Patents

Literature

423 results about "Limewater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Limewater is the common name for a dilute aqueous solution of calcium hydroxide. Calcium hydroxide, Ca(OH)₂, is sparsely soluble at room temperature in water (1.5 g/L at 25 °C). "Pure" (i.e. less than or fully saturated) limewater is clear and colorless, with a slight earthy smell and an astringent/bitter taste. It is basic in nature with a pH of 12.4.

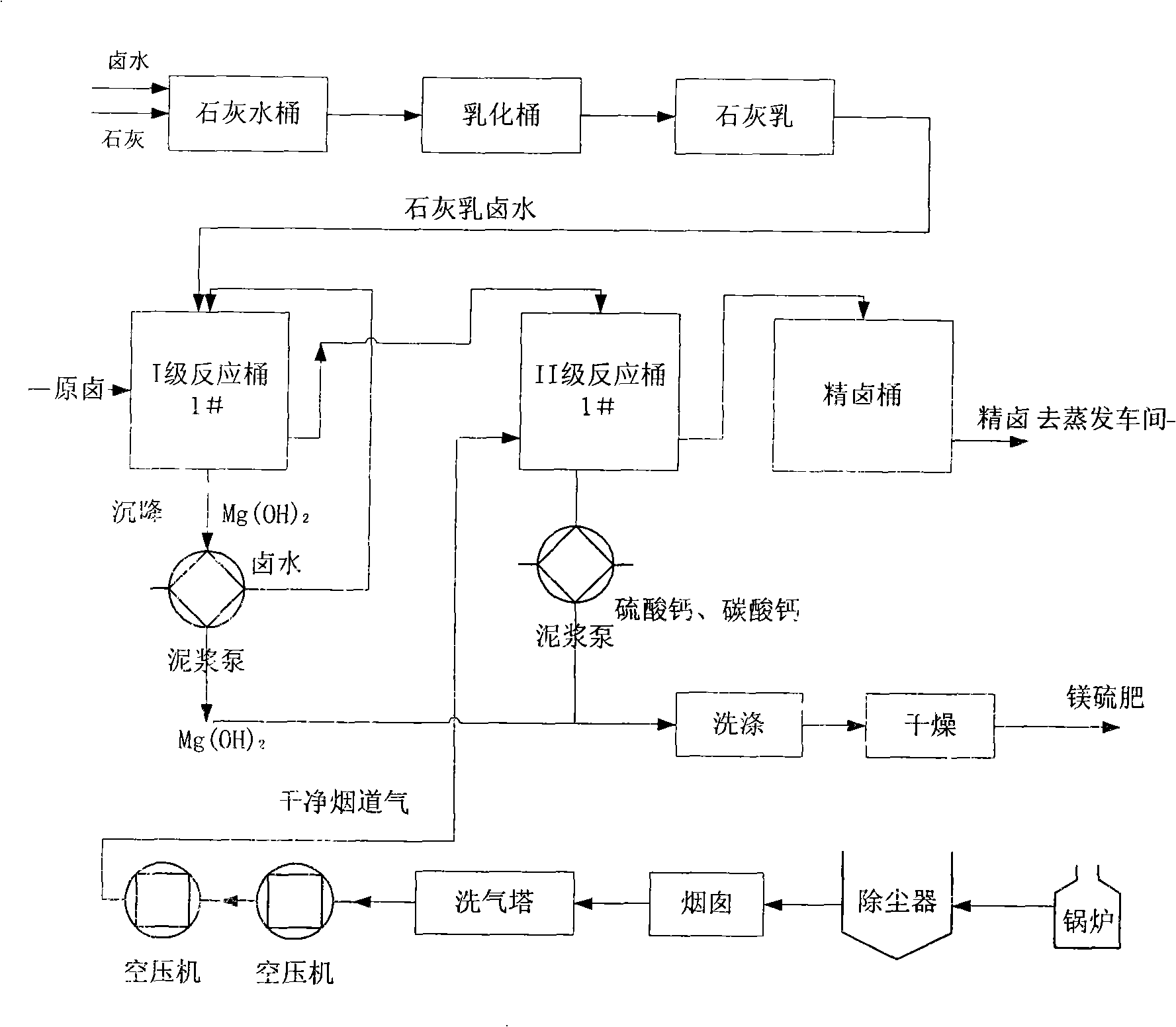

Technological process for purifying bittern

InactiveCN101289200AReduce purification costsImprove purification qualityAlkali metal chloridesSlurryCalcium carbonate precipitation

The invention provides a brine purification technical method which comprises that: a first step is that limewater is added into brine so that reaction happens to calcium hydroxide in the limewater and magnesian ion in the brine to generate magnesium hydrate sedimentation, the magnesian ion in the brine is removed, excessive calcium hydroxide is used for causticizing the sodium sulfate in the brine into sodium hydroxide; a second step is that flue gas is put into the brine after the magnesian ion is removed for carrying out reaction between carbon dioxide in the flue gas and the sodium hydroxide causticized in the brine to generate sodium carbonate which reacts with calcium ion in the brine to generate calcium carbonate sedimentation, the calcium ion in the brine is removed; a third step is that slurry produced in the first step and the second step is collected; and a fourth step is that refined brine after being treated by the first step and the second step is recycled. The technical method can reduce the pollution to environment, can save energy, and can reduce the consumption of raw brine and the purification cost of the brine at the same time, thereby conforming to the requirements of the strategy of sustainable development.

Owner:CHINA NATIONAL SALT INDUSTRY CORPORATION +1

Treatment of aluminum electrolytic-cell waste lining

A process for reclaiming the used liner of aluminum electrolyzer includes such steps as crushing, mixing it with powdered coal ash and calcium lime, grinding, sphericizing, calcining, grinding, immersing in lime milk for removing residual soluble Fe ions, and filtering to obtain NaOH solution and the dregs used as the raw material to prepare cement and refractory.

