Patents

Literature

252results about How to "Low regeneration energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively treating high salt content organic industrial wastewater

ActiveCN101585620AUnique methodSimple processMultistage water/sewage treatmentWater/sewage treatment by neutralisationSocial benefitsIndustrial effluent

The present invention provides a method for comprehensively treating high salt content organic industrial wastewater, and relates to the field of the organic material preparing technique. The method of the invention mainly comprises the following steps: executing acid-alkali adjustment to the organic wastewater until pH=7-9, preheating to 30-60 DEG C; introducing the wastewater into a triple effect evaporator for executing triple effect evaporation, executing salting out to the evaporated wastewater which is condensed to a certain degree so that the solid and liquid are separated; separating the concentrated liquid for continuing the condensation; when the separated liquid satisfies a certain requirement, atomizing into an incinerator for incinerating and discharging according to the standard, and introducing the triple effect evaporation condensation water into a biochemical treating system. The method of the invention can totally dispose and remove the organic matter in the high salt content organic industrial wastewater so that the high salt content organic industrial wastewater can be charged according to the standard. The method of the invention has the advantages of unique method, simple technical process, easy operation, low operation cost, large treating capacity, low regeneration energy consumption, no easy forming of secondary pollution after abandon, better economic and social benefit, and wide application range. The method of the invention can be widely applied for the treating of the high salt content organic wastewaters of garbage penetrating fluid, dye intermediate wastewater, etc.

Owner:HEBEI JIANXIN CHEM IND CO LTD

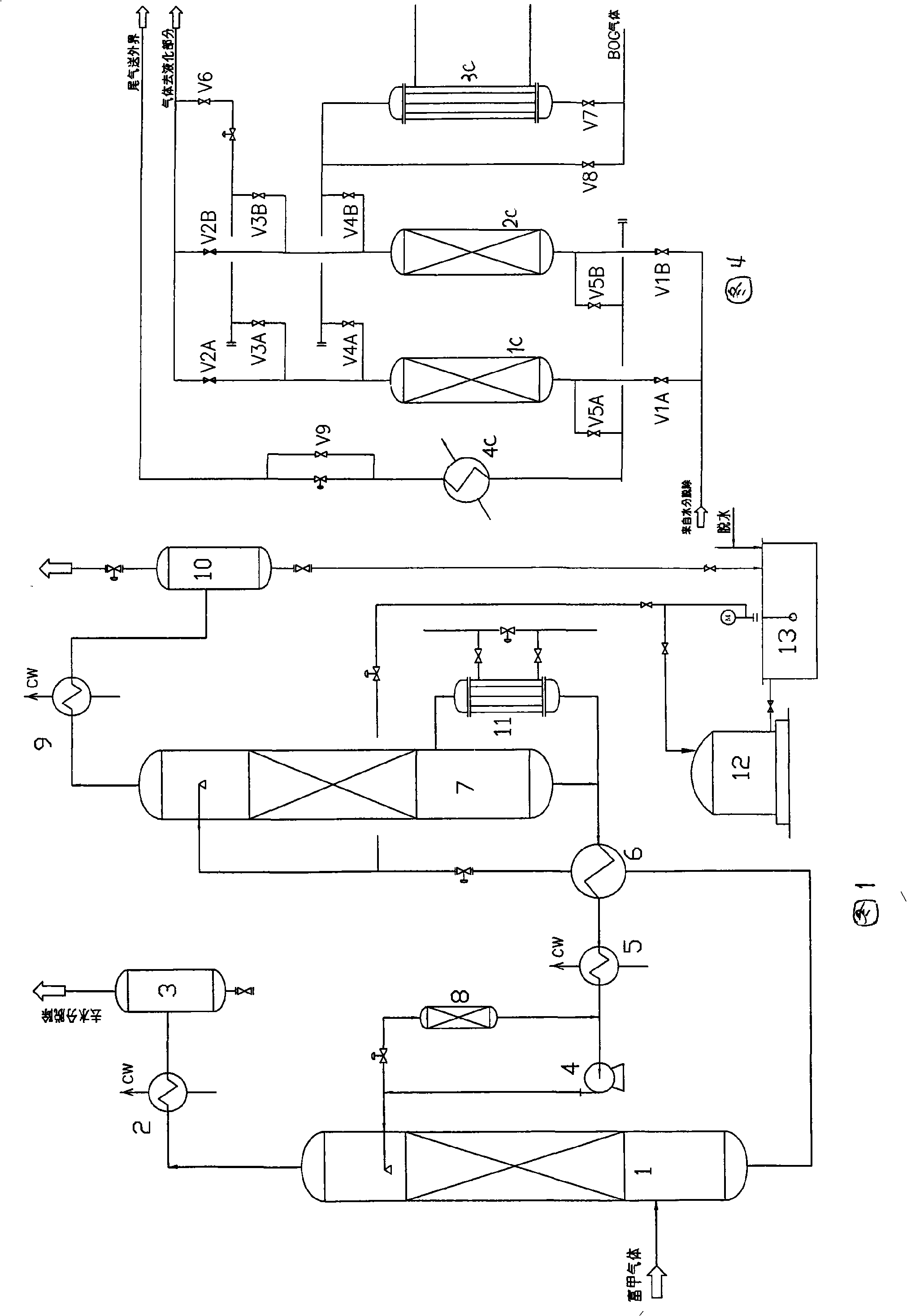

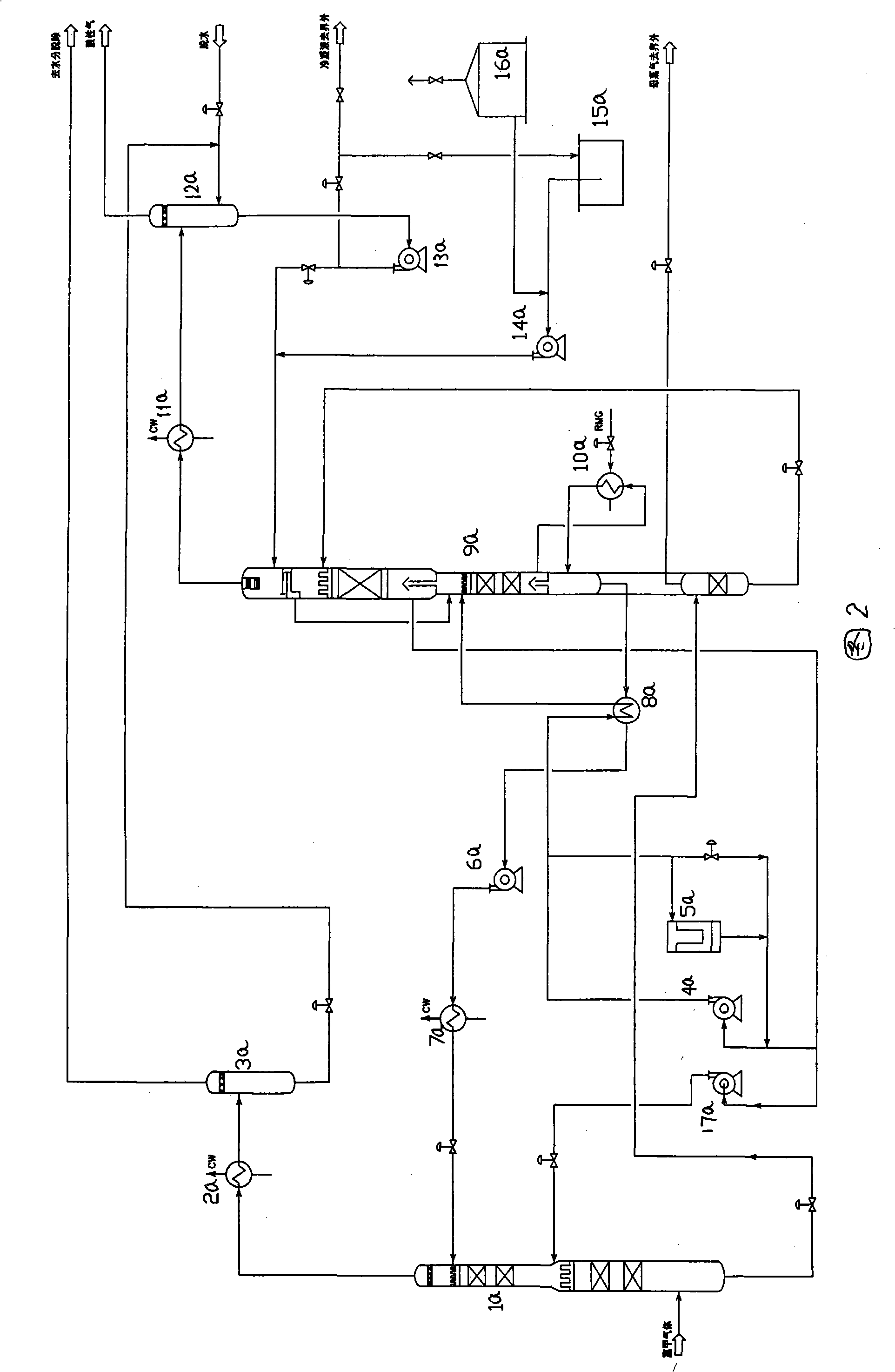

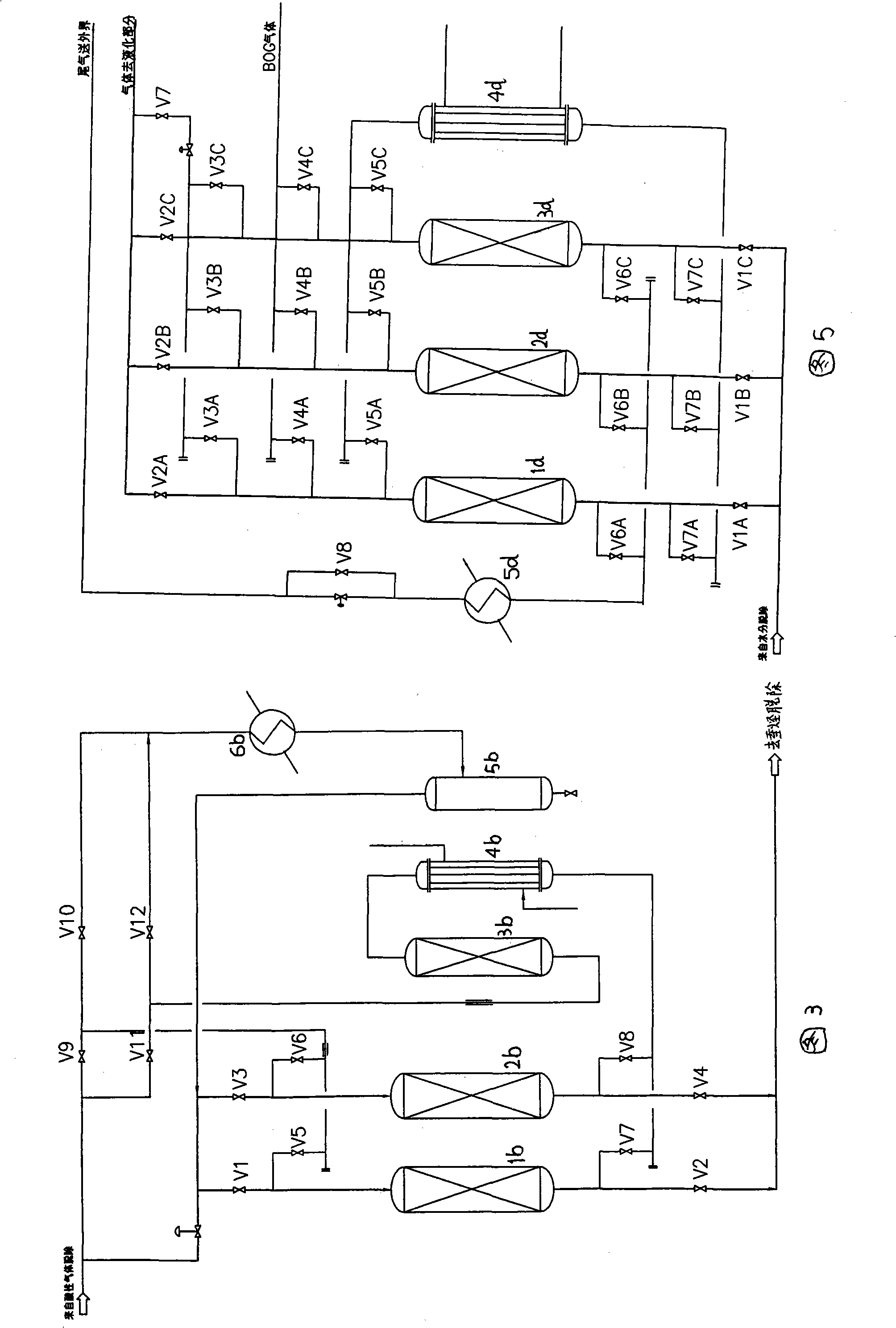

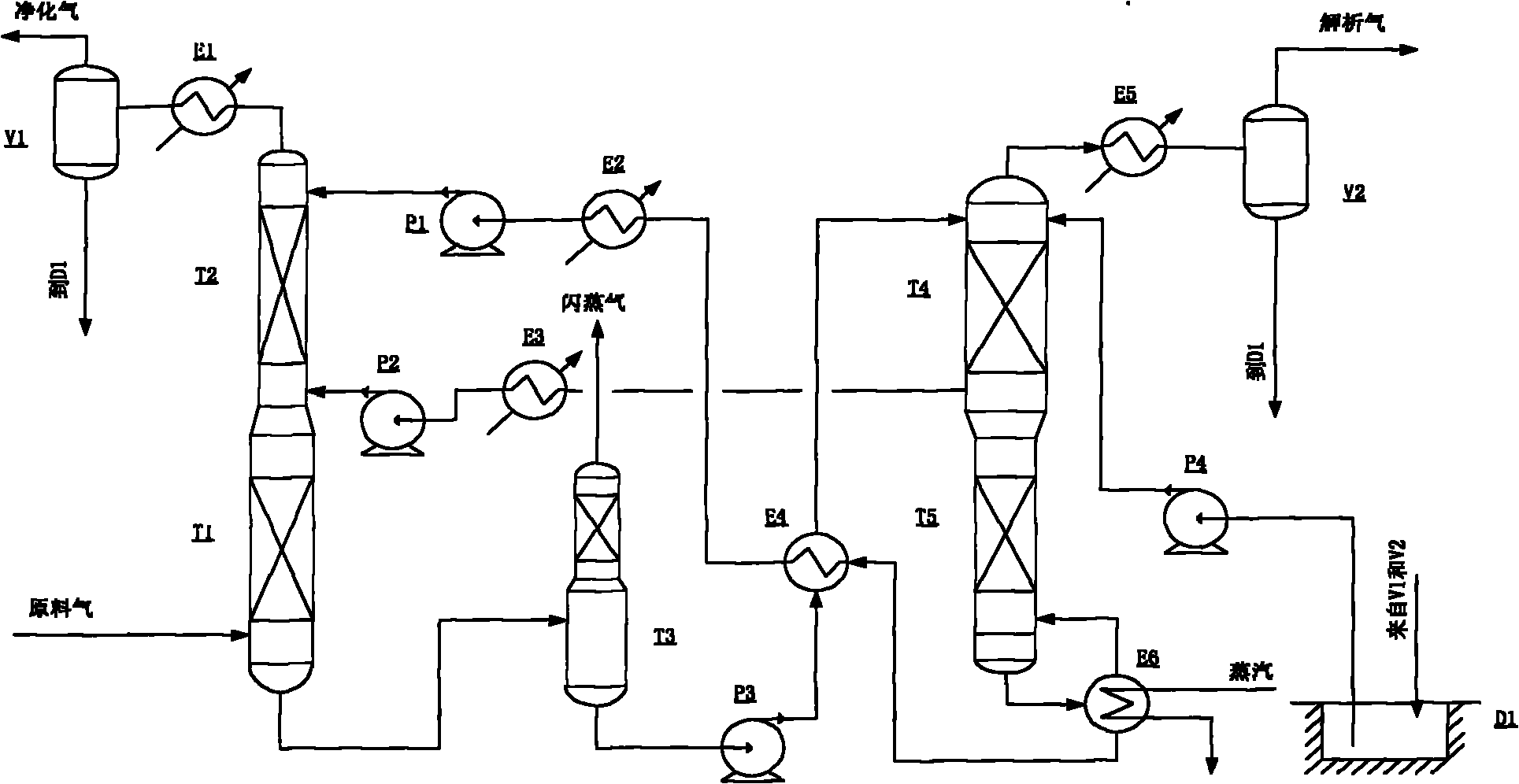

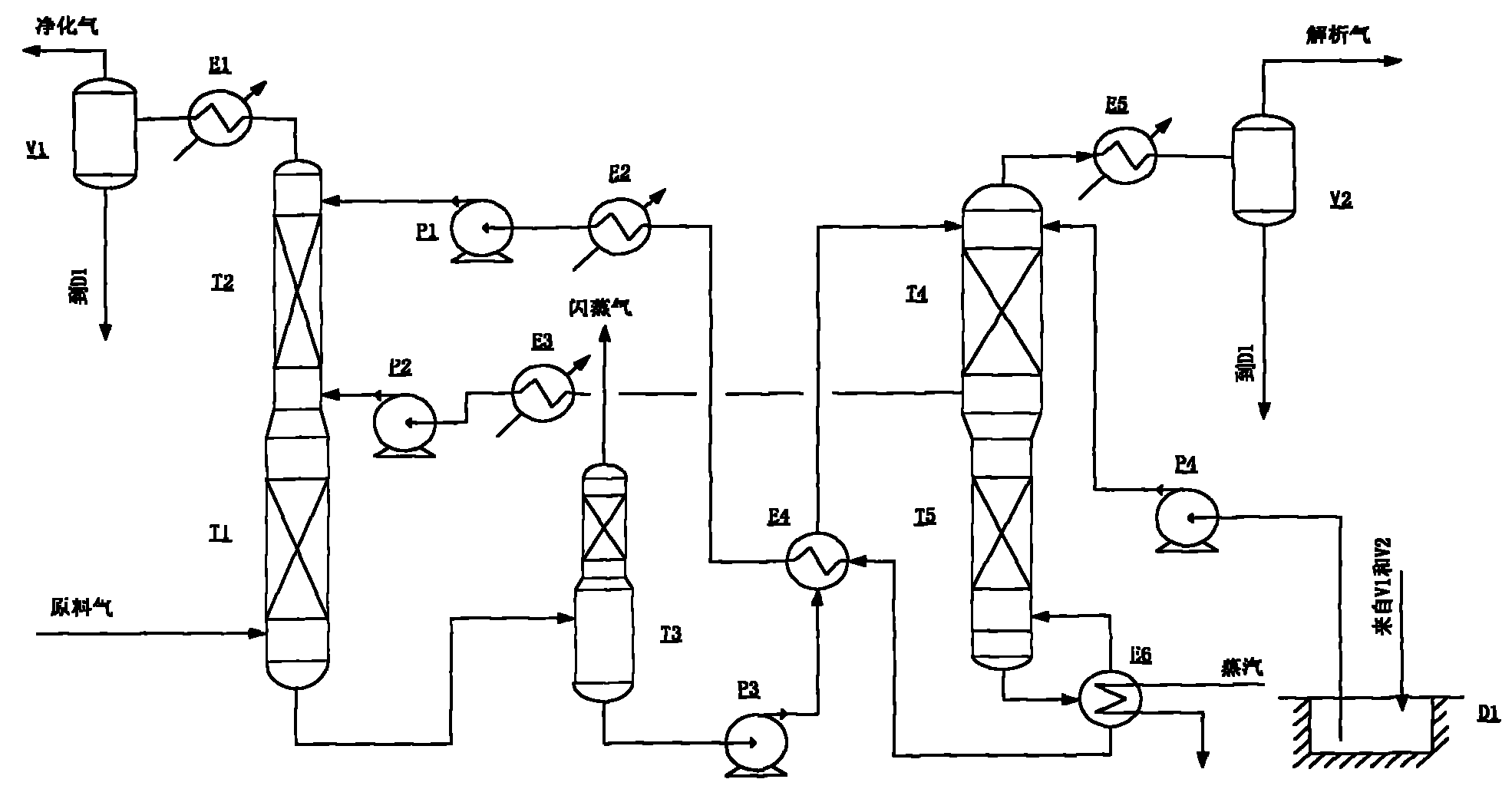

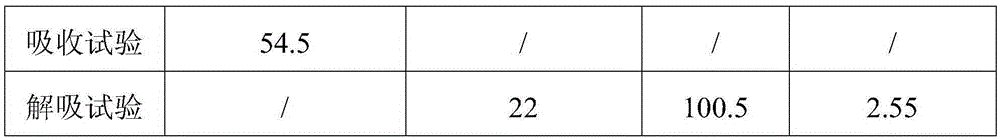

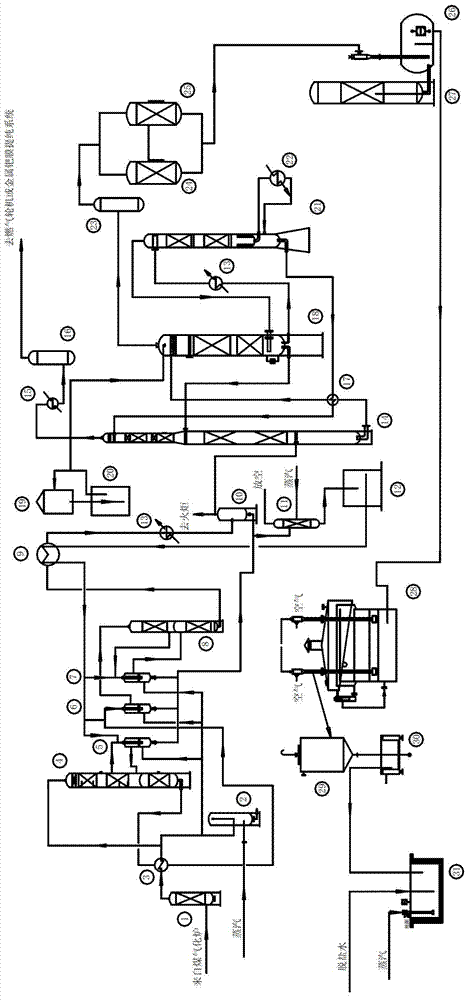

Front end combination purification technique for producing liquefied natural gas from mixture gas rich-containing methane

The invention discloses a front-end combined purification process used to produce liquefied natural gas from mixed gas richly containing methane, which comprises four unit parts: acid gas removal, drying and dehydration, heavy hydrocarbon removal and demercuration. The mixed gas firstly undergoes a purification treatment through composite amine solution, CO2, H2S and HCN acid gases in the mixed gas are removed to the concentration less than or equal to 20ppm; the moisture in the gas is removed to a dew point at normal pressure less than or equal to minus 70 DEG C through isopiestic drying and dehydration treatment, then heavy hydrocarbon components above C5 are removed to the concentration less than or equal to 10ppm through temperature-changing pressure-changing absorption and purification treatment; finally the mercury content is removed to the value less than or equal to 0.001mu g / Nm<3> through the demercuration of demercuration adsorbent. The process has better purification effect than the conventional process route, improves the utilization rate of the raw materials and decreases the energy consumption during the purification; and the operation indexes of the units are easier to control.

