Patents

Literature

63results about How to "Keep the relative position unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

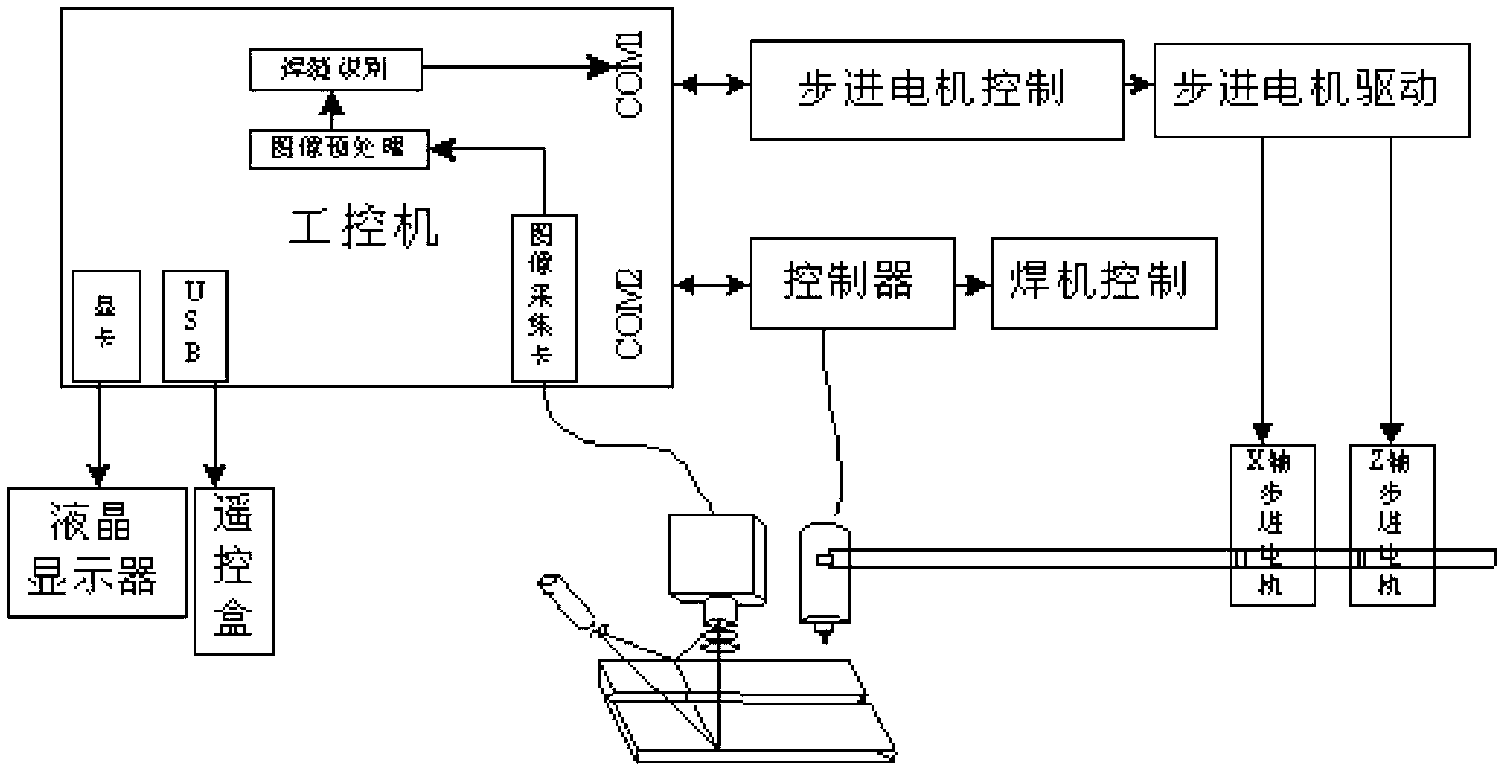

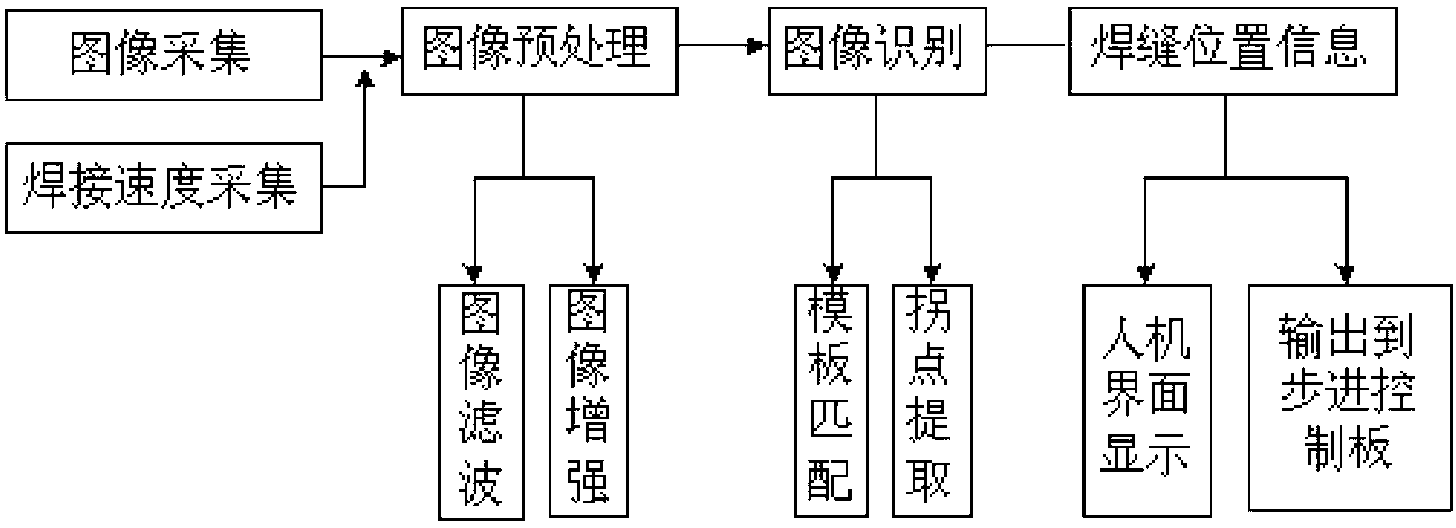

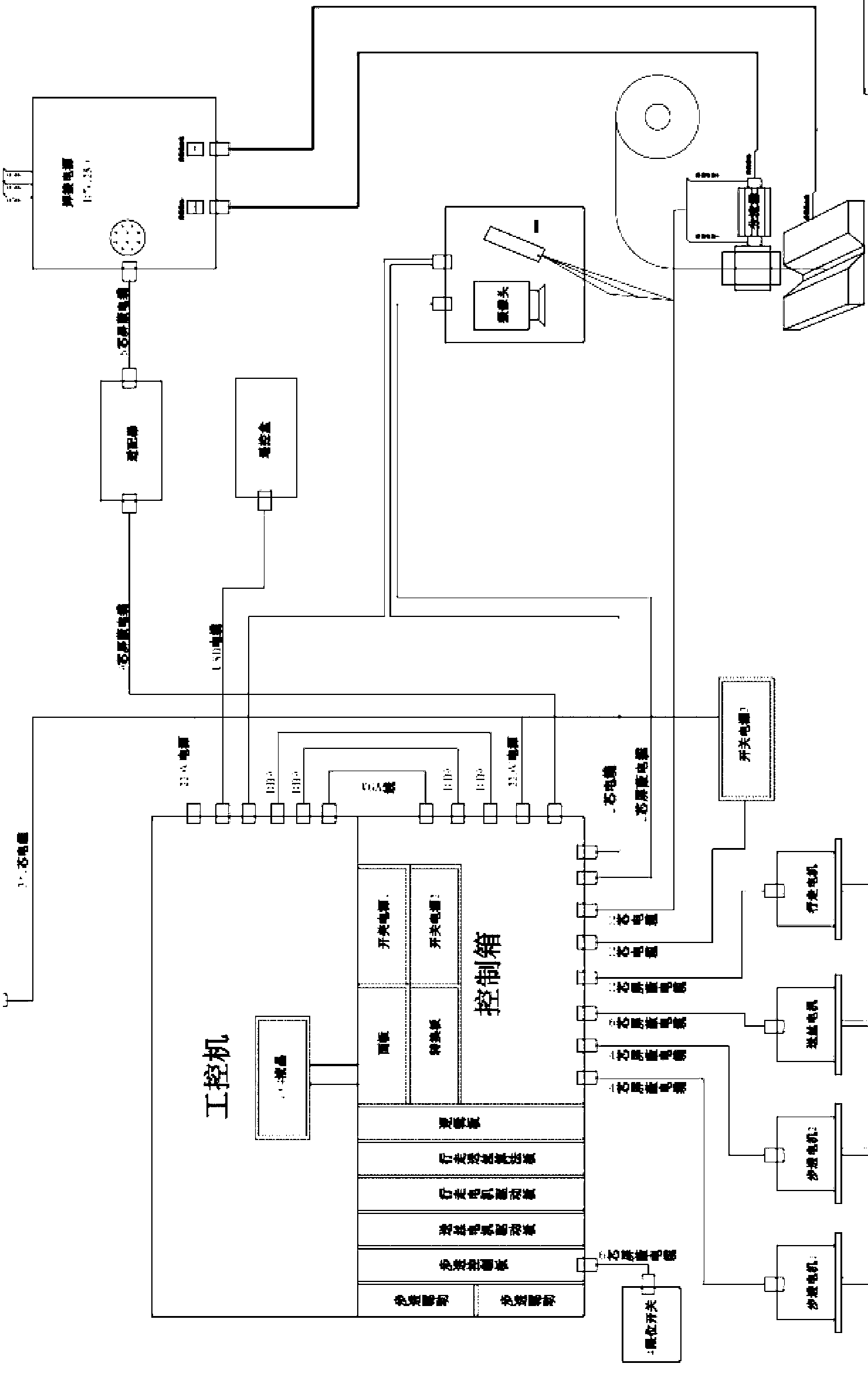

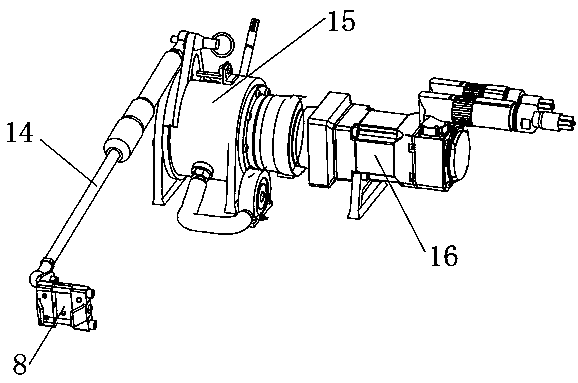

Laser visual tracking system

InactiveCN103203526AImprove anti-interference abilityEliminate lead errorArc welding apparatusComponent Object ModelMachine control

The invention discloses a laser visual tracking system, which mainly comprises an industrial personal computer, wherein a COM 1 (Component Object Model) port of the industrial personal computer is connected with an X axis motor and a Z axis motor through a motor control and drive circuit; output ends of the X-axis motor and the Z-axis motor are connected with a welding torque; the controller of the welding torque and a welding machine control circuit are connected with the industrial personal computer; the industrial personal computer is also connected with a laser sensor for acquiring information on the welding torque and a workpiece in real time and delivering the acquired information to the industrial personal computer; the laser sensor is a visual sensing module and mainly comprises a camera and a laser diode; the camera is vertically aligned with the workpiece; a laser is slantwise arranged and forms an angle of 30 degrees with the laser; laser emitted by the laser irradiates the workpiece to form a narrow light strip; after the light strip is reflected or refracted by the workpiece, the light strip enters the camera to image, and the image is transferred to the industrial personal computer for processing; after the image is analyzed and processed by the industrial personal computer, an action command is emitted to the welding torque, the X-axis motor and the Z-axis motor.

