Patents

Literature

357 results about "Tert-Butylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

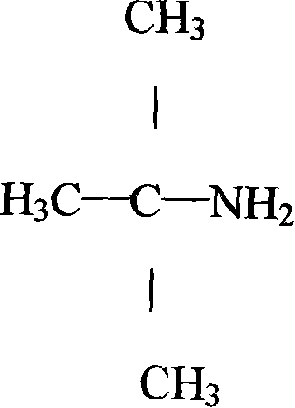

Tert-Butylamine is an organic chemical compound with the formula (CH₃)₃CNH₂. It is a colorless liquid with a typical amine-like odor. tert-Butylamine is one of the four isomeric amines of butane, the others being n-butylamine, sec-butylamine and isobutylamine.

Sacubitril derivatives and medicine compositions, preparation methods and application thereof

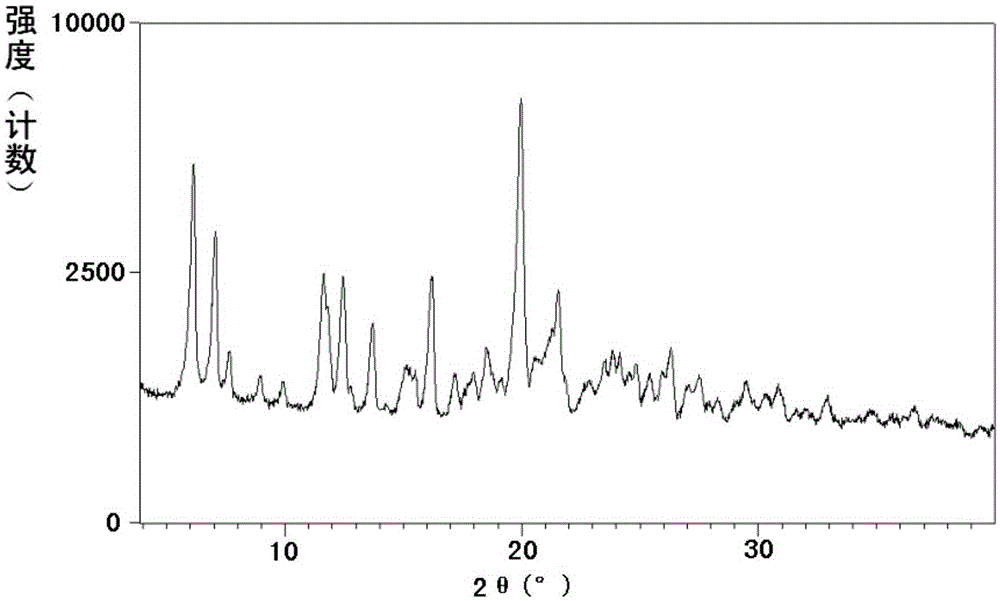

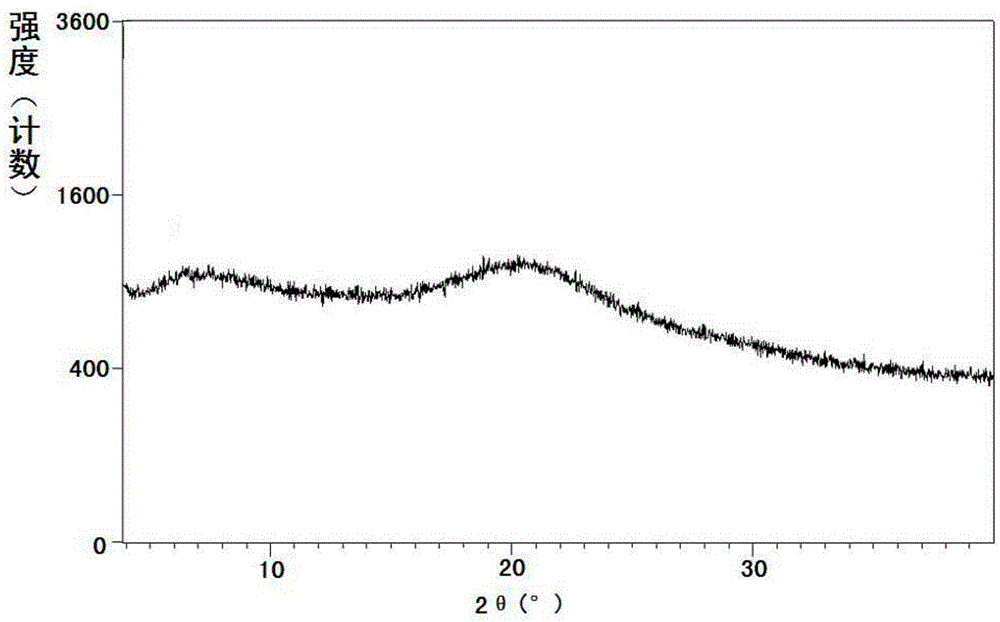

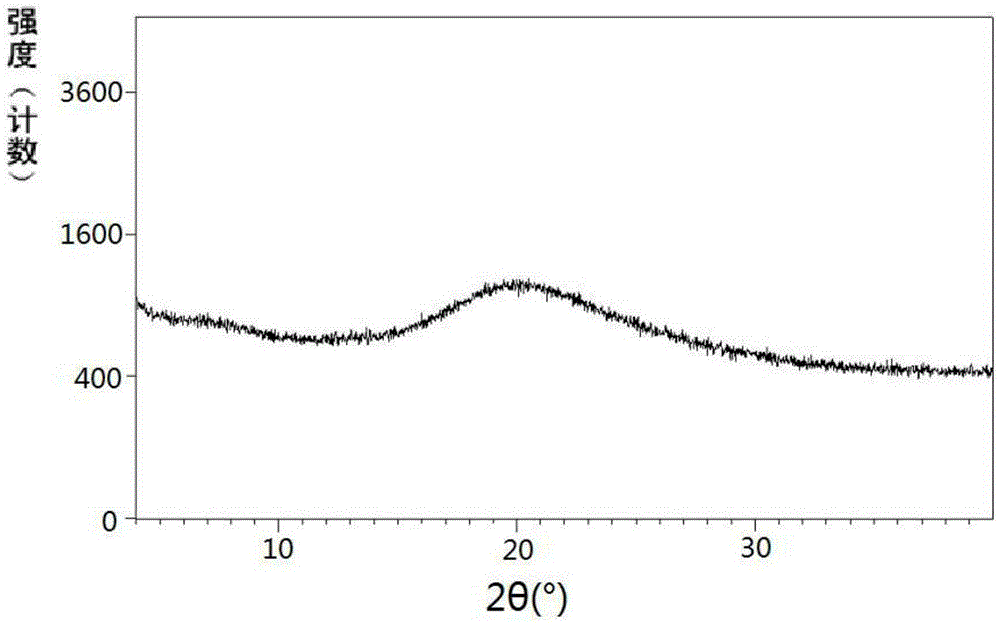

ActiveCN105693543AEasy to prepareCrystal form controllableAmino compound purification/separationOrganic compound preparationEthylenediamineArginine

The invention provides sacubitril derivatives and medicine compositions, preparation methods and application thereof and belongs to the fields of medicine compounds and preparation thereof. The sacubitril derivatives comprise sacubitril lithium salt, sacubitril kali salt, sacubitril magnesium salt, sacubitril calcium salt, sacubitril strontium salt, sacubitril zinc salt, sacubitril ferric salt, sacubitril ammonium salt, sacubitril diethylamine salt, sacubitril ethylenediamine salt, sacubitril piperazine salt, sacubitril N-(2-ethoxyl)-pyrrolidine salt, sacubitril choline salt, sacubitril cholamine salt, sacubitril diethanol amine salt, sacubitril triethanolamine salt, sacubitril tromethamine salt, sacubitril meglumine salt, sacubitril diisopropylamine salt, sacubitril tert-butylamine salt, sacubitril N, N'-bis-benzyl ethylenediamine salt, sacubitril L-lysine salt, sacubitril L-arginine salt or sacubitril L-histidine salt.

Owner:SICHUAN HAISCO PHARMA CO LTD

Heavy metal sewage treatment agent

InactiveCN104118921ARemove reachEasy to remove by filtrationWater/sewage treatment by ion-exchangeWater/sewage treatment by flocculation/precipitationCelluloseCarbamate

The invention relates to a heavy metal sewage treatment agent which is prepared from dodecyl diethylene triamine, dimethyl diallyl ammonium chloride, acrylamide, dibenzoyl peroxide, powdered activated carbon, ethylene diamine tetraacetic acid, tert-butylamine, carbamate, dithiocar-bamate, thiocarbamic acid ester, starch, cellulose, water soluble starch xanthate ester, sodium silicate, potassium peroxodisulfate, sodium hydrosulfite, strong base and water. The heavy metal sewage treatment agent disclosed by the invention is formed by being modified with a high-molecular compound; the mixture contains a plurality of active groups which can be complexed, chelated, absorbed and exchanged with heavy metal, so that heavy metal ions in the aqueous solution can be removed; the heavy metal sewage treatment agent has good removal effect on heavy metal ions, the removal rate is above 97%, and furthermore, the heavy metal sewage treatment agent has stronger Ca2+ and Mg2+ resistant capability; the removal rate of cadmium-containing sewage is 99.8%, which meets the national emission standard; and the removal rate of chromium-containing sewage is above 99.6%.

Owner:江西省恩皓环保有限公司

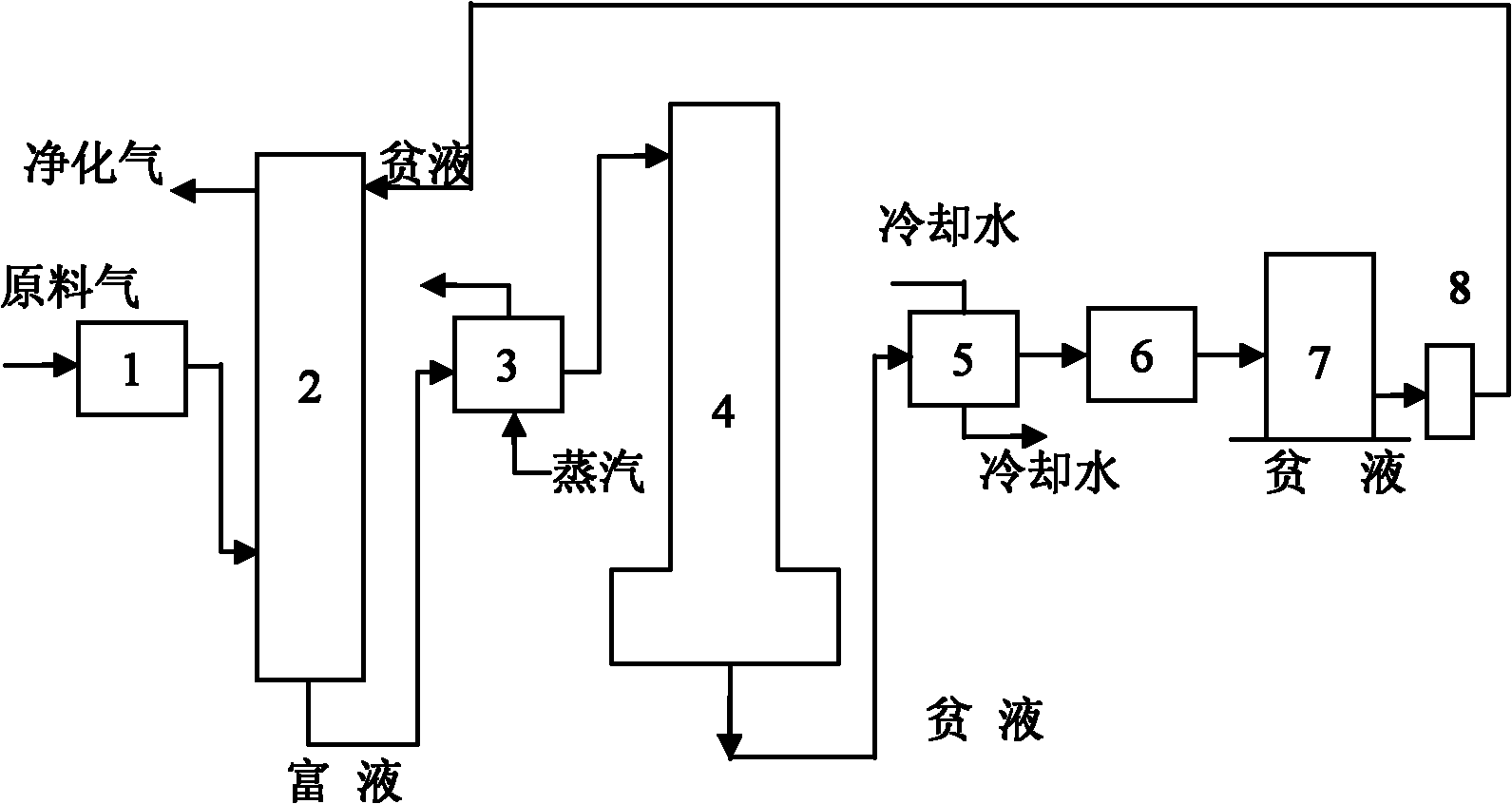

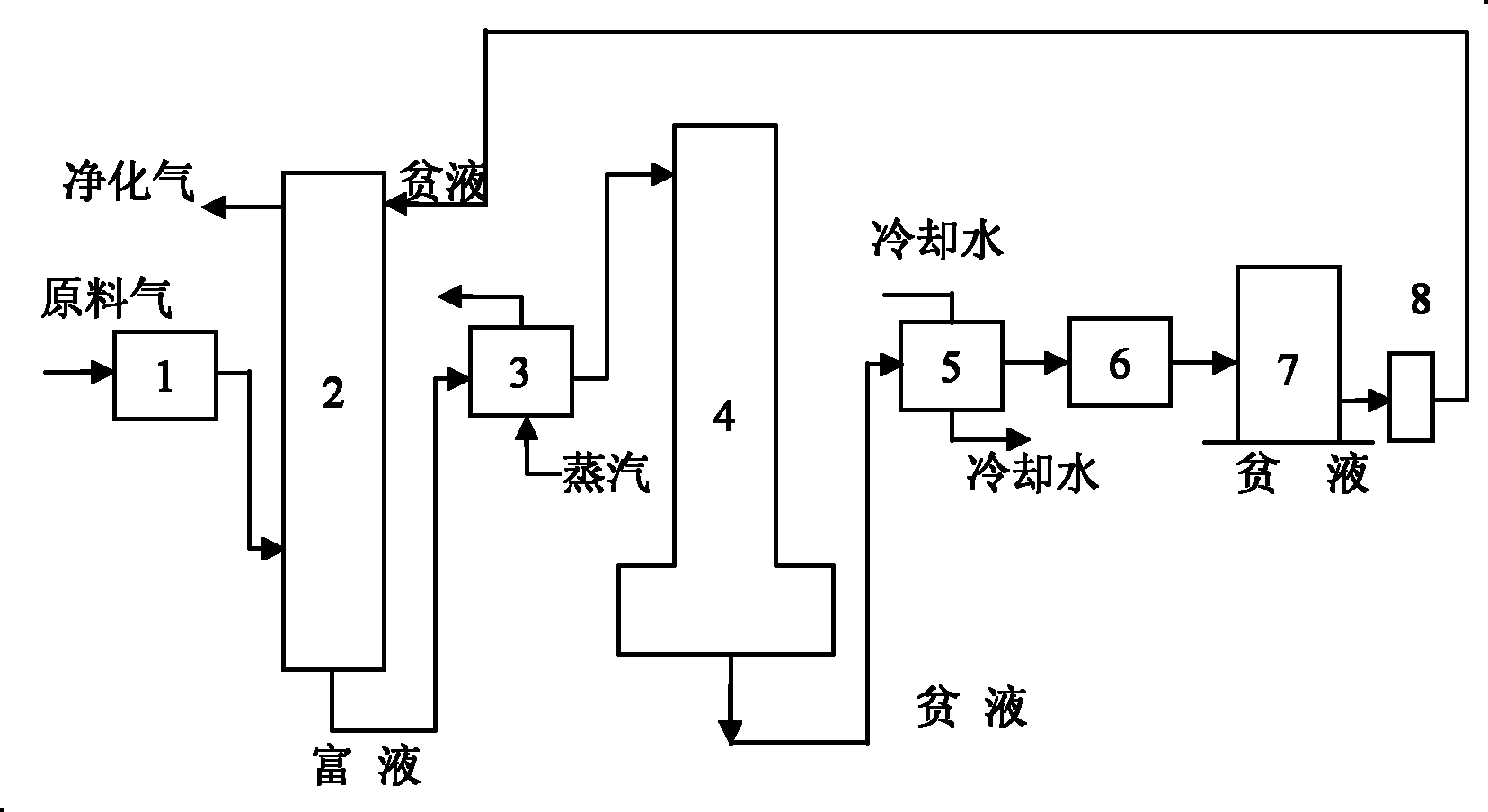

High-efficient desulfurizing agent for removing hydrogen sulfide and organic mercaptan from mixed gas

InactiveCN101844035AHigh mercaptan removalHigh acid gas loadDispersed particle separationSulfolaneTert-Butylamine

The invention discloses a high-efficient desulfurizing agent for removing hydrogen sulfide and organic mercaptan from mixed gas, which comprises serotonin, wherein the serotonin consists of N-methyl diethanolamine and ethoxy ethanol tert-butylamine, and also comprises sulfolane and N-Hydroxyethyl piperidine. The weight ratio of the serotonin in the desulfurizing agent is 70 to 85 percent; the weight ratio of the sulfolane in the desulfurizing agent is 5 to 10 percent; and the weight ratio of the N-Hydroxyethyl piperidine in the desulfurizing agent is 10 to 20 percent. By mixing physical and chemical solvent and abstracting the advantages of the physical and chemical solvent, so on the premise that the removal effect of H2S is ensured, the organic sulfur can be removed high efficiently; and the desulfurizing agent has large acid gas load, strengthens the reaction speed between the H2S and MDEA and TBEE, so the consumption of the desulfurizing agent is small during the gas purification process, and the regeneration energy consumption of the solvent is low.

