Waste water circulating and reusing process for starch processing

A technology for wastewater recycling and starch processing, which is applied in the fields of neutralization water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of secondary pollution and large equipment investment, and achieve water saving, low investment and operation. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

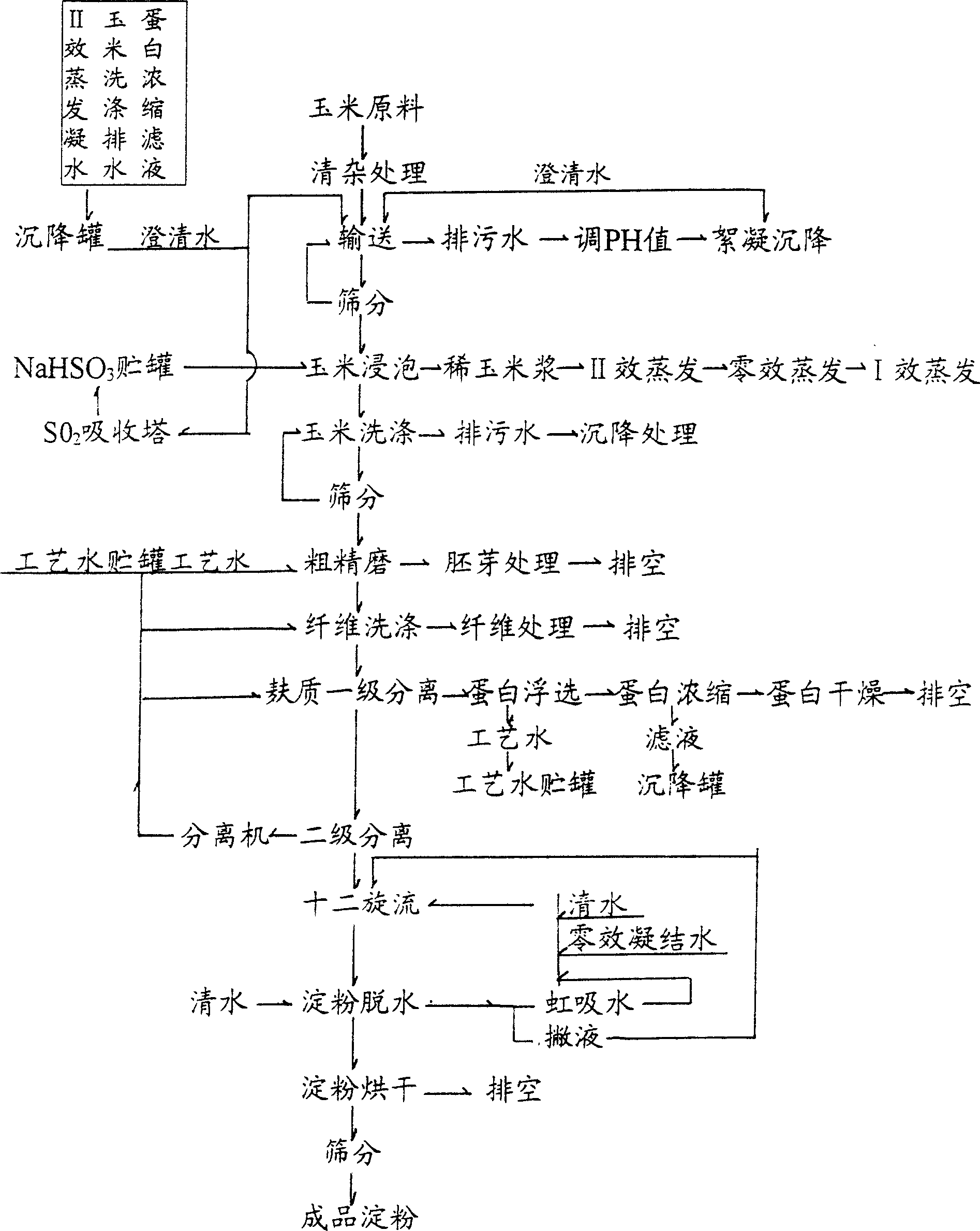

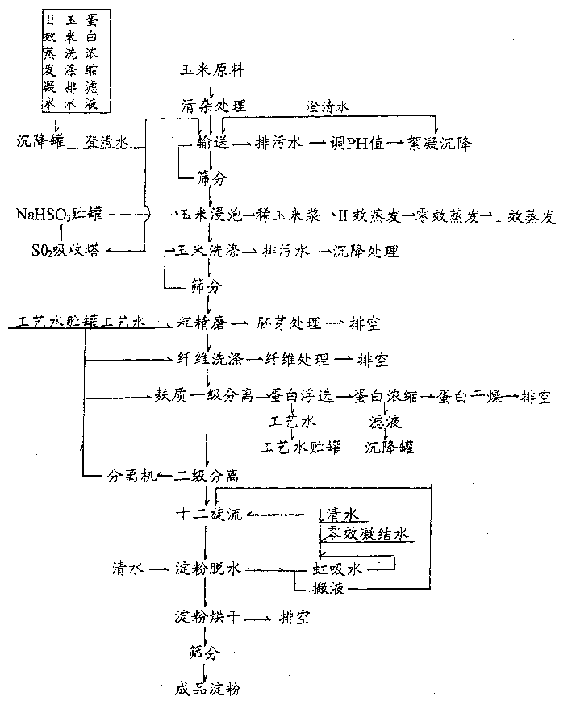

[0016] The entire process is shown in the figure. After the corn is cleaned of impurities, it is sent to the foaming workshop with water for foaming. There is a gravity sieve on the foaming tank for screening. After the pH value of the water is adjusted to 5.0-5.2, it is flocculated and settled by the settler, and the clarified water is recycled for transportation of corn. The water used in the foaming workshop is mainly for acid production, and the acid production uses process water to make sodium bisulfite to soak corn, which does not affect the soaking effect and saves energy wasted due to heating of clean water. After soaking, dilute corn steep liquor is subjected to three-effect evaporation, the water vapor generated by corn steep liquor evaporation and the secondary steam used for evaporating corn steep liquor are fully recycled, the condensed water of second-effect evaporation is sent to the settling tank, and the condensed water of zero-effect evaporation is sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com