Owner:成都五环新锐化工有限公司

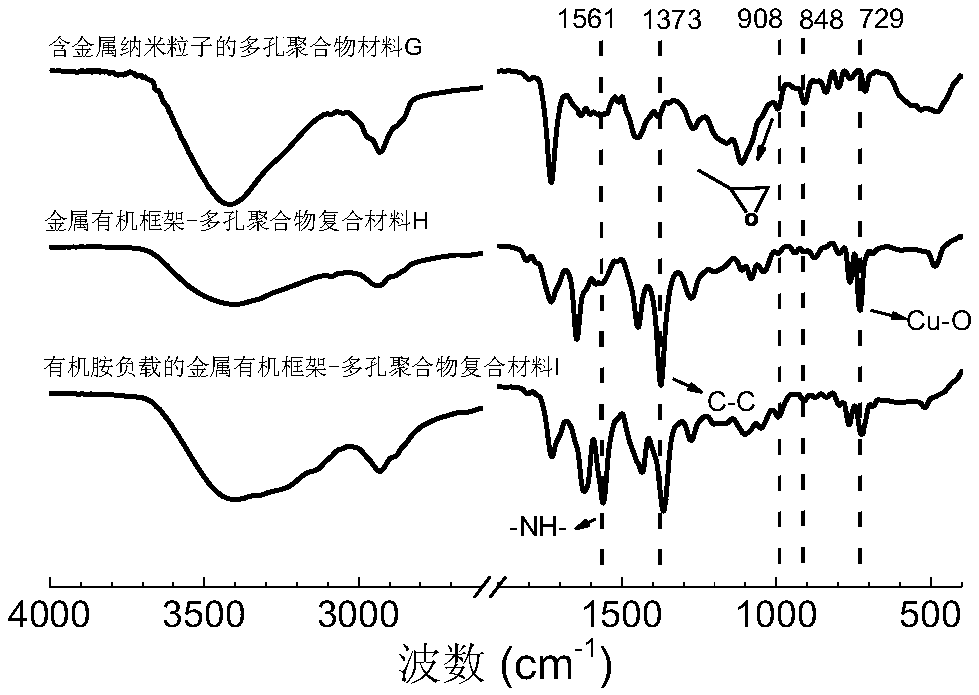

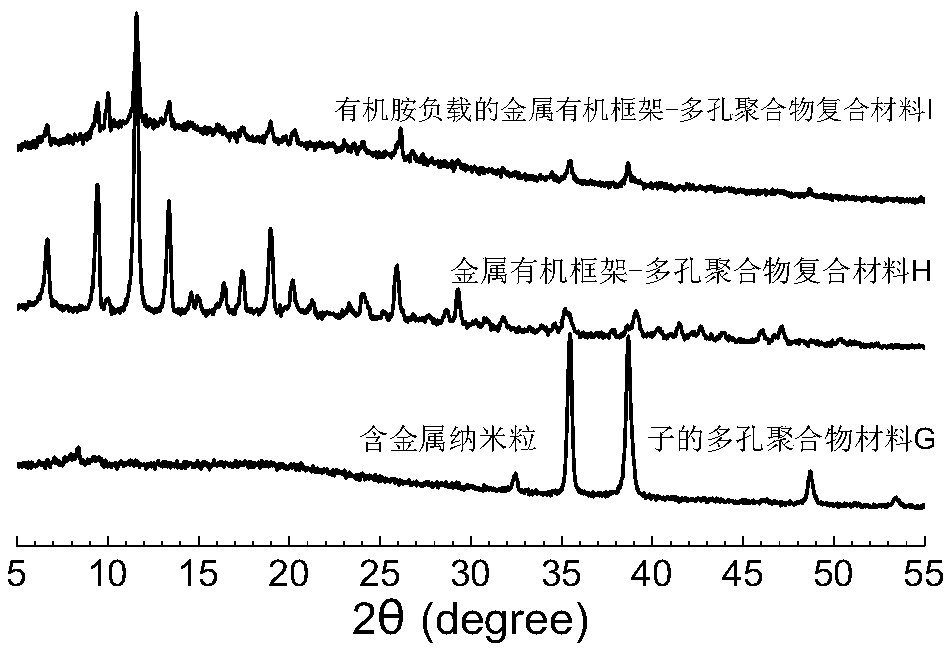

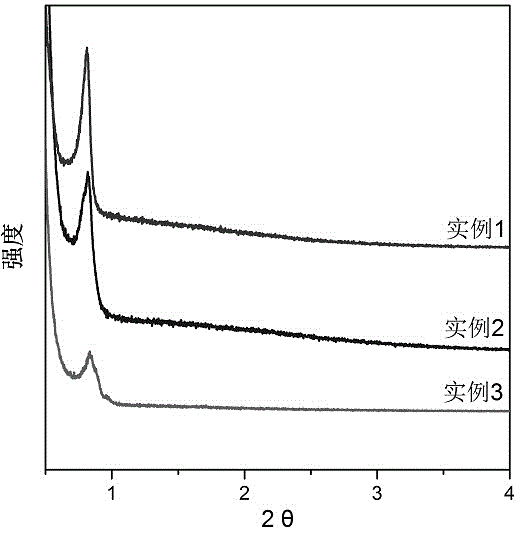

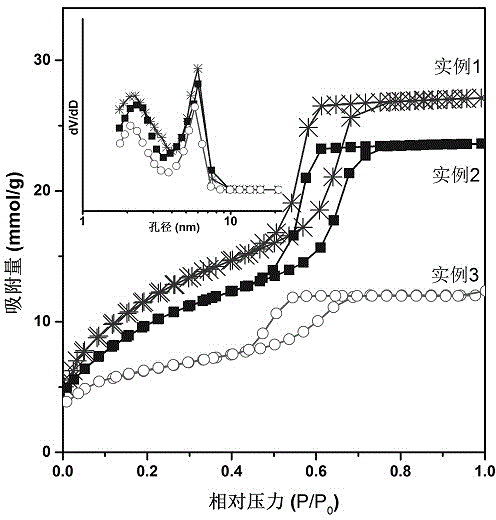

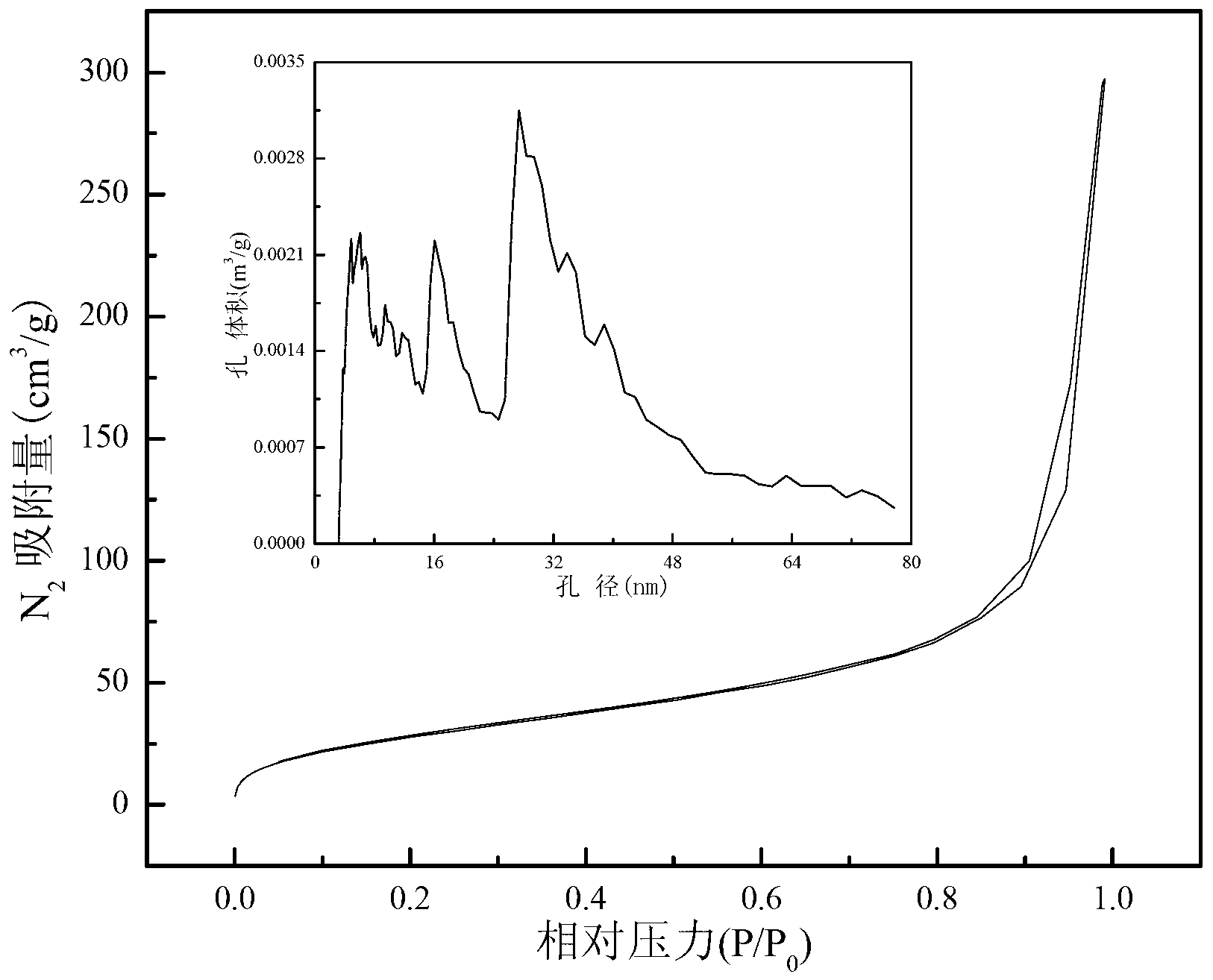

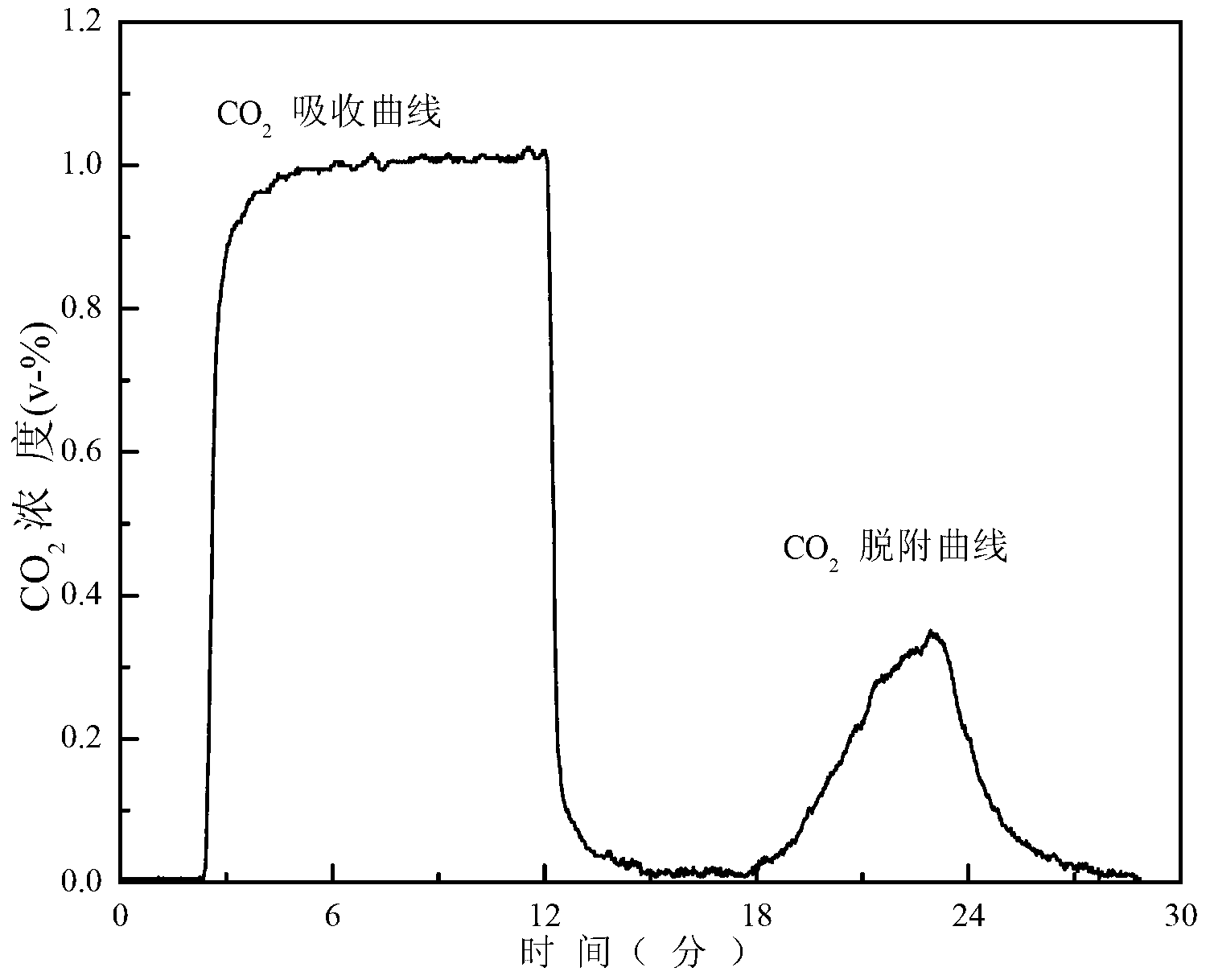

Organic amino supported metallic organic framework-porous polymer composite material as well as preparation method and application thereof

ActiveCN108786755ALarge specific surface areaHigh adsorption capacity/rate/selectivityProductsOther chemical processesEmulsionDesorption

The invention discloses an organic amino supported metallic organic framework-porous polymer composite material. The material consists of organic amino, a metallic organic framework material and a porous polymer of multi-stage pore structures which are mutually communicated, wherein metallic organic framework crystal granules are embedded into pore wall surfaces of pore walls of the porous polymer; the organic amino is bonded with the pore wall surfaces of the porous polymer through chemical bonds and bonded with the surface of the metallic organic framework through chemical bonds or coordination bonds; the composite material has a specific surface area greater than or equal to 50m<2> / g. The invention further provides a preparation method of the organic amino supported metallic organic framework-porous polymer composite material. The preparation method comprises the following three steps: carrying out high inner phase emulsion template crosslinking copolymerization, carrying out MOF (Metallic Organic Framework) in-situ growth or MOF multi-time growth, and carrying out organic amino supporting. The organic amino supported metallic organic framework-porous polymer composite materialdisclosed by the invention is used for capturing and separating CO2 and has the advantages of being high in CO2 adsorption capacity / velocity / selectivity, rapid in desorption speed, high in adsorption / desorption circulation stability, excellent in high-temperature and moisture resistance, and the like.