Owner:河南华慧有色工程设计有限公司 +1

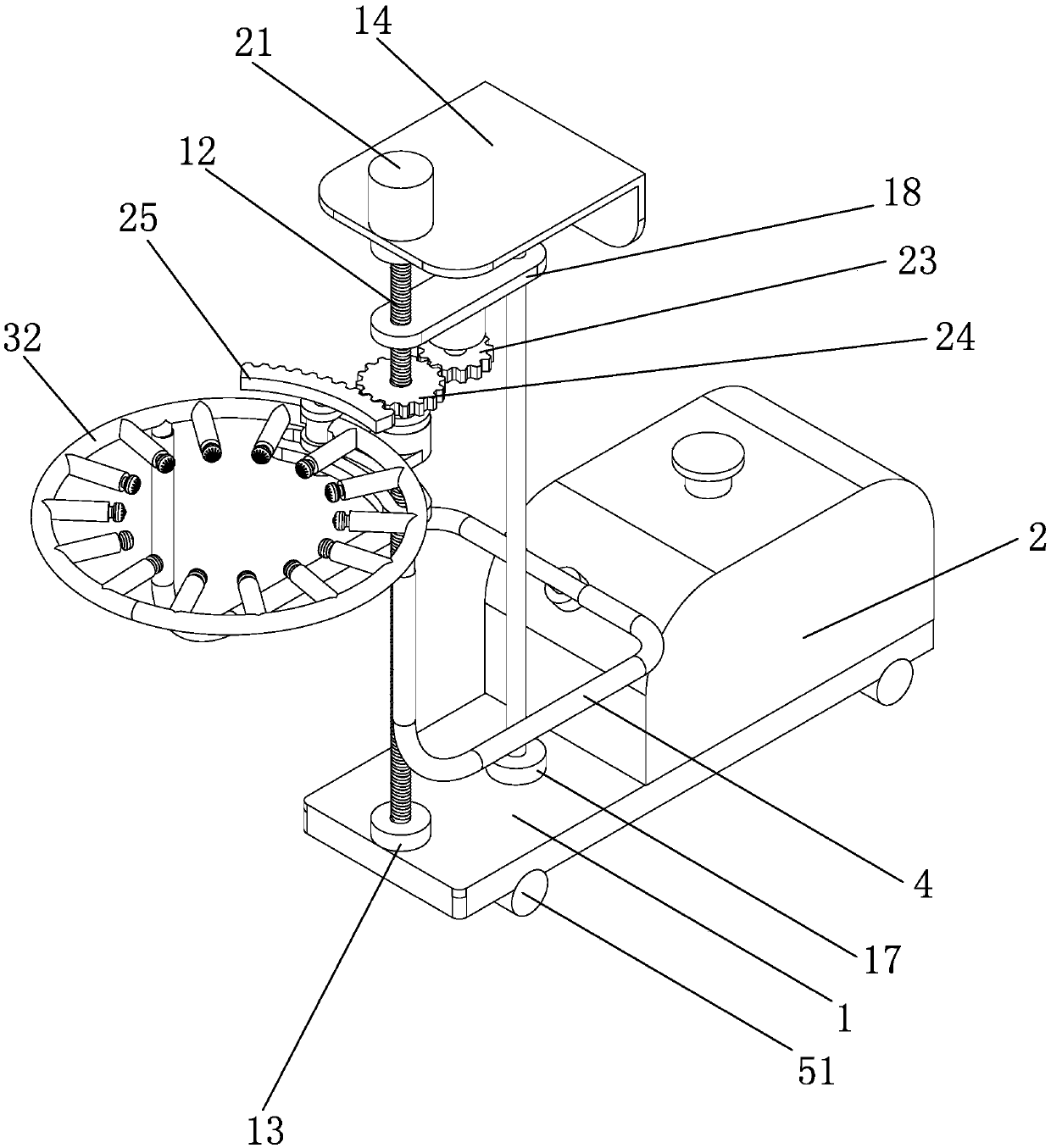

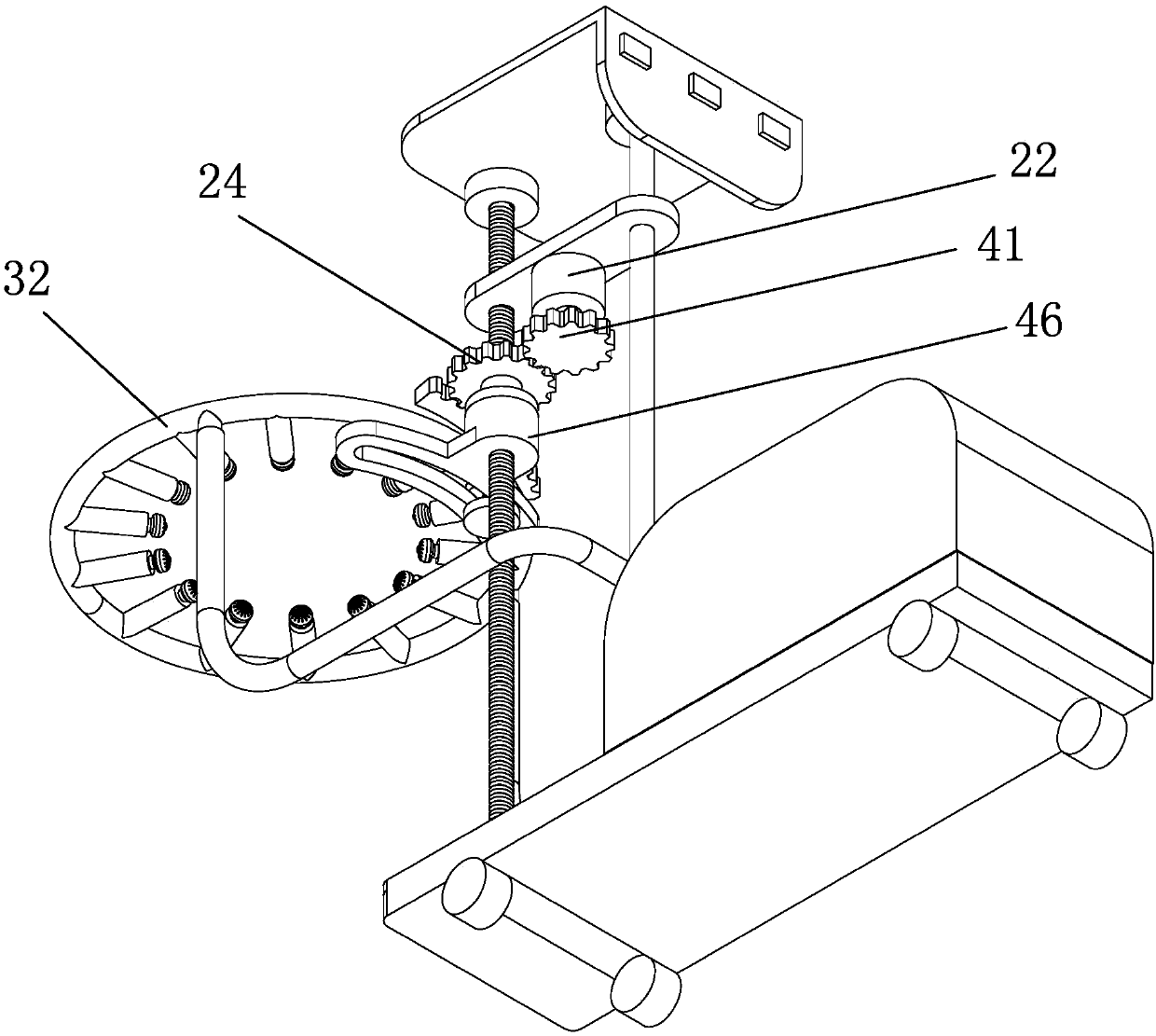

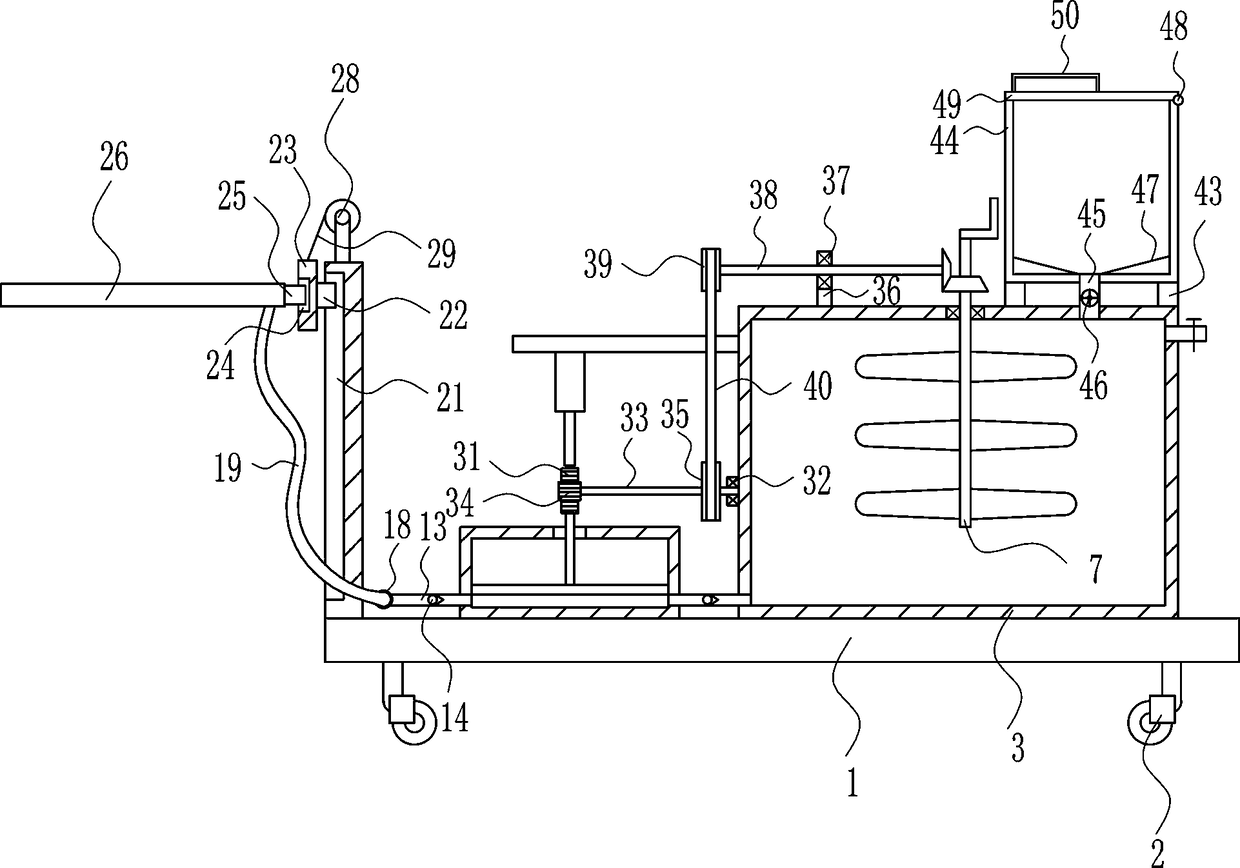

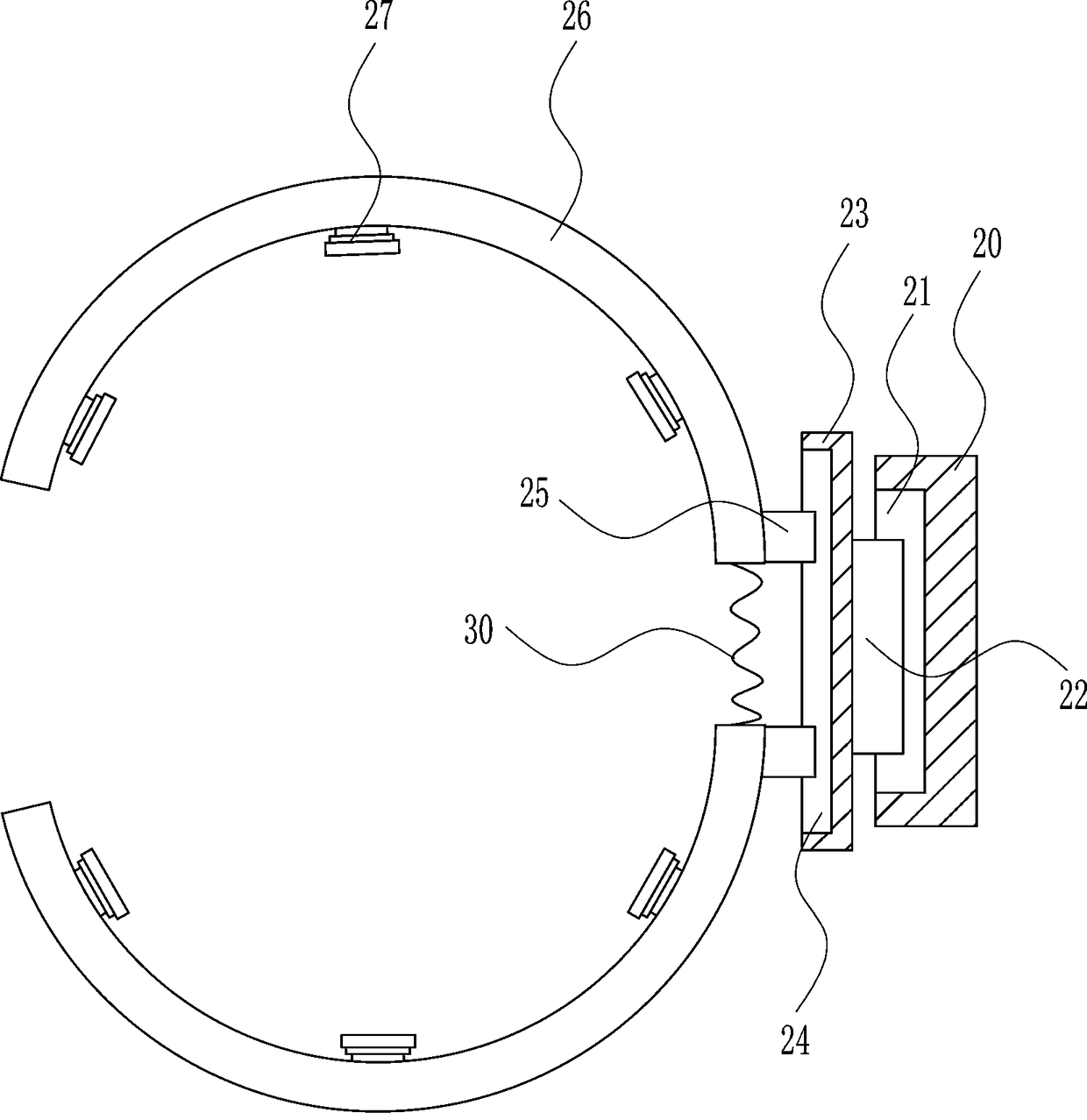

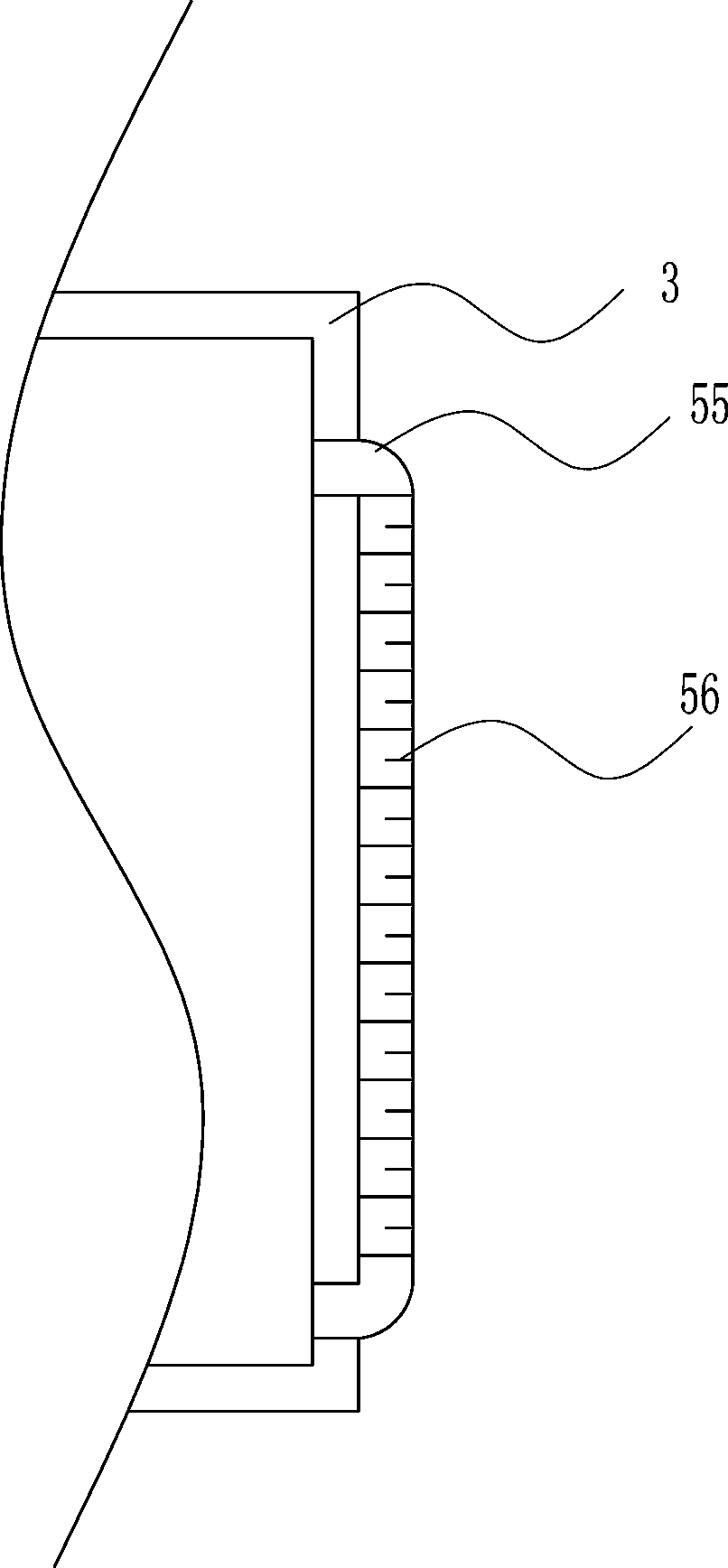

Tree brushing machine capable of conveniently spraying lime water

InactiveCN107694784AComplete efficientlySimple structureLiquid spraying apparatusPlant protectionWater storage tankEngineering

The invention discloses a tree brushing machine capable of conveniently spraying lime water. The tree brushing machine comprises a base, wherein a water storage tank is arranged on the upper part of the base. The tree brushing machine is characterized in that a first water outlet pipe is arranged on the outer wall surface of the water storage tank; a spraying mechanism capable of spraying the trunk is arranged in front of the base; connecting pipes are inserted between the spraying mechanism and the first water outlet pipe; a lifting mechanism capable of driving the spraying mechanism to moveup and down is arranged on the upper part of the base; and a reciprocating swing mechanism capable of enabling the spraying mechanism to move is arranged between the spraying mechanism and the liftingmechanism. The tree brushing machine capable of conveniently spraying the lime water is simple in structure and convenient to use; the lime water is pumped into the spraying mechanism from the waterstorage tank through a water pump, then spraying is carried out on the trunk through adjusting the flow rate by an adjusting valve, and the movement of the spraying mechanism is controlled through thelifting mechanism and the reciprocating swing mechanism at the same time so that the spraying can be uniformly carried out on the trunk at a uniform speed; and spraying can be carried out through a machine instead of manpower, thus work can be efficiently completed and waste of manpower and time can be avoided, and the requirements of people can be met.

Owner:林广华

Method for processing waste cell-lining of aluminum cell using coal slack

InactiveCN101357367AEfficient use ofWide variety of sourcesSolid waste disposalGranularityCell lining

Owner:KUNMING UNIV OF SCI & TECH

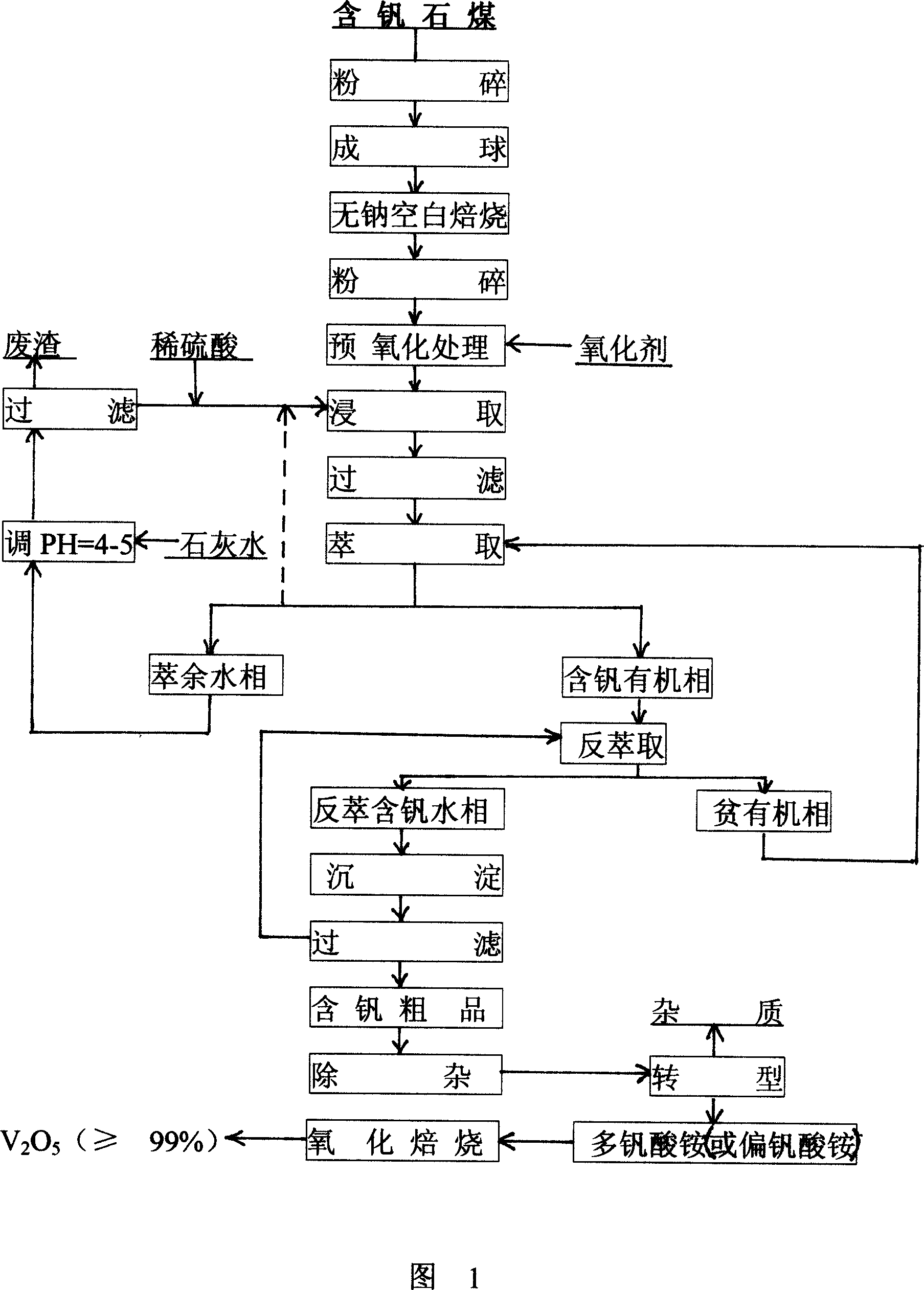

Process for producing vanadium pentoxide from vanadiferous coal stone

This invention relates to a new method for producing V2O5 with coal containing V stones aiming at providing a kind of coal with V stones to be Na-free spacing baked, pre-oxidized to be picked-up by diluted H2SO4 directly to get a V salt solution then to be extracted by TOA organic solvent to increase yield of V products and reduce cost of H2SO4 characterizing in crushing coal with V stones to spheres to be processed by Na-free spacing baking to get rid of carbon and crushed and added with oxidation agent for pre-oxidation process, adding diluted H2SO4 for leaching and filtering it, which is extracted to get V with water organic phase to be counter-extracted, heated, deposited and filtered to get rough products with V, and the final product V2O5 with the content of 99% is got after oxidizing and baking poly-V ammonium or ammonium metavanadate after being purified, and the rest solution after extraction is added with limewater and filtered to be recovered for leaching.

