Patents

Literature

75 results about "Visual tracking system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for significant image selection using visual tracking

InactiveUS20060109238A1Easy to identifyLocal control/monitoringSurgeryDisplay deviceSystem identification

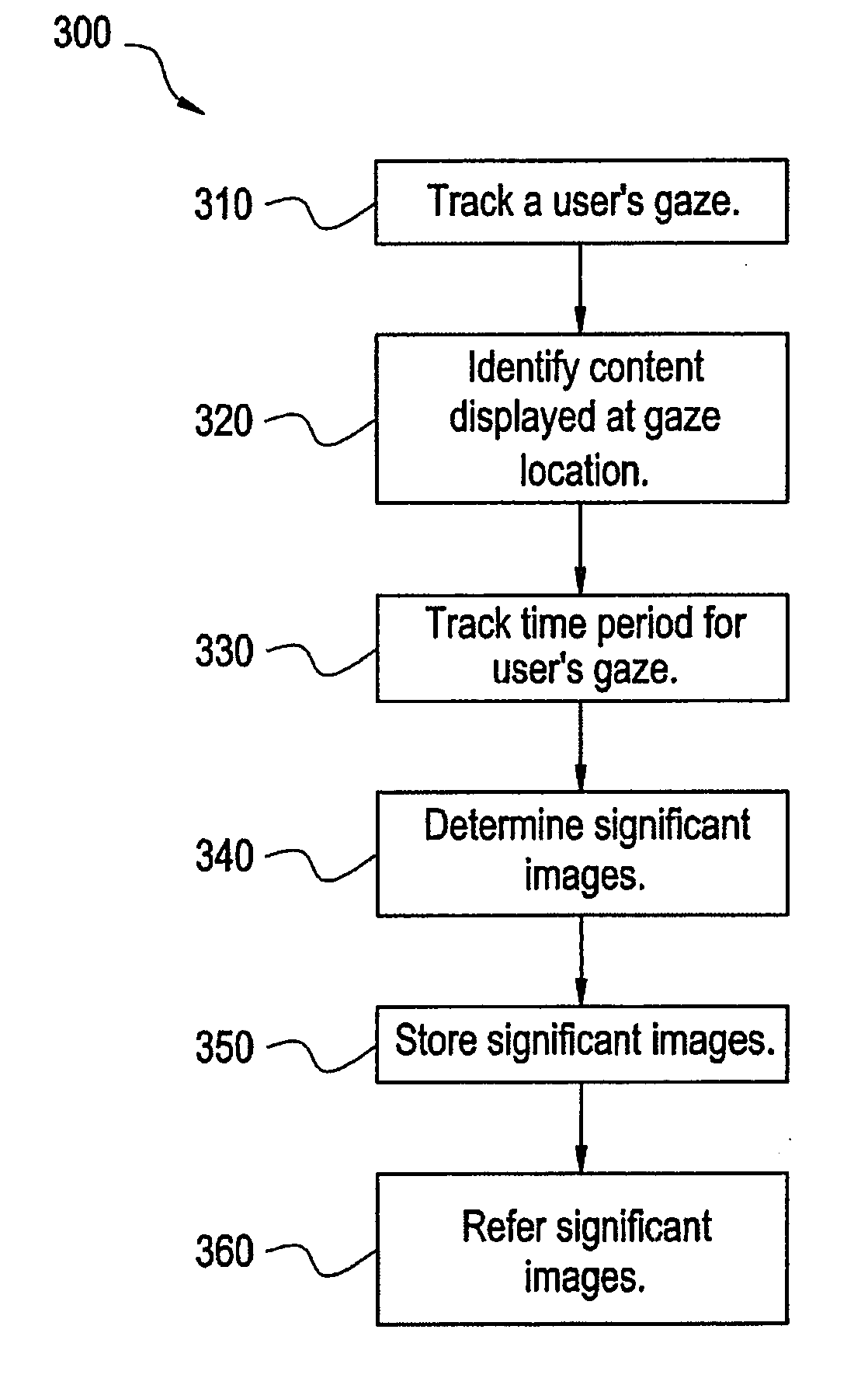

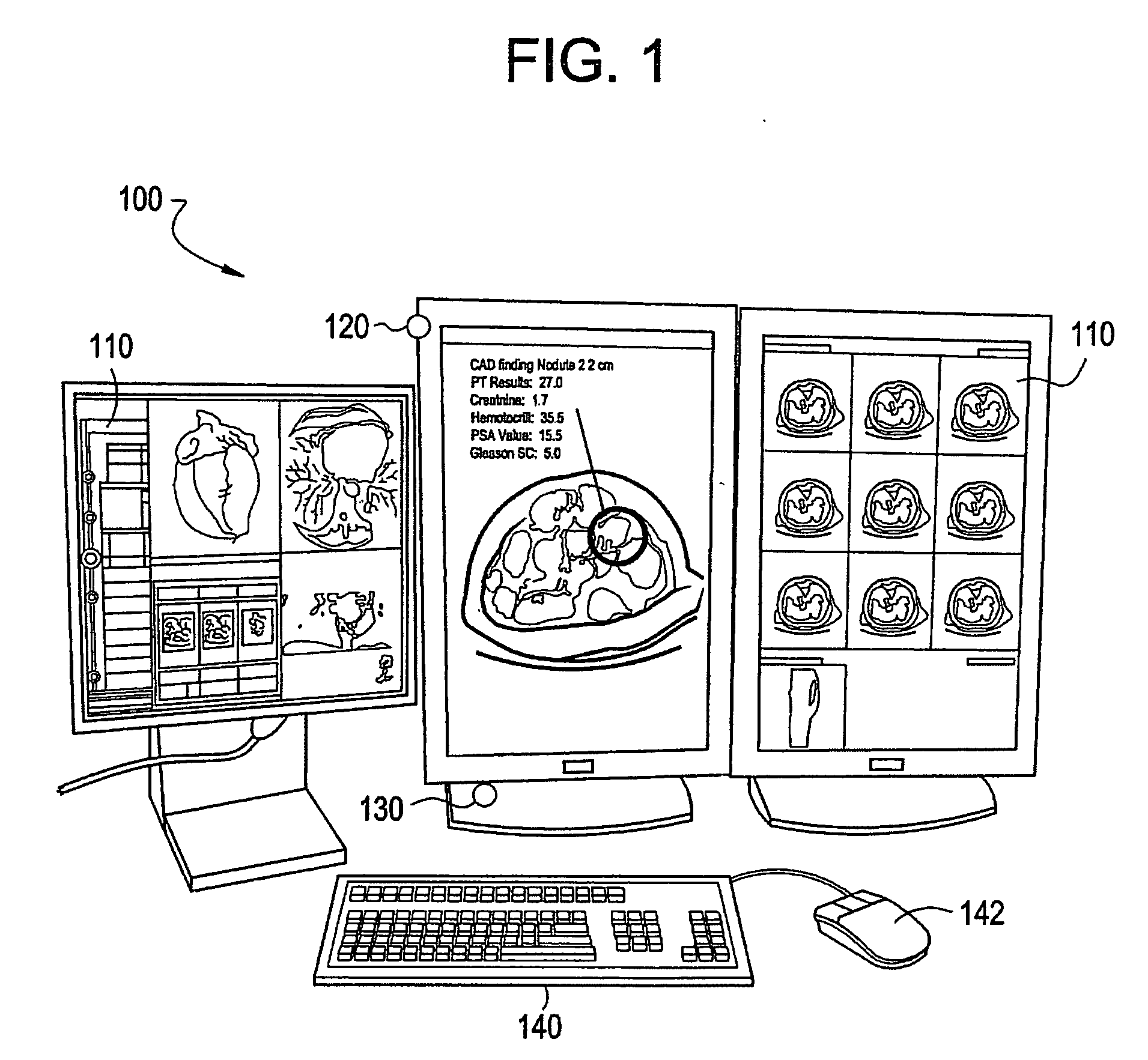

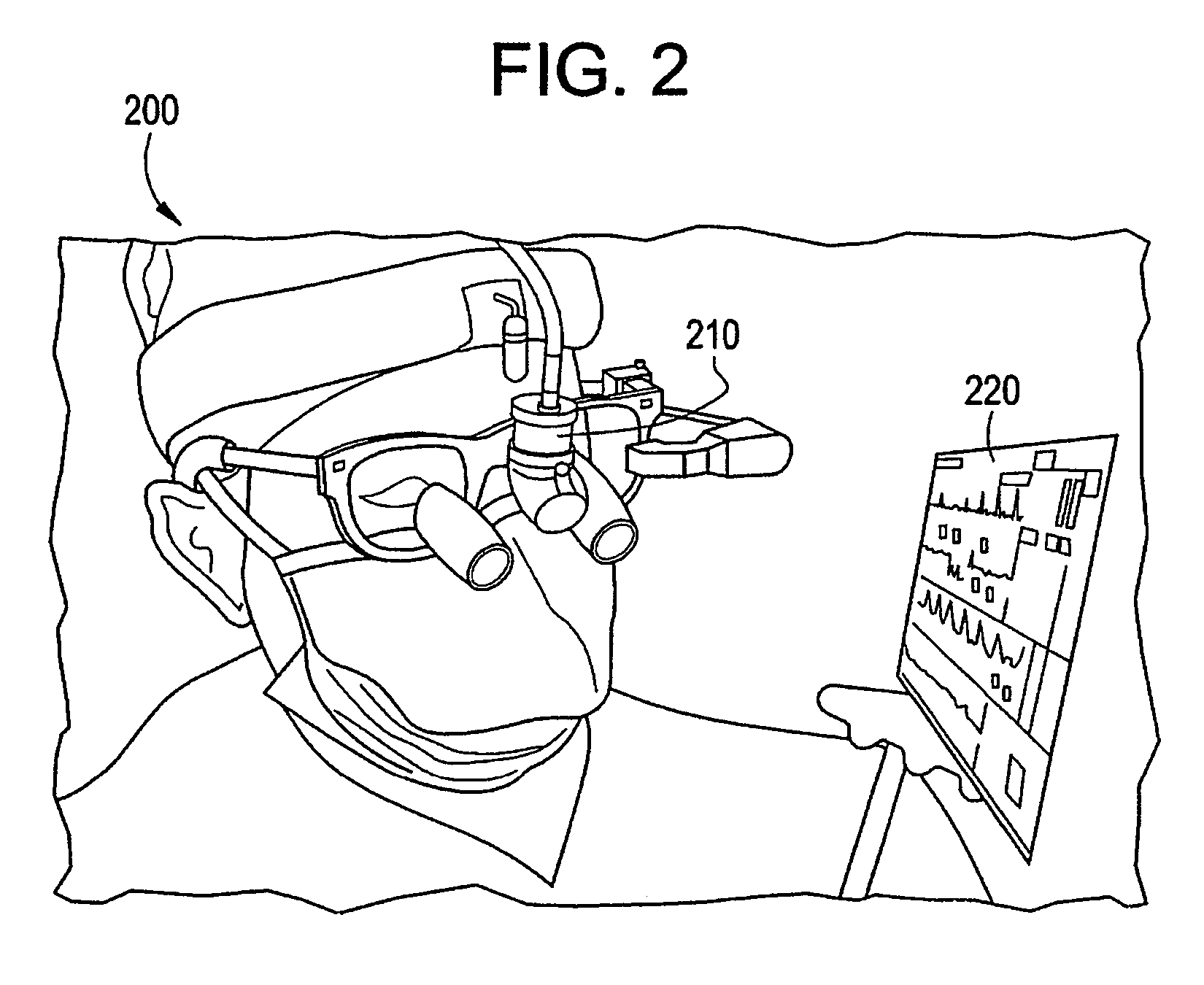

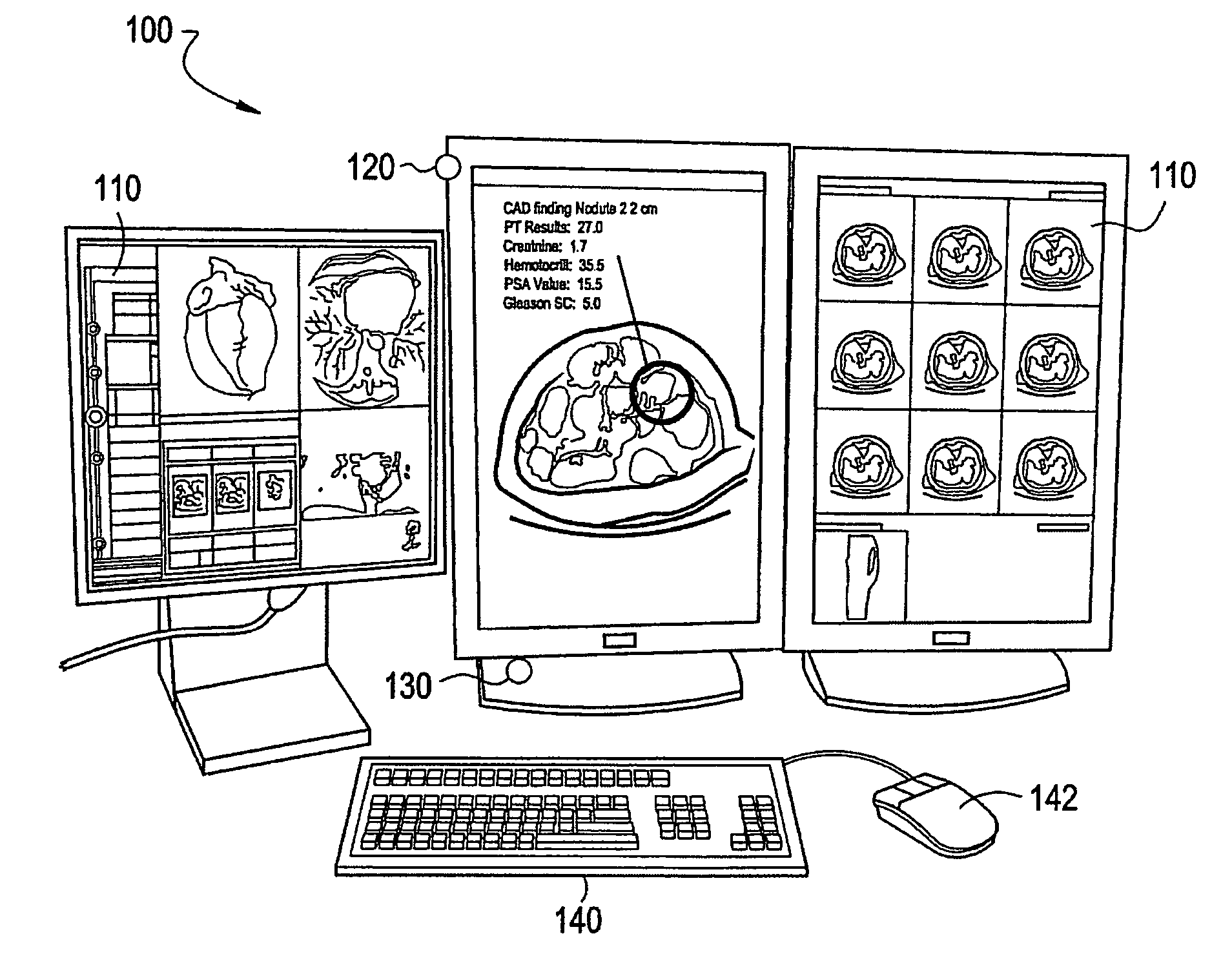

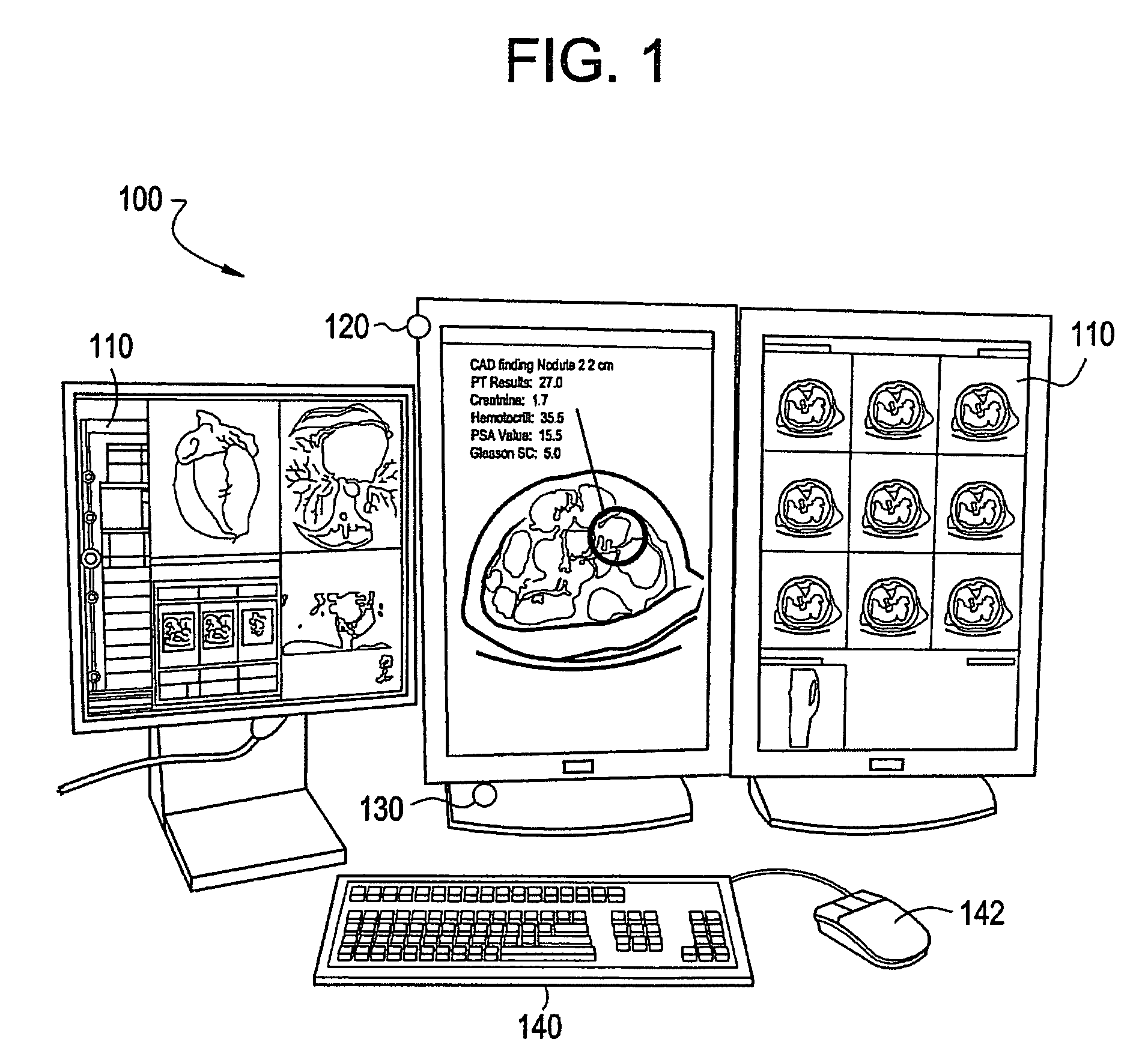

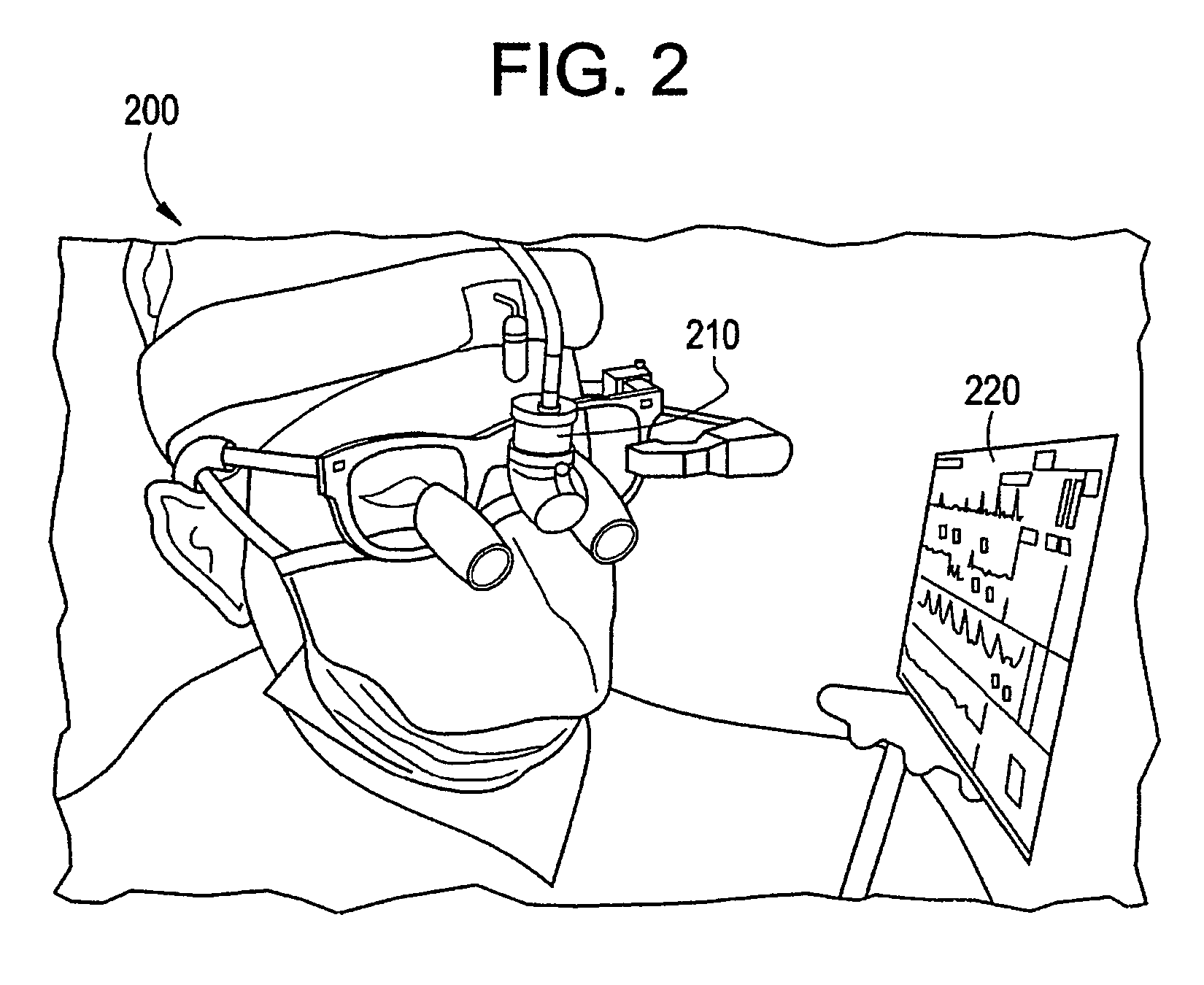

Certain embodiments of the present invention provide a method and system for improved identification of significant images using visual tracking. Certain embodiments of the system include a visual tracking system capable of tracking a user gaze with respect to a display device and a significant image selector for identifying at least one significant image based on user viewing time. The visual tracking system identifies an image at which a user is gazing records a viewing time during which the user is looking at the image. In an embodiment, the visual tracking system records viewing times for one or more users. In an embodiment, meta-data is associated with one or more significant images to identify the images as significant images, for example. The system may further include a database or table storing significant image information.

Owner:GENERAL ELECTRIC CO

System and method for significant image selection using visual tracking

InactiveUS7573439B2Easy to identifyLocal control/monitoringSurgeryDisplay deviceSystem identification

Certain embodiments of the present invention provide a method and system for improved identification of significant images using visual tracking. Certain embodiments of the system include a visual tracking system capable of tracking a user gaze with respect to a display device and a significant image selector for identifying at least one significant image based on user viewing time. The visual tracking system identifies an image at which a user is gazing records a viewing time during which the user is looking at the image. In an embodiment, the visual tracking system records viewing times for one or more users. In an embodiment, meta-data is associated with one or more significant images to identify the images as significant images, for example. The system may further include a database or table storing significant image information.

Owner:GENERAL ELECTRIC CO

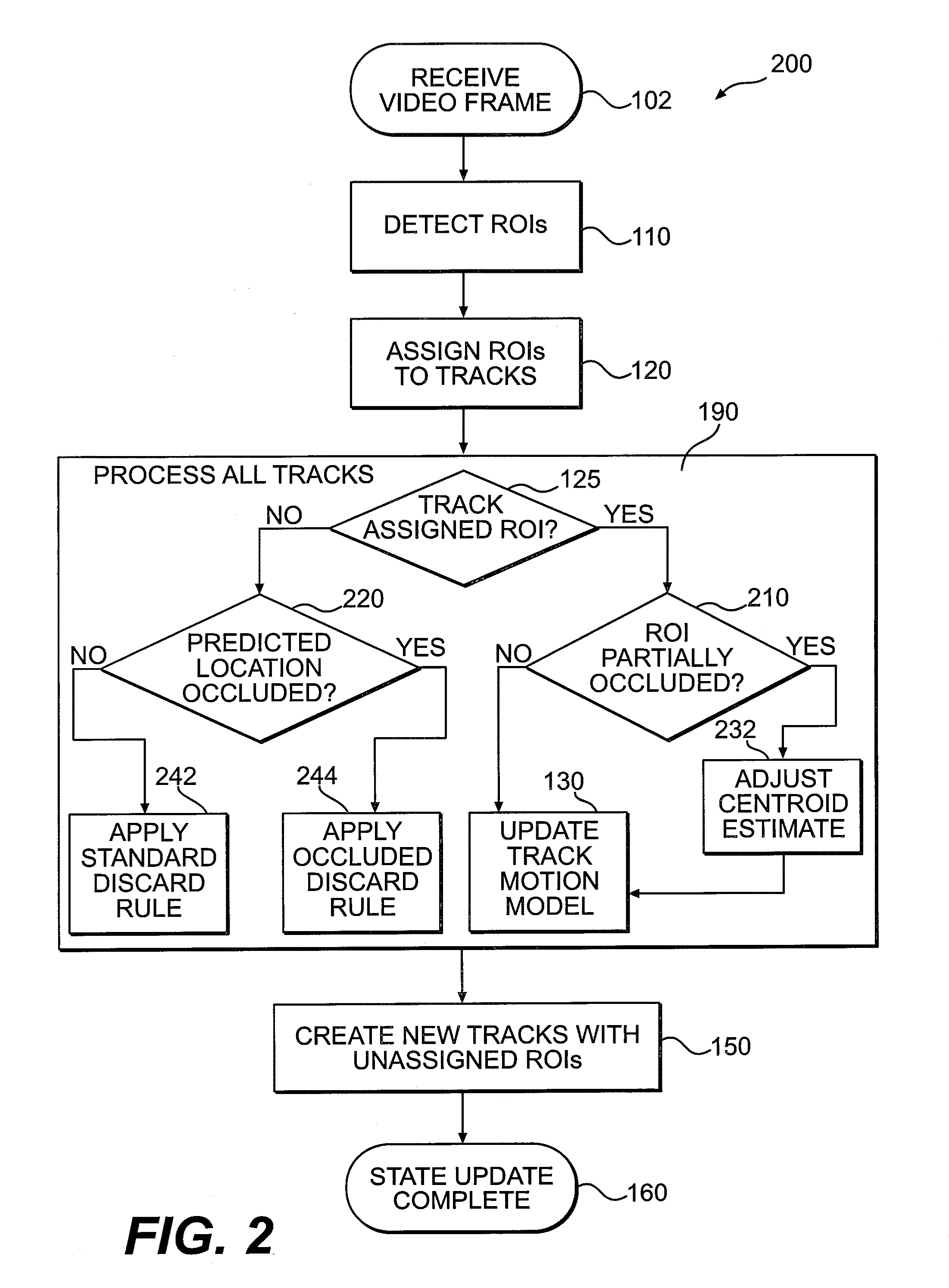

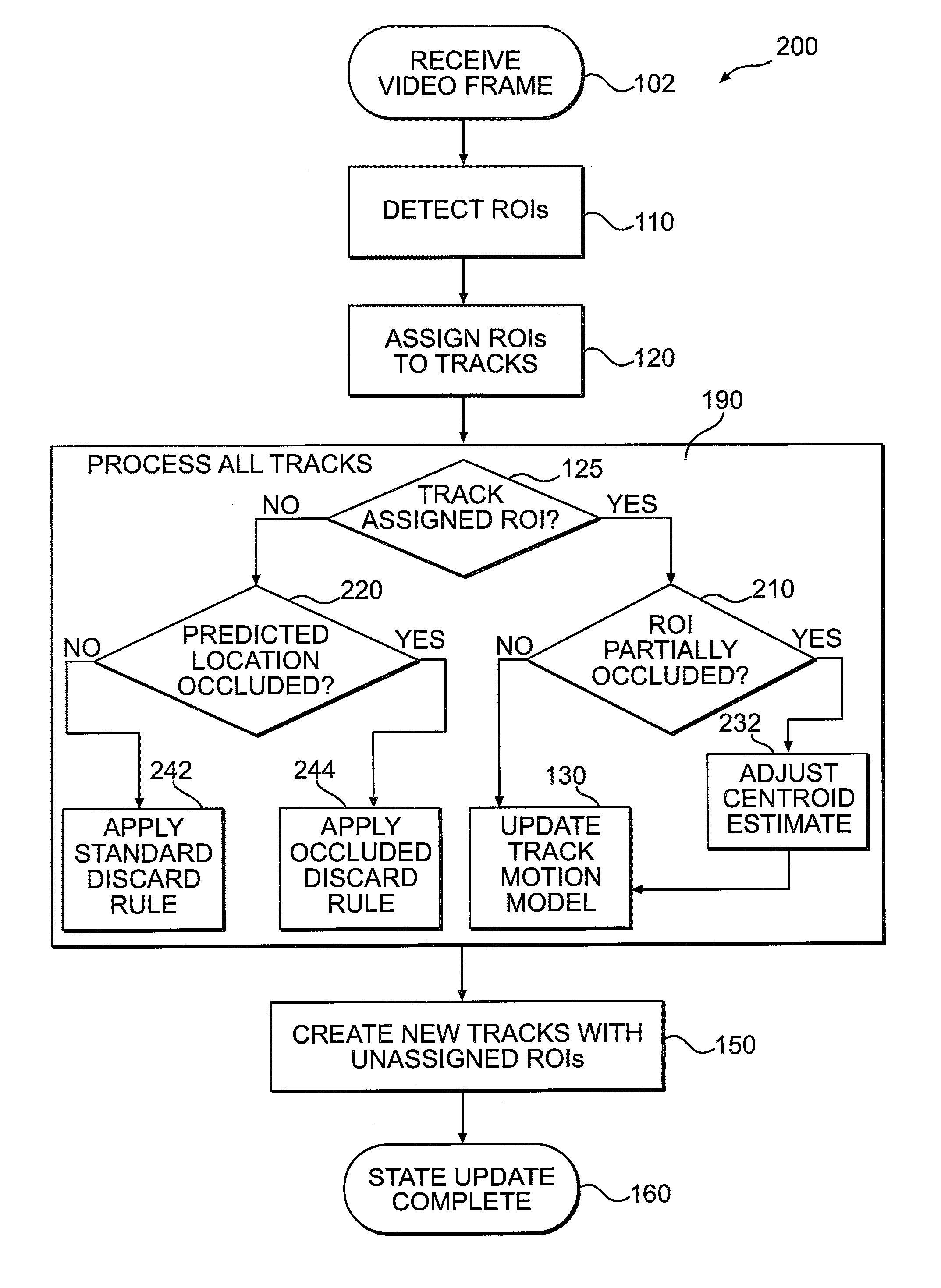

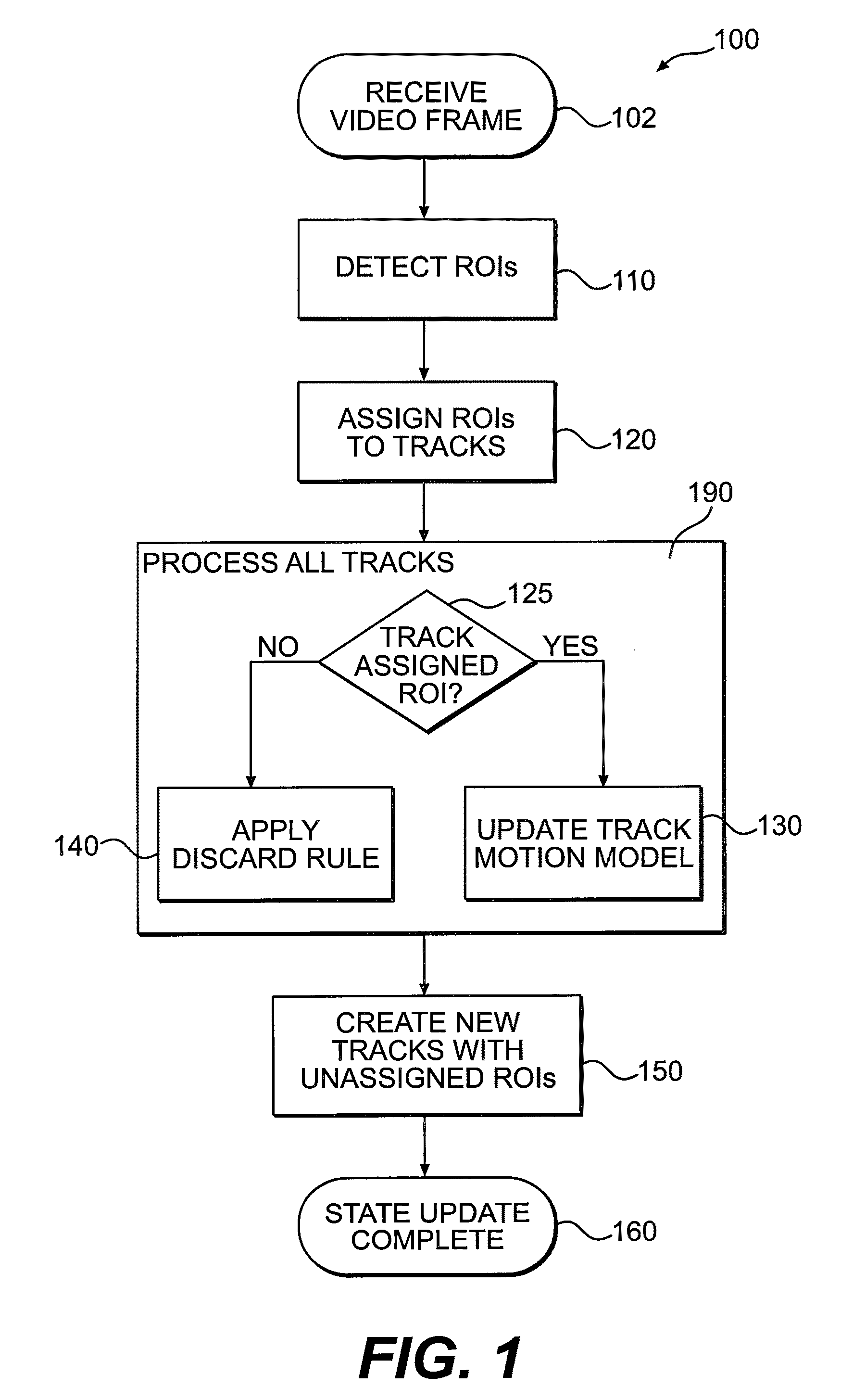

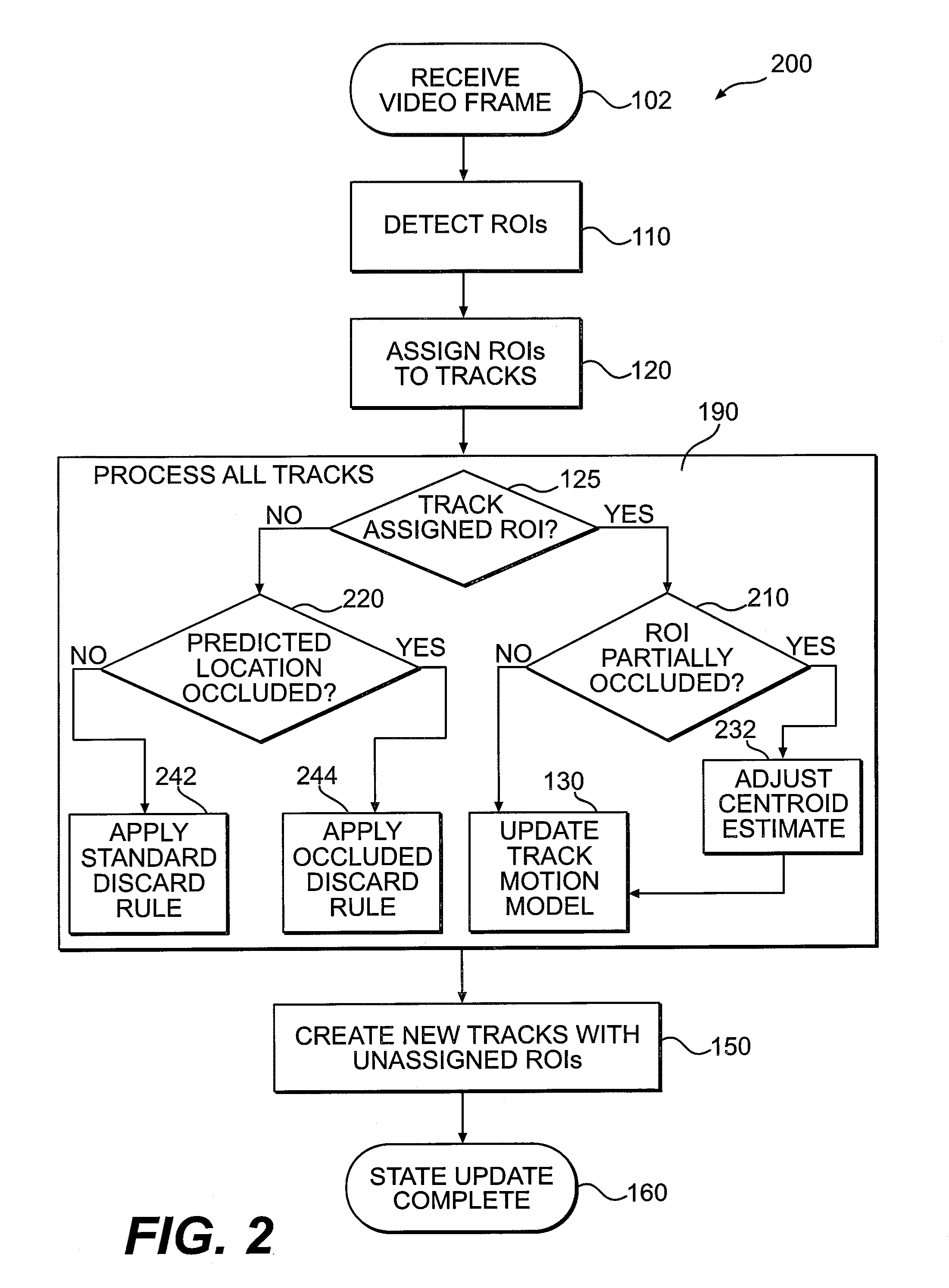

System and method for visually tracking with occlusions

ActiveUS20110116684A1Overcome disadvantagesExtended durationImage enhancementImage analysisComputer visionVisual tracking system