Owner:ZHEJIANG UNIV

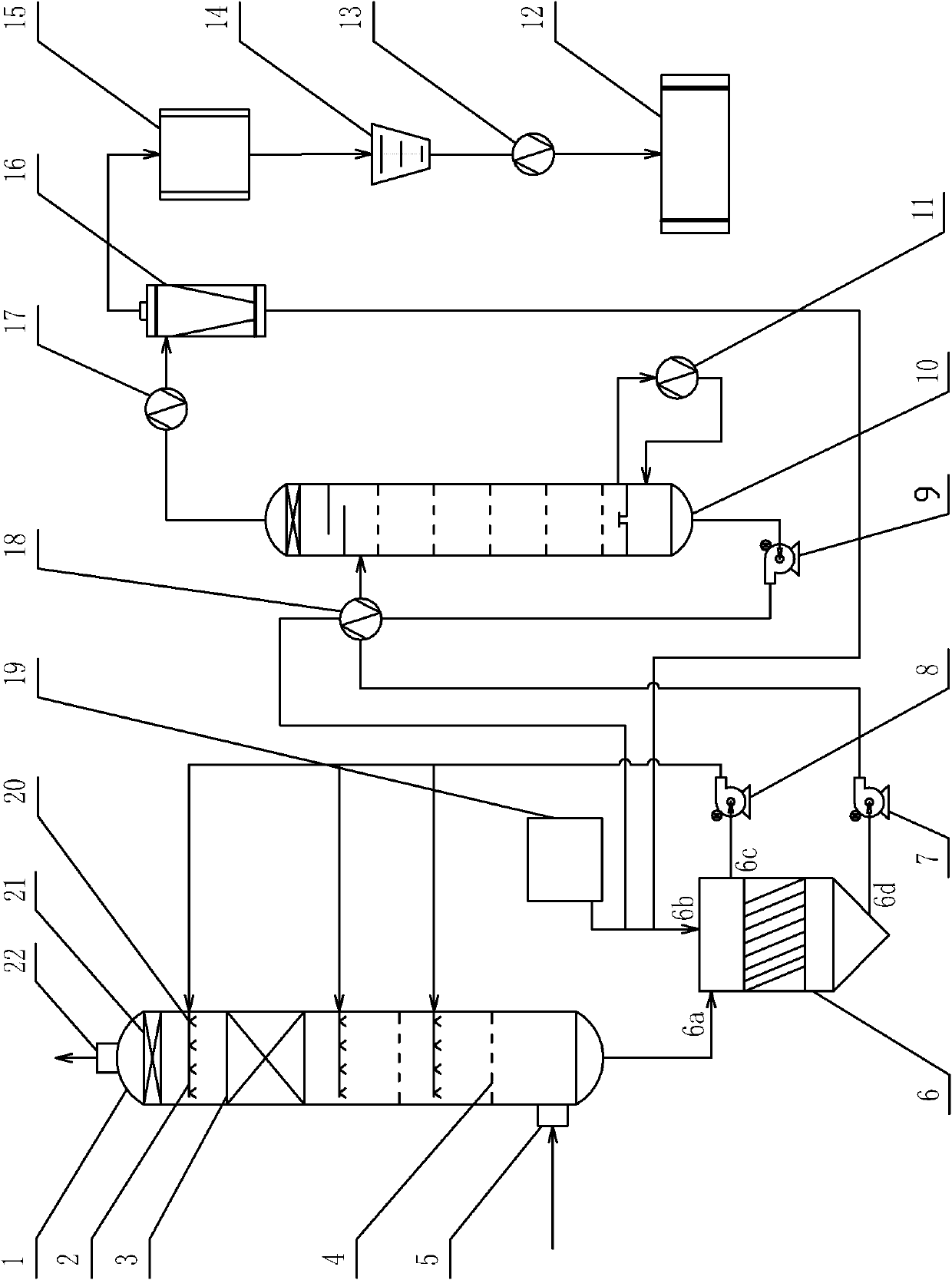

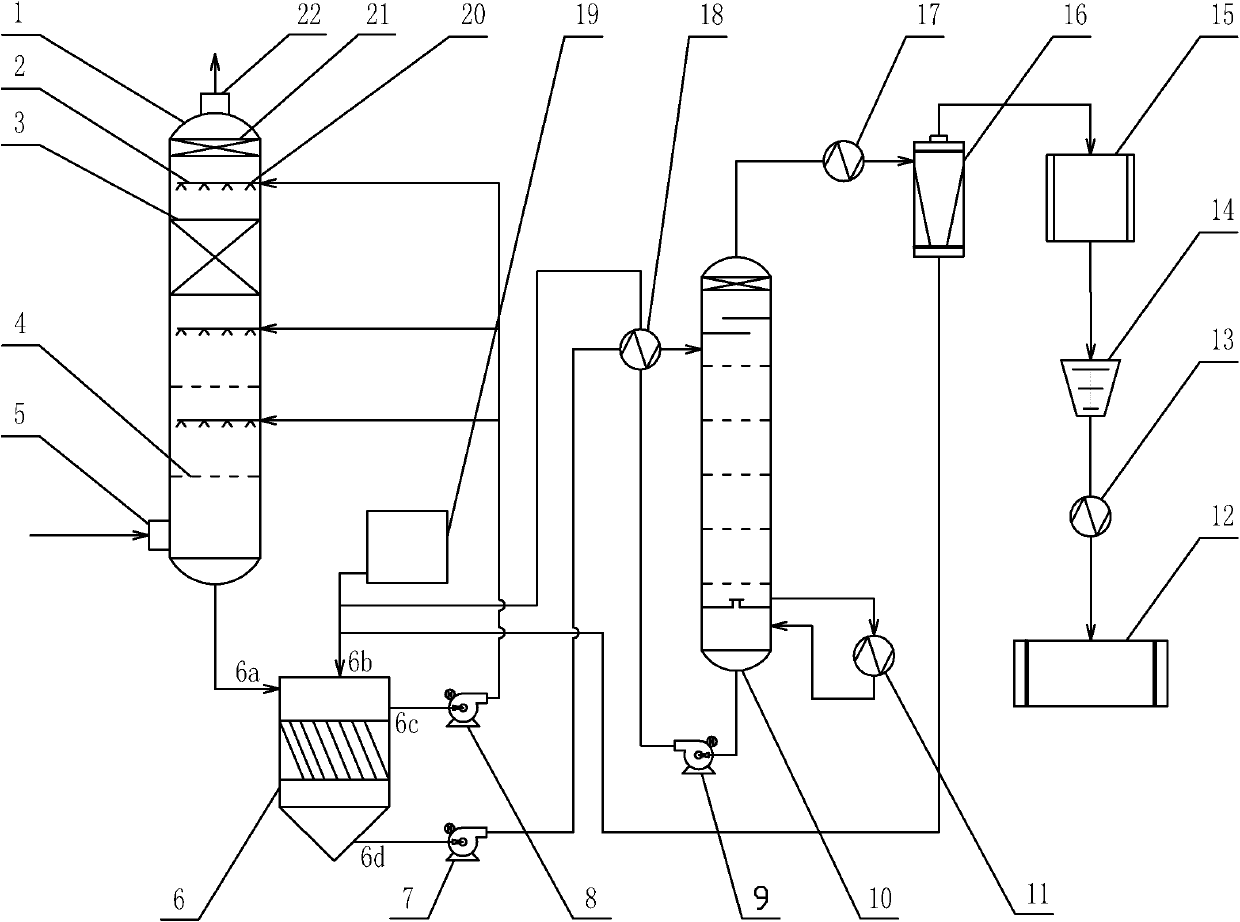

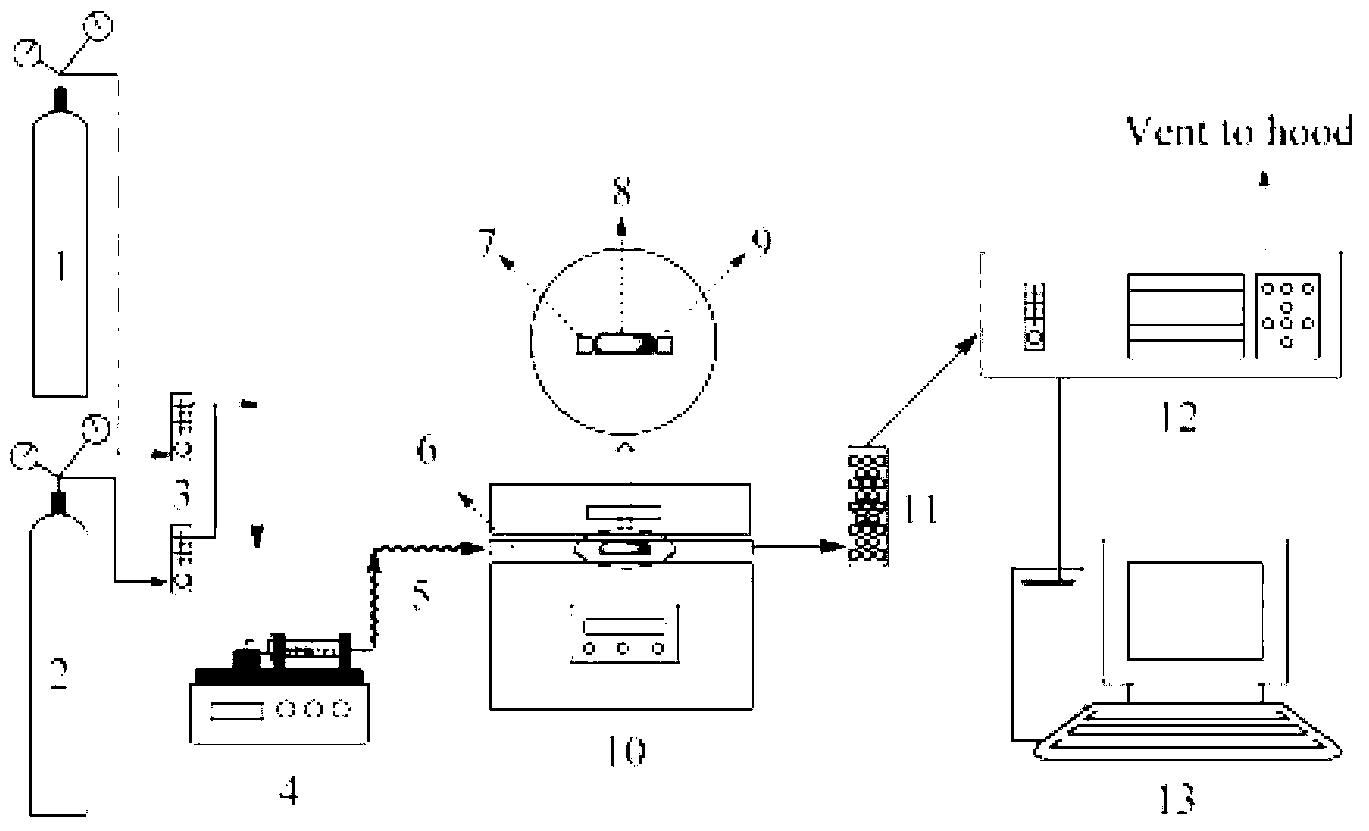

Method for catching carbon dioxide in flue gas by active sodium carbonate and apparatus thereof

InactiveCN102000486ALow costLow regeneration energy consumptionGas treatmentCarbon compoundsHydration reactionSodium bicarbonate

The invention relates to a method for catching carbon dioxide in flue gas by active sodium carbonate and an apparatus thereof. The method comprises the following steps of: firstly, combining alkylol amine and CO2 into a zwitterions intermediate product with an alkylol amine activator-added sodium carbonate water solution as a CO2 absorbent; then carrying out hydration reaction to dissociate again for recycling; neutralizing H<+> generated in the hydration reaction with an alkaline ion CO3<2->; and combining HCO3<-> generated in the hydration reaction and the metallic ion Na<+> to separate gradually to finally obtain a sodium bicarbonate slurry. The sodium bicarbonate slurry is subjected to resolving and regeneration to obtain CO2 gas and a sodium carbonate solution. The CO2 gas is prepared into a liquid state through conventional treatment. The apparatus mainly comprises an absorbing tower, a tilted plate sedimentation tank, a regenerating tower, a cooler, a gas-liquid separator, a dryer, a compressor, a condenser, and the like which are connected through pipelines. The invention has the characteristics of simple process flow and apparatus combination, low investment and running cost and capability of being suitable for large flow rate and low concentration of the flue gas of the tail part of a power station boiler; and the expensive alkylol amine is replaced to prepare the liquid carbon dioxide with high purity.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

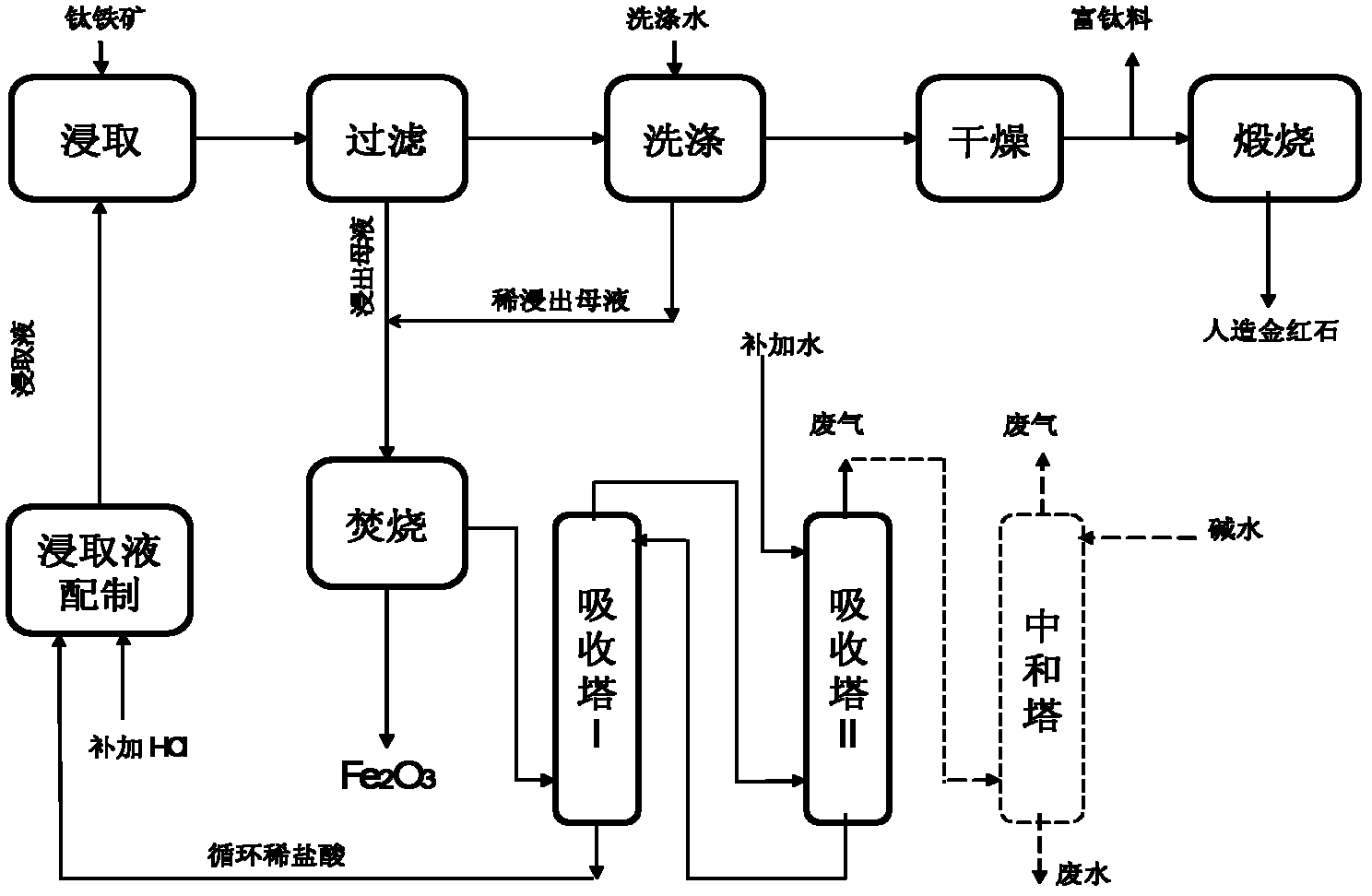

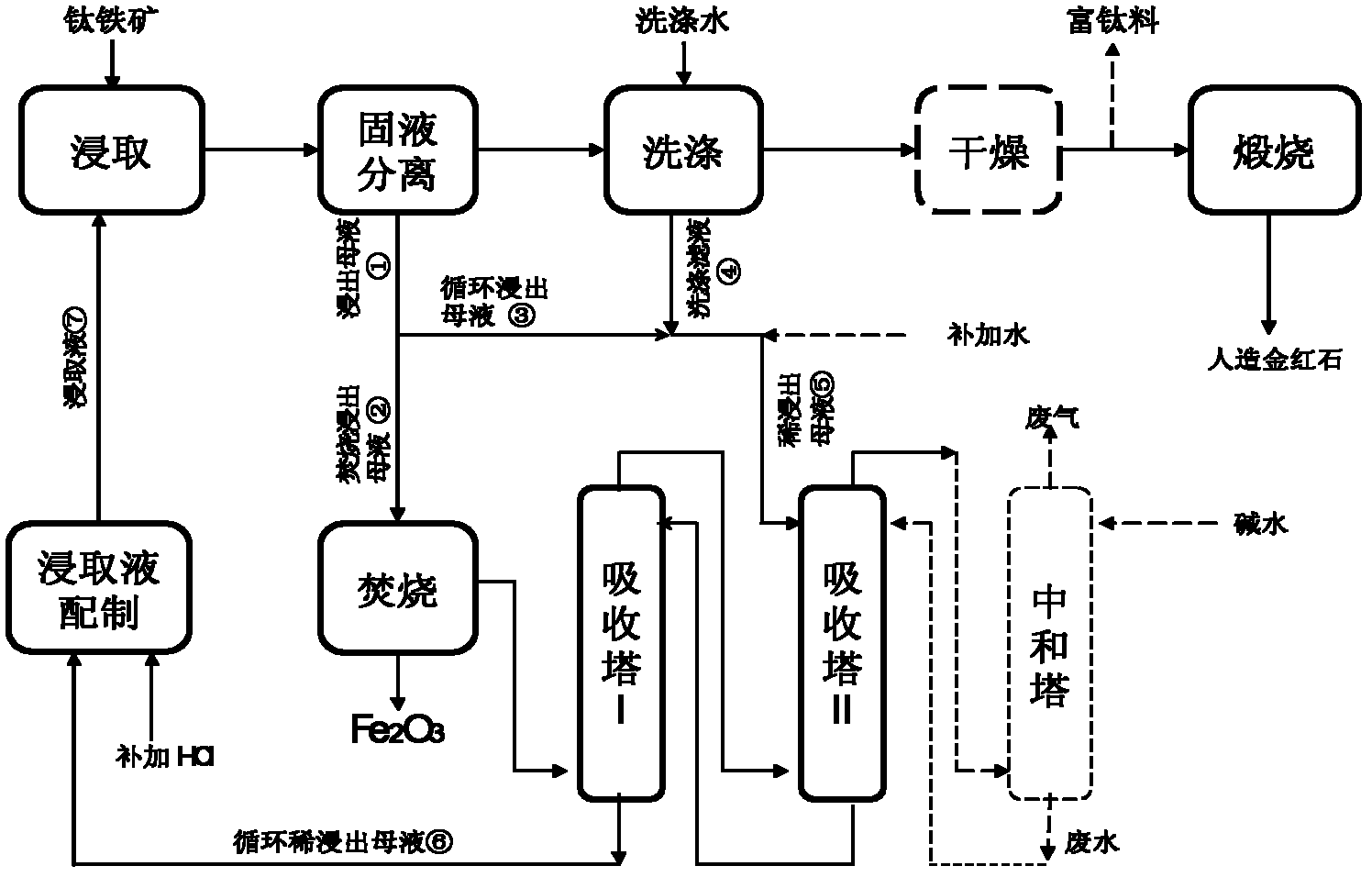

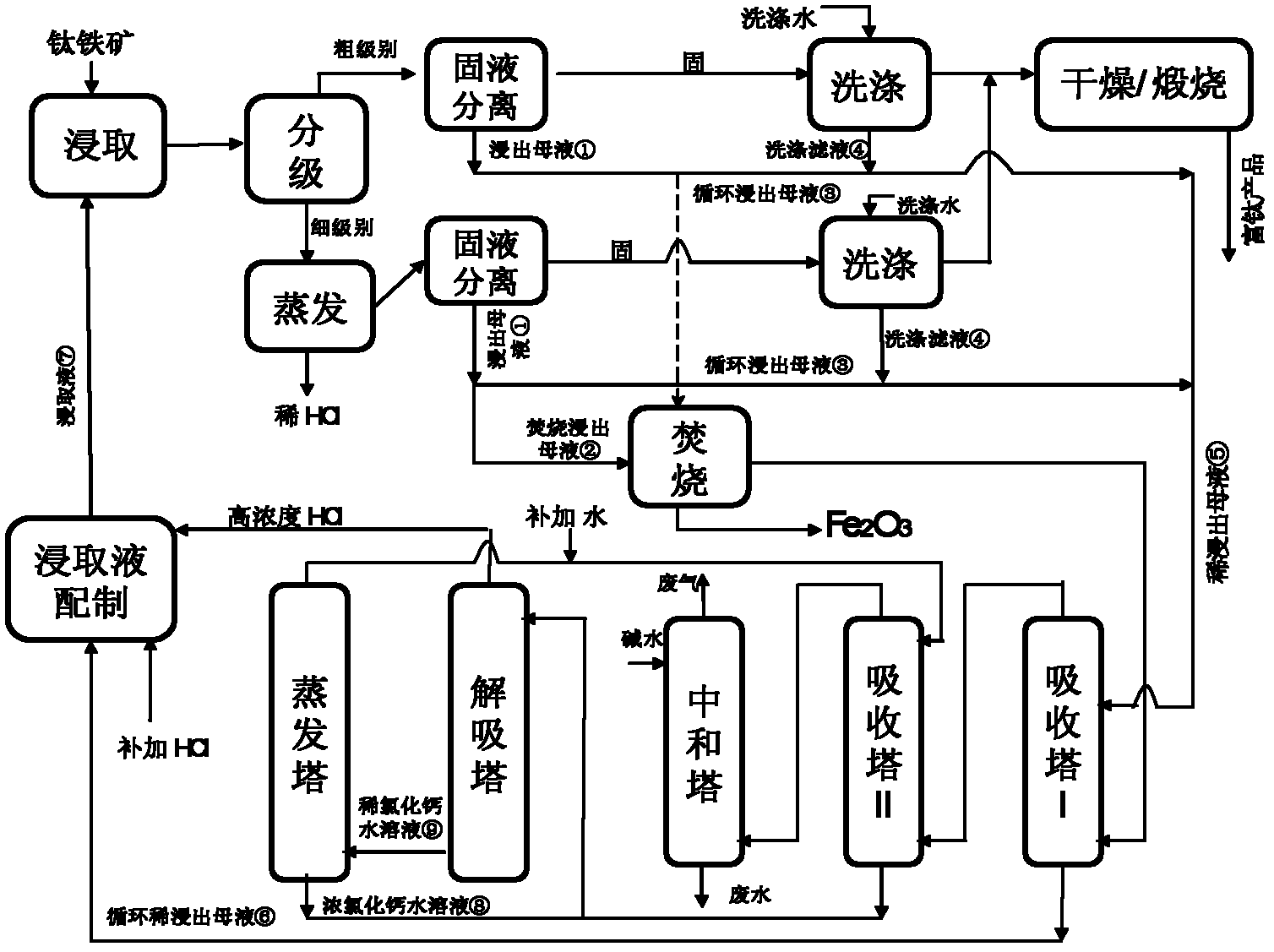

Method for treating hydrochloric acid leachate of ferrotitanium materials

InactiveCN102352437AReduce incinerationReduce processing energy consumptionPregnant leach solutionMaterial balance

The invention provides a method for treating hydrochloric acid leachate of ferrotitanium materials. The method comprises the following steps of: dividing and burning leached mother liquid which is obtained by leaching the ferrotitanium materials by using hydrochloric acid leaching liquid; recovering hydrogen chloride obtained by burning for regeneration and cyclic utilization of the leaching liquid. By the method provided by the invention, the leachate is divided according to material balance of the leach elements (mainly comprising iron) of the hydrochloric acid leachate; and one part of theleachate after division is burned and the other part of the leachate is directly or indirectly absorbed by the hydrochloric acid to return to the leaching procedure, so that completely closed circuitcirculation is formed. By the method provided by the invention, the defect of overlarge energy consumption in the burning procedure after the ferrotitanium materials are leached by the conventional hydrochloric acid can be overcome and the burning quantity of the leached mother liquid can be reduced by 40 to 55 percent, so that the energy consumption of the whole process can be reduced by 35 to 45 percent. The method has a good industrial application prospect.

Owner:沙立林 +1

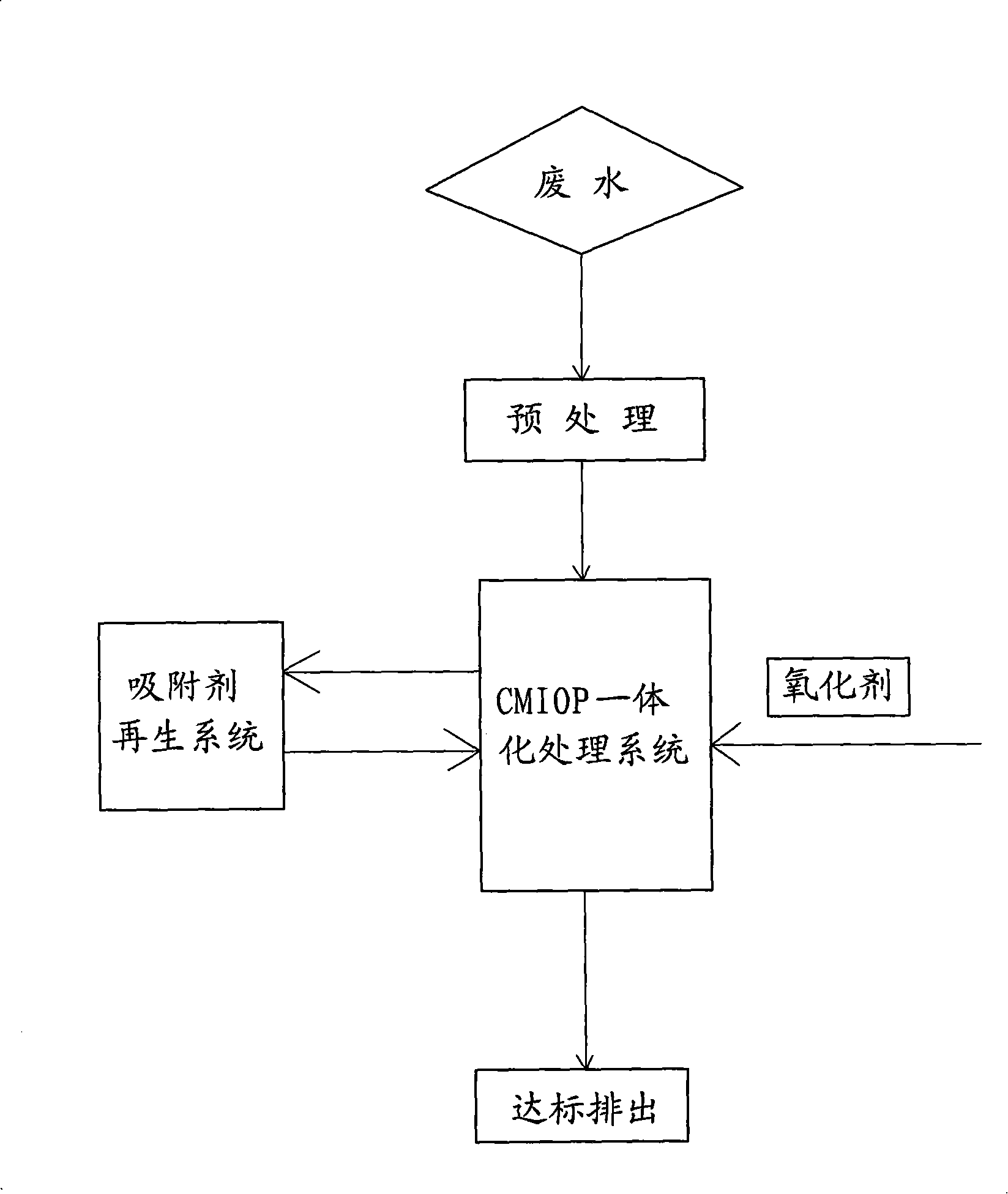

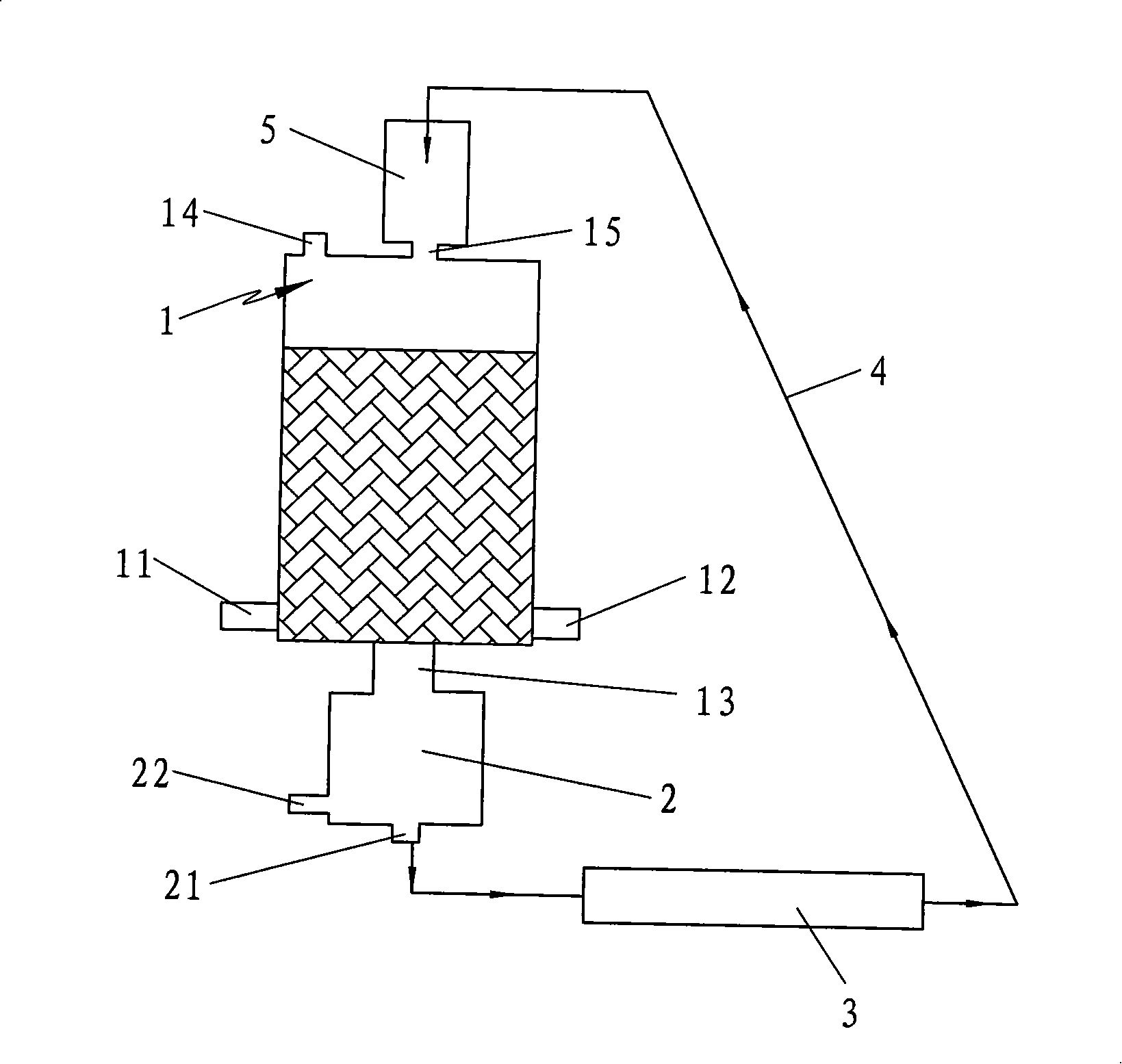

Innocent treatment method and apparatus for catalytic oxidation of waste water induced by continuous microwave-ultraviolet