Owner:邓镇炎

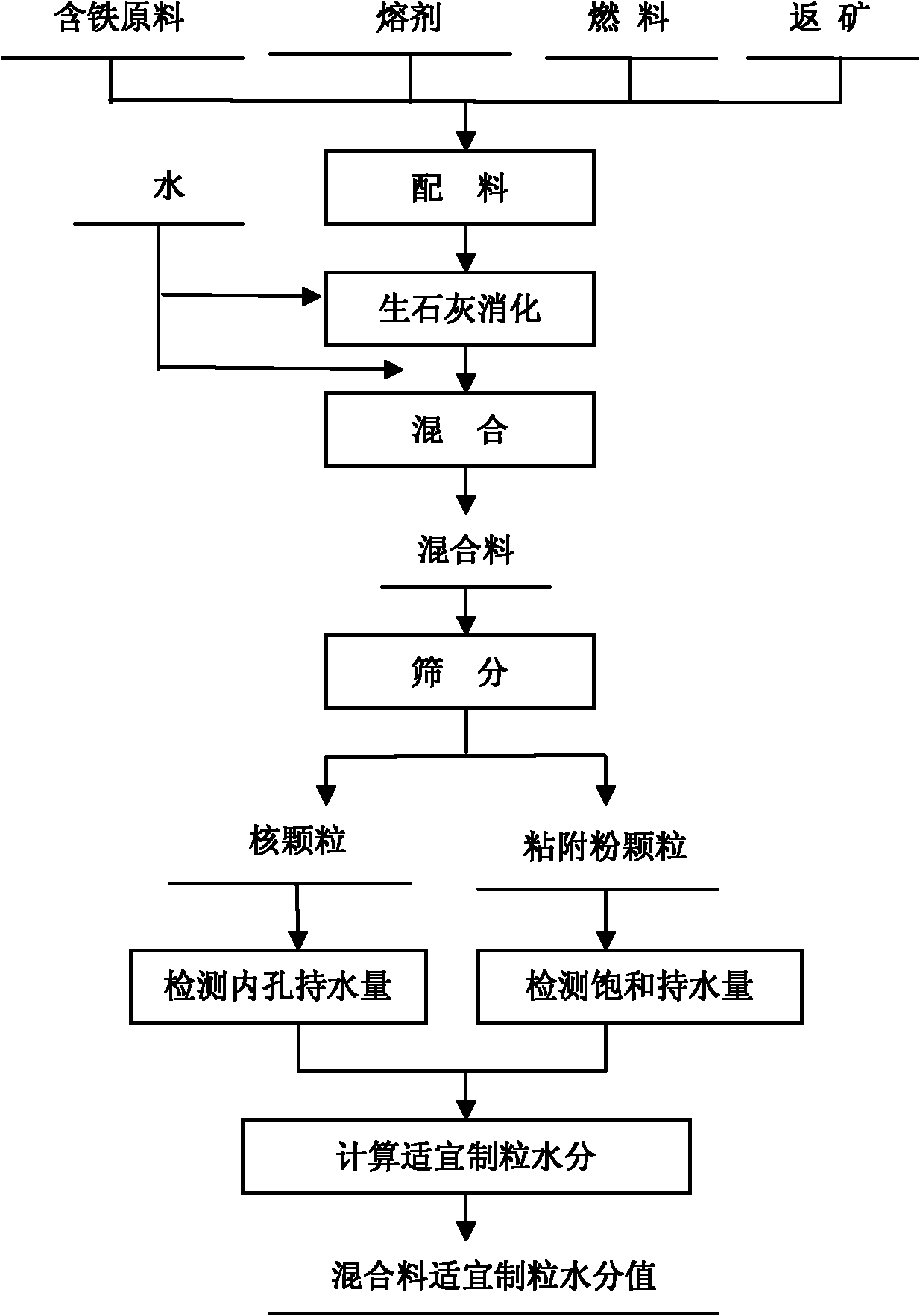

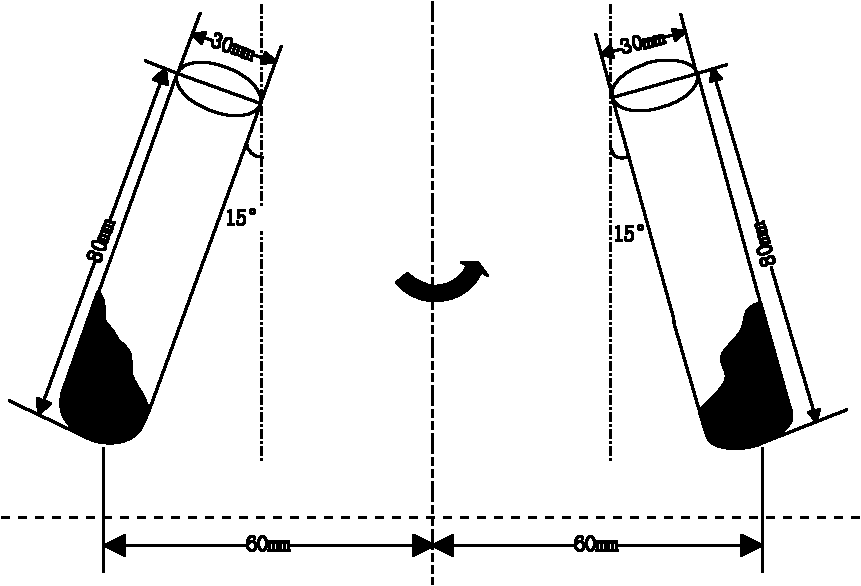

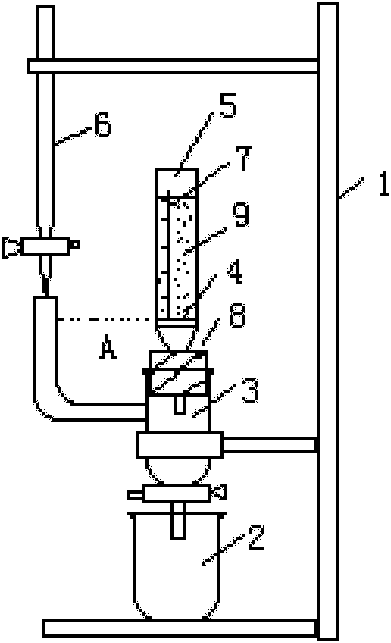

Method for quickly testing appropriate granulation moisture content of iron ore sinter mixture

InactiveCN101974680AShort detection cycleSmall amount of sampleParticle size analysisIronstoneCentrifugation

The invention discloses a method for quickly testing the appropriate granulation moisture content of an iron ore sinter mixture. The appropriate granulation moisture content refers to the moisture content required by the granulated mixture for obtaining optimal breathability. The moisture includes the moisture of the raw materials and the added water during mixing and granulation. The method comprises the following steps: 1) preparing a slurry mixture of which the humidity is 10 to 20 percent from iron ore, solvent, coke powder and sinter return ore; 2) rinsing and sieving the mixture by using saturated lime water as a medium, obtaining adhesive powder and shell grains and testing the content Xa of the adhesive powder; 3) testing the inner hole water-holding capacity of the shell grains by centrifugation; 4) testing the saturated water-holding capacity of the adhesive poser by using saturated water absorption process; and 5) calculating the appropriate moisture content required for the granulation of the mixture according to a formula. The method has the characteristics of simple operation and high accuracy. Based on an absolute error range from -0.3 to +0.3, the accuracy of the prediction of the appropriate moisture content reaches 93.3 percent according to the results of the tests of the moisture content of mixtures prepared by 30 material mixing schemes.

Owner:CENT SOUTH UNIV

Method for utilizing solid waste ardealite to prepare gypsum whiskers

ActiveCN105088347AImprove thermal stabilityPolycrystalline material growthFrom normal temperature solutionsChemistryLimewater

The invention discloses a method for utilizing solid waste ardealite to prepare gypsum whiskers. According to the method, the industrial solid waste ardealite is used as a raw material. Firstly, the ardealite is subjected to washing pretreatment including the three working procedures of washing, centrifugal dewatering and lime neutralizing treatment; the ardealite is evenly stirred with water in a reactor, an upper-layer flotage of supernatant liquid is filtered out after standing, then the ardealite is slowly stirred to obtain uniform slurry, centrifugal separation, dewatering and vacuum drying are performed to obtain purified ardealite, and waste liquid produced after washing is neutralized with lime water and then can be recycled; secondly, an appropriate amount of purified ardealite is calcined, the calcined ardealite is shaken up with mixed liquor prepared from glycerine and water in certain proportion in a tubular furnace, the mixture is calcined at the 4 DEG C / min temperature rise speed under the 500 DEG C temperature condition for 2 hours, and calcined semi-hydrated gypsum whiskers can be obtained through crystallization reaction. The gypsum whiskers are prepared by means of a one-step method, energy is saved, the environment is protected, a process and the devices are novel, and the method is simple and convenient to operate and advanced in technology and facilitates industrialization.

Owner:HEFEI UNIV

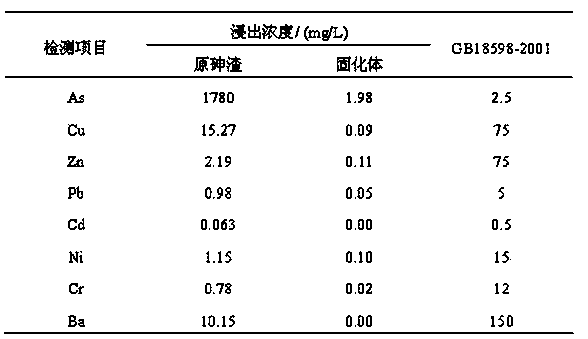

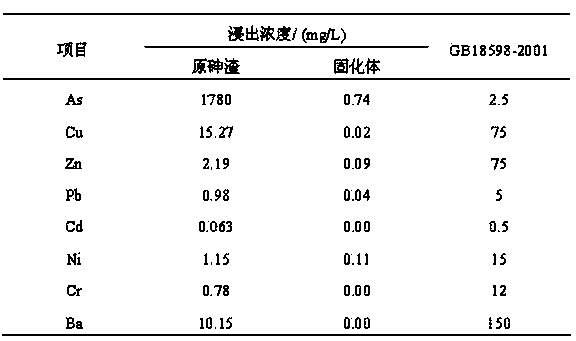

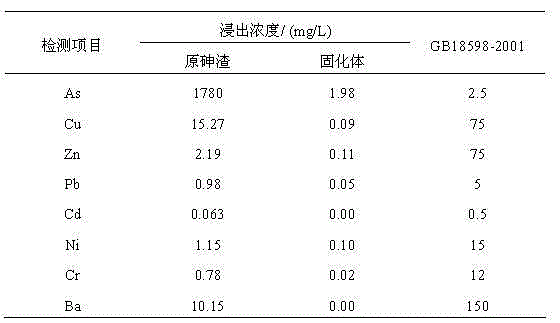

Stable curing method of strongly acidic arsenic sulfide waste residues

ActiveCN104174634AReduce leachingReduce contentSolid waste disposalTransportation and packagingCalcium hydroxideSludge

The invention discloses a stable curing method of strongly acidic arsenic sulfide waste residues. The stable curing method comprises the following steps: (1) adding heavy-metal sludge to to-be-treated strongly acidic arsenic sulfide residues, and stirring, so as to obtain muddy materials; (2) adding calcium hydroxide powder to the muddy materials obtained in the step (1) in the state of stirring, and continuing to stir until all yellow substances in the muddy materials disappear; (3) adding yellow sand and cement to the materials obtained after stirring in the step (2); (4) cooling the stirred materials obtained in the step (3) to room temperature, transferring to a forming die, taking out from the die after forming, and curing at room temperature, so as to obtain solidified bodies which conforms to the landfill standard. According to the stable curing method, the heavy-metal sludge is used as an arsenic stabilizer, so as to control waste by waste; sources of the materials such as the heavy-metal sludge, the lime, the cement and the yellow sand required for treating the strongly acidic arsenic sulfide waste residues are wide, and additionally, other drugs do not need to be added; compared with other methods, the stable curing method has the advantage of low treatment cost.

Owner:扬州杰嘉工业固废处置有限公司

A writing brush bristle brush degreasing treatment process

The invention discloses a writing brush bristle brush degreasing treatment process, which includes: firstly spraying ash on the bristle brush of the writing brush, and then using an electric heating plate with temperature of 70-90 DEG C to press on the bristle brush of the writing brush to perform heating degreasing, wherein, the heating time is 30-60 minutes. Compared with the traditional limewater degreasing method, the invention can relatively thoroughly remove the animal fat residual on the pen point writing brush, better holds the fabric character and elasticity of the feather itself, thereby having better writing results and feeling; and the writing brush of the pen point is not easy to brush off and drop feather, the writing brush is sharp and has good product quality, the process is relatively simple, has short handling time and the entire degreasing process can be controlled in 60 minutes, thereby greatly improving corporation production efficiency.

Owner:HUZHOU CITY SHANLIAN SHUANGXI HU WRITING BRUSH

Process for extracting rutin from sophora japonica

InactiveCN101817857AMix thoroughlyExtract completelySugar derivativesSugar derivatives preparationSulfite saltFiltration

The invention discloses a process for extracting rutin from sophora japonica, which comprises the following steps of: (1) preparing and crushing sophora japonica, putting the crashed sophora japonica into an extraction tank, washing and moistening the crashed sophora japonica with boiling water, and then, introducing an extraction solvent for carrying out reverse percolation extraction, wherein the extraction solvent is a mixture of saturated lime water, borax and sodium sulfite, the proportioning by weight of the saturated lime water to the borax to the sodium sulfite is 1000:4-6:0.5-1.5, and the pressure of the reverse percolation extraction is 0.2-0.3MPa; and (2) carrying out cascade filtration on the reverse percolation extraction solution, adding hydrochloric acid after cooling to regulate the pH value to 3-4, crystallizing, taking out crystals, washing the crystals with water to the neutrality, and drying the crystals to obtain finished products. Compared with the prior art, in the invention, by using reverse percolation extraction to replace percolation extraction and combining the extraction solvent with special proportioning, the rutin in the sophora japonica can be extracted more completely, thus the extraction rate is high, and residues in the percolation solution are few and can be filtered more easily; and the invention has the advantages of simple and convenient operation and short production cycle, and the product purity can reach more than 97.5%.