Owner:四川省精细化工研究设计院

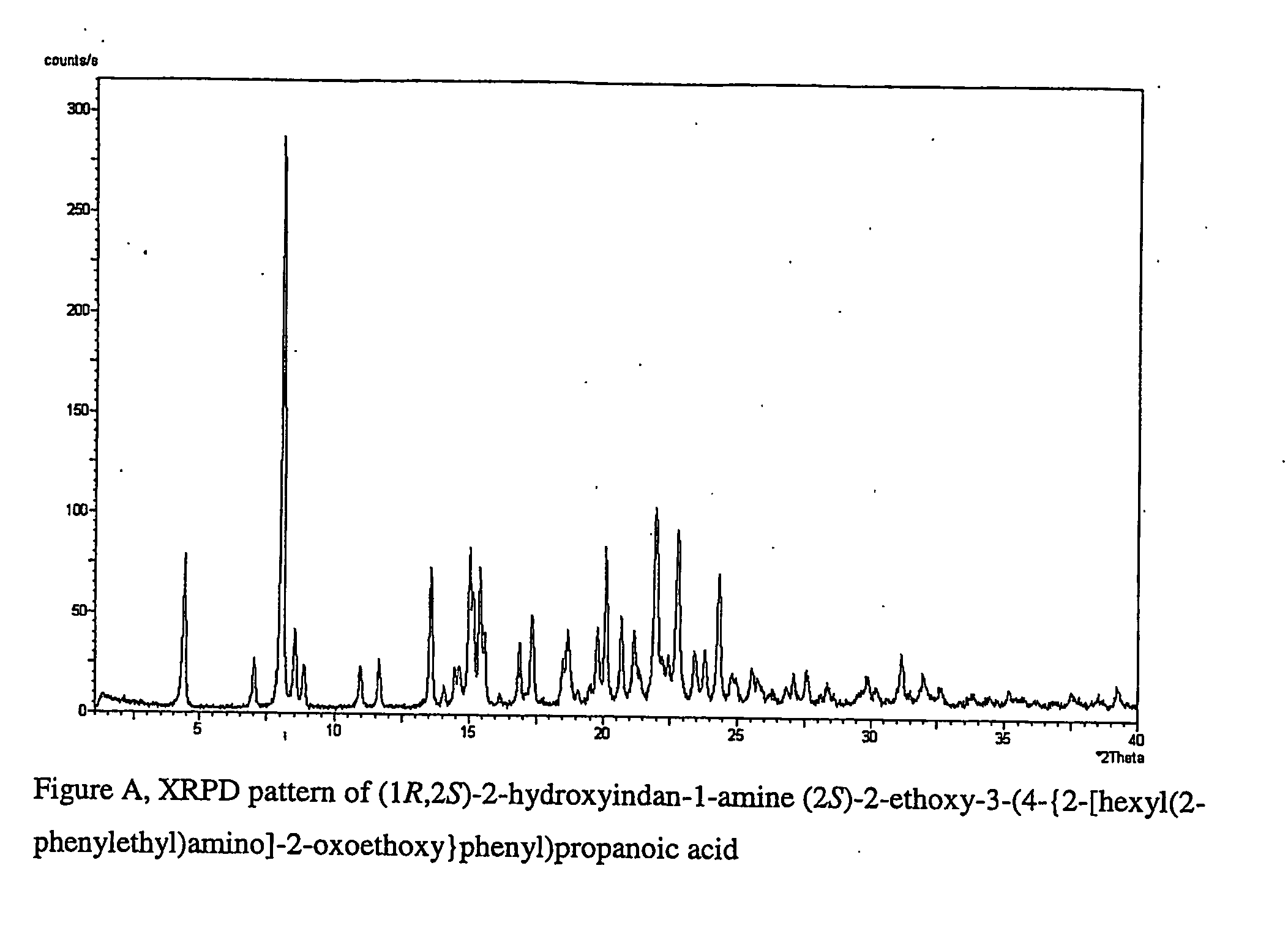

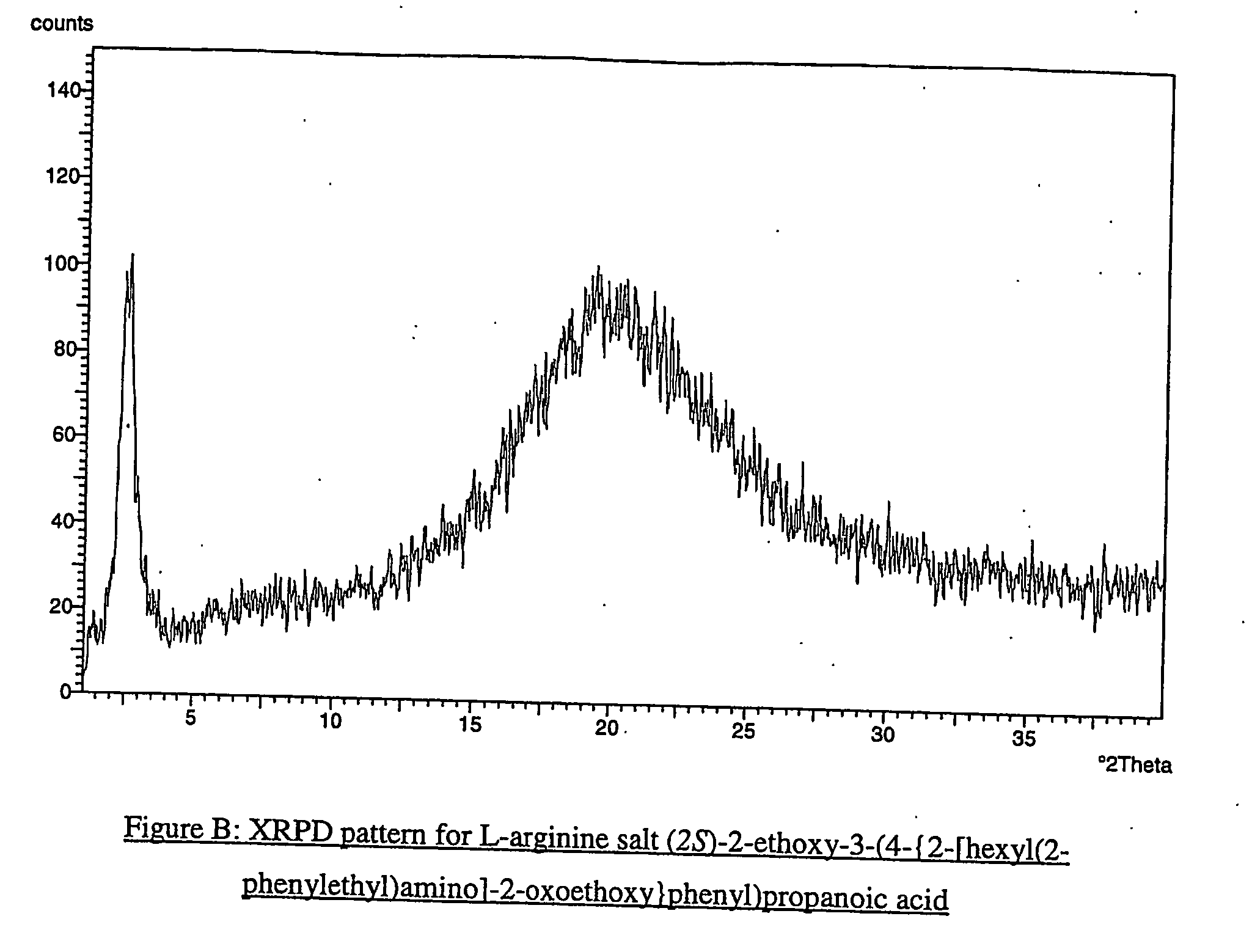

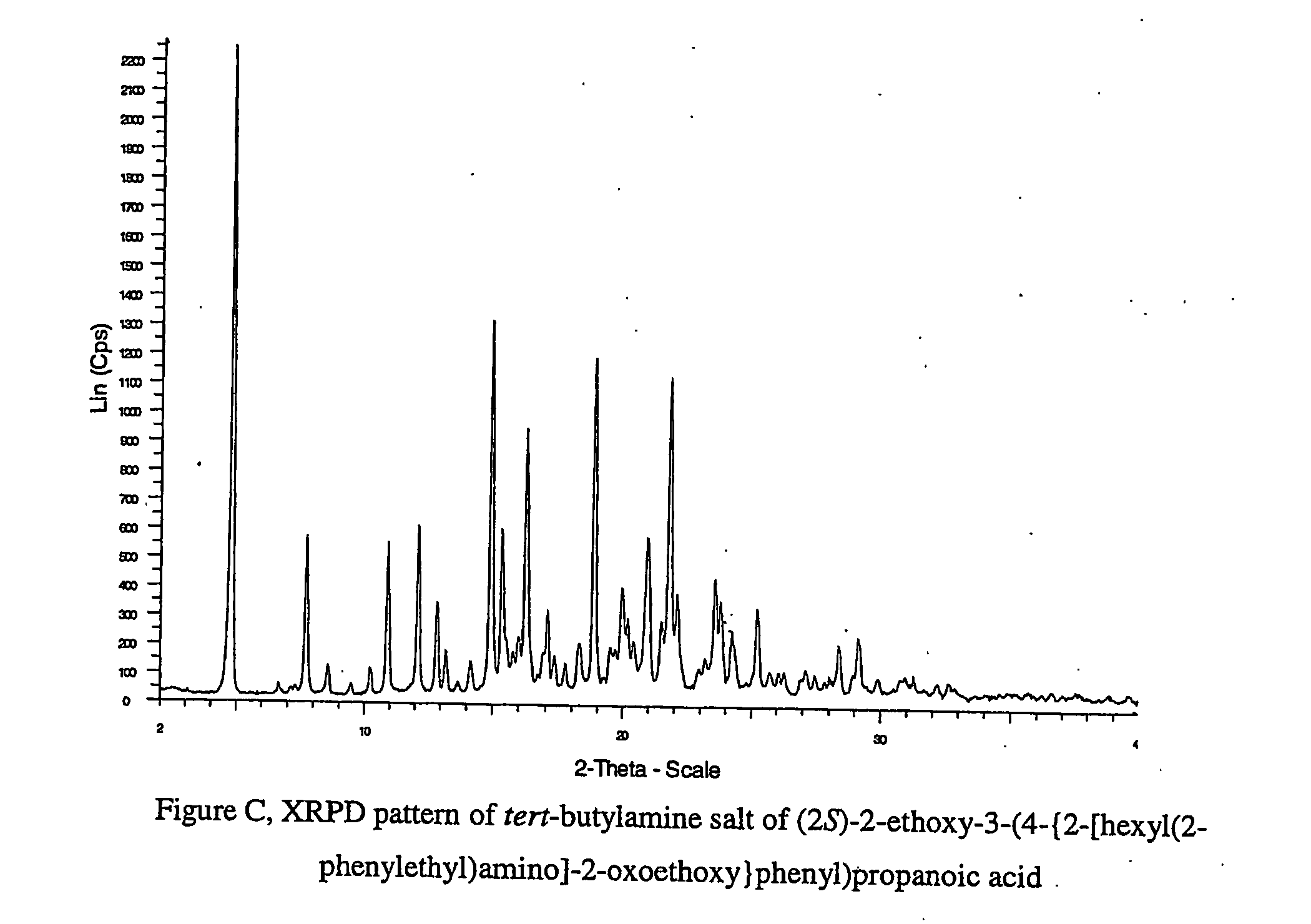

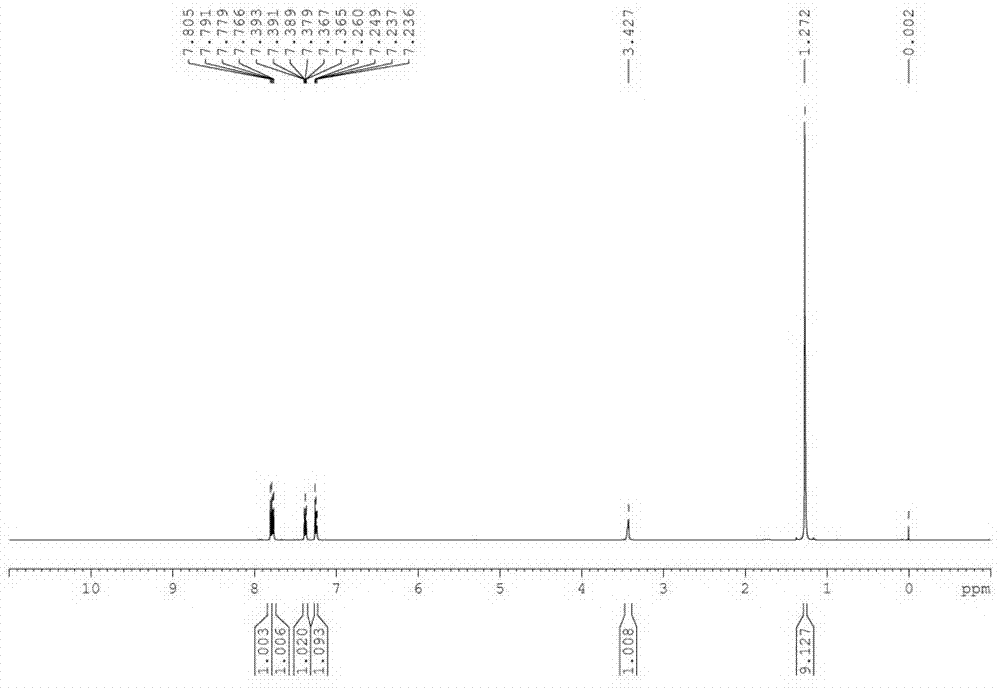

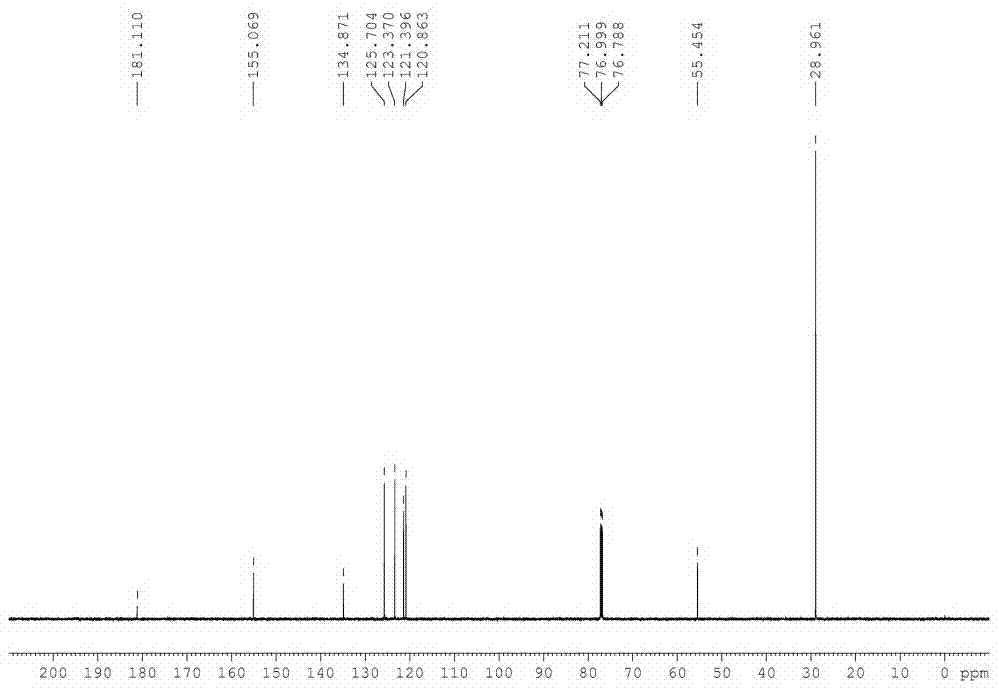

Pharmaceutically useful salts of carboxylic acid derivatives

A compound selected from one or more of the following: a (1R,2S)-2-hydroxyindan-1-amine salt of (2S)-2-ethoxy-3-(4-{2-[hexyl(2-phenylethyl)amino]-2-oxoethoxy}phenyl)propanoic acid; an L-arginine salt of (2S)-2-ethoxy-3-(4-{2-[hexyl(2-phenylethyl)amino-2-oxoethoxyphenyl)propanoic acid; a tert-butylamine salt of (2S)-2-ethoxy-3-(4-{2-[hexyl(2-phenylethyl)amino-2-oxoethoxyphenyl)propanoic acid; a choline salt of (2S)-2-ethoxy-3-(4-{2-[hexyl(2-phenylethyl)amino]-2-oxoethoxy}phenyl)propanoic acid; an adamantylamine salt of (2S)-2-ethoxy-3-(4-{2-[hexyl(2-phenylethyl)amino]-2-oxoethoxy}phenyl)propanoic acid; a N-benzyl-2-phenylethanaminium salt of (2S)-2-ethoxy-3-(4-{2-[hexyl(2-phenylethyl)amino]-2-oxoethoxy}phenyl)propanoic acid; a N-benzyl-2-(benzylamino) ethanaminium salt of (2S)-2-ethoxy-3-(4-{2-[hexyl(2-phenylethyl)amino]-2-oxoethoxy}phenyl)propanoic acid; or a tris(hydroxymethyl)methylamine salt of (2S)-2-ethoxy-3-(4-{2-[hexyl(2-phenylethyl)amino]-2-oxoethoxy}phenyl)propanoic acid.

Owner:ASTRAZENECA AB

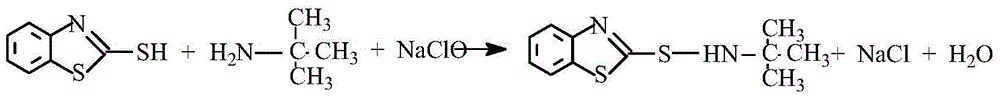

Method for preparing sulfenamide thiofide by catalyzing oxidization of molecular oxygen in water phase

ActiveCN106866577AHigh catalytic activityImprove reaction efficiencyOrganic chemistryChemical recyclingPhthalocyanineBy-product

The invention relates to a method for preparing sulfenamide thiofide by catalyzing oxidation of molecular oxygen in a water phase. According to the method, a water-soluble transition metal phthalocyanine compound is utilized as a catalyst, and 2-mercaptobenzothiazole generates oxidation cross coupling reaction with amine (tert-butylamine or cyclohexane) for 1 to 30 hours to generate sulfenamide thiofide in the water phase under the conditions that oxygen (or air) pressure is 0,01 to 1MPa, and temperature is 40 to 100 DEG C. Reaction of the preparation method disclosed by the invention is performed in the water phase, other organic solvents are prevented from being added, catalyst activity is high, reaction efficiency is high, the catalyst can be used repeatedly, a synthesizing technology is concise, product selectivity is high, by products are few, waste is little, environmental friendliness is achieved, and the preparation method has stronger industrial application prospect.