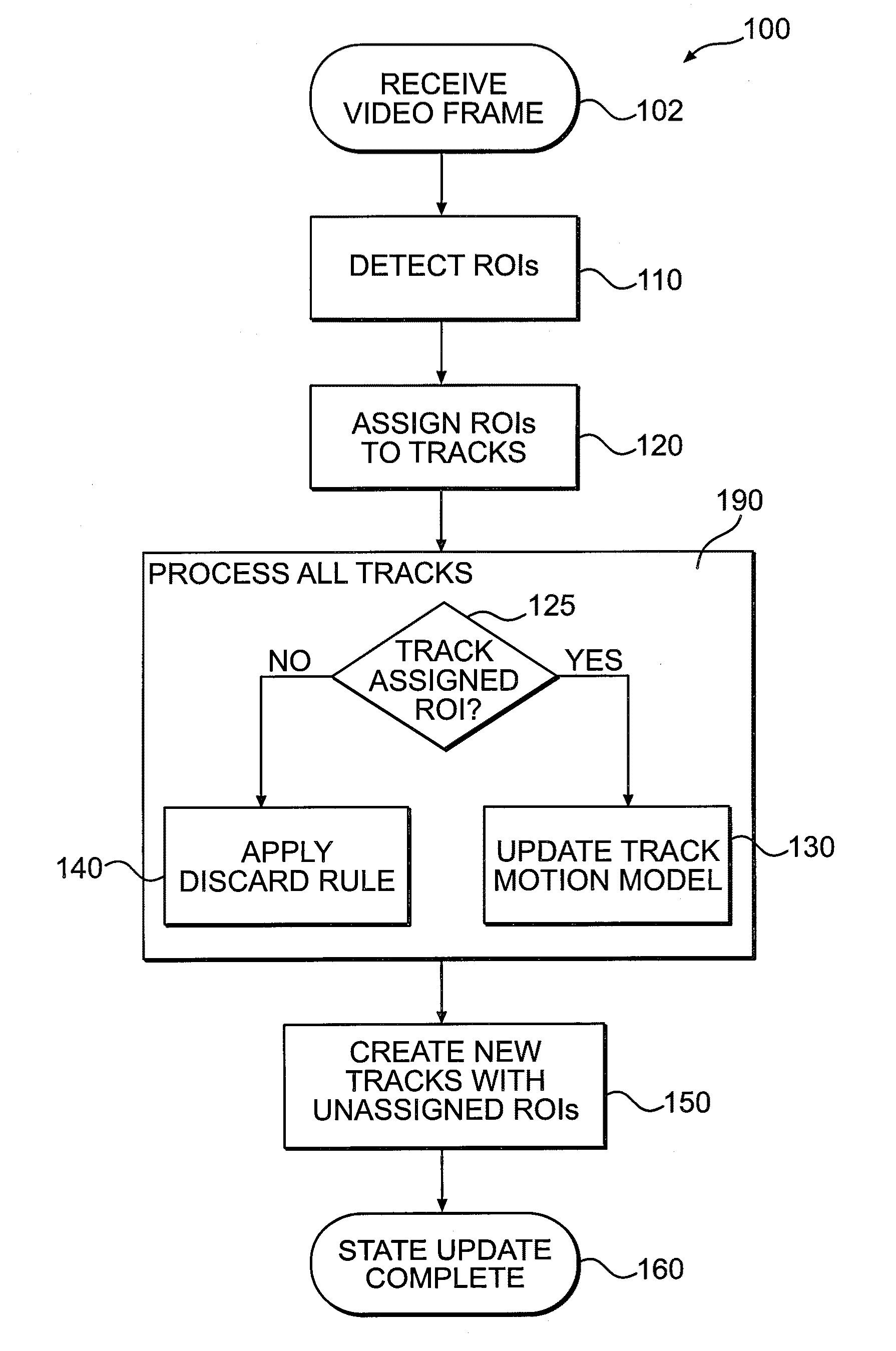

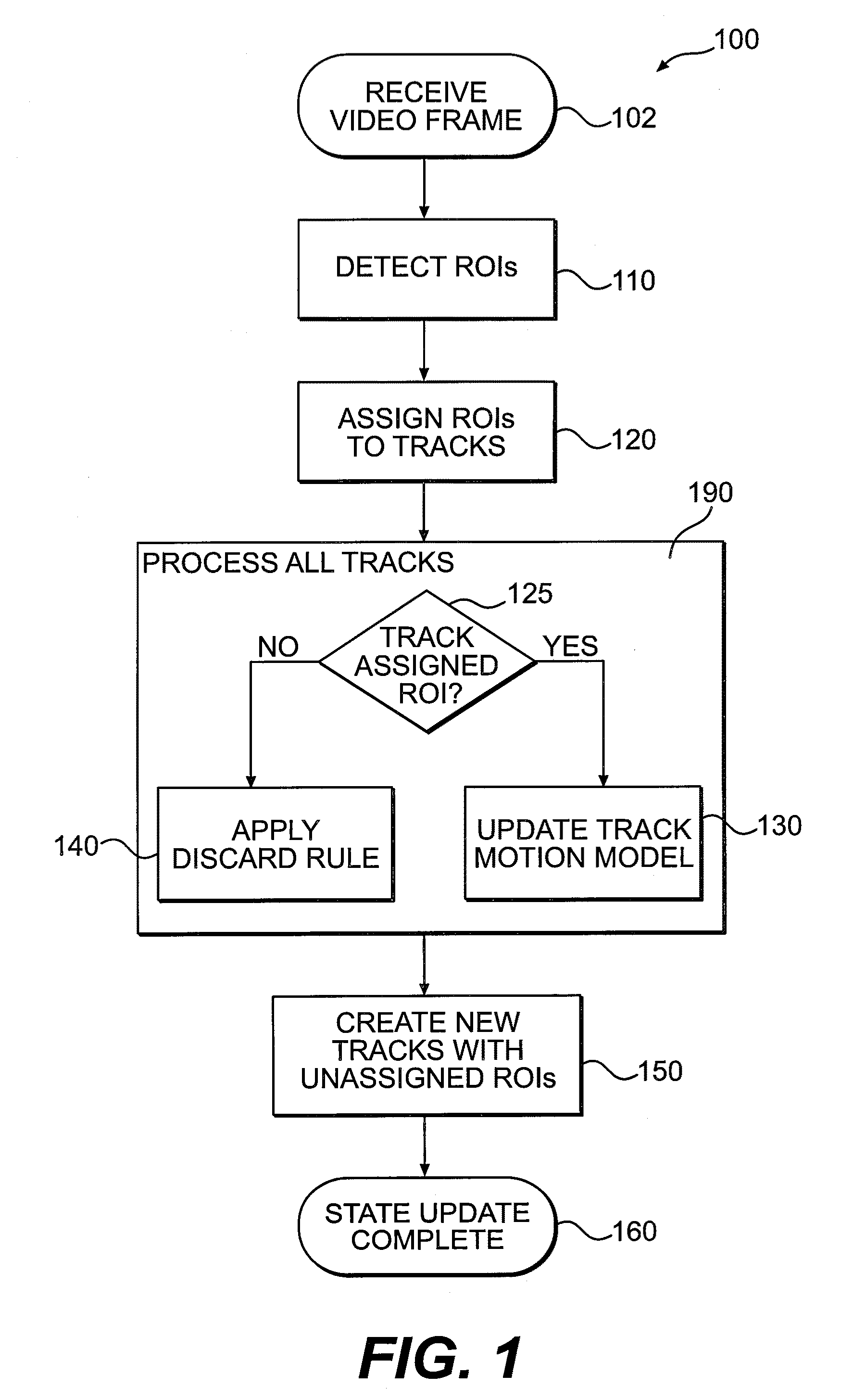

Described herein are tracking algorithm modifications to handle occlusions when processing a video stream including multiple image frames. Specifically, system and methods for handling both partial and full occlusions while tracking moving and non-moving targets are described. The occlusion handling embodiments described herein may be appropriate for a visual tracking system with supplementary range information.

Owner:21ST CENTURY TECH

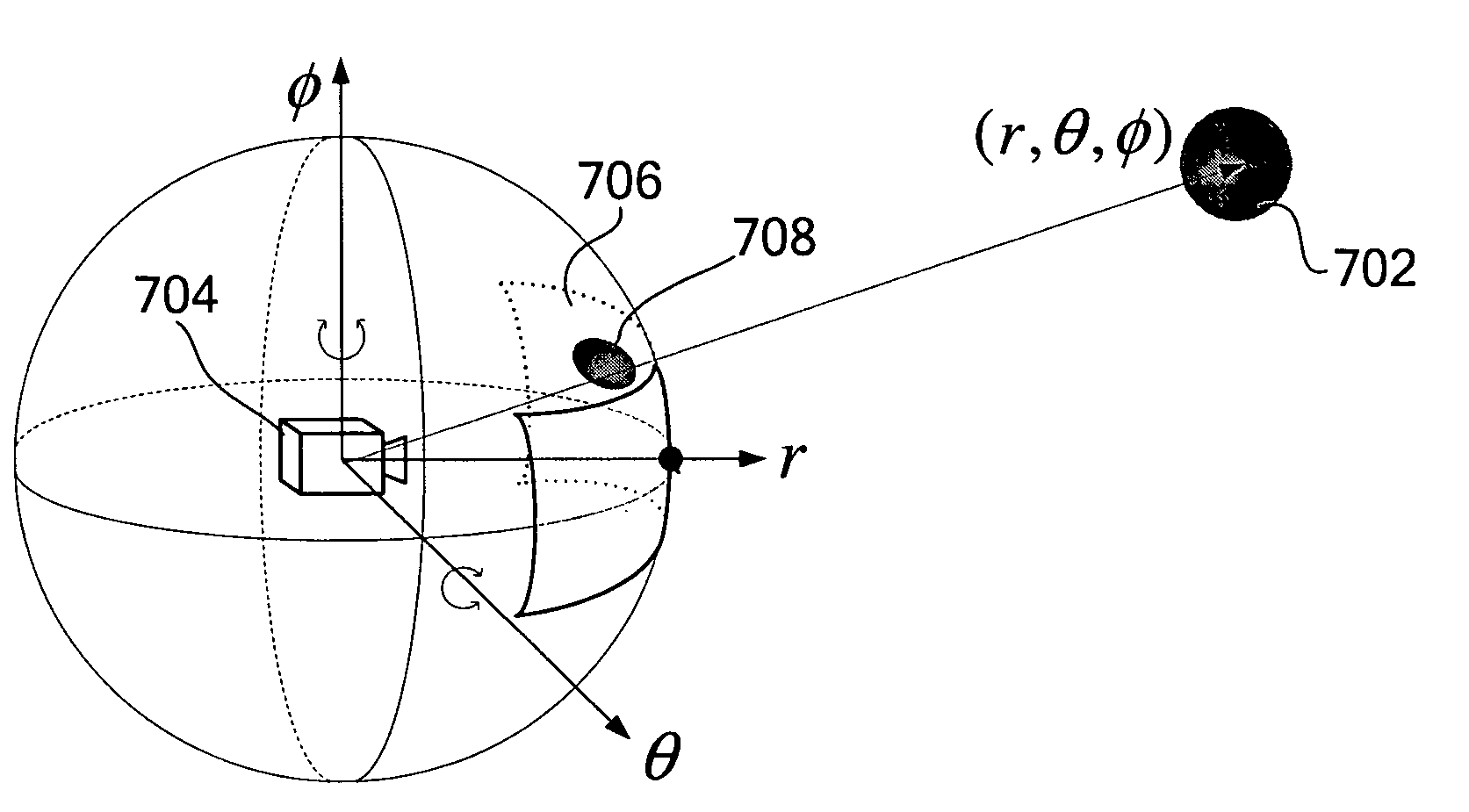

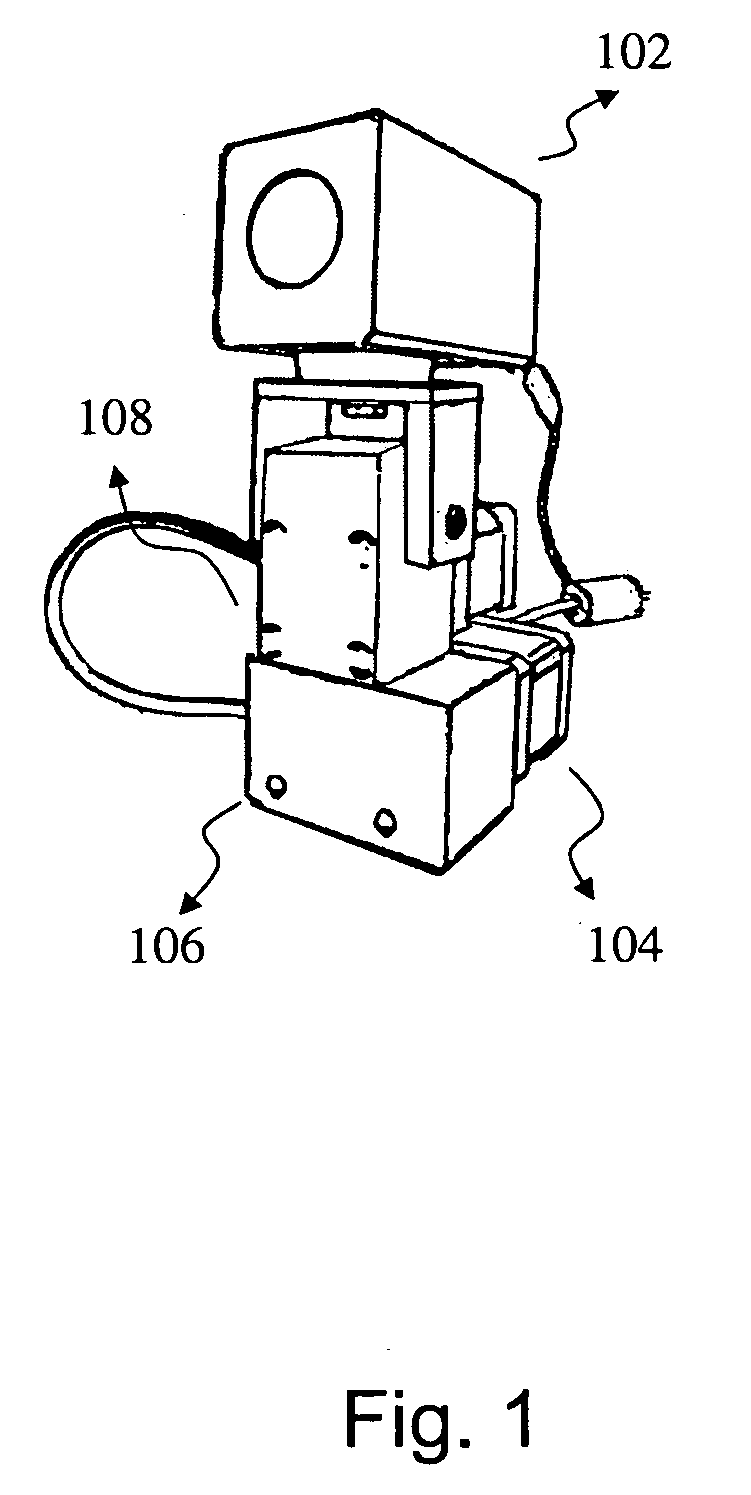

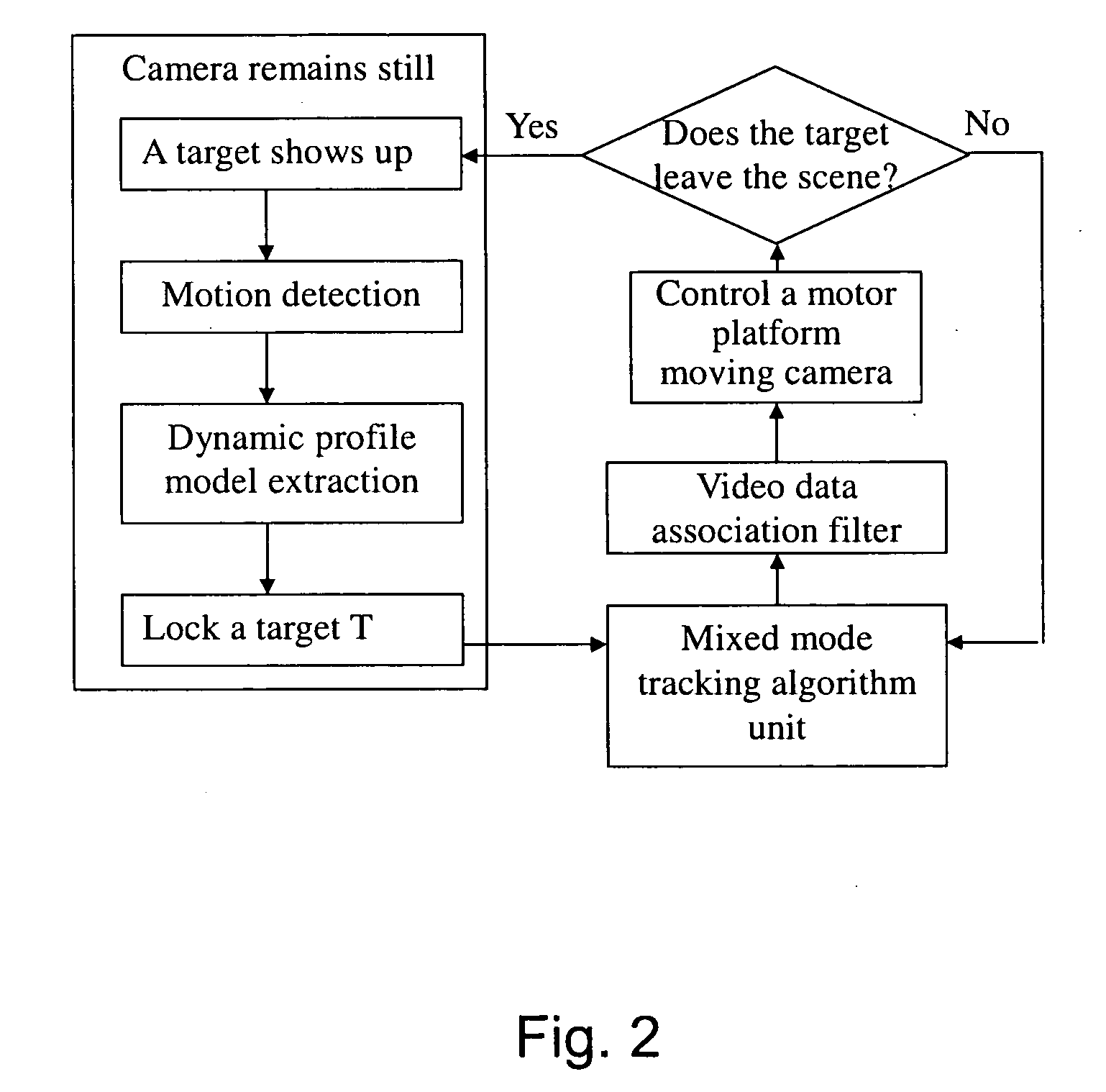

Visual tracking system and method thereof

ActiveUS20090262977A1MaximizeLow image contrastImage enhancementTelevision system detailsComputer visionOptimal matching

The present invention provides a visual tracking system and its method comprising: a sensor unit, for capturing monitored scenes continuously; an image processor unit, for detecting when a target enters into a monitored scene, and extracting its characteristics to establish at least one model, and calculating the matching scores of the models; a hybrid tracking algorithm unit, for combining the matching scores to produce optimal matching results; a visual probability data association filter, for receiving the optimal matching results to eliminate the interference and output a tracking signal; an active moving platform, for driving the platform according to the tracking signal to situate the target at the center of the image. Therefore, the visual tracking system of the present invention can help a security camera system to record the target in details and maximize the visual information of the intruding target.

Owner:NAT TAIWAN UNIV

Laser visual tracking system

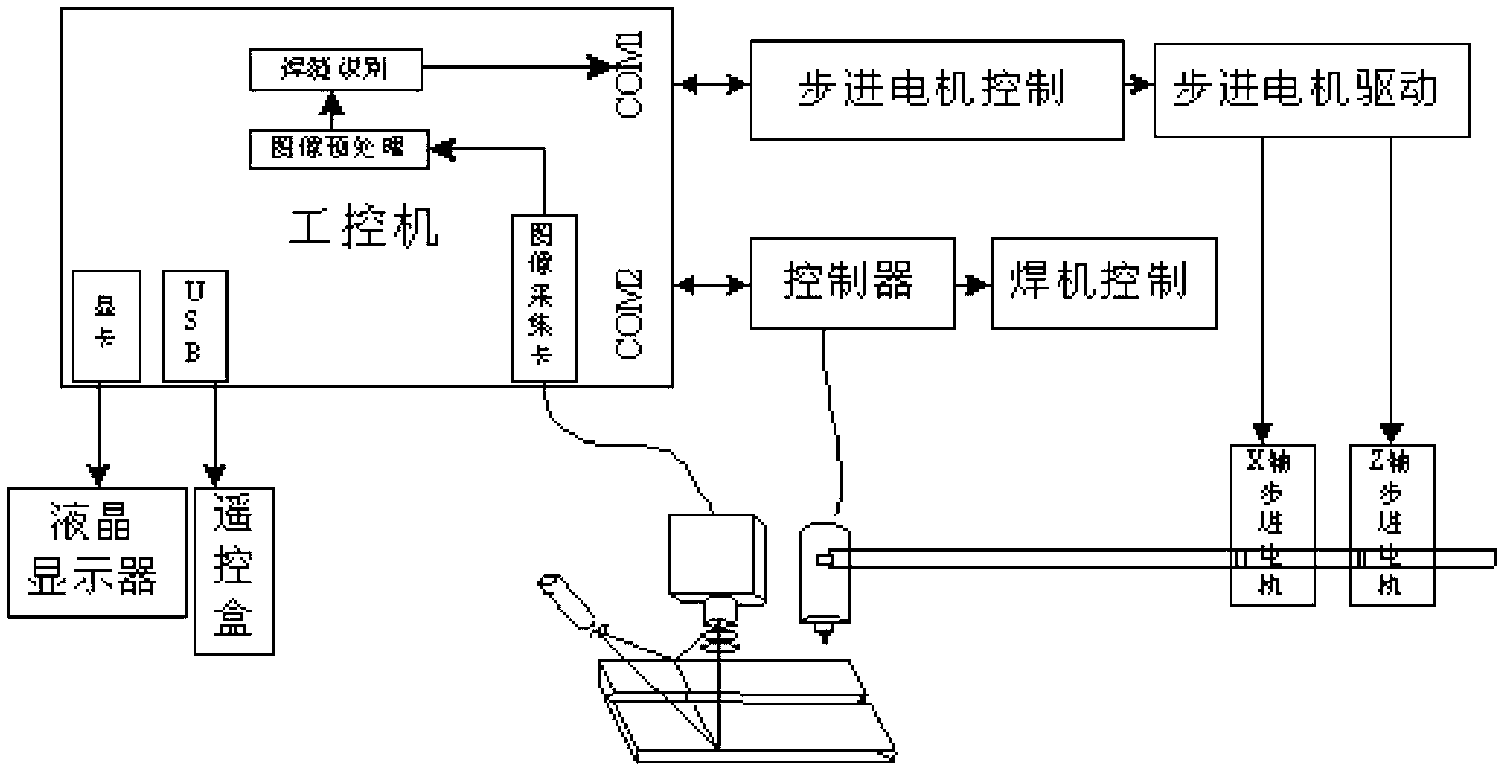

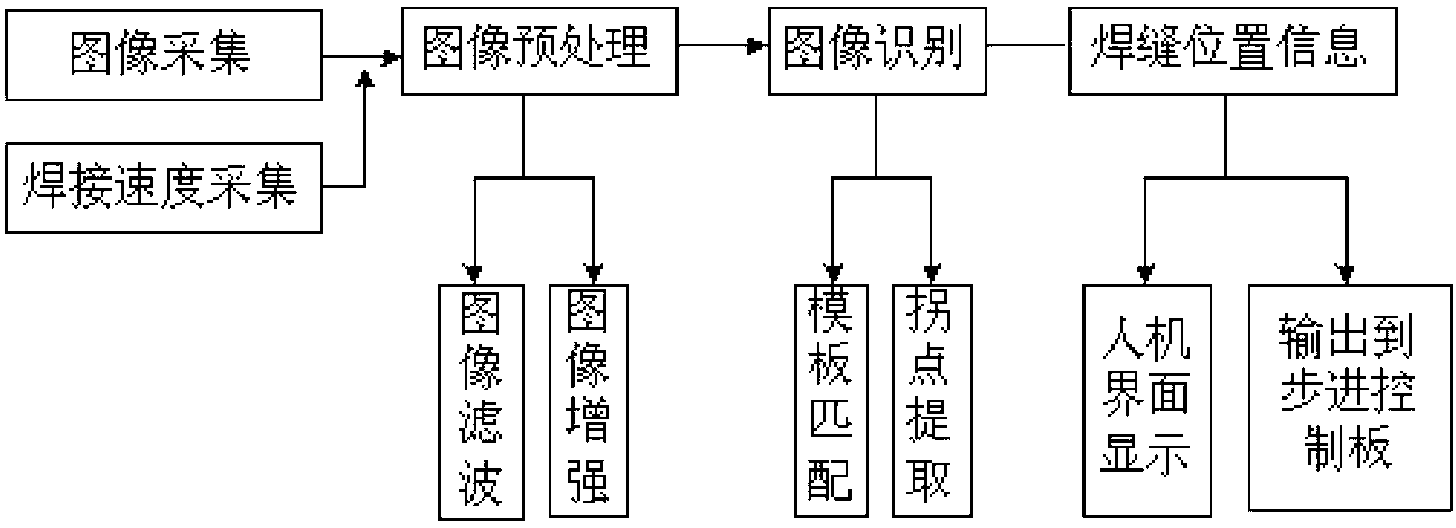

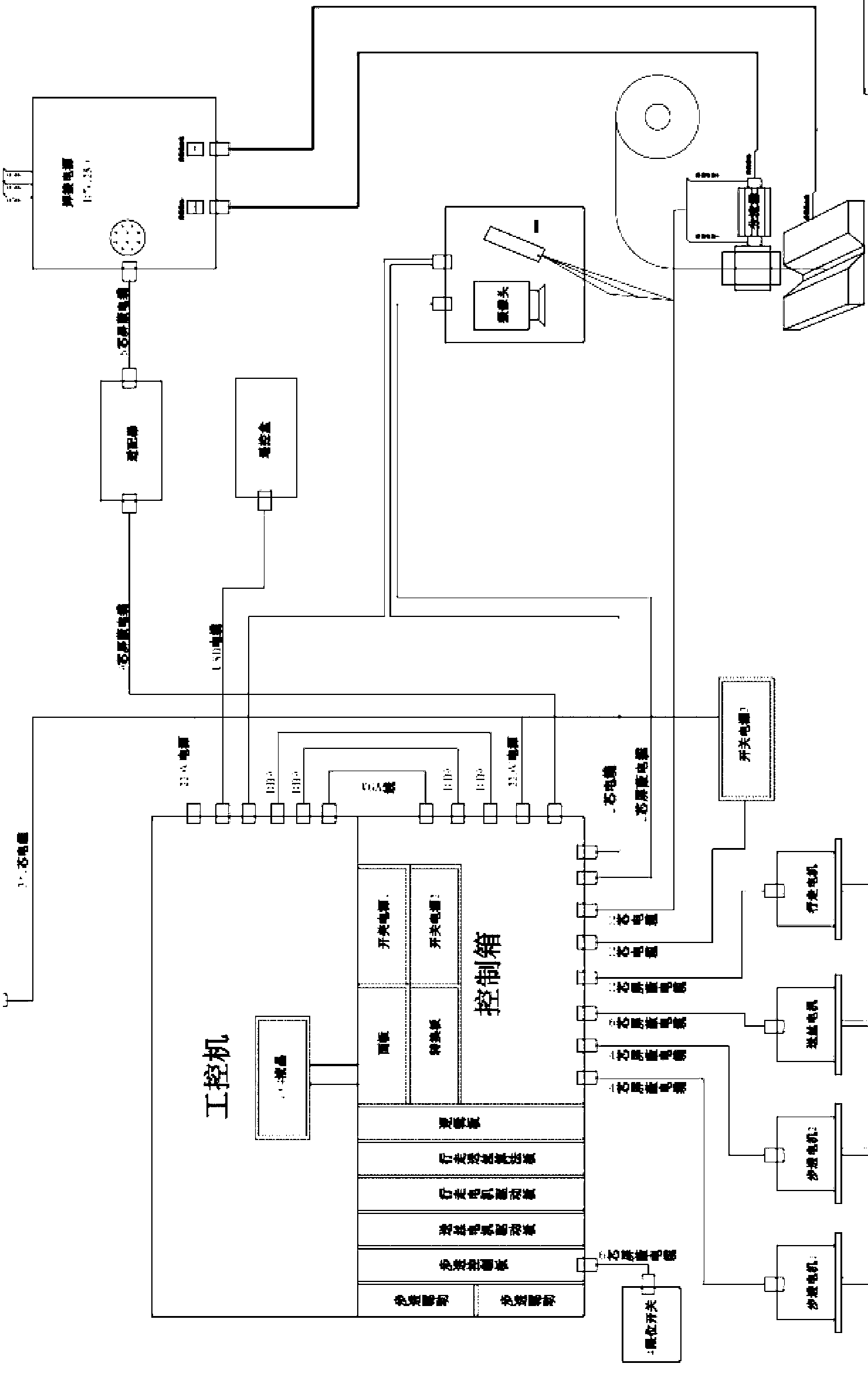

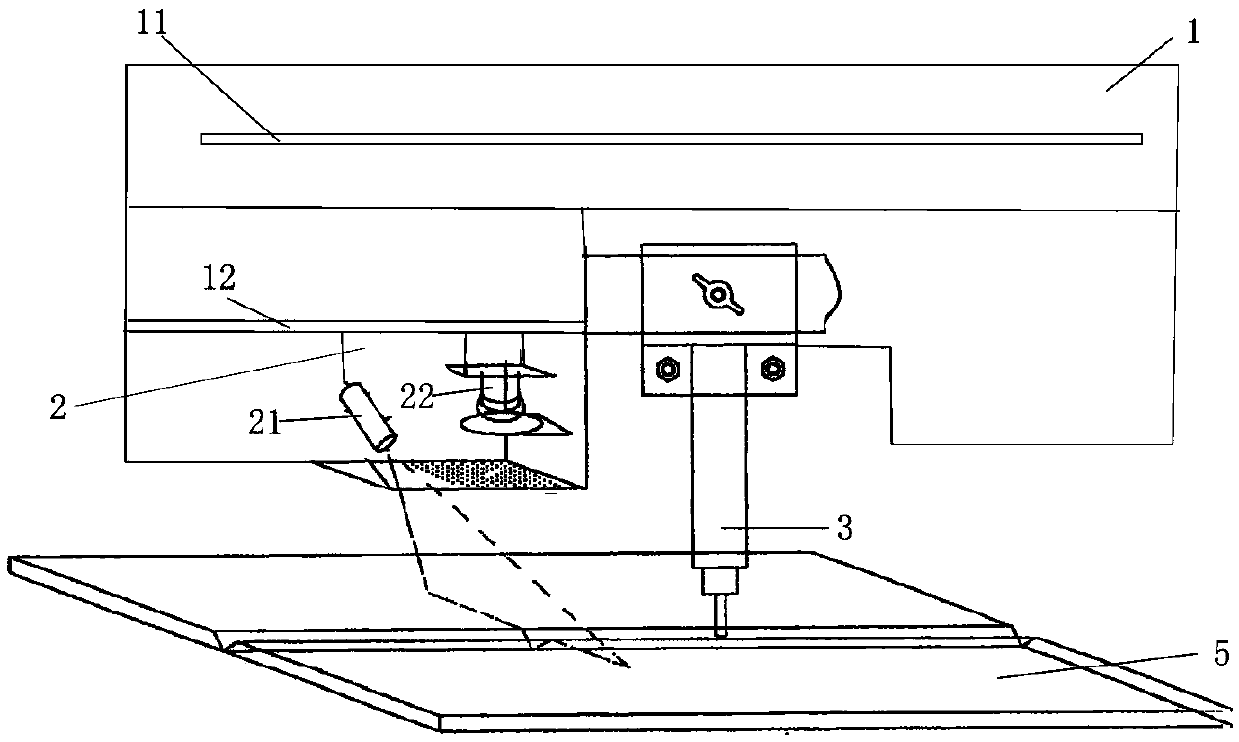

InactiveCN103203526AImprove anti-interference abilityEliminate lead errorArc welding apparatusComponent Object ModelMachine control

The invention discloses a laser visual tracking system, which mainly comprises an industrial personal computer, wherein a COM 1 (Component Object Model) port of the industrial personal computer is connected with an X axis motor and a Z axis motor through a motor control and drive circuit; output ends of the X-axis motor and the Z-axis motor are connected with a welding torque; the controller of the welding torque and a welding machine control circuit are connected with the industrial personal computer; the industrial personal computer is also connected with a laser sensor for acquiring information on the welding torque and a workpiece in real time and delivering the acquired information to the industrial personal computer; the laser sensor is a visual sensing module and mainly comprises a camera and a laser diode; the camera is vertically aligned with the workpiece; a laser is slantwise arranged and forms an angle of 30 degrees with the laser; laser emitted by the laser irradiates the workpiece to form a narrow light strip; after the light strip is reflected or refracted by the workpiece, the light strip enters the camera to image, and the image is transferred to the industrial personal computer for processing; after the image is analyzed and processed by the industrial personal computer, an action command is emitted to the welding torque, the X-axis motor and the Z-axis motor.