Owner:桂林市振达生物制药有限公司

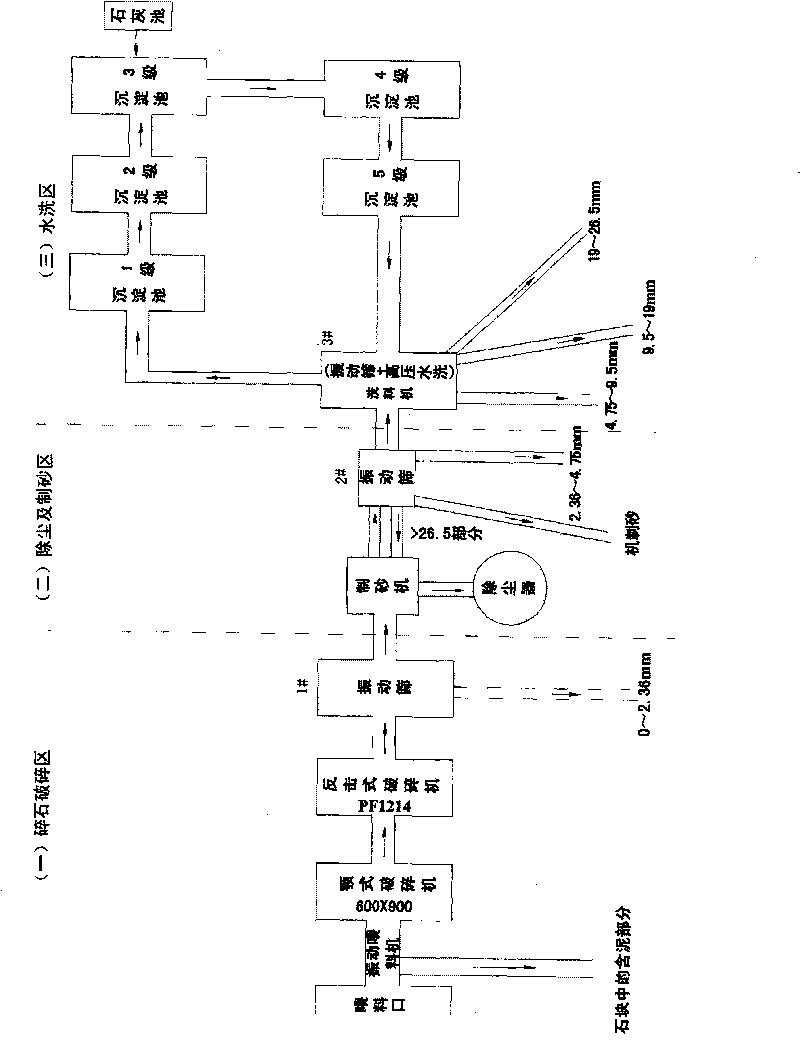

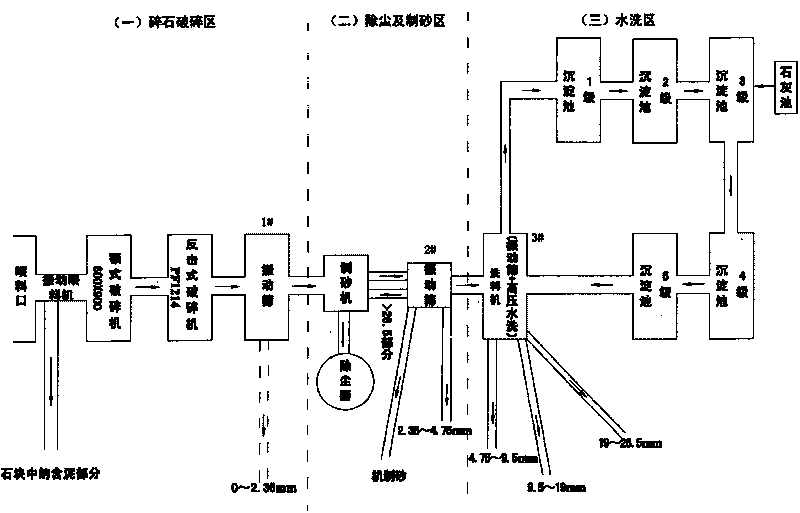

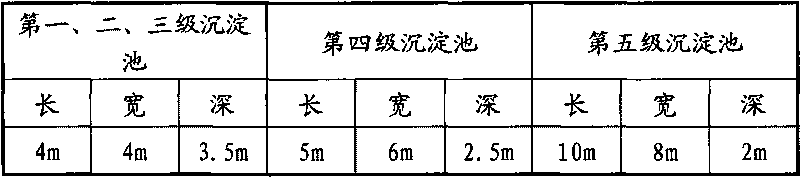

Technique for crushing and water washing of aggregates on asphalt pavement of high-speed highway

InactiveCN101691732AImprove adhesionReduce pollutionRoads maintainenceEngineeringHigh pressure water

The invention relates to a technique for the crushing and the water washing of aggregates on an asphalt pavement of a high-speed highway, which comprises the following steps: selecting stone blocks at a feeding opening; crushing and sieving stone materials; manufacturing sand by a sand manufacturing machine and removing dust; washing coarse aggregates which are greater than 4.75mm by water; and flushing sewage, precipitating and recycling. By crushing three times, sieving four times, adopting the sand manufacturing machine to match with high-power dust removal equipment, arranging fan drum cloth at a discharge port of the sand manufacturing machine and arranging a water spraying facility for spraying water in a proper amount, the invention can effectively reduce dust emission and pollution to an ambient environment; the aggregates can be quickly and effectively washed in an omnibearing way by arranging a high-pressure water spraying pipe network above a vibration sieve, by washing the aggregates through limewater the surface cleanness and the surface alkalinity of the aggregates can be enhanced, and the adhesion property of asphalt is reinforced; and a five-level settling tank technology is adopted, flushing water is recycled, the cleanness of the used water is ensured, and water resources can be saved.

Owner:JIANGXI GANYUE EXPRESSWAY +2

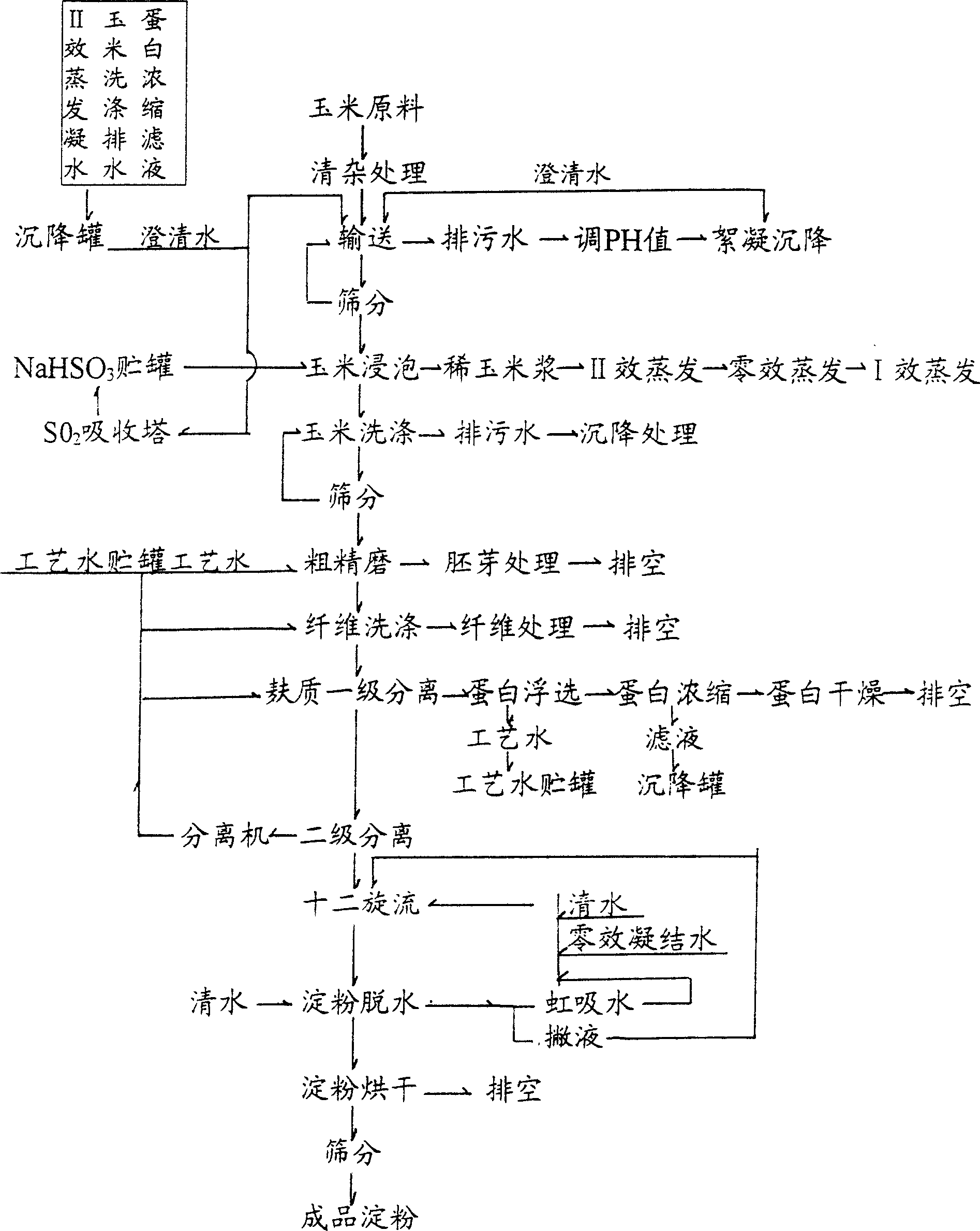

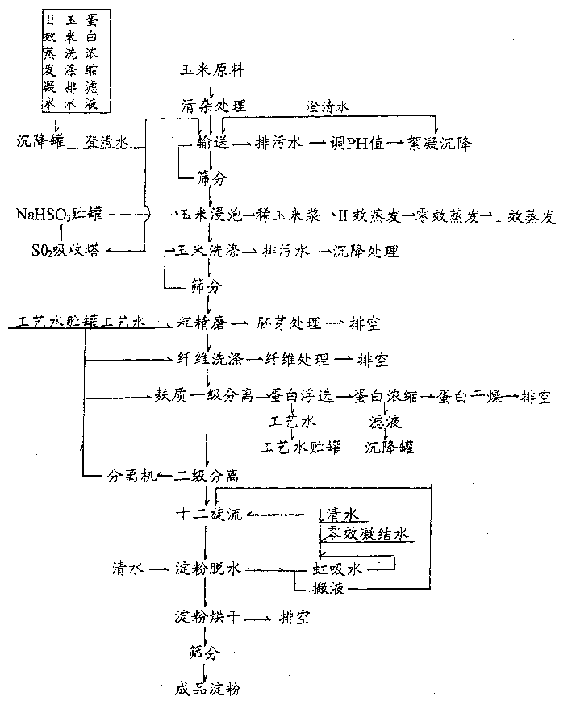

Waste water circulating and reusing process for starch processing

InactiveCN1506320ALess investmentLow running costWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationFiberWater saving

The present invention discloses waste water circulating and reusing process in starch producing process. The waste water after corn conveying is pH regulated to 5.0-5.2 with lime water and flocculated and deposited in the depositor, and the processed water is used in corn conveying and corn soaking. Water after use in protein floating step is used mainly in milling corn, plumule washing, fiber washing, starch separation and other steps to replace clear water. The present invention can lower the water consumption greatly and reduce environmental pollution. The water consumption is only 1.2-2 cu m for producing one ton of starch.

Owner:HEILONGJIANG LONGFENG CORN DEV

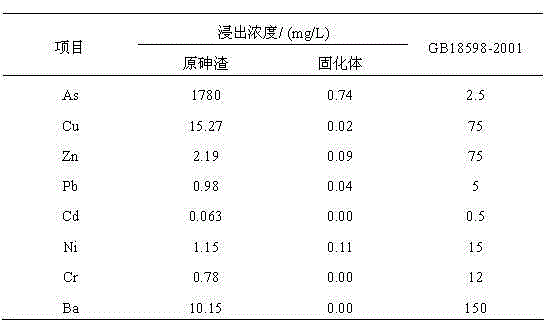

Stable curing method of arsenic sulfide waste slag

ActiveCN105215047AReduce leachingReduce contentSolid waste disposalTransportation and packagingCalcium hydroxideSlag

The invention discloses a stable curing method of arsenic sulfide waste slag. The method comprises the following steps: (1) heavy metal sludge is added in arsenic sulfide slag to be treated for stirring to obtain a slurry material; (2) calcium hydroxide powder is added in the slurry material obtained in the step (1) in the stirring state for continuous stirring until red substances in the slurry material are all disappeared; (3) yellow sand and cement are added in the material obtained by stirring in the step (2); and (4) the stirring material obtained in the step (3) is cooled to the normal temperature, is transferred to a forming mold for molding, is taken out from the mold, and is maintained at the normal temperature to obtain a curing body accordant with the landfill standard. The method uses the heavy metal sludge as an arsenic stabilizing agent for treating wastes by wastes; the sources of such materials as heavy metal sludge, lime, cement and yellow sand needed to treat the strong-acid arsenic sulfide waste slag are wide; other medicaments are not needed to be added; and compared with other methods, the method is lower in treatment cost.

