Patents

Literature

1038 results about "Electro-slag remelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroslag remelting (ESR), also known as electro-flux remelting, is a process of remelting and refining steel and other alloys for mission-critical applications in aircraft, thermal power stations, nuclear power plants, military technology, etc.

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

Anticorrosion, wear-resistant plastic die steel 4Cr16Mo and its mirror large-die-block preparing and producing method

ActiveCN1676653AImprove lateral performanceMeet mirror polishing requirementsHeat treatment process controlProcess efficiency improvementChemical compositionWear resistant

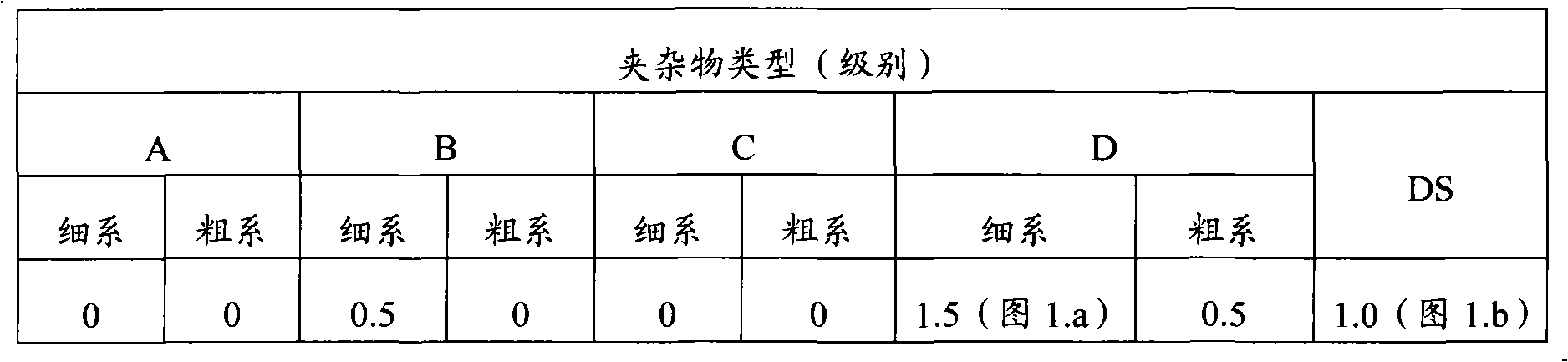

It is a new preparation and production method of corrosion-resistant and anti-abrasive plastic die steel 4Cr16Mo and its big mirror module. The characteristic is about its chemical composition. There are 0.33-0.43%C, 0.30-1.00%Mn, 0.30-1.00%Si, less than 0.045%S, less than 0.045%P, 14-18%Cr, 0.10-1.00%Ni, 0.80-1.50%Mo besides Fe. The method includes double refinement consisting of the primer smelting in electric furnace and vacuum handling outside the furnace and electroslag remelting, and necessary stress relieving annealing static ingot and electroslag ingot to refine electroslag ingot of component-uniform. After that, it uses hot machining forging technology and necessary stress relieving annealing of module to make the electroslag ingot into big module (thickness: 500mm, width:1200mm, length: 2500mm). At last, special heat-treat module modified treatment technology is used to bring out big highly corrosion-resistant and highly anti-abrasive plastic die steel module. This kind of module has stable quality and the nature reaching the standard(dirty component A<=2.0, B<=2.0, C thinness<=2.0, C thickness<=1.5, D<=2.0). To sum up, it has significant economic and social efficiency.

Owner:宝武特种冶金有限公司

Ultra pure electroslag remelting method for high-performance corrosion resistant alloy

ActiveCN102912151AImprove performanceImprove organizationIncreasing energy efficiencyCorrosion resistant alloySolution treatment

The invention relates to an ultra pure electroslag remelting method for a high-performance corrosion resistant alloy, and the method comprises the following steps of: preparing the following ingredient components of a self-fluxing electrode bar in parts by weight: 25-34 parts of Ni, 25-29 parts of Cr, 2.5-4.5 parts of Mo and 30-45 parts of Fe, and carrying out vacuum induction melting, so as to obtain the self-fluxing electrode bar; slowly melting the self-fluxing electrode bar in melted electroslag remelting slag charge comprising the following components in parts by weight: 55-80 parts of CaF2, 5-25 parts of CaO, 5-15 parts of Al2O3 and 5-10 parts of MgO, purifying, and recrystallizing in a crystallizer, so as to obtain an electroslag ingot; and forging the electroslag ingot into a bar material at the temperature of 1130+ / -5 DEG C, and carrying out solution treatment, so that the high-performance corrosion resistant alloy is obtained. By utilizing the ultra pure electroslag remelting method provided by the invention, the content of harmful elements such as sulphur and phosphorus in the alloy can be reduced, the impurity distribution of the alloy is improved, fining of structure can be facilitated, and the hot workability and yield of the alloy can be improved.

Owner:CHONGQING MATERIALS RES INST

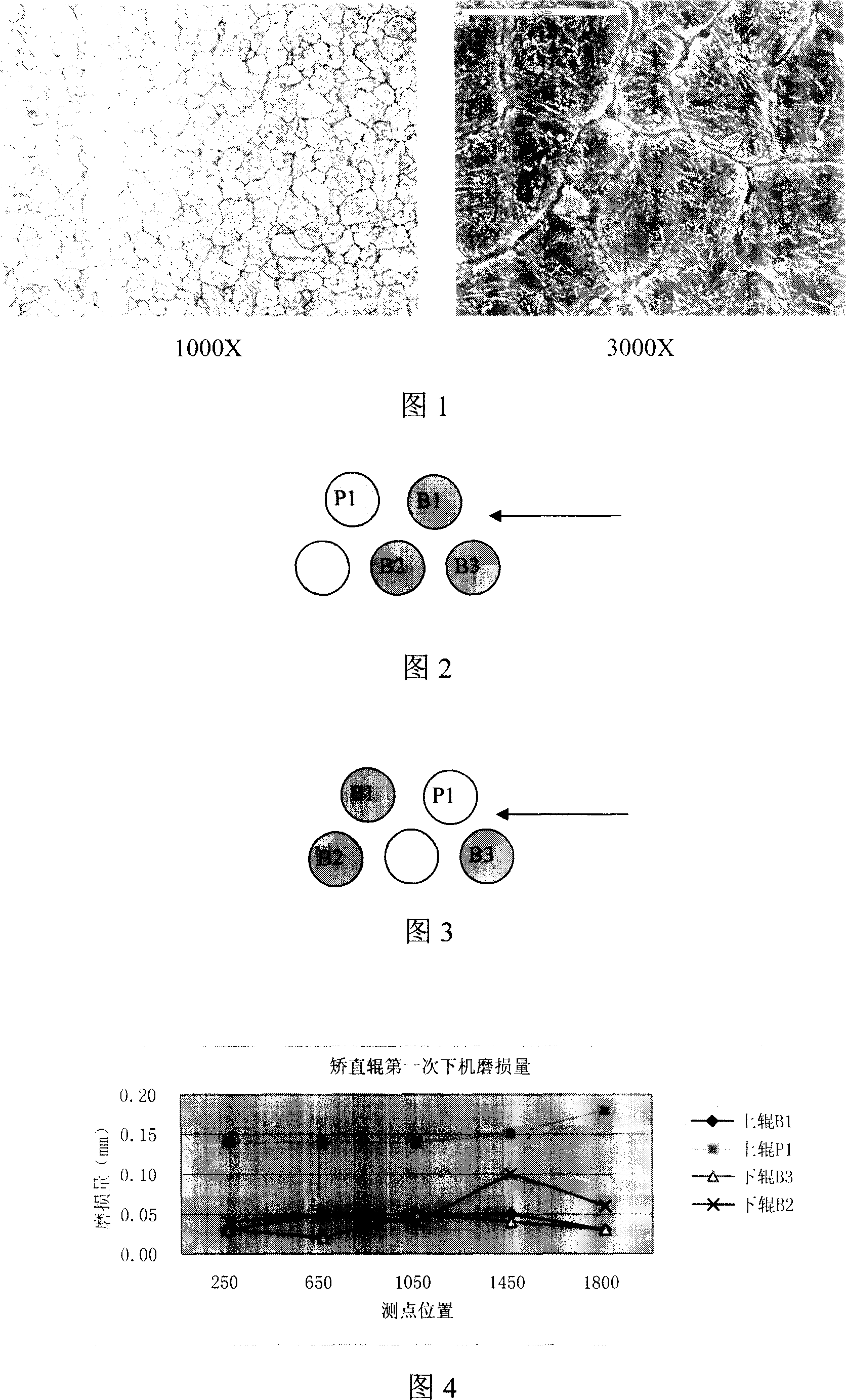

Leveler roll and manufacturing process thereof

ActiveCN101153377AReduce contentChange sizeIncreasing energy efficiencyFurnace typesStrip steelMachining

The invention relates to a straightening roll and the manufacturing process thereof, wherein, the composition of the roll includes 0.60wt percent to 1.10wt percent of C, 0.20wt percent to 1.0wt percent of Si, 0.20wt percent to 0.60wt percent of Mn, 0.20wt percent to 1.00wt percent of Ni, 4.00wt percent to 6.00wt percent of Cr, 0.20wt percent to 1.00wt percent of Mo, 0.10wt percent to 0.50wt percent of V, less than or equal to 0.02wt percent of P, less than or equal to 0.02wt percent of S and the rest, Fe and other inevitable impurities; the manufacturing process of the roll includes: electric furnace smelting to secondary refining to ingot casing to electrode rolling to electrode rough machining to electroslag remelting to ingot casing to hydrogen diffusion annealing to forging to conditioning treatment to ultrasonic flaw detection and microscopic and macroscopic test to rough machining to quenching and tempering heat treatment to semifinishing to final heat treatment to finish machining to finished product. The invention increases the service life of the straightening roll and the surface quality of strip steel and eliminates the bottleneck in straightening high strength plate during production.