Owner:CHENGDU XIONGGU JIASHI ELECTRICAL

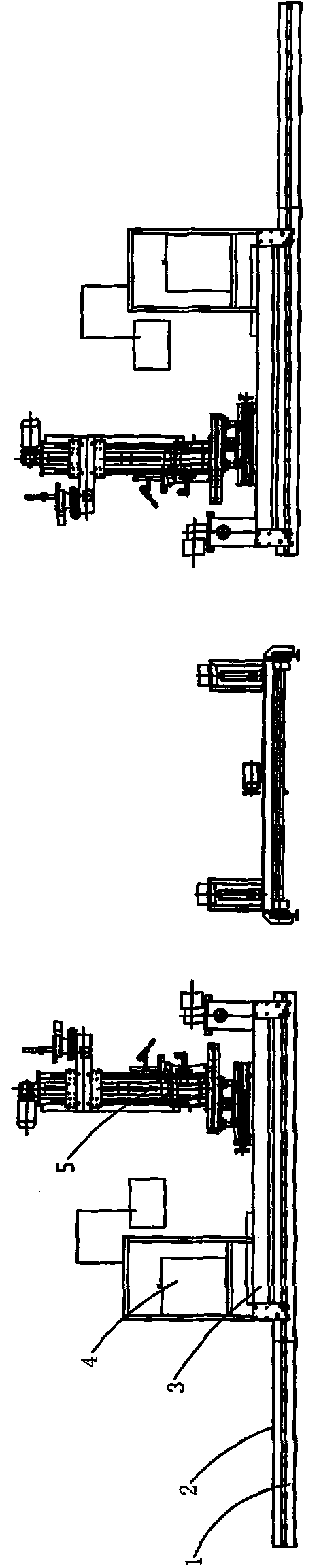

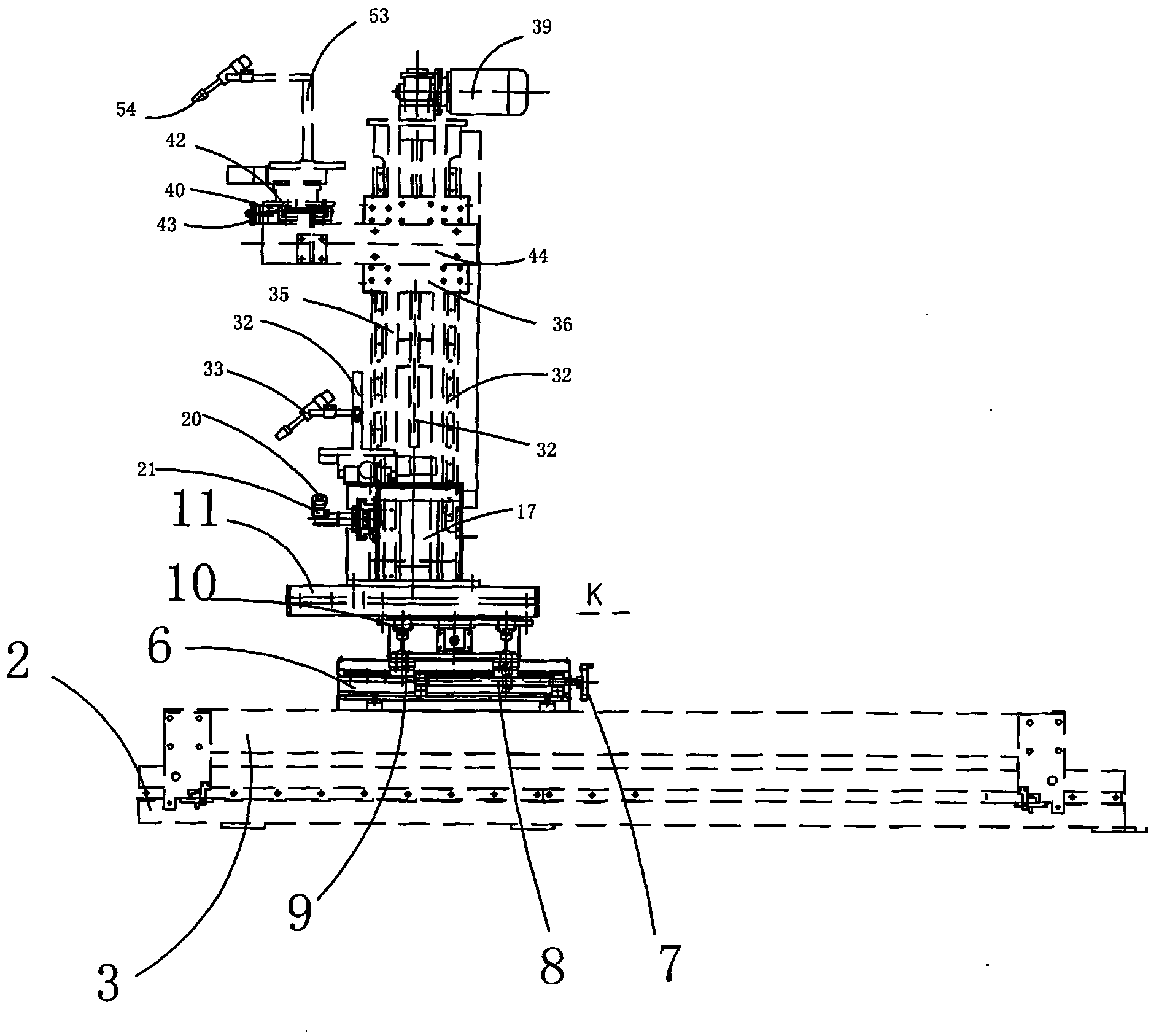

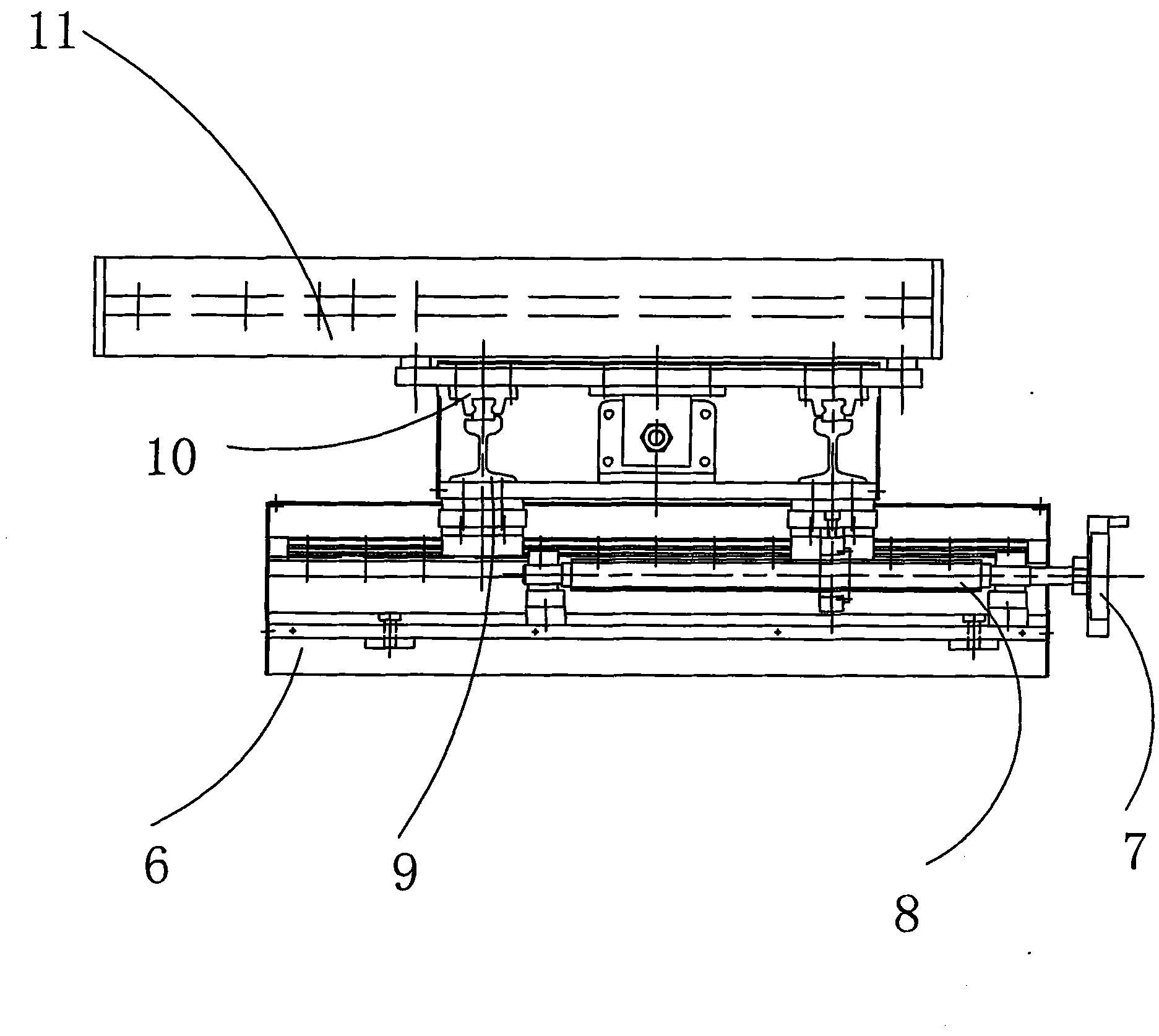

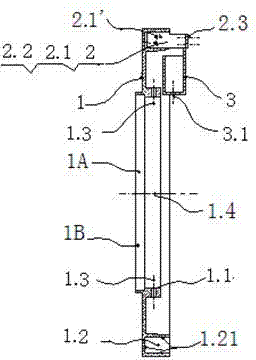

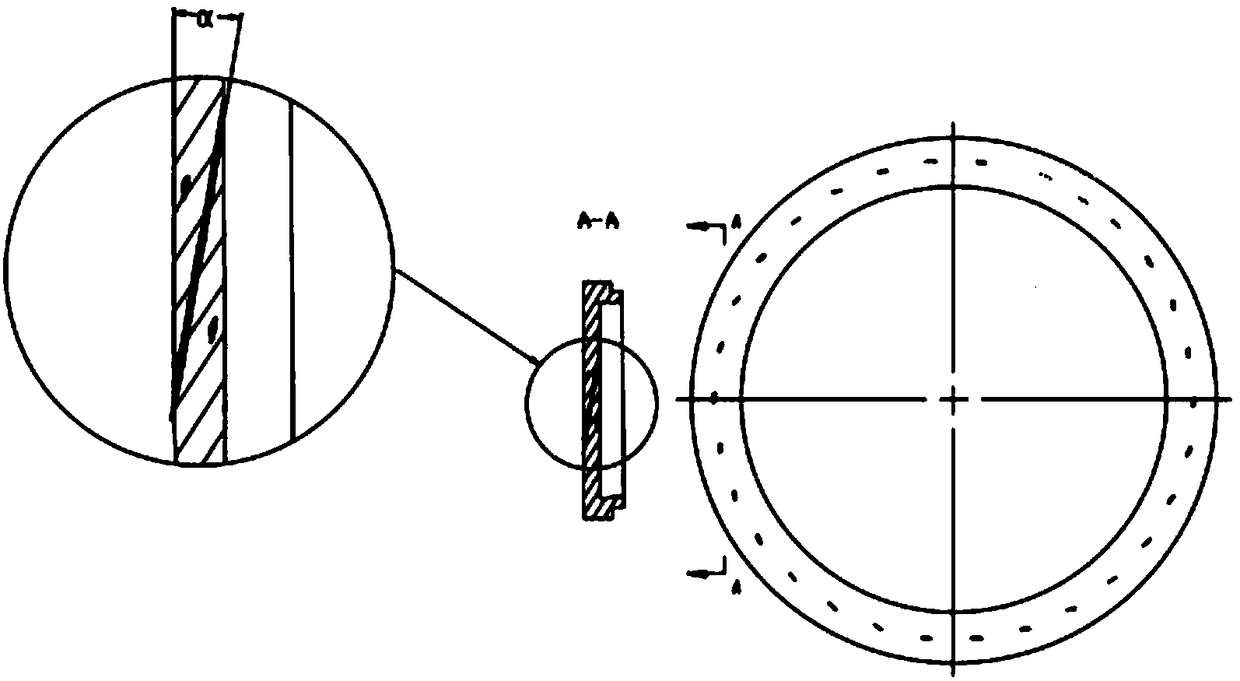

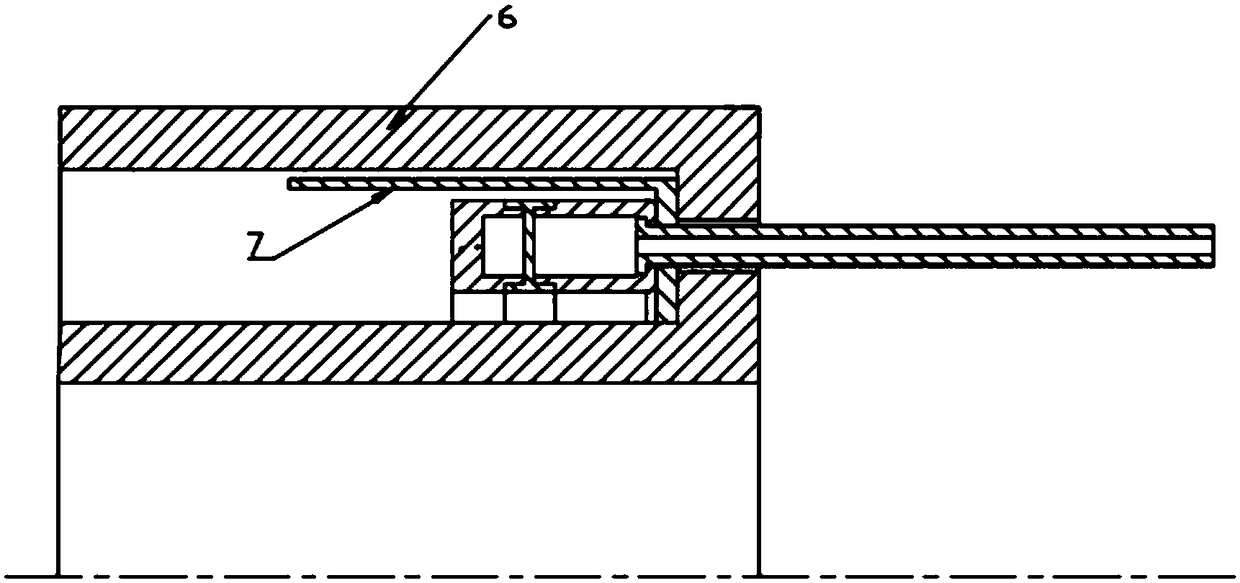

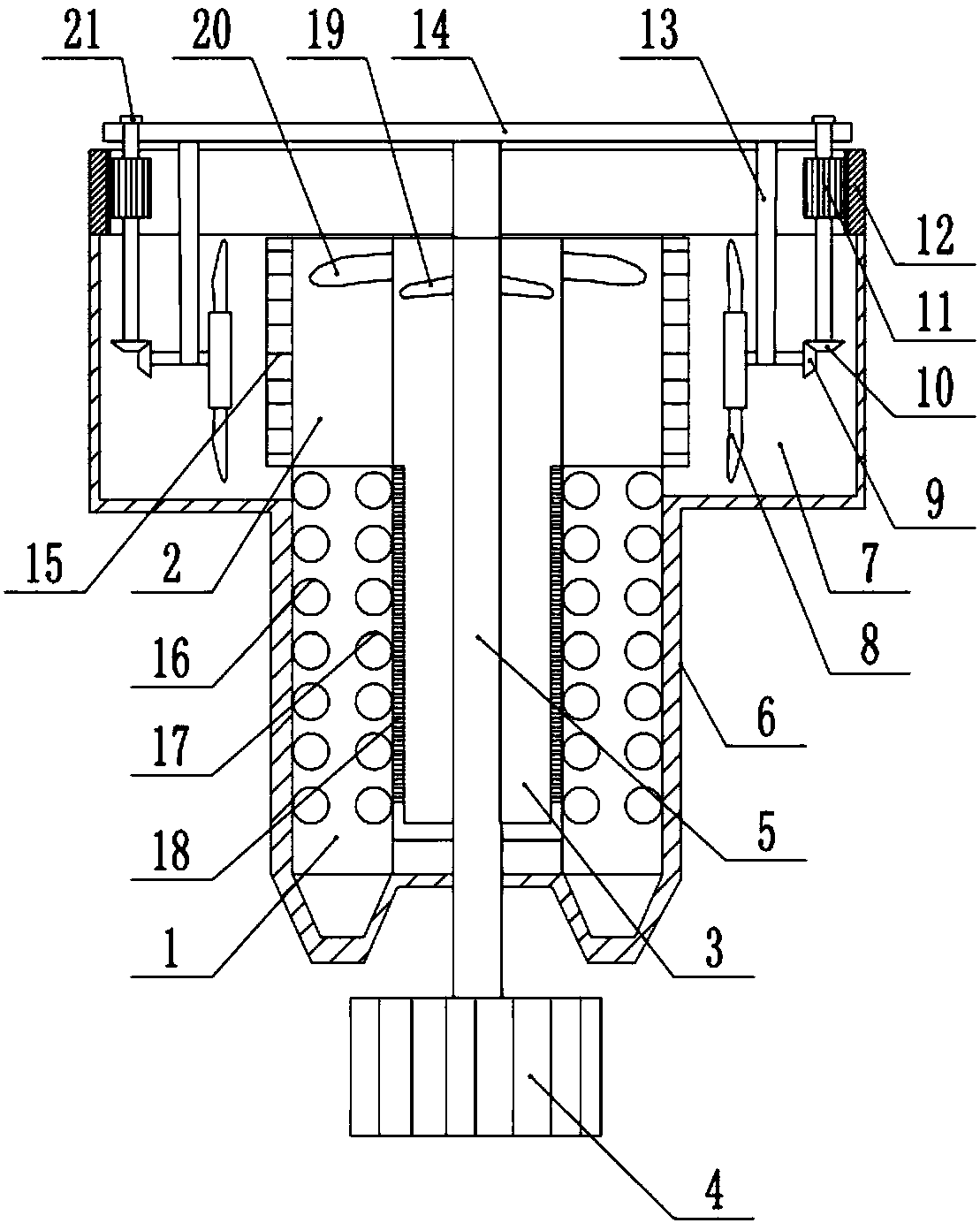

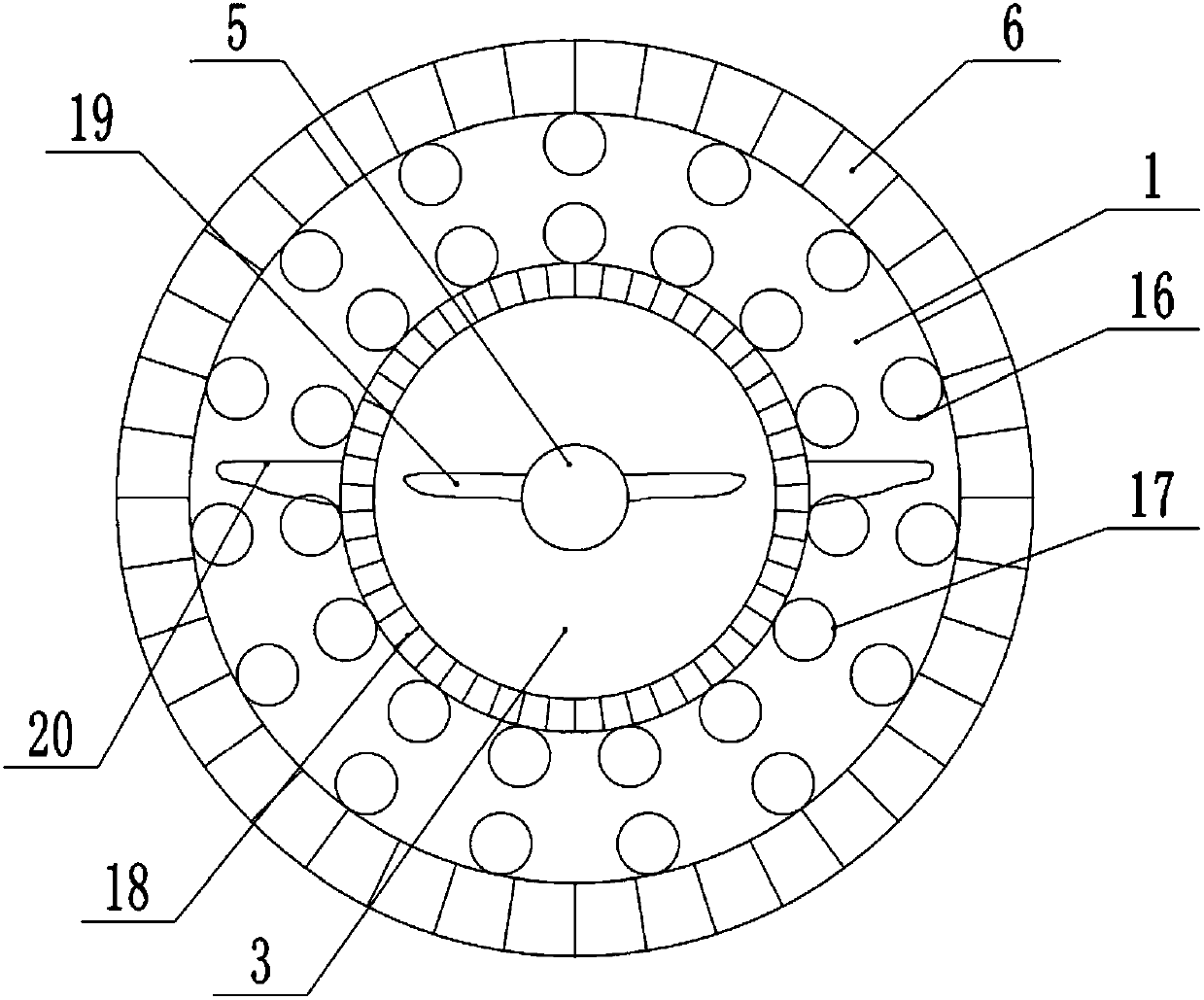

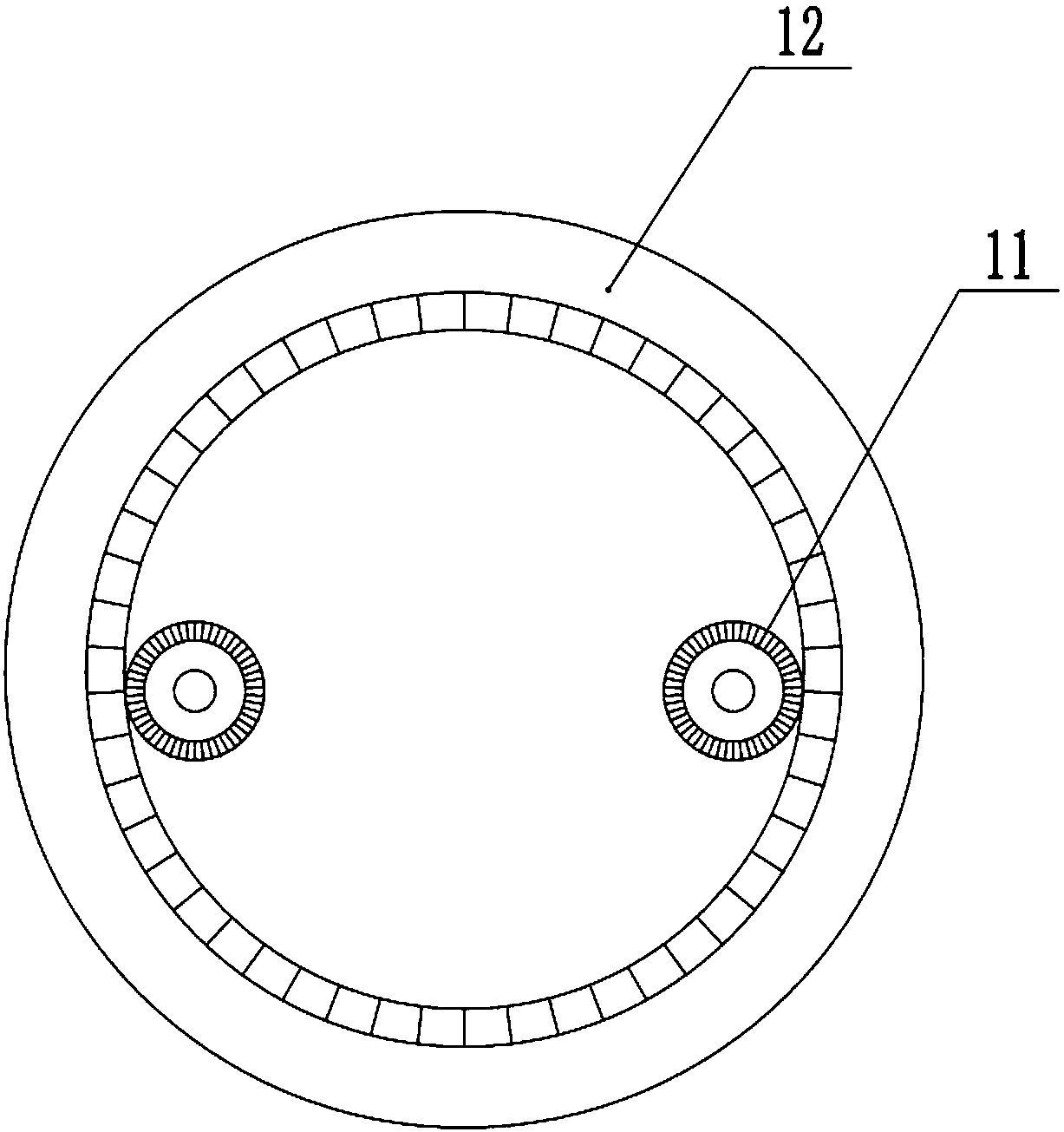

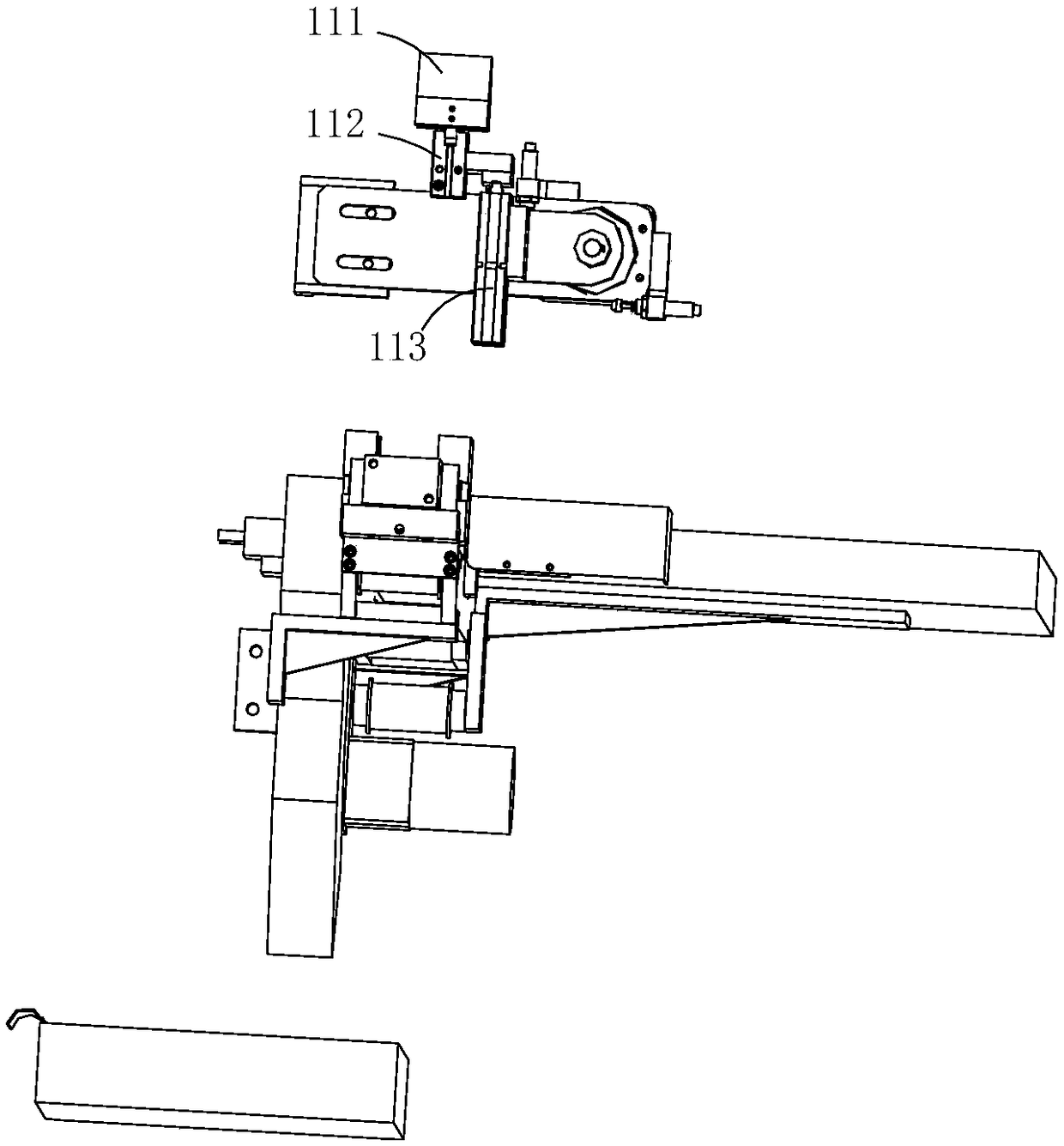

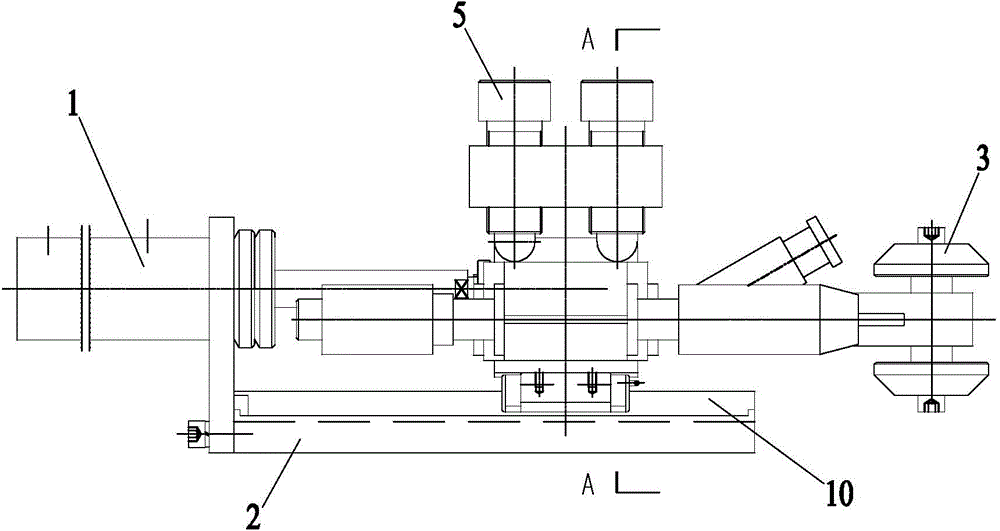

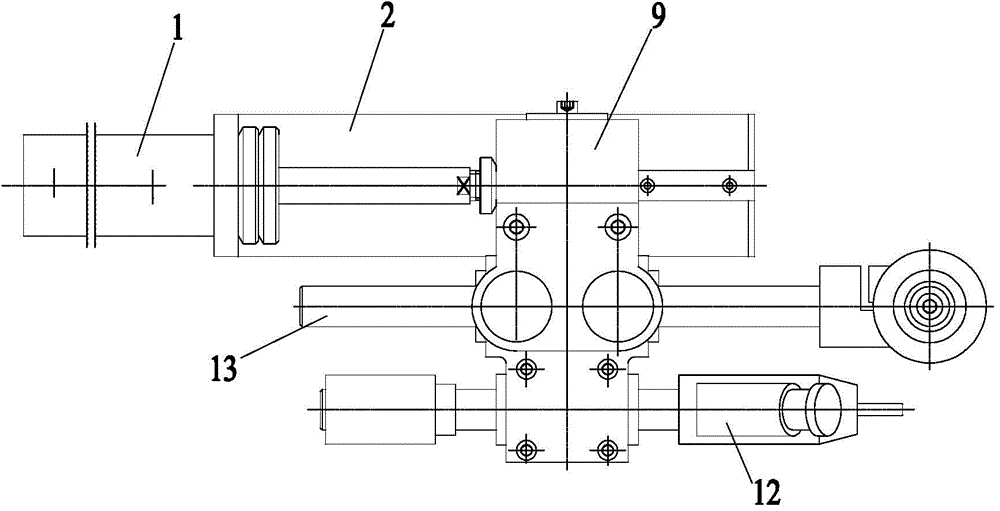

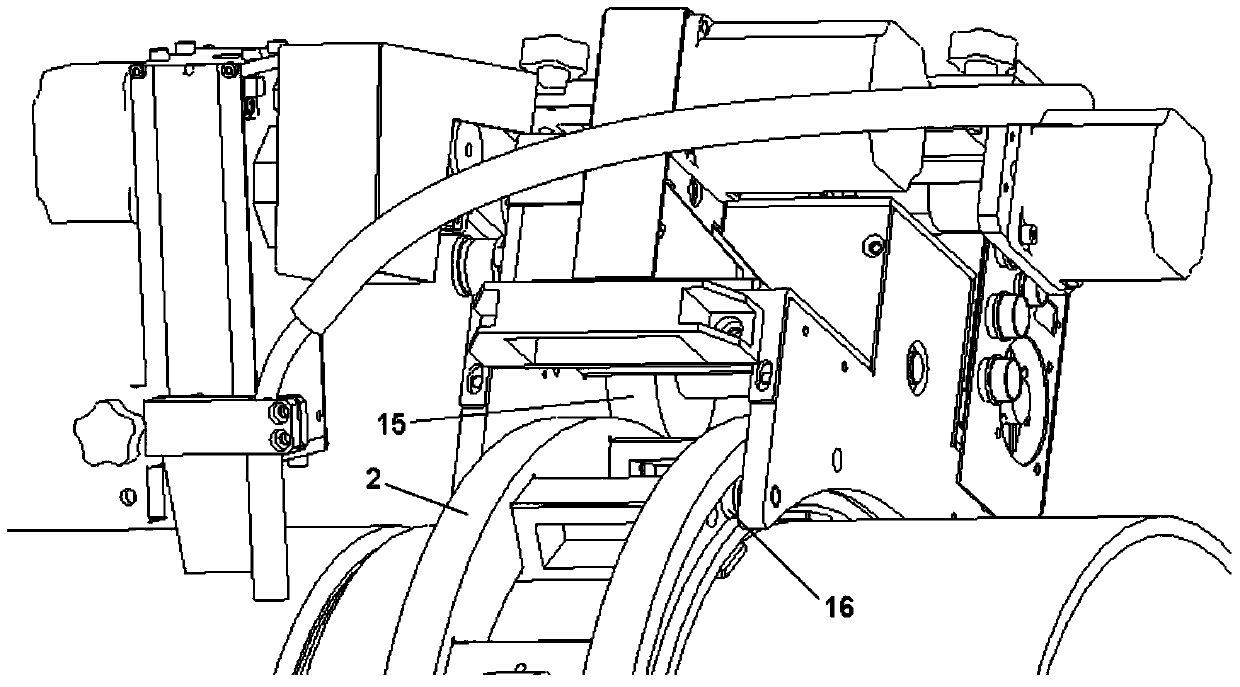

Automatic straight pipe flange welding machine

InactiveCN102009254AReduce playKeep the relative position unchangedElectrode supporting devicesWelding accessoriesWeld seamEngineering

The invention relates to a welding machine, particularly to an automatic straight pipe flange welding machine which is suitable for both plug-in type flange assembly type welding and butt-joint type flange assembly welding. The automatic straight pipe flange welding machine comprises a base, wherein base guide rails are arranged on the base, a trolley base is arranged on the base guide rails, a control system is arranged on one side of the trolley base, a welding torch machine is arranged on the trolley base and comprises a longitudinal adjusting mechanism, a lateral adjusting mechanism, an inner welding torch mechanism, an outer welding torch mechanism and a roller adjusting mechanism, wherein the inner welding torch mechanism consists of an inner welding torch upright post device and aninner welding torch device, and the outer welding torch mechanism includes an outer welding torch upright post device and an outer welding torch device. The automatic straight pipe flange welding machine has high automatic degree, improves welding efficiency, reduces grinding time and waste of welding materials, guarantees welding quality, and attractive formation of weld seams, is convenient to operate, saves labor, and lightens labor intensity.

Owner:HANGZHOU XINCHENGXIANG ELECTROMECHANICAL TECH

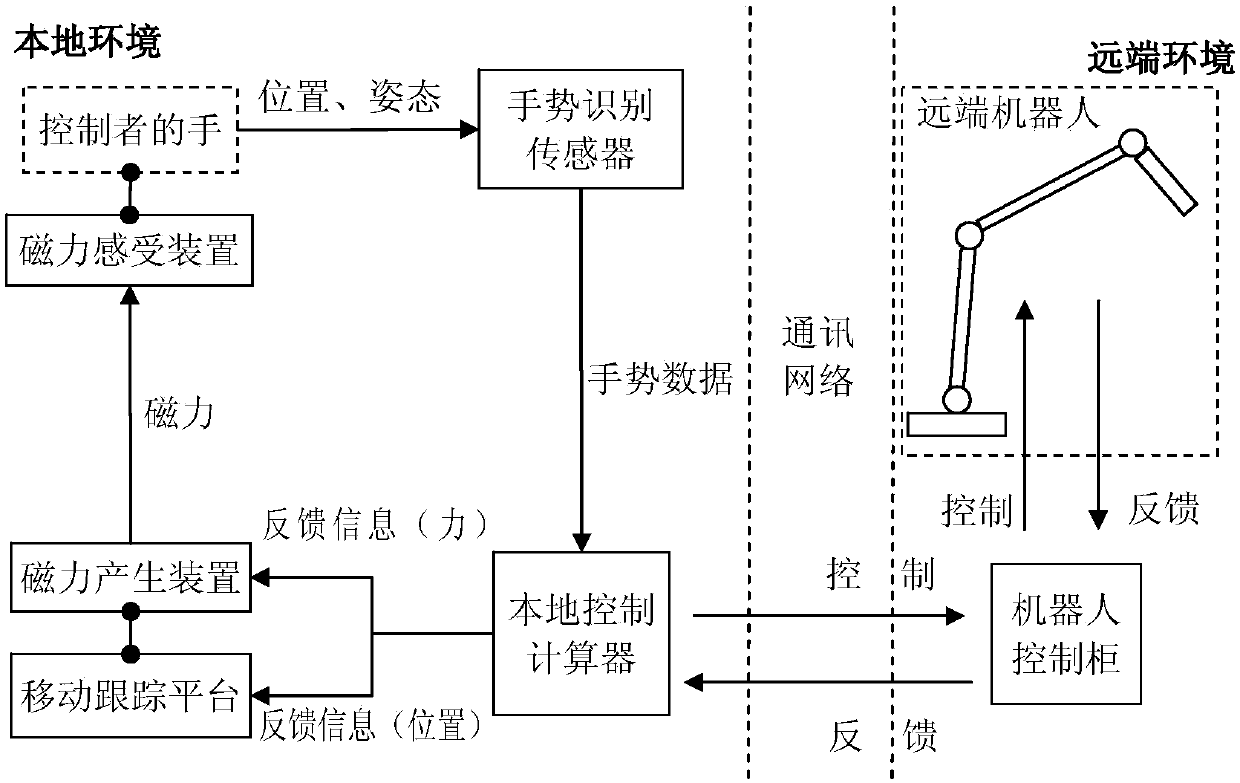

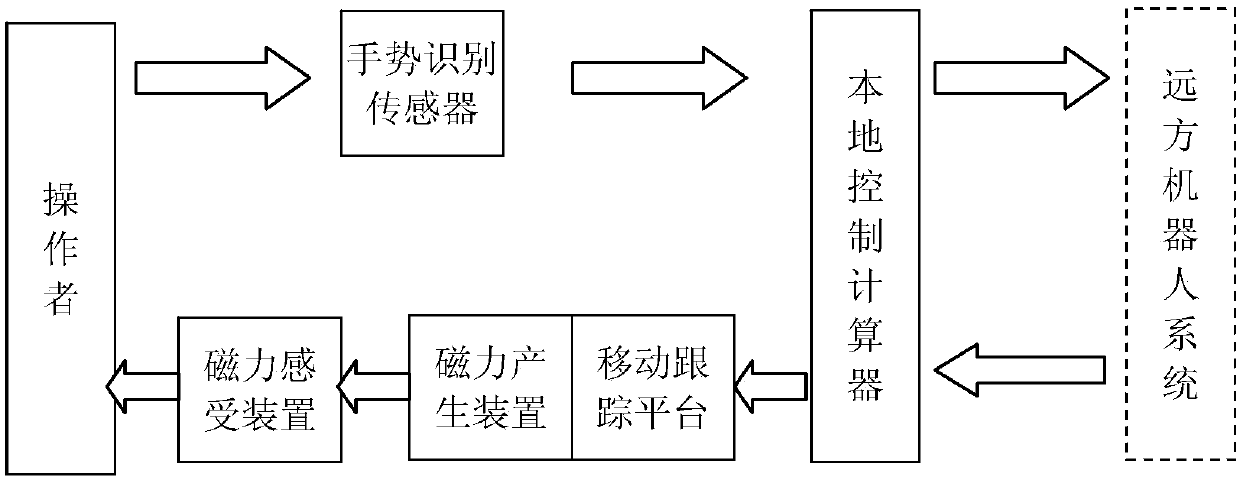

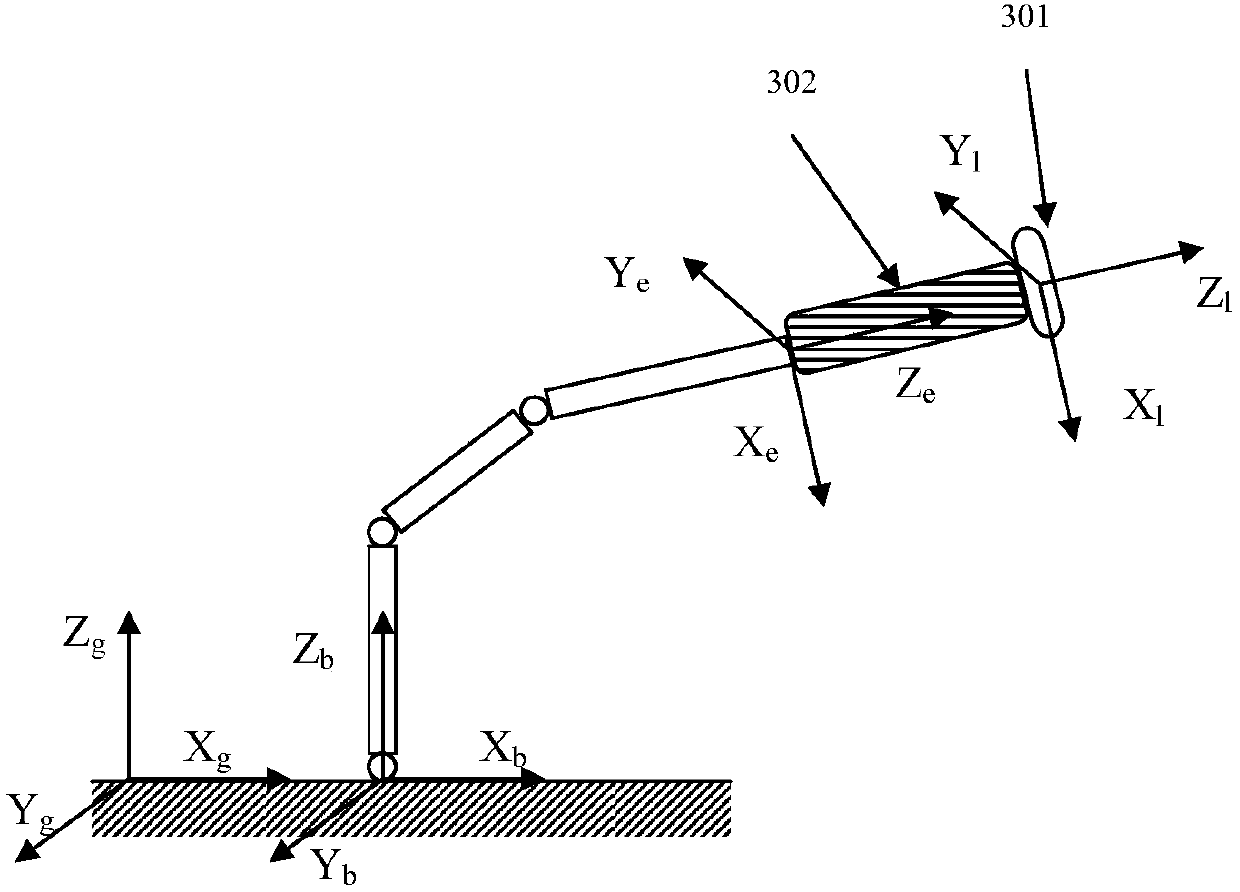

Force feedback man-machine interaction system and method based on electromagnetic theory and mobile tracking

InactiveCN108406725ASolve the problem of magnetic field attenuationKeep the relative position unchangedInput/output for user-computer interactionProgramme-controlled manipulatorInteraction systemsElectromagnetic theory

The invention provides a force feedback man-machine interaction system and method based on the electromagnetic theory and mobile tracking. By the adoption of the force feedback man-machine interactionsystem and method, a manipulator is allowed to use gestures to control a robot and meanwhile can feel force feedback in the operation process. The interaction system includes five parts of a local control calculator, a mobile tracking platform, a gesture recognition sensor, a magnetic force generating device and a magnetic force sensing device. The interaction method is divided into two parts ofcontrol and feedback. The control part uses the non-contact gesture based on a visual interface as control information, while the feedback part uses the non-contact force magnetic force as feedback information to reduce the physical limitation when interacting, meanwhile a mobile tracking function is added, and it is ensured that the magnetic force generating device and the magnetic force sensingdevice can keep relative positions and postures of the magnetic force generating device and the magnetic force sensing device unchanged, so that the problem of too little stress caused by the attenuation of a magnetic field is reduced.