Owner:YANGZHOU JIEJIA IND SOLID WASTE HANDLING CO LTD

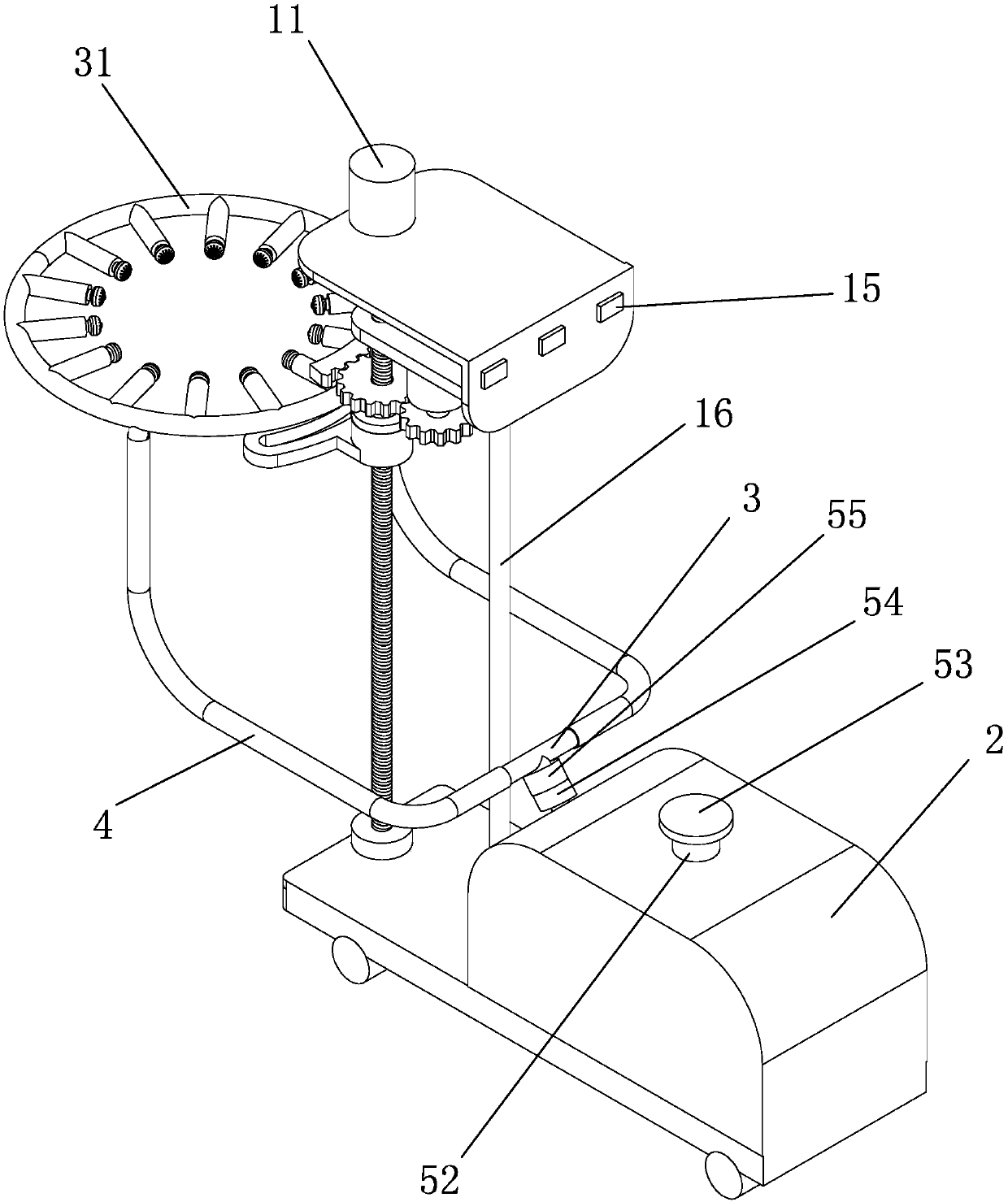

Limewater sprinkling device used for trees in municipal administration

The invention relates to a sprinkling device, in particular to a limewater sprinkling device used for trees in municipal administration. Therefore, the technical problem is resolved by providing the limewater sprinkling device used for trees in municipal administration. The device can automatically and uniformly sprinkle limewater. In order to the above technical problem, the invention provides the limewater sprinkling device used for trees in municipal administration. The device comprises a first installation board, wheels, a water tank, a water inlet pipe, a first valve, a first bearing seat, a first rotary shaft, blades, a rotary shaft, a fixing board, an air cylinder, a cylinder body and the like. The wheels are symmetrically installed on the left and right sides of the bottom of the first installation board forward and backward. The right side at the top of the first installation board is equipped with the water tank. The water inlet pipe is arranged at the upper part on the rightwall of the water tank. The first valve is arranged on the right part of the water inlet pipe. The effect of automatically sprinkling and uniformly limewater is exerted. People shut down the air cylinder such that atomization nozzles can sprinkle limewater to tree trunks more completely and uniformly.

Owner:农克俭

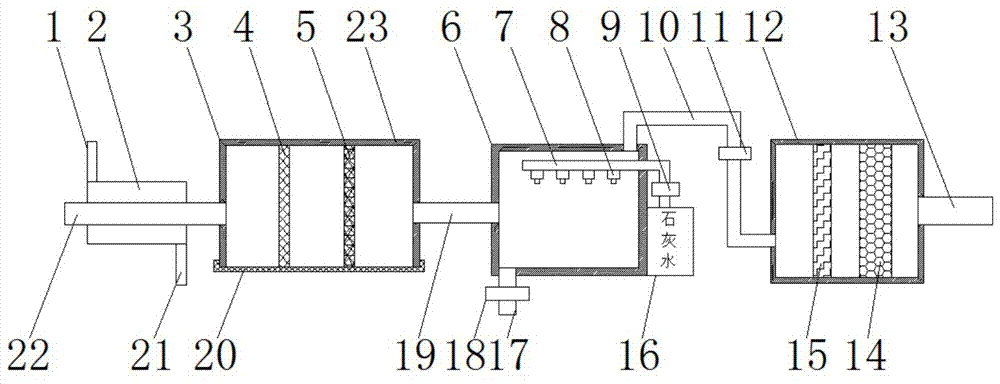

Pharmaceutical factory flue gas treatment equipment

PendingCN107115782AAccelerate the speed of entering the deodorization boxImprove processing efficiencyCombination devicesGas treatmentHazardous substanceLiquid storage tank

The invention discloses pharmaceutical factory flue gas treatment equipment, which comprises an air inlet pipe, an air outlet pipe, a water jacket, a sealing cover, a pressure pump, lump coke, a deodorant layer and a liquid storage tank. The water in the water jacket is heated by using high-temperature flue gas, and the heated water can be used for other applications to realize the full utilization of energy; the flowing of the water in the water jacket cools down the high-temperature flue gas, so as to prevent the high-temperature flue gas from damaging the equipment; the filtered dust falls on the top of the sealing cover under the action of gravitation; the dust in a dust disposal tank is cleaned by dismounting the sealing cover, which is convenient and rapid and improves the practicability of the equipment; the limewater in the liquid storage tank is sprayed out from a spray nozzle after passing through a drainage pipe to desulfurize the flue gas in he a desulfurizing reaction chamber; the lump coke is used to adsorb the sulfur dioxide, nitrogen oxides and other residual harmful substances in the flue gas; and the deodorant layer is used for deodorizing and sterilizing the flue gas.

Owner:LUOYANG LONGMEN PHARMA

Seaweed amino acid rare-earth compound foliage fertilizer and its preparing method

InactiveCN1944353AImprove photosynthetic efficiencyPromote growthOrganic fertilisersFertilizer mixturesPhosphoric acidRare earth

The present invention relates to agricultural technology, and is seaweed amino acid RE compound foliage fertilizer and its preparation process. The preparation process includes the following steps: 1. crushing seaweed into superfine seaweed powder; 2. adding seaweed powder and compound amino acid powder into 1-6N phosphoric acid or acetic acid solution and maintaining at 60-120 deg.c for 2-40 hr to acidolyze to obtain mixture solution of seaweed oligose, polypeptide and amino acid; 3. regulating the pH of the mixture solution to 5-7 with ammonia water, sodium hydroxide or lime water, and adding metal salt mother liquid and RE mother liquid; and 4. adding water and regulating pH to 5-7 with ammonia water, sodium hydroxide or lime water to obtain the compound foliage fertilizer. The compound foliage fertilizer can raise the photosynthesis efficiency of plant and promote plant growth.