InactiveCN101333013AFast adsorption rateImprove adsorption capacityWater/sewage treatment by irradiationWater/sewage treatment by sorptionSorbentCatalytic oxidation

The invention discloses a wastewater harmless treatment method by continuous microwave-ultraviolet inducing catalysis oxidation and equipment thereof, belonging to the technical field of wastewater treatment process. In the invention, after being pretreated, wastewater flows through an adsorbent reaction bed and carries out microwave-inducing catalysis oxidation reaction, organic matter in wastewater can be quickly decomposed into small molecular inorganic matter and the adsorbent in the reaction bed is recycled by an adsorbent regeneration system; and finally the wastewater is purified and discharged. The invention adopts microwave radiation to improve the adsorption rate of the adsorbent, the regeneration mode of the adsorbent has fast regeneration speed, low energy consumption and no secondary pollution, the continuous process of continuous regeneration and continuous adsorption of the adsorbent can be realized, the batch-type or sequencing-batch-type operation processing mode of the traditional adsorbent can be changed, and the processing capacity of the system can be greatly enhanced.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

Activated charcoal gas cleaning method and device thereof

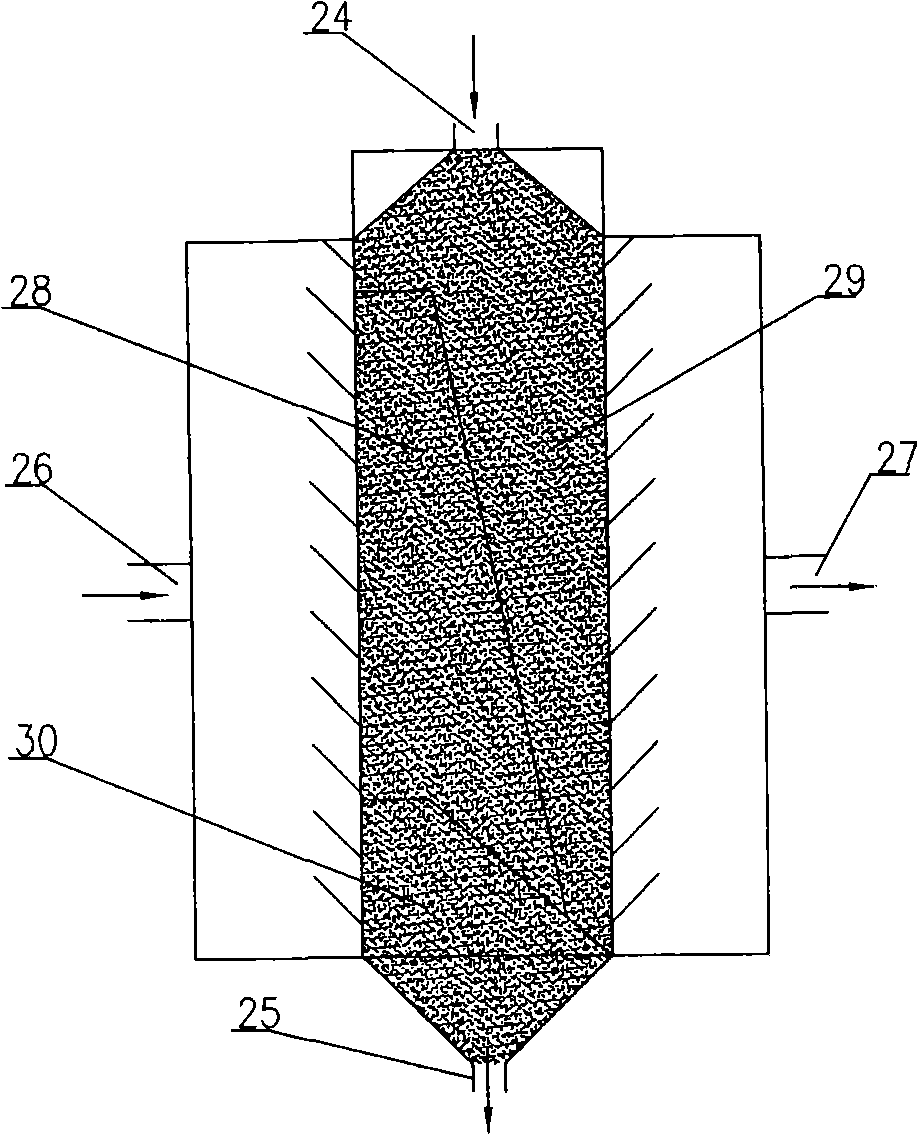

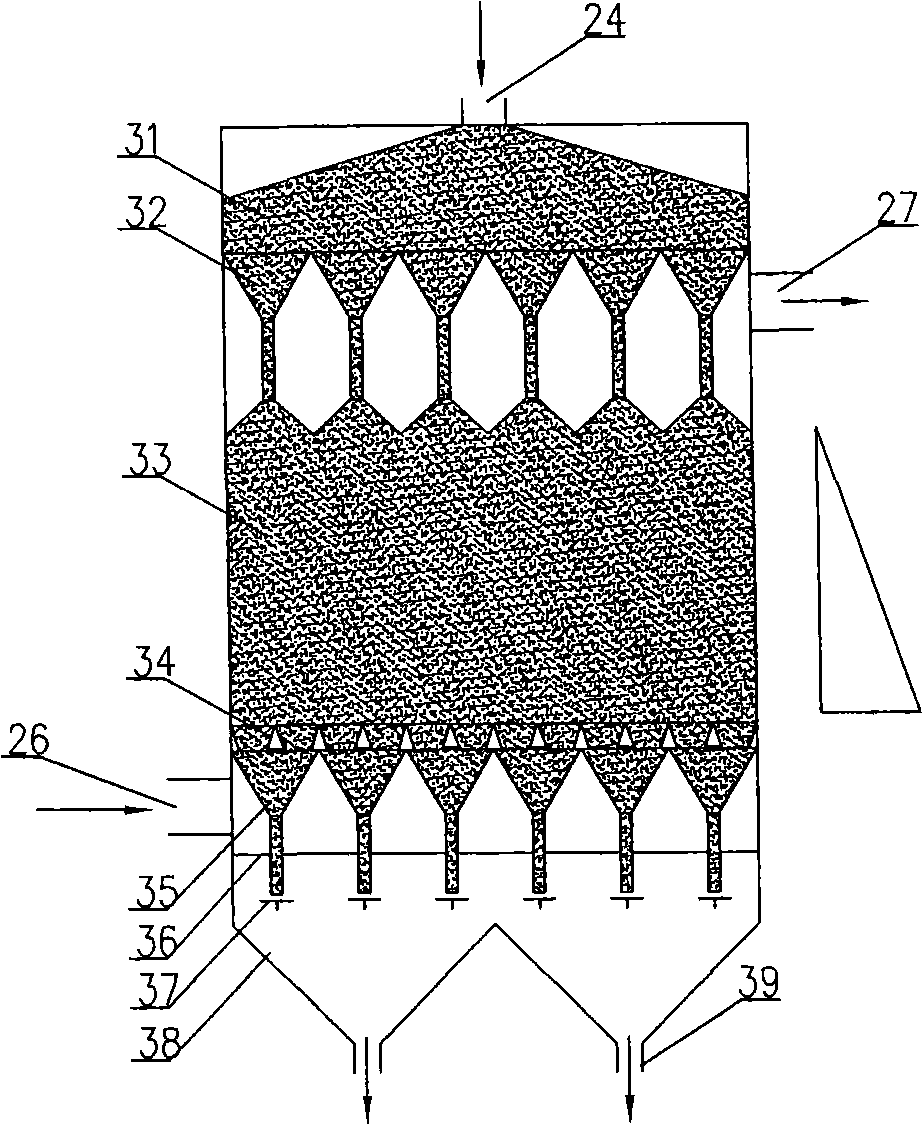

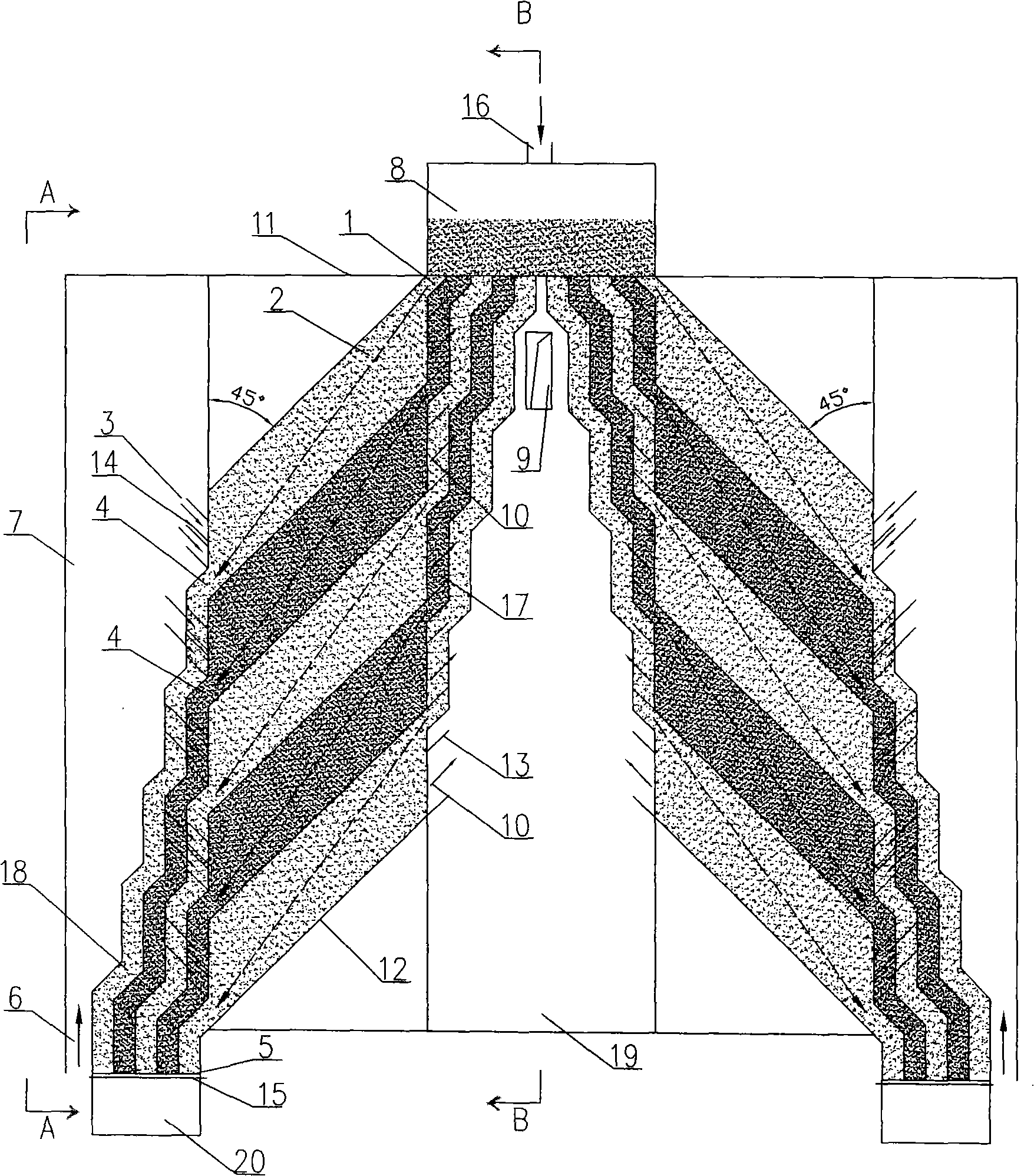

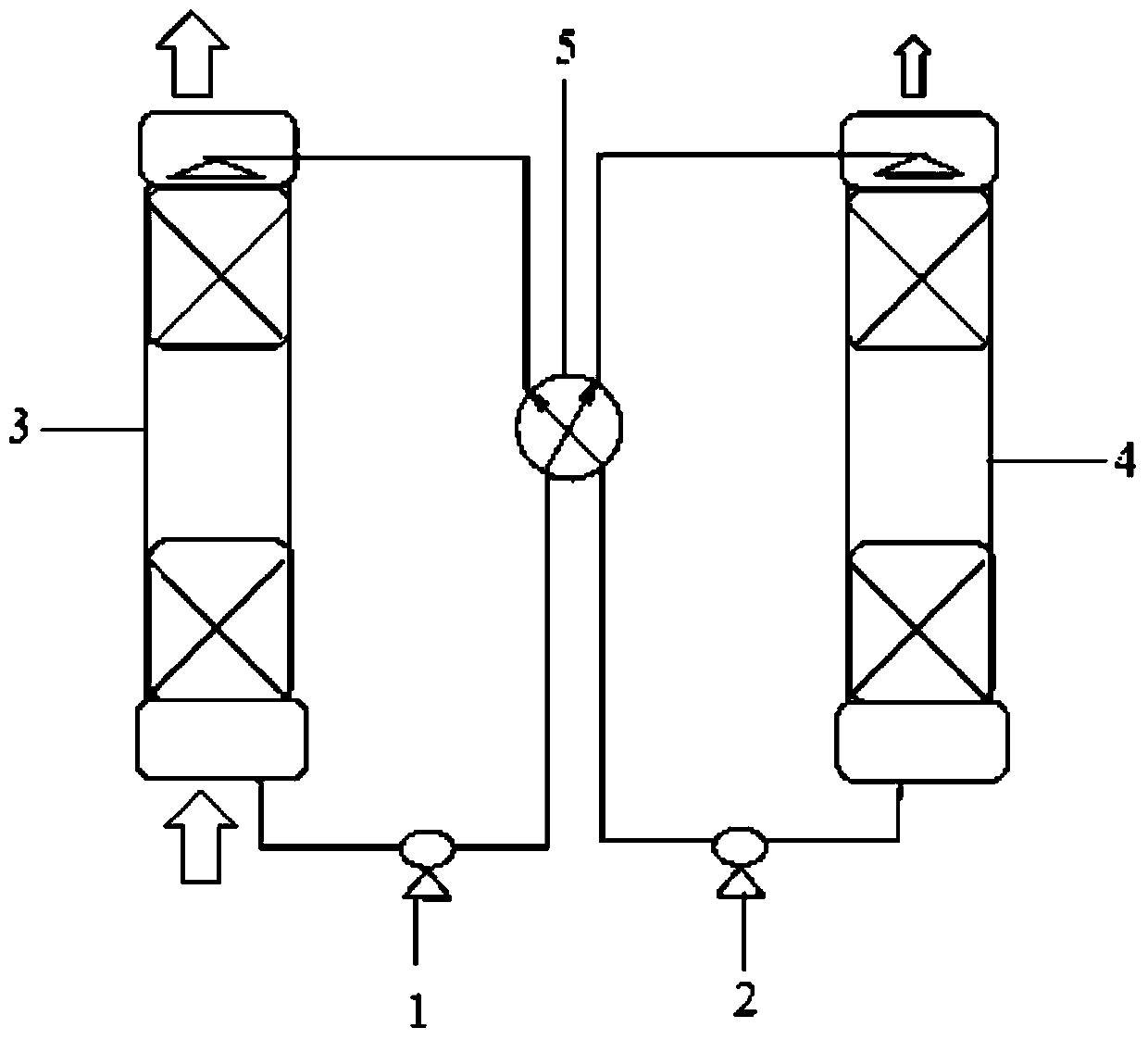

ActiveCN101310827AImprove adsorption efficiencySave steelOther chemical processesDispersed particle separationProcess engineeringProduct gas

The invention provides an active coke gas purifying method and a device thereof with high desulfurization and denitrification efficiency, energy conservation, little resistance of a bed layer, high utilization rate of the space in an absorption tower and low construction cost. The device comprises a main feed inlet and a gas main outlet which are arranged at the upper part of the absorption tower, a main discharge outlet and a gas main inlet which are arranged at the lower part of the absorption tower and an active coke bed layer which is positioned in the absorption tower, and the active coke bed layer is tilted and has an included angle Alpha with the vertical line. The method has the following steps: gas enters the active code bed layer from the gas main inlet, gas in the tilted bed layer is flowed to the top from the bottom; active coke simultaneously enters the active coke bed layer from the main feed inlet, the active coke in the tilted bed layer is flowed to the bottom from the top; the gas is exhausted from the gas main outlet after the fully tilted convection contact is formed between the gas and the active coke, and the active coke after the saturation by absorption can be discharged from the main discharge outlet.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

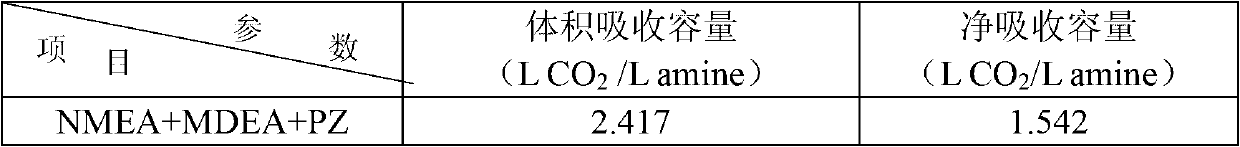

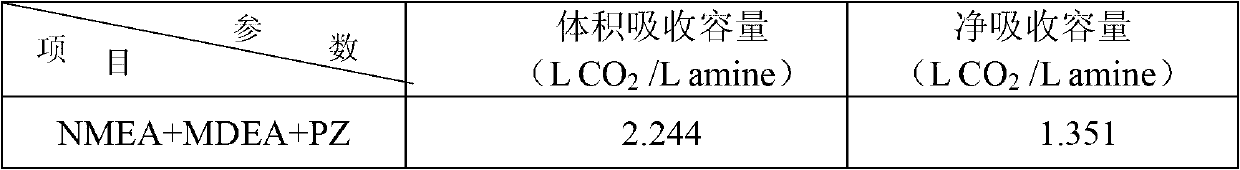

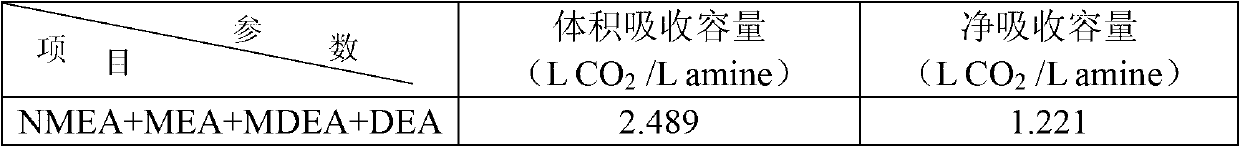

Composite organic alcohol amine absorbing agent for carbon dioxide

InactiveCN104190210AReduce lossLow regeneration energy consumptionDispersed particle separationAir quality improvementCompound organicAlcohol

The invention relates to a composite organic alcohol amine absorbing agent for carbon dioxide, belonging to the technical field of chemical materials. The absorbing agent is prepared from the following components in percentage by weight: 80-99.97% of a main absorbing agent, 0-19% of an auxiliary absorbing agent, 0.01-1% of an antioxidant, 0.01-1% of a corrosion inhibitor, 0-1% of an absorption enhancing agent, 0.01-1% of a complexing agent, 0-0.1% of a defoaming agent and 0-1% of a surface active agent. When being used under normal pressure, the absorbing agent is at -20-70 DEG C for absorbing carbon dioxide and is at 70-120 DEG C for desorbing carbon dioxide. The absorbing agent has low regeneration energy consumption, low solution loss, high absorbing efficiency and has high feasibility when being applied to flue gases in power plants and the like.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Decompression regeneration system and method for hollow fiber membrane contactor of carbon dioxide enriched absorbent solution

ActiveCN101822931ALow regeneration energy consumptionAvoid volatile lossSemi-permeable membranesProductsChemistryDecompression operation

The invention discloses decompression regeneration system and method for a hollow fiber membrane contactor of a carbon dioxide enriched absorbent solution. The method comprises the steps of: heating the carbon dioxide enriched absorbent solution by a heater, and enabling the pressurized carbon dioxide enriched absorbent solution to enter the tube pass of the hollow fiber membrane contactor for regeneration by a booster pump and a liquid flow meter; outputting the obtained barren solution of the absorbent solution after regeneration from the lower end of the tube pass of the hollow fiber membrane contactor; blowing steam by the low temperature generated by a blowing steam generator under the action of a vacuum pump, and feeding the steam from the lower end of the tube pass of the hollow fiber membrane contactor for assisting regeneration; and dewatering the regenerated CO2 by a condenser under the actions of the blowing of the steam with low temperature and the suction of the vacuum pump to obtain the CO2 gas with high concentration. In the invention, the decompression operation is carried out in the membrane contactor for replacing the traditional heating regeneration method, the regeneration energy consumption of the CO2 absorbent solution is reduced, and the problem of high energy consumption of CO2 separation from fire coal and flue gas by using the chemical absorbent method can be solved.

