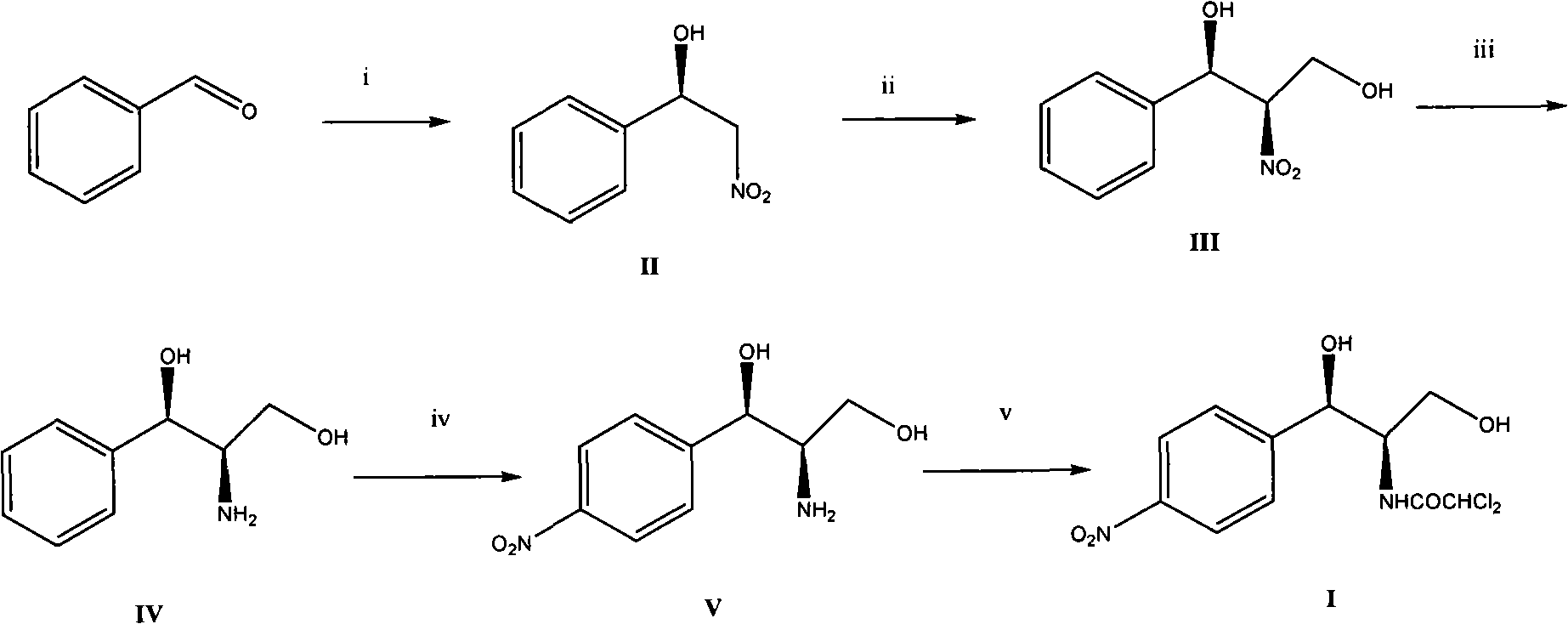

ActiveCN102391143ARaw materials are easy to getAvoid splittingOrganic compound preparationCarboxylic acid amides preparationBenzaldehydeAntibiotic Y

The invention relates to a method for preparing broad-spectrum antibiotic chloramphenicol. In the method, benzaldehyde and 2-nitroethyl alcohol are taken as raw materials; (1R, 2R)-2-nitro-1-phenyl-1,3-propanediol is obtained through synthesizing the raw materials under the presence of a chiral catalyst; (1R, 2R)-2-amino-1-phenyl-1,3-propanediol is obtained through hydrogenization to reduce; and the chloramphenicol is obtained through carrying out nitrification and dichloro-acetylation on the intermediate. With the adoption of the method provided by the invention, the chiral separation and the reduction of aluminum isopropoxide which are commonly used in industry nowadays can be avoided, the three wastes are reduced, the raw materials and reagents are cheap and easy to get, the synthetic steps are little, the yield is high, and thus, the method is more suitable for industrial production.

Owner:WUHAN WUYAO PHARMA

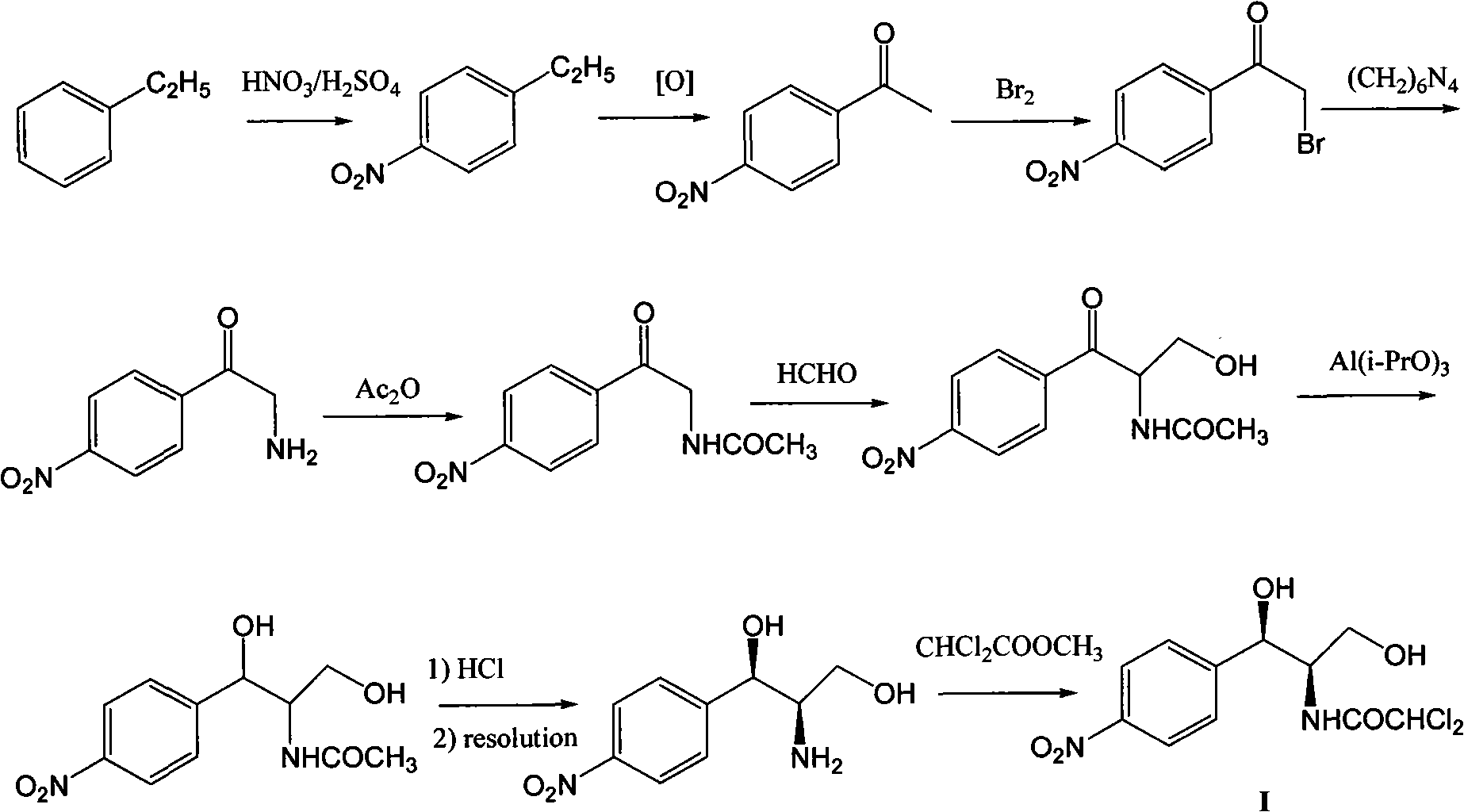

Method for preparing chloramphenicol

ActiveCN102399161ARaw materials are cheap and easy to getLow costOrganic compound preparationCarboxylic acid amides preparationBenzaldehydeNitration

The invention relates to a method for preparing a broad spectrum antibiotic of chloramphenicol. The method comprises the following steps of: synthesizing (R)-2-nitro-1-benzylcarbinol by using benzaldehyde and nitromethane as raw materials in the presence of a chiral catalyst; reacting with formaldehyde to obtain (1R,2R)-2-nitro-1-benzyl-1,3-propanediol, and performing hydrogenation reduction to obtain (1R,2R)-2-amino-1-benzyl-1,3-propanediol; and performing nitration and dichloro acetylization on the intermediate at low temperature to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, the raw materials and reagents are cheap and readily available, the method comprises a few synthesizing steps, the yield is high, and the method is more suitable for industrial production.