Owner:BAOSHAN IRON & STEEL CO LTD

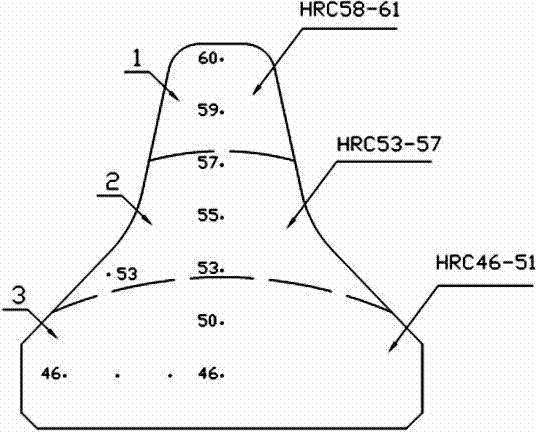

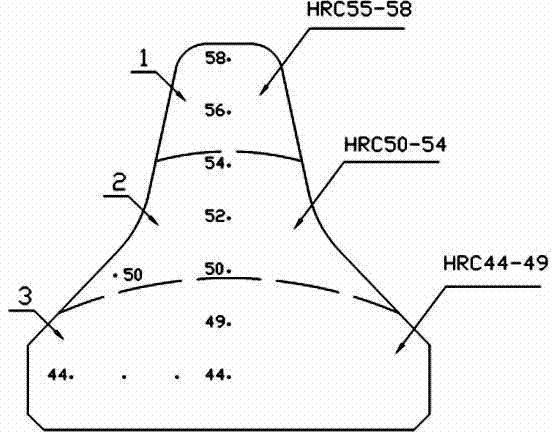

Disk-shaped roller cutter ring and manufacture method thereof

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

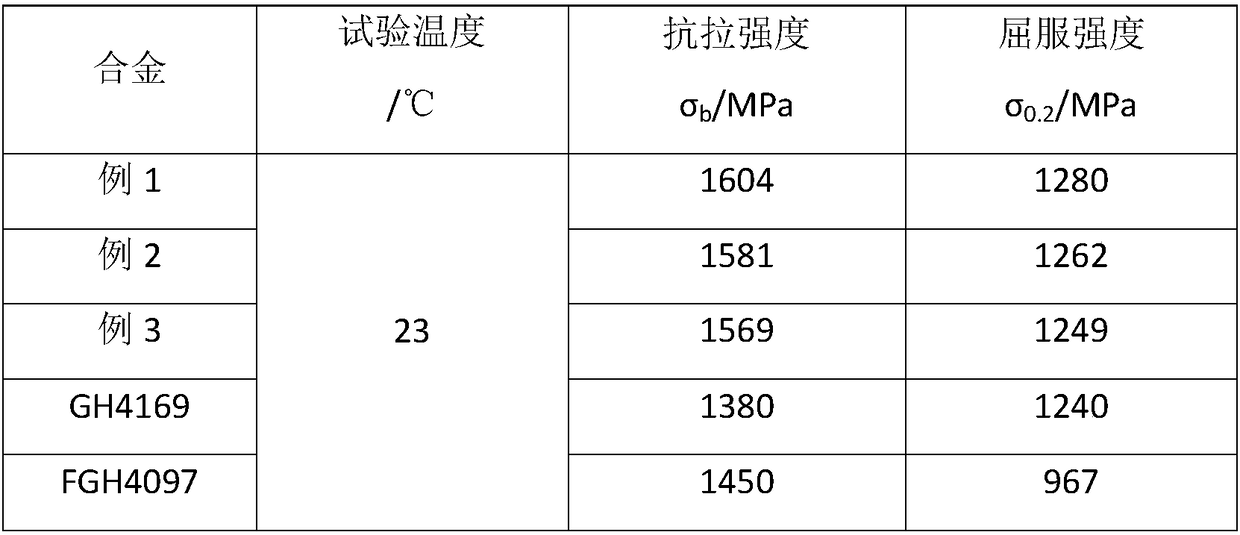

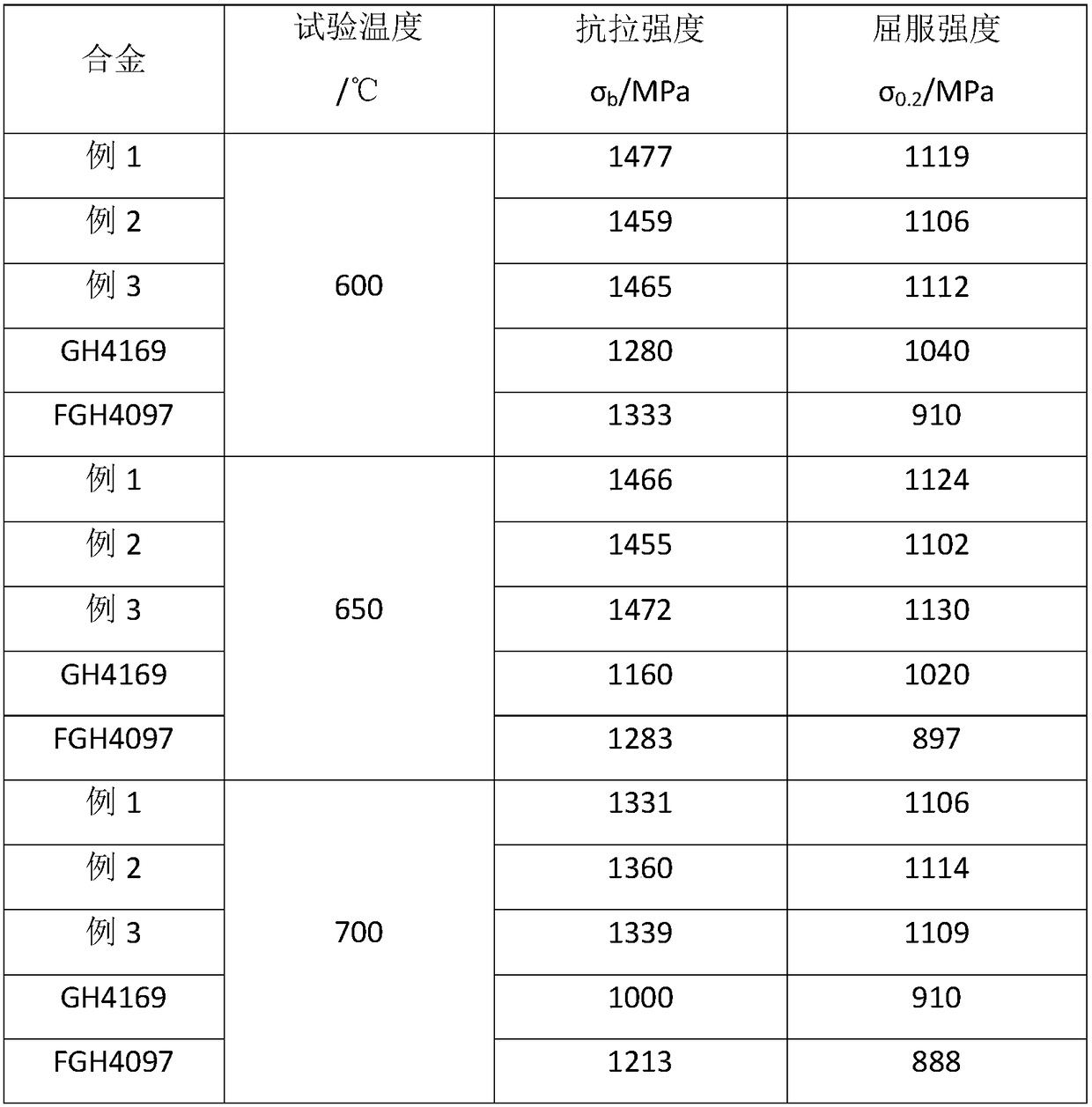

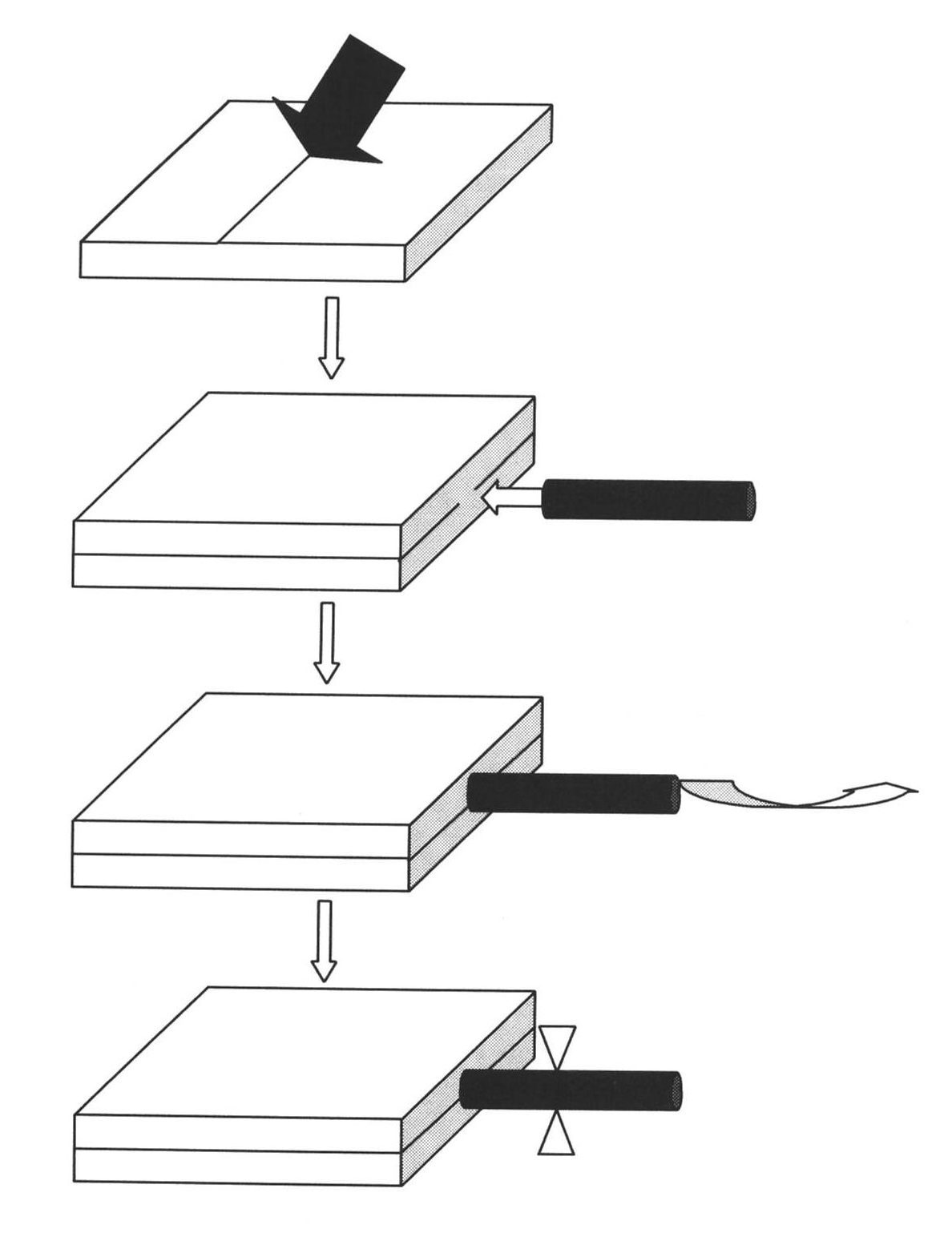

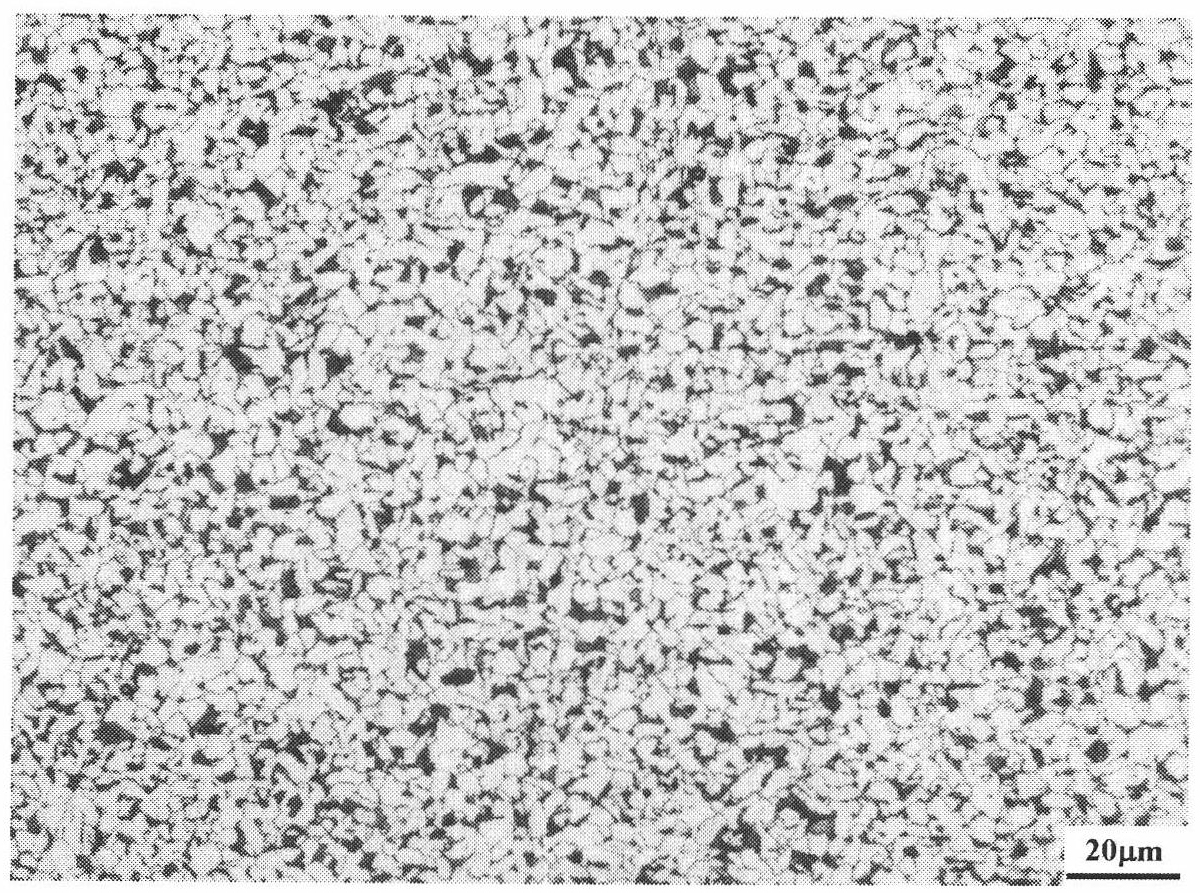

High-intensity nickel based wrought superalloy and preparation method thereof

ActiveCN108441705AHigh room temperature tensile strengthImprove heat strengthIncreasing energy efficiencyHigh intensityElectro-slag remelting

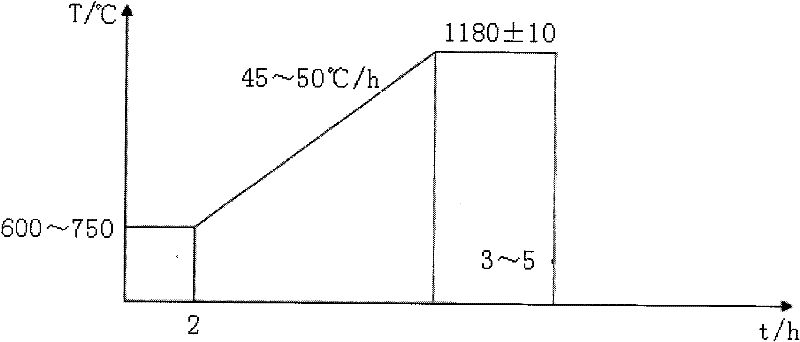

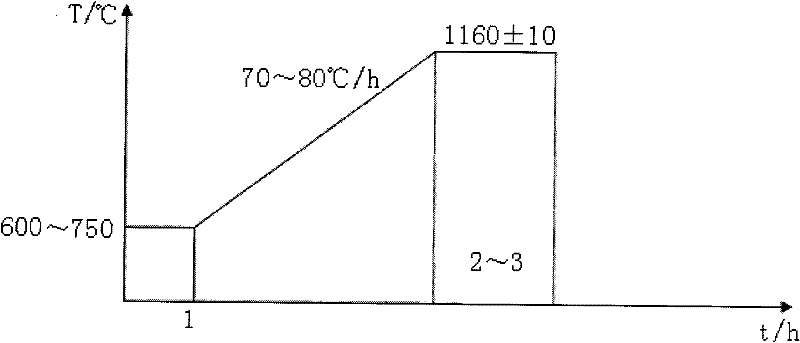

The invention belongs to the technical field of nickel based wrought superalloy, and particularly relates to a high-intensity nickel based wrought superalloy and a preparation method thereof. The high-intensity nickel based wrought superalloy comprises the following main elements in percentage by mass: 10.0-25.0% of Cr, 10.0-20.0% of Co, 0.1-6.0% of Mo, 0.1-6.0% of W, 0.1-6.0% of Al, 0.1-6.0% of Ti, 0.05-1.5% of Nb, 0.1-2.0% of Fe, 0.001-0.10% of C, 0.001-0.05% of B, 0.01-0.1% of Zr, 0.001-0.10% of Ce, 0.001-0.10% of Mg, 0.01%-0.5% of Hf, and the balance Ni and inevitable impurity elements. The preparation method comprises the steps of preparing a high-purity cast ingot by vacuum induction smelting, electroslag remelting and vacuum self-consumption remelting; performing high-temperature diffusion to uniformly anneal the cast ingot under the temperature ranging from 1170-1190 DEG C; heating the annealed cast ion to reach the temperature of 1130-1160 DEG C, maintaining the temperature for 2-4h; then forging the cast ingot into a bar as required through a quick forging press, and thermally processing a bar sample to obtain the alloy material meeting the design demand.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

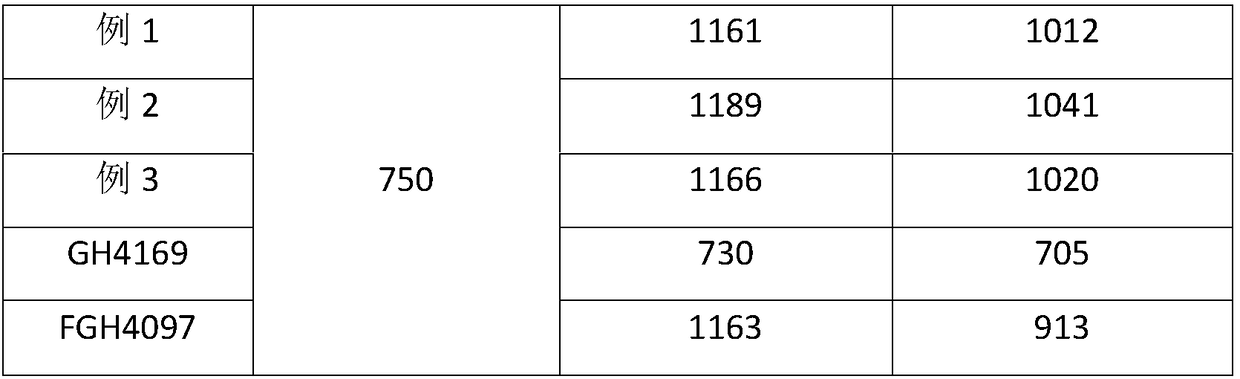

Method for producing super-thick plate by packrolling welding process

InactiveCN102009332AAvoid difficultiesImprove internal qualityNon-electric welding apparatusThick plateEngineering

The invention discloses a method for producing a super-thick plate by a packrolling welding process, which mainly comprises the steps of: cutting the continuously cast blank, cleaning surface of the blank blocks, aligning and overlaying the blank blocks in same size, welding the surrounding of the combined surface after the blank blocks are fastened, vacuumizing the combined gaps, sealing and finally hot rolling. The hot rolling accumulation rolling reduction is controlled within 40% to 70%. Compared with the traditional super-thick plate production method, the invention has the advantages that the blank blocks are from the continuously cast blank so that the quality of the blank is better than a mould ingot and the production efficiency is better than that of the blank produced by electroslag remelting, the processing cost is low, and the production efficiency is high; and the invention has low requirements on the equipment and is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