Owner:ZHEJIANG UNIV

Cage type carbon dioxide adsorption material as well as preparation method and application thereof

InactiveCN103120931ALow priceEffectively fixedOther chemical processesDispersed particle separationMolecular sieveFlue gas

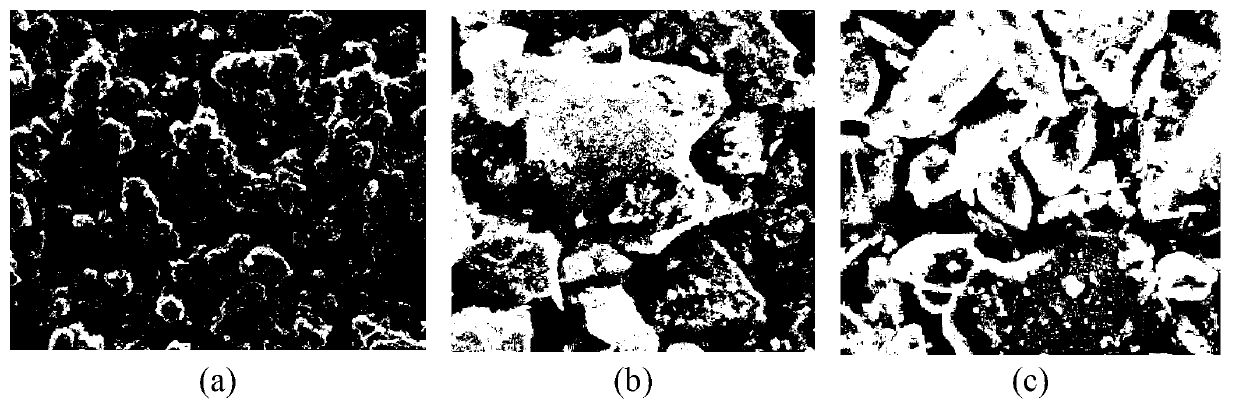

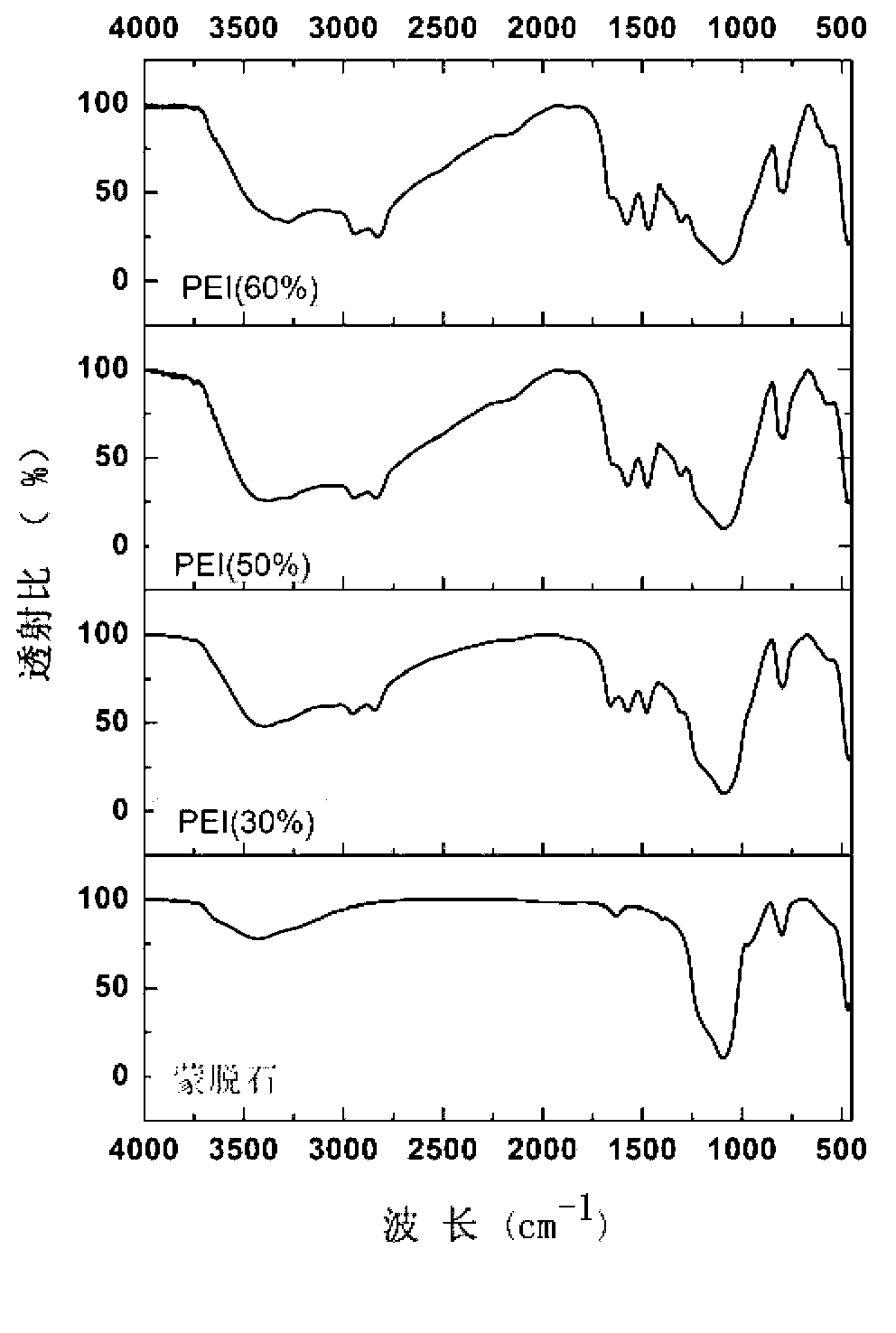

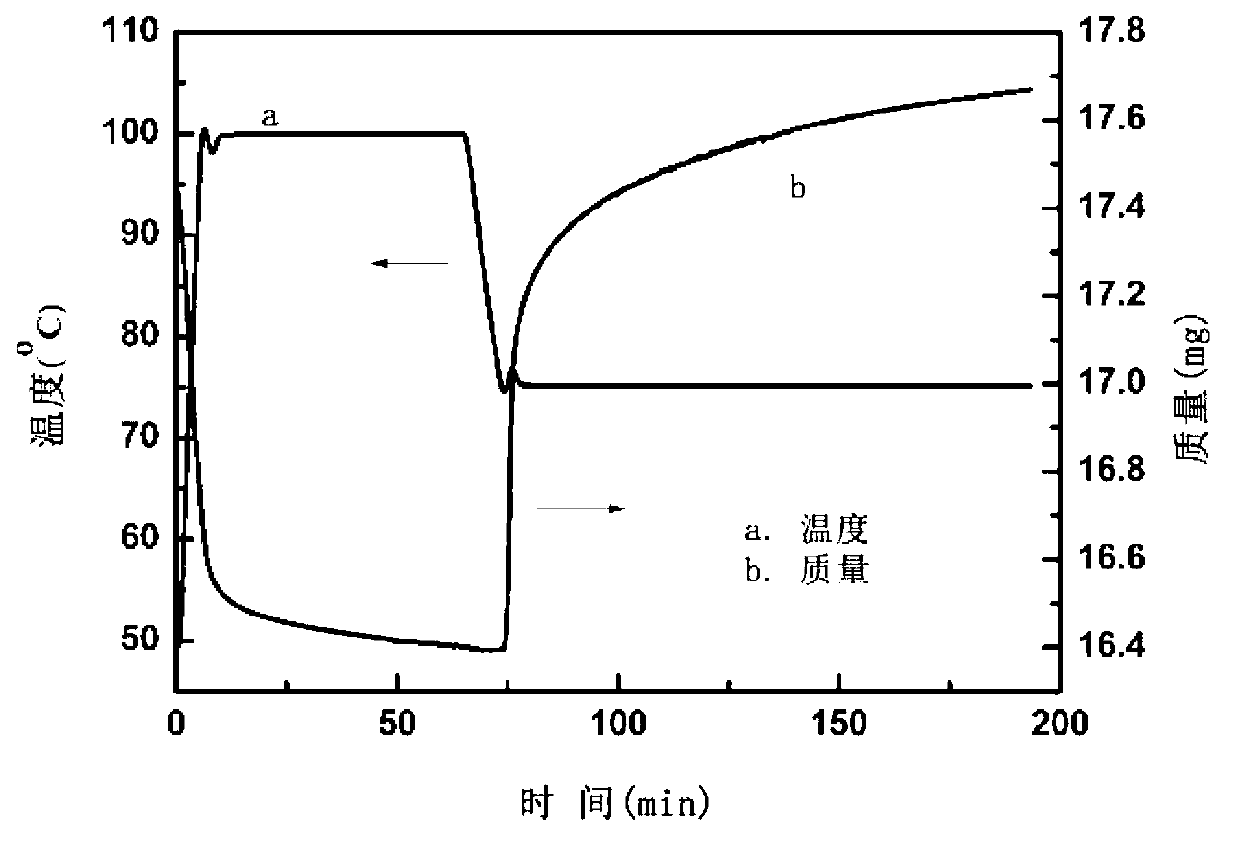

The invention discloses a cage type carbon dioxide adsorption material as well as a preparation method and an application thereof. The preparation method comprises acidation modification of montmorillonite and synthesis of the cage type carbon dioxide adsorption material. In a preparation process of the cage type adsorption material, an impregnation method is adopted, organic matter is directly covered on the inner surface of a mesoporous molecular sieve, the preparation method is simpler in process and low in energy consumption, desorption and regeneration are easy, and energy consumption and cost in an industrial application process can be greatly reduced. Effective loading capacity of organic amine in the composite material is 10-60%, the composite material has good adsorption and desorption capabilities and good stability, as acidified montmorillonite is adopted as a base material, cost is greatly reduced compared with other molecular sieve porous materials, and the requirement of an industrial process, especially removal of carbon dioxide gas in flue gas, to adsorbent material can be met.

Owner:SUN YAT SEN UNIV +1

Decarburization solution for recovering and removing carbon dioxide gas from carbon dioxide flooding produced gas of oilfield

ActiveCN103143236AGood stabilityLow regeneration energy consumptionProductsCarbon compoundsCarbon dioxide floodingEnvironmental chemistry

The invention discloses a decarburization solution for recovering and removing carbon dioxide gas from the carbon dioxide flooding produced gas of an oilfield, comprising a main absorbing component, an activating component, a corrosion inhibitor, an antioxidant, a defoamer and water, wherein the main absorbing component is K2CO3 or MDEA (methyldiethanolamine); an auxiliary absorbing component is DIPA (diisopropanolamine) or MEA (mono edawnol amine) or MMEA (methyl monoethanolamine) or AEEA (aminoethylethanolamine) or DMEA (dimethylethanolamine); the activating component is DEA (diethanol amine) or PZ (zinc dimethyldithiocarbamate) or AEP (polyoxyethylene potassium dodecyl phosphate) or TETA (triethylene tetramine) or DETA (diethylenetriamine) or TEPA (tetraethylenepentamine) or glycine; the corrosion inhibitor is V2O5; the antioxidant is sodium metavanadate or potassium tartrate; the defoamer is dimethyl silicon oil or hexanol or heptanol or octanol; and the ratio of the main absorbing component to the auxiliary absorbing component to the activating component to the corrosion inhibitor to the antioxidant to the defoamer is (0.2 to 0.3): (0.03 to 0.05): (0.01 to 0.03): (0.005 to 0.008): (0.005 to 0.008): (0.0005 to 0.001).

Owner:CHINA PETROCHEMICAL CORP +2

Organic amine solvent for capturing carbon dioxide

InactiveCN104548903ALess corrosiveLow regeneration energy consumptionDispersed particle separationAir quality improvementPropanolFossil fuel

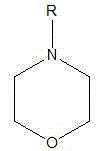

The invention provides an organic amine solution for capturing low partial pressure carbon dioxide and belongs to the field of a gas isolation technology. The solvent comprises 10-40% of a main absorption component, 5-20% of an auxiliary absorption component, 0.05-1.0% of a corrosion inhibitor, 0.05-1.0% of an antioxidant and 30-90% of a mixed solvent. The main absorption component is one or more components selected from glycinate, polyetheramine, morpholine and its derivative and polyethylene glycol dimetyl ether. The auxiliary absorption component is one or more components selected from diethylaminoethanol, 2-amino-2-methyl-1-propyl alcohol, N-methyldiethanolamine and hydroxyethyl ethylenediamine. The solution provided by the invention has characteristics of little operation loss, high resistance to oxidation, low energy consumption for regeneration and the like. The solvent is mainly used for capturing carbon dioxide in various gas sources, such as fossil fuel tail gas, chemical reaction tail gas, natural gas and the like. The solvent has good social benefit and economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

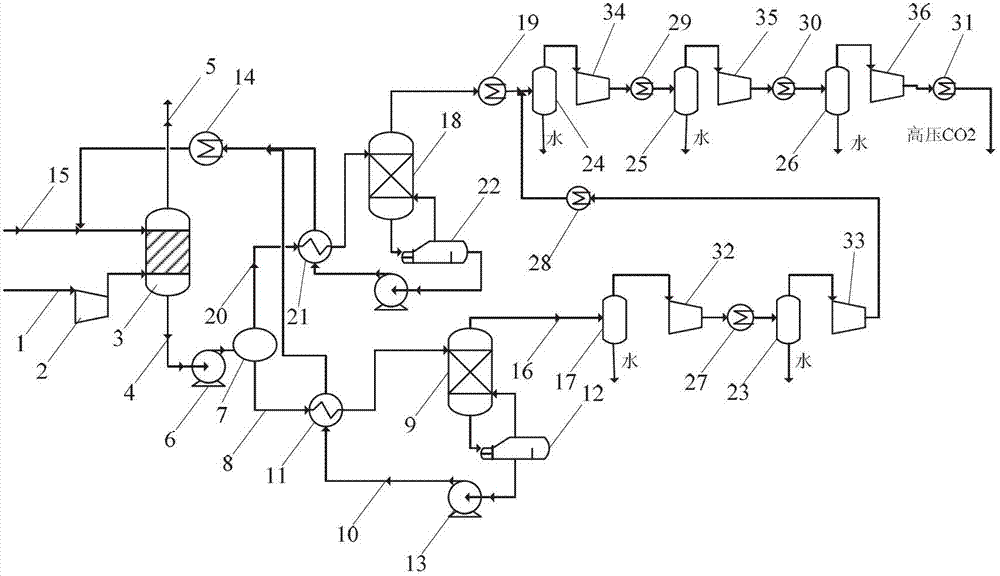

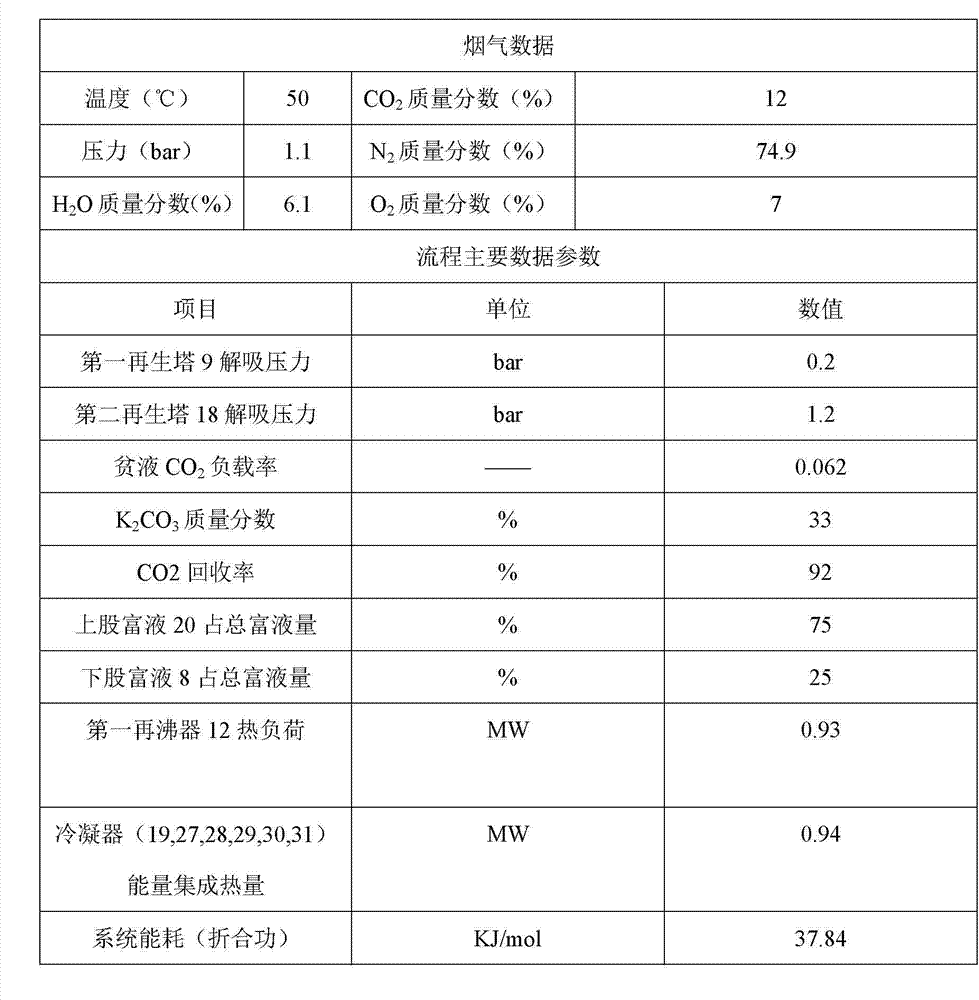

Method and system for reducing consumption in capturing process of CO2 through chemical absorption

ActiveCN102895860AReduce heat loadLow regeneration energy consumptionDispersed particle separationBy chemical separationWater vaporDesorption

The invention relates to a method and a system for reducing consumption in a capturing process of CO2 through chemical absorption, belongs to the fields of energy utilization, energy conservation and environmental protection. Based on the common CO2 capturing process, the method comprises the following steps that: an absorbent in an absorption tower is used for absorbing CO2 in flue gas and forming a pregnant solution, the obtained pregnant solution is divided into two branches, the two branches of pregnant solution is subjected to CO2 separation in two regeneration towers with different pressures, and waste heat generated during a high-pressure desorption process of the pregnant solution is taken as a heat source of a low-pressure desorption process; CO2 air flows mixed with water vapor after treatment by the regeneration towers are treated by multiple stages of gas-liquid separators, condensers and compressors, so that high-pressure liquid-station CO2 is obtained. With the adoption of the method and the system provided by the invention, the heat consumption during the whole desorption process is reduced, so that the efficient desorption of the pregnant solution flows is realized; under the premise that the capturing rate is 92%, the regenerated energy consumption of an optimal system obtained after improvement of the process is 37.84KJ (reduced work) / mol, and is reduced by 19.77% compared with the energy consumption of 47.16KJ (reduced work) / mol before improvement, and therefore, a new method is provided for reducing the energy consumption for capturing the CO2 with the low energy consumption in thermal power plants.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

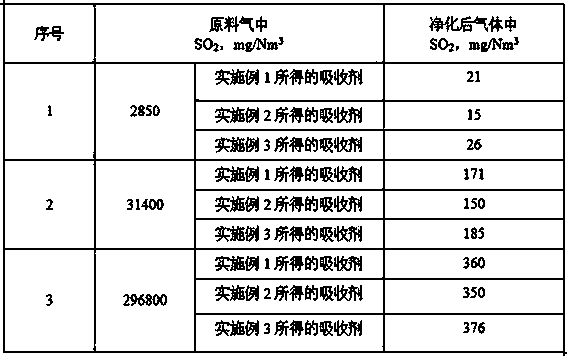

Absorbent for recycling sulfur dioxide from industrial waste gas and recycling method

The invention particularly relates to an amine salt solution absorbent and a method for recycling sulfur dioxide from industrial waste gas. The absorbent is prepared by virtue of the following steps: firstly, mixing piperazine and water and uniformly agitating, and adding ethylene oxide to react under an agitating state; secondly, taking a reaction product and boric acid to react to obtain an organic amine salt; finally, dissolving the organic amine salt into water to prepare an amine salt water solution to obtain the absorbent. An absorption method comprises the following steps: carrying out countercurrent contact on the absorbent and a gas flow containing sulfur dioxide gas so as to dissolve the sulfur dioxide into the absorbent to remove the sulfur dioxide; meanwhile, contacting an absorption solution absorbing the sulfur dioxide with steam to be regenerated, so as to realize cyclic utilization. The preparation method is simple, the reaction efficiency is high, few reaction by-products are obtained, the yield is high, the price of a solvent is low, the period is short and the production cost is low; the capacity of the prepared absorbent is large and the sulfur dioxide can be completely recycle; the absorbent can be cyclically utilized and the regeneration energy consumption is low.

Owner:江苏蓝电环保股份有限公司

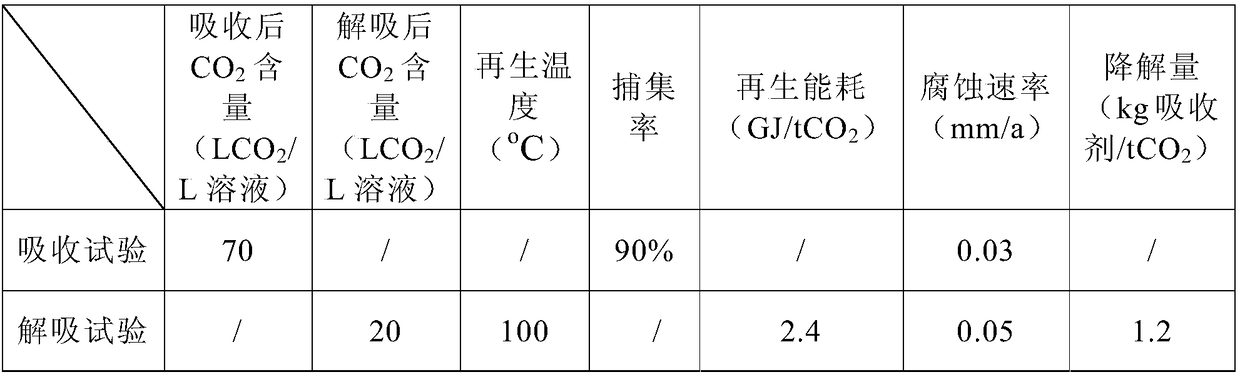

Phase change absorbent for capturing CO2 in waste gas

ActiveCN109331610ALarge absorption capacityIncrease capture rateDispersed particle separationAir quality improvementNanoparticleAntioxidant

The invention provides a phase change absorbent for capturing CO2 in the waste gas. The phase change absorbent for capturing the CO2 in the waste gas comprises an alkylol amine absorbent, an amine absorbent, a nanoparticle, a corrosion inhibitor, an antioxidant, a defoamer and water, the mass ratio of the alkylol amine absorbent to the amine absorbent, to nanoparticles to the corrosion inhibitor to the antioxidant to the defoamer to the water in the phase change absorbent for capturing CO2 in the waste gas is (15%-20%):(5%-10%):(0.01%-0.1%):(0.01%-0.2%):(0.01%-0.2%):(0.01%-0.1%):(70%-80%). Thephase change absorbent for capturing CO2 in the waste gas increases the absorptive capacity of CO2, increases the capturing rate of CO2, reduces the corrosion rate of equipment, improves the self-stability, reduces the regeneration temperature, reduces the energy consumption of regeneration, and improves the degradation effect.