Owner:WILLING NEW MATERIALS TECH CO LTD

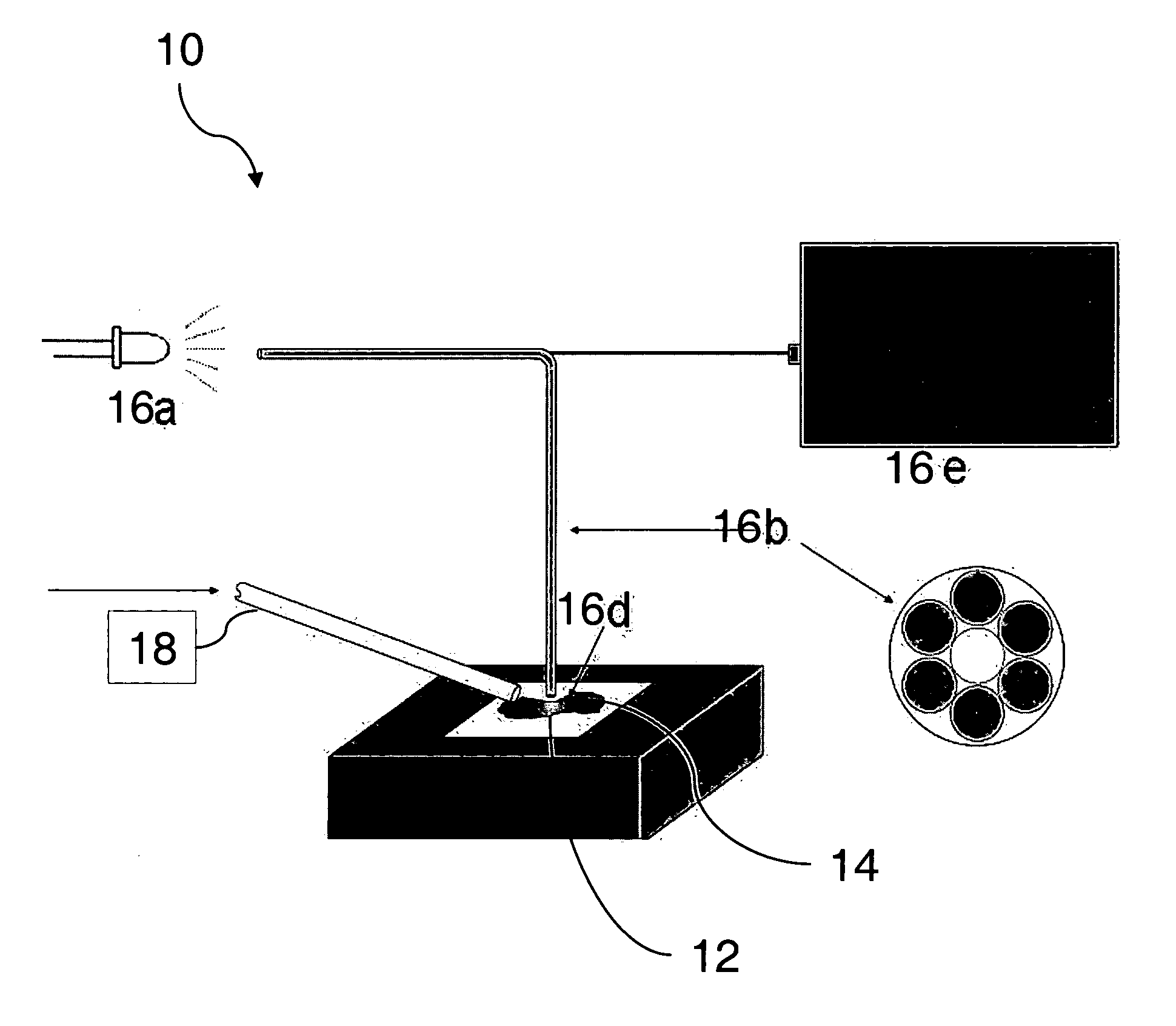

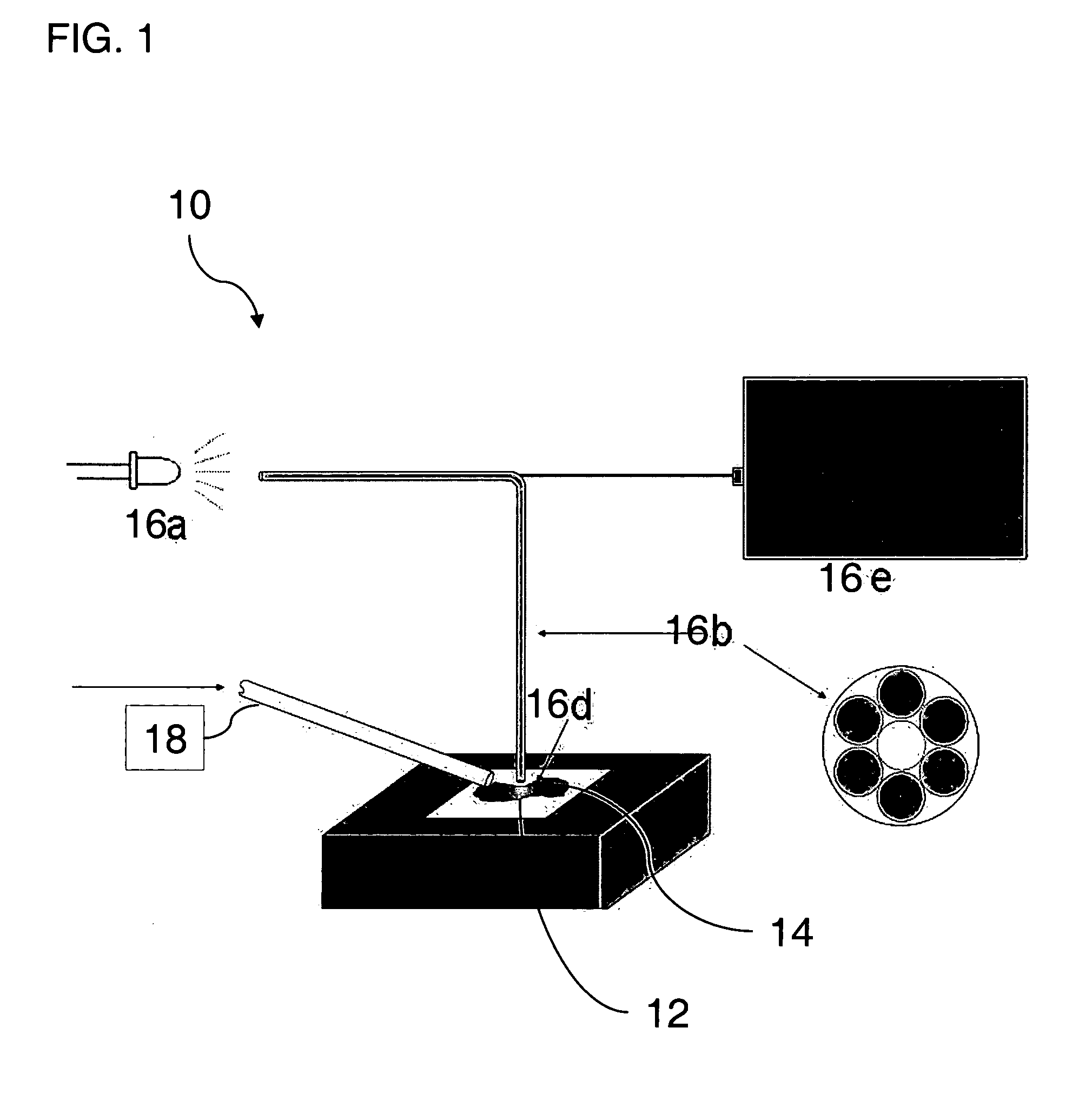

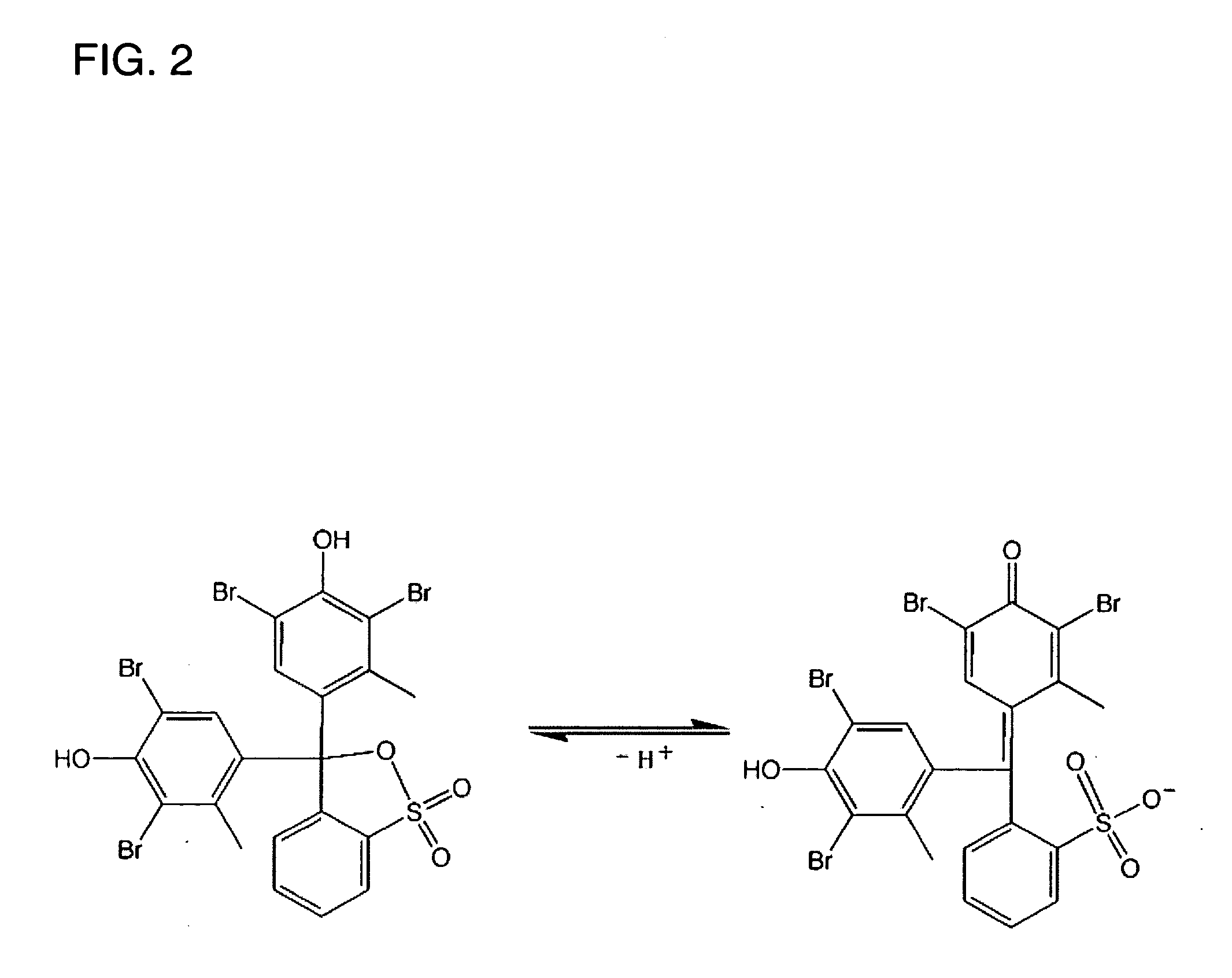

Optical gas sensor based on dyed high surface area substrates

InactiveUS20060263257A1Material analysis by observing effect on chemical indicatorComponent separationMicrosphereColor changes

A new optical sensing method for detection of analyte vapors down to ppb levels is described. The sensor is based on the use of a visible indicator, such as Bromocresol green, adsorbed onto a high surface area substrate, such as a silica sphere matrix. When the analyte gas is adsorb onto the matrix, the indicator undergoes a color change. The color change in turn is detected with a suitable spectrometer. Sensor performance is demonstrated for an exemplary amine sensor for the aliphatic amines tert-butylamine, diethylamine and triethylamine and also for pyridine and aniline. The microsphere sensor is more sensitive than other prior art optical amine sensor designs. The sensor response varies with temperature, with lower sensitivity and faster response at higher temperatures allowing for adjustment to prioritize sensitivity or speed. The sensor response is also highly reproducible and fully reversible.

Owner:CALIFORNIA INST OF TECH

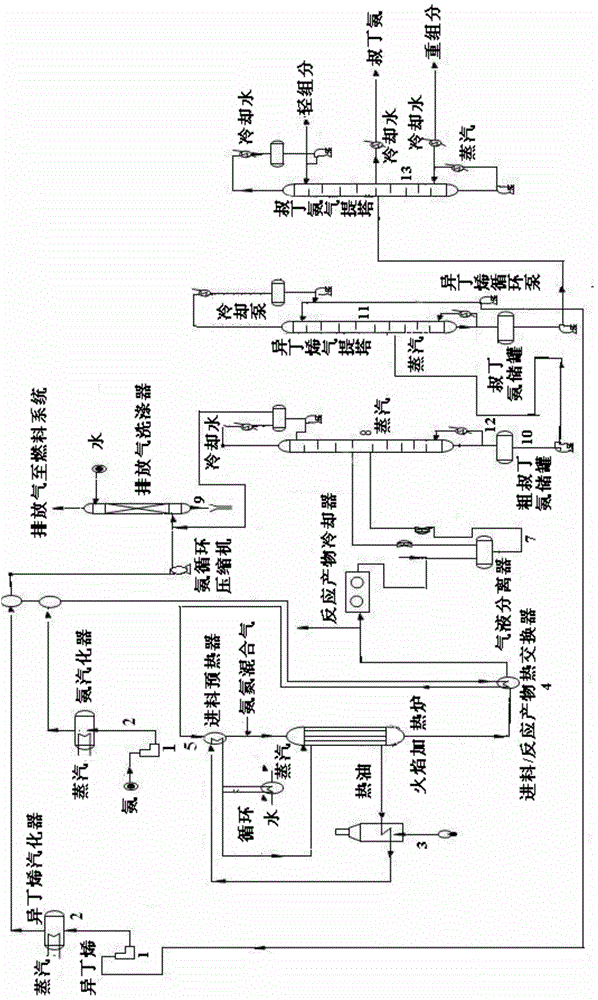

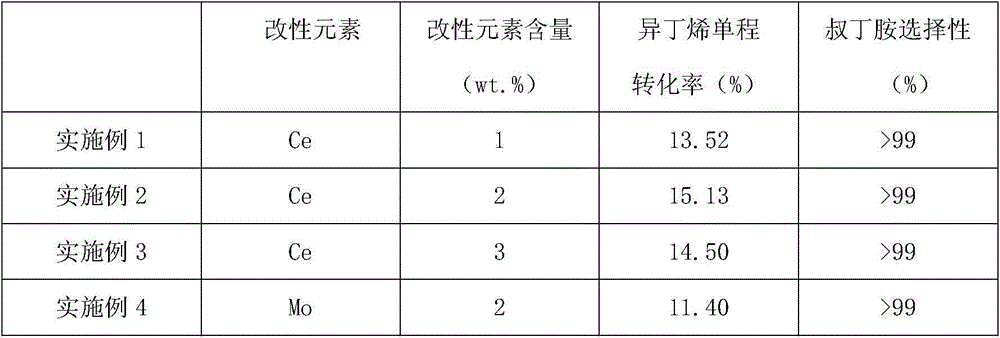

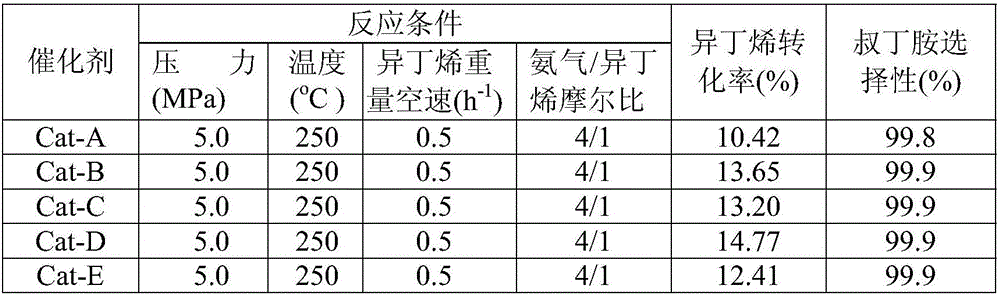

Method for producing tert-butylamine by direct catalytic amination of isobutene

ActiveCN104418754AAvoid pollutionInhibit aggregationOrganic-compounds/hydrides/coordination-complexes catalystsAmino compound preparation by condensation/addition reactionsRare-earth elementReaction temperature

The invention relates to a method for producing tert-butylamine by direct catalytic amination of isobutene, which is characterized by comprising the following steps: continuously injecting an olefin raw material and ammonia into a multitubular fixed bed reactor filled with a catalyst for direct amination reaction, wherein the feed mole ratio of the olefin raw material to ammonia is 1:0.5-1:4; and performing rectification separation of the reaction products to obtain tert-butylamine with purity of 99.9%. In the process of the invention, the molecular sieve catalyst is subjected to element modification so as to realize optimal adjustment of surface acidity, thus polymerization of the olefin is prevented, and the service life and the reaction selectivity of the catalyst are improved. The molecular sieve catalyst used in the invention is modified by rare earth elements or transition metal elements and organic halides and has improved catalytic performance, a special process operation method is adopted, thus the process of the invention is carried out at a low reaction temperature and reaction pressure, the olefin conversion rate and the amide selectivity are improved when compared with the prior art, and the service life of the catalyst is prolonged.

Owner:王荣发

Environment-friendly preparation method of tert-butylamine

InactiveCN102633647AExtended service lifeLow reaction temperatureMolecular sieve catalystsAmino compound preparation by condensation/addition reactionsPtru catalystArgon atmosphere

The invention discloses an environment-friendly preparation method of tert-butylamine. Isobutylene and liquid ammonia are directly subjected to amination under the action of a catalyst to prepare the tert-butylamine. The catalyst uses a Y-type zeolite molecular sieve as the matrix, and the active component elements and modifying elements account for 10-30%. The Y-type zeolite molecular sieve is modified by the following steps: exchanging the Y-type zeolite molecular sieves with an NH4Cl aqueous solution, washing, drying in a nitrogen or argon atmosphere, and carrying out heat treatment by roasting to obtain an H-type zeolite molecular sieve; and carrying out dipping treatment on the H-type molecular sieve with metal salt, drying in a nitrogen or argon atmosphere, roasting to obtain the modified Y-type zeolite molecular sieve. The modified Y-type zeolite molecular sieve catalyst must be activated before use. The invention has the advantages of mild reaction conditions, high selectivity, high yield, environment friendliness and low catalyst modifying cost, and is suitable for industrial production.

Owner:ZHEJIANG HUANGMA TECH

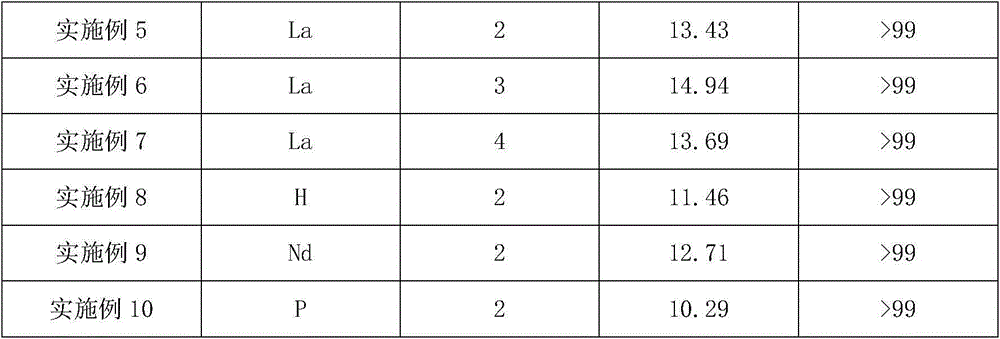

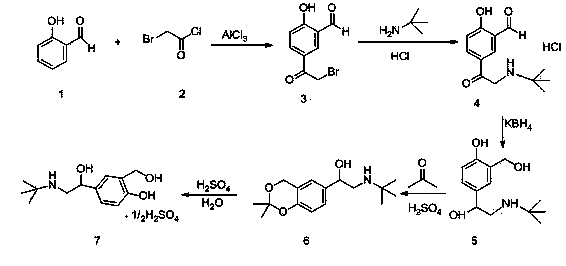

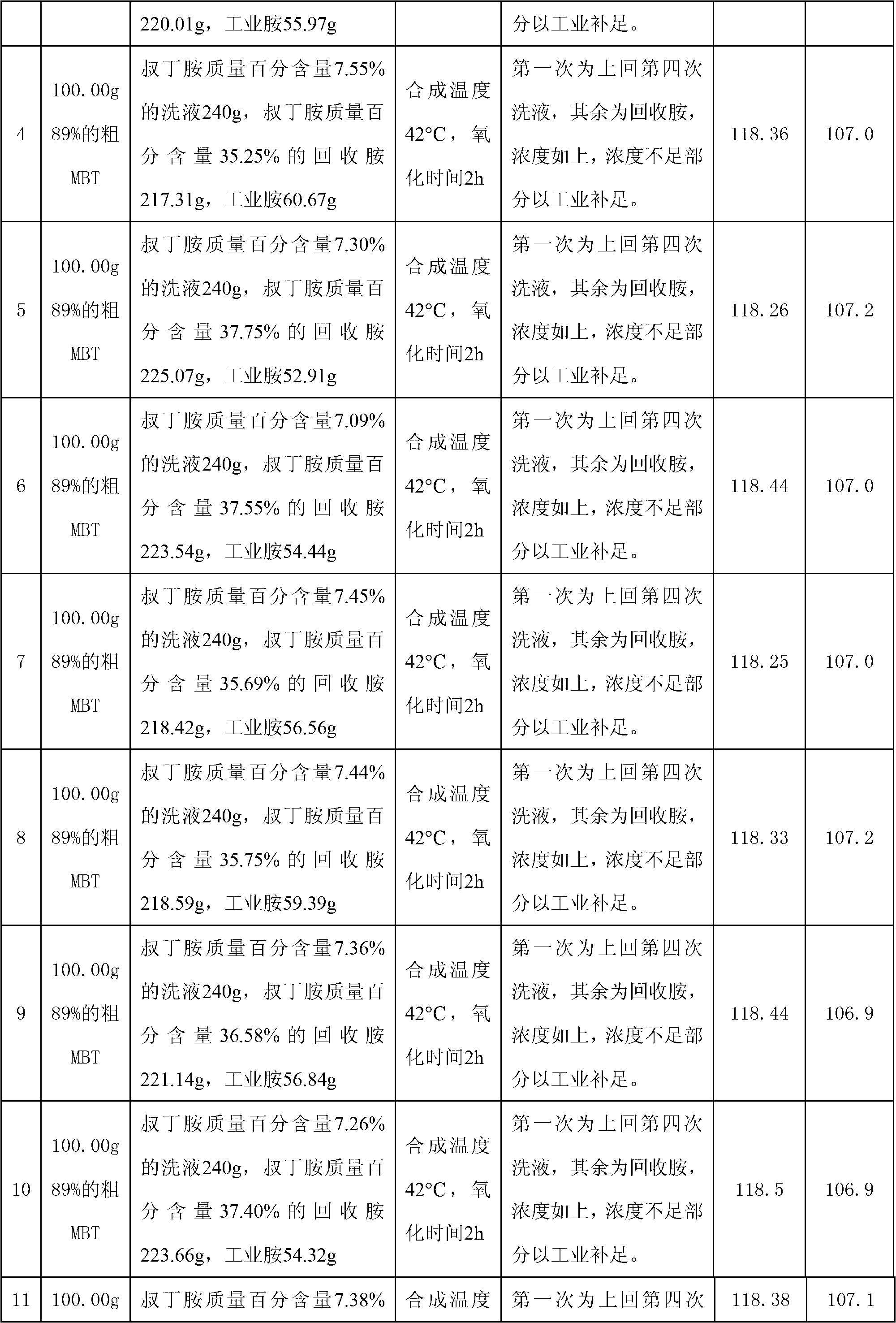

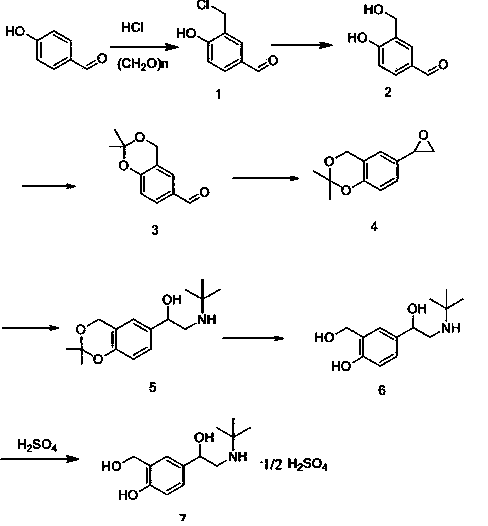

Production technology for synthetizing salbutamol sulphate

InactiveCN104356009AShort reaction stepsMild reaction conditionsOrganic compound preparationAmino-hyroxy compound preparationChemical synthesisSalicylaldehyde

The invention discloses a production technology for synthetizing salbutamol sulphate, and relates to the field of chemical synthesis. The production technology comprises the following steps: firstly, performing an Friedel-crafts acylation reaction on salicylal to obtain a chemical compound 3, performing a substitution reaction of tert-butylamine, protecting dihydroxy by propylidene under the catalysis of concentrated sulfuric acid through the reduction of potassium borohydride or sodium borohydride, then performing extraction for desalting, and generating a hydrolysis reaction under acid conditions to obtain sulphuric acid salbutamol. The production technology disclosed by the invention is easy to control and operate, raw materials are simple and easy to obtain, the total mol yield is as high as 40%, the product purity is as high as 99.5%, and the product cost is low.