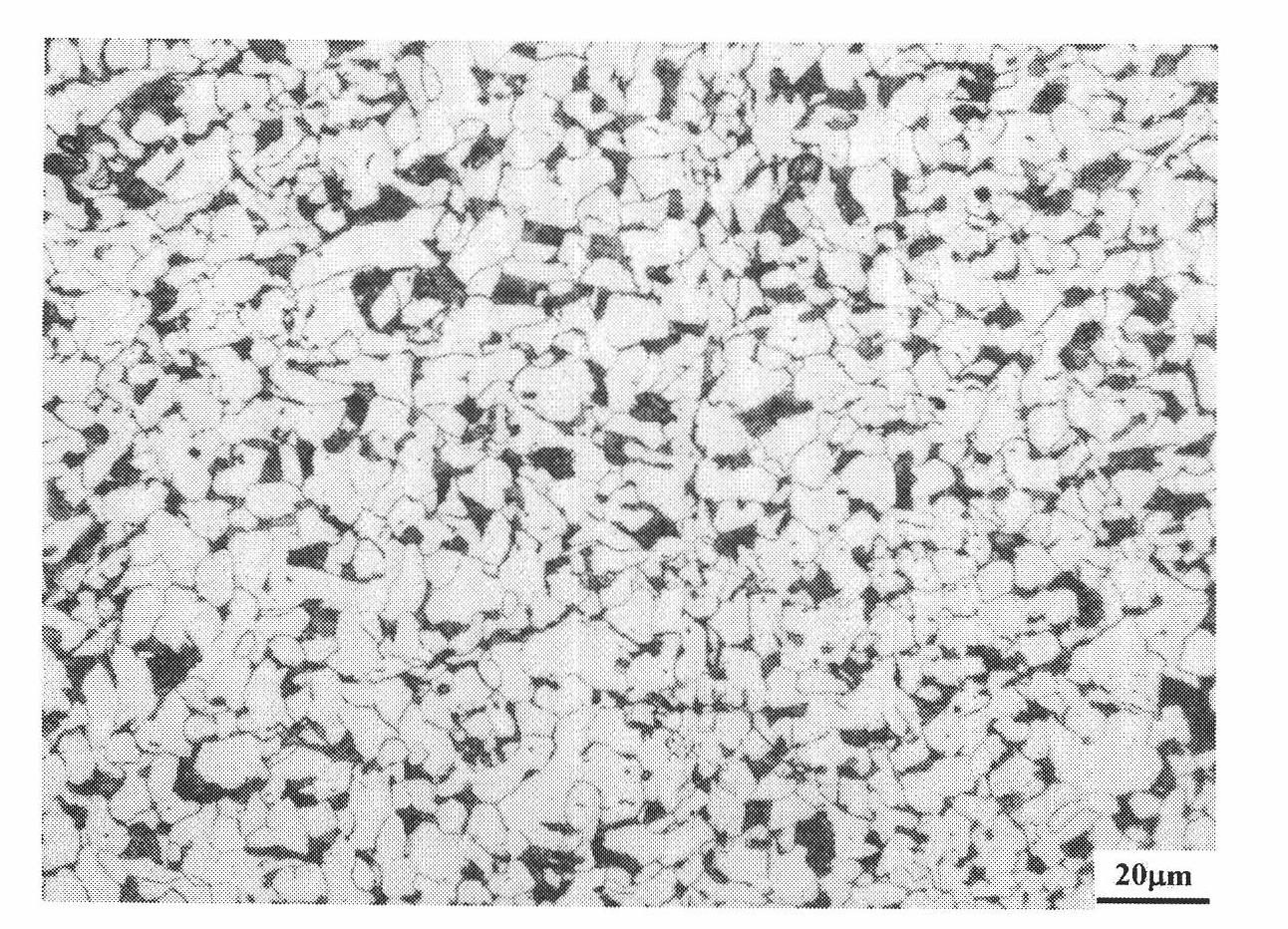

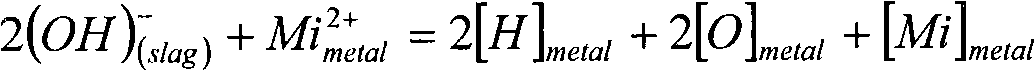

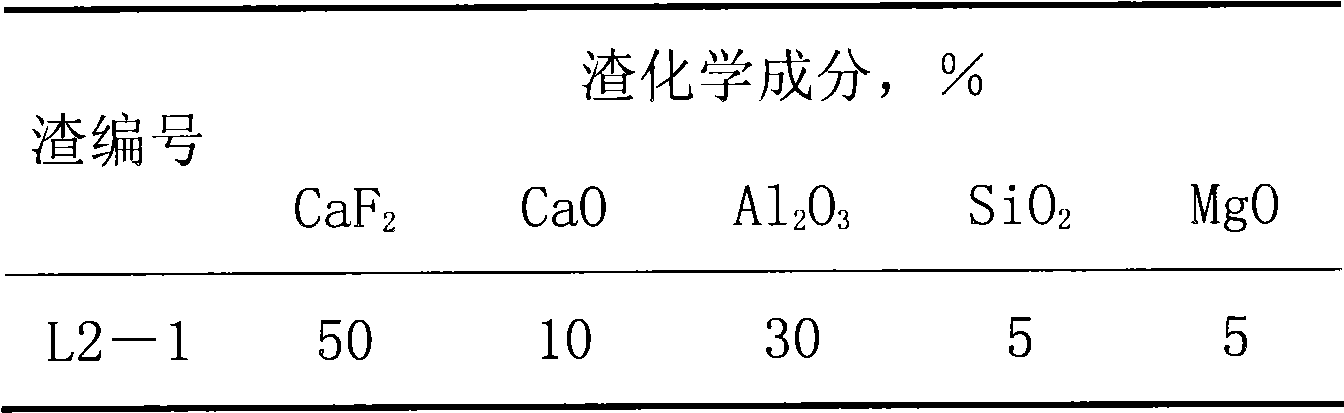

Electroslag remelting slag system with low hydrogen permeability, preparation method and using method thereof

The invention discloses an electroslag remelting slag system with low hydrogen permeability, and a preparation method and a using method thereof. The slag system is prepared from the following chemical compositions in percentage by weight: 45 to 50 percent of CaF2, 10 to 15 percent of CaO, 30 to 35 percent of Al2O3, 5 to 10 percent of SiO2, and 5 to 10 percent of MgO, wherein the MgO is adopted toreplace partial CaO. The preparation method is to crush the compositions into particles after melting, and bake the particles. The using method adopts pre-melting slag and argon protection to carry out electroslag remelting. Compared with the prior art, the slag system and the methods have the advantages that: the slag system has low hydrogen permeability, can effectively reduce the hydrogen content in steel in the remelting initial stage to ensure that the hydrogen content in the steel in the normal remelting stage is maintained at a lower level, and the hydrogen content in the remelted steel is less than 1.5ppm.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Novel manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel

ActiveCN102418042AImprove cleanlinessImprove segregationMetal-working apparatusProcess efficiency improvementCarbideHot working

The invention discloses a manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel, and the purpose is to solve the problems of quite severe ununiformity of large-section forging material eutectic carbides and the increase of defects of internal cracks and surface cracks during the forging process caused by segregation deterioration of cast structure carbides of large steel ingots. By using steel-making technical measures such as LF refining, VD degassing, aluminium wire feeding, and the like, the invention improves the molten steel cleanliness, the control of electroslag remelting output power, and the homogenization treatment before forging, and improves the segregation of eutectic carbides and the hot-working plasticity of steel; by controlling the forging heating numbers and various deformation amounts of large high-carbon high-chromium steel ingots, large granular carbides are crushed; the ununiformity of eutectic carbides is improved; crack defects during the forging process are prevented; and the produced high-carbon high-chromium steel large-section forging materials has ununiformity of eutectic carbides of up to grade 4-grade 6; the results of ultrasonic inspection are at good levels of E / e grade, D / d grade.

Owner:FUSHUN SPECIAL STEEL SHARES

Martensite stainless steel and preparation method for flat strip of martensite stainless steel

ActiveCN102251191AHigh strengthHigh hardnessIncreasing energy efficiencySolution treatmentMartensitic stainless steel

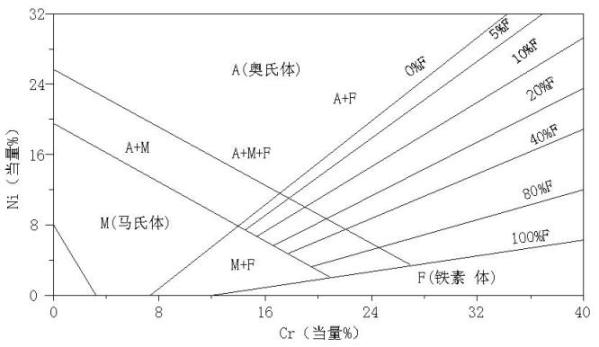

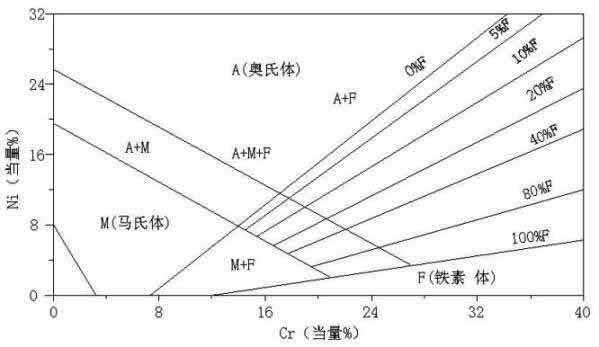

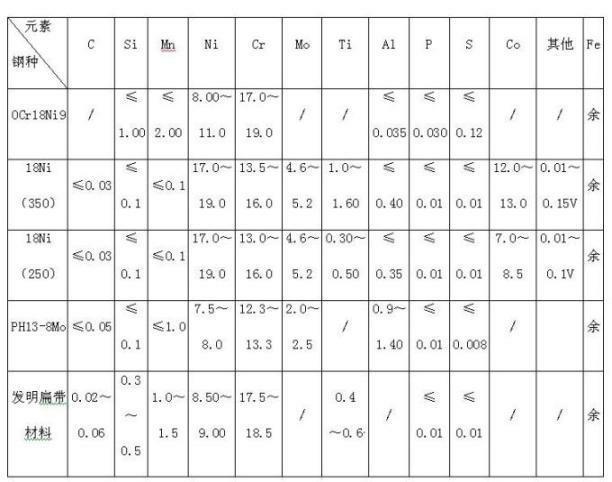

The invention discloses martensite stainless steel and preparation method for flat strips of martensite stainless steel. The martensite stainless steel comprises following chemical components by weight percentage: C 0.02 to 0.06%, Si 0.3 to 0.5%, Mn 1.0 to 1.5%, Ni 8.5 to 9.0%, Cr 17.5 to 18.5%, Ti 0.4 to 0.6%, P no more than 0.009% and S no more than 0.009%, with the balance being Fe. The preparation method for flat strips of the martensite stainless steel comprises the following steps: a) weighing above-mentioned chemical components at desired weight percentage; b) carrying out vacuum induction melting; c) carrying out casting to obtain remelt electrode bars; d) carrying out electroslag remelting to obtain steel ingots; e) forging steel ingots into billets; f) processing billets into round strips; g) carrying out solid solution treatment; h) drawing treated blanks into wires; i) preparing flat strips. According to the invention, equivalents of nickel and chromium are strictly controlled, the ratio of C to Ti and alloy elements are optimized, EVR smelting is carried out and such alloying elements as C, Si, Mn and Ti are added, thereby enabling formation of a metastable austenite structure; a predeformed phase-changed martensite wire material is obtained by wire drawing; and the ultra high strength deformed flat strips of martensite stainless steel are obtained by flat strip rolling.

Owner:CHONGQING MATERIALS RES INST

Method of manufacturing a rotating apparatus disk

InactiveUS7316057B2Semiconductor/solid-state device detailsSolid-state devicesDeposition processVacuum arc remelting