Owner:CHENGDU XIONGGU JIASHI ELECTRICAL

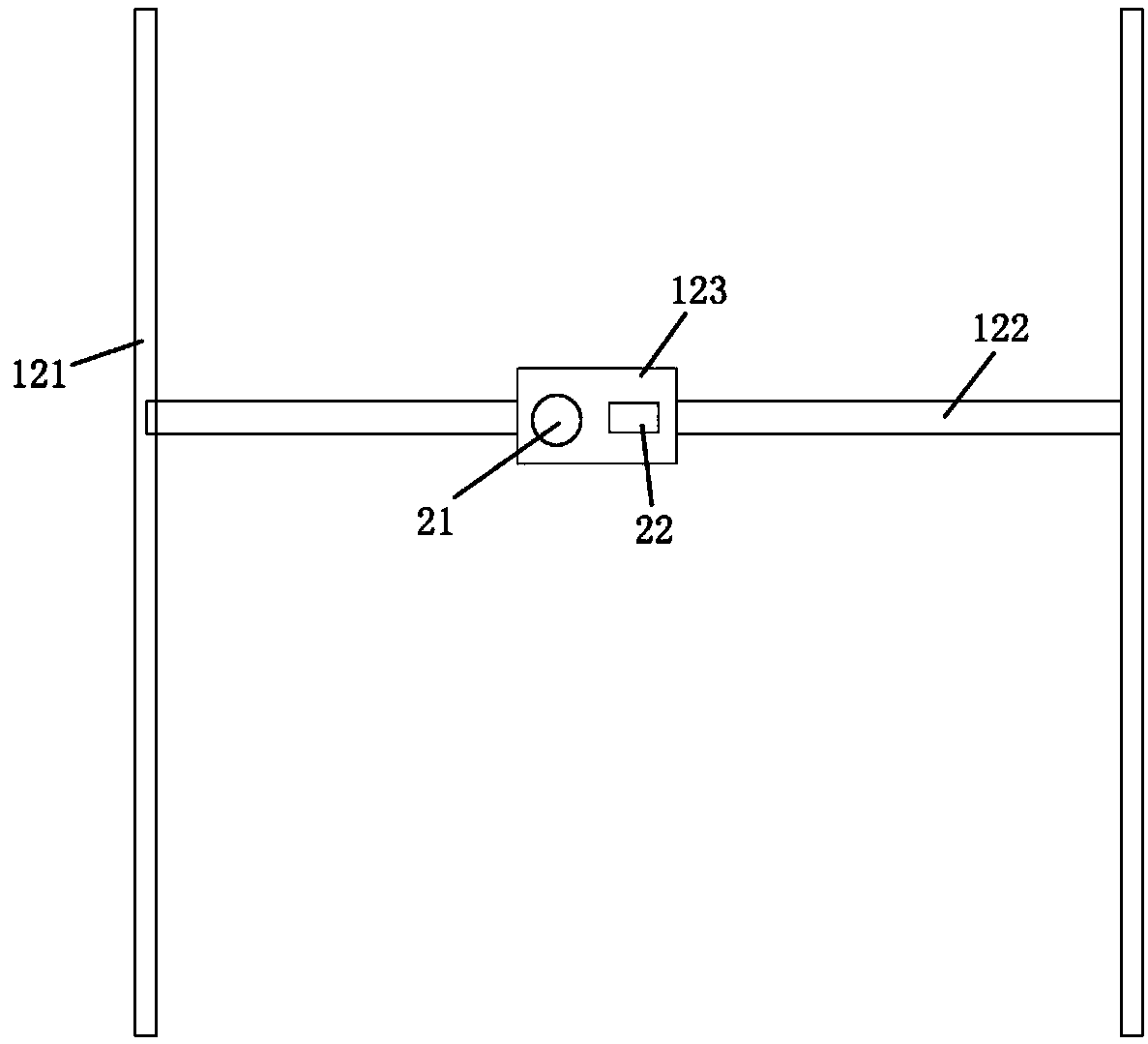

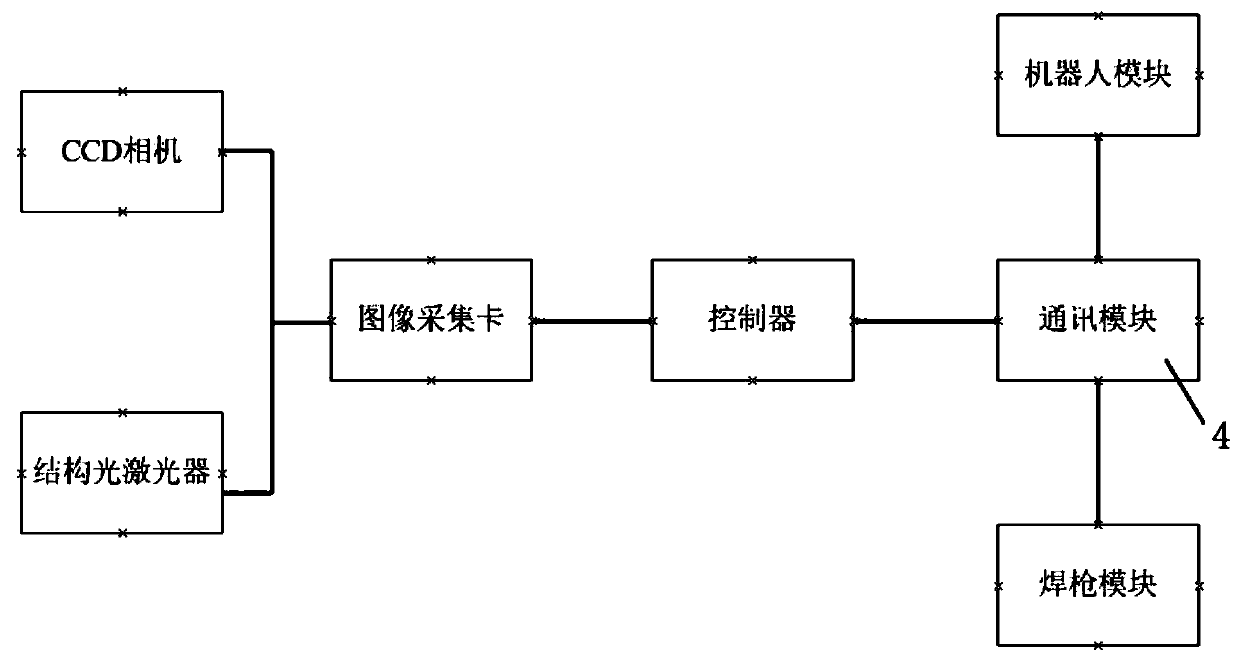

Welding seam visual tracking system based on laser structured light and method

The invention provides a welding seam visual tracking system based on laser structured light. The system comprises a visual tracking module, a robot module, a welding gun module and a communication module, wherein the visual tracking module comprises a CCD camera, a structured light laser device, an image acquisition card and a controller for processing the laser weld image; the CCD camera and thestructured light laser device in the visual tracking module are installed on the robot module through a three-dimensional motion measuring system, the controller is used for performing data transmitting to the robot module and the welding gun module through the communication module; and a coordinate identification device is arranged in the robot module and used for determining the identificationpoint serving as a reference, the method used by the system controls the use of a welding gun through a series of image processing. According to the system and the method, automatic correct deviationof the welding robot in real time in the welding process can be realized, the quality of the welding seam is improved, the application range of the welding robot is expanded, the application of the welding seam visual sensing tracking technology can improve the quality and precision of a welding part, the production cycle of products is shortened, and the production efficiency of the product is improved.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

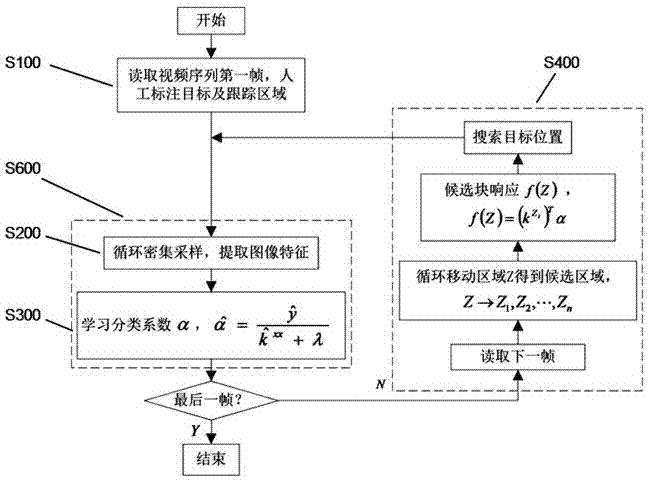

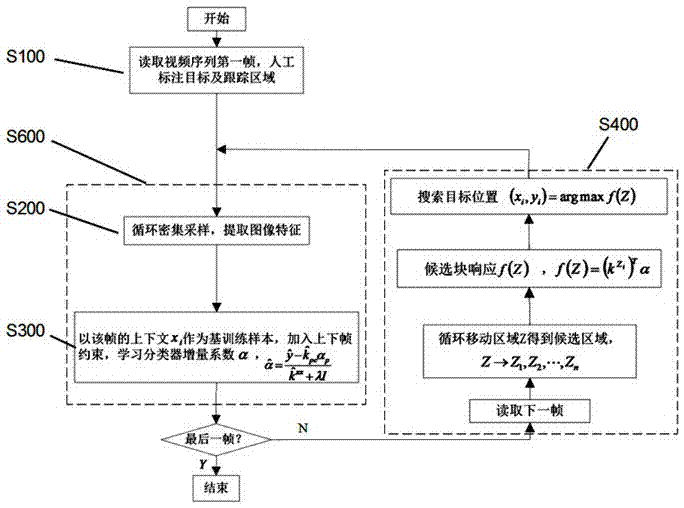

Visual tracking method and visual tracking system under moving background

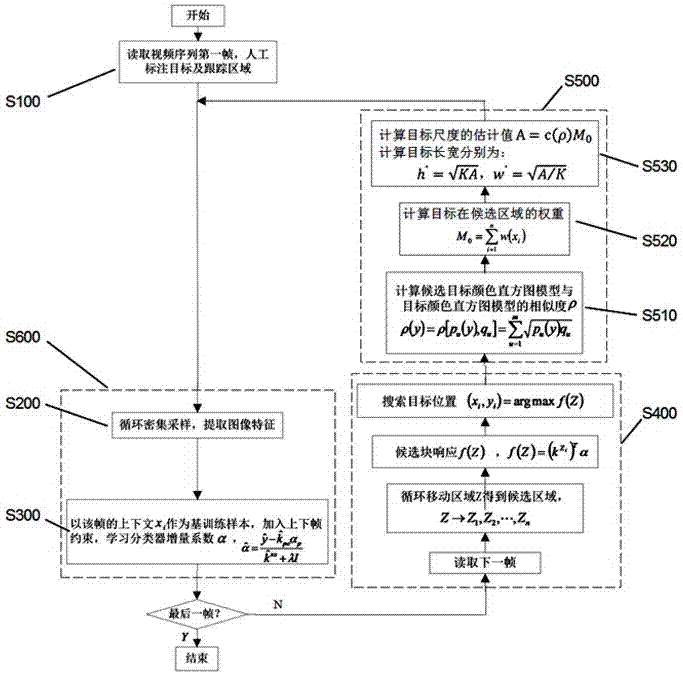

PendingCN107403175AImprove real-time performanceImprove adaptabilityCharacter and pattern recognitionFeature extractionImaging Feature

The invention discloses a visual tracking method and a visual tracking system under a moving background. The visual tracking method comprises the following steps: reading a first frame of a video and labelling a target and a tracking area; circularly and densely acquiring the labelled target and an image of the tracking area, extracting a feature; taking a context area Xi around the target as a basic training sample, adding upper and lower frame constraints, and obtaining a learning classifier increment coefficient a; circularly moving a detection area z in the next frame to obtain a candidate block, substituting into a classifier to achieve that f(z)=(K<z>)<T>a and a target position that (xi, yi)=arg max f(z); returning to the step B, taking a context where the target center (xi, yi) is located as the basic training sample in the step C, obtaining the classifier increment coefficient a, updating a model, and continuing to update the next frame. The visual tracking system comprises a target initializing module, an image feature extracting module, a classifier initial training module, a rapid target detecting module, and a classifier training module. The tracked target can be accurately tracked when the target rapidly moves and the scale changes.

Owner:KUNMING UNIV OF SCI & TECH

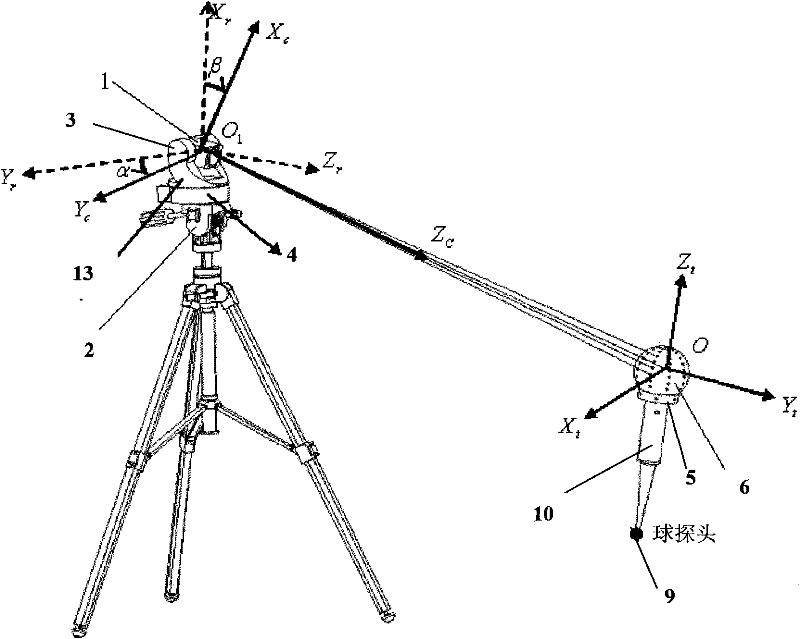

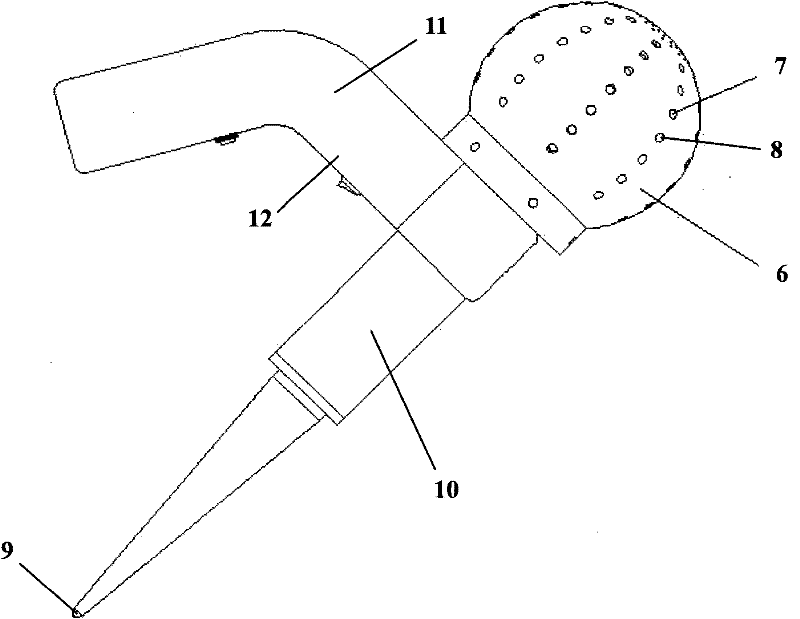

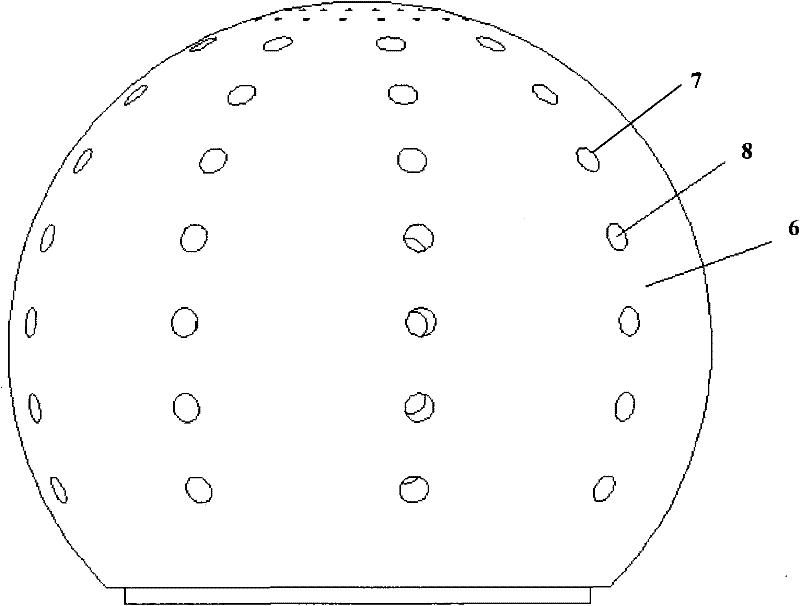

Large-space visual tracking 6D measurement system and measurement method

InactiveCN102288106AAssembly precisionImprove adaptabilityAngle measurementTelevision system detailsCombined useCoordinate-measuring machine

The invention discloses a large-space visual tracking six-dimensional measurement system and method. The system mainly comprises a self-zooming visual tracking camera and a color paseudorandom coding six-freedom degree measuring head. The gesture and space position coordinates of the measuring head are confirmed by utilizing the position change of a hole center with color paseudorandom coding expression on a target ball so as to realize the measurement of large-size space six-freedom degree. The system can be combined with a joint arm coordinate measuring machine to realize local high-precision measurement and positioning and can be also combined with assembly equipment of electric drilling, and the like to realize the precise assembly of large equipment.

Owner:HEFEI UNIV OF TECH

Inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method

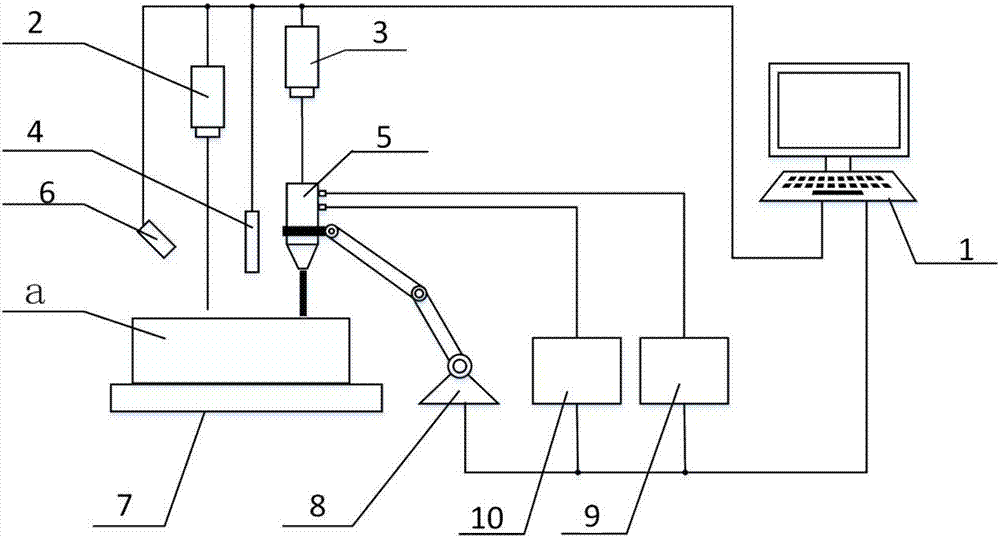

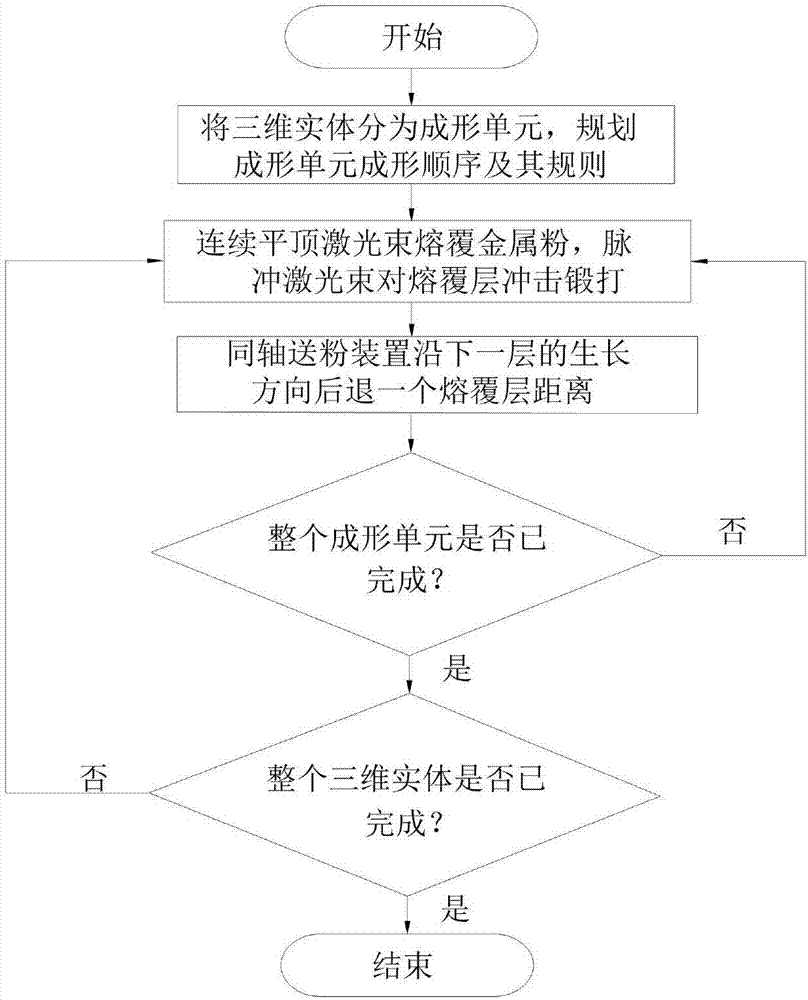

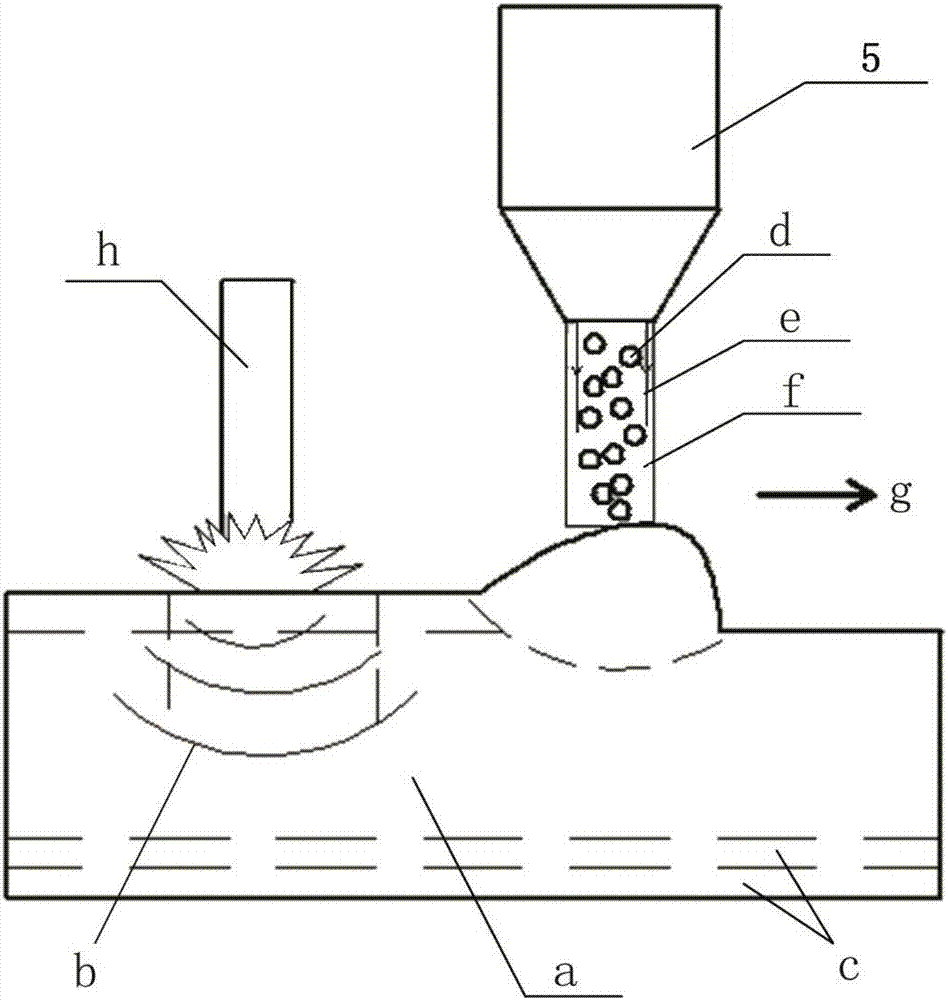

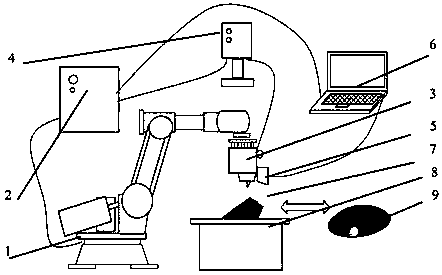

ActiveCN107262713ASolve undermeltSolve the problem of impenetrabilityAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsInductor

The invention relates to an inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method. The device comprises a master controller, a pulse laser device, a continuous laser device, a temperature inductor, a coaxial powder feeding device, a visual tracking system, a workbench, a mechanical arm, a metal powder container and a gas container. The pulse laser device, the continuous laser device, the temperature inductor and the visual tracking system are all arranged above the workbench. The mechanical arm tightly clamps the coaxial powder feeding device, so that the coaxial powder feeding device is located between the continuous laser device and the workbench, and is coaxial with the continuous laser device. The coaxial powder feeding device communicates with the metal powder container and the gas container. The pulse laser device, the continuous laser device, the temperature inductor, the visual tracking system, the mechanical arm, the metal powder container and the gas container are all connected with the master controller. The inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method can solve the problems of insufficient fusion and incomplete fusion of the Gaussian light spot edges, inner defects of gas holes, incomplete fusion, cracks and shrinkage are effectively eliminated, and the inner stress state of a formed part is greatly improved.

Owner:GUANGDONG UNIV OF TECH

Method for automatically tracking unilateral sewing laser visual sense paths of composite material three-dimensional structural member

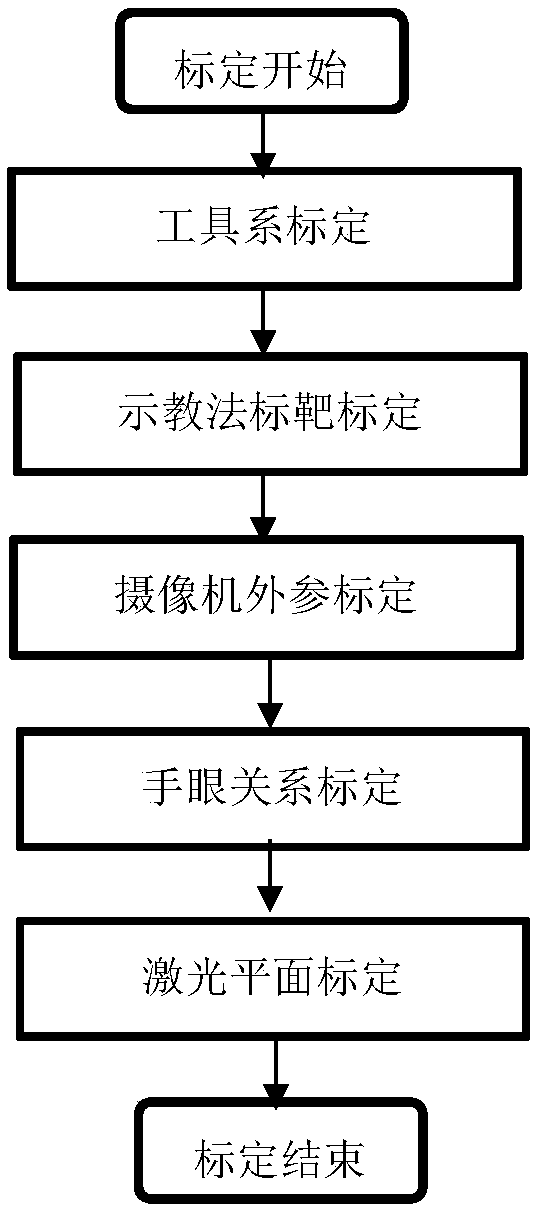

ActiveCN109591011ARapid positioningImprove calibration efficiencyProgramme-controlled manipulatorProgramme-controlled sewing machinesLaser lightVisual perception

The invention discloses a method for automatically unilateral sewing laser visual sense paths of a tracking composite material three-dimensional structural member. The method comprises the following steps of performing demarcating with a three-stripe laser light source visual tracking system and performing real-time extraction on robot operation paths. According to the method disclosed by the invention, an eye-in-hand manner is adopted; laser stripes of a laser seam tracker are projected to the surface of a three-dimensional target, and corresponding three-dimensional position information is obtained, so that the relative pose relationship between the wrist of a robot and the laser visual sense system is determined; and the shape of a space curved surface character workpiece is matched bya laser visual system in a real-time manner, and the working path of the robot is extracted for tracking calculation. Compared with a conventional plane target, the method can effectively improve thedemarcating efficiency and the demarcating accuracy; the working plane of a three-stripe laser light source can be demarcated at the same time, and on the other side, the quick positioning of the space curved surface character workpiece and tracking requirement of unilateral sewing paths can be realized.