Owner:SHANGHAI JIAO TONG UNIV

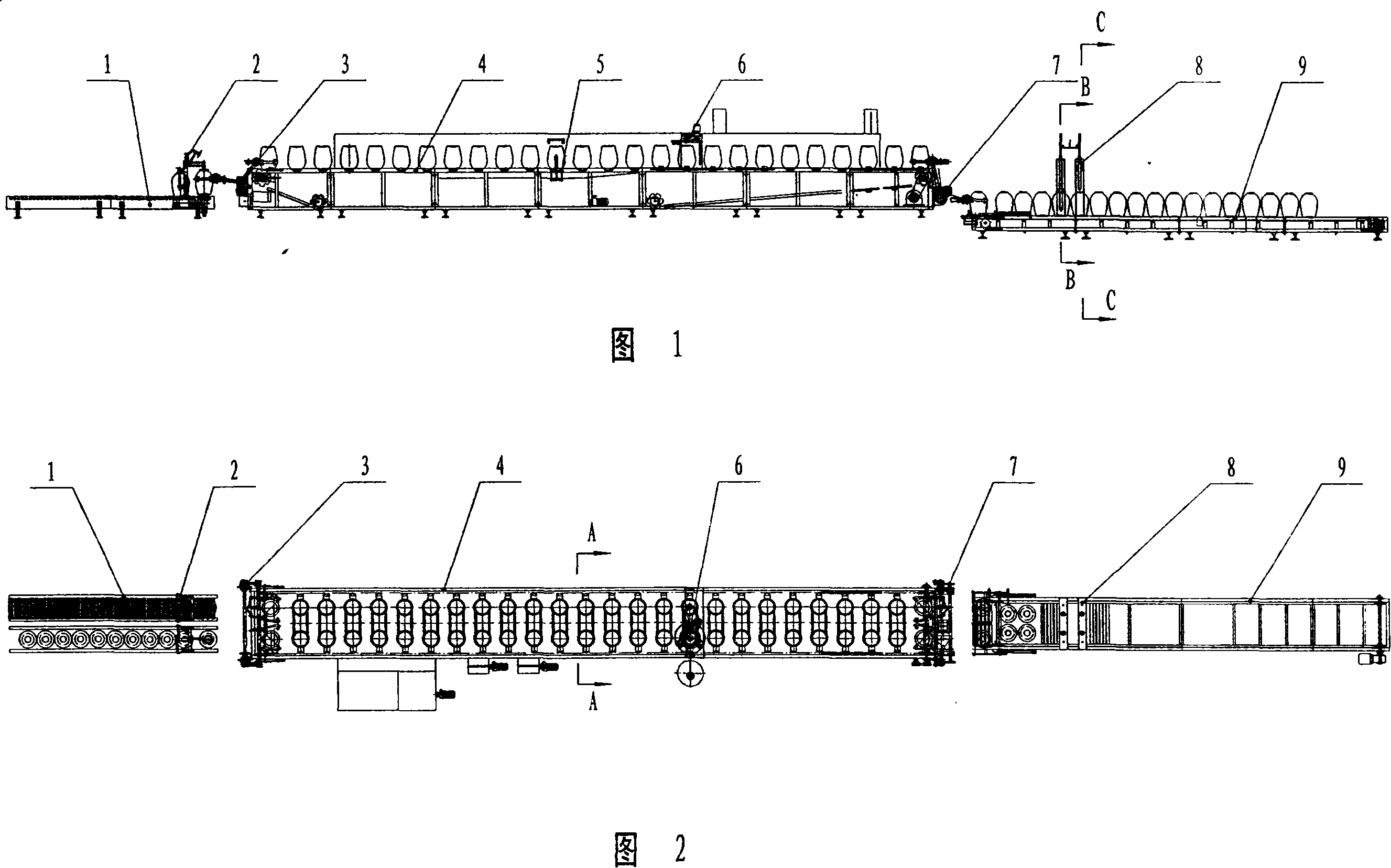

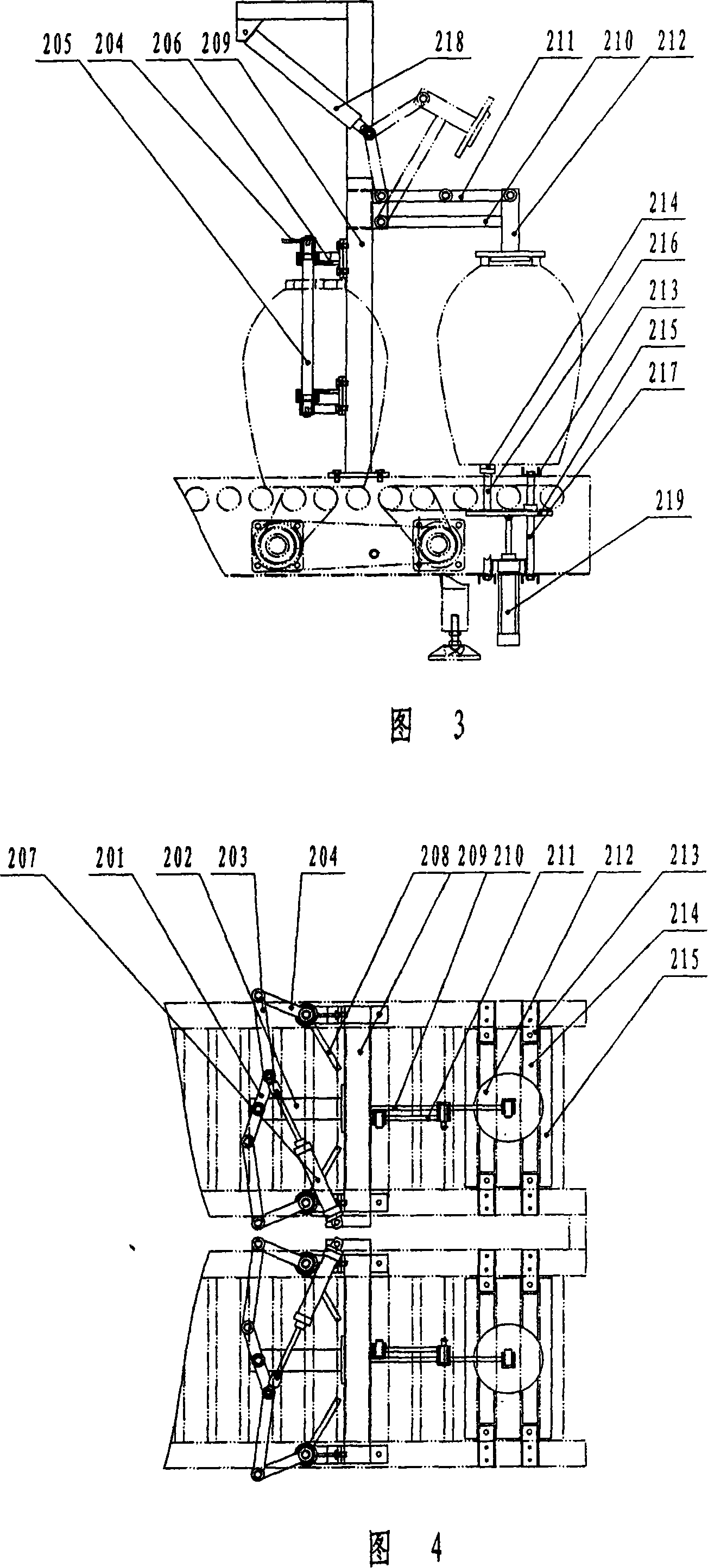

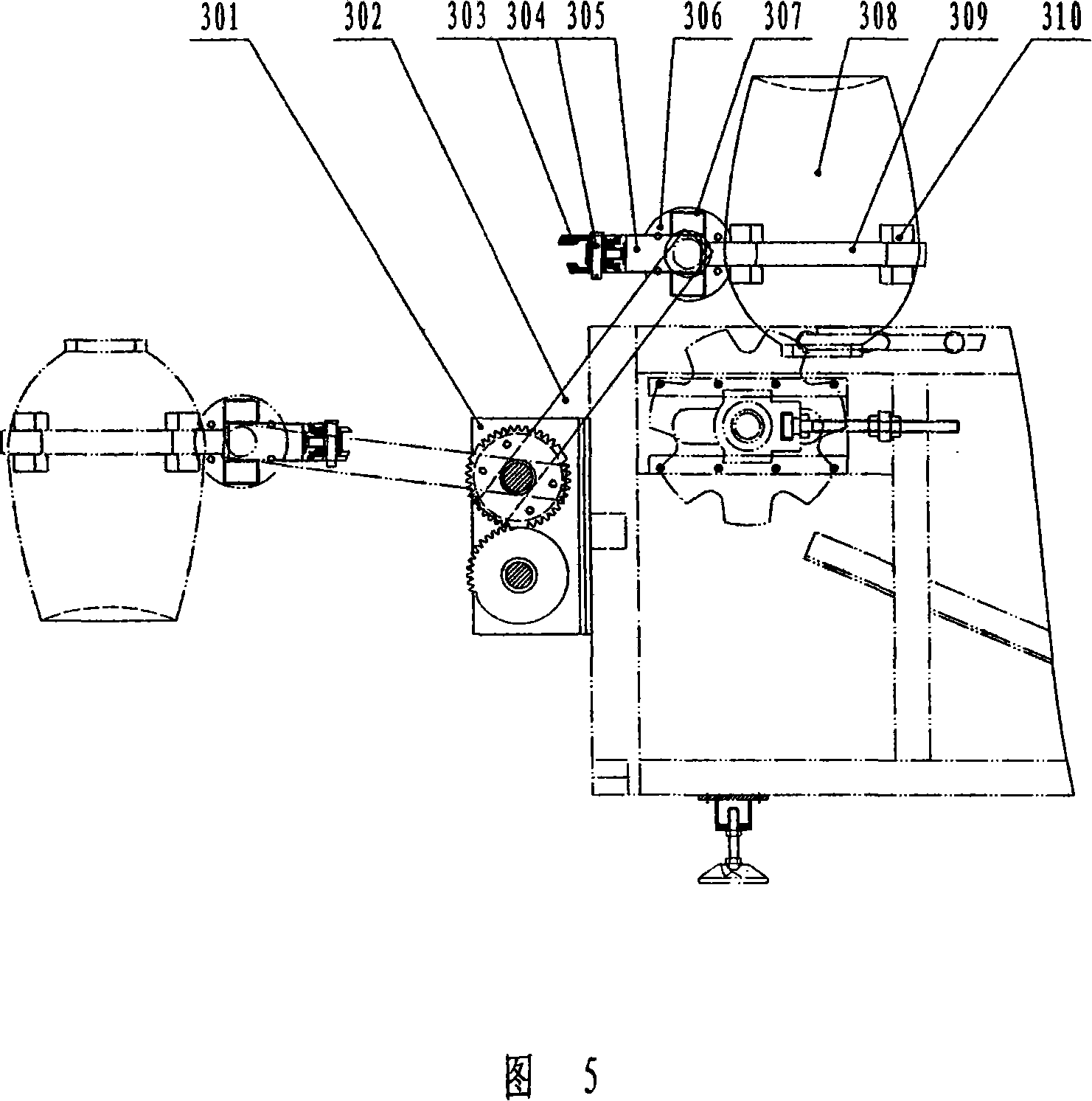

Wine crock cleaning and filling machine set

ActiveCN101125635AAchieving Pipeline OperationsContinuous productionBottle-handling machinesAutomatic controlLimewater

The invention provides an oinochoe washing filling machine unit, which is used for the mechanization package of the jarred wine, comprising a jar transmission mechanism, a positioning mechanism, a washing mechanism, a limewater brushing mechanism and a filling mechanism; wherein, the transmission mechanism is provided with a first transmission machine, a second transmission machine and a third transmission machine; wherein, the first transmission machine is provided with the positioning mechanism; a first manipulator is arranged between the first transmission machine and the second transmission machine, while a second manipulator is positioned between the second transmission machine and the third transmission machine; moreover, the second transmission machine is provided with the washing mechanism and the limewater brushing mechanism, and the third transmission machine is provided with the filling mechanism; whereas, a motor, an air cylinder, an electromagnetic valve, a vacuum valve and a steam heater and a photoelectric detector which are related in the mechanisms are all connected with an electronic automatic control system. The invention automatically complete a mechanism manner of the processes of washing jars in different shapes, brushing limewater and filling wine, further realizes an operation line and a continuous production, thereby improving the production efficiency and saving a large amount of labor as well as releasing the labor intensity.

Owner:象山恒大机械制造有限公司 +1

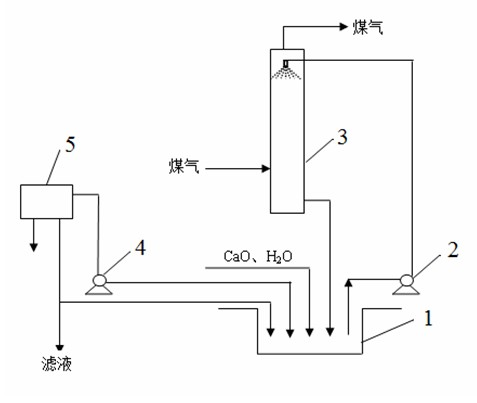

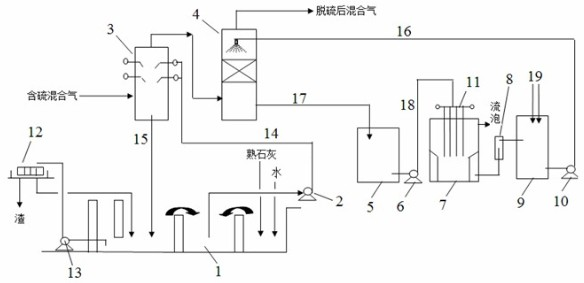

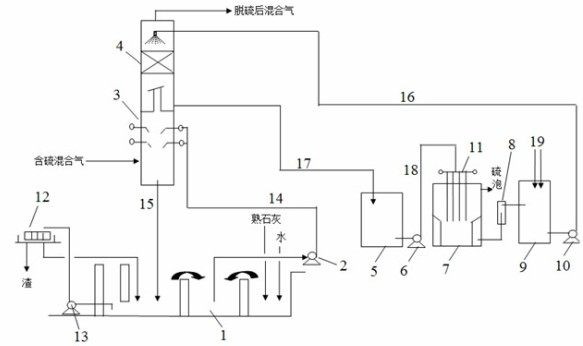

Method and device for synchronously removing H2S, CO2 and SO2 from sulfur-containing mixed gas

InactiveCN102120135APrevent bringing inFully contactedDispersed particle separationBy chemical separationProduct gasTower

The invention discloses a method and a device for synchronously removing H2S, CO2 and SO2 from a sulfur-containing mixed gas. The method comprises: firstly, removing the CO2 and SO2 in the mixed gas by using lime water solution and separating out precipitates; secondly, removing the H2S and the small amount of residual CO2 and SO2 by using caustic soda solution, and reacting in the presence of a catalyst; and finally, converting the H2S into sulfur bubble product. The special device comprises a combined washing tower, a lime water circulating tank, a caustic soda solution circulating tank, a filter, an enriched liquid tank, a regeneration tower, a liquid level regulator and other equipment. In the invention, the sulfur dioxide and carbon dioxide are removed first, then the hydrogen sulfide is removed, the alkaline solution used for removing the hydrogen sulfide is solution of sodium hydroxide, and the sodium hydroxide forms sodium carbonate after the carbon dioxide is absorbed so the absorbing capacity is improved.

Owner:江苏中显集团有限公司

Method for preparing concentrated sugarcane juice

ActiveCN101985666AQuality assuranceGuarantee quality and safetySugar juice boiling/evaporationSugar juice purificationChemical reactionPhosphate

The invention discloses a method for preparing concentrated sugarcane juice. In the traditional method for preparing the concentrated sugarcane juice, phosphoric acid and lime water are added after sugarcane is squeezed into juice to generate a chemical reaction to generate phosphate, so that impurities are precipitated out from the sugarcane juice. The concentrated sugarcane juice prepared by the traditional method is deep in color, reddish and astringent due to the residual phosphate radical and lime water in the sugarcane juice and enzyme and pigment in the sugarcane. In the method, any additives and other chemical medicaments are not added in the preparation process, so the quality safety of products is guaranteed, the nutrient and the flavor of the sugarcane juice are maintained to the utmost extent, the concentrated sugarcane juice prepared by the method has good color and luster and rich flavor and is fresh, sweet and delicious, and the problem that the concentrated sugarcane juice is off-color and has bad mouthfeel for a long time due to the influence of the pigment, the enzyme, the lime and the phosphoric acid is solved.

Owner:TIANYE INNOVATION

Organic rice cultivating method

InactiveCN104521493AImprove qualityGreat tasteCultivating equipmentsPlant cultivationFarmyard manureHardness

The invention discloses an organic rice cultivating method which includes the steps: firstly, drying and selecting seeds, eliminating blighted grains and injured seeds, removing impurities and tares (seeds), soaking and sterilizing the seeds by the aid of limewater with the concentration of 1% for 2-3 days, and eliminating seed soaking by the aid of chemical agents in the whole process; flatly preparing and treating soil, plowing a bed surface to reach more than 10cm, uniformly spreading thoroughly decomposed farmyard manure and the like in a field to fertilize nursery soil, and mixing the farmyard manure into 5-10cm seedbed soil; performing seeding and planting. The bed surface is flat, fine and free of large-grain soil and root remains, and the usage of the farmyard manure is 7.5-10.0kg / m<2>. By the method, pollution-free high-quality rice can be provided for numerous consumers, and is excellent in quality, better in taste, regular in grain shape, white in color, high in transparency, proper in hardness, high in stickiness and rich in various amino acids, vitamins and rare selenium elements need by human bodies.

Owner:FOSHAN CITY GAOMING DISTRICT JINHE TOWNSHIP AGRI DEV CO LTD

Cultivation of prawn by sodium chloride I-shaped saline-alkali water

The invention is concerned with the method that uses sodium chloride I type of saline water to breed prawn, includes the prawn seed, the culture pond with sand and mud, the fertilizer water, the bait casting, and the increasing oxygen for water, the characteristic is: uses sodium chloride I type water as the breeding water, the temperature of the water is 18 centigrade to 34 centigrade, the salinity is 0.5 per mill to 40 per mill , the pH value is 7.6 to 8.6, the alkalinity of the carbonate is under 10me / L; sterilizes the breeding pond by calces; filters the inputting water by the 60 bolting silk; the seedling quantity is 60 thousand to 90 thousand per hectare; puts the industrial calcium chloride in the pond every ten days when the pH value of the water quality is under 8.6, namely 75 - 120 kg per hectare; puts the industrial hydrochloric acid in the pond when the alkalinity of the carbonate is over 10me / L, namely 150 - 300 kg per hectare, puts 50 kg calcium chloride in the pond next day.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Corrosion-resistant concrete for salty environment, and manufacturing method and construction technique thereof

InactiveCN103626457ADevelop and maintain strengthSimplify the construction processCement productionSlagSalt content

The invention discloses a corrosion-resistant concrete for salty environment, and a manufacturing method and construction technique thereof. The salty environment is salty soil of which the salt content is 1-30 wt% and the water content is 20-150 wt%, or a brine environment of which the salinity is 10-500 g / L. The concrete is prepared from slag, light-calcined magnesium oxide, lime, water, aggregate and mineral admixture. Under the interactions among the components of the concrete and between the concrete and salts in the salty environment, the method ensures the concrete to solidify, harden, produce and develop in the salty environment and to maintain the strength for a long time. The concrete can satisfy the requirements of constructions and components for strength and durability when being used in various salty environments, including salty soil and brine.