Owner:SOUTH CHINA UNIV OF TECH

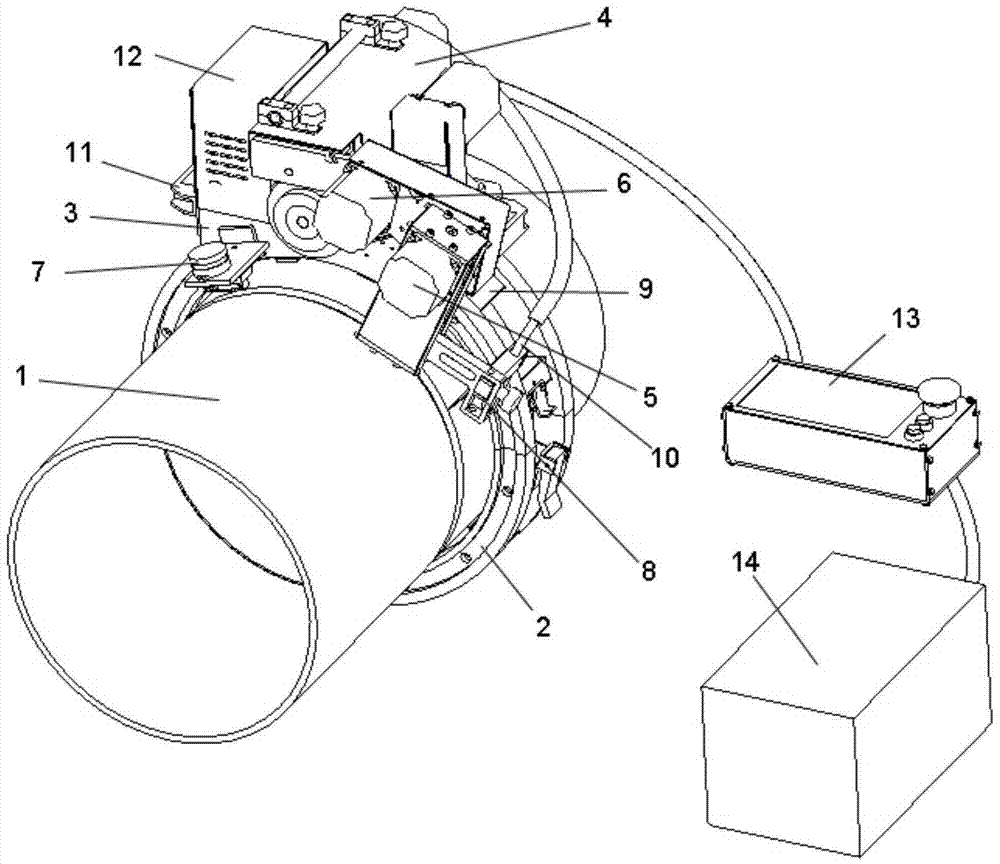

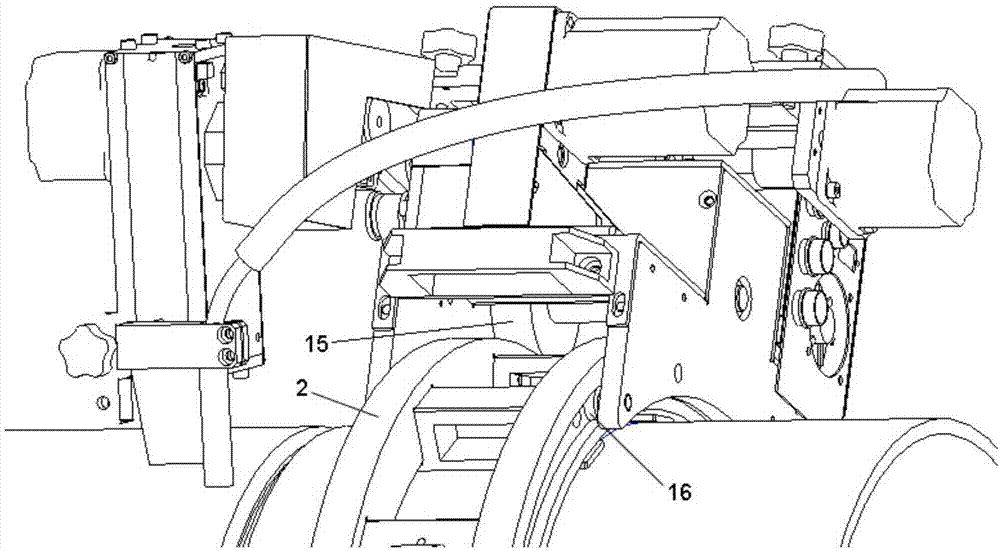

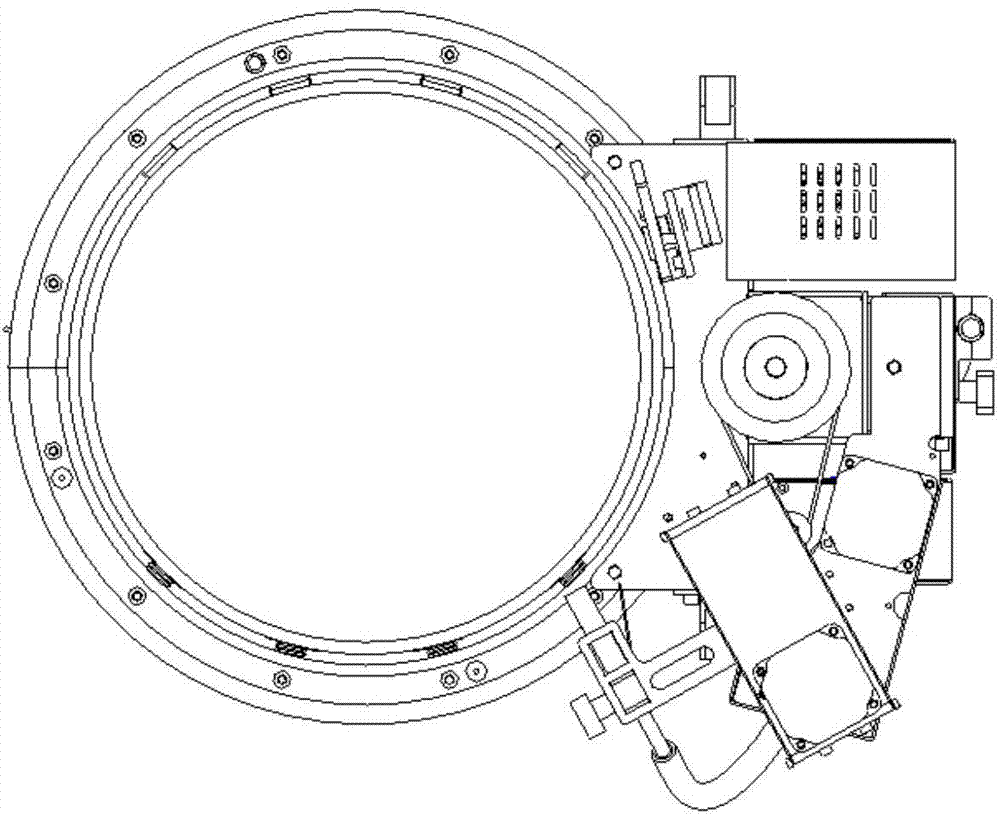

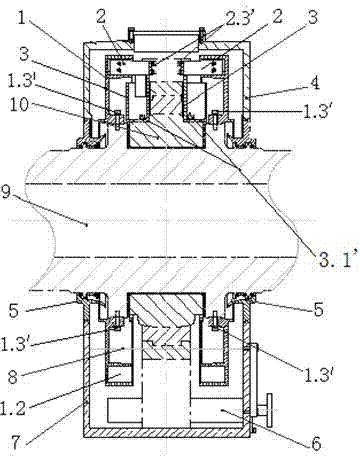

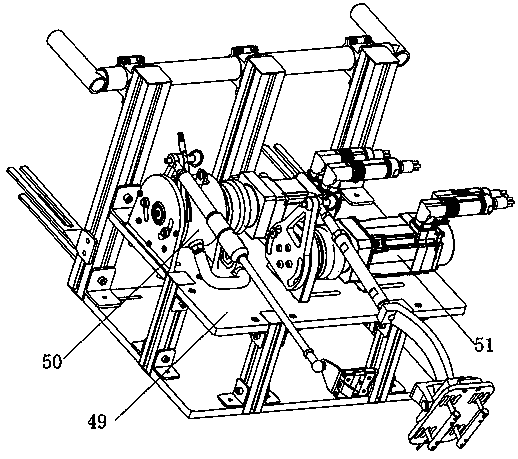

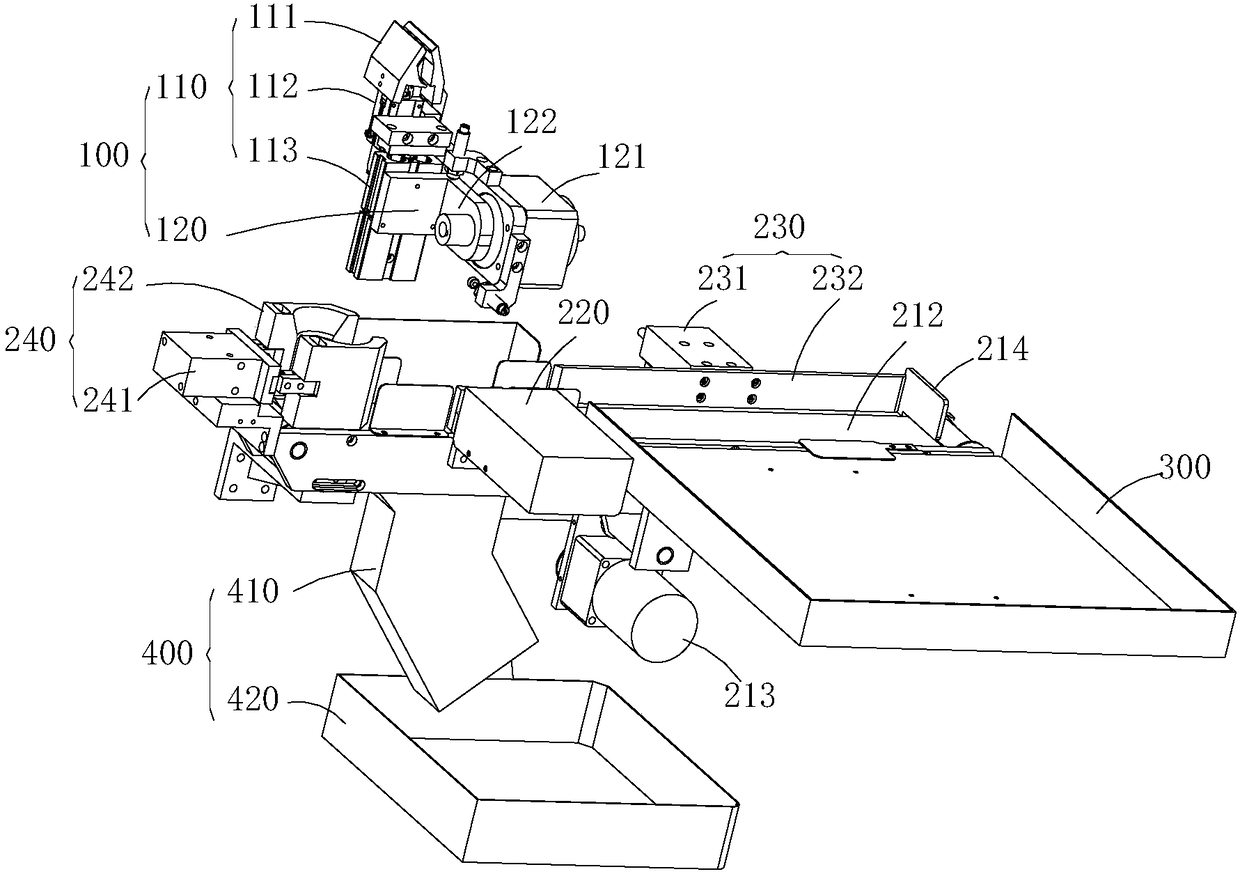

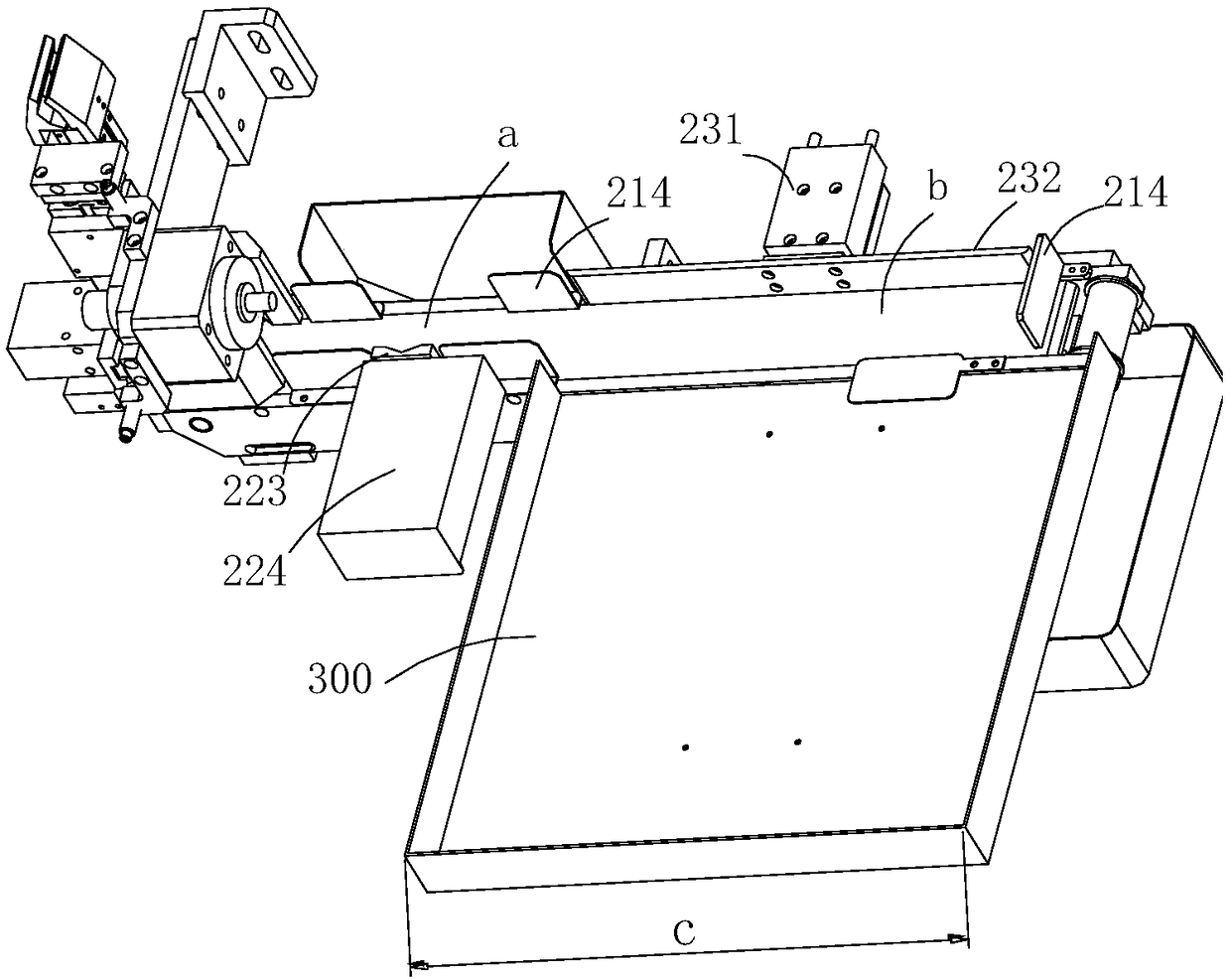

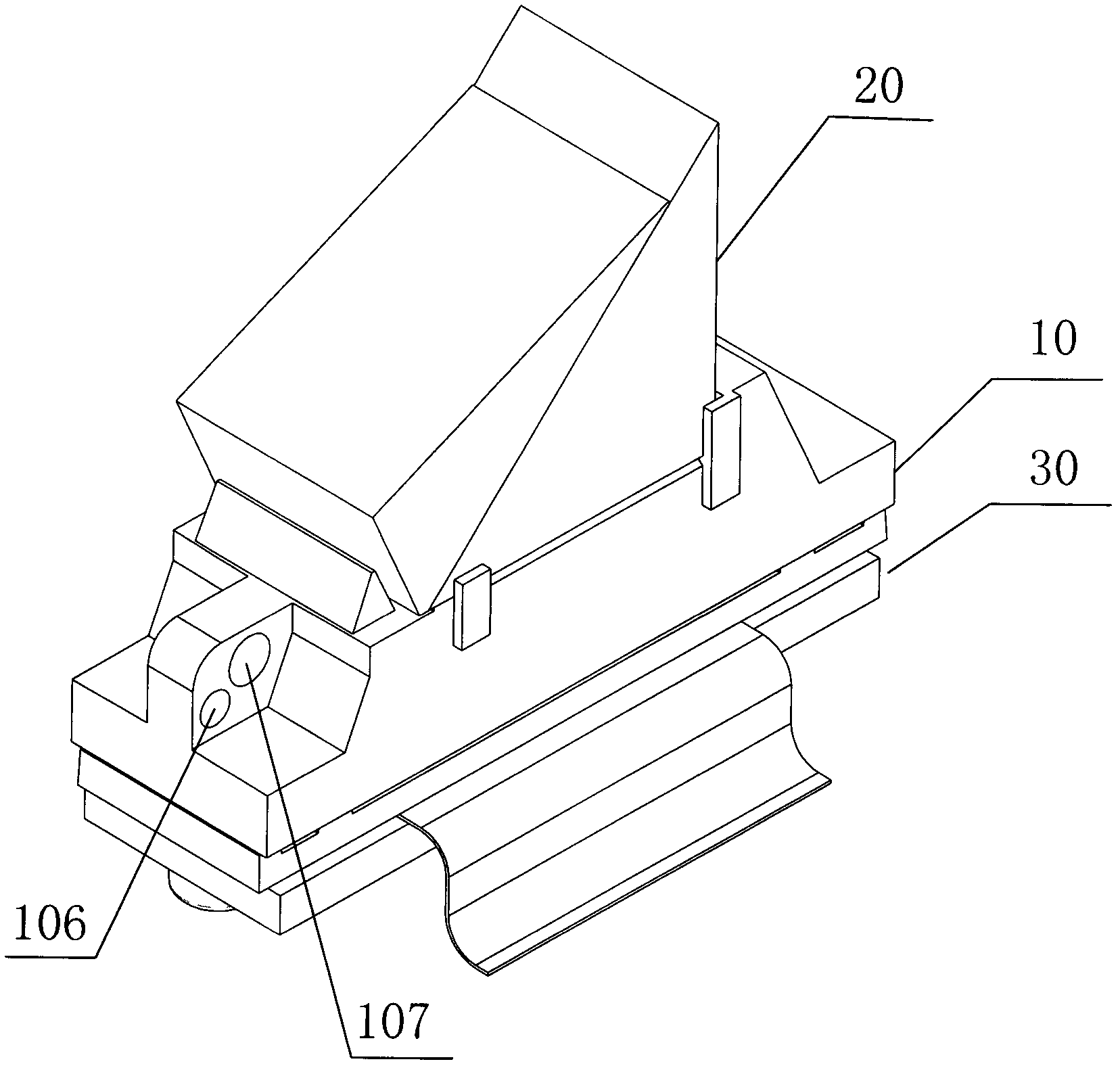

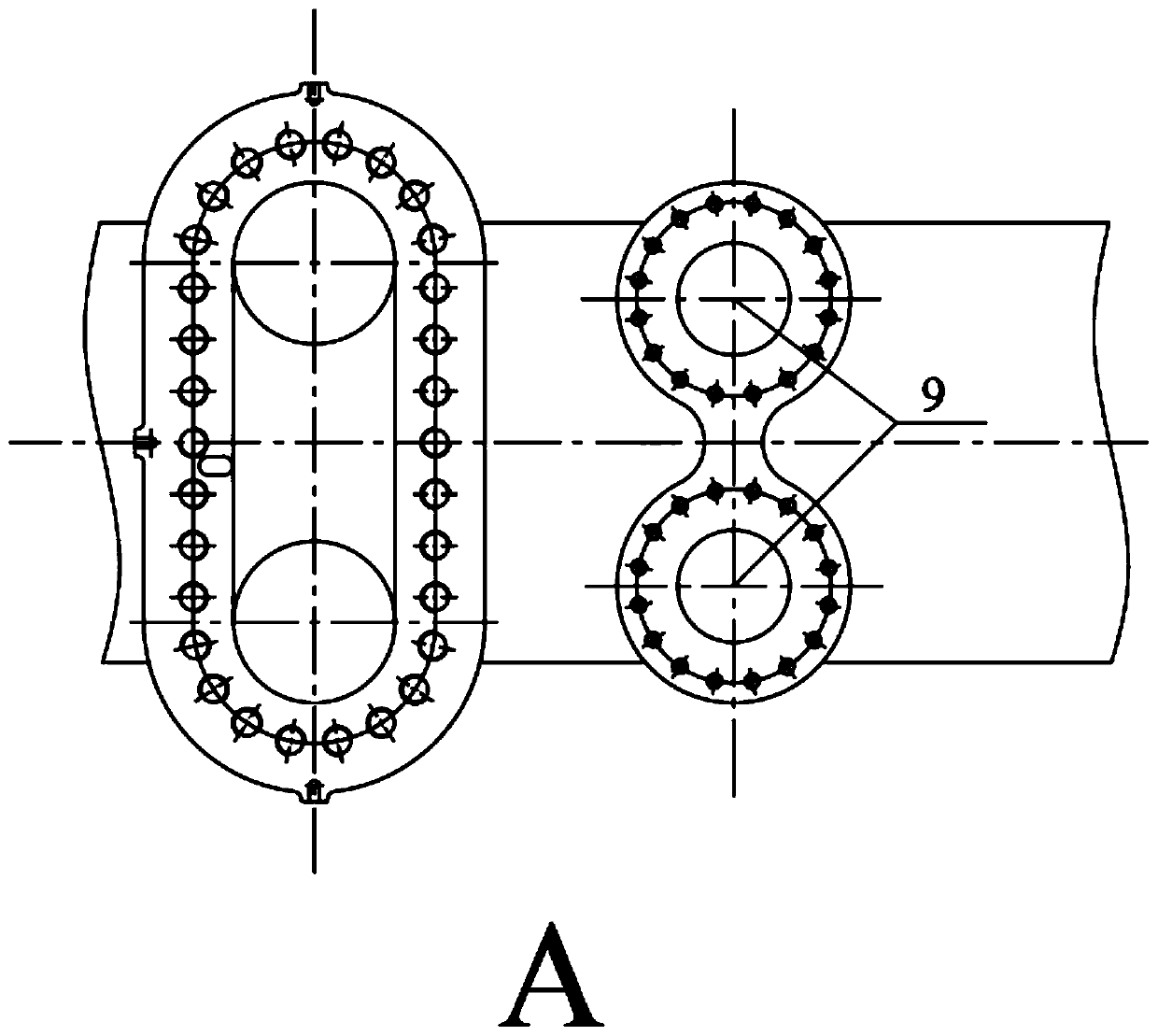

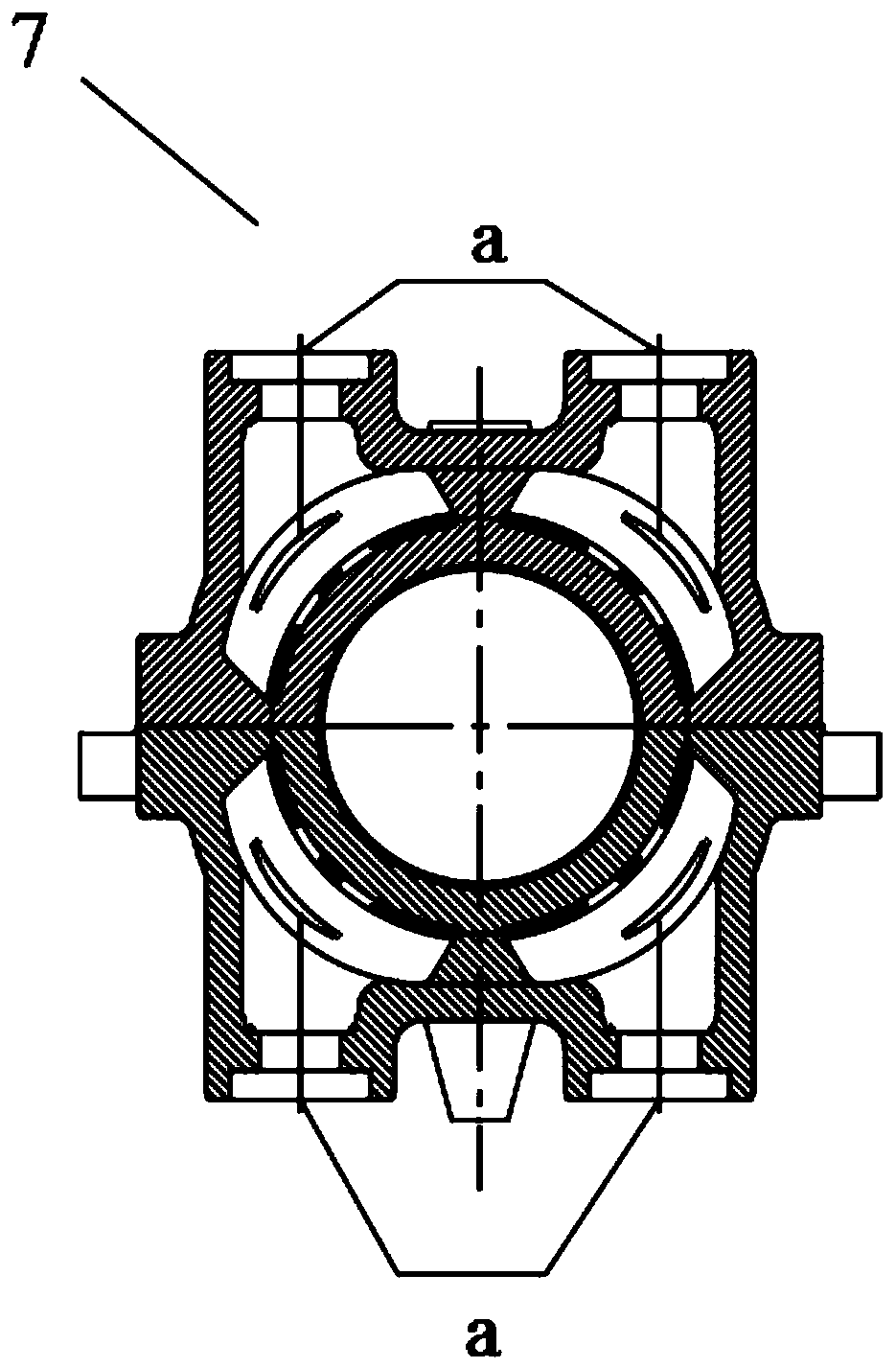

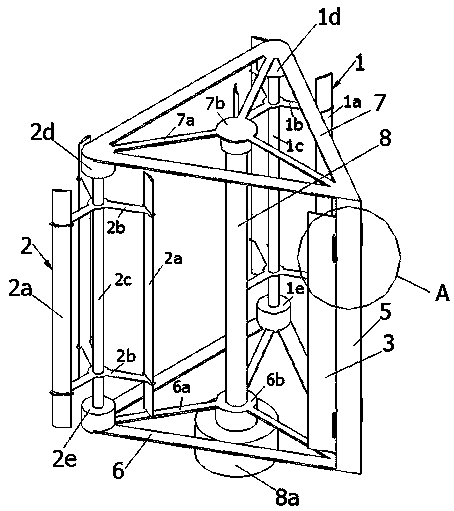

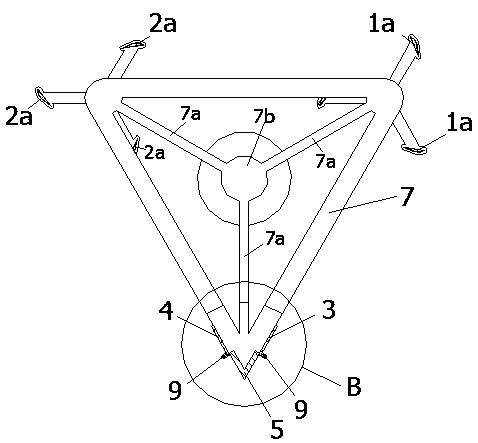

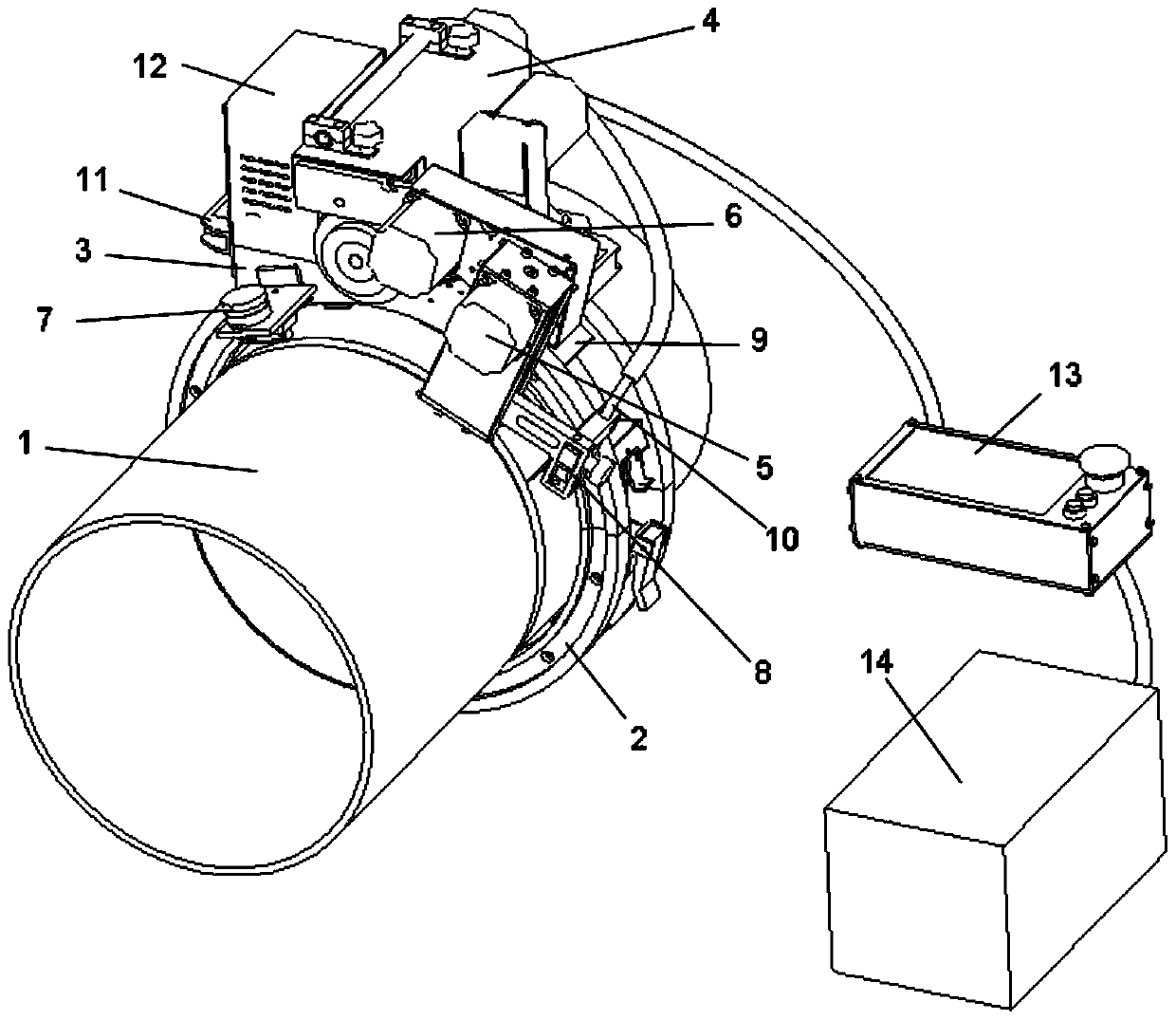

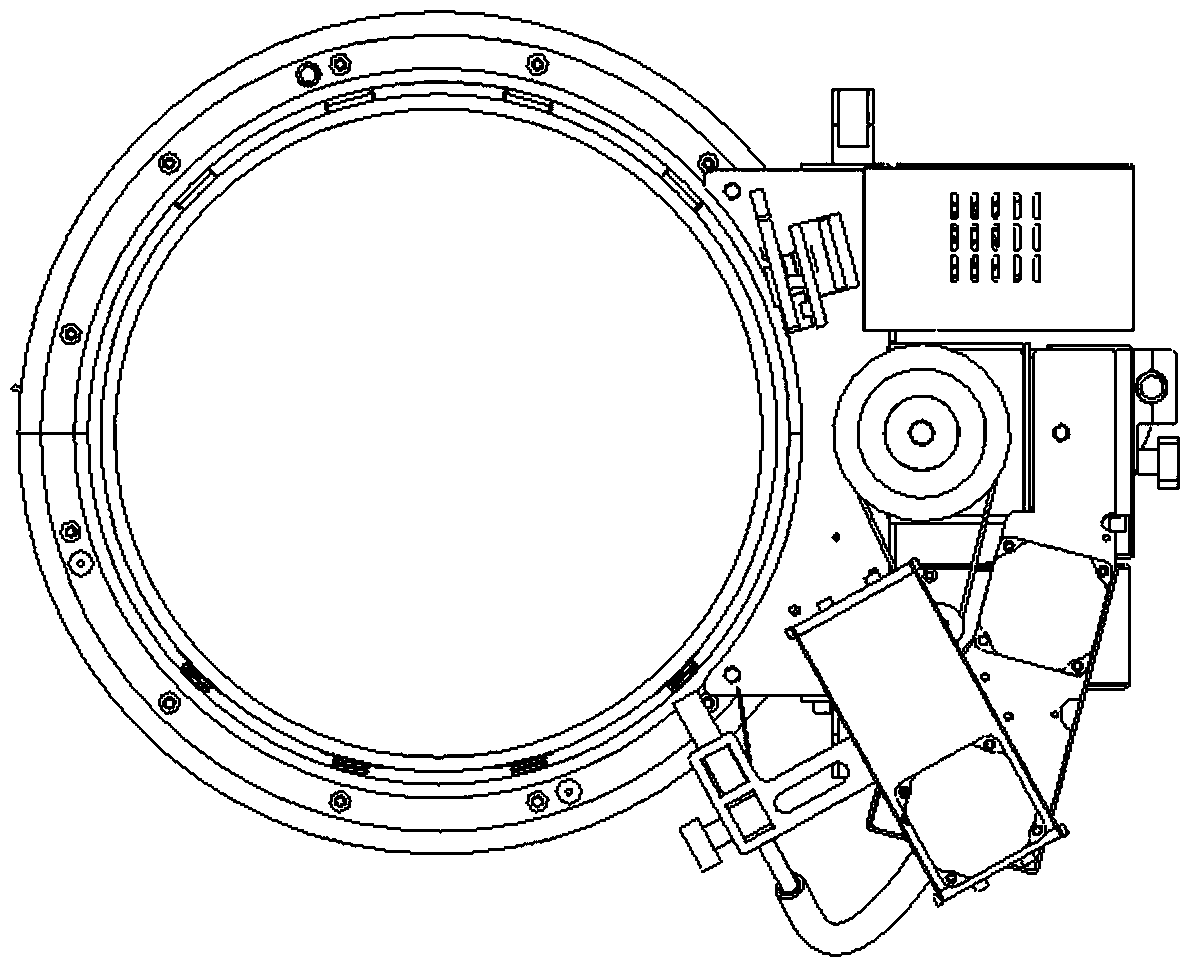

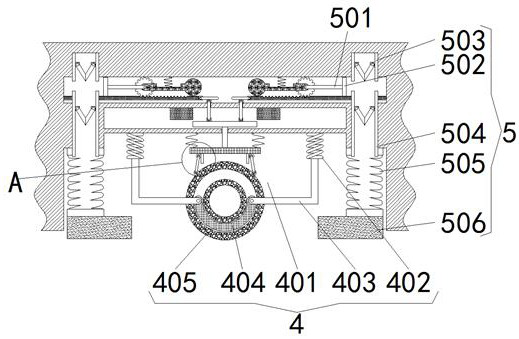

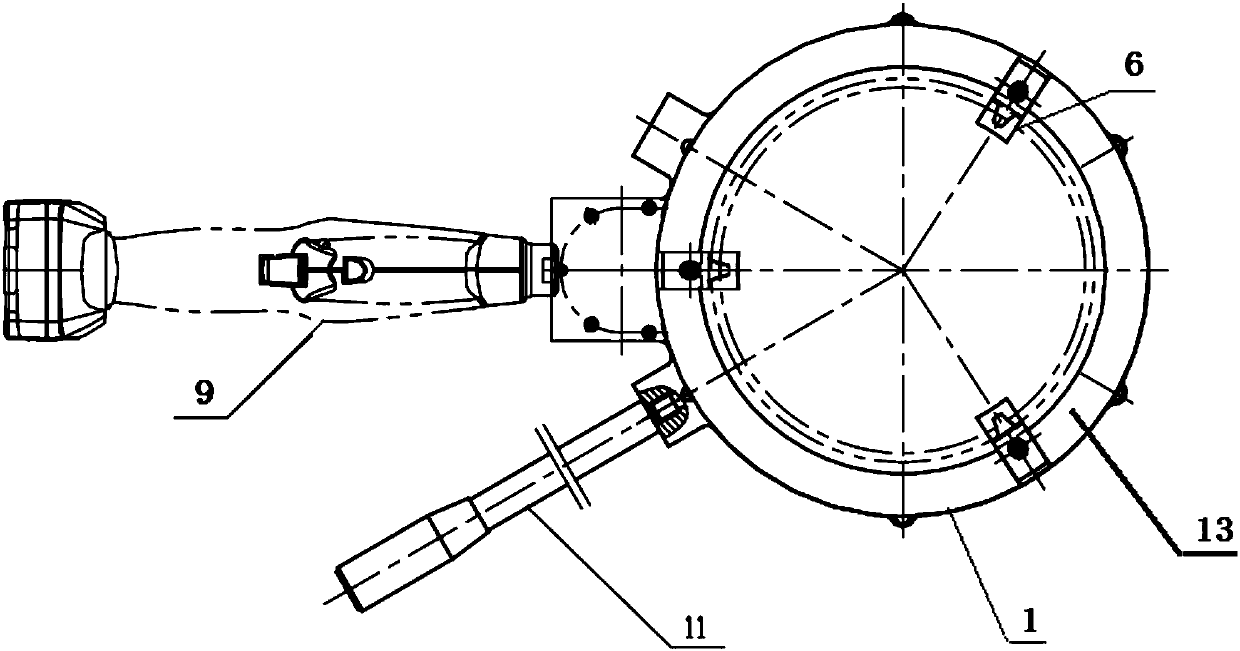

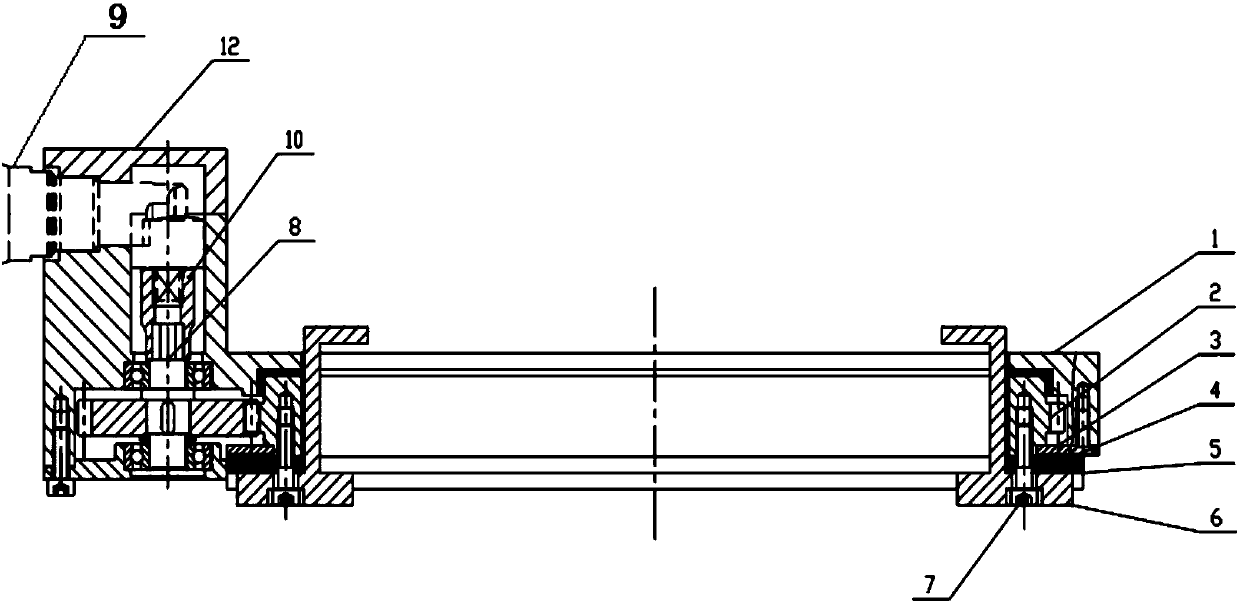

Pipeline all-position operation machine and control method thereof

ActiveCN104708220AFix workSolve quality problemsWelding/cutting auxillary devicesAuxillary welding devicesRadial motionIndependent motion

The invention belongs to the field of mechanical automation, and particularly relates to a pipeline all-position operation machine and control method thereof. The operation machine comprises a guide rail, a motion unit, an executive terminal, a driving unit and a control unit, wherein the motion unit conducts peripheral motion along the guide rail; one end of the motion unit is connected with the executive terminal; the output end of the control unit is connected with the input end of the driving unit; the output end of the driving unit is connected with a driving motor of the motion unit; the driving unit receives pulse signals sent out by the control unit and drives the driving motor of the motion unit to conduct corresponding motions; the motion unit comprises a peripheral motion mechanism, an axial motion mechanism, a radial motion mechanism and a swing mechanism which are capable of conducting independent motion driven by motors; the peripheral motion mechanism is provided with a scan mechanism. The operation machine has the function of automatically conducting pipeline cutting and welding, the defect of manual operation on irregular pipelines is overcome, and real-time detection and automatic adjustments are achieved.

Owner:深圳雷瑞智动机械设备有限公司

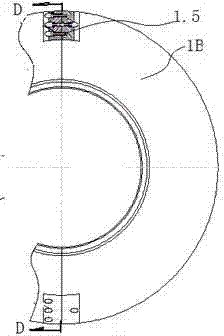

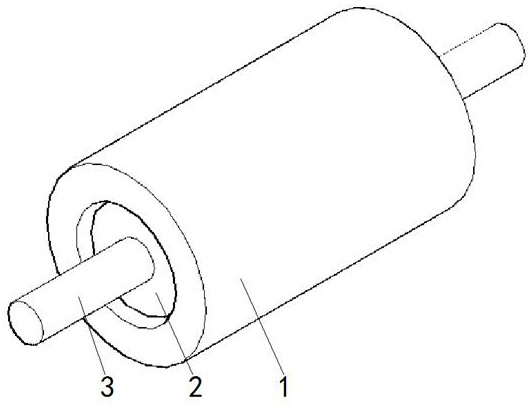

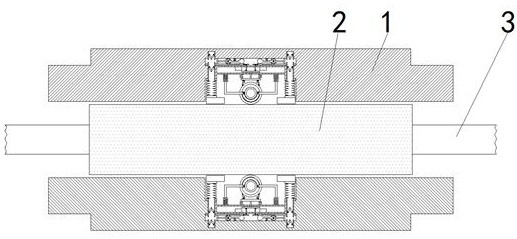

Contact mechanical oil carrying device for sliding bearing

ActiveCN102418833AAchieve regulationKeep the relative position unchangedLubrication elementsBearing unit rigid supportCircular discLow speed

The invention relates to a contact mechanical oil carrying device for a sliding bearing. The mechanical oil carrying device is suitable for propulsion motors and wind power generation equipment, particularly ship propulsion motors. The mechanical oil carrying device comprises an oil carrying disc, an oil scraping device and an oil receiving device; the oil carrying disc is a whole annular circular disc which is formed by combining two semi-rings; one end face of the annular circular disc is provided with an annular oil carrying groove; the oil carrying disc is fixedly connected with a rotation shaft; one end of a support of the oil scraping device is provided with an oil scraping plate, and the support is fixedly connected with the upper part of the oil receiving device; and the oil receiving device has a box shape, and the bottom of the oil receiving device is fixedly connected with the sliding bearing, namely the upper part of a bearing bush, and is also provided with an oil outlet which is communicated with an oil injection hole of the sliding bearing. The mechanical oil carrying device has an extremely excellent oil scraping effect, realizes the reliable lubrication of the bearing in high and low speed and an inclination state, has the advantages of compact and simple structure, high reliability, and the like, is convenient to maintain, radically solves the oil supply problem of a self-lubricating sliding bearing, and provides technical support for engineering application of a large-diameter self-lubricating sliding bearing.

Owner:武汉长海电力推进和化学电源有限公司

Rotational flow gas outlet structure for magnetic focusing hall thruster

InactiveCN108457827AExtended stayIncreasing the thicknessMachines/enginesUsing plasmaEngineeringIonization

The invention relates to a rotational flow gas outlet structure for a magnetic focusing hall thruster and belongs to the field of hall thrusters. The rotational flow gas outlet structure solves the problem of the poor ionization characteristic of an existing high-specific-impulse krypton working medium hall thruster. The rotational flow gas outlet structure comprises a top guide plate, a middle guide plate, a gas distributor base, an installation pillar, a gas guide tube, a discharge channel and a positive pole. The top guide plate, the middle guide plate and the gas distributor base are arranged in parallel from top to bottom and are fixedly connected to form a primary buffer chamber and a secondary buffer chamber in a laser welding manner. The primary buffer chamber and the secondary buffer chamber are coaxially arranged in the discharge channel, and the top guide plate guides neutral gas through inclined holes to rotate in the discharge channel. The positive pole is arranged on theportion, close to the top guide plate, inside the discharge channel. The gas guide tube and the installation pillar are welded to both sides of the bottom of a gas distributor. By the adoption of therotational flow gas outlet structure, the utilization rate of a working medium is increased effectively, and especially the effect on the improvement of the ionization performance of the krypton working medium is outstanding.