Owner:WUHAN WUYAO SCI & TECH

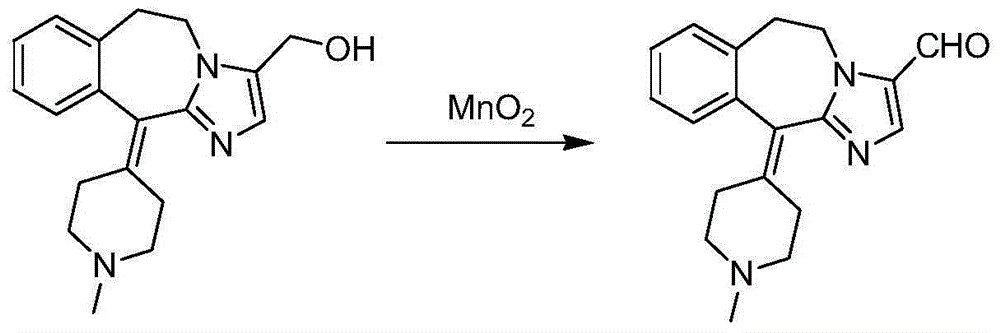

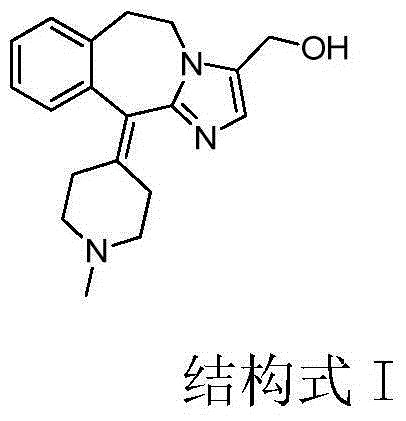

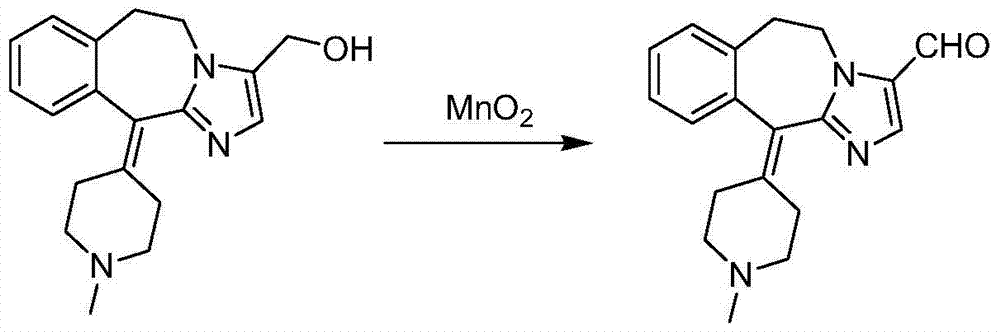

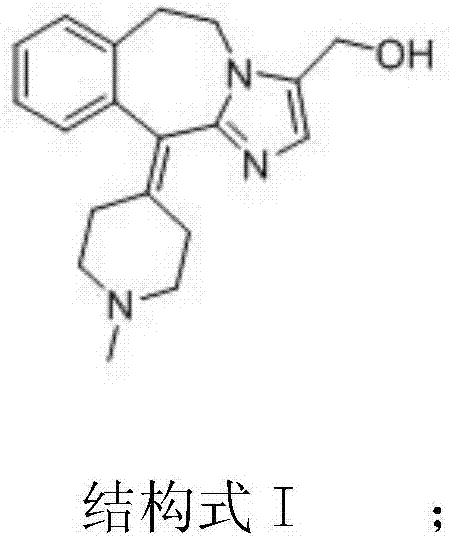

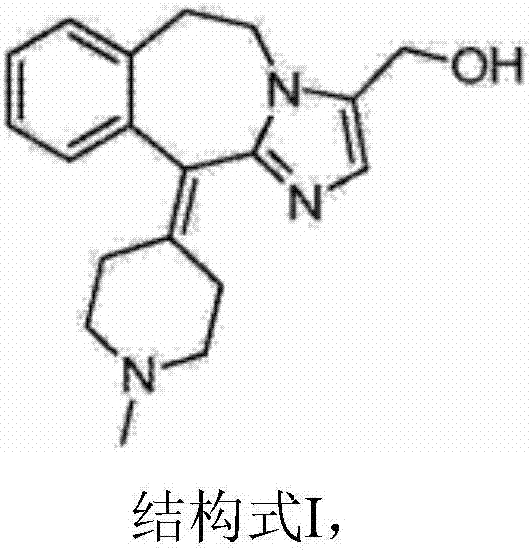

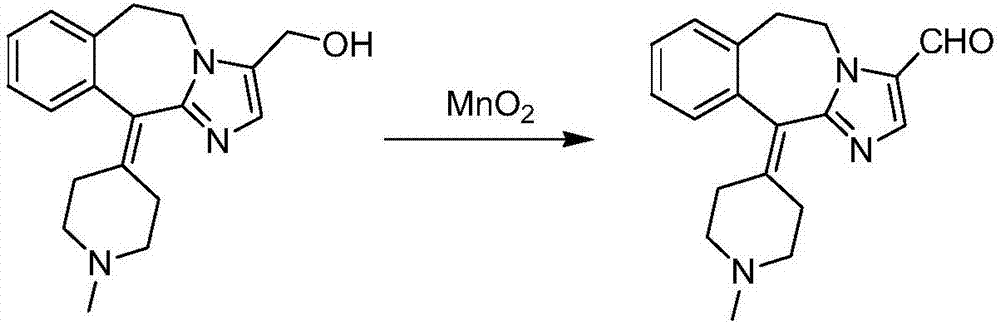

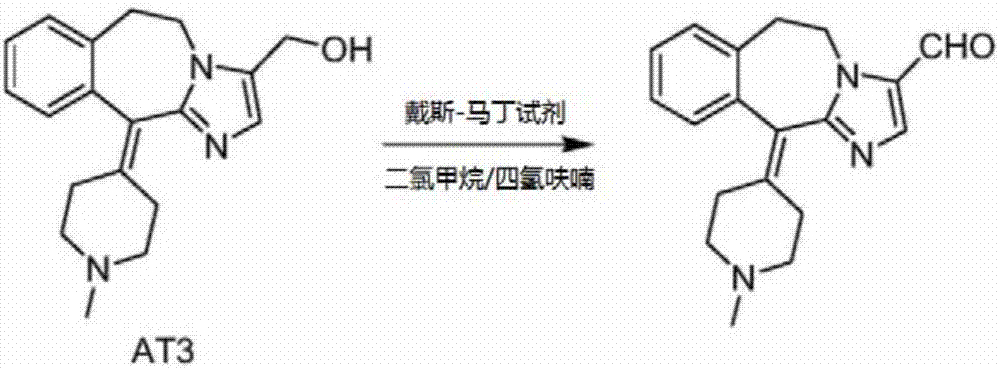

Novel oxidation method for preparing alcaftadine

The invention relates to a novel oxidation method for preparing a histamine H1 receptor antagonist--alcaftadine. The method comprises the step of using a Dess-Martin periodinane as an oxidation reagent to oxidize an intermediate--6,11-dihydro-11-(1-methyl-4-piperidylidene)-5H-imidazo[2,1-b][3]benzazepine-3- methanol so as to obtain the alcaftadine. The novel oxidation method for preparing the alcaftadine is simplified and has the advantages of simple operation, environment-friendly process, cheap and easily-available raw materials and reagents, high yield and more applicability to industrial production.

Owner:WUHAN WUYAO SCI & TECH

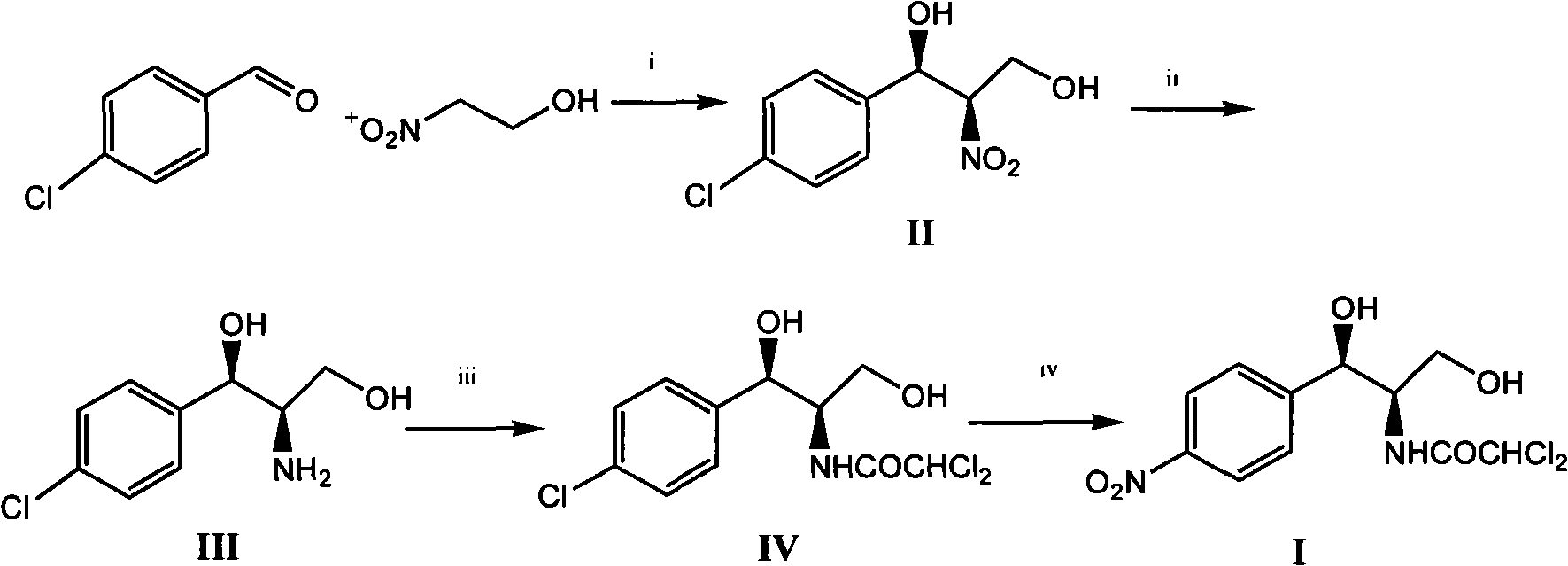

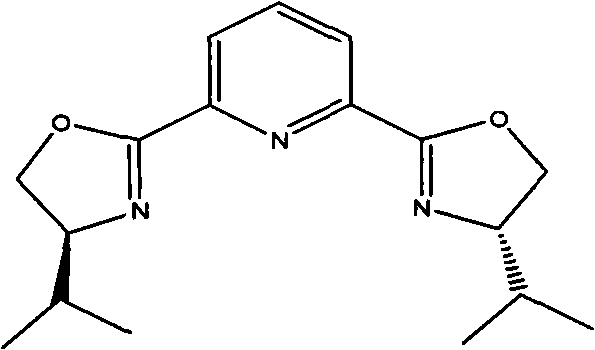

Method for preparing chloramphenicol from 4-chloro-benzaldehyde

ActiveCN102399163AHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparationBenzaldehydeP-chlorobenzaldehyde

The invention relates to a method for preparing a broad spectrum antibiotic of chloramphenicol. The method comprises the following steps of: synthesizing (1R,2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol by using 4-chlorobenzaldehyde and 2-nitroethylalcohol as raw materials in the presence of a chiral catalyst, and performing catalytic hydrogenation to obtain (1R,2R)-2-amino-1-(4-chlorophenyl)-1,3-propanediol; and performing nitro substitution and dichloro acetylization on the intermediate to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, the raw materials and reagents are cheap and readily available, p-chlorobenzaldehyde is selected as a raw material, the method comprises a few synthesizing steps, the yield is high, and the method is suitable for industrial production.