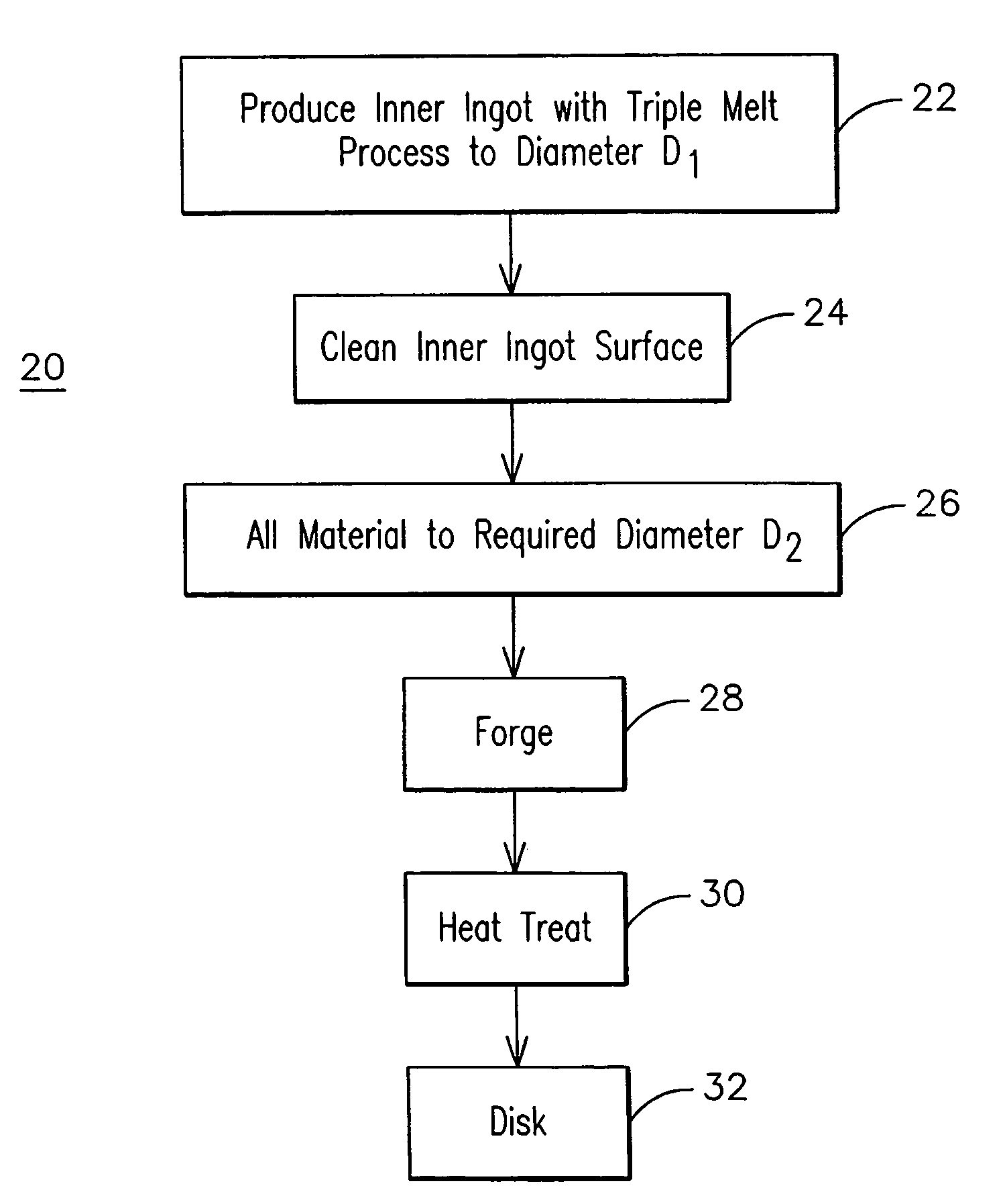

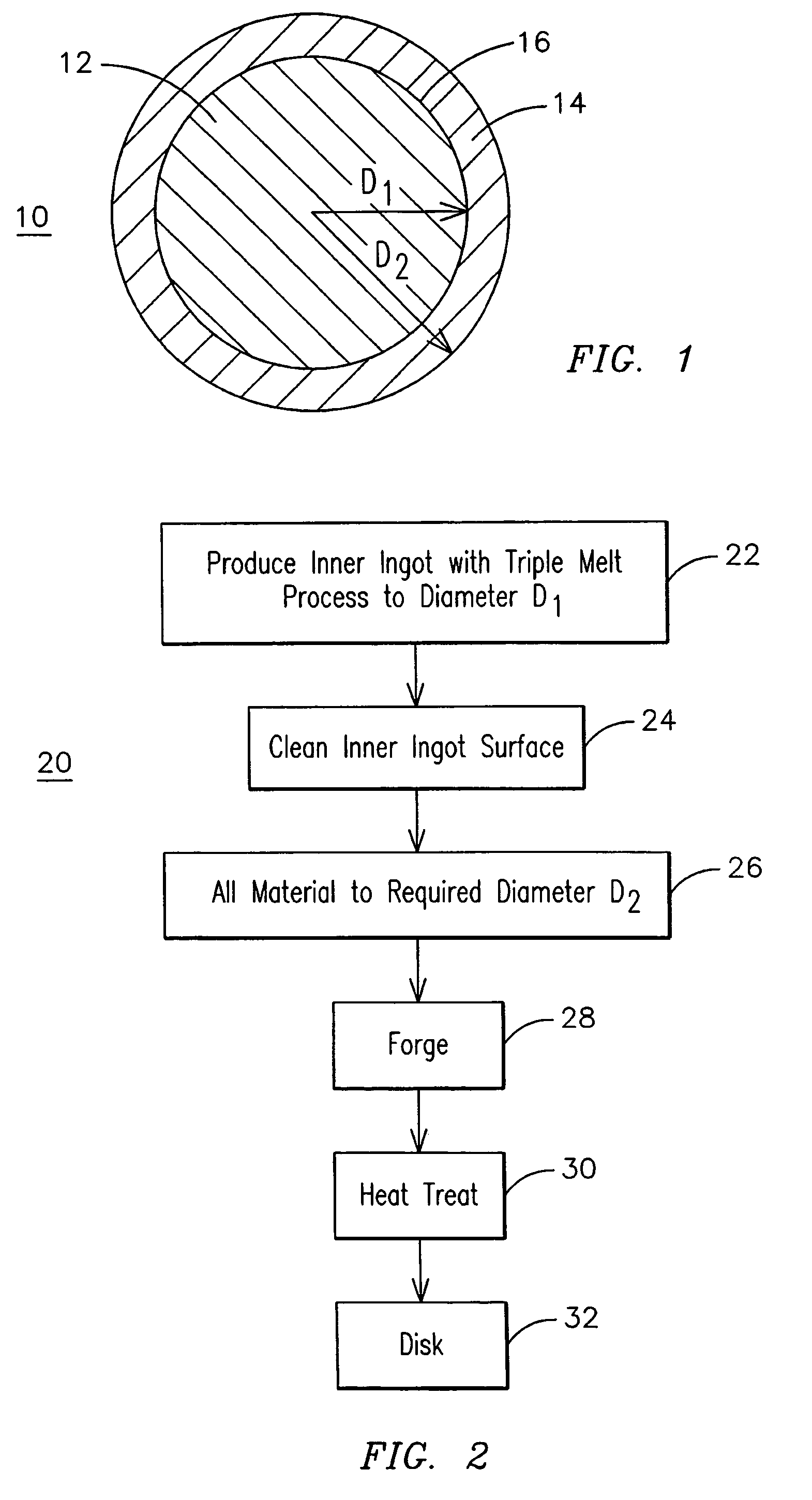

A method (20) of fabricating a large component such as a gas turbine or compressor disk (32) from segregation-prone materials such as Alloy 706 or Alloy 718 when the size of the ingot required is larger than the size that can be predictably formed without segregations using known triple melt processes. A sound inner core ingot (12) is formed (22) to a first diameter (D1), such as by using a triple melt process including vacuum induction melting (VIM), electroslag remelting (ESR), and vacuum arc remelting (VAR). Material is than added (26) to the outer surface (16) of the core ingot to increase its size to a dimension (D2) required for the forging operation (28). A powder metallurgy or spray deposition process may be used to apply the added material. The added material may have properties that are different than those of the core ingot and may be of graded composition across its depth. This process overcomes ingot size limitations for segregation-prone materials.

Owner:SIEMENS ENERGY INC

Electroslag remelting method for difficult-processing high alloy stainless steel and electroslag remelting slag system adopting electroslag remelting method

InactiveCN102925712AImprove or increase thermoplasticityHigh yieldIncreasing energy efficiencySlagAlloy

The invention relates to an electroslag remelting method for difficult-processing high alloy stainless steel and an electroslag remelting slag system adopting the electroslag remelting method. The slag system comprises the components in parts by weight: 46-72 parts of CaF2, 15-28 parts of CaO, 24-10 parts of Al2O3 and 8-2 parts of MgO, wherein the content of impurities is less than 1.0%. The electroslag remelting slag system and the electroslag remelting method reduce the contents of harmful elements in steel, improve the purity, optimize the organization, particularly and remarkably improve the processing performance of the difficult-processing high alloy stainless steel and greatly improve the material yield.

Owner:CHONGQING MATERIALS RES INST

High performance corrosion-proof rare earth super strength dual-phase stainless steel and its smelting tech.

InactiveCN100999806AImprove mechanical propertiesImprove corrosion resistanceRare earthPetrochemical

The present invention relates to one kind of Fe-base RE-adding high performance anticorrosive high strength two phase stainless steel and its smelting process. The stainless steel has proper amount of RE added for modifying and micro alloying, N to replace Ni, properly regulated Cr, Ni, Cu, Mo, Si, Mn and other alloy elements, and added W to raise performance. During smelting, composite active metal elements Re, Mg and Ca are used in treating molten steel; and in electroslag remelting, the RE steel electrode is remelted in a five-component slag system comprising ReO2, MgO, CaO, CaF2 and Al2O3 in the weight ratio of 10 to 10 to 10 to 50 to 20 to result in new material with obviously raised mechanical strength, and improved heat working performance, heat resisting performance and hydrochloric acid corrosion resisting performance. The present invention is suitable for making anticorrosive apparatus for petrochemical, papermaking and other industry.

Owner:丁桂荣

Corrosion-resistance iron-based austenite oil well pipe and manufacturing method thereof

InactiveCN104962836AMeet the slow strain test requirementsAchieve smoothSolid solutionElectro-slag remelting

The invention discloses a corrosion-resistance iron-based austenite oil well pipe and a manufacturing method thereof. The main chemical components of the oil well pipe include C larger than 0 and smaller than or equal to 0.03%, Si larger than 0 and smaller than or equal to 1.00%, Mn larger than 0 and smaller than or equal to 2.50%, P smaller than or equal to 0.03%, S smaller than or equal to 0.03%, 20.0%-28.0% of Cr, 20.0%-38.0% of Ni, 3.0%-5.0% of Mo and 0.50%-2.00% of Cu. The manufacturing method includes the first step of smelting; the second step of billet pouring; the third step of electroslag remelting; the fourth step of homogenizing annealing; the fifth step of billet forging; the sixth step of pipe billet preparing; the seventhly step of hot extruding, wherein a seamless steel pipe is formed through pipe billet preheating, power frequency induction furnace heating, pipe billet broaching, secondary induction heating and extruding; the eighth step of solid solution treating; and the ninth step of conducting of a deformation strengthening mode in cold drawing, wherein the percentage reduction of area is controlled within 20-40%, and the oil well pipe is manufactured. According to the corrosion-resistance iron-based austenite oil well pipe and the manufacturing method thereof, the wall thickness of the manufactured oil well pipe ranges from 15 mm to 40 mm, the yield strength is 760 MPa or higher, the tensile strength is 793 MPa or higher, the impact energy is 100 J or higher, the corrosion resistance is good, and the requirement for strictest and slow-strain tests is met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