Owner:HARBIN INST OF TECH

Automatic driving robot for indoor rotating hub test

ActiveCN111220396AImprove general performanceReal-time temperature monitoringVehicle testingManipulatorControl theoryMechanical engineering

The invention relates to an automatic driving robot for an indoor rotating hub test. The robot comprises an adjustable base, an accelerator pedal robot and a brake pedal robot, wherein the acceleratorpedal robot and the brake pedal robot are arranged on the adjustable base side by side; the accelerator pedal robot comprises an accelerator pedal clamping device, an accelerator pedal executing mechanism and an accelerator pedal power mechanism. The accelerator pedal executing mechanism comprises a telescopic rod and a hollow connector, wherein the telescopic rod is movably mounted in the hollowconnector; one end of the hollow connector is in threaded connection with an expansion sleeve assembly; one end of the telescopic rod penetrates through the expansion sleeve assembly to be connectedwith the accelerator pedal clamping device, and the other end of the hollow connector is sleeved with a guide connector; one end of the guide connector is connected with an iron connector, a magnet isinstalled at the other end of the hollow connector, one end of the guide connector is rotationally connected with an accelerator rocker arm, and the accelerator rocker arm is connected with an accelerator pedal power mechanism. The robot is high in cost performance, high in environment adaptability, safe, reliable and wide in application range.

Owner:CATARC AUTOMOTIVE QUALITY INSPECTION CENT NINGBO

Rice processing equipment

ActiveCN108043491APrevent containingKeep the relative position unchangedGrain huskingGrain polishingTransverse planeBroken rice

The invention relates to rice processing equipment. The rice processing equipment comprises an outer cylinder and an inner cylinder, and an annular cavity is formed between the inner cylinder and theouter cylinder; a transverse filter plate is inserted in the cavity; a first cavity body is formed above the filter plate and internally provided with a first negative pressure fan connected to the outer wall of the inner cylinder, and a bran shell recycling box is arranged on the outer side of the first cavity body; a second cavity body is formed below the filter plate, a discharging opening is formed in the bottom of the second cavity body, and inner polishing pellets and outer polishing pellets are arranged in the second cavity body; a third cavity body is formed in the inner cylinder, anda vertical rod penetrates through the interior of the third cavity body; the bottom end of the vertical rod is connected with a motor, and the top end of the vertical rod is connected with a transverse plate; the vertical rod is connected with a second negative pressure fan; an inner gear ring is arranged between the transverse plate and the outer cylinder, and a vertical rotating shaft is rotatably arranged on the transverse plate; the rotating shaft is connected with a straight gear engaged with the inner gear ring, and the bottom of the rotating shaft is rotatably connected with a transverse shaft; and one end of the transverse shaft is connected with a third negative pressure fan. According to the scheme, both bran shells and broken rice are prevented from entering the bran shell recycling box, and thus the bran shells and the broken rice are separated.

Owner:重庆市合川区云天食品科技有限公司

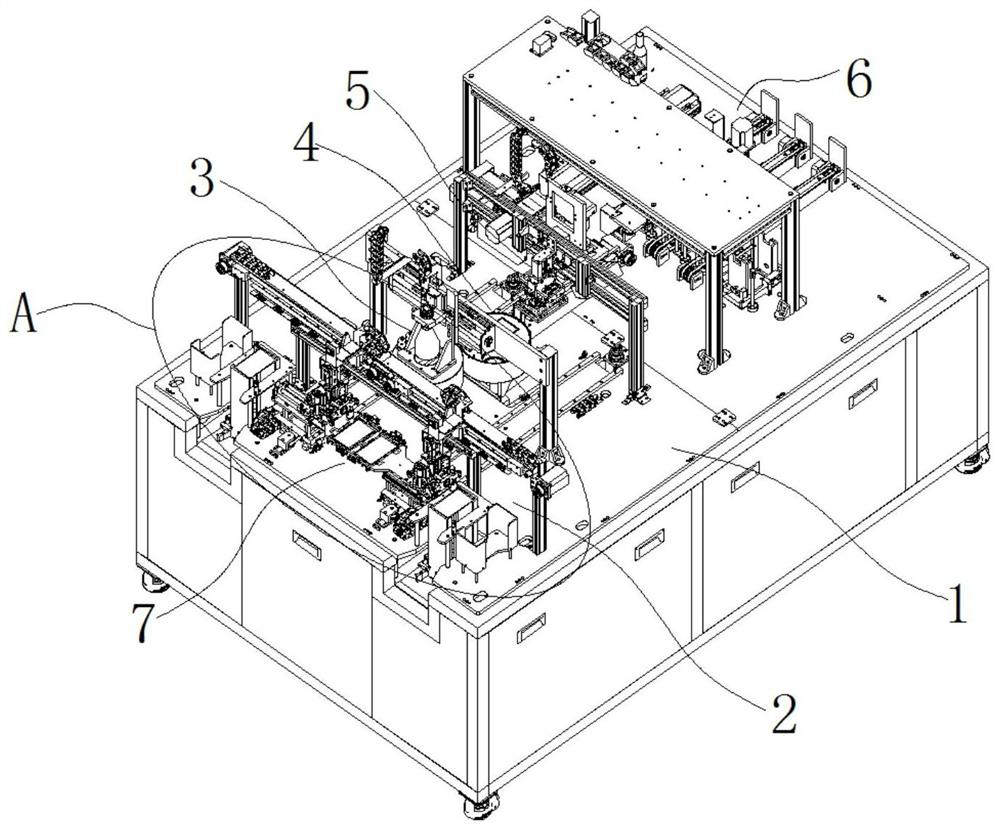

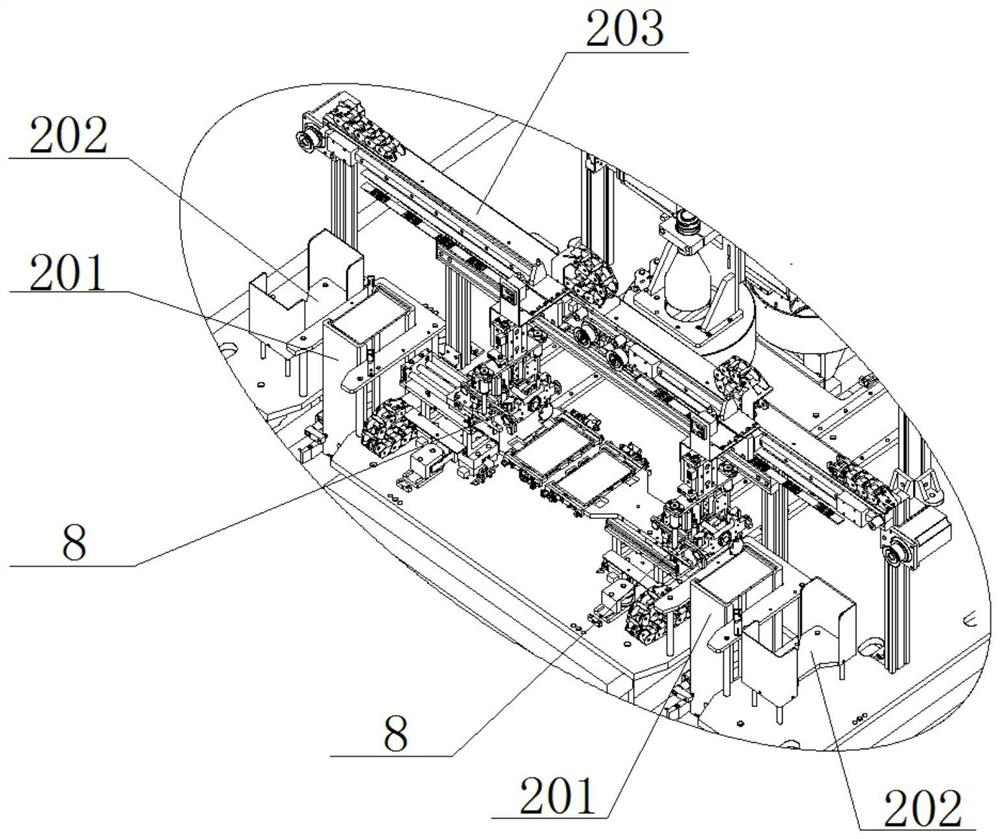

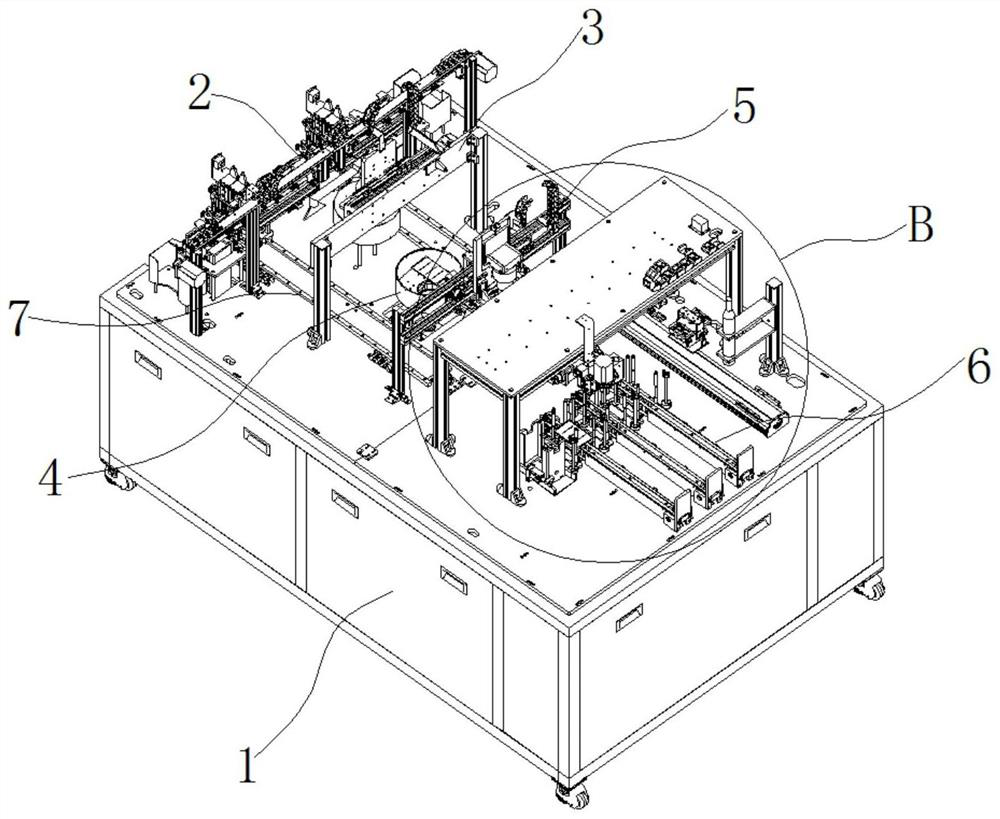

Testing method of LED frame products

PendingCN112147150AReduce labor intensityKeep the relative position unchangedOptically investigating flaws/contaminationUsing optical meansProduct testingProcess engineering

The invention discloses a testing method of LED frame products. The testing method adopts an LED frame product testing system for testing, and comprises the following steps that two material frame bins filled with materials are respectively placed in two material frame lifting mechanisms for feeding, and separation paper is laid between adjacent material frame products; grabbing mechanisms grab and convey the material frame products in the material frame lifting mechanisms correspondingly below the grabbing mechanisms into conveying devices to be conveyed and suck and convey the separation paper into a separation paper storage mechanism of a feeding device, and the two grabbing mechanisms work alternately in sequence; the two conveying devices alternately work in sequence to convey the material frame products, and in the conveying process of the material frame products, the material frame products sequentially pass through a first optical detection device, a second optical detection device and a third optical detection device to be subjected to multiple times of optical detection; and a material receiving device is used for classifying, stacking and collecting the material frame products subjected to optical detection. The testing method of LED frame products has the advantages of being high in automation degree, accurate in test result, and capable of reducing the labor intensity of workers, improving the working efficiency and improving the product yield.