Owner:BEIHANG UNIV

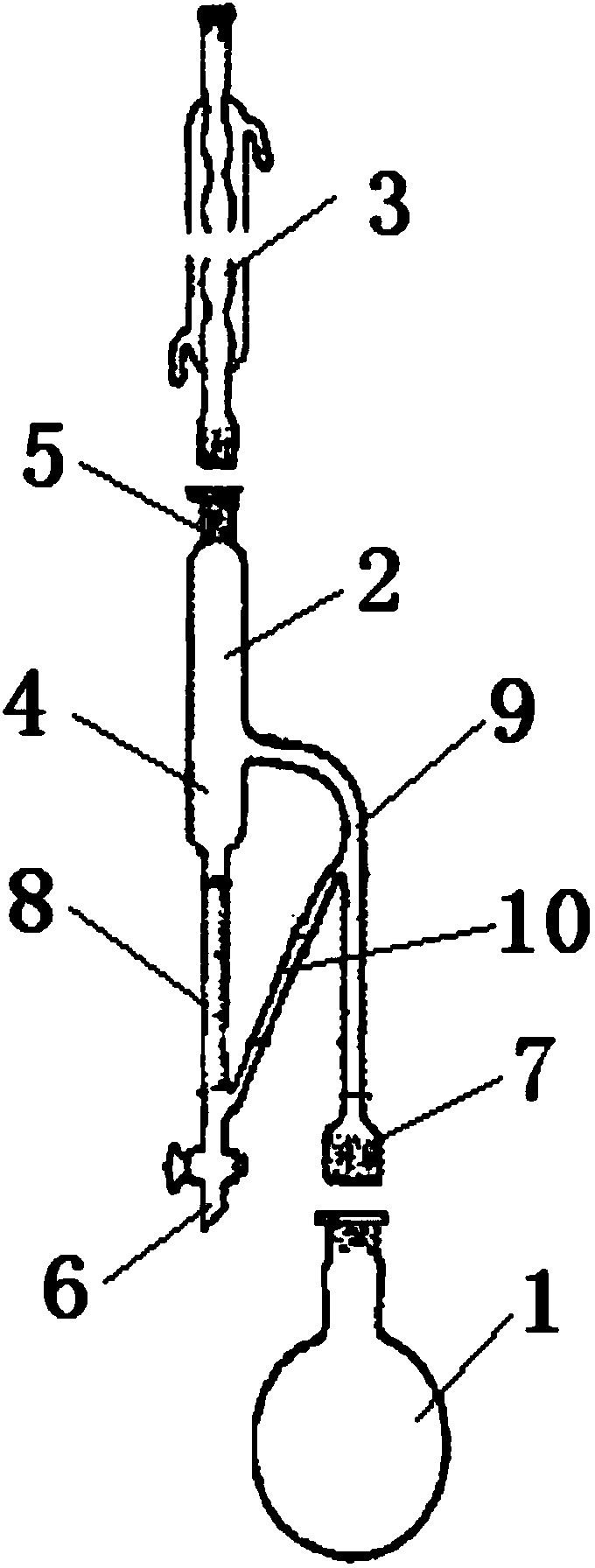

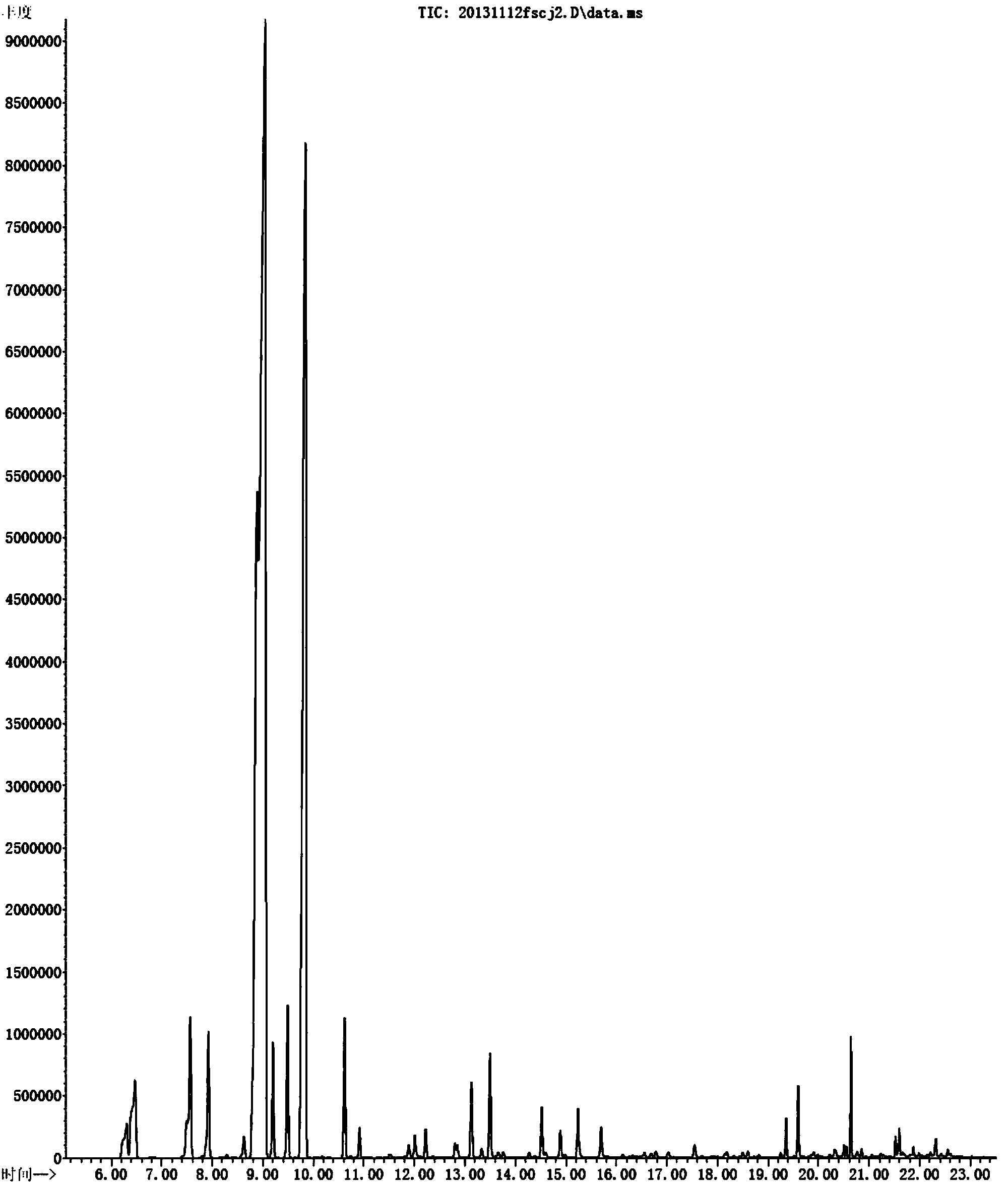

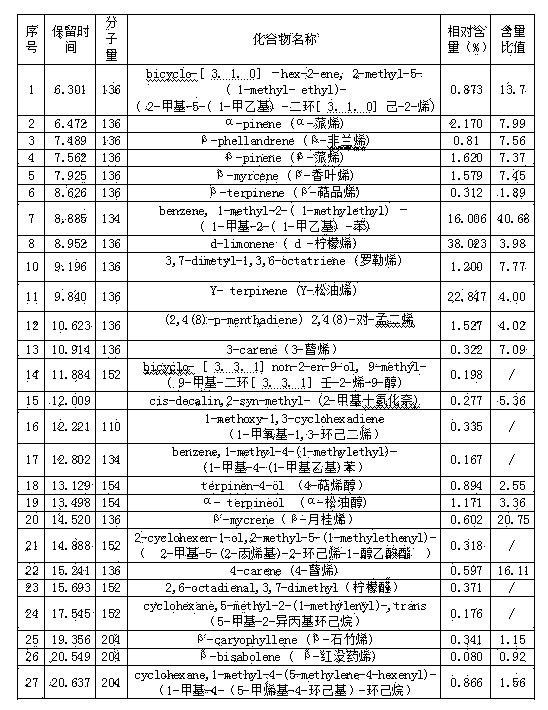

Method for extracting essential oil from fresh bergamot and application of essential oil in cigarettes

InactiveCN103952239AOvercome the shortcomings of low precision and difficult separation of emulsificationVarious ingredientsTobacco treatmentEssential-oils/perfumesPulp and paper industryEnvironmental engineering

Owner:CHINA TOBACCO ZHEJIANG IND

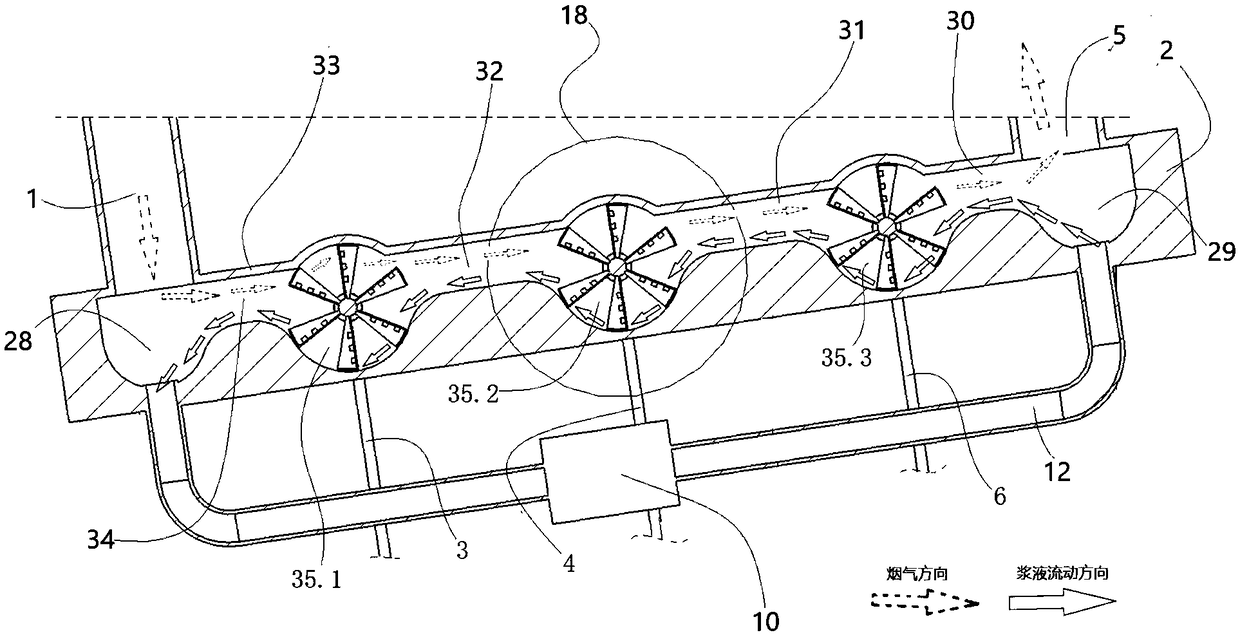

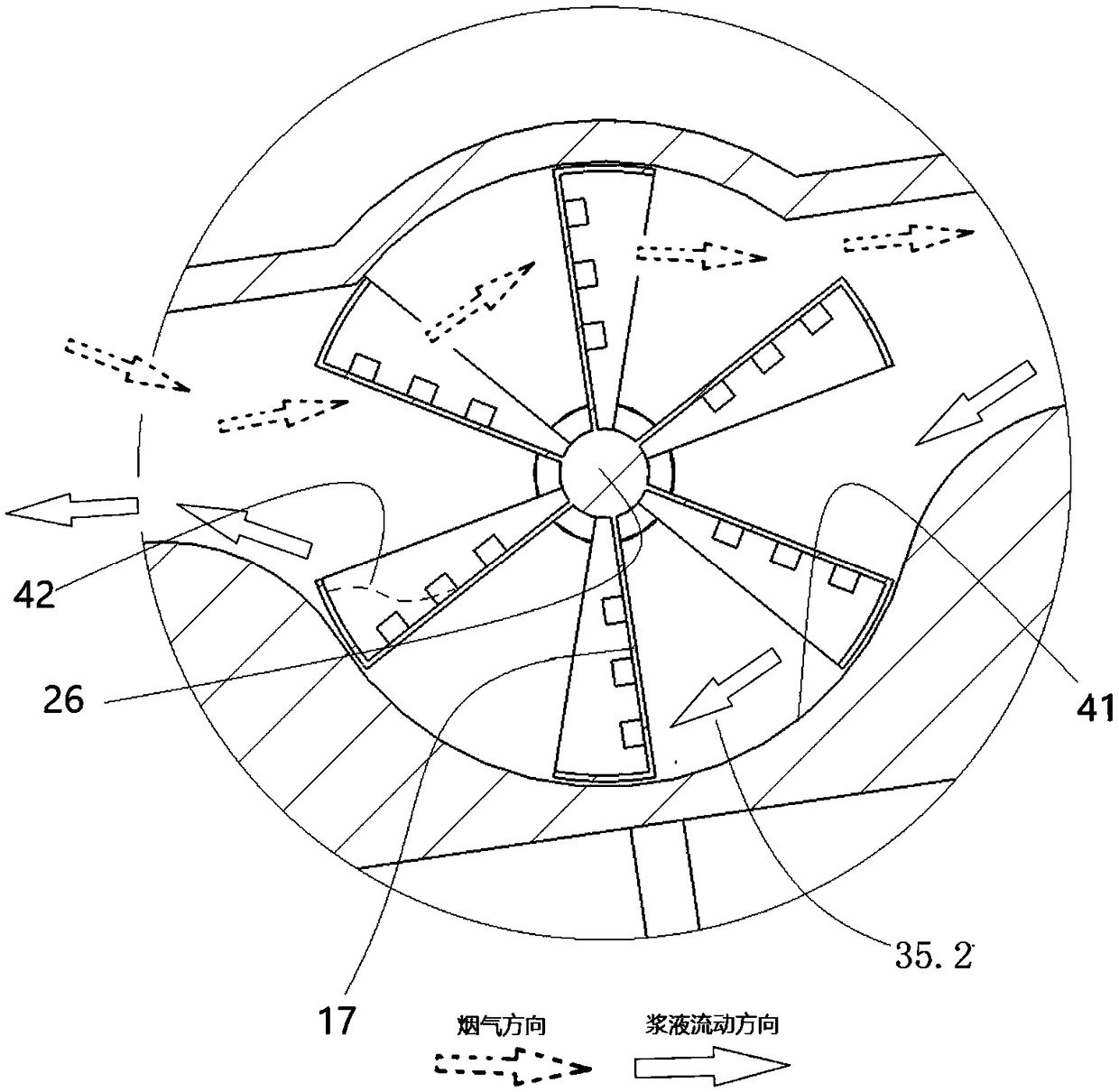

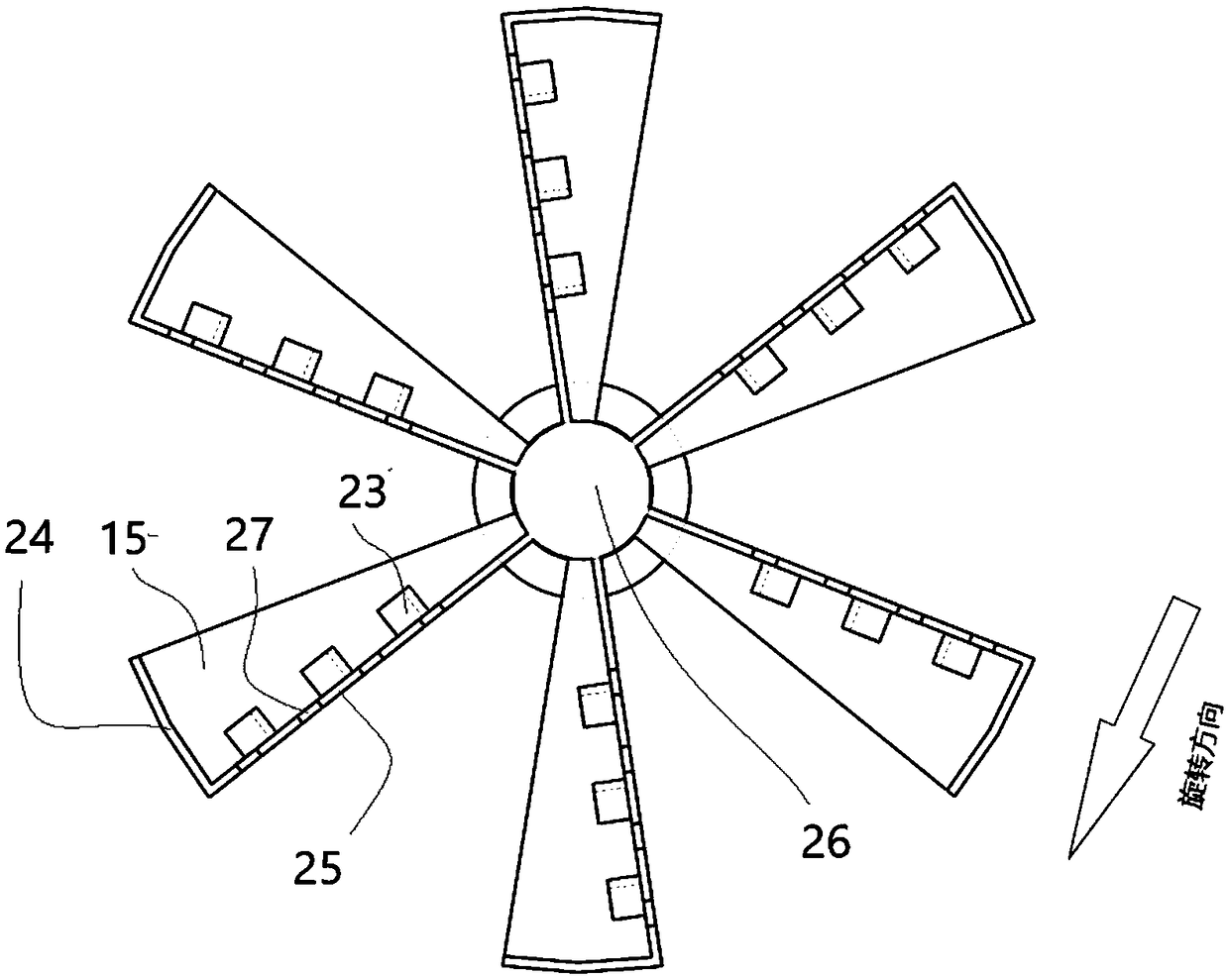

Flue gas desulfurization apparatus and desulfurization method thereof

ActiveCN109351169AAchieve absorptionSimple structureGas treatmentDispersed particle separationImpellerEngineering