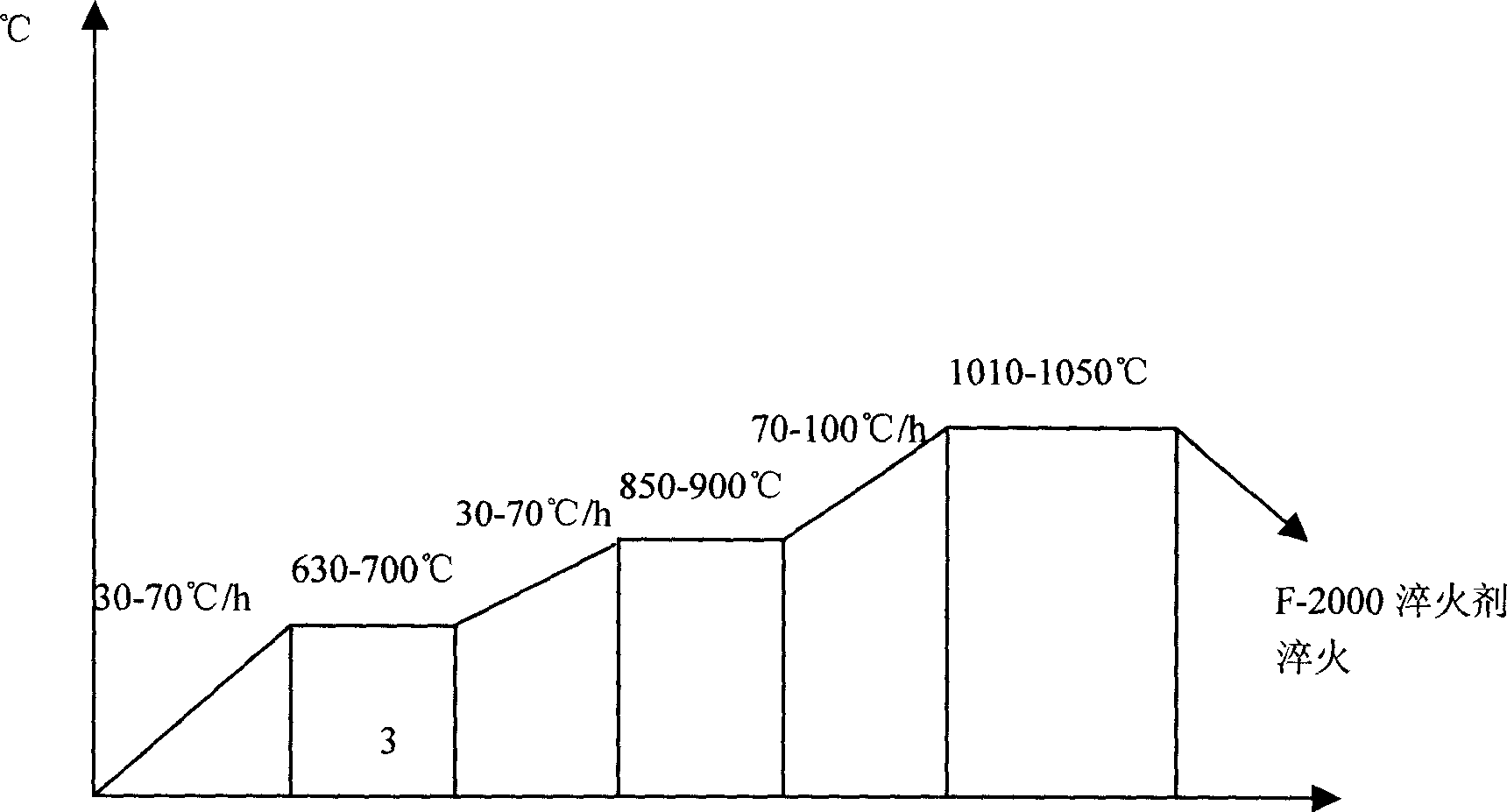

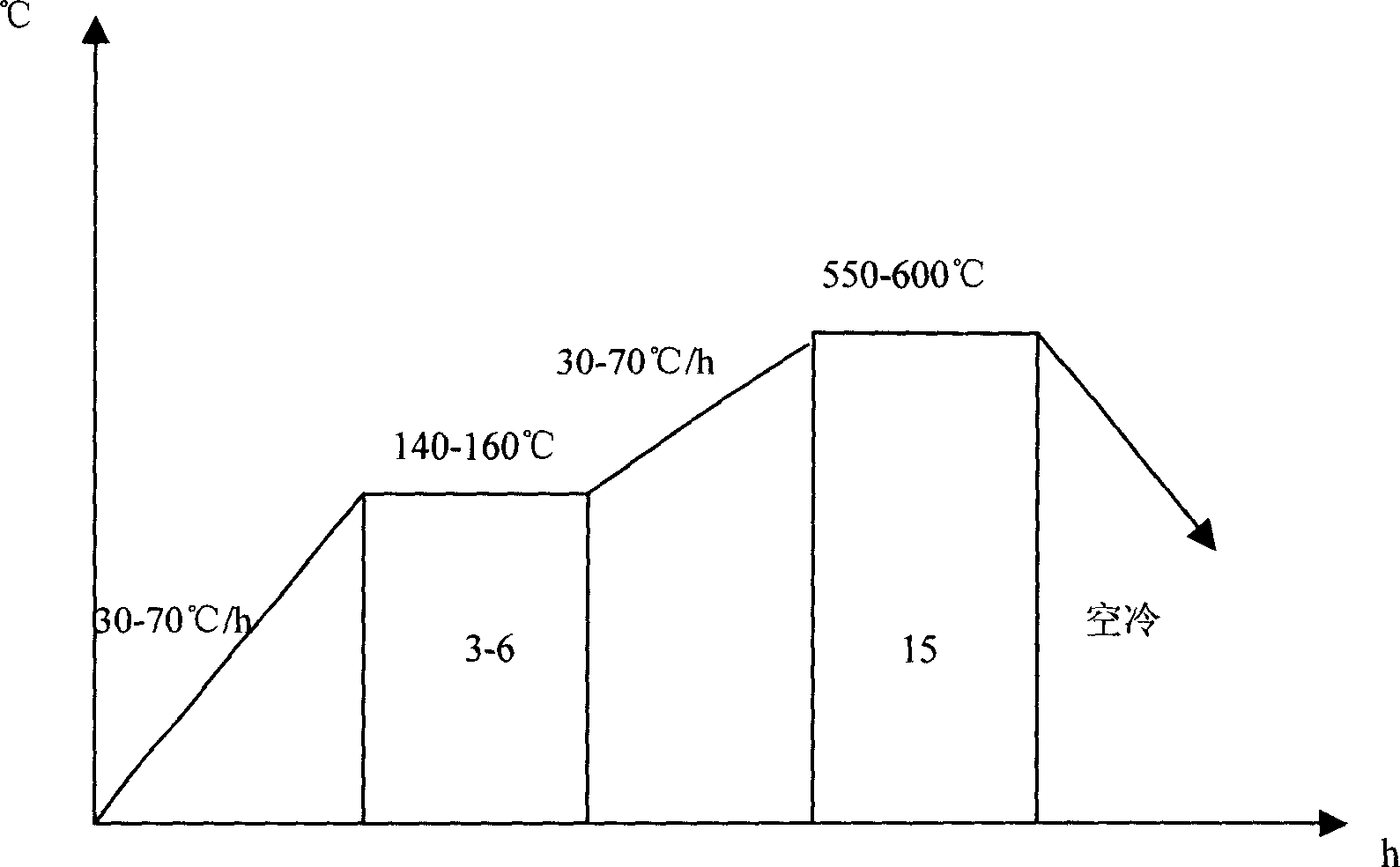

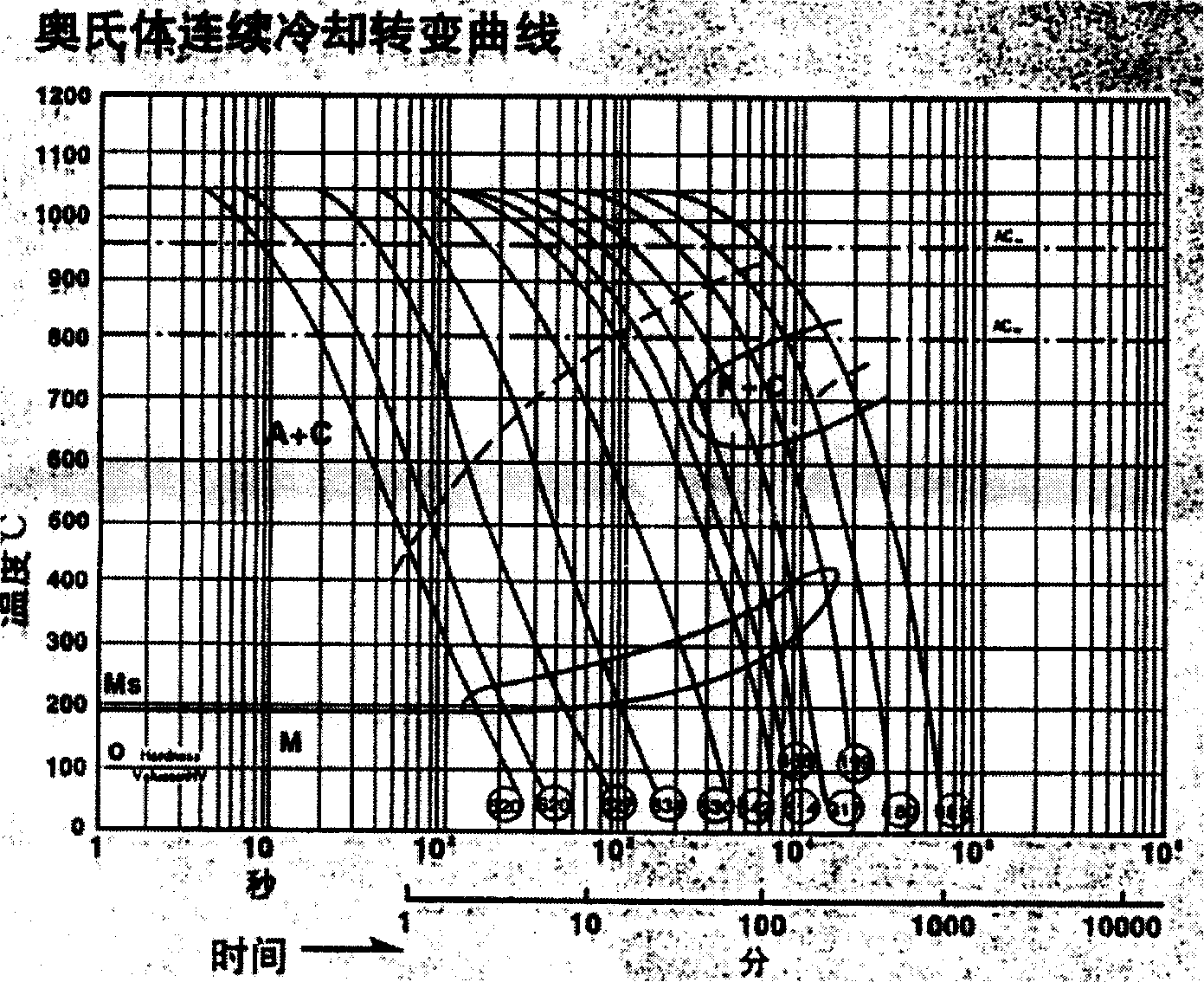

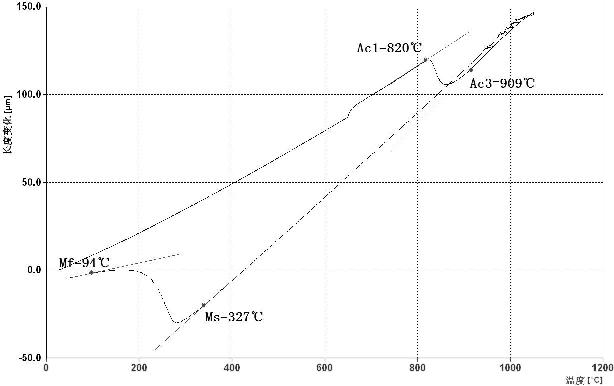

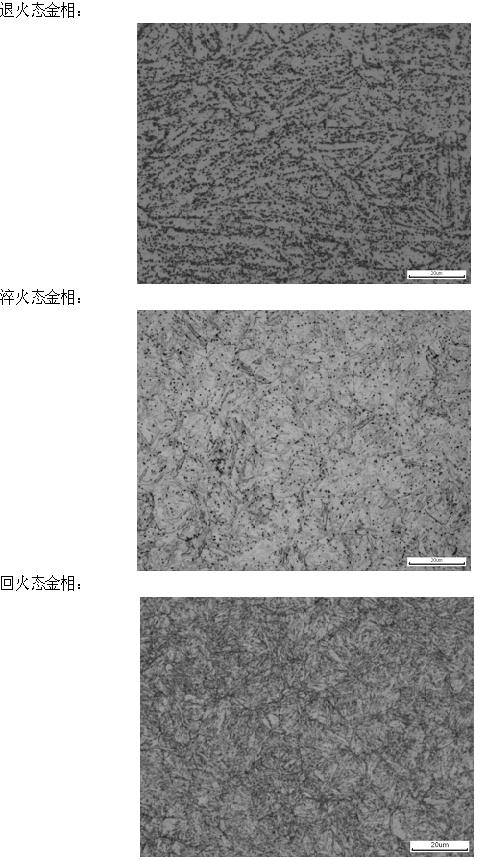

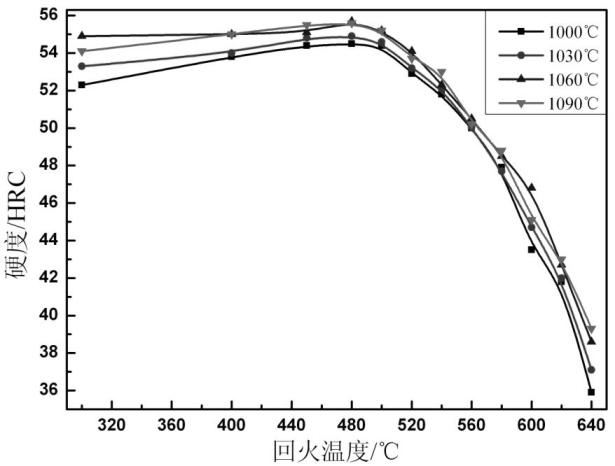

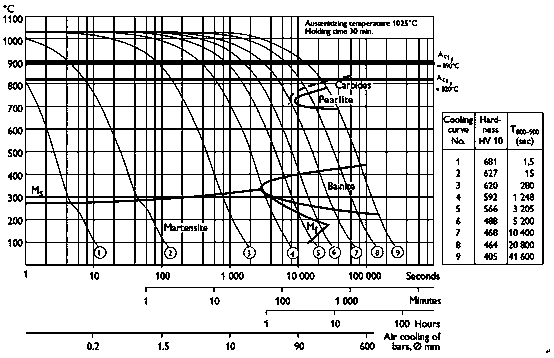

Chromium-molybdenum-vanadium hotwork tool-die steel and heat treatment process thereof

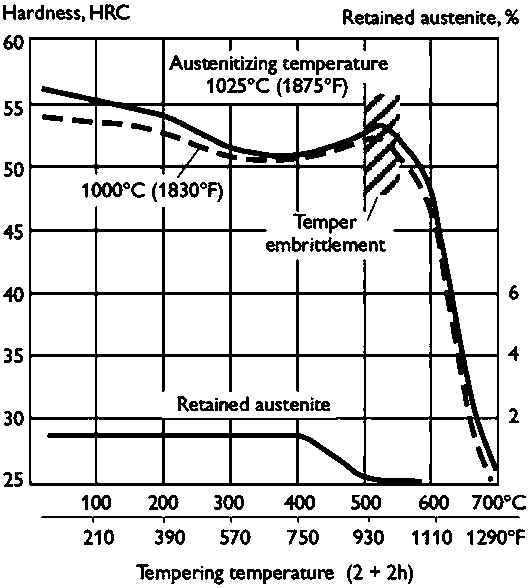

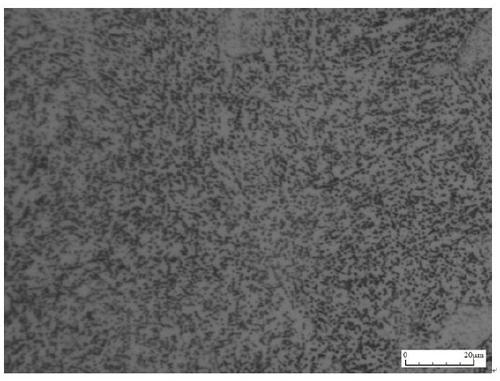

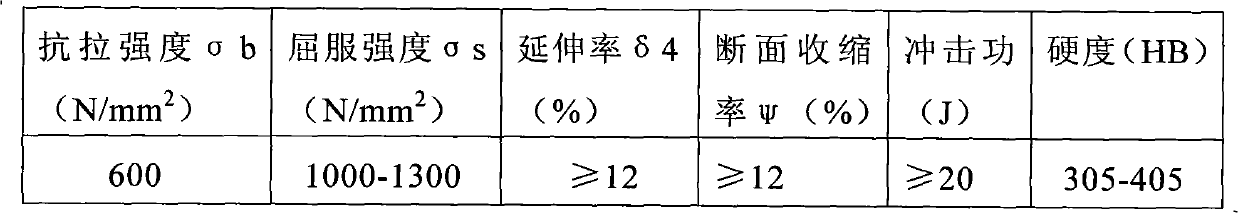

The invention relates to low-cost chromium-molybdenum-vanadium hotwork tool-die steel and a heat treatment process thereof and belongs to the technical field of alloy steel manufacturing processes. The steel comprises the following components by weight percent: 0.3-0.4% of C, 0.6-1.2% of Si, 0.6-1.2% of Mn, 3.5-4.5% of Cr, 0.8-1.2% of Mo, 0.4-0.8% of V, less than 0.02% of P, less than 0.02% of S and the balance of Fe. The preparation process of the hotwork tool-die steel is as follows: mixing, smelting, casting and then remelting electroslag; carrying out homogenization treatment at 1200-1280 DEG C for 8-10 hours, then forging, and carrying out ultrafining heat treatment and isothermal annealing treatment; and finally quenching and tempering, namely heating steel ingots to 1000-1100 DEG C to be austenitized and carrying out tempering two to three times at 560-620 DEG C after carrying out oil quenching or high pressure gas quenching. The hotwork tool-die steel has the advantages of high heat stability and roughness and good heat fatigue property.

Owner:SHANGHAI UNIV

Hot-work die steel for extrusion wheel and manufacturing method thereof

InactiveCN102534391AImprove hardenabilityReduced temper softening resistanceMetal-working apparatusTemperingThermal fatigue

The invention relates to hot-work die steel for an extrusion wheel and a manufacturing method of the die steel. The invention adopts the technical scheme that the manufacturing method comprises the following steps: hot-forging after scrap steel or molten iron and scrap steel are smelted in an electric furnace and are subjected to electroslag remelting or vacuum induction melting and then carry out spheroidizing annealing at a temperature of 700-880 DEG C; quenching at a temperature of 1,020-1,120 DEG C and tempering at a temperature of 530-650 DEG C, wherein the hot-work die steel has a hardness of up to 40-52HRC and a tensile strength of up to 1,850-1,955MPa. The hot-work die steel comprises the following chemical components in percentage by weight: 0.30-0.50wt% of C, 0.80-1.20wt% of Si, 0.2-0.5wt% of Mn, 3.00-5.00wt% of Cr, 1.00-1.50wt% of Mo, 0.70-1.20wt% of V, 0.005-0.03wt% of N and less than 0.030wt% of P, less than 0.030wt% of S and the balances of Fe and inevitable impurities. The steel has the characteristics of low cost, good thermal fatigue property, high heat stability and excellent comprehensive property and can be used for manufacturing the extrusion wheel of a continuously-extrusion-molded coating machine and other hot-work dies.

Owner:WUHAN UNIV OF SCI & TECH

Smelting production method of low activation martensitic steel for fusion reactor

InactiveCN101328522AReduce manufacturing costMeet the design requirementsIncreasing energy efficiencyQuality levelSteel bar

The invention relates to a method for producing a low-activation martensitic steel for a fusion reactor by melting. The method comprises: step one, a charging material is smelted in a vacuum induction furnace: (1) when a vacuum degree is between 0.1 and 10 Pa, argon gas is passed through the vacuum induction furnace till the vacuum degree is between 0.005 and 0.08MPa, and a smelting temperature is between 1450 and 1650 DEG C; (2) alloys are added in sequence: firstly, pure Fe is melted; Cr and W are added into the furnace; then Ta and V are added into the furnace, and finally C and Mn are added into the furnace; simultaneously, the level of an oxygen content in the pure Fe is observed; before Cr is added, a little of C is added into the furnace for carrying out deoxidation treatment; (3) on-line detection is carried out to the compositions of alloy elements; the alloy elements are added according to a detection result; and (4) after the compositions are qualified, a mixture is cast under the vacuum at a casting temperature of between 1450 and 1550 DEG C. Step two, according to the compositions and the inner quality level of a cast ingot which is obtained by vacuum induction and melting, whether the cast ingot is remelted and refined in a vacuum electroslag remelting furnace or a common electroslag remelting furnace with argon protection. Step three, a needed CLAM steel bar material is prepared by the production of forging, cogging and hot rolling. The method has the characteristics of simple smelting operation, stable process and low production cost; the compositions and impurities of the produced CLAM steel meet the design requirement; and the method has no aliquation of the compositions and tissues and high degree of purity and is suitable for the application of the fusion reactor.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

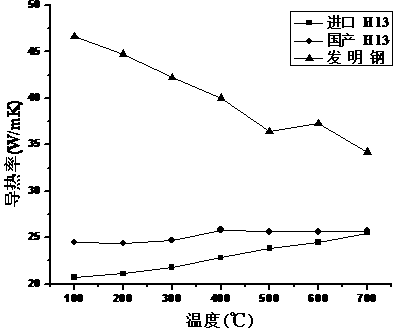

Belonging to the technical field of alloy steel preparation processes, the invention relates to an ultrahigh thermal conductivity wear-resistant hot stamping die steel and a manufacturing method thereof. Current hot stamping die steel on the market is mainly various improved H13, H11 and other high alloy hot work die steel. The steel provided by the invention comprises the following components by mass percent: 0.33-0.40% of C; less than 0.30% of Si; less than 0.30% of Mn; 1.0-2.0% of W; 4.0-5.0% of Mo; less than 0.30% of Cr; 0.10-0.20% of V; and the balance Fe and inevitable impurities. And in the impurity elements, S is smaller than or equal to 0.01%; P is smaller than or equal to 0.01%; and O is smaller than or equal to 30ppm. The steel is characterized in that: simple C, Mo and W are adopted as the main elements to coordinate the ratio of carbides; low Mn, low Cr and low Si content are maintained; after electric furnace smelting, electroslag remelting, annealing, high temperature homogenization, forging and annealing, the material has good machining properties; and after heat treatment, the material has excellent impact toughness, tempering stability and thermal fatigue performance. With ultrahigh thermal conductivity, the steel can be more suitable for hot stamping.