Owner:江阴新基电子设备有限公司

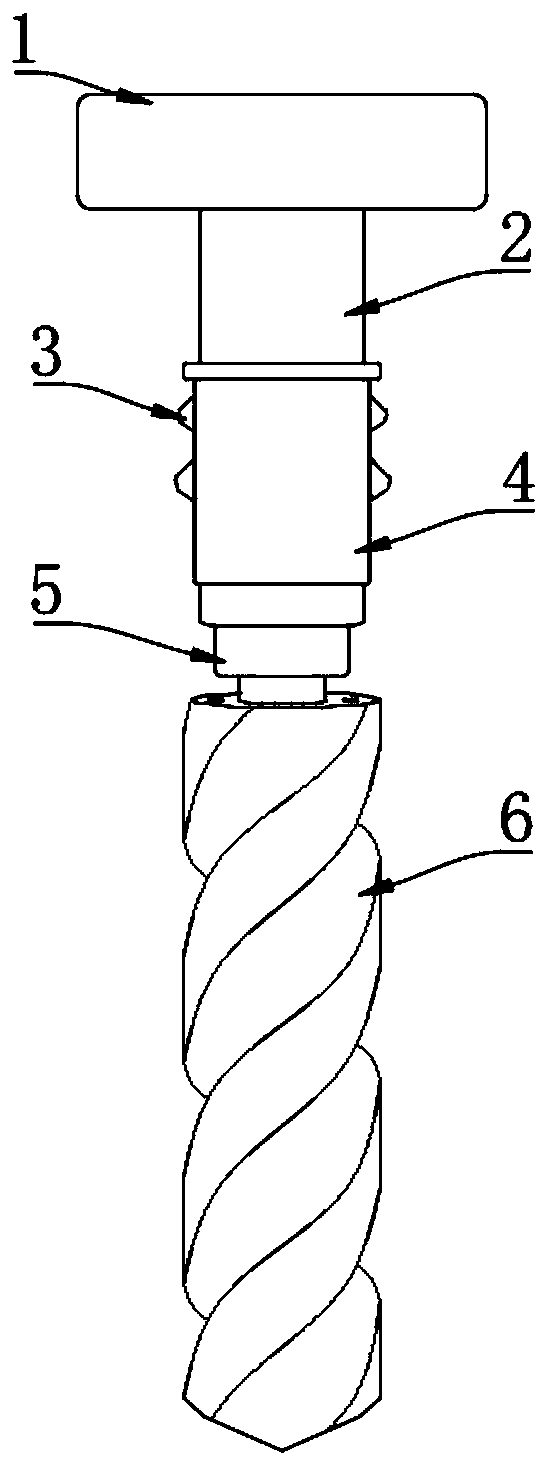

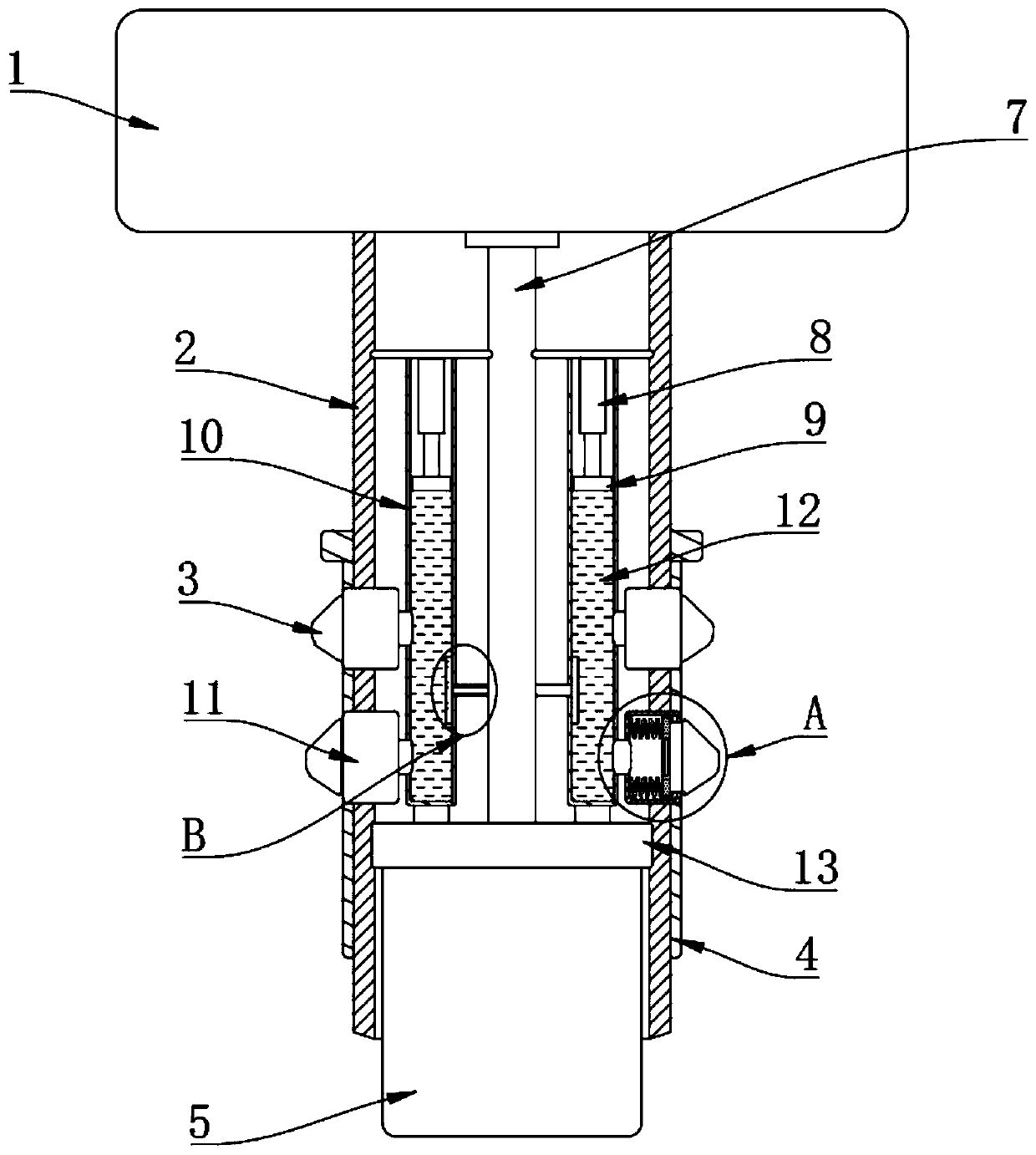

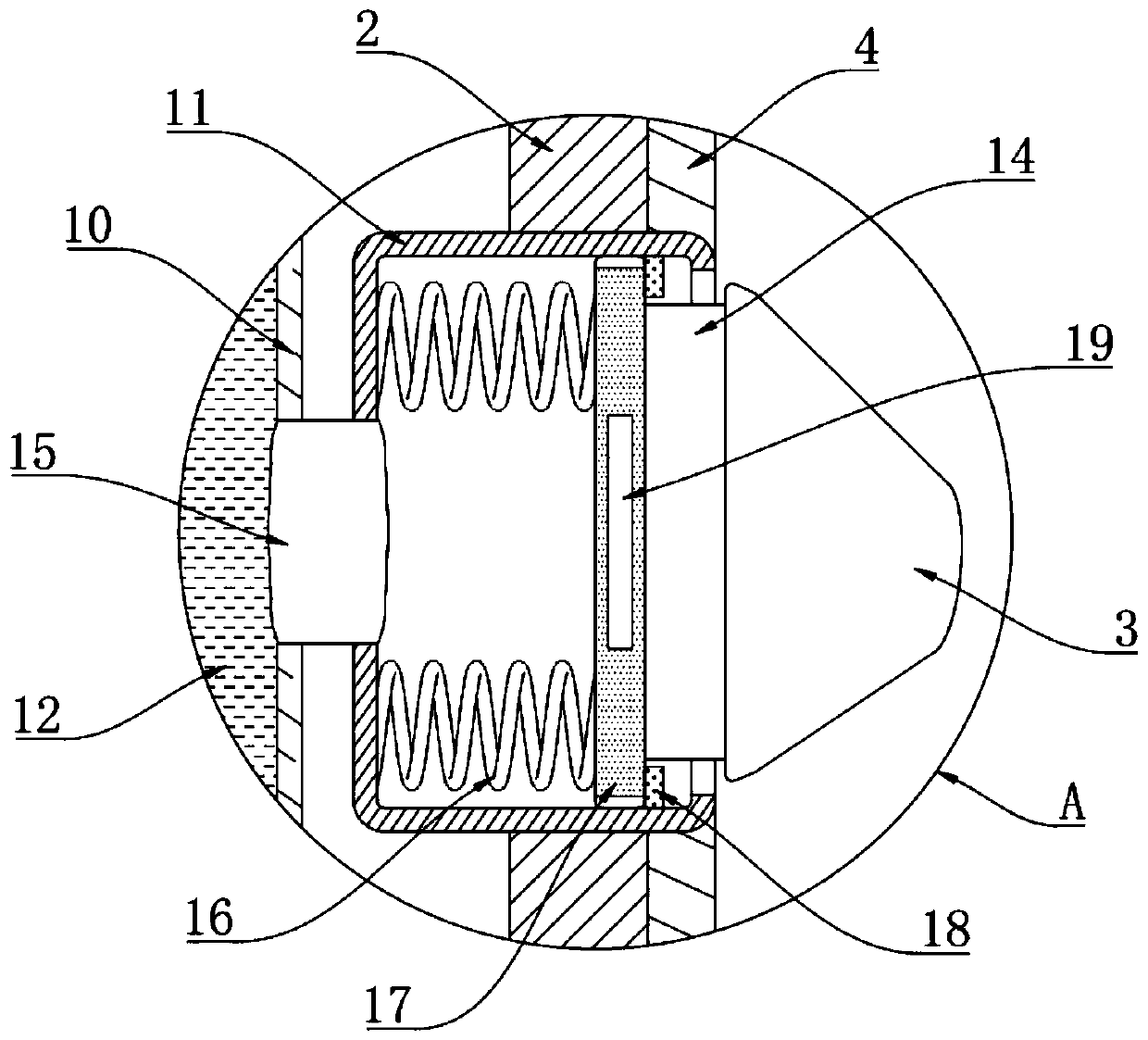

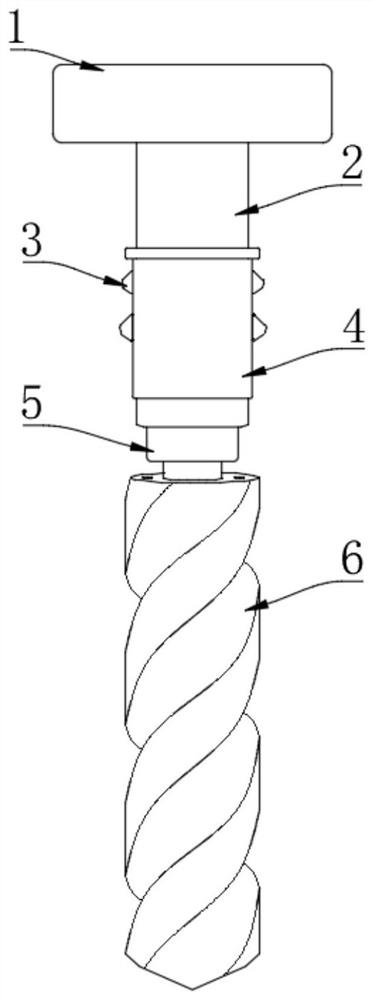

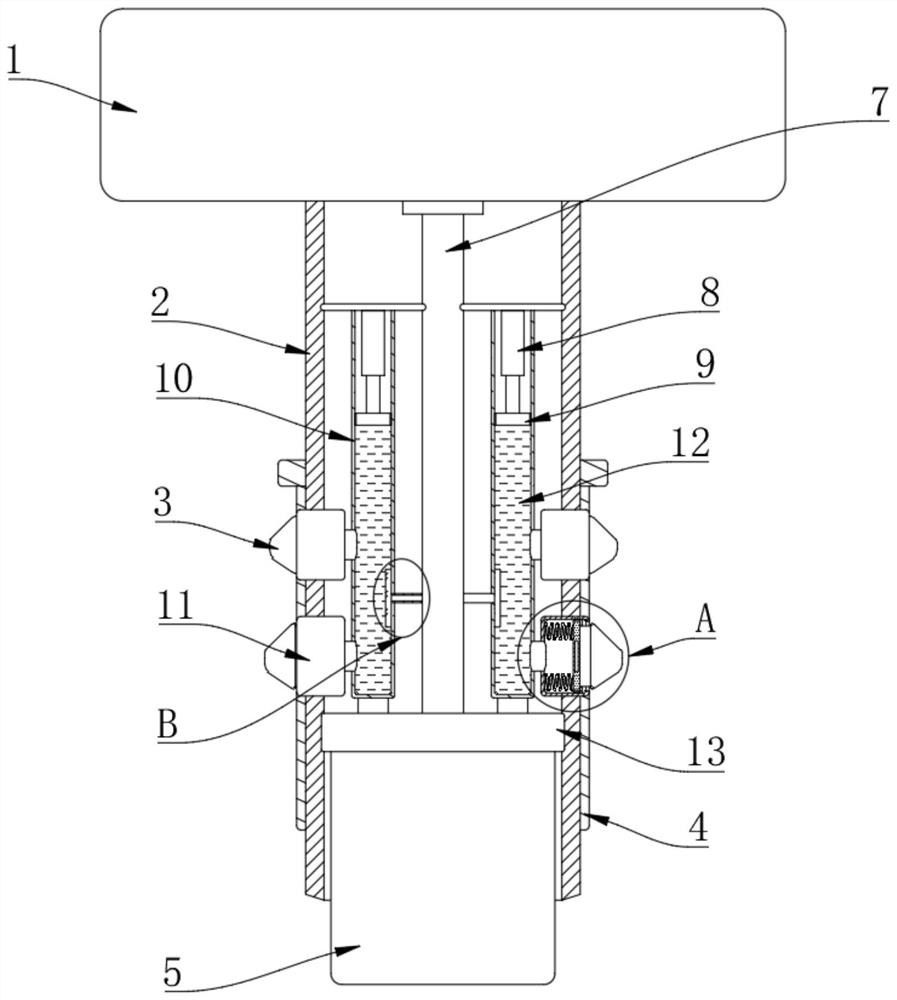

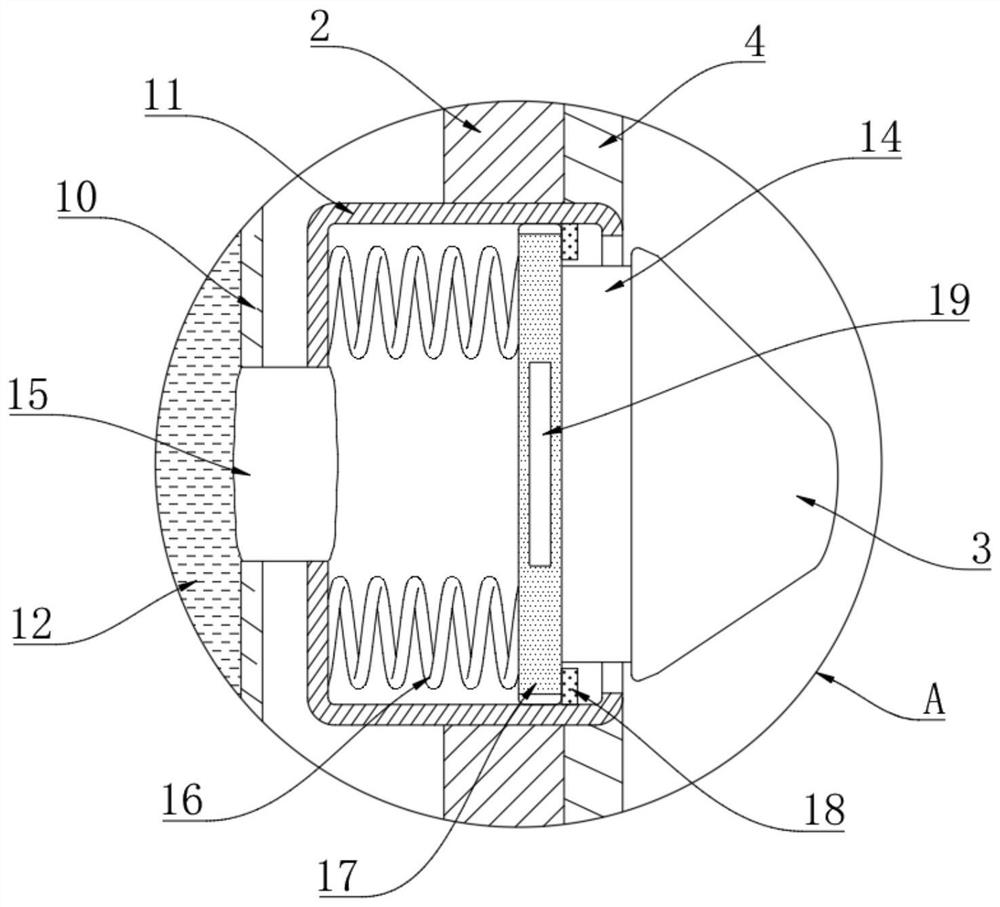

Drilling and chamfering integrated device for steel pipe machining

ActiveCN110860725AAvoid being affected by centrifugal forceReduce forceTransportation and packagingMeasurement/indication equipmentsSteel tubeDrill hole

The invention discloses a drilling and chamfering integrated device for steel pipe machining. The device comprises a knife holder and an inner ring sleeve. The lower end of the inner ring sleeve is provided with a drill bit through a fixed base, a hollow column and multiple insulation cylinders are fixedly mounted between the fixed base and the knife holder, a conductive bar is connected between the hollow column and each insulation cylinder, a pressurizing mechanism is arranged in each insulation cylinder, multiple knife returning boxes are symmetrically mounted on the side wall of the innerring sleeve, reset mechanisms are arranged in the knife returning boxes, an electromagnetic valve is arranged between each knife returning box and the corresponding insulation cylinder, and the side wall, away from the hollow column, of each knife returning box is slidingly provided with a chamfering knife in a penetrating manner. The device can be used for a drilling and chamfering device for conventional steel pipe machining to be used, in the chamfering process, according to actual machining needs, chamfering knives of different specifications can be rapidly replaced, knife retreating, replacing, aligning and other tedious operation are not needed, and the machining precision and the machining efficiency are further improved.

Owner:武义威进科技有限公司

Capacitor electric core placing device

PendingCN108217186AKeep the relative position unchangedIncrease productivityConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to a capacitor electric core placing device. The capacitor electric core placing device comprises a clamping mechanism, a conveying control mechanism, a qualified product holdingmechanism and an unqualified product holding mechanism. The clamping mechanism places electric cores obtained after winding onto the conveying control mechanism. The unqualified product holding mechanism is connected with the structure, located on a first conveying portion, of the conveying control mechanism, and the qualified product holding mechanism is connected with the structure, located ona second conveying portion, of the conveying control mechanism. The extending direction of the qualified product holding mechanism is perpendicular to the conveying direction of the conveying controlmechanism. After receiving the electric cores, the conveying control mechanism places the unqualified electric cores into the unqualified product holding mechanism and conveys the qualified electric cores to the second conveying portion in sequence; and after the second conveying portion is full of the electric cores, the conveying control mechanism simultaneously pushes the electric cores on thesecond conveying portion into the qualified product holding mechanism in the direction perpendicular to the conveying direction, and the relative positions of all the electric cores are kept unchanged. The capacitor electric core placing device can improve production efficiency.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

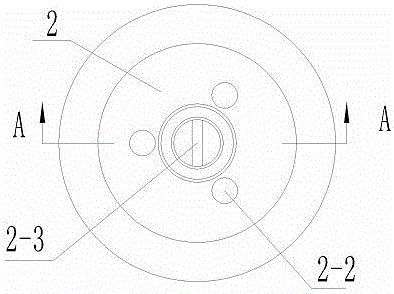

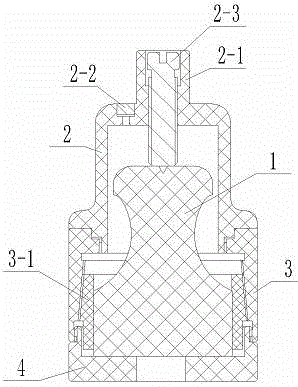

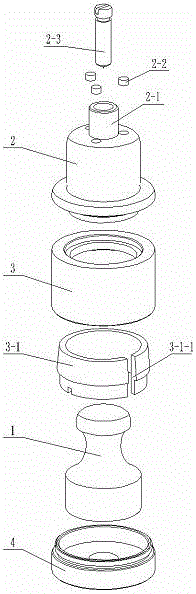

Seal clamping device for sealing machine

ActiveCN105082799AMeet clamping and fixing needsRealize one machine with multiple functionsStampingContraction jointMagnet

The invention discloses a seal clamping device for a sealing machine and belongs to the field of office equipment. The seal clamping device structurally comprises a positioning nut matched with a rack, and a seal positioning mechanism fixedly connected with the positioning nut. The seal clamping device is characterized in that magnets are arranged at the upper end of the positioning nut to serve alignment connecting pieces; the seal positioning mechanism comprises a conical inner thread fixing sleeve and a conical outer thread opening and closing lock sleeve matched with a conical inner thread; an inner body of the conical outer thread opening and closing lock sleeve is matched with an outer body of a positioning seal body; and the seal positioning mechanism is positioned at the lower end of the positioning nut through a threaded structure. Due to the fact that the conical outer thread opening and closing lock sleeve with different inner locking cavity shapes is designed for adapting to replacement of round, square and even elliptical seals, and in addition, the conical shape and the design of a contraction joint of the conical outer thread opening and closing lock sleeve are used for meeting the requirement for clamping and fixing of seals of the same kind and different specifications, and thus the seal clamping device can have multiple purposes.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

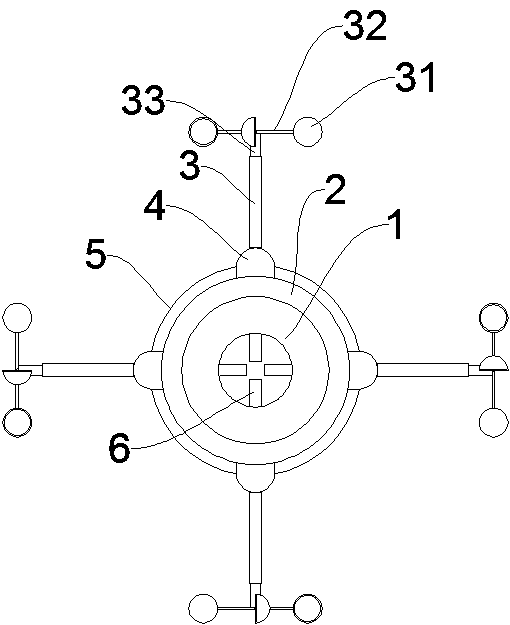

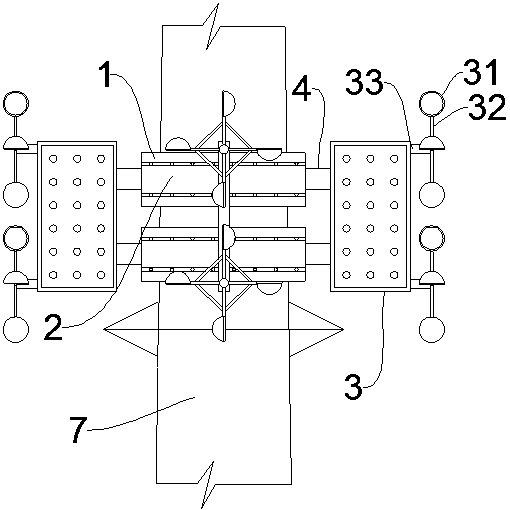

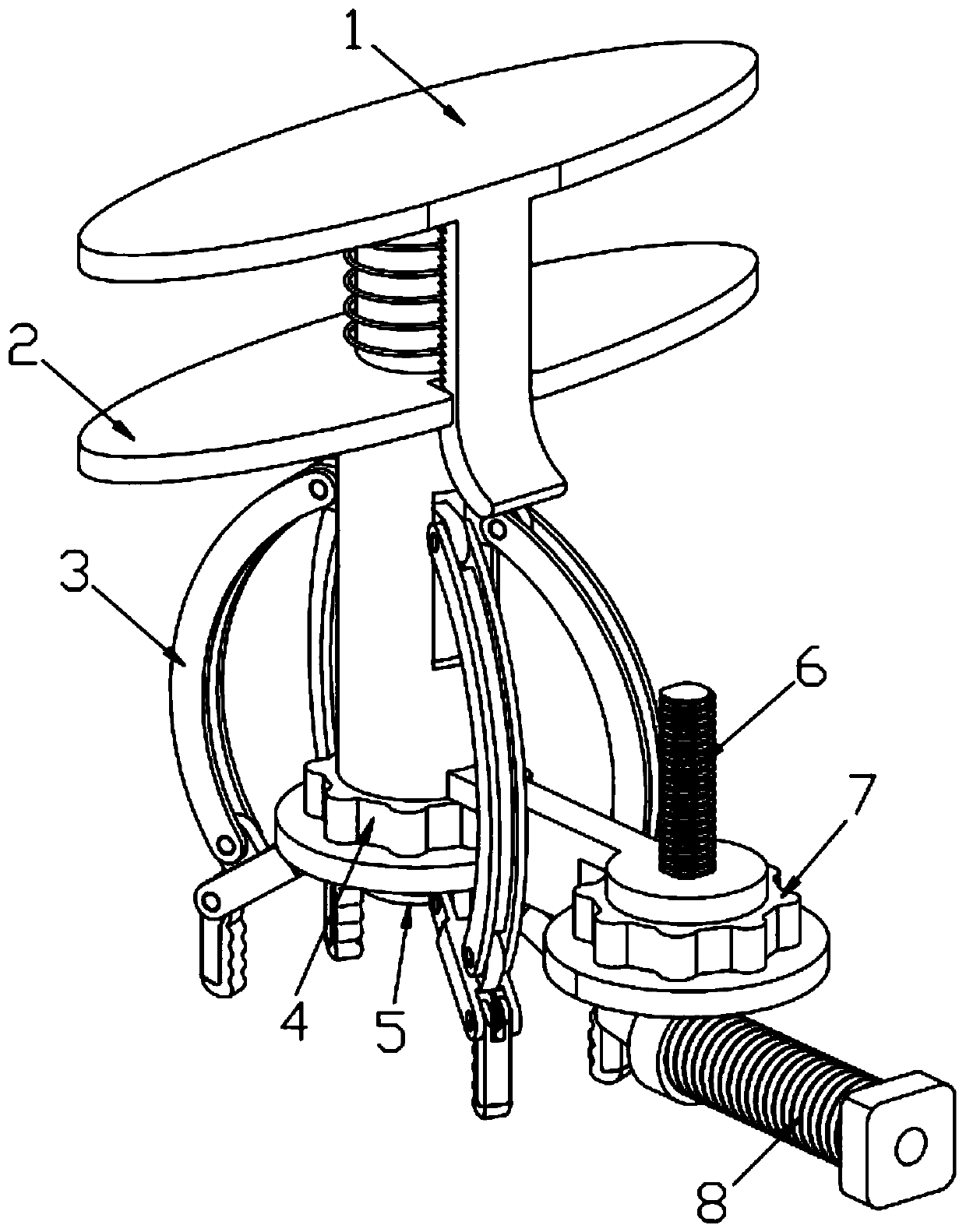

Double-spin vortex breaking device for inhibiting vortex-induced vibration of steel tube high-rise structure

The invention provides a double-spin vortex breaking device for inhibiting vortex-induced vibration of a steel tube high-rise structure. The device comprises two annular bases which are arranged parallelly and vertically, and the outer wall of each base is rotationally sleeved with an annular rotating arm; the outer wall of each rotating arm is fixedly provided with four connecting arms, and the connecting arms are arranged uniformly around the axes of the rotating arms; the upper and lower bases are fixedly connected through rectangular plates, one edges of the rectangular plates are fixedlyconnected with the connecting arms of the upper and lower bases, the corresponding other edges of the rectangular plates are provided with two rotating rods, and the two rotating rods are parallel tothe connecting arms; one ends, away from the rectangular plates, of the rotating rods are rotationally provided with connecting rods, and the other ends of the connecting rods are fixedly provided with four hemispherical shell-shaped wind cups respectively. In short, the double-spin vortex breaking device has the advantages that the vortex-induced vibration of the steel tube high-rise structure generated in the transverse wind direction is inhibited, the safety of the steel tube high-rise structure is improved, and the economic loss is reduced.

Owner:ZHENGZHOU UNIV

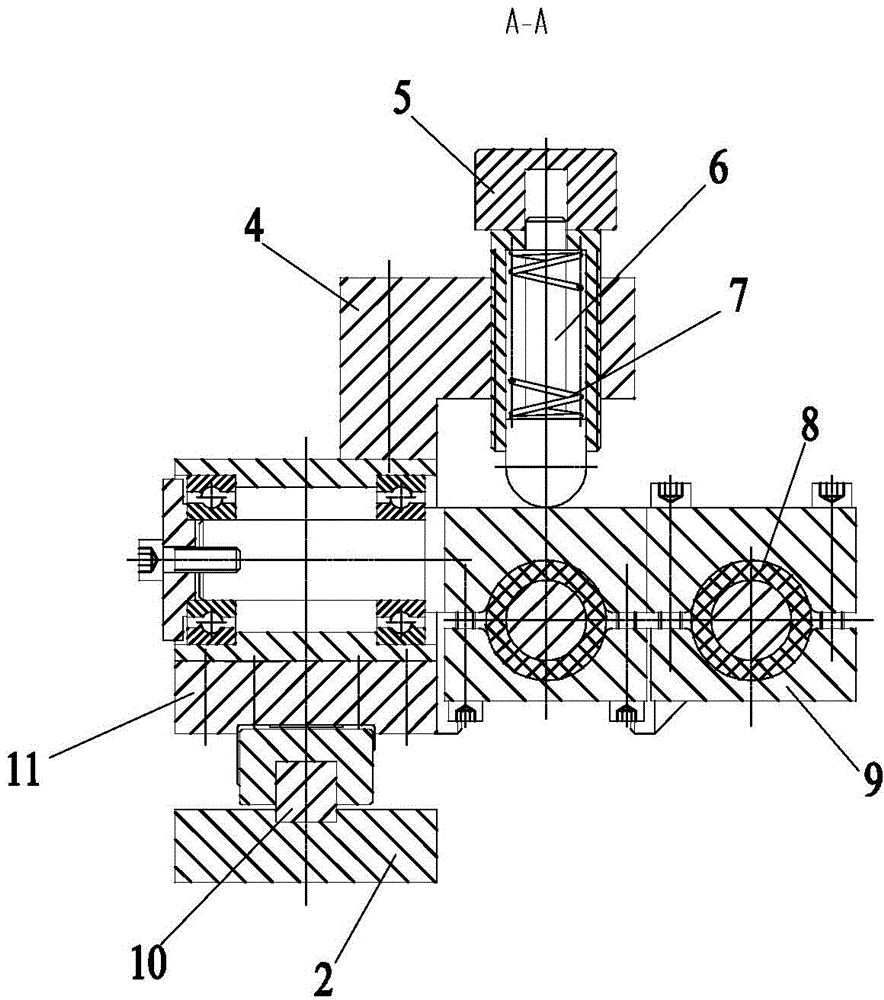

Welding gun adjusting mechanism

ActiveCN104439811ASimple structureReasonable designWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSlide plate

The invention belongs to the technical field of welding equipment and relates to a welding gun adjusting mechanism. The welding gun adjusting mechanism comprises a mounting seat, an adjusting air cylinder is fixed on a side plate of the mounting seat, sliding rails are arranged on the upper surface of the mounting seat, a sliding plate is slidably connected to the sliding rails, the top of the sliding plate is connected with a welding gun fixing seat, a guide shaft and a welding gun are arranged on the welding gun fixing seat, insulating bushes are arranged among the guide shaft, the welding gun and the welding gun fixing seat, a fixing block is arranged on the welding gun fixing seat, adjusting handles are connected on the fixing block in a threaded manner, a spring seat is arranged in a shaft hole of each adjusting handle, and a compression spring is arranged on each spring seat. The welding gun adjusting mechanism has the advantages that the welding gun adjusting mechanism is simple in structure, and during operation, the welding gun fixing seat and the welding gun are driven to move back and forth on the mounting seat by the adjusting air cylinder according to practical situations, so that horizontal position movement is achieved; in the vertical direction, the compression spring compresses guide wheels between an H-beam flange plate and a web plate, so that relative positions between the welding gun and the H-beam flange plate as well as between the welding gun and the web plate are not changed.

