Method for treating hydrochloric acid leachate of ferrotitanium materials

A hydrochloric acid leaching and leaching technology, which is applied in the field of hydrometallurgy, can solve the problem of large amount of incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

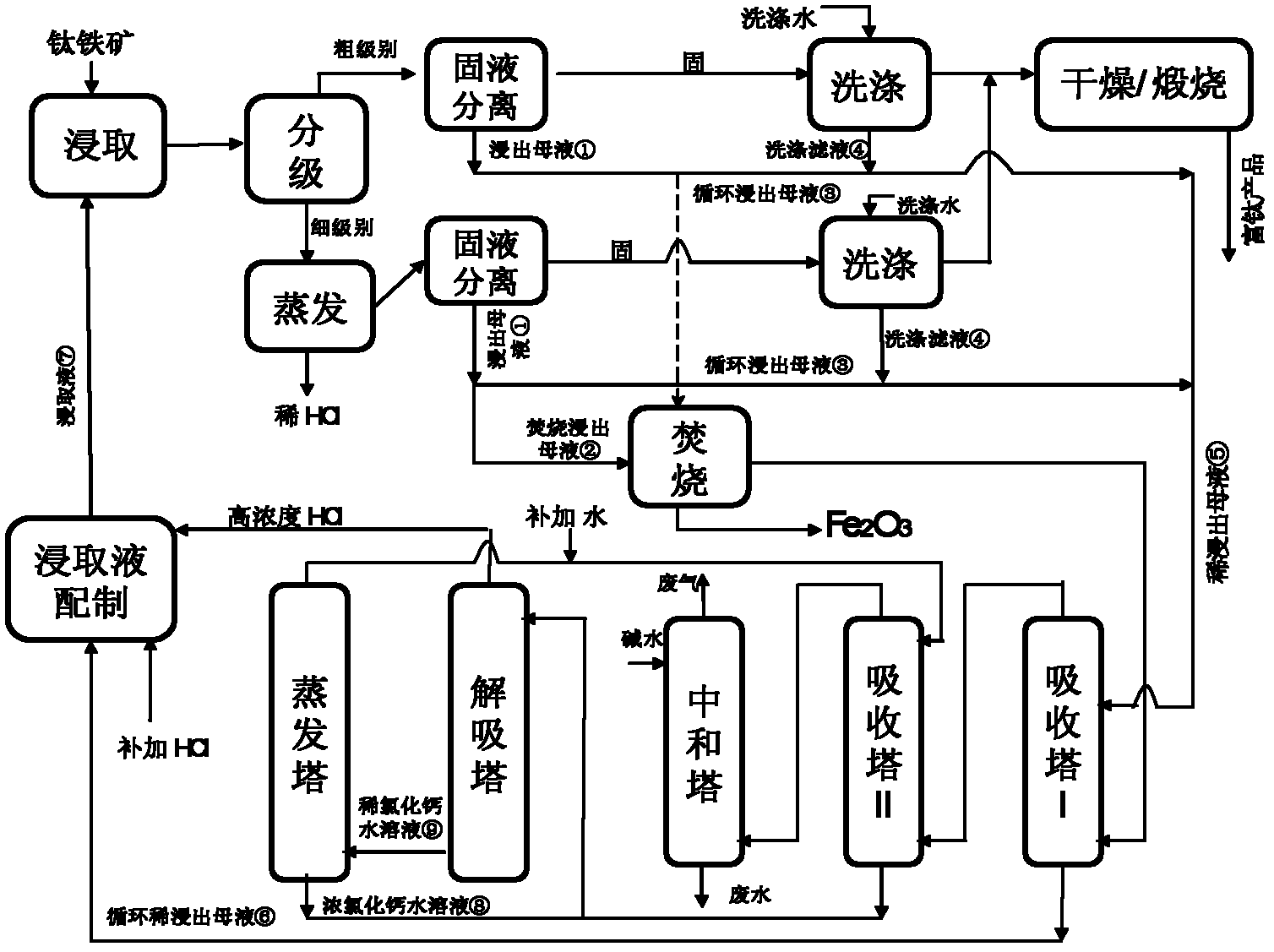

[0127] Embodiment 1 directly leaches titanium concentrate hydrochloric acid and adopts direct heating (referring to image 3 )

[0128] The main chemical composition of the rock-type low-oxide titanium concentrate in Panxi area is shown in Table 7.

[0129] Table 7. Main chemical composition of Panzhihua rock-type low-oxide titanium concentrate (wt.%)

[0130] ingredients

al 2 o 3

CaO

TF

MgO

SiO 2

TiO 2

V 2 o 5

Raw ore (titanium concentrate)

0.9

0.81

33.14

2.4

3.41

47.64

0.1

[0131] The hydrochloric acid pressure direct leaching of titanium concentrate generally adopts the leaching solution with the mass concentration of hydrochloric acid of 20% and the leaching temperature of 120 to 150°C.