Owner:扬州市三药制药有限公司

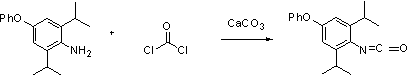

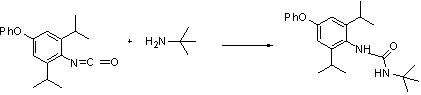

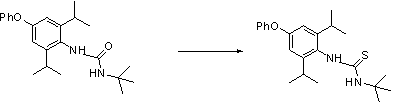

Synthesis process for diafenthiuron as thiourea insecticide and acaricide

InactiveCN102993075AMild reaction conditionsEasy to operateOrganic chemistryThioureaSynthesis methods

The invention discloses a synthesis research method for diafenthiuron as a novel thiourea insecticide and acaricide. The synthesis method comprises the following steps of: firstly, synthesizing an N-2,6-diisopropyl-4-phenoxylphenyl)isocyanate intermediate by taking 2,6-diisopropyl-4-aminobiphenyl ether and triphosgene as raw materials; then, subjecting the generated N-2,6-diisopropyl-4-phenoxylphenyl)isocyanate intermediate and tert-butylamine to a reaction to generate 3-(2,6-diisopropyl-4-phenoxylphenyl)-1-tert-butyl urea; and then, subjecting the 3-(2,6-diisopropyl-4-phenoxylphenyl)-1-tert-butyl urea and phosphorus pentasulfide to a reaction under the action of potassium carbonate to finally generate diafenthiuron. The synthesis process is a more effective method for synthesizing the diafenthiuron, which has the advantages of mild reaction conditions, simplicity in operation, cheaper raw materials, lower toxicity and the like.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

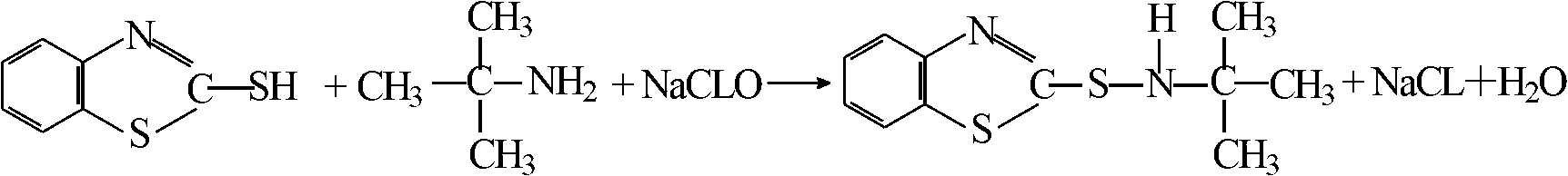

Clean production method of rubber vulcanizing accelerator TBBS

InactiveCN101717380AReduce consumptionImprove conversion rateOrganic chemistryPotassium iodineAccelerant

The invention discloses a clean production method of a rubber vulcanizing accelerator TBBS, relating to the clean production method of the rubber vulcanizing accelerator TBBS. The cleaning production method is characterized by comprising the following steps of: a, preparing mixing liquid by 1 wt% of accelerators M, 1.5 to 2.4 wt% of tert-butylamine, 0.01 to 0.02 wt% of catalysts and 8 to 14 wt% of water; b, dropwise adding 27.5 wt% hydrogen peroxide in the solution with the flow rate of 50 to 110 ml / min, wherein the oxidizing temperature is 30 to 50 DEG C, and the oxidizing time is 120 to 180 min; c, sampling, detecting by using ammonium sulfate and starch potassium iodide reagents, and stopping adding the hydrogen peroxide when materials are brown in color through detection; and d, filtering and drying to obtain the rubber vulcanizing accelerator TBBS. The invention has the advantages of simple production process, low raw material consumption, high yield, cleanness, environment protection and energy saving; the yield of the accelerator TBBS is higher than 99%, and the product quality is higher than the national primary standard; waste water generated in the technology contains no salt and is easy for biochemical treatment; and the invention reduces environmental pollution and equipment corrosion.

Owner:河南省开仑化工有限责任公司

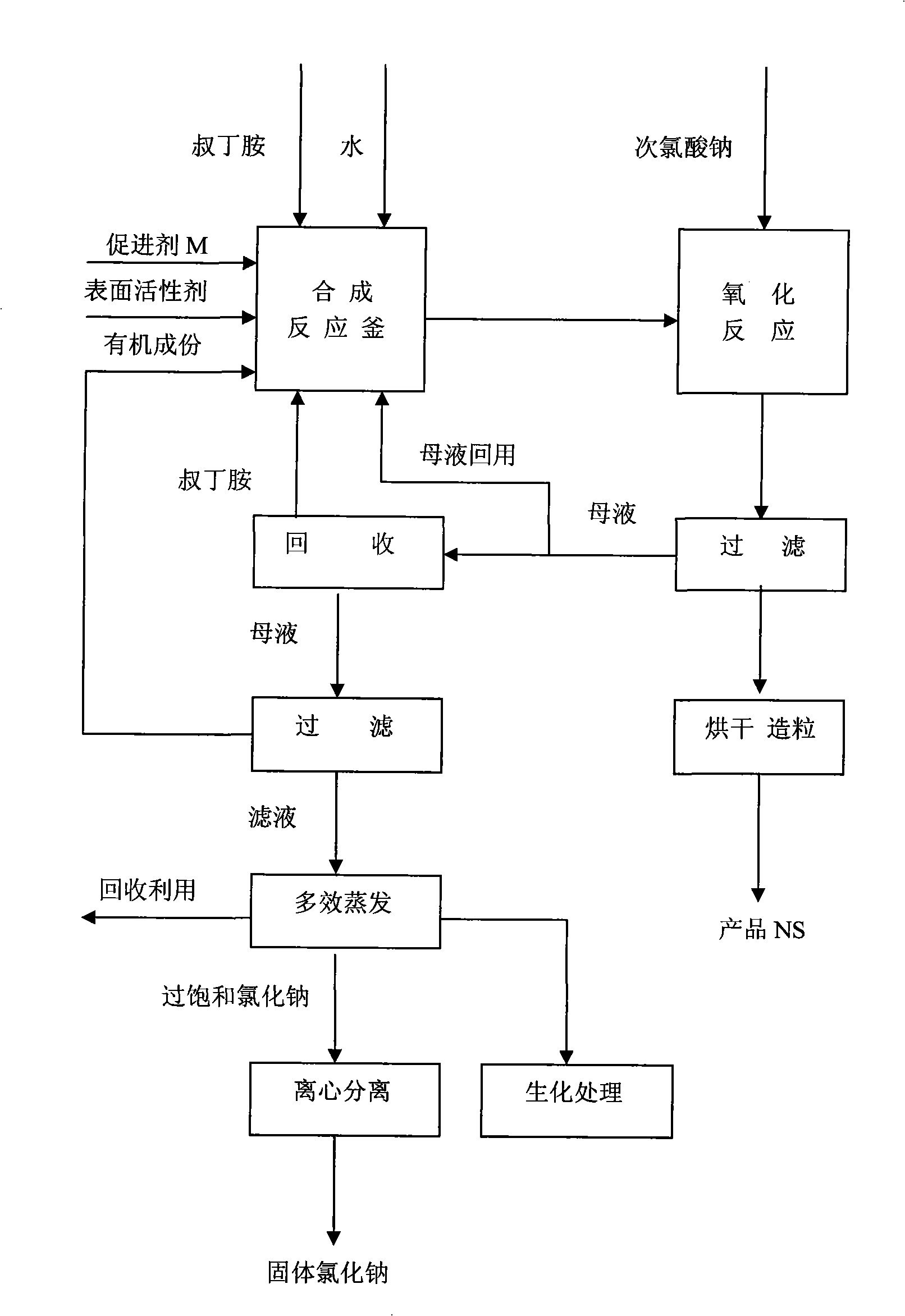

Process for treating waste water of rubber vulcanization accelerator NS production

ActiveCN101407344AEfficient extractionSolve intractableAmino compound purification/separationWater/sewage treatment by heatingVulcanizationEvaporation

The invention provides a thiofide NS wastewater treatment process as follows: process water, a raw material M, a surfactant are blended and stirred according to proportion, then tert-butylamine is added into a synthesis reaction kettle for fully beating; after warming and activating, an NS slurry is obtained by dropping sodium hypochlorite solution to carry out oxidation synthesis reaction at a certain temperature, a part of filtered NS mother liquor is returned to the NS synthesis reaction kettle to apply, a part of filtered NS mother liquor is vacuum-distilled to recover tert-butylamine, organic components such as NS dissolved in tert-butylamine are separated out, the recycled mother liquid is filtered, the separated organic substances are put into the synthesis reaction kettle to continue reaction, the filter liquor is led to carry out multiple effect evaporation, sodium chloride saturated solution is obtained, and a part of the evaporable water is returned to the device to recycle, while the other part thereof is carried out biochemical treatment.

Owner:SHANDONG YANGGU HUATAI CHEM +1

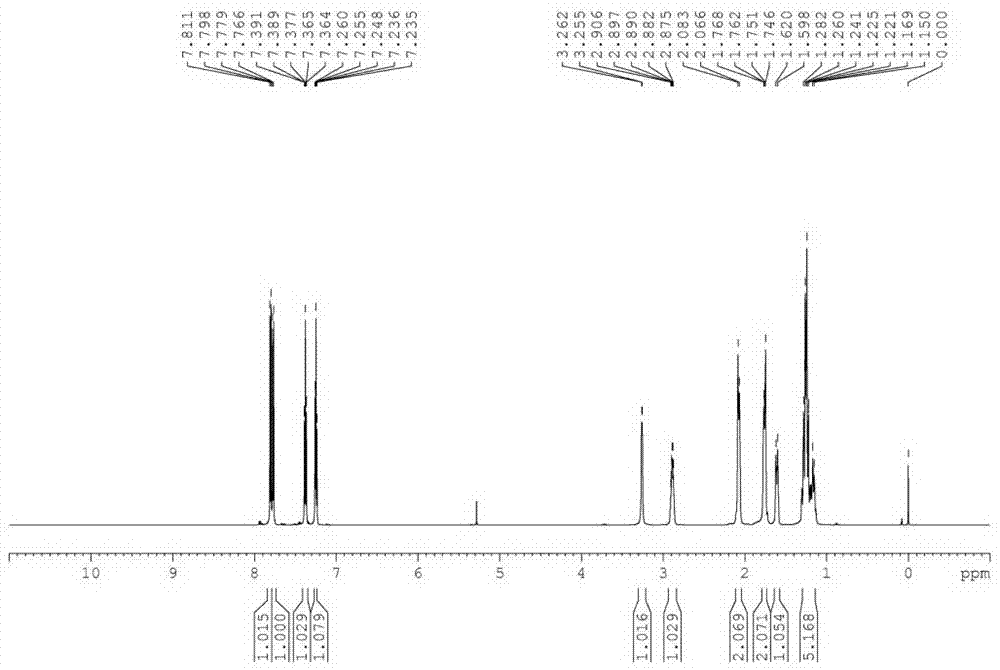

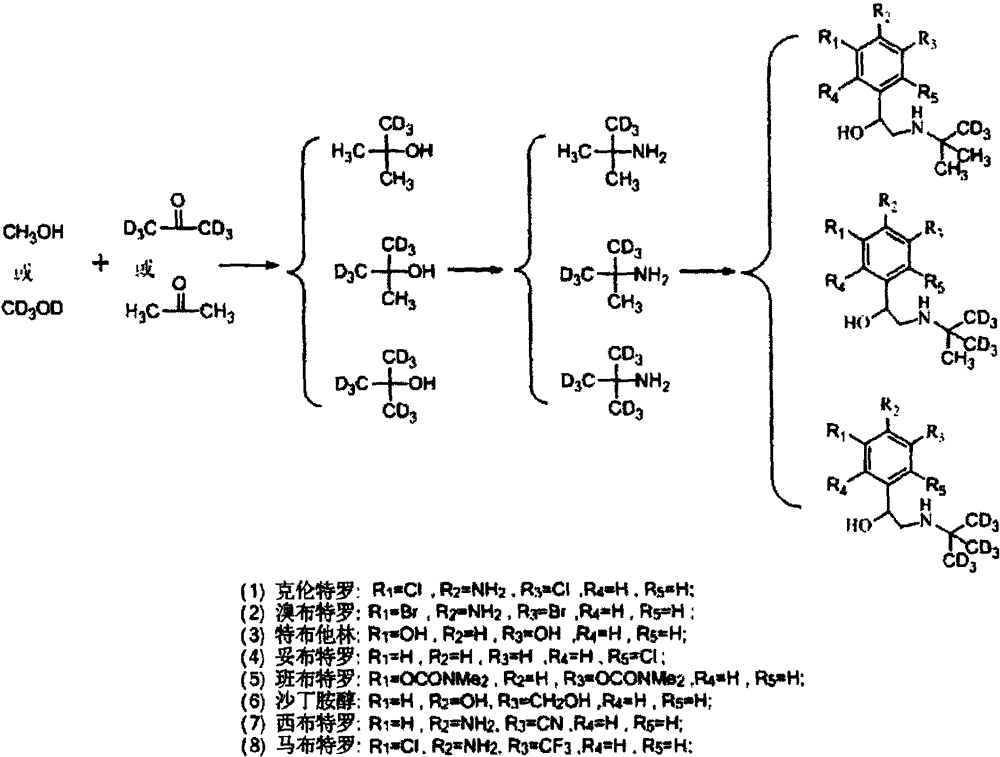

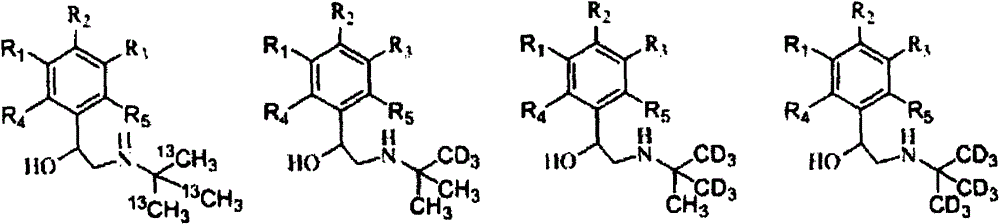

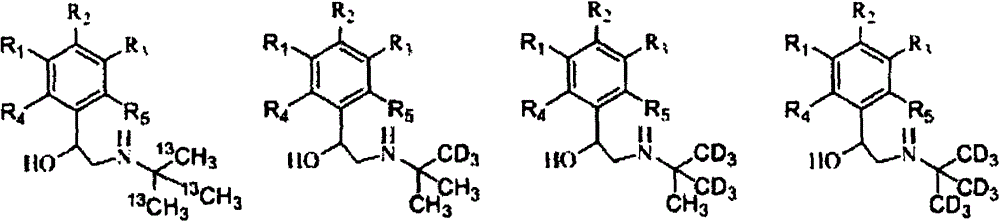

Synthesis method of stable isotope-labeled beta receptor agonist type compound

ActiveCN104478740AEasy to synthesizeSimple process routeCarbamic acid derivatives preparationCarboxylic acid nitrile preparationStable Isotope LabelingTert-Butylamine

The invention relates to a synthesis method of a stable isotope-labeled beta receptor agonist type compound. The synthesis method comprises the following steps: (1) by taking stable isotope-labeled methanol as a raw material, reacting with acetone or stable isotope-labeled acetone, and ammonifying to obtain stable isotope-labeled tert-butylamine; and (2) by taking a bromoketone type compound as a precursor of the beta receptor agonist type compound, reacting with stable isotope-labeled tert-butylamine to prepare the stable isotope-labeled beta receptor agonist type compound. Compared with the prior art, the method for preparing the stable isotope-labeled beta receptor agonist, provided by the invention, is simple, safe and reliable, the chemical purity of the product after separation and purification is above 99.0%, the isotopic abundance is above 98.0% atom, and the product can fully meet the requirements of residual detection in the field of food safety.

Owner:SHANGHAI RES INST OF CHEM IND

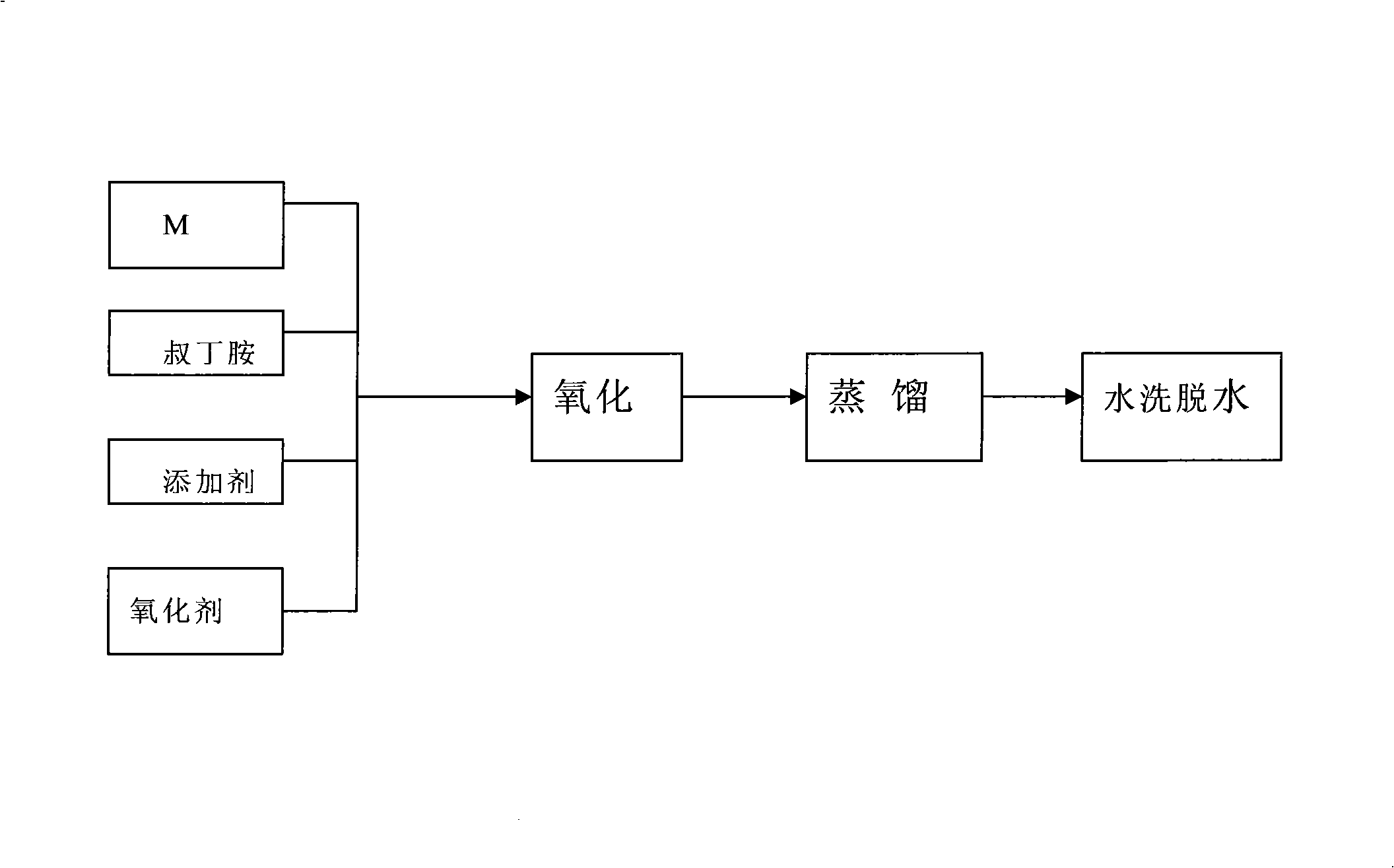

Process for preparing rubber accelerator TBBS

InactiveCN101343257AReduce consumptionEmission reductionOrganic chemistryTert-ButylamineDistillation

The invention provides a production method of a rubber promoter TBBS, sequentially comprising the following steps of: a. oxidation reaction: materials of M, tert-butylamine and an additive are added with water for even agitation and is then added with an oxidizing agent for oxidation, all materials are present in a weight ratio of M: tert-butylamine: water=1:1.2-4.0: 11-15; b. recovery of tert-butylamine through material distillation after the oxidation; and c. putting the distillated residual material in a centrifuge for dewatering by washing until the pH value is equal to 7, so as to obtain the TBBS finished product. The production method has the advantages of optimized process flow, increased M conversion rate, reduced dissolution of product in tert-butylamine, greatly reduced tert-butylamine consumption, lowered distillation load by 70 percent, reduced energy consumption, reduced wastewater discharge by over two third, saved energy, more importantly, non saline matter in the process wastewater, and easy biochemical treatment.