Owner:SHANGHAI UNIV +1

Mold steel electroslag re-melting slag system and use method of mold steel electroslag re-melting slag system

InactiveCN102605190AQuality improvementReduce contentIncreasing energy efficiencyRefining (metallurgy)Slow cooling

The invention provides a mold steel electroslag re-melting slag system and a use method of the mold steel electroslag re-melting slag system and belongs to the technical field of metallurgy engineering refining. The slag system consists of the following ingredients in percentage by mass: 65 to 70 percent of CaF2, 20 to 25 percent of Al2O3, 5 to 10 percent of SiO2 and 5 to 10 percent of MgO. A slag required by the refining is prepared according to the mass percentage being 4 to 6 percent of the mass of a mold steel electrode ingot to be refined. The use method comprises the following process steps of preparation and baking of electroslag re-melting slag, preparation of re-melting self consumption electrodes, arc smelting of electroslag re-melting, normal smelting of electroslag re-melting, smelting later-period feeding filling, electroslag steel ingot slow cooling heat insulation and electroslag re-melting steel ingot demolding. After the electroslag ingot heat insulation is completed, the demolding is immediately converted into the subsequent nodulizing annealing treatment. When the system and the method provided by the invention are adopted for refining, the sulfur and phosphor contents in mold steel are further reduced, in addition, the contents of active elements such as C, Si and Mn in the steel do not basically generate burnt loss, and the quality of the mold steel electroslag re-melting steel ingot is further improved.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

Method for self-spreading moltenslag refounding CuCr alloy contact material

The present invention is self-spreading fusion casting-electroslag remelting process for preparing CuCr alloy as contact material, and belongs to the field of alloy material preparing technology. Consumable electrode rod of CuCr alloy is first obtained with the materials including CuO, Cr2O3 and Al powder as well as proper amount of CaF2 and other additive and through a self-spreading fusion casting process, and then re-smelted in an electroslag furnace to further eliminate impurities, with the melt being water cooled to solidify and to obtain the CuCr alloy ingot. The process of the present invention has low cost, low power consumption and simple operation, and can obtain CuCr alloy ingot with high purity, homogeneous components, high density and no macrosegregation.

Owner:NORTHEASTERN UNIV

High-silicon high-manganese type high-thermal stability hot work die steel and thermal treatment process thereof

The invention relates to high-silicon high-manganese type high-thermal stability hot work die steel and a thermal treatment process thereof, and belongs to the technical field of alloy steel manufacturing process. The hot work die steel is characterized in that the ratio of high silicon to high manganese in chemical components is kept to be 1 to 1 and main alloy elements by mass percent comprise 0.25-0.45% of C, 0.8-2.0% of Si, 0.8-2.0% of Mn, 3.5-4.5% of Cr, 0.6-1.2% of Mo, 0.4-0.8% of V, less than 0.02% of P, less than 0.02% of S and Fe for the rest. A preparation process for the hot work die steel comprises the steps as follows: firstly, preparing materials, smelting and casting; secondly, carrying out electroslag remelting; carrying out high temperature homogenization thermal treatment, and carrying out multi-direction forging hot working; thirdly, carrying out superfine thermal treatment and isothermal annealing treatment; and lastly, carrying out quenching and tempering thermal treatment, namely heating to be 980-1100 DEG C for austenitizing, carrying out oil cooling or mist cooling, and tempering for two to three times at a temperature of 540-600 DEG C. The hot work die steel has the advantages of high thermal stability, high flexibility and good thermal fatigue performance.

Owner:SHANGHAI UNIV

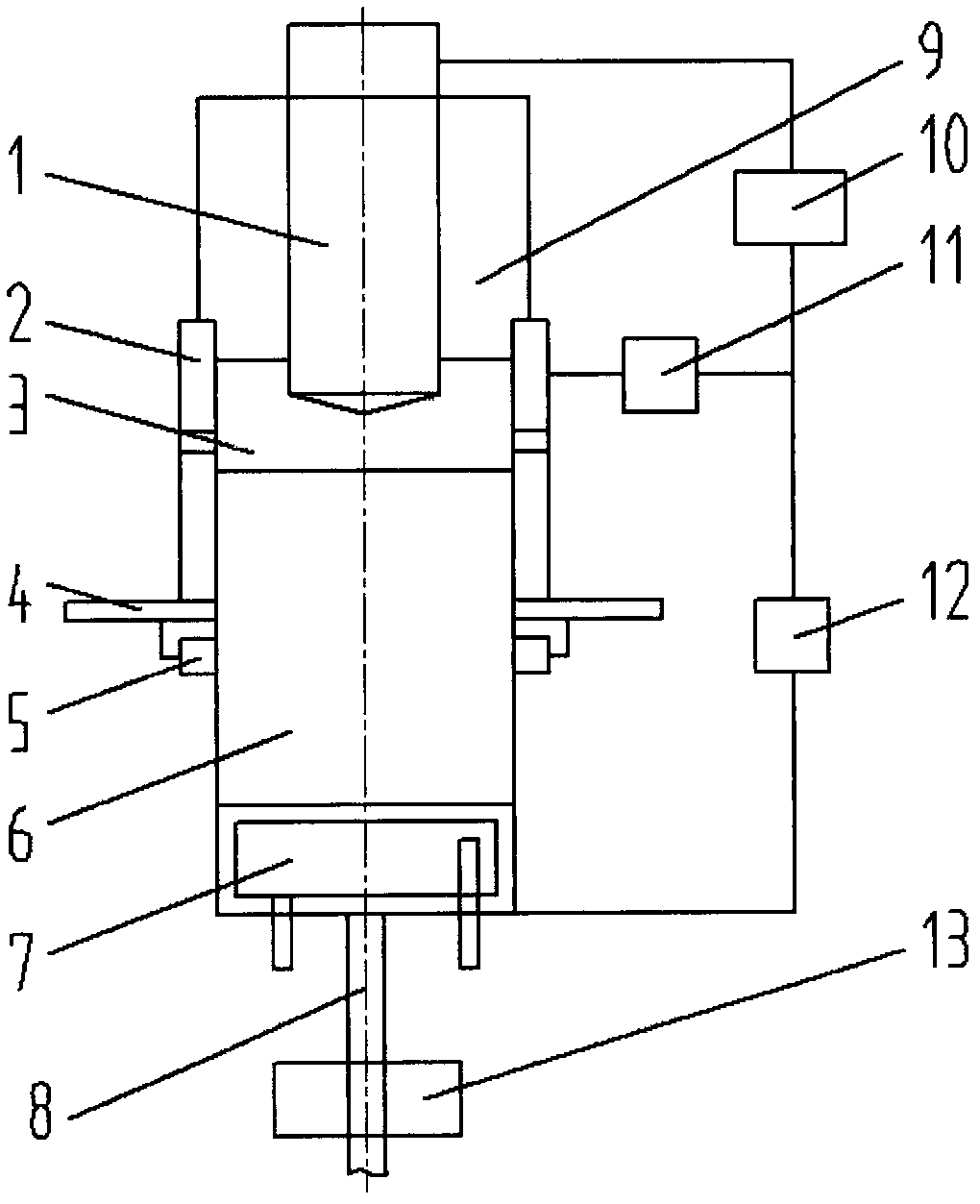

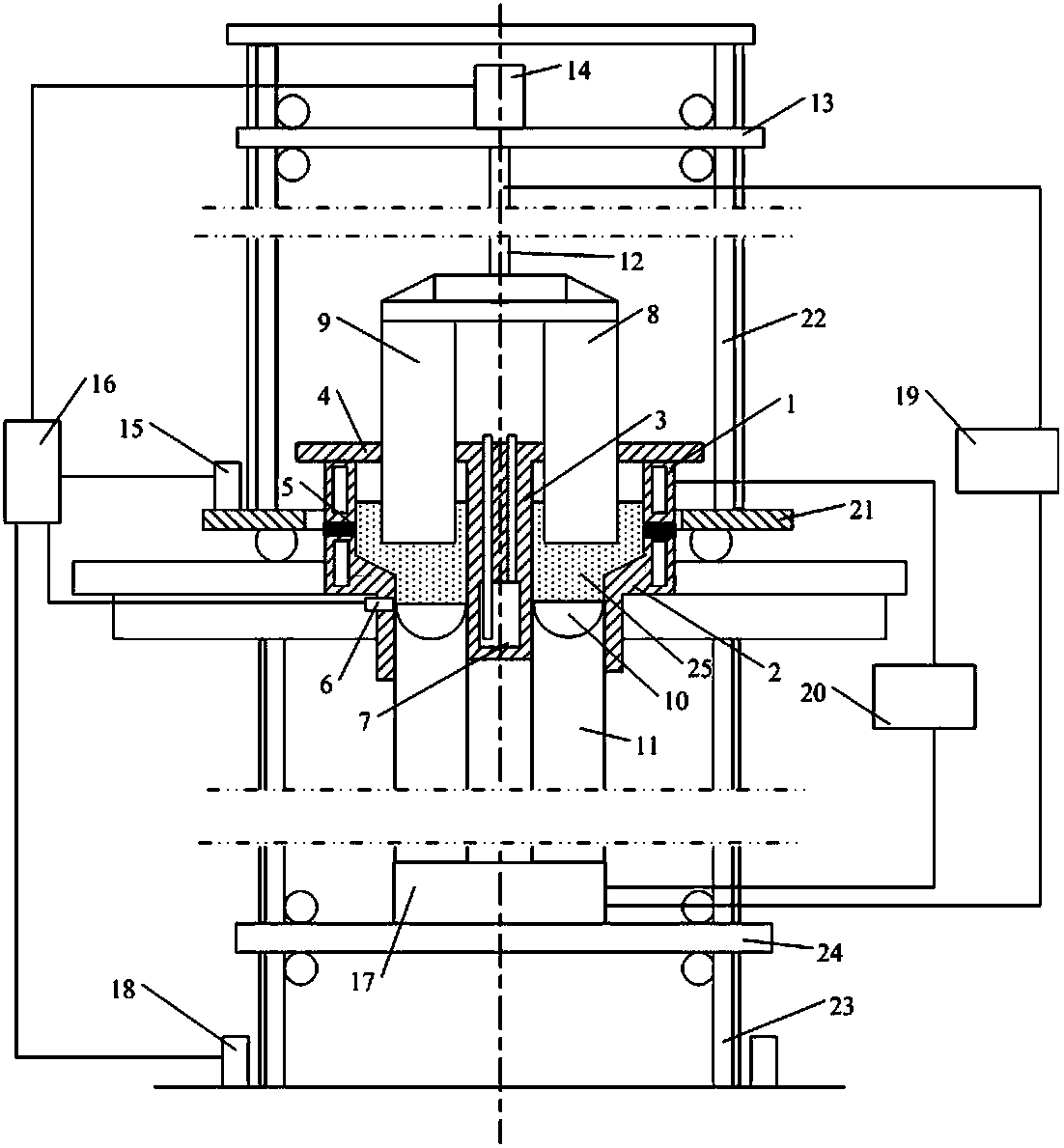

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348AEliminate aggregationEliminate coagulation and looseningElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

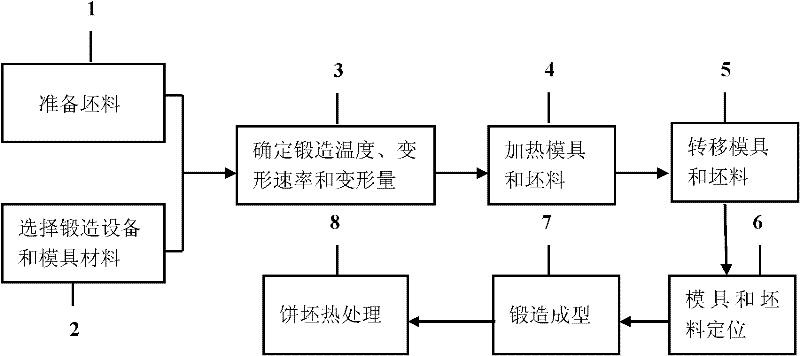

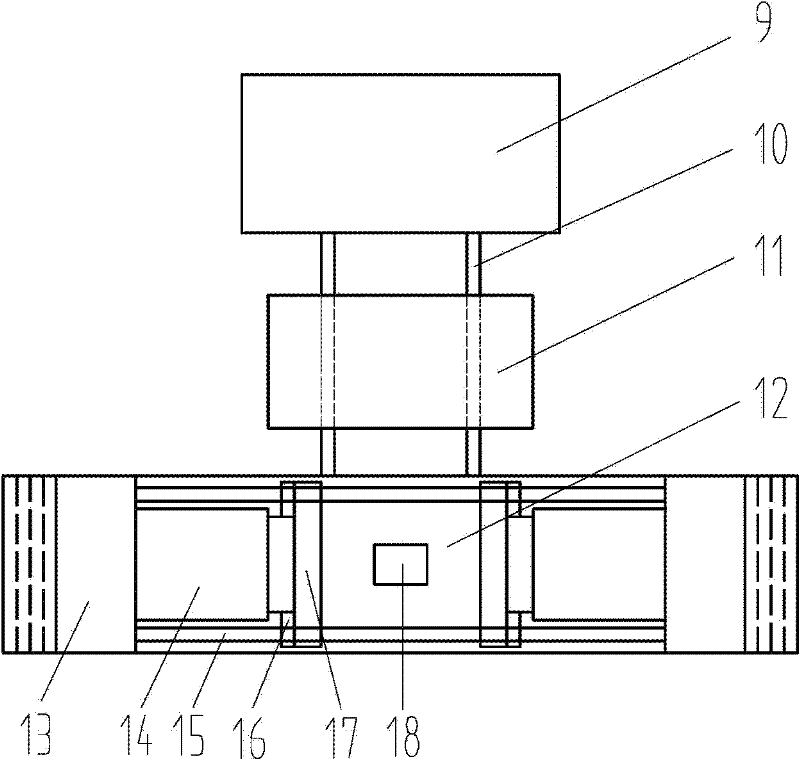

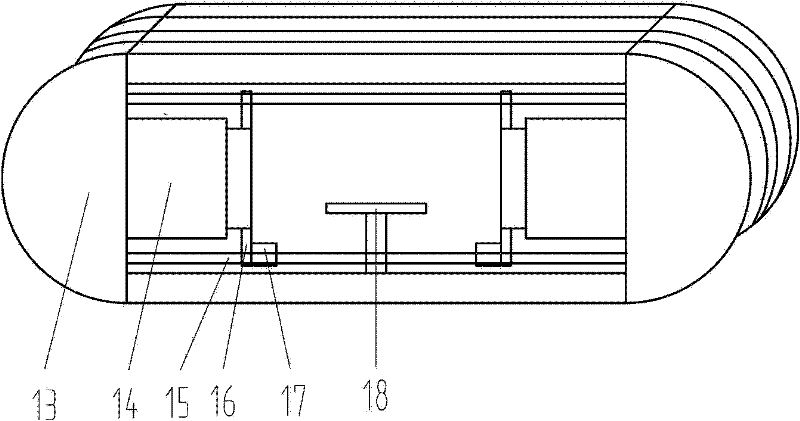

Quick isothermal forging method and device for preparing less-deformable alloy cake blank

ActiveCN102303083AReduce manufacturing costReduce the cost of forging processForging press detailsFlow stressHigh volume manufacturing

The invention discloses a quick isothermal forging method and device for preparing a less-deformable alloy cake blank. The device comprises a heating device, an automatic feeding device, a horizontal hydraulic forging device, a blank positioning device and a flame heating device. A mould material used by the device is a nickel-based alloy with creep strength which is higher than the flow stress of a forged high-temperature alloy under corresponding forging temperature and deformation rate. In the method, a homogenized electroslag remelting continuous directional solidification technology or other processes with maneuverability can be selected for preparing a high-alloyed less-deformable alloy directional solidification billet, as well as a fine grain billet prepared by adopting the processes, such as powder metallurgy and the like. The method and the device have the advantages of short production period, convenience for control and low cost, and are suitable for mass production of large-size high-clean and uniform tissue high-alloying less-deformable alloy cake blanks.

