High-efficient desulfurizing agent for removing hydrogen sulfide and organic mercaptan from mixed gas

A technology of mixed gas and organic mercaptans, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of large solvent usage, small acid gas load, and large energy consumption for solvent regeneration to achieve good degassing Elimination effect, low regeneration energy consumption, and small usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

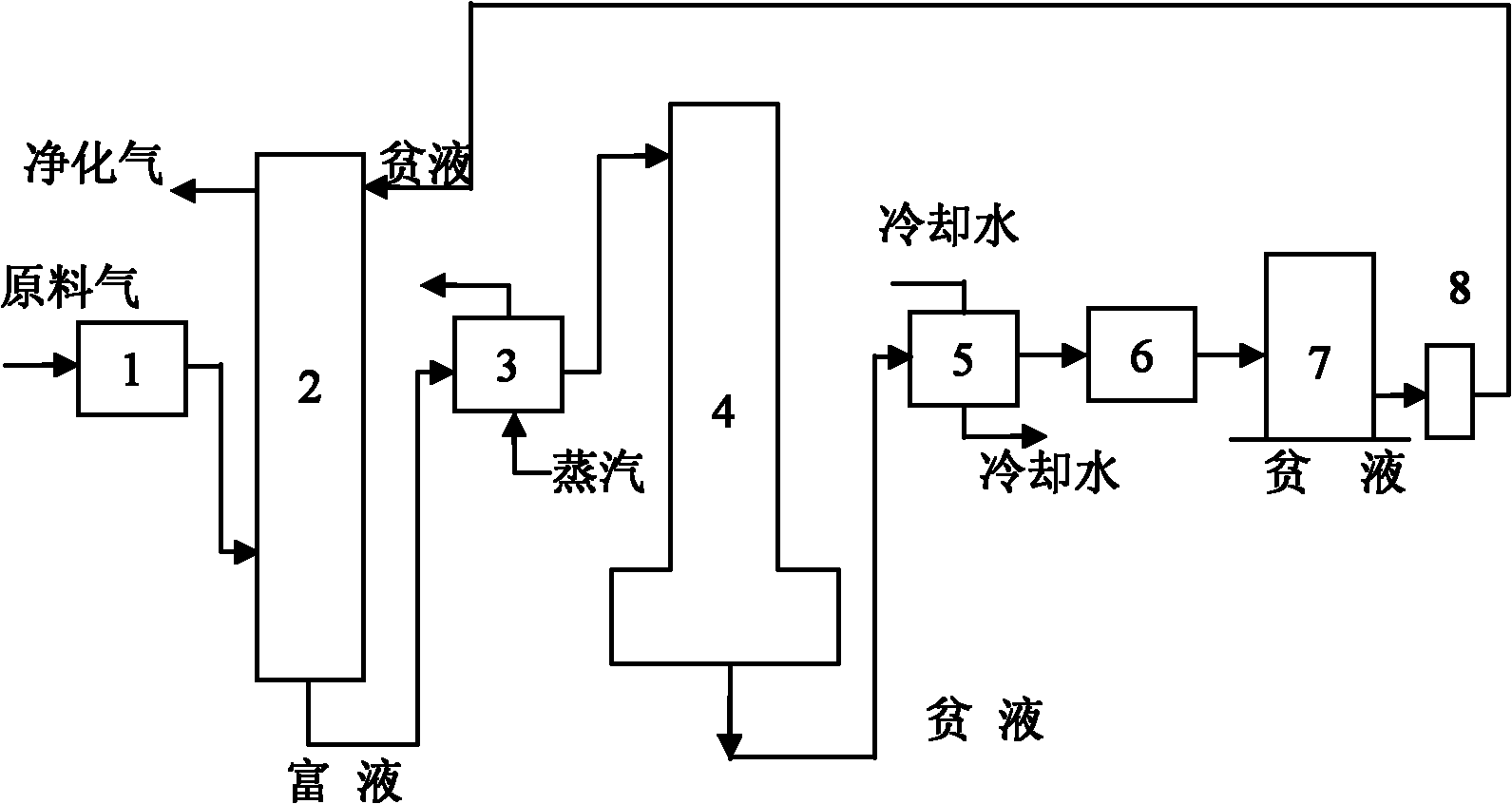

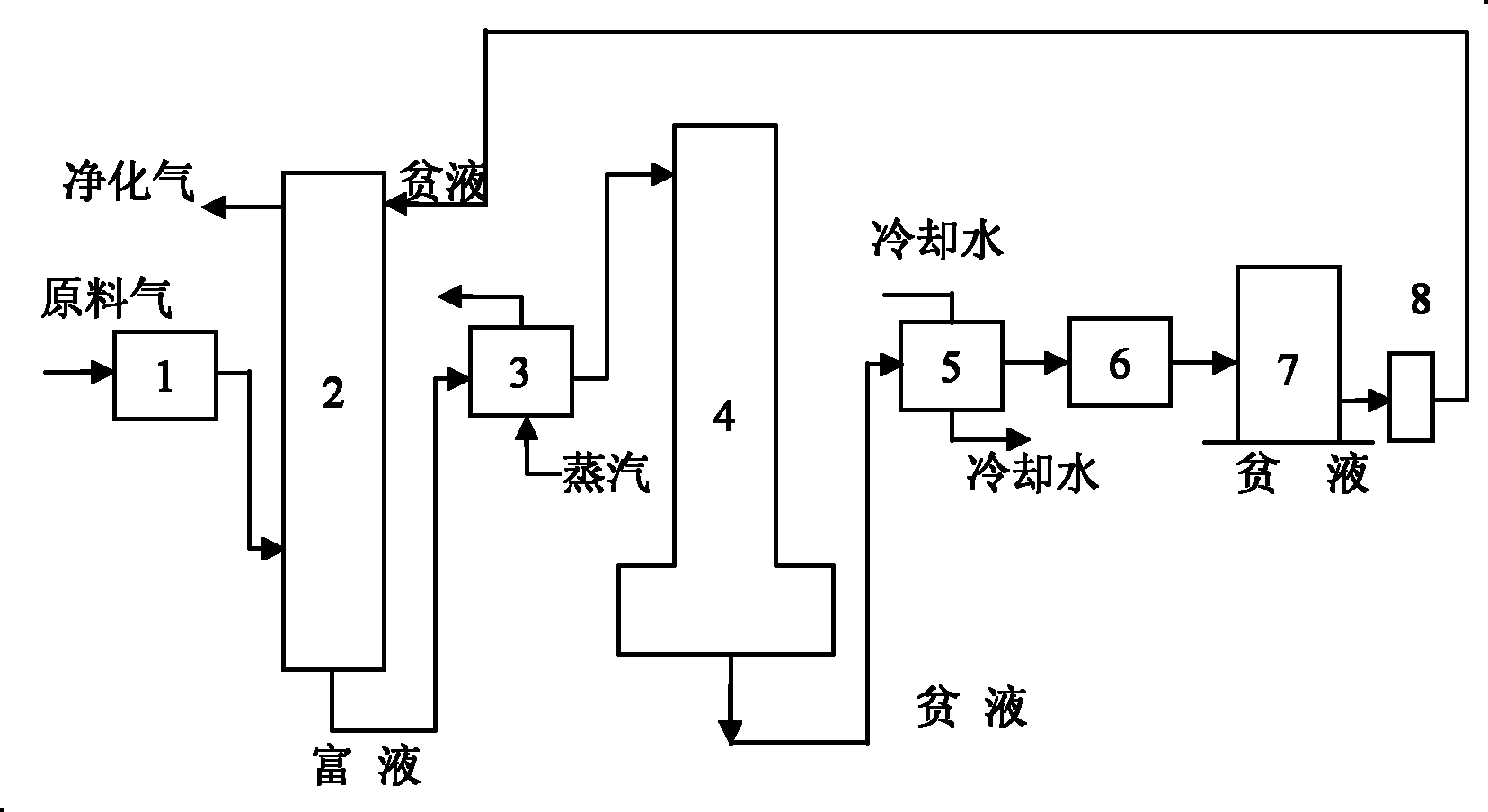

Method used

Image

Examples

Embodiment 1

[0029] Example 1, the new high-efficiency composite desulfurizer of the present invention is composed of the following raw materials by weight percentage: 75% of N-methyldiethanolamine, 9.99% of tert-butylaminoethoxyethanol, 5% of sulfolane, and 10% of N-hydroxyethylpiperidine %, defoamer 0.01%, the desulfurizer with the above specific gravity is prepared into a 45% solution with water; the gas composition for raw material is: low-carbon hydrocarbon 89.5%, H 2 S4.2%, CO 2 6.26%, the gas purification of methyl mercaptan 216PPm, ethanethiol 142PPm, and isopropyl mercaptan 37PPm, the H in the purified gas 2 S is 10PPm, CO 22.1%, mercaptan 101PPm, mercaptan removal rate 74.4%, the acid gas load of solvent 0.65mol (H 2 S+CO 2 ) / mol amine.

Embodiment 2

