Patents

Literature

212results about How to "Prevent deformation and cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

MEMS gas sensor and manufacturing method thereof

ActiveCN104181203AAvoid failureInhibit sheddingDecorative surface effectsSolid-state devicesInsulation layerSilicon dioxide

The invention relates to the technical field of gas detection, and in particular relates to an MEMS gas sensor. The MEMS gas sensor comprises a monocrystalline silicon substrate, a porous silicon layer which is formed on the upper surface of the monocrystalline silicon substrate and has thickness downwards, a heat insulation trough formed on the lower surface of the monocrystalline silicon substrate in an inverse manner, a lower insulation layer, a heating layer, an upper insulation layer and a gas sensitive layer, wherein the bottom surface of the heat insulation trough is positioned just under the porous silicon layer; the heat insulation trough comprises one or multiple trench groups; the lower insulation layer covers the porous silicon layer and the upper surface of the monocrystalline silicon substrate and comprises a first silicon dioxide layer, a second silicon dioxide layer and a silicon nitride layer from bottom to top in sequence; the heating layer, the upper insulation layer and the gas sensitive layer are arranged above the lower insulation layer. The invention also correspondingly discloses a manufacturing method of the MEMS gas sensor. By virtue of the structures of porous silicon and the heat insulation trough, the heat insulation effect is enhanced; the lower insulation layer effectively prevents the heat insulation layer warping to break away from the heating layer at high temperature; meanwhile, under the supporting of the porous silicon layer, deformation and cracks, which are caused by non-uniform stress, of the lower insulation layer are prevented, and thus the service life of the gas sensor is prolonged.

Owner:SUZHOU LEANSTAR ELECTRONICS TECH

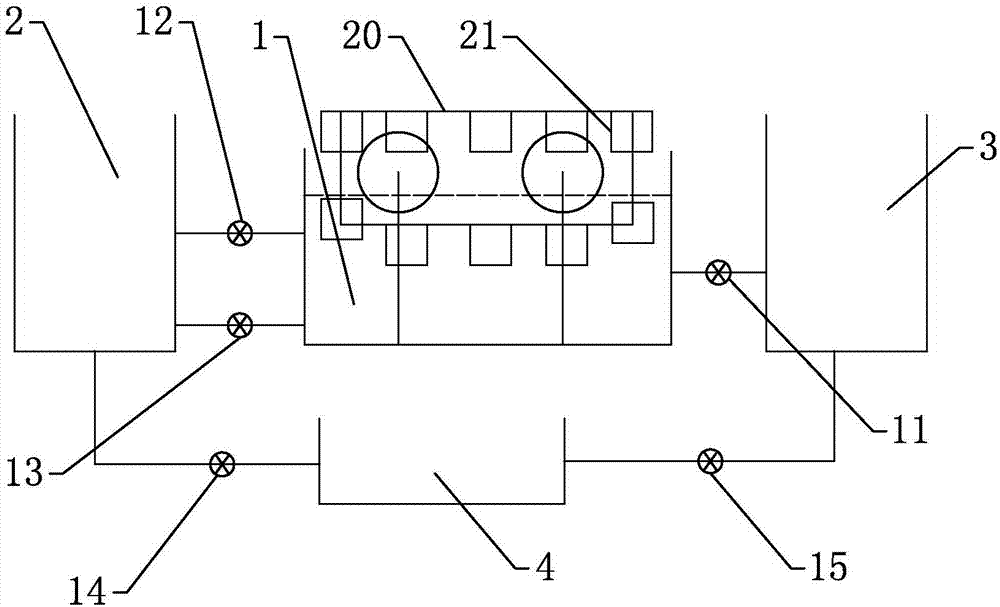

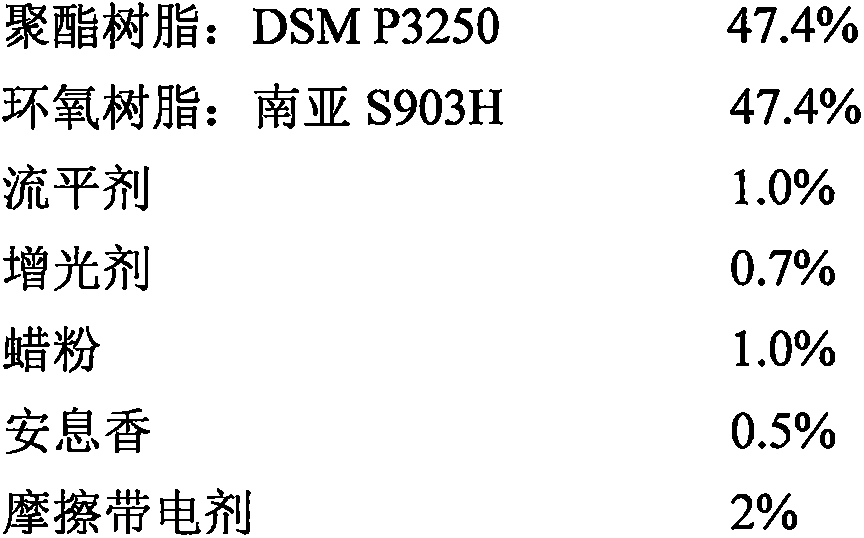

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348AEliminate aggregationEliminate coagulation and looseningElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

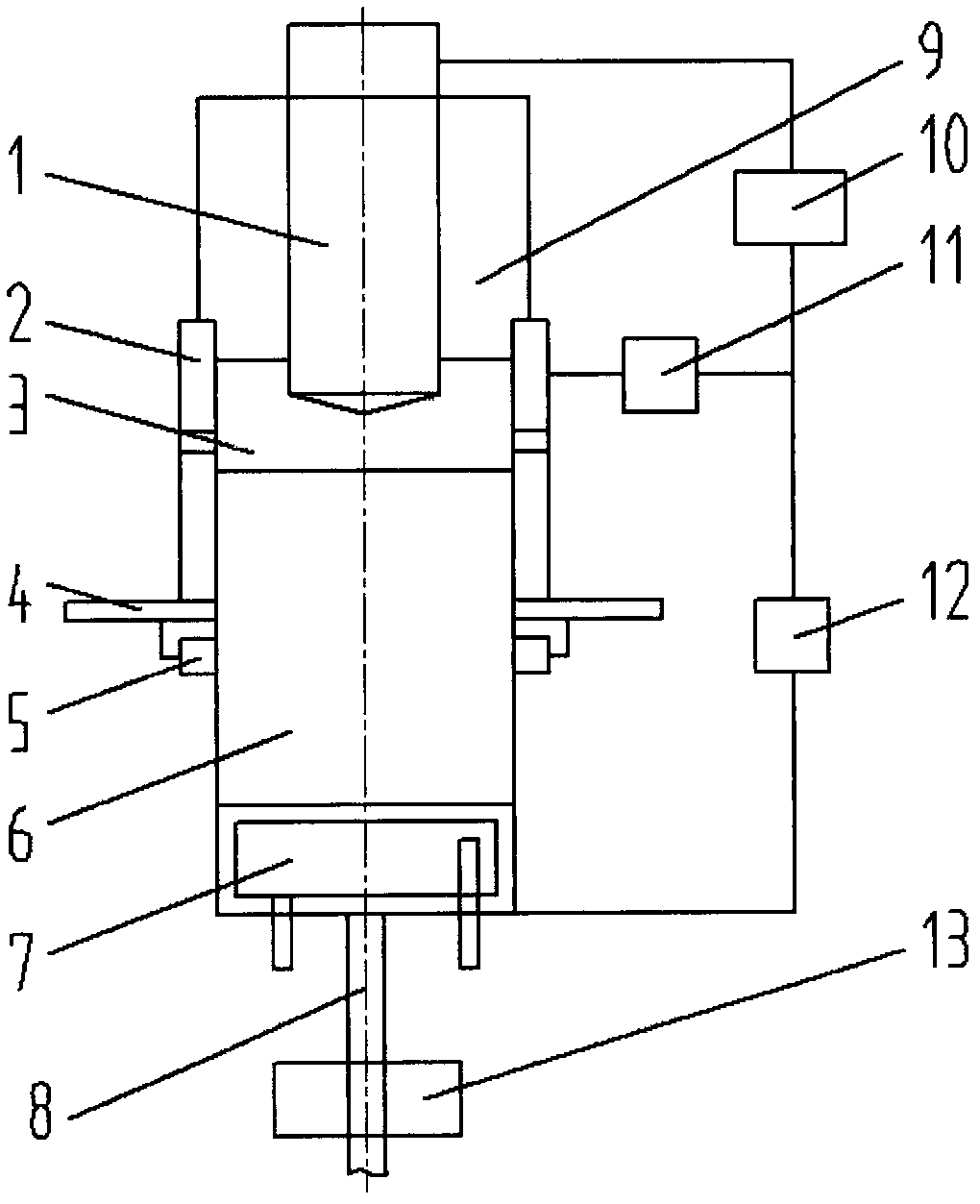

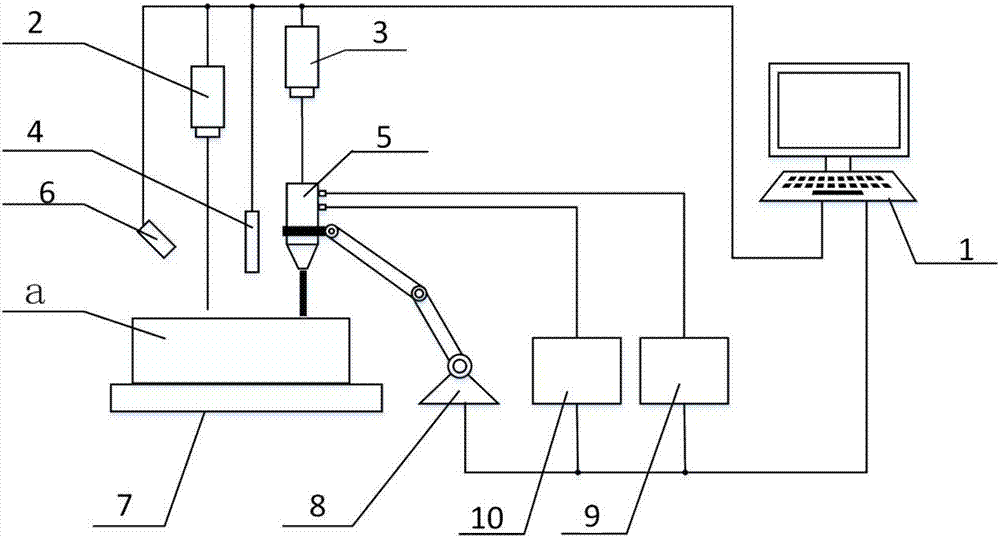

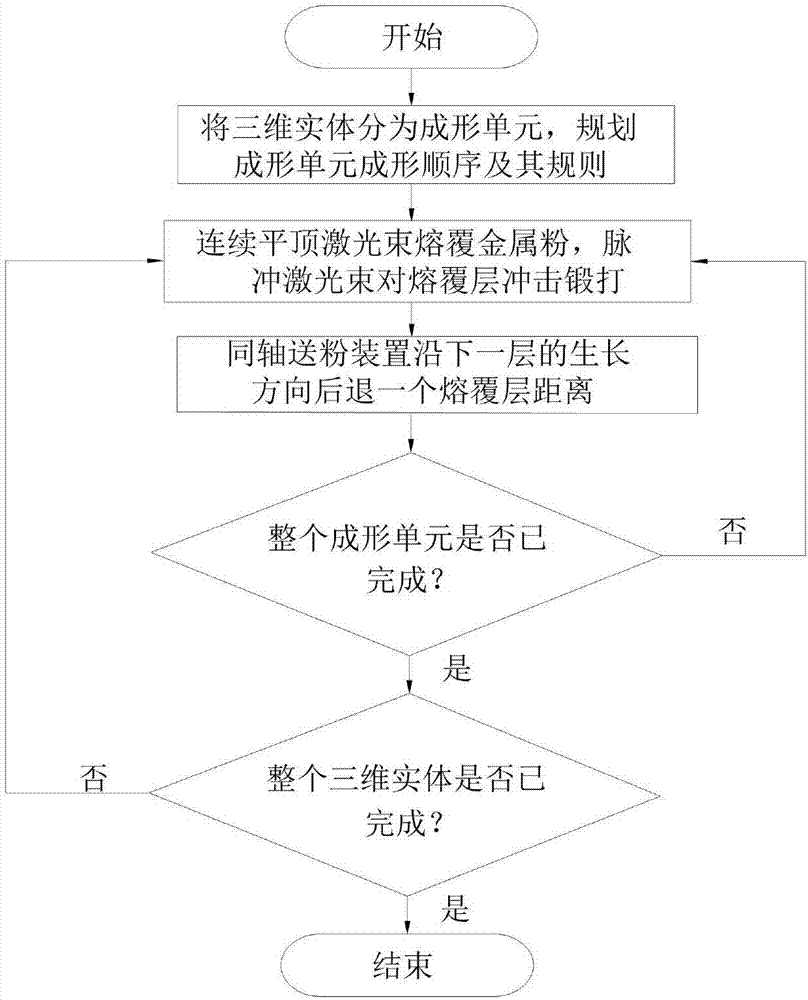

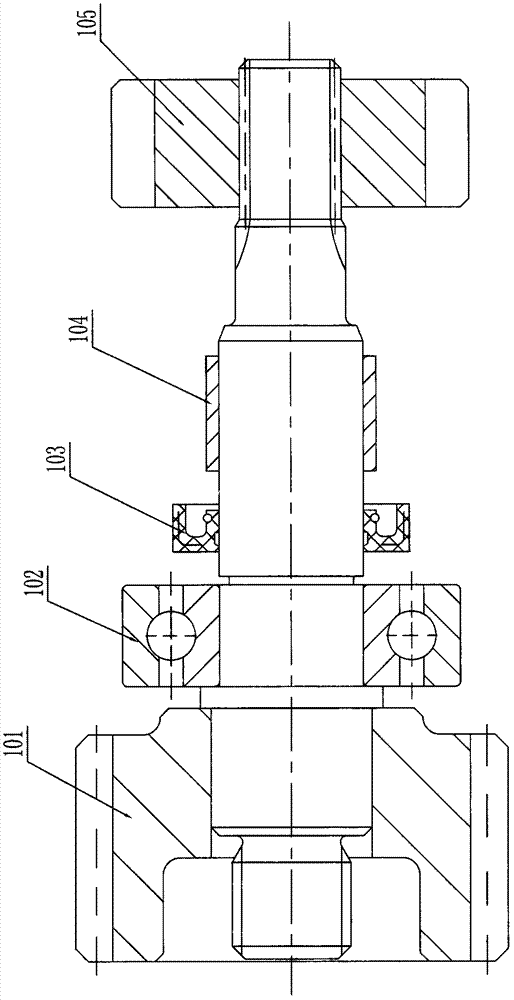

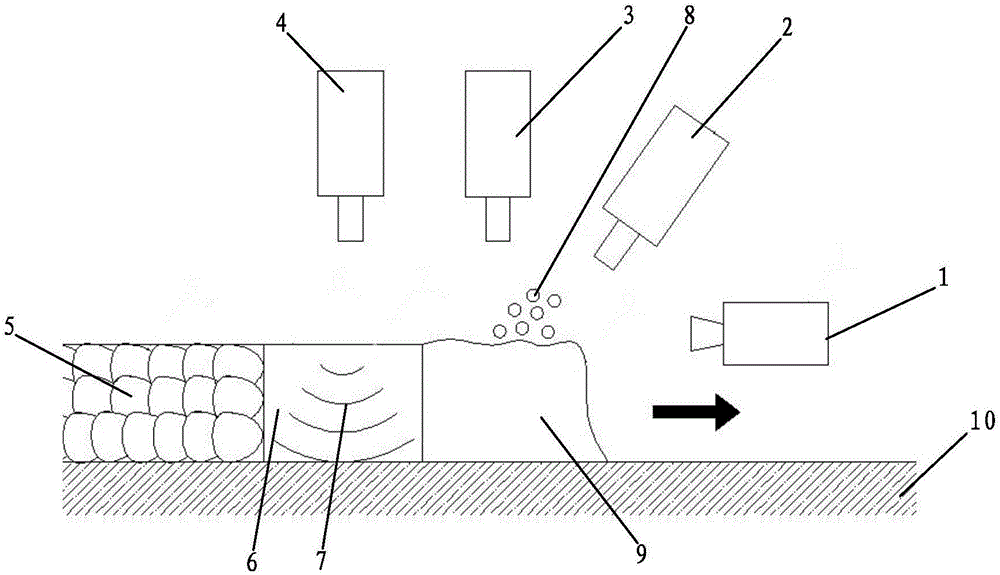

Inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method

ActiveCN107262713ASolve undermeltSolve the problem of impenetrabilityAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsInductor

The invention relates to an inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method. The device comprises a master controller, a pulse laser device, a continuous laser device, a temperature inductor, a coaxial powder feeding device, a visual tracking system, a workbench, a mechanical arm, a metal powder container and a gas container. The pulse laser device, the continuous laser device, the temperature inductor and the visual tracking system are all arranged above the workbench. The mechanical arm tightly clamps the coaxial powder feeding device, so that the coaxial powder feeding device is located between the continuous laser device and the workbench, and is coaxial with the continuous laser device. The coaxial powder feeding device communicates with the metal powder container and the gas container. The pulse laser device, the continuous laser device, the temperature inductor, the visual tracking system, the mechanical arm, the metal powder container and the gas container are all connected with the master controller. The inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method can solve the problems of insufficient fusion and incomplete fusion of the Gaussian light spot edges, inner defects of gas holes, incomplete fusion, cracks and shrinkage are effectively eliminated, and the inner stress state of a formed part is greatly improved.