Owner:TIANJIN POLYTECHNIC UNIV

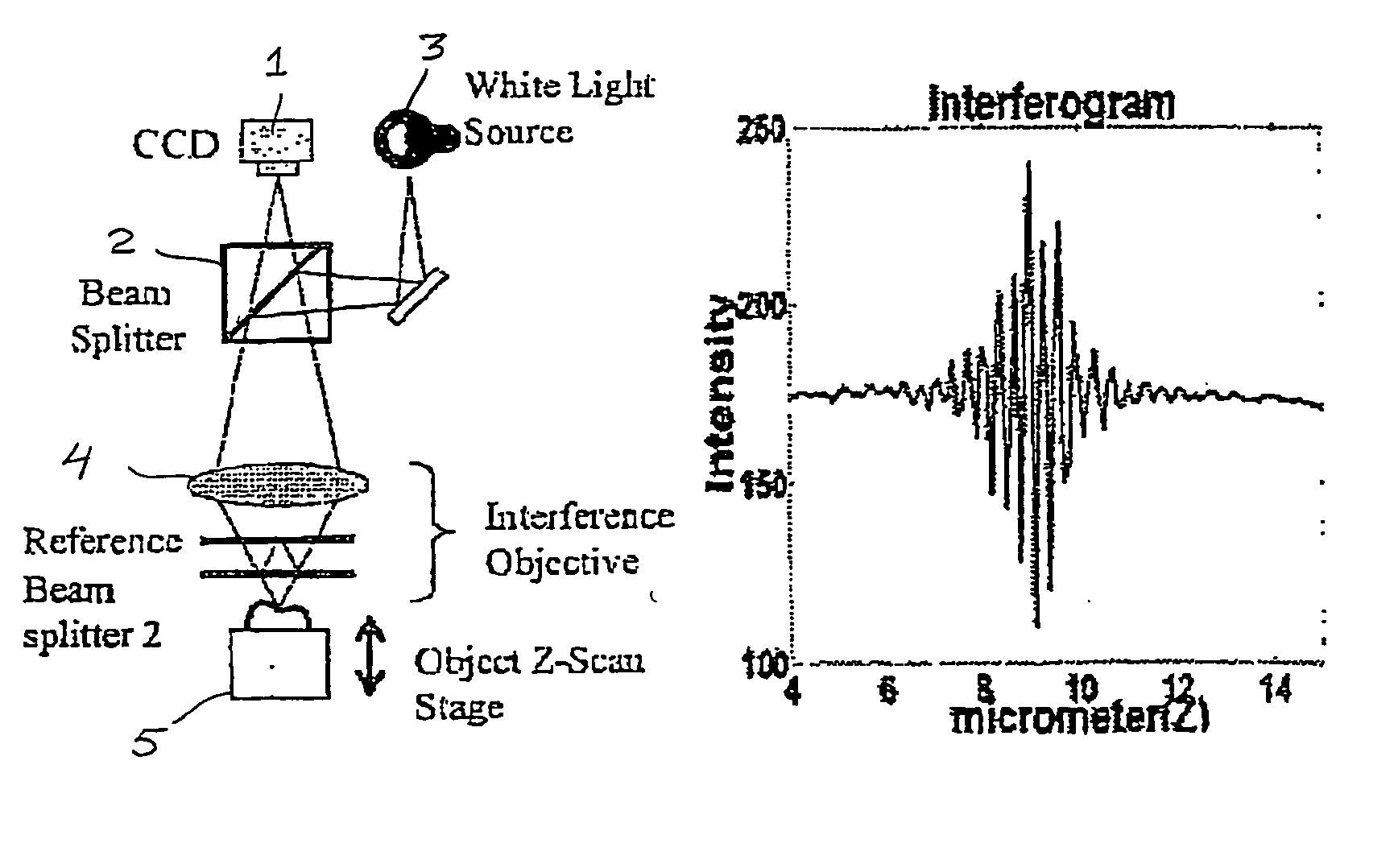

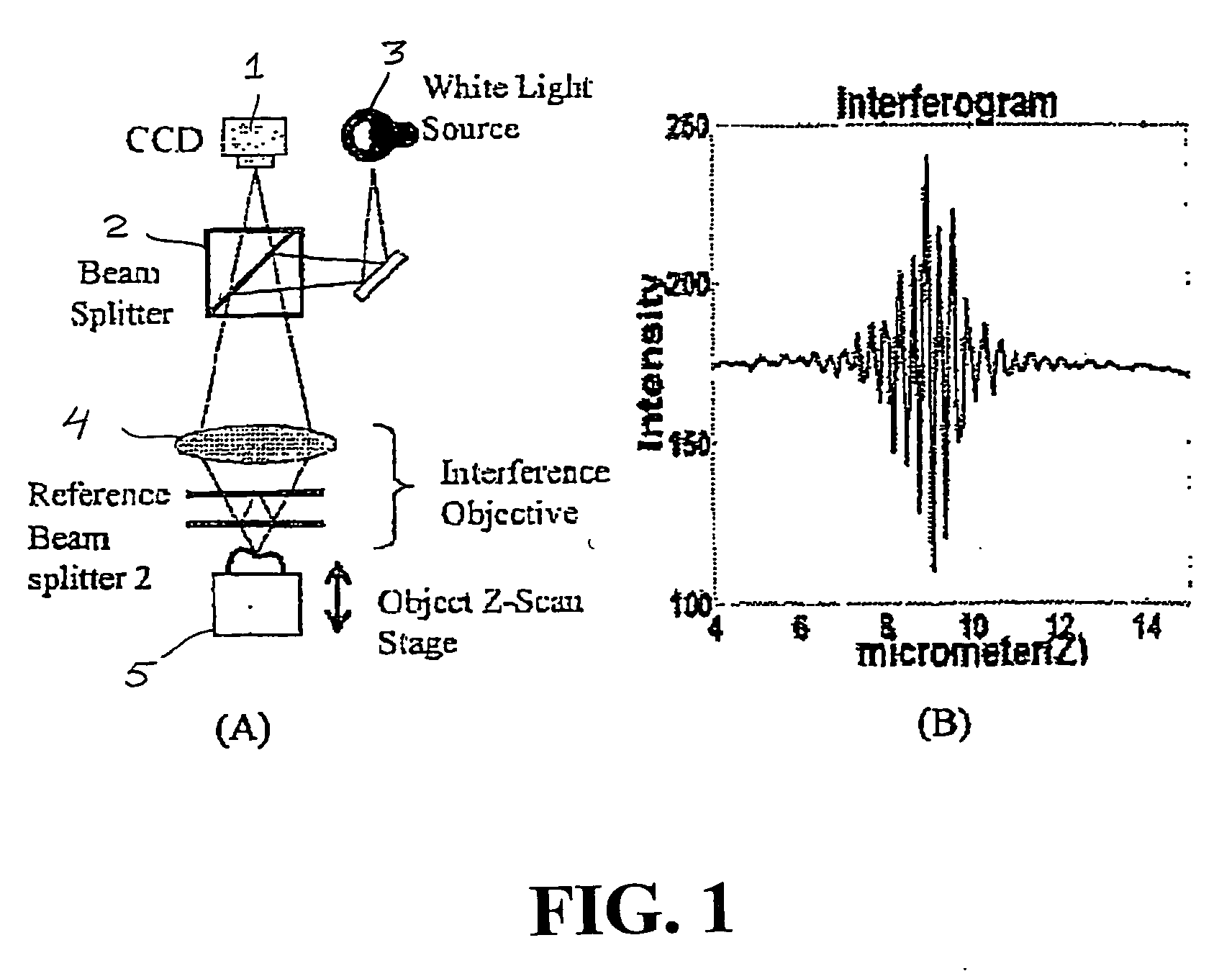

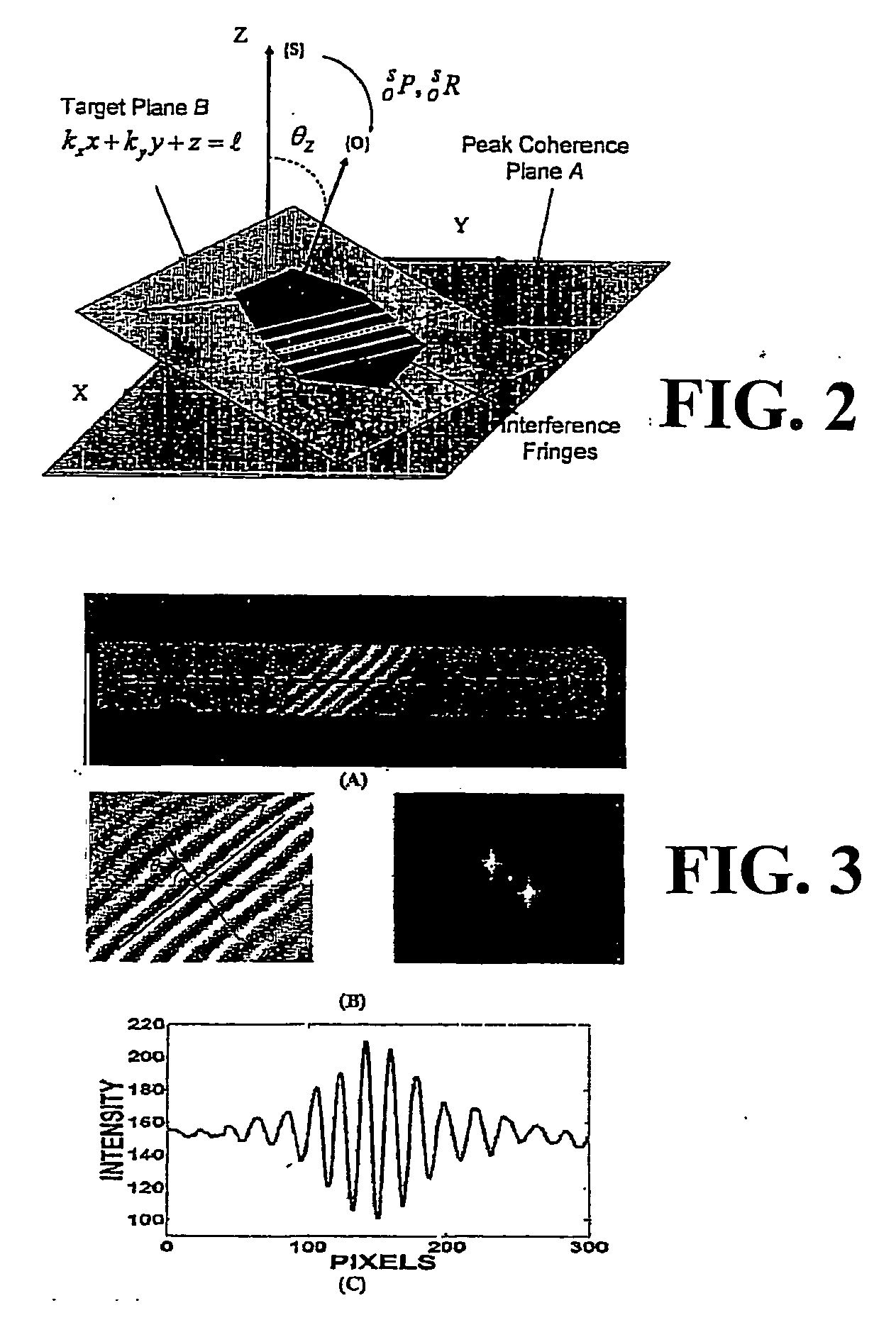

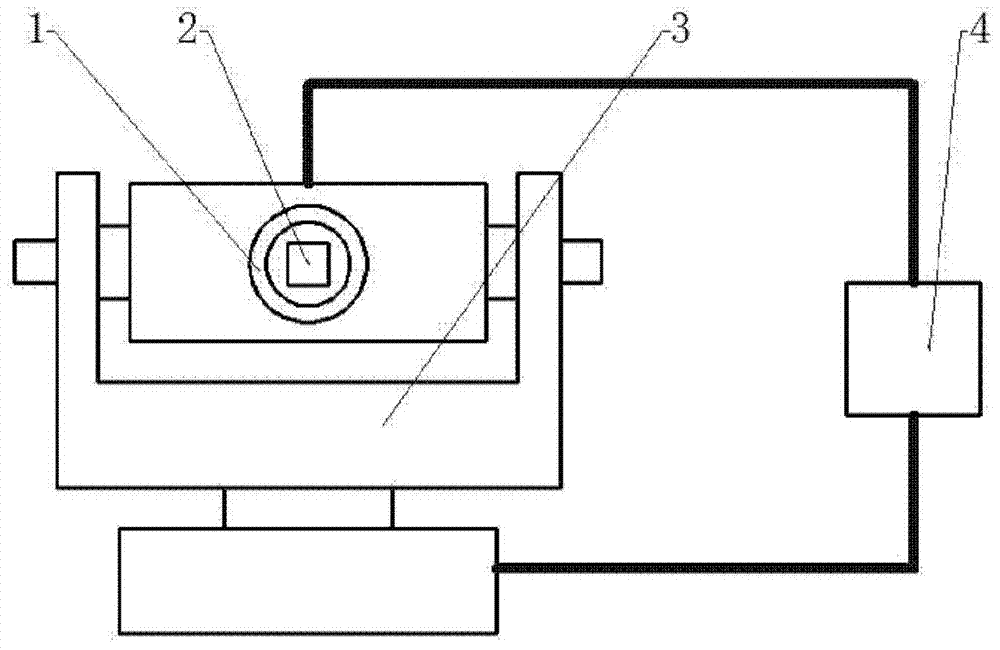

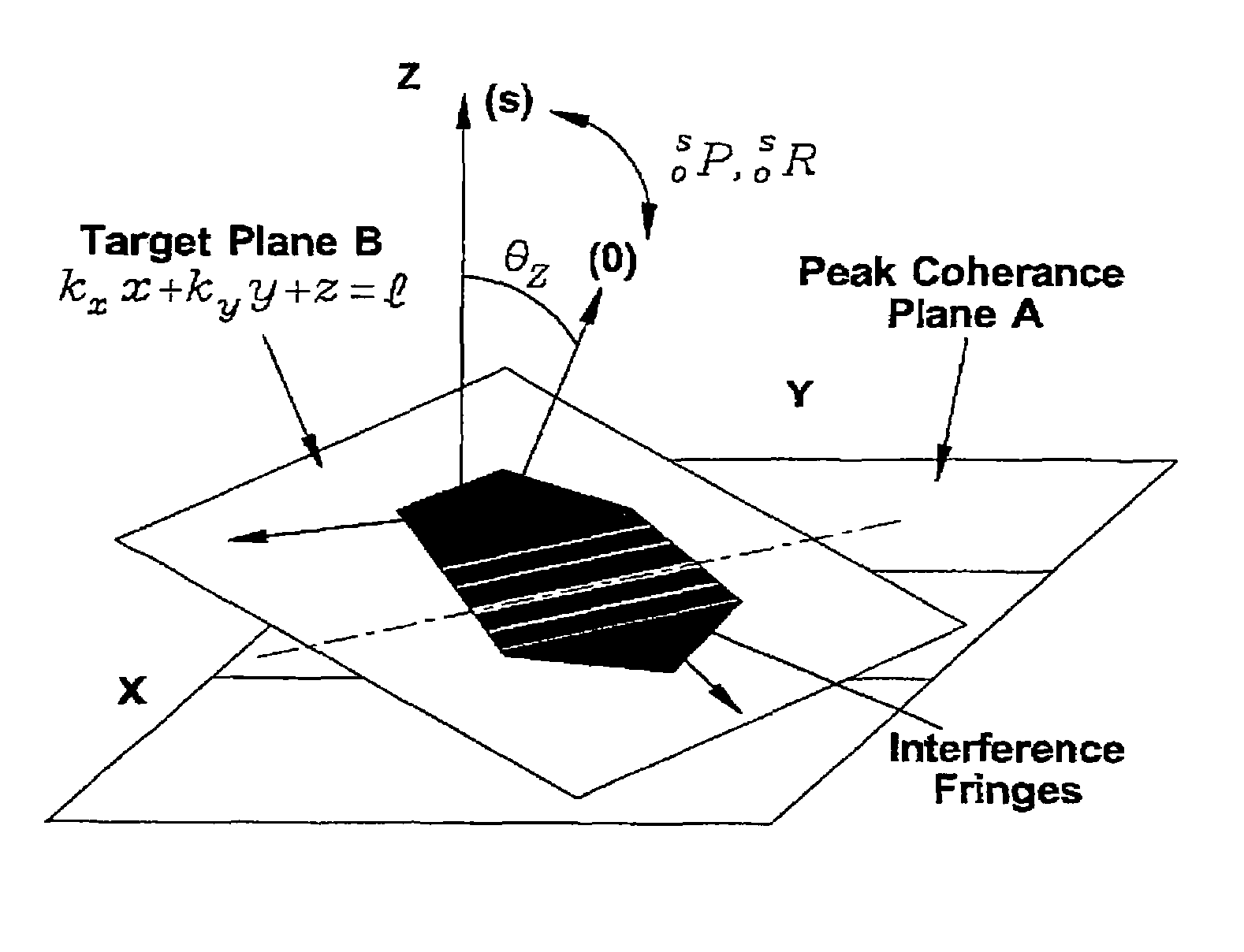

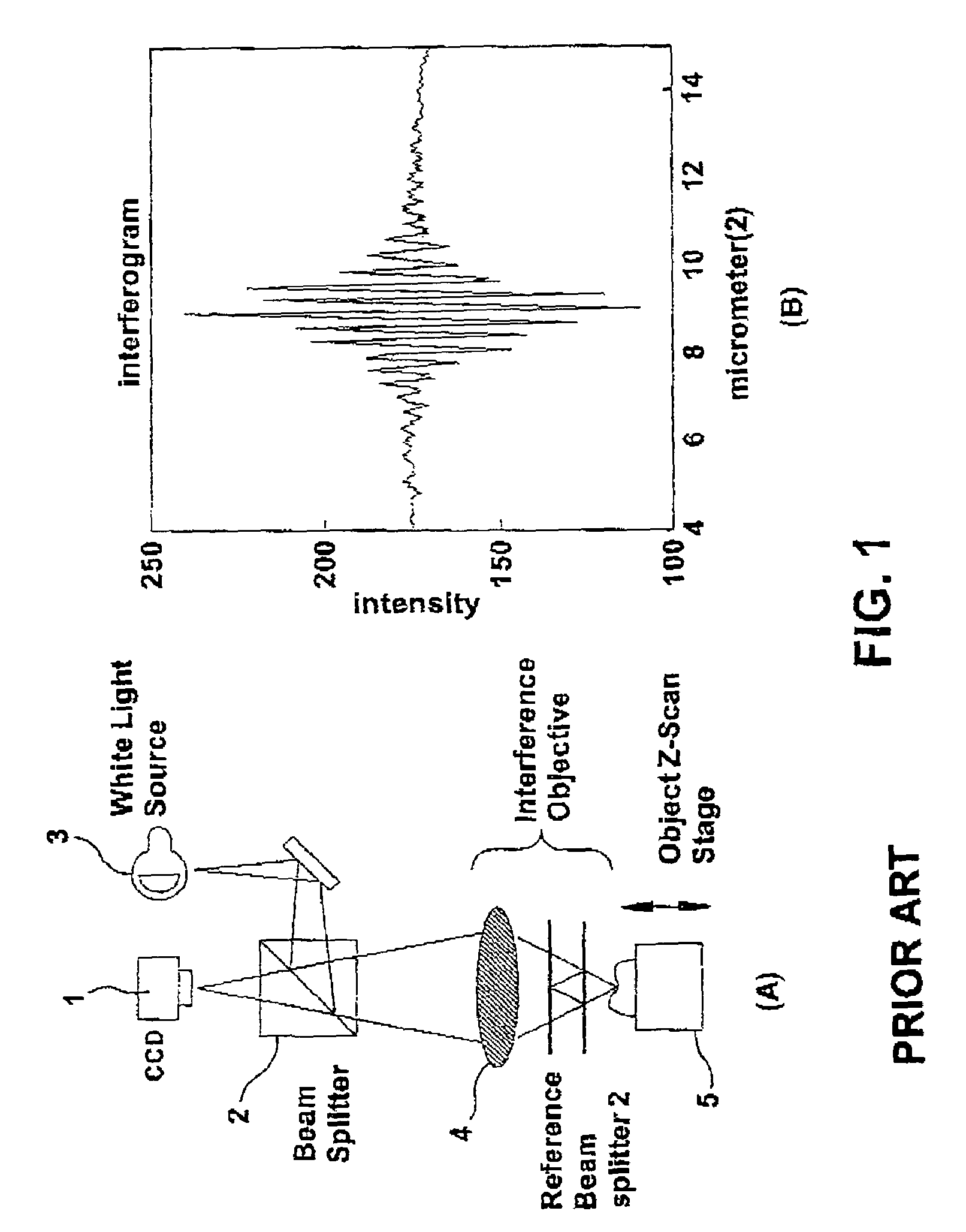

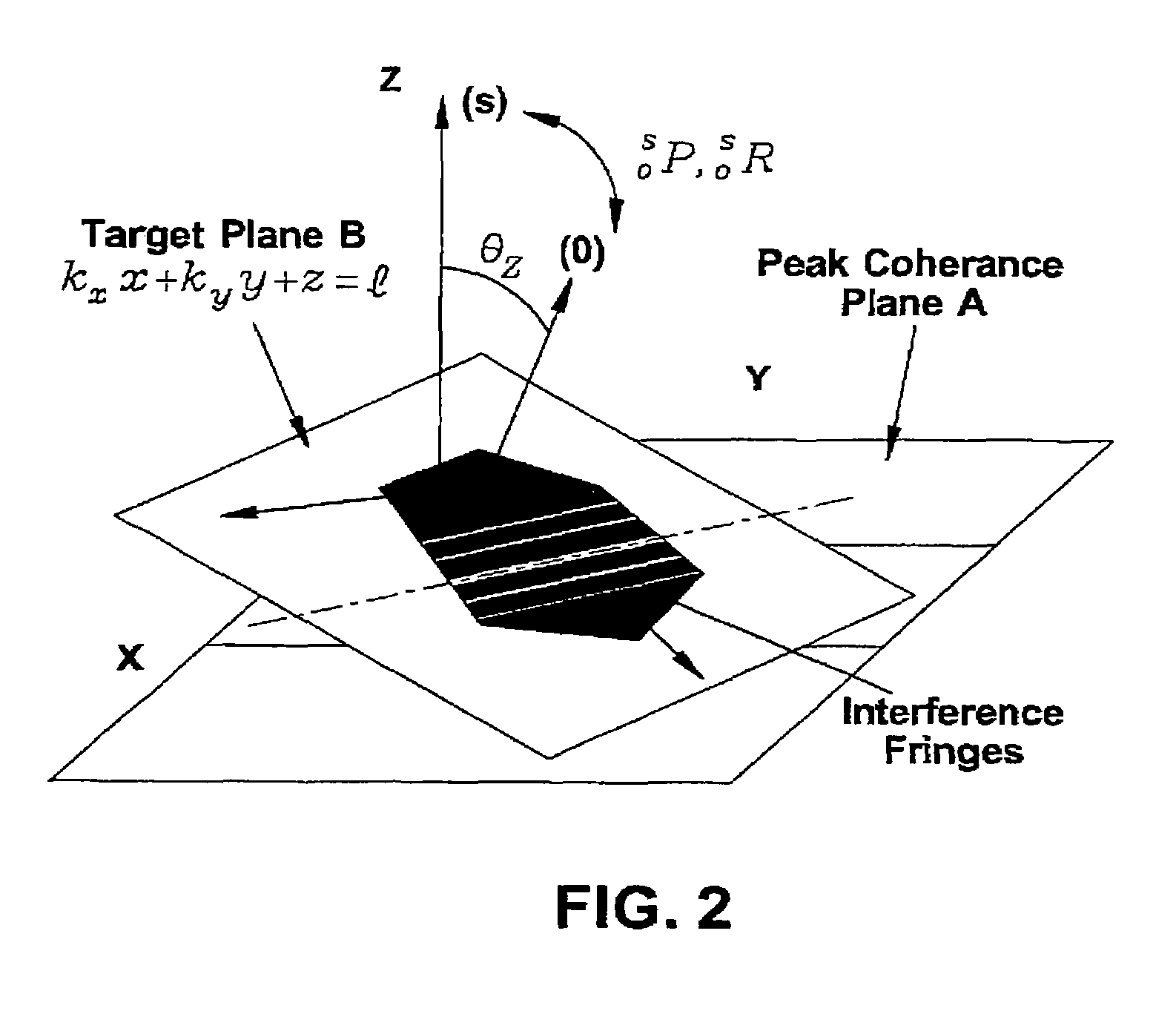

Methods and systems for ultra-precise measurement and control of object motion in six degrees of freedom by projection and measurement of interference fringes

A system and method for active visual measurement and servo control using laterally sampled white light interferometry (L-SWLI) for real-time visual tracking of six-degree-of-freedom (6 DOF) rigid body motion with near-nanometer precision. The visual tracking system is integrated with a 6 DOF motion stage to realize an ultra precision six-axis visual servo control system. Use of L-SWLI obtains the complete pose of the target object from a single image frame to enable real-time tracking. Six-degree-of-freedom motions are obtained by measuring the fringe pattern on multiple surfaces of the object or from a single surface with additional information gained from conventional image processing techniques.

Owner:OHIO STATE INNOVATION FOUND

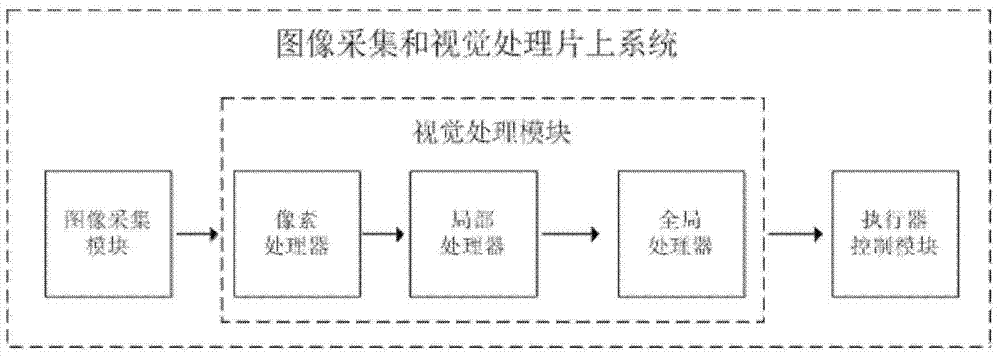

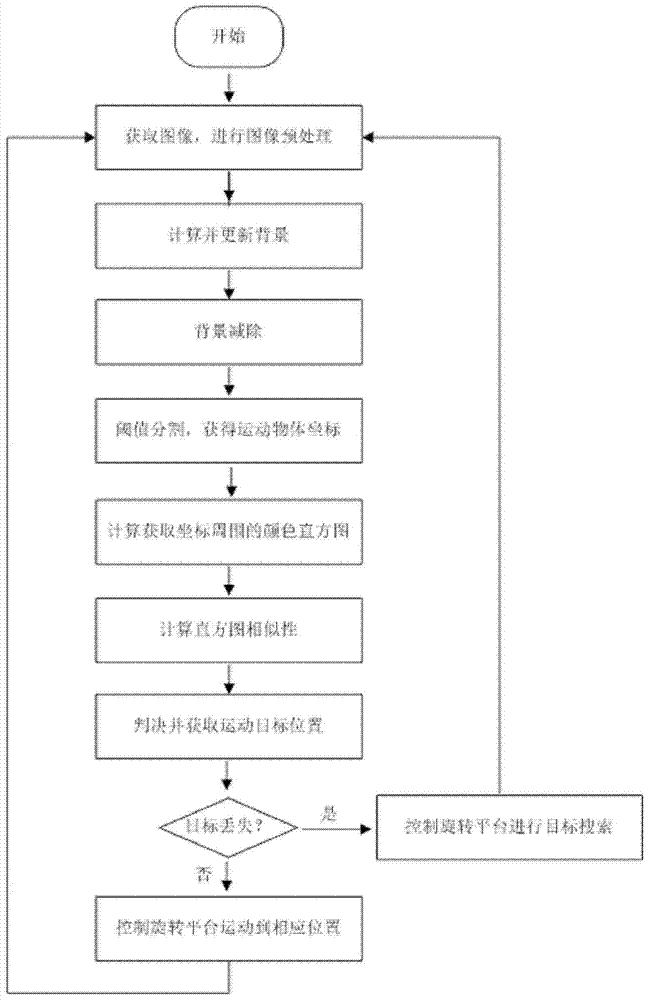

Visual tracking system and method based on high-speed image sensor

InactiveCN103544714AEliminate transfer bottlenecksFast trackImage enhancementImage analysisComputer moduleField of view

The invention discloses a visual tracking system and method based on a high-speed image sensor. The system comprises an optimal lens, an image collecting and visual processing on-chip system, a high-speed rotating platform and a power management module, wherein the optical lens is used for tracking a target and carrying out imaging on the target, the image collecting and visual processing on-chip system is used for achieving image collection and visual analysis, the high-speed rotating platform is used for enabling the optical lens and the image collecting and visual processing on-chip system to be mounted, and the power management module is used for supplying proper and stable power sources for all parts in the system to ensure the normal work of the system. According to the visual tracking system and method based on the high-speed image sensor, the image collecting and visual processing on-chip system is used for collecting and analyzing the target, the rotating platform is driven to move according to the position of the target, the effect that the target is located in the view center of the system is ensured, and the operation that the position, the speed and other information of the target are obtained is ensured. The system is high in integrated degree, precision and speed, low in cost and capable of completing high-speed target tracking tasks which cannot be completed through a traditional tracking system.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

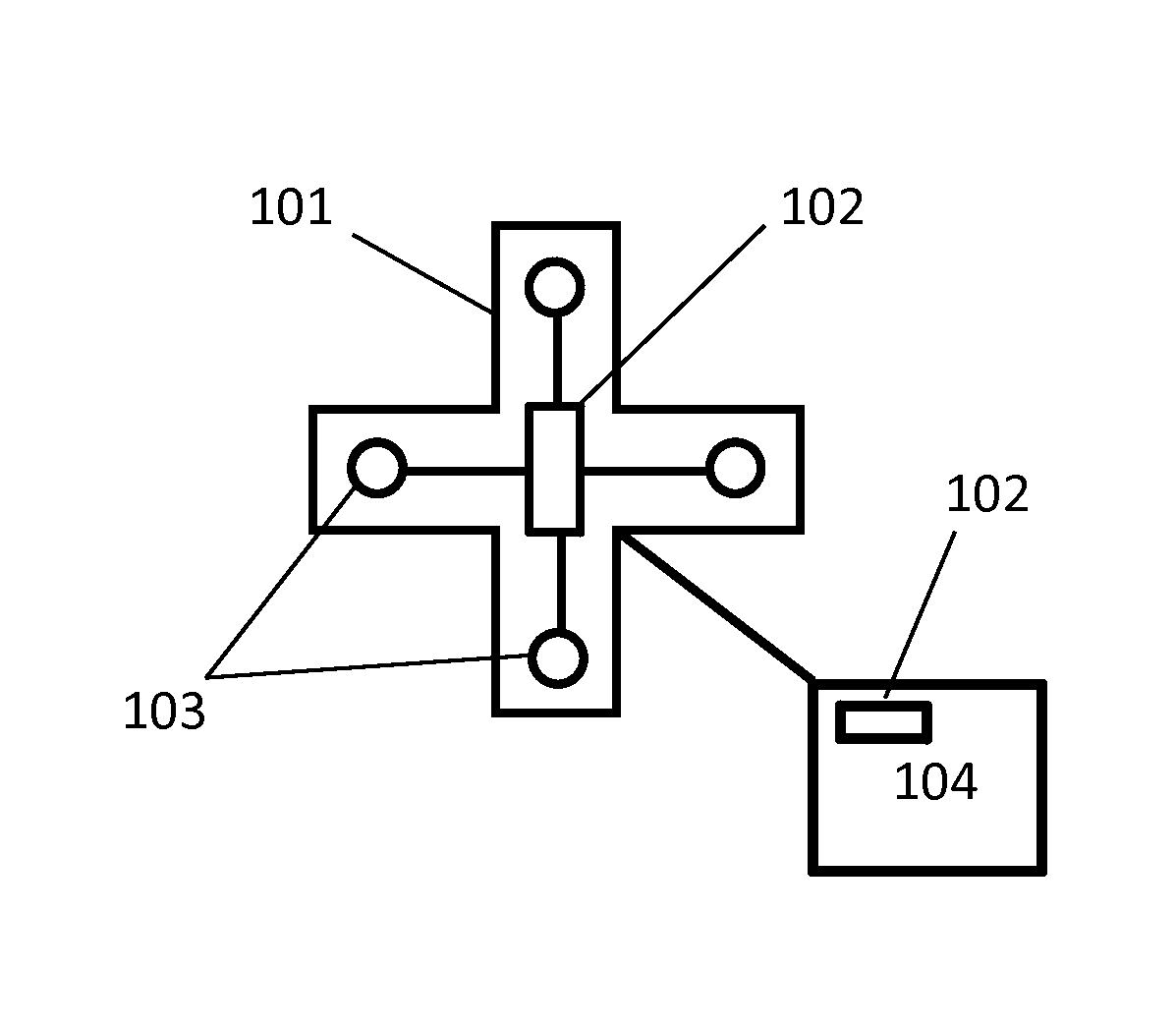

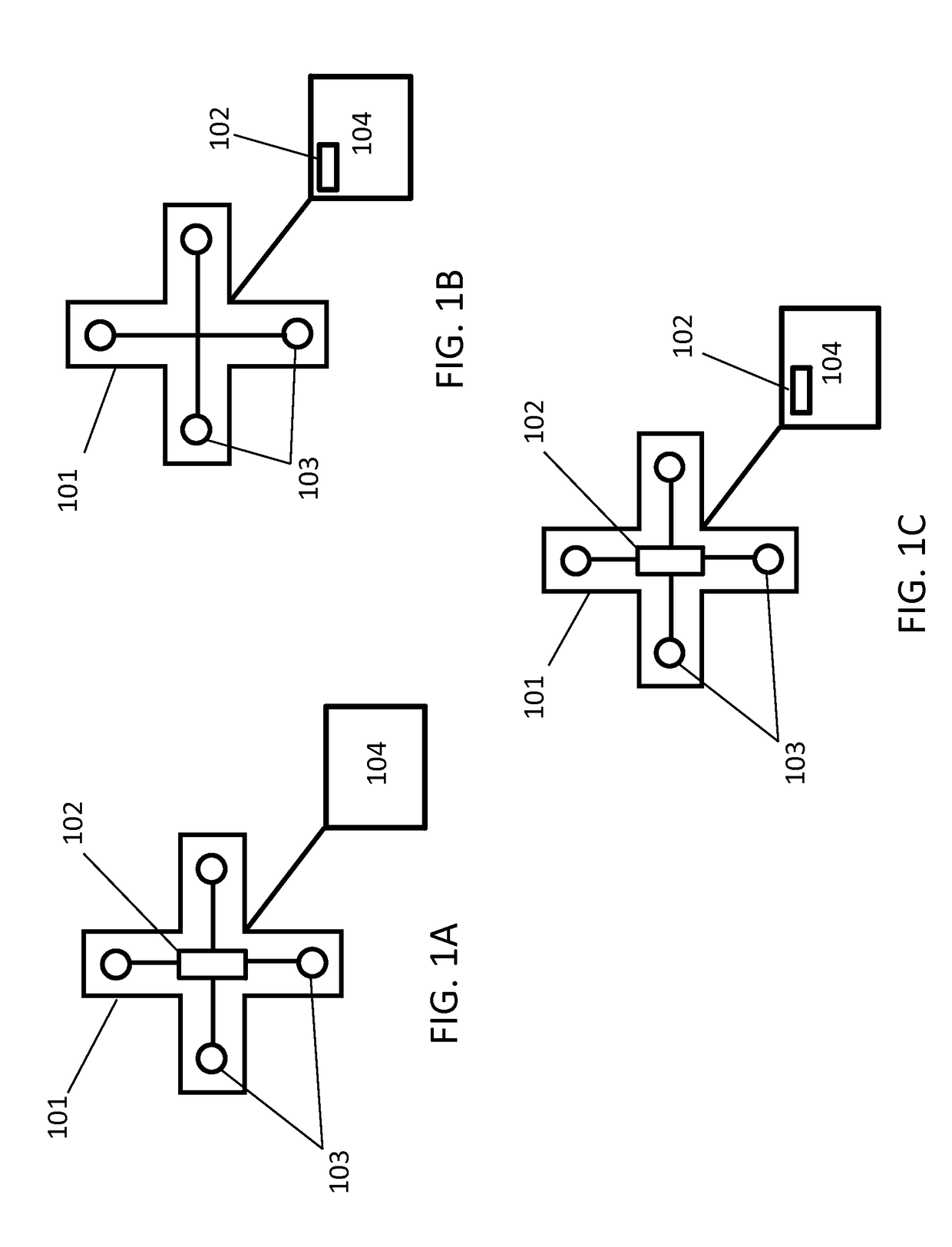

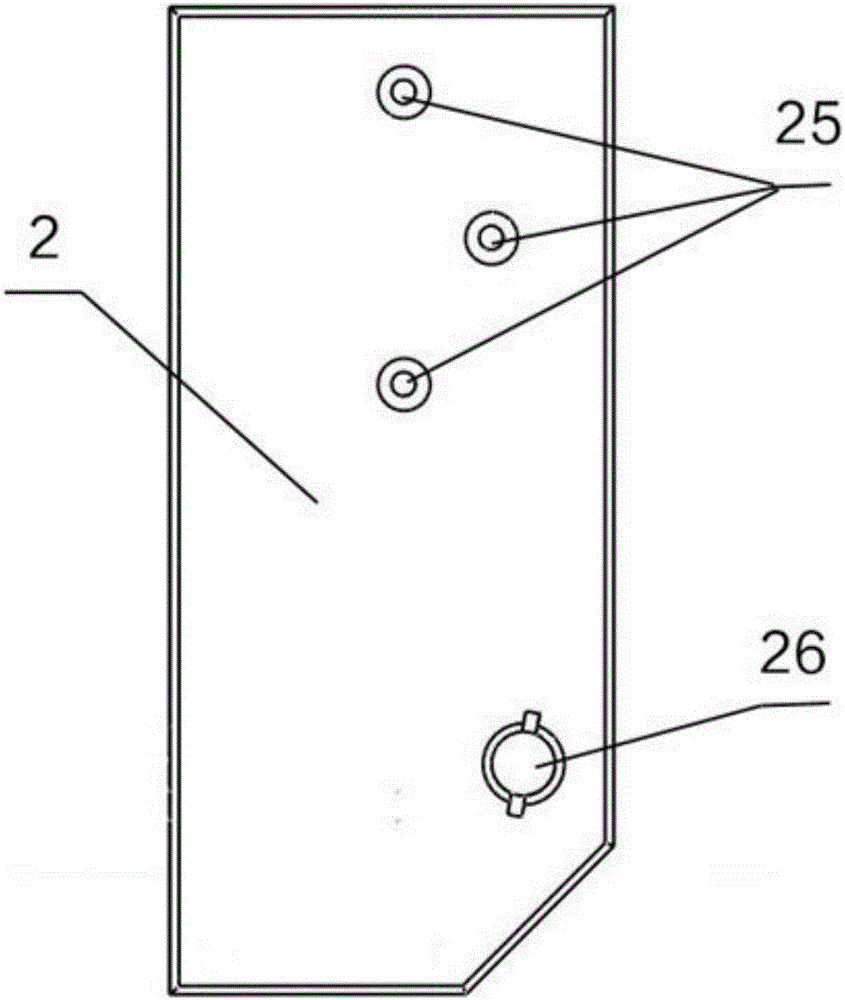

Visible light communication system for transmitting data between visual tracking systems and tracking markers