Owner:GRAND PHARM (CHINA) CO LTD

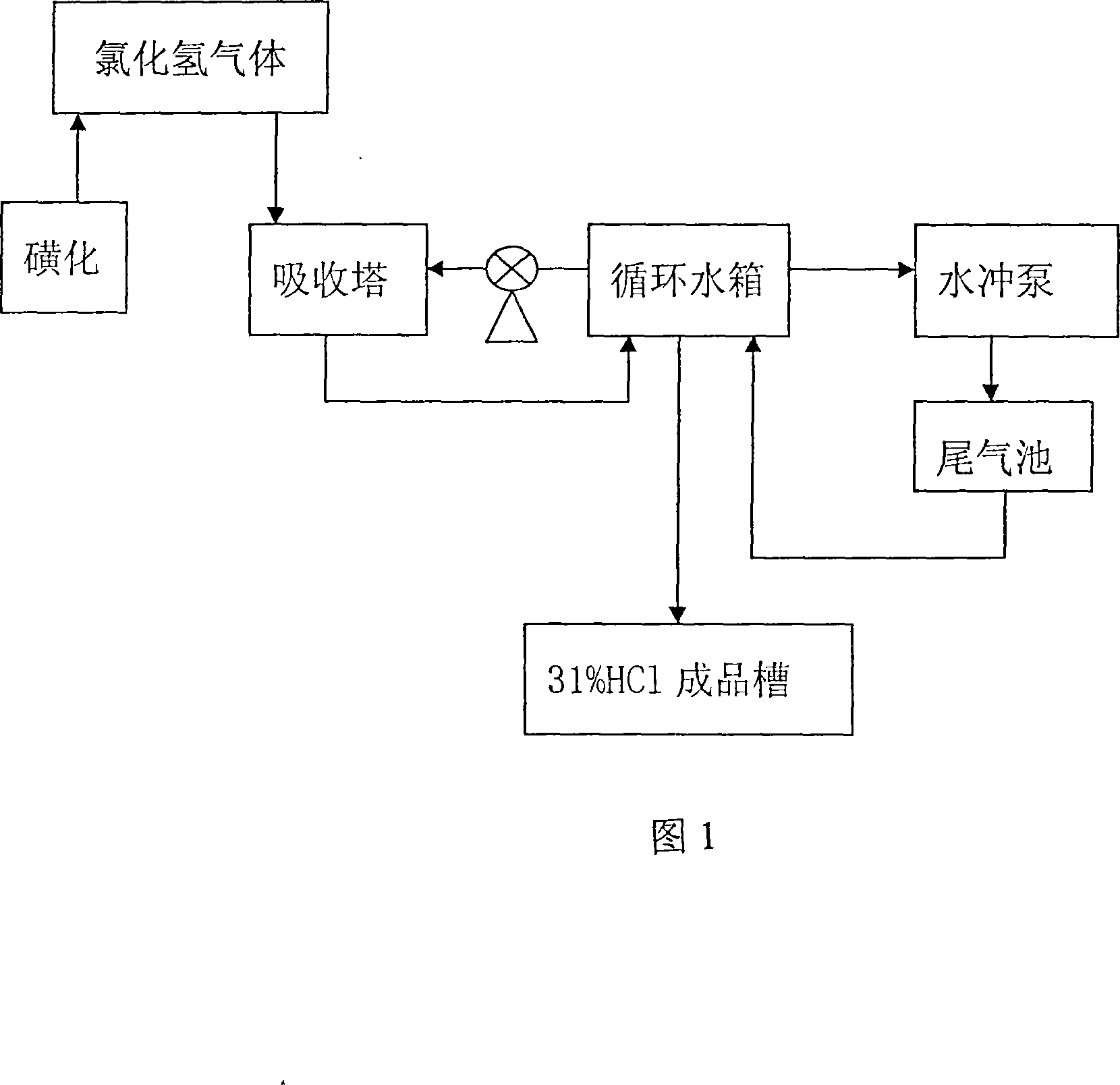

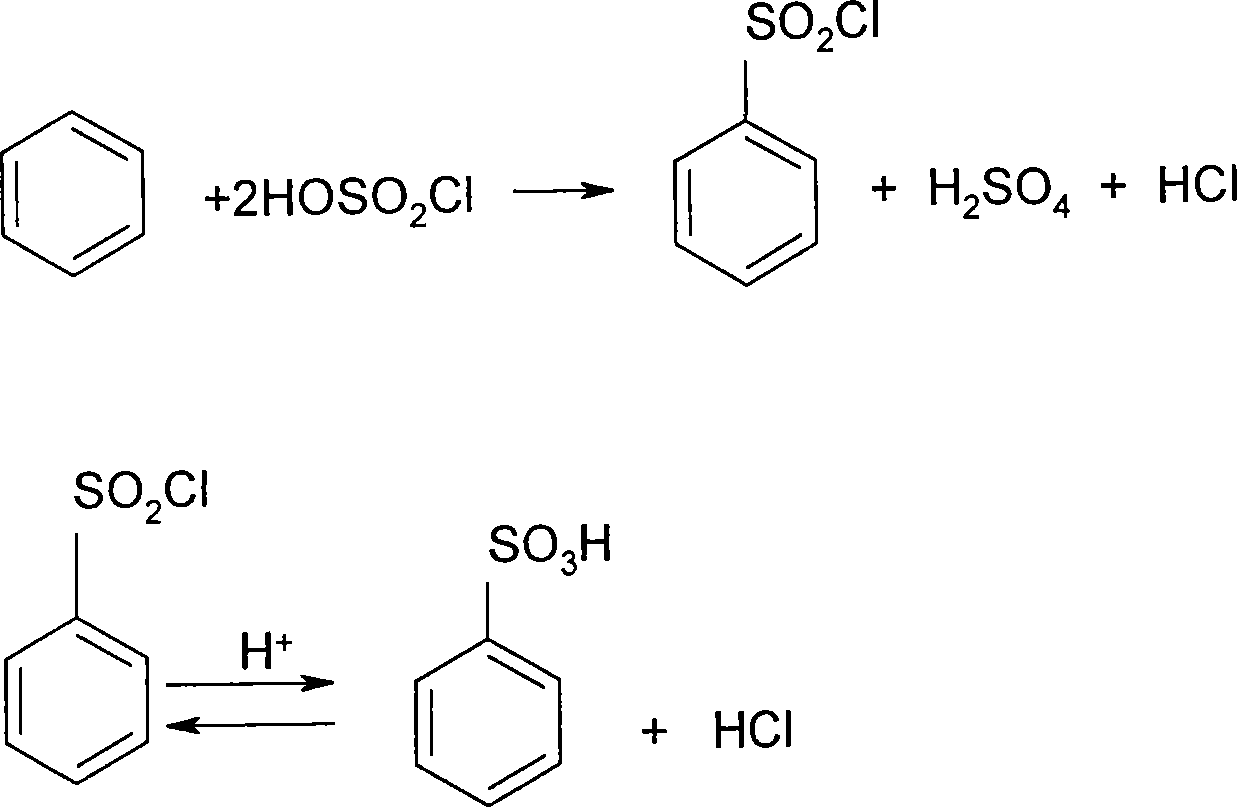

Method for recovering hydrochloric acid from HCL gas during the production process of benzene sulfochloride

ActiveCN101177242ARelieve pressureIncrease repeated cycle absorptionChlorine/hydrogen-chlorideHydrometerPositive pressure

The invention relates to a method for HCI hydrochloric acid gas recovery in the process of producing benzene sulfone chloride; based on the planar absorption apparatus, the prior positive pressure chlorosulfonation is changed into a bleed chlorosulfonation by adding a water pump and a circulation water tank at the end of tail gas, so that the pressure inside a reaction kettle and a pipeline can be reduced; the unabsorbed HCI tail gas is completely absorbed by the water pump cyclically through implementing a circulation absorption technology in the state of negative pressure. The invention has the advantages that the HCI gas which is generated in the process of sulphonation can be absorbed cyclically by adopting the negative pressure reactivity, so the smoky HCI gas in the air is removed; based on the planar absorption apparatus, the water pump and the circulation tank are added for implementing the circulation absorption under the state of negative pressure, when the absorbed concentration reaches 31% (the specific gravity is up to 1.155 which is measured by a hydrometer), the reclamation can be implemented; the invention can be used in manufacturing the products of rubber strengthening agent white black carbon so as to improve the economic benefit; the invention also can be better to solve the problem in environmental protection.