The invention discloses a flue gas desulfurization apparatus, comprising a desulfurization tank which is of inclined rectangular tank structure. A desulfurization inclined passage as inclined as the desulfurization tank is arranged in a tank body of the desulfurization tank; the inclined lower end of the desulfurization inclined passage is provided with a low liquid-storing trough; all desulfurizing stirring blades above liquid levels in a first desulfurizing blade-wheel rotation chamber, a second desulfurizing blade-wheel rotation chamber and a third desulfurizing blade-wheel rotation chamber, and a plurality of hollow desulfurizing holes are continuously wetted by a slurry; flue gas is continuously wetted by the lime slurry at the hollow desulfurizing holes when passing through the hollow desulfurizing holes; sulfur dioxide is mixed in water to form sulfurous acid; the sulfurous acid reacts with calcium carbonate in the lime slurry to generate calcium sulfite; therefore, sulfur dioxide in the flue gas is absorbed.

Owner:胜利油田华胜电业建筑有限责任公司

Pawpaw candied fruit and preparation method thereof

InactiveCN101199311AThe production process is reliableWith whiteningConfectionerySweetmeatsPapaya familyBitter taste

The invention is a papaya preserve and the method of preparation. The papaya preserve uses papaya as a material, wherein, the invention comprises 75-150 parts of papaya; 60-90 parts of white granulated sugar; 0.25-0.4 part of citric acid and 1-5 parts of lime. The materials are washed selectively during preparation and are removed of peel and seed, then the materials are taken out for drying water after chopping the materials; the materials are put into limewater for being rinsed and de-limed by clean water after soaking so as to remove the bitter taste of lime, and the materials are taken out from water and dried; the treated papaya is put into a can and is poured with the granulated sugar for preparing hot sugar liquid and citric acid which are soaked in the raw sugar liquid; the materials are boiled with sugar again for two times and then the papaya is taken out for being dried of sugar liquid; and the invention is finished by baking and packaging. The invention has advantages of reliable making process and sweet and delicious taste, and has effects of whitening, beauty treatment and freckle removing.

Owner:TIANJIN POLYTECHNIC UNIV

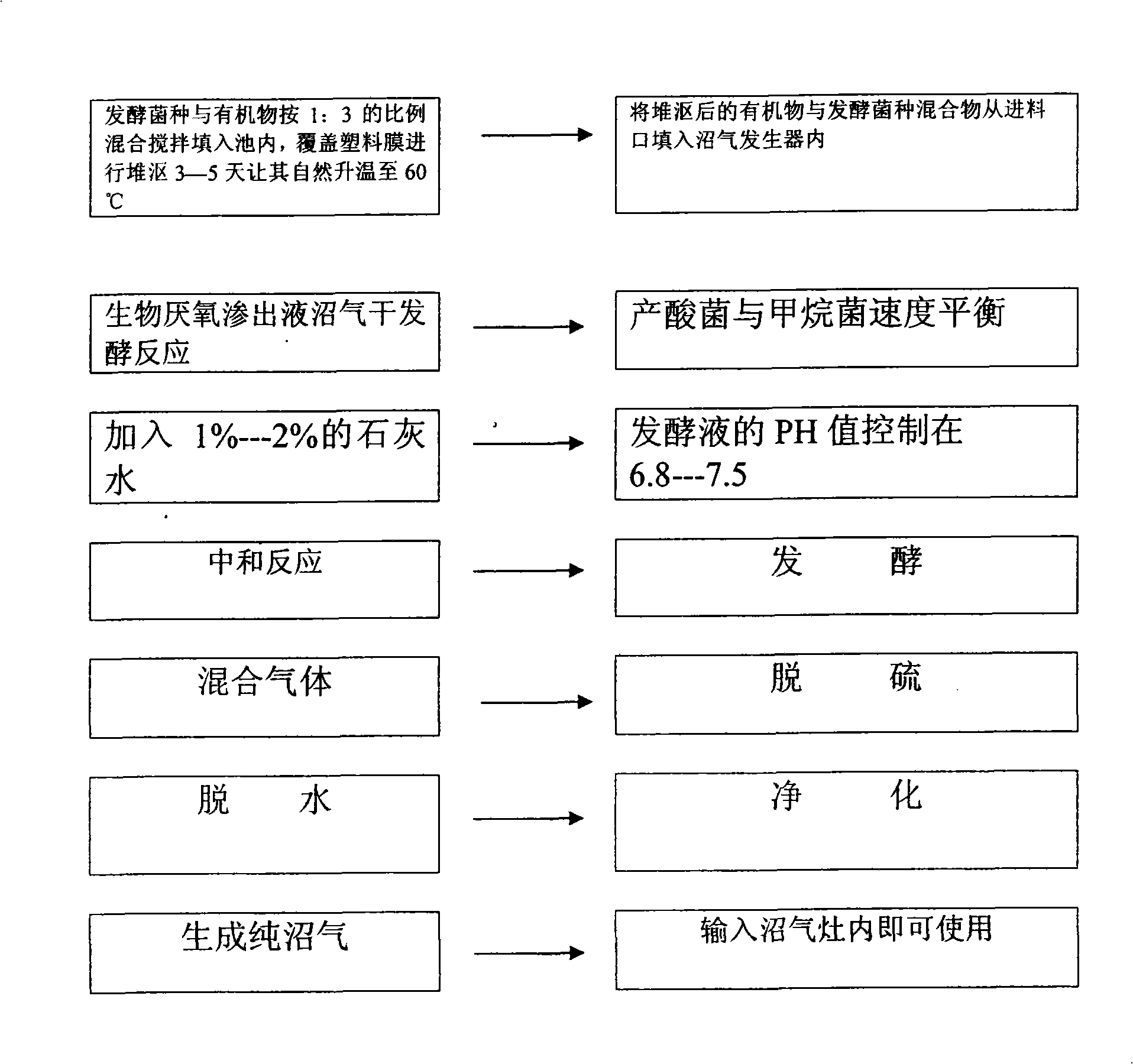

Method for preparing bio anaerobic effusion methane by dry fermentation

InactiveCN101337757ALess energy consumptionIncrease gas productionBio-organic fraction processingWaste based fuelBiotechnologyAnaerobic bacteria

The invention relates to a method which utilizes organisms of straws, chicken manure, cattle manure, pig manure, sheep manure and horse manure to mix and agitate with zymogeneous bacteria. The method comprises the following steps: firstly filling the organisms in a ground pool, covering the upper part of the organisms for 3 to 5 days by using a plastic film; then refilling the organisms in a marsh gas generator after the temperature is up to 60 DEG C; adding 1 to 2 percent of limewater, so as to neutralize organic acid generated; controlling the pH value to be within 6.8 to 7.5, so that acid-producing bacteria and methane bacteria are subjected to the dry fermentation of anaerobic exudate and marsh gas; after the speed is balanced, generating anaerobic bacteria, and generating mixed gas; and generating pure march gas after the mixed gas is desulfurized, dehydrated and purified. The gas production amount of the organisms per kilogram averagely reach 0.35m<3>, the gas production rate averagely is 0.398m<3>. The method is widely applied to cooking and illuminating in a family.

Owner:李明华

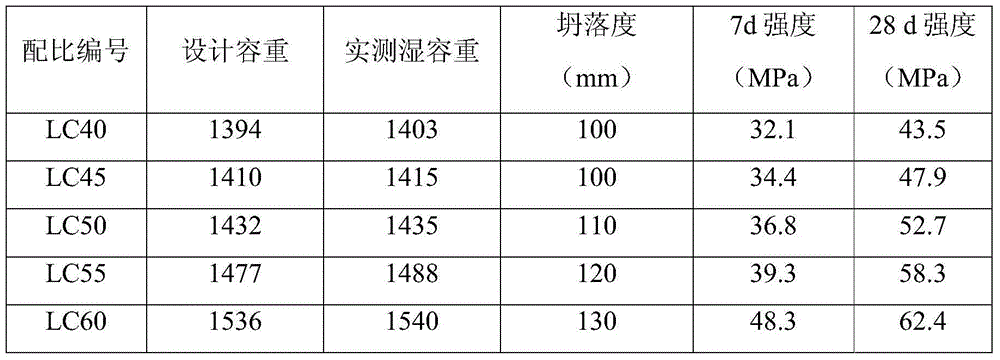

High-strength and high-durability lightweight aggregate concrete and preparation method thereof

The invention discloses high-strength and high-durability lightweight aggregate concrete and a preparation method thereof, and relates to lightweight aggregate concrete. Each cubic meter of concrete comprises the following raw materials by weight: 200-380kg of cement, 150-250kg of silica fume, 650-750kg of 5-15mm ceramsite, 180-240kg of water and 4-10kg of a polycarboxylate superplasticizer. The preparation method comprises the following steps: firstly, soaking shale-sintered lightweight ceramisite in saturated limewater, fishing out ceramisite floating on the surface, and reserving the settled ceramisite for later use; respectively weighing the settled ceramisite, the silica fume, the cement, the polycarboxylate superplasticizer and water according to the ratio for later use; adding the settled ceramisite to a stirrer to stir in advance; adding the cement and the silica fume to the stirrer to stir in advance, and then stopping the stirrer; starting the stirrer; firstly adding water which accounts for 1 / 3 of the total amount to the running stirrer, stirring, and simultaneously adding the rest water and the polycarboxylate superplasticizer to the specified amount; and further stirring until mixing evenly, so as to obtain the high-strength and high-durability lightweight aggregate concrete.

Owner:建发合诚工程咨询股份有限公司 +1

Vetiver substrate for culturing edible mushrooms

InactiveCN101830757AExtended absorption timeWide variety of sourcesFertilizer mixturesChrysopogon zizanioidesEdible mushroom

The invention discloses a vetiver substrate for culturing edible mushrooms, which can comprehensively replace main raw materials for culturing the edible mushrooms, such as floristic chestnuts, cotton seed hulls, wheat straws and the like, comprises a main component of vetiver and is prepared by the following steps: drying, crushing and soaking to wet with limewater the vetiver, adding accessories and other materials into the wet vetiver, filling the mixture into sterilizing bags for sterilization, and performing cooling, sterilization, inoculation, mushroom formation, color change, debagging and fruiting management. The substrate radically develops a derived valuable channel for turning waste into wealth for the long-term development of the vetiver, and ecologically, reduces timber harvesting rate in response to the appeal of the state, simultaneously solves the problem that mushroom farmers cannot bear big bulge in the prices of the conventional substrates, such as the cotton seed hulls, and increases the yield of the edible mushrooms due to the close texture of the vetiver.

Owner:南阳天冠种业有限公司

Polyvinyl alcohol saturated limewater expansive soil conditioner, preparation method and application thereof

InactiveCN101851515AImprove permeabilityMeet engineering application requirementsBuilding constructionsExcavationsLimewaterChemistry

The invention discloses an expansive soil conditioner, which is solution prepared by polyvinyl alcohol and saturated limewater according to a certain weight ratio; and the preparation method comprises the following steps: taking the polyvinyl alcohol and the saturated limewater according to the certain weight ratio, doping an appropriate amount of anhydrous ethanol, heating the mixture in a water bath, fully stirring, dissolving the polyvinyl alcohol in the limewater, placing in the water bath for a certain time, and taking supernatant liquid which is used as the conditioner of the saturated limewater solution of the polyvinyl alcohol; and spraying the conditioner on the surface of dry expansive soil, carrying out the second spraying of the conditioner after the surface of the expansive soil is dry and carrying out a plurality of times of spraying of the conditioner in such way, thereby forming a surface conditioning layer with a certain thickness and eliminating or reducing expansion and contraction properties of a coil body in the conditioning layer; and the test result shows that the free expansion ratio of the expansive soil which is taken out from 90cm to the soil surface is reduced from the original 50 to 27 through the free expansion test, thereby meeting the requirement of engineering construction.

Owner:HOHAI UNIV

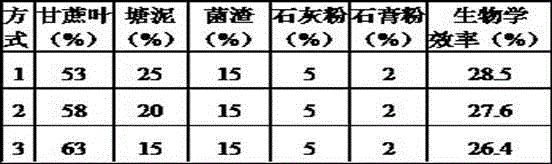

Method for preparing straw mushroom cultivation material from sugarcane leaf blades and sugarcane leaf tips

The invention relates to a straw mushroom cultivation material. The straw mushroom cultivation material is characterized by taking sugarcane leaf blades and sugarcane leaf tips as main raw materials and taking pond sludge, mushroom dreg, lime powder, gypsum powder and the like as adjuvants, wherein the moisture content of the cultivation material is 60-62%. The invention further relates to a method for preparing the cultivation material. The method has the advantages that sugarcane leaves and sugarcane tips are subjected to sunlight exposure, limewater pre-wetting and ventilated composting and fermentation, so that macromolecular substances, such as crude fibers and the like, are decomposed into simple substances which are conducive to the absorption of straw mushroom mycelia, and the growth of the straw mushroom mycelia is promoted; the cultivation material is reasonable in proportioning ratio and balanced in nutrition, so that the growth vigor of straw mushrooms is good, the yield is high, and the biological efficiency reaches 26.4-28.5%; not only is a solution for the innocent treatment of sugarcane leaves provided, but also a novel matrix for cultivating the straw mushrooms is found.

Owner:邬方成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com