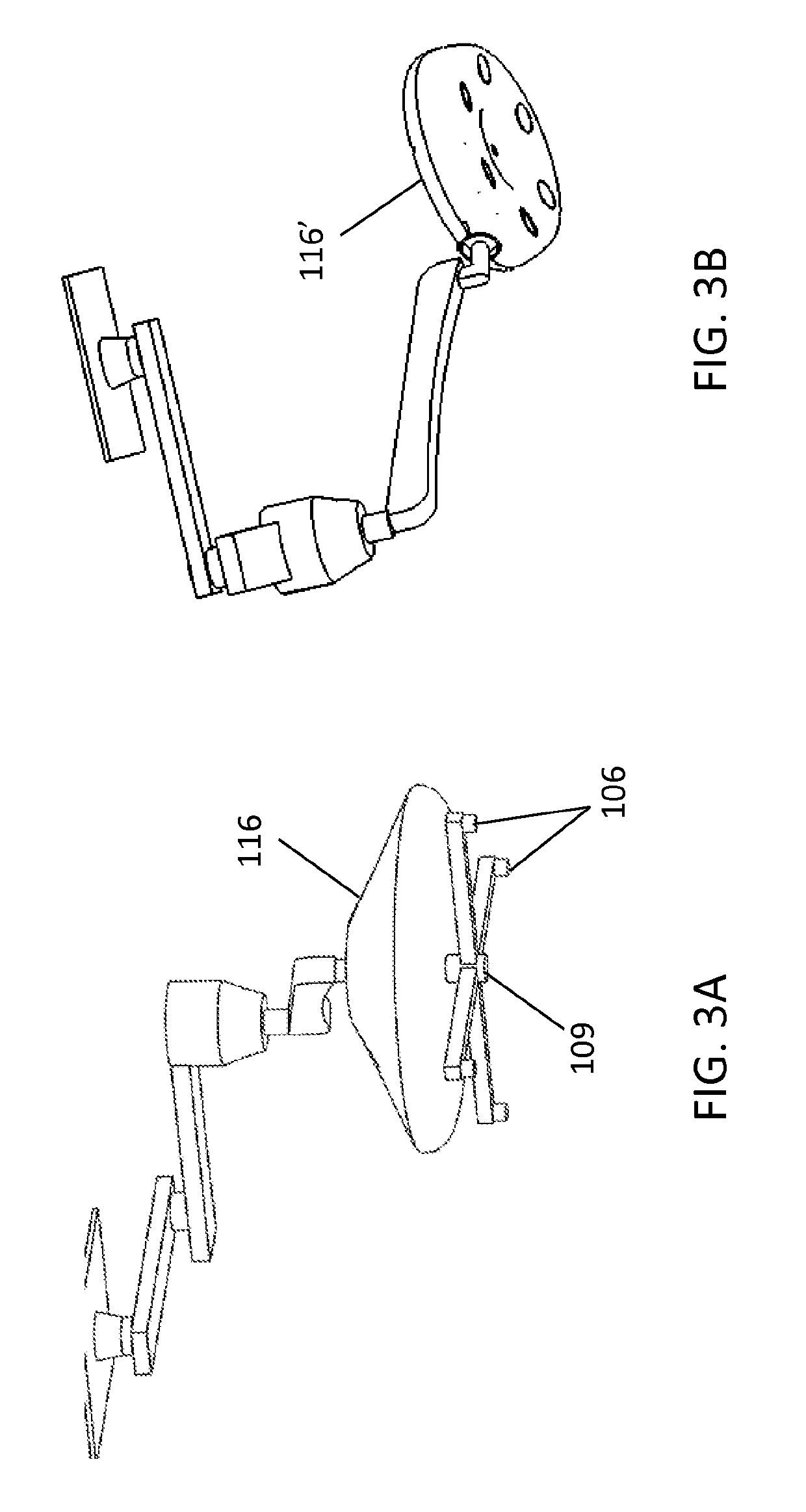

ActiveUS20170245945A1Promote resultsEfficient executionSurgical navigation systemsLine-of-sight transmissionComputer-aidedOptical tracking

An optical tracking system includes at least one tracking array for generating and optically transmitting data between 1 and 2,000 MB / s. At least one tracker for optically receiving the optically transmitted data between 1 and 2,000 MB / s is also provided. The tracking system is used not only for tracking objects and sending tracking information quickly but also providing the user or other components in an operating room with additional data relevant to an external device such as a computer assisted device. Orthopedic surgical procedures such as total knee arthroplasty (TKA) are performed more efficiently and with better result with the optical tracking system.

Owner:THINK SURGICAL

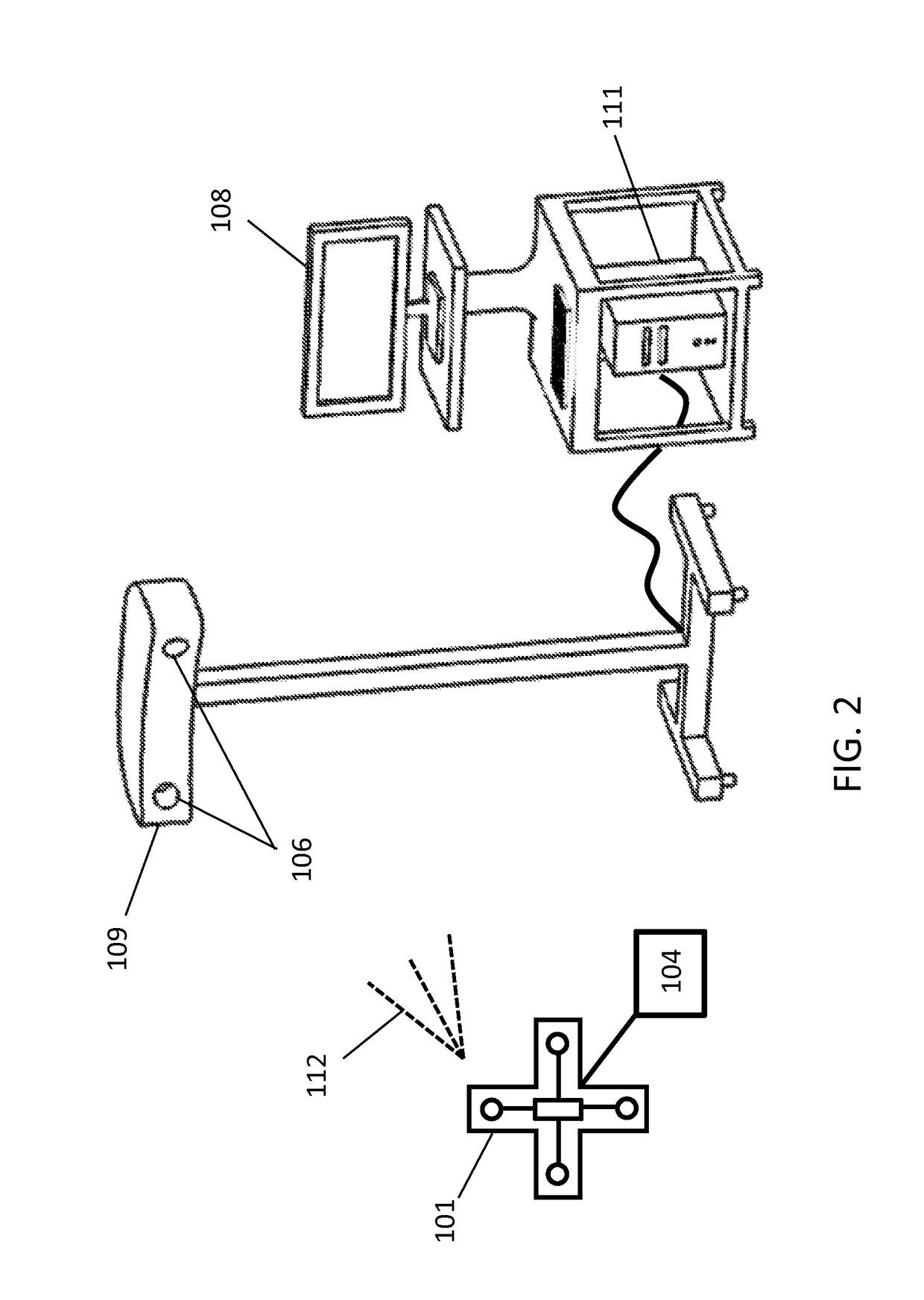

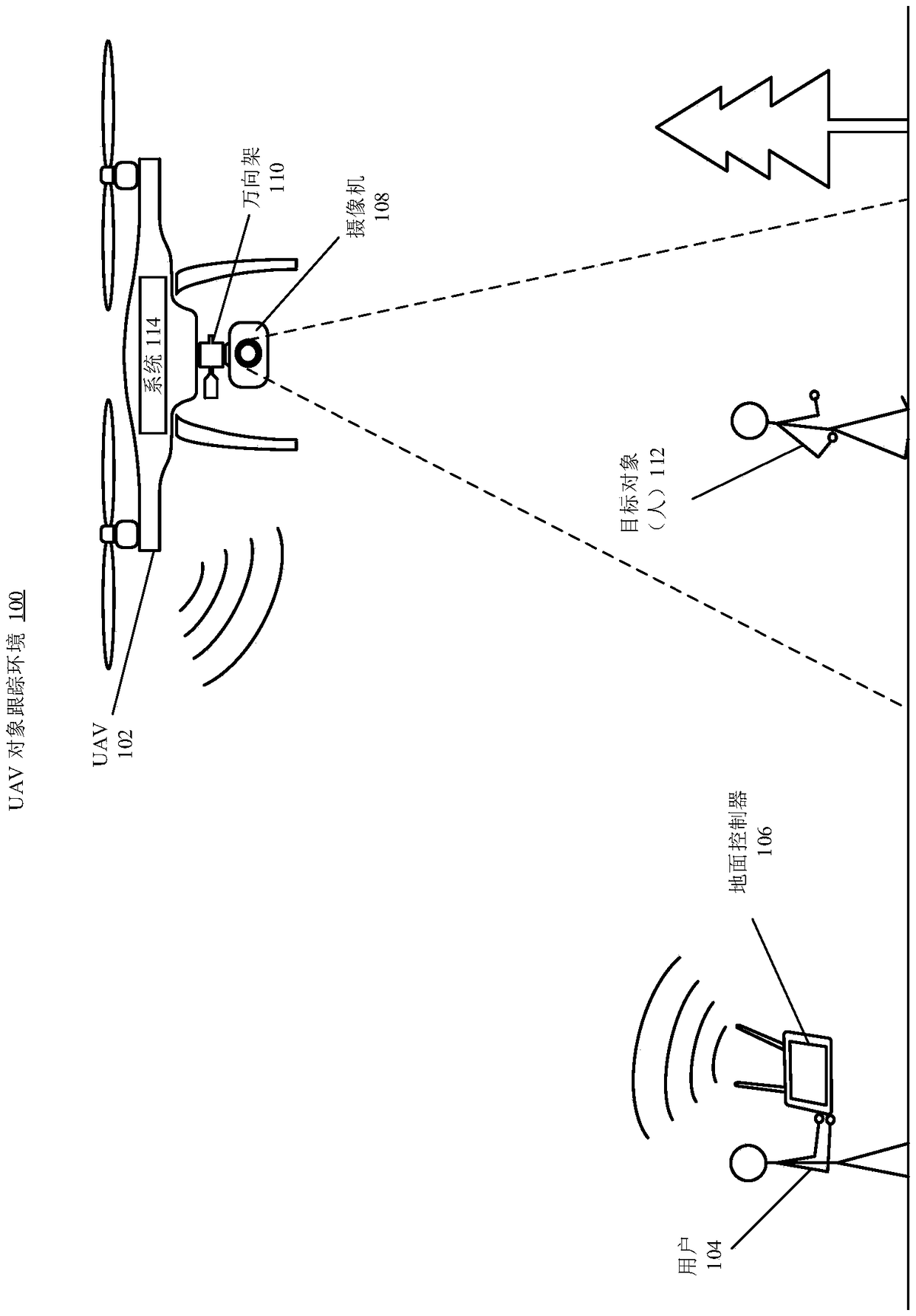

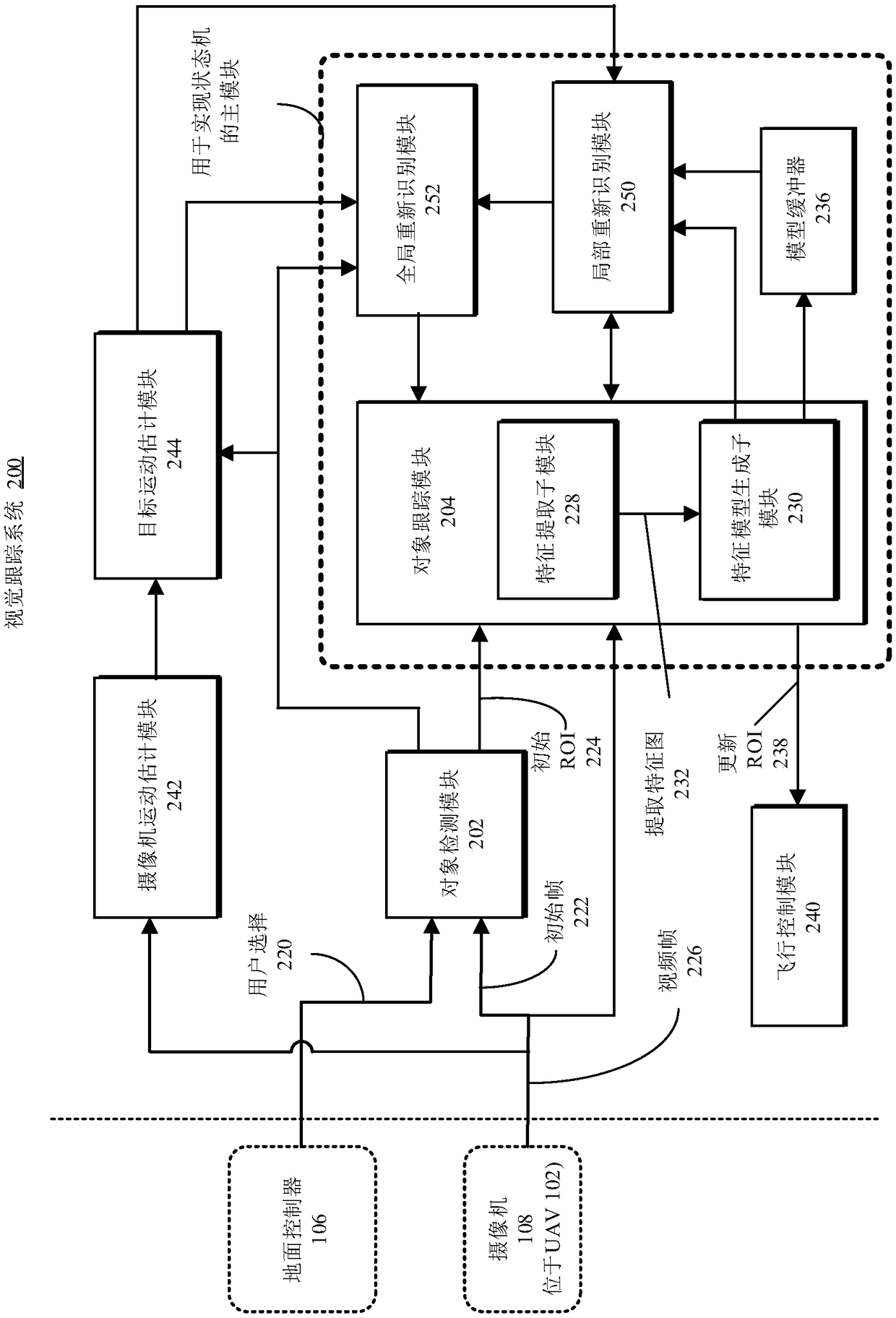

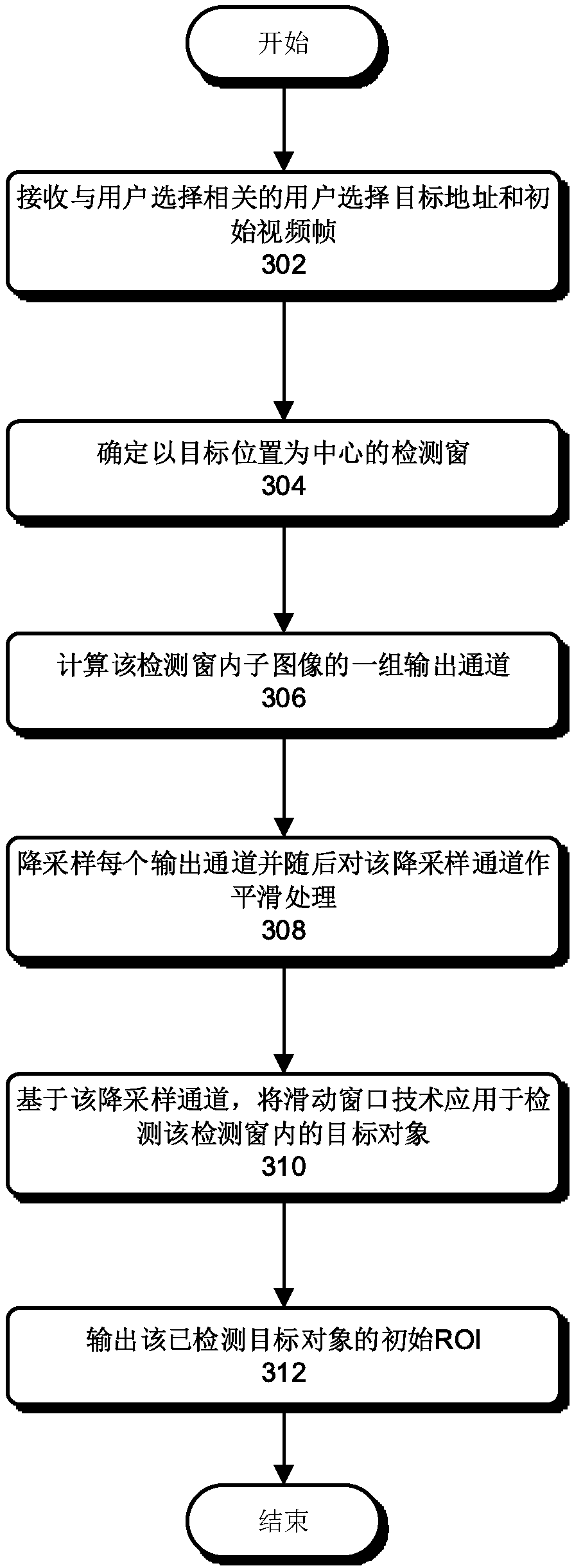

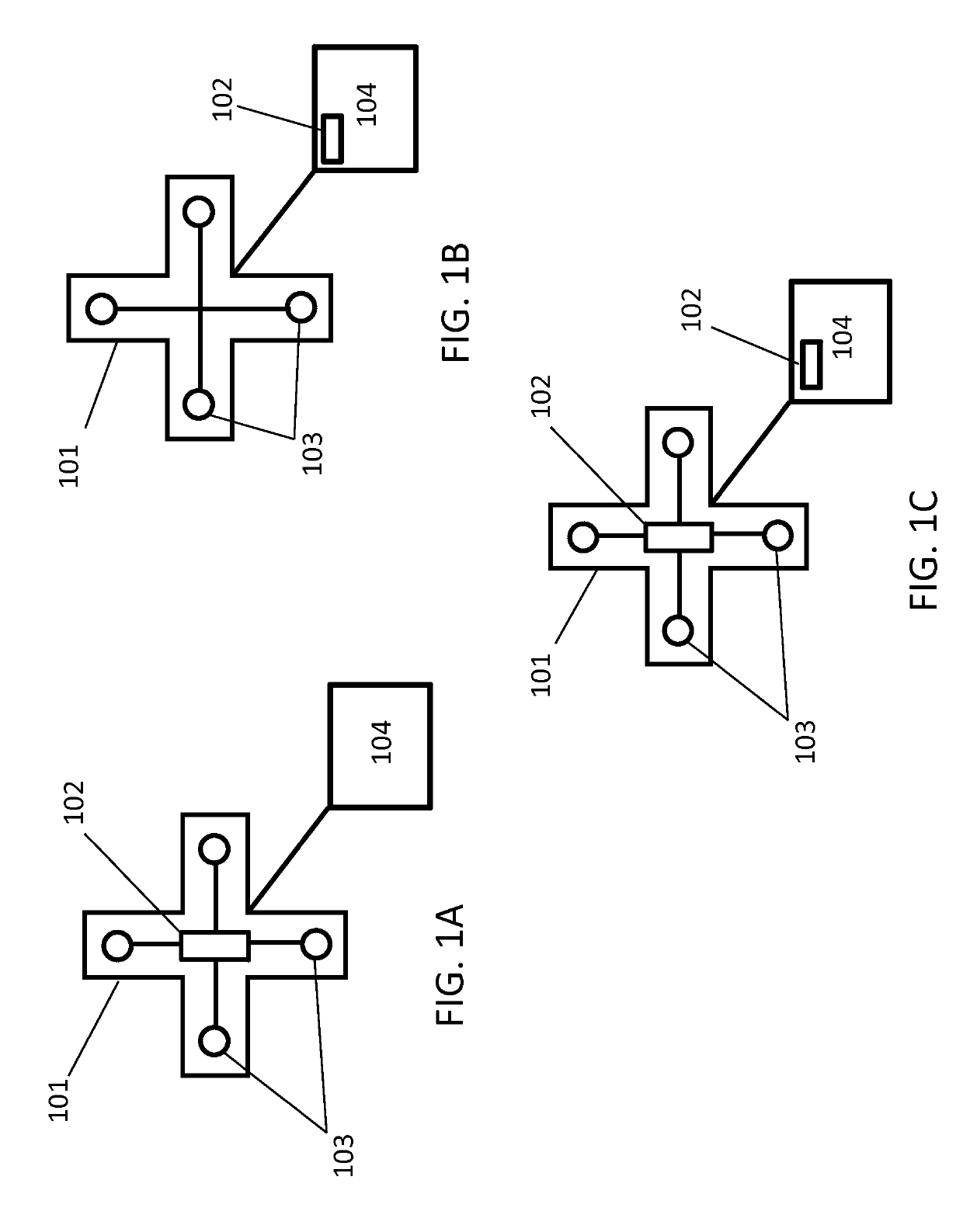

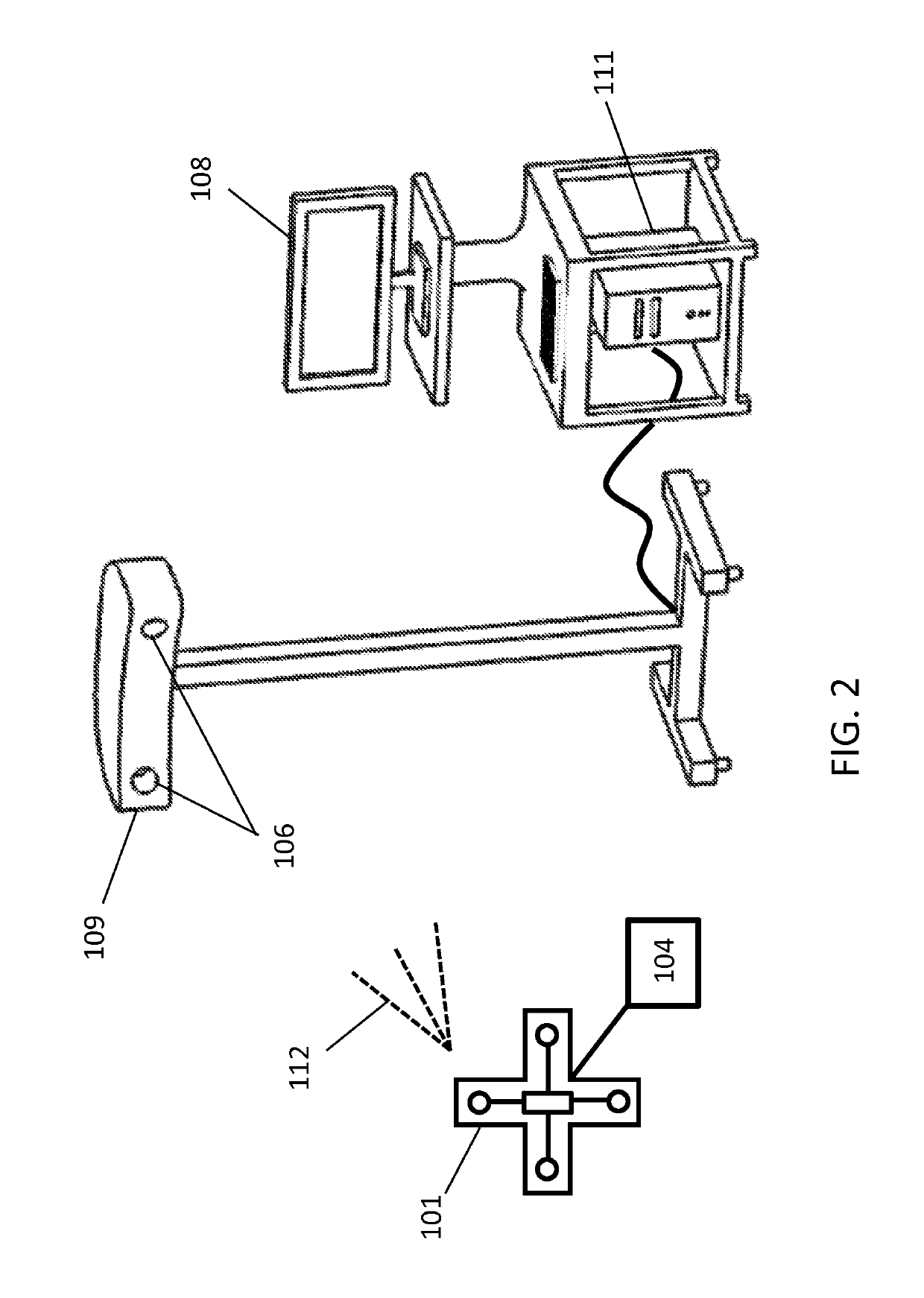

High-performance visual object tracking method and system for embedded vision system

A real-time visual tracking system is provided. An unmanned aerial vehicle (UAV) for real-time visual tracking of a moving object includes a processor, a memory coupled to the processor, and a cameracoupled to the processor and the memory, wherein the camera is used to capture video of the moving object; the UAV also includes a visual tracking module for receiving a first frame video image and afirst position of the target object and a second frame video image after receiving the first frame video image; a first search window is placed in the first frame video image and a second search window in the second frame video image, the position of the second search window in the second frame video image being the same as the position of the first search window in the first frame video image; acorrelation map between a first image block in the first search window and a second image block in the second search window is calculated; an update position of the target object in the second frame video image is determined based on the calculated correlation map.

Owner:ALTUMVIEW SYST INC

Visible light communication system for transmitting data between visual tracking systems and tracking markers

ActiveUS10507063B2Promote resultsEfficient executionSurgical navigation systemsDiagnostic markersComputer-aidedOrthopedic surgery procedures

An optical tracking system includes at least one tracking array for generating and optically transmitting data between 1 and 2,000 MB / s. At least one tracker for optically receiving the optically transmitted data between 1 and 2,000 MB / s is also provided. The tracking system is used not only for tracking objects and sending tracking information quickly but also providing the user or other components in an operating room with additional data relevant to an external device such as a computer assisted device. Orthopedic surgical procedures such as total knee arthroplasty (TKA) are performed more efficiently and with better result with the optical tracking system.

Owner:THINK SURGICAL

System and method for visually tracking with occlusions

ActiveUS8611591B2Overcome disadvantagesExtended durationImage enhancementImage analysisTrack algorithmVisual perception

Described herein are tracking algorithm modifications to handle occlusions when processing a video stream including multiple image frames. Specifically, system and methods for handling both partial and full occlusions while tracking moving and non-moving targets are described. The occlusion handling embodiments described herein may be appropriate for a visual tracking system with supplementary range information.