Owner:SHANDONG SUNSINE CHEM

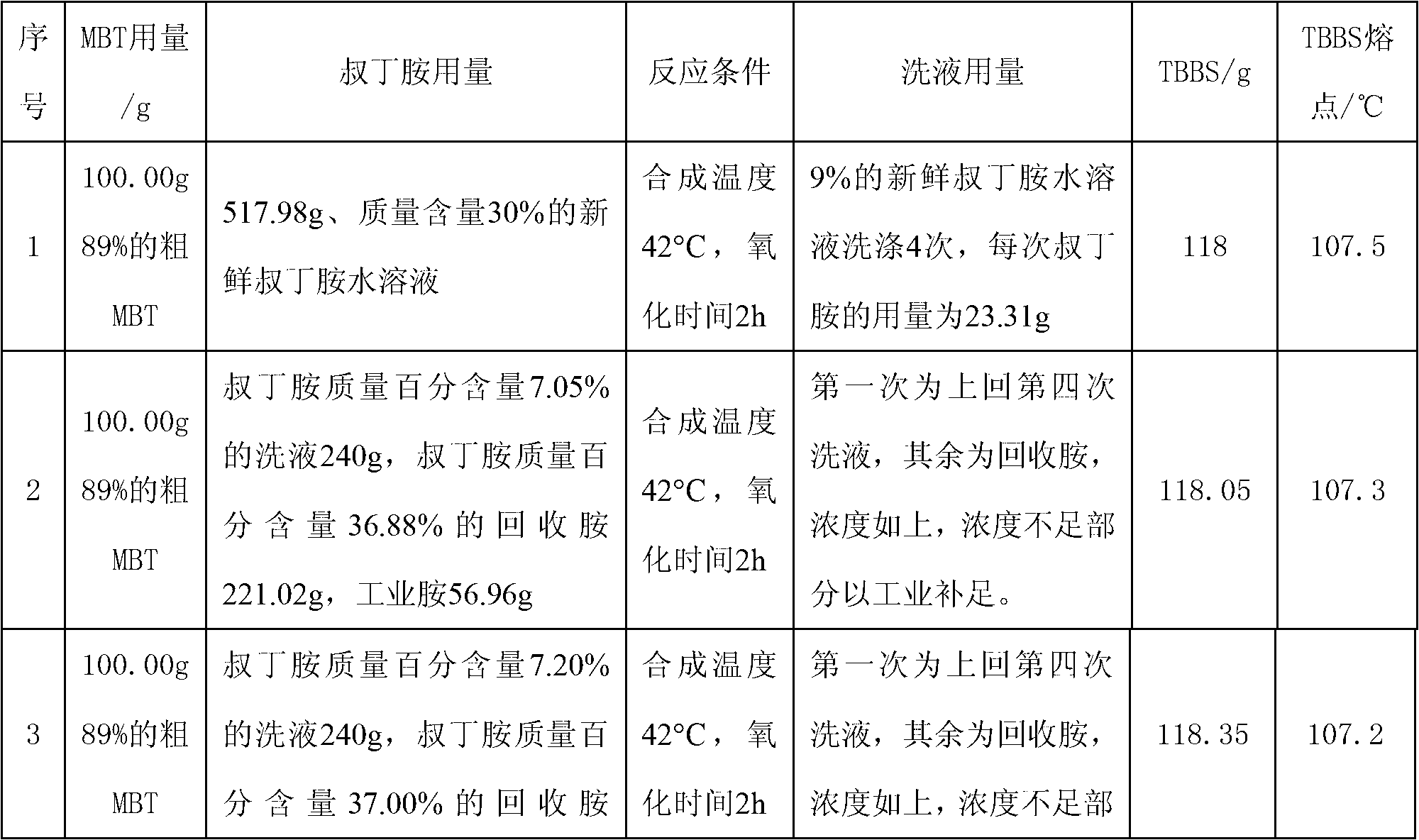

Synthesis method of rubber vulcanization accelerator TBBS (N-tert-butyl-2-benzothiazolesulfenamide)

InactiveCN102838563AEliminate the refining processReduce the generation of "three wastes"Organic chemistrySynthesis methodsSolvent

The invention relates to a synthesis method of a rubber vulcanization accelerator TBBS (N-tert-butyl-2-benzothiazolesulfenamide), which comprises the following steps: adding crude MBT (2-mercaptobenzthiazole) into a reactor filled with a tert-butylamine water solution, stirring evenly, and adding an oxidizer sodium hypochlorite for oxidation synthesis; and after the reaction reaches the end point, carrying out vacuum filtration, washing the filter cake with the tert-butylamine water solution for 2-5 times, washing with water to a neutral state, and drying the filter cake to obtain the qualified vulcanization accelerator TBBS. The mother liquor obtained by carrying out vacuum filtration on the reaction product and the washing liquid obtained by washing the material for the first time are distilled to recycle the tert-butylamine, and the washing liquid obtained after the second time can be repeatedly used as a reaction solution or washing liquid. The MBT crude product is used as the raw material to directly synthesize the accelerator TBBS without adding coke remover or any other raw material; and thus, the technique saves the MBT refinement process, does not need to add other solvents, is simple to operate, and has the advantages of low cost, low environmental pollution and high yield.

Owner:KEMAI CHEM

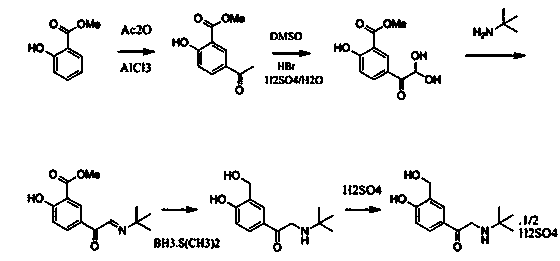

New process for synthesizing salbutamol and sulfate of salbutamol

ActiveCN103951568AMild reaction conditionsEasy to purifyOrganic compound preparationAmino-hyroxy compound preparationBenzaldehydeAminolysis

The invention discloses a new process for synthesizing salbutamol. The process comprises the steps that (1) chloromethylation reaction: reactants namely p-hydroxy benzaldehyde and paraformaldehyde react under an acidic condition to generate a compound 1; (2) hydrolysis reaction: the compound 1 is subjected to hydrolysis reaction under a weakly alkaline condition to generate a compound 2; (3) propylidene protective reaction: dihydroxy of a reactant 2 is subjected to propylidene protection under catalysis of concentrated sulfuric acid; (4) epoxidation reaction: a reactant 3 reacts to obtain a compound 4 by using the effect of strong base under the effects of a ylide reagent and a phase transfer catalyst; (5) aminolysis ring-opening reaction: the compound 4 is heated and refluxed in tert-butylamine, and is subjected to aminolysis ring-opening reaction to obtain a compound 5; (6) hydrolysis de-protective reaction: the compound 5 is subjected to hydrolysis reaction under the acidic condition to obtain salbutamol. The new process disclosed by the invention is mild in reaction condition, easy in purification, and simple and easily-available in raw materials; the total molar yield of the process reaches up to 45%, and the product quality reaches up to more than 99.5%.

Owner:SUZHOU HOMESUN PHARMA

Solid acid catalyst and preparation method and applications thereof

ActiveCN108654594AReduce manufacturing costLow costMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by condensation/addition reactionsLanthanideSolid acid

The invention relates to a solid acid catalyst and a preparation method and applications thereof. The catalyst includes lanthanide rare earth metal ions, halogen and a carrier. The carrier includes aboron-silicon composite oxide and silicon oxide; and the boron-silicon composite oxide is an amorphous compound, and can be obtained by mixing boron source and silicon source compounds, adjusting pH to form gel, adding a surfactant as a pore forming agent during a gel synthesizing process, and performing hydrothermal reaction, hole expansion with ammonia, drying and roasting, etc. According to thecatalyst, the amorphous boron-silicon composite having a high specific surface area and specific pore size distribution is molded to form the carrier and a lanthanide rare earth metal oxide which canform a specific acid site and the halogen are added for modification. The catalyst can be used for direct amination of isobutene to prepare tert-butylamine; and high isobutene one-way conversion rateand tert-butylamine selectivity can be achieved, and the catalyst has good stability.

Owner:WANHUA CHEM GRP CO LTD

Method for synthesizing TBBS (Tertiarybutyl Benzothiazole Sulfenamide) by mechanically applying mother solution

The invention discloses a method for synthesizing TBBS (Tertiarybutyl Benzothiazole Sulfenamide) by mechanically applying a mother solution, comprising the following steps of: adding water or mother solution and a rubber accelerator according to the mass ratio of 1:2-6 in a kettle for pulping, wherein the mechanical apply ratio of the mother solution is 20-100 percent; adding tert-butylamine, wherein the mol ratio of the tert-butylamine to the rubber accelerator is 1:1.05-5; dropping an NaCLO oxidant solution in the material at the temperature of 20-70DEG C, detecting the ending point with copper acetate and starch potassium iodide and stopping dropping the oxidant at the ending point; and carrying out the filtering, the washing and the drying to obtain the accelerator TBBS product. The invention has the advantages that: the mother solution is directly recycled, thereby not only reducing the discharge of high-salinity sewage, the pressure of distilling and recovering the tert-butylamine and energy consumption, but also according with the environment-friendly policy of the state. The accelerator TBBS has over 98 percent of yield, 98 percent of purity and over 105DEG C of melting point. The invention also has the advantages that the method has simple process and is easy to industrialize and the mother solution is directly recycled, thereby reducing the discharge of high-salinity sewage, the pressure of distilling and recovering the tert-butylamine and energy consumption; in addition, the yield of the product is improved and the consumption of the tert-butylamine is reduced, so that the invention reduces the production cost and accords with the environment-friendly policy of the state.

Owner:KEMAI CHEM

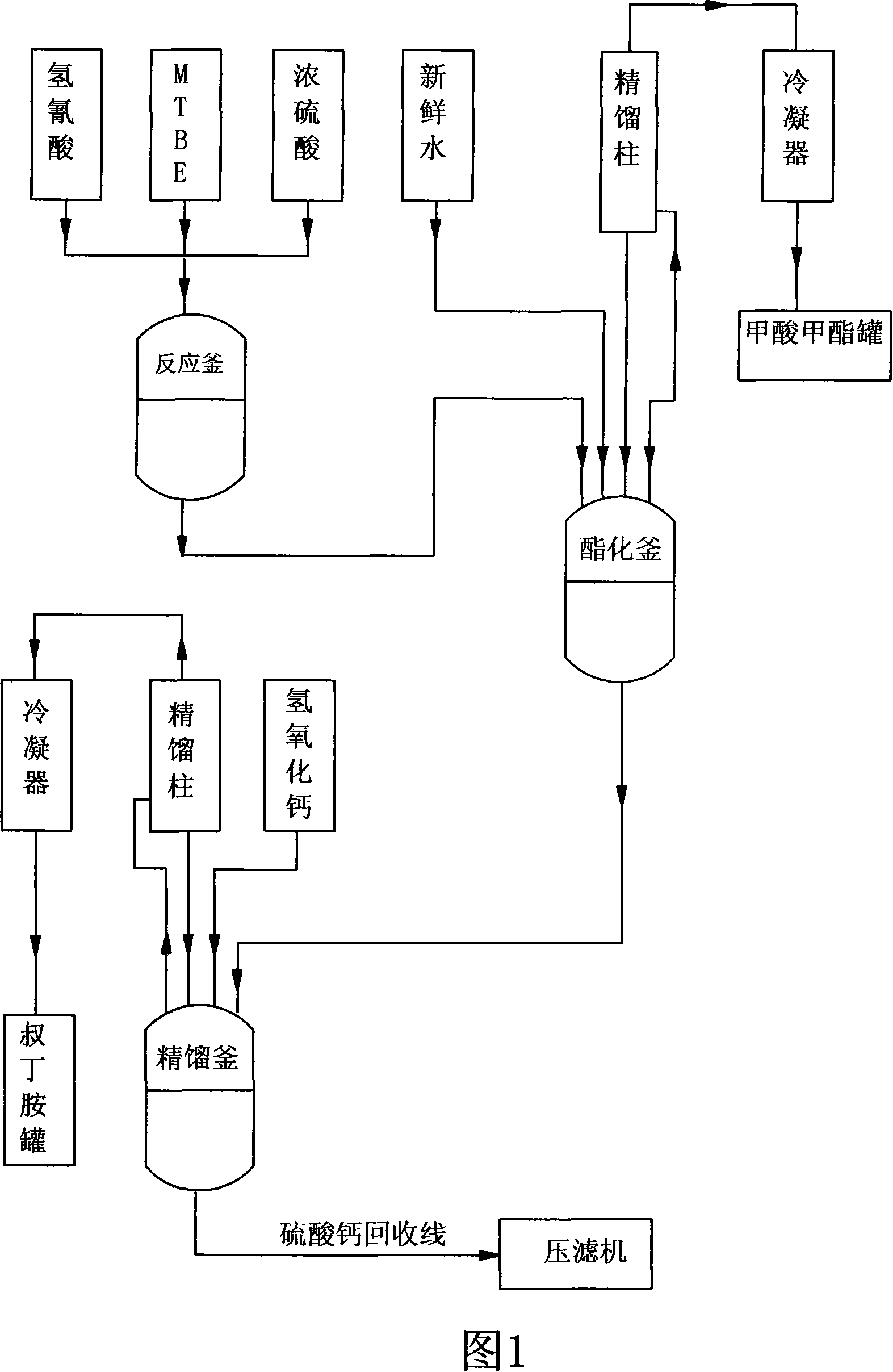

Technique for synthesizing tert-butylamine

ActiveCN101108806APromote hydrolysisPromote esterification reactionOrganic compound preparationAmino compound preparationTert-ButylamineCALCIUM HYDROXIDE SOLUTION

The invention belongs to the fine chemical field, which is mainly used for the synthesis of rubber accelerator NS and the intermediate raw material of the rifampicin-tert-butylamine. The invention is characterized in that: the methyl tert-butyl ether-hydrocyanic acid method is adopted to produce tert-butylamine; under normal pressure, the methyl tert-butyl ether is added with hydrocyanic acid and is added with concentrated sulphuric acid to carry out fully catalytic reaction; the methanol produced in the catalytic reaction is fully adopted and is added with water to perform hydrolysis, deep hydrolysis and esterification, and methyl formate and methanol without react completely are distilled; sulphates in calcium hydroxide solution and the butylamine to replace the butylamine to gain the butylamine through rectification and produce the byproduct calcium sulfate. The invention adopts the water instead of the methanol to carry out the hydrolysis and esterification and neutralizes the raw materials and adopts the calcium hydroxide to produce butylamine, which has the advantages of simple process, short production period, high yield, stable product quality, low production cost and small environment pollution.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

Preparation method of catalyst applied to tert-butylamine production through direct amination of isobutene and application

ActiveCN106040289AHigh selectivityHigh reactivityMolecular sieve catalystsAmino compound preparation by condensation/addition reactionsMolecular sieveTert-Butylamine

The invention provides a preparation method of catalyst applied to tert-butylamine production through direct amination of isobutene and an application. The catalyst is an overall F-ZSM-11 binder-free molecular sieve. The preparation method of the catalyst comprises steps as follows: performing hydrothermal treatment on a mixture formed by an ammonium fluoride and silica binder and an HZSM-11 molecular sieve raw powder in a tetrabutyl ammonium hydroxide aqueous solution or steam to form the overall F-ZSM-11 binder-free molecular sieve; performing further drying and roasting to prepare the needed catalyst. In a tert-butylamine production process through direct amination of isobutene, the catalyst has the characteristics of high reactivity, low reaction pressure and temperature and high target product selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

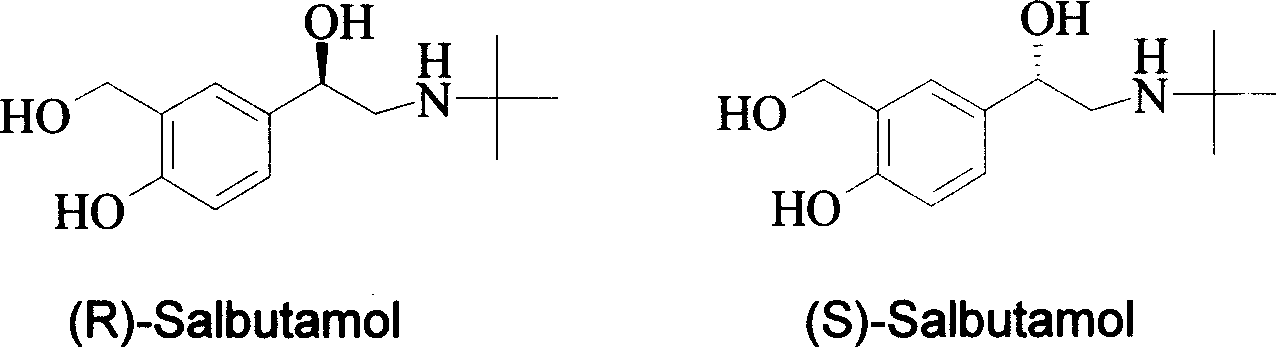

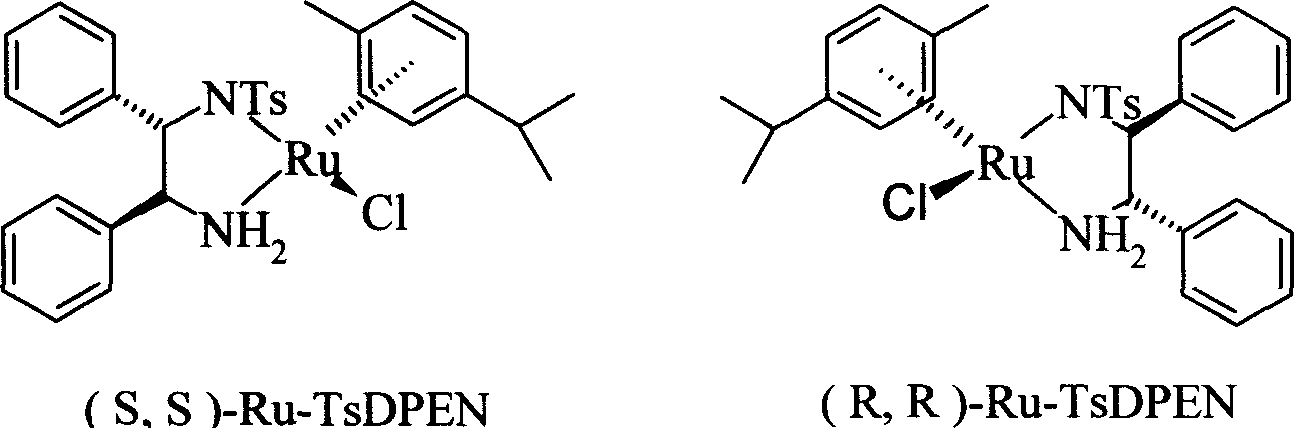

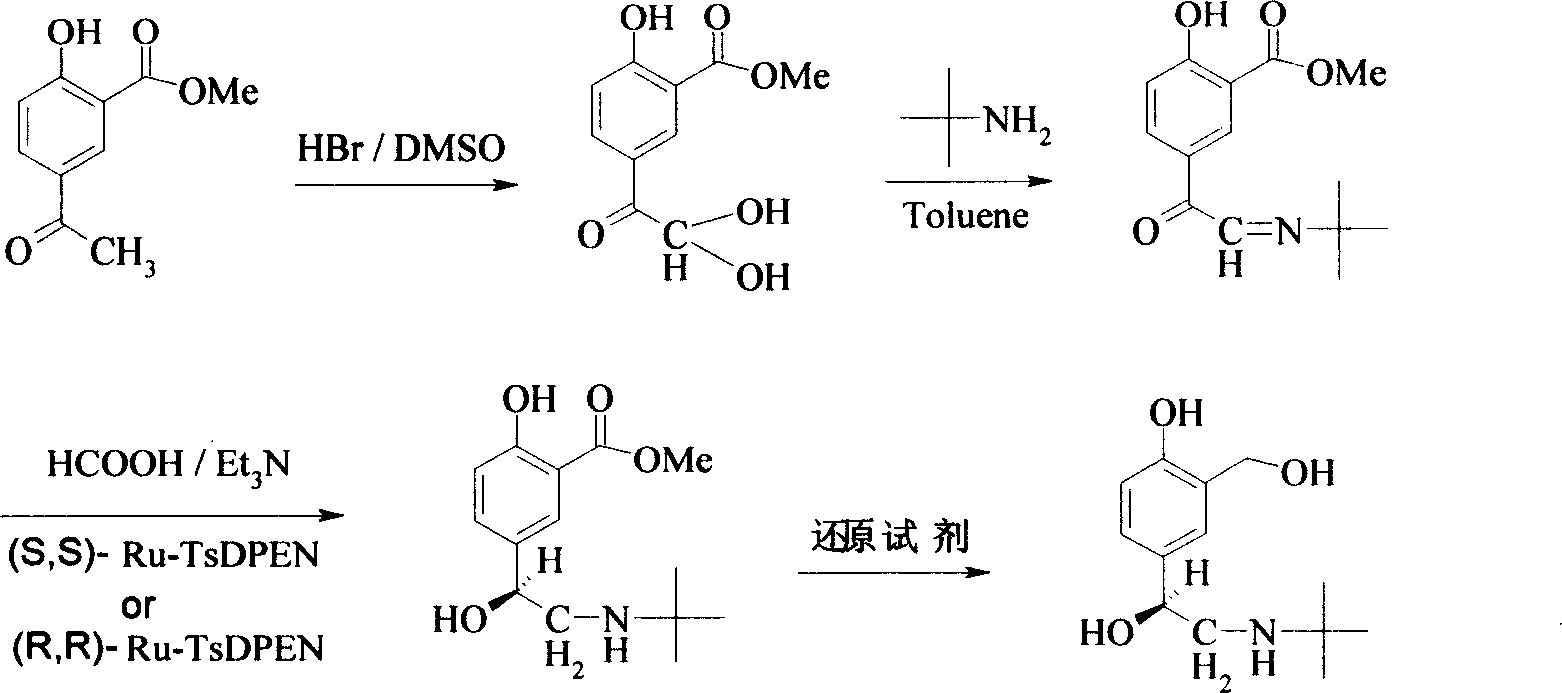

Method for asymmetrical hydrogen transfer of alpha-imino keton for synthesizing chirality salbutamol

InactiveCN1733701AEfficient Synthesis of Chiral SalbutamolGood choiceOrganic compound preparationAmino-hyroxy compound preparationMethyl salicylateKetone

Disclosed is a method for asymmetrical hydrogen transfer of alpha-imino keton for synthesizing chirality salbutamol which comprises, using 5-acetyl methyl salicylate as raw material, oxidizing with oxidation agent into 5-(1,1-)dihydroxy)-acetyl-2-hydroxybenzoate, then reacting with tert-butylamine, obtaining alpha-imine ketone compound. Then using (S,S)-Ru-TsDPEN or (R,R)-Ru-TsDPEN as catalyst, subjecting the alpha-imine ketone compound to asymmetrical hydrogen migration in formylic acid, triethylamine and inert organic solvent system, thus obtaining the optically pure product of (R) or (S)-5-[2-[(1,1-dimethylethyl)amino]-1-ethoxyl]-2-hydroxybenzoate, finally deoxidizing the (R) or (S)-5-[2[(1,1-dimethylethyl)amino]-1-ethoxyl]-2-hydroxybenzoate to obtain the optically pure (R) or (S) chiral salbutamol.