Owner:GUANGDONG UNIV OF TECH

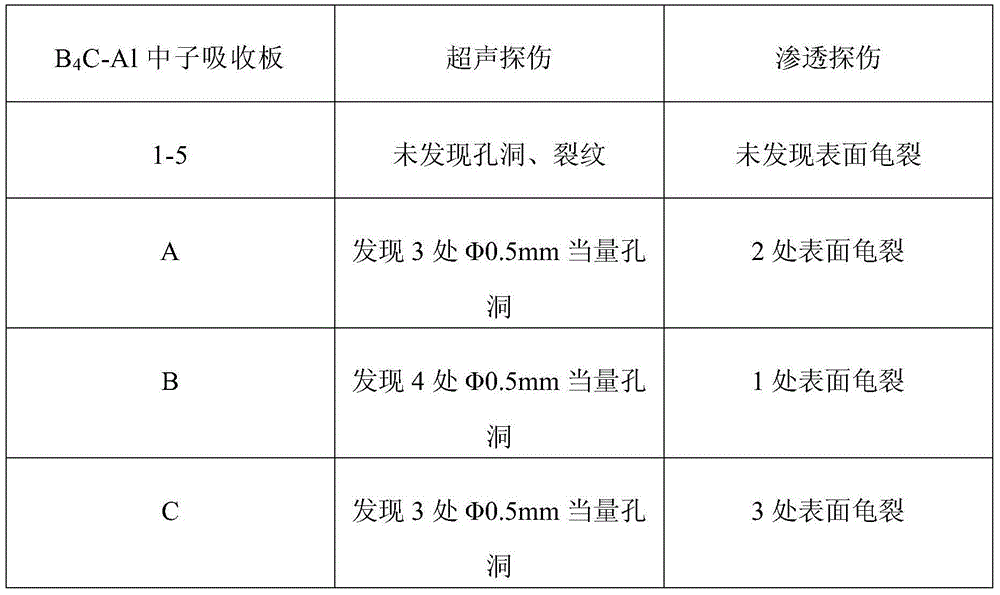

Large-dimension B4C-Al neutron absorption plate and preparation method thereof

InactiveCN104372191ANo need for sintering processOvercoming the problem of further increase in defectsShieldingNuclear reactorNuclear power

A disclosed preparation method for a large-dimension B4C-Al neutron absorption plate comprises: 1) crushing boron carbide powder, aluminium powder and silicon powder and mixing uniformly, so as to obtain a mixed powder with the particle size of 3.5-63 mu m; 2) putting the mixed powder into a can, vacuumizing at 200-350 DEG C, sealing, and then performing heat isostatic pressing processing on the sealed can under the conditions that the pressure is 80-150 MPa, the temperature is 400-600 DEG C and the time is 20 min; 3) removing the can at the outer side of the blank material, performing multiple times of rolling at 450-600 DEG C, controlling the deformation amount of each time rolling to be 10-20%, so as to obtain a plate with the needed thickness; and 4) processing the plate. The invention also discloses the dimension of the B4C-Al neutron absorption plate obtained by using the above method. The prepared B4C-Al neutron absorption plate is applicable to nuclear industry fields such as nuclear reactors, nuclear power stations and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Lightweight fireproof foaming cement door inner filling material and preparation method thereof

InactiveCN101143777AIncrease gas productionWith thermal insulationSolid waste managementCeramicwareReducing agentWeight light

The invention discloses a lightweight flame retardant and foamy filling material of cement doors and manufacturing method thereof, comprising magnesium oxide, magnesium sulphate, fly ash, high alumina refractory cement, calcium chloride, water proofing agent, water reducing agent and foaming agent, with bulk density ranging between 200 kg / m3 and 500kg / m3; the ingredients are formulated by weight at a rate of: magnesium oxide (40 percent -55 percent), magnesium sulfate (15 percent-40 percent), fly ash (5 percent-20 percent), high alumina refractory cement (5 percent-20 percent), calcium chloride (2 percent-6 percent), water proofing agent (2 percent5 percent), water reducing agent (0.2 percent1.5 percent) and foaming agent (0.1 percent-0.5 percent). With the technical solution, the product has the advantages of high strength, light weight, flame retardancy, sound insulation, weather resistance, thermal resistance, energy efficient, freedom from toxicity, harm and irradiation, low manufacturing cost, simple process, etc, which can be widely employed for fire / theft proof metal interior door, building material and like sectors.

Owner:ZHEJIANG MEIXIN IND CO LTD

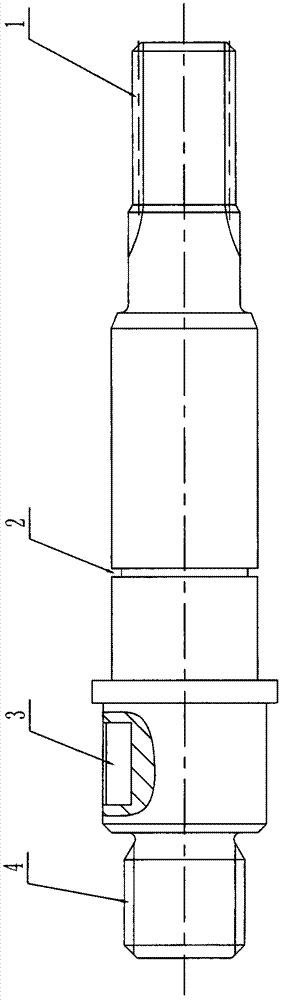

Oil pump shaft machining process

An oil pump shaft machining process includes steps of 1) feeding a blank; 2) turning two end faces and perforating a central hole; 3) roughly turning an outer circle with margin of 0.5 mm; 4) performing quenched-tempered heat treatment; 5) repairing and grinding the central hole; 6) finely turning an outer circle, grooving, turning a thread, and reserving grinding allowance of 0.3 mm after finely turning the outer circle; 7) milling a key slot; 8) cold rolling a spline; 9) locally quenching the outer circle surface at high frequency; 10) annealing at the low temperature, heating to 150-180 DEG C during annealing at the low temperature and preserving temperature for 2.5 hours; 11) repairing and grinding the central hole; 12) finely grinding the outer circles. By the oil pump shaft machining process, contact positions of a machined oil pump shaft with a deep groove ball bearing, an oil seal and a slide bearing are good in wear resistance, and the machined oil pump shaft is high in small-modulus spline machining efficiency, good in tooth form structure, resistant to impact and high in strength.

Owner:ZHEJIANG BODA TECH

Ink-jet penetrated polished semitransparent ceramic sheet, and preparation method thereof

The invention relates to an ink-jet penetrated polished semitransparent ceramic sheet. The ink-jet penetrated polished semitransparent ceramic sheet comprises a semitransparent green body containing an ink dyeing assistant agent, and an ink jet penetrating layer penetrating into the semitransparent green body. According to a preparation method, the ink dyeing assistant agent is added into the semitransparent green body, and ink jet penetrating technology is adopted, so that penetration of patterns into the semitransparent green body is realized, polishing is carried out directly after sintering, green body surface particle flatness is excellent, stain resistance is excellent, pattern wear resistance is excellent, and requirements on highlight products are satisfied, adding of a transparent glaze layer onto the surface of the green body is not necessary, cost is reduced, a problem that bonding of the glaze layer with the green body is poor is solved, production deformation cracking is avoided, the preparation method of the green body is simple, adding of non-transparent preform body is unnecessary, and in addition, the semitransparent green body contains the ink dyeing assistant agent, so that the color of the patterns used for decoration is bright, sharpness is high, and decoration requirements can be satisfied preferably.

Owner:MONALISA GRP CO LTD

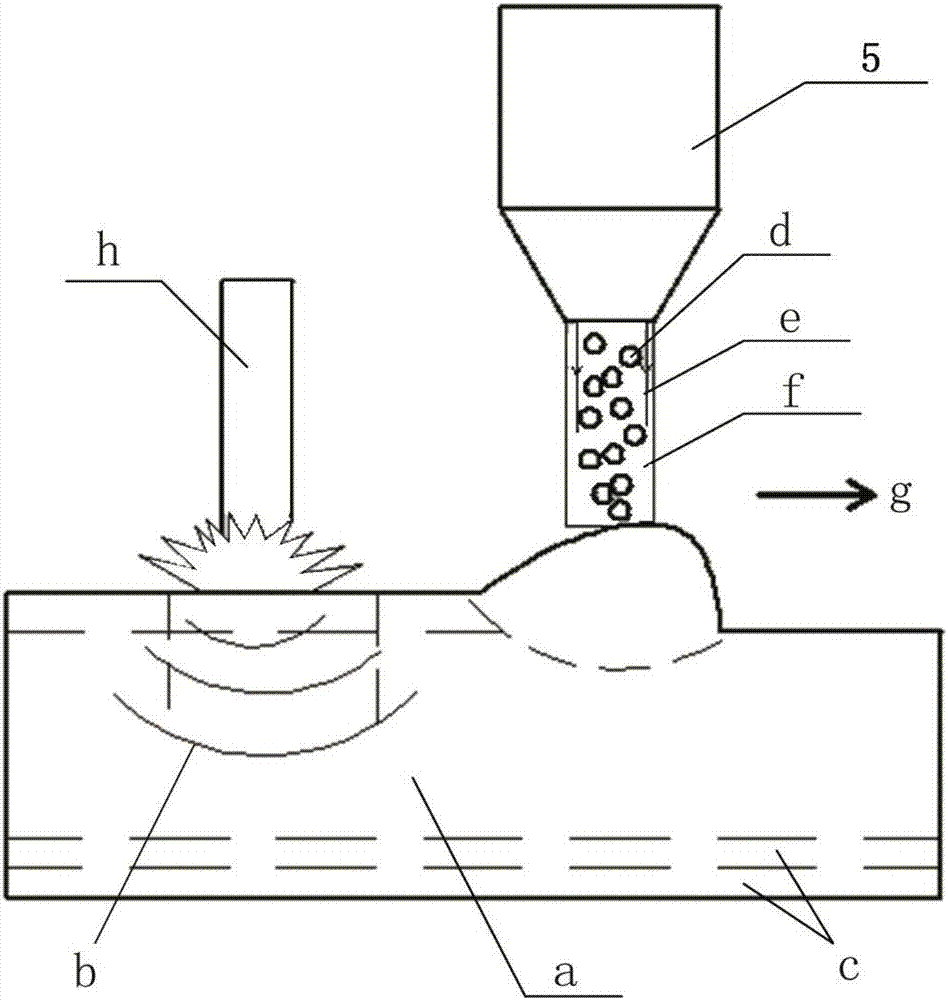

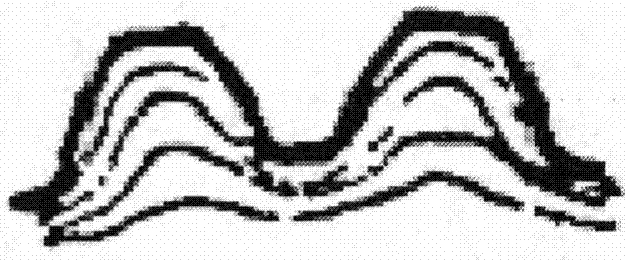

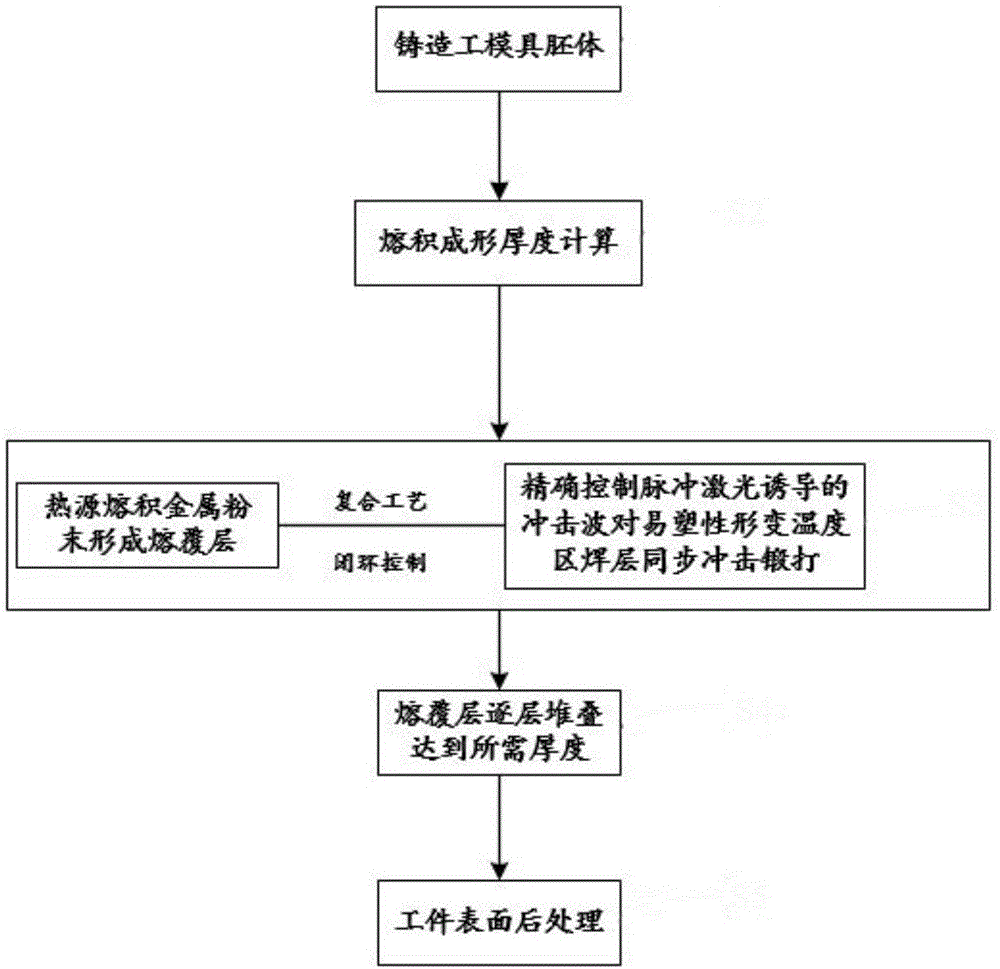

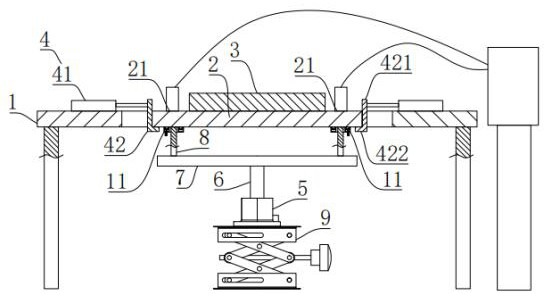

Mould melting-deposition forming and laser impact forging composite additive manufacturing method and device

InactiveCN107520449AQuality improvementImprove efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyMetal powderMetal mold

The invention discloses a mould melting-deposition forming and laser impact forging composite additive manufacturing method. The mould melting-deposition forming and laser impact forging composite additive manufacturing method comprises the following steps that (1) a mould blank body is cast; (2) the melting-deposition forming thickness is calculated; (3) metal powder is subjected to melting deposition through a heat source to form cladding layers, a controller controls a laser generator to conduct impact forging on a melting-deposition metal area at the plastic deformation temperature synchronously, the cladding layers are stacked layer by layer till the thickness of the cladding layers reach the thickness value in the step (2), and thus a workpiece is formed; and (4) the surface of the workpiece is treated. The invention further provides a mould melting-deposition forming and laser impact forging composite additive manufacturing device. The method adopts melting-deposition forming and laser impact forging composite manufacturing, melting-deposition forming and impact forging are conducted simultaneously, parameters are mutually coordinated and restrained in the process, thus, thermal stress, deformation and cracking can be avoided, the microstructure of a metal part is optimized, internal defects of pores, non-fusion, shrinkage porosity and the like are avoided, and the forming quality and efficiency of additive manufacturing of a metal mould are improved.