Owner:21ST CENTURY TECH

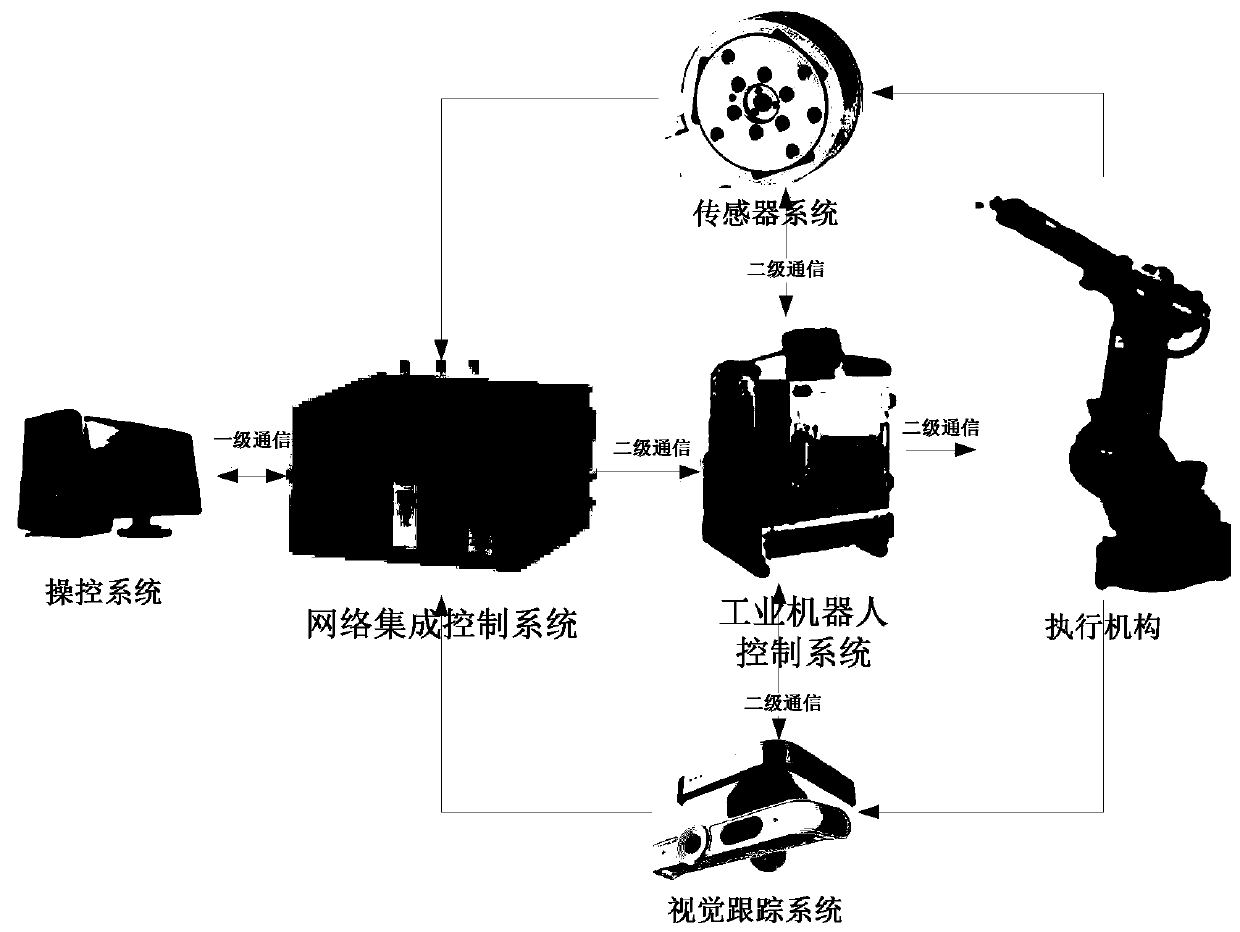

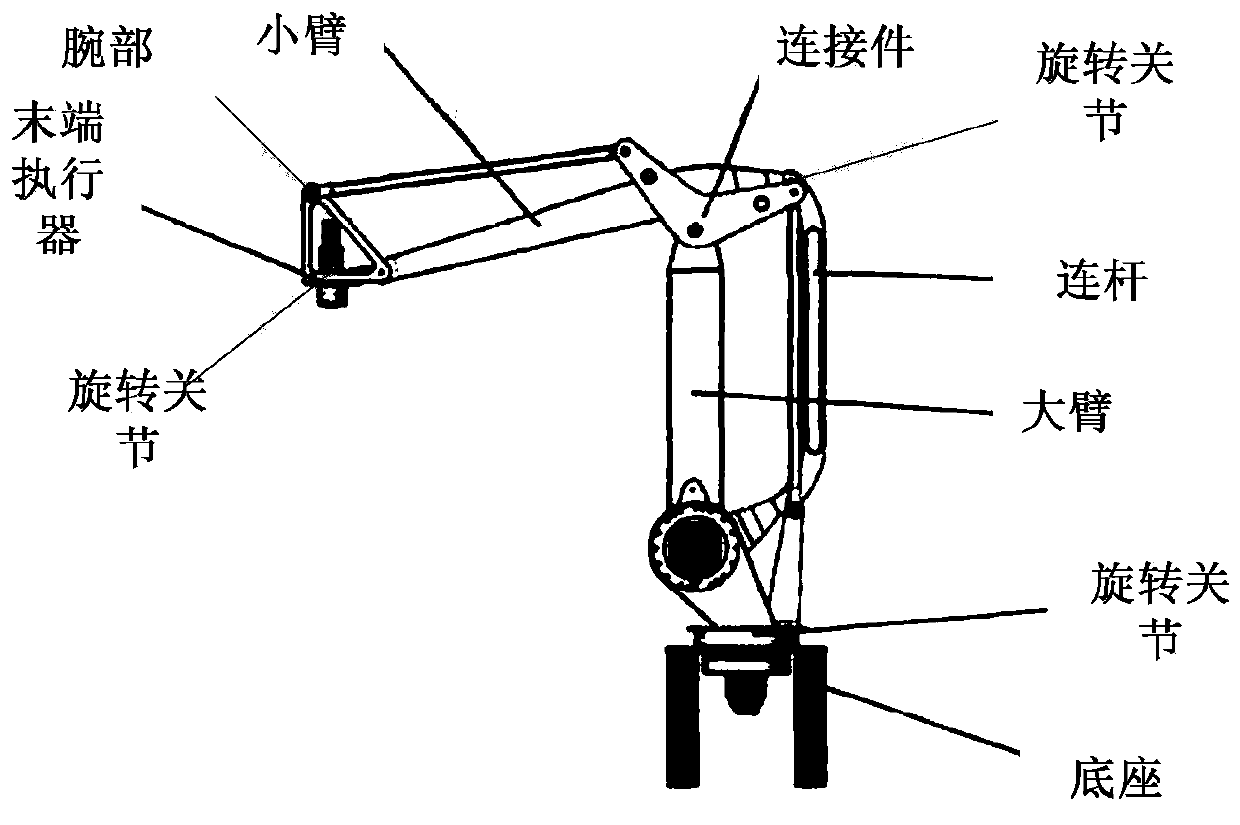

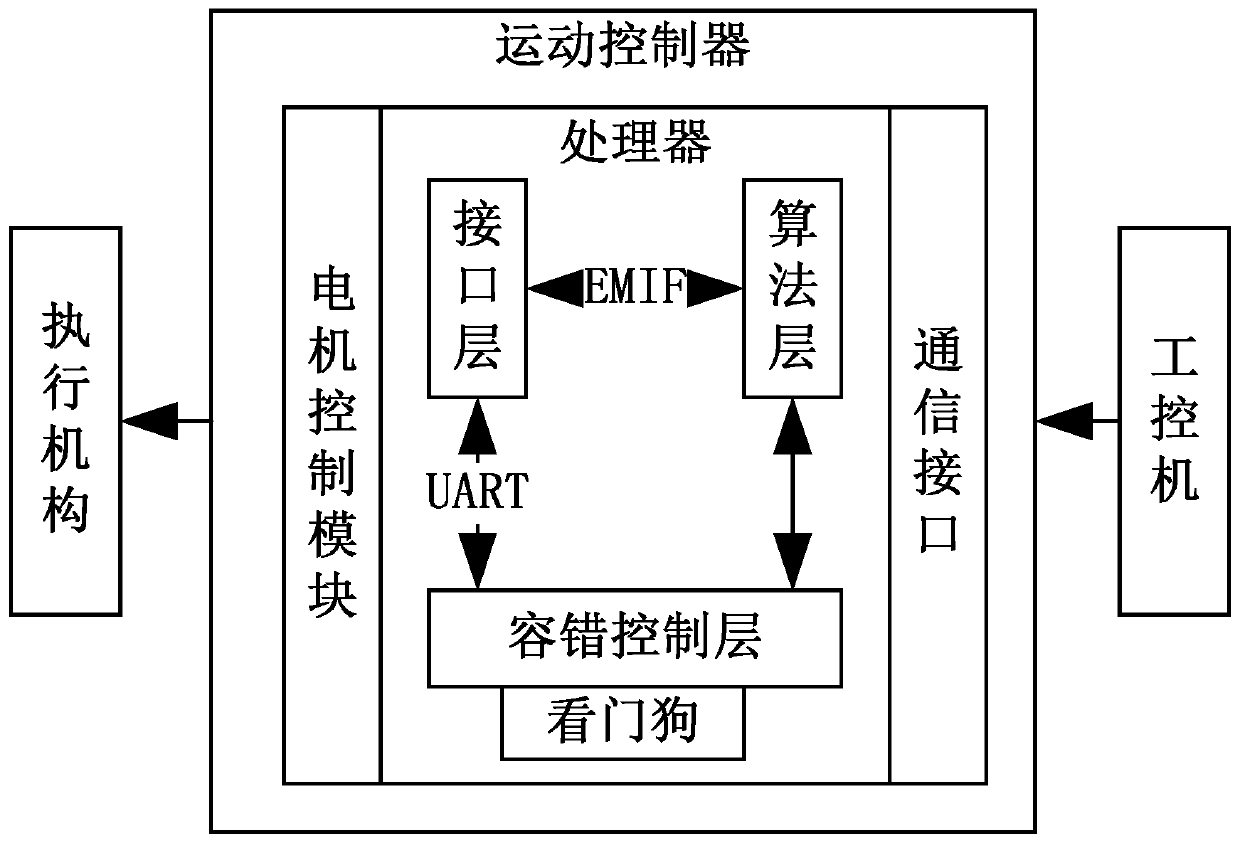

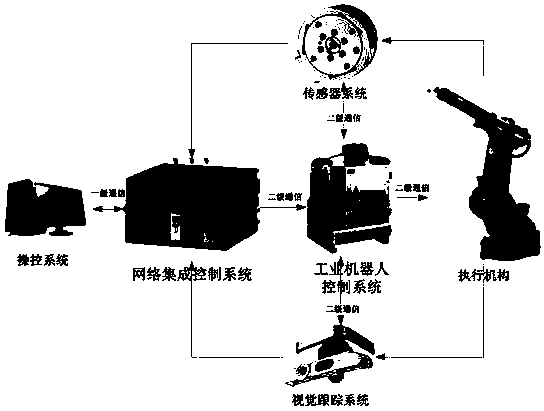

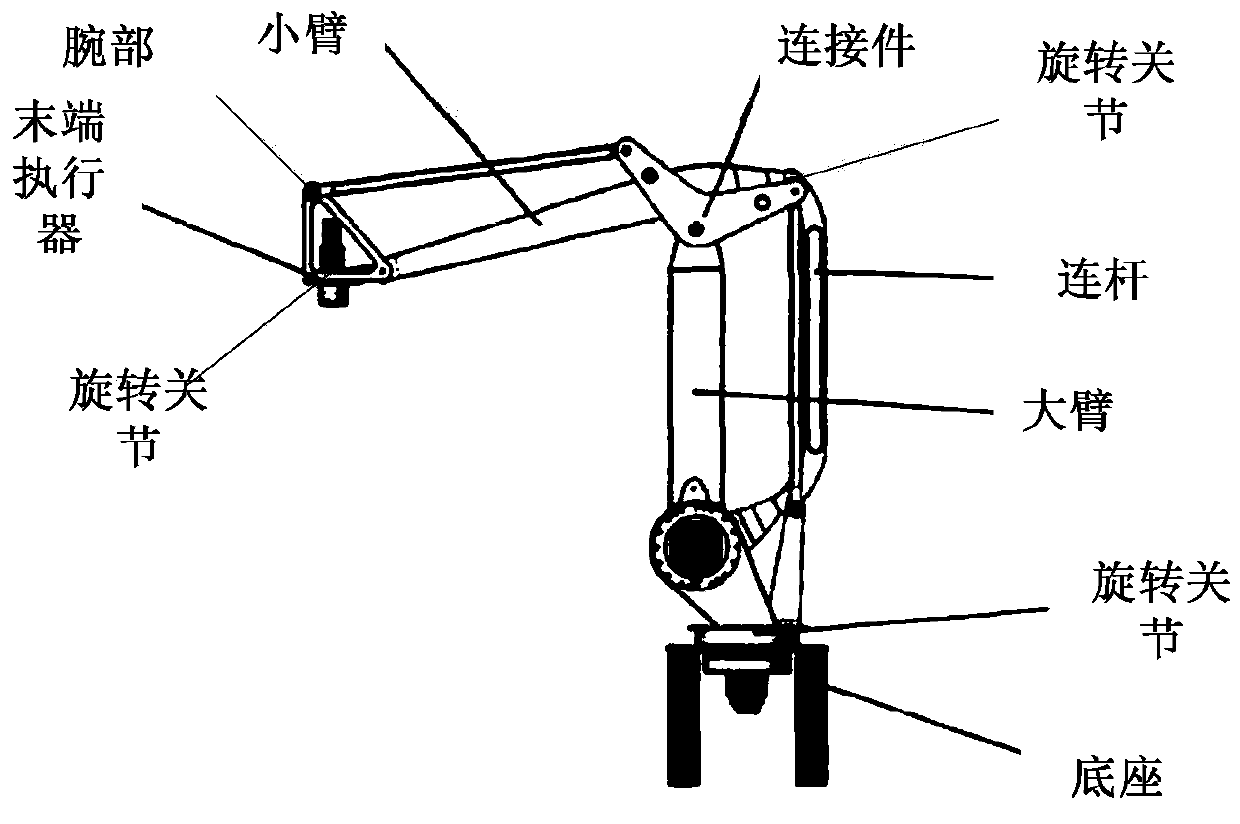

Industrial robot platform with dual-core motion controller

InactiveCN110666802AAchieve precise and stable controlImprove reliabilityProgramme-controlled manipulatorDual coreMotion controller

The invention relates to an industrial robot platform with a dual-core motion controller. The industrial robot platform comprises an industrial robot control system, a sensor system, a control system,a network integrated control system, a visual tracking system and an actuating mechanism, wherein the sensor system is connected to the industrial robot control system; a processor is a system on chip and comprises an interface layer, an algorithm control layer and a fault tolerant control layer; the interface layer is of an FPGA structure and is responsible for information exchange with a motorcontrol module and controlling a servo device; the algorithm control layer is of an ARM and DSP dual-core structure, the ARM core is responsible for various peripheral drives, and the DSP end is responsible for a large number of matrix floating point class calculation such as kinematic modeling, trajectory planning; and the fault-tolerant control layer uses a 32-bit controller, carries out real time monitoring on the interface layer and the algorithm control layer, and carries out fault-tolerant planning on faults according to feedback and operating commands, so that the safe and reliable operation of a system is ensure, the fault-tolerant control layer uses a servo calibration method, and meanwhile, a visual feedback interface is expanded, so that secondary correction of the later visualfeedback is realized.

Owner:张焕焕

Radiotherapy bed device

InactiveCN102872541AIncrease flexibilityHigh positioning accuracyX-ray/gamma-ray/particle-irradiation therapyTherapeutic bedEngineering

The invention discloses a radiotherapy bed device which comprises a therapeutic bed top, an intelligent mechanical arm and a visual tracking system. The intelligent mechanical arm comprises mechanical arms for bearing the therapeutic bed top and an intelligent positioning control device for controlling actions of the mechanical arms. The visual tracking system comprises two cameras, an intelligent positioning control device for controlling actions of the cameras and sensors mounted on the therapeutic bed top. The intelligent mechanical arm is used to place patients and the therapeutic bed top to a preset therapy position in an accelerator room, the visual tracking system can be used to guarantee positioning precision of the patients, work efficiency is improved greatly, and service efficiency of an expensive accelerator is also improved.

Owner:SUZHOU LINATECH MEDICAL SCI & TECH CO LTD

Internet of things locker

InactiveUS20160189498A1Zero possibility of losingIndividual entry/exit registersTransmissionPublic placeComputer science

The present invention relates to a re-usable internet based locking device that uses electronic keys (either single or a combination to be distributed to multiple parties) for opening and closing the locking device. It enables the institutions to offer highly secure, vault-grade locking device to their user in public places. These kiosks have security and surveillance levels that match bank ATMs. In addition, an optional visual tracking system allows the users to view the contents of their locking device, thus providing additional comfort regarding safety of their valuables in the locking device. A peripheral surveillance system with internal power backup and wireless internet connectivity is provided for alerting the central monitoring station if any distress is found in and around the kiosk.

Owner:IDAAX TECH PTE LTD +1

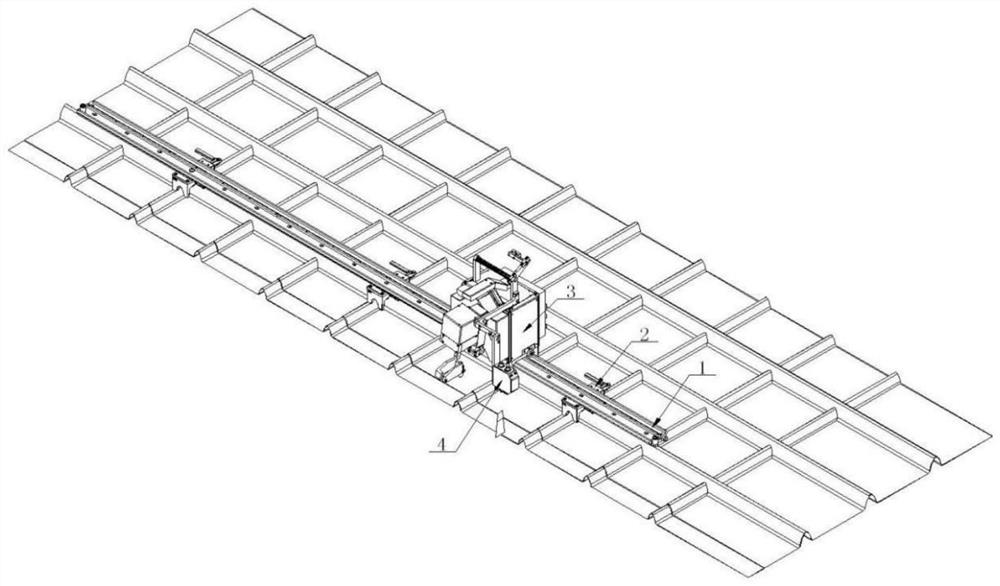

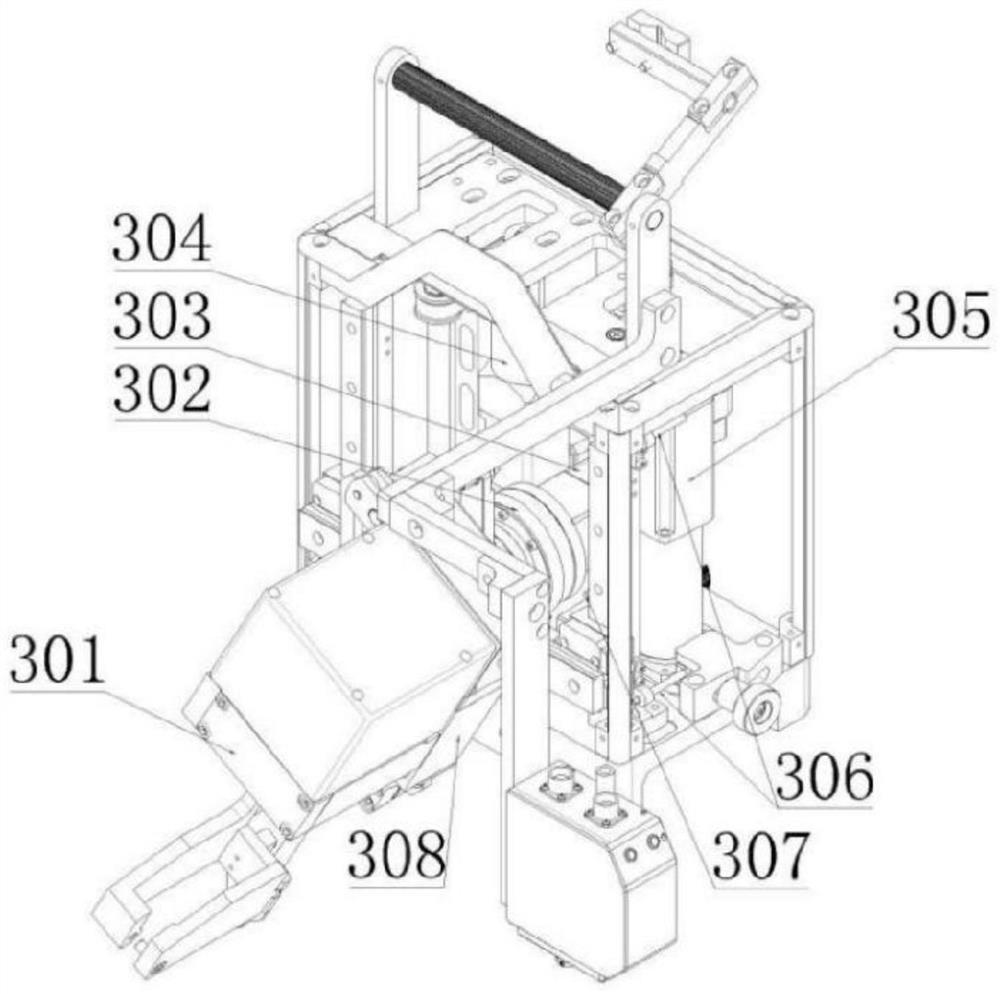

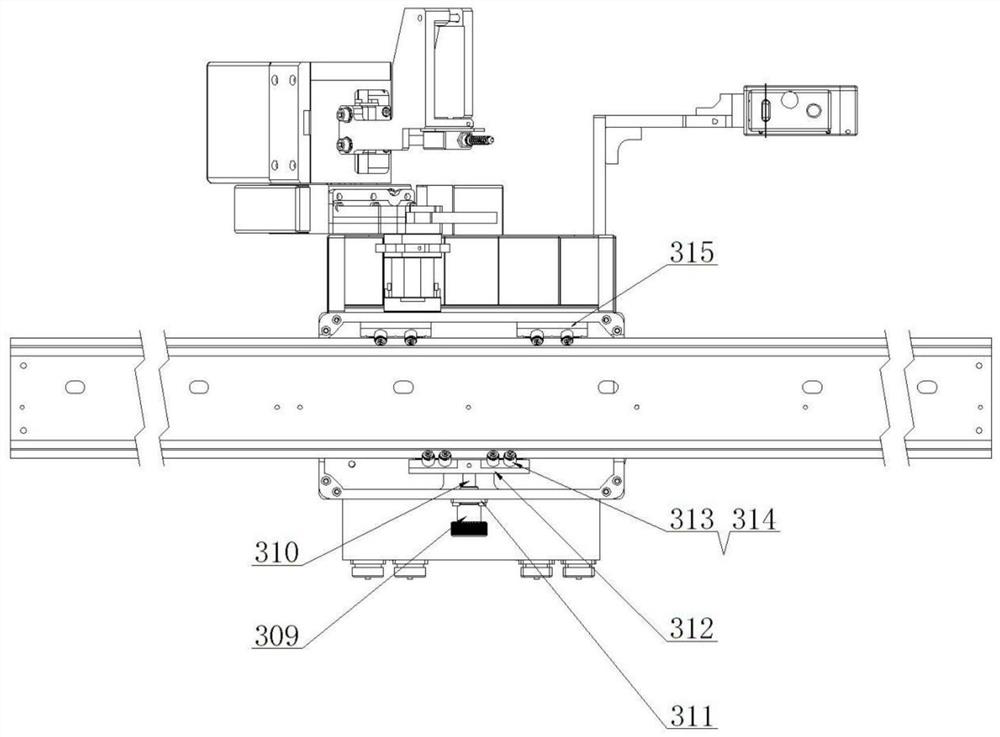

Intelligent welding machine for inner wall of fuel cabin of LNG ship

PendingCN113333926AHigh output torqueIdeal automatic adjustmentPlasma welding apparatusLaser sensorWeld seam

The invention discloses an intelligent welding machine for the inner wall of a fuel cabin of an LNG ship, and relates to the technical field of plasma intelligent welding machines. The intelligent welding machine comprises a linear track, connecting clamps between the track and a welding base material, an intelligent welding machine body, a 3D visual tracker and the like. the automatic welding machine body is provided with a five-axis servo gear motor linkage and corresponding movement track component (a ball screw is used for transmission), a laser sensor is used for measuring the height distance between the end surface of a welding gun and a weld seam in real time, each connecting clamp is provided with a positioning clamping jaw, a movable clamping jaw, a push-pull type quick clamp body and a track connecting block, a 3D visual tracking system is used for collecting the three-dimensional overall dimension of the weld seam, analyzing the optimal walking route in the welding process and correcting the welding position and angle deviation during in the welding process, a remote controller has the manual alignment and adjustment functions and the remote operation function, and plasma water-cooling welding application is mainly introduced for meeting the welding requirement of thin stainless steel plates (stable welding performance and small deformation).

Owner:南京顶瑞科技有限公司

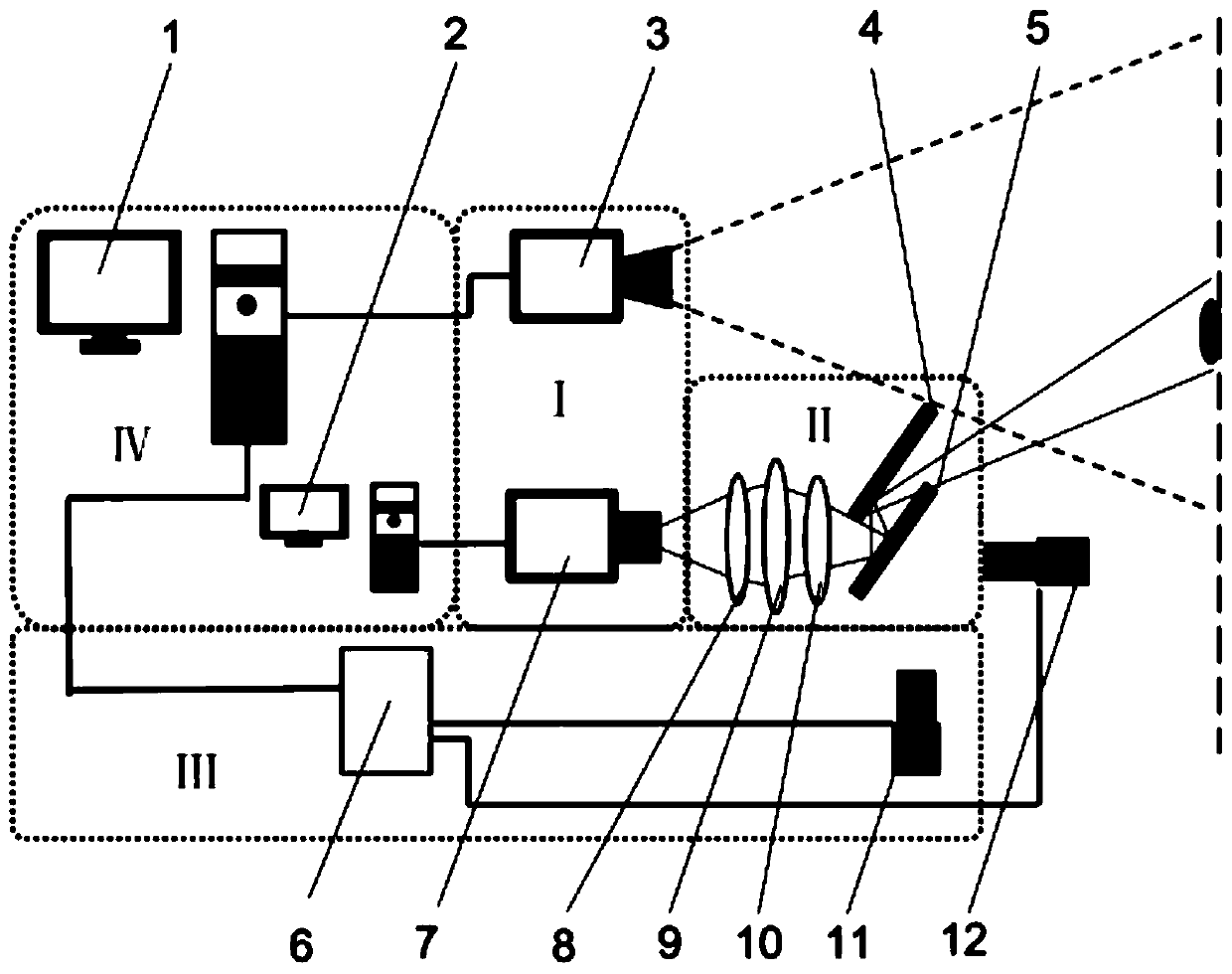

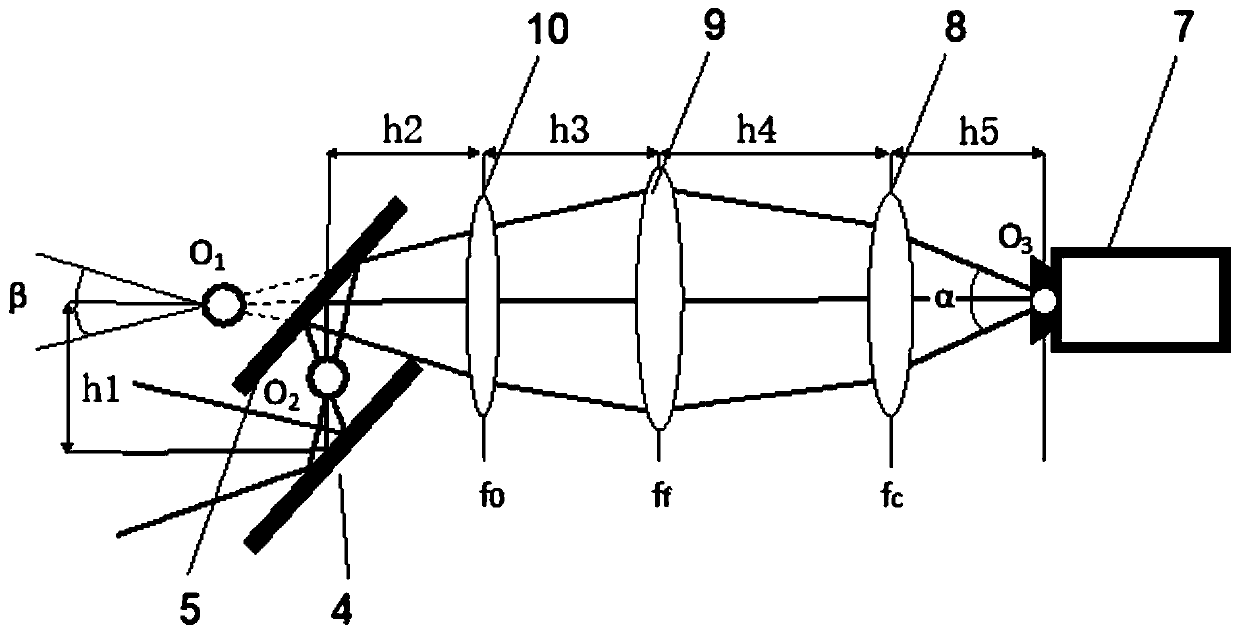

Visual tracking system and method

ActiveCN110225226ANo blurGuaranteed clarityTelevision system detailsColor television detailsVisual perceptionImage acquisition

The invention belongs to the field of visual tracking and discloses a visual tracking system and method. The system comprises an image acquisition device, a light path conversion device and a light path adjustment device. The image acquisition device comprises a first camera and a second camera which are fixed in relative positions, and the first camera is used for acquiring an image and performing visual tracking to predict the position of a to-be-tracked target. The light path conversion device is arranged between the to-be-tracked target and the second camera and is used for clearly imagingthe to-be-tracked target on the second camera. The light path adjusting device adjusts the light path of the light path conversion device in real time according to the position of the to-be-tracked target, so that the target is always located at the imaging center of the second camera. The visual tracking method comprises the following steps: obtaining each frame of image by using a first cameraand carrying out visual tracking to predict the position of a target in each frame of image; and adjusting a light path in real time according to the position of the target to clearly image the targetat the center of the second camera. The method has the advantages of high speed, high robustness, good adaptability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

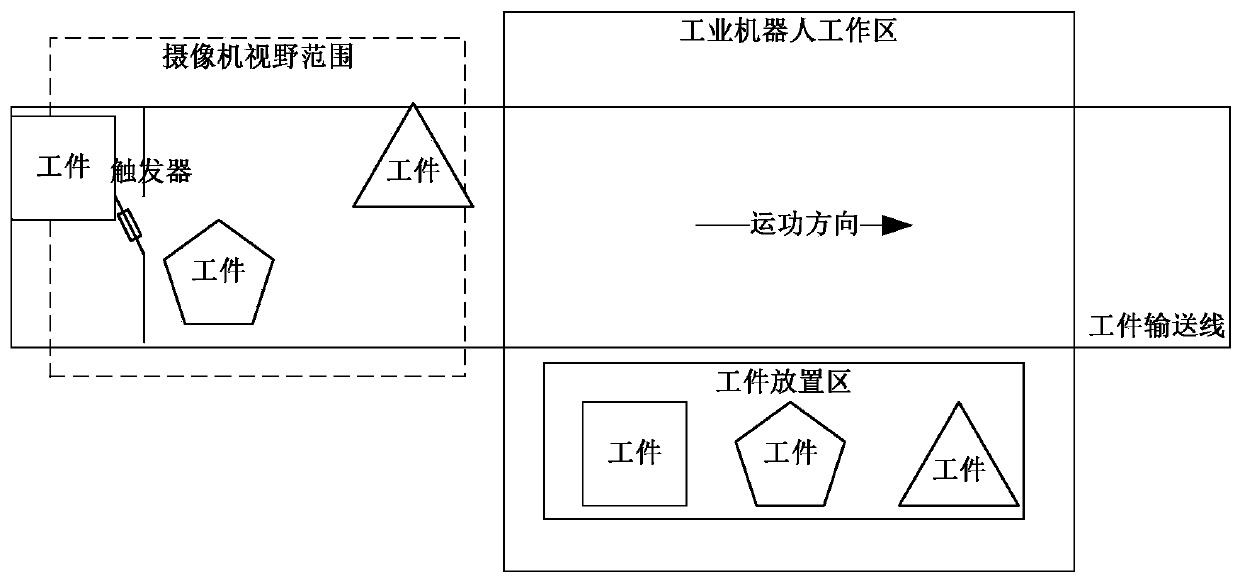

Grabbing industrial robot matched with regular-shaped workpiece

InactiveCN110640741AQuick identificationImprove reliabilityProgramme-controlled manipulatorCharacter and pattern recognitionIndustrial roboticsVisual perception

The invention discloses a grabbing industrial robot matched with a regular-shaped workpiece. The grabbing industrial robot comprises an industrial robot control system, a sensor system, a control system, a network integrated control system, a visual tracking system and an execution mechanism, wherein the sensor system is connected with the industrial robot control system; and the image recognitionprocess of the workpiece comprises the following steps that 1, gray scale transformation is carried out; 2, contrast equalization is carried out; 3, median filtering is carried out on a grayscale image; 4, workpiece positioning is carried out; 5, a Hough transform is adopted to detect an inclination angle in a rectangular area, and interpolation rotation is carried out according to the detected inclination angle, so that the workpiece in the rectangular area is horizontally arranged; and 6, shape identification is carried out.