Owner:CENT IRON & STEEL RES INST

Super austenitic stainless steel pipe manufacturing process

InactiveCN102274854AIncrease the outer diameterReduce manufacturing costMetal rolling arrangementsSolution treatmentMetallurgy

The invention discloses a manufacturing process of a super austenitic stainless steel pipe, which comprises the following steps: A, billet preparation: the steel ingot is forged and formed after electroslag remelting and punched; B, the pipe billet is heated to 1190-1250°C; C. The tube billet is cross-rolled and pierced by a cross-rolling piercer; D. Tube rolling by a periodic tube mill; E. Solution treatment; F. Deep processing of waste tubes; G. Finishing and grinding to finished products. The beneficial effect of the invention is that the outer diameter of the product is greatly increased to 406mm by adopting the manufacturing process of piercing and periodic rolling, and the manufacturing cost and the manufacturing cycle are reduced at the same time.

Owner:SICHUAN SANZHOU SPECIAL STEEL PIPE

High-performance hot work die steel and manufacturing technology thereof

InactiveCN109280849AImprove thermal stabilityReduce carbon contentManufacturing technologyHeat stability

The invention relates to high-performance hot work die steel and manufacturing technology thereof. The high-performance hot work die steel comprises, by mass percent, 0.20%-0.30% of C, 0.40%-0.80% ofSi, 0.40%-0.80% of Mn, 3.10%-4.00% of Cr, 1.60%-2.00% of Mo, 0.5%-1.00% of W, 0.10%-0.30% of V, smaller than 0.010% of P, smaller than 0.005% of S and the balance Fe. The manufacturing process of thedie steel includes the following steps that burdening, smelting and pouring are conducted; then electroslag remelting is conducted; high-temperature diffusion heat treatment is conducted, then multidirectional forging hot working is conducted, and controlled cooling is conducted after forging; then secondary carbide refining heat treatment and isothermal annealing treatment are conducted; and finally, quenching and tempering heat treatment are conducted. The high-performance hot work die steel and manufacturing technology thereof have the beneficial effect that the quenching degree, the heat stability, the impact toughness and the thermal fatigue performance of the hot work die steel are superior to H13 steel, the hot work die steel can be machined into large die casting dies with the weight of the single piece reaching 5 tons or higher, and the good use performance is achieved; and in addition, the steel ingot smelting cost can be reduced, and the service life of dies is prolonged.

Owner:RUGAO HONGMAO HEAVY FORGING

Manufacturing method of valve part

ActiveCN102019534AGuaranteed eligibilityReduce riskValve arrangementsFurnace typesSolution treatmentCrazing

The invention relates to a manufacturing method of a valve part, and the method comprises the following steps: forging electroslag remelting ingot billets, cogging, polishing, finishing carrying out flaw detection and blanking; heating the billets to 1140-1160 DEG C, preserving heat again for 90 minutes, and carrying out upsetting, drawing down, upsetting, drawing down, chambering, billet separation, drawing down and rounding forming treatments on the billets; carrying out flaw detection on the obtained billets; and finally, carrying out solution treatment, air cooling stabilized treatment and age-hardening treatment on a sample. Compared with the prior art, the invention has the advantages that the eligibility of the billets is ensured, the risk brought by carrying out normal forging once is lowered, the inner and outer temperature difference of the billets is reduced, scrap caused by unreasonable heating is solved, the phenomena of centre burst and crack of a forging are avoided, the yield is improved, and the eligibility of the obtained forgings is more than 98%.

Owner:上海腾辉有色铸造有限公司 +2

A kind of high temperature resistant martensitic stainless steel and its manufacturing method

ActiveCN102260826AGuaranteed high temperature performanceHigh strengthMartensitic stainless steelUltimate tensile strength

The invention discloses a high temperature resistant martensitic stainless steel, comprising the following chemical components: 0.11-0.15 wt% of C, 0.50-0.80 wt% of Mn, no larger than 0.10 wt% of Si, 9.80-11.50 wt% of Cr, 0.60-0.80 wt% of Ni, 1.00-1.30 wt% of Mo, 0.13-0.23 wt% of V, no larger than 0.10 wt% of Al, 0.09-0.15 wt% of Nb, 0.25-0.40 wt% of W, 0.050-0.080 wt% of N, no larger than 0.010 wt% of P, no larger than 0.005 wt% of S, and the balance consisting of Fe and inevitable impurities. Accordingly, the invention further discloses a method for smelting with vacuum induction and electro slag remelting to produce the martensitic stainless steel. The produced martensitic stainless steel has low content of impurity elements, good quality of steel, excellent high temperature resistance, good combination of strength and toughness, and high yield.

