Laser visual tracking system

A visual tracking and laser technology, applied in the field of laser visual tracking system, can solve the problems of small adaptable range of sensors, unobvious weld seam outline, weak anti-interference ability, etc., achieve strong anti-interference ability, wide application range, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The best embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

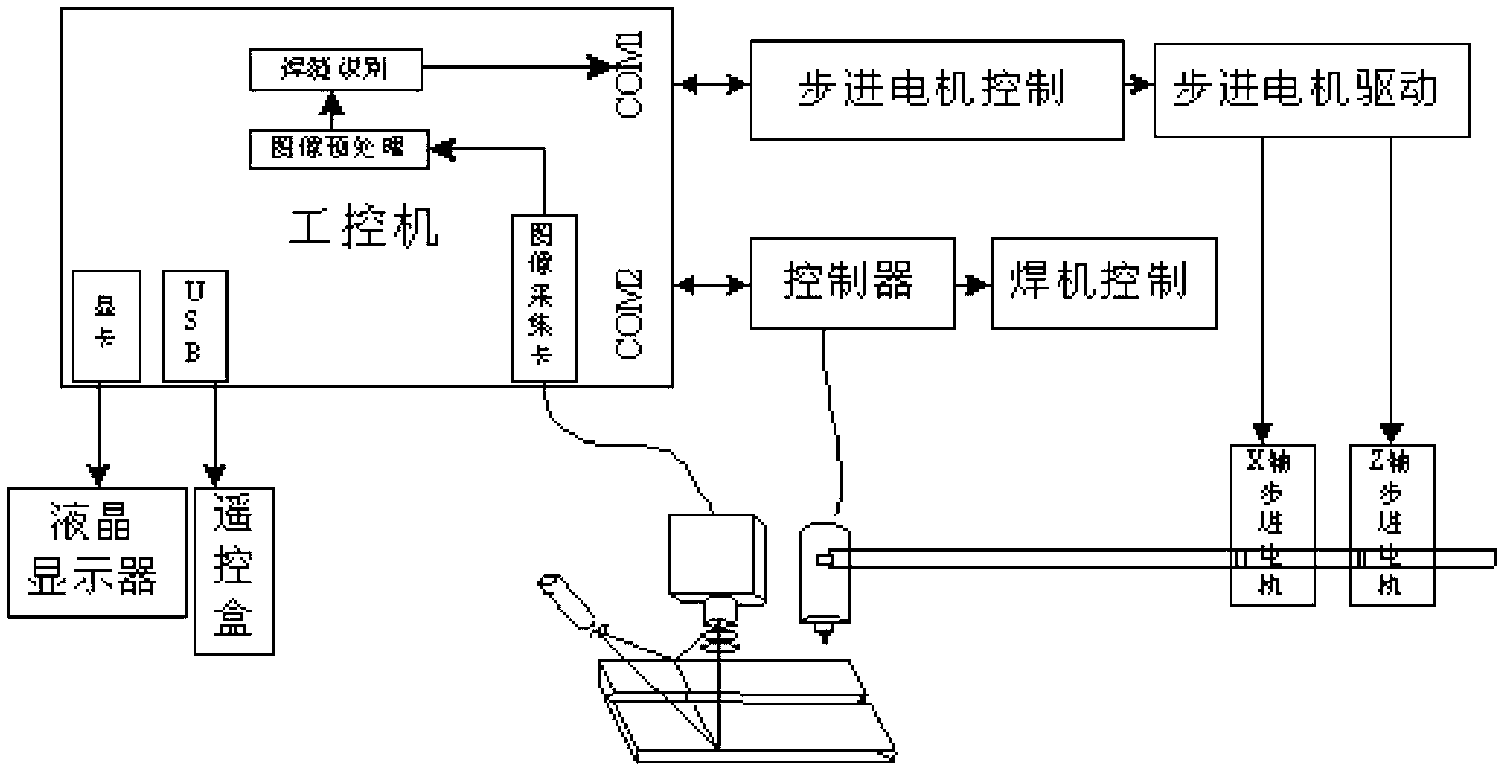

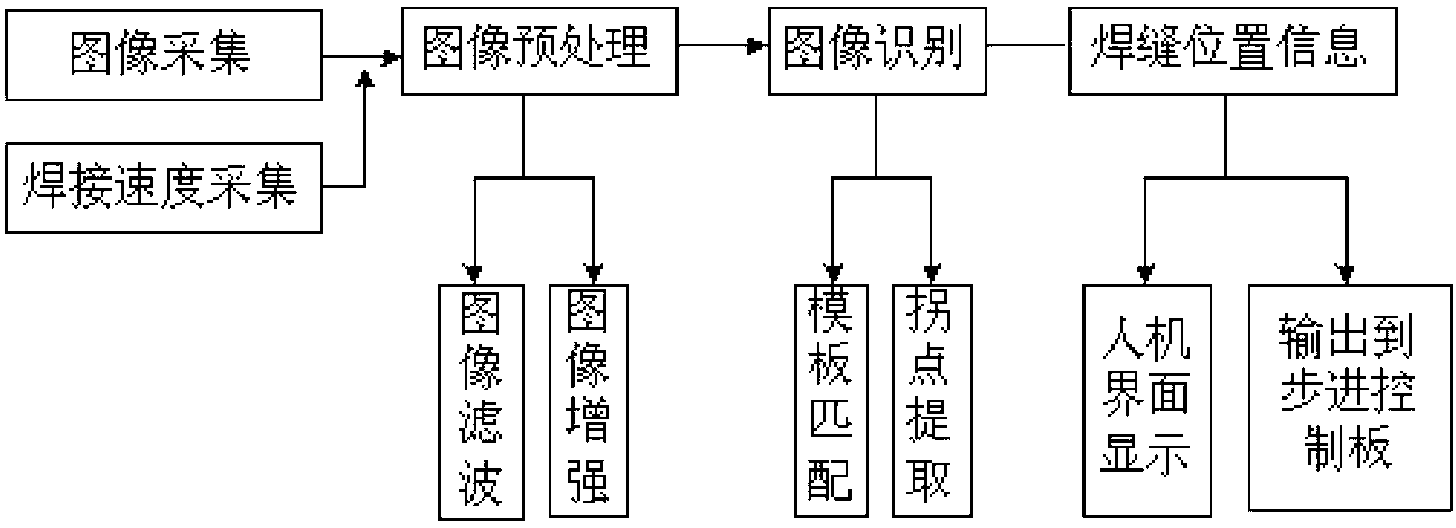

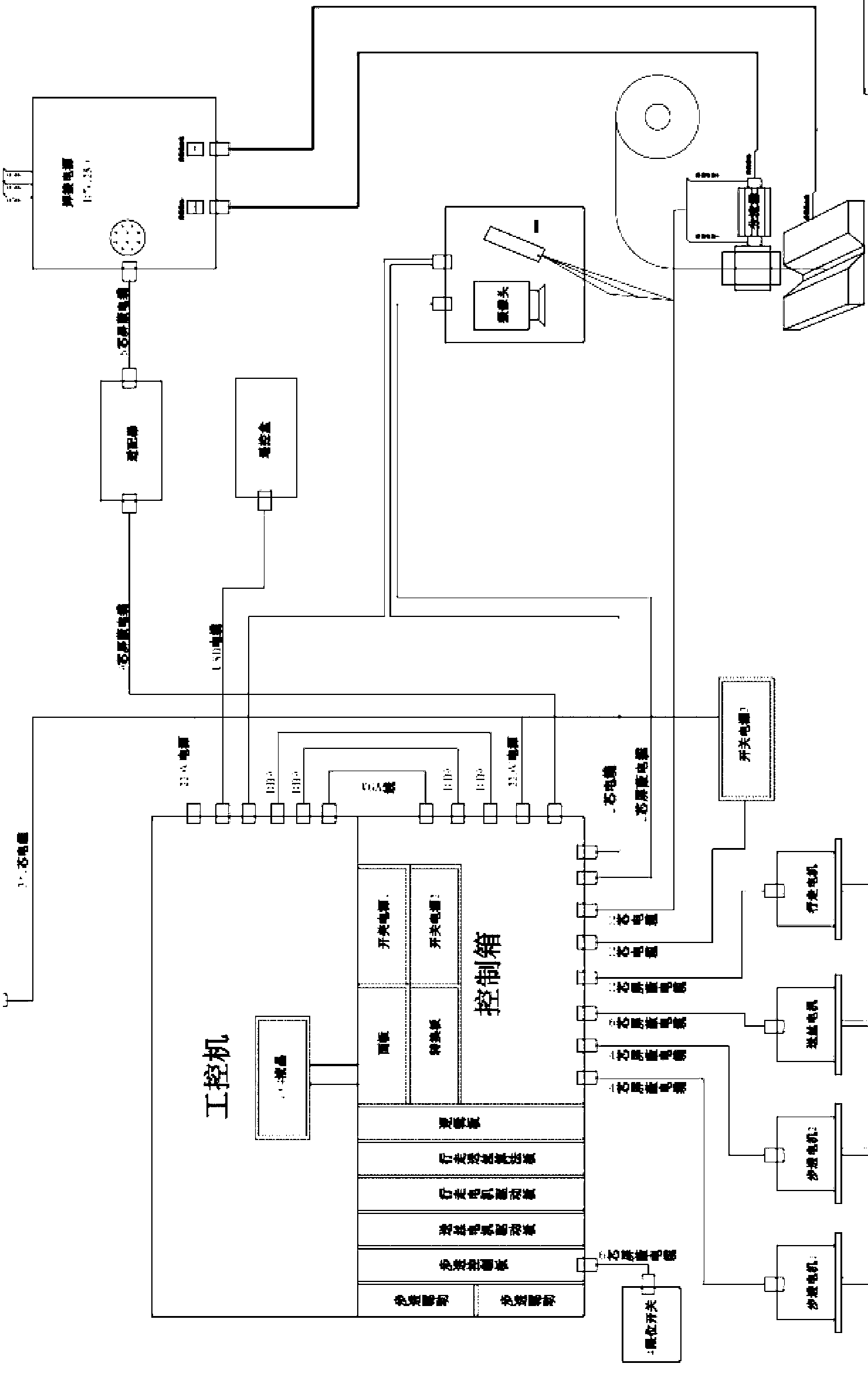

[0034] The welding seam tracking system based on laser vision is attached figure 1 As shown, it mainly includes an industrial computer, an X-axis motor, a Z-axis motor, a welding cabinet, a camera, and a laser diode. The COM1 port of the industrial computer is connected to the motor control and drive circuit, and is connected to the X-axis through the motor control and drive circuit. Motor, Z-axis motor, and then control the operation of X-axis motor and Z-axis motor. The output terminals of X-axis motor and Z-axis motor are connected to the welding cabinet, and the welding cabinet is driven by the X-axis motor and Z-axis motor. The controller and the welding machine control circuit, and the controller and the welding machine control circuit are connected to the COM2 port of the industrial computer, through which the industrial computer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frame rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com