Owner:镇江惠隆化工有限公司

Method for synthesizing chloramphenicol from 4-chloro-benzaldehyde

ActiveCN102399162AHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparation4-chlorobenzaldehydeBenzaldehyde

The invention relates to a method for synthesizing a broad spectrum antibiotic, namely, chloramphenicol. The method comprises the following steps of: synthesizing (1R,2R)-2-nitro-1-(4-chlorophenyl)-1,3-propanediol by using 4-chlorobenzaldehyde and 2-nitroethylalcohol as raw materials in the presence of a chiral catalyst, and performing catalytic hydrogenation to obtain (1R,2R)-2-amino-1-(4-chlorophenyl)-1,3-propanediol; and performing dichloro acetylization and nitro substitution on the intermediate to obtain the chloramphenicol. By the method, the common chiral resolution and aluminum isopropoxide reduction in the industry at present can be avoided, three wastes are reduced, and the raw materials and reagents are cheap and readily available; 4-chlorobenzaldehyde is selected as a raw material, nitro substitution is adopted, and the generation of byproducts in nitration reaction is reduced; moreover, the method comprises a few synthesizing steps, the yield is high, and the method is more suitable for industrial production.

Owner:WUHAN WUYAO SCI & TECH

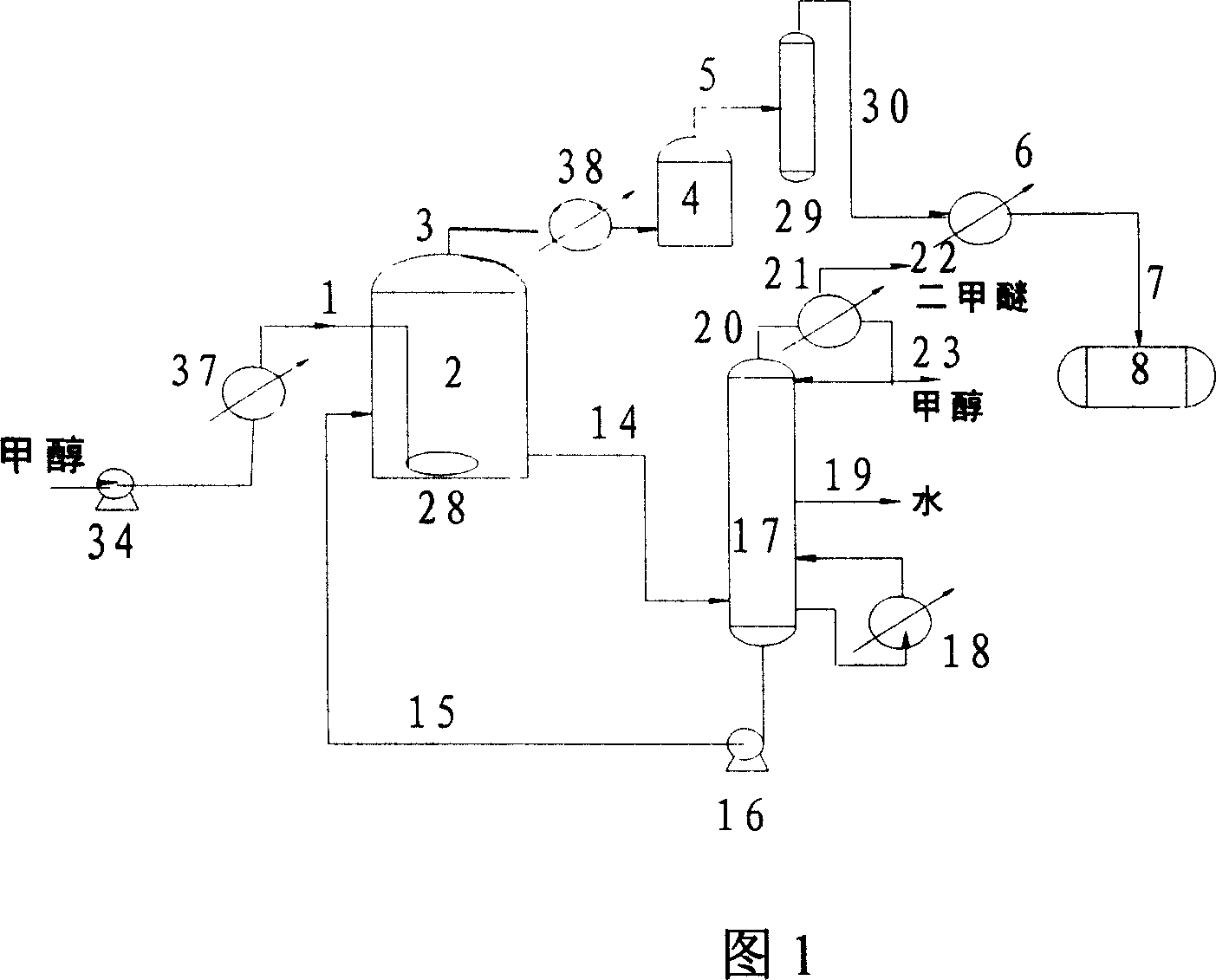

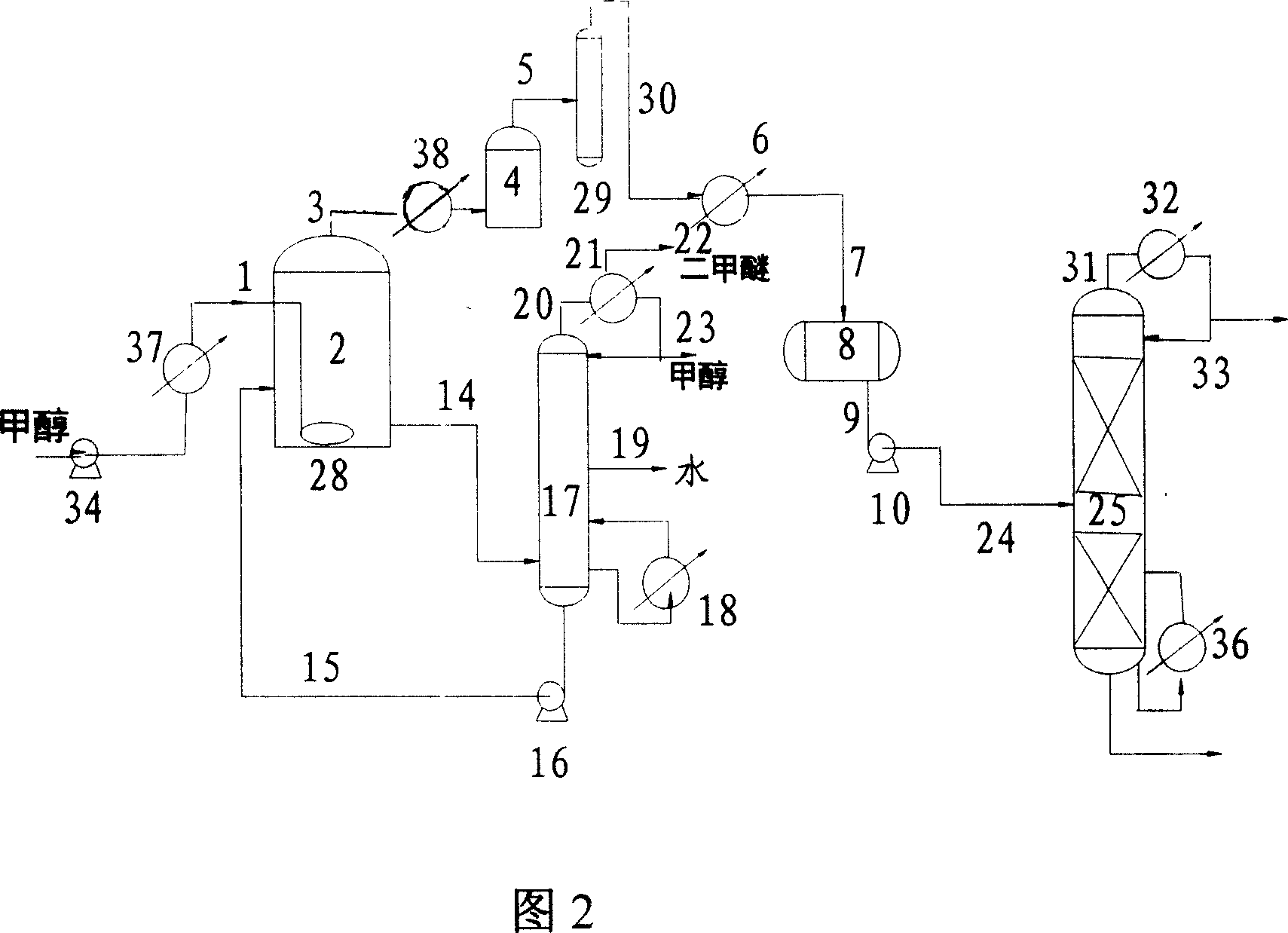

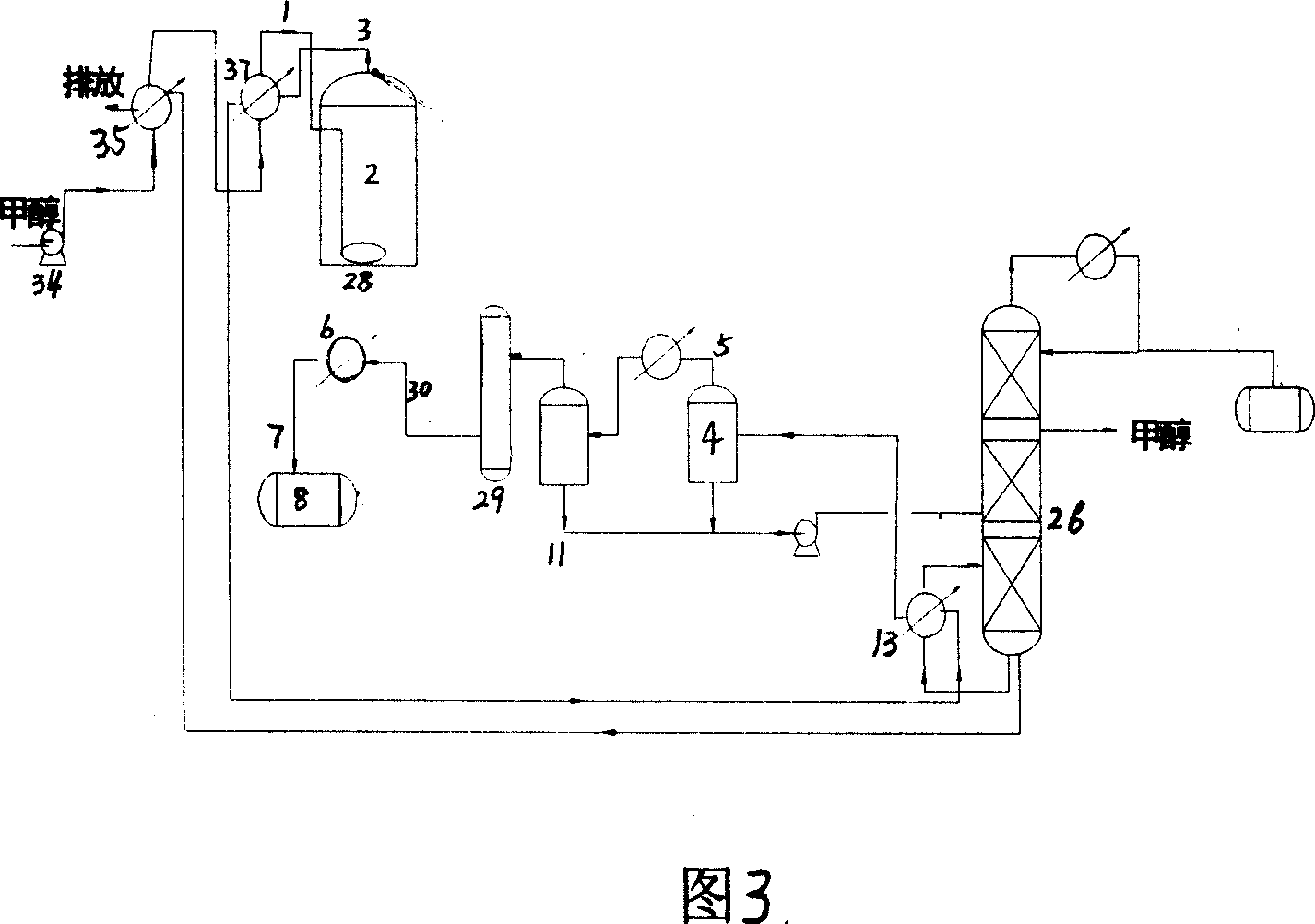

Method for preparing dimethyl ether by liquid phase compression

InactiveCN1923780AEasy to handleSolve the shortcoming of pressurized liquefaction with a compressor in the production of dimethyl etherEther preparation by compound dehydrationPhosphoric acidFluorosulfuric acid

The invention discloses a manufacturing method of dimethyl ether through liquid-phase pressurizing method, which comprises the following steps: adopting carbinol as raw material; loading in the bubbling tower reactor with 20% concentrated sulfuric acid and phosphoric acid based on methanesulfonic acid or fluorosulfuric acid as catalyst; controlling the temperature at 120-380 deg.c and pressure at 0.3-3.5Mpa; dehydrating; separating the gas; drying; condensing to obtain the product.

Owner:水煤浆气化及煤化工国家工程研究中心

Preparation method of 4-hydroxybiphenyl

PendingCN111825532ALow costProperly solve the three wastes problemOrganic compound preparationCarbonyl compound preparation by condensationPtru catalystBiochemical engineering

The invention discloses a preparation method of 4-hydroxybiphenyl, and belongs to the field of preparation of chemical intermediates. According to the preparation method, biphenyl is used as an initial raw material, and 4-hydroxybiphenyl can be obtained through acylation reaction and oxidation reaction. The preparation method comprises the following steps of: (1) adding biphenyl into a solvent, adding a catalyst, then dropwise adding an acylating agent, sampling and detecting, washing after the reaction is finished, concentrating and crystallizing; and (2) adding a solvent into the product todissolve, adding an oxidant, sampling, detecting, washing with water, filtering, crystallizing, drying and distilling the product to obtain the product with the content of more than 99.5%. The methodis low in production cost, environment-friendly in process, high in yield and suitable for industrial production.