Owner:宝武特种冶金有限公司

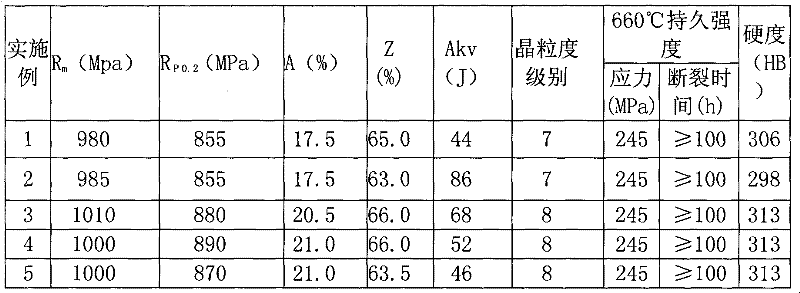

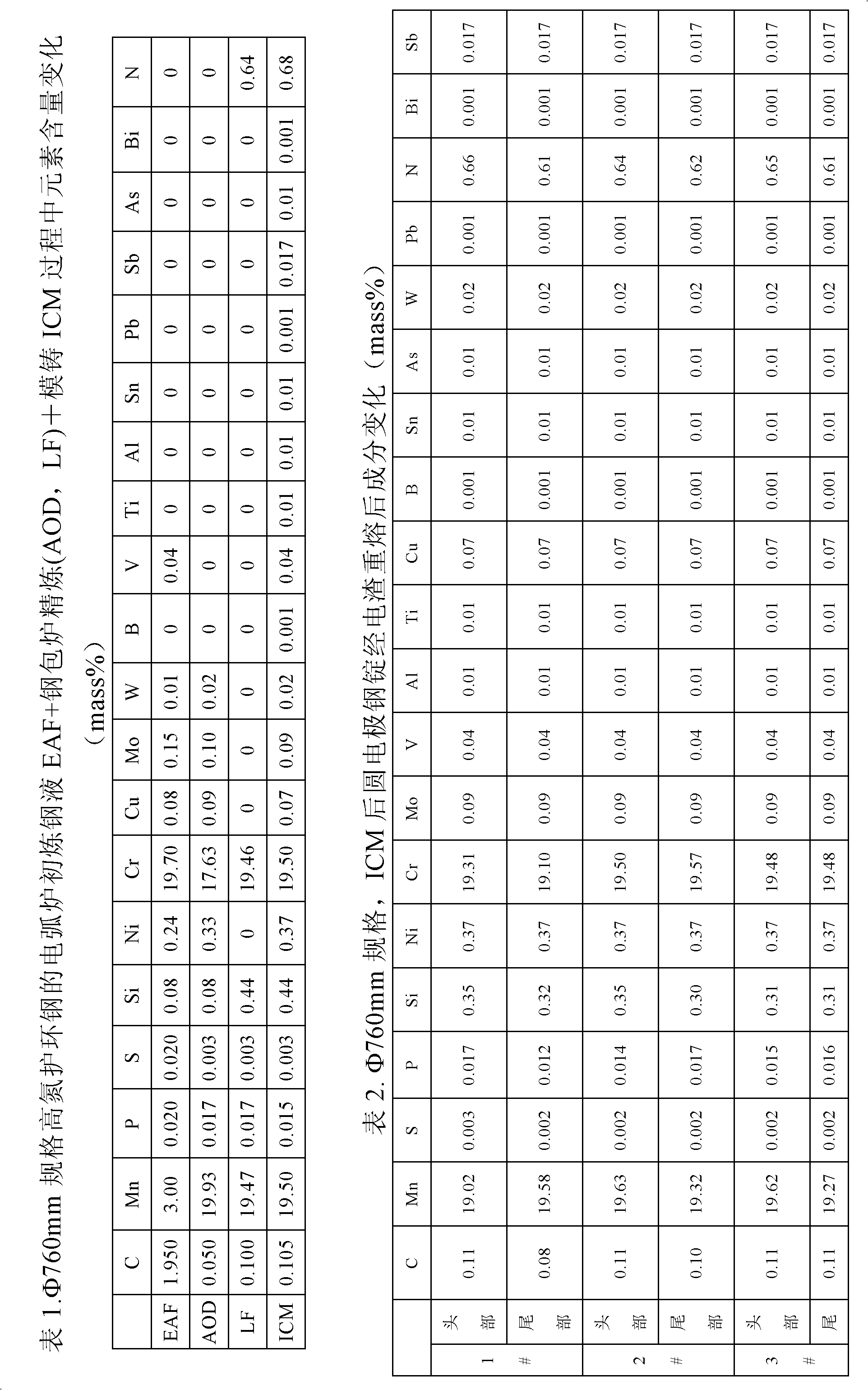

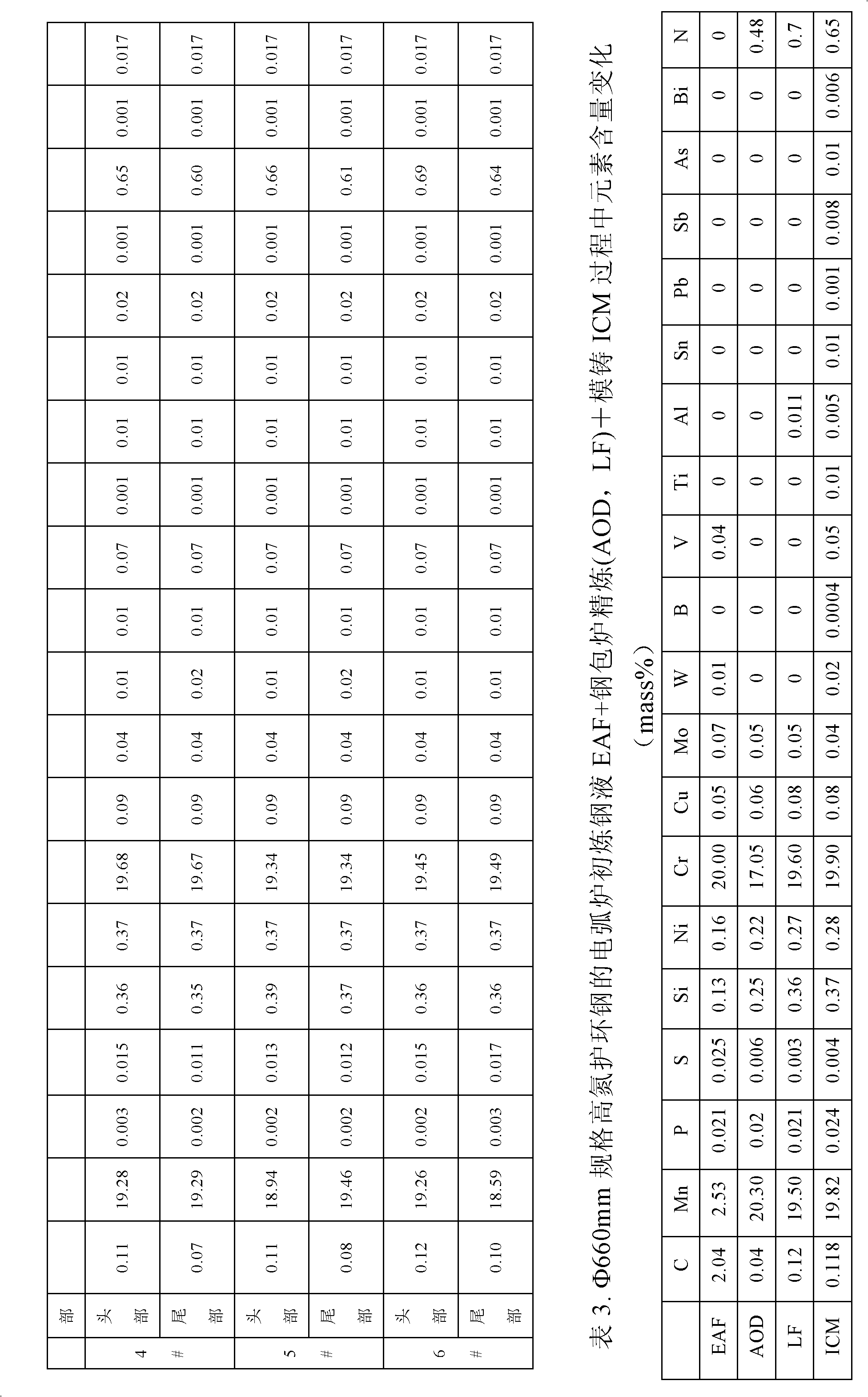

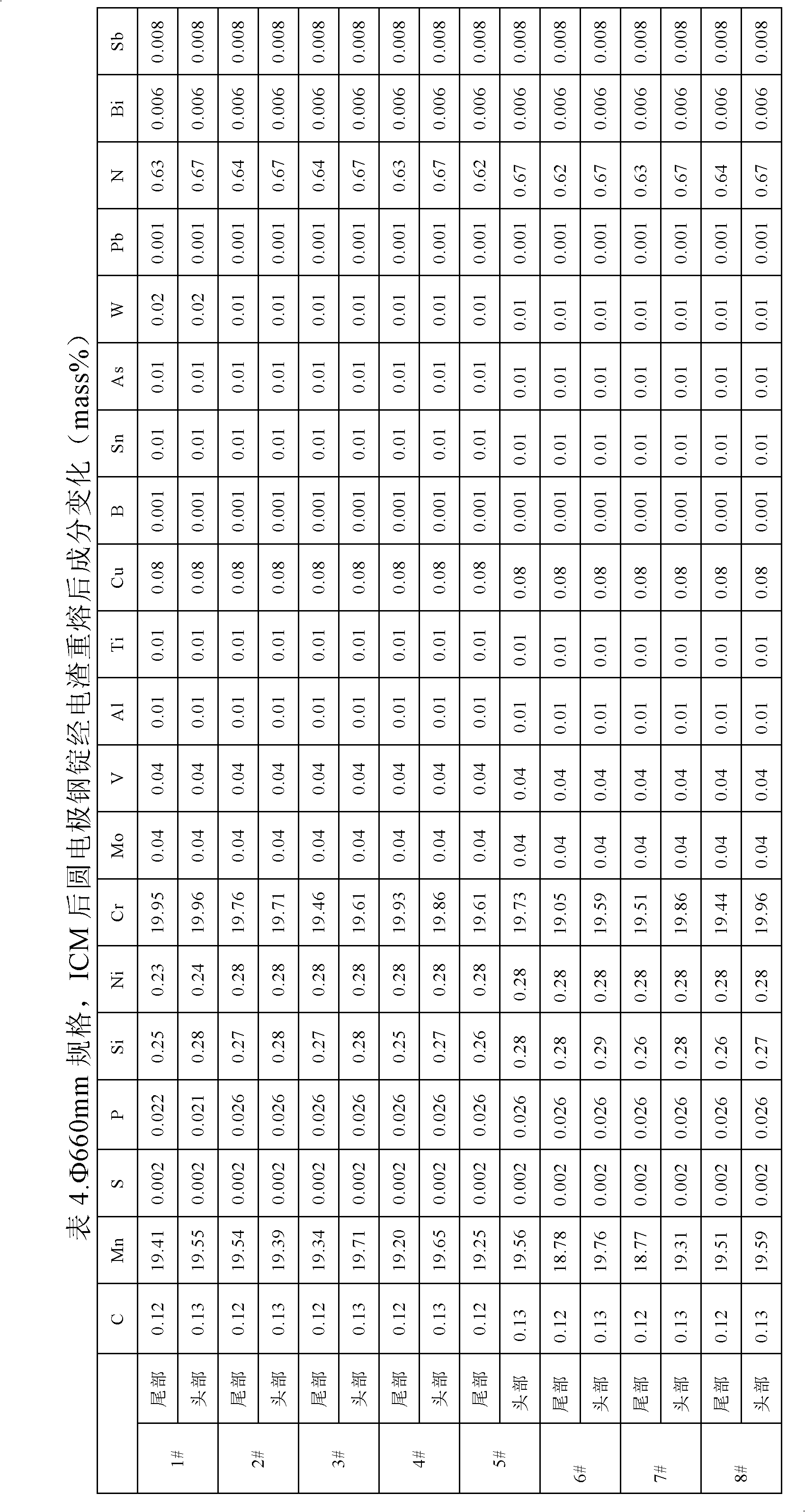

Production method for steel ingot of large-sized high-nitrogen retaining ring steel

ActiveCN102758144AEffective control of contentEffective control of melting speedProcess efficiency improvementElectric arc furnaceDie casting

The invention relates to a production method for a steel ingot of large-sized high-nitrogen retaining ring steel. The production method comprises the following steps: 1) smelting and casting: optimizing raw materials, primarily smelting molten steel EAF by using an electric arc furnace, refining AOD and LF by using a ladle furnace, performing die casting on ICM and pouring an electrode of phi 422 to 510 mm; 2) performing hot charging and annealing; 3) remelting electroslag into the steel ingot of phi 660 to 800 mm; and 4) sampling, detecting the components, performing flaw detection, peeling electroslag and steel ingot sand, detecting size and appearance and putting into a storage. In the steel ingot of the high-nitrogen retaining ring steel manufactured by the method, the phi is 660 to 800 mm, the weight is more than 5 tons, the nitrogen content is over 0.6 weight percent, the nitrogen is distributed into the steel ingot uniformly, and the |[N] head-[N]tail| of the head and the tail of the steel ingot is less than or equal to 0.05 weight percent.

Owner:宝武特种冶金有限公司

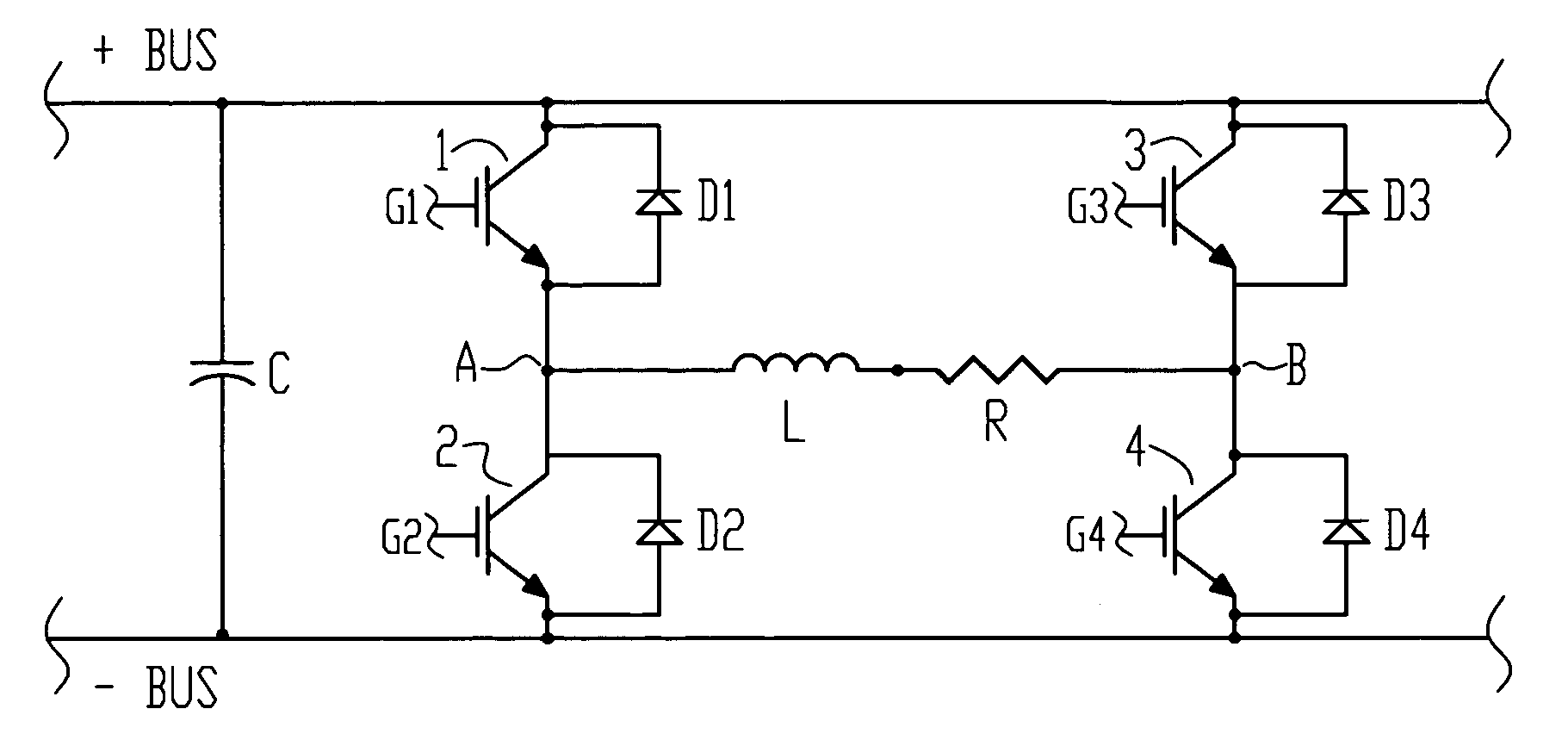

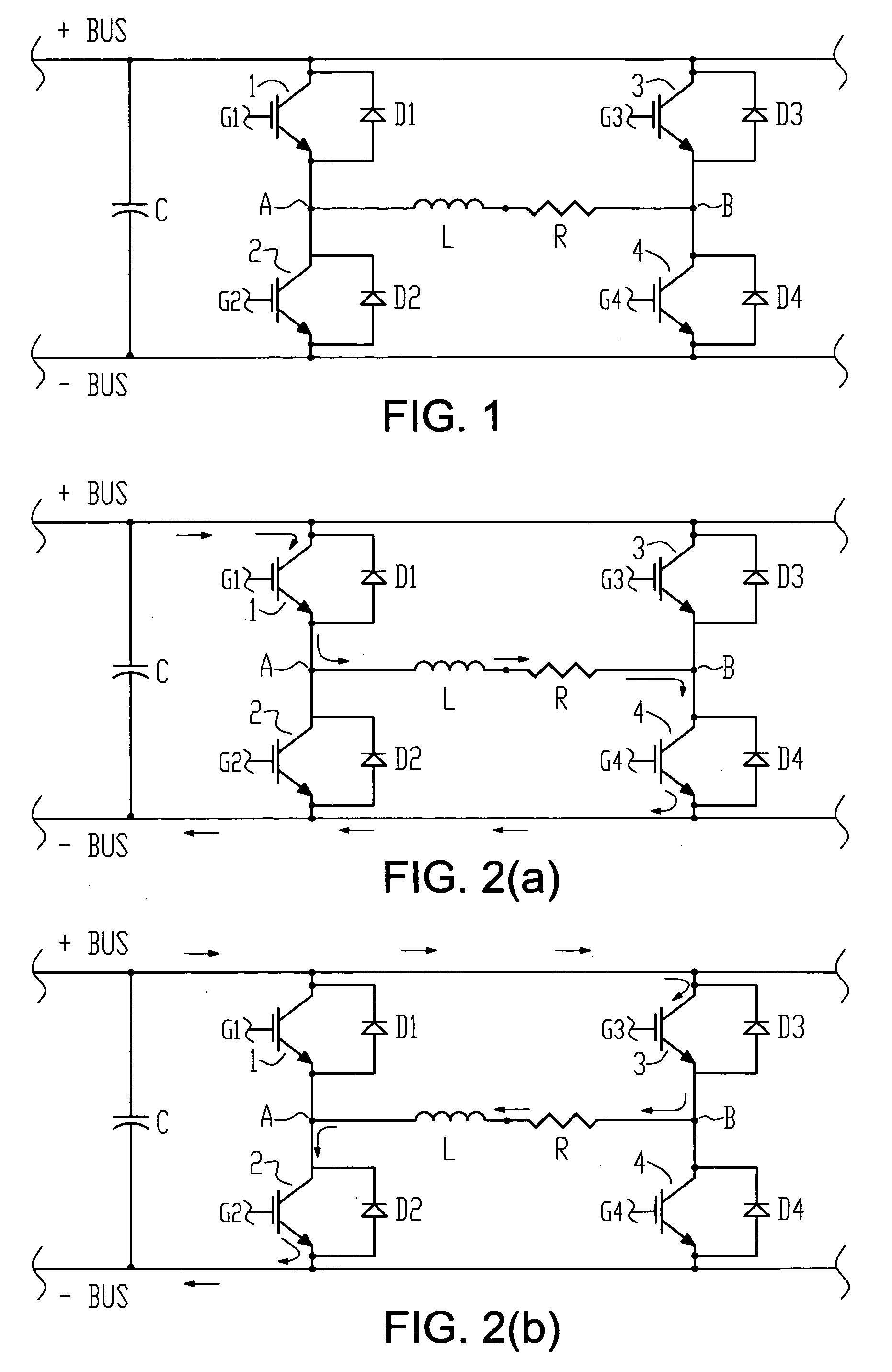

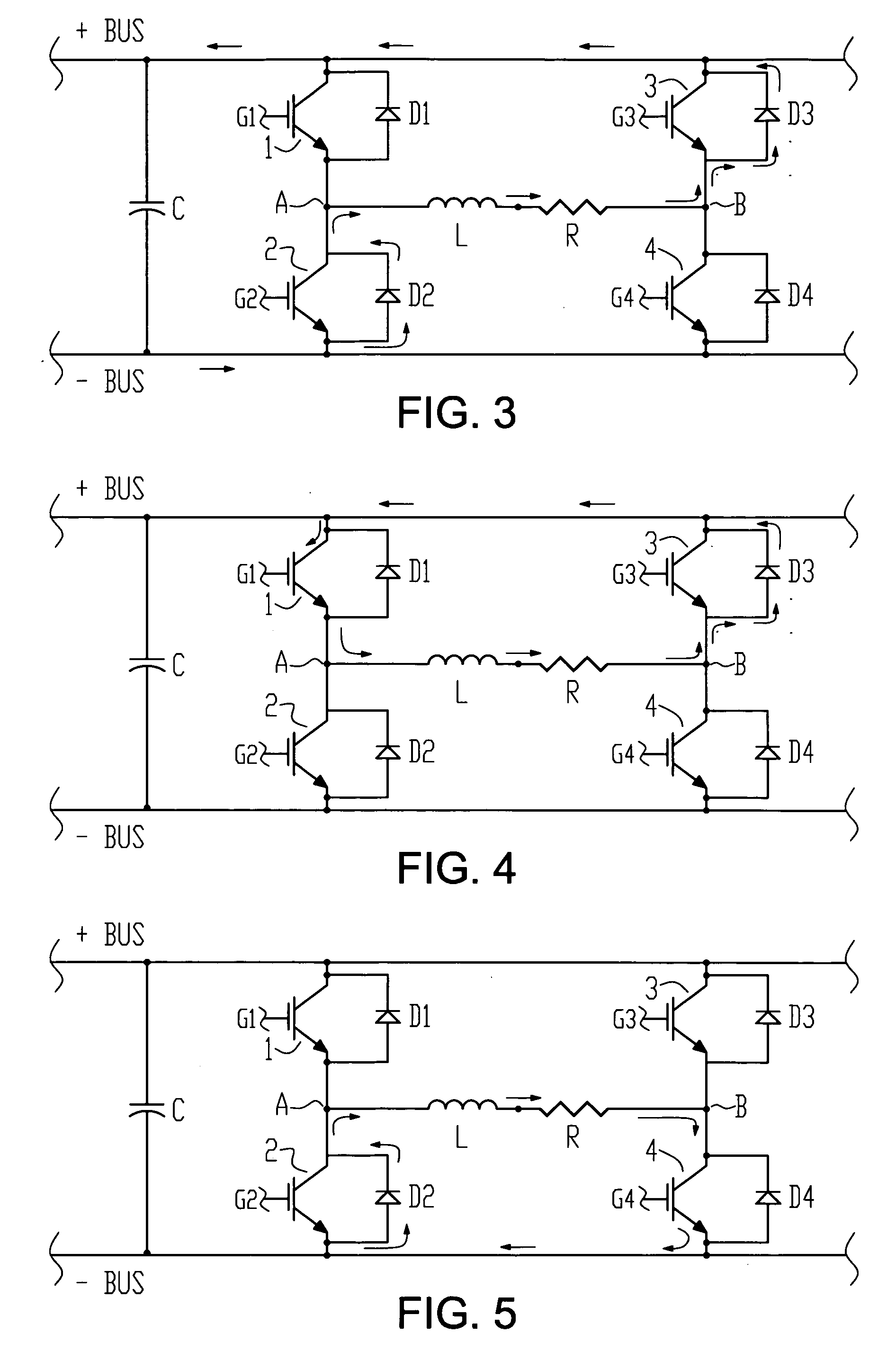

Pulse width modulated power inverter output control

ActiveUS20070047612A1Reduce switchingEfficient power electronics conversionAc-dc conversionPower inverterSlag

A method is provided for output control of a pulse width modulated power inverter used with a substantially resistive, single phase, ac load such as an electro-slag remelting furnace. In one application of the method, during each of the inverter's half cycle outputs, active switching devices are alternatively pulsed on and off during the half cycle so that only half of the switching transients in the half cycle are handled by one of the active switching devices.

Owner:CONSARC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com