Owner:GUANGDONG UNIV OF TECH

Alloyed powder for directly printing metal parts in 3D (three-dimensional) manner and preparation method of alloyed powder

ActiveCN104668553ANo lossPrevent solidificationTransportation and packagingMetal-working apparatusStructural deformationMicrosphere

The invention provides alloyed powder for directly printing metal parts in a 3D (three-dimensional) manner. The alloyed powder is characterized in that nanometer aluminum is adhered to the surface of oxide of iron through a layer of thin tin powder to form iron-base alloy microspheres, the grain size of the microspheres is 2-10 micrometers, the sphericity is greater than 95%, and the alloyed powder comprises the following materials in part by weight: 60-70 parts of iron oxide, 30-40 parts of nanometer aluminum and 0.1-0.5 part of tin powder. The alloyed powder can be directly used for printing the metal parts in the 3D manner. When the alloyed powder is used for directly printing the metal parts in the 3D manner, the iron oxide is gradually reduced through aluminum, structure deformation caused by direct fusion molding of metal, cooling crystallization is uniform, the strength of a molded piece is improved by formed aluminum oxide, the porosity of products is reduced, and the compactness is high. The alloyed powder can be used for directly printing the high-precision metal parts which have complication shapes.

Owner:康硕(河南)智能制造有限公司

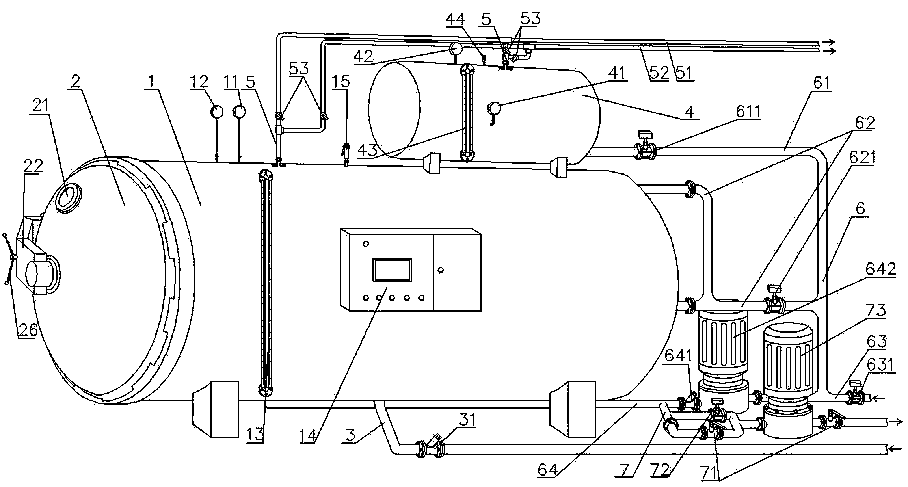

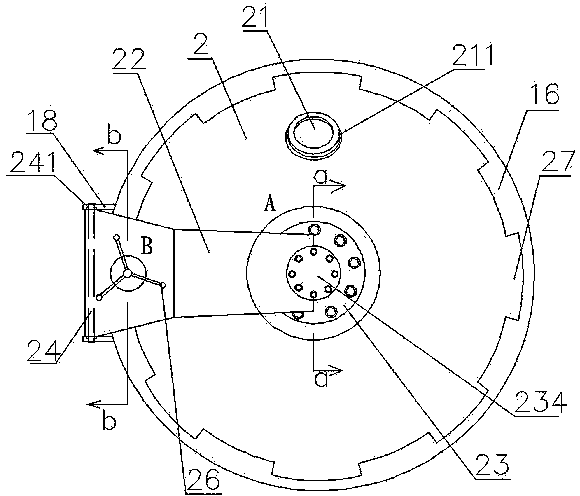

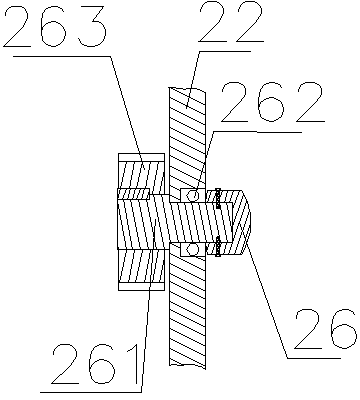

Full-automatic sterilizing quality-guaranteeing steamer and sterilizing technology

ActiveCN103385525AGuaranteed reasonablenessSafe storageFood processingFood preservationTemperature controlAutomatic control

The invention relates to a full-automatic sterilizing quality-guaranteeing steamer and a sterilizing technology which are suitable for sterilizing and quality guaranteeing of fully closed box-packed fast food. The steamer comprises a pot body, a pot cover, a steam pipe, a return water storage tank, a vent pipe, a water cycle pipeline and a drain pipe, wherein the water cycle pipeline comprises a return water pipe, a chief spray pipe, a water inlet pipe and a water outlet pipe, the pot body is provided with a thermometer I, a pressure gauge I, a water-thermometer I and a reducing valve I, and is connected with an automatic control box, the pot cover is hermetically connected with the pot body, the pot body is connected with the steam pipe, the vent pipe, the chief spray pipe and the water outlet pipe, the return water storage tank is connected with the return water pipe and the vent pipe, the drain pipe is communicated with the water outlet pipe, the inner cavity of the pot body comprises a temperature control sensor, a water outlet hole, a steam heating pipe, an upper spray pipe and a side spray pipe, and the upper spray pipe and the side spray pipe are communicated with the chief spray pipe. The steamer can be used for automatically and accurately controlling the temperature, pressure and time, guaranteeing the sterilizing quality through heating and cooling by gradient, and saving energy and water because the hot and cold spray water is used and stored reasonably.

Owner:HANGZHOU GUANHUAWANG FOOD

Machine-spraying quick-demulsifying solidification film formation creep waterproof coating and preparation method thereof

ActiveCN103525307AGood adhesionIncrease viscosityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention discloses a machine-spraying quick-demulsifying solidification film formation creep waterproof coating and a preparation method thereof, belonging to the technical field of waterproof coating. The waterproof coating is formed from the components A and B by atomization mixing in air and dehydration curing, wherein the component A comprises the following components in percentage by weight: 5-20% of thermoplastic elastomer polymer, 20-50% of asphalt, 30-50% of water, 1-5% of emulsifier, 5-20% of rubber latex and 0-20% of filler; the component B consists of the following components in percentage by weight: 30-40% of demulsifier and 60-70% of water. The waterproof coating overcomes the shortcomings of a common elastomer, such as quick aging in a high-stress state for a long time, stretching fatigue and the like, and always keeps good viscosity and re-bonding ability; the problem of internal stress of a waterproof layer is thoroughly solved, so that the waterproof layer has the characteristics of strong sustained bonding ability, high elongation and low-temperature flexibility; the material has good adhesive property, good heat resistance and good low-temperature flexibility, and the creep property in a shear state can exceed 0.1N / mm.

Owner:浙江鲁班建筑防水有限公司

Forging process for forge piece

ActiveCN107282839AShort heating timeIncrease production rateHandling devicesSurface finishSurface cleaning

The invention discloses a forging process for a forge piece and aims to provide a forging process for a forge piece with high structural strength and surface smoothness. According to the technical scheme of the forging process, the forging process for the forge piece is characterized by comprising the following steps of (1) charging, (2) heating, (3) dummying, (4) die forging forming, (5) trimming , (6) heat treatment, (7) surface cleaning, (8) flaw detection and (9) inspection. The forging process is suitable for a forging machining process.

Owner:TAIZHOU YUPENG MACHINE FORGING

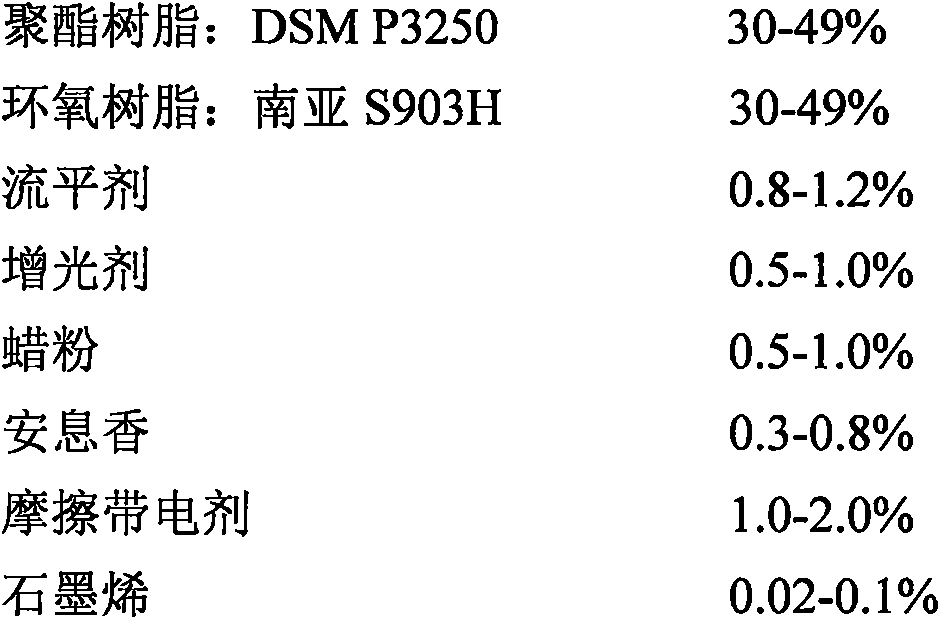

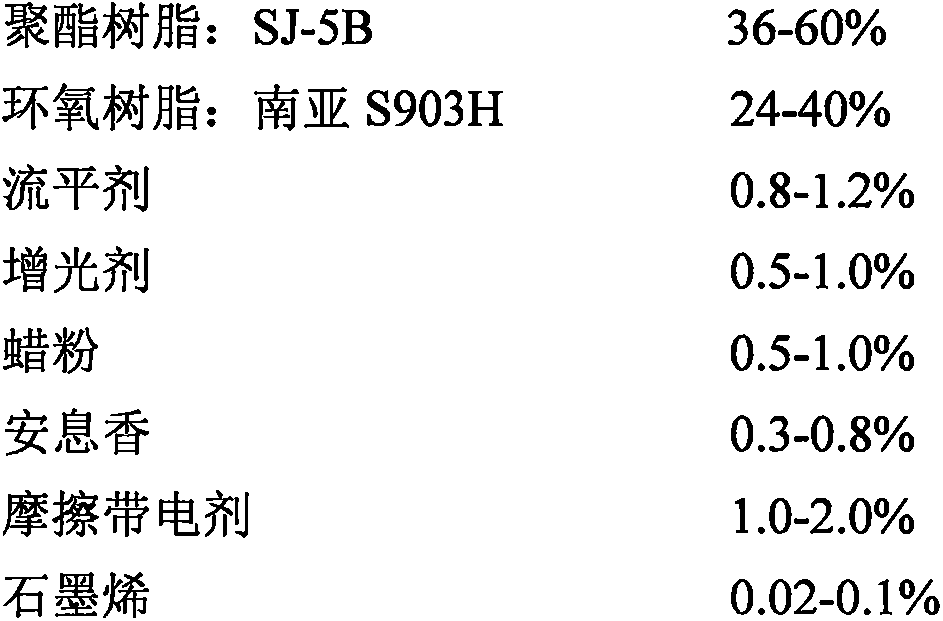

Graphene transparent powder coating for tribo gun to spray MDF plate

InactiveCN106634468AUniform thicknessNo powder accumulationPretreated surfacesPowdery paintsEpoxyWax

The invention relates to a transparent powder coating, specifically to a graphene transparent powder coating for tribo gun to spray an MDF plate. The graphene transparent powder coating is prepared from the following raw materials in percentages: 30 to 60% of polyester resin, 24 to 48% of epoxy resin, 0.8 to 1.2% of a leveling agent, 0.5 to 1.0% of a gloss enhancer, 0.5 to 1.0% of wax powder, 0.3 to 0.8% of benzoin, 1.0 to 2.0% of a triboelectric charging additive and 0.02 to 0.1% of graphene. According to the invention, powder coating is realized by using a tribo gun through addition of the triboelectric charging additive; by adopting a method of spraying a powder coating with the tribo gun, no Faraday effect is generated; meanwhile, no free ions are generated; charged powder ions may not mutually exclude; a formed coatingn film has good leveling properties; and through addition of graphene, the transparent powder coating can be improved in glossiness, adhesive force, water resistance, conductivity, flexibility, etc.

Owner:燕园众欣纳米科技(北京)有限公司

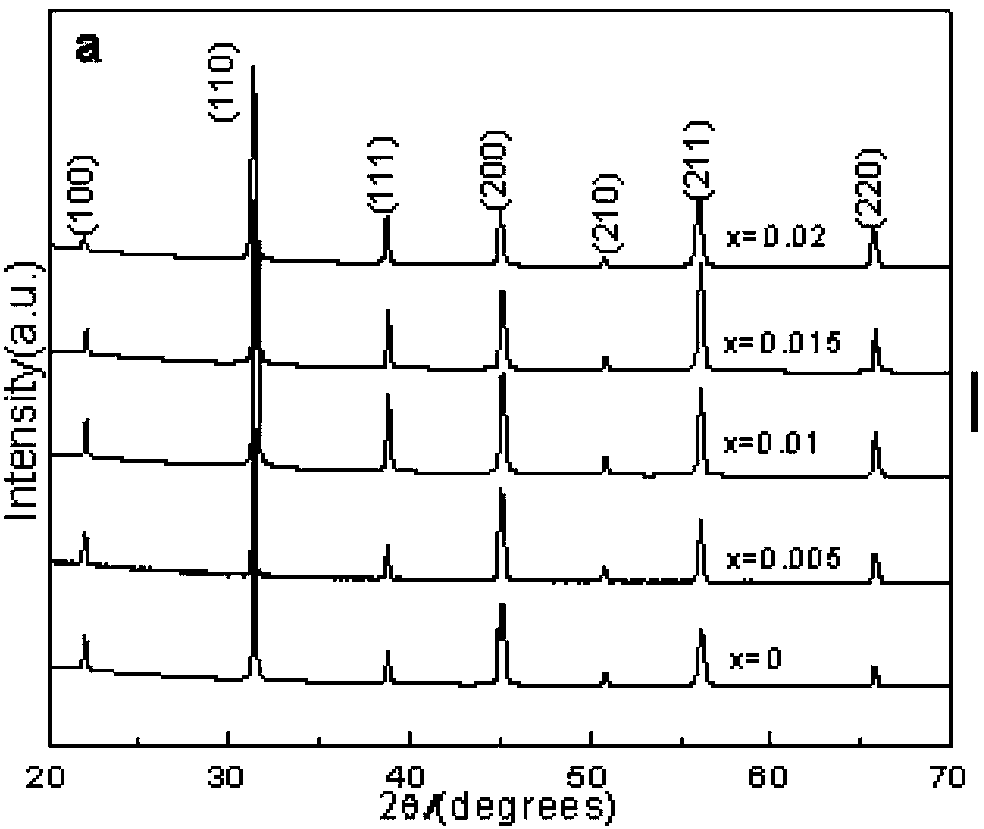

Niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material

InactiveCN103373849AHigh piezoelectric constantIncrease the piezoelectric constant d <sub>33<</sub> ZirconateSlurry

The invention discloses a niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material which is prepared through the following method comprising the steps of: weighting raw materials BaCO3, ZrO2, TiO2, CaCO3, MnO2 and Nb2O5 according to the stoichiometric ratio of elements in the chemical general formula: Ba0.85Ca0.15Ti0.895-xZr0.1Mn0.005NbxO3; carrying out ball milling on the raw materials for 10-16h by taking absolute ethyl alcohol as a medium, and drying the ball-milled slurry to obtain dry powder; and placing the dry powder into the air, and pre-sintering the dry powder at the temperature of 1100-1300 DEG C for 1-4h to obtain the niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material. The Ba0.85Ca0.15Ti0.895-xZr0.1Mn0.005NbxO3 leadless piezoelectric ceramic with a perovskite type structure, which is obtained by using the traditional solid state sintering method and industrial raw materials, has more excellent performance. Shown by mass data statistics, the leadless piezoelectric ceramic prepared by using the niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material disclosed by the invention has the piezoelectric constant d33 of 335pC / N, the electromechanical coupling factor kp of 39.5% and the dielectric loss of less than 2%. In addition, the niobium oxide doped barium calcium zirconate titanate leadless piezoelectric ceramic powder material is stable in preparation process and better in industrial prospect.