Owner:HANN NEW MATERIAL TECH CO LTD

Electroplating sludge treating and utilizing process

InactiveCN101066827BLow costReduce consumptionSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processNickel saltSlag

The electroplating sludge treating and utilizing process includes the following steps: 1. adding alkali to stoved electroplating sludge, roasting, leaching out soluble metal in dilute alkali solution, and filtering to obtain alkali leached slag and alkali leached liquid; 2. adding acid to the alkali leached liquid, filtering to obtain hydrolyzed slag and hydrolyzed liquid, and preparing bichromate with the hydrolyzed liquid; and 3. dissolving the alkali leached slag in acid solution, filtering, electrodepositing the filtrate and filtering to obtain electrodeposited solution, depurating the electrodeposited solution and crystallizing to obtain nickel salt. The process has low power consumption and low cost, and can convert most of Cr, Cu and Ni in electroplating sludge into bichromate, nickel salt, copper powder and other side product.

Owner:台州盛世环境工程有限公司

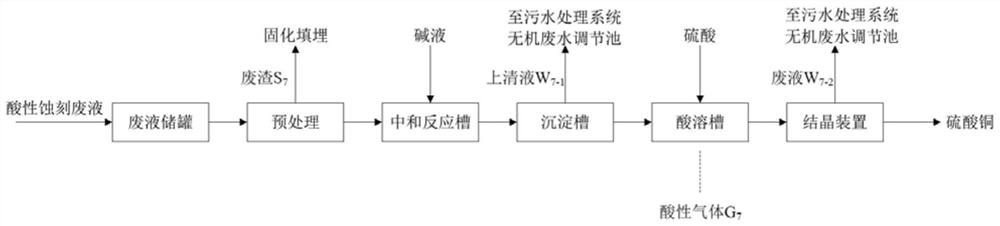

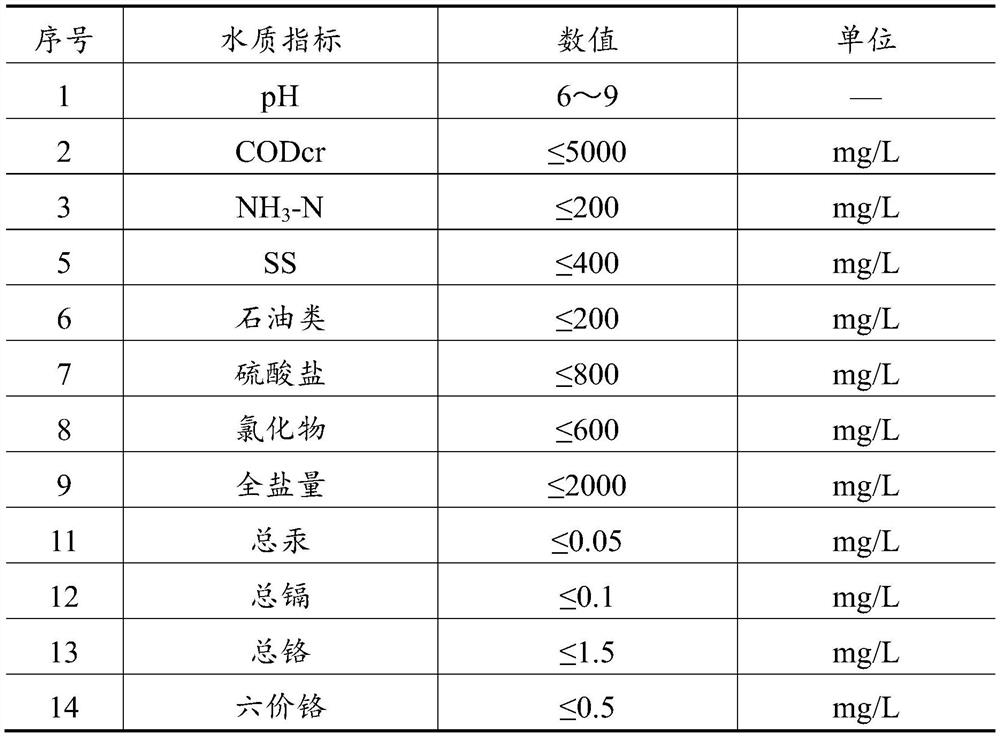

Acidic copper-containing etching liquid treatment method and system

InactiveCN111943423AImplementation processRealize comprehensive utilizationWater treatment parameter controlWater contaminantsSolution treatmentDesalination

The invention provides an acidic copper-containing etching solution treatment method which comprises the following steps: (1) adjusting the pH value of an acidic copper-containing etching solution to0.08-0.12, and adding an oxidant to oxidize copper in the acidic copper-containing etching solution into bivalent copper ions to obtain a mixed system A; (2) adding alkali into the mixed system A to adjust the pH value of the mixed system A to 7.5-8 so as to convert bivalent copper ions in the mixed system A into copper hydroxide precipitates; (3) dissolving the solid precipitate obtained in the step (2) with a sulfuric acid solution to obtain a mixed system B; (4) crystallizing the mixed system B to obtain solid copper sulfate; and (5) performing triple-effect evaporation desalination treatment on wastewater generated after crystallization of the mixed system B in the step (4) to obtain condensate and crystalline salt. According to the method disclosed by the invention, up-to-standard discharge treatment of the acidic copper-containing etching solution is realized, and the acidic copper-containing etching solution is converted into a copper sulfate product, so that the environmental problem is solved, and the economic benefit is achieved; in addition, the system is simple in structure and small in occupied area.