[0030] Example 2, the new high-efficiency composite desulfurizer of the present invention is composed of the following raw materials by weight percentage: 70% of N-methyldiethanolamine, 9.98% of tert-butylaminoethoxyethanol, 10% of sulfolane, and 10% of N-hydroxyethylpiperidine %, defoamer 0.02%, the desulfurizer with the above specific gravity is prepared into a 45% solution with water; the composition of the raw material gas is: low-carbon hydrocarbon 90.1%, H 2 S4.4%, CO 2 5.45%, the gas purification of methyl mercaptan 256PPm, ethanethiol 182PPm, isopropyl mercaptan 47PPm, H in the purified gas 2 S is 9PPm, CO 2 2.2%, mercaptan 96PPm, mercaptan removal rate 80.2%, the acid gas load of solvent 0.68mol (H 2 S+CO 2 ) / mol amine.

Embodiment 3

[0031] Example 3, the new high-efficiency composite desulfurizer of the present invention is composed of the following raw materials by weight percentage: 60% of N-methyldiethanolamine, 19.99% of tert-butylaminoethoxyethanol, 5% of sulfolane, and 15% of N-hydroxyethylpiperidine %, defoamer 0.01%, the desulfurizer with the above specific gravity is prepared into a 45% solution with water; the gas composition for raw material is: low-carbon hydrocarbon 89.5%, H 2 S4.2%, CO 2 6.26%, the gas purification of 256PPm of methyl mercaptan, 182PPm of ethanethiol, and 47PPm of isopropyl mercaptan, the H in the purified gas 2 S is 10PPm, CO 2 2.4%, mercaptan 84PPm, mercaptan removal rate 82.6%, the acid gas load of solvent 0.65mol (H 2 S+CO 2 ) / mol amine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com