Owner:GUIZHOU UNIV

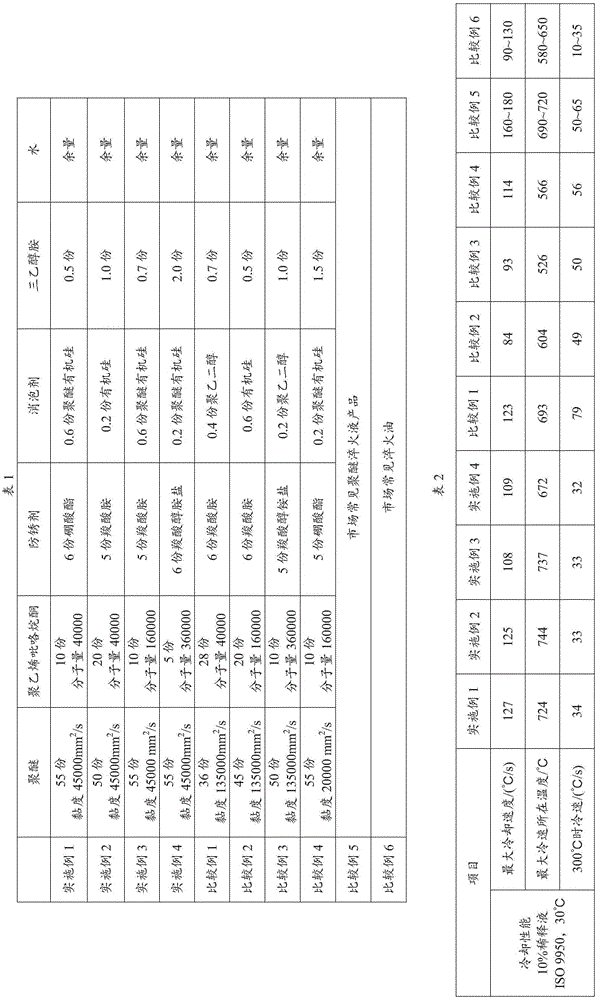

Quench bath composition and application thereof

InactiveCN105274293AReduce cooling rateReduce quenching deformationQuenching agentsRust converterCarbon steel

The invention relates to a quench bath composition and application thereof. The problems that due to the fact that the cooling speed of an existing quenching bath is too high, workpieces made of materials high in quenching degree are prone to deforming and cracking, the application range of the quenching bath is limited, and quenching oil with the high cost cannot be replaced are mainly solved. The quench bath composition is composed of, by weight, 45-70 parts of polyalkylene glycol, 2-30 parts of polyvinylpyrrolidone, 0.5-8 parts of antirust agent, 0.005-0.2 part of antifoaming agent, 0.1-5 parts of triethanolamine and 20-80 parts of water. According to the technical scheme, the problems are solved well, and the quench bath composition can be used for quenching of materials high in quenching degree or small and medium low-carbon steel.

Owner:CHINA PETROLEUM & CHEM CORP

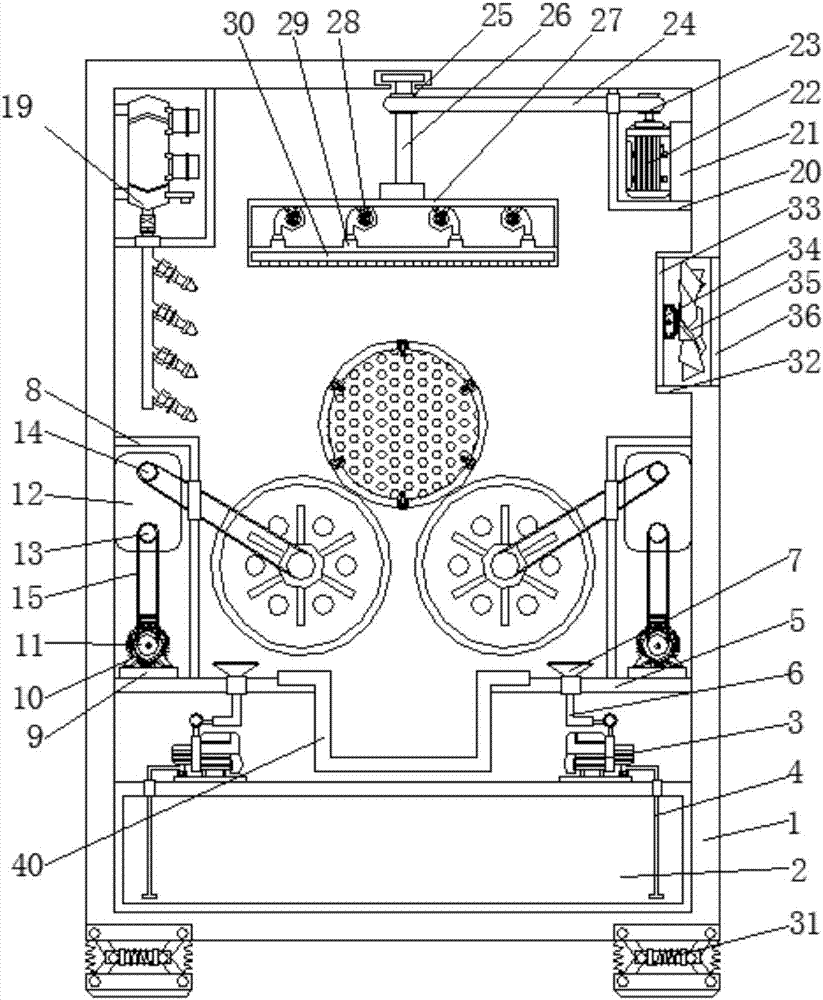

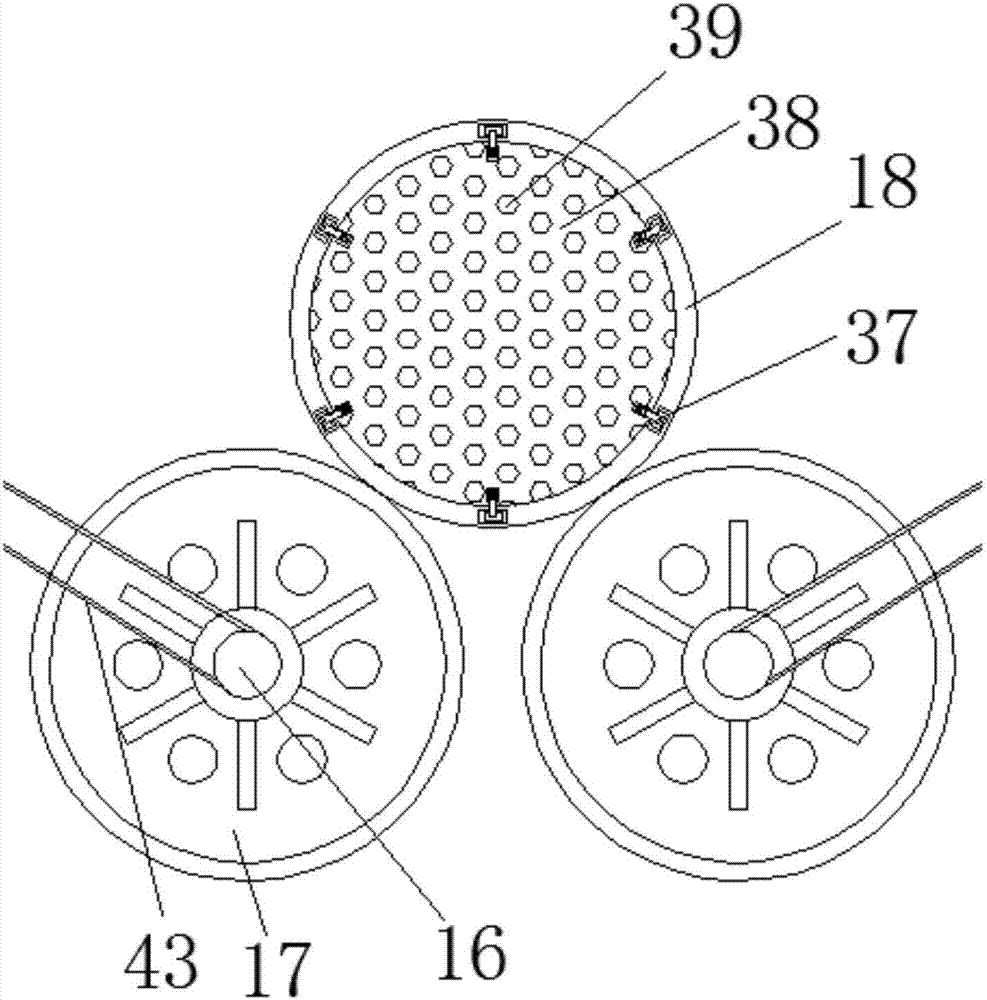

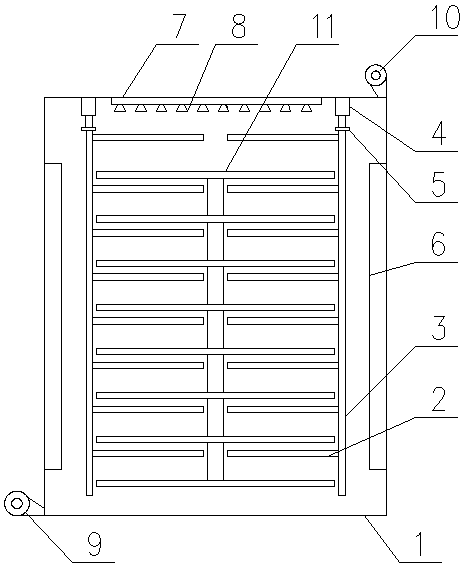

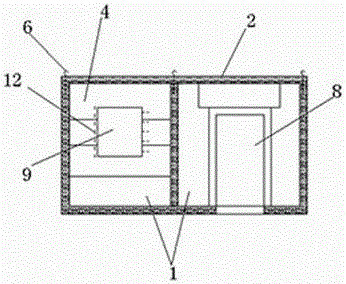

Novel dual-purpose steam drying device for wood

InactiveCN107218782APrevent deformation and crackingHeating evenlyDrying gas arrangementsDrying machines with non-progressive movementsPulp and paper industryDual purpose

The invention discloses a novel dual-purpose wood steam drying device, which comprises a box body, a water tank is fixedly connected to the bottom of the inner wall of the box body, a high-temperature steam generator is fixedly connected to both sides of the top of the water tank, and one side of the high-temperature steam generator is connected to the There is a suction pipe, and the side of the suction pipe away from the high-temperature steam generator runs through the water tank and extends to the bottom of the inner wall of the water tank. The two sides of the inner wall of the box body and the upper part of the water tank are fixedly connected with supporting horizontal plates, and the side of the high-temperature steam generator far away from the suction pipe The side is connected with a steam pipe, and the steam pipe runs through the bottom of the support horizontal plate and extends to the top of the support horizontal plate. The invention relates to the technical field of wood processing machinery. This new dual-purpose wood steam drying device solves the phenomenon of uneven drying of the current wood drying device, which easily leads to deformation and cracking of wood, and effectively improves production efficiency and drying quality. At the same time, the drying cylinder can be directly replaced with logs The design achieves the purpose of being practical, convenient and versatile.

Owner:安吉县瑞旺竹木制品厂

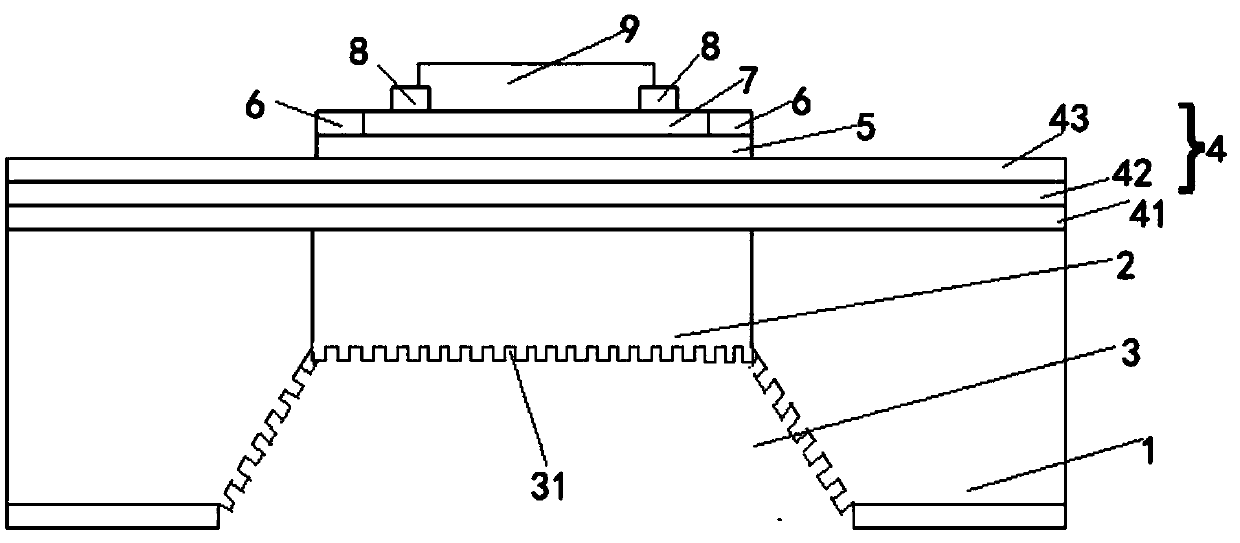

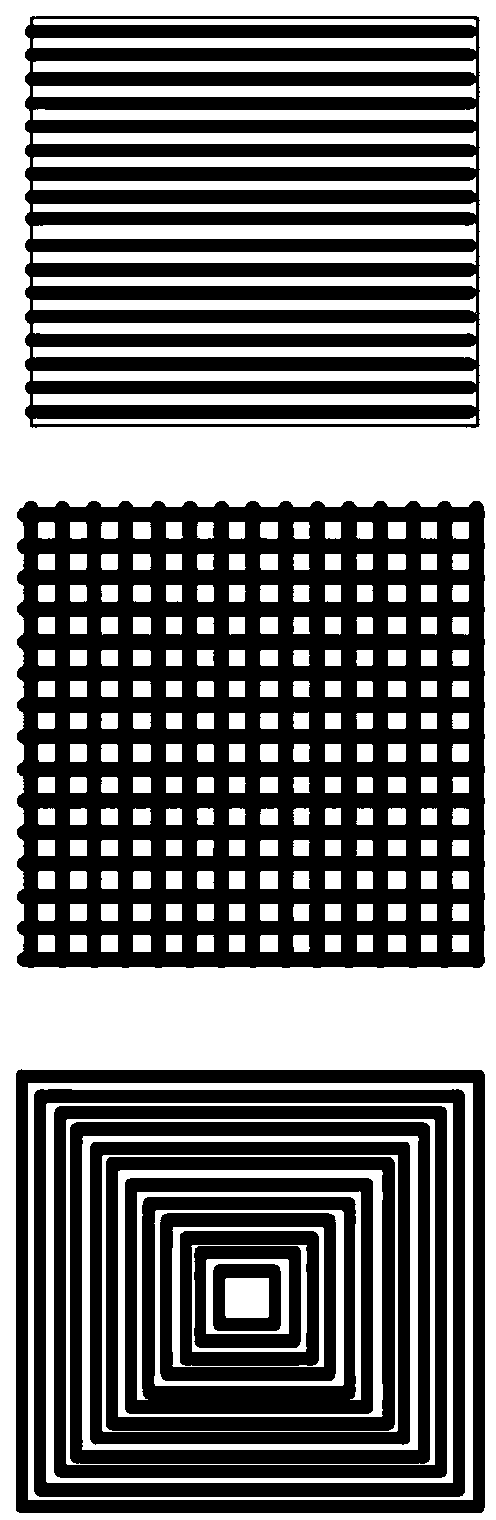

Heating body with heating mesh inlaid on surface porous ceramic and preparation method thereof

The invention discloses a heating body with a heating mesh inlaid on the surface of porous ceramic and a preparation method thereof. The heating body comprises a ceramic substrate and the heating meshinlaid on the ceramic substrate, wherein the ceramic substrate is a ceramic body; the interior of the ceramic body has a porous structure; and the heating mesh is inlaid on the surface of the ceramicsubstrate. The preparation method for the heating body with the heating mesh inlaid on the surface of the porous ceramic comprises the following preparation steps: preparation of materials, i.e., preparation of a ceramic slurry and the heating mesh; hardening molding in a mold cavity; sintering of a green ceramic heating body; and baking of the green ceramic heating body. The heating body with the heating mesh inlaid on the surface of the porous ceramic and the preparation method thereof provided by the invention have the following advantages which are deficient for a conventional product during implementation: stable structure, fast heating speed, uniform temperature distribution, good use experience, insusceptibility to generating deformation and cracking for the heating mesh, long service life, good use economy, etc.