Owner:无锡洲翔成套焊接设备有限公司

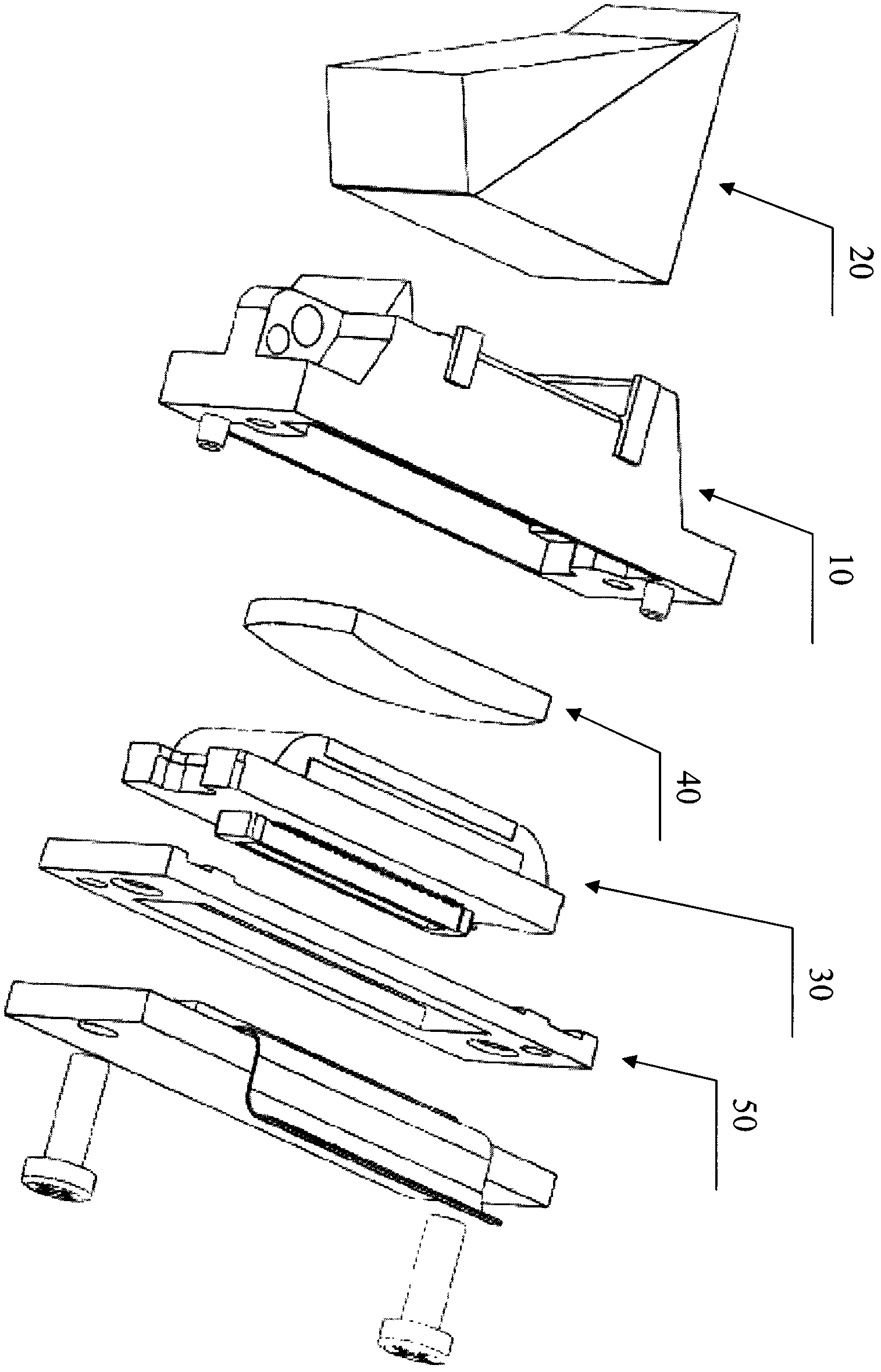

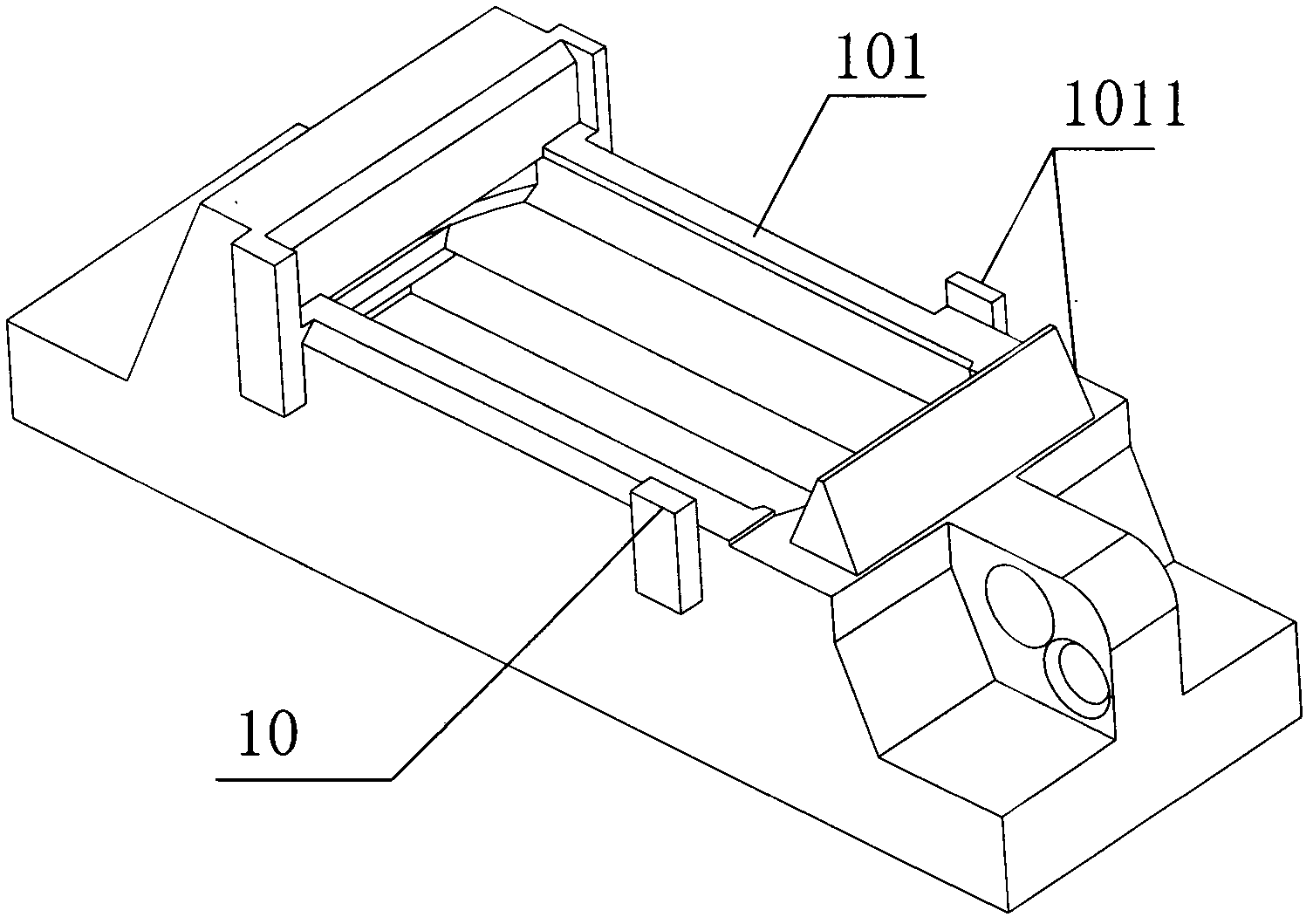

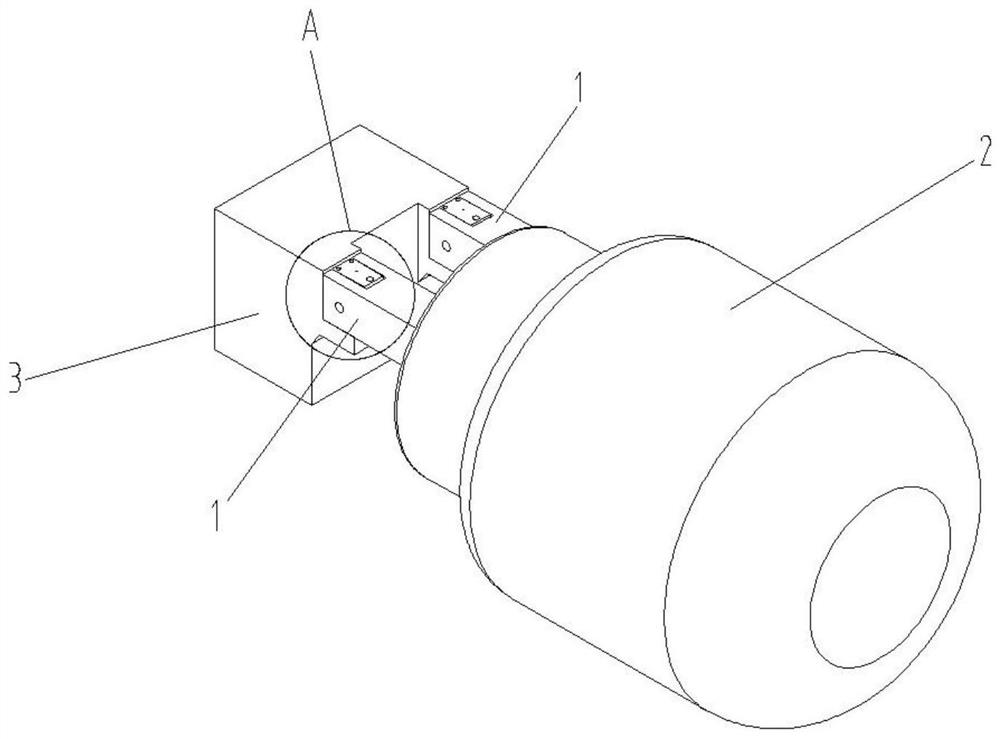

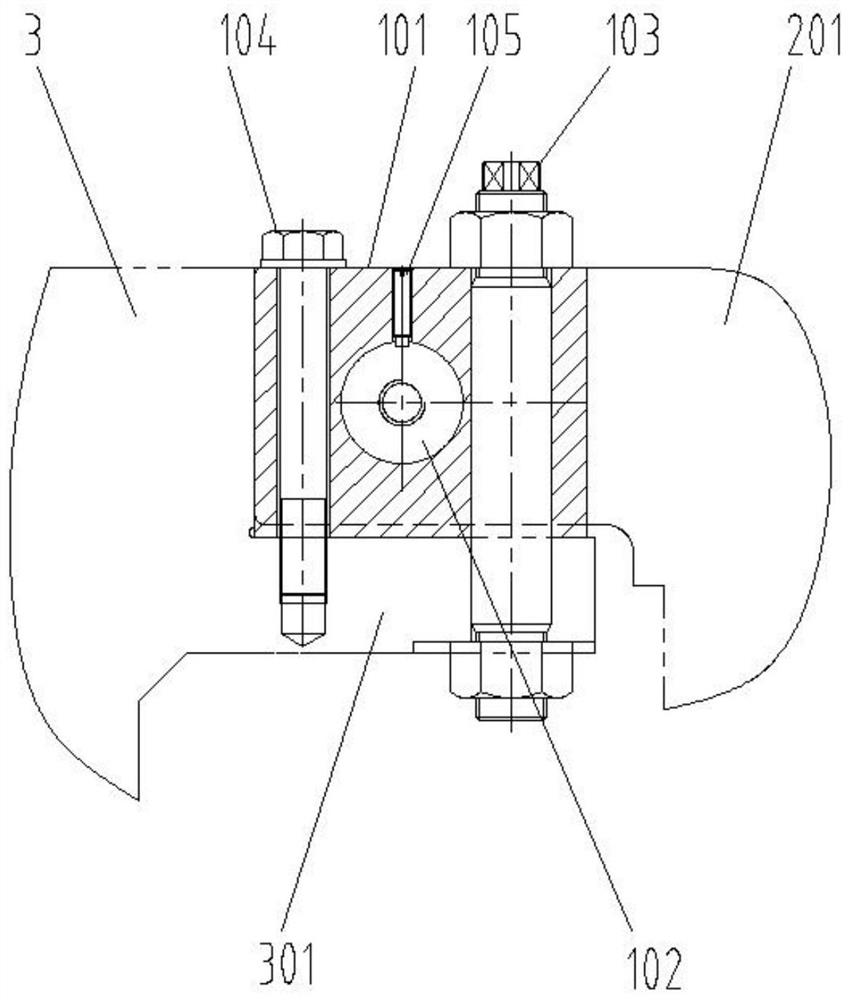

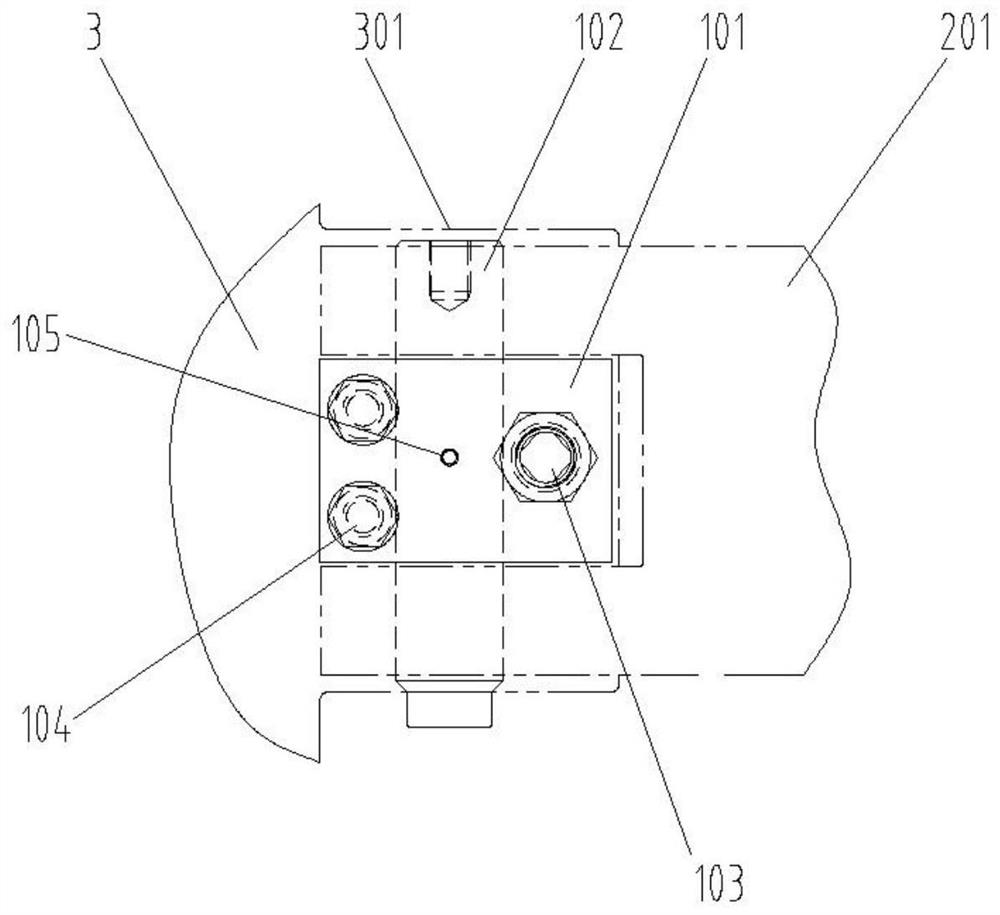

Imaging module of projector and projector using the same

InactiveCN103105716AKeep the relative position unchangedEasy to assemblePrismsProjectorsPrismProjector

The invention discloses an imaging module of a projector. The imaging module of the projector comprises a prism, a light modulator and a hollow connecting support frame, wherein the prism and the light modulator are connected on the front face and the back of the connecting support frame in a relatively parallel mode to form into a whole. The imaging module integrates the prism and the light modulator into a whole through the connecting support frame so as to ensure that relative positions of the prism and the light modulator are not changed, parallelism of the prism and the light modulator can be effectively ensured, and consistency of optical performance is ensured. In addition, due to the integral design, maintenance and protection of the modulator are convenient, adjustment is reduced at the same time, assembling efficiency is improved, tool equipment is simplified, and production efficiency is further improved. In addition, the invention further provides the projector using the imaging module.

Owner:BUTTERFLY TECH SHENZHEN

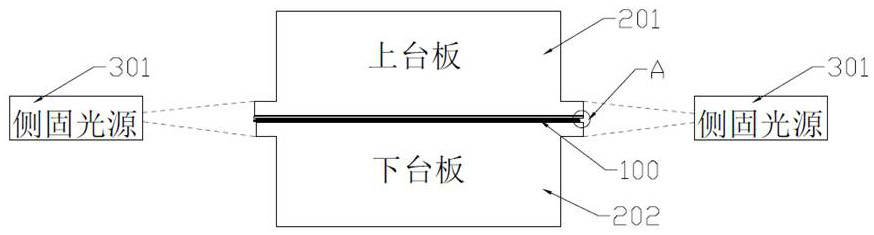

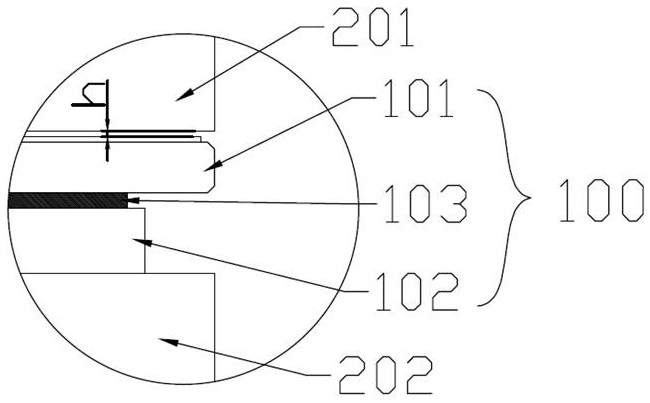

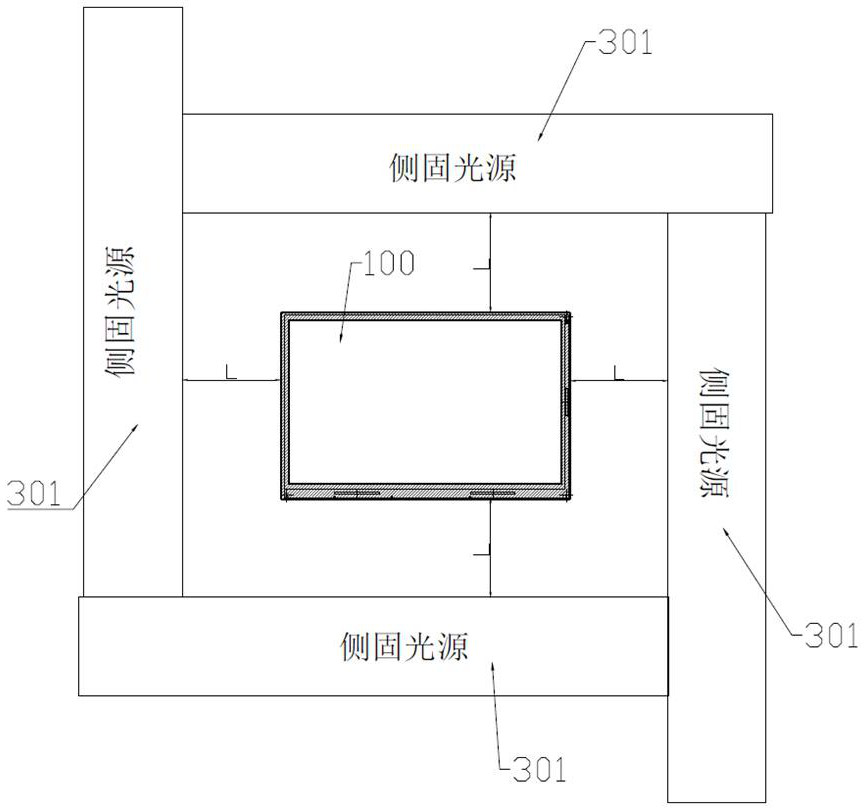

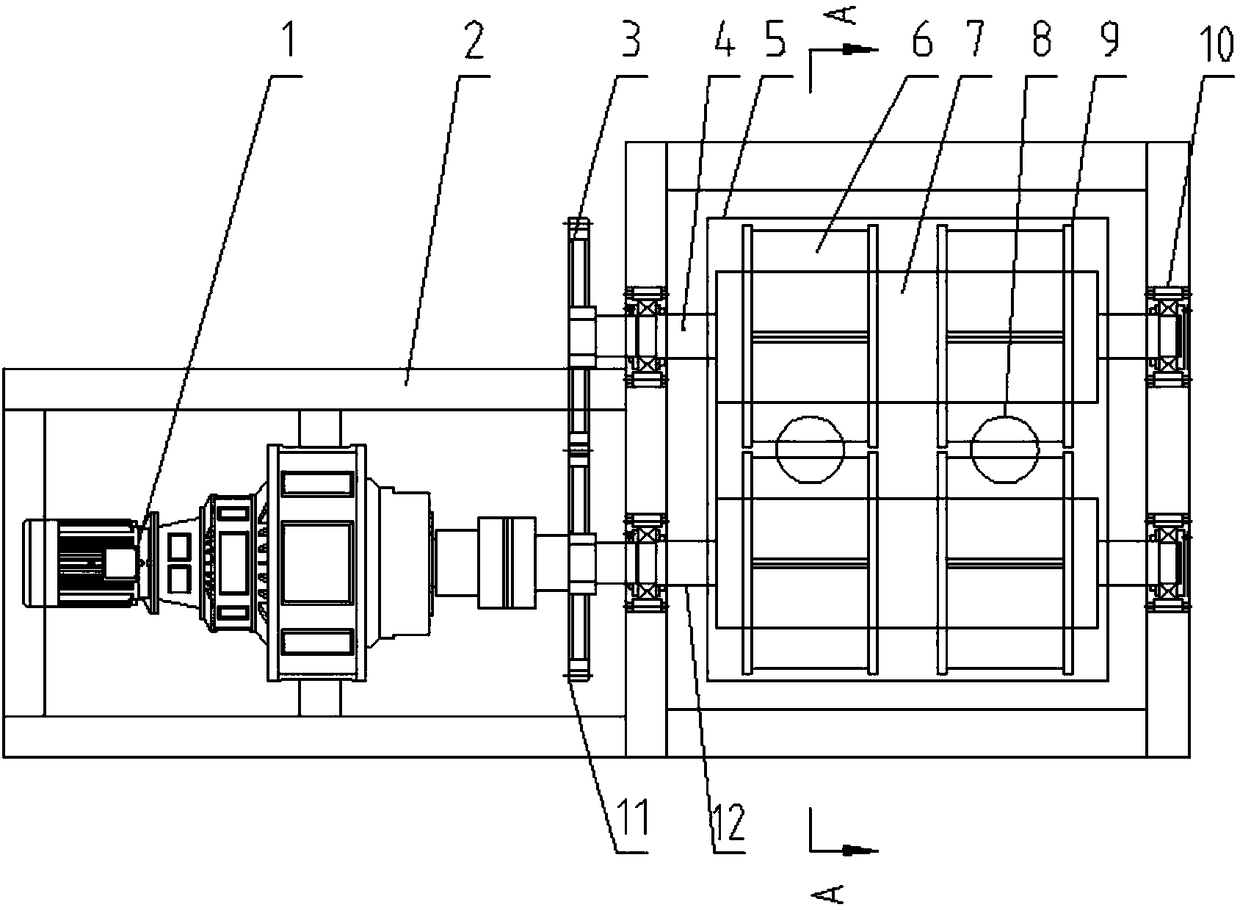

A method for fully laminating a display module

ActiveCN109555766BKeep the relative position unchangedAvoid easy flow problemsMaterial gluingPretreated surfacesMechanical engineeringPhysics

The invention discloses a full lamination manufacturing method of a display module. The display module includes a first substrate and a second substrate; the full lamination manufacturing method includes the following steps: (1). Coating: coating the first substrate with optical glue; (2). Alignment and bonding: first use the alignment adjustment system to align the first substrate and the second substrate on the horizontal plane; then attach the first substrate and the second substrate, and adjust the alignment by moving in the vertical direction System, control the thickness of the display module within the specified range; (3). Side curing: Use the curing device to simultaneously expose and cure the four sides of the display module located in the bonding station. In the present invention, after the first substrate and the second substrate are aligned and bonded, the display module is directly exposed and cured at the bonding station, and the display module does not need to move its position, which simplifies the process steps. Moreover, the process of moving the display module to the next station is avoided.

Owner:TRULY SEMICON

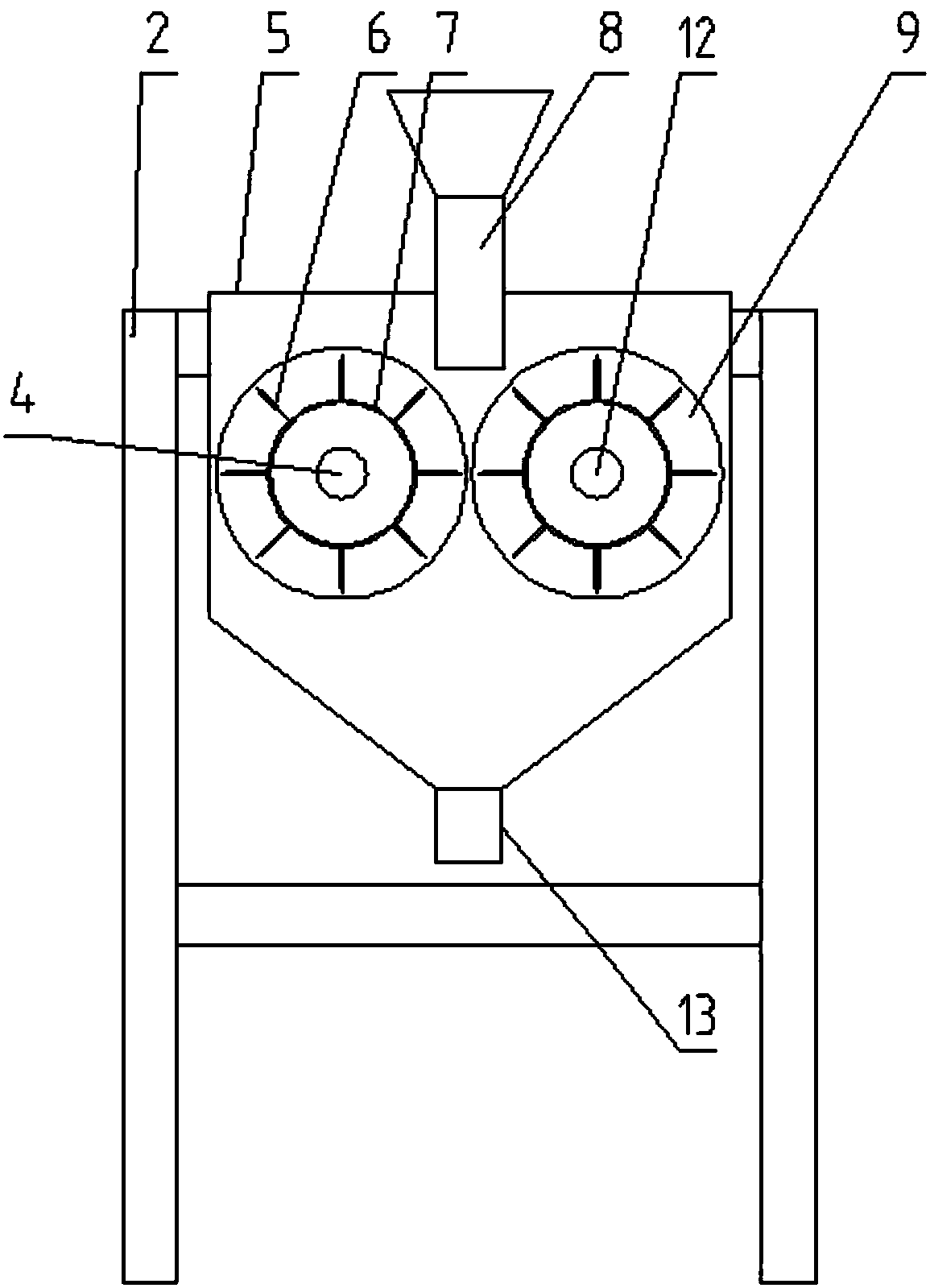

Seed stem cutting device of cassava planting machine

The invention discloses a seed stem cutting device of a cassava planting machine. A driven gear is meshed with a driving gear. The driven gear is fixed to the end of a driven shaft. The driving gear is fixed to the front part of a driving shaft. The front end of the driving shaft is connected to a main shaft of a gear motor through a coupler. Two seed stem cutting devices are used and are arrangedin a case. The seed stem cutting device comprises cutters, rotating drums and retaining plates. The two rotating drums are respectively fixed on the driven shaft and the driving shaft. The cutters are fixed to the rotating drums. Two ends of the cutter are fixedly provided with the retaining plates. The case is fixed on a support. The gear motor is fixed to the support. A top plate of the case isfixedly provided with a charging pipe. The lower part of the charging pipe is inserted into the case. The seed stem cutting device has the advantages of good cutting uniformity and good stability.