Owner:CHINA PETROCHEMICAL CORP +2

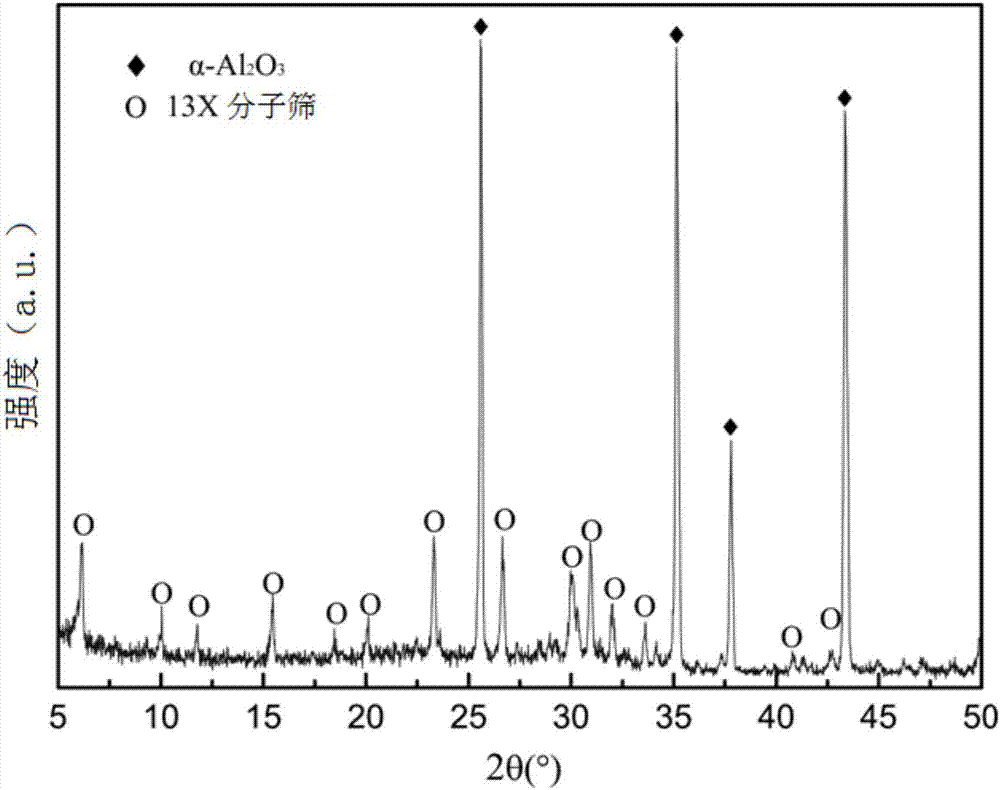

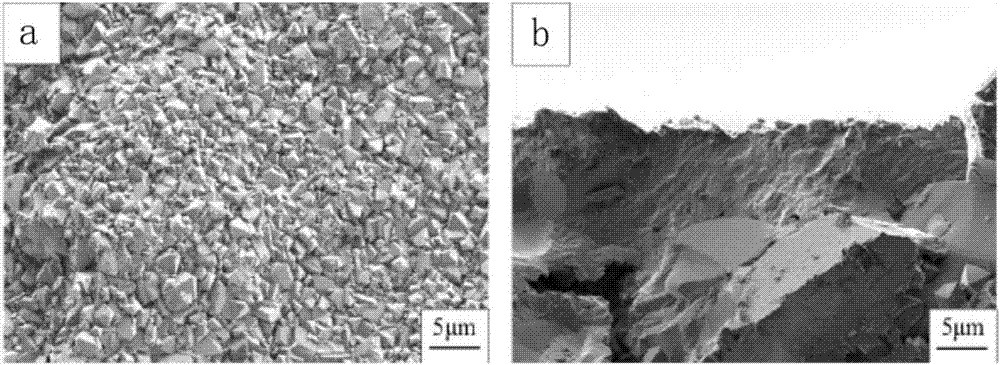

Molecular sieve ceramic membrane material for olefin purification as well as preparation method and application of molecular sieve ceramic membrane material

ActiveCN107970781AReduce mass transfer resistanceReduce energy consumptionSemi-permeable membranesOther chemical processesMolecular sieveBonding strength

The invention relates to a molecular sieve ceramic membrane material for olefin purification as well as a preparation method and application of the molecular sieve ceramic membrane material. In the molecular sieve ceramic membrane material, the particle sizes of molecular sieve particles supported on the surface of the ceramic material are 0.1-3 [mu]m, and the thickness of a molecular sieve layeris 3-5 [mu]m; during preparation, ceramic material pretreatment, molecular sieve seed crystal pre-coating and sealed crystallization are sequentially carried out; and the molecular sieve ceramic membrane material is used for removing a polar oxygenated compound in a gaseous olefin flow to be 1ppm or below. Compared with the prior art, the molecular sieve ceramic membrane material prepared by the preparation method of the invention has the molecular sieve layer with higher mechanical strength, larger specific surface area and uniform thickness, in addition, the molecular sieve layer has no longitudinal or horizontal cracks, has no air pores in the surface and is high in bonding strength and not easy to fall off; and when the polar oxygenated compound in the olefin flow is adsorbed, the purification depth is 1ppm or smaller, so that not only is the mass transfer resistance lower, but also the energy consumption is lower, and the regeneration capacity is high.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

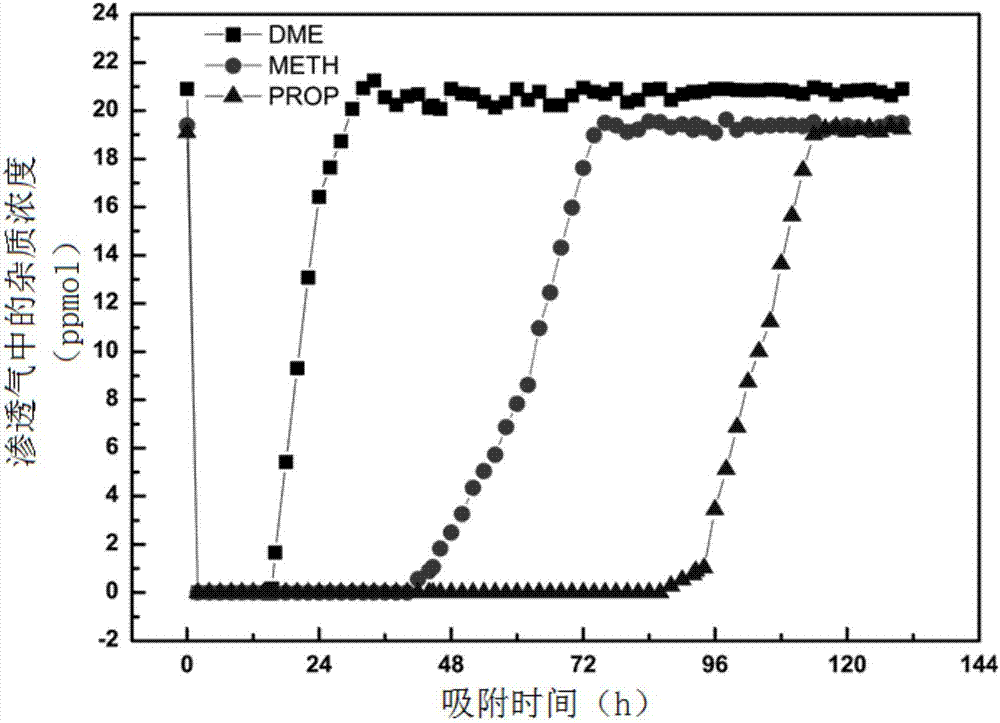

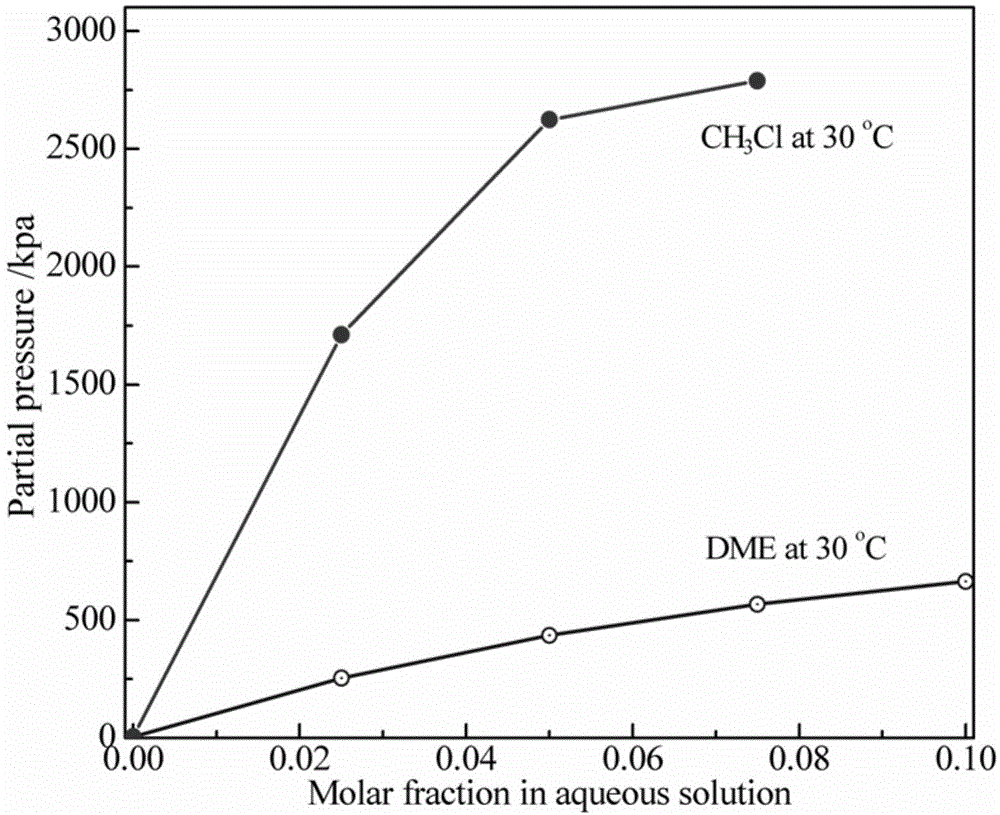

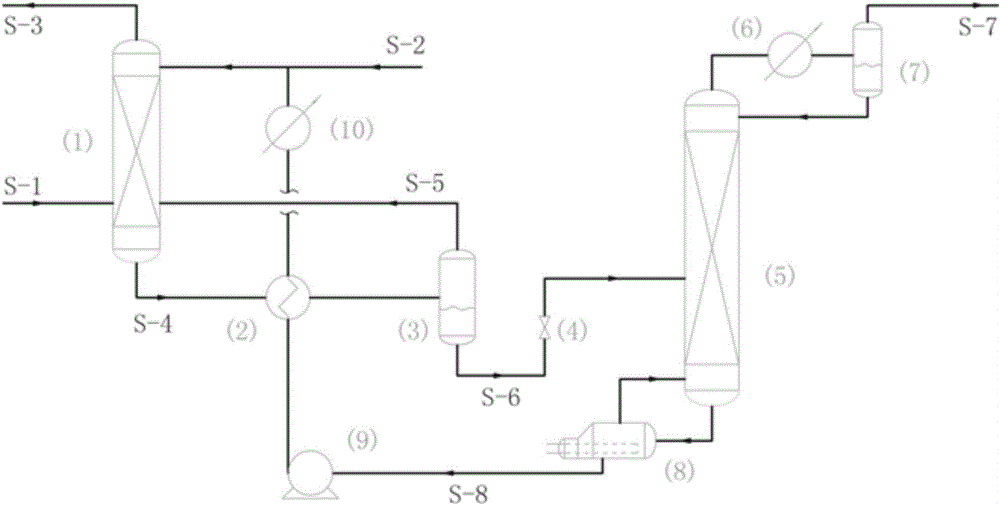

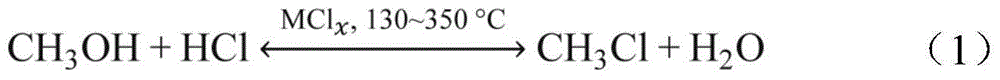

Separation process of removing dimethyl ether impurities in chloromethane through water absorption

InactiveCN104926595ASafe removalAchieve recyclingEther separation/purificationHalogenated hydrocarbon separation/purificationSolubilityChemical reaction

The invention provides a separation method and process of removing dimethyl ether impurities in chloromethane by using water as an absorbent, and belongs to the field of gas separation and purification. Based on the chemical theory that hydrogen bonds are formed by polar gas molecules and water, a significant difference of water solubility properties between chloromethane and dimethyl ether is used, water is used as an absorbent or a mixture of water and another material is used as an absorbent to replace traditional concentrated sulfuric acid, and a joint process formed by combining absorption and rectification is used, so as to separate a mixture of chloromethane and dimethyl ether safely and efficiently in low cost. By using the separation method and process, in which water is used as the absorbent, to treat a passivated tail gas produced by a dehydration apparatus, the removal rate of dimethyl ether is greater than 99%, the concentration of purified chloromethane can reach 99 mol%, and the recovery rate of the chloromethane can be kept at about 98%. Furthermore, because a chemical reaction is avoided, separated dimethyl ether from which chloromethane is removed through hydrolysis can be used as a byproduct, thus increasing the economic benefit.

Owner:DALIAN UNIV OF TECH

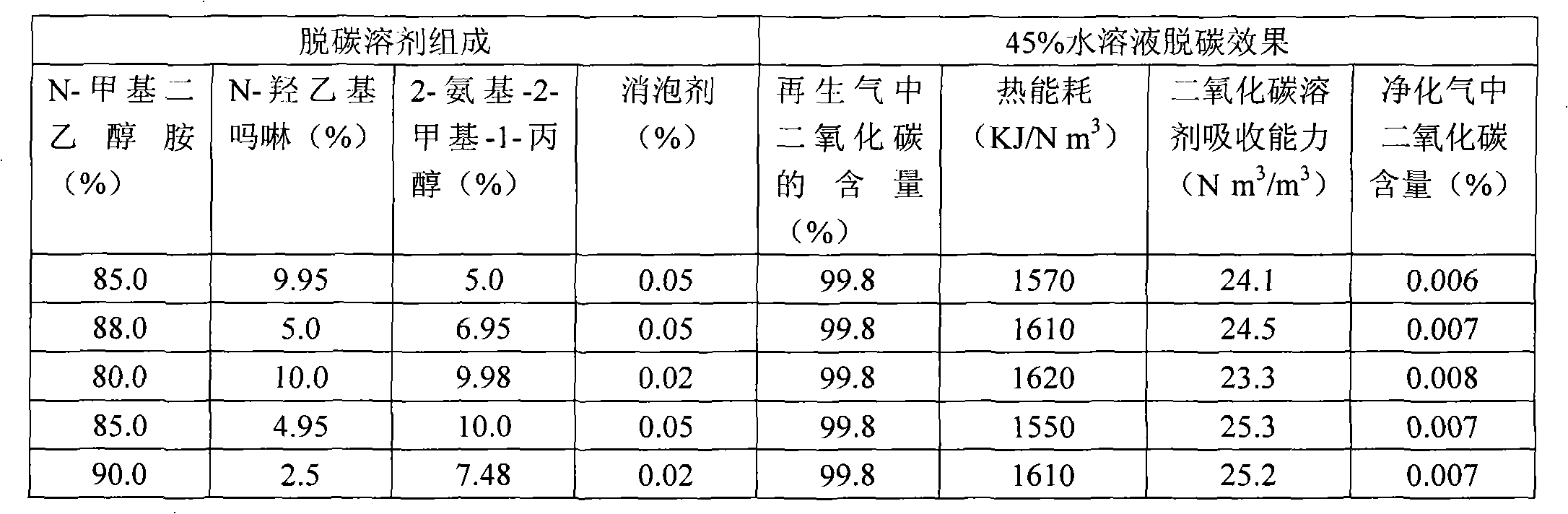

Novel high-efficient compound decarbonization solvent

ActiveCN101816878AHigh boiling pointReduce volatilityProductsCarbon compoundsAbsorption capacityCo2 absorption

The invention discloses a novel high-efficient compound decarbonization solvent which comprises N-methyldiethanolamine and an active agent. The active agent is a mixture which consists of at least two of N-hydroxyethyl morpholine, 2-amino-2-methyl-1-propanol and piperazine, wherein the weight ratio of the N-hydroxyethyl morpholine is 80 to 90 percent; the weight ratio of the active agent is 10 to 20 percent and a defoaming agent is also added into the compound decarbonization solvent. The novel high-efficient compound decarbonization solvent has the advantages of high carbon dioxide absorption capacity, high purification degree, low regeneration energy consumption, and no foams after long-term use of the decarbonization solvent.

Owner:四川精事达科技有限公司

Liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent

InactiveCN110052117AAchieve enrichmentReduce total fluid volumeDispersed particle separationAir quality improvementFluid phaseEnvironmental engineering

The invention provides a liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent. The liquid-liquid phase-change absorbent for capturing the carbon dioxidecomprises, by mass, 20%-60% of synergist, 10%-50% of organic amine, 0%-5% of auxiliary agent and the balance water. The liquid-liquid phase-change absorbent for capturing the carbon dioxide has the advantages that the liquid-liquid phase-change absorbent can be automatically layered into liquid-liquid phases when loading a certain amount of CO2 in the absence of energy consumption, wherein CO2 gathers in a rich phase layer, and a lean phase layer hardly loads CO2, so that CO2 can be effectively concentrated in the rich phase, the total amount of liquid entering a regenerating column is decreased through desorption of the CO2 rich phase, and energy consumption for regeneration and capture cost are reduced.

Owner:HUANENG POWER INT INC +1

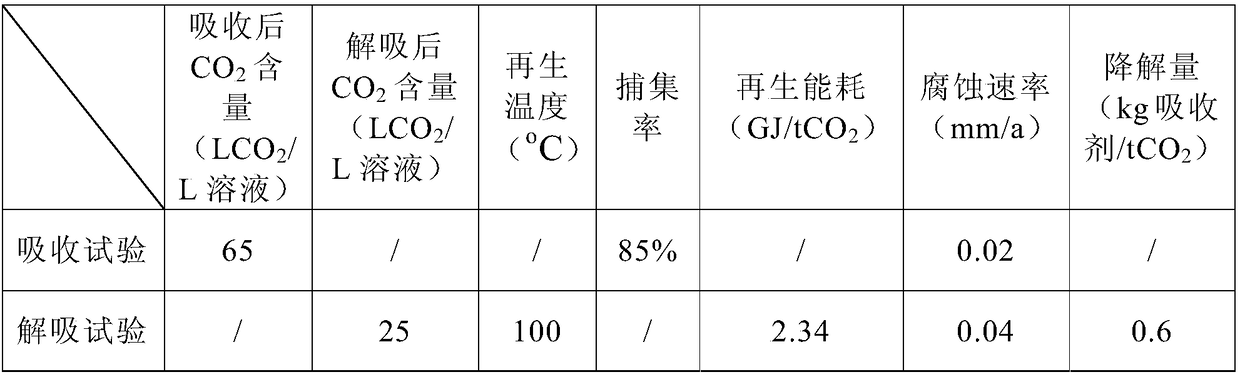

Double phase absorption system for removing CO2 from flue gas

InactiveCN105396447AEffective absorptionEffective implementation of absorptionDispersed particle separationAir quality improvementOrganic solventDouble phase

The invention provides a double phase absorption system for removing CO2 from flue gas. The system is composed of an alkylol amine absorbent, an amine absorbent, an activator, a consumption reduction agent, water and an organic solvent. The double phase absorption system for removing CO2 from flue gas has the advantages of strong absorption capability, fast absorption rate, low regeneration temperature and low energy consumption in the regeneration process.