Owner:EAST CHINA NORMAL UNIV

Rubber composition and tire

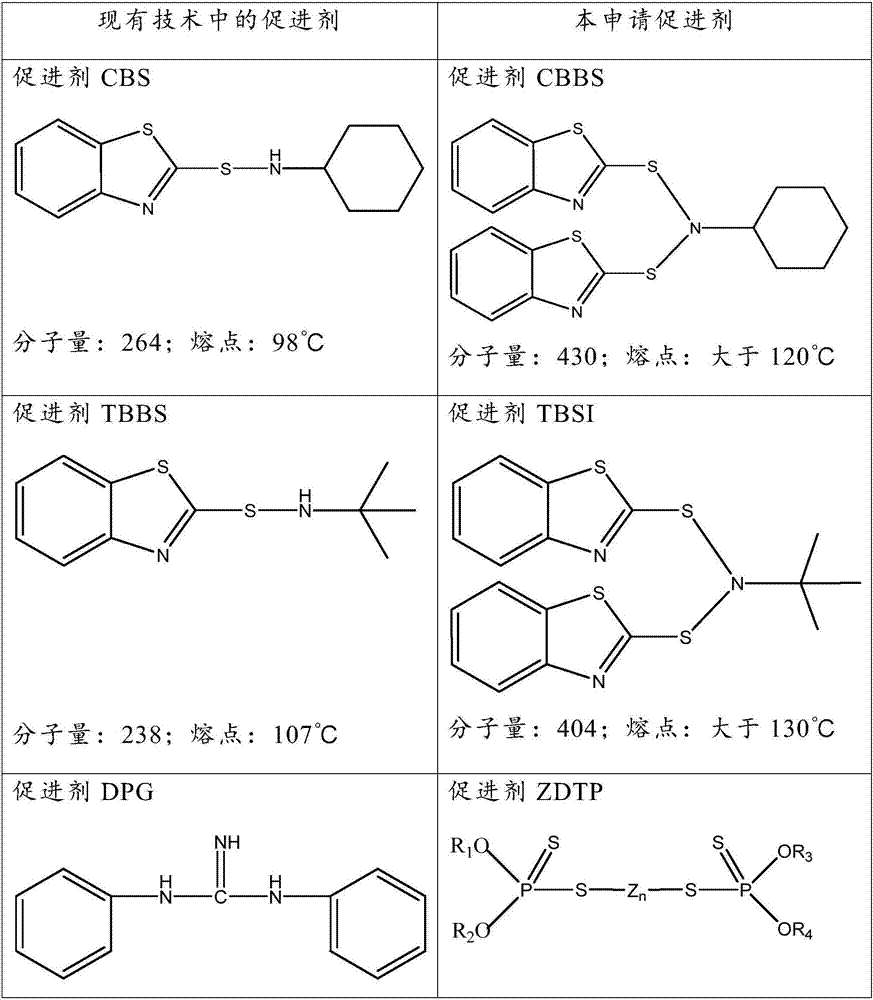

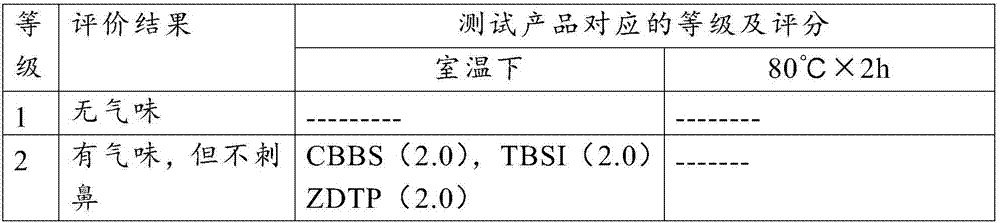

The invention provides a rubber composition. The rubber composition mainly comprises at least one type of polar or non-polar rubber, at least one type of fillers, at least one type vulcanizing agents, at least one type of accelerators, optional scotch retarders and optional aromatic substances. Each accelerator is a chemical compound with two or more X-Y single bonds, wherein the X selectively represents O and S elements, and the Y selectively represents N and P elements. The environment-friendly rubber composition and a tire (spare tire in particular) prepared from the rubber composition have the advantages that the rubber composition comprises the modified accelerators and the modified scotch retarders, accordingly, generation of organic volatile matters such as aniline, cyclohexylamine, tert-butylamine and imine with pungent odor can be reduced, and the problem of odor of existing tires can be solved; substances such as carbon black and zinc oxide with fine powder can be omitted, and accordingly dust hazards on operators in production procedures can be reduced; the rubber composition comprises the added aromatic substances, and accordingly fragrant smell of the tire further can be enhanced.

Owner:ZHEJIANG GEELY HLDG (GRP) CO LTD +1

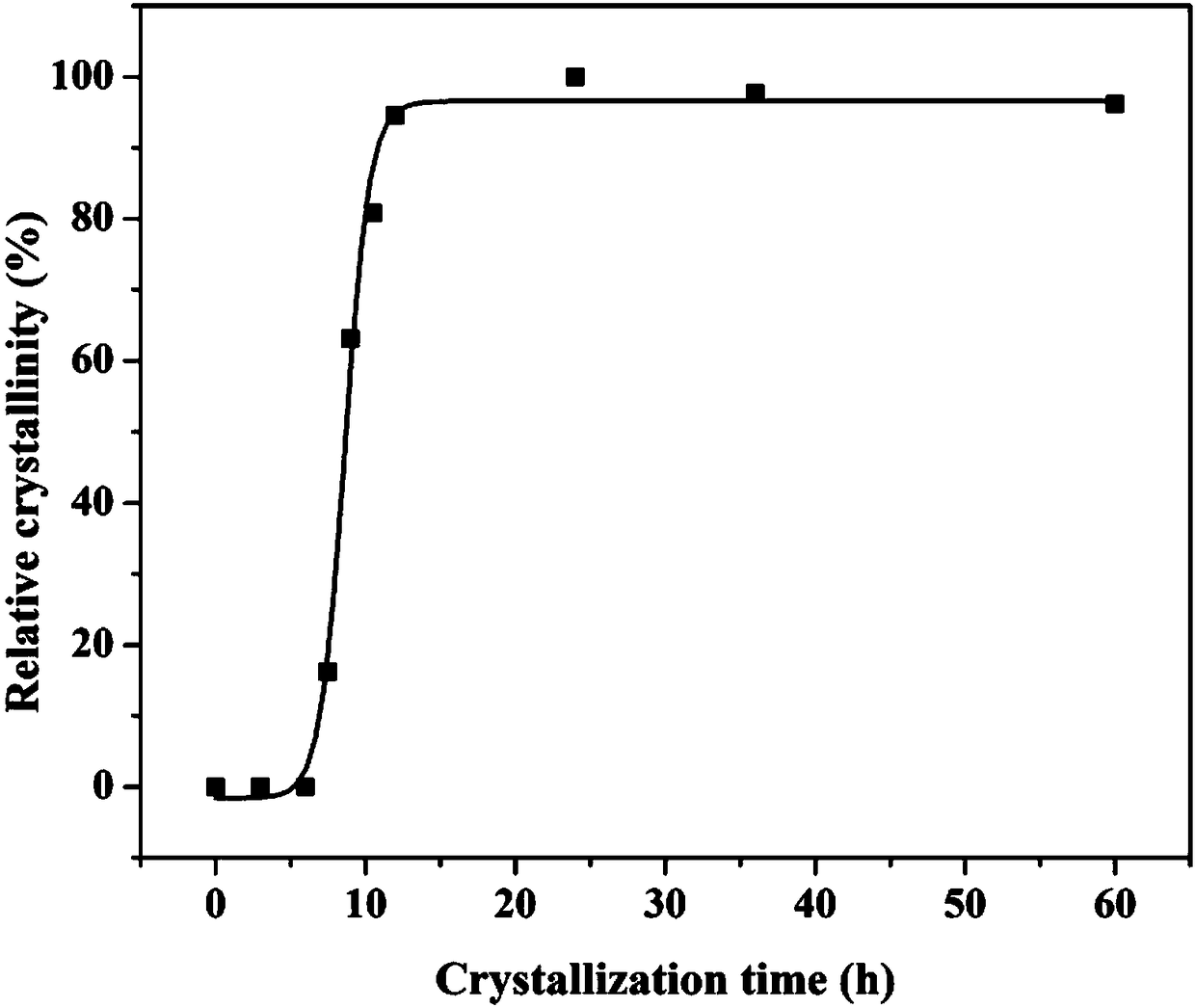

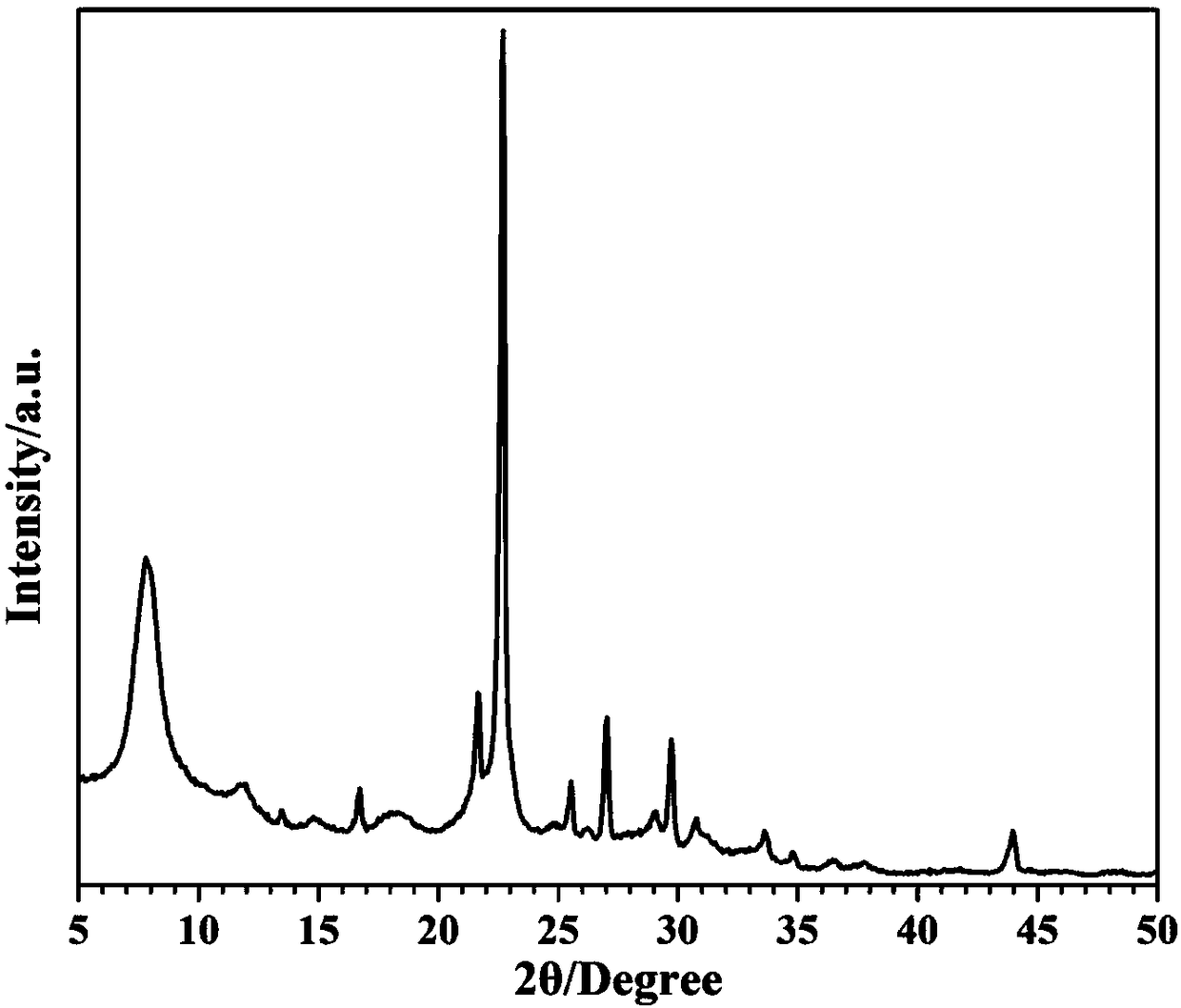

Method for promoting Beta molecular sieve synthesis

InactiveCN108217684AShort crystallization timeLower crystallization temperatureMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveTert-Butylamine

The invention provides a method for promoting Beta molecular sieve synthesis. According to the method, a silicon source, an aluminum source, inorganic alkali, a microporous template agent and crystalgrowth promoters R are sufficiently mixed; the obtained gel is subjected to short-time hydrothermal crystallization for fast preparing a Beta molecular sieve. The synthesized product is formed by stacking and connecting primary nanometer particles; the primary particle diameter is 10 to 30nm; the synthesis process is fast; the materials can be directly crystallized for 10 to 60 hours at the propertemperature; the crystal growth promoters are 2-pyrrolidone, N-methyl-2-pyrrolidone, N-ethyl-2-pyrrolidone or N-isopropyl-2-pyrrolidone or a mixture of the 2-pyrrolidone, N-methyl-2-pyrrolidone, N-ethyl-2-pyrrolidone, N-isopropyl-2-pyrrolidone. The cheap crystal growth promoters are used for fast preparing the Beta molecular sieve by a one-step method; the conventional crystal seed method is replaced for fast obtaining the Beta molecular sieve; the method belongs to the economic and fast Beta molecular sieve obtaining method. In addition, the prepared Beta molecular sieve also has the excellent catalyst performance; high isobutene conversion rate and tert-butylamine selectivity are shown in the isobutene amination reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