Owner:安徽维力拓网络科技有限公司

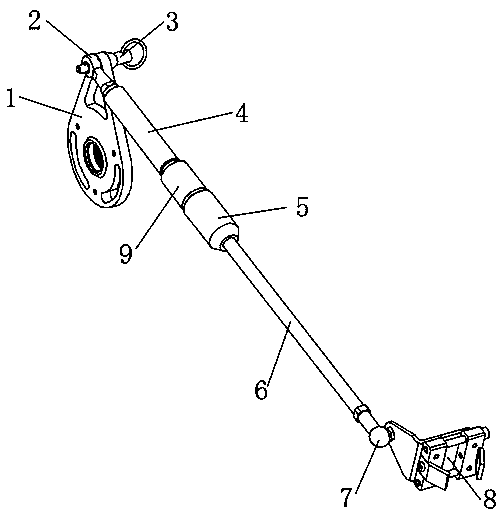

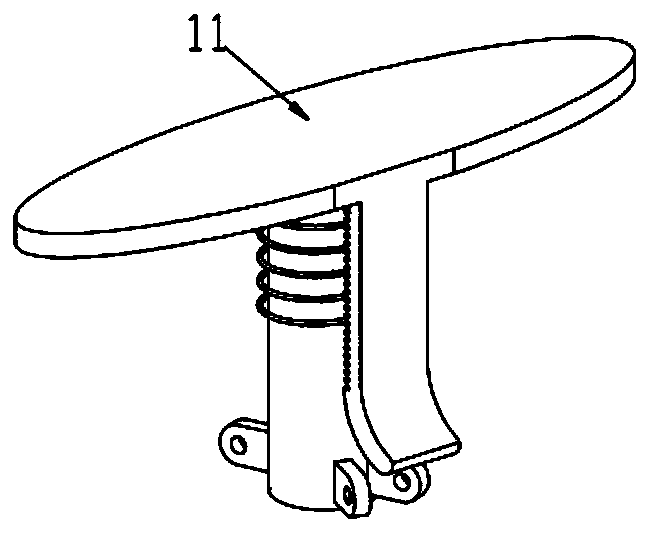

Clamp-type patella anchor guider

PendingCN109700502AKeep the relative position unchangedReasonable designBone drill guidesEngineeringGuide tube

The invention discloses a clamp-type patella anchor guider, relates to the field of medical instruments, and solves the shortcomings of drilling from the middle of the lateral position of patella according to experience. The product comprises a push rod, a main body, a movable part, a top plate, an adjustment screw and a guiding tube, the push rod is installed on the upper part of the main body, the movable part is hinged to the lower part of the main body, the top plate is installed at the bottom end of the main body and a fine adjustment knob is arranged between the top plate and the main body in a screwing mode, both the adjustment screw and the guiding tube are hinged to the main body, and the lower part of the adjustment screw is in screwing connection with a second fine adjustment knob. The product provides a better fixing effect by a first elastic pad on a clamping jaw and the top plate, and ensures that the relative position of the guider and the patella is unchanged after being fixed; the product ensures the accuracy of the drilling position through the fine adjustment of the components on one side of the guiding tube; and the product is simple in structure, convenient tooperate and high in positioning precision, effectively improves the operation efficiency in the operation, and improves the fixation effect of the patella anchor.

Owner:上海节惠生物科技有限公司

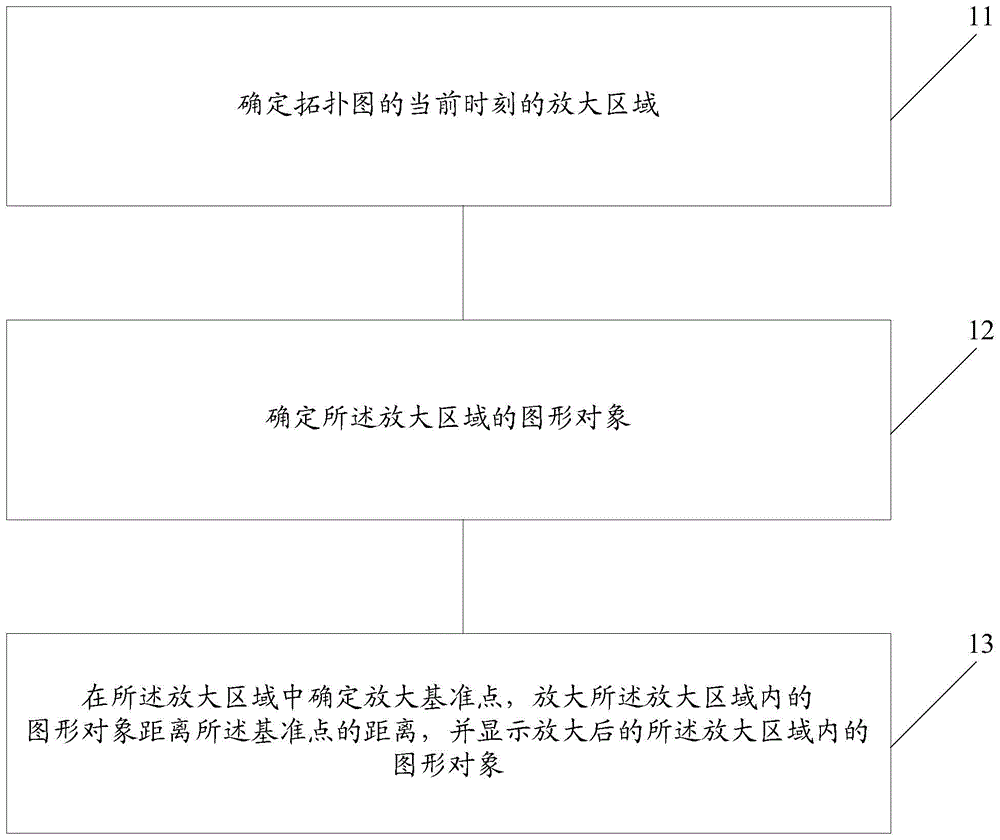

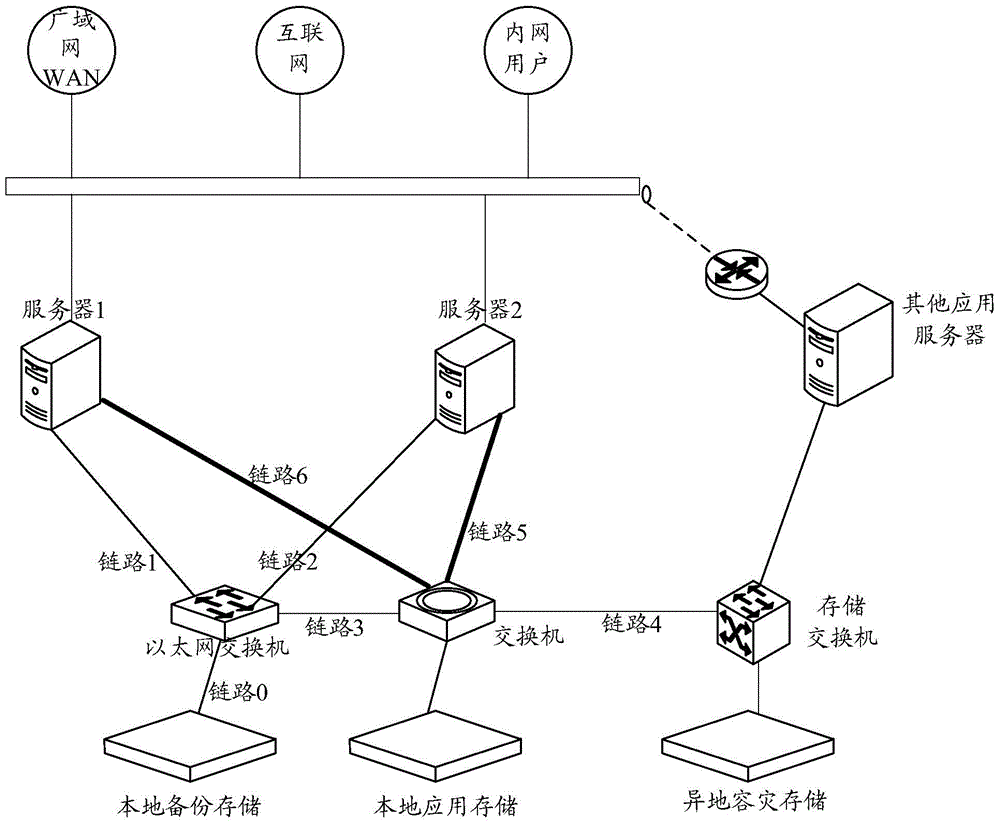

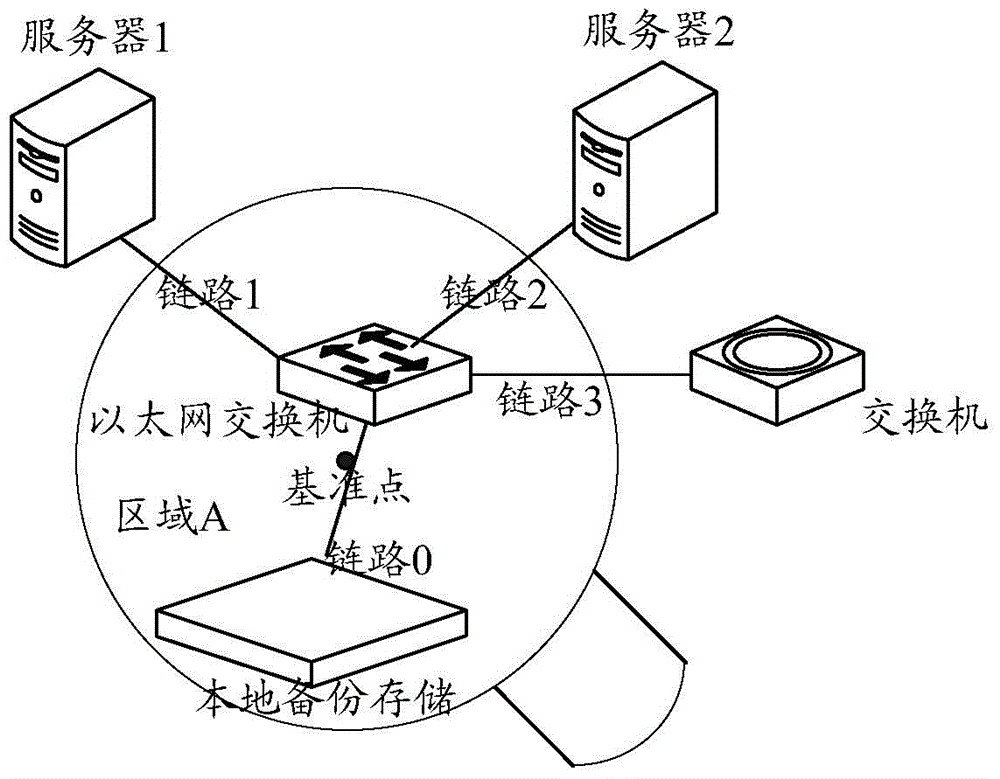

Pattern amplifying method and device in topological graph

InactiveCN104573158AZoom in on absolute distanceKeep the relative position unchangedGeometric image transformationData switching networksGraphicsPresent method

Disclosed is a method for magnifying a graphic within a topology diagram, said method comprising: determining a current magnification area of a topology diagram; determining a graphic object contained in the magnification area; within the magnification area, determining a magnification reference point, magnifying the distance that the graphic object contained in the magnification area is from the reference point, and displaying the magnified graphic object contained in the magnification area. The present method also comprises a device for magnifying a graphic within a topology diagram.

Owner:ZTE CORP

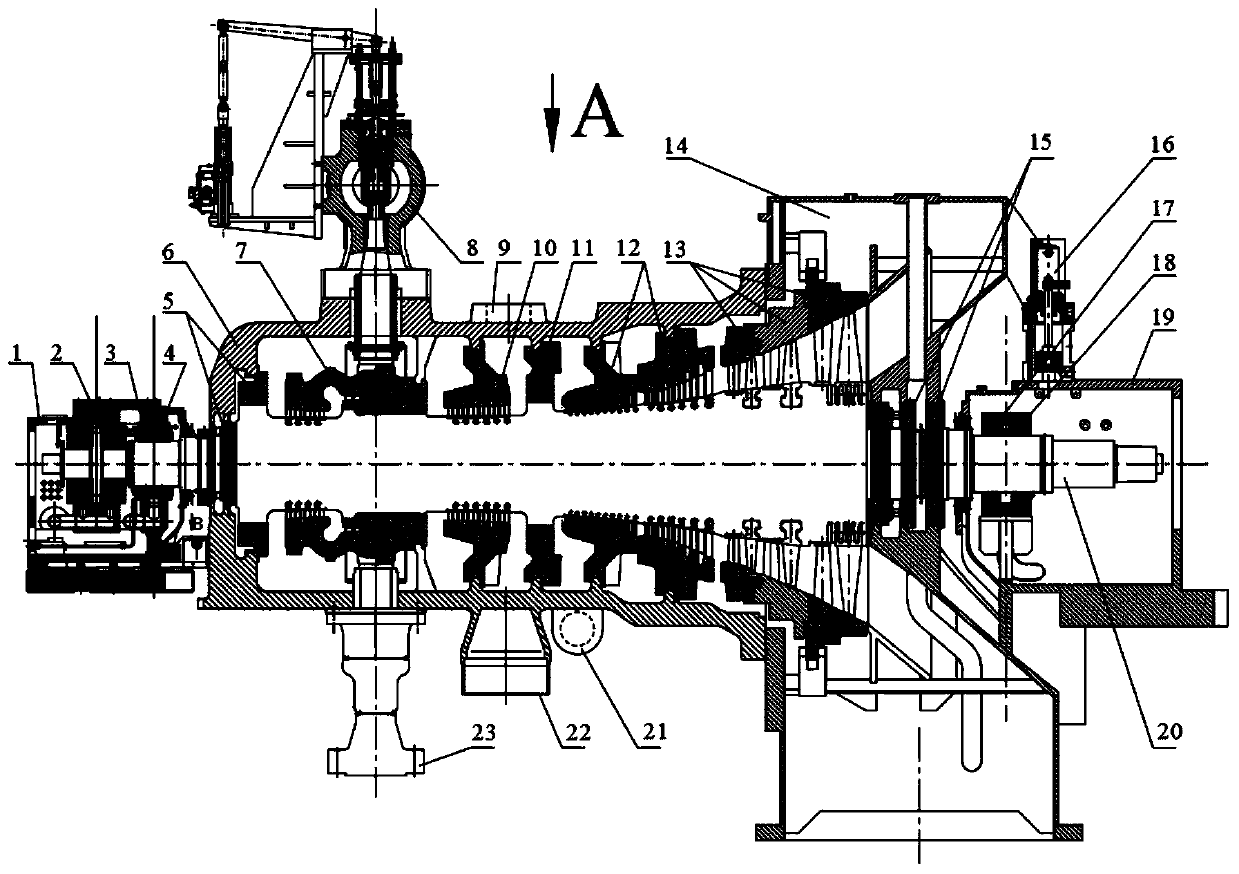

Steam turbine for cracking gas device and cracking gas system

PendingCN110608071AKeep the relative position unchangedSolve technical problems of slewing reliabilityStatorsMachines/enginesHeat stabilityAxial thrust

The invention provides a steam turbine for a cracking gas device and a cracking gas system, and relates to the technical field of steam turbines. The overall structure adopts a single-cylinder single-steam-exhaust arrangement, and a rotor system is supported through transverse bearings of various models and sizes, so that it is guaranteed that the system has a sufficient avoidance interval, excellent vibration performance and excellent anti-interference performance. The full-arc steam admission structure is adopted, the steam admission flow channel is optimized, the structural strength and rigidity are improved, a backflow structure is designed for through flow, and the axial thrust of the steam turbine is effectively lowered; a high-temperature side guiding structure is adopted, cold andhot state clearance change caused under a high-temperature running environment and a working condition emergence condition can be prevented, and the centring problem of steam cylinders of the steam turbine is solved; a detachable split valve-adjusting quick-closing valve structure is adopted, and the installing and overhauling mode is simplified; through the mode of multi-point supporting, the rigidity and heat stability of the steam exhaust cylinder are optimized, therefore, the industrial steam turbine with the power per unit of 100 MW can drive compressor units with the annual output of 1.5million tons of ethylene cracking gas, and the requirements of the compressor units for the working conditions and rotation speed change are met.

Owner:HANGZHOU STEAM TURBINE

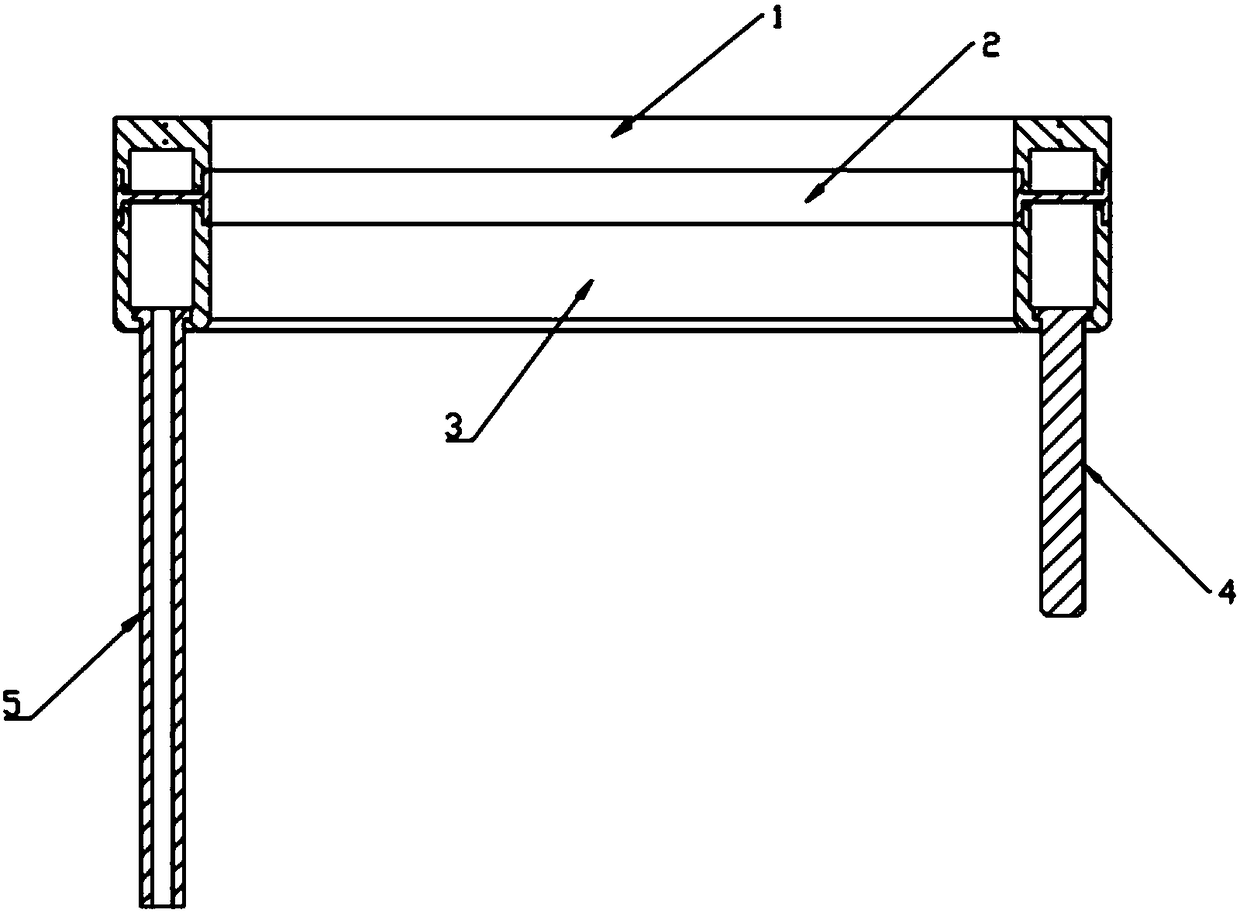

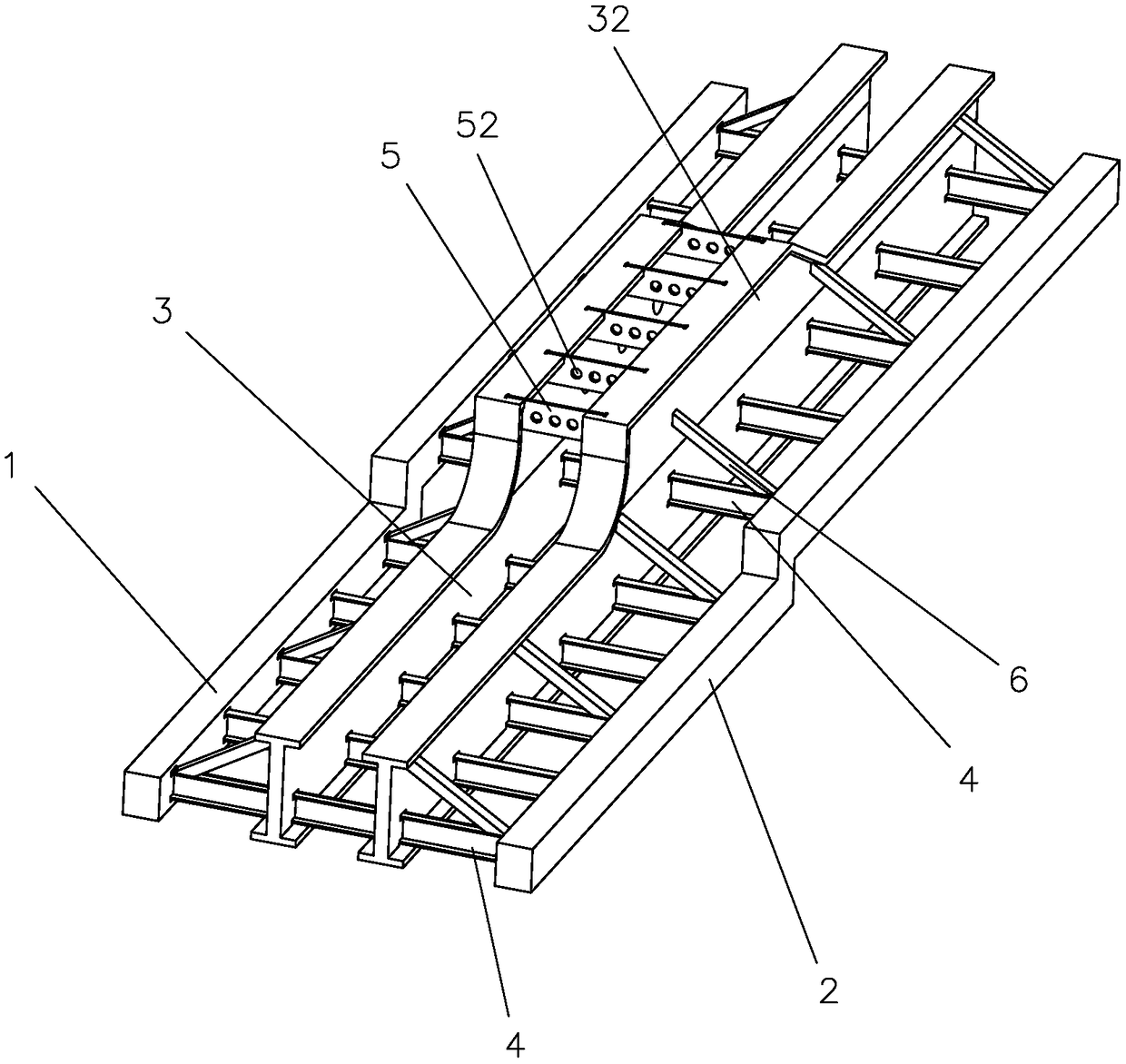

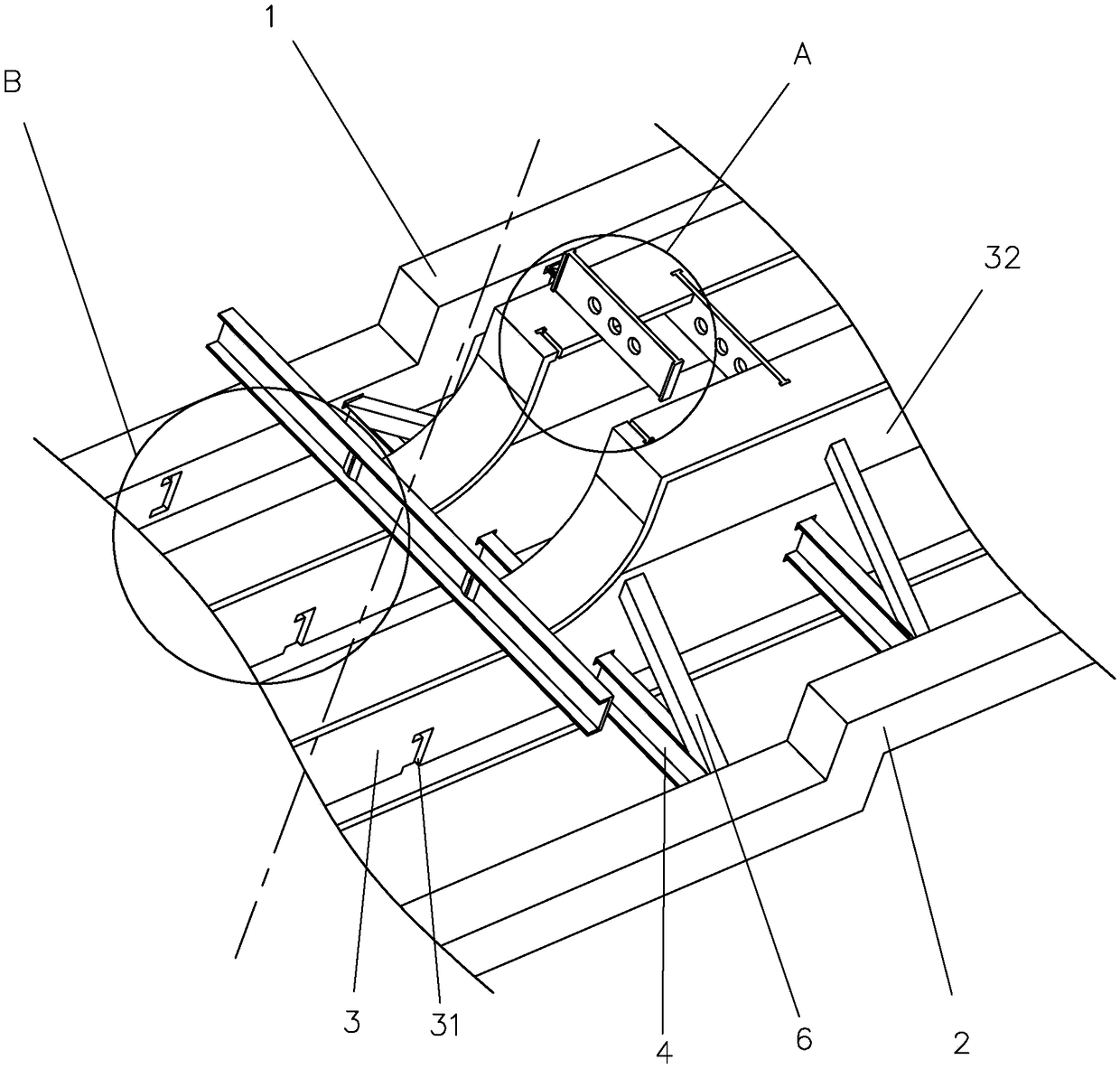

Crossbeam structure of semitrailer and welding process thereof

InactiveCN109367626AAvoid errorsKeep the relative position unchangedUnderstructuresWelding apparatusAerospace engineeringWelding process

The invention discloses a crossbeam structure of a semitrailer and a welding process thereof and belongs to the field of crossbeam structures of vehicles. The technical scheme is as follows: the structure comprises a left wing plate and a wing web plate, two web plates are arranged between the left wing plate and the right wing plate, a plurality of connecting plates with arched sections are arranged between the left wing plate and the right wing plate, a plurality of arched insertion holes are formed in each web plate, two ends of each connecting plate separately penetrate the insertion holesand are fixed to the side walls of the left wing plate and the right wing plate, an extension plate is integrally connected to the middle of each web plate, a plurality of T-shaped slots are separately formed in opposite side of each extension plate, a positioning plate is arranged between two extension plates, two ends of each positioning plate are fixedly connected to a clamping plate verticalto the positioning plate, separately, and two ends of each positioning plate and the clamping plate stretch into the T-shaped slots, separately. Therefore, the position of a part of the crossbeam is determined conveniently for welding, so that a certain error can be avoided.