Owner:SHENZHEN HUACHENGDA PRECISION IND CO LTD

Lightweight fireproof filling material for metal door produced by expansion perlite and preparation method thereof

InactiveCN101215179AAct as waterproof and water-blockingWith thermal insulationThermal insulationAdhesive

The invention discloses a lightening fireproof filling material for producing metal door by expanded perlite and a process for preparation. The material comprises expanded perlite, magnesium oxide, magnesium sulfate, calcium hydroxide, aqueous adhesive and water proofing agent, the volume weight is between 200-300kg / m3, the proportionings of each component according to weight percentage respectively are that the expanded perlite takes 45-65, the magnesium oxide takes 15-25, the magnesium sulfate takes 5-15, the calcium hydroxide takes 0.5-4 and the aqueous adhesive takes 2-5. Employing the technical scheme, the product has the advantages of high mechanical strength, light weight, high grade of fire resistance, good effect of sound absorption and acoustic insulation, strong anti-weatherability, heat insulation, heat preservation and energy conservation, easy production and no poison, on hazard and no radiation and the like. The product can be widely used in metal door industry, architectural materials industry and the related industries.

Owner:ZHEJIANG MEIXIN IND CO LTD

Anti-deformation wood drying equipment

InactiveCN107631574ADry evenlyPrevent deformation and crackingDrying gas arrangementsDrying solid materialsPulp and paper industryWood drying

The invention provides anti-deformation wood drying equipment. The anti-deformation wood drying equipment comprises a drying furnace body, a heating device mounted in the drying furnace body, a mist spraying device and a ventilating device. The anti-deformation wood drying equipment is characterized in that a group of net plate supports are arranged in the drying furnace body; net plate pressing plates are arranged on each net plate support; the net plate pressing plates are connected together through connecting rods; the connecting rods are connected with hydraulic oil cylinders; and pressuresensors are arranged in the positions where the connecting rods are connected with the hydraulic oil cylinders. With the anti-deformation wood drying equipment, wood cracking, deformation and the like can be effectively prevented, and the drying effect is good.