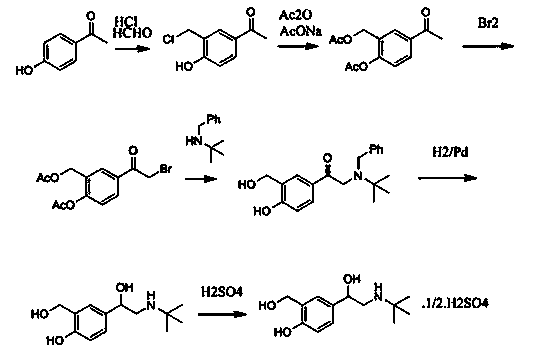

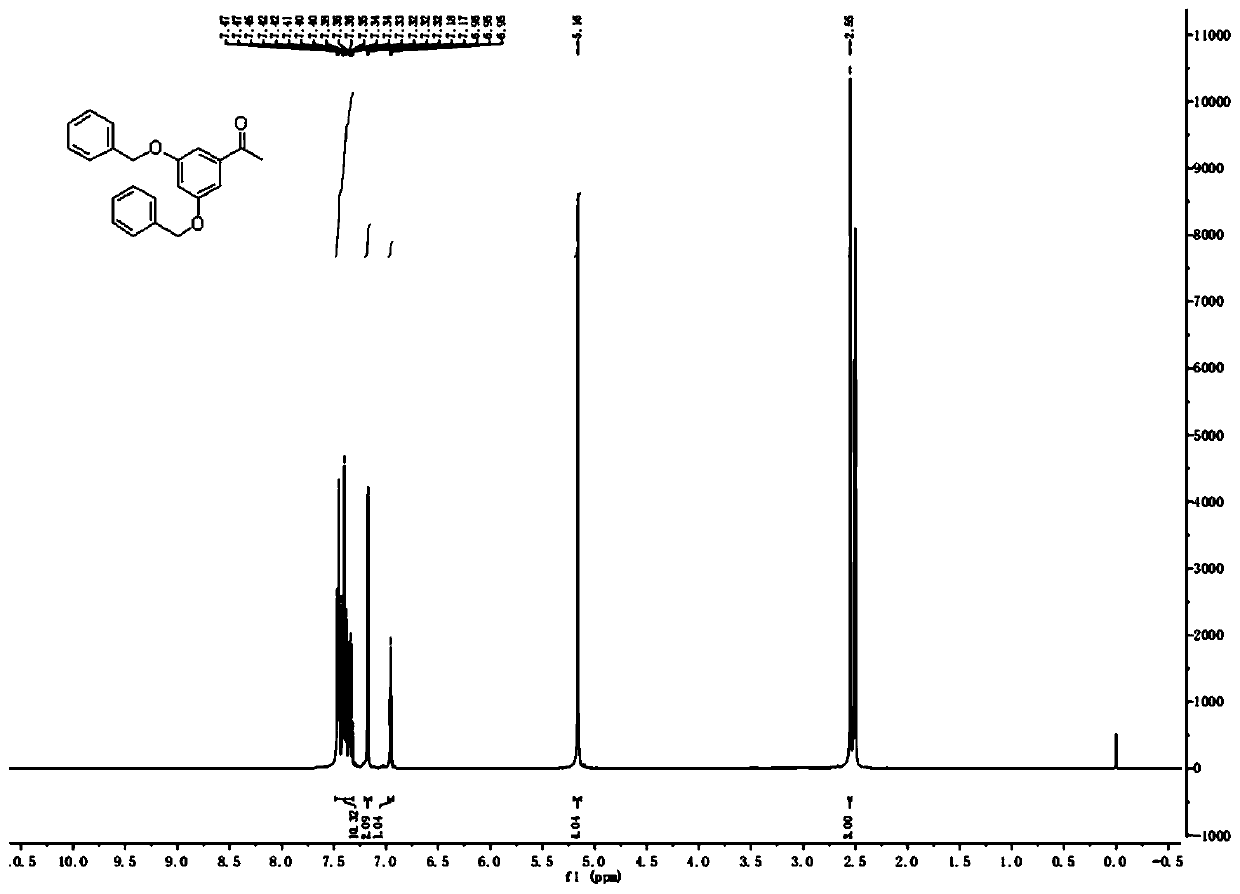

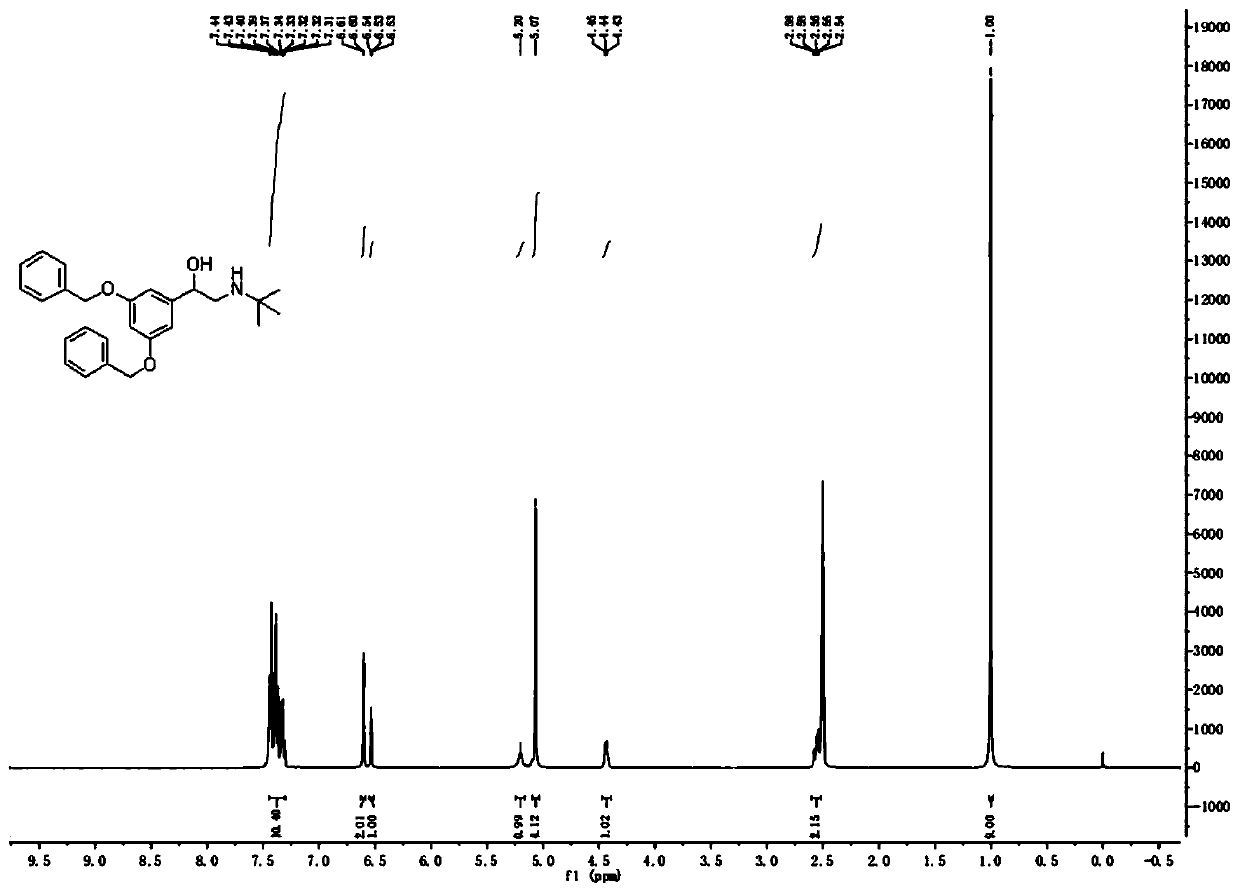

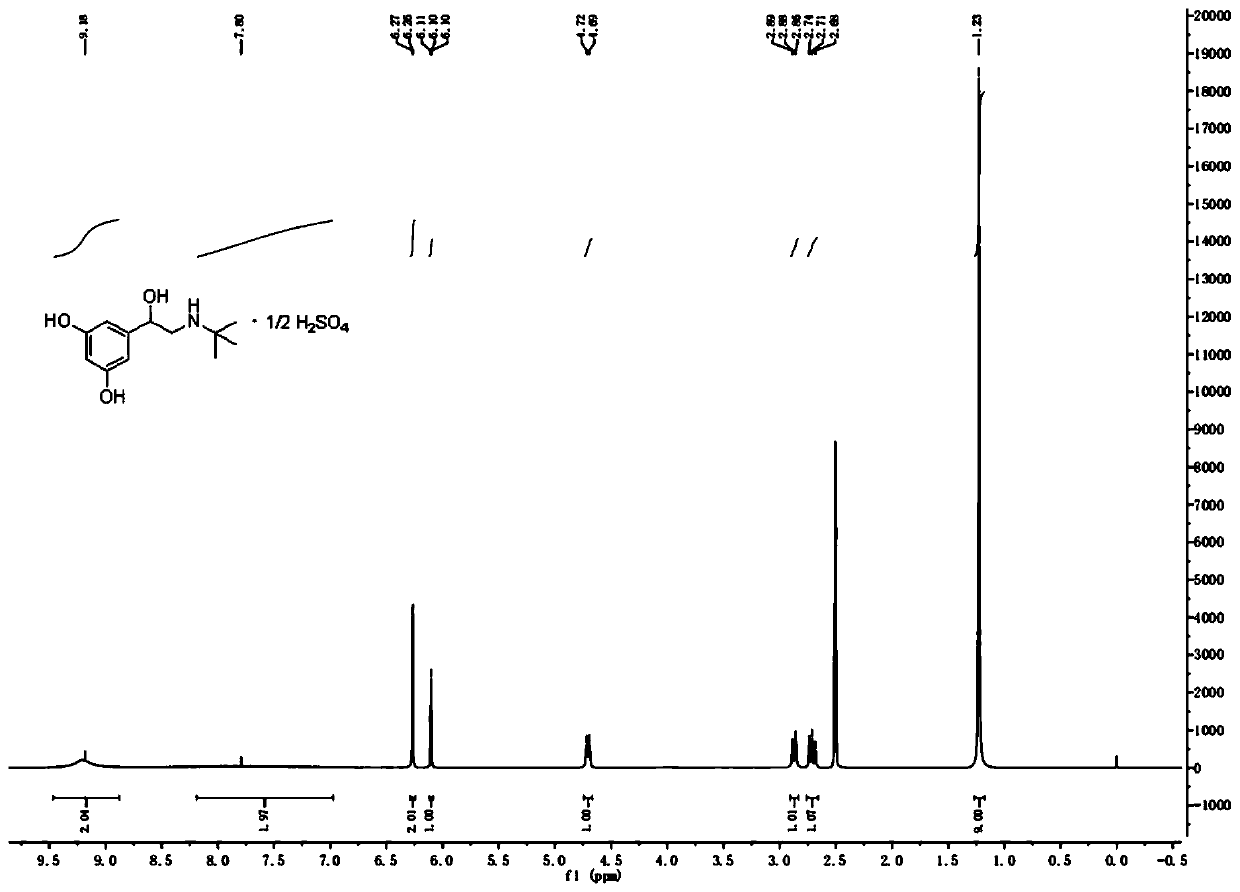

Preparation method of terbutaline sulfate

ActiveCN110950765AReduce usageAvoid high temperature and high pressure reactionsOrganic compound preparationCarbonyl compound preparationAcetophenonePhenyl group

The invention discloses a preparation method of terbutaline sulfate. The method comprises the steps: taking 3,5-dihydroxyacetophenone as an initial raw material, firstly, carrying out benzyl protection to obtain 3,4-dibenzyloxyacetophenone, carrying out copper bromide bromination and DMSO oxidation on 3,5-dibenzyloxyacetophenone to obtain 3,5-dibenzyloxyacetophenone aldehyde, carrying out reductive amination on 3,5-dibenzyloxyacetophenone aldehyde and tert-butylamine to generate 1-[3,5-di(benzyloxy)phenyl]-2-(tert-butylamino)ethanol, and finally carrying out hydrogenation debenzylation and sulfuric acid salification, to obtain terbutaline sulfate. Compared with the prior art, the method has the advantages that the used raw materials and auxiliary materials are cheap and easily available, the use of high-risk and highly-toxic reagents is avoided, high-temperature and high-pressure reaction is avoided, the operation is simple and convenient, the reaction conditions are mild, and the defects of long steps, low yield, potential safety hazards and the like in the prior art are overcome.

Owner:ZHEJIANG PHARMA COLLEGE

Preparation method for terbutaline hemisulfate

InactiveCN106831452AReduce usageSolve the shortcomings of large pollutionOrganic compound preparationCarbonyl compound preparationTert-ButylamineReaction step

The invention discloses a preparation method for terbutaline hemisulfate. The method comprises the following steps: by adopting 3, 5-resacetophenone as a raw material, performing bromination reaction by directly using a bromination reagent without protecting hydroxide radical, then reducing carbanyl group; condensing with tert-butylamine, finally, forming salt with sulfuric acid, thereby obtaining terbutaline hemisulfate. The method can overcome the defects of deprotection after hydroxide radical protection, usage of various high-risk toxic reagents, long reaction steps and low yield in the present technology.

Owner:HANGZHOU BIO SINCERITY PHARMA TECH CO LTD

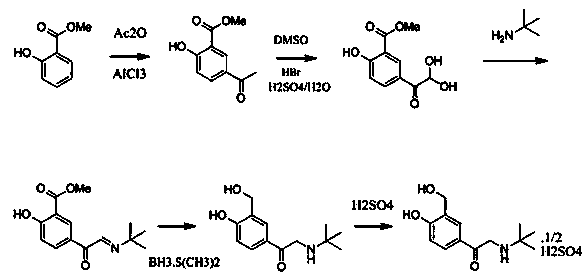

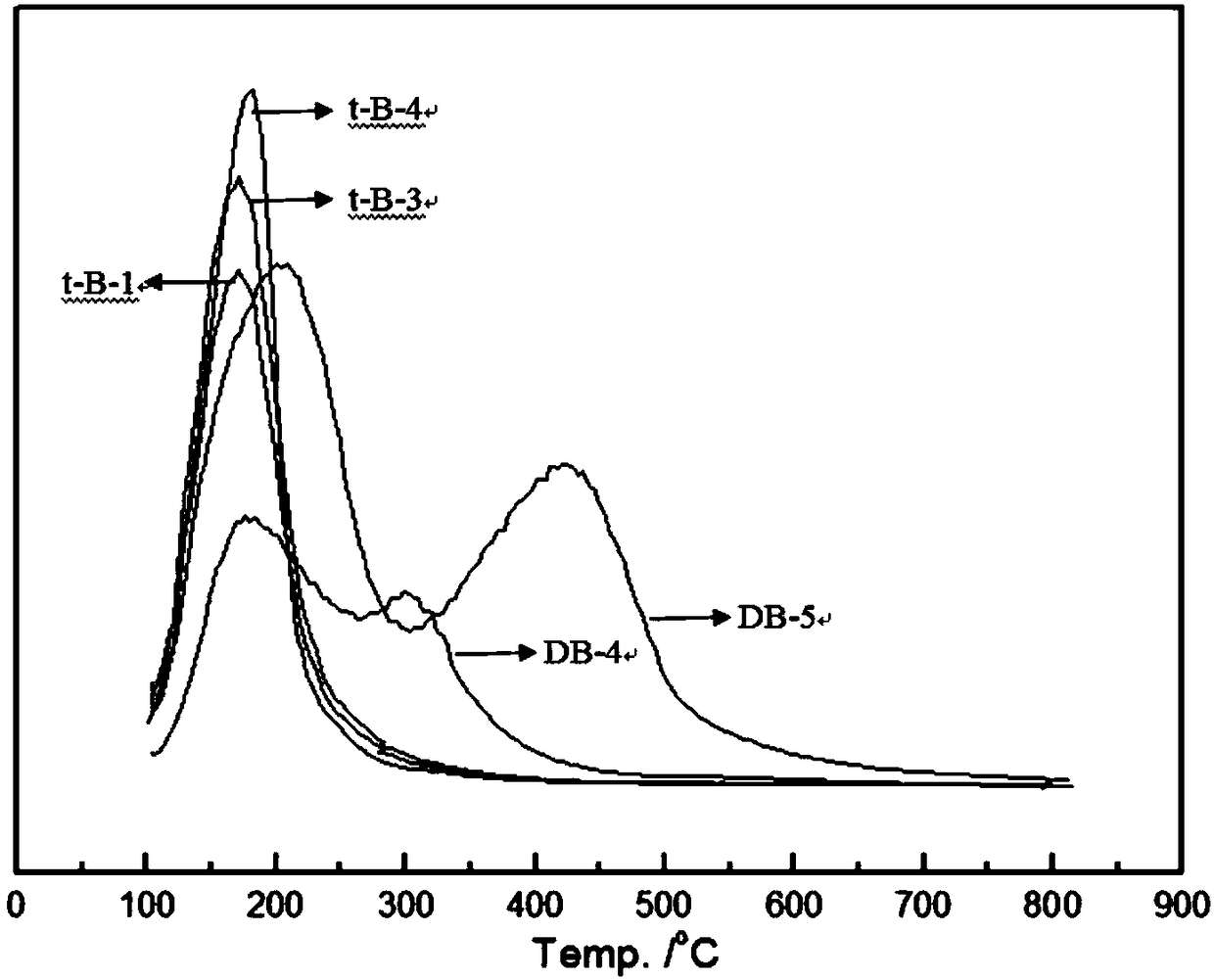

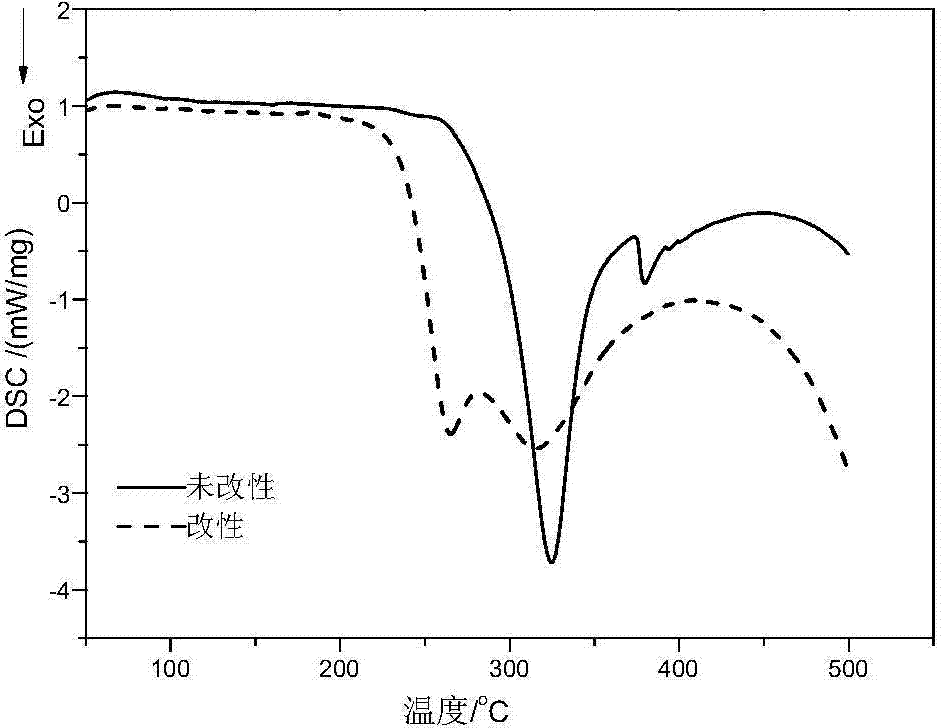

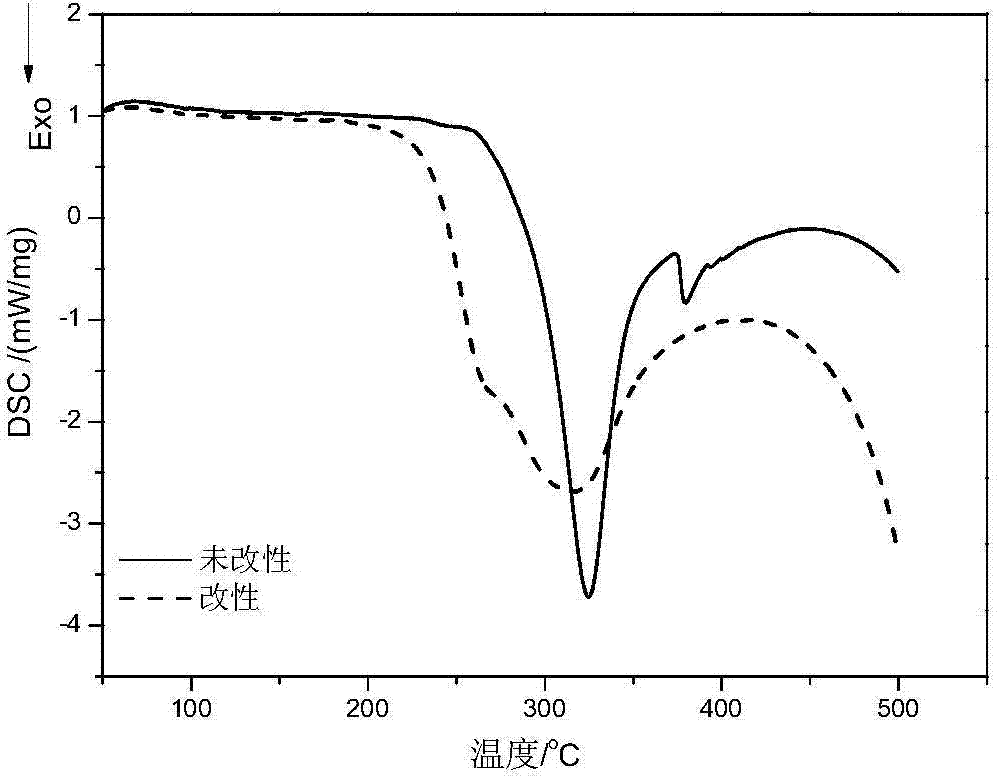

Method for preparing carbon fibers from acrylic fibers

ActiveCN104775187ANo residueReduce the onset temperature of the thermal stabilization reactionFibre chemical featuresPolymer scienceCarbon fibers

The invention provides a method for preparing carbon fibers from acrylic fibers. According to the method, the acrylic fibers are prepared by use of a dry-spraying wet spinning or wet spinning technique; the acrylic fibers are impregnated into an aqueous solution of ammonium acetate, ammonium formate, guanidine hydrochloride, ethylenediamine tetraacetic acid, triethylamine, urea, trimethylamine, dicyandiamide, normal hexyl amine, dihexylamine, cyanamide, amylamine, diethylamine, hexyldiamine, tert-butylamine or n-butylamine for modification for a certain time, and then dried, and finally, the acrylic fibers are pre-oxidized and carbonized to prepare the carbon fibers. Experiments prove that the modified acrylic fibers are capable of remarkably reducing the starting temperature of thermal stabilizing reaction of the acrylic fibers and expanding the exothermic peak, and therefore, the controllability of the pre-oxidation process can be improved, the low cost production of the carbon fibers is realized finally, and meanwhile, the strength and the elasticity modulus of the carbon fibers can be improved favorably to meet the requirements on the properties on the carbon fibers in the industrial areas.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