Owner:SINOPEC ENERGY & ENVIRONMENTAL ENG CO LTD

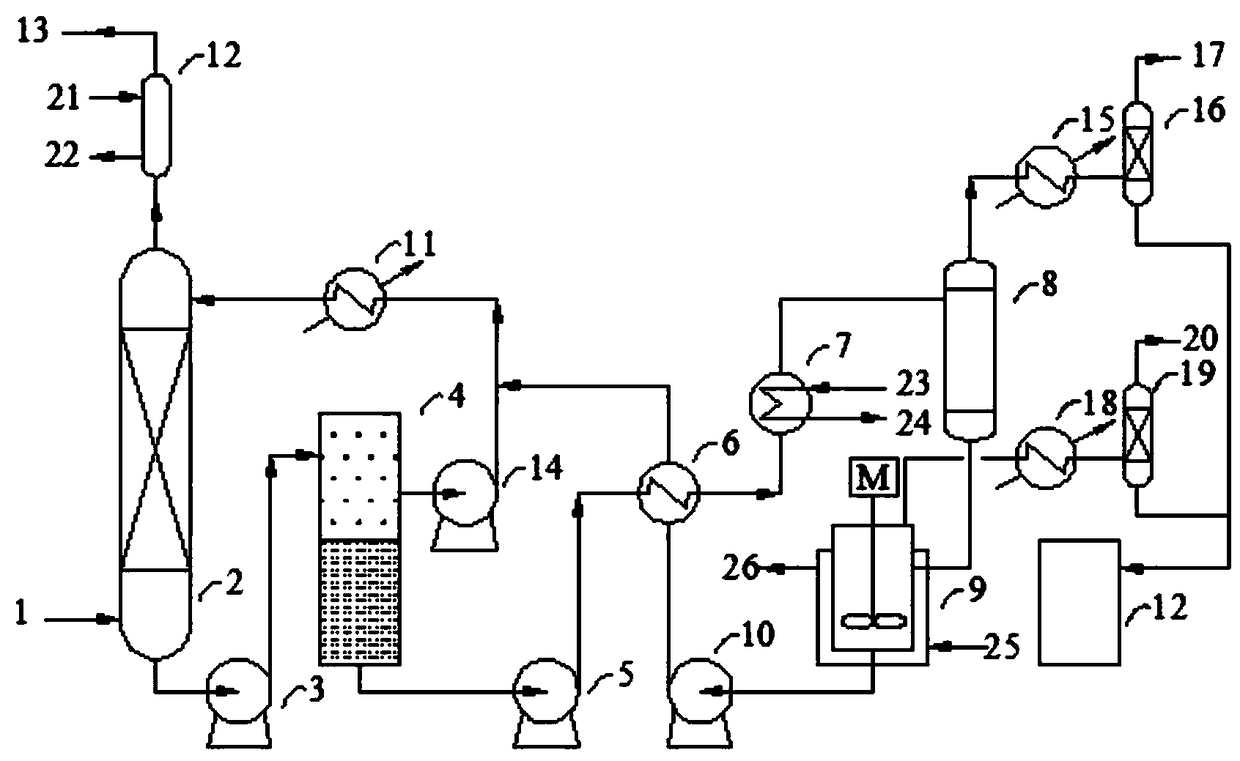

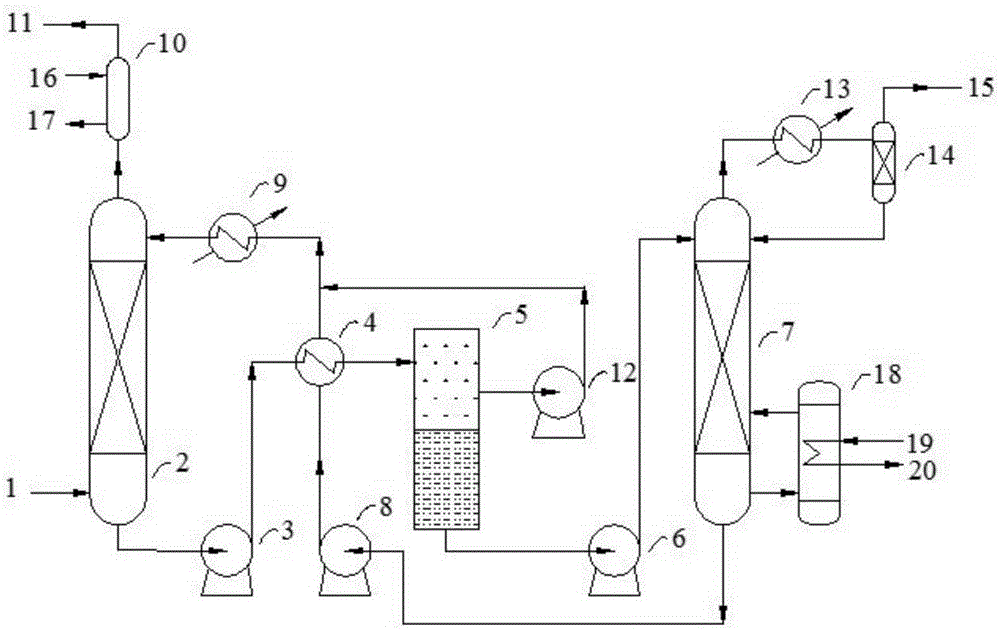

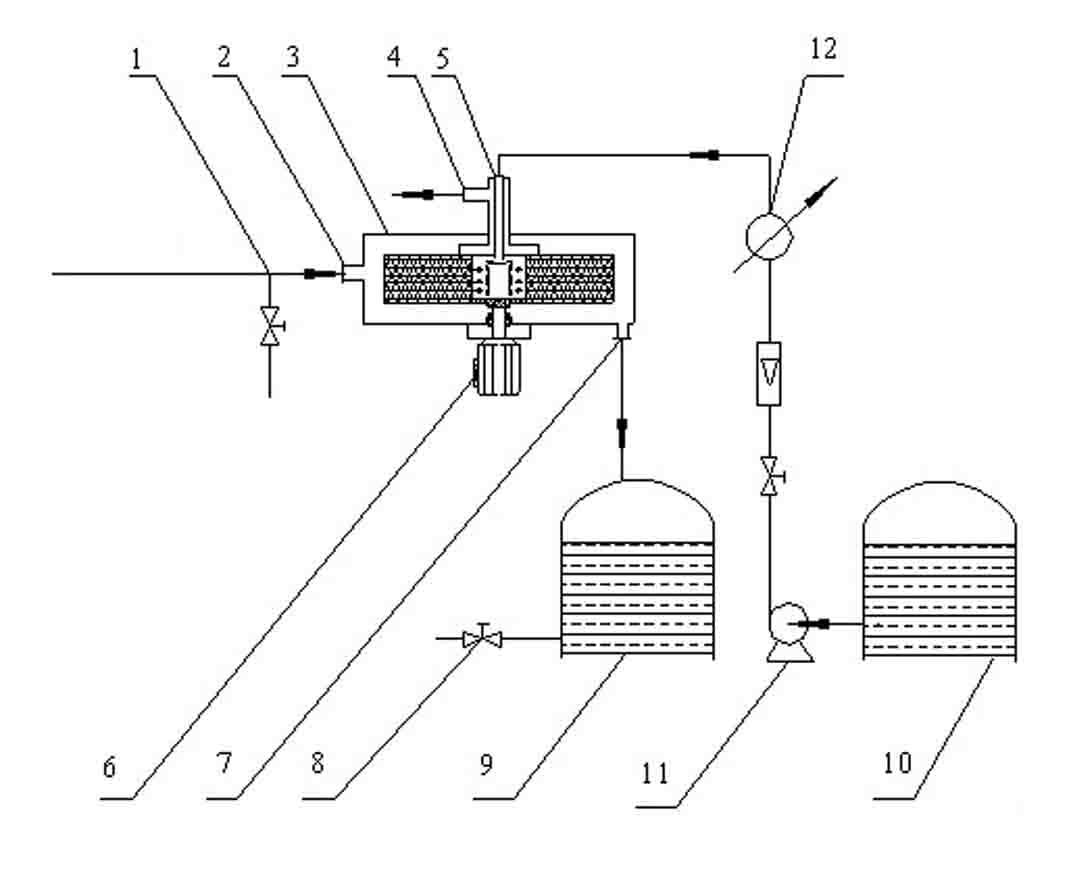

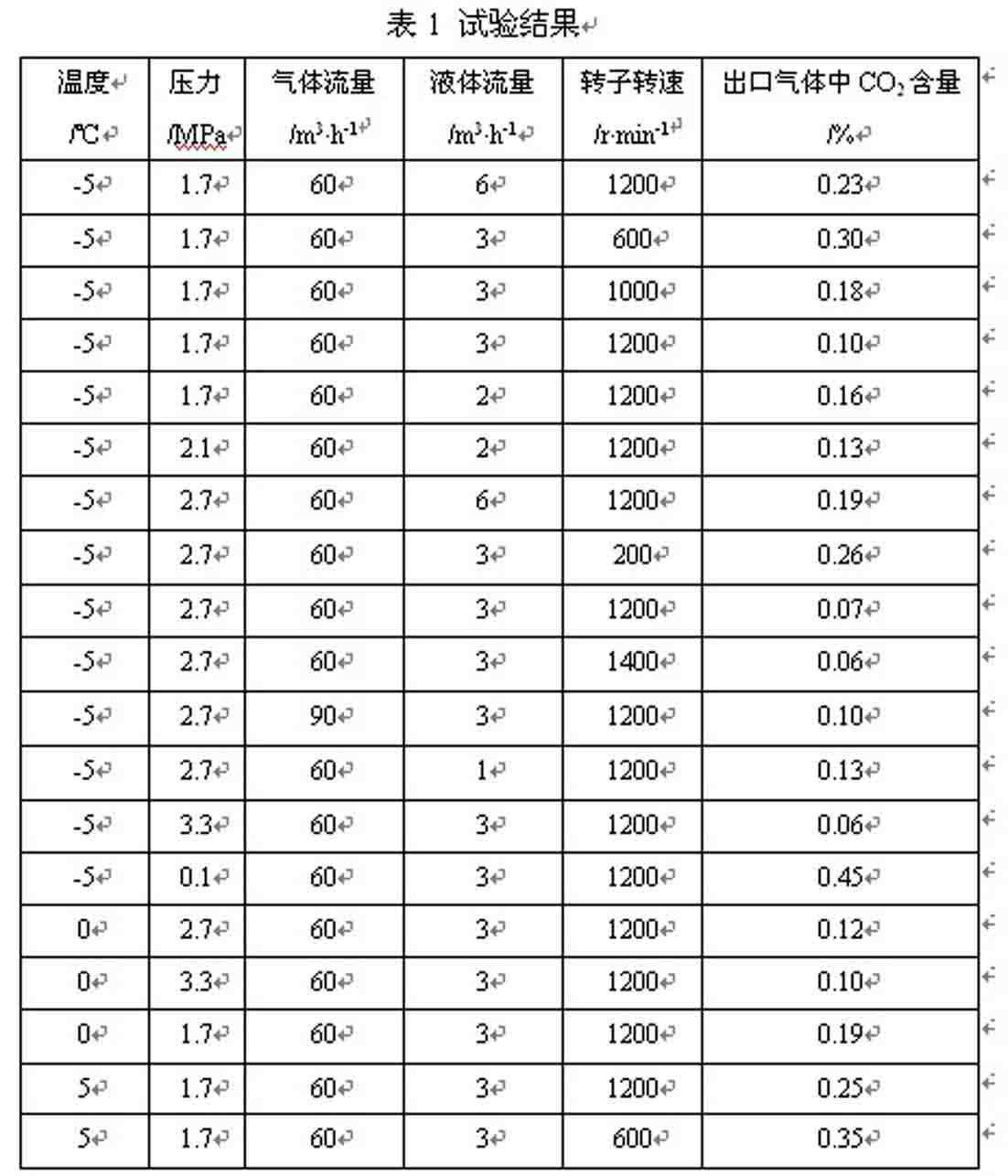

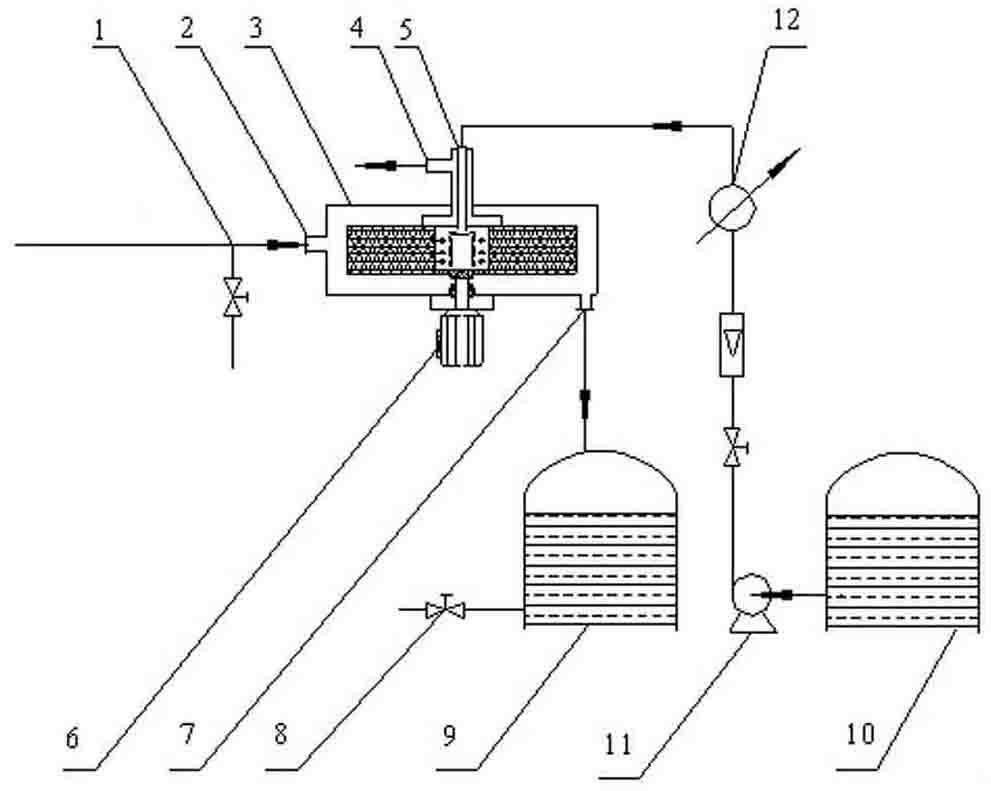

Method and device for removing CO2 from conversion gas of synthetic ammonia

The invention belongs to the technical field of CO2 removal from conversion gas of synthetic ammonia, in particular relates to a method and device for removing CO2 from conversion gas of synthetic ammonia. The method comprises the steps: the conversion gas of synthetic ammonia and an absorption solution are subjected to countercurrent contact and crosscurrent contact in a high gravity machine, and tremendous centrifugal force is generated by means of high-speed rotation of filler so that the absorption solution comes into contact with gas to complete the removal of CO2. The device comprises the high gravity machine, wherein the gas, namely the conversion gas of synthetic ammonia, is fed to a conversion section through a gas inlet of the high gravity machine, a gas outlet of the high gravity machine is connected with a purified gas section, a liquid inlet of the high gravity machine is connected with a lean solution tank filled with NHD solvent via a lean solution pump, an ammonia cooler is arranged between the liquid inlet of the high gravity machine and the lean solution pump, and a liquid outlet of the high gravity machine is connected with a pregnant solution tank. The method and the device have the advantages: the technological flow is simple, the maintenance cost of equipment is lowered, and the regeneration energy consumption of the entire decarbonization procedure is reduced.

Owner:ZHONGBEI UNIV

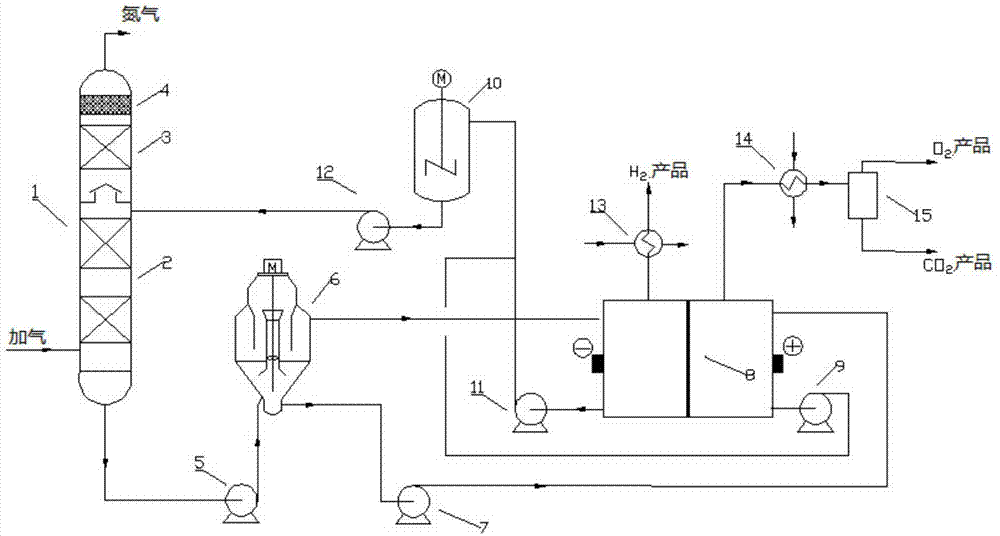

Carbon dioxide capturing system for concentration conversion and electrolysis regeneration

ActiveCN104722177ALow regeneration energy consumptionRealize integrationProductsElectrolysis componentsElectrolysisElectrochemistry

The invention discloses a carbon dioxide capturing system for concentration conversion and electrolysis regeneration. The bottom of an adsorption column is connected with a feed liquid inlet of a crystallizer; the crystallizer is connected with an inlet of an anode zone of an electrolysis regeneration tank; an overflow inlet of the crystallizer is connected with a cathode inlet of the electrolysis regeneration tank; an electrolysis liquid outlet of the electrolysis regeneration tank is connected with an inlet of a stirring type mixing tank; a barren liquor outlet in the bottom of the stirring and mixing tank is connected with a barren liquor inlet in the upper section of an absorption section; a gas outlet of the cathode zone of the electrolysis regeneration tank is connected with a gas inlet of a first cooler; a gas outlet of the anode zone is connected with a gas inlet of an O2 / CO2 separator; a CO2 pregnant solution is concentrated, so that a component loading CO2 is concentrated or separated further in the pregnant solution, and based on the electrochemistry principle, the CO2 pregnant solution is electrolyzed to generate hydrogen, oxygen and CO2 gas; the regeneration energy consumption and capturing cost can be reduced maximally; electricity energy, such as house supply or wind and light abandoned electricity can be fully utilized, and the abandoned electricity storage energy conversion, CO2 capturing and chemical engineering utilization are integrated.

Owner:HUANENG CLEAN ENERGY RES INST

Absorbent which gathers carbon dioxide in flue gas or synthesis gas

InactiveCN102989295ALow regeneration energy consumptionReduce consumptionProductsReagentsPetrochemicalSolvent

The invention discloses an absorbent which gathers carbon dioxide in flue gas or synthesis gas, comprising the following components by weight percentage: 5-25wt% of 2- methylamino (ethanol), 5-25wt% of primary amine, secondary amine or tertiary amine and 60-90% of water. As the 2- methylamino (ethanol) is a secondary amine which has a higher boiling point compared than other secondary amine, the degradation loss of solvent is less. The absorbent of the invention can be used for gathering various normal-pressure gas mixture, such as carbon dioxide in flue gas or synthesis gas discharged by the enterprises of coal-fired power plants, petrochemical industry and the like. The absorbent has large absorbing volume for carbon dioxide at low partial pressure, the regeneration effect is good and the energy consumption for unit carbon dioxide gathering amount is low.