Owner:JIANGSU ZHUODA INFORMATION TECH CO LTD

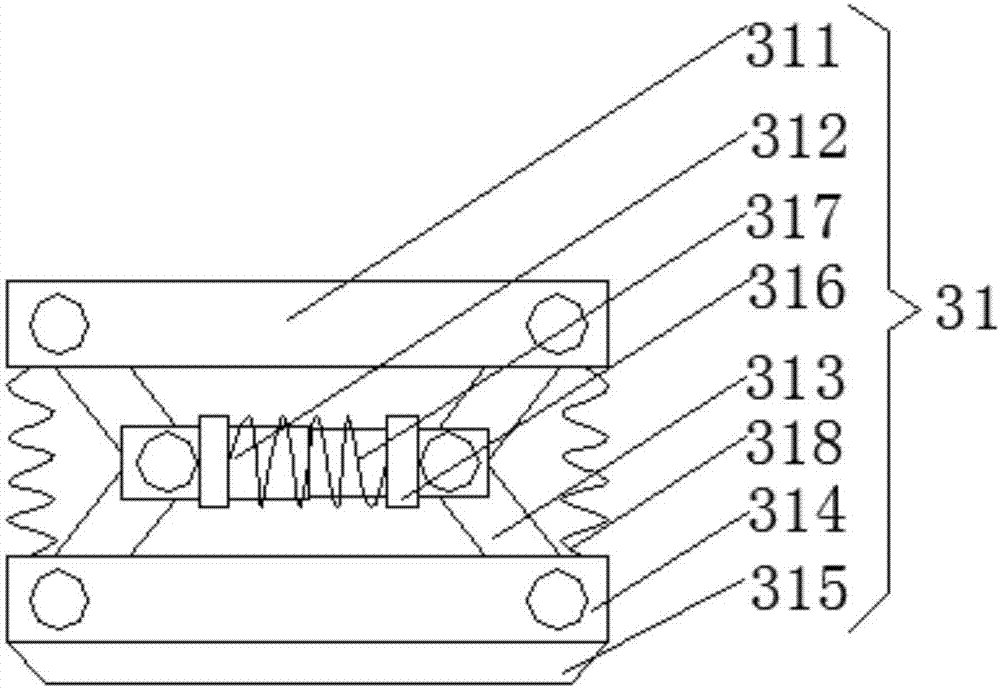

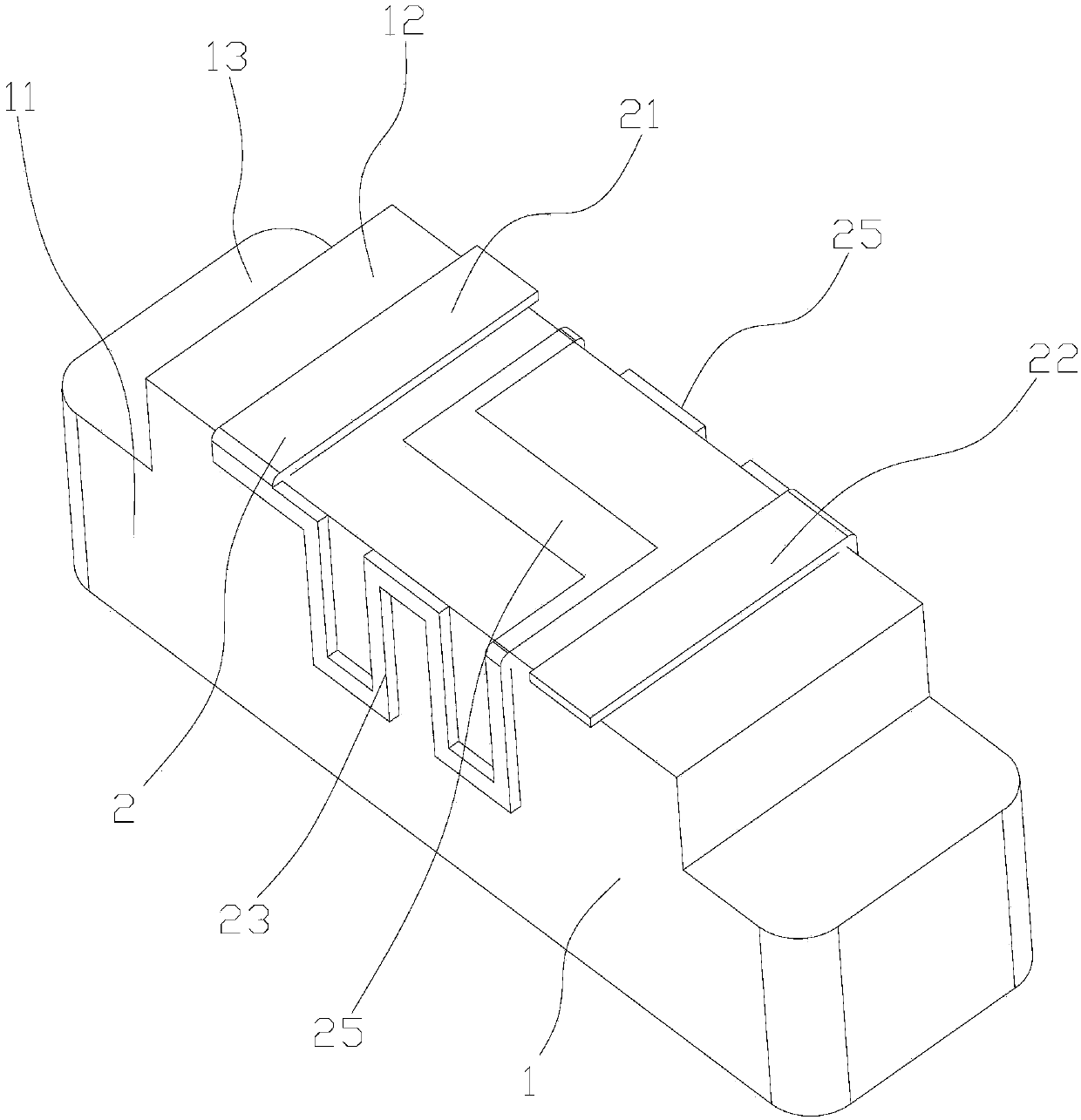

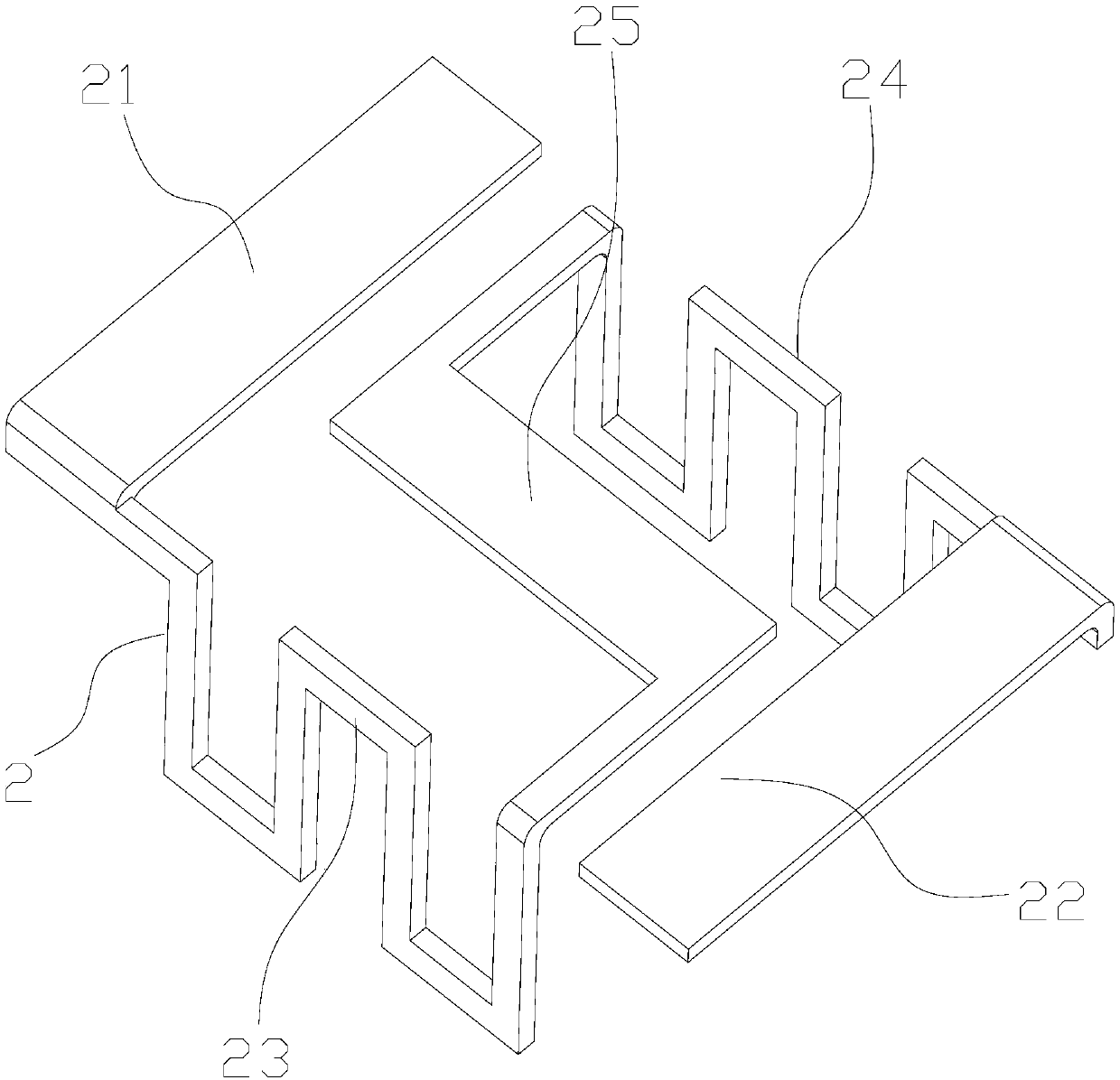

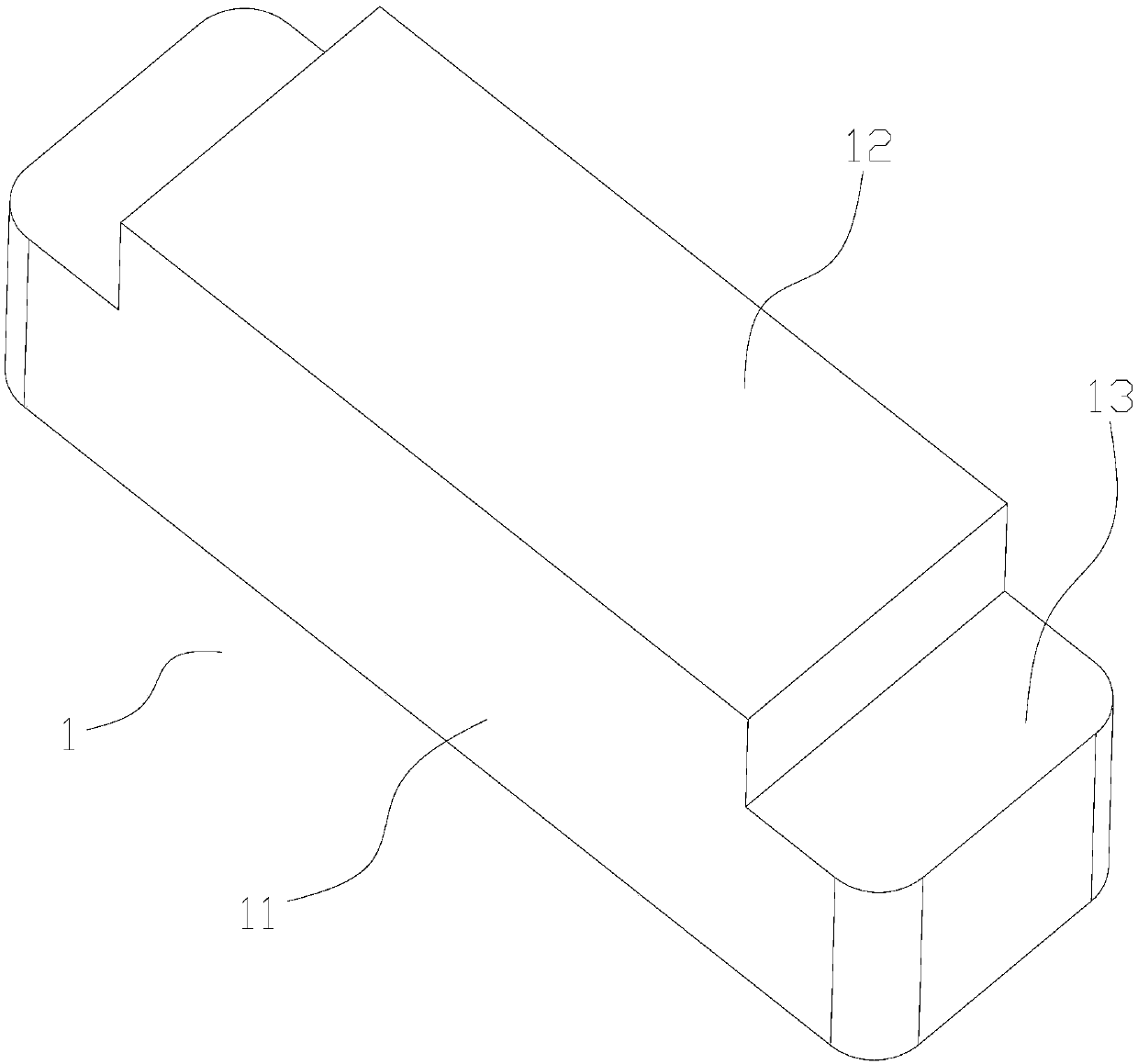

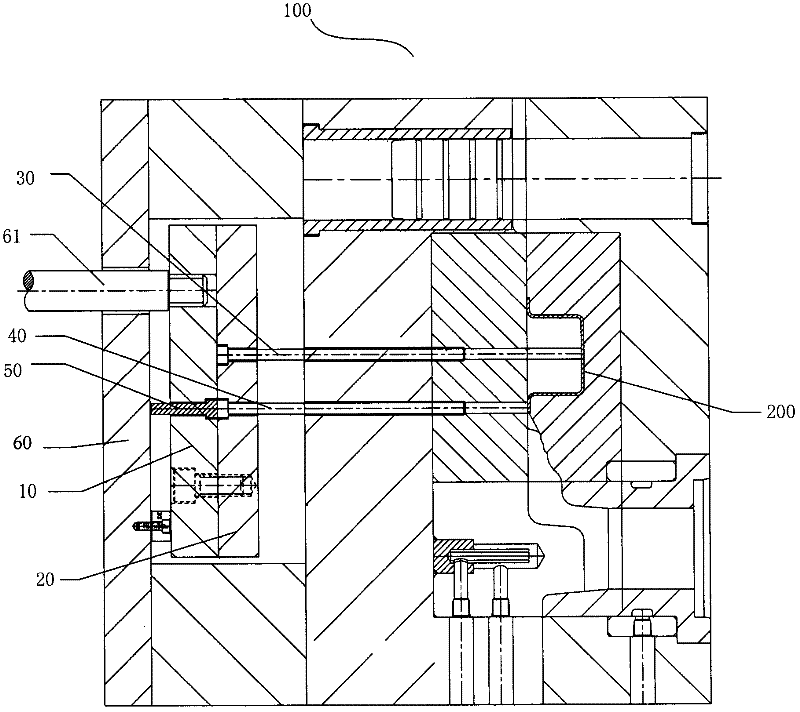

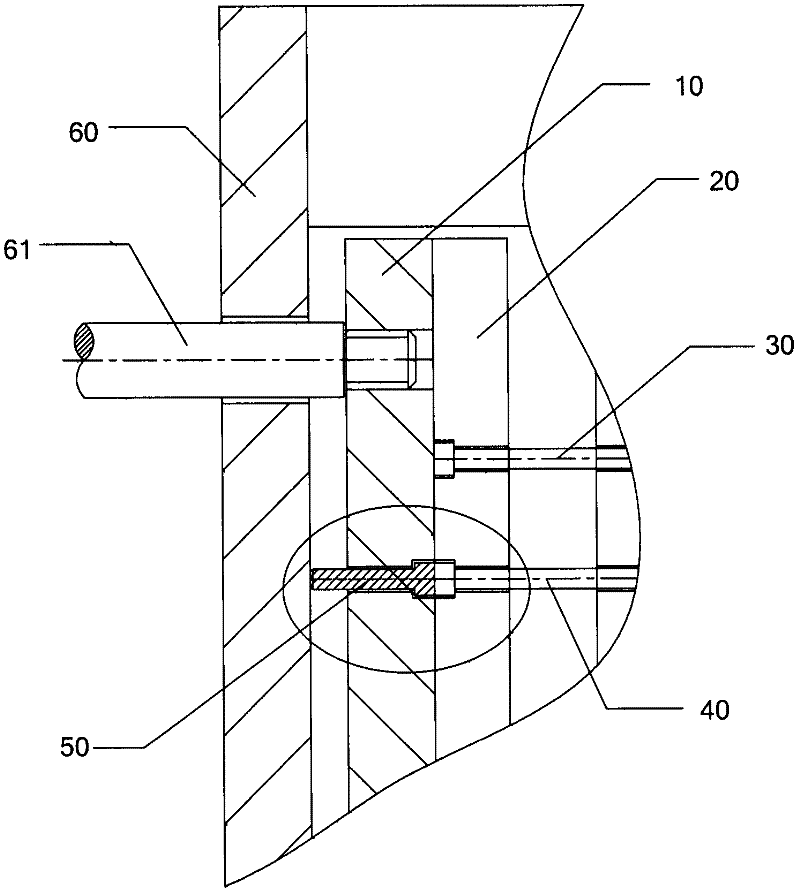

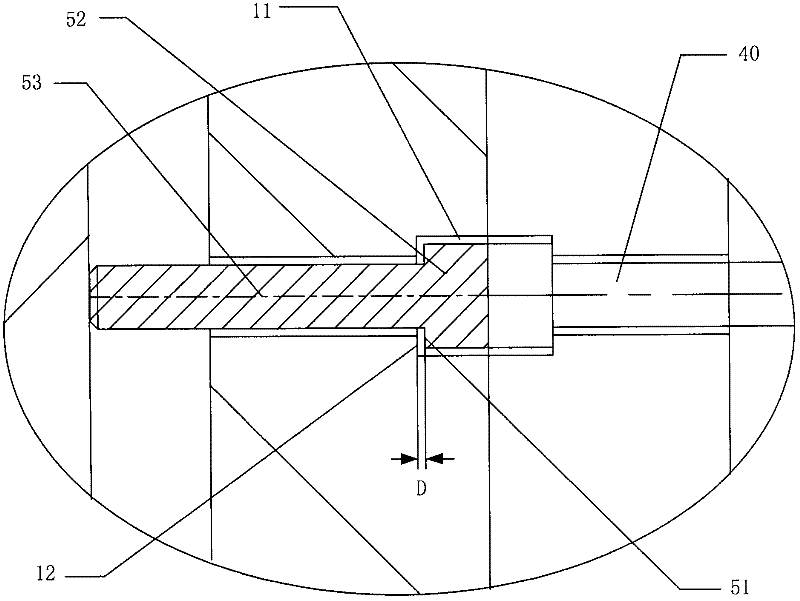

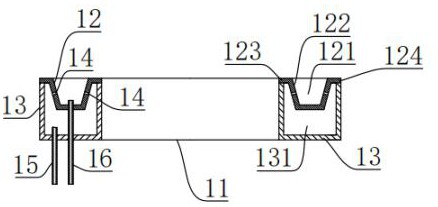

Demolding mechanism, demolding method and die-casting device

The invention relates to the field of die-casting manufacture, in particular to a demolding mechanism, a demolding method and a die-casting device. The demolding mechanism comprises an ejector pin base plate and an ejector pin fixing plate, wherein the ejector pin base plate is connected with a die-casting machine ejector rod penetrating through a mold base plate, and the ejector pin fixing plate is connected with the ejector pin base plate and is provided with a first ejector pin and a second ejector pin in penetrating mode. The first ejector pin is in butt joint with the ejector pin base plate which is provided with an ejector pin ejector rod in butt joint with the second ejector pin. The ejector pin ejector rod comprises a first step located in a sink hole of the ejector pin base plate, the sink hole is provided with an ejecting face corresponding to a first step, a delay distance is reserved between the ejecting face and the first step, and the first step can move in the sink hole through the match between the ejector rod and the ejector pin base plate to enable the second ejector pin to be ejected out in delay mode. Therefore, the demolding mechanism, the demolding method and the die-casting device can achieve secondary ejection of a die-casting mold, the delay distance for the secondary ejection can be controlled accurately, and the defects of cracking, efficiency losing and ejection deformation of parts with deep cavities and thin walls can be effectively overcome.

Owner:ANHUI TATFOOK TECH CO LTD

Preparation method of high-strength alumina ceramic substrate

InactiveCN108129139AImprove adhesionPrevent deformation and crackingAluminium hydroxideSodium aluminate

The invention discloses a preparation method of a high-strength alumina ceramic substrate, and belongs to the technical field of ceramic substrate preparation. Carbon dioxide is introduced into a sodium aluminate solution, then ultrafine aluminum hydroxide crystal grains can be formed, the ultrafine aluminum hydroxide crystal grains are mixed with a precursor sol, and tape casting is performed toobtain a tape-casted raw material tape with good cohesiveness. Because the thermal expansion coefficient of the sol is high, the bonding toughening effect is played, and thus cracking and deformationof the alumina ceramic substrate during sintering molding are avoided; mullite whiskers can grow after the sol in micro through holes of the alumina ceramic substrate is sintered and then cooled, alumina particles of the alumina ceramic substrate are wound by the whiskers, the whiskers are beneficial for uniform distribution of internal stress, the relative displacement between alumina and the silicate crystal grains is reduced, and the whiskers can inhibit aggregation and growth of the crystal grains and can effectively reduce pores in ceramics, so that the compactness of a sintered body is improved, the crystal grains in the alumina ceramic substrate are distributed uniformly, the crystal grain distribution is compact, the mechanical strength is enhanced, and the application prospect isbroad.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

Method for preventing deformation and cracking of pines

InactiveCN107379178APrevent deformation and crackingDeformation and cracking are easyImpregnation spraying apparatusWood treatment detailsFiberBatch processing

The invention mainly relates to the technical field of wood product processing, and discloses a method for preventing deformation and cracking of pines. The method comprises arrangement, refrigeration, fermentation, primary drying, humidification and secondary drying; the method is simple and convenient in batch processing; no poisonous reagent is added in the treatment process to achieve safety and health; the water content of the treated pines is stable, and the water absorbing capacity is reduced, so that deformation and cracking are radically prevented, the service life is prolonged by 14.5%, and the use value of pine products is obviously improved; the cut pines are cut according to needed lengths; pine barks are retained; the protecting effect of the pine barks is improved, so that the color change in the pine treatment process is inhibited, and later unified bleaching treatment is convenient; and pine sections are put in a treatment chamber to gradually cool for refrigeration, so that the water in the pines is reduced under low-temperature environment, gaps among pine fibers are increased, the resistance of the pines to temperature and humidity is improved, the influence of environmental change to the pines is relieved, and deformation and cracking of the pines are prevented.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

Flame cutting process of medium and high carbon steel plate

InactiveCN108044221AImprove acceptance rateReduce manufacturing costGas flame welding apparatusSlagSteel plates

The invention discloses a flame cutting process of a medium and high carbon steel plate, and belongs to the technical field of steel plate manufacturing. The process aims at ensuring the steel plate cutting face quality. A numerical control flame cutting machine is adopted, after a steel plate to be cut is placed on the numerical control flame cutting machine, the surface of the steel plate to becut is perpendicular to a cutting nozzle of the numerical control flame cutting machine, the cutting nozzle is perpendicular to the surface of the steel plate, the height between the cutting nozzle and the surface of the steel plate is 25 to 30 mm, according to the steel plate thickness value, cutting parameters are set, the right-angle position formed through the surface of the steel plate to becut and the side face serves as the cutting point, the flame strength of the cutting nozzle is adjusted, the length of secondary flames reaches the bottom of the steel plate to be cut, before cutting,preheating is carried out at the cutting point, after the set preheating time is achieved, cutting oxygen is opened, when slag to be melted flows downwards along the edge, the cutting nozzle is movedforwards, when the slag is discharged from the bottom, the moving speed of the cutting nozzle is increased to be normal, and after the steel plate is cut, stacking for slow-cooling or high-temperature tempering is carried out. The flame cutting process is used for cutting the medium and high carbon steel plate with the thickness of 50 to 250 mm.

Owner:高伟红

Integral autoclaved aerated concrete wallboard and production process thereof

ActiveCN105696744ATightly boundImprove surface qualityConstruction materialWallsReinforced concreteRebar

The invention provides an integral autoclaved aerated concrete wallboard and a production process thereof and relates to the technical field of assembled building wallboards. The integral autoclaved aerated concrete wallboard comprises autoclaved aerated concrete boards, reinforced concrete side frames and steel pins or / and bolts. The integral autoclaved aerated concrete wallboard is characterized in that the autoclaved aerated concrete boards are spliced into a wallboard surface by virtue of a transverse mounting manner, a vertical mounting manner or a transverse-vertical mixed mounting manner; and when the autoclaved aerated concrete boards are spliced, each reinforcing rib is arranged at an interval of one or several autoclaved aerated concrete boards; and the reinforced concrete side frames are produced by concrete poured rebar mesh cages and are fixedly connected to the peripheries of the wallboard surface by virtue of the steel pins or / and the bolts (3). The integral autoclaved aerated concrete wallboard has the positive effects that the problems of cracking and leakage of a wall body can be fundamentally solved, the integral autoclaved aerated concrete wallboard can be hoisted once by virtue of a crane, the construction speed is high, the restriction of weather conditions is low, the labor is saved, the construction cycle can be effectively shortened, the construction cost can be saved, and the construction quality can be improved.