Owner:张焕焕

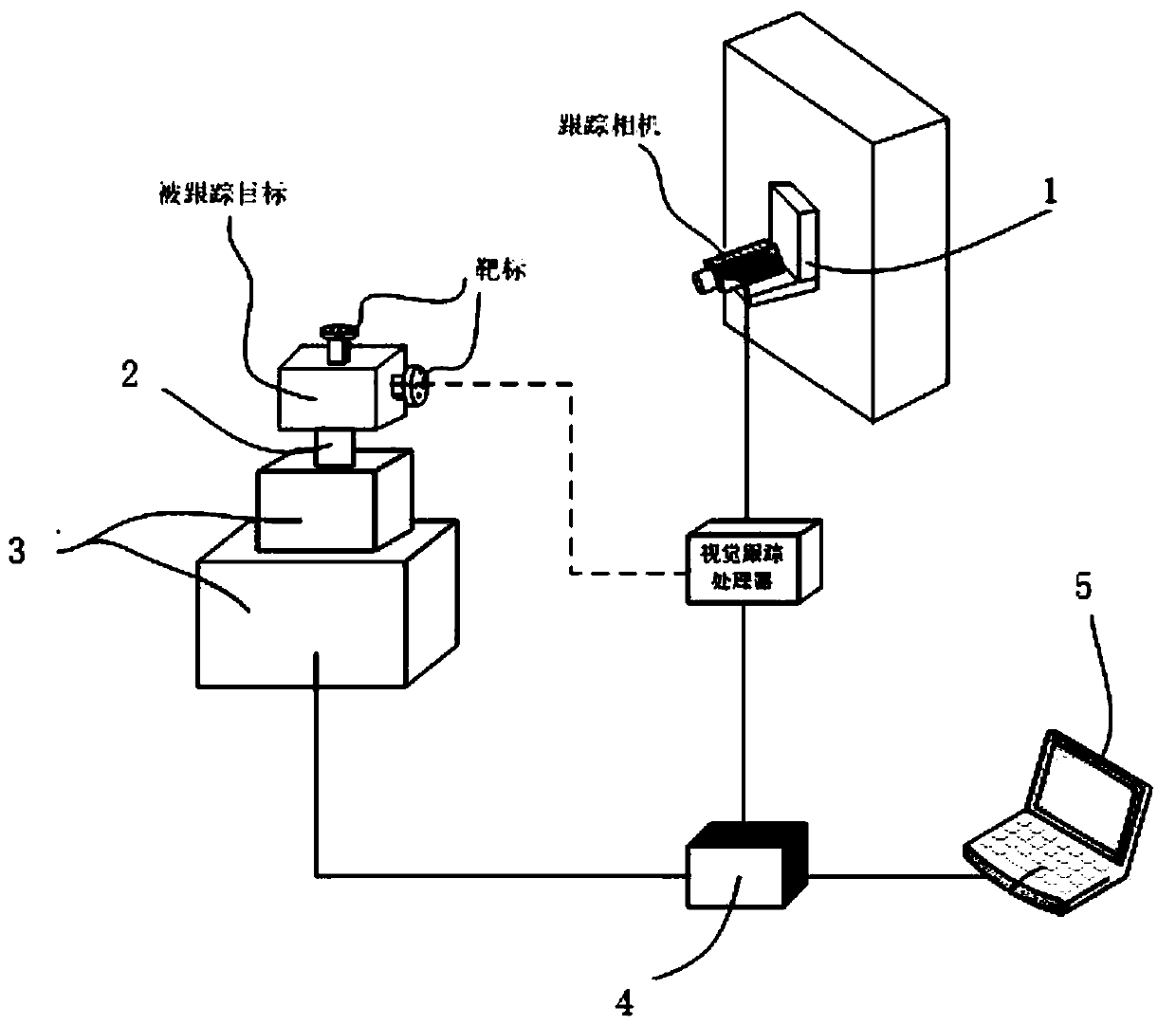

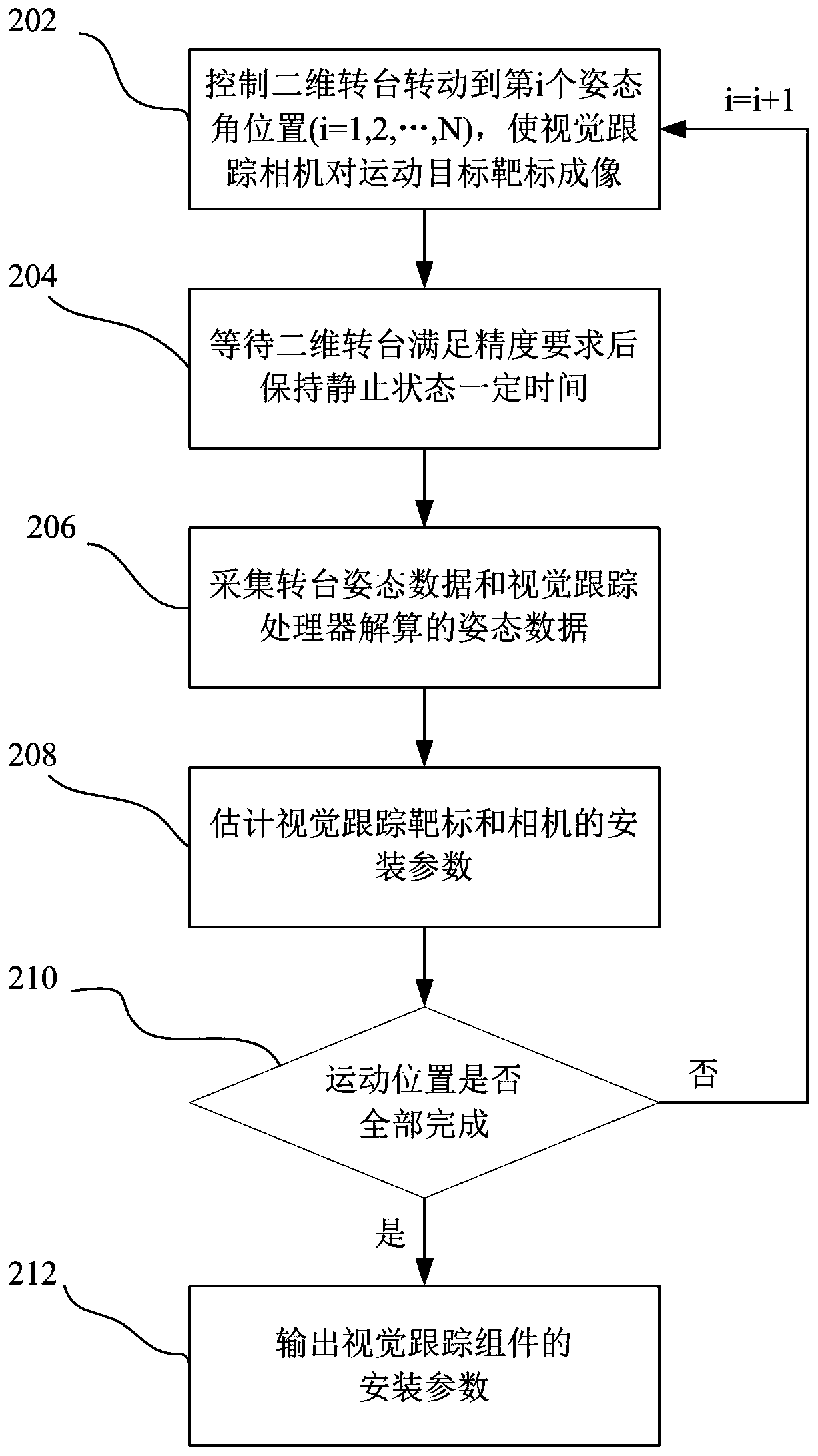

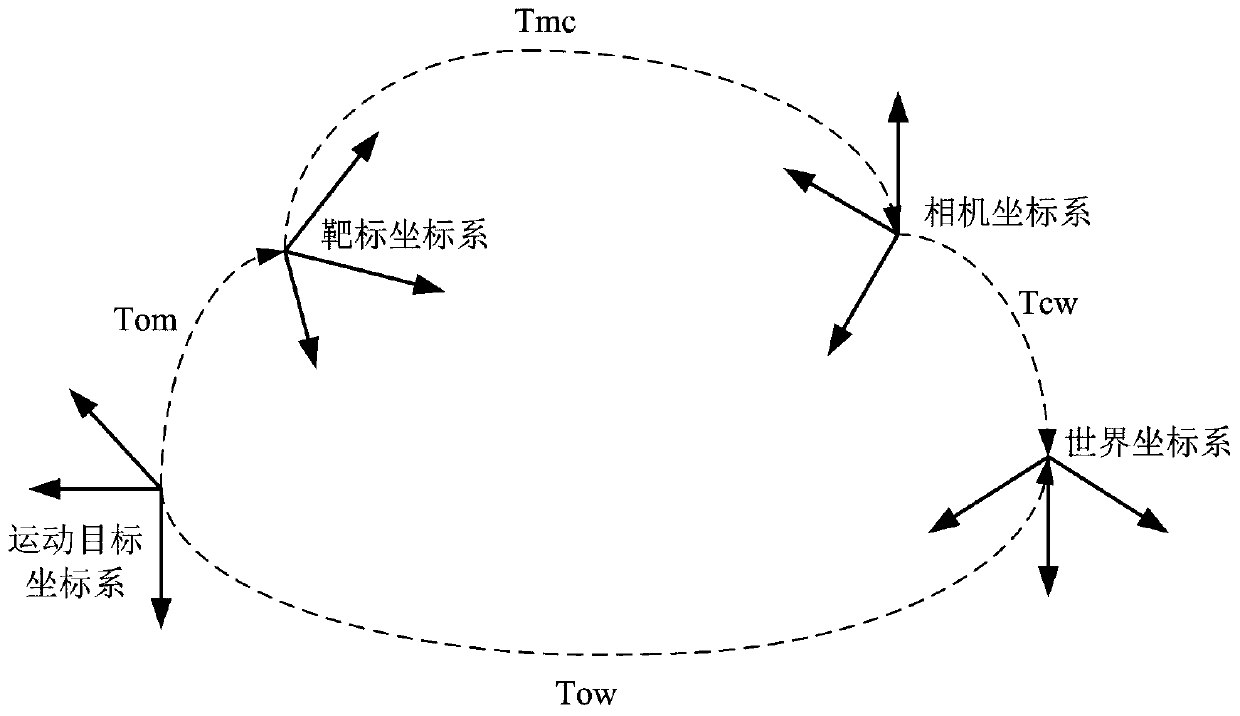

Installation parameter calibration device and method for visual tracking assembly

ActiveCN111489399AImprove calibration accuracyEliminate the unknownImage analysisData acquisitionData acquisition module

The invention discloses an installation parameter calibration device and method for a visual tracking assembly. The device comprises a camera installation support, a target installation support, a two-dimensional turntable, a data acquisition module and a calibration computer. The two-dimensional turntable is controlled to rotate. at each rotating position, a data acquisition module is used for acquiring attitude data of the two-dimensional rotary table and attitude data output by the visual tracking system and sending the data to a calibration computer; the calibration computer converts installation parameter calibration of the visual tracking assembly into state estimation by adopting an extended Kalman filtering algorithm; the installation parameters of the visual tracking assembly to be calibrated are used as state variables, attitude data output by the two-dimensional turntable are converted, obtained attitude matrix elements are used as measurement vectors, and a first-order linearized measurement matrix is constructed by using attitude calculation data of a visual tracking system and the state variables at the last moment. A visual tracking system is introduced into the calibration process to form a closed loop, so that unmodeled errors can be eliminated, and the calibration precision is improved.

Owner:TIANJIN UNIV

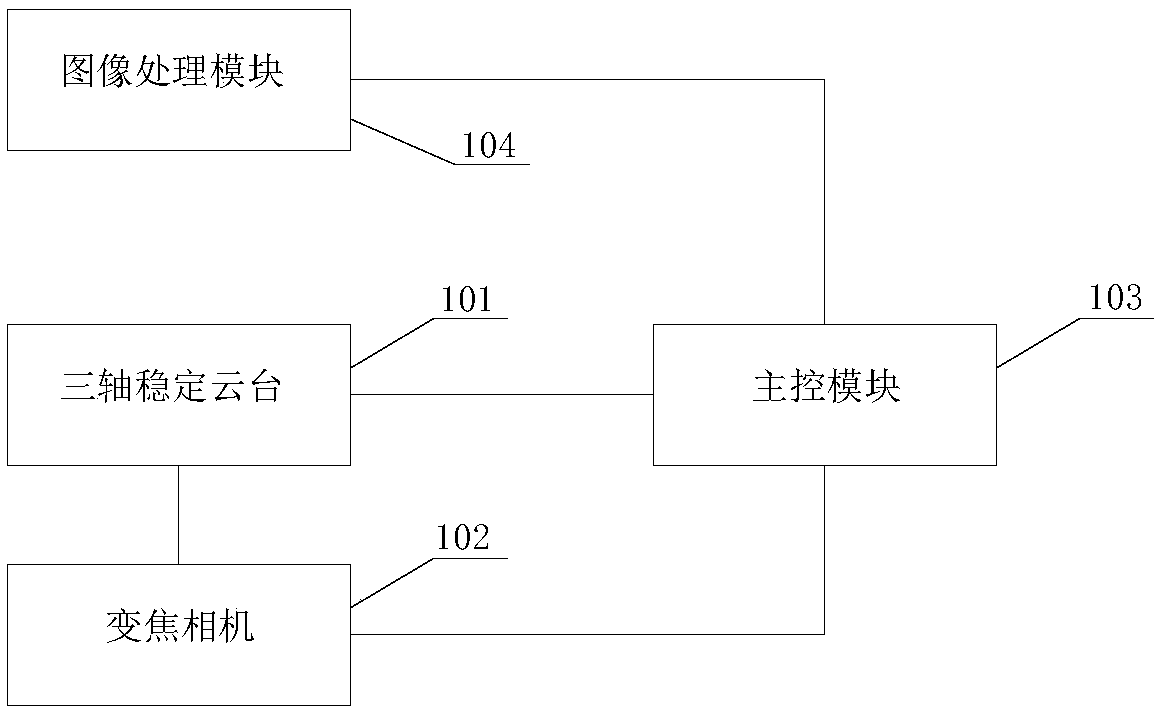

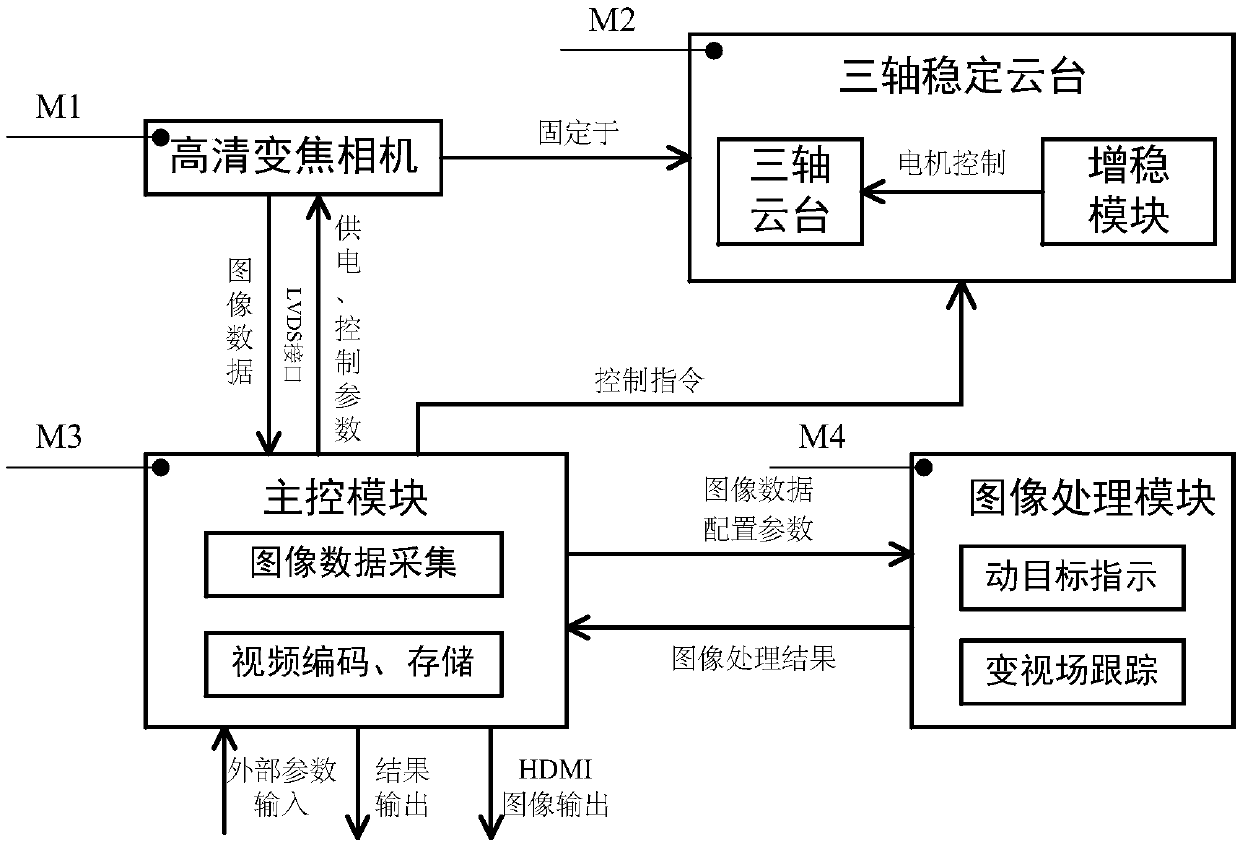

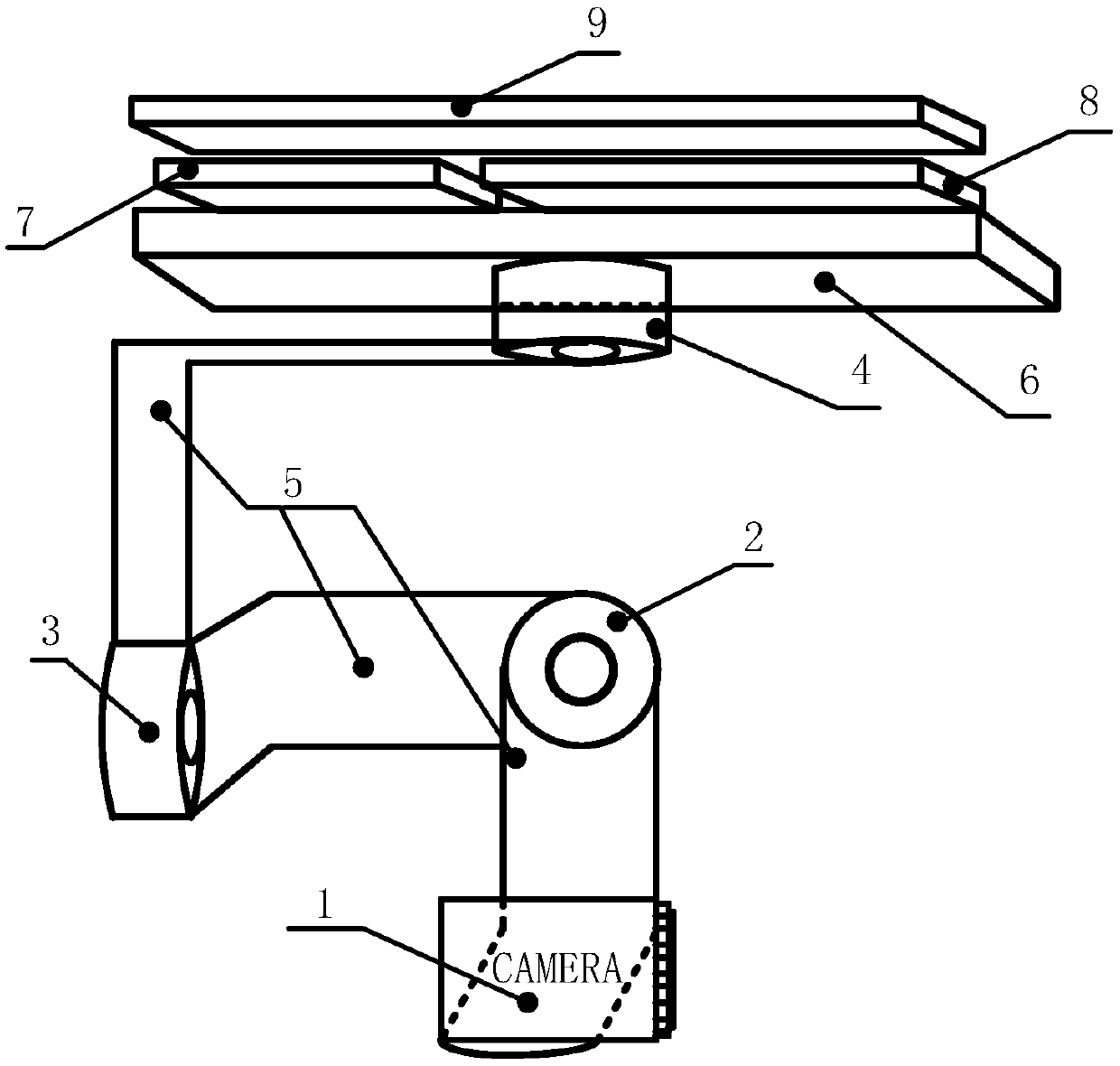

Visual tracking system for drone and control method thereof

InactiveCN109688323AEasy to useTelevision system detailsColor television detailsImaging processingVisual tracking system

An embodiment of the invention provides a visual tracking system for a drone, and a control method thereof, wherein the system comprises the following parts: a three-axis stable pan / tilt, set on the drone and connected to a zoom camera; a main control module, configured to send camera parameters to the zoom camera such that the zoom camera captures an image according to camera parameters and outputs the captured image to the main control module, further receive an externally transmitted control command, and save the image according to the control command or send the image and configuration parameters to the image processing module; and an image processing module, configured to process the image sent by the main control module according to the configuration parameters, and return the processing result to the main control module; accordingly, the main control module is further configured to output control information to the three-axis stable pan / tilt according to the processing result sothat the three-axis stable platform controls the attitude of the zoom camera. The embodiment of the invention has the advantages of simple structure, high intelligence degree and convenient use.

Owner:杭州视语智能视觉系统技术有限公司

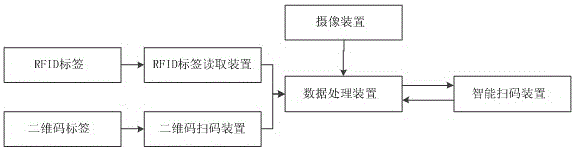

Visual tracking system based on RFID and two-dimensional code technology

InactiveCN106355416AEasy to determineSimple structureCo-operative working arrangementsCommerceComputer hardwareData information

The invention discloses a visual tracking system based on a RFID (radio frequency identification device) and a two-dimensional code technology, wherein unique identification of a wine bottle is stored and filled with a two-dimensional code label; a two-dimensional code scanning device transmits unique read identification to a data processing device; data information of the wine bottle is stored and filled with the RFID label and displayed with identification character strings; a RFID label reading device transmits data information read to the data processing device; the data processing device makes unique identification associate with data information, stores associated data and analyzes unique identification in the two-dimensional code information transmitted by an intelligent scanning device; data information matching with unique identification stored and analyzed is transmitted to the intelligent scanning device with the identification character strings; the intelligent scanning device transmits the two-dimensional code information read to the data processing device and receives identification character string information transmitted by the data processing device. The system is simple in structure, convenient to use and relatively high in practicability.