Owner:HUANENG CLEAN ENERGY RES INST

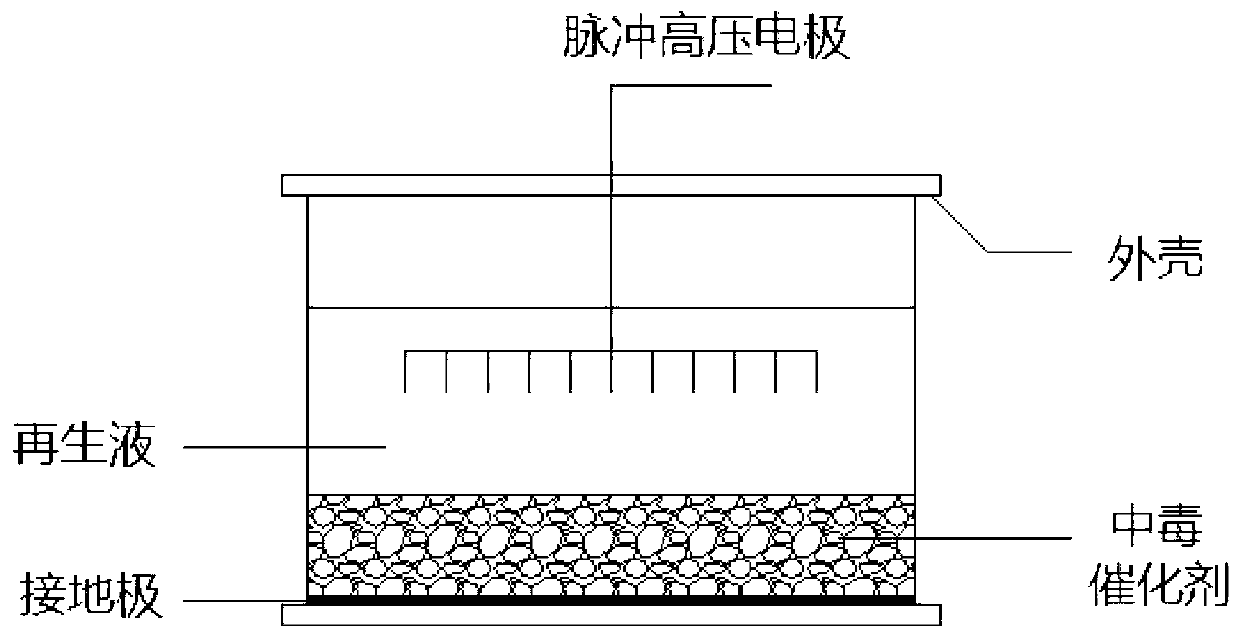

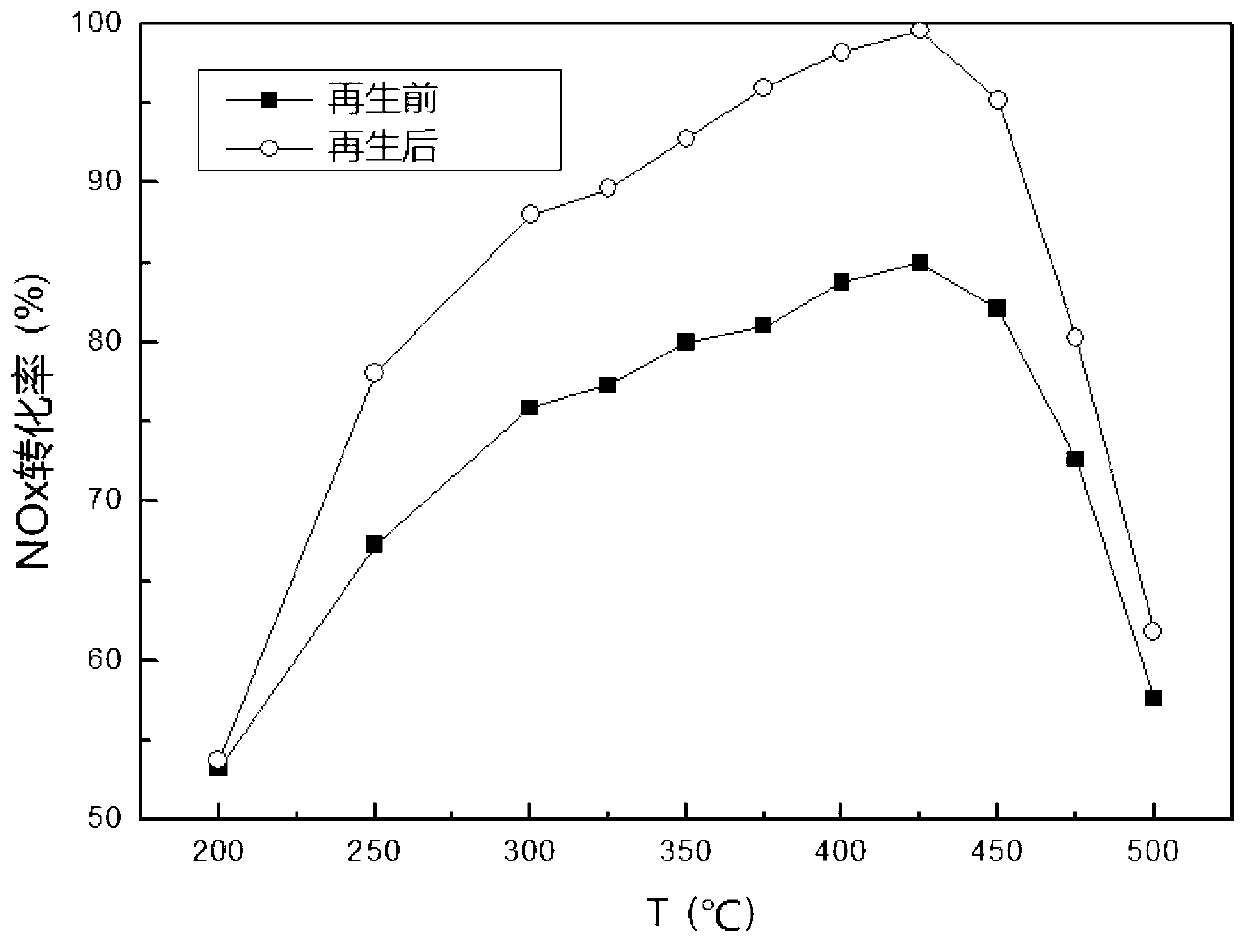

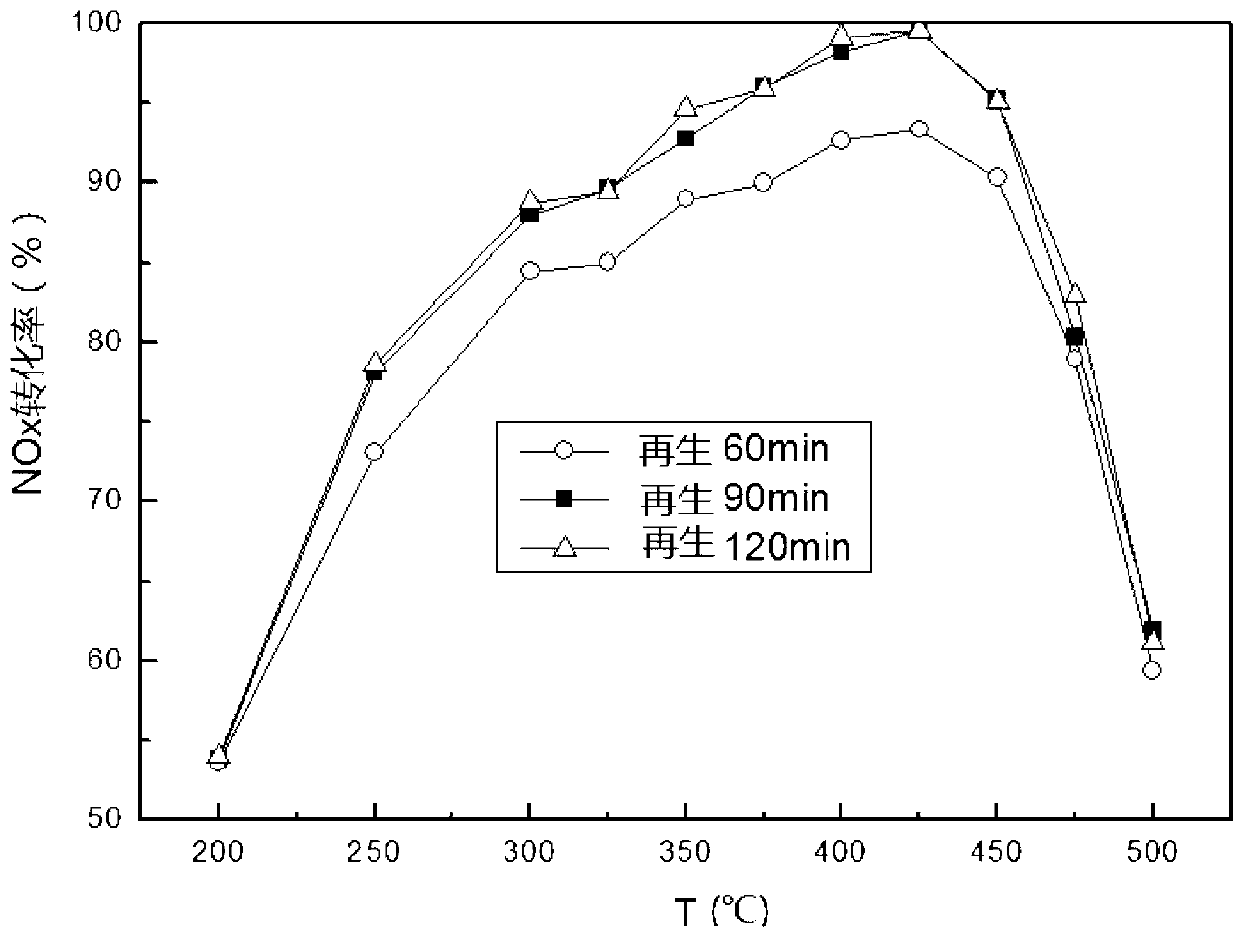

Method and device for regenerating vanadium and tungsten denitration catalyst

InactiveCN102989484ALow regeneration energy consumptionReduce recycling costsDispersed particle separationEnergy based chemical/physical/physico-chemical processesRegenerative processActive component

The invention discloses a method and a device for regenerating a vanadium and tungsten denitration catalyst. In the method, low-temperature plasma reinforced liquid phase regeneration is adopted for denitration catalysts of the series of toxic V2O5-WO3(MoO3) / TiO2 used in actual industry. The method mainly comprises active component repair and pore canal structure recovery of the toxic V2O5-WO3(MoO3) / TiO2 catalysts. The device mainly comprises a shell, a discharge electrode, a grounding electrode and a high-voltage pulse power supply. The method and the device for regenerating the vanadium and tungsten denitration catalyst have the advantages that vanadium and tungsten and other active components lost in a use and regeneration process of the catalyst are supplemented; the pore canal structure of the catalyst is dredged, and the specific surface area is increased; the regeneration efficiency of the catalyst is high; and a regeneration process is simple in technology and low in energy consumption.

Owner:HANGZHOU DIANZI UNIV

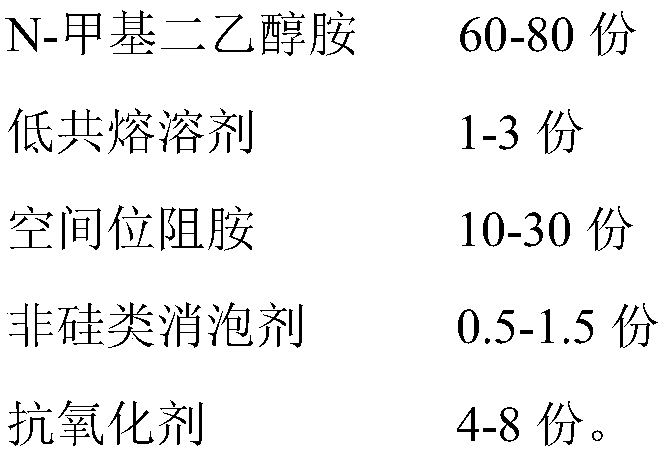

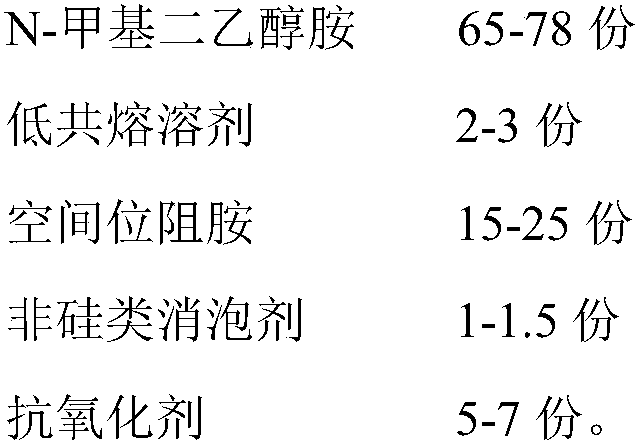

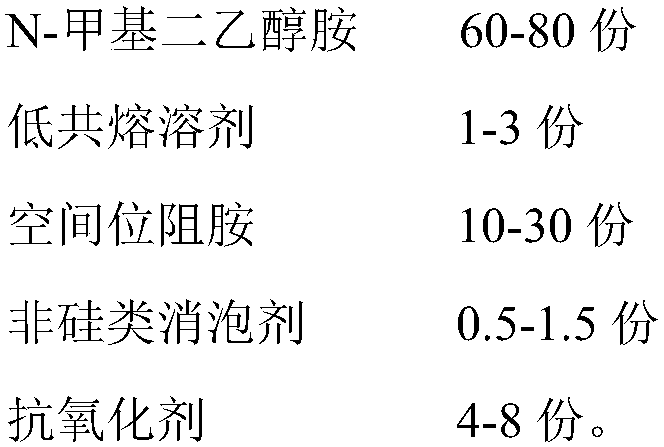

High-selectivity compound desulfurizer and preparation method thereof

ActiveCN108816196ASimple processLow regeneration energy consumptionGas treatmentOther chemical processesAbsorption capacityAntioxidant

The invention specifically relates to a high-selectivity compound desulfurizer and a preparation method thereof, belonging to the field of gas purification techniques. The high-selectivity compound desulfurizer comprises the following raw materials by weight: 60-80 parts of N-methyldiethanolamine, 1-3 parts of an eutectic solvent, 10-30 parts of sterically hindered amine, 0.5-1.5 parts of a non-silicon defoaming agent and 4-8 parts of an antioxidant. The compound desulfurizer provided by the invention overcomes the shortcomings of current refinery gas desulfurization processes, and is simple in process and applicable to desulfurization of most refinery acidic gases. According to the invention, N-methyldiethanolamine, the eutectic solvent and sterically hindered amine are compounded, and the supplementation effect and synergism of the above three components enhance the respective desulfurization effect of the components; and the high-selectivity compound desulfurizer has high purification depth, large absorption capacity, low energy consumption for regeneration, environment friendliness and other advantages.

Owner:淄博凯美可工贸有限公司

Preparation method of magnesium oxide-mesoporous carbon composite material

InactiveCN104014302ALarge specific surface areaIncrease loadOther chemical processesCarbon compositesSalt solution

The invention discloses a preparation method of a magnesium oxide-mesoporous carbon composite material. The method is characterized by comprising the following steps: oxidizing the surface of a carbon material by adopting mesoporous carbon as a carrier, so that the carbon material is more likely to adsorb a metal salt solution; eliminating water impurities in pores in a vacuum drying box, so that the pores are adequately opened; adding a magnesium nitride solution onto the carbon material to be completely absorbed; and roasting the carbon material under the inert gas after the solution is completely volatized, so that the magnesium nitride is decomposed into magnesium oxide to be remained in the pores of the mesoporous carbon. The magnesium oxide-mesoporous carbon composite material prepared by the method is high in specific surface area and high in magnesium oxide loading capacity; when being applied to the carbon dioxide adsorption at a high temperature, the magnesium oxide-mesoporous carbon composite material has the following good properties: the adsorption capacity of CO2 at the temperature of 50 to 80 DEG C and the pressure of 0.1MPa to 0.2MPa is 2.0 to 2.5 mmol / g, the adsorption agent can be reduced and regenerated at the temperature of 350 to 500 DEG C, and the magnesium oxide-mesoporous carbon composite material is a CO2 adsorption material with a promising application prospect.

Owner:SHANGHAI UNIV

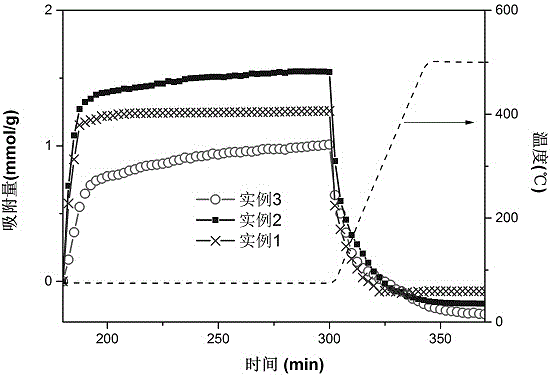

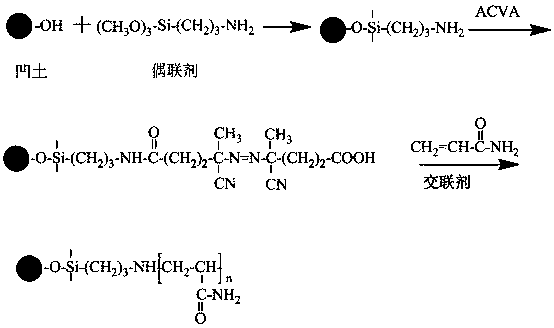

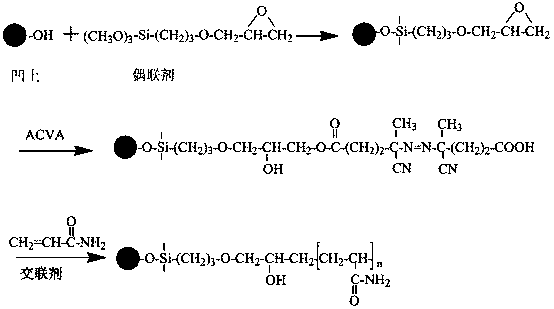

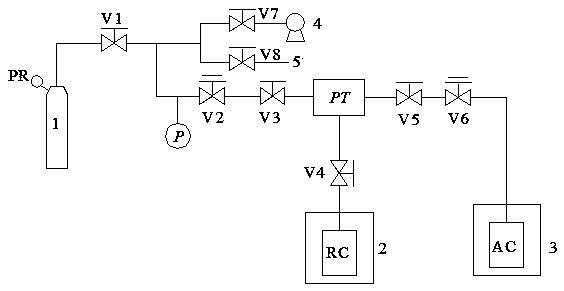

Preparation method of attapulgite based CO2 adsorption material with polyacrylamide grafted surface

InactiveCN105363424ALarge adsorption capacityStable chemisorption stateOther chemical processesDispersed particle separationPolymer scienceOrganic chemistry

The invention discloses a preparation method of an attapulgite based CO2 adsorption material with a polyacrylamide grafted surface. The method includes: reacting a silane coupling agent with attapulgite clay to conduct surface functionalization, thus obtaining modified attapulgite clay; then introducing the azo group ACVA to the modified attapulgite clay to obtain an ATP / ACVA composite material; and finally, subjecting the prepared ATP / ACVA composite material and a monomer to graft copolymerization, thus obtaining a composite adsorbent with an amino functional group. The preparation method provided by the invention has the advantages of simplicity, easy operation, mild reaction conditions, easy industrial production, reusability, wide application prospect, and large adsorption capacity and strong selectivity to CO2.

Owner:HUAIYIN TEACHERS COLLEGE

Solid absorbent with high CO2 adsorption capacity and preparation method thereof

InactiveCN103230778AFast decarbonizationFastOther chemical processesDispersed particle separationSupercritical dryingCorrosion

The invention discloses a solid absorbent with high CO2 adsorption capacity and a preparation method thereof. The solid absorbent comprises active components and a carrier; the active components are alkali carbonate and an amino group at the surface of the carrier, and are 15-60% of total quality of the solid absorbent; the molar ratio of the alkali carbonate and the amino group is 1 to (0.5-25); and the carrier is monox, and is 40-85% of total quality of the solid absorbent. The preparation method comprises the following steps of mixing and stirring the materials into emulsion; putting the emulsion into air to form cross-linking gel; putting the gel into a sealed dryer; soaking the gel by ethanol; and drying and screening the gel by a supercritical drying method, so as to prepare the solid absorbent with high CO2 adsorption capacity. The absorbent is low in price, stable in structure, high in carbonic acid conversion ratio, not easy to inactivate, and small in corrosion on equipment, and has certain mechanical strength, and high cyclic utilization rate; and the preparation method of the absorbent is convenient to operate, and low in expenses.

Owner:SOUTHEAST UNIV

IGCC (Integrated Gasification Combined Cycle) based pre-combustion CO2 capture system

The invention relates to an IGCC (Integrated Gasification Combined Cycle) based pre-combustion CO2 capture system, which comprises a sulfur-resistant conversion device, an MDEA (Methyl Di Ethanol Amine) desulfurization and decarbonization device and a sulfur and carbon separating device, wherein the sulfur-resistant conversion device is used for converting CO in a synthesis gas into a mixed gas consisting mainly of CO2-H2 in a converting furnace, and the MDEA desulfurization and decarbonization device comprises an absorption tower and a desorption tower; the absorption tower is used for receiving the mixed gas in the sulfur-resistant conversion device and for absorbing CO2 and H2S gases, and the desorption tower is used for receiving CO2 and H2S containing rich solution in the absorption tower and for desorbing CO2 and H2S; the sulfur and carbon separating device comprises a desulfurization purifier for receiving the CO2 and H2S gases in the desorption tower; and H2S gas is absorbed by an H2S absorber, and finally the CO2 gas is obtained. According to the IGCC based pre-combustion CO2 capture system, CO2 and H2S are simultaneously removed by a lean solution-half-lean solution MDEA method, so that the absorption rate of CO2 is improved, and the exhaust to air is reduced; and the heat generated by the conversion process of gas is fully utilized to heat MDEA rich solution for regeneration, and the consumption of medium-pressure steam is reduced.

Owner:HUANENG POWER INTERNATIONAL +1

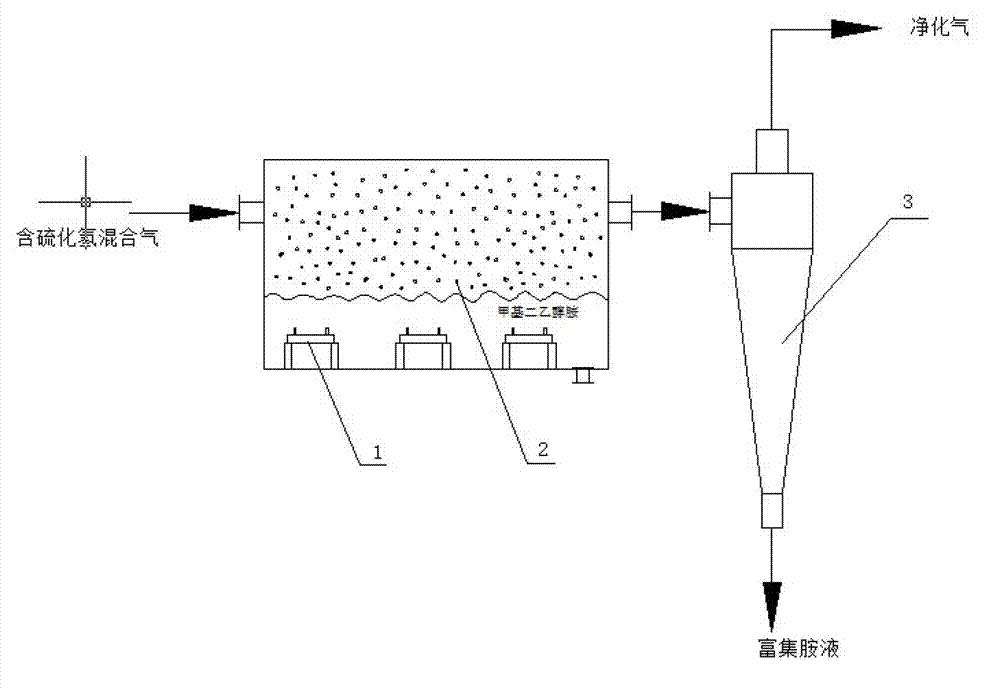

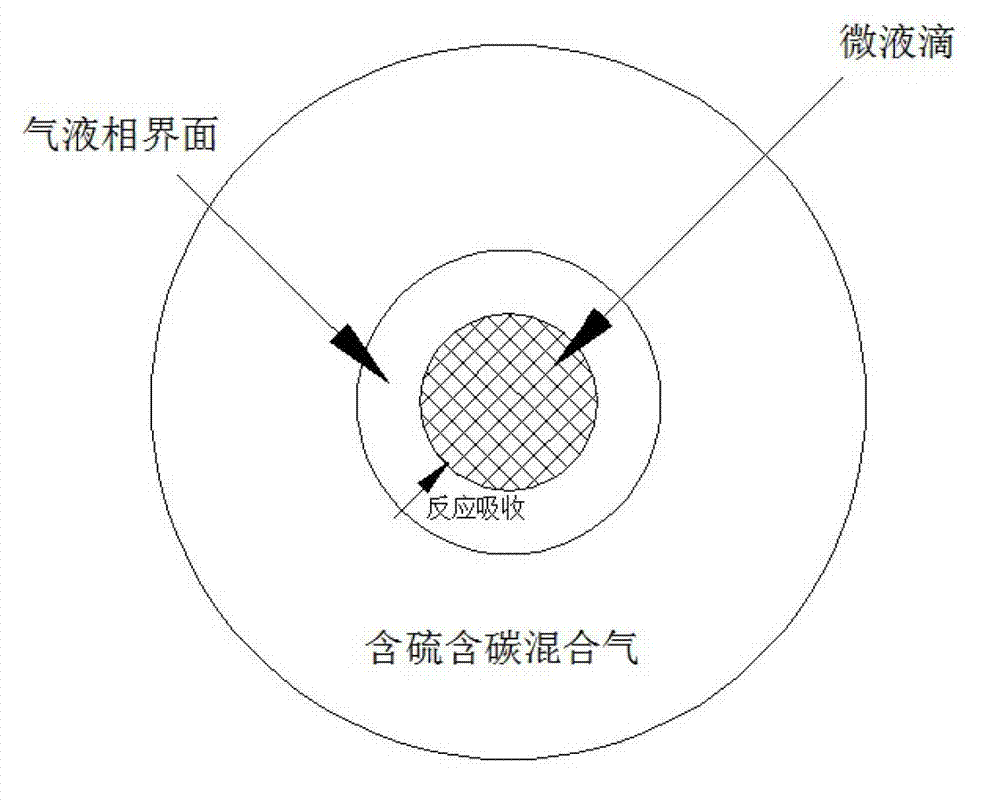

Method and device for selectively removing hydrogen sulfide by use of ultrasonically atomized liquid droplets

ActiveCN102806001AReduce lossReduce absorptionDispersed particle separationCycloneUltrasonic atomization

The invention relates to a method and device for selectively removing hydrogen sulfide by use of ultrasonically atomized liquid droplets, and provides a method for selectively removing hydrogen sulfide by use of ultrasonically atomized liquid droplets. The method comprises (i) atomizing a methyldiethanolamine solution by ultrasonic atomization to give liquid droplets with a size of 10-15mum; (ii) uniformly mixing the obtained methyldiethanolamine liquid droplets with a gas containing hydrogen sulfide and spraying the mixture into a cyclone within time shorten than one second; (iii) in the cyclone, allowing the methyldiethanolamine liquid droplets to absorb the hydrogen sulfide in the gas while separating the methyldiethanolamine liquid droplets in the cyclone field of the cyclone, and aggregating to form a hydrogen sulfide-rich methyldiethanolamine solution; and (iv) recycling the hydrogen sulfide-rich methyldiethanolamine solution, atomizing by ultrasonic atomization to give liquid droplets, and cyclically using the liquid droplets in the step (ii). Also provided is a device for selectively removing hydrogen sulfide by use of ultrasonically atomized liquid droplets.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com