Owner:五莲县易通新型建材科技有限公司

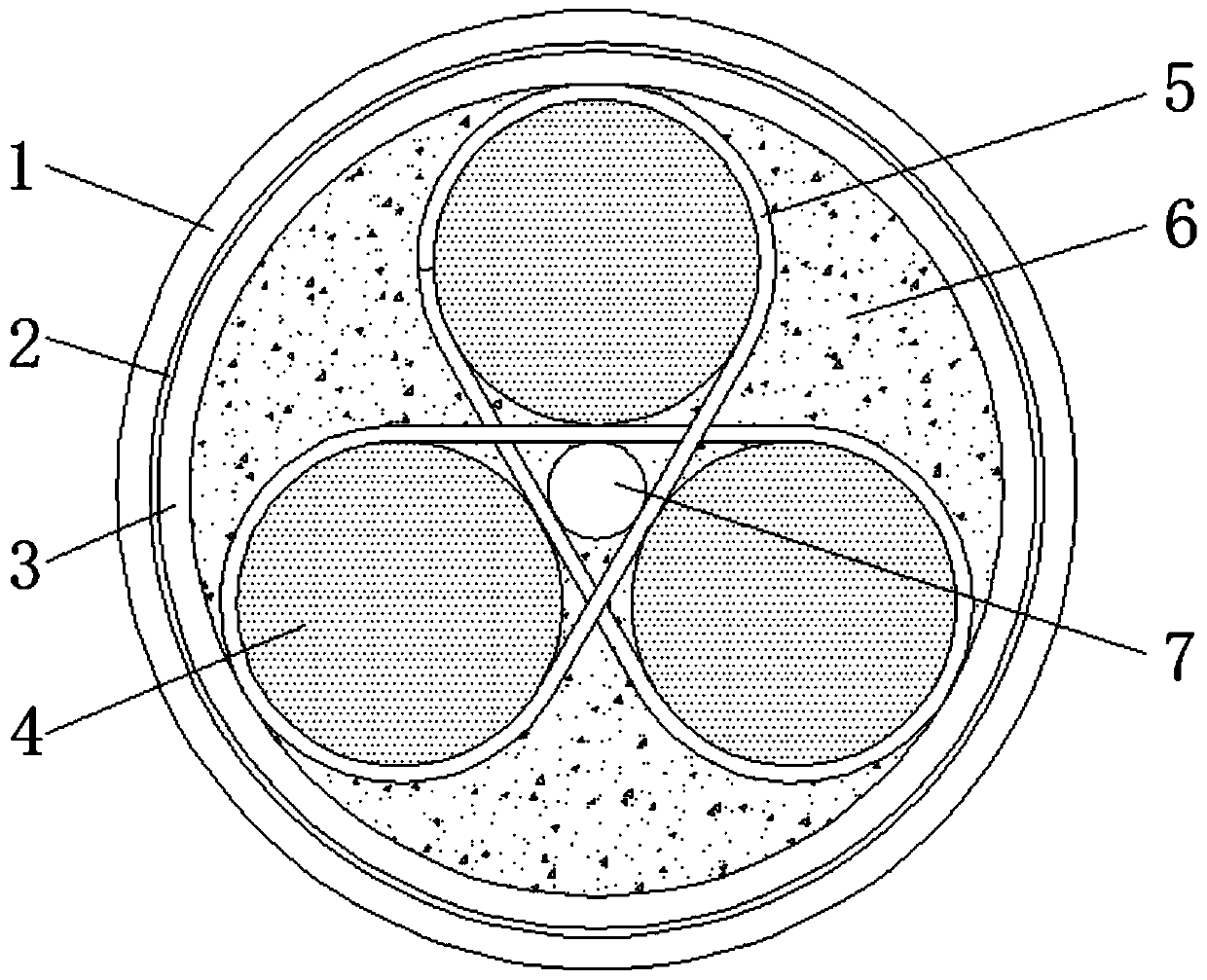

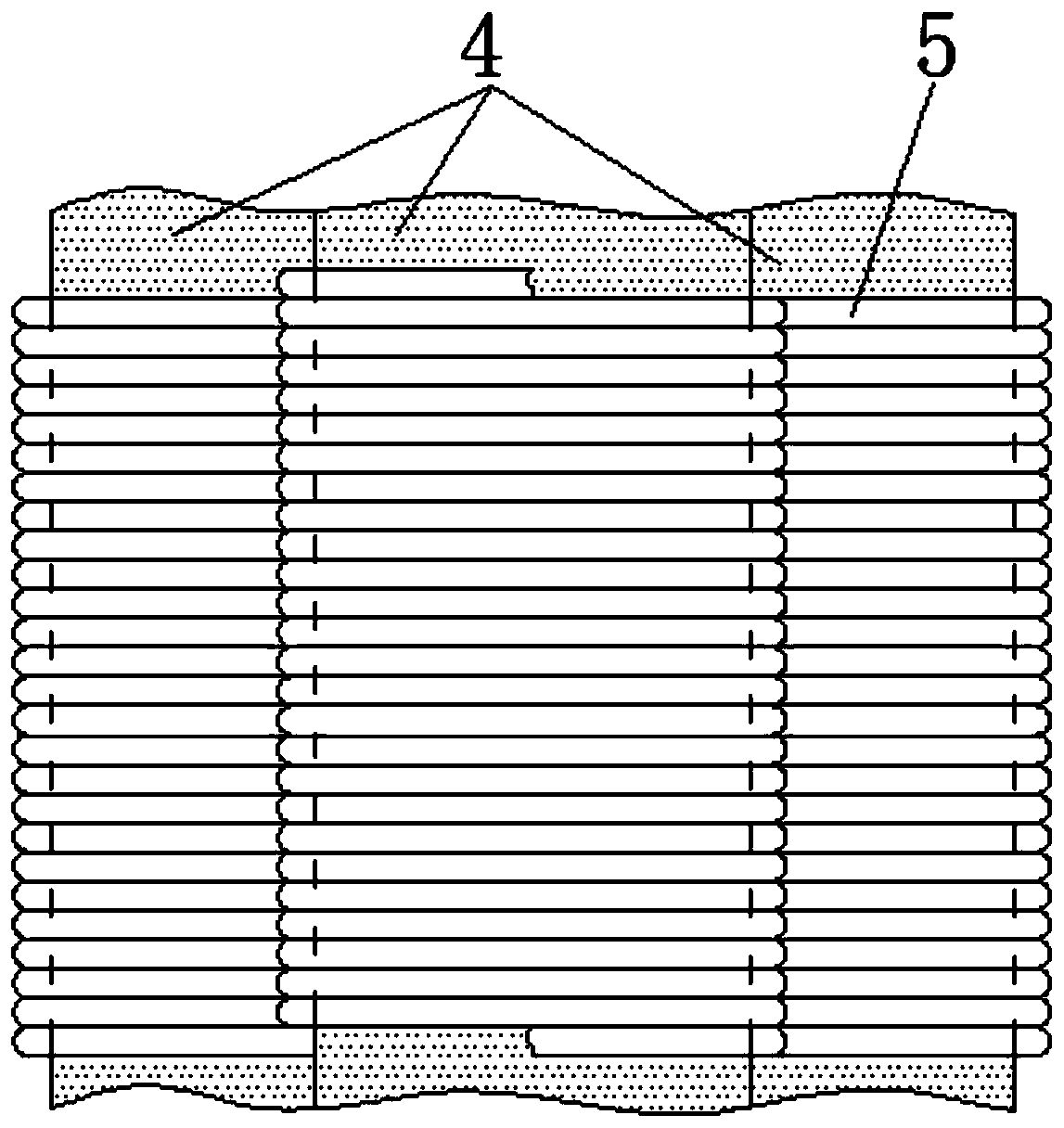

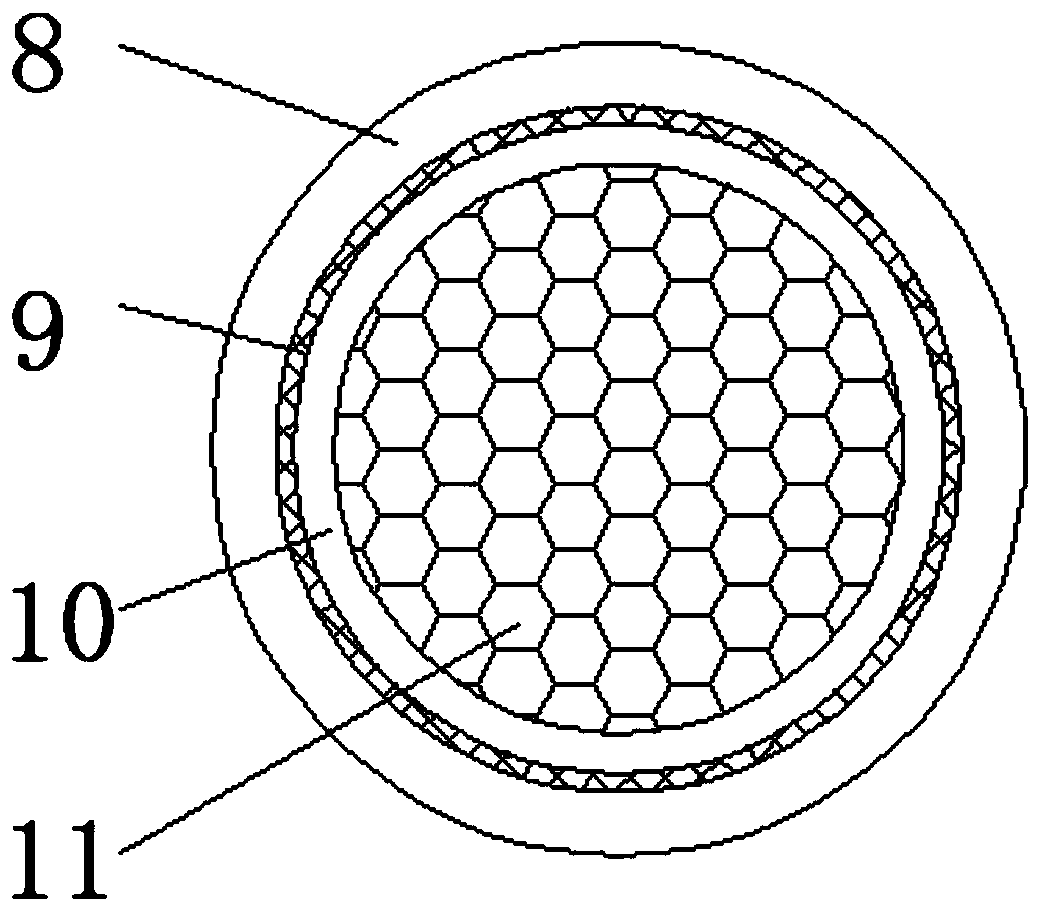

Cold-resistant, corrosion-resistant, flame-retardant and anti-interference double-sheath cable

ActiveCN110993171APrevent slippageImprove flame retardant performanceInsulated cablesCable/conductor manufactureEngineeringMoisture resistance

The invention discloses a cold-resistant, corrosion-resistant, flame-retardant and anti-interference double-sheath cable. The cable comprises an outer sheath, an anti-torsion layer, an inner sheath, awater-blocking filler and a cable core; the inner sheath is extruded on the outer side of the cable core, the anti-torsion layer is wrapped on the outer side of the inner sheath, and the outer sheathis extruded on the outer side of the anti-torsion layer; and the cable core comprises three wire cores, a tensile rope and a fixing rope. The inner sheath, the anti-torsion layer and the outer sheathare sequentially wrapped on the outer side of the cable core; double protection can be effectively performed on the cable; the cold resistance, moisture resistance and corrosion resistance of the cable are improved; the wire core can be effectively fixed and dragged through the fixing rope; the cable core is prevented from deforming and breaking due to mutual extrusion in the bending process, thefriction force between the cable core and the sheath can be effectively improved through the circularly wrapped fixing rope, the slippage between the cable core and the inner sheath is avoided, the generated stress is homogenized and eliminated through the ductility of the fixing rope, the cracking and deformation of the cable are avoided, and the service life of the cable is prolonged.

Owner:JINAN SHENGTONG POWER CABLE

Substrate residual stress control method in component additive manufacturing process and component additive manufacturing equipment

ActiveCN113118466AAvoid compromising dimensional accuracyAvoid warpingAdditive manufacturing apparatusIncreasing energy efficiencyStrain gaugeMechanical engineering

The invention provides a substrate residual stress control method in the component additive manufacturing process and component additive manufacturing equipment. The substrate residual stress control method comprises the following steps of S1, establishing a three-dimensional entity model of an additive manufacturing structural component and a substrate by utilizing three-dimensional software; S2, carrying out analog simulation analysis on the additive manufacturing process so as to obtain a stress distribution result of the substrate in the additive manufacturing process; S3, determining a substrate stress concentration area in the additive manufacturing process according to the stress distribution result of the substrate; S4, polishing the upper surface or the lower surface of the stress concentration area of the substrate so as to obtain a metallic luster surface; S5, coating the metallic luster surface with a coupling agent, and carrying out additive manufacturing production on the substrate; S6, measuring the residual stress value sigma of the metallic luster surface once every n seconds by utilizing an ultrasonic strain gauge, wherein the substrate area with sigma continuously measured for three times greater than a set threshold value is a to-be-destressed area; S7, carrying out ultrasonic impact strengthening on the to-be-destressed area; and S8, returning to the step S6. The method and the equipment have the advantage that the buckling deformation of the substrate is small.

Owner:广东华研智能科技有限公司

Wood modification working liquid used for wet plate processing and use method thereof

InactiveCN104924388AImprove performanceEasy to modifyWood treatment detailsThermal wood treatmentOrganic baseInorganic compound

The invention discloses a wood modification working liquid used for wet plate processing and a use method thereof. The wood modification working liquid used for wet plate processing is prepared from, by weight, inorganic base resin, namely an alkaline silica solution with 2-30% of silicon dioxide by weight, organic base resin, namely water soluble urine aldehyde resin impregnation liquid with 2-30% by solid content, waterproof agents with 0.2-20% by solid content, 0.05-3% of silane coupling agents, 0.2-1% of emulsifying agents, 1-10% of fire-retardant preservative and the balance water through mixing. The wood modified working liquid adopts matching of the inorganic component and the organic component, so that wood has the functions of preventing corrosion and insects, retarding inflaming, being waterproof and the like. All the components are not polymerized by themselves and can meet production requirements; the combination capacity of the components with the wood is high; the leach resistance is high; the obtained modified wood is good in stability, high in waterproof performance and good in corrosion prevention and fire resistance.