[0132] The direct leaching of titanium concentrate with hydrochloric acid is characterized by fast leaching speed, high leaching rate, high leaching temperature, and serious produc...

Embodiment 2

[0140] Embodiment 2 titanium concentrate hydrochloric acid direct leaching and adopts indirect heating (referring to Figure 4 )

[0141] In this example, titanium concentrate is directly leached with hydrochloric acid and indirect heating is adopted. The difference from Example 1 lies in the heating method. When indirect heating is used, the leaching solution is not diluted. Now, the mass concentration of hydrochloric acid produced and recovered by the Ruther method is consistent with the mass concentration of hydrochloric acid required by the leaching solution ⑦, so it is not necessary to increase the hydrochloric acid concentration process as in Example 1. The specific process is as Figure 4 shown.

Embodiment 3

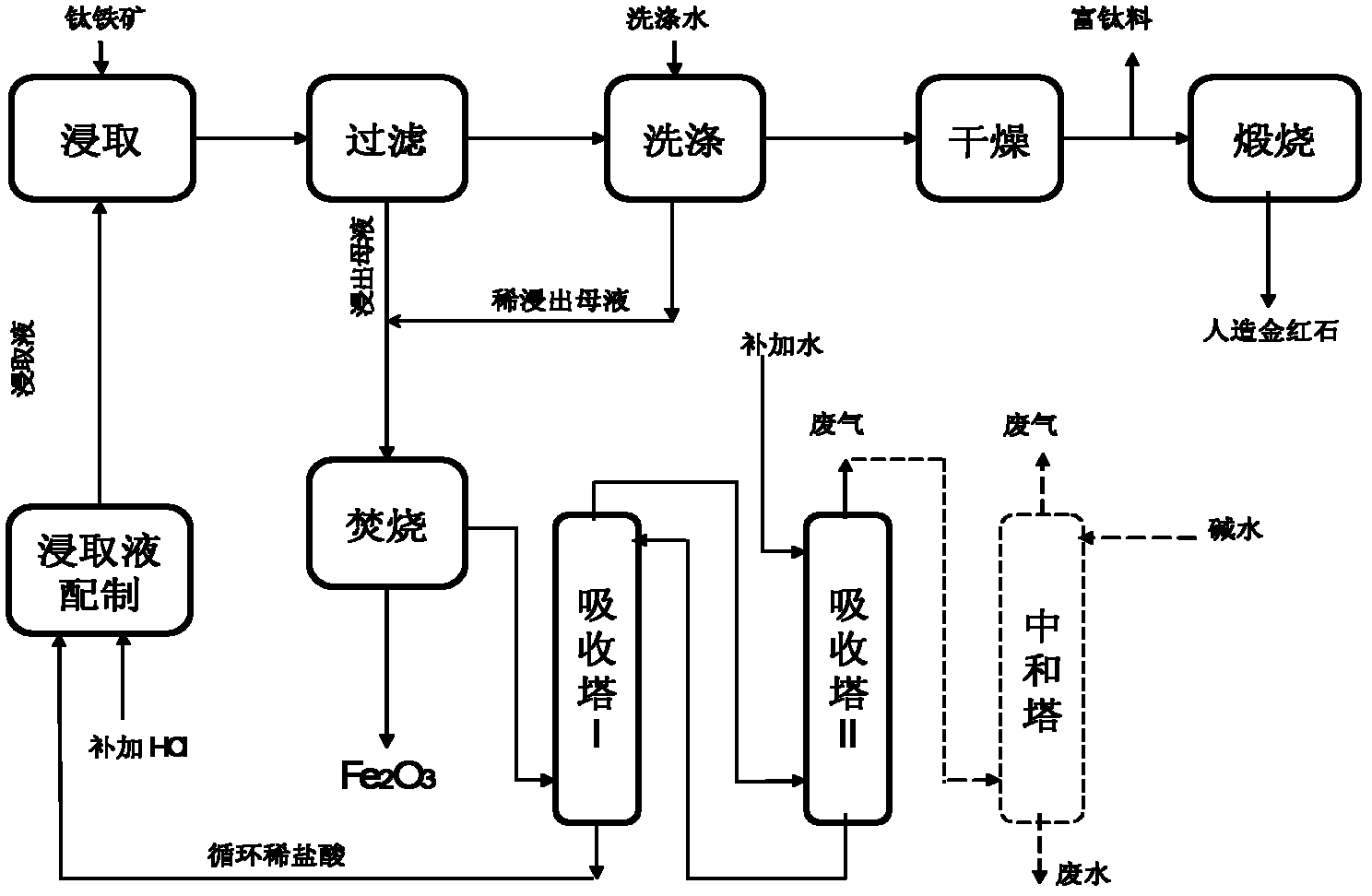

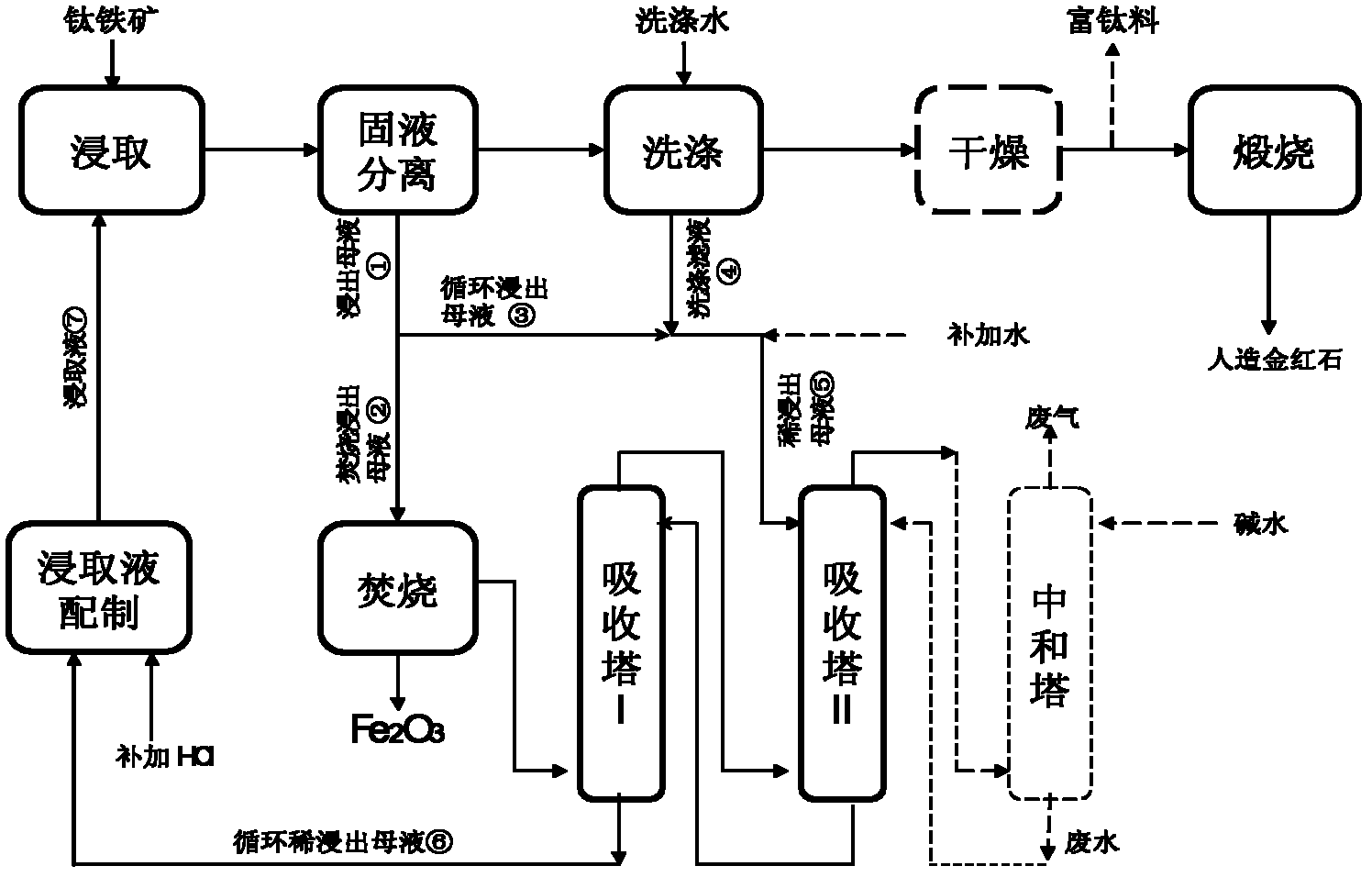

[0142] Embodiment 3 modified titanium concentrate hydrochloric acid atmospheric pressure leaching and adopts indirect heating (referring to figure 2 )

[0143] In order to control product refinement, improve the leaching rate of iron and make the leaching process easier to control, oxidation-reduction methods are often used to modify ilmenite. Firstly, the ilmenite is oxidized to oxidize the divalent iron in the ilmenite to ferric iron, and then the ferric iron is reduced to ferrous iron. The modified ilmenite is leached at normal pressure at 90 to 110° C. and 18 to 22% hydrochloric acid mass concentration. Because the leaching temperature is low, the heating method can be maintained by preheating the leaching solution and indirect heating. The specific process is as figure 2 shown.

[0144] For ilmenite with a higher degree of oxidation, such as sand-type ilmenite, this process is preferred to treat the leaching mother liquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com