Owner:山东东顺环保科技有限公司

Method for synchronously producing poultry and vegetables

PendingCN110692451ASave land resourcesImprove land productivityPlant cultivationCultivating equipmentsPesticideVermin

The invention belongs to the high-tech field of agricultural comprehensive cultivation, and particularly discloses a method for synchronously producing poultry and vegetables. The method includes thesteps of building a greenhouse, manufacturing a movable frame, sowing and transplanting, breeding poultry, building a flat frame shade shed and planting vegetables under the flat frame greenhouse. Through the synchronous production method, the traditional vegetable planting and poultry breeding are combined together, so that the poultry can peck at multiple pests and reduce the usage amount of pesticides; meanwhile, poultry excrement and residual waste water are converted into organic fertilizers required by vegetable growth, and thus not only the excellent quality of multiple vegetables is ensured, but also the problem of 'three wastes' is effectively solved in the poultry breeding process, and the aims of saving cost, producing more in one place and producing high yield and ecological comprehensive breeding are achieved.

Owner:尹华粤

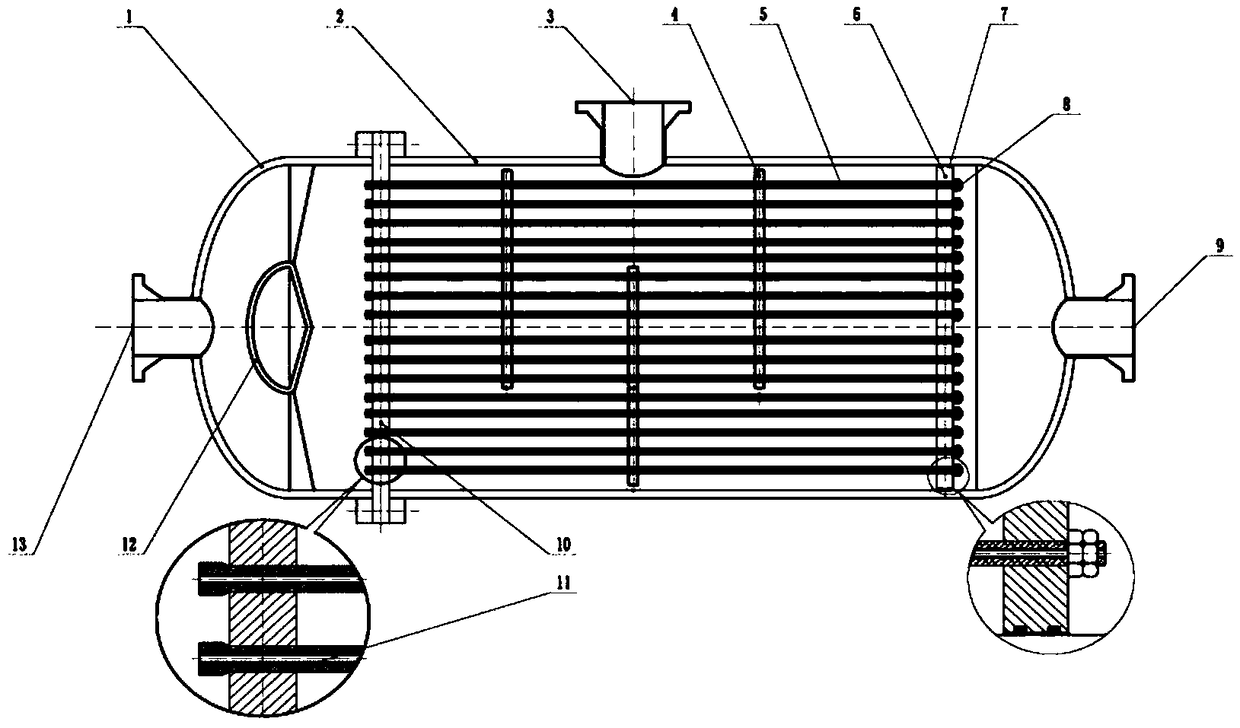

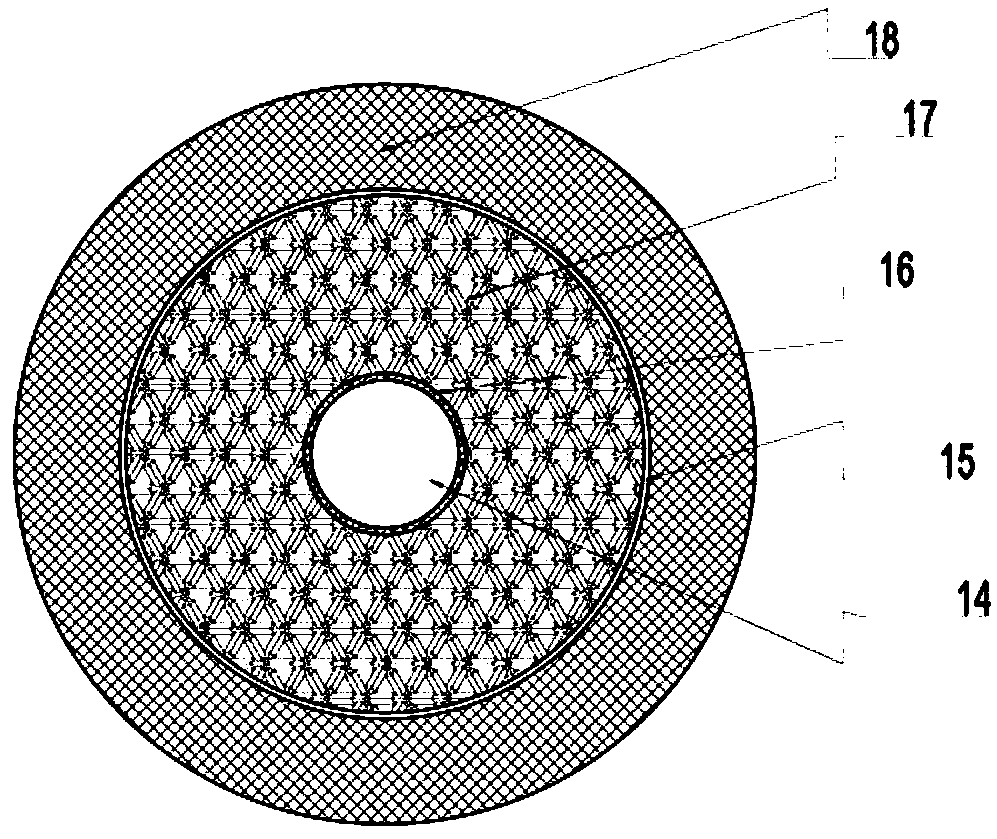

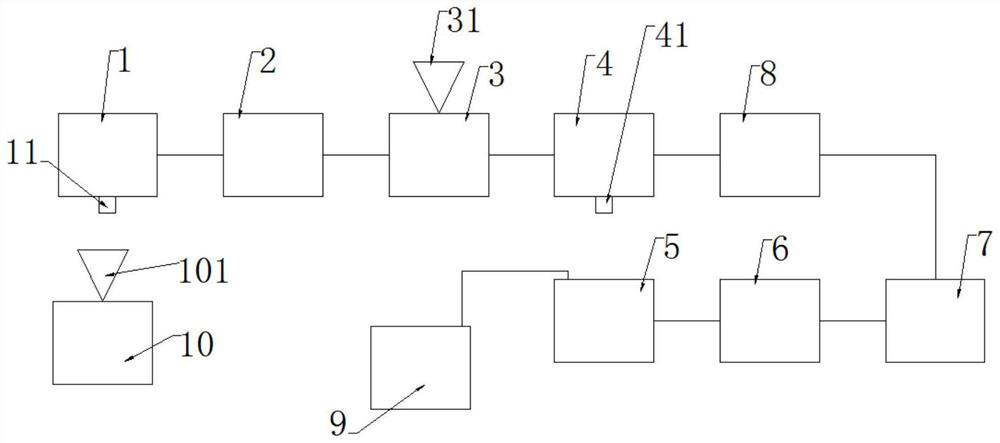

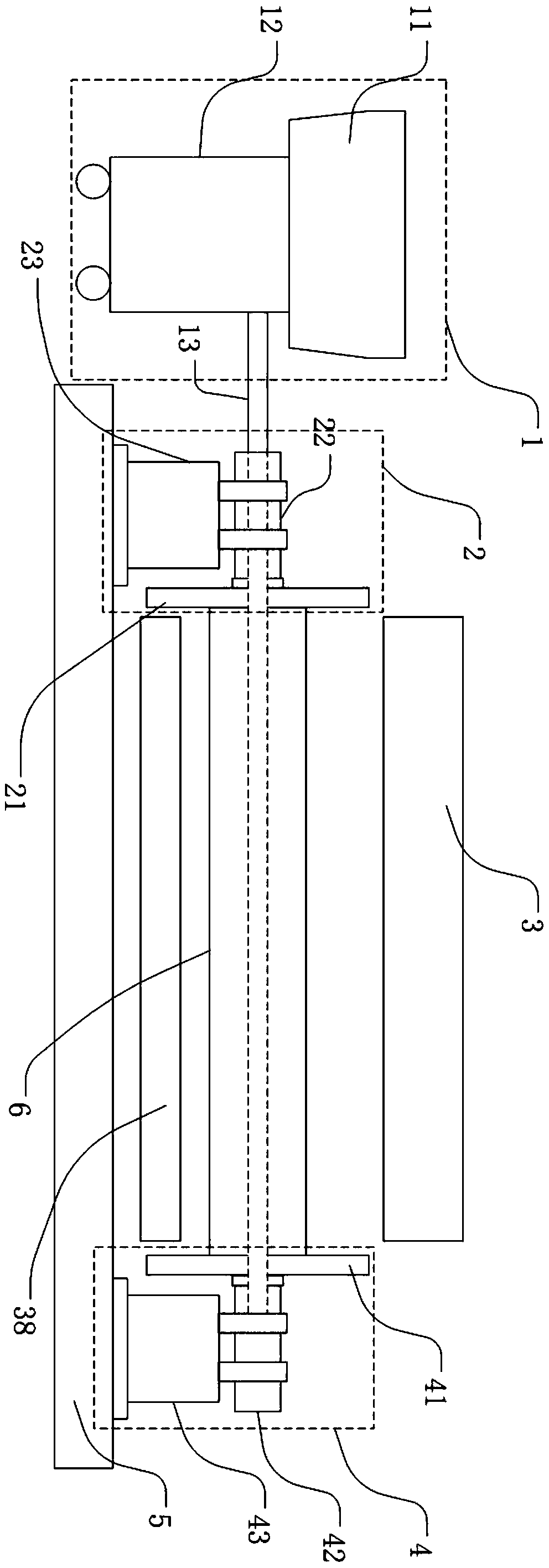

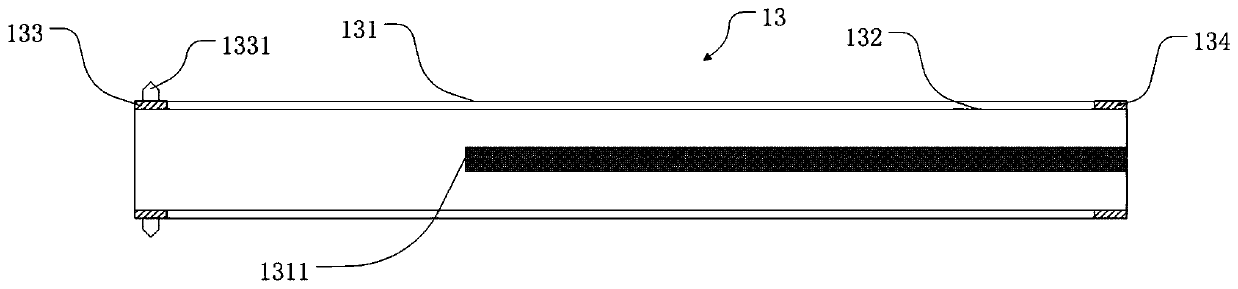

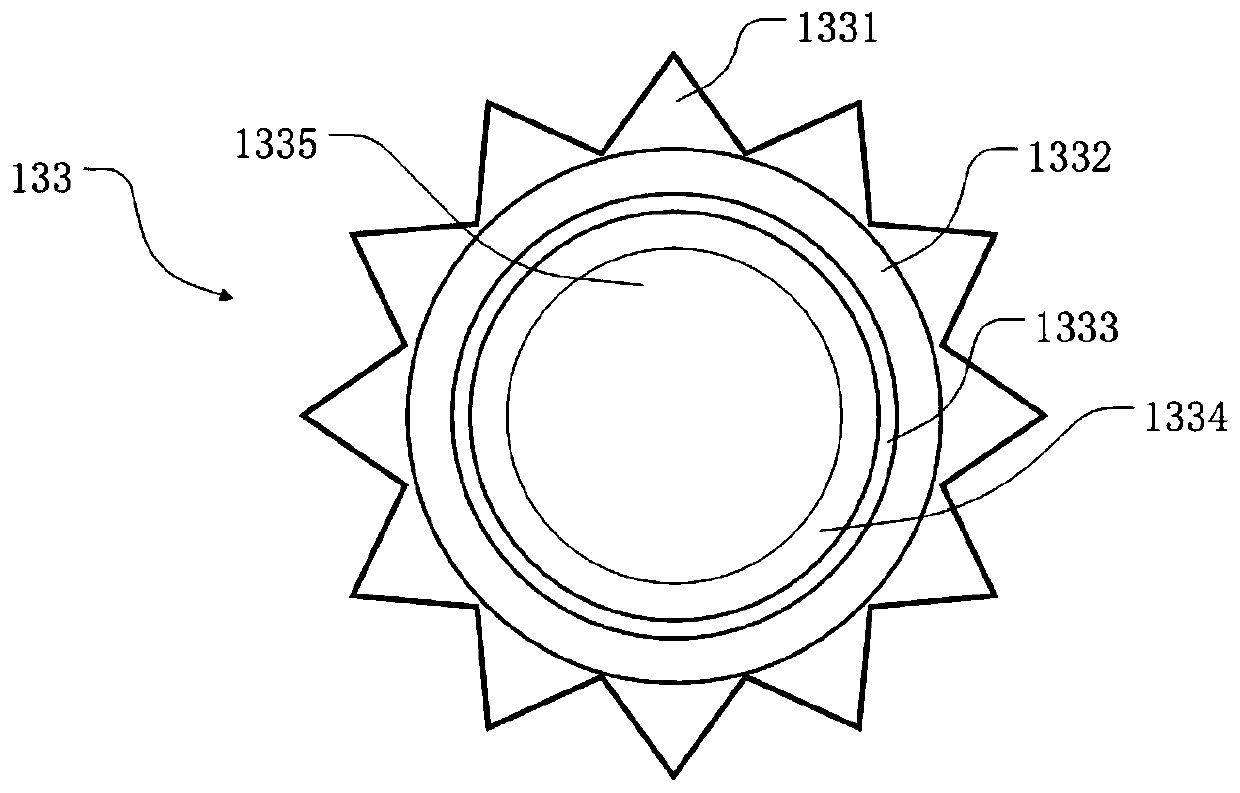

Steel pipe inner and outer plastic dipping production system

ActiveCN111068990AIncrease profitReduce pollutionPretreated surfacesCoatingsPipeMechanical engineering

The invention provides a steel pipe inner and outer plastic dipping production system. The steel pipe inner and outer plastic dipping production system comprises a steel pipe inner wall feeding device(1), a first steel pipe fixing device (2), a steel pipe outer wall feeding device (3), a second steel pipe fixing device (4) and a base (5), wherein the first steel pipe fixing device (2) and the second steel pipe fixing device (4) are arranged at two opposite ends of the base (5) respectively, the first steel pipe fixing device (2)and the second steel pipe fixing device (4) clamp the steel pipesin the length direction of the steel pipes; the steel pipe inner wall feeding device (1) is inserted into the steel pipes (6) to dip the inner walls of the steel pipes(6); the steel pipe outer wall feeding device (3) is located above the first steel pipe fixing device (2) and the second steel pipe fixing device (4), and the outer walls of the steel pipes are subjected to plastic dipping. The system has the advantages that the construction time is short, and the utilization rate of the plastic dipping material is high.

Owner:SHANDONG SHANGHE POWER TECH

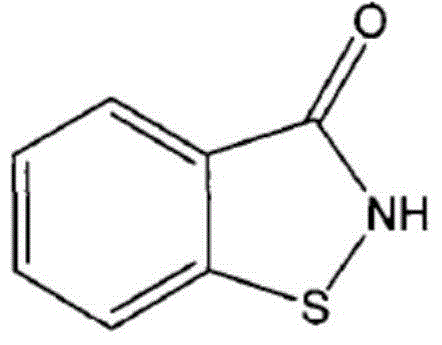

Solid waste reutilization technique in BIT (1,2-benzoisothiazolyl-3-one) production

The invention discloses a solid waste reutilization technique in BIT (1,2-benzoisothiazolyl-3-one) production, which comprises the following steps: mixing solid waste in BIT product with a solvent, and adding an acylation reagent while keeping the temperature at 0-60 DEG C to continuously release gas; while keeping the temperature at 20-30 DEG C, adding ammonia gas, ammonia water or ammonium chloride until the pH value is 9, and keeping the temperature at 30-80 DEG C for 3 hours; and adding water, introducing chlorine gas, heating to 50-90 DEG C, filtering out the solid, distilling the filtrate to recover the solvent, dissolving the solid in alkali, adding activated carbon for decolorization, filtering, regulating the pH value to 2-5 with hydrochloric acid, precipitating the solid, and centrifuging to obtain the solid. The technique analyzes the variety of byproducts in the solid residue and the specific chemical structure of each coproduct after the final solvent recovery in the existing BIT production technique, calculates the main components in all the byproducts, and provides a synthesis route according to the main components.