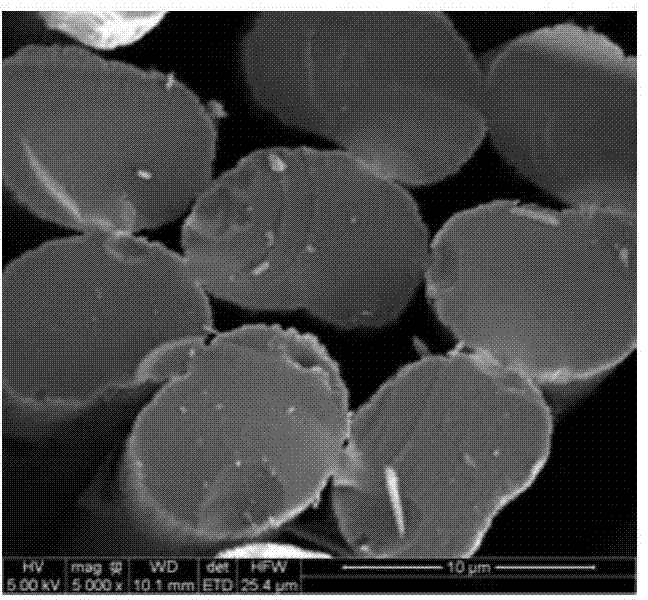

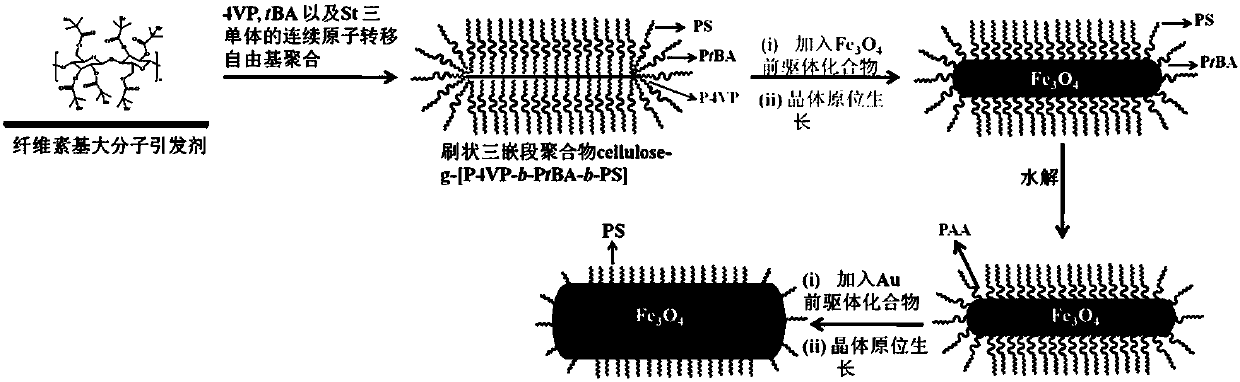

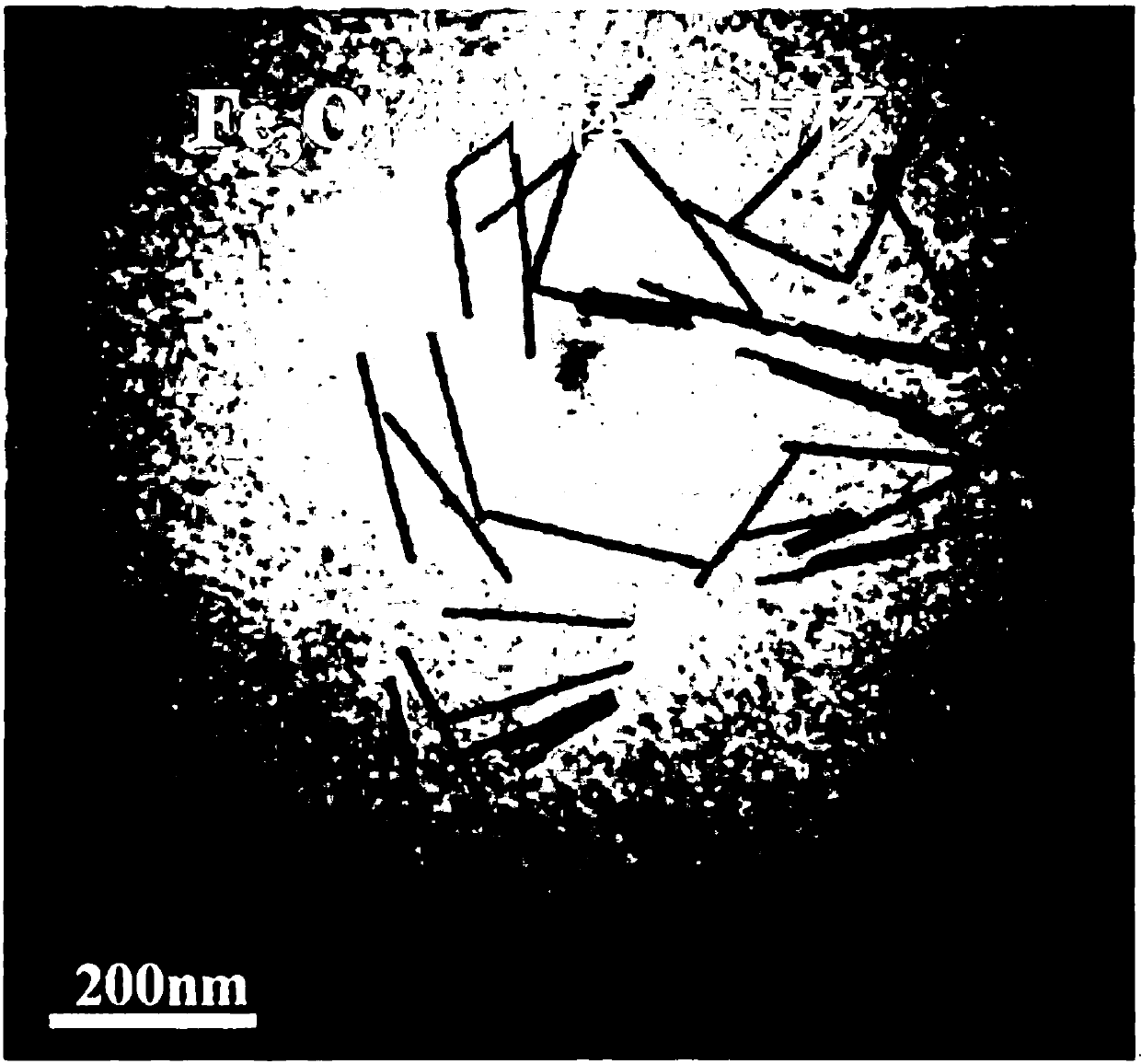

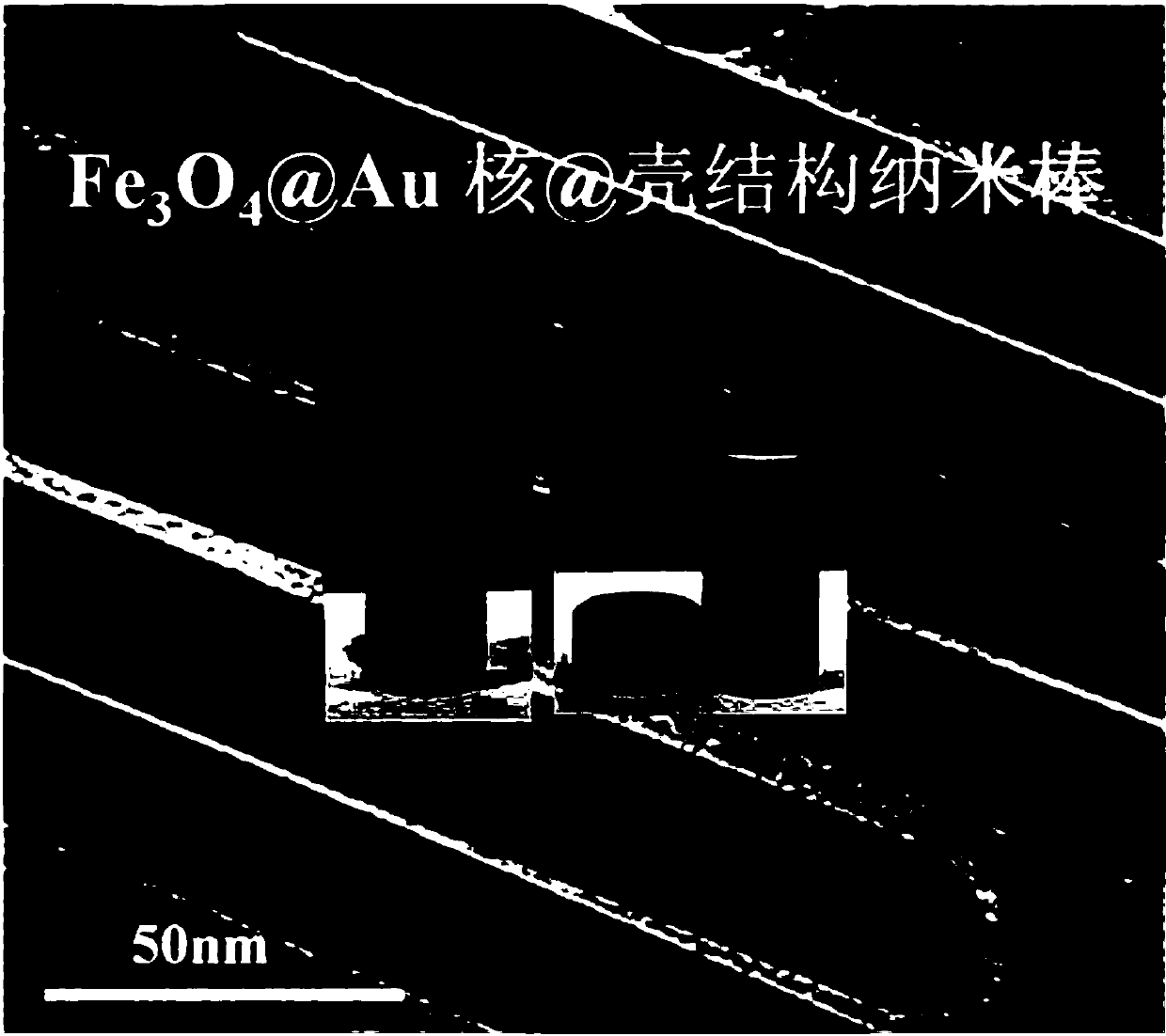

Preparation method capable of achieving large-scale preparation of Fe3O4@Aucore@shell structured nanorods with controllable size and dispersion

ActiveCN107552806AHigh graft densityOvercome the shortcomings of high matching requirementsMaterial nanotechnologyCelluloseChemical reaction

The invention discloses a preparation method capable of achieving large-scale preparation of super-paramagnetic Fe3O4@Au-core@shell structured nanorods with controllable size and dispersion, and belongs to the field of intersection of multiple subjects such as macromolecular living polymerization methods, functional polymer molecule design and inorganic crystal growth. The method comprises the following steps that (1), cellulose used for modifying hydroxide radical serves as a macromolecular initiator, and by means of a continuous polymerization ATRP technology and a linked chemical reaction,a series of brush-shaped triblock polymers cellulose-g-[P4VP-b-PAA-b-PS] and cellulose-g-[P4VP-b-PAA-b-PEG] are prepared separately, wherein the triblock polymers each comprise two template structureunits; (2), a solution-phase synthesis method serves as a basis, a certain quantity of the above-mentioned prepared brush-shaped triblock polymers serves as a monomolecular template, first section P4VP serves as a template phase, FeCl2.4H2O, FeCl3.6H2O and NH3.H2O serve as a precursor compound system, and then super-paramagnetic Fe3O4 nanorods are firstly prepared to serve as cores; and (3), similarly, a Fe3O4 nanorod system with the surface coated with a second template phase PAA serves as the monomolecular template, chloroauric acid serves as a precursor compound, tert-butylamine boron serves as a reducing agent, and then the gold nanorod shell structure is prepared.

Owner:郑州科斗科技有限公司

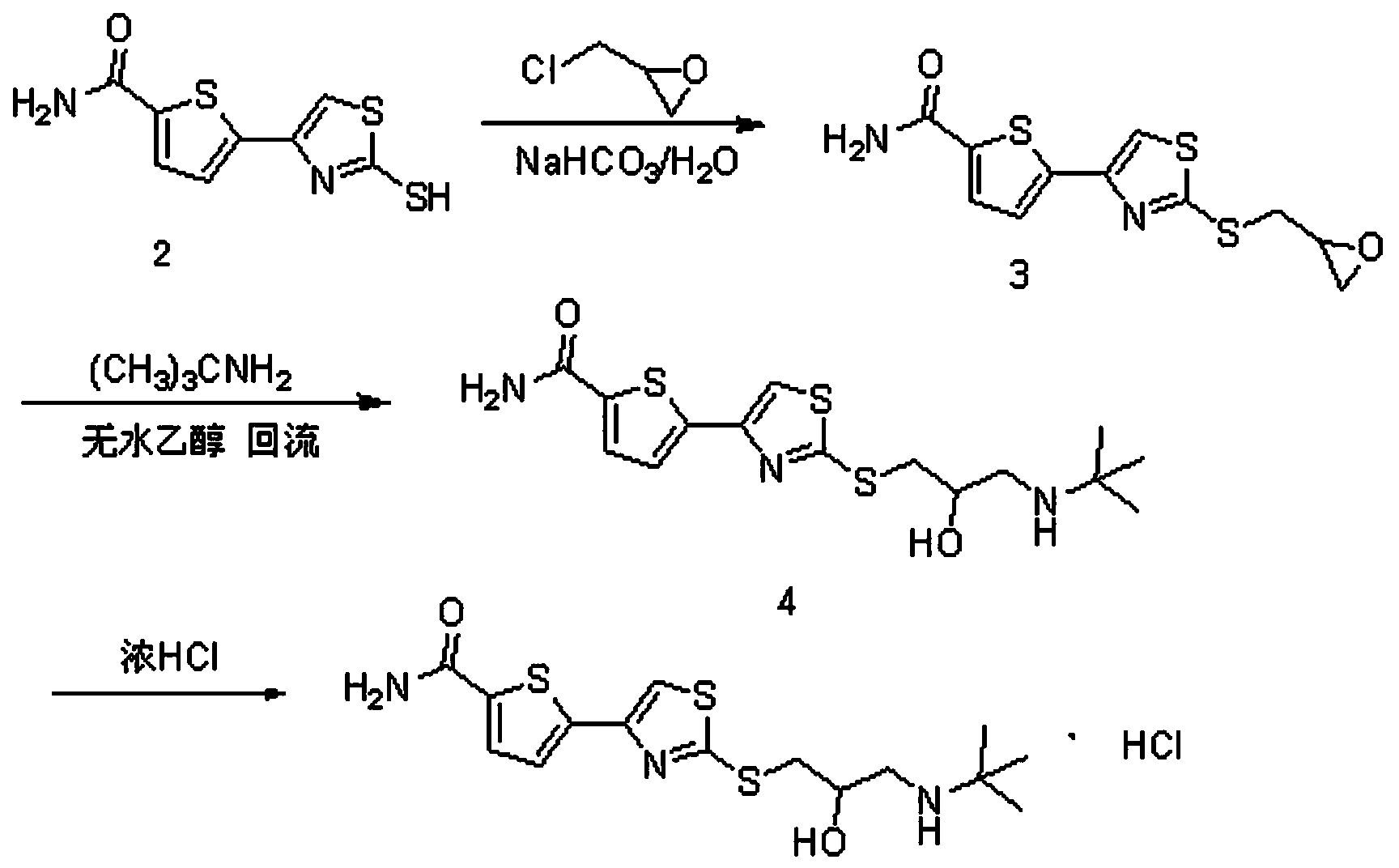

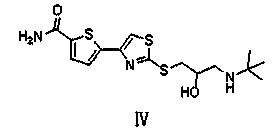

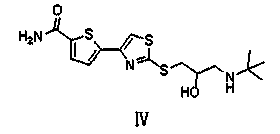

Preparation method of arotinolol hydrochloride

The invention relates to a preparation method of arotinolol hydrochloride. The preparation method comprises the following steps: (1) preparing 2-[2,3-glycidyl-4-(5-carbamyl-2-thienyl)] thiazole; (2) dissolving 2-[2,3-glycidyl-4-(5-carbamyl-2-thienyl)] thiazole in absolute ethyl alcohol, adding tert-butylamine and performing a reflux reaction to obtain arotinolol; and (3) dissolving arotinolol in dimethyl sulfoxide and then adding concentrated hydrochloric acid to generate the arotinolol hydrochloride. The preparation method disclosed by the invention is short in production period, simple in process, high in yield, safe and reliable, and the arotinolol hydrochloride prepared by the method disclosed by the invention is high in purity.

Owner:SHIJIAZHUANG GERUI PHARMA CO LTD

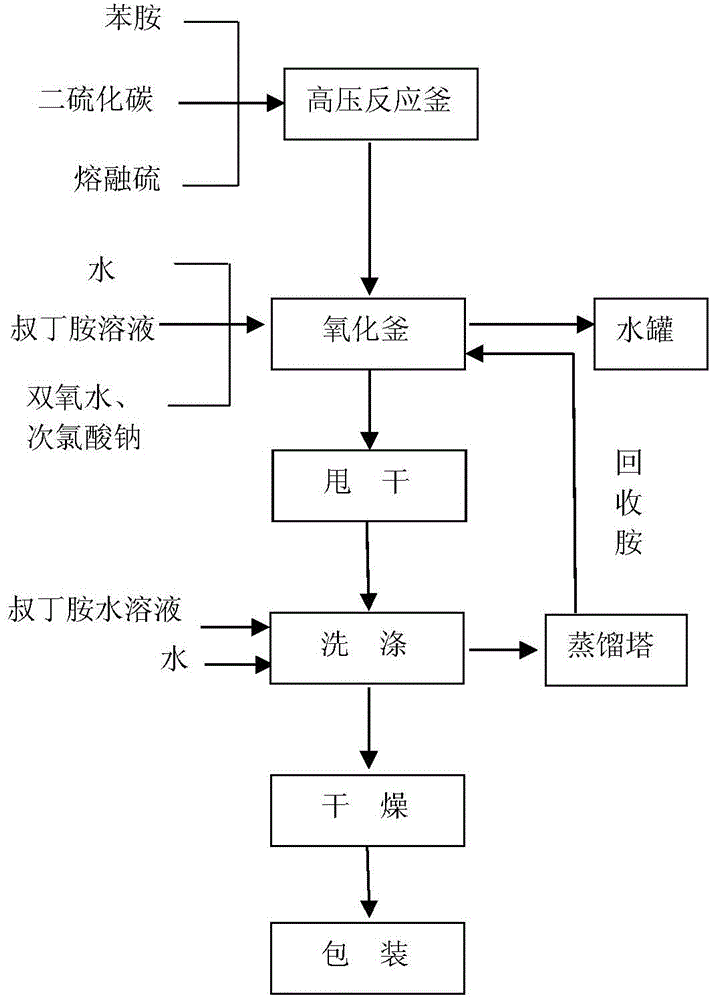

Preparation method of rubber vulcanizing accelerator TBBS

InactiveCN104610193AReduce pollutionReduce Process Safety RisksOrganic chemistryPotassium iodineAccelerant

The invention relates to a preparation method of a rubber vulcanizing accelerator TBBS. The preparation method comprises the following steps: (1), synthesizing a crude product MBT, to be specific, directly adding molten sulfur as raw material sulfur, and eliminating the procedure of dissolving sulfur by carbon disulfide so as to reduce the potential risks of production; (2), synthesizing the accelerant TBBS by the crude product MBT, to be specific, adding the molten crude MBT in an oxidization kettle which contains water and starts stirring, after stirring the molten crude MBT and the water, cooling, and draining; adding a tert-butylamine water solution into the oxidization kettle, after uniformly stirring, adding hydrogen peroxide so as to perform oxidation synthesis, dripping sodium hypochlorite in the later period, and determining the end by using ammonium sulfate and a potassium iodide solution; performing suction filtration after reaction, washing filter cakes by the tert-butylamine water solution, washing the washed filter cakes with water till being neutral, and drying the filter cakes so as to obtain the qualified vulcanizing accelerator TBBS. According to the preparation method disclosed by the invention, the crude MBT is used as raw materials to directly synthesize the accelerant TBBS, the environment-friendly hydrogen peroxide is used as an oxidizing agent, the refining process of MBT is eliminated, waste water containing salt is generated, and little pollution to the environment is caused.

Owner:内蒙古科迈化工有限公司

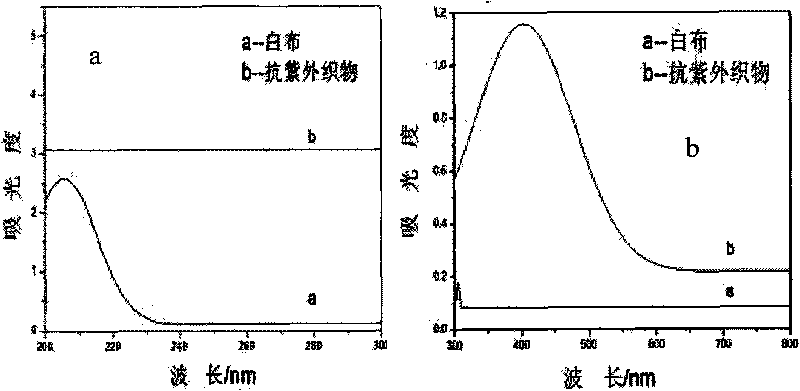

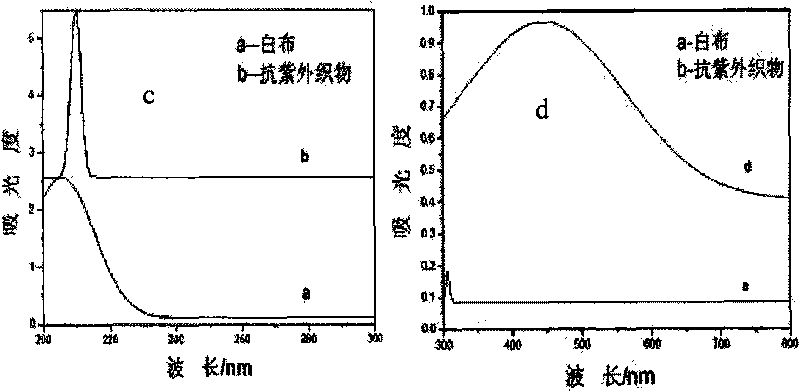

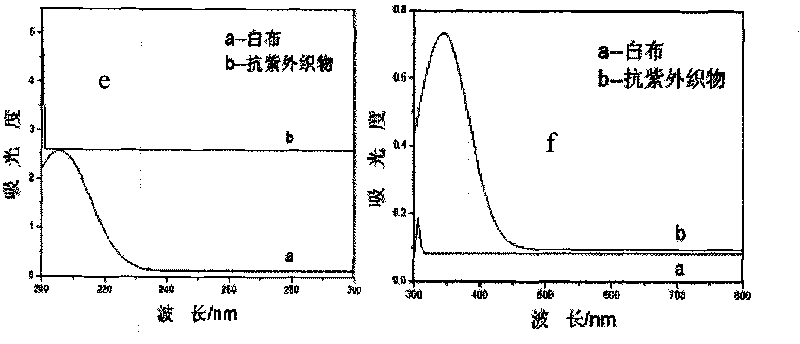

Nano ultraviolet screener and method for preparing high-performance uvioresistant fabric

The invention relates to a method for preparing a nano ultraviolet screener and application thereof, belonging to the technical field of fabric aftertreatment. The method comprises the following steps of: dissolving Ce(NO3).6H2O in deionized water to form a transparent solution the concentration of which is 16.7*10-3-0.2mol / L; adding the Ce(NO3).6H2O solution, toluene, oleic acid and tert-butylamine to a container at a time, and heating for 2-72 hours at the temperature of 160-220 DEG C; fetching an upper oil layer after the reaction is ended, adding alcohol and centrifugalizing, and drying the obtained solid for 24-72 hours at the temperature of 60-80 DEG C to obtain the nano ultraviolet screener; dispersing the prepared nano ultraviolet screener in a dissolvant, ultrasonically dispersing for 2-30 min, putting fabrics in the solution and soaking for 2-30 min; taking out the fabrics and drying for 2-40 min at the temperature of 20-80 DEG C to obtain the high-performance uvioresistant fabric. The invention has simple preparation method, low cost and simple conditions; and the uvioresistant fabric generating chemical integration with nano materials can be prepared.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com