Owner:CHANGCHUN UNIV

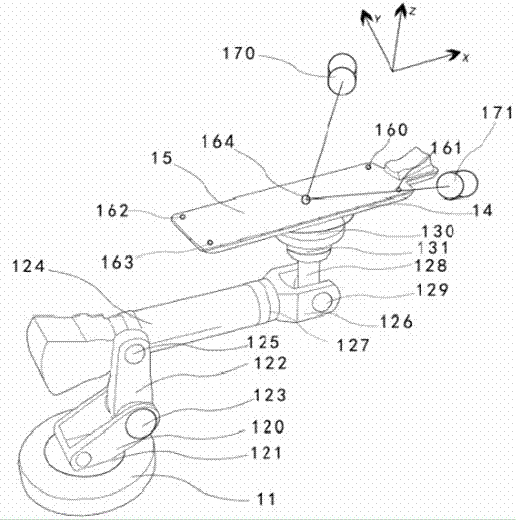

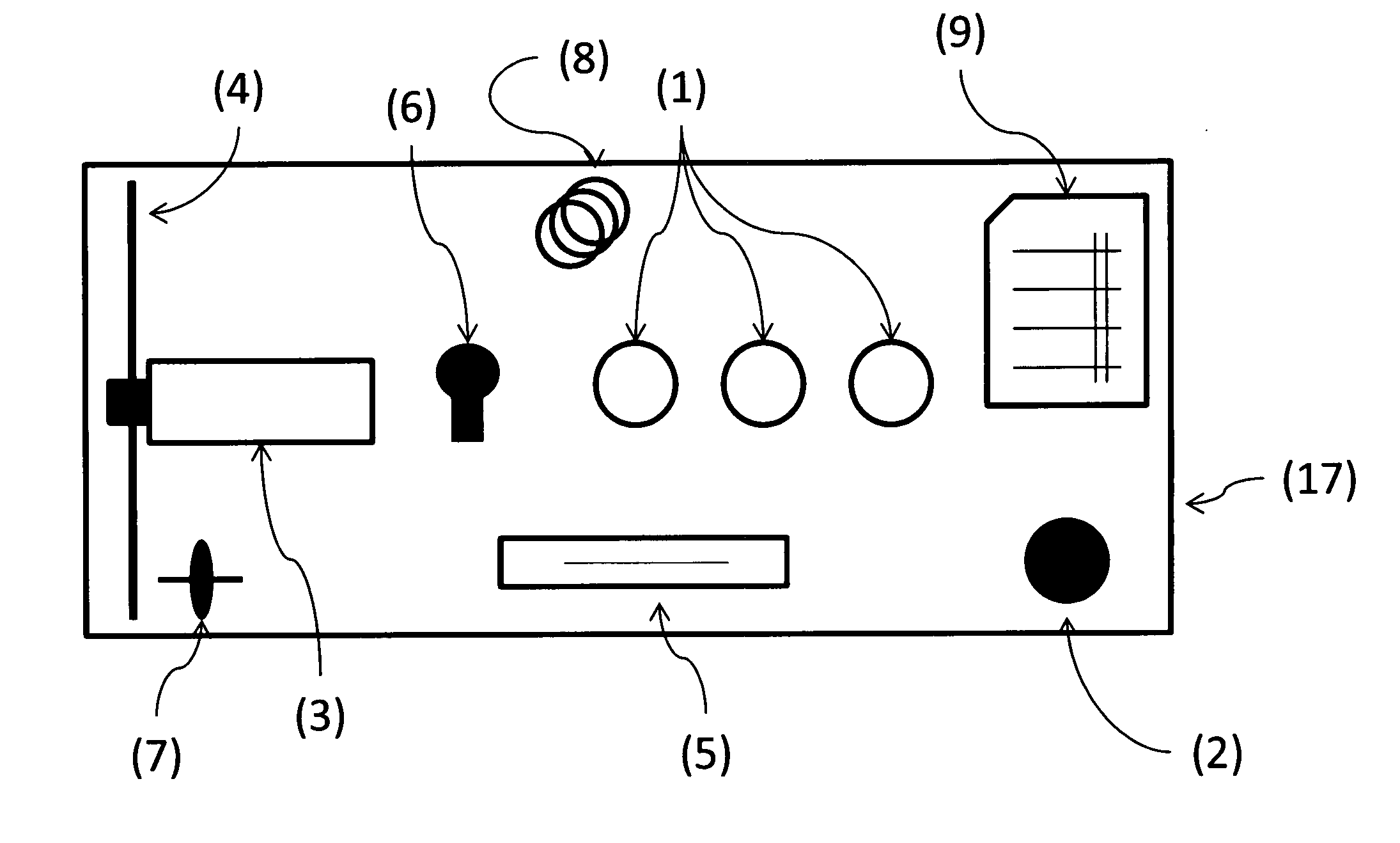

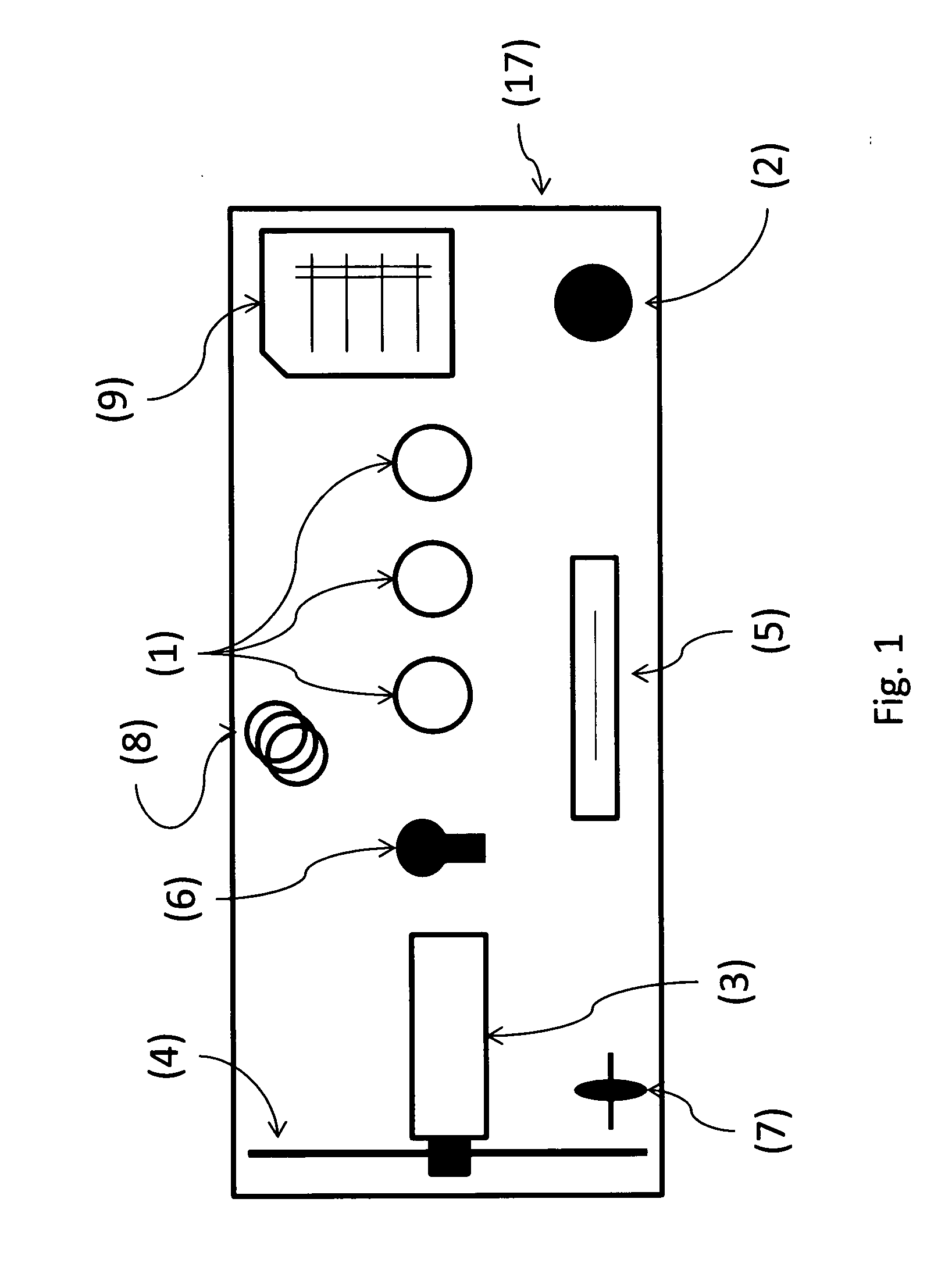

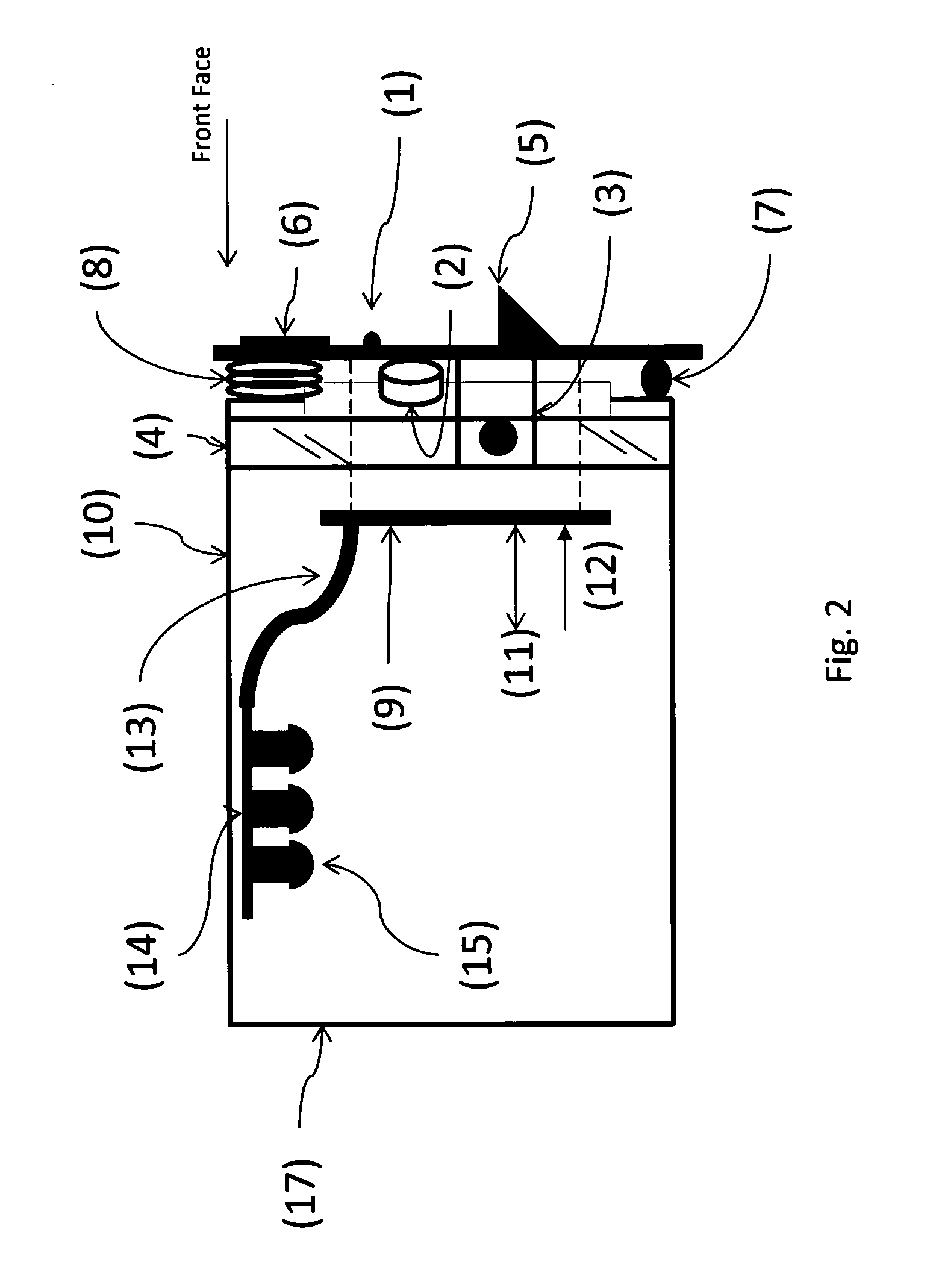

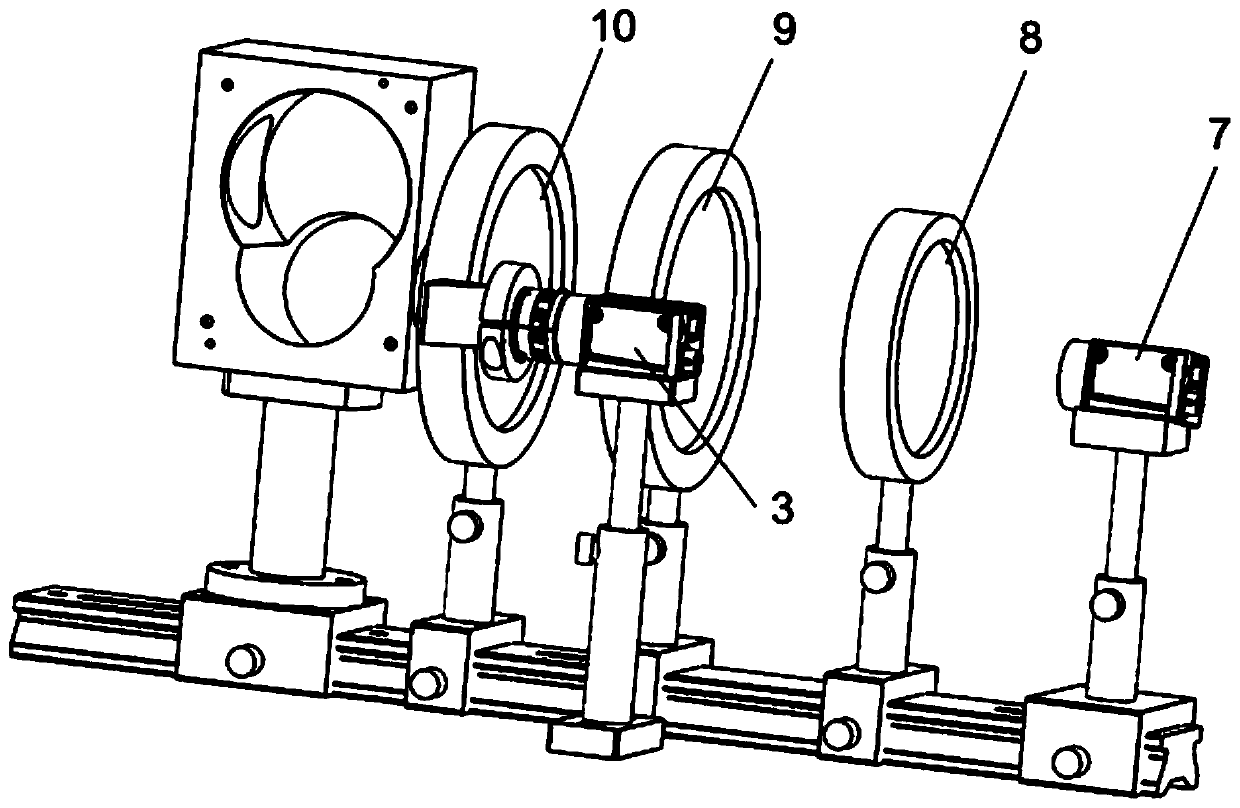

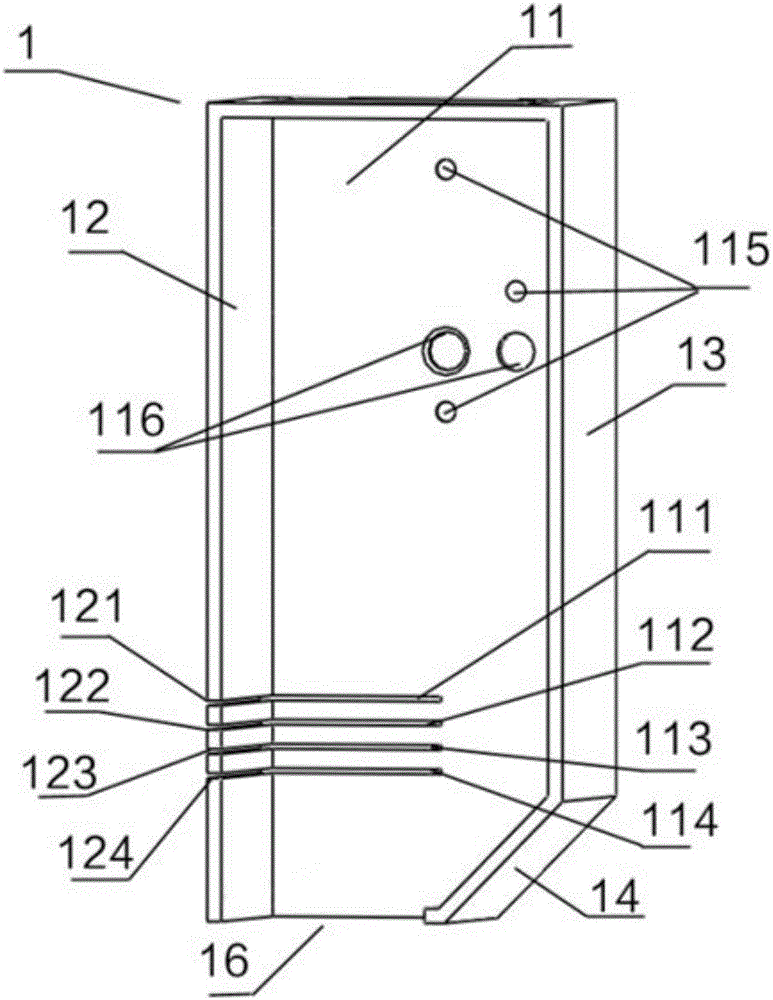

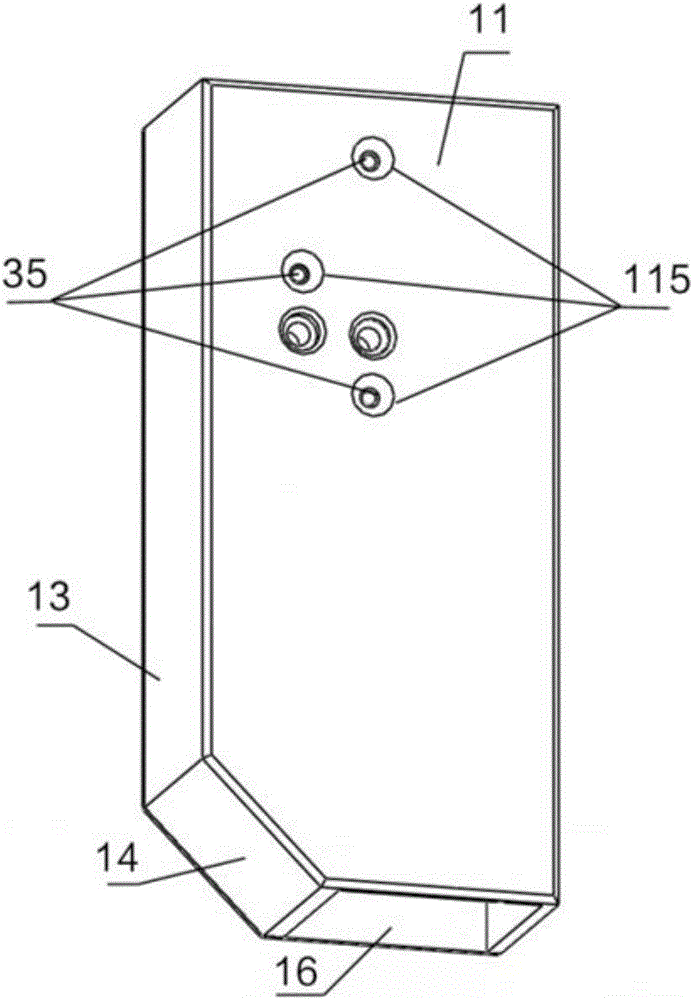

Intelligent and compact type welding line visual tracking system

InactiveCN106041377ACompact structureHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

The invention discloses an intelligent and compact type welding line visual tracking system which comprises a shell, a laser device, a camera, a light path adjusting module, drive device installing fixing parts and a control system. The camera, the light path adjusting module and the laser device are connected with the shell through the installing fixing parts. The installing fixing parts are installed in the shell. The light path adjusting module is used for adjusting a light path of a laser beam emitted by the laser device. A drive device is detachably connected with the outer portion of the shell. The control system is electrically connected with the camera, the light path adjusting module, the laser device and the drive device. Compared with the prior art, the intelligent and compact type welding line visual tracking system has the beneficial effects that high-precision and real-time positioning of the position of a welding line is achieved through the system, and the irradiation position of the laser beam on a to-be-welded workpiece can be automatically adjusted by rotating a reflecting lens; a fast focusing function can be achieved through the camera on the system, and the relative positions of the system and the to-be-welded workpiece can be automatically adjusted through the system; and the system is compact in structure, convenient to install and suitable for various working conditions.

Owner:GUANGDONG INST OF INTELLIGENT MFG

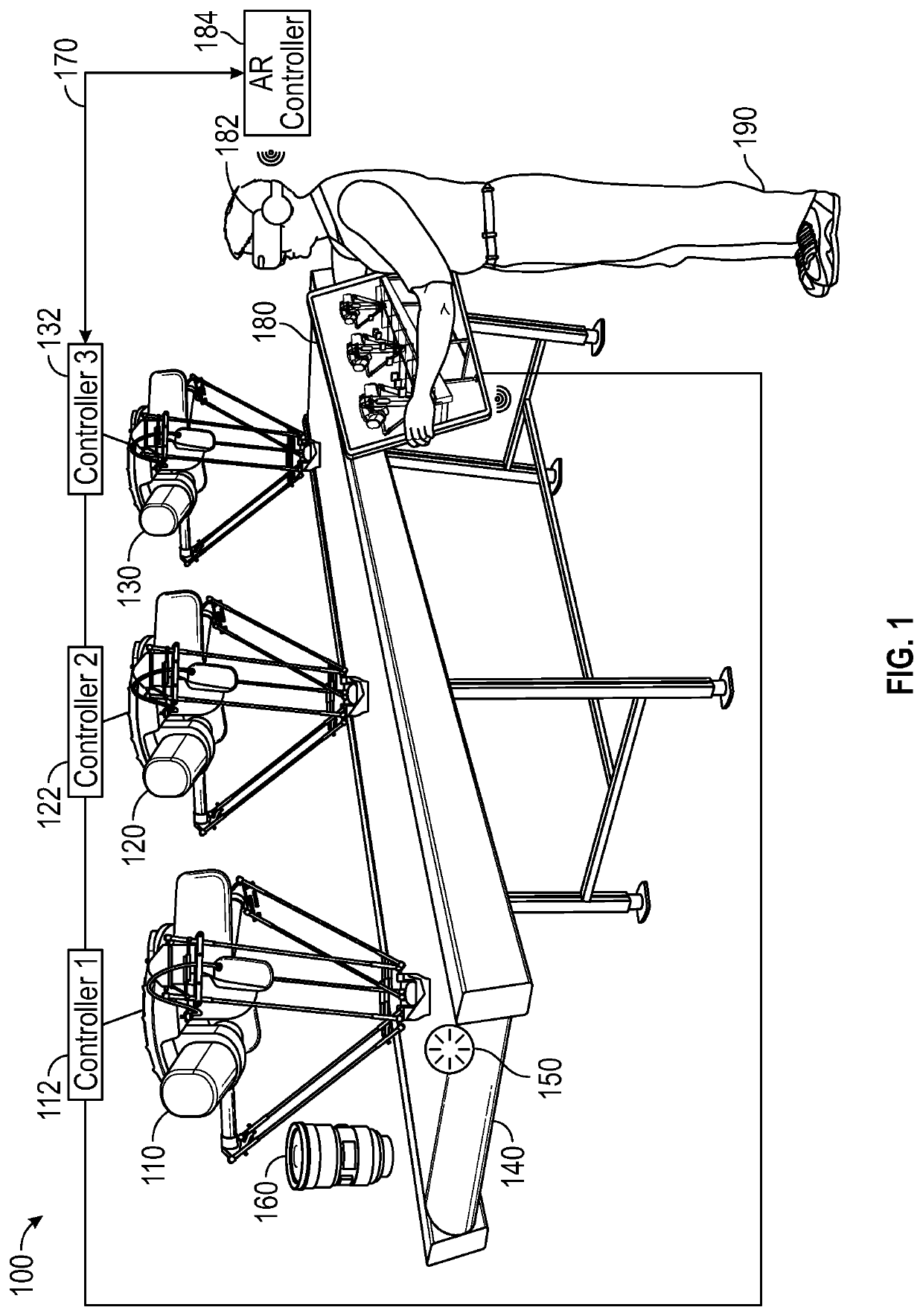

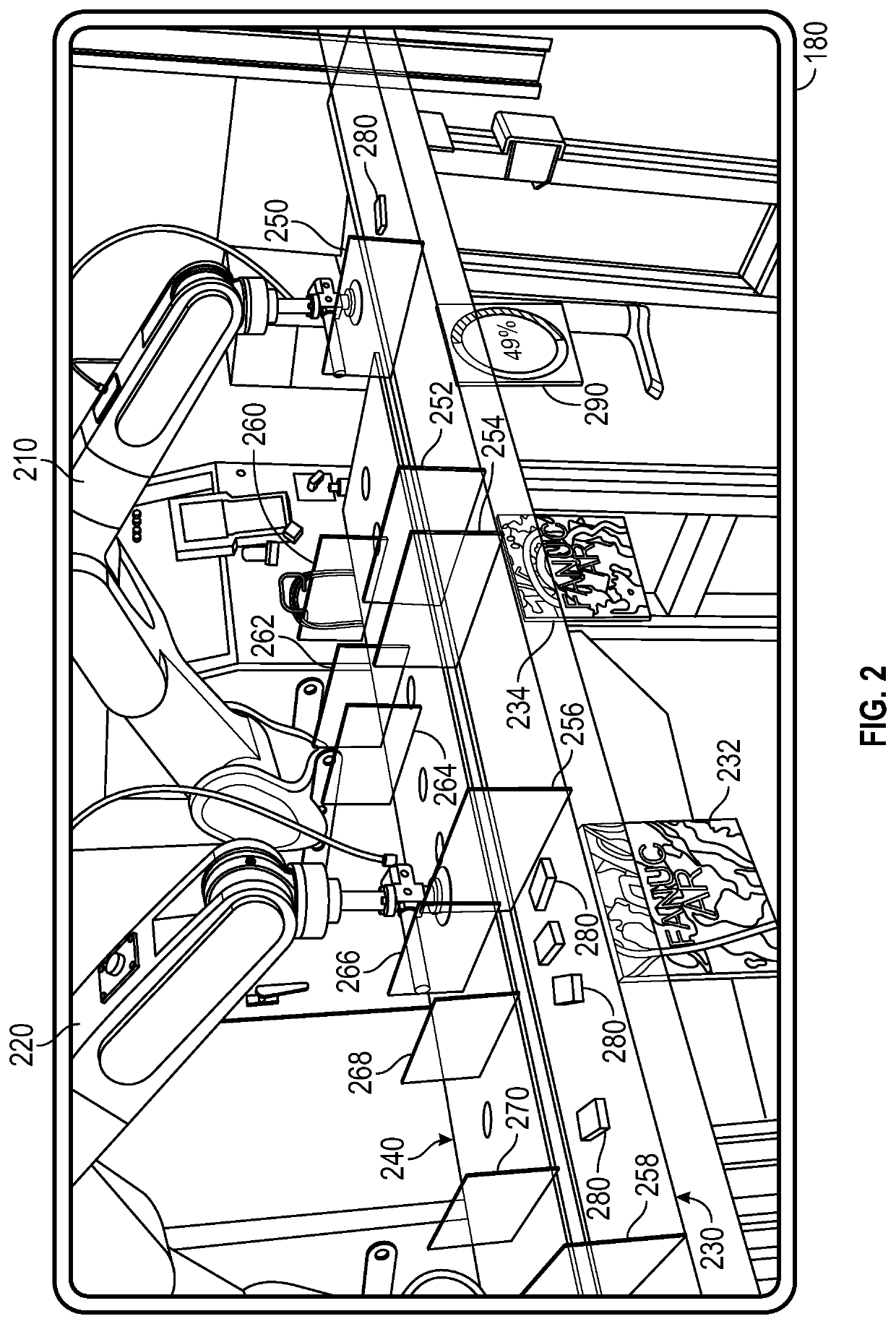

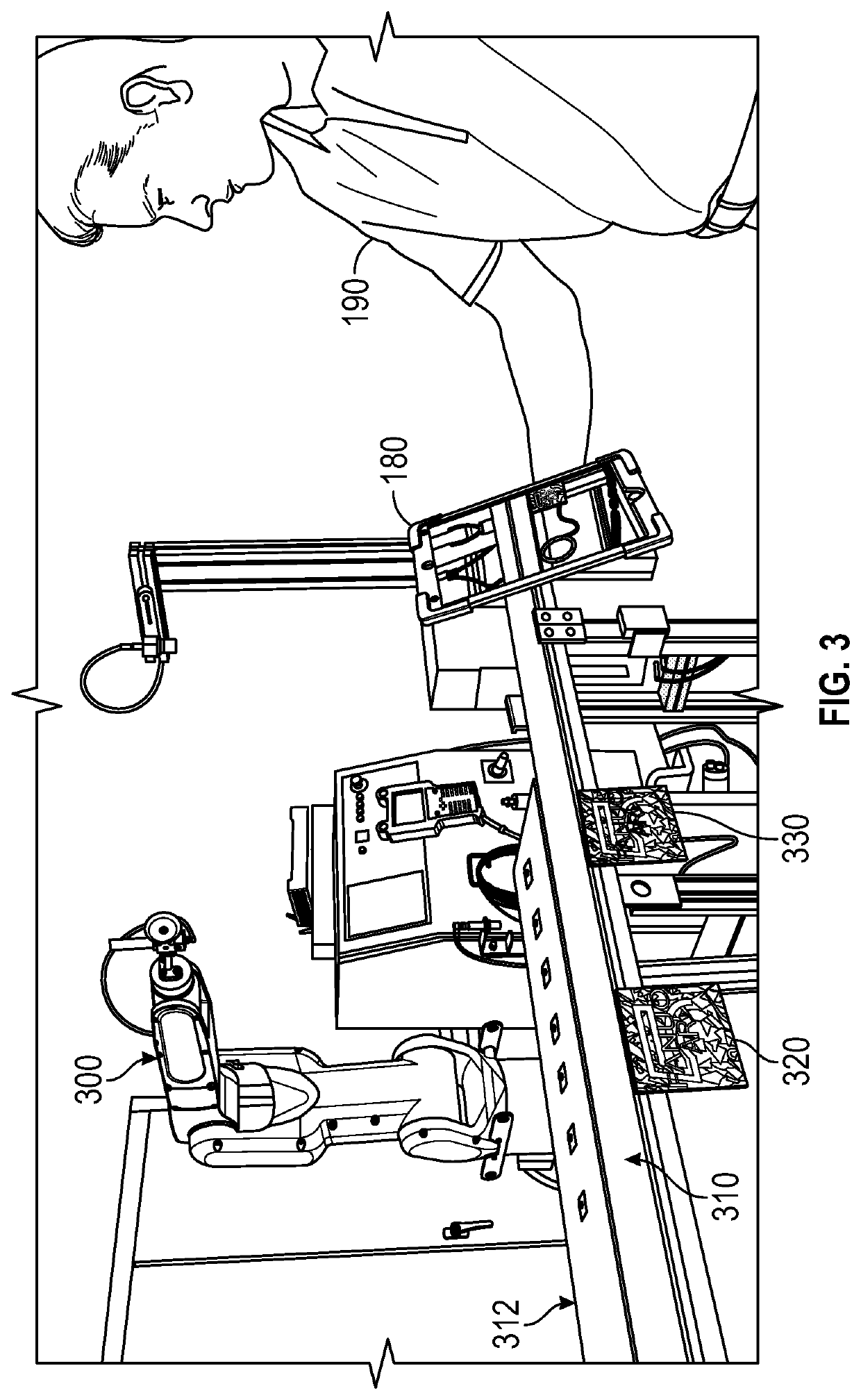

Augmented reality visualization for robotic picking system

ActiveUS20190389069A1Programme controlInput/output for user-computer interactionSimulationConveyor belt

An augmented reality (AR) system for production-tuning of parameters for a visual tracking robotic picking system. The robotic picking system includes one or more robots configured to pick randomly-placed and randomly-oriented parts off a conveyor belt and place the parts in an available position, either on a second moving conveyor belt or on a stationary device such as a pallet. A visual tracking system identifies position and orientation of the parts on the feed conveyor. The AR system allows picking system tuning parameters including upstream, discard and downstream boundary locations to be visualized and controlled, real-time robot pick / place operations to be viewed with virtual boundaries, and system performance parameters such as part throughput rate and part allocation by robot to be viewed. The AR system also allows virtual parts to be used in simulations, either instead of or in addition to real parts.

Owner:FANUC ROBOTICS NORTH AMERICA

Methods and systems for ultra-precise measurement and control of object motion in six degrees of freedom by projection and measurement of interference fringes

A system and method for active visual measurement and servo control using laterally sampled white light interferometry (L-SWLI) for real-time visual tracking of six-degree-of-freedom (6 DOF) rigid body motion with near-nanometer precision. The visual tracking system is integrated with a 6 DOF motion stage to realize an ultra precision six-axis visual servo control system. Use of L-SWLI obtains the complete pose of the target object from a single image frame to enable real-time tracking. Six-degree-of-freedom motions are obtained by measuring the fringe pattern on multiple surfaces of the object or from a single surface with additional information gained from conventional image processing techniques.

Owner:OHIO STATE INNOVATION FOUND

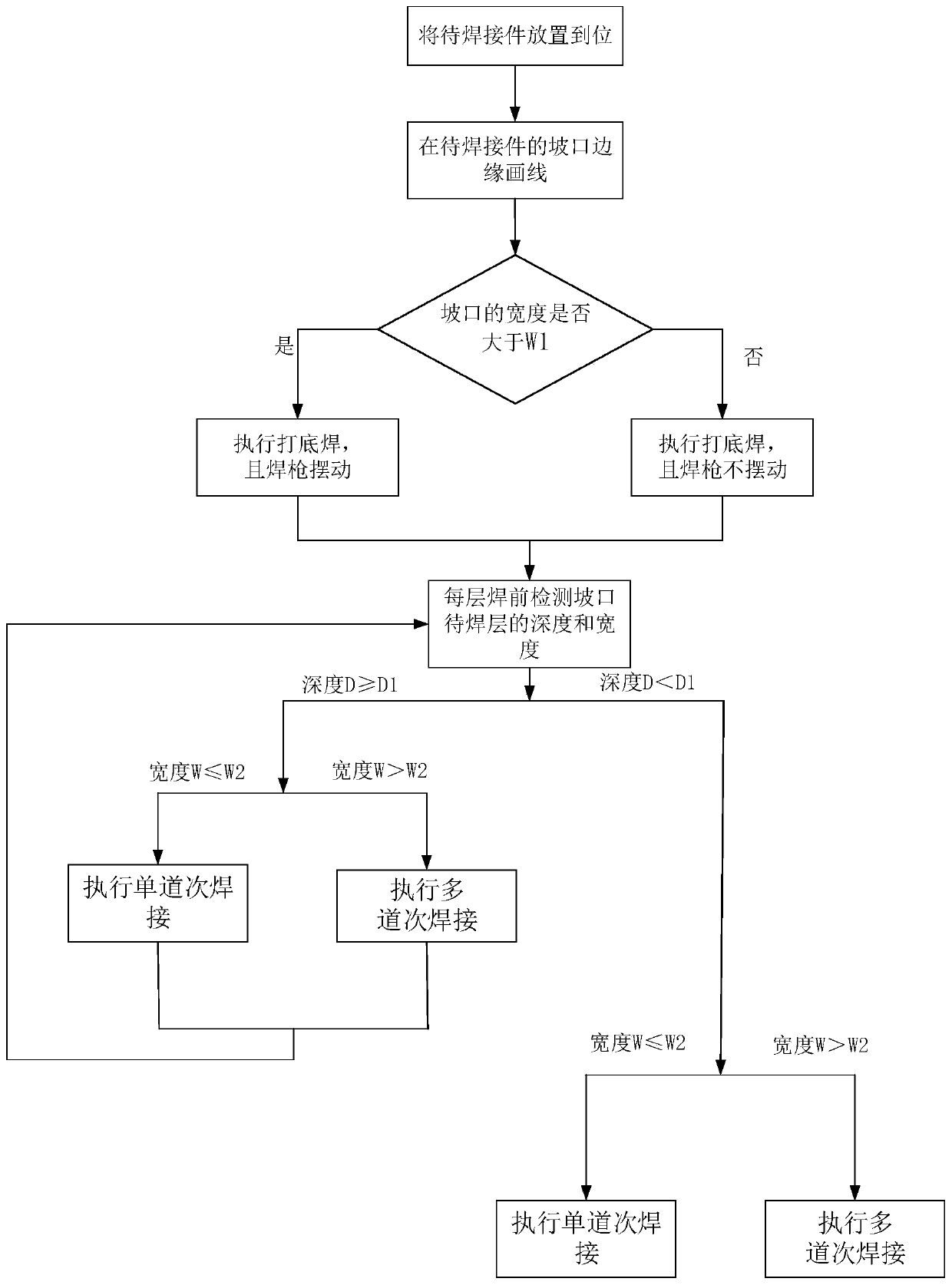

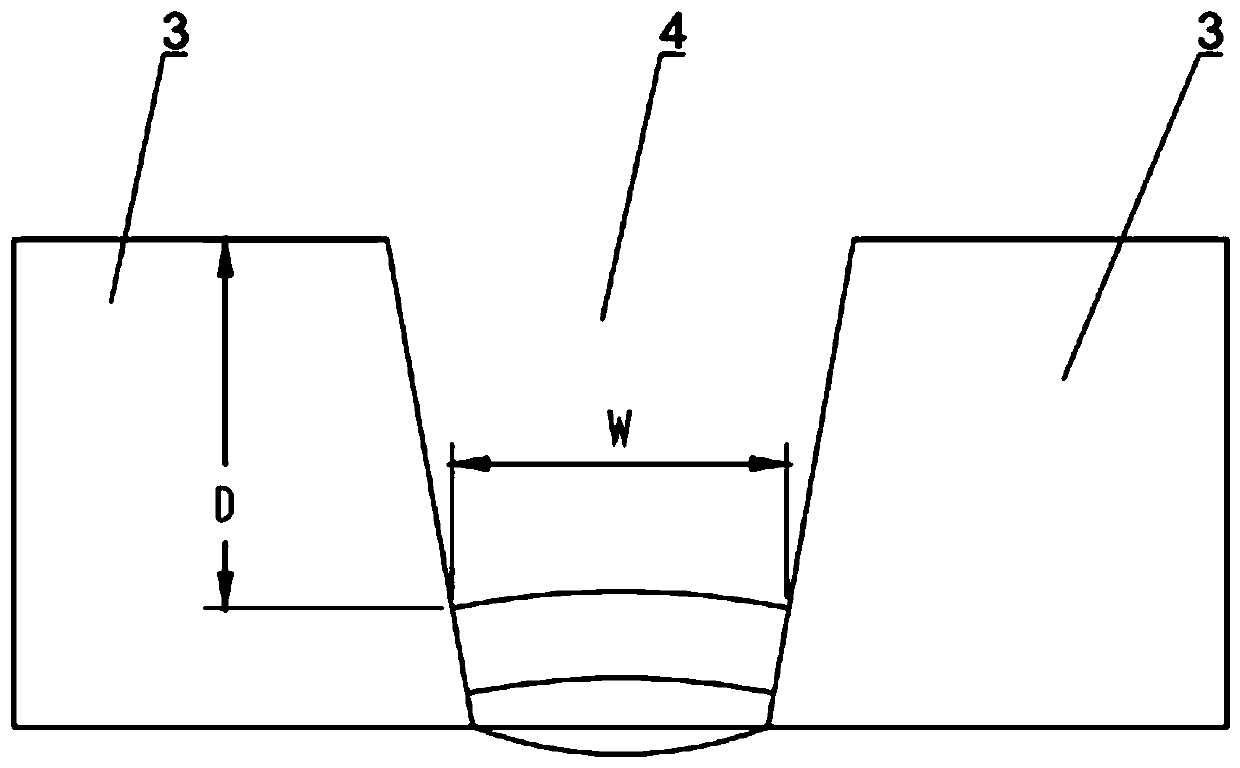

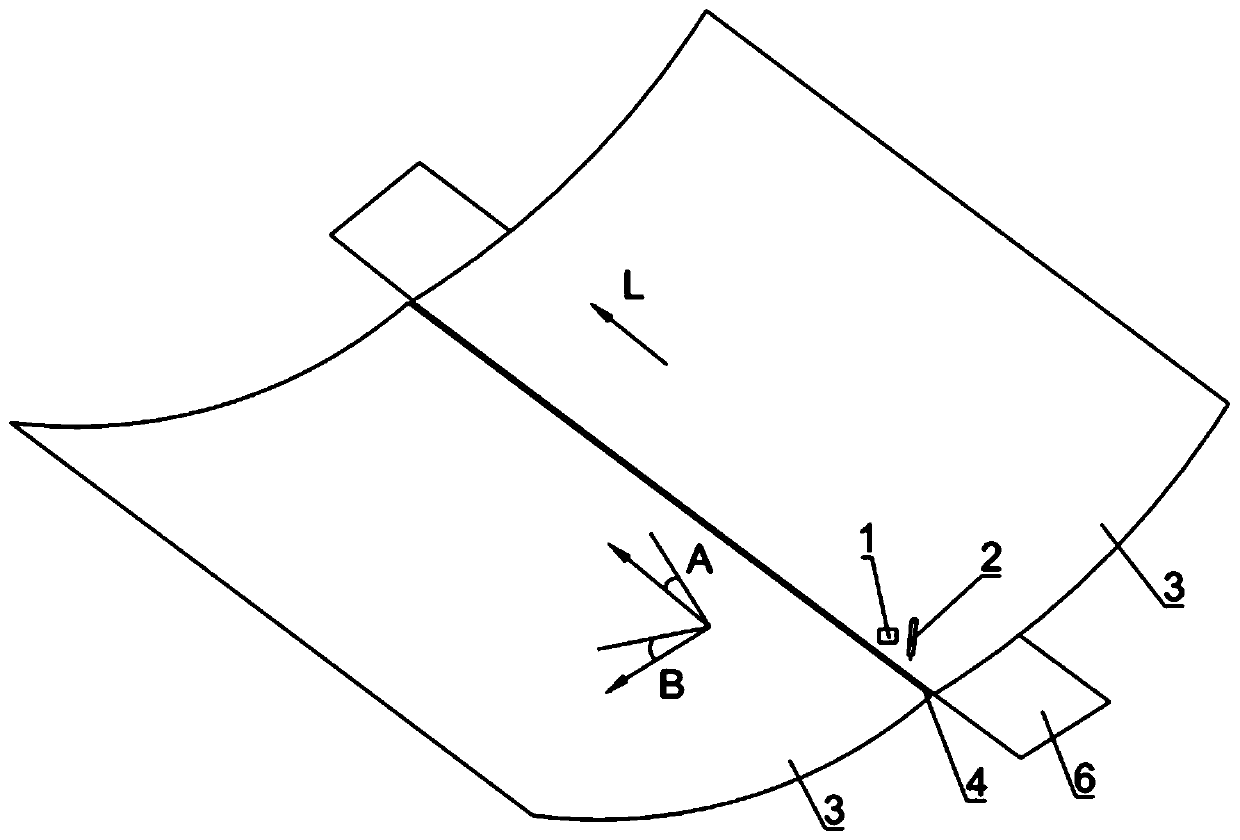

Automatic welding method and welding device of ship curved plate

ActiveCN110681951AAvoid manual operationImprove performanceArc welding apparatusStructural engineeringWeld seam

The invention relates to the technical field of ship manufacturing, and particularly discloses an automatic welding method and welding device of a ship curved plate. The automatic welding method of the ship curved plate comprises a welding execution procedure. The welding execution procedure comprises the following steps of executing backing weld; executing at least one of filling welding and cosmetic welding; in each welding procedure, at least carrying out one layer of welding, before executing of each layer of welding, through a visual tracking system, recognizing the depth of a layer to bewelded and the width of the layer to be welded of a groove, and according to the depth and the width, selecting welding process parameters; and enabling a welding gun mechanism to be electrically connected with the visual tracking system, and enabling the welding gun mechanism to adjust a motion track through the visual tracking system. Manual operation of the welding gun mechanism can be avoided, in the welding process, arc breaking is not needed, and the property and the quality of a welding seam are improved. According to the automatic welding method of the ship curved plate, the propertyand the quality of the welding seam can be improved, and welding way deviation and cumulative departure in the welding process can be avoided.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

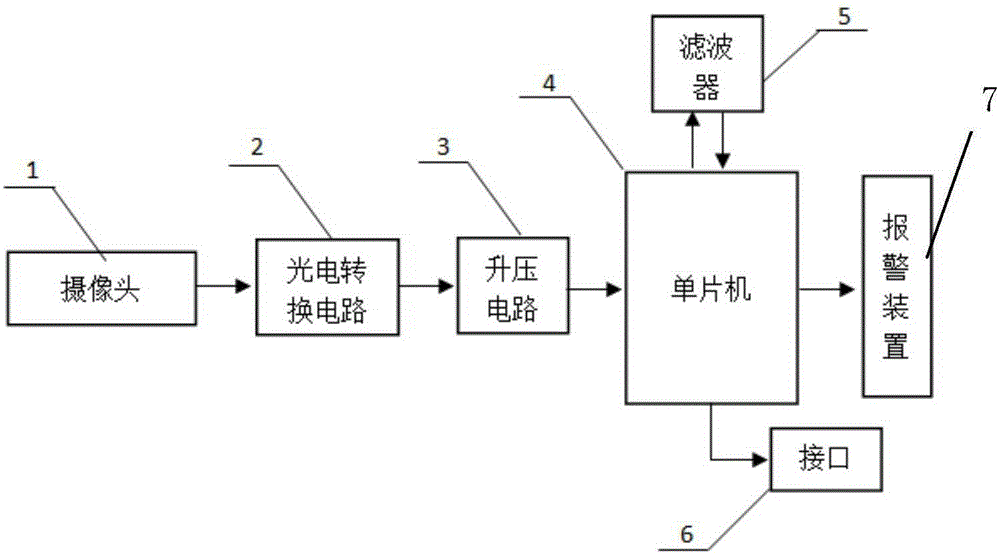

Underwater measurement lifesaving device based on visual analysis

InactiveCN105187764ASolve the inability to directly observeSolve the dangerClosed circuit television systemsBurglar alarmUnderwater explosionVision based

The invention belongs to the field of underwater measurement and lifesaving research, and specifically relates to an underwater measurement lifesaving device based on visual analysis which can measure the underwater motion of people in real time, analyze the underwater behaviors of people and alarm automatically. The underwater measurement lifesaving device comprises a visual tracking system, a photoelectric conversion circuit, an amplifying circuit, a single chip microcomputer, a filter, an interface, an alarm device, and a waterproof shell. Due to the adoption of the visual tracking system, the motion process of a target person can be observed in real time, the underwater motion of the target person can be analyzed intelligently, and an alarm can be given automatically when danger occurs. Therefore, the time for danger finding is shortened, the efficiency of underwater lifesaving is improved, and the economical efficiency is improved.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com