Owner:YANGPUJIU JUTAI WOOD TECH CO LTD

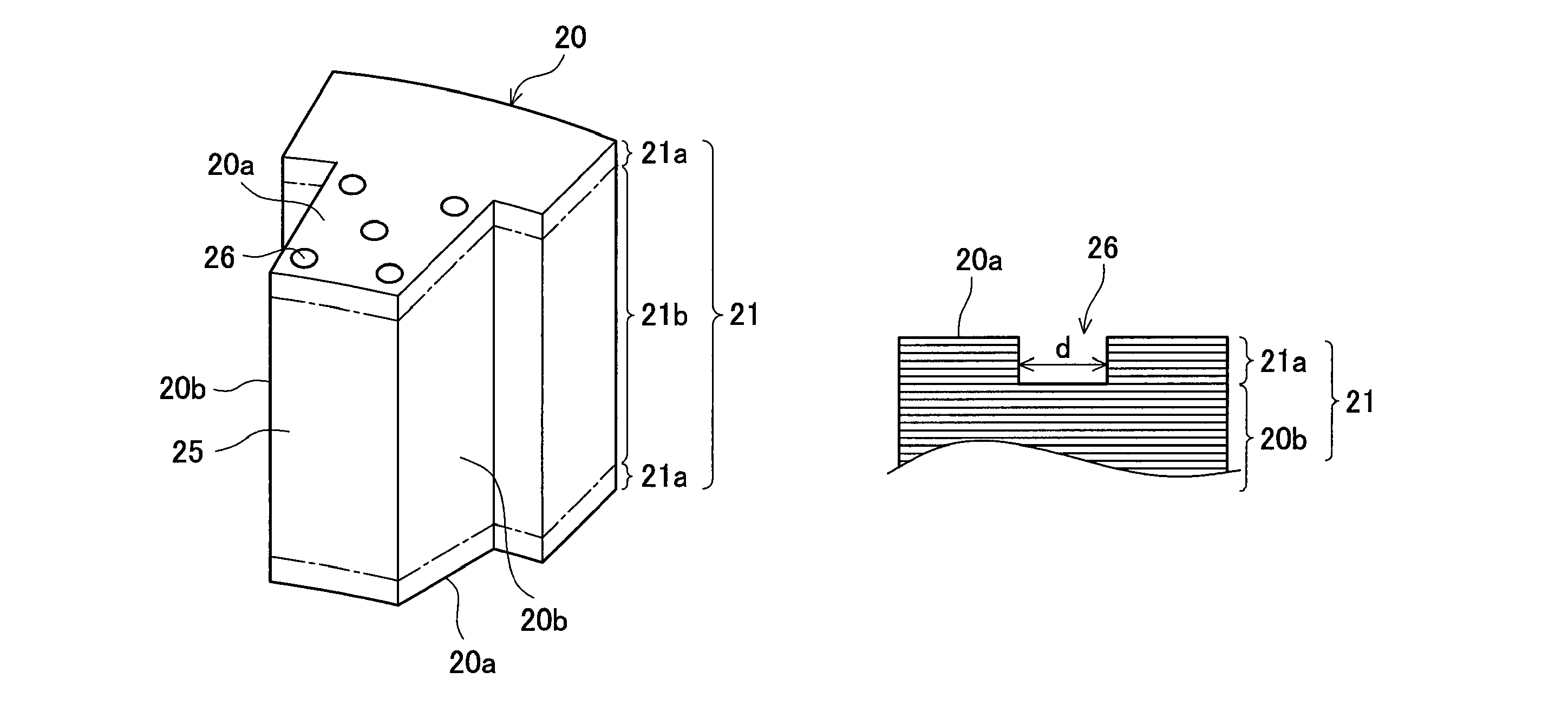

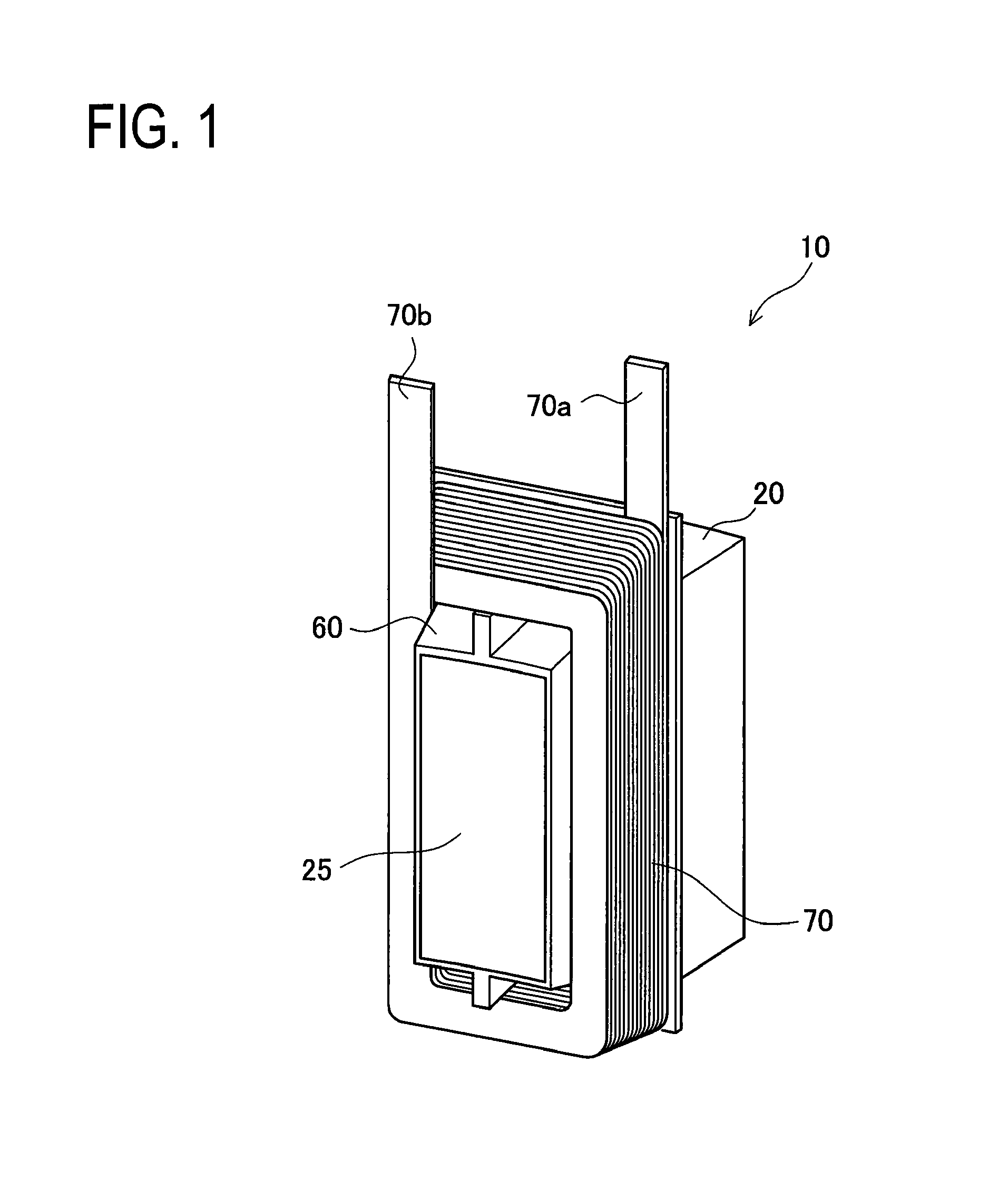

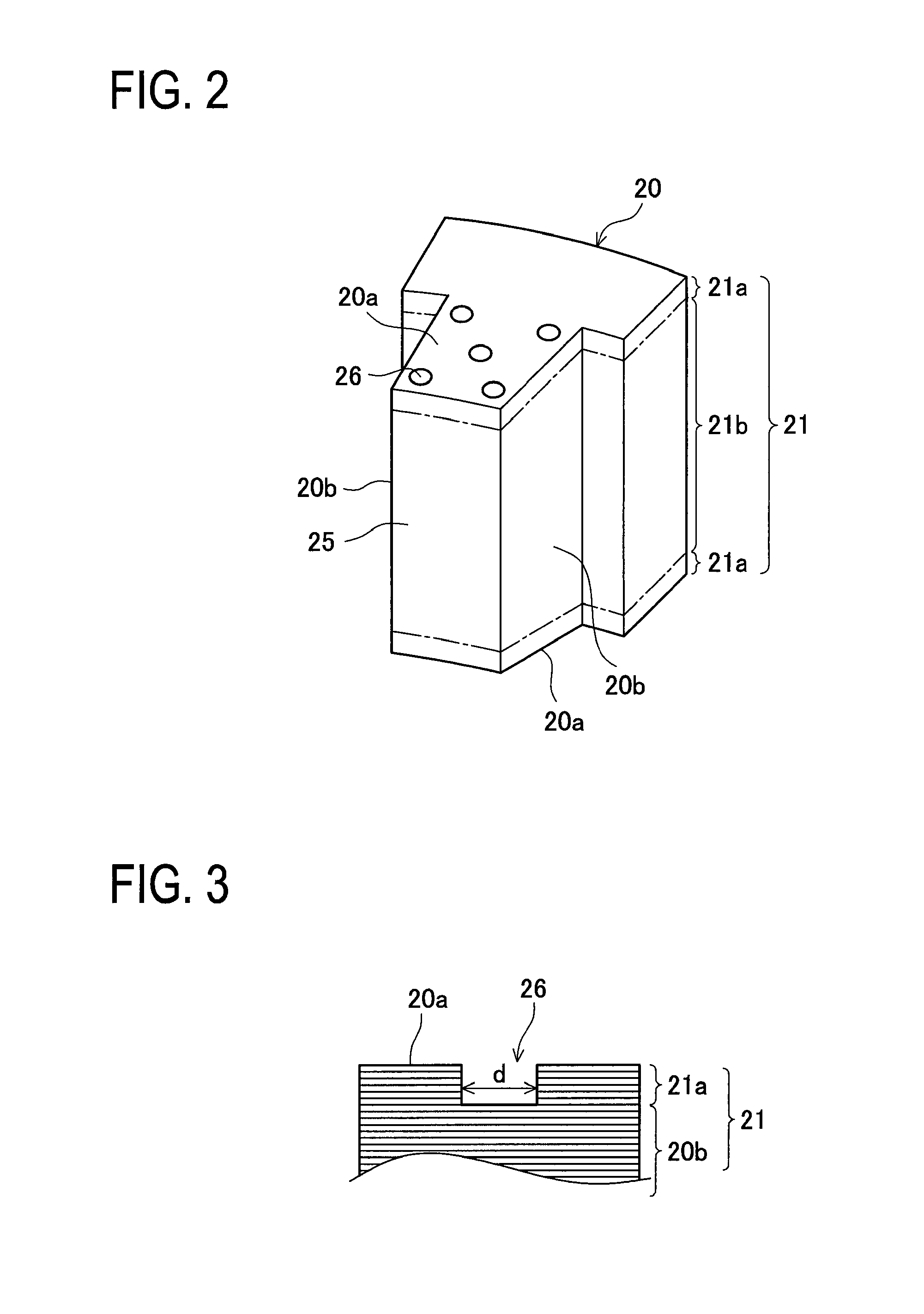

Split stator and manufacturing method thereof

InactiveUS8729748B2Improve insulation reliabilityAvoid deformationWindingsManufacturing dynamo-electric machinesStatorEngineering

Disclosed are a split stator and a manufacturing method thereof with which insulation reliability can be improved by preventing deformation or cracking of the insulator by eliminating slippage of the insulator at the coil end face. A slip prevention mechanism that prevents slippage of the insulator is provided at the coil end face, and using insert molding, the insulator is integrally molded to a split stator core provided with the slip prevention mechanism.

Owner:TOYOTA JIDOSHA KK

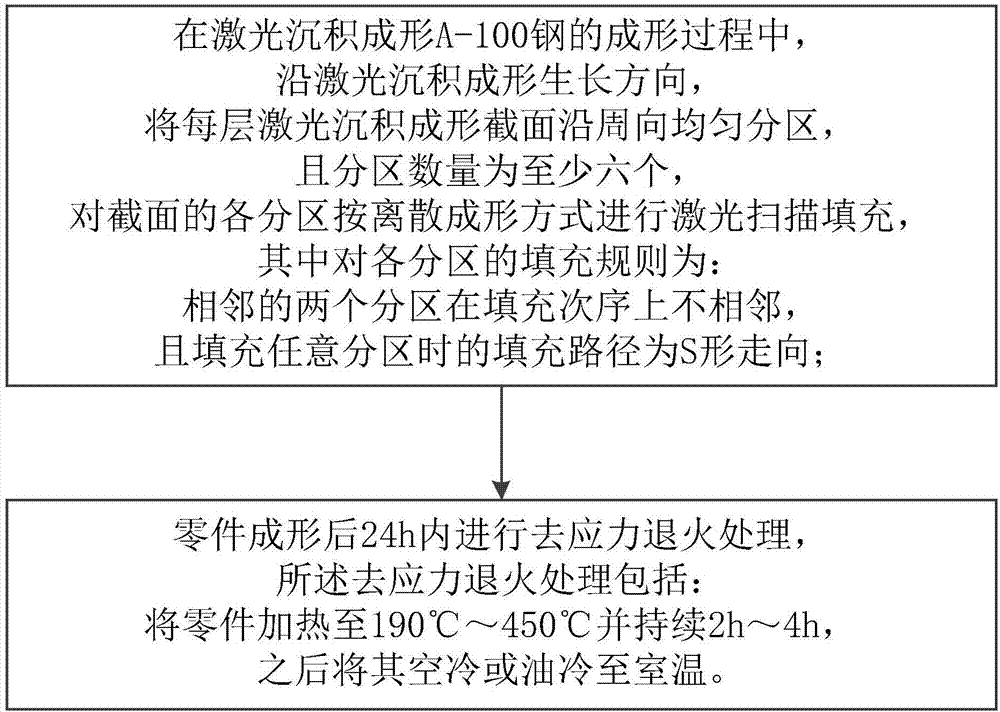

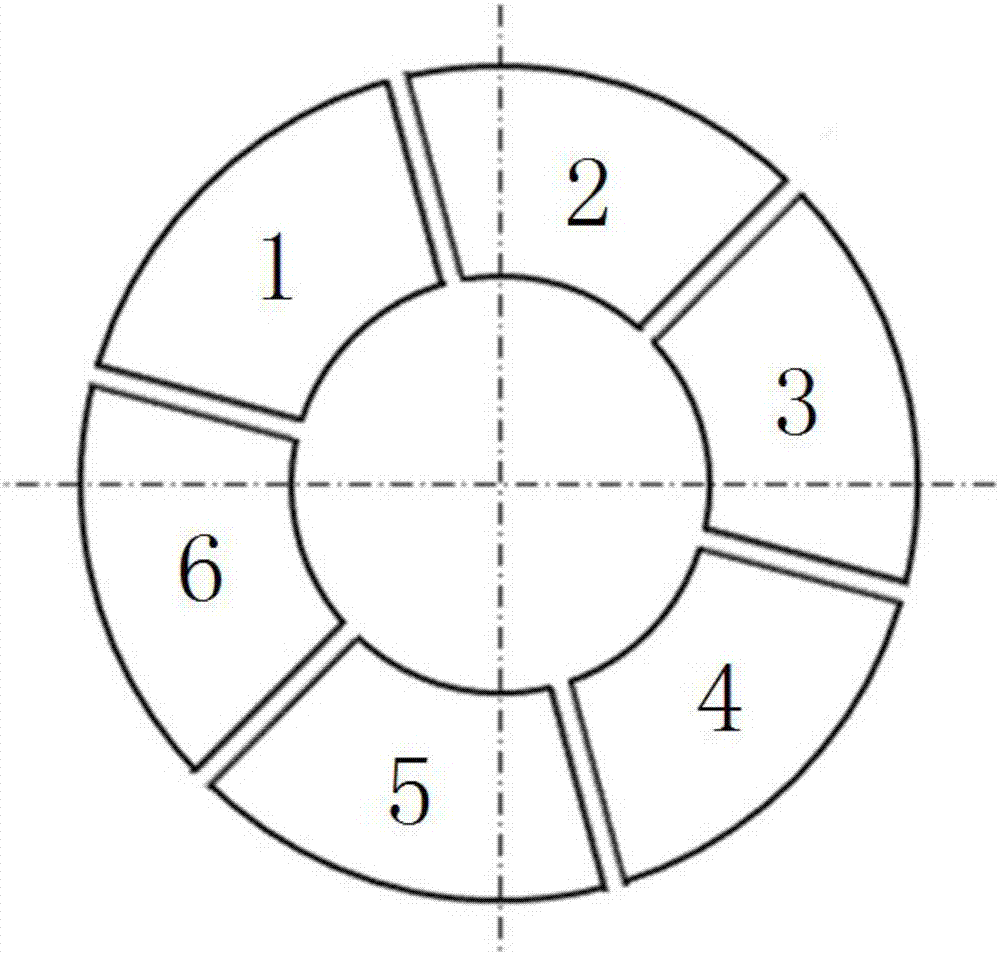

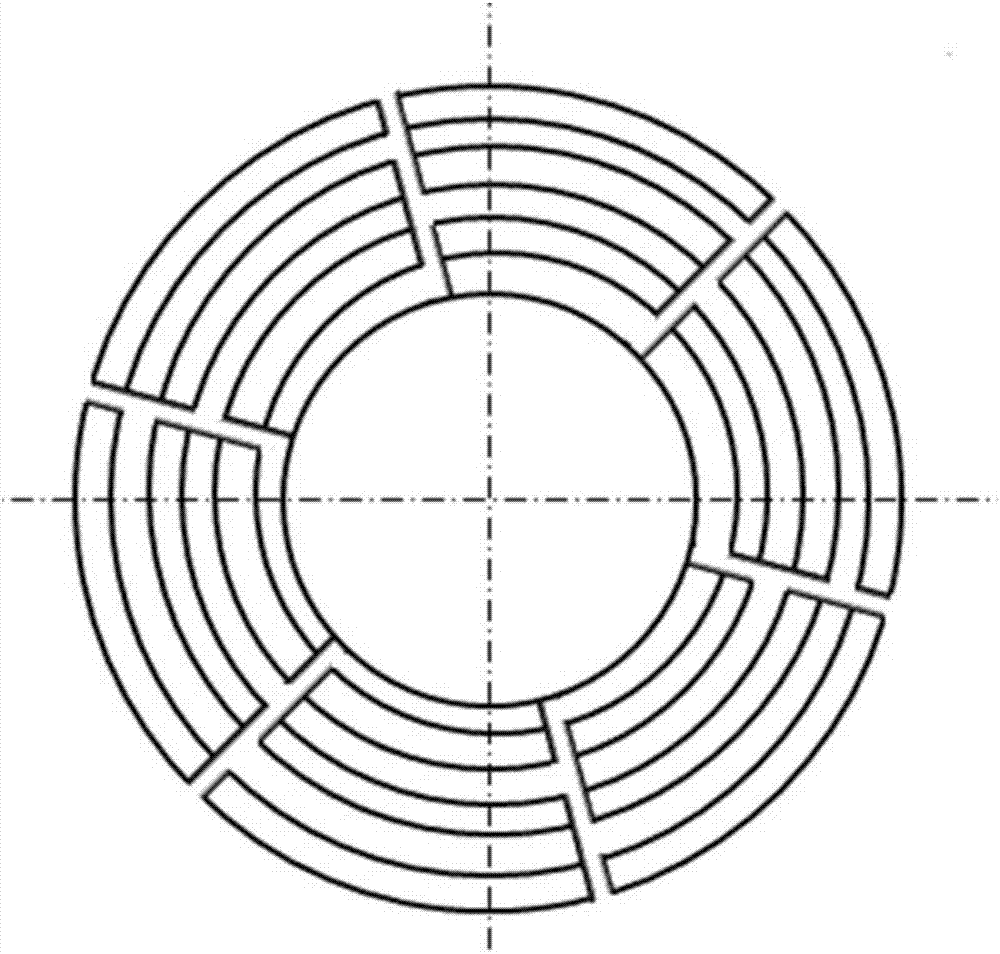

Method for preventing deformation cracking of laser deposition formed A-100 steel structure

InactiveCN107287589APrevent deformation and crackingReduce structural thermal stressAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyStructure of the Earth

The invention relates to the technical field of aeronautical manufacturing, and in particular, provides a method for preventing deformation cracking of a laser deposition formed A-100 steel structure. The method comprises the following steps: (1) in the forming process of laser deposition formation of A-100 steel, each layer of laser deposition formed section is peripherally and uniformly zoned in the laser deposition forming growth direction; at least six subareas are provided; the laser scanning filling is performed on each subarea of the section according to a discrete forming mode; filling rules of each subarea are as follows: two adjacent subareas are not near on the filling sequence; and a filling path when filling any subarea is S-shaped; and (2) the stress relief annealing is performed on a part after formation within 24 h, and comprises the procedures of heating of the part to 190-450 DEG C for lasting by 2-4 h and air cooling or oil cooling to the room temperature. The method can effectively reduce generation of the heat stress of overall structure of the laser direct deposition formed A-100 steel.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Nano inorganic enhancer

The invention discloses a nano inorganic enhancer which consists of the following raw materials in percentage by weight: 5-20 percent of water-reducing agent, 30-70 percent of silicon dioxide derivative, 5-25 percent of nano-activated alumina and 0-20 percent of rare earth chloride. The nano inorganic enhancer disclosed by the invention is suitable for the preparation of inorganic building materials such as mortar, concrete, permeable bricks and permeable concrete floors. The nano inorganic enhancer disclosed by the invention has the benefits that the consumption of cement is reduced, the concrete flowability is enhanced, the concrete strength is improved, cracking and deformation are prevented, and the durability of the concrete is improved.

Owner:上海每天生态科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com