Owner:石家庄金多利专用汽车有限公司

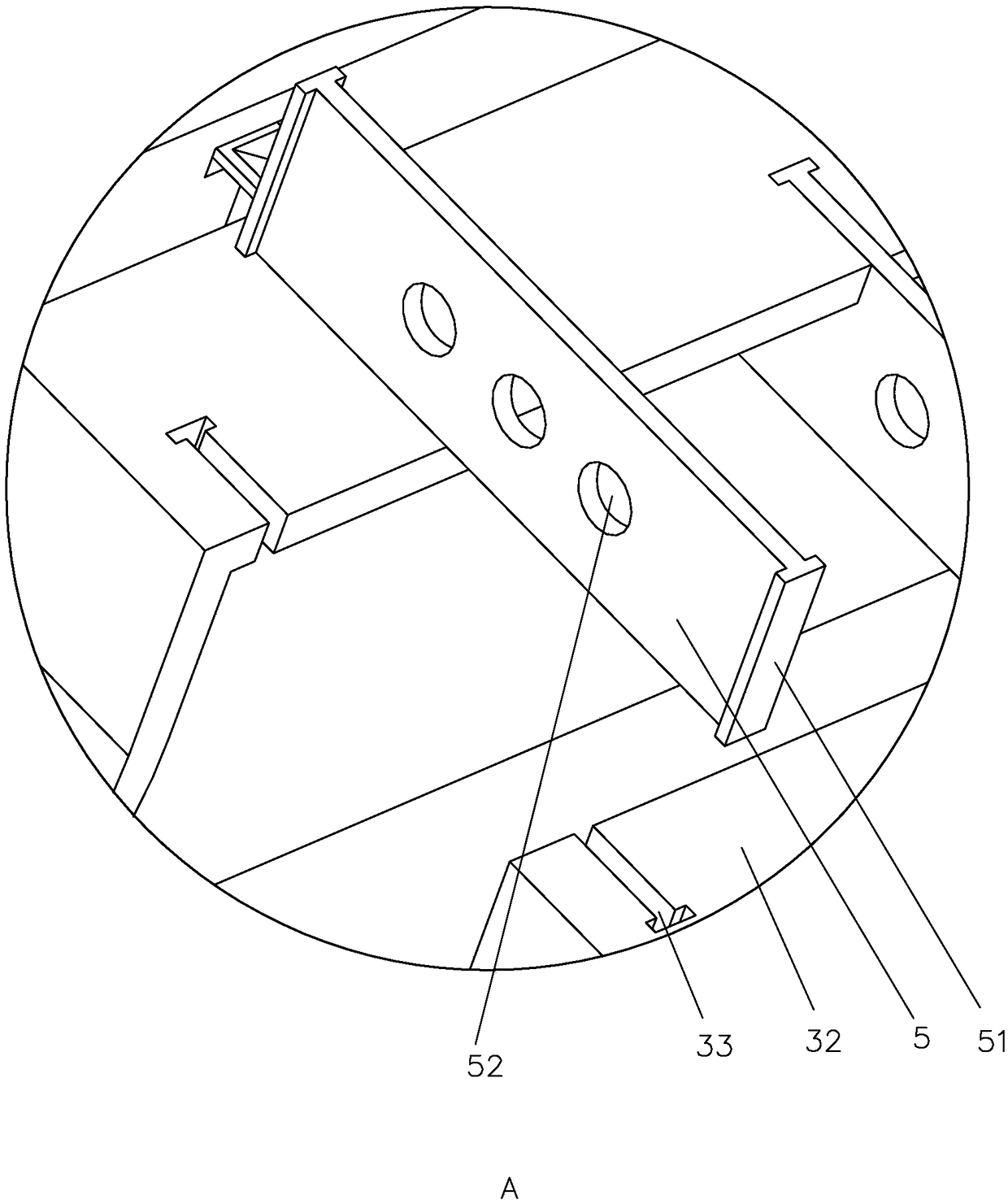

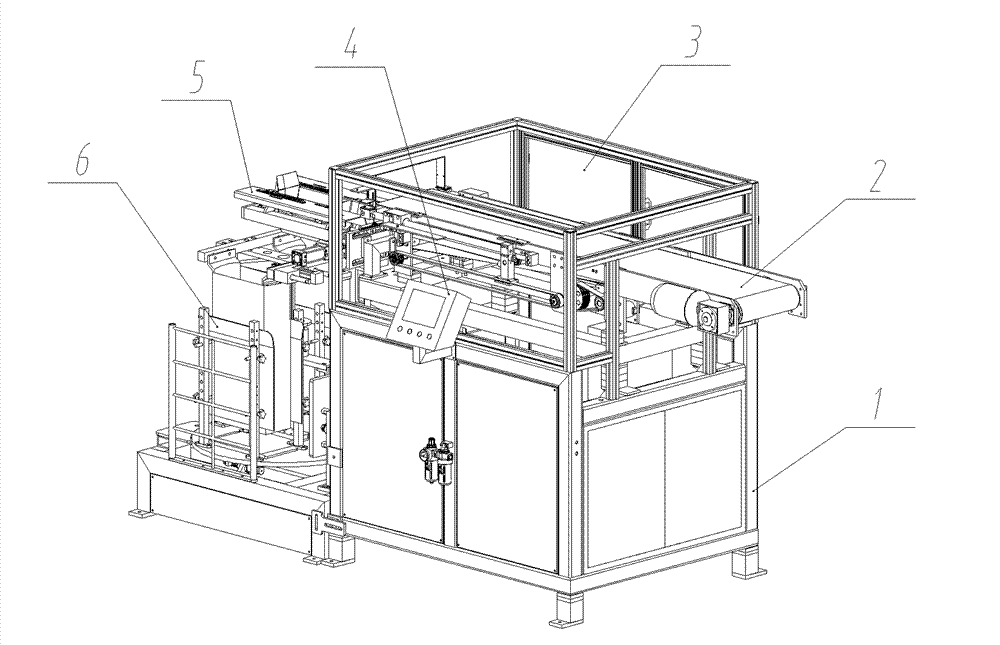

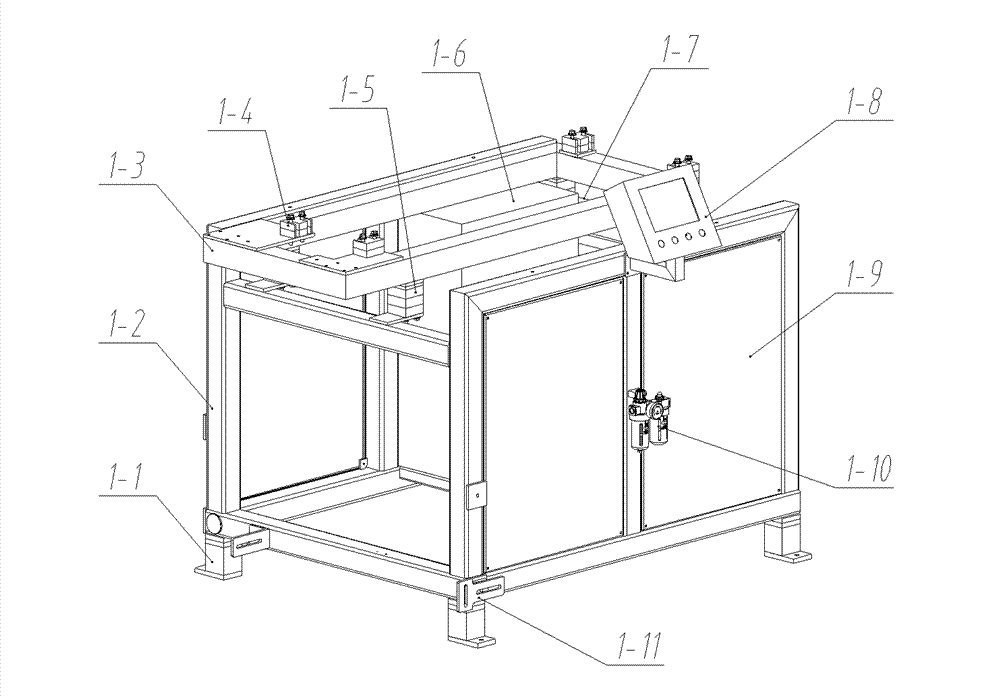

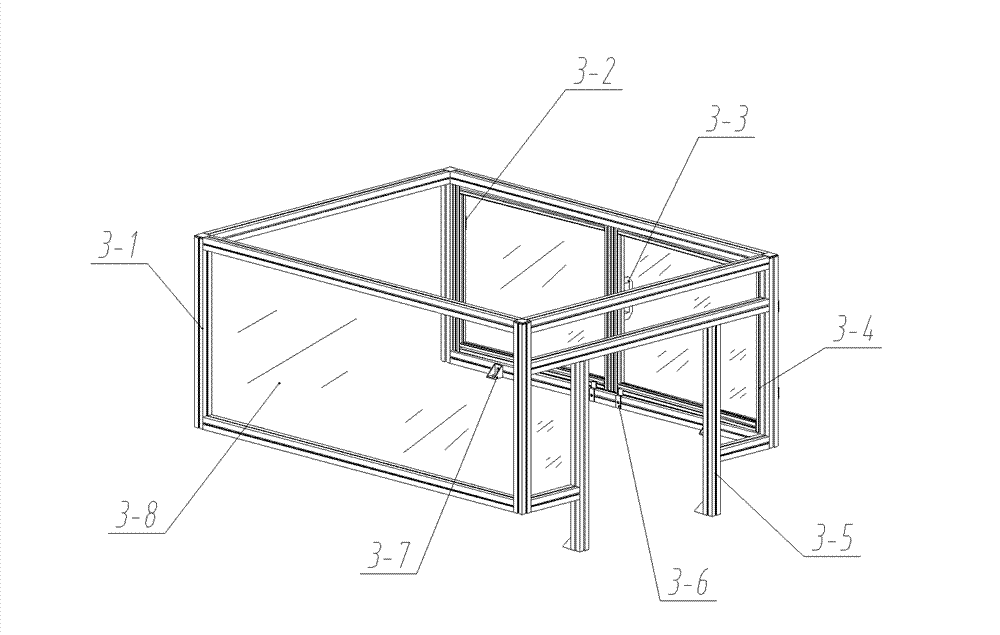

Automatic drop-out type bagging machine

ActiveCN102219058BCompact structureEasy maintenancePackaging automatic controlControl systemEngineering

The invention relates to an automatic drop-out type bagging machine comprising a rack part, an extensible belt conveyor part, a control system, a tray arranging part, and an automatic rotation bagging device, wherein the extensible belt conveyor part is installed on a support platform of the rack part, the tray arranging part is arranged above the front of one side of the rack part, and is connected with extensible belt conveyor part, the control system is directly embedded in a control cabinet of the rack part, an operating platform of the control system is installed in the middle position above the front side of a rack, the control system respectively controls the extensible belt conveyor part, the tray arranging part and the automatic rotation bagging device, the automatic rotation bagging device is fixed at one side of the rack of the rack part by two connecting plates and is arranged below a tray of the tray arranging part, and the central line of a bagging station of the automatic rotation bagging device is in the same line with the central lines of the tray arranging part and the extensible belt conveyor part. The automatic drop-out type bagging machine is reasonable in structure, simple in operation, high in efficiency and high in stability, and can alleviate the labor intensity of operating workers.

Owner:WUHAN RENTIAN PACKAGING TECH

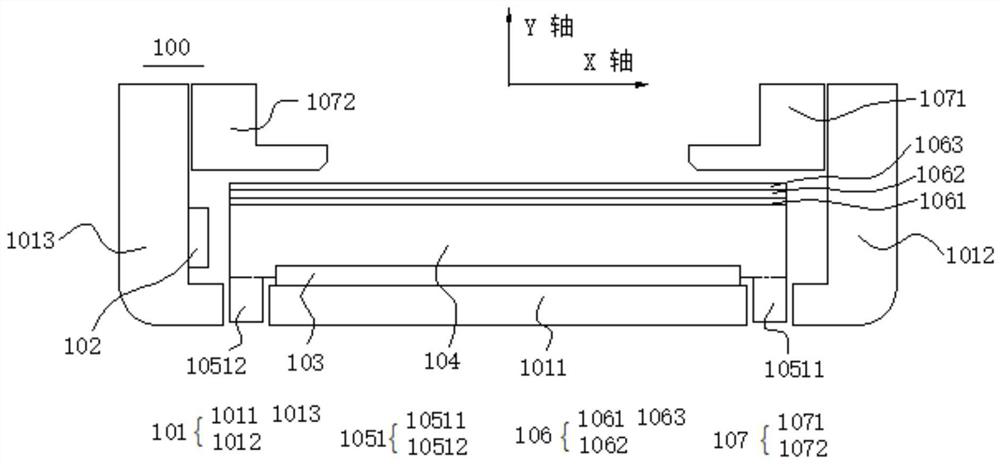

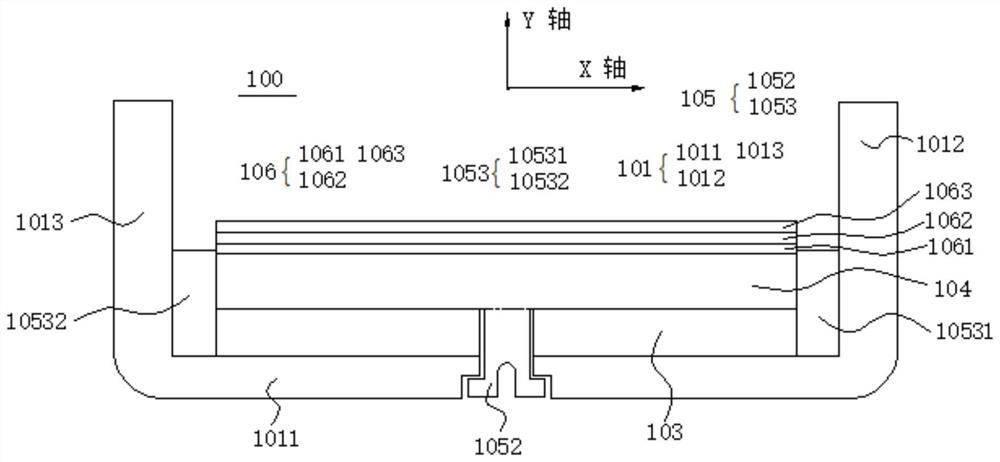

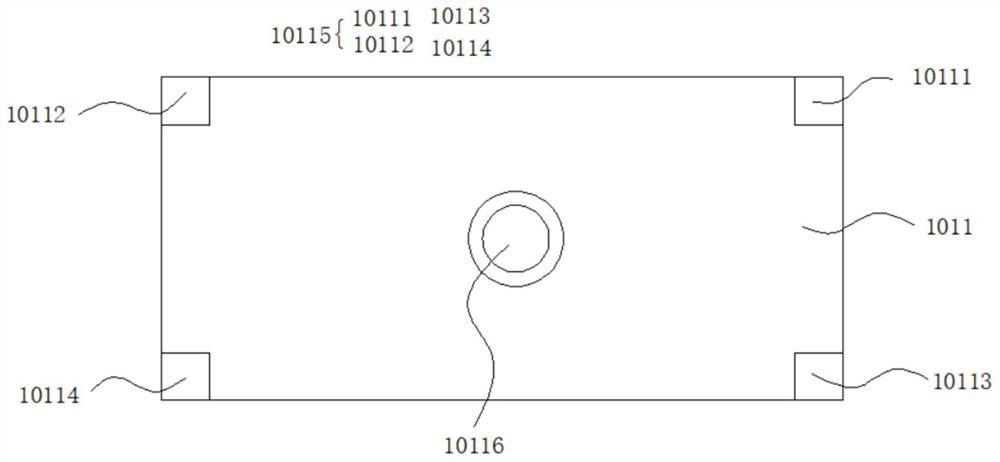

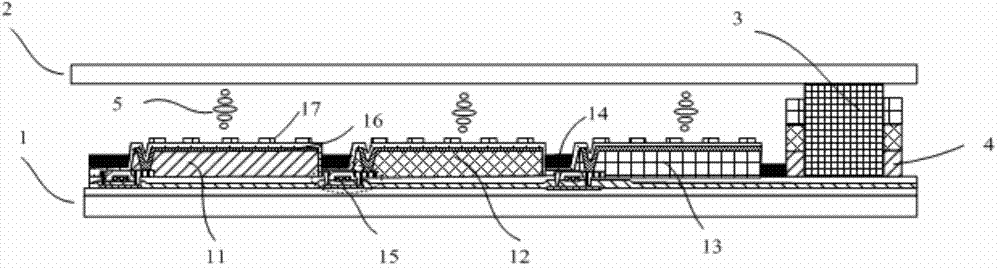

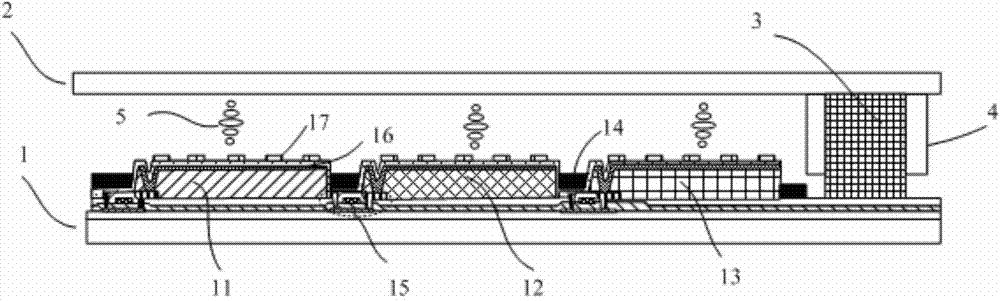

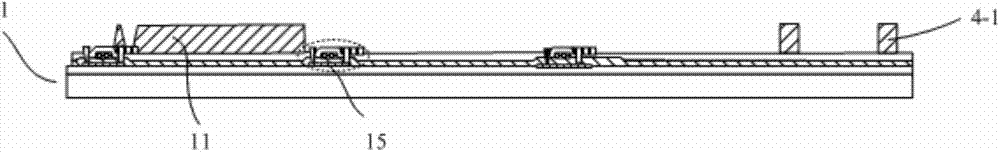

Backlight module and vehicle-mounted display

InactiveCN111679505AImprove stabilityNo slidingOptical light guidesNon-linear opticsLight guideIn vehicle

The embodiment of the invention provides a backlight module and a vehicle-mounted display. The backlight module comprises a middle frame, an LED light bar, a light guide plate and a back frame, wherein the LED light bar is fixedly arranged on the inner side of the side plate of the back frame; the light guide plate is arranged in an accommodating cavity; and a fixed connecting piece is arranged onone side of the light guide plate facing the back frame. Therefore, the light guide plate and the back frame are of an integrated structure, the light guide plate and the optical film material in thebacklight module can be guaranteed not to slide on the four sides and the center in the back-and-forth vibration process of a vehicle, the relative position between the light guide plate and the optical film material is kept unchanged, the display stability of the vehicle-mounted displayer is improved, and the use experience and satisfaction of a user are improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Drilling and chamfering integrated device for steel pipe machining and using method

InactiveCN111774620AAvoid being affected by centrifugal forceReduce forceTransportation and packagingMeasurement/indication equipmentsEngineeringMachining

The invention discloses a drilling and chamfering integrated device for steel pipe machining and a using method. The drilling and chamfering integrated device comprises a tool holder and an inner ringsleeve. The lower end of the inner ring sleeve is provided with a drill bit through a fixing seat. A hollow column and a plurality of insulating cylinders are fixedly arranged between the fixing seatand the tool holder. Conductive rods are connected between the hollow column and the insulating cylinders. A pressurizing mechanism is arranged in each insulating cylinder. A plurality of tool returnboxes are symmetrically mounted on the side wall of the inner ring sleeve. A reset mechanism is arranged in each tool return box. An electromagnetic valve is arranged between each tool return box andthe corresponding insulating cylinder. Chamfering tools are mounted on the side walls, away from the hollow column, of the tool return boxes in a sliding and penetrating manner. The drilling and chamfering integrated device can be used as a drilling and chamfering device for conventional steel pipe machining, chamfering tools of different specifications can be rapidly replaced according to actualmachining requirements in the chamfering process, tedious operations such as tool retracting, tool changing and tool alignment are not needed, and the machining precision and the machining efficiencyare further improved.

Owner:梁军

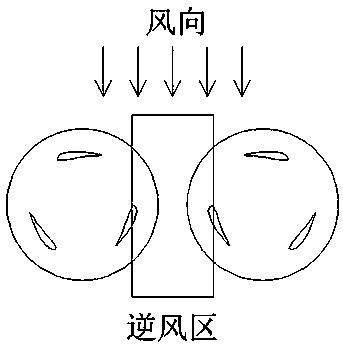

Passive rectifying device applied to double vertical axis fans

PendingCN107762723AAvoid extra loadKeep the relative position unchangedRenewable energy generationMachines/enginesAerospace engineeringWind speed

The invention discloses a passive rectifying device applied to double vertical axis fans, and belongs to the technical field of wind power generation. The passive rectifying device applied to the double vertical axis fans comprises the two vertical axis fans, a supporting platform used for mounting the vertical axis fans, and a rectifying device arranged on a framework. When the passive rectifyingdevice is utilized, the rectifying device is firstly in contact with air, a part of air is forced to change direction, wind velocity in the middle zones of the fans is decreased, and wind velocity onthe two sides is increased; and resistance of blades in an adverse wind zone is reduced through a rectified wind filed, thrust of the blades in a favorable wind zone is improved, the purpose of increasing the rotation speed of the fans is achieved, and starting wind velocity of the fans can be effectively decreased.

Owner:DALIAN UNIV OF TECH

Novel cat claw structure used for small steam turbine

PendingCN111946408AAchieve connectionFree expansionMachines/enginesEngine componentsEngineeringCat's claw

The invention provides a novel cat claw structure used for a small steam turbine. Connection of a steam cylinder and a bearing seat is achieved, the structure is novel, it can be effectively guaranteed that the relative positions of the steam cylinder and the bearing seat are not changed, and meanwhile the smooth free expansion of the steam cylinder is guaranteed. According to the technical scheme, the novel cat claw structure comprises a bearing seat supporting plate, a fixed block, a steam cylinder connecting piece and a transverse pin; and the fixed block is fixed to the bearing seat supporting plate, one end of the steam cylinder connecting piece is fixedly connected with the steam cylinder, the other end of the steam cylinder connecting piece is of a U-shaped fork structure, the fixedblock is arranged in the U-shaped fork, the two sides of the U-shaped fork are each provided with a through hole, the two through holes are coaxial, coaxial through holes are also formed in the positions, corresponding to the two through holes, of the fixed block, the transverse pin is arranged in the through holes in a penetrating manner, and therefore the U-shaped fork is connected with the fixed block.

Owner:CHINA CHANGJIANG ENERGY CORP GROUP

Liquid crystal panel and display device

InactiveCN104516157AKeep the relative position unchangedThere will be no problem of box alignment deviationNon-linear opticsLiquid-crystal displayDisplay device

The invention provides a liquid crystal panel and a display device, belongs to the technical field of display, and solves the problem of alignment deviation during box alignment due to process reasons for two substrates of an existing liquid crystal panel. The liquid crystal panel comprises a first substrate and a second substrate which are opposite, and a spacer arranged between the first substrate and the second substrate, wherein the spacer is arranged on one of the first substrate and the second substrate; a clamping groove corresponding to the spacer is formed in the other of the first substrate and the second substrate and used for clamping the spacer corresponding to the clamping groove to ensure that the first substrate and the second substrate are relatively fixed in position. The display device comprises the liquid crystal panel.

Owner:BOE TECH GRP CO LTD +1

A pipeline all-position operating machine and its control method

ActiveCN104708220BSolving Soldering MismatchesCooperate closelyWelding/cutting auxillary devicesAuxillary welding devicesIndependent motionRadial motion

The invention belongs to the field of mechanical automation, and particularly relates to a pipeline all-position operation machine and control method thereof. The operation machine comprises a guide rail, a motion unit, an executive terminal, a driving unit and a control unit, wherein the motion unit conducts peripheral motion along the guide rail; one end of the motion unit is connected with the executive terminal; the output end of the control unit is connected with the input end of the driving unit; the output end of the driving unit is connected with a driving motor of the motion unit; the driving unit receives pulse signals sent out by the control unit and drives the driving motor of the motion unit to conduct corresponding motions; the motion unit comprises a peripheral motion mechanism, an axial motion mechanism, a radial motion mechanism and a swing mechanism which are capable of conducting independent motion driven by motors; the peripheral motion mechanism is provided with a scan mechanism. The operation machine has the function of automatically conducting pipeline cutting and welding, the defect of manual operation on irregular pipelines is overcome, and real-time detection and automatic adjustments are achieved.

Owner:深圳雷瑞智动机械设备有限公司

Novel electronic component resistor sleeve penetrating equipment

ActiveCN114792591AReduce frictionKeep the relative position unchangedThermistorsResistor detailsElectrical resistance and conductanceElectronic component

The invention provides novel electronic component resistor sleeve penetrating equipment which comprises a shell, a thermal resistor is arranged in the shell, connecting wires are fixedly connected to the two sides of the thermal resistor, a positioning mechanism is arranged in the shell, and a tightening mechanism is arranged in the shell. According to the novel electronic component resistor sleeve penetrating equipment, during use, the sleeve shell is inserted into the side face of a thermal resistor to protect the thermal resistor, when the inner wall of the shell is plasticized, the extrusion force between the inner wall of the shell and the side face of the thermal resistor is reduced, the friction force between the inner wall of the shell and the side face of the thermal resistor is reduced, and under the action of vibration, when the shell moves relative to the thermal resistor, the thermal resistor is protected. When the casing is plasticized and moves relative to the thermal resistor, the positioning mechanism restores the movement of the casing through the extrusion wheel to ensure that the relative position between the casing and the thermal resistor is unchanged, so that the effect that the thermal resistor cannot be continuously protected due to the change of the relative position between the casing and the thermal resistor when the casing is plasticized and moves relative to the thermal resistor is achieved.

Owner:南通迈威智能科技有限公司

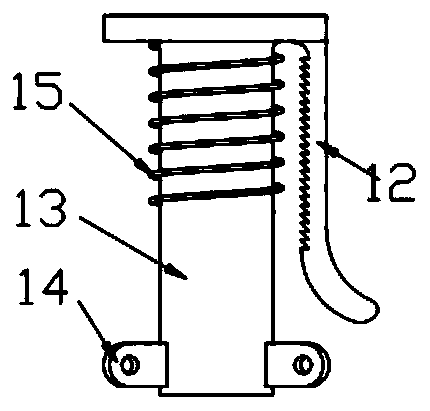

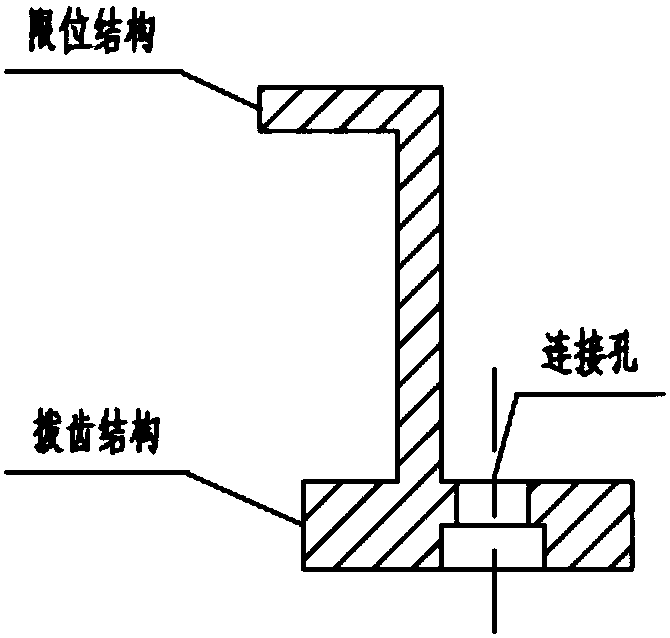

Dismounting tool of main bolt and main nut of reactor pressure vessel and using method thereof

PendingCN109968282AKeep the relative position unchangedMeet disassembly requirementsMetal-working hand toolsReactor pressure vesselEngineering

The invention relates to a dismounting tool of a main bolt and a main nut of a reactor pressure vessel and a using method thereof. The dismounting tool comprises a body structure, an external power device and a handle, wherein the body structure comprises a round base, a large gear is embedded in the base, the large gear is positioned on the base through a copper ring, moreover, the copper ring isfixed on the base through a screw A, a rotating ring is arranged on the lower end surface of the large gear, three clamping groove type slideways are arranged on the rotating ring, a shifting tooth is arranged in each clamping groove type slideway, moreover, the shifting teeth, the rotating ring and the large gear are connected into a whole through a screw B, a limiting structure is arranged right above the shifting teeth, and is used for clamping the dismounting tool on the upper end surfaces of the main bolt and the main nut so as to limit the axial position of the dismounting tool, and aninner gear determined by the three shifting teeth is meshed with an outer gear on the main bolt and the main nut. The handheld tool for electrically dismounting the main bolt and the main nut of the reactor pressure vessel is provided.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com