Vacuum/gas shield electroslag remelting continuous directional solidification device and method

A gas shielding and electroslag remelting technology, applied in the field of electroslag remelting, can solve the problems of unsuitability for ingot casting, large equipment, low efficiency, etc., and achieve the effect of improving deformation plasticity, preventing shape and distribution, and wide application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

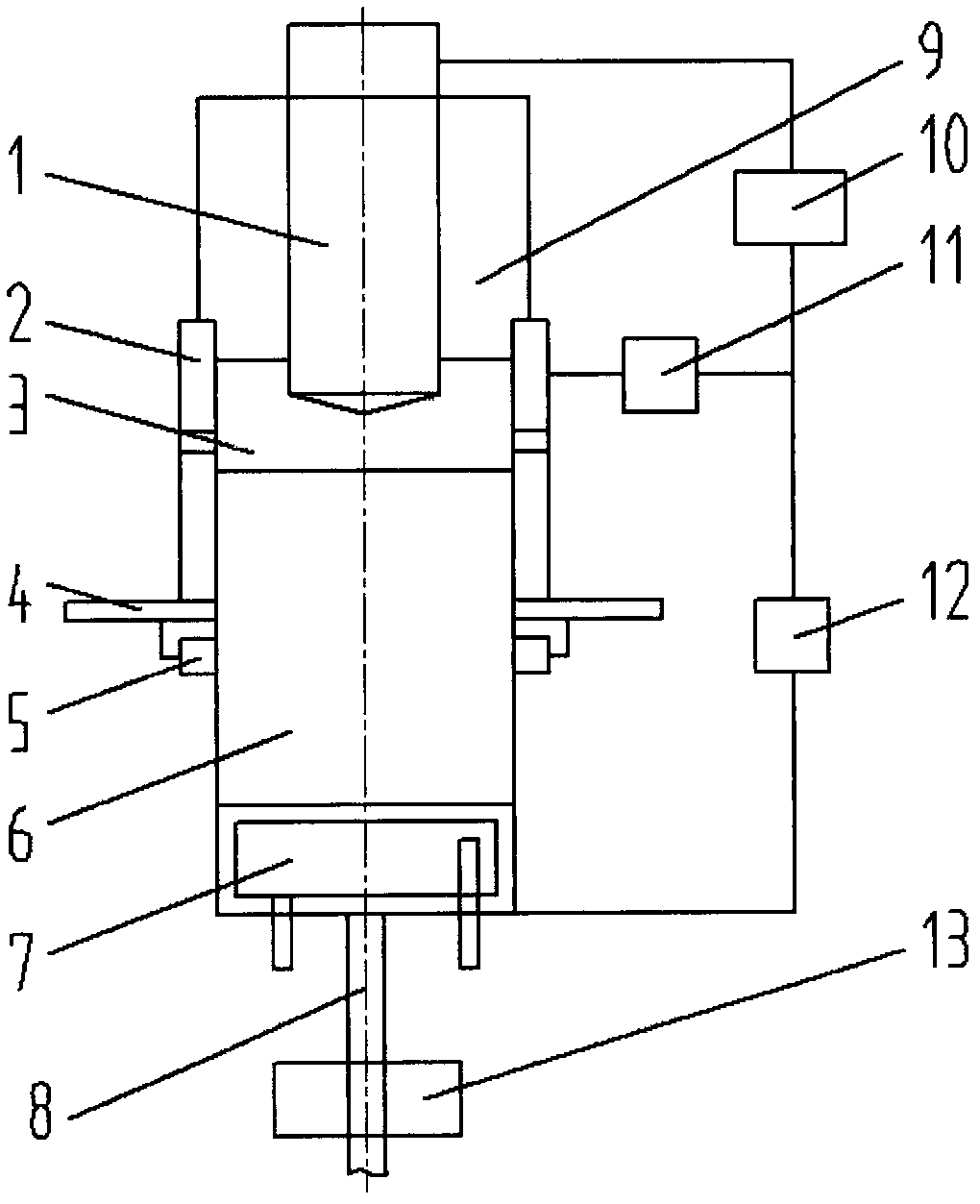

[0048] Example 1 Preparation of Φ155 FGH96 Alloy Directional Solidification Ingot .

[0049] The water-cooled crystallizer 2 has a diameter D=Φ160 mm and a height of 200 mm, and is placed on the working platform 4 .

[0050] The equipment used has a double-loop design, one loop is: transformer - self-consumed electrode - slag pool - ingot - water-cooled chassis - rectifier - transformer (called longitudinal current); the other loop is: transformer - self-consumed electrode - Slag pool—conductive module of crystallizer—rectifier—transformer (called lateral current), by controlling the distribution ratio of longitudinal current and lateral current, the slag pool can obtain a uniform temperature field, thereby further controlling the shape of the molten metal pool.

[0051]Place the water-cooled chassis 7 at the lower end of the water-cooled crystallizer 2, pour in pre-melted 100mm deep slag, insert the consumable electrode 1 with a diameter of 100mm into the slag pool 3 for ar...

Embodiment 2

[0052] Example 2 Preparation of Φ105 FGH96 Alloy Directional Solidification Ingot .

[0053] The water-cooled crystallizer 2 has a diameter D=Φ110 mm and a height of 150 mm, and is placed on the working platform 4 .

[0054] Place the water-cooled chassis 7 at the lower end of the water-cooled crystallizer 2, pour in pre-melted slag with a depth of 60 mm, insert the consumable electrode 1 with a diameter of 70 mm into the slag pool 3 for arcing, and make the consumable electrode 1 melting; when the liquid level of the slag pool 3 rises to 30mm, the ingot is drawn, and the ingot drawing speed is controlled at 2-20mm / min, which is adjusted by controlling the output voltage of the magnetic modulation transformer 10 and the insertion depth of the consumable electrode 1 into the slag pool The voltage and current of the system, in this embodiment, make the voltage 40V; then adjust the longitudinal current rectifier 12 and the lateral current rectifier 11 to control the distributio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com