Owner:DAFENG YUELONG CHEM

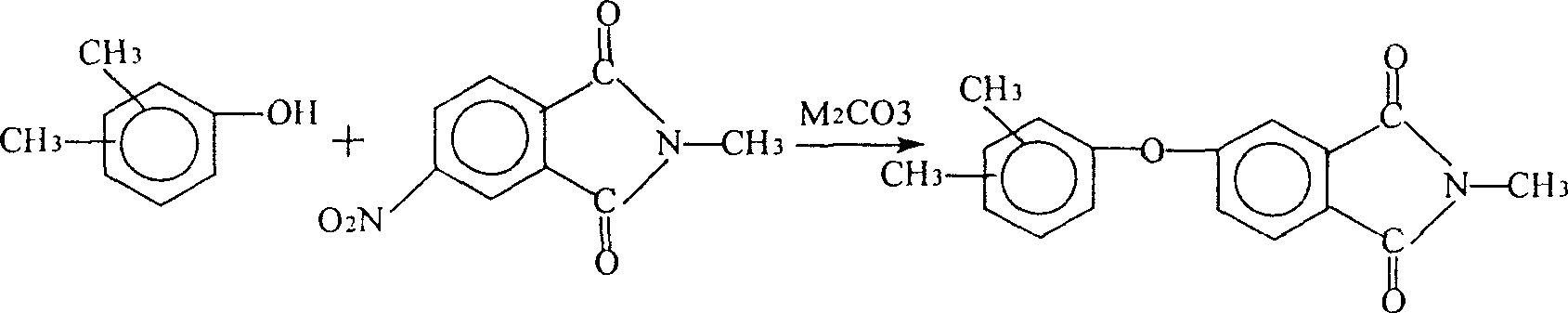

Prepn process of N-methyl-4-(dimethyl phenoxy) phthalimide

In the presence of tetrabutyl bromide and inside N, N-dimethyl acetylamide, dimethyl phenol, N-methyl-4-nitro phthalimide and anhydride alkali metal carbonate react at 130-135 deg.c for 12 hr; the reacted solution is filtered while being hot; the filtrate is cooled to room temperature to separate out crystal; and through filtering, yellowish solid crystal N-methyl-4-(dimethyl phenoxy) phthalimide is obtained in the yield of 92-95 %. The product of the present invention is the intermediate product of ODPA as the important polyimide.

Owner:SHANGHAI PLASTICS RES INST CO LTD

A new oxidation method for synthesizing alcatadine

ActiveCN105130993BImprove conversion rateLess impuritiesOrganic chemistryBenzeneHistamine H1 Receptor Antagonists

Owner:WUHAN WUYAO SCI & TECH

Method for synthesizing chloramphenicol from 4-chloro-benzaldehyde

ActiveCN102399162BHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparation4-chlorobenzaldehydeBenzaldehyde

Owner:WUHAN WUYAO SCI & TECH

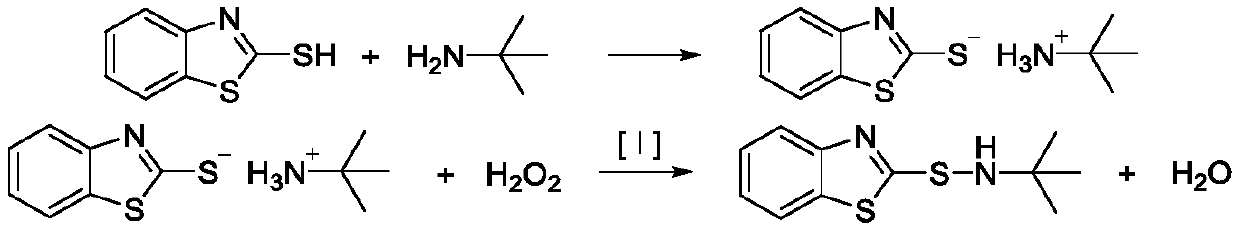

Process for preparing NS by oxidizing M tert-butyl ammonium salt with hydrogen peroxide

ActiveCN111303074ASolve the three wastes problemFix security issuesOrganic chemistryChemical synthesisTert-Butylamine

The invention discloses a process for preparing NS by oxidizing M tert-butylammonium salt with hydrogen peroxide, relates to a new synthesis process, in particular to a new NS synthesis process, and belongs to the technical field of chemical synthesis. The method is characterized by comprising the following steps: mixing and pulping a raw material M and tert-butylamine, adding a small amount of iodized salt (KI, NaI, KIO3, I2 and the like), dropwise adding an oxidant hydrogen peroxide under the condition of stirring and heating, and performing oxidation synthesis to obtain the product NS. Themethod provided by the invention not only overcomes the problem that a large amount of waste salt, waste gas and wastewater are generated in the preparation of NS by a traditional process, but also overcomes the problem that a hydrogen peroxide process is unstable, green, environment-friendly and clean production is realized, and the product has the advantages of high initial melting point, high purity and high yield.

Owner:CHEM TECH ACAD OF SHANDONG PROVINCE

Method for preparing broad-spectrum antibiotic chloramphenicol

ActiveCN102391143BRaw materials are easy to getAvoid splittingOrganic compound preparationCarboxylic acid amides preparationAlcoholBenzaldehyde

The invention relates to a method for preparing broad-spectrum antibiotic chloramphenicol. In the method, benzaldehyde and 2-nitroethyl alcohol are taken as raw materials; (1R, 2R)-2-nitro-1-phenyl-1,3-propanediol is obtained through synthesizing the raw materials under the presence of a chiral catalyst; (1R, 2R)-2-amino-1-phenyl-1,3-propanediol is obtained through hydrogenization to reduce; and the chloramphenicol is obtained through carrying out nitrification and dichloro-acetylation on the intermediate. With the adoption of the method provided by the invention, the chiral separation and the reduction of aluminum isopropoxide which are commonly used in industry nowadays can be avoided, the three wastes are reduced, the raw materials and reagents are cheap and easy to get, the synthetic steps are little, the yield is high, and thus, the method is more suitable for industrial production.

Owner:WUHAN WUYAO PHARMA

Vanadium-nitrogen alloy additive and preparation method thereof

InactiveCN105018774AEnergy savingSolve the three wastes problemPulverizerPharmaceutical preservatives

The invention discloses a vanadium-nitrogen alloy additive and a preparation method thereof and belongs to the new material field of special alloy manufacturing and the like. First a carbon material is smashed through a Raymond mill (or a pulverizer), the smashed carbon material and beta-cyclodextrin are placed in a stainless steel vacuum double helix mixer according to the proportion of (27-28):1, are evenly mixed for 1-3 h and then placed in a stainless steel bicone vacuum drying machine, the temperature is controlled to be 55-75 DEG C, and the product is obtained in 3-5 h. The carbon material serves as a raw material, beta-cyclodextrin serves as an excipient, and the carbon material and beta-cyclodextrin are mixed in the stainless steel vacuum double helix mixer and dried in the stainless steel bicone vacuum drying machine to produce the vanadium-nitrogen alloy additive; and the raw material is easy to obtain and the cost is low. The method is stable in process, free of three wastes and suitable for mass production.

Owner:ANHUI TIANGANG BIOTECH

A kind of oxidation method for preparing alcatadine

ActiveCN104987337BImprove conversion rateLess impuritiesOrganic chemistryBenzeneHistamine H1 Receptor Antagonists

The invention relates to a novel oxidation method for preparing a histamine H1 receptor antagonist--alcaftadine. The method comprises the step of using a Dess-Martin periodinane as an oxidation reagent to oxidize an intermediate--6,11-dihydro-11-(1-methyl-4-piperidylidene)-5H-imidazo[2,1-b][3]benzazepine-3- methanol so as to obtain the alcaftadine. The novel oxidation method for preparing the alcaftadine is simplified and has the advantages of simple operation, environment-friendly process, cheap and easily-available raw materials and reagents, high yield and more applicability to industrial production.

Owner:WUHAN WUYAO SCI & TECH

Preparation method of 4-(2,4-dichlorophenoxy) phenol

InactiveCN102126935ALow priceSolve the three wastes problemOrganic chemistryOrganic compound preparationChemistryNitrosylsulfuric acid

The invention relates to a preparation method of 4-(2,4-dichlorophenoxy) phenol. The method is characterized by comprising the following steps of: diazotizing 4-(2,4-dichlorophenoxy) aniline in a sulfuric acid medium with nitrosylsulfuric acid; and hydrolyzing in the sulfuric acid medium to obtain the 4-(2,4-dichlorophenoxy) phenol. The adopted nitrosylsulfuric acid is an industrial byproduct which absorbs sulfur dioxide, and has very low price. Due to the adoption of a new process, the problem of three wastes is solved, and the production cost is lowered.

Owner:YIFAN AGRI CHEM PLANT ZHEJIANG PROV

Synthetic method of methyl ethyl ketone peroxide with no three wastes produced

ActiveCN109796392AImprove securityEliminate security risks caused by instabilityOrganic compound preparationPeroxy compound preparationMethyl ethyl ketone peroxideButanone

The invention provides a synthetic method of methyl ethyl ketone peroxide with no three wastes produced. According to the technical scheme, hydrogen peroxide and butanone are subjected to reaction through reverse dropping of butanone by using dimethyl phthalate as a solvent; after reaction, a hydrophilic solvent is added into the reaction product so that a finished liquid is homogenous. The synthetic method has the advantages that the technical prejudice, where mixing butanone and a solvent is before the adding of an acid catalyst and the dropping of hydrogen peroxide, in the traditional synthetic method is broken through; the method, where hydrogen peroxide is used as a base material and acidity of the hydrogen peroxide is utilized to allow autonomous catalysis, is utilized, adding otheracids is not required by the method, butanone is subjected as a raw material to reaction with dimethyl phthalate acting as a solvent, no water is required after reaction, a fixed quantity of one solvent is added to the system before a stabilizer mixture is added, and mixing well is just required; the reaction process is very stable, no three wastes are produced during the synthesis of the finishedproduct, and the finished product has very good stability and good service performance.

Owner:淄博圣马化工有限公司

Method for treating waste food residues

InactiveCN108690367ATake advantage ofSolve the three wastes problemArtificial dyesFood industryEconomic benefits

The invention discloses a method for treating waste food residues. The method comprises the following steps: soaking mushroom residues with an E solvent for 6 to 12 h, carrying out filtering, then preparing a feed from filter residues, and subjecting a filtrate to high-temperature evaporative concentration and drying to prepare edible brown pigment which has a color index of 37000 EBC and stable performance and is applicable to the food industry and the medicine industry. The prepared feed has high protein content. The method of the invention allows the waste residues, i.e., the mushroom residues, obsessing the food industry for years to become the edible brown pigment and the feed with high economic benefits, treats waste gas, waste water and industrial residues, and achieves good effect.

